Growing method of gallium arsenide monocrystalline

A growth method, gallium arsenide technology, applied in the field of gallium arsenide single crystal growth, can solve the problems that restrict the development and application of high-brightness LEDs, and achieve the low crystallization rate of growth, reduce production costs, and meet the requirements of preparation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

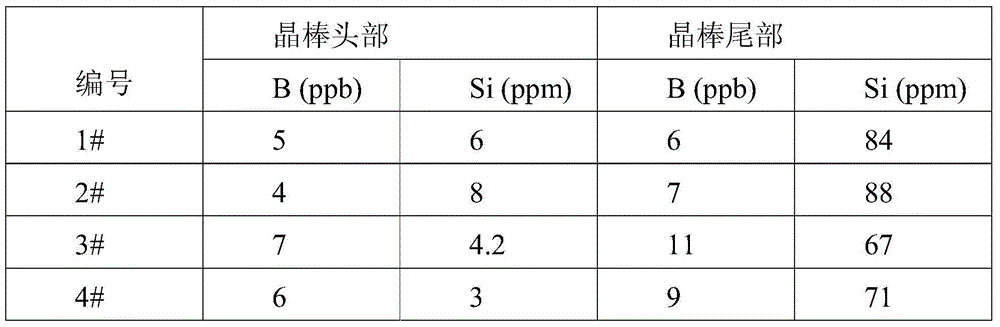

Examples

Embodiment 1

[0026] (1) Grind four 2-inch quartz crucibles (numbered 1#, 2#, 3#, 4#) with 100-mesh diamond sandpaper until the surface is smooth without obvious steps, then wash with deionized water, and then wash with 10% Wash with dilute NaOH solution for 15 minutes, then wash with deionized water, and finally wash with hot water at 60°C;

[0027] (2) Put the cleaned and dried quartz crucible into a quartz tube with high-purity gallium, wherein the amount of high-purity gallium in the quartz tube is to make the melted gallium soak the quartz crucible completely, and then put the quartz tube Put it into a vertical heating furnace body, vacuumize the jig on the quartz tube, turn on the vacuum pump to vacuumize, and wait until the vacuum degree is stable to 10 -1 After Pa, turn off the vacuum pump to stop vacuuming and fill the quartz tube with argon gas. After the pressure in the quartz tube reaches a standard atmospheric pressure, close the gas valve to stop filling the argon gas, and tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com