Optical regulation lens frame suitable for mobile process full-solid state high power laser

A high-power laser and mobile processing technology, applied in the direction of laser parts, optics, optical components, etc., can solve the problem of lens cooling and other problems, and achieve the effect of reliable positioning, small deformation and stable positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

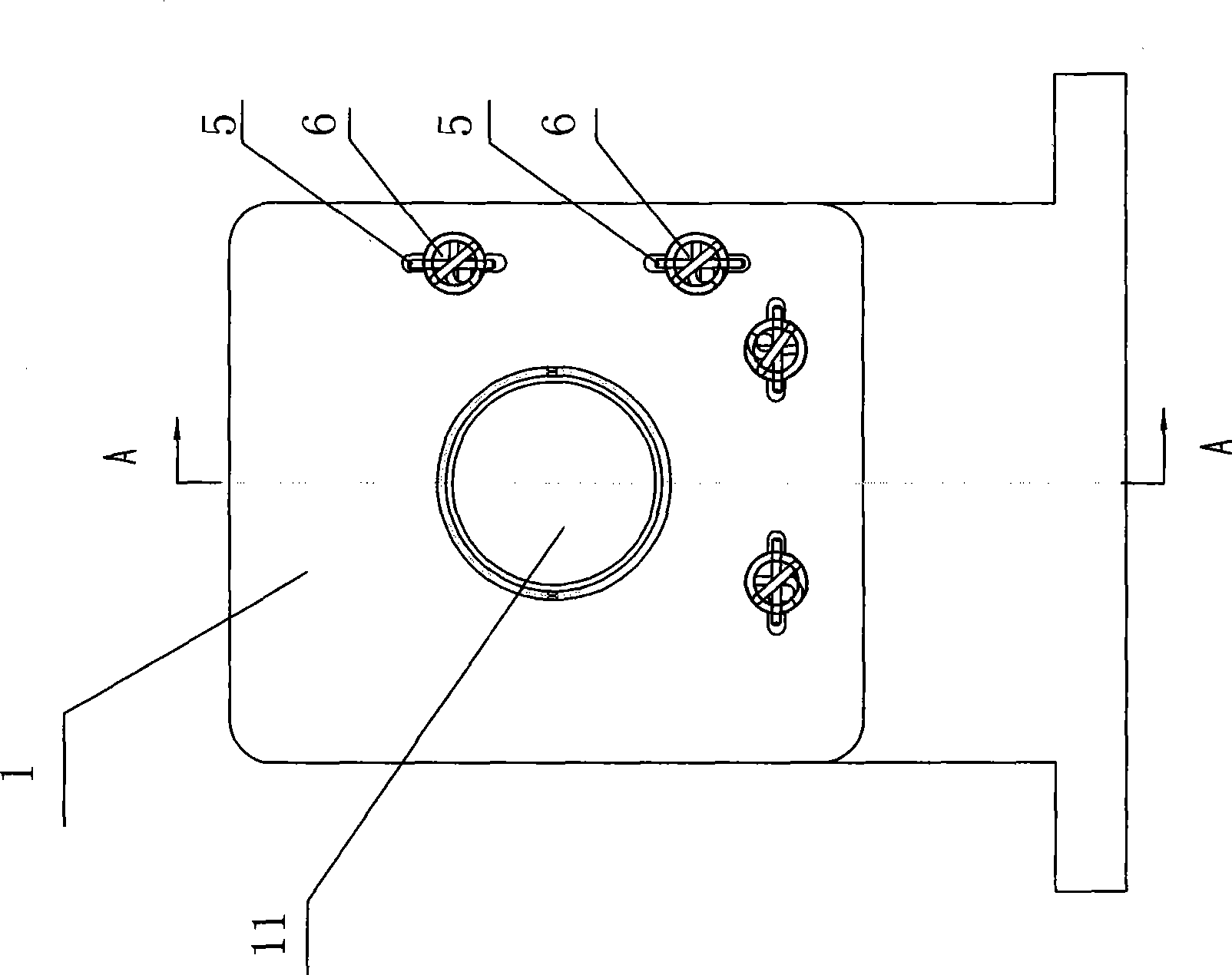

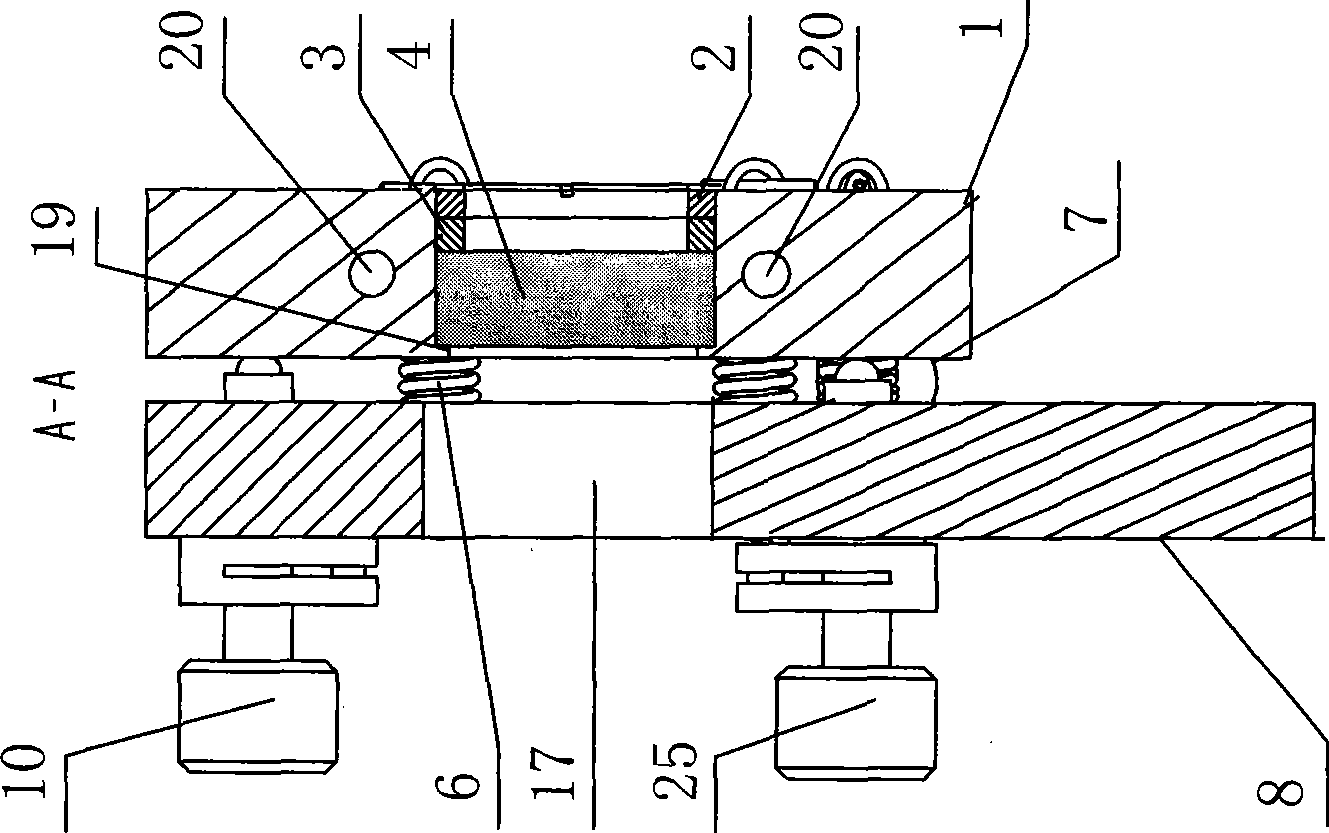

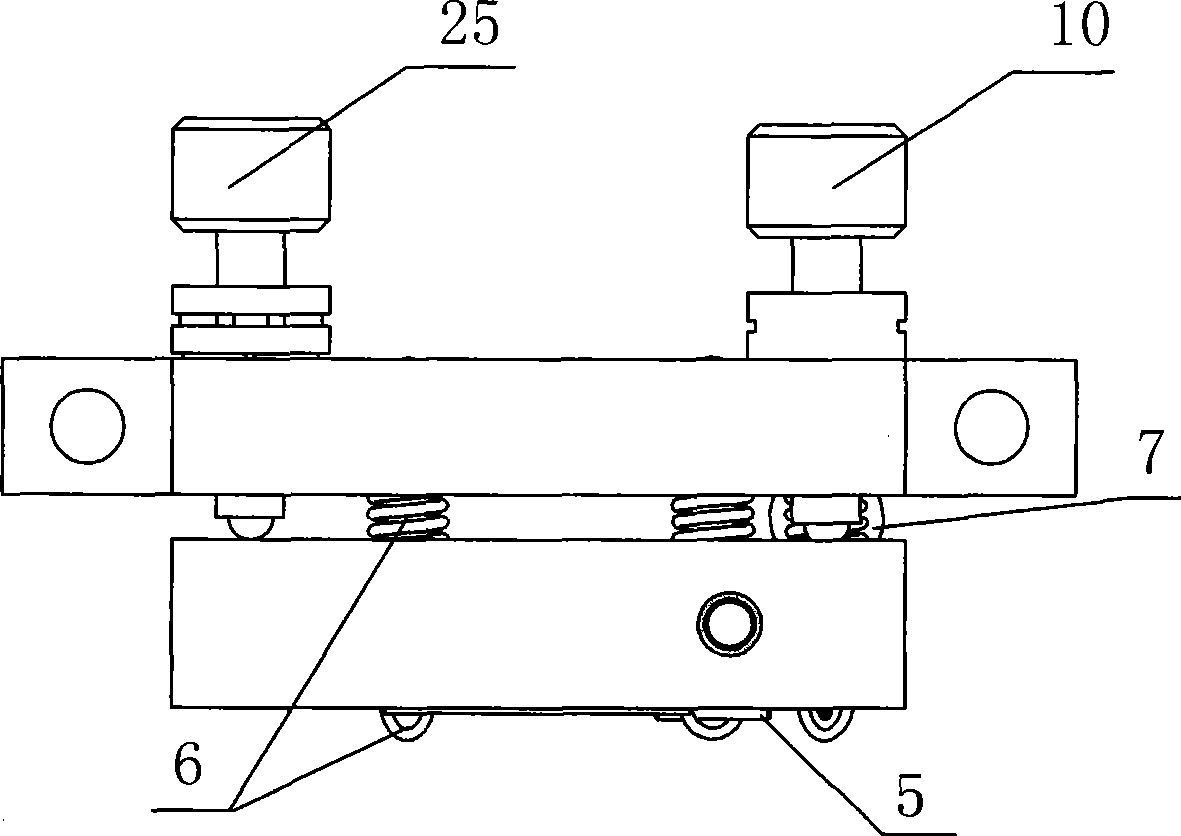

[0039] An optical adjustment mirror frame suitable for mobile processing of all solid-state high-power lasers, including a mirror frame 1, a bracket 8, four tension springs 6, a retaining ring 3, a retaining ring 2, and a fine-tuning screw pair 10; figure 1Shown in -16, the front center of the picture frame 1 is provided with a lens hole 11, and a card platform 19 is arranged in the lens hole 11, and a lens 4 is installed on the card platform 19, and a copper retaining ring 3 is installed on the outside of the lens 4. A copper retaining ring 2 is installed on the outside of the copper retaining ring 3, and the copper retaining ring 2 is rotatably connected with the inner wall of the lens hole 11 through threads, and the copper retaining ring 2 is used to press the copper retaining ring 2 through the threads by means of end face compression. The baffle ring 3 of copper, the baffle ring 3 of copper tightly presses the eyeglass 4 again; Four picture frame tension spring holes 12 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com