Patents

Literature

157results about How to "Increase capillary force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Disposable urea sensor and system for determining creatinine and urea nitrogen-to-creatinine ratio in a single device

ActiveUS20070131548A1Fast response timeMeasure concentrationImmobilised enzymesBioreactor/fermenter combinationsUrea nitrogenCreatinine rise

A disposable urea sensor has a laminated body having a fluid sample inlet end and an electrical contact end, a fluid sample inlet, a substantially flat sample chamber in communication between the fluid sample inlet and a vent opening, the sample chamber being adapted to collect a fluid sample through the fluid sample inlet, a working electrode and a reference electrode within the sample chamber, and a reagent matrix disposed on the working electrode wherein the reagent matrix contains urease.

Owner:NOVA BIOMEDICAL

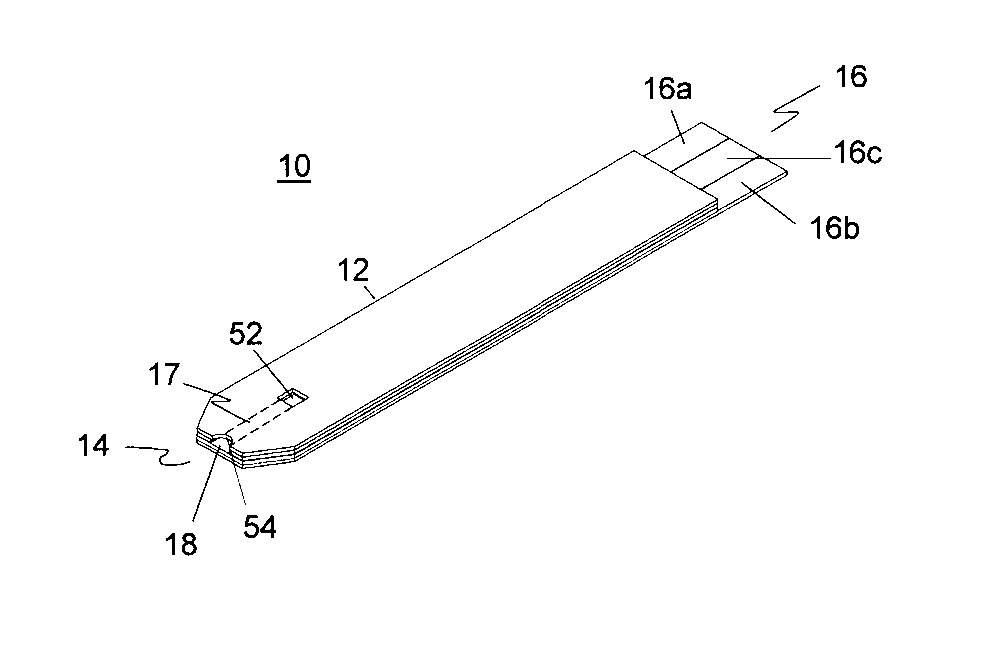

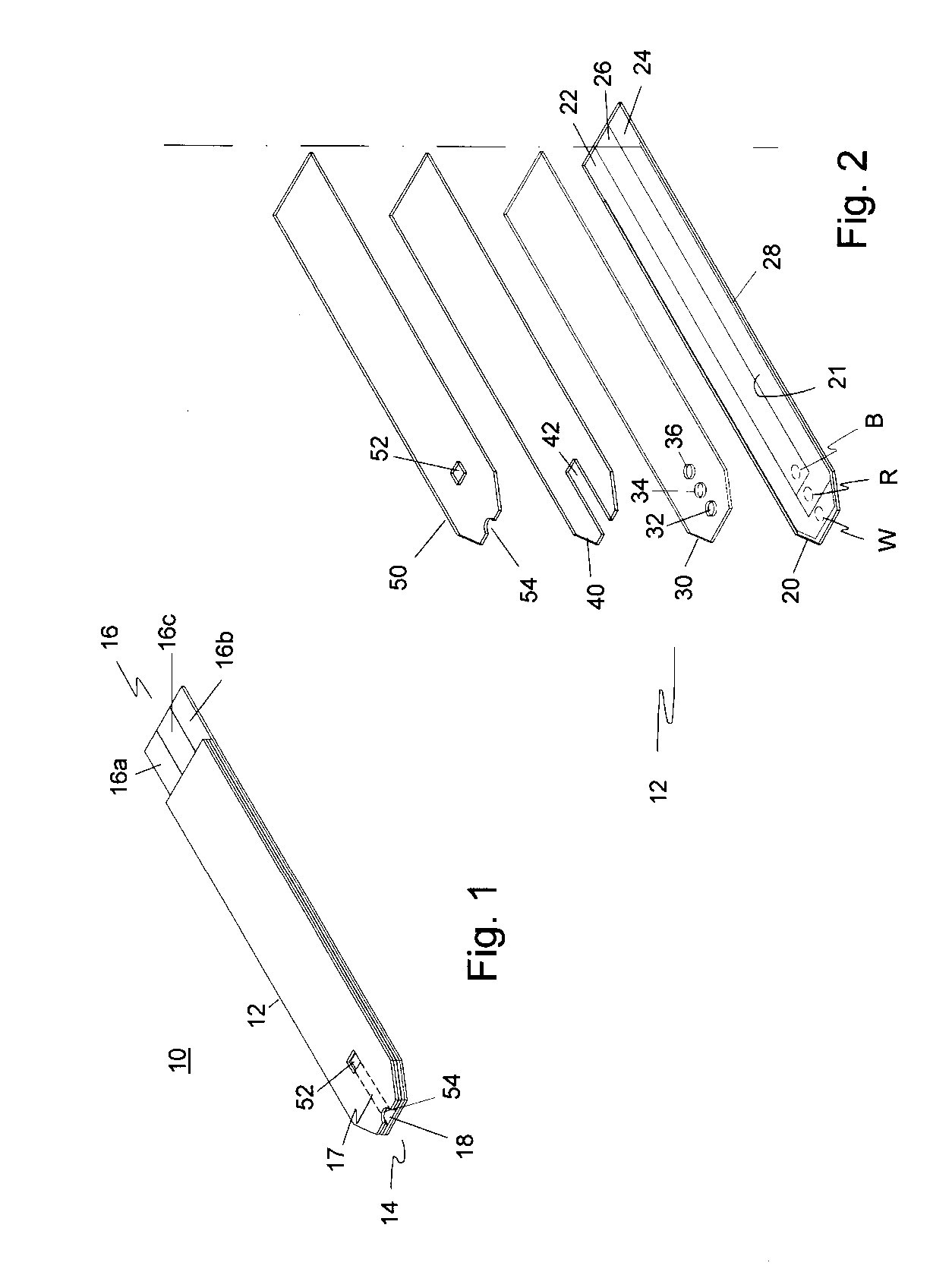

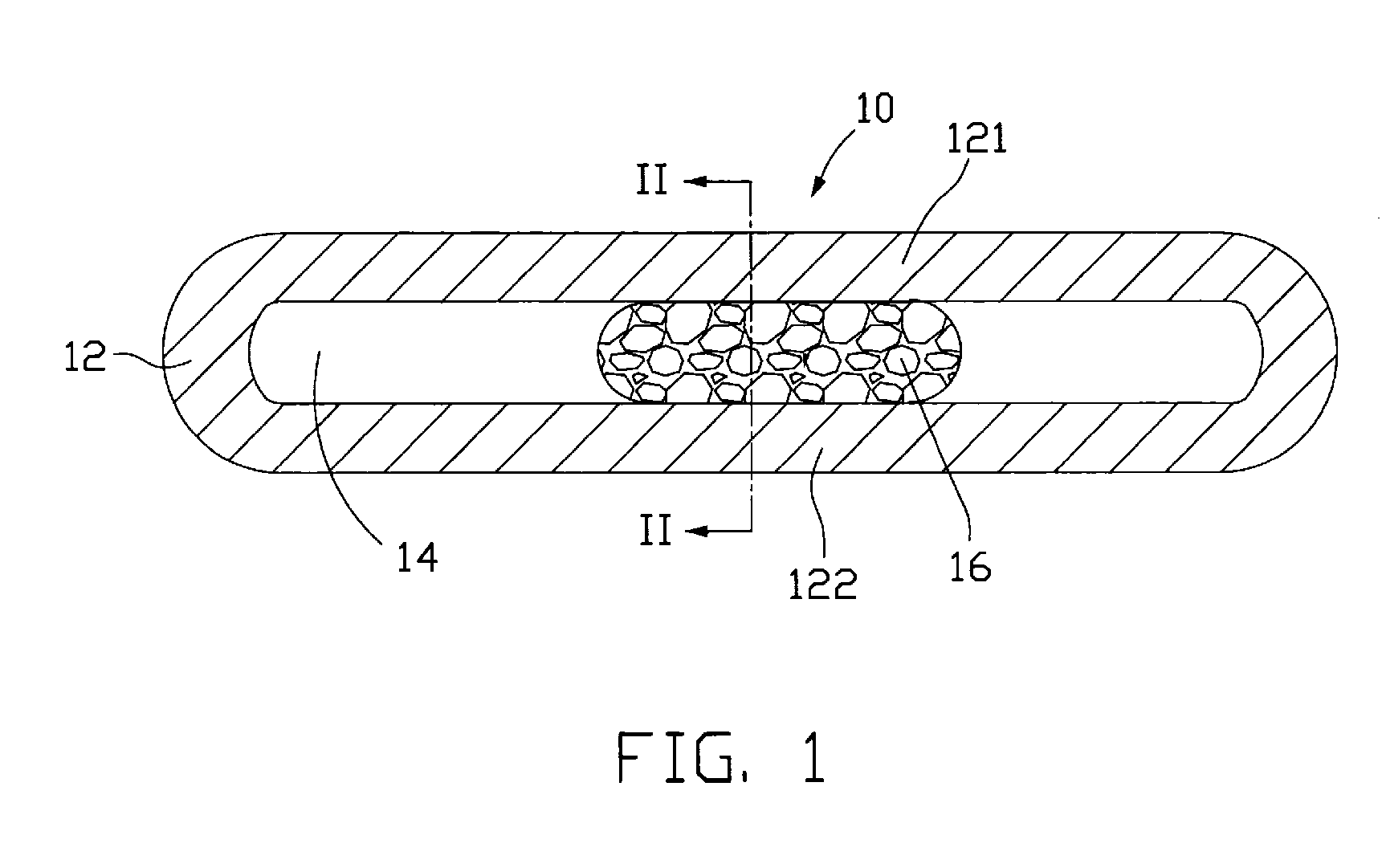

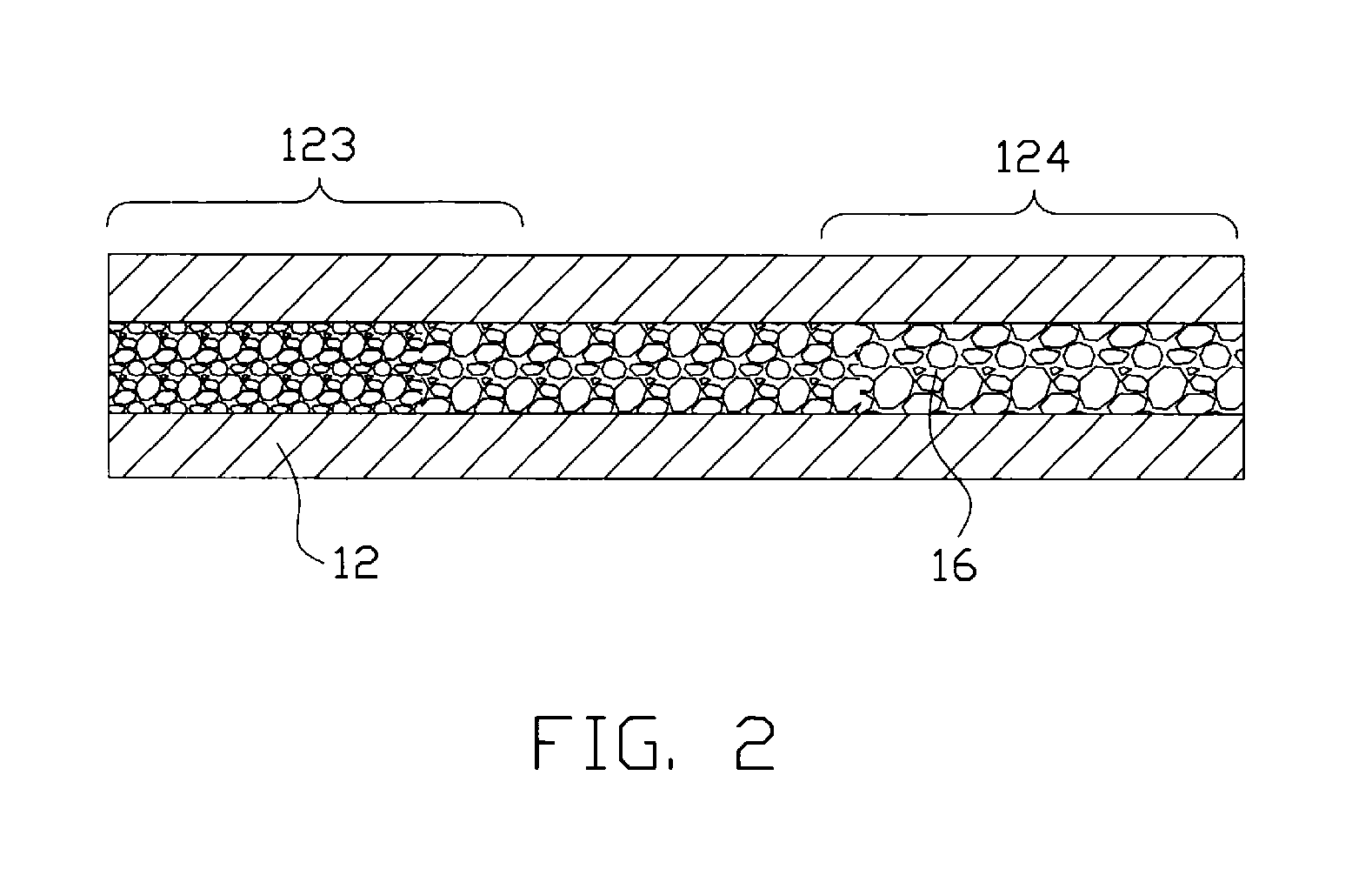

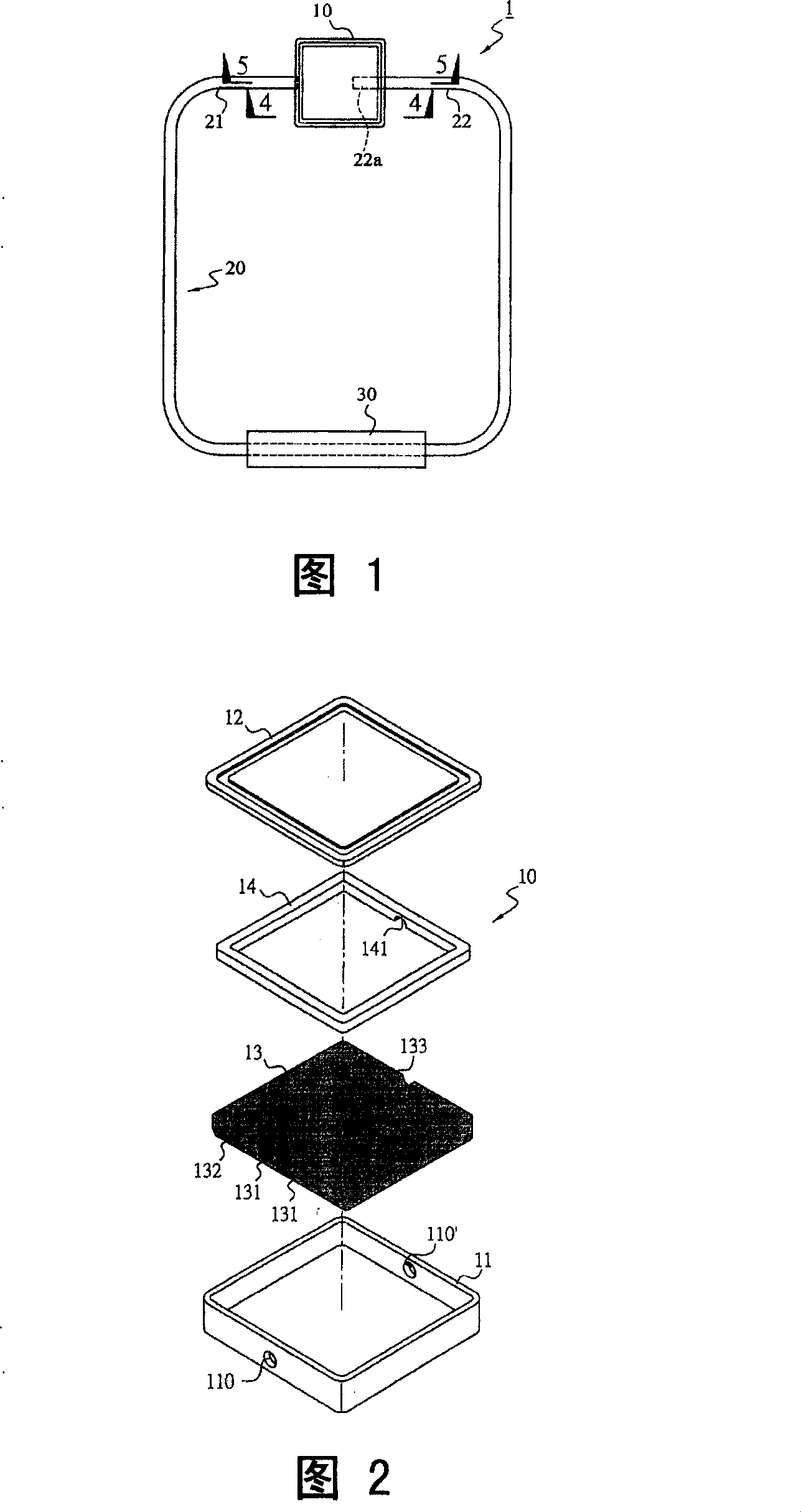

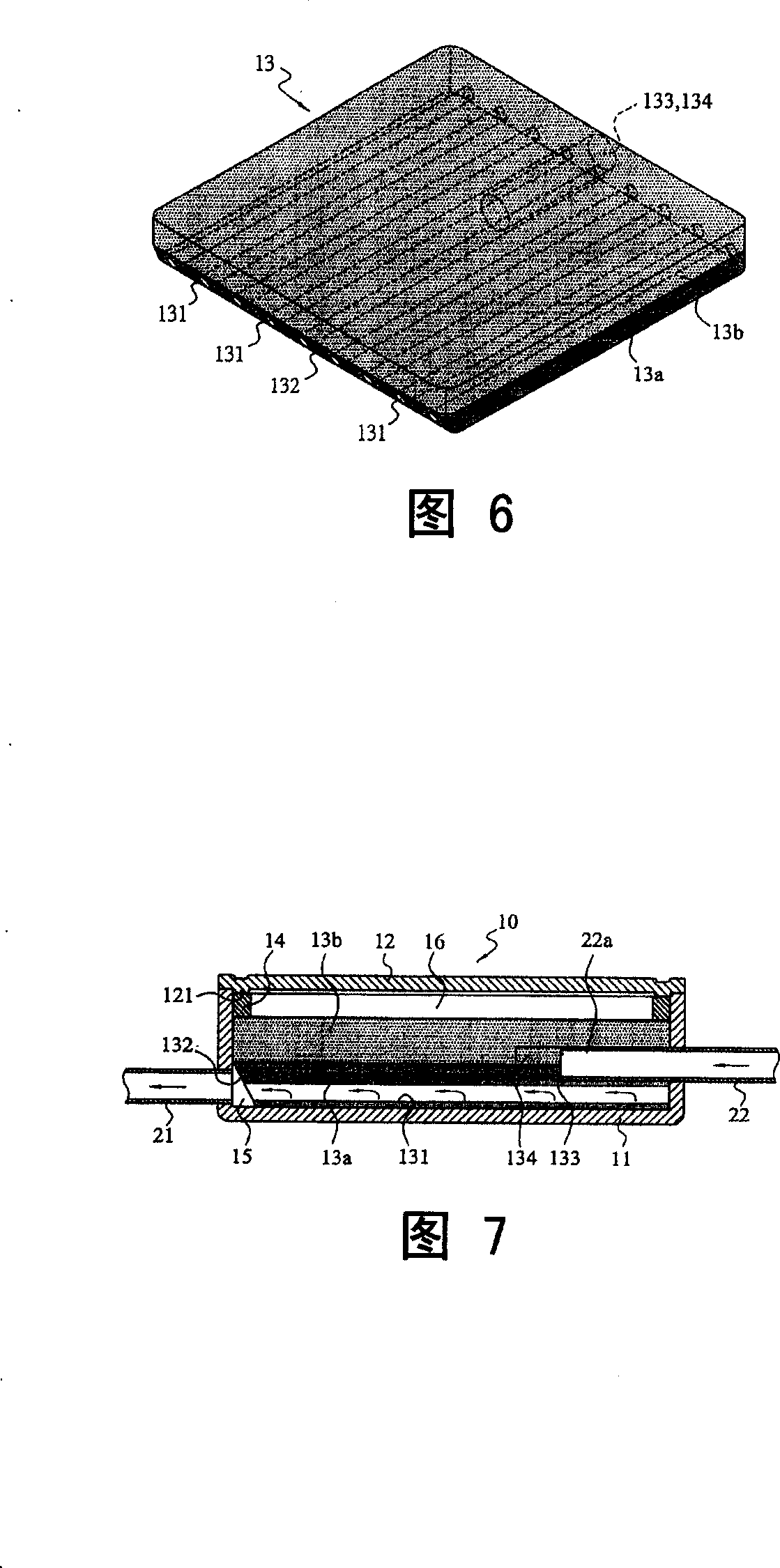

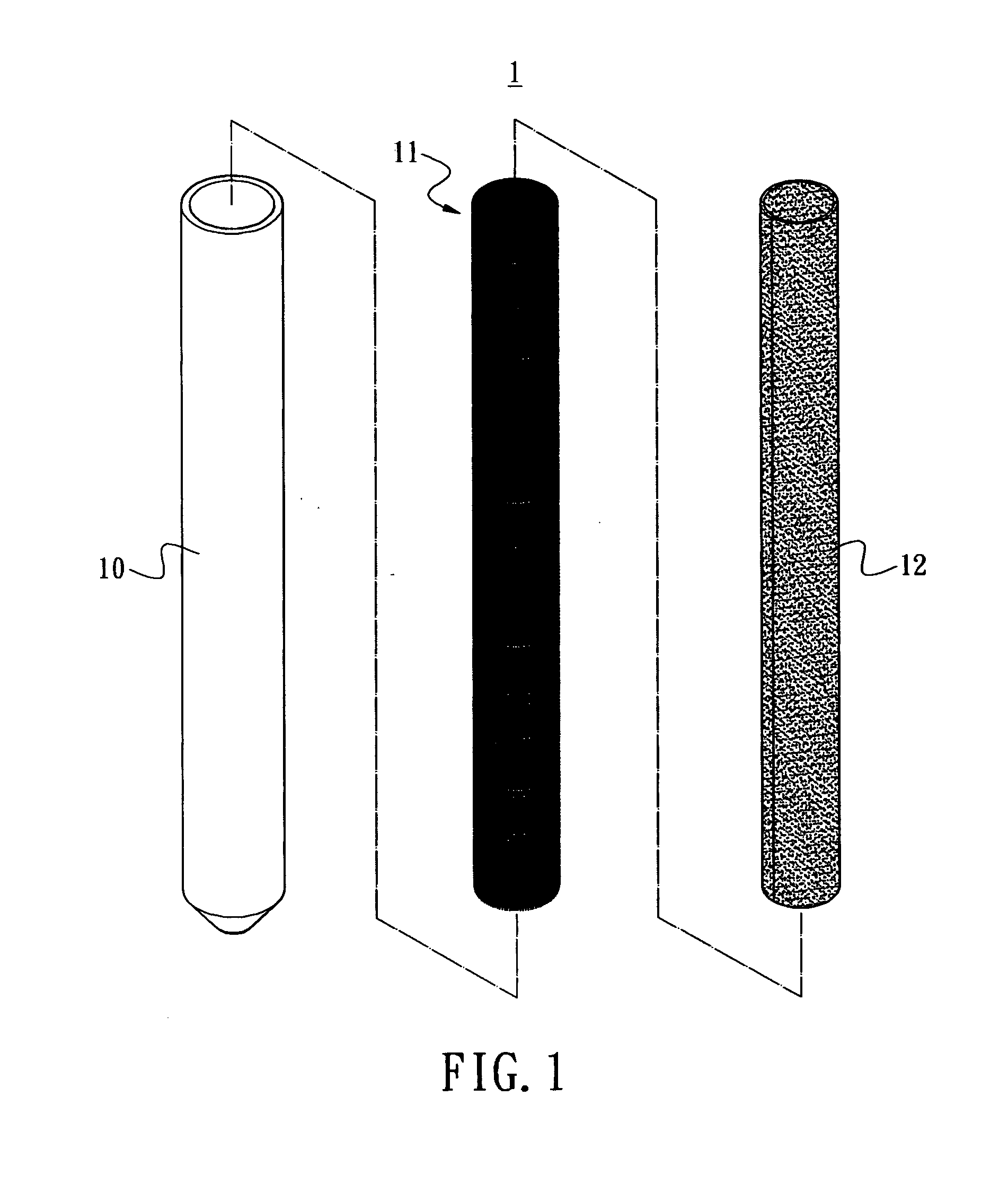

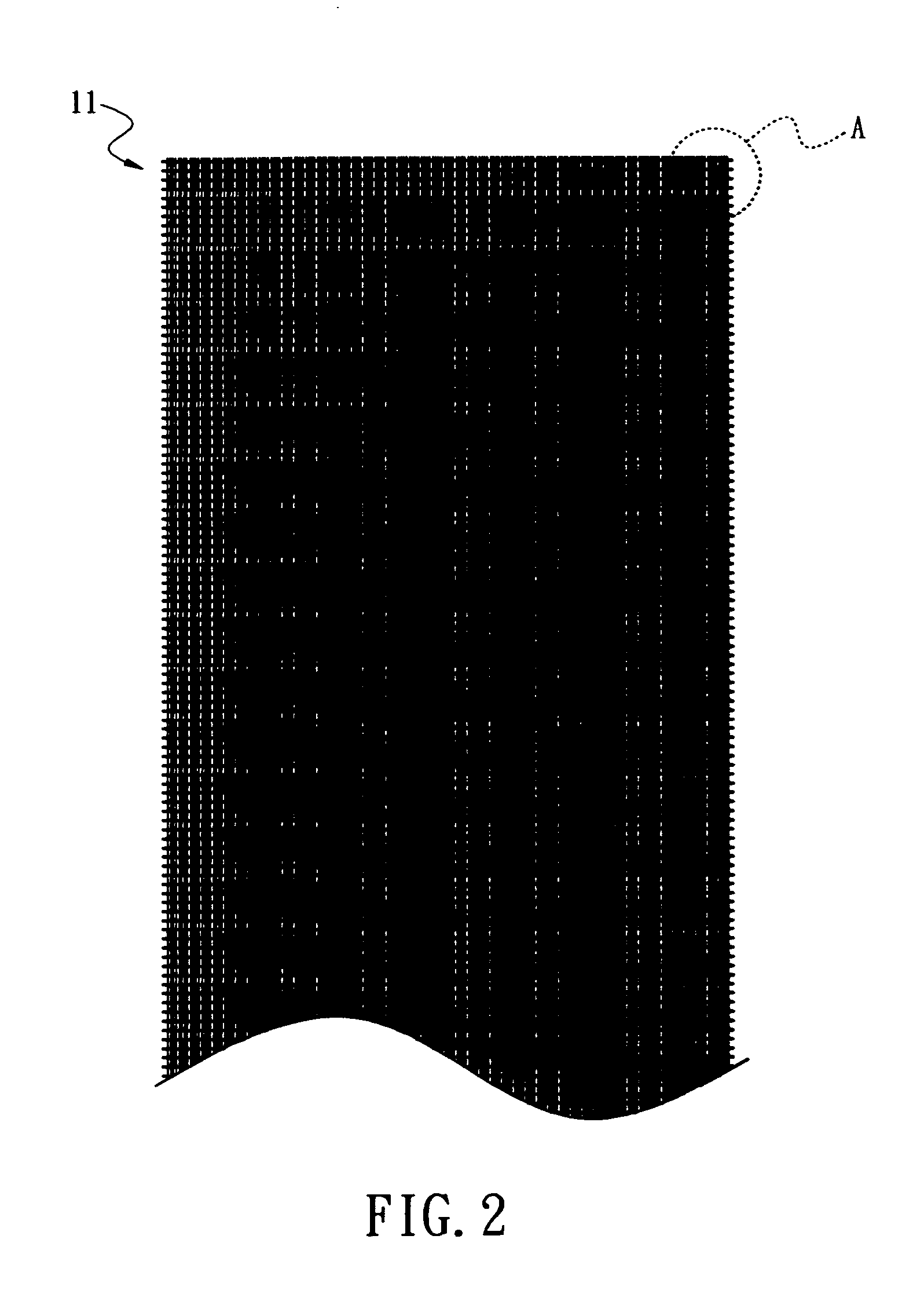

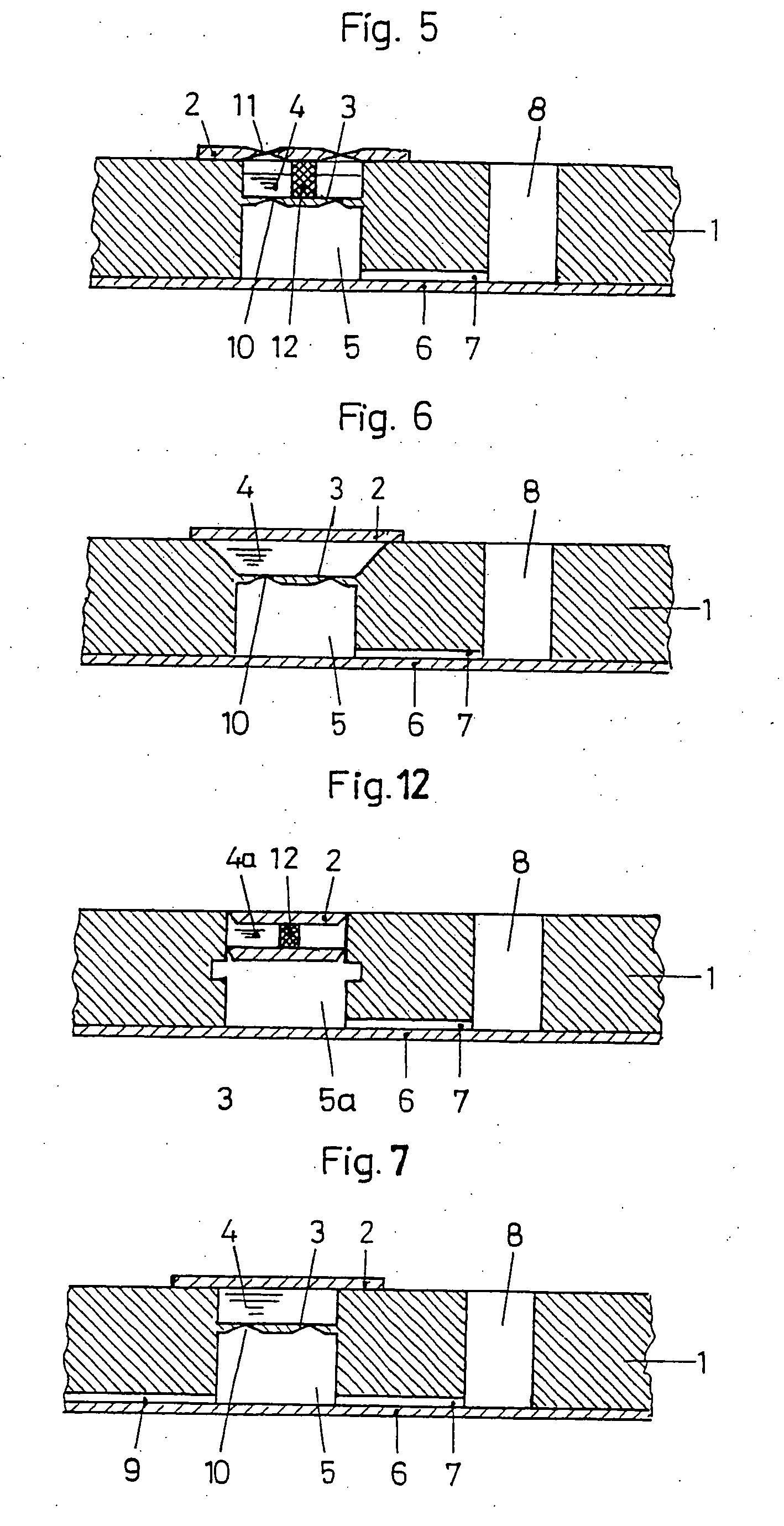

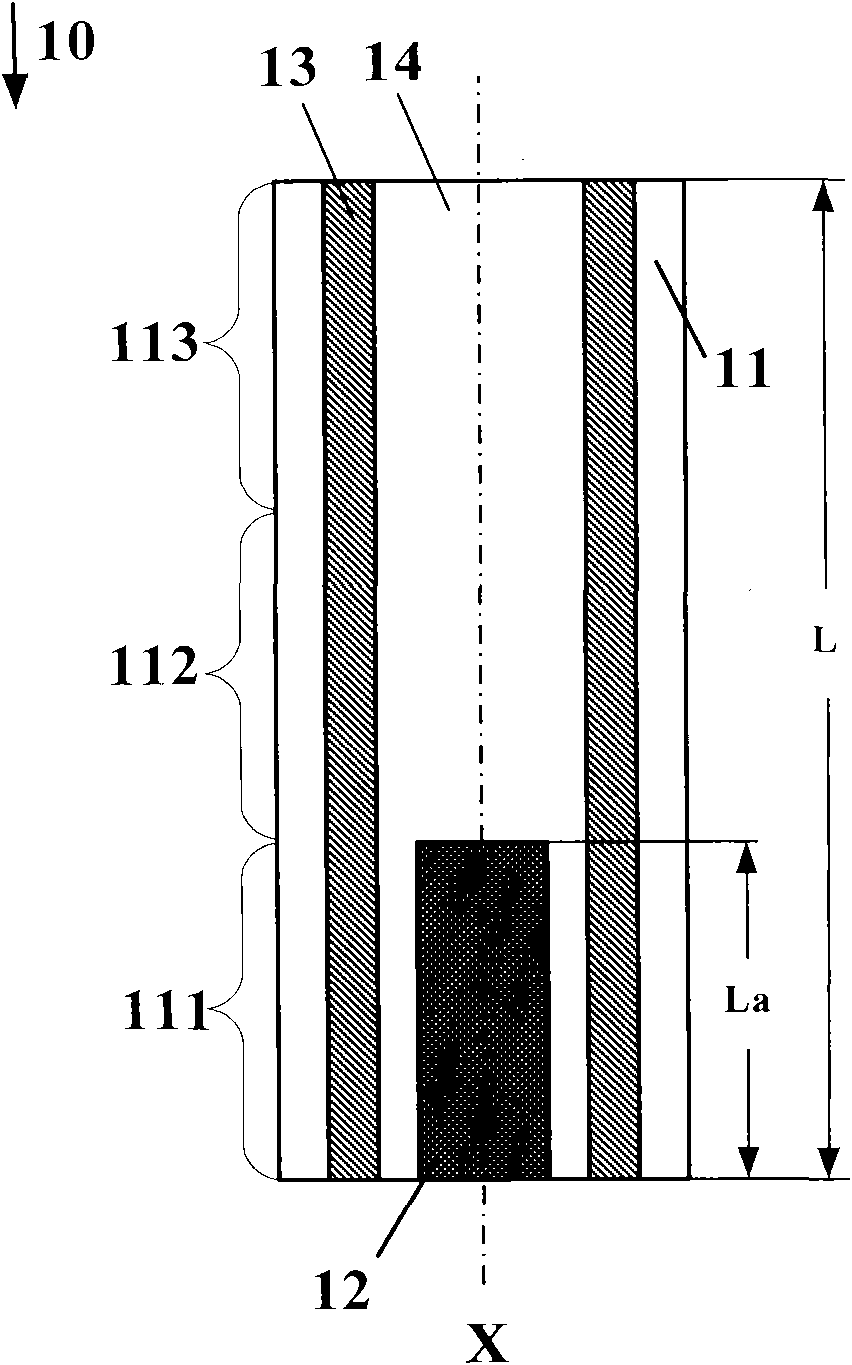

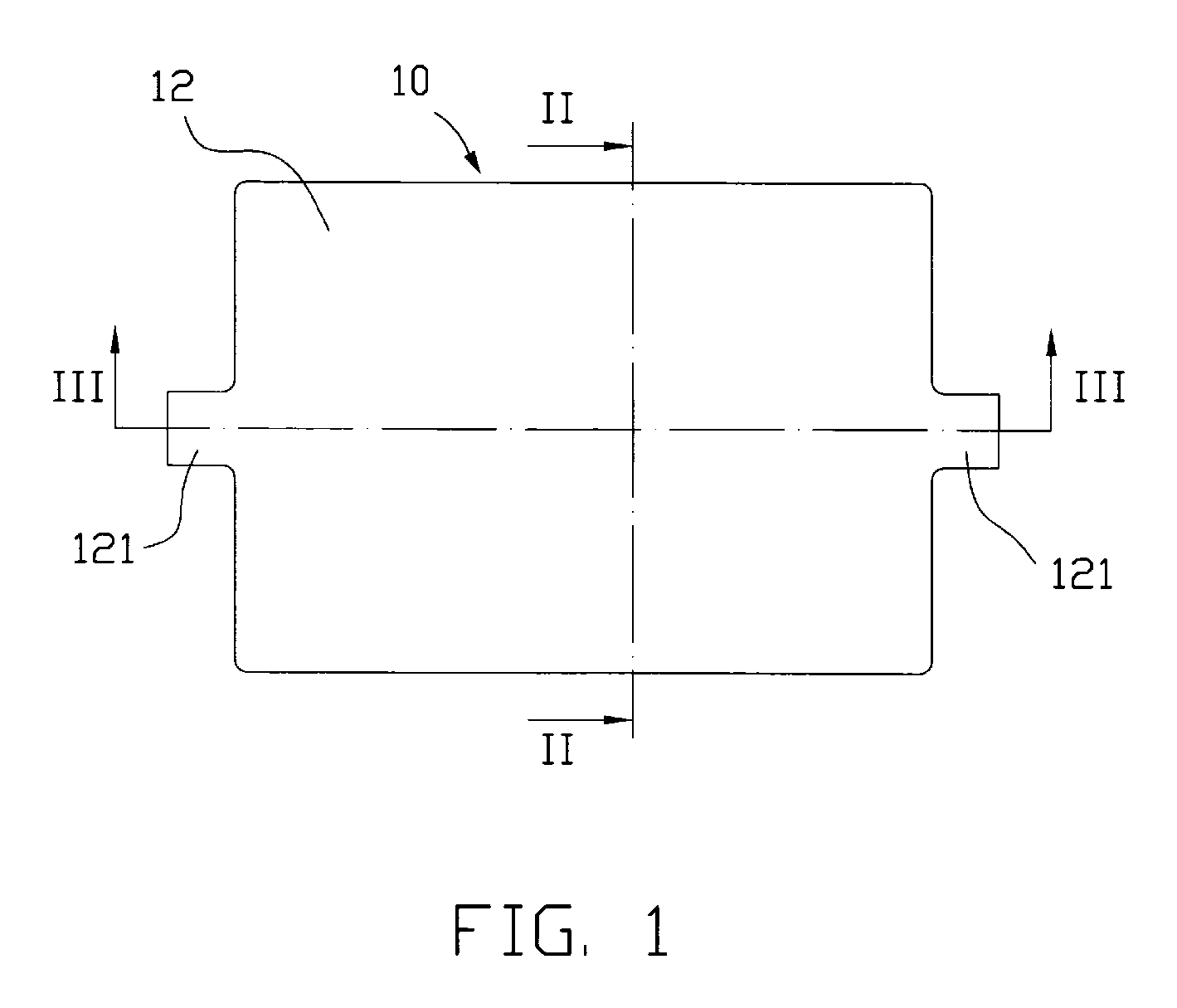

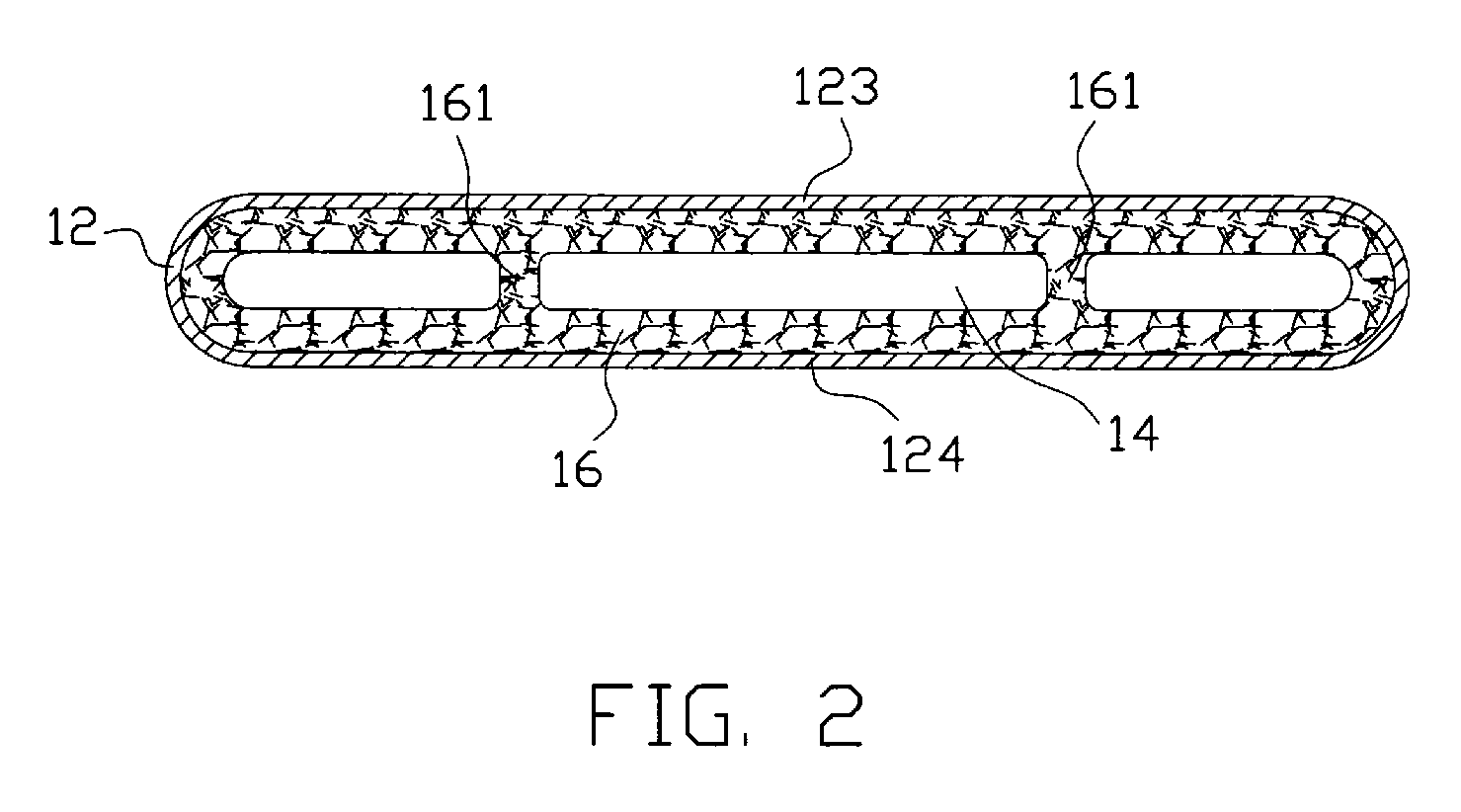

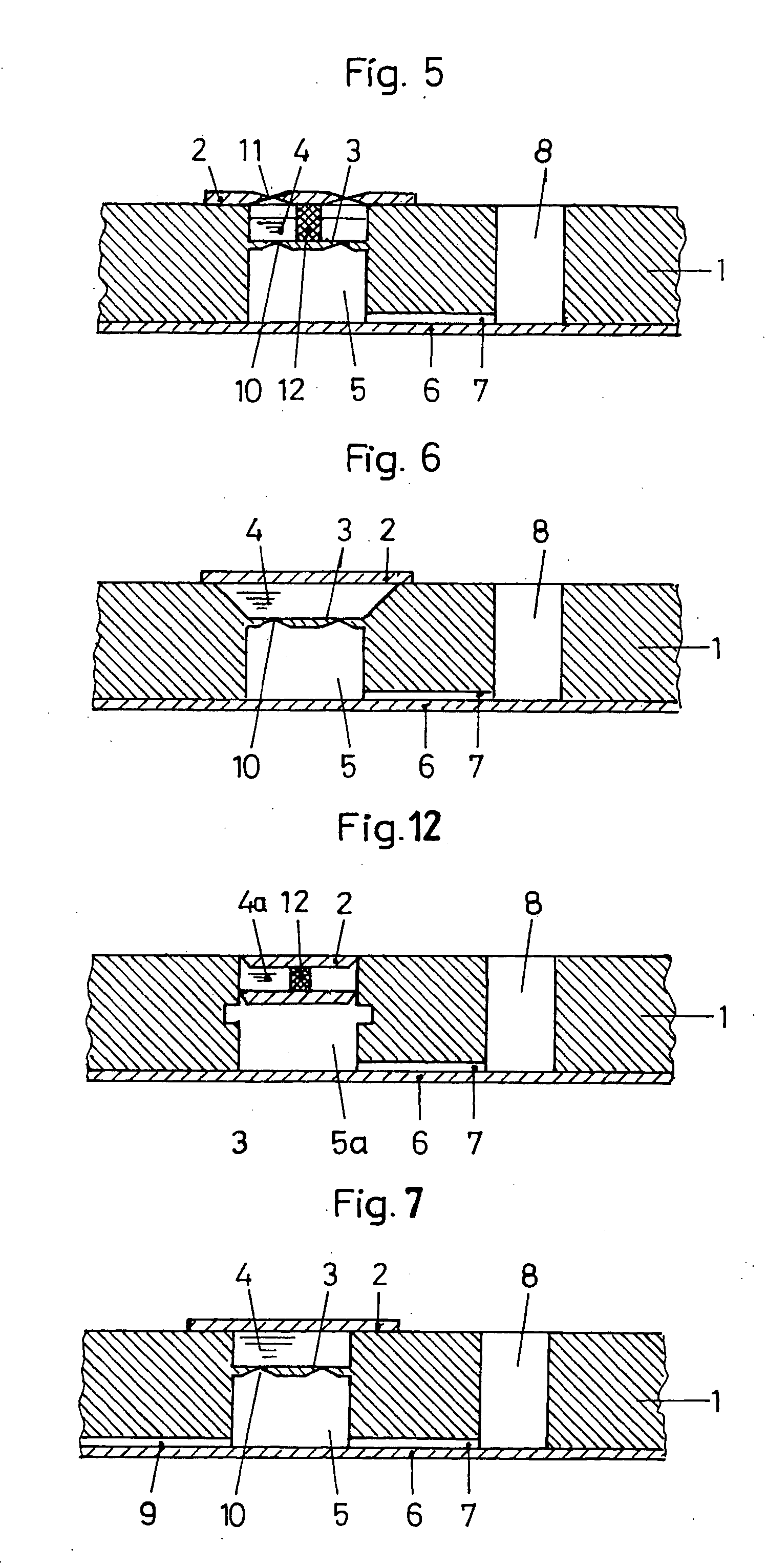

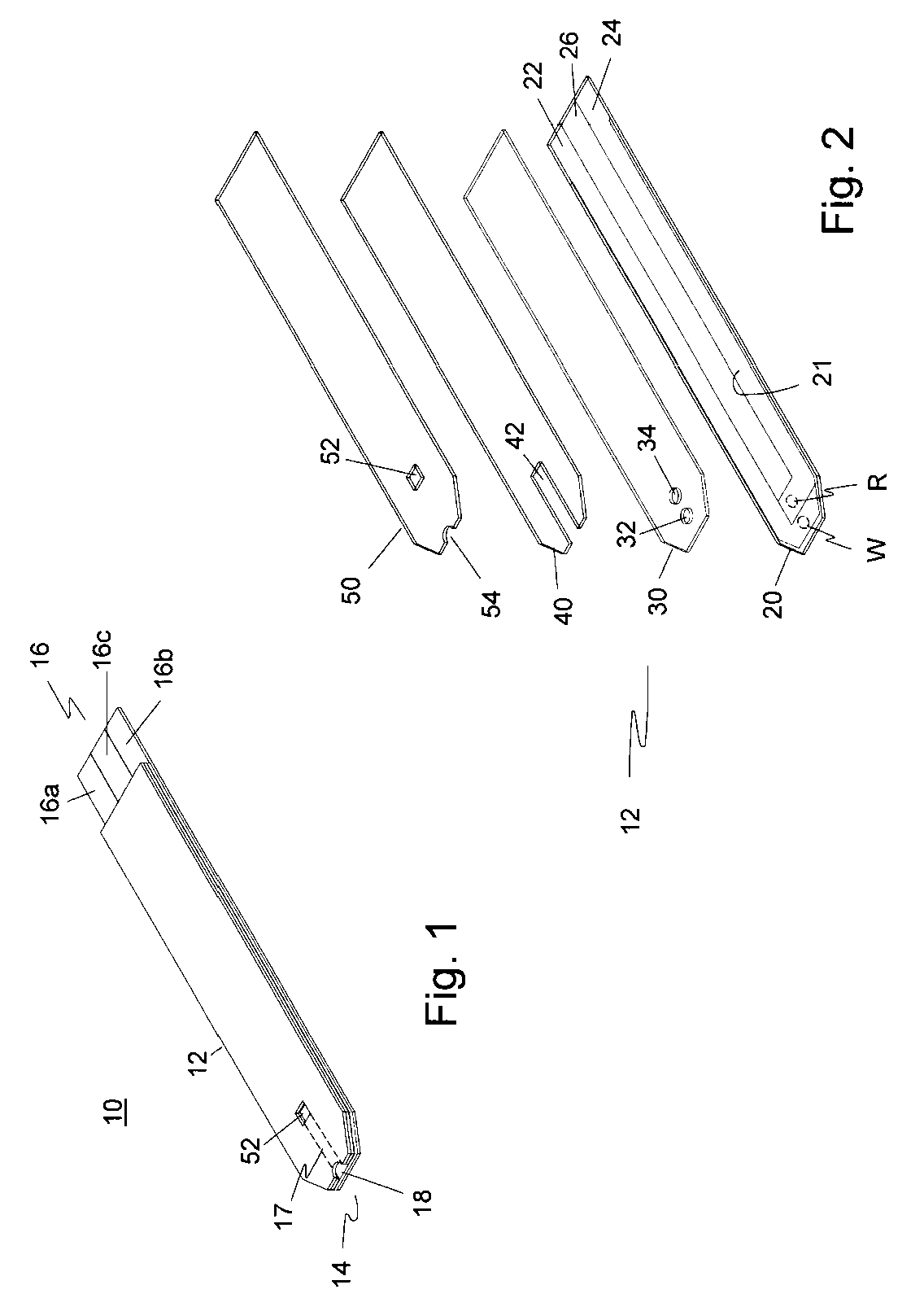

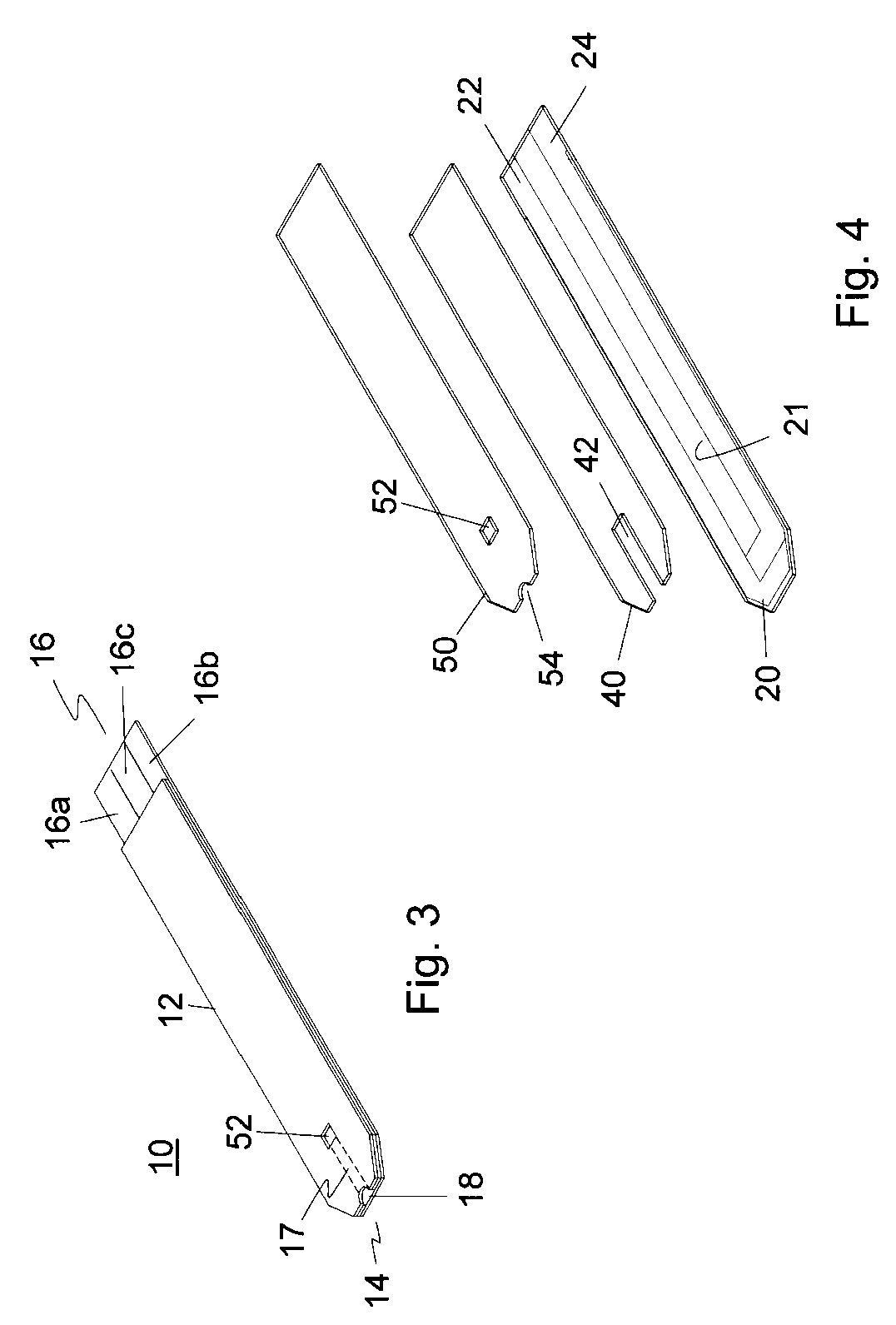

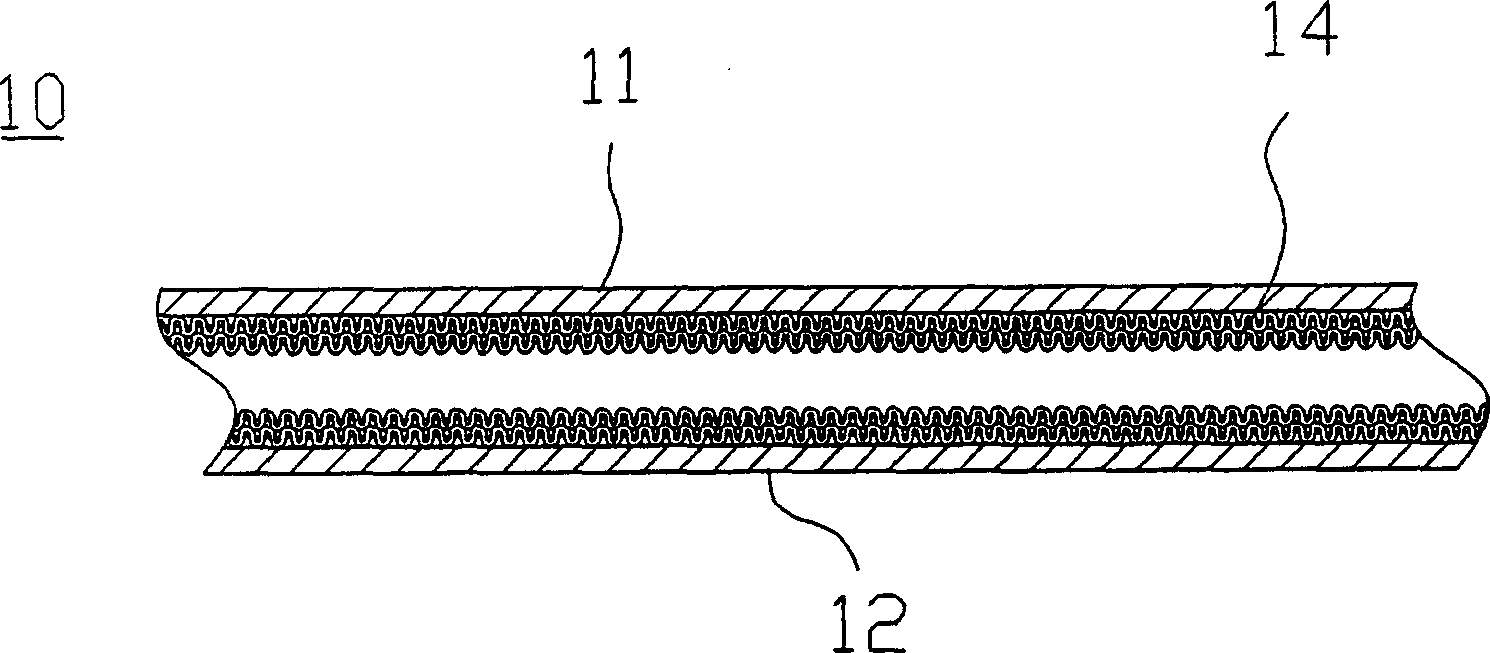

Flat type heat pipe

InactiveUS20070006993A1Lower resistanceIncrease capillary forceSemiconductor/solid-state device detailsSolid-state devicesEngineeringMetal foam

A flat type heat pipe (10) is disclosed which includes a metal casing (12) and a wick structure (16) arranged inside the metal casing. The metal casing has an evaporating section (123) and a condensing section (124). The wick structure extends from the evaporating section towards the condensing section of the metal casing and has a first section in conformity with the condensing section of the metal casing and a second section in conformity with the evaporating section of the metal casing. The first section has a pore size larger than that of the second section of the wick structure. The wick structure includes a metal foam.

Owner:HON HAI PRECISION IND CO LTD

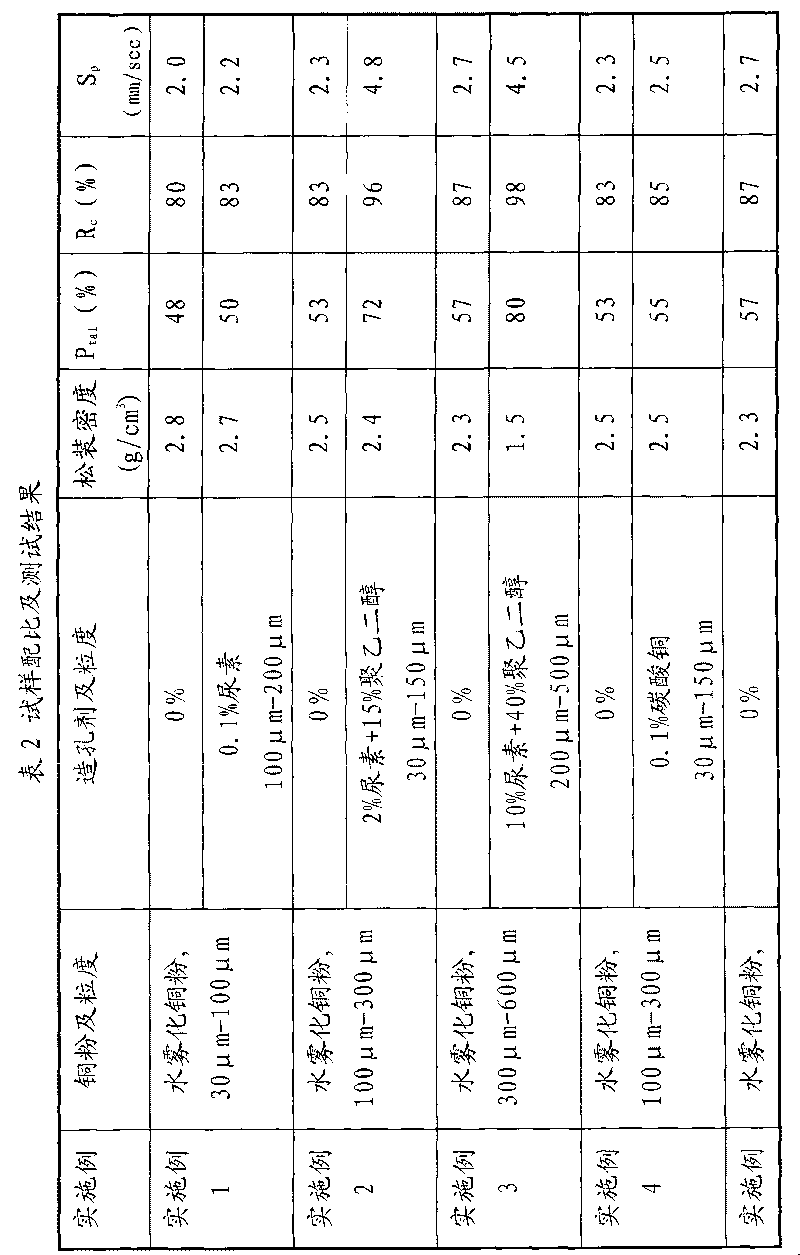

Compound copper powder for manufacturing capillary structure of inner wall of heat pipe

InactiveCN101704103AHigh porosityImprove capillary forceIndirect heat exchangersHeat transfer efficiencyCopper

The invention provides compound copper powder for manufacturing a capillary structure inside a heat pipe, which is a mixture consisting of copper powder and pore-forming agent powder. The compound copper powder ensures that a more favorable capillary structure layer can be produced under the condition of not changing the conventional heat pipe manufacturing process. The compound copper powder obtained by the invention is ram-jolted and sintered and then is prepared into the capillary structure layer with high porosity; and the effective porosity and the through hole ratio thereof are greatly improved compared with that of ordinary copper powder, and the permeability is also greatly improved compared with that of materials fired by the ordinary copper powder, which greatly improves the heat transfer efficiency of the heat pipe.

Owner:SCM METAL PROD SUZHOU

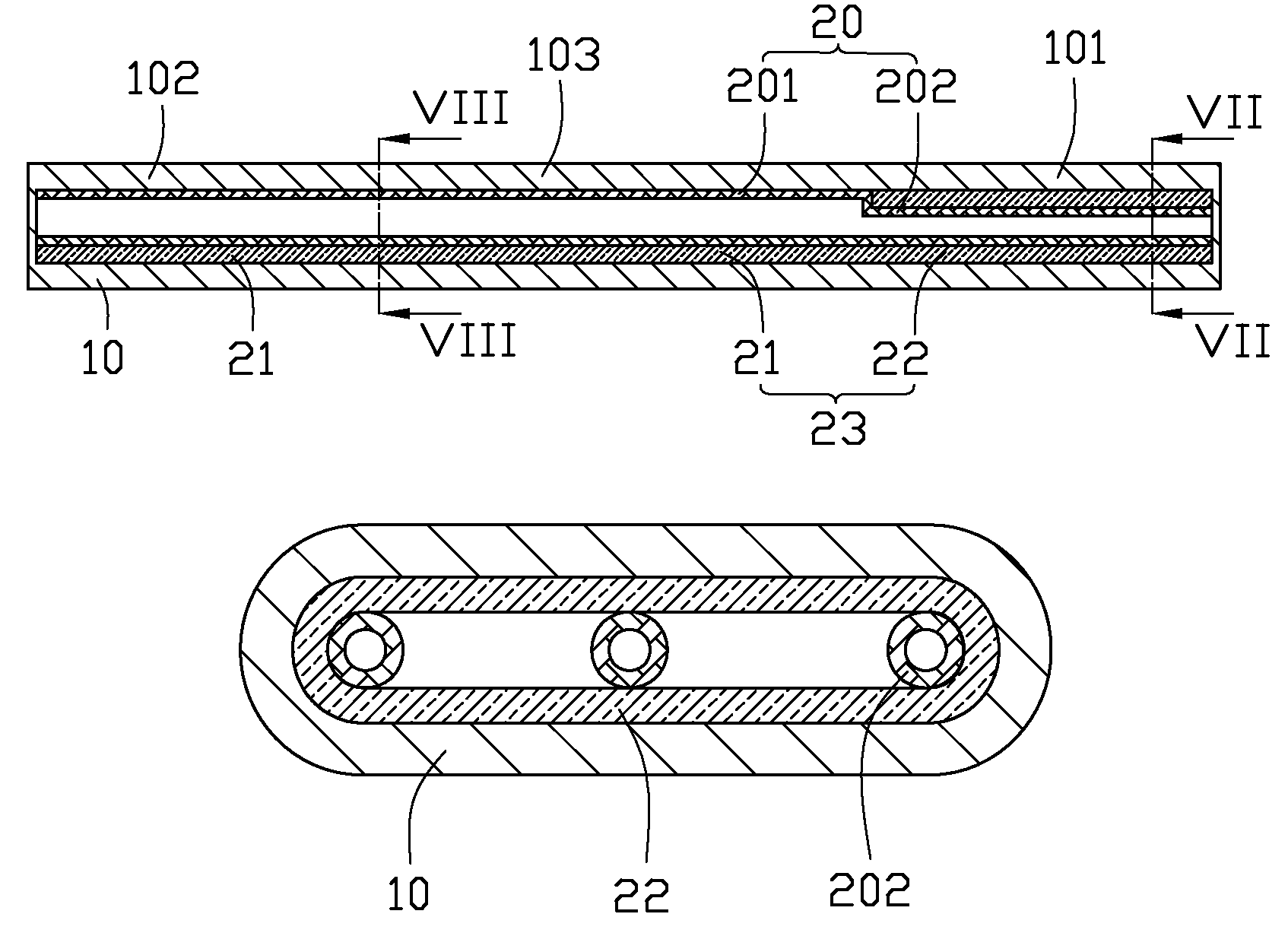

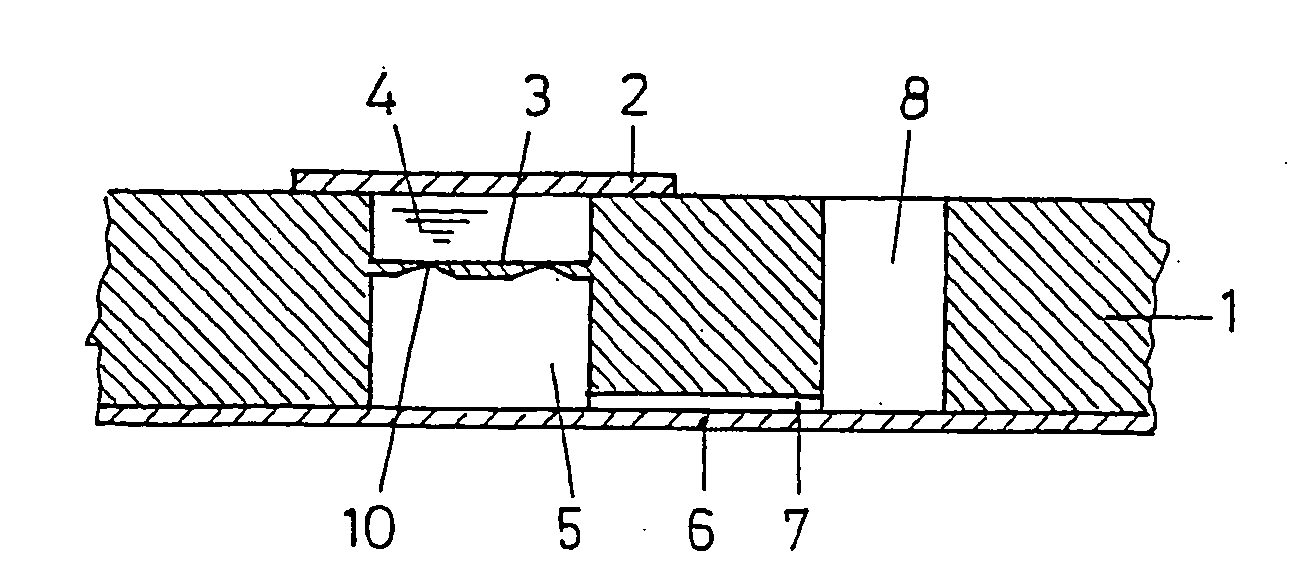

Heat pipe with composite wick structure

InactiveUS7845394B2Lower overall flow resistanceReduce heat transferSolid-state devicesIndirect heat exchangersMechanical engineeringHeat pipe

A heat pipe includes an elongated casing (10), a wick (13), at least one artery mesh (12), and working medium filling in the casing. The casing has an evaporating section (101) and a condensing section (102). The wick is disposed on an inner wall of the evaporating section. The at least one artery mesh includes a large portion (121) and a small portion (122) with an outer diameter smaller than that of the large portion. The small portion is located within and contacts with the wick, and the large portion contacts with the inner wall of the condensing section of the casing. The working medium saturates the wick and the at least one artery mesh.

Owner:HON HAI PRECISION IND CO LTD

Disposable oxygen sensor and method for correcting oxygen effect on oxidase-based analytical devices

ActiveUS20060278537A1Easy to manufactureAccurate measurementImmobilised enzymesBioreactor/fermenter combinationsAnalyteOxygen sensor

A system and method for correcting the oxygen effect on oxidase-based analyte sensors includes an oxygen sensor with a working electrode, a reagent matrix disposed on at least the working electrode that contains a reduced form of a redox mediator, an oxidase and a peroxidase, an oxidase-based analyte sensor, a means for determining the oxygen concentration in a portion of a fluid sample using the oxygen sensor, means for determining an analyte concentration in another portion of the fluid sample using the oxidase-based analyte sensor, and means for using the oxygen concentration in the fluid sample to determine a corrected analyte concentration in the fluid sample.

Owner:NOVA BIOMEDICAL

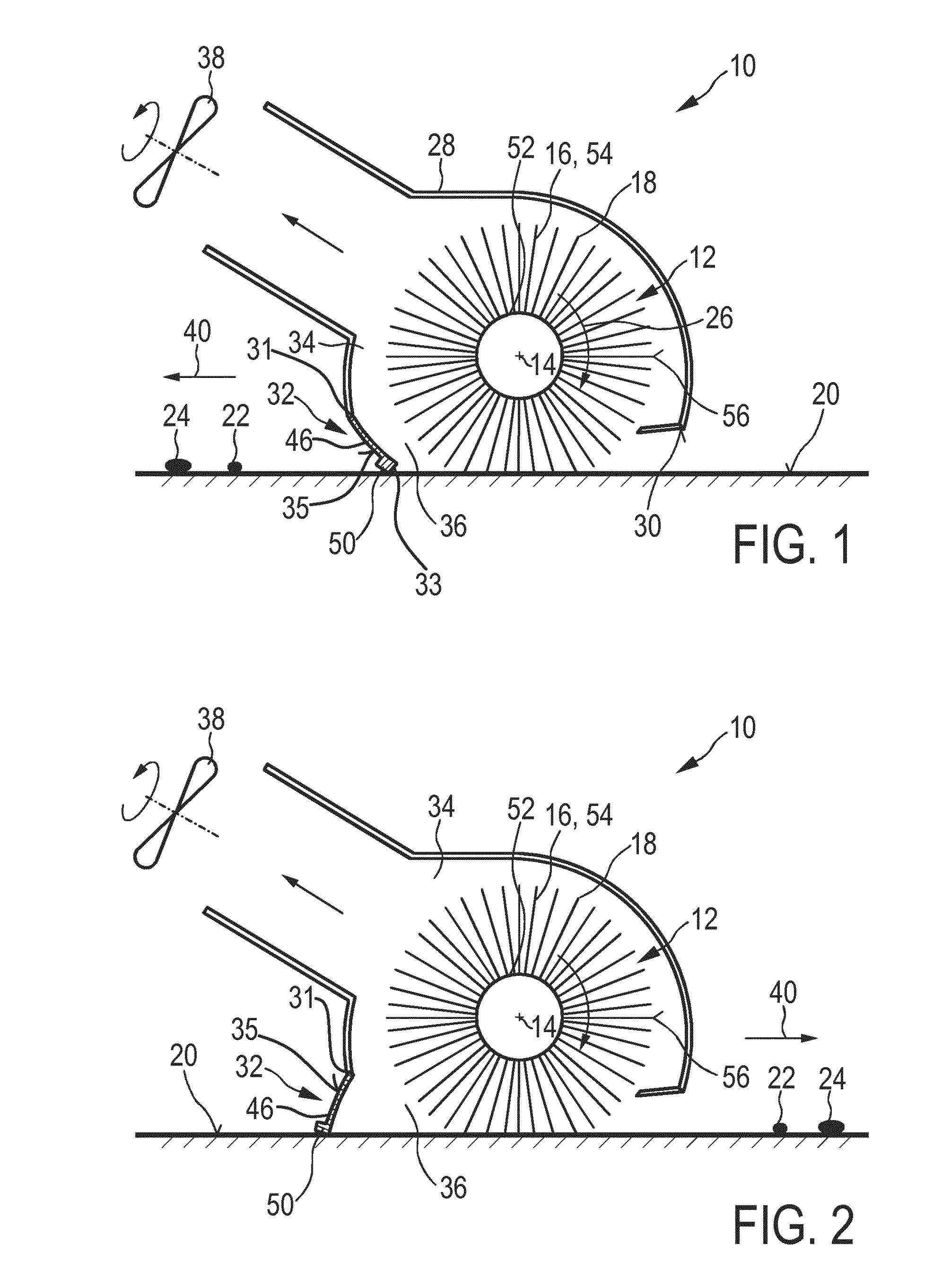

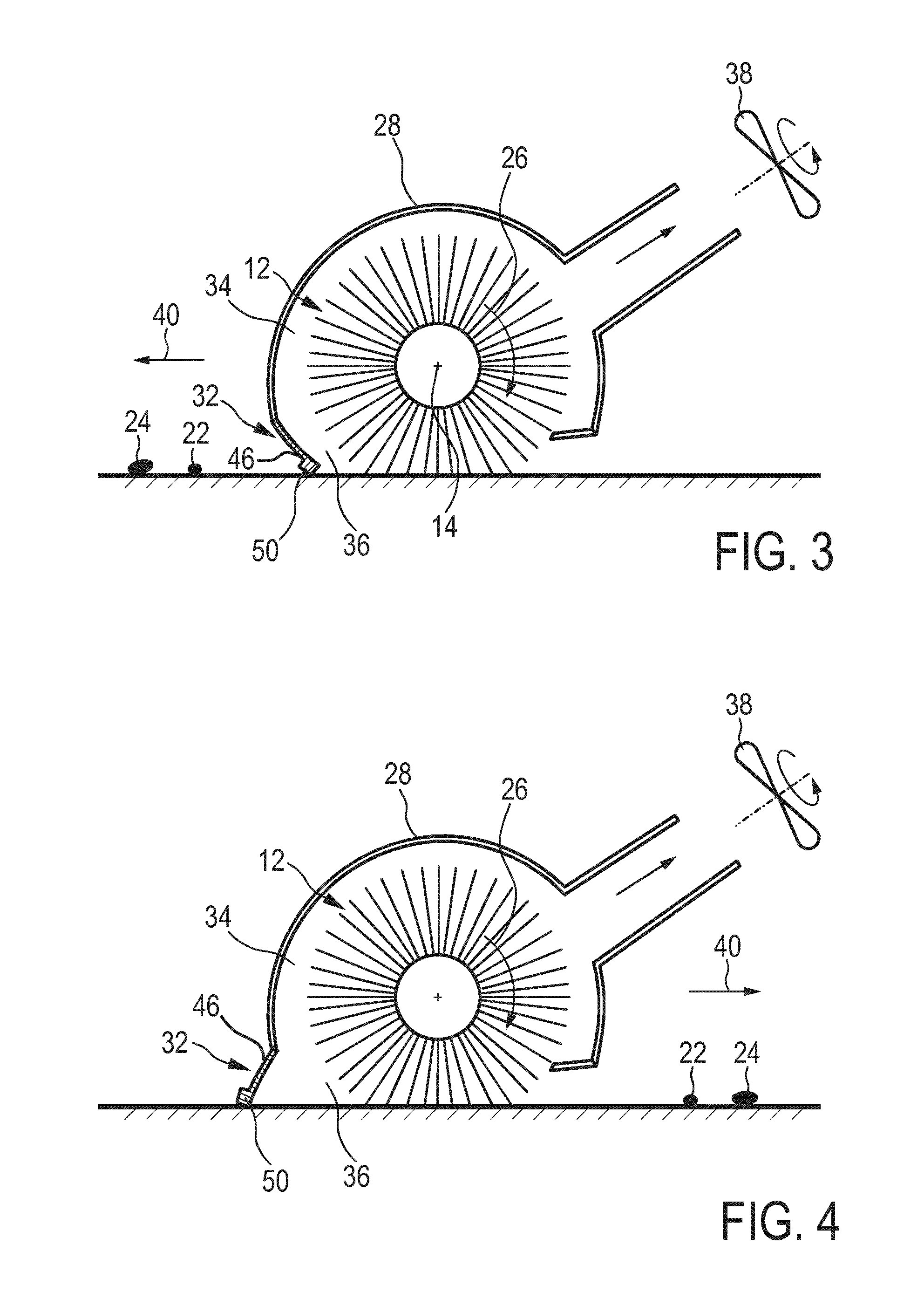

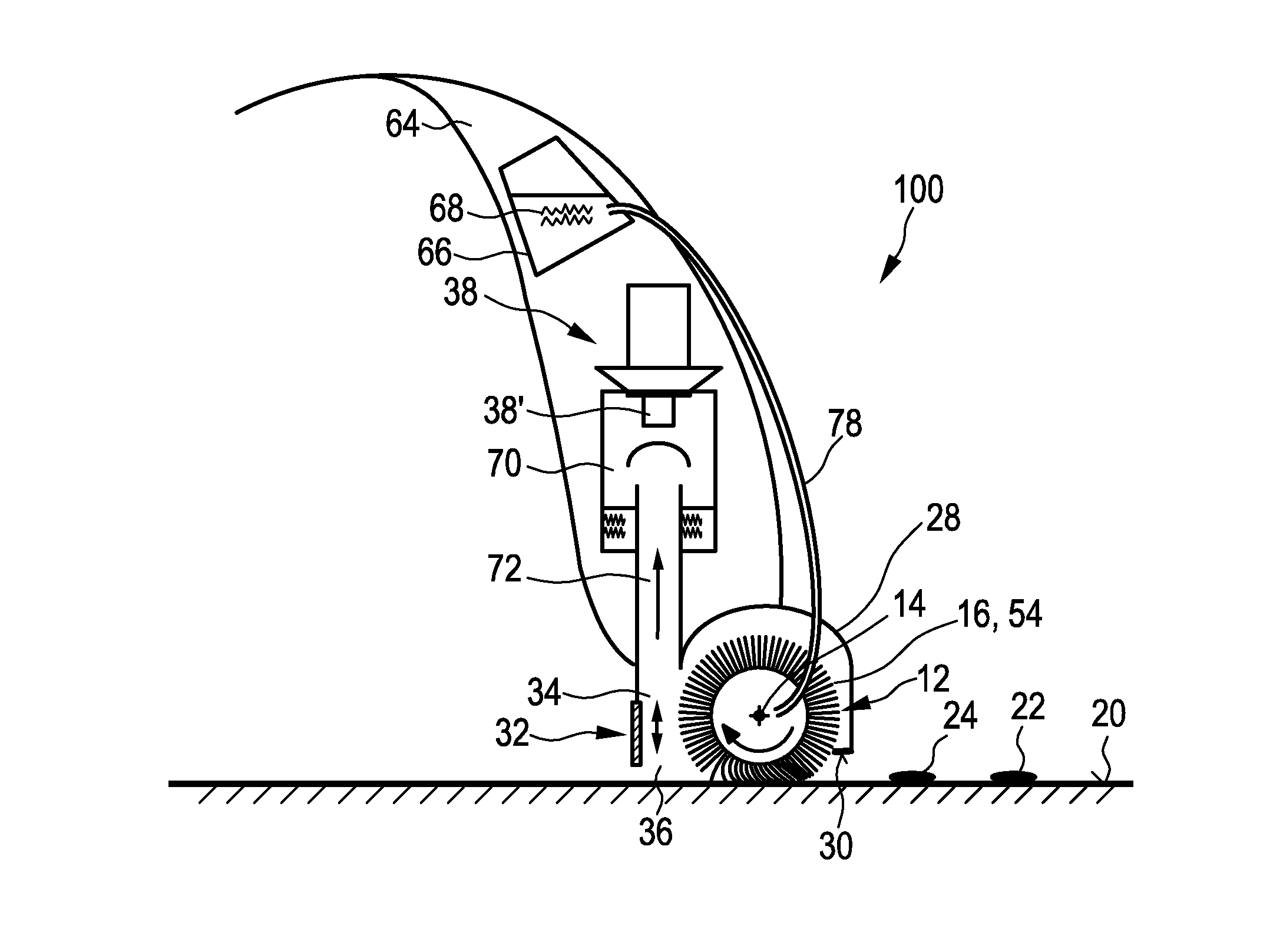

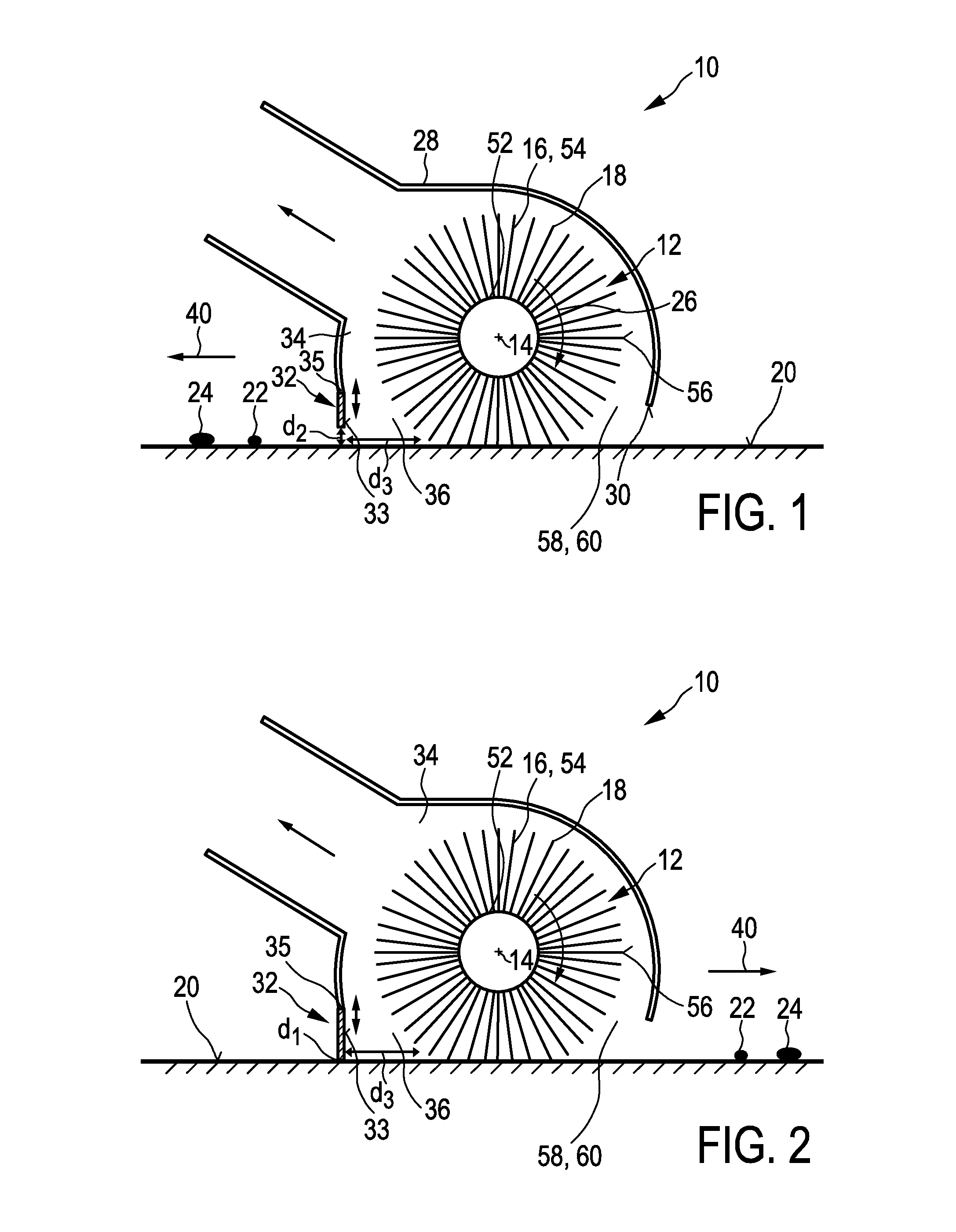

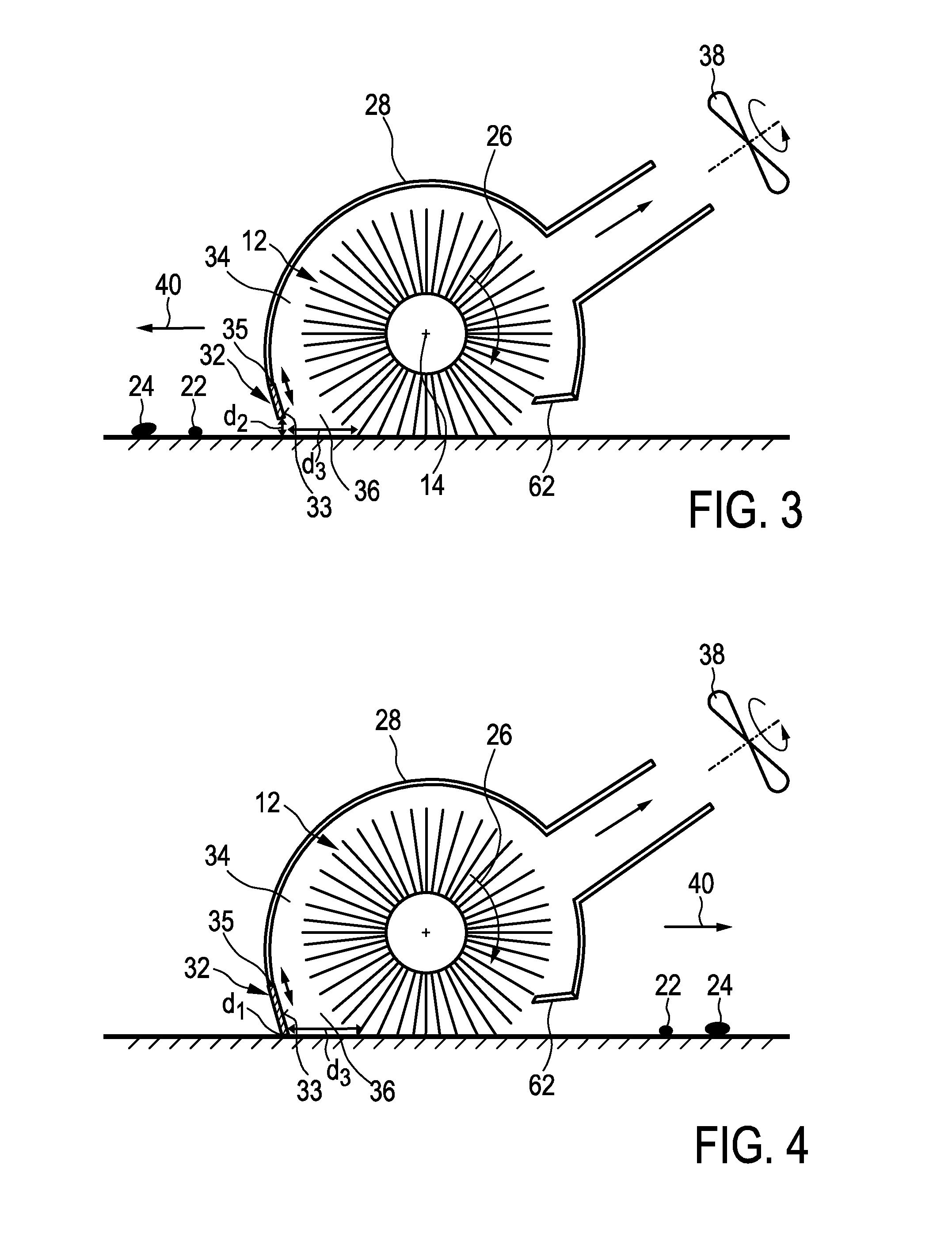

Nozzle arrangement with brush and squeegee

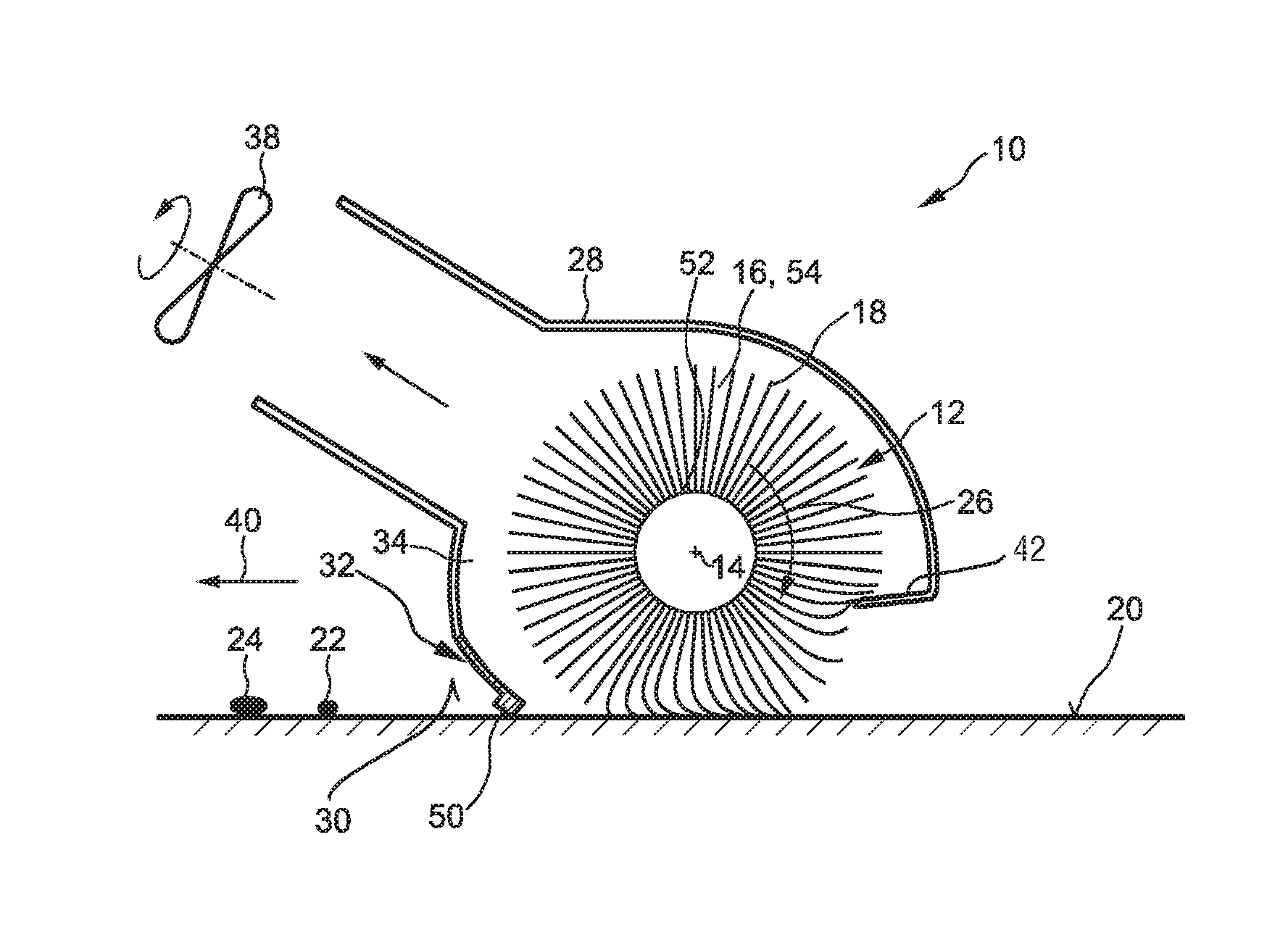

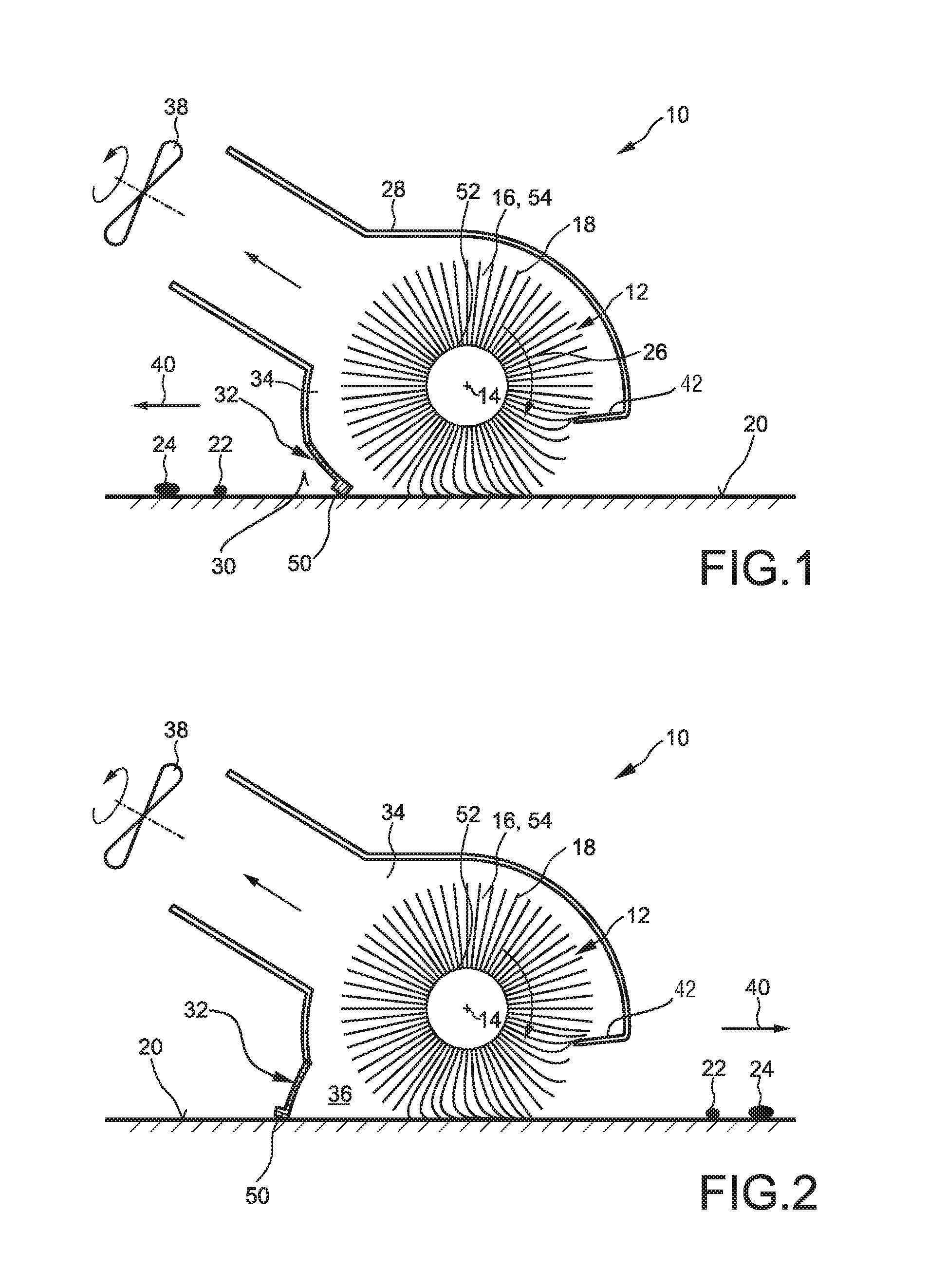

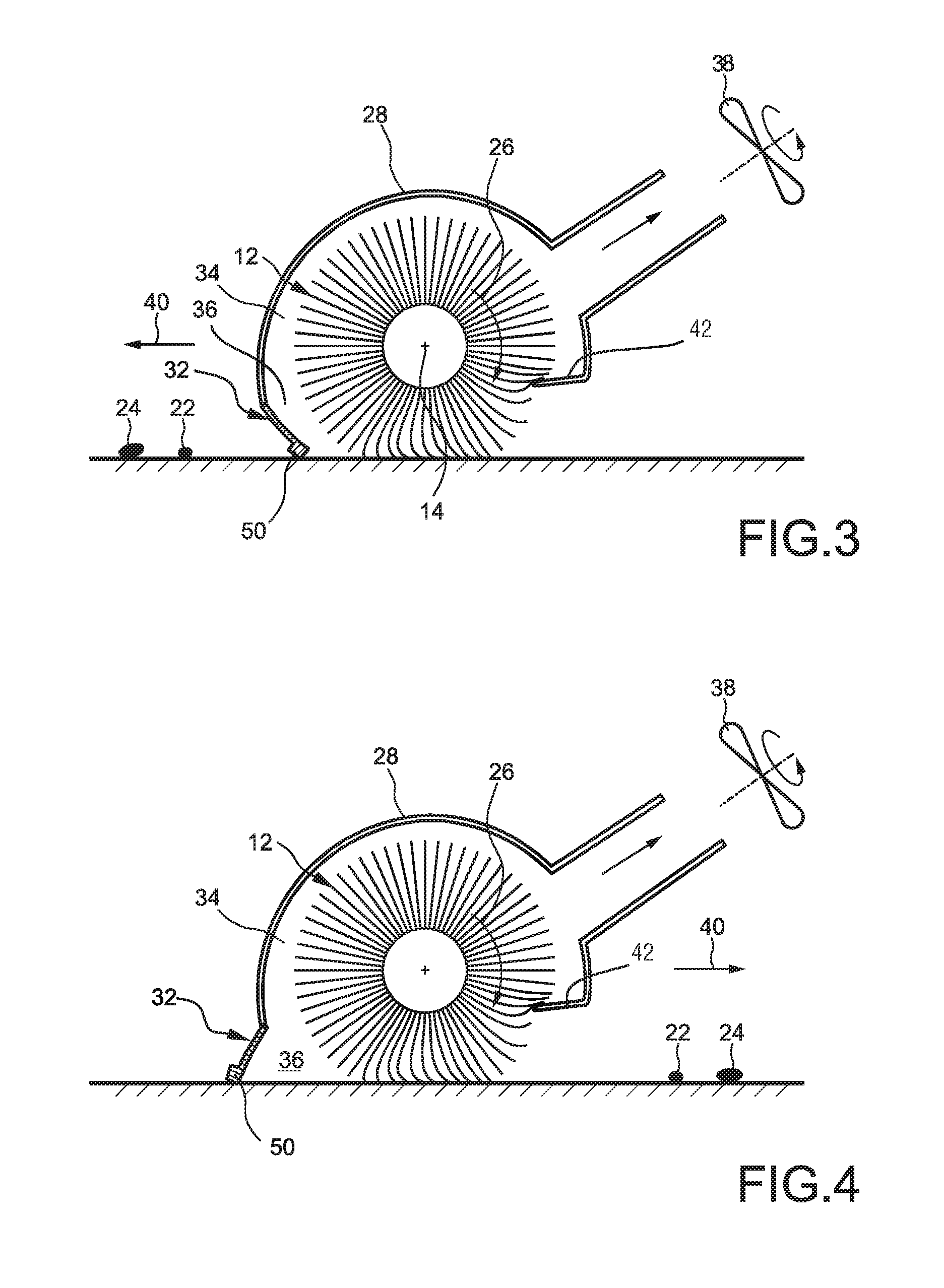

ActiveUS20150250367A1Enhance fast removal of liquidIncrease capillary forceCarpet cleanersFloor cleanersEngineeringMicrofiber

Nozzle arrangement (10) of a vacuum cleaning device (100) for cleaning a surface (20), comprising: —a nozzle housing (28); —a brush (12) rotatable about a brush axis (14), said brush (12) being provided with flexible microfiber brush elements (16) having tip portions (18) for contacting the surface to be cleaned (20) and picking up dirt and liquid particles (22, 24) from the surface to be cleaned (20) during the rotation of the brush (12); —a drive means for rotating the brush (12); —a single squeegee element (32) for wiping dirt and liquid particles (22, 24) across or off the surface to be cleaned (20) by contacting said surface (20) with its free end (33), wherein said squeegee element (32) extends along a longitudinal direction (48), which is arranged substantially parallel to the brush axis (14), and is attached with its fixed end (33) to the bottom side (30) of the nozzle housing (28) on a side of the brush (12) where the brush elements (16) enter the nozzle housing (28) during the rotation of the brush (12).

Owner:VERSUNI HLDG BV

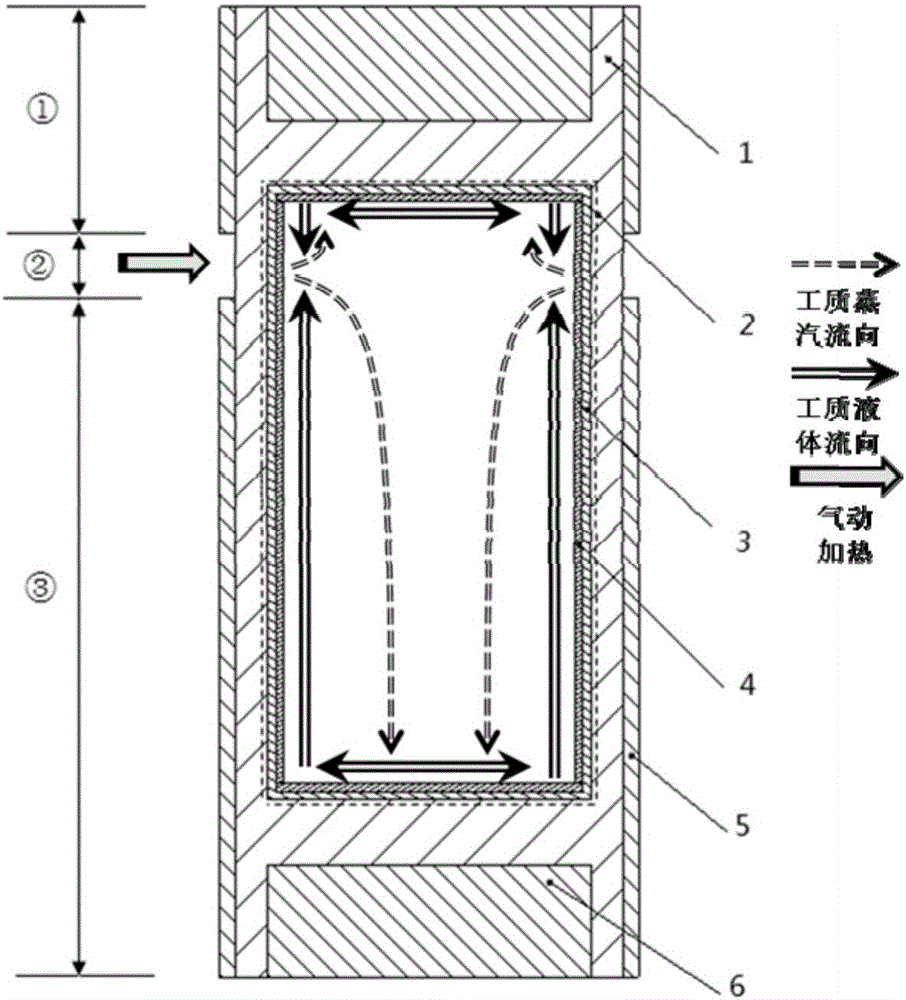

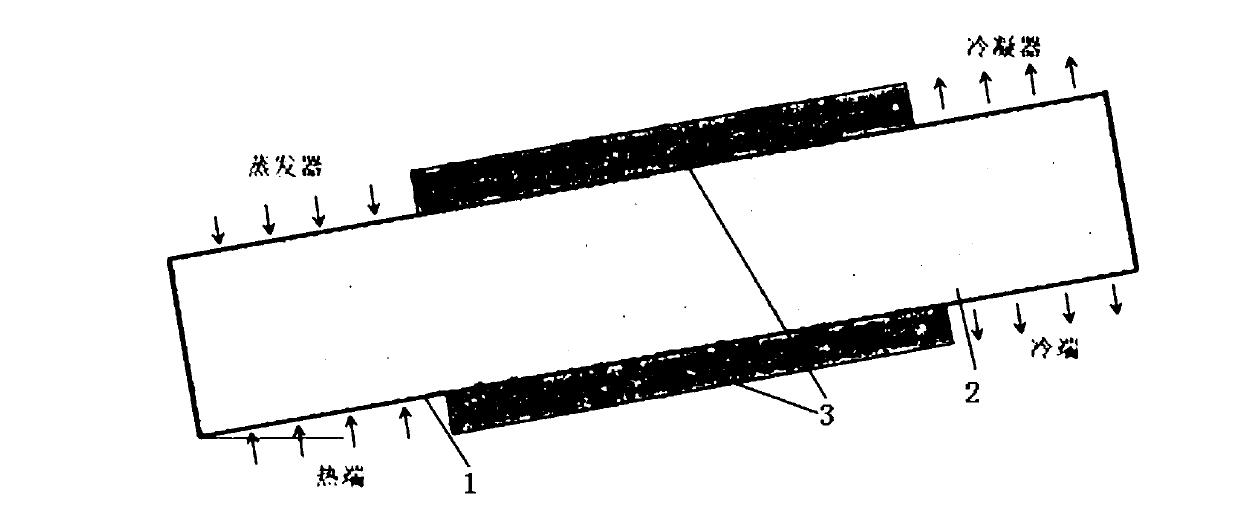

Loop heat-conducting device

InactiveCN101026946ADoes not increase flow resistanceIncrease capillary forceDigital data processing detailsSemiconductor/solid-state device detailsHeat conductingEngineering

The loop heat conducting equipment includes vaporizer and condenser connected to each other through circle pipe so as to constitute circulation loop of liquid working medium. The vaporizer possesses core body of capillary structure (CBCS) inside. Multiple tunnels are formed in CBCS. One end of tunnels is converged to vapor chamber, which is connected to one end of the circle pipe to form the output end of gas state working medium. After through the condenser, the other end of the circle pipe as the input end of formed liquid working medium is connected to the vaporizer. Extending into and contacting with inner CBCS, end of the circle pipe forms compensated chamber of liquid working medium on up portion of CBCS. Using gas and liquid separated circulation loop, the invention reaches optimal efficiency of heat elimination. Features are: simple structure, and easy of measure yield.

Owner:YEH CHIANG TECH CORP

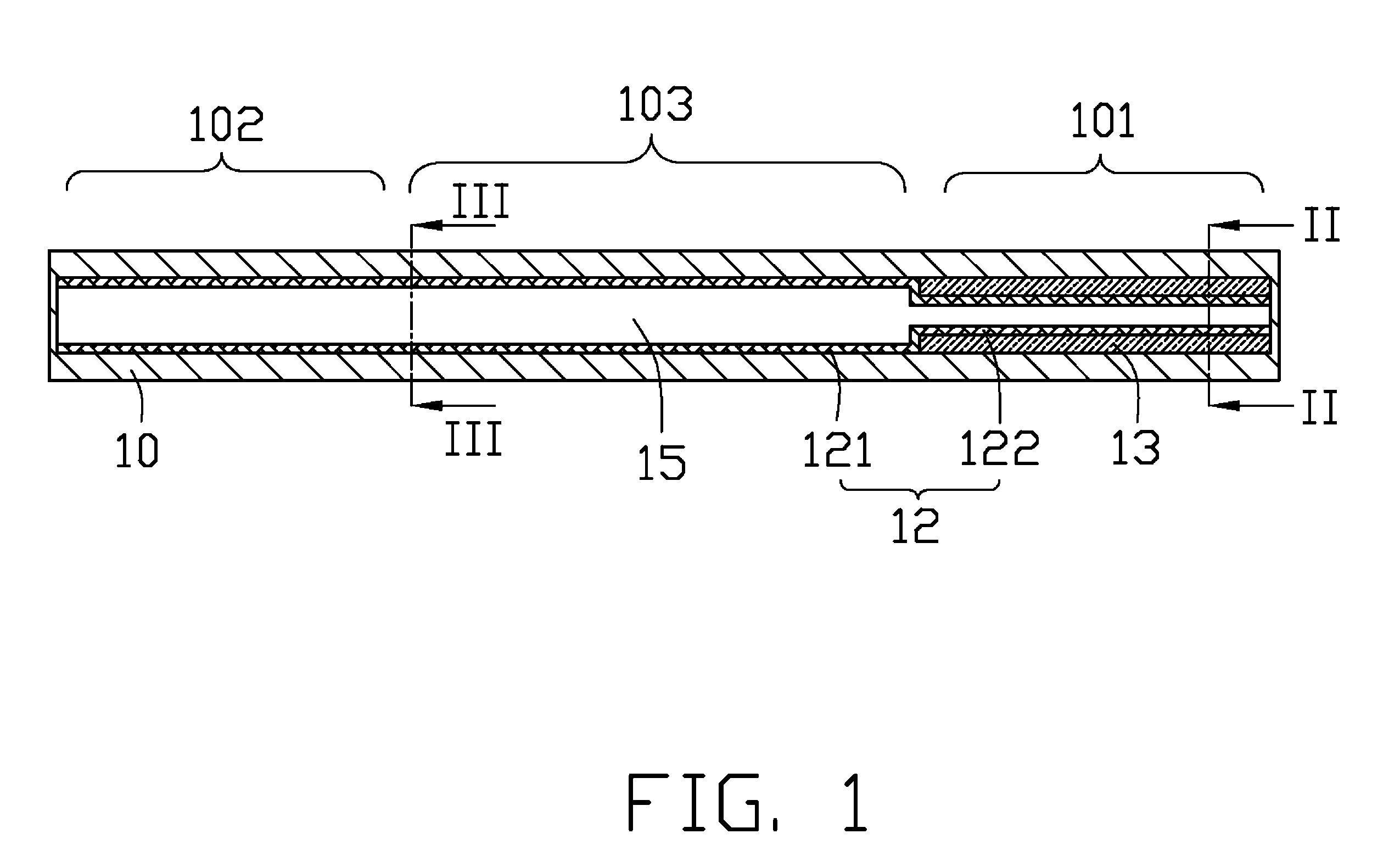

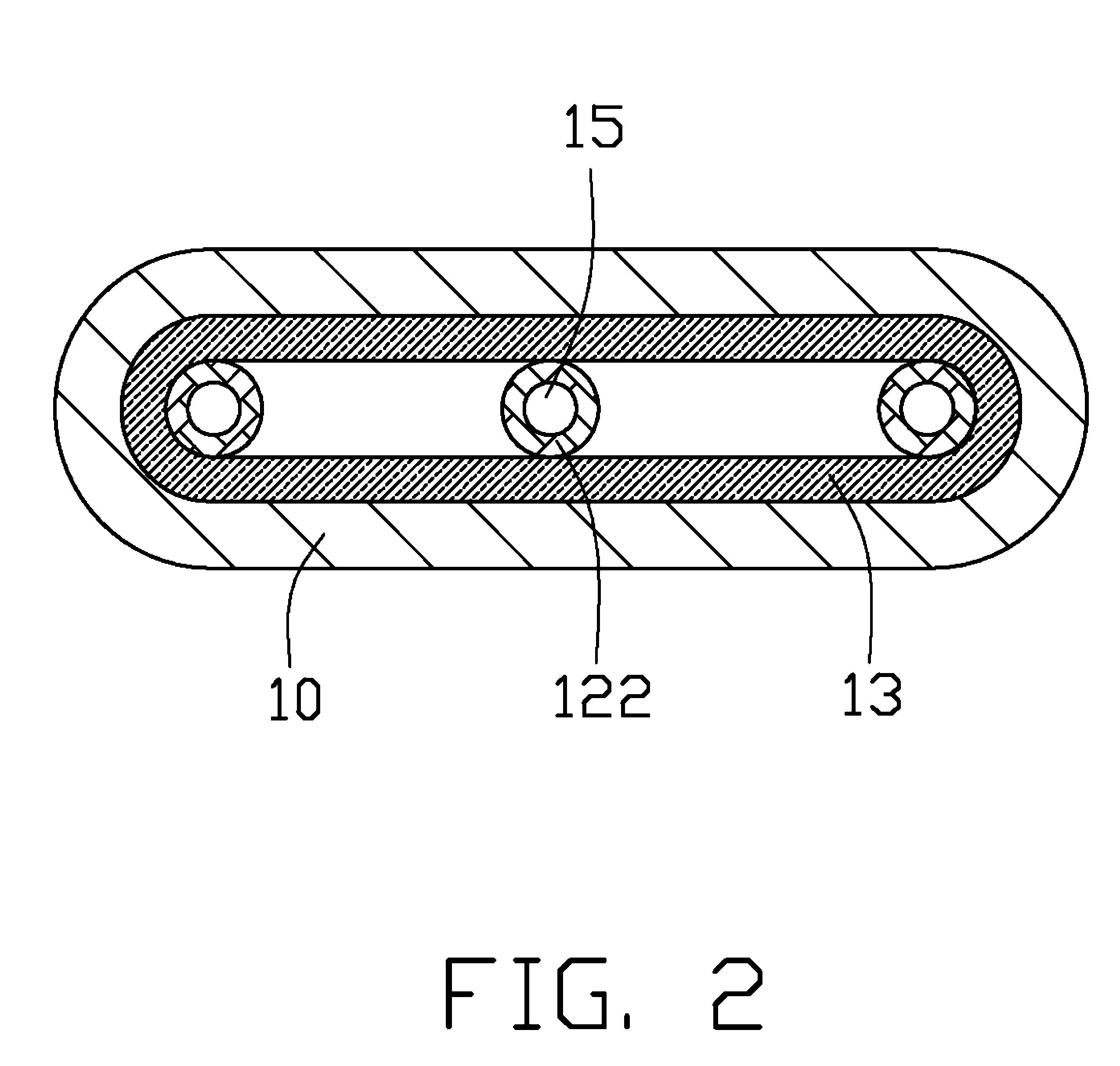

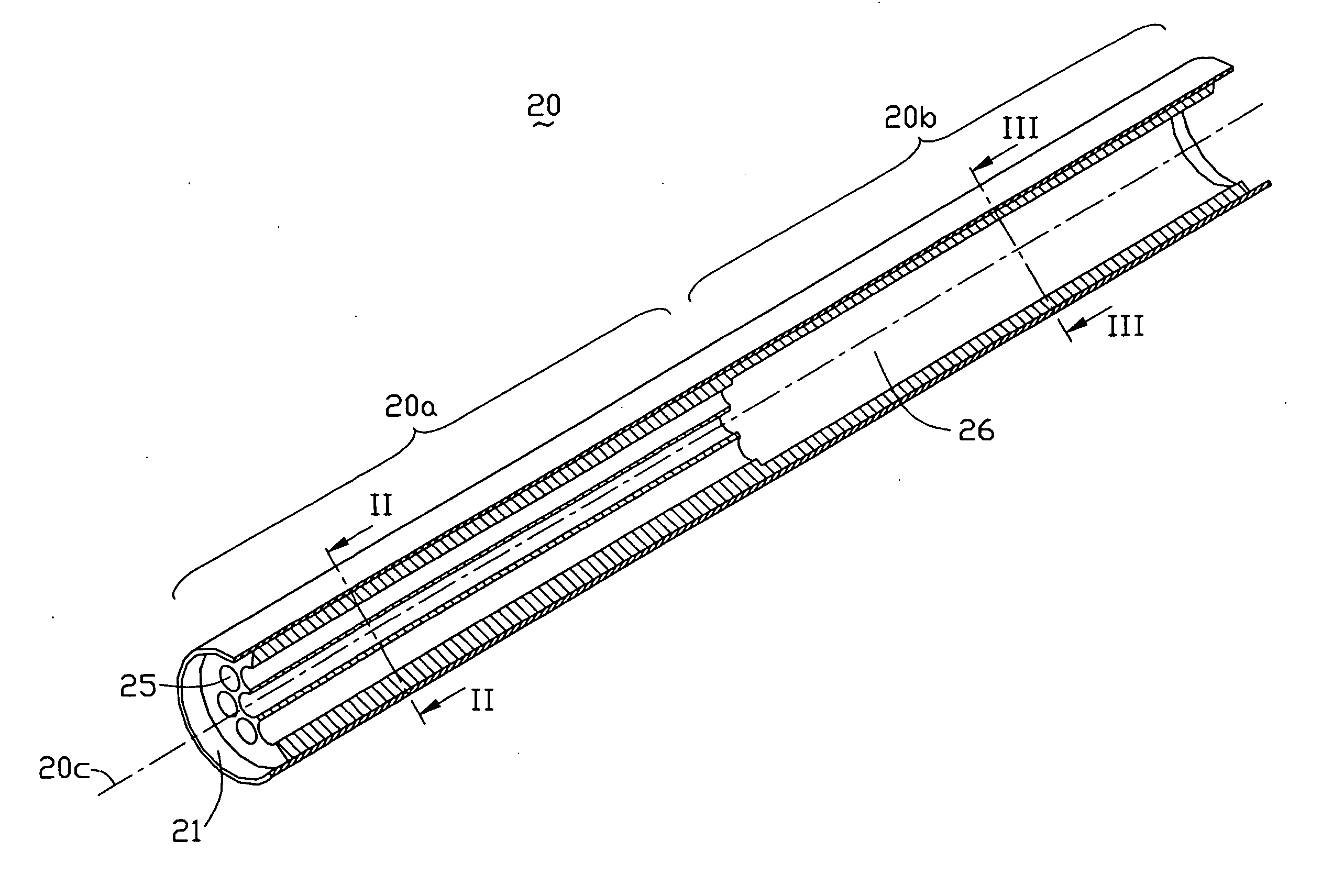

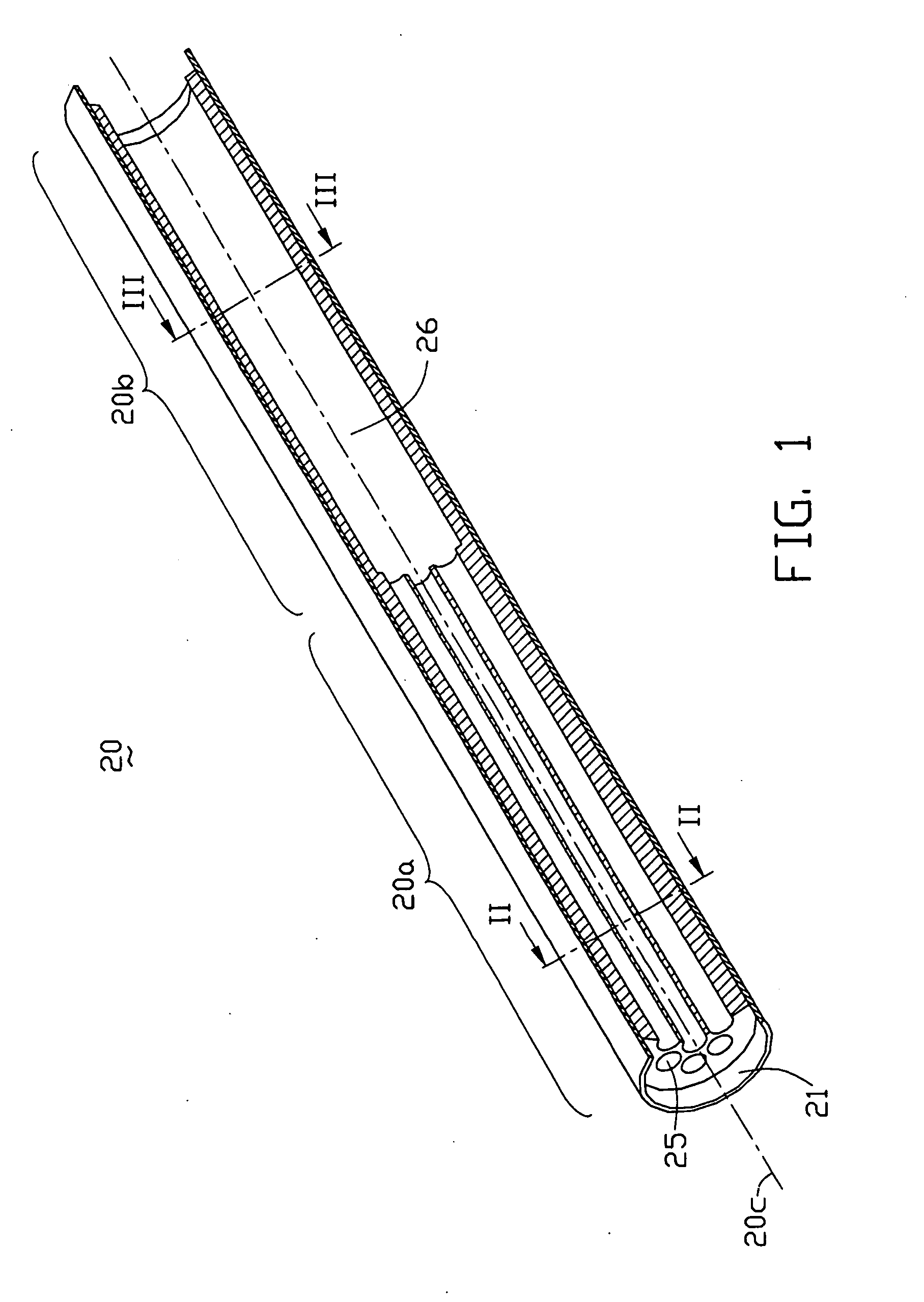

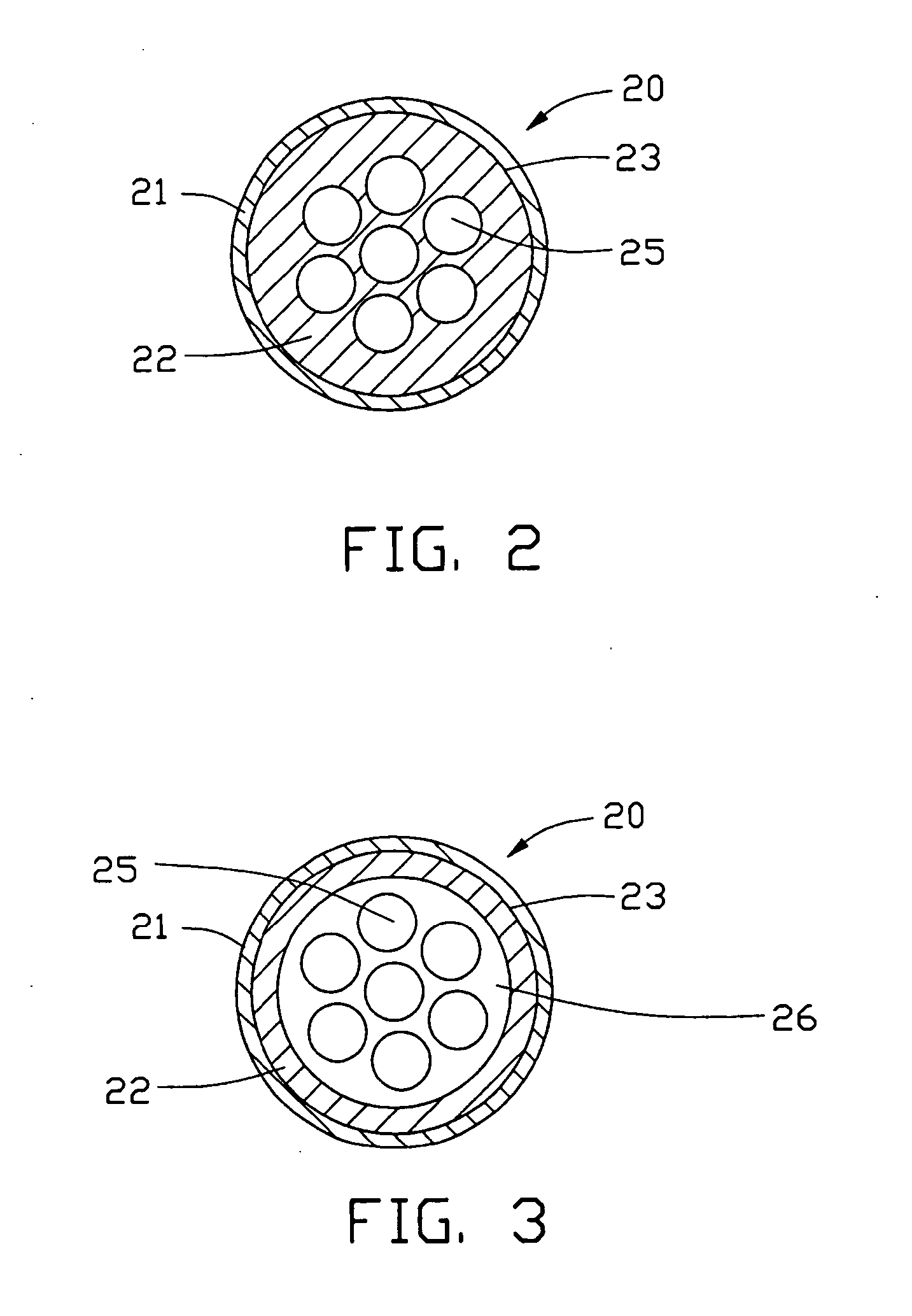

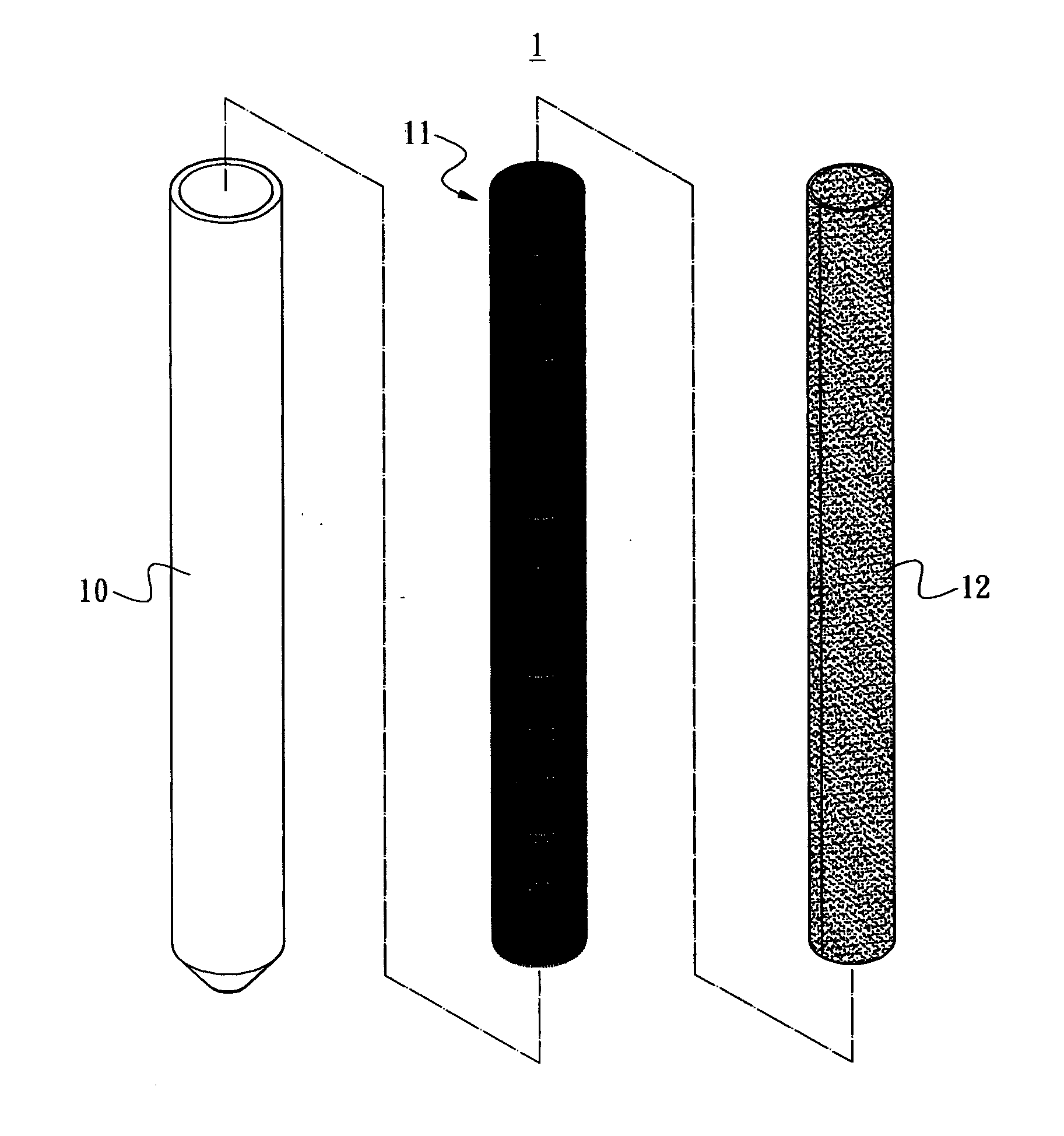

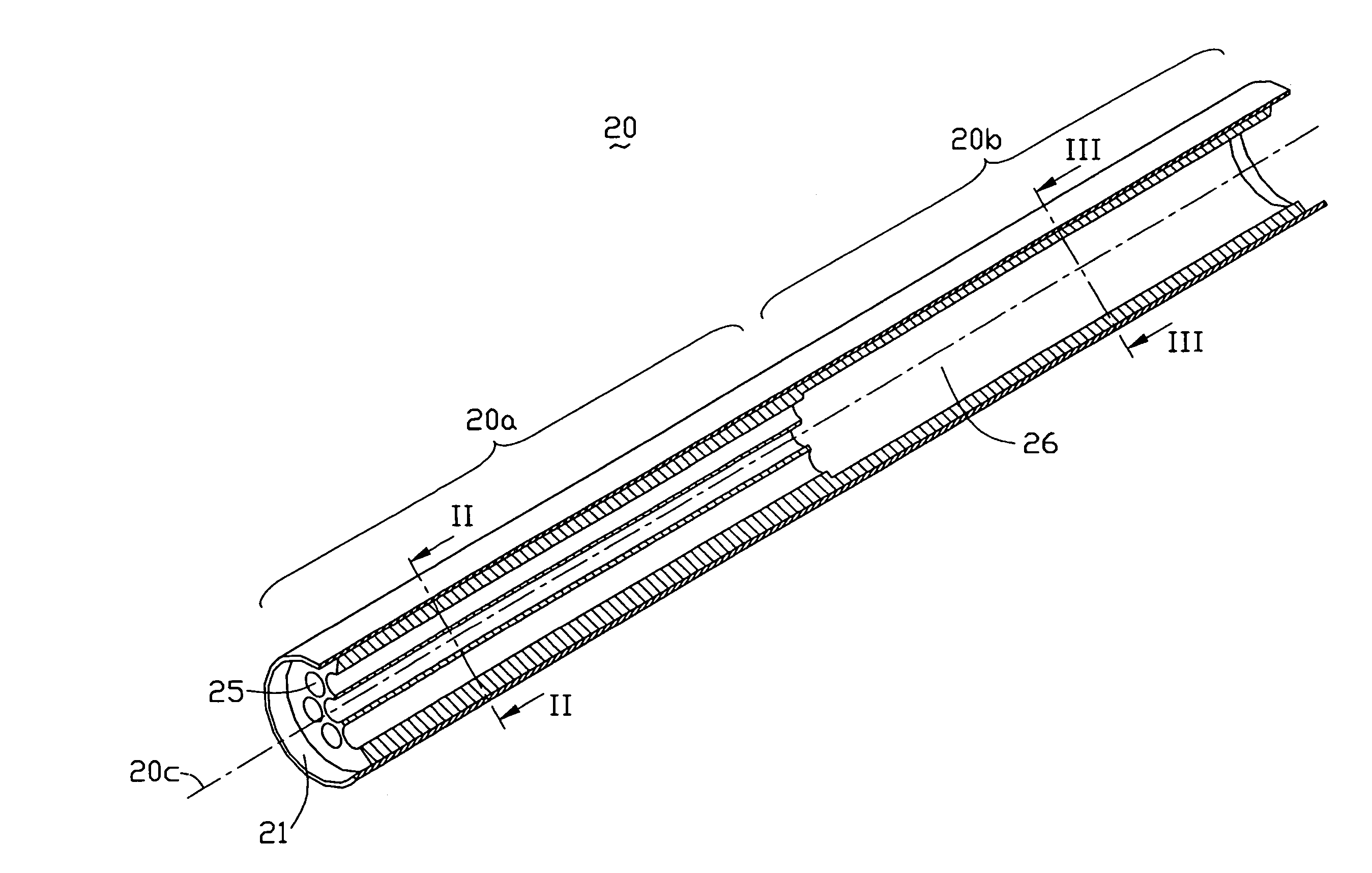

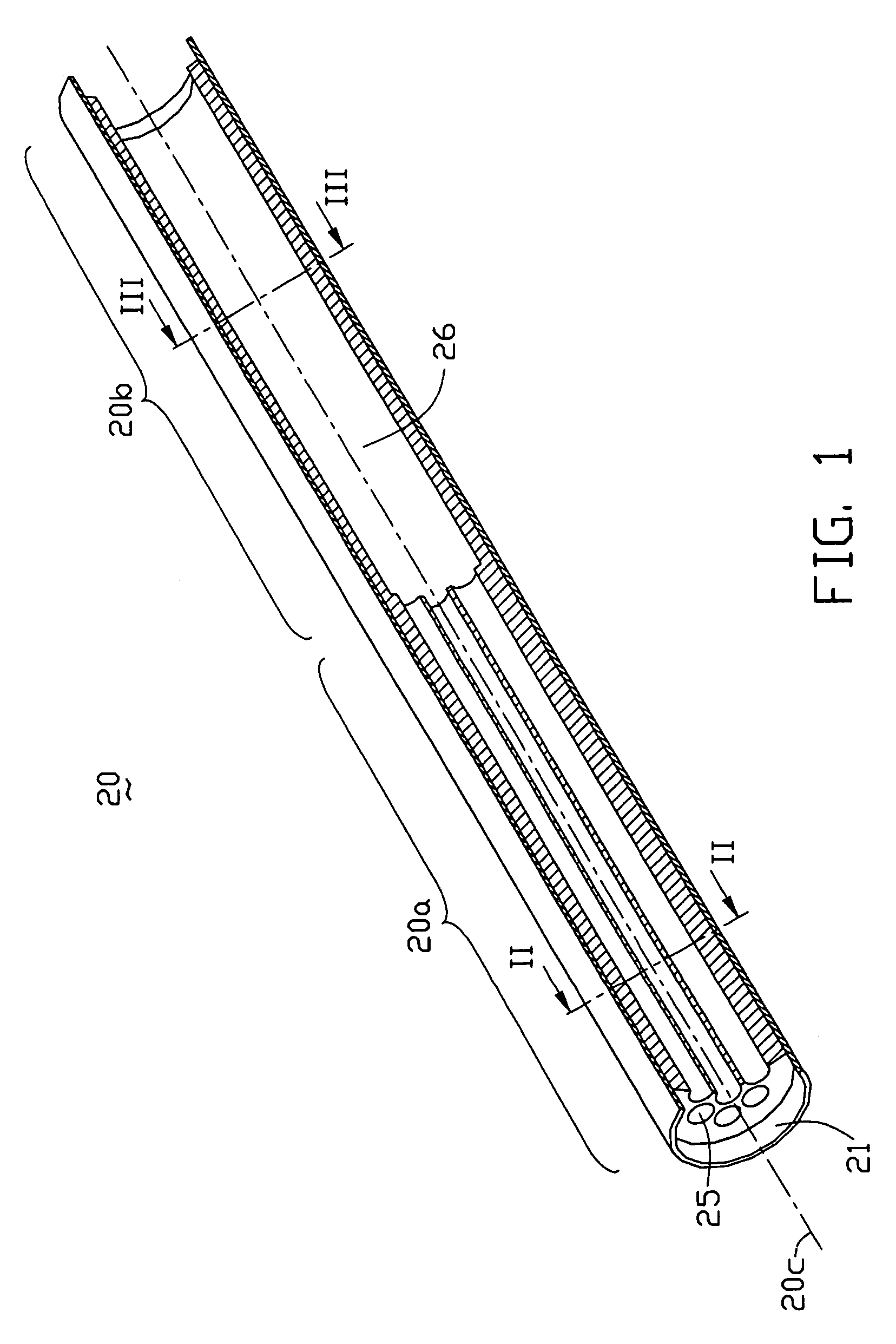

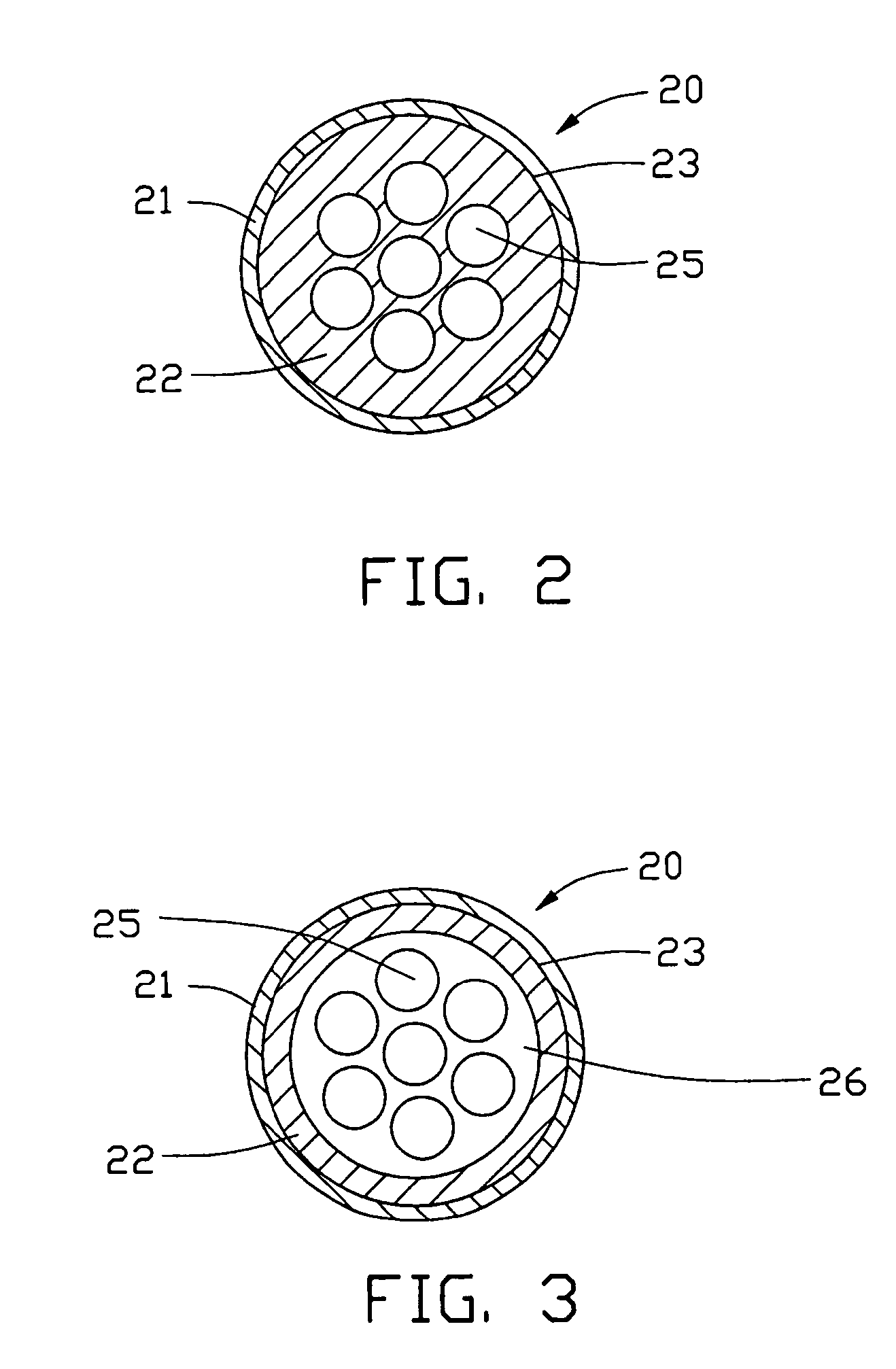

Heat pipe having wick structure

InactiveUS20060016580A1Reduce thermal resistanceHigh areaSolid-state devicesIndirect heat exchangersNano sizeWorking fluid

A heat pipe (20) includes a pipe (21), a wick (22) formed on an inner wall (23) of the pipe, and a working fluid (not shown) sealed in the pipe and soaked in the wick. The wick is formed by sintering nano-size metal powder disposed inside the pipe. First through holes (25) are defined in the wick in an evaporator section (20a) of the heat pipe. A central one of the first through holes is aligned along an axis 20c of the heat pipe, and other first through holes are parallel to the axis 20c. A second through hole (26) is defined in the wick in a condenser section (20b) of the heat pipe. The second through hole communicates with the first through holes, whereby the working fluid flows through the first and second through holes. These characteristics give the wick low thermal resistance, a high evaporator surface area, and high capillary force.

Owner:HON HAI PRECISION IND CO LTD

Glucose biosensor and method

ActiveUS7955484B2The result is accurateMinimize interference from dissolved oxygenImmobilised enzymesBioreactor/fermenter combinationsD-GlucoseGlucose polymers

A system for more accurately measuring glucose in a sample includes a first glucose-sensing electrode incorporating a quantity of glucose oxidase, a second glucose-sensing electrode incorporating a quantity of PQQ-glucose dehydrogenase, a reference electrode, and means for selecting between a first glucose measurement made with the first glucose-sensing electrode and a second glucose measurement made with the second glucose-sensing electrode.

Owner:NOVA BIOMEDICAL

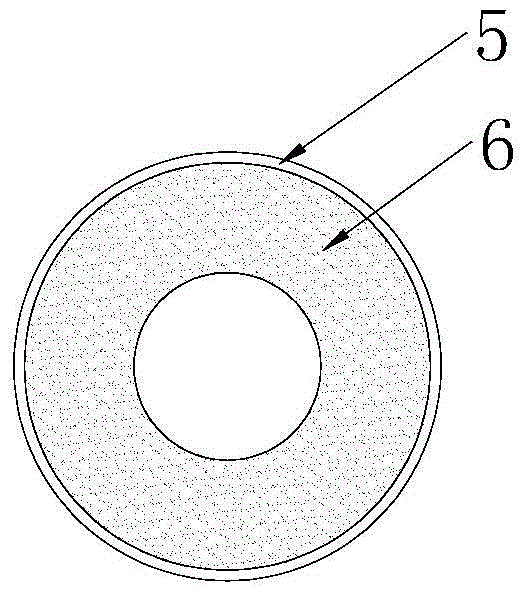

Wick structure of heat pipe

A wick structure is attached on an internal sidewall of a heat pipe. The wick structure is a one-layer woven wick. At least one weaving direction of the meshes of the woven wick contains a plurality of fiber bundles each including two more woven fibers to weave to a plurality of single fiber. As such, the fiber bundles of the one-layer woven wick provide enhanced capillary force like a multi-layer wick structure.

Owner:JAFFE

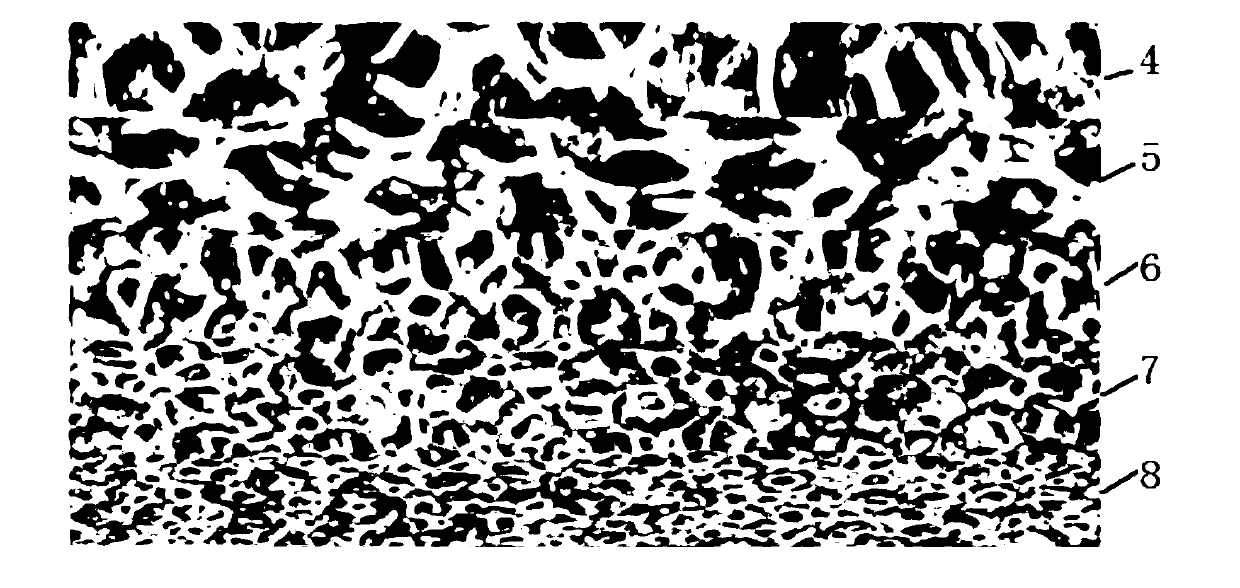

Sintering type heat pipe and manufacturing method thereof

InactiveCN1844833AImprove performanceReduce resistanceIndirect heat exchangersCapillary actionHeat pipe

The invention relates to a sintered heat tube, which comprises a metallic tube. Wherein, the inner wall of tube has porous capillary structure formed by sinter powder; the porous capillary structure has several layers along the radius of heat tube, while each layer has several sections along the axle of heat tube; said capillary structure is formed by embedding different powder particles into the tube, using core rod as the control of thickness to be sintered on the inner wall. Said porous capillary structure can realize variable three-dimensional grade porous size and supply lower reflux resistance and improved capillary function, to improve the property of heat tube.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

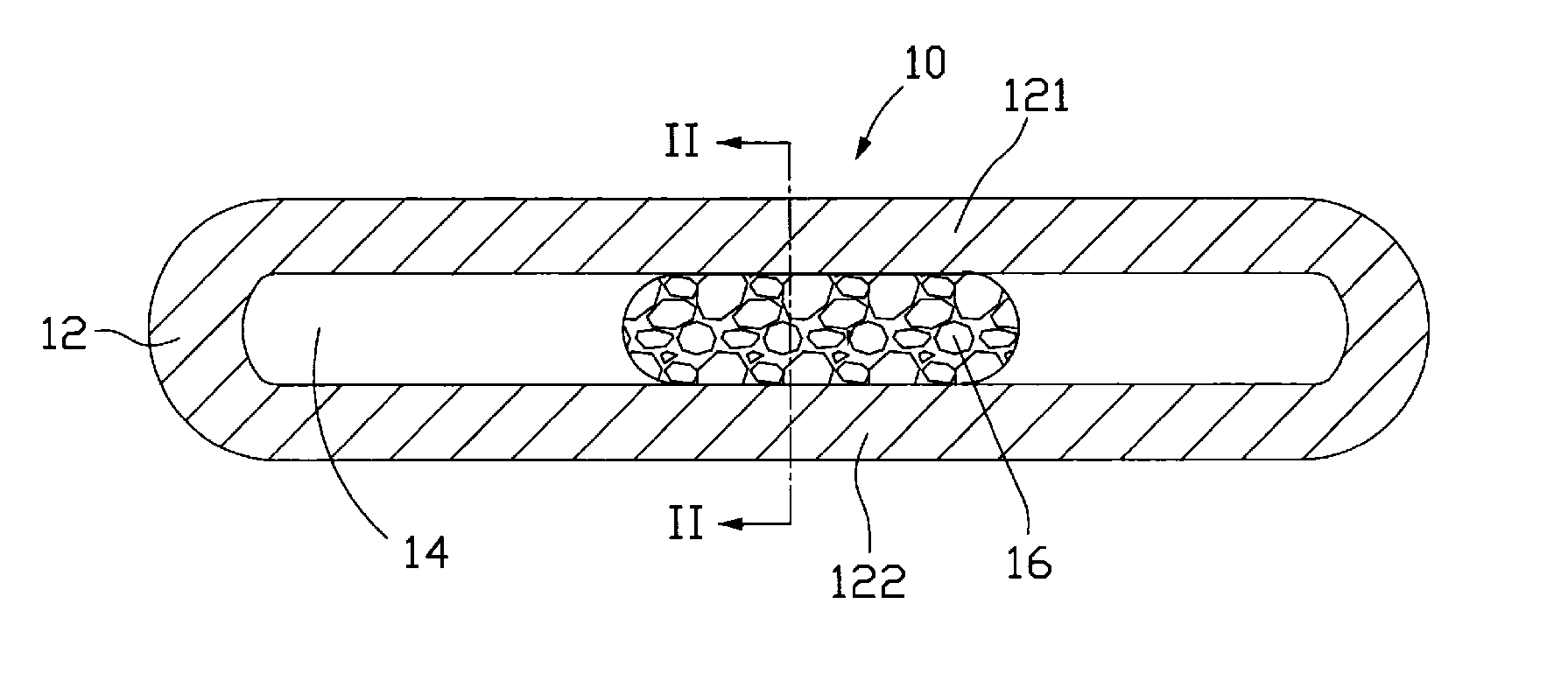

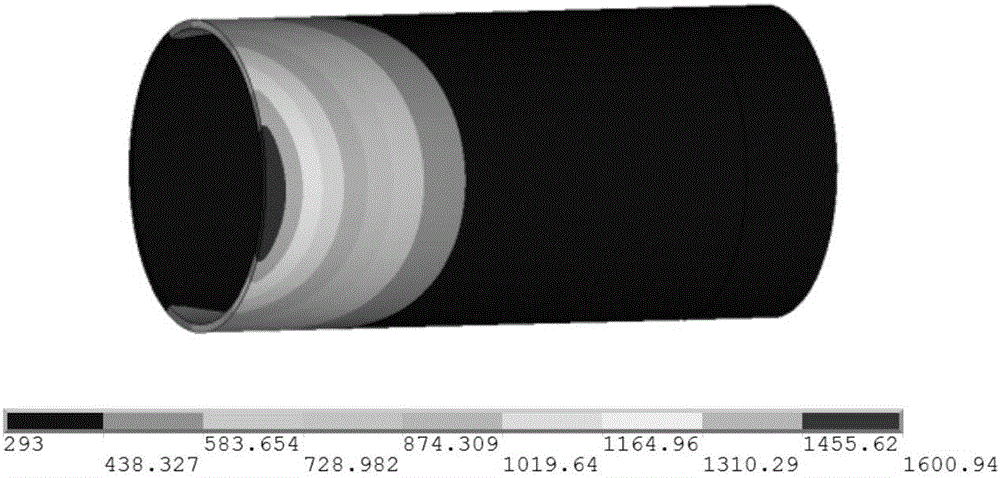

Heat pipe having wick structure

InactiveUS7124810B2Reduce thermal resistanceHigh areaSemiconductor/solid-state device detailsSolid-state devicesWorking fluidNano size

A heat pipe (20) includes a pipe (21), a wick (22) formed on an inner wall (23) of the pipe, and a working fluid (not shown) sealed in the pipe and soaked in the wick. The wick is formed by sintering nano-size metal powder disposed inside the pipe. First through holes (25) are defined in the wick in an evaporator section (20a) of the heat pipe. A central one of the first through holes is aligned along an axis 20c of the heat pipe, and other first through holes are parallel to the axis 20c. A second through hole (26) is defined in the wick in a condenser section (20b) of the heat pipe. The second through hole communicates with the first through holes, whereby the working fluid flows through the first and second through holes. These characteristics give the wick low thermal resistance, a high evaporator surface area, and high capillary force.

Owner:HON HAI PRECISION IND CO LTD

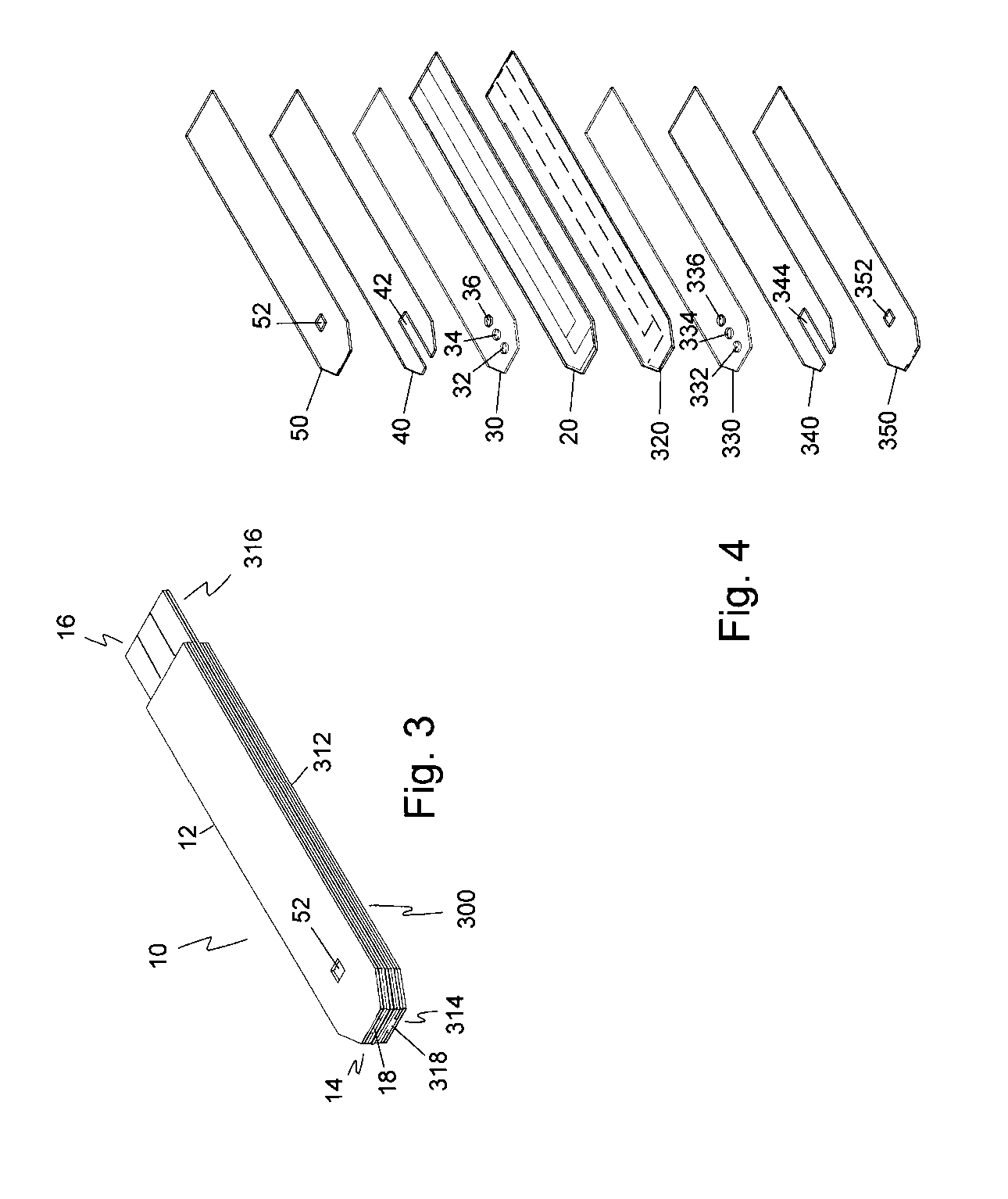

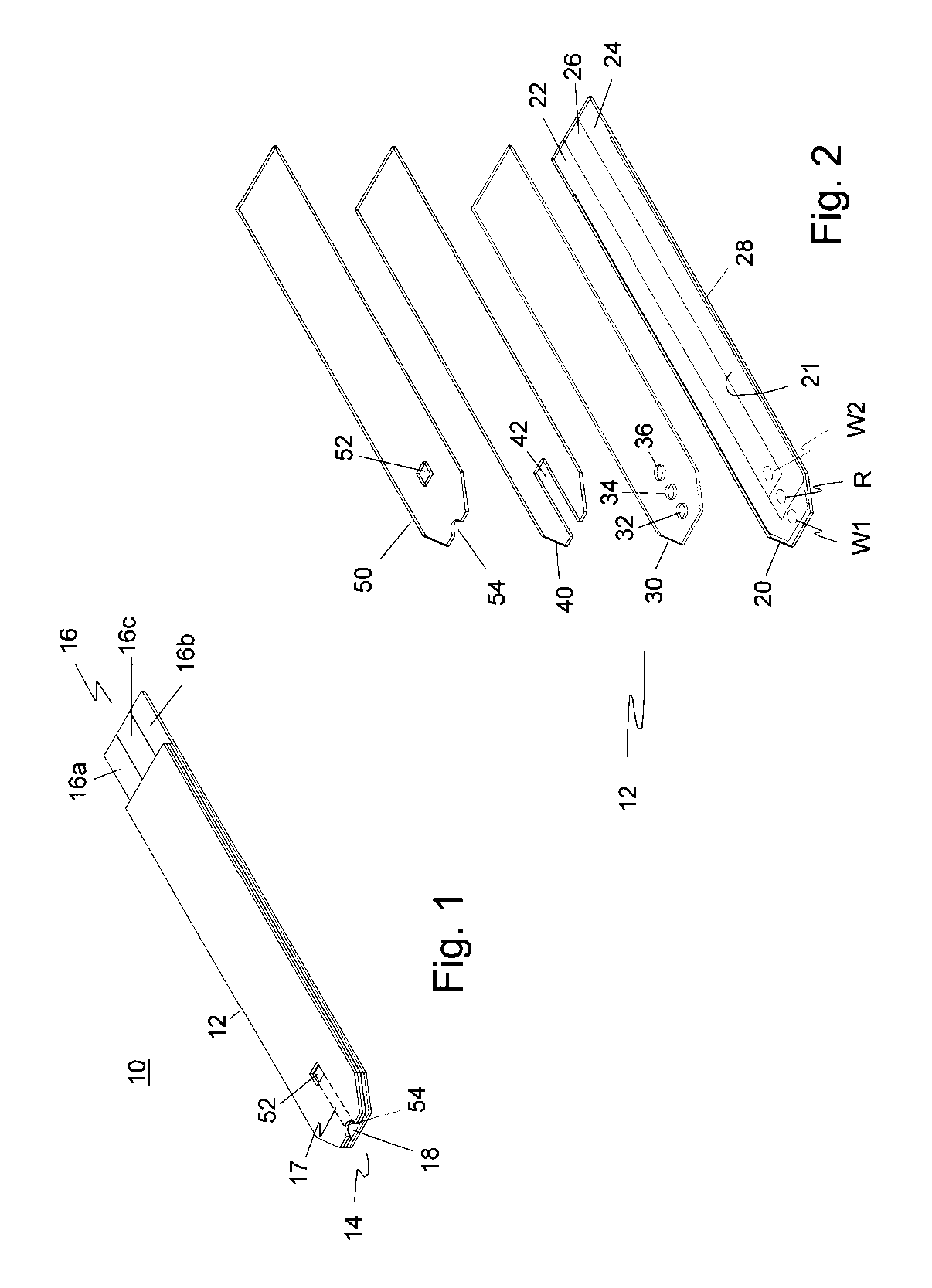

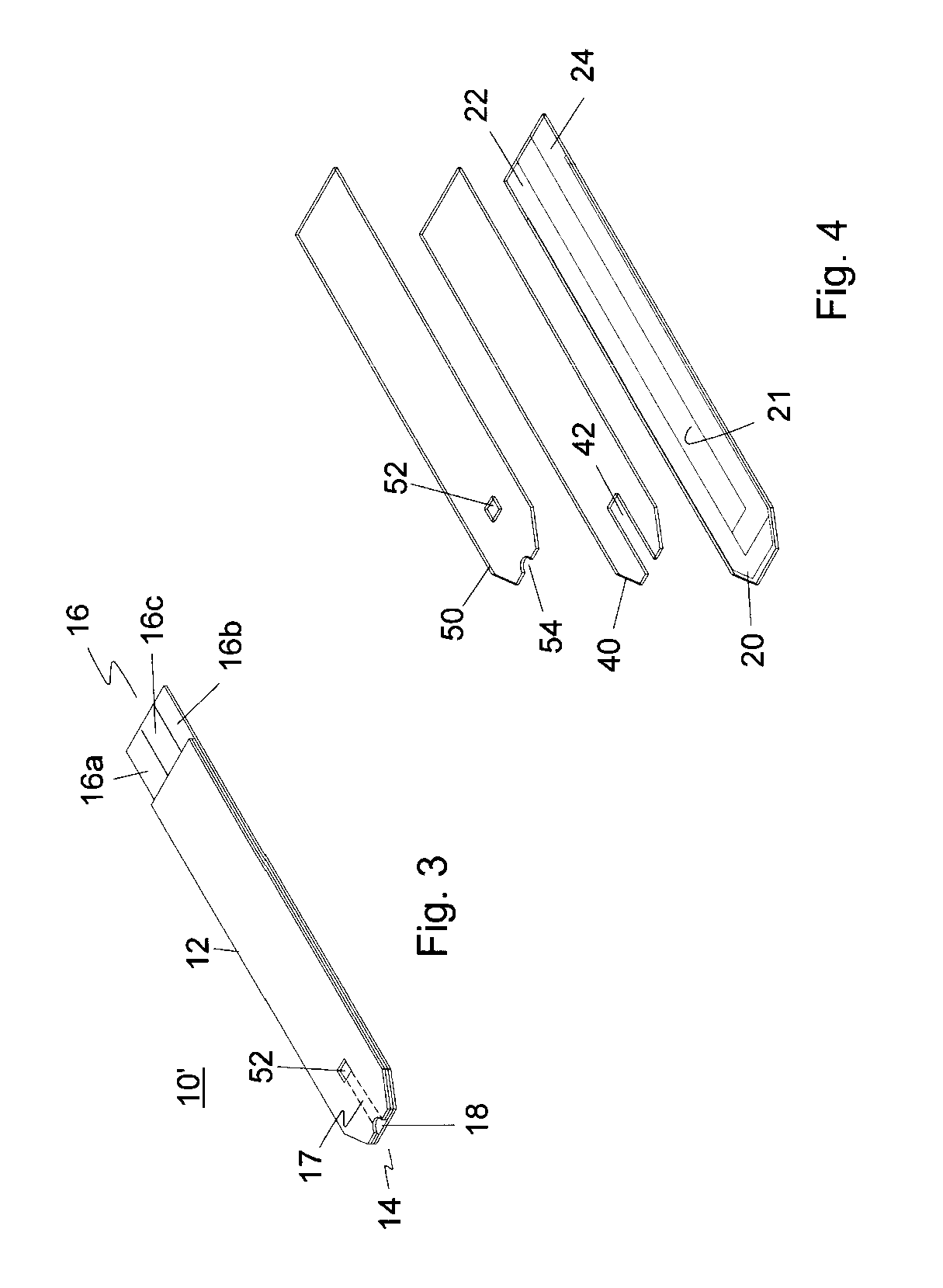

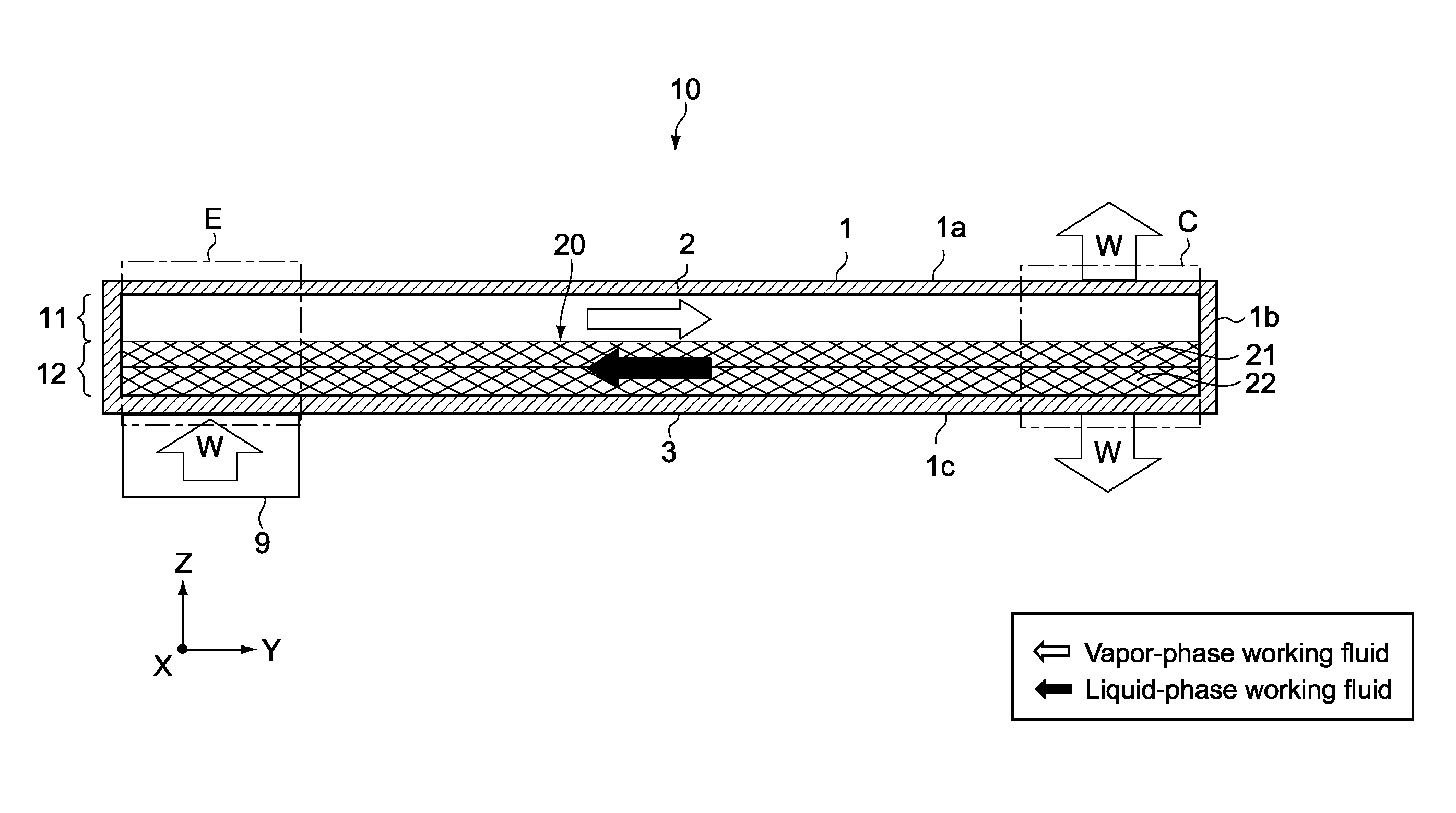

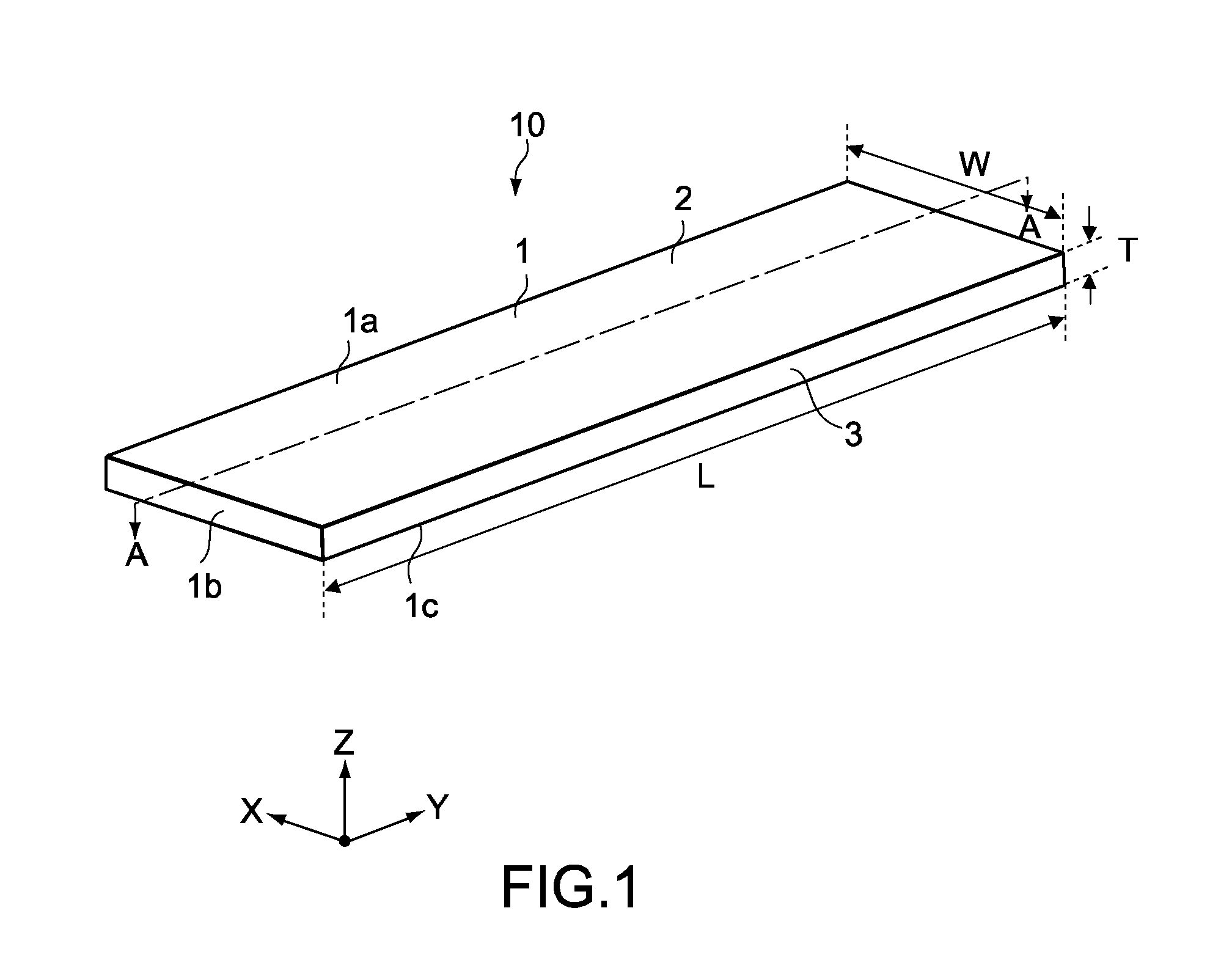

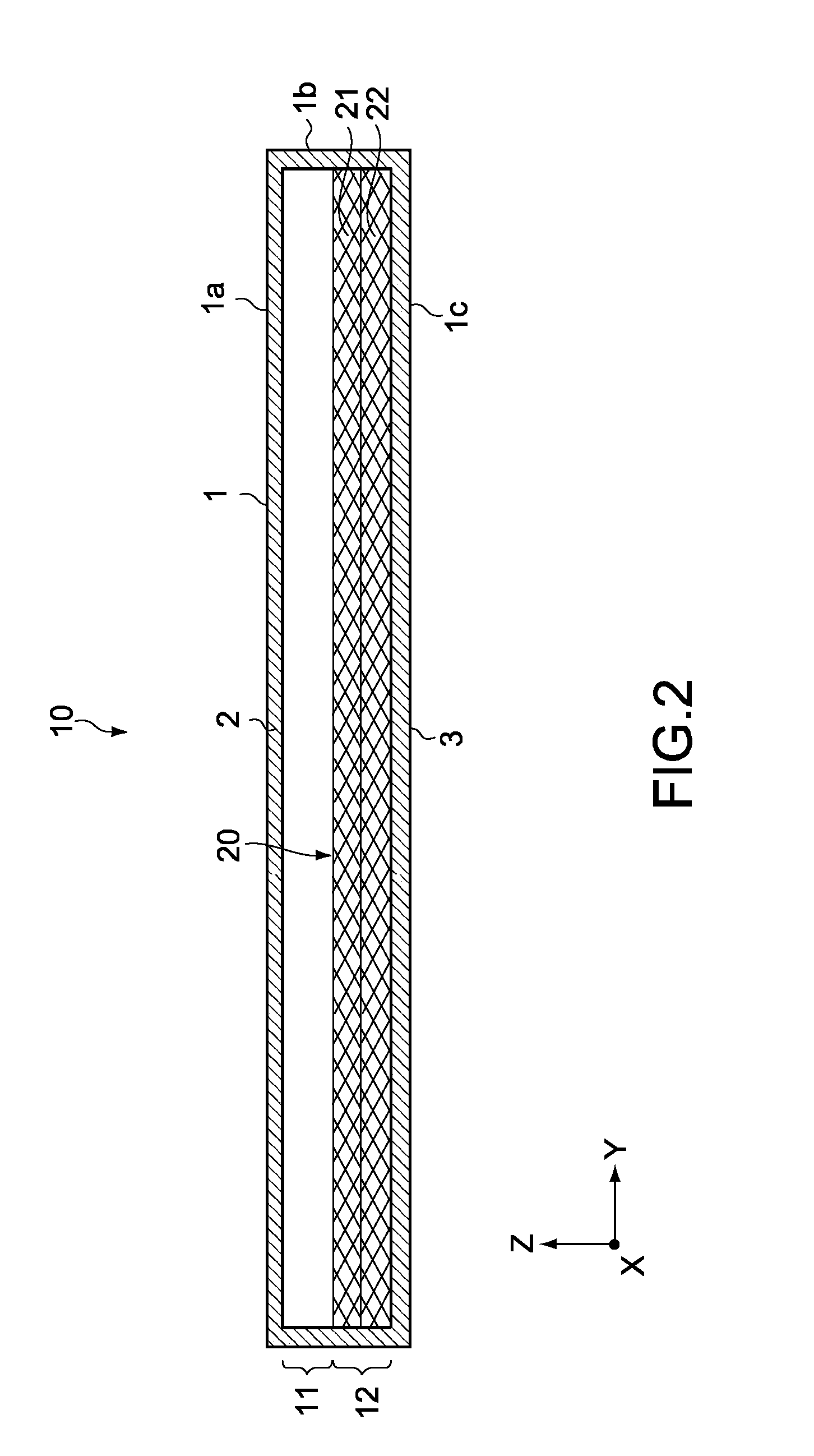

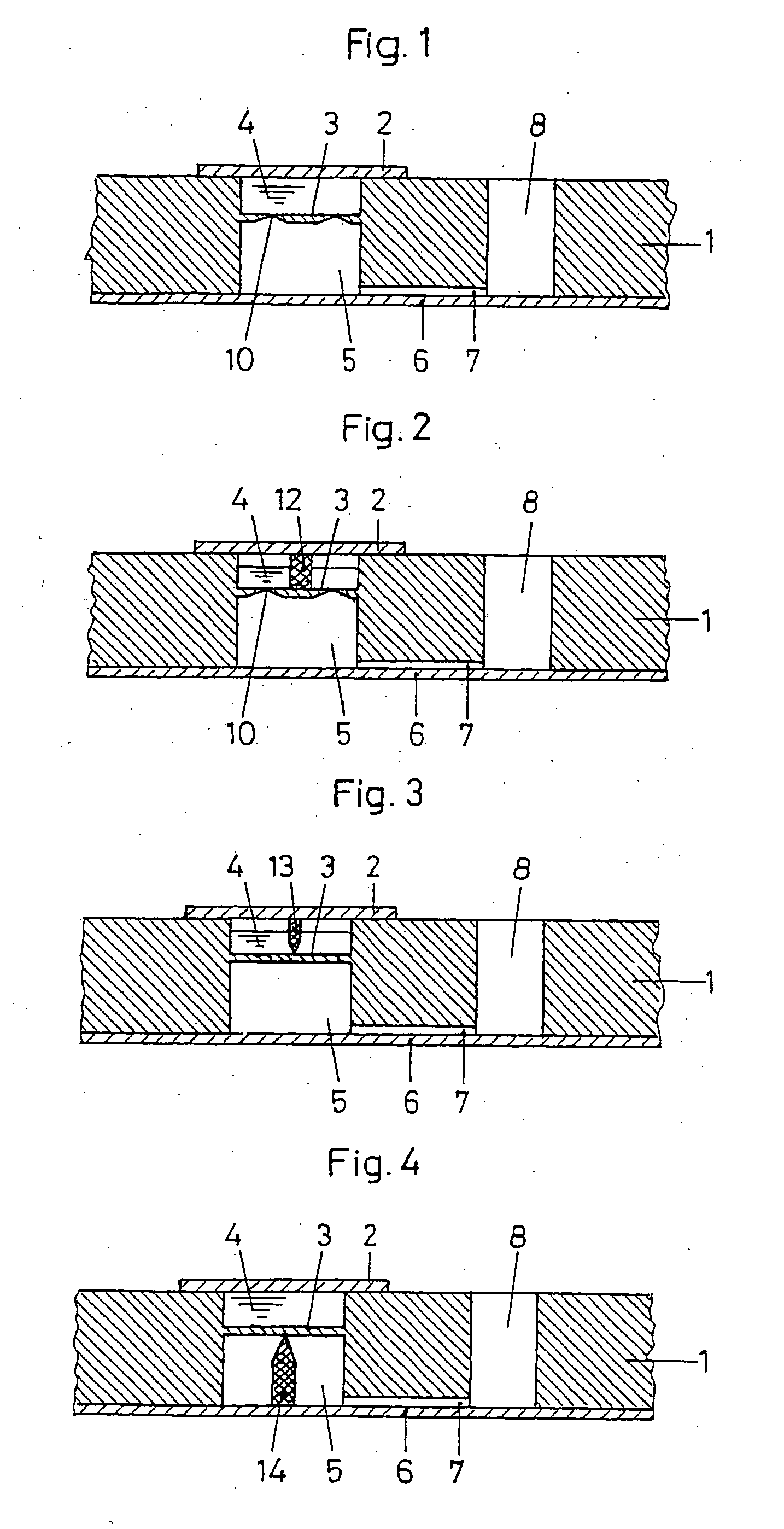

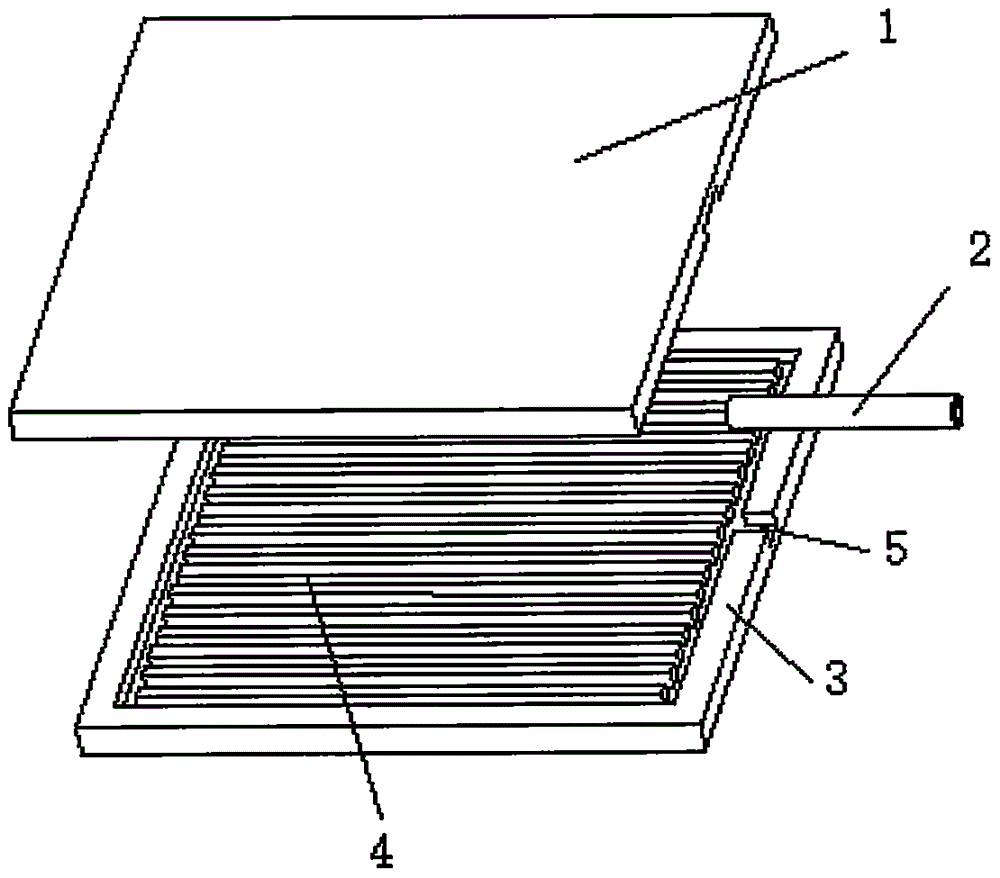

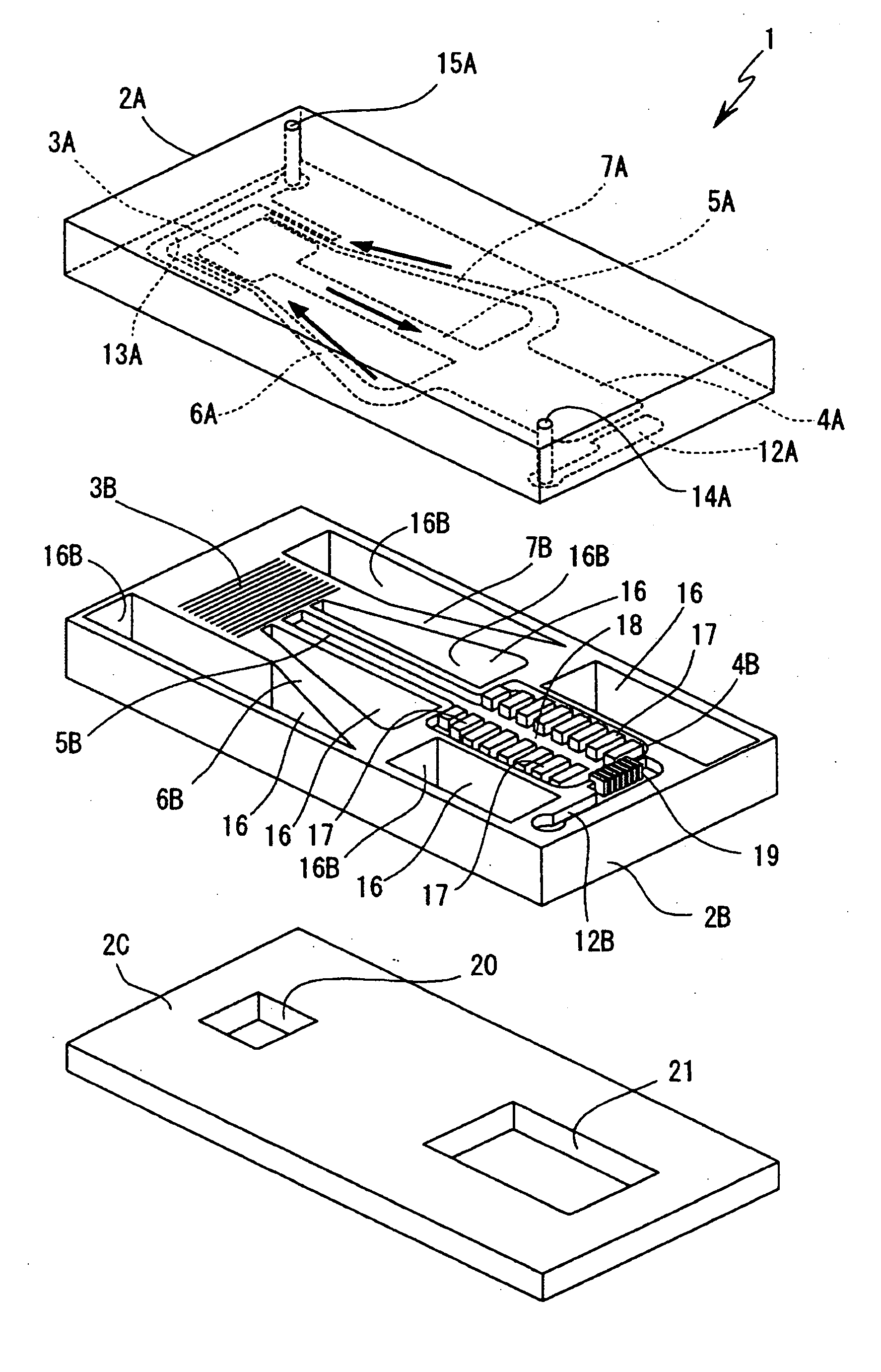

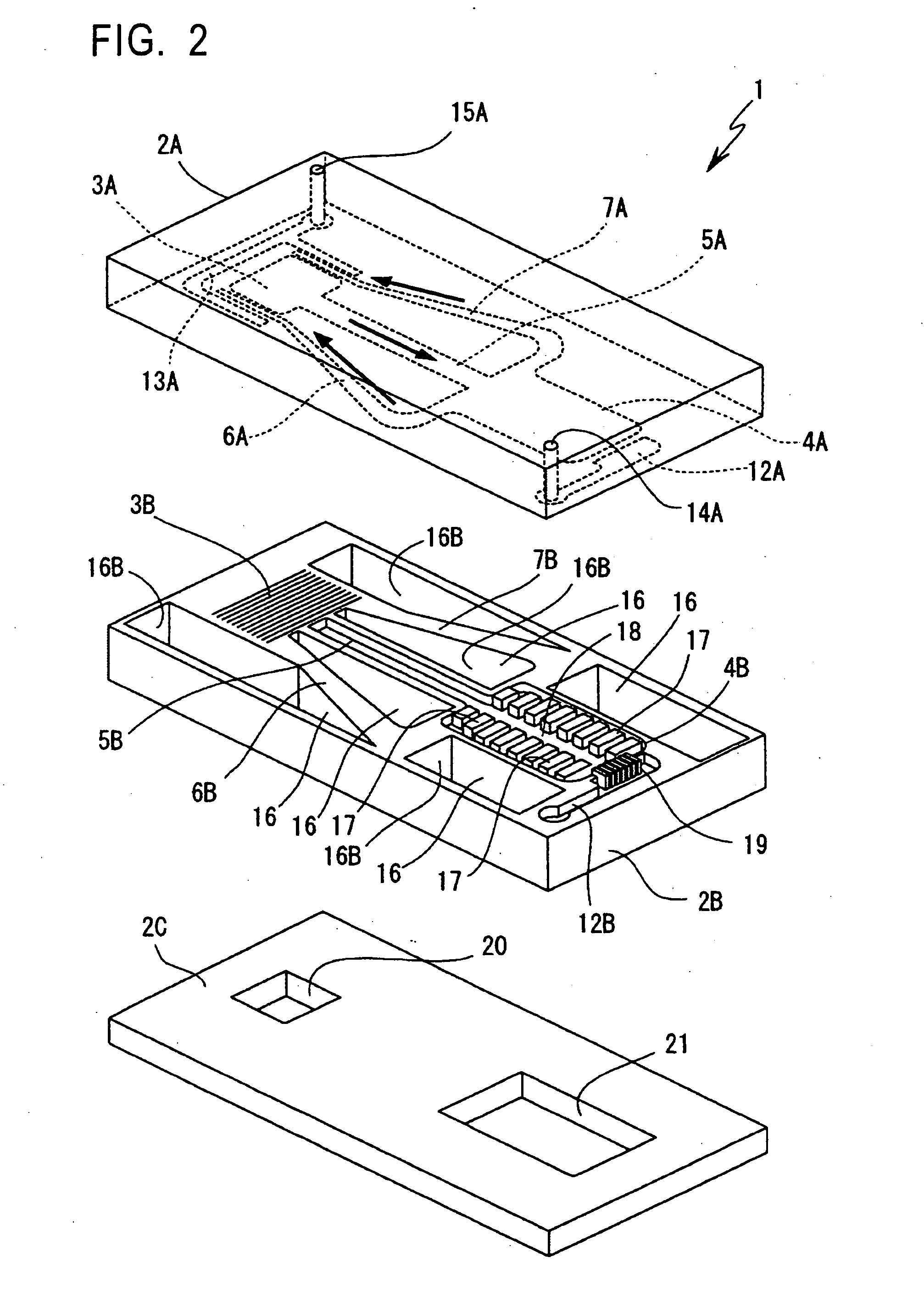

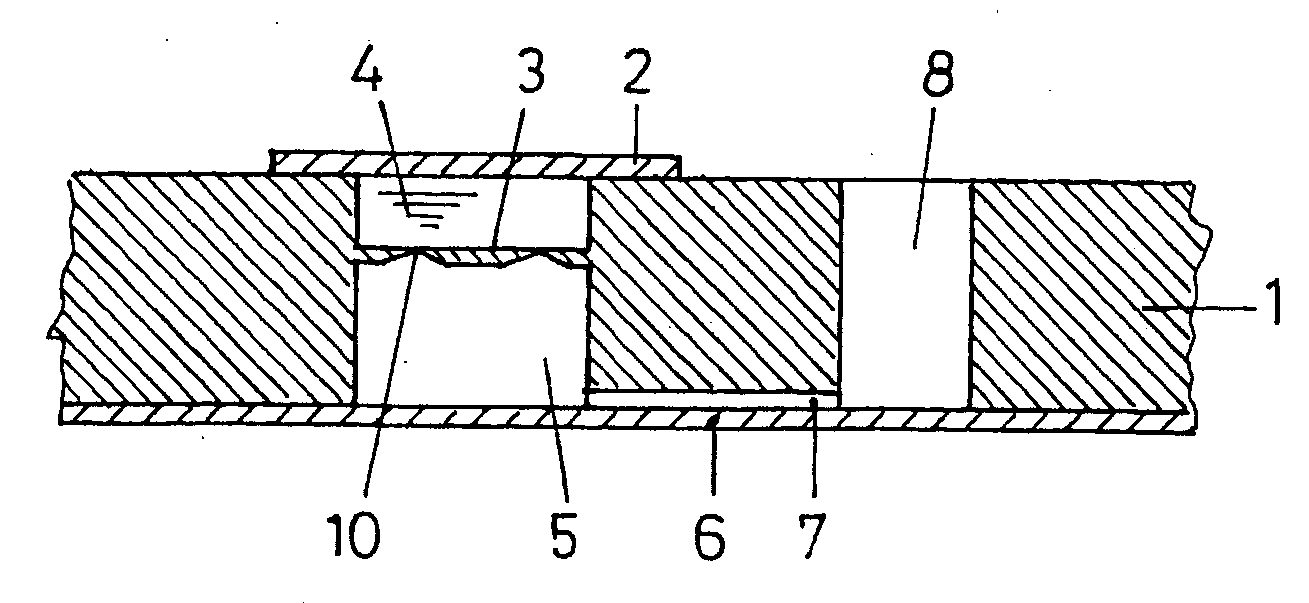

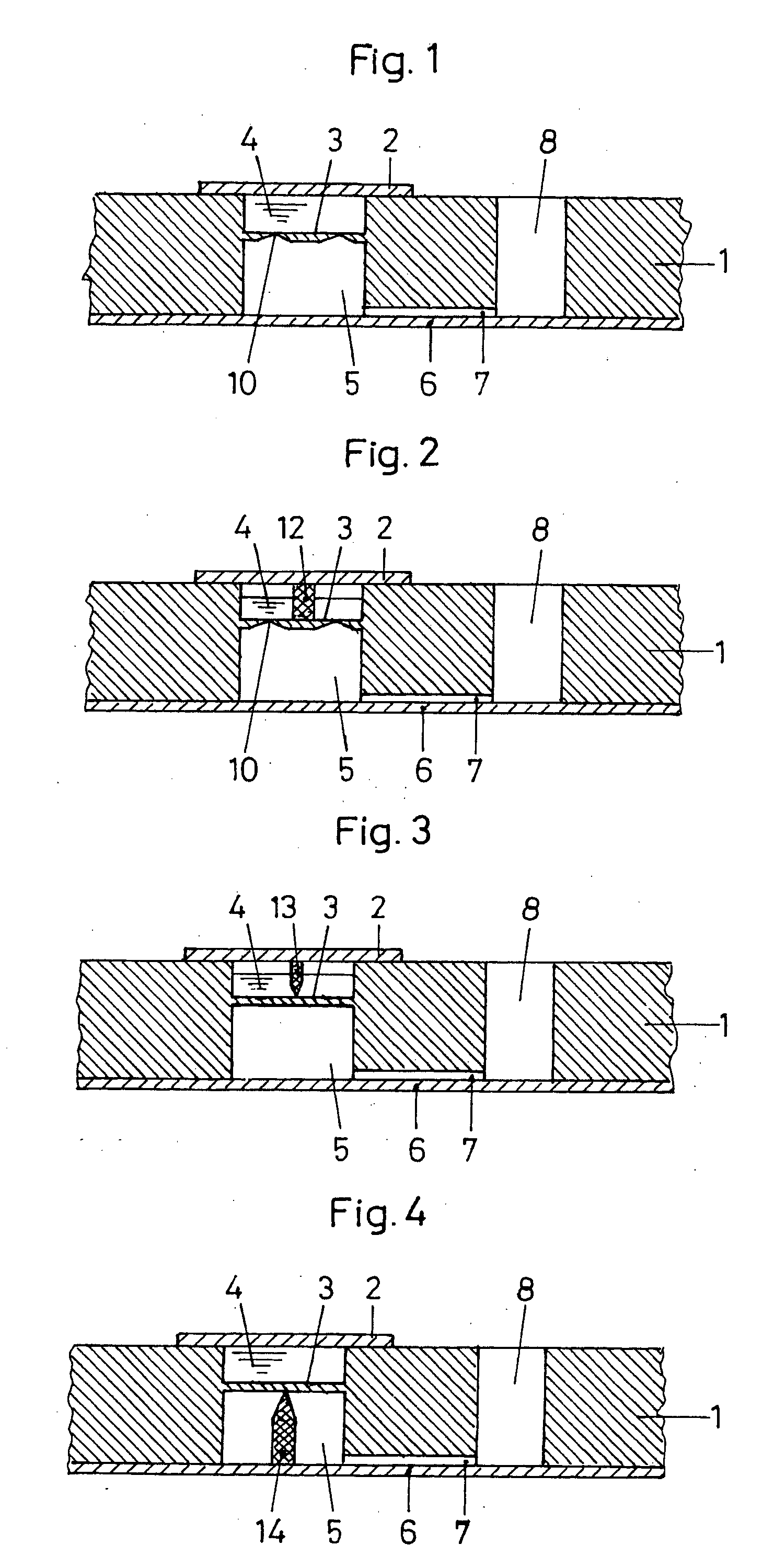

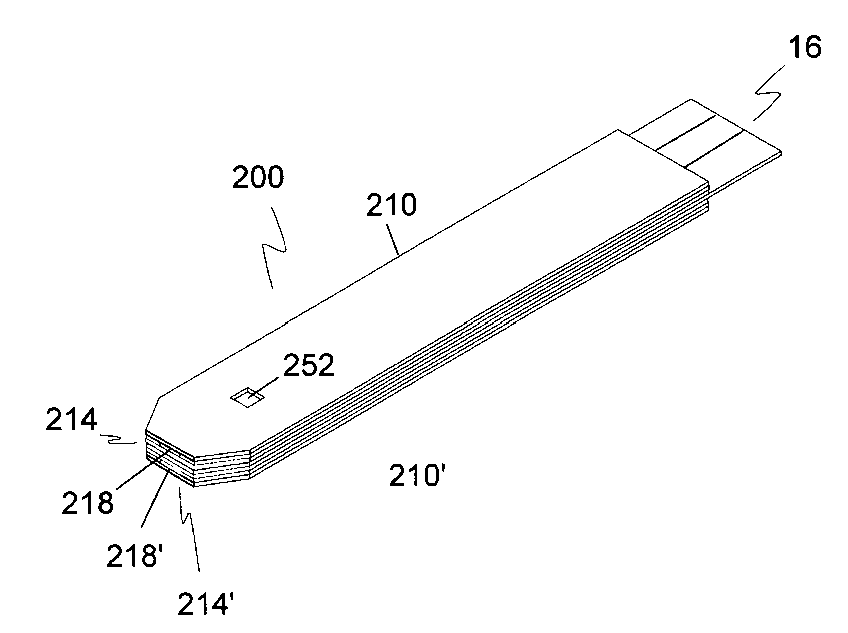

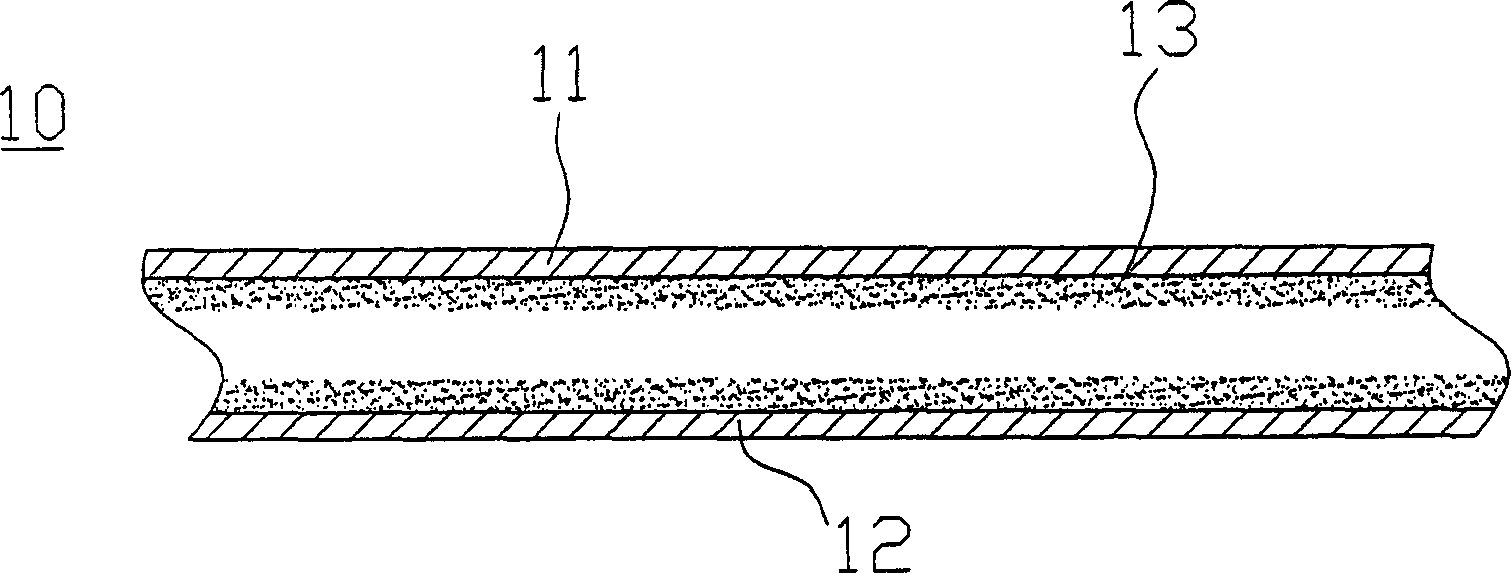

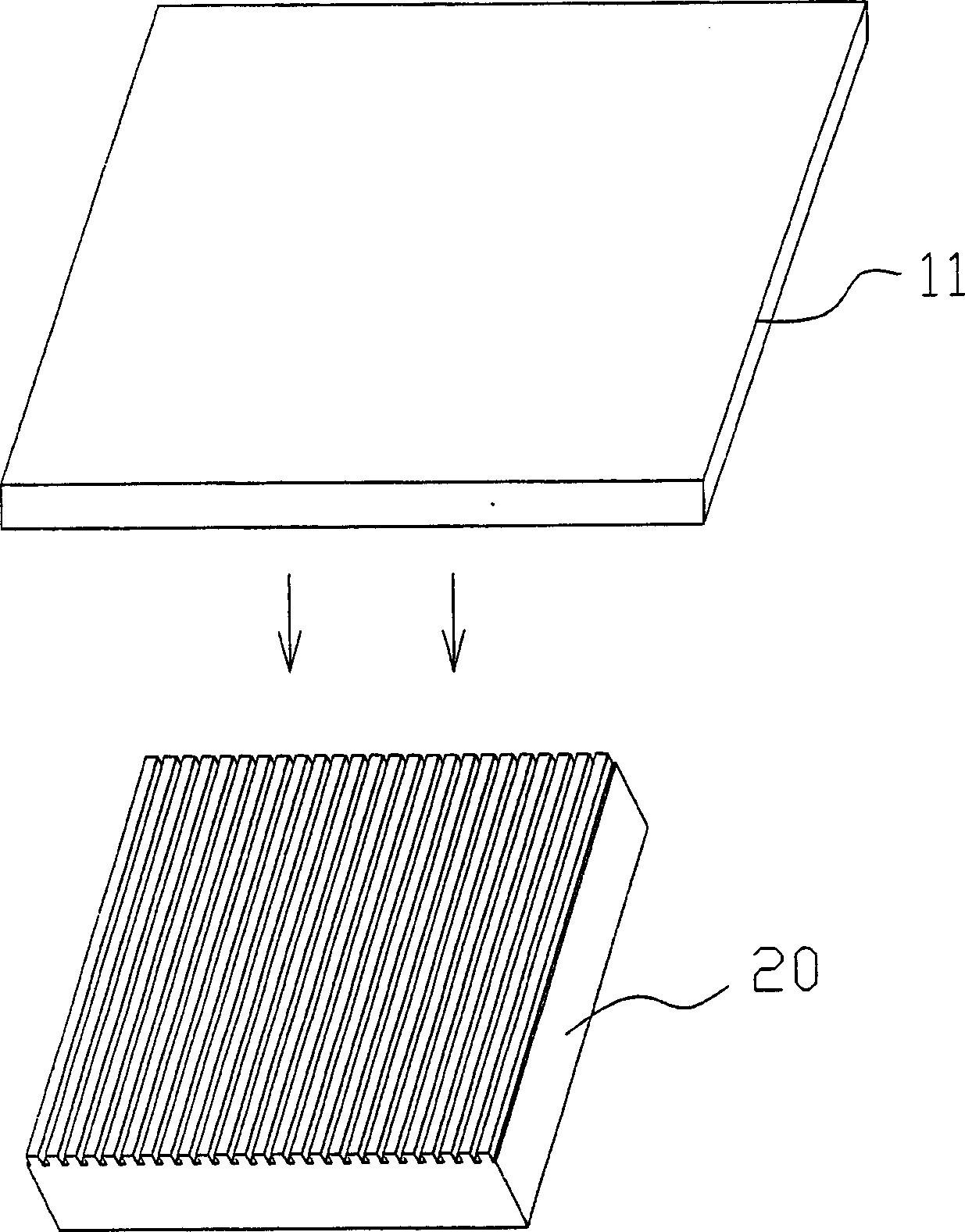

Heat-transporting device, electronic apparatus, and method of producing a heat-transporting device

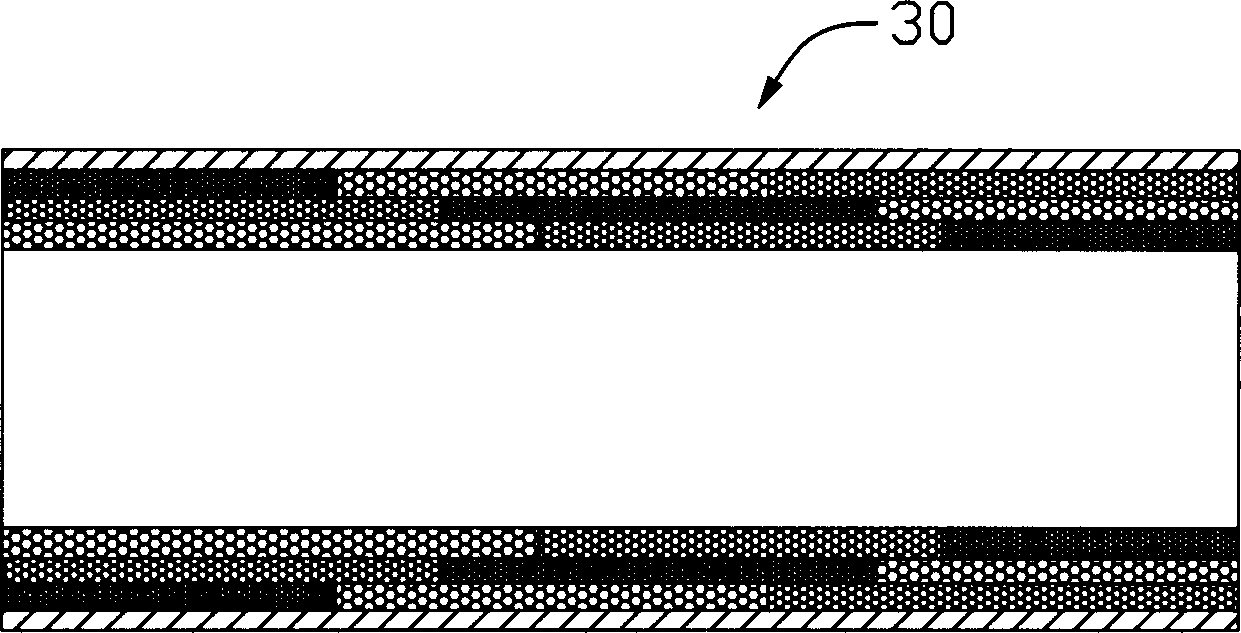

InactiveUS20100157533A1Low costImprove performanceDigital data processing detailsSemiconductor/solid-state device detailsWorking fluidGas phase

A heat-transporting device includes a working fluid, a vessel, a vapor-phase flow path, and a liquid-phase flow path. The working fluid transports heat using a phase change. The vessel seals in the working fluid. The vapor-phase flow path causes the working fluid in a vapor phase to circulate inside the vessel. The liquid-phase flow path includes a laminated body and causes the working fluid in a liquid phase to circulate inside the vessel, the laminated body including a first mesh member and a second mesh member and being formed such that the first mesh member and the second mesh member are laminated while weaving directions thereof differ relatively.

Owner:SONY CORP

Microstructured device for removable storage of small amounts of liquid and a process for removal of the liquid stored in this device

ActiveUS20090074626A1Easy constructionAdvantage in productionValve arrangementsAnalysis using chemical indicatorsRemovable mediaEngineering

Owner:KADEL KLAUS +1

Flat heat radiating pipe and manufacturing method thereof

InactiveCN102147201ADecreased maximum heat transferNot easy to deformIndirect heat exchangersEvaporationEngineering

The invention discloses a flat heat radiating pipe which comprises a pipe cavity with two closed ends and a pipe wall enclosing the pipe cavity along the axial direction, wherein the pipe wall comprises arc walls positioned at two sides and a flat wall for connecting the arc walls, the pipe cavity and the pipe wall are sequentially defined as an evaporation section, a heat insulation section and a condensation section along the axial direction; the pipe cavity is internally provided with a main capillary structure and an auxiliary capillary structure, wherein the main capillary structure is in contact with the flat wall of the evaporation section or in contact with the flat walls of the evaporation section and the heat insulation section; the auxiliary capillary structure is in contact with the arc wall positioned at least one side, the pipe cavity between the main capillary structure and the auxiliary capillary structure is filled with a working medium; and a main gas channel of a heat radiating pipe has enough space so that capillary force of the flat heat radiating pipe is improved and conveying capacity of the working medium is increased, and thus heat transfer efficiency of the flat heat radiating pipe is increased. The invention also provides a manufacturing method of the flat heat radiating pipe.

Owner:KUN SHAN DOTOP METAL TECH CO LTD

Novel flat plate thiele tube and preparation method thereof

InactiveCN105865243AStart fastPromote refluxIndirect heat exchangersHeat transfer modificationThiele tubeCopper

The invention proposes a new type of flat heat soaking pipe and discloses its laser preparation method, which includes an upper plate, a lower plate and liquid injection and air extraction pipes, all components are made of copper material, the lower plate of the flat heat pipe is the evaporation section, the upper plate It is the condensation section and the middle section is the heat insulation section. The inner wall of the upper and lower plates is processed with a groove structure. The groove structure is processed into a grooved composite pin-fin structure by laser according to the working principle of the heat pipe. Laser etching can be sequentially processed on the surface of the copper plate to obtain different Characteristic complex shape microstructures. The invention can improve the boiling performance of the evaporating section and the start-up performance of the heat pipe, and the steam cooling performance of the condensing section. The pin-fin structure can not only strengthen the strength of the heat pipe and reduce the interface shear force, but also facilitate the rapid reflux and dripping of the condensate on the upper plate to the lower plate. A cycle is formed to improve the heat transfer performance of the heat pipe.

Owner:GUANGDONG UNIV OF TECH

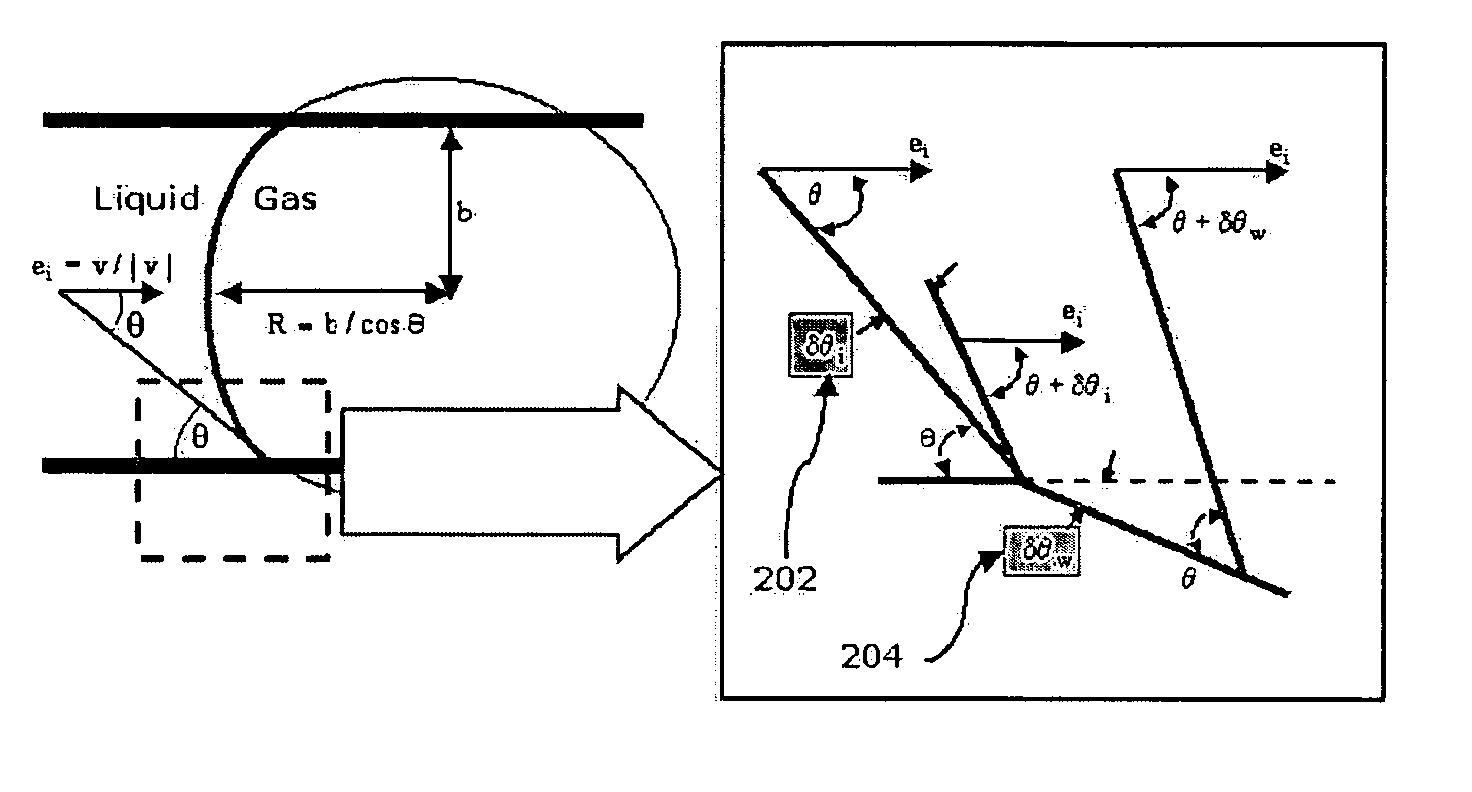

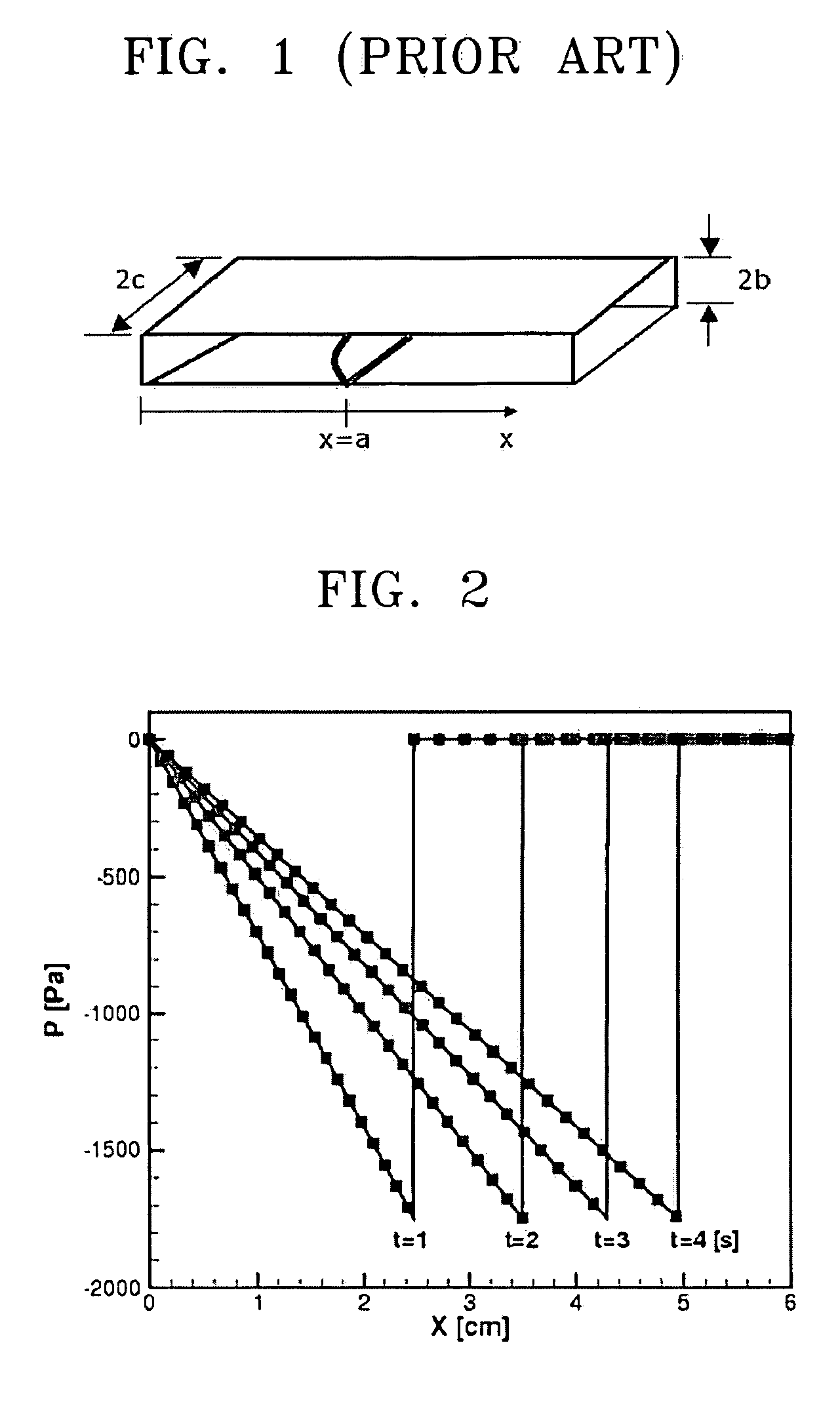

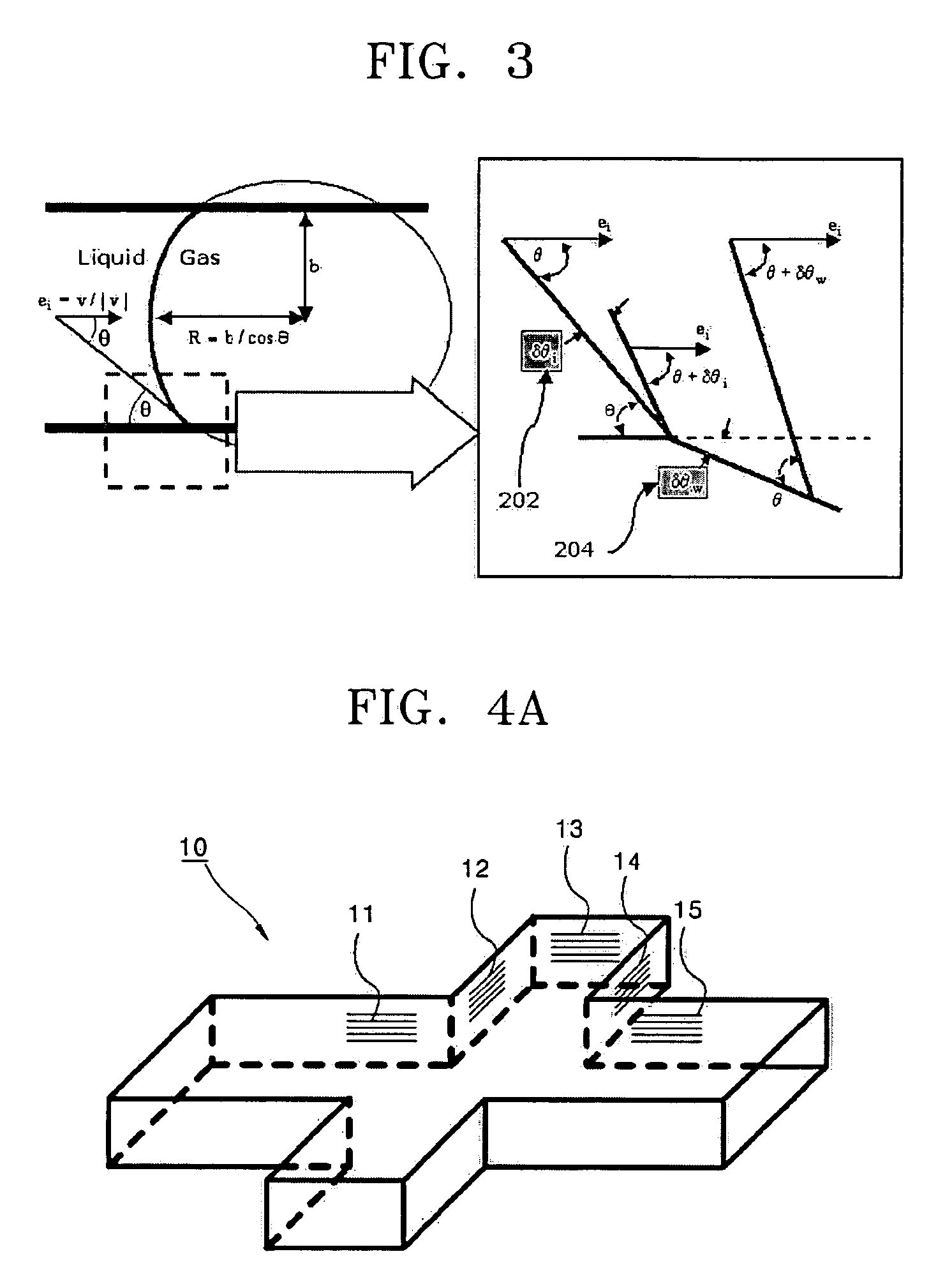

Microfluidic device, and diagnostic and analytical apparatus using the same

InactiveUS20060039829A1Easy to manufactureEasy to useCellsAnalysis using chemical indicatorsEngineeringEnergy requirement

A diagnostic and analytical apparatus including the microfluidic device having: an inlet portion with a first cross-section, a flow delaying portion with a second cross-section that is larger than the cross-section of the inlet portion thereby reducing the interfacial curvature of the microfluid entering from the inlet portion by capillary force and the flow rate of the microfluid, and a flow recovery portion having a third cross-section that is smaller than the cross-section of the flow delaying portion. The flow of a very small volume of fluid can be quantitatively regulated through a channel having a particular design that can induce spontaneous flow by capillary force without additional manipulation processes and energy requirement.

Owner:LG LIFE SCI

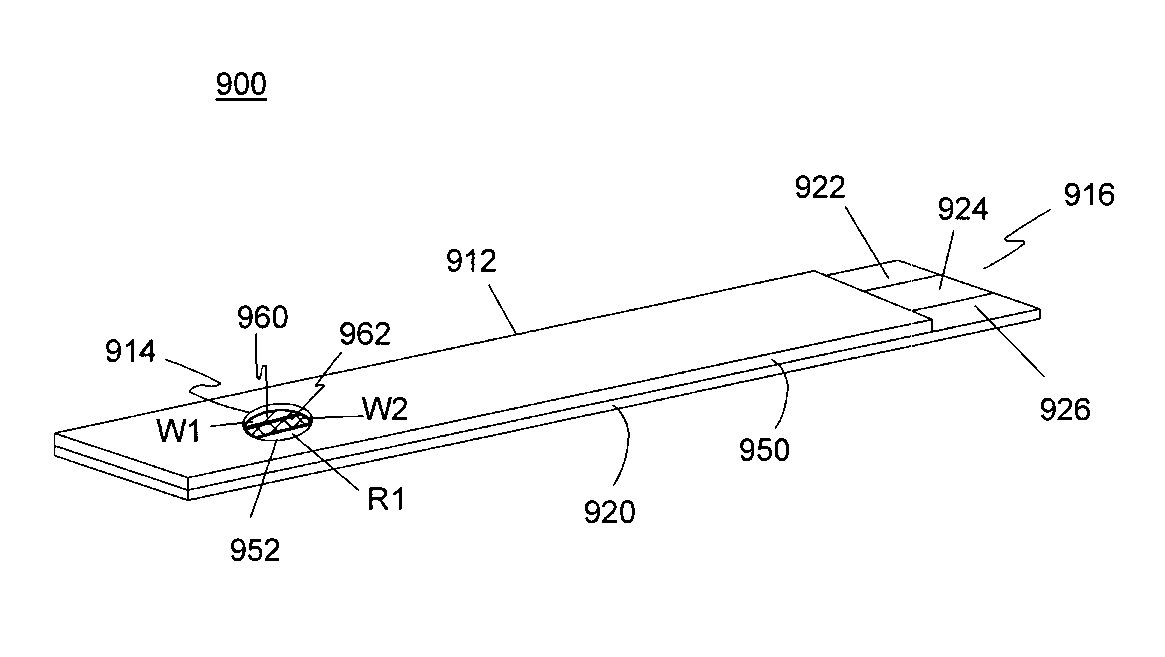

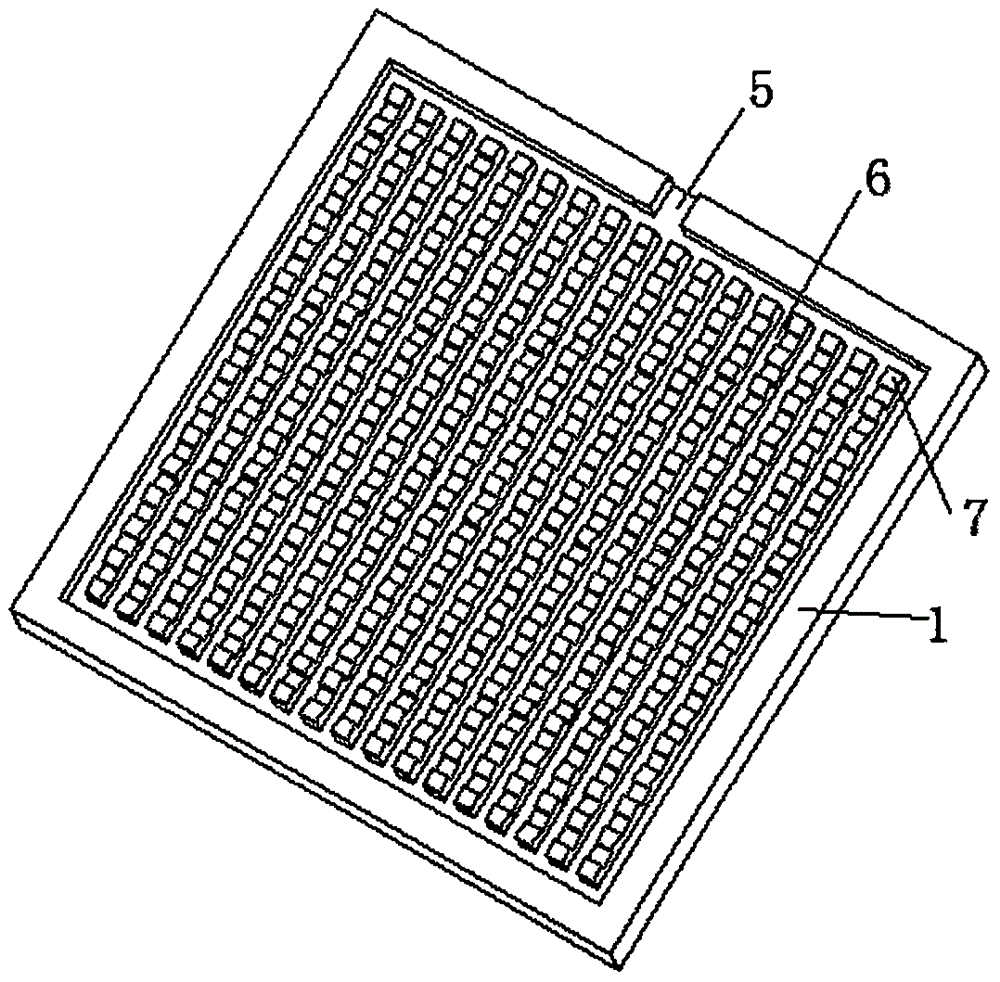

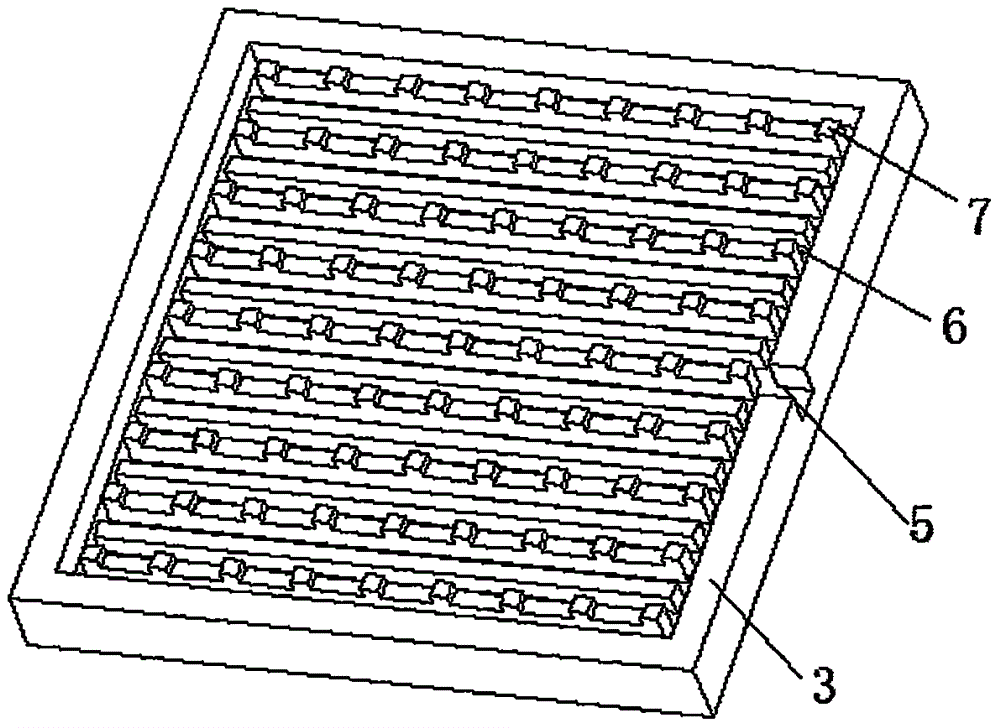

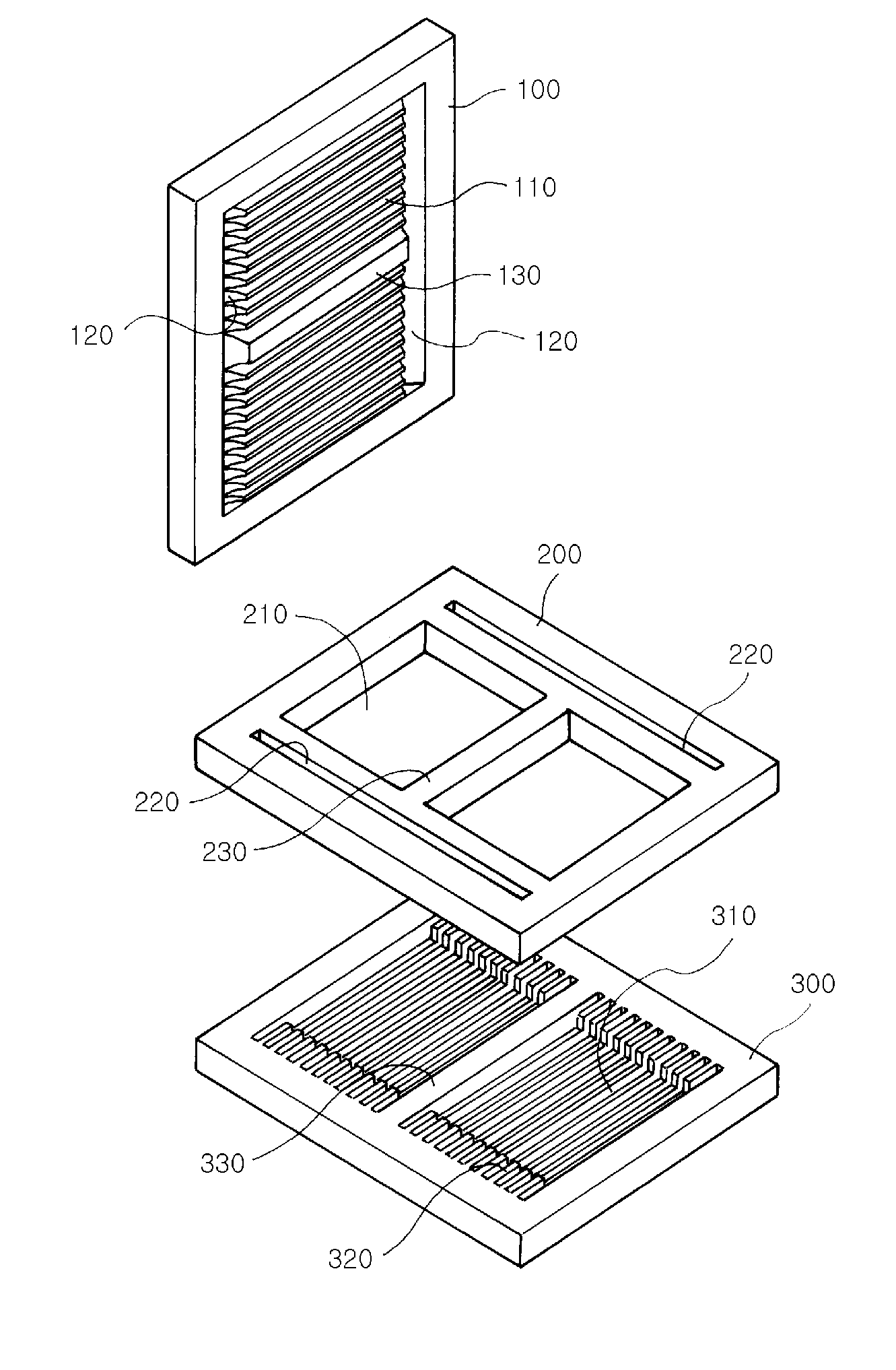

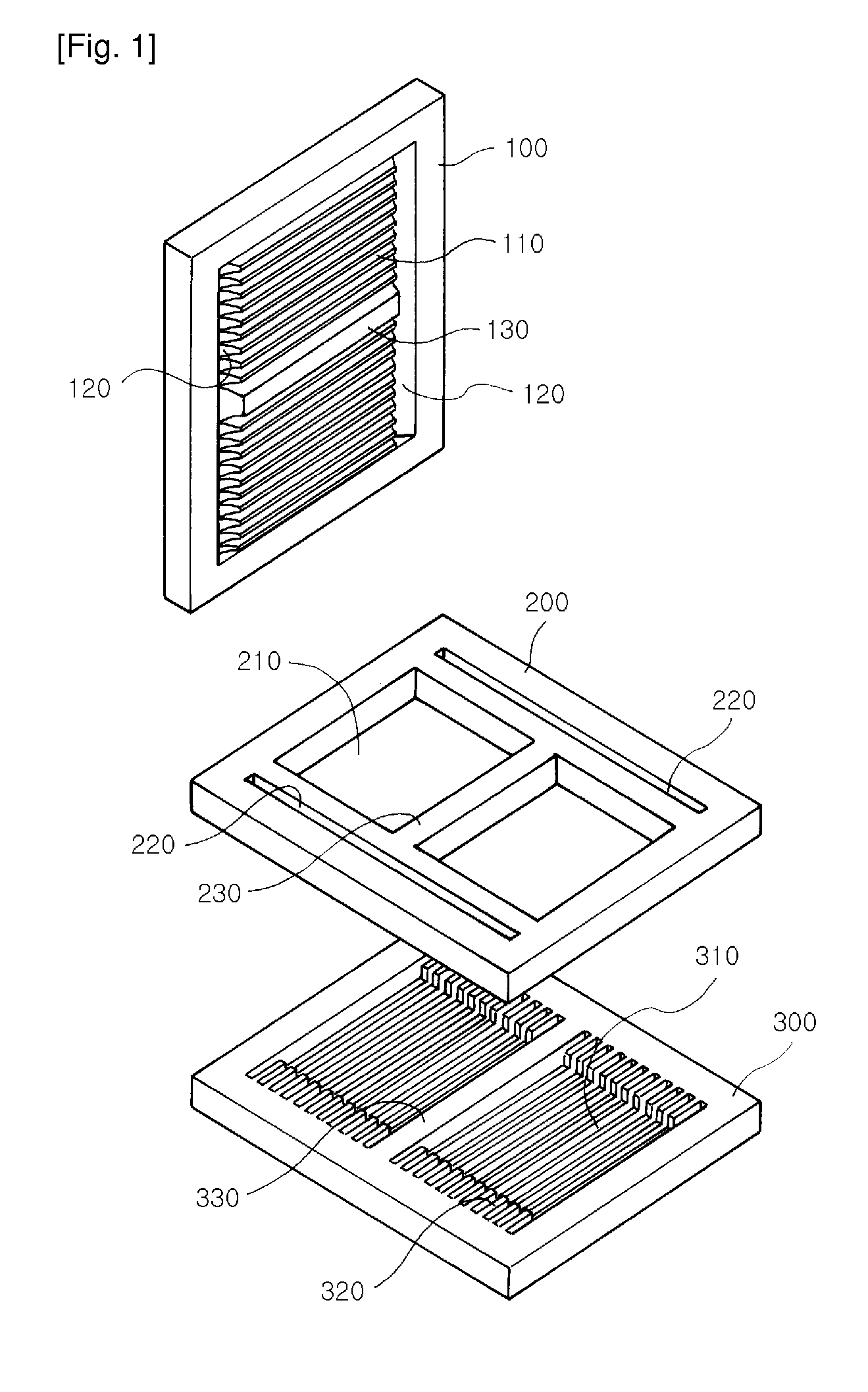

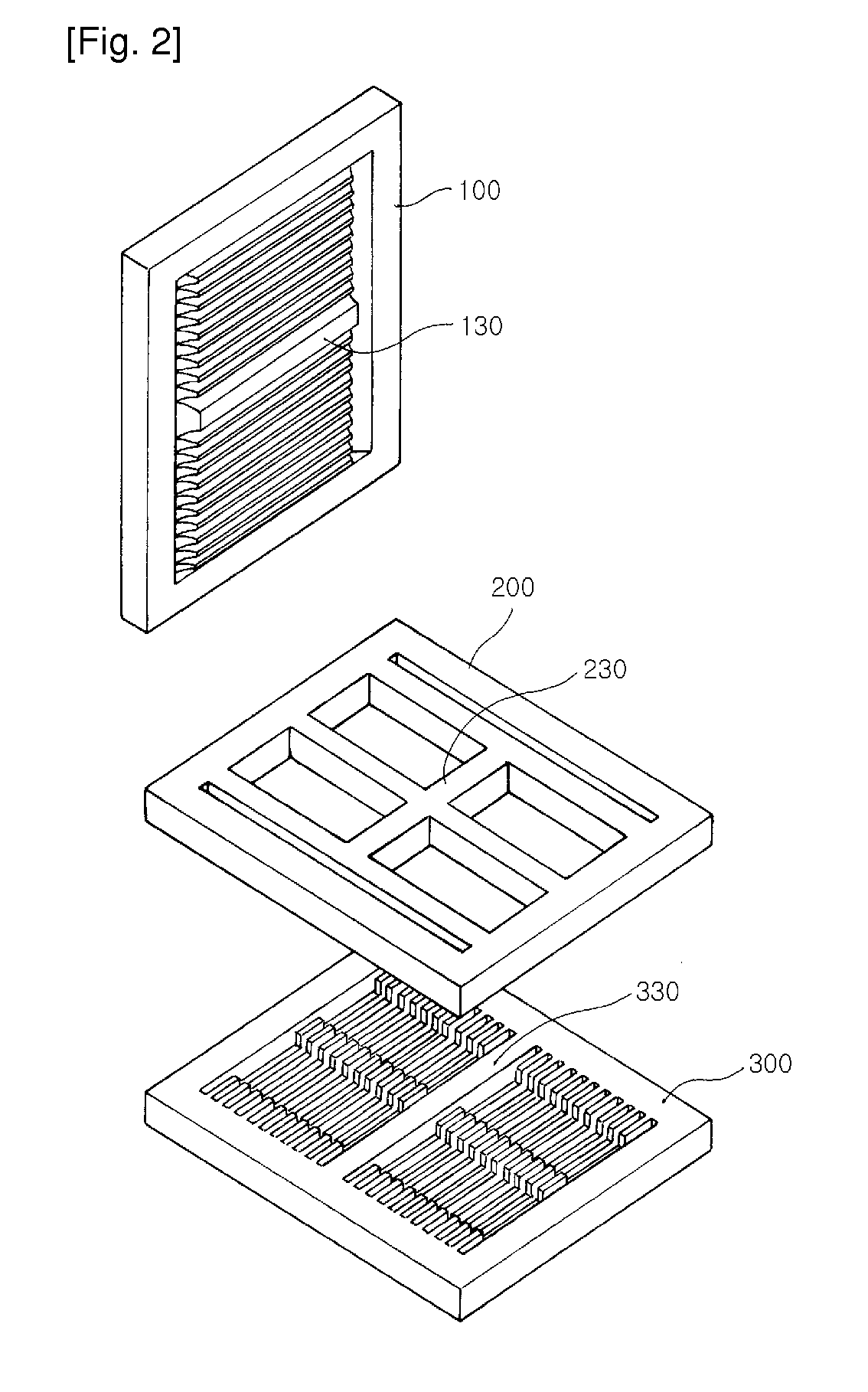

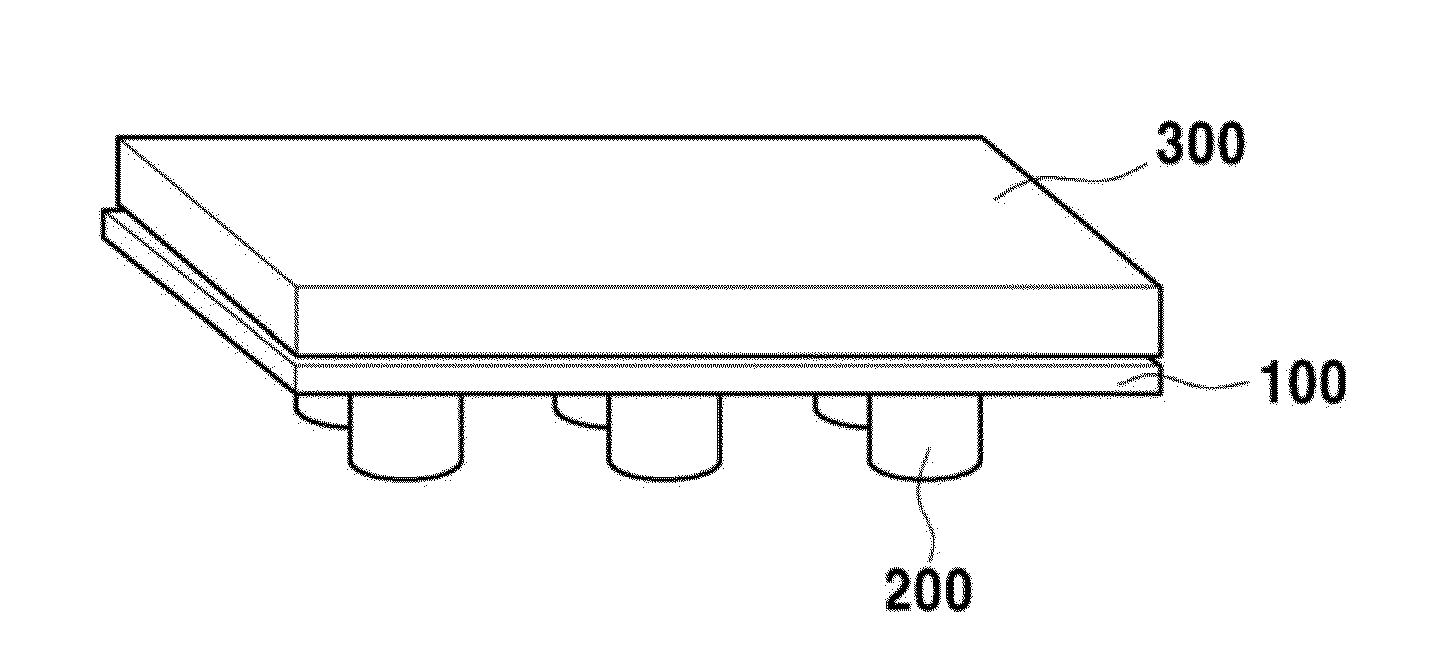

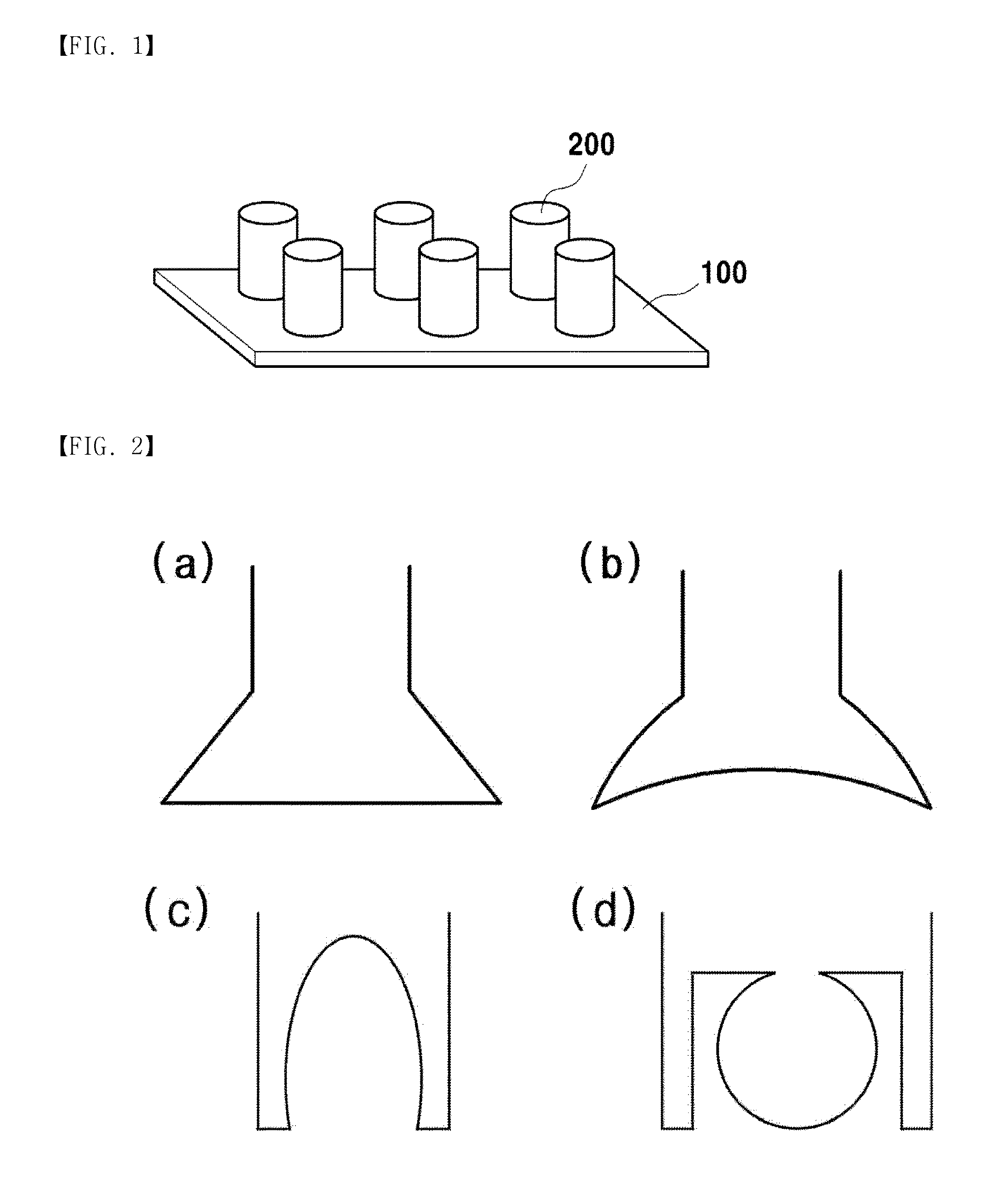

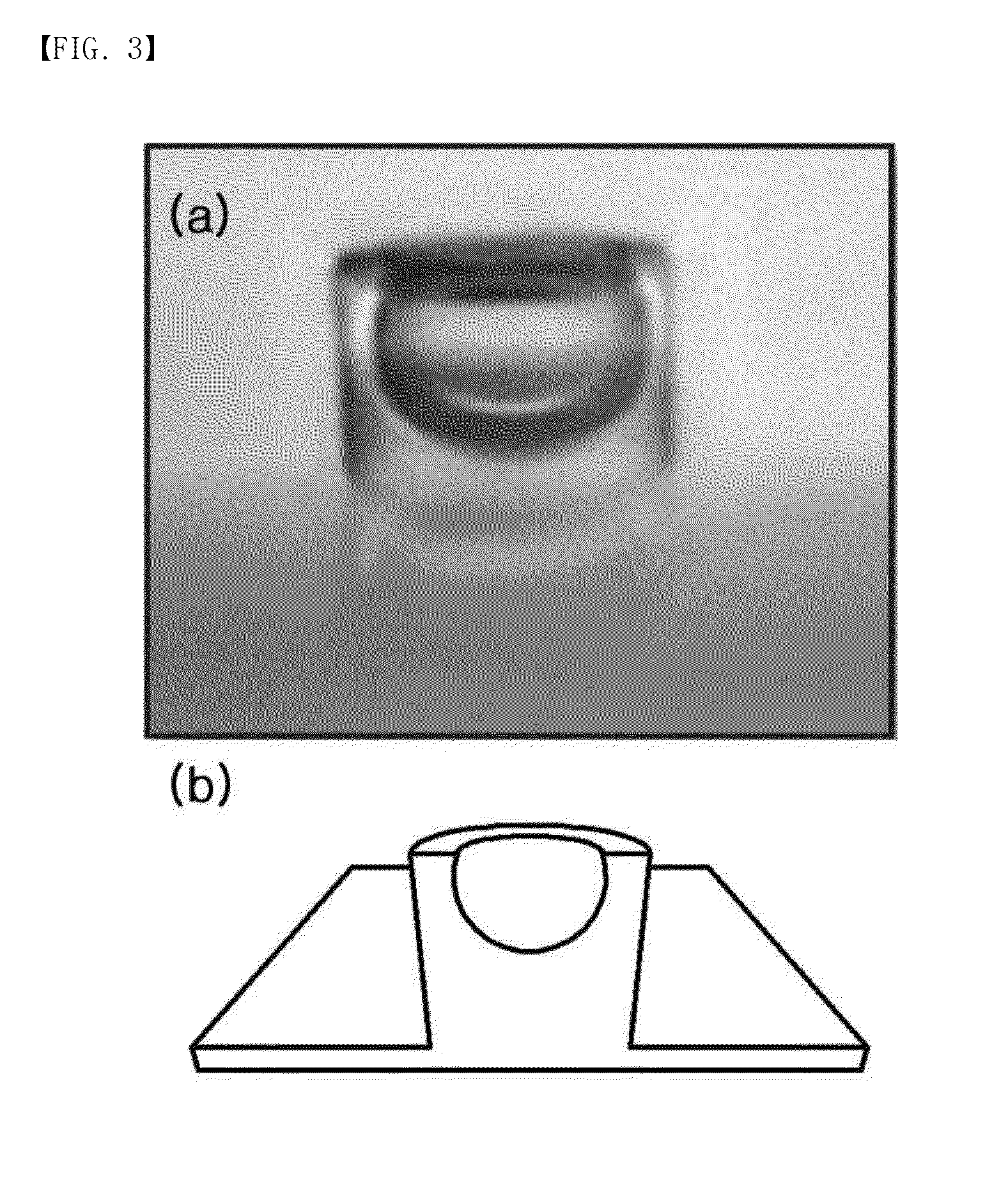

Flat plate type micro heat spreading device

InactiveUS20100258278A1Increase capillary forcePrevent backflowSemiconductor/solid-state device detailsSolid-state devicesEngineeringPersonal computer

A flat plate type heat spreading device is provided. The flat plat type heat spreading device can reduce heat by generating phase transition of liquid by using heat of a heat source so as to solve various problems caused by heat generated in components of electronic devices such as personal computers or mobile phones. Specifically, the flat plate type heat spreading device includes a lower plate for evaporating liquid, a middle plate combined with an upper surface of the lower plate, which separately includes a path through which evaporated vapor passes and a path through which condensed fluid flows into the lower plate, and an upper plate combined with an upper surface of the middle plate, which condenses the evaporated vapor.

Owner:ELECTRONICS & TELECOMM RES INST

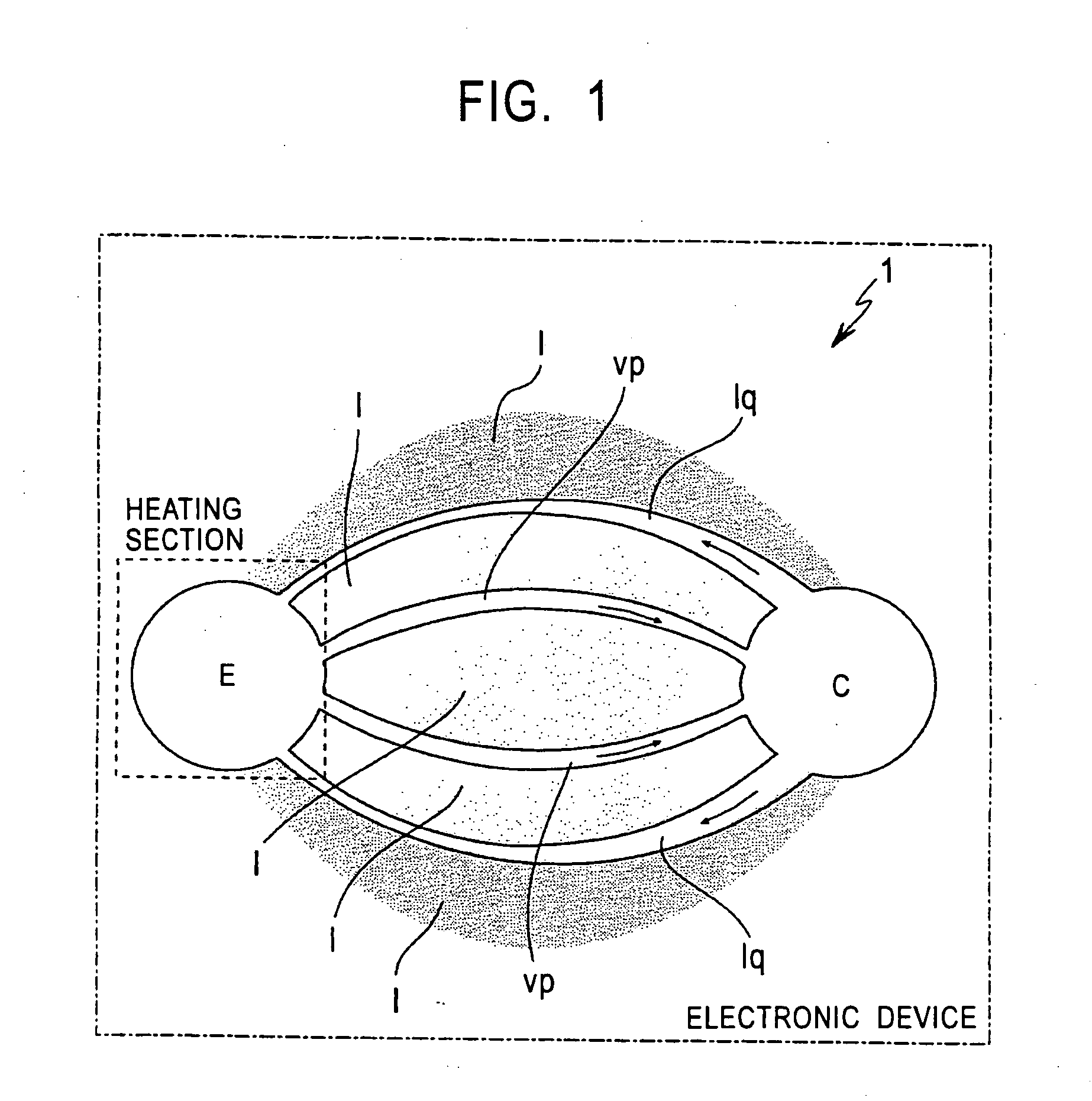

Heat transport device and electronic device

InactiveUS20050126760A1Improve transportation capacityImprove heat transfer efficiencySemiconductor/solid-state device detailsSolid-state devicesWorking fluidGas phase

A heat transport device includes an evaporator, a condenser, and a vapor channel and a plurality of liquid channels that connect the evaporator and the condenser. The evaporator generates a capillary force to circulate working fluid. This structure prevents the performance deterioration and malfunction due to the entry of vapor-phase working fluid into the liquid channels. Since the cross-sectional areas of the liquid channels gradually decrease from the condenser toward the evaporator, the capillary force at the liquid channels can be increased, and vapor-phase working fluid is prevented from entering the liquid channels. Wicks and the portions of the liquid channels adjacent thereto are filled with liquid-phase working fluid even after dryout occurs, stable operation is achieved.

Owner:SONY CORP

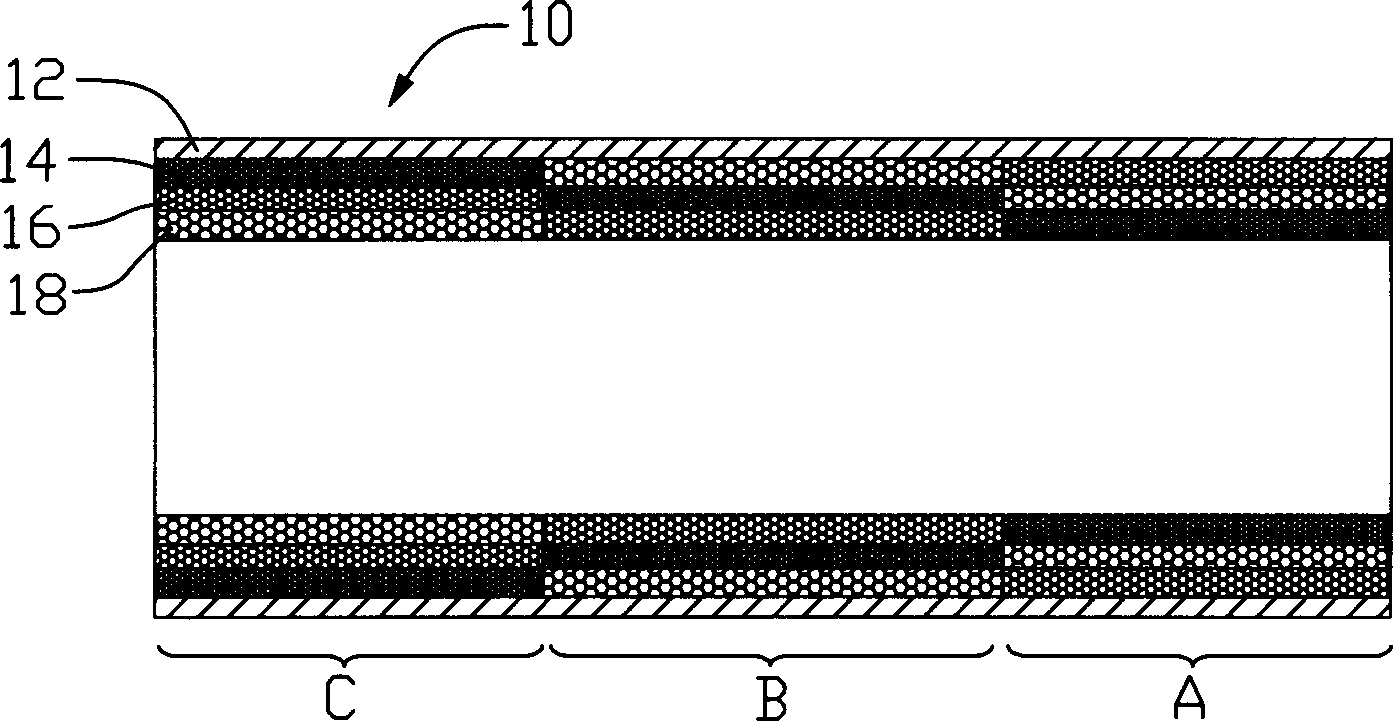

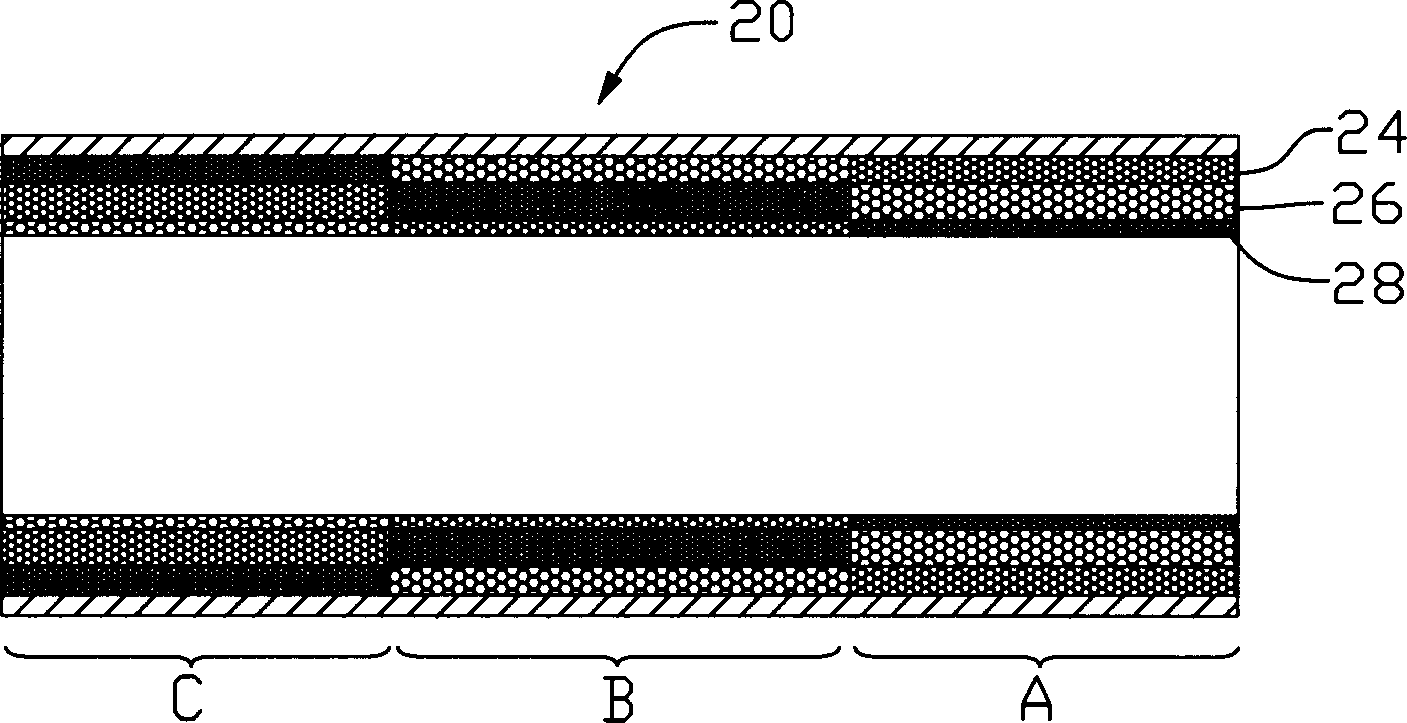

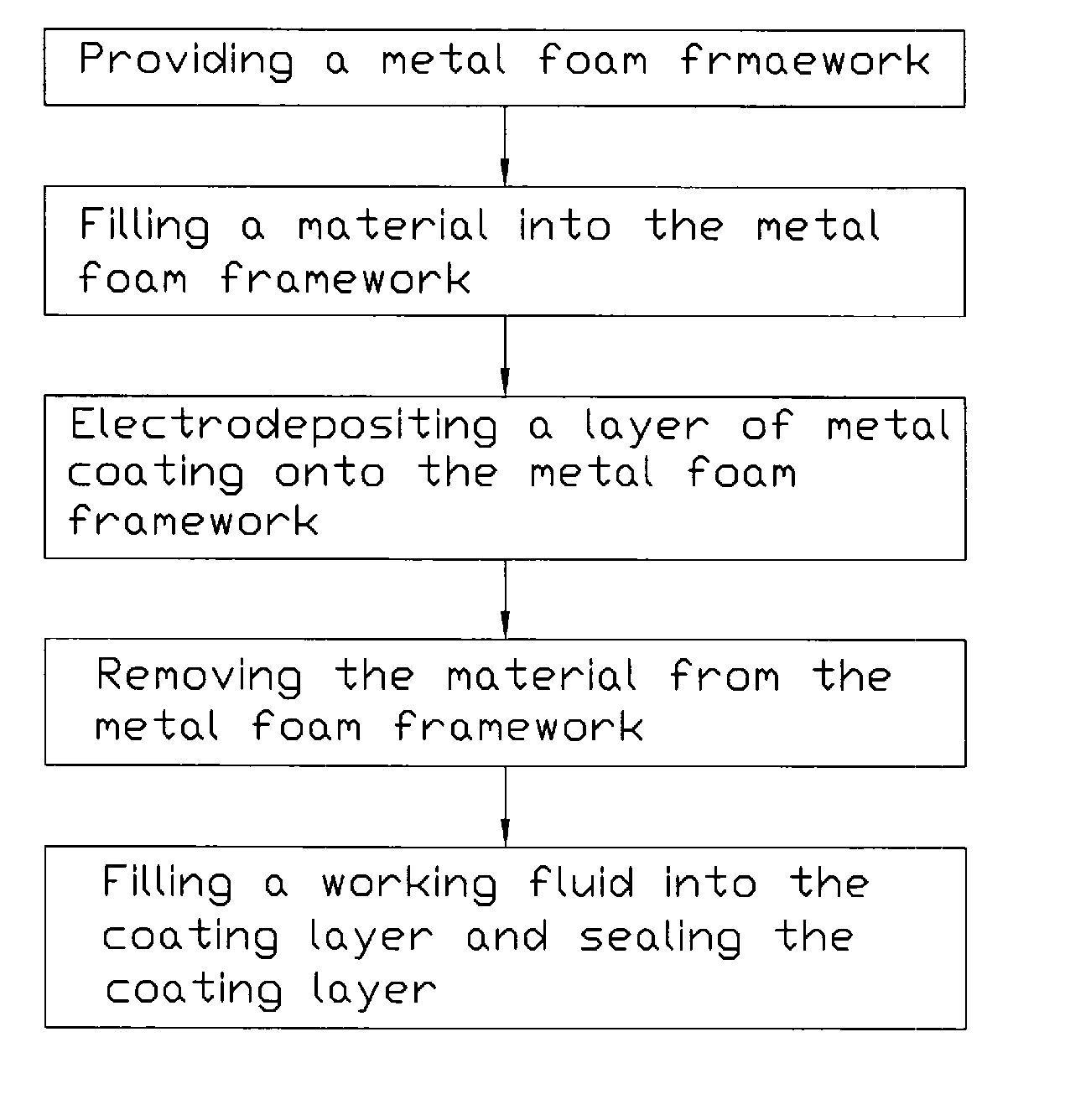

Heat spreader with vapor chamber defined therein and method of manufacturing the same

InactiveUS20070017814A1Easy to controlImprove reliabilityElectroforming processesEngineeringMetal foam

A heat spreader (10) and a method for manufacturing the heat spreader are disclosed. The heat spreader includes a metal casing (12) and a wick structure (16) lines an inner surface of the metal casing. The metal casing defines therein a chamber (14) and includes an evaporating section (126) and a condensing section (127). The wick structure is in the form of metal foam and occupies a portion of the chamber. In one embodiment, the wick structure has a pore size gradually increasing from the evaporating section towards the condensing section of the metal casing. The heat spreader is manufactured by electrodepositing a layer of metal coating (70) on an outer surface of a metal foam framework (20). The metal coating becomes the metal casing and the metal foam framework becomes the wick structure.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

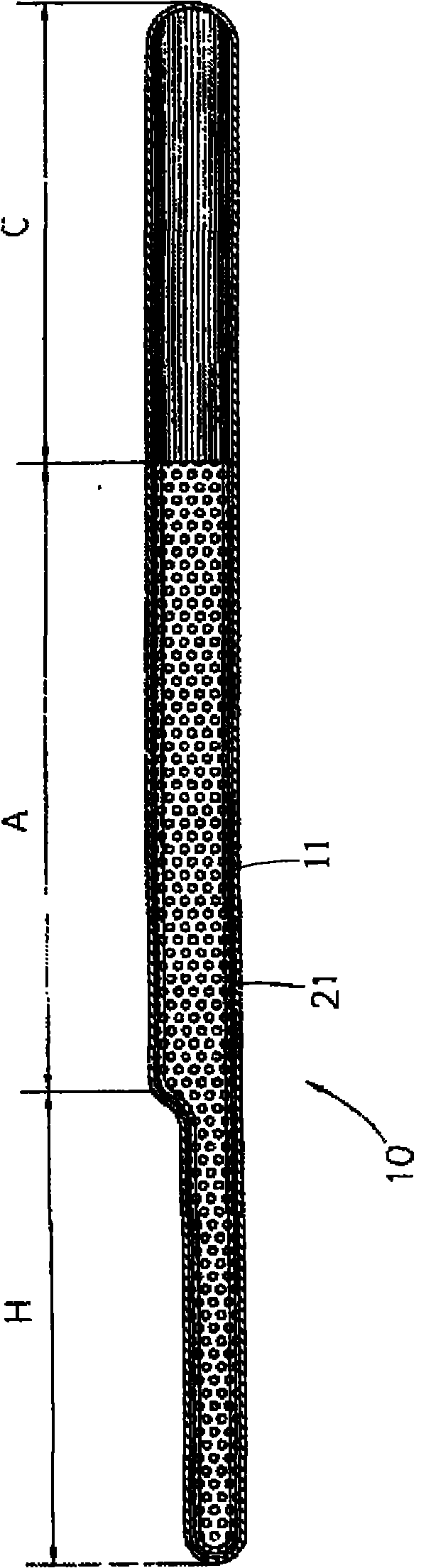

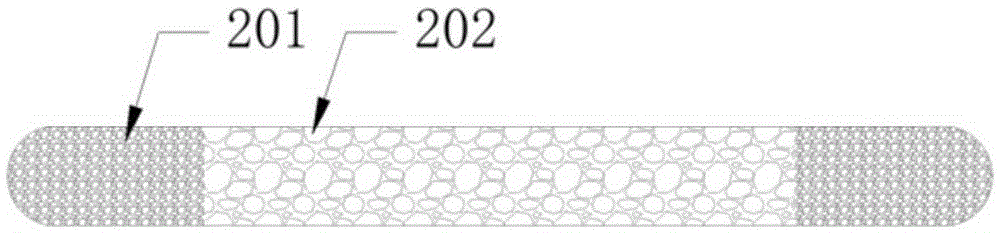

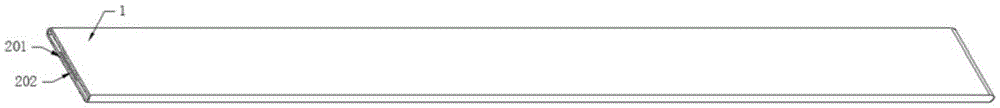

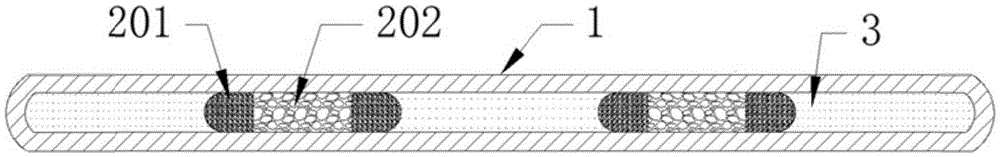

Variable-parameter liquid absorption core ultrathin heat pipe

ActiveCN105403085AOptimizing the gas-liquid cycle processImprove performanceIndirect heat exchangersCondensation processPorosity

The invention provides a variable-parameter liquid absorption core ultrathin heat pipe. Small-bore and high-porosity structures (201) are adopted in the areas on the two sides, in the width direction, of a liquid absorption core (2). A large-bore and small-porosity structure (202) is adopted in the area in the middle, in the width direction, of the liquid absorption core (2). According to the small-bore and high-porosity structures (201) of the areas on the two sides of the liquid absorption core (2), when the heat pipe works, a gas-liquid interface area in the liquid absorption core can be enlarged, the flow of working media participating in the evaporation and condensation process is increased, and the capillary drive force of the area is improved; meanwhile, by means of the large-bore and small-porosity structure of the area in the middle, the amount of working medium liquid stored in the liquid absorption core is increased, the resistance for the working media flowing to the two sides of the liquid absorption core is lowered, and working medium liquid can be supplemented to the areas on the two sides more easily; and the circulating speed of gas-liquid working media is increased, and efficient running of the ultrathin heat pipe is achieved.

Owner:SHANGHAI LIZHENG SATELLITE APPL TECH CO LTD

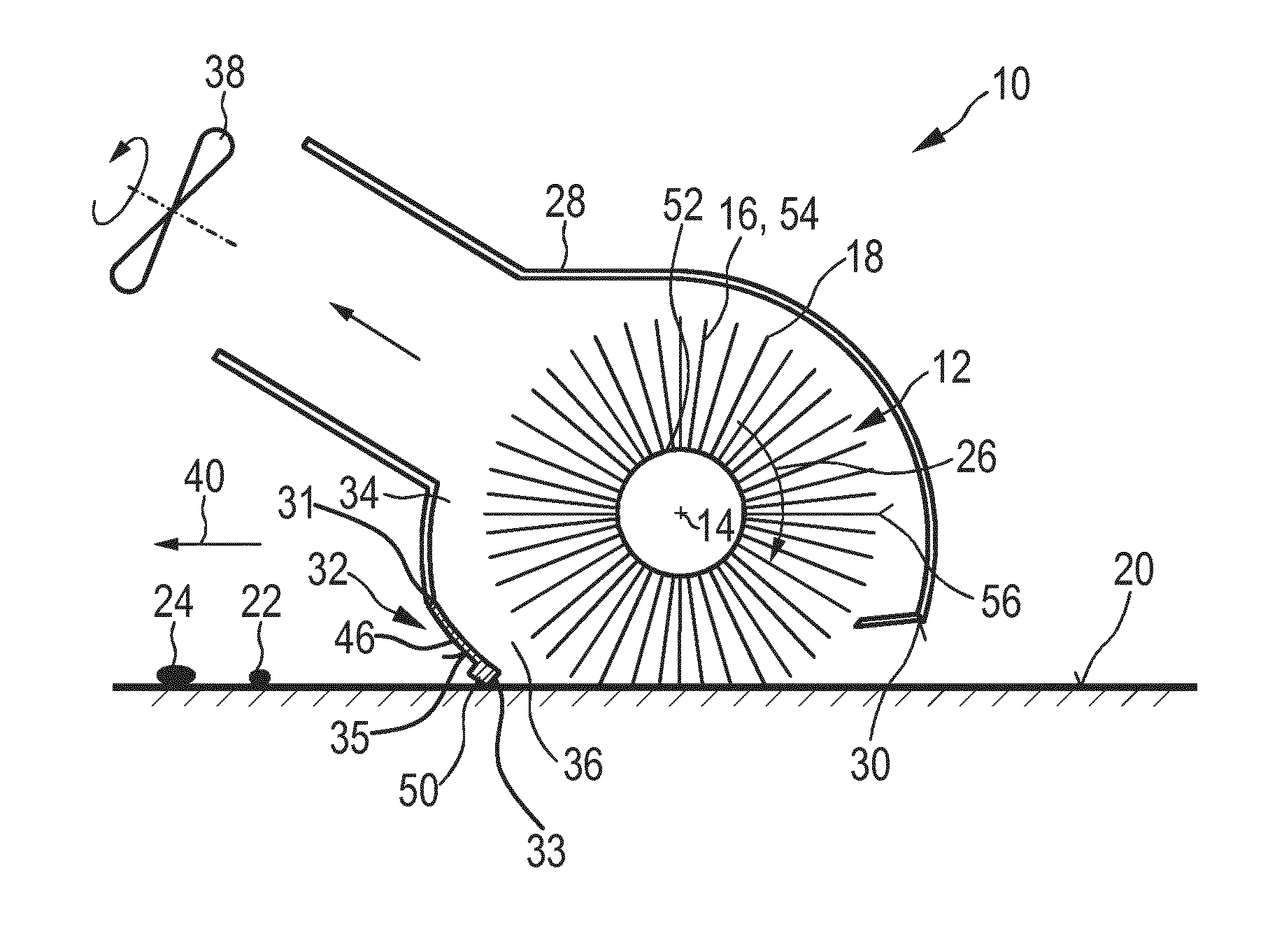

Floor nozzle for vacuum cleaner

The present invention relates to a cleaning device for cleaning a surface, with a nozzle arrangement (10) comprising: —a brush (12) rotatable about a brush axis (14), said brush (12) being provided with brush elements (16) having tip portions (18) for contacting the surface to be cleaned (20) and picking up dirt particles (22) and / or liquid (24) from the surface (20) during the rotation of the brush (12), —a drive means for driving the brush (12) in rotation, —a bouncing element (32) comprising a bouncing surface (33) that is configured to let the dirt particles (22) and / or liquid (24), that are released from the brush (12) during rotation, rebound to the brush (12), said bouncing surface (33) being spaced apart from the brush (12) and extending substantially parallel to the brush axis (14), and —an adjustment means (35) for adjusting the position of the bouncing element (32) relative to the surface (20) depending on a direction of movement (40) of the device, wherein the adjustment means (35) is adapted to arrange the bouncing element (32) in a first position in which the bouncing element (32) has a first distance d1 to the surface (20), when the cleaning device is moved in a forward direction, in which the bouncing element (32) is, seen in the direction of movement of the device (40), located behind the brush (12), and to arrange the bouncing element (32) in a second position in which the bouncing element (32) has a second distance d2 to the surface, when the cleaning device is moved in an opposite backward direction, wherein d2 is greater than d1 and equal to d3*tan(α), d3 being the distance between the bouncing surface (33) and the position of the brush (12) where the tip portions (18) lose contact from the surface to be cleaned (20) during the rotation of the brush (12), and α being an angle that is equal to or smaller than 20°.

Owner:VERSUNI HLDG BV

Microstructured device for removable storage of small amounts of liquid and a process for removal of the liquid stored in this device

InactiveUS20050093087A1Easy constructionAdvantage in productionValve arrangementsDispensing apparatusEngineeringElectrical and Electronics engineering

Owner:BOEHRINGER INGELHEIM MICROPARTS

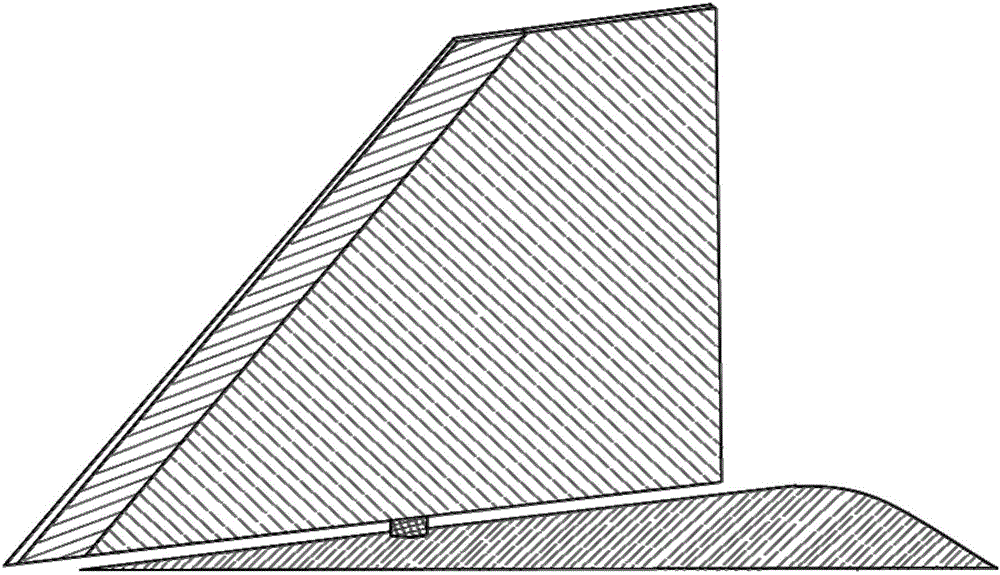

Hypersonic aircraft dredging-type rudderpost heat protection structure

ActiveCN106809375AIsothermalizationImprove thermal stress distributionAircraft controlGround installationsInsulation layerEngineering

The invention relates to a hypersonic aircraft dredging-type rudderpost heat protection structure. The rudderpost is designed as a hollow structure, the upper surface of the hollow cavity is positioned above the rudderpost mounting gap and is isolated from the control surface through a heat-insulation layer, and the lower surface is positioned inside the aircraft body and is isolated from the control actuator through a phase-change material or heat sink. The side wall of the hollow cavity is provided with a channel which is parallel to the rudderpost bus, a capillary core is welded with the surface of the channel, the hollow cavity is filled with a working medium, and the heat quantity of aerodynamic heating at the rudderpost gap is dredged to the inner wall of the whole hollow cavity through the phase change and dispersion of the working medium in the hollow cavity. The part of the rudderpost inside the aircraft body and the external surface of the control surface part are respectively provided with a heat-insulation layer.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

Disposable oxygen sensor and method for correcting oxygen effect on oxidase-based analytical devices

ActiveUS7611621B2Easy to manufactureAccurate measurementImmobilised enzymesBioreactor/fermenter combinationsAnalyteOxygen sensor

A system and method for correcting the oxygen effect on oxidase-based analyte sensors includes an oxygen sensor with a working electrode, a reagent matrix disposed on at least the working electrode that contains a reduced form of a redox mediator, an oxidase and a peroxidase, an oxidase-based analyte sensor, a means for determining the oxygen concentration in a portion of a fluid sample using the oxygen sensor, means for determining an analyte concentration in another portion of the fluid sample using the oxidase-based analyte sensor, and means for using the oxygen concentration in the fluid sample to determine a corrected analyte concentration in the fluid sample.

Owner:NOVA BIOMEDICAL

Dry bonding system and wearable device for skin bonding including the same

ActiveUS20160206243A1Sufficient adhesion forceSuperiority in repeated attachmentLayered productsAdhesive dressingsBiomedical engineering

Owner:RES & BUSINESS FOUND SUNGKYUNKWAN UNIV

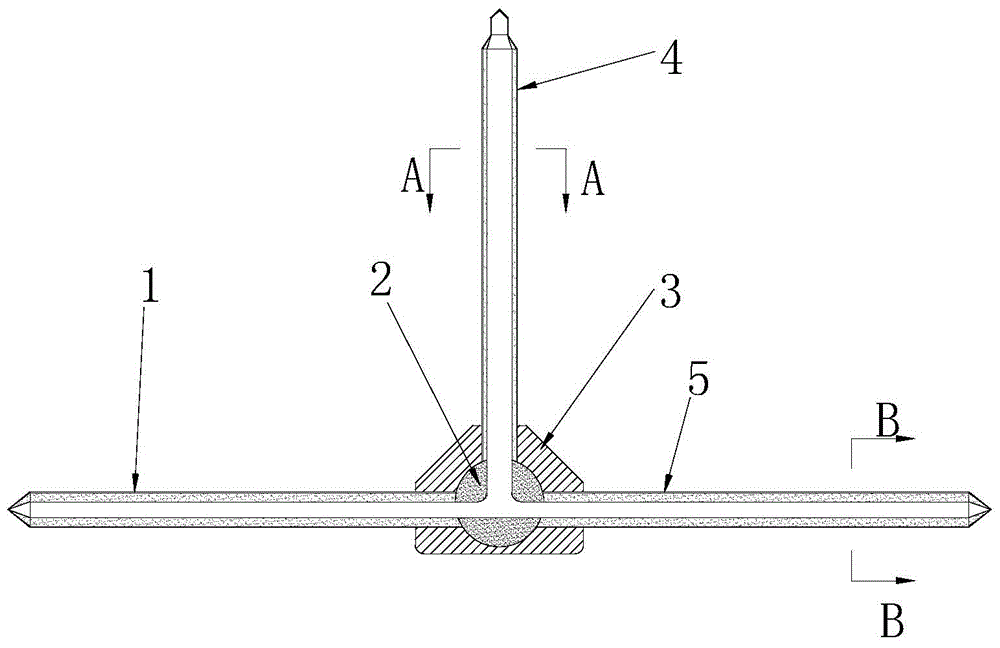

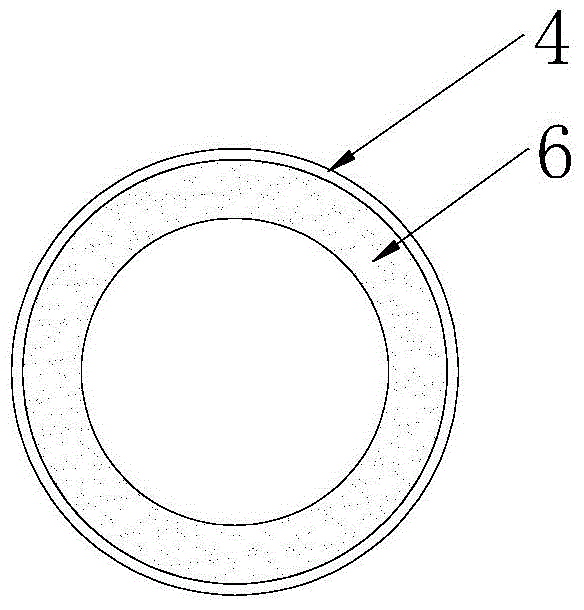

Multi-branch distribution heat pipe and manufacturing method thereof

ActiveCN104567501AIncrease capillary forceImprove heat transfer performanceIndirect heat exchangersCooling/ventilation/heating modificationsMiniaturizationEngineering

The invention discloses a multi-branch distribution heat pipe. The multi-branch distribution heat pipe comprises a multi-channel pipe joint, a first pipe casing, a second pipe casing and a third pipe casing, wherein one end of the first pipe casing, one end of the second pipe casing and one end of the third pipe casing are sealed; the multi-channel pipe joint is provided with connecting openings, wherein every connecting opening is used for connecting with the corresponding pipe casing; an empty sealing chamber which is communicated with the connecting openings is formed in the multi-channel pipe joint; the other end of every pipe casing is in insertion joint with the corresponding connecting opening of the multi-channel pipe joint to form a T-shaped structure, wherein the T-shaped structures are communicated with each other; the inner wall of every pipe casing is provided with a layered porous capillary layer; the inner sealing chamber of the multi-channel pipe joint is filled with capillary layer connectors which are used for maintaining the communication of the pipe casings. The invention also provides a manufacturing method of the multi-branch distribution heat pipe. According to the multi-branch distribution heat pipe and the manufacturing method thereof, the spatial hierarchical porous capillary layers and the sintering heat pipe are high in capillary force and heat transfer capability and accordingly the radial thermal resistance can be obviously improved; meanwhile the space required by heat dissipation is saved and accordingly a flexible, reliable and stable heat dissipation environment can be provided for the miniaturization development of electronic equipment; the cost is low and accordingly the multi-branch distribution heat pipe is suitable for industrialized production.

Owner:SOUTH CHINA UNIV OF TECH

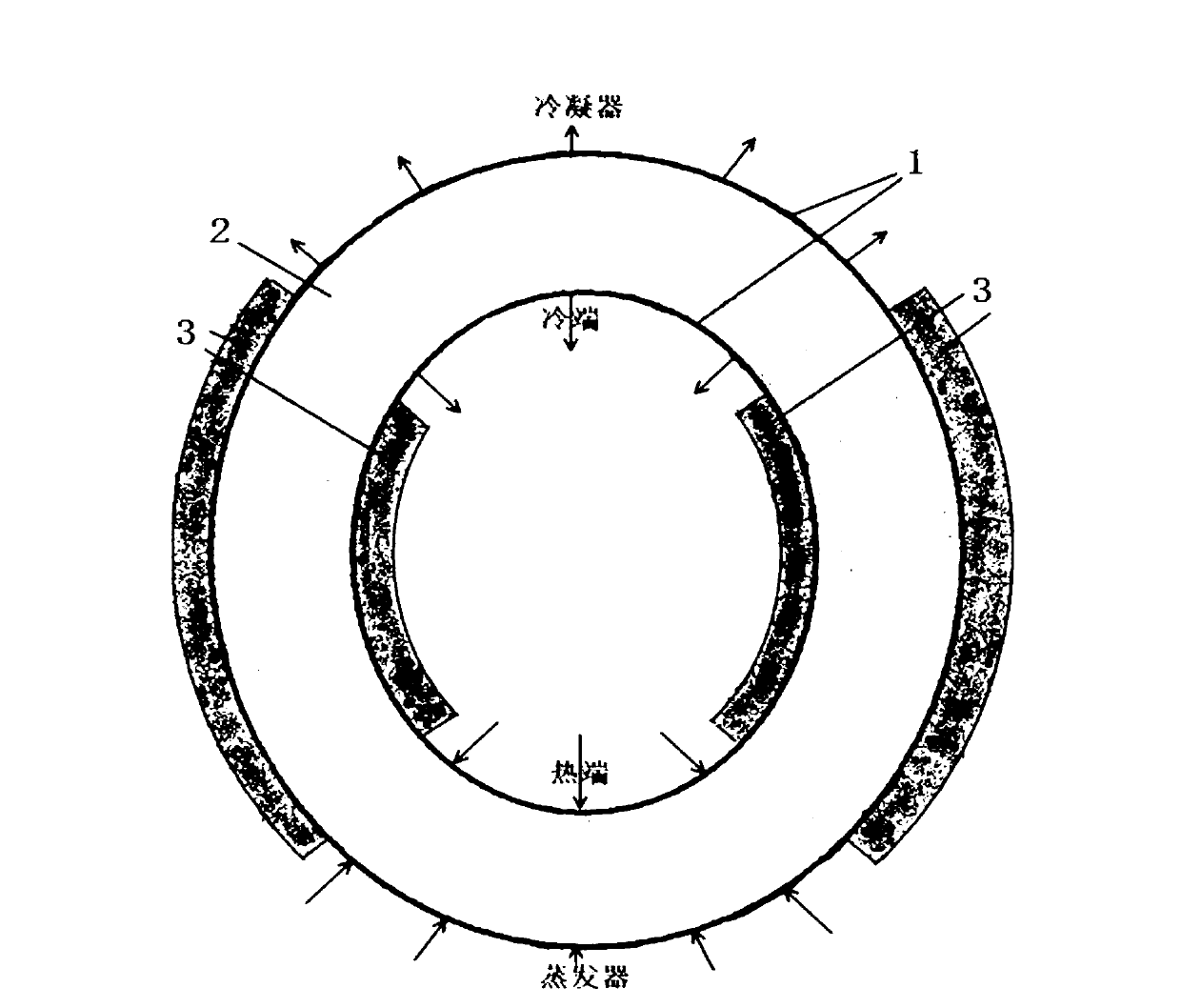

Through hole metal foam heat pipe heat exchange device with gradient topographic characteristics

InactiveCN103134365ALess consumablesReduce volumeFoundry mouldsIndirect heat exchangersThermal insulationPipe insulation

The invention provides a through hole metal foam heat pipe heat exchange device with gradient topographic characteristics and relates to the technical field of rigid heat conductors. The through hole metal foam heat pipe heat exchange device with gradient topographic characteristics comprises a heat pipe and through hole metal foams sintered on the inner wall of the heat pipe. A heat insulation section is arranged on the outer layer in the middle of the heat pipe, and two ends are respectively arranged at the cold end and the hot end of heat exchange environment. The structure of the through hole metal foams is that inner through holes are structures with gradient density, namely porosity factor is the same, and hole density is increased or reduced gradually along the perpendicular direction of the wall surface of the heat pipe; or hole density is the same, and the porosity factor is increased or reduced gradually along the perpendicular direction of the wall surface of the heat pipe; the hole density and the porosity factor are the same, and used materials are changed according to layers. The through hole metal foam heat pipe heat exchange device with gradient topographic characteristics increases heat exchange surface area, facilitates flow and heat exchange of fluid expanded gradually because of being heated, enhances capillary force, and enables the heat pipe to have high heat exchange efficiency under the condition of same heat exchange effect. Metal consumption is small, and volume is small.

Owner:SHANGHAI JIAO TONG UNIV

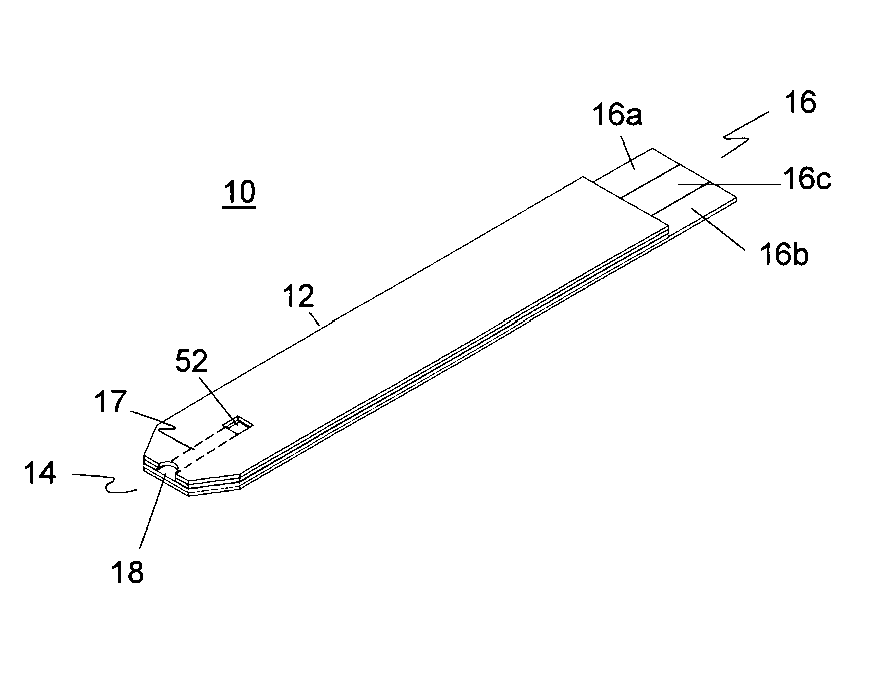

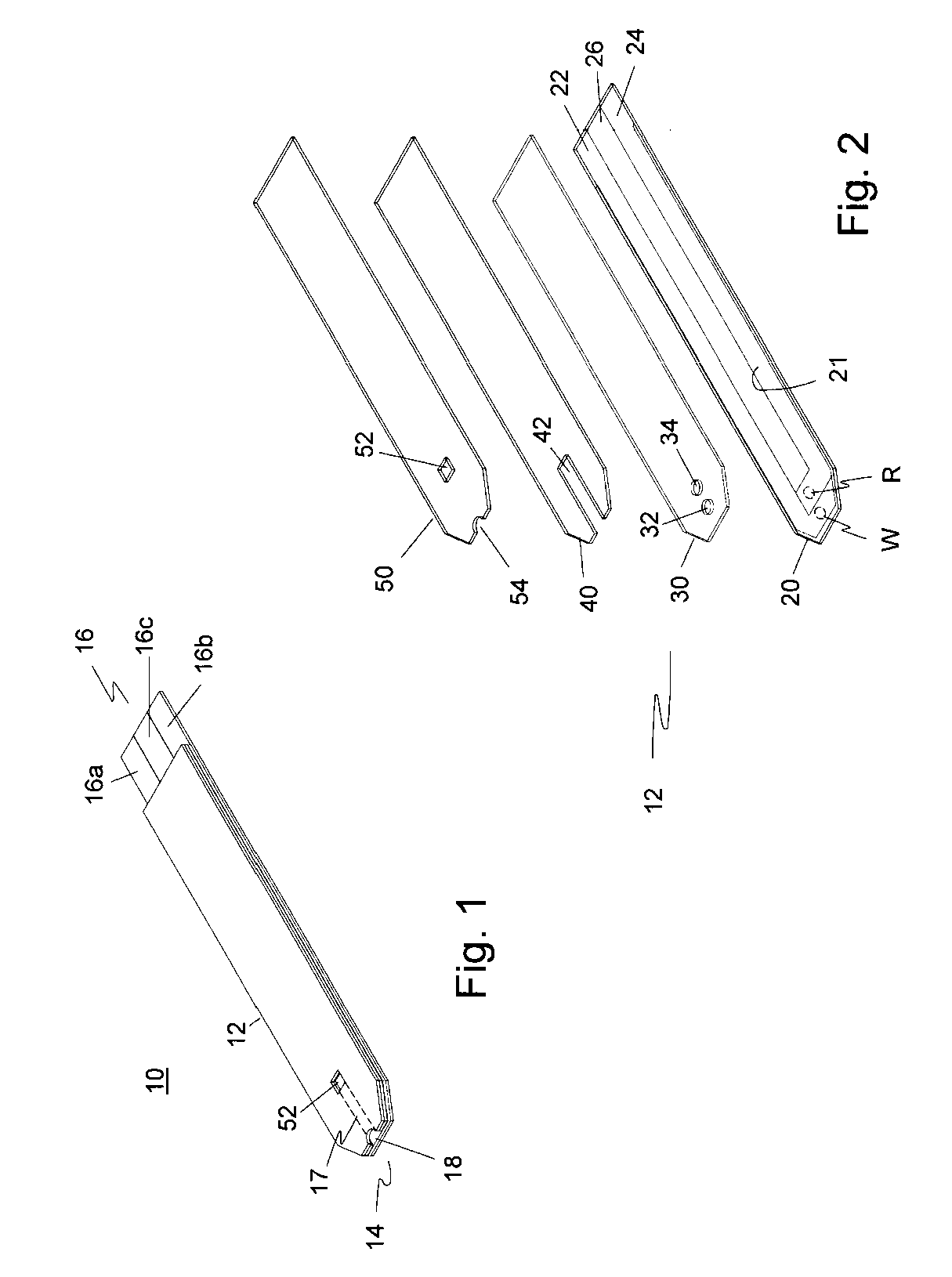

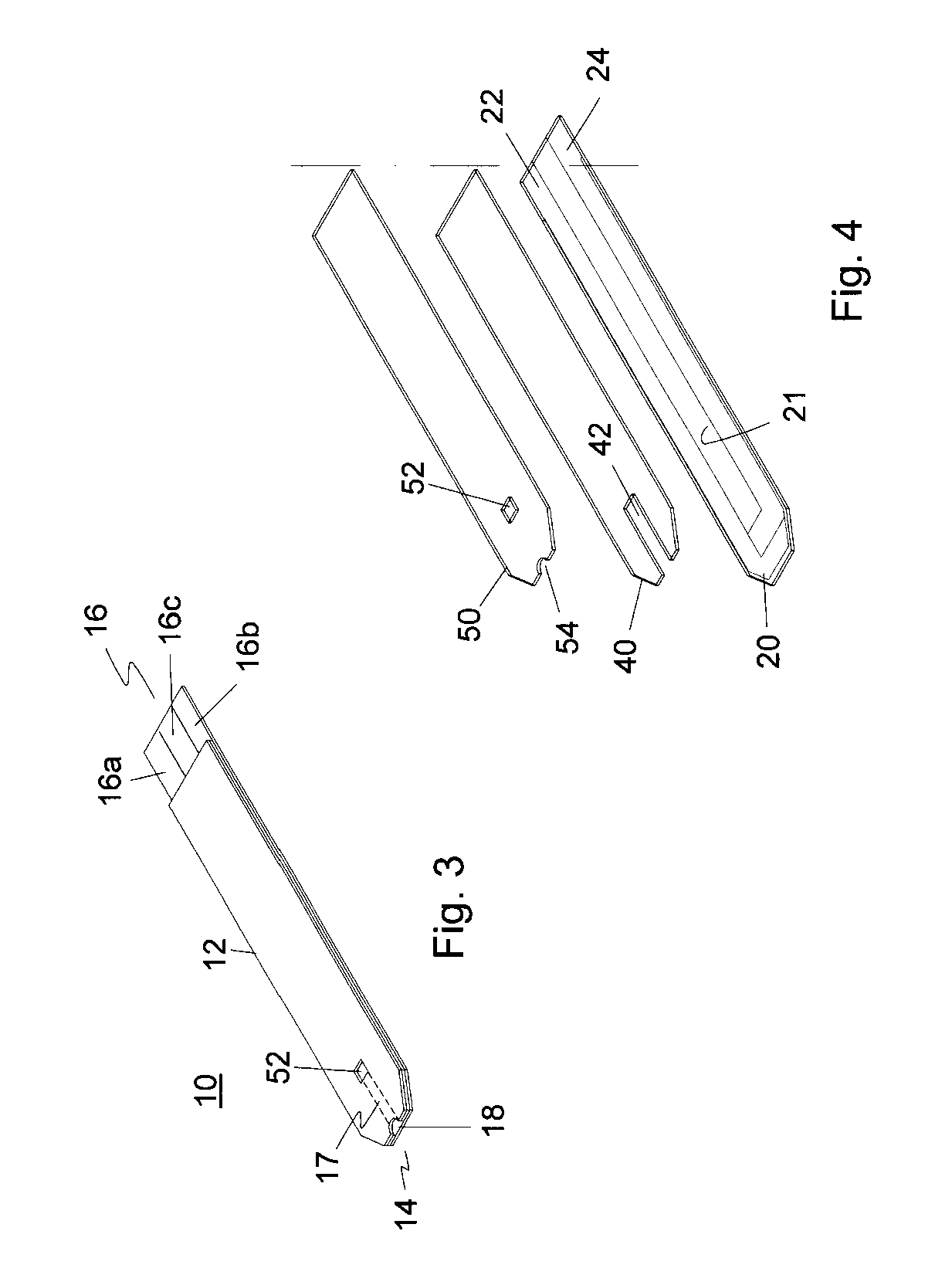

Nozzle arrangement of a cleaning device for cleaning a surface

ActiveUS20150327743A1Reduce quality problemsIncrease flexibilityCarpet cleanersBrush bodiesEngineeringNozzle

The present invention relates to a nozzle arrangement (10) of a cleaning device (100) for cleaning a surface (20), comprising: a nozzle housing (28); a rotating brush (12) that is rotatable about a brush axis (14) and comprises a substantially cylindrical core element (52) with flexible brush elements (16) that are arranged on a circumferential surface (56) of the core element (52), wherein said brush elements (16) are configured to contact the surface to be cleaned (20) and pick up dirt and liquid particles (22, 24) from the surface to be cleaned (20) during a rotation of the rotating brush (12); a drive for driving the rotating brush (12); a liquid supplying arrangement (58) for supplying a cleansing liquid (68) to the rotating brush (12); a wiping element (32) for wiping dirt and liquid particles (22, 24) across or off the surface to be cleaned (20), wherein said wiping element (32) extends along a longitudinal direction (48), which is arranged substantially parallel to the brush axis (14), and wherein said wiping element (32) is arranged on a first longitudinal side (27) of the rotating brush (12) where the brush elements (16) enter the nozzle housing (28) during the rotation of the rotating brush (12); and at least one side sealing element (62a, b) for sealing a lateral side (82a, b) of the nozzle housing (28), wherein the at least one side sealing element (62a, b) is spaced apart from a transverse side (80a, b) of the core element (52) that is transverse to the circumferential surface (56)

Owner:VERSUNI HLDG BV

Structure of heat sink and manufacturing method

InactiveCN1832156AIncrease capillary forceImprove permeabilitySemiconductor/solid-state device detailsSolid-state devicesWorking fluidHeat sink

This invention discloses a radiating device, which can be a uniform heat cavity combined with any heating components. The device includes a closed cavity and a capillary structure formed on the inside wall of said cavity, in which, said capillary structure includes multiple grooves formed on the inside wall of the cavity and porous powder sintered under high temperature on the inside wall , thus the radiating device has good capillary force of sintered capillary structure and penetrability of groove structure to speed up the radiation backflow of the working liquid and increase the radiation efficiency of the device.

Owner:DELTA ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com