Patents

Literature

2694results about How to "Guaranteed structural strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

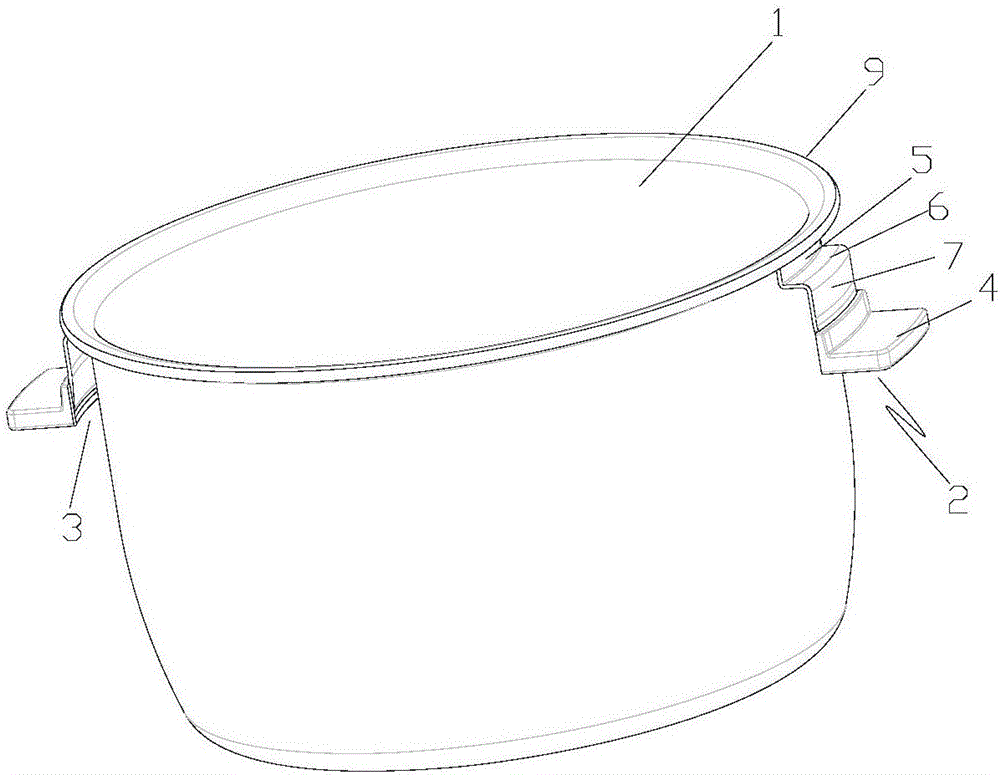

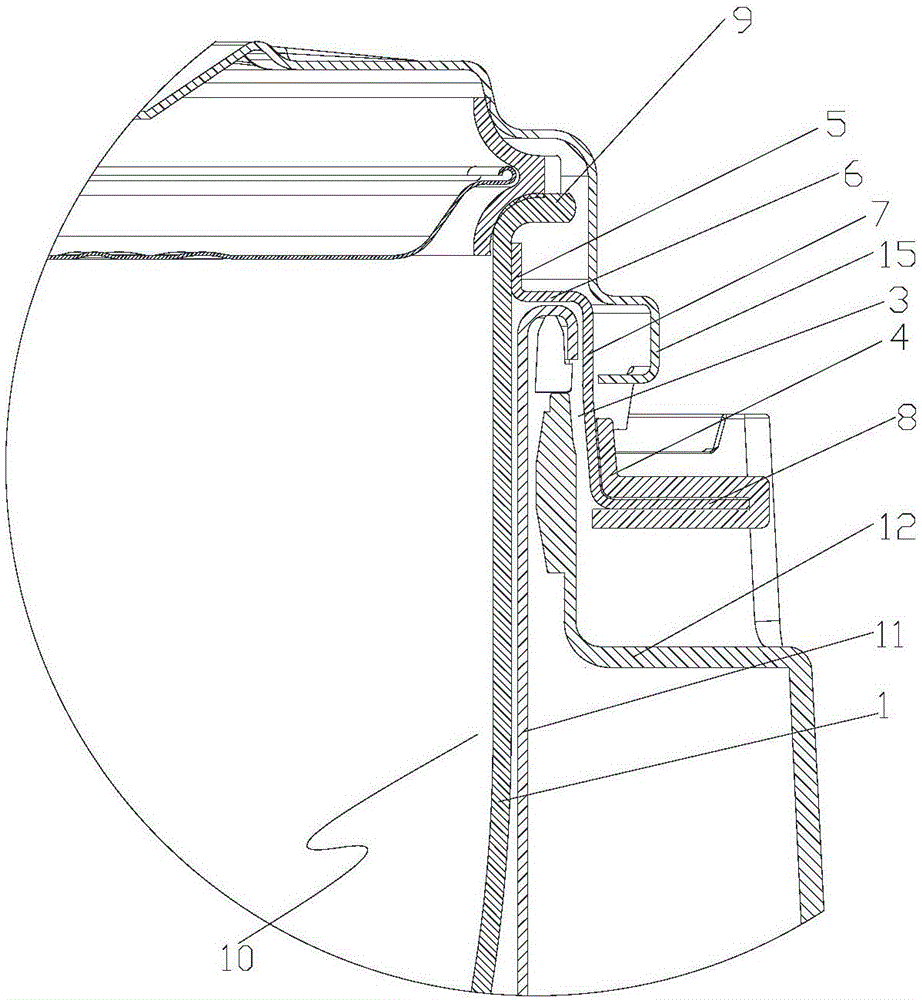

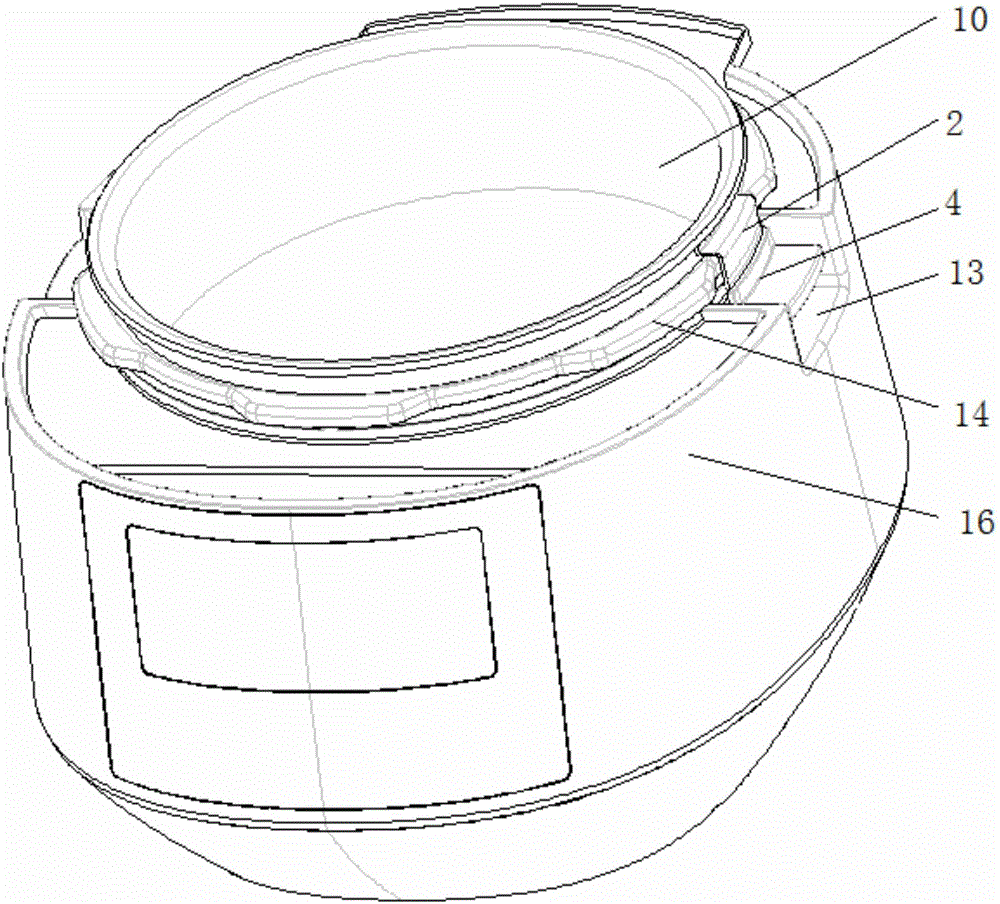

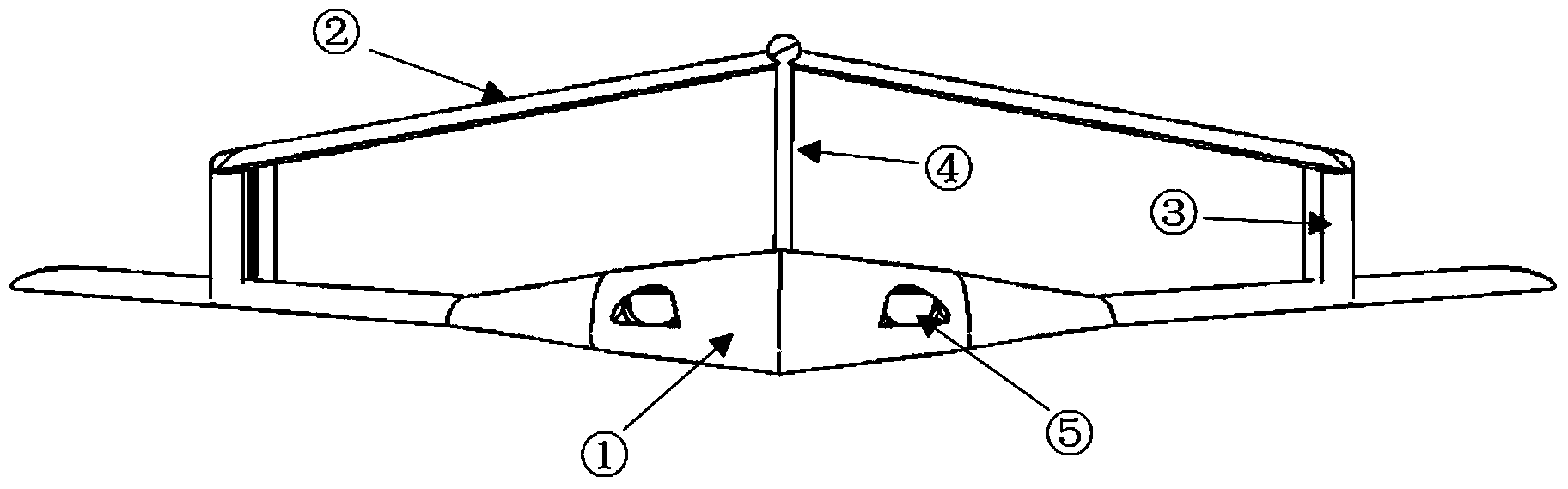

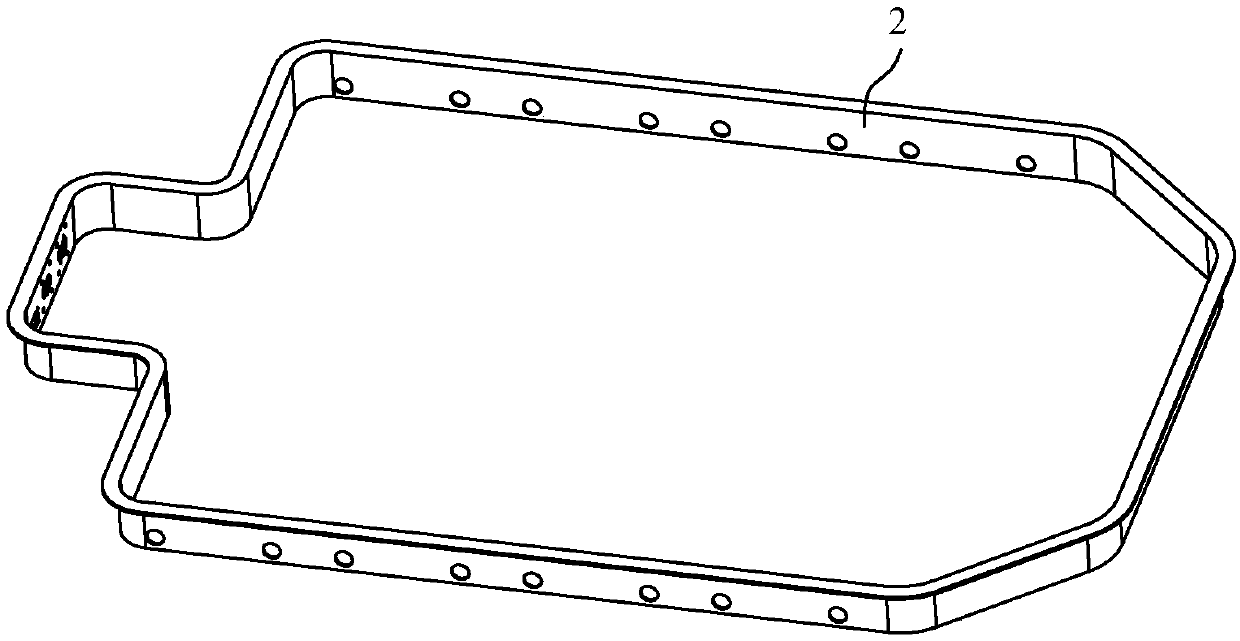

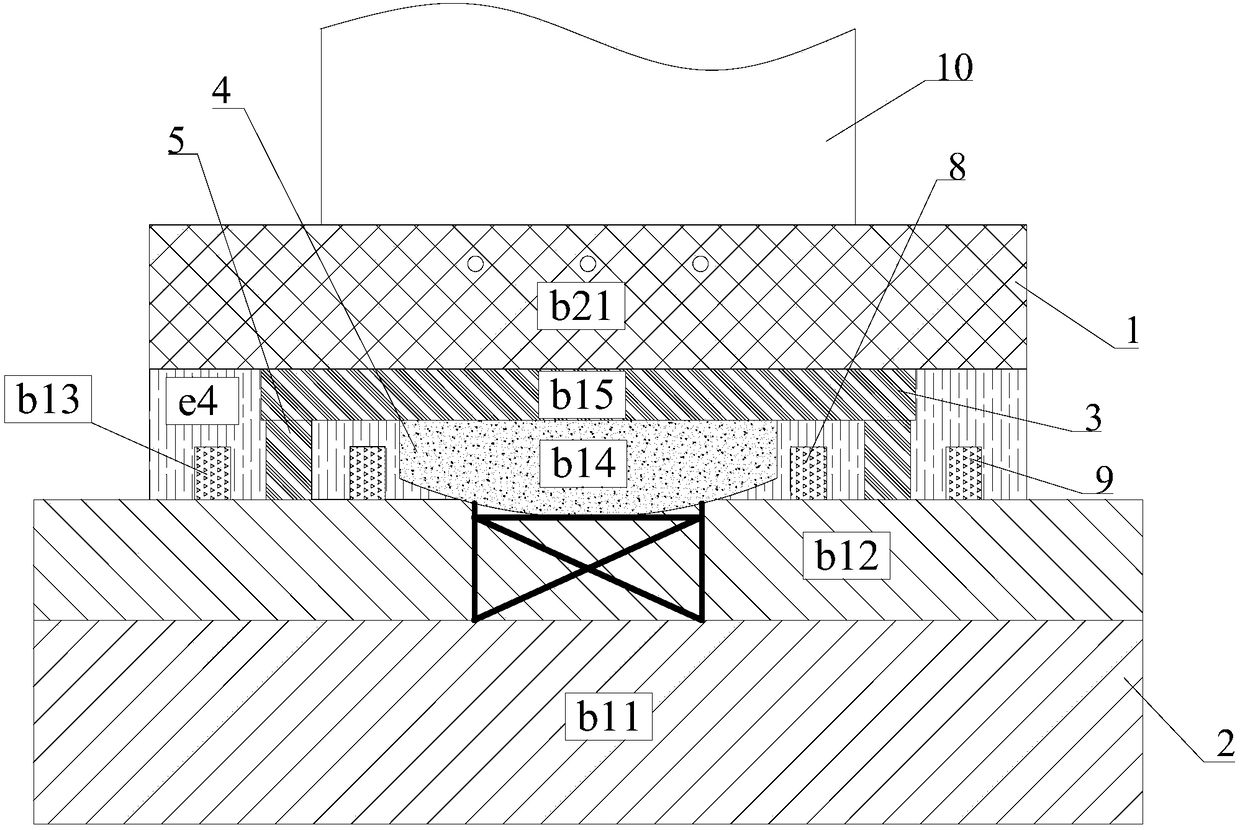

Inner pot and electric pressure cooker

ActiveCN106108631AAvoid flangingAvoid destructionPressure-cookersEngineeringUltimate tensile strength

The invention provides an inner pot and an electric pressure cooker. The inner pot comprises a body (1) and a lifting handle (2) arranged on the periphery of the body (1). An installation groove (3) is formed between the lifting handle (2) and the periphery of the body (1). The inner pot helps solve the problem in the prior art that that poor strength of the structure of an outer pot is caused due to a gap in the outer pot for the lifting handle.

Owner:GREE ELECTRIC APPLIANCES INC

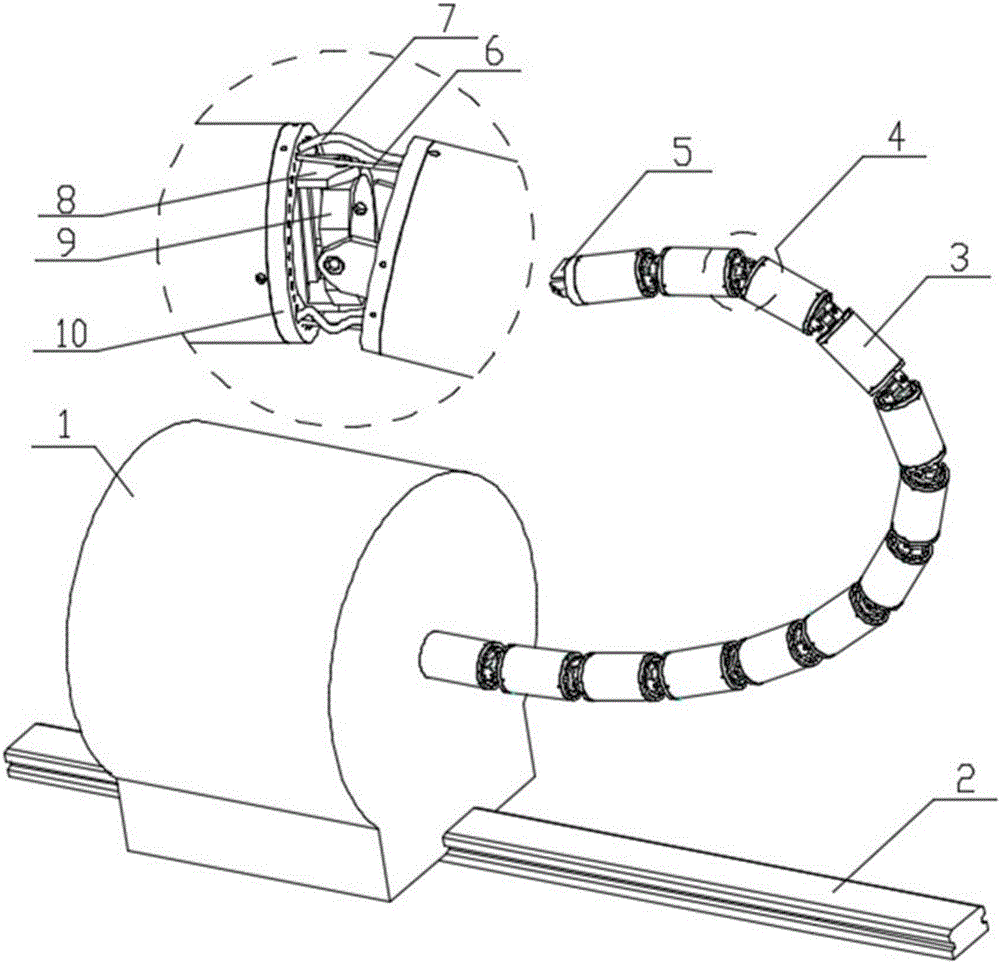

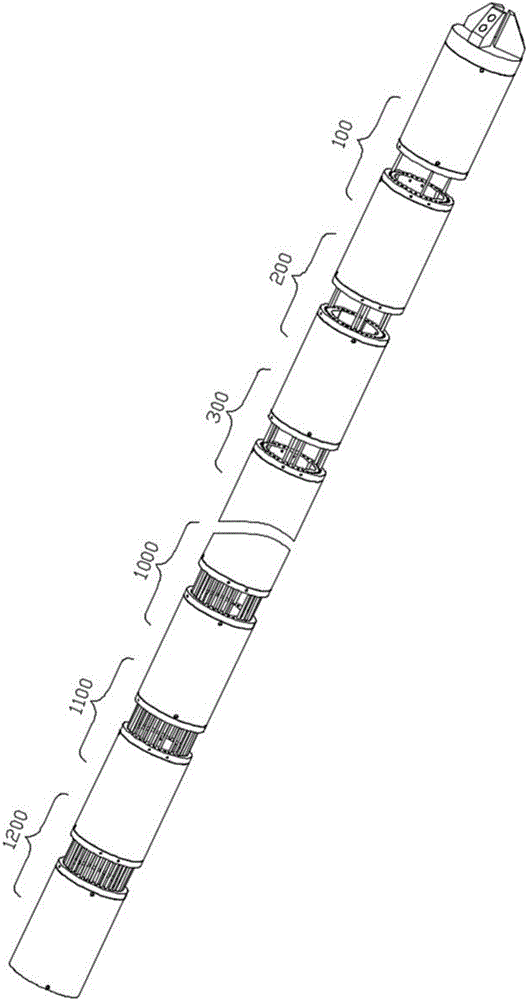

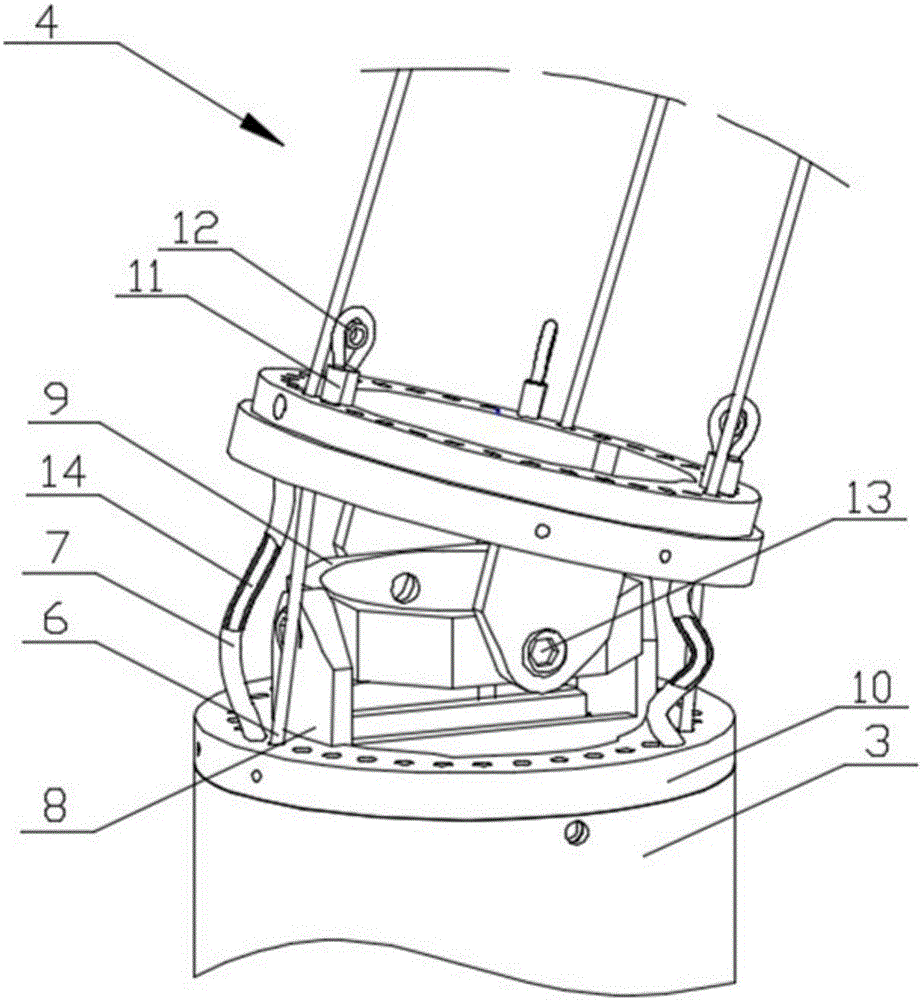

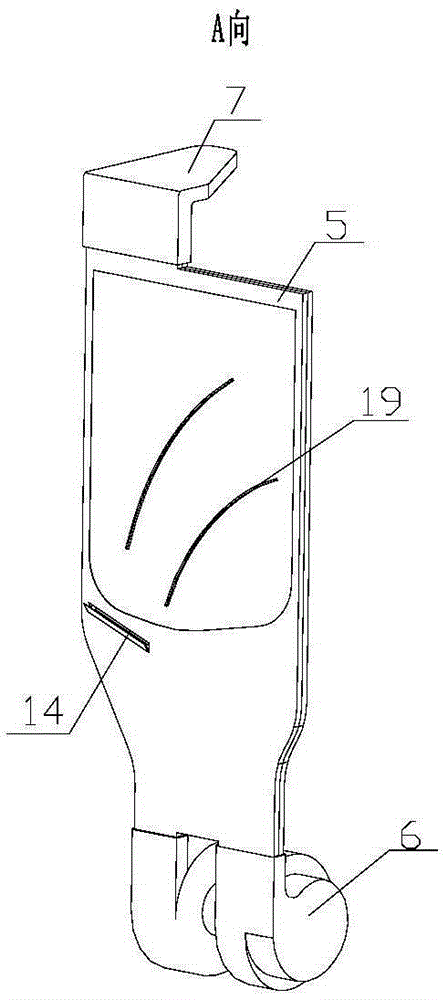

Motion-decoupled rope-driven non-individual body mechanical arm and robot

InactiveCN105014689ADoes not affect changes in rope lengthAchieving Motion DecouplingProgramme-controlled manipulatorJointsEngineeringSacroiliac joint

The invention provides a motion-decoupled rope-driven non-individual body mechanical arm and a robot. The mechanical arm comprises mechanical arm sleeves, traction rope sets and knuckles, wherein the number of the mechanical arm sleeves, the number of the traction rope sets and the number of the knuckles are more than one. The mechanical arm sleeves are sequentially arranged, and the adjacent mechanical arm sleeves are hinged to form a mechanical arm body through the knuckles. The front end of the mechanical arm body is used for being connected with a rope-driven base. The traction rope sets are used for driving the corresponding knuckles. The traction rope sets and the knuckles are in one-to-one correspondence. One end of each traction rope set is connected with the corresponding knuckle, and the other end of each traction rope set is used for being connected with the rope-driven base after sequentially penetrating through through-holes in multiple knuckle rope guiding discs arranged on the front side of the corresponding knuckle. The mechanical arm has multiple degrees of freedom, is thin and long in body type and suitable for survey and operation in narrow spaces, and has large application potential.

Owner:SHANGHAI JIAO TONG UNIV

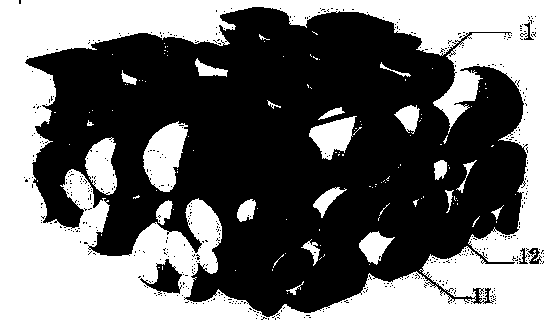

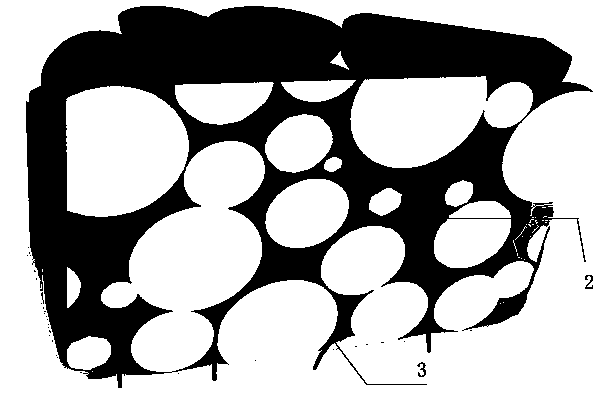

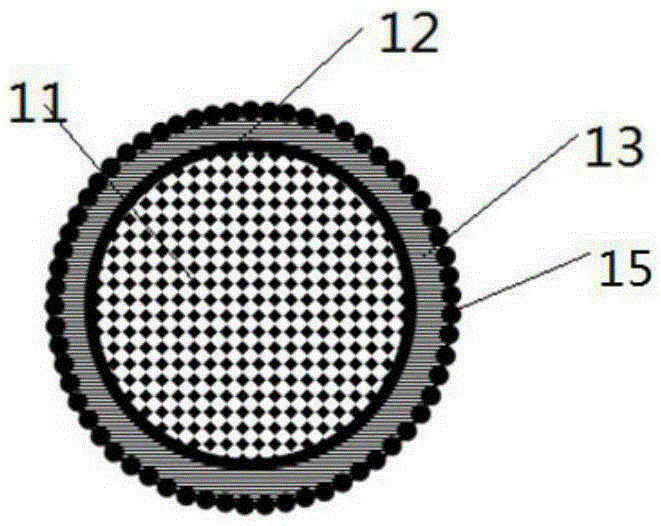

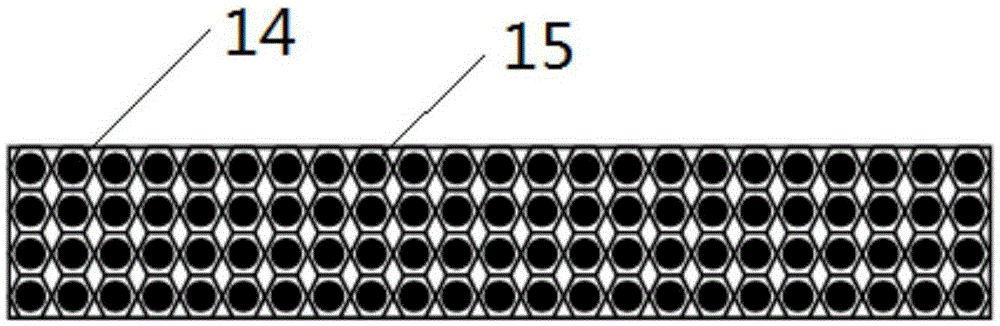

Micro-particle sound-absorbing board and preparation method thereof

ActiveCN104108902AGuaranteed structural strengthImprove the sound absorption coefficientSolid waste managementSound producing devicesFilm-coated tabletAngular coefficient

The invention discloses a micro-particle sound-absorbing board and a preparation method thereof. The micro-particle sound-absorbing board comprises a binding agent and sound-absorbing particles, wherein the outer surfaces of the sound-absorbing particles is coated with a layer of the binding agent; the angular coefficient of the particles coated with the binding agent is less than 1.3; the sound-absorbing particles comprise skeleton particles and filling particles; the skeleton particles are used for forming a skeleton of the sound-absorbing board; the filling particles enter pores among the skeleton particles to form sound-absorbing gaps; the average diameter of a cross section of the sound-absorbing gap is 0.07mm. Meanwhile, a two-section manufacturing process namely first-film-coating and second-curing-shaping of the sound-absorbing board can be used for avoiding an excessive amount of the binding agent from blocking the gap among the particles and further improving the angular coefficient of the particles. Therefore, the micro-particle sound-absorbing board and the preparation method of the micro-particle sound-absorbing board can be used for ensuring the structural strength of the sound-absorbing board and improving the sound-absorbing coefficient of the sound-absorbing board at the same time, and can obtain relatively good sound-absorbing effects.

Owner:ZISEN ENVIRONMENTAL TECHNOLOGY CO LTD

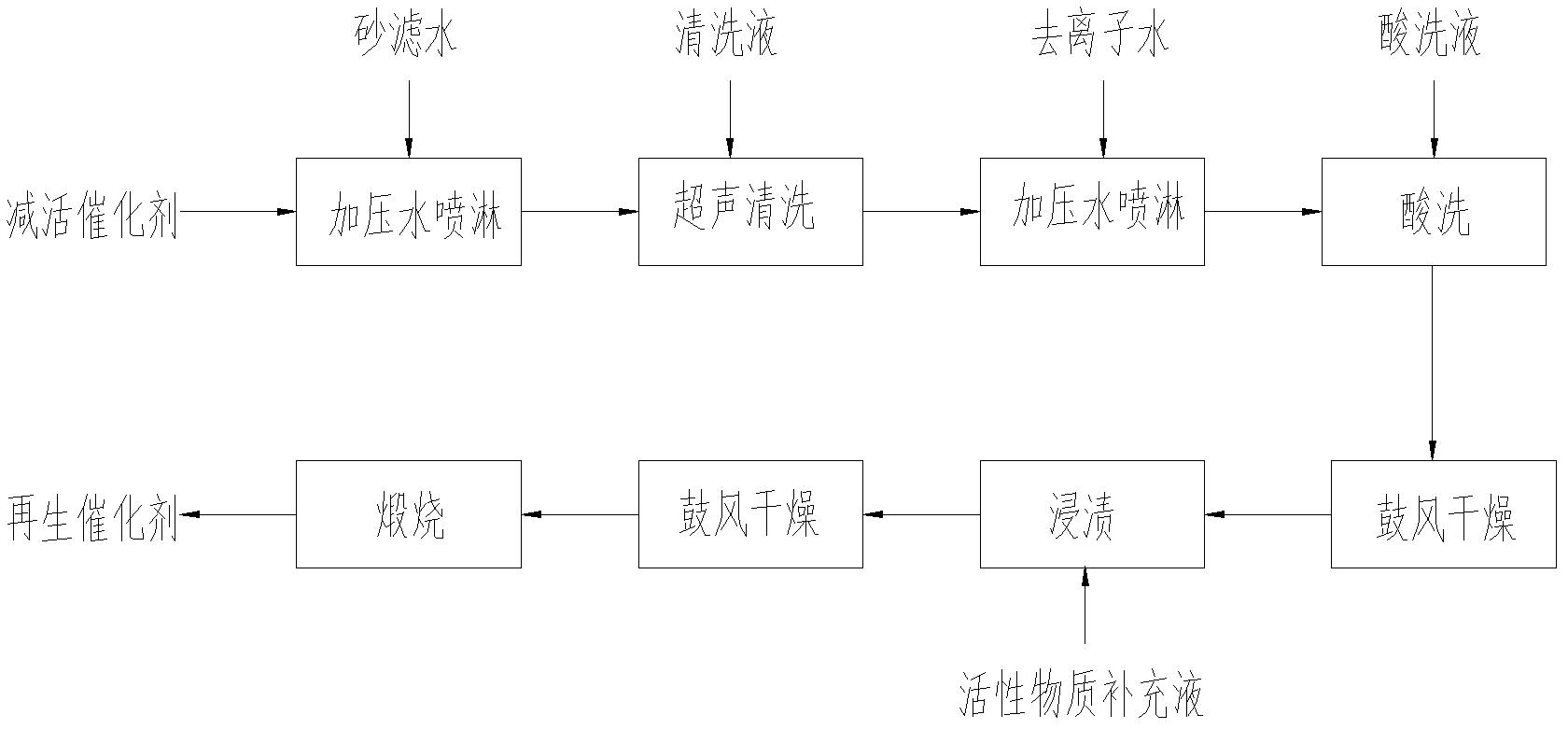

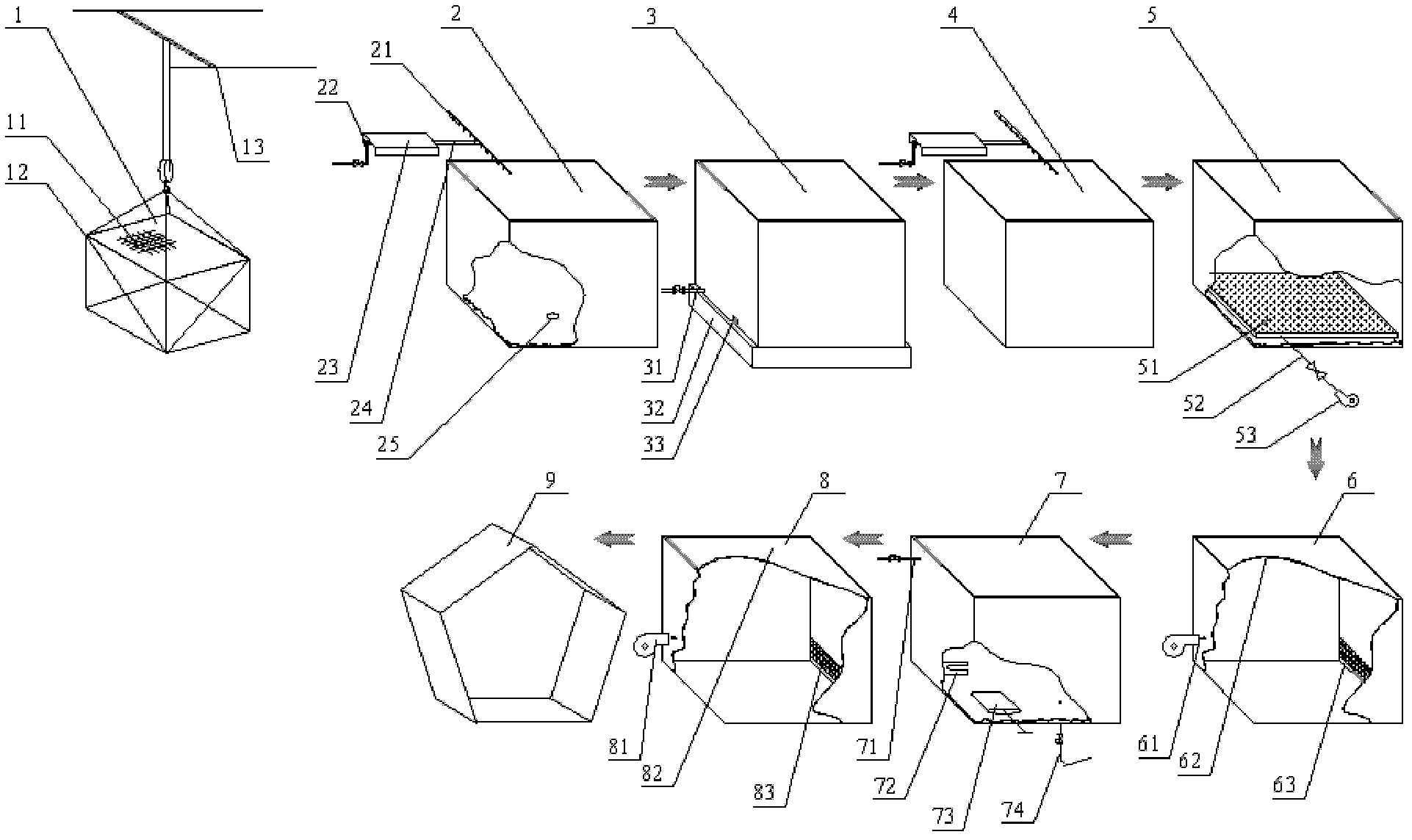

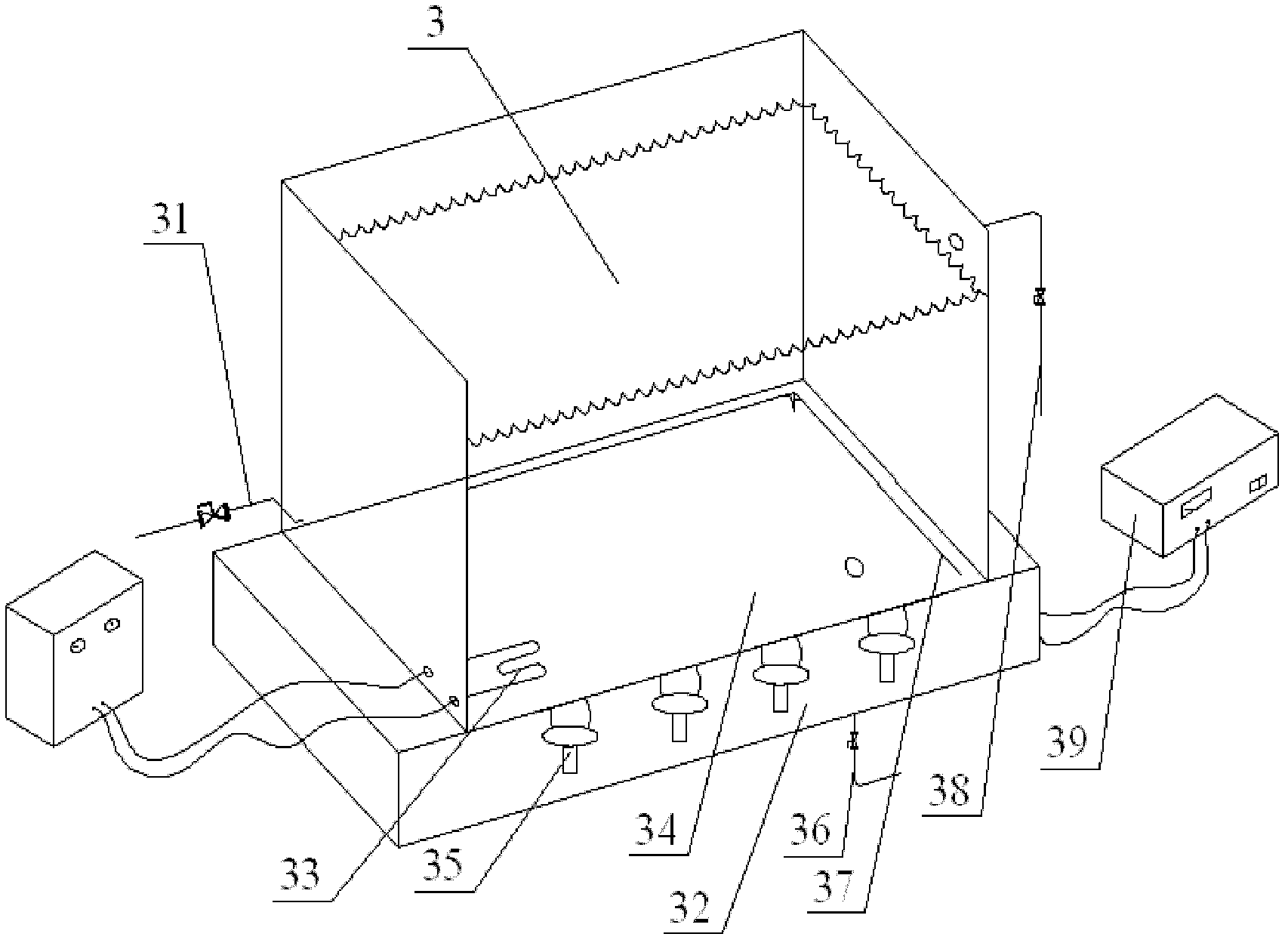

Regeneration technology of V-Ti-based honeycomb SCR denitration catalyst, and apparatus thereof

InactiveCN102658170AGuaranteed structural strengthImprove surface conditionDispersed particle separationCatalyst regeneration/reactivationActive componentHoneycomb

The invention discloses a regeneration technology of a V-Ti-based honeycomb SCR denitration catalyst, and an apparatus thereof. A deactivated catalyst in the technology is regenerated through steps of pressurized water spraying, ultrasonic cleaning, secondary pressurized water spraying, air blow drying, active component supplement, secondary air blow drying, step calcining, and the like. Parameters of the regeneration technology, which comprise components of a cleaning solution, a pickling solution and an active supplement solution, are provided. By adopting the technology, the denitration activity of the deactivated catalyst is recovered, the structural strength of the catalyst is maintained, and the SO2 oxidation frequency is reduced. The apparatus used for realizing the technology comprises a pressurized water spraying pool, an ultrasonic cleaning pool, a secondary pressurized water spraying pool, a pickling pool, an air blow drying pool, an active component supplement pool, a secondary air blow drying pool, a calciner and the like which are sequentially arranged, and the device can realize the hoisting transport regeneration of a regeneration module, and has the characteristics of simplicity, convenient operation, and high efficiency.

Owner:XI AN JIAOTONG UNIV

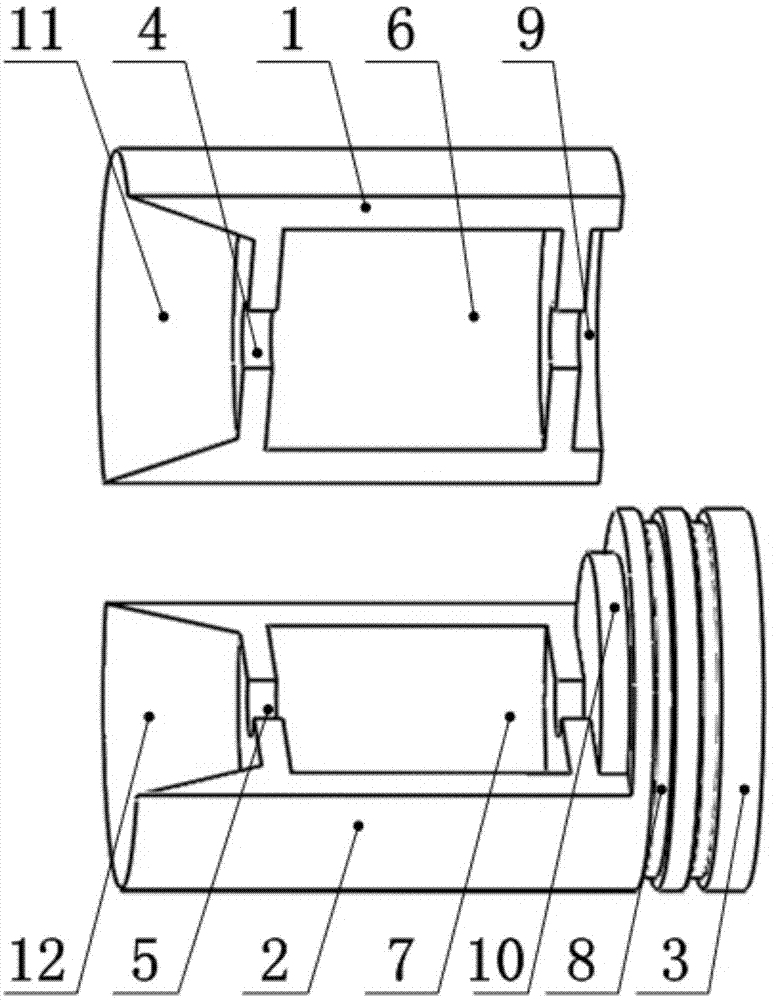

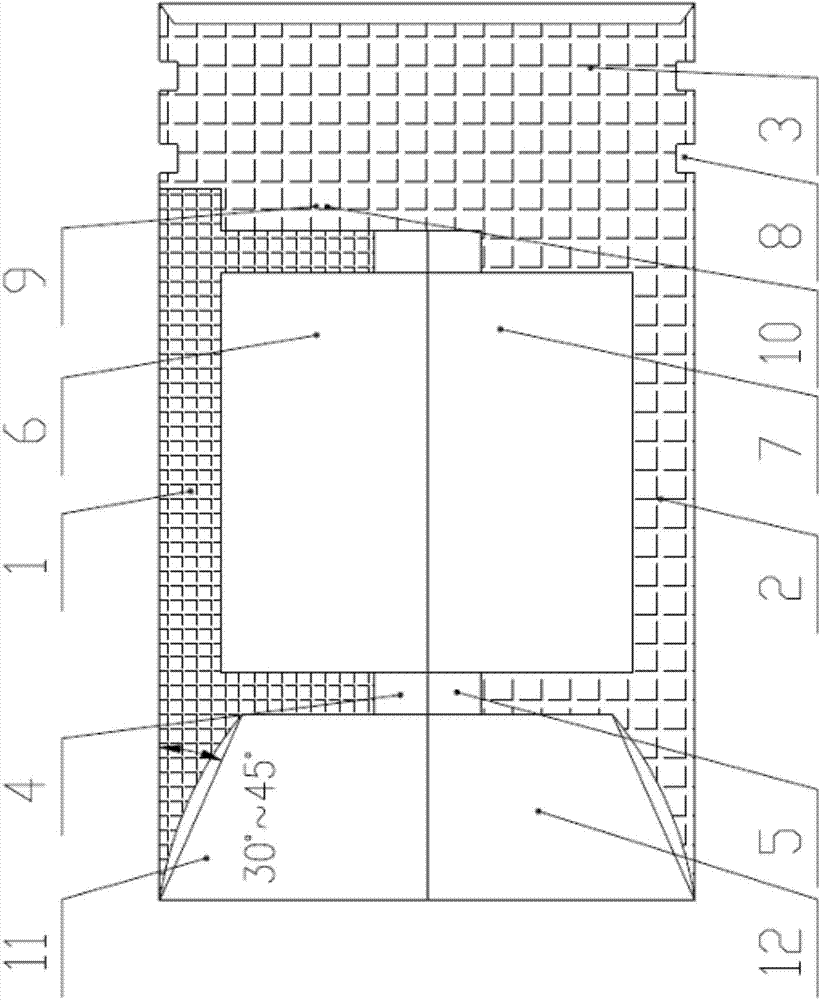

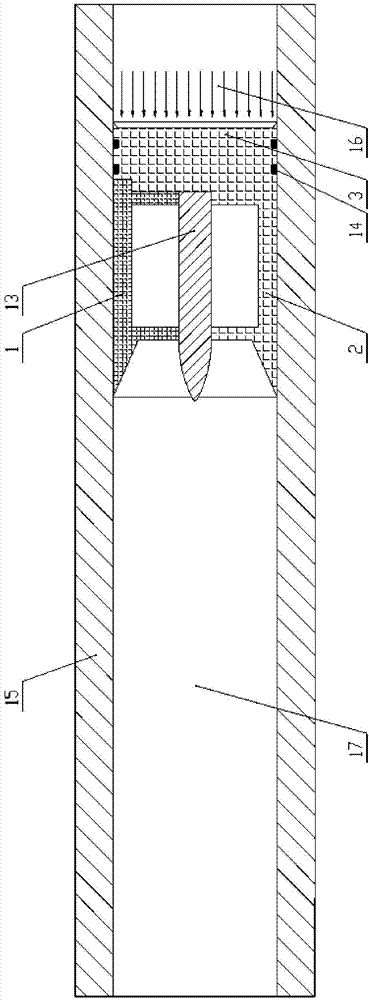

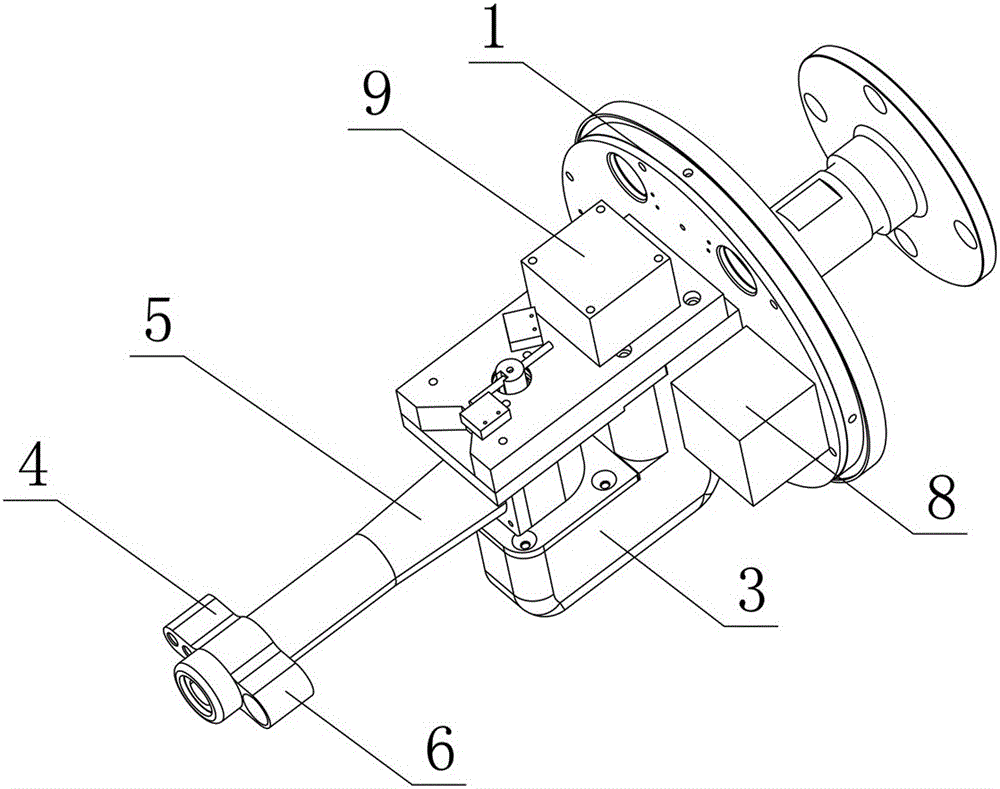

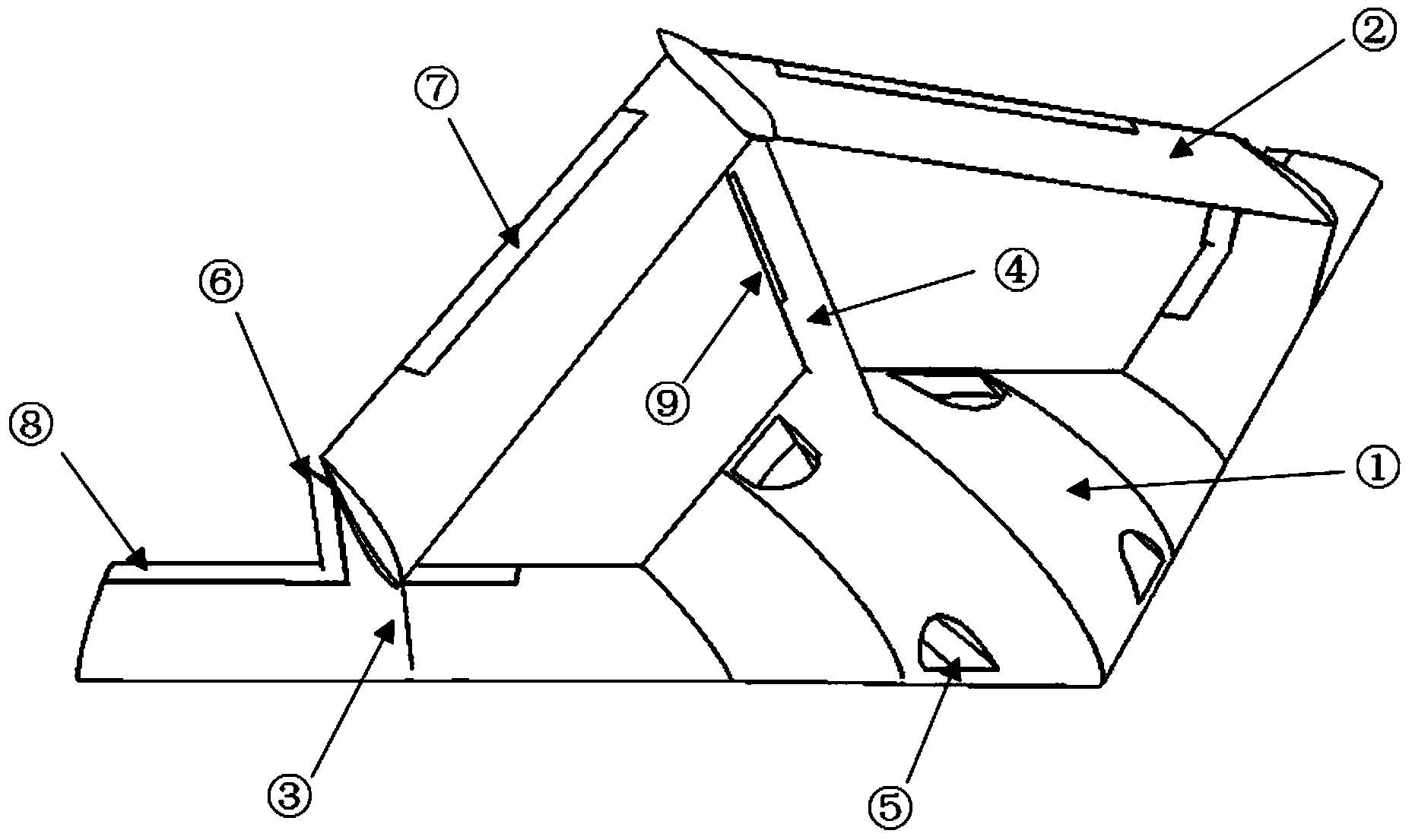

Light-gas gun pneumatic separation sabot

ActiveCN104729364ARealize automatic separationGuaranteed structural strengthProjectilesAerodynamic dragExternal ballistics

The invention relates to a light-gas gun pneumatic separation sabot, and aims at solving the problems that for an existing sabot, an additional device is needed to conduct separation on the sabot, the effect is not ideal and the cost is increased. The light-gas gun pneumatic separation sabot is composed of an upper supporting disc, a lower supporting disc and a base plate; the upper supporting disc and the lower supporting disc are two corresponding semi-cylinders. An upper half bullet hole is formed in the center of the upper supporting disc, and the middle of the upper half bullet hole is hollowed out to be of a hollow structure; the lower supporting disc and the base plate are formed to be a whole, a lower half bullet hole is formed in the center of the lower supporting disc, and the middle of the lower half bullet hole is hollowed out to be of the hollow structure; two seal grooves are carved on the base plate. The upper half bullet hole of the upper supporting disc corresponds to the lower half bullet hole of the lower supporting disc, a semicircle notch of the upper supporting disc is engaged with a boss of the lower supporting disc, under the condition of not adding a separating device, automatic separation of the sabot and a bullet is achieved through air resistance in a target chamber, and the light-gas gun pneumatic separation sabot has the advantages of improving the external ballistic property of the bullet and reducing the firing cost.

Owner:NORTHWEST INST OF NUCLEAR TECH

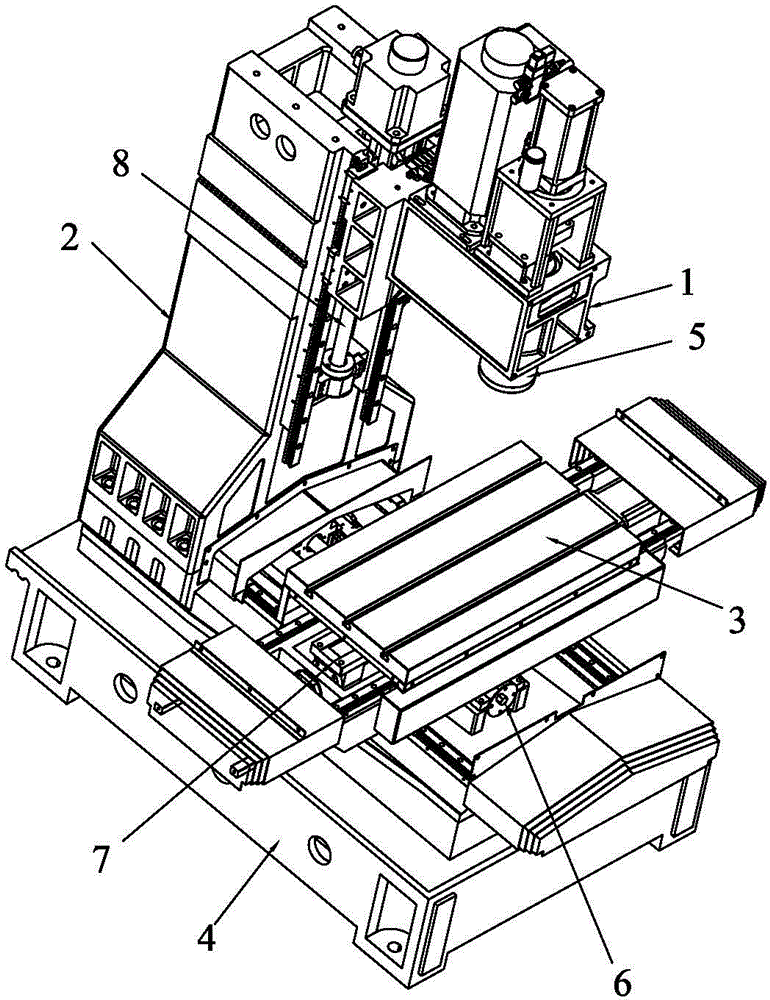

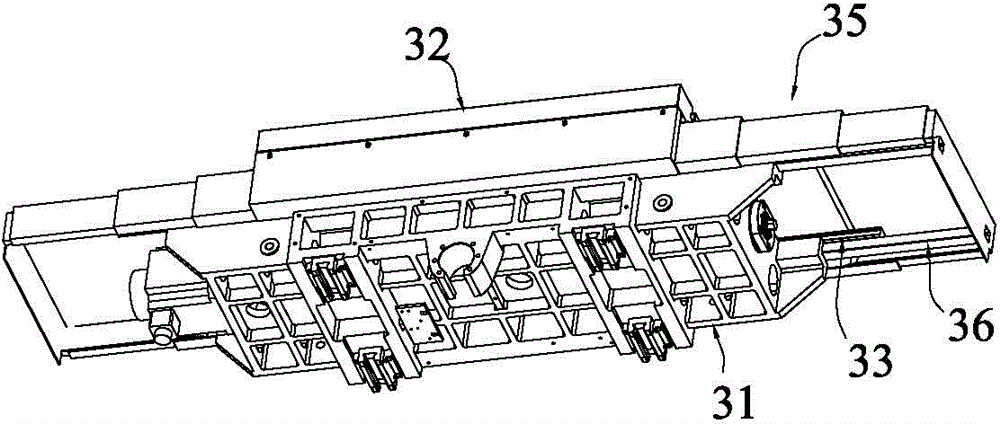

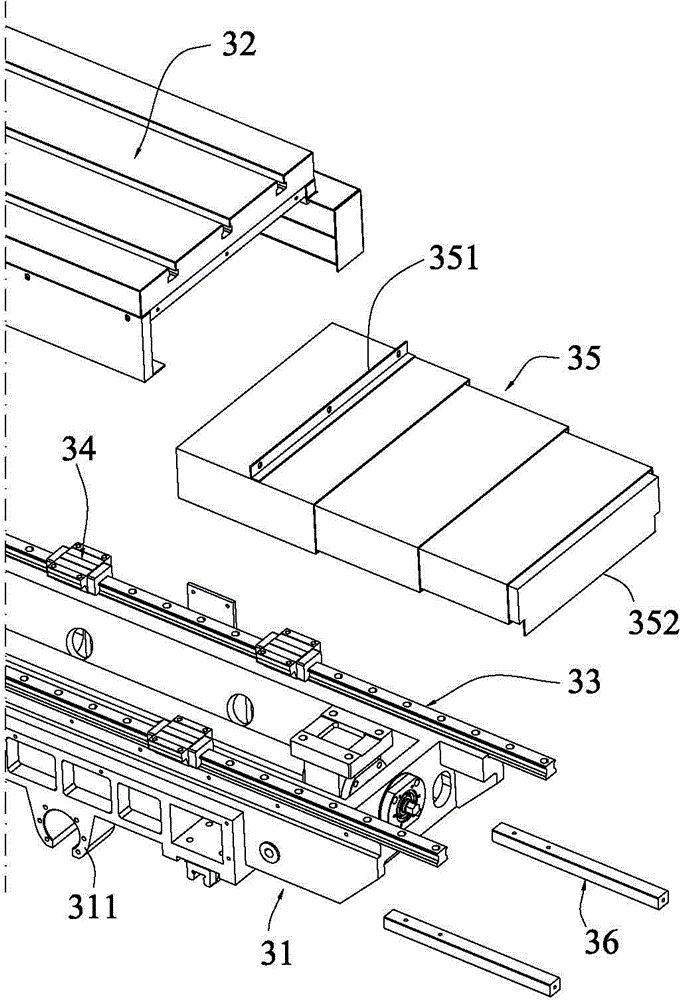

High-precision vertical type machining center

ActiveCN104802038AReasonable structural designImprove rigidity and stabilityLarge fixed membersMetal working apparatusAutomatic controlProcessing accuracy

The invention discloses a high-precision vertical type machining center comprising a pedestal, an upright column, a worktable, a spindle case, a PLC controller, a machining spindle component, a Y-axis movement mechanism, an X-axis movement mechanism and a Z-axis movement mechanism. The worktable comprises a saddle, a worktable plate, a telescopic protecting cover, and a sliding rail extension bracket. The saddle is installed on the Y-axis movement mechanism. The X-axis movement mechanism comprises a linear sliding rail and a sliding block. One end of the telescopic protecting cover is connected with the worktable plate; the other end is connected with the sliding rail extension bracket. The high-precision vertical type machining center is reasonable in structural design. An automatic control is conducted by the PLC controller, and the purpose of the automatic machining can be achieved by clamping once, with fast machining speed, high precision and good working stability. Moreover, by reasonably designing the worktable, the rigidity and the stability of the entire structure are increased, thereby effectively reducing the vibration. With the high machining precision, the stable running, and the good protecting effect, the cutting chips or other foreign materials are effectively prevented from dropping onto the guide rail, thus the service life is long.

Owner:普锐米勒机床(东莞)有限公司

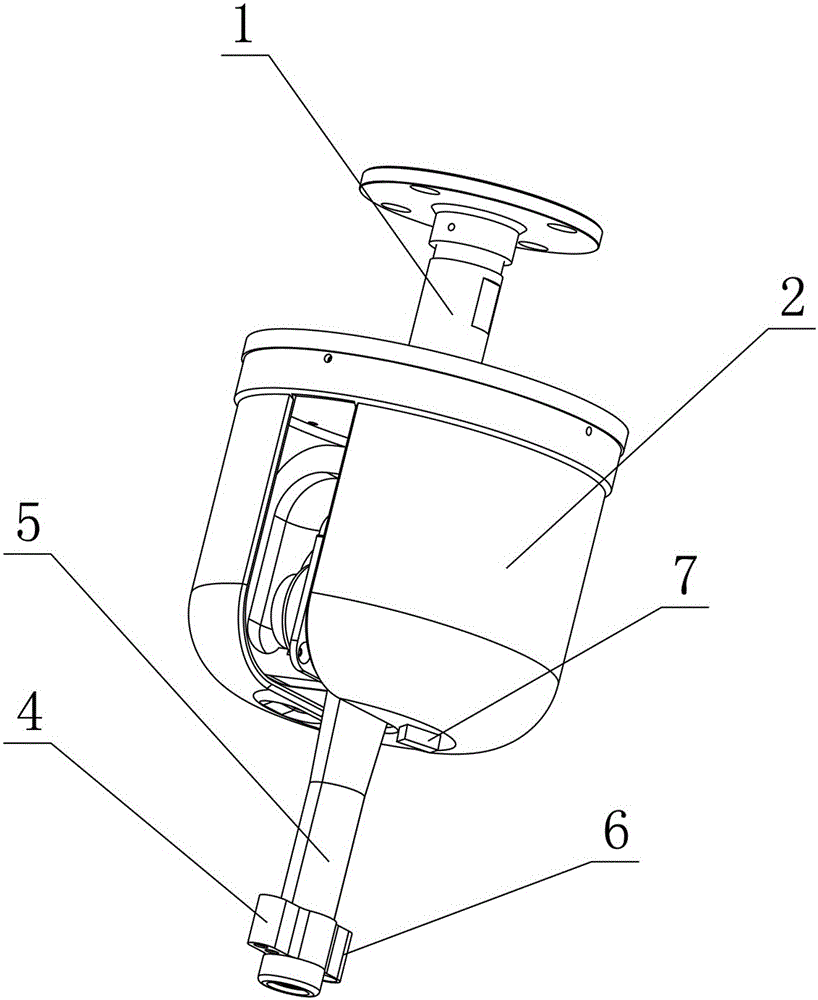

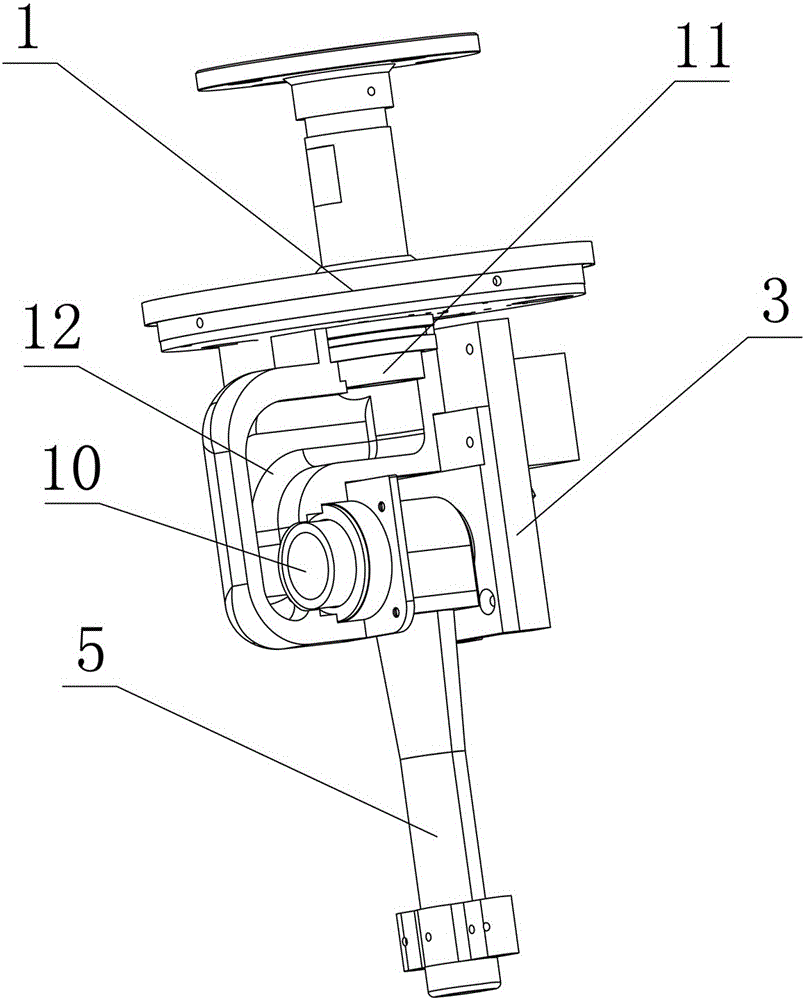

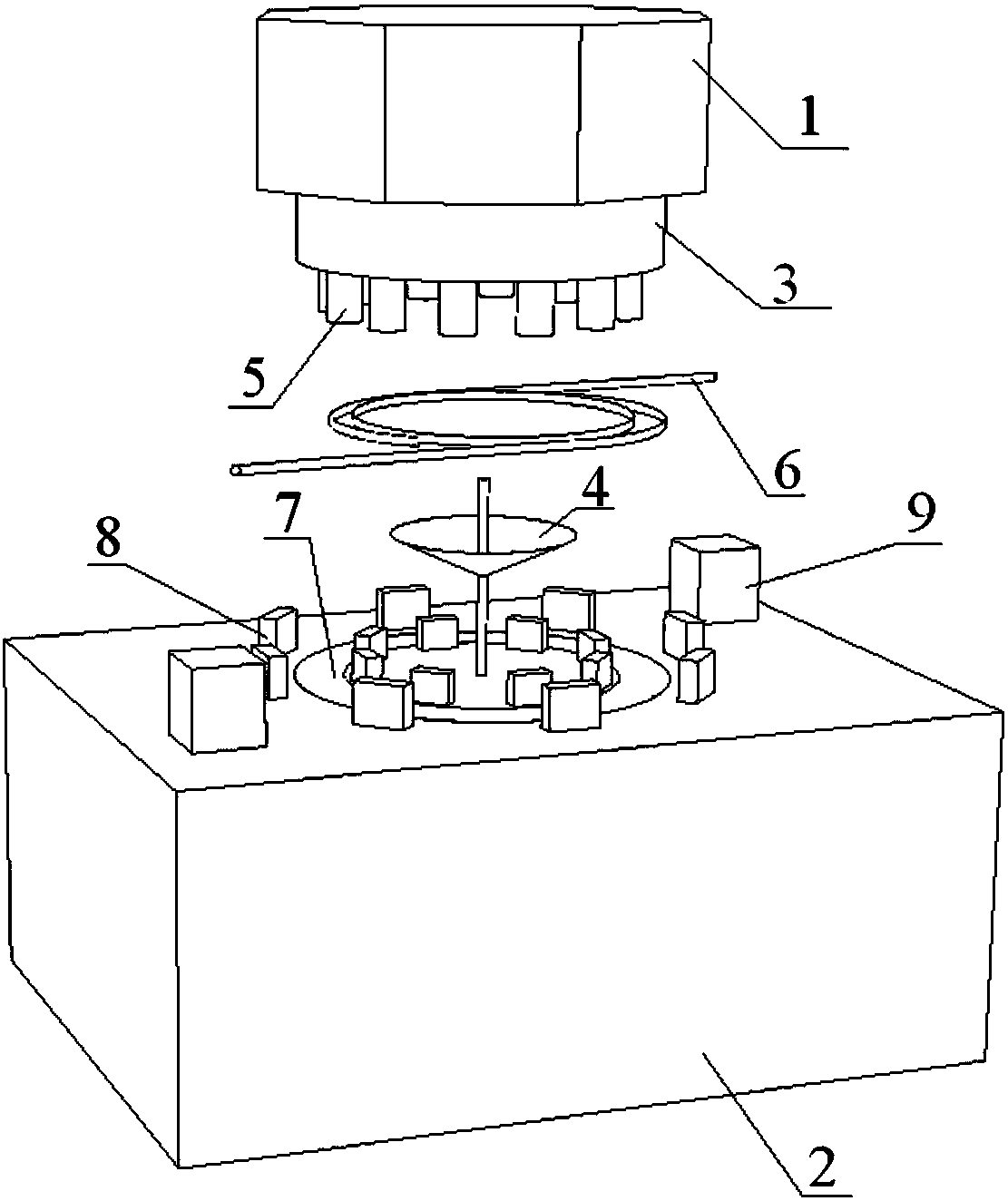

Automatic tracking and positioning fire water monitor and automatic tracking and positioning jet flow fire-extinguishing method

The invention provides an automatic tracking and positioning fire water monitor and an automatic tracking and positioning jet flow fire-extinguishing method. The automatic tracking and positioning fire water monitor comprises a base, a support, a shell, a fire water monitor body, an infrared thermal imaging sensor, a processor, a water pump electric control valve, a horizontal stepping motor and a longitudinal stepping motor. The processor draws the coordinates of a thermal image in real time and judges the coordinates of the kindling point according to a preset temperature threshold value, and the thermal image is sent by the infrared thermal imaging sensor in real time. The fire water monitor body is positioned to the coordinates of the kindling point rapidly and tracks the coordinates of the kindling point in real time until the processor controls the water pump electric control valve to be opened and the fire water monitor body sprays water. The automatic tracking and positioning fire water monitor has the advantages of being scientific in design, rapid and accurate in positioning and capable of realizing movable fire tracking. The use method includes the steps of (1) clearing, (2) scanning, (3) judgment, (4) fire extinguishing, (5) water stop detection, (6) fire-extinguishing finishing and the like, and has the advantages of being simple, efficiency, capable of realizing movable fire tracking, complete in scanning coverage and capable of preventing detection omission.

Owner:河南联纵消防科技有限公司

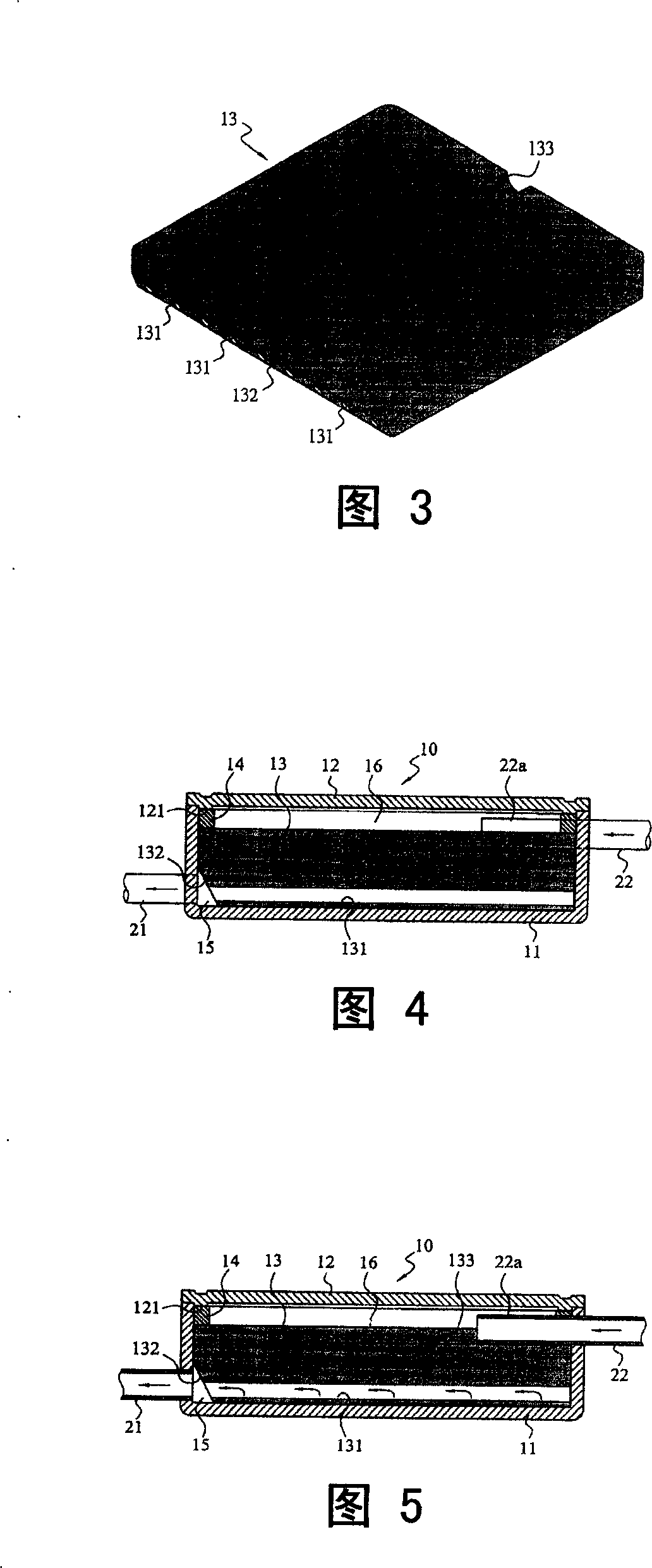

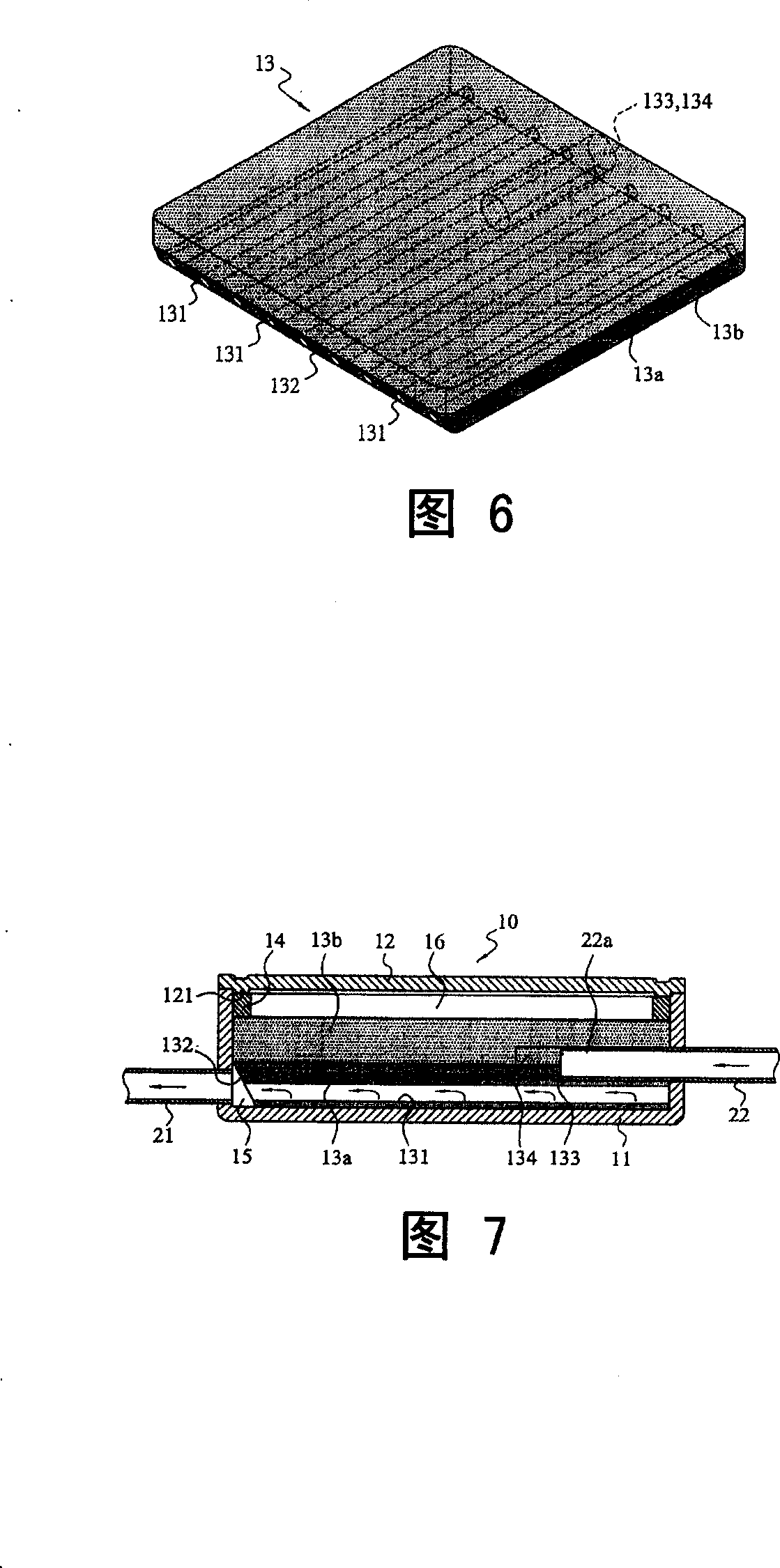

Loop heat-conducting device

InactiveCN101026946ADoes not increase flow resistanceIncrease capillary forceDigital data processing detailsSemiconductor/solid-state device detailsHeat conductingEngineering

The loop heat conducting equipment includes vaporizer and condenser connected to each other through circle pipe so as to constitute circulation loop of liquid working medium. The vaporizer possesses core body of capillary structure (CBCS) inside. Multiple tunnels are formed in CBCS. One end of tunnels is converged to vapor chamber, which is connected to one end of the circle pipe to form the output end of gas state working medium. After through the condenser, the other end of the circle pipe as the input end of formed liquid working medium is connected to the vaporizer. Extending into and contacting with inner CBCS, end of the circle pipe forms compensated chamber of liquid working medium on up portion of CBCS. Using gas and liquid separated circulation loop, the invention reaches optimal efficiency of heat elimination. Features are: simple structure, and easy of measure yield.

Owner:YEH CHIANG TECH CORP

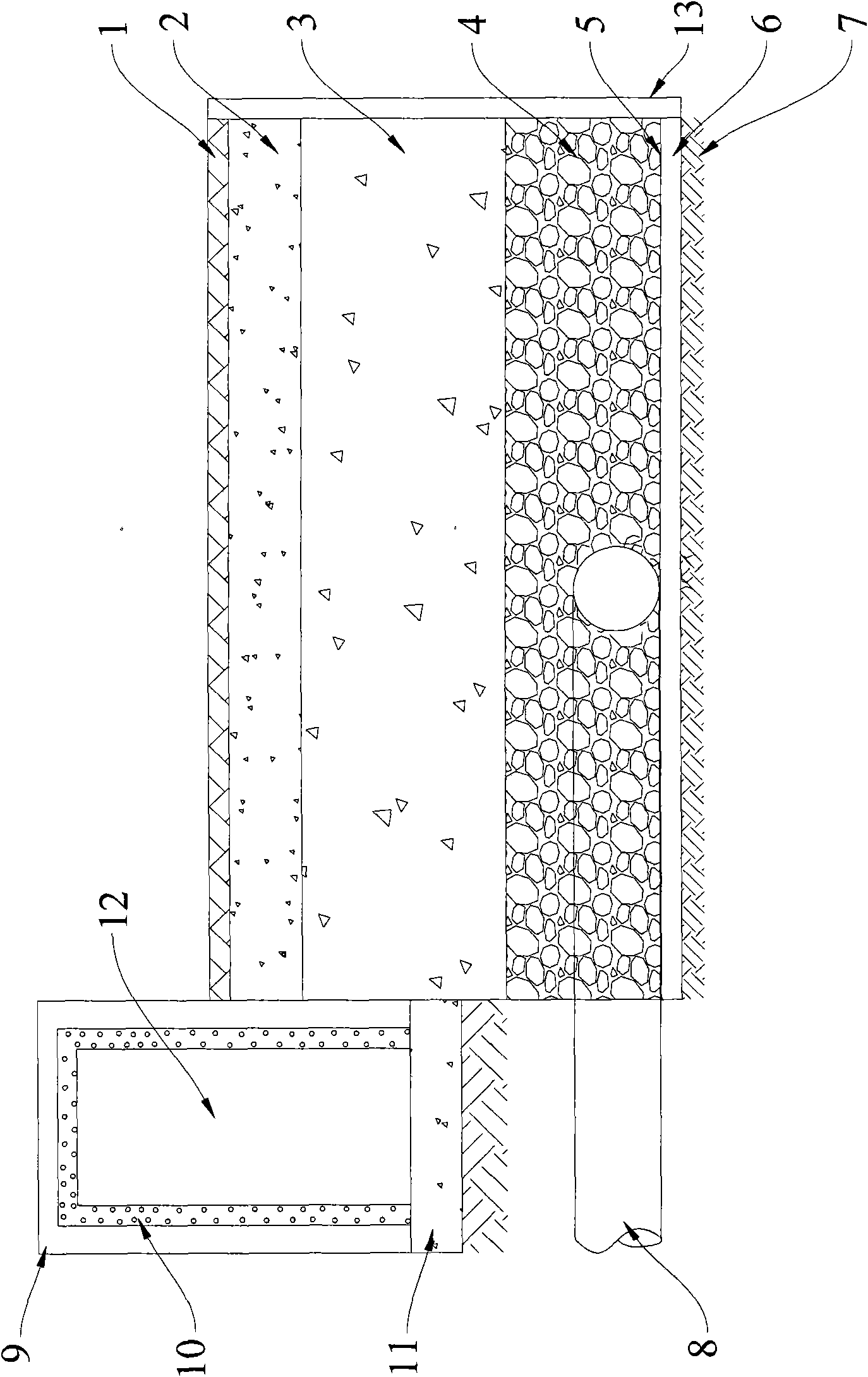

Road drainage system

ActiveCN101649592ADrain in timeGuaranteed trafficGround-workPaving gutters/kerbsSurface layerRoad surface

The invention discloses a road drainage system comprising a road surface drainage part and a road side drainage part, wherein the road surface drainage part is orderly provided with a base layer, a waterproof layer and a non-watertight layer from bottom to top; the upper part of the waterproof layer is provided with a road surface drainage groove; the road side drainage part comprises non-watertight curbstones and road side drainage grooves; the non-watertight curbstones are arranged on both sides of a road and adjacent to the road surface drainage part; the road side drainage grooves are arranged under the non-watertight curbstones; the non-watertight curbstone comprises a non-watertight surface layer and a non-watertight strengthening layer; the non-watertight surface layer contains non-watertight material; the non-watertight strengthening layer is adjacent to the inner surface of the non-watertight surface layer and a cavity is arranged in the non-watertight strengthening layer. The road drainage system is provided with the road surface drainage part and the road side drainage part; the road side drainage part is provided with a guide cavity; and the rain water is drained in time after quickly penetrating through the thinner non-watertight surface layer, thereby ensuring the normal traffic of vehicles and the passerby traffic.

Owner:RENCHSAND ECO ENVIRONMENT PROTECTION SCI & TECH CO LTD

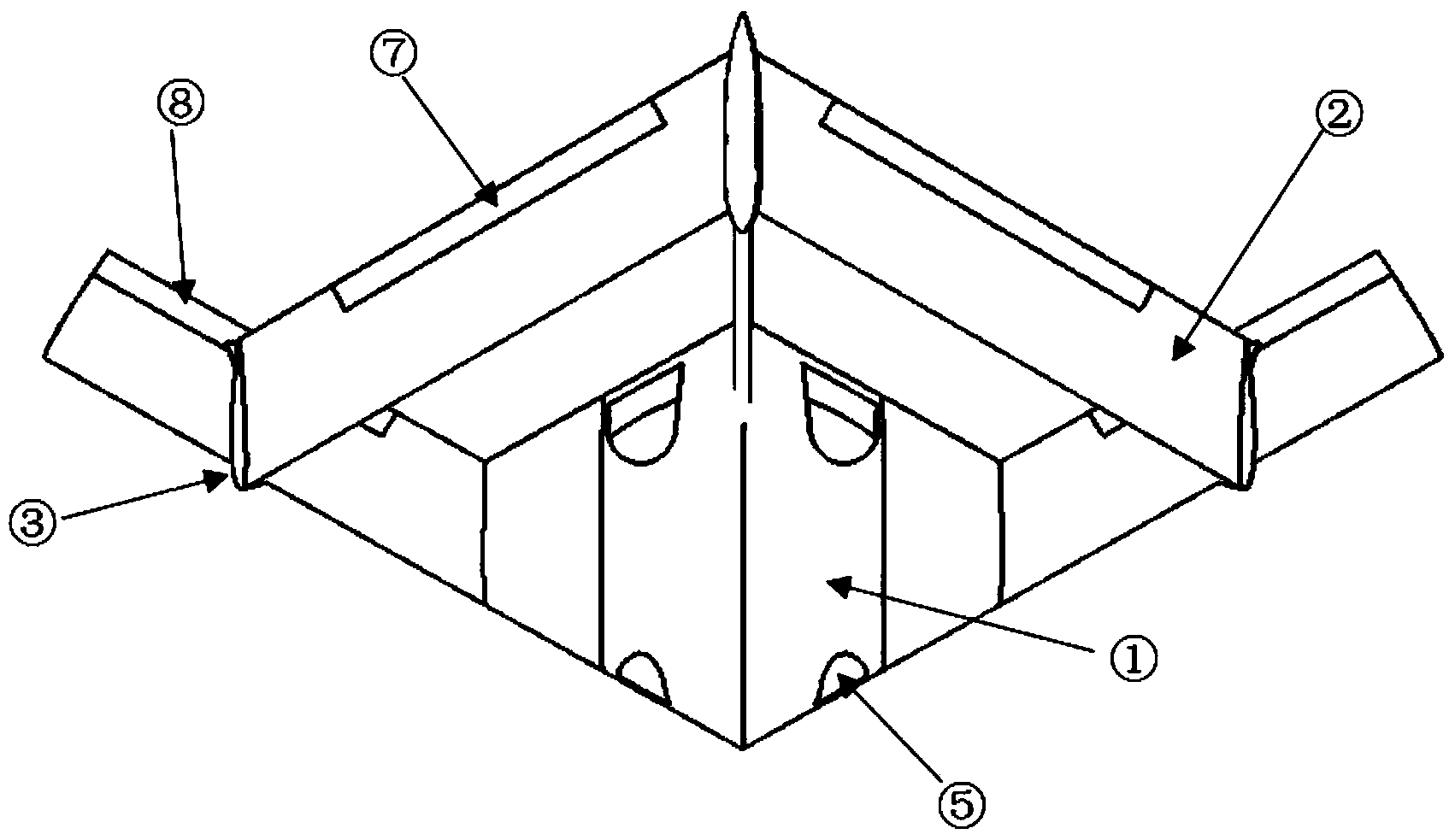

Airplane with combined-wing layout of flying wing and forward-swept wings

ActiveCN103552682AGood aerodynamic liftOptimize layoutAircraft stabilisationWingsJet aeroplaneInlet channel

The invention provides an airplane with a combined-wing layout of a flying wing and forward-swept wings. The airplane is characterized in that thin-wing type vertical columns A and B are additionally arranged at the 70% wingspan positions of the outer sides of two side wings of a flying-wing airplane with backward-swept wings, a thin-wing type vertical column C is additionally arranged at the tail part of the flying-wing airplane, and horizontal forward-swept wings are additionally arranged at the top ends of the three thin-wing type vertical columns A, B and C so as to form the combined-wing layout of the flying wing and the forward-swept wings; elevators are arranged on the horizontal forward-swept wings and a rudder is arranged on the vertical column C; a duct type air inlet channel is adopted on the upper wing surface of the flying wing, and cracking type drag rudders are distributed at the thin-wing type vertical columns A and B. The airplane provided by the invention has the advantages that under the condition that the structure strength is effectively guaranteed, the effective aspect ratio of the wings is increased, the induced drag is reduced, the lift-drag characteristics of the airplane are improved, the stealth performance of the airplane is improved, direct-force control of the airplane in the vertical direction is realized and the detecting accuracy under the maneuvering condition is improved.

Owner:BEIHANG UNIV

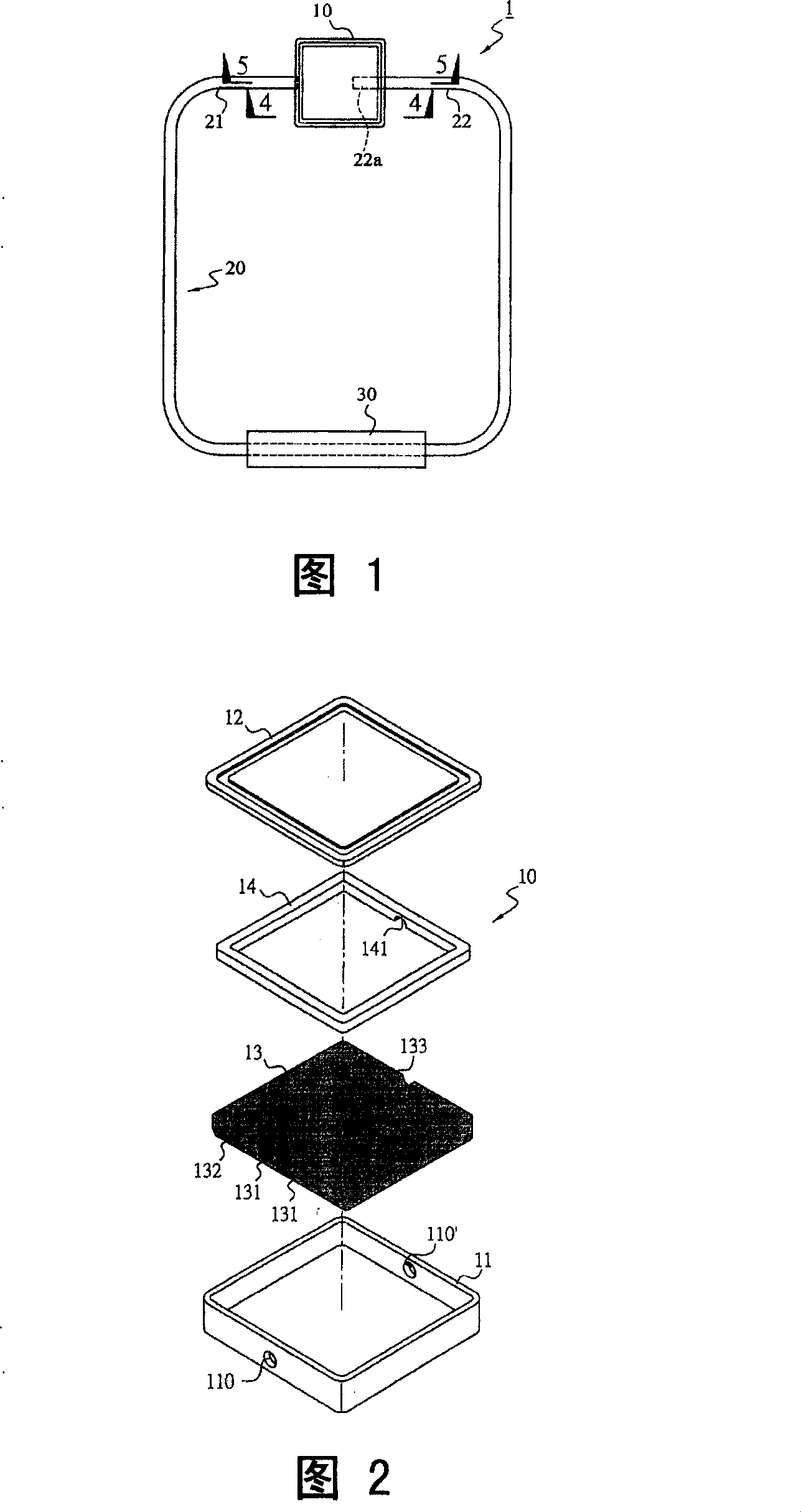

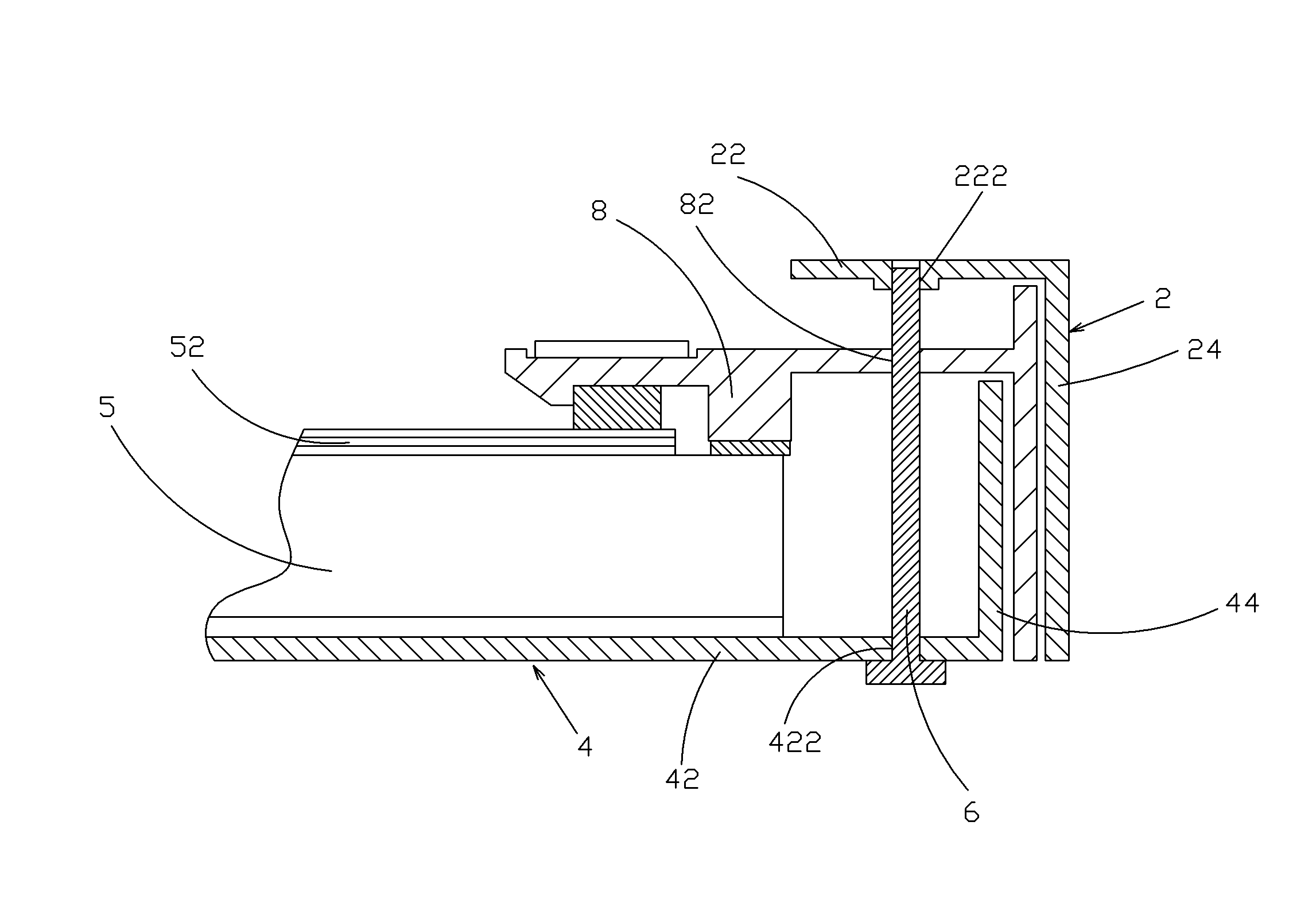

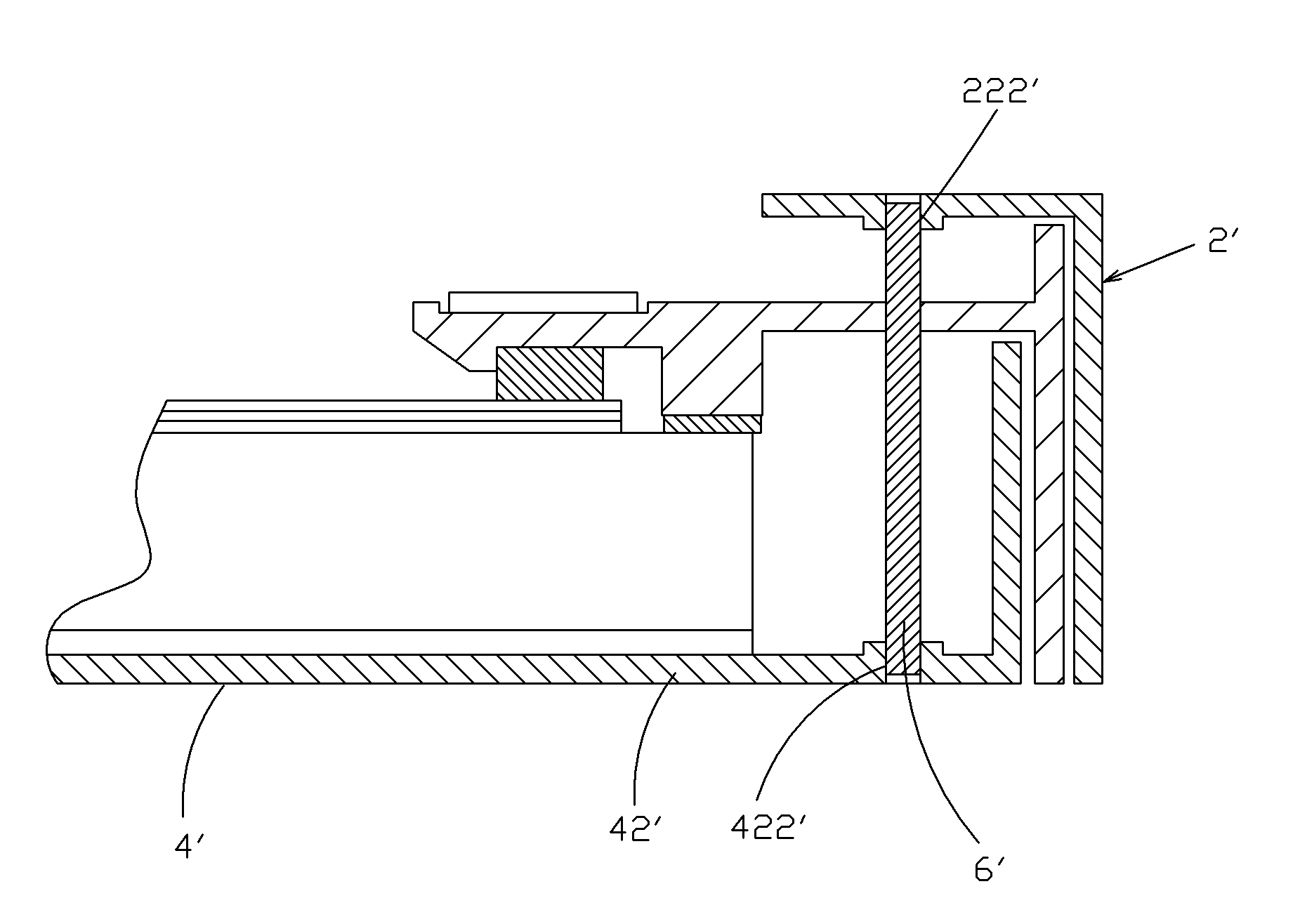

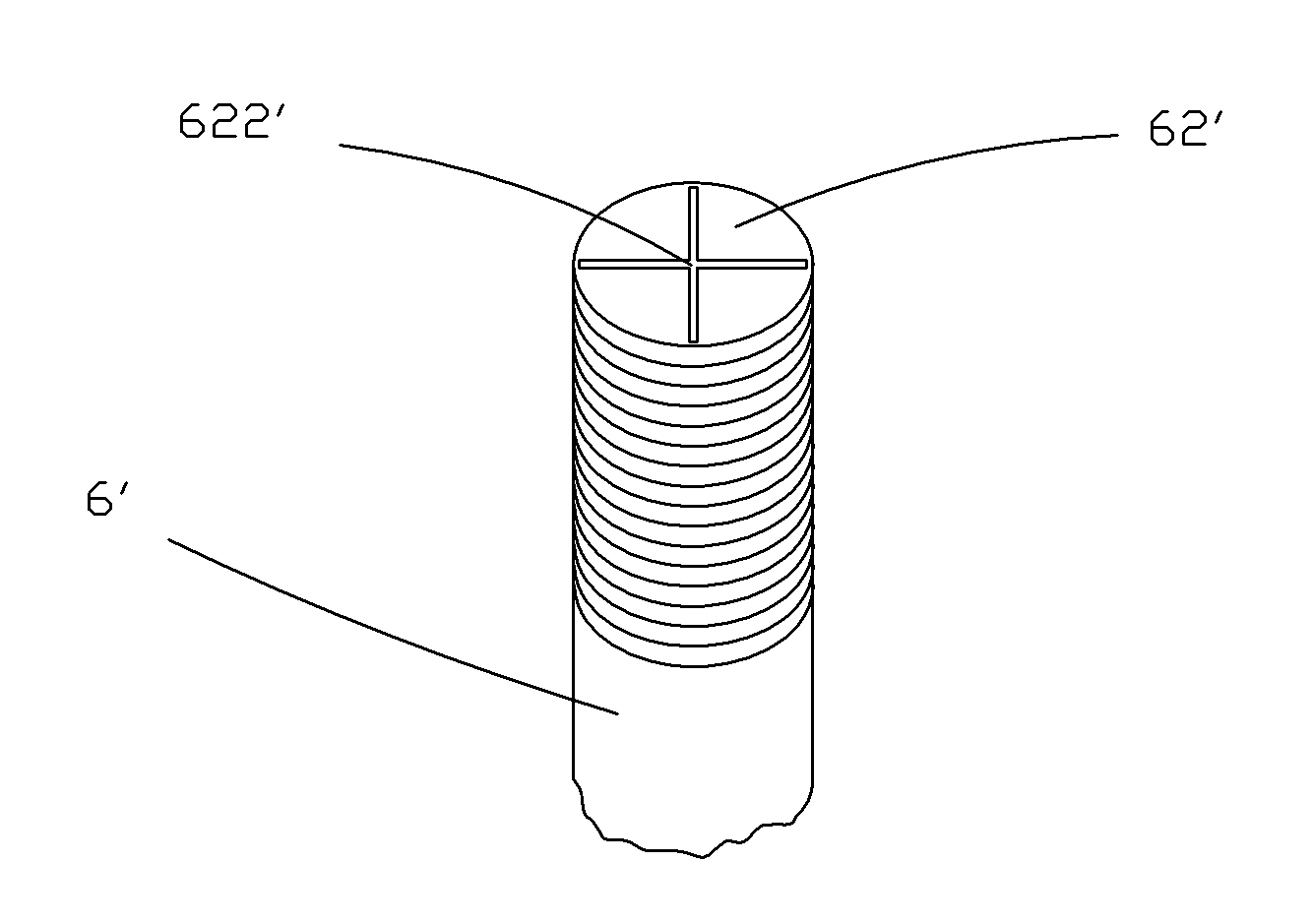

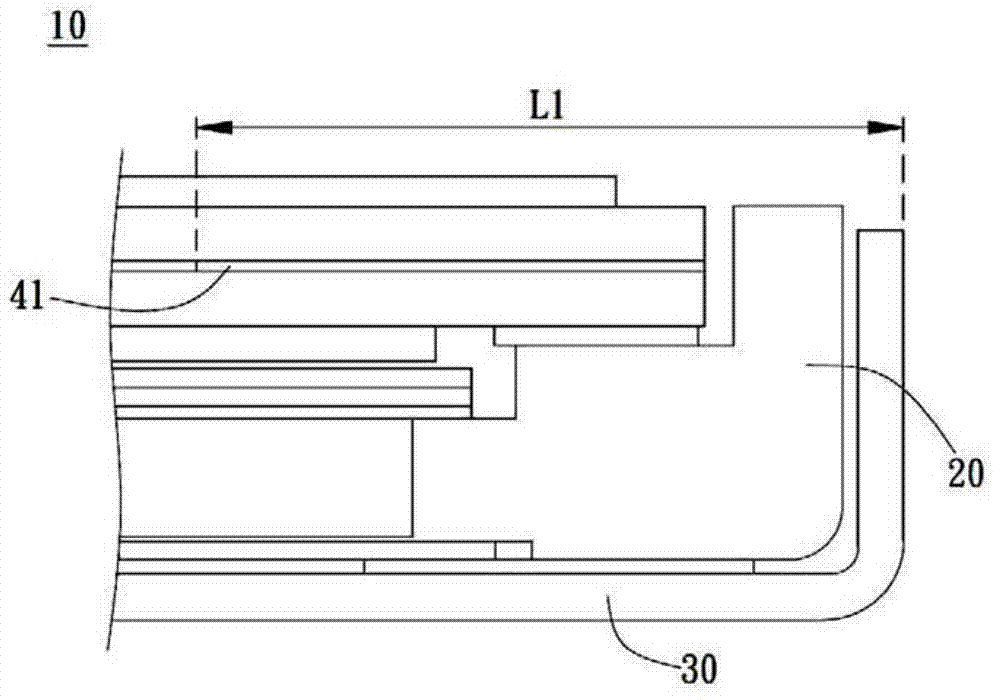

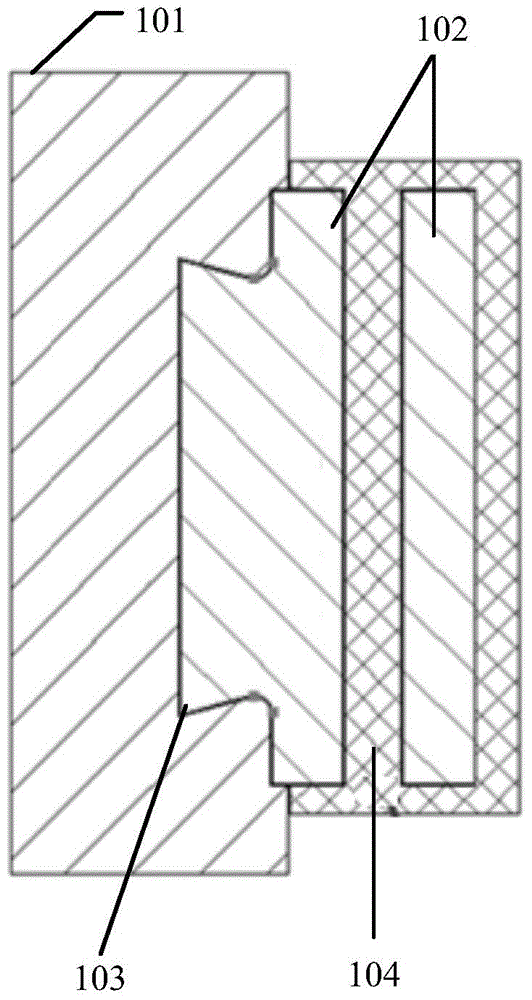

Backlight module with narrow frame of liquid crystal display device

InactiveCN102384413AConducive to narrow borderGuaranteed structural strengthOptical light guidesNon-linear opticsLiquid-crystal displayEngineering

The invention provides a backlight module with a narrow frame of a liquid crystal display device. The backlight module comprises the frame, a back plate, a connection piece and a rubber frame which is arranged on the back plate; the frame comprises a bottom plate opposite to a front panel; the front panel of the frame concaves inwards to form a first tapping hole with an inner thread; the bottom plate of the back plate is provided with a hole part corresponding to the tapping hole; the rubber frame is provided with a through hole corresponding to the hole part; the connection part passes through the through hole; and both ends are respectively in a fit connection with the first tapping hole on the front panel of the frame and the hole part on the bottom plate of the back plate so that the frame is locked with the back plate. According to the backlight module provided by the invention, space positions of the rubber frame and the back plate are saved; meanwhile, material is avoided be cut by the rubber frame in a large area to avoid convex hulls on the frame and the back plate, therefore, the structure intensity of the rubber frame is ensured, and the frame of the backlight module is easy to narrow.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

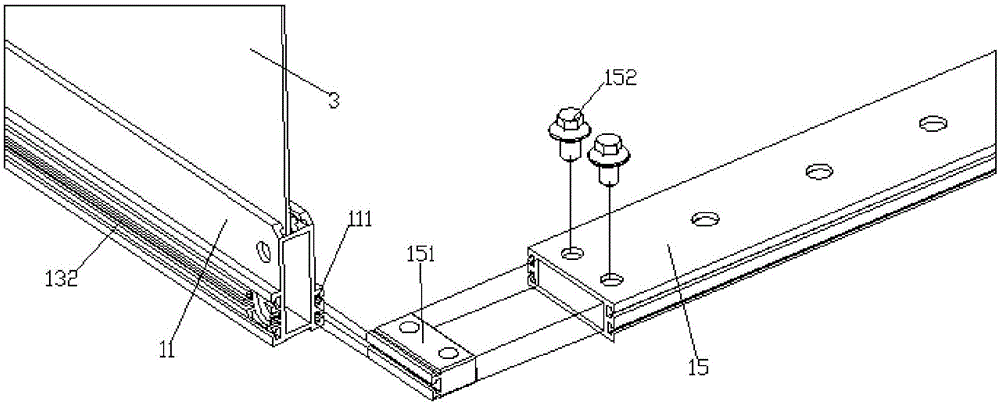

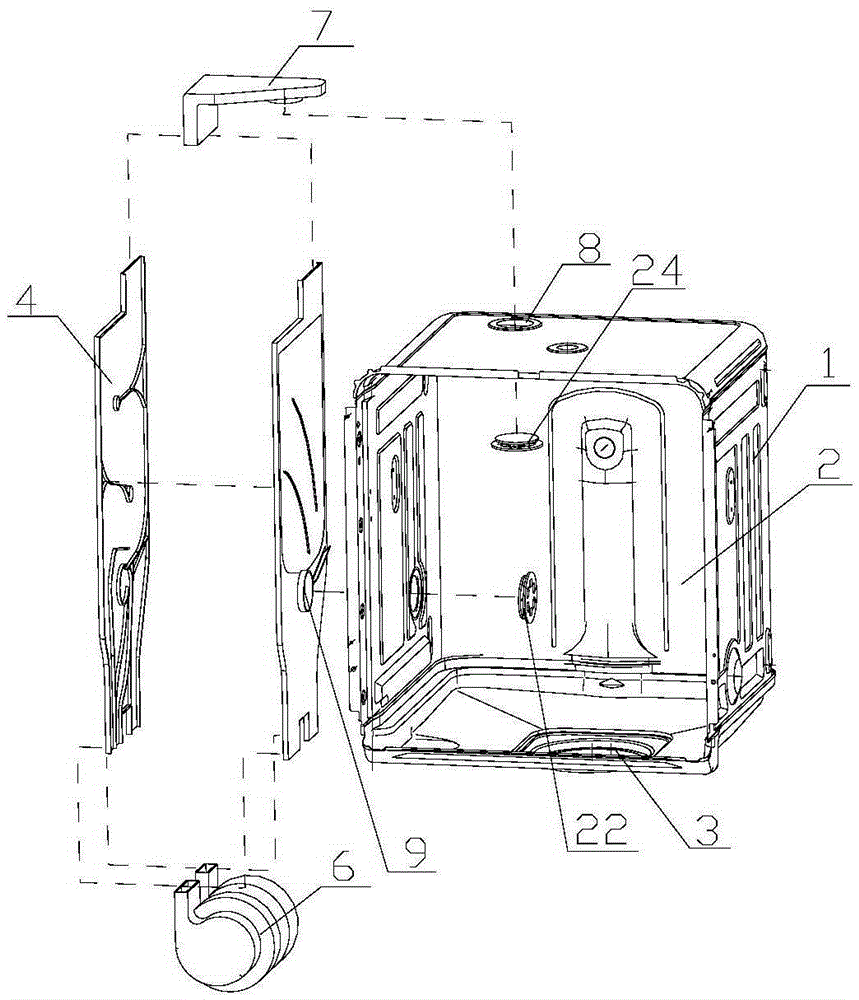

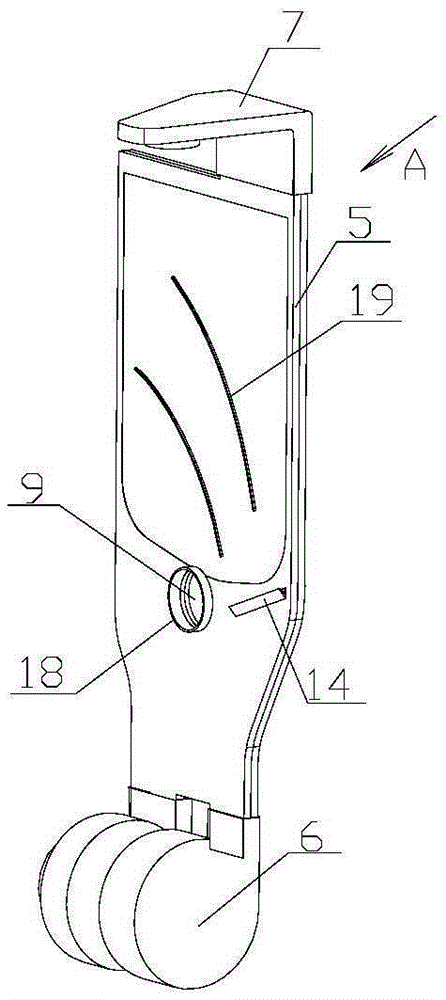

Frame for LED display screen

InactiveCN104270926AReduce difficultyGuaranteed structural strengthRack/frame constructionIdentification meansRear quarterLED display

The invention is suitable for the technical field of display screen structures, and discloses a frame for an LED display screen. The frame comprises a hollow body formed by combining a plurality of lateral plates connected end to end, connecting parts are arranged at the portions where the lateral plates are connected end to end, reinforcing ribs connected with the lateral plates are arranged in a hollow part of the body, each lateral plate is connected with the adjacent lateral plate of the frame through a connecting assembly, a handle part and a foot stepping part are arranged on each lateral plate, each handle part is used for hand holding and climbing force exertion during maintenance, and each foot stepping part is used for foot stepping force exertion during maintenance. The frame for the LED display screen is light in quality, various and attractive in appearance, high in production efficiency, low in manufacturing cost and high in structure intensity, direct climbing can be achieved during maintenance, and the maintenance convenience is improved.

Owner:SHENZHEN AOTO ELECTRONICS

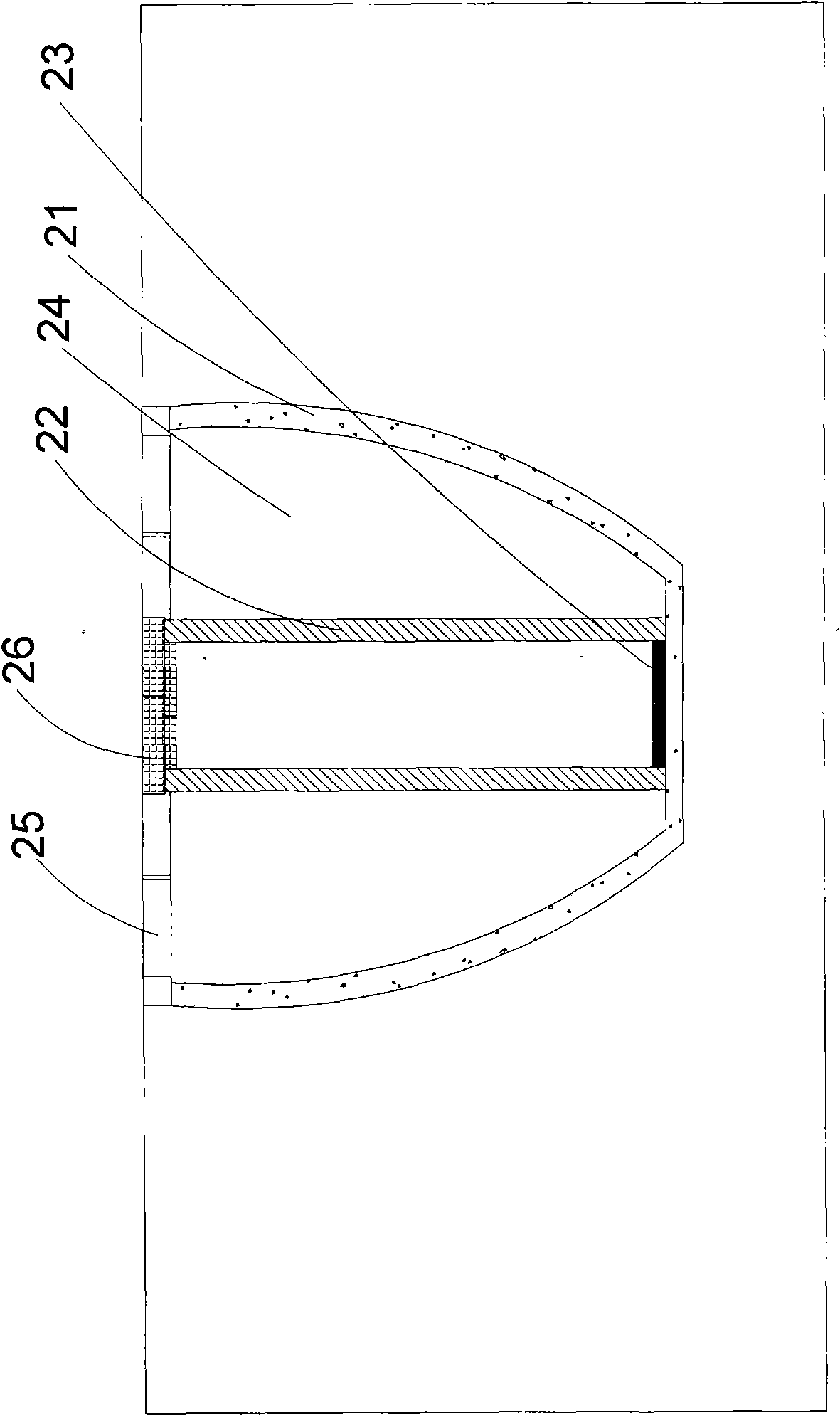

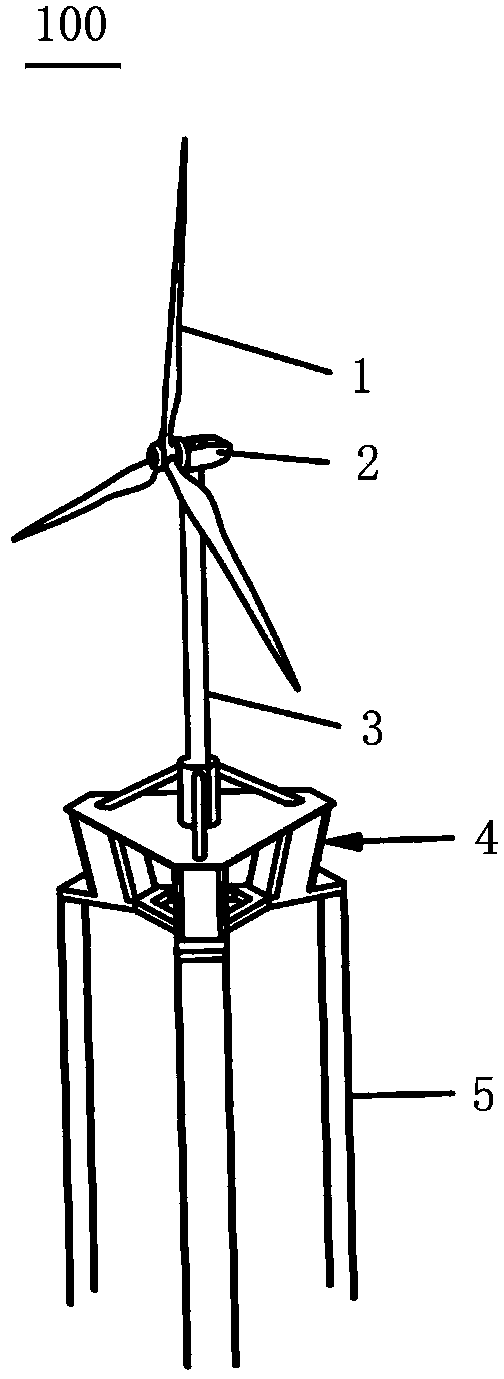

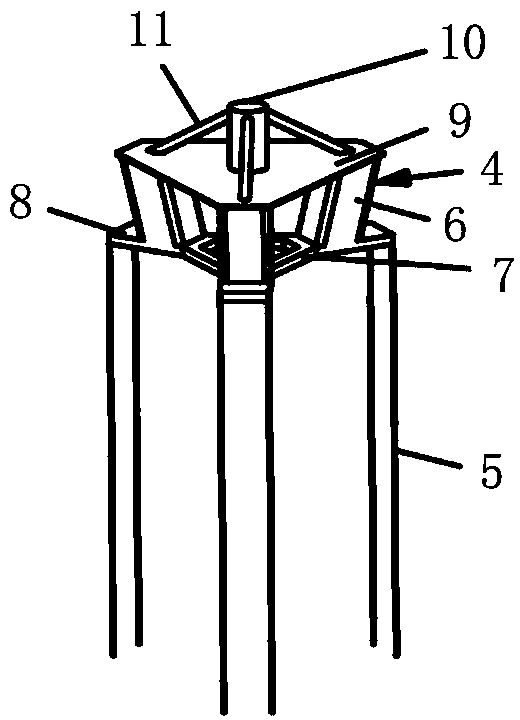

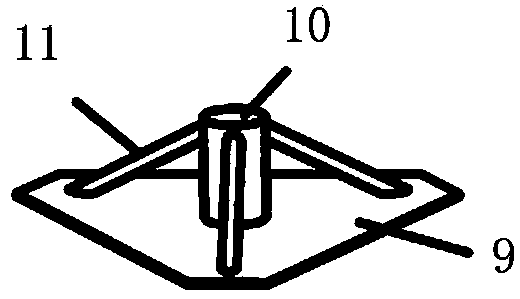

Floating fan base with flare type tension legs, marine wind-driven generator and construction method

ActiveCN103818523AStable stateOvercome the defect of excessive horizontal movementFinal product manufactureWind motor supports/mountsWind drivenEngineering

The invention discloses a floating fan base with flare type tension legs, a marine wind-driven generator and a construction method. The floating fan base comprises a top supporting platform, a bottom supporting structure, at least three hollow stand columns and a ballast regulating system, wherein the top supporting platform is used for supporting a pylon, blades and a wind-driven generator set; the bottom supporting structure is connected with multiple tension legs; the top supporting platform is connected with the bottom supporting structure via the hollow stand columns, the hollow stand columns are arranged around the vertical center line of the floating fan base, and each stand column inclines outwards from a lower end to an upper end relative to the vertical center line of the floating fan base; the ballast regulating system is arranged in the stand columns and / or the bottom supporting structure. The marine wind-driven generator of the base with the structure has excellent movement performance, integral wet towing can be performed, and the floating fan base and the marine wind-driven generator are convenient to manufacture, assemble and mount.

Owner:XINJIANG GOLDWIND SCI & TECH

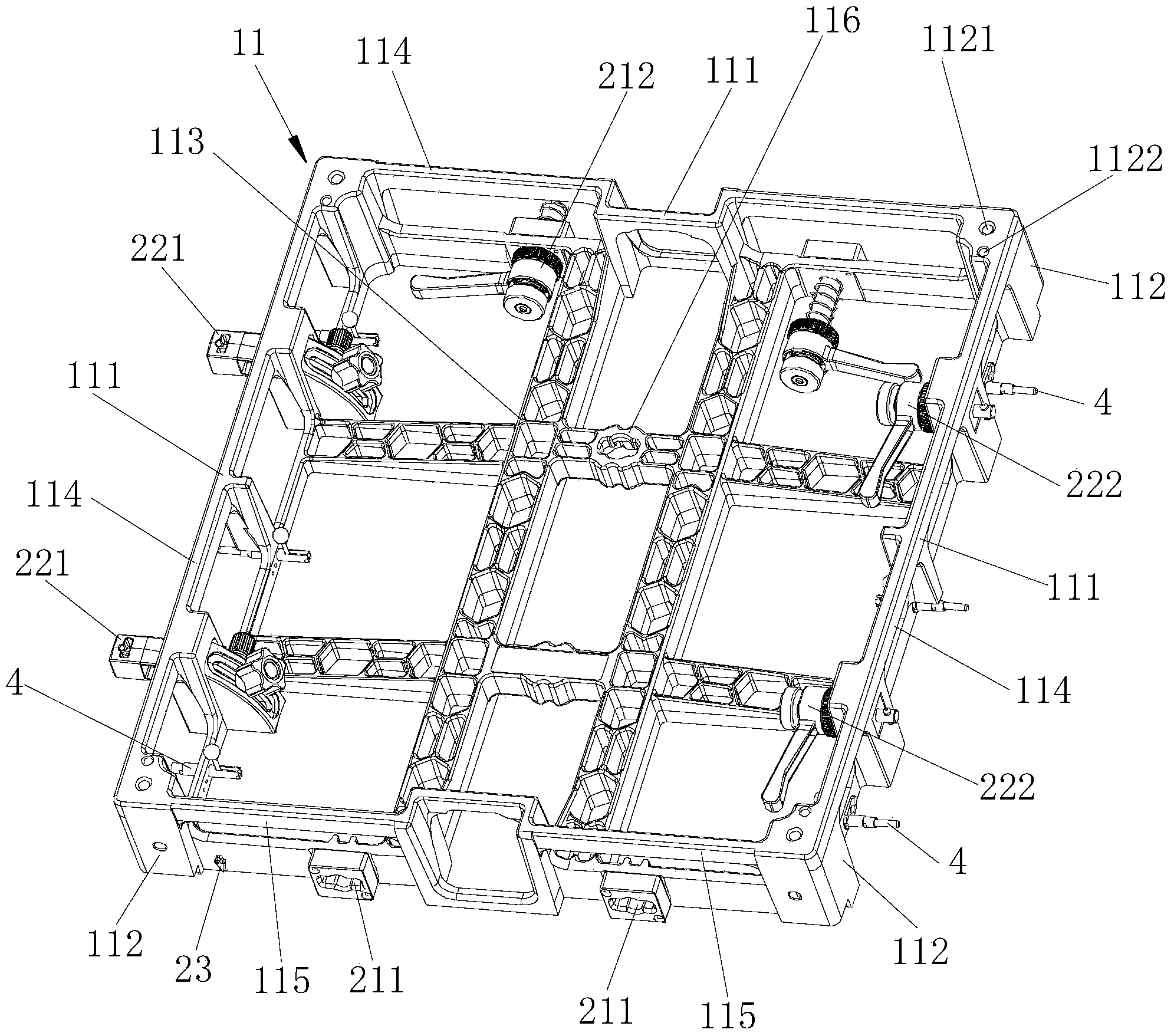

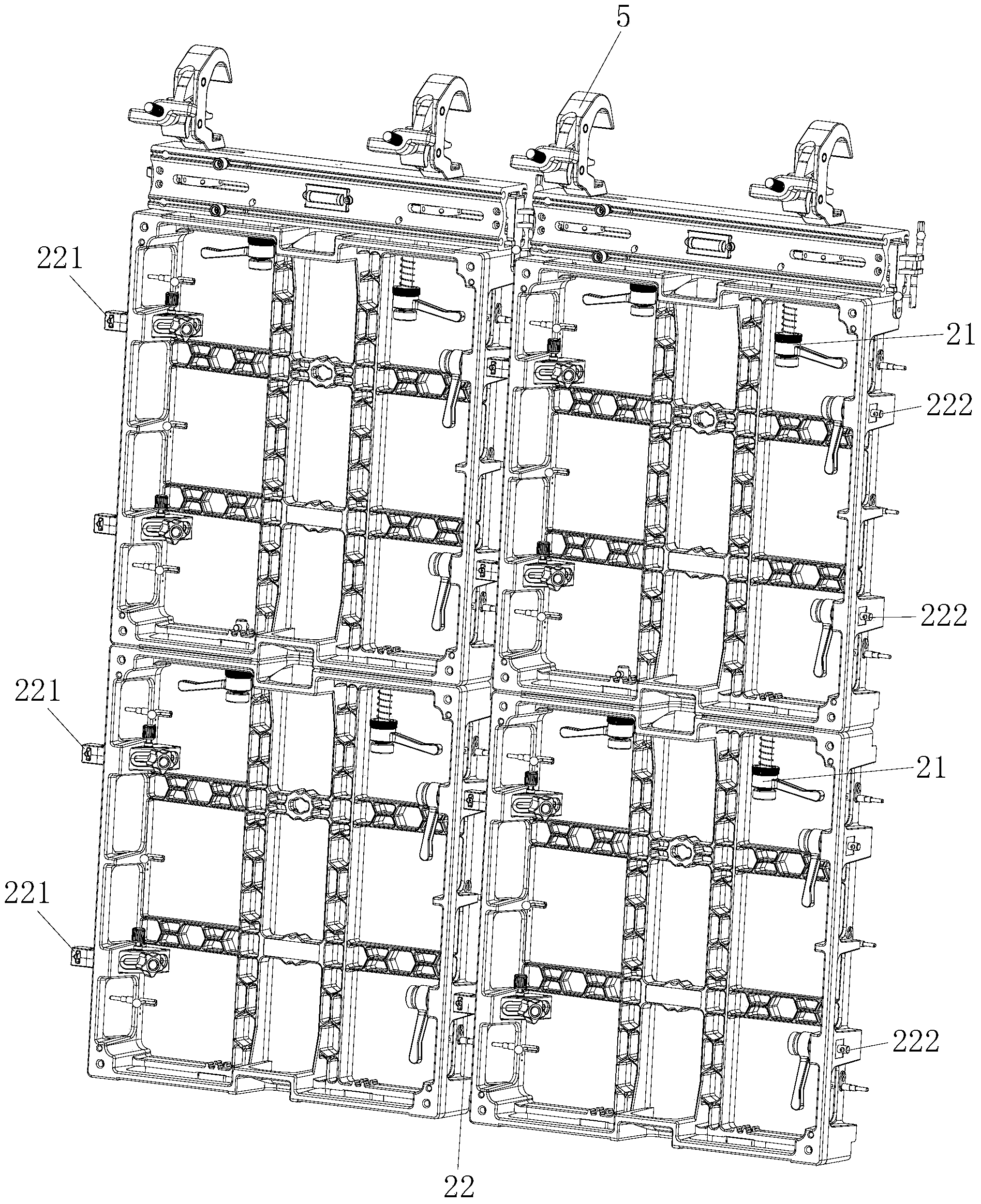

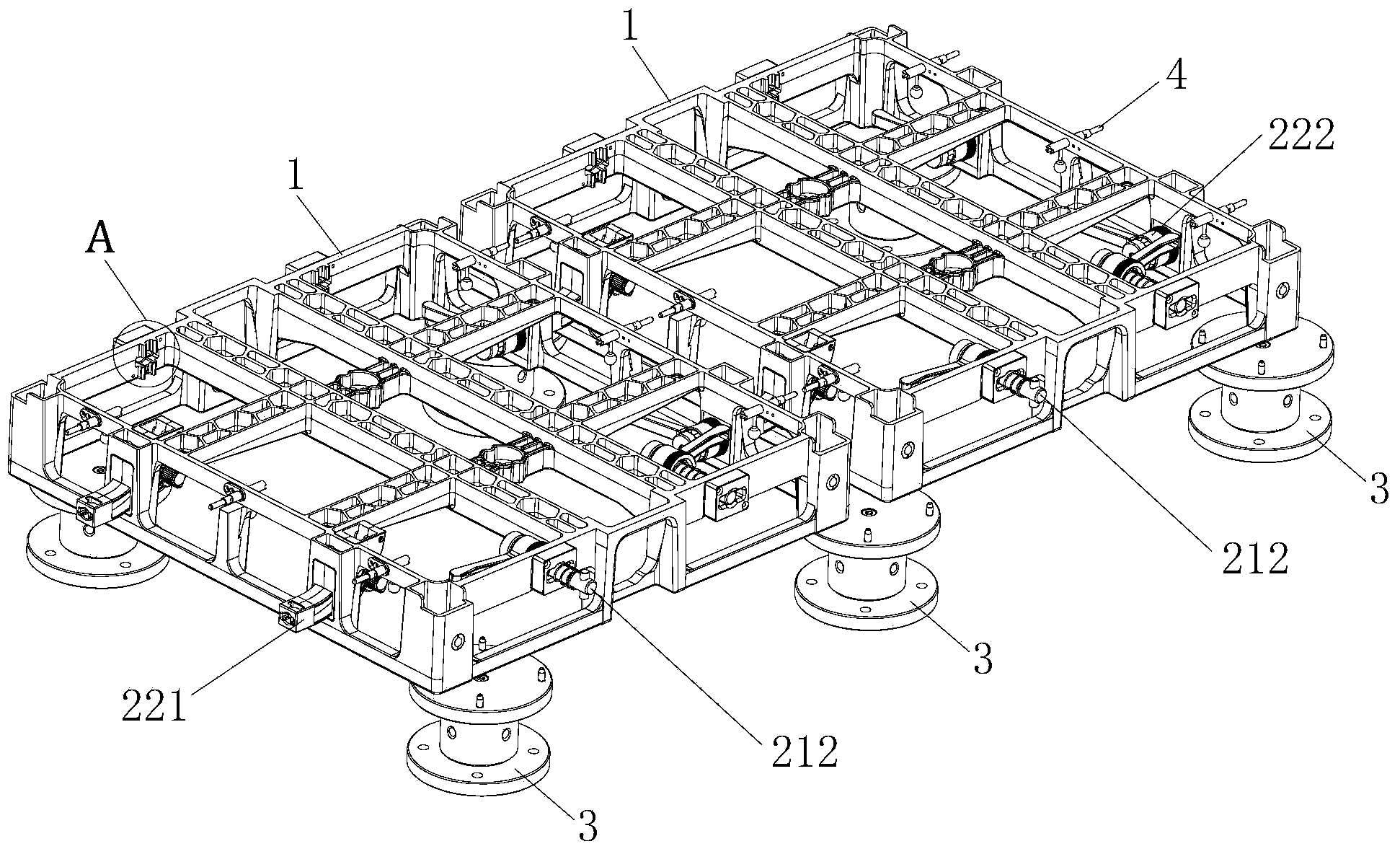

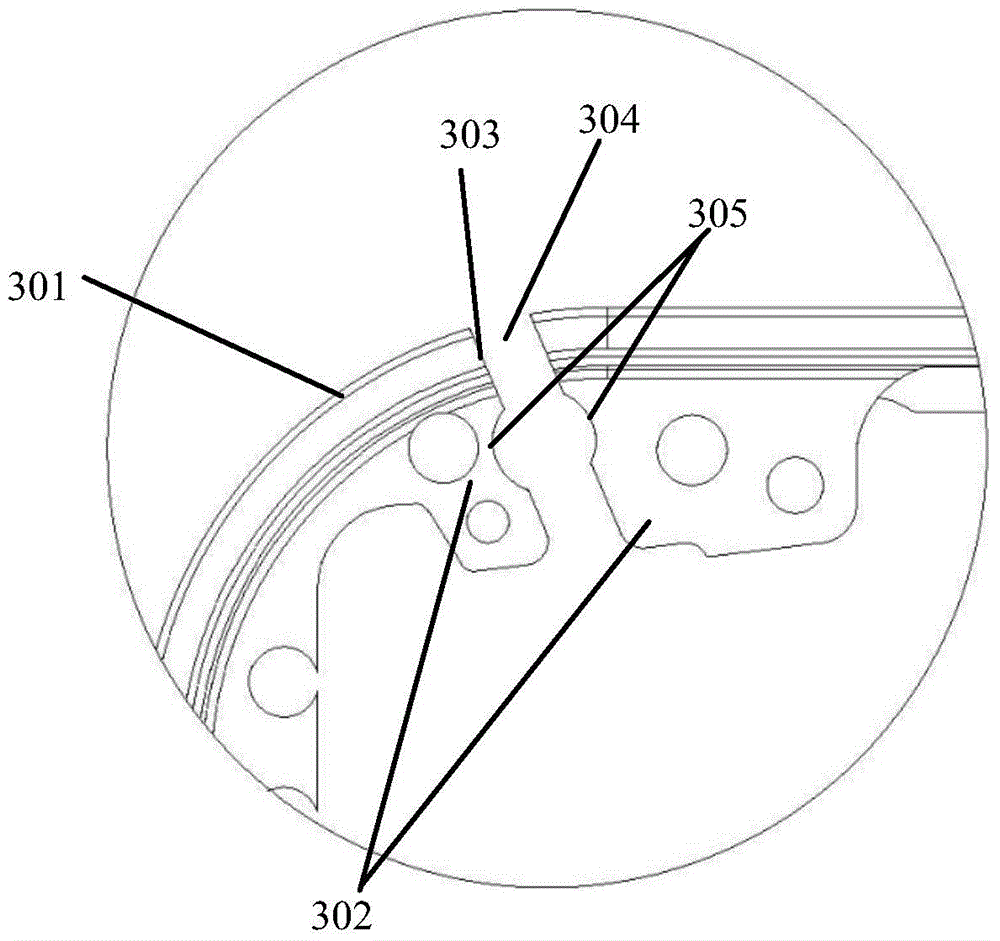

Battery pack frame

PendingCN106711368AExpandableIncrease energy densityCell component detailsEconomic benefitsBattery pack

The invention relates to a battery pack frame, which comprises a movable plug-in type frame body used for the placing of battery modules, wherein the movable plug-in type frame body is mainly formed by splicing a plurality of linear cross beams, linear longitudinal beams and liner vertical beams through corner connecting pieces. According to the scheme provided by the invention, the linear cross beams, the linear longitudinal beams and the liner vertical beams are plugged in and spliced to form the movable plug-in type frame body, and according to the required size dimension of the battery frame, the linear cross beams, the linear longitudinal beams and the liner vertical beams with different length dimensions are selected and are then spliced and fixed through the corner connecting pieces, so that a battery pack has extensibility, the development of a mold is reduced, and the installation dimension requirements of different vehicle models are met; in addition, the battery pack frame is convenient to install and disassemble, and the economic benefit of the battery pack frame is improved.

Owner:苏州奥杰汽车工业有限公司

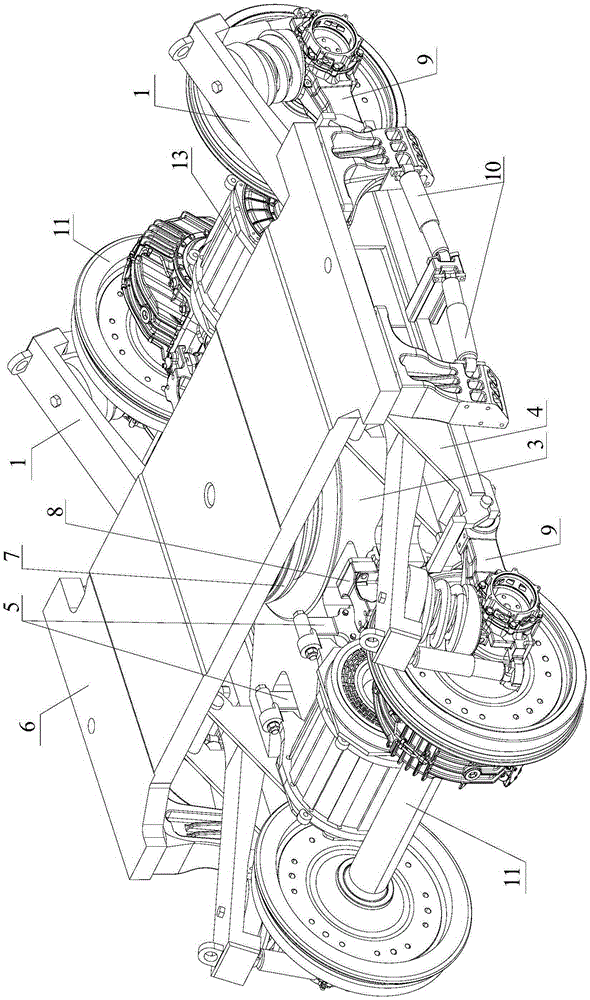

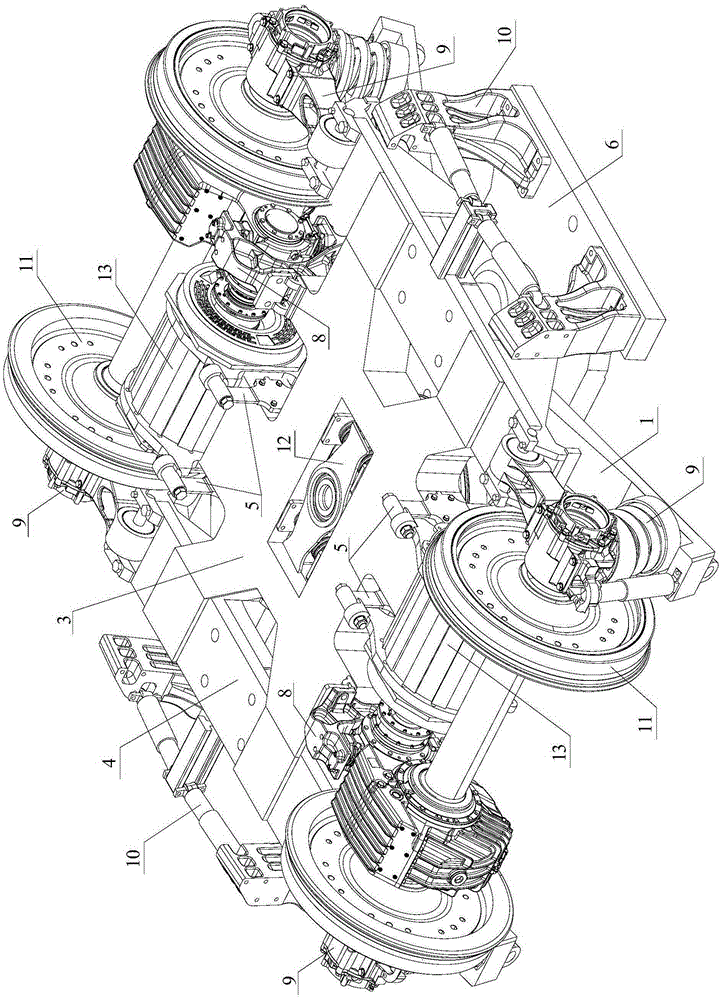

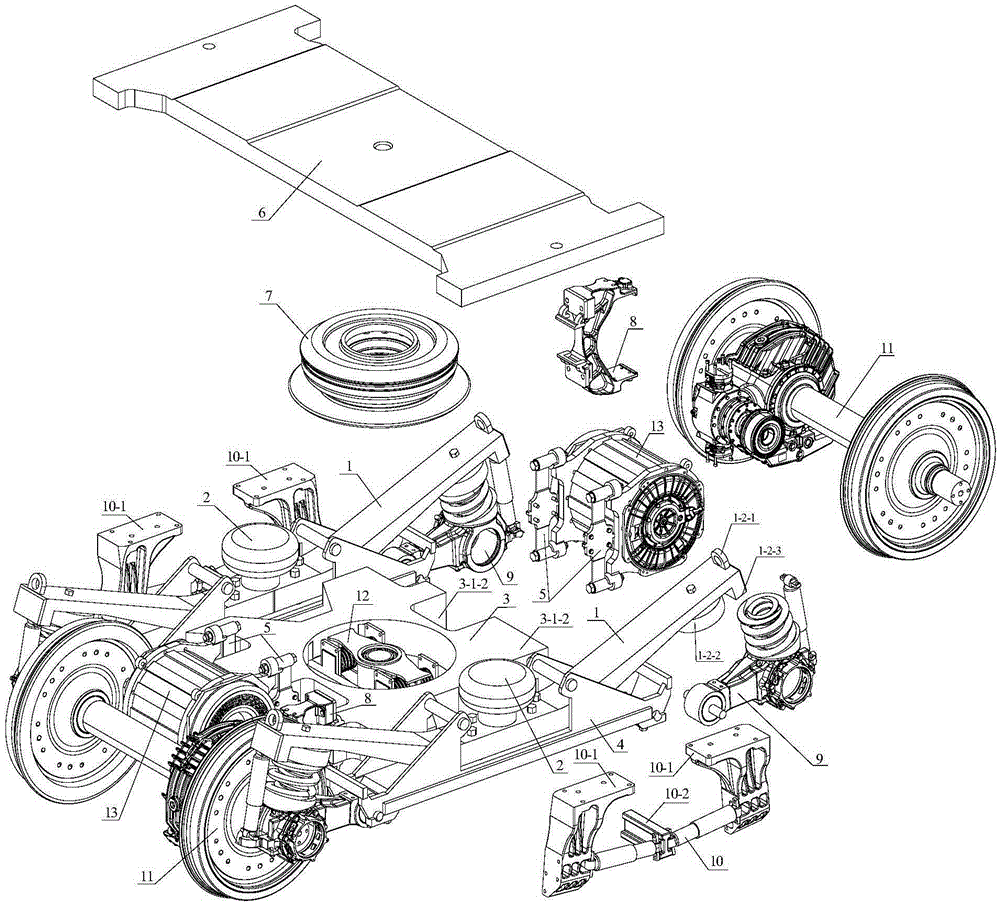

Ultra high speed test CRH (China Railway High-Speed) train bogie

ActiveCN105313913AFacilitate batch manufacturingEasy to sort and storeElectric motor propulsion transmissionRailway transportBogieUltra high speed

The invention relates to an ultra high speed test CRH train bogie and belongs to the field of railway vehicle bogie devices with elastic deformation buffering capacity, the problem of welding stress centralization is solved by a horizontal and longitudinal beam integrated type tray frame, and a wing-shaped elastic support arm of an elastic frame can have a damping effect by own elastic deformation. According to the novel bogie, by the aid of matching usage of the elastic frame and motor suspension devices with vibration absorption functions, high cut-down and inhibition effects can be realized on motor vibration, and accordingly, the vibration frequency control difficulty of a power system is reduced greatly and surplus vibration damping buffering components can be effectively cut down, so that redundant components can be simplified greatly, the structure dimension is shortened, and the weight is reduced. Master pin backward titling structures of traction wheel sets can swing consistently in S shapes. The ultra high speed test CRH train bogie can overcome inherent mutual contradiction of dual requirements on two aspects of lightweight design and speed lifting of a 500km / h ultra high speed train and is a novel breakthrough in the field of localization ultra high speed bogies.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

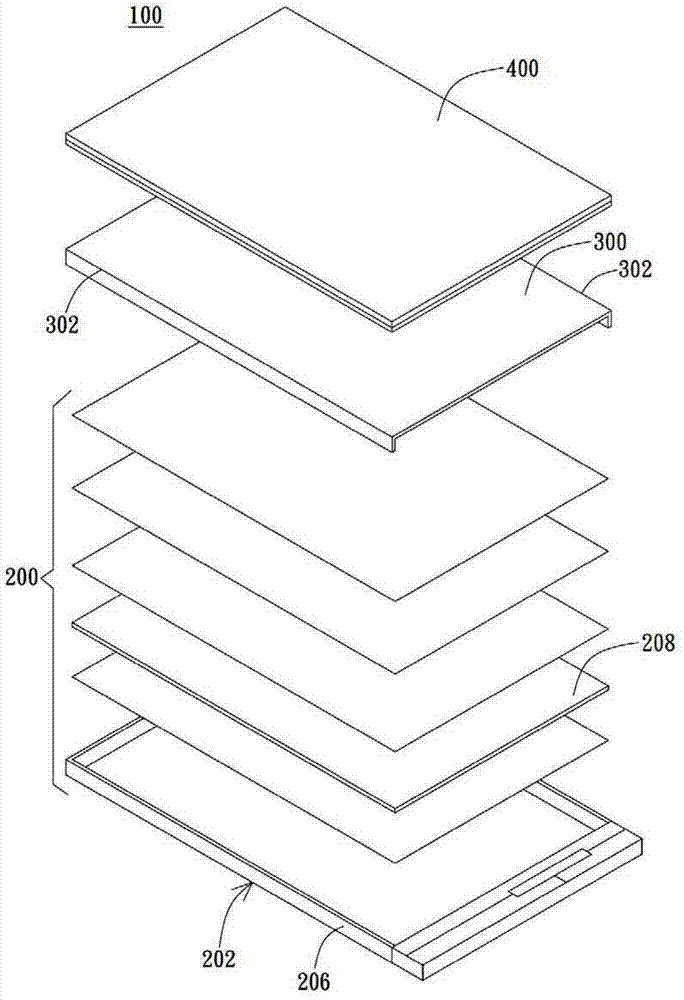

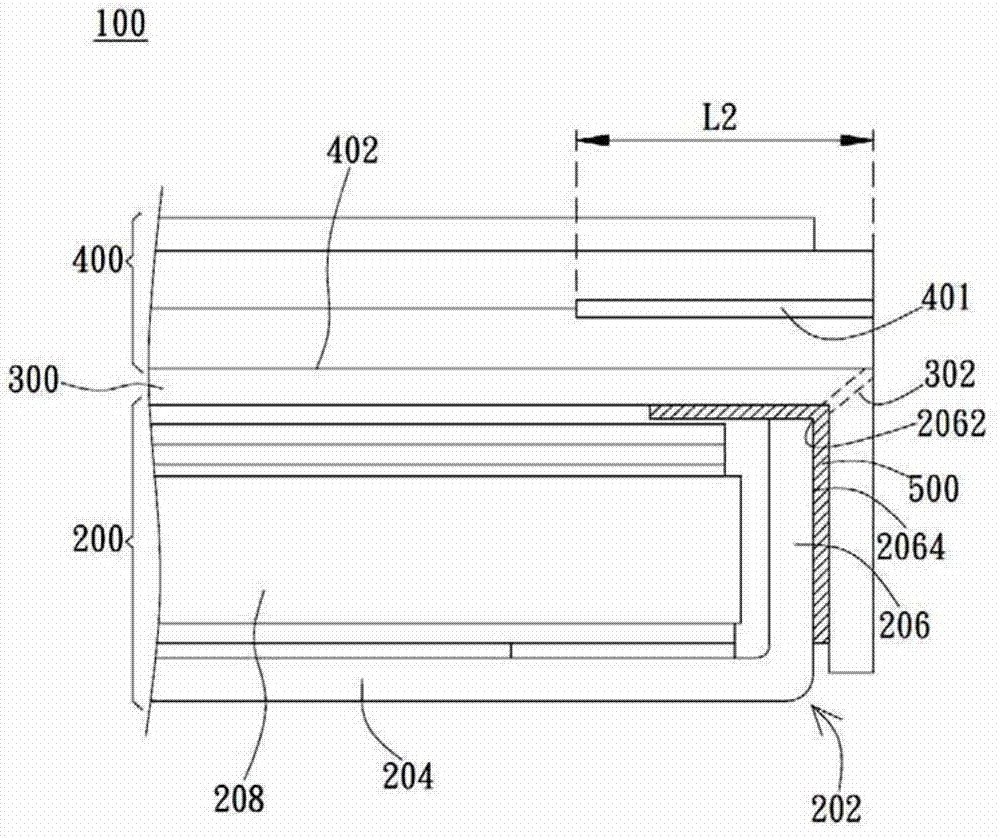

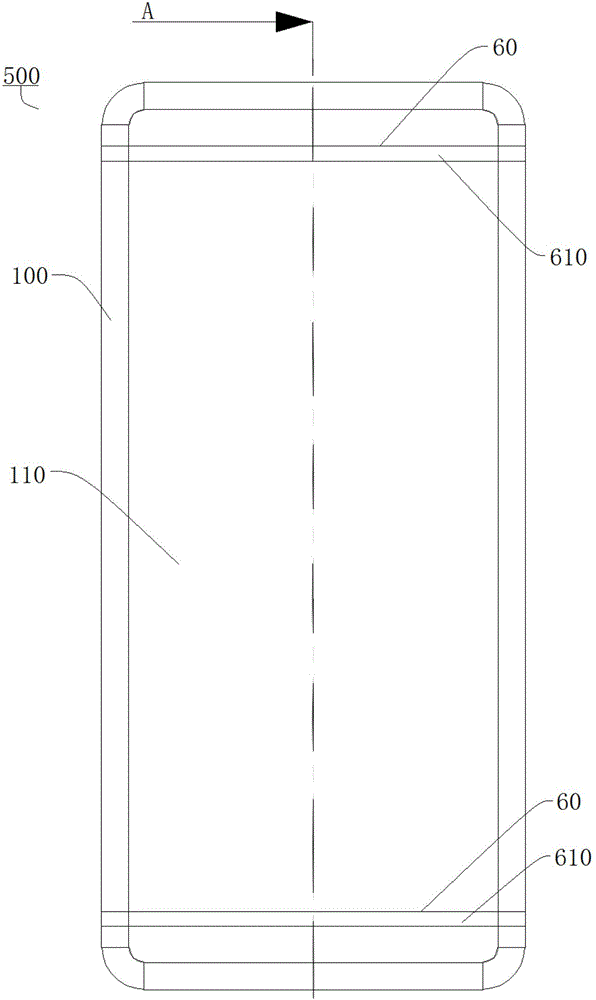

Frame narrowing display device and producing method thereof

ActiveCN102737548ANarrow border widthGuaranteed structural strengthAdhesivesIlluminated signsDisplay deviceEngineering

The invention discloses a frame narrowing display device and a producing method thereof. A backlight module of the display device comprises an outer frame and a light source module. The outer frame comprises a base plate and a side wall connected to the side edge of the base plate. The light source module is disposed in the outer frame and in the side wall. An optical film sheet is disposed above the backlight module and covers the light source module. The side edge of the optical film sheet protrudes outside of the side wall and is bended to partially overlap with the side wall. A display panel is disposed at a face of the optical film sheet with the back side of the film sheet facing the backlight module.

Owner:AU OPTRONICS CORP

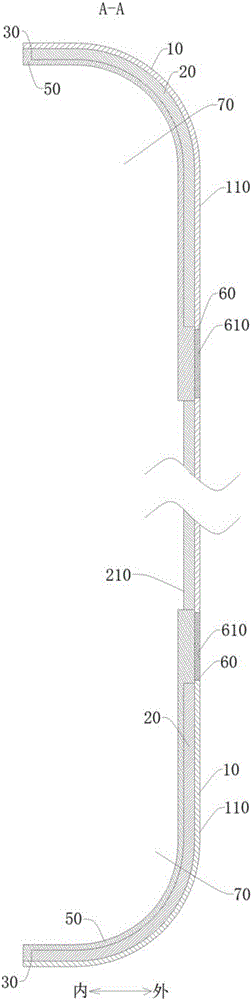

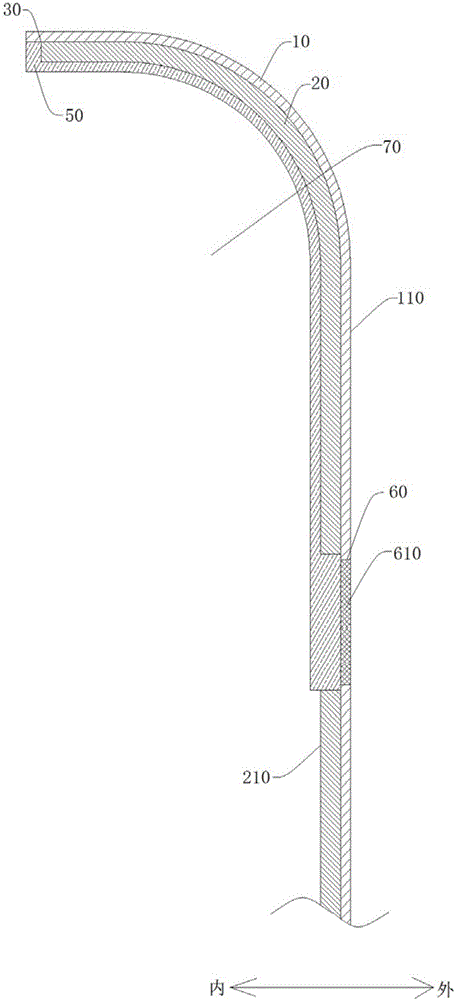

Terminal, terminal shell and method for manufacturing shell

InactiveCN106713568AImprove structural strengthImprove aestheticsTelephone set constructionsMetallurgyMetal

The invention discloses a terminal, a terminal shell and a method for manufacturing the shell. The shell comprises a first metal layer and a second metal layer, wherein the material of the second metal layer is different from that of the first metal layer, and the second metal layer is stacked with the first metal layer. According to the terminal shell provided by the embodiment of the invention, the terminal shell is constructed by stacking the first metal layer and the second metal layer of the different materials, and the overall performance of the terminal shell can be improved by using the characteristics of different metal materials, so that the shell has higher structural strength and aesthetic appearance, and besides, the weight of the shell can be effectively lightened, and the light and thin design of the terminal can be realized conveniently. Moreover, the terminal shell has the advantages of being simple in structure, convenient in processing, low in production cost, and the market competitiveness of terminal products is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Battery pack shell for new energy vehicle and manufacturing method of battery pack shell

InactiveCN107706328AGuaranteed structural strengthGuaranteed durabilityCell component detailsEngineeringElectrical and Electronics engineering

The invention discloses a battery pack shell for a new energy vehicle and a manufacturing method of the battery pack shell for the technical field of battery packs. The battery pack shell comprises abottom plate, a side frame and an upper cover, wherein a stamped and formed metal plate is adopted by the bottom plate; an extruded metal section is adopted by the side frame; the metal section is bent and then the end part is docked to form the side frame with a closed loop structure; a bottom plate connection end is formed at the bottom of the side frame; an upper cover connection end is formedat the top of the side frame; the bottom plate connection end of the side frame is connected with the bottom plate in a welding manner and a battery pack accommodating cavity is formed in the side frame; and the upper cover is matched with the upper cover connection end to cover the battery pack accommodating cavity. A whole plate stamping form is adopted by the bottom plate of the battery pack shell, so that the connection reliability of the bottom plate and a vehicle body floor is ensured while the stiffness is improved; and the section is short in mold making period and low in price and thestructure is large in design space, so that the side frame is formed by bending the section and carrying out tailor-welding, the side frame is connected with the bottom plate in a welding manner andthe welding strength and the strength reliability of the battery pack can be effectively ensured.

Owner:GUANGZHOU XIAOPENG MOTORS TECH CO LTD

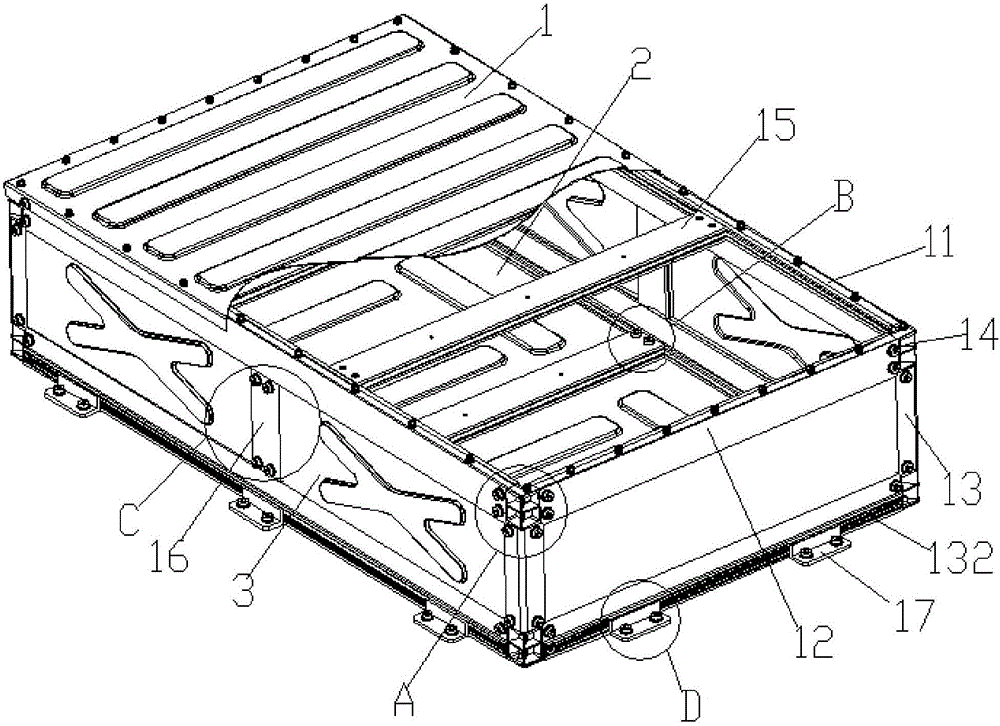

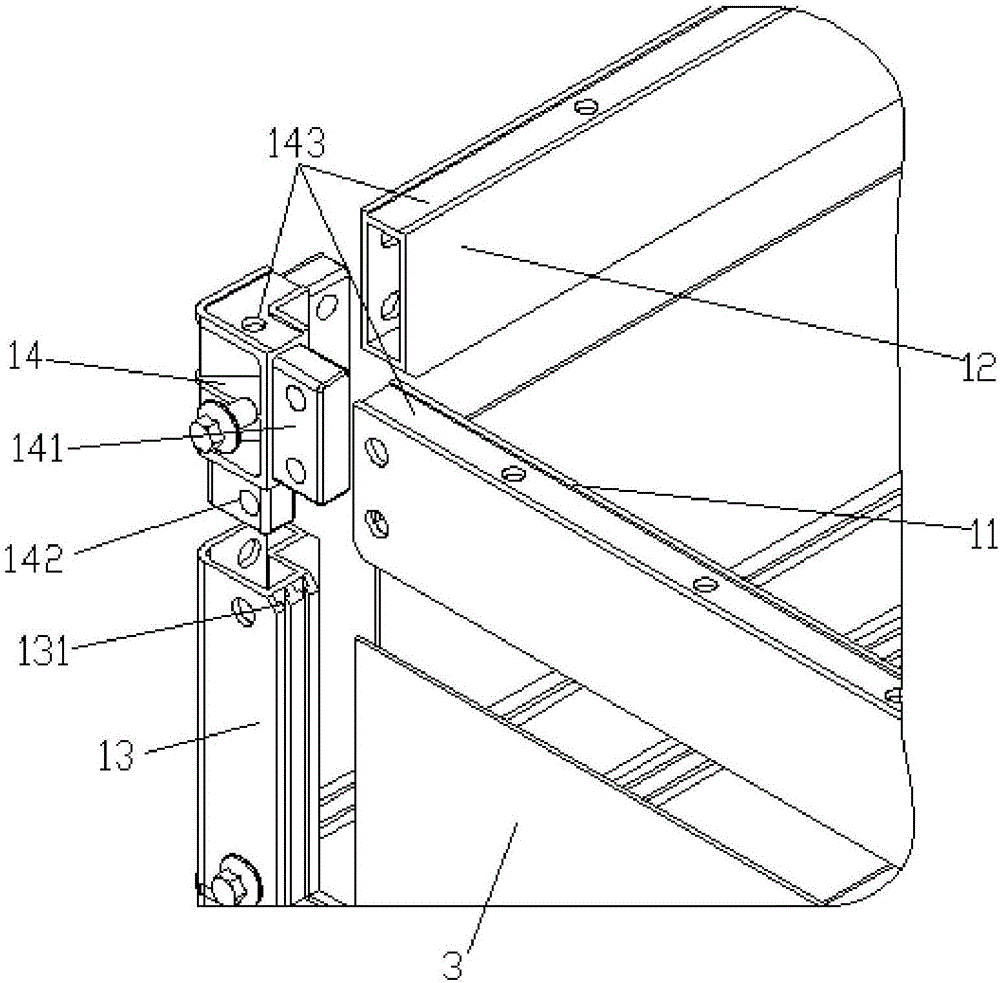

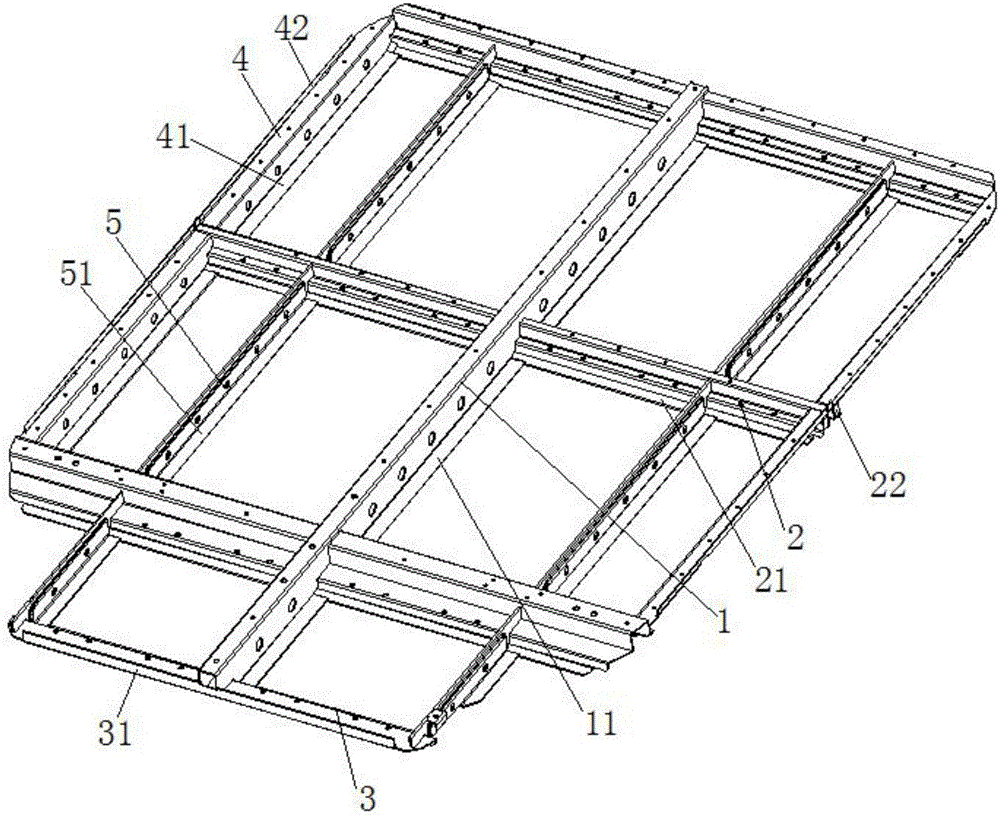

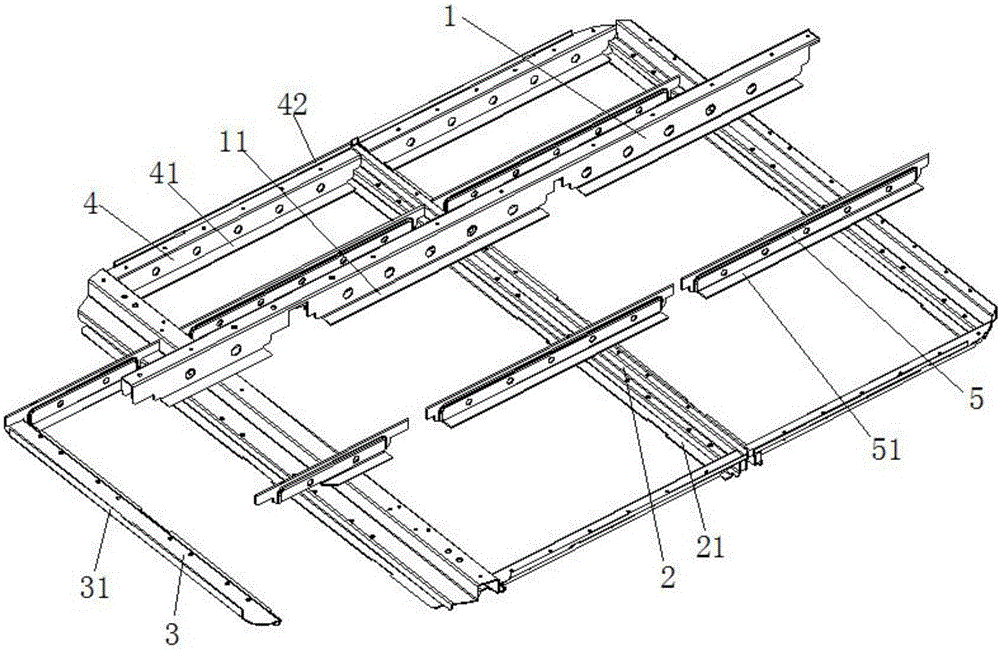

Split mounting type battery box module fixing frame and power battery box provided with same

PendingCN106299192AImprove the fixing strengthImprove installation strengthCell component detailsPower batteryKeel

The invention relates to a split mounting type battery box module fixing frame. The split mounting type battery box module fixing frame comprises a longitudinal beam keel, multiple cross beam keels and multiple boundary beams, wherein the multiple cross beam keels are arranged at intervals in parallel, and the longitudinal beam keel is perpendicularly arranged in the middle of the multiple cross beam keels and clamped on the multiple cross beam keels; the ends of every two adjacent cross beam keels are connected through the boundary beams, first side plates are horizontally arranged on the two sides of the bottom of each cross beam keel respectively, second side plates are horizontally arranged on the two sides of the bottom of the longitudinal beam keel respectively, and a third side plate is horizontally arranged on the bottom of each boundary beam; limiting notches are formed in the first side plates corresponding to the second side plates and the third side plates, and the two ends of each second side plate and the two ends of each third side plate stretch into the corresponding limiting notches respectively and abut against the corresponding first side plates; the first side plates, the second side plates and the third side plates are all fixed to the bottom wall of an electric box, and fold fins used for being connected with the side wall of the electric box are arranged at the two ends of each cross beam keel respectively. The split mounting type battery box module fixing frame has the advantages that the whole module fixing frame is convenient to assemble and disassemble, high in structural strength and high in stability.

Owner:江苏和中普方新能源科技有限公司

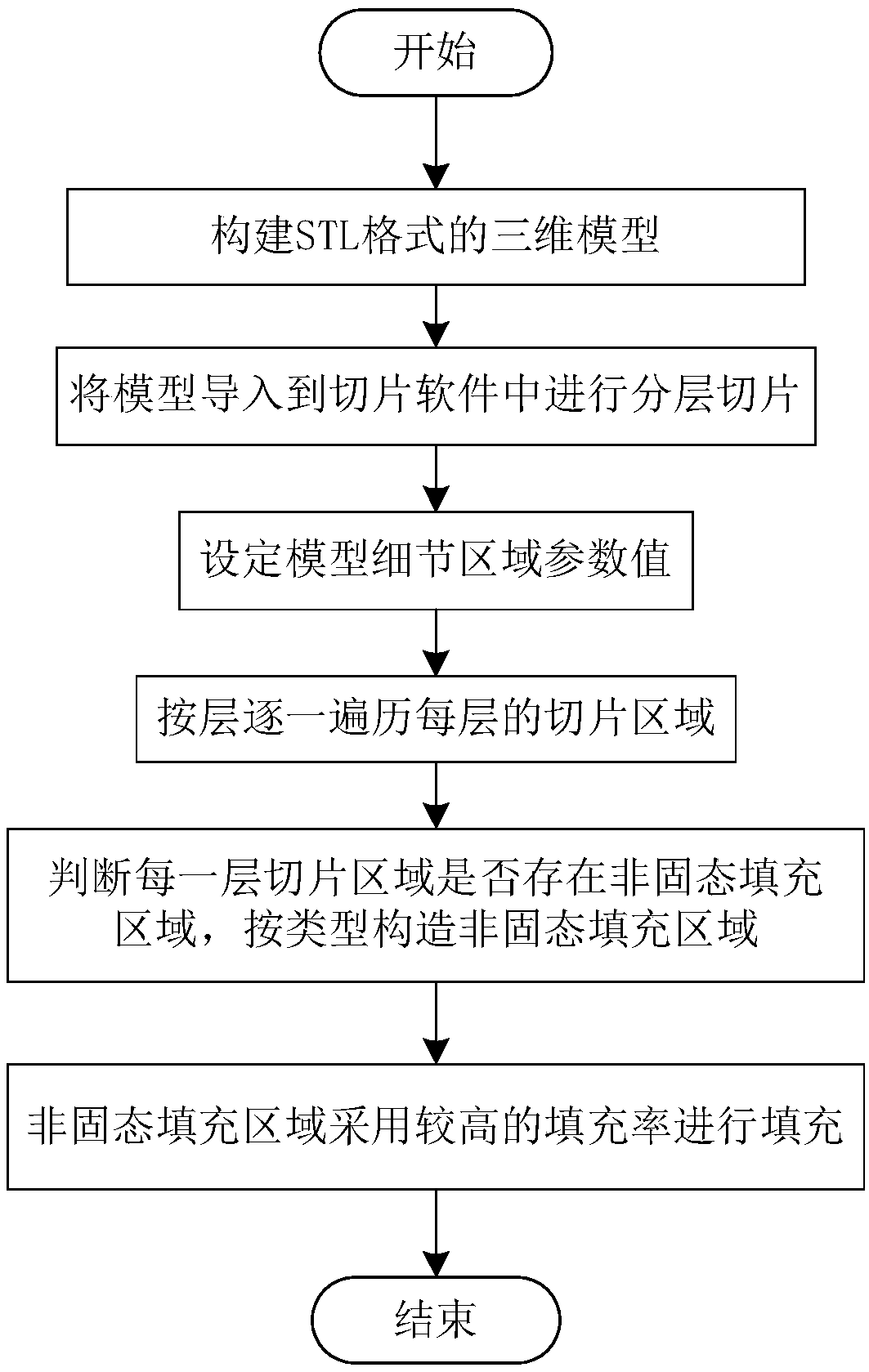

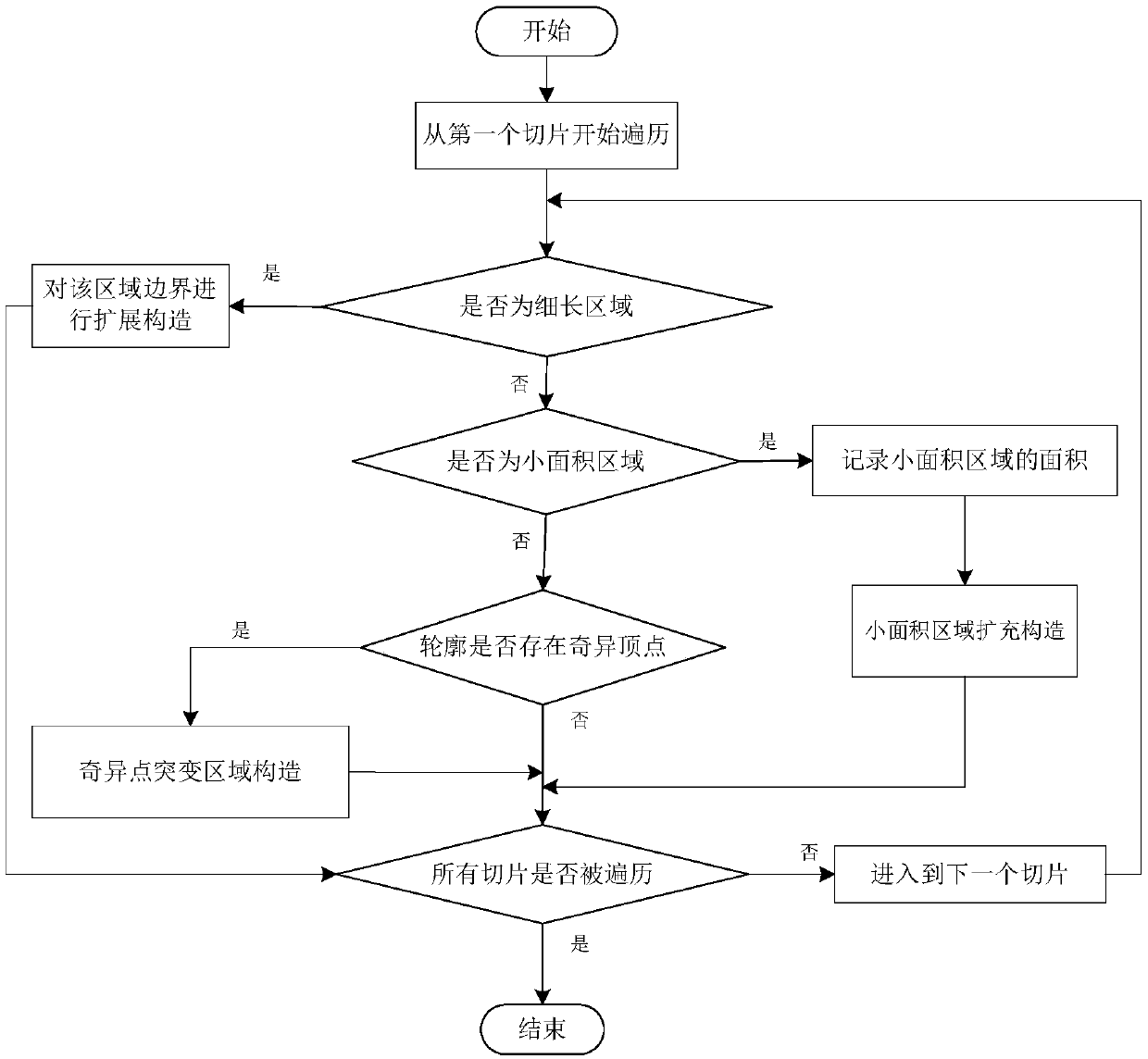

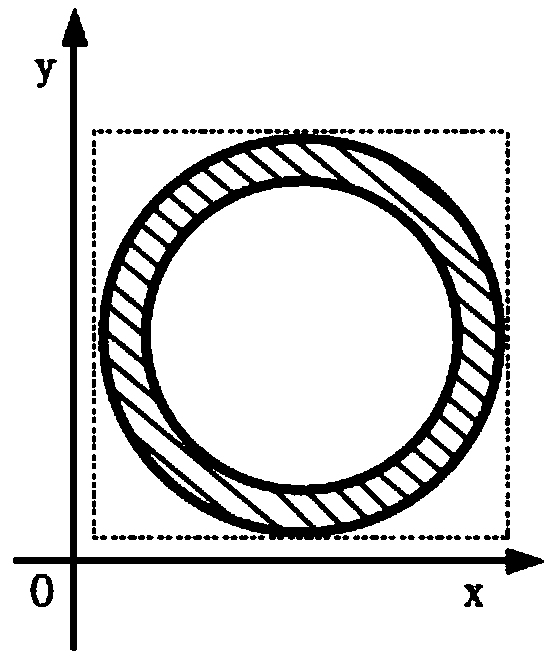

Three-dimensional printing variable-filling method based on contour features

ActiveCN109094013AShorten molding timeGuaranteed structural strengthAdditive manufacturing apparatus3D object support structuresFilling ratePopulated area

The invention discloses a three-dimensional printing variable-filling method based on contour features. The method comprises the following steps of establishing a three-dimensional model in an STL format; importing the three-dimensional model into slicing software and carrying out layered slicing on the three-dimensional model through the slicing software to form the section contour information ofeach layer of the three-dimensional model; dividing a slicing layer filling area into a solid filling area adopting low-filling-rate printing and a non-solid filling area adopting high-filling-rate printing, and setting the parameter value of the non-solid filling area of the model; traversing the slicing area of each layer step by step and layer by layer, and judging whether a non-solid fillingarea exists in the slicing area of each layer or not; if yes, constructing the non-solid filling areas according to types according to the contour features of the slicing areas, and forming a master non-solid filling area in a combined mode; printing the constructed master non-solid filling area layer by layer with a high filling rate, and printing the solid filling areas with a low filling rate.By means of the three-dimensional printing variable-filling method based on the contour features, the forming time is effectively shortened, and the structure strength is ensured.

Owner:SOUTHEAST UNIV

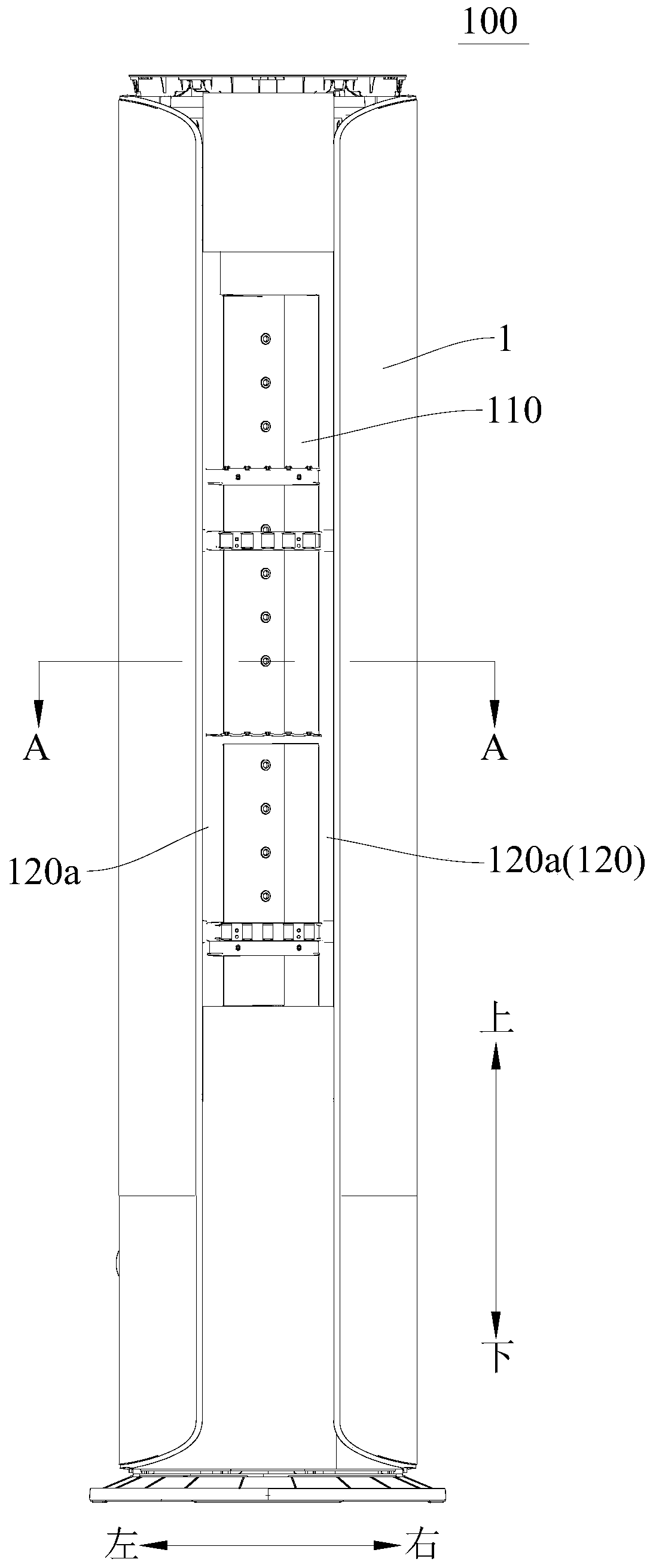

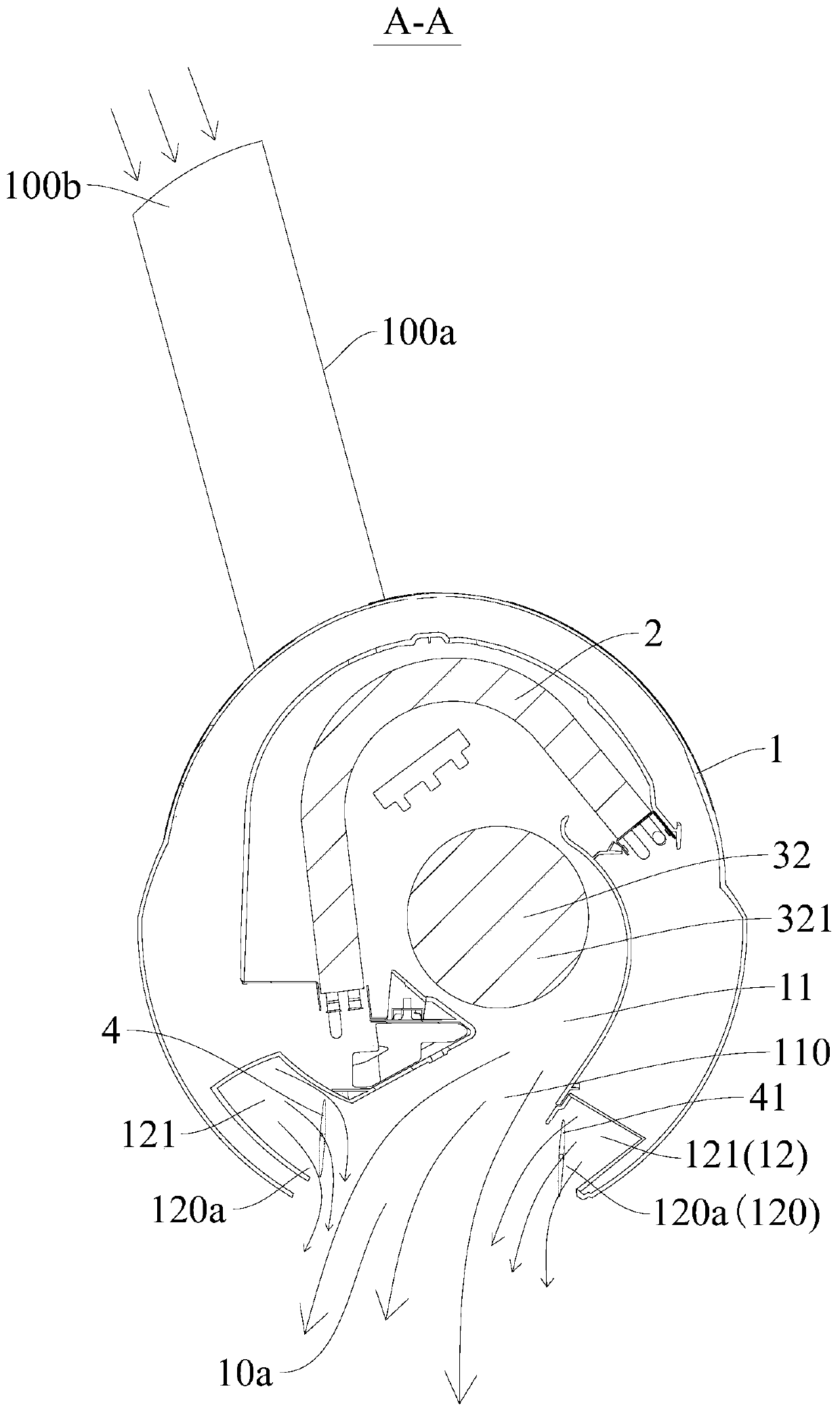

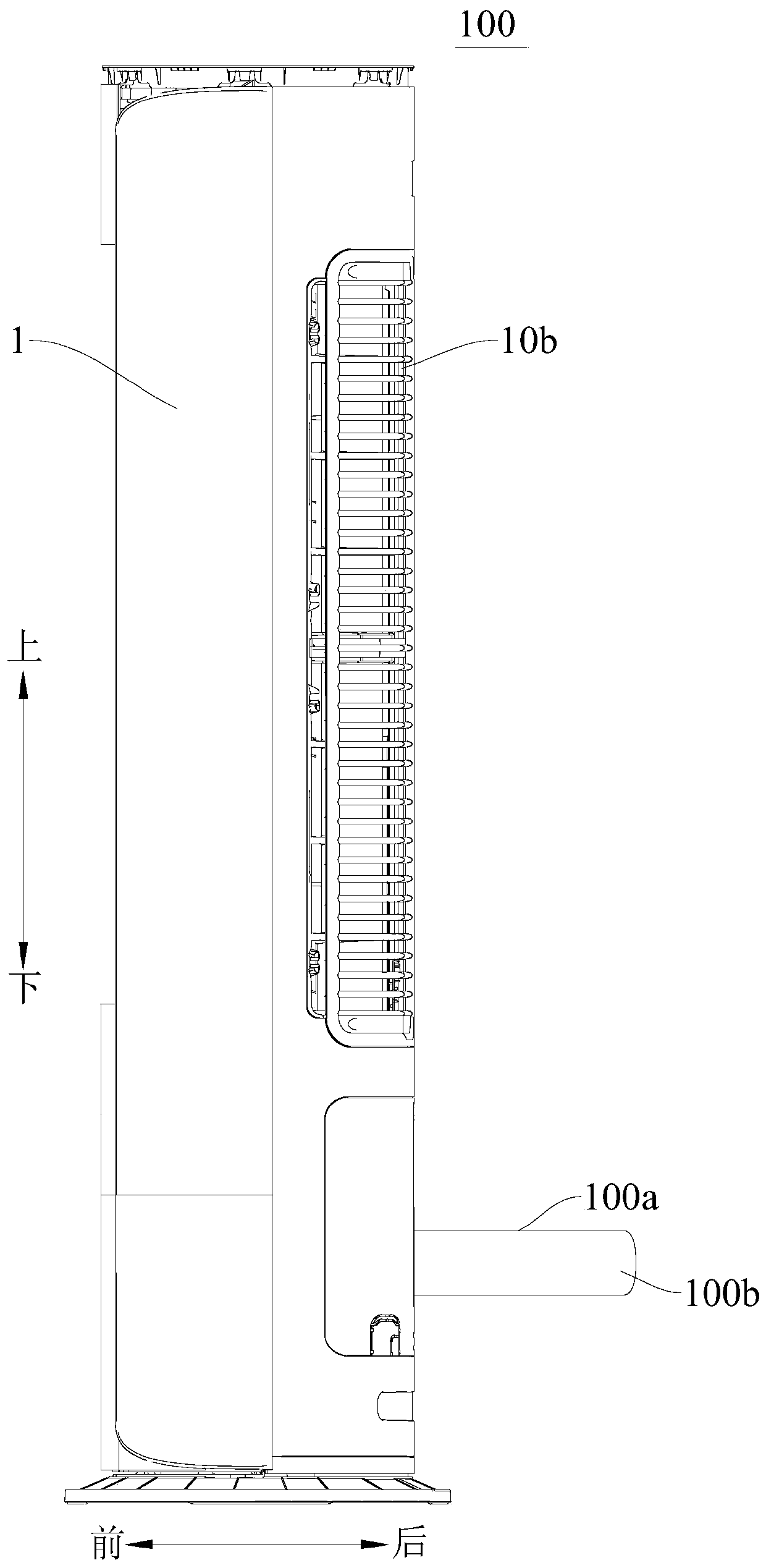

Air-conditioner

PendingCN109990389AGuaranteed heating effectLarge air temperature differenceDucting arrangementsLighting and heating apparatusFresh airEngineering

The invention discloses an air conditioner which comprises a machine shell and a heat exchange device, wherein the machine shell is provided with an air outlet; the machine shell is internally provided with a heat exchange air duct and a fresh air duct; an outlet of the heat exchange air duct and an outlet of the fresh air duct are both formed in the air outlet, so that out-flowing air of the fresh air duct and out-flowing air of the heat exchange air duct are mixed on the inner side of the air outlet and are jointly sent out through the air outlet; and the heat exchange device is arranged inthe machine shell and exchanges heat with air flow flowing into the heat exchange air duct. The air conditioner has good cooling and heating effects, the user experience comfort degree is improved, and the processing procedure of the machine shell is simplified.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

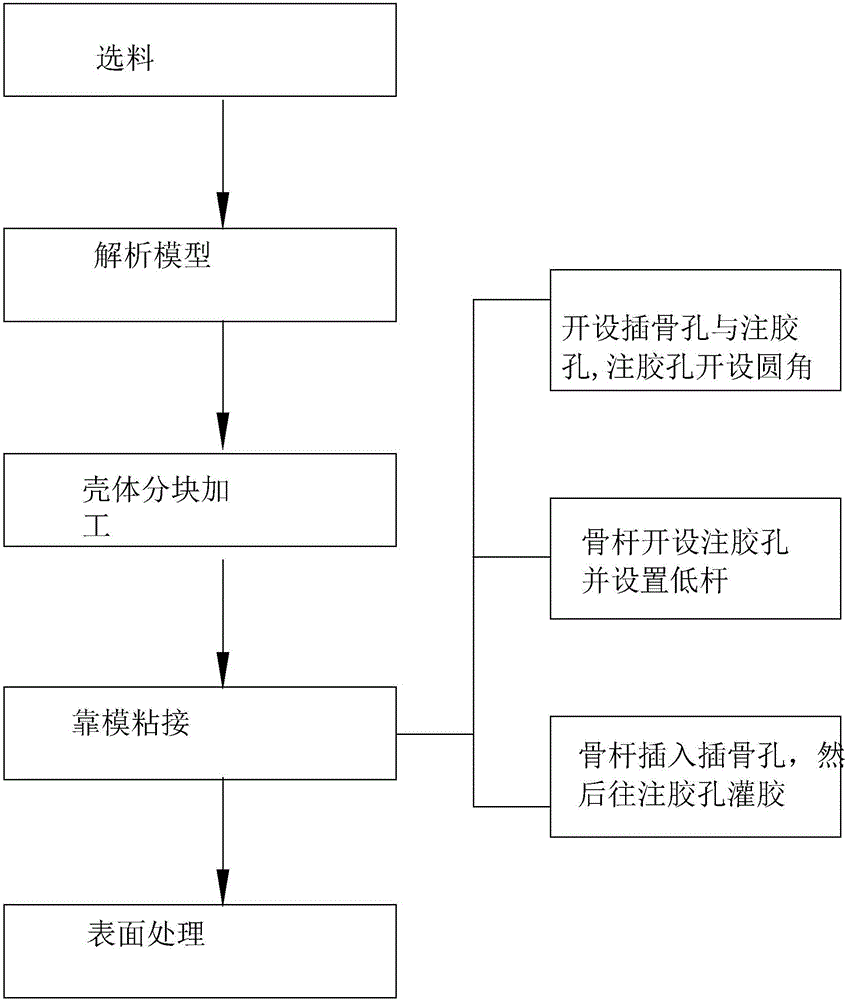

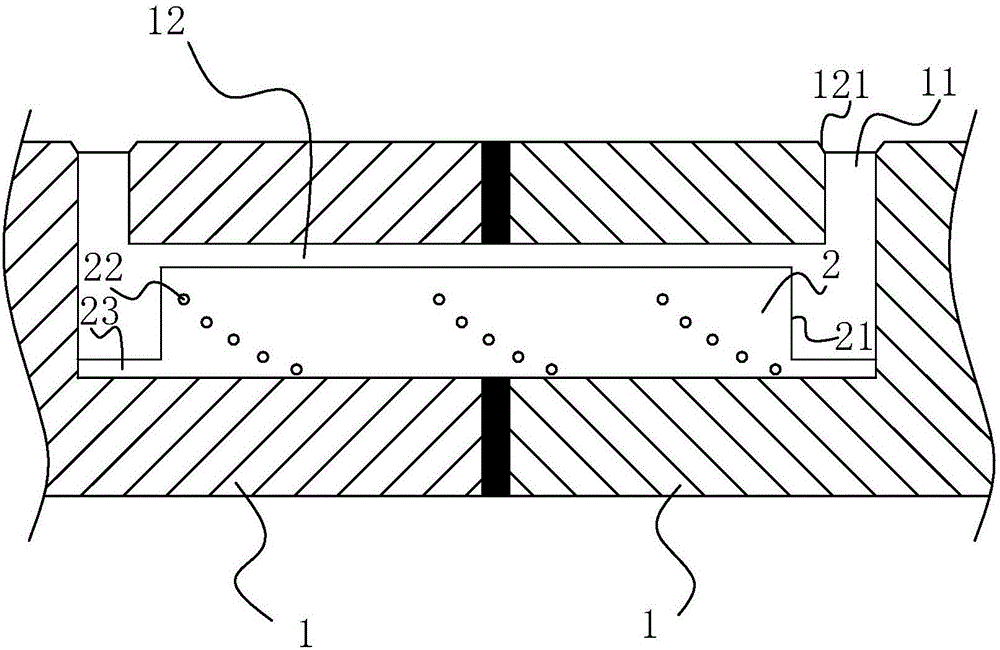

Medical device case machining process

The invention discloses a medical device case machining process. According to the technical scheme, the medical device case machining process comprises the following steps of selecting materials according to preset conditions; performing model analysis, including decomposing an input equipment model in characteristics, curved surfaces and planar surfaces; performing case blocked machining including dividing a case into a plurality of independent small pieces according to the external dimensions of equipment, engraving and milling precise parts and curved parts through a modern science and technology CNC (computerized numerical control) machining center, and engraving flat parts into required sizes through a flat engraving machine; performing profiled bonding, including punching bone inserting holes in neighboring independent small pieces, forming glue injecting holes in the bone inserting holes, inserting a bone rod into the bone inserting holes of two independent small pieces to be jointed, and assembling the jointed two independent small pieces through chemical glue; performing surface treatment, including grinding and then polishing the surface of a bonded case. The structural strength of every two independent small pieces is enhanced through the bone rod; the bone rod is inserted inside the independent small pieces, so that space occupation of the outside space of the independent small pieces by the bond rod can be reduced, and the case assembling difficulty can be lowered.

Owner:深圳市佳鑫一帆科技有限公司

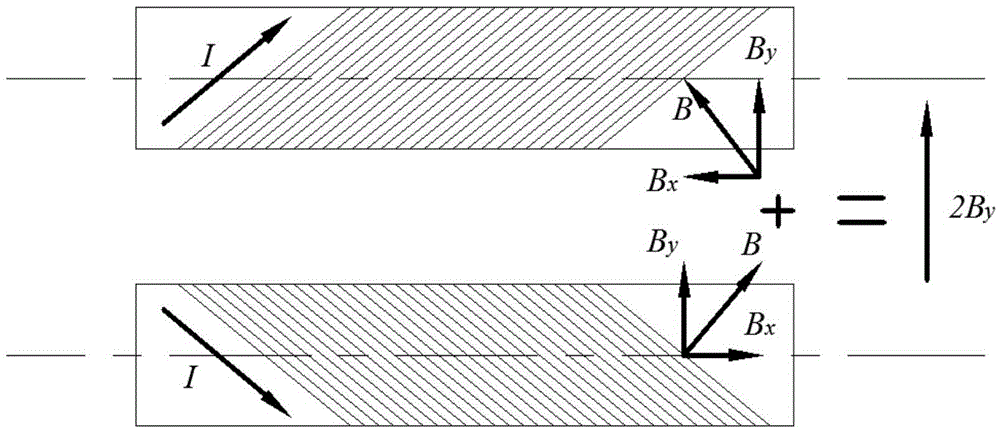

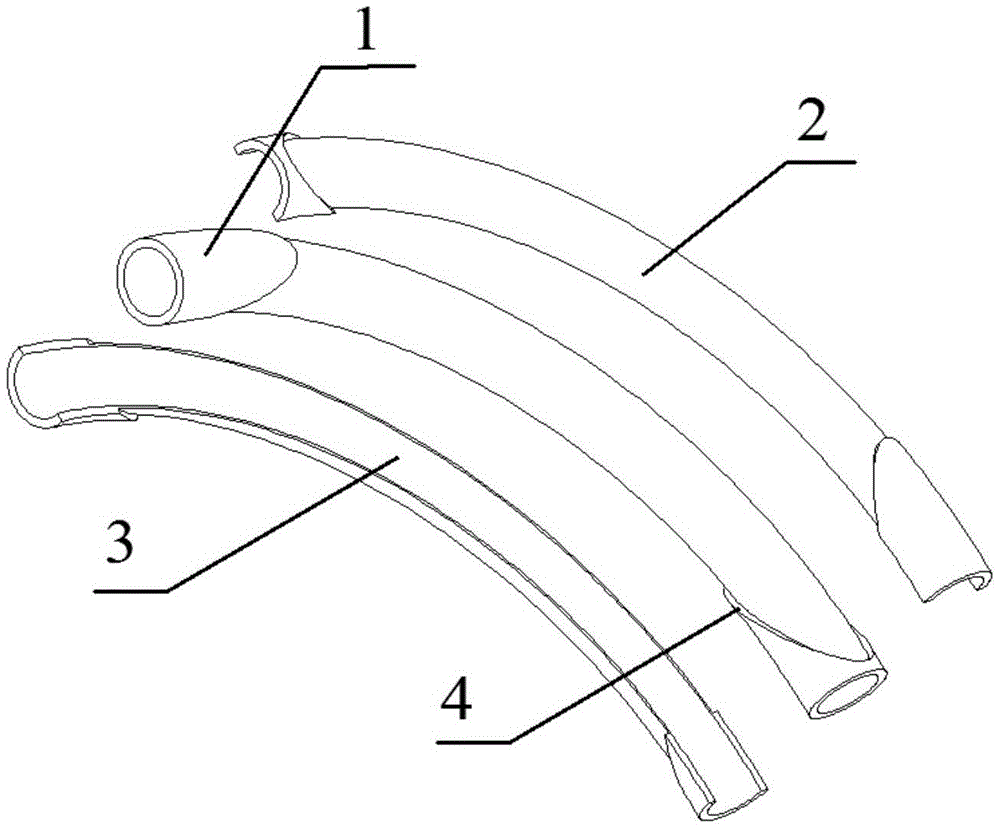

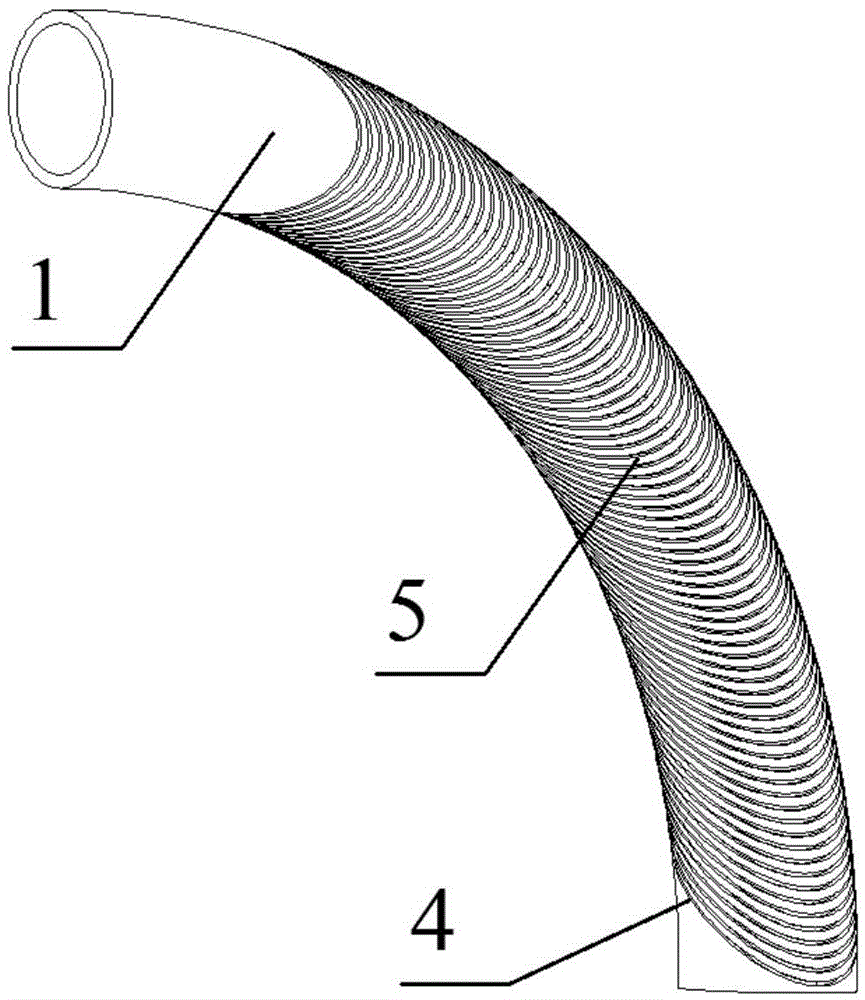

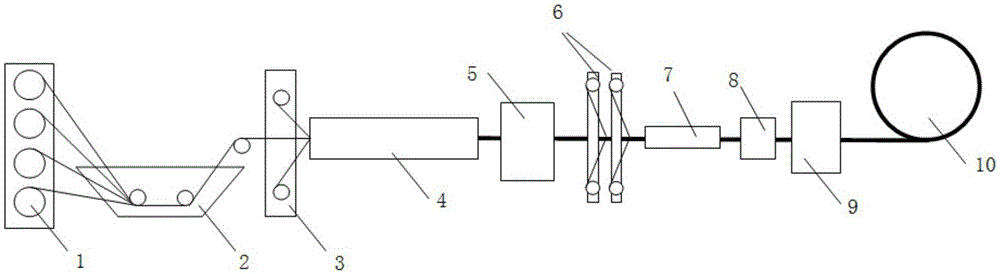

High temperature superconducting bending magnet structure appropriate for superconducting rotary rack technology

ActiveCN105469926ASmall sizeReduce weightSuperconducting magnets/coilsBending magnetsElectrical conductor

The invention discloses a high temperature superconducting bending magnet structure appropriate for a superconducting rotary rack technology. The high temperature superconducting bending magnet structure comprises a YBCO high temperature superconductor of a special structure, an inner coil and an outer coil which are coaxially nested, an outer conductor fixed layer, a conductor insulating layer, a stainless steel support layer, a clamping groove, a double cooling structure, an iron yoke beam magnetic layer and an aluminum shell. According to the high temperature superconducting bending magnet structure, deflection of ion beams in the superconducting rotary rack bending magnet can be realized, and the size, weight and cost of the bending magnet are effectively reduced; moreover, the requirements such as low temperature cooling, structural strength and quenching protection during the operation of the high temperature superconducting magnet can be realized; and a stable high-strength magnetic field can be generated in an iron beam conveying area by using the special YBCO superconductor structure and a winding manner. Finally, the miniaturization, light weight and low cost of the magnet structure are finally realized, and the development of the high temperature superconducting magnet in the medical field of ion beams is promoted.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

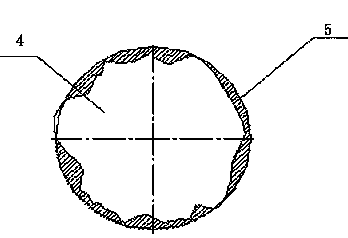

Continuous carbon fiber sucker rod with wear-resistant protective layer and preparation method thereof

ActiveCN105298403AImprove anti-eccentric wear characteristicsLong application lifeDrilling rodsDrilling casingsWear resistantHardness

The invention discloses a continuous carbon fiber sucker rod with a wear-resistant protective layer and a preparation method thereof. The continuous carbon fiber sucker rod comprises a sucker rod body, a glass fiber layer coated on the surface of the sucker rod body, and a wear-resistant layer coated at the outer side of the glass fiber layer, wherein the wear-resistant layer comprises a fiber-reinforced fabric and a thermoplastic resin layer coated on the surface of the fiber-reinforced fabric, and hard wear-resistant particles are uniformly mixed in the thermoplastic resin layer, so that the hard wear-resistant particles are uniformly distributed on the surface of the wear-resistant layer. The hard wear-resistant particles are uniformly distributed on the surface of the sucker rod, and by virtue of the high hardness and high wear resistance of inorganic hard particles and the ball form formed with the mesh fabric structure, the eccentric wear resistance of the wear-resistant layer on the surface of the composite sucker rod is strengthened. Meanwhile, the part where the hard wear-resistant particles are in contact with the interface of the sucker rod body plays a role of interface mechanical meshing, thereby preventing the wear-resistant protective layer from slipping and layering from the surface of the sucker rod.

Owner:SHANDONG UNIV

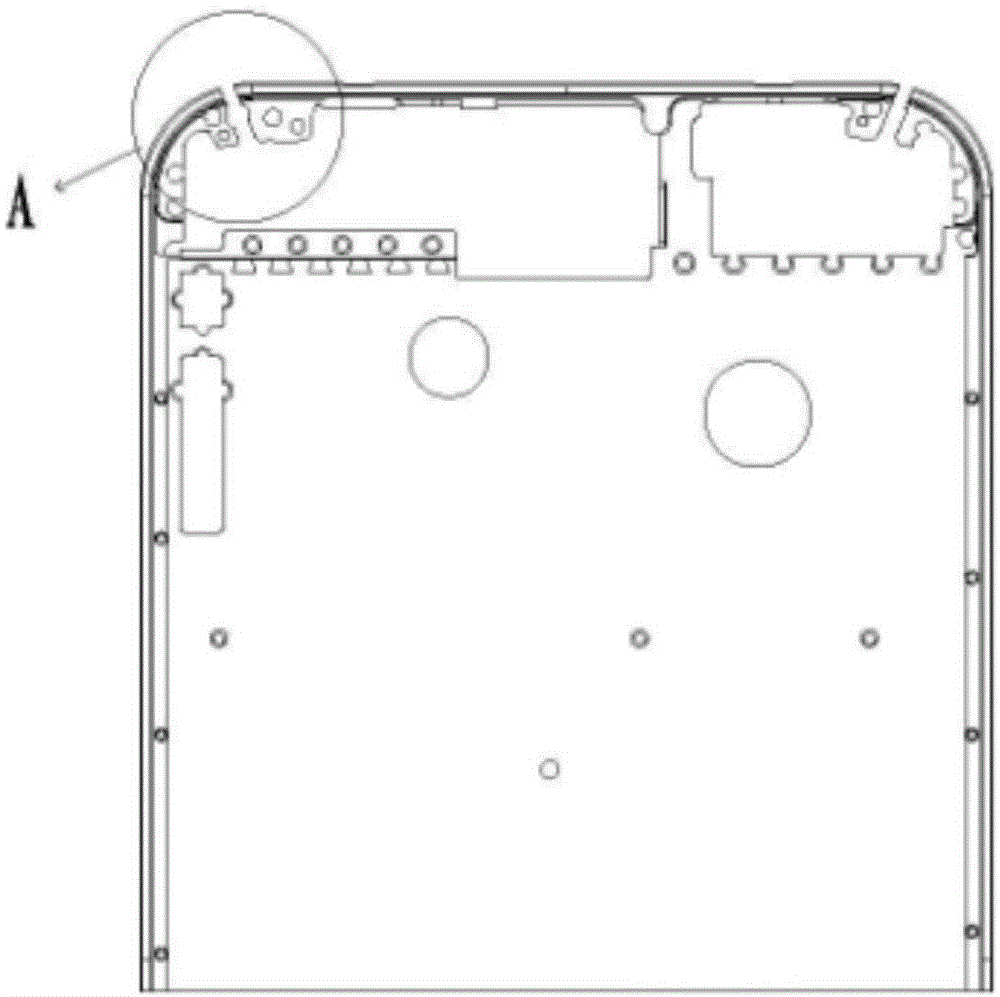

Mobile phone metal frame structure and manufacturing method

InactiveCN104869197AGuaranteed structural strengthReduce CNC machiningTelephone set constructionsBatch productionMobile phone

The embodiment of the invention discloses a mobile phone metal frame structure and a manufacturing method thereof. Through the adoption of the mobile phone metal frame structure and the manufacturing method, plenty of CNC processing time of a mobile phone metal frame can be reduced, and the batch production of the product is facilitated. The mobile phone metal frame structure comprises a metal frame body and a metal component, wherein a connecting part is arranged on the metal frame body; the metal component is embedded into the metal frame body through the connecting part. Therefore, on the basis of guaranteeing the structural strength, plenty of CNC processing time is greatly reduced.

Owner:集怡嘉数码科技(深圳)有限公司

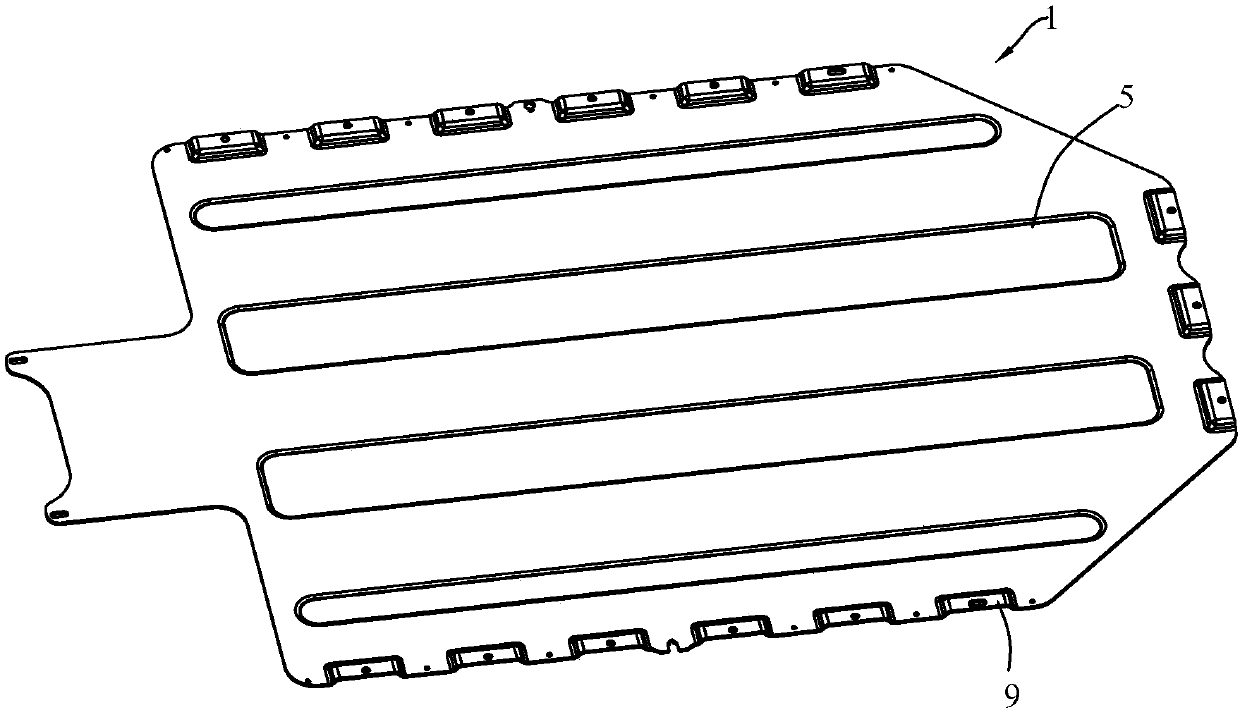

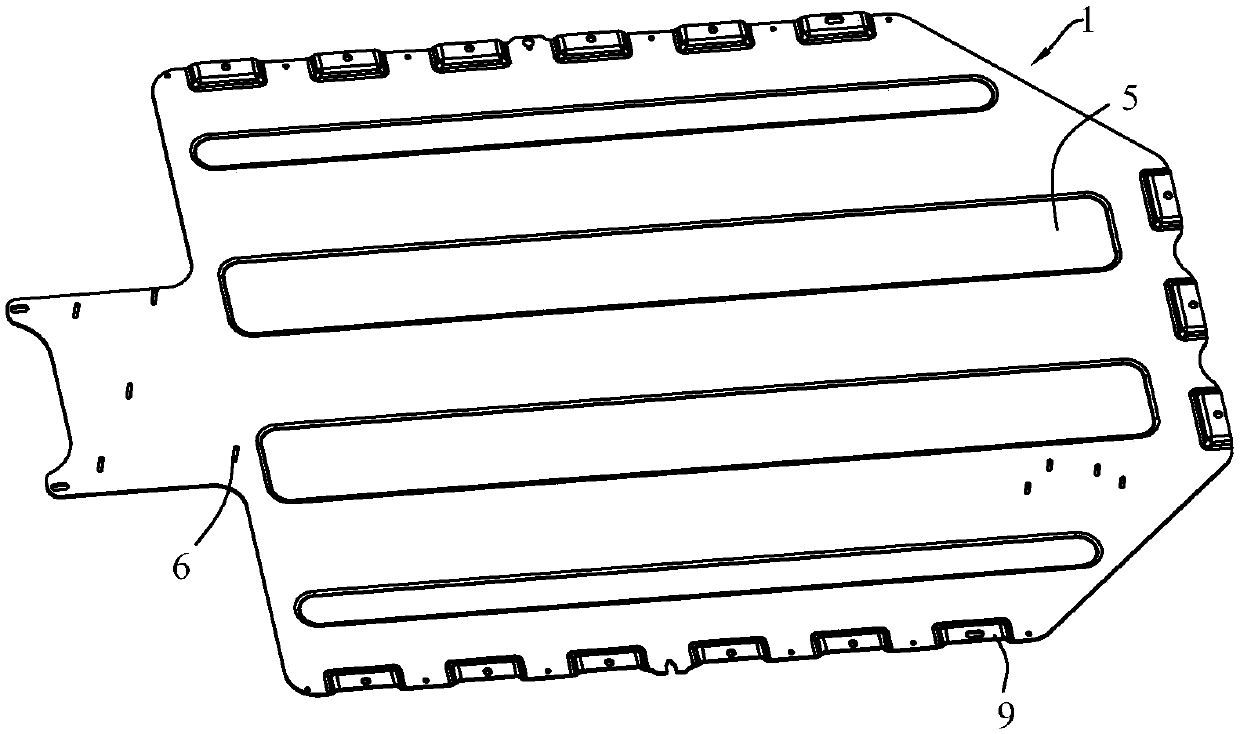

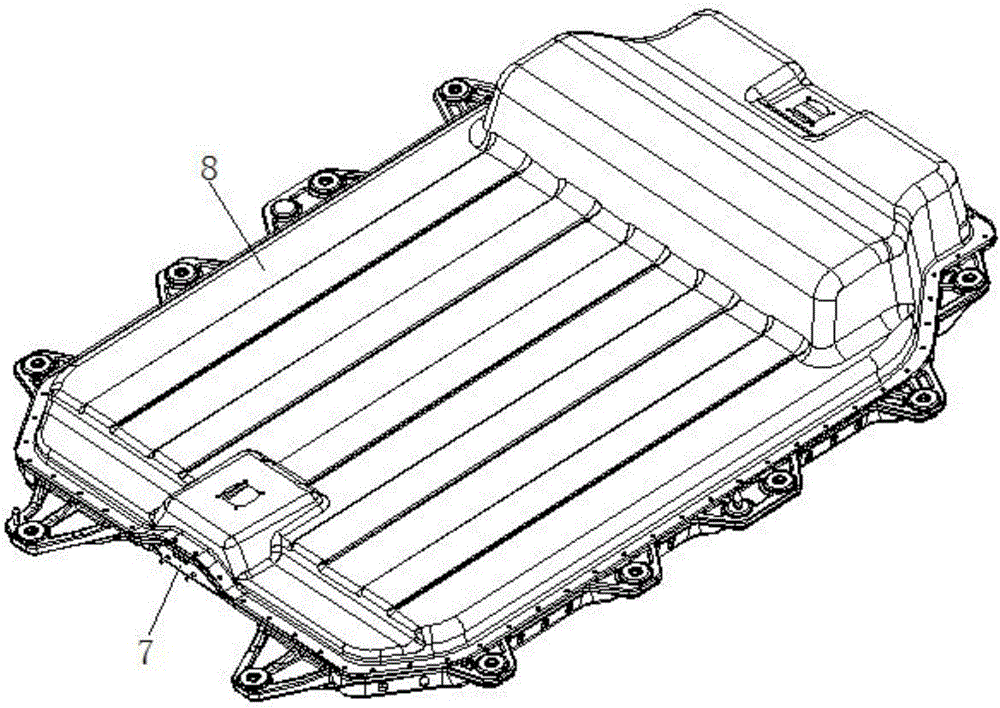

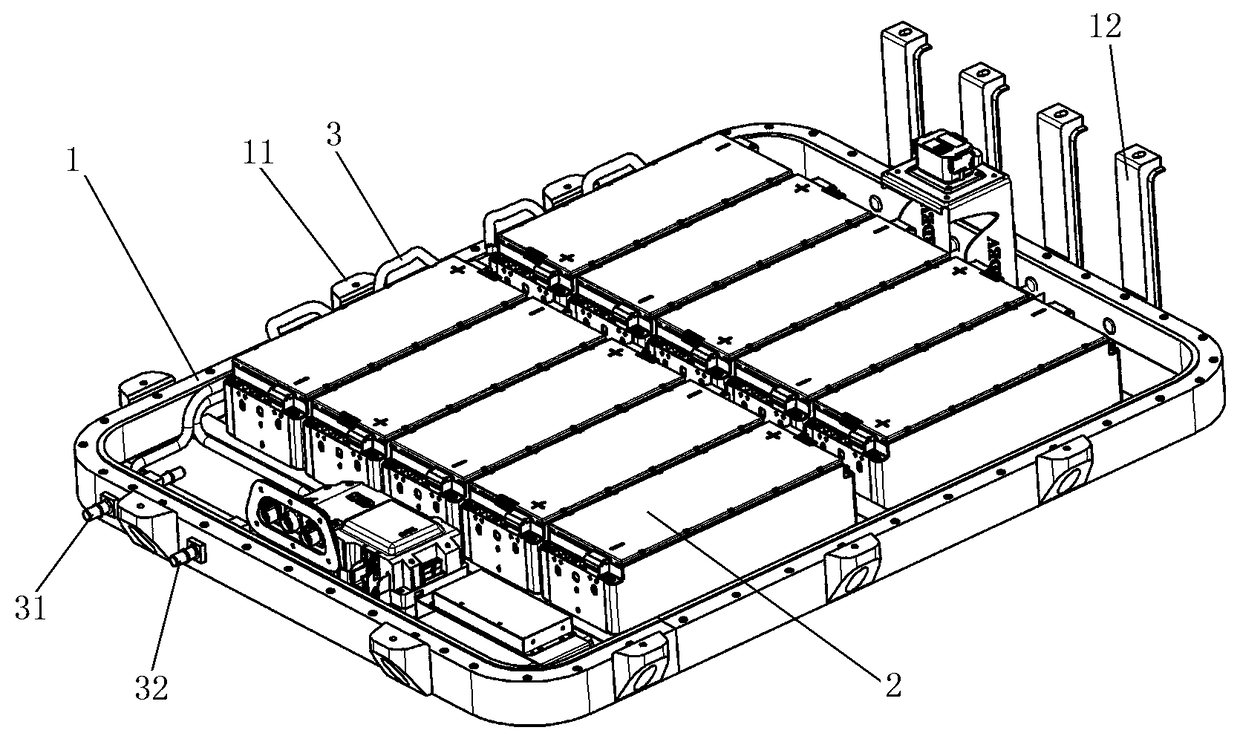

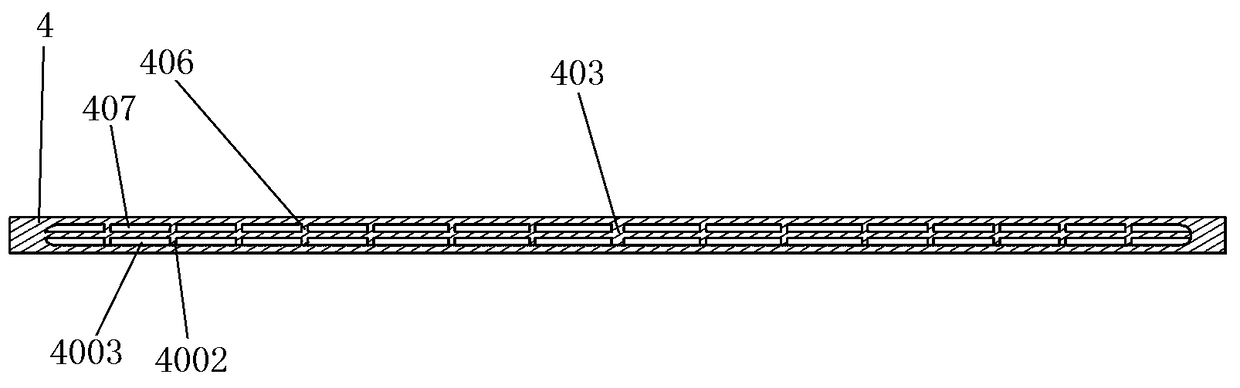

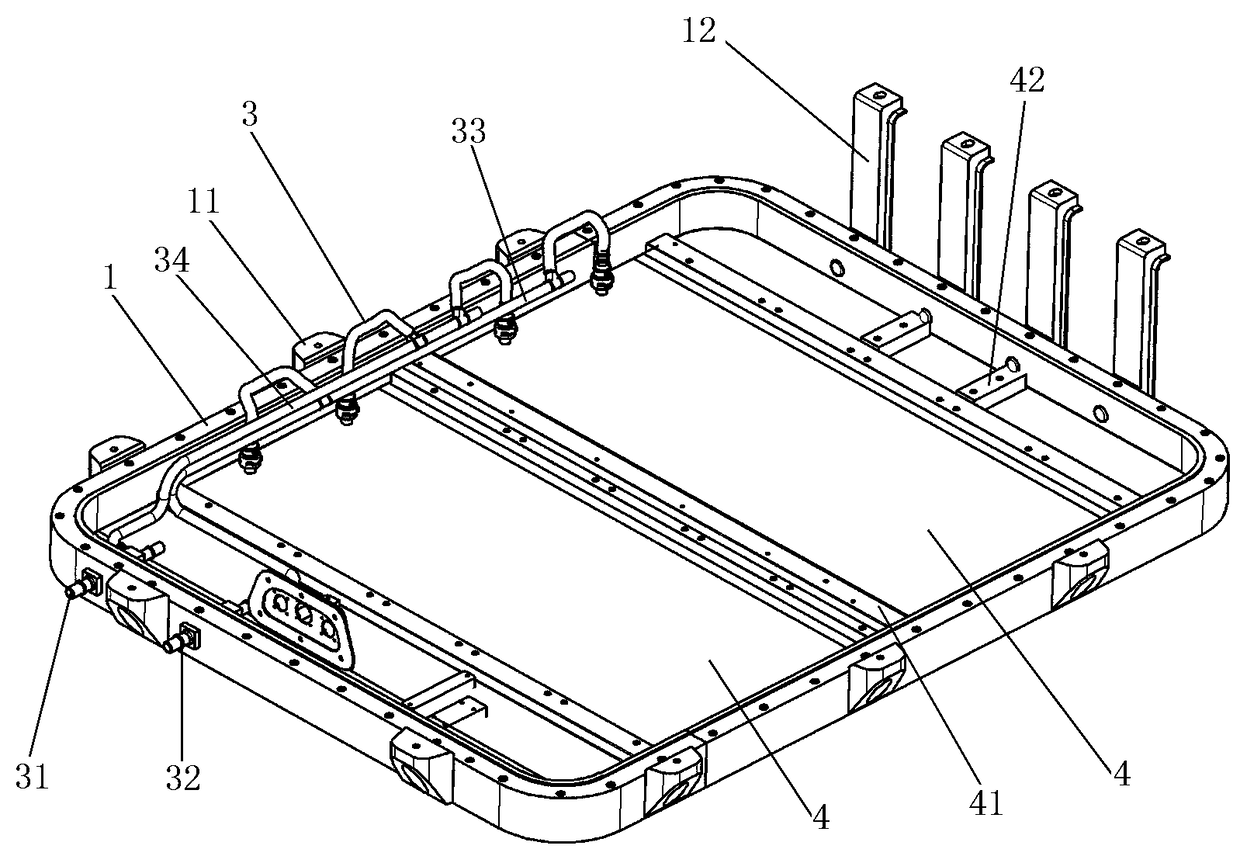

Electric vehicle, battery box body thereof, and battery box

PendingCN109411661AReduce weightGuaranteed structural strengthSecondary cellsCell component detailsThermal insulationElectric vehicle

The invention relates to an electric vehicle, a battery box body thereof, and a battery box. A cooling structure is arranged on a bottom plate assembly of the battery box and comprises two or more layers of hollow channels which are formed at intervals in vertical direction, the upper hollow channel forms a cooling channel used for allowing cooling liquid to circulate, and the lower hollow channelis filled with a thermal insulation material; and in the operating process of the battery box, the cooling liquid in the cooling channel can cool a battery module in the battery box. Meanwhile, the lower hollow channel is filled with the thermal insulation material, thus a thermal insulation layer is formed, heat in the external environment is prevented from being transmitted into the battery box, through the thermal insulation material, the heat in the external environment is prevented from influencing the cooling liquid, and the problem that properties of the battery box are influenced accordingly is solved; and after the bottom plate assembly is filled with the thermal insulation material, the weight of the bottom plate assembly can also be lowered obviously, hollow structures are arranged, and thus the structural strength of the bottom plate assembly can further be ensured.

Owner:HENAN SUDA ELECTRIC AUTOMOBILE TECH

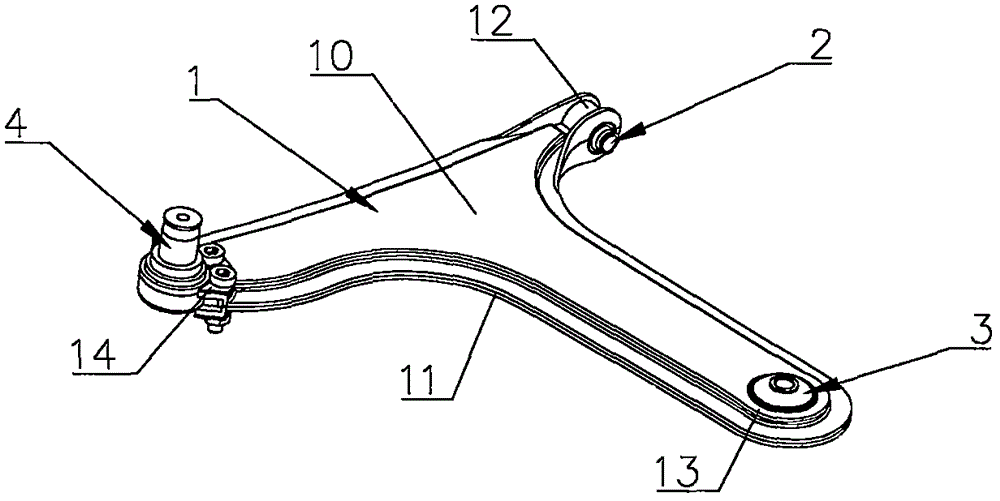

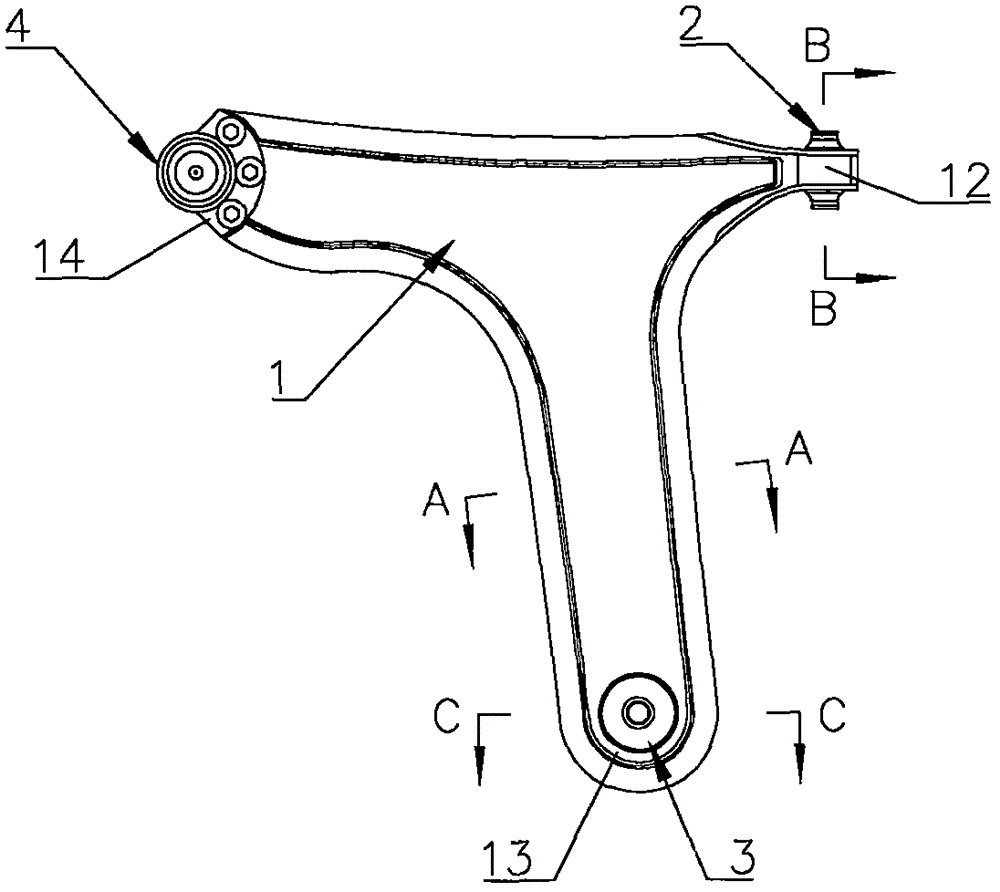

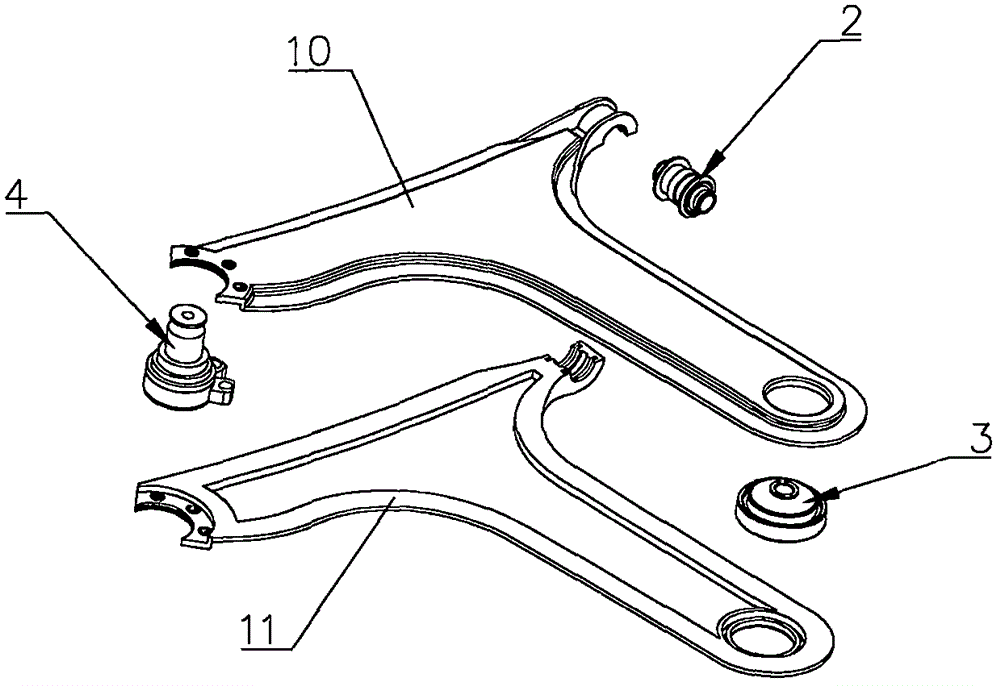

Carbon fiber composite McPherson suspension control arm and preparation method thereof

ActiveCN105730174ALow costGuaranteed structural strengthPivoted suspension armsControl armEngineering

The invention relates to a light-weight suspension system of an automobile, in particular to a carbon fiber composite McPherson suspension control arm. The carbon fiber composite McPherson suspension control arm comprises a control arm body, a first bushing connected with an automobile body, a second bushing connected with a steering knuckle and a ball pin, wherein the control arm body is made of a carbon fiber composite and is hollow in the middle part; a first bushing end on which the first bushing is mounted, a second bushing end on which the second bushing is mounted, and a ball pin end to which the ball pin is connected are respectively arranged on the control arm body. The control arm disclosed by the invention has the advantages of being light in mass, high in intensity, high in impact resistance and the like, and the thickness can be designed, realization of the light weight of automobile parts is facilitated, and the development requirements of a conventional automotive technology for the respects of being energy-saving, environmentally-friendly, safe and the like are met; in addition, the invention further provides a preparation method of the control arm.

Owner:SUN YAT SEN UNIV

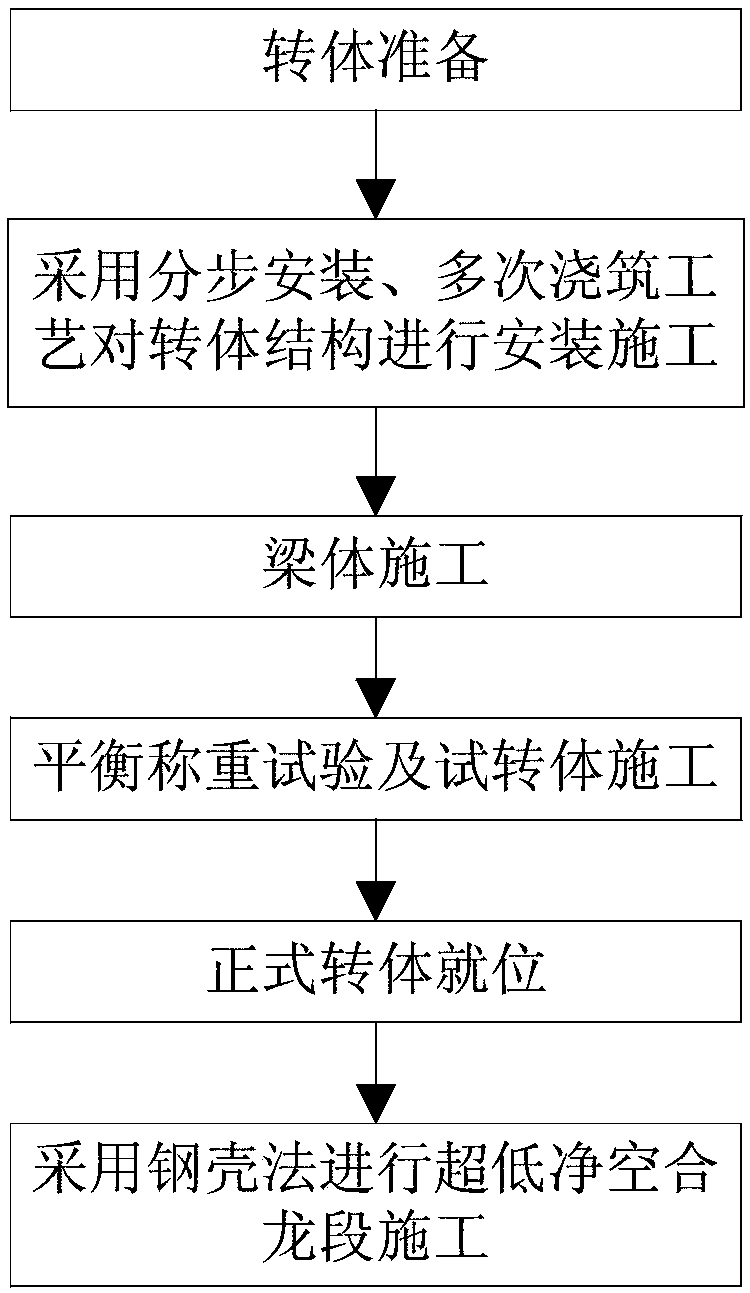

Construction method of low-clearance swing bridge across operational line

ActiveCN108589556AGuaranteed rotationReduce friction coefficientBridge erection/assemblySwing bridgeOperational amplifier

The invention discloses a construction method of a low-clearance swing bridge across an operational line. The construction method comprises the steps of preparing for swing, installing and constructing a swing structure by virtue of the techniques of step-by-step installation and multiple pouring, performing beam body construction, performing a balance weighing test and trial swing construction, allowing formal swing to be in place, and using a steel shell method to perform the construction of an ultra-low-clearance closure segment. The construction method of the low-clearance swing bridge across the operational line adopts a spherical hinge multistep installation precise control technique, a balance weighing test pre-weighting technique, a swing parameter correction and precise positioning technique and a closure segment ultra-low-clearance steel shell construction technique to meet specifications, precision of design drawings and quality requirements, and leads the way in swing spherical hinge installation precision, swing balance stability and precision control. The construction method solves the difficult problem of insufficient clearance under the bottom of the bridge, and ensures the safety of the operational line.

Owner:CHINA RAILWAY 23RD CONSTR BUREAU LTD +1

Condensing device for dish-washing machine and dish-washing machine provided with condensing device

ActiveCN106551666ARapid condensationSpeed up the flowTableware washing/rinsing machine detailsWater vaporEngineering

The invention relates to a condensing device for a dish-washing machine and the dish-washing machine provided with the condensing device. The condensing device comprises an inner container, a condenser and draught fans. One end of the condenser communicates with the inner container through an air inlet, and the other end of the condenser is connected with the draught fans. An air supply opening communicating with the inner container is formed in one side plate of the condenser. Airflow is conveyed into the condenser and supplied into the inner container through the air supply opening so that water vapor can enter the condenser through the air inlet to form inner airflow circulation, meanwhile, cooling airflow is conveyed to the outer surface of the condenser to form outer airflow circulation, and power is provided for inner airflow circulation and outer airflow circulation through the two draught fans correspondingly or through one draught fan at the same time. The condensing device has inner airflow circulation and outer airflow circulation at the same time, the flowing speed of airflow on the outer surfaces of the side plates of the condenser can be increased, the surface temperature of the condenser can be reduced, fast condensation of the water vapor in the condenser can be facilitated, and the condensation efficiency can be greatly improved.

Owner:QINGDAO HAIER DISHWASHER +1

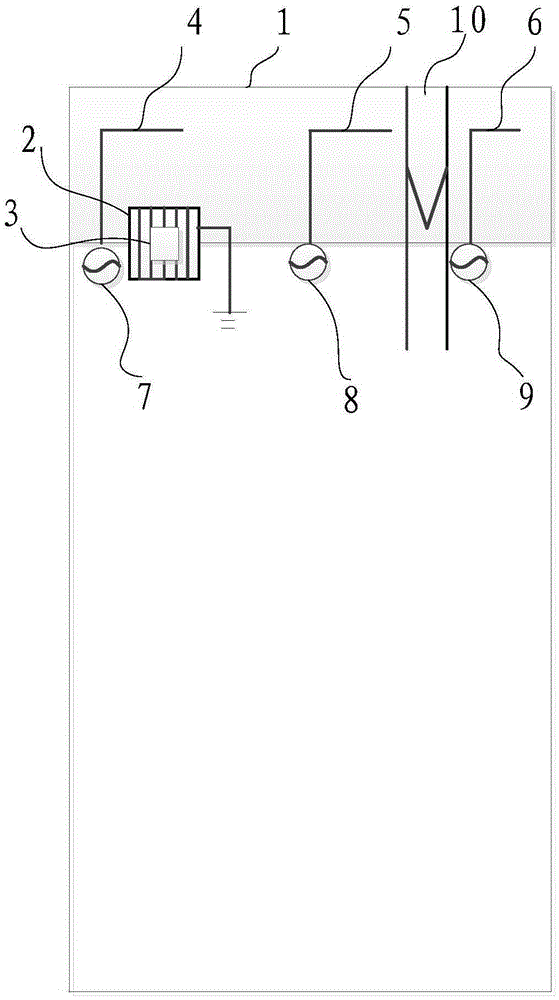

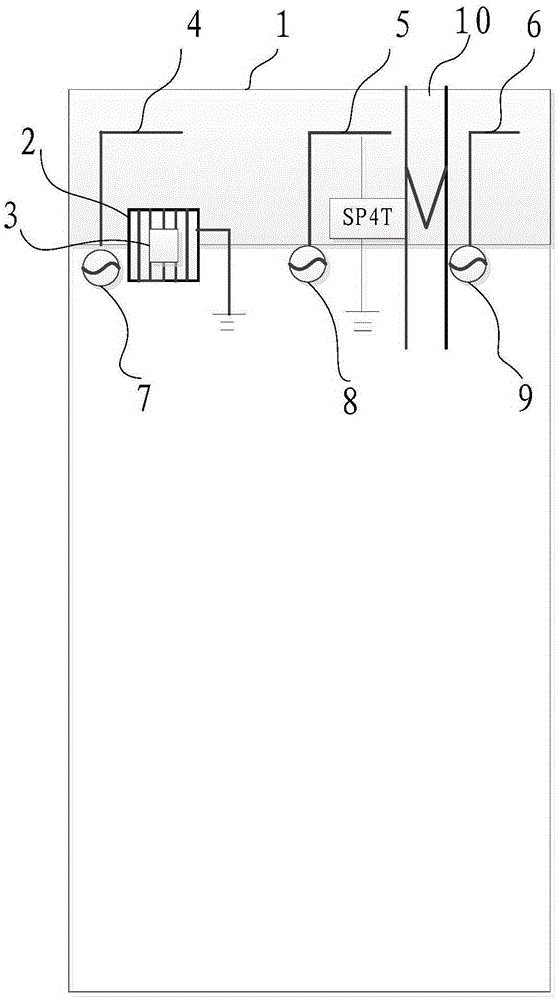

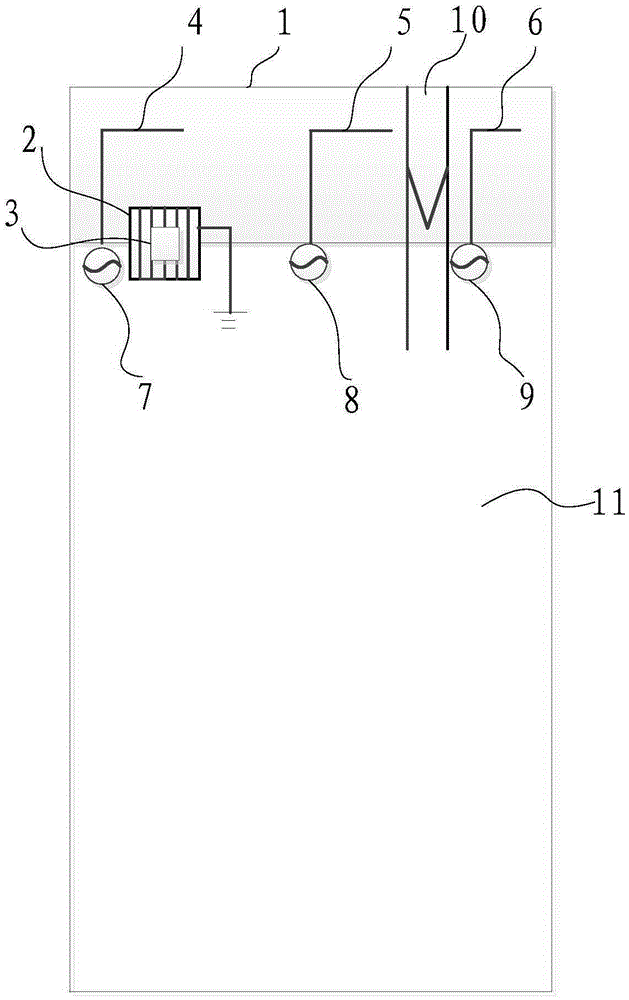

Antenna device and mobile terminal

ActiveCN105305079AGuaranteed structural strengthAvoid damageTelevision system detailsAntenna supports/mountingsComputer terminalAntenna feed

The embodiment of the invention discloses an antenna device and a mobile terminal. The antenna device disclosed by the embodiment of the invention comprises an antenna support, a camera and metal parts with openings, wherein a plurality of antennas are disposed on the antenna support, and the antennas are connected to corresponding antenna feed points on a mobile terminal mainboard; the metal part is disposed on the antenna support and located between the two adjacent antennas; the camera is disposed under the metal part; and the metal part is equipped with a signal transmission terminal and the signal transmission terminal is grounded. The antenna device and the mobile terminal disclosed by the embodiment of the invention are grounded by the signal transmission terminal on the metal part and can release static electricity on the device. Meanwhile, a good isolation degree is formed between two electric wires adjacent to the metal part because of the metal part grounding.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com