Patents

Literature

159 results about "Double wedge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In geometry, a double wedge is the (closure of) the symmetric difference of two half-spaces whose boundaries are not parallel to each other. For instance, in the Cartesian plane, the union of the positive and negative quadrants forms a double wedge, and more generally in two dimensions a double wedge consists of the set of points within two vertical angles defined by a pair of lines. In projective geometry double wedges are the projective duals of line segments.

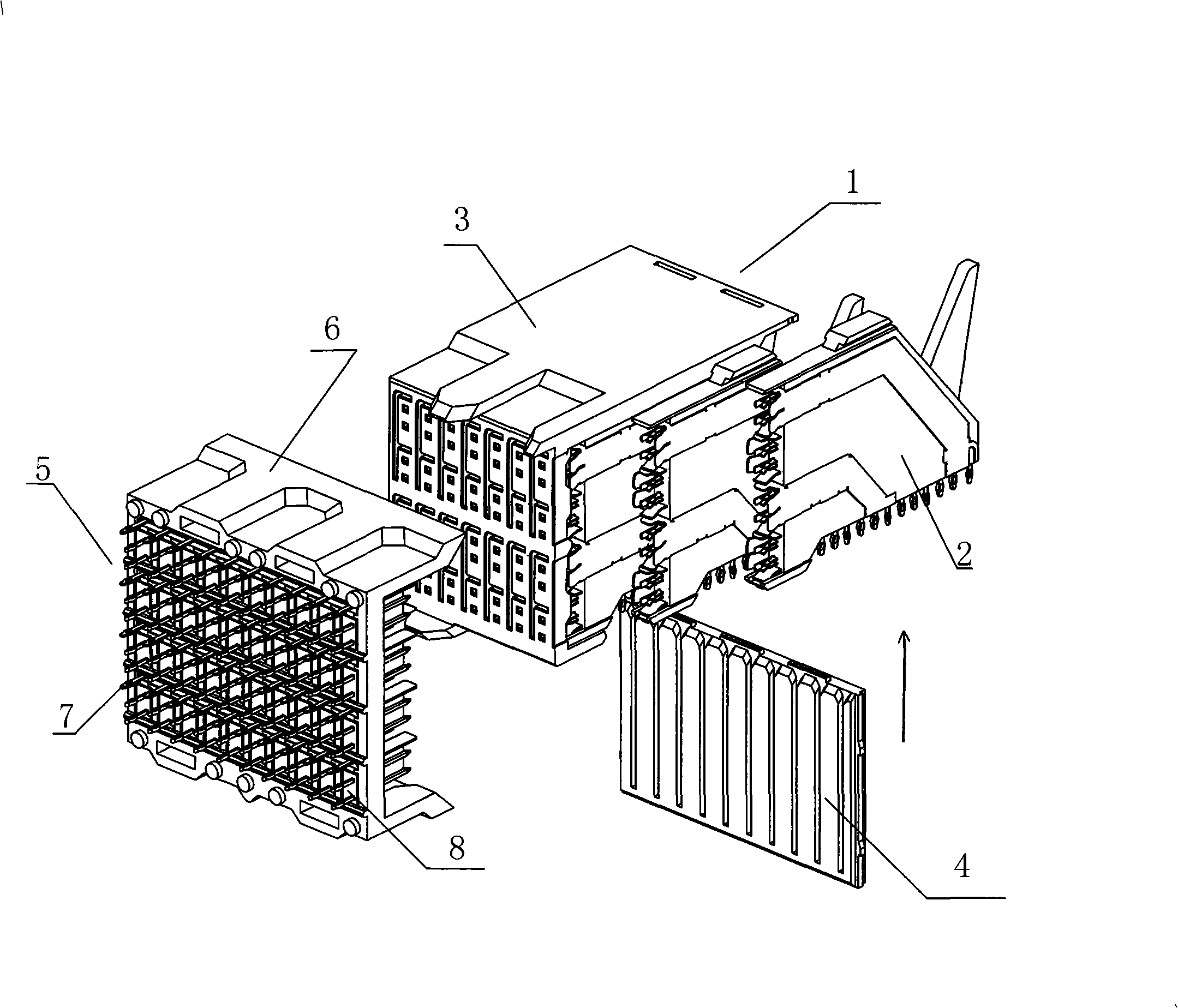

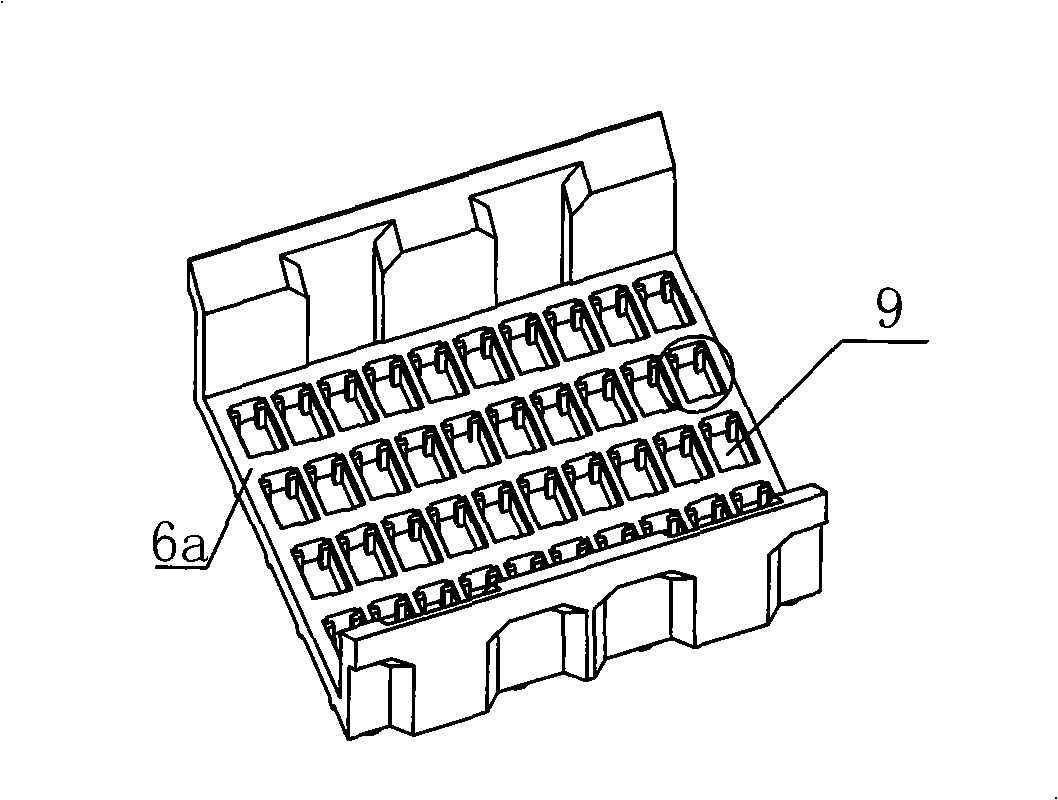

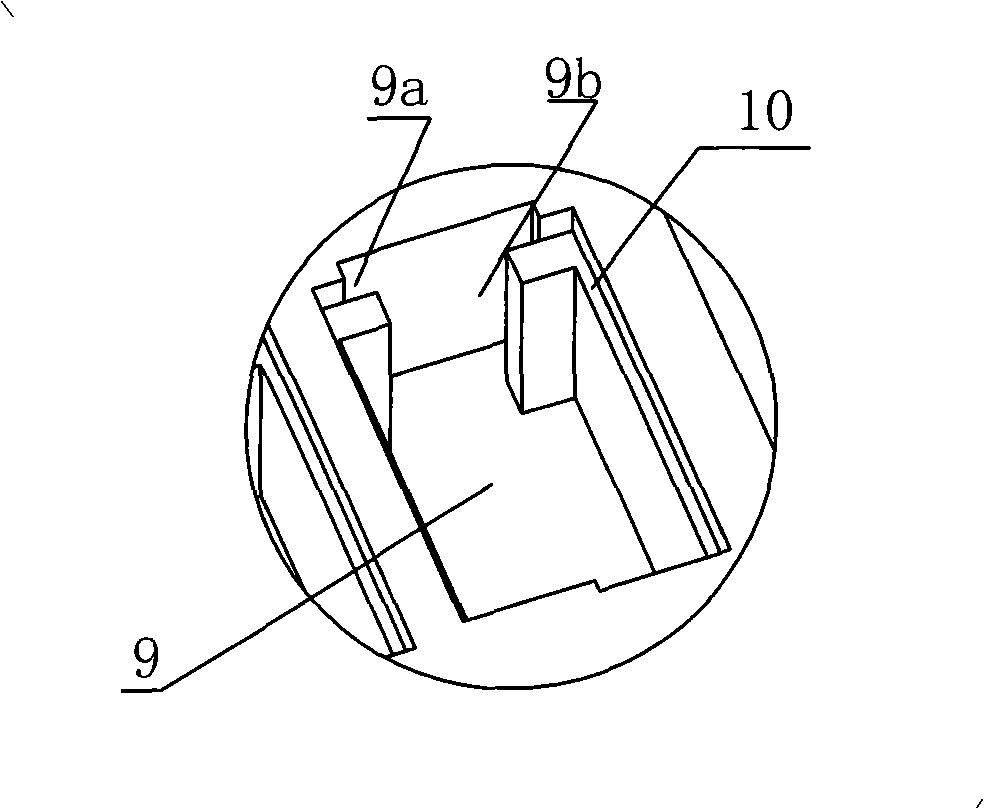

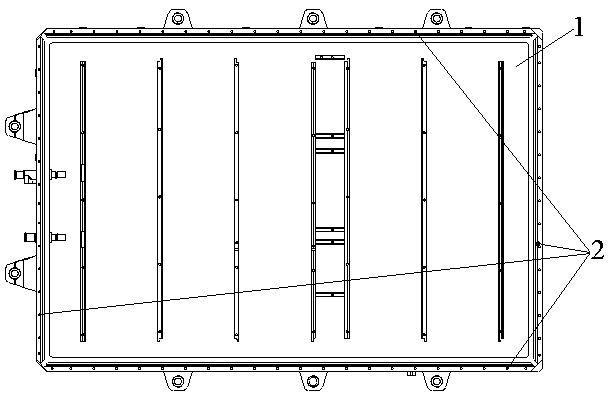

High speed high-density connector with modular structure for back board

InactiveCN101330172AStable structureCompact structureCoupling protective earth/shielding arrangementsInterference fitState of art

The invention provides a high-speed high-density backboard connector with a modularized structure. The electric connector comprises a pore connector and a pin connector, wherein the pore connector comprises a casing, a cover plate and a plurality of veneer sheet components; and the pin connector comprises a pedestal, a laterally-grounded shielding piece and differential pair signal pin units. The pin connector adopts the modularized structure. The differential signal pin units and the laterally-grounded shielding piece are arranged in the pedestal in a dense array. The modularized structure is fixed in the pin connector by adopting the interference fit or the double-wedge. Compared with the prior art, the backboard connector has the advantages of stable, compact and easily-expansible structure, complementary shielding and high-density and high-quality signal running characteristic.

Owner:GUIZHOU SPACE APPLIANCE CO LTD

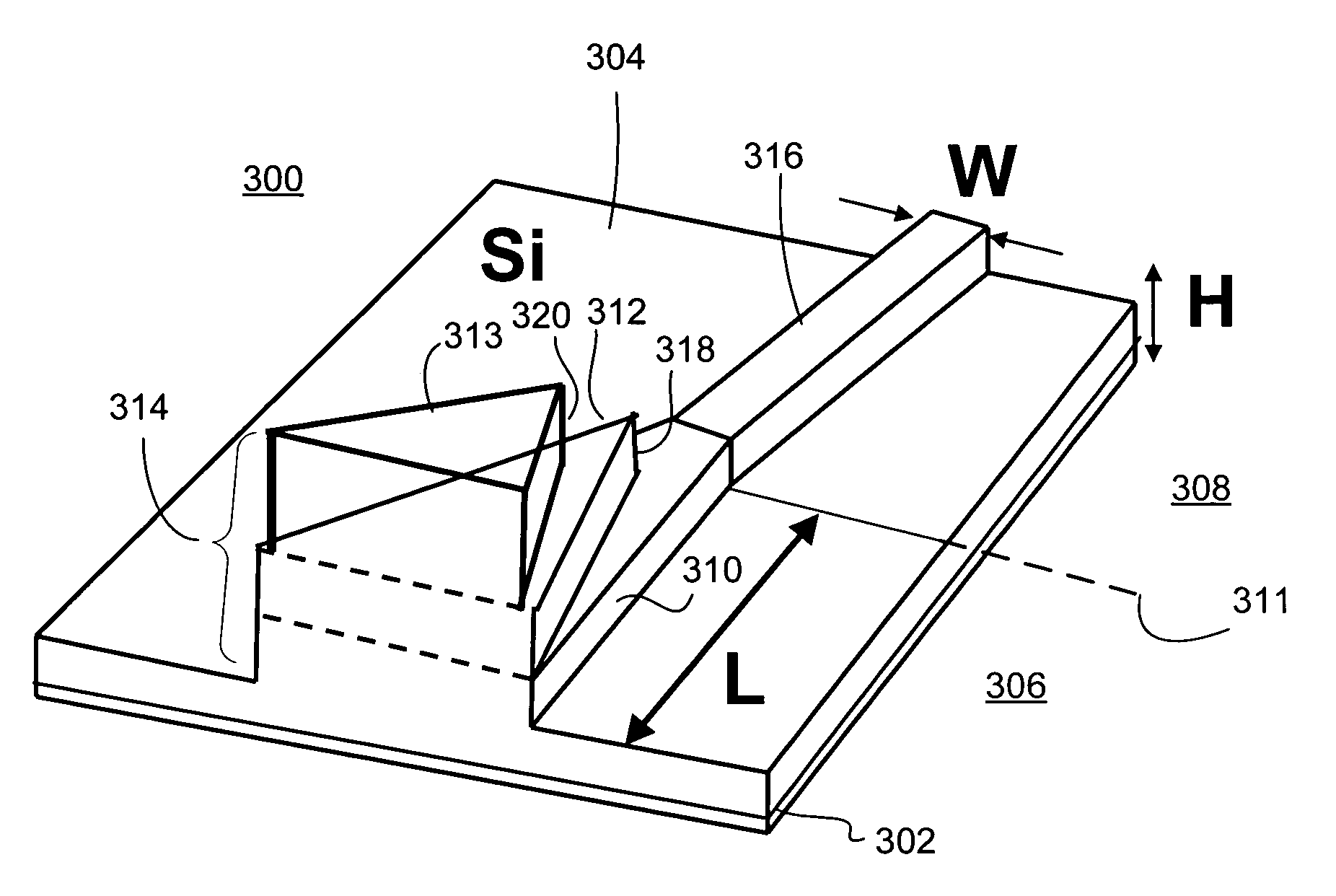

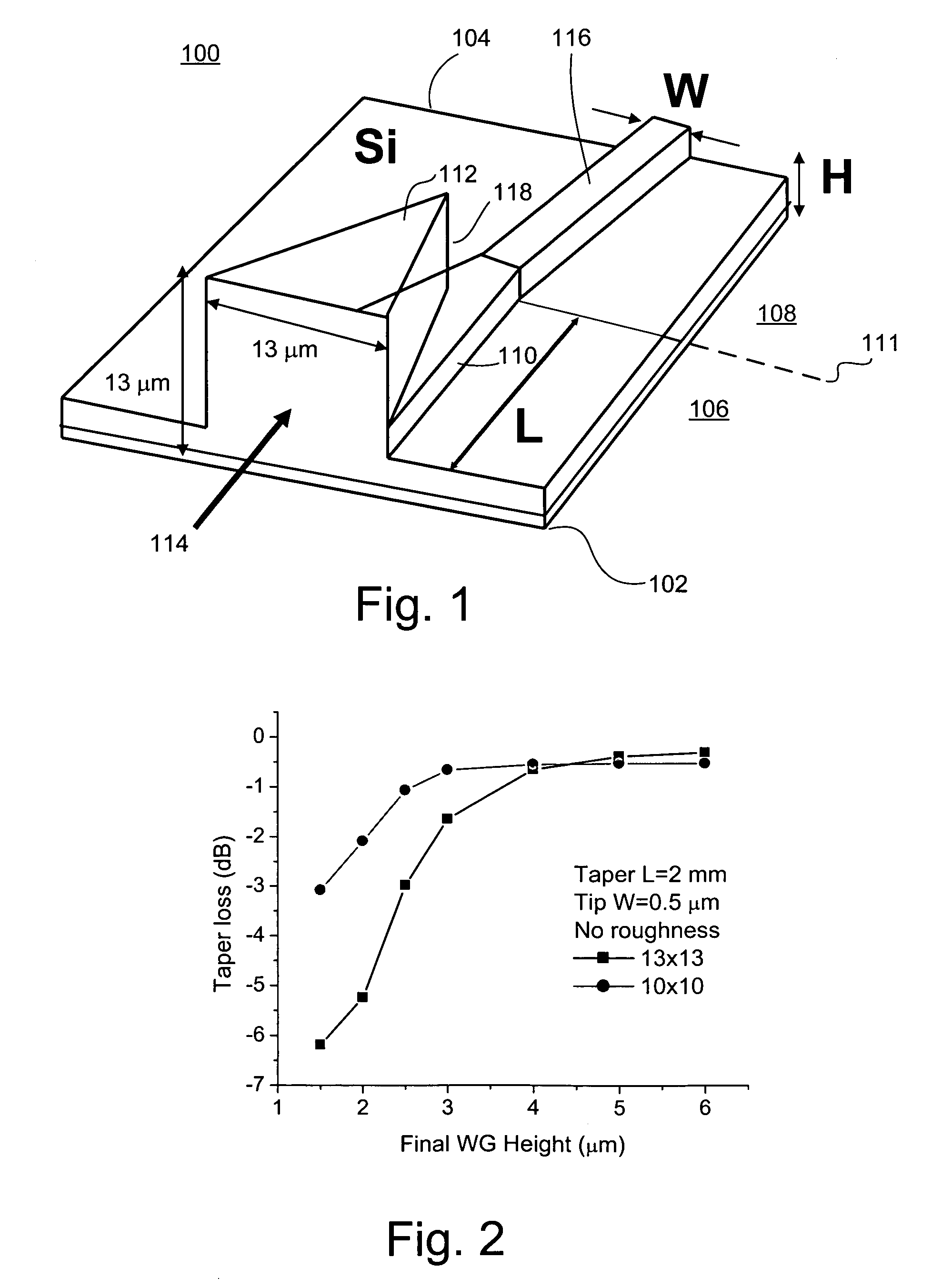

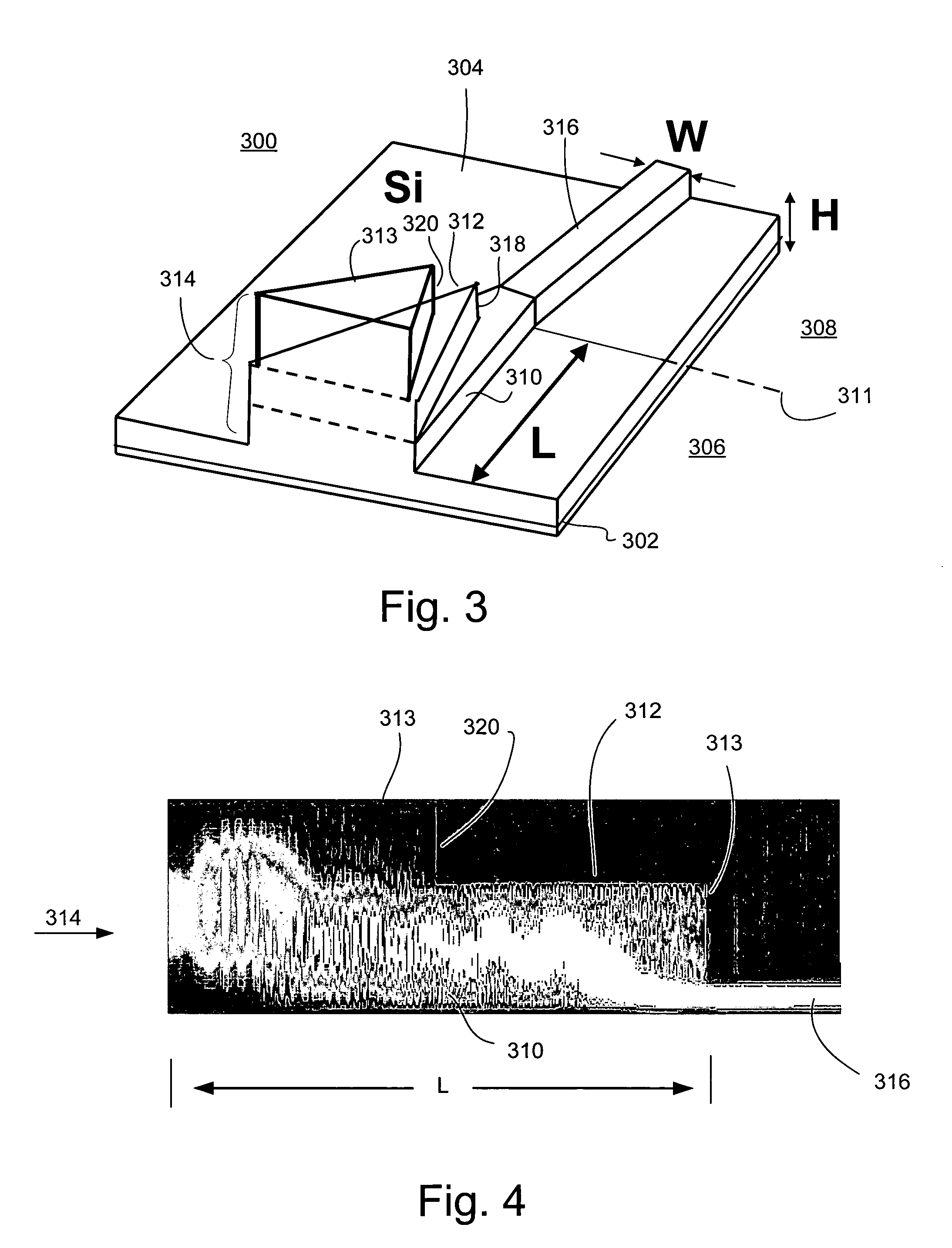

Dual “cheese wedge” silicon taper waveguide

An optical device may include a fiber or waveguide that is intended to be coupled to another waveguide having a significantly larger / smaller cross-sectional size. As such, two wedge shaped waveguides may be positioned atop a tapered waveguide. The dual wedge design may allow for shorter taper lengths and smaller final waveguide cross section dimensions.

Owner:INTEL CORP

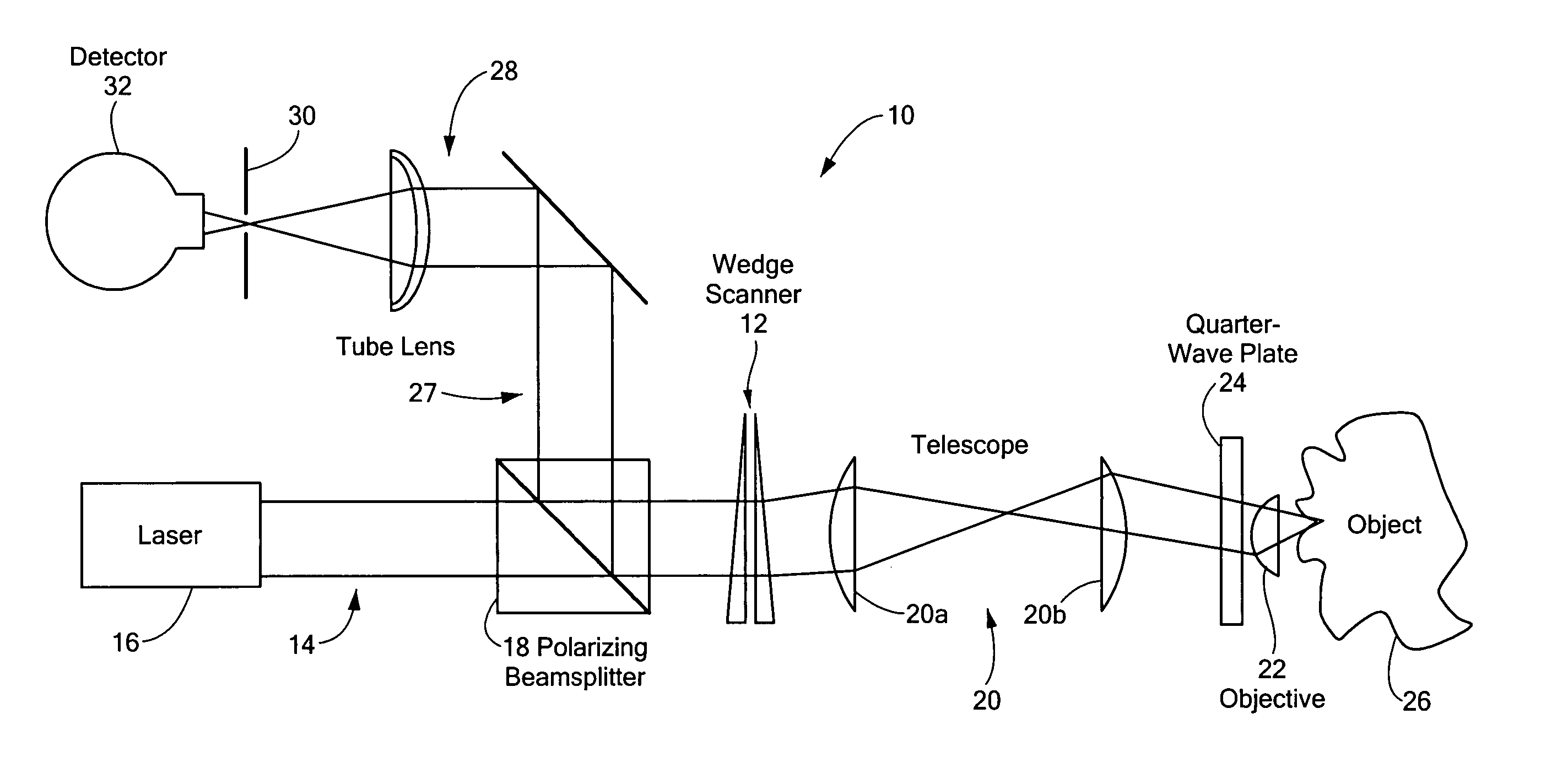

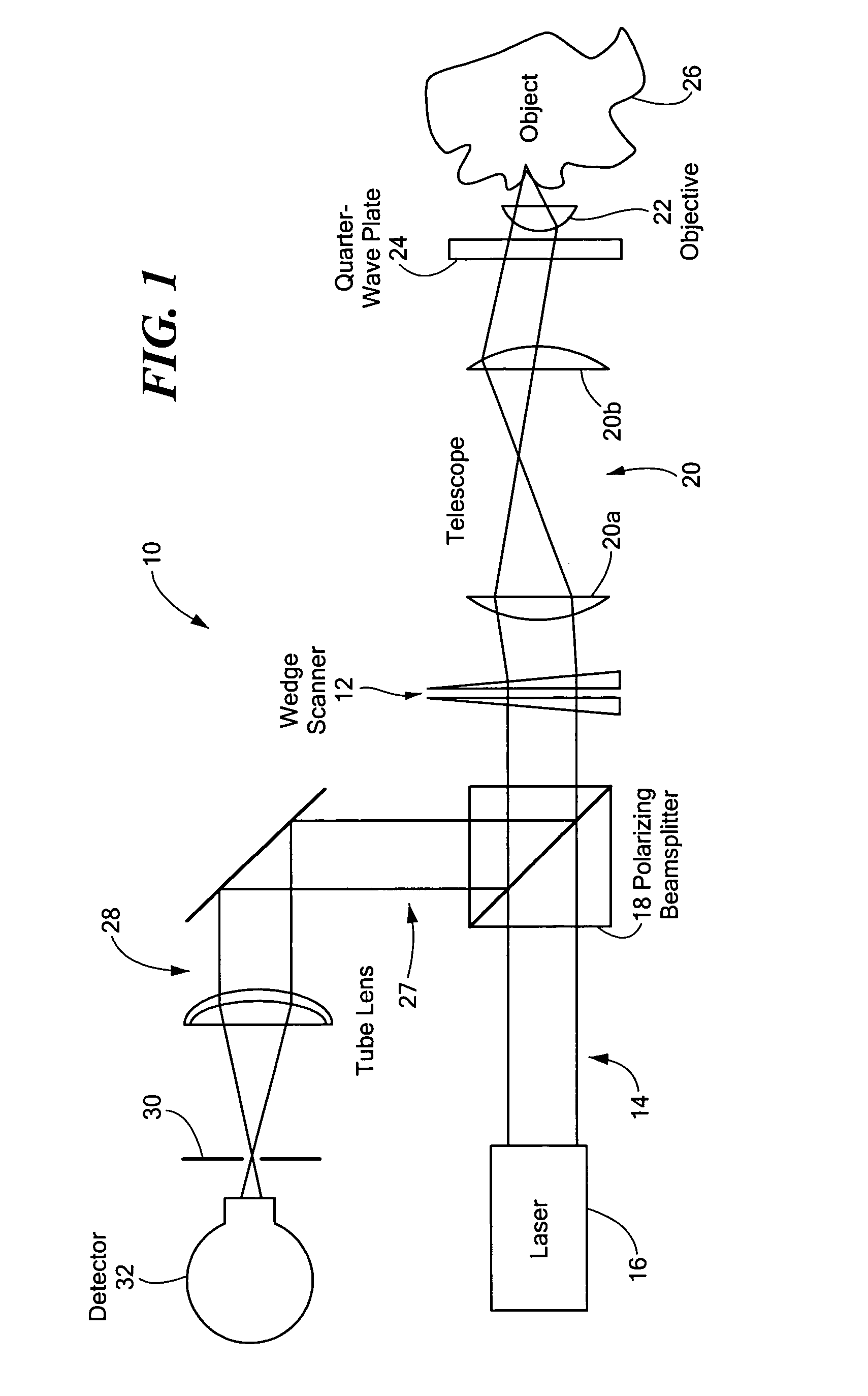

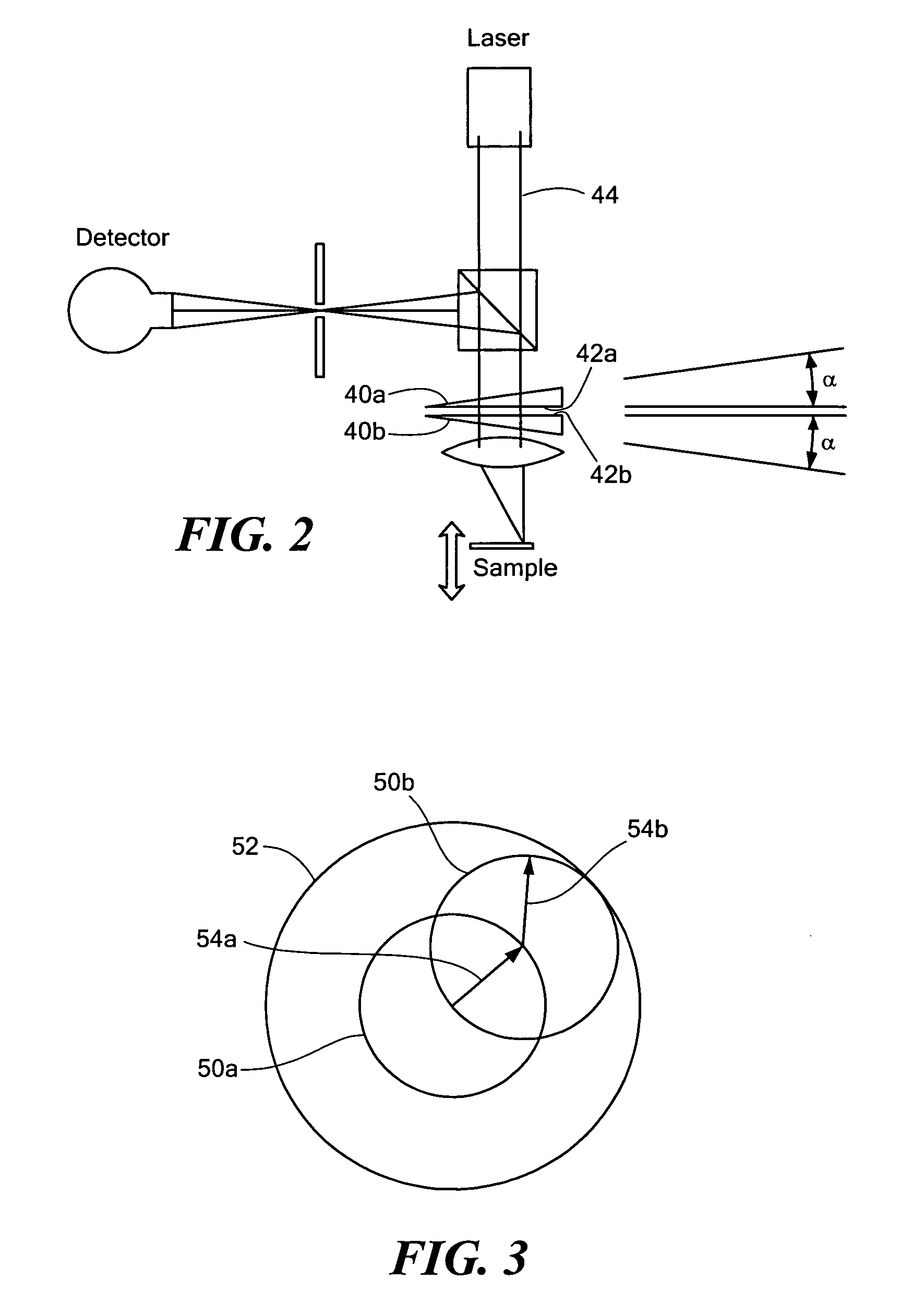

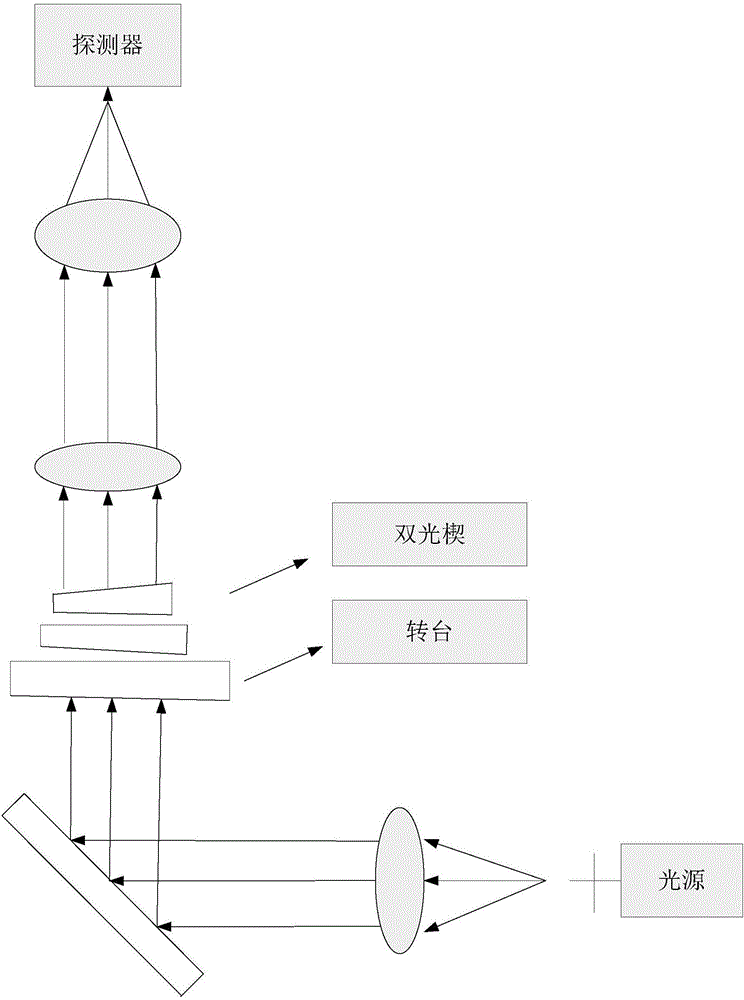

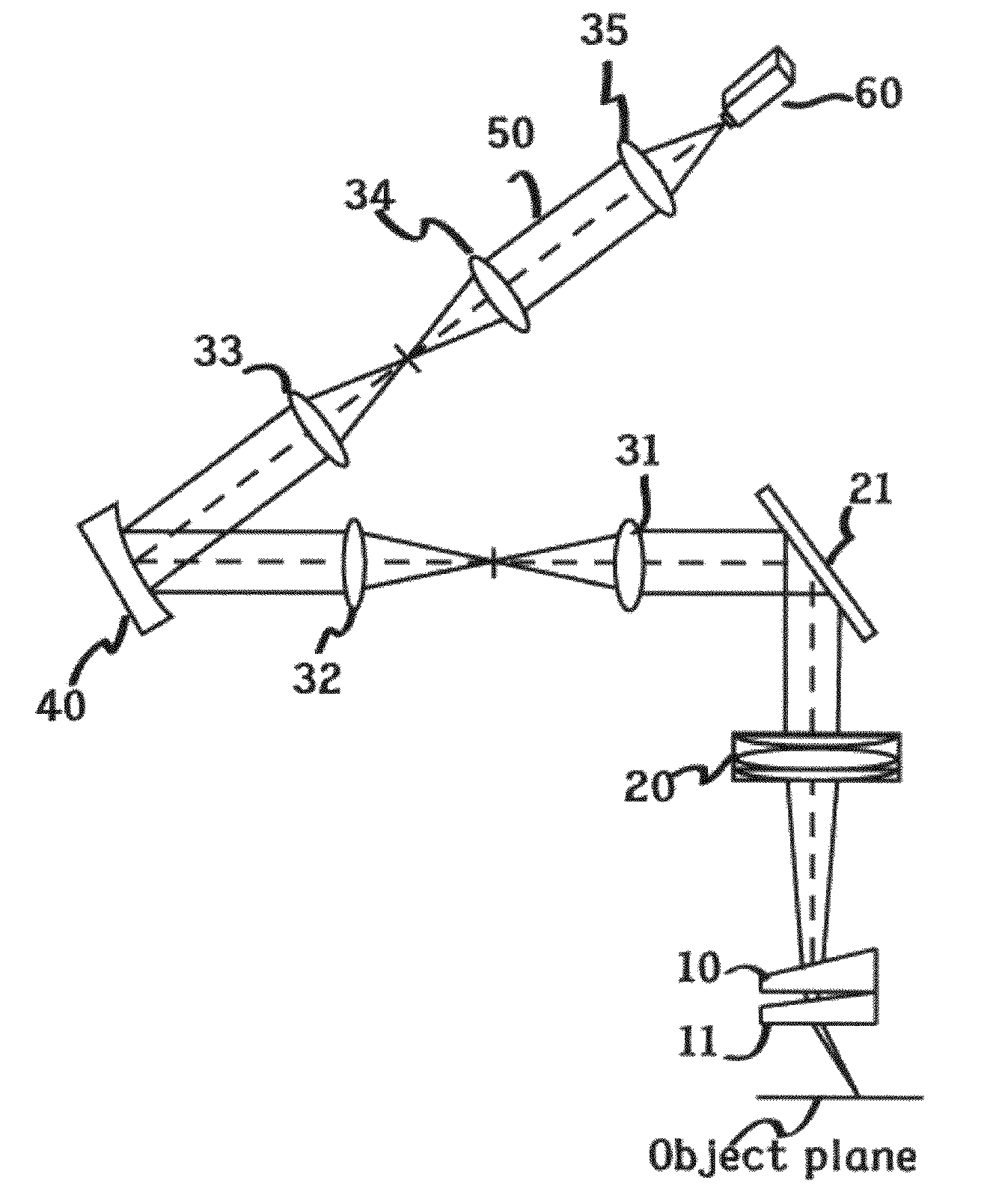

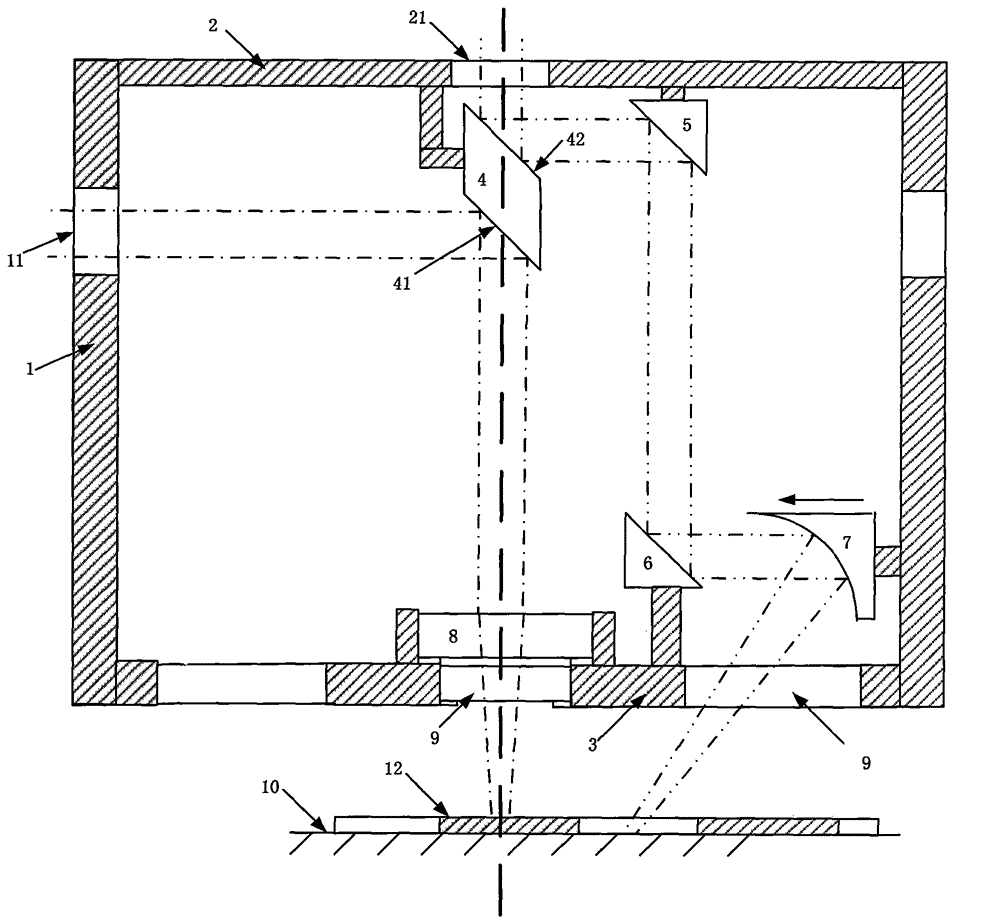

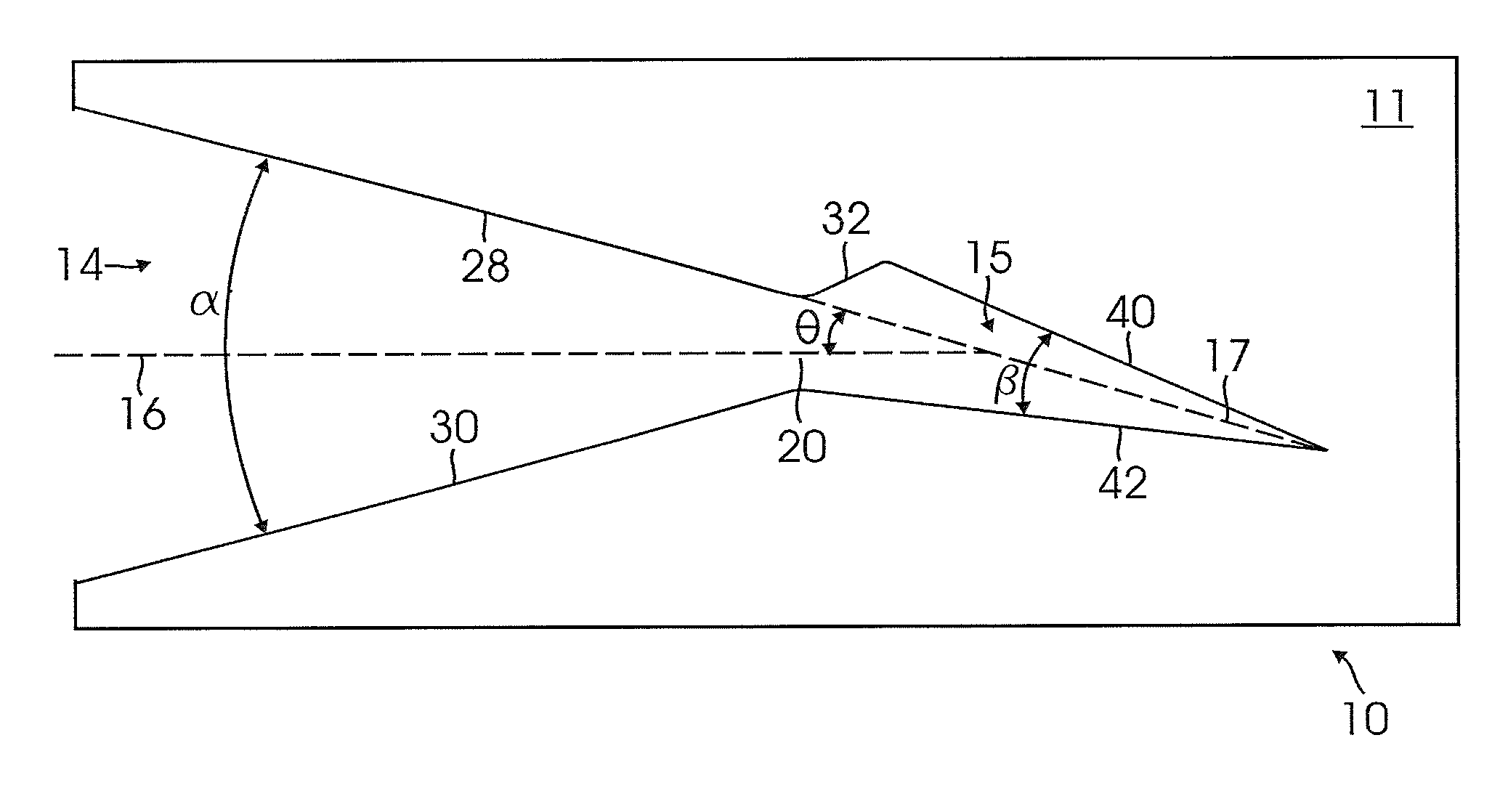

Confocal reflectance microscope system with dual rotating wedge scanner assembly

A confocal reflectance microscope system incorporates a dual-wedge laser scanner assembly. The scanner assembly incorporates a pair of rotatably mounted prisms, each prism having an angle selected to deviate a light beam from a light source by a desired angle. Each prism is mounted for rotation at a desired speed of rotation and in a desired direction to scan the light beam over the target. An image is built up from successive reflected signals returned from the target.

Owner:NORTHEASTERN UNIV

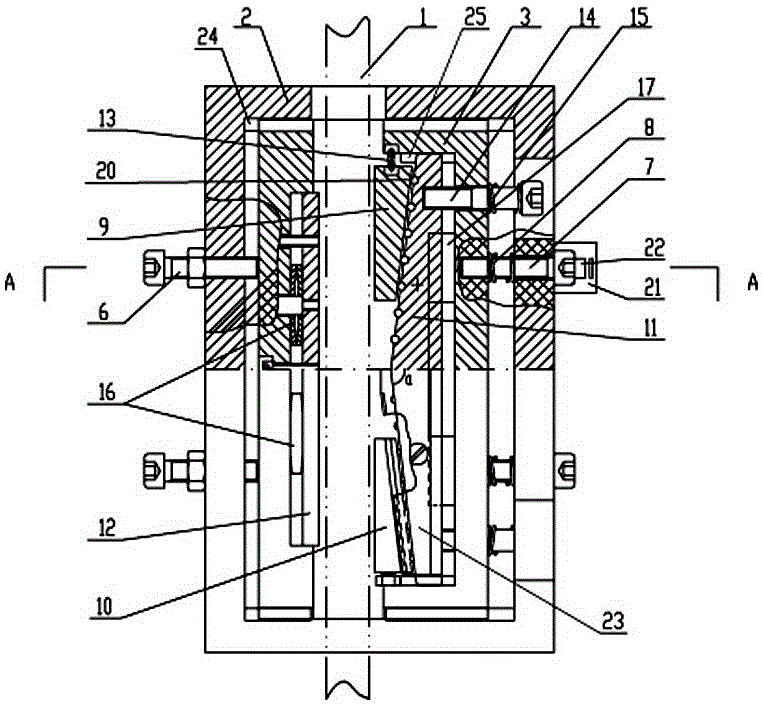

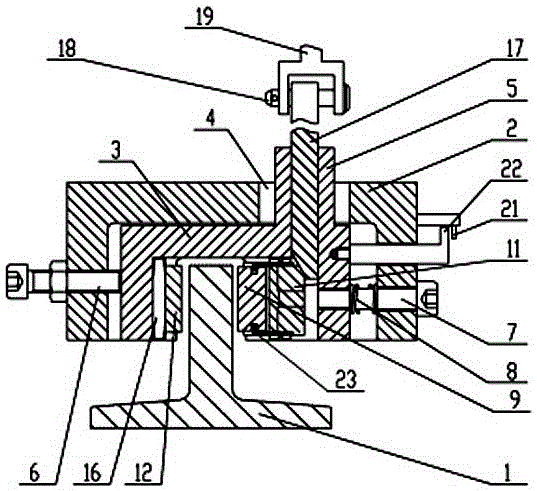

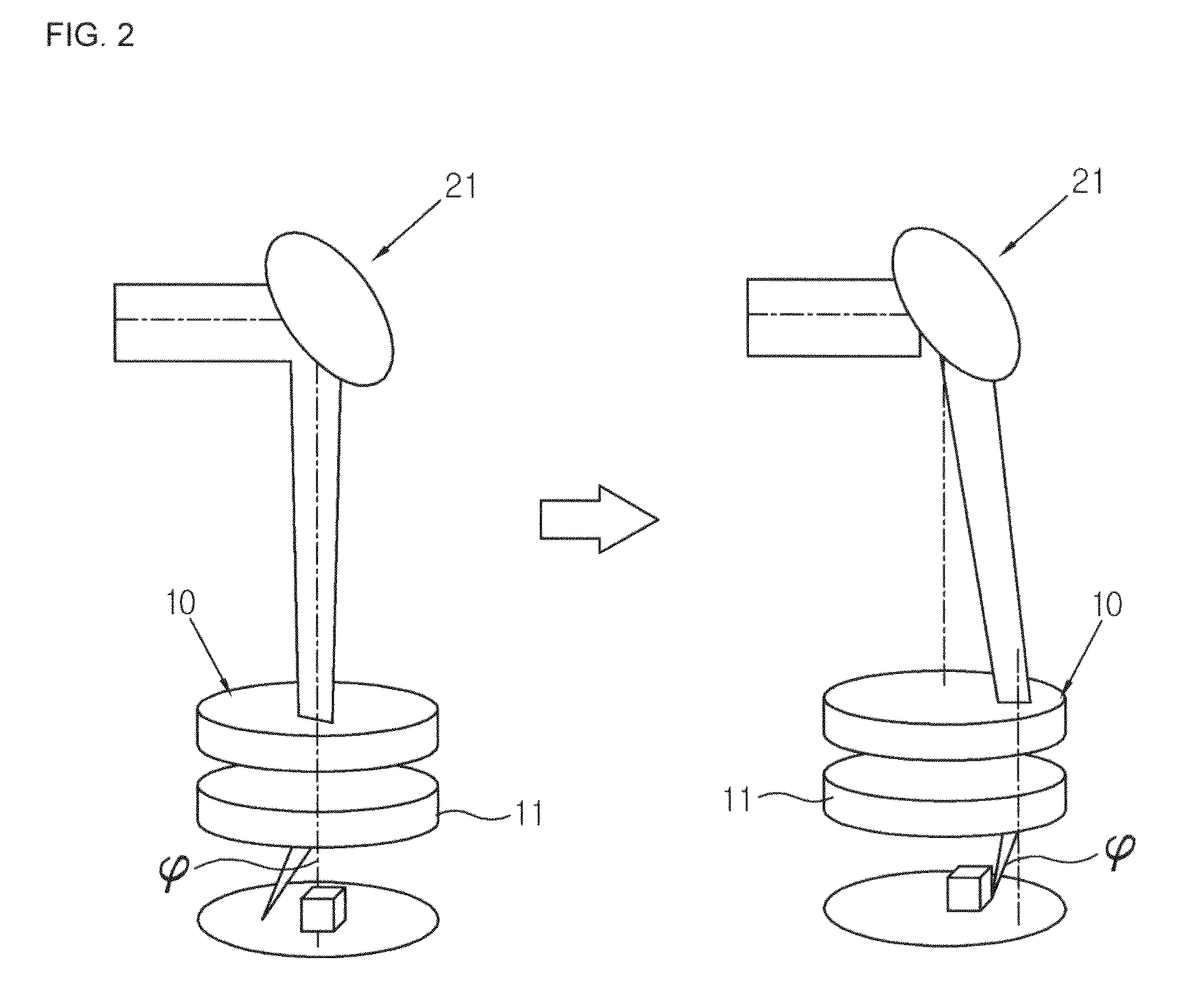

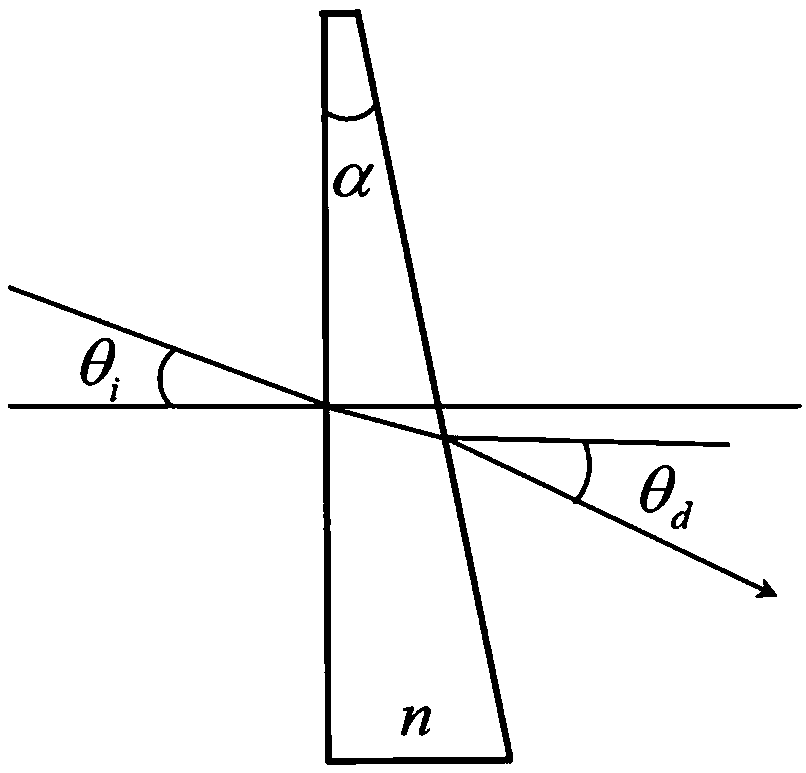

Light beam scanning mechanism based on rotation double wedge lenses

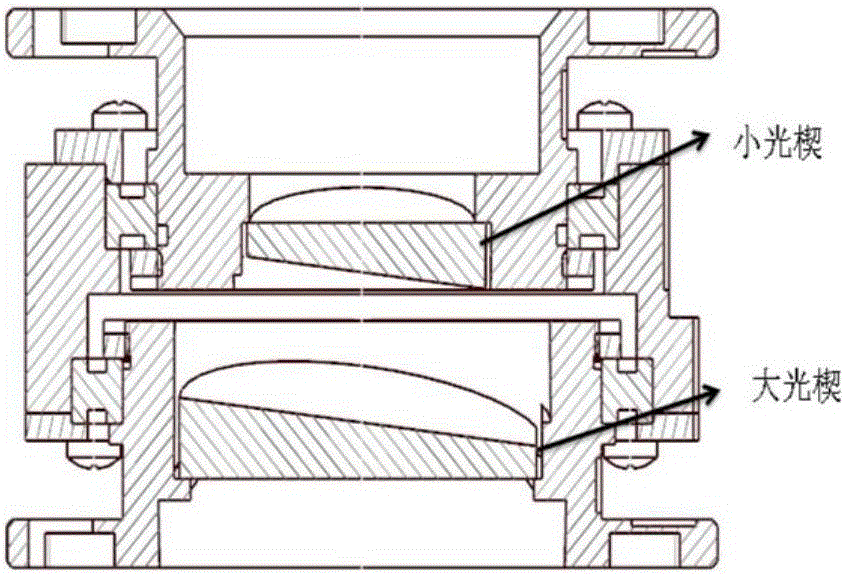

ActiveCN102928978AAvoid the effective light rangeReduce pressure deformationOptical elementsOptical ModuleMotor drive

The invention discloses a light beam scanning mechanism based on rotation double wedge lenses and belongs to the technical field of photoelectronic imaging probing technique. The light beam scanning mechanism comprises two sets of optical modules, wherein each set of optical module comprises an optical wedge lens, a lens frame, a big gear, a small gear, a motor, a bearing, a support and an angle measurement coded disc, the optical wedge lens is installed inside the lens frame which is installed on the support through the bearing, the lens frame is cylindrical, the angle measurement coded disc is installed on one lateral end face of the lens frame, the big gear is installed on the other lateral end face of the lens frame, and a gear shaft of the motor drives the big gear to rotate through the small gear to drive the optical wedge lens on the lens frame to rotate. The two optical wedge lenses perform drive rotation respectively to achieve light beam scanning. Rotation of the optical wedge lenses adopts single transmission driving, rotation control of the two wedge lenses has no mutual coupling influences, and movement speed and movement direction of the light beam scanning mechanism are not mutually interfered, and a multi-scanning mode can be achieved.

Owner:BEIHANG UNIV

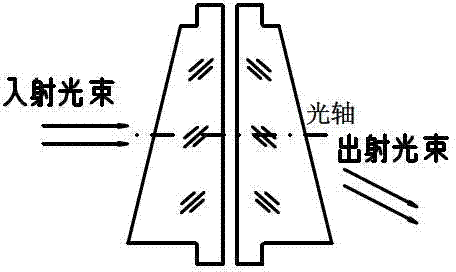

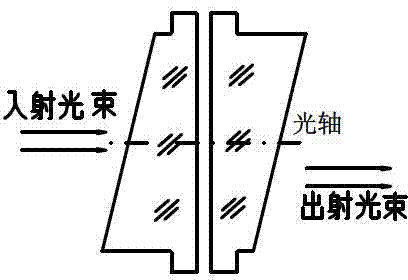

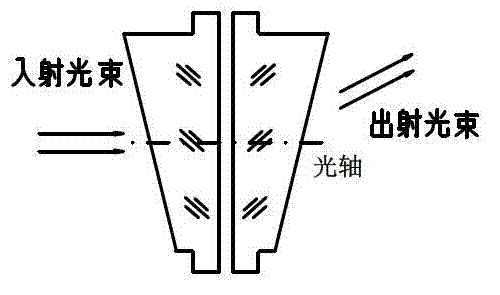

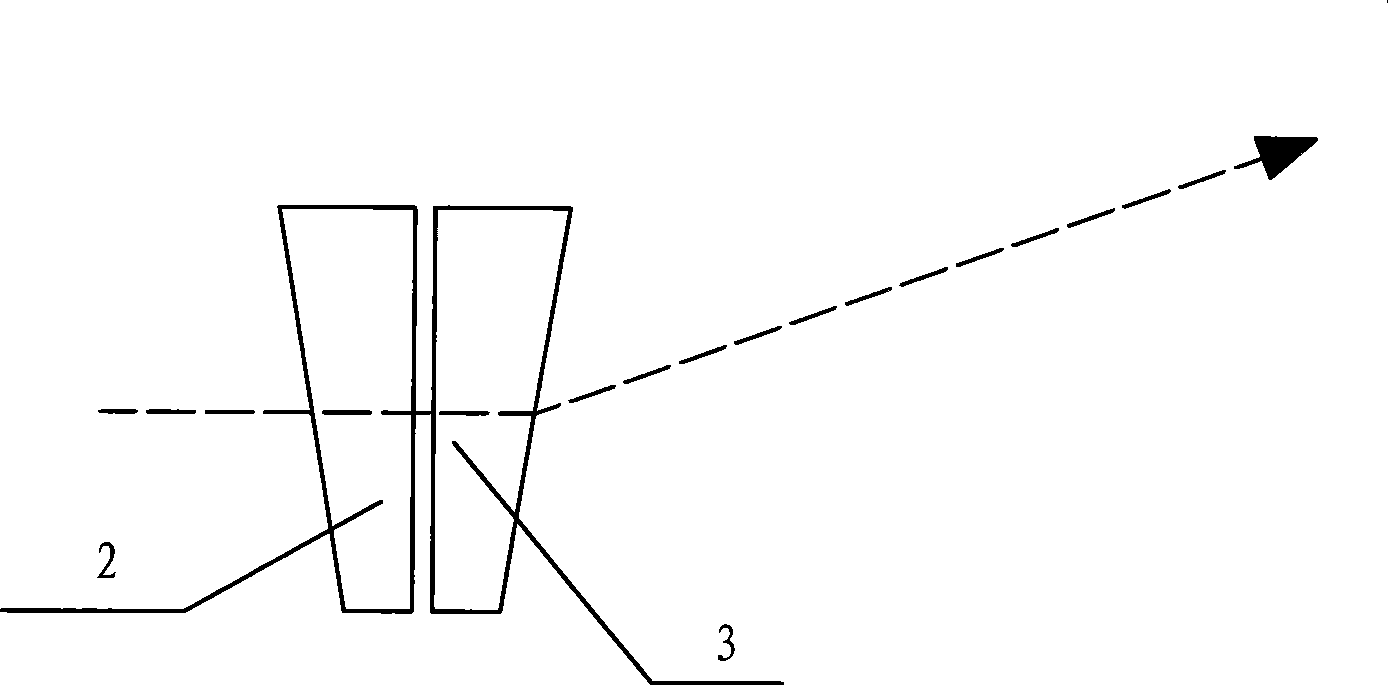

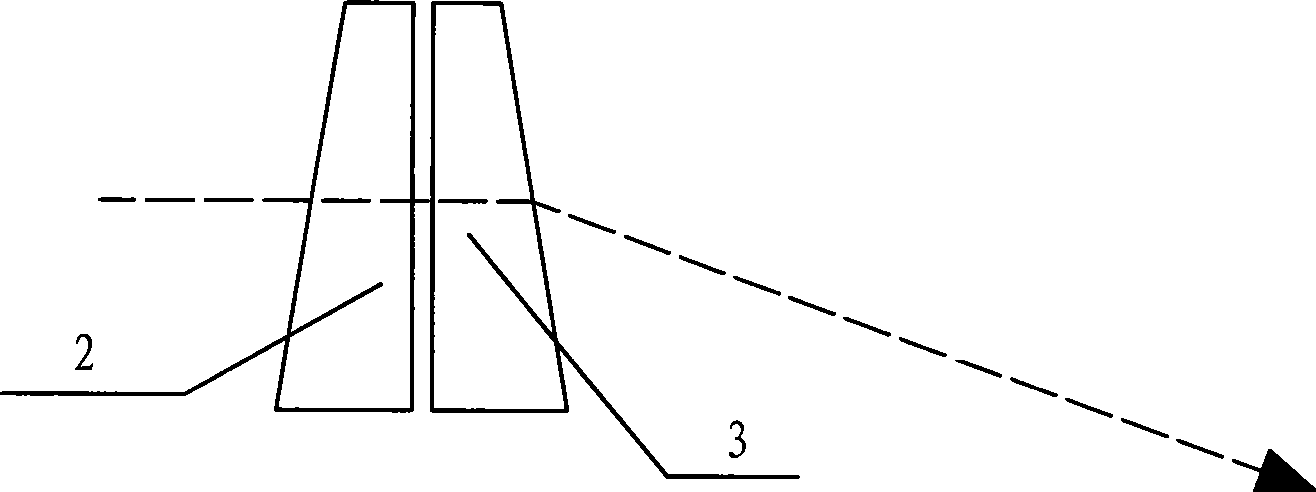

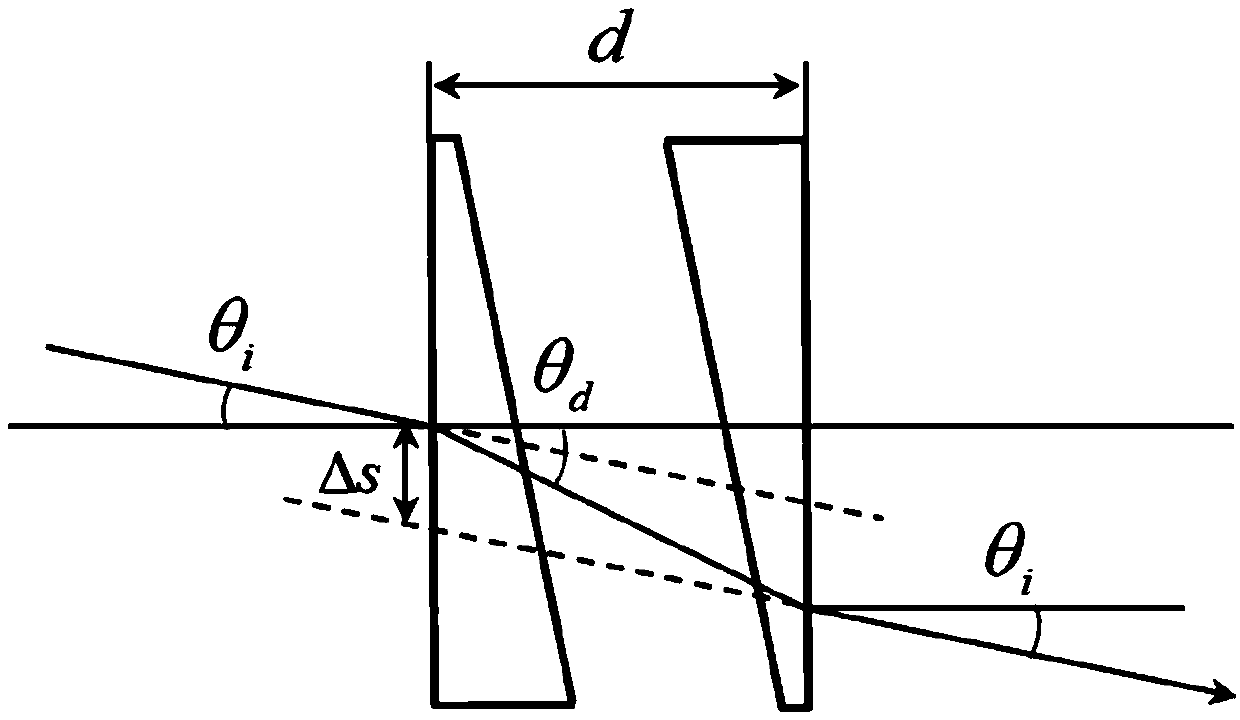

Double-wedge centering assembly and adjustment method

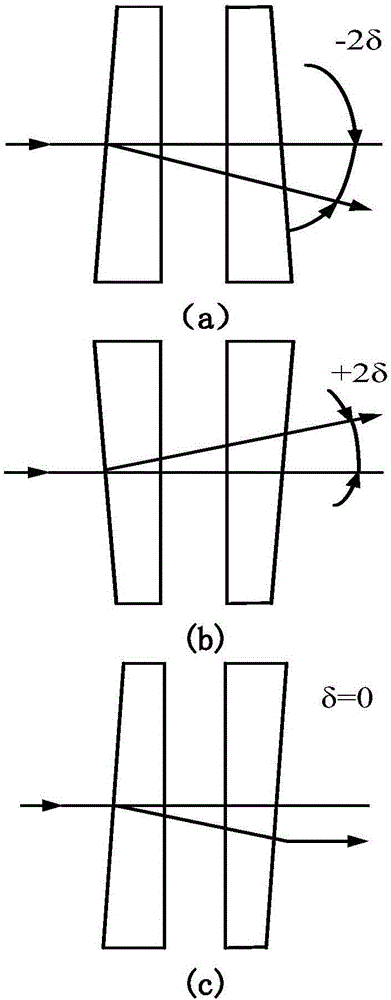

ActiveCN106501914AThe adjustment process is controllableThe adjustment process is adjustableMountingsParallel plateOptical axis

The invention puts forward a double-wedge centering assembly and adjustment method. A transmission type center deviation measurement method is adopted. When the deflection angle is zero, the double wedges are equivalent to a parallel plate, and the center deviation of incident parallel light after the light passes through the double wedges is zero. The double wedges are rotated to determine the zero position, the zero position is bonded and fixed, and the positions of the double wedges are detected by use of the method after curing. By using the double-wedge centering assembly and adjustment method put forward by the invention, the double-wedge assembly and adjustment process is controllable and adjustable, and it is ensured that the optical axis can be set to zero after double-wedge assembly and adjustment.

Owner:LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

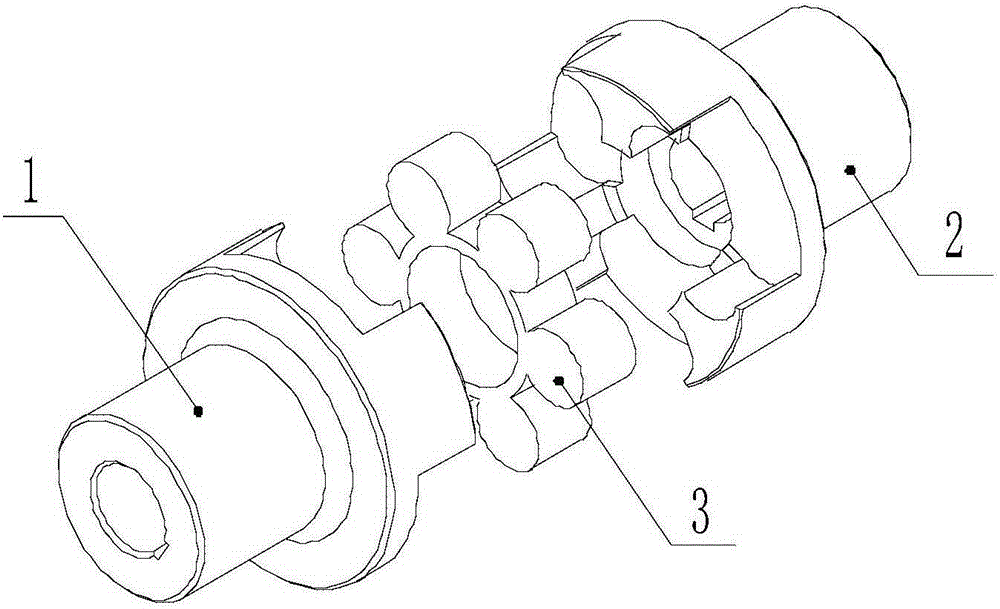

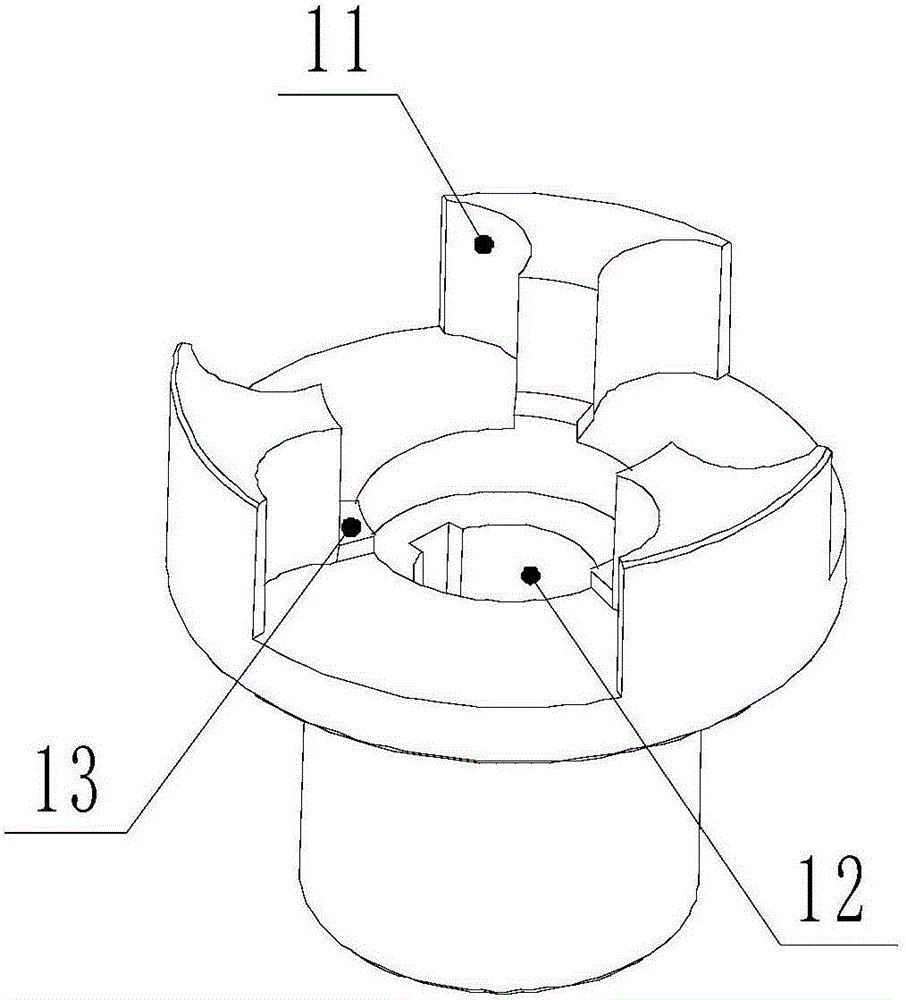

Coupling with elastic spider

The invention discloses a coupling with an elastic spider. The coupling mainly comprises a left half coupling, a right half coupling and the elastic spider, wherein both the left half coupling and the right half coupling are provided with center holes, quincuncial double wedges are arranged on the end face of the left half coupling and the right half coupling respectively, a cylindrical hole is formed in the center of the elastic spider, bosses are arranged on the left half coupling and the right half coupling respectively and are located on the inner sides of the double wedges, the two side faces of each double wedge are shaped like concave arcs, the elastic spider is installed between the left half coupling and the right half coupling, and a cylindrical boss of the elastic spider is installed in a gap between the double wedges of the left half coupling and the right half coupling.

Owner:ZHENJIANG SUODA COUPLING

Polar coordinate reading type two-dimensional position sensitive detector with double wedge-strip anodes

InactiveCN104090290AReduce crosstalkHigh resolutionX/gamma/cosmic radiation measurmentCoincidencePhysics

The invention discloses a polar coordinate reading type two-dimensional position sensitive detector with double wedge-strip anodes. The wedge-strip anodes are partitioned into specific patterns formed by wedge electrodes, strip electrodes and compensation electrodes, wherein the six wedge electrodes, the strip electrodes and the compensation electrodes of one wedge-strip anode and the six wedge electrodes, the strip electrodes and the compensation electrodes of the other wedge-strip anode are respectively matched to form the two symmetric semi-circular wedge-strip patterns, all the electrodes are disconnected from one another, and the three types of electrodes of the wedge-strip anodes are arranged in the radial direction. When the detector is used for measuring an annular area to be detected, the distance and the polar angle between a particle and the center can be directly measured. The double wedge-strip anodes can achieve the coincidence measurement that the particle can be detected in the two semi-circular areas, and have the advantage that the dead zone is small.

Owner:UNIV OF SCI & TECH OF CHINA

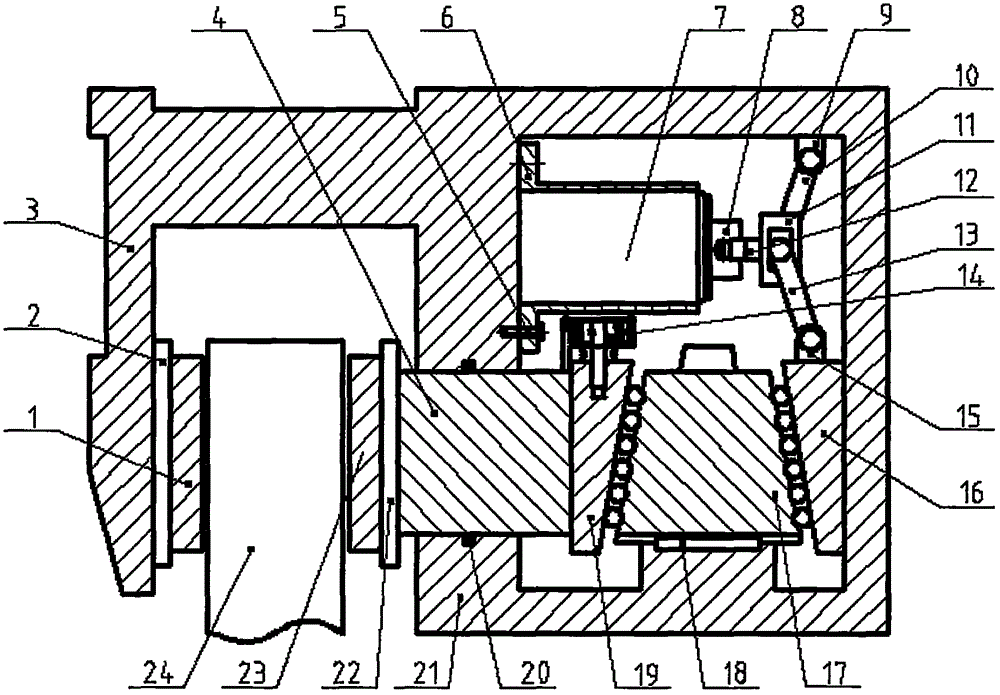

Double-wedge automotive electromechanical brake

ActiveCN105805192ASave energyReduce energy consumptionAxially engaging brakesBraking discsLinear motionDrive motor

The invention discloses a double-wedge automotive electromechanical brake which comprises a brake caliper and a brake disc, wherein friction plates are arranged on two sides of the brake disc; the rear brake disc is fixedly connected with a piston; the piston can axially move along the brake caliper, and is connected with a left wedge through a clearance adjuster; a trapezoidal sliding block is mounted between the left wedge and a right wedge; balls are mounted on two sides of the trapezoidal sliding block; a nut shaft outputted from a motor is connected with a link mechanism, so that the rotary motion of the brake driving motor can be converted into linear motion; the lower connecting rod of the link mechanism is connected with the right wedge; and both the link mechanism and a wedge mechanism have a force increasing effect. The double-wedge automotive electromechanical brake provided by the invention has both the force increasing and automatic clearance adjusting functions; the clearances between the friction plates and the brake disc can be automatically adjusted, so as to guarantee the constancy of a brake response; and furthermore, the double-wedge automotive electromechanical brake is simple in structure, convenient to mount and lower in energy consumption.

Owner:绩溪麦克威自动化科技有限公司

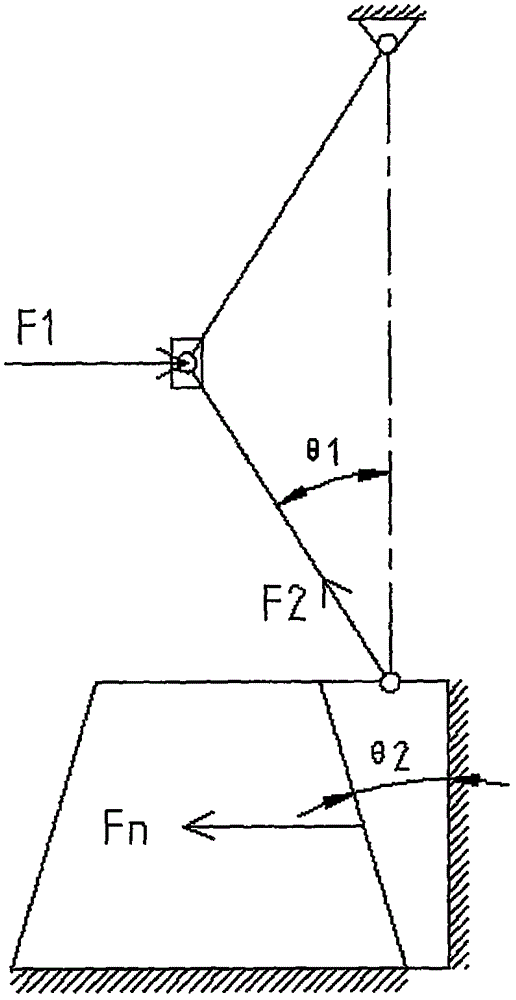

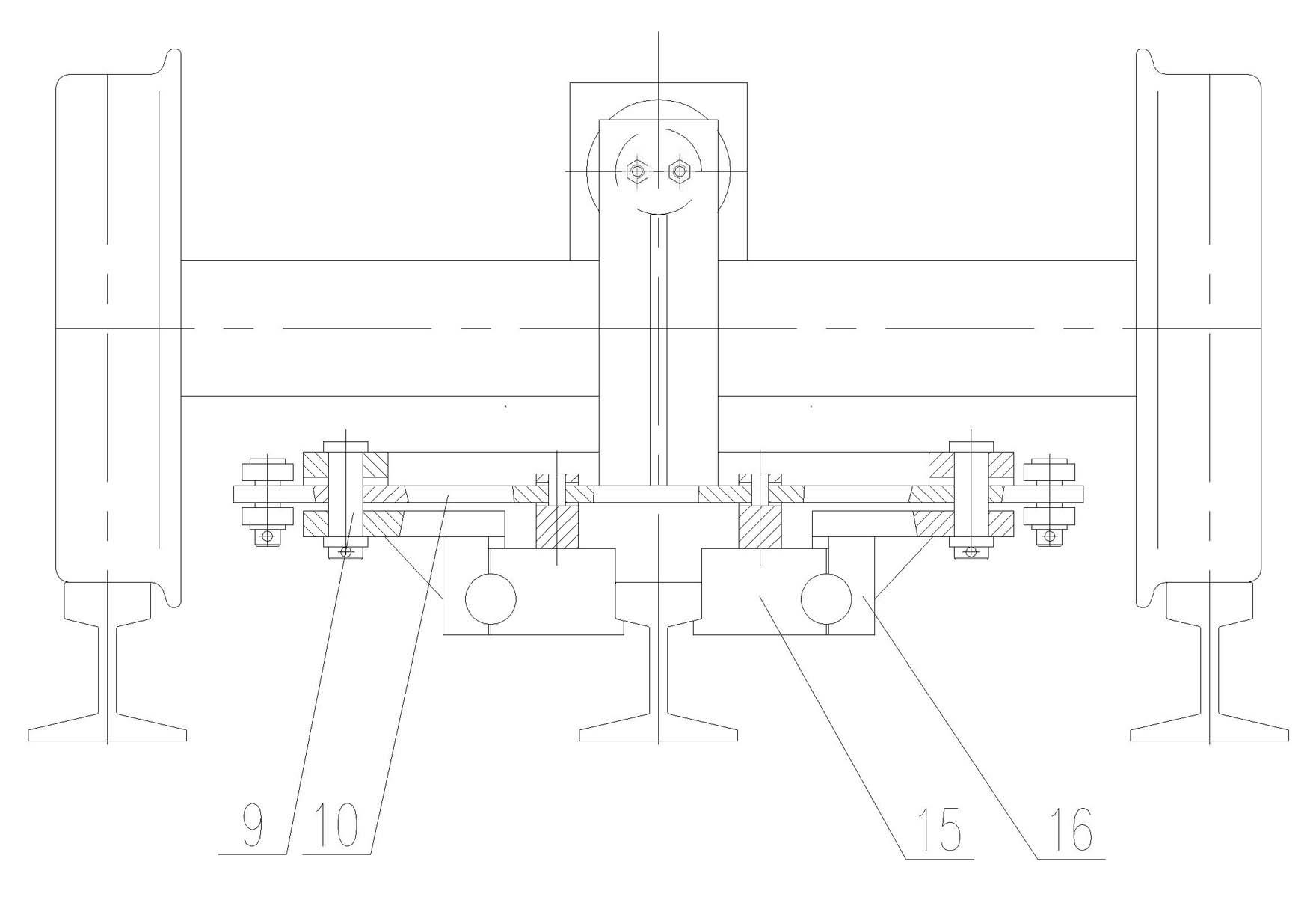

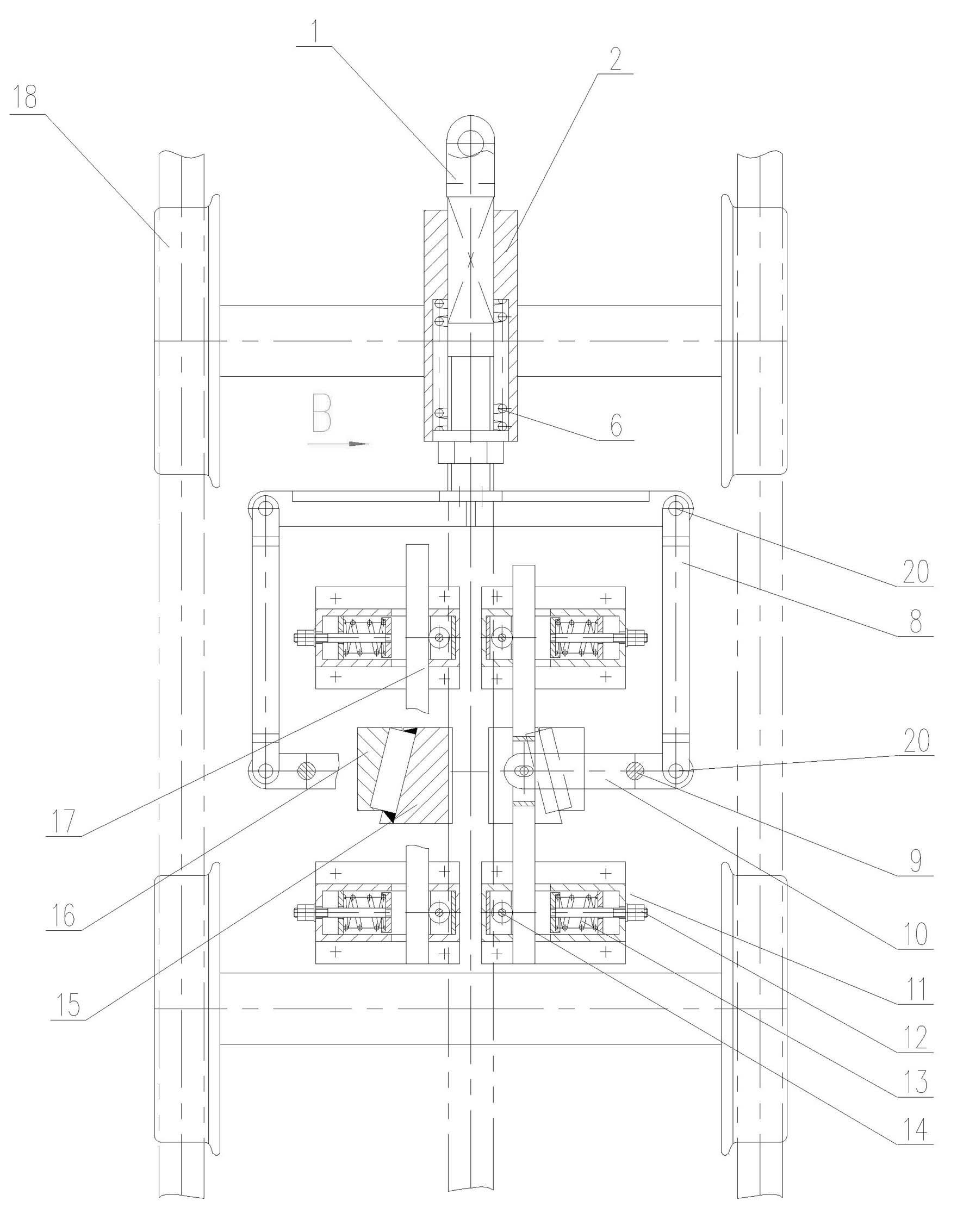

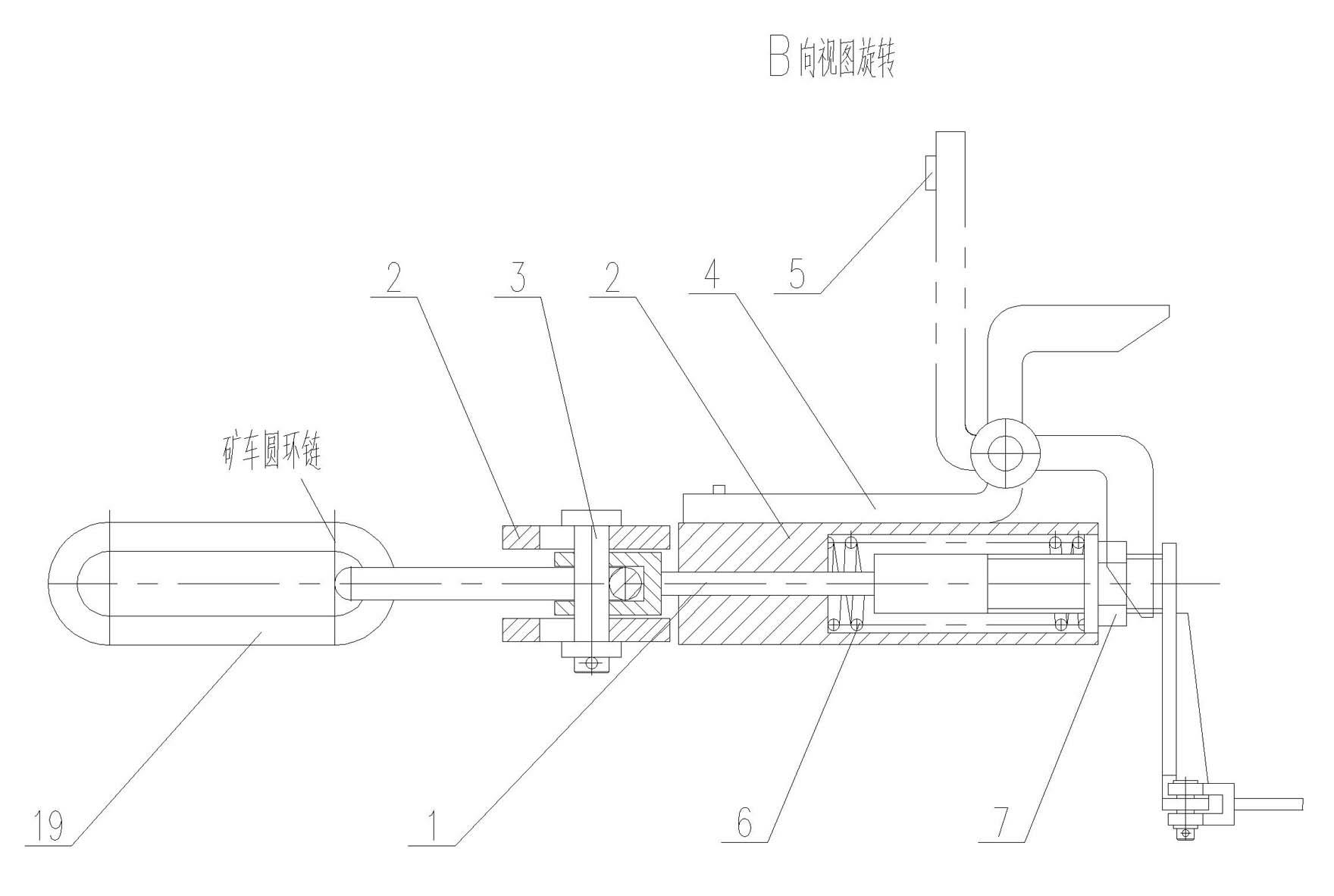

Double-wedge block braking system for transportation monorail of inclined shaft mine car rail

InactiveCN102673602AAchieve tractionTraction does not hinderTrack-braking member co-operationCar drivingSpring force

The invention relates to transportation of a mine car rail, in particular to a double-wedge block braking system for a transportation monorail of an inclined shaft mine car rail. The braking system comprises a frame, wherein a pull rod is arranged on the frame; a brake spring is arranged at the lower end of the pull rod; a brake key is also arranged on the frame; a key baffle plate is arranged on the brake key; the pull rod is connected with a frame structure formed by a connecting rod and a rod through a bolt; a guide rod is arranged in the frame; the upper side and the lower side of the guide rod are provided with a guide rod support respectively; the guide rod supports are fixedly provided with springs and sliding rollers through regulating nuts; a movable wedge block and a fixed wedge block are arranged on the guide rod; and a protruded wing is arranged on the lower side of the movable wedge block. Once rope breaking accidents occur in a winch for dragging a mine car group, a brake vehicle between two mine cars drives the movable wedge block to move under the action of spring force, the movable wedge block is tightly wedged between the fixed wedge block and the rail, and the brake vehicle is blocked on a brake rail, so that the whole mine car group can be braked.

Owner:XUZHOU UNIV OF TECH

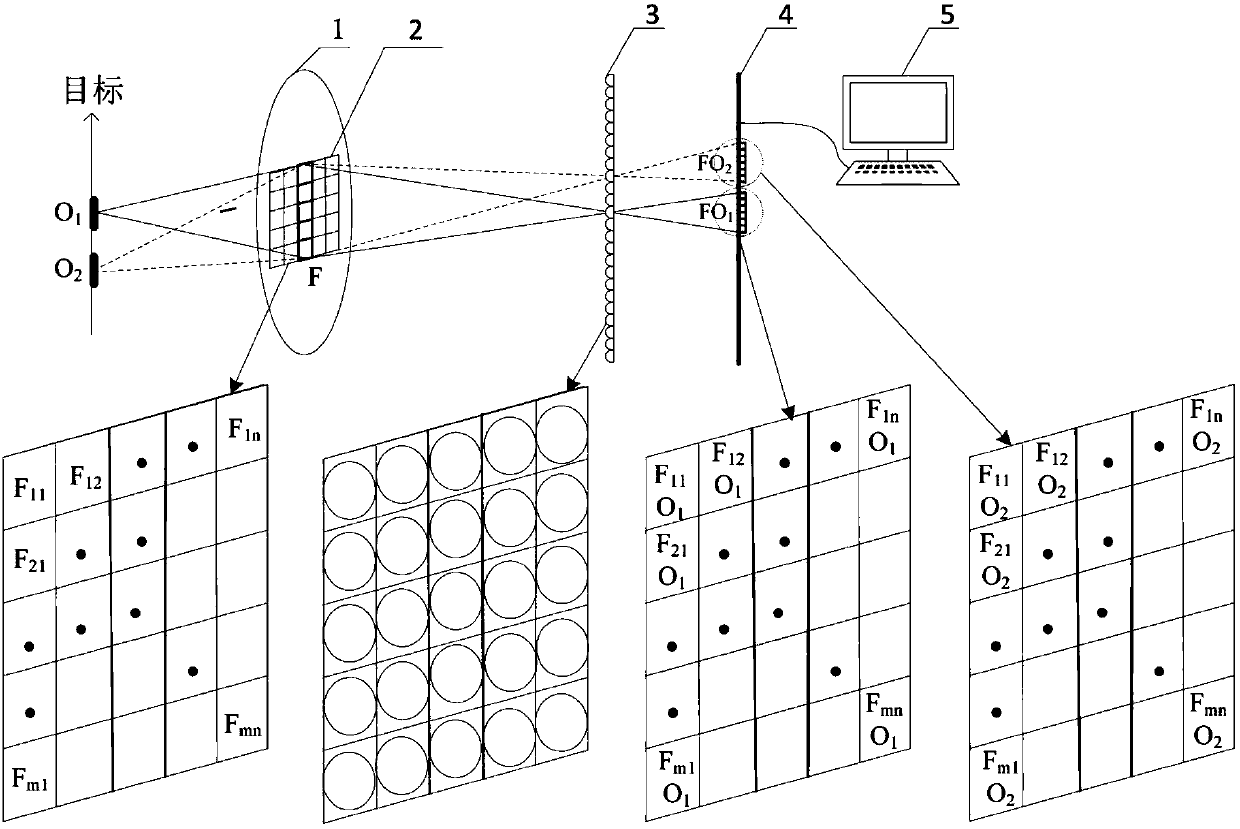

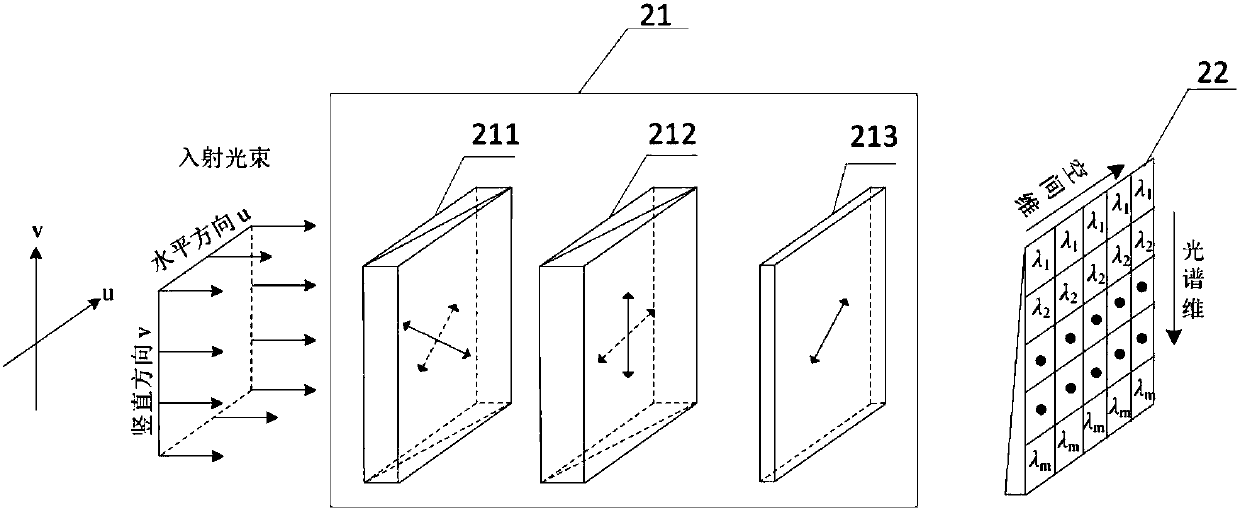

Snapshot type compact mini full polarization spectrum detecting device and method of light field imaging

InactiveCN106872037AEffective associationImprove time resolutionPolarisation spectroscopyPolarizerVisual perception

The invention discloses a snapshot type compact mini full polarization spectrum detecting device and method of light field imaging. The device comprises an object lens, a light field modulation unit, a micro-optical array, a surface array detector and a data collecting, processing and displaying system; the object lens, the light field modulation unit, the micro-optical array and the surface array detector are arranged successively along the direction of incident light; the light field modulation unit is arranged in an aperture diaphragm position of the object lens, the micro-optical array is arranged in an image plane position of the object lens, and the surface array detector is arranged in the rear focal plane of the micro-optical array, and connected with the data collecting, processing and displaying system; the light field modulation unit comprise a polarization modulation module and a spectral optical filter array; and the polarization modulation module comprises a first double-wedge retardation plate, a second double-wedge retardation plate and a linear polarizer arranged successively in the direction of the incident light. The device is suitable for detecting all-optical information of a dynamic or rapid-change object, can effectively avoid negative influence caused by factors as object change, jittering noise or ambient change, and the device and method have potential application values in the fields including astronomy observation, space detection, remote sensing of the earth, machine vision and biomedical diagnosis.

Owner:XI AN JIAOTONG UNIV

Two-way safety gear used for preventing lift car from moving accidentally

InactiveCN105016166AReduce distanceAchieve the purpose of stoppingElevatorsShortest distancePush pull

The invention discloses a two-way safety gear used for preventing a lift car from moving accidentally. The two-way safety gear is clamped on a guide rail and comprises an inner shell arranged in an inner cavity of an outer shell. A horizontal positioning screw and a first horizontal movable screw with an elastic piece are arranged between the outer shell and the inner shell. Flat gear bodies are arranged on the portions, on the left side and the right side of the guide rail, of the inner cavity of the inner shell respectively. An upper wedge gear body and a lower wedge gear body which are symmetrical about the horizontal middle line of the inner shell are arranged on the portions, on the left side and the right side of the guide rail, of the inner cavity of the inner shell respectively. Double wedge blocks which are symmetrical about the horizontal middle line of the inner shell are arranged on the portions, on the left side and the right side of the guide rail, of the inner cavity of the inner shell respectively. The double wedge blocks are connected with the inner shell through second horizontal movable screws with elastic pieces. Movable push-pull rods extending out of a horizontal pipe cavity of the inner shell are arranged on the portions, on the rear right sides of the double wedge blocks, in the inner cavity of the inner shell. The contact faces between the front ends of the movable push-pull rods and the double wedge blocks are inclined faces. The movable push-pull rods are connected with safety gear transmission mechanisms through horizontal pin shafts. The two-way safety gear is simple in structure, safe and reliable. The braking force of the two-way safety gear directly acts on the lift car and the guide rail. The two-way safety gear has the good short-distance and short-time braking effect for the accidental movement of the lift car.

Owner:卫小兵 +1

Synchronization fertilizer apparatus of sowing machine

InactiveCN101116386AIncrease productionPromote growthSeed depositing seeder partsFertiliser and seeding apparatusAgricultural engineeringCam

The invention discloses a synchronous device for a drill, comprising a seed and fertilizer combination box. A seeding wheel and a fertilizing wheel are respectively arranged at the bottom of the seed and fertilizer combination box. A movable cover plate is arranged under the fertilizing wheel of the seed and fertilizer combination box. The movable cover plate is provided with a crank shaft at the top which is used to control the movement of the movable plate. The crank shaft is connected with a rolling wheel at the top. A seeding wheel shaft of the seeding wheel is provided with a cam which has at least a double wedge arranged at the rolling shaft. The movable cover plate arranged under the fertilizing wheel of the invention is usually under the status of closing the fertilizing opening. When the double wedge of the cam rotating to the crank shaft, the double wedge moves the crank shaft to rotate and bring along the rotation of the movable cover plate so as to open the fertilizing opening and let the fertilizer fall off. When the double wedge leaves the crank shaft, the crank shaft returns and makes the movable cover plate return to close the fertilizer opening and stop fertilizing. Meanwhile, seeding starts. Since the drill is moving forward, the seeding opening just rotates to the fertilizing opening when seeding, realizing quantified and positioned seeding and fertilizing.

Owner:王晓春

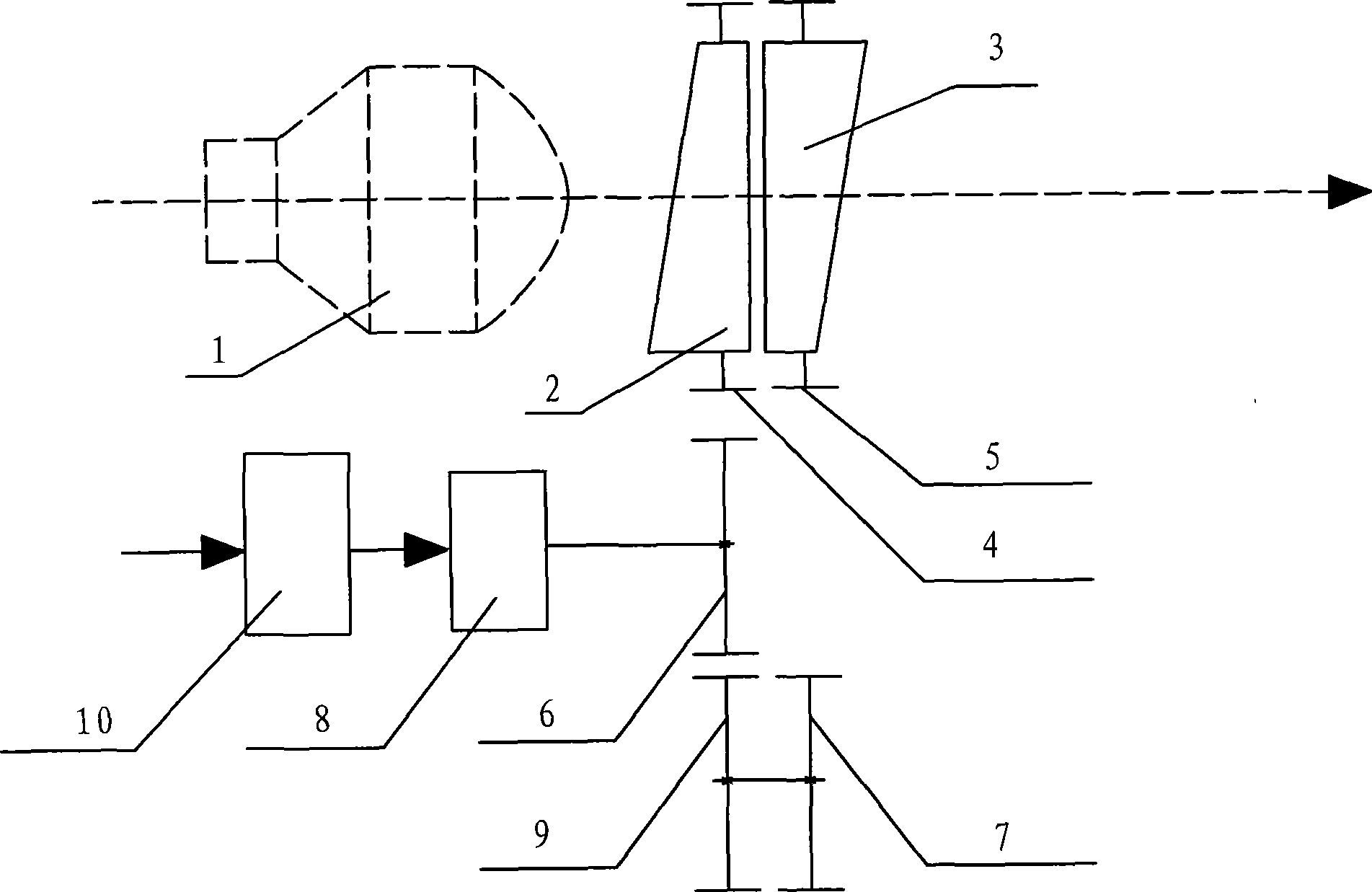

Automobile cornering illuminating apparatus and control method

InactiveCN101503077AAchieve high beamRealize low beam horizontal steeringOptical signallingElectric machineryWedge prism

The invention relates to an illuminating apparatus and a control method thereof, in particular to an automobile bend road illuminating apparatus and a control method thereof, belonging to the field of automobile illumination. The automobile bend road illuminating apparatus comprises a light source, two wedge prisms which are sequentially arranged in front of the light source and respectively arranged in different driven gears, and driving gears that are meshed with the driven gears and driven by a motor. The invention has the advantages that under the condition that no energy consumption is increased, the illuminating apparatus utilizes the light source of the existing headlight and refraction of 'double-wedge prisms' without whole movement to realize the level steering of upper beam or lower beam of the light and keep light distribution in line with a standard requirement and constant, thus reducing the cost and improving the illuminating effect.

Owner:郭廷麟 +1

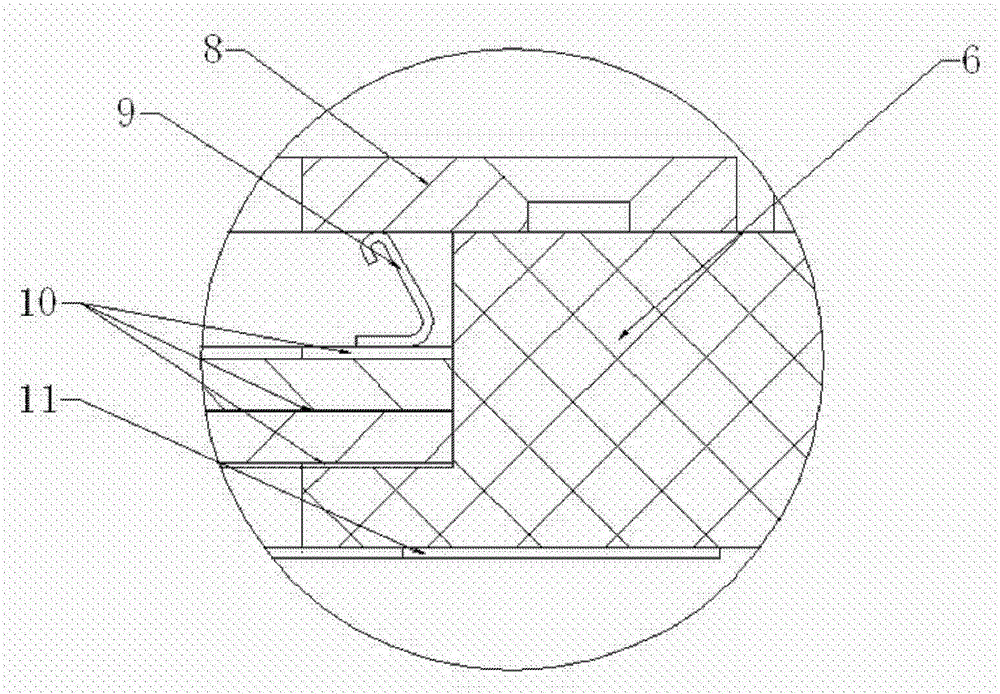

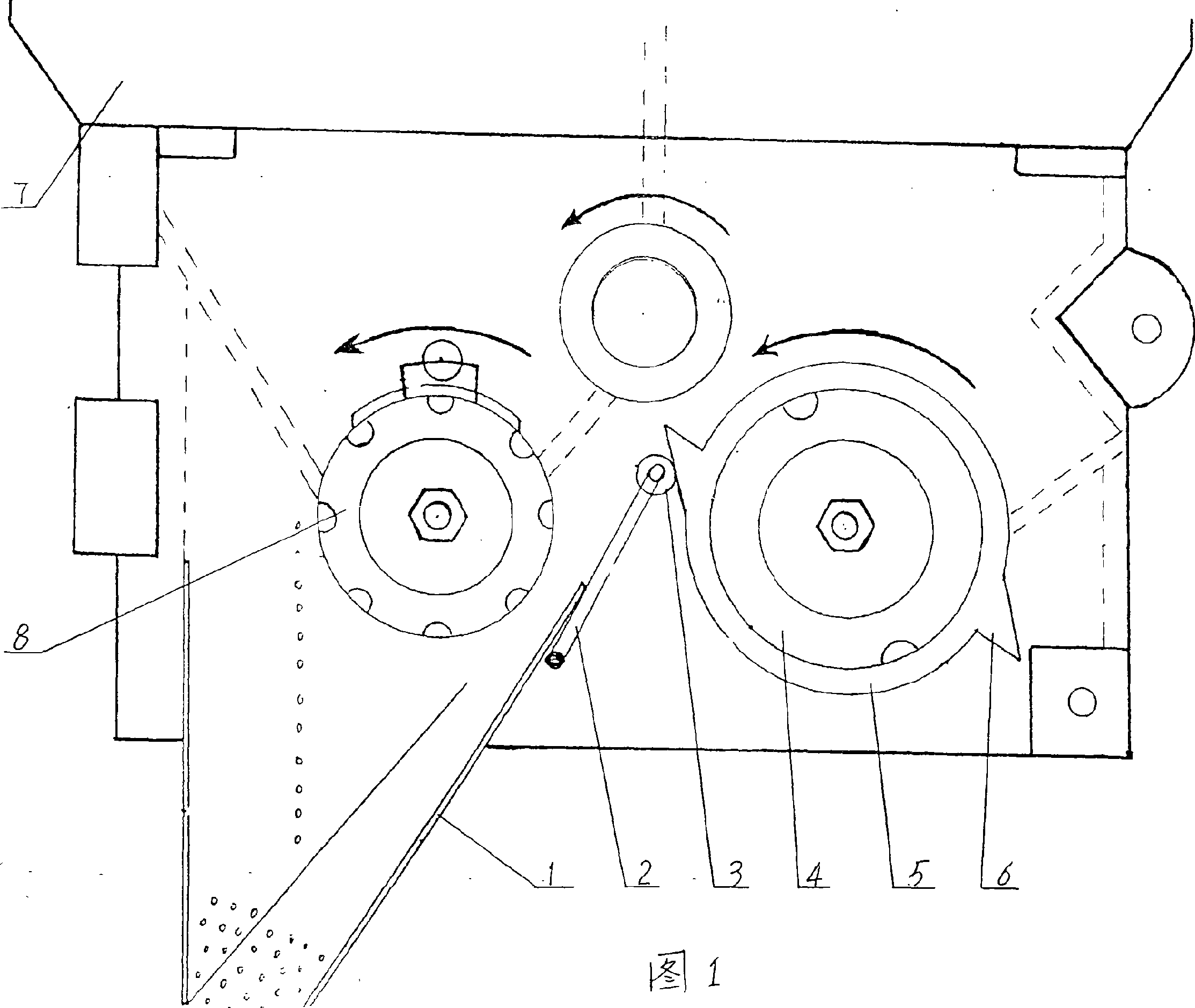

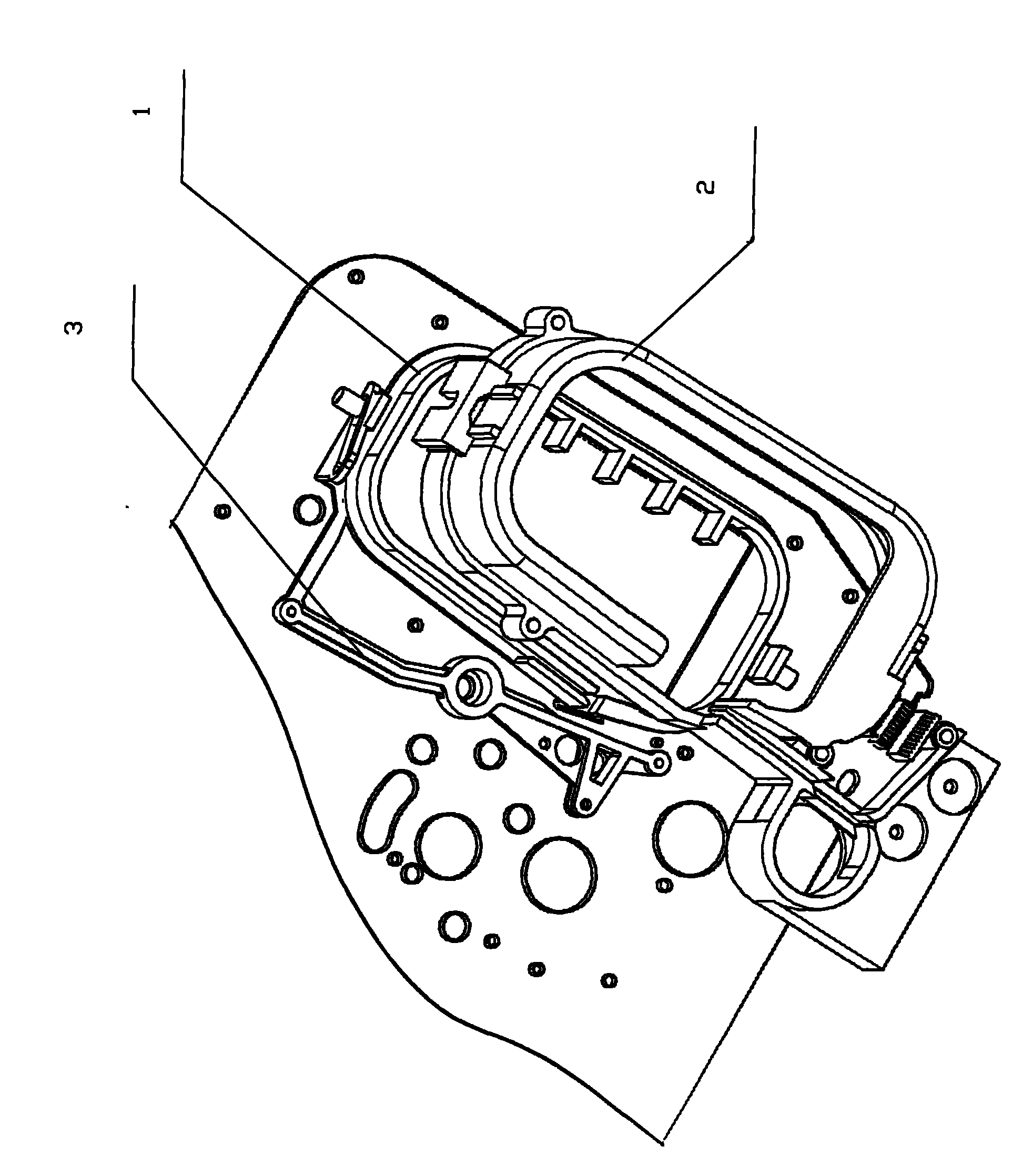

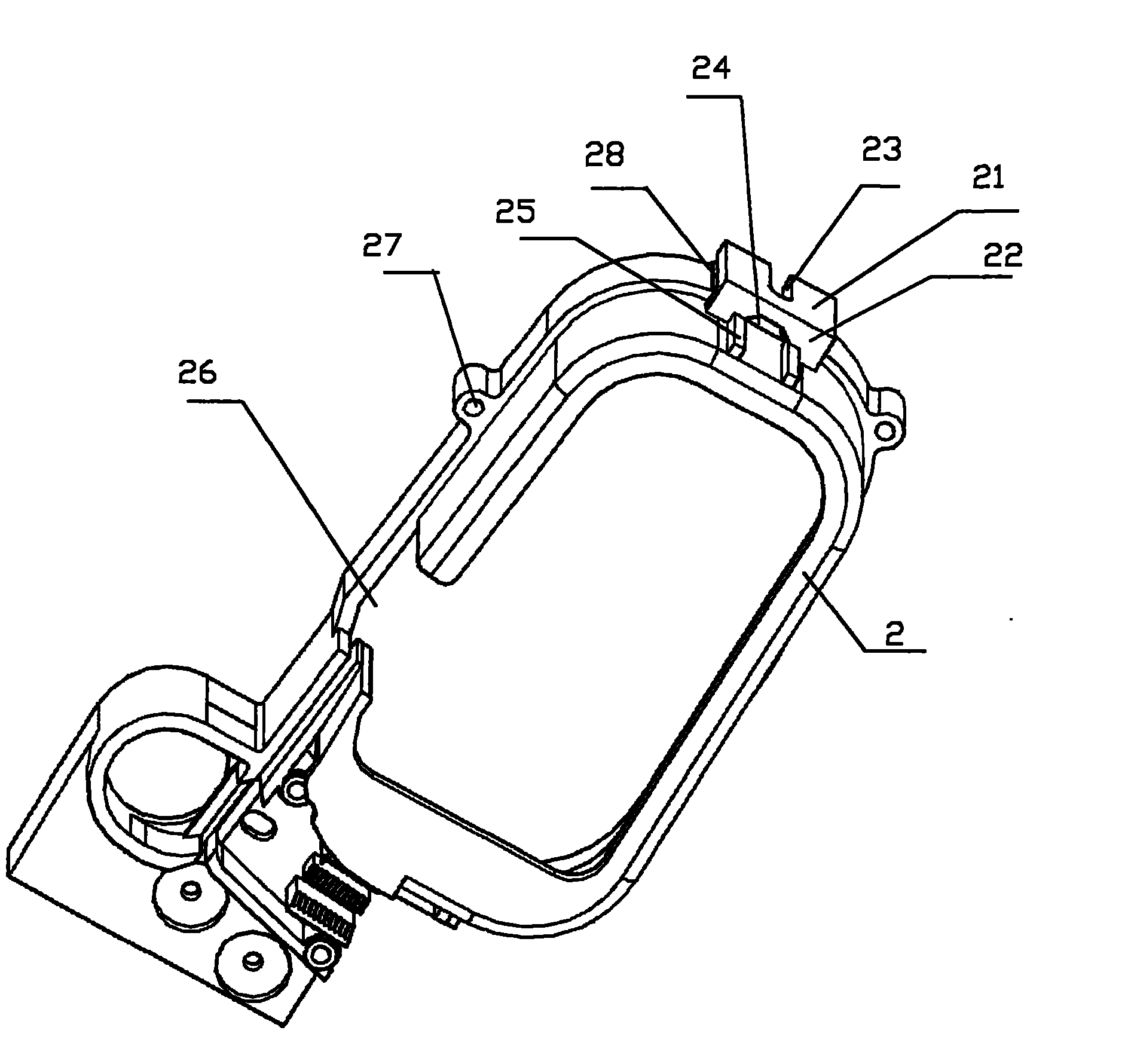

Automatic folding and unfolding device of cash counting and bundling all-in-one machine

InactiveCN101954986ACompact structureAccurate and reliablePaper article packagingBundling machine detailsEngineeringCam

The invention relates to an automatic folding and unfolding device of a cash counting and bundling all-in-one machine. The device comprises a kidney-shaped inner frame, a kidney-shaped outer frame and a control mechanism, wherein the inner frame and the outer frame are made of an inequilateral bar section; the longer side and the shorter side of the inner fame respectively correspond to the longer side and the shorter side of the outer frame so as to form a kidney-shaped pipeline, and the cross section of an inner cavity in the pipeline is rectangular; and the control mechanism comprises a control shaft as well as a cam, a rolling wheel, an oscillating bar, a hinged pin, an upper double-wedge plate, a lower double-wedge plate and a reset spring which are arranged on the control shaft. When the oscillating bar oscillates under the drive of the rolling of the rolling wheel, the inner frame and the outer frame are controlled to be folded or unfolded through the oscillation of the oscillating bar. By utilizing the folding of the inner frame and the outer frame, an kidney-shaped guide strip frame is formed so that a bundling strip can freely pass through in the pipeline to form a kidney-shaped circle; and then, the inner frame axially moves in parallel under the drive of the control mechanism, and the unfolded guide strip frame is in a kidney-shaped bundling strip loop which can be shrunk to bundle cashes. Compared with the similar products, the whole action is controlled relying on the cam on the control shaft, therefore, the invention has the advantages of precise and reliable action, less faults and high cost performance.

Owner:SHANGHAI LONGRUN M&E TECH

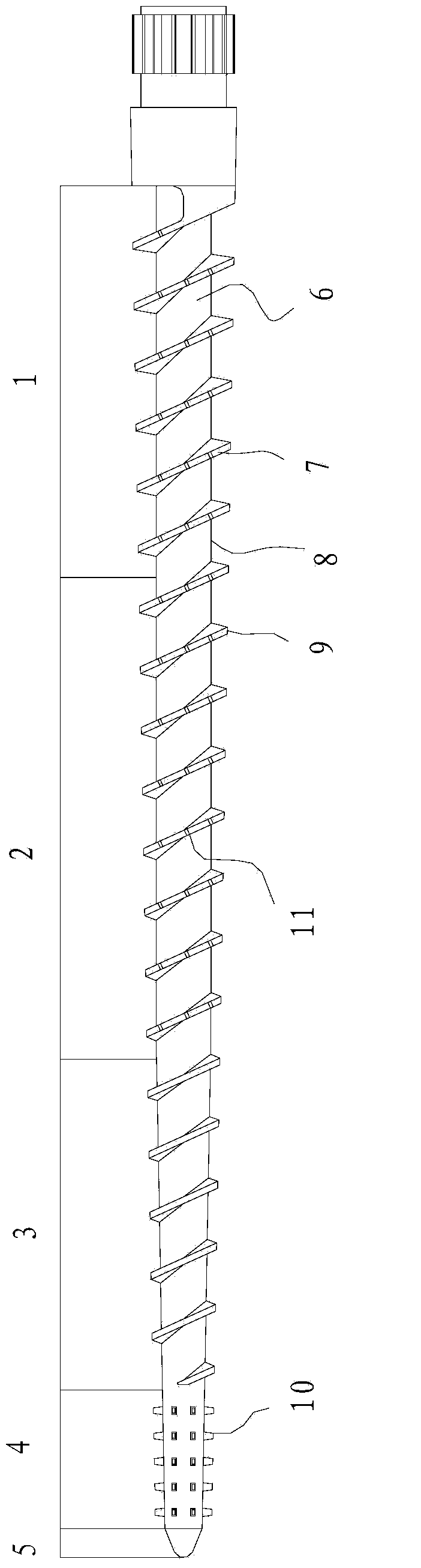

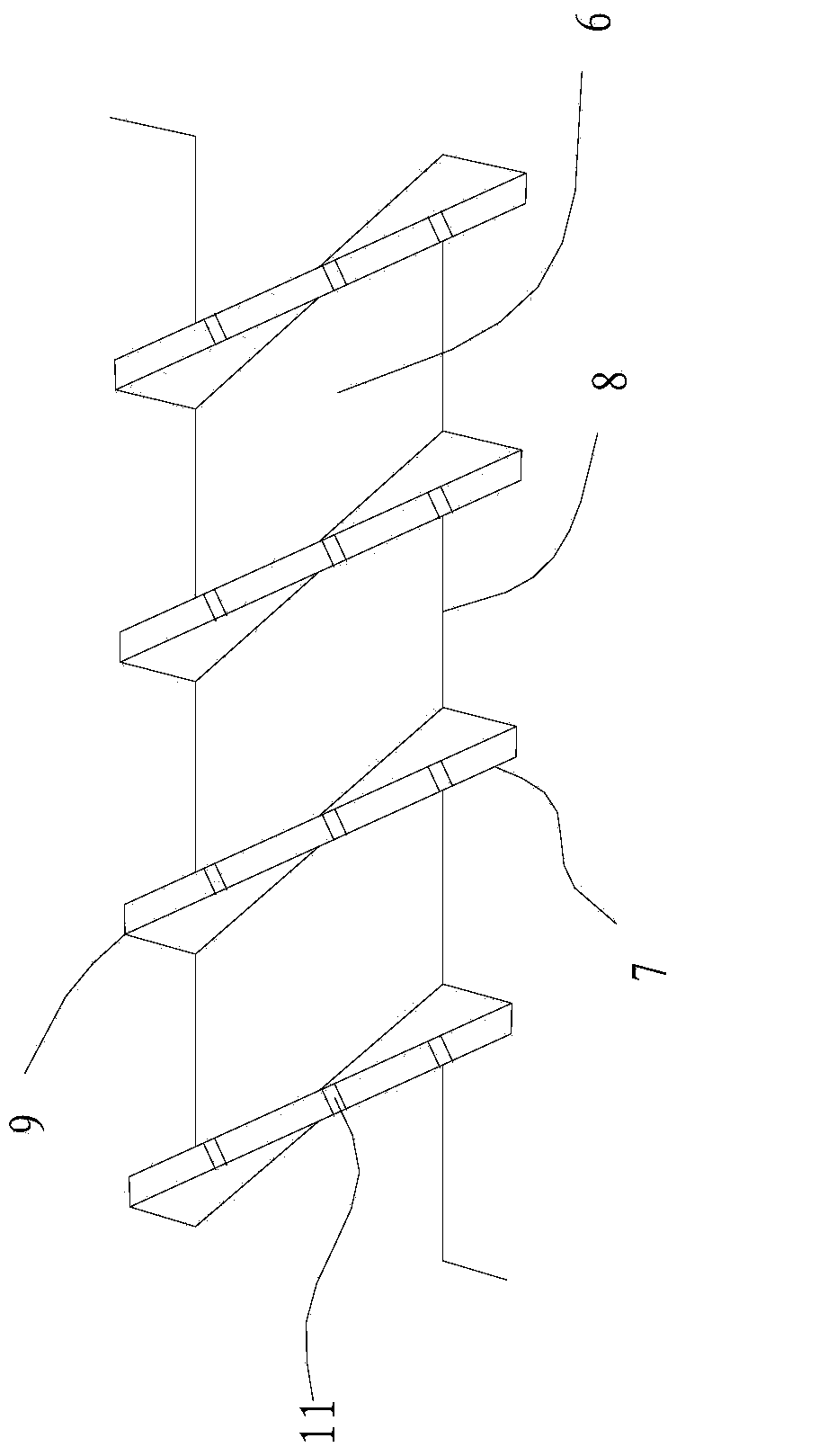

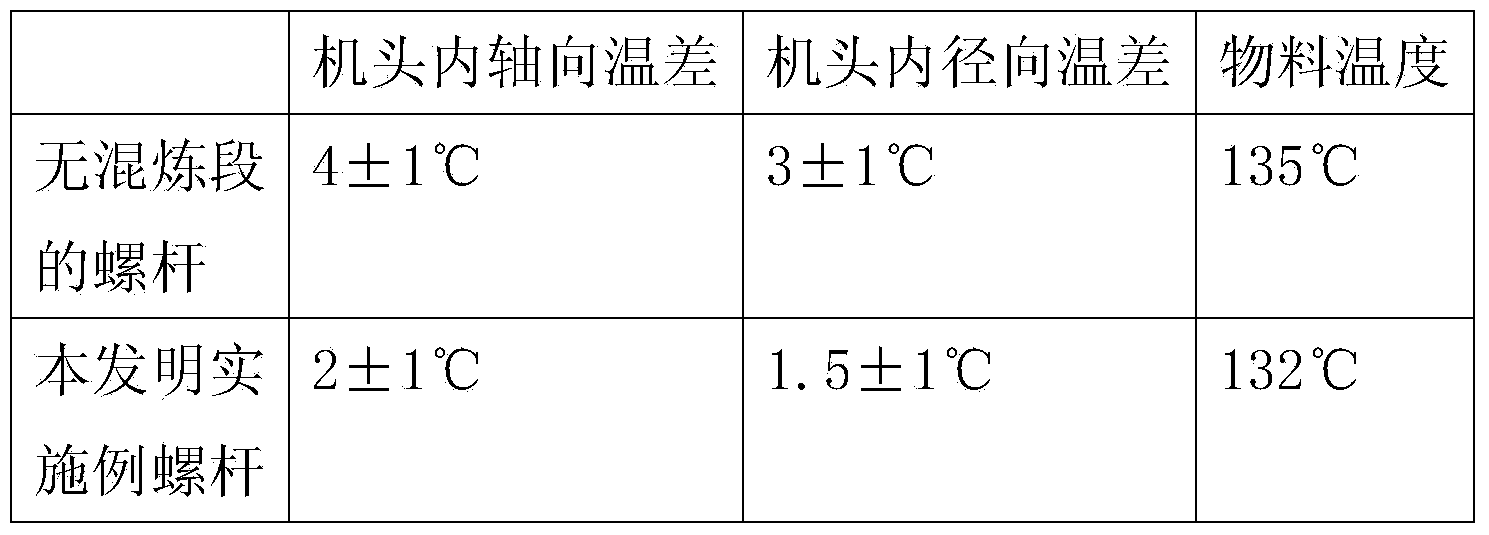

Extruding screw for single screw extruder

The invention discloses an extruding screw for a single screw extruder. The extruding screw is characterized in that the diameter of the tail part of the screw is greater than that of the head part of the screw, and the conic angle between the connection of the outer diameter of threads and the axis of the screw is 0.6-2 DEG; the material charging section, the compressing section, the metering section and the mixing section with double wedges arranged on the surface, of a single screw structure are distributed in sequence; the bottom diameter of the threads of the material charging section is the same as that of the threads of the compressing section and are parallel to the axis of the screw respectively; a plurality of spiral grooves with the rotating direction opposite to that of the threads of the material charging section are formed in the threads of the material charging section and the compressing section respectively; the bottom diameter of the threads of the metering section is parallel to the outer diameter of the threads, and the width of the spiral grooves close to the side of the compressing section is smaller than that of the spiral grooves close to the side of the mixing section, on the metering section. According to the invention, the extruding screw has the advantages that the extruding screw is simple in structure and convenient to process, the equipment investment is reduced a lot, the extruding screw can be widely applied to processing loose materials and plastic raw materials with high compression ratio and multi-components, the service life is long, and the energy consumption is low.

Owner:RIFENG ENTERPRISE GRP CO LTD +1

Variable view imaging system with combination of telecentric scanner and double wedge prisms

A variable view imaging system for observation of micro object with variable view orientation and position includes a telecentric lens group, a scanning mirror, wedge prisms, a deformable mirror and related optical elements. The combination of a scanning mirror and a telecentric lens group decouples the motion of scanning mirror and the view angle. The view angle is determined only by the angle of the wedge prisms. This design increases the zenith angle of the view and simplifies the kinematics of the system. The wedge prisms and the scanning mirror can supply a flexible view in a compact way. The wavefront error induced by the wedge prisms is corrected by the deformable mirror. In order to achieve the desired view state during operation, the scanning mirror angle and the wedge prisms angle are calculated iteratively based on the kinematics and Jacobian matrix of system.

Owner:KOREA ADVANCED INST OF SCI & TECH

Rotating beam preheating laser shock wave micro-texturing machining device and method

ActiveCN104526157AImprove processing efficiencyLow Laser Pulse EnergyLaser beam welding apparatusShock waveEngineering

The invention provides a rotating beam preheating laser shock wave micro-texturing machining device. The laser shock wave micro-texturing machining device comprises a first laser unit, a second laser unit, a composite machining head and a machining head driving mechanism. The composite machining head is of a hollow sleeve shape and is installed on the machining head driving mechanism, and the composite machining head is driven by the machining head driving mechanism to rotate around the axis of the composite machining head. The composite machining head comprises an annular cylinder wall, an upper cover plate, a lower cover plate, a double-wedge-shaped reflector, a first 45-degree reflector, a second 45-degree reflector, a reflective focusing mirror, a focusing lens and a protective mirror. Continuous laser beams are adopted for heating the peripheral region of a micro-texturing position, so that the temperature of the peripheral region of the micro-texturing position is increased, and meanwhile the micro-texturing position is also heated through heat conduction; thus, under the action of pressure of laser shock waves with the peripheral region preheating effect, a micro-texturing pit is deeper, and micro-texturing machining efficiency is easily promoted when the pulse laser beams are used for generating the shock waves. The invention further provides a rotating beam preheating laser shock wave micro-texturing machining method.

Owner:ZHEJIANG JIATAI LASER SCI & TECH CO LTD

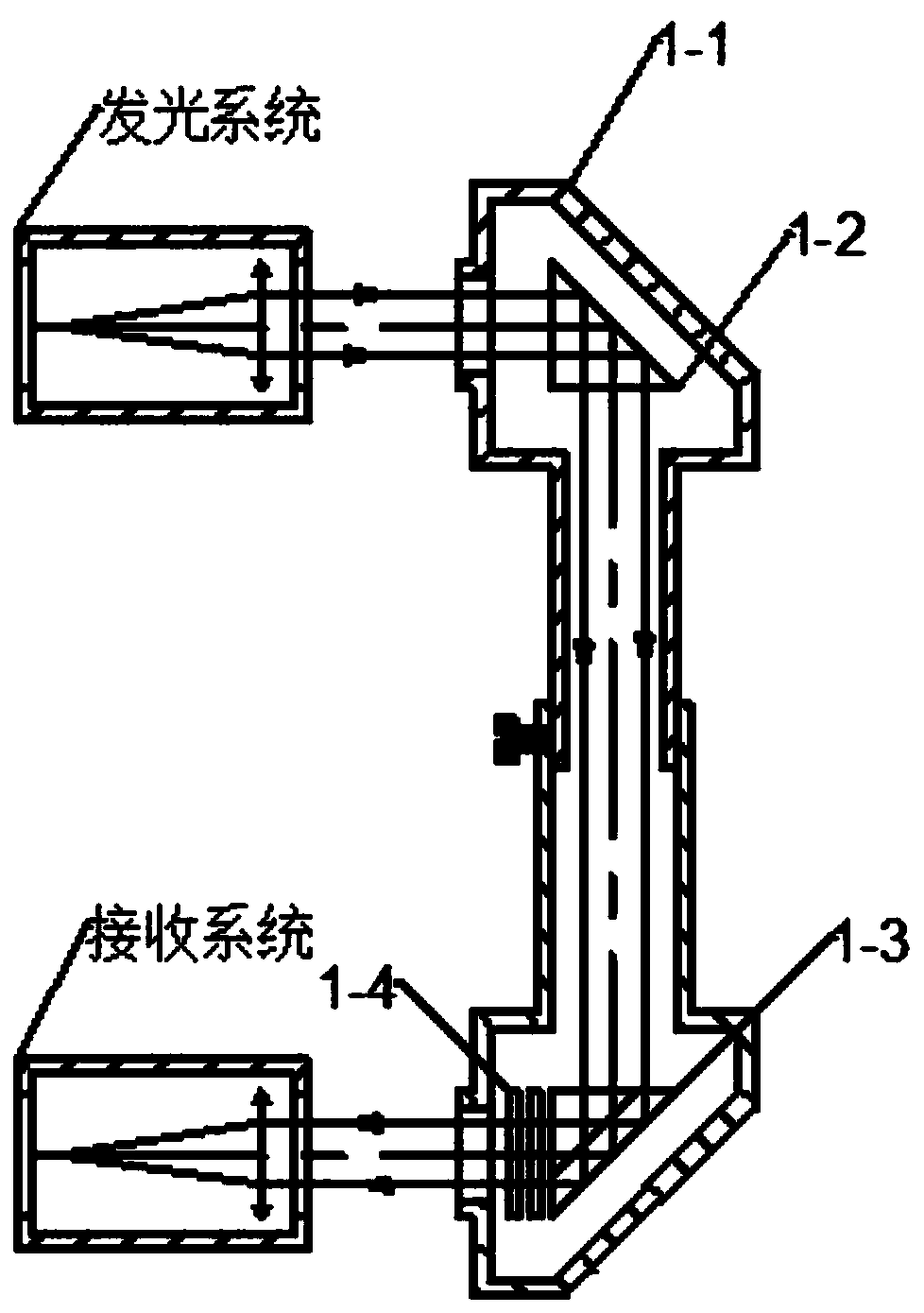

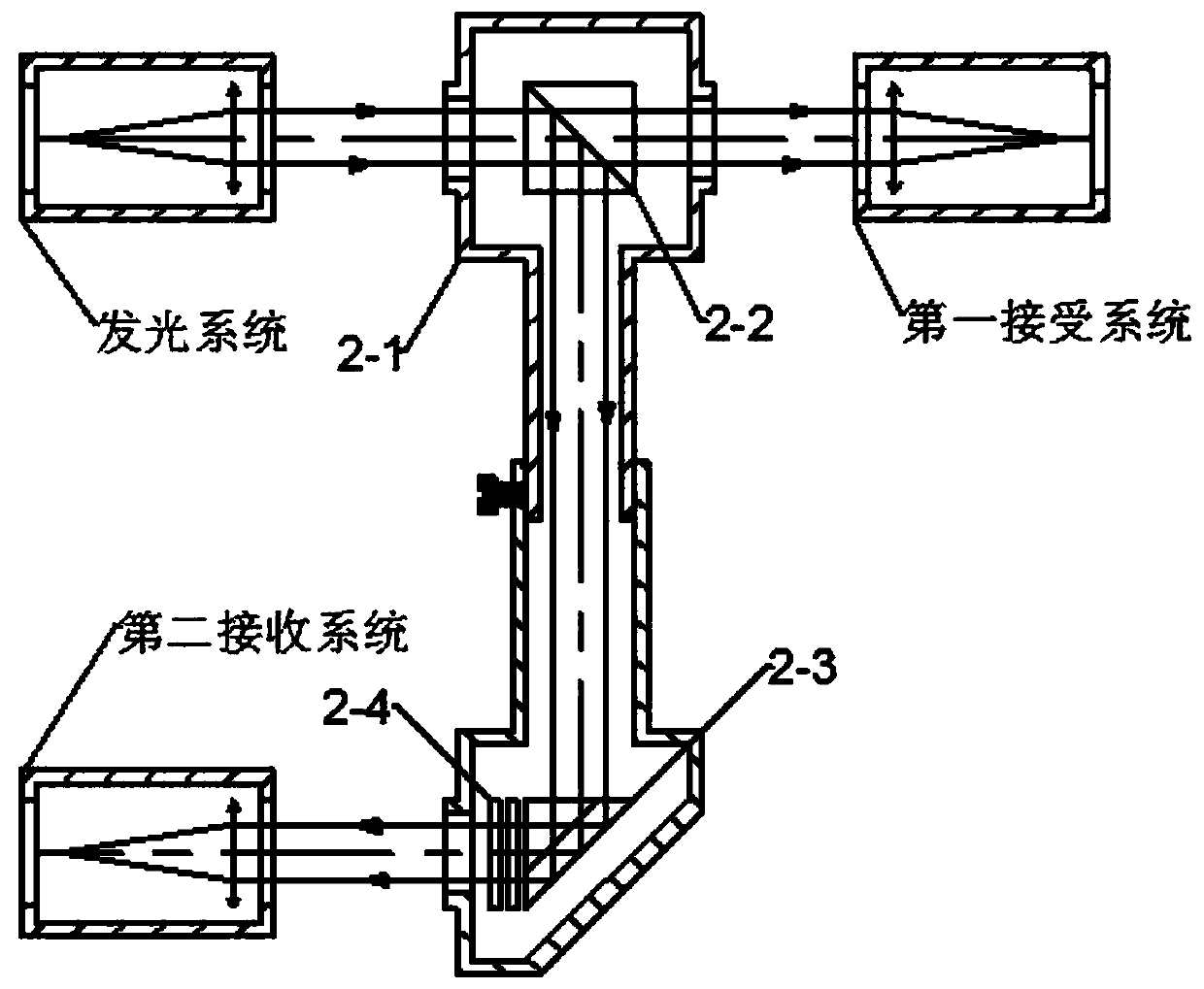

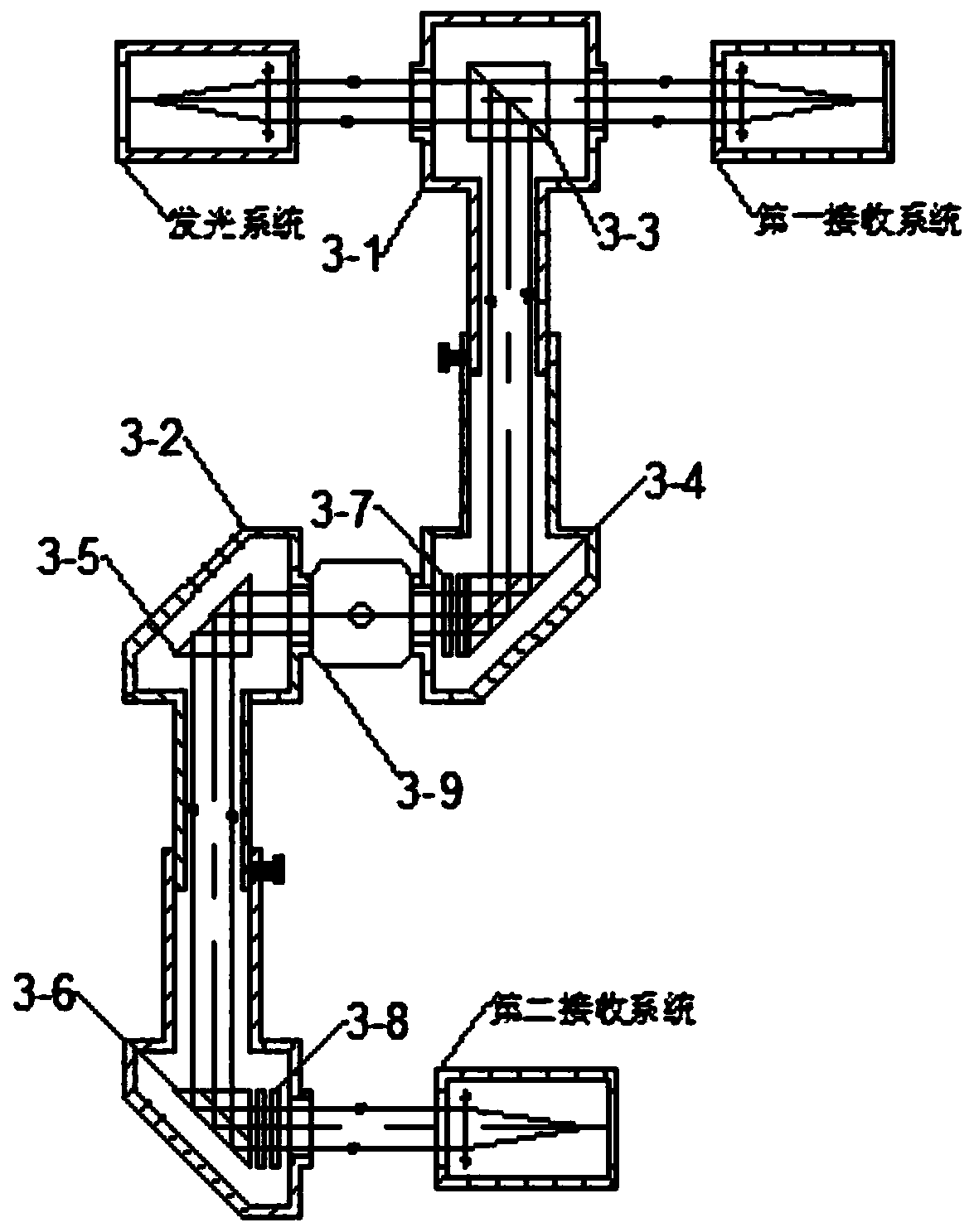

Optical axis parallelism detection device with wide-range hole enlargement

ActiveCN109870294ASolve targeted problemsHigh precisionUsing optical meansTesting optical propertiesExit planeOptical axis

The invention discloses an optical axis parallelism detection device with wide-range hole enlargement, belongs to the technical field of optical parallelism detection and solves the problem of big influence from diameter thereof in the prior art. The device comprises an extension type lens barrel, a rectangular prism, a rectangular ridge prism and double wedges; the rectangular prism and the rectangular ridge prism are arranged at the two ends of the extension type lens barrel respectively; the extension type lens barrel is provided with a light vent hole respectively in one side of the incident plane of the rectangular prism and one side of the exit plane of the rectangular ridge prism; the double wedges are arranged at one side of the exit plane of the rectangular ridge prism; and incident light emitted by a light emitting system of a to-be-detected device after passing through the rectangular prism enters the rectangular ridge prism for reflection, and the reflected light enters a receiving system of the to-be-detected device after passing through the double wedges. The device has a small volume and light weight, can realize detection of parallel beams with relatively big spatial distance and is suitable for wide-spectrum detection.

Owner:CHANGCHUN UNIV OF SCI & TECH

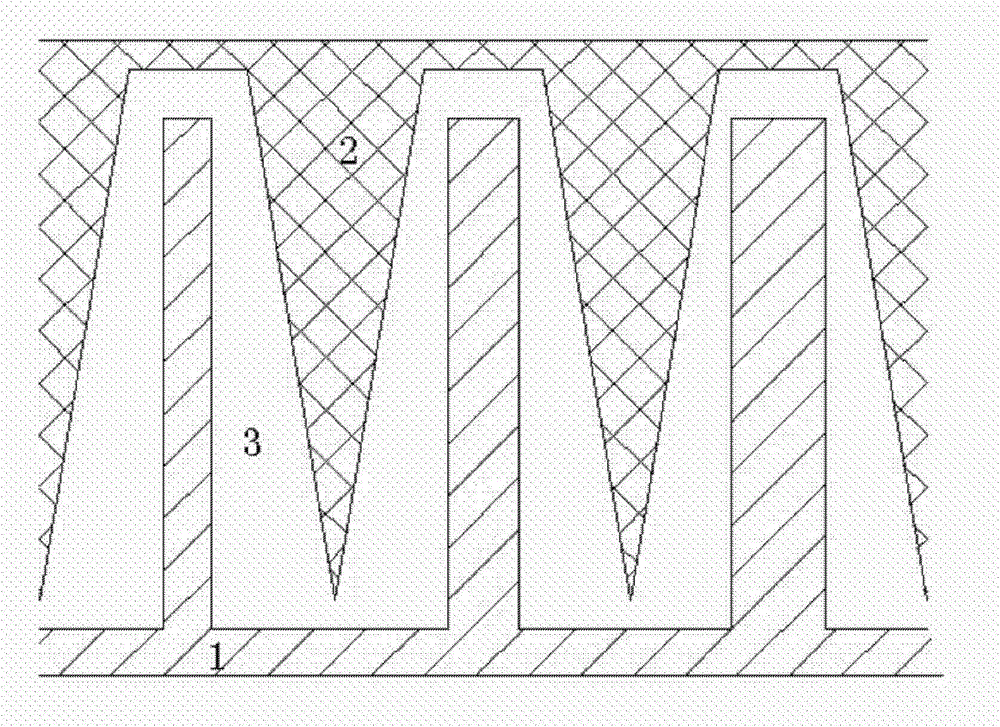

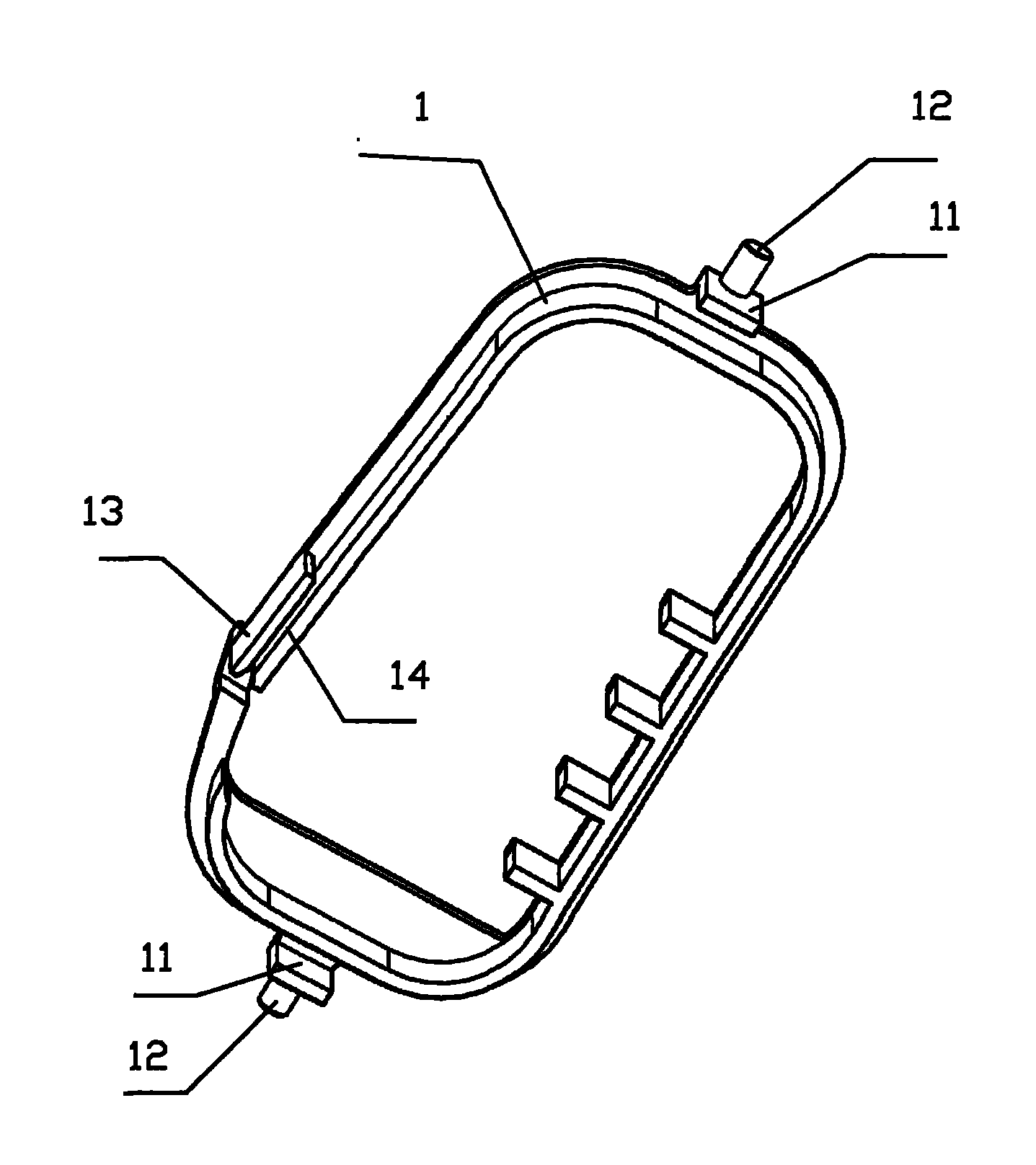

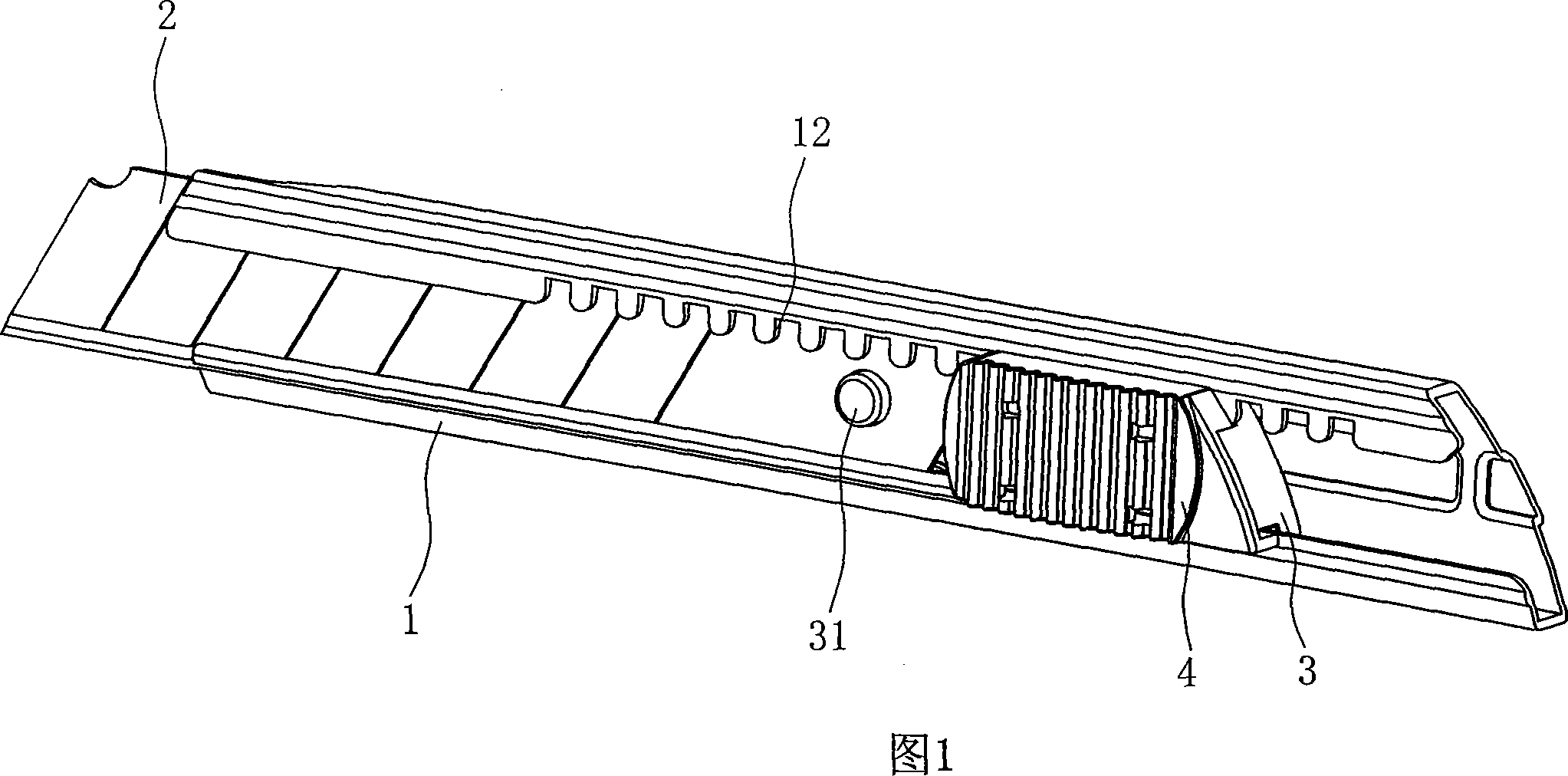

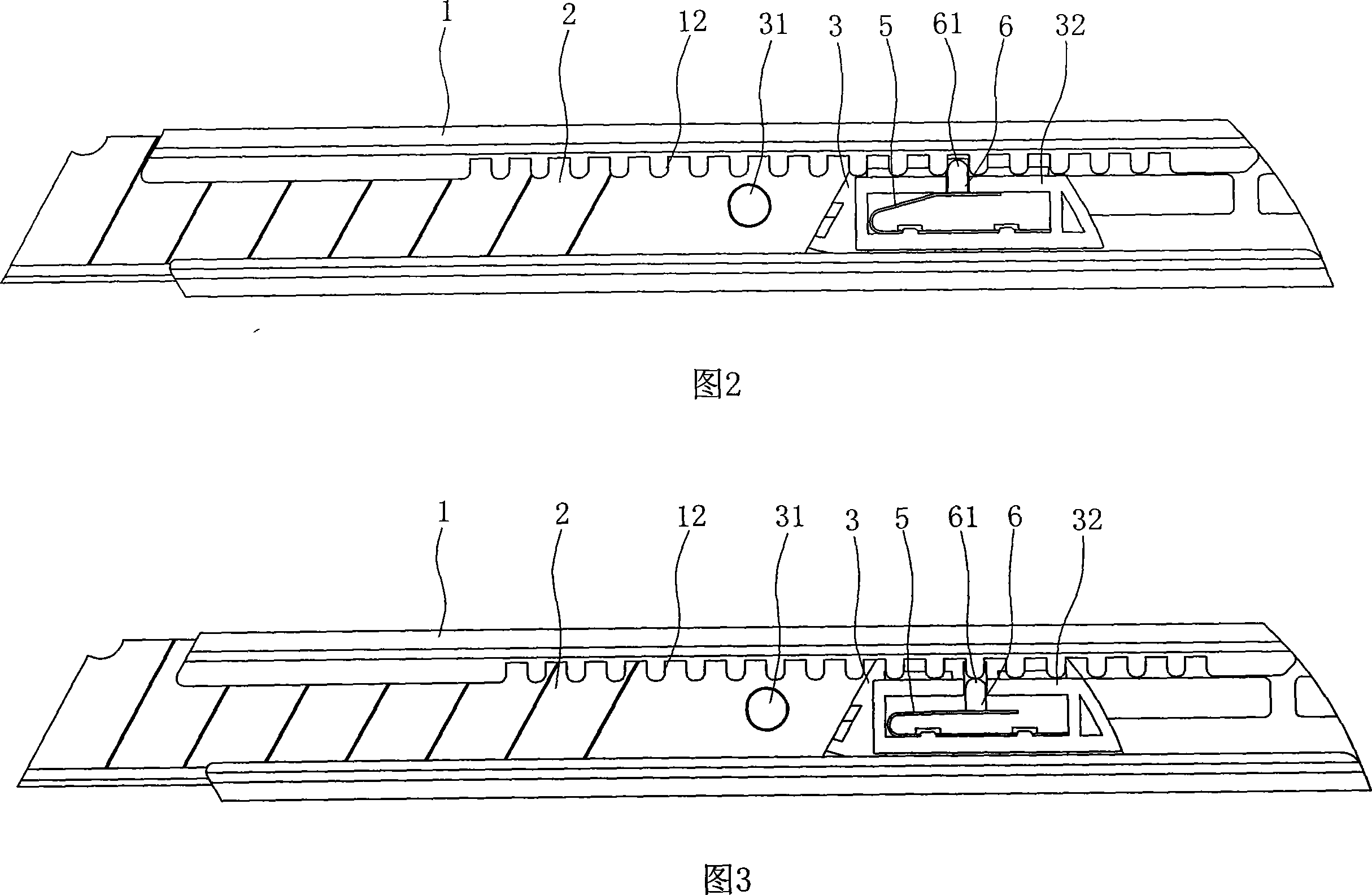

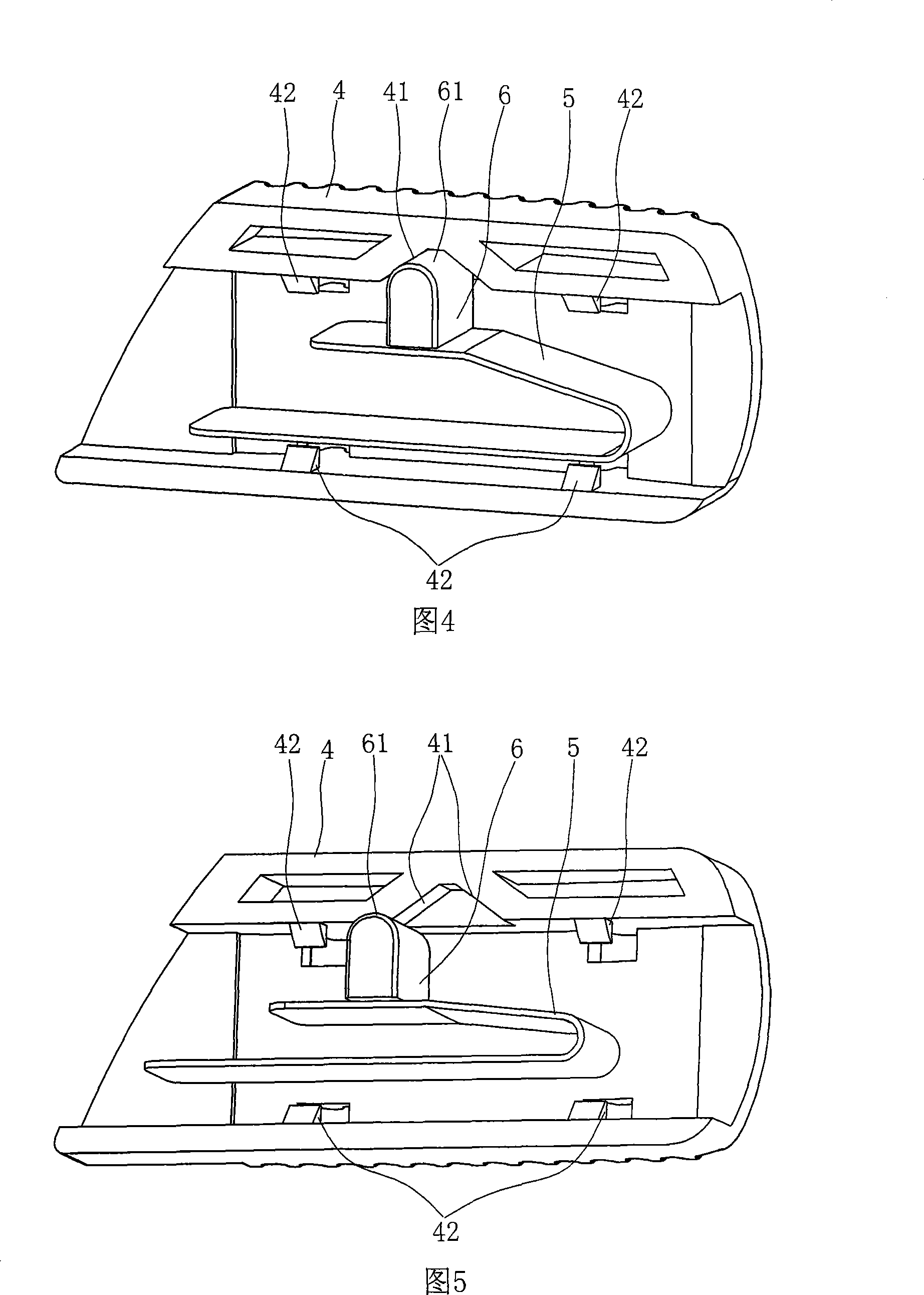

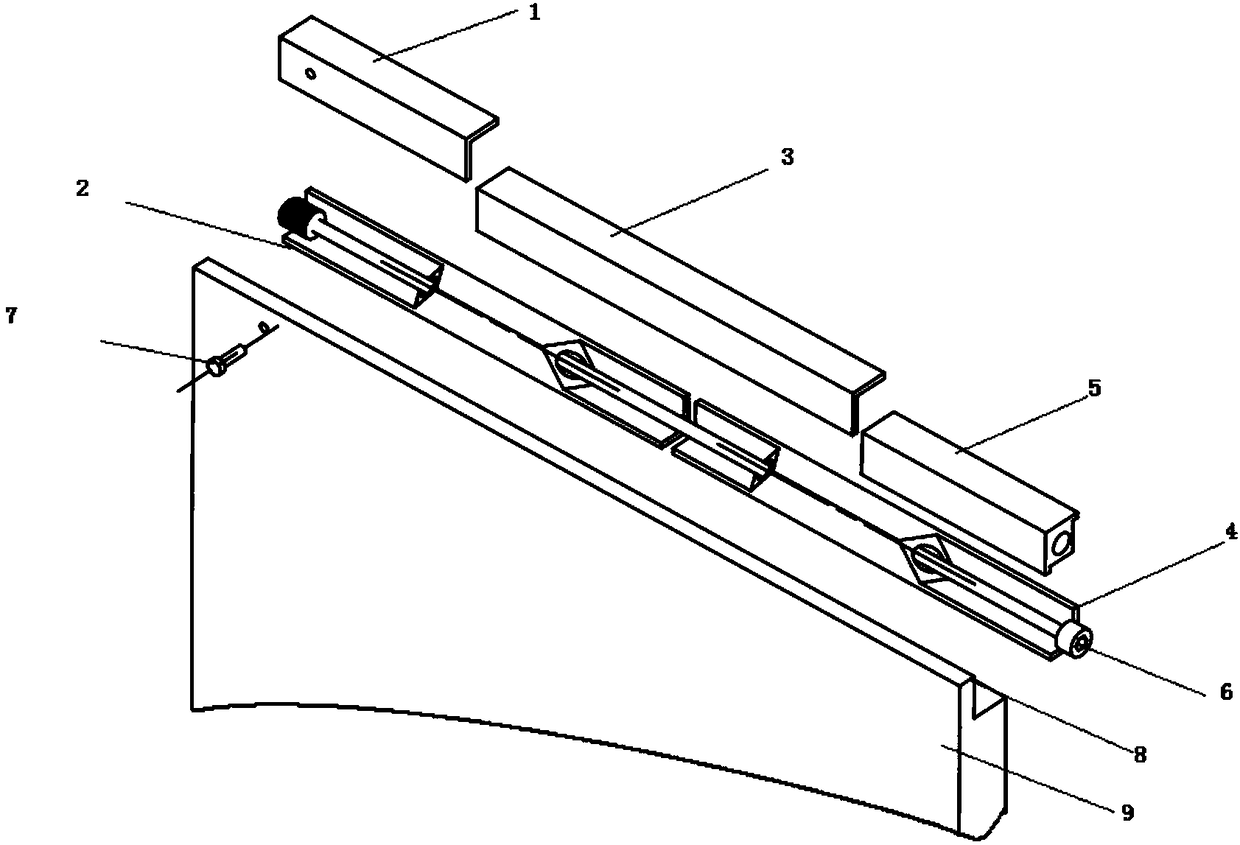

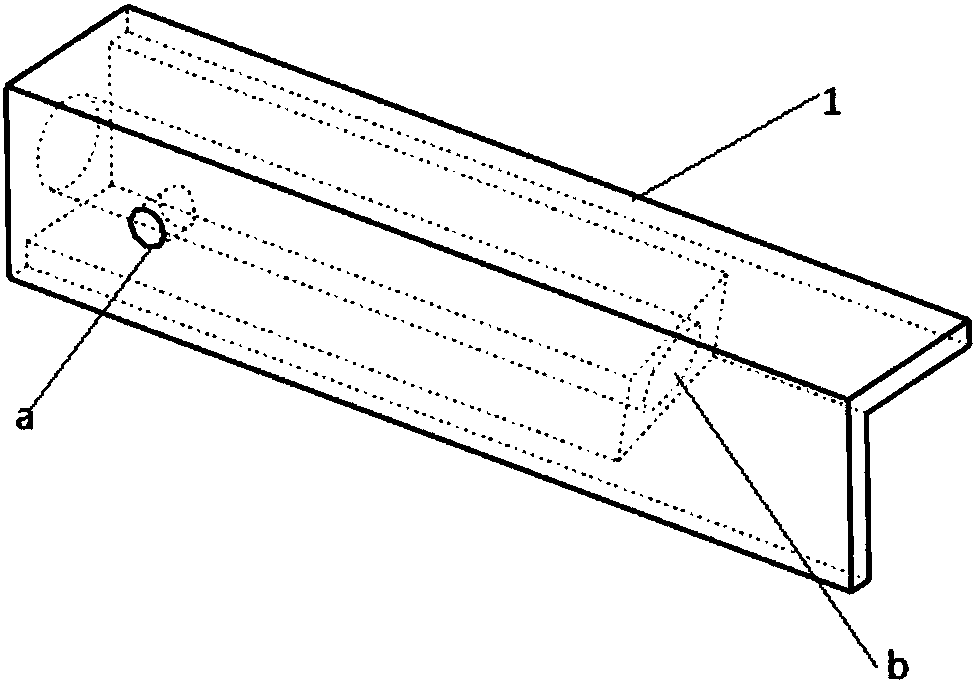

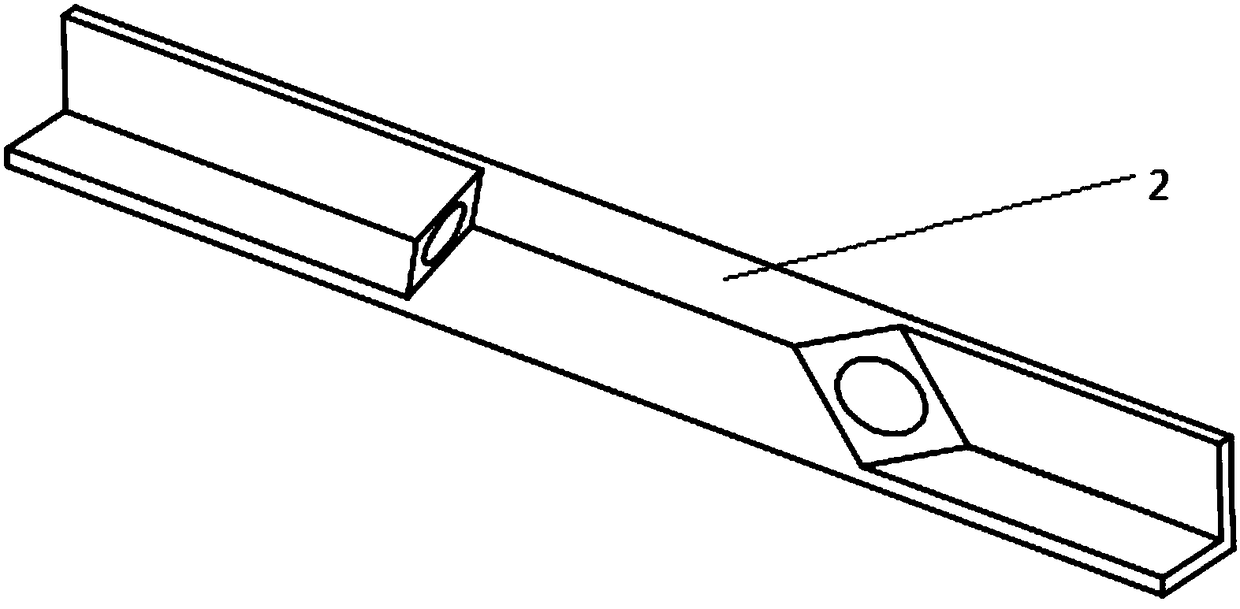

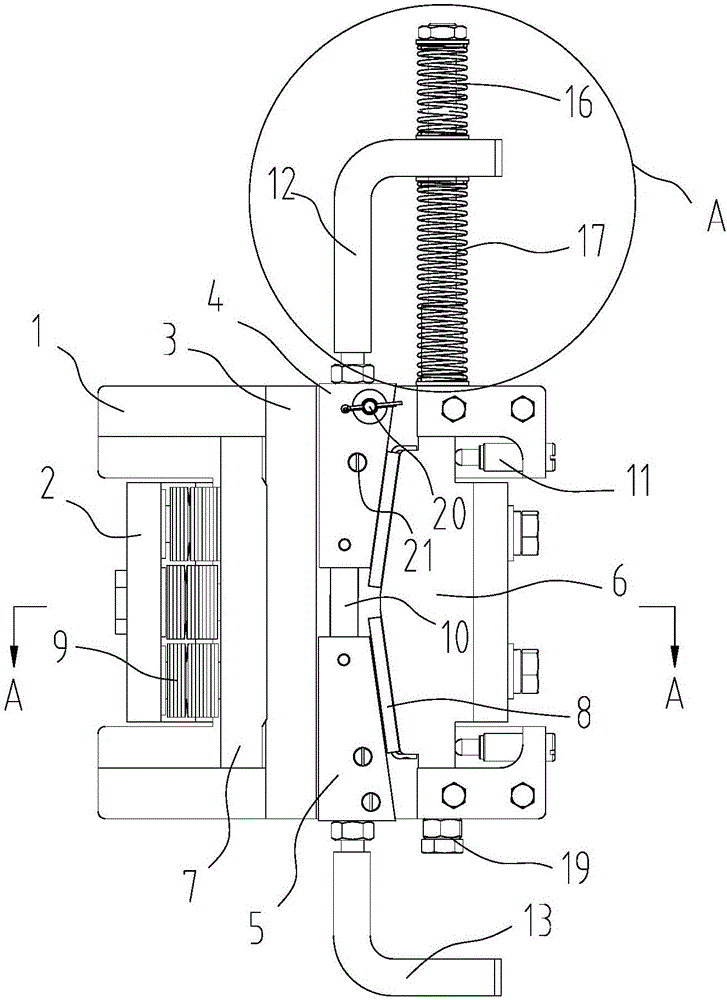

Craft knife capable of automatically locking blade position

InactiveCN101224585ASimple structureCooperate with each other firmlyMetal working apparatusEngineeringKnife blades

The invention relates to a craftsman knife, which can automatically lock a blade and includes a knife case (1), a blade (2), a knife file (3) and a push cover (4), wherein, a continuous double wedge (12) is arranged on the knife case (1), the knife file (3) is arranged behind the blade (2), an elastic element and a locking piece (6) the head (61) of which is rounded off, are arranged in the knife file (3), the elastic element has the tendency to push the head (61) of the locking piece (6) into a space between the double wedge (12) on the knife case (1), an inclined plane (41) is arranged at the back of the push cover (4) at each side of the head (61) of the corresponding locking piece (6), the two inclined planes (41) are opposite to each other, and can all squeeze the head (61) of the locking piece (6) out of the double wedge (12) on the knife case (1). Compared with the prior art, the invention realizes the locking of the blade relative to the knife case through the joint effect of the elastic element, the locking piece and the inclined plane on the pushing cover, the mutual coordination is firm, thus guaranteeing the quick and effective locking and unlocking of the blade relative to the knife case; furthermore, the parts are arranged in the craftsman knife in a simple way, and is easy to manufacture.

Owner:周晓刚

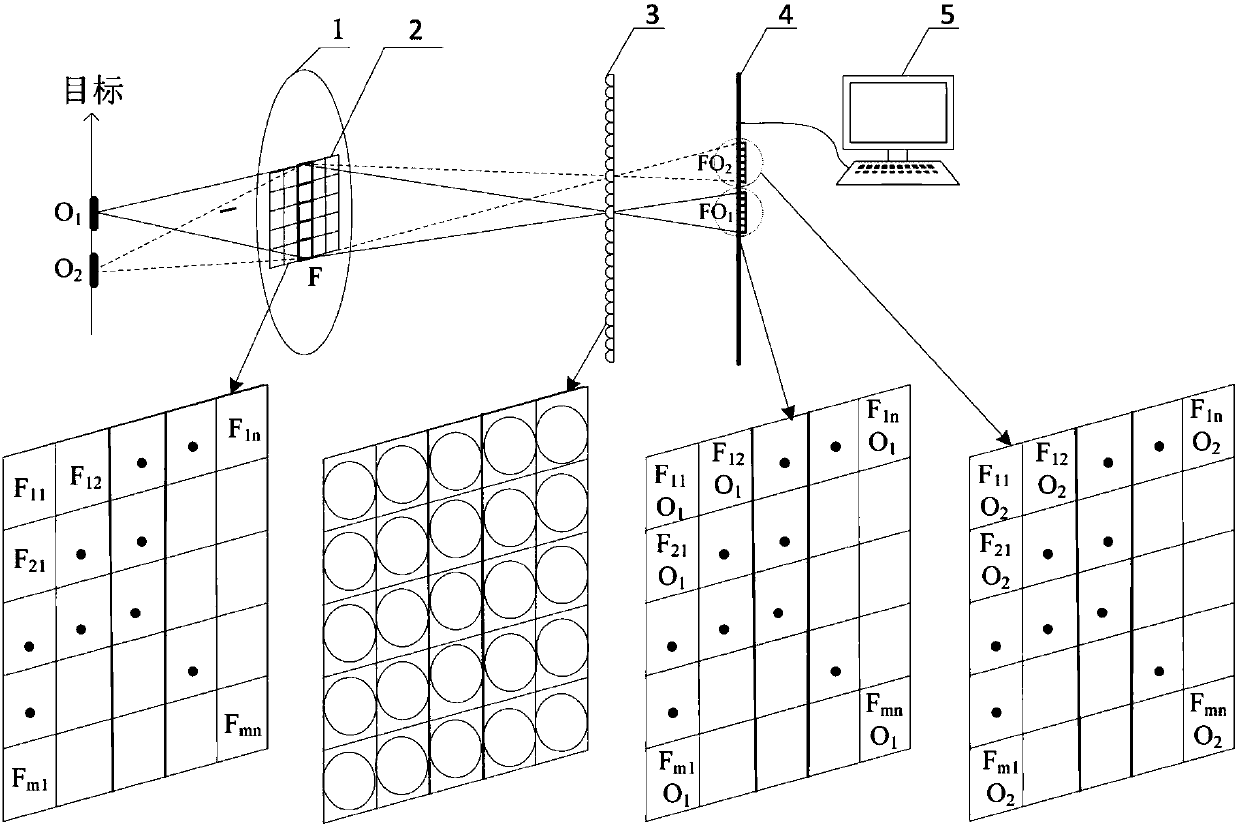

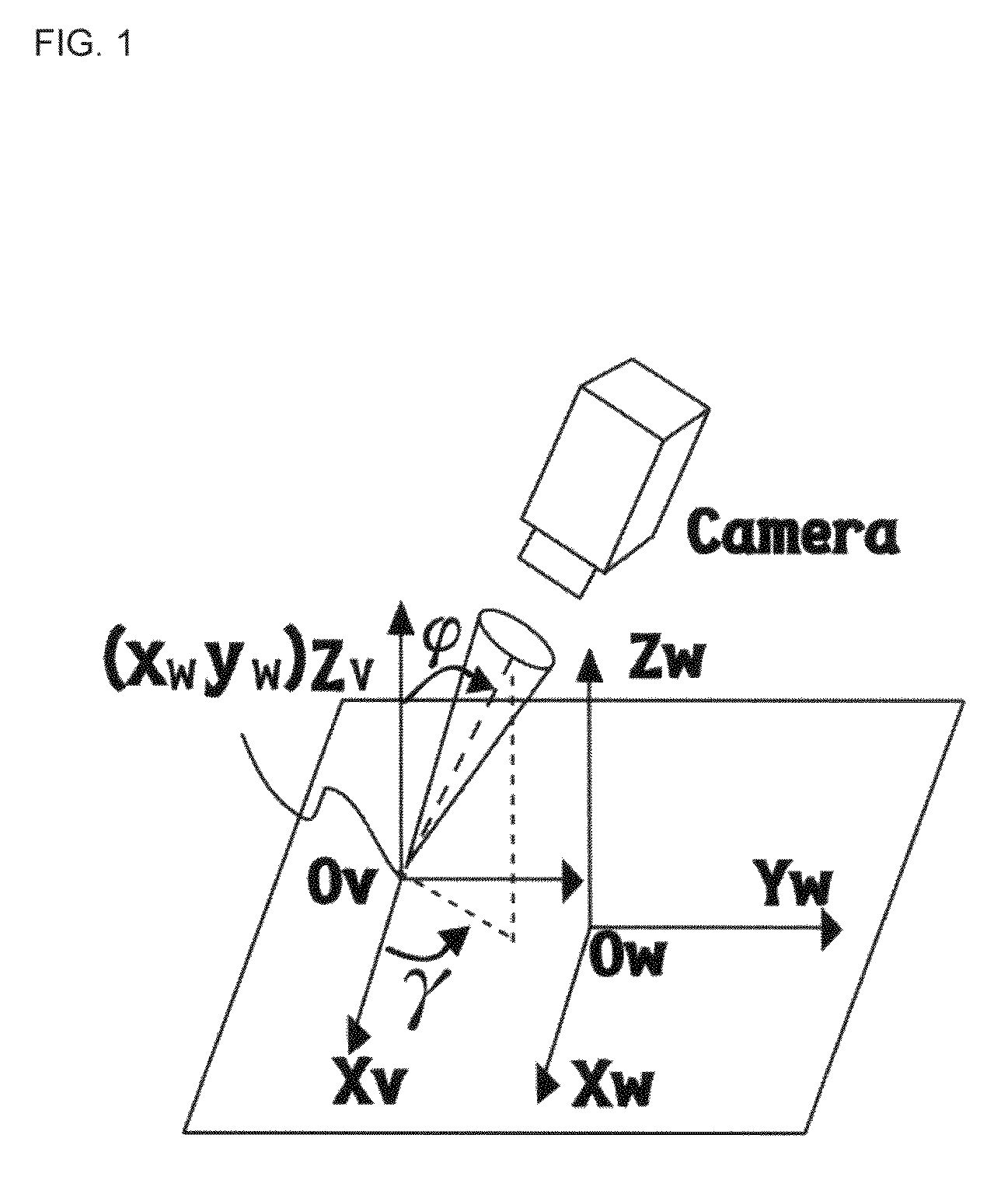

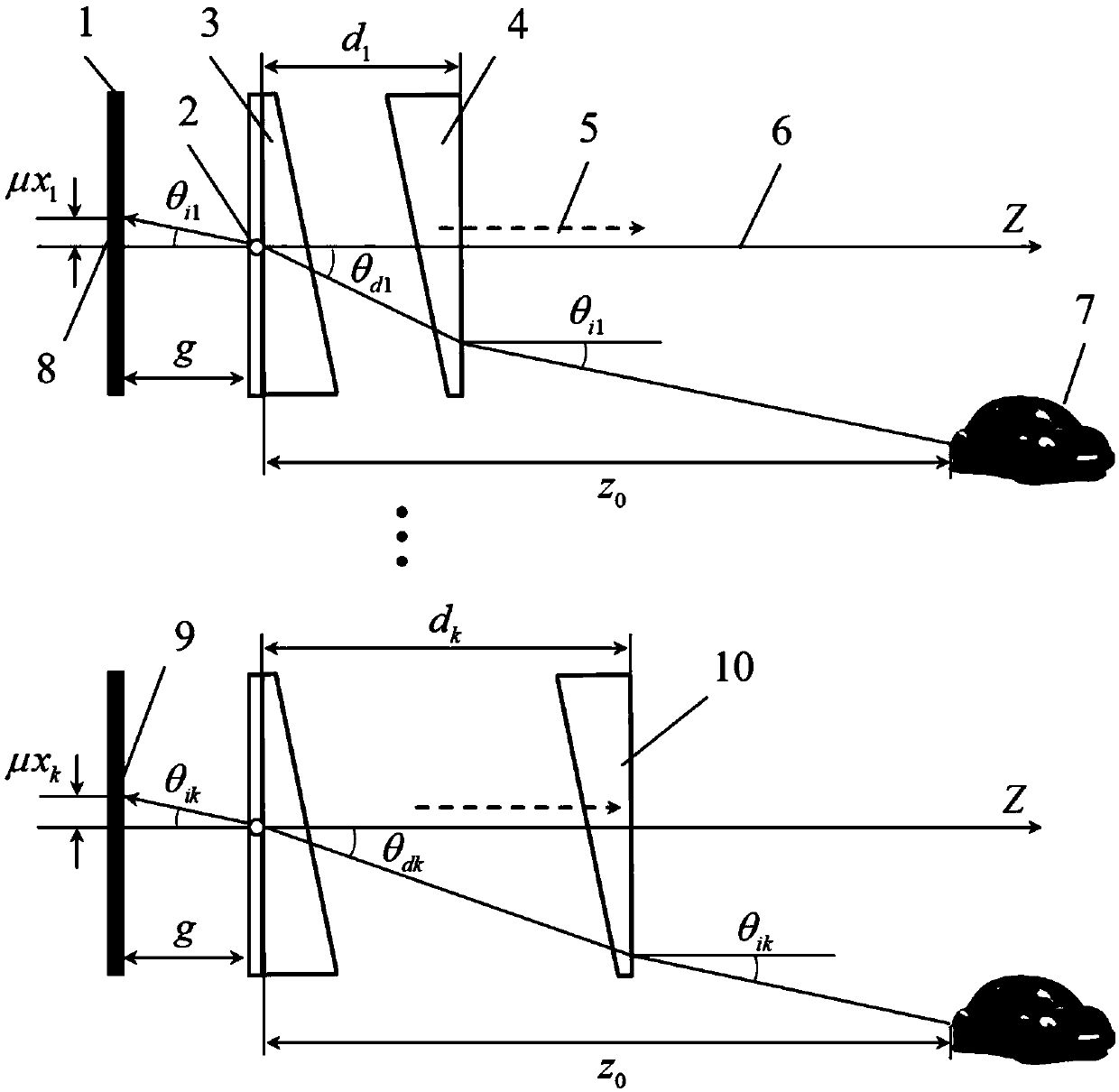

Axial distributed three-dimensional imaging method based on double wedged prisms

InactiveCN109597275AAccurate reconstructionEfficient reconstructionDetails involving processing stepsReconstruction from projectionVirtual spaceOptical axis

The invention relates to an axial distributed three-dimensional imaging method based on double wedged prisms. The method includes two processes of acquisition of multi-visual-angle element images andreconstruction of a three-dimensional image. The acquisition process of the multi-visual-angle element images includes steps: maintaining a camera and a first prism still by employing the refraction effect of a light beam by the double wedged prisms, and intermittently acquiring the multi-visual-angle element images, regarded as 3D scenes, of a traverse perspective and a vertical perspective of atarget object through one-dimensional movement of a second prism along an optical axis. The reconstruction process of the three-dimensional image includes steps: performing back projection of the recorded element images to a virtual space scene through a virtual pinhole according to a back projection algorithm, superposing the amplified and shifted element images on the same reconstruction plane,and selecting a pixel average value of a new overlapping region to form a constructed image of the three-dimensional image. Compared with the prior art, according to the method, an approach for real-time dynamic display of space scene integrated imaging is provided, and the application of the integrated imaging technology enriched.

Owner:TONGJI UNIV

Planar beam dump

Owner:THE BOEING CO

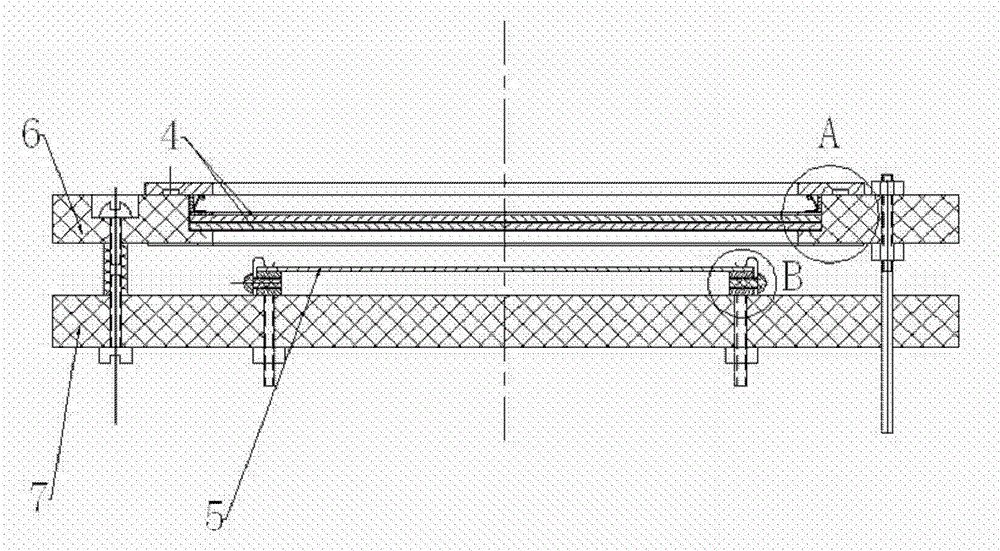

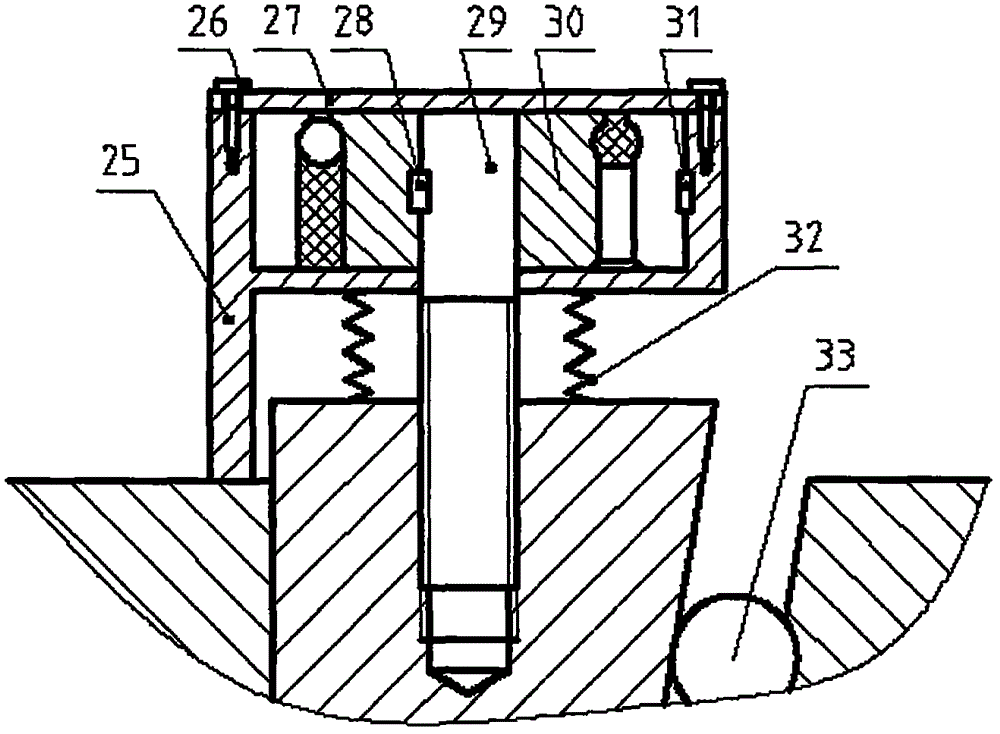

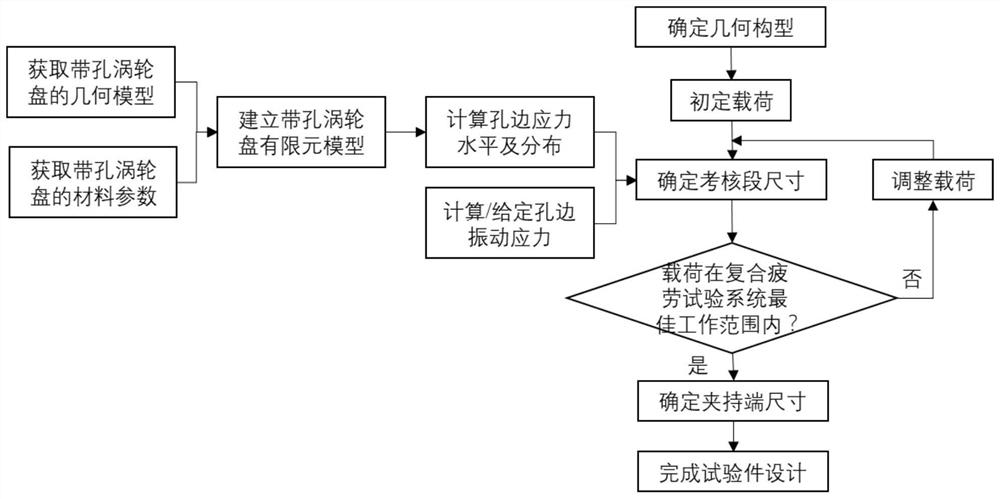

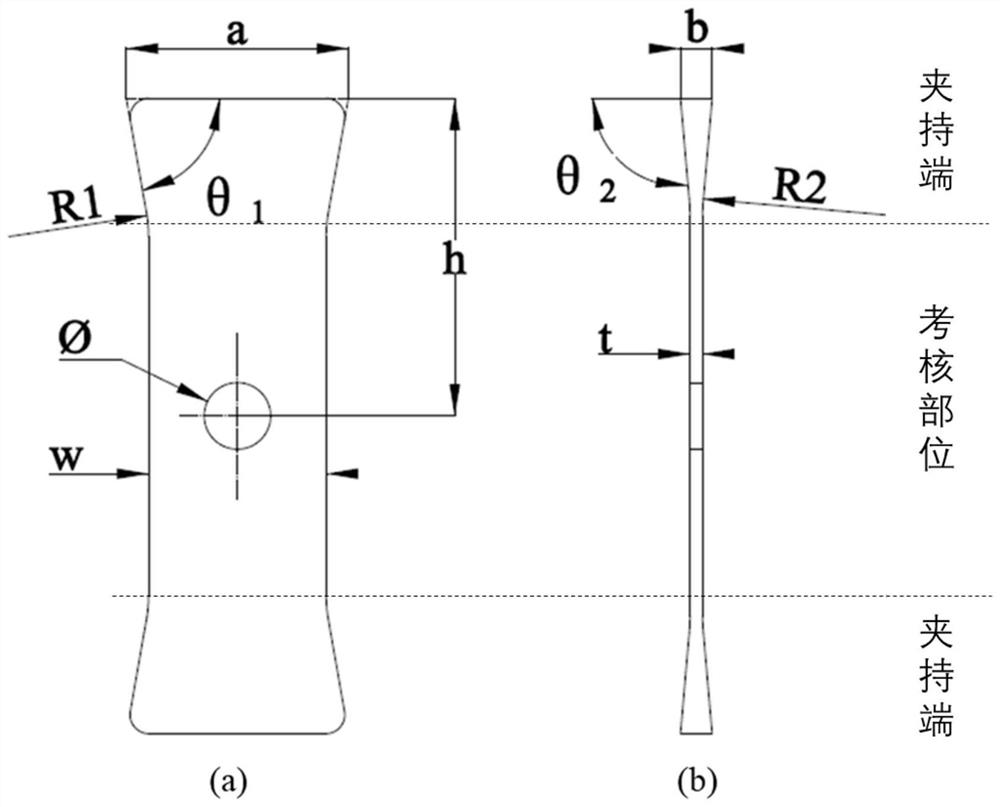

High-low cycle composite fatigue test piece of turbine disc cold extrusion reinforced hole structure and design method

ActiveCN112100765AImprove carrying capacityReliable loadGeometric CADDesign optimisation/simulationStress concentrationElement analysis

The invention discloses a high-low cycle composite fatigue test piece design method for a turbine disc cold extrusion reinforced hole structure, and the method comprises the steps: obtaining a geometric model of a perforated turbine disc, and simplifying a non-key region; obtaining working conditions of the turbine disc and material performance parameters under all the working conditions; and establishing a finite element analysis model of the perforated wheel disc, and conducting calculating to obtain a hole edge equivalent stress maximum point and a stress gradient. A flat test piece with acenter hole is used as a basic shape, uniaxial tensile loading is used as a basic load form, an examination section of a turbine disc hole structure test piece is designed, and the maximum stress value and distribution of the stress concentration position of the hole edge of the test piece accord with the condition of a real structure by adjusting the width of the test piece, finely adjusting thetensile load and the like. By the modes of adjusting the thickness of the test piece, the frequency and magnitude of the exciting force and the like, the maximum vibration stress value of the hole edge is equal to the maximum vibration stress value of a real wheel disc hole structure, and it is ensured that the loads are all within the optimal working range of the high-low cycle composite fatiguetest system; and a test piece double-wedge-shaped clamping end is designed, and thus the low stress level of the clamping end and the low stress concentration degree of a transition section are guaranteed.

Owner:BEIHANG UNIV

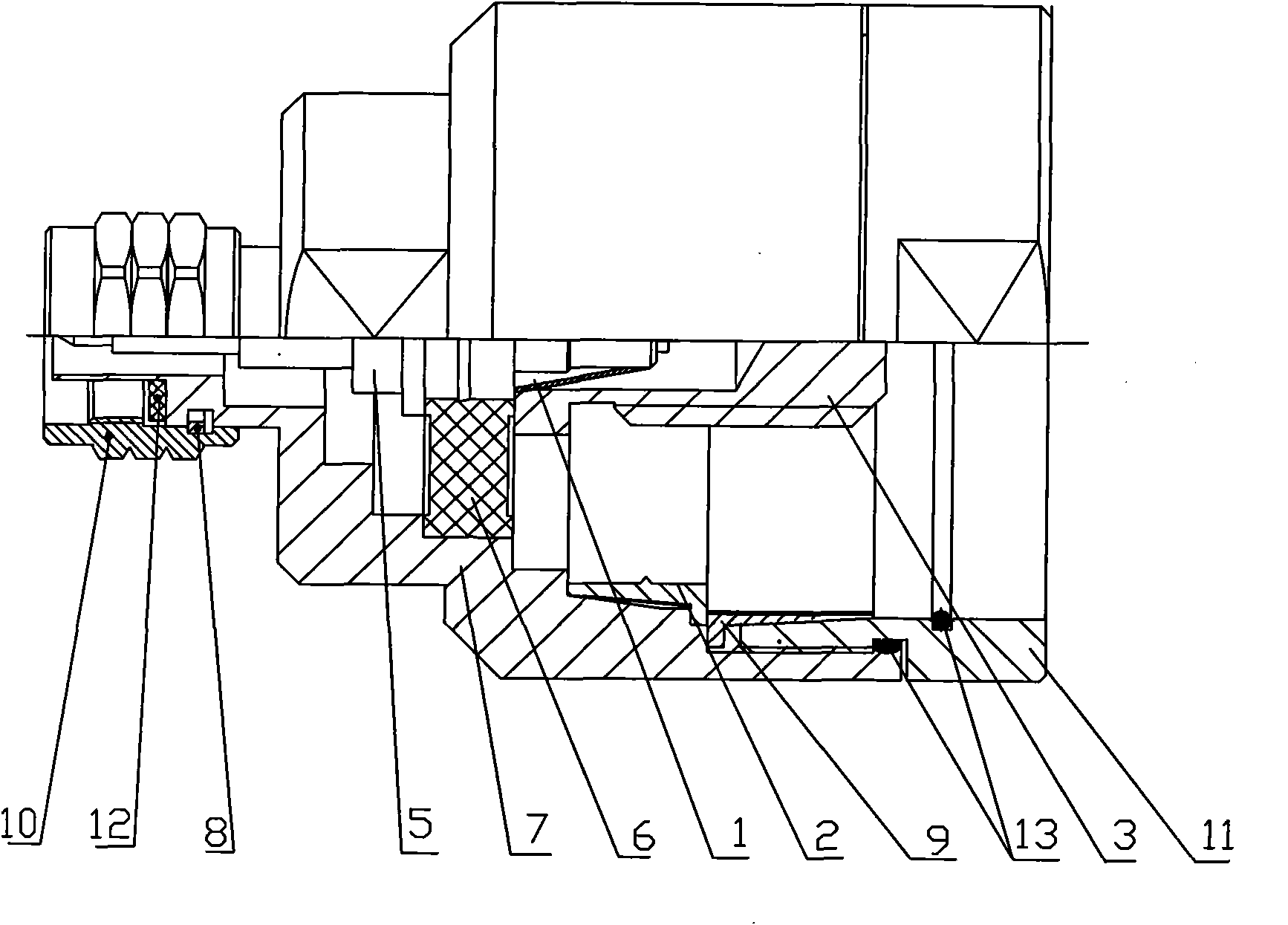

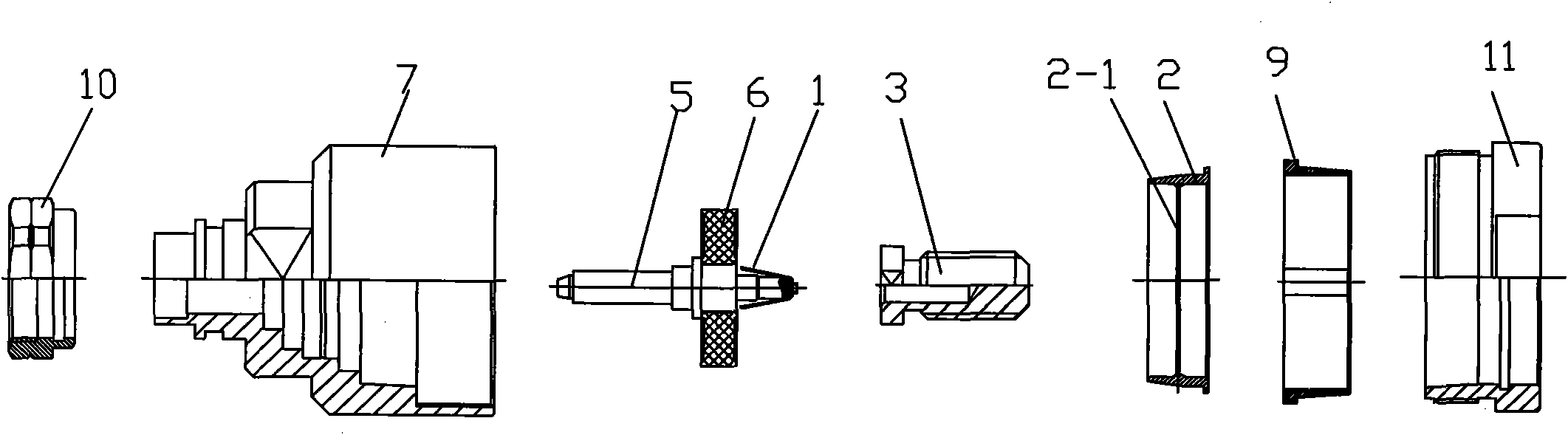

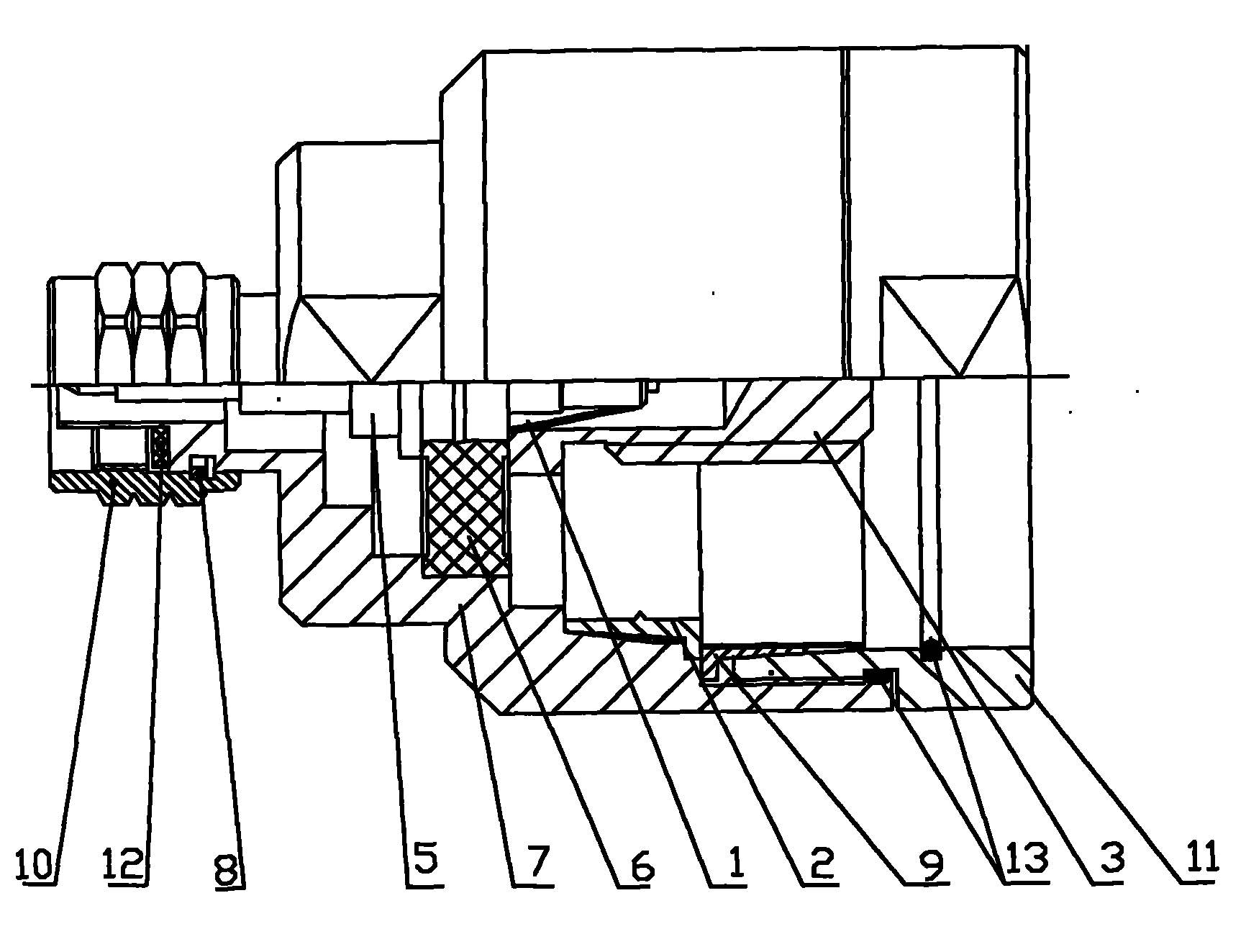

Double wedge type radio frequency connector

InactiveCN101841108AClamp firmlyNo need to repairRelieving strain on wire connectionCoupling contact membersElectrical conductorScrew thread

The invention relates to a double wedge type radio frequency connector, which belongs to the technical field of communication transmission facilities. The connector comprises a front shell, a rear turn buckle and an inner conductor, wherein one end, close to the rear turn buckle, of the front shell is in adjacent connection with a first taper hole with a positioning stage; an inner hole, close to an external screw thread segment of the front shell, of the rear turn buckle is a second taper hole; a first C-shaped outer taper ring is assembled in the first taper hole, a second C-shaped outer taper ring is assembled in the second taper hole, and the opening of the first C-shaped outer taper ring and the opening of the second C-shaped outer taper rings are wider than an axial convex rib of a cable protective cover; and when the front shell and the rear turn buckle are connected and screwed through screw threads, the opposite end surfaces of the first and second C-shaped outer taper rings contact in a way of pressing against each other, and the inner diameters of the first and second C-shaped outer taper rings tend to reduce simultaneously. When the double wedge type radio frequency connector is used, the shell is wedged, connected and clamped with the outer conductor and the outer circle of a cable reliably at the same time; and the axial convex rib part of the cable protective cover is not required to be removed, so connection operation is obviously simplified and very convenient.

Owner:ZHENJIANG ZHENGKAI ELECTRONICS

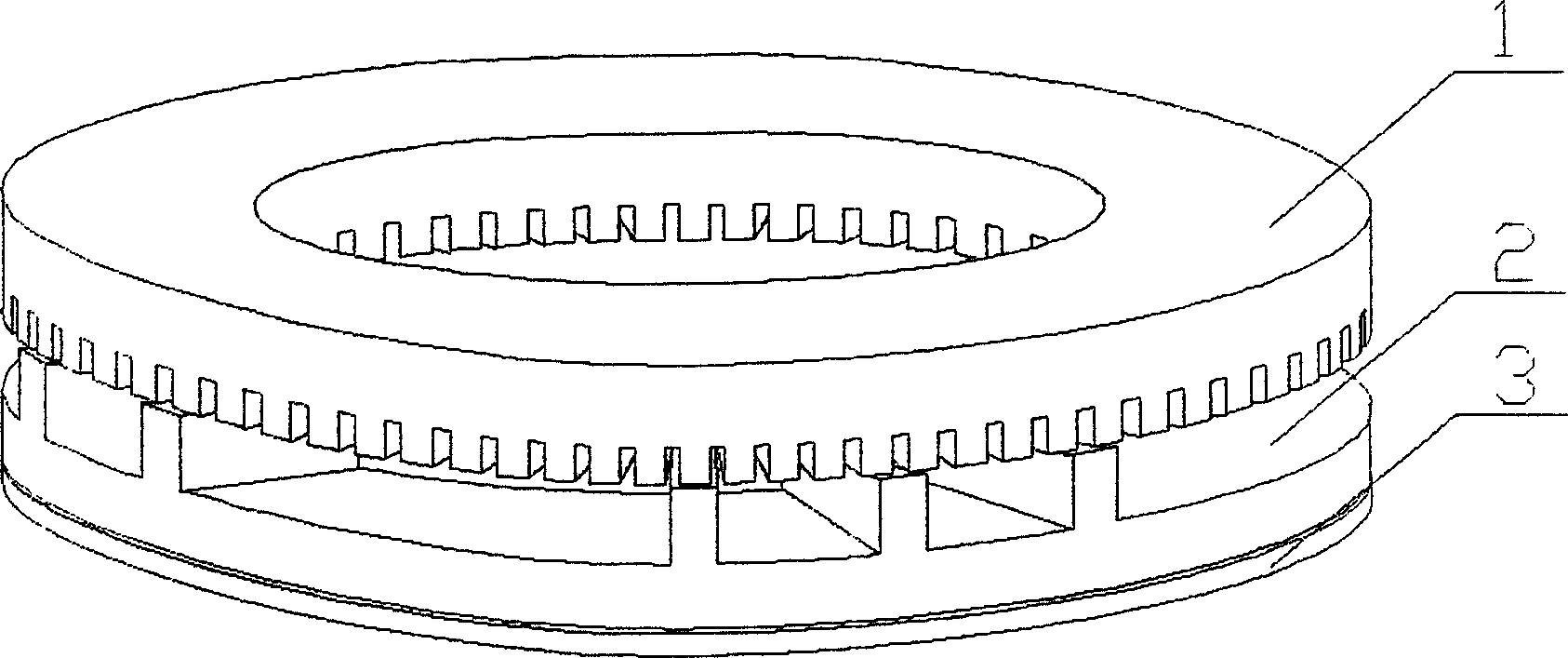

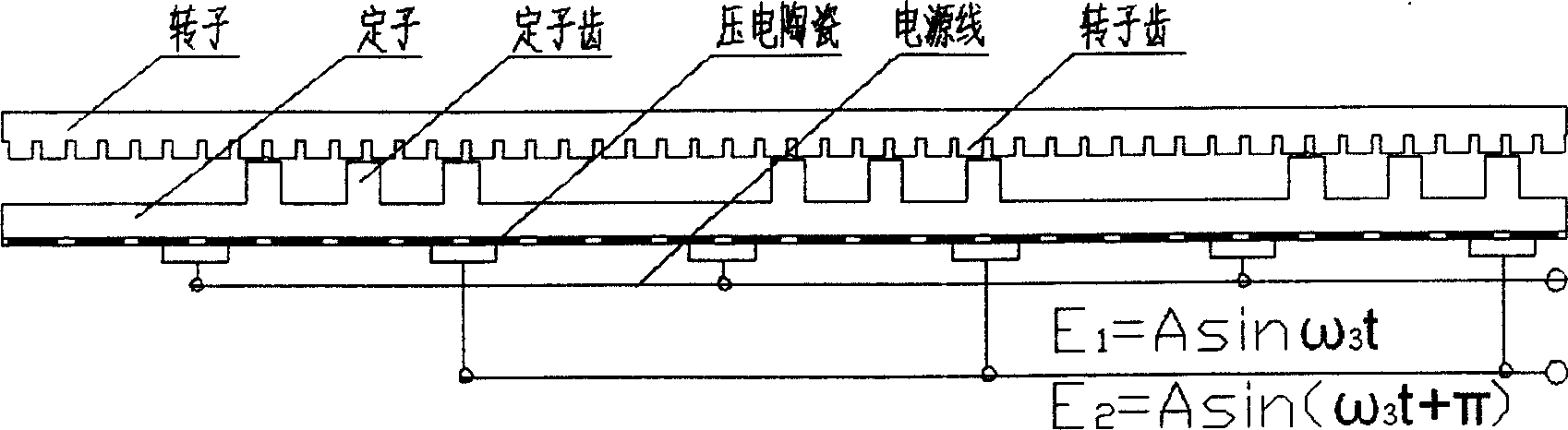

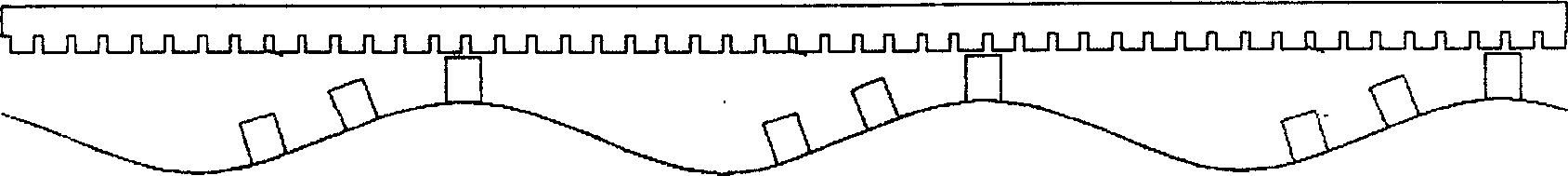

Standing wave frequency change step ultrasonic electric machine

InactiveCN1688097APiezoelectric/electrostriction/magnetostriction machinesDriver circuitElectric machine

A stationary wave frequency conversion step-by-step supersonic motor is composed of three parts: a stator, a rotor and a piezoelectric ceramics, among which, the top face of the stator has double wedges, the bottom face is adhered with a piezoelectric ceramic ring, the bottom face of the rotor has uniform dividing grooves, the end face of the ring rotor with grooves presses on the double wedges of the stator top face. The piezoelectric ceramic ring excites the stator to crease and vibrate, several stator double wedges move obliquely on the rotor to drive the rotor, when it rotates over half of the teeth space, the driving tooth of the stator corresponding to it is placed at the groove of the rotor, which can't be driven, its first step space is finished. The switch supply excites another vibration type of the stator that the corresponding driving tooth is in the middle of the groove of the rotor to drive it for the second step movement, the motor works like this continuously to realize progress.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

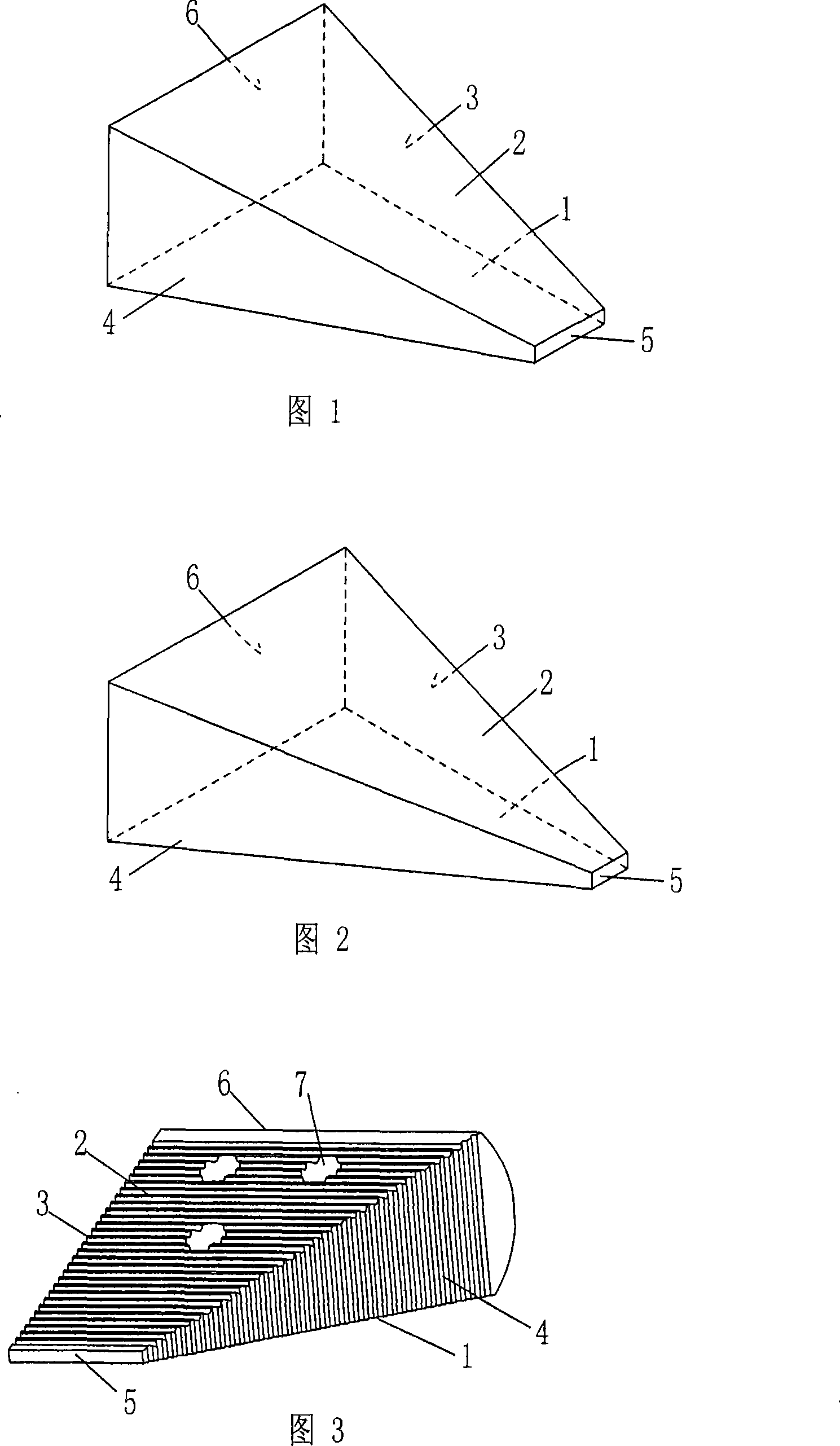

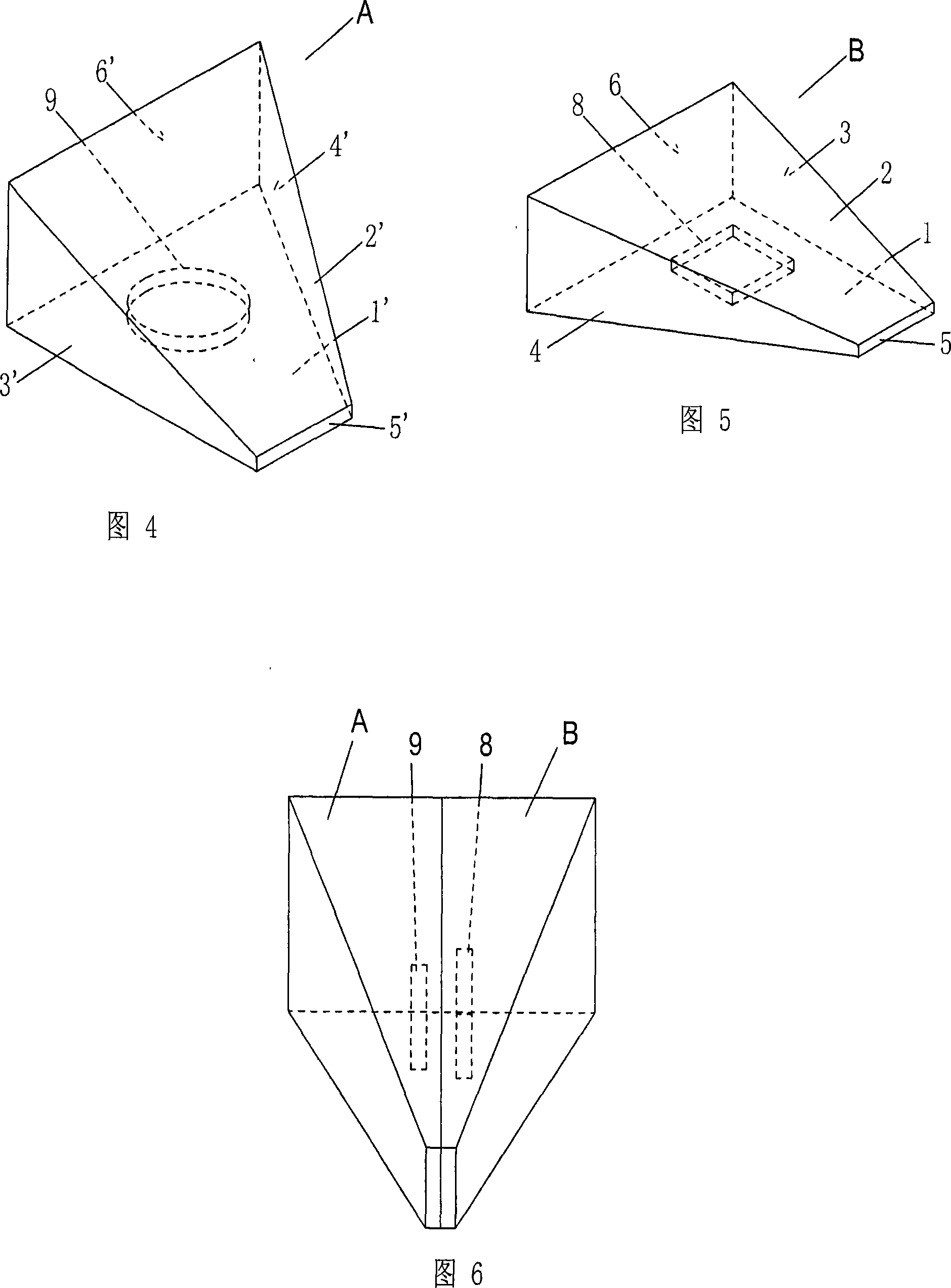

Integral limiting device for door with double-wedge shaped structure

The invention relates to a monomeric limiter with a double-wedge shaped structure used for a door. The invention comprises a main body of the monomeric double-wedge shaped structure, the main body adotps a hexahedron, and is provided with a bottom surface, one face relative to the bottom surface is a first load bearing bevel face, one side of the bottom surface is upwardly and vertically extends out the lateral surface, one face relative to the lateral surface is a second load bearing bevel face, the distance between the small end of the first load bearing bevel face and the bottom surface is slightly smaller than the smallest gap between the lower rim of the door and the ground, and the distance between the big end of the second load bearing bevel face and the lateral surface is 1.5 to 3.5 times of the distance between the big end of the first load bearing bevel face and the bottom surface; the distance between the small end of the second load bearing bevel face and the lateral face is not smaller than the distance between the small end of the first load bearing bevel face and the bottom surface, and not larger than 0.9 time of the distance between the big end of the first load bearing bevel face and the bottom surface. The invention adopts the monomeric structure, the application range of the gap is wide, the invention is inserted in the gap between the lower rim of the door and the ground, the touch of the load bearing bevel face and the lower rim of the door prevents the closing of the door, and ensures that the door is under the required opening state, the cost is inexpensive, the use and the preservation are convenient, and the invention has no blocking to the passing.

Owner:王嘉 +1

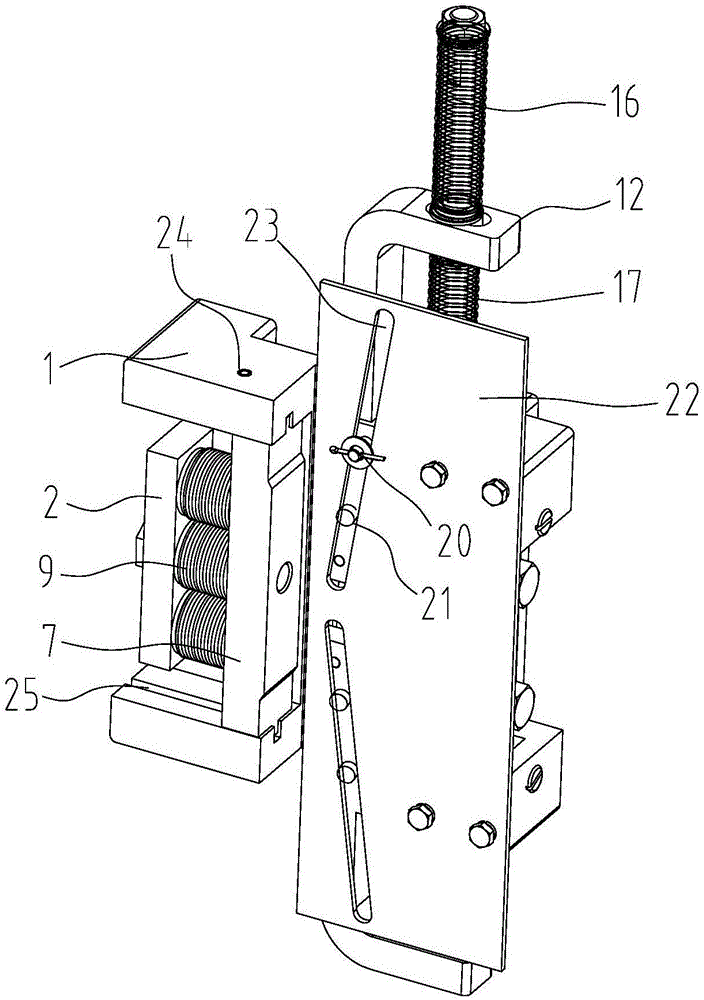

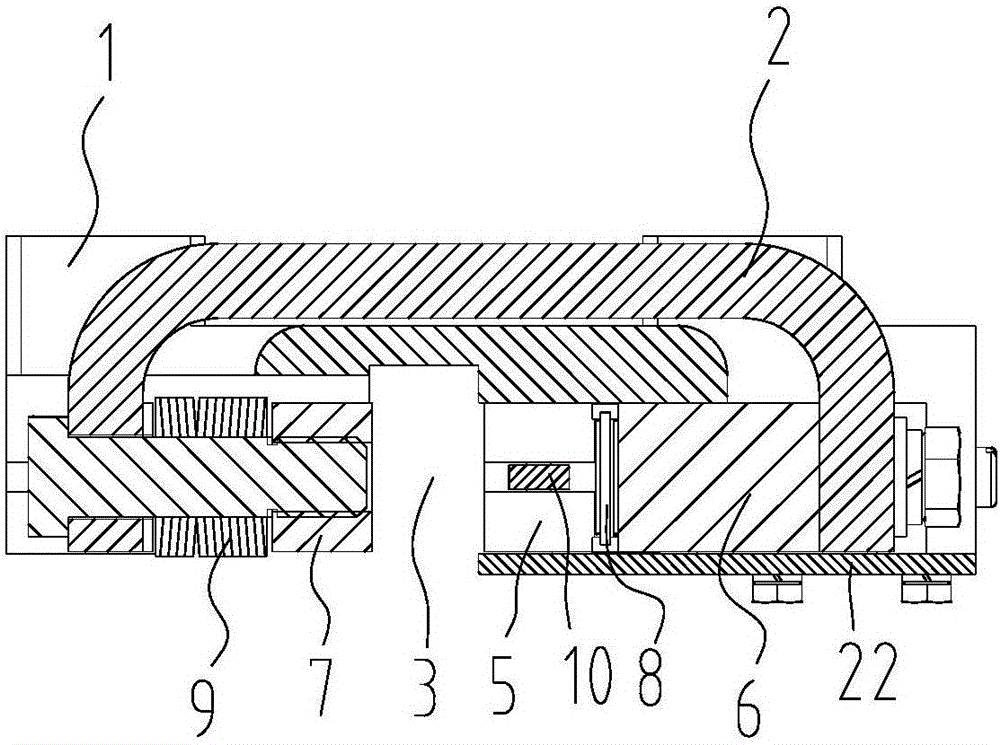

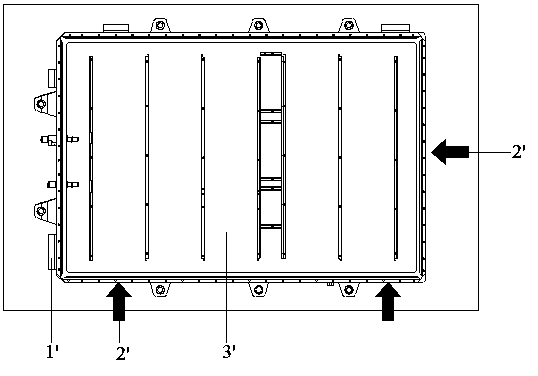

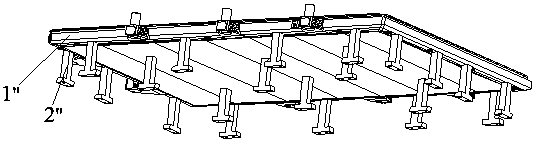

Double motion freedom degree low thermal resistance locking device

ActiveCN108430189ASolve the problem of small contact area and large contact thermal resistanceSmall heat transfer temperature differenceClamping/extracting meansCooling/ventilation/heating modificationsVibration amplitudeDiagonal

The invention brings forward a double motion freedom degree low thermal resistance locking device. Via the device, contact thermal resistance can be remarkably reduced, vibration amplitude of an LRM module can be lowered, and vibration resistance performance of the module can be improved. The device is realized via the following technical solution: a one-way wedge face fixing block (1) fixed on anangle plate, a rear wedge face block angle plate moving section (2), a double wedge face block middle angle plate moving section (3), a one-way wedge face front angle plate moving section (4), and aone-way wedge face driving slide block (5) are orderly connected in series at an interval of 3-5 millimeters via long screw rods so as to form a cuboid-shaped locking bar comprising four moving pairsconnected in series, the locking bar is mounted fixedly in L-shaped gap slot of the LRM module, all angle plate moving sections are driven spirally via screw rods (6) to gradually retract along interval gaps among all sections, staggered sliding motion is generated along a direction of a diagonal line of a cuboid, distensible force is generated between walls of gap slots of the LRM module and a cold plate (10), and double motion locking and heat transfer of the LRM module can be realized.

Owner:10TH RES INST OF CETC

Bidirectional safe pliers for elevator

ActiveCN106241549AAvoid lateral displacementPrevent deformation of guide railElevatorsMechanical engineeringDouble wedge

The invention relates to bidirectional safe pliers for an elevator. The bidirectional safe pliers for the elevator comprise a bracket, a flat pliers body, a wedge pliers body group, a double-wedge block and a linkage frame, wherein the bracket is provided with a guide rail groove; the flat pliers body and the wedge pliers body group are arranged on the two sides of the guide rail groove of the bracket respectively; the double-wedge block is matched with the wedge pliers group; the linkage frame is connected with the flat pliers body and the double-wedge block; the wedge pliers body group comprises an upper wedge pliers body and a lower wedge pliers body which are symmetrical; the double-wedge block is correspondingly provided with two wedge surfaces which are matched with the upper wedge pliers body and the lower wedge pliers body respectively; the bidirectional safe pliers for the elevator also comprises a guide mechanism which is used for limiting the upper wedge pliers body and the lower wedge pliers body to sliding along the respective matched wedge surfaces; the upper wedge pliers body and the lower wedge pliers body are connected through a linkage piece; one of the wedge pliers bodies serves as a trigger mechanism of the bidirectional safe pliers; and a reset mechanism applied to the wedge pliers bodies is arranged on the bracket. The bidirectional safe pliers realize bidirectional braking and protect a guide rail maximally.

Owner:浙江西子富沃德电机有限公司

Two-way centering positioning and double-wedge floating self-locking type fixing tool

PendingCN110181212AGuaranteed Position RequirementsAddressing the Effects of FinishingWelding/cutting auxillary devicesAuxillary welding devicesMachining deformationSelf locking

The invention discloses a two-way centering positioning and double-wedge floating self-locking type fixing tool which comprises a tool main body; a to-be-clamped product is fixed on the tool main body; the tool main body is further provided with a two-way automatic centering mechanism, a double-wedge self-locking floating supporting mechanism and an automatic guiding and compression mechanism; thetwo-way automatic centering mechanism realizes positioning of the to-be-clamped product in a horizontal direction; all contact points of the double-wedge self-locking floating supporting mechanism ina vertical direction are attached to the to-be-clamped product in a floating manner; and the automatic guiding and compression mechanism vertically acts downward to press the to-be-clamped product. By means of the mode, the two-way centering positioning and double-wedge floating self-locking type fixing tool can effectively guarantee the positioning requirements for the product in the horizontaldirection and floating attachment of all the contact points in the vertical direction to the product, eliminates the influence of product machining deformation on subsequent further finish machining,realizes complete constraint of the product, ensures the quality of the product and meets the requirements for batch production.

Owner:纽维科精密制造江苏有限公司

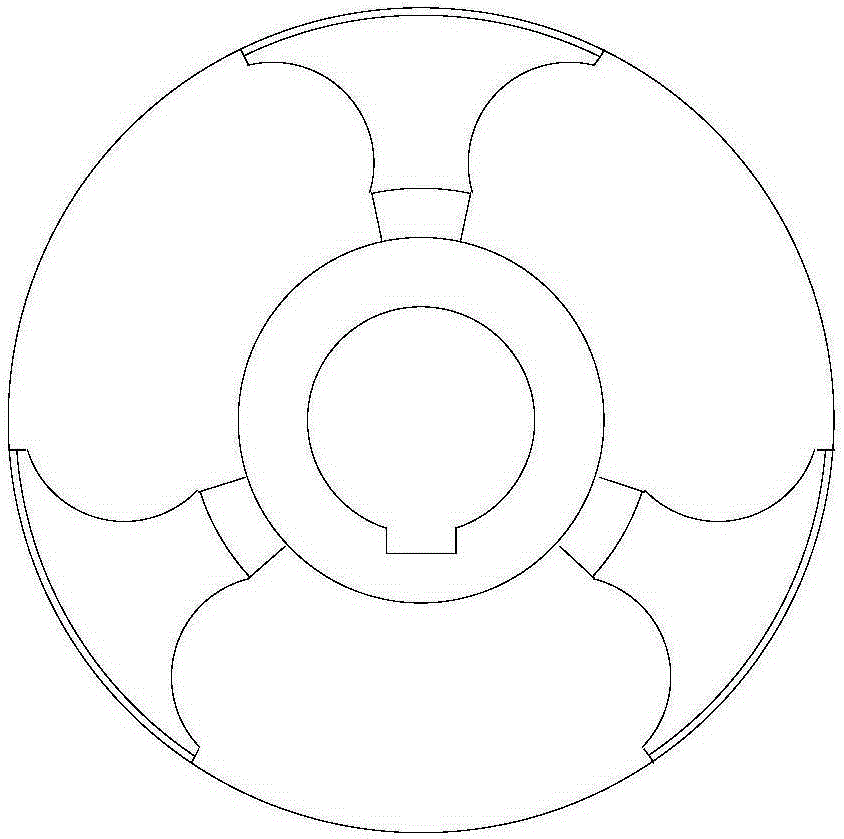

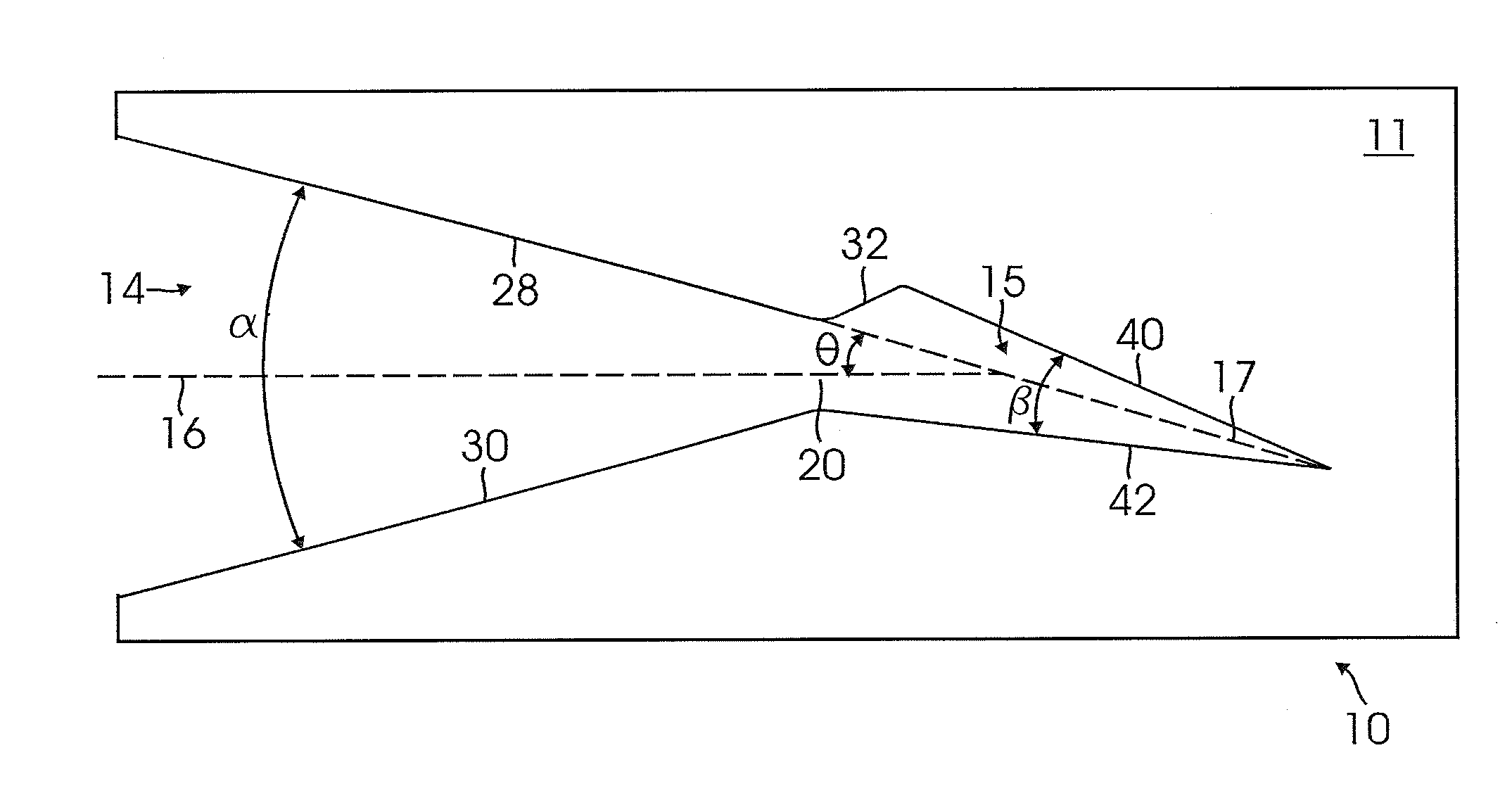

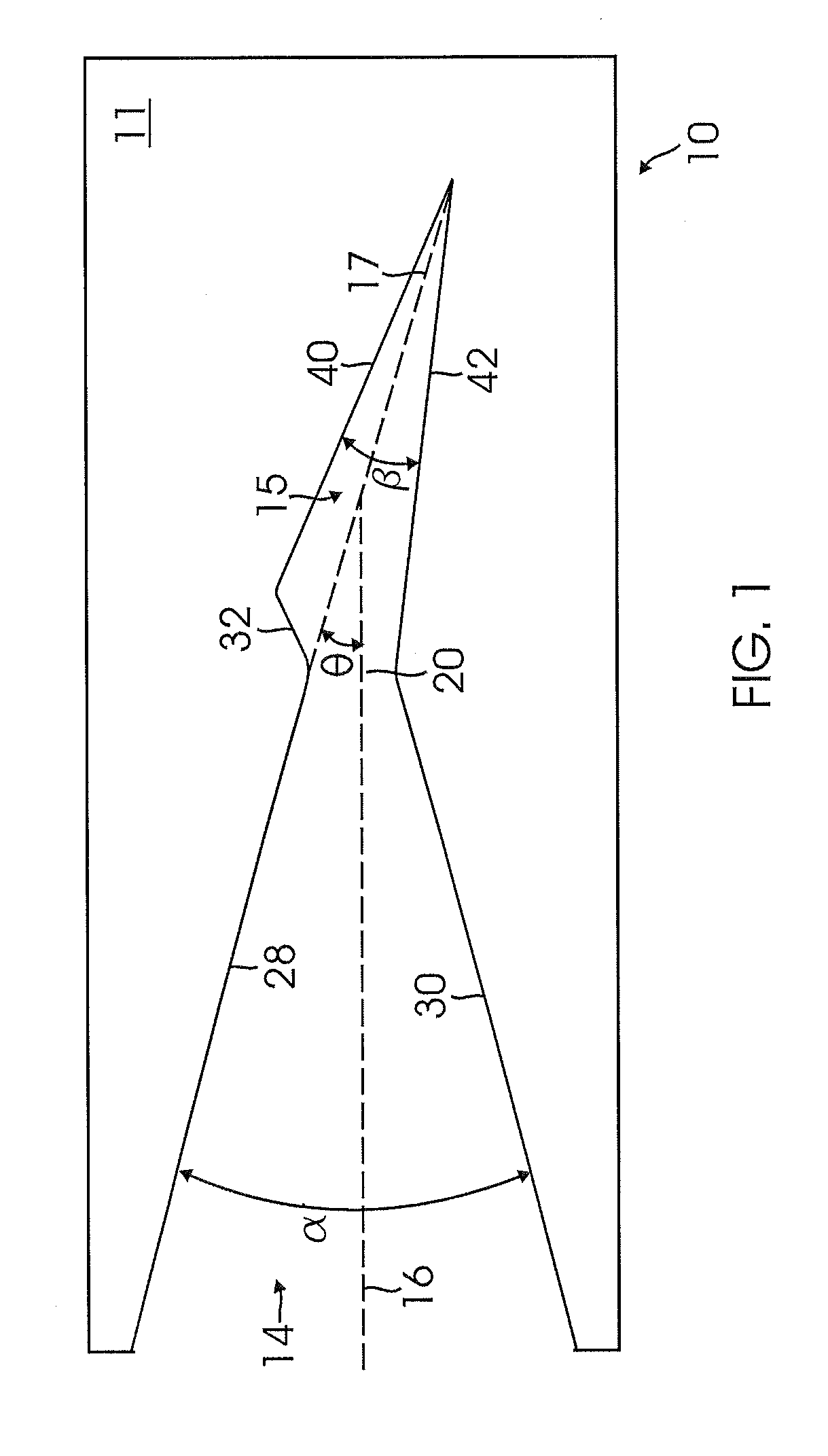

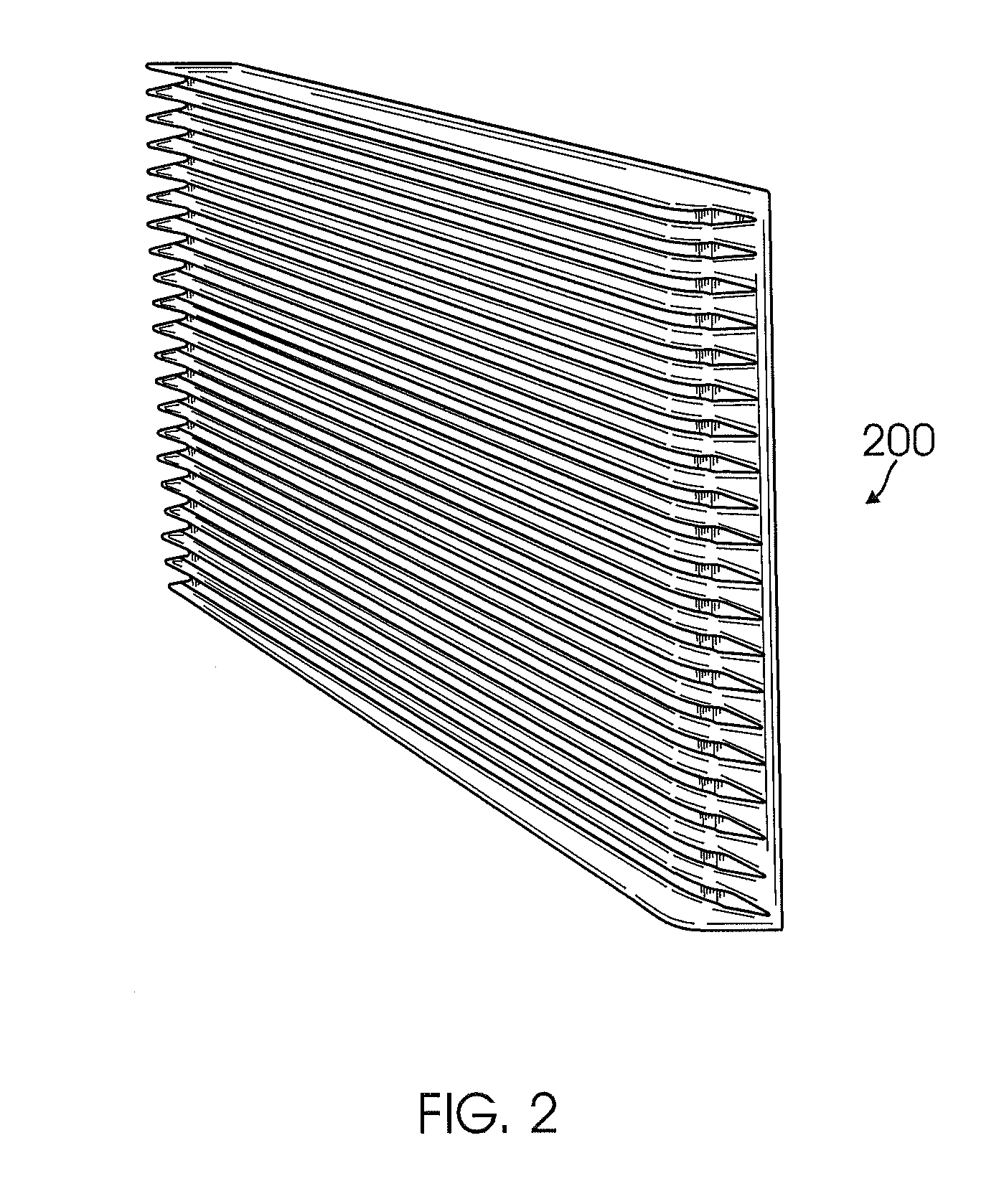

Planar beam dump

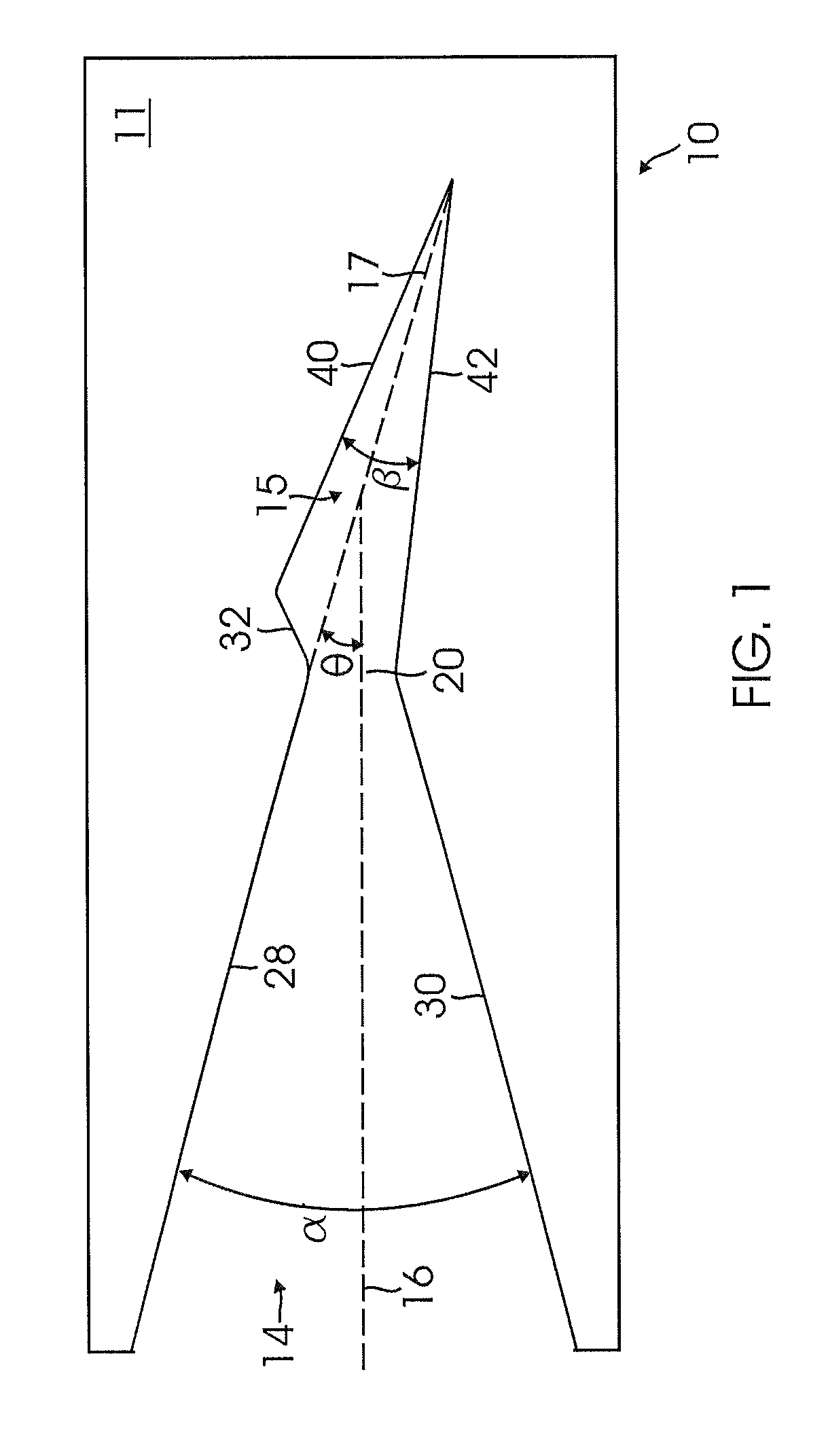

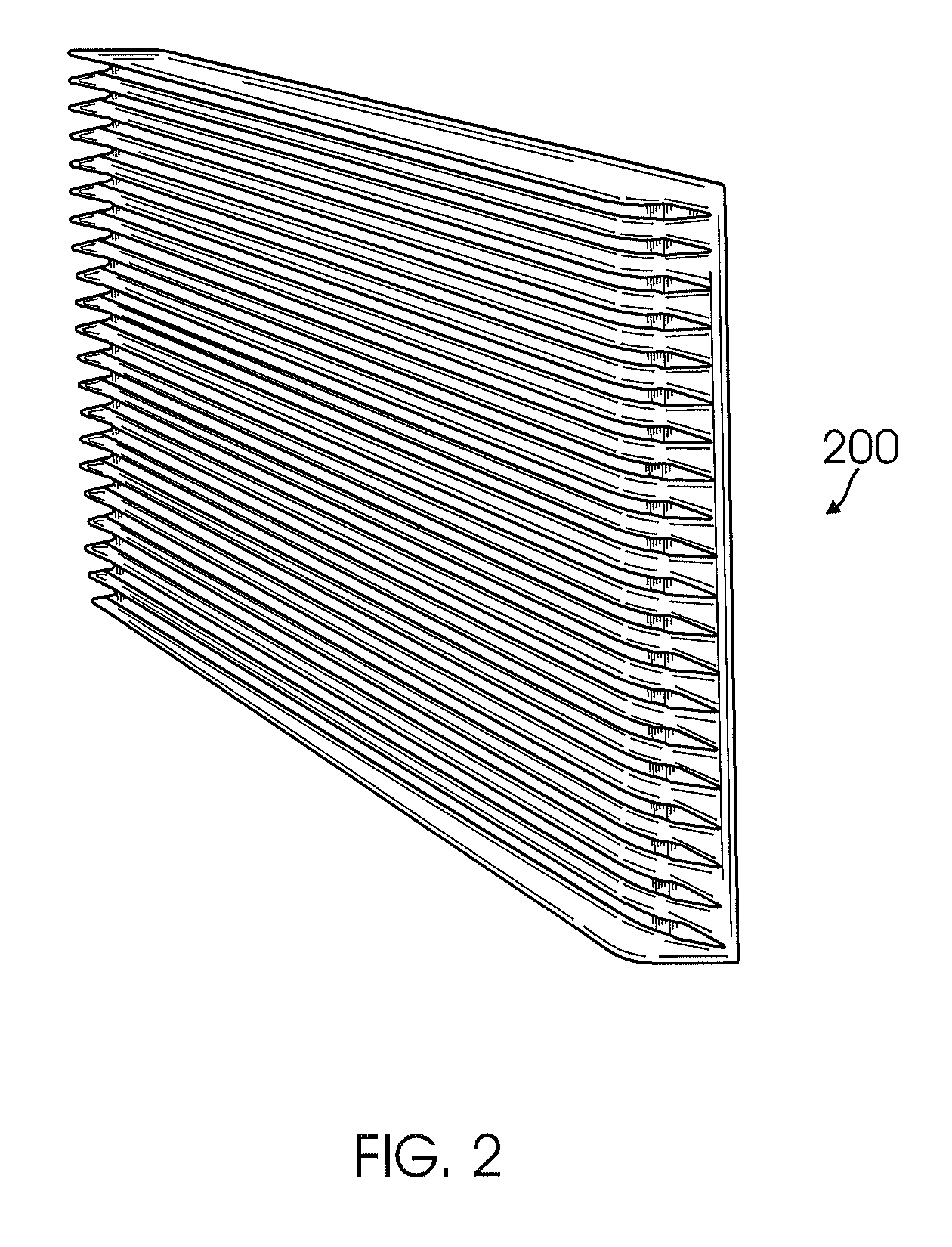

In one embodiment, a device for capturing radiation includes: a panel defining a plurality of double wedge chambers, wherein each double wedge chamber includes a first wedge-shaped chamber that tapers into an opening for a second wedge-shaped chamber, and wherein a longitudinal axis of the first wedge-shaped chamber is not collinear with a longitudinal axis of the second wedge-shaped chamber.

Owner:THE BOEING CO

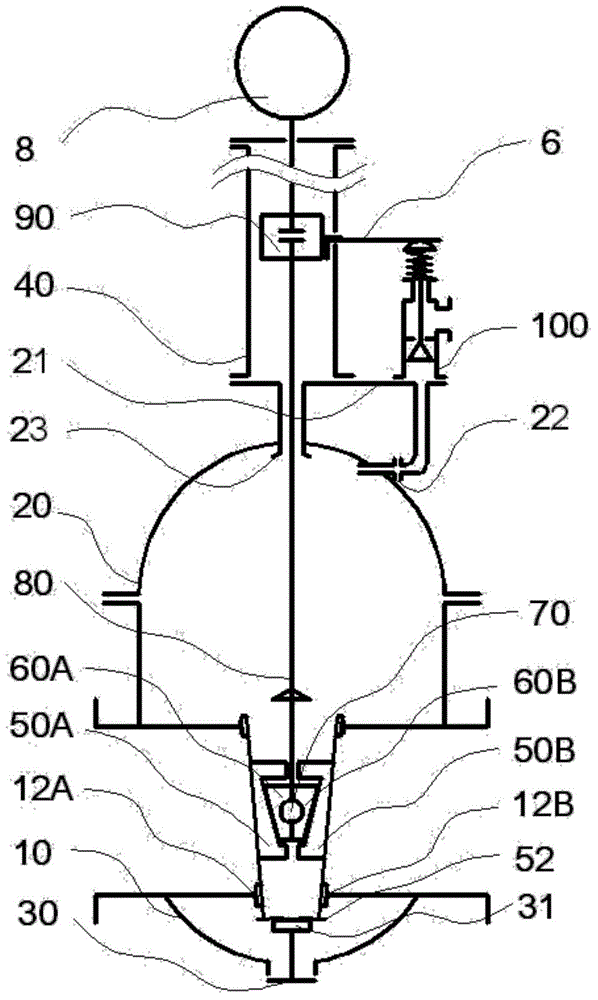

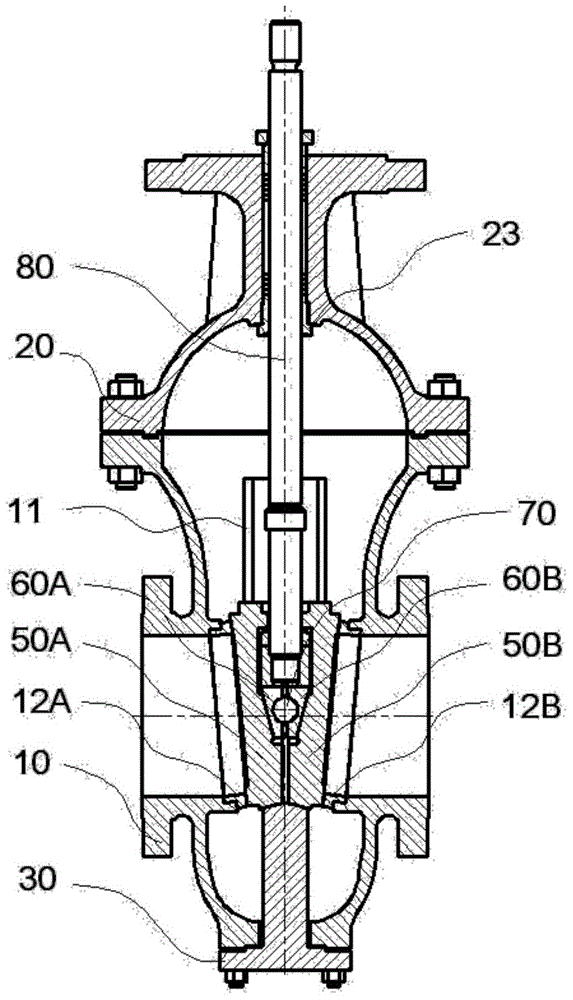

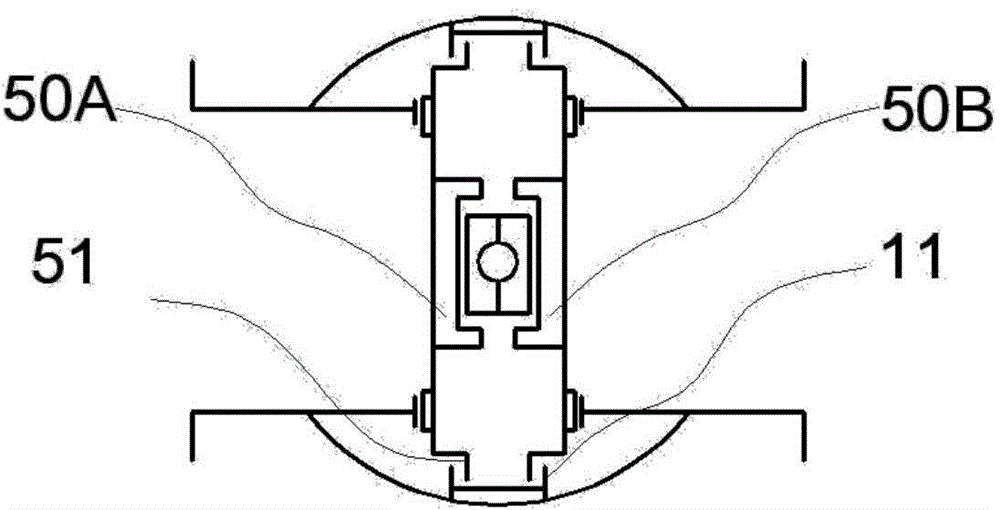

Double wedge-type gate valve with additional auxiliary air valve

ActiveCN104806777AFlexible moving processGuaranteed a tight fitSlide valveEngineeringTemperature difference

The invention aims to provide a double wedge-type gate valve with an additional auxiliary air valve. The double wedge-type gate valve comprises a valve body, wherein the valve body is provided with a valve seat hole and a flow channel; the upper part of the valve body is connected with a valve cover through a flange; the lower part of the valve body is connected with a bottom cover through a flange; an additional auxiliary air valve base is arranged above the valve cover; the additional auxiliary air valve base is connected with one or more additional auxiliary air valves. The double wedge-type gate valve disclosed by the invention is provided with a double-gate plate structure; bidirectional forced sealing can be realized; only the friction force at the inclined surface of a wedge block is required to be overcome when the valve is opened; after the wedge block is moved, the gate plate can also move flexibly. The double wedge-type gate valve with the additional auxiliary air valve meets the cutting requirement of a reactor, is unique in structure, reliable in sealing, flexible in action and long in service life, and is particularly suitable for the working conditions with a high temperature or a great temperature difference.

Owner:BEIJING AEROSPACE PETROCHEM TECH & EQUIP ENG CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com