Dual “cheese wedge” silicon taper waveguide

a silicon taper waveguide and taper technology, applied in the field of tapered optical waveguides, can solve the problems of inability to achieve good fiber-silicon waveguide coupling and inability to reduce losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016]In optical systems it may be challenging to efficiently couple light into and out of a chip. Particularly difficult may be the coupling of light from a standard optical fiber or external light source to a silicon waveguide owing to the differences in size, shape and refractive indices (n) between typical optical fibers and silicon waveguides. For example, a single-mode fiber core (n=1.5) usually has a diameter of 8 μm with a symmetric mode, while a silicon waveguide (n=3.5) is typically only a few micrometers in width with an asymmetric mode.

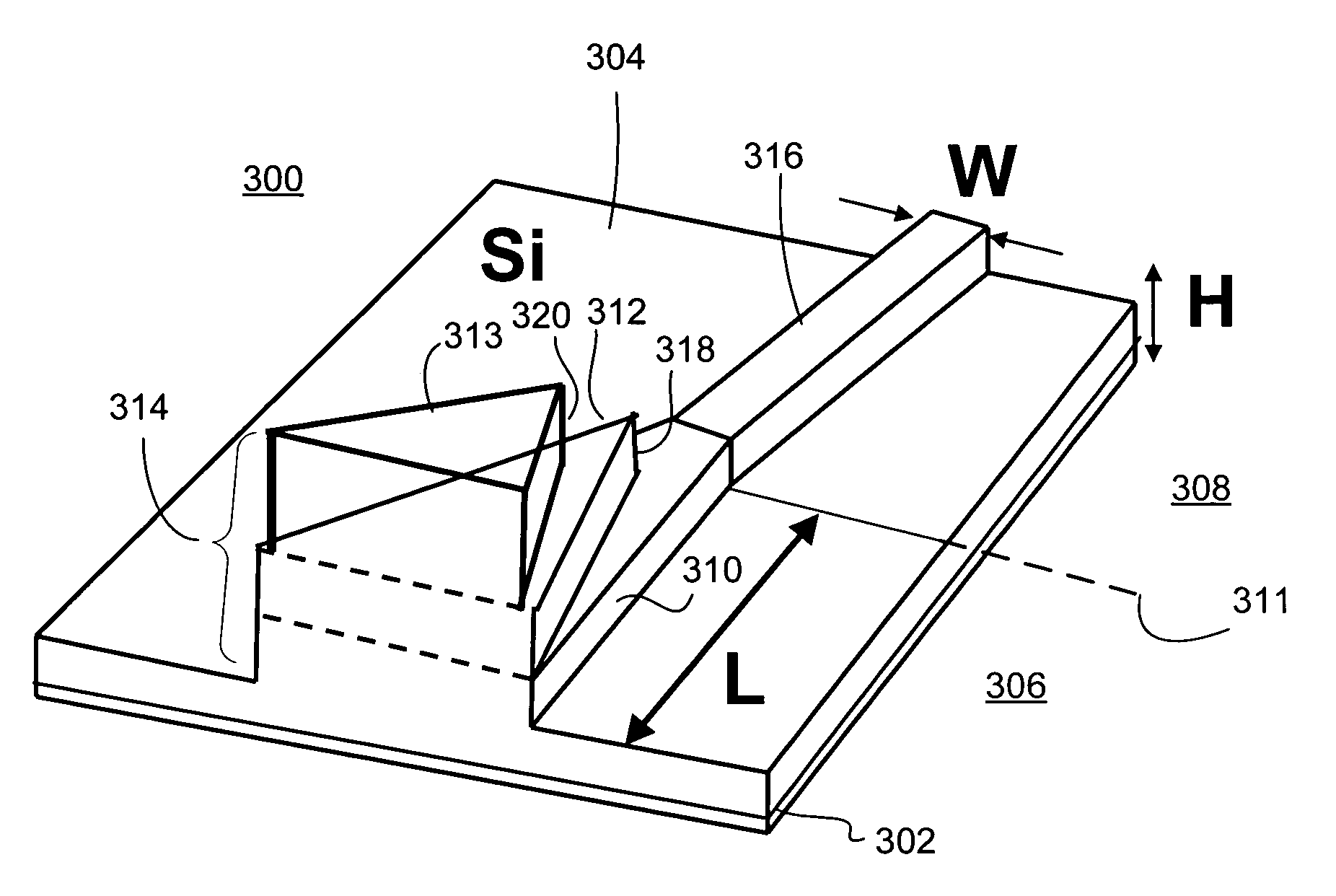

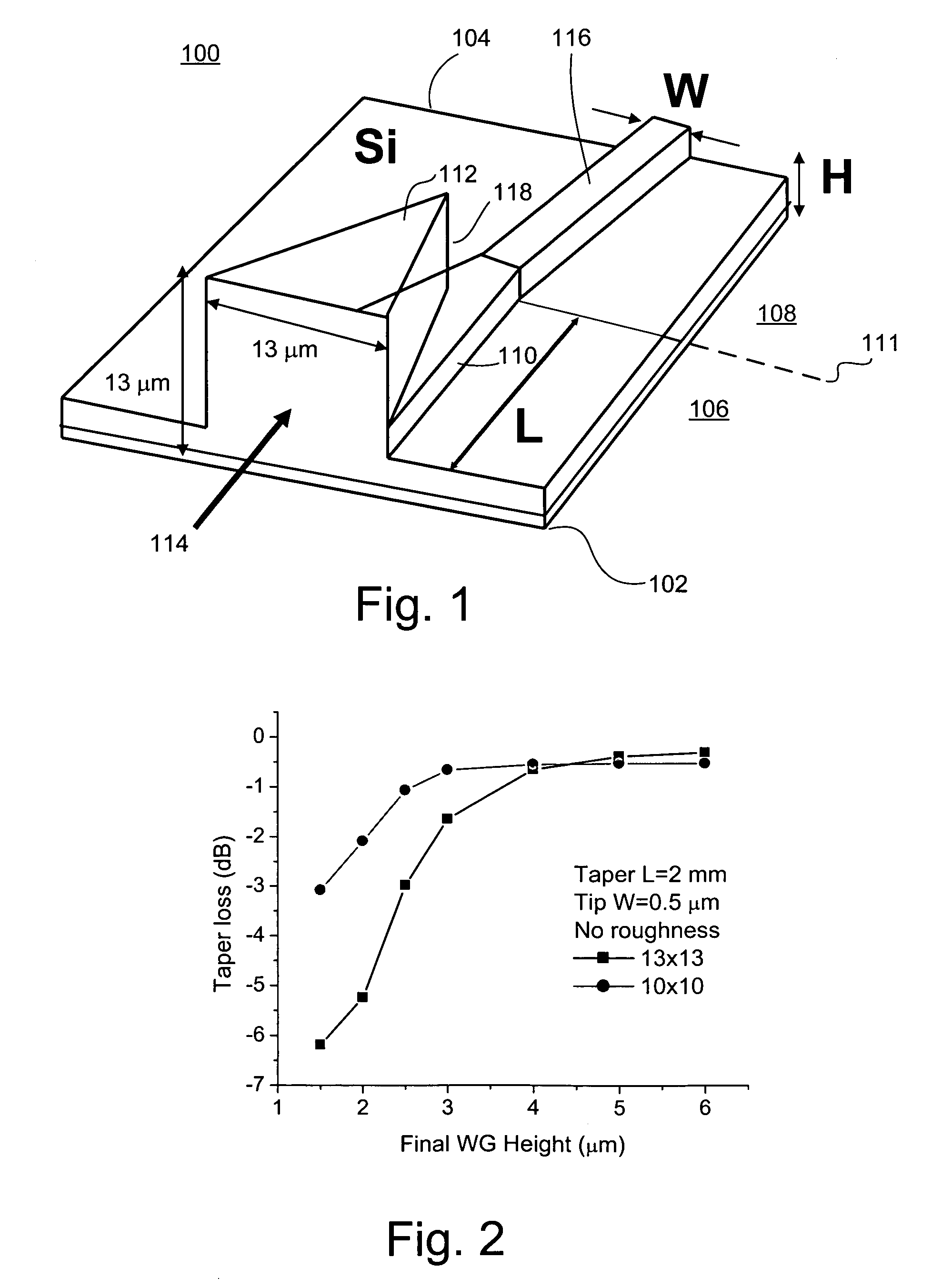

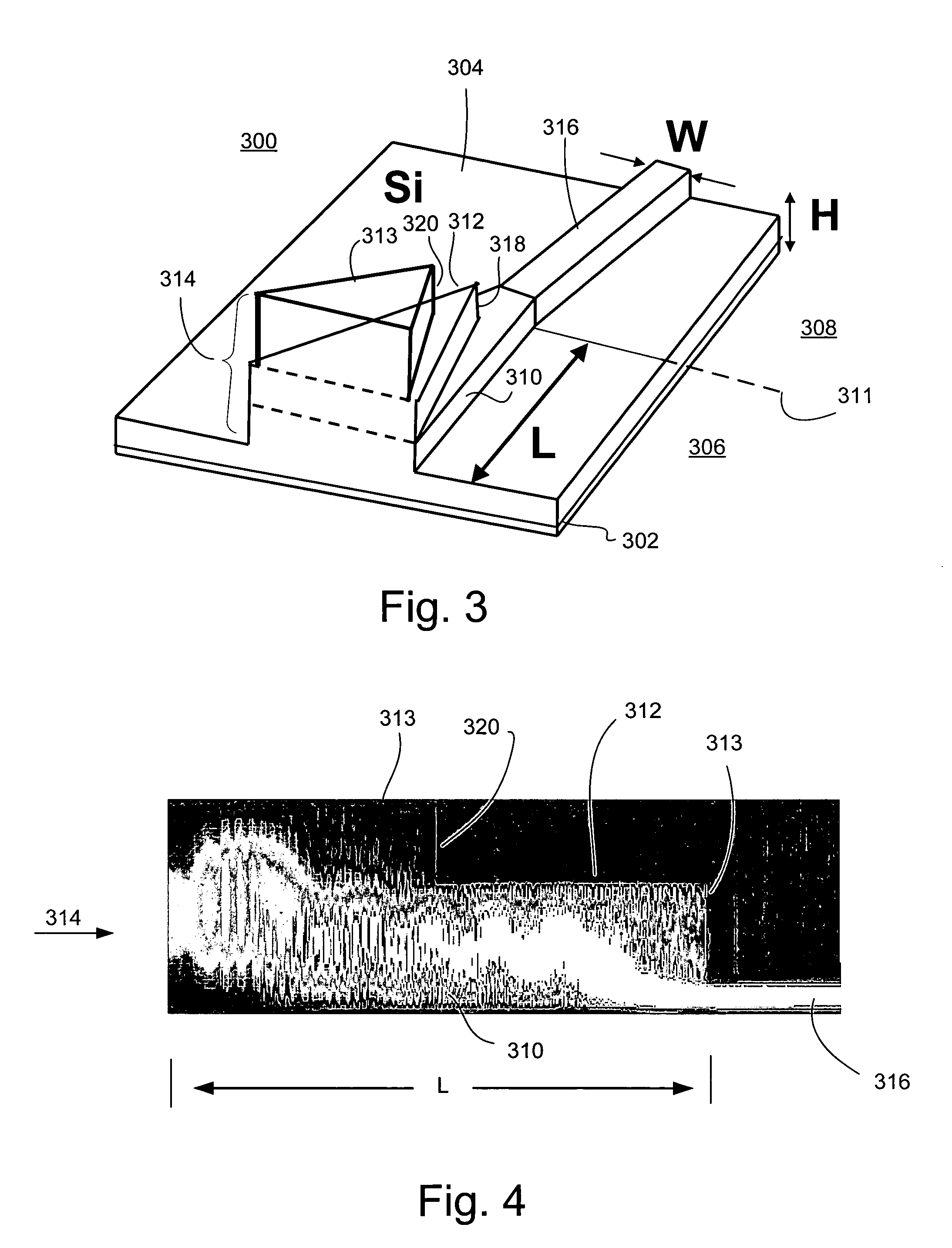

[0017]One method to address the aforementioned disparities may be to use a waveguide taper according to embodiments of the invention. Referring to FIG. 3, there is shown a plan view of a “dual cheese wedge” tapered waveguide 300. The waveguide 300 may be formed on a silicon-on-insulator (SOI) substrate comprising an insulator layer 302 and a silicon layer 304. The waveguide 300 generally comprises a tapered section 306 and an output wavegu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com