Integral limiting device for door with double-wedge shaped structure

A double-wedge and limiter technology, which is applied to the fastening devices of wings, building structures, building fastening devices, etc., can solve the problems of increased production costs and complex structures, and achieve increased contact area and wide gap range , the effect of structural simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

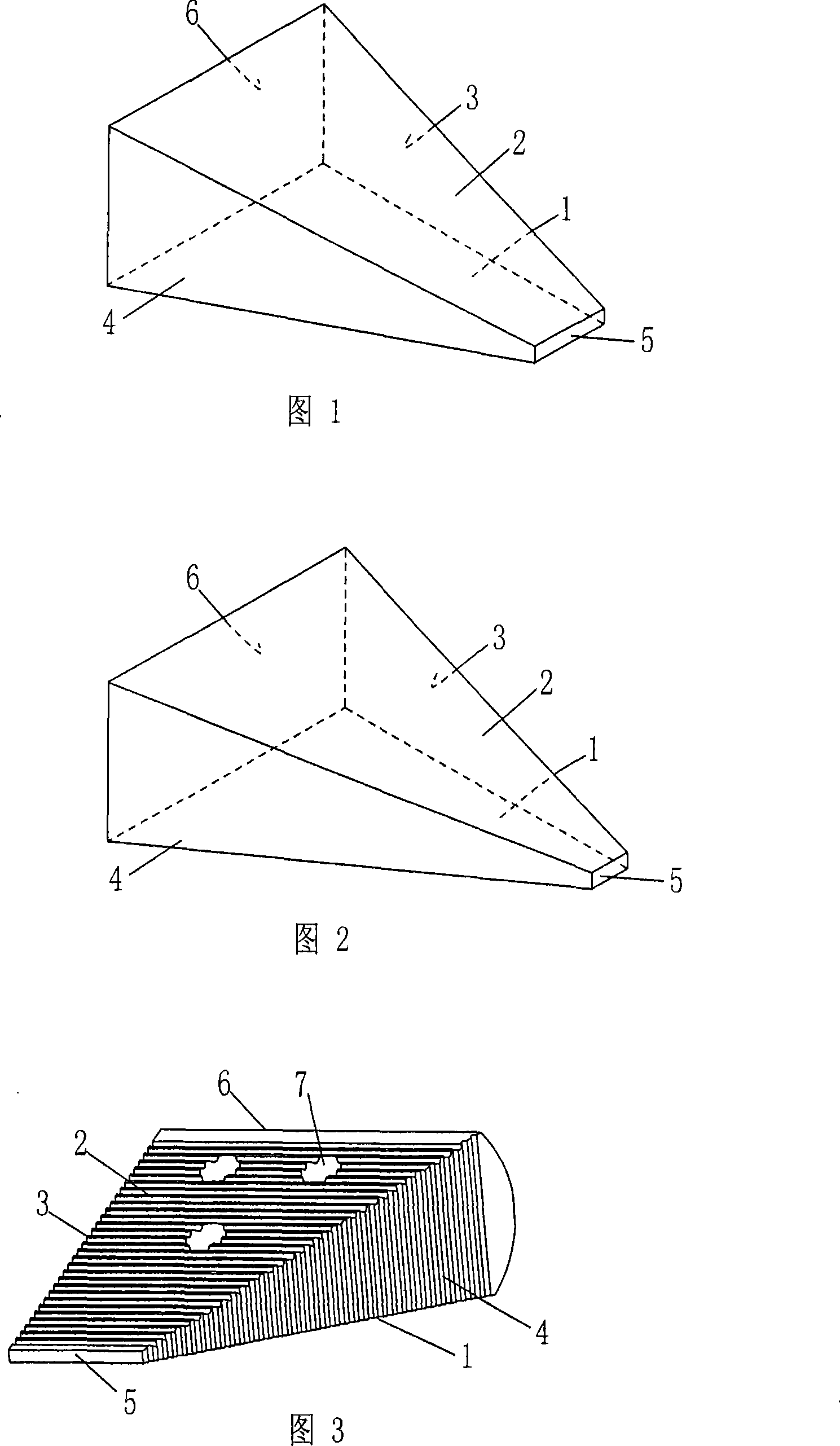

Embodiment 1

[0027] Referring to Fig. 1, embodiment 1 has a double-wedge-shaped door unit limiter, including a single double-wedge structure main body, which is a hexahedron with a bottom surface 1, and the opposite side of the bottom surface 1 is the first bearing slope 2, and the bottom surface 1 A side 3 extends vertically upward from one side, and the opposite side of the side 3 is the second bearing slope 4. The distance between the small end of the first bearing slope 2 and the bottom surface 1 is slightly smaller than the minimum gap between the lower edge of the door and the ground. The distance between the large end of the bearing slope 4 and the side surface 3 is 1.5-3.5 times the distance between the large end of the first bearing slope 2 and the bottom surface 1, and the distance between the small end of the second bearing slope 4 and the side surface 3 is the first bearing slope. 0.5-0.8 times the distance between the big end of the slope 2 and the bottom surface 1 .

[0028] ...

Embodiment 2

[0036] Referring to Fig. 2 , the door unit limiter with double wedge structure in embodiment 2 is basically the same as embodiment 1, including a single double wedge structure main body, the double wedge structure body is a hexahedron, has a bottom surface 1, and the opposite side of bottom surface 1 It is the first bearing slope 2, one side of the bottom surface 1 extends vertically upwards a side 3, and the side opposite to the side 3 is the second bearing slope 4, the distance between the small end of the first bearing slope 2 and the bottom surface 1 is slightly smaller than the door bottom edge and The minimum gap between the ground, the distance between the large end of the second bearing slope 4 and the side surface 3 is 1.5-3.5 times the distance between the large end of the first bearing slope 2 and the bottom surface 1; the distance between the small end of the second bearing slope 4 and the side surface The distance between 3 is not less than the distance between the...

Embodiment 3

[0039] With reference to Fig. 3, embodiment 3 has double-wedge-shaped single-body limiter for doors comprising a single double-wedge-shaped plastic main body, which is a hexahedron with a bottom surface 1, and the opposite side of bottom surface 1 is the first load-bearing inclined surface 2, and the bottom surface 1. A side 3 extends vertically upward from the left side, and the opposite side of the side 3 is the second bearing slope 4. The surfaces of the first bearing slope 2 and the second bearing slope 4 can be provided with convex and concave stripes in the transverse direction; the big end surface 6 of the plastic main body is a circle The arc surface, the small end face 5 of the small head is an arc surface, the distance between the small end of the first bearing slope 2 and the bottom surface 1 is slightly smaller than the minimum gap between the lower edge of the door and the ground, the second bearing slope 4 large end and the side surface The distance between 3 is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com