Patents

Literature

217results about How to "Reduce heat release" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

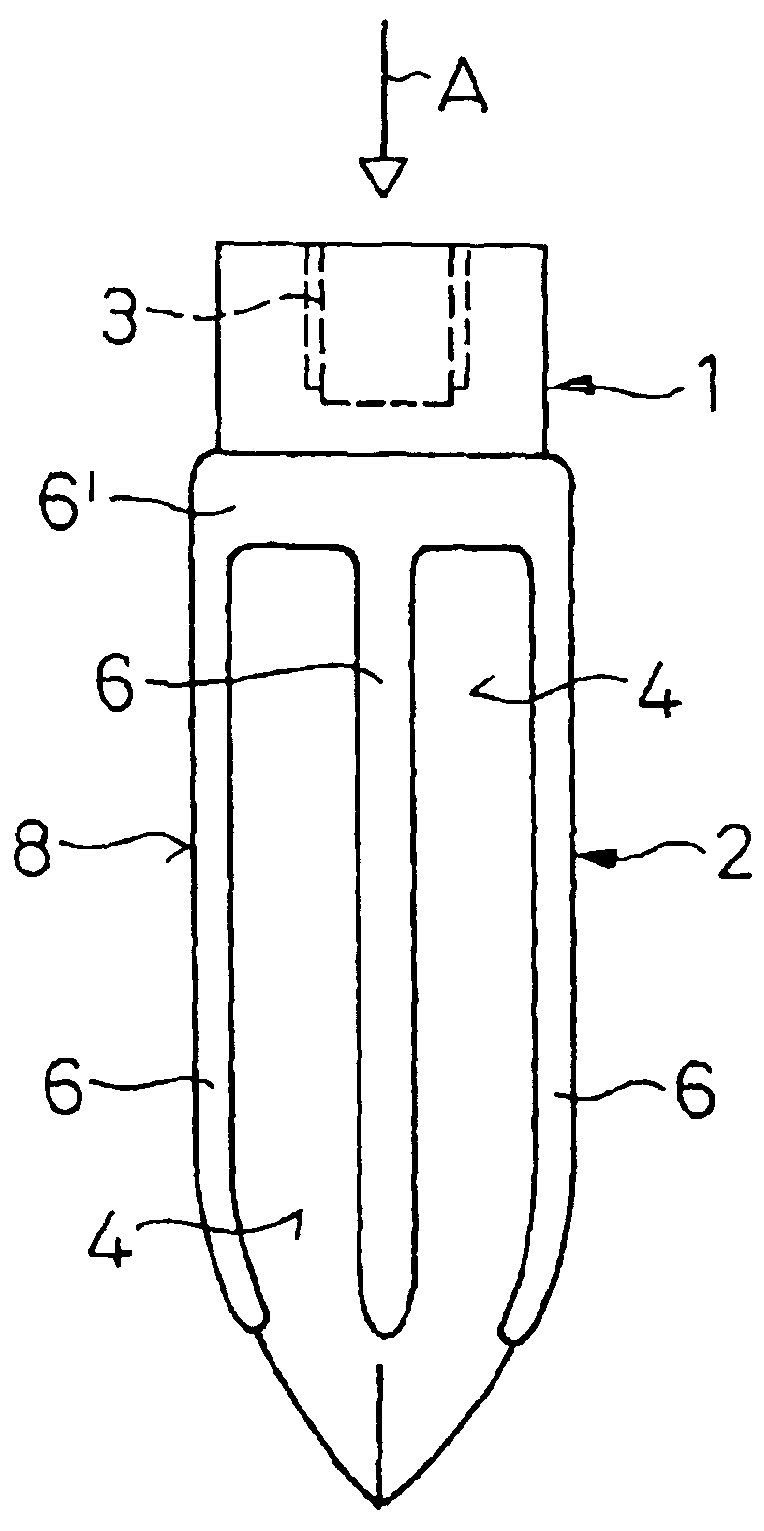

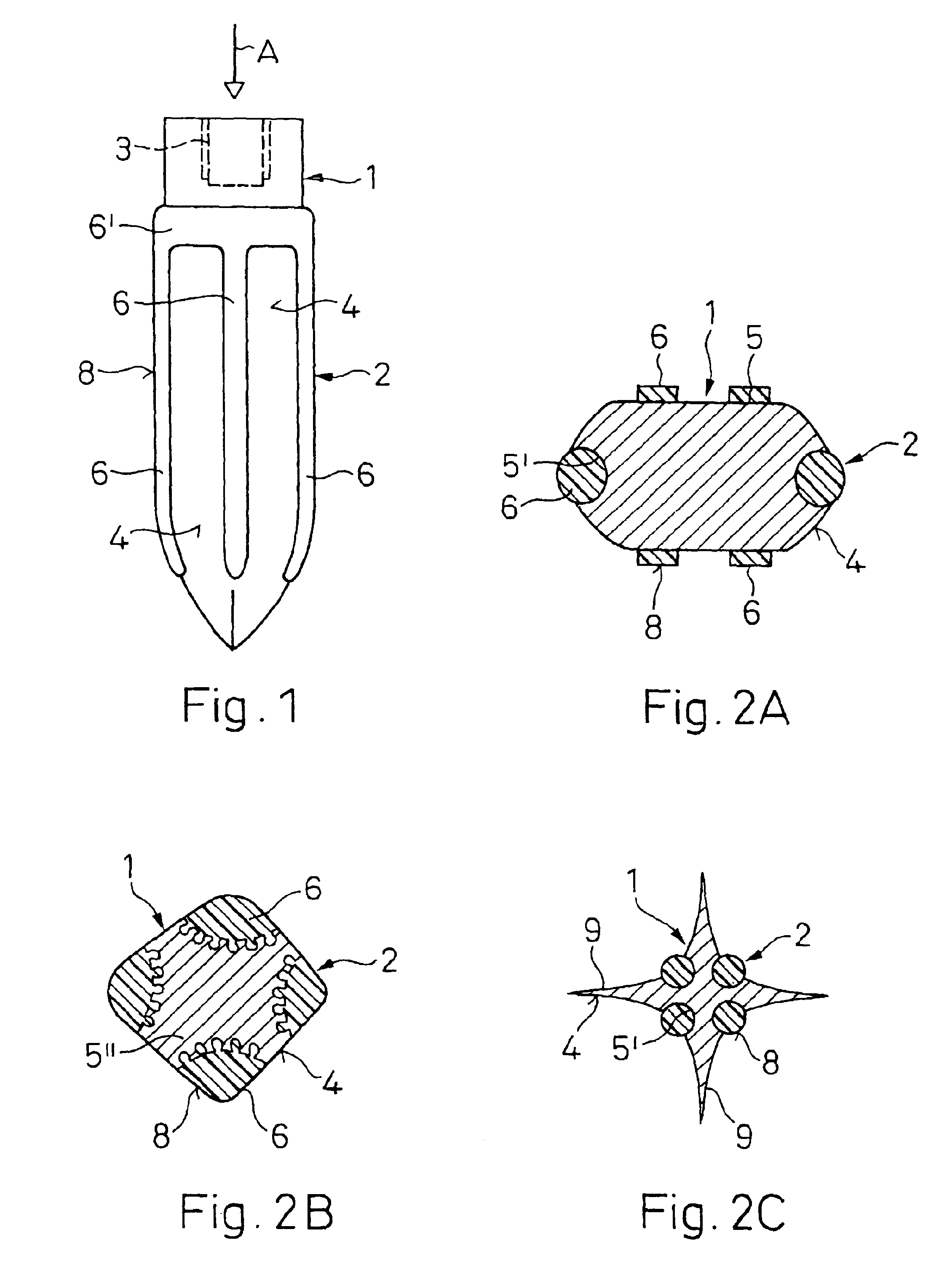

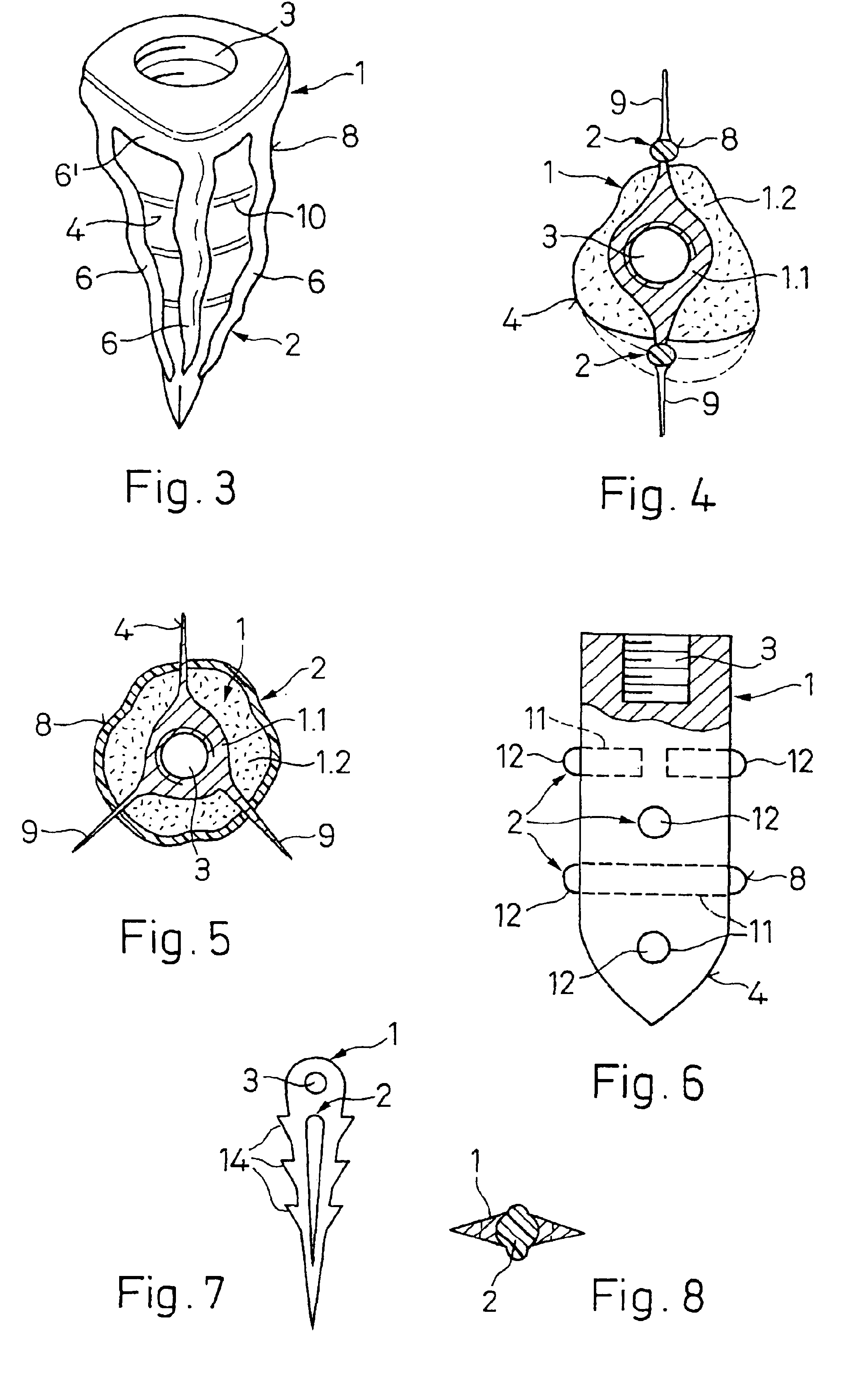

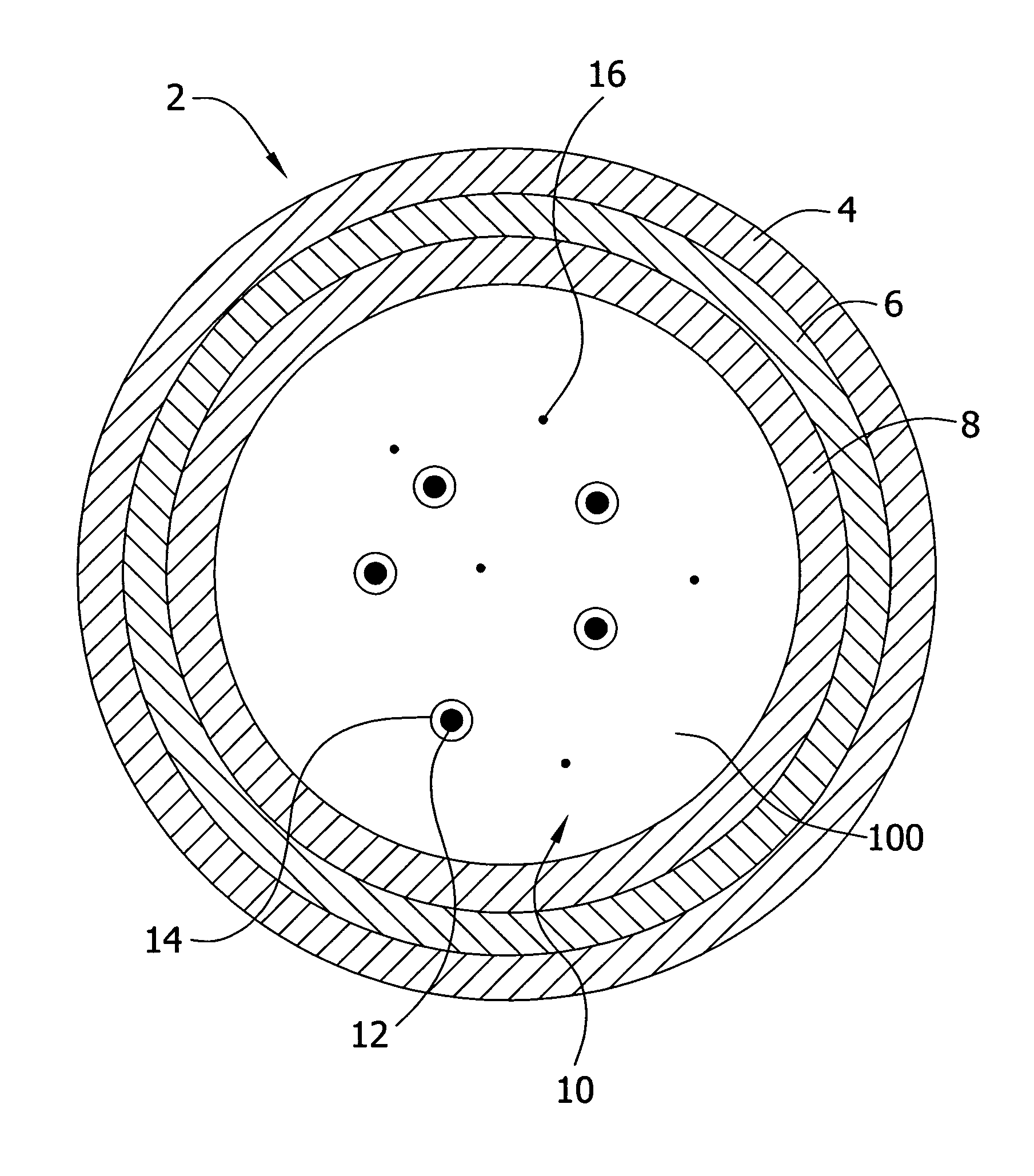

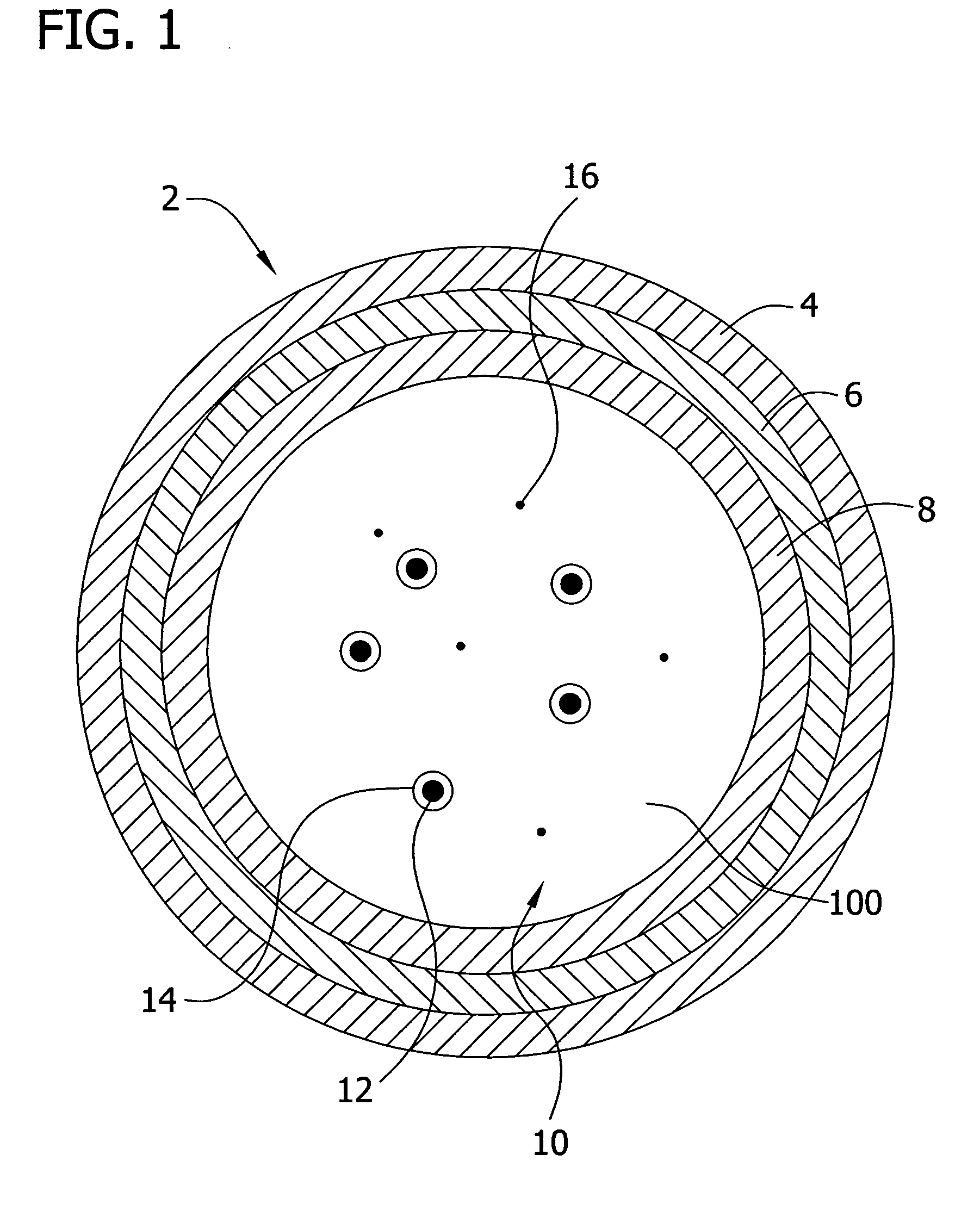

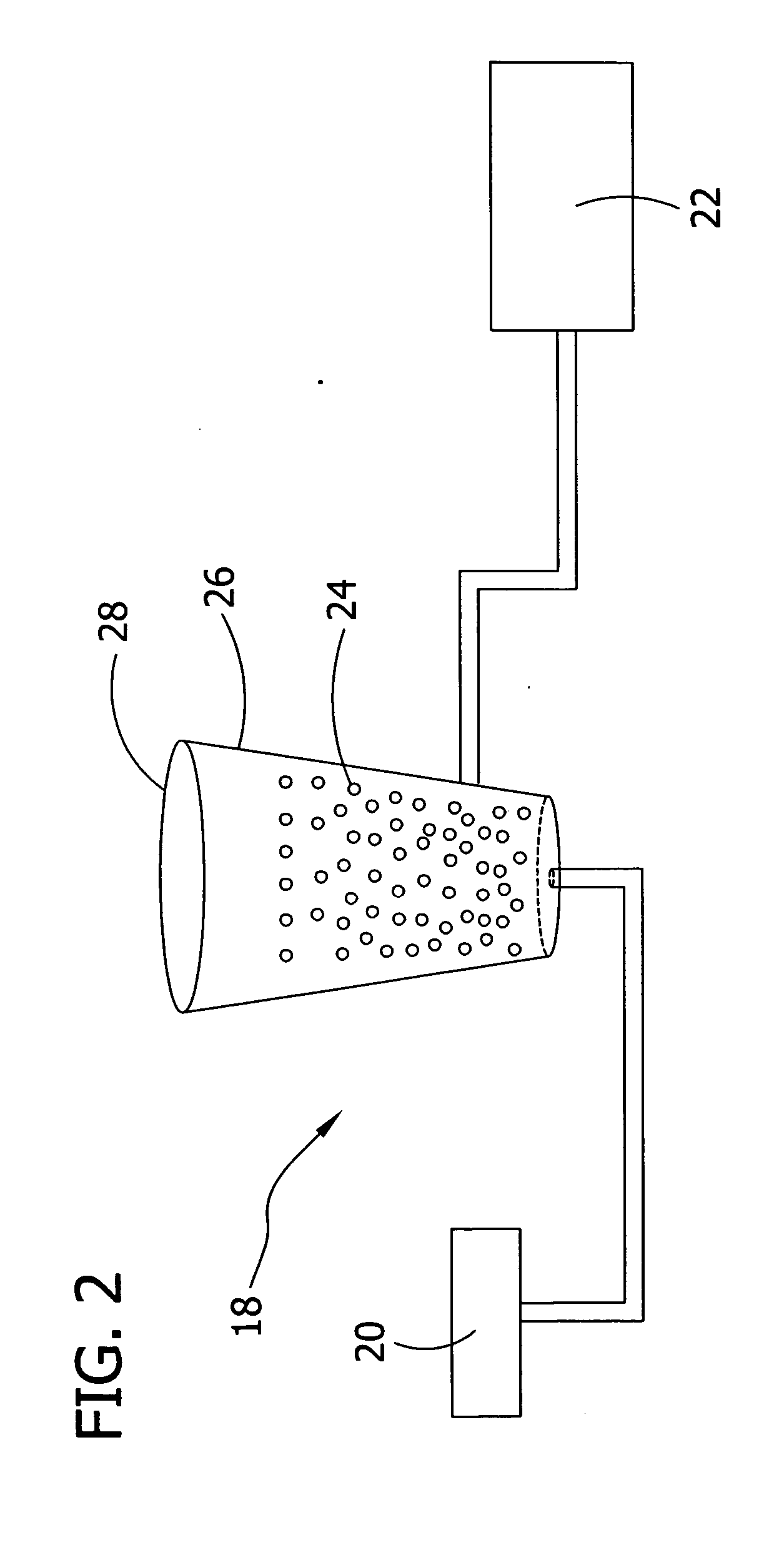

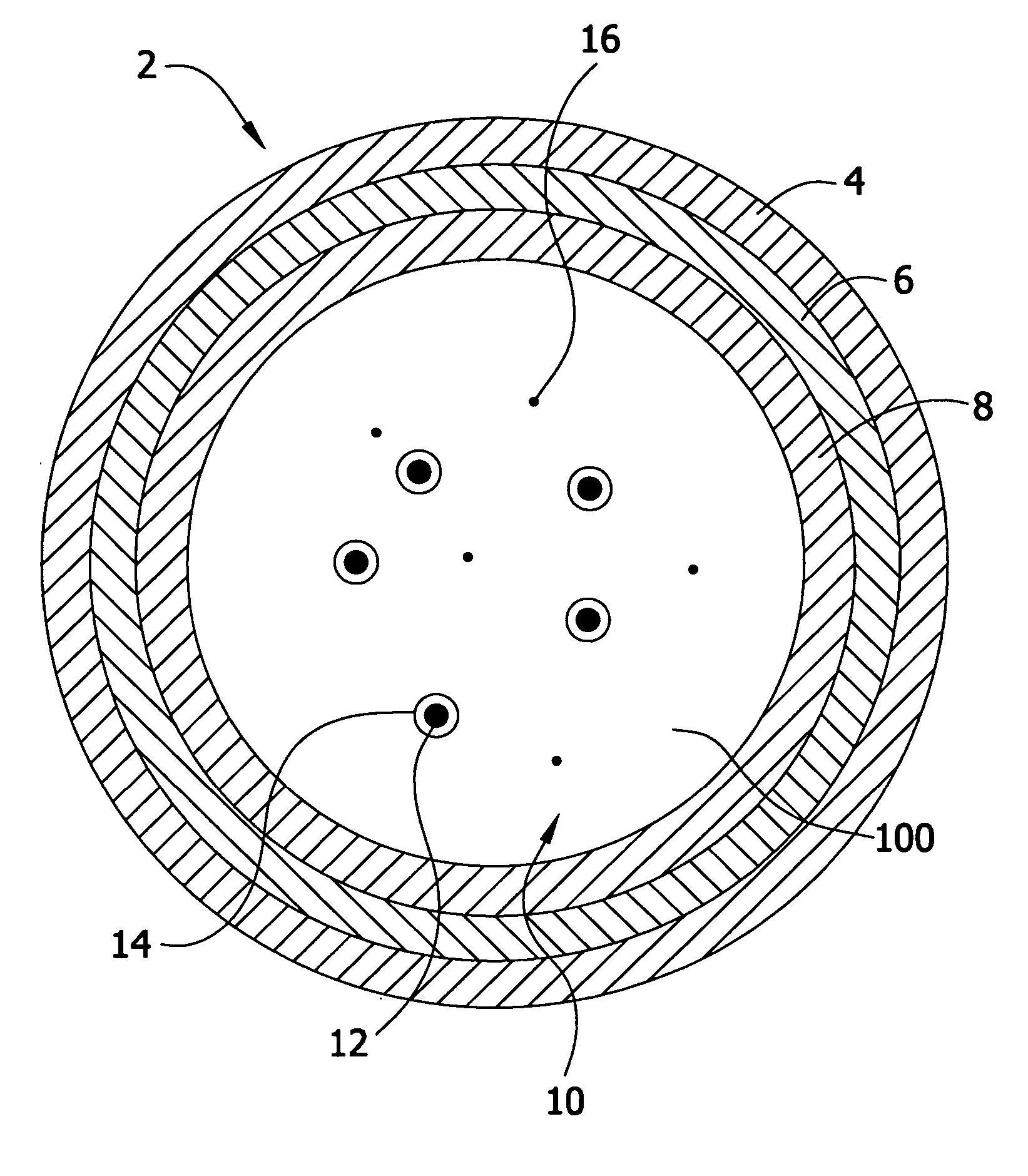

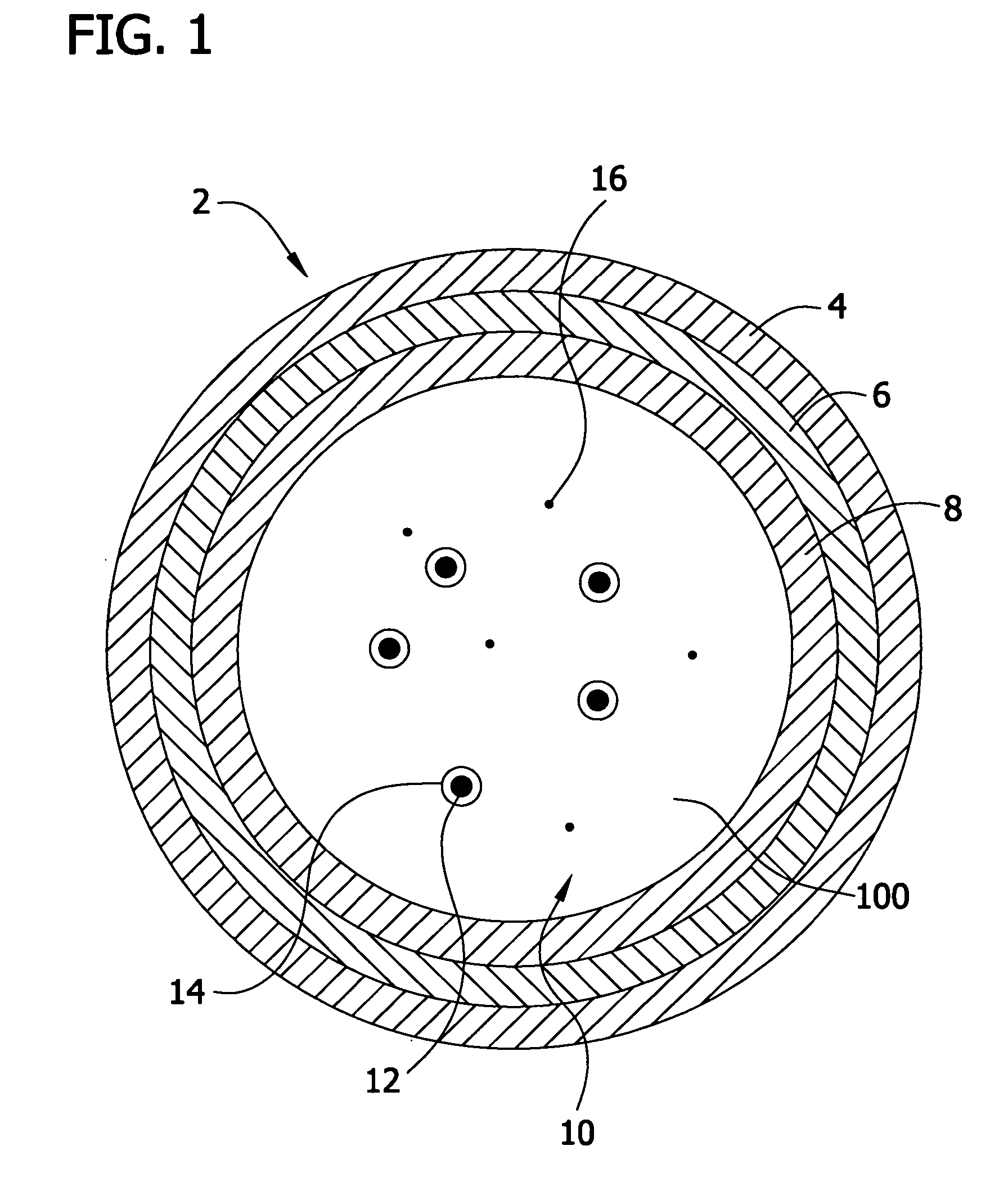

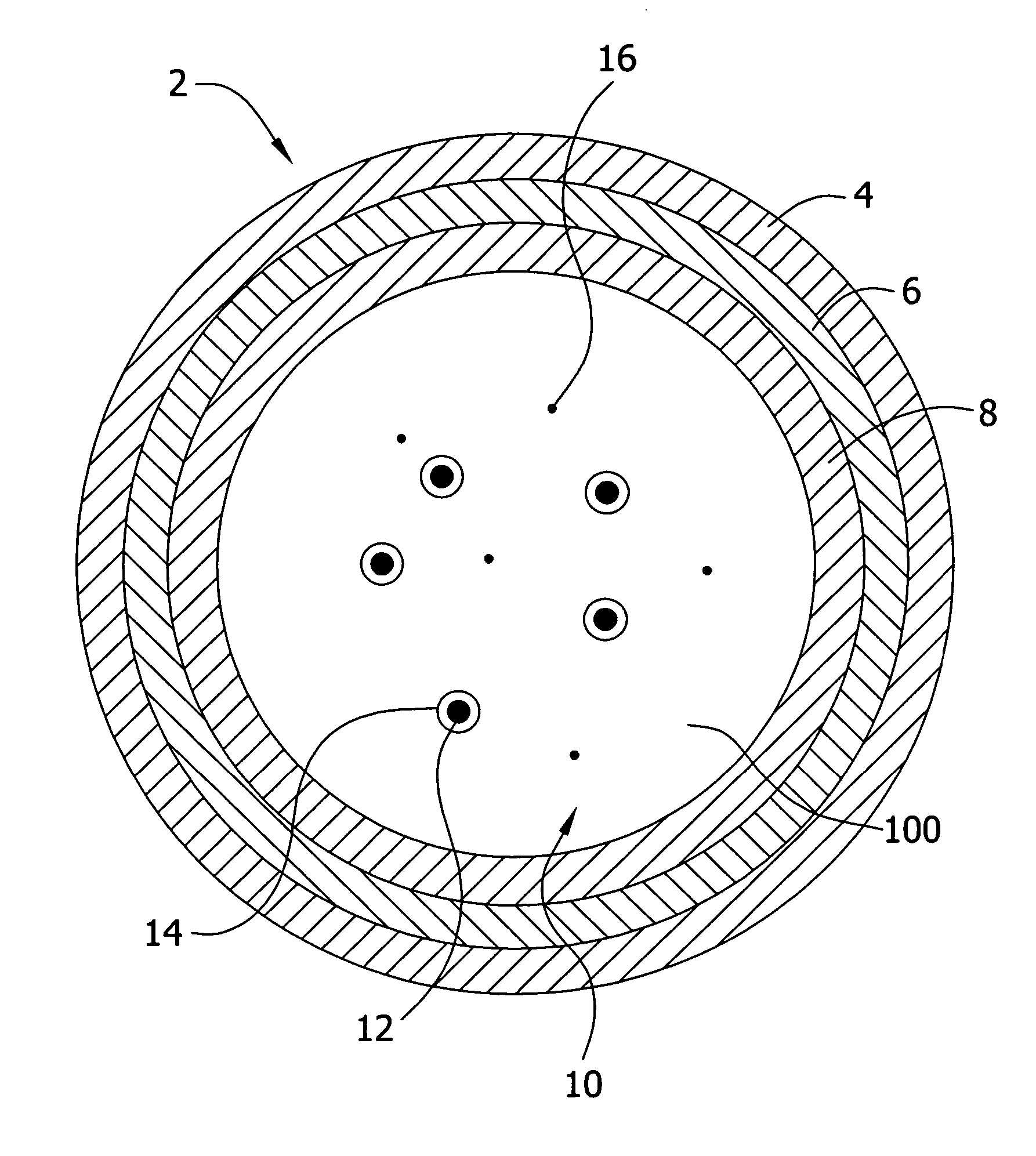

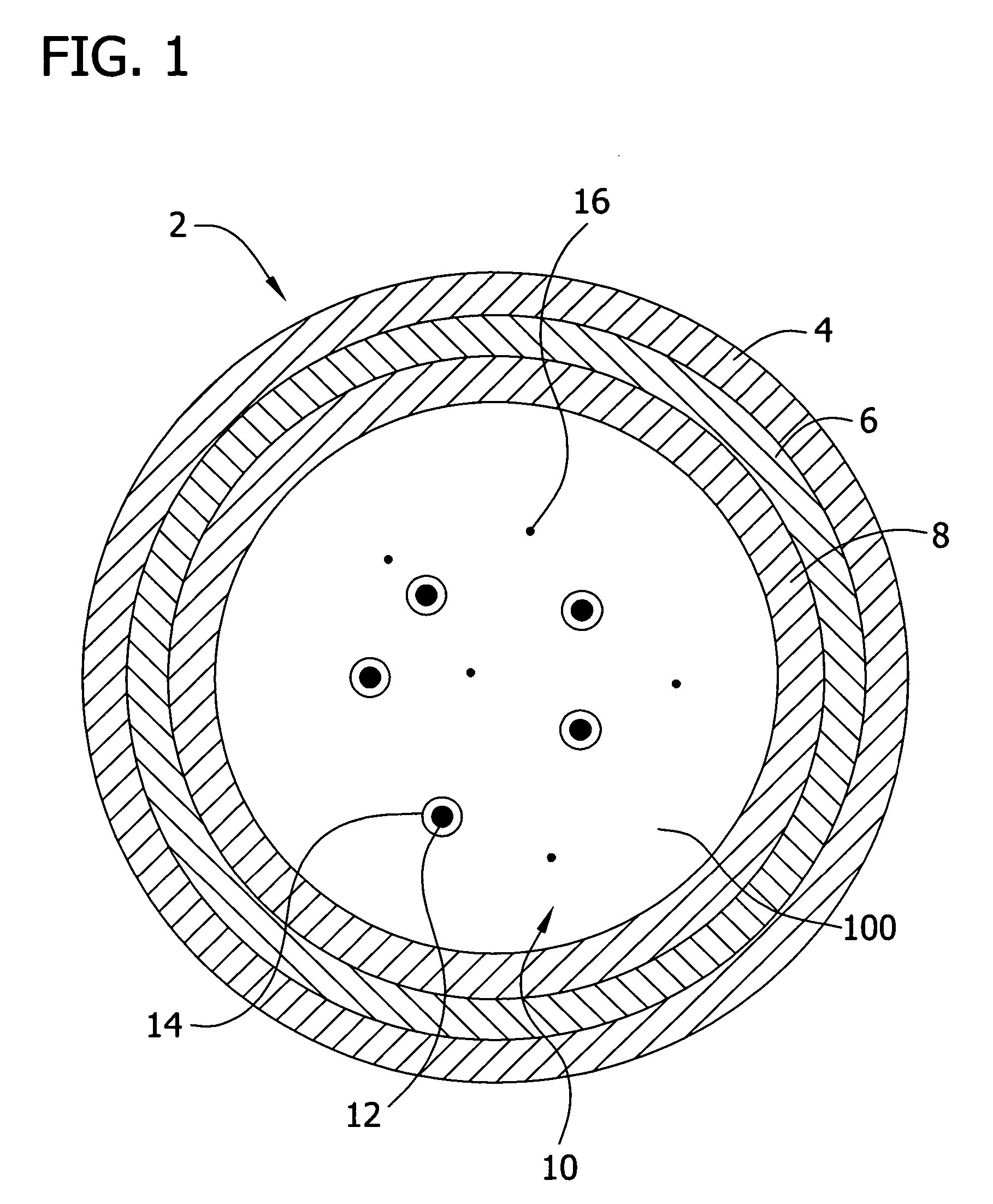

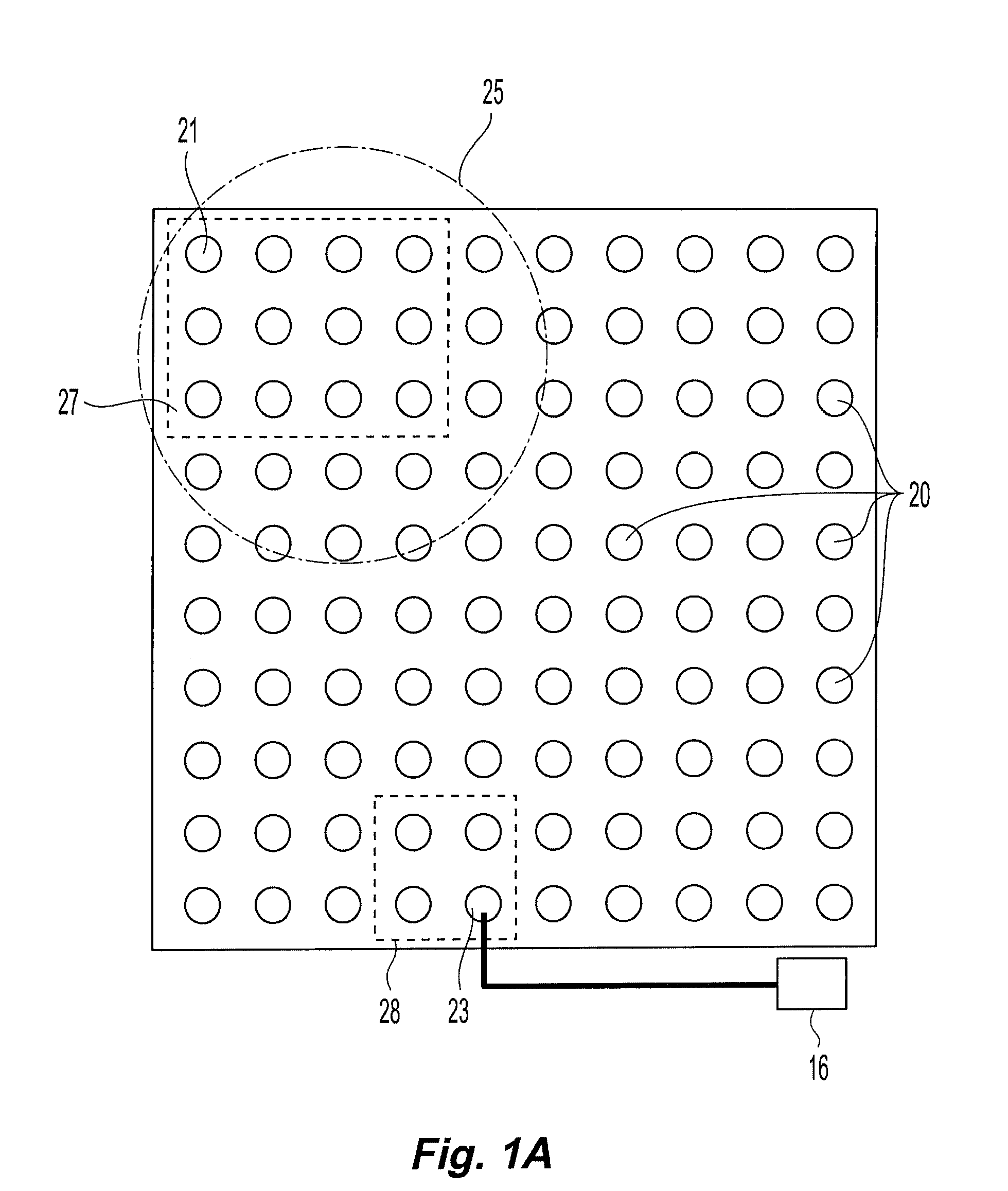

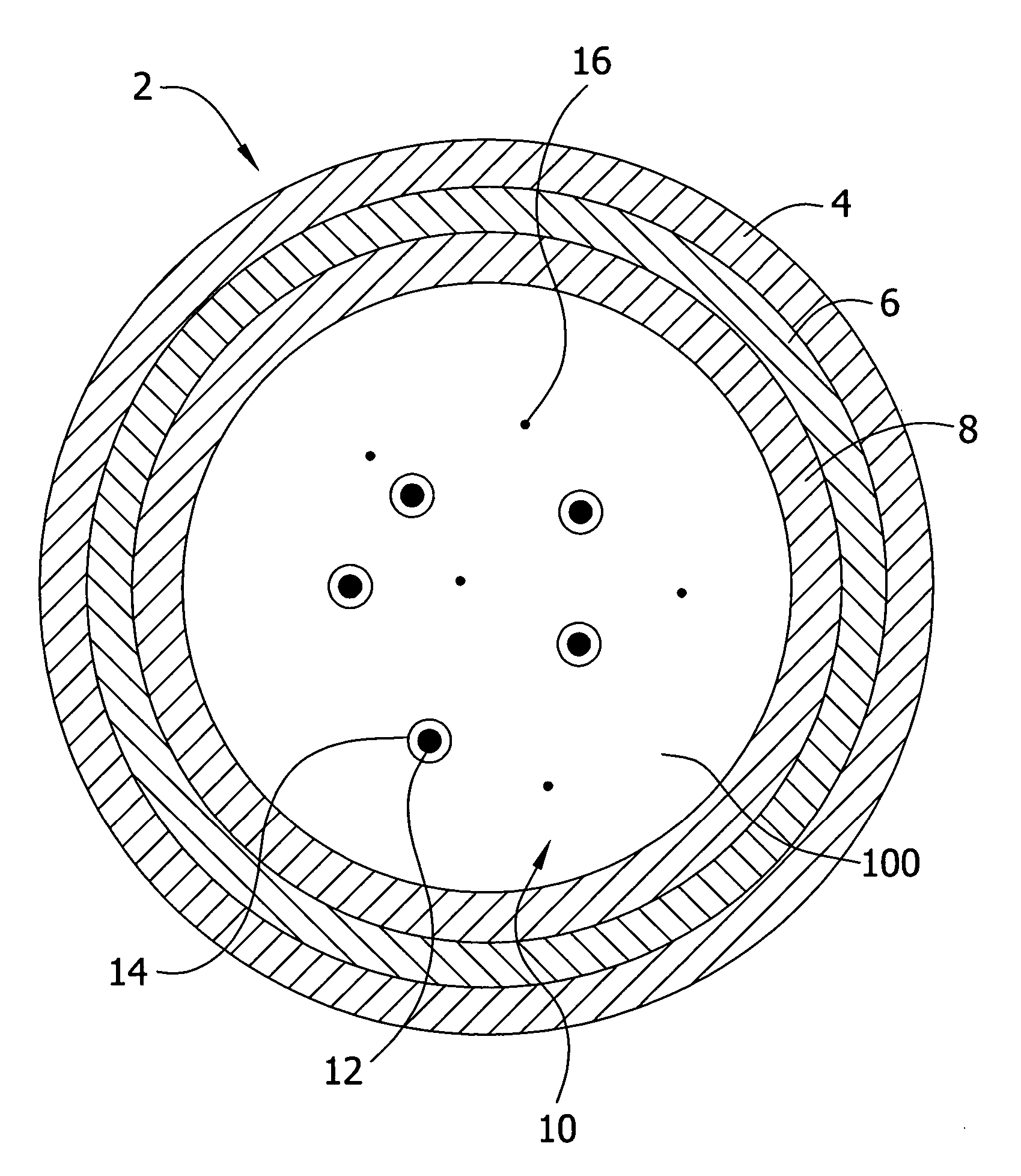

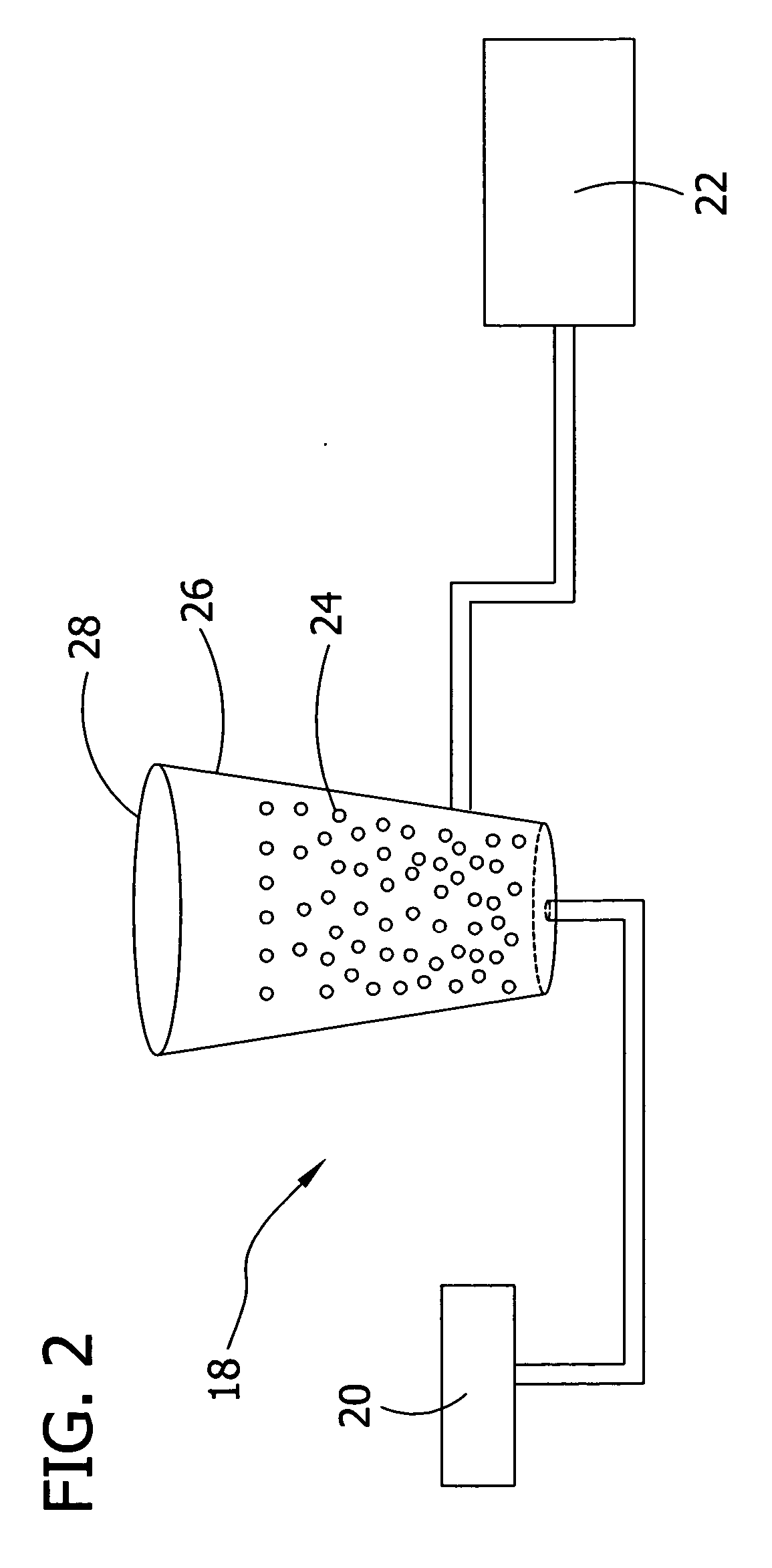

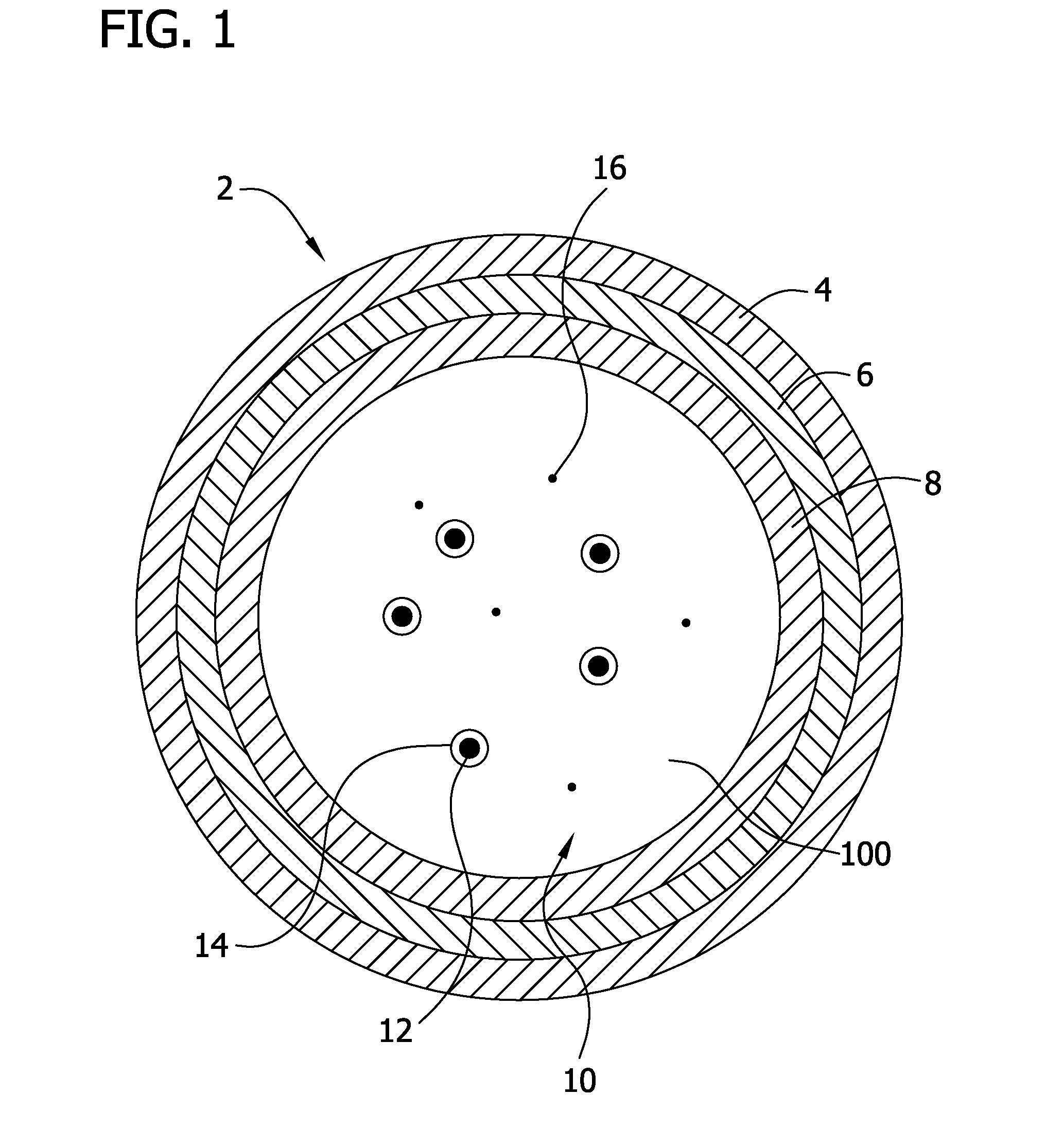

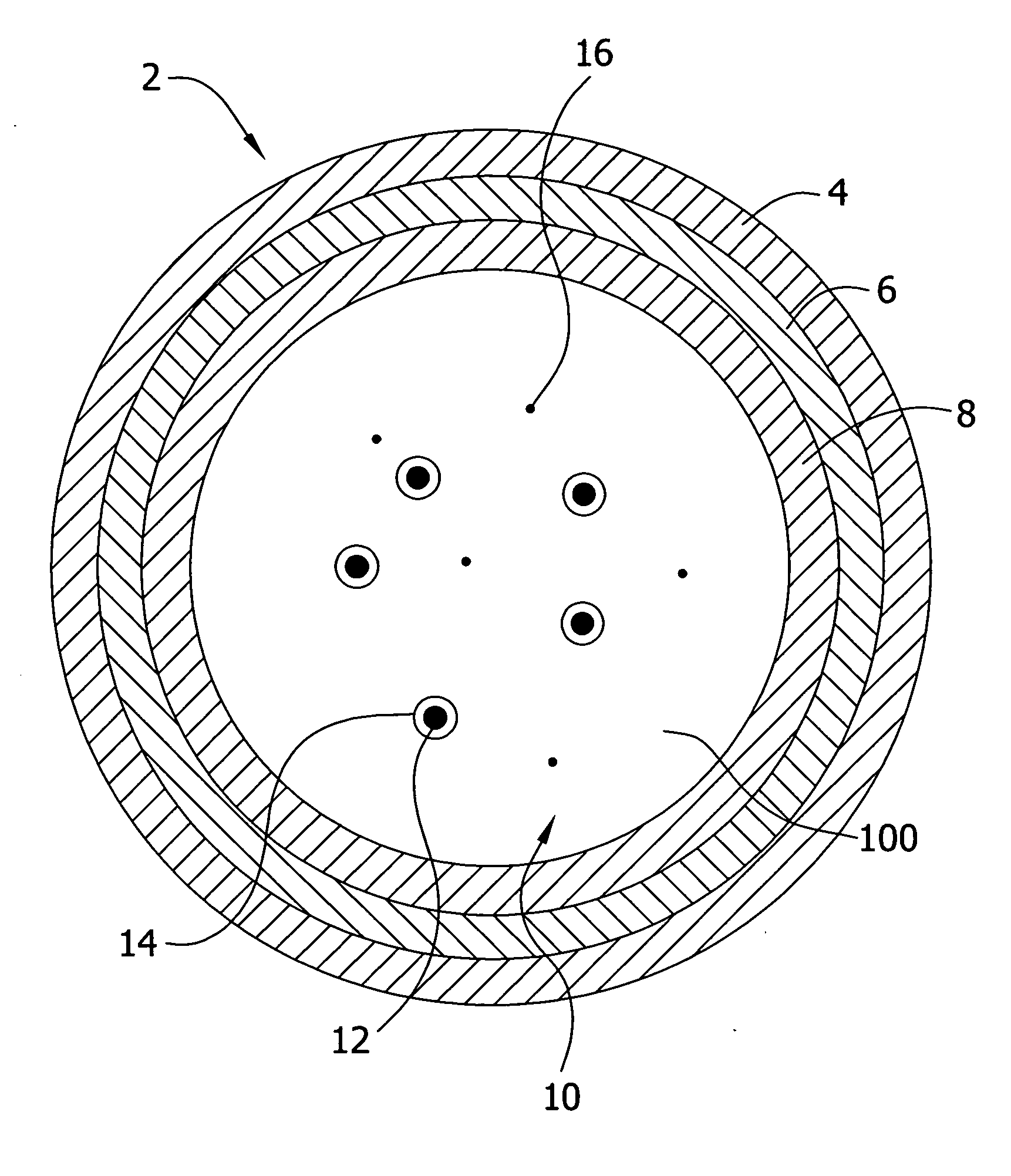

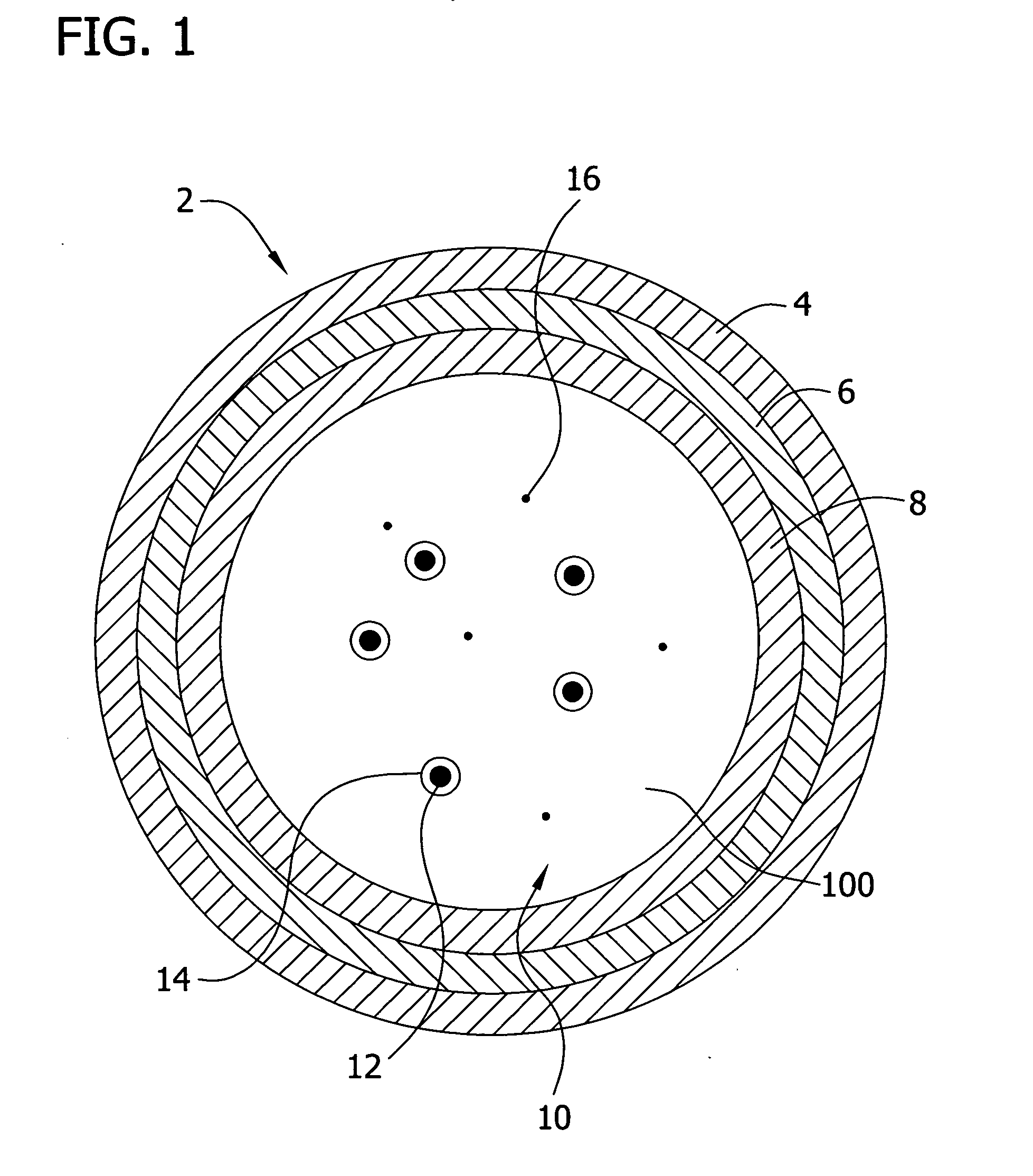

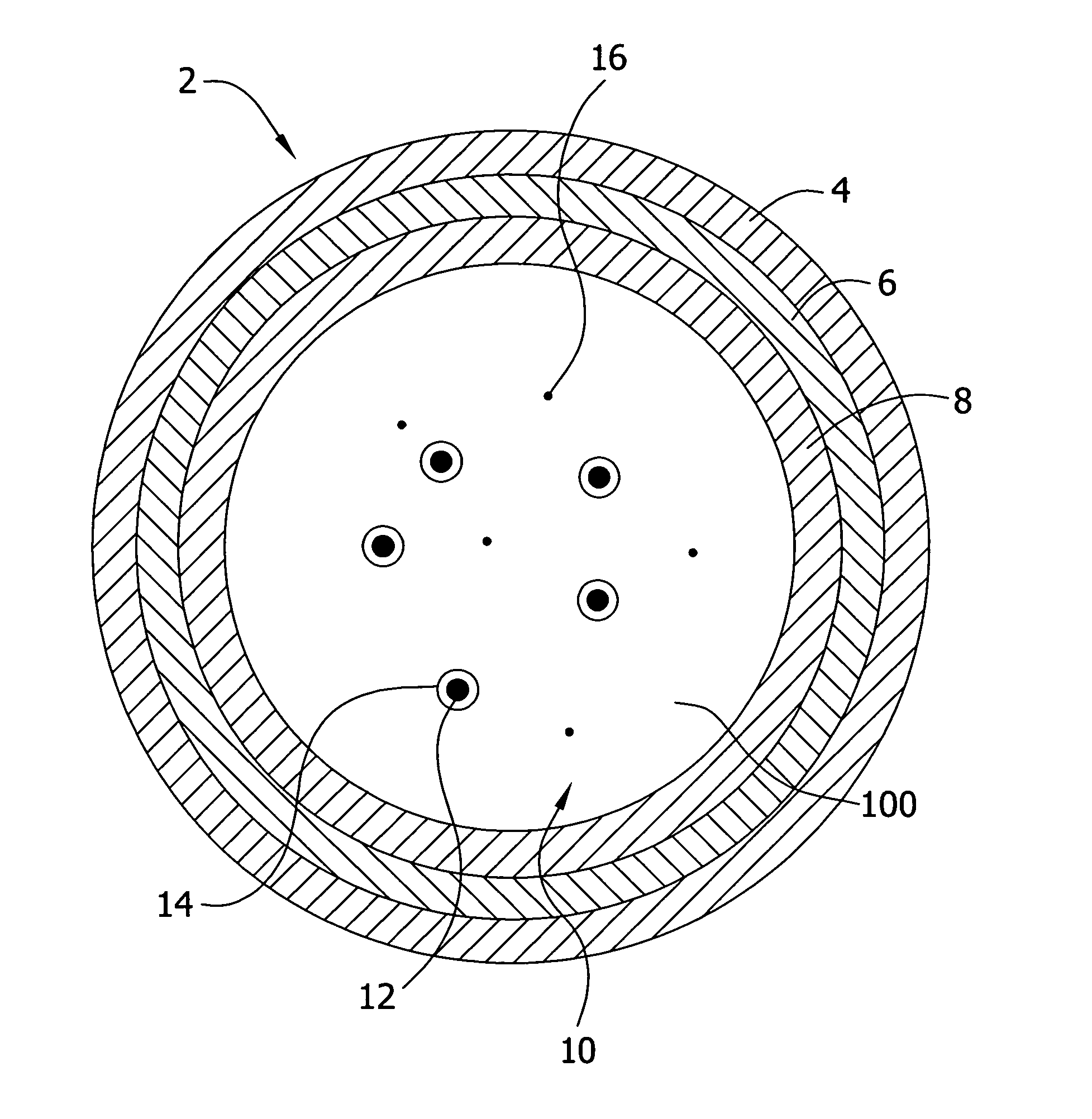

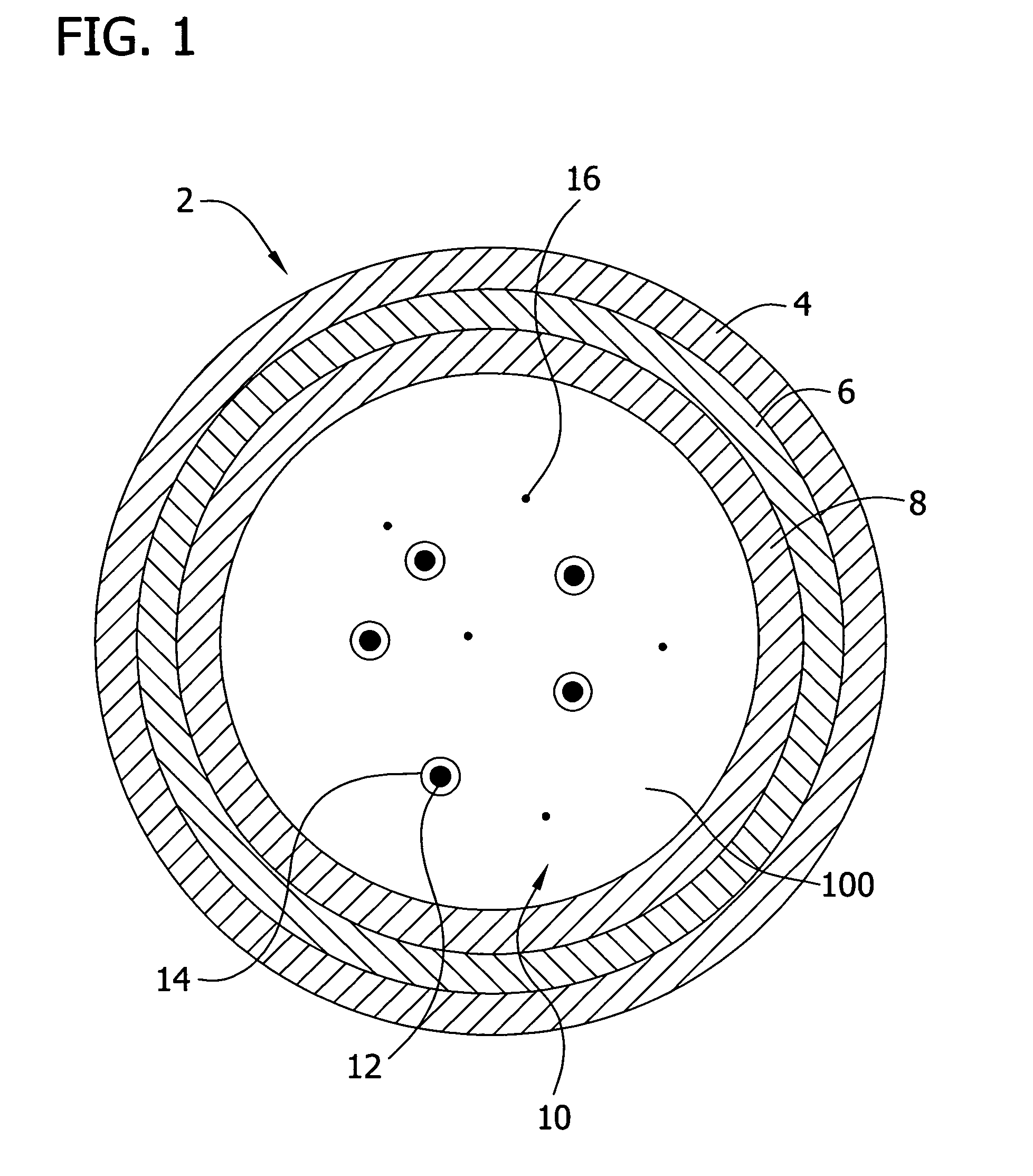

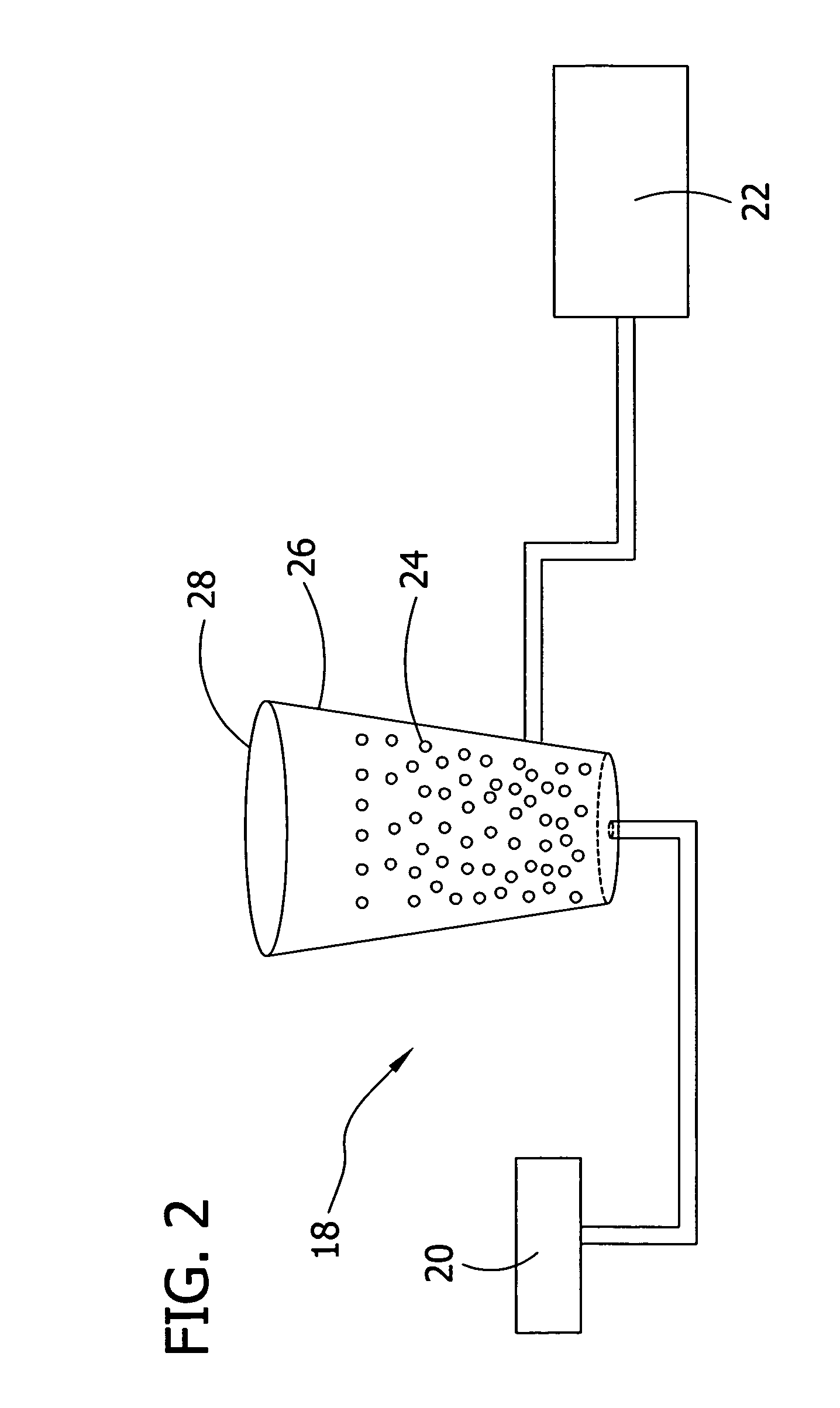

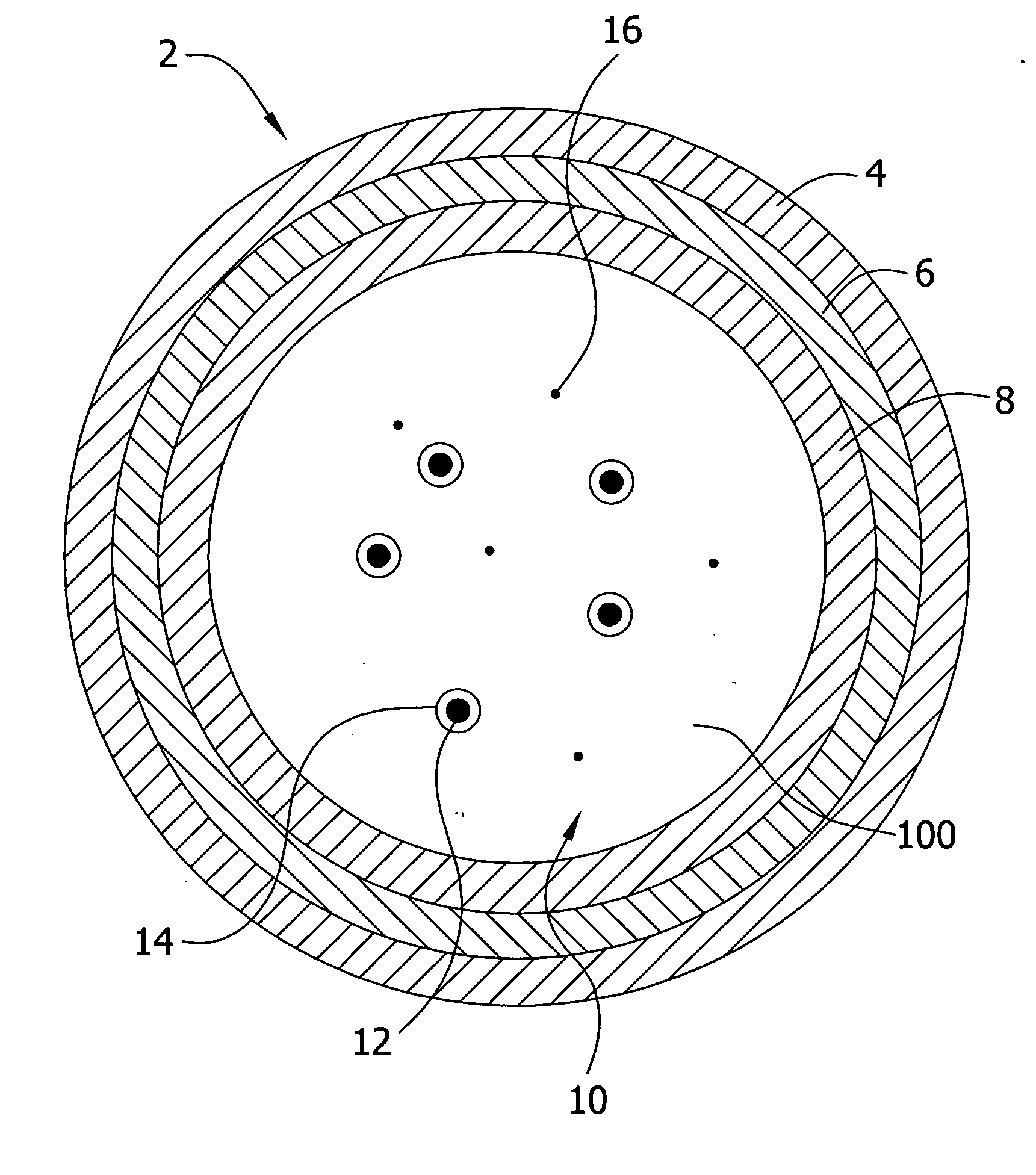

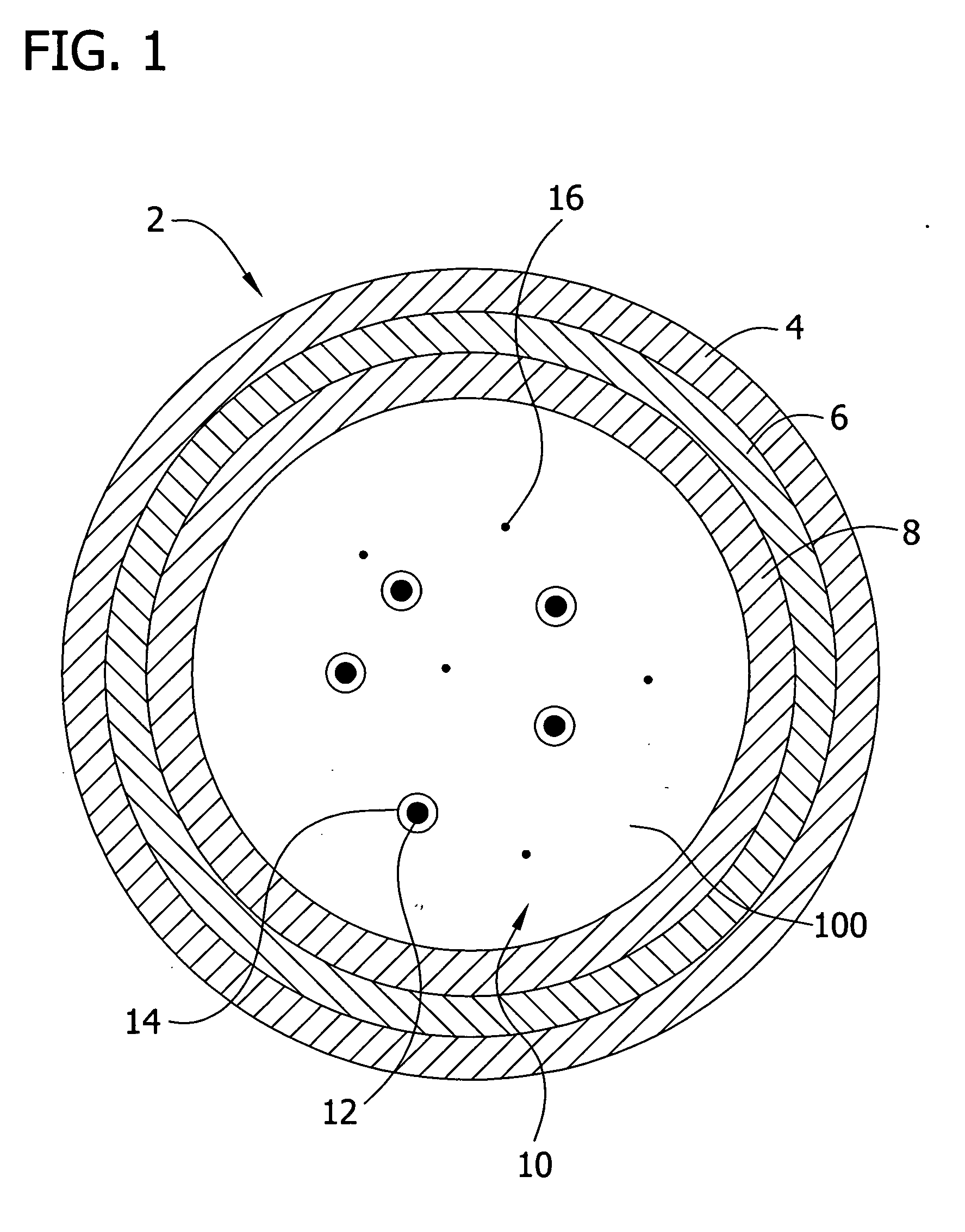

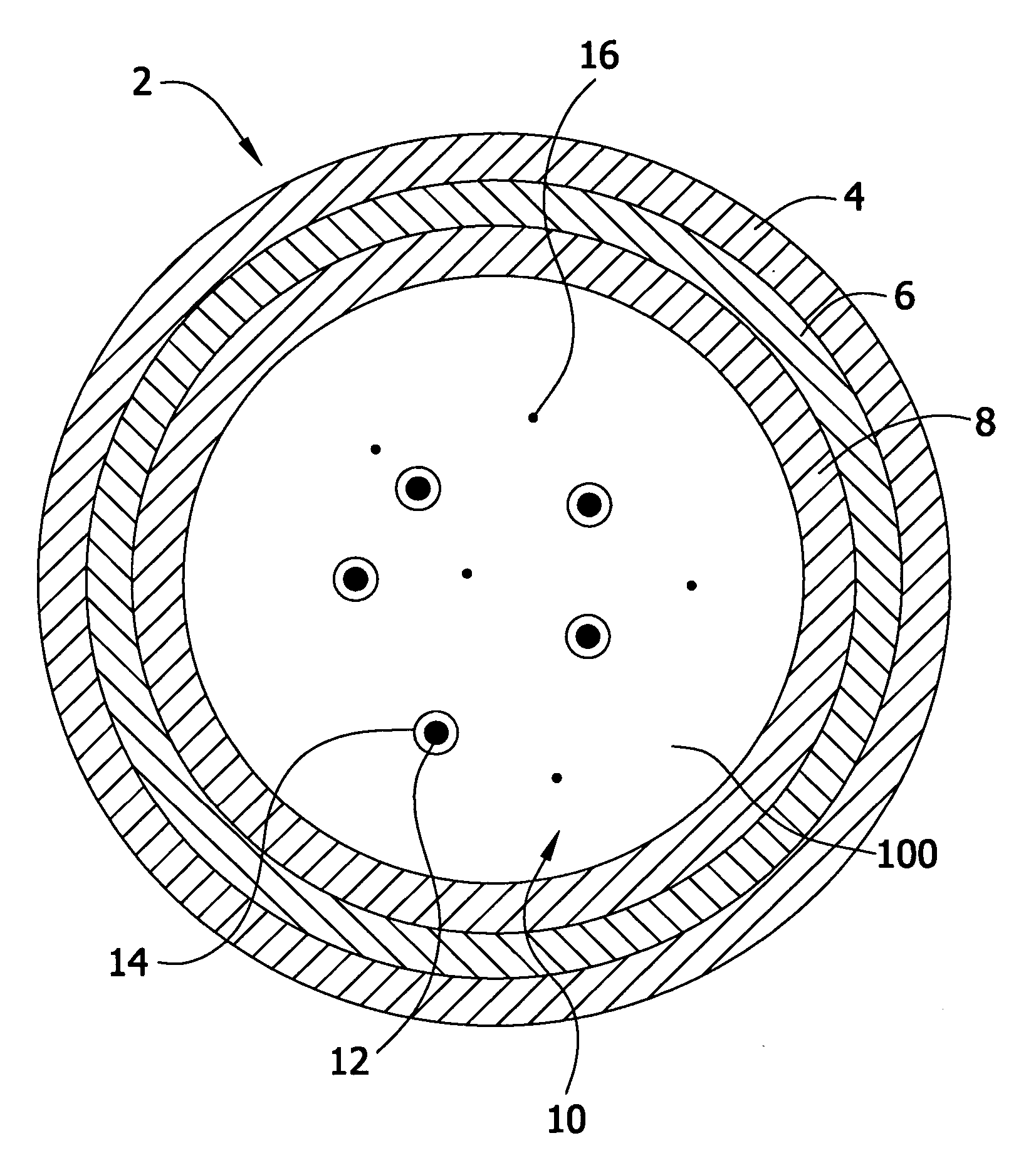

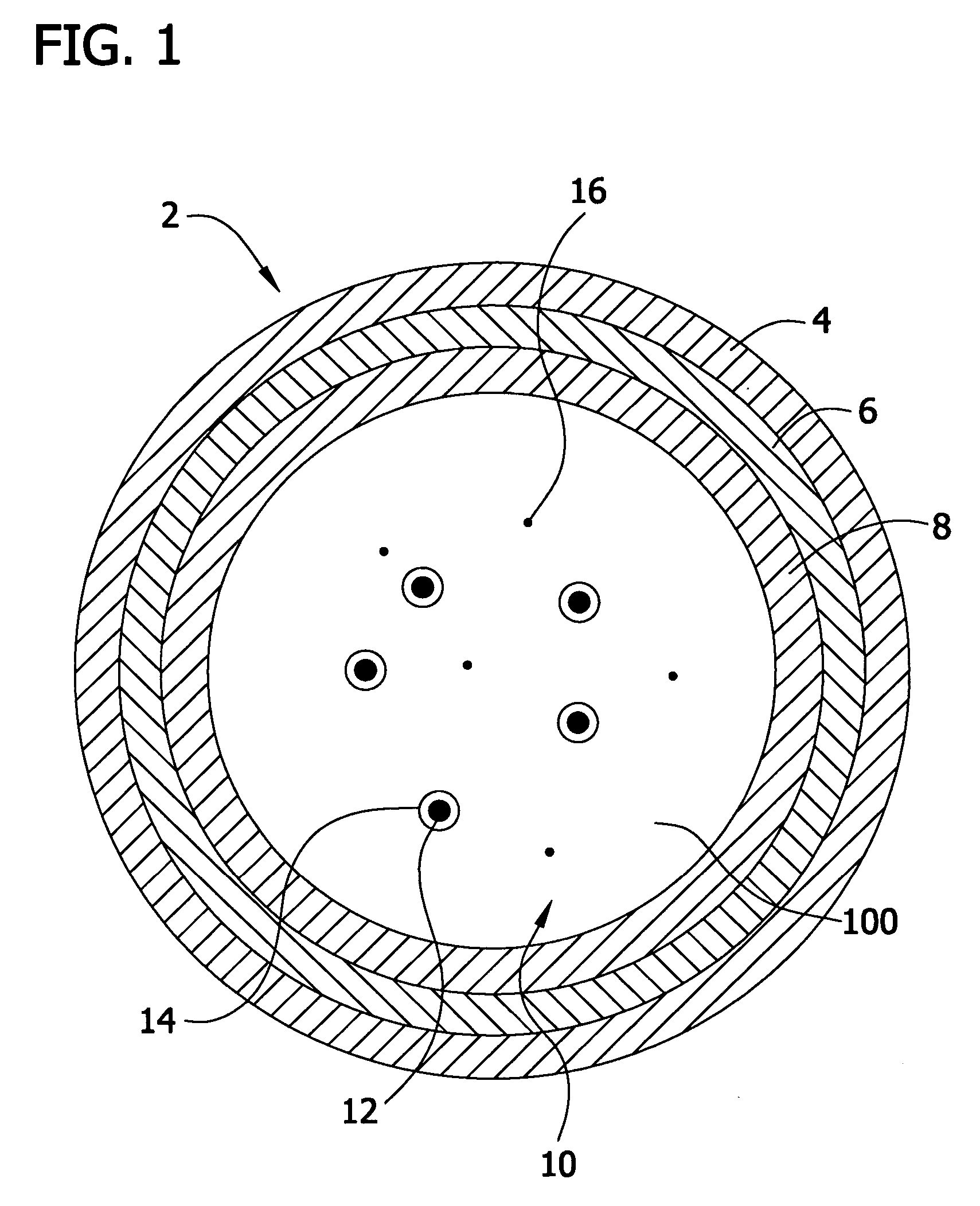

Implant to be implanted in bone tissue or in bone tissue supplemented with bone substitute material

InactiveUS6921264B2High softening temperatureLow softening temperatureDental implantsInternal osteosythesisBone tissueGrowth promoting

An implant (1) to be implanted in bone tissue, e.g. a dental implant or an implant for an orthopedic application, comprises surface regions (4) of a first type which have e.g. osseo-integrative, inflammation-inhibiting, infection-combating and / or growth-promoting properties, and surface regions (8) of a second type which consist of a material being liquefiable by mechanical oscillation. The implant is positioned in an opening of e.g. a jawbone and then mechanical oscillations, e.g. ultrasound is applied to it while it is pressed against the bone. The liquefiable material is such liquefied at least partly and is pressed into unevennesses and pores of the surrounding bone tissue where after resolidification it forms a positive-fit connection between the implant and the bone tissue. The surface regions of the two types are arranged and dimensioned such that, during implantation, the liquefied material does not flow or flows only to a clinically irrelevant degree over the surface regions of the first type such enabling the biologically integrative properties of these surface regions to start acting directly after implantation. The implant achieves with the help of the named positive fit a very good (primary) stability, i.e. it can be loaded immediately after implantation. By this, negative effects of non-loading are prevented and relative movements between implant and bone tissue are reduced to physiological measures and therefore have an osseo-integration promoting effect.

Owner:WOODWELDING

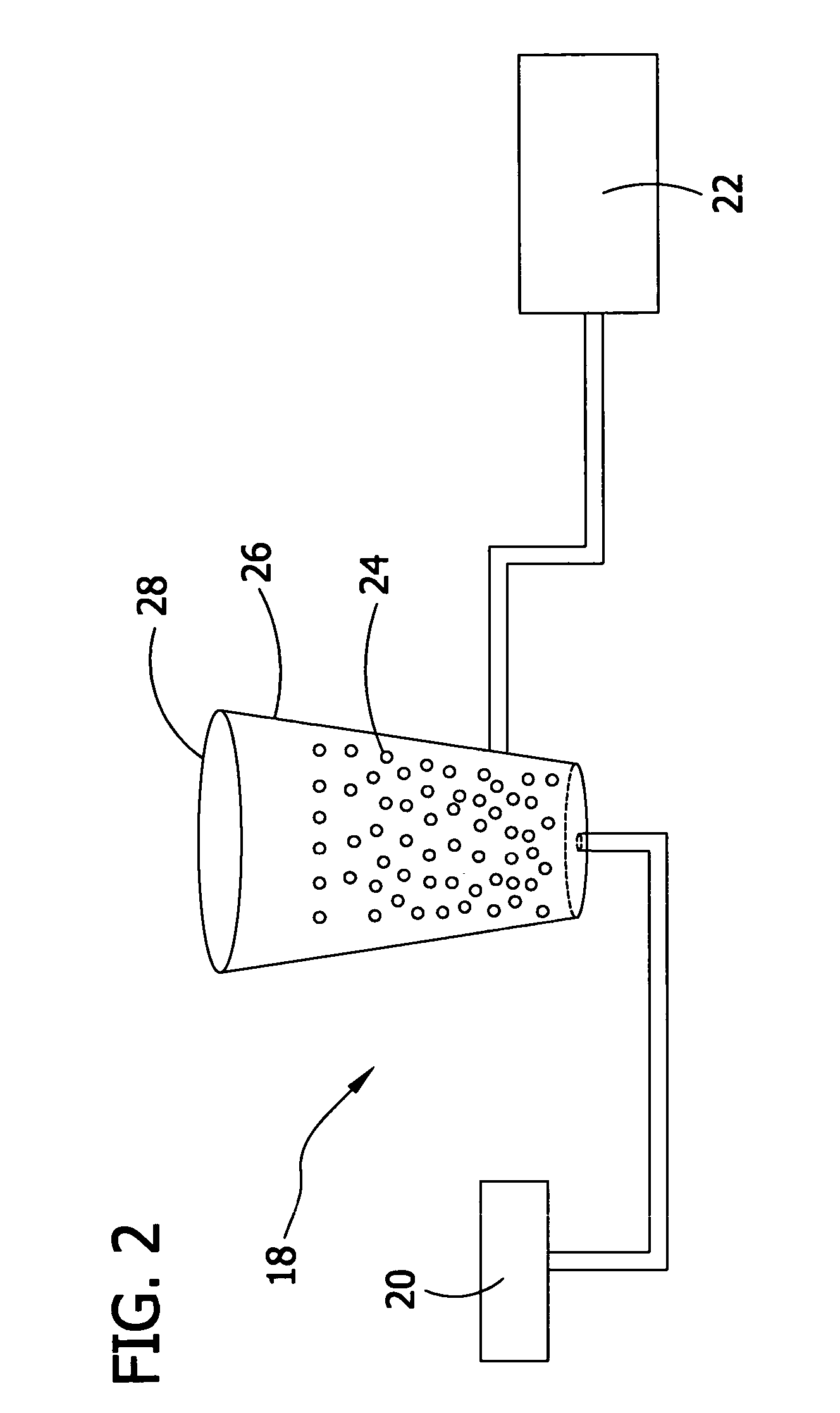

Cleansing composition including microencapsulated delivery vehicles

InactiveUS20070149435A1Improve performanceReduce heat releaseCosmetic preparationsToilet preparationsDelivery vehicleActive agent

Microencapsulated delivery vehicles comprising an active agent are disclosed. In one embodiment, the microencapsulated delivery vehicles are heat delivery vehicles capable of generating heat upon activation. The microencapsulated heat delivery vehicles may be introduced into wet wipes such that, upon activation, the wet wipe solution is warmed resulting in a warm sensation on a user's skin. Any number of other active ingredients, such as cooling agents and biocides, can also be incorporated into a microencapsulated delivery vehicle.

Owner:KIMBERLY-CLARK WORLDWIDE INC

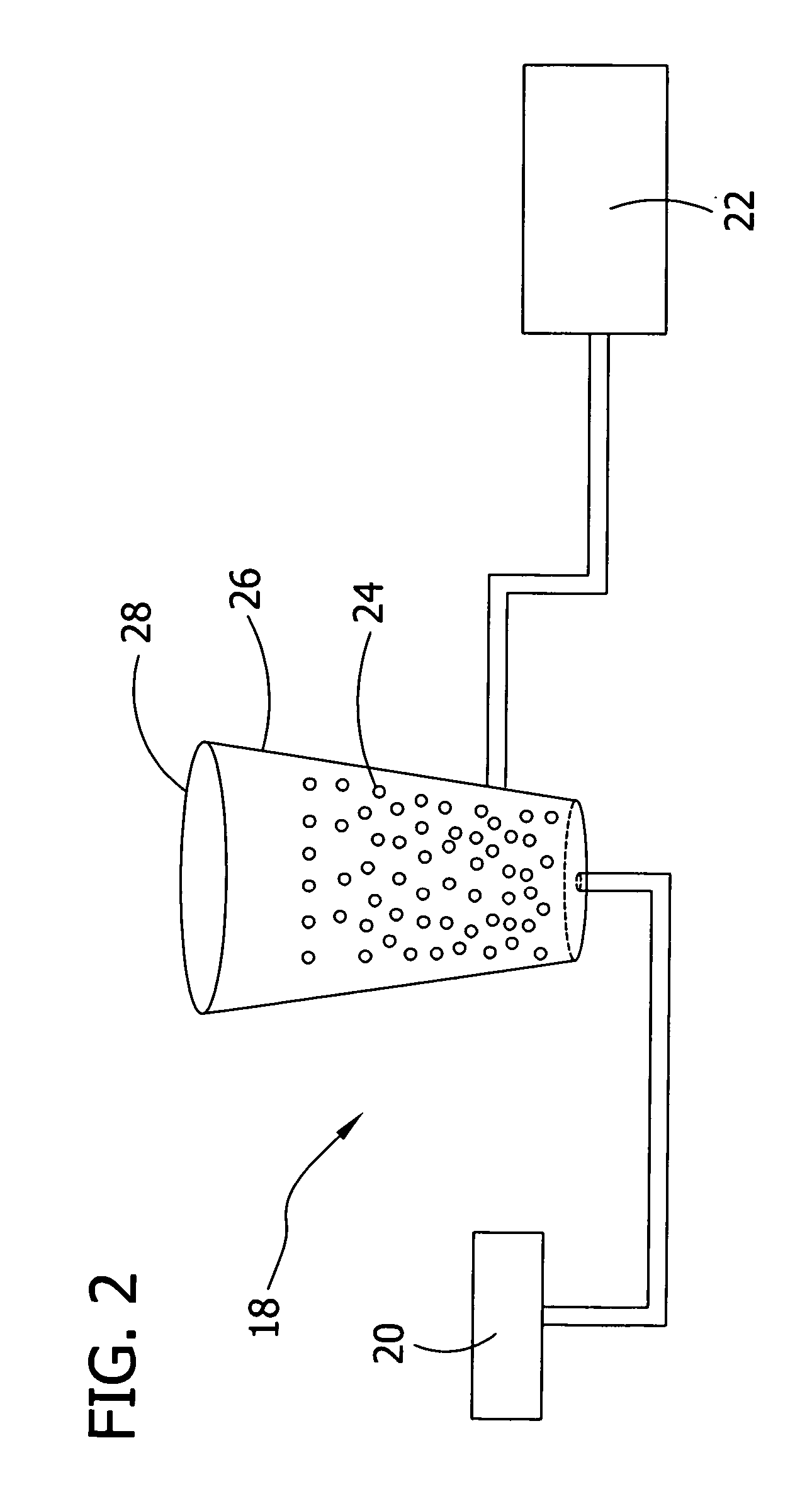

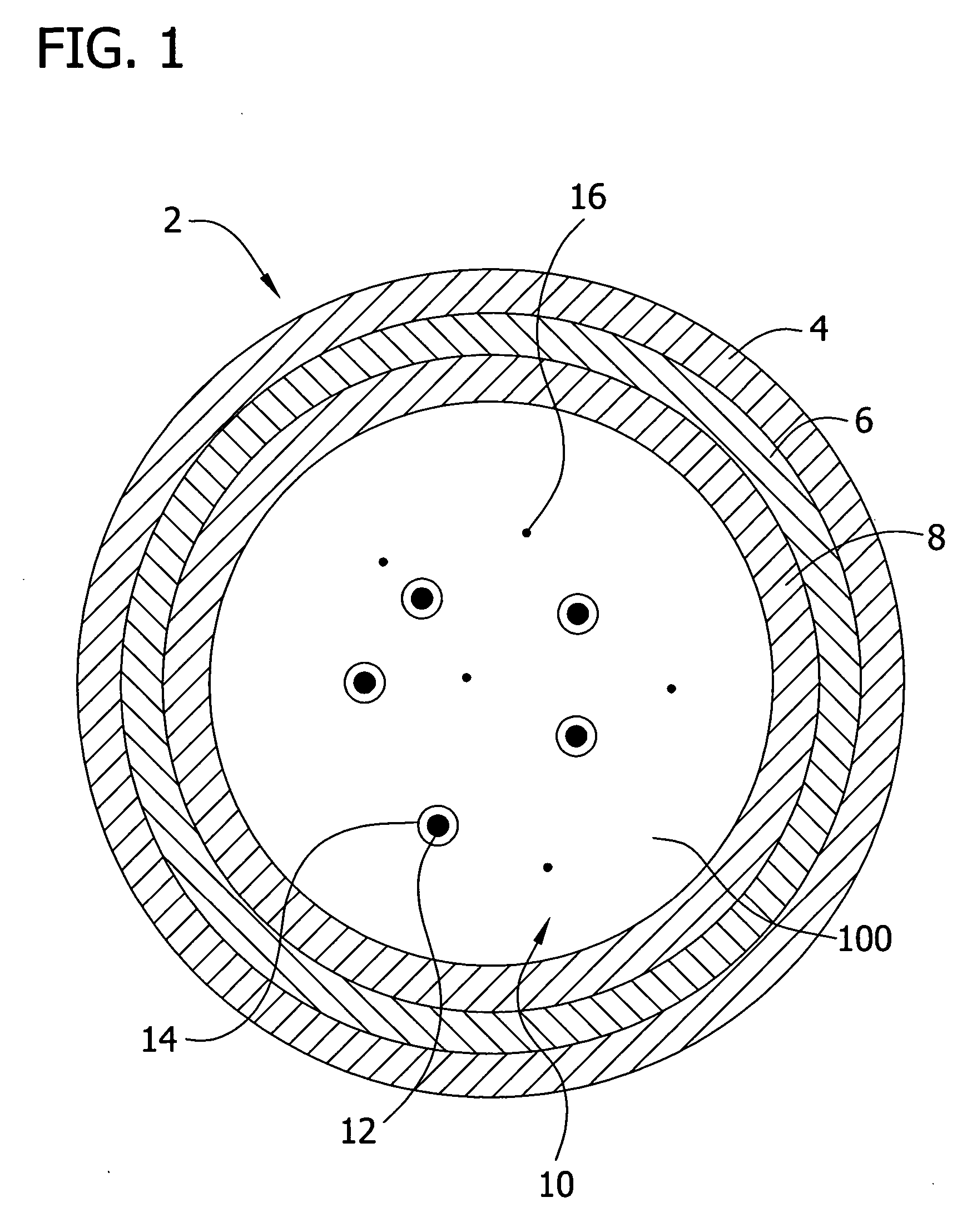

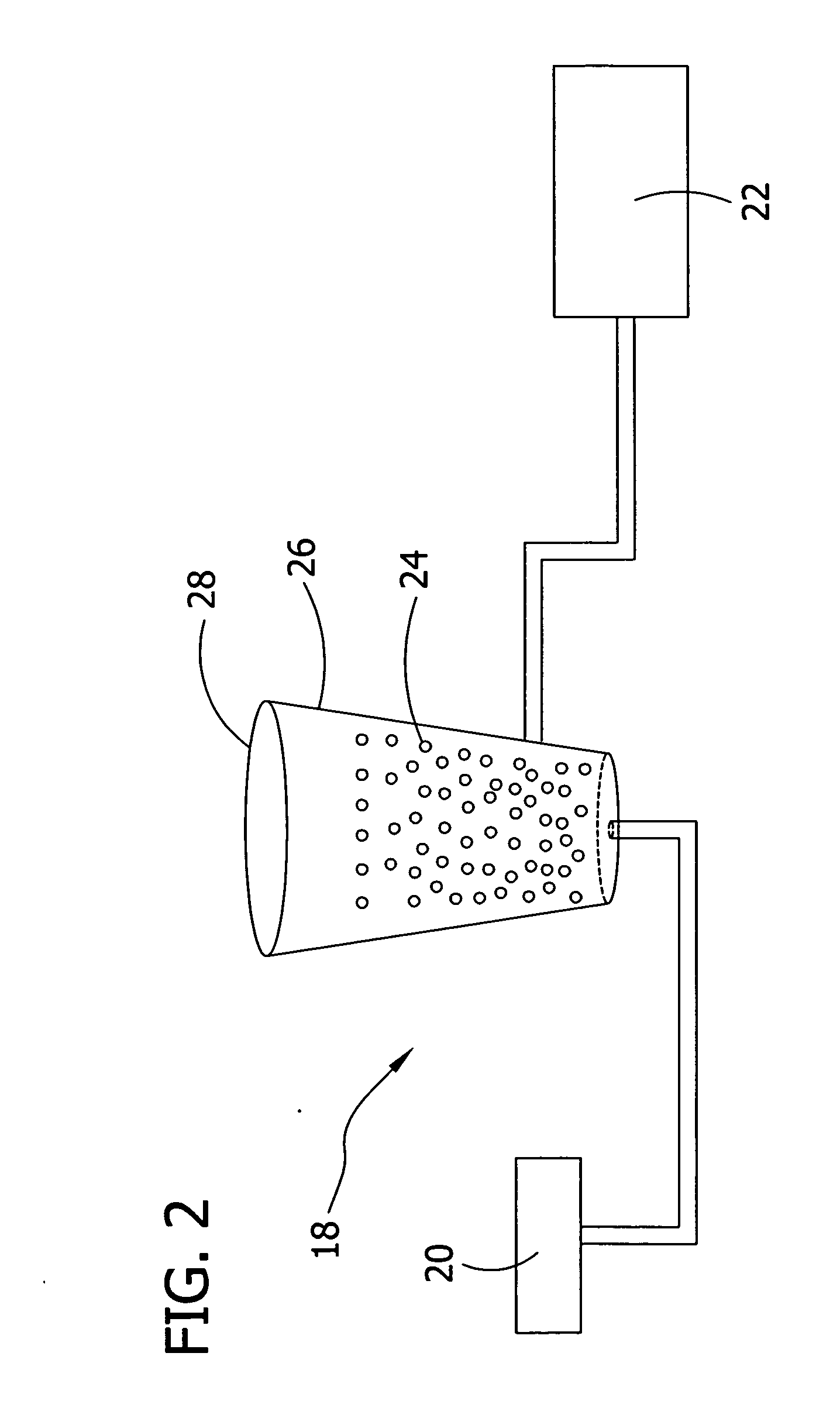

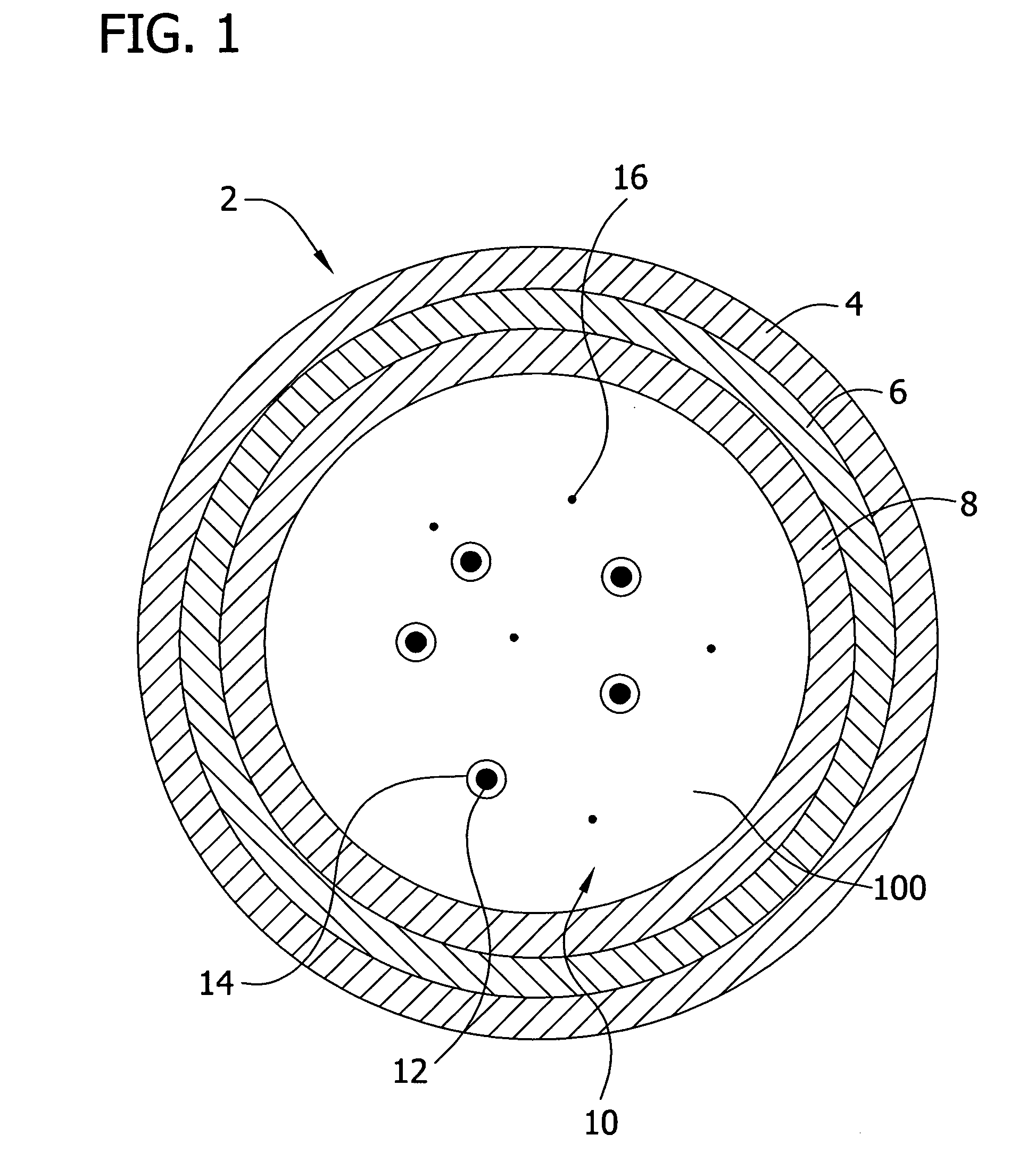

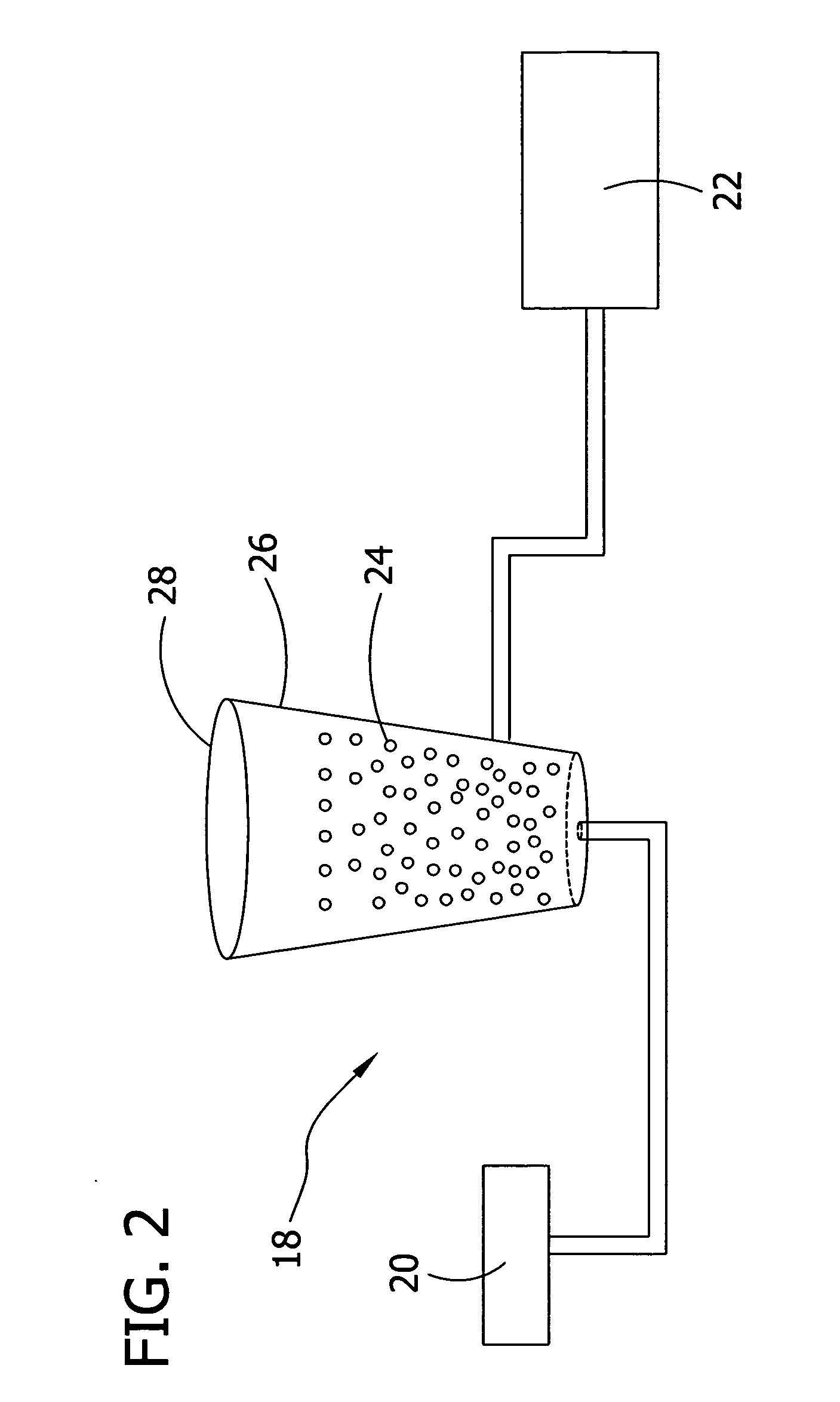

Microencapsulated heat delivery vehicles

InactiveUS20070145326A1Improve performanceReduce heat releasePowder deliveryCosmetic preparationsDelivery vehicleActive agent

Microencapsulated delivery vehicles comprising an active agent are disclosed. In one embodiment, the microencapsulated delivery vehicles are heat delivery vehicles capable of generating heat upon activation. The microencapsulated heat delivery vehicles may be introduced into wet wipes such that, upon activation, the wet wipe solution is warmed resulting in a warm sensation on a user's skin. Any number of other active ingredients, such as cooling agents and biocides, can also be incorporated into a microencapsulated delivery vehicle.

Owner:KIMBERLY-CLARK WORLDWIDE INC

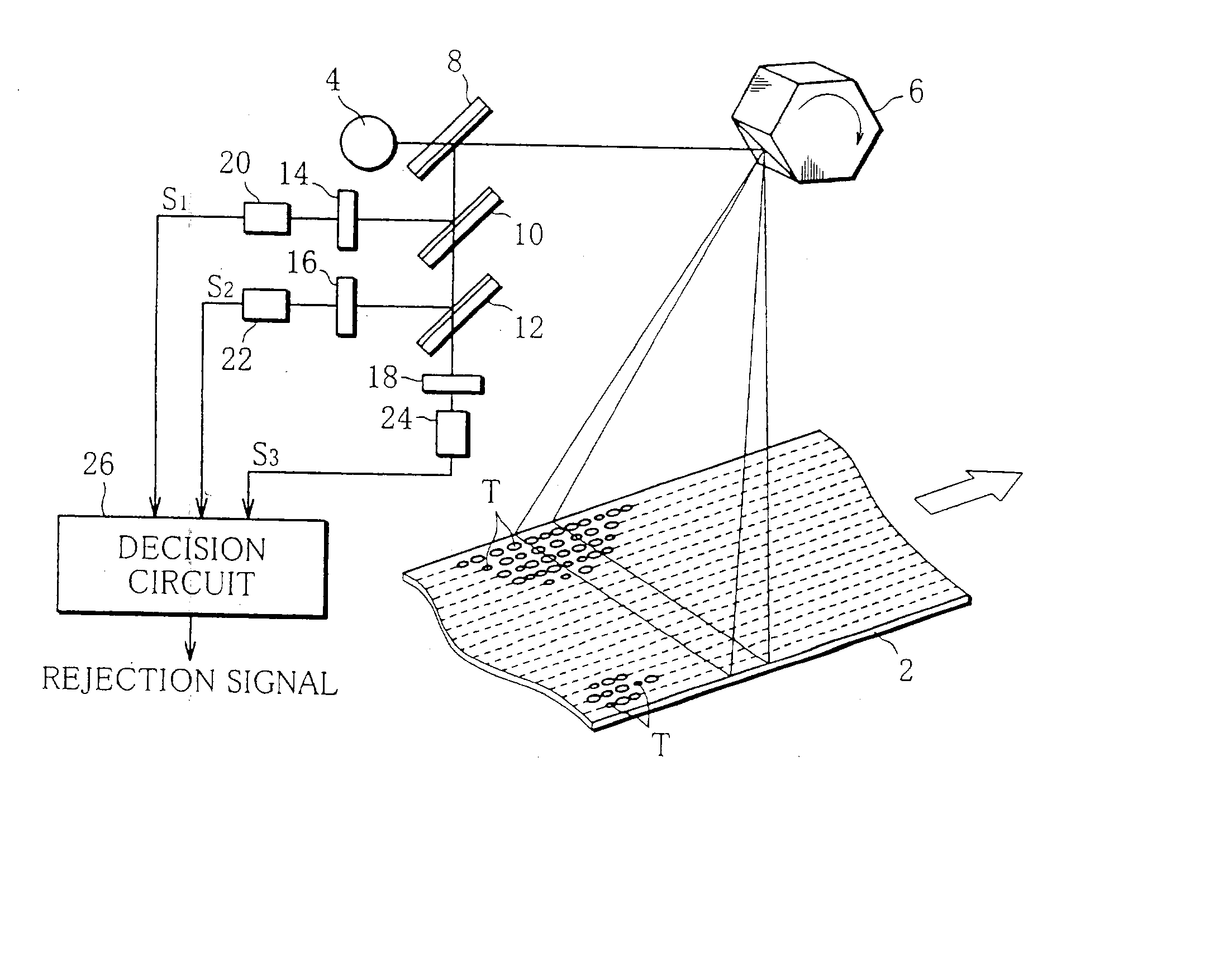

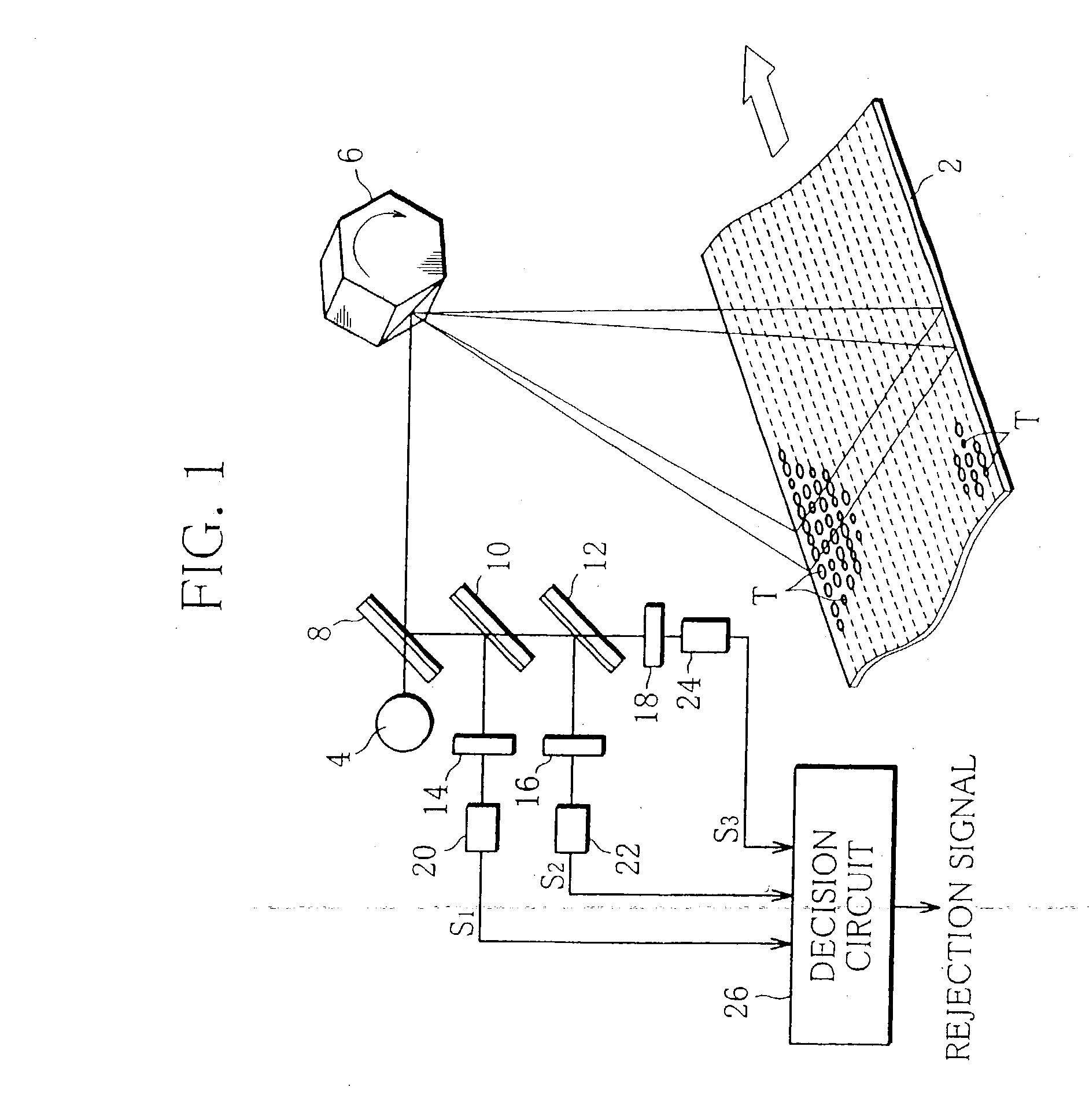

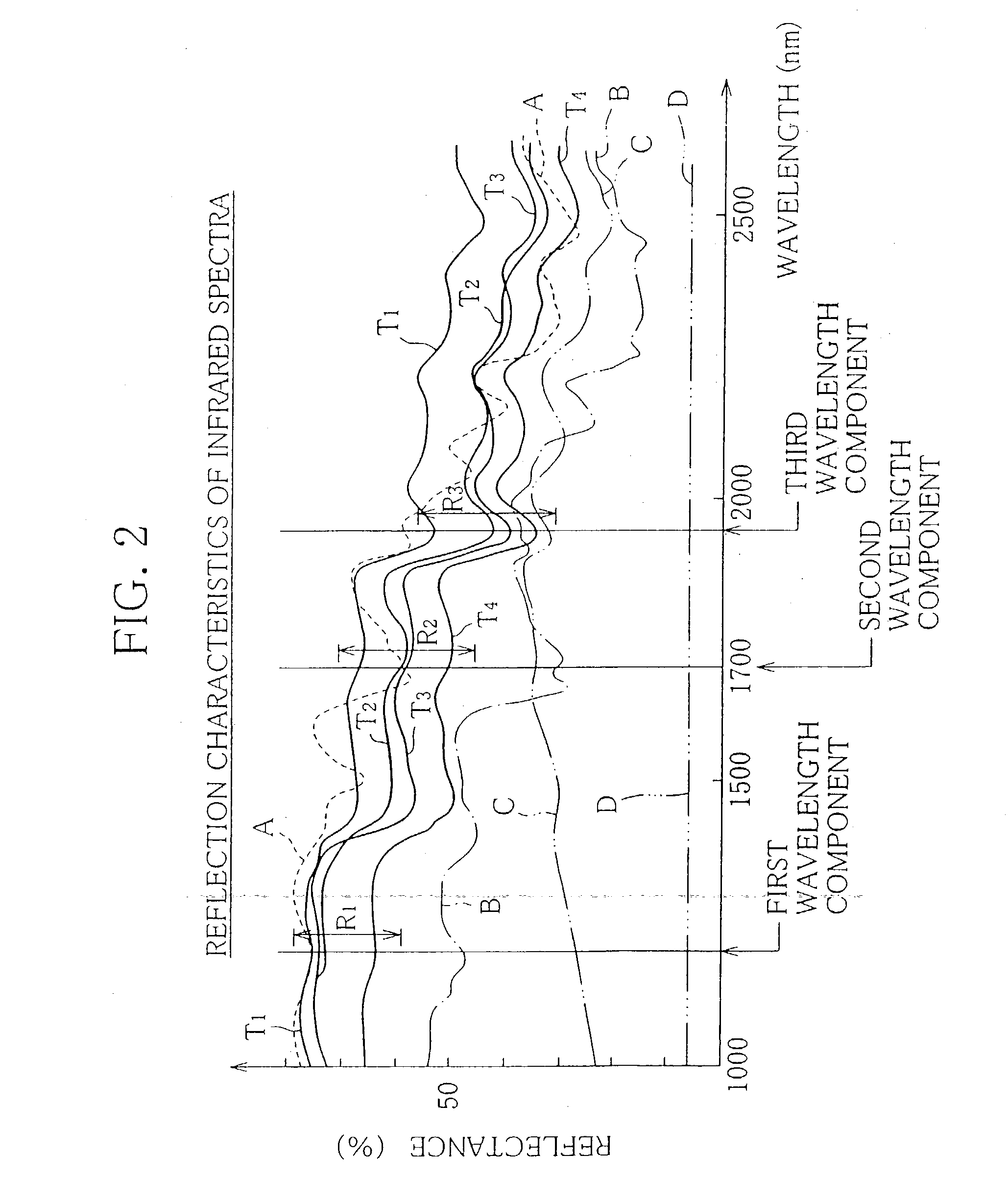

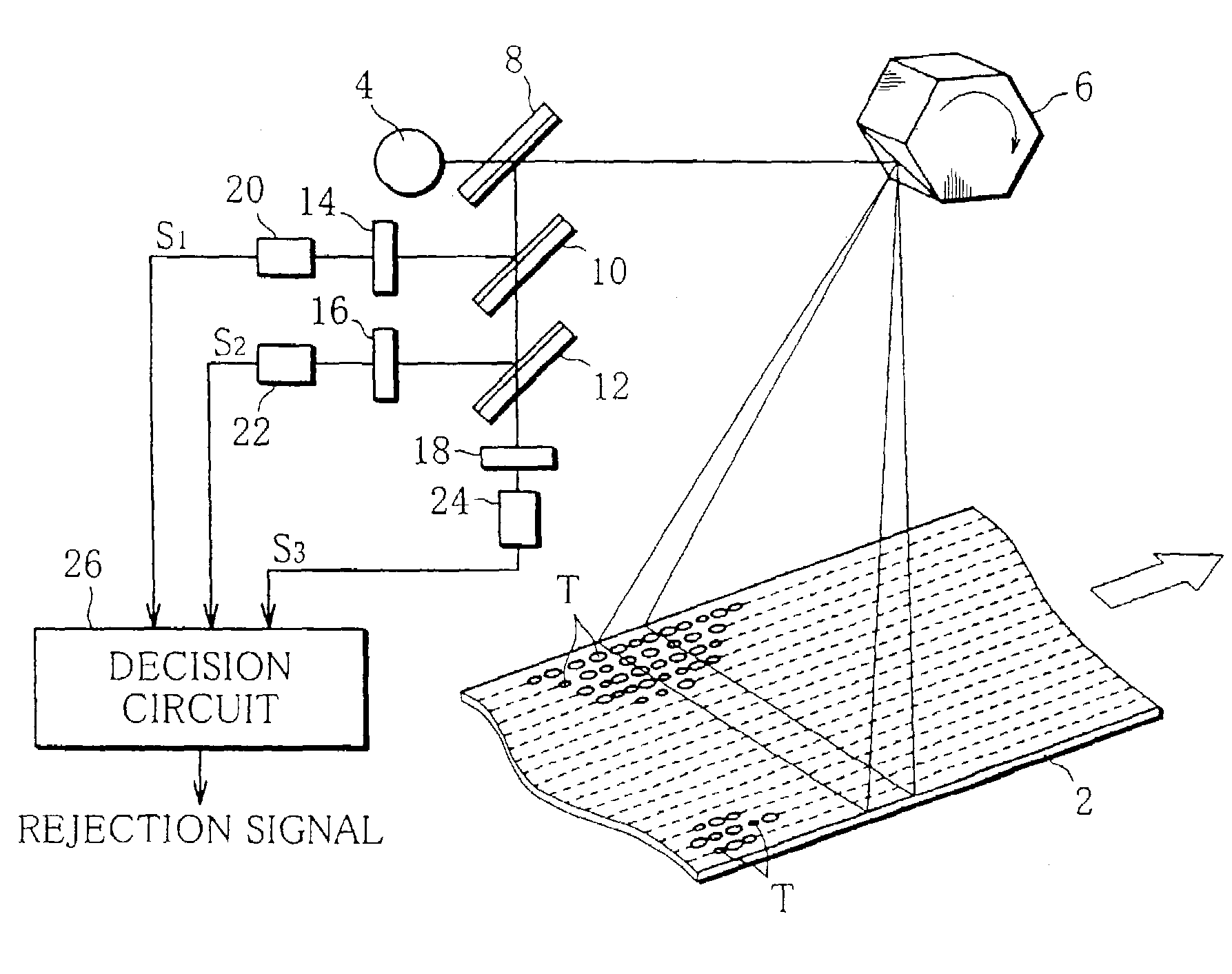

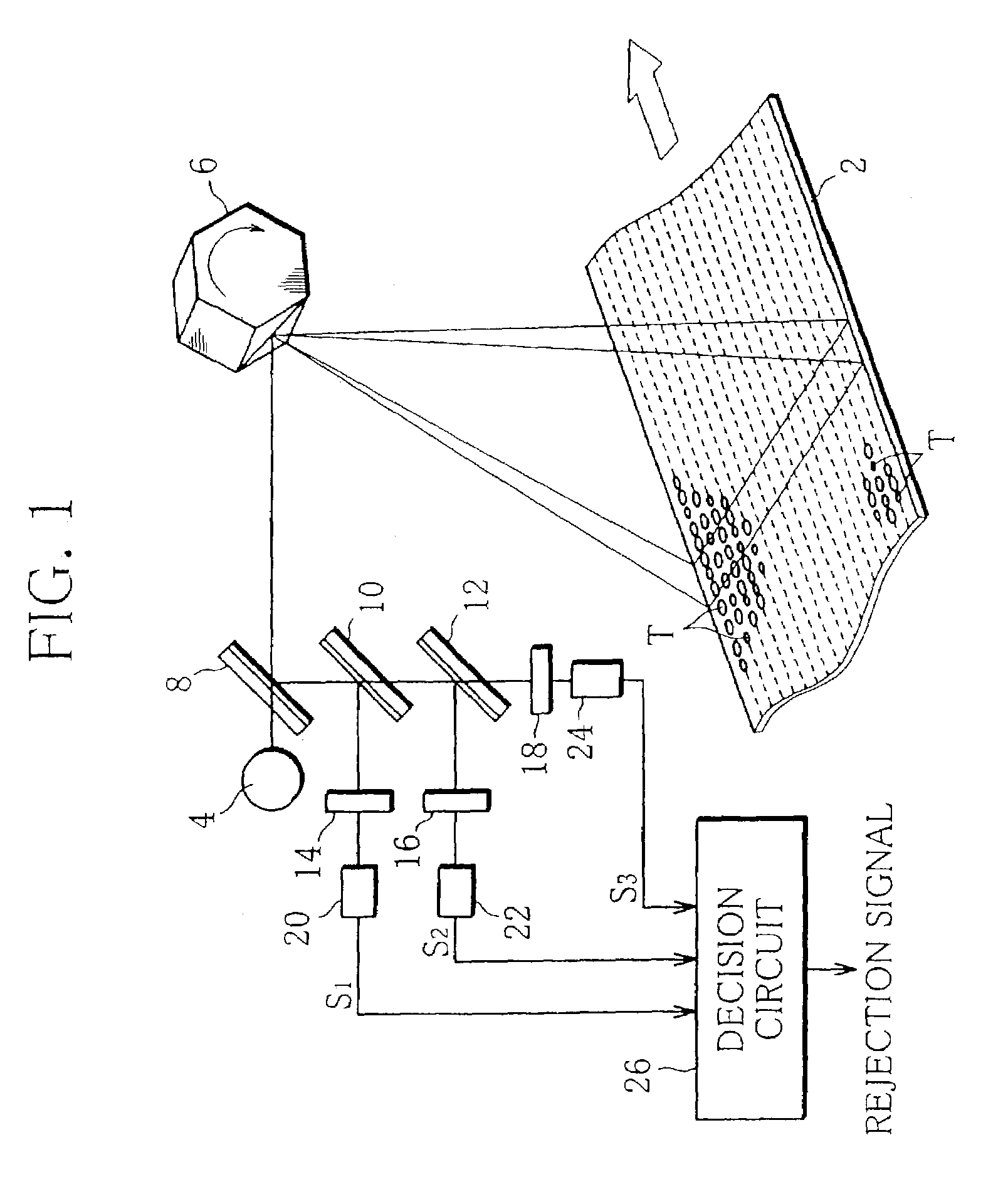

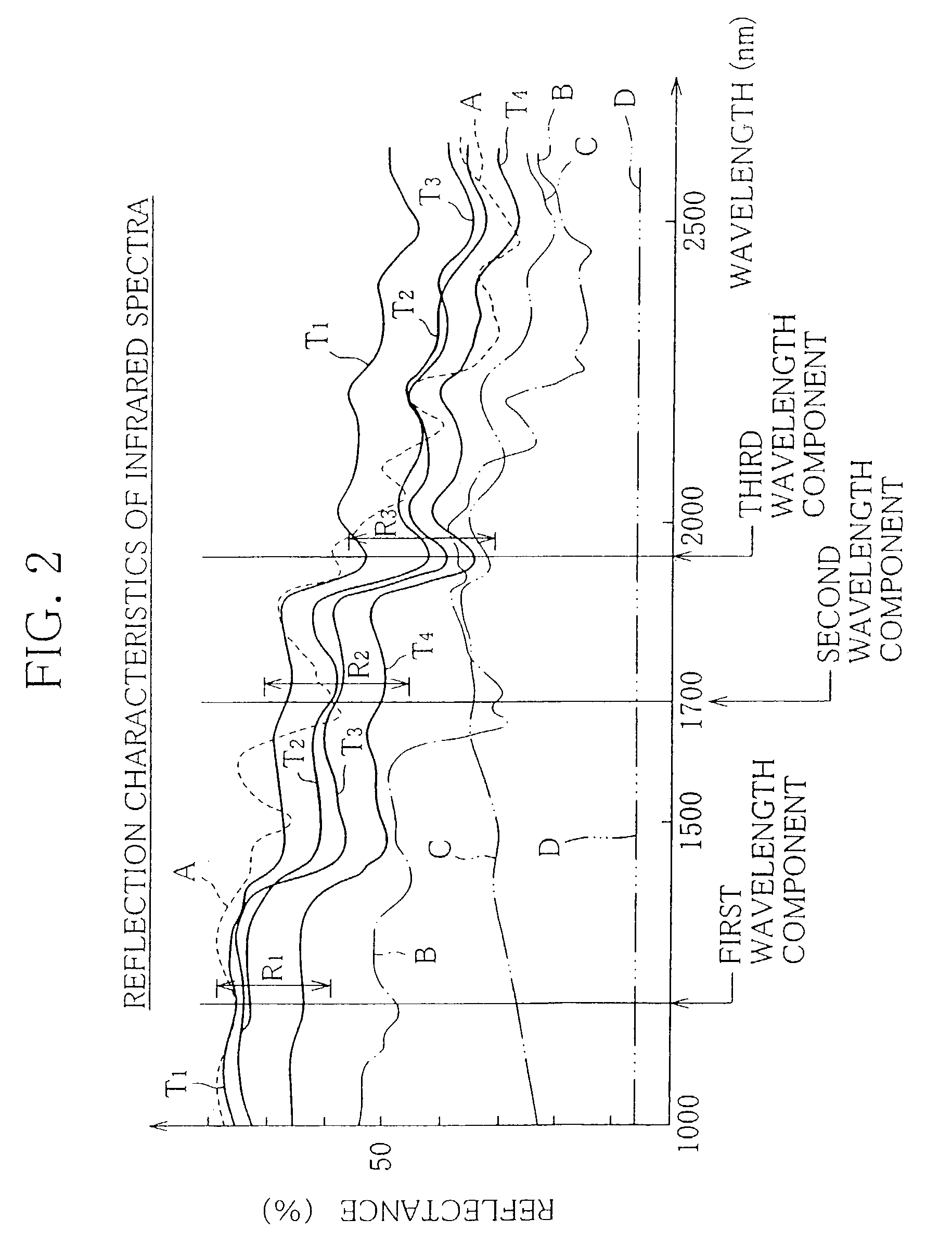

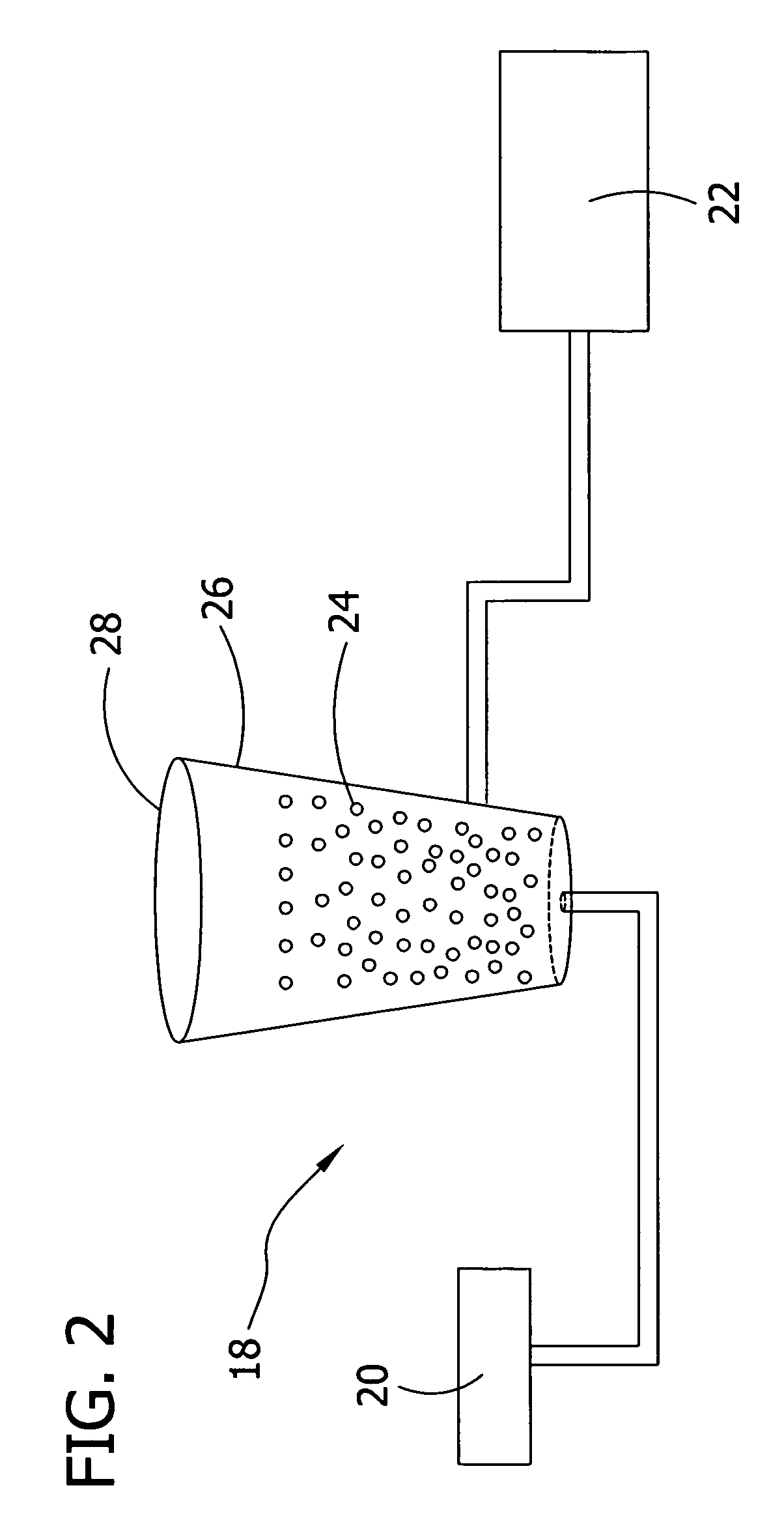

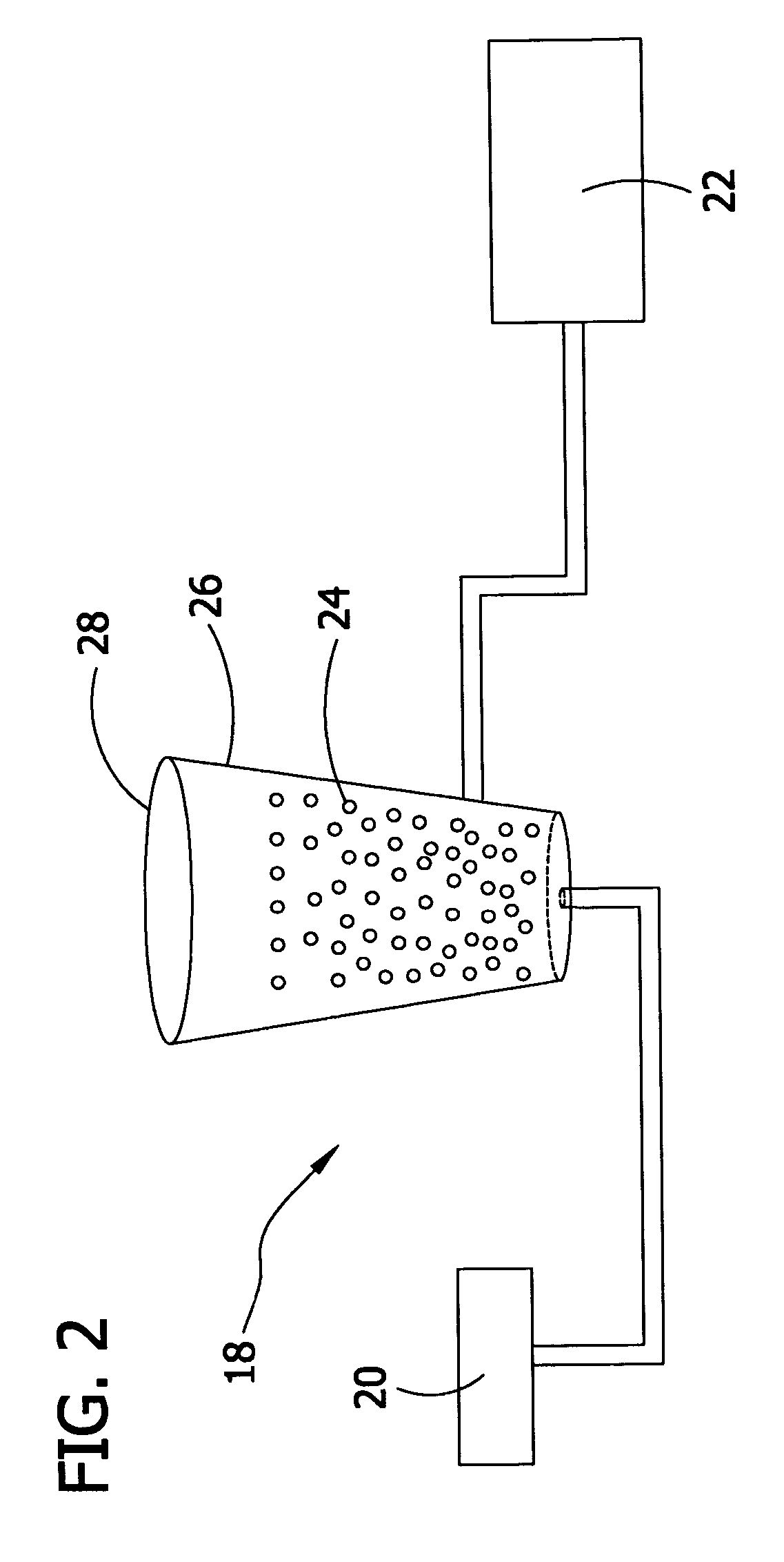

Apparatus for detecting impurities in material and detecting method therefor

InactiveUS20030197126A1Accurate detectionAvoid overall overheatingTobacco preparationRadiation pyrometryInfraredLength wave

In an apparatus and a method for detecting impurities in a material, infrared rays or a plurality of specific wavelength components of the infrared rays are applied to a material on a conveyor, the respective reflection intensities of the specific wavelength components reflected by the material are measured, the measured reflection intensities and the reflection intensities of specific wavelength components inherent to the material are compared, and impurities in the material are detected according to the result of the comparison.

Owner:JAPAN TOBACCO INC

High-strength environment-friendly flame-retarding fiberboard and manufacturing method thereof

ActiveCN101905475AReduce the temperatureDelay in pyrolysis combustion reactionWood working apparatusDomestic articlesFiberSocial benefits

The invention discloses a high-strength environment-friendly flame-retarding fiberboard which comprises the following raw materials of plant fibers, flame retardants, adhesives and waterproofing agents, wherein the weight ratio of the plant fibers to the flame retardants to the adhesives to the waterproofing agents is 100:(3-30):(3-30):(0.1-4). The invention also discloses a manufacturing method of the high-strength environment-friendly flame-retarding fiberboard. Not only are the mechanical properties of the flame-retarding fiberboard obviously improved, but also the combustion property can conform to the regulations of GB8624 Class B or Class C, and the formaldehyde emission, the smoke volume produced and the smoke toxicity are also reduced. Thus, the high-strength environment-friendly flame-retarding fiberboard has good quality and low price, can be widely applied to the fields of building furnishings, flame-retarding furniture production, flame-retarding floor production, wooden fireproof door production, ship and vehicle furnishings and the like, and has good economical and social benefits.

Owner:北京盛大华源科技有限公司 +1

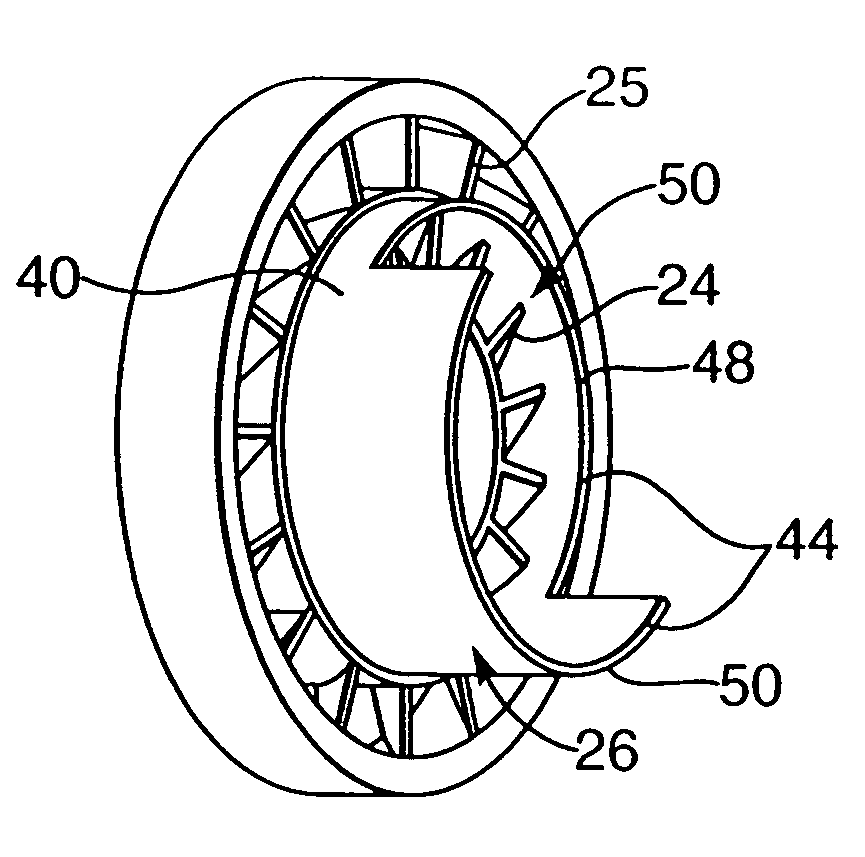

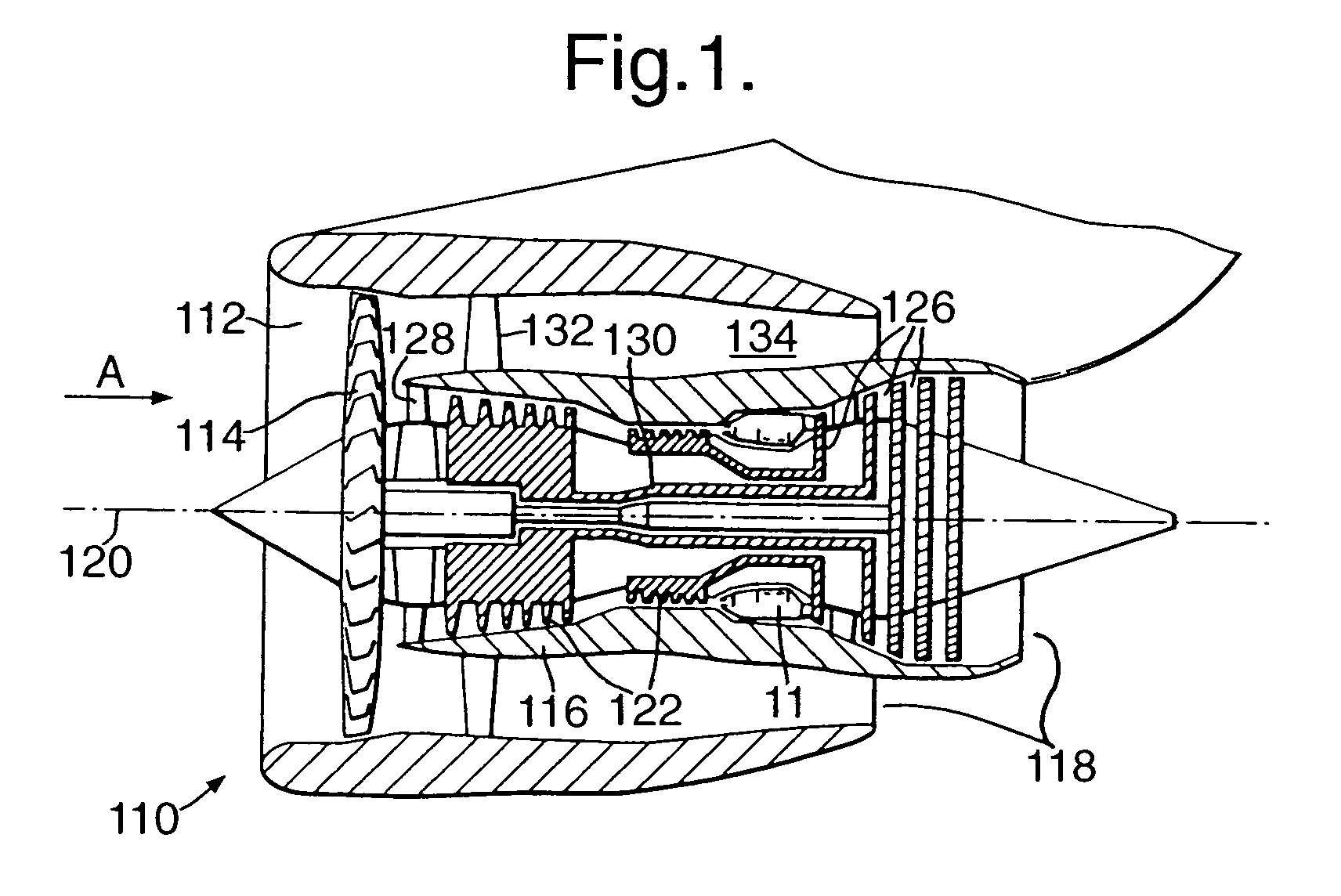

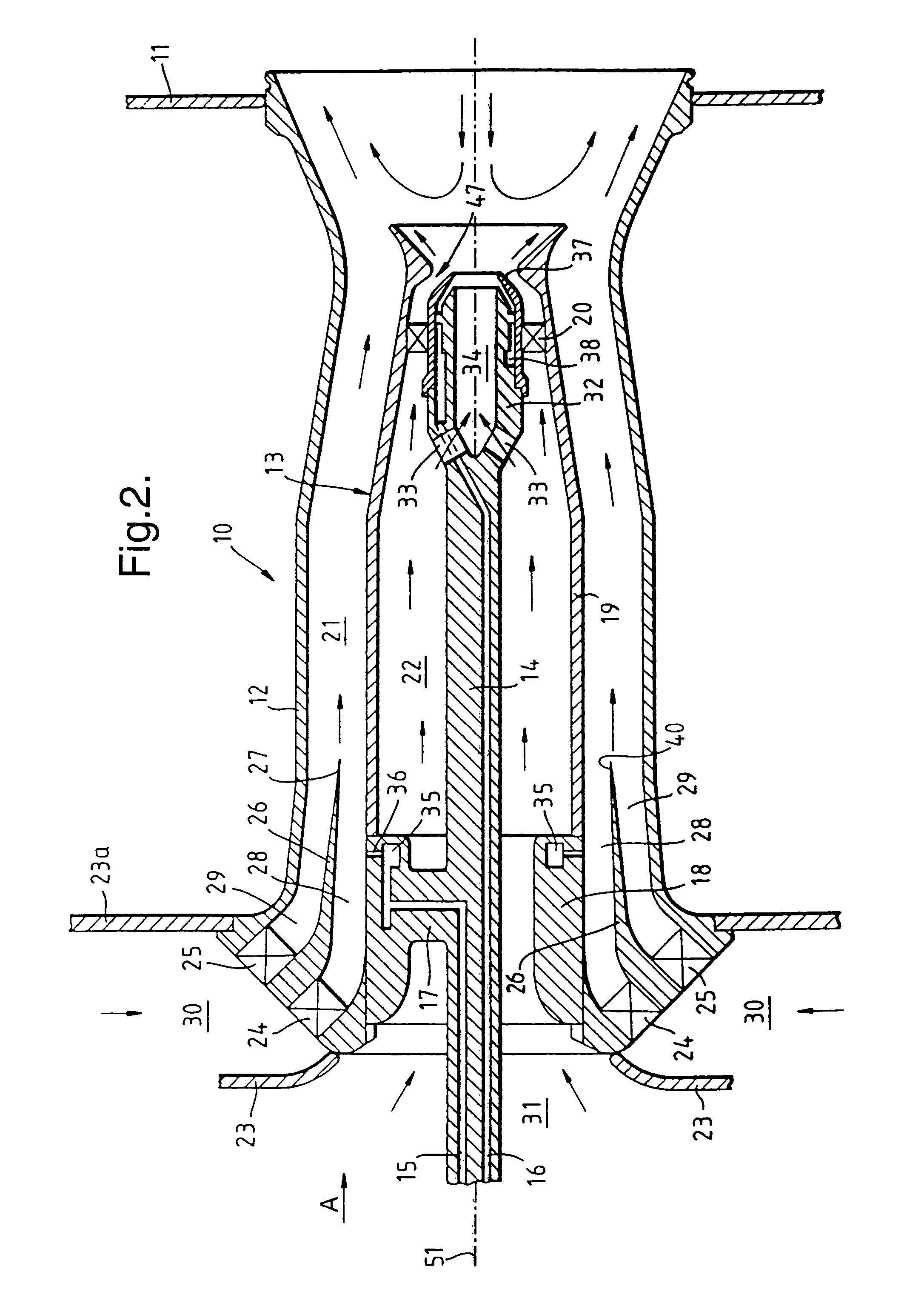

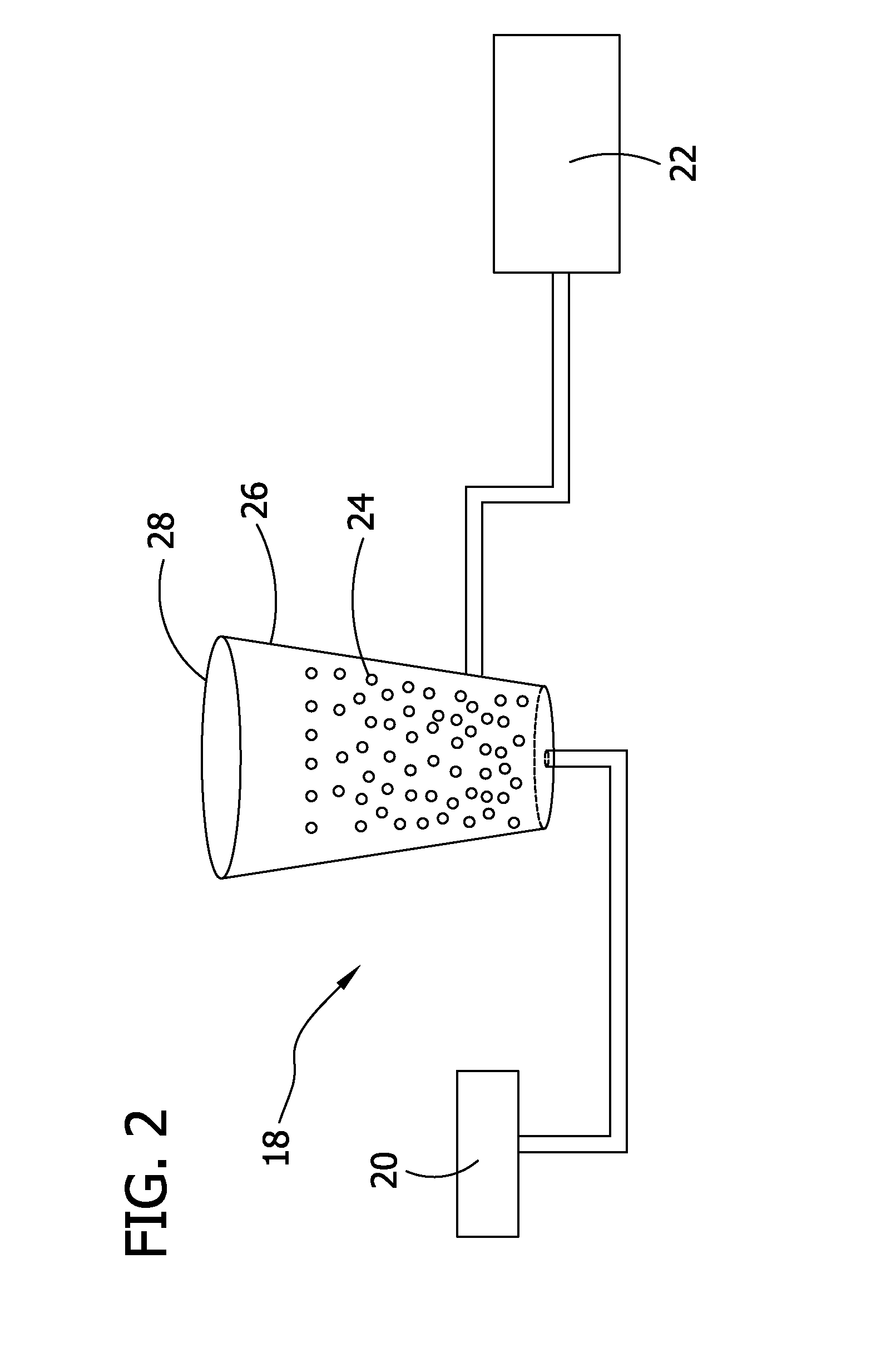

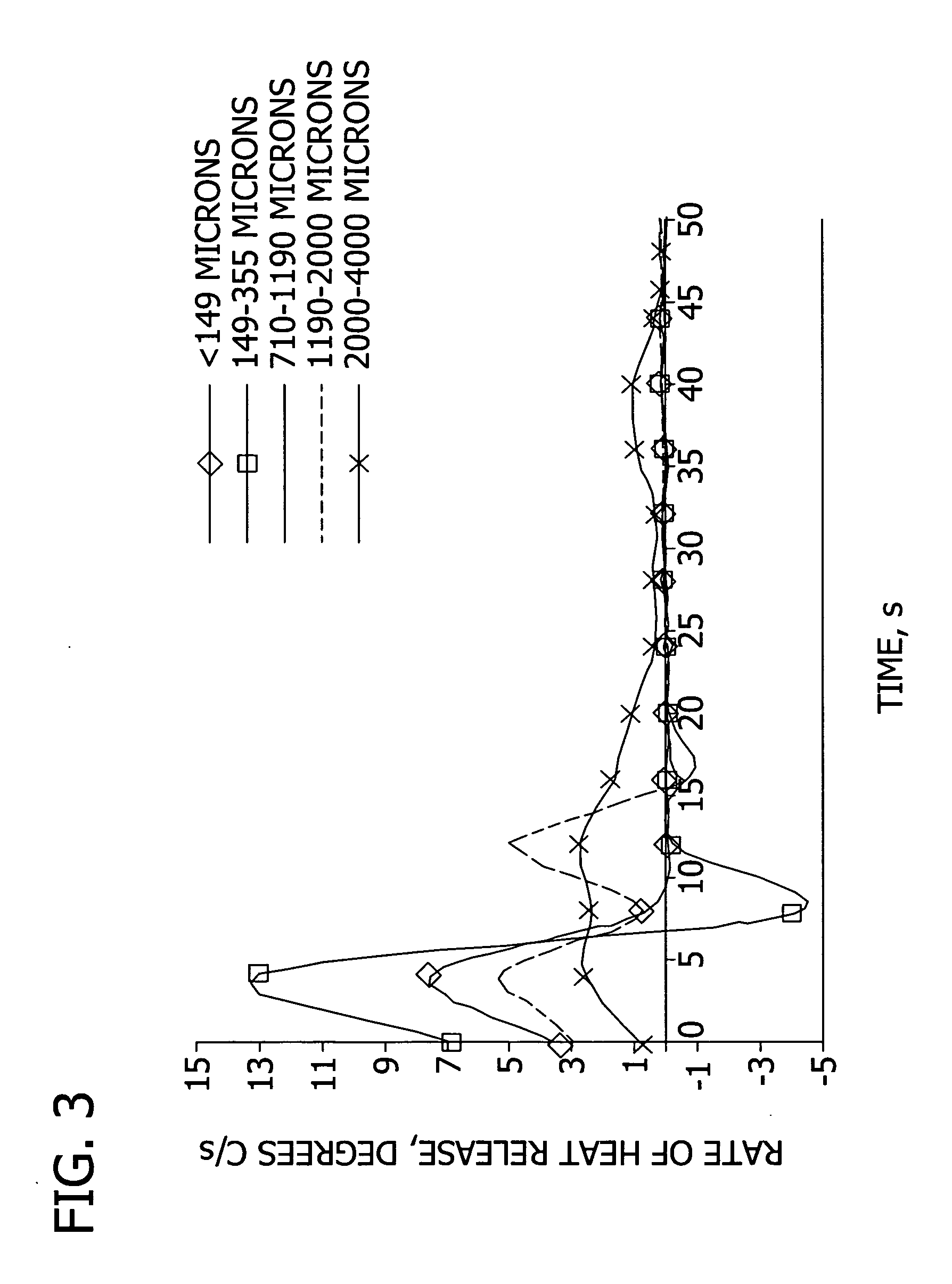

Fuel injection apparatus

ActiveUS7266945B2Reduce combustion instabilityReduce net heat release fluctuationBurnersLiquid fuel feeder/distributionInjectorAirflow

A fuel injection apparatus (10) for a gas turbine engine (110) comprising a prefilmer (26), the prefilmer (26) comprises a body (50), the body (50) defines an axis (51), an annular surface (40) and a downstream edge (44), the prefilmer (26) arranged so that when working in operative association with the fuel injection apparatus (10) fuel impinges on the surface (40) and flows, by means of a passing airflow, to the downstream edge (44), from where the fuel is shed, characterized in that the fuel injector (10) further comprises a means for circumferentially varying the residence time of the fuel across the surface (40).

Owner:ROLLS ROYCE PLC

Processes for producing microencapsulated heat delivery vehicles

InactiveUS20070145617A1Provides thermal stabilityImprove performanceLiposomal deliveryMicroballoon preparationActive agentDelivery vehicle

Microencapsulated delivery vehicles comprising an active agent are disclosed. In one embodiment, the microencapsulated delivery vehicles are heat delivery vehicles capable of generating heat upon activation. The microencapsulated heat delivery vehicles may be introduced into wet wipes such that, upon activation, the wet wipe solution is warmed resulting in a warm sensation on a user's skin. Any number of other active ingredients, such as cooling agents and biocides, can also be incorporated into a microencapsulated delivery vehicle.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Modified amino resin expansion type water flame-proof paint

InactiveCN101117510AImprove flame retardant performanceIncreased resistance to ignitionFireproof paintsEmulsion paintsPliabilityMelamine

The present invention relates to amino resin intumescent aqueous flame retardant coating, in particular to an intumescent aqueous flame retardant coating. The present invention eliminates the release of harmful organic volatile compounds of the inflaming-retardant coating in use, improving poor fire resistant performance of dewatering catalyst due to a high disassembling temperature, solving the problems of long manufacturing period, low efficiency and high cost of the inflaming-retardant wood materials. The materials for the present invention comprises amino resin, polyvinyl acetal resin, dewatering catalyst, melamine, charring agents, dope assistant, antifoaming agent, palette filling and water. The present invention has storage for a long time, good cohesion, slow and low emission of heat and low emission of smoke, enjoying good flexibility and good strike-resistant performance; furthermore, the present invention can be manufactured easily and used conveniently and can be easily popularized without emission of harmful organic volatile in use. Compared with a prior wooden inflaming-retardant liquid, the present invention has the advantages of simple process, convenient operation, low cost and high efficiency.

Owner:NORTHEAST FORESTRY UNIVERSITY

Fire resistant paint, articles of manufacture, an apparatus for manufacture and a process for manufacture thereof

InactiveUS20130288031A1Reduce volatilityLow heat release rateFireproof paintsWater-setting substance layered productFlame spreadHeat resistance

A fire and heat resistant composition for providing or enhancing the fire resistance of a material. The composition consists of both chemical and physical integration. Physical application is a coating composition containing materials including a fire and heat resistance means, lower peak heat release means, lower heat released per unit time means, higher temperature gradient means, low flame spread means, high ignition delay means, low peak heat release means, low total heat release means, high thermal stability means, elastic and coating thickness encasement means and heat. Chemical applications consist of chemical additive which are naturally more fire safe.

Owner:L M J NATION SECURITY

Ceiling-only dry sprinkler systems and methods for addressing a storage occupancy fire

ActiveUS20080319716A1Minimizing overall hydraulic demandReduce heat releaseFire rescueSpecial data processing applicationsDelayed periodsSystems design

A ceiling-only dry sprinkler system configured to address a storage occupancy fire event with a sprinkler operational area sufficient in size to surround and drown the fire. The system and method preferably provide for the surround and effect by activating one or more initial sprinklers, delaying fluid flow to the initial activated sprinklers for a defined delay period to permit the thermal activation of a subsequent one or more sprinklers so as to form the preferred sprinkler operational area. The sprinklers of the operational area are preferably configured so as to provide sufficient fluid volume and cooling to address the fire-event with a surround and drown configuration. The defined delay period is of a defined period having a maximum and a minimum. The preferred sprinkler system is adapted for fire protection of storage commodities and provides a ceiling only system that eliminates or otherwise minimizes the economic disadvantages and design penalties of current dry sprinkler system design.

Owner:TYCO FIRE PRODS LP

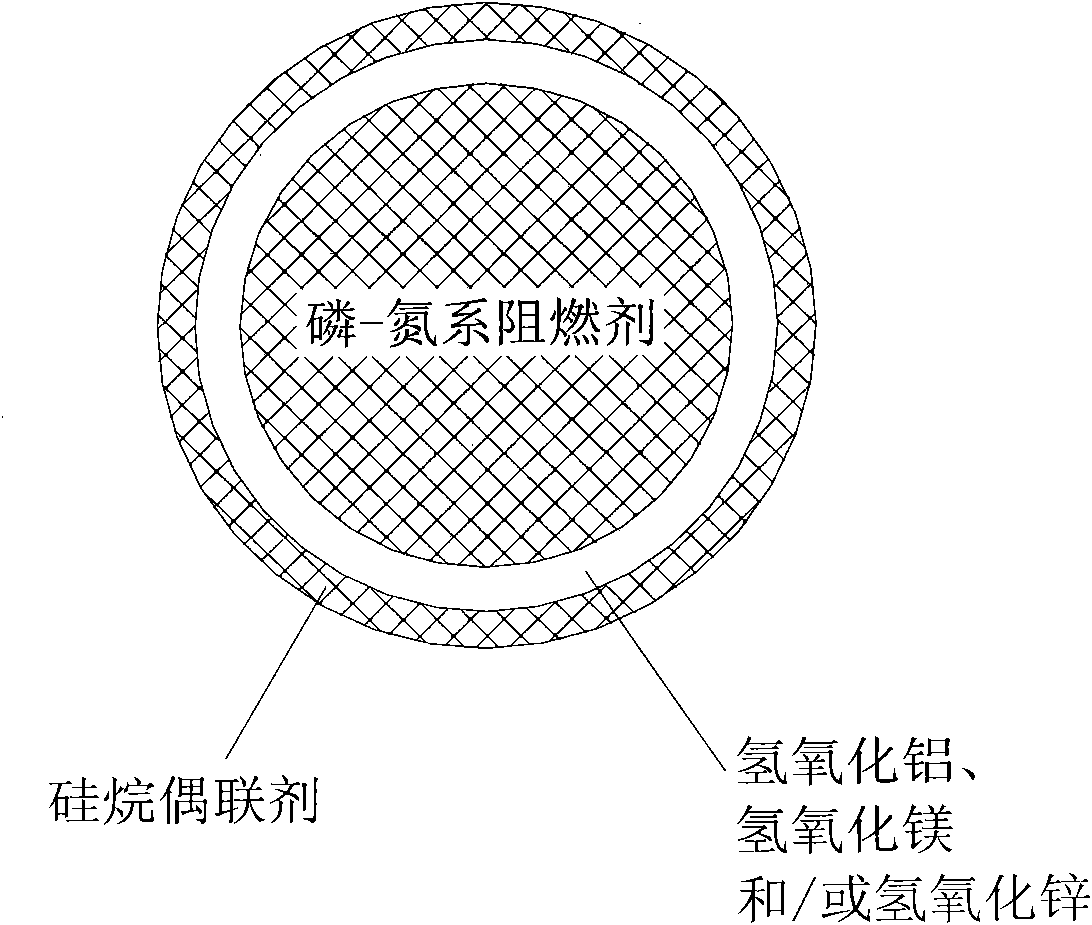

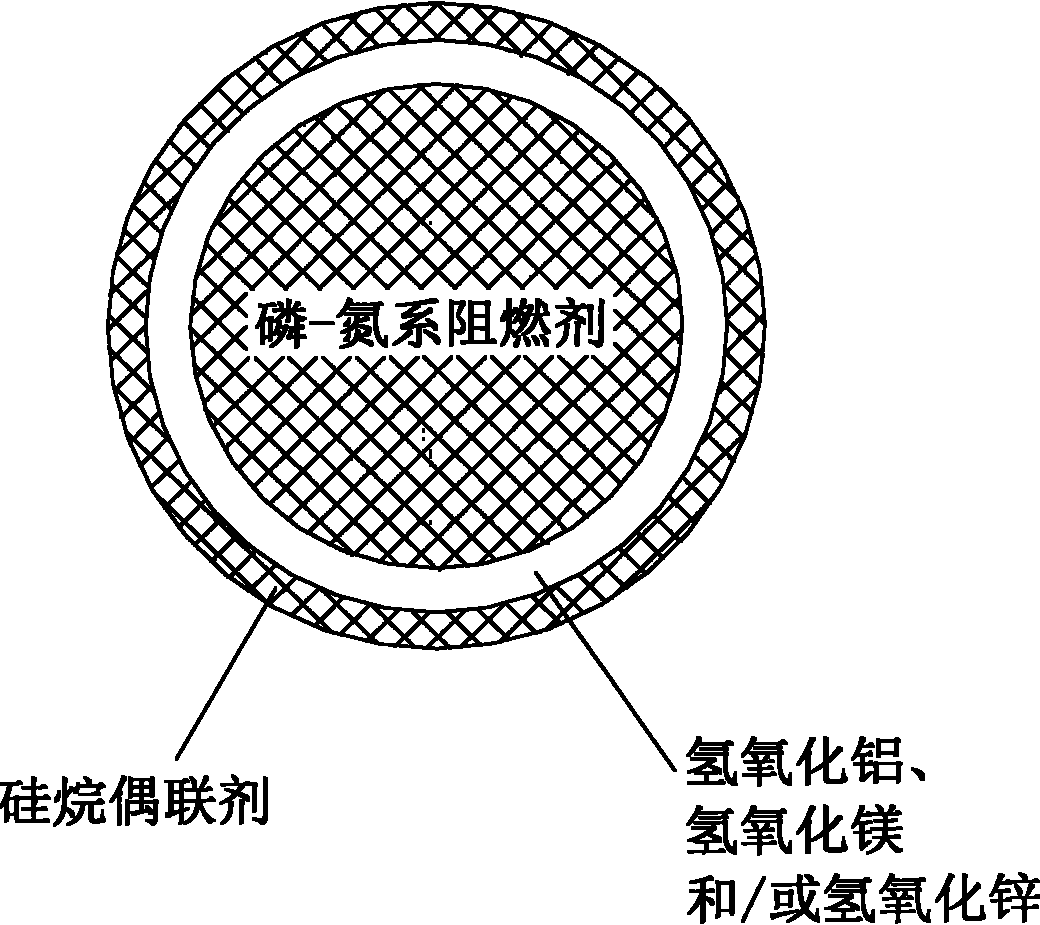

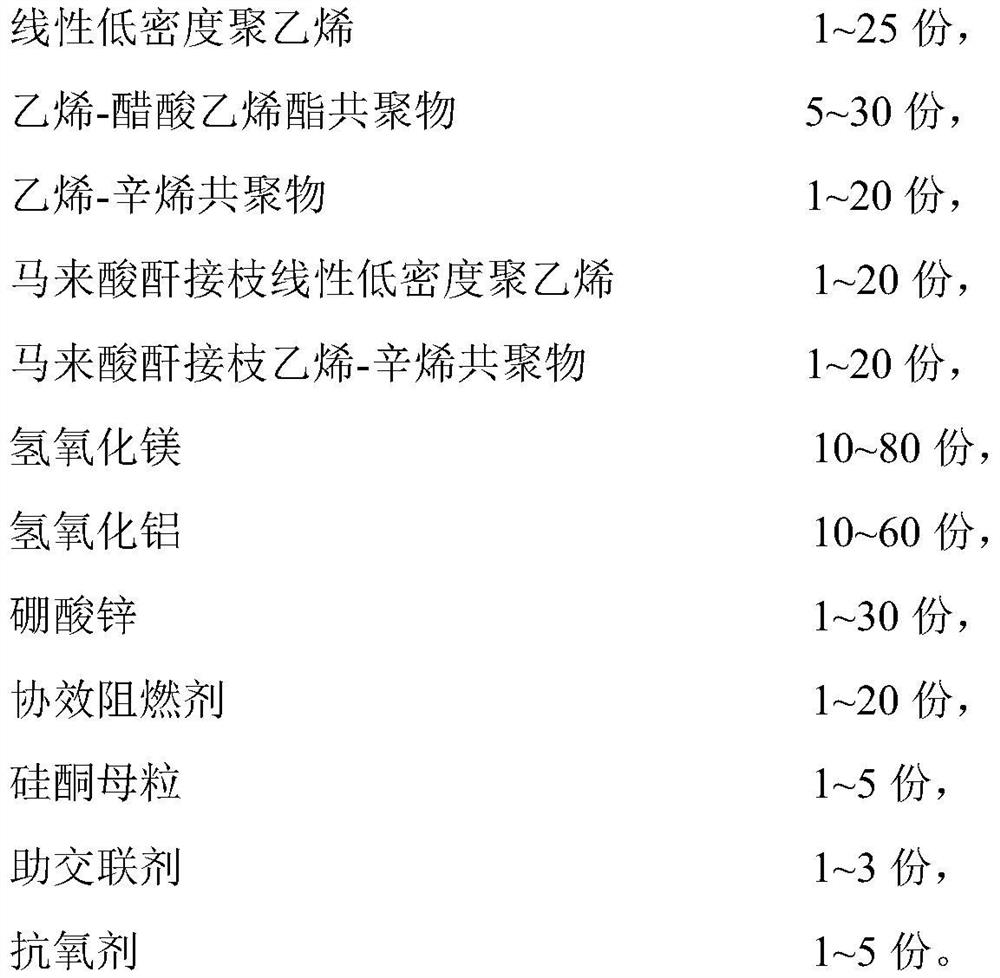

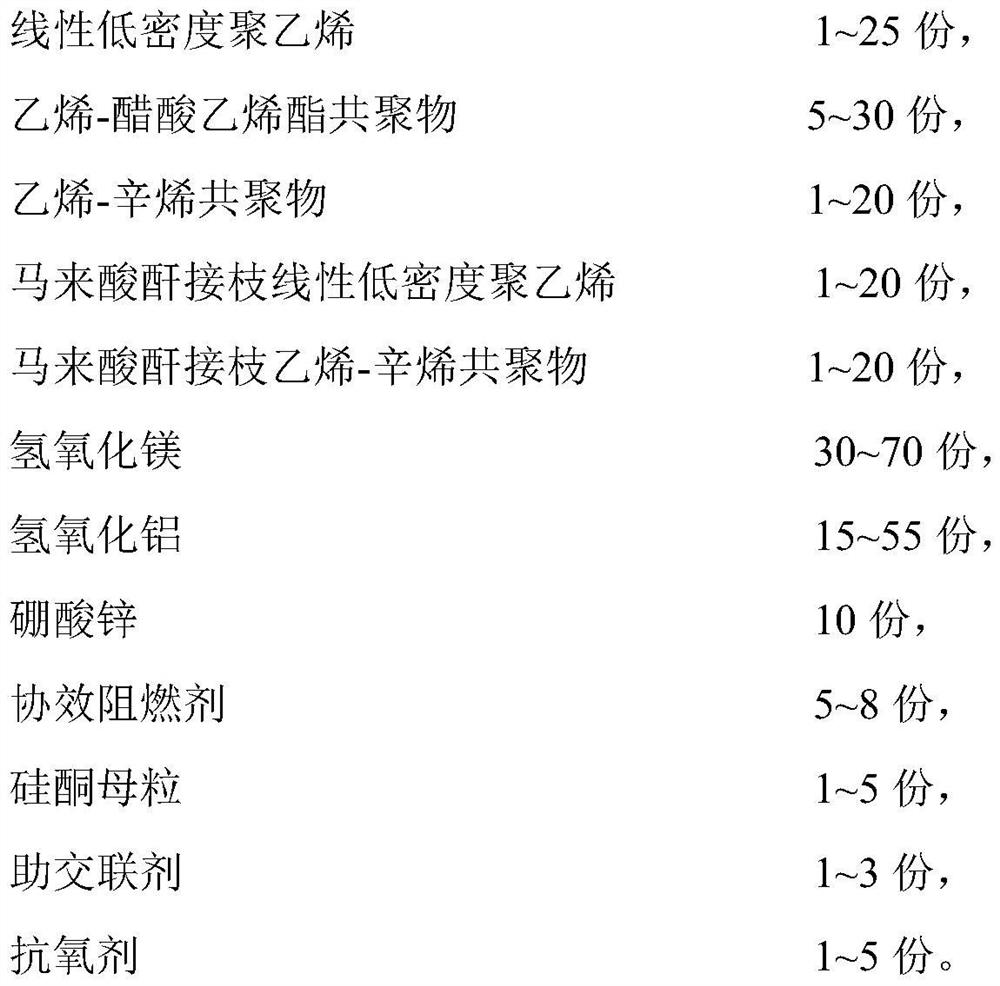

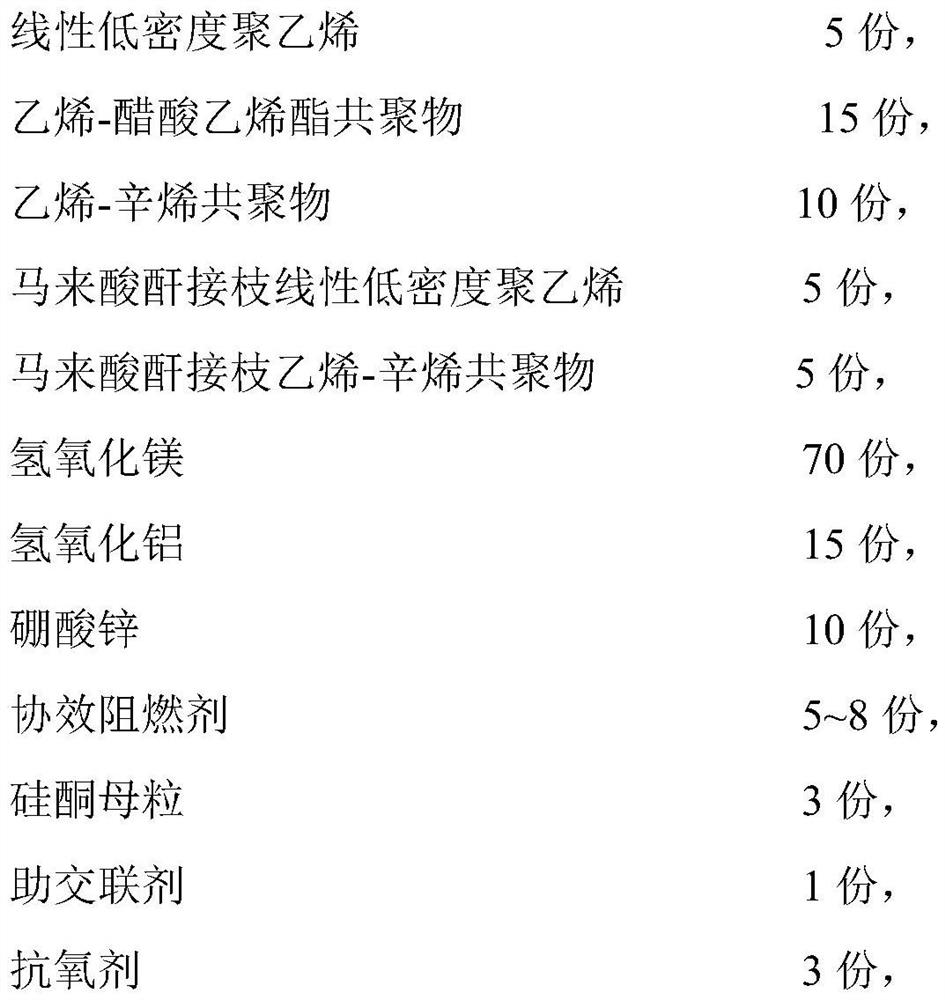

Irradiation crosslinking low-smoke halogen-free polyolefin cable material as well as preparation method and application thereof

PendingCN112759823AImprove toughness and strengthHigh mechanical strengthPlastic/resin/waxes insulatorsCross-linkLinear low-density polyethylene

The invention discloses an irradiation crosslinking low-smoke halogen-free polyolefin cable material as well as a preparation method and application thereof. The irradiation crosslinking low-smoke halogen-free polyolefin cable material is prepared from the following components in parts by weight: 1 to 25 parts of linear low-density polyethylene, 5 to 30 parts of ethylene-vinyl acetate copolymer, 1 to 20 parts of ethylene-octylene copolymer, 1 to 20 parts of maleic anhydride grafted linear low-density polyethylene, 1 to 20 parts of maleic anhydride grafted ethylene-octylene copolymer, 30 to 80 parts of magnesium hydroxide, 10 to 30 parts of aluminum hydroxide, 1-30 parts of zinc borate, 1-20 parts of a synergistic flame retardant, 1-5 parts of silicone master batch, 1-3 parts of an assistant crosslinker and 1-5 parts of an antioxidant. Specific preparation raw materials are adopted for modifying the low-smoke halogen-free polyolefin cable material, the defects of flame retardance and mechanical performance of an existing flame-retardant wire and cable material are overcome, the cable material with good mechanical performance and flame retardance is provided, and the low-smoke halogen-free polyolefin cable material is suitable for being widely applied to preparation of wires or cables.

Owner:KINGFA SCI & TECH CO LTD +1

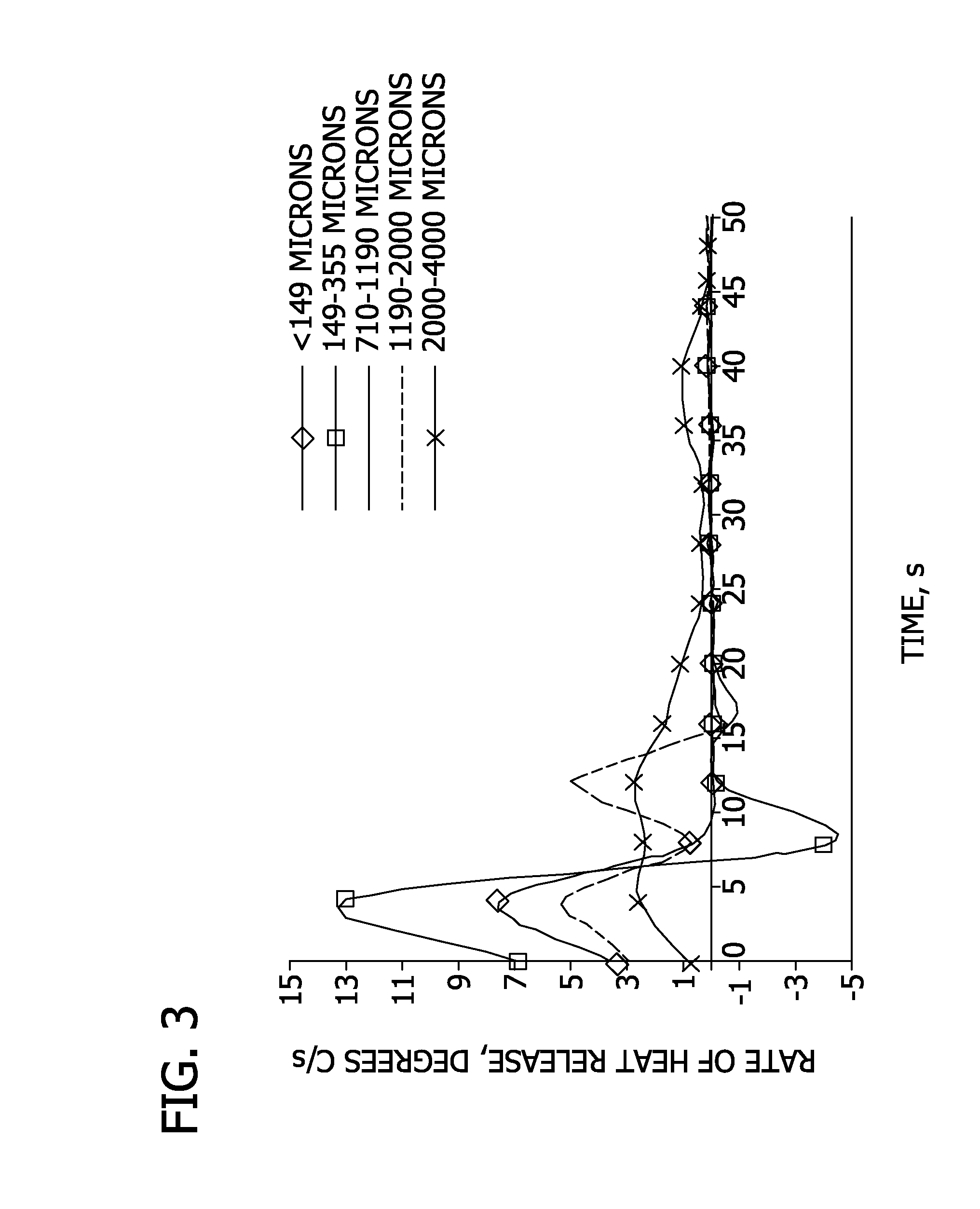

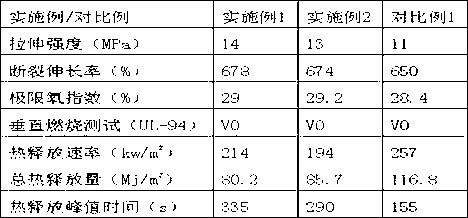

Nano composite expansion flame-retardant polyurethane foam plastic and preparation thereof

The invention discloses a nano composite expansion flame retardant polyurethane foamed plastic and a preparation method thereof. The nano composite expansion flame retardant polyurethane foamed plastic is characterized in that the preparation method comprises the following steps: evenly mixing 40 to 80 percent of polyol, 0.1 to 3 percent of foaming agent, 0.1 to 2 percent of foam stabilizer, 0.1 to 2 percent of catalyst, 0.5 to 4 percent of expandable graphite, 0.5 to 9 percent of halogen free phosphate ester or phosphonate ester and 0.5 to 5.5 percent of organic modified nano inorganic filler by weight percentage; and then mixing the mixture evenly with two or more isocyanate polyisocyanate compounds in the weight ratio of 1:2-2:1, and injecting the mixture into a die at 5 to 40 DEG C for foaming. The obtained nano composite expansion flame retardant polyurethane foamed plastic product effectively reduces the heat release rate and the total heat release amount of the material, improves the oxygen index and the vertical firing flame retardant property of the material, reduces the effect of an expansion type flame retardant on reducing the mechanical properties of the material, and meets the requirements of fire safety and project application.

Owner:UNIV OF SCI & TECH OF CHINA

Microencapsulated delivery vehicles including cooling agents

InactiveUS20070148448A1Improve performanceReduce heat releaseCosmetic preparationsExothermal chemical reaction heat productionActive agentDelivery vehicle

Microencapsulated delivery vehicles comprising an active agent are disclosed. In one embodiment, the microencapsulated delivery vehicles are heat delivery vehicles capable of generating heat upon activation. The microencapsulated heat delivery vehicles may be introduced into wet wipes such that, upon activation, the wet wipe solution is warmed resulting in a warm sensation on a user's skin. Any number of other active ingredients, such as cooling agents and biocides, can also be incorporated into a microencapsulated delivery vehicle.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Synthetic inorganic flame retardants, methods for their preparation, and their use as flame retardants

InactiveUS20110213065A1High flame retardant efficiencyImprove thermal stabilitySilicaAlkali metal silicatesAlkaline earth metalPhosphate

Quite unexpectedly, by suitably modifying the crystal structure of hydrogarnets of the general formula MII3MrI-III2(OH)12 (where MII denotes divalent metal ions, especially alkaline earth metal ions, of Group IIA of the periodic table and MIII denotes trivalent metal ions of Group IIIA of the periodic table, especially aluminum) with suitable amounts of incorporated silicate and / or phosphate, flame retardants having both a higher flame retardant efficiency than such traditional mineral flame retardants as ATH and MDH, and a higher thermal stability than ATH can be produced. It has also been found that synthetic hydrogarnets of the general formula MII3MrIII2(OH)12(where MII and MIII are as defined above) having cubic crystal and these synthetic hydrogarnets also show high flame retardant efficiency.

Owner:ALBEMARLE CORP

Method of Manufacturing Self-Warming Products

InactiveUS20070148198A1Provides thermal stabilityFunction increaseCosmetic preparationsExothermal chemical reaction heat productionActive agentDelivery vehicle

Microencapsulated delivery vehicles comprising an active agent are disclosed. In one embodiment, the microencapsulated delivery vehicles are heat delivery vehicles capable of generating heat upon activation. The microencapsulated heat delivery vehicles may be introduced into wet wipes such that, upon activation, the wet wipe solution is warmed resulting in a warm sensation on a user's skin. Any number of other active ingredients, such as cooling agents and biocides, can also be incorporated into a microencapsulated delivery vehicle.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Apparatus for detecting impurities in material and detecting method therefor

InactiveUS7227148B2Accurate detectionAvoid overall overheatingTobacco preparationRadiation pyrometryInfraredLength wave

Owner:JAPAN TOBACCO INC

Wipes including microencapsulated delivery vehicles and phase change materials

InactiveUS20070148447A1Provides thermal stabilityImprove performanceCosmetic preparationsExothermal chemical reaction heat productionDelivery vehicleActive agent

Microencapsulated delivery vehicles comprising an active agent are disclosed. In one embodiment, the microencapsulated delivery vehicles are heat delivery vehicles capable of generating heat upon activation. The microencapsulated heat delivery vehicles may be introduced into wet wipes such that, upon activation, the wet wipe solution is warmed resulting in a warm sensation on a user's skin. Any number of other active ingredients, such as cooling agents and biocides, can also be incorporated into a microencapsulated delivery vehicle.

Owner:KIMBERLY-CLARK WORLDWIDE INC

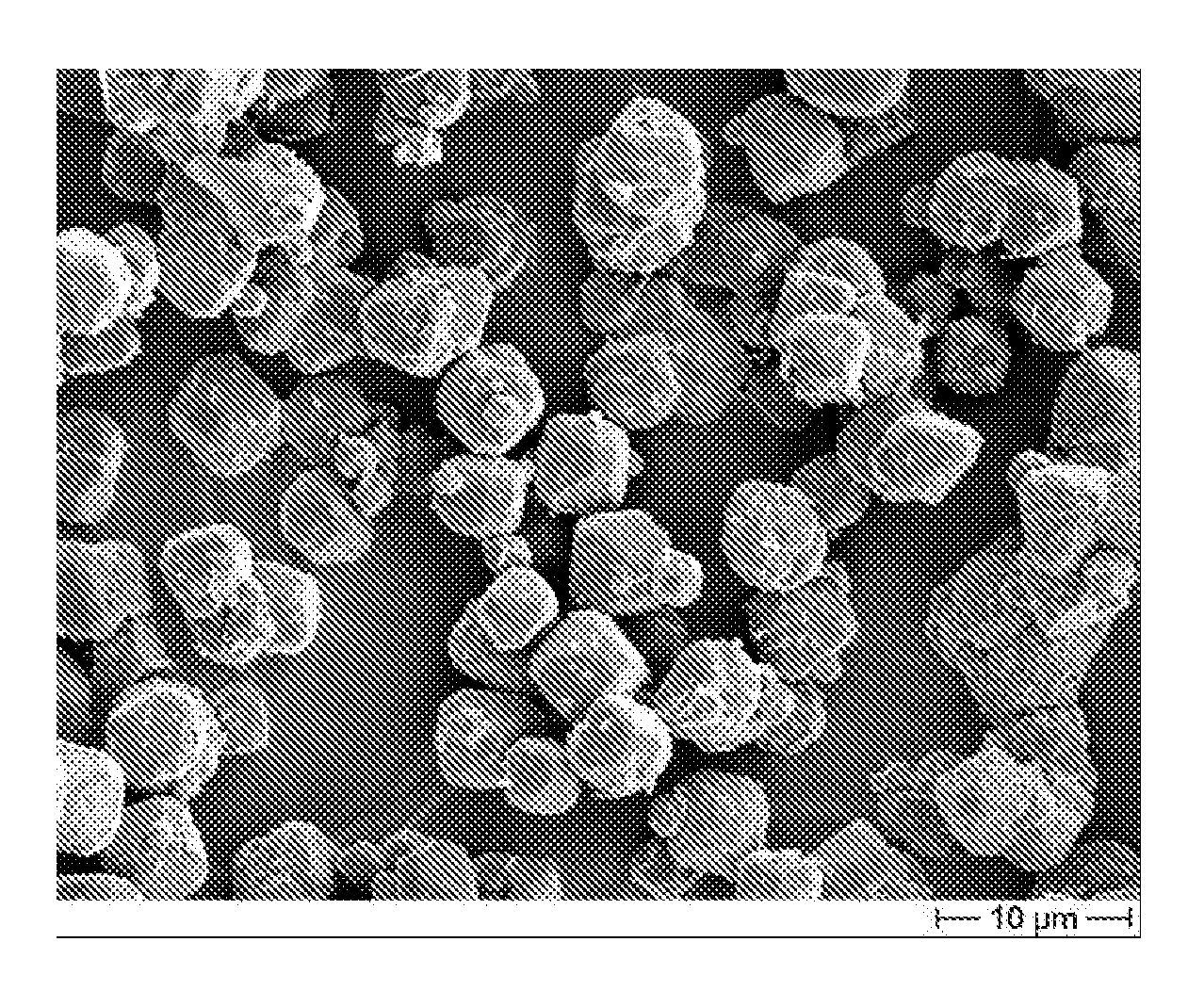

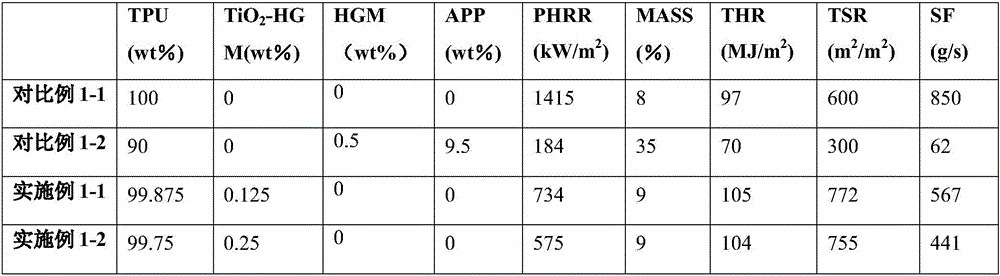

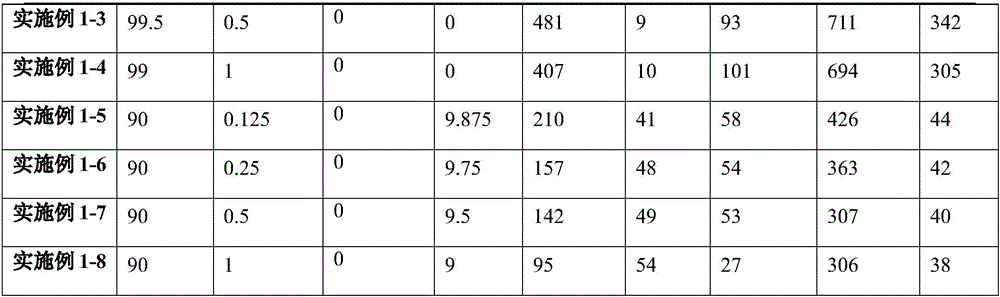

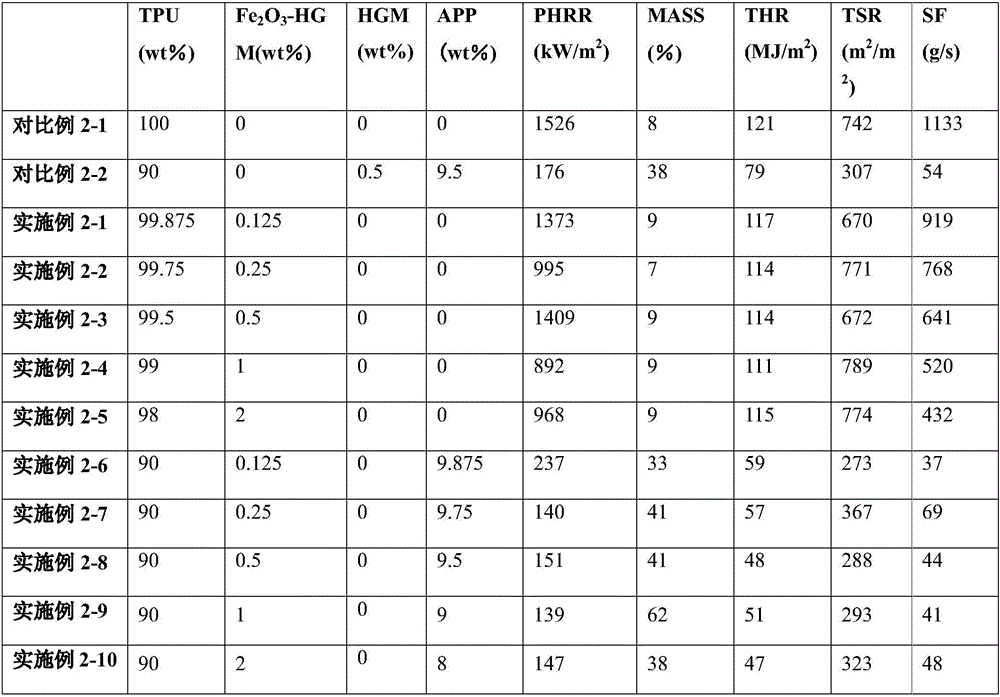

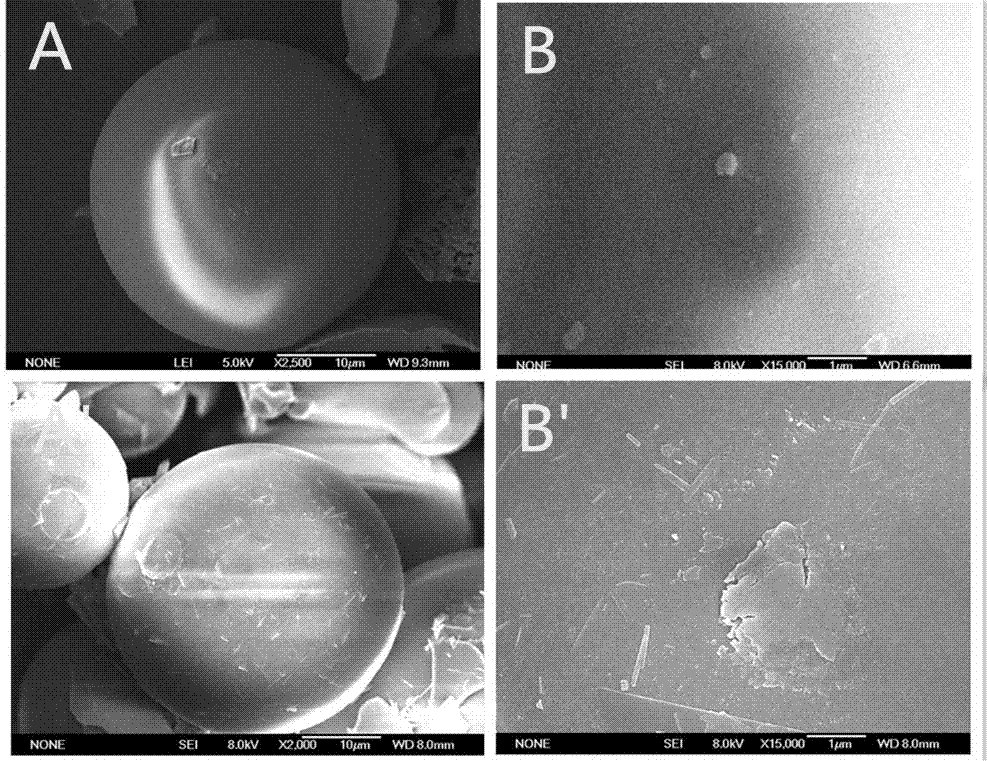

Surface modifying method of hollow glass beads and flame-retardant application thereof

InactiveCN106009044ASimple processEasy to operatePigment treatment with organosilicon compoundsIonFire retardant

The invention relates to a surface modifying method of hollow glass beads and a flame-retardant application thereof. The surface modifying method of the hollow glass beads comprises the following steps: (1) performing ultrasonic washing of the hollow glass beads by using a sodium hydroxide solution; (2) repeatedly washing the hollow glass beads obtained in the step (1) with deionized water and absolute ethyl alcohol respectively, and drying; and (3) dissolving the treated hollow glass beads in a mixed solution of ethanol and deionized water, and performing reflux, heating and stirring; in the heating process, dropwise adding a solution for obtaining a coating, and then adding the sodium hydroxide solution while keeping a neutral environment; and stirring for 5h, performing suction filtration and drying. In the invention, the modified hollow glass beads are adopted as a flame retardant to prepare a flame-retardant thermoplastic polyurethane composite; cone calorimeter experiments indicate that the parameters of the composite such as heat release rate, total heat release, smoke generation rate and smoke factor are remarkably reduced while the residual mass of carbon residues is greatly increased.

Owner:QINGDAO UNIV OF SCI & TECH

Wipes including microencapsulated delivery vehicles and phase change materials

InactiveUS7914891B2Improve performanceReduce heat releaseCosmetic preparationsExothermal chemical reaction heat productionDelivery vehicleActive agent

Microencapsulated delivery vehicles comprising an active agent are disclosed. In one embodiment, the microencapsulated delivery vehicles are heat delivery vehicles capable of generating heat upon activation. The microencapsulated heat delivery vehicles may be introduced into wet wipes such that, upon activation, the wet wipe solution is warmed resulting in a warm sensation on a user's skin. Any number of other active ingredients, such as cooling agents and biocides, can also be incorporated into a microencapsulated delivery vehicle.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Methods of making microencapsulated delivery vehicles

InactiveUS20070145618A1Provides thermal stabilityImprove performanceLiposomal deliveryMicroballoon preparationActive agentMicroencapsulations

Microencapsulated delivery vehicles comprising an active agent are disclosed. In one embodiment, the microencapsulated delivery vehicles are heat delivery vehicles capable of generating heat upon activation. The microencapsulated heat delivery vehicles may be introduced into wet wipes such that, upon activation, the wet wipe solution is warmed resulting in a warm sensation on a user's skin. Any number of other active ingredients, such as cooling agents and biocides, can also be incorporated into a microencapsulated delivery vehicle.

Owner:KIMBERLY-CLARK WORLDWIDE INC

High-flame-retardancy paint

InactiveCN106366740AHigh tensile strengthImprove adsorption capacityFireproof paintsPolyurea/polyurethane coatingsWater basedDimethyl methylphosphonate

The invention discloses a high-flame-retardancy paint which is prepared from a water-based acrylate emulsion, a water-based polyurethane resin, aluminasol, an epoxy resin, polydimethylsiloxane, zinc oxide, hollow glass microspheres, nano zirconium oxide, montmorillonite, nano silicon dioxide, a film forming aid, a defoaming agent, a leveling agent, a wetting agent, a flame retardant and water. The flame retardant is formed by mixing boron oxide, dimethyl methyl phosphonate, phosphorus pentoxide, tri(2-chloropropyl) phosphate, guanylurea phosphate, ammonium polyphosphate, pentaerythritol, melamine and hexamethyl disiloxane. The high-flame-retardancy paint has the advantages of favorable water resistance, favorable wear resistance, excellent flame retardancy and long service life.

Owner:ANHUI JINDUN PAINT

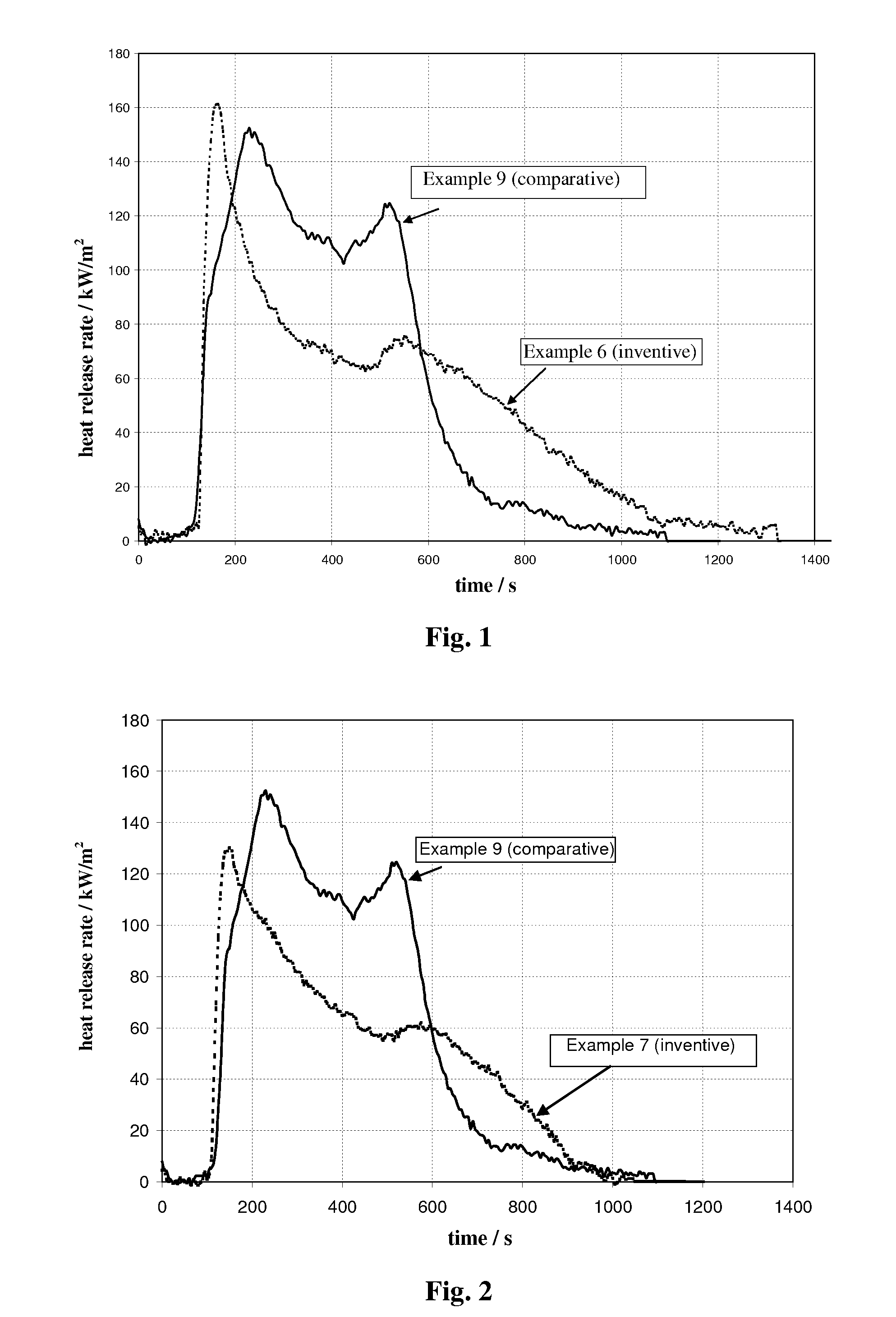

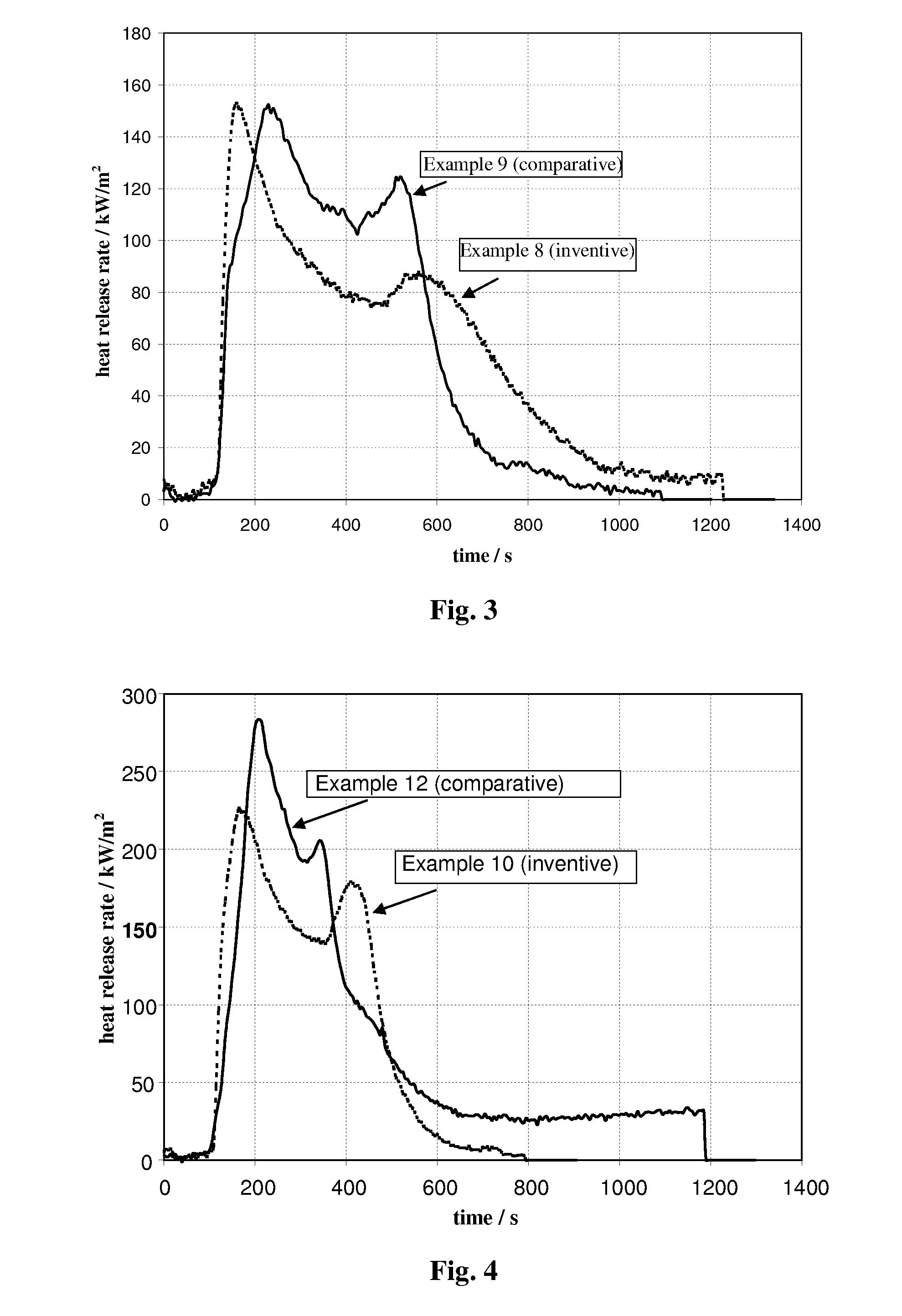

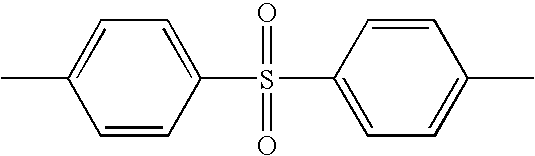

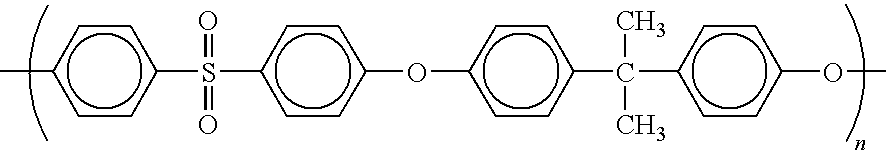

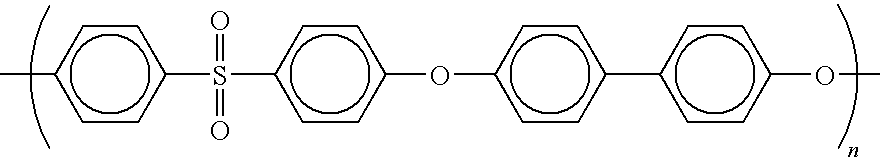

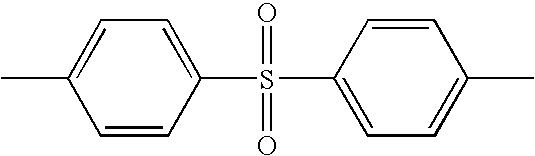

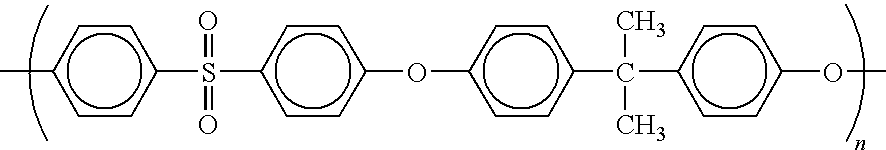

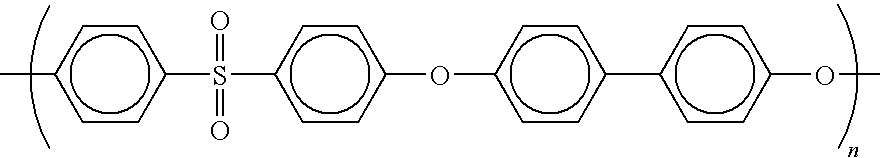

Transparent and flame retardant polysulfone compositions

ActiveUS20090283476A1High transparencyReduce heat releaseUltrafiltrationWater/sewage treatment bu osmosis/dialysisDiphenyl sulfonePolysulfone

A polysulfone having a first polyphenylene sulfone unit (i.e. PPSU unit) based on one biphenol group and one diphenyl sulfone group and a second sulfone unit (i.e. PSU-AF unit) based on one hexafluorobisphenol A group and one diphenylsulfone group. The polysulfone is transparent and has a total heat release and peak heat release of less than 65 kW·min / m2 and 65 kW / m2, respectively. Compositions containing the polysulfone and articles made by molding and / or extruding the polysulfone.

Owner:SOLVAY ADVANCED POLYMERS LLC

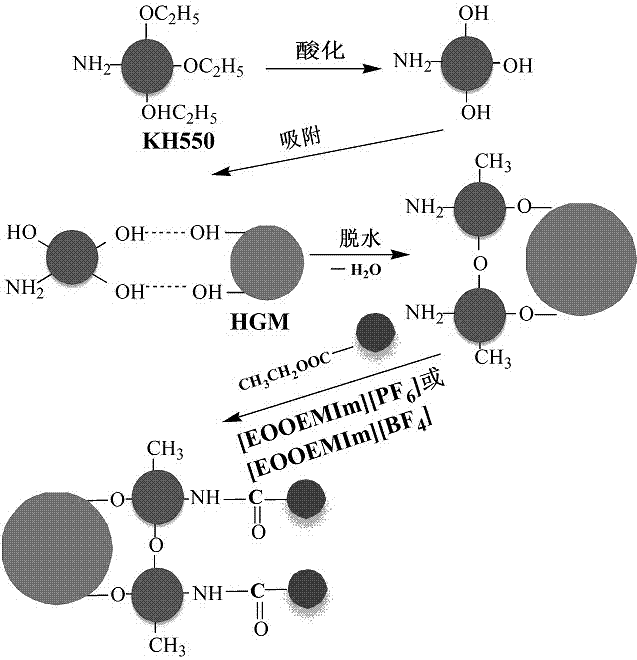

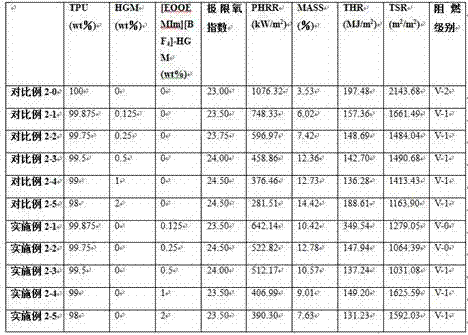

Method of modifying hollow glass microbeads with ionic liquid and flame-retarding thermoplastic polyurethane elastomer with the modified hollow glass microbeads as flame retardant

The invention discloses a method of modifying hollow glass microbeads with an ionic liquid and a flame-retarding thermoplastic polyurethane elastomer with the modified hollow glass microbeads as a flame retardant. The method includes the steps of: 1) treating the hollow glass microbeads with a hydrochloric acid solution; 2) after the acid treatment, repeatedly washing and drying the hollow glass microbeads; 3) activating the hollow glass microbeads, adding a silane coupling agent, and performing mechanical stirring reflux; 4) stopping the reaction and cooling the reaction product to room temperature, and performing suction filtration with acetonitrile, ethanol and deionized water and drying the reaction product; 5) adding the ionic liquid to the silanized hollow glass microbeads and performing mechanical stirring reflux; 6) stopping the reaction and cooling the reaction product to room temperature, performing suction filtration successively with ethanol, a mixed solution of ethanol and deionized water, and ethanol, and drying the reaction product. By means of the hollow glass microbeads modified with the ionic liquid as the flame retardant for preparing flame-retarding thermoplastic polyurethane (TPU) elastomer, not only is oxygen index of the composite material improved, but also the vertical combustion performance, which reflects melt-dripping resistance, is improved, so that heat release rate is reduced and smoke is significantly inhibited.

Owner:JIANGSU STERRIC CHEM IND

Low-smoke low-toxicity flame-retardation hard polyurethane foam plastics and preparation method thereof

The invention discloses low-smoke low-toxicity flame-retardation hard polyurethane foam plastics and a preparation method thereof. The low-smoke low-toxicity flame-retardation hard polyurethane foam plastics comprise the following raw materials: 100 parts of polyether polyol, 120-150 parts of isocyanate, 10-20 parts of an intumescent flame retardant, 1-3 parts of a metallic compound, 0.5-2 parts of attapulgite, 1-5 parts of a foaming agent, 1-4 parts of a foaming stabilizer, and 3-6 parts of a foaming catalyst. The preparation method comprises the following steps: mixing, casting and foaming. The low-smoke low-toxicity flame-retardation hard polyurethane foam plastics have good flame resistance, and achieve a V-0 grade in an UL94 vertical combustion test. At the same time, an expandable charcoal layer formed after combustion of the fire retardant, and the added metallic compound and the attapulgite are capable of absorbing and catalyzing toxic gas, effectively reduce heat release rate and total heat release rate of the materials, and can solve the problem of large flue gas generation amount of the foam plastics prepared by the additive-type flame retardant.

Owner:HEFEI GENIUS NEW MATERIALS

Wipes including microencapsulated delivery vehicles and processes of producing the same

InactiveUS20070148446A1Provides thermal stabilityImprove performanceCosmetic preparationsExothermal chemical reaction heat productionActive agentDelivery vehicle

Microencapsulated delivery vehicles comprising an active agent are disclosed. In one embodiment, the microencapsulated delivery vehicles are heat delivery vehicles capable of generating heat upon activation. The microencapsulated heat delivery vehicles may be introduced into wet wipes such that, upon activation, the wet wipe solution is warmed resulting in a warm sensation on a user's skin. Any number of other active ingredients, such as cooling agents and biocides, can also be incorporated into a microencapsulated delivery vehicle.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Halogen-free expanded flame retardant cable outer sheath material composition and preparation method thereof

InactiveCN103102579ALow priceLow costPlastic/resin/waxes insulatorsInsulated cablesAntioxidantMechanical property

The invention relates to a halogen-free expanded flame retardant cable outer sheath material composition and a preparation method thereof, and belongs to the technical field of cable material. The material is characterized by comprising an ethylene-vinyl acetate copolymer binder, an antioxidant, an ethylene vinyl acetate grafted maleic anhydride copolymer compatilizer, an antioxidant, an ammonium polyphosphate flame retardant, a pentaerythritol flame retardant, a release agent, and further comprising 1-3% of halloysite nanotubes and 1-2% of a silane coupling agent. The invention introduces halloysite nanotubes into the halogen-free expanded flame retardant ethylene-vinyl acetate cable sheath material to realize the purpose of flame retardant modification without affecting properties of the material, and at the same time to enhance the mechanical properties of the material. The invention has the advantages of simple process, easy operation and control, low cost of raw materials and wide range of sources; and the halogen-free expanded flame retardant cable sheath material prepared from the halogen-free expanded flame retardant cable outer sheath material composition provided by the invention has good mechanical and flame retardant properties.

Owner:JIANGSU BAOYUAN GAOXIN ELECTRIC +1

Microencapsulated delivery vehicles

InactiveUS20070148459A1Provides thermal stabilityImprove performanceCosmetic preparationsExothermal chemical reaction heat productionDelivery vehicleActive agent

Microencapsulated delivery vehicles comprising an active agent are disclosed. In one embodiment, the microencapsulated delivery vehicles are heat delivery vehicles capable of generating heat upon activation. The microencapsulated heat delivery vehicles may be introduced into wet wipes such that, upon activation, the wet wipe solution is warmed resulting in a warm sensation on a user's skin. Any number of other active ingredients, such as cooling agents and biocides, can also be incorporated into a microencapsulated delivery vehicle.

Owner:KIMBERLY-CLARK WORLDWIDE INC

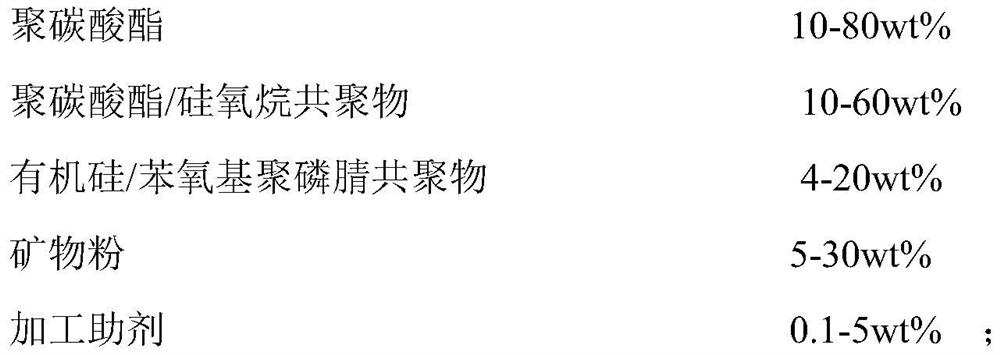

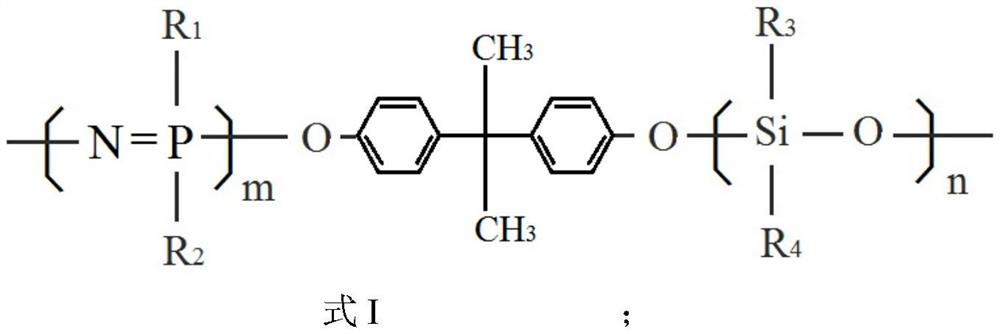

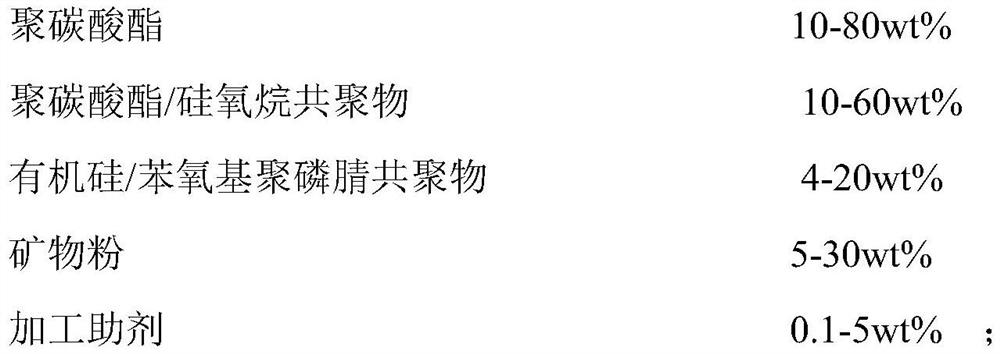

Low-smoke-density low-heat-release halogen-free flame-retardant PC material and preparation method and application thereof

ActiveCN112409770AImproved smoke density and heat release propertiesDesign sciencePolycarbonateOrganosilicon

The invention belongs to the technical field of polymer composite materials, and discloses a low-smoke-density low-heat-release halogen-free flame-retardant PC material and a preparation method and application thereof. The low-smoke-density low-heat-release halogen-free flame-retardant PC material is prepared from the following raw materials in percentage by weight: 10-80wt% of polycarbonate, 10-60wt% of polycarbonate siloxane copolymer, 4-20wt% of organic silicon / poly(bis(phenoxy)phosphazene) copolymer, 5-30wt% of mineral powder and 0.1-5 wt% of processing aid. The structural formula of the organosilicon / poly(bis(phenoxy)phosphazene) copolymer is shown as a formula I in the specification. The balance of mechanical properties, flame retardancy and processability of the PC material is fullyconsidered, the organic silicon / poly(bis(phenoxy)phosphazene) copolymer is creatively adopted as the flame retardant and smoke suppressant, and the smoke suppression and heat absorption effects of the inorganic mineral powder are assisted, so that the smoke density and heat release amount of the material during combustion are effectively reduced.

Owner:SICHUAN COREMER CO LTD

Transparent and flame retardant polysulfone compositions

ActiveUS8110639B2High transparencyReduce heat releaseSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisDiphenyl sulfonePolysulfone

A polysulfone having a first polyphenylene sulfone unit (i.e. PPSU unit) based on one biphenol group and one diphenyl sulfone group and a second sulfone unit (i.e. PSU-AF unit) based on one hexafluorobisphenol A group and one diphenylsulfone group. The polysulfone is transparent and has a total heat release and peak heat release of less than 65 kW·min / m2 and 65 kW / m2, respectively. Compositions containing the polysulfone and articles made by molding and / or extruding the polysulfone.

Owner:SOLVAY ADVANCED POLYMERS LLC

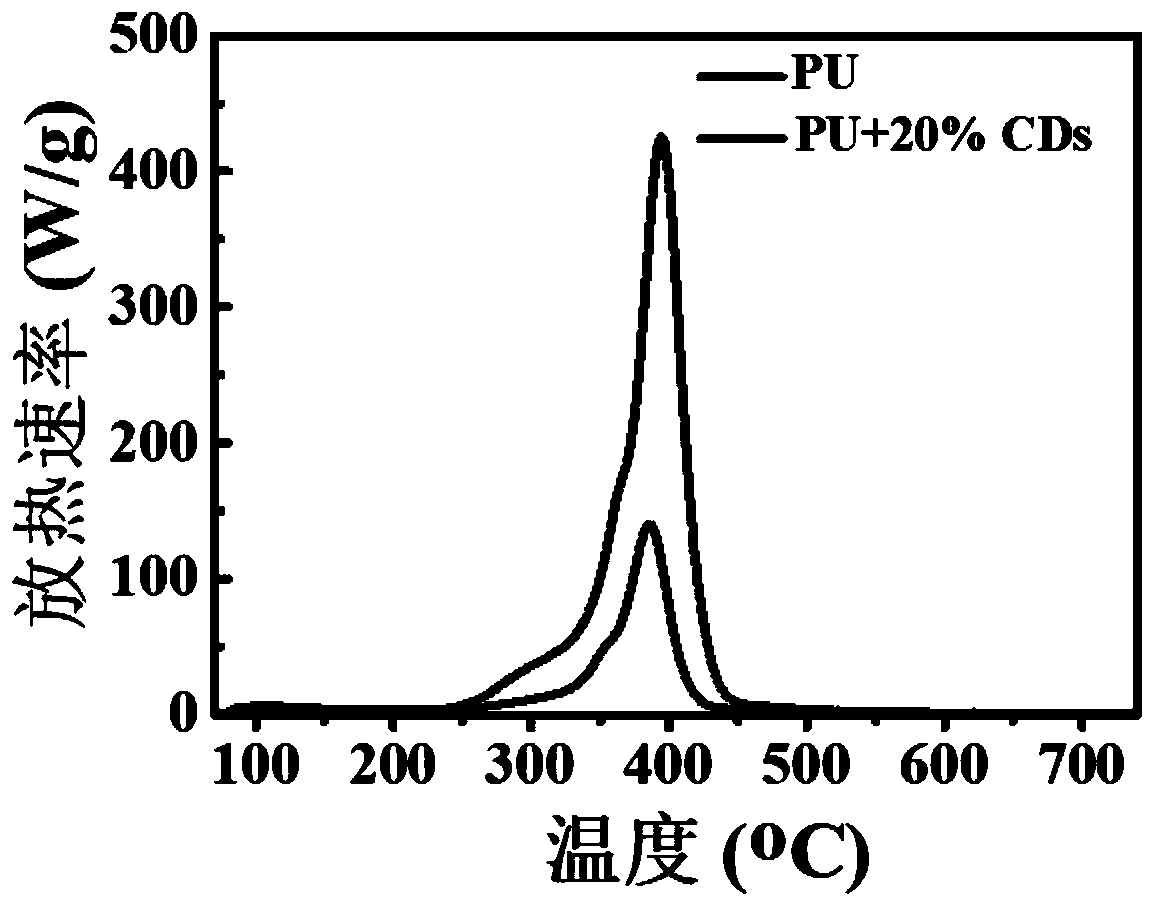

Carbon quantum dot-polymer composite material, and preparation method and application thereof

The invention discloses a carbon quantum dot-polymer resin composite material, and a preparation method and an application thereof. The carbon quantum dot-polymer resin composite material is a composite material prepared from carbon quantum dots and a polymer resin material through melt blending, wherein a mass ratio of the carbon quantum dots to the polymer resin material is 1:(2.3-10). The invention also discloses an application of the carbon quantum dot-polymer resin composite material in different fields. The carbon quantum dot-polymer resin composite material has the advantages of simplicity in operation, mild conditions, and easiness in large-scale preparation. The flame retardant application of the carbon quantum dots as a green halogen-free flame retardant in polymers is disclosedfor the first time. The carbon quantum dot-polymer resin composite material has the advantages of good flame retardant effect, greenness, environmental protection and the like, and provides a new ideafor the preparation of brand new environmentally-friendly halogen-free flame retardants.

Owner:NANJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com