Patents

Literature

30results about How to "Improve boundary conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

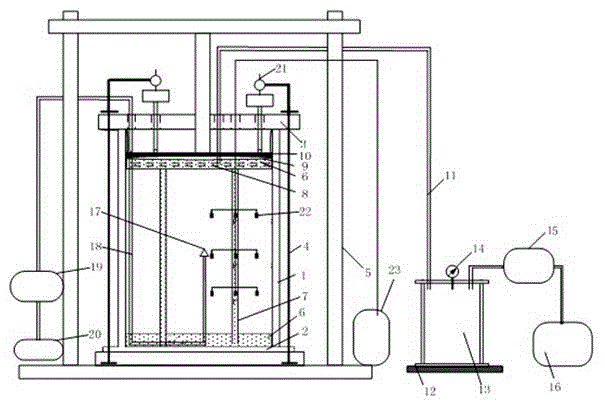

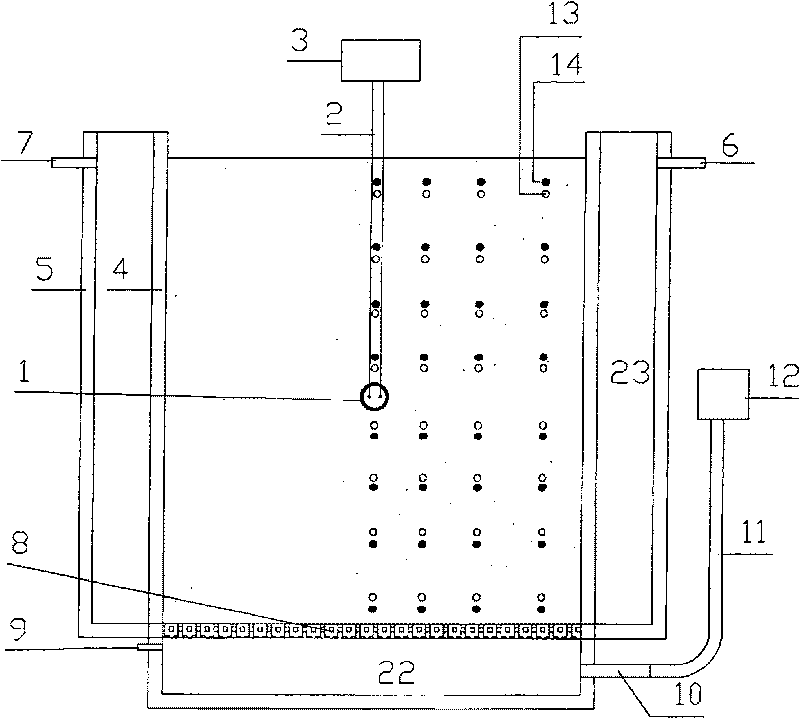

Indoor model testing device and testing method employing air-pressure splitting vacuum preloading method

ActiveCN102707034AEasy constructionLow costEarth material testingSoil preservationPore water pressureData acquisition

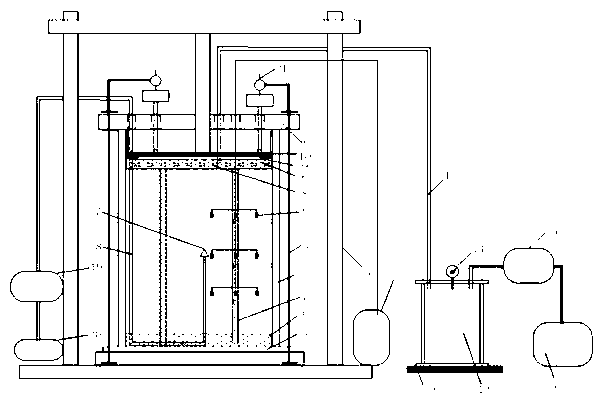

The invention discloses an indoor model testing device employing an air-pressure splitting vacuum preloading method. The indoor model testing device comprises a model groove, a pile-loading system, a vacuum loading system, an air-pressure splitting system and a measuring system, wherein the model groove comprises a plastic cylinder, a plastic cylinder base, a plastic cylinder top cover and reinforcing steel bars; the pile-loading system is a lever type loading device; the vacuum loading system comprises a drainage system, a sealing system and a vacuum-pumping system; the air-pressure splitting system comprises an air nozzle, an air conveying pipe, a pressure flow speed controller and an air compressor; and the measuring system comprises a displacement sensor, a pore water pressure meter and a data acquirer. The invention also discloses an application method of the indoor model testing device employing the air-pressure splitting vacuum preloading method. The indoor model testing device is reasonable and simple in structure and convenient to operate and can be used for performing model test of reinforcing soft soil by using the air-pressure splitting vacuum preloading method.

Owner:SOUTHEAST UNIV

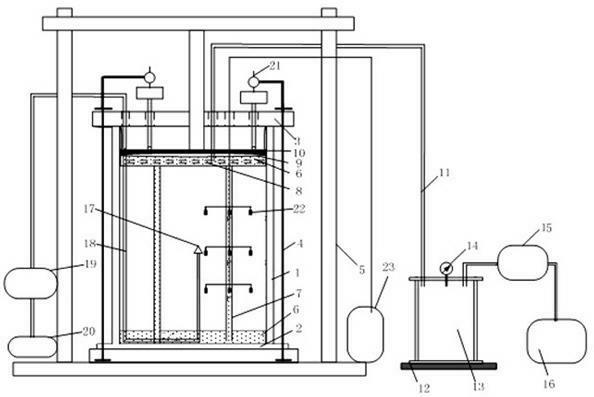

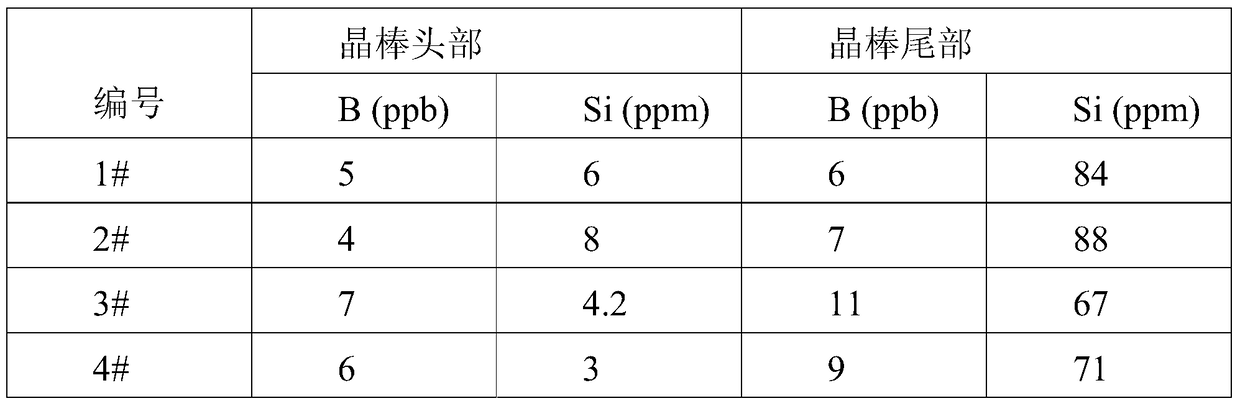

Growing method of gallium arsenide monocrystalline

ActiveCN106319630ASolving the problem of not wetting with quartz cruciblesSolve the problem of low crystal growth ratePolycrystalline material growthFrom frozen solutionsGallium arsenateSeed crystal

The invention provides a growing method of gallium arsenide monocrystalline. The method comprises the following components: (1) a quartz crucible is cleaned; (2) the quartz crucible is placed in a quartz tube which contains gallium of high purity, vacuum-pumping and inflation operation are repeatedly carried out for the quartz tube, and finally inert gas or nitrogen is filled; (3) the quartz tube is heated till the temperature in the quartz tube reaches to 1240 DEG C or above and insulation is carried out, and the quartz tube is cooled to room temperature; (4) the quartz crucible is taken out from the quartz tube and is immersed in acid, deionized water is used for washing, absolute ethyl alcohol is used for carrying out dehydration treatment, and the quartz crucible is placed in a drying box for standby; (5) seed crystal, polycrystalline materials, and the balance being arsenic are placed in the quartz crucible in order according to charging requirements, the quartz crucible is placed in a quartz ampoule, and vacuum-pumping, baking and soldering and sealing treatment are carried out; (6) a traditional VGF method is used for accomplishing the growth of gallium arsenide monocrystalline. PBN crucibles are not used, a liquid sealing agent B2O3 is not used, and GaAs monocrystalline is not polluted by extra introduction of B element from the source.

Owner:广东先导微电子科技有限公司

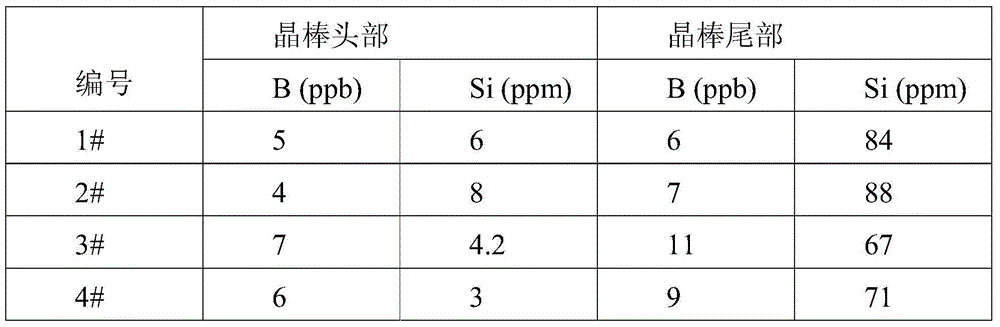

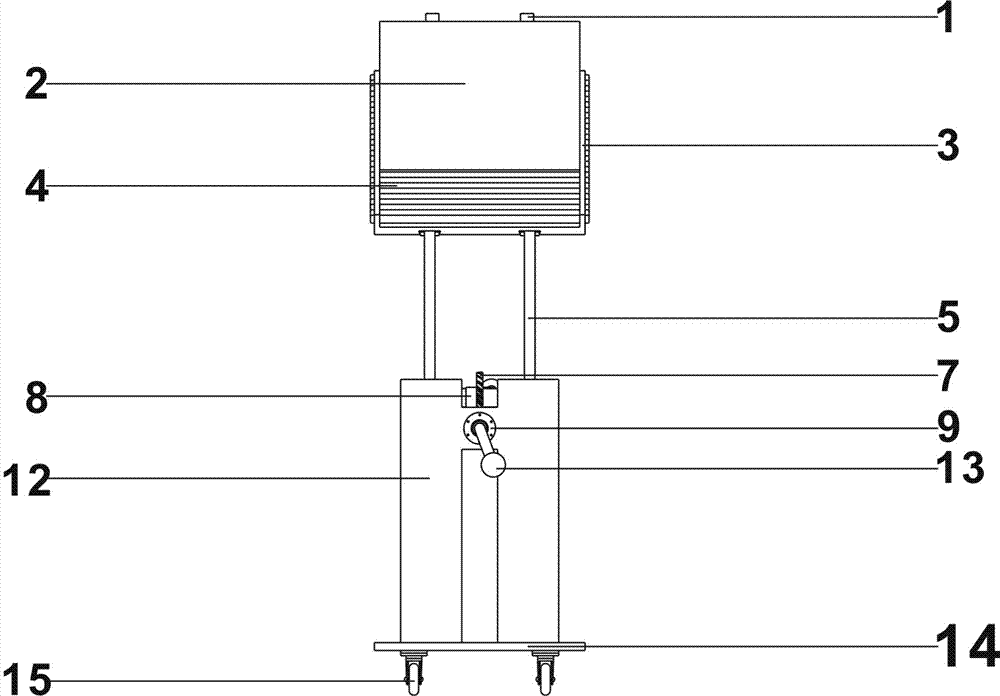

Manual rack type dead-weight loading device for landslide physical model test

ActiveCN103033607AReduce production intensitySimple structureEarth material testingDrive shaftLandslide

The invention discloses a manual rack type dead-weight loading device for a landslide physical model test. The device comprises a bottom plate, a sliding surface adjusting mechanism and a thrust loading mechanism, wherein the sliding surface adjusting mechanism is located on the bottom plate and comprises a sliding panel, two groups of racks and gears which are mutually meshed, two transmission shafts, two groups of worm wheels and worms which are mutually meshed, two rocking handles and a guide holder; the guide holder is fixed on the bottom plate; vertical guide grooves are formed at the front part and the rear part of the guide holder respectively; one group of racks are located in the guide groove at the front part of the guide holder, while the other group of racks are located in the guide groove at the rear part of the guide holder; each group of racks and one of worm wheels are arranged on the guide holder through the transmission shafts; each worm is connected with one of the rocking handles; the front end of the sliding panel is hinged with the tops of the group of racks which are located at the front part of the guide holder, while the rear end of the sliding panel is arranged on the group of racks which are located at the rear part of the guide holder; the thrust loading mechanism comprises a loading platform; the bottom of the loading platform is in sliding fit with the top surface of the sliding panel; and the loading platform can slide along the sliding panel forth and back.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

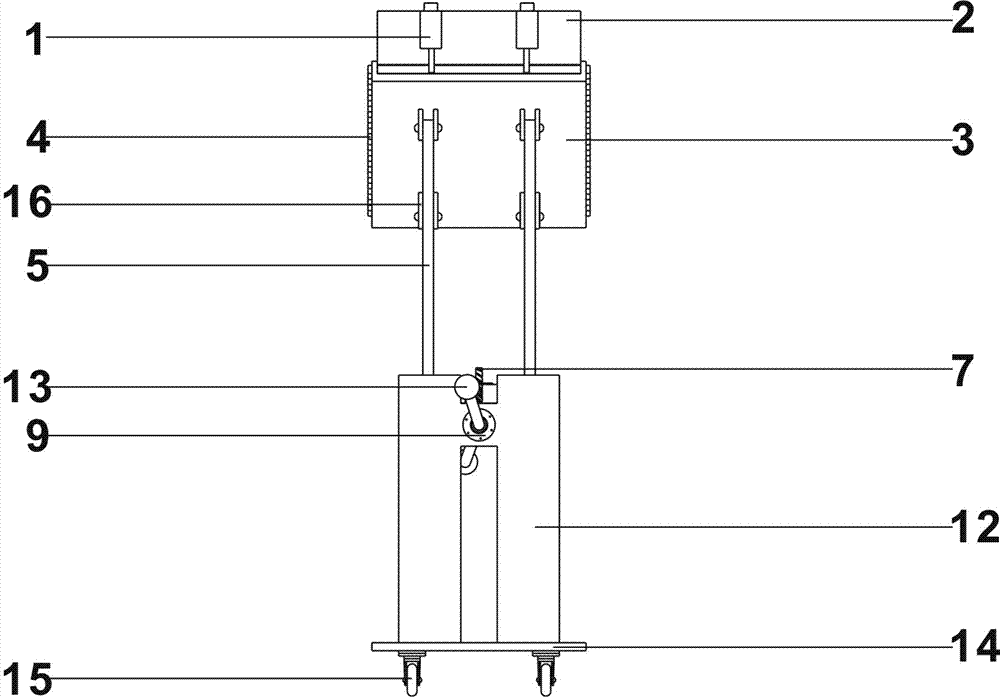

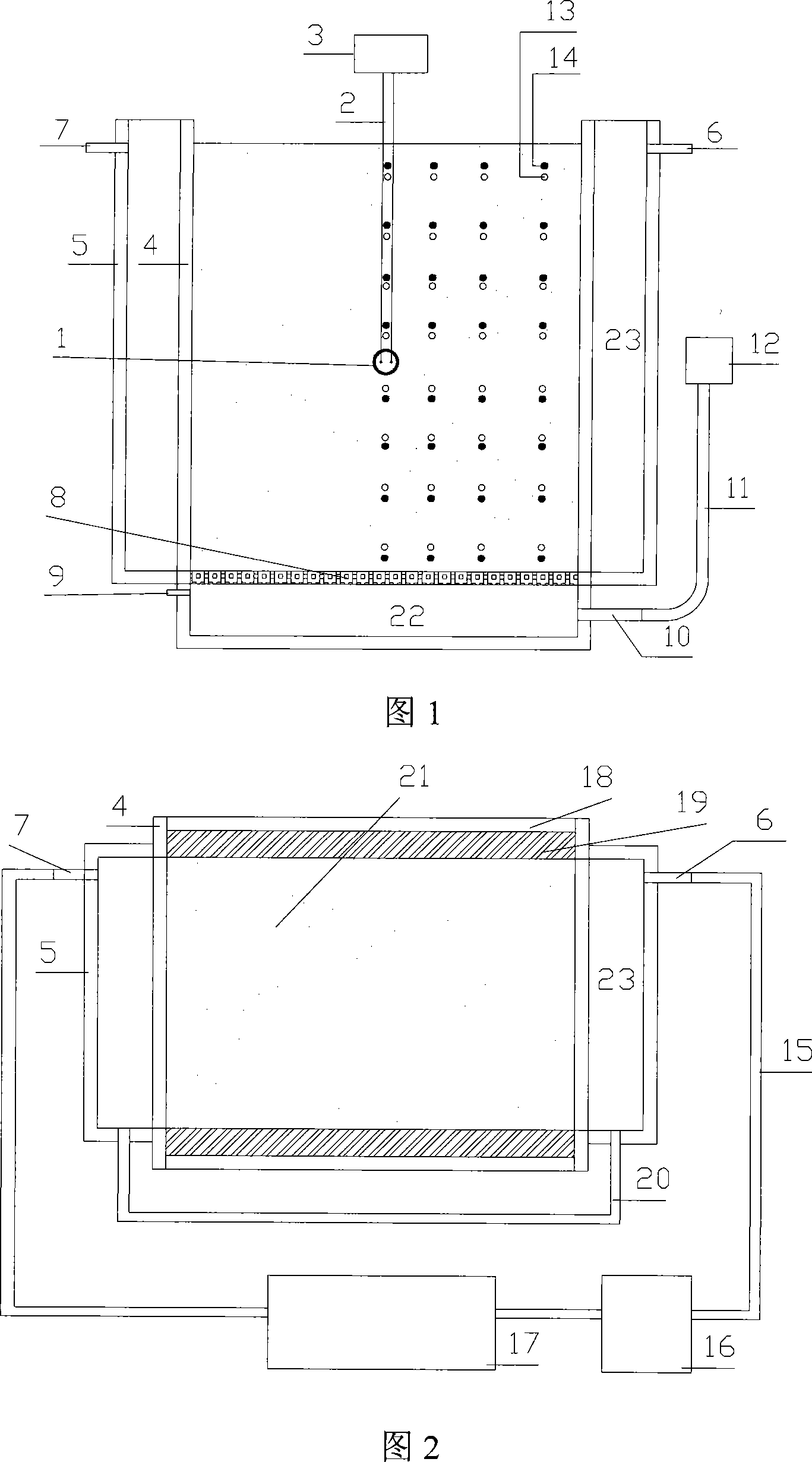

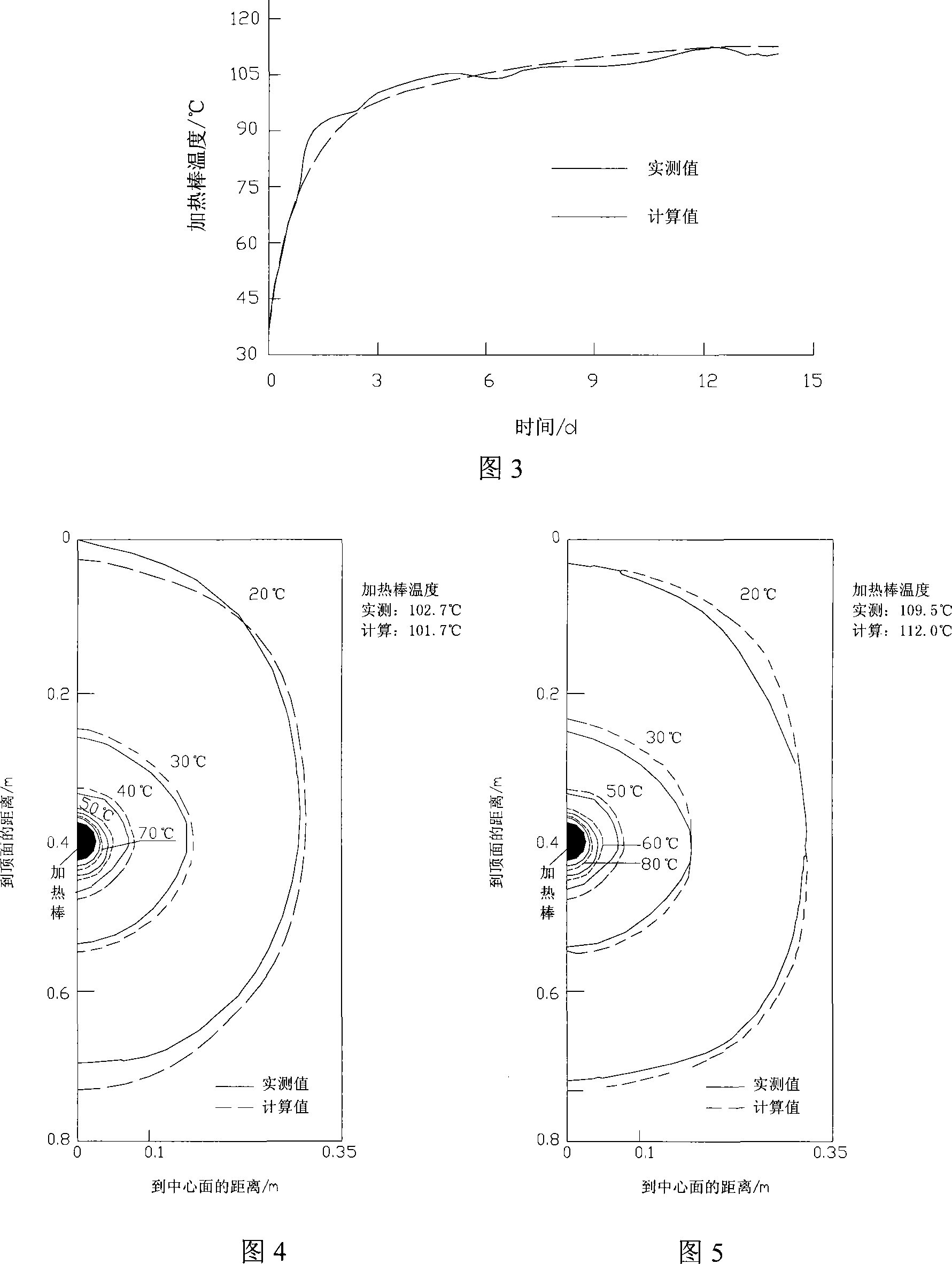

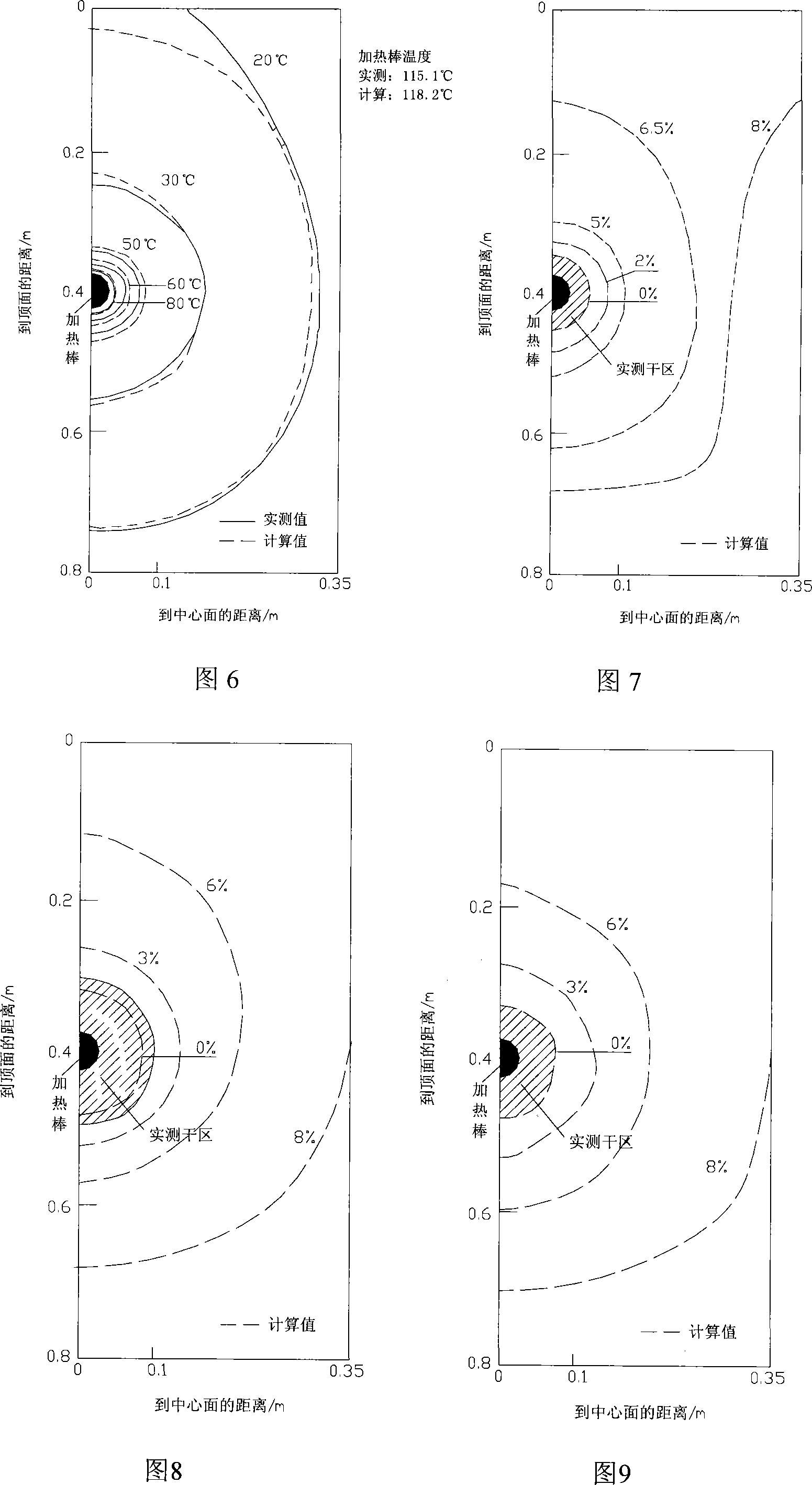

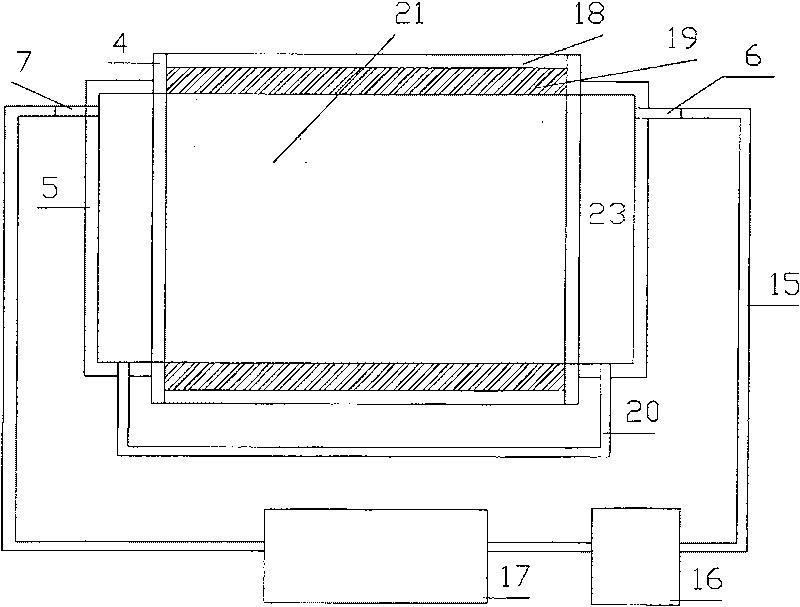

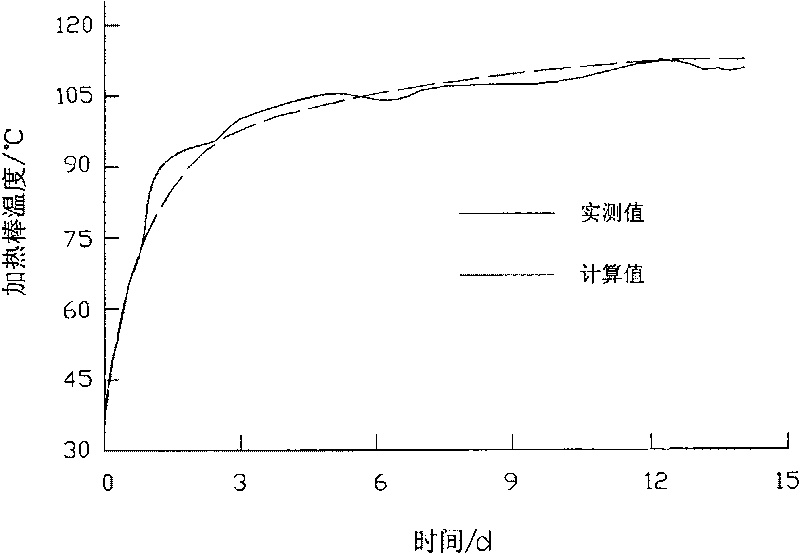

Soil hot-wet coupling carrying model trial device

InactiveCN101082618ARealize the process of heat transfer and moisture transferReasonable physical simulation conditionsMaterial analysisExhaust valveCoupling

The invention discloses a thermohydrocoupling migration model testing device, which comprises the following parts: heating rod, soil sample box, thermostatic circulating tank, porous permeable board, martensitic bottle, thermometric probe, water testing probe, foam plastic board, wherein the porous permeable board is set on the bottom of the soil sample box, which is welded with four walls of soil sample box; the valve and vent valve are set on two sides opposite to the lower face of porous permeable board and soil sample box; the valve connects martensitic bottle through pipe; the temperature-testing element is set in the inner wall of the heating rod; a steel baffle is set at two sides of the front and back of soil sample box separately; the bottom, left and right sides of steel baffle is welded with inner sides of soil sample box and lateral board; the foam plastic board is cushioned on the inner side of steel baffle. The invention has reasonable structure, simple and convenient operation, which realizes heat and wet transmission of soil.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

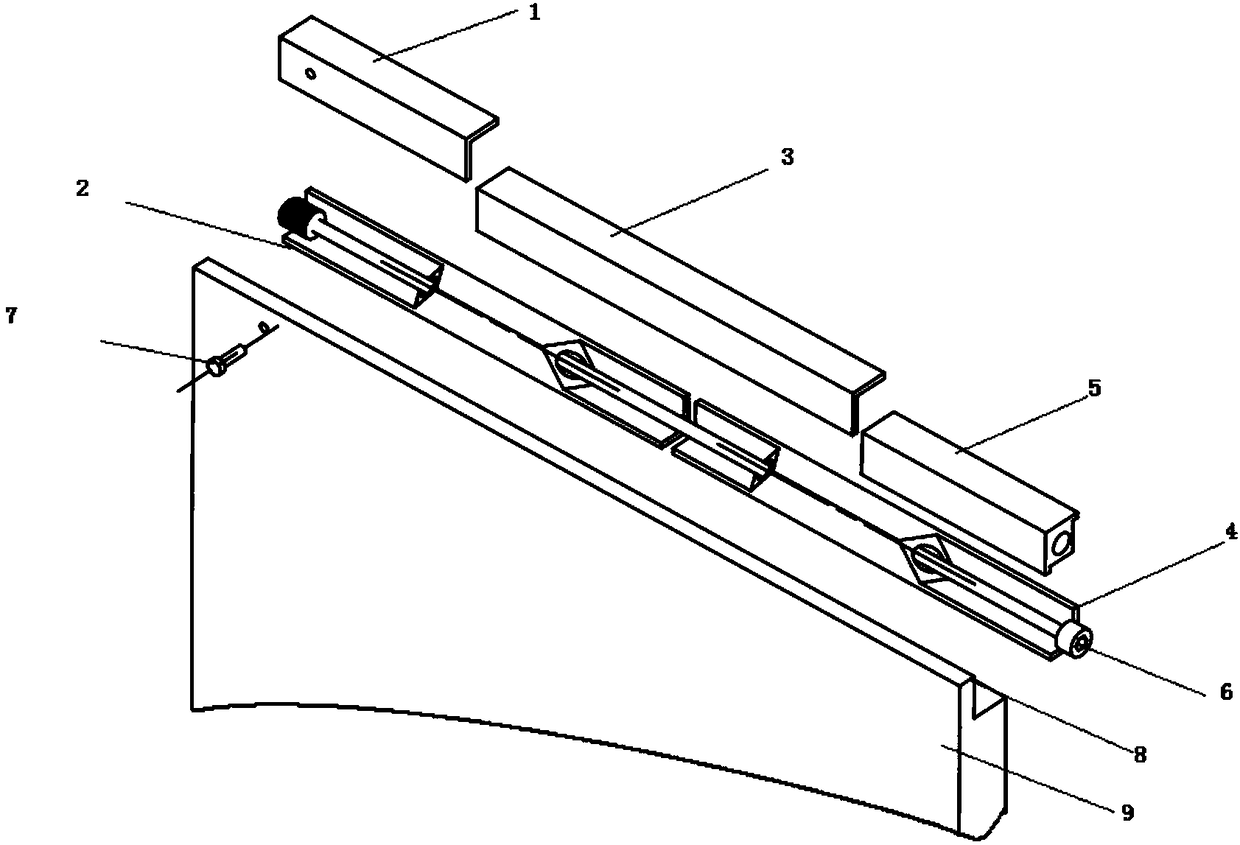

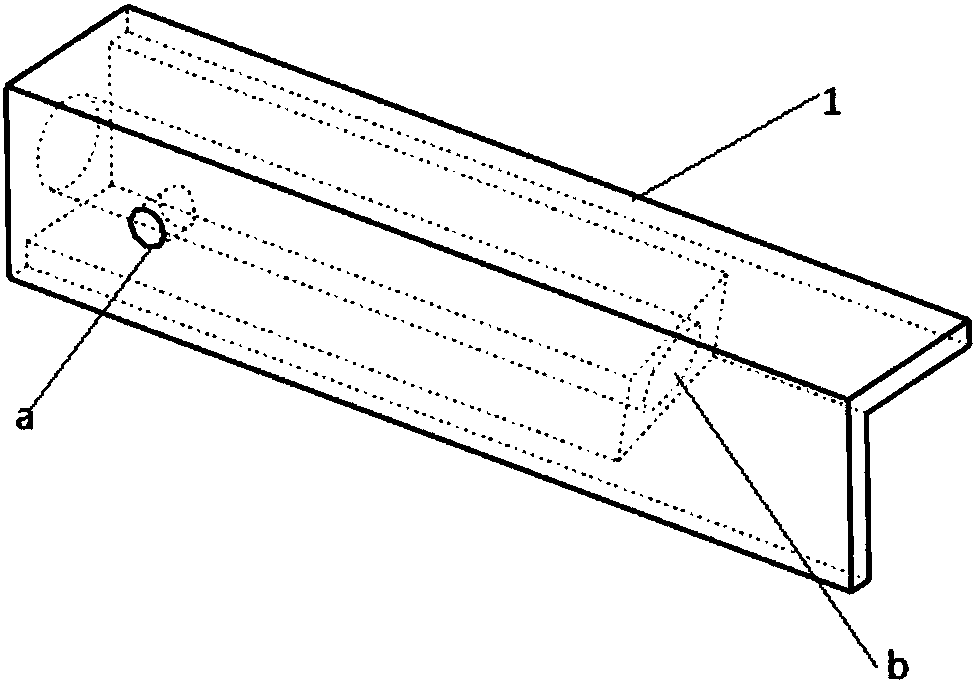

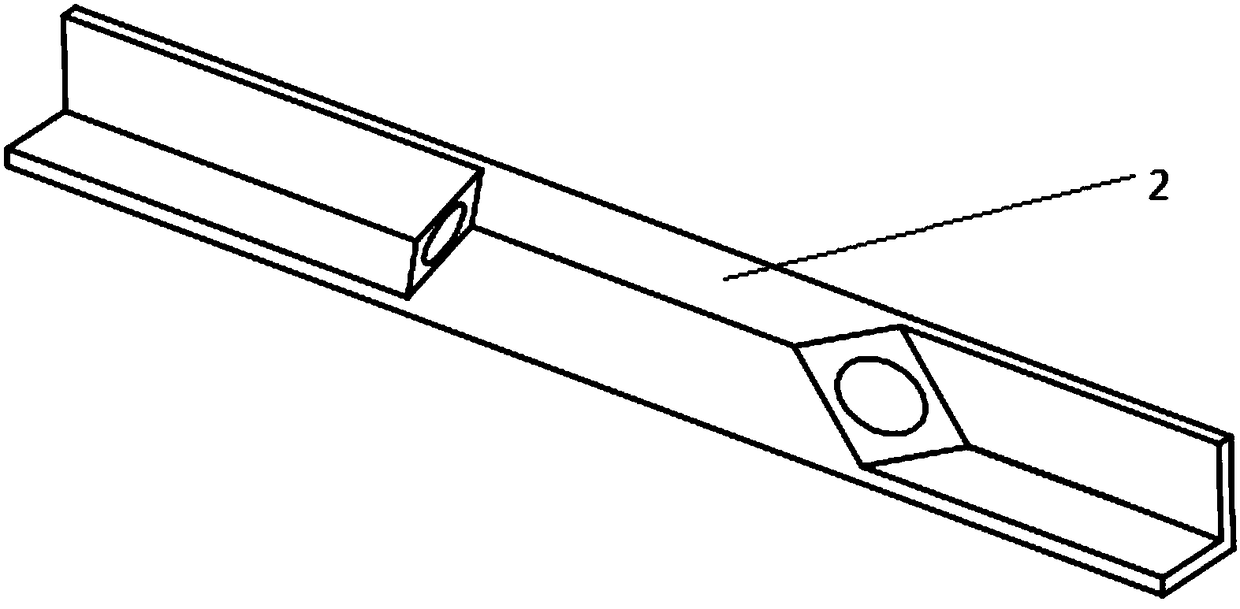

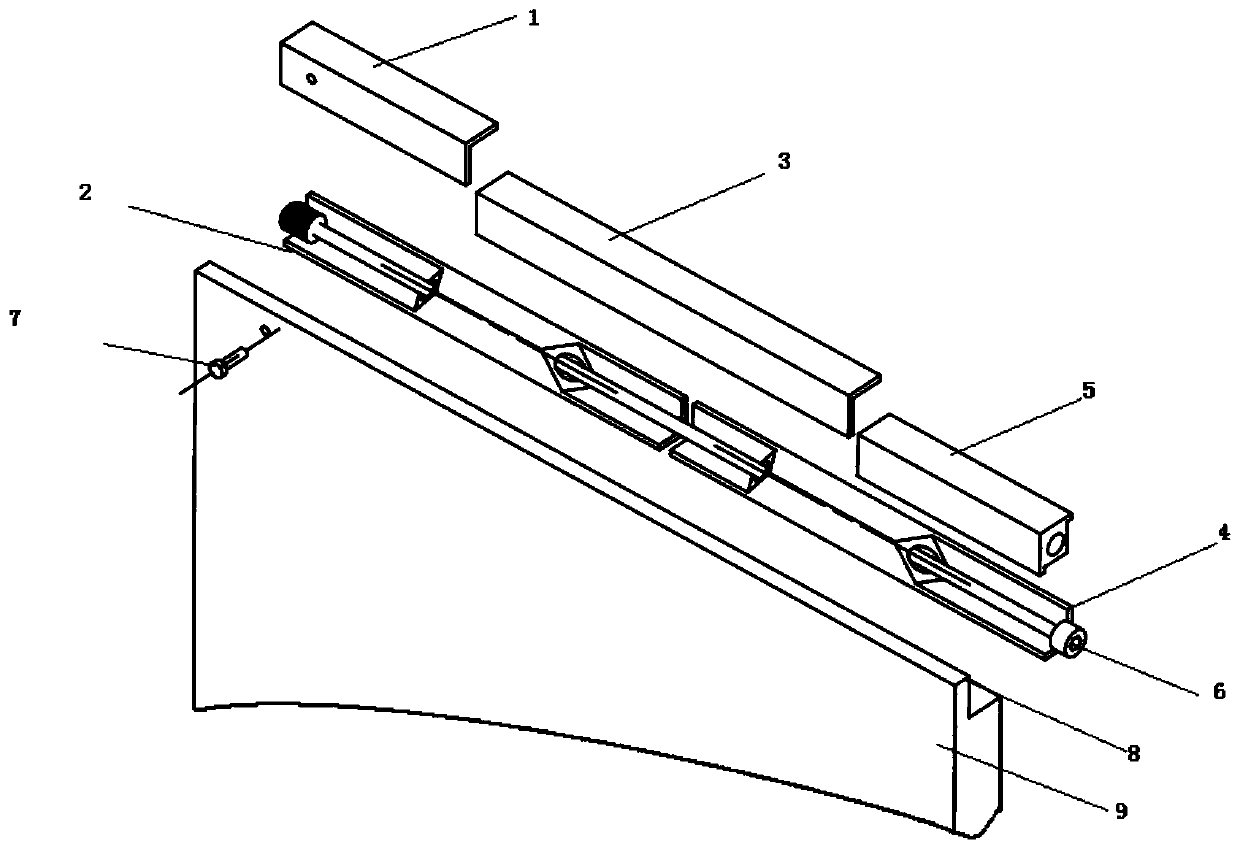

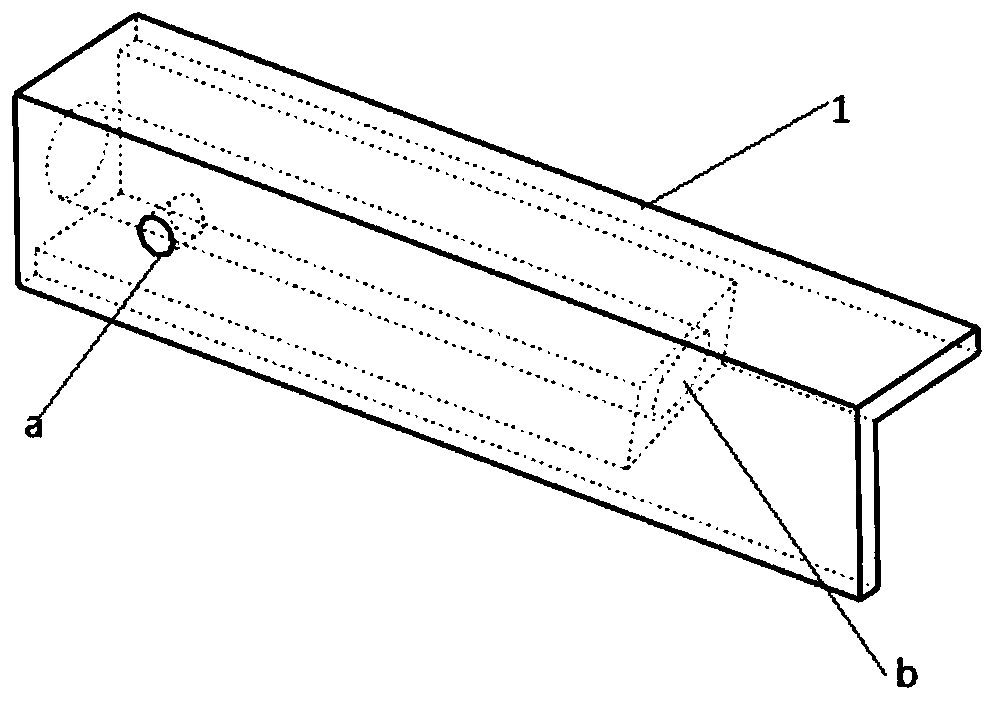

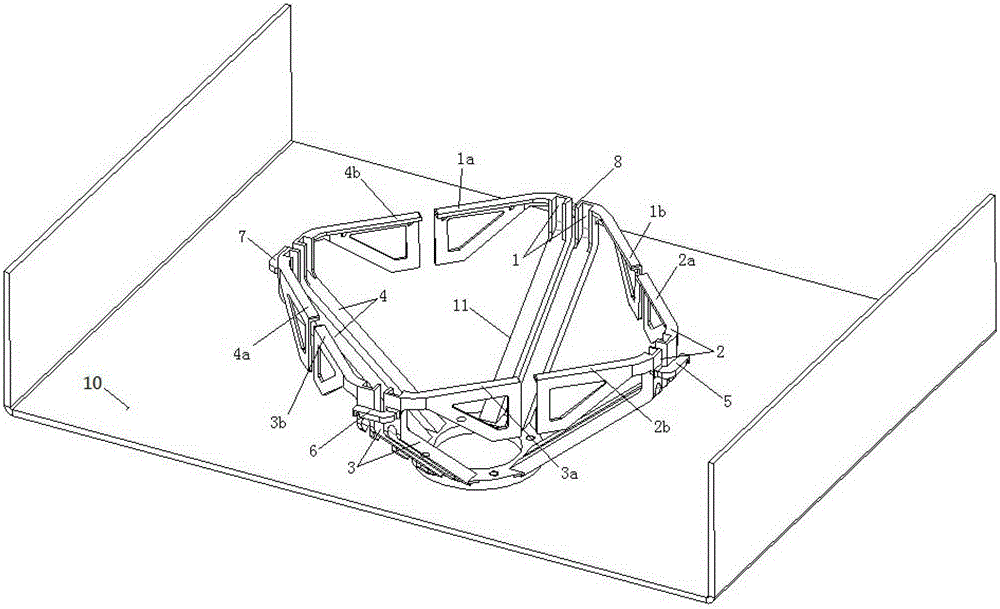

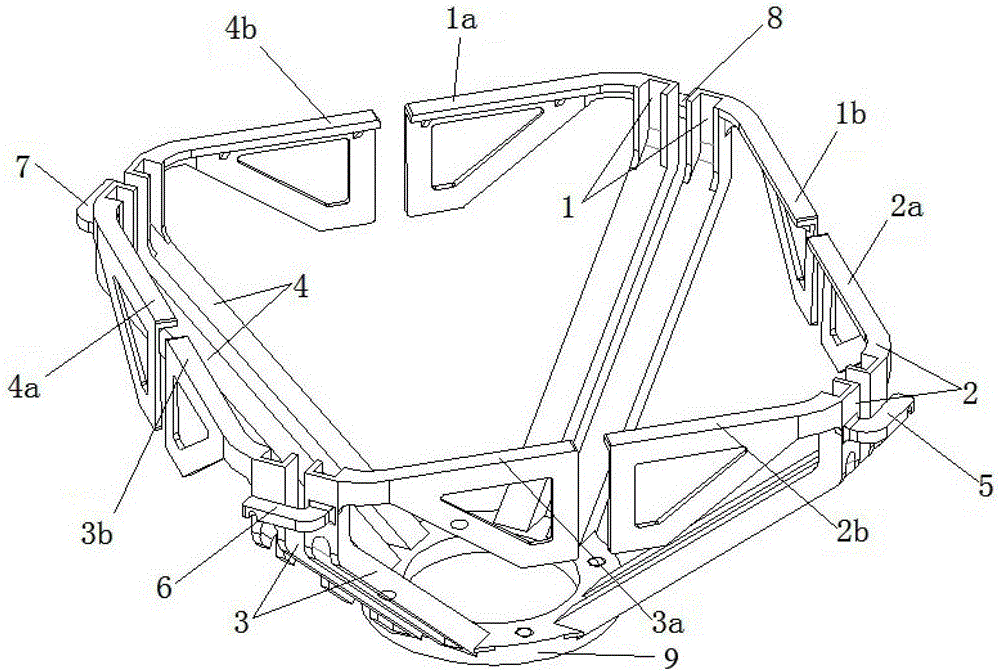

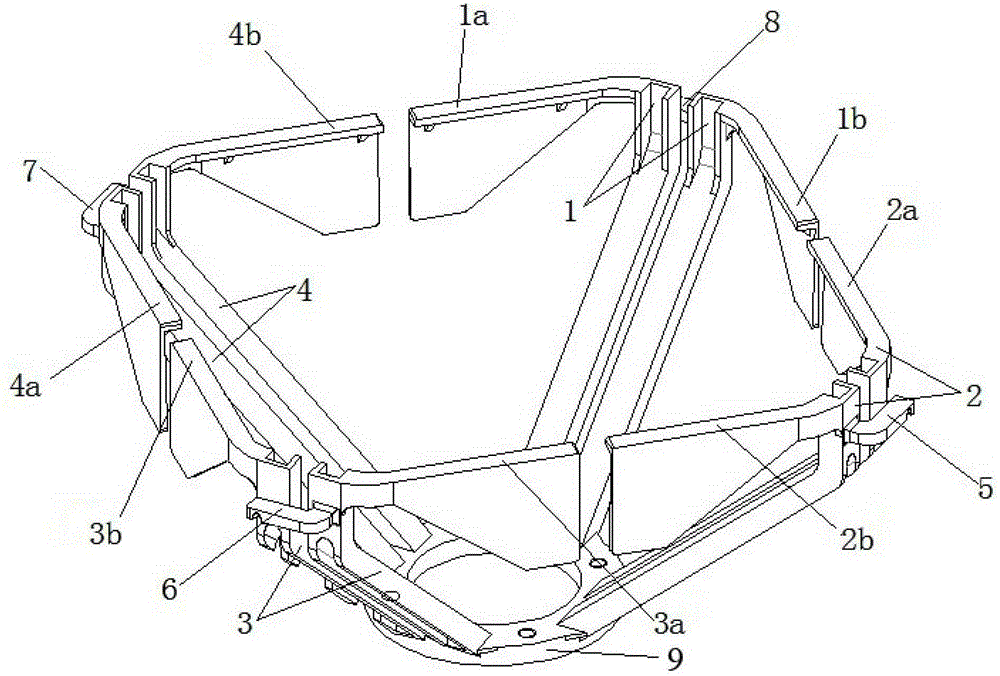

Double motion freedom degree low thermal resistance locking device

ActiveCN108430189ASolve the problem of small contact area and large contact thermal resistanceSmall heat transfer temperature differenceClamping/extracting meansCooling/ventilation/heating modificationsVibration amplitudeDiagonal

The invention brings forward a double motion freedom degree low thermal resistance locking device. Via the device, contact thermal resistance can be remarkably reduced, vibration amplitude of an LRM module can be lowered, and vibration resistance performance of the module can be improved. The device is realized via the following technical solution: a one-way wedge face fixing block (1) fixed on anangle plate, a rear wedge face block angle plate moving section (2), a double wedge face block middle angle plate moving section (3), a one-way wedge face front angle plate moving section (4), and aone-way wedge face driving slide block (5) are orderly connected in series at an interval of 3-5 millimeters via long screw rods so as to form a cuboid-shaped locking bar comprising four moving pairsconnected in series, the locking bar is mounted fixedly in L-shaped gap slot of the LRM module, all angle plate moving sections are driven spirally via screw rods (6) to gradually retract along interval gaps among all sections, staggered sliding motion is generated along a direction of a diagonal line of a cuboid, distensible force is generated between walls of gap slots of the LRM module and a cold plate (10), and double motion locking and heat transfer of the LRM module can be realized.

Owner:10TH RES INST OF CETC

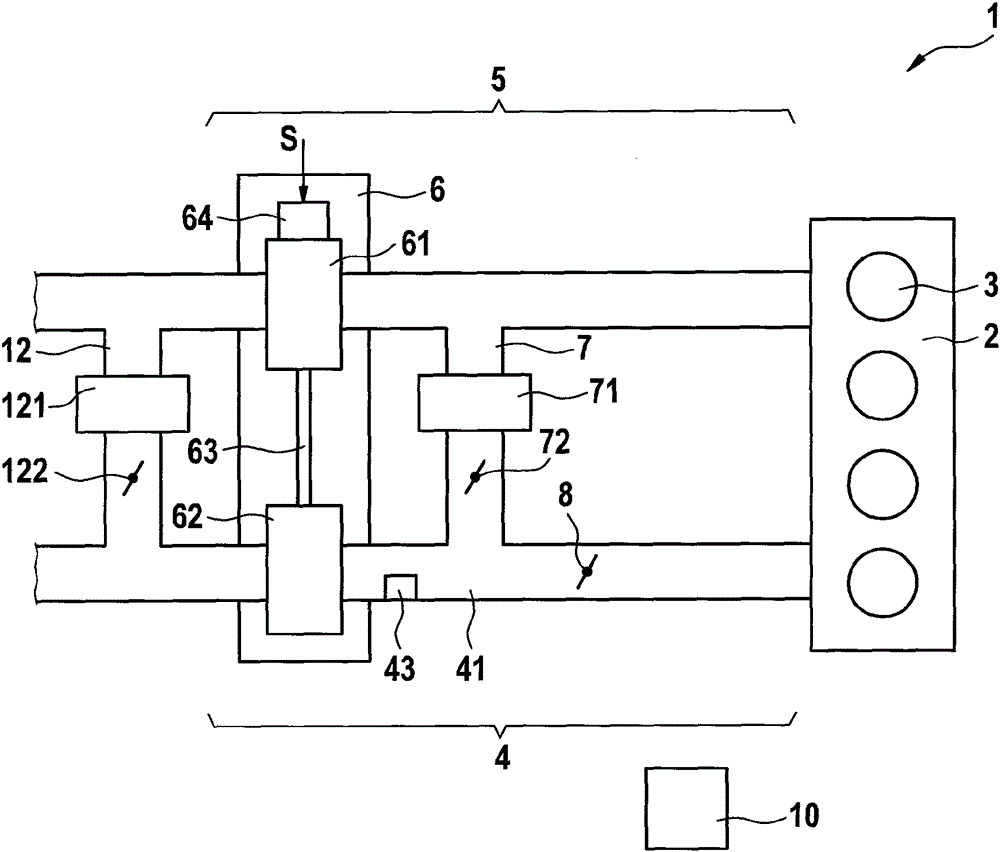

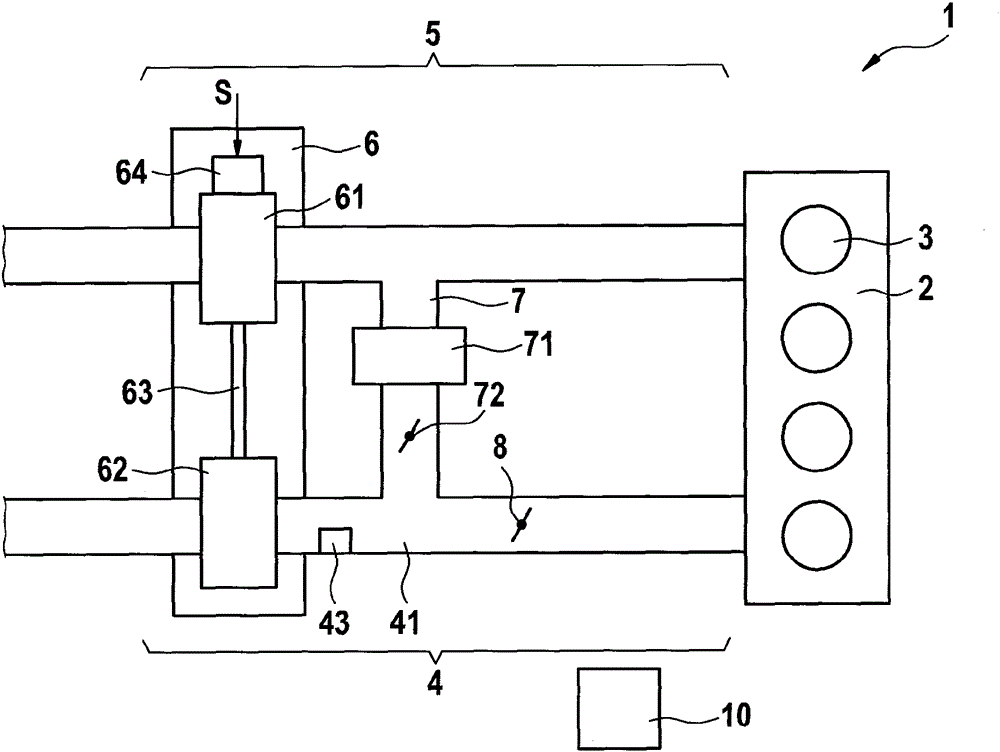

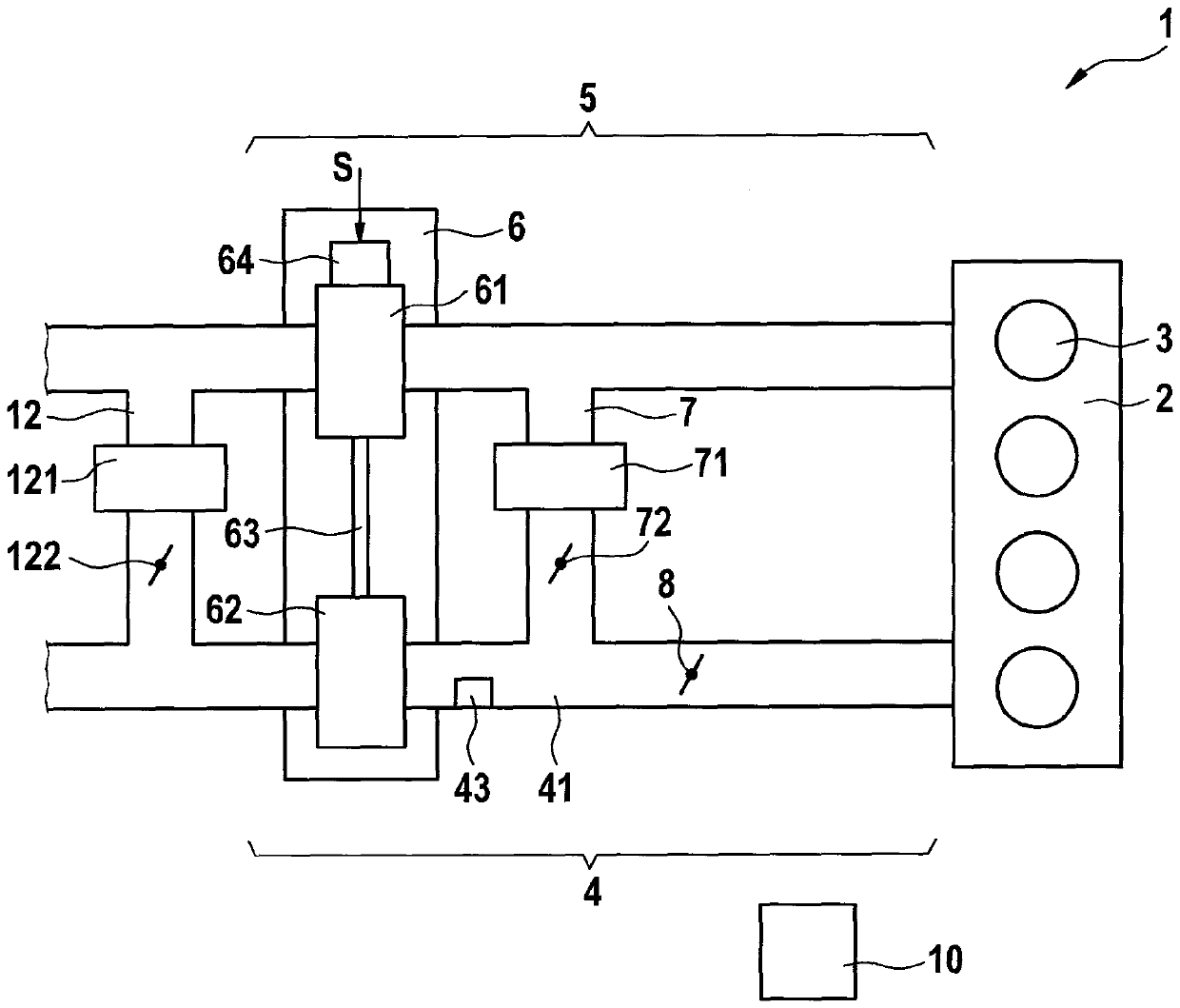

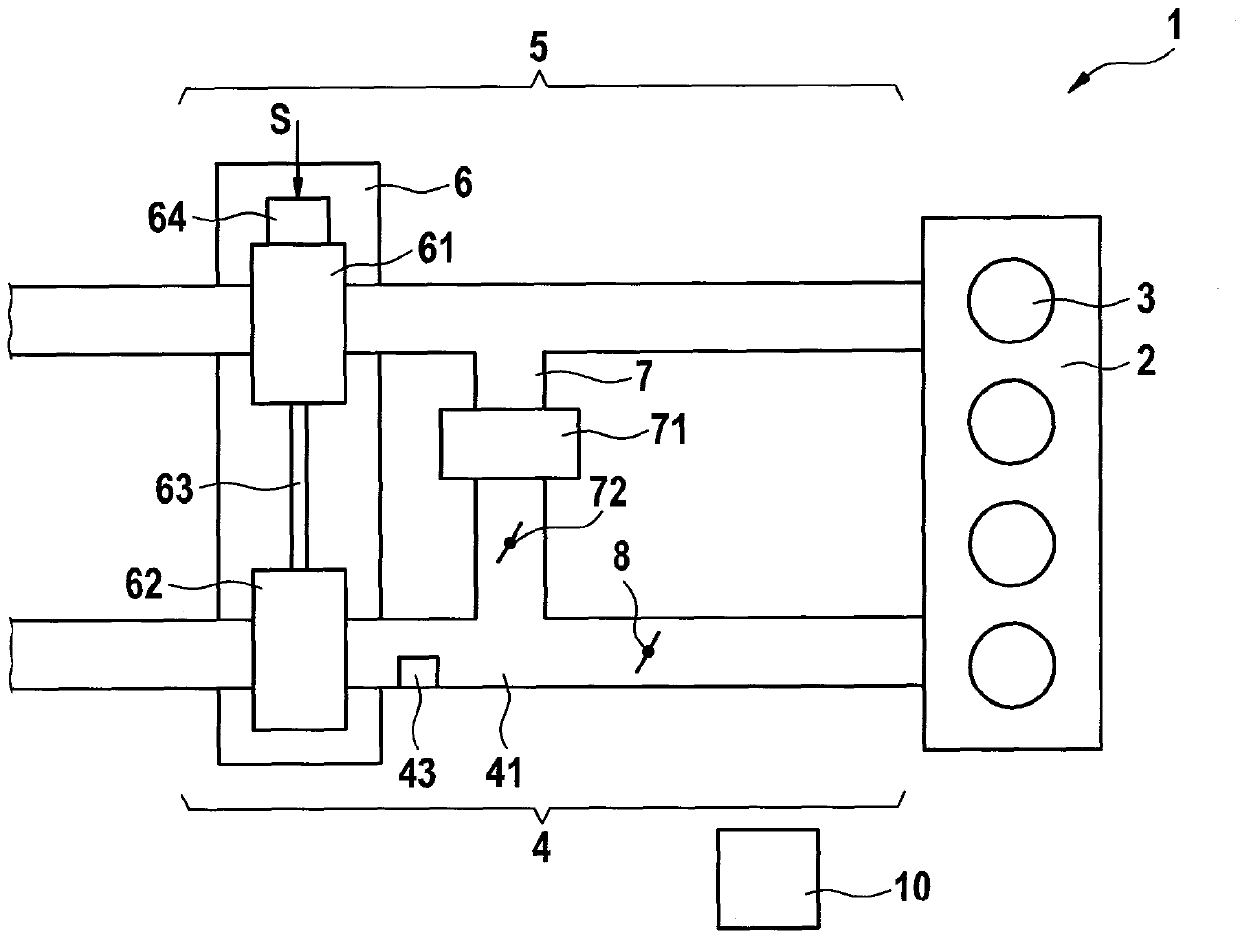

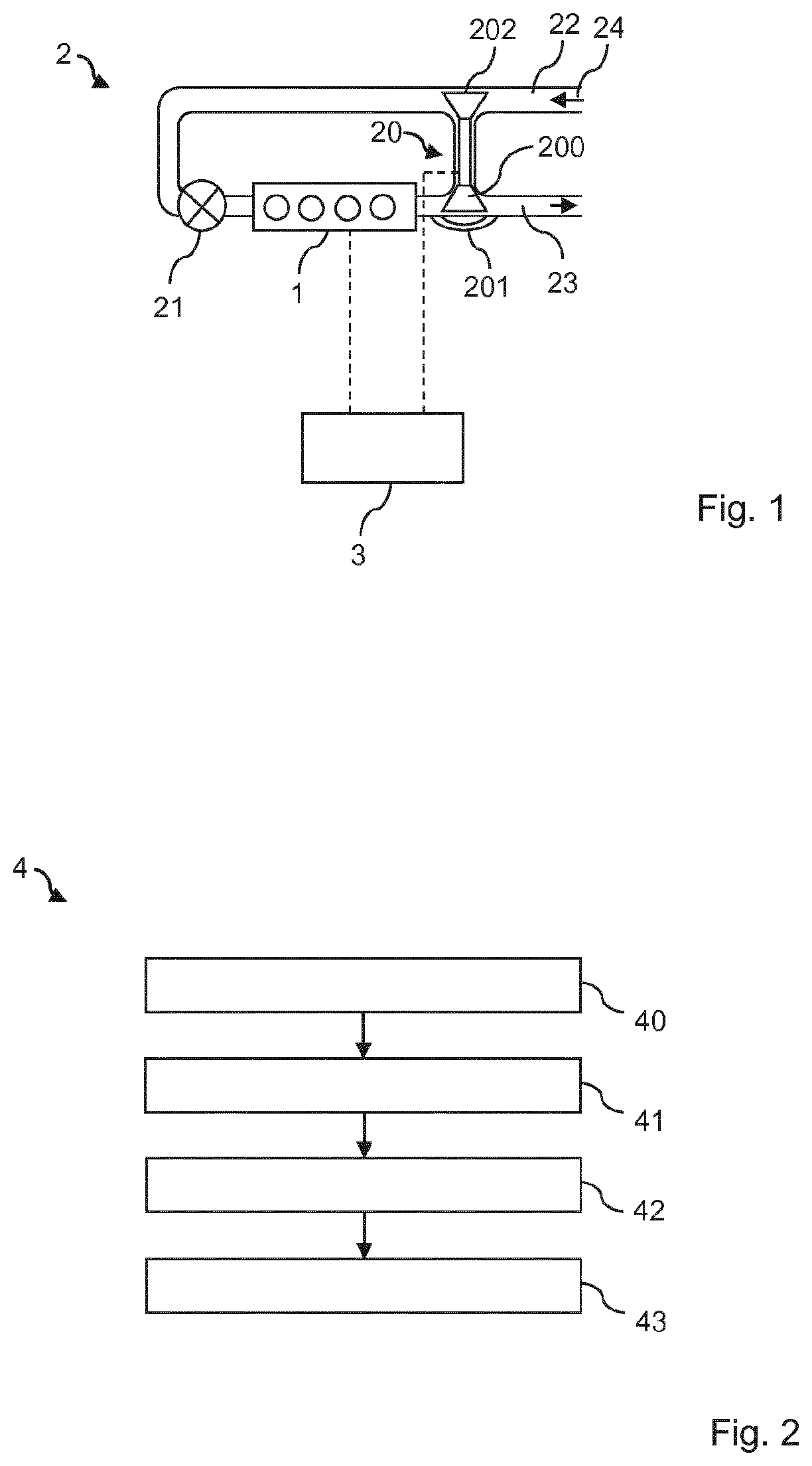

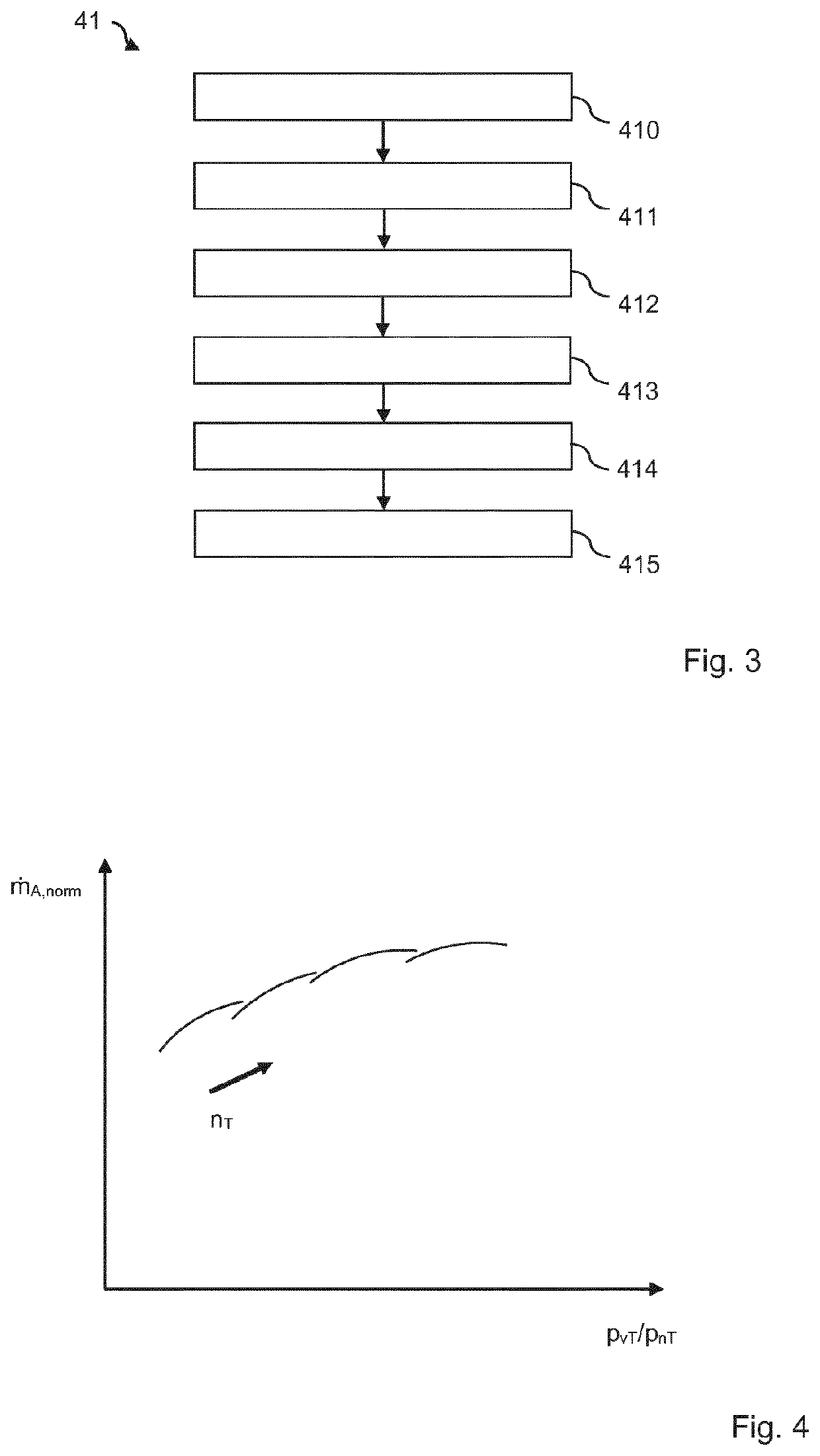

Method ande device for operating internal combustion engine having exhaust gas recirculation device

ActiveCN105370424AFast and flexibleIncrease boost pressureElectrical controlInternal combustion piston enginesExhaust fumesEngineering

The invention relates to a method for operating an internal combustion engine (2) having a exhaust gas-driven supercharging device (6). The method comprises following steps: making an exhaust gas recirculation adjustment in order to be used for adjusting combustion exhaust amount recirculated in an intake system (4) and / or making an supercharge pressure adjustment in order to be used for adjusting supercharge pressure based on corresponding rated value; detecting the requirement for rapid torque; correcting rated value of exhaust gas recirculation and / or supercharge pressure adjustment based on the requirement for rapid torque in order to increase exhaust gas enthalpy of the supercharging device (6).

Owner:ROBERT BOSCH GMBH

Indoor model testing device and testing method employing air-pressure splitting vacuum preloading method

ActiveCN102707034BEasy constructionLow costEarth material testingSoil preservationPore water pressureData acquisition

Owner:SOUTHEAST UNIV

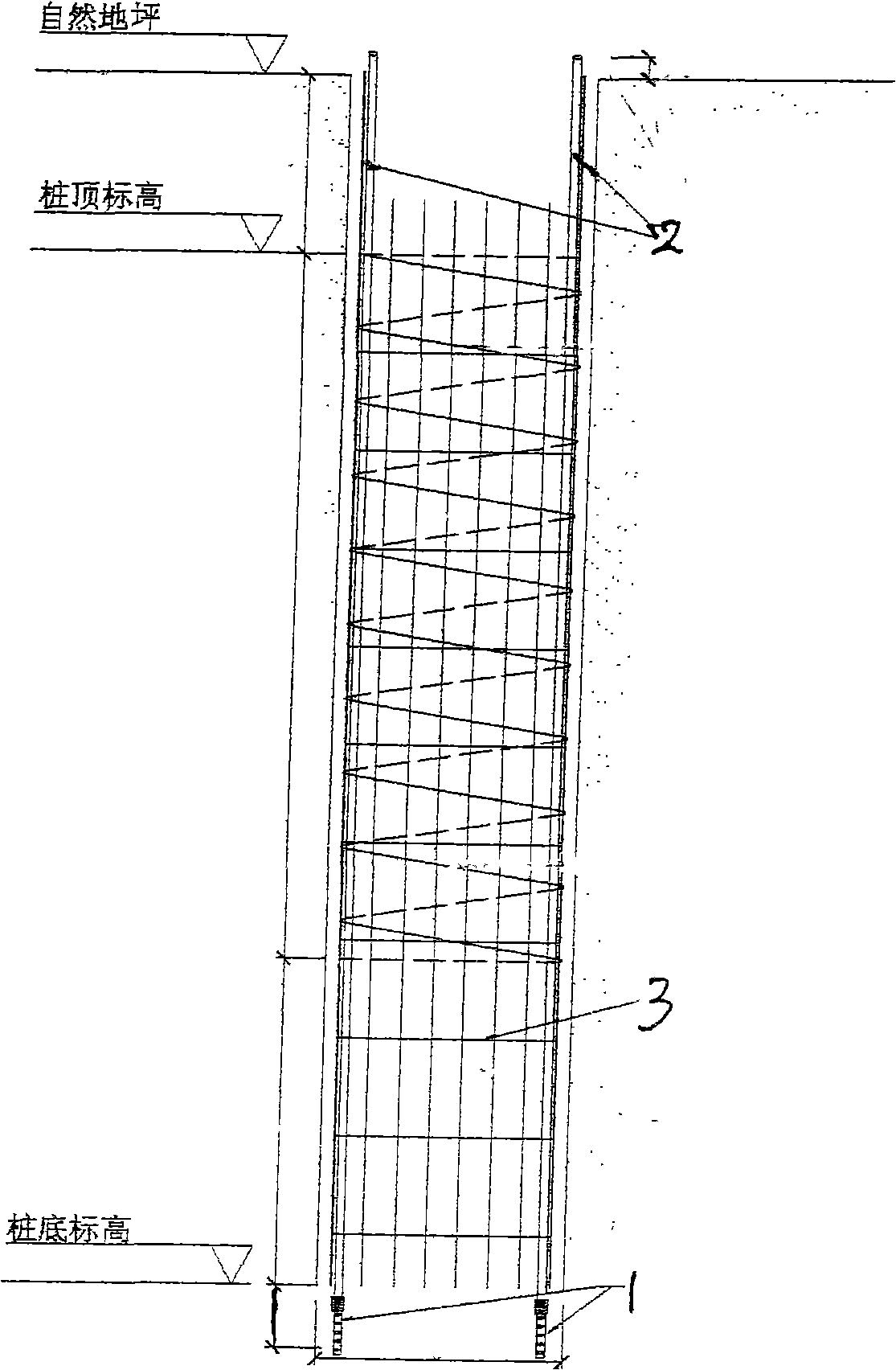

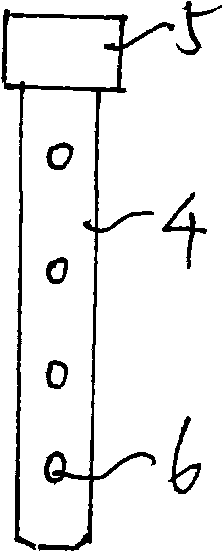

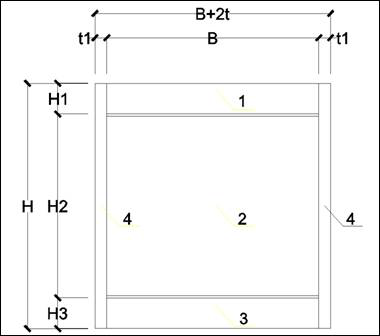

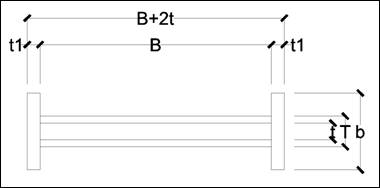

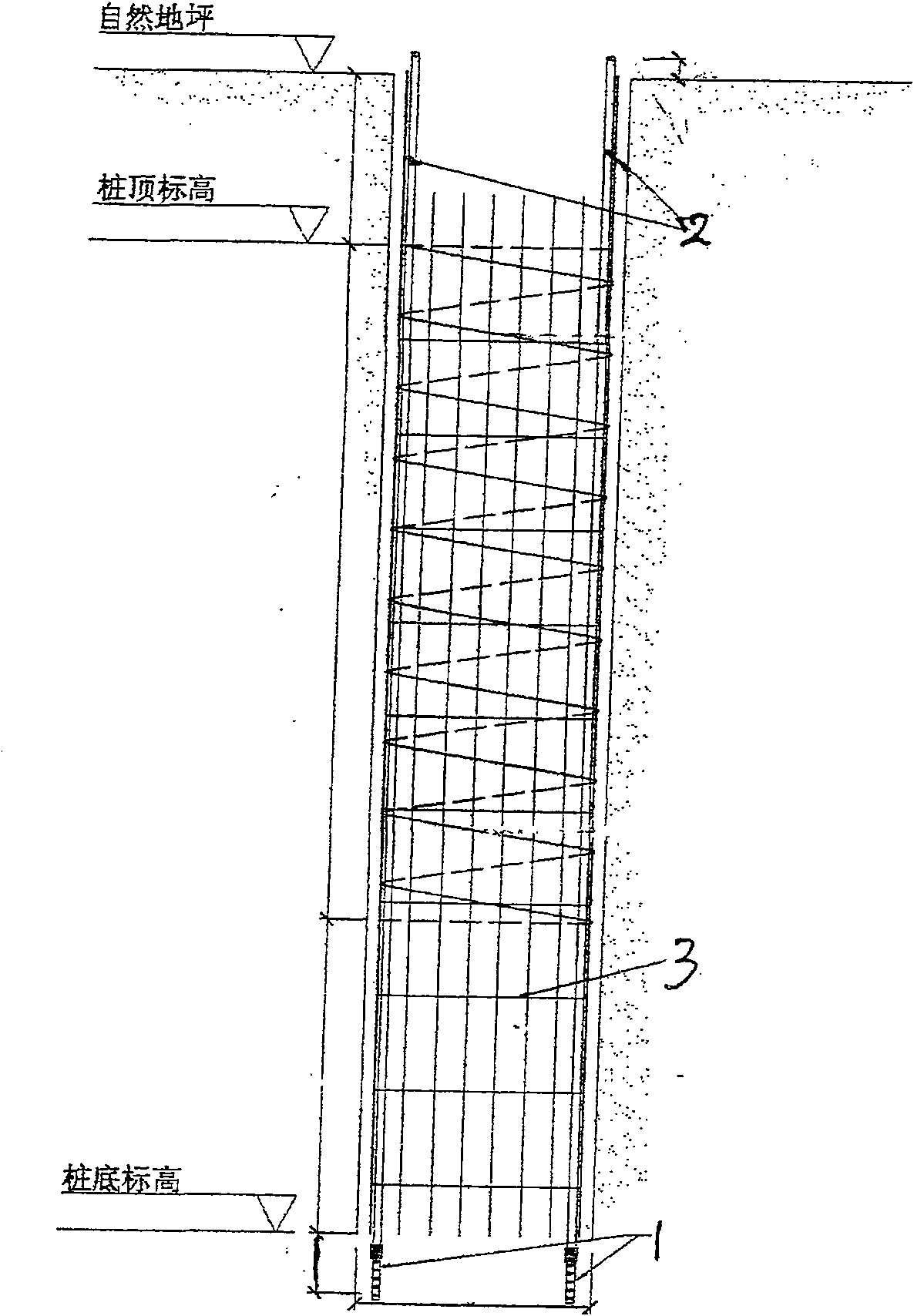

Pile bottom post-grouting method

The invention discloses a method for post-grouting in the bottom of a pile, which comprises the following steps: in the process of constructing the pile by drilling holes, a grouting pipeline is prearranged in the bottom of the pile and grout is injected. The method has good grouting effect and high success rate of grouting.

Owner:JIANGSU NANTONG NO 2 CONSTR ENG GRP

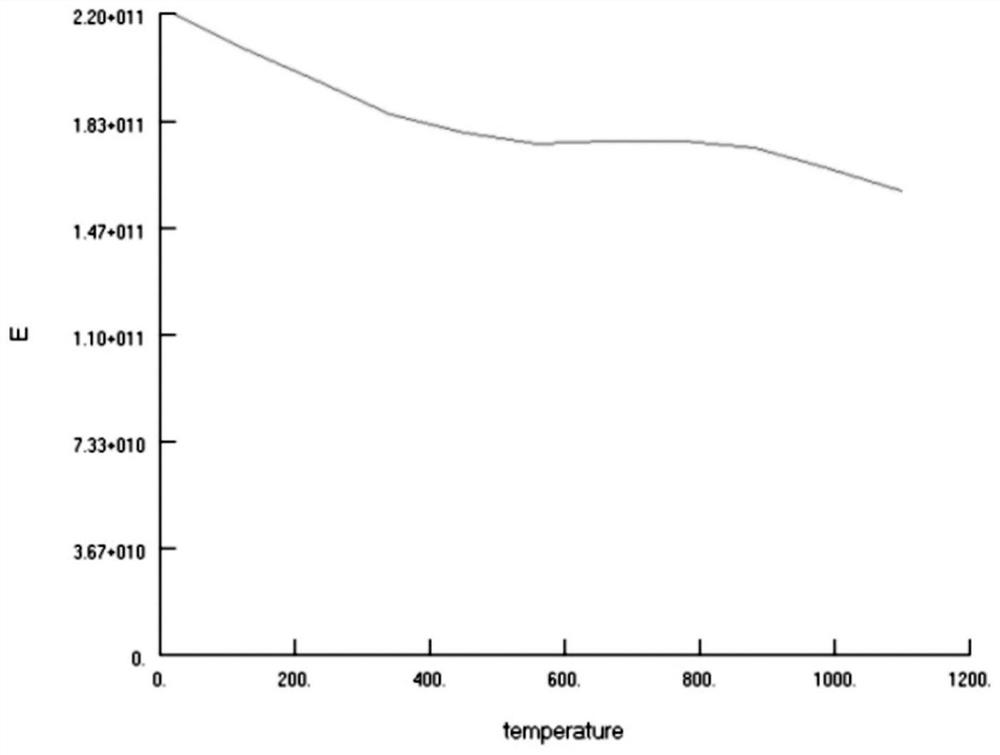

Dissimilar material brazing gap control method and system

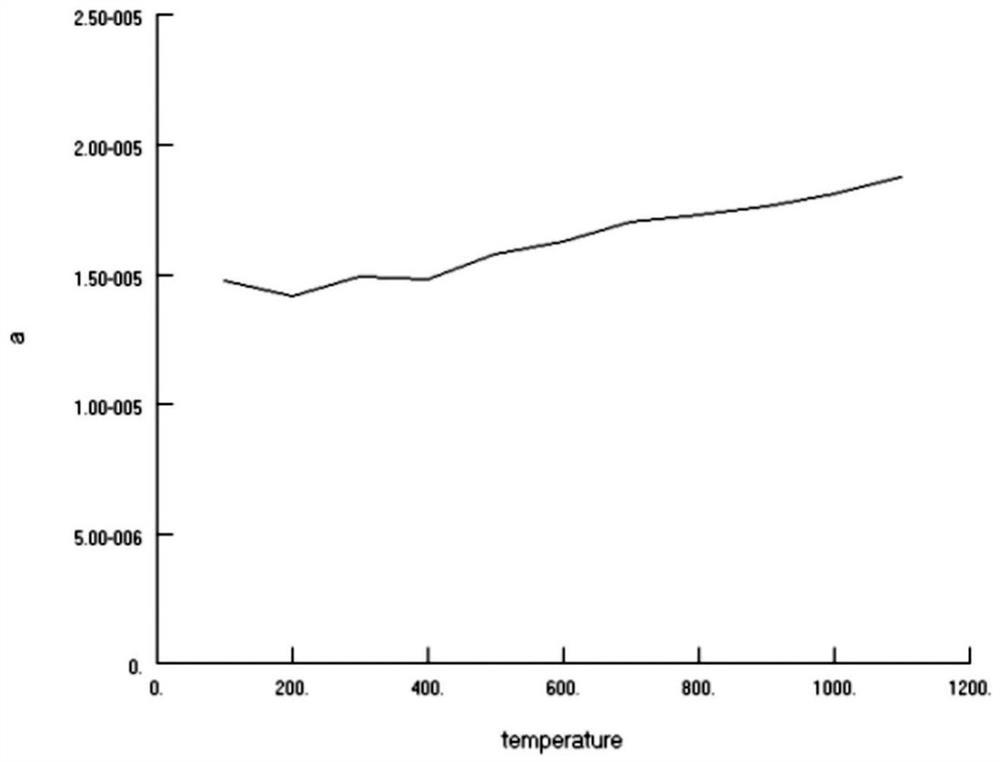

ActiveCN113510327AImprove boundary conditionsGood capillary actionWelding/soldering/cutting articlesMetal working apparatusNumerical controlStructure analysis

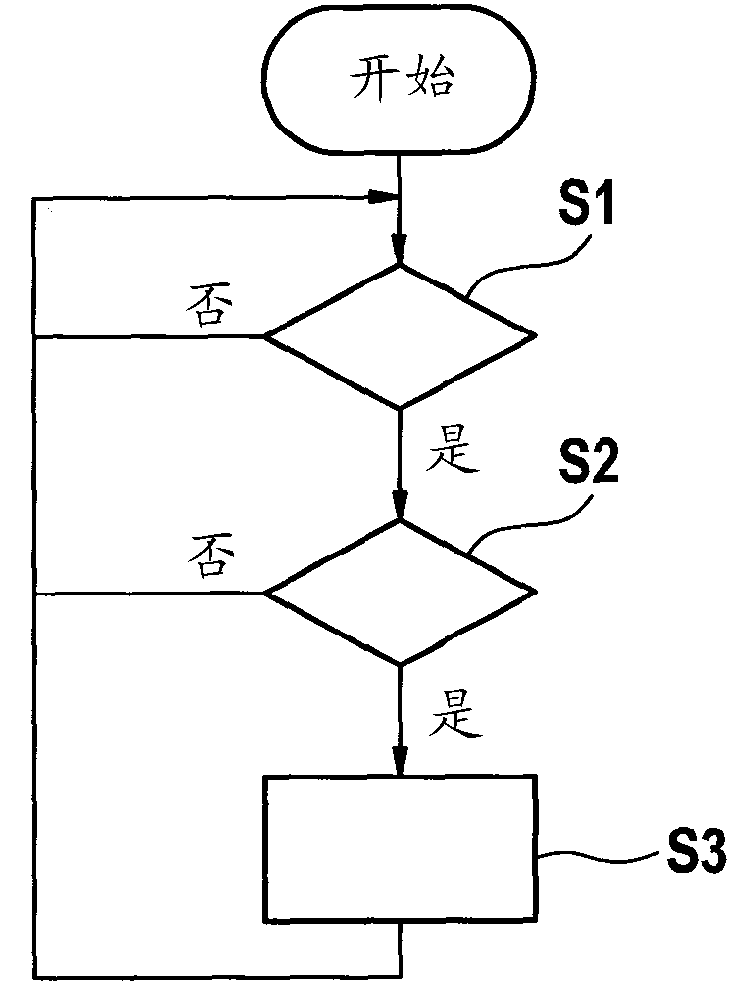

The invention provides a dissimilar material brazing gap control method and system. The dissimilar material brazing gap control method comprises the steps of: presetting assembly gap values according to the actual structures of all workpieces to be assembled; determining performance parameters of all the workpieces; according to the brazing structures of all the workpieces and the brazing filler metal joint filling requirements, determining the positions of brazing seams and the boundary conditions of thermal structure analysis; according to the boundary conditions of thermal structure analysis and the performance parameters of all the workpieces, analyzing thermal displacement changes of all the workpieces, and working out brazing gap values among all the workpieces; performing comparison and re-calculation according to the brazing gap values among all the workpieces and a preset brazing gap range of a brazing material to obtain an optimal assembly gap range among the workpieces; and performing a process test according to the optimal assembly gap range to determine the actual assembly gap among the workpieces. According to the method, the initial assembly gap of the workpieces and the brazing gap are linked through simulation analysis, so that numerical control over the brazing gap of the dissimilar materials is achieved, and the brazing quality of products is guaranteed.

Owner:SHANGHAI INST OF SPACE PROPULSION

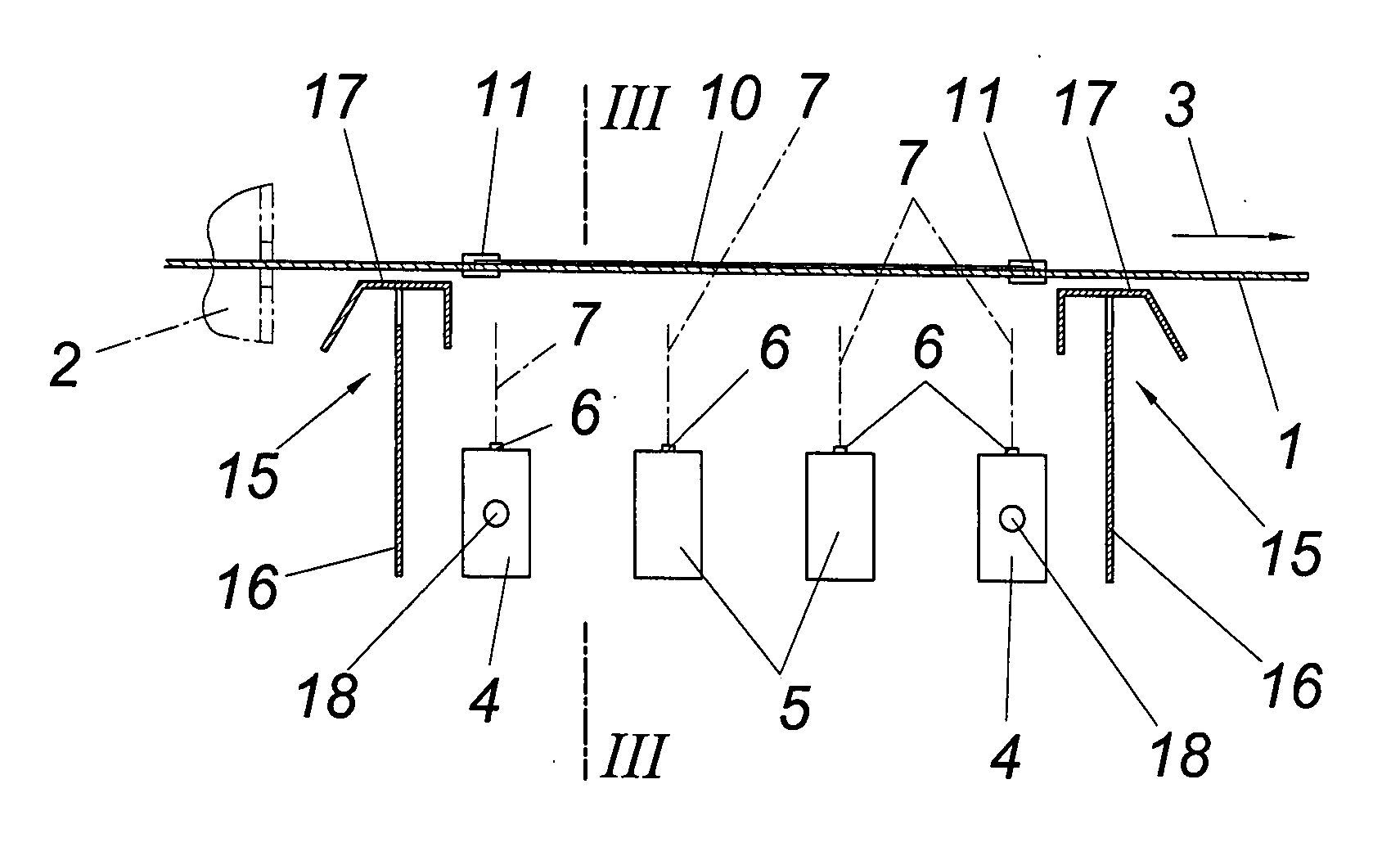

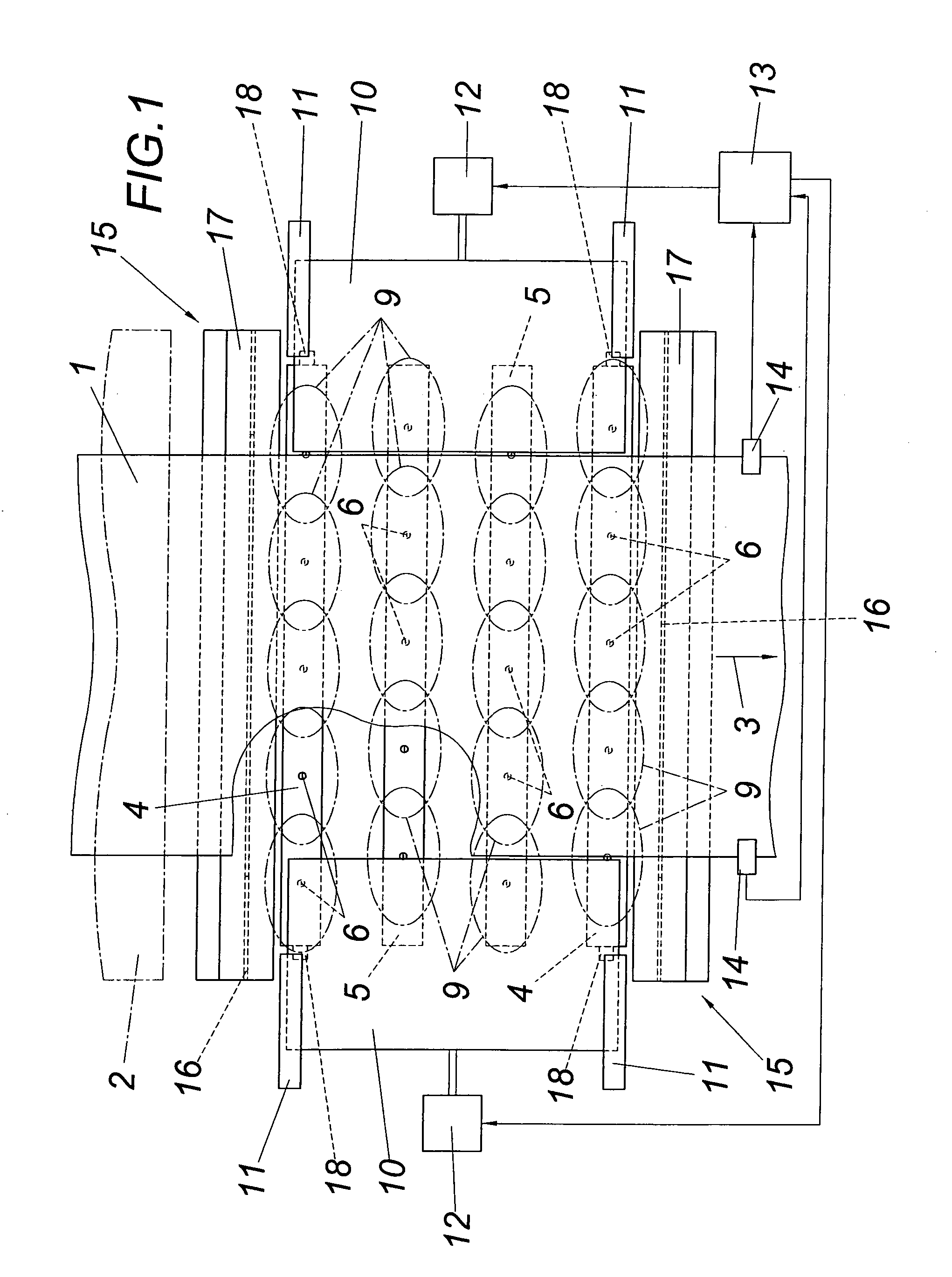

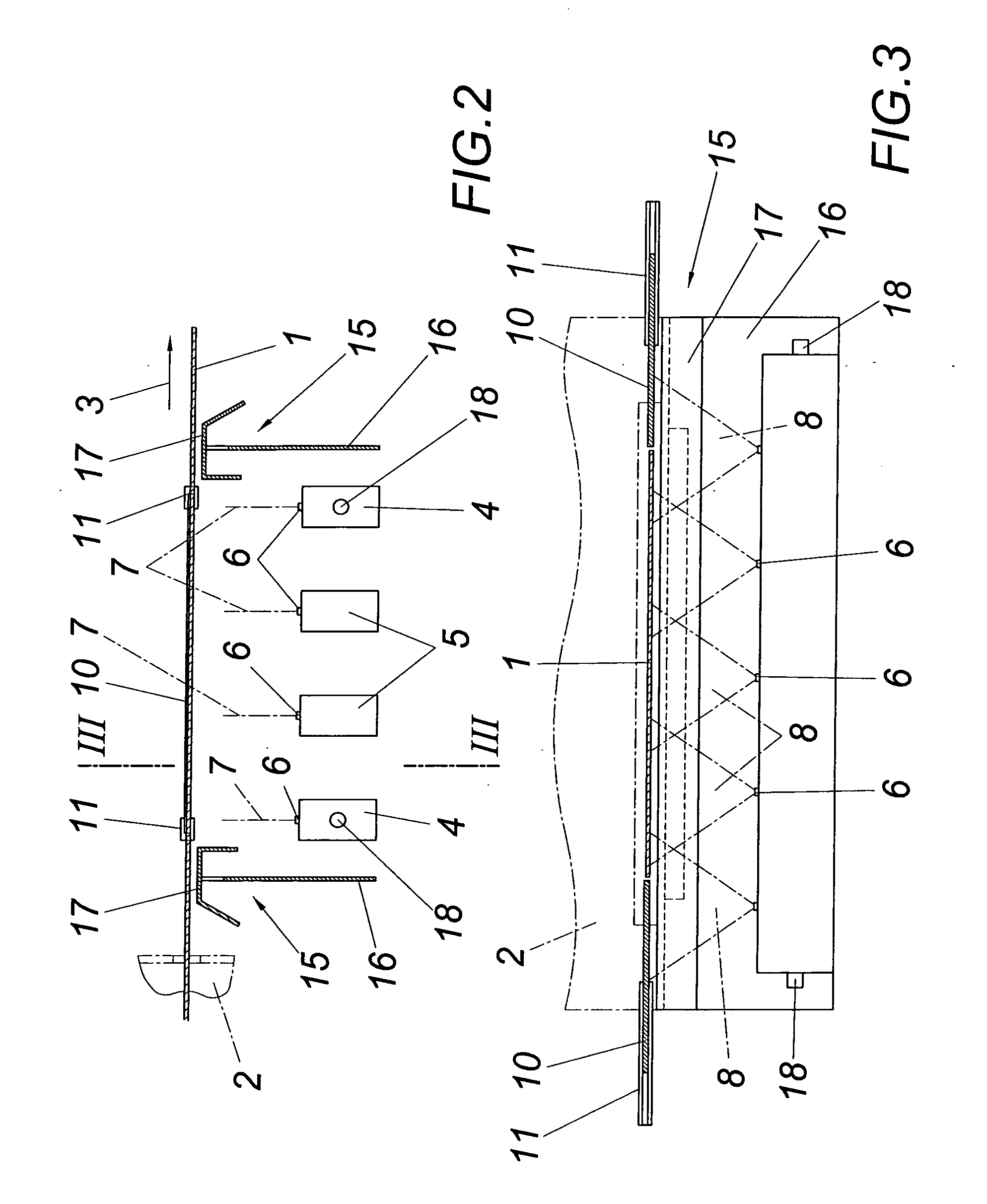

Apparatus for cooling a strip of sheet metal

InactiveUS20060027163A1Uneven distributionGuaranteed cooling effectLiquid surface applicatorsFurnace typesEngineeringMetal

An apparatus is described for cooling a strip (1) of sheet metal with nozzles (6) for a cooling liquid to be sprayed onto the bottom side of the strip, which nozzles are arranged beneath the strip (1) in transversal rows relative to the feeding direction (3) of the strip. In order to provide advantageous cooling conditions it is proposed that the nozzles (6) configured as fan jet nozzles form a common middle spraying surface (7) for each transversal row and that covers (10) are provided in the spraying region of the nozzles (6) which are laterally adjacent to the strip (1) of sheet metal.

Owner:EBNER-INDUSTRIEOFENBAU GMBH

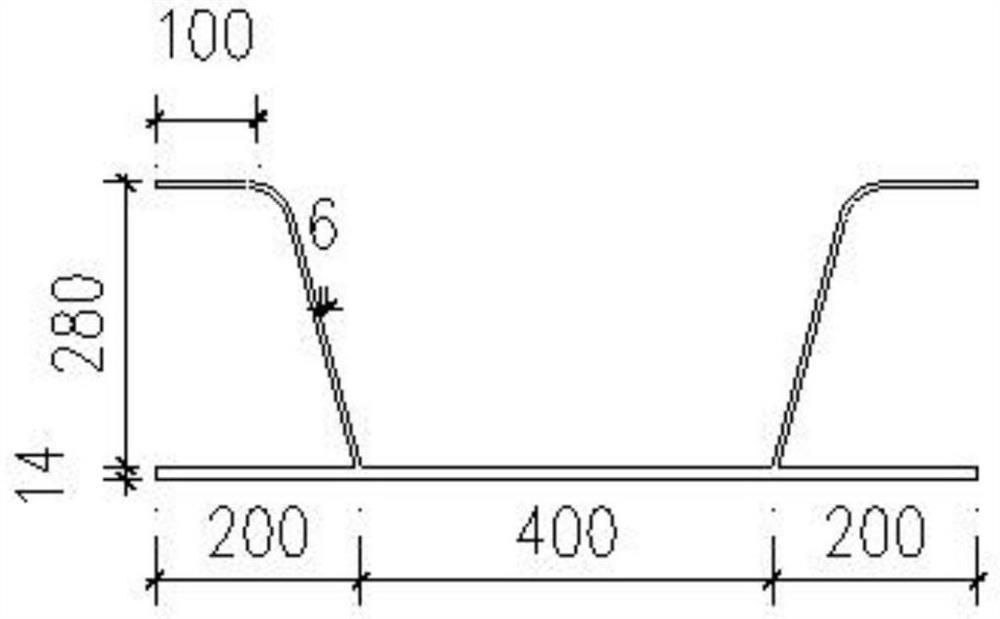

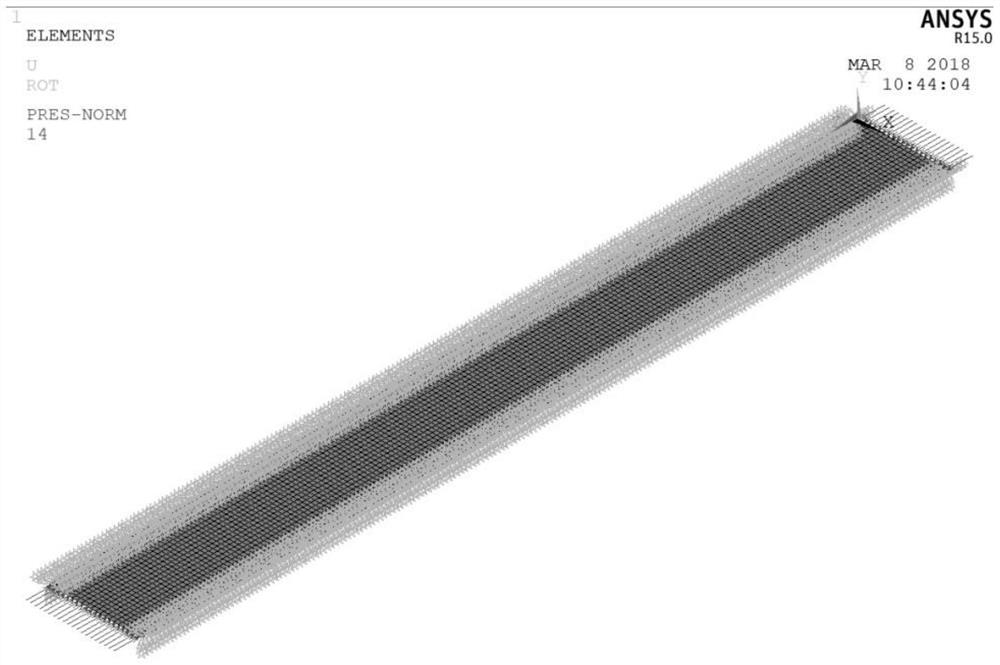

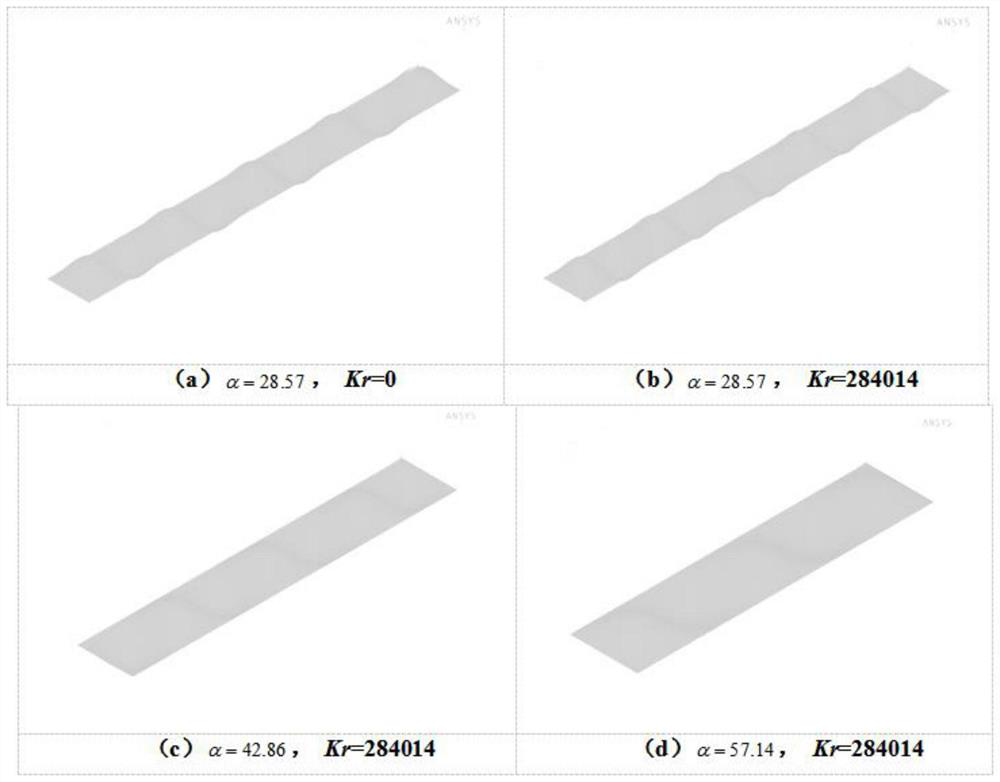

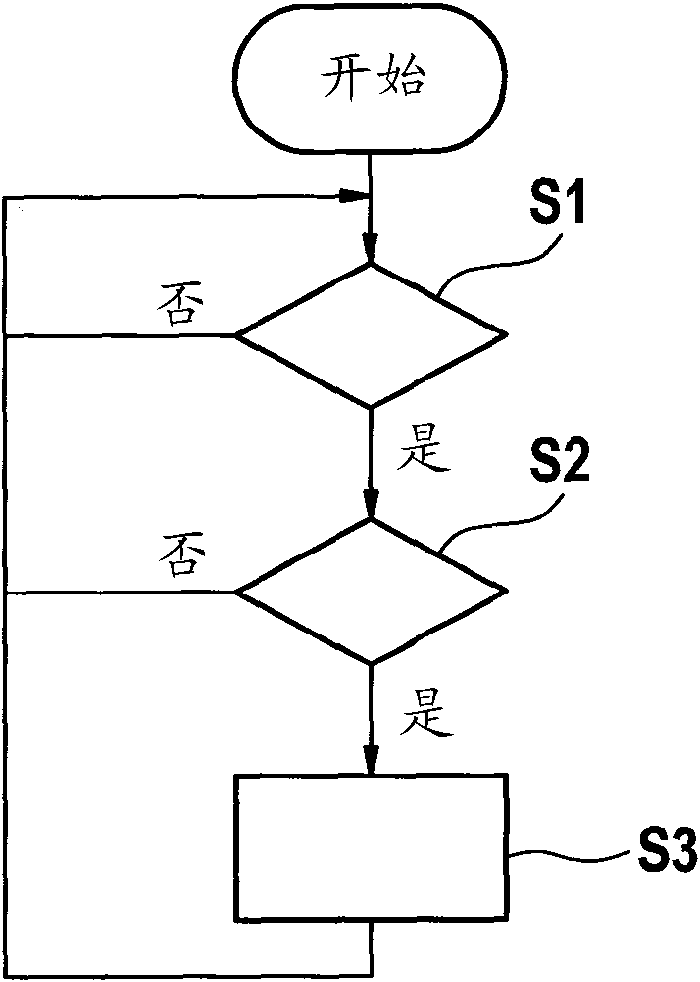

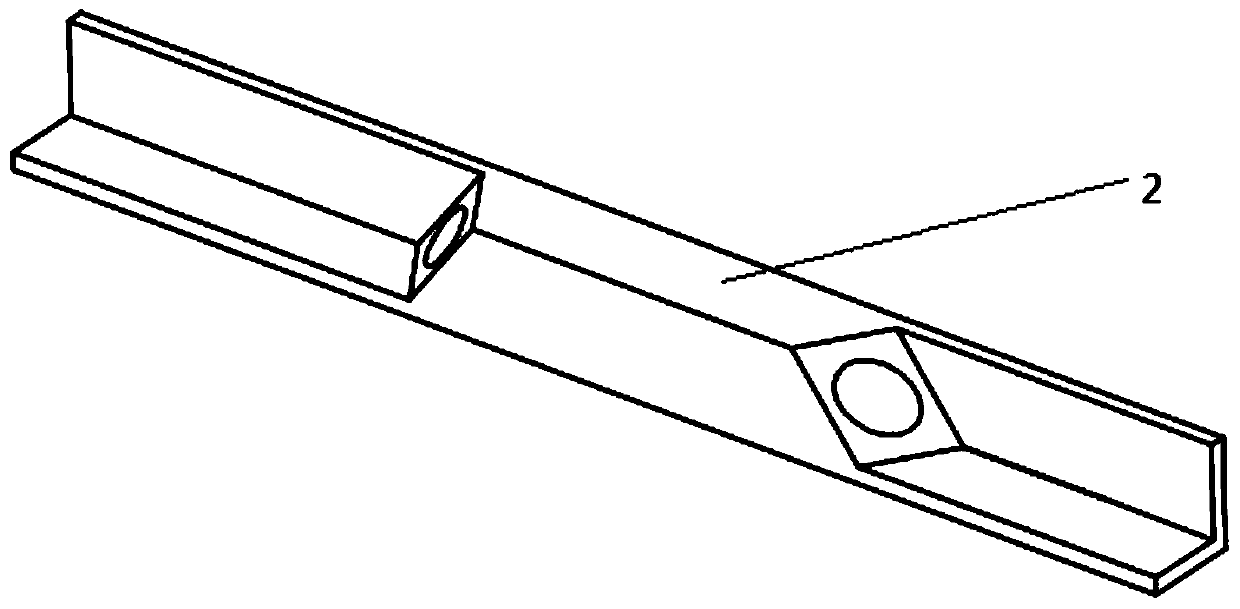

Method for calculating stable bearing capacity of U-shaped stiffening plate under action of axial compression

PendingCN113779847AFit closelyImprove boundary conditionsDesign optimisation/simulationConstraint-based CADAxial compressionCritical load

The invention discloses a method for calculating the stable bearing capacity of a U-shaped stiffening plate under the action of axial compression. The method comprises the following steps: step 1, assuming conditions; step 2, obtaining the total potential energy of the U-shaped stiffening plate; step 3, obtaining a flexural surface function; step 4, critical load of the stiffening plate; step 5, determining elastic constraint rigidity; and step 6, comparing the theoretical solution with an ANSYS numerical solution. The invention aims to provide the method for calculating the stable bearing capacity of the U-shaped stiffening plate under the action of the axial compression, the stable bearing capacity of the U-shaped stiffening plate under the action of the axial compression can be more accurately simulated and calculated, the maximum error is 0.42%, and the result coincidence is better.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

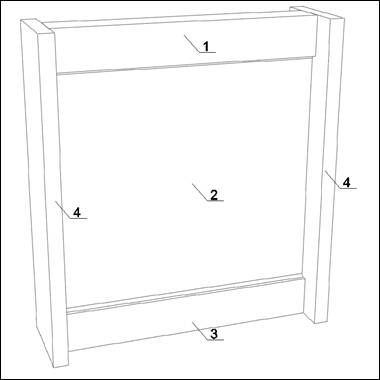

Novel metal shearing type damper

PendingCN111764525AImprove energy consumptionImprove boundary conditionsProtective buildings/sheltersShock proofingSteel platesAbnormal shaped

The invention discloses a metal shearing type damper structure form. The metal shearing type damper structure form comprises a core plate lower end special-shaped connecting section, a middle sectionenergy consumption section capable of controlling a core plate to be reasonable in slenderness ratio, a core plate upper end special-shaped connecting section and flange plates on the two sides, the upper section, the middle section and the lower section of the core plate are formed by integrally machining a mild steel plate, it is guaranteed that steel performance of the energy consumption section is fully exerted, and stress is reasonably transmitted. Under the same load, the size, the weight and the manufacturing cost of a damper are greatly reduced, accurate simulation can be carried out through numerical simulation, consistency of damper unit parameters in an actual product and the overall structural design is kept, and the metal shearing type damper structure form is wide in application range, efficient and reliable.

Owner:ZHEJIANG JIANKE DAMPING SCI & TECH CO LTD

Pile bottom post-grouting method

The invention discloses a method for post-grouting in the bottom of a pile, which comprises the following steps: in the process of constructing the pile by drilling holes, a grouting pipeline is prearranged in the bottom of the pile and grout is injected. The method has good grouting effect and high success rate of grouting.

Owner:JIANGSU NANTONG NO 2 CONSTR ENG GRP

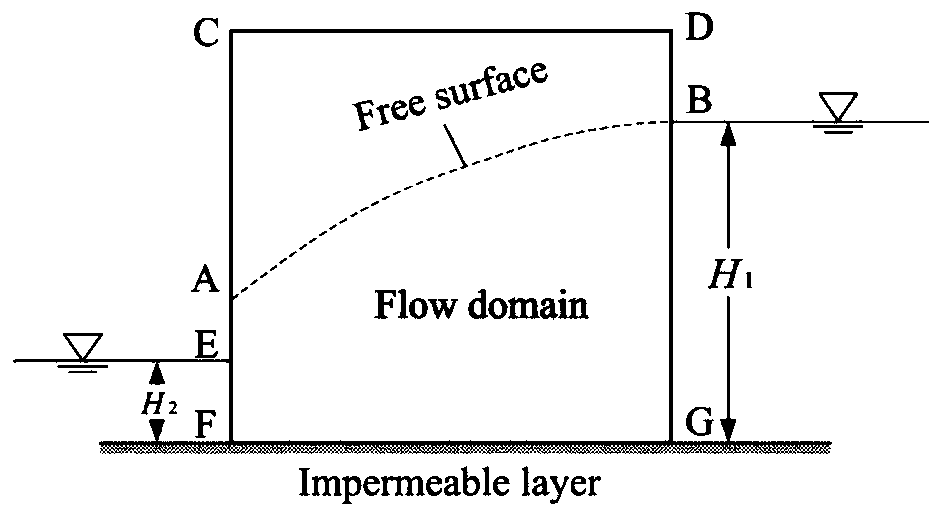

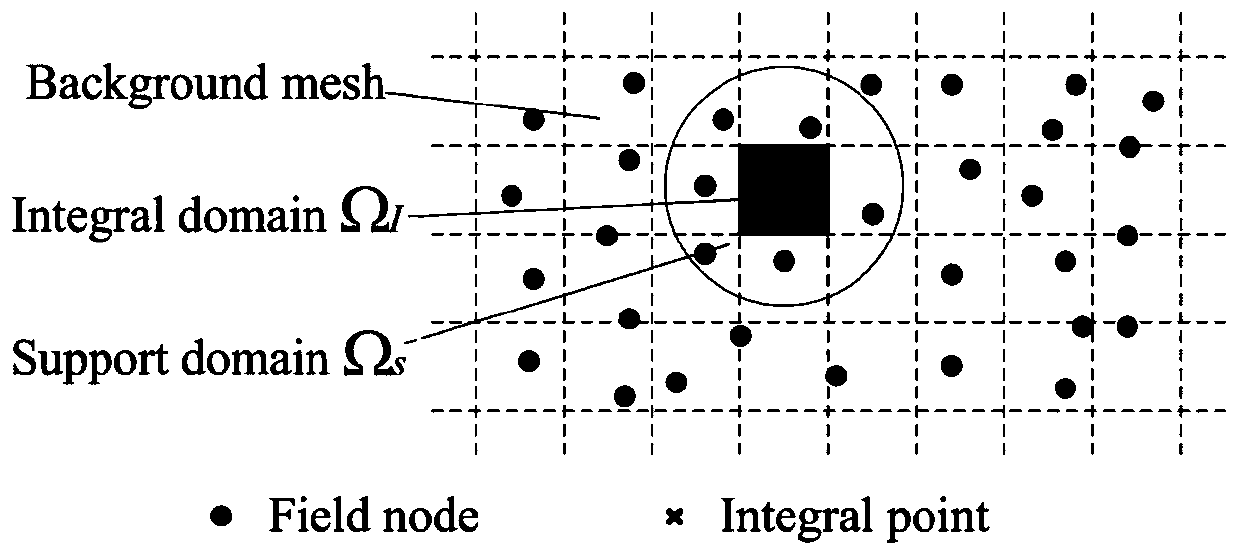

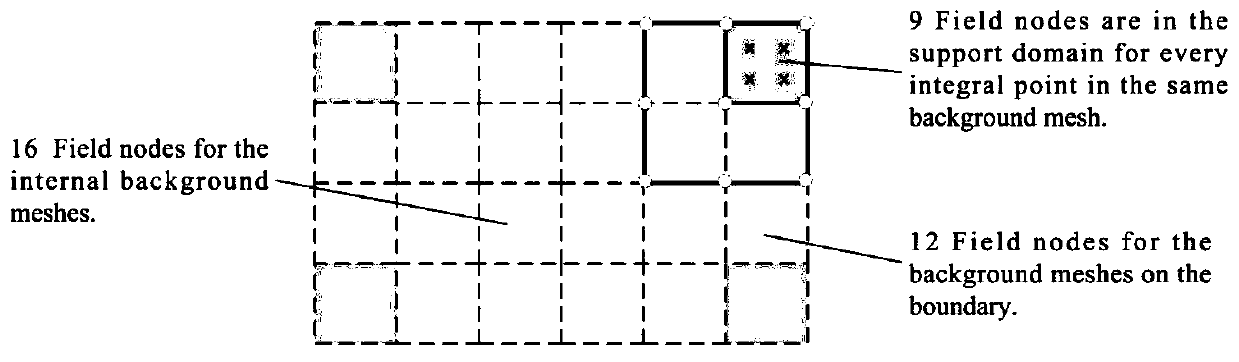

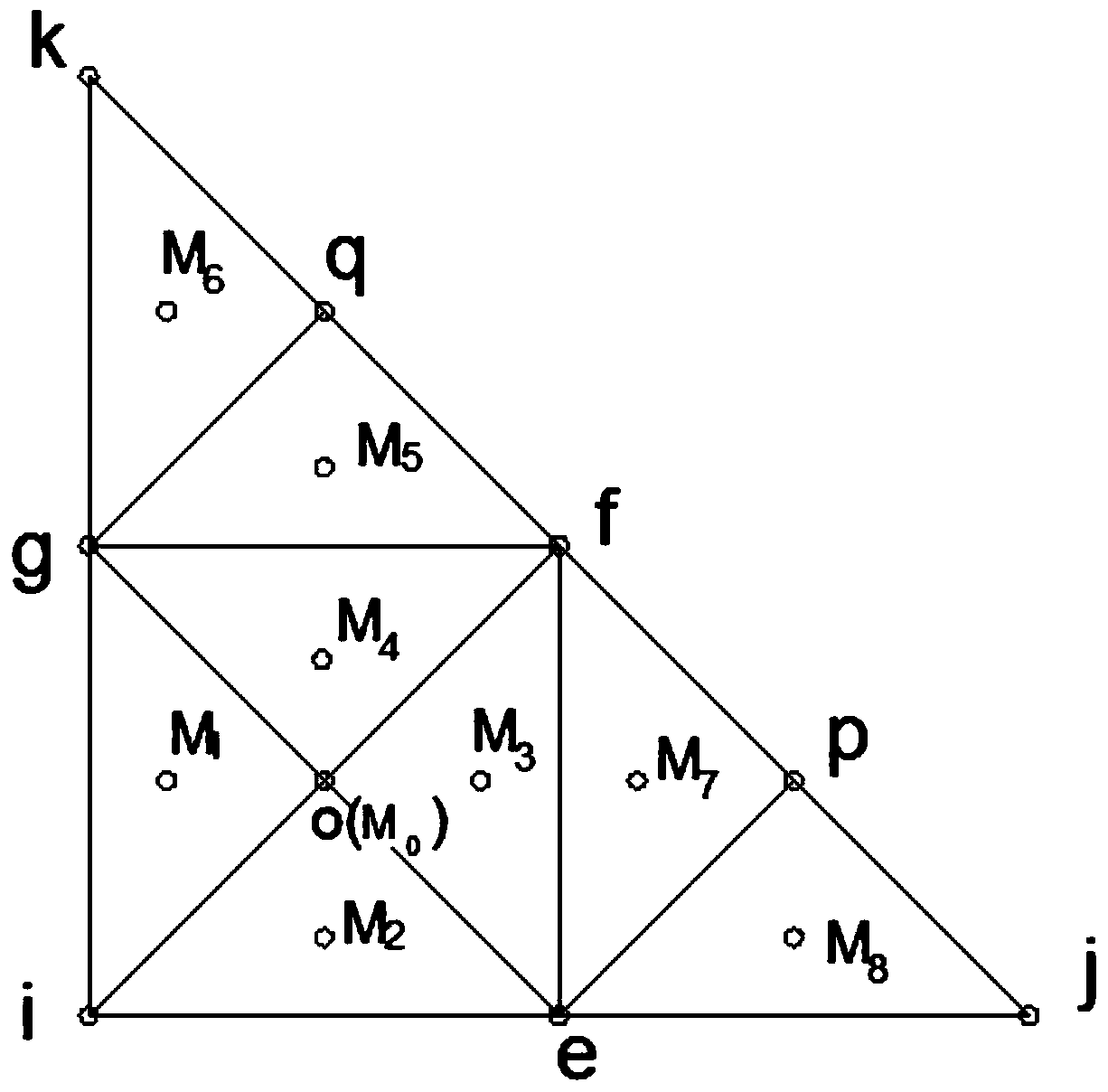

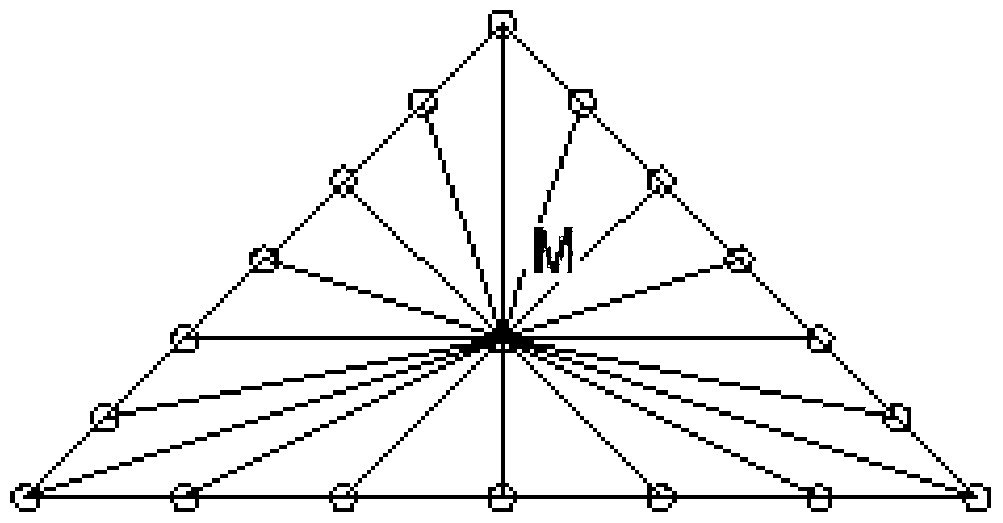

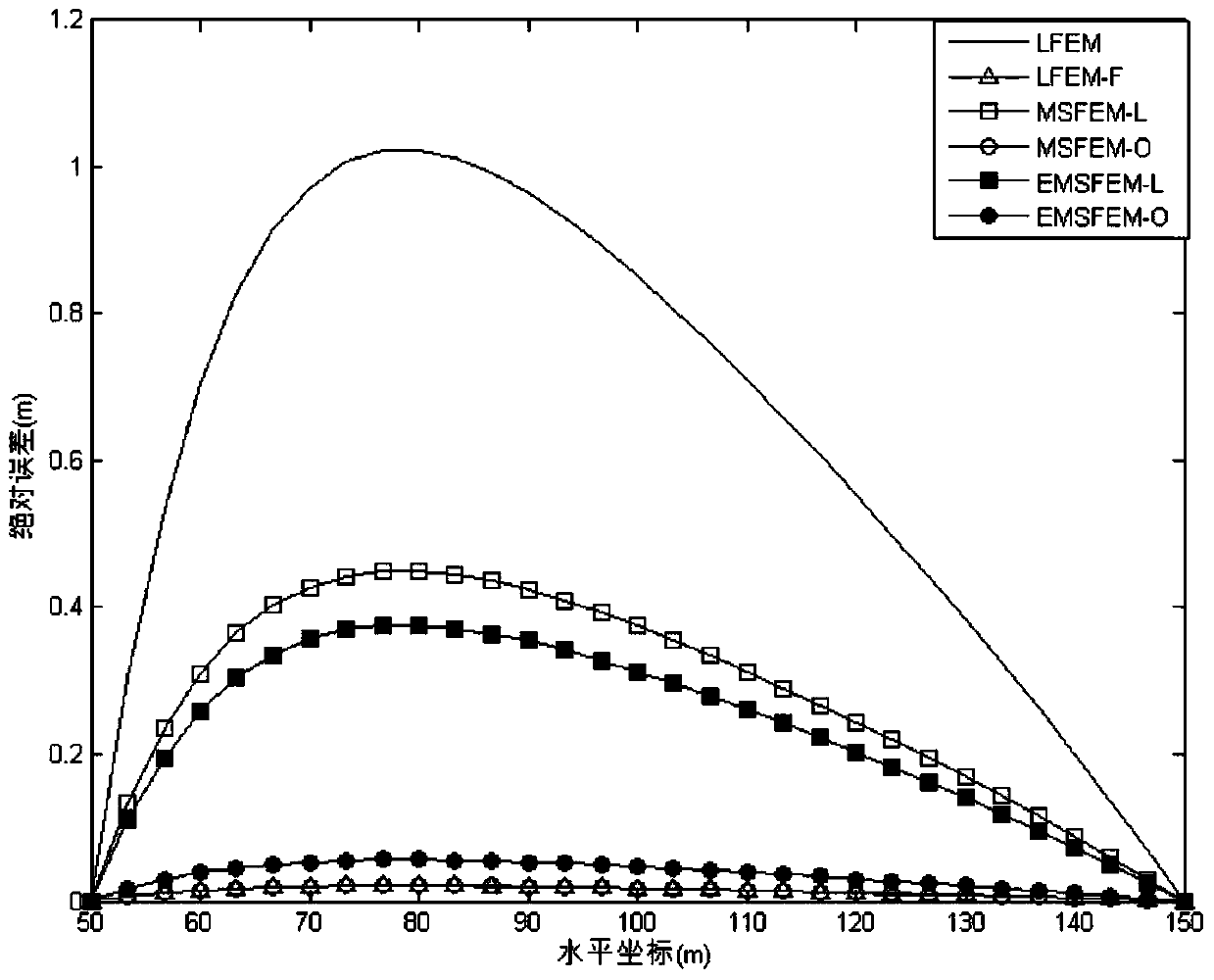

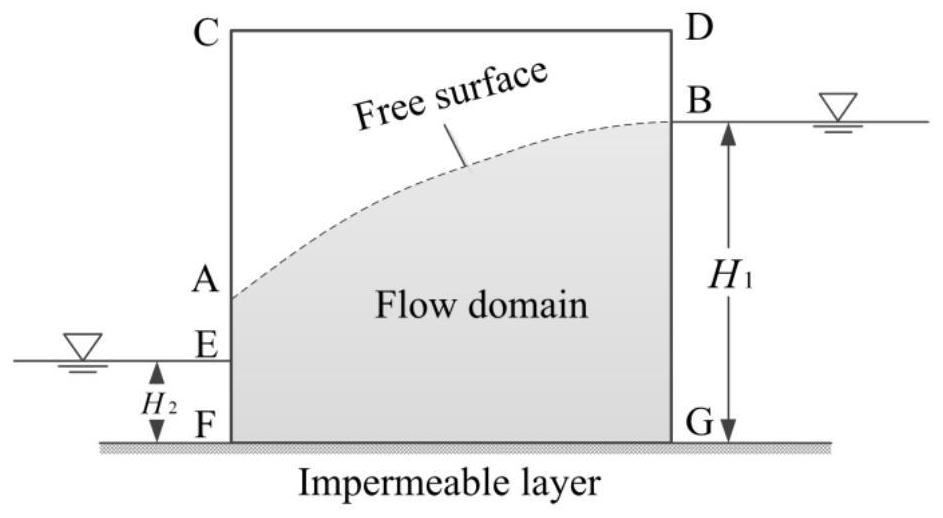

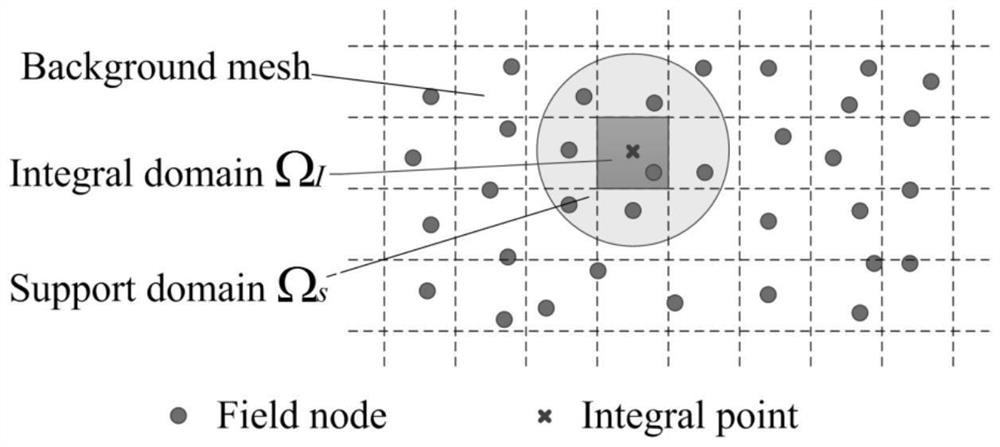

Optimization algorithm for solving seepage free surface based on radial base point interpolation method

ActiveCN110443432AMake sure it's fully alignedGuaranteed integral accuracyClimate change adaptationForecastingNODALMatrix differential equation

The invention relates to a meshless method seepage free surface solving method based on a radial base point interpolation method. The meshless method seepage free surface solving method comprises thefollowing steps: 1) determining a control equation; 2) determining boundary conditions; 3) determining an RPIM control equation; solving a partial differential equation by adopting RPIM, dispersing aproblem domain into a series of field nodes, introducing an integral rigidity matrix into a background grid in order to facilitate integration and assembly, integral points existing in the backgroundgrid, each integral point having a support domain, and interpolating the field nodes in the support domains to obtain information on the integral points. According to the method, the seepage free surface can be solved conveniently and quickly, the precision is high, the working process can be simplified, and engineering practice can be better guided.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

Growth method of gallium arsenide single crystal

ActiveCN106319630BSolving the problem of not wetting with quartz cruciblesSolve the problem of low crystal growth ratePolycrystalline material growthFrom frozen solutionsSeed crystalMaterials science

The invention provides a growing method of gallium arsenide monocrystalline. The method comprises the following components: (1) a quartz crucible is cleaned; (2) the quartz crucible is placed in a quartz tube which contains gallium of high purity, vacuum-pumping and inflation operation are repeatedly carried out for the quartz tube, and finally inert gas or nitrogen is filled; (3) the quartz tube is heated till the temperature in the quartz tube reaches to 1240 DEG C or above and insulation is carried out, and the quartz tube is cooled to room temperature; (4) the quartz crucible is taken out from the quartz tube and is immersed in acid, deionized water is used for washing, absolute ethyl alcohol is used for carrying out dehydration treatment, and the quartz crucible is placed in a drying box for standby; (5) seed crystal, polycrystalline materials, and the balance being arsenic are placed in the quartz crucible in order according to charging requirements, the quartz crucible is placed in a quartz ampoule, and vacuum-pumping, baking and soldering and sealing treatment are carried out; (6) a traditional VGF method is used for accomplishing the growth of gallium arsenide monocrystalline. PBN crucibles are not used, a liquid sealing agent B2O3 is not used, and GaAs monocrystalline is not polluted by extra introduction of B element from the source.

Owner:广东先导微电子科技有限公司

Method and device for operating an internal combustion engine with exhaust gas recirculation

ActiveCN105370424BFast and flexibleIncrease boost pressureElectrical controlInternal combustion piston enginesExhaust fumesExhaust gas recirculation

The invention relates to a method for operating an internal combustion engine (2) with an exhaust gas-driven supercharging device (6), the method comprising the following steps: - Implementing an exhaust gas recirculation control for adjusting the recirculation to the intake system (4 ) and / or implement a boost pressure regulation for adjusting the boost pressure on the basis of the corresponding nominal value; - detect a rapid increase in the torque requirement; and - upon detection of said torque In the event of a rapid increase in the torque requirement, the setpoint values of the exhaust gas recirculation control and / or the boost pressure control are corrected in order to increase the exhaust gas enthalpy provided at the booster device ( 6 ).

Owner:ROBERT BOSCH GMBH

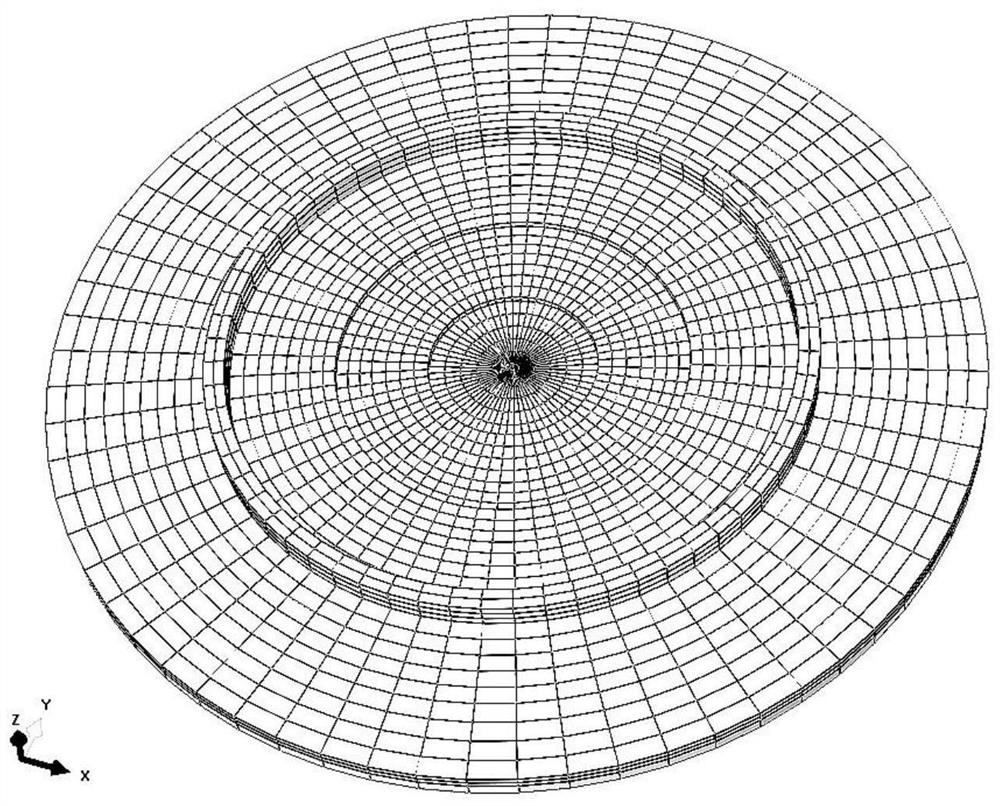

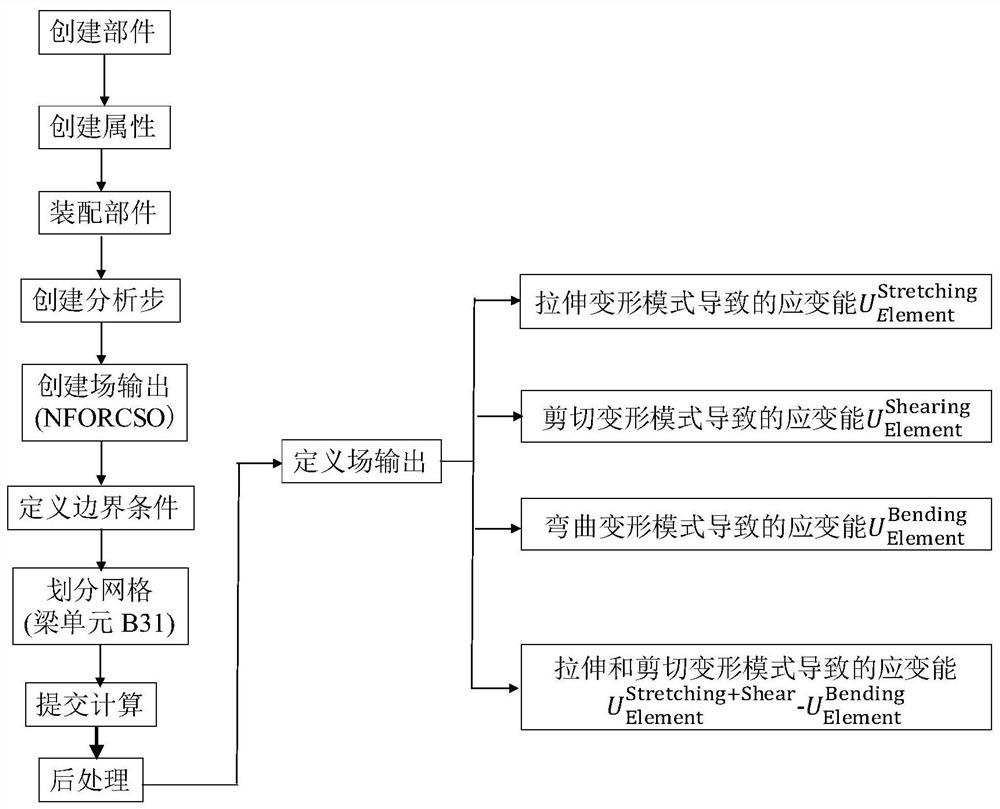

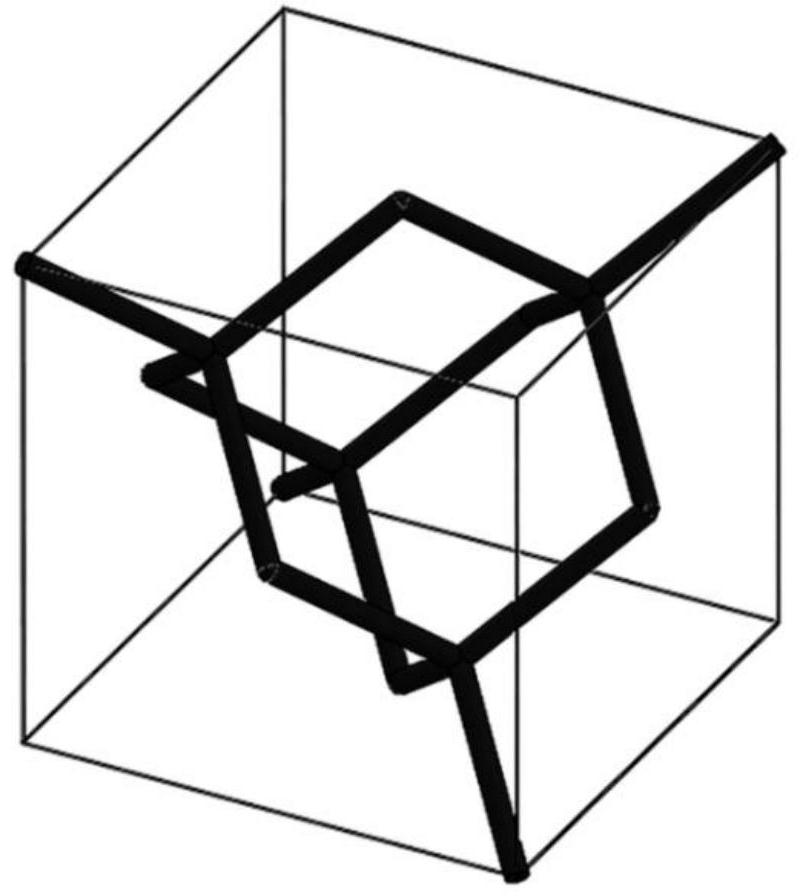

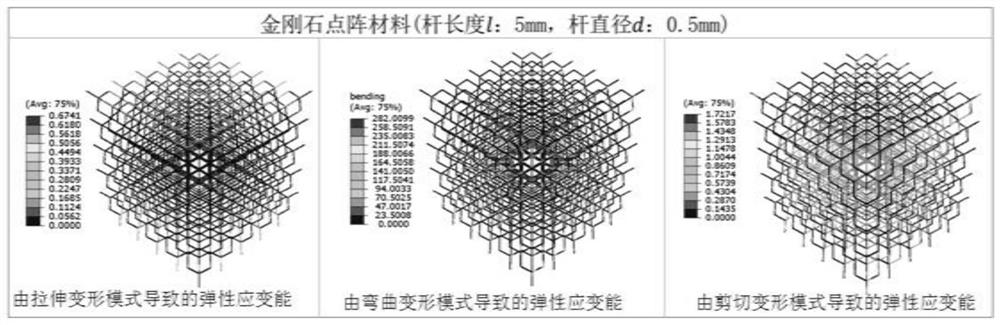

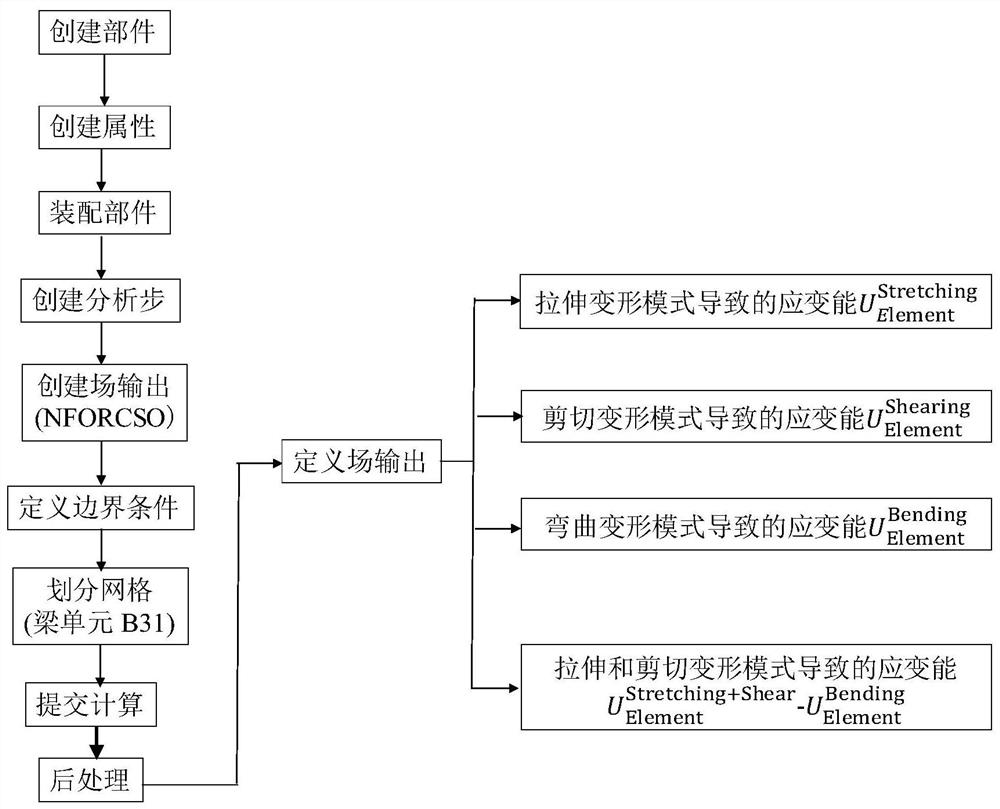

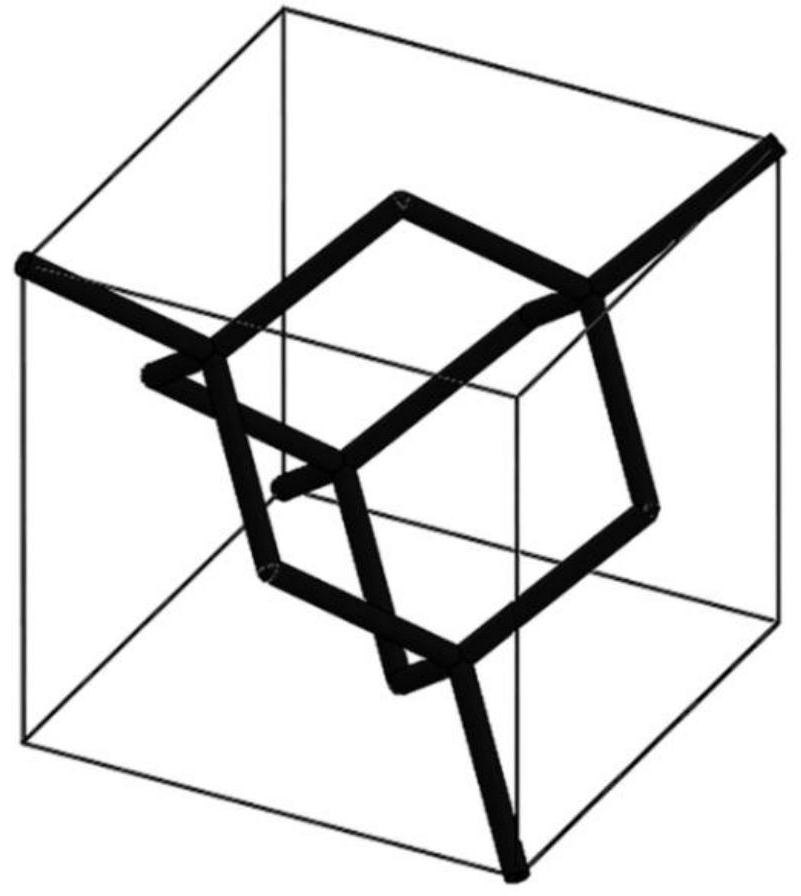

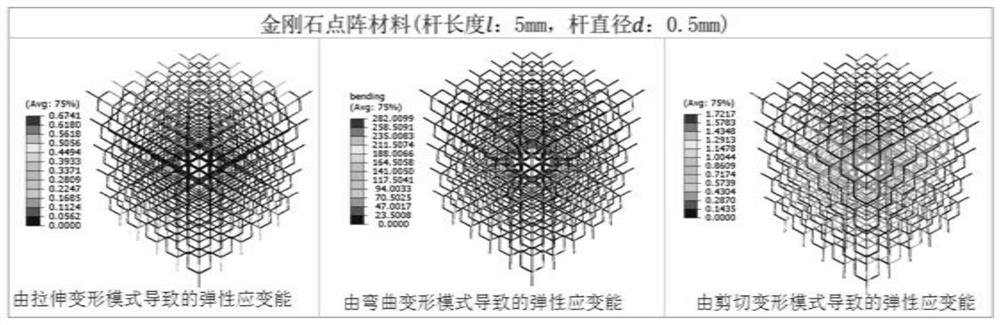

A Finite Element Analysis Method for the Deformation Mode of Lattice Material

ActiveCN113343539BImprove boundary conditionsFast convergenceDesign optimisation/simulationSpecial data processing applicationsDot matrixElement analysis

The invention discloses a finite element analysis method for a lattice material deformation mode, and belongs to the technical field of material mechanical performance analysis. The method includes establishing the finite element analysis model of the lattice material deformation mode, which sequentially includes creating parts, creating properties, assembling parts, creating analysis steps, creating field output variables, defining boundary conditions, dividing meshes, submitting calculations, and postprocessing Composed of sub-step units, a secondary finite element analysis is performed on the field output variable NFORCSO in ABAQUS / Standard mode, where the axial force, bending moment and shear force of the beam unit correspond to the tensile, bending and shear deformation modes, respectively, Obtain the strain energy caused by the three deformation modes of beam elements: tension, bending, and shear. The strain energy of the three-dimensional structure of the lattice material is the sum of the strain energies of all beam elements, which can realize the deformation of the lattice material during compression. Pattern quantification and visualization.

Owner:上海医钛科技有限公司 +1

Double freedom of motion low thermal resistance locking device

ActiveCN108430189BSmall heat transfer temperature differenceReduce thermal contact resistanceClamping/extracting meansCooling/ventilation/heating modificationsVibration amplitudeMechanical engineering

The invention brings forward a double motion freedom degree low thermal resistance locking device. Via the device, contact thermal resistance can be remarkably reduced, vibration amplitude of an LRM module can be lowered, and vibration resistance performance of the module can be improved. The device is realized via the following technical solution: a one-way wedge face fixing block (1) fixed on anangle plate, a rear wedge face block angle plate moving section (2), a double wedge face block middle angle plate moving section (3), a one-way wedge face front angle plate moving section (4), and aone-way wedge face driving slide block (5) are orderly connected in series at an interval of 3-5 millimeters via long screw rods so as to form a cuboid-shaped locking bar comprising four moving pairsconnected in series, the locking bar is mounted fixedly in L-shaped gap slot of the LRM module, all angle plate moving sections are driven spirally via screw rods (6) to gradually retract along interval gaps among all sections, staggered sliding motion is generated along a direction of a diagonal line of a cuboid, distensible force is generated between walls of gap slots of the LRM module and a cold plate (10), and double motion locking and heat transfer of the LRM module can be realized.

Owner:10TH RES INST OF CETC

Finite element analysis method for lattice material deformation mode

ActiveCN113343539AImprove boundary conditionsFast convergenceDesign optimisation/simulationSpecial data processing applicationsElement analysisStrain energy

The invention discloses a finite element analysis method for a lattice material deformation mode, and belongs to the technical field of material mechanical property analysis. The method comprises the steps that a finite element analysis model of the lattice material deformation mode is established, the finite element analysis model is composed of sub-step units which sequentially comprise component creating, attribute creating, component assembling, analysis step creating, field output variable creating, boundary condition defining, grid dividing, calculation submitting and post-processing, secondary finite element analysis is carried out on the field output variable NFORCSO under the ABAQUS / Standard mode, wherein the axial force, the bending moment and the shearing force of the beam units correspond to stretching, bending and shearing deformation modes respectively, strain energy caused by the stretching, bending and shearing deformation modes of the beam units is obtained, and the strain energy of the lattice material three-dimensional structure is the sum of the strain energy of all the beam units, and the quantitative and visual effect of the deformation mode of the lattice material in the compression process can be achieved.

Owner:上海医钛科技有限公司 +1

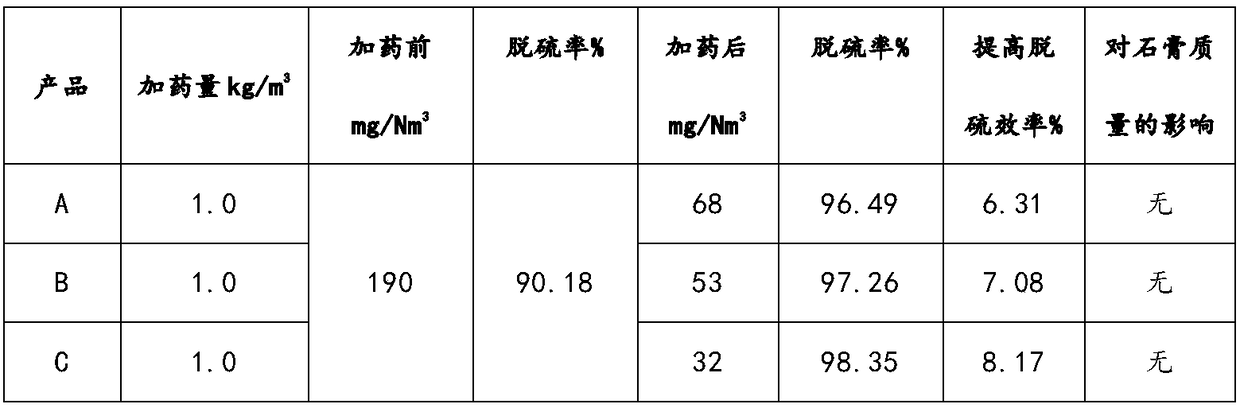

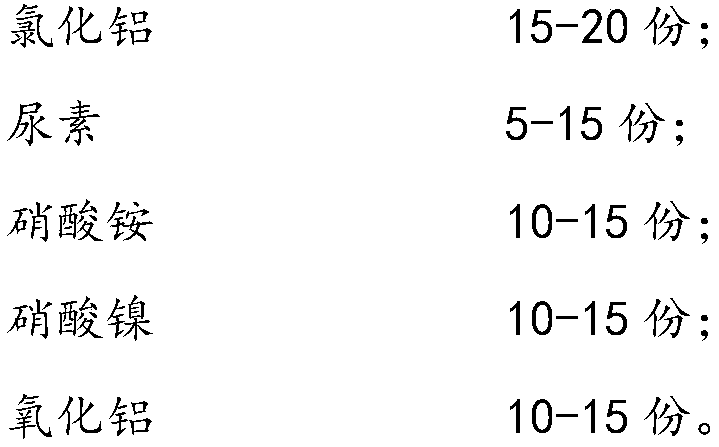

Desulfurization catalyst and preparation method thereof

InactiveCN109364971AImprove boundary conditionsEnhanced desulfurization processGas treatmentDispersed particle separationExhaust gasUrea

The invention relates to a desulfurization catalyst. The desulfurization catalyst contains the following components in parts by weight: 15-20 parts of aluminum chloride, 5-15 parts of urea, 10-15 parts of ammonium nitrate, 10-15 parts of nickel nitrate and 10-15 parts of aluminum oxide. According to the desulfurization catalyst, boundary conditions of the reaction between limestone slurry and SO2can be effectively improved, the desulfurization process of the reaction can be intensified, the desulfurization efficiency can be improved, the adaptability of a desulfurization system for the changeof sulfur content of fire coal can be improved, the energy consumption can be reduced, and the standardized discharge of SO2 in exhaust gas can be guaranteed.

Owner:XINJIANG ENVIRONMENTAL ENG TECH

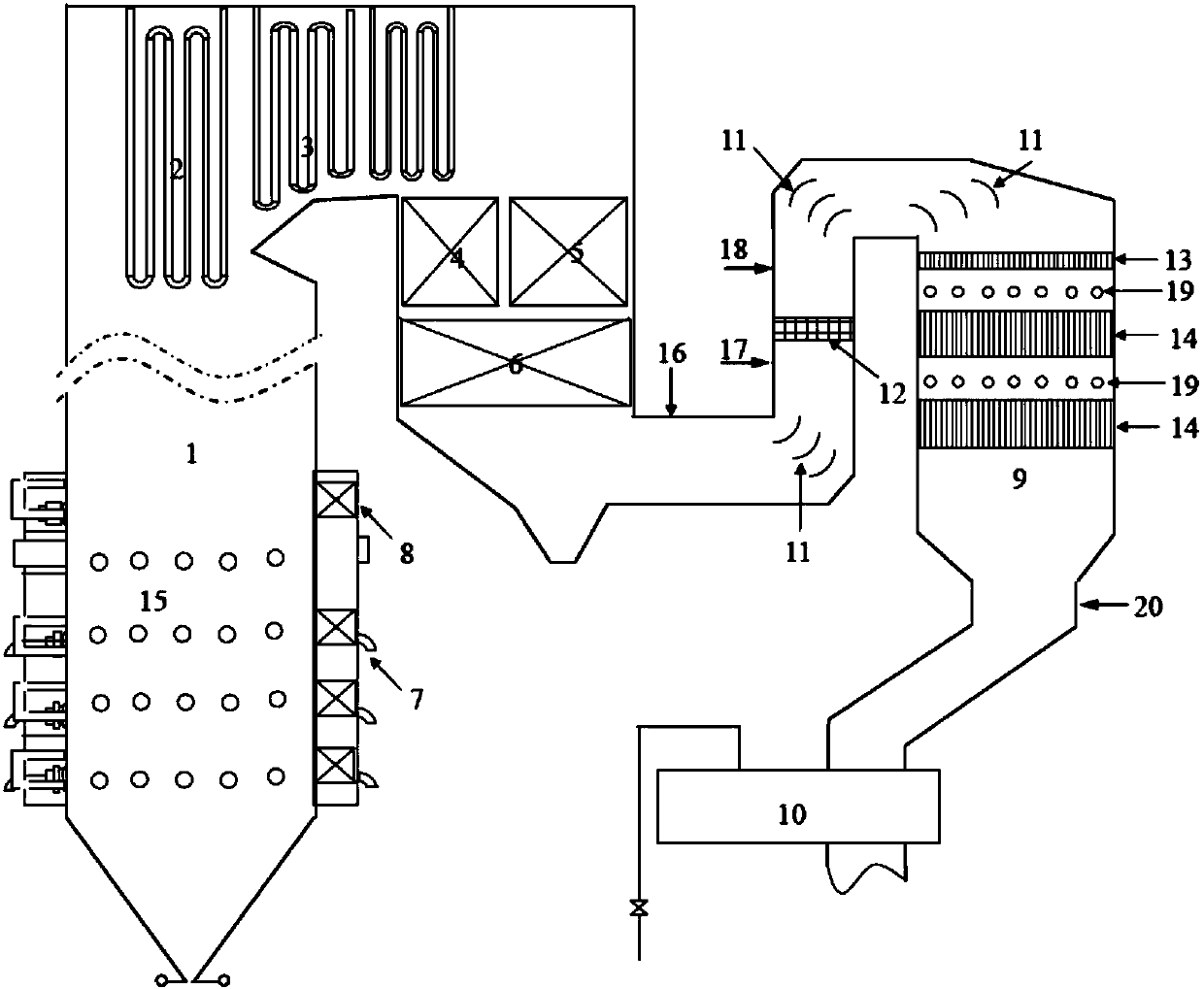

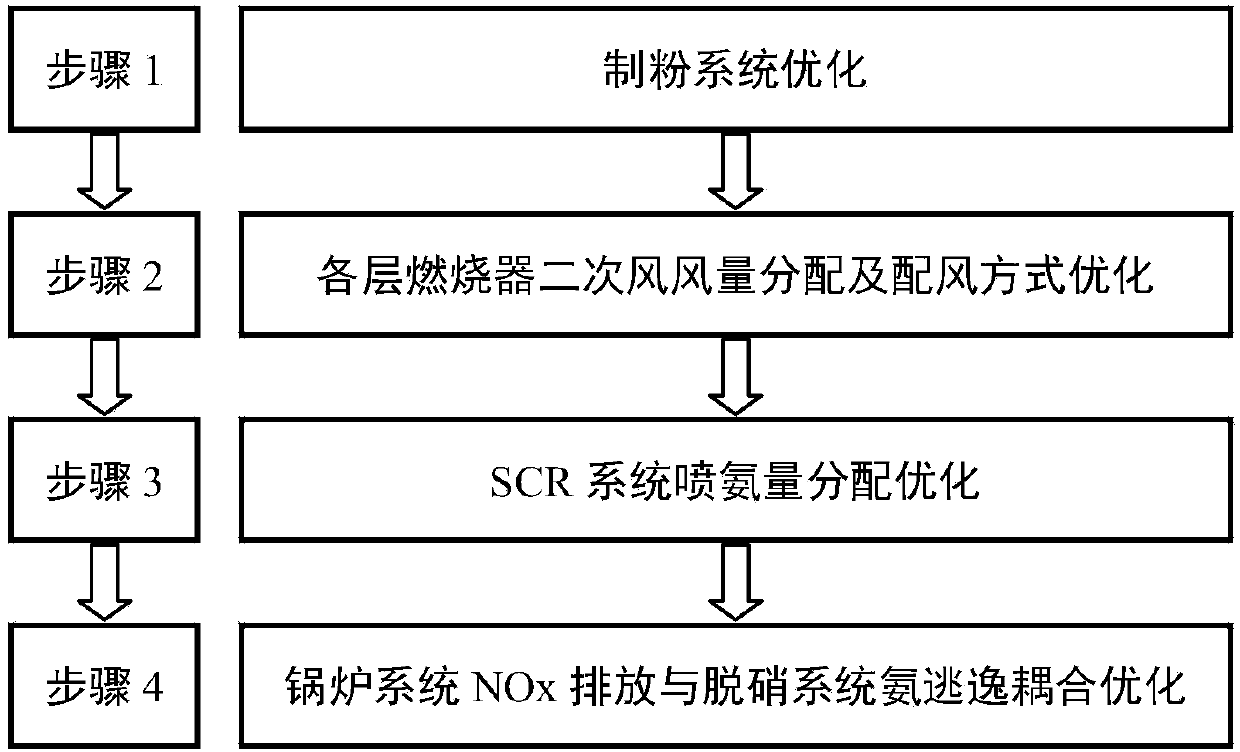

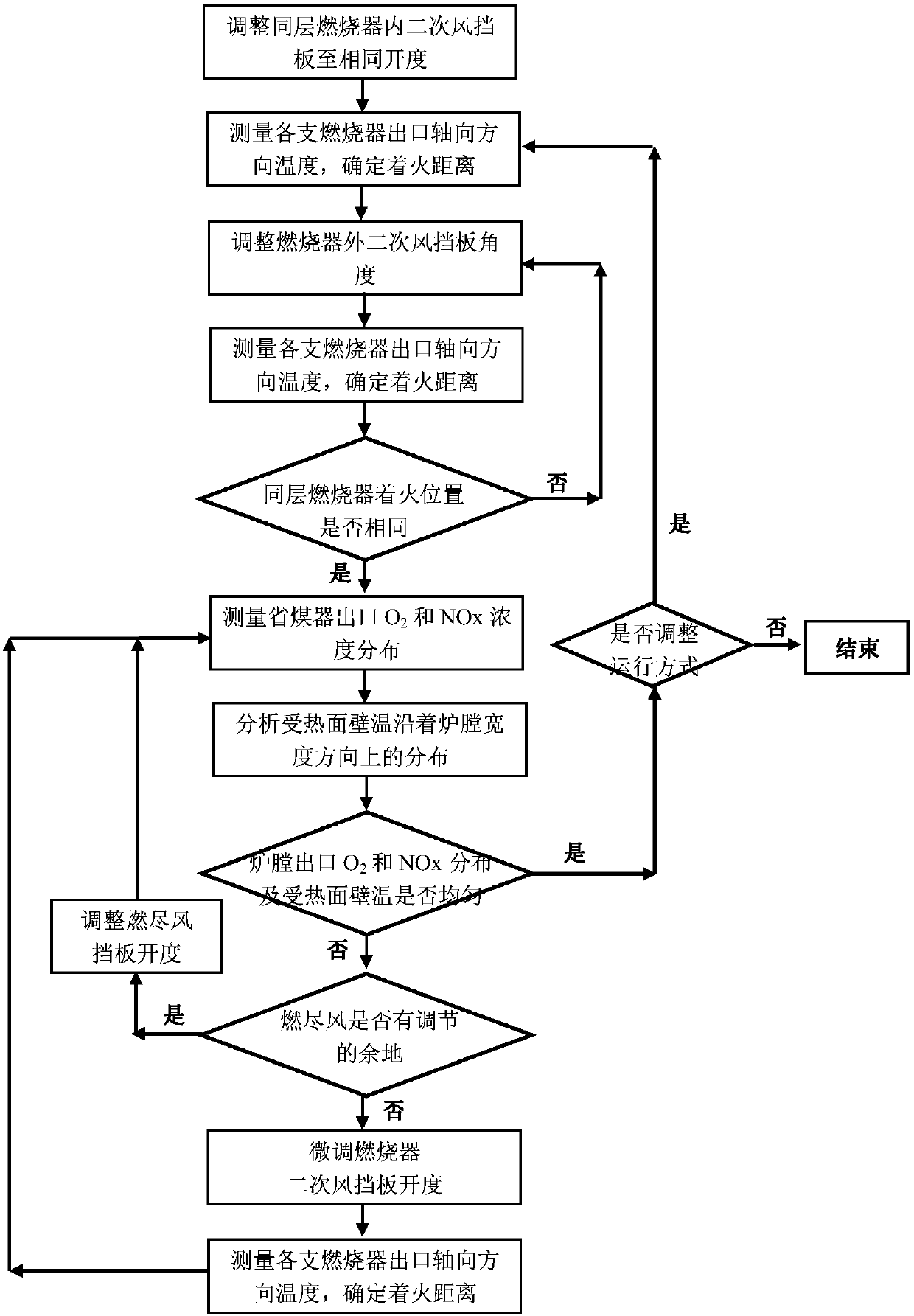

Collaborative optimization method for coal-fired power plant boiler system and denitrification system operation

ActiveCN105953259BImprove economyImprove securityFuel supply regulationFuel feeding arrangementsOperation modeEngineering

The invention provides a coal-fired power plant boiler system and denitration system operation collaborative optimization method. The method comprises the following steps: the operation of a powder preparation system is optimized and adjusted; the operation of a combustion system is optimized and adjusted; the operation of a denitration system is optimized and adjusted; the coal-fired boiler NOx emission control and the SCR denitration system ammonia escape control are coupled for optimization and adjustment; an optimal operation oxygen quantity range of a coal-fired boiler under different loads and an optimal openness range of a burnt wind nozzle in the optimal oxygen quantity operation range are determined by combining the reductive atmosphere distribution characteristics in a near wall area of a hearth water cooling wall and the denitration ammonia escape conditions; and an optimal denitration efficiency range of the denitration system under different loads is determined. The three system operation collaborative optimization methods, provided by the invention, see the boiler system and the denitration system as a large system; the mutual correlation and influence among the three systems are decoupled from the angle of the large system; and the most economical and safest operation mode of the large system is obtained through optimization.

Owner:GUODIAN NANJING ELECTRIC POWER TEST RES CO LTD

A broadband dual-polarized antenna unit and a broadband antenna

ActiveCN103311675BSimple structureEasy to manufactureRadiating elements structural formsPolarised antenna unit combinationsCode division multiple accessOptoelectronics

Owner:GUANGDONG BROADRADIO COMM TECH

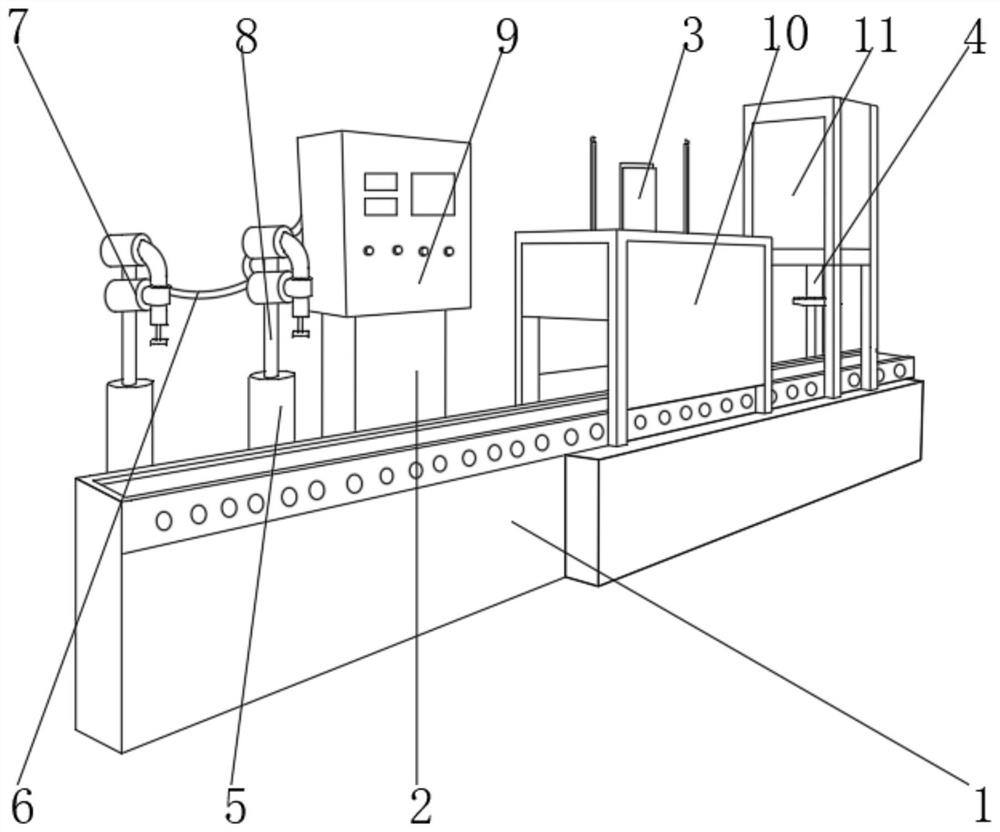

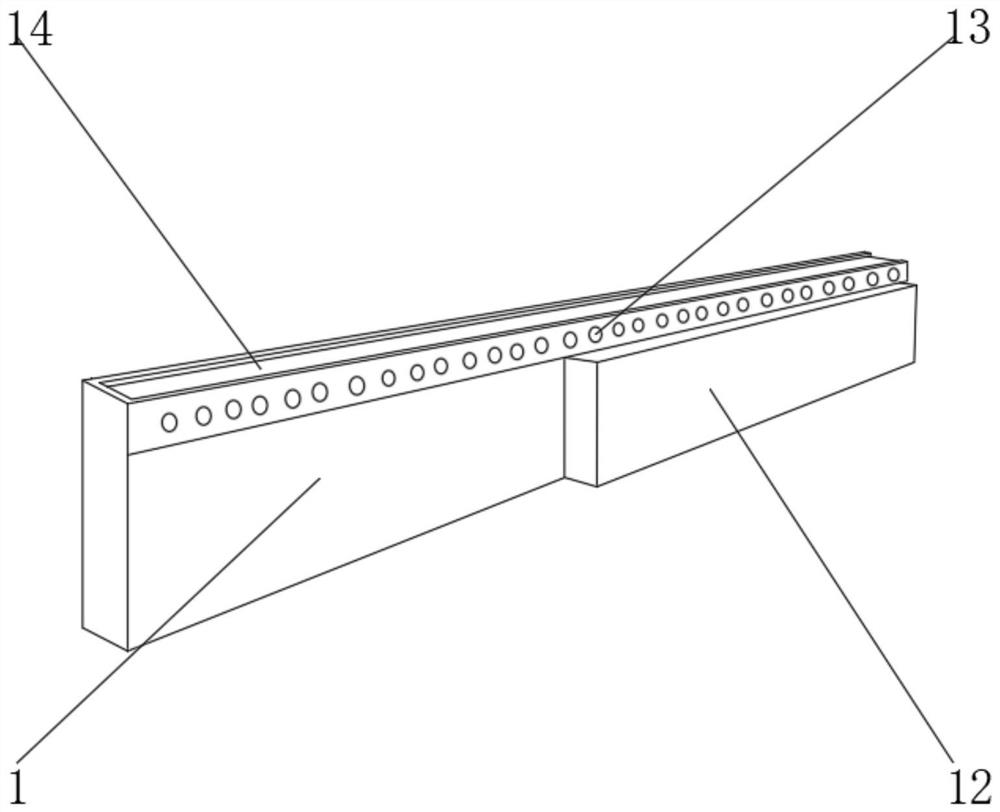

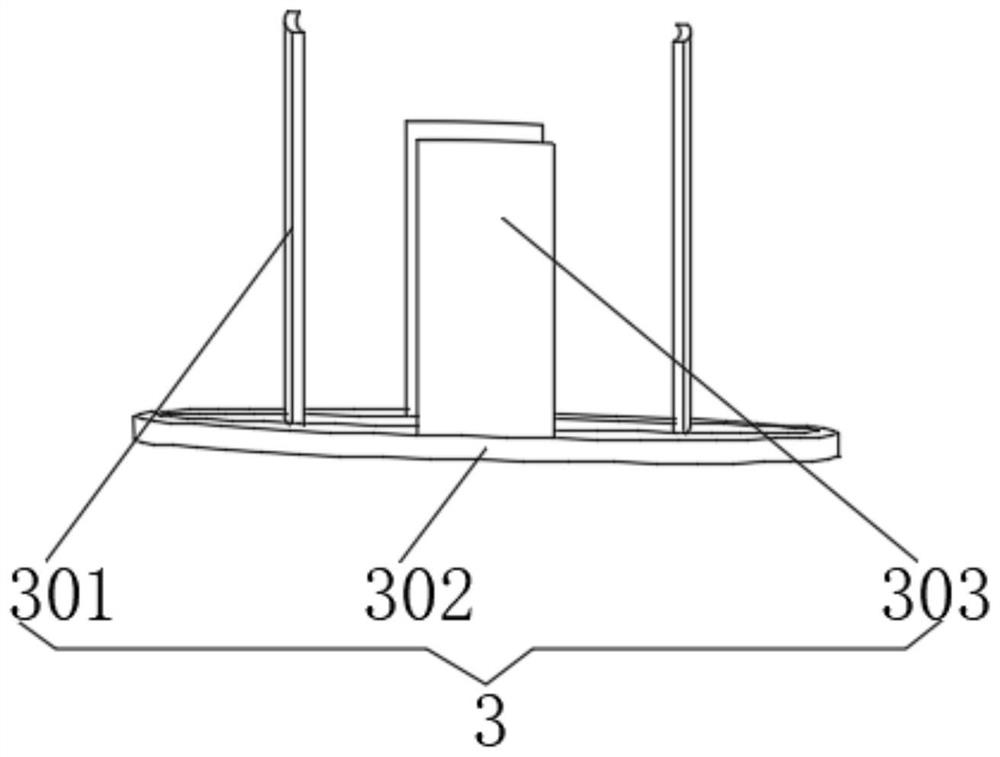

Fluorine-modified acrylic resin composite anticorrosive coating preparation process and device

PendingCN113638028AEasy to coverImprove air tightnessAnodisationElectrophoretic coatingsAcrylic resinAir tightness

The invention discloses a fluorine-modified acrylic resin composite anticorrosive coating preparation process and device. The preparation device comprises a device case, one side of the device case is fixedly connected with an air cylinder base, the inner side of the air cylinder base is fixedly connected with a coating conveying pipe, and the upper end of the coating conveying pipe is fixedly connected with a spray head filling mechanism. According to the fluorine-modified acrylic resin composite anticorrosive coating preparation process and device, a connecting box, an adjustable barrel cover placing mechanism and a multi-application cover pressing mechanism are arranged, filling barrels with different sizes can be conveniently covered by adding the adjustable barrel cover placing mechanism, one barrel has one cover through a movable cover fixing plate and a flap wheel, the covering size can be changed by adjusting the movable cover fixing plate, barrel covers of special sizes can be effectively sealed and packaged by additionally arranging the multi-application cover pressing mechanism, cover pressing is conducted by adjusting a telescopic pressing assembly and a telescopic connecting rod according to different sizes, and the air tightness of cover pressing and packaging is improved.

Owner:泰兴市华盛银洋新材料科技有限公司

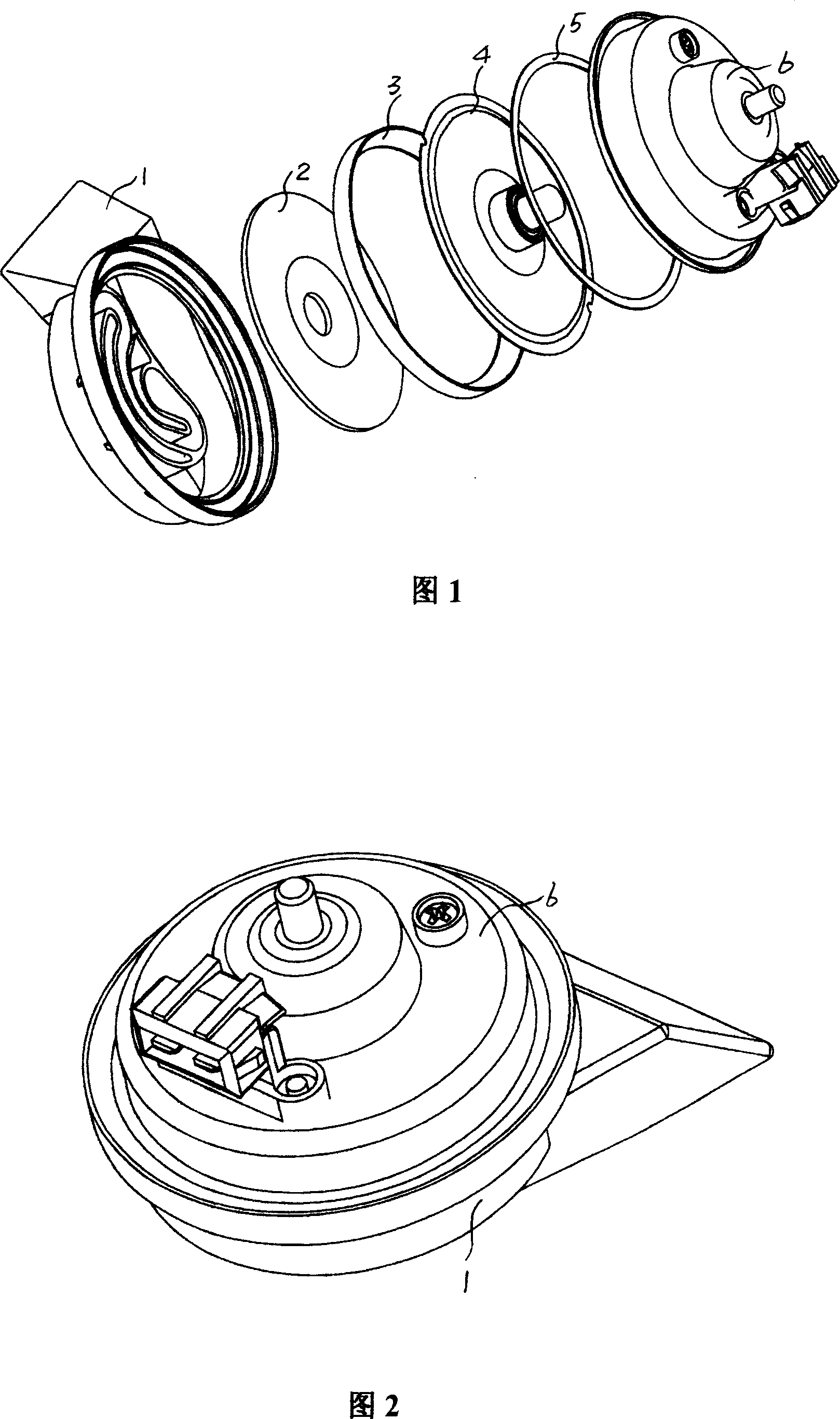

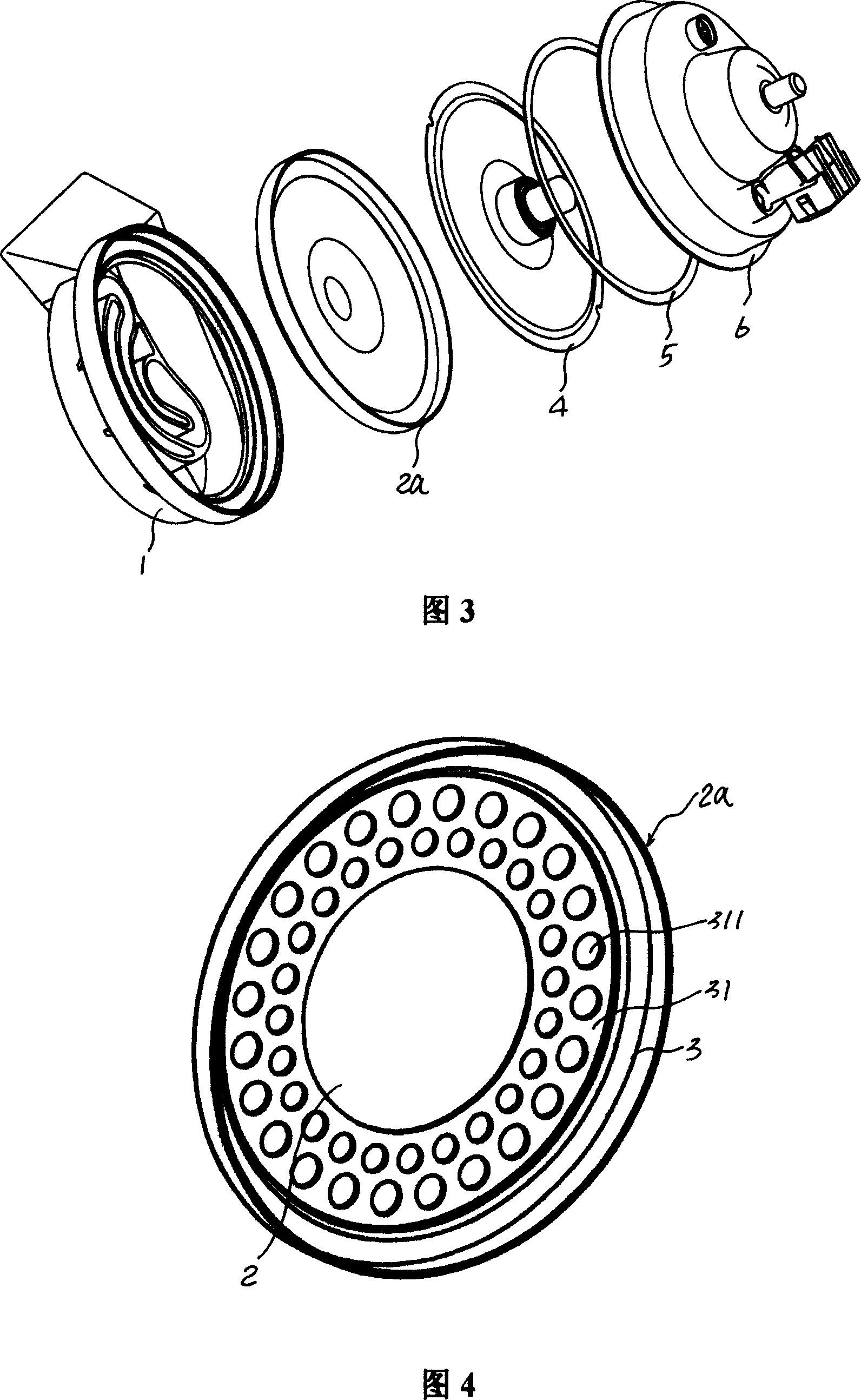

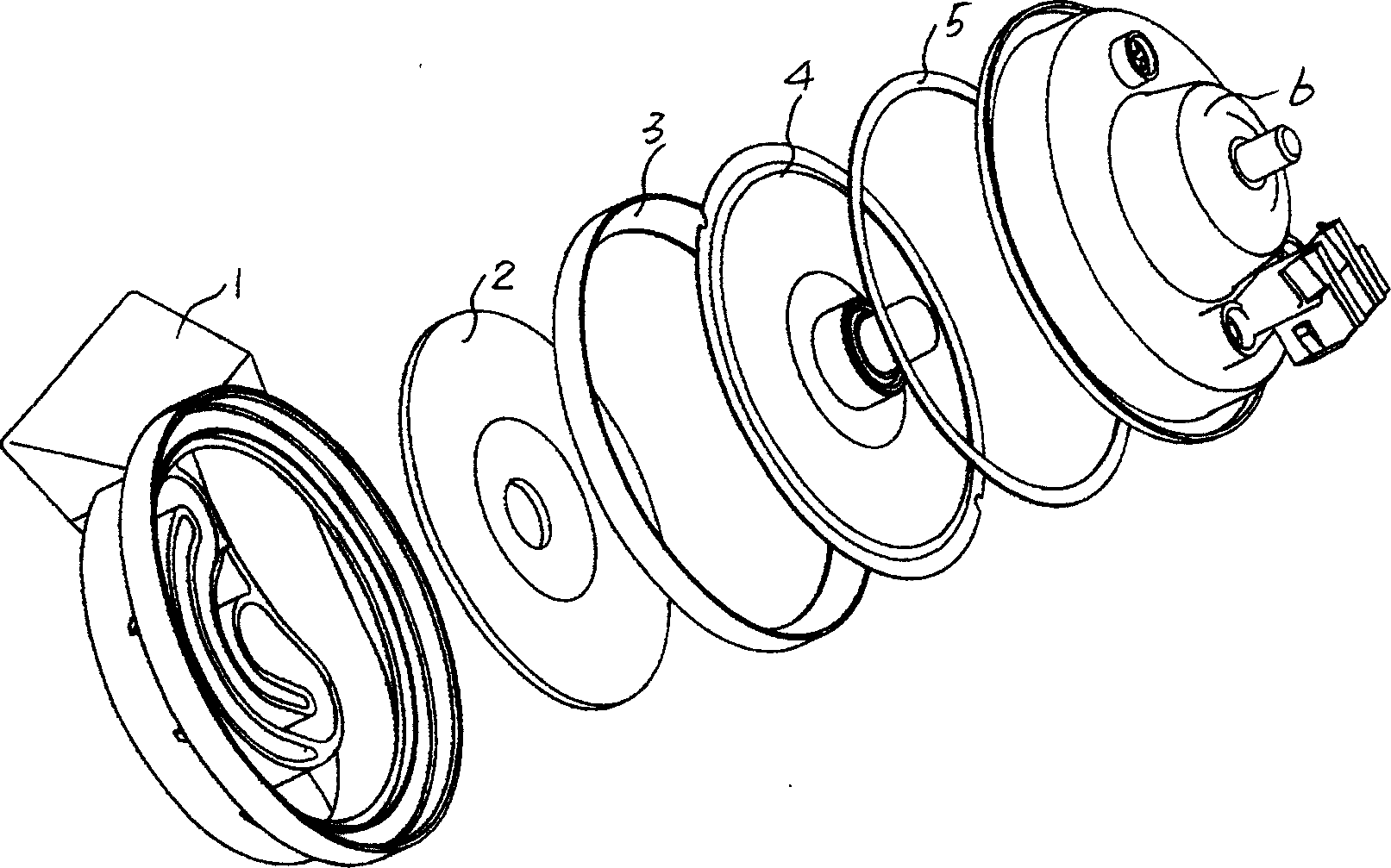

A method of manufacturing a spiral electric horn

ActiveCN1956605BIncrease the sound pressure levelHigh product consistencyElectrical transducersEconomic benefitsEngineering

The invention discloses a manufacturing method of a spiral electric horn, which comprises firstly preparing a loudspeaker tube, a diaphragm component, a liner, a chassis component, a tight ring and a cover plate component of the speaker tube, wherein the cover plate of the speaker tube is made of a composite The method is integrated with the reinforcement surface of the tight ring, so that the tight ring is embedded on the speaker cover plate as an insert to form the tight ring and speaker cover assembly; then the tight ring and speaker cover assembly are combined with Diaphragm components, liners and chassis components are riveted together to form a horn sub-assembly; finally, the horn sub-assembly and the loudspeaker are welded together by ultrasonic waves to form a spiral electric horn. The spiral electric horn prepared by the method of the present invention improves the boundary conditions of the diaphragm vibration system, improves the sound pressure level of the spiral electric horn and the consistency of the product, and greatly improves the sound transmission quality of the spiral horn. The service life is prolonged, and it has good social and economic benefits.

Owner:SHANGHAI SIIC TRANSPORTATION ELECTRIC

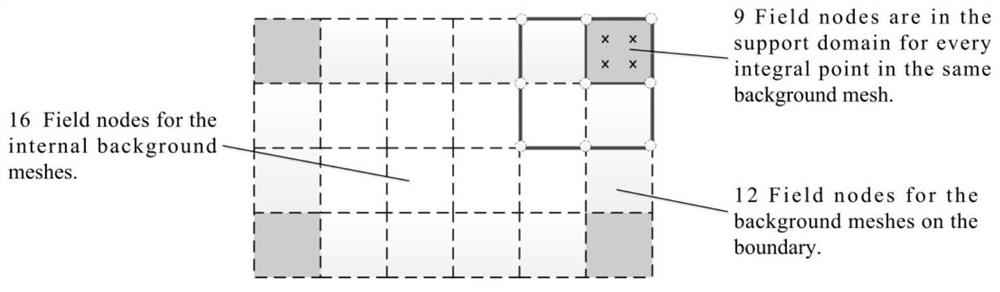

Efficient multiscale finite element method for simulating two-dimensional water flow in porous media

ActiveCN105701315BSave on construction costsIncrease flexibilityDesign optimisation/simulationSpecial data processing applicationsPorous mediumDecomposition

The invention discloses an efficient multi-scale finite element method for simulating two-dimension water flow movement in porous media. The method comprises the steps that a problem needing to be solved is converted into a variation form; boundary conditions of a research area are determined, coarse grid unit dimension is set, the research area is divided, and coarse grid units are obtained; middle grid unit dimension is set, and each coarse grid unit is divided into middle grid units; fine grid unit dimension is set, and each middle grid unit is divided into fine grid units; the degenerate ellipse type problem on the coarse grid units is converted into subproblems of the number of the middle grid units through the area decomposition technique, and values of a multi-scale primary function on all nodes of the middle grid units are obtained by solving the subproblems; a total stiffness matrix can be obtained through the variation form, and a system of simultaneous equations of a water head total stiffness matrix and a right end term is solved through an effective calculation method; water heads of all nodes on the research area are obtained. Compared with a traditional finite element method and a multi-scale finite element method, the calculation efficiency is higher.

Owner:NANJING UNIV

An Optimal Algorithm for Solving Seepage Free Surface Based on Radial Cardinal Point Interpolation Method

ActiveCN110443432BMake sure it's fully alignedGuaranteed integral accuracyClimate change adaptationForecastingAlgorithmIntegration point

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

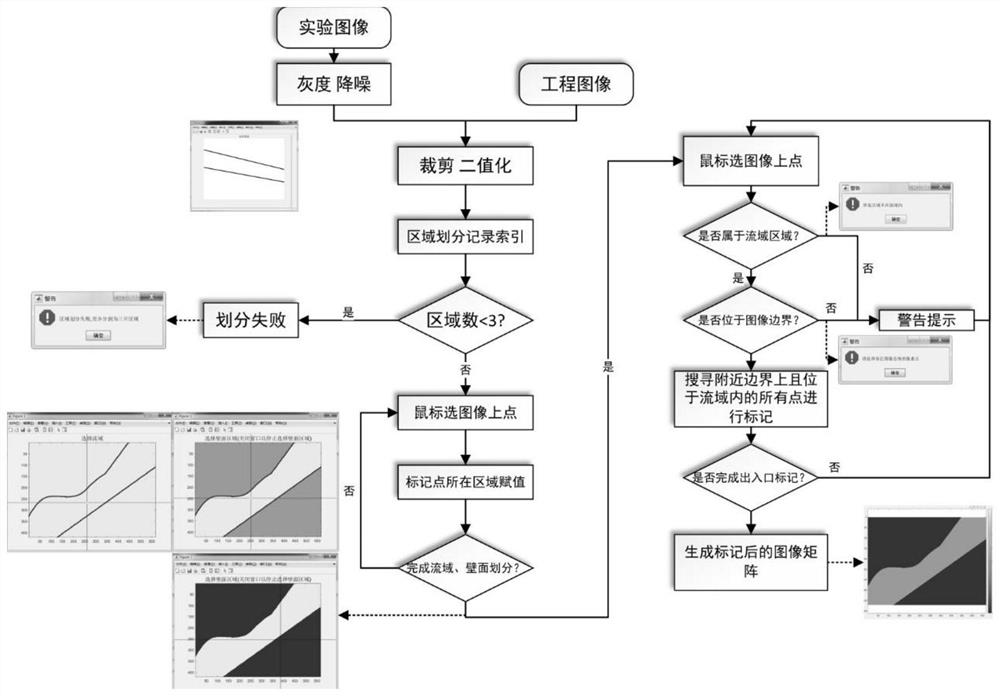

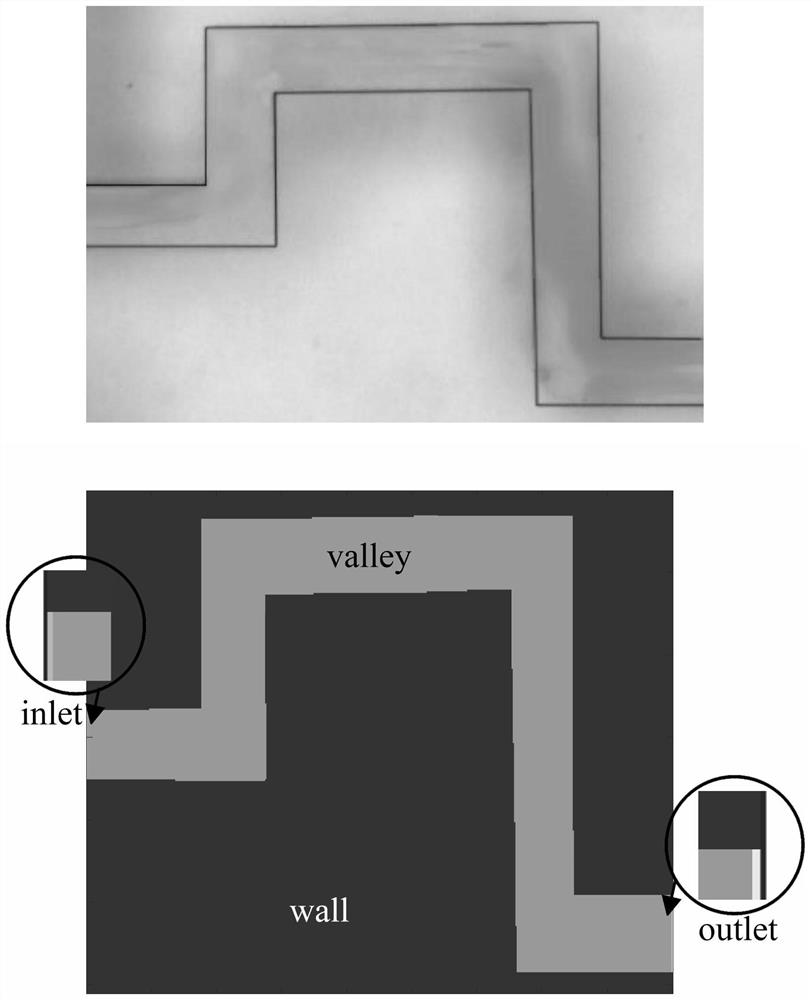

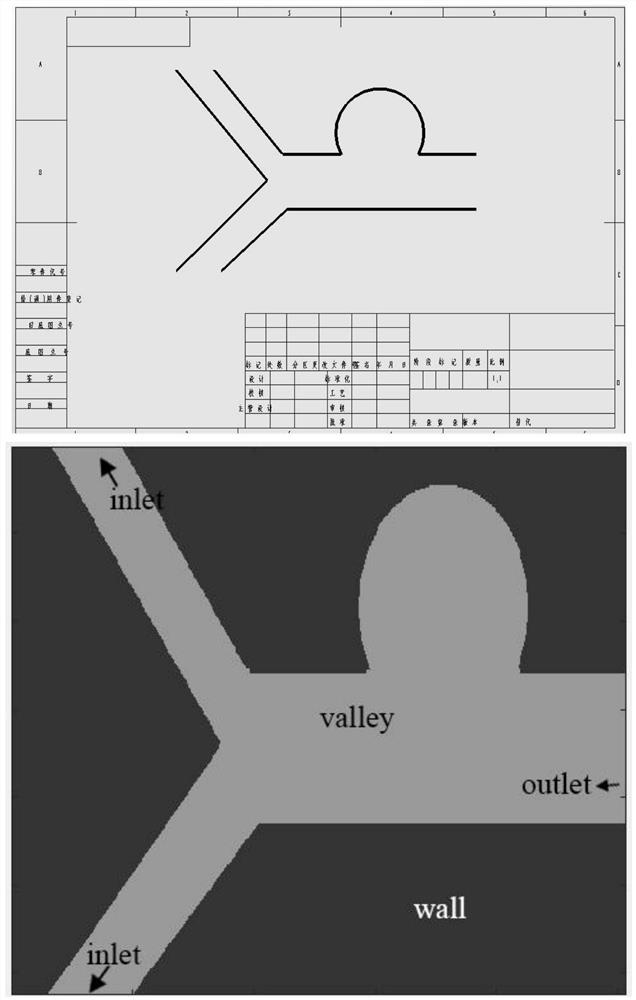

LBM computational domain planning method based on image recognition

PendingCN112446386AImprove boundary conditionsCharacter and pattern recognitionRegion selectionAlgorithm

The invention discloses an LBM computational domain planning method based on image recognition, which surpasses the limitation that a mathematical expression required by a traditional specified computational domain expresses a computational domain and boundary conditions, and can divide the computational domain into an integer matrix containing predefined label information based on any closed image (engineering image or actual experimental image). According to the method, after a closed image is input, a plurality of regions are automatically divided through a series of preprocessing, pixel points in the regions can be selected, a drainage basin and a wall surface region are planned according to a predefined integer label, pixel points near the edge of the image are selected to automatically identify a boundary entrance and exit, and planning is also carried out according to a predefined integer. Finally, a matrix with various predefined integer information is output, and different regions and entrances and exits are distinguished by different integers, so that corresponding boundary conditions can be defined according to the predefined integers when the LBM method is used.

Owner:BEIJING UNIV OF TECH

Soil hot-wet coupling carrying model trial device

InactiveCN101082618BRealize the process of heat transfer and moisture transferReasonable physical simulation conditionsMaterial analysisExhaust valveCoupling

The invention discloses a thermohydrocoupling migration model testing device, which comprises the following parts: heating rod, soil sample box, thermostatic circulating tank, porous permeable board,martensitic bottle, thermometric probe, water testing probe, foam plastic board, wherein the porous permeable board is set on the bottom of the soil sample box, which is welded with four walls of soilsample box; the valve and vent valve are set on two sides opposite to the lower face of porous permeable board and soil sample box; the valve connects martensitic bottle through pipe; the temperature-testing element is set in the inner wall of the heating rod; a steel baffle is set at two sides of the front and back of soil sample box separately; the bottom, left and right sides of steel baffle is welded with inner sides of soil sample box and lateral board; the foam plastic board is cushioned on the inner side of steel baffle. The invention has reasonable structure, simple and convenient operation, which realizes heat and wet transmission of soil.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

Method for determining a basic boost pressure of a gas conducting system of an internal combustion engine, and engine controller for carrying out a method of this type

ActiveUS20200173346A1Stabilizes charge regulationReduce consumptionElectrical controlInternal combustion piston enginesTurbochargerControl theory

A method for determining a basic boost pressure of a gas conducting system of an internal combustion engine with a turbocharger that has a compressor, a turbine, a shaft connecting the compressor and the turbine, and a turbocharger actuator for varying a flow velocity through the turbine or a pressure ratio across the turbine. The method comprises calculation of an exhaust gas back pressure at the open turbocharger actuator position, wherein the flow velocity through the turbine or the pressure ratio across the turbine is minimal in the open turbocharger actuator position, and determination of the basic boost pressure as a function of the calculated exhaust gas back pressure at the open turbocharger actuator position. An engine controller for carrying out a method for determining a basic boost pressure is also provided.

Owner:VOLKSWAGEN AG

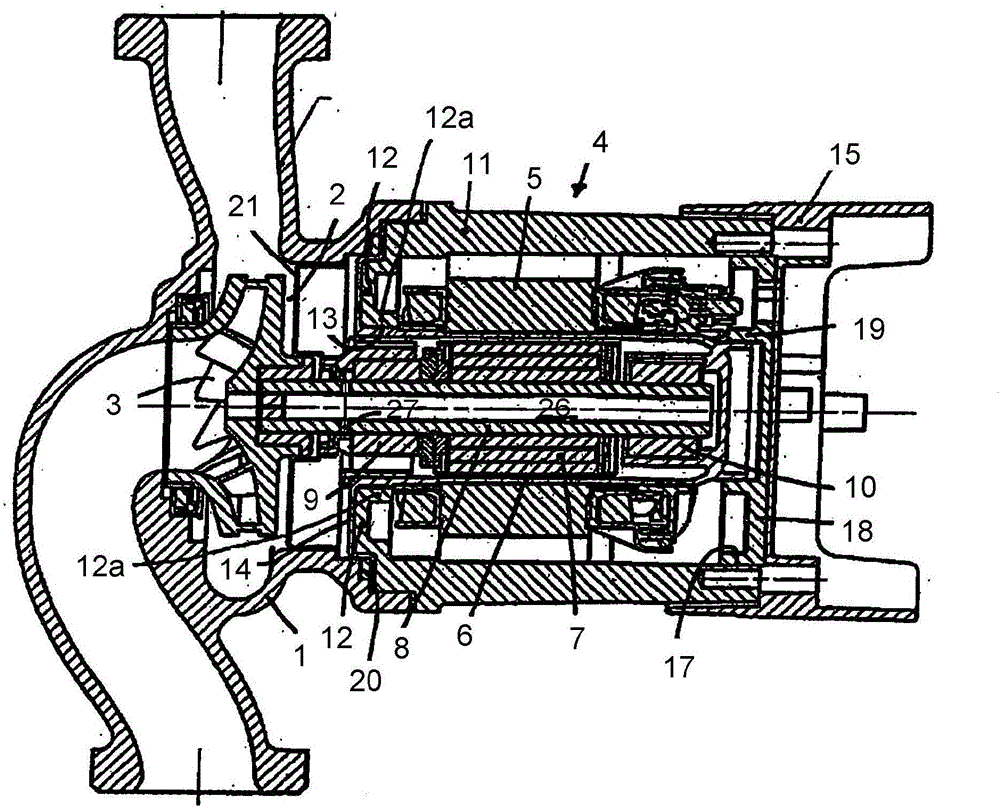

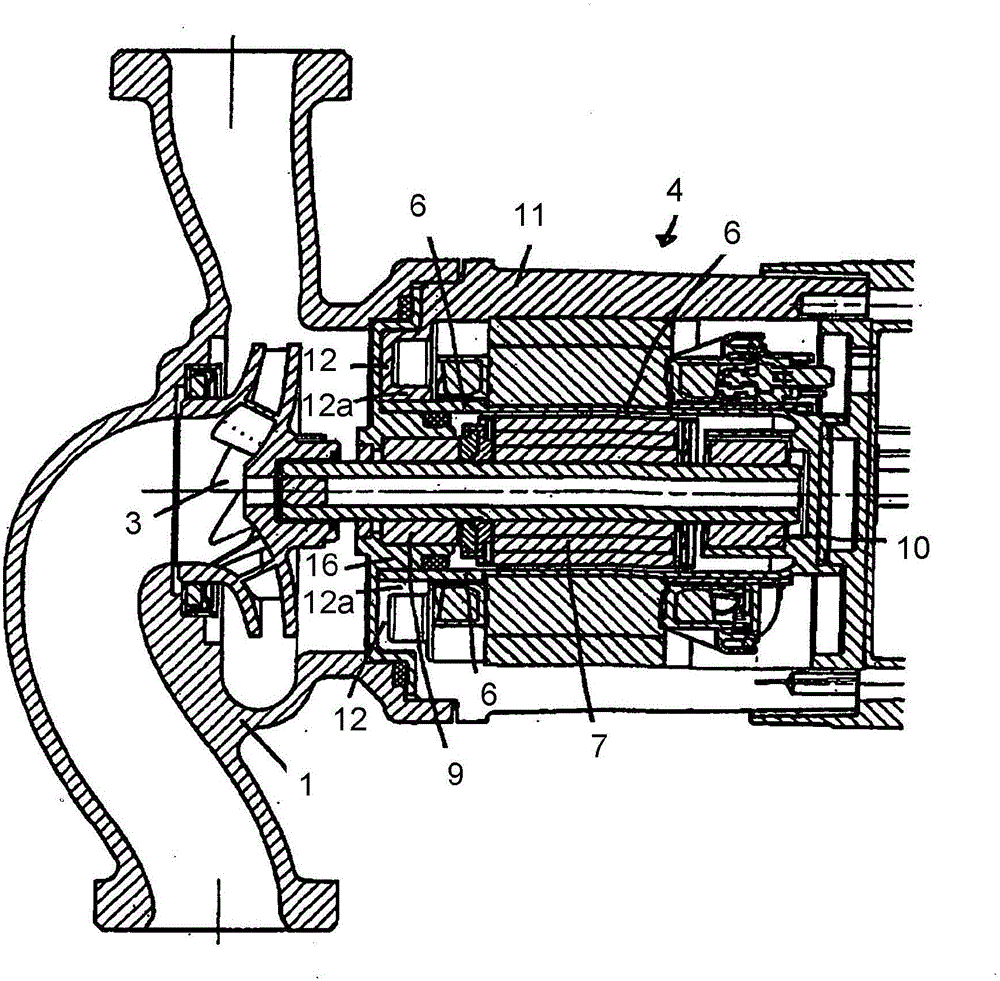

Wet motor pump

InactiveCN105849414AImprove convenienceEasy to manufacturePump installationsNon-positive displacement fluid enginesImpellerEngineering

The invention relates to a wet motor pump comprising a stator (5) surrounded by a motor casing (4), and a rotor (7) which is separated from the stator by a can (6), runs in a rotor chamber formed by the can, and is connected to a pump impeller (3) via a shaft (8). At the end facing the pump impeller, the motor casing forms an inward-oriented motor casing flange (12), the inner end of which forms an annular extension (12a) that rests externally on the can either directly or via an intermediate layer.

Owner:WILO SE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com