Patents

Literature

508results about "Exothermal chemical reaction heat production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

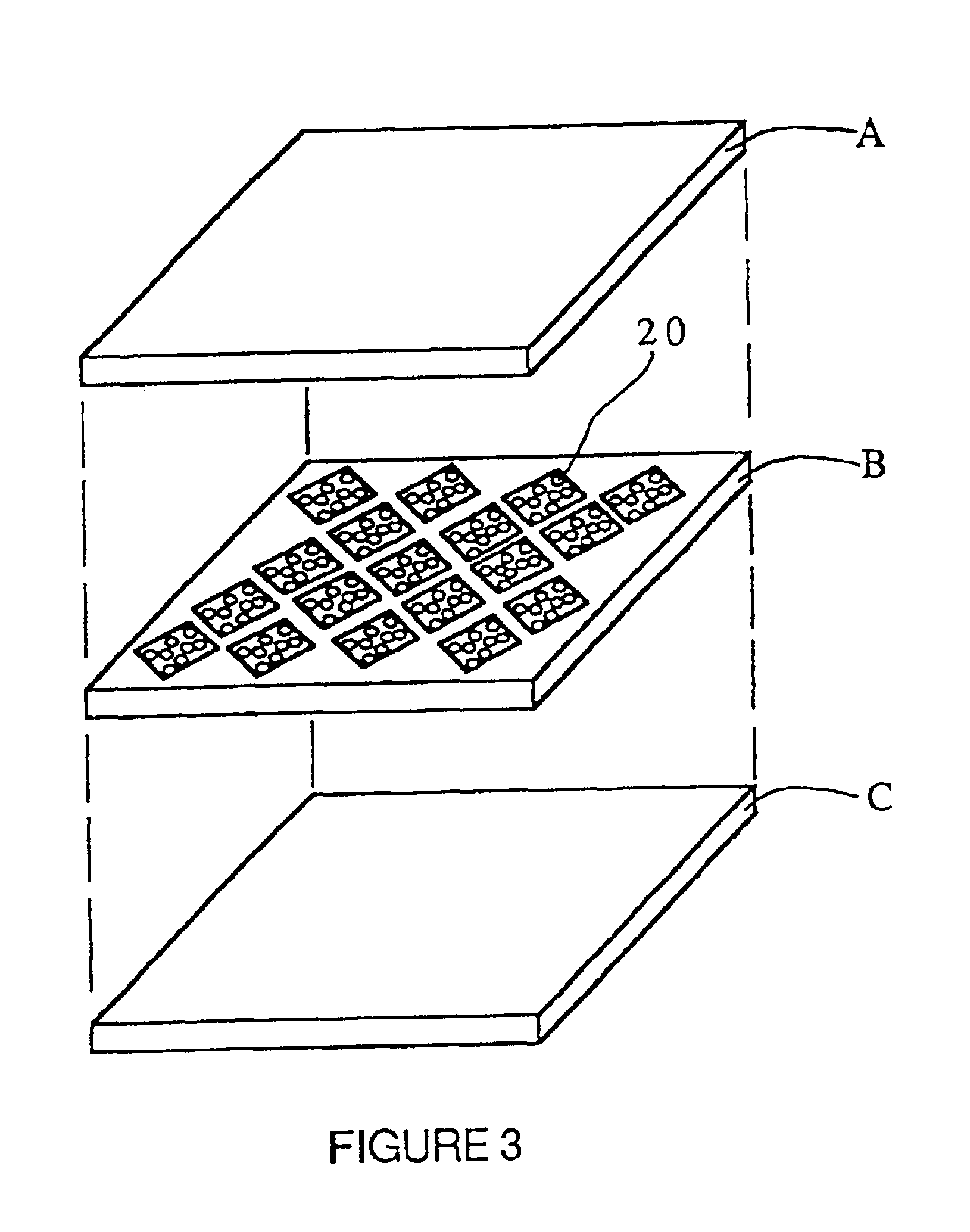

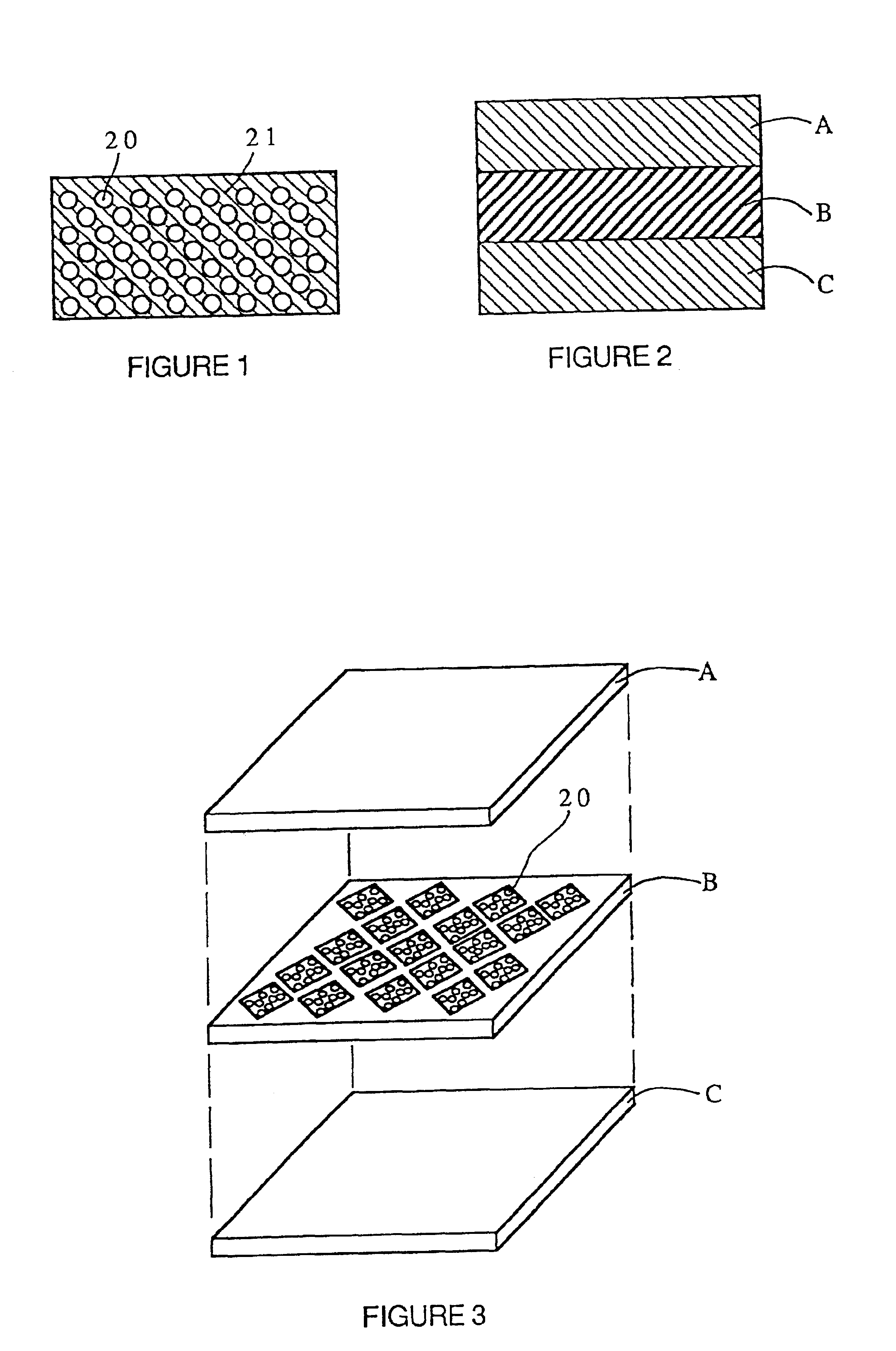

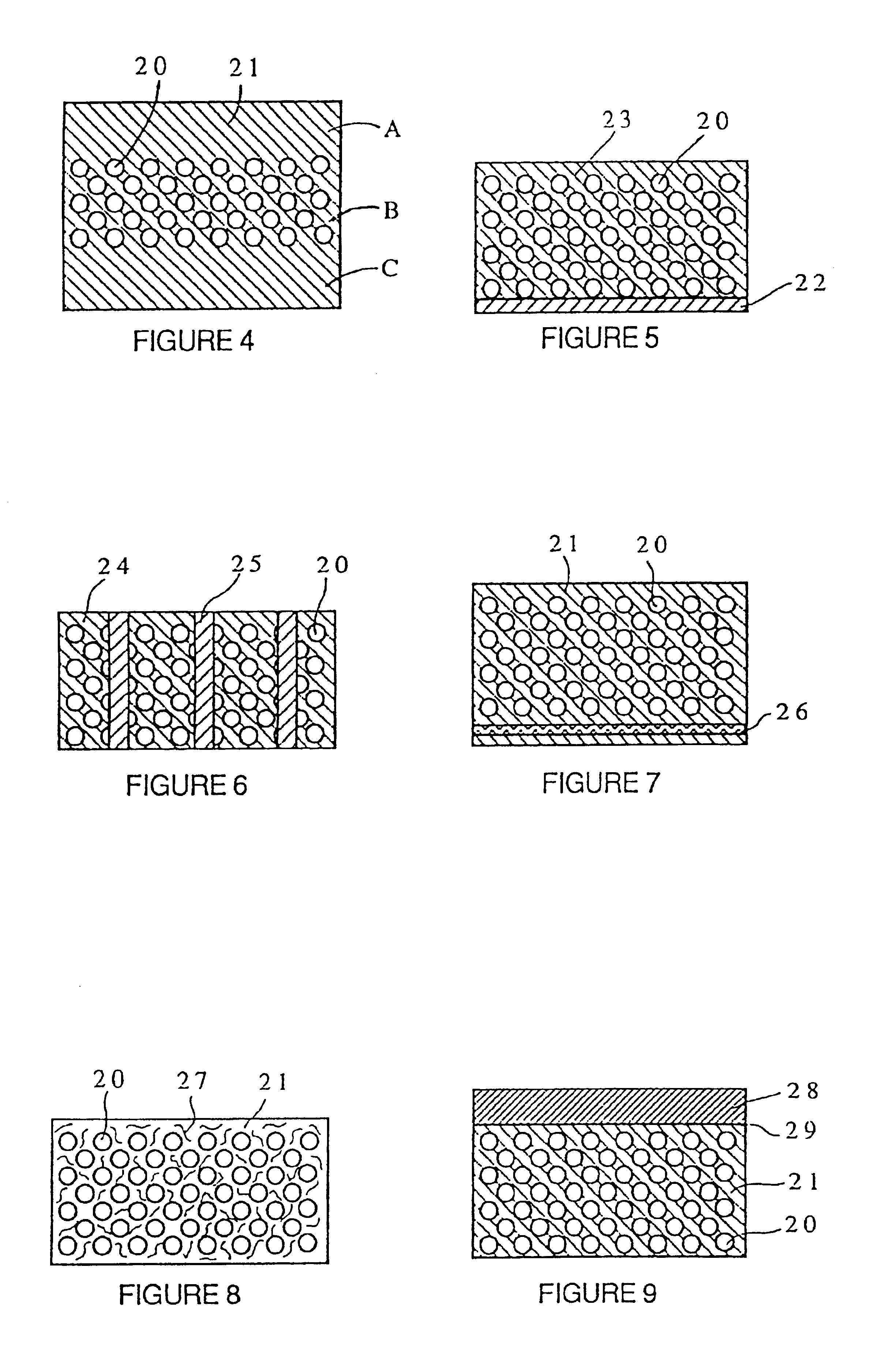

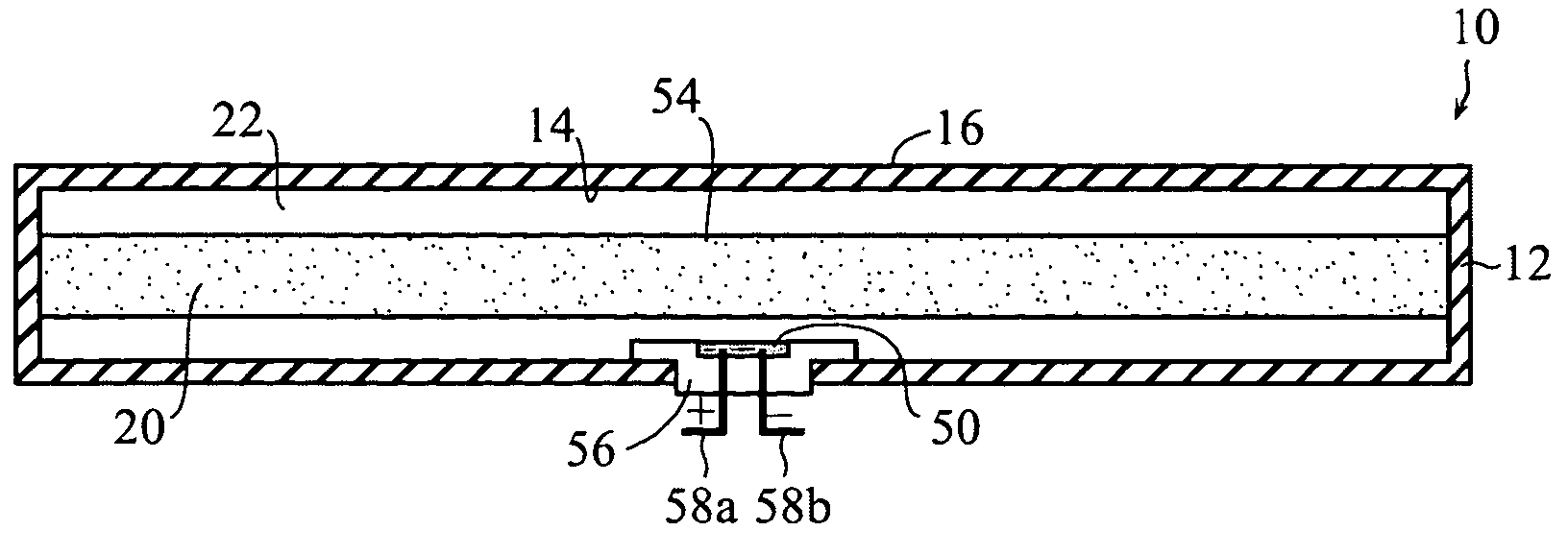

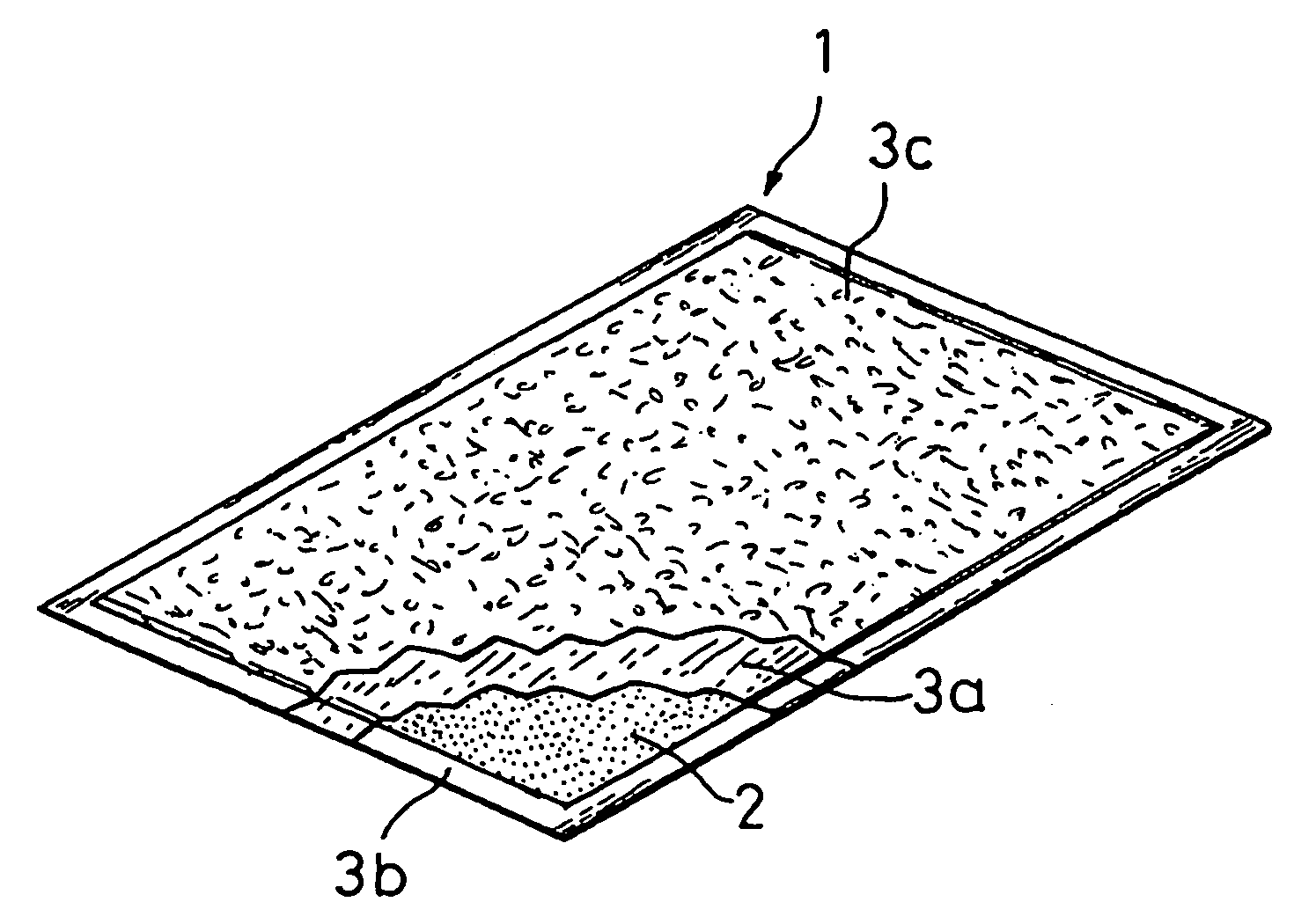

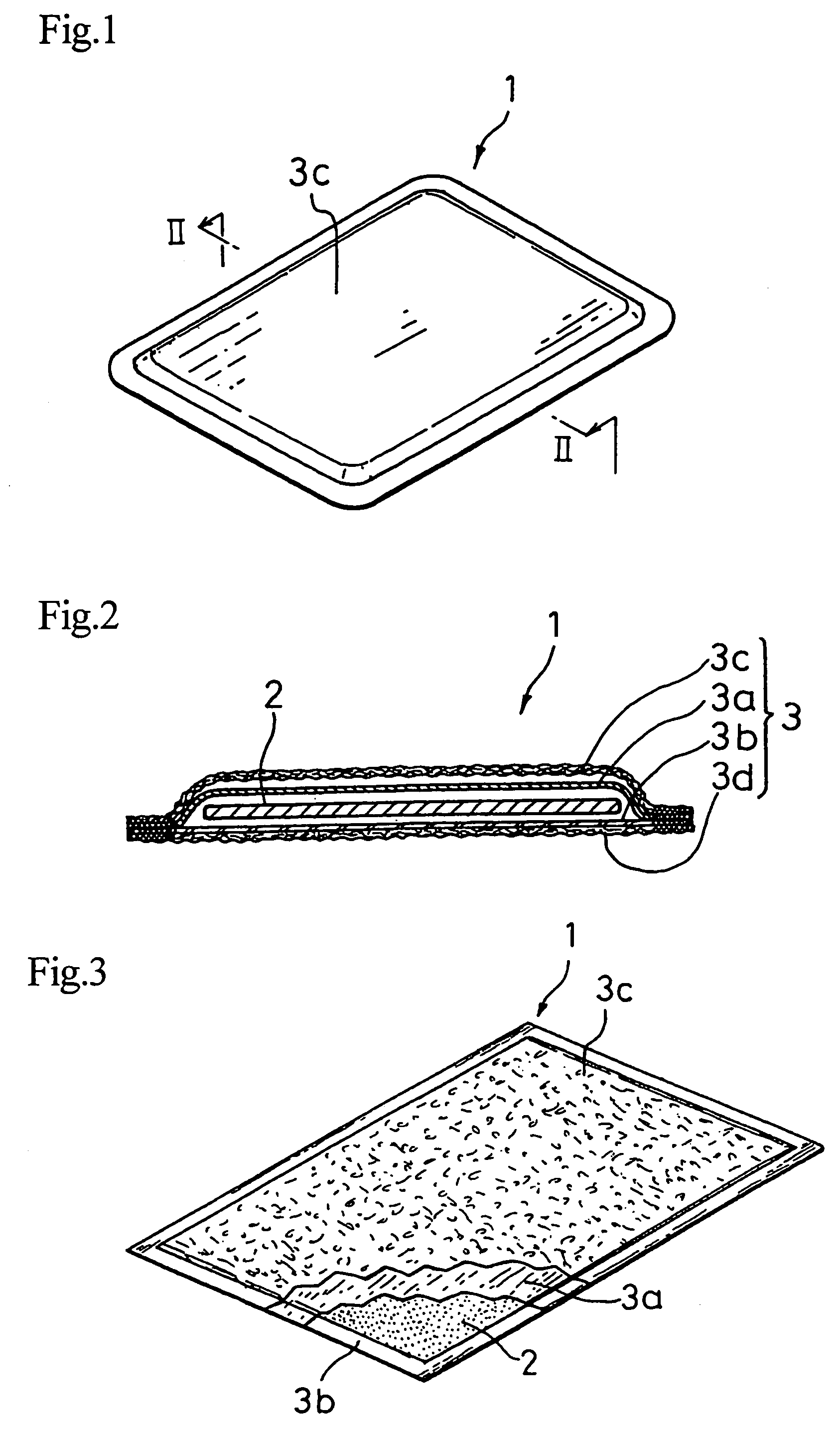

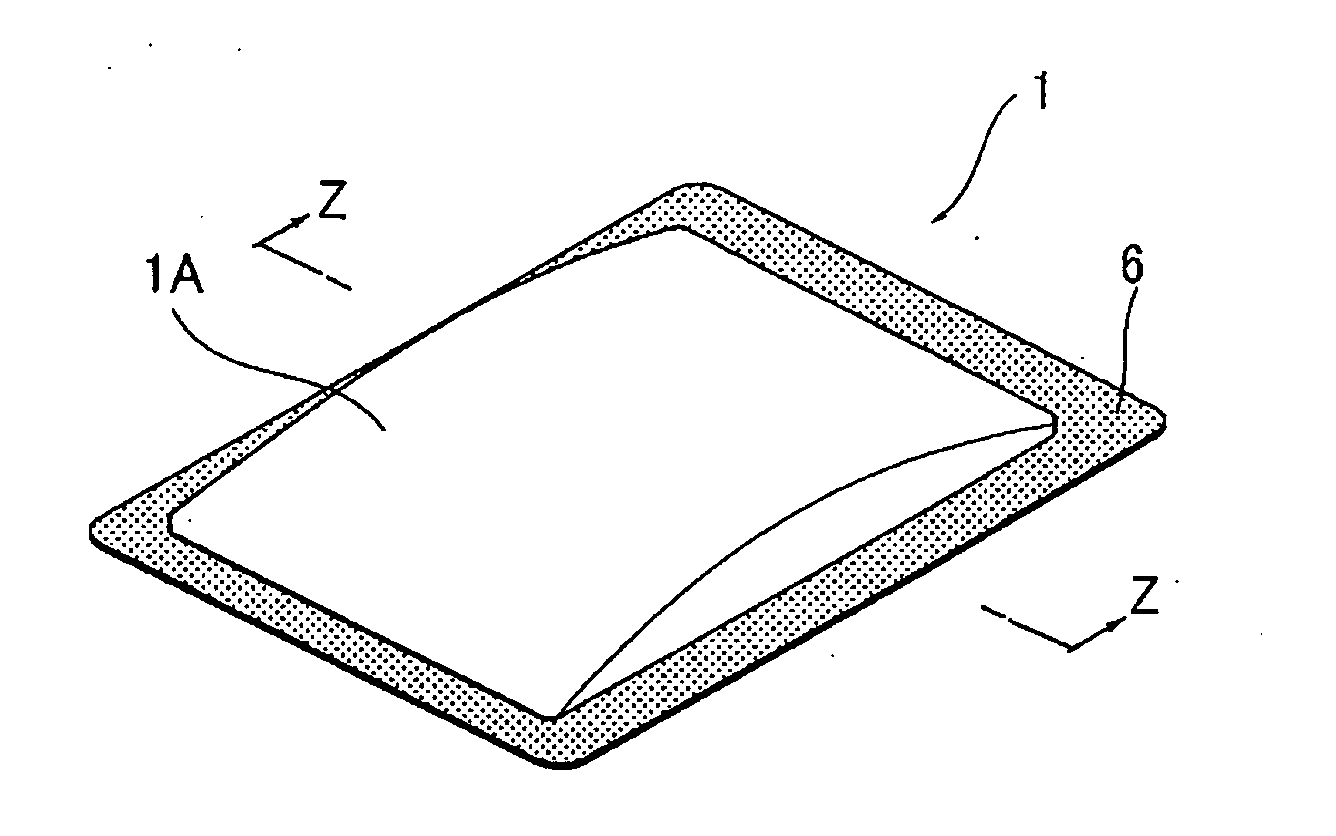

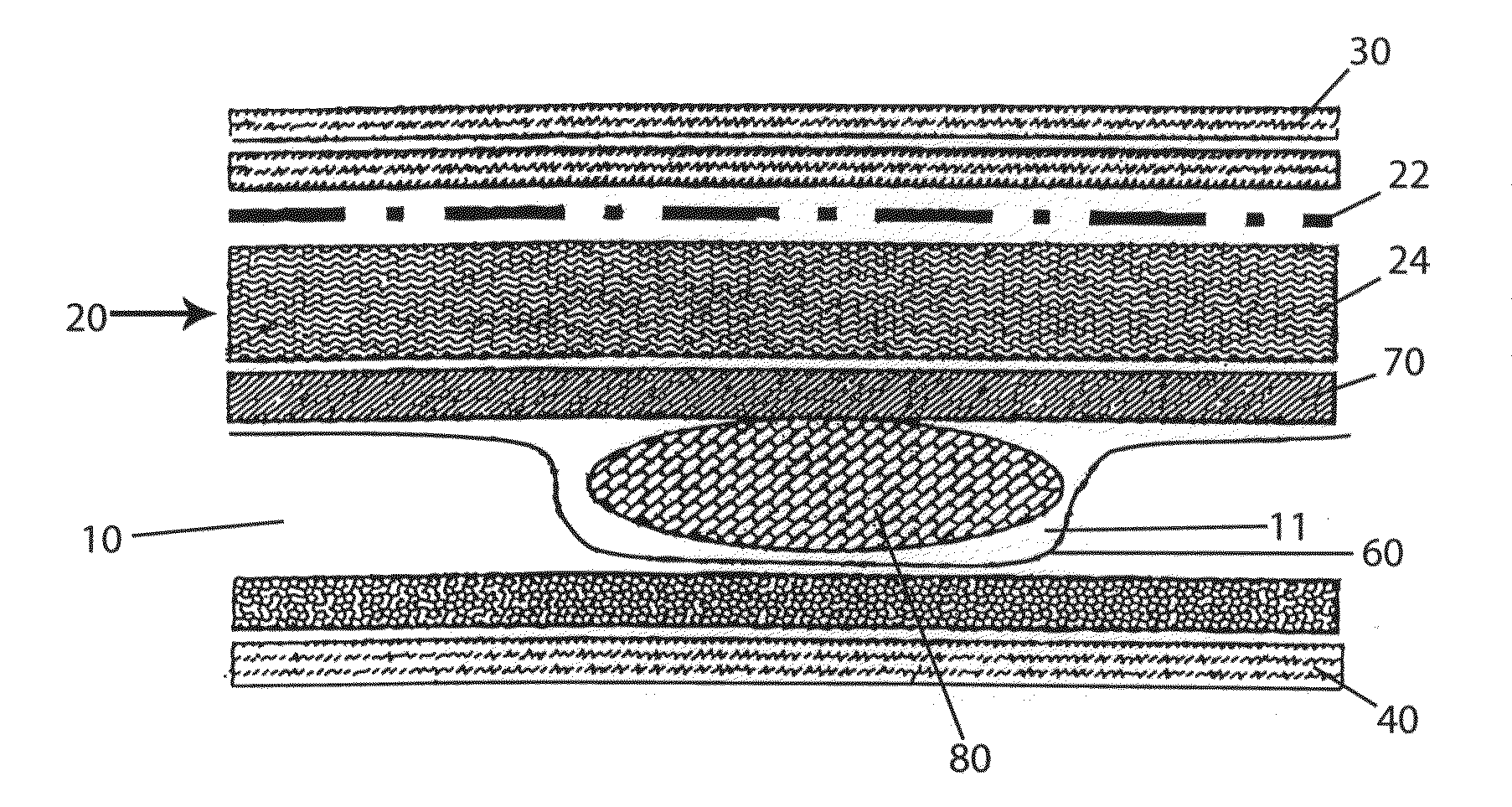

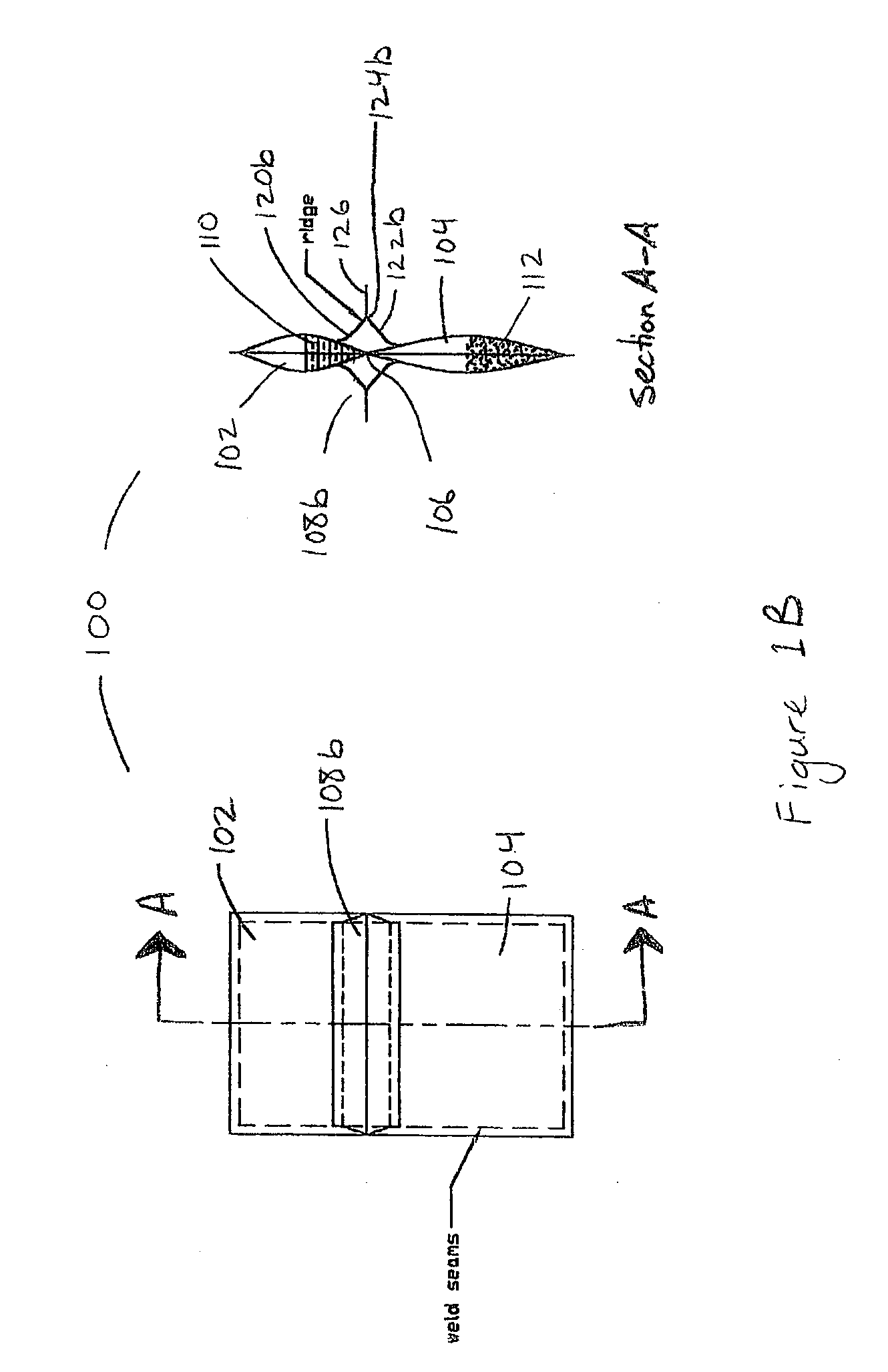

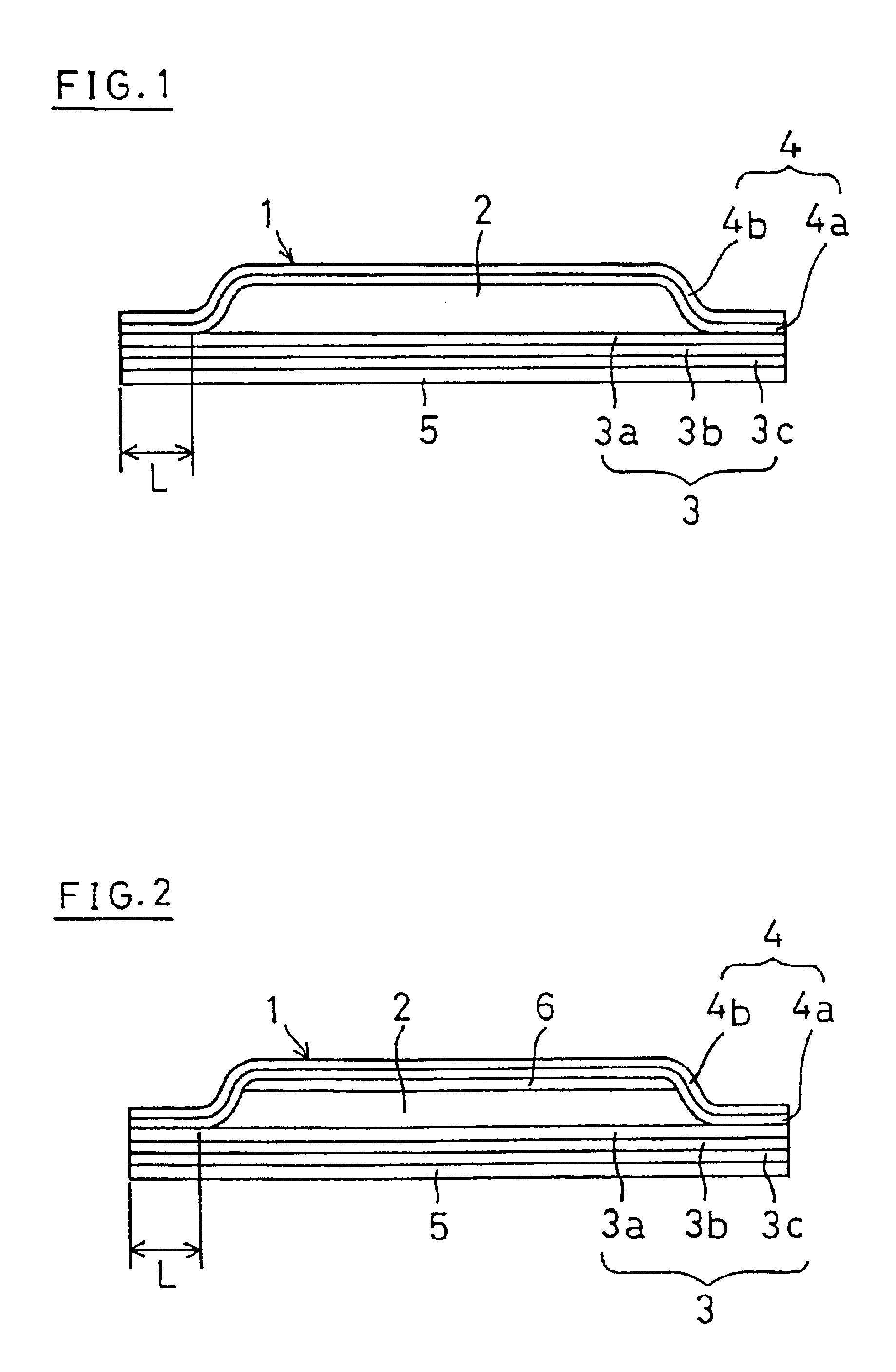

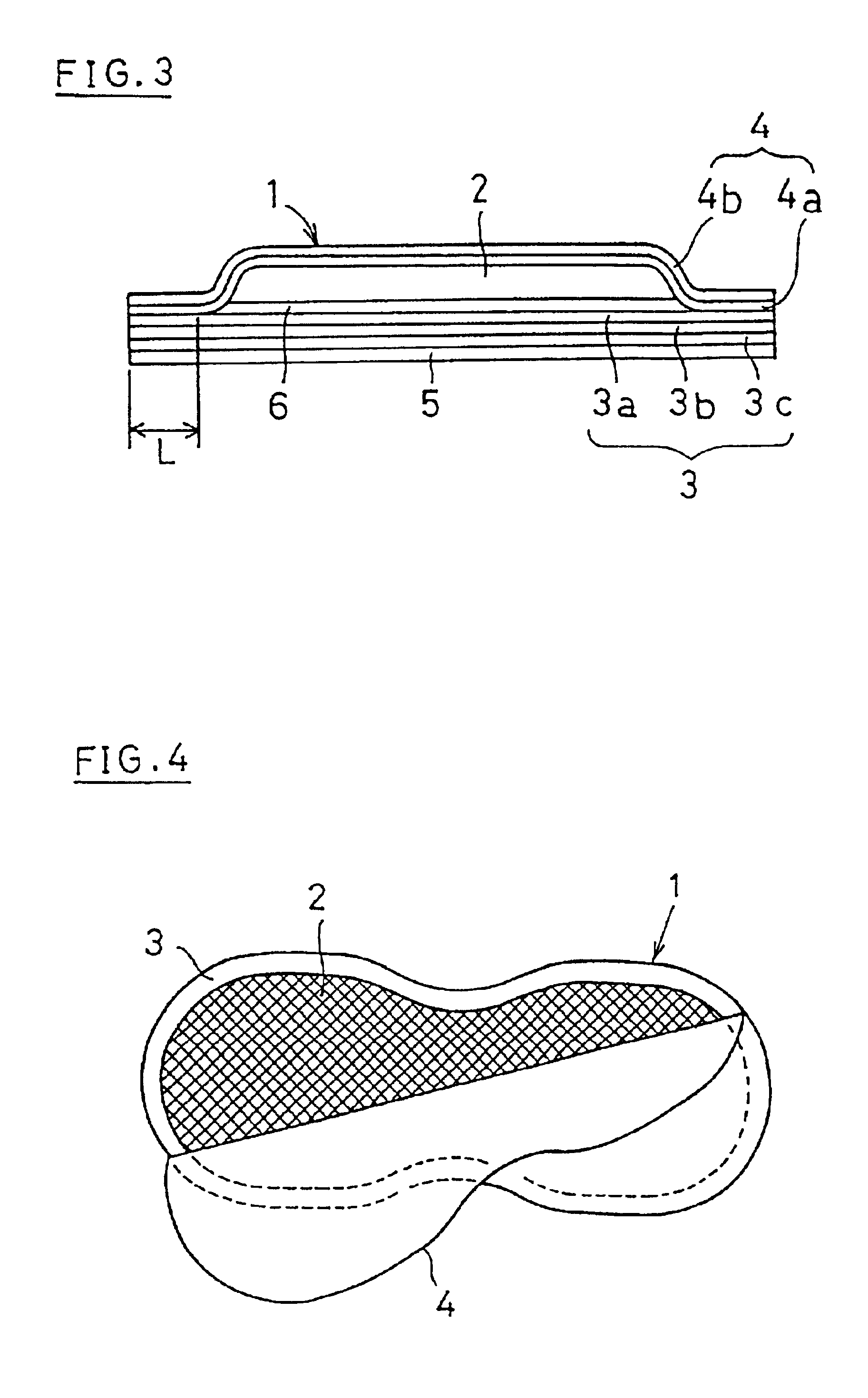

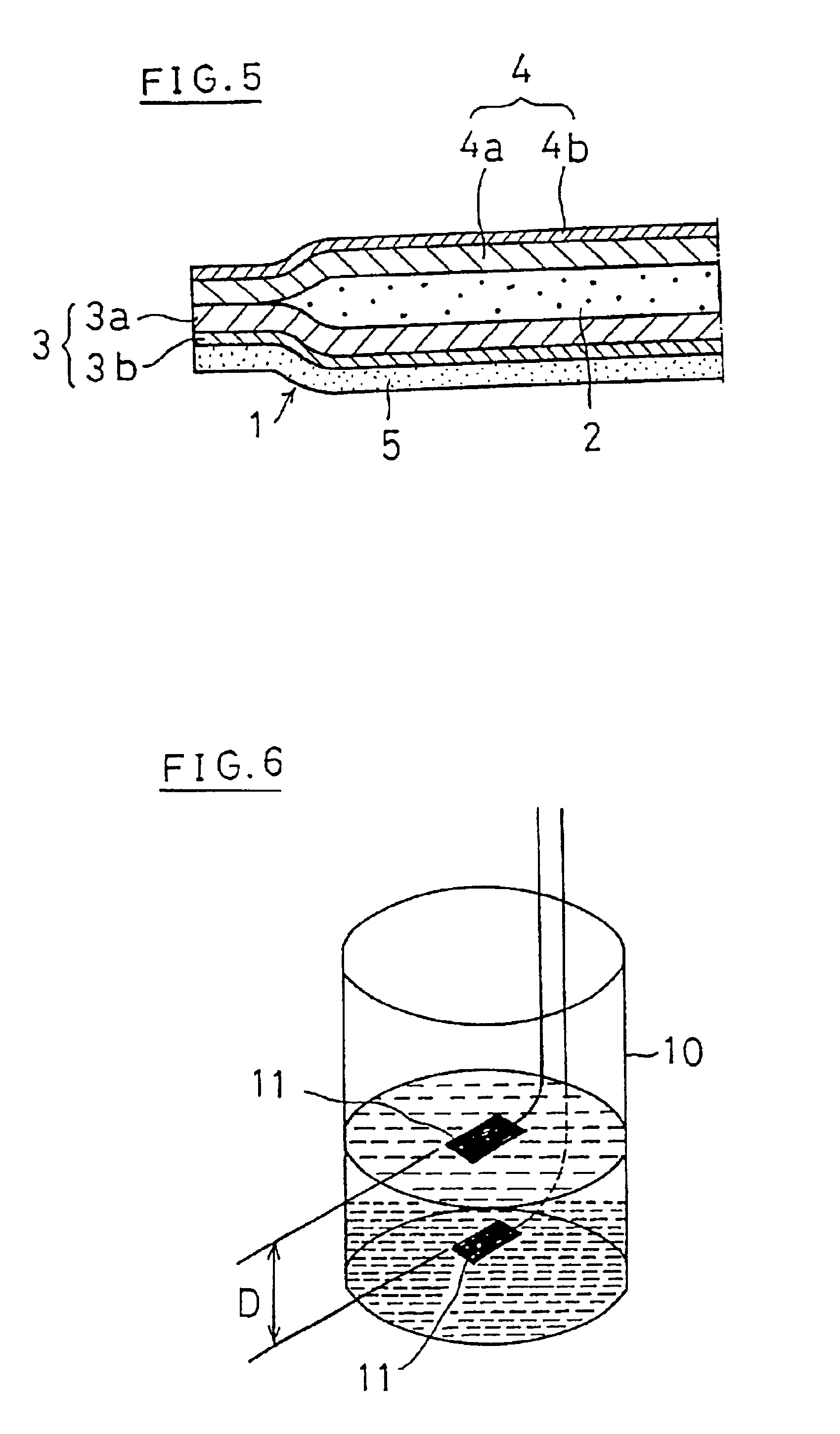

Phase change material thermal capacitor clothing

InactiveUS6855410B2Good thermal controlFast regenerationExothermal chemical reaction heat productionNatural cellulose pulp/paperSOCKSThermal insulation

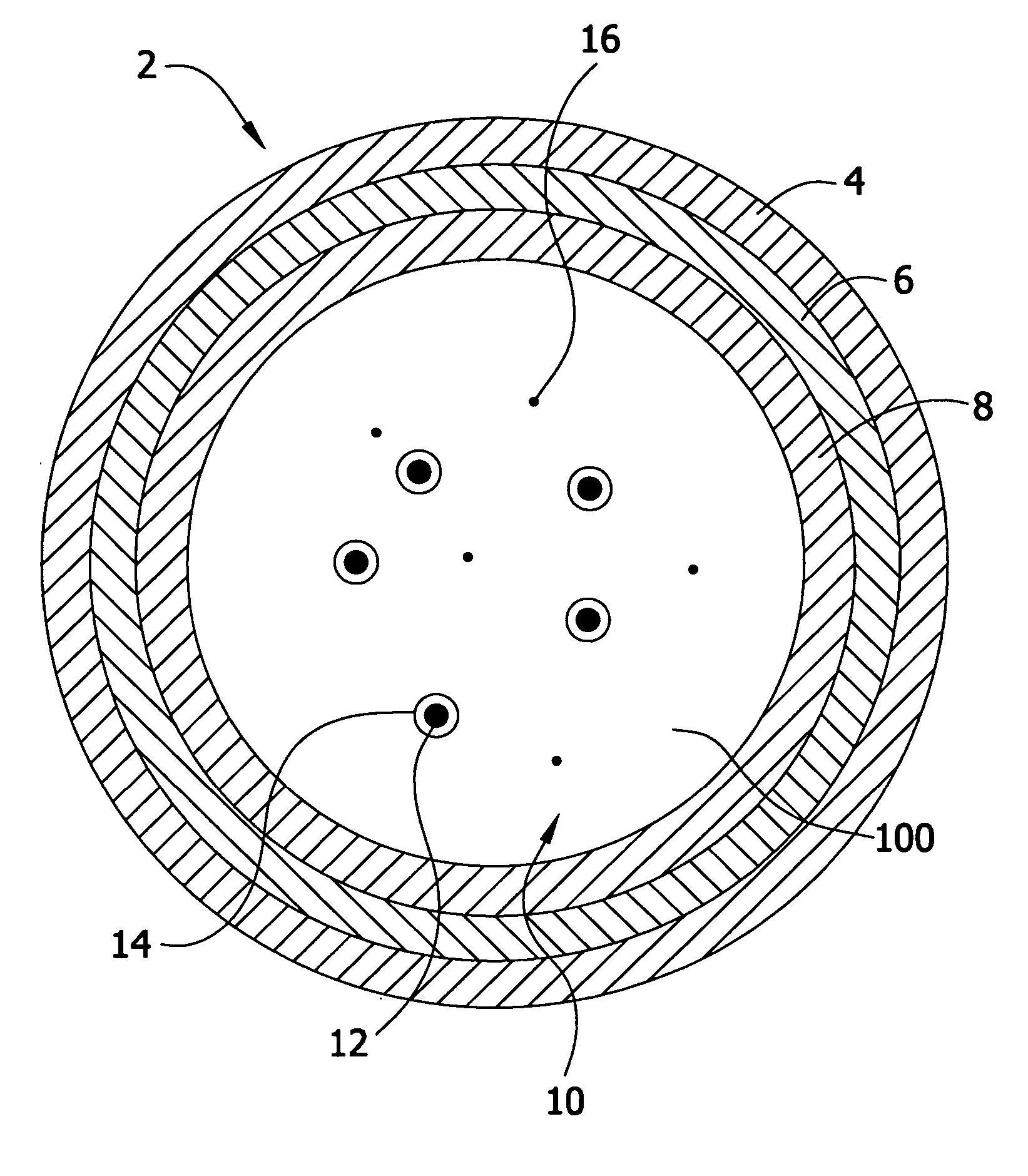

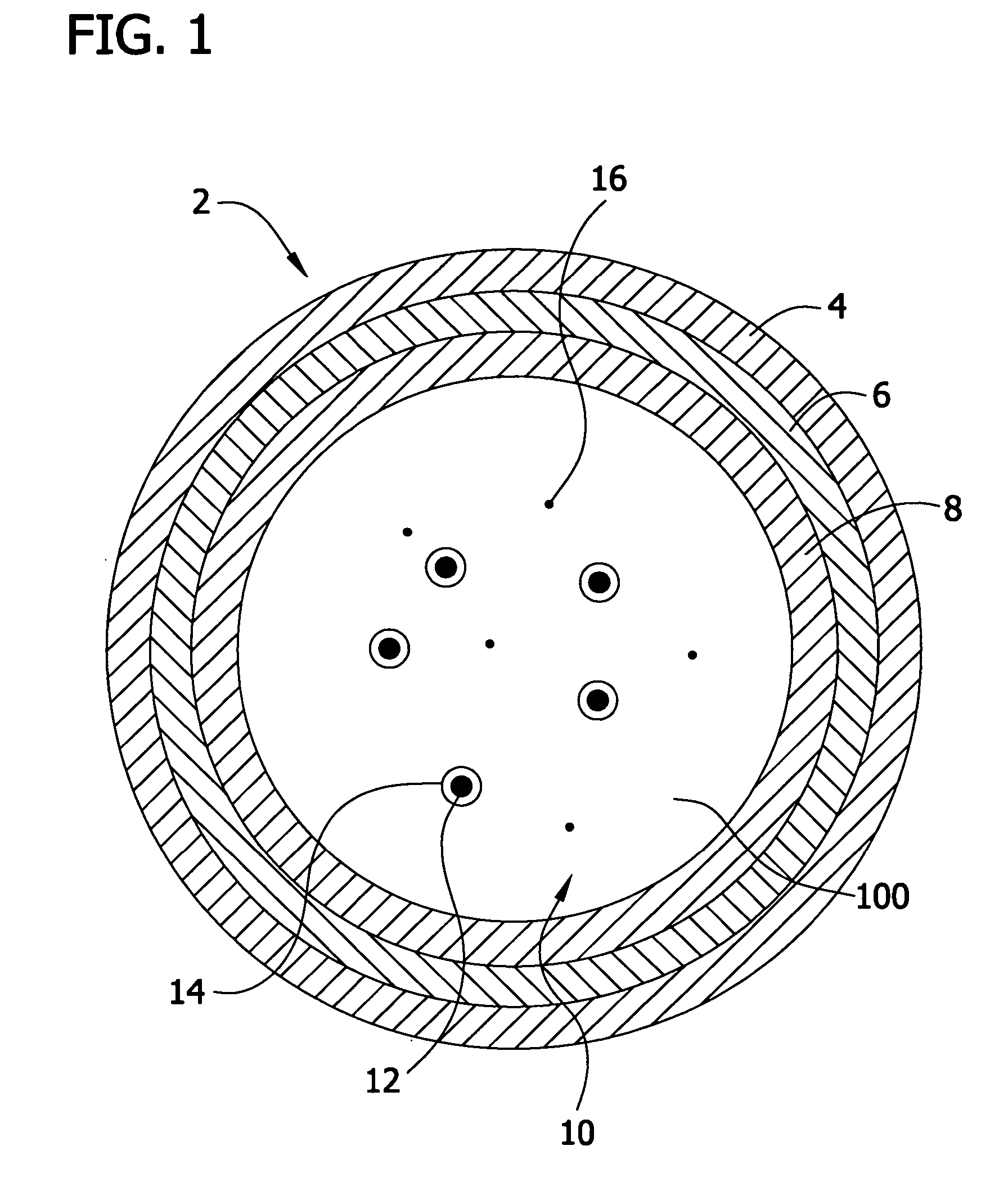

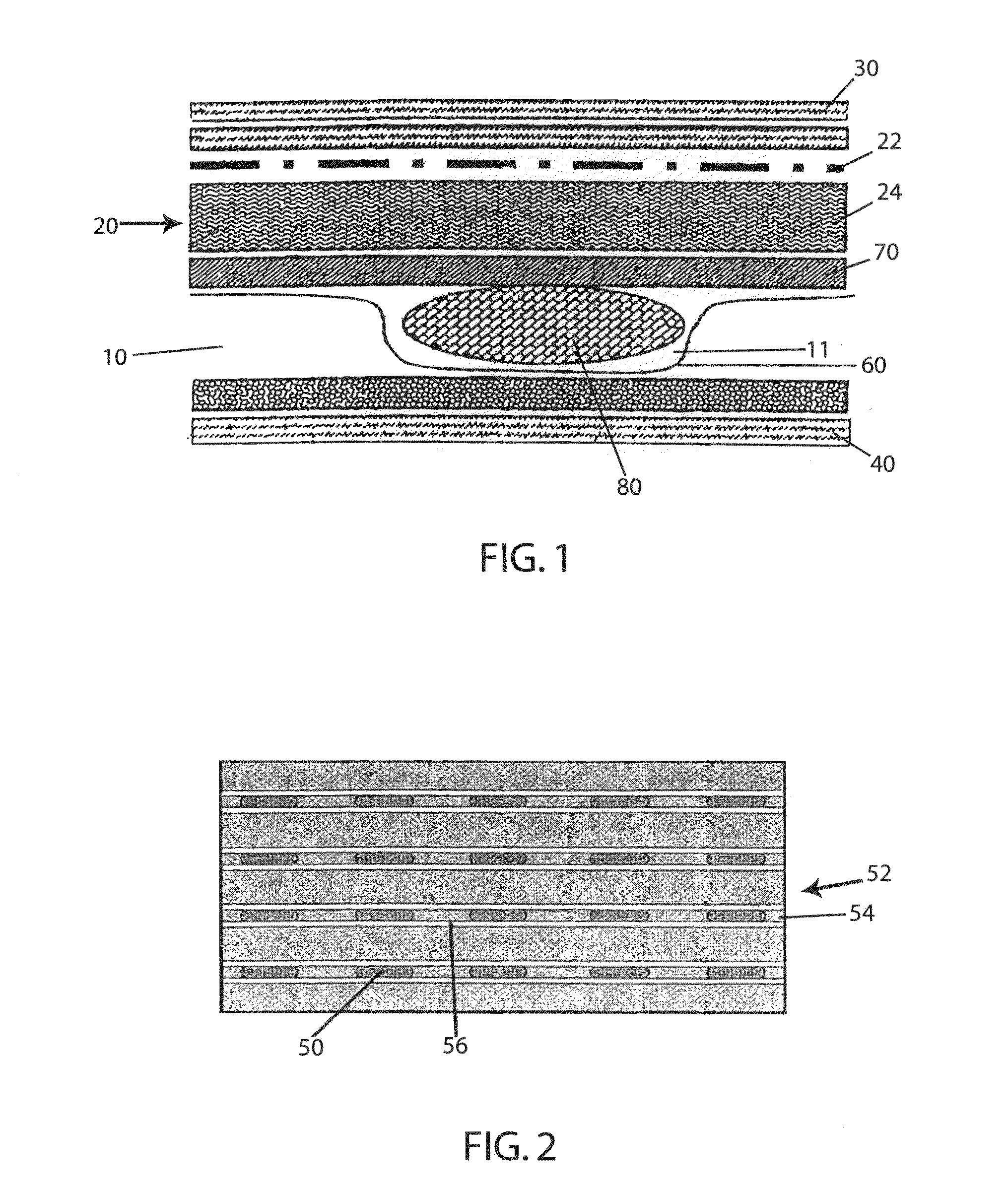

An apparatus and method for metabolic cooling and insulation of a user in a cold environment. In its preferred embodiment the apparatus is a highly flexible composite material having a flexible matrix containing a phase change thermal storage material. The apparatus can be made to heat or cool the body or to act as a thermal buffer to protect the wearer from changing environmental conditions. The apparatus may also include an external thermal insulation layer and / or an internal thermal control layer to regulate the rate of heat exchange between the composite and the skin of the wearer. Other embodiments of the apparatus also provide 1) a path for evaporation or direct absorption of perspiration from the skin of the wearer for improved comfort and thermal control, 2) heat conductive pathways within the material for thermal equalization, 3) surface treatments for improved absorption or rejection of heat by the material, and 4) means for quickly regenerating the thermal storage capacity for reuse of the material. Applications of the composite materials are also described which take advantage of the composite's thermal characteristics. The examples described include a diver's wet suit, ski boot liners, thermal socks, gloves and a face mask for cold weather activities, and a metabolic heating or cooling blanket useful for treating hypothermia or fever patients in a medical setting and therapeutic heating or cooling orthopedic joint supports.

Owner:BUCKLEY THERESA M

Self-contained heating unit and drug-supply unit employing same

InactiveUS20050079166A1Exothermal chemical reaction heat productionSemiconductor/solid-state device manufacturingSolid fuelEngineering

Heating units, drug supply units and drug delivery articles capable of rapid heating are disclosed. Heating units comprising a substrate and a solid fuel capable of undergoing an exothermic metal oxidation reaction disposed within the substrate are disclosed. Drug supply units and drug delivery articles wherein a solid fuel is configured to heat a substrate to a temperature sufficient to rapidly thermally vaporize a drug disposed thereon are also disclosed.

Owner:ALEXZA PHARMA INC

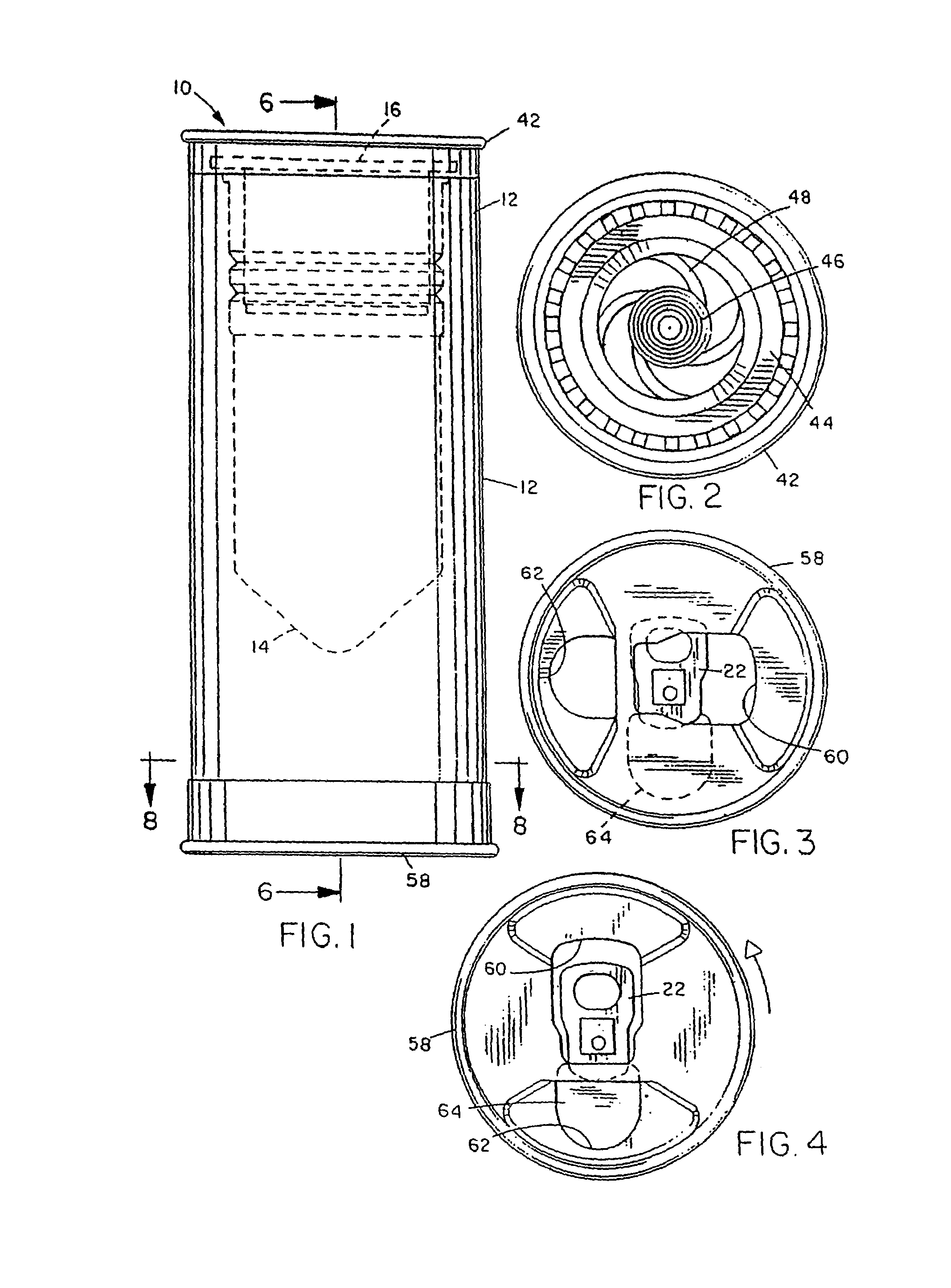

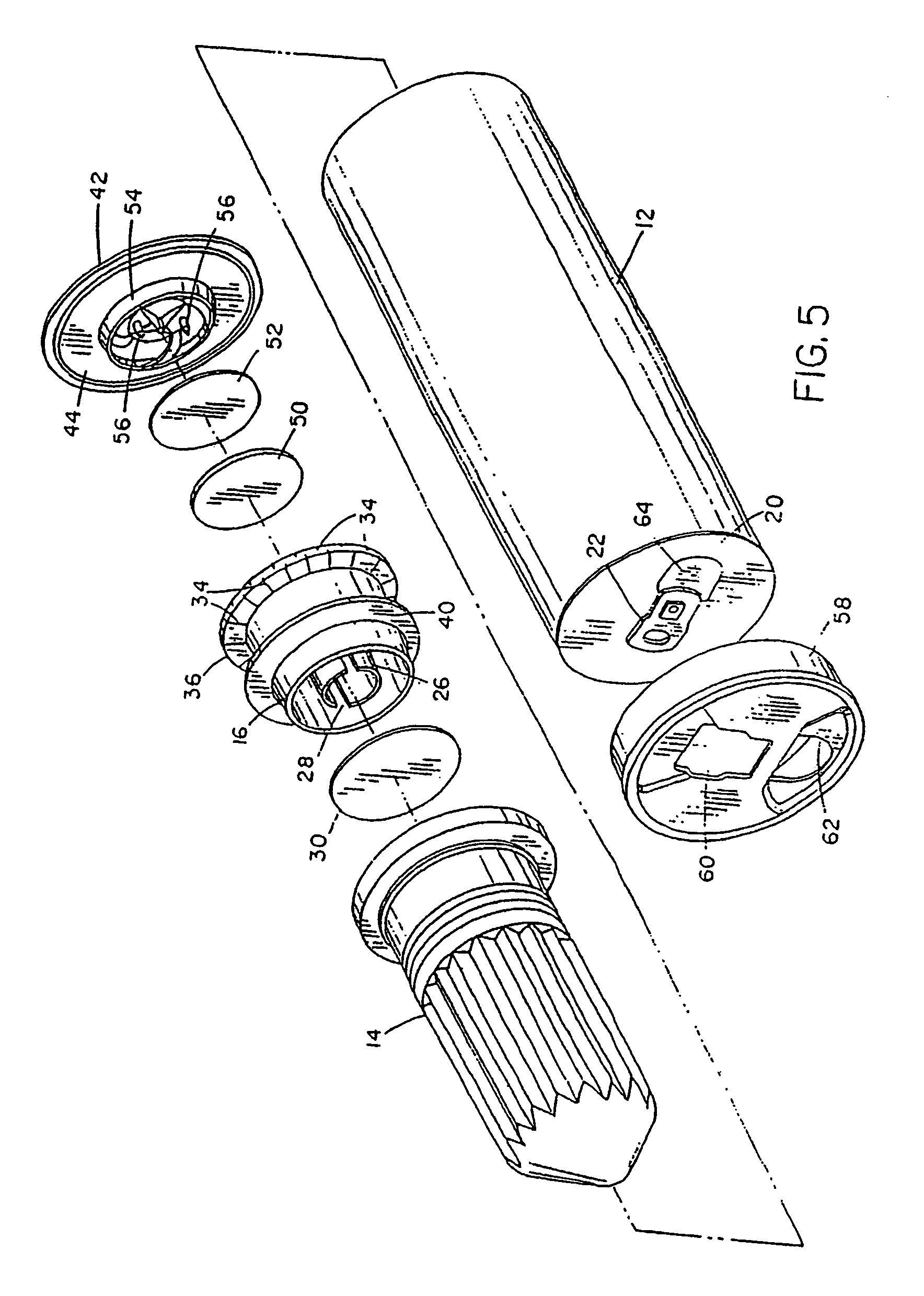

Portable beverage bottle heaters and coolers

InactiveUS20080178865A1Less-costly to implementExothermal chemical reaction heat productionDomestic cooling apparatusEngineeringBottle

A portable temperature changing apparatus for containers includes a cylindrical annular moisture-proof pouch divided into a first compartment filled with a liquid and a second separate compartment holding a solid material capable of producing an endothermic or exothermic reaction upon mixing with the liquid. The seal separating the two separate compartments can be ruptured partially, when desired, enabling communication of the liquid with the solid to activate the temperature altering reaction. A flexible foam insulating layer surrounds the exterior of the annular cylindrical pouch providing insulation, damage protection, and labeling.

Owner:RETTERER SHELLEY

Portable heat source

InactiveUS6248257B1Excursion can be restrictedPromotes even distributionExothermal chemical reaction heat productionOther chemical processesAqueous solutionAcid anhydride

A portable heat source that may be used to warm food, beverage or other supplies. The heater contains a heat-producing composition that is a solid that may be stored for long periods of time, and activated by addition of water or an aqueous solution. Heat-producing compositions contain an acidic anhydride, an acidic salt, a basic anhydride or a basic salt. Preferred heat-producing compositions contain a mixture of an acidic anhydride or salt together with a basic anhydride or salt, such that addition of water to both acidic and basic anhydrides produces heat as well as acid and base respectively; subsequent reaction of the acid and base produces additional heat, as well as a safe, neutral product that is easily disposed. The invention further consists of means and methods for regulating the rate of heat production in heaters by the addition of inert additives to heat-producing compositions and the application of processing methods that regulate access of water to heat-producing compounds. Addition of inert materials and shaping, agglomerating, pelleting and like processing of heat-producing materials are applied to produced heat at a rate compatible with the rate at which the food or other materials can absorb the heat. The invention further consists of devices incorporating the materials to be heated in an advantageous arrangement with the heater composition.

Owner:TDA RES

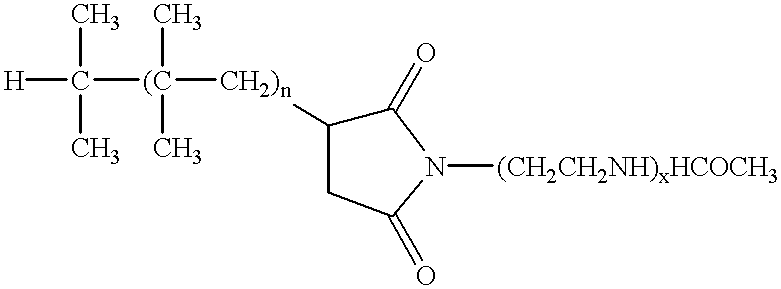

Delivery of drug esters through an inhalation route

The present invention relates to the delivery of drug esters through an inhalation route. Specifically, it relates to aerosols containing drug esters that are used in inhalation therapy. In a method aspect of the present invention, a drug ester is delivered to a patient through an inhalation route. The method comprises: a) heating a coating of a drug ester, on a solid support, to form a vapor; and, b) passing air through the heated vapor to produce aerosol particles having less than 5% drug ester degradation product. In a kit aspect of the present invention, a kit for delivering a drug ester through an inhalation route is provided which comprises: a) a thin coating of a drug ester composition and b) a device for dispensing said thin coating as a condensation aerosol.

Owner:ALEXZA PHARMA INC

Delivery of drug esters through an inhalation route

The present invention relates to the delivery of drug esters through an inhalation route. Specifically, it relates to aerosols containing drug esters that are used in inhalation therapy. In a method aspect of the present invention, a drug ester is delivered to a patient through an inhalation route. The method comprises: a) heating a composition, wherein the composition comprises a drug ester, to form a vapor; and, b) allowing the vapor to cool, thereby forming a condensation aerosol comprising particles with less than 5% drug ester degradation product. In a kit aspect of the present invention, a kit for delivering a drug ester through an inhalation route is provided which comprises: a) a thin coating of a drug ester composition and b) a device for dispensing said thin coating as a condensation aerosol.

Owner:ALEXZA PHARMA INC

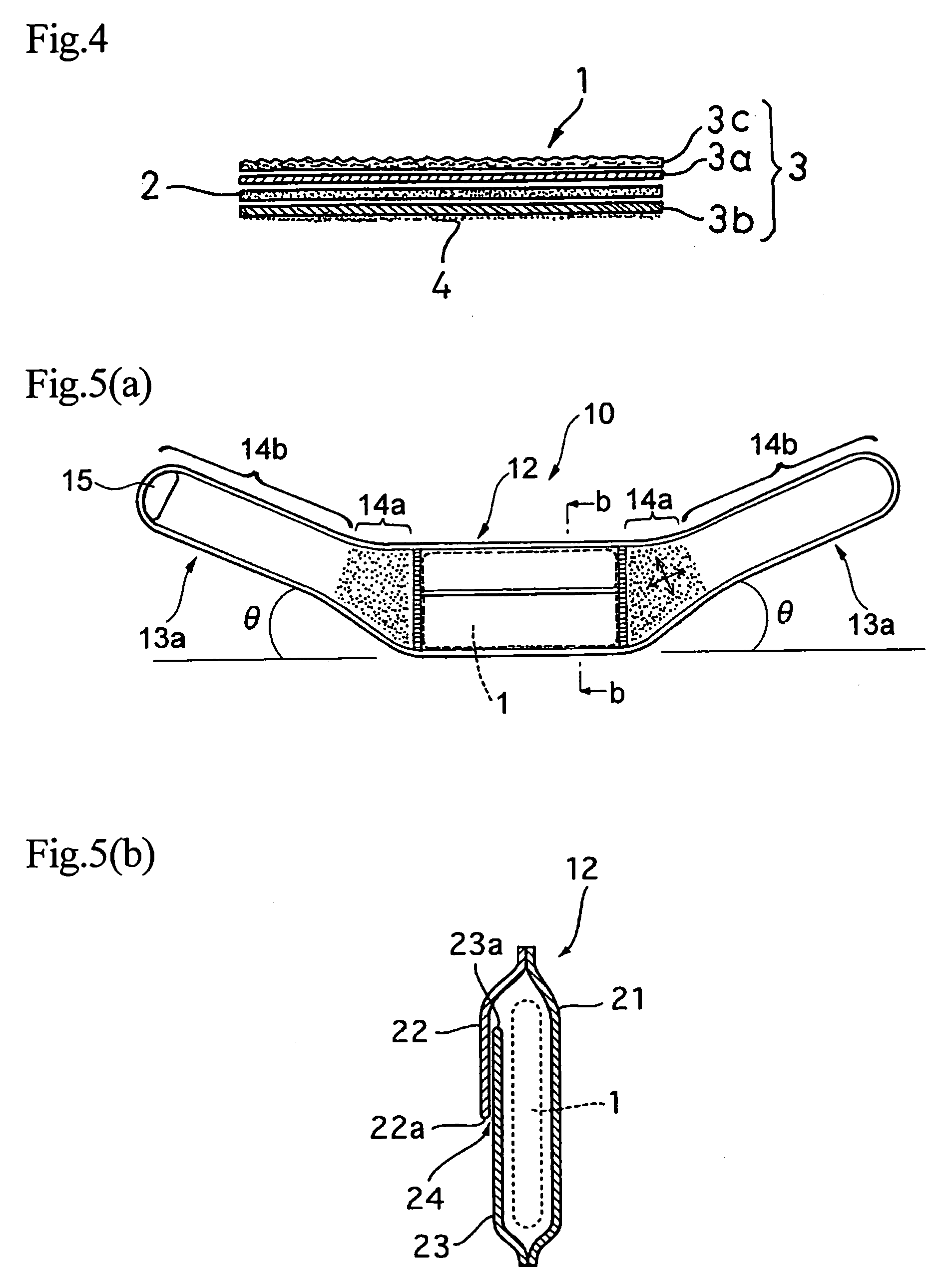

Steam-generating warming article

InactiveUS7652228B2Exothermal chemical reaction heat productionOther chemical processesFiberEngineering

Owner:KAO CORP

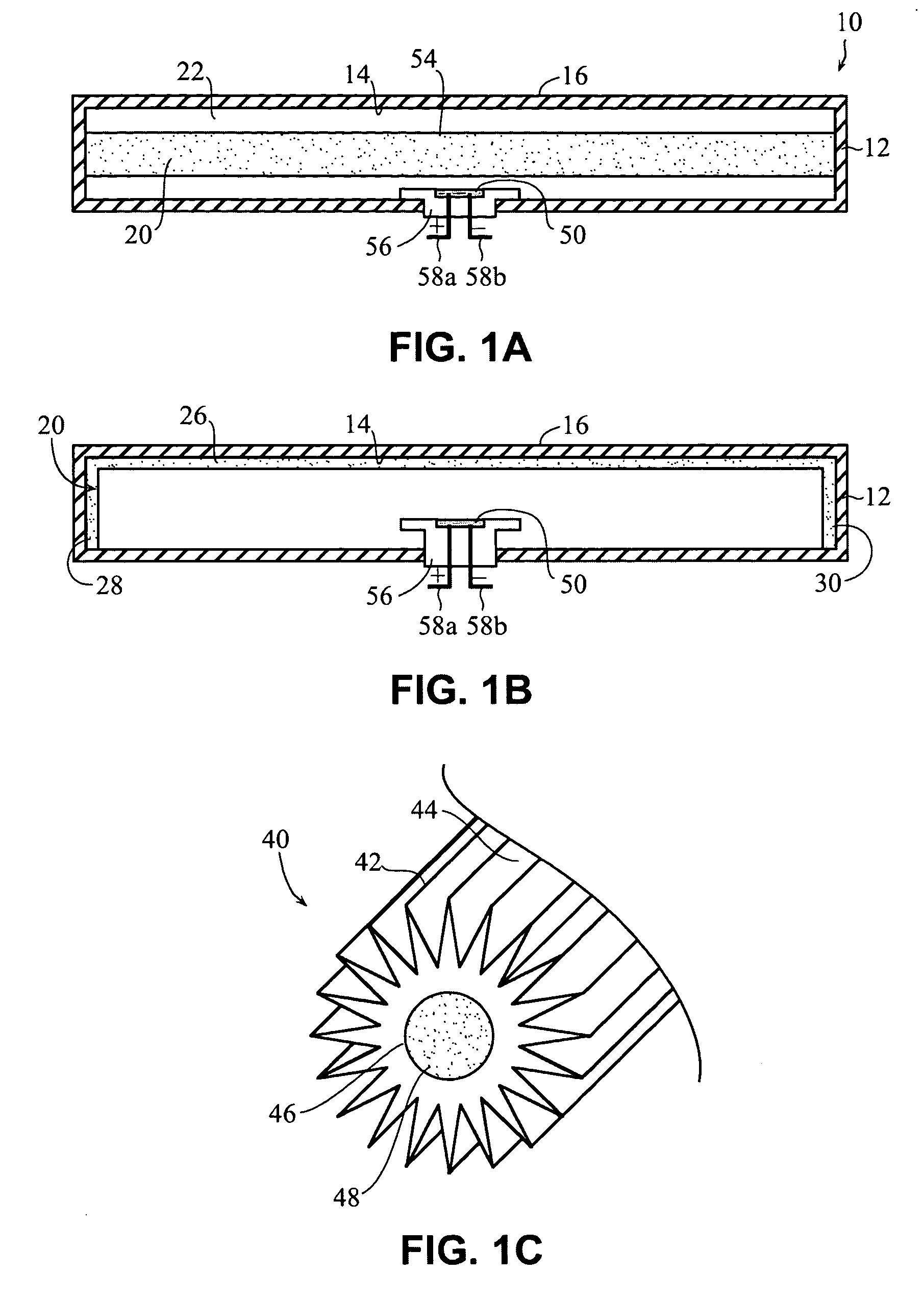

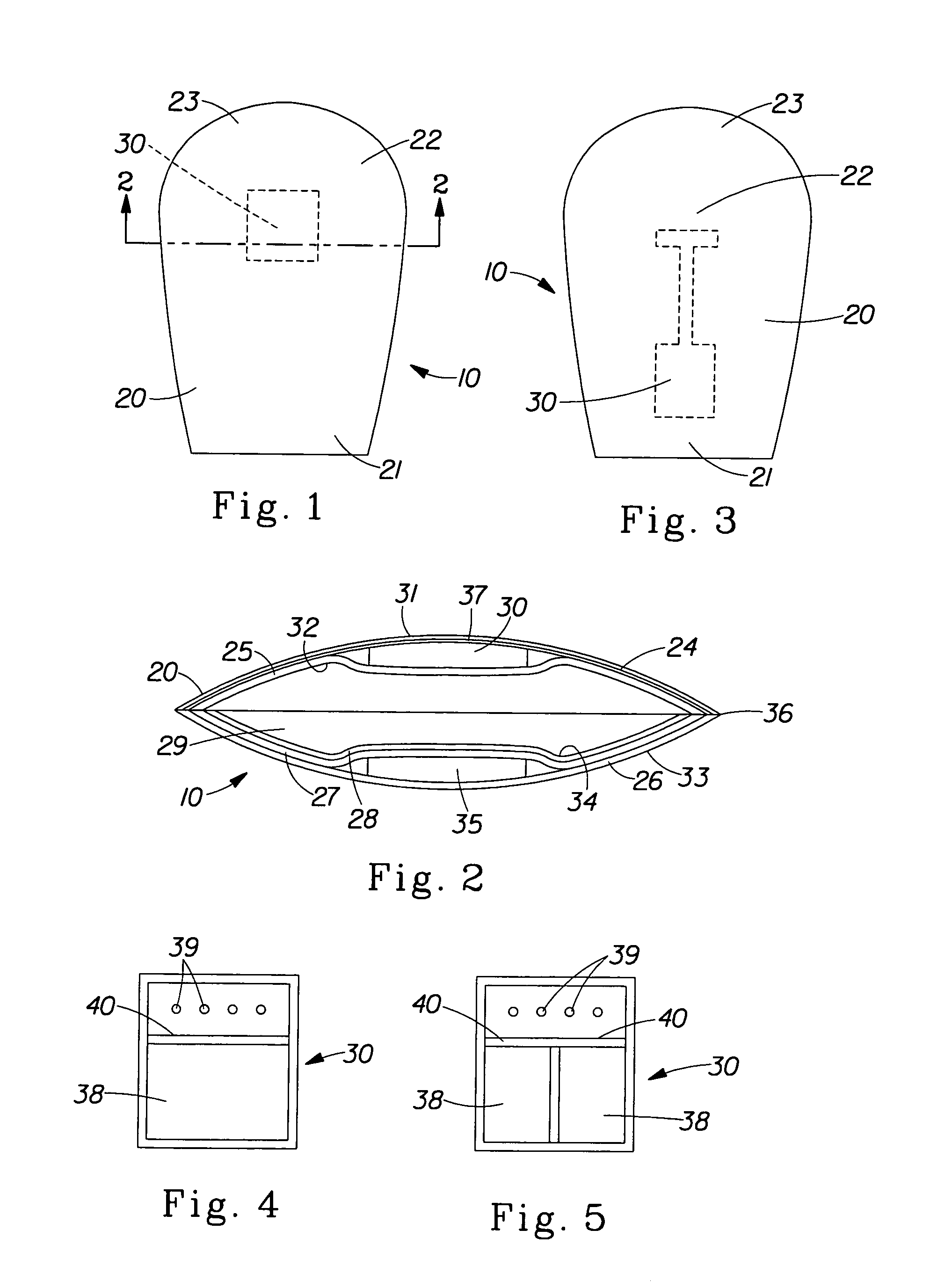

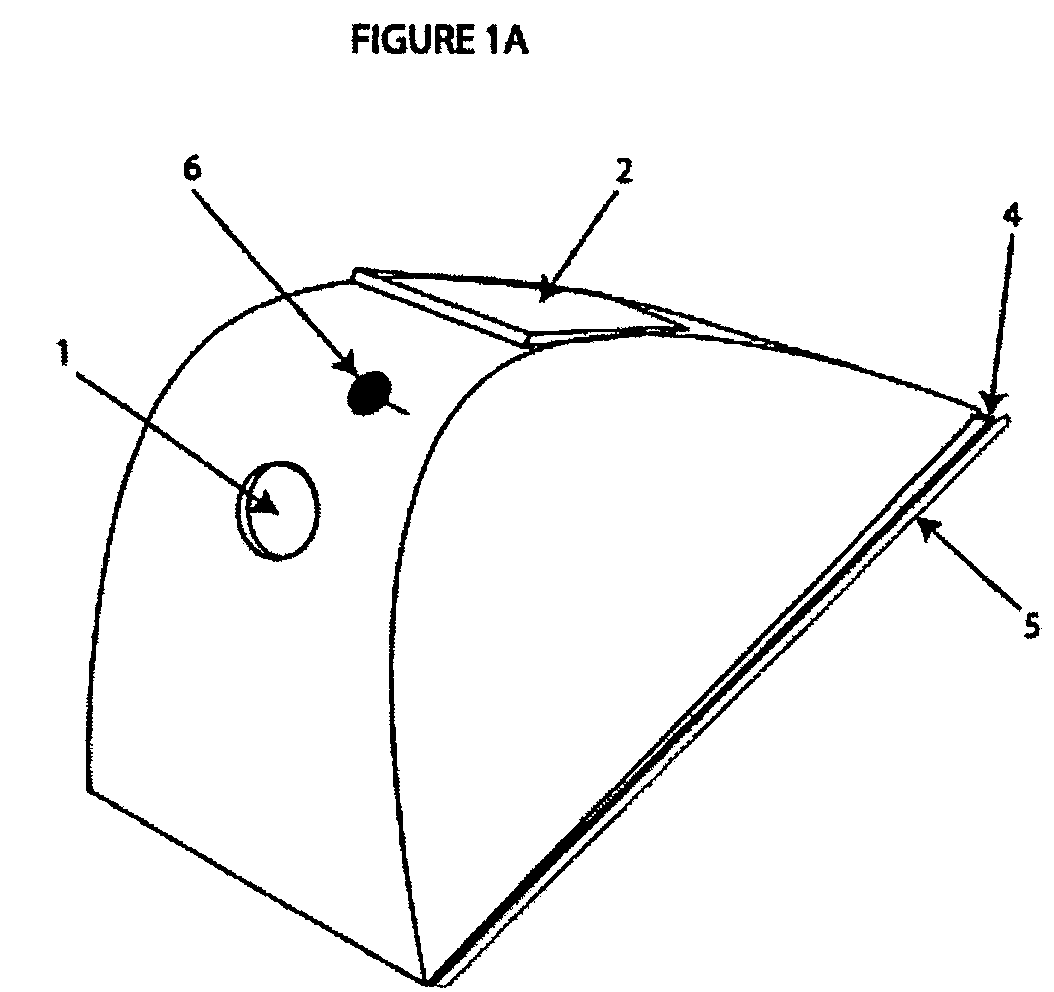

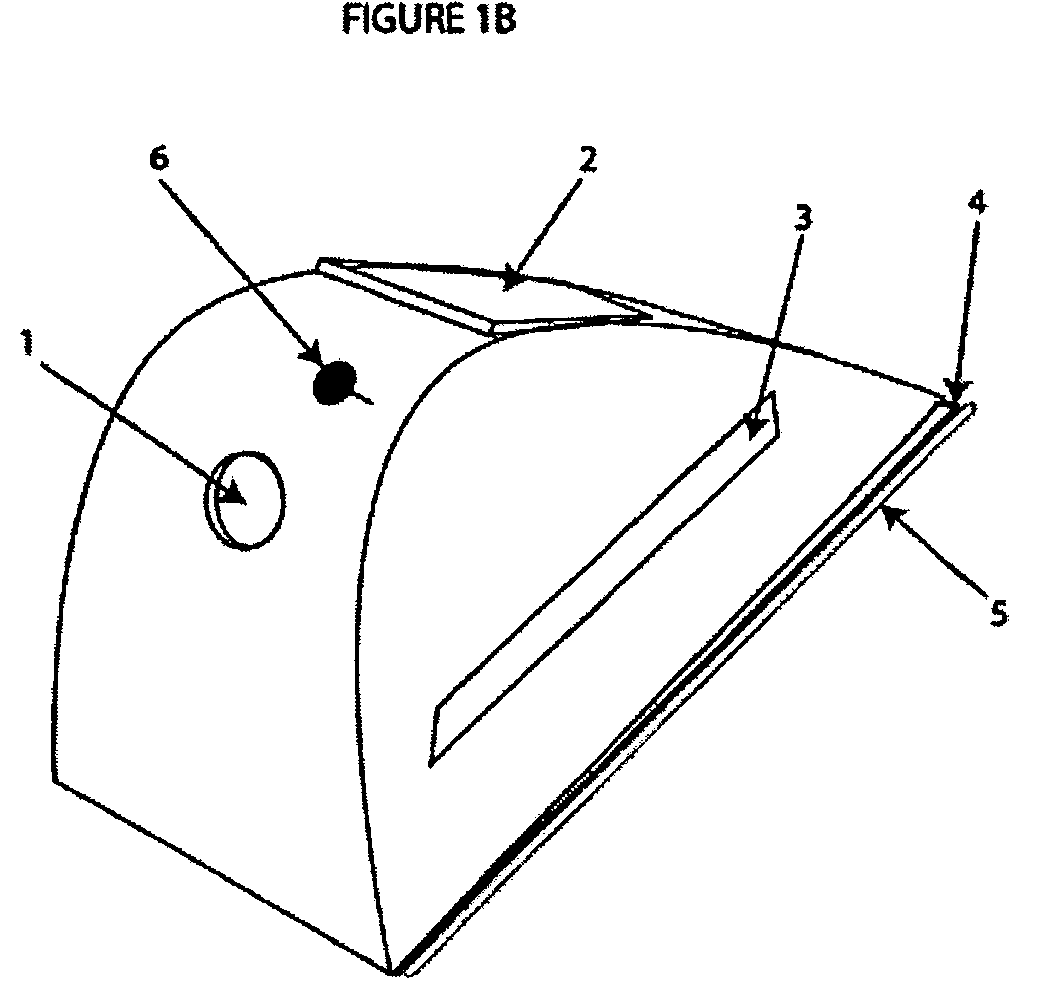

Semi-enclosed applicator having a temperature changing element

InactiveUS7021848B1Exothermal chemical reaction heat productionDomestic cooling apparatusTarget surfaceBiomedical engineering

A semi-enclosed applicator (10) for distributing a substance onto a target surface is disclosed having a first side (24) having a first internal surface (32) and a first external surface (31); a second side (26) having a second internal surface (34) and a second external surface (33); an internal cavity (29) between the first and second internal surfaces that is externally accessible, and a temperature changing element. The flexible film pouch (30) contains a product located proximately to the first side (24).

Owner:THE PROCTER & GAMBLE COMPANY

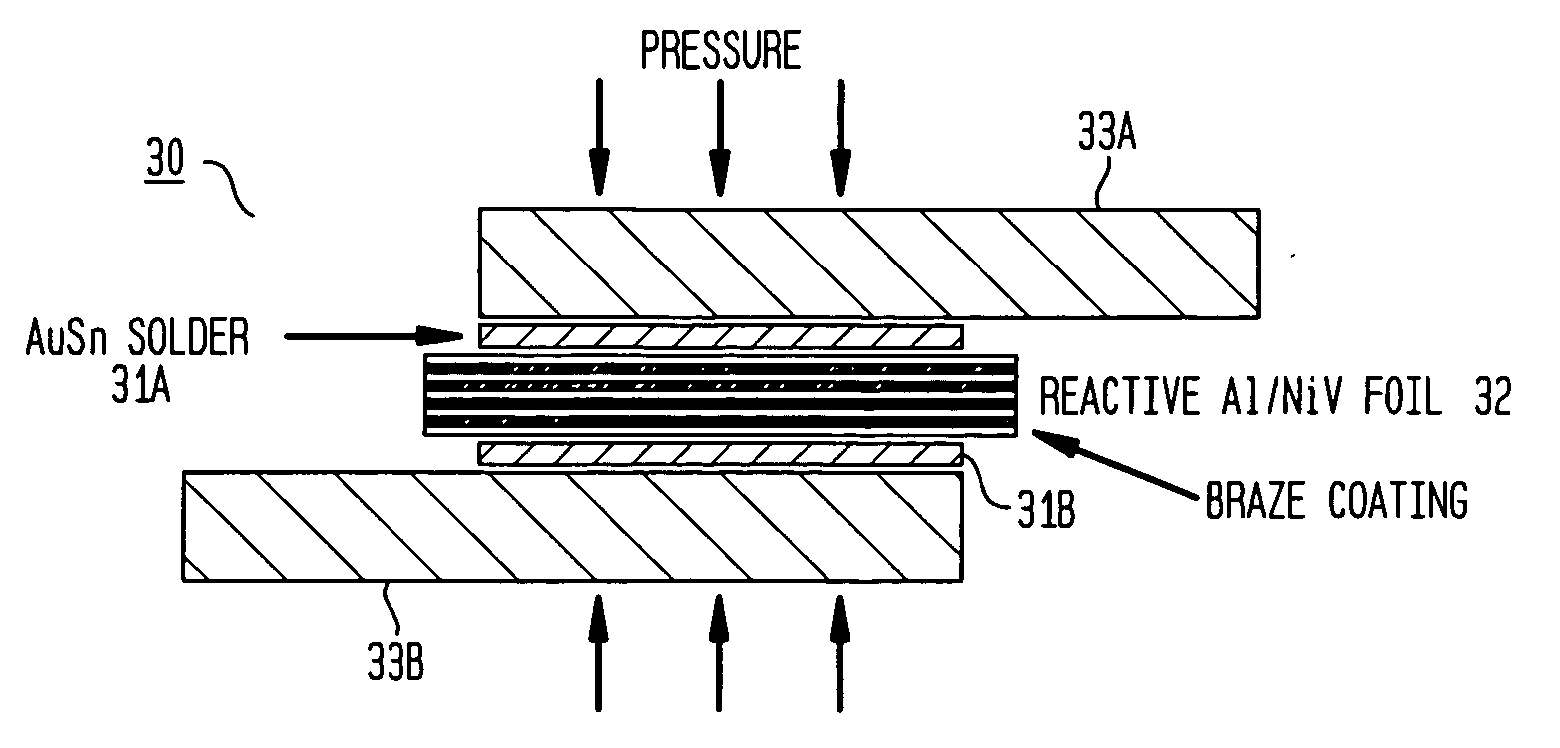

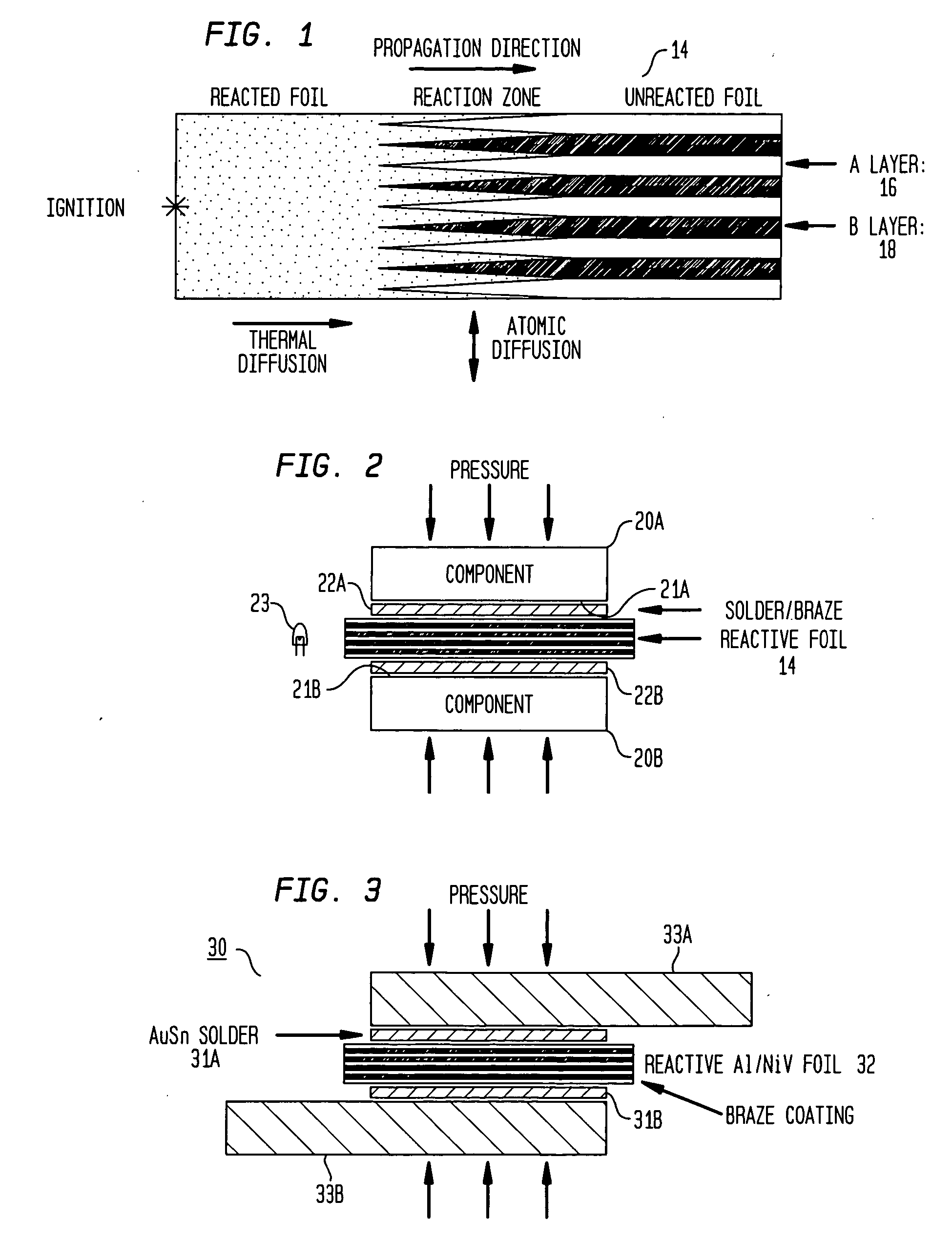

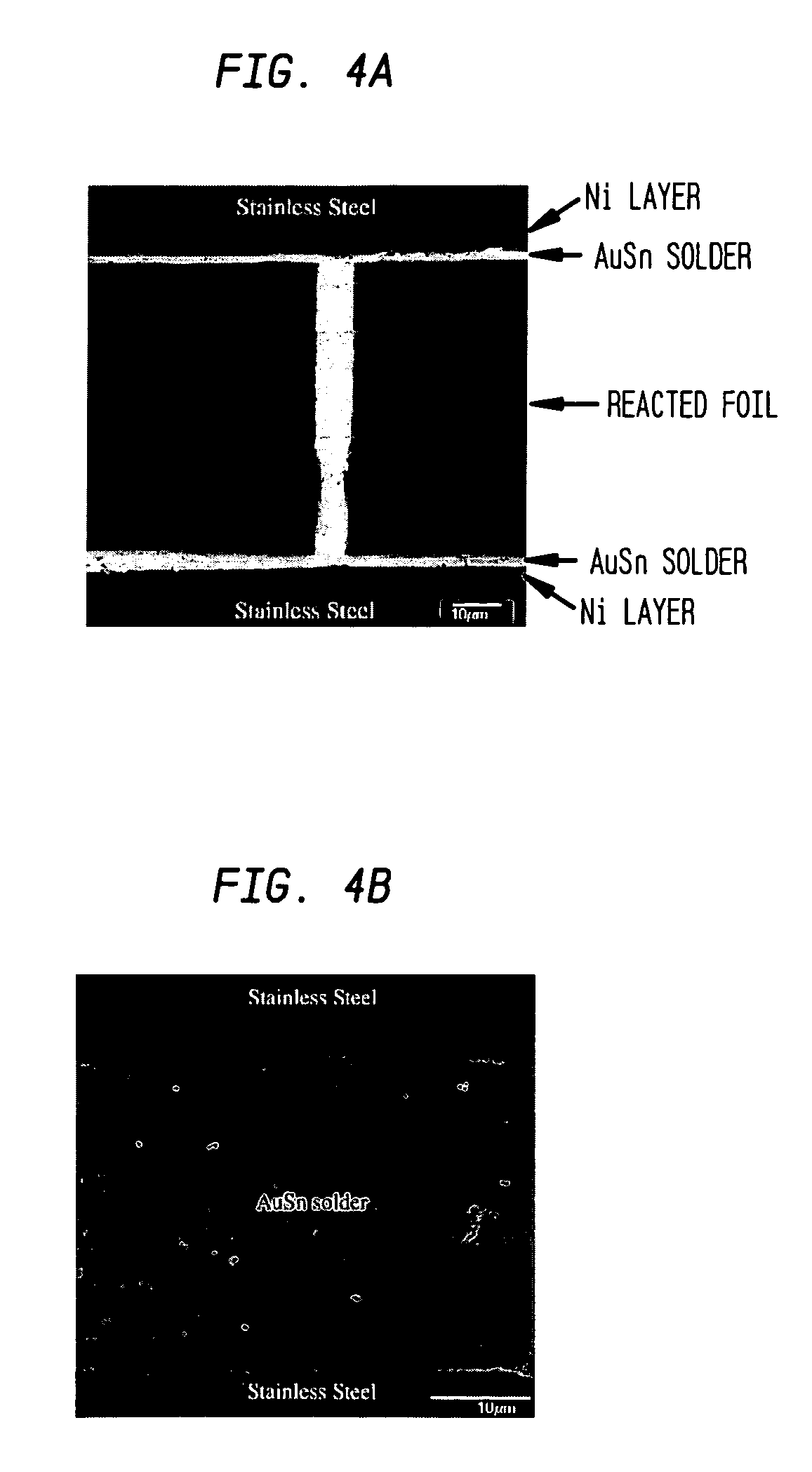

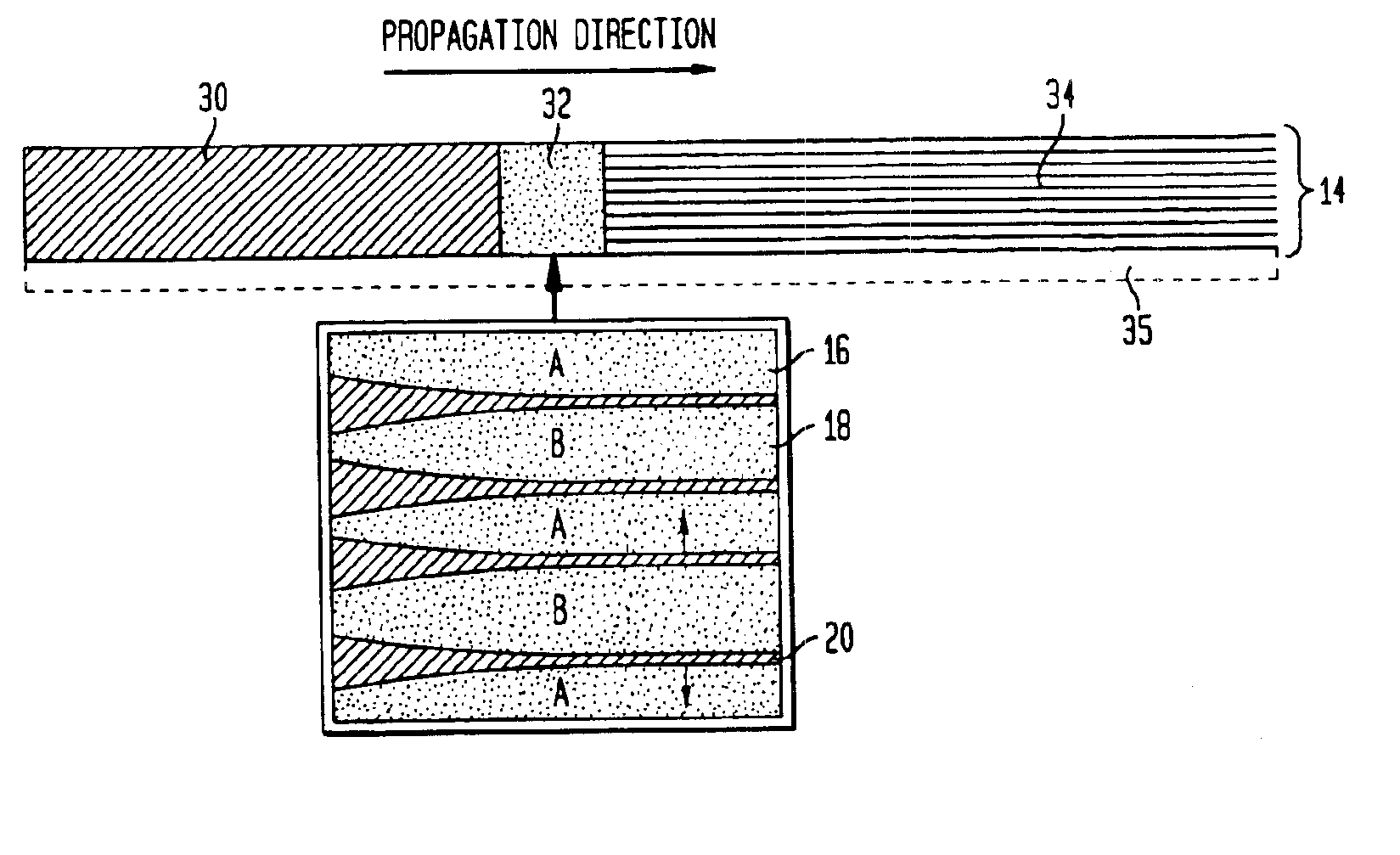

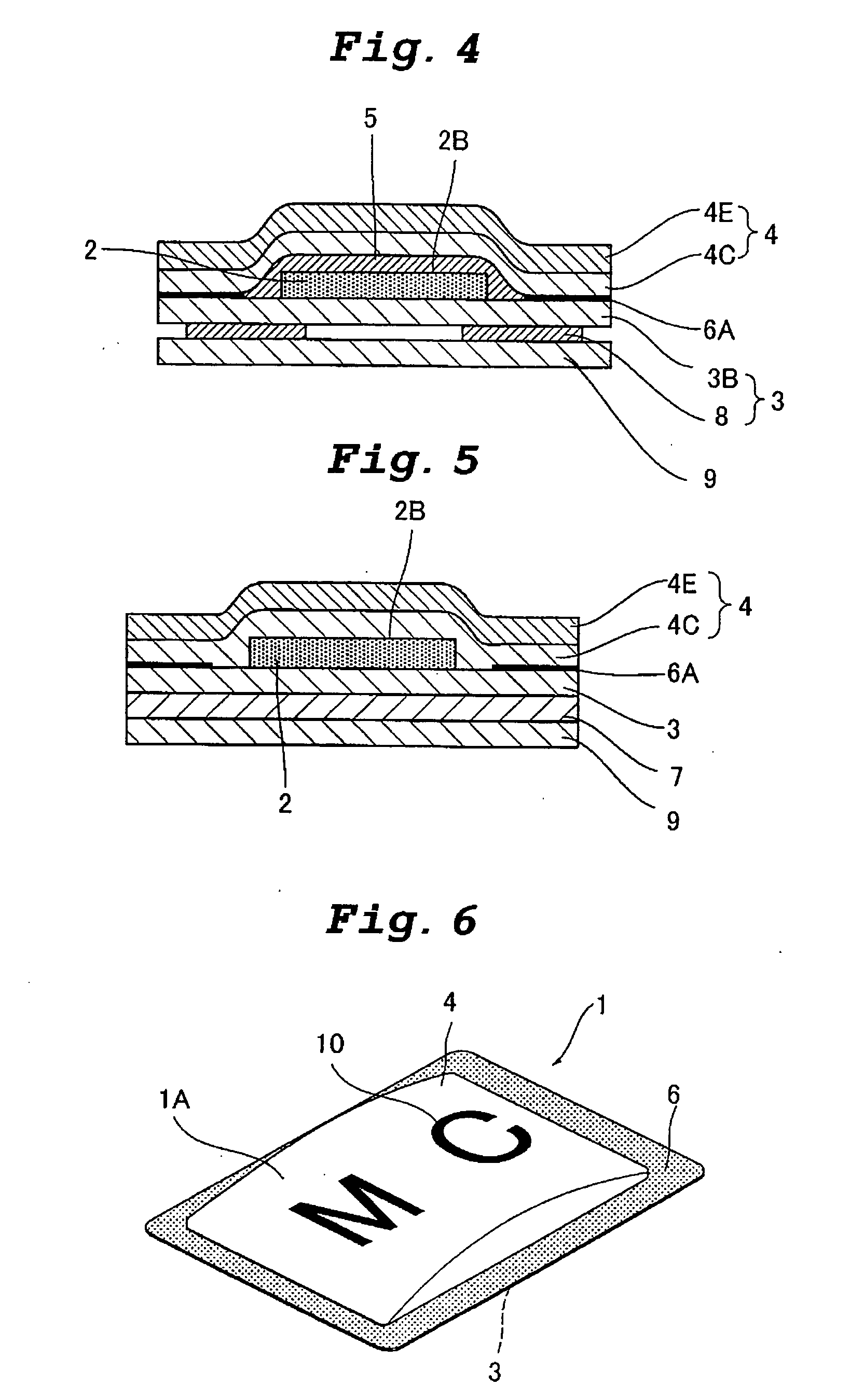

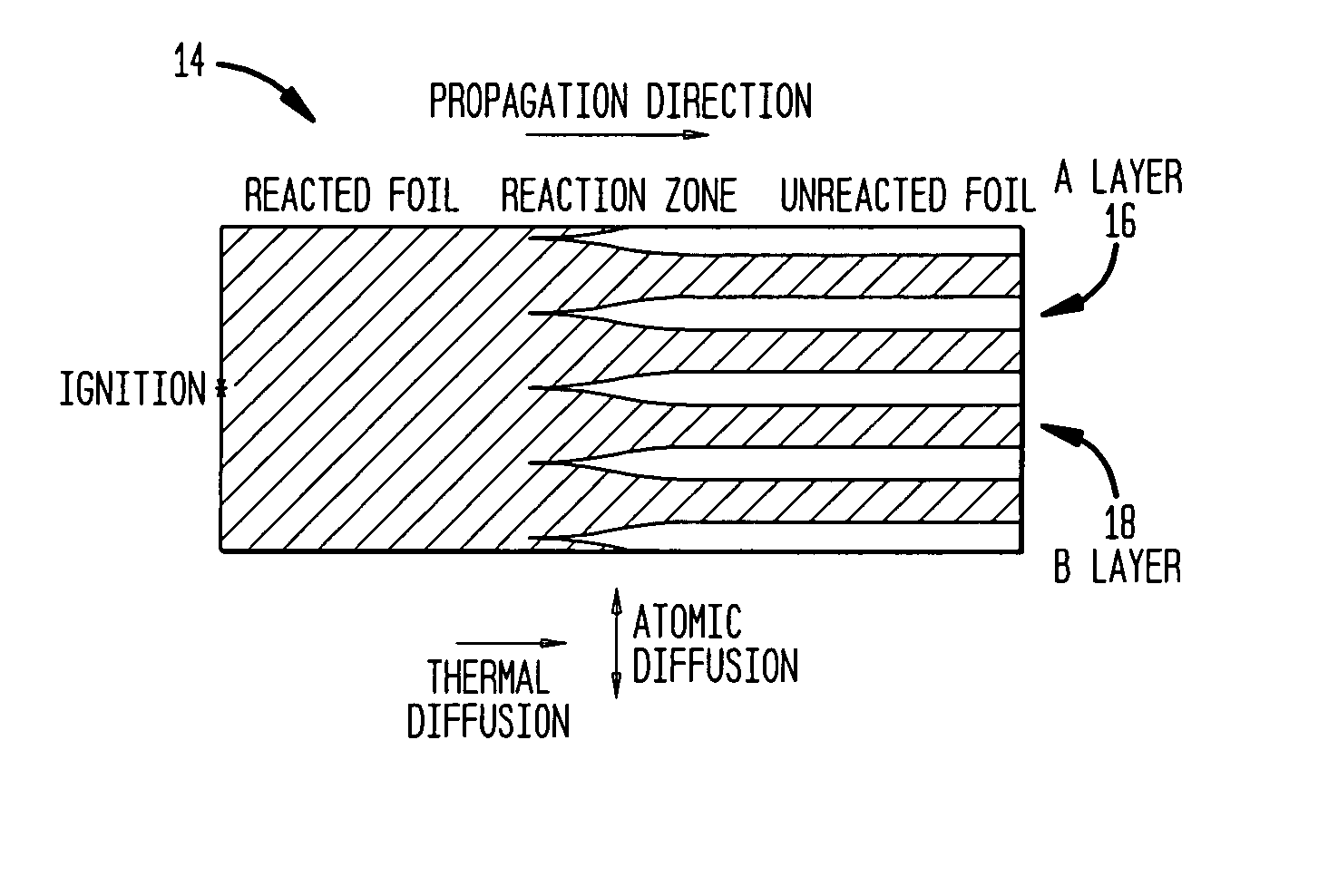

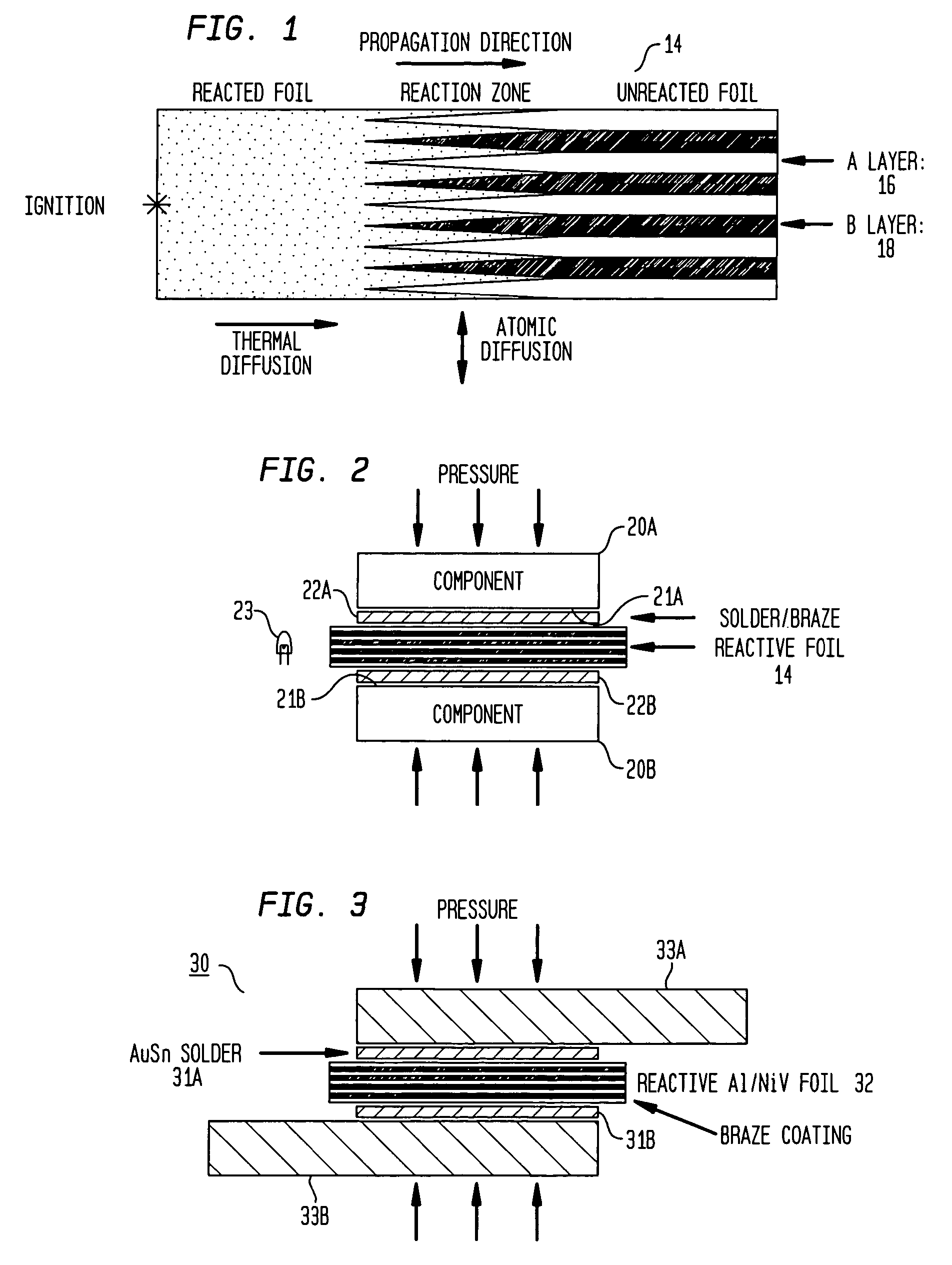

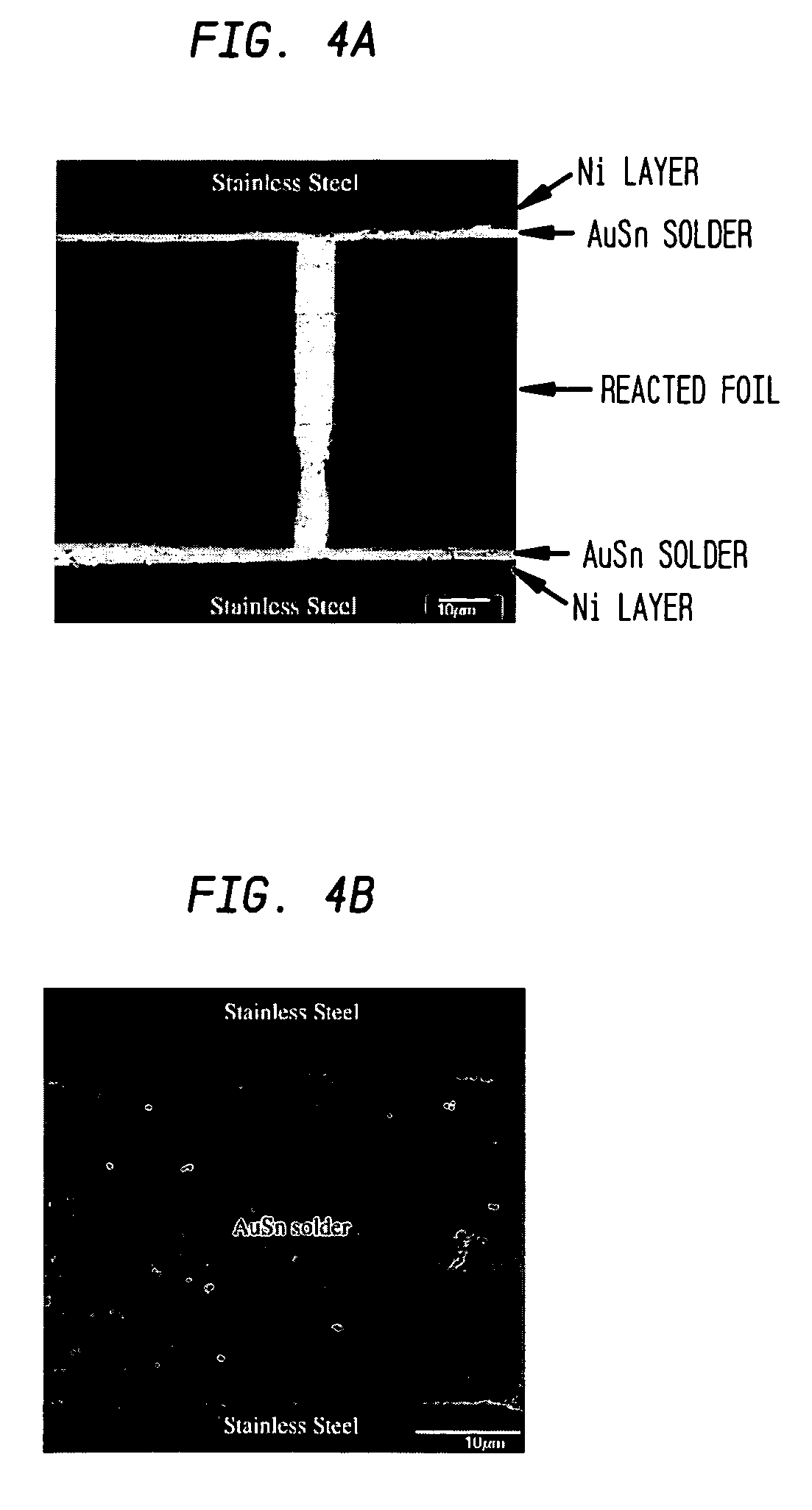

Nanostructured soldered or brazed joints made with reactive multilayer foils

InactiveUS20050051607A1Reduce coolingImprove microstructureExothermal chemical reaction heat productionVacuum evaporation coatingRoom temperatureSlow cooling

Self-propagating formation reactions in nanostructured multilayer foils provide rapid bursts of heat at room temperature and therefore can act as local heat sources to melt solder or braze layers and join materials. This reactive joining method provides very localized heating to the components and rapid cooling across the joint. The rapid cooling results in a very fine microstructure of the solder or braze material. The scale of the fine microstructure of the solder or braze material is dependant on cooling rate of the reactive joints which varies with geometries and properties of the foils and components. The microstructure of the solder or braze layer of the joints formed by melting solder in a furnace is much coarser due to the slow cooling rate. Reactive joints with finer solder or braze microstructure show higher shear strength compared with those made by conventional furnace joining with much coarser solder or braze microstructure. It is expected that the reactive joints may also have better fatigue properties compared with conventional furnace joints.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

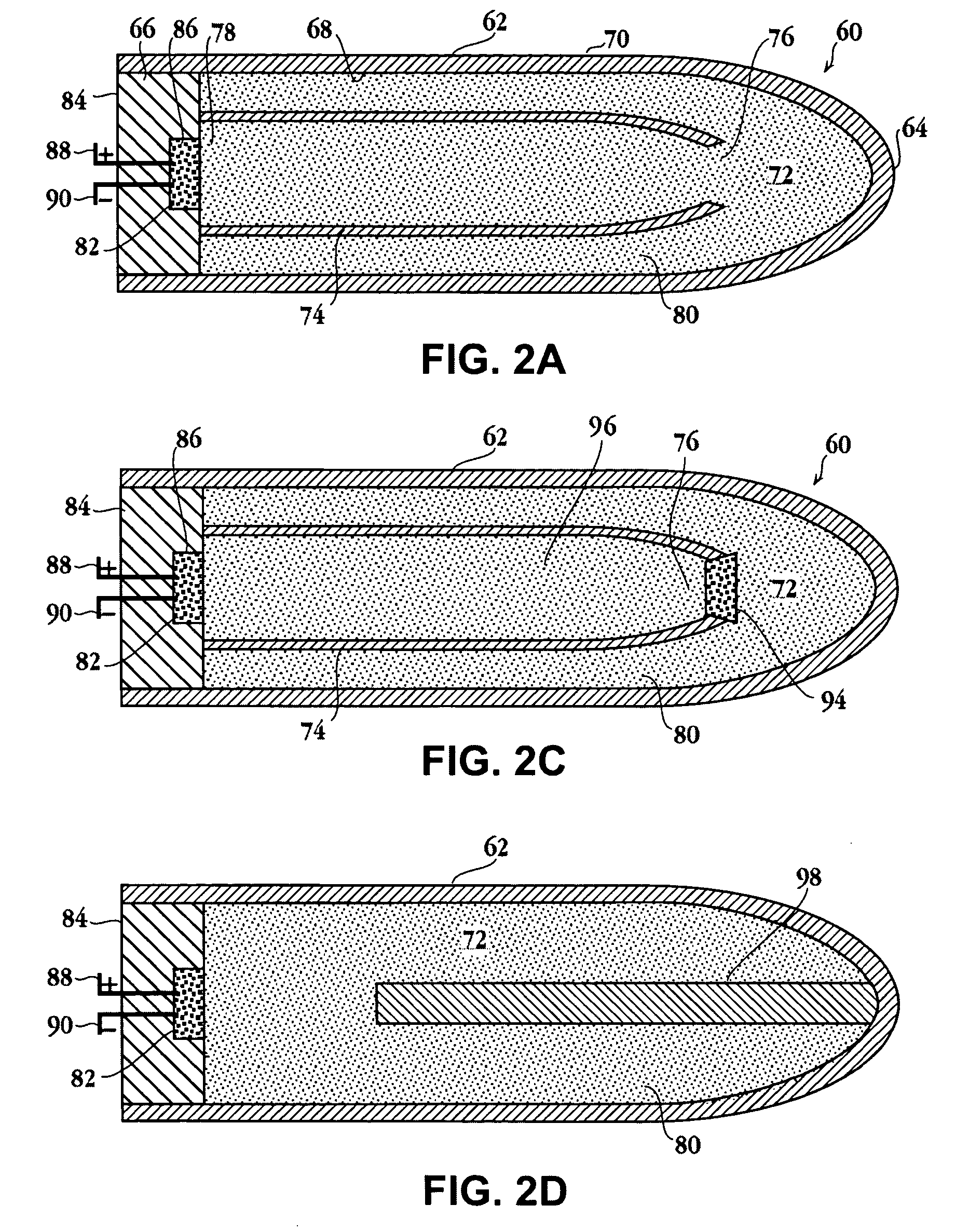

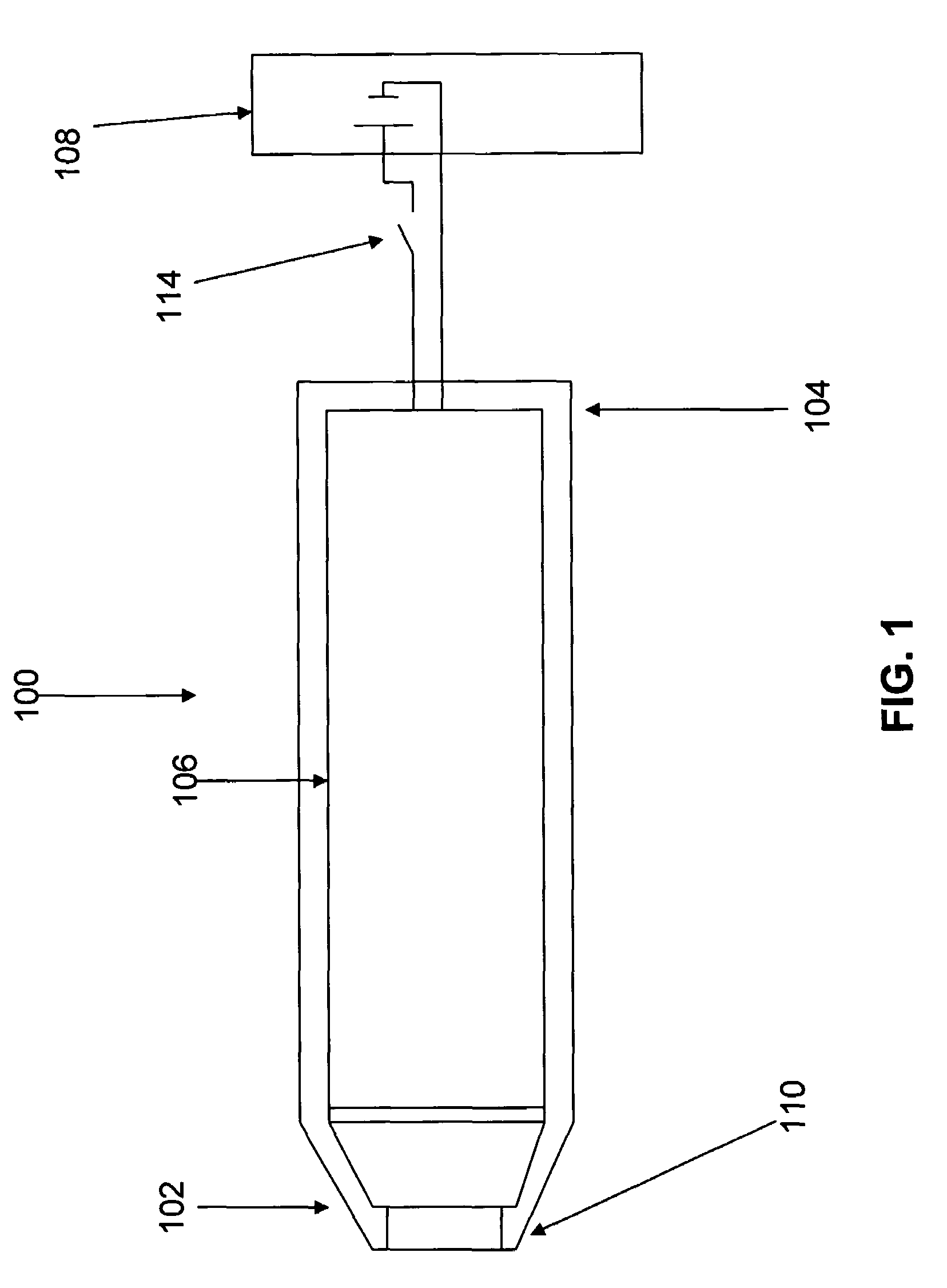

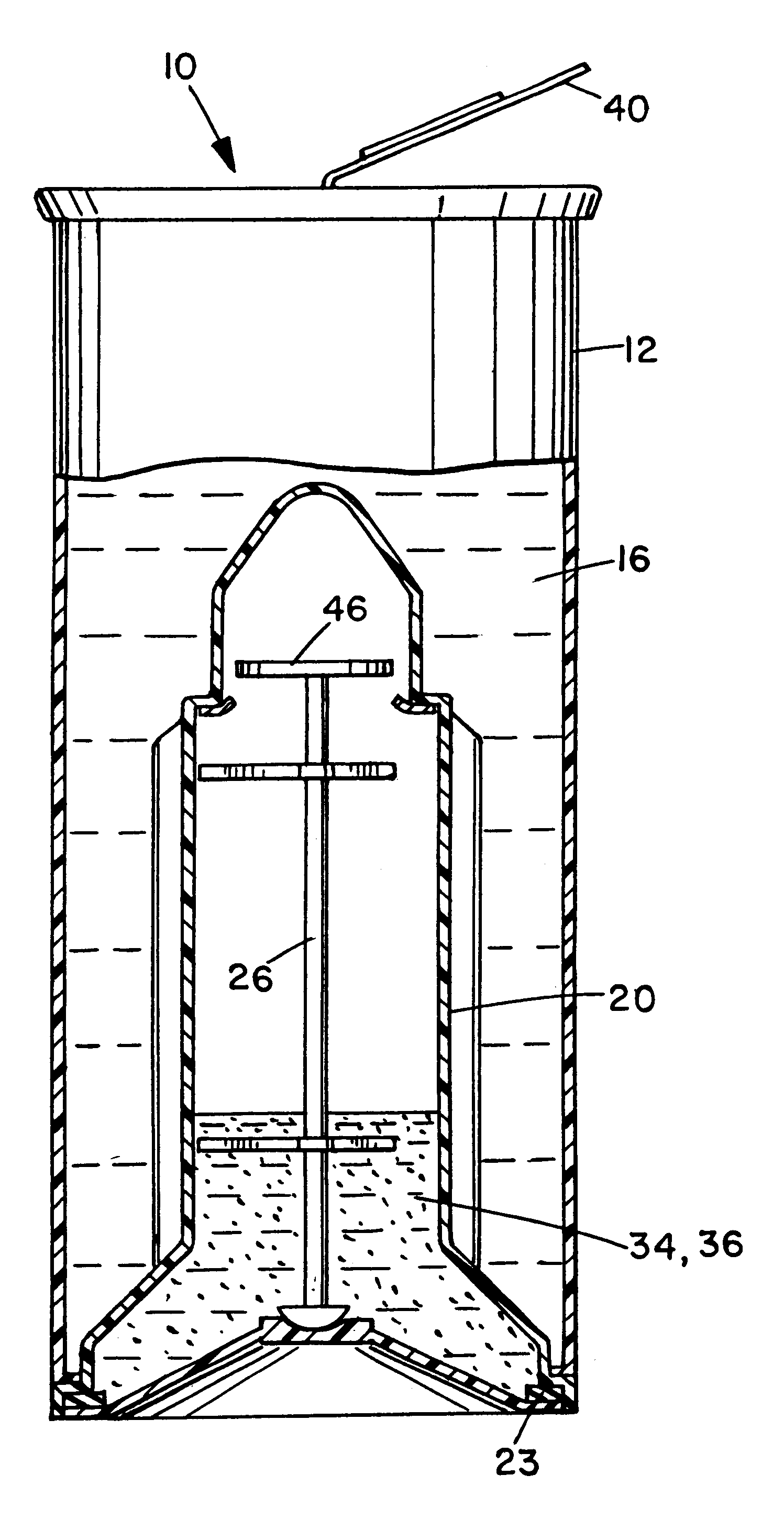

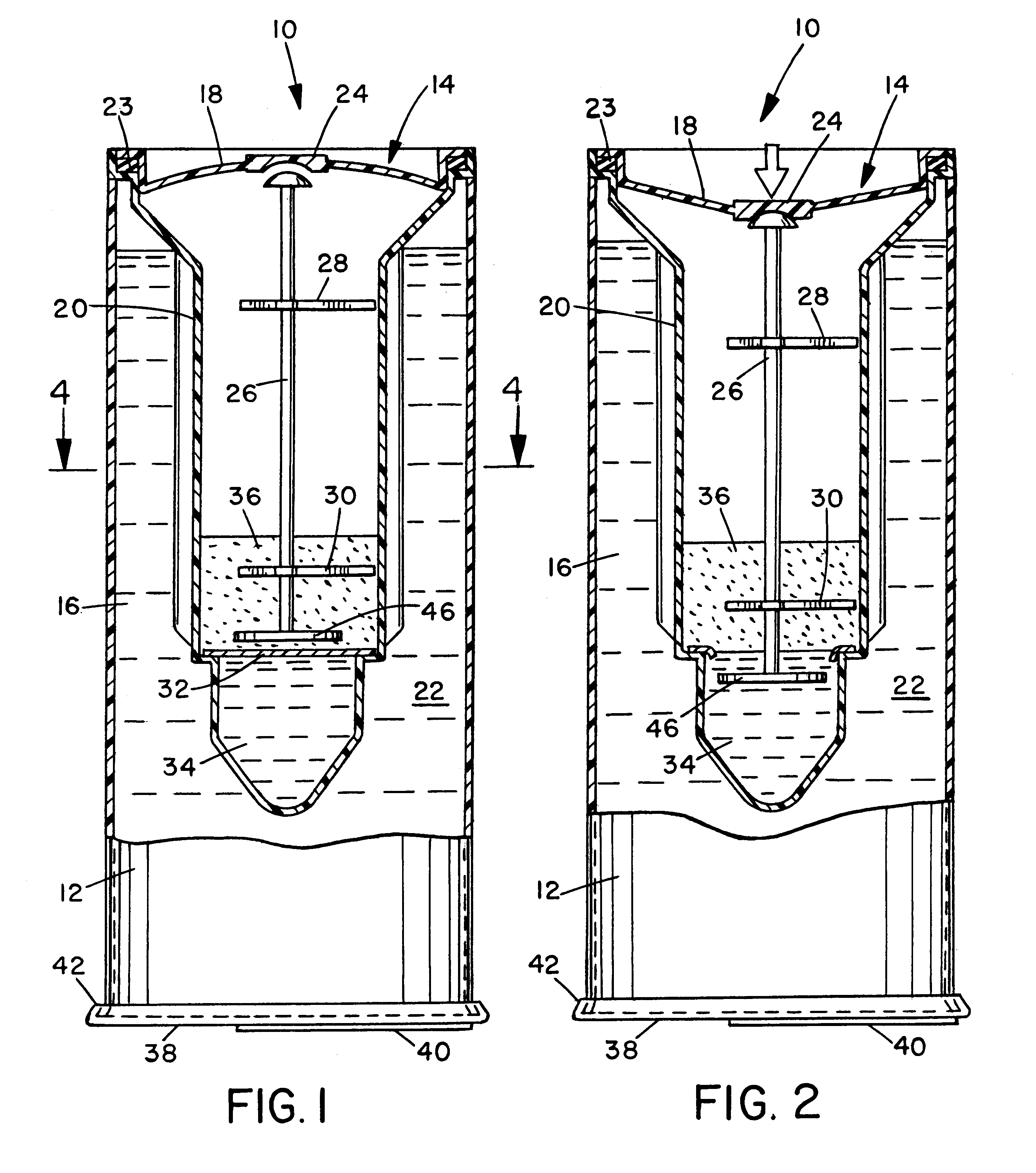

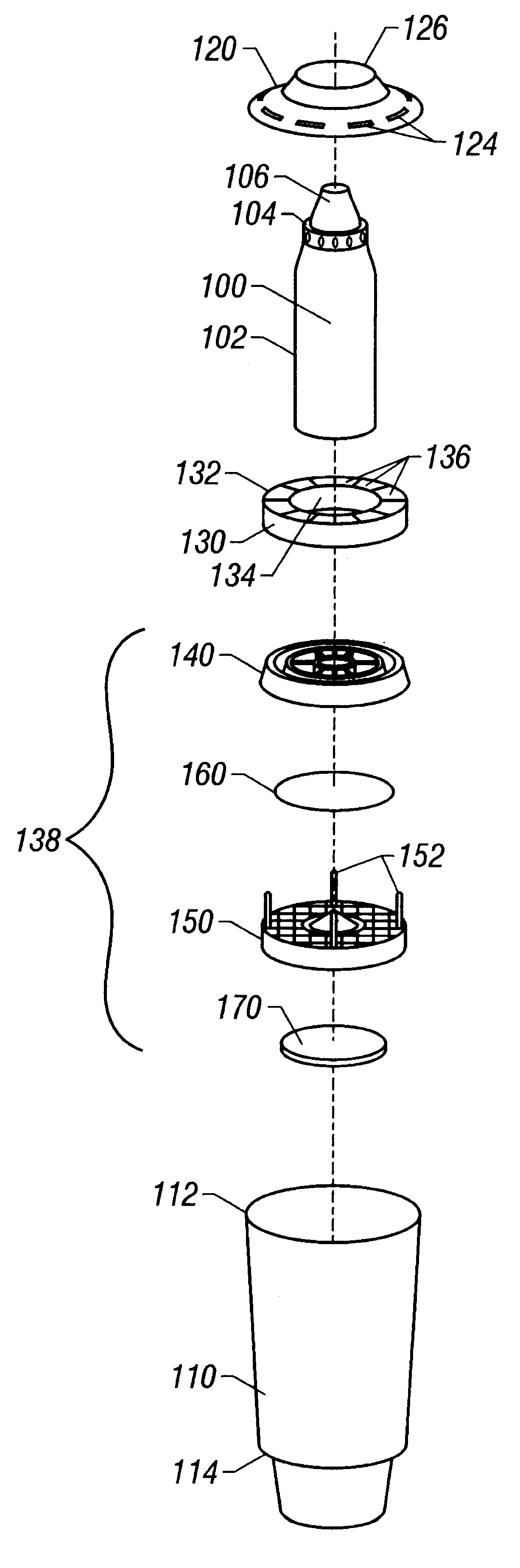

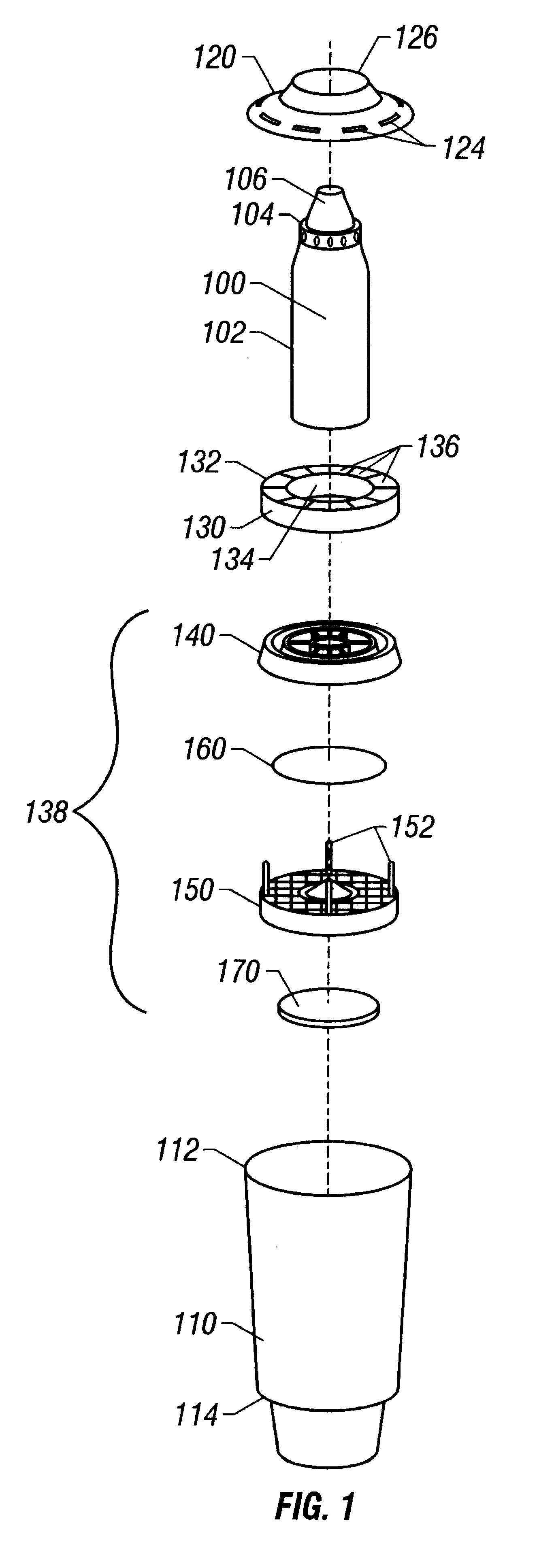

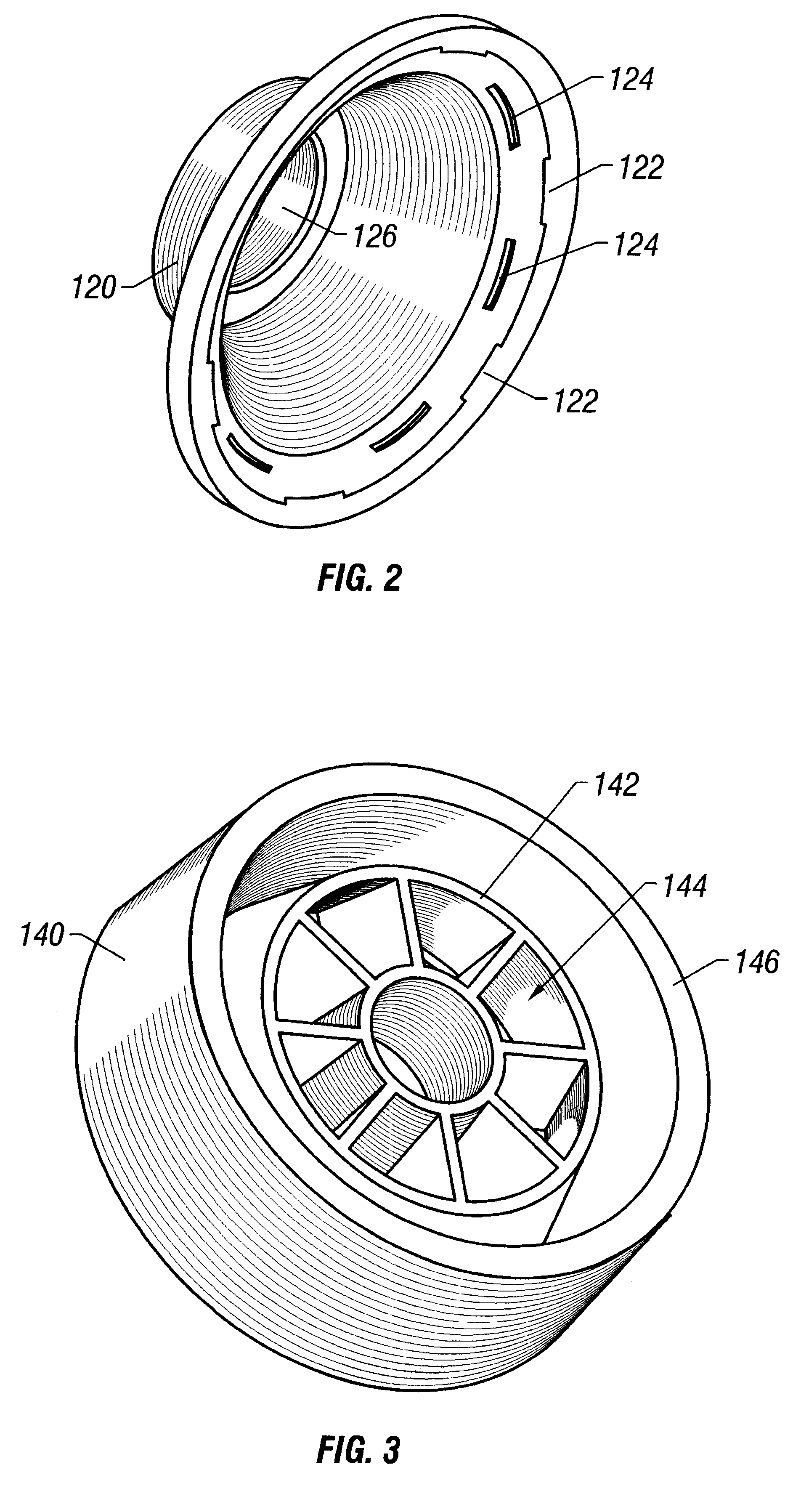

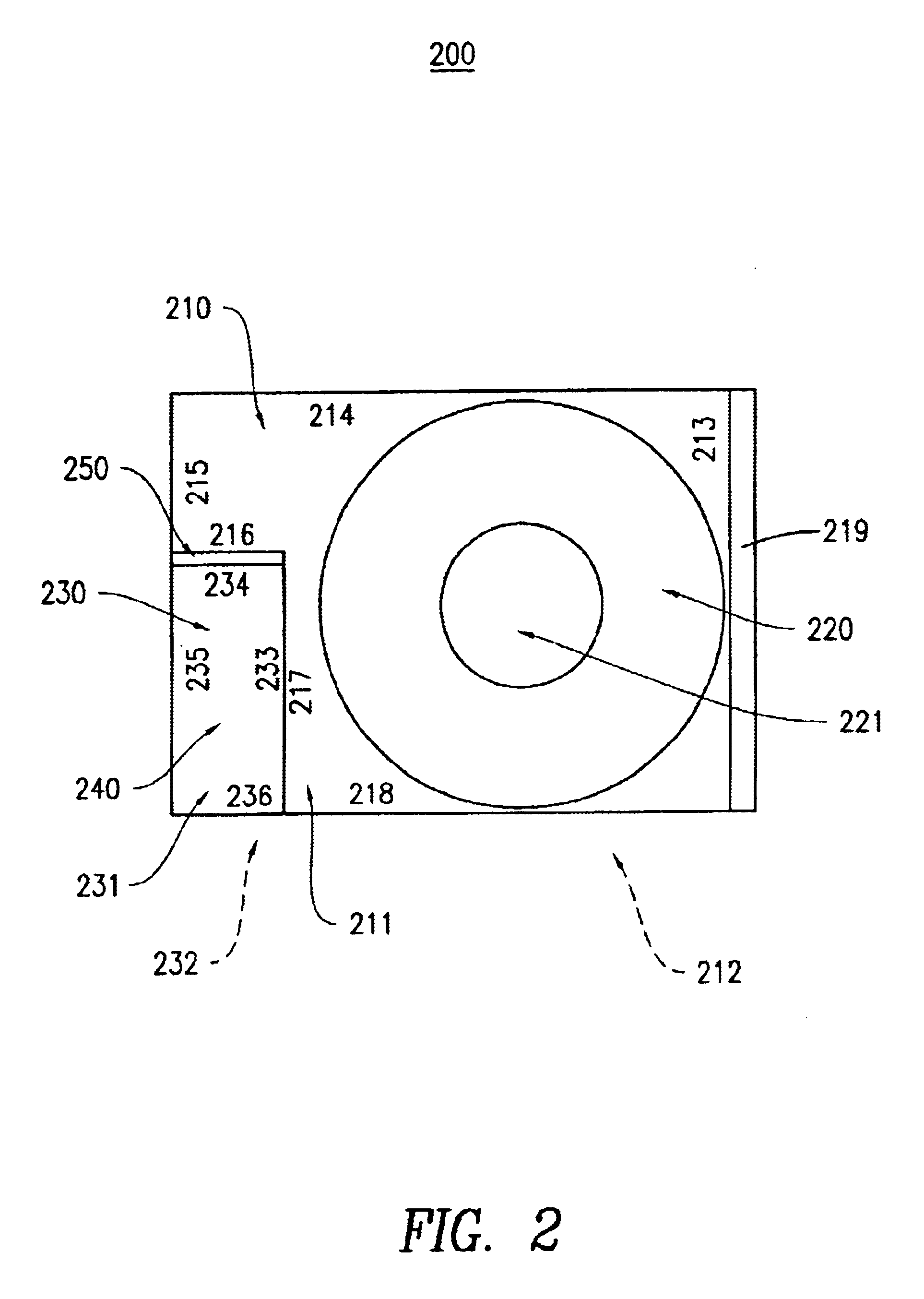

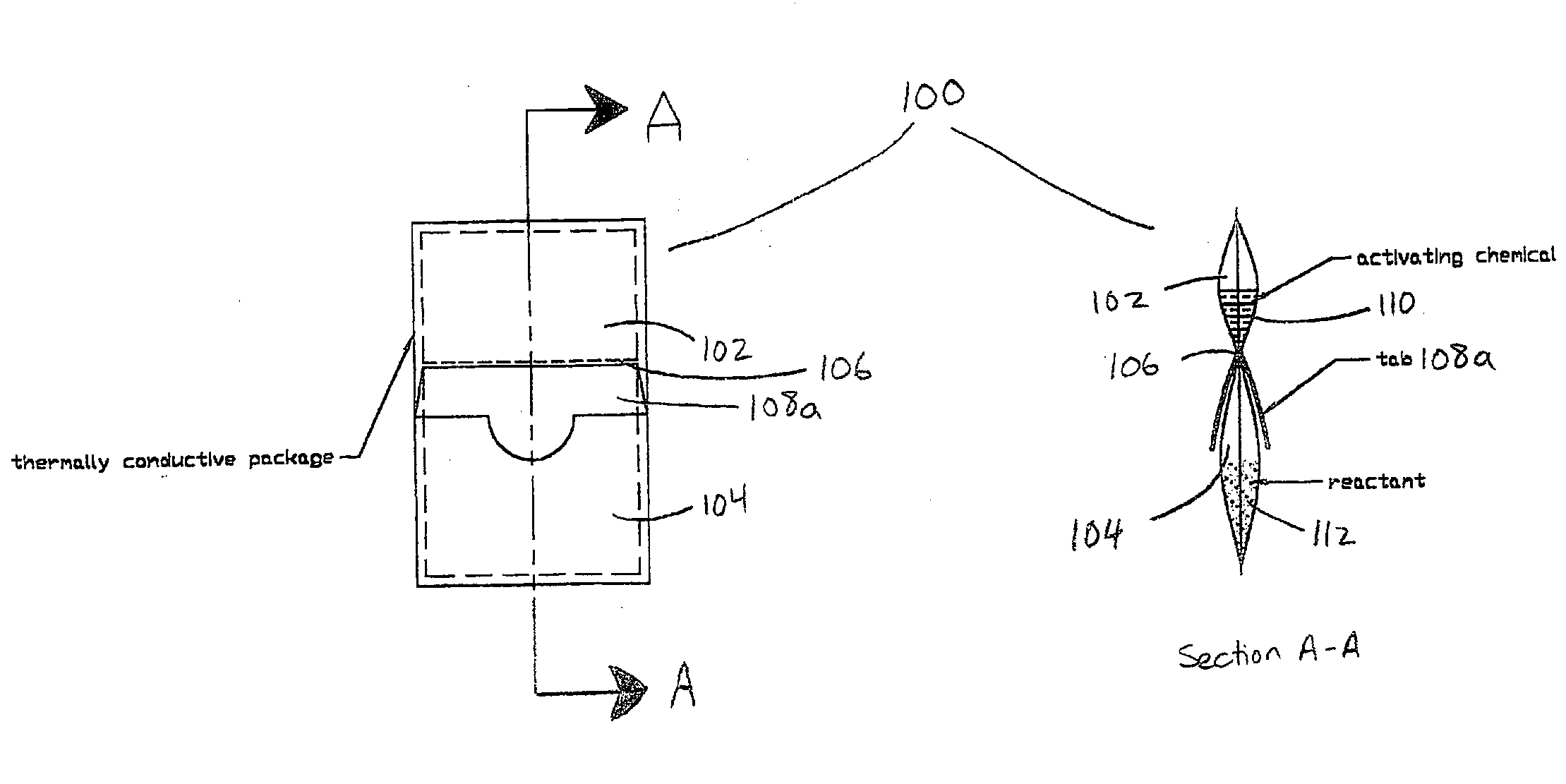

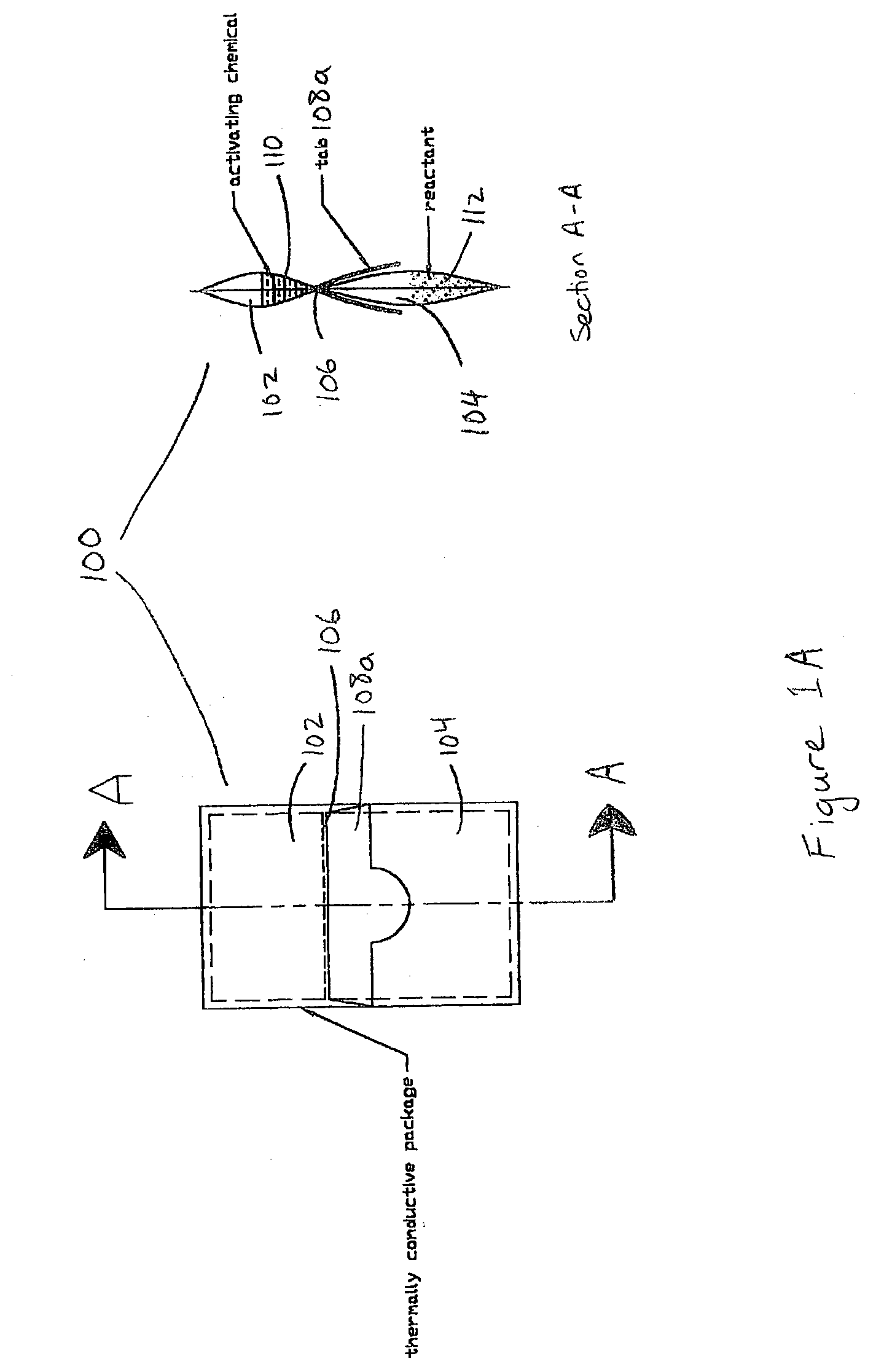

Container with self-heating module having liquid reactant and breakable reactant barrier at distal end of module

InactiveUS6178753B1Exothermal chemical reaction heat productionOther heat production devicesEngineeringActuator

A self-heating or self-cooling container has a container body, a closure at one end of the body through which the contents of the container can be consumed, and a thermic module at the other end of the body having an actuator portion and an elongated reaction chamber portion that extends distally into the container body and contains a liquid reactant relatively more distally from the actuator portion than a solid reactant separated from the liquid reactant by a breakable barrier. When a user actuates the thermic module, an elongated actuator member punctures the barrier. The user can then immediately invert the container, allowing the liquid reactant to drain through the puncture into the solid reactant in the reaction chamber. The reactants mix and produce a reaction that, depending upon the reactants, either heats or cools the container contents by conduction through the thermic module wall. An advantage is that the user does not need to wait to invert the container after actuating it. Rather, the user can actuate the container, immediately invert it, wait until the contents reach the desired temperature, and consume the contents through the closure.

Owner:ONTRO

Heat cells comprising exothermic compositions having absorbent gelling material

ActiveUS20070068508A1Improve temperature consistencyImproved sustained temperatureExothermal chemical reaction heat productionOther heat production devicesPolymer chemistry

Owner:BRIDGES CONSUMER HEALTHCARE LLC

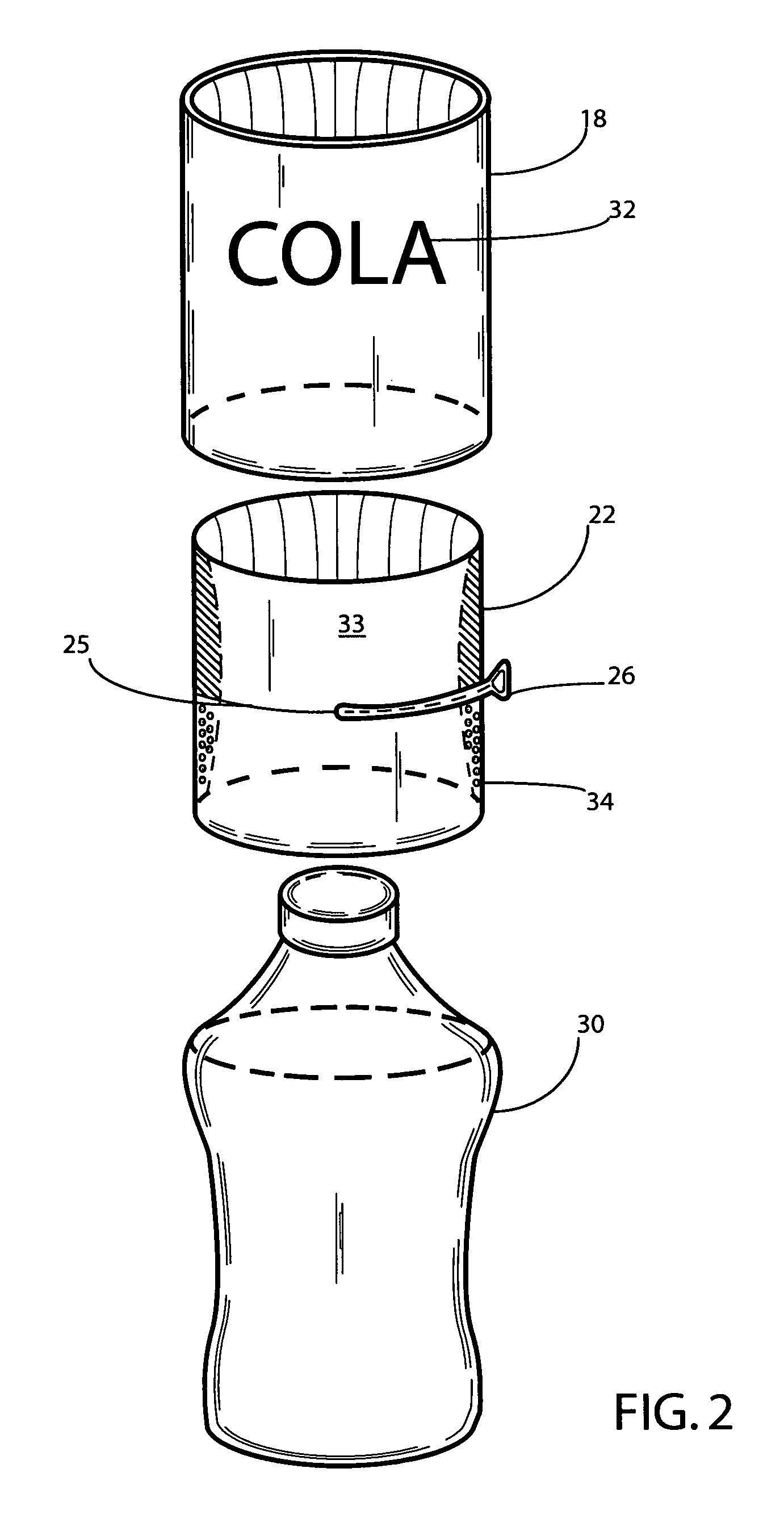

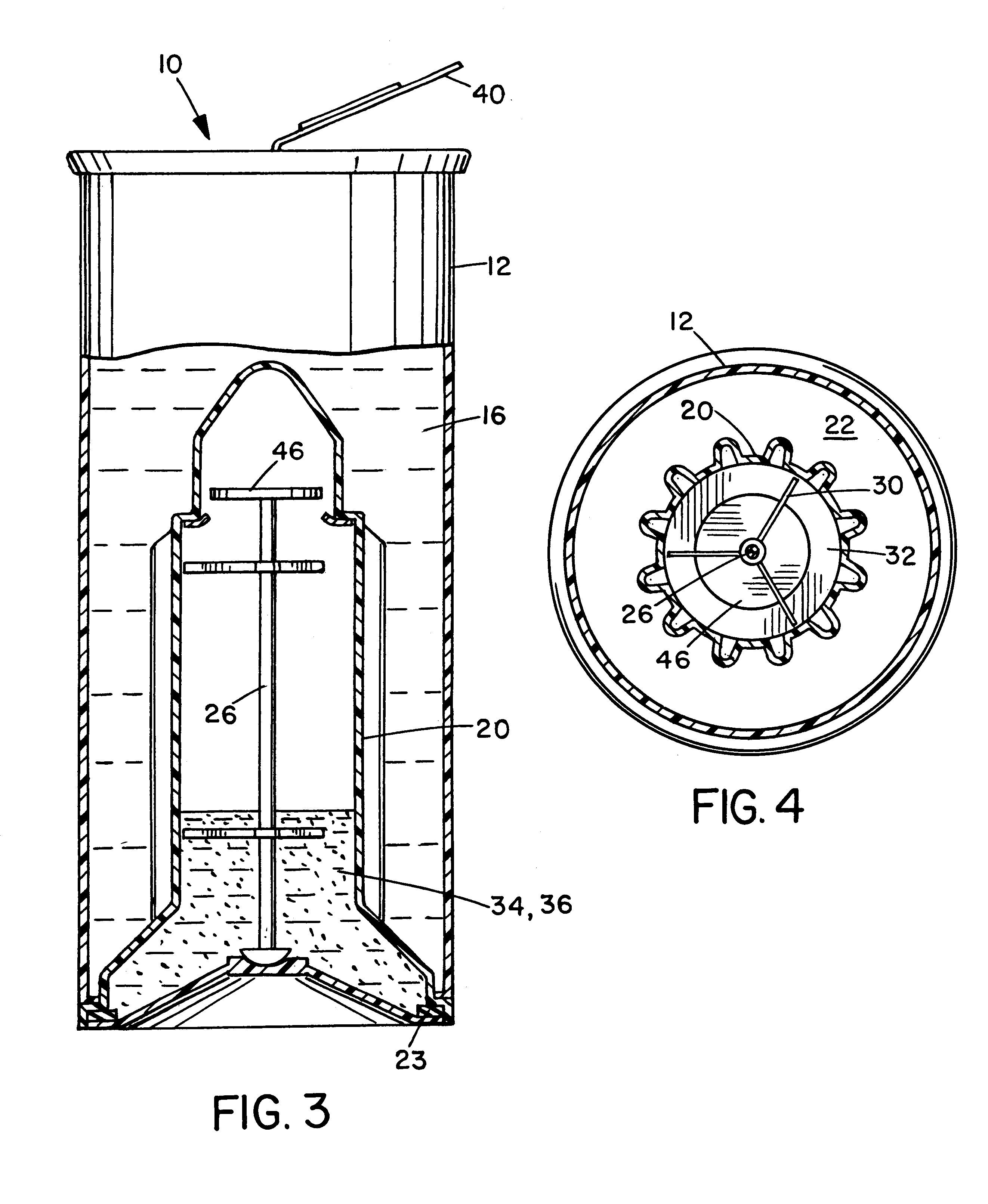

Self-contained temperature-change container assemblies

InactiveUS6877504B2Exothermal chemical reaction heat productionOther heat production devicesSteel woolEngineering

A container assembly heats or cools a product inside an inner container. An outer jacket at least partially surrounds the inner container, with a first internal volume and a second internal volume in the space between the outer jacket and the inner container. A first temperature-change reagent is contained inside the first internal volume, and a second temperature-change reagent is held in the second internal volume, with a reagent separator between the two. Several penetrators are disposed to penetrate the reagent separator to produce openings through the separator and through which the two reagents can mix. Steel wool inside the first internal volume acts as a steam condenser. The outer jacket includes a jacket top ring secured around an upper surface of a standard can, a jacket body secured to the jacket top, and a flexible jacket bottom that carries several spikes molded onto the jacket bottom.

Owner:SELF HEATING TECH CORP

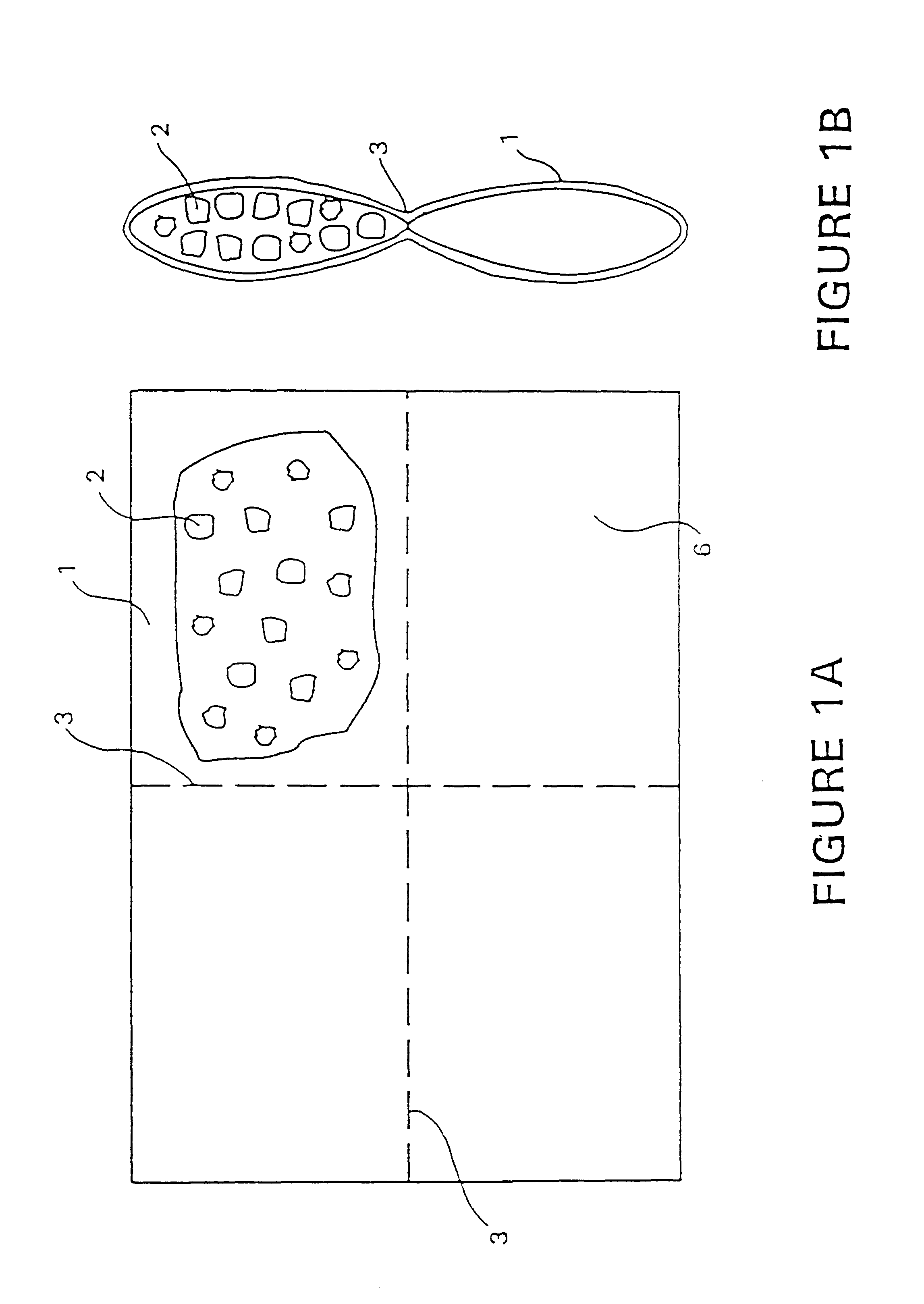

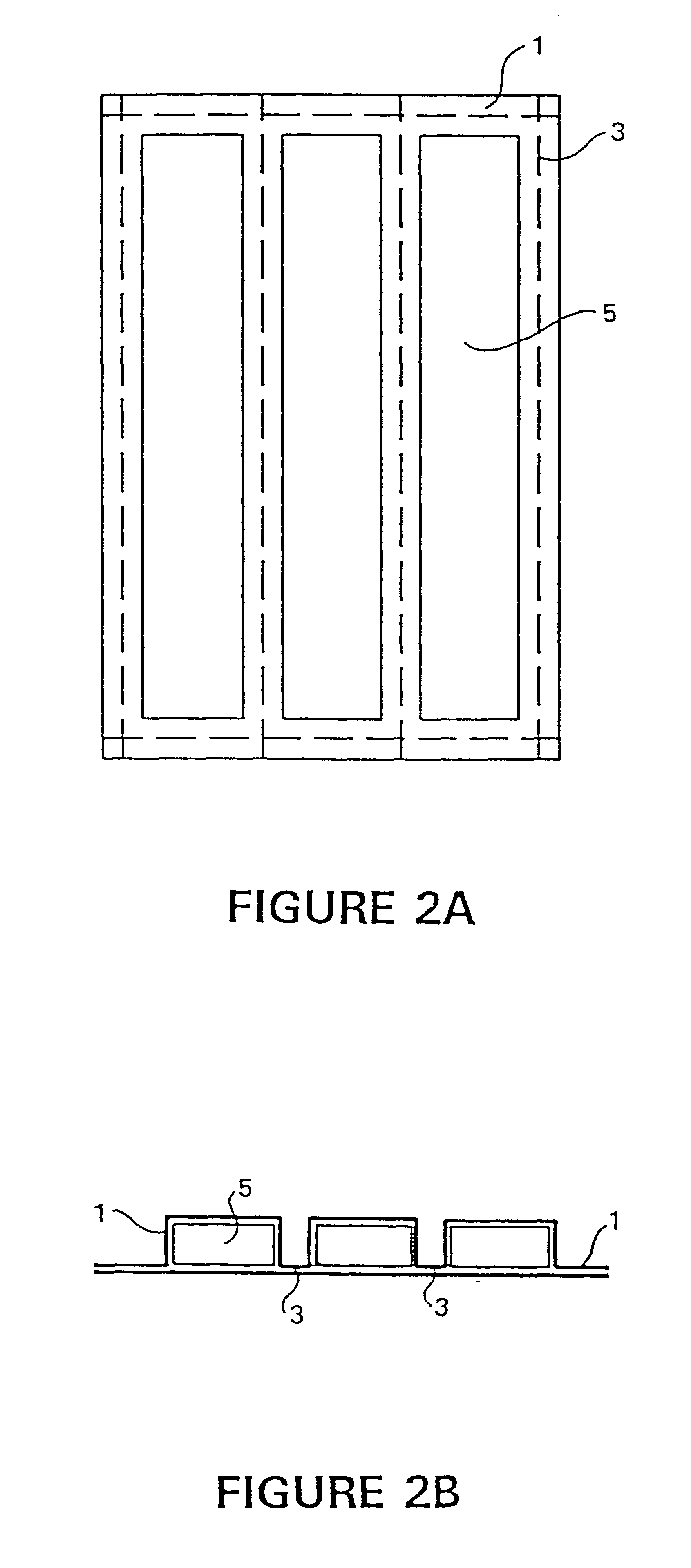

Fibrous materials exhibiting thermal change during use

InactiveUS20050136765A1Exothermal chemical reaction heat productionSynthetic resin layered productsFiberThermal variation

Fibrous sheet materials, such as are useful as facial tissue, bath tissue and paper towels, for example, are provided with chemical agents, such as certain salts, which create a temperature change in the sheet when exposed to a particular stimulant, such as water, for example. These materials can provide a soothing feel to the user, either in the form of cooling or heating, depending upon the particular chemistry involved.

Owner:KIMBERLY-CLARK WORLDWIDE INC

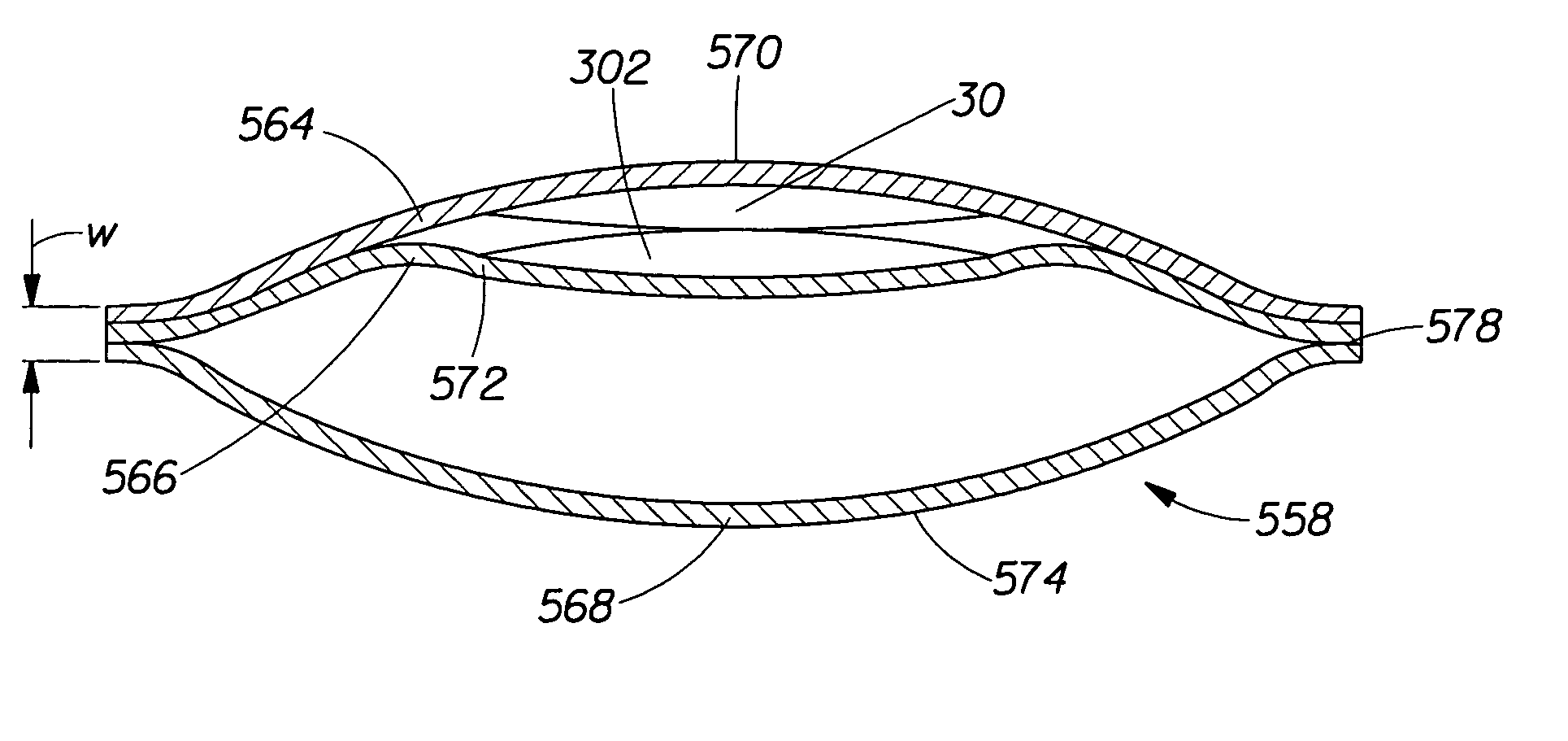

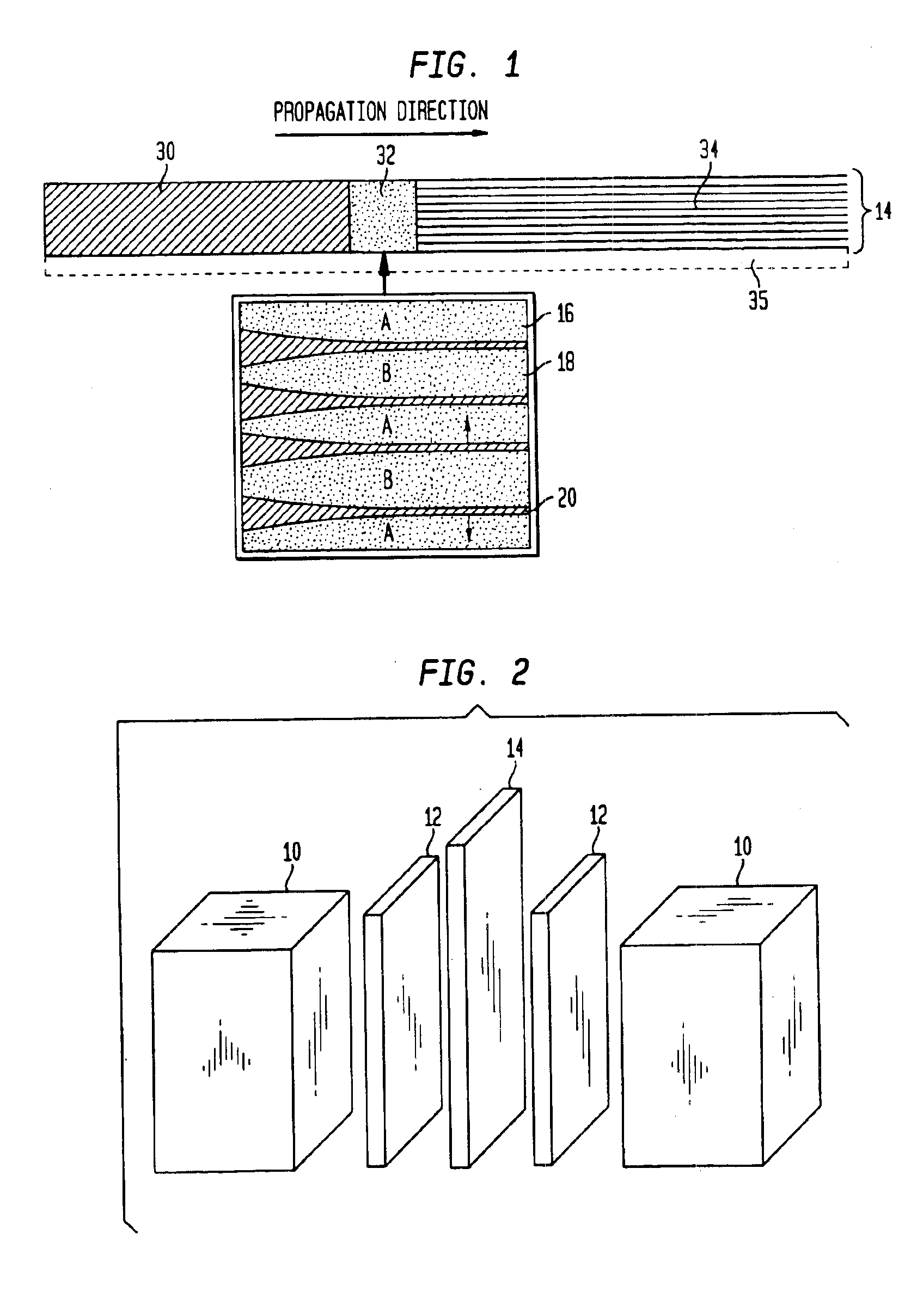

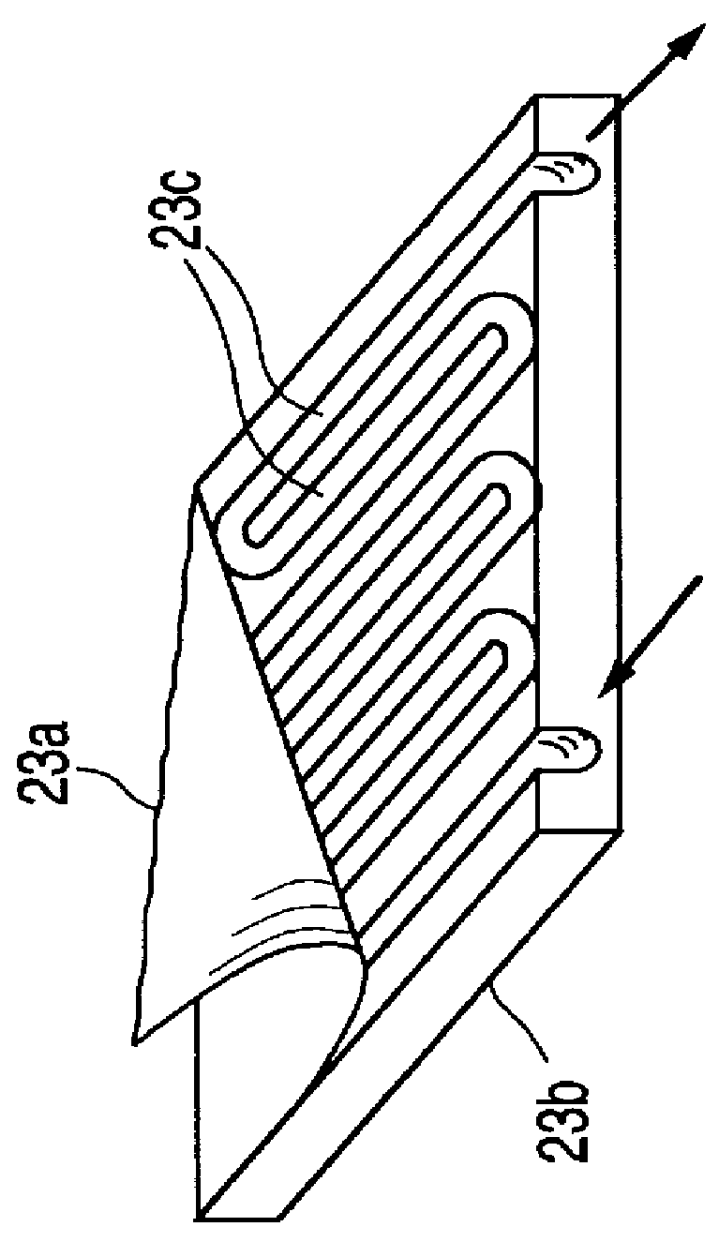

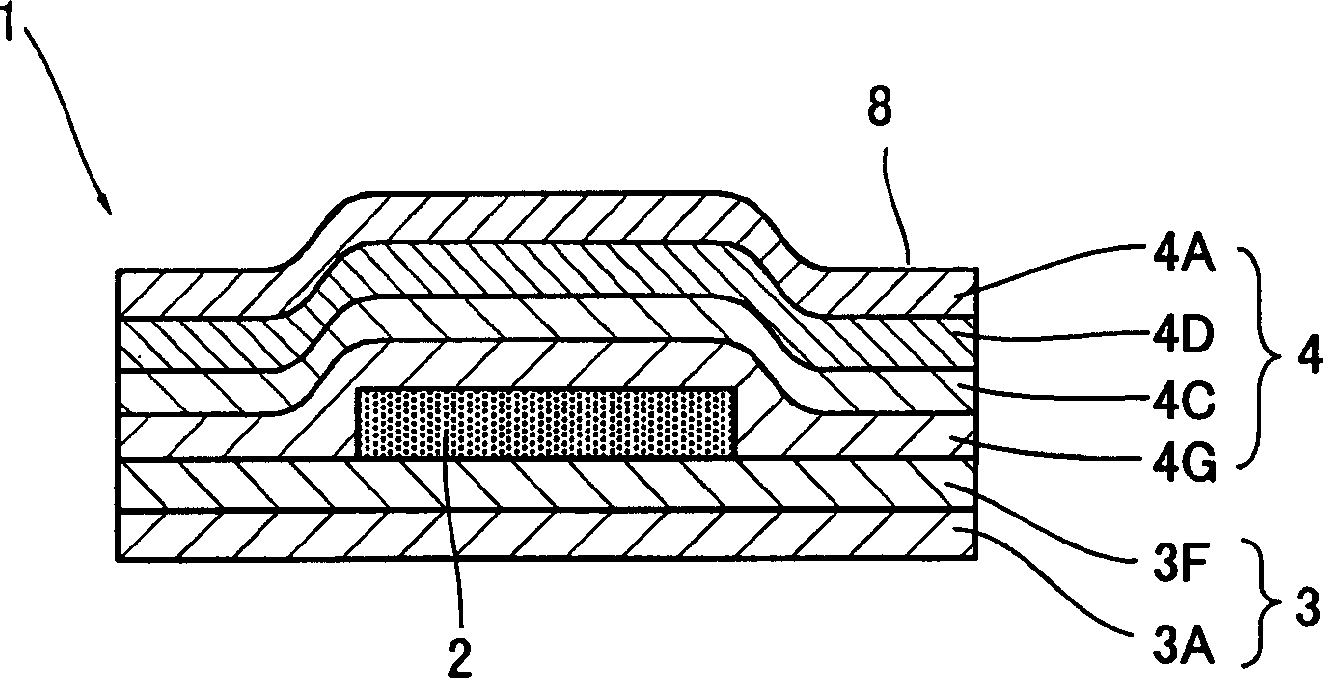

Composite reactive multilayer foil

InactiveUS6863992B2Increase heatFast bondingExothermal chemical reaction heat productionVacuum evaporation coatingThermal energyRoom temperature

Reactive foils and their uses are provided as localized heat sources useful, for example, in ignition, joining and propulsion. An improved reactive foil is preferably a freestanding multilayered foil structure made up of alternating layers selected from materials that will react with one another in an exothermic and self-propagating reaction. Upon reacting, this foil supplies highly localized heat energy that may be applied, for example, to joining layers, or directly to bulk materials that are to be joined. This foil heat-source allows rapid bonding to occur at room temperature in virtually any environment (e.g., air, vacuum, water, etc.). If a joining material is used, the foil reaction will supply enough heat to melt the joining materials, which upon cooling will form a strong bond, joining two or more bulk materials.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

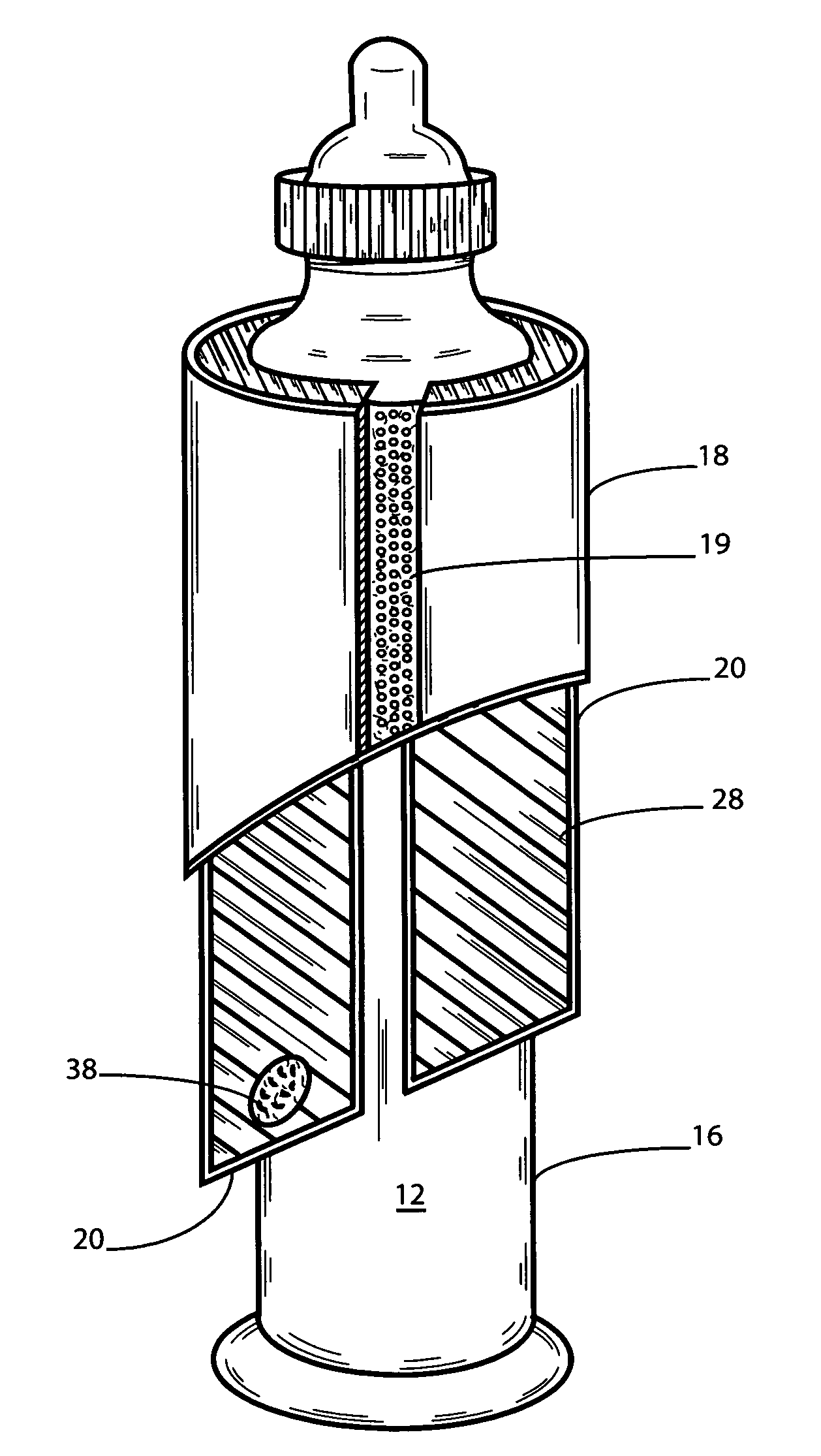

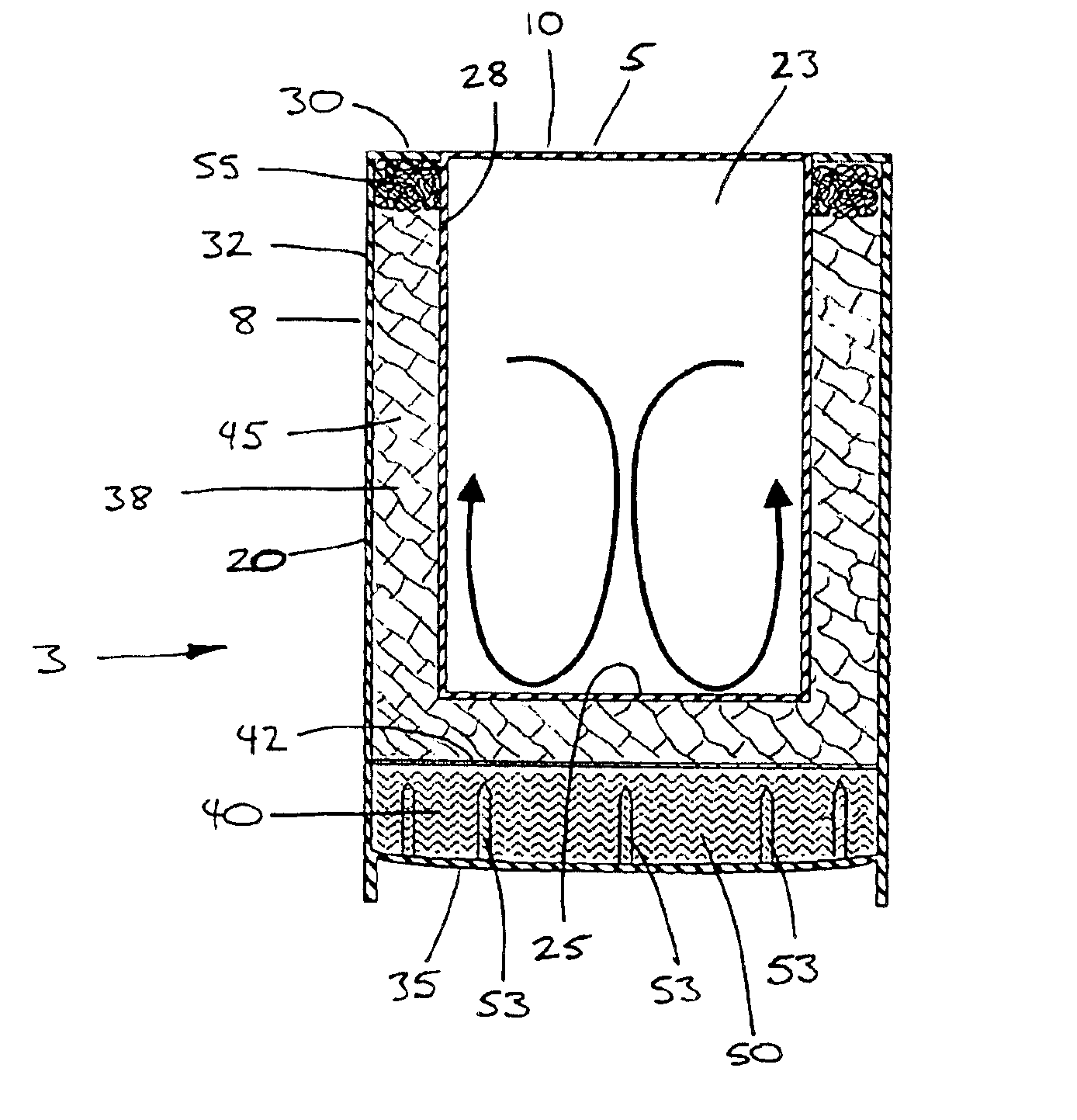

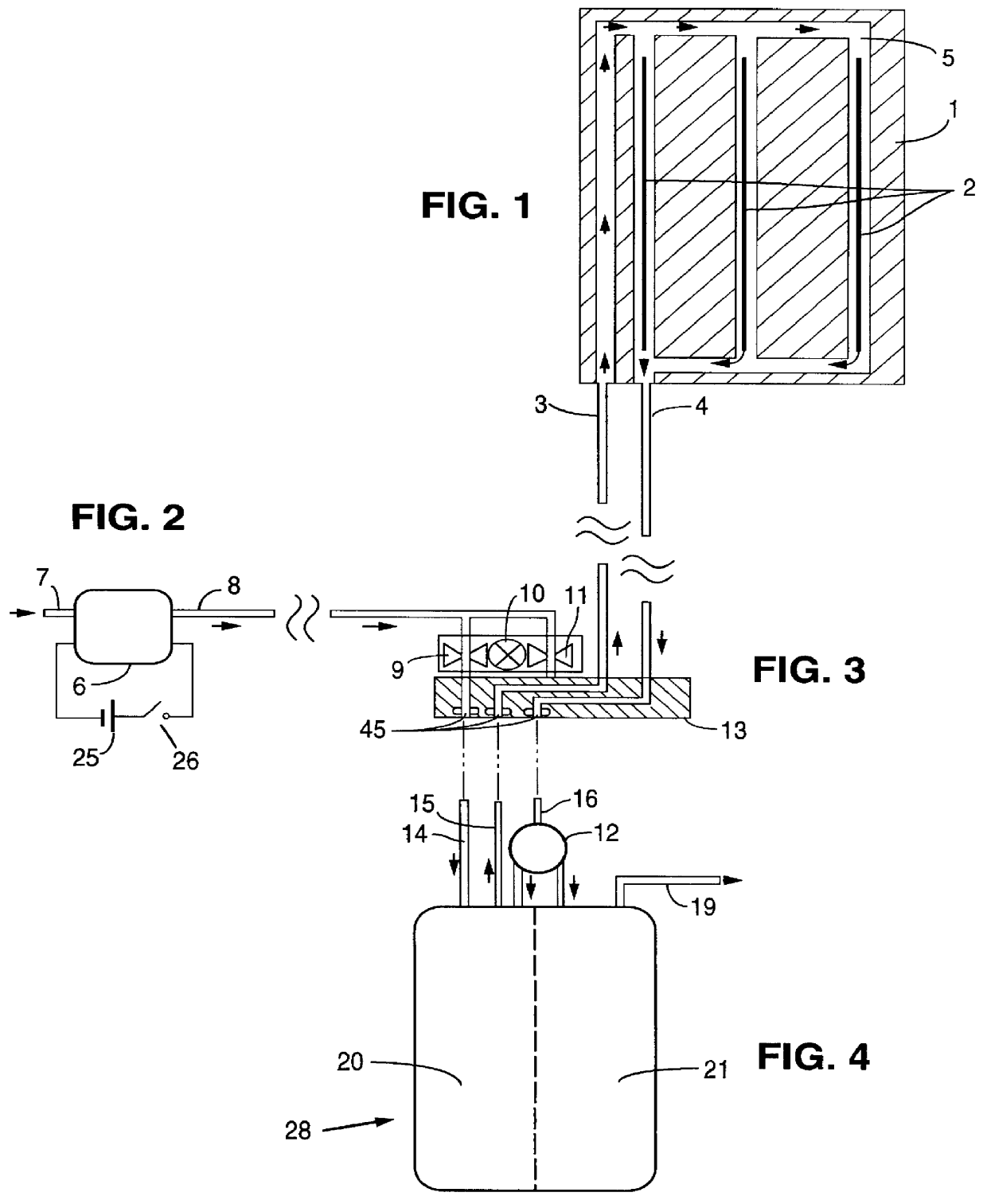

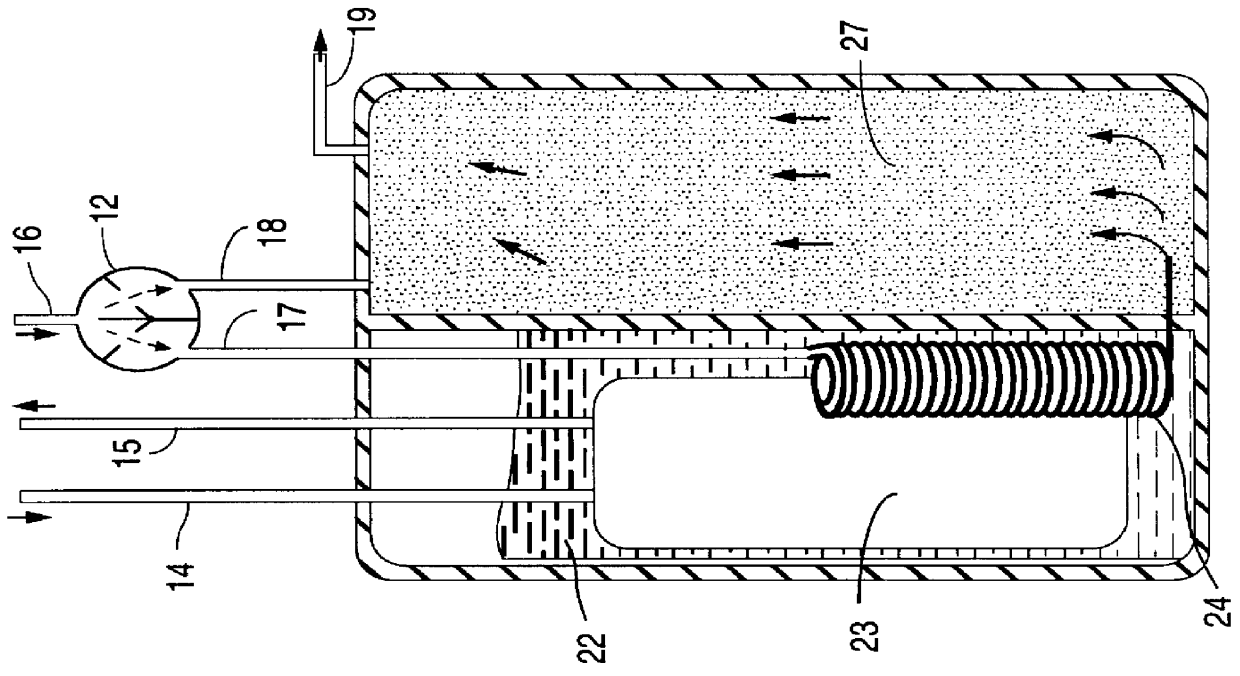

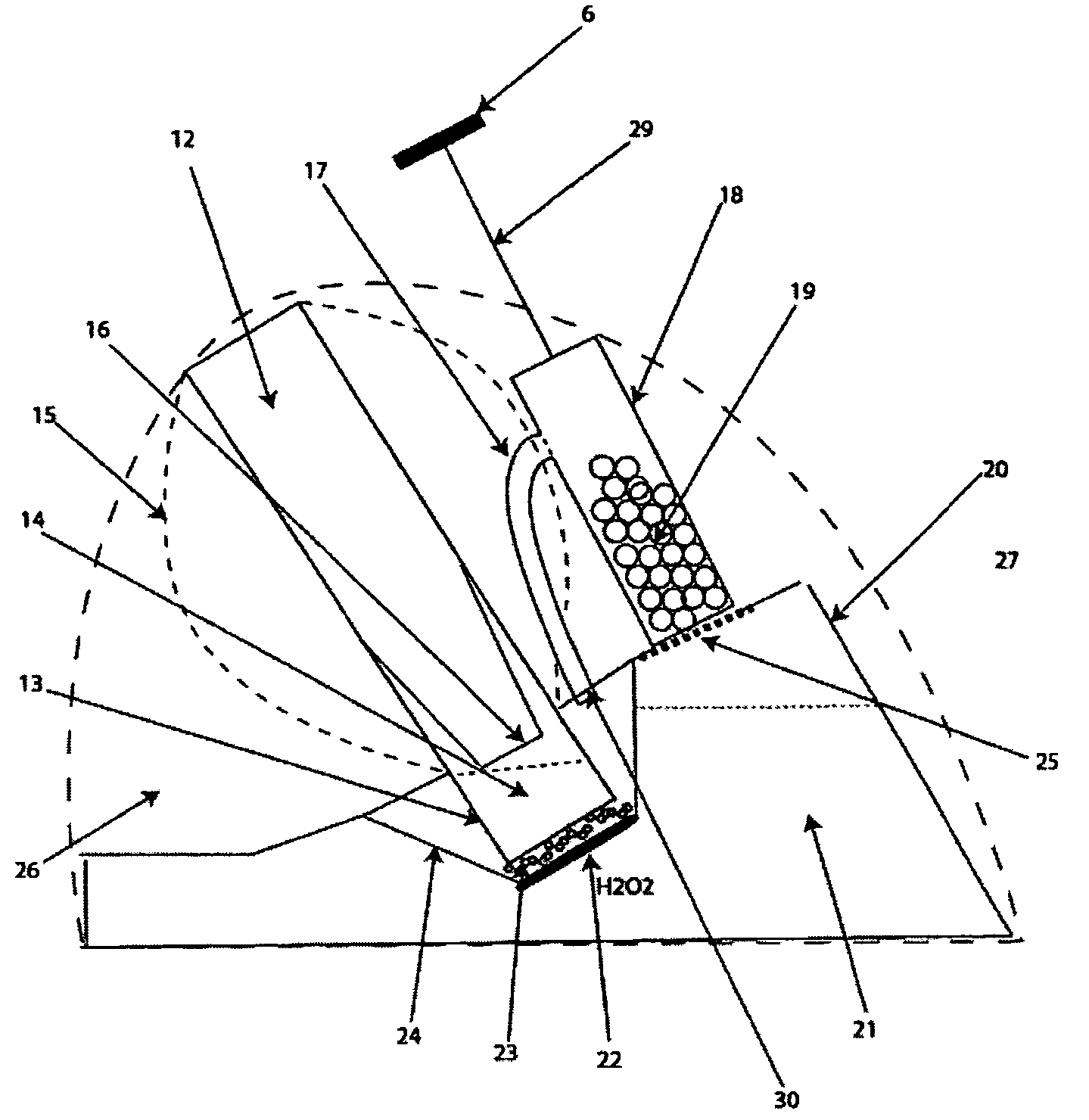

Baby bottle warmer

InactiveUS6234165B1Exothermal chemical reaction heat productionOther heat production devicesEngineeringSaline solutions

A method and apparatus utilizing an exothermic reaction to generate a heated gas that warms a baby bottle, providing a baby bottle warmer that is portable, convenient to use, simple, and lightweight. In one embodiment, a heating vessel holds the baby bottle and a vessel top removably attaches to an upper section of the heating vessel. A solution release mechanism situated in a lower section of said heating vessel includes a solution container having an activating liquid disposed therein, and a device for puncturing the solution container responsive to pressure supplied by insertion of the baby bottle. A heating element situated below the solution release mechanism includes a material for exothermically reacting with the activating liquid to generate the heated gas. In one embodiment, when a baby bottle is inserted into the bottle warmer, an upper and lower unit are pressured together to release a saline solution onto a magnesium wafer. Some embodiments of the baby bottle warmer comprise a system for spacing apart the lower and upper units, which is useful for storage and / or travel. Upon insertion of the baby bottle and application of pressure, the system disengages, thereby allowing the upper and lower units to move together.

Owner:KEVIN A CREIGHTON +1

Exothermic composition and exothermic element

InactiveUS20060154006A1Envelopes/bags making machineryExothermal chemical reaction heat productionSolid componentWater insoluble

In a heat generating composition which generates heat by contacting with air, a heat generating composition which is characterized in that an exothermic substance, a reaction promoter, water and a carbon component are essential components, water mobility value thereof is 20 or less, maximum particle size of water-insoluble solid components excluding the reaction promoter and water is 1 mm or less where 80% or more thereof has a particles size of 300 μm or less, water in the heat generating composition does not function as a barrier layer and exothermic reaction takes place when contacted to the air. A heat generating composition having a molding property and a shape-holding property and also having an exothermic characteristic whereby exothermic reaction is able to start by contacting to the air immediately after the molding and a heat generating body using the same are provided.

Owner:MYCOAL PRODS CORP

Methods of controlling multilayer foil ignition

InactiveUS20050142495A1Exothermal chemical reaction heat productionPhotomechanical apparatusEngineeringEnergy source

Embodiments of the invention include a method of simulating an ignition of a reactive multilayer foil. Other embodiments include various methods of igniting a reactive multilayer foil by transferring energy from an energy source to a reactive multilayer foil.

Owner:REACTIVE NANOTECH +1

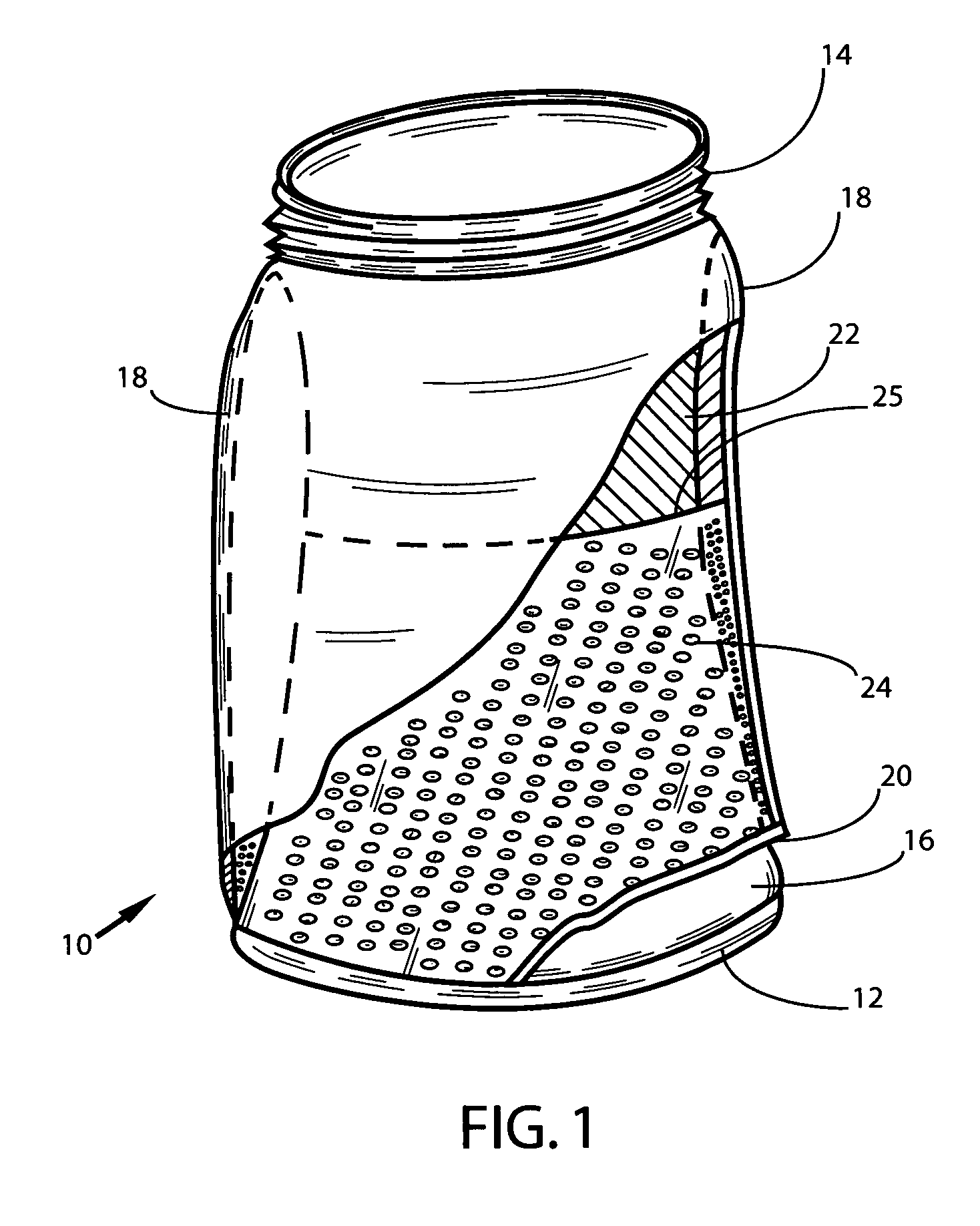

Containers and packagings for regulating heat transfer

InactiveUS7836722B2Exothermal chemical reaction heat productionDomestic cooling apparatusEngineeringLatent heat

A food container includes an upper wall, a lower wall, and a side wall extending between the upper wall and the lower wall. At least one of the upper wall, the lower wall, and the side wall includes a plurality of microcapsules containing a phase change material. The phase change material has a latent heat in the range of 40 J / g to 400 J / g and a transition temperature in the range of 0° C. to 100° C. The phase change material provides thermal regulation based on at least one of absorption and release of the latent heat at the transition temperature.

Owner:OUTLAST TECH LLC

Microencapsulated heat delivery vehicles

InactiveUS20070145326A1Improve performanceReduce heat releasePowder deliveryCosmetic preparationsDelivery vehicleActive agent

Microencapsulated delivery vehicles comprising an active agent are disclosed. In one embodiment, the microencapsulated delivery vehicles are heat delivery vehicles capable of generating heat upon activation. The microencapsulated heat delivery vehicles may be introduced into wet wipes such that, upon activation, the wet wipe solution is warmed resulting in a warm sensation on a user's skin. Any number of other active ingredients, such as cooling agents and biocides, can also be incorporated into a microencapsulated delivery vehicle.

Owner:KIMBERLY-CLARK WORLDWIDE INC

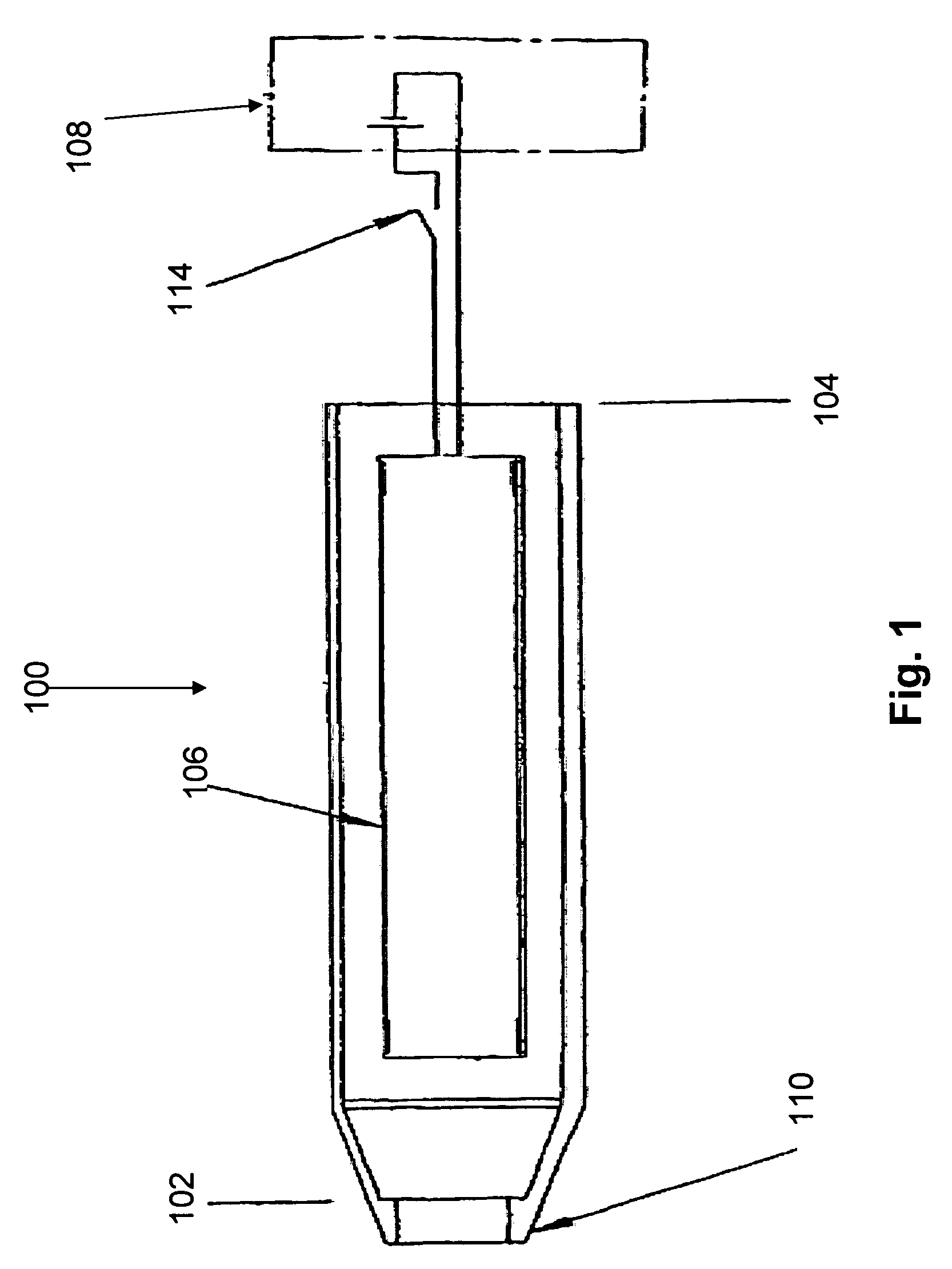

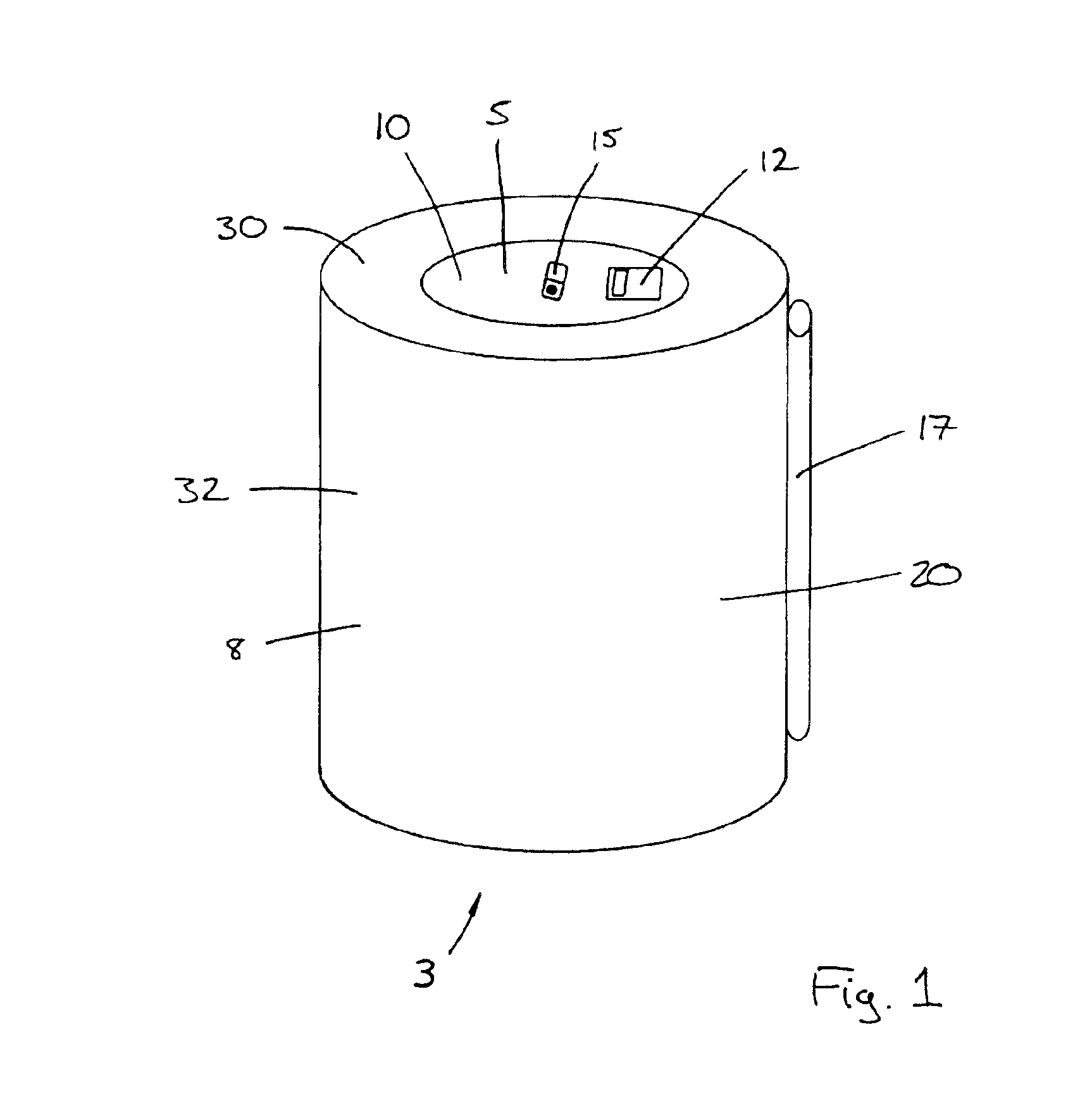

Container with integral module for heating or cooling the contents

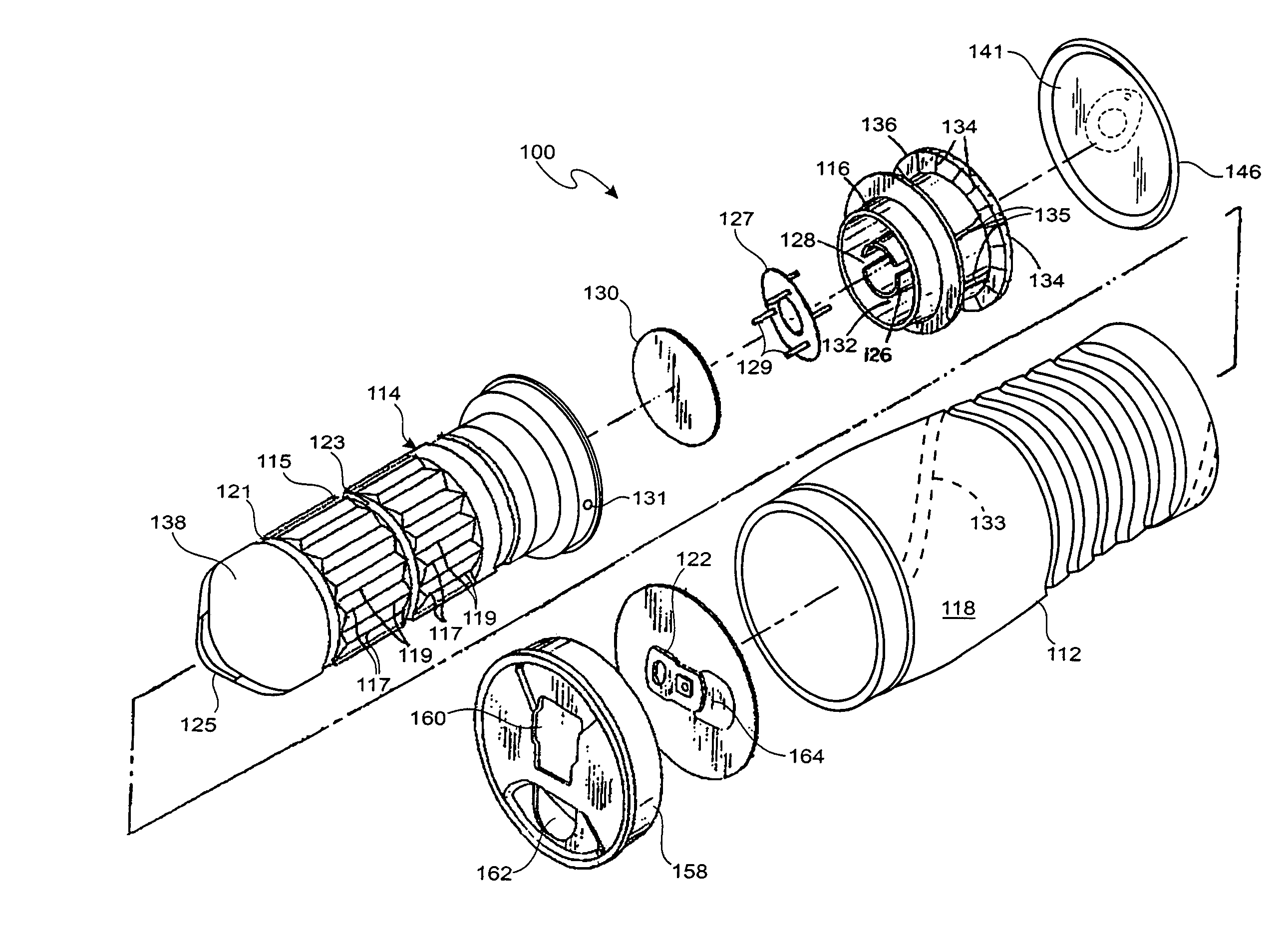

InactiveUS7117684B2Inhibits oxidation and spoilageAvoid failureExothermal chemical reaction heat productionOther heat production devicesChemical reactionAdhesive

A container comprises a container body for containing contents to be heated or cooled, a thermic module at one end of the body, and a closure at the other end of the body. Within the thermic module, an internal exothermic (or, alternatively, endothermic) chemical reaction is initiated to heat its contents when a user actuates the thermic module. The thermic module includes a heat exchanger portion extending proximally into the container and a thermic module cap distal to the heat exchanger portion. The heat exchanger portion has a pleated wall to improve the heat transfer to the contents of the container. The container includes a rotatable cover adhered to the container end over the closure with heat-sensitive adhesive that prevents a user from accessing the contents until a certain temperature is reached. The container further includes a full panel pull-off which covers and protects the actuator from being actuated until the pull-of lid is removed from the full panel pull-off. The thermic module may also include a filter disposed in interfering relation with the thermic module vents, including a portion between the inner and outer actuator buttons, to block egress of any particles of the solid reactant or the reaction product.

Owner:GRP II PARTNERS L P AS LENDER +7

Portable heat generating device

InactiveUS6062210APromotes spontaneous flameless combustionReduce necessityExothermal chemical reaction heat productionOther heat production devicesElastomerThermal energy

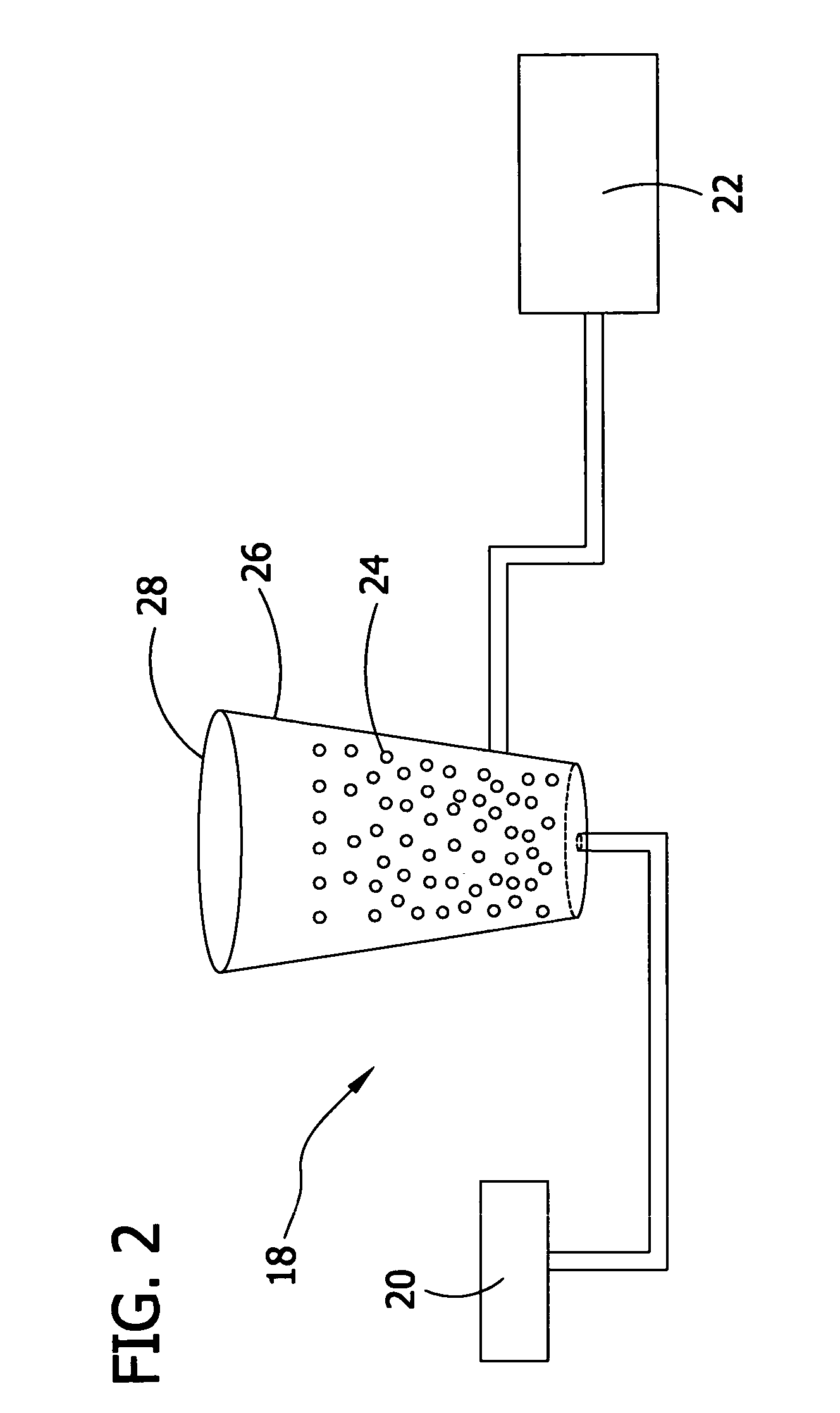

A portable heat generating device in which fuel vapor and an oxygen supply (e.g. air) are directed through channels contained within a thin, flexible and compliant elastomeric sheet of material. Elongated catalytic heat elements, placed strategically within the channels, spontaneously interact with the fuel-air stream liberating heat energy. Means and methods are defined that permit flameless catalytic combustion to be uniformly extended over the length of each heat element, lowering power density but maintaining the overall power generated, permitting the use of many types of low temperature materials like plastics, polymers, and elastomers in the construction of the heater. The heat generation process is started by pumping an air stream into a reservoir containing a fuel source (e.g. methanol) thereby saturating the air stream with fuel vapor. The fuel vapor is mixed with a another stream of air to achieve a particular fuel / air ratio and directed into channels within the elastomeric sheet, reacting with the catalytic heat elements to produce flameless combustion. The warm exhaust gas is directed to a thermally controlled diverter valve. The valve senses the temperature of the liquid fuel supply and diverts some or all of the warm exhaust gas, as necessary, to heat the fuel and keep its temperature within a specified range. Exhaust by-products are passed into a miniature scrubber module adjacent to the fuel module. The scrubber absorbs any noxious components in the exhaust stream that may occur during start-up or rapid changes in operating condition.

Owner:CLIFFORD G WELLES

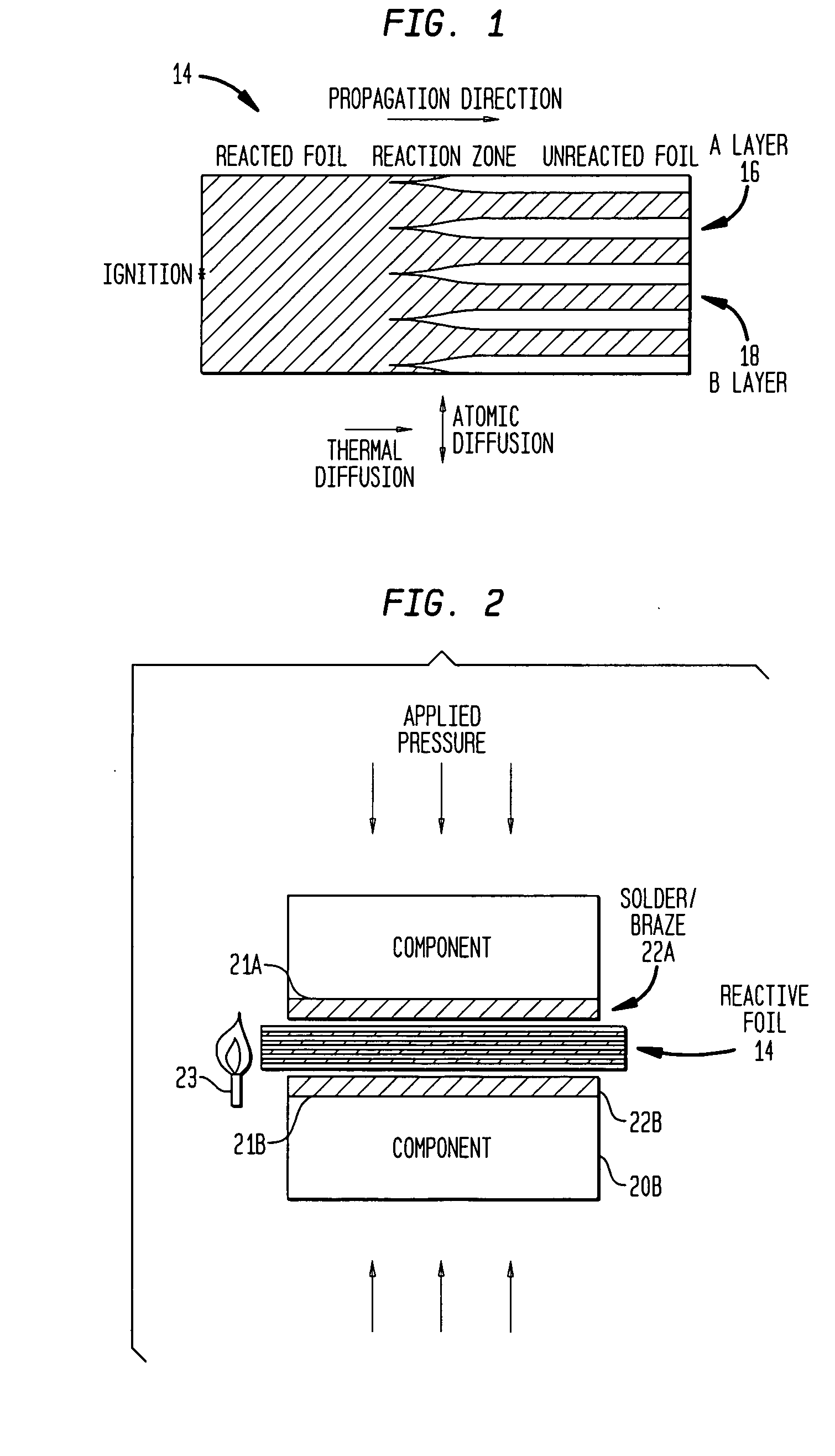

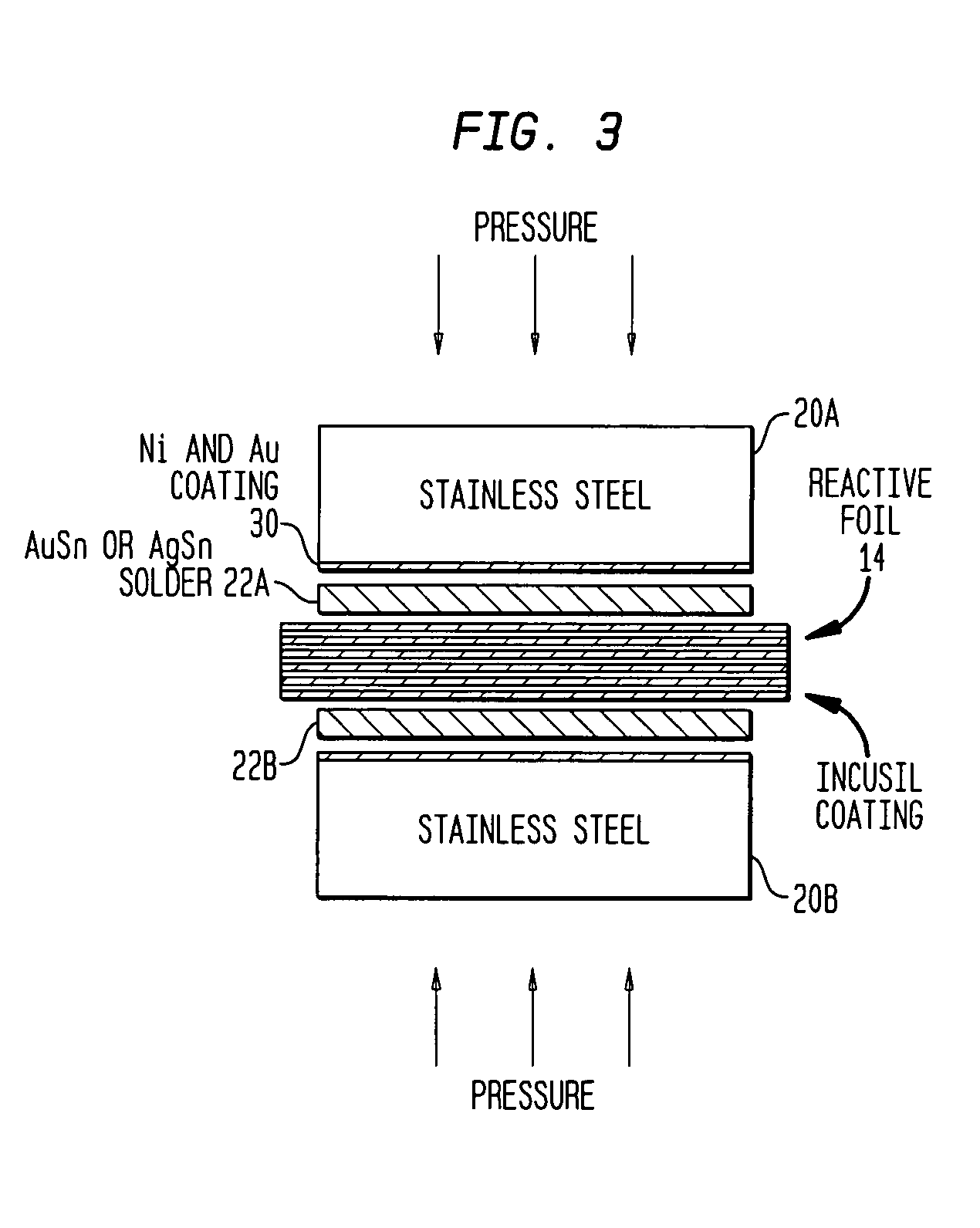

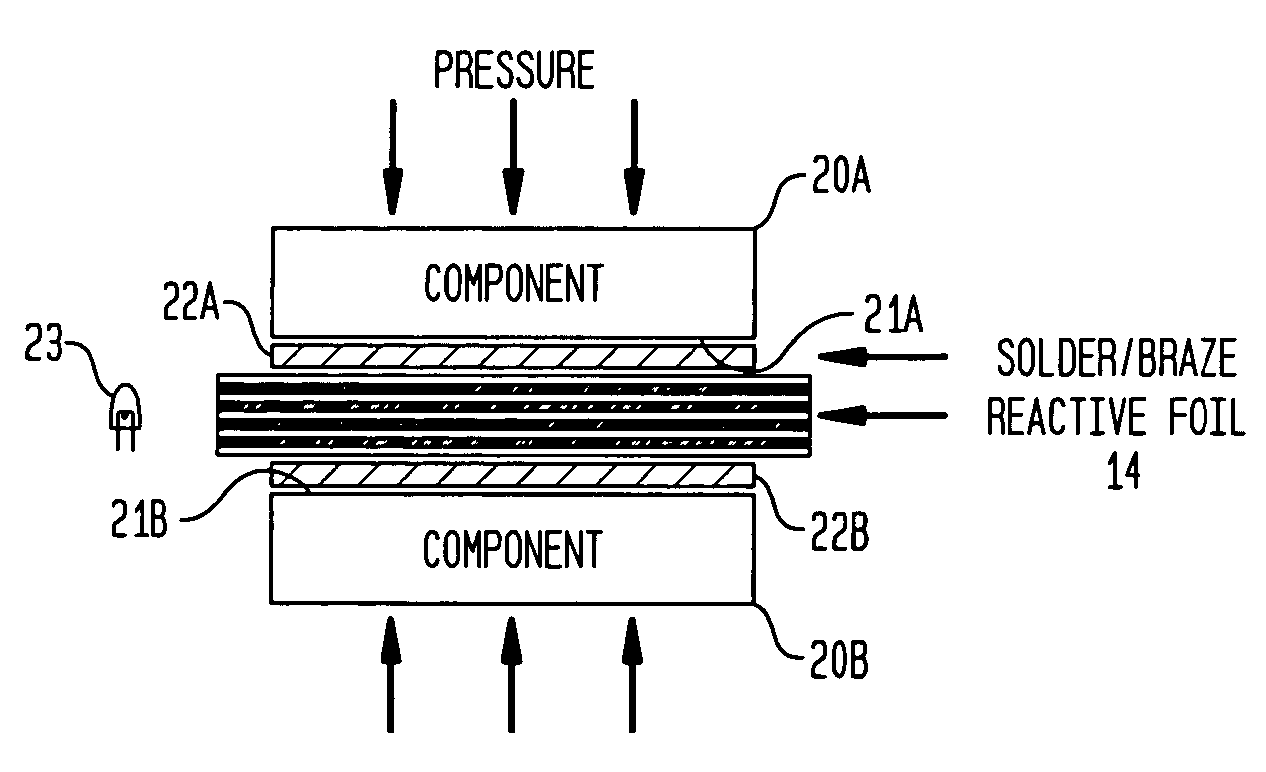

Method of joining using reactive multilayer foils with enhanced control of molten joining materials

InactiveUS20050082343A1Reducing applied pressureExtended durationExothermal chemical reaction heat productionVacuum evaporation coatingCopperMaximum pressure

In accordance with the invention, bodies of materials are joined by disposing between them a reactive multilayer foil and one or more layers of meltable joining material such as braze or solder. The bodies are pressed together against the foil and joining material, and the foil is ignited to melt the joining material. The pressing is near the critical pressure and typically produces a joint having a strength of at least 70-85% the maximum strength producible at practical maximum pressures. Thus for example, reactively formed stainless steel soldered joints that were heretofore made at an applied pressure of about 100 MPa can be made with substantially the same strength at a critical applied pressure of about 10 kPa. Advantages of the process include minimization of braze or solder extrusion and reduced equipment and processing costs, especially in the joining of large bodies.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

Nanostructured soldered or brazed joints made with reactive multilayer foils

InactiveUS7361412B2Reduce coolingImprove microstructureExothermal chemical reaction heat productionVacuum evaporation coatingRoom temperatureSlow cooling

Self-propagating formation reactions in nanostructured multilayer foils provide rapid bursts of heat at room temperature and therefore can act as local heat sources to melt solder or braze layers and join materials. This reactive joining method provides very localized heating to the components and rapid cooling across the joint. The rapid cooling results in a very fine microstructure of the solder or braze material. The scale of the fine microstructure of the solder or braze material is dependant on cooling rate of the reactive joints which varies with geometries and properties of the foils and components. The microstructure of the solder or braze layer of the joints formed by melting solder in a furnace is much coarser due to the slow cooling rate. Reactive joints with finer solder or braze microstructure show higher shear strength compared with those made by conventional furnace joining with much coarser solder or braze microstructure. It is expected that the reactive joints may also have better fatigue properties compared with conventional furnace joints.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

Exothermic composition and exothermic article using composition, and method for producing exothermic article

InactiveCN1491271AAccurate Guaranteed QuantityHas dispersion stabilityExothermal chemical reaction heat productionHeat-exchange elementsDispersion stabilityChemical composition

It relates to a heat-generating composition having such dispersion stability that withstands continuous molding, and has excellent drainage property, excellent heat-generating characteristics, excellent molding property and excellent shape retaining property, without becoming viscous, and relates to a heat-generating body using the same and a process for producing the heat-generating body. It contains, as essential components, a heat-generating substance generating heat upon reaction with oxygen, a carbon component, an oxidation promoter and water, characterized in that the composition further contains a water separation-preventing stabilizer in a proportion of from 0.001 to 0.25 part by mass per 100 parts by mass of the heat-generating composition, and has a water mobility value of from 7 to 40 and a separation degree of from 0 to 30.

Owner:MYCOAL

Method and apparatus for heating and applying warm antifog solution to endoscopes as well as a distal lens protector

InactiveUS7311660B2Avoid condensationImprove protectionExothermal chemical reaction heat productionOther heat production devicesCombined useTemperature difference

Owner:COVIDIEN LP

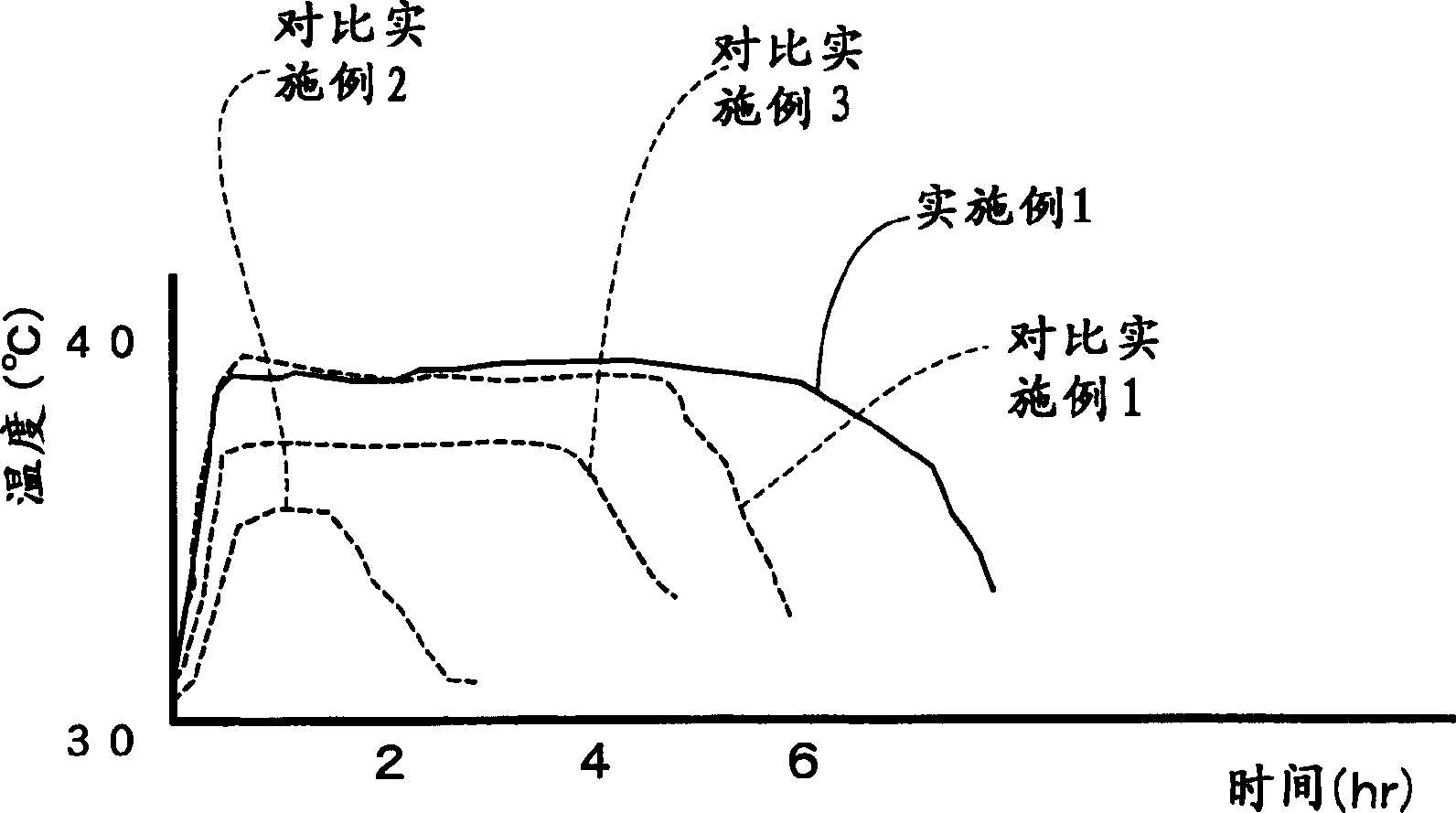

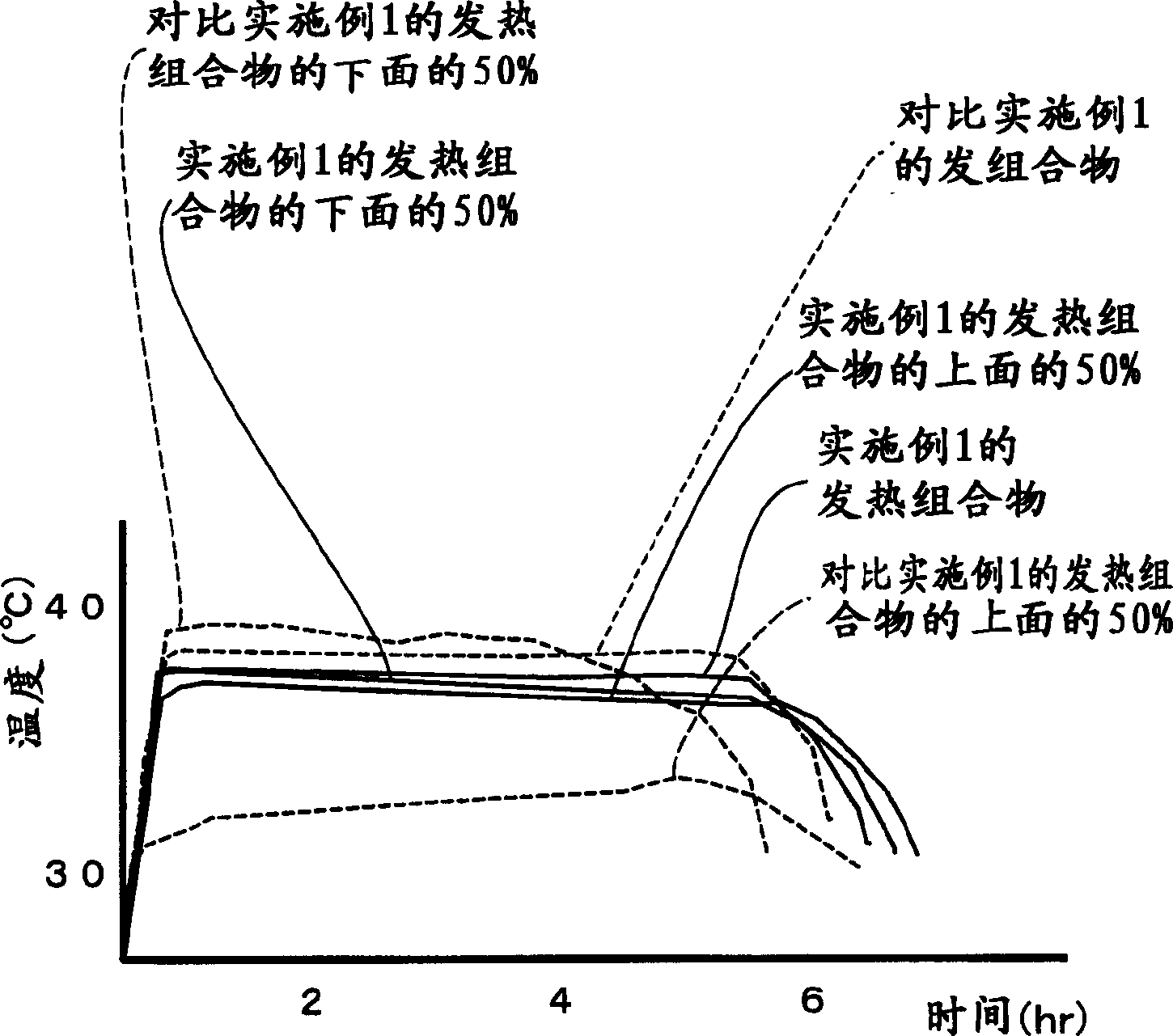

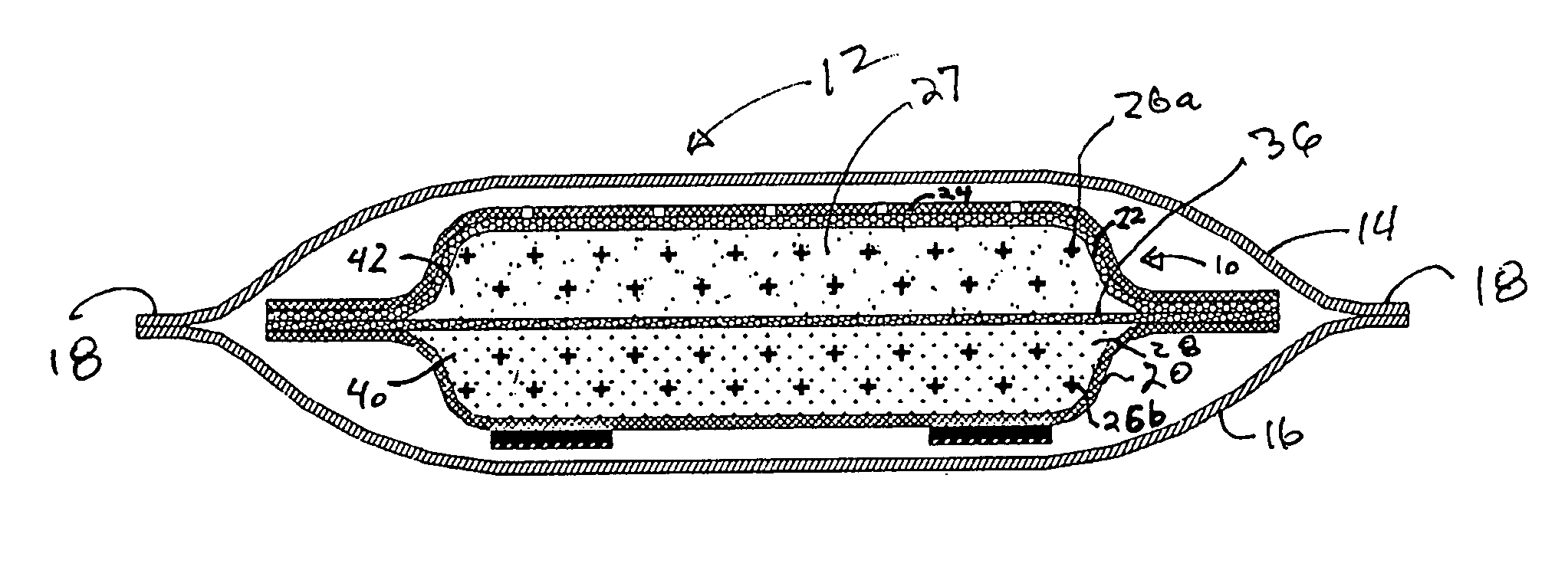

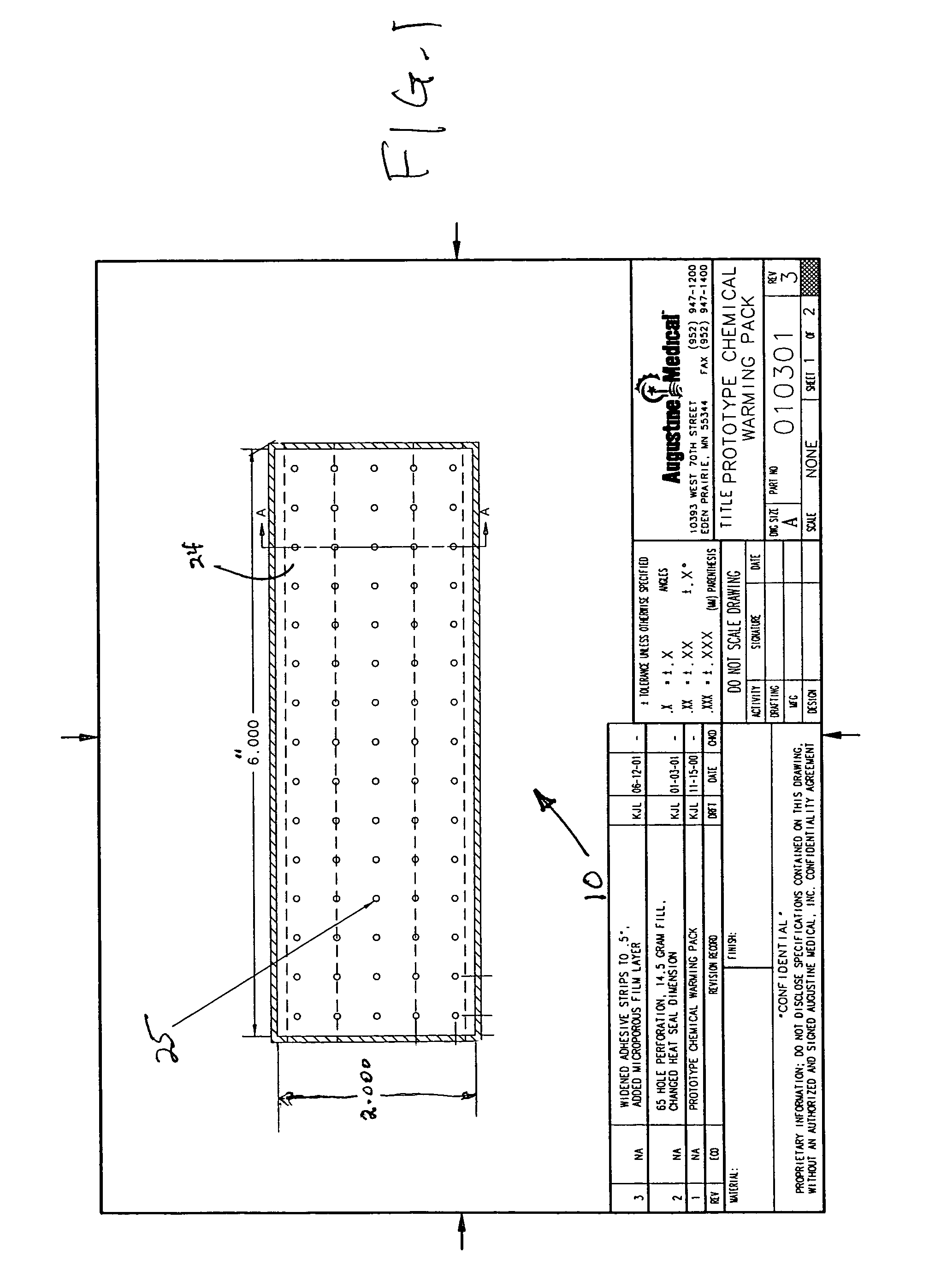

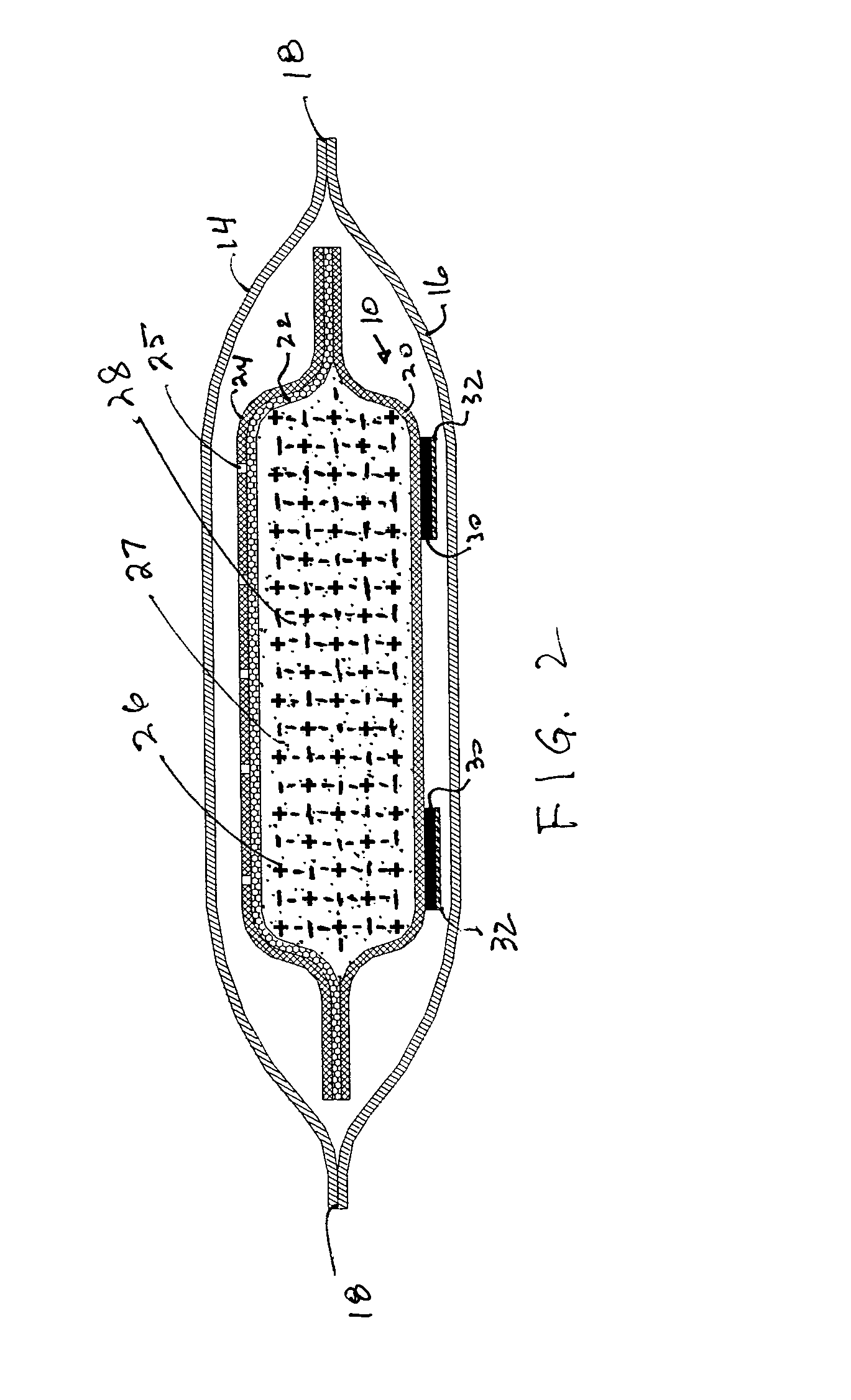

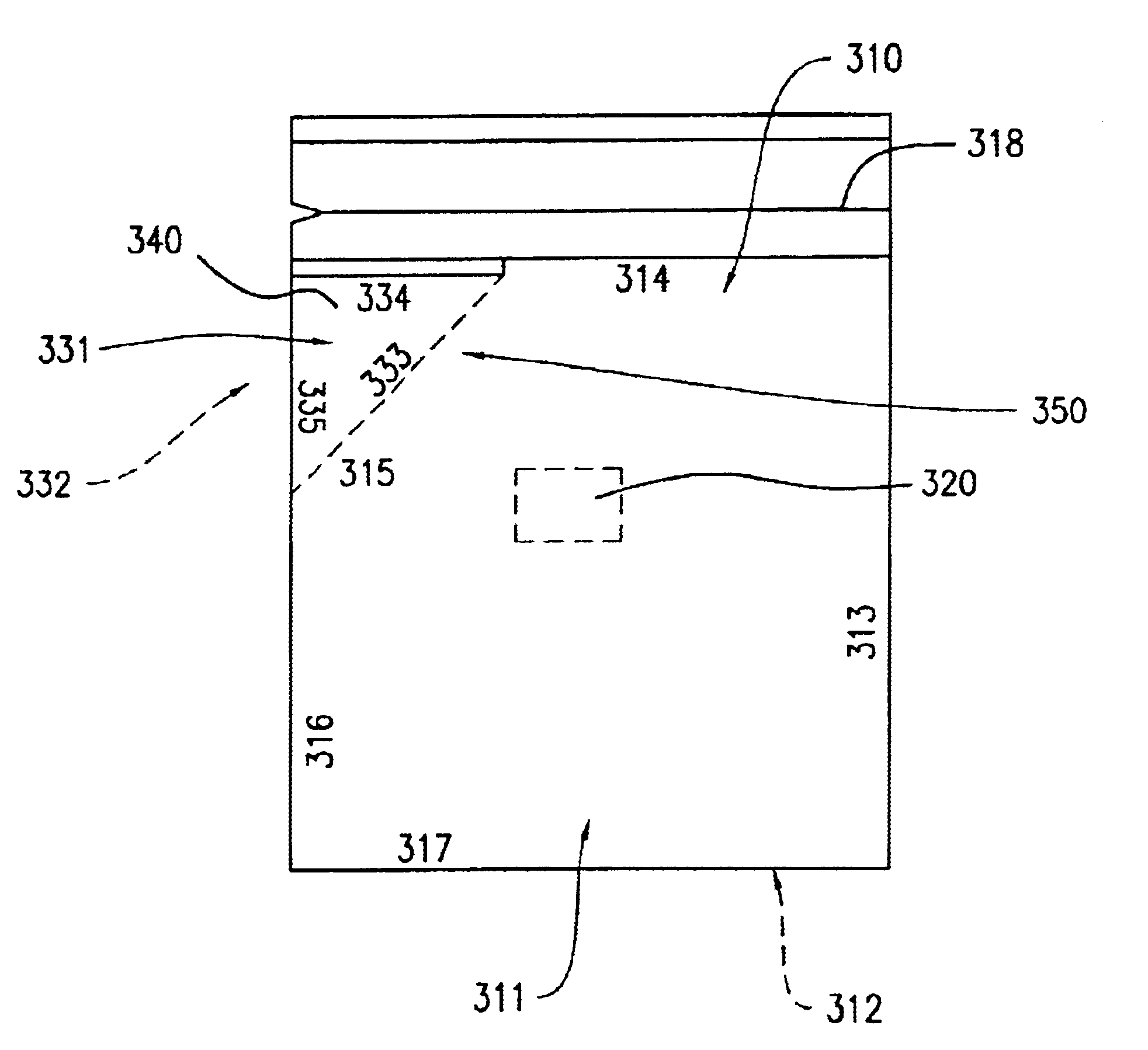

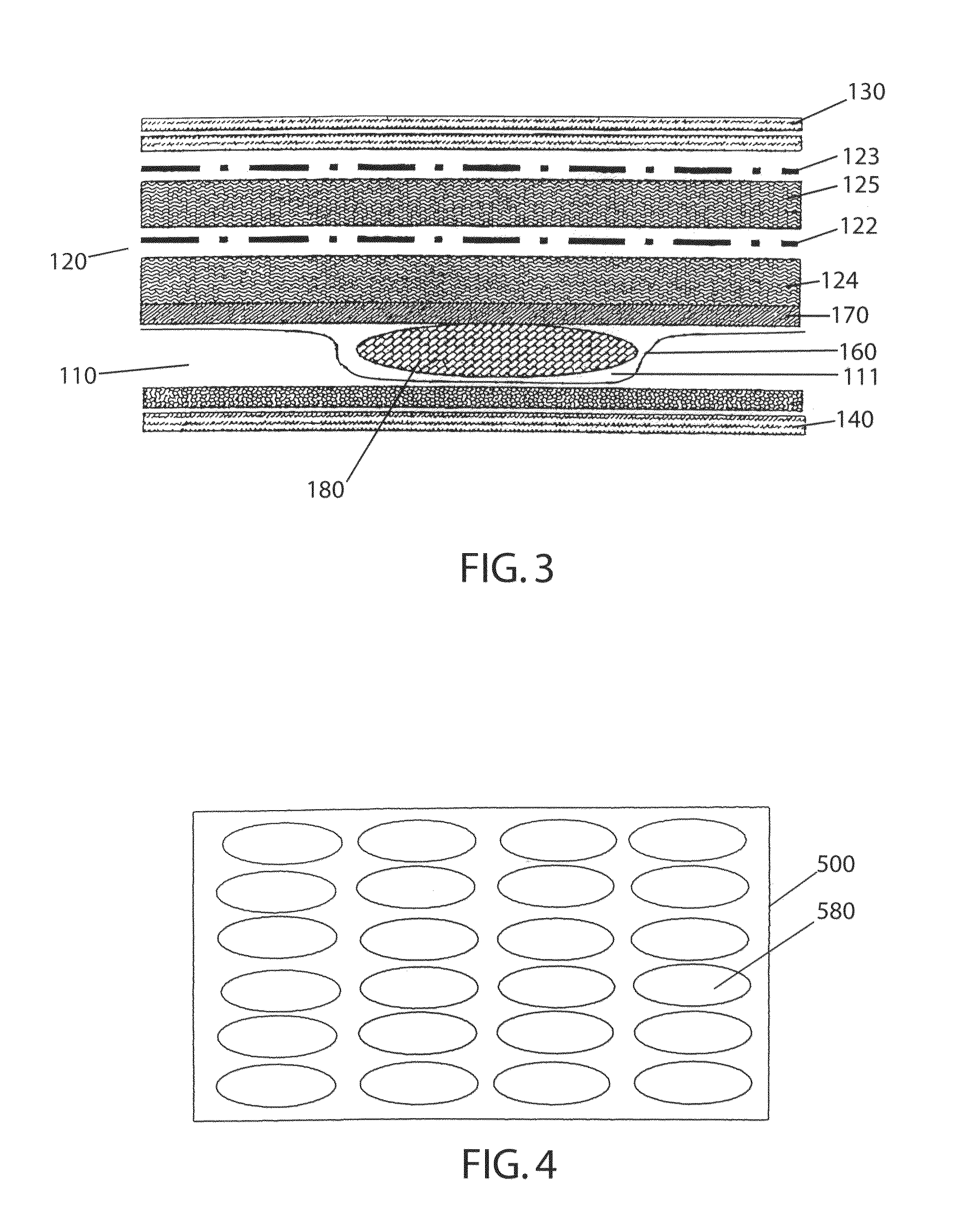

Warming pack with temperature uniformity and temperature stabilization

InactiveUS7041123B2Reduce the temperatureReduce temperature changesExothermal chemical reaction heat productionDomestic cooling apparatusChemical reactionConstant rate

A warming pack includes a container in the form of a pack, pouch, or bag in which reactants for an exothermic chemical reaction are distributed in one or more flexible matrixes that prevent them from shifting. The rate of the reaction is controlled and the reaction is thermally buffered in order that heat be produced at a constant rate.

Owner:GEN ELECTRIC CAPITAL +1

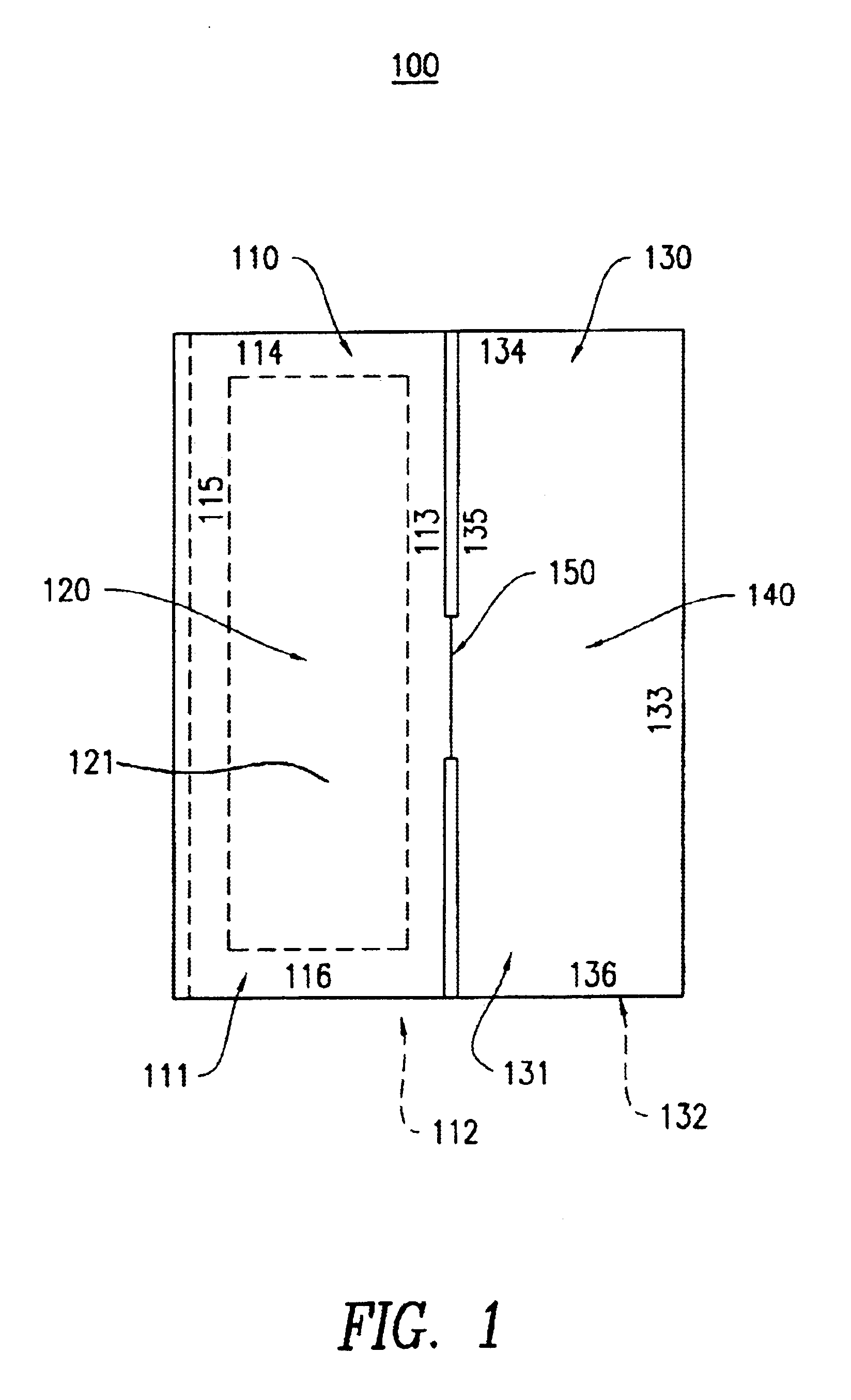

Compartmentalized storage system for temporarily storing and subsequently mixing at least two different substances

InactiveUS6866145B2Ready-for-oven doughsExothermal chemical reaction heat productionComputer scienceProcess engineering

The present invention is directed to a compartmentalized storage system for temporarily storing and subsequently mixing at least two different substances. The compartmentalized storage system comprises a first storing compartment, with an optional a tearable seal, containing a solid sorbing substrate, such as a wipe, and a first substance. The compartmentalized storage system further comprises a second storing compartment having a second substance. The first and the second compartments are attached to each other by at least one common side, which common side comprises a frangible seal connecting the first and the second compartments. By applying force to the frangible seal, the seal will break and thereby allow the second substance in the second storing compartment to be mixed with the solid sorbing substrate and the first substance in the first storing compartment.

Owner:BUSH BOAKE ALLEN LTD

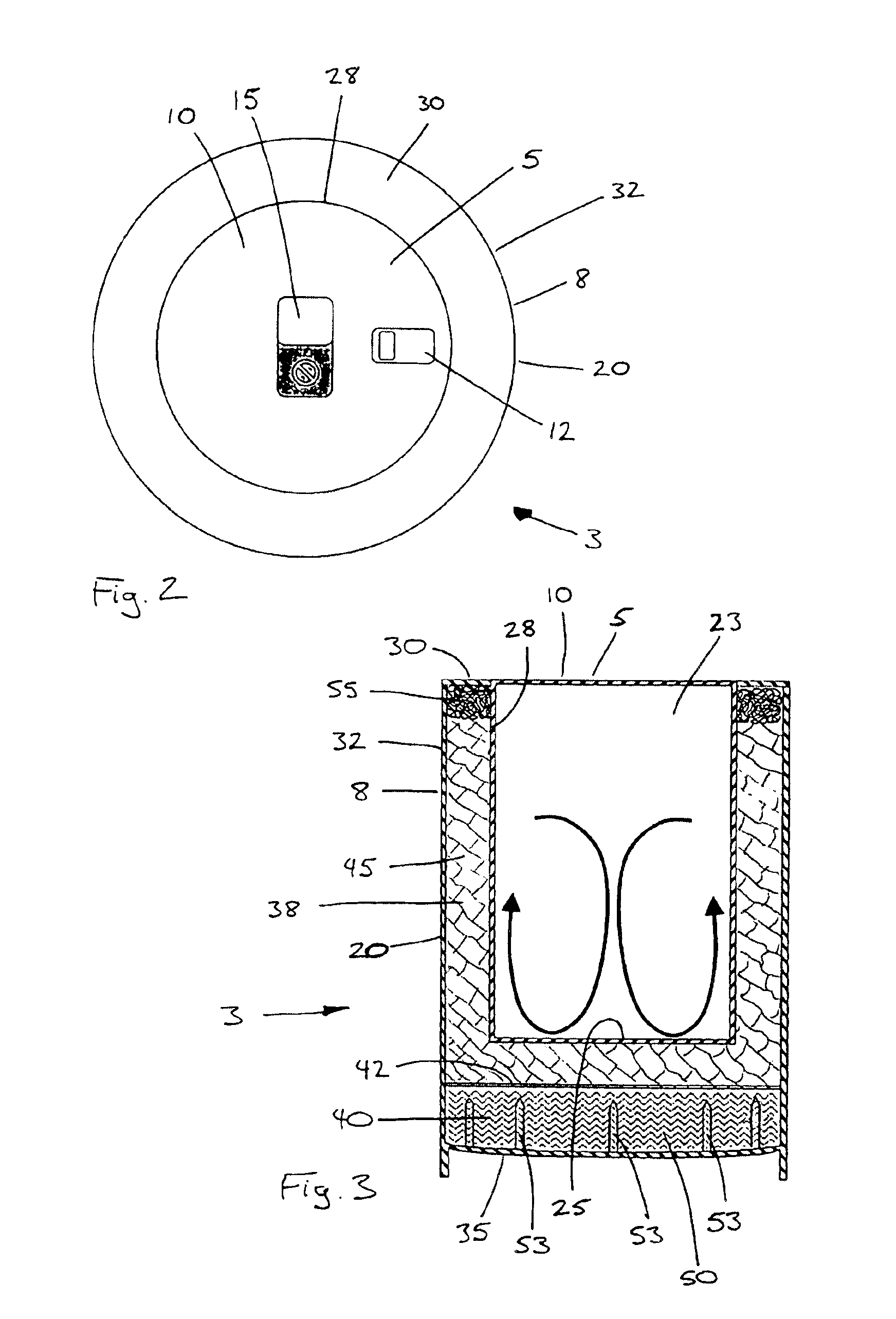

Portable moist heat system

ActiveUS20090287280A1Increase speedImproved controllable uniform applicationExothermal chemical reaction heat productionNervous disorderBlood flowWater vapor

A portable moist heat delivery system comprising a water vapor generating portion comprising a water vapor source and a heat source; a water vapor-air regulating portion, said water vapor-air regulating portion comprising a water vapor-air mixing layer, and a water vapor-air distribution layer; said water vapor generating portion and said water vapor-air regulating portion being in fluid communication; and said water vapor-air regulating portion having a latent heat delivery surface disposed adjacent said water vapor-air regulating portion which delivers moist heat at a preselected temperature range wherein about 15% to about 95% of the moist heat is latent heat of condensation. Methods include delivering improved pain relief, blood flow, relaxation, and reduced cardiac workload.

Owner:BRIDGES CONSUMER HEALTHCARE LLC

Trigger mechanism for self-heating/cooling packages or containers universally applied to both rigid and non-rigid packages and containers

InactiveUS20030116452A1Exothermal chemical reaction heat productionHeat storage plantsEngineeringMechanical engineering

A package is provided including a first sealable envelope containing a first agent, a second sealable envelope containing a second agent adjacent the first sealable envelope and a frangible seal separating the first sealable envelope from the second sealable envelope and a triggering mechanism located on an exterior of the package, the triggering mechanism having a first portion attached to the package at a first point adjacent the first sealable envelope and a second portion attached to the package at a second point adjacent the second sealable envelope such that, if the first portion and the second portion of the triggering mechanism are pulled, the frangible seal is stressed to rupture, allowing the first agent to communicate with the second agent.

Owner:SARIC JERKO +1

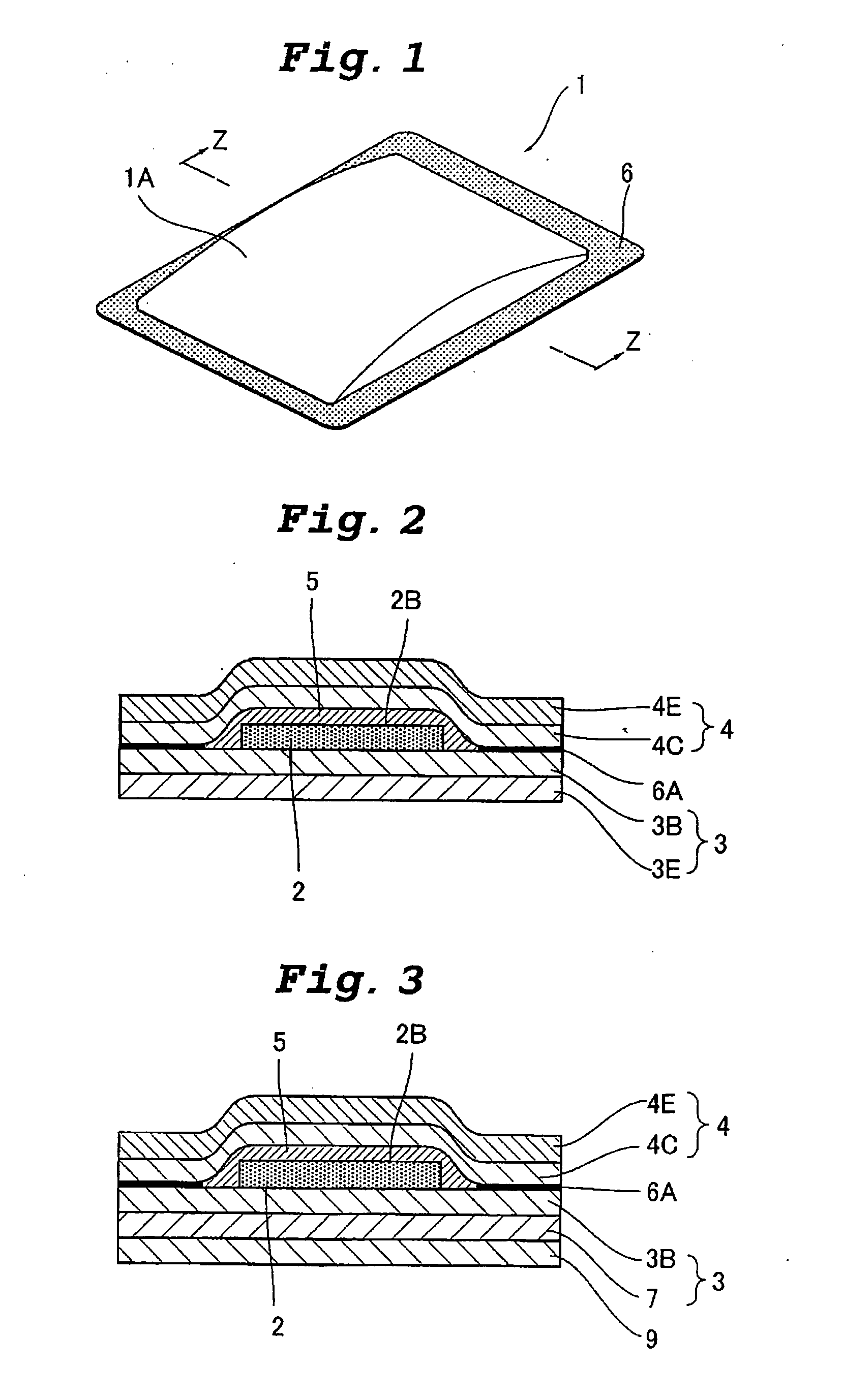

Method for manufacturing thin body warming devices

InactiveUS6863682B2Avoid exothermic reactionsSmall film thicknessExothermal chemical reaction heat productionMechanical working/deformationMetal chlorideTackifier

The present invention relates to the use of an exothermic composition having, as essential components, a water absorptive polymer and / or tackifier, carbon component and / or metal chloride and features that the product is as a whole ink-like or cream-like in a method of manufacturing an exothermic device.

Owner:GENCHI KENKYUSHO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com