Novel flat plate thiele tube and preparation method thereof

A flat heat pipe and heat soaking pipe technology, applied in heat exchange equipment, lighting and heating equipment, heat transfer modification and other directions, can solve the problems of increasing the process, damage to the strength of the pipe wall, low processing efficiency, etc., to increase the strength of the pipe wall, The effect of reducing the thickness of the liquid film and reducing the heat transfer resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] The invention provides a novel flat heat soaking tube and a preparation method thereof, the main process of which is as follows:

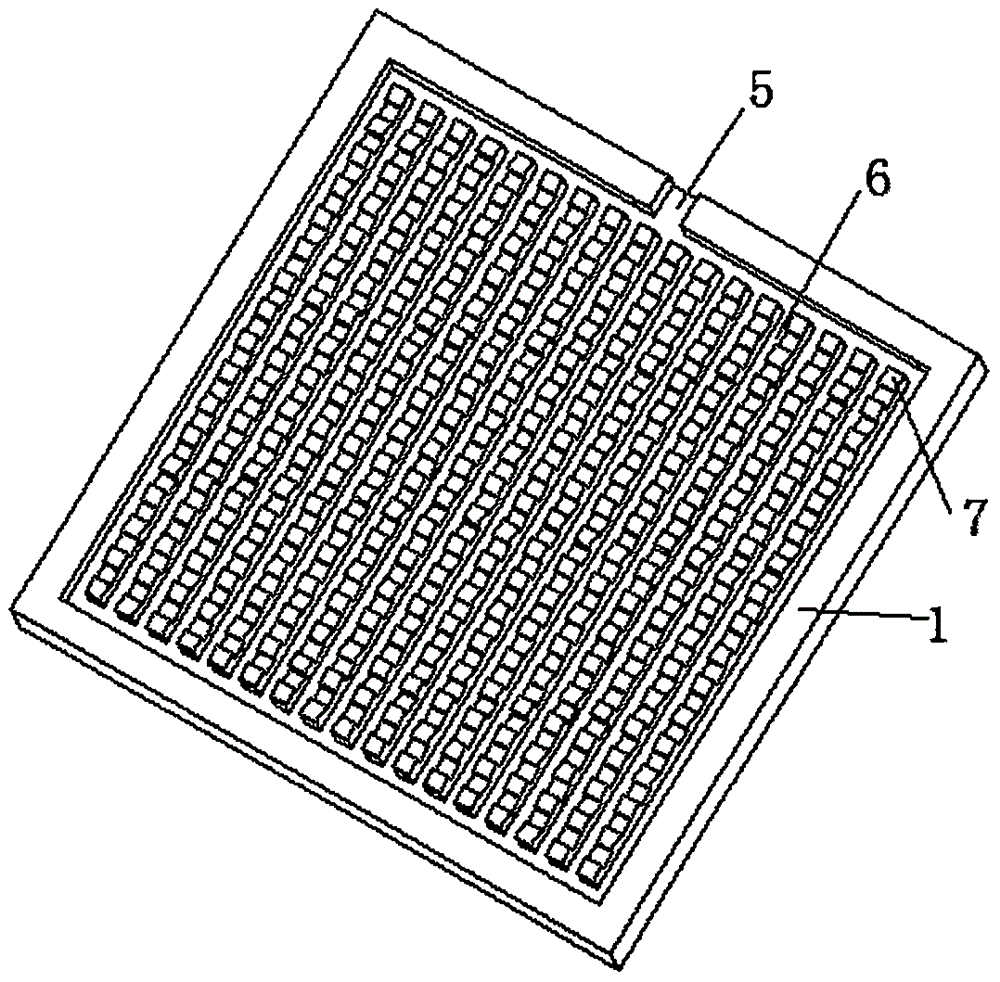

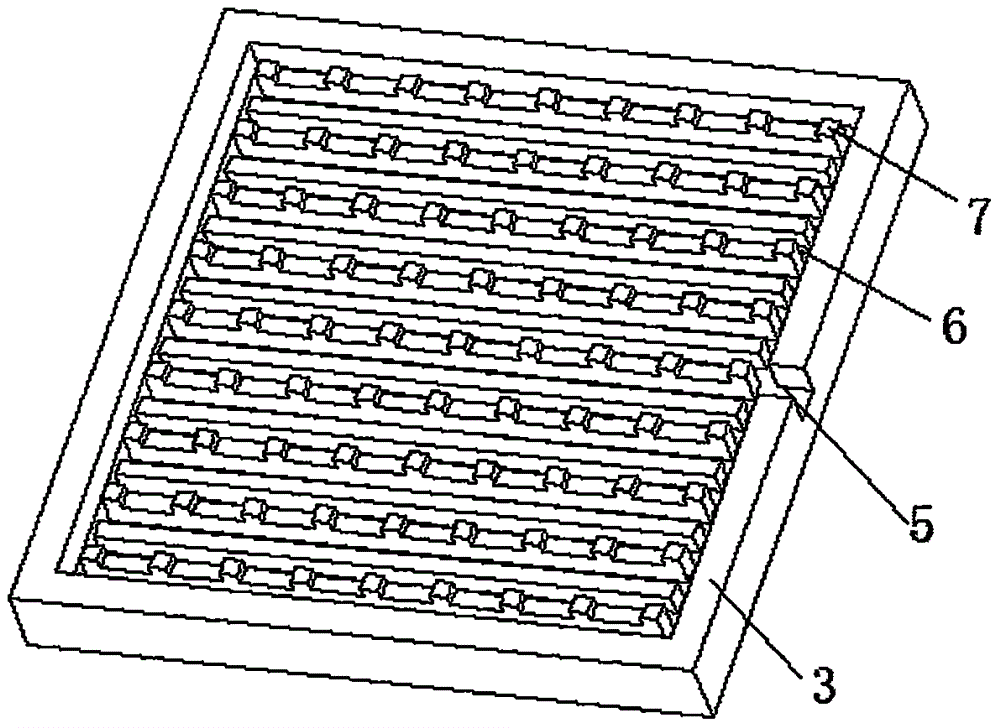

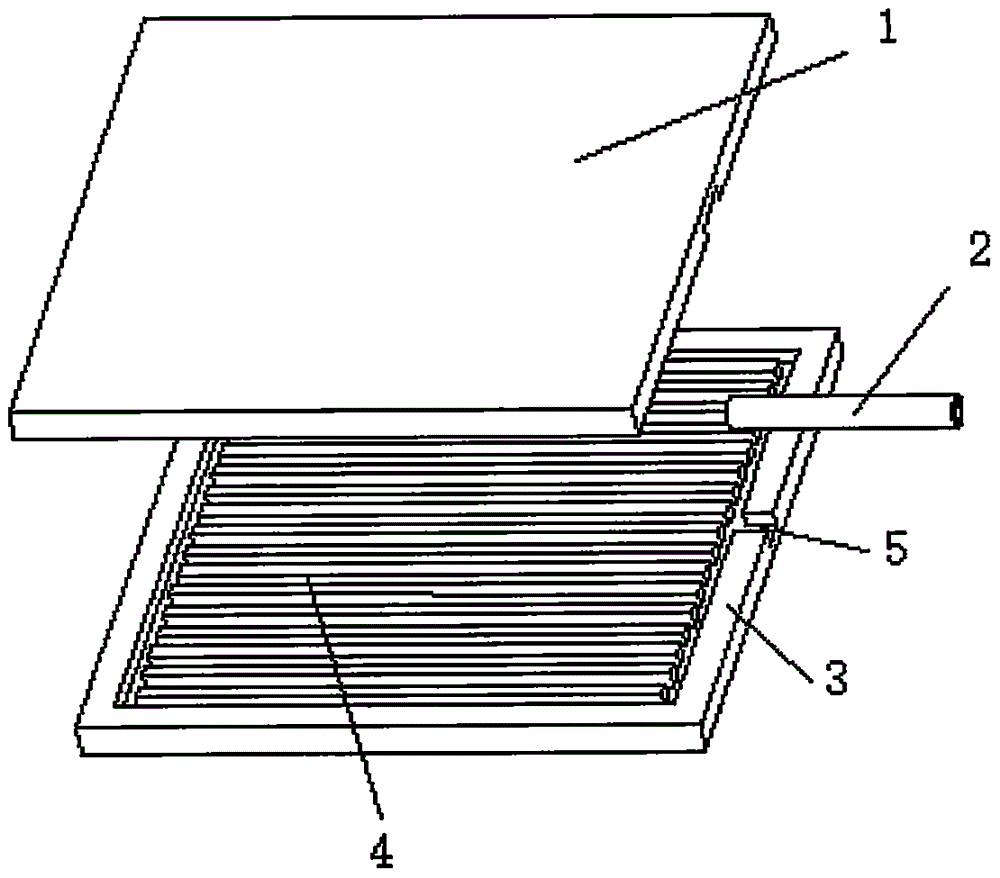

[0024] (1) The novel flat heat soaking tube includes a red copper upper plate 1, a red copper lower plate 3, and a liquid injection and exhaust pipe 2. The inner wall of the upper plate 1 is processed with a grooved composite pin-fin structure 4 and coated with There are low surface energy substances, the liquid injection and exhaust pipe 2 cooperates with the opening 5 of the upper and lower plates, the inner wall of the lower plate 3 is processed with a grooved composite pin-fin structure 4, and the upper plate 1 of the flat heat pipe is a condensation section , The lower plate 3 is the evaporating section, and the section between the two is called the adiabatic section.

[0025] (2) Place the copper plate whose surface has been cleaned and dried on the workbench of the multifunctional laser, and focus it well.

[0026] (3) According to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com