Low-smoke-density low-heat-release halogen-free flame-retardant PC material and preparation method and application thereof

A smoke density and low heat technology, applied in the field of low smoke density, low heat release, halogen-free flame retardant PC material and its preparation, can solve the problem of releasing a large amount of smoke and heat, achieve simple operation, scientific design, improve smoke density and heat release performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

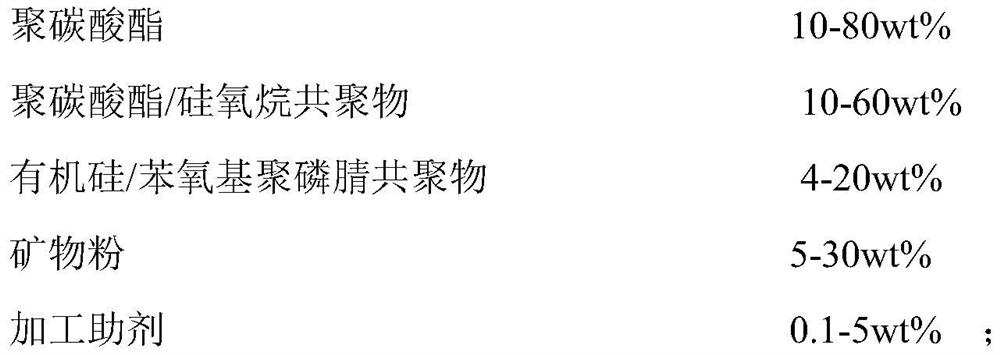

Method used

Image

Examples

Embodiment 1-3

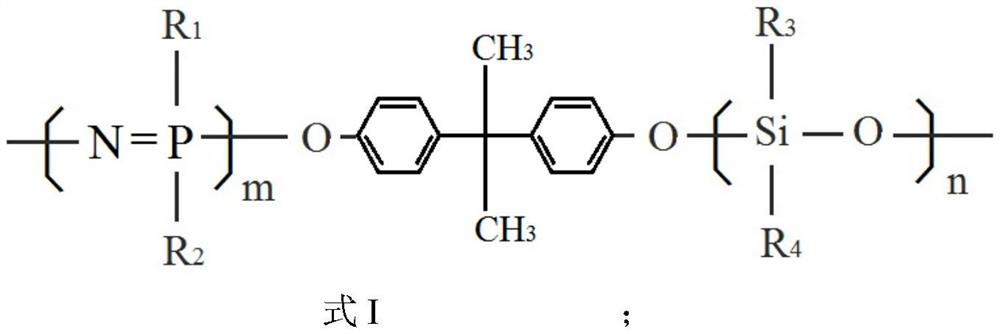

[0061] Examples 1-3 disclose the synthesis method of the organosilicon / phenoxyphosphazene of the present invention.

Embodiment 1

[0063] This embodiment discloses the synthesis method of organosilicon / phenoxyphosphazene of the present invention, specifically:

[0064] ①. Use 40g of hexachlorocyclotriphosphazene to open the ring at 250°C to prepare linear chlorine-containing polyphosphazene. After the reaction is complete, stop heating and set aside;

[0065] ②. At high temperature (160°C), pass 200g of 5wt% NaOH aqueous solution into 100g of xylene containing 10g of bisphenol A and immediately separate the water. When bisphenol A disodium salt is formed and precipitated, use iso Propanol is dissolved, and finally all the solvent is evaporated to obtain dry bisphenol A disodium salt, and finally the prepared bisphenol A disodium salt is dissolved in xylene to prepare 10% bisphenol A disodium salt-xylene solution;

[0066] ③. The linear chlorine-containing polyphosphazene prepared in step ①, 10g methyltrichlorochlorosilane, 80g 10wt% bisphenol A phenol disodium-xylene solution were reacted at 80°C for 2h,...

Embodiment 2

[0068] This embodiment discloses the synthesis method of organosilicon / phenoxyphosphazene of the present invention, specifically:

[0069] ①. Use 45g of hexachlorocyclotriphosphazene to open the ring at 250°C to prepare linear chlorine-containing polyphosphazene. After the reaction is complete, stop heating and set aside;

[0070] ②.Using xylene as a solvent, put 200g of 5wt% NaOH aqueous solution into 100g of xylene containing 10g of bisphenol A at high temperature (160°C) and immediately separate the water, when bisphenol A disodium salt is formed and precipitated Then dissolve it with isopropanol, and finally evaporate all the solvents to obtain dry bisphenol A disodium salt, and finally dissolve the prepared bisphenol A disodium salt in xylene to prepare 15wt% bisphenol A disodium salt salt-xylene solution;

[0071] ③. The linear chlorine-containing polyphosphazene prepared in step ①, 13g ethyltrichlorochlorosilane, 90g 15wt% bisphenol A phenol disodium-xylene solution we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt finger | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com