Craft knife capable of automatically locking blade position

A utility knife and blade technology, applied in the field of utility knives, can solve the problems of short product life, frequent ratchet movement relative to the knife shell, and failure of the locking mechanism, etc., to achieve easy manufacturing, long service life, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

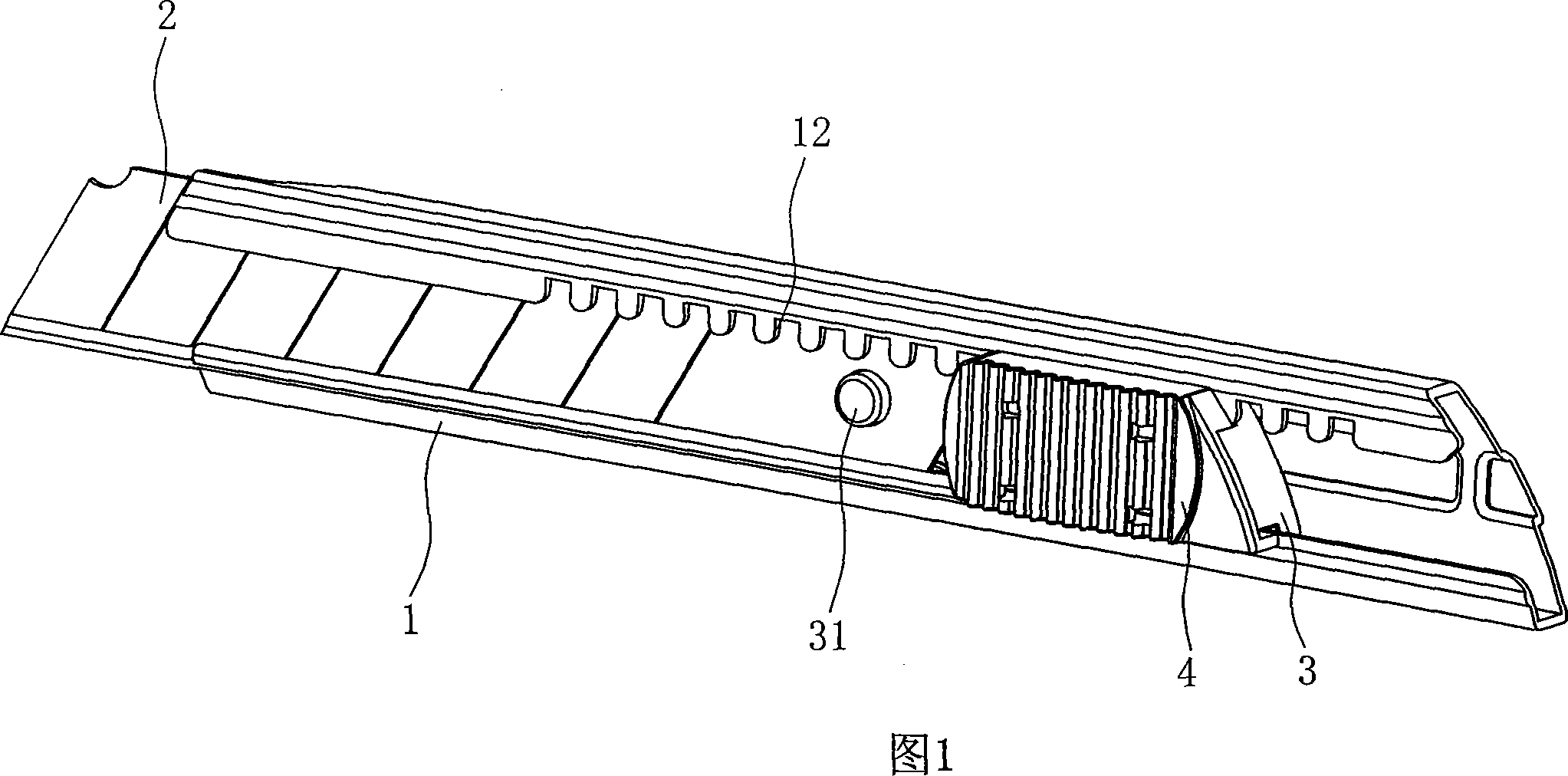

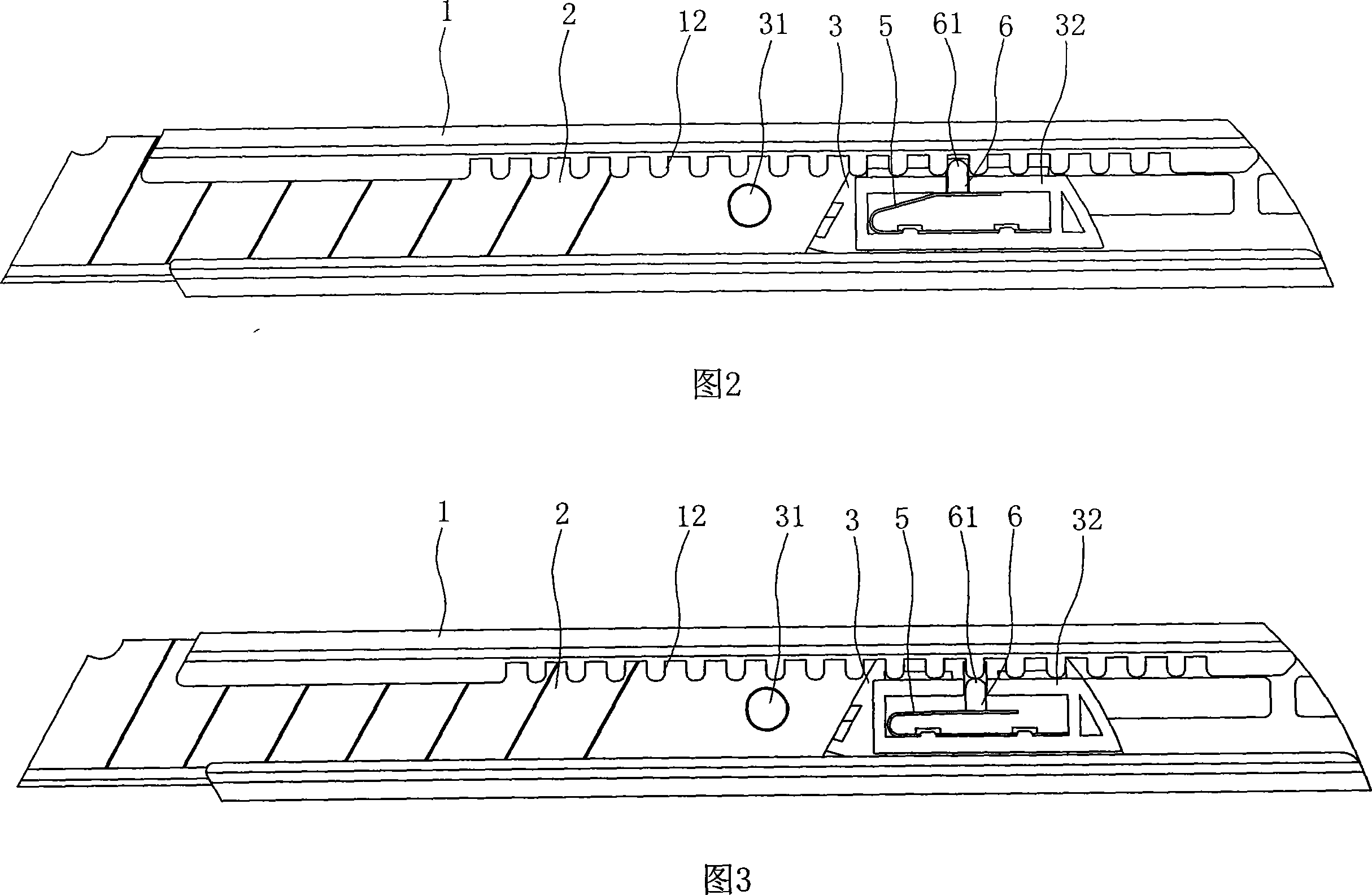

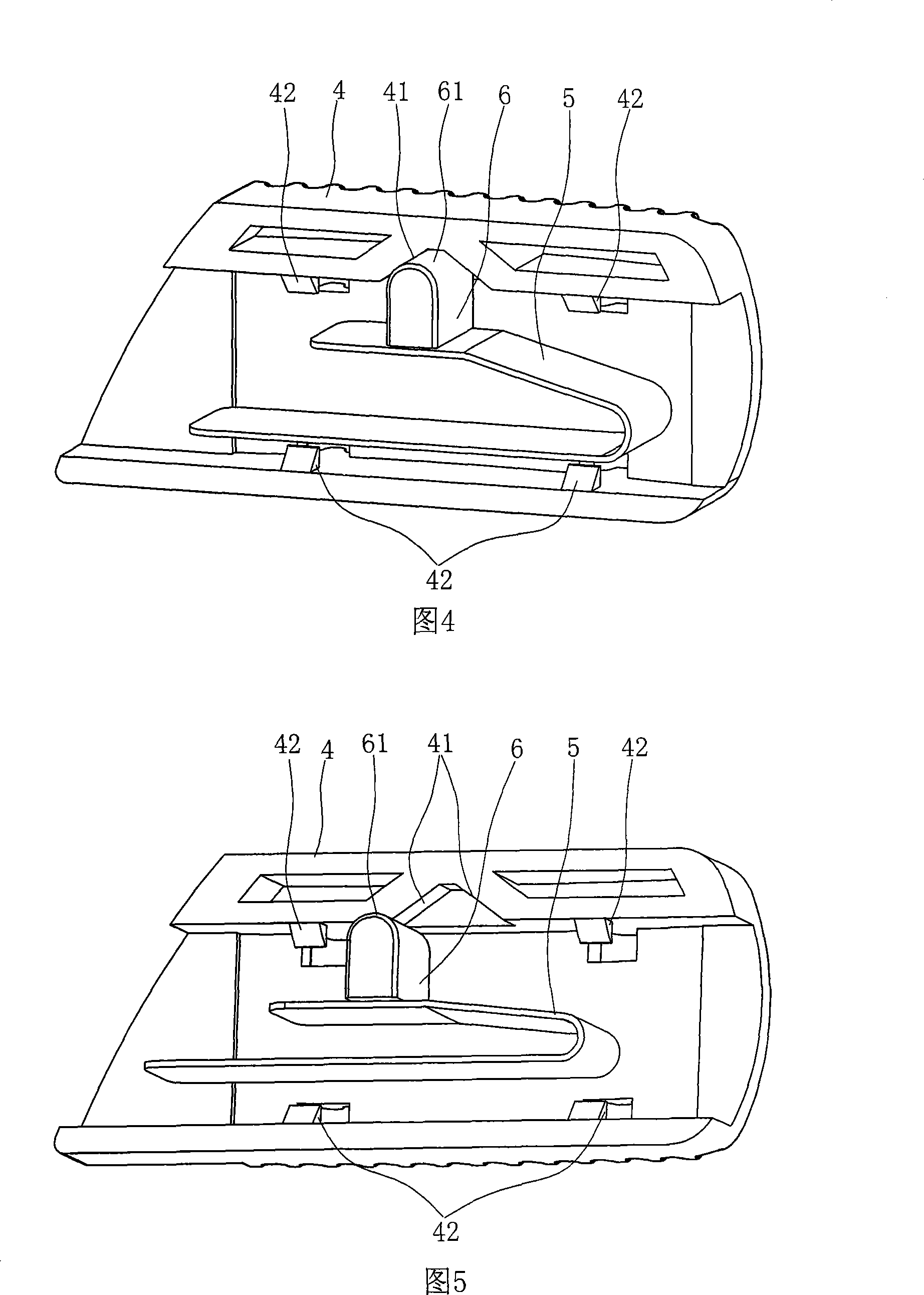

[0020] As shown in Figures 1 to 6, the utility knife with automatic blade locking includes a knife case 1 with a chute 11, and a blade 2 that is inserted in the chute 11 of the knife case 1 and can move back and forth relative to the knife case 1. With the knife seat 3 and the push cover 4 which is arranged on the surface of the knife seat 3 and can push the knife seat 3 to move;

[0021] Wherein, the inner edge of the cutter housing 1 on one side of the chute 11 is provided with a continuous protruding tooth 12, and the head of the protruding tooth 12 is smoothly transitioned;

[0022] The knife seat 3 is arranged on the rear portion of the blade 2, and the front portion of the knife seat 3 is provided with a boss 31, and the boss 31 is inserted into the socket 21 on the blade 2 to block the blade 2, thereby The knife seat 3 together with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com