Patents

Literature

323 results about "Protruding tooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Upper front teeth that protrude beyond normal contact with the lower front teeth are prone to injury, often indicate a poor bite of the back teeth (molars), and may indicate an unevenness in jaw growth. Commonly, protruded upper teeth are associated with a lower jaw that is short in proportion to the upper jaw.

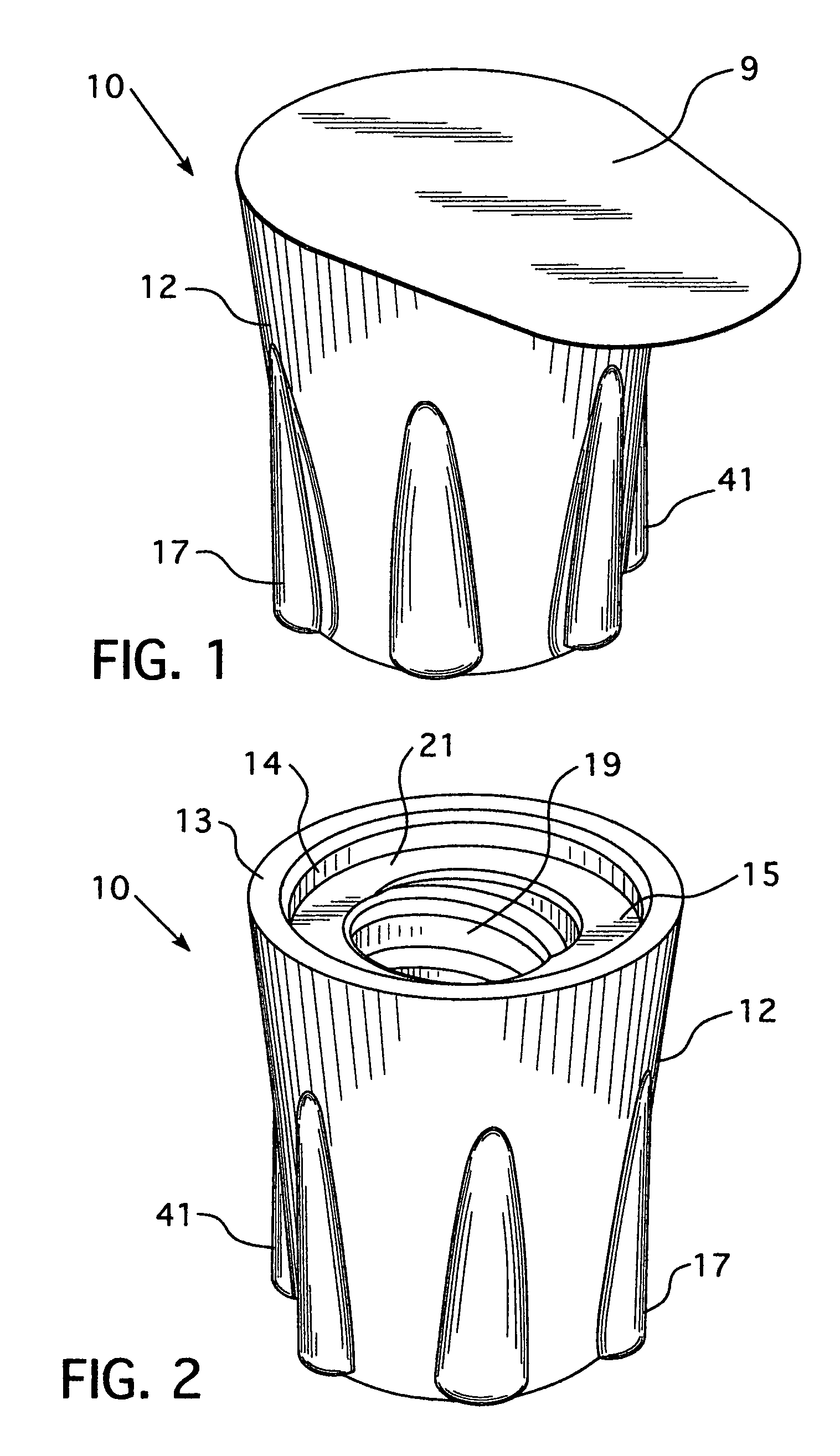

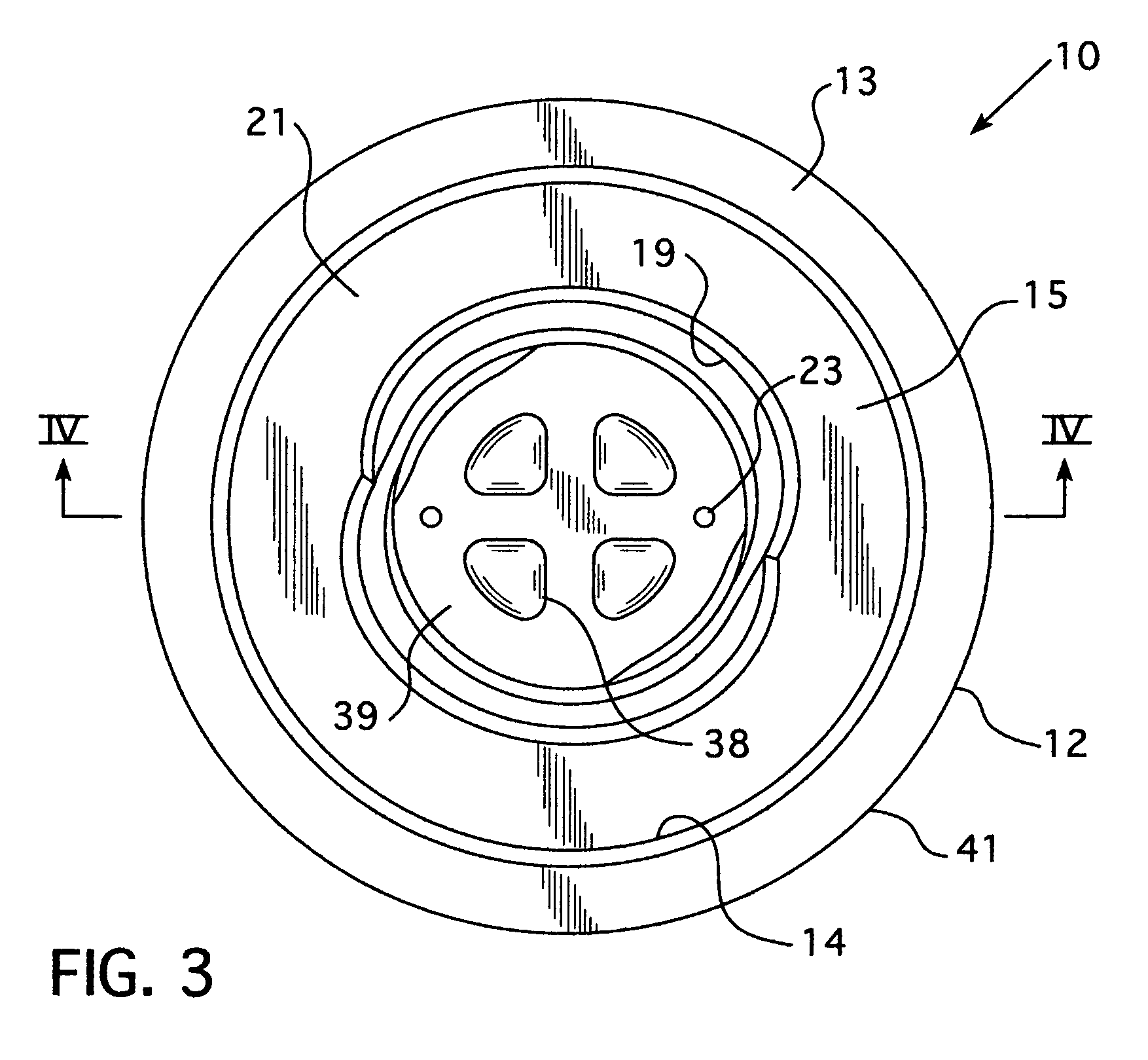

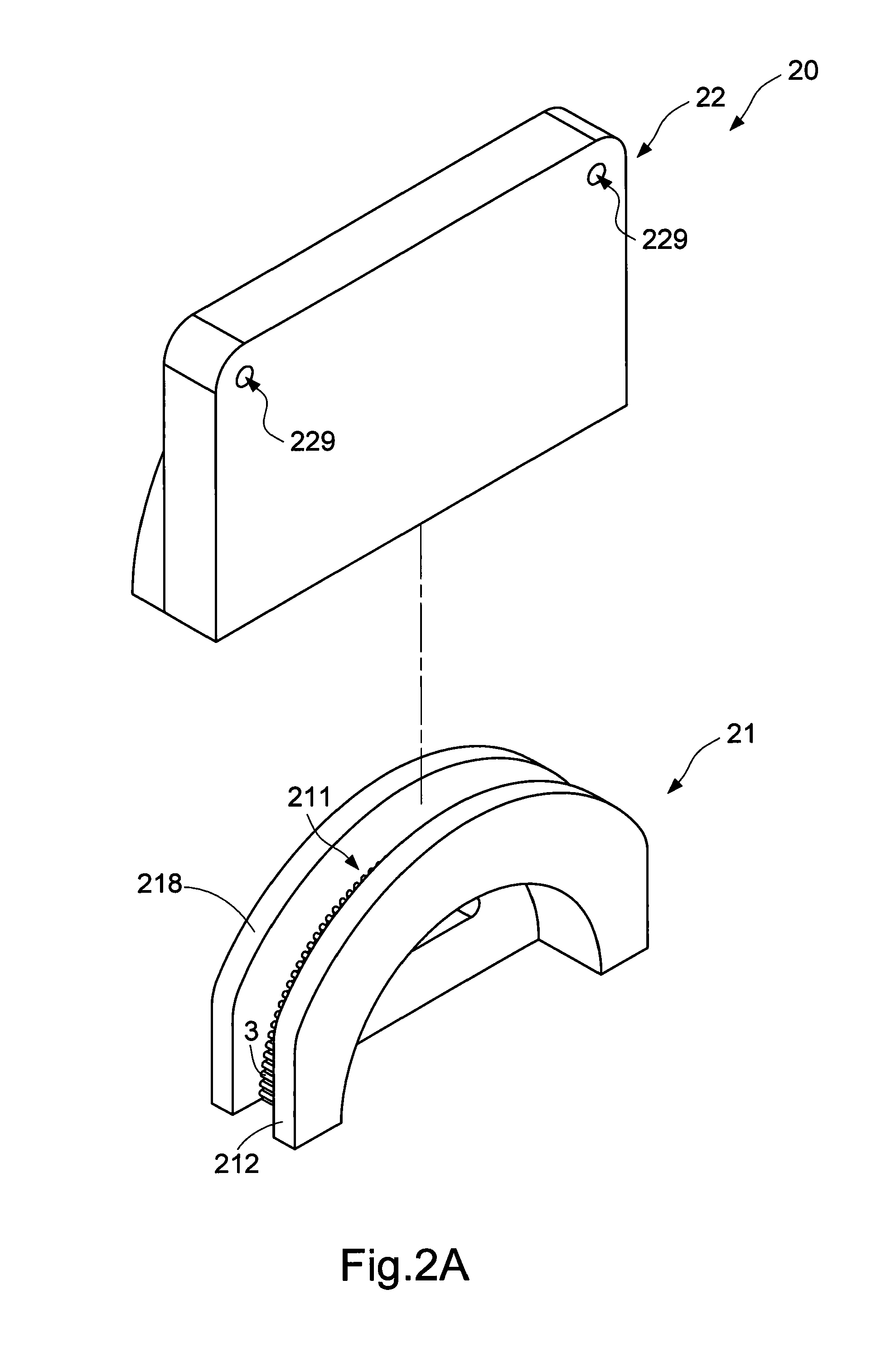

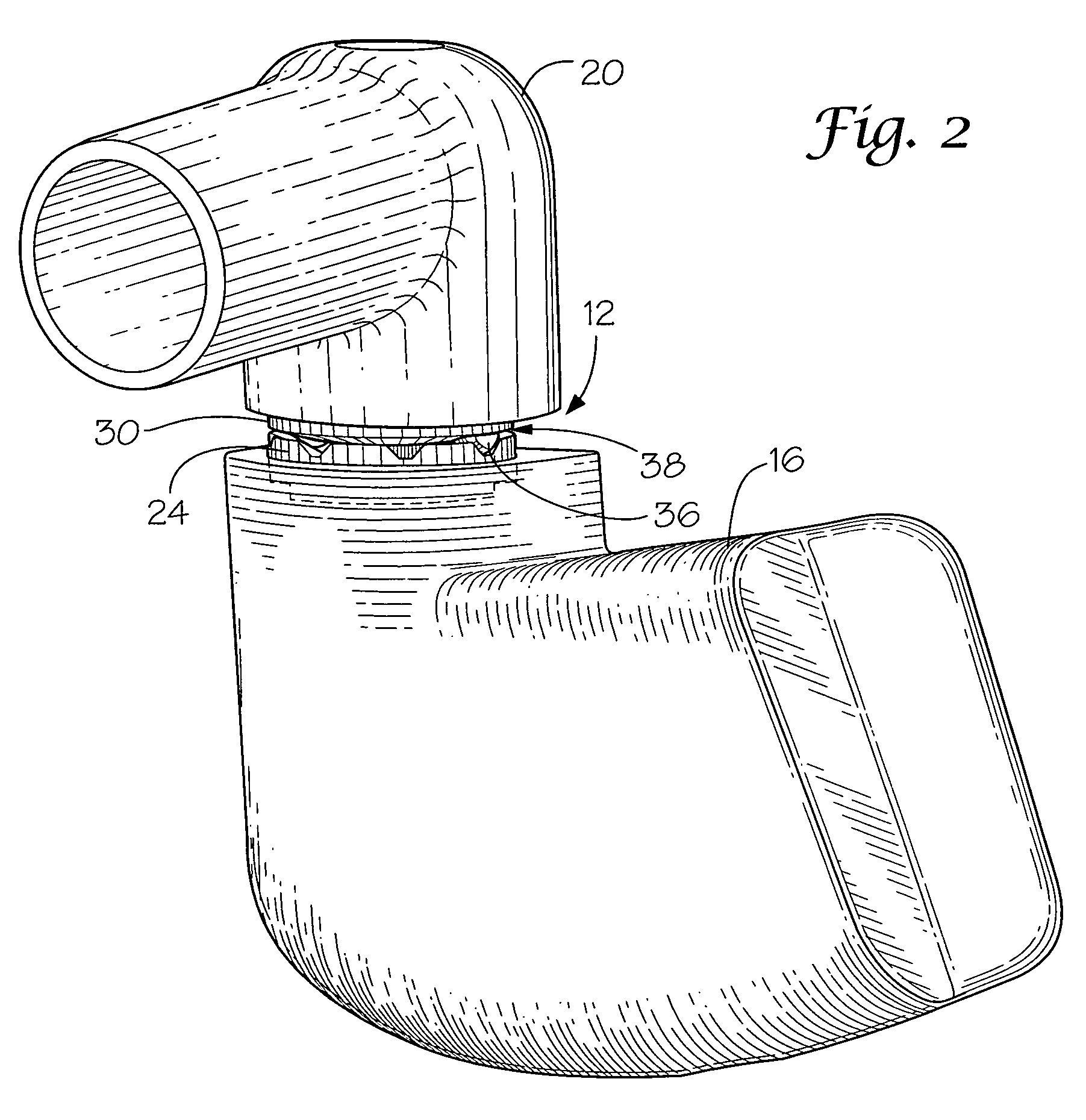

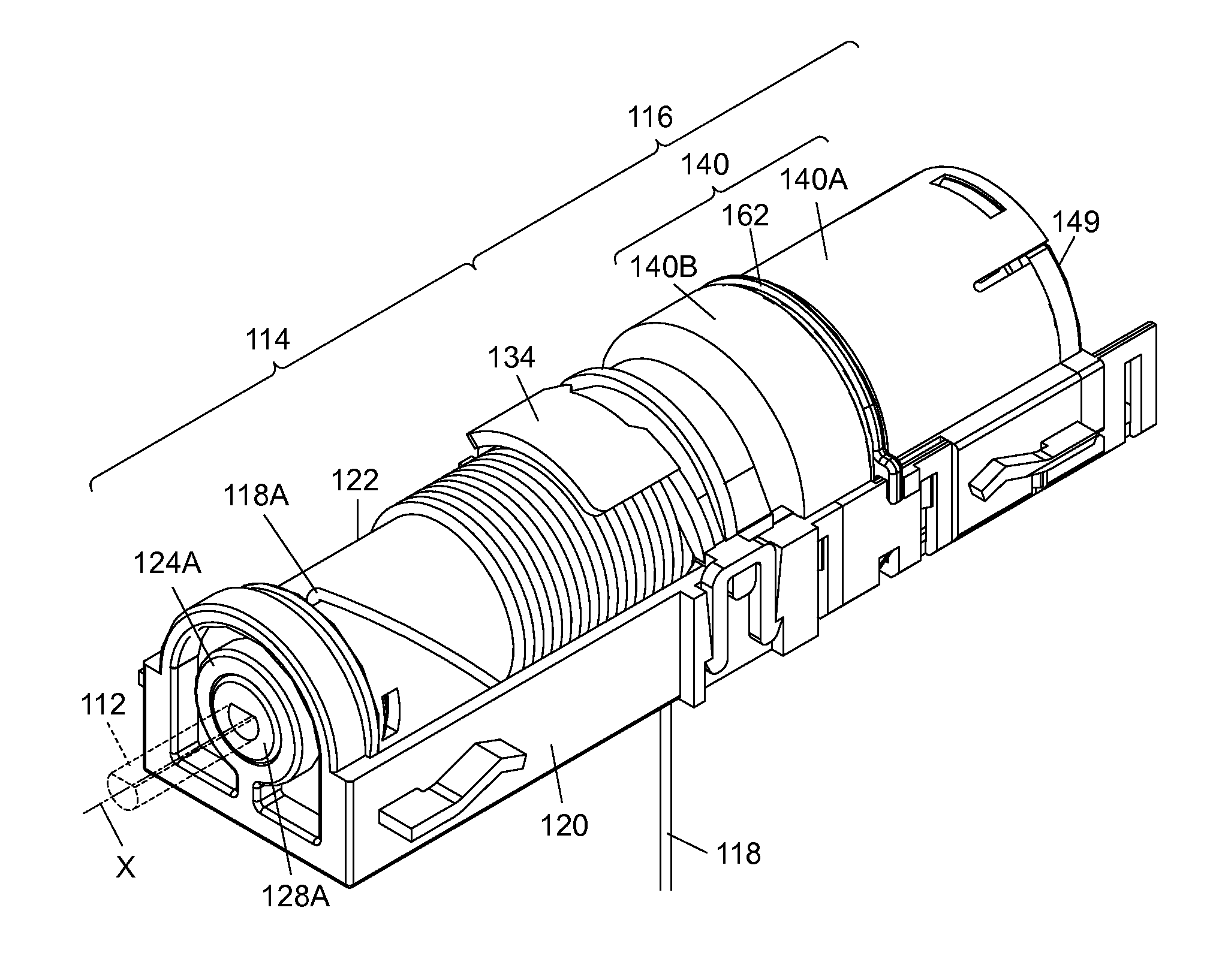

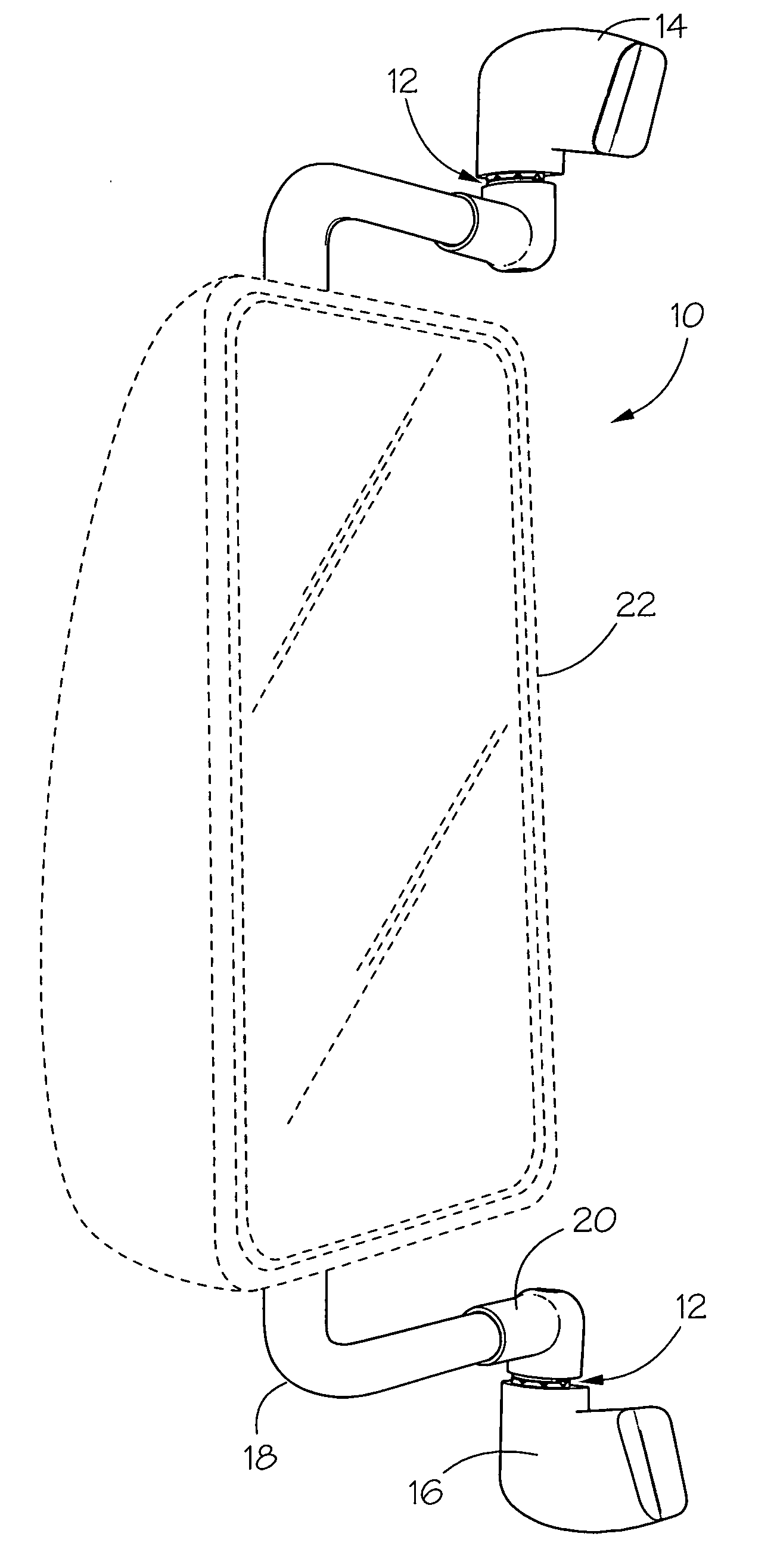

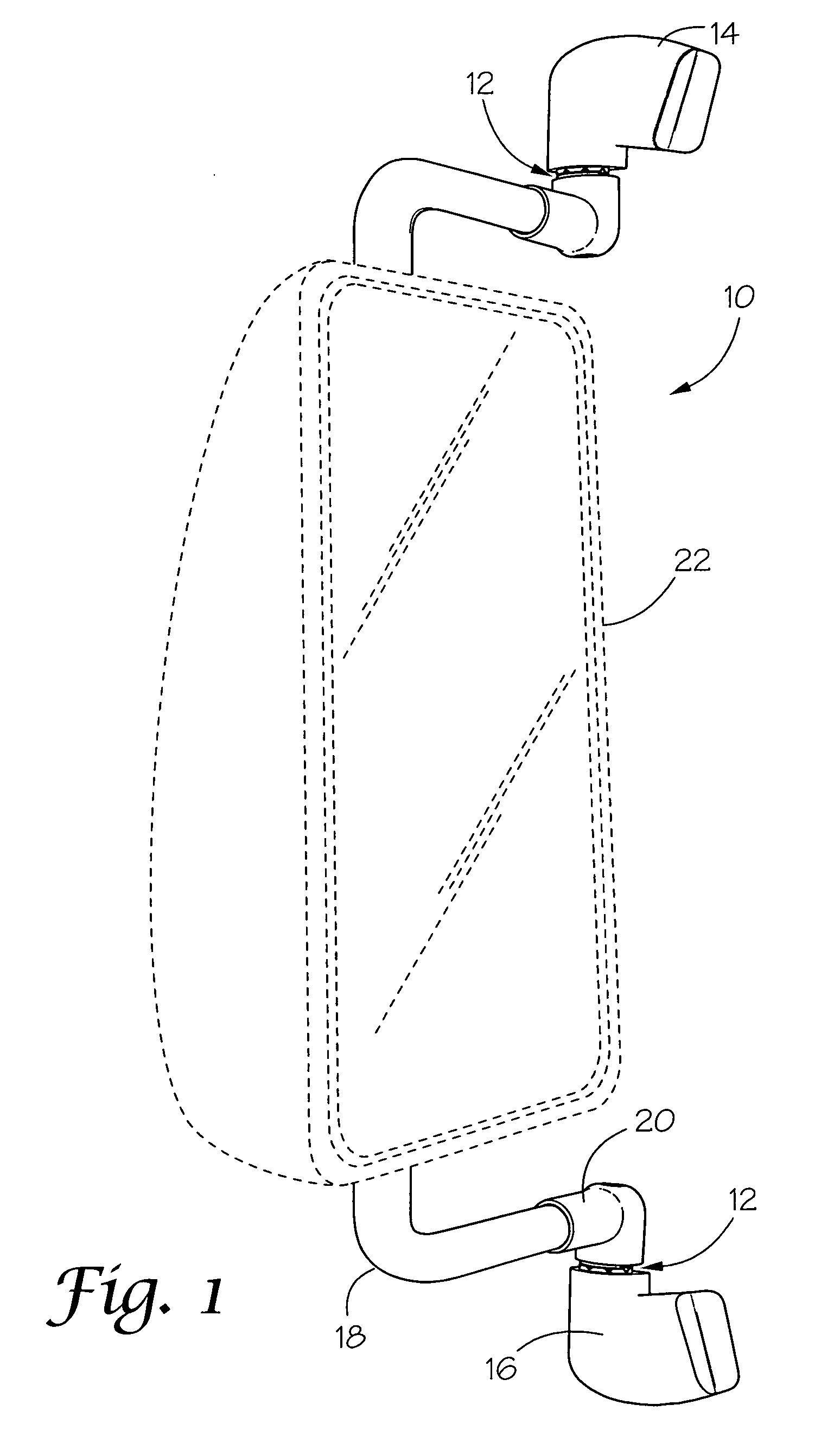

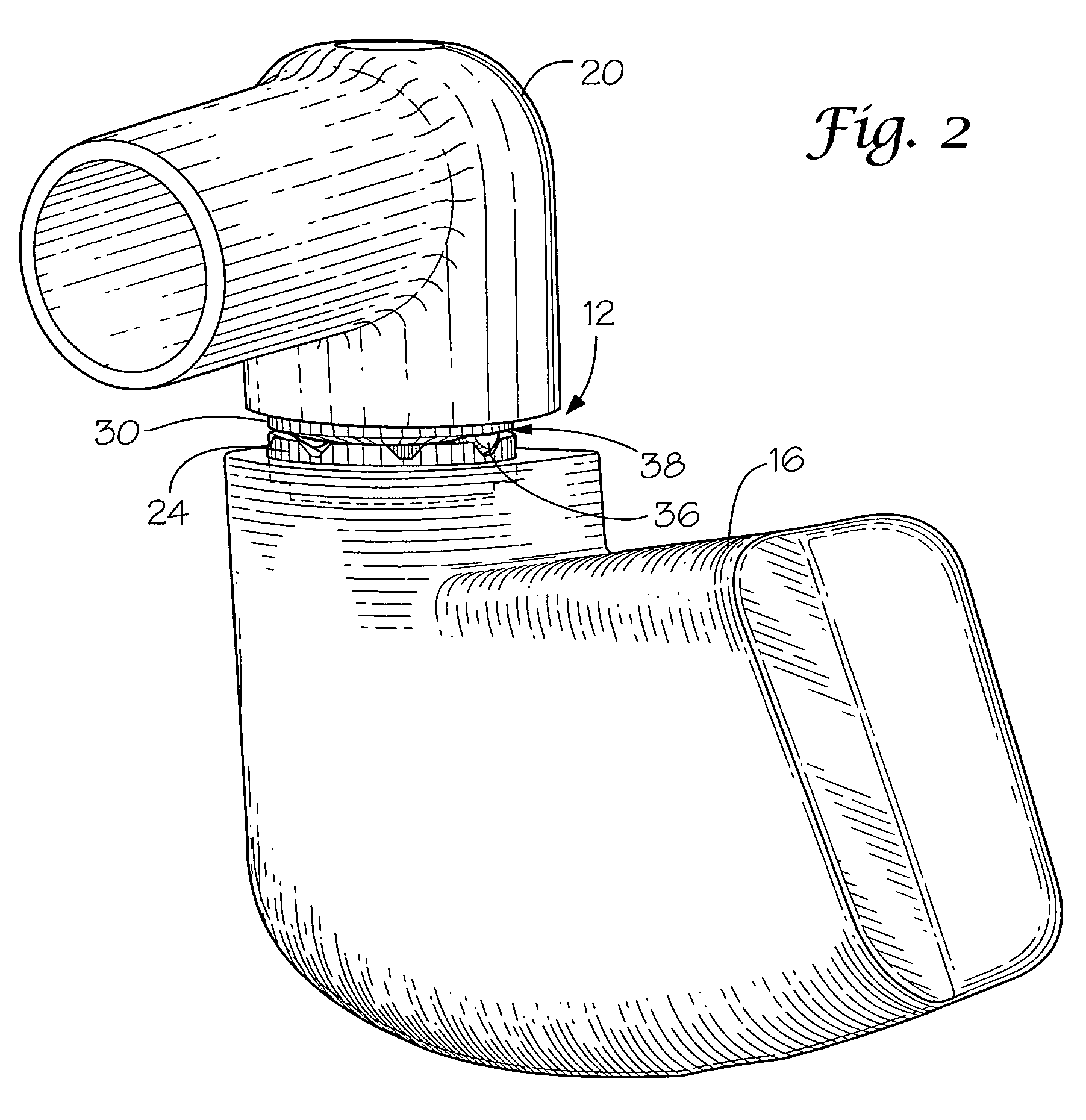

Apparatus and method for sterilizing a tubular medical line port

InactiveUS20100050351A1Avoid accessMedical devicesFlexible article cleaningBiomedical engineeringMedical treatment

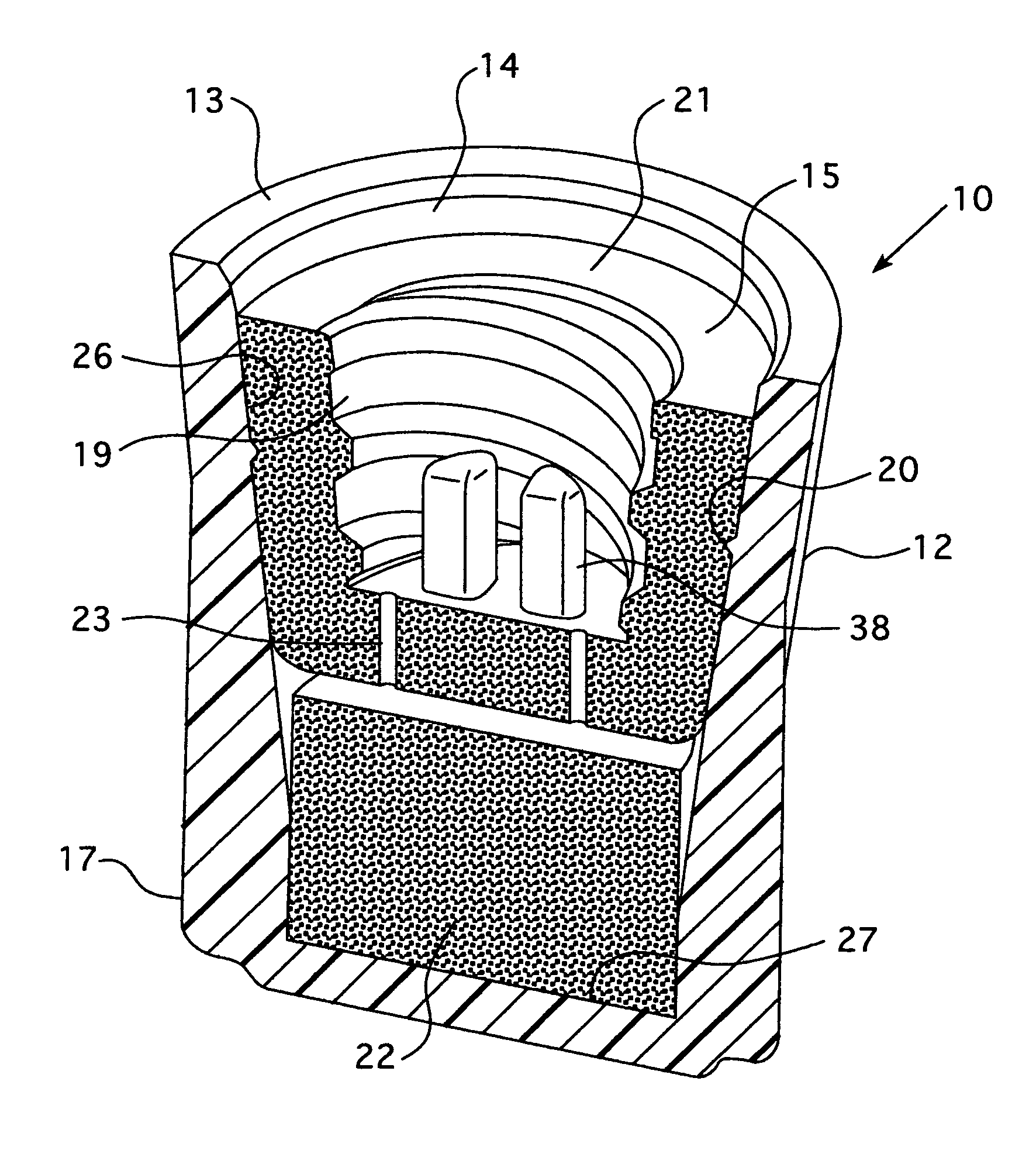

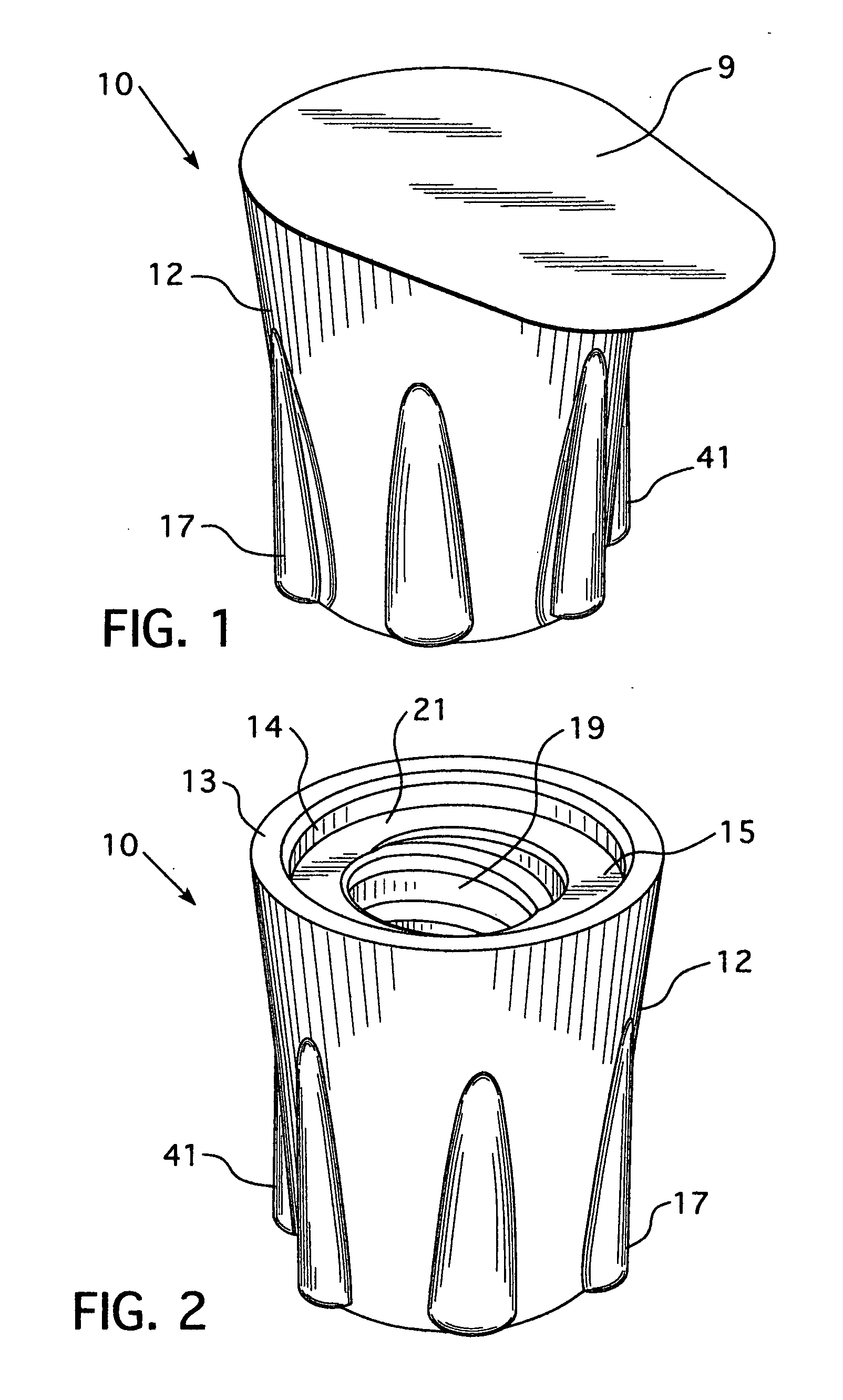

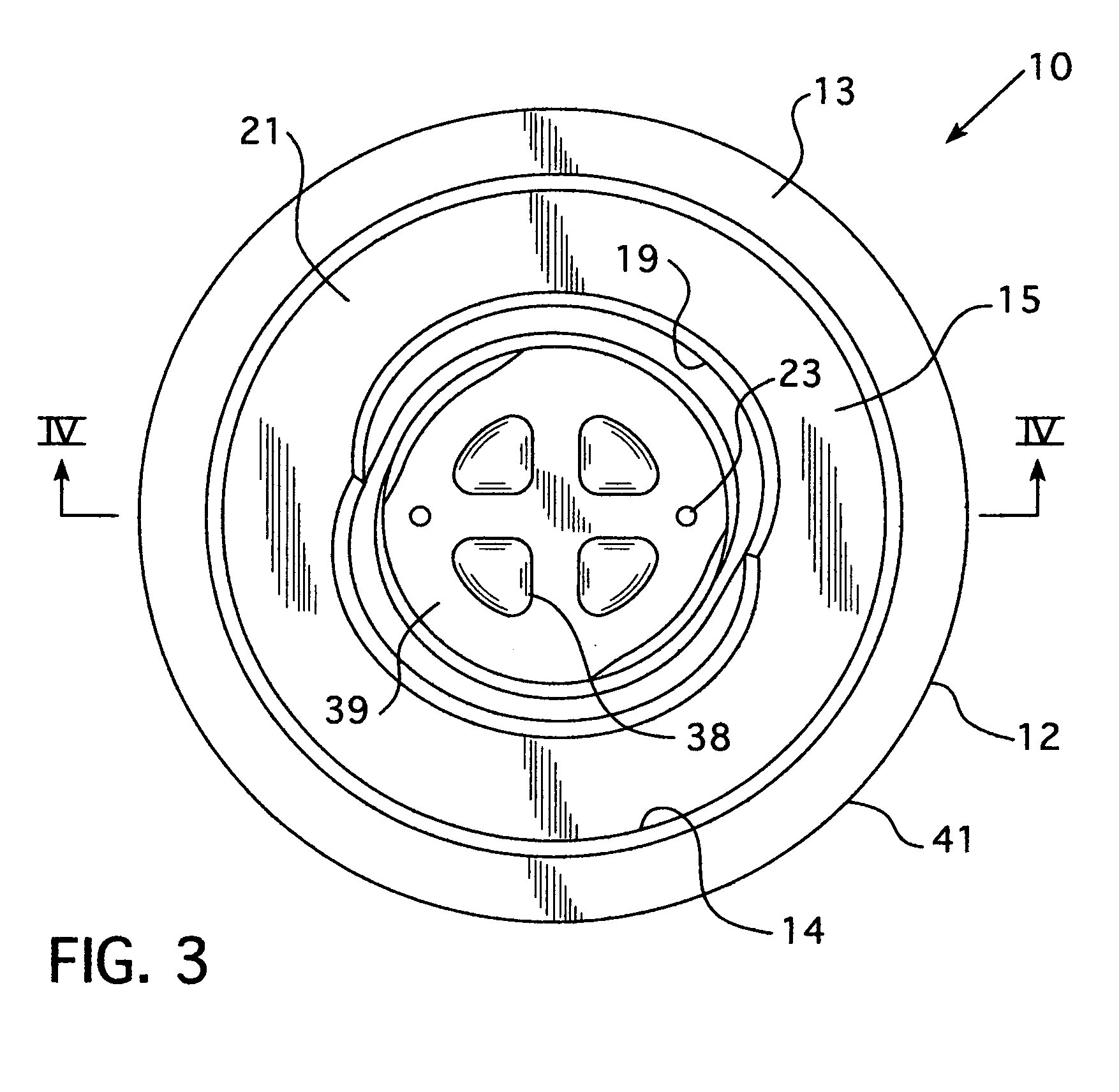

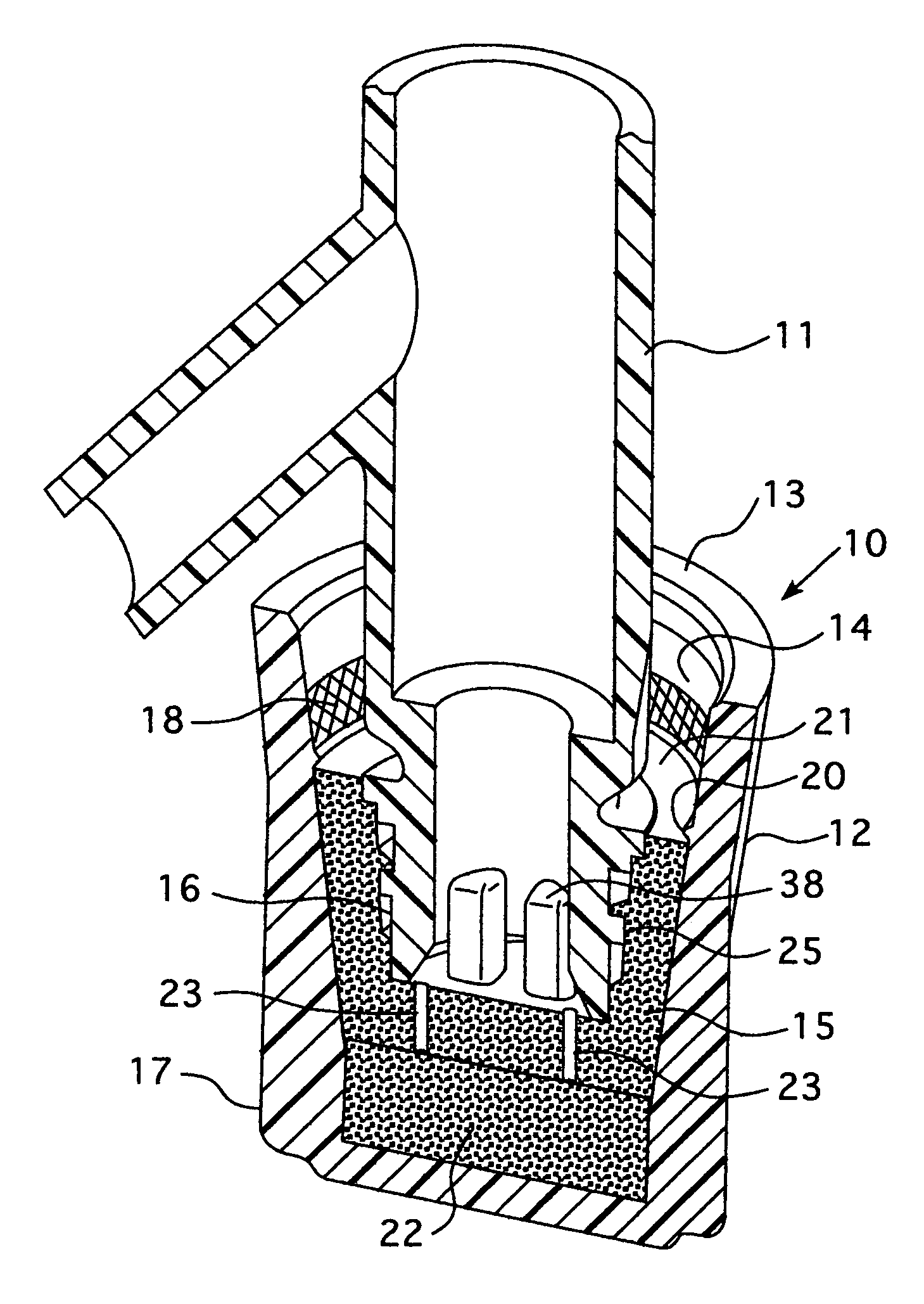

An apparatus for sterilizing a tubular medical line port, having a cap with an open distal end and a cavity therein which is dimensioned to receive an outer scrubbing member and the medical line port. Outer disinfected-impregnated scrubbing member is coaxially received in the cavity and has a socket therein dimensioned for engaging exterior side surfaces of the tubular medical line port when inserted into the socket for thereby scrubbing exterior surfaces of the port with the scrubbing member by rotating the cap. The outer scrubbing member is axially displacable downwardly in the cavity by insertion of the medical line port therein from an upper position prior to use to a lower position where it is retained to thereby indicate that the apparatus has been used and should not therefore be reused. A reuse prevention insert is also provided in the cavity of the cap and is displacable with the outer scrubbing member from the upper position prior to use to the lower position during and after use. This insert is provided with inwardly protruding teeth that are biased for inward compression and thereby prevent re-access of a medical line port into the socket of the scrubbing member after removal of the medical line port.

Owner:REDEV AUTHORITY OF THE COUNTY OF ERIE +1

Apparatus and method for sterilizing a tubular medical line port

An apparatus for sterilizing a tubular medical line port, having a cap with an open distal end and a cavity therein which is dimensioned to receive an outer scrubbing member and the medical line port. Outer disinfected-impregnated scrubbing member is coaxially received in the cavity and has a socket therein dimensioned for engaging exterior side surfaces of the tubular medical line port when inserted into the socket for thereby scrubbing exterior surfaces of the port with the scrubbing member by rotating the cap. The outer scrubbing member is axially displacable downwardly in the cavity by insertion of the medical line port therein from an upper position prior to use to a lower position where it is retained to thereby indicate that the apparatus has been used and should not therefore be reused. A reuse prevention insert is also provided in the cavity of the cap and is displacable with the outer scrubbing member from the upper position prior to use to the lower position during and after use. This insert is provided with inwardly protruding teeth that are biased for inward compression and thereby prevent re-access of a medical line port into the socket of the scrubbing member after removal of the medical line port.

Owner:REDEV AUTHORITY OF THE COUNTY OF ERIE +1

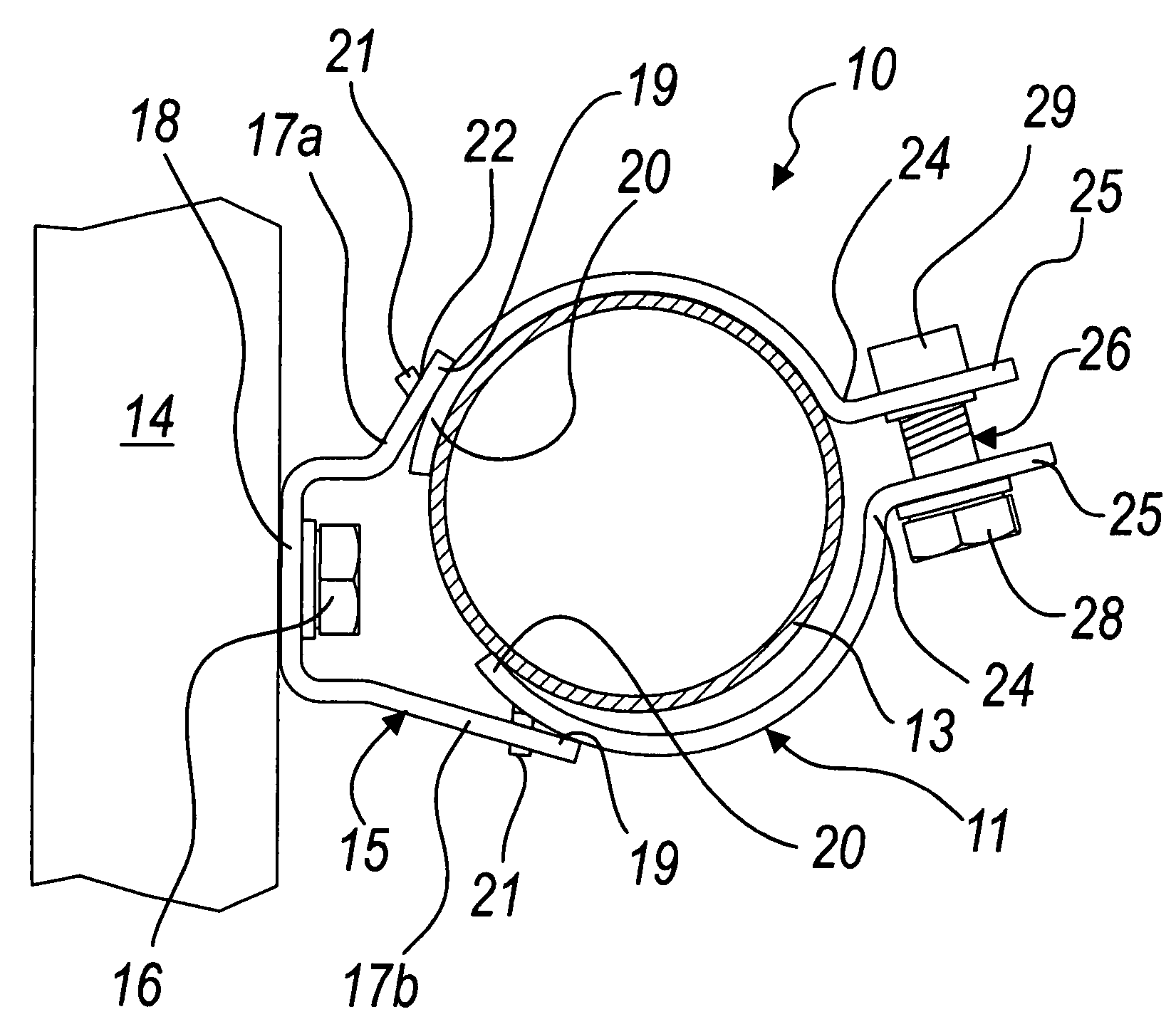

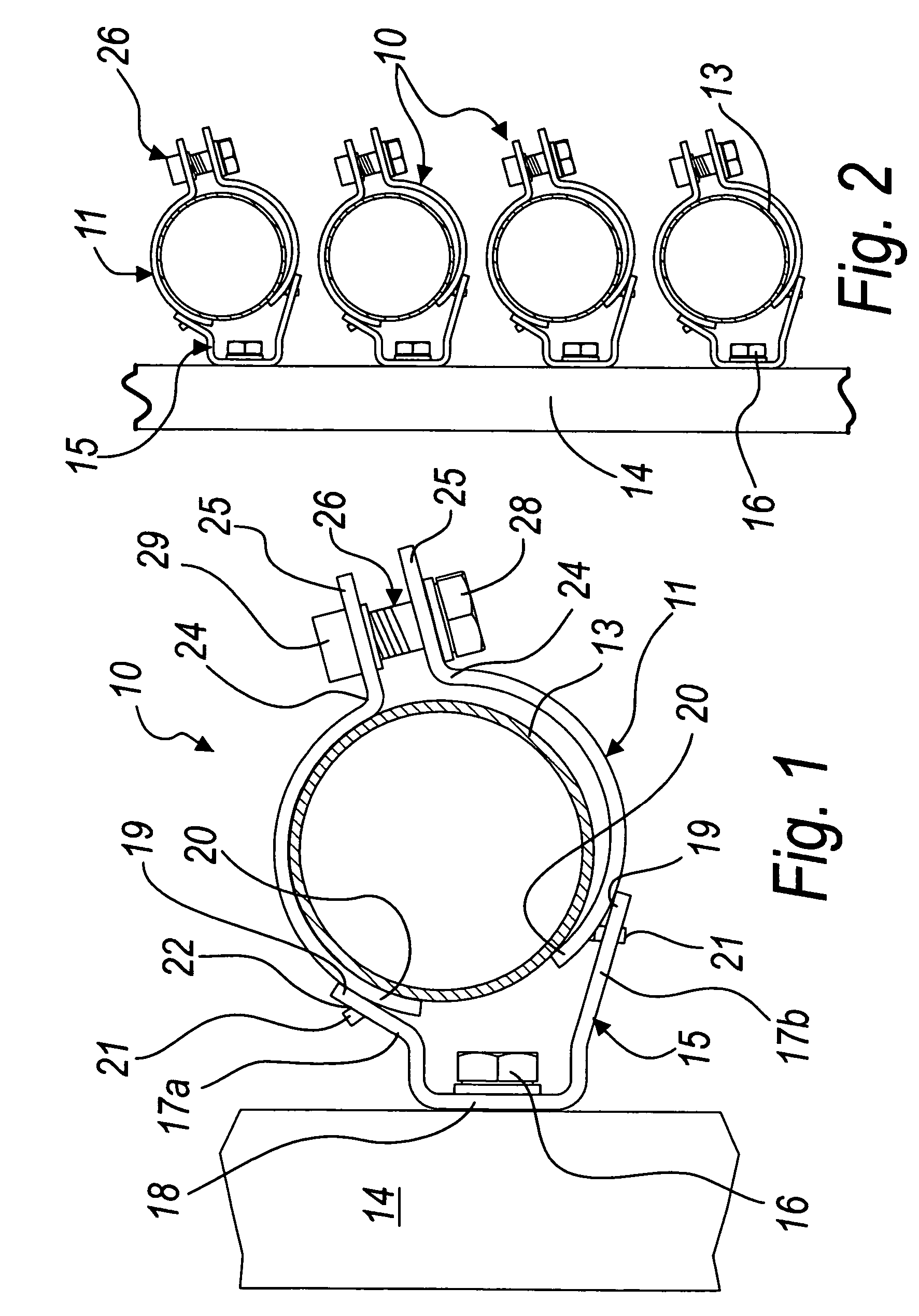

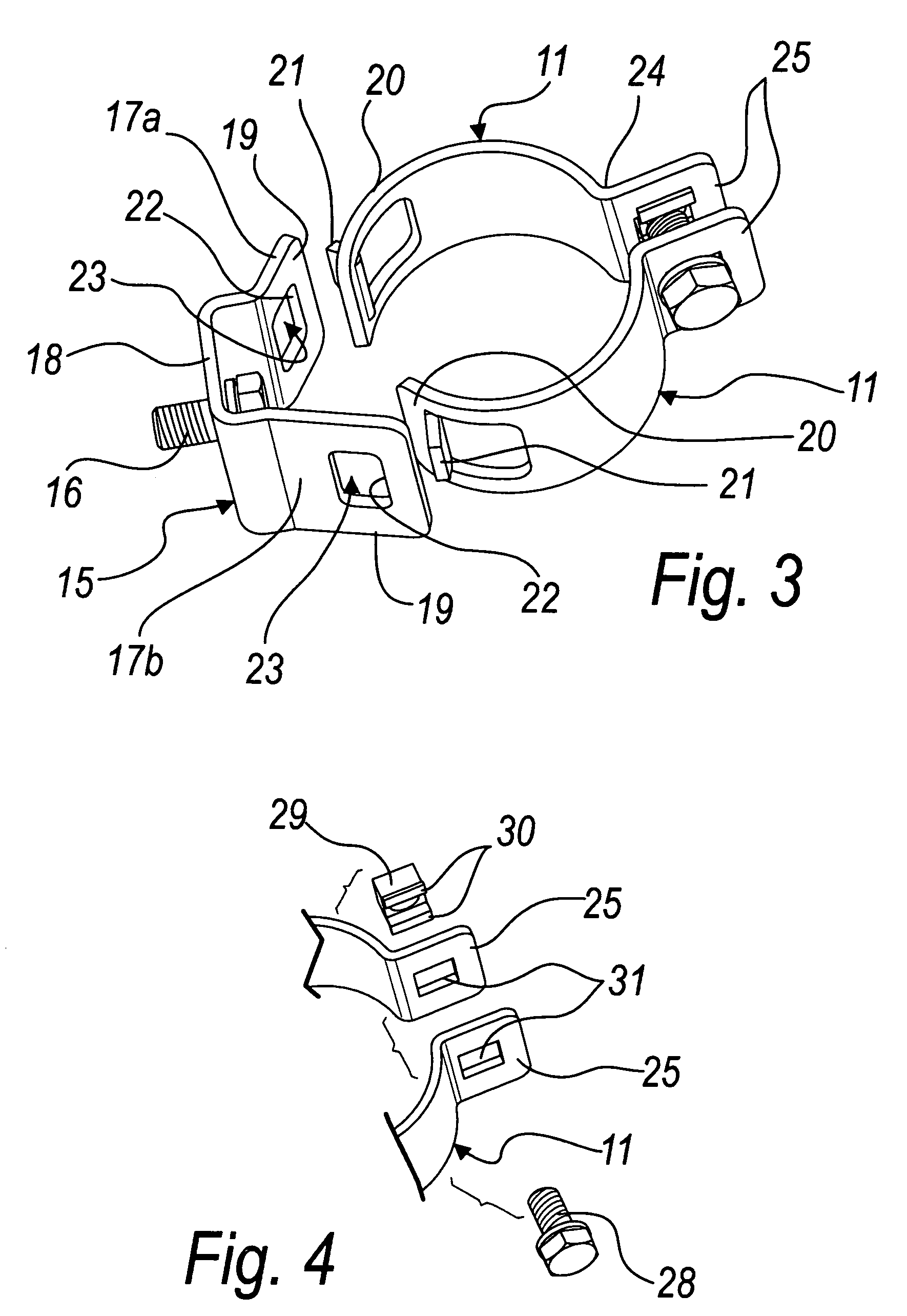

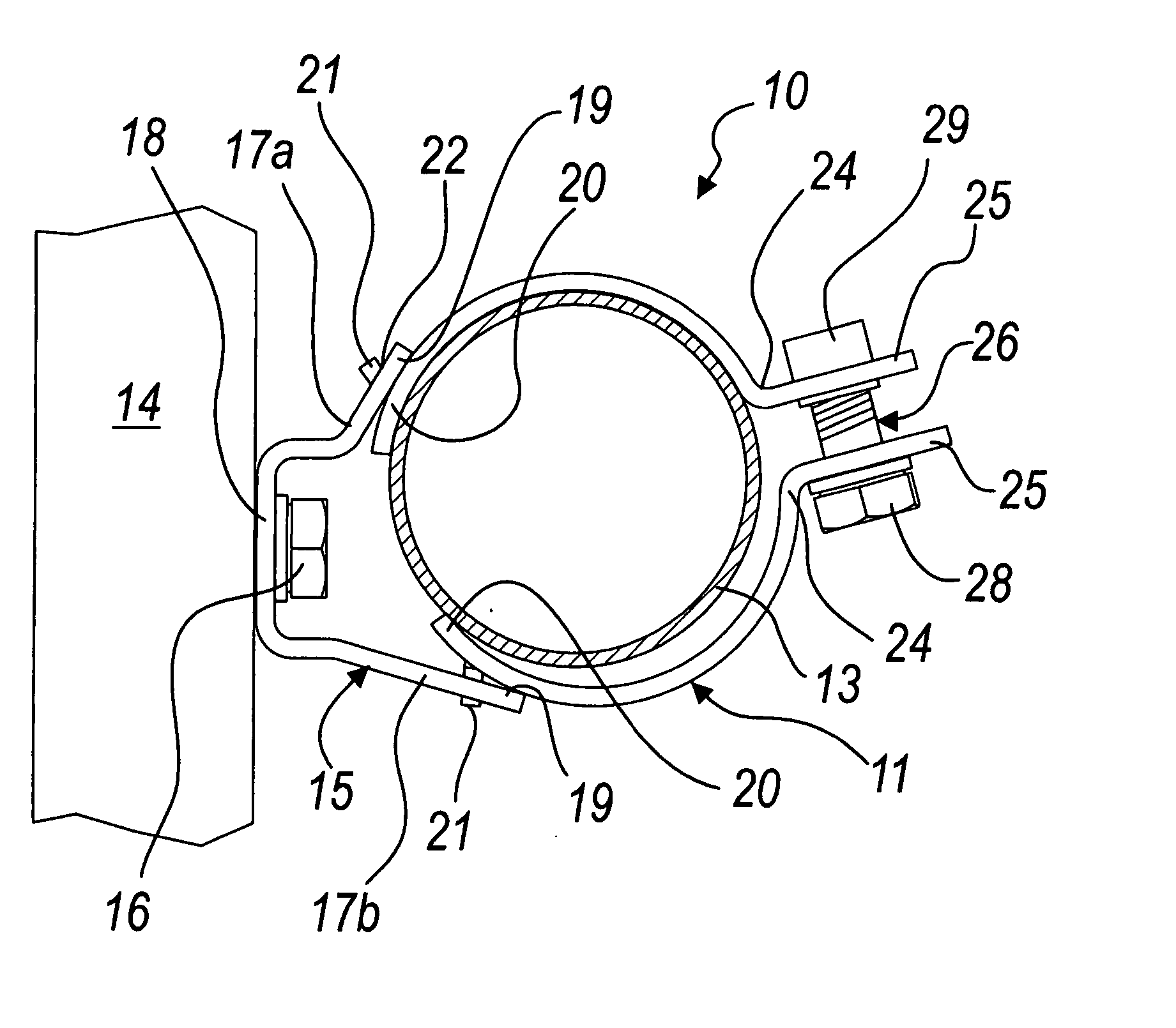

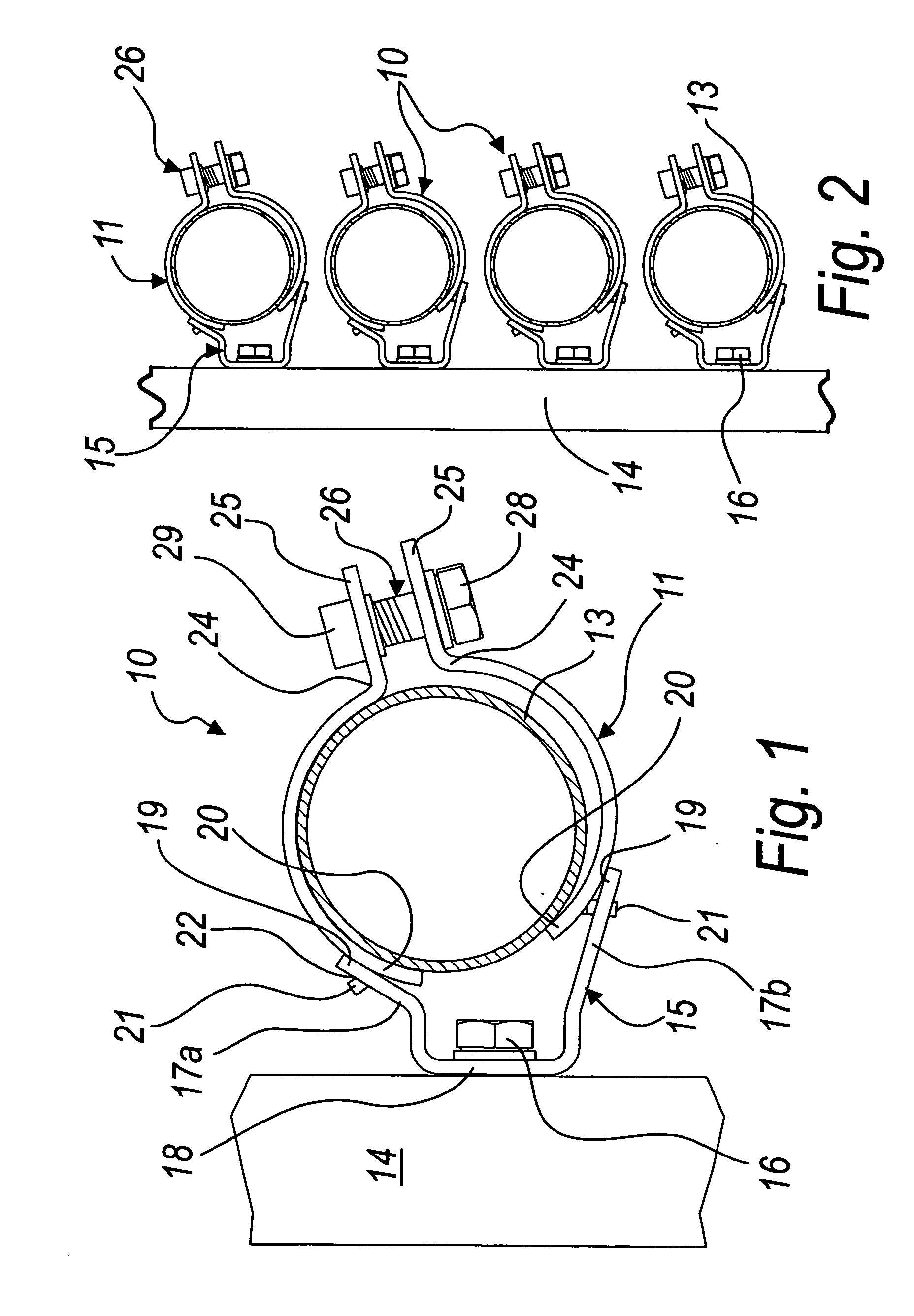

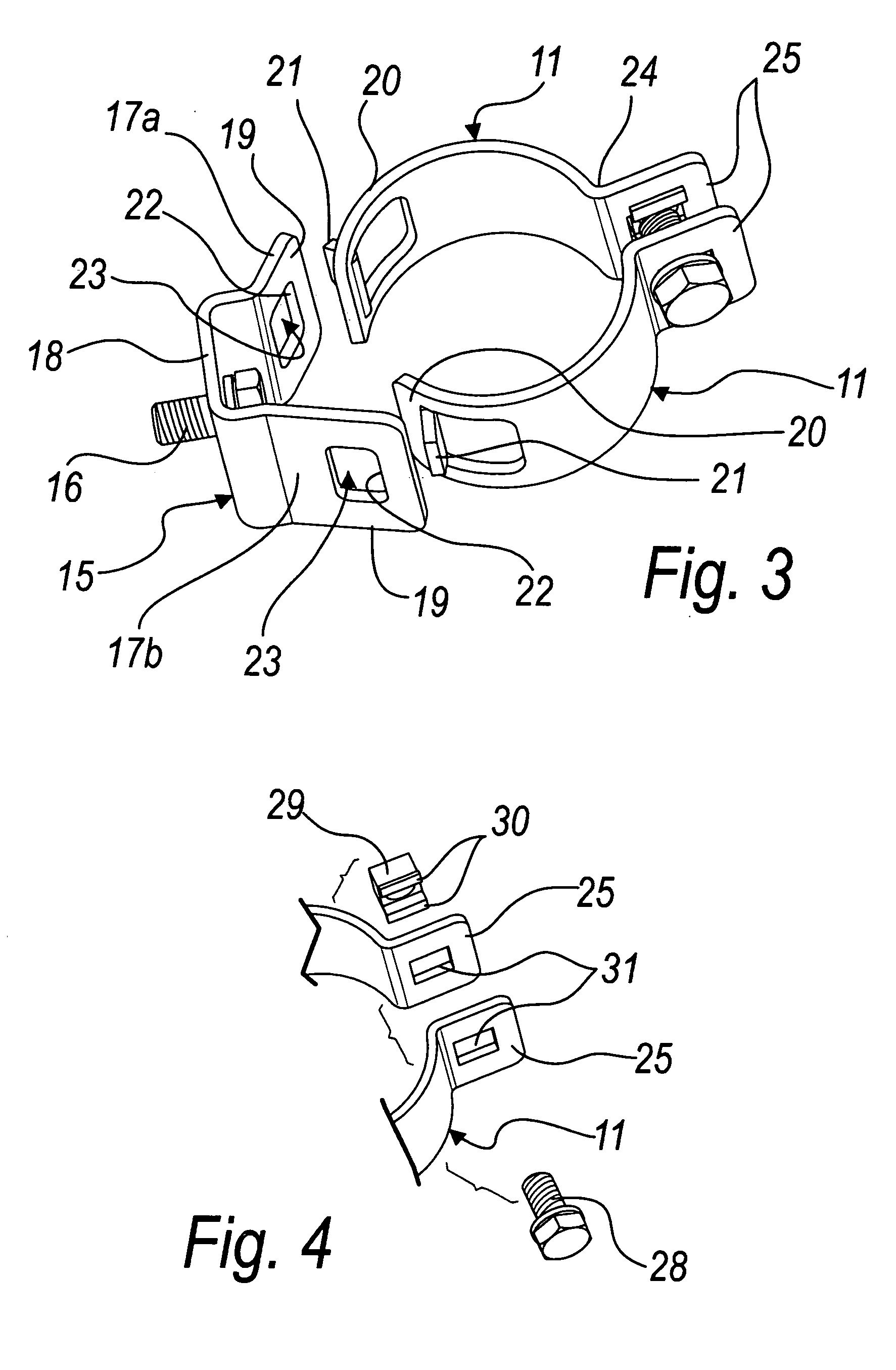

Device for fixing pipes to supporting structures

InactiveUS7384018B2Effective protectionClosely arrangedPipe supportsStands/trestlesAbutmentEngineering

A device for fixing pipes to supporting structures, comprising two C-shaped circular strips mutually oppositely coupled so as to surround mutually opposite portions of a pipe to be fixed to the supporting structure, and a fixing bracket, which is provided with two mutually opposite cantilevered wings. Respective first ends of the circular strips are engaged on the facing portions of the free ends of the two cantilevered wings. Protruding teeth are provided on each of the first ends, arranged in abutment against a corresponding engagement portion provided on a respective cantilevered wing.

Owner:MORETTO SPA

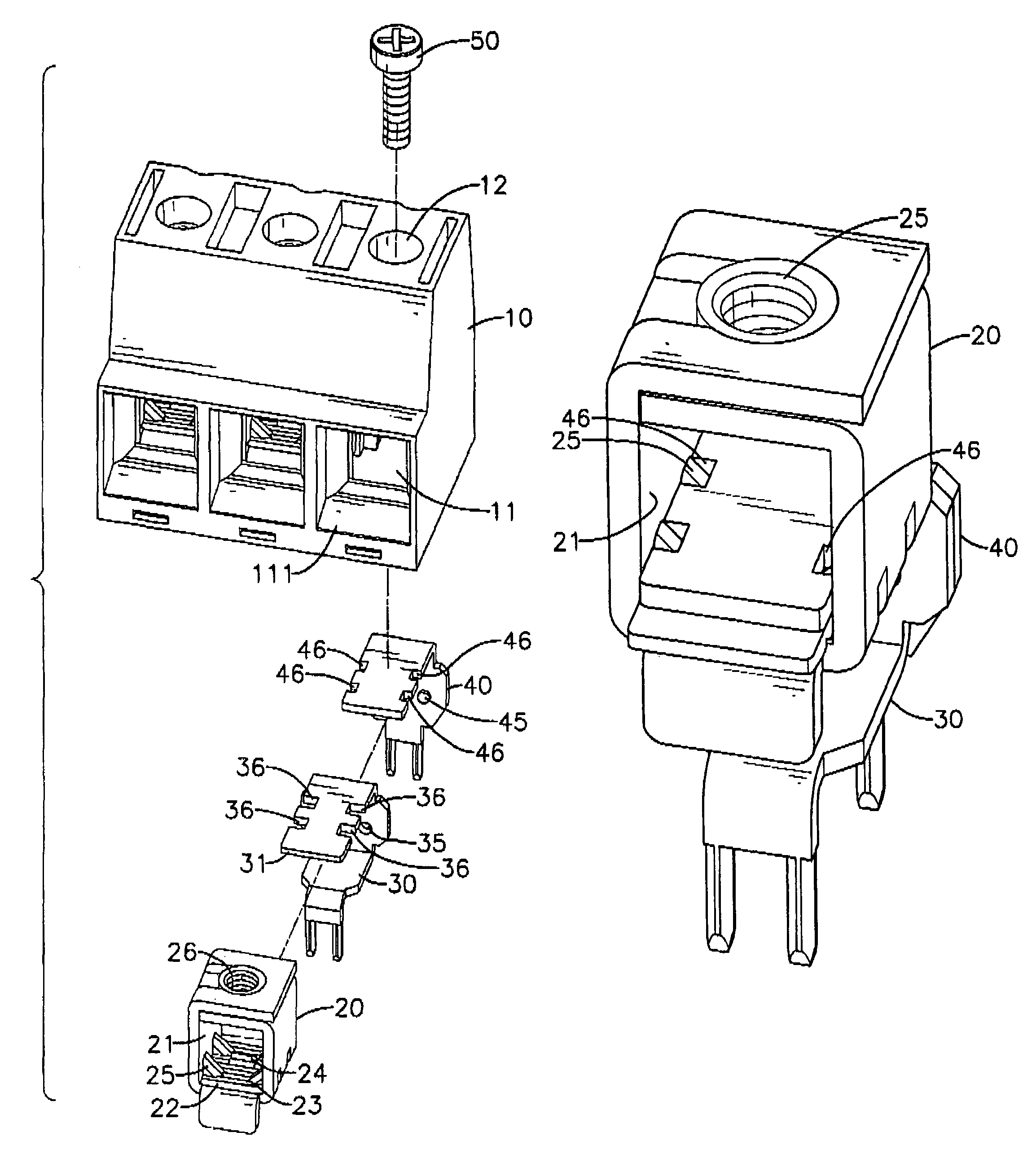

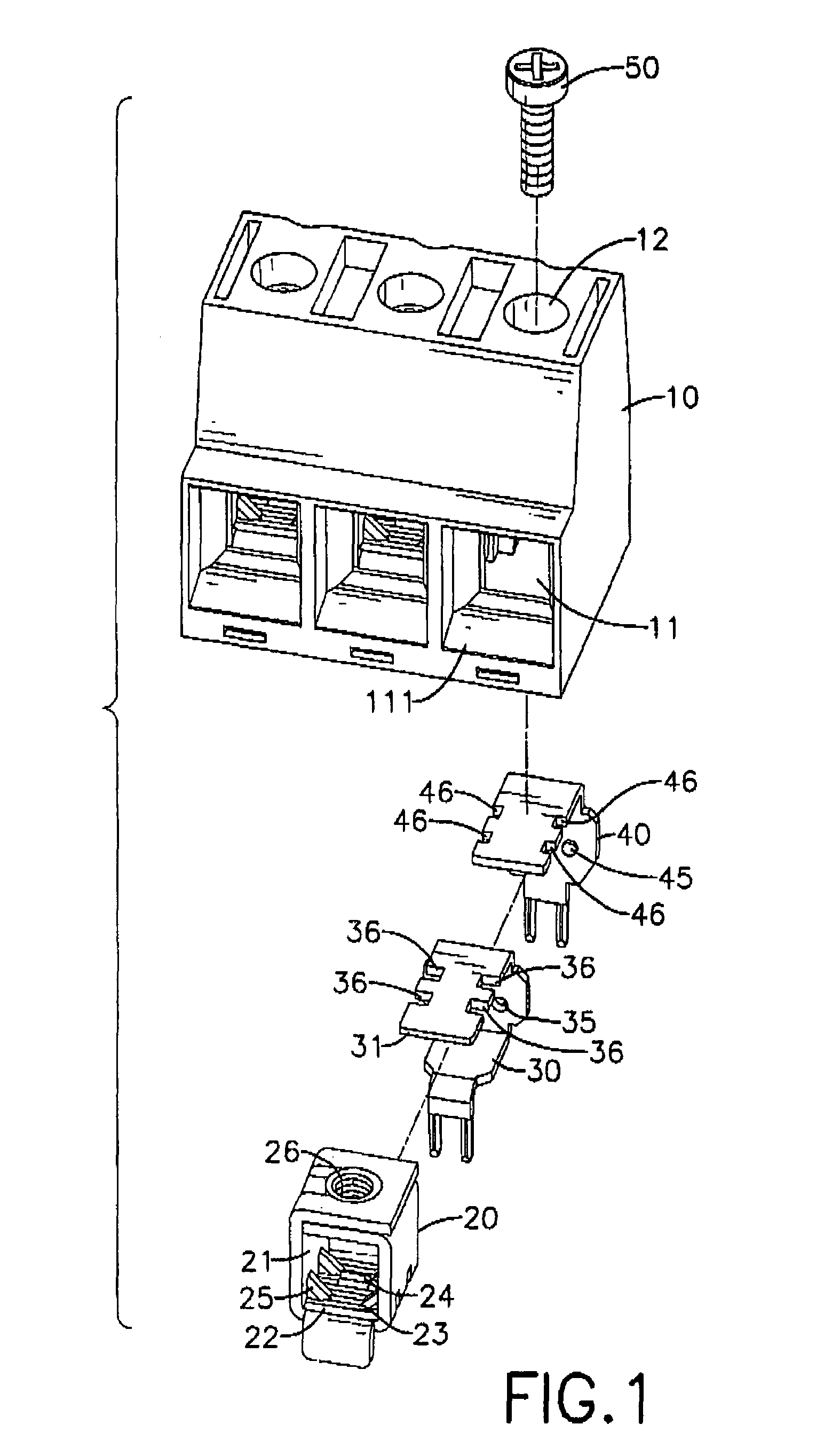

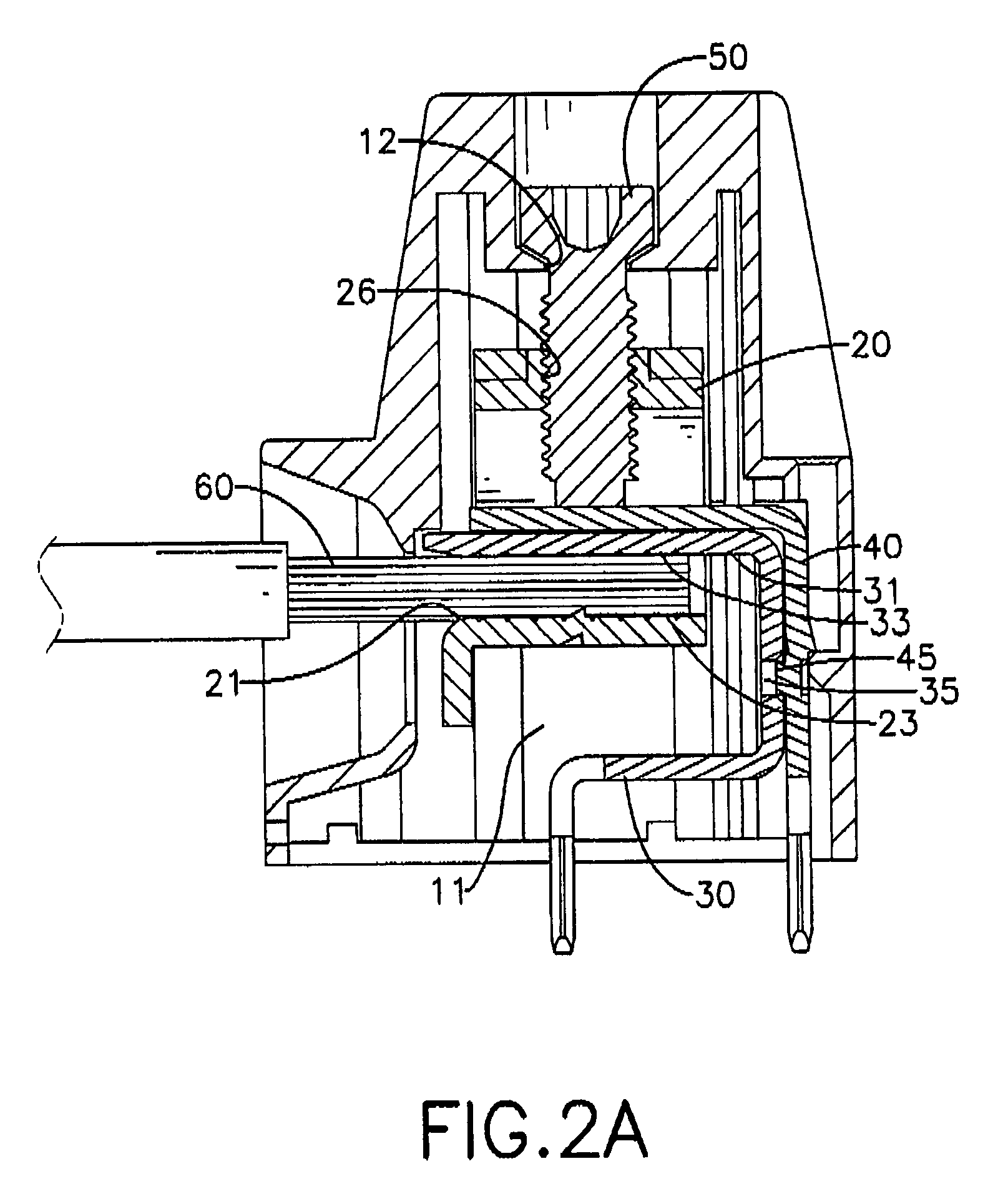

Terminal contact and clamp assembly for a cable terminal block and method for processing the same

A terminal contact and clamp assembly has a cage clamp and an inner contact. The cage clamp has a top, a bottom, a through hole multiple bottom teeth and at least one protruding tooth. The bottom has an inner bottom surface. The bottom teeth are formed on the inner bottom surface. The at least one protruding tooth is formed on and protrudes up from the inner bottom surface and has a top end higher than the inner bottom surface. The inner contact is mounted in the through hole. The at least one protruding tooth deeply bites an exposed wire core of a cable and prevents the cable from slipping out of the terminal contact and clamp assembly.

Owner:WU CHIH YUAN

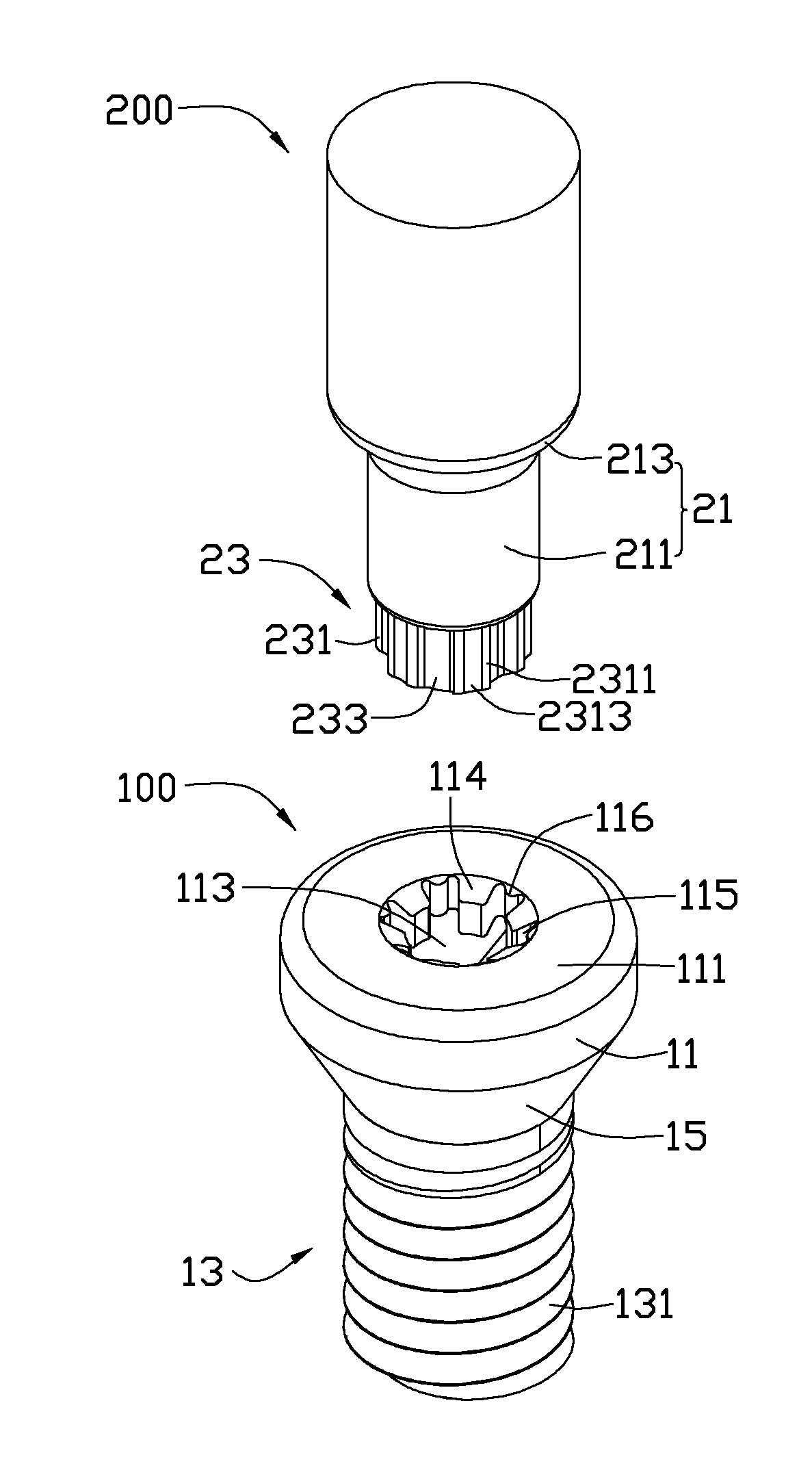

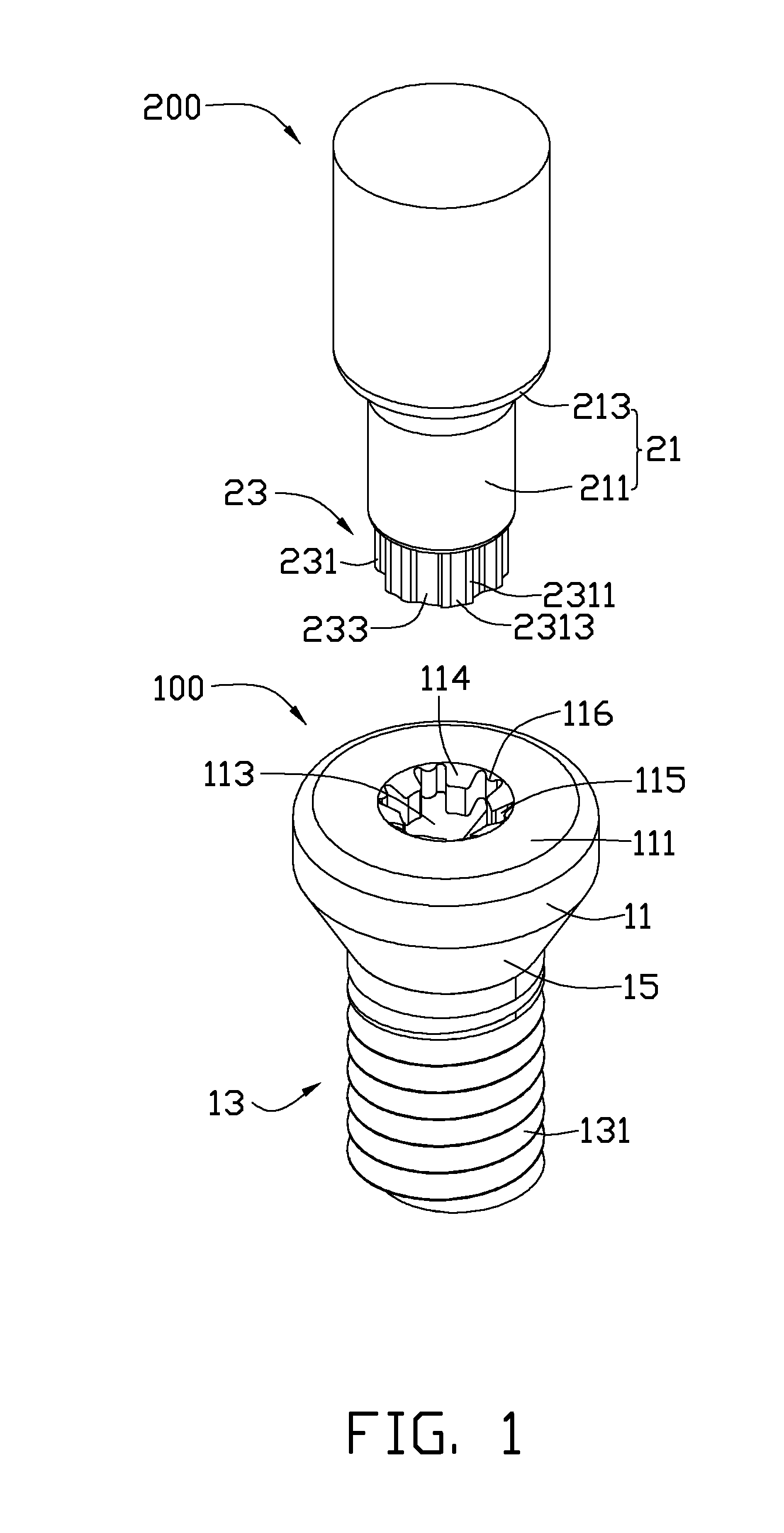

Fastener, driver engaging with the fastener and punch producing the fastener

A fastener includes a connecting portion and a head portion connected with the connecting portion. The head portion defines an engaging hole and includes a plurality of protruding teeth separately formed on an inner peripheral wall of the engaging hole, respectively, toward a central axis of the engaging hole of the head portion, and a plurality of recesses are formed between every two adjacent protruding teeth, respectively. The head portion further includes a plurality of resisting projections separately formed on the inner peripheral wall of the engaging hole, toward the central axis of the engaging hole, and received within the corresponding plurality of the recesses of the head portion, respectively. The present disclosure further provides a driver engaging with the fastener and a punch producing the fastener.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

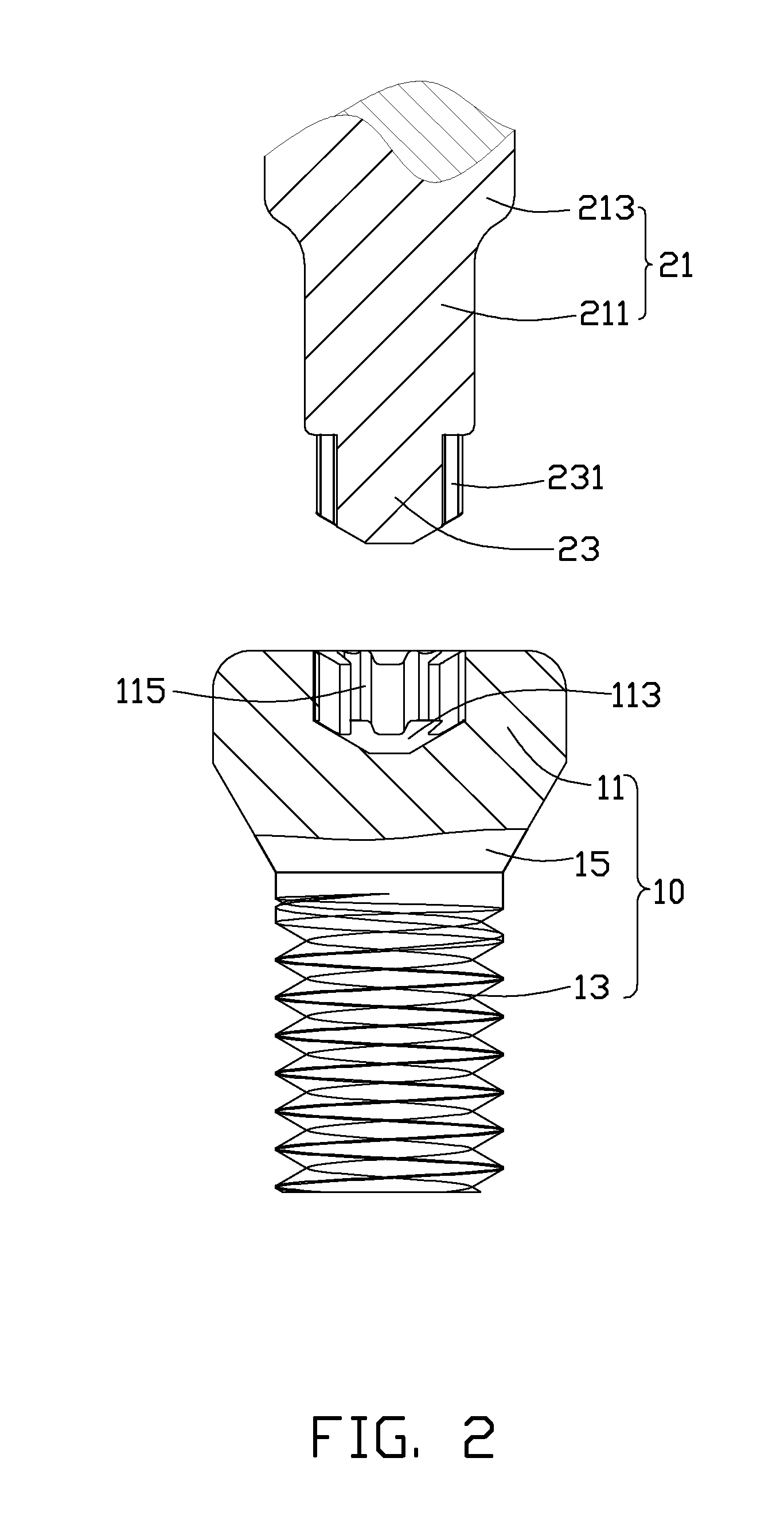

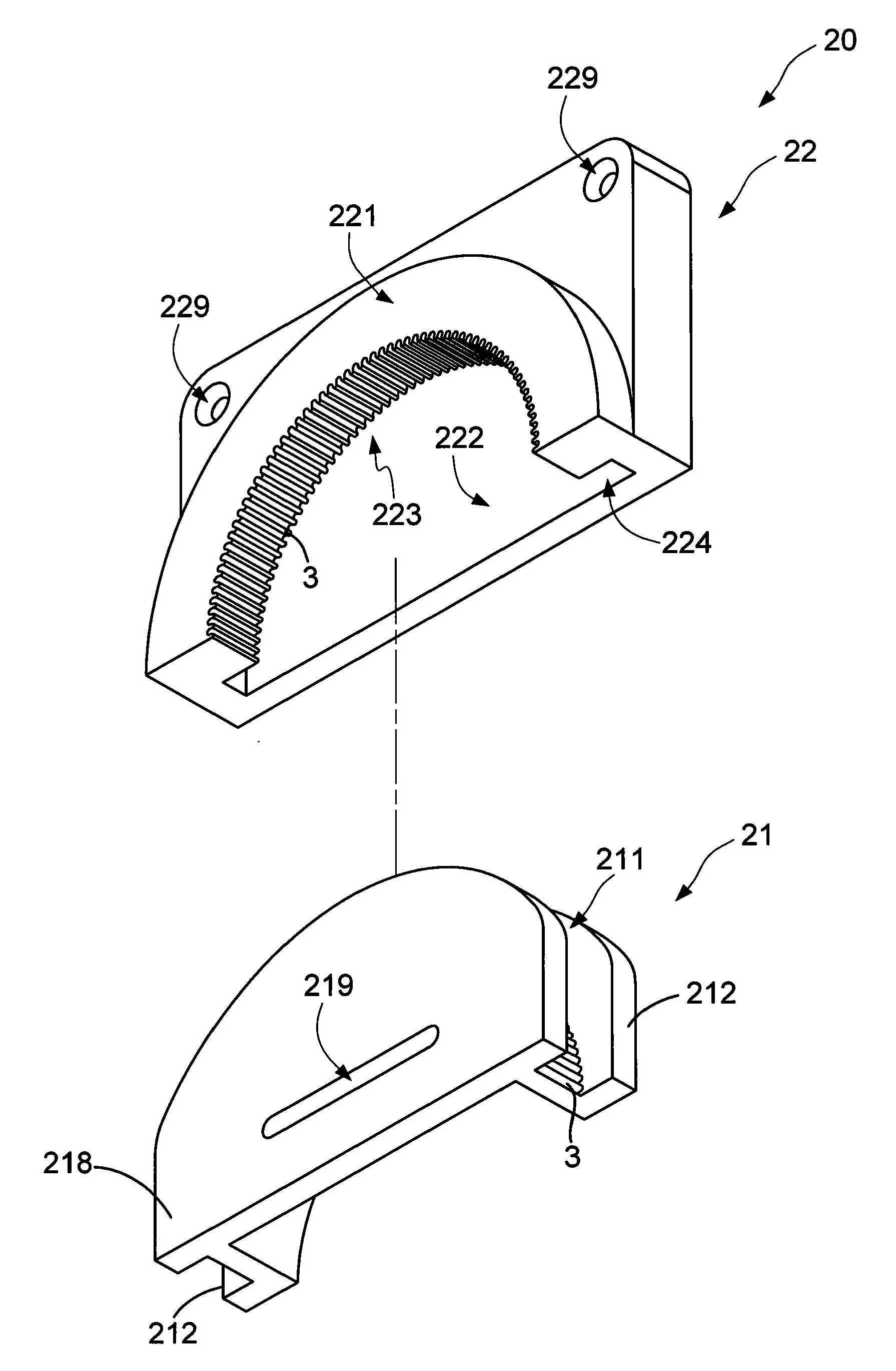

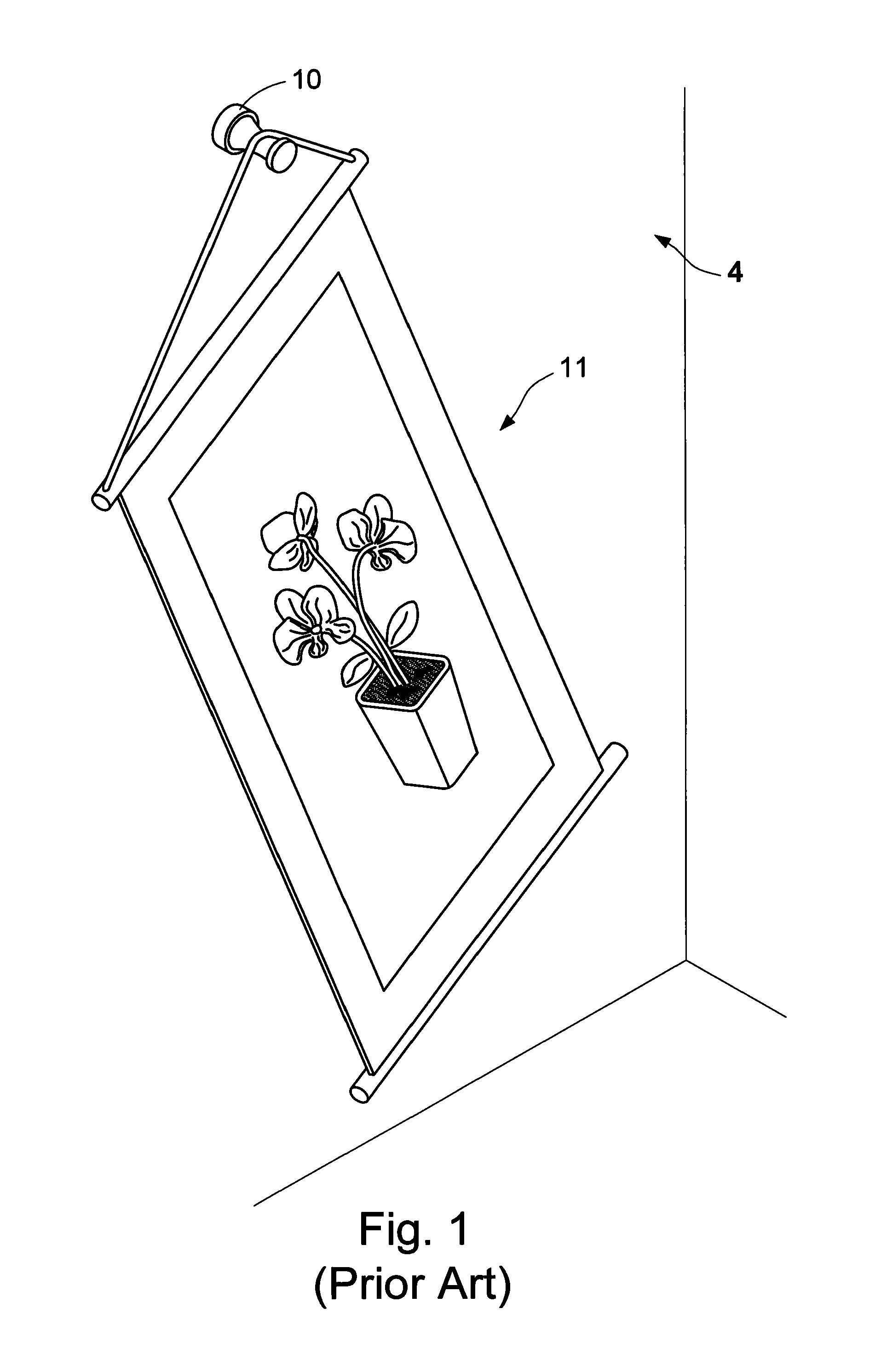

Wall mount hanger

InactiveUS20120112022A1Reduce user inconvenienceReduce inconvenienceCandle holdersLighting support devicesEngineeringMechanical engineering

A wall mount hanger includes a hanging section and a sleeve section. The hanging section is protrusively disposed on a wall surface and has a first arc surface and a stop portion. The first arc surface has plural protruding teeth, and the stop portion is protrusively disposed on the first arc surface. The sleeve section has a first surface and a second surface lower than the first surface. A second arc surface and a slot are disposed between the first surface and the second surface. The second arc surface has plural protruding teeth. The protruding teeth of the second arc surface are engaged with the protruding teeth of the first arc surface. Since the sleeve section and the hanging section are engaged with each other through the protruding teeth, the sleeve section can be rotated fixed to a required angle relative to the hanging section.

Owner:CHENG CHENG GE

Device for fixing pipes to supporting structures

InactiveUS20070040075A1Effective protectionClosely arrangedPipe supportsStands/trestlesEngineeringAbutment

A device for fixing pipes to supporting structures, comprising two C-shaped circular strips mutually oppositely coupled so as to surround mutually opposite portions of a pipe to be fixed to the supporting structure, and a fixing bracket, which is provided with two mutually opposite cantilevered wings. Respective first ends of the circular strips are engaged on the facing portions of the free ends of the two cantilevered wings. Protruding teeth are provided on each of the first ends, arranged in abutment against a corresponding engagement portion provided on a respective cantilevered wing.

Owner:MORETTO SPA

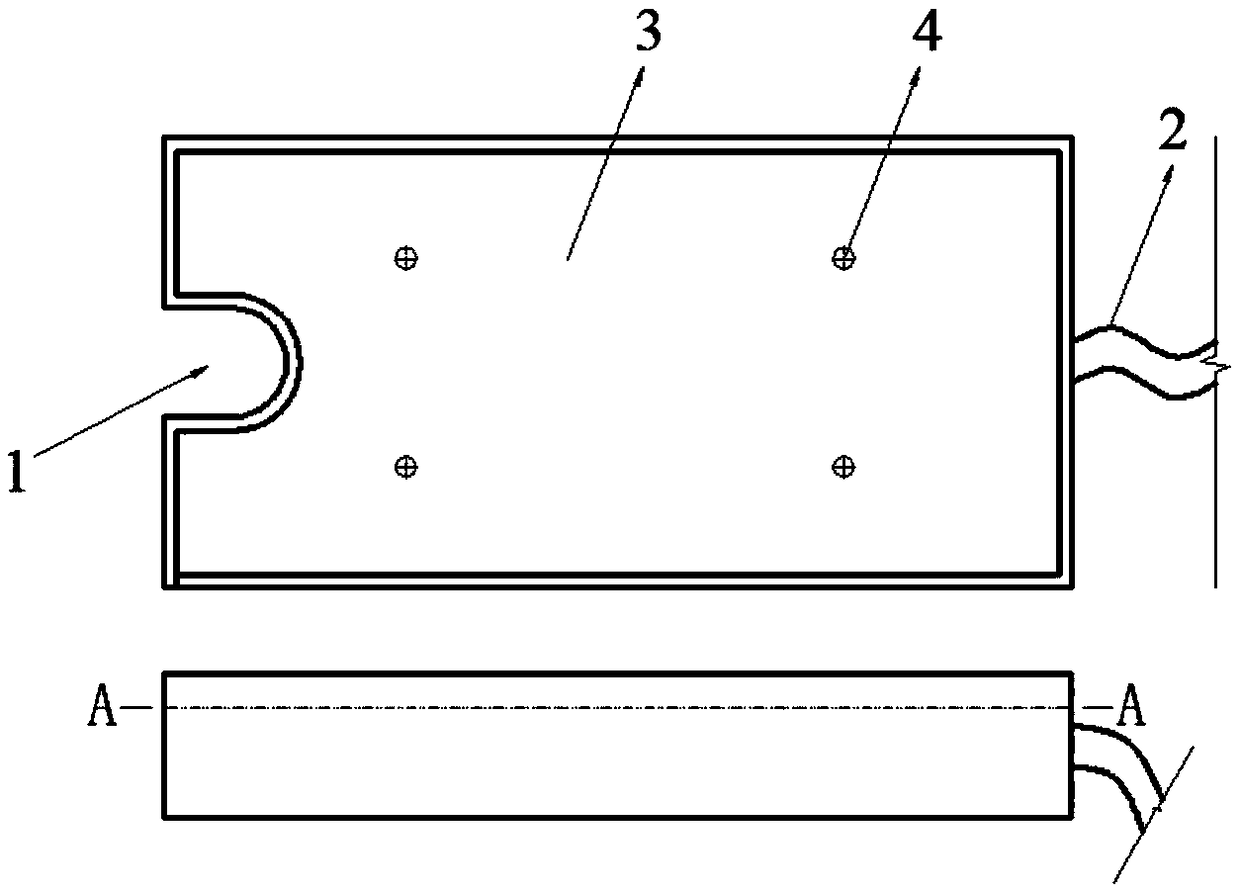

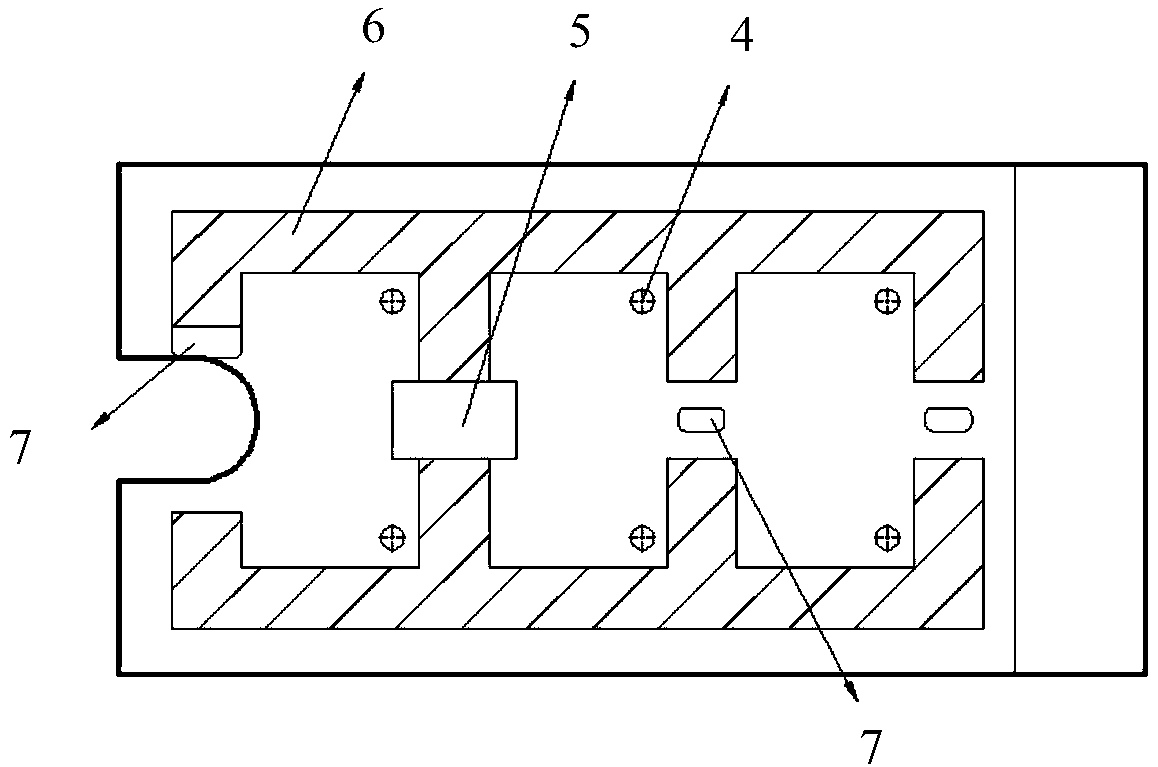

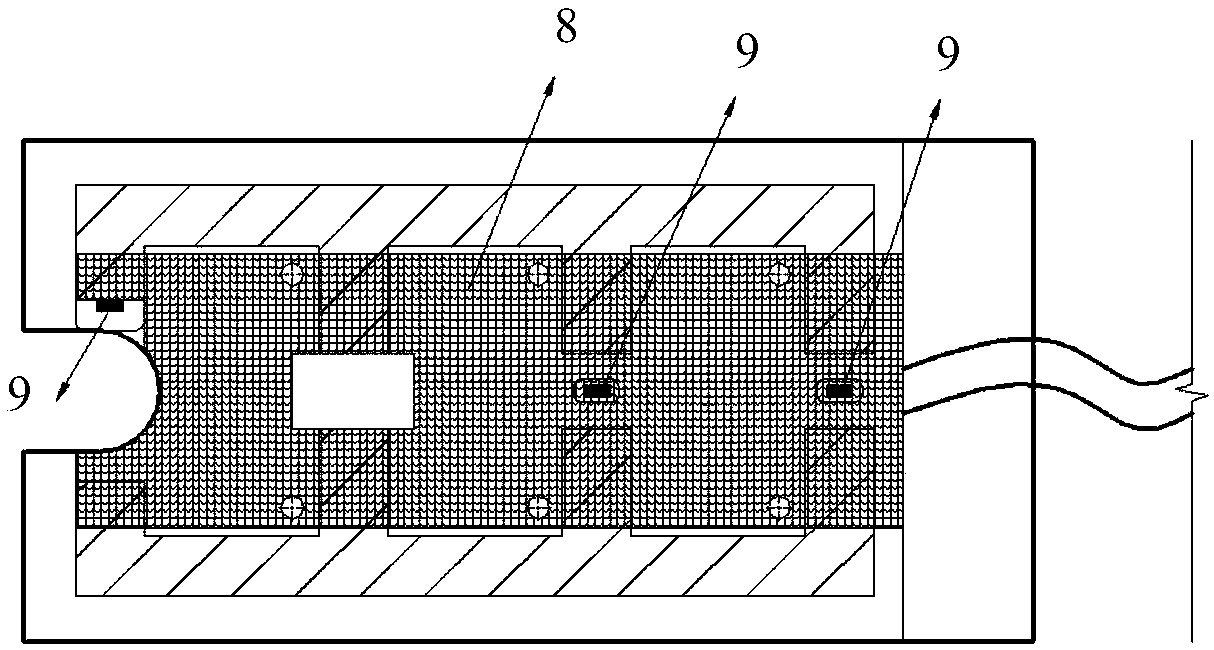

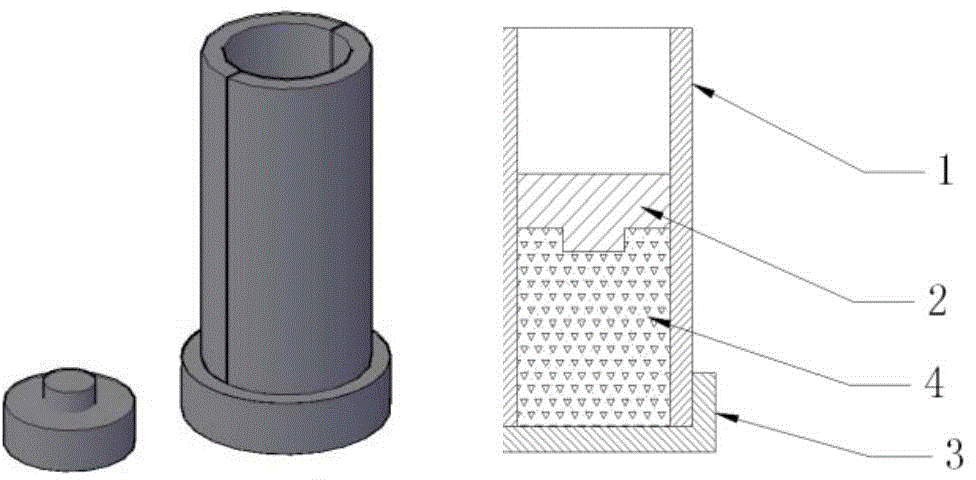

Non-destructive dynamic monitoring sensor for corrosion of reinforcing steel bar in concrete based on magnetic field and system

InactiveCN109374726AHigh precisionImprove stabilityMaterial magnetic variablesNon destructiveDynamic monitoring

The invention relates to the monitoring technique of corrosion of reinforcing steel bars in construction engineering, and aims to provide a non-destructive dynamic monitoring sensor for corrosion of areinforcing steel bar in concrete based on a magnetic field and a system. A slot for clamping a to-be-detected reinforcing steel bar is formed in one end of a shell of the sensor; two epsilon-type protruding teeth and oppositely arranged stainless steel frames are arranged in the shell, and mounting positions of Hall sensors are retained among other opposite teeth beside a permanent magnet arranged between one opposite teeth; end opposite teeth of the stainless steel frame and a mounting position of a Hall sensor are arranged on two sides of the slot, the Hall sensors are fixed to a data collection plate and the main body parts are located in the mounting positions. The corrosion rate of the reinforcing steel bar is monitored by mean of a magnetic field principle, so that the precision and the stability are relatively high; non-destructive and dynamic monitoring of the corrosion rate of the reinforcing steel bar in concrete can be achieved. The corrosion rate of the reinforcing steelbar in concrete can be given directly quantitively. The instrument device is small in size, convenient to carry and convenient to operate in an engineering site.

Owner:ZHEJIANG UNIV +1

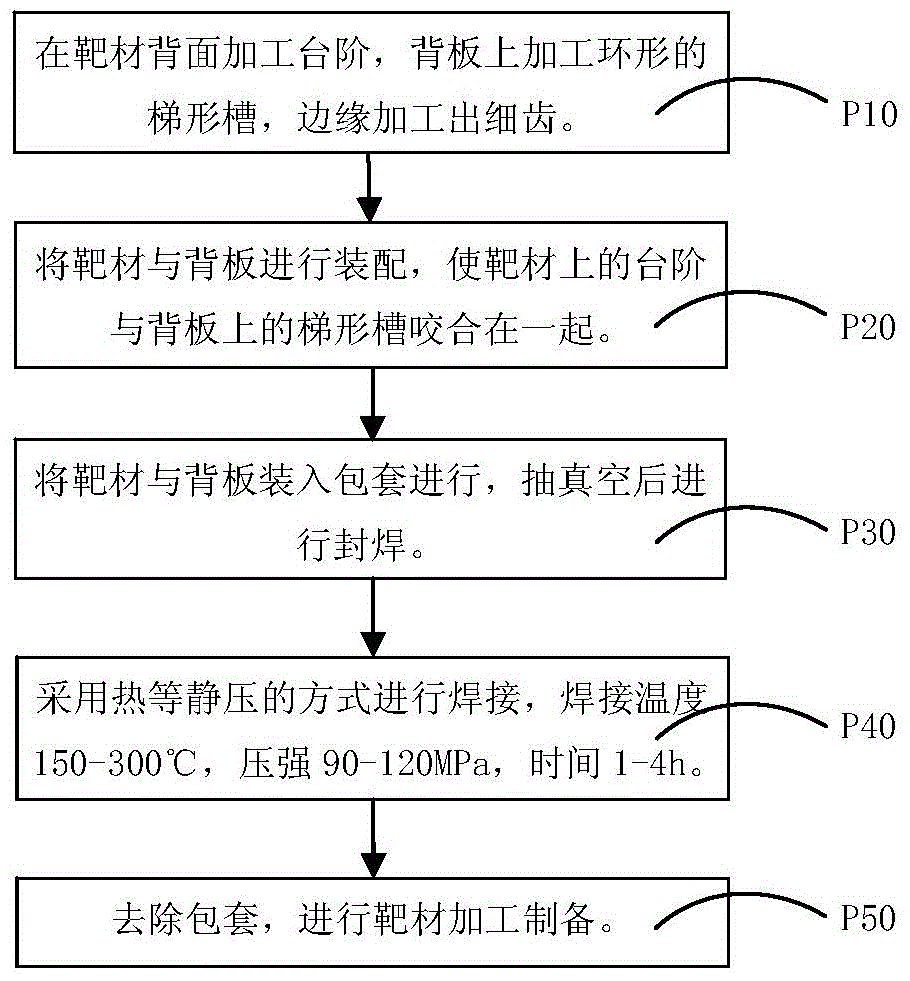

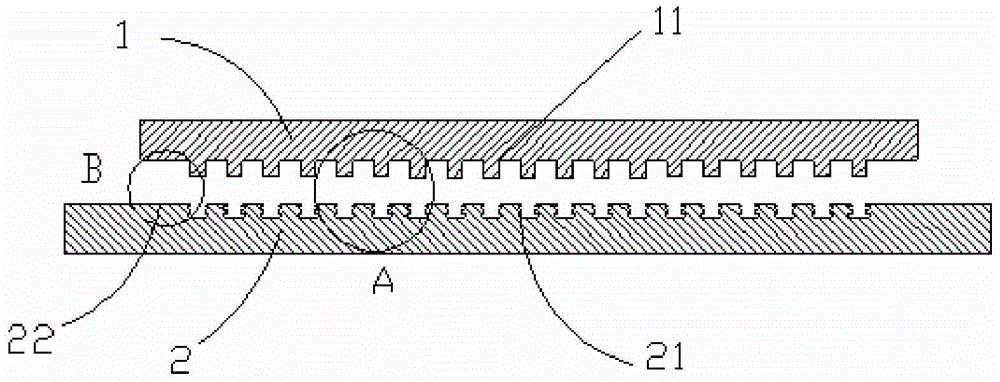

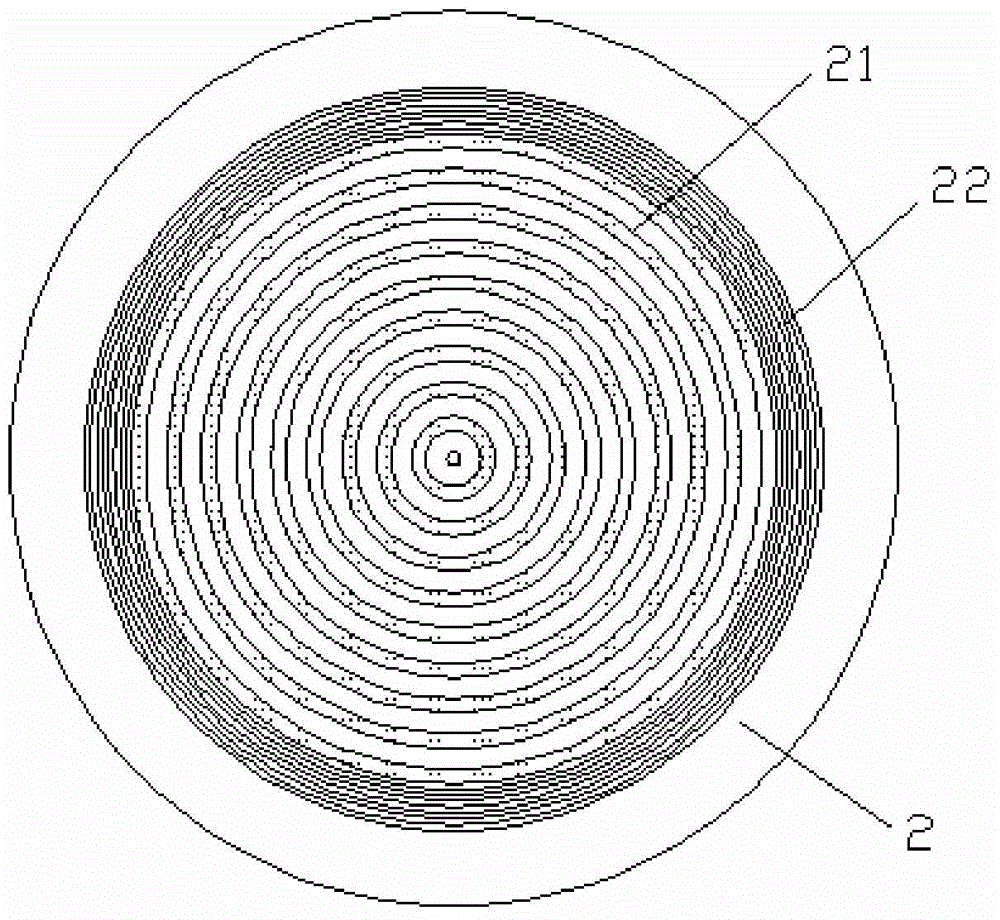

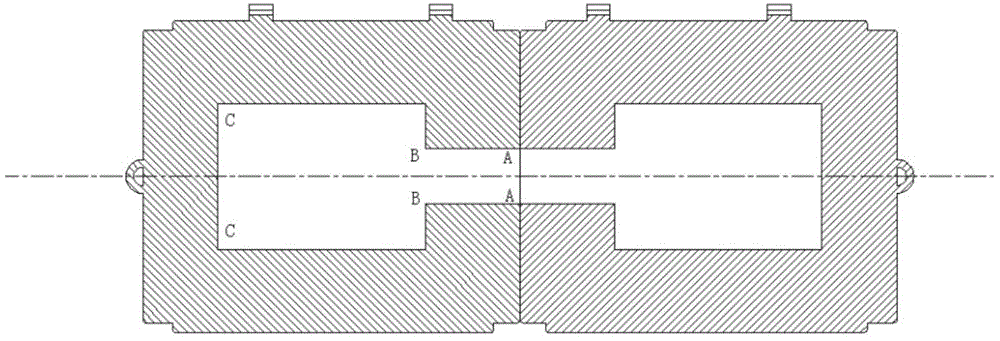

Welding method of aluminum alloy sputtering target material for integrated circuit package material

InactiveCN104625389AFine grainStrong reliabilityWelding/cutting auxillary devicesArc welding apparatusSputteringGrain growth

A welding method of an aluminum alloy sputtering target material for an integrated circuit package material comprises the steps that a protruding tooth of a certain shape and size is machined on the welding face of the target material, a corresponding groove is machined in a back plate, the target material and the back plate are put into a wrapping sleeve for carrying out vacuum seal welding after being assembled and combined, then a hot isostatic pressure method is adopted for enabling the groove to be completely filled with the material, and the target material is connected with the back plate. Due to the fact that welding temperature is low, aluminum alloy grain growth can be avoided, the welding intensity between the target material and the back plate is high, the target material is small in overall deformation, and subsequent machining is facilitated.

Owner:GRIKIN ADVANCED MATERIALS

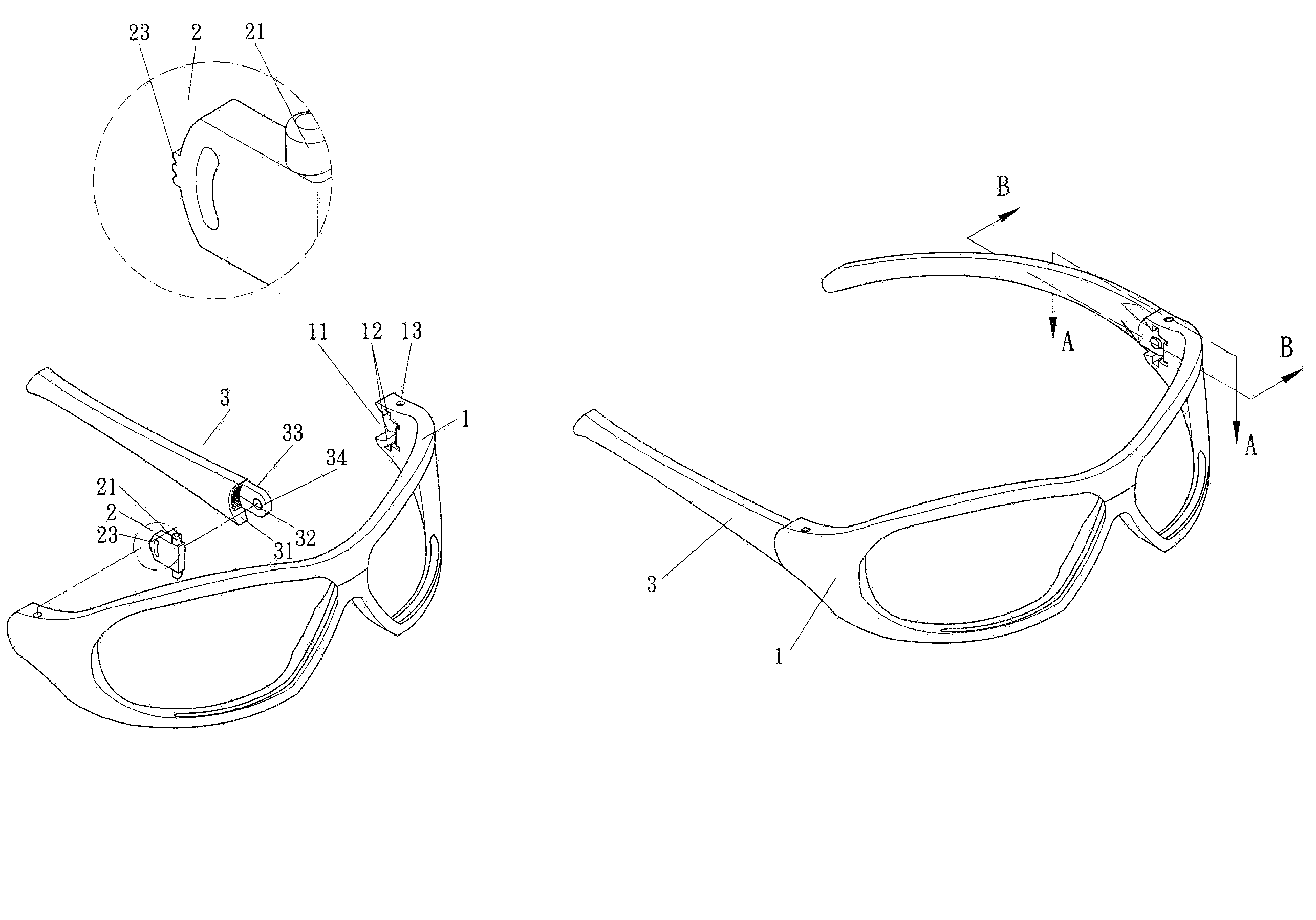

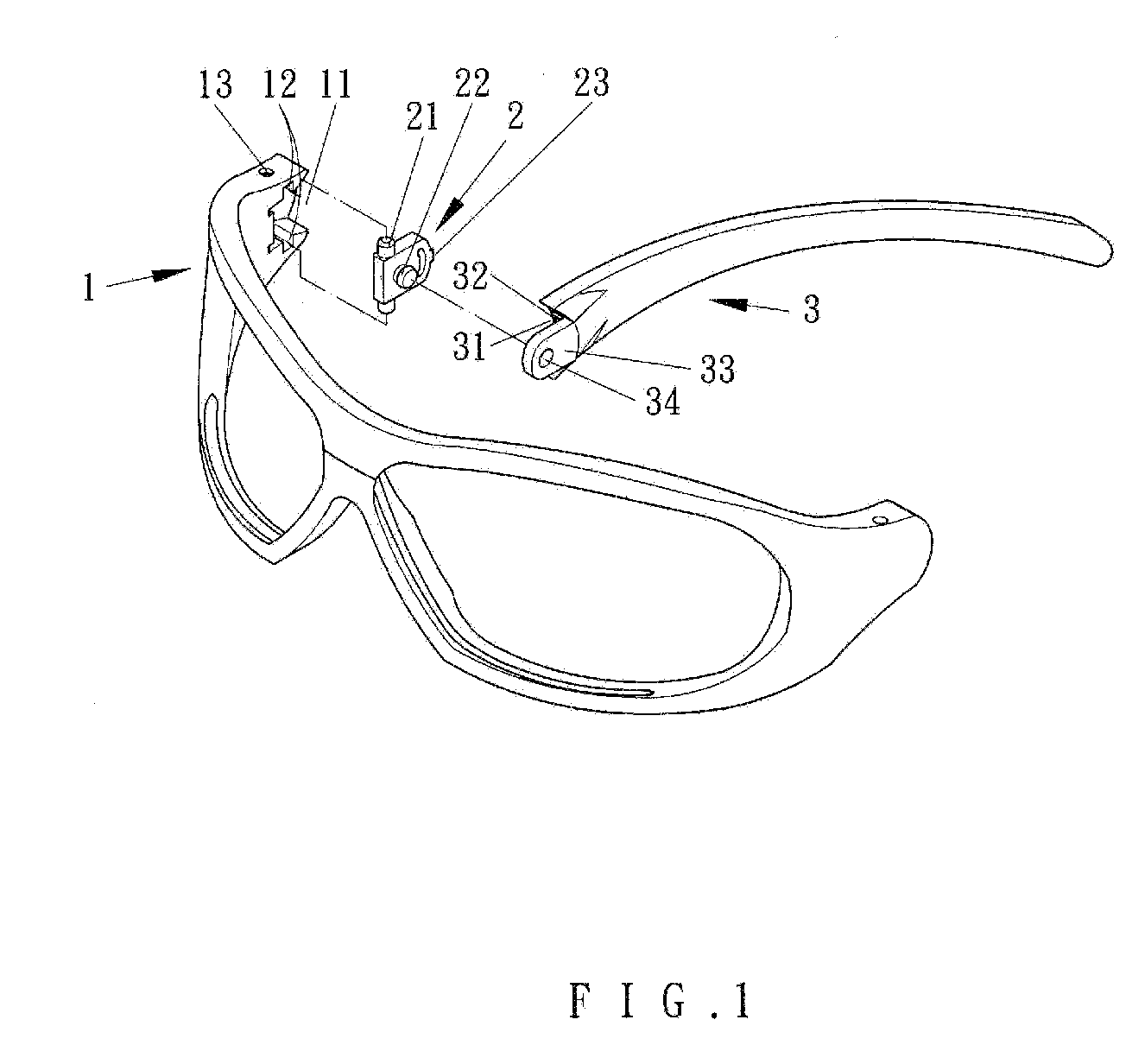

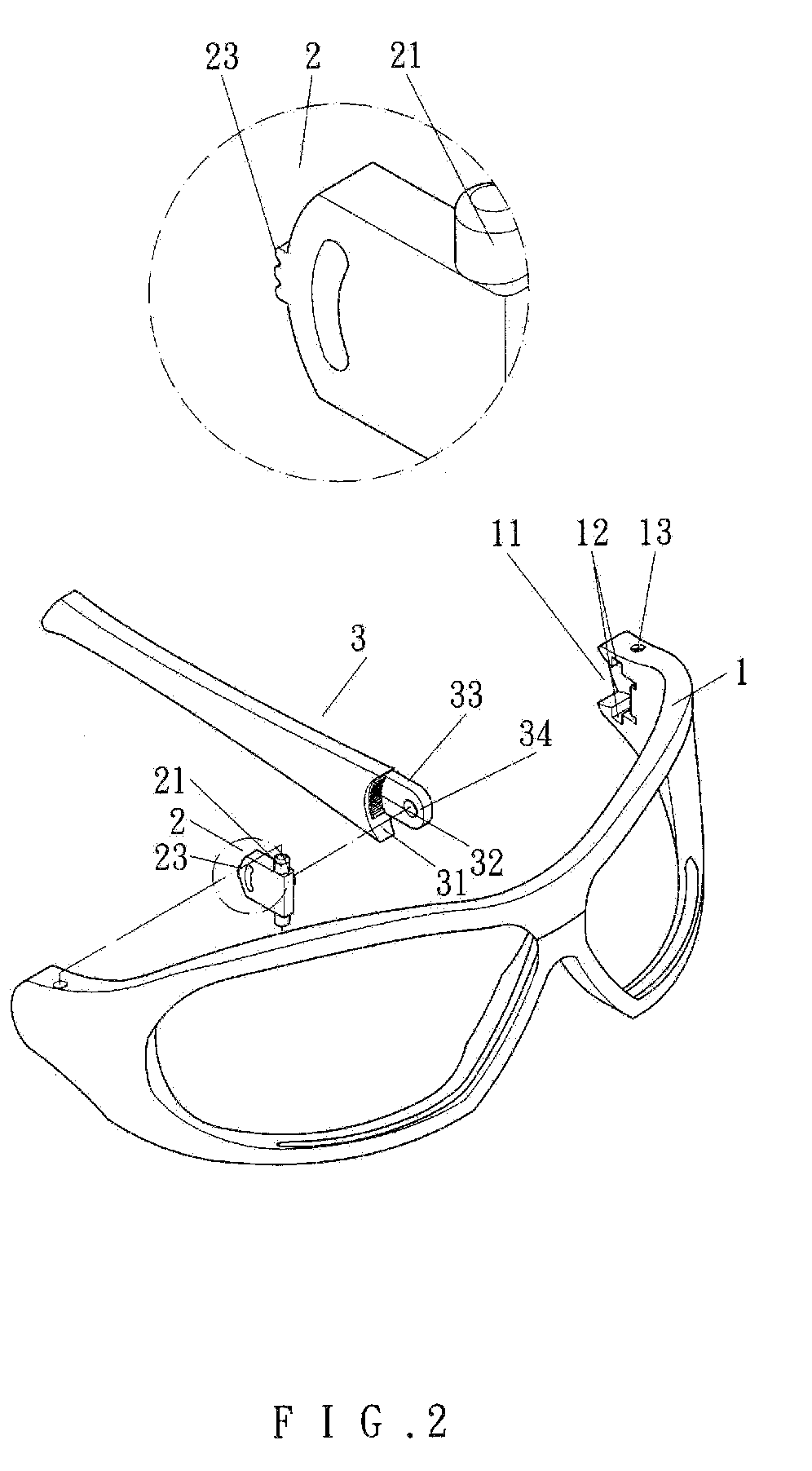

Tool-free adjustable eyeglasses with variegated temples

InactiveUS7300150B1Versatile designSmall overall lengthSpectales/gogglesNon-optical partsEngineeringMechanical engineering

A pair of eyeglasses with a unitary appearance by having the connecting piece concealed includes three parts: a lens-seat, two connecting pieces, and two temple assemblies. The unique alignment of the three parts in assembly allows for variegated design in the temple assembly, which can also be a restraining buckle strap. The adjustable temple assemblies can be easily assembled with the lens-seat without tools, which is rotatable relative to the lens-seat via different positions in meshing between the parallel teeth of the retaining piece (extending outwards from the temple assembly), and the protruding teeth of the connecting piece, thereby permitting an optimal adjustment of an inclination angle of the temple assembly.

Owner:CHEN JOY

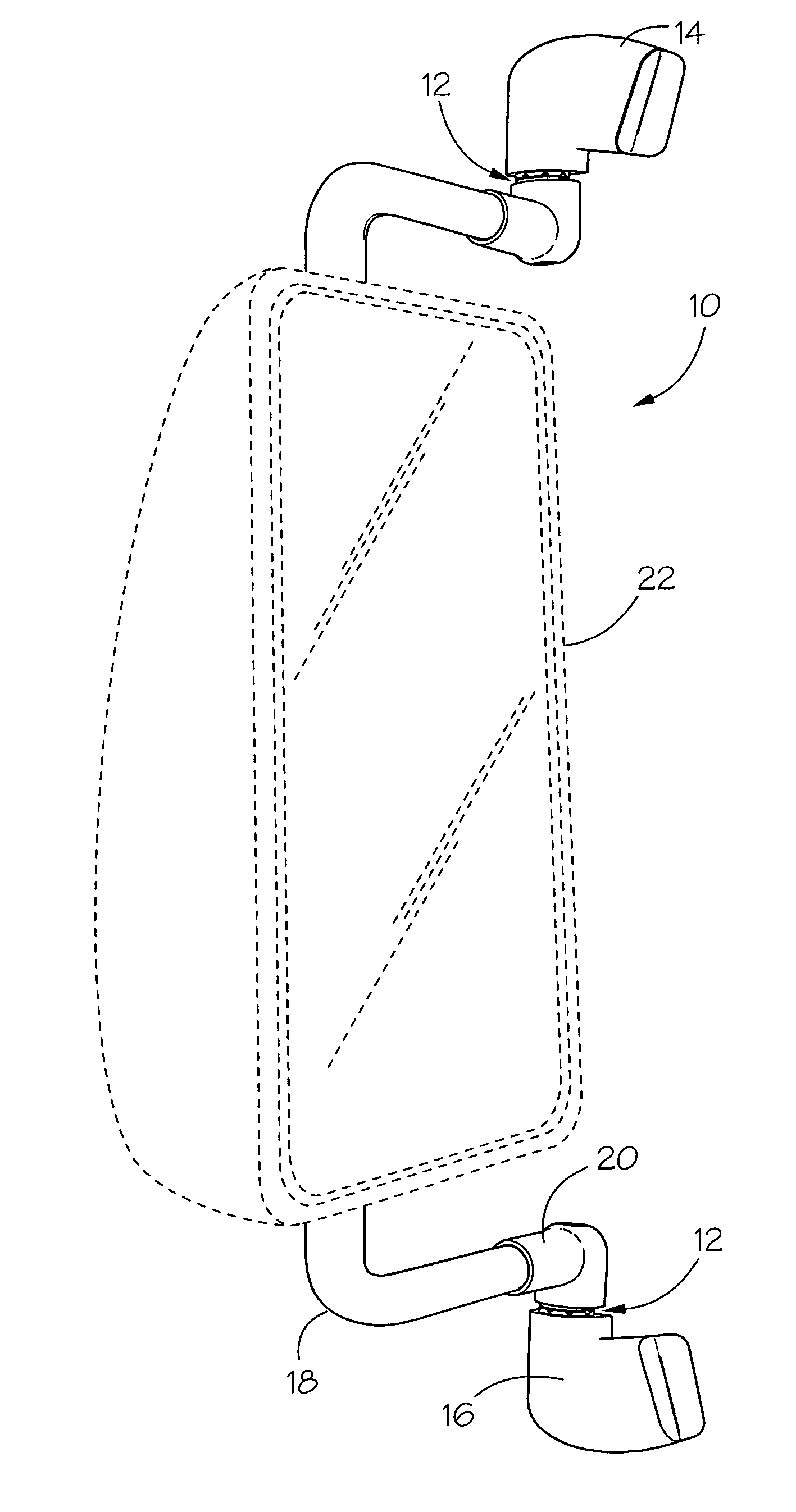

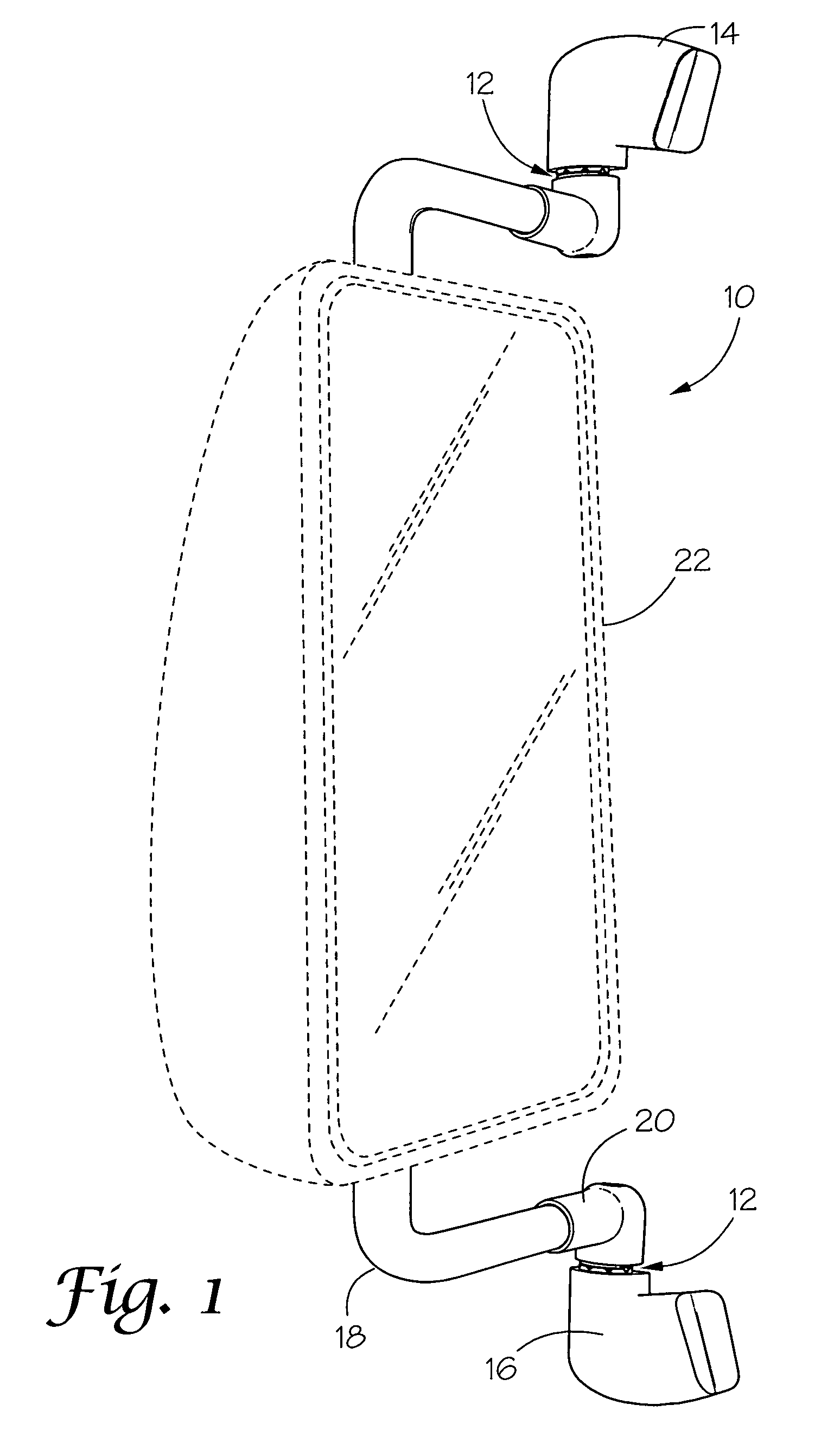

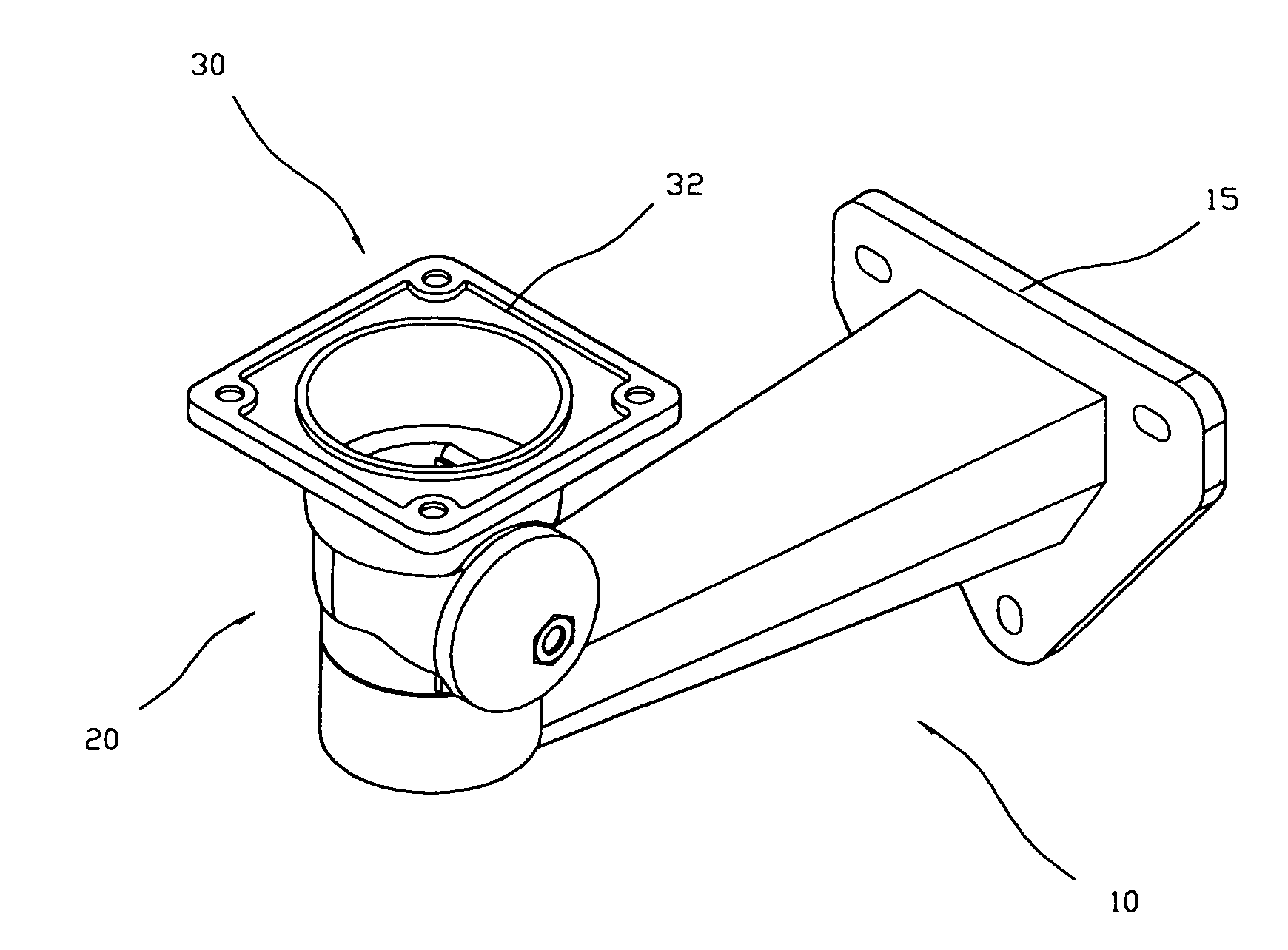

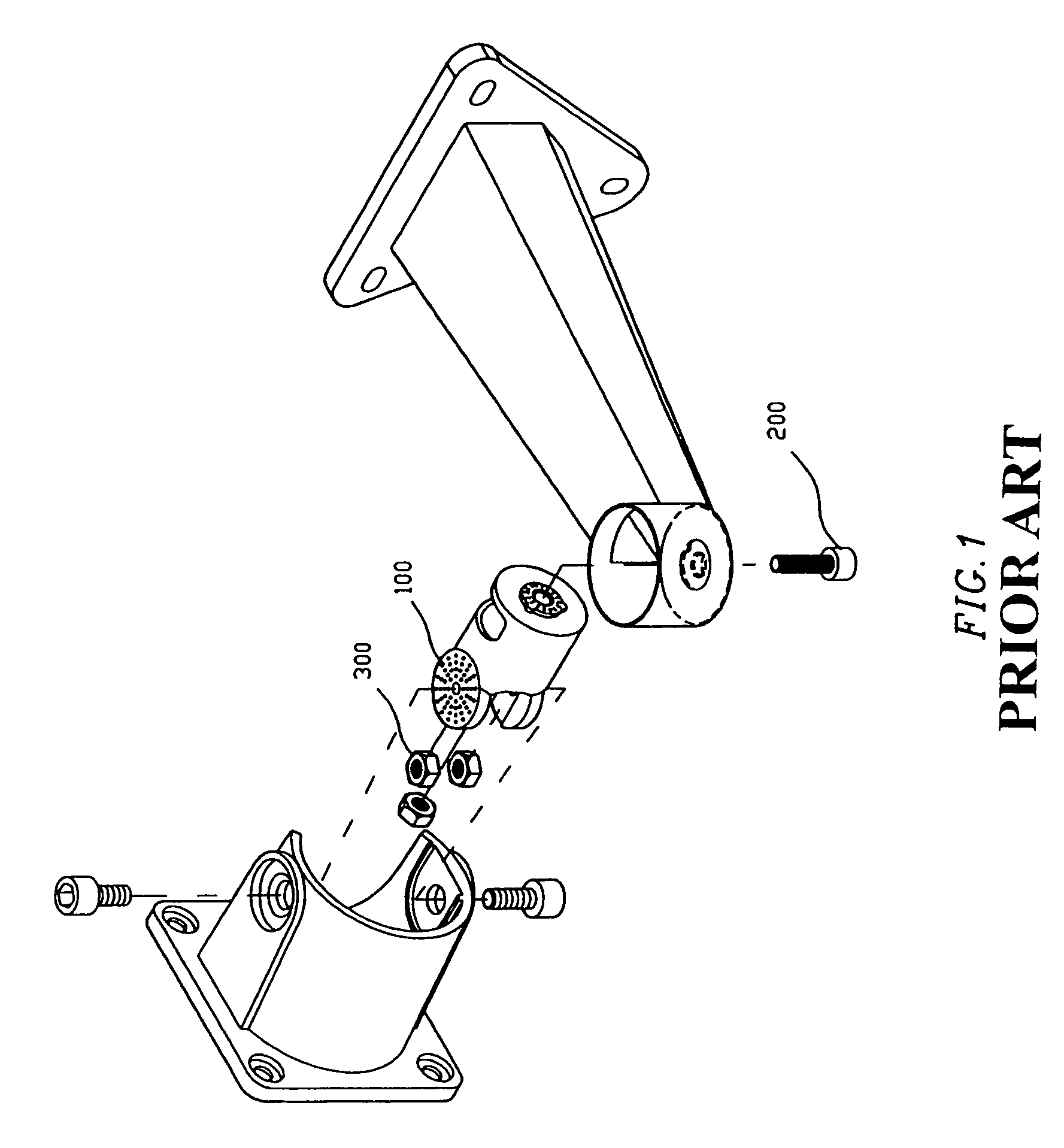

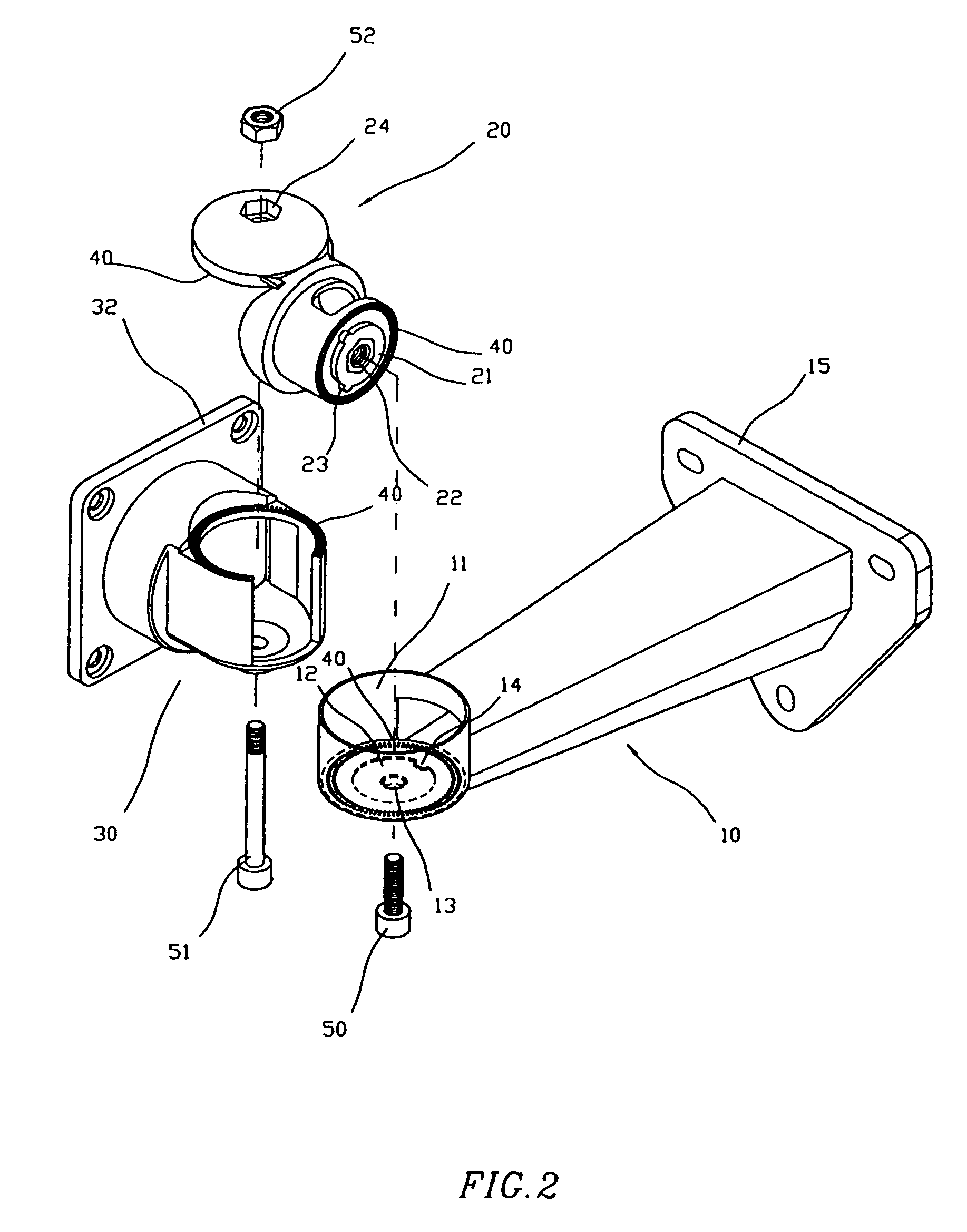

Multi-axis pivoting detent joint assembly for an exterior vehicle mirror

A mirror assembly comprising a mounting bracket for attachment to a vehicle exterior; a first pivot plate on the mounting bracket having a concave upper surface with a series of grooves formed therein; a support arm pivotally carried on the first pivot plate of the mounting bracket; and, a second pivot plate carried by the support arm having a base surface with a plurality of protruding teeth engaging the grooves in the first pivot plate so that a pivot gap is defined between the upper surface of the first pivot plate and the base surface of second pivot plate; whereby the pivot gap allows the teeth to both pivot and slide in the grooves of the first pivot plate so that the support arm is pivotal in a multi-axis arrangement with the mounting bracket to accommodate misalignment between the mounting bracket and the support arm during installation on a vehicle.

Owner:LANG MEKRA NORTH AMERICA LLC

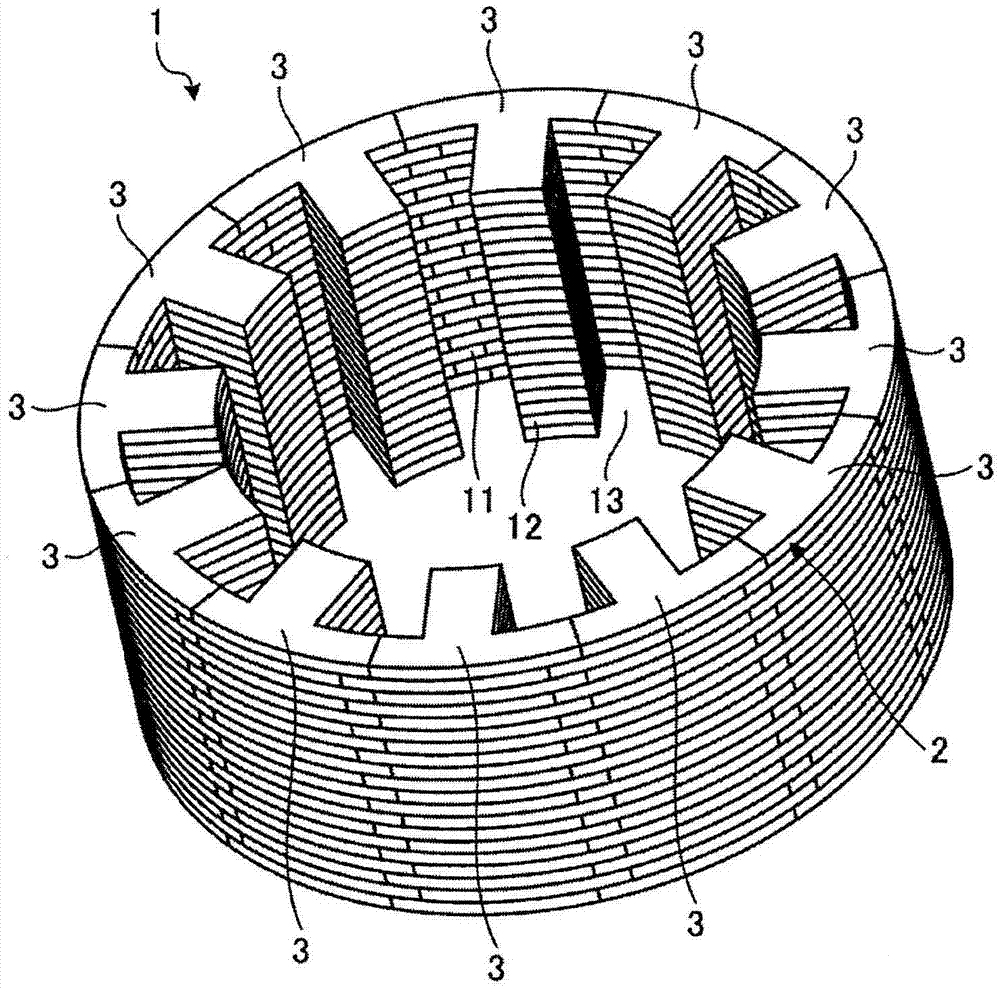

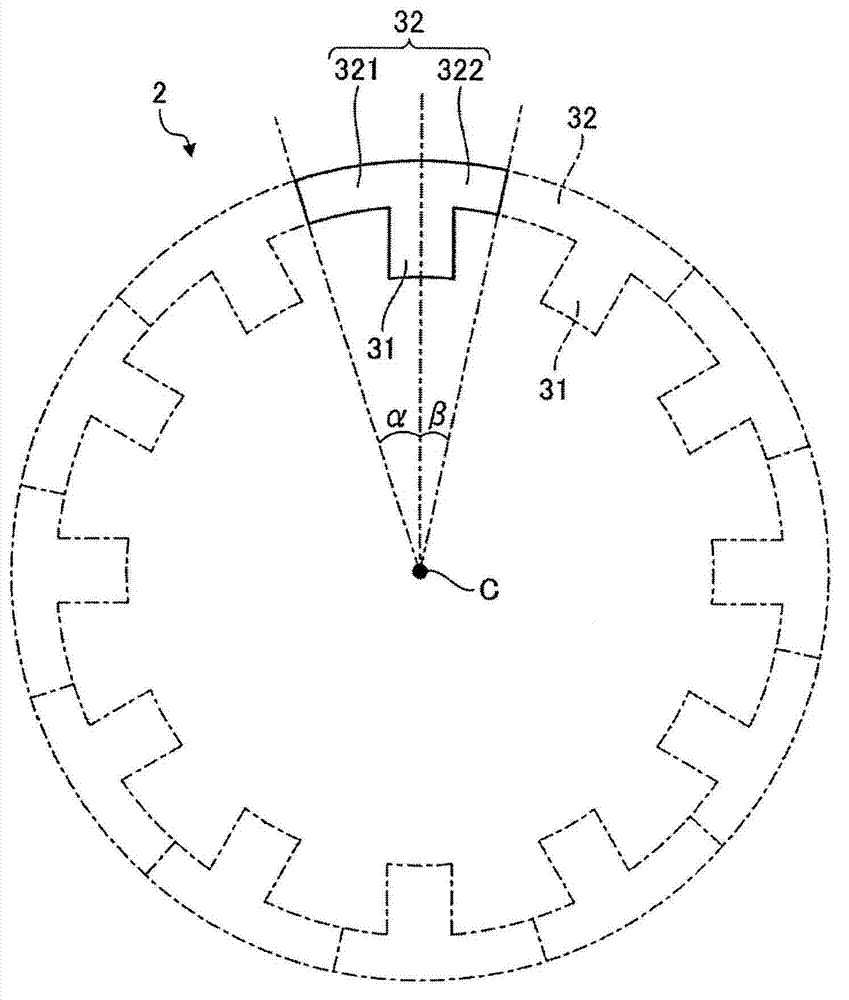

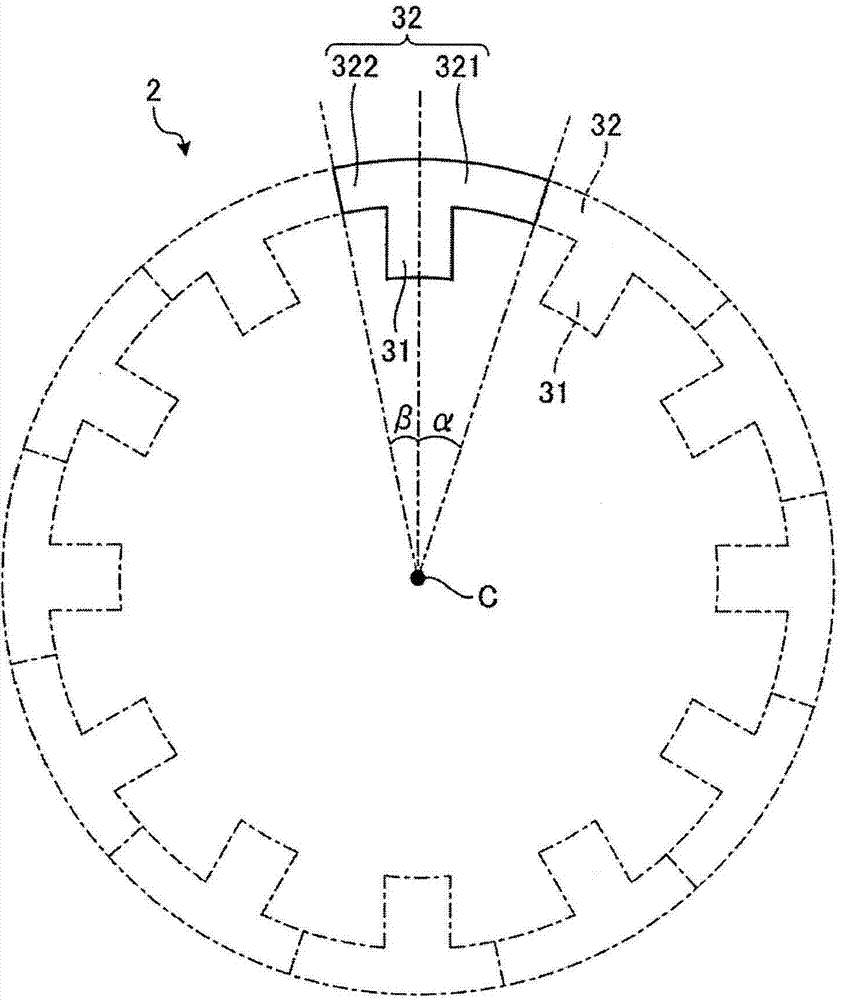

Stator core, split core block, stator manufacturing method and rotary electric machine

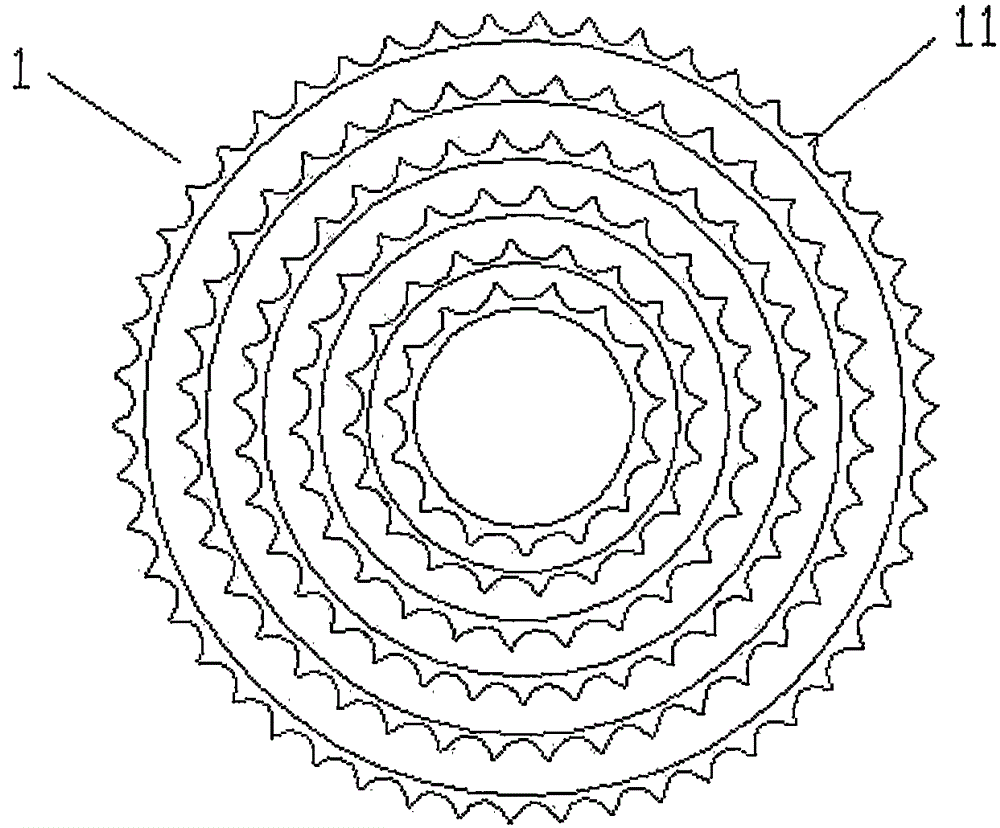

InactiveCN103715786AReduce lossMagnetic circuit stationary partsManufacturing stator/rotor bodiesElectric machineProtruding tooth

The invention provides a stator core, a split core block, a stator manufacturing method and a rotary electric machine. The stator core is formed by laminating a plurality of annular core plates one on top of another. The stator core includes a cylindrical yoke and a plurality of radially protruding teeth arranged at a specified interval along a circumferential direction of the yoke. Each of the core plates includes a plurality of annularly-arranged split cores each having a yoke portion forming the yoke and a tooth portion protruding from the yoke portion and forming the teeth. The yoke portion includes a first yoke section and a second yoke section extending different lengths at opposite lateral sides of the tooth portion.

Owner:YASKAWA DENKI KK

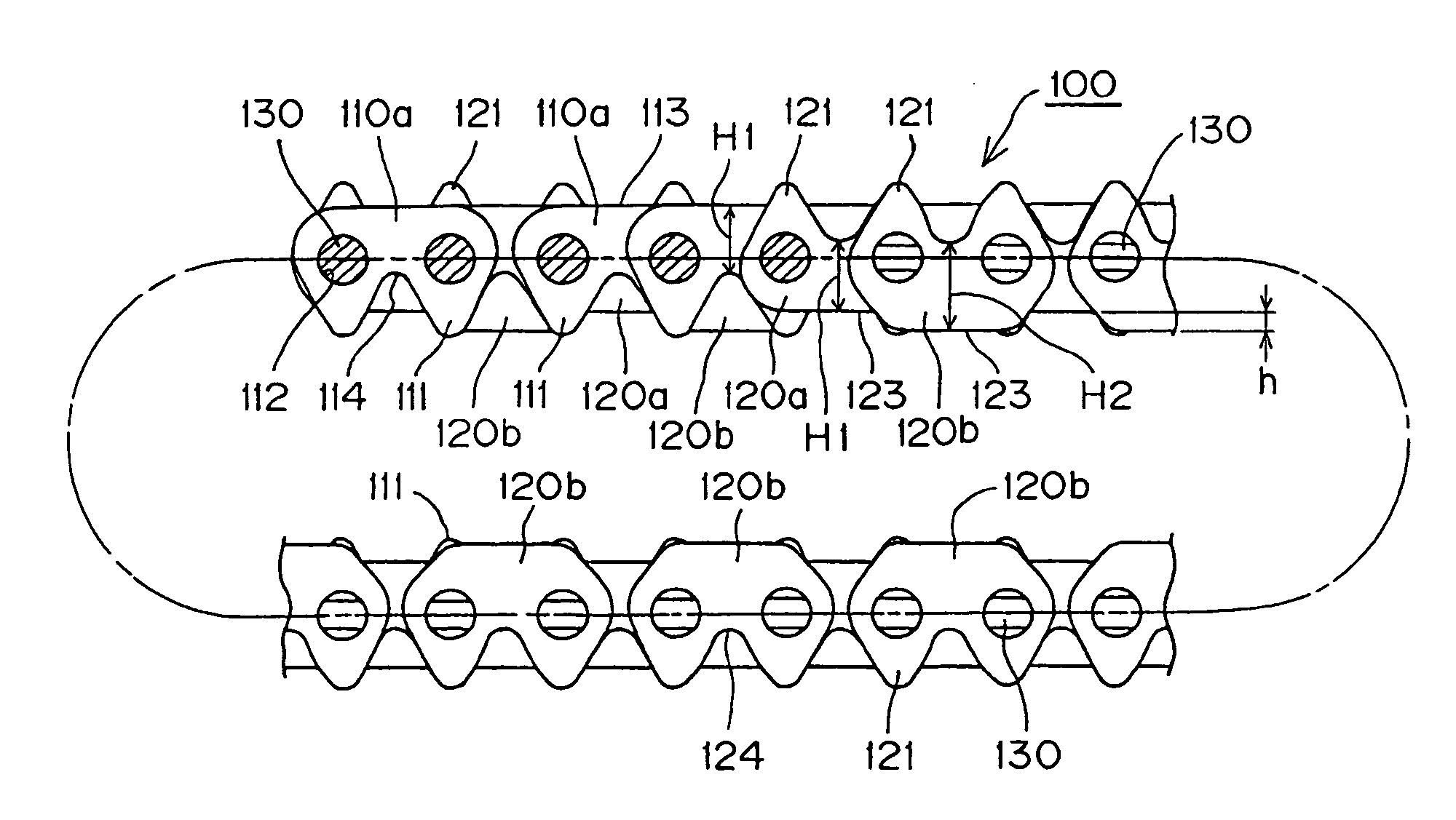

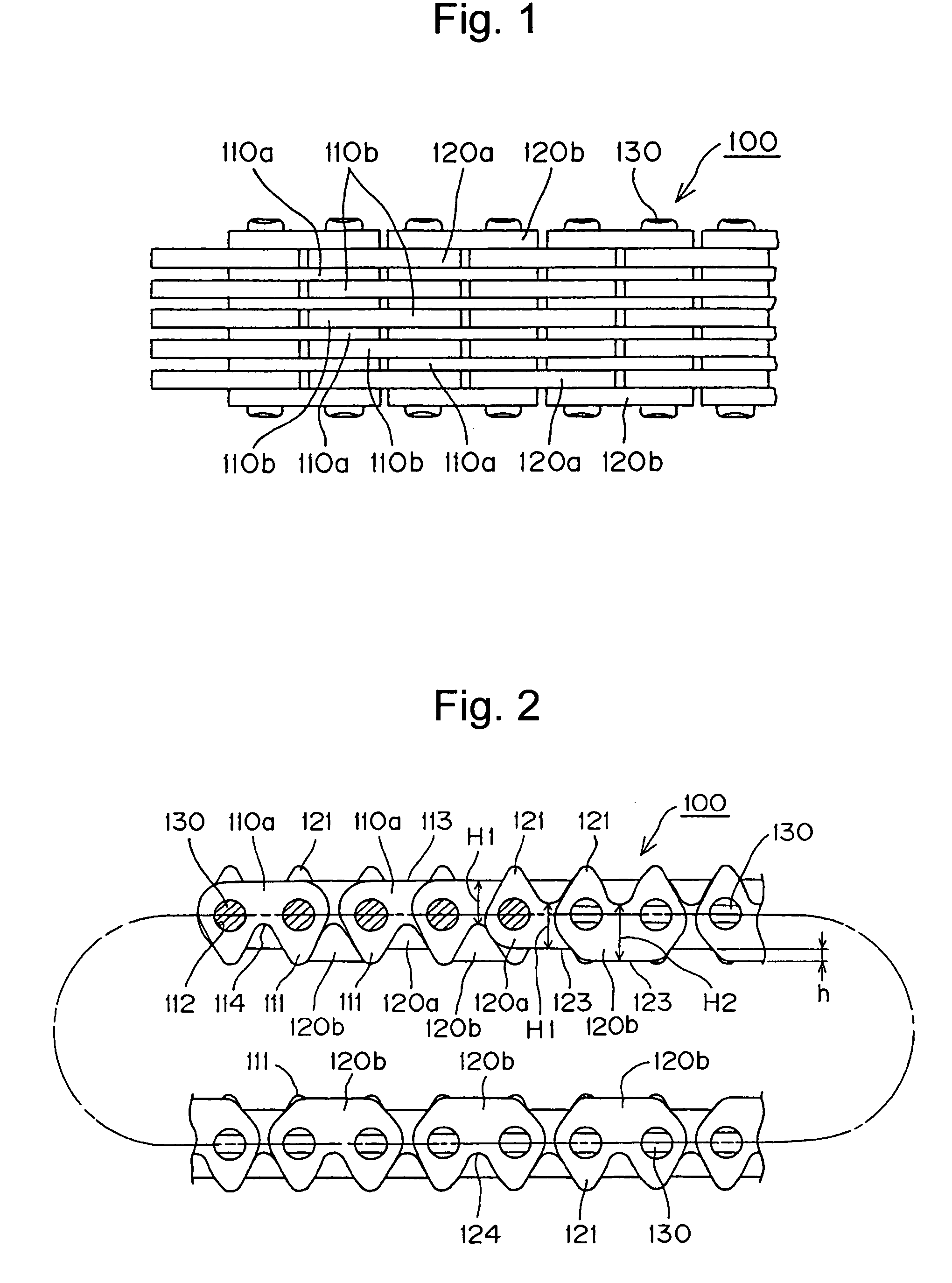

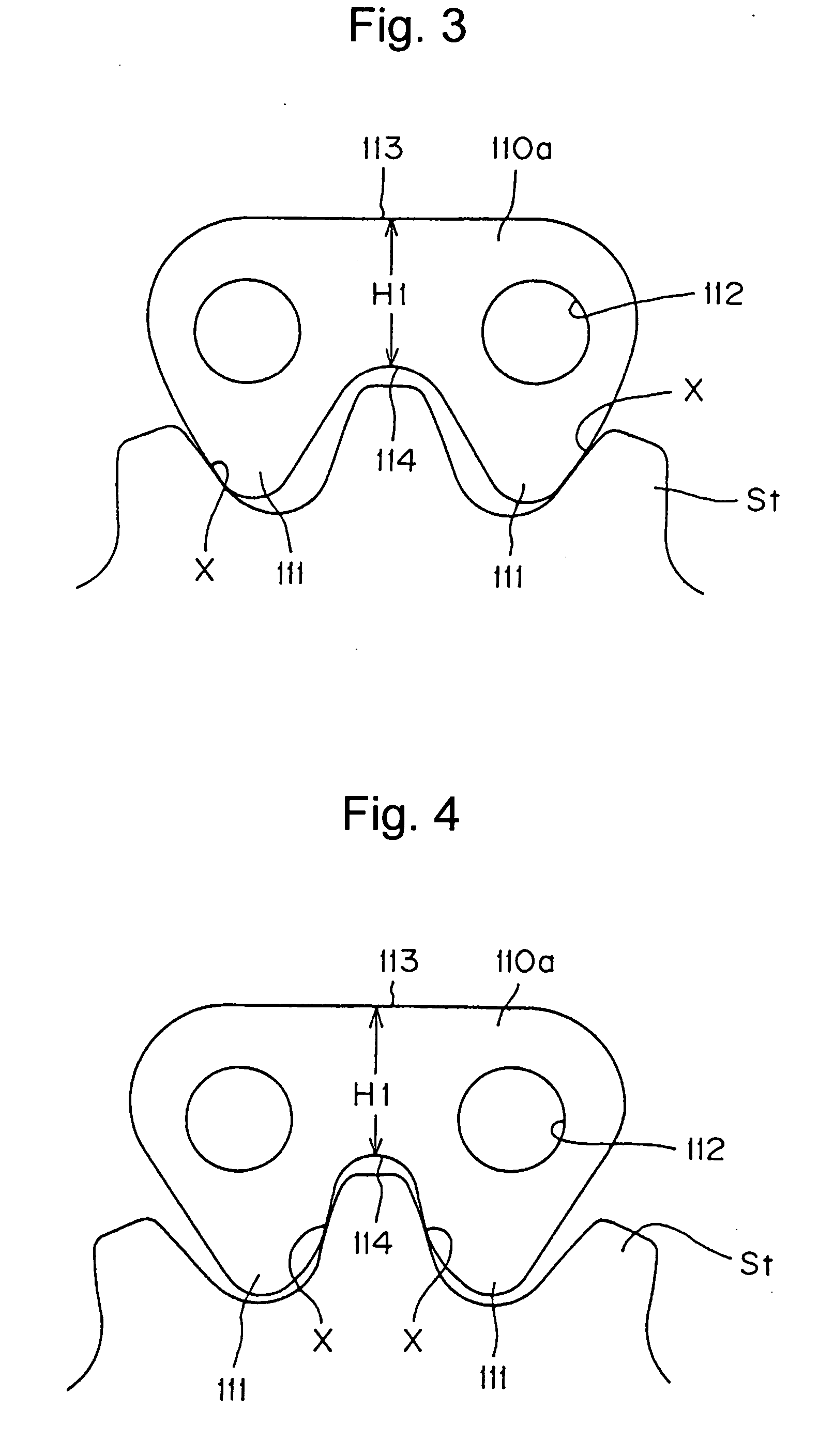

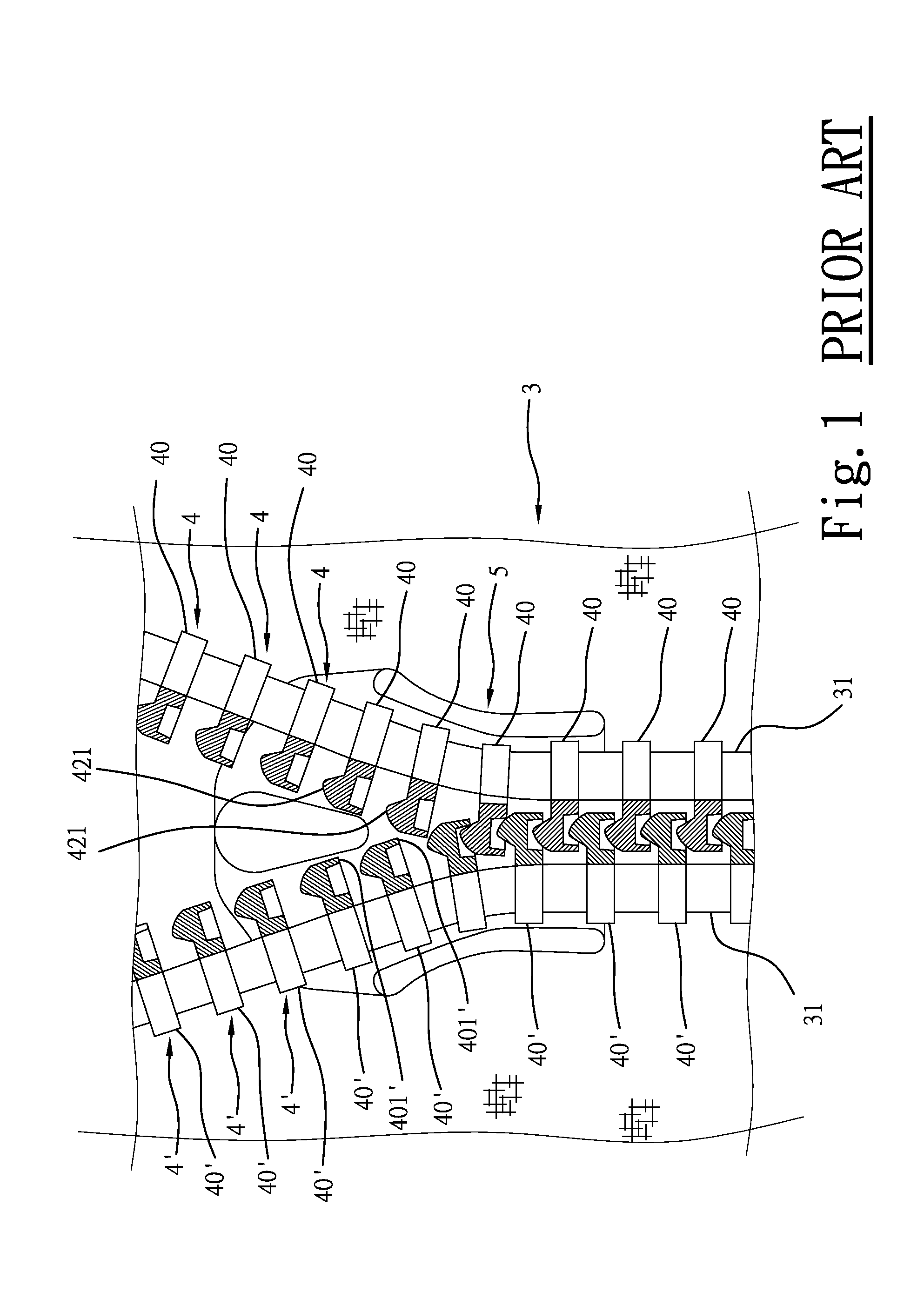

Double-sided engagement type silent chain

ActiveUS20070111835A1Improve fatigue strengthSuppress generationGearingFurnace typesEngineeringMechanical engineering

In a double-sided engagement silent chain having inner link plates with inwardly protruding teeth, outermost link plates with outwardly protruding teeth, and outer link plates with outwardly protruding teeth, adjacent the outermost link plates, the plates are composed of a bainite and martensite mixed plate material. The bainite mixing ratio in the outermost link plates is higher than the bainite mixing ratio of the inner link plates and the adjacent outer link plates. The martensite mixing ratio of the inner link plates and of the adjacent outer link plates is higher than the martensite mixing ratio in the outermost link plates. The heights of the backs of the outermost link plates, measured from the tooth gap bottoms, are greater than the corresponding heights of the backs of the inner link plates, and may be equal to or greater than the heights of the backs of the adjacent outer tooth plates.

Owner:TSUBAKIMOTO CHAIN CO

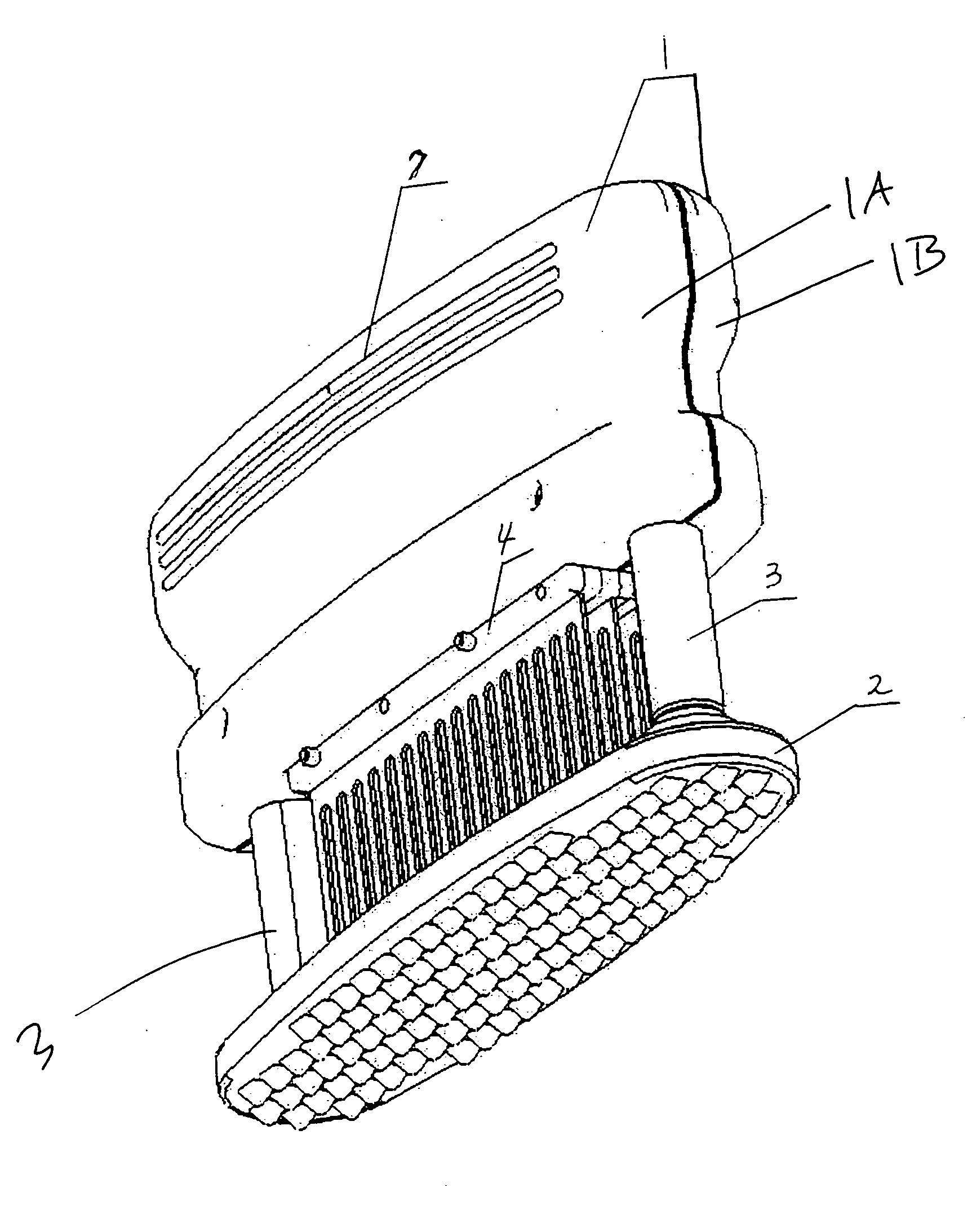

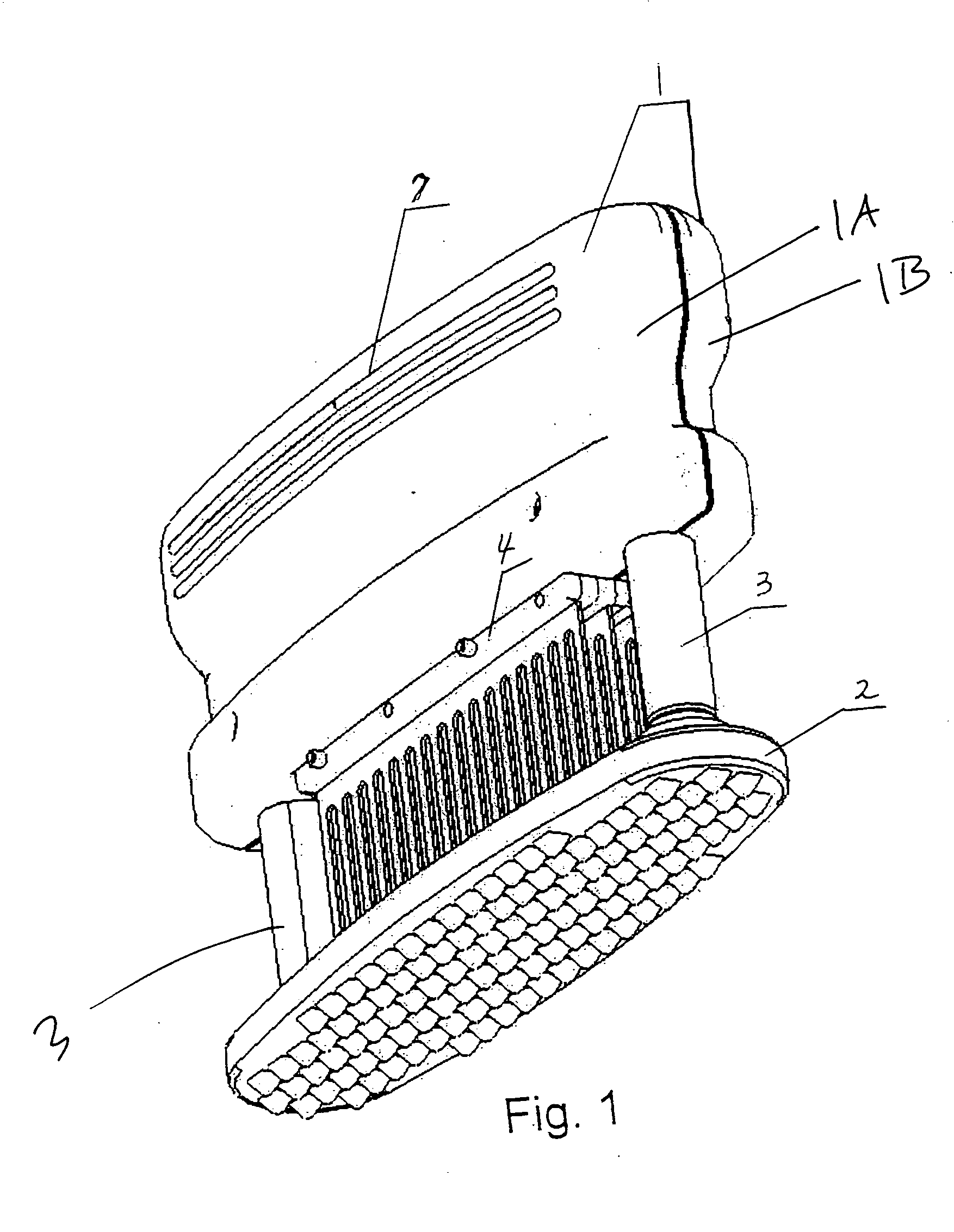

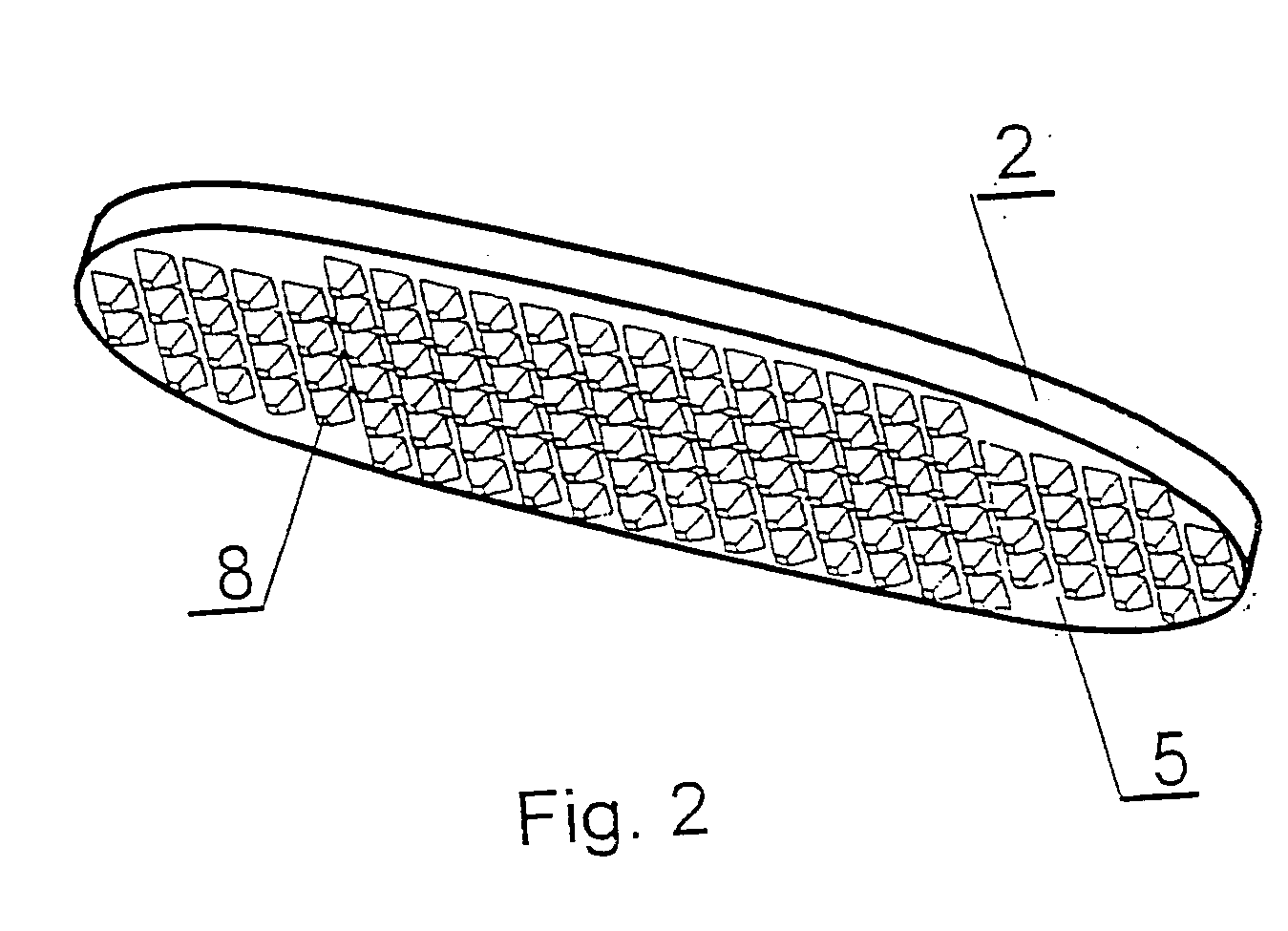

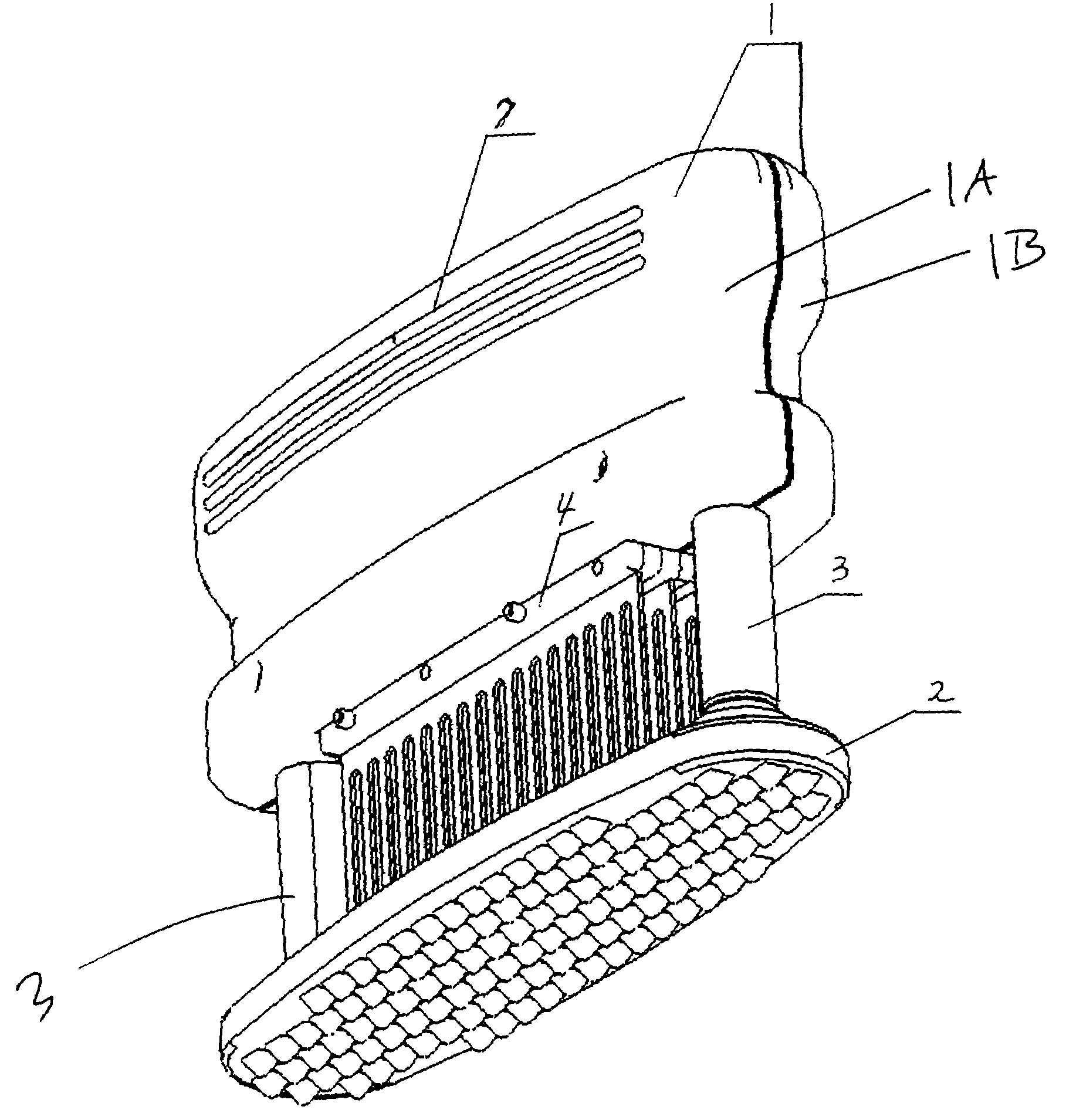

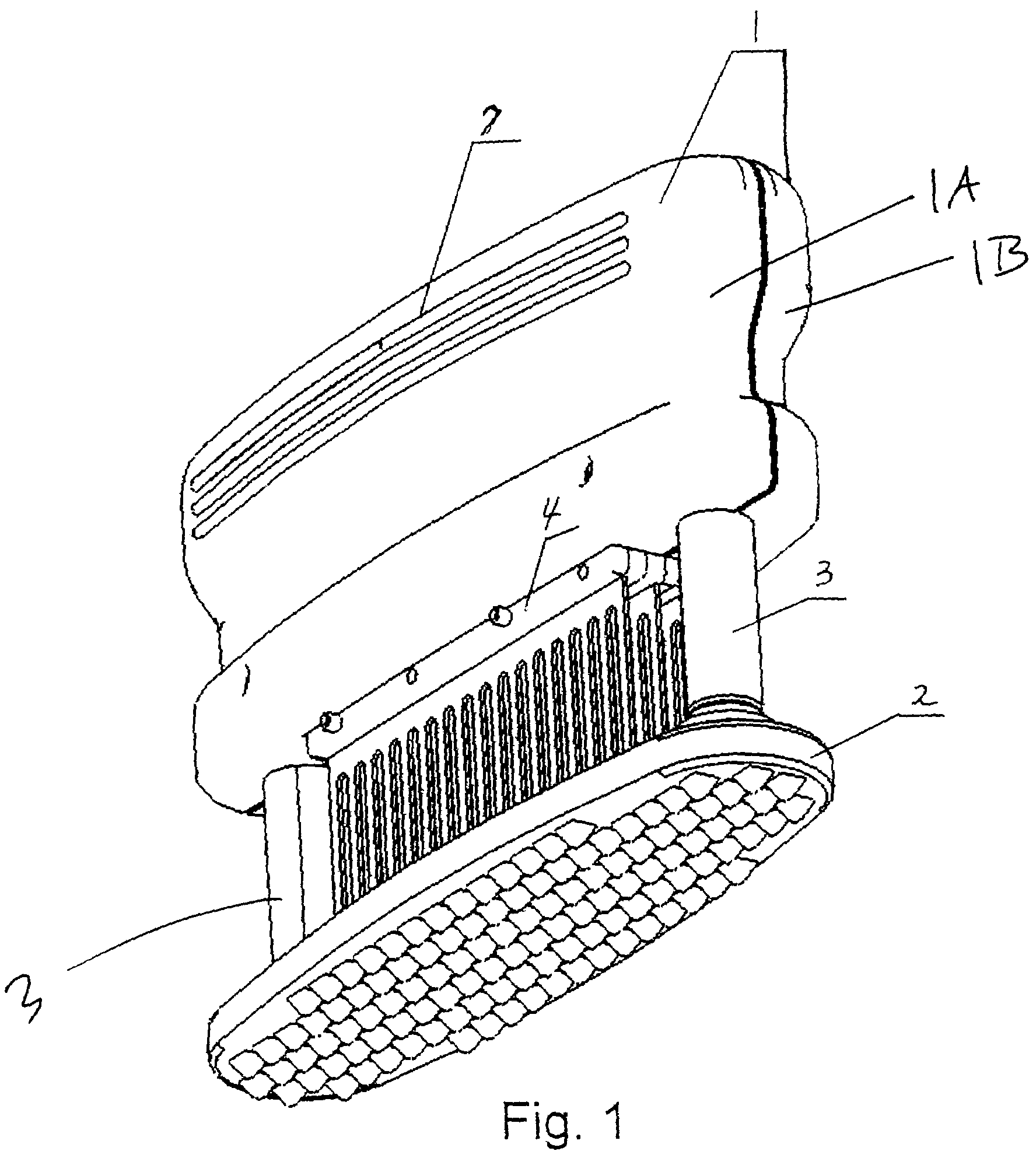

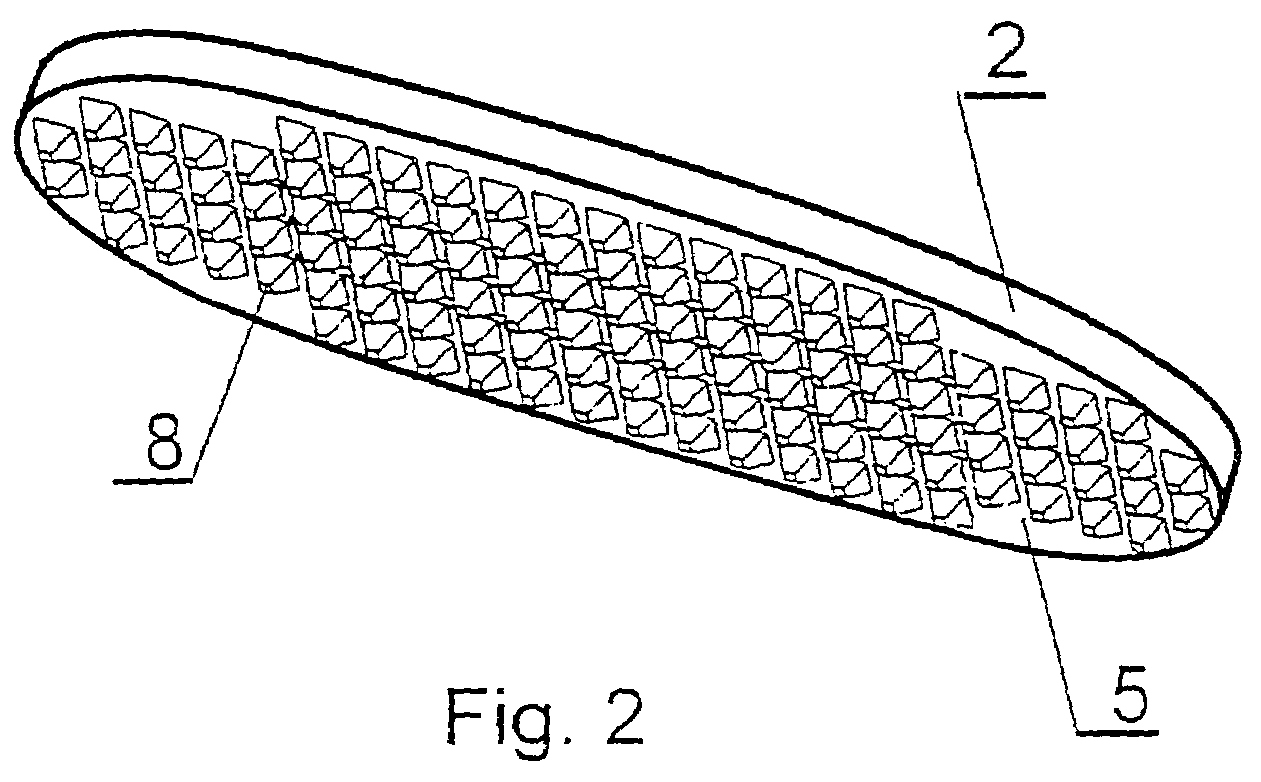

Double function-hand operated meat tenderizer

ActiveUS20050239388A1Suitable for useQuick disassemblyPiercing-based meat tenderisingPoultry processingFunction handProtruding tooth

Disclosed is a double function-hand operated meat tenderizer according to the preferred embodiment of the present invention includes a handle being formed of two components, a blade assembly being detachably mounted between the two components of the handle, a plurality of columns where upper ends of the columns are mounted on the handle, and a comb being mounted on lower ends of the columns for being slidably movable toward and away from the handle. The comb has plurality of flow-through slots and protruding teeth extending from a bottom surface of the comb.

Owner:GOROWSKI VICTOR

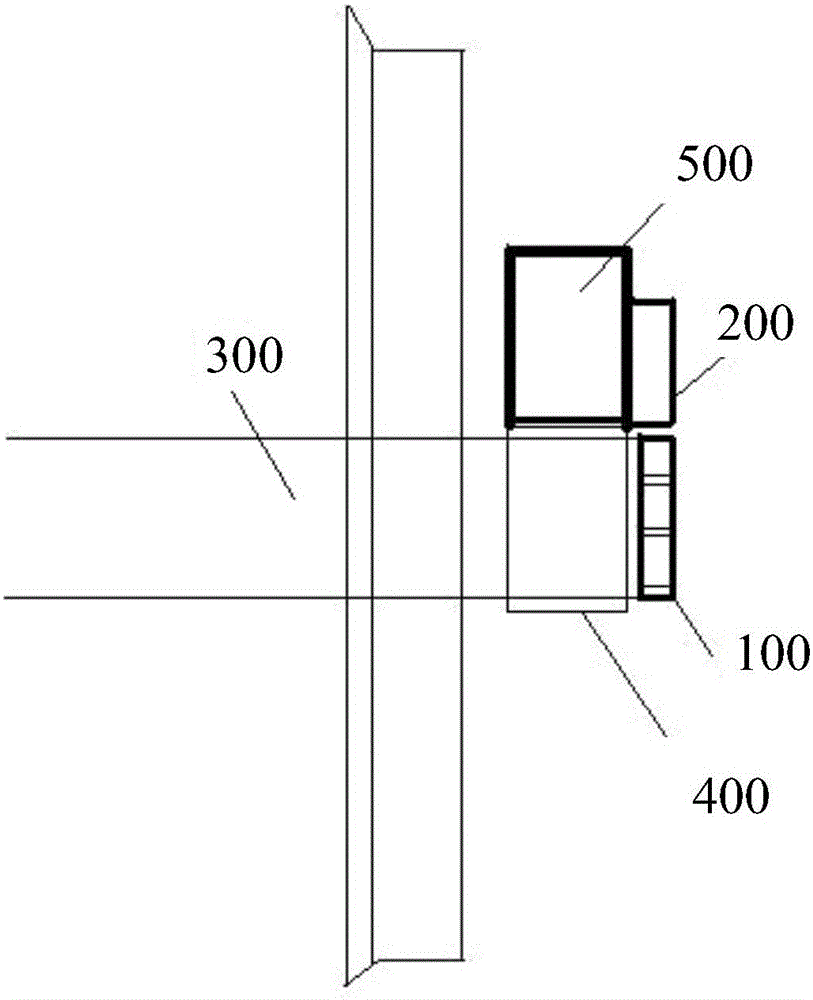

Supporting frame for CCTV camera enclosure

A support frame for CCTV camera enclosure is disclosed. The support frame comprises a support body supporting the structure of the support frame; a rotating section mounted onto the support body and the rotating section horizontally rotated with respect to the axial hole via the support body; a securing section mounted onto the rotating section and the securing section being rotated vertically; and a contact face with protruded teeth corresponding to the rotating section and the securing section to secure the CCTV camera in a best position.

Owner:LAI SIMON

Double function-hand operated meat tenderizer

ActiveUS7182685B2Suitable for useQuick disassemblyPiercing-based meat tenderisingPoultry processingEngineeringFunction hand

Disclosed is a double function-hand operated meat tenderizer according to the preferred embodiment of the present invention includes a handle being formed of two components, a blade assembly being detachably mounted between the two components of the handle, a plurality of columns where upper ends of the columns are mounted on the handle, and a comb being mounted on lower ends of the columns for being slidably movable toward and away from the handle. The comb has plurality of flow-through slots and protruding teeth extending from a bottom surface of the comb.

Owner:GOROWSKI VICTOR

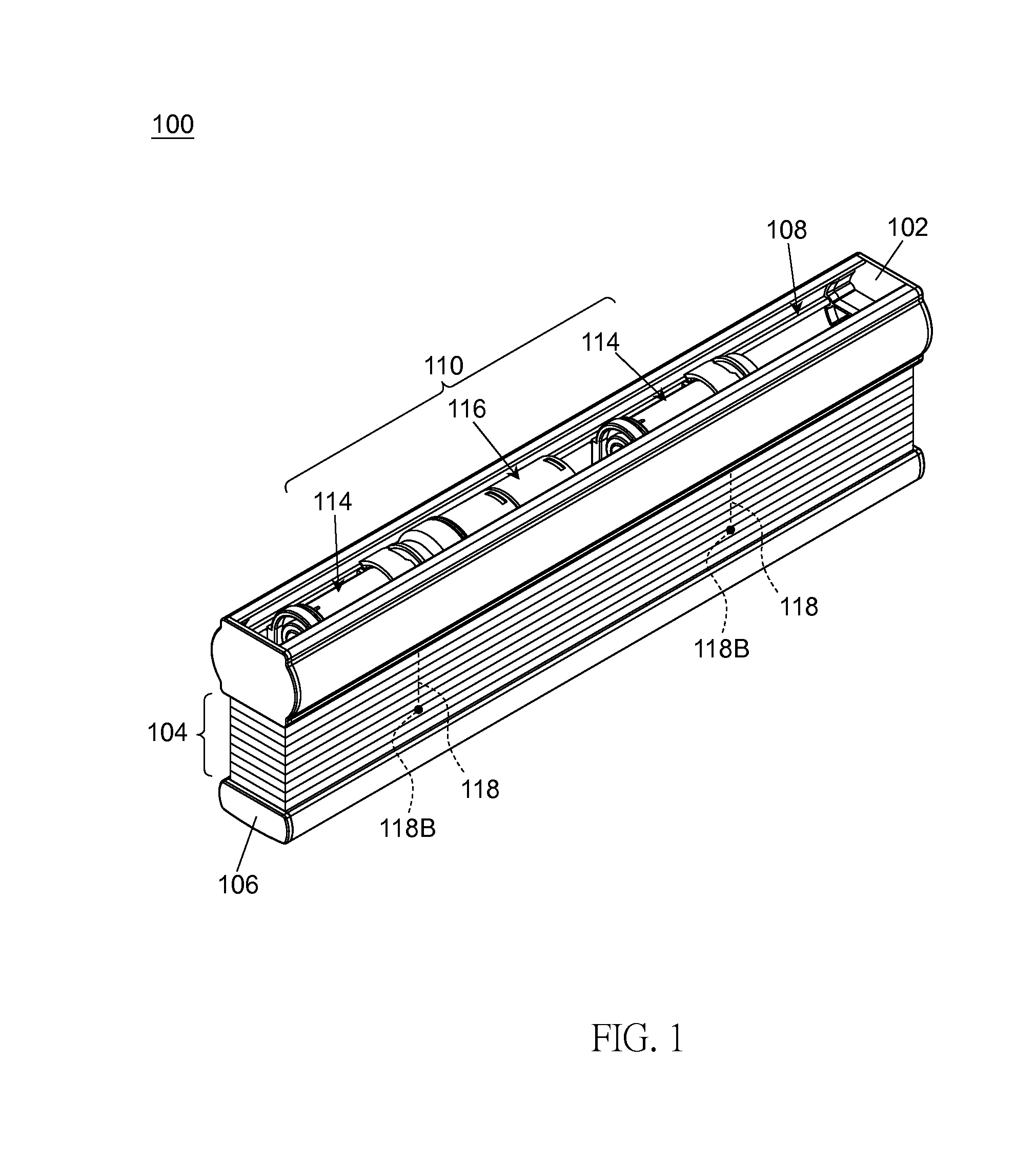

Window Shade and Control System Thereof

InactiveUS20160208551A1Large displacement rangeDoor/window protective devicesToothed gearingsControl systemDrive shaft

A control system for a window shade includes a suspension member, a first and a second casing portion, a rotary drum, a torsion spring, a coupling member, a transmission axle, a central gear, a ring and planetary gears. The rotary drum is pivotally connected with the first casing portion, and is rotatable to wind and unwind the suspension member. The torsion spring can bias the rotary drum for winding the suspension member, and has a first and a second end respectively affixed with the second casing portion and a coupling member. The transmission axle is disposed through the torsion spring, and is rotationally coupled with the rotary drum and the central gear. The ring is affixed with the second casing portion and has protruding teeth. The planetary gears are pivotally supported by the coupling member, and are respectively meshed with the central gear and the teeth of the ring.

Owner:TEH YOR CO LTD

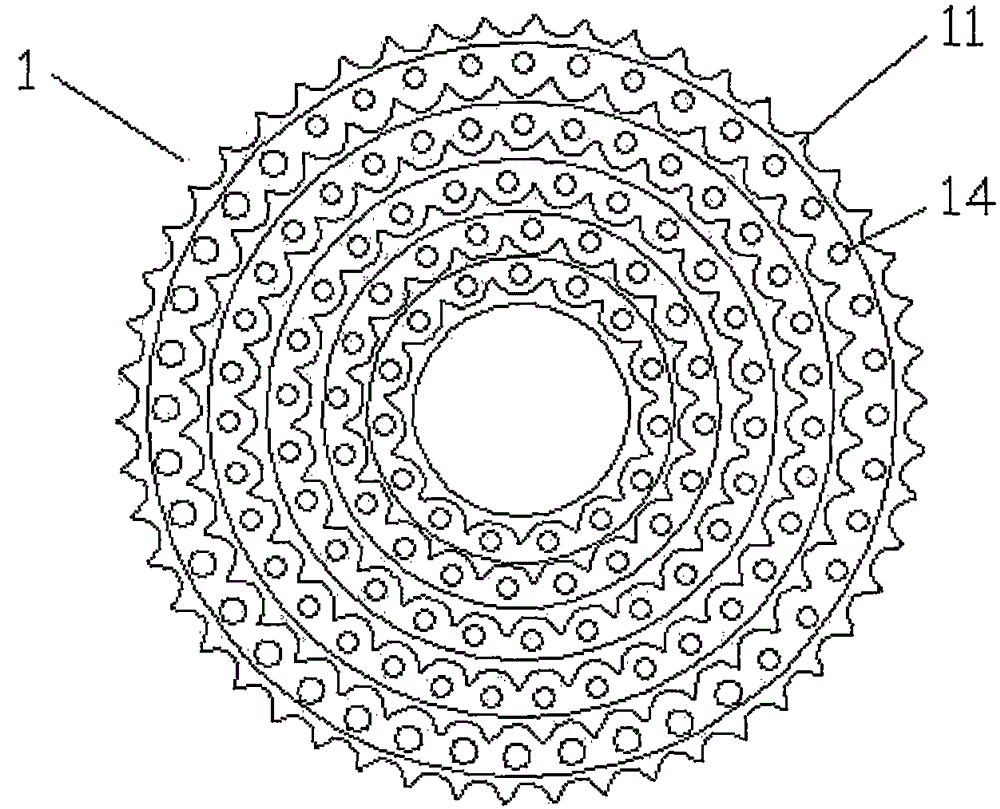

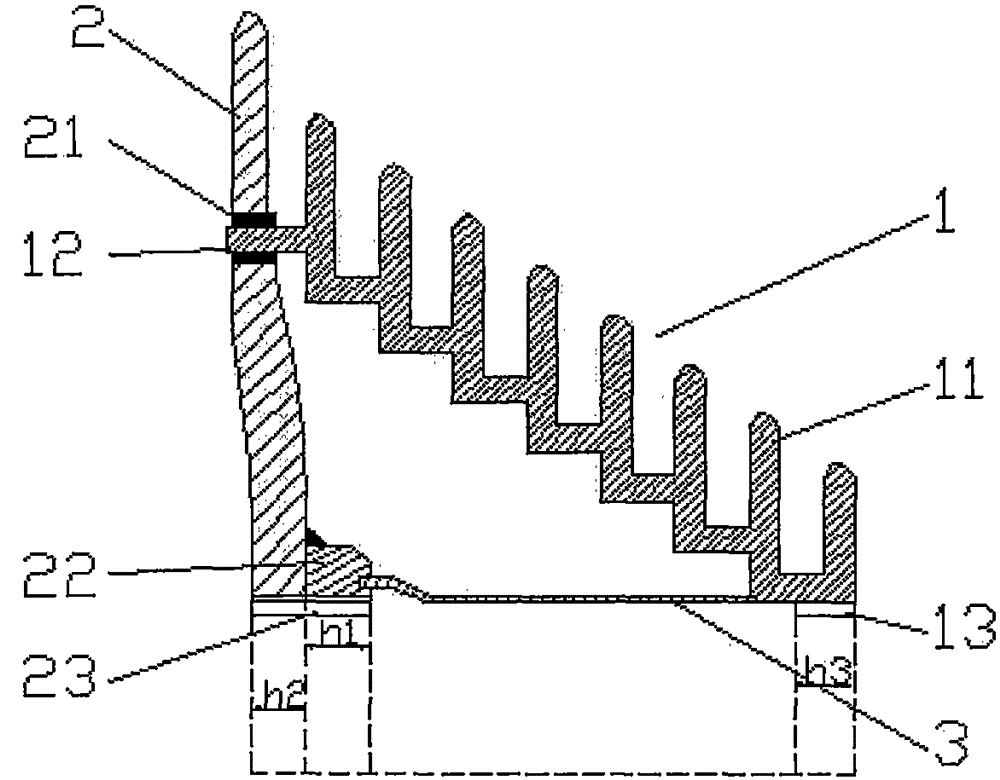

Light large-torque high-rigidity variable speed bicycle chain wheel assembly structure

InactiveCN105015695AGuaranteed structural strengthGuaranteed stiffnessChain/belt transmissionSprocketEngineering

The invention relates to the field of variable speed bicycles, in particular to a light large-torque high-rigidity variable speed bicycle chain wheel assembly structure. The light large-torque high-rigidity variable speed bicycle chain wheel assembly structure comprises an integral stepped pulley, a single-piece tooth and a supporting cylinder. The supporting cylinder is installed between the integral stepped pulley and the single-piece tooth. A plurality of different-radius layer teeth of the integral stepped pulley are integrally connected layer by layer to form a hollow tower model. The sides, close to the single-piece tooth, of the inner side layer teeth are provided with protruding teeth. Tooth holes corresponding to the protruding teeth are formed in the single-piece tooth. The protruding teeth are in interference connection with the tooth holes in the single-piece tooth. The inner diameter portion of the single-piece tooth and the inner diameter portion of the smallest layer tooth of the integral stepped pulley are provided with a single-piece tooth inner spline and a stepped pulley inner spline. The light large-torque high-rigidity variable speed bicycle chain wheel assembly structure can be light on the premise of ensuring the structural strength, rigidity and large transmission torque of a chain wheel.

Owner:郑英

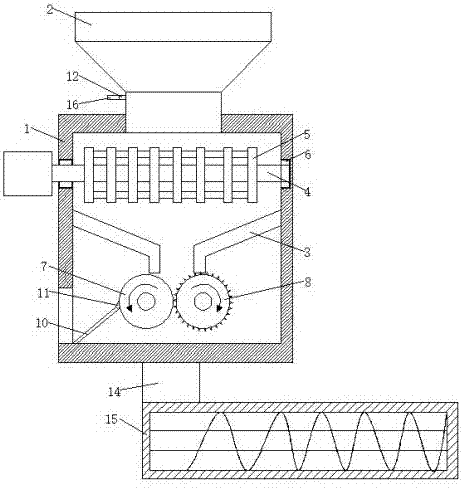

High-quality biomass fuel processing device

PendingCN107149961AReduce sizeAvoid cloggingBiofuelsSolid fuelsPulp and paper industryProtruding tooth

The invention discloses a high-quality biomass fuel processing device. The high-quality biomass fuel processing device comprises a shell. A first funnel is arranged on the upper side of the shell. The shell is internally provided with a second funnel, and a horizontal rotary rod is arranged on the side, close to the first funnel, of the second funnel. Hammer pieces are arranged on the side wall of the rotary rod at equal intervals. The two ends of the rotary rod are provided with first antifriction bearings which are arranged on the shell. An adsorption roller and a smashing roller are arranged on the side, far away from the rotary rod, of the second funnel. The two ends of the adsorption roller and the two ends of the smashing roller are provided with second antifriction bearings which are arranged on the shell. Protruding tooth tips are arranged on a cutting roller. A magnetic rod is arranged on the inner side of the adsorption roller, and an oblique plate is arranged on the side, far away from the smashing roller, of the adsorption roller. The high-quality biomass fuel processing device is simple in structure, the feeding speed is effectively controlled, a feed port cannot be blocked, the smashing effect is good, the service life of the smashing roller is long, meanwhile, iron sundries are cleared away in time, and the fuel processing quality is good.

Owner:榕江荣百腾环保能源制造有限公司

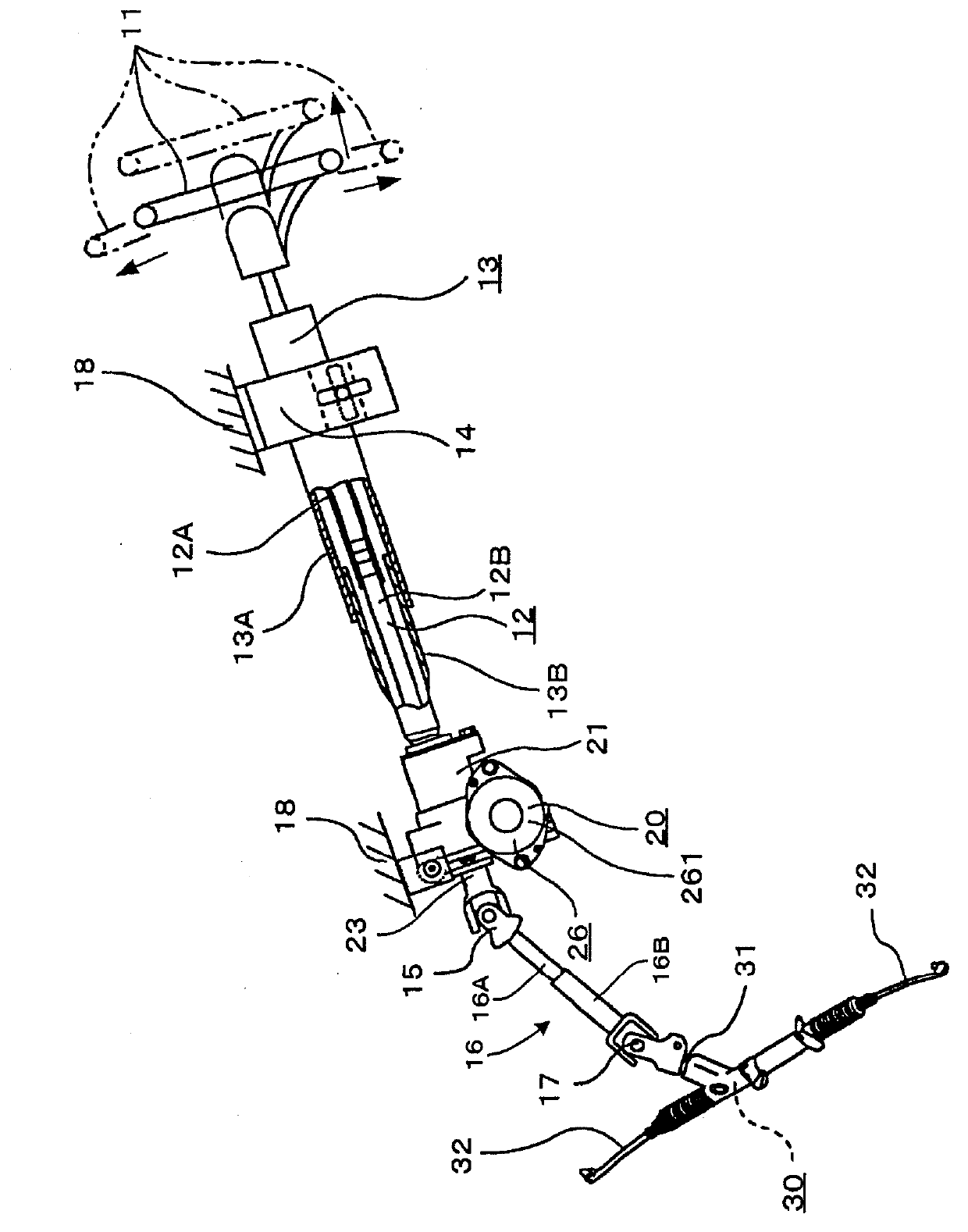

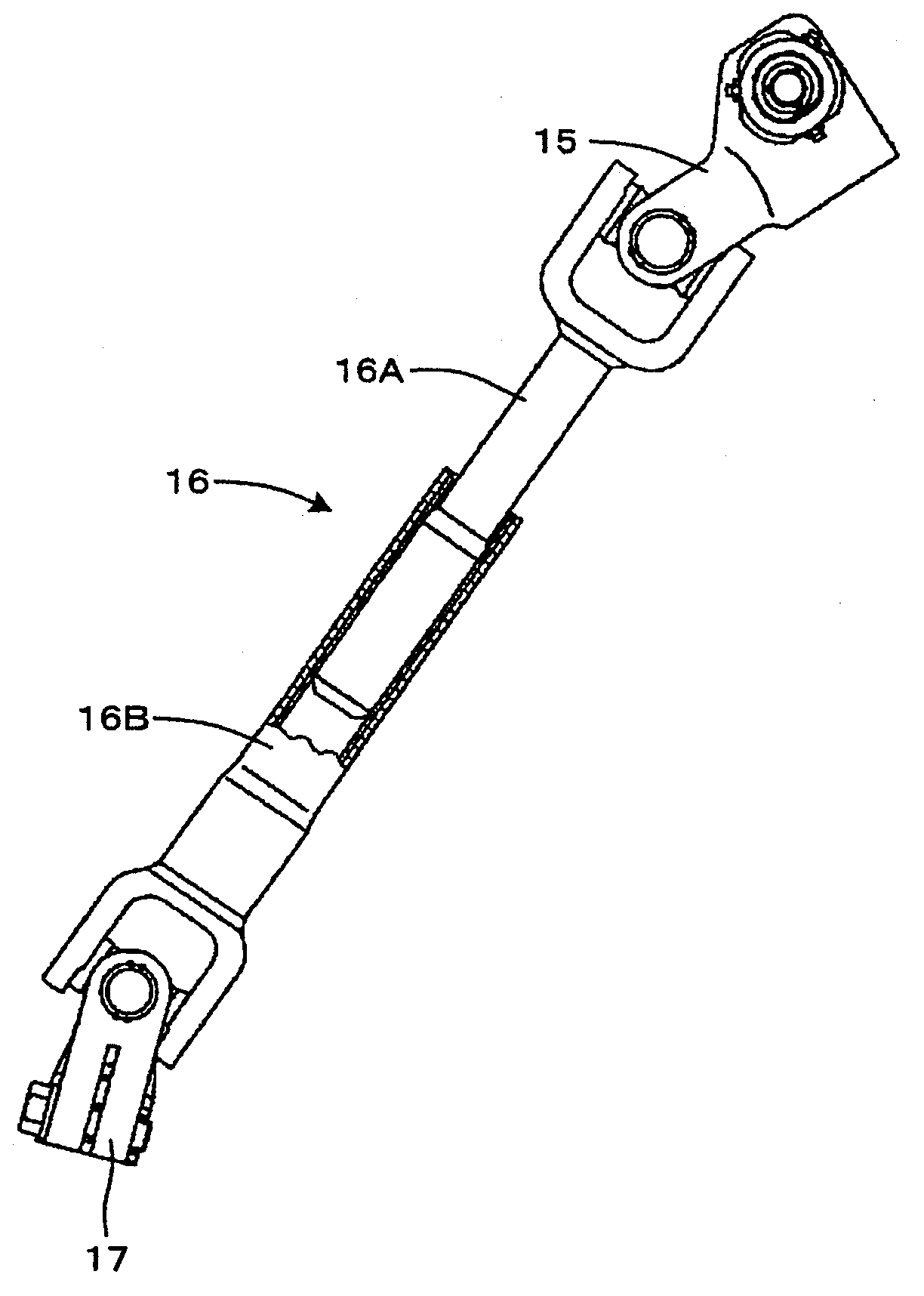

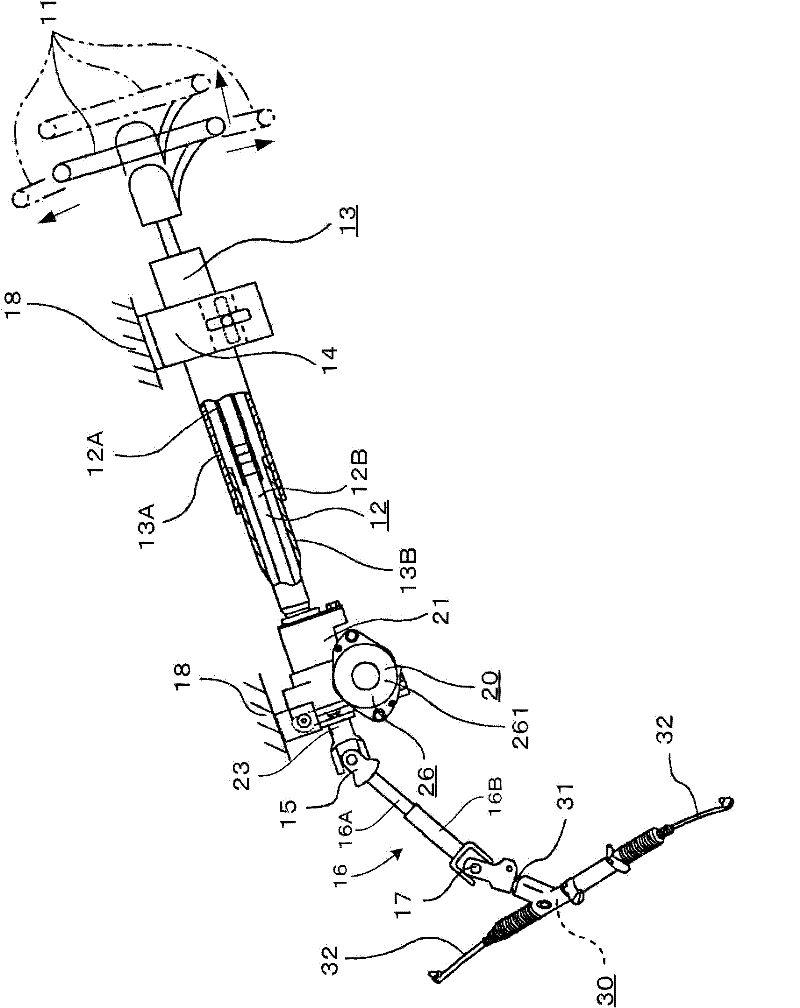

Telescopic shaft

Owner:NSK LTD

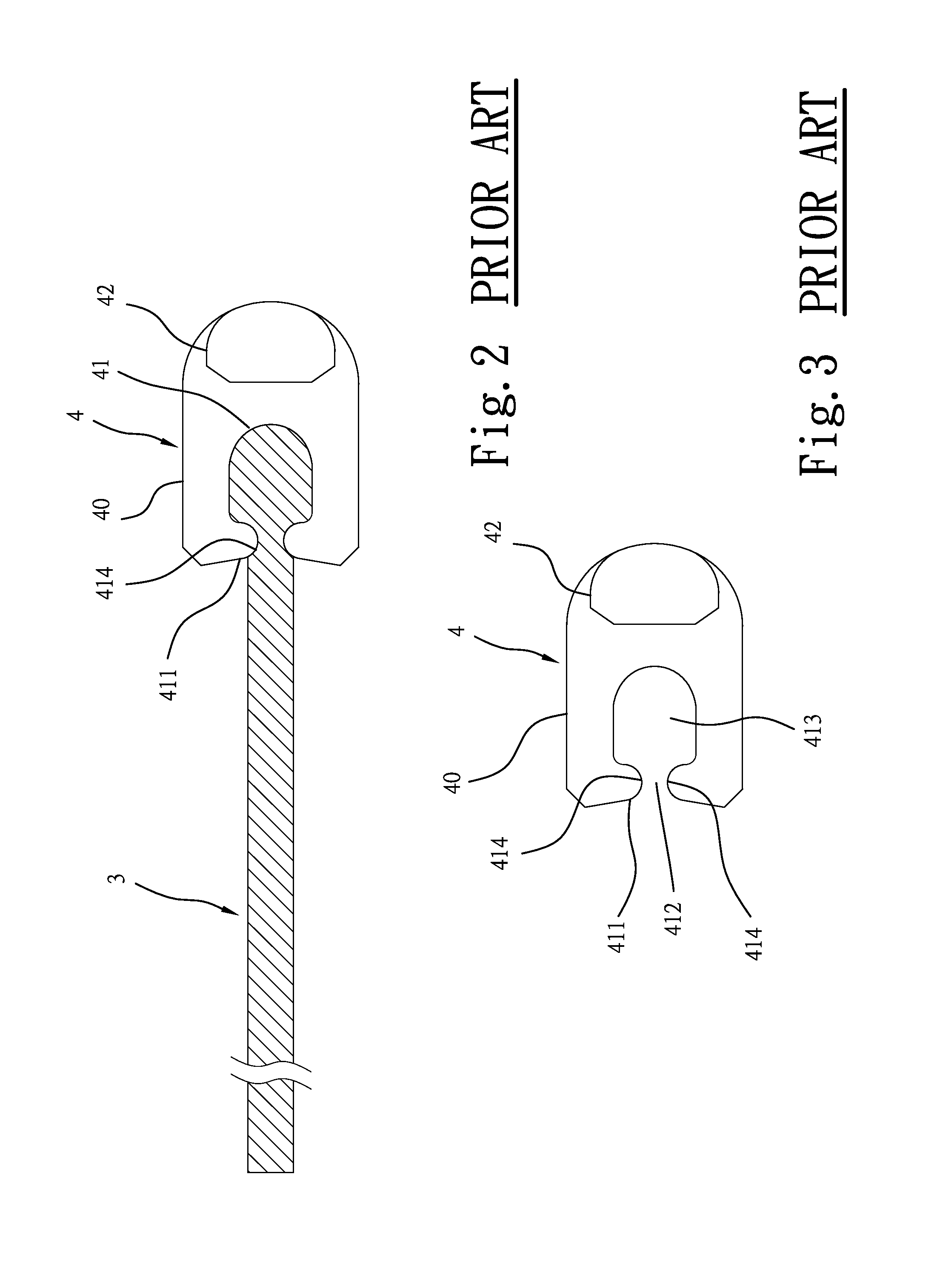

Metal Tooth For Zipper

InactiveUS20120036685A1Increase engagementAvoid vibrationSnap fastenersSlide fastenersEngineeringProtruding tooth

In a metal zipper, each metal tooth has a mounting hole located on one end of the base thereof, two first engagement portions and two second engagement portions formed integral with the base at two opposite sides of the mounting hole for engaging into the top and bottom sides of the inner edge of the respective zipper tape to deform the respective inner edge during installation so that engagement between the zipper tape and the metal tooth is enhanced, avoiding vibration of the metal tooth relative to the zipper tape during operation of the metal zipper and prolonging the lifespan of the metal zipper. Further, each metal tooth has a concave surface portion formed in the protruding tooth head thereof so that less friction is produced when the metal zipper is closed or opened.

Owner:WANG CHING TSUN

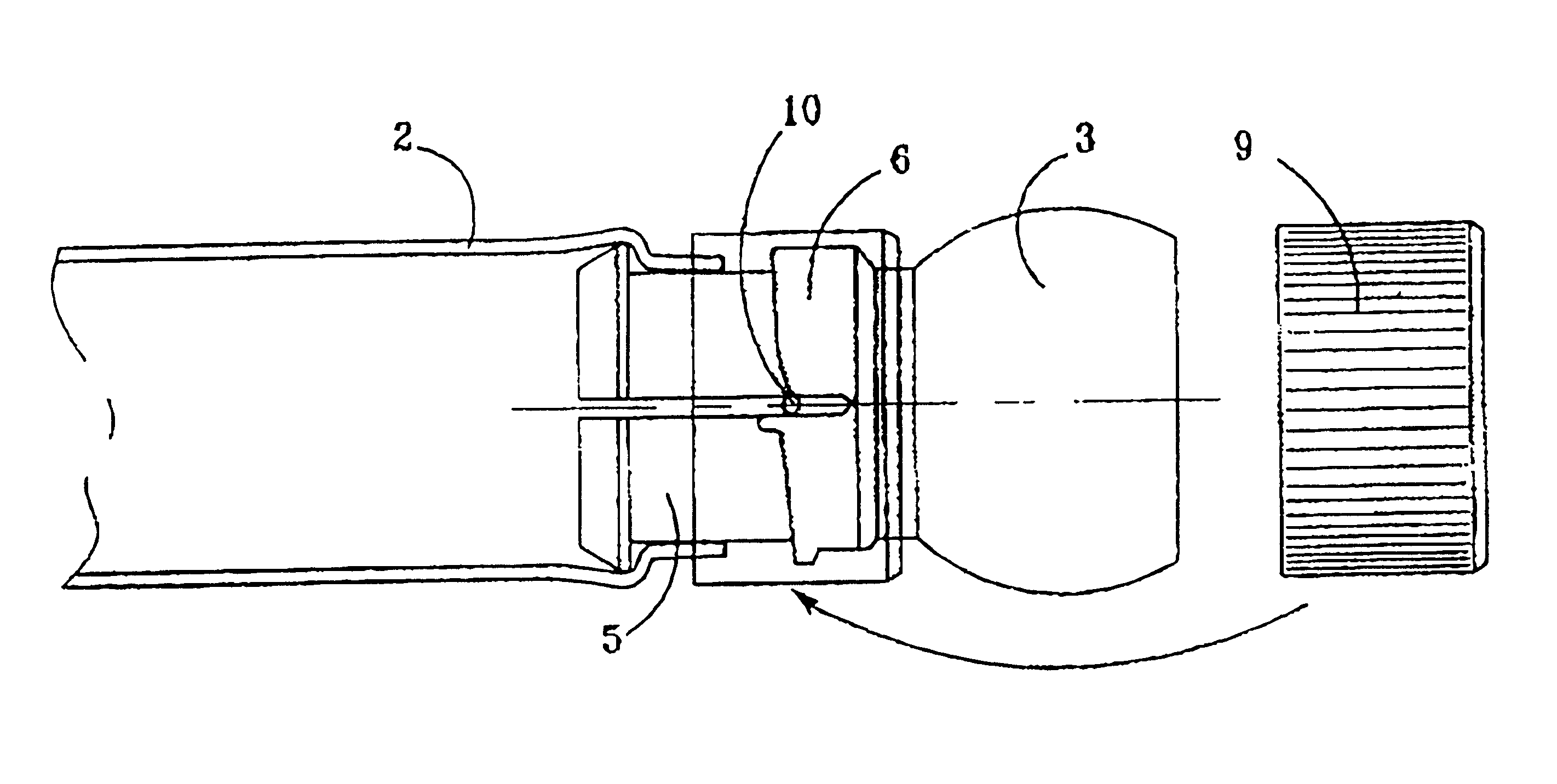

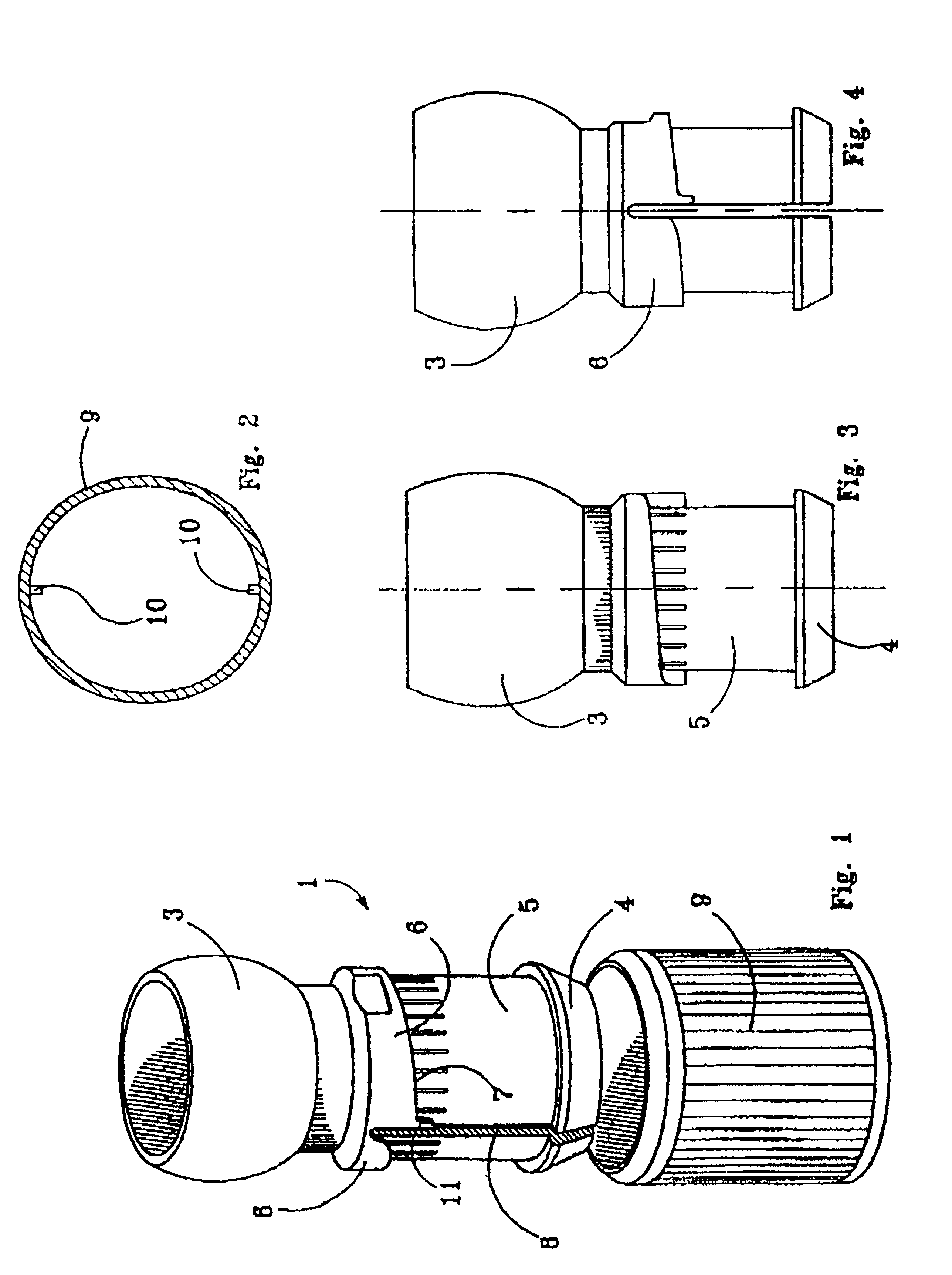

Sheath clamp for a welding torch cable

InactiveUS6419417B1Poor effectivenessFloorsWelding/cutting auxillary devicesAxial displacementElectric cables

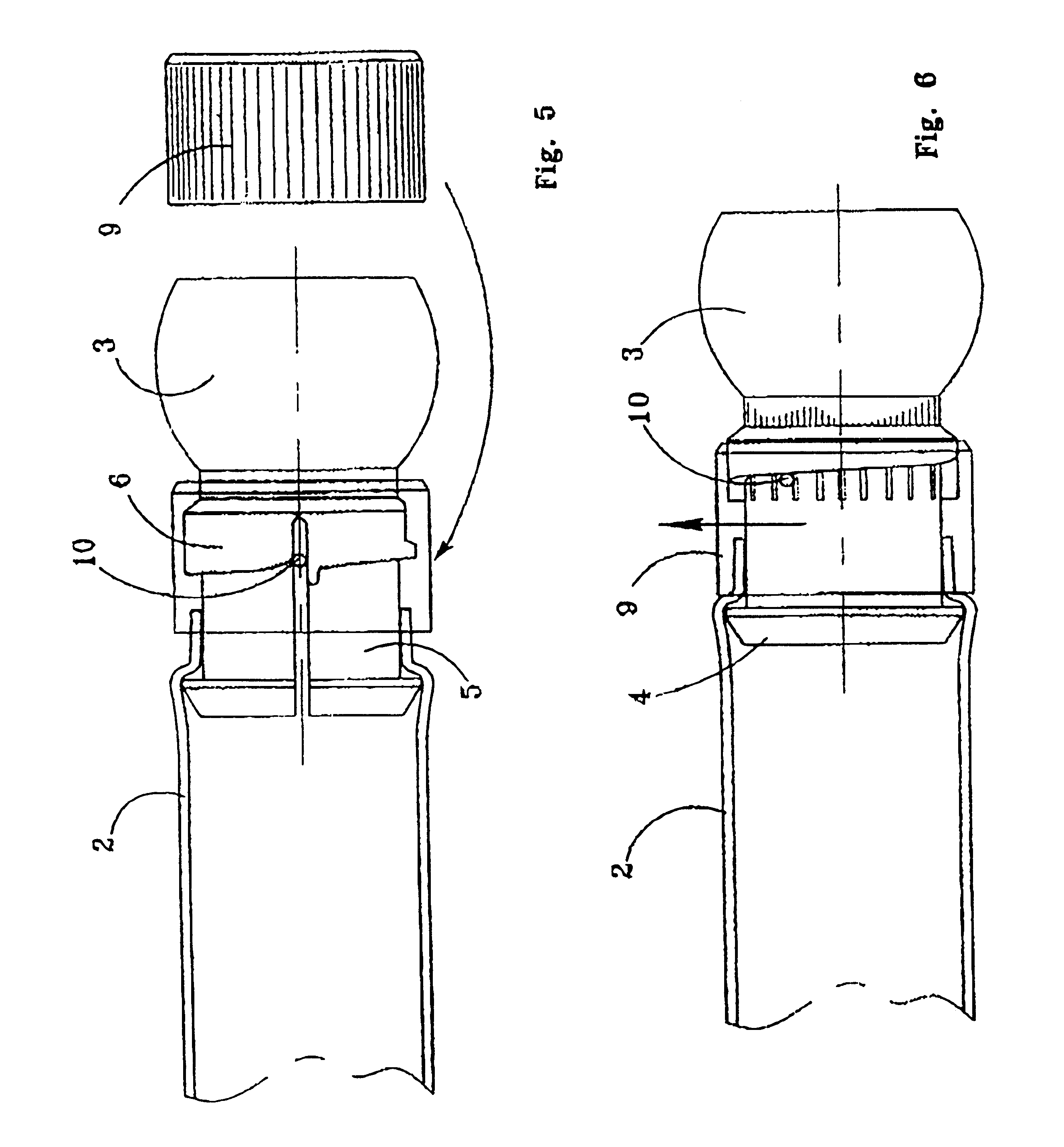

A sheath clamp for a welding torch, comprising a sleeve (5) having a spherical head (3) adapted to be inserted into a seat in the torch and a flange axially spaced from the head, with a collar (9) slidably mounted on the sleeve (5), and means for urging the collar (9) along the axis of the sleeve in order to clamp a sheath (2), fitted over the sleeve (5), against the flange (4). Preferably the collar (9) is provided with at least one inwardly protruding tooth (10), preferably two inner opposed teeth, and the sleeve has a reduced diameter portion between the flange (4) and the spherical head (3), which is bounded by inclined raised walls (7) which can be engaged by the tooth (10) of the collar (9), so that rotation of the ring causes an axial displacement of the collar along the sleeve (5).

Owner:TRAFIMET SPA

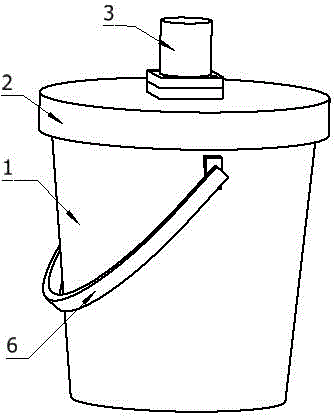

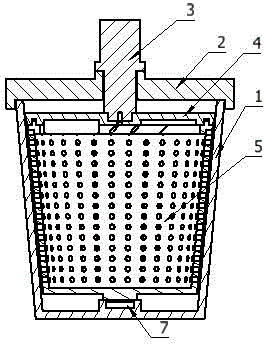

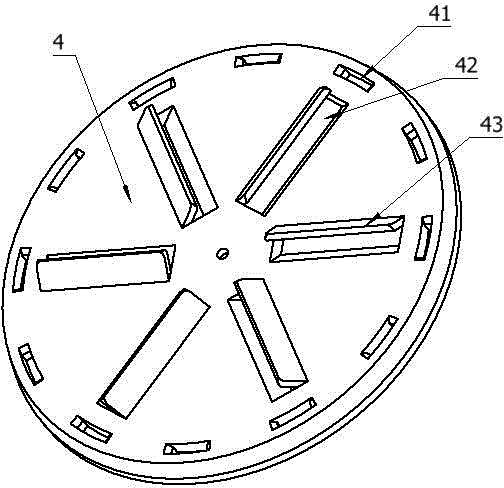

Water bucket washing machine

ActiveCN104611879AEasy to useEasy to carryOther washing machinesWashing machine with receptaclesPulp and paper industryProtruding tooth

The invention relates to a water bucket washing machine which comprises a water bucket, a motor, a water disk and a dewatering bucket. A bucket cover is arranged at the upper end of the water bucket. A bearing is arranged on the bottom face inside the bucket. The motor is arranged at the upper end of the bucket cover. The water disk is fixed to an output shaft of the motor through a screw. The lower end of the water disk is sequentially provided with circumferentially-distributed blades and tooth grooves outwards relative to the axis of the water disk. Protruding teeth corresponding to the tooth grooves are arranged at the upper end of the dewatering bucket, and a stepped shaft is arranged at the lower end of the dewatering bucket. The head of the stepped shaft is arranged in an inner hole in the bearing. The protruding teeth are arranged in the tooth grooves. The side face of the dewatering bucket is provided with a plurality of water holes. The water bucket washing machine is easy to use, convenient to carry and low in cost.

Owner:SUZHOU VOCATIONAL UNIV

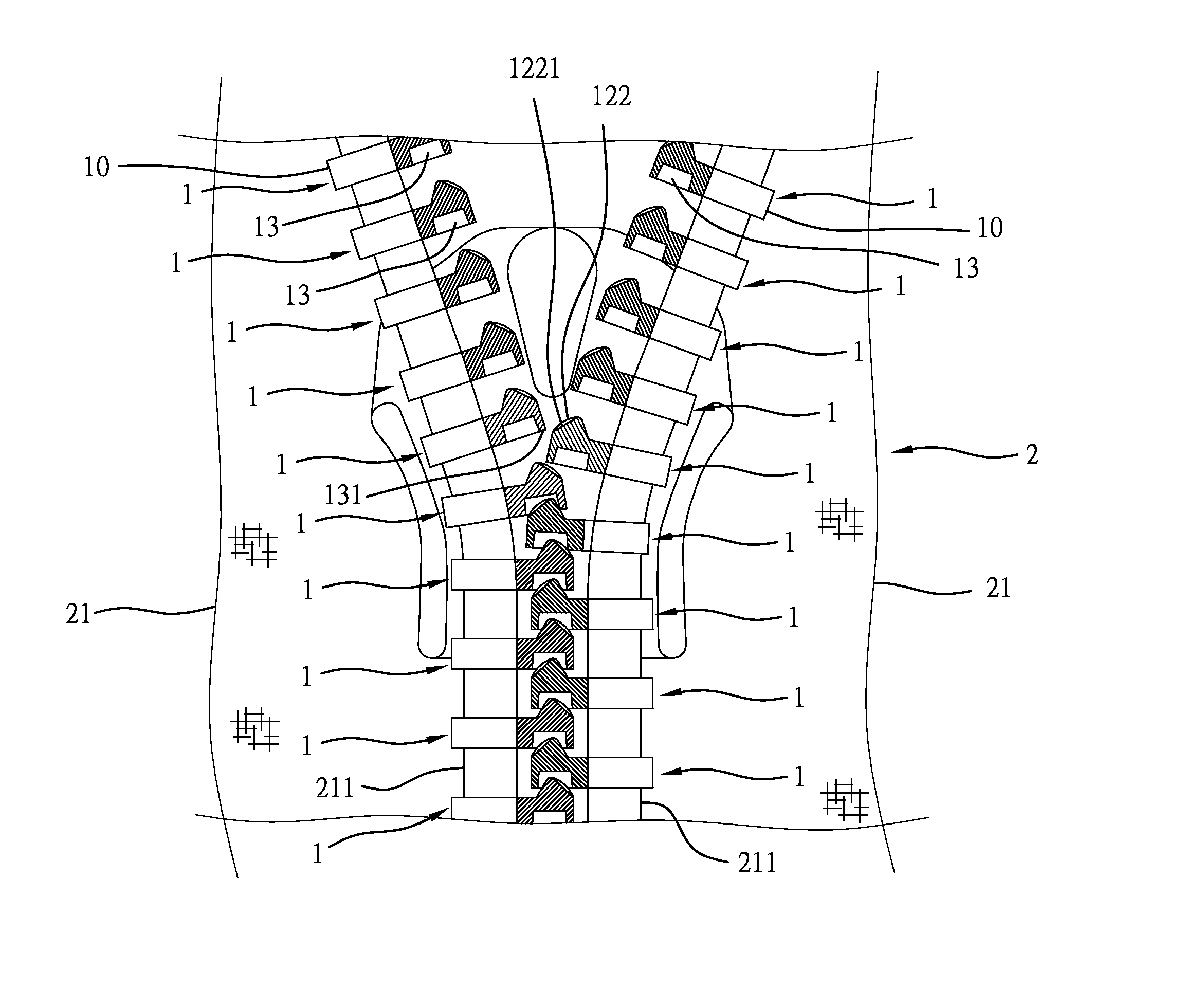

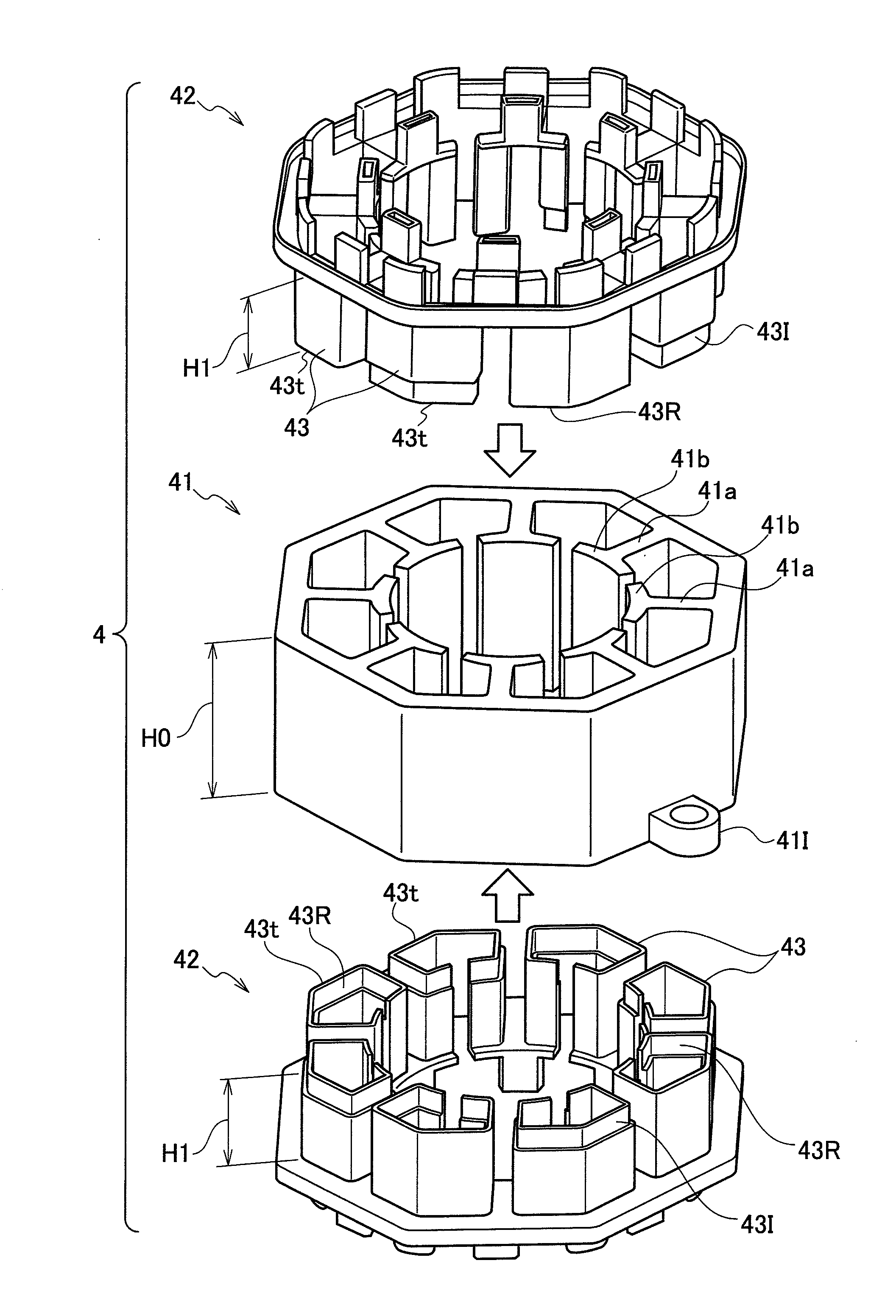

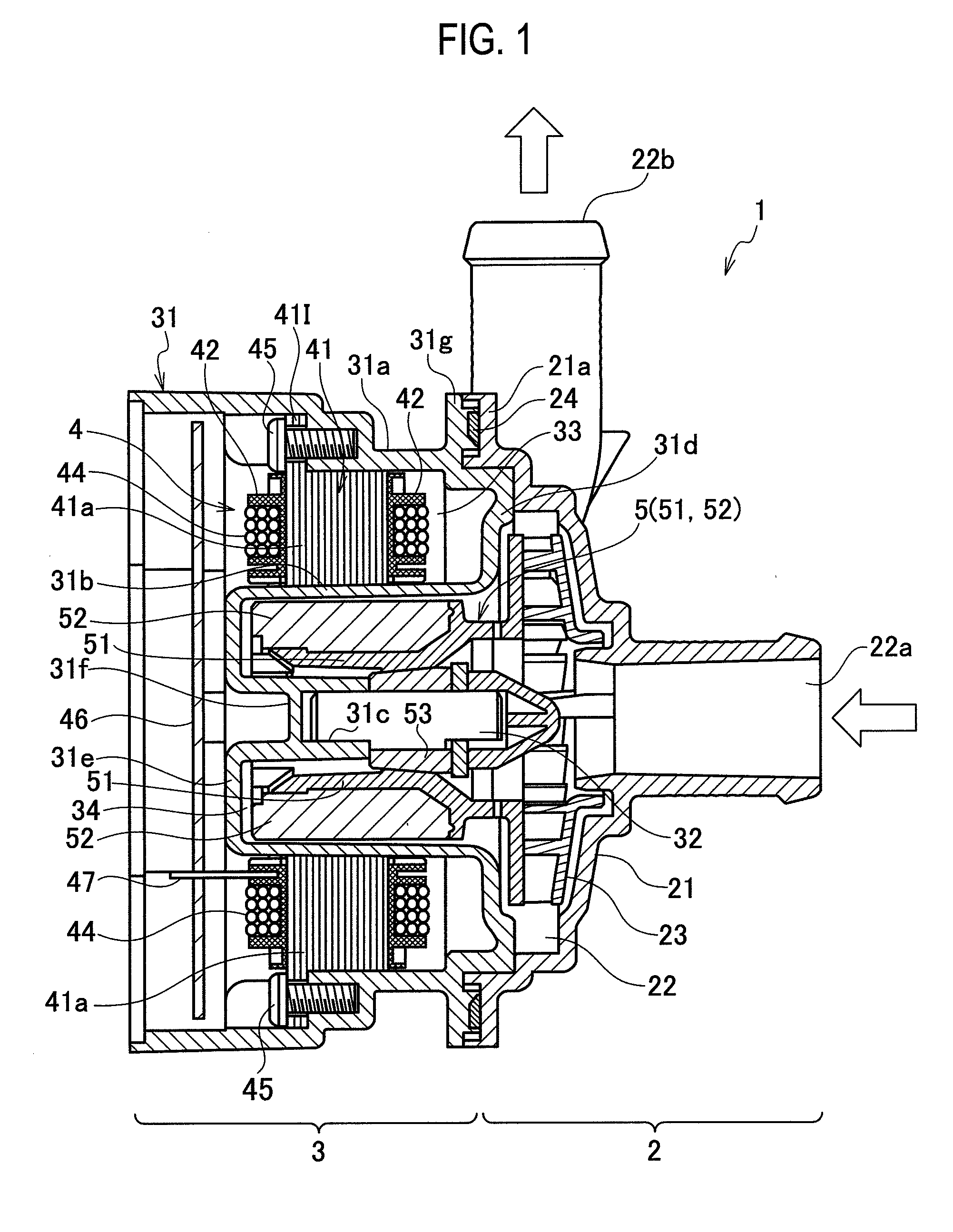

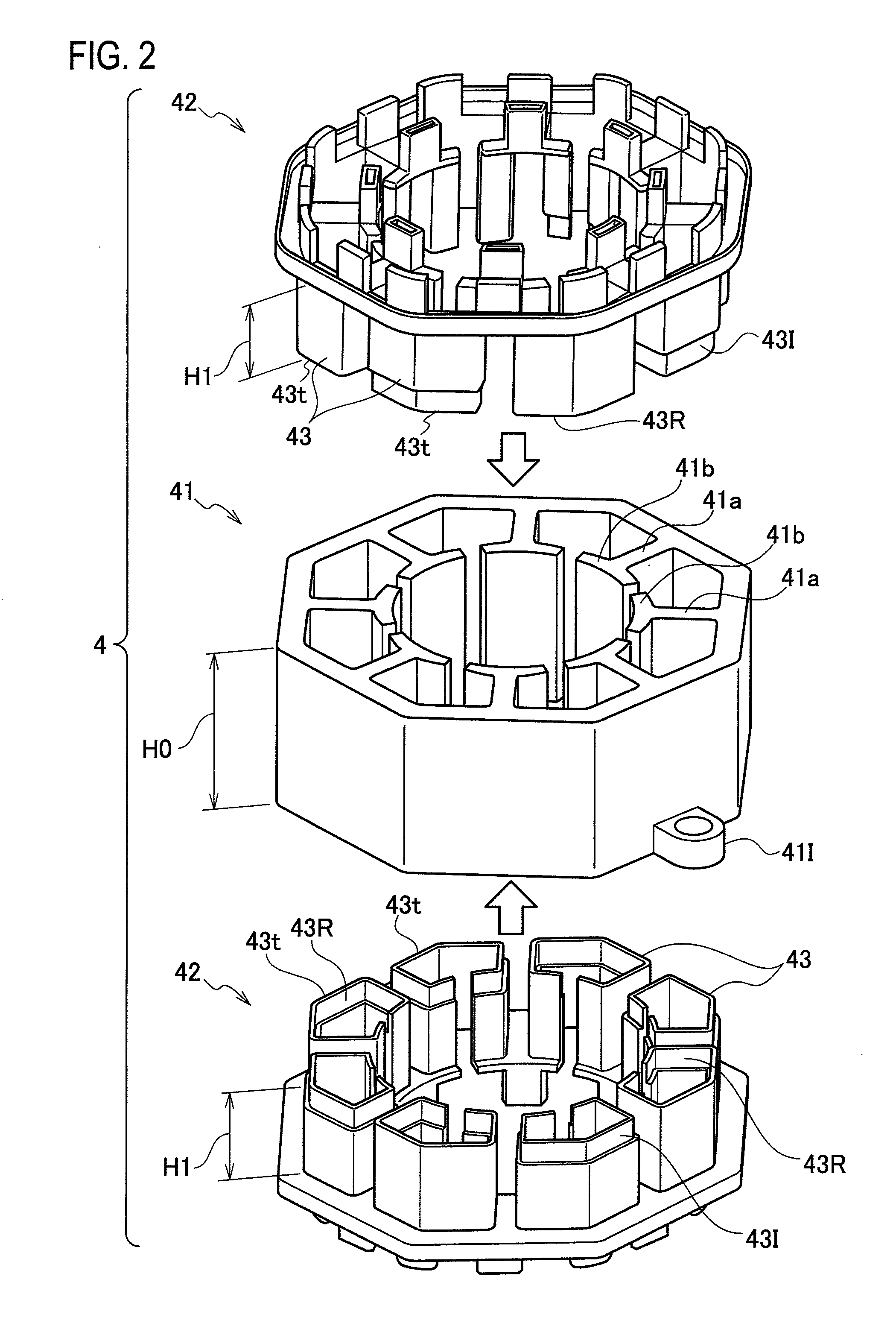

Insulator structure of motor, and motor-integrated pump

InactiveUS20100264774A1Low production costWindings insulation shape/form/constructionMotor insulationEngineering

An insulator structure of a motor, includes: a stator core having a plurality of protruding tooth portions which are disposed along an inner periphery of the stator core or an outer periphery of the stator core; a pair of first and second insulators respectively mounted to a first end portion and a second end portion in an axial direction of the stator core, wherein a plurality of cover portions are provided for each of the pair of the first and second insulators so as to cover the plurality of the respective tooth portions; and a winding wound around a tooth portion of the tooth portions covered with the respective cover portions, the winding being capable of causing a magnetic force to the tooth portion by an energizing; wherein with the pair of the first and second insulators, the cover portion's second head end portion in an axial direction of the first insulator in the axial direction and the cover portion's first head end portion in an axial direction of the second insulator in the axial direction mate with each other, the cover portion having the head end portion in the axial direction provided with a first fitting portion and the cover portion having the head end portion in the axial direction provided with a second fitting portion fittable with the first fitting portion are provided for each of the pair of the first and second insulators, the cover portion provided with the first fitting portion and the cover portion provided with the second fitting portion are so disposed as to face each other in such a configuration as to interpose therebetween a center axis of the stator core, and the first insulator and the second insulator which is substantially the same as the first insulator in configuration and is reversed in the axial direction are configured to face each other, such that the first fitting portion of the first insulator mates with the second fitting portion of the second insulator.

Owner:PANASONIC CORP

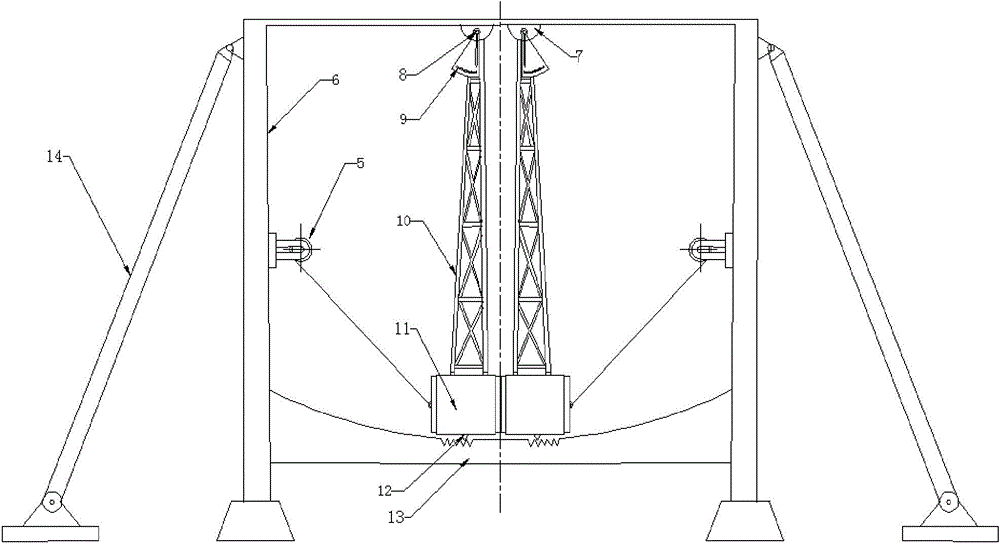

Device and method for testing power capability of composite explosives

InactiveCN104359607AHigh inert componentsAccurate measurementMaterial exposibilityMeasurement of explosion forceDetonatorTest power

The invention discloses a device and method for testing the power capability of composite explosives. The device for testing the power capability of the composite explosives is composed of winches, supports, support supporting rods, bearing bases, rotary shafts, swing arms, pendulum bobs, pendulum bob protruding teeth, a one-way limiter and angulometers. Before a test, explosive samples to be tested are prepared through special pressing molds, the samples to be tested are placed in inner cavities of the pendulum bobs and detonated through detonators, after detonation, the two pendulum bobs swing circumferentially around the rotary shafts under the limitation of the swing arms, the pendulum bobs are controlled by the one-way limiter and the pendulum bob protruding teeth to swing to the highest point and then stay still, the angulometers are used for measuring the swing angles of the pendulum bobs, and the power capability of the composite explosives after detonation is calculated and measured through the swing angles of the two pendulum bobs. According to the device and method, the improvement is made on the basis of a traditional ballistic trajectory mortar method, the conversion efficiency for converting chemical energy into mechanical energy of detonation can be improved through the two-pendulum-bob structure, and therefore the test result and the quantitative expression of the power capability of the composite explosives are more accurate.

Owner:XIAN MODERN CHEM RES INST

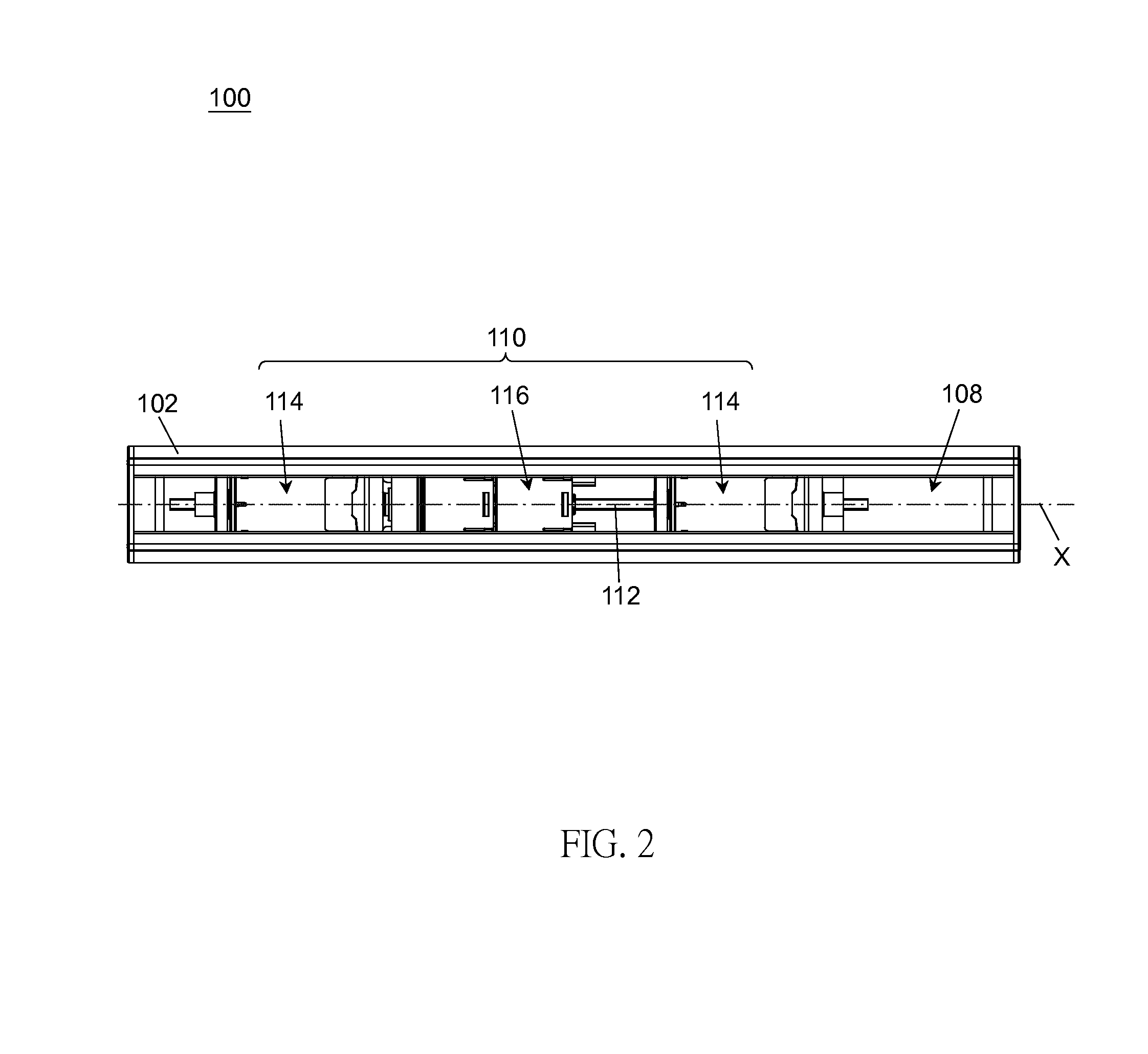

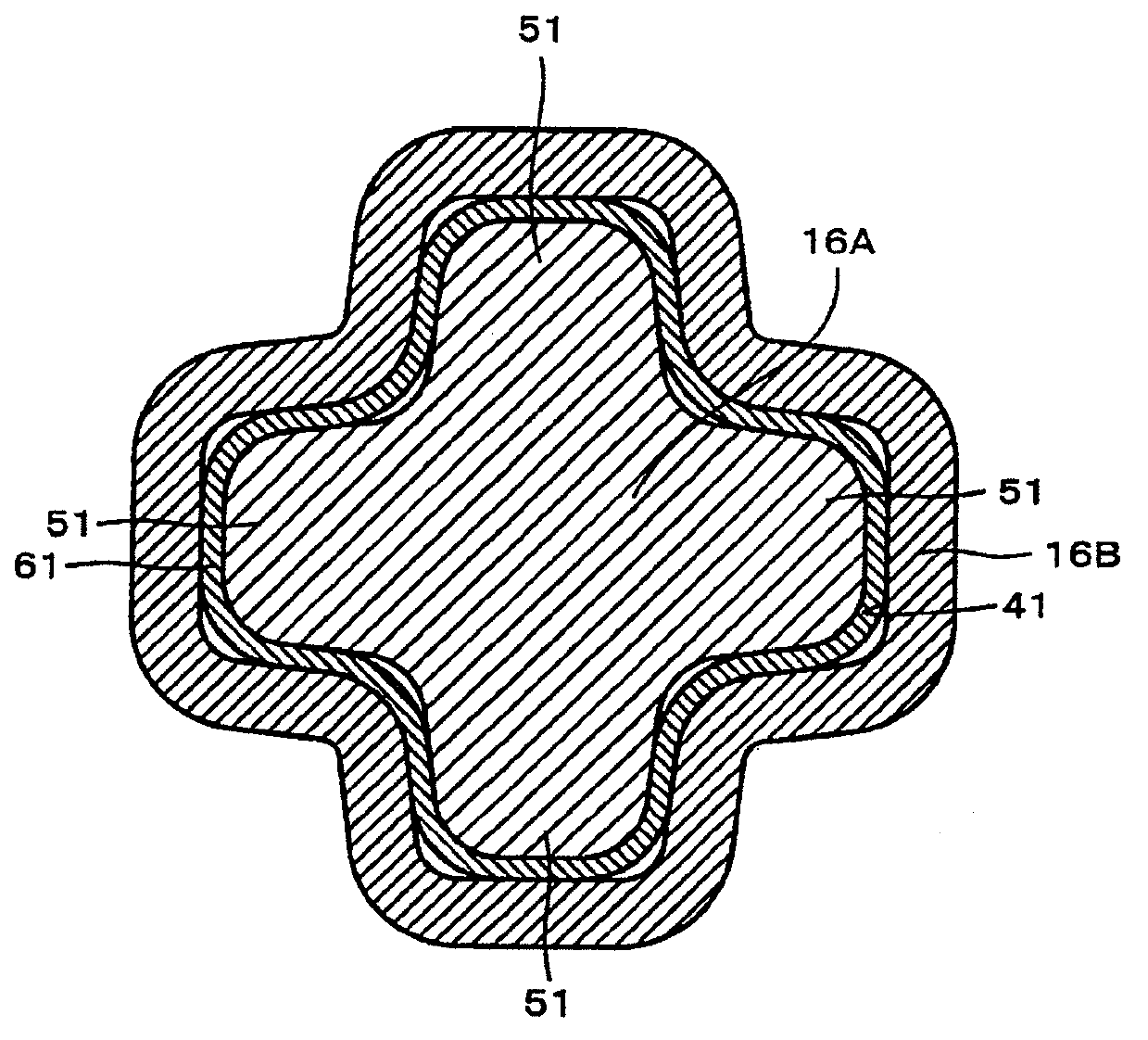

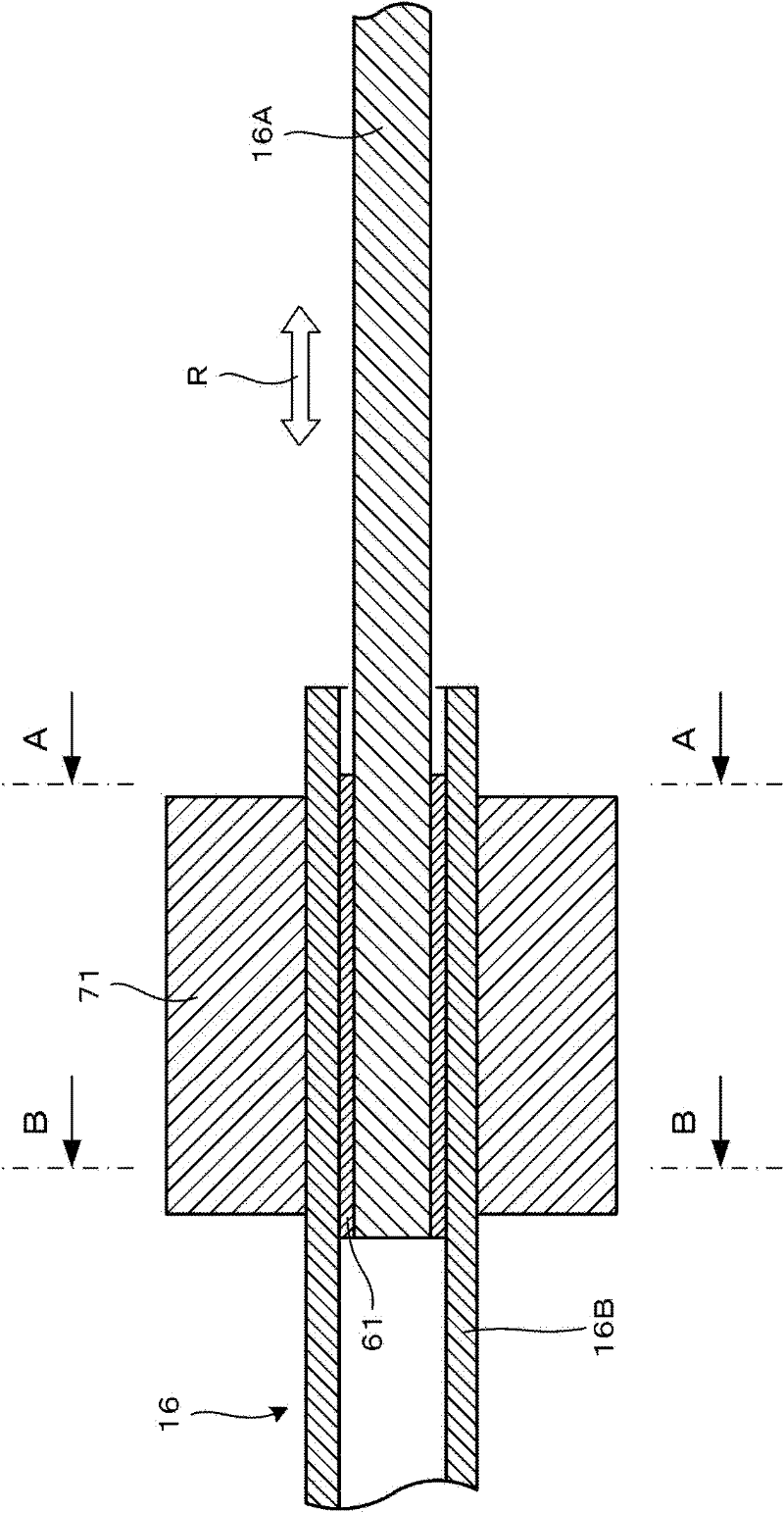

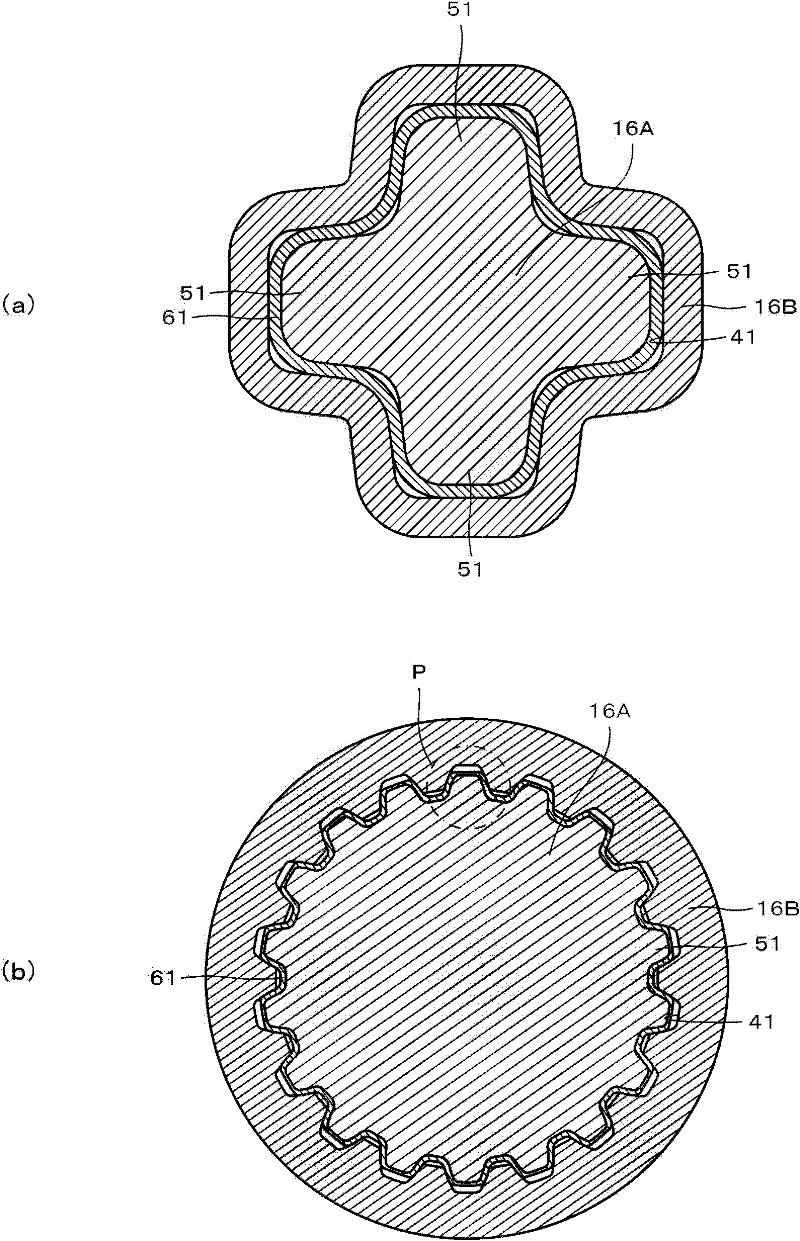

Method for manufacturing telescopic shaft and telescopic shaft manufactured by same

To provide a method for manufacturing a telescopic shaft having a coated section which reduces sliding resistance, the telescopic shaft being configured in such a manner that a variation in the sliding resistance depending on the position of sliding of the telescopic shaft is reduced and that lubricating oil exhibits satisfactory lubricating performance. [Solution] Clearance sections (613) are formed in a coated section (61) so that portions of the tooth flanks (412) of the tooth grooves (41) of a female shaft (16B), the portions being located near the tooth tops (411A) between the tooth grooves (41), do not come into contact with portions of the coated section (61) on the tooth flanks of protruding teeth (51), the portions being located near the roots of the protruding teeth (51). The amount of plastic deformation obtained by compressing the coated section (61) by subjecting an intermediate shaft (16) to break-in operation is in the range from 1 micrometer to 10 micrometers. This means that the depth (a1) of the clearance sections (613) before the coated section (61) is plastically deformed by compressive stress applied thereto is preferably 10 micrometers or greater. Even after the coated section (61) is plastically deformed, the clearance sections (613) are maintained recessed from a plastically deformable surface (614) by a depth (a2).

Owner:NSK LTD

Multi-axis pivoting detent joint assembly for an exterior vehicle mirror

A mirror assembly comprising a mounting bracket for attachment to a vehicle exterior; a first pivot plate on the mounting bracket having a concave upper surface with a series of grooves formed therein; a support arm pivotally carried on the first pivot plate of the mounting bracket; and, a second pivot plate carried by the support arm having a base surface with a plurality of protruding teeth engaging the grooves in the first pivot plate so that a pivot gap is defined between the upper surface of the first pivot plate and the base surface of second pivot plate; whereby the pivot gap allows the teeth to both pivot and slide in the grooves of the first pivot plate so that the support arm is pivotal in a multi-axis arrangement with the mounting bracket to accommodate misalignment between the mounting bracket and the support arm during installation on a vehicle.

Owner:LANG MEKRA NORTH AMERICA LLC

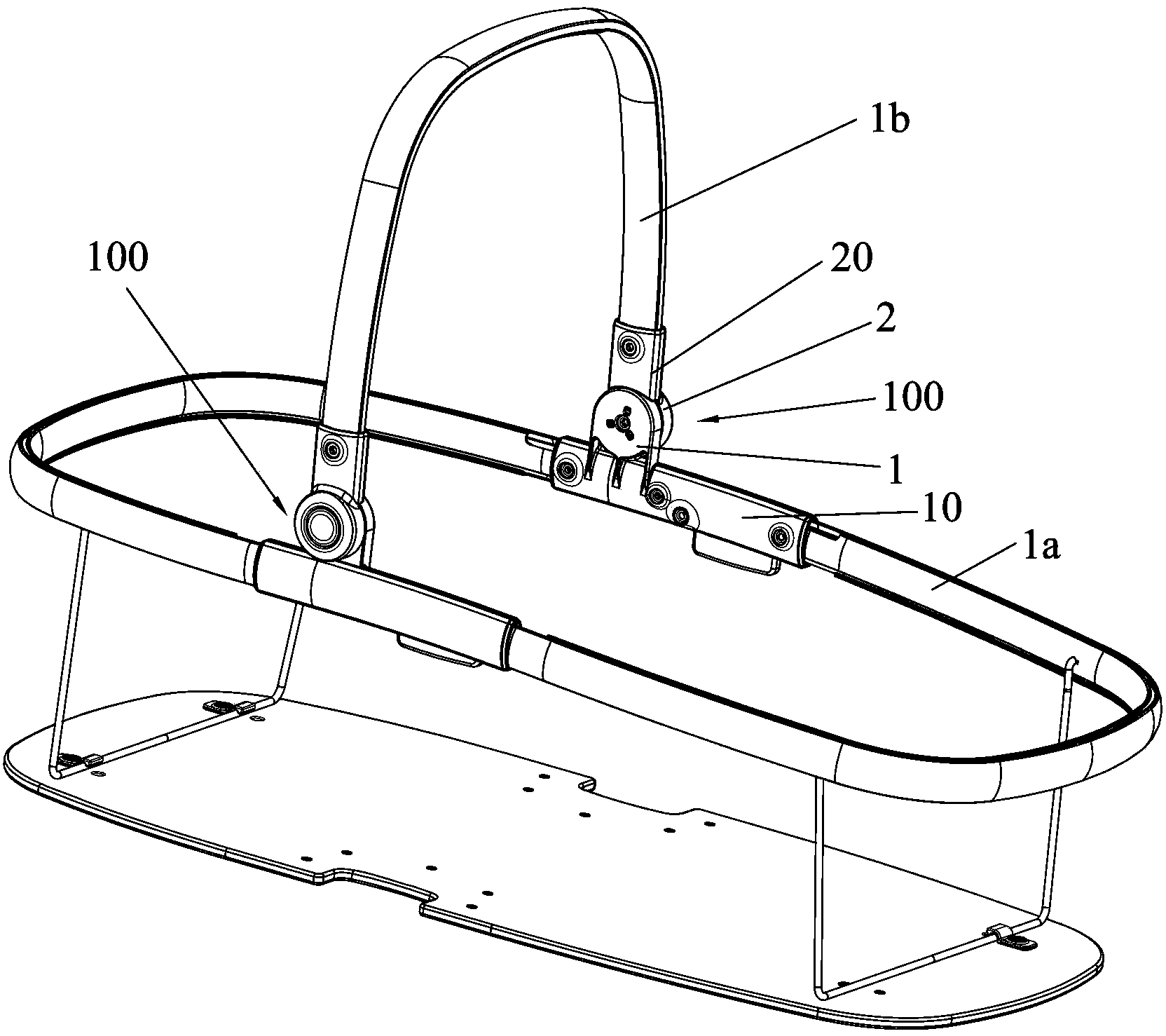

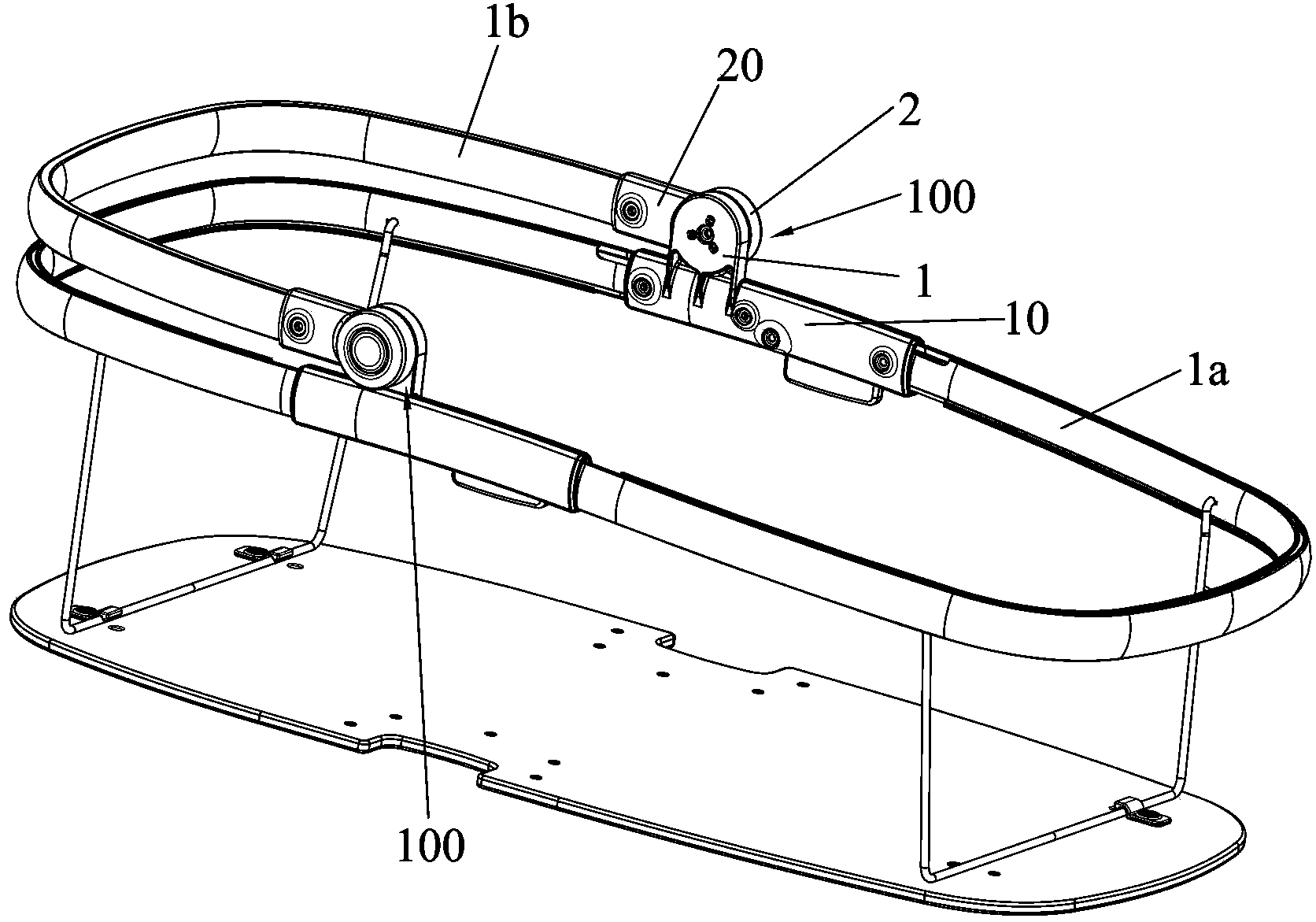

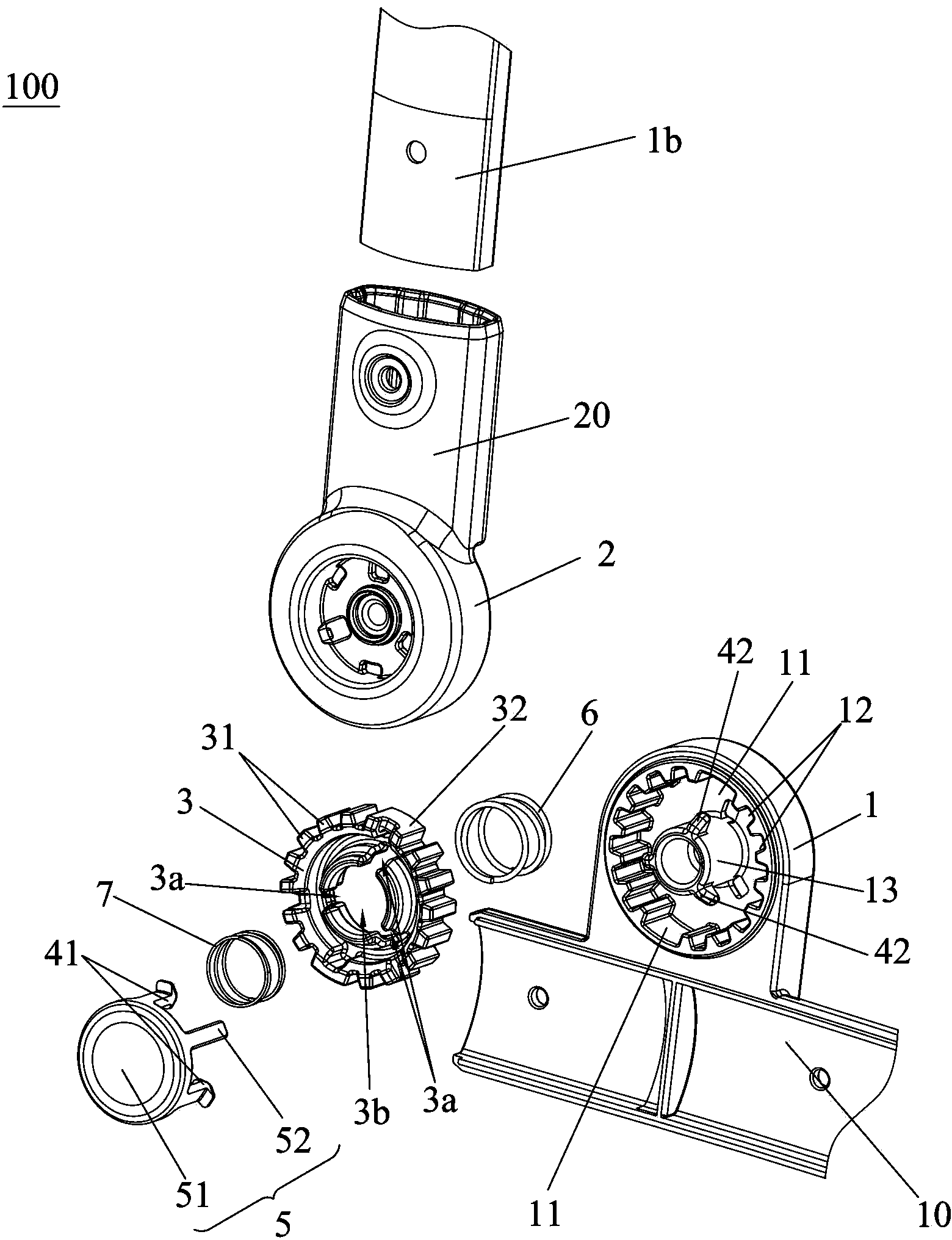

Joint device

The invention discloses a joint device in the field of infant equipment. The joint device comprises first pivot seats, second pivot seats, clamping parts, triggering mechanisms and limiting modules. The first pivot seats are provided with first main tooth grooves, and the second pivot seats are in pivot joint to the first pivot seats and are provided with second main tooth grooves. The clamping parts are movably arranged between the first pivot seats and the second pivot seats and comprise main protruding teeth, the triggering mechanisms are movably connected to the clamping parts in an abutting mode, and the triggering mechanisms are operated to move the locking positions where the main protruding teeth are clamped in the first main tooth grooves and the second main tooth grooves to the unlocking positions where the main protruding teeth are clamped into the main tooth grooves and disengaged from the second main tooth grooves, so that the first pivot seats and the second pivot seats are pivoted to the folding position from the unfolding position. The limiting modules are linked to the clamping parts and the triggering mechanisms, respond to the first pivot seats and the second pivot seats to fall to the unfolding positions and respond to the triggering mechanisms to move the clamping parts to the unlocking positions from the locking positions. The limiting modules exert the limiting action for the clamping parts to be restrained to the unlocking positions.

Owner:WONDERLAND NURSERYGOODS CO LTD

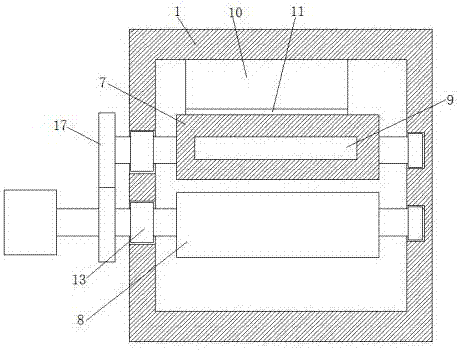

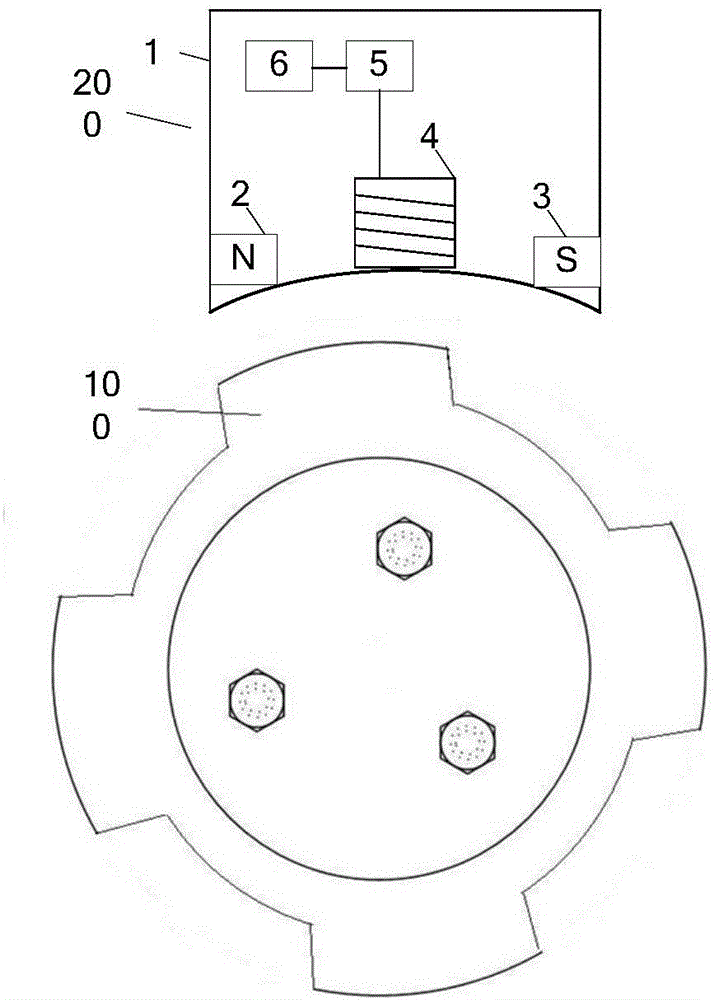

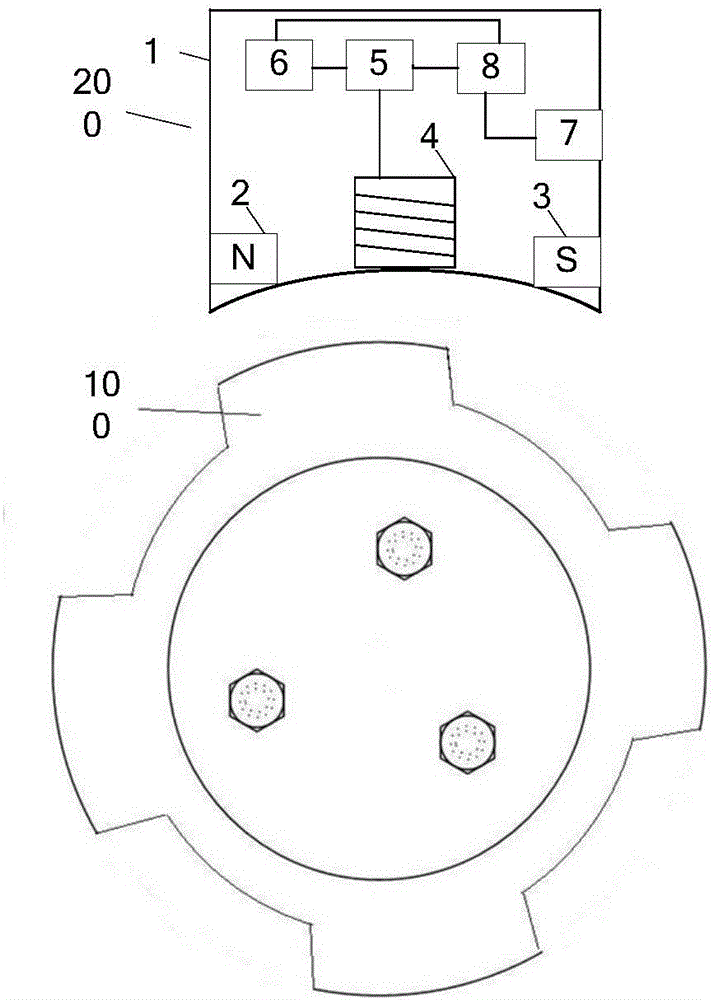

Axle power generation device, self-powered sensor and vehicle state information monitoring device

ActiveCN106026595ARealize power generationRealize vehicle status detectionSynchronous machinesMechanical energy handlingPower sensorElectromagnetic induction

The invention discloses an axle power generation device, a self-powered sensor and a vehicle state information monitoring device. The axle power generation device comprises a magnetic-conducting fluted disc and a power generation unit, wherein the magnetic-conducting fluted disc is provided with at least one protruding tooth part or a plurality of protruding tooth parts; the plurality of protruding tooth parts are evenly arranged at intervals; the magnetic-conducting fluted disc is fixed on an axle; the power generation unit comprises a shell, an electromagnetic induction coil, an N-pole permanent magnet and an S-pole permanent magnet; the electromagnetic induction coil is fixed in the shell; the N-pole permanent magnet and the S-pole permanent magnet are arranged at two sides of the electromagnetic induction coil respectively; and the power generation unit is arranged at the position with a preset distance from the outer side of the magnetic-conducting fluted disc. The axle power generation device can be applied to power supply of any vehicle equipment with power supply inconvenience; and power generation, vehicle state detection and vehicle state system monitoring can be achieved under the condition free of external power supply.

Owner:北京世纪中桥物流有限公司

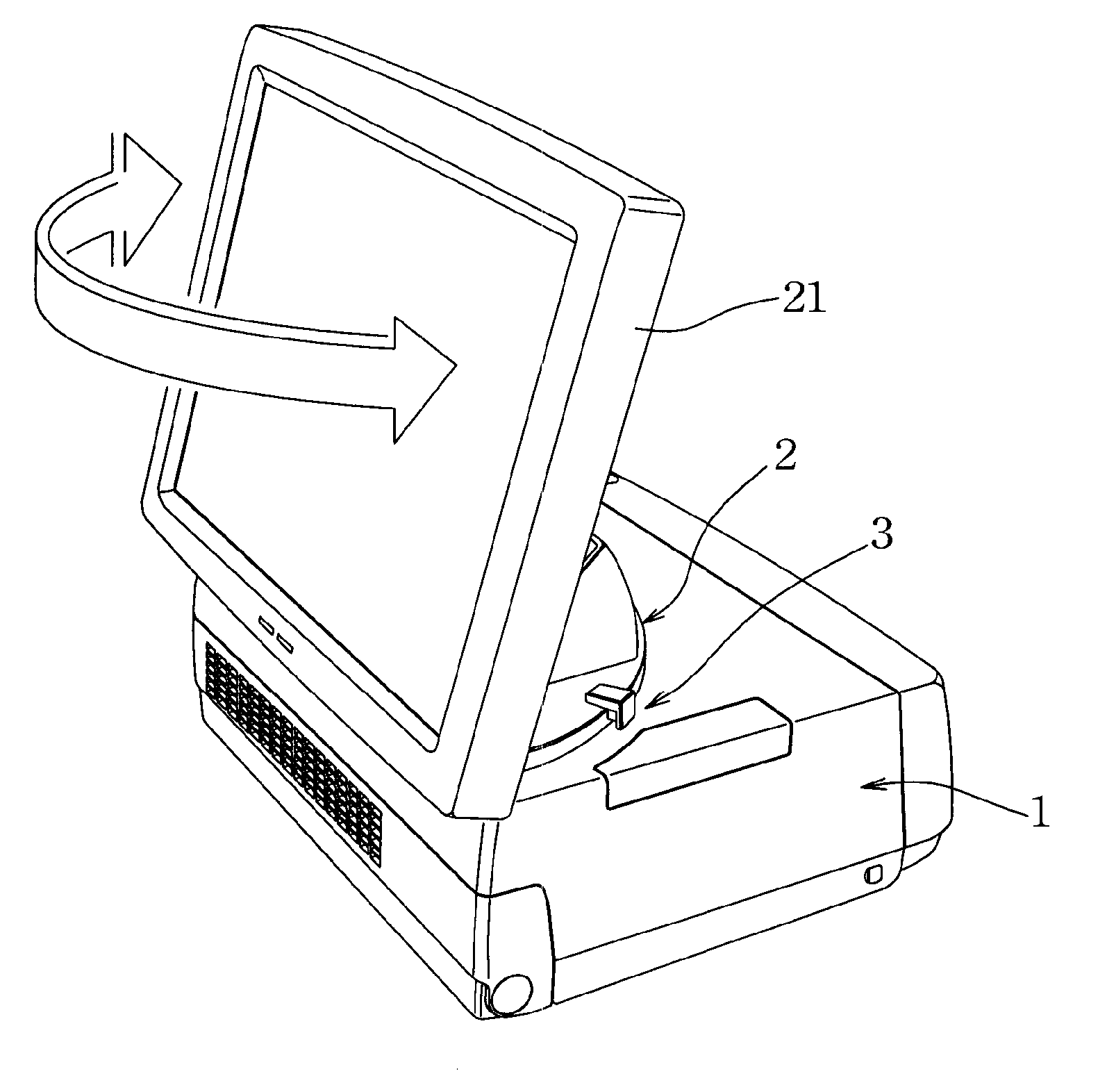

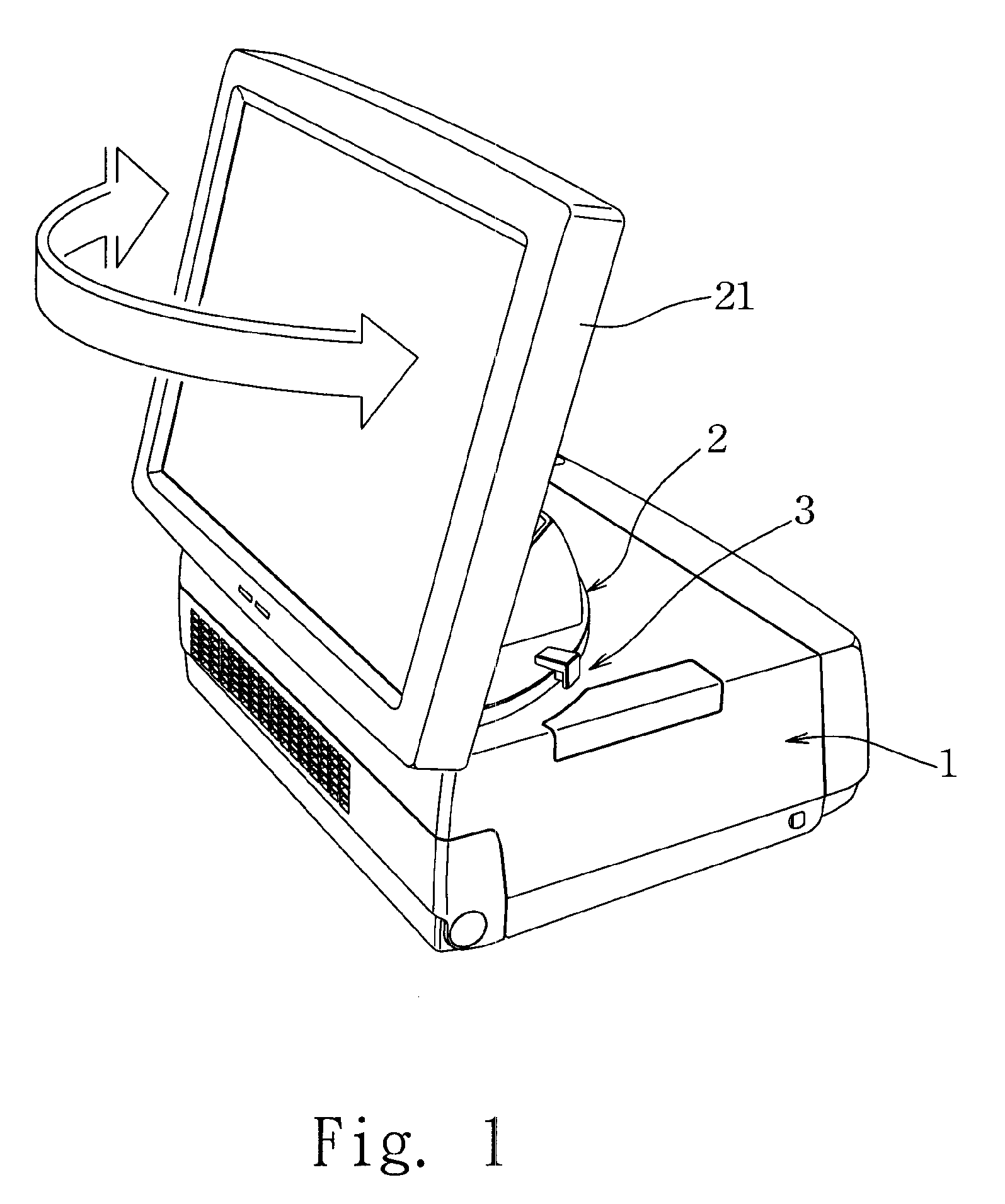

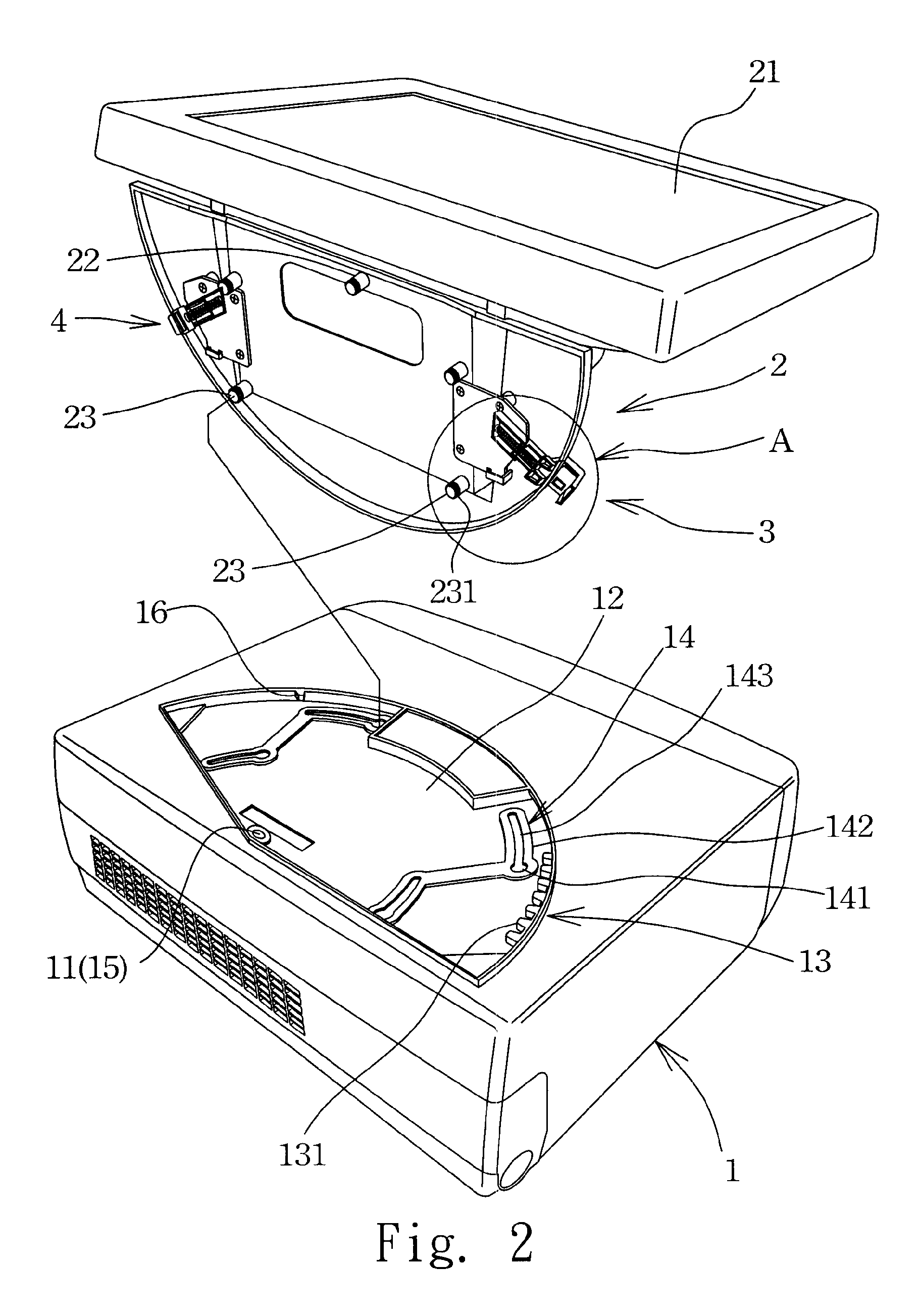

Mechanism for adjusting a rotary angle of an LCD

InactiveUS20070030632A1Guaranteed uptimeLimit scopeDigital data processing detailsStands/trestlesRotary engineProtruding tooth

A mechanism for adjusting a rotary angle of an LCD includes: a lower base with a sector rack and arcuate sliding grooves disposed at the top surface thereof; an upper base disposed with an LCD at an upper portion thereof, the bottom surface of the upper base being disposed with sliding posts for movably engaging with the arcuate sliding grooves; and a positioning mechanism including a positioning spring and a positioning push button. The positioning spring constantly urges the positioning push button to mate with one of the protruding teeth of the rack, thereby positioning the rotary angle of the upper base and the LCD. When the positioning push button is inwardly pushed, the positioning push button is disengaged from the protruding tooth thereby enabling the LCD to rotate right and left. The adjusting mechanism further includes an inhibiting mechanism for restricting the rotating scope of the LCD.

Owner:POSIFLEX TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com