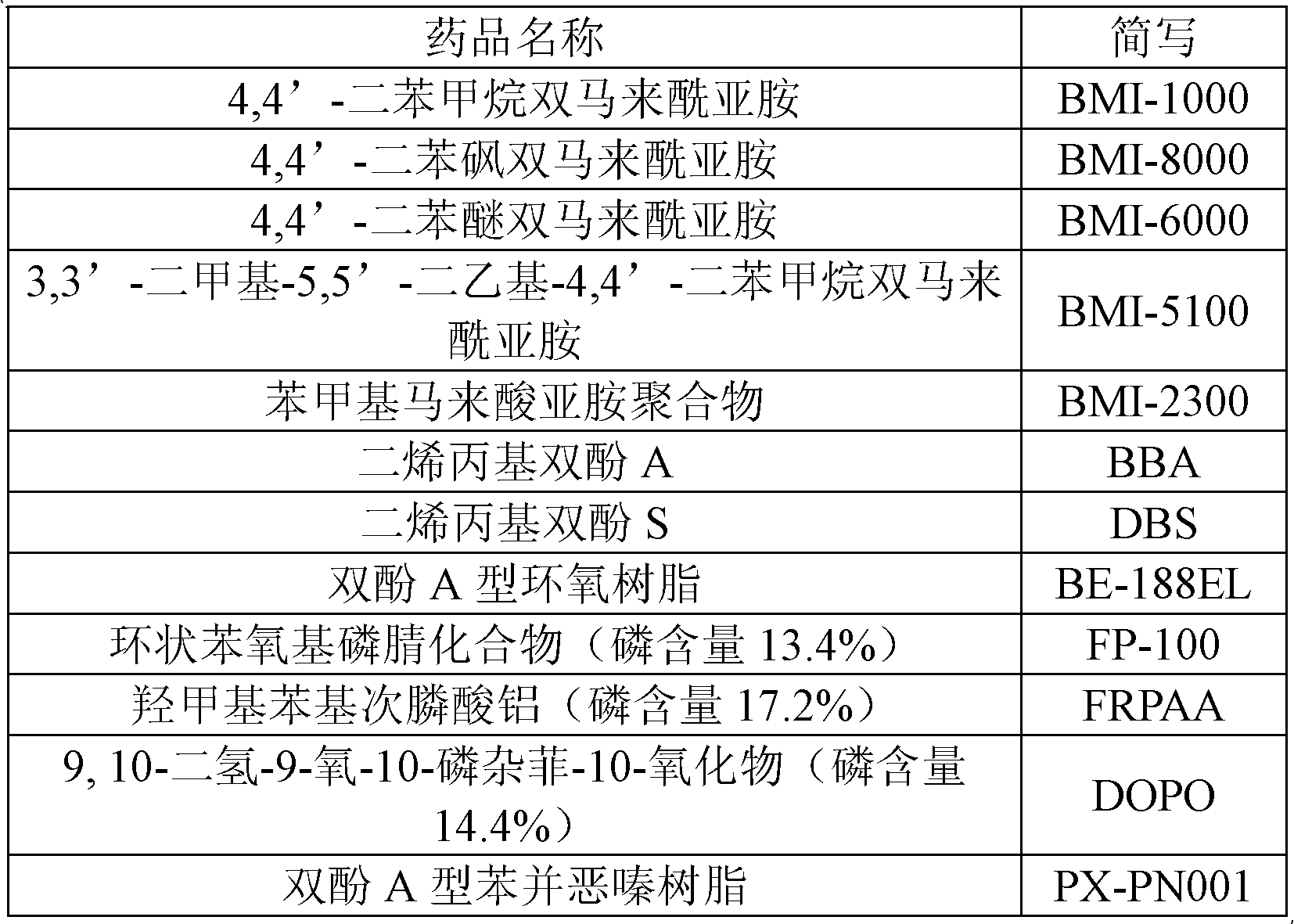

Patents

Literature

6952 results about "Bisphenol A" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

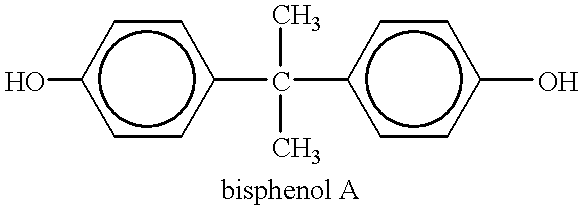

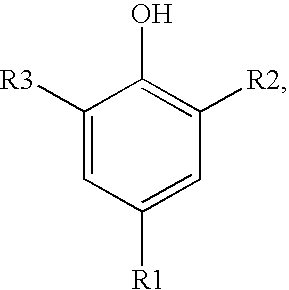

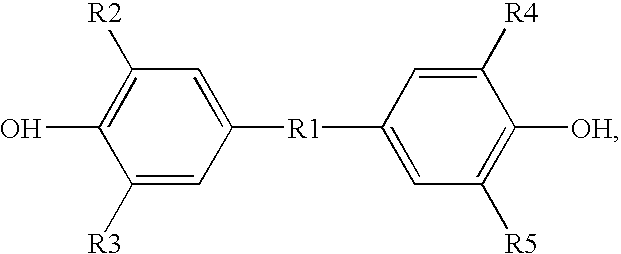

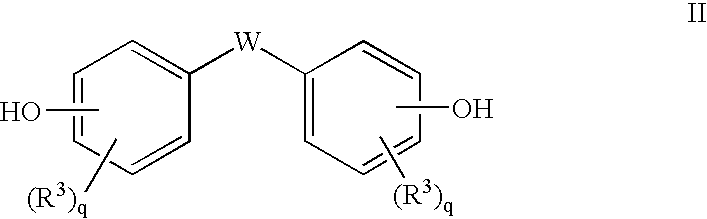

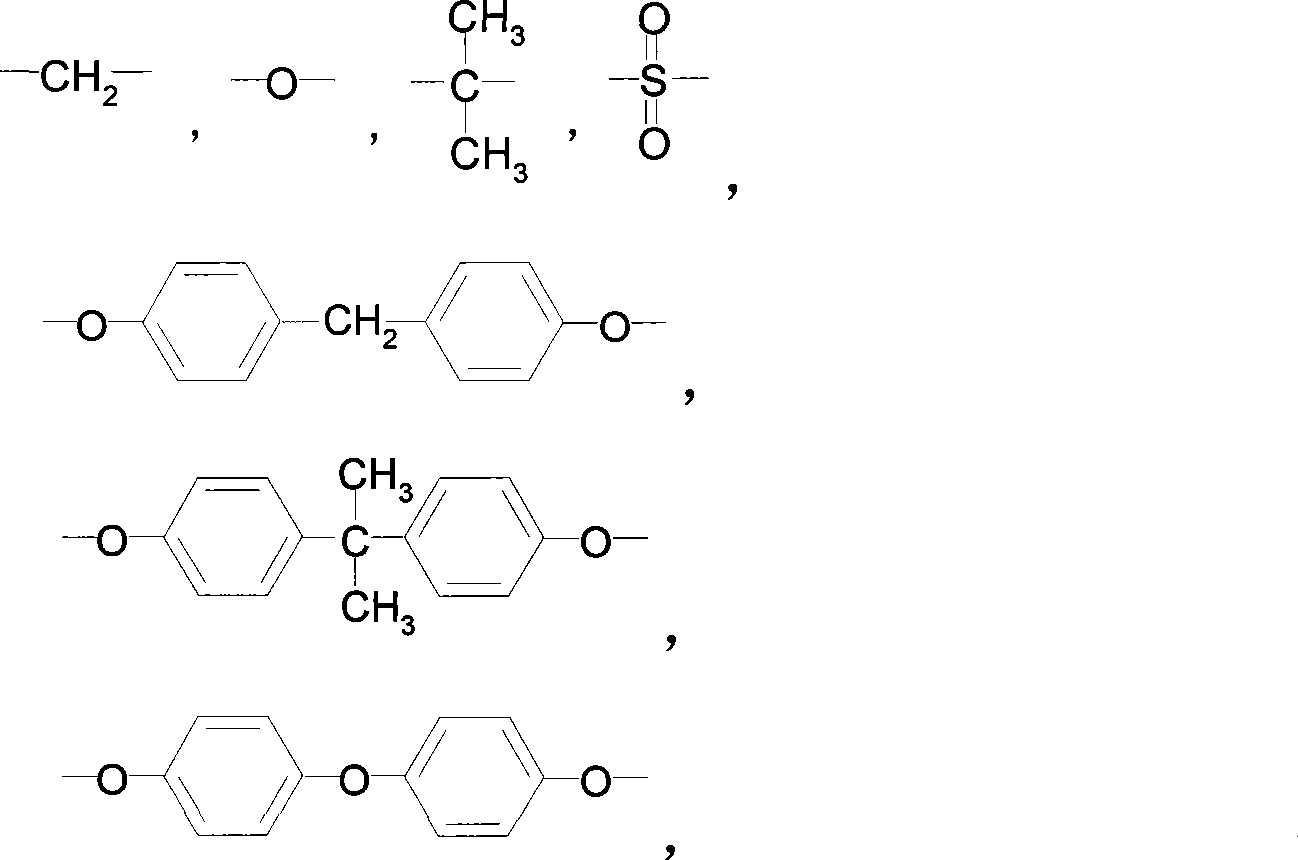

Bisphenol A (BPA) is an organic synthetic compound with the chemical formula (CH₃)₂C(C₆H₄OH)₂ belonging to the group of diphenylmethane derivatives and bisphenols, with two hydroxyphenyl groups. It is a colorless solid that is soluble in organic solvents, but poorly soluble in water (0.344 wt % at 83 °C).

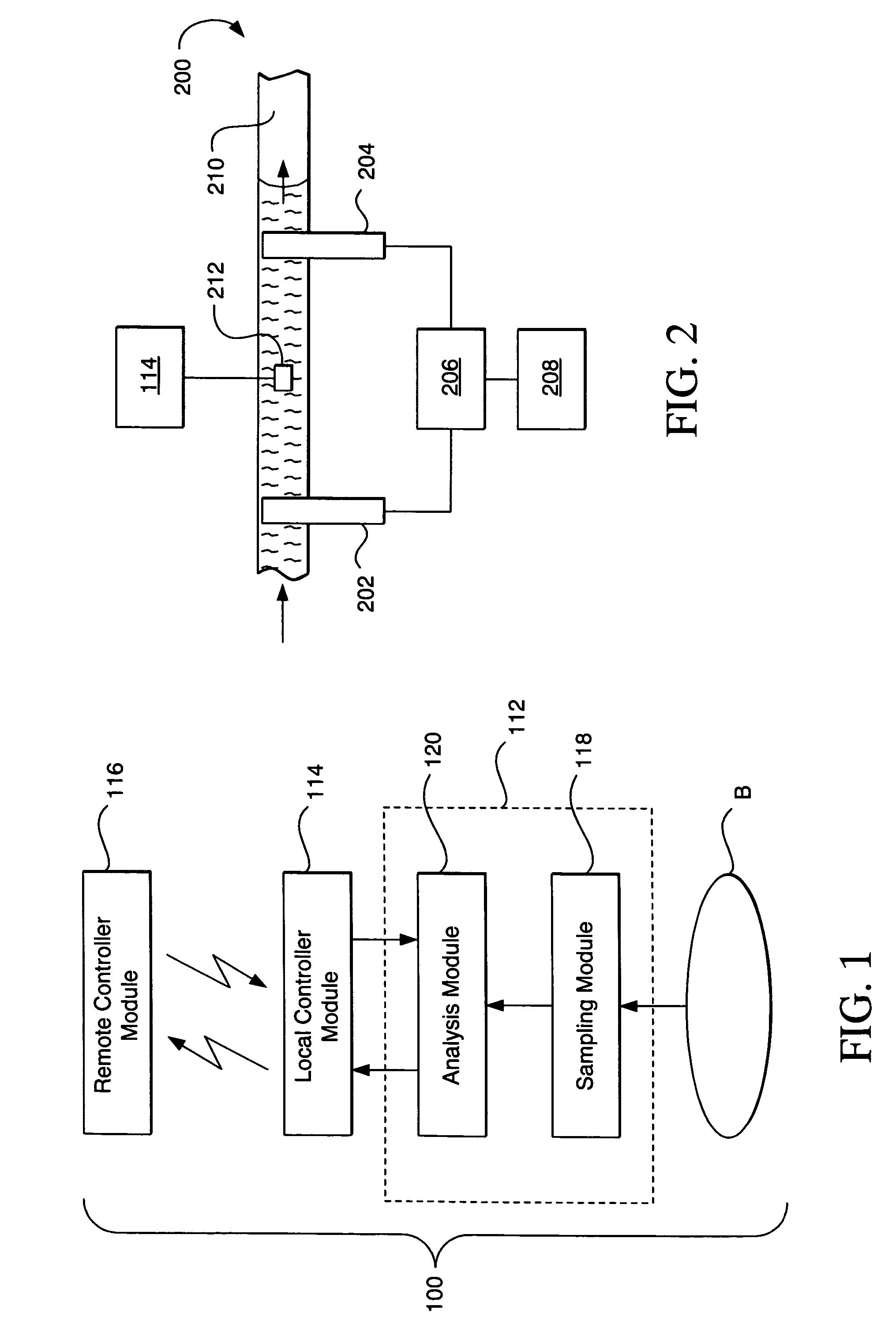

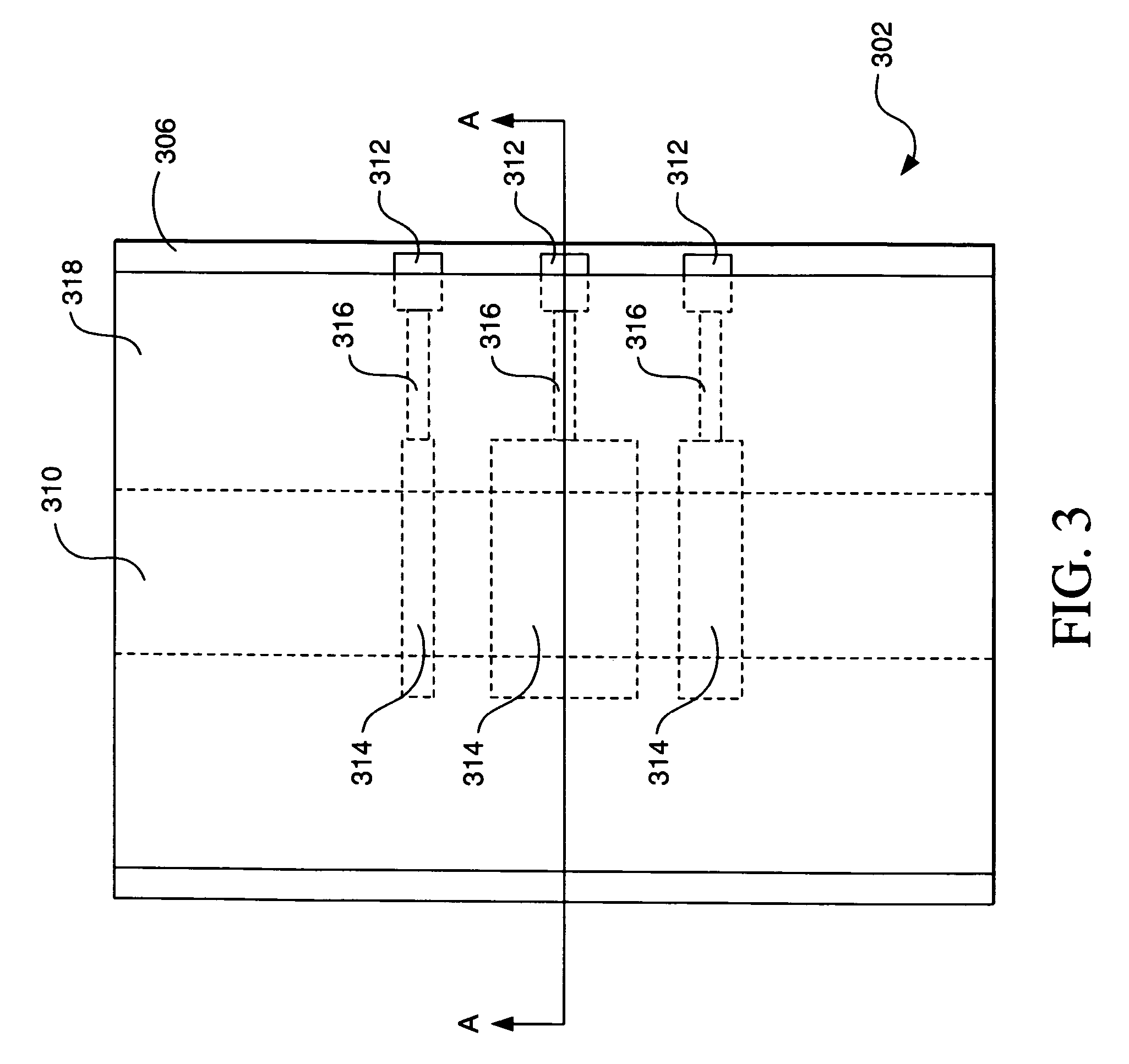

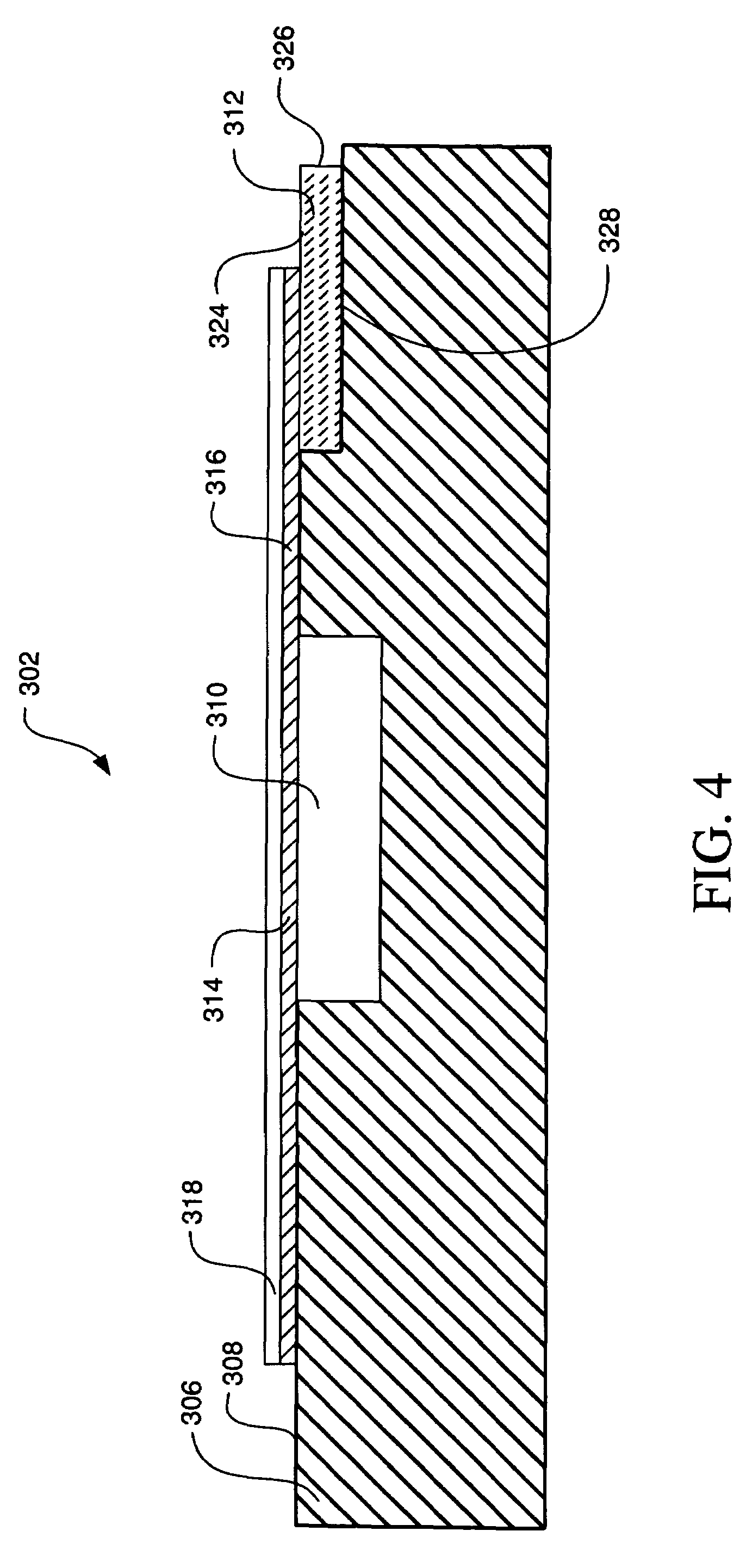

Fusible conductive ink for use in manufacturing microfluidic analytical systems

Owner:LIFESCAN IP HLDG LLC

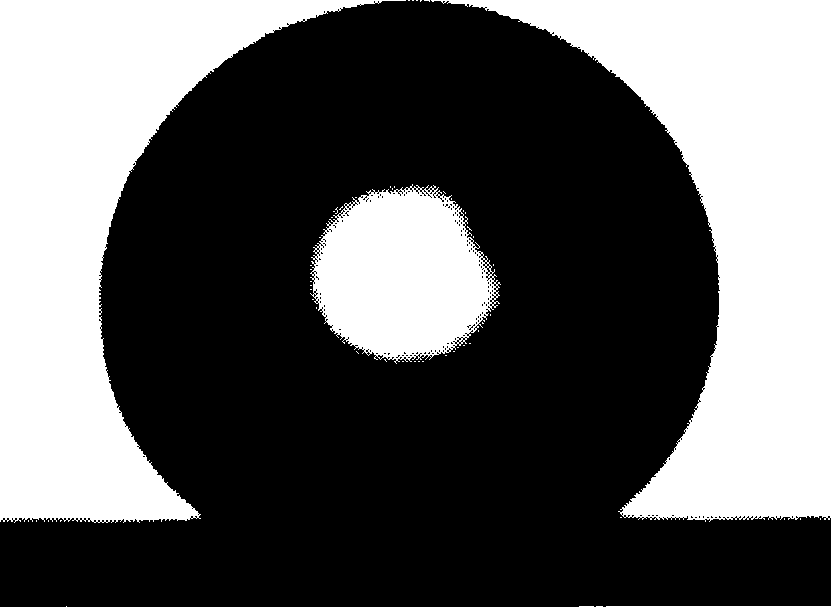

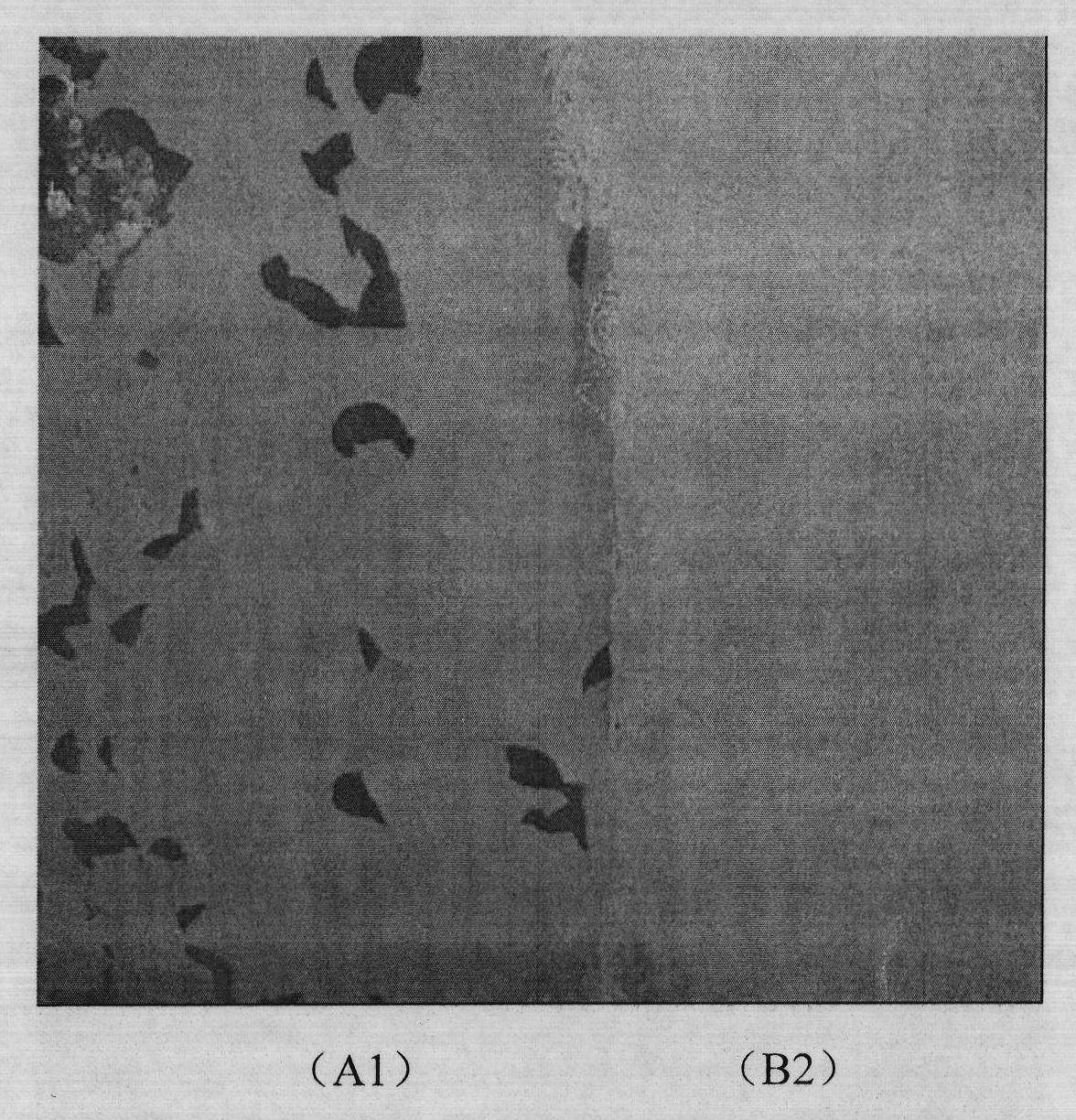

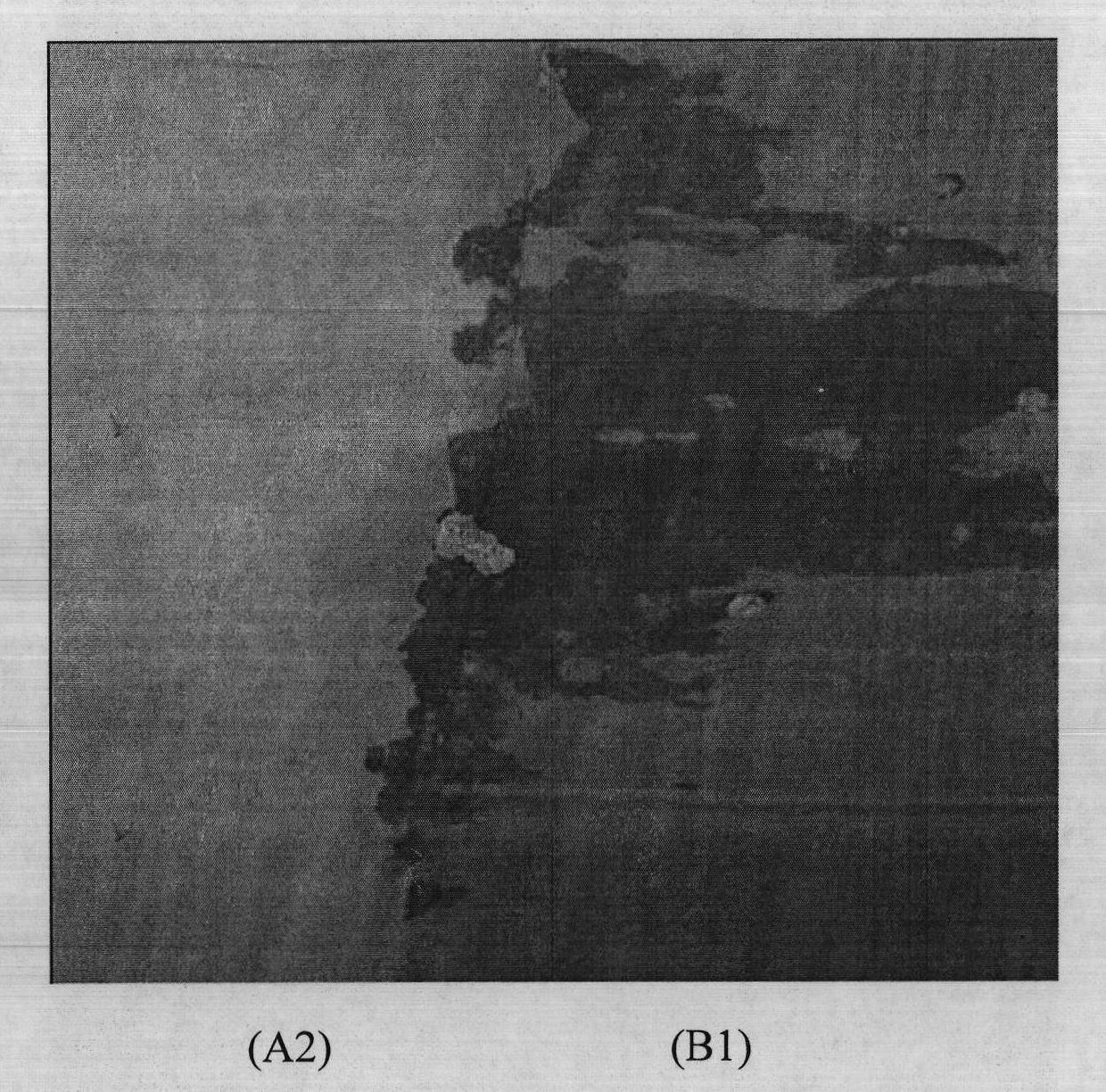

Super-hydrophobic and super-oleophilic oil-water separation mesh membrane and preparation method thereof

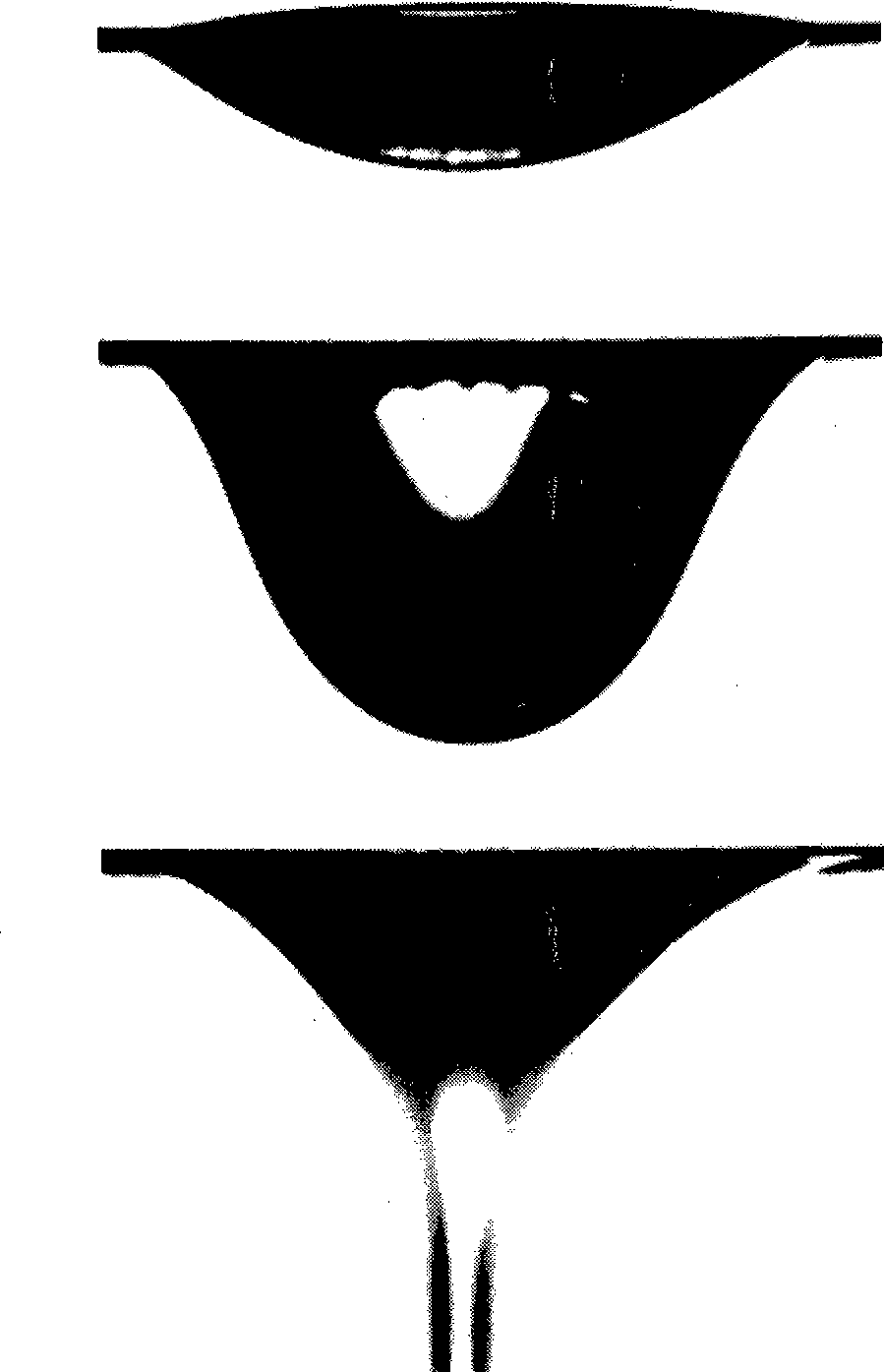

The invention pertains to the technical fields of chemistry, chemical industry and functional macromolecular materials, in particular relates to a super-hydrophobic and super-oleophilic oil-water separation mesh membrane and a preparation method thereof. The super-hydrophobic and super-oleophilic oil-water separation mesh membrane is prepared with a dip-coating method which comprises the steps that a proper treating agent is selected, epoxy group-terminated oligomeric siloxane is copolymerized with bisphenol A on a proper condition; the oligomeric siloxane-bisphenol A copolymer is mixed evenly with the treating agent to form a solution; the oligomeric siloxane-bisphenol A copolymer is cured on a fabric net of 100 meshes to 400 meshes to obtain the super-hydrophobic and super-oleophilic oil-water separation mesh membrane. The mesh membrane contains no fluorin, and has high hole penetration and good oil / water separation effect. The preparation method of the mesh membrane is simple.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Conditioning deodorization antibiotic mildew-proof wallpaper

The present invention relates to a humidity-regulating, odor-removing, antibacterial and mould-proof wallpaper, which can effectively regulate the air humidity, absorb the polluting gases in the air and inhibit the reproduction of bacteria and mould. The wallpaper is produced by the drying, cooling and embossing of a basal paper and pasty material coated on the basal paper. According to weight percentages, the pasty material is made from 20 percent to 60 percent of PVC, 25 percent to 50 percent of filling, 5 percent to 15 percent of titanium pigment, 3 percent to 5 percent of the mixture of nano-ZnO and nano-TiO2, 1.5 percent to 3.5 percent of mould inhibitor, 1.5 percent to 3.5 percent of plasticiser, 0.5 percent to 2.5 percent of viscosity depressant, 1.5 percent to 2.5 percent of stabilizer and 0.5 percent to 1.0 percent of bisphenol A. Firstly, the PVC is made into paste and then uniformly mixed with the bisphenol A and the plasticiser; secondly, after being uniformly mixed with the filling, the paste is uniformly mixed with the titanium pigment, the nano-ZnO, the nano-TiO2 and the mould inhibitor and then the stabilizer; and finally, the viscosity depressant is added to regulate the viscosity of the paste in order to obtain the pasty material, which is then coated on the basal paper. The wallpaper has the advantages of no toxicity, no offensive odor, environment-friendliness, long service life, waterproofness and no deformation.

Owner:HONGQIJU CONSTR GRP CO LTD

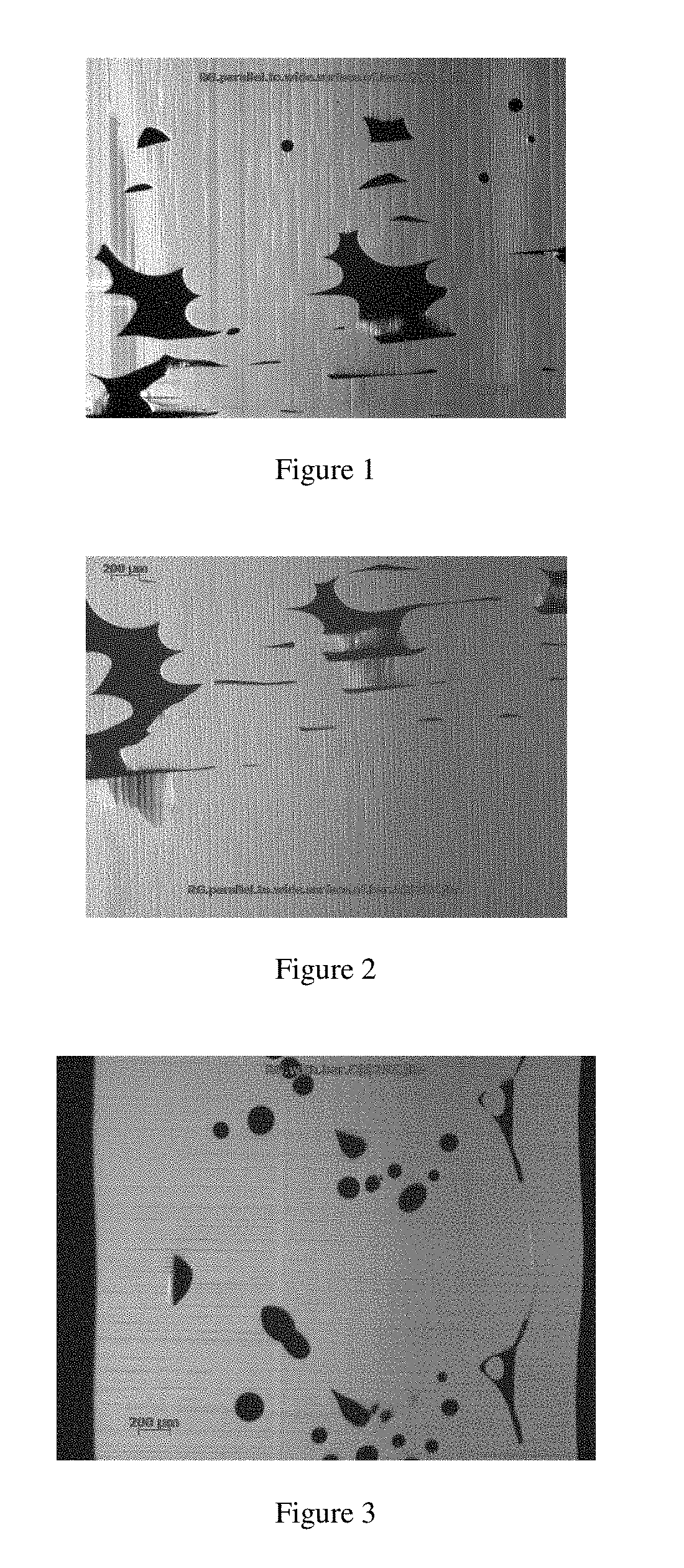

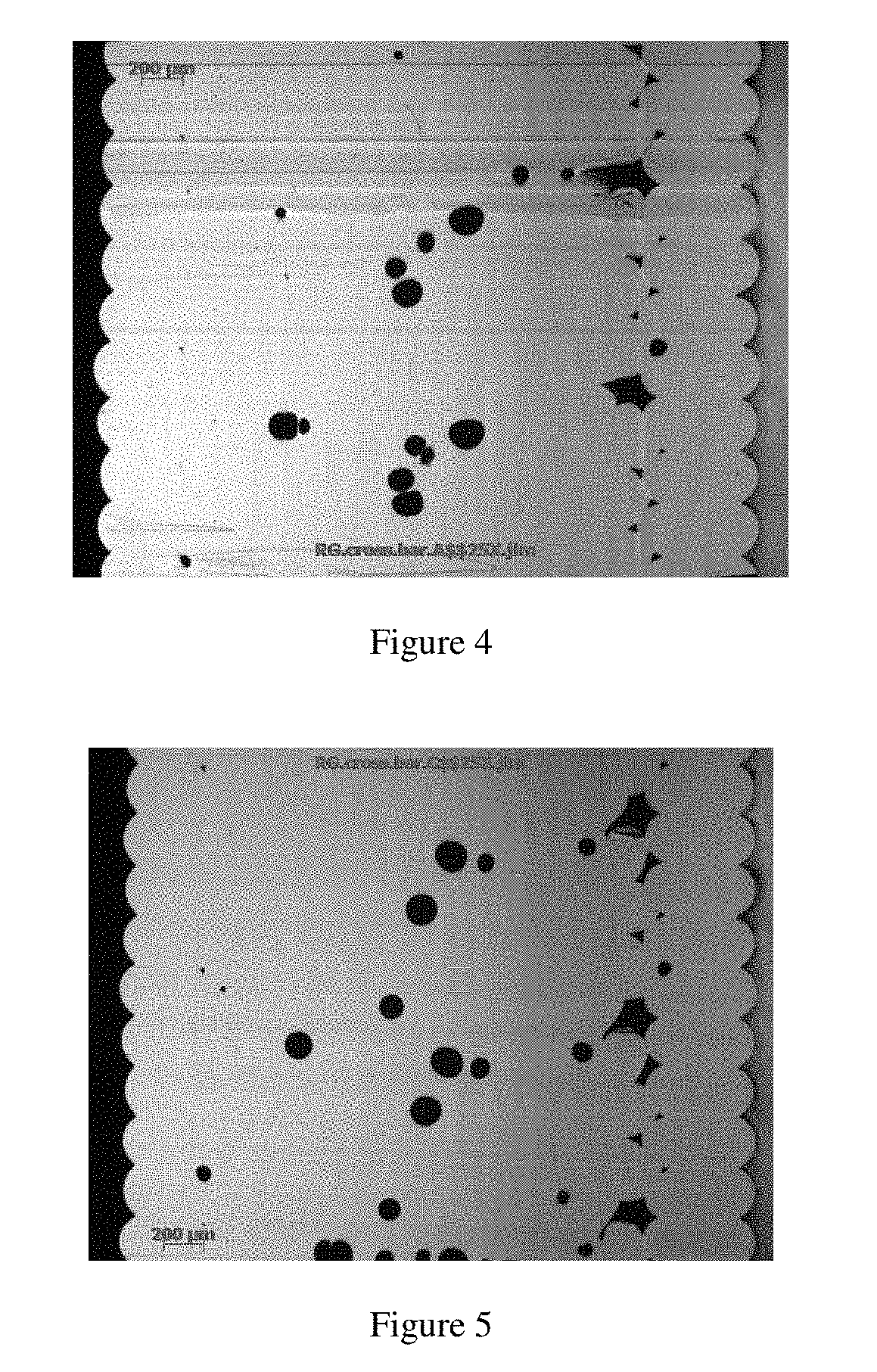

Reduced density article

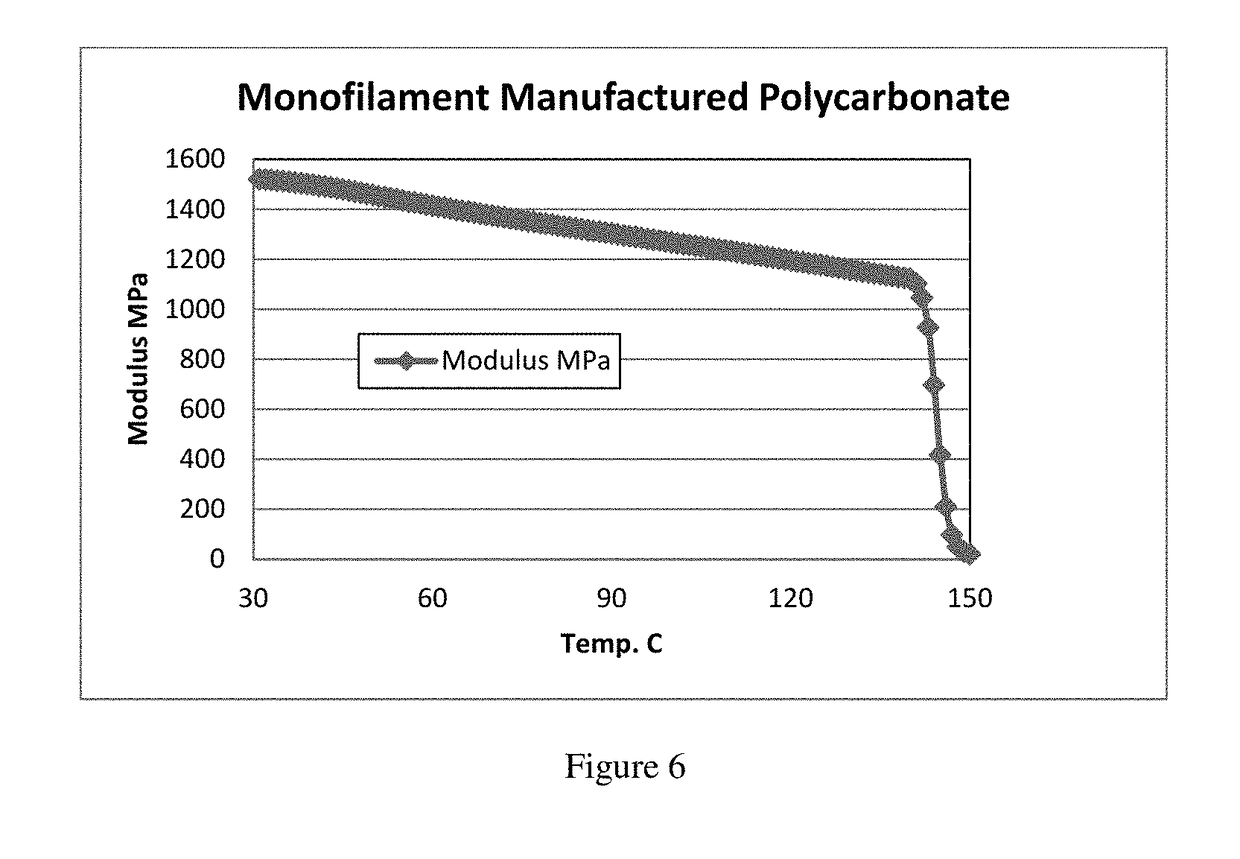

InactiveUS10087556B2Additive manufacturing apparatusIncreasing energy efficiencyMicro structurePolymer science

A reduced density article of manufacture, and process for making same, made from a thermoplastic polycarbonate composition. The reduced density article of manufacture has (1) a certain density and (2) a certain micro structure containing from 1% to 20% by volume of voids wherein at least 80% of the voids are high aspect voids and less than 20% of the voids are spherical voids with a diameter of 10 to 100 microns. The polycarbonate thermoplastic composition comprises at least 50 mole % of a certain bisphenol A. The reduced density article of manufacture is made by a monofilament additive manufacturing technique.

Owner:SHPP GLOBAL TECH BV

Epoxy resin embedding glue and method for producing the same

The invention relates to an epoxy resin potting adhesive which consists of component A and component B. By weight portion, the component A consists of 90-130 portions of bisphenol A type epoxy resin, 240-320 portions of filling, 15-25 portions of thinner, 10-25 portions of toughener, 1-2.5 portions of defoamer and 0.8-2 portions of black pigment, and the component B consists of 60-130 portions of estolide and 1-3 portions of imidazole accelerator. The mixing proportion of the component A and the component B is (3-5):1. The invention also provides a preparation method of the epoxy resin potting adhesive. The epoxy resin potting adhesive provided by the invention has low cost and long resting period; after being mixed, the component A and the component B have low viscidity, good wetting quality, good heat resistance, good defoaming performance, good fluidity and long operating time and are solidified between 70 DEG C and 160 DEG C; a product after solidifying has bright surface, good mechanical performance and insulating performance and high glass transition temperature; and the quality of a potting component is stable.

Owner:NICHE TECH KAISER SHANTOU

Storage stable autodepositable dispersions of epoxy resins and processes therefor and therewith

InactiveUS6096806AIncreased particle refinementSolvent extractionIon-exchanger regenerationStandard hydrogen electrodePolymer chemistry

PCT No. PCT / US96 / 12540 Sec. 371 Date Feb. 17, 1998 Sec. 102(e) Date Feb. 17, 1998 PCT Filed Aug. 7, 1996 PCT Pub. No. WO97 / 07163 PCT Pub. Date Feb. 27, 1997Epoxy resins, particularly those based on bisphenol A, can constitute the principal film forming polymer component of a storage stable autodepositable composition wherein the particle size distribution of all the film forming polymers in the composition satisfies certain criteria of size distribution, and an accelerator component which is an acid, oxidizing agent or complexing agent is present in amount sufficient to provide an oxidation-reduction potential at least 100 mV more oxidizing than a standard hydrogen electrode. Such dispersions can conveniently be prepared using a two stage process in which a solution of the film forming polymers is emulsified into water to form a preliminary dispersion and this preliminary dispersion is subjected to at least one particle size refinement stage in which the preliminary dispersion is forced through a narrow aperture.

Owner:HENKEL KGAA

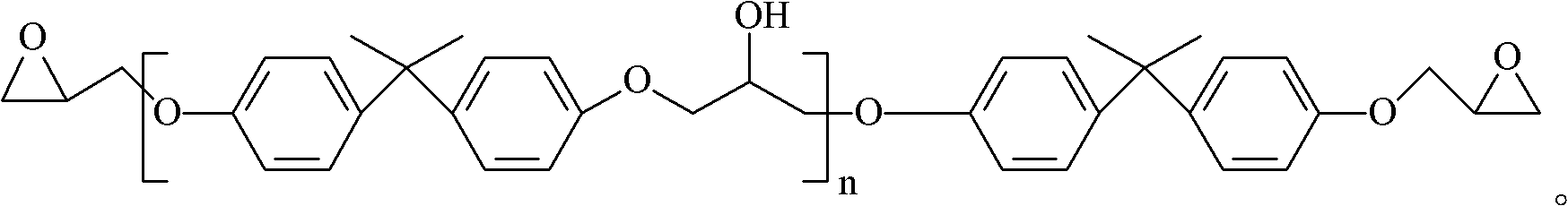

Photoimageable coating composition and composite article thereof

InactiveUS20050266335A1Photosensitive materialsPhotomechanical coating apparatusResistPhotoacid generator

A photoimagable composition suitable for use as a negative photoresist comprising: (A) at least one epoxidized polyfunctional bisphenol A formaldehyde novolak resin; (B) at least one polycaprolactone polyol reactive diluent, wherein the amount of component (A) is from about 95% to about 75% by weight of the sum of (A) and (B) and the amount of component (B) is from about 5% to about 25% by weight of the sum of (A) and (B); (C) at least one photoacid generator in an amount from about 2.5 to about 12.5 parts per hundred parts of resin and reactive diluent, which initiates polymerization upon exposure to actinic radiation; and (D) a sufficient amount of solvent to dissolve (A), (B) and (C); wherein the solvent comprises 2-pentanone, 3-pentanone, and 1,3-dioxolane and mixtures thereof.

Owner:MICROCHEM CORP +1

Novel fast-set anticorrosion and wear-resistant epoxy powder coating and preparation process thereof

InactiveCN102492353AImprove anti-corrosion performanceSimple preparation processAnti-corrosive paintsPowdery paintsWear resistantWear resistance

The invention relates to the field of chemical coating, in particular to epoxy powder coating applied to material conveying steel belts in oilfield oil pumping pipelines or coal transportation in the oil industry. In a formula, the coating comprises the following components in percentage by weight: 32-56% of epoxy resin, 8-14% of curing agent, 30-50% of pigments and fillers, 2-10% of resin modifier and 2-6% of assistant, wherein the epoxy resin in the formula is bisphenol A type epoxy resin, a mixture of the bisphenol A type epoxy resin and phenolic aldehyde modified epoxy resin, and phenolic aldehyde modified epoxy resin, and the curing agent is phenolic hydroxyl resin. The epoxy powder coating disclosed by the invention belongs to fast-set anticorrosion and wear-resistant epoxy powder coating, has the granularity being 10-125 mu m, is applied under general curing conditions that the curing temperature is 180-200 DEG C and the curing time is 3-10min, can be regulated according to user needs and is superior to like products in anticorrosion performance, coating film mechanical performance and wear resistance, a preparation process is simple, the labour productivity can be obviously increased, and the epoxy powder coating is suitable for industrialized production.

Owner:JIANGSU LANLING POLYMER MATERIAL CO LTD

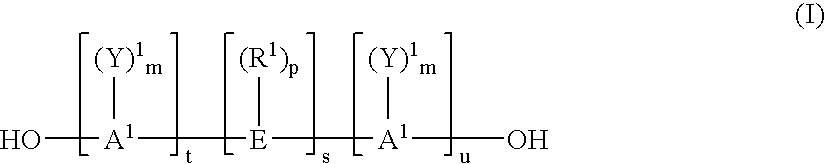

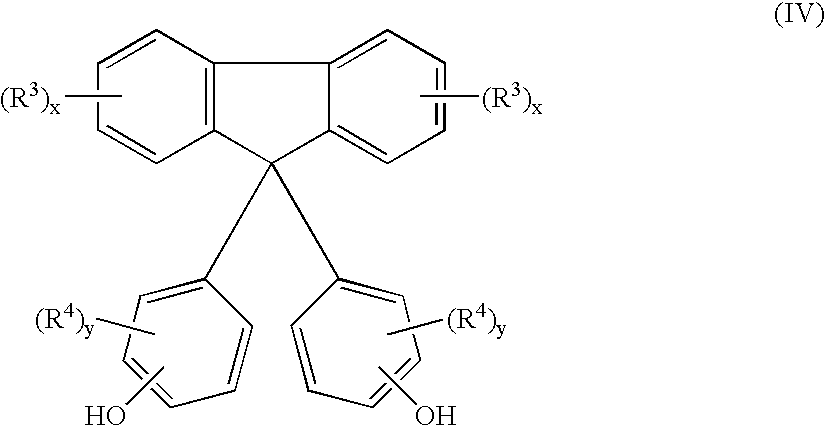

Permanent resist composition, cured product thereof, and use thereof

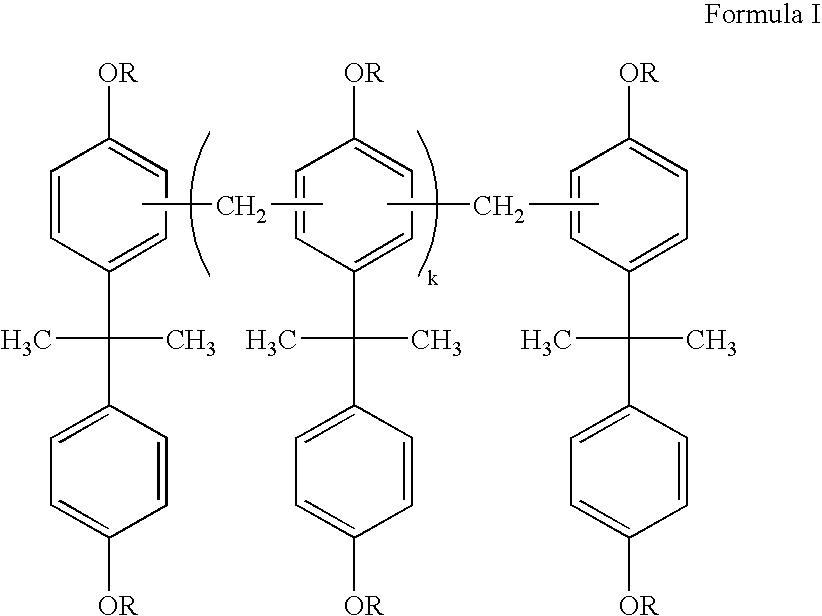

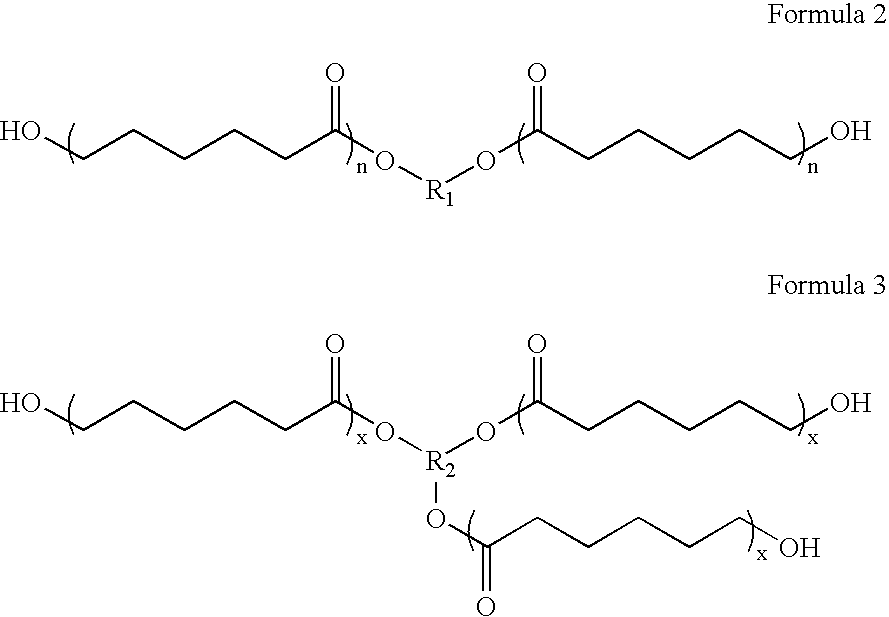

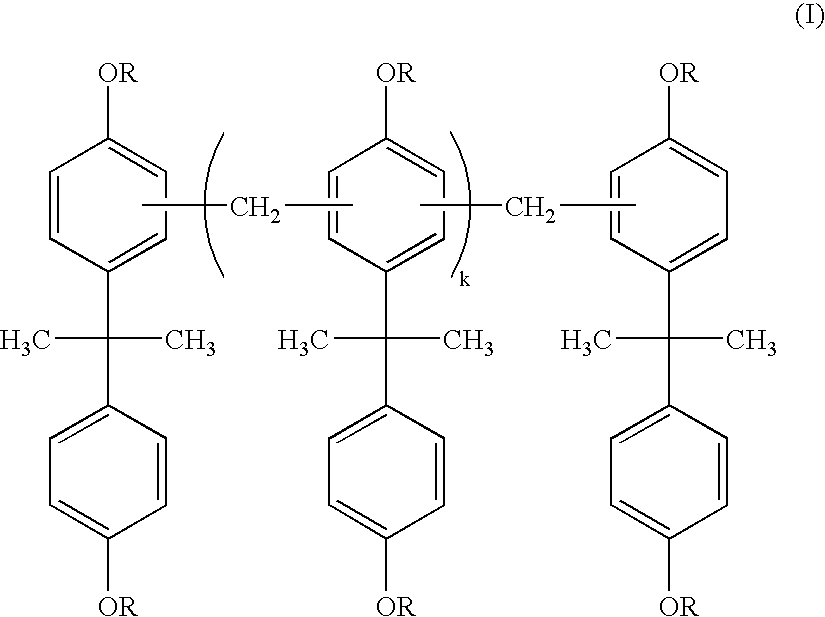

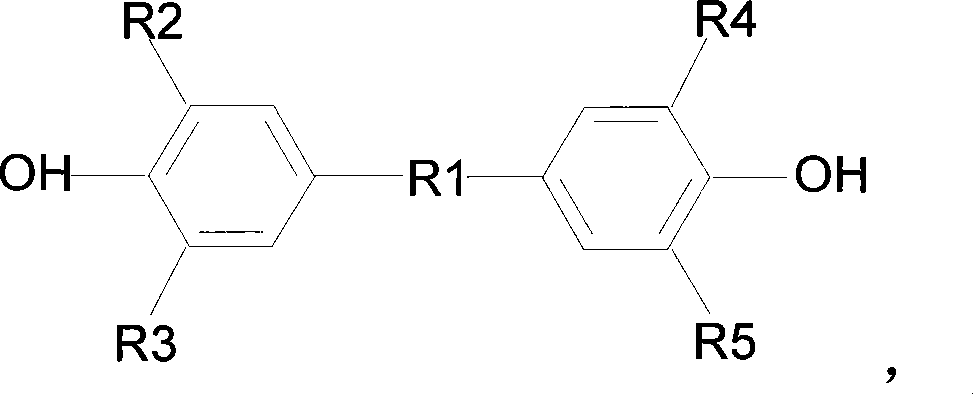

InactiveUS20050260522A1High densityImprove film adhesionNanoinformaticsPhotomechanical apparatusPolymer sciencePhotoacid generator

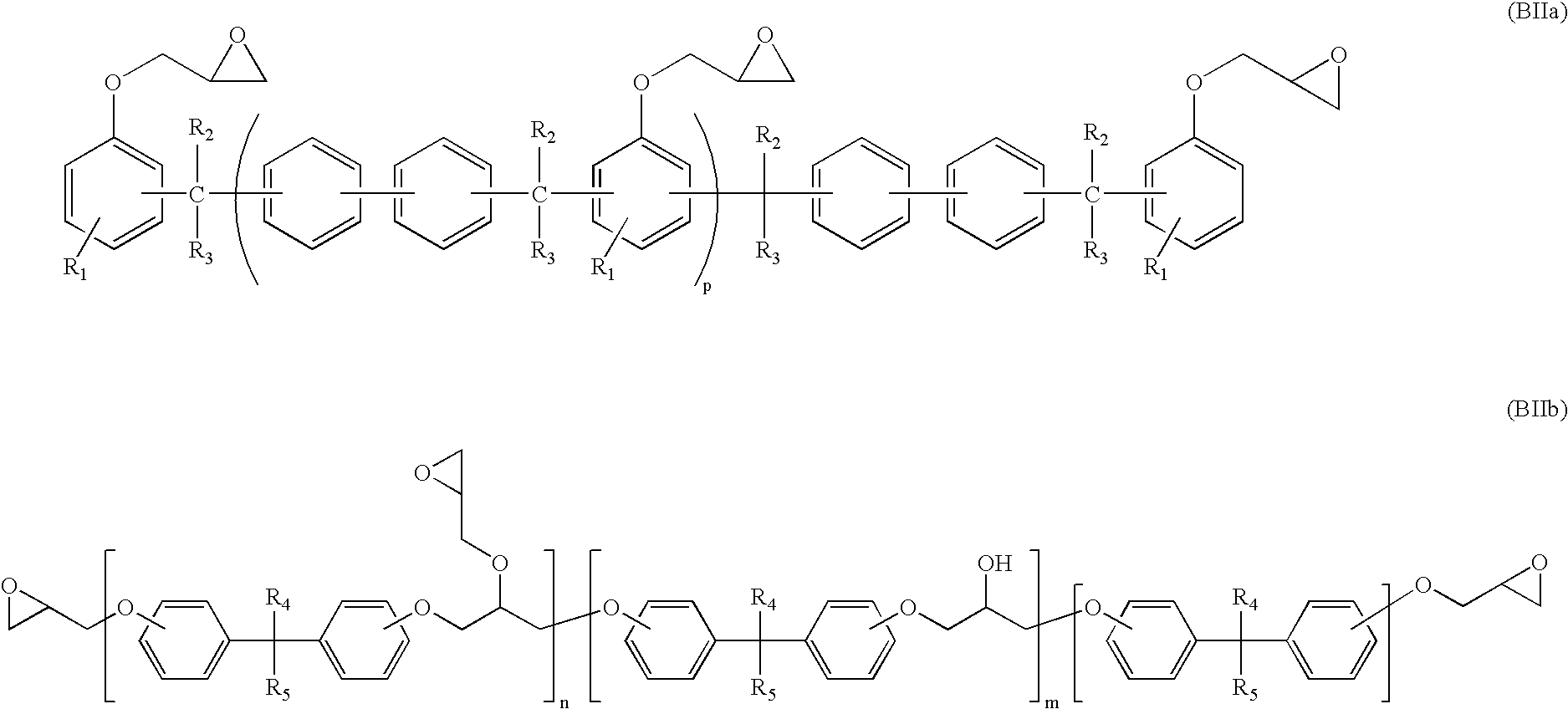

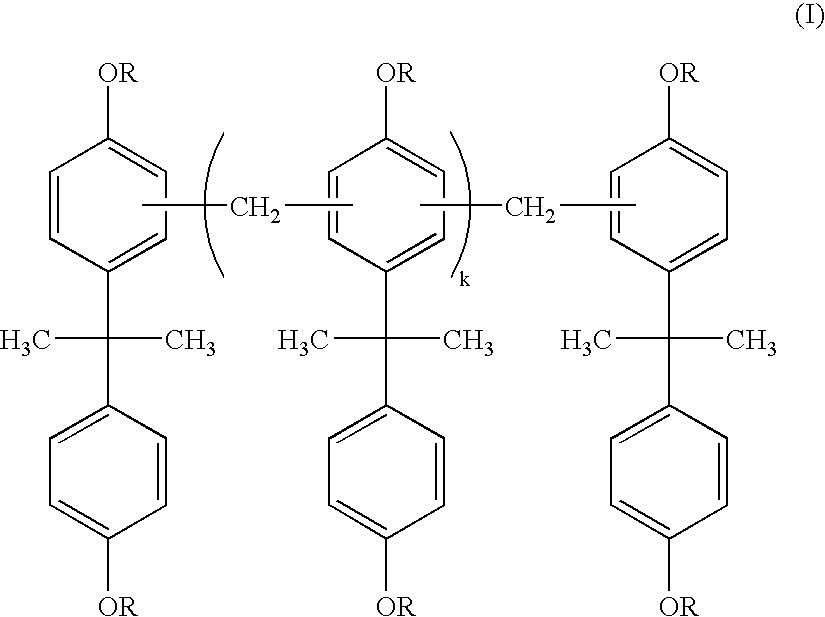

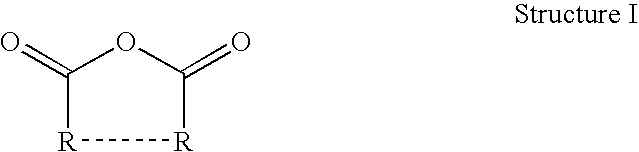

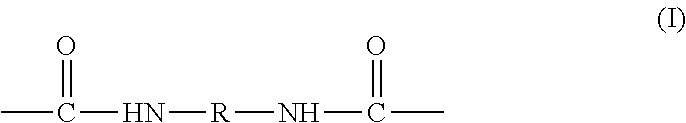

A permanent photoresist composition comprising: (A) one or more bisphenol A-novolac epoxy resins according to Formula I; wherein each group R in Formula I is individually selected from glycidyl or hydrogen and k in Formula I is a real number ranging from 0 to about 30; (B) one or more epoxy resins selected from the group represented by Formulas BIIa and BIIb; wherein each R1, R2 and R3 in Formula BIIa are independently selected from the group consisting of hydrogen or alkyl groups having 1 to 4 carbon atoms and the value of p in Formula BIIa is a real number ranging from 1 to 30; the values of n and m in Formula BIIb are independently real numbers ranging from 1 to 30 and each R4 and R5 in Formula BIIb are independently selected from hydrogen, alkyl groups having 1 to 4 carbon atoms, or trifluoromethyl; (C) one or more cationic photoinitiators (also known as photoacid generators or PAGs); and (D) one or more solvents.

Owner:MICROCHEM CORP +1

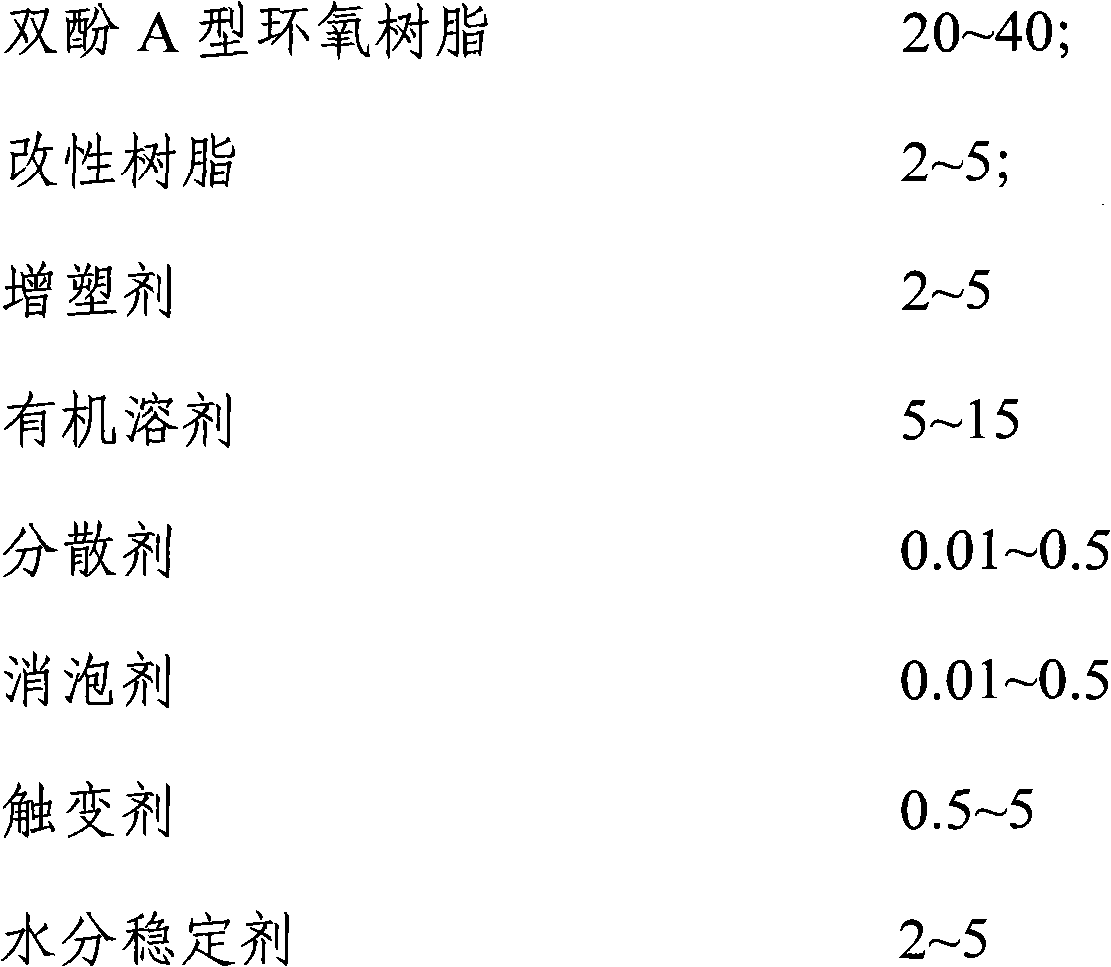

Epoxy coating and preparation method and application thereof

ActiveCN102618148AImprove the shortcomings of hard and easy to crack and poor flexibilityHigh mechanical strengthRosin coatingsAnti-corrosive paintsResin coatingPolyurethane coating

The invention provides a novel epoxy coating and a preparation method thereof. The coating not only has excellent corrosion resistance, but also has excellent compatibility with a base material or a lower coating film, particularly an epoxy coating, a polyurethane coating, a fluorocarbon coating or an alkyd resin coating. The epoxy coating comprises a main paint and a curing agent, wherein the main paint contains bisphenol A epoxy resin and modifying resin for modifying the bisphenol A epoxy resin; and the curing agent contains polyamino amide and cardanol modified phenolic amine.

Owner:北京红狮科技发展有限公司

Antireflective coating for microlithography

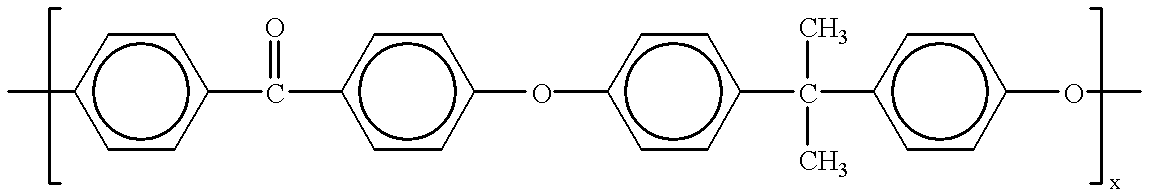

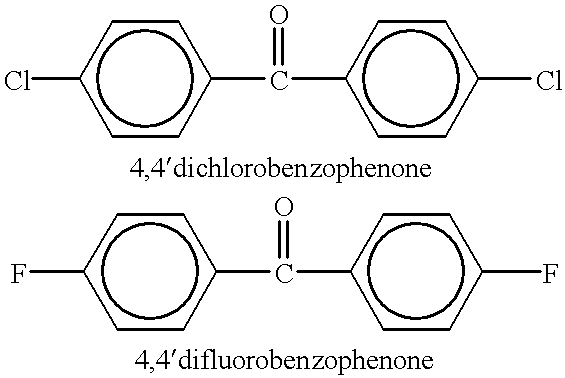

InactiveUS6207787B1Photosensitive materialsSemiconductor/solid-state device manufacturingAnthraceneBenzophenone

A co-polymer of benzophenone and bisphenol A has been shown to have DUV absorption properties. Therefore, the co-polymer has particular utility as an antireflective coating in microlithography applications. Incorporating anthracene into the co-polymer backbone enhances absorption at 248 nm. The endcapper used for the co-polymer can vary widely depending on the needs of the user and can be selected to promote adhesion, stability, and absorption of different wavelengths.

Owner:IBM CORP

Room-temperature curing epoxy structural adhesive composition and preparation method thereof

InactiveCN101818037AIncreased shear strengthHigh T-peel strengthEpoxy resin adhesivesNitrile rubberAdhesive

The invention relates to a room-temperature curing epoxy structural adhesive composition, which comprises a component A and a component B, wherein the component A comprises bisphenol A epoxy resin, toughness modified bisphenol A epoxy resin, silane coupling agent, thixotropic agent and colorant; and the component B comprises polyamide, polyether amine, a filler and a curing accelerator; the toughness modified bisphenol A epoxy resin is liquid nitrile rubber-modified bisphenol A epoxy resin and / or polymer-toughened bisphenol A epoxy resin with a nuclear shell structure; meanwhile, the invention also provides a method for preparing the room-temperature curing epoxy structural adhesive compositiion. The structural adhesive of the invention has the advantages of good toughness, strong high-temperature strength, short curing time, simple preparation method, and the like.

Owner:HENKELCHINAINVESTMENT

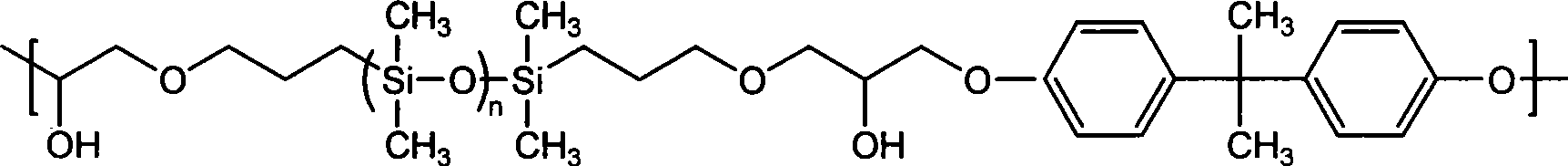

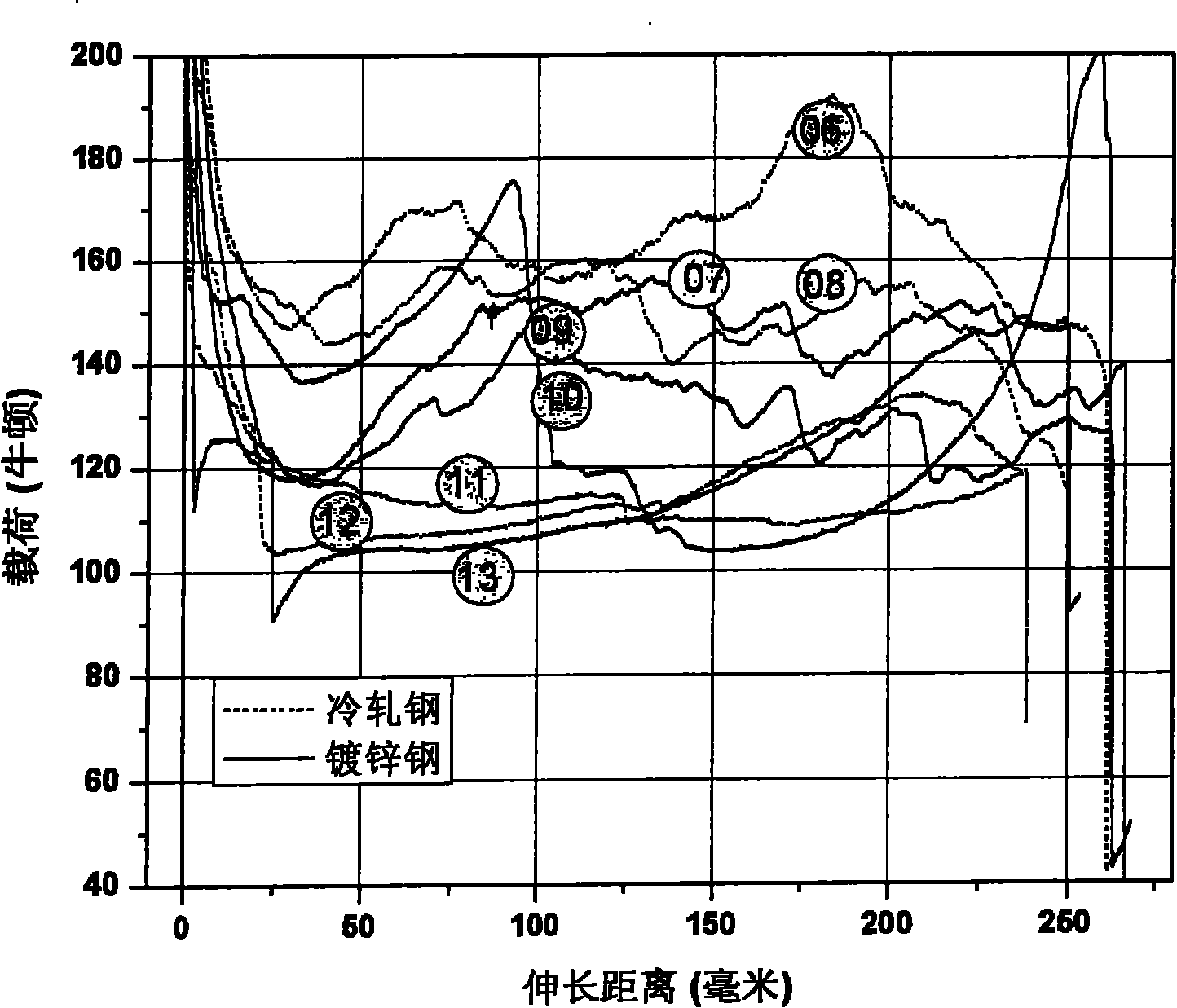

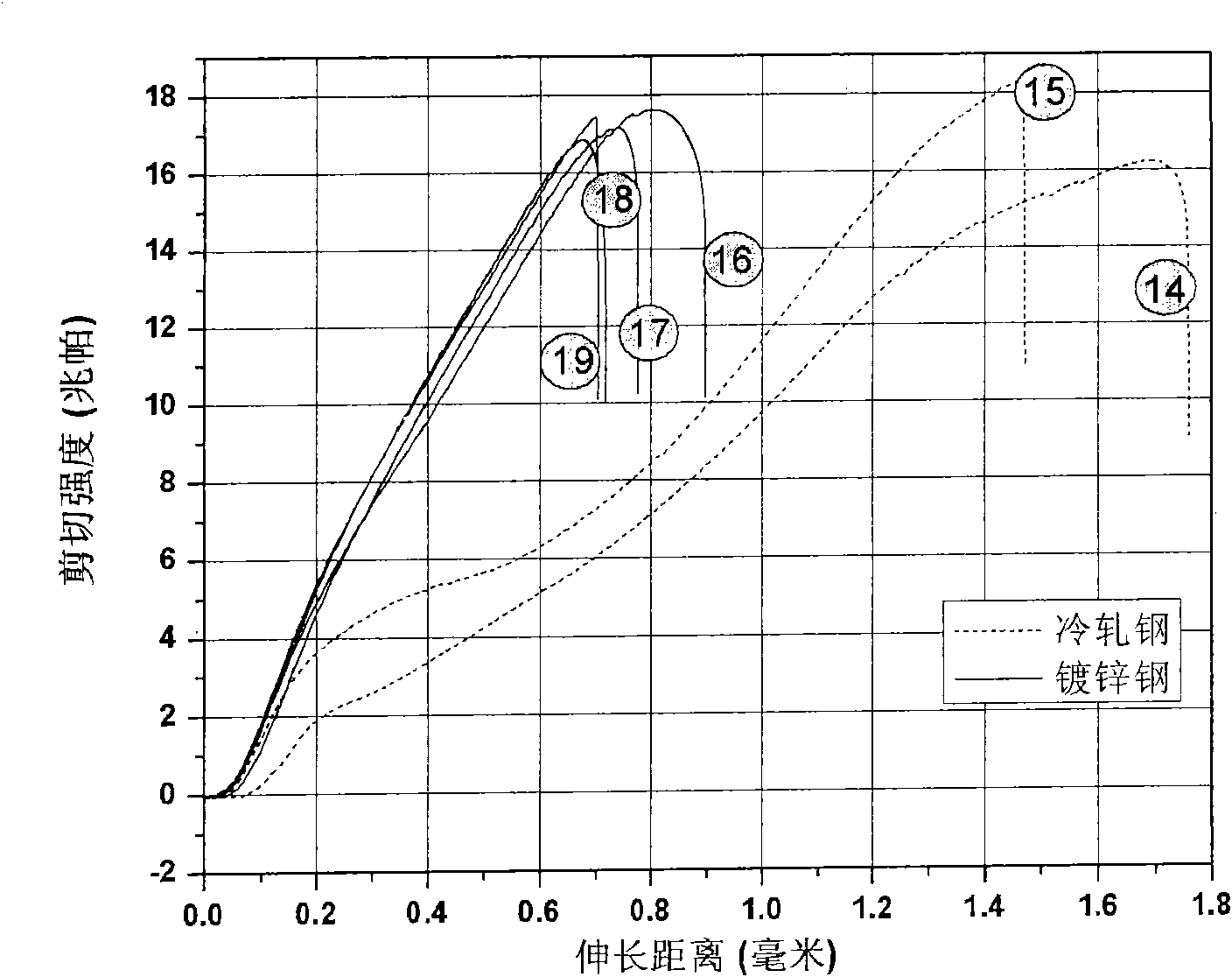

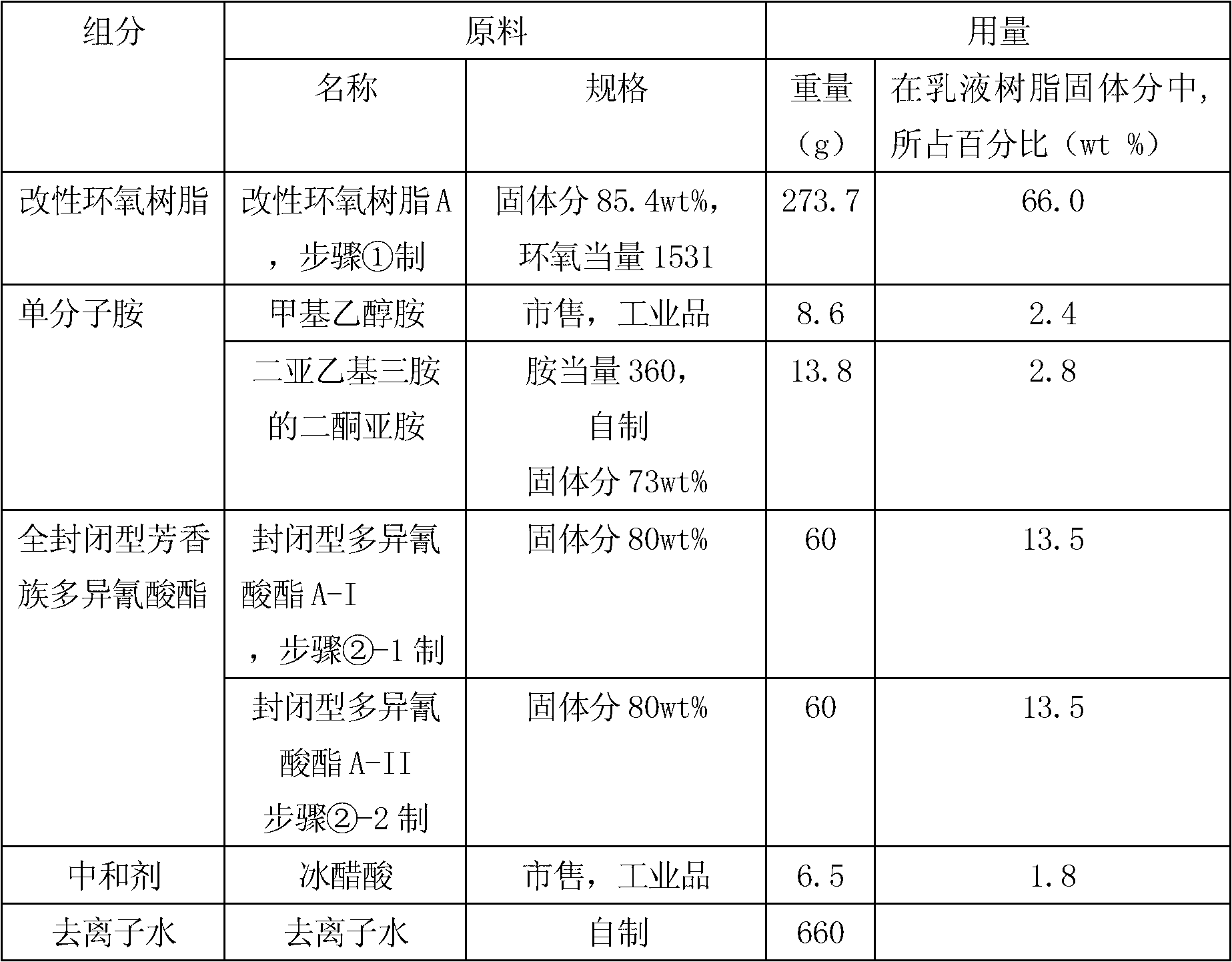

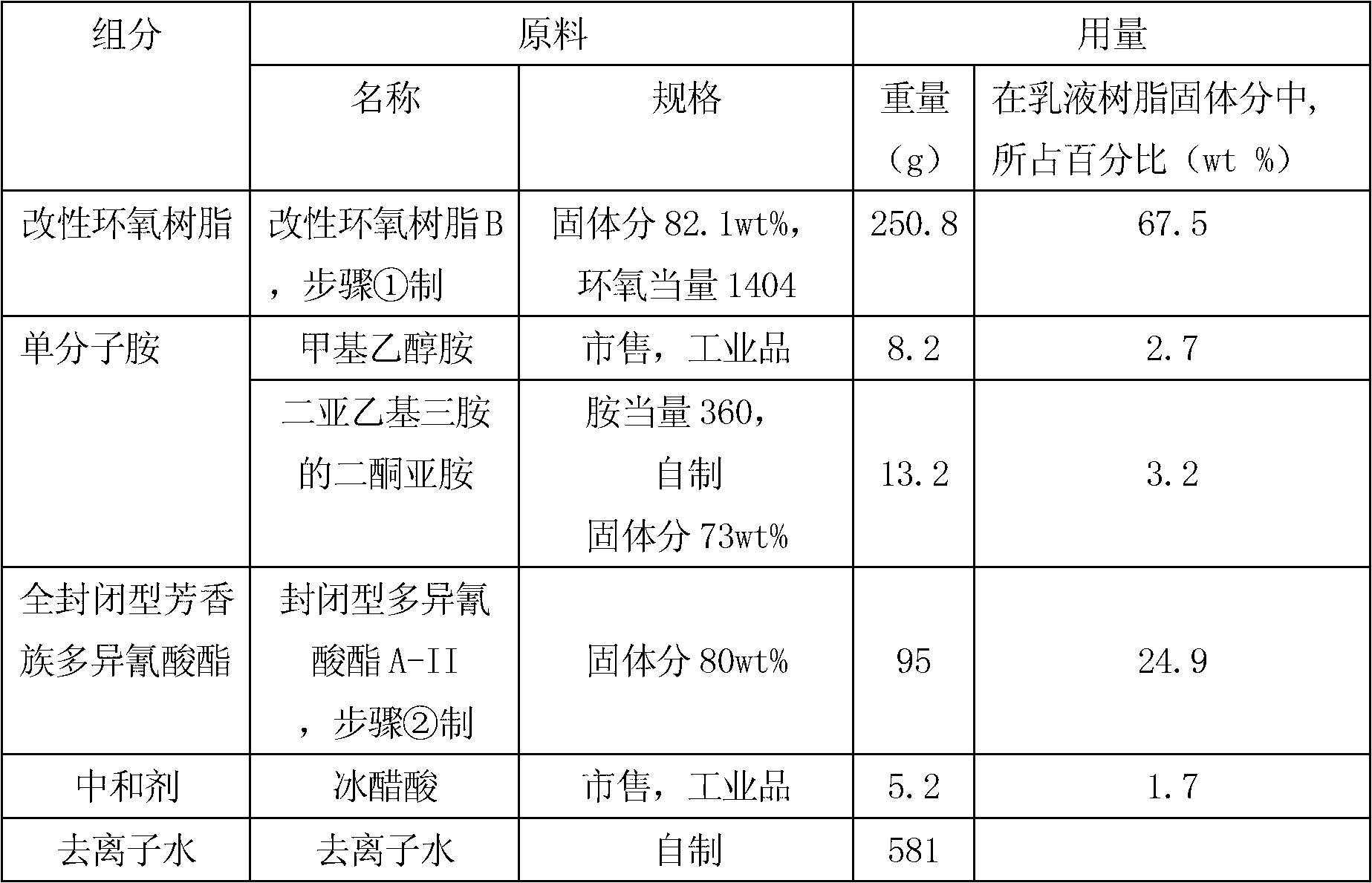

Resin emulsion for cathode electrophoretic coating with high throwing power and preparation method thereof

ActiveCN102838846ASuitable glass transition temperatureIncrease construction voltagePaints for electrolytic applicationsEpoxy resin coatingsOrganic acidEmulsion

The invention relates to resin emulsion for cathode electrophoretic coating with high throwing power and a preparation method of the resin emulsion, wherein the emulsion is obtained by the following steps: heating and mixing modified epoxy resin aminated by various single molecular amines and one or two of fully-closed aromatic polyisocyanates; using organic acid to neutralize the mixture; and using de-ionized water to disperse the mixture, wherein the weight ratio of raw materials in the resin emulsion solid is as follows: 45-70wt% of modified epoxy resin, 4-10wt% of total single molecular amines, 20-40wt% of fully-closed aromatic polyisocyanates and 1.6-3.5wt% of organic acid; the modified epoxy resin is obtained by replacing part of solvent with plasticizer, and using flexible polymer to extend chain of bisphenol A epoxy resin to be of molecular weight of 1500-3000; in the modified epoxy resin solid, the content of flexible polymer is 10-35% and the content of the plasticizer is 4-14%. The resin emulsion is stable and low in solvent content; the film has smooth appearance and throwing power of more than 22cm.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

Chromium-free environment-friendly epoxy anticorrosion primer

Owner:DE LAITTERN ENVIRONMENTAL COATING BEIJING

Organic-inorganic hybridization ultraviolet cured paint for protecting metallic surface

InactiveCN101307194AReduce pollutionSimple operation processLiquid surface applicatorsCoatingsSilanesStrong acids

The invention relates to organic-inorganic hybrid ultraviolet cured paint for metal surface protection. The paint comprises the following components in percentage by weight: 10 to 25 percent of epoxy modified silicon dioxide gel-resin, 15 to 30 percent of bisphenol-A epoxy acrylic ester, 5 to 15 percent of urethane acrylate, 35 to 45 percent of reactive diluent, 2 to 5 percent of toughener, 4 to 6 percent of photoinitiator, 0.5 to 0 percent of addition agent, wherein the epoxy modified silicon dioxide gel-resin is prepared by hydrolyzing a mixture of ethyl orthosilicate and gamma-glycidoxy propyl trimethoxy silane by a sol-gel method first and then adding diethylenetriamine. The paint film formed after the curing of paint has good strength, hardness, flexibility and strong acid and base resistance. The invention solves the problems that the organic-inorganic hybrid paint has high requirement on curing and common ultraviolet cured paint has poor adhesive force and flexibility when cured on metal base materials.

Owner:JIANGSU UNIV OF SCI & TECH

Thermosetting Resin Composition and Application Thereof

InactiveUS20100240811A1Excellent dielectric propertiesIncrease thermal resistanceBiocideOrganic chemistryTetrabromobisphenol ASolvent

The present invention discloses a thermosetting resin composition including: a bi-functional or multi-functional epoxy resin, a SMA uses as a curing agent, an allyl phenol such as diallyl bisphenol A used as a co-curing agent and a toughening agent a low-bromine or high-bromine BPA epoxy resin or tetrabromobispheno A (TBBPA or TBBA) uses as a flame retardant agent, and an appropriate solvent. After the resin composition of the invention is cured, the resin composition has lower dielectric property and better thermal reliability and tenacity. A copper clad laminate made of an enhanced material such as glass fiber has lower dielectric constant (Dk) and loss tangent (Df), high Tg, high thermal decomposition temperature (Td), better tenacity and PCB manufacturability, and thus very suitable to be used as a copper clad laminate and a prepreg for manufacturing PCBs or applied as a molding resin material for contraction, automobile and air navigation.

Owner:ITEQ DONGGUAN +1

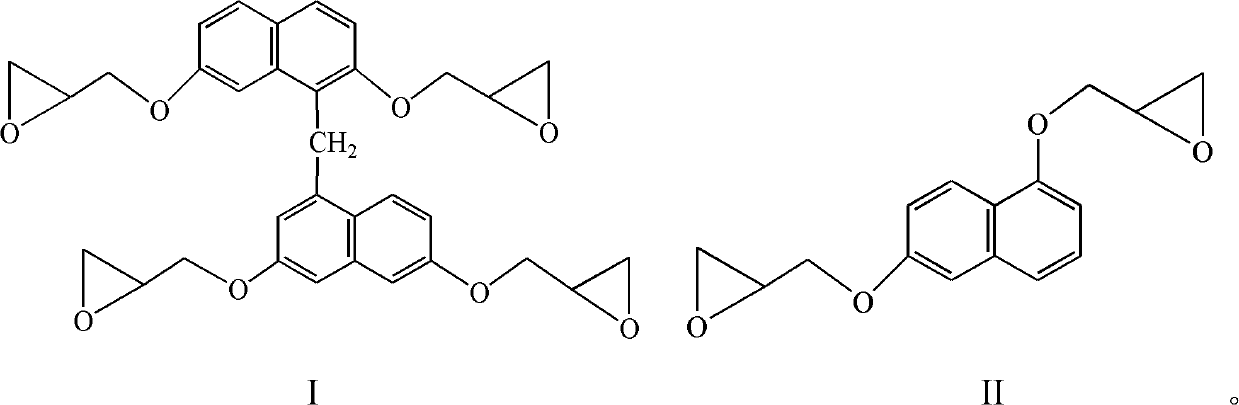

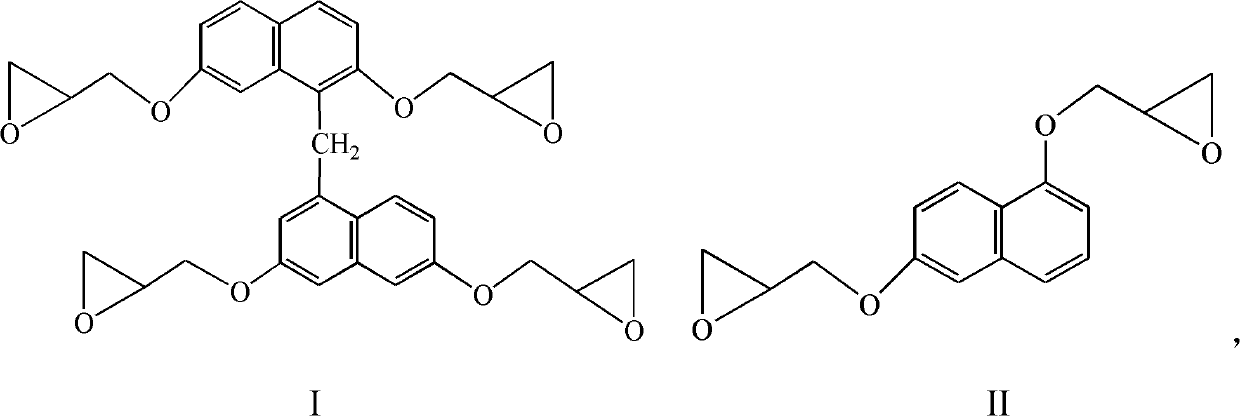

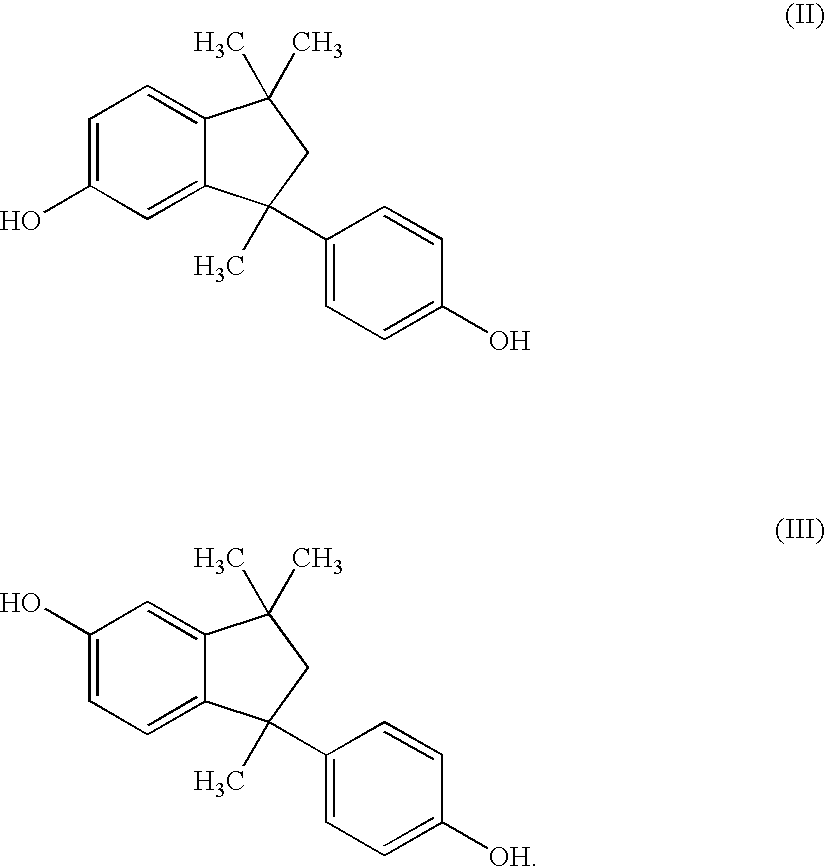

Molecular glass photoresist containing bisphenol A skeleton structure as well as preparation method and application thereof

ActiveCN103304385AOrganic compound preparationPhotomechanical coating apparatusSolventNanoimprint lithography

The invention relates to a series of molecular glass photoresists (I and II) based on bisphenol A as a main body structure and a preparation method thereof. The molecular glass photoresists are compounded with a photo-acid generator, a crosslinking agent, a photoresist solvent and other additives to produce positive or negative photoresists; the positive or negative photoresists are placed on a silicon wafer through a spin coating method to prepare a photoresist coating layer with uniform thickness. The photoresist formula can be used in modern lithography technologies, such as 248nm lithography, 193nm lithography, extreme ultraviolet lithography, nanoimprinting lithography and electron beam lithography, and is especially suitable for an extreme ultraviolet (EUV) photo-lithographic process.

Owner:GUOKE TIANJI (BEIJING) NEW MATERIAL TECH CO LTD

Resin composition, prepreg and metal-foil-clad laminate

ActiveUS20090247032A1Improve suppression propertiesHigh multilayerPrinted circuit aspectsSynthetic resin layered productsMetal foilCopper foil

A vinyl-compound-based resin composition containing a terminal vinyl compound (a) of a bifunctional phenylene ether oligomer having a polyphenylene ether structure, a naphthol aralkyl type cyanate ester resin (b), a bisphenol A cyanate ester resin (c), a brominated flame retardant (d) and an inorganic filler (e), which resin composition is for use in a printed wiring board for high multilayer and high frequency and is improved in moldability and copper foil peel strength, which are conventional problems, without any decrease in electric characteristics and heat resistance after moisture absorption while keeping flame retardancy, a prepreg comprising the above resin composition and a glass woven fabric, a metal-foil-clad laminate obtained by disposing a metal foil on one side or both sides of a stack of at least one prepreg and laminate-molding the resultant set, and a resin sheet obtained by applying a solution of the above resin composition to a surface of a metal foil or a film.

Owner:MITSUBISHI GAS CHEM CO INC

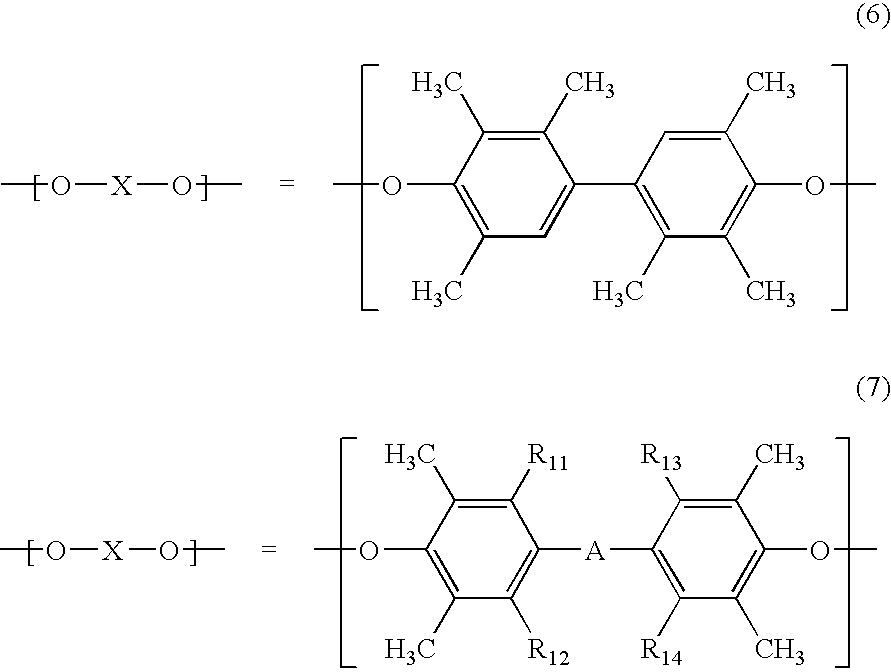

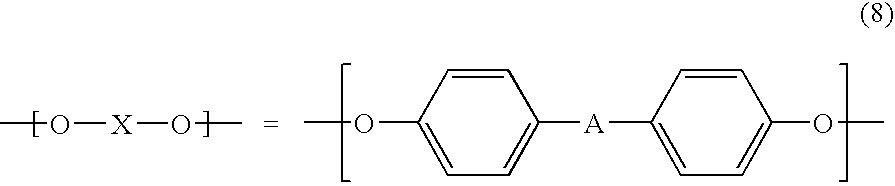

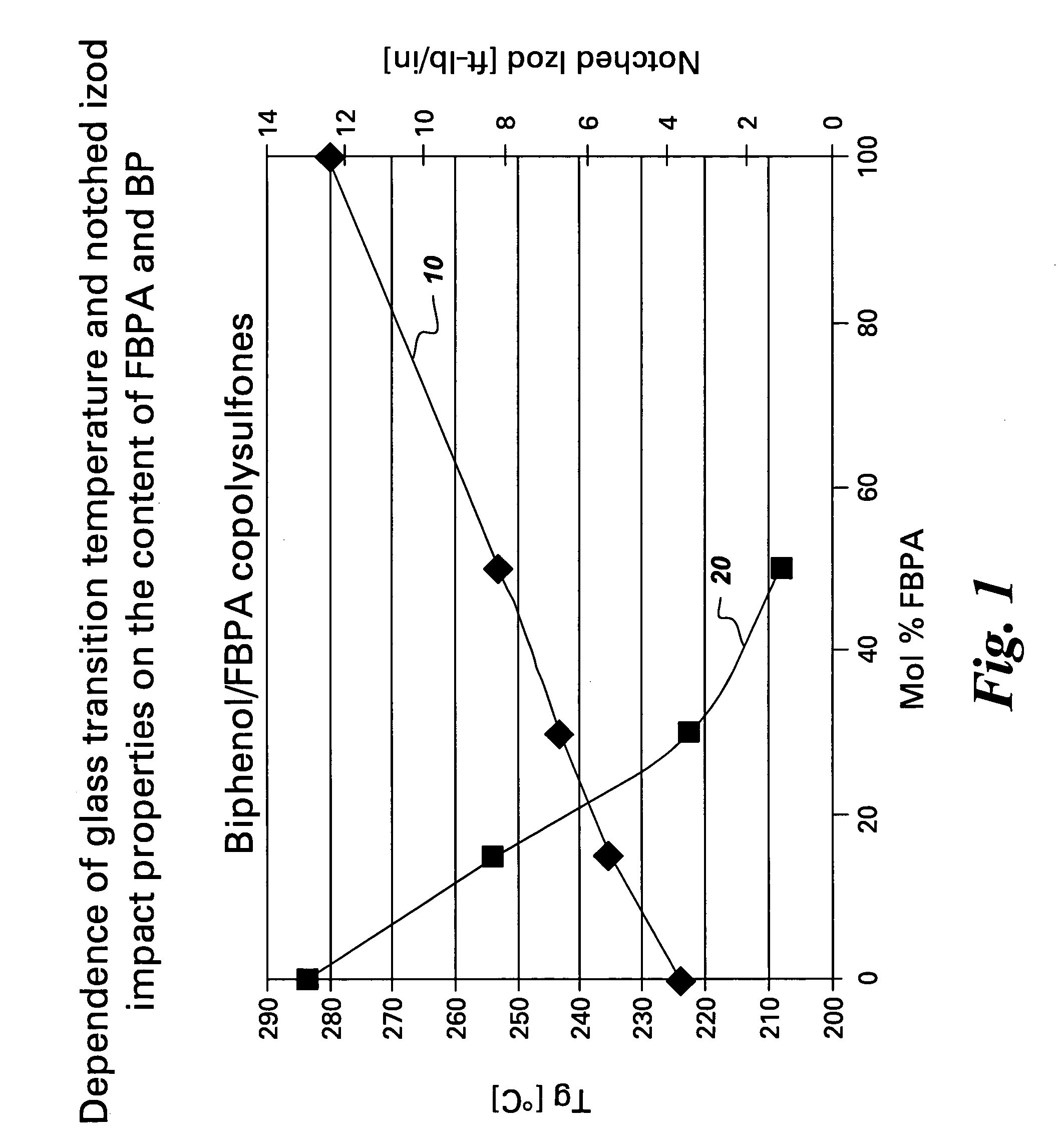

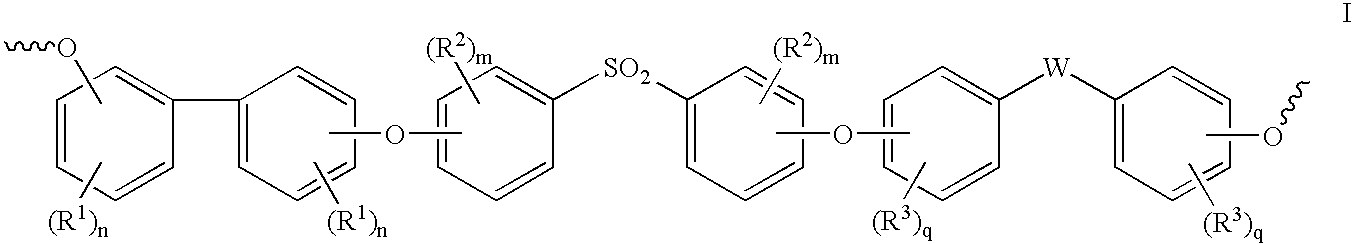

Polyethersulfone compositions with high heat and good impact resistance

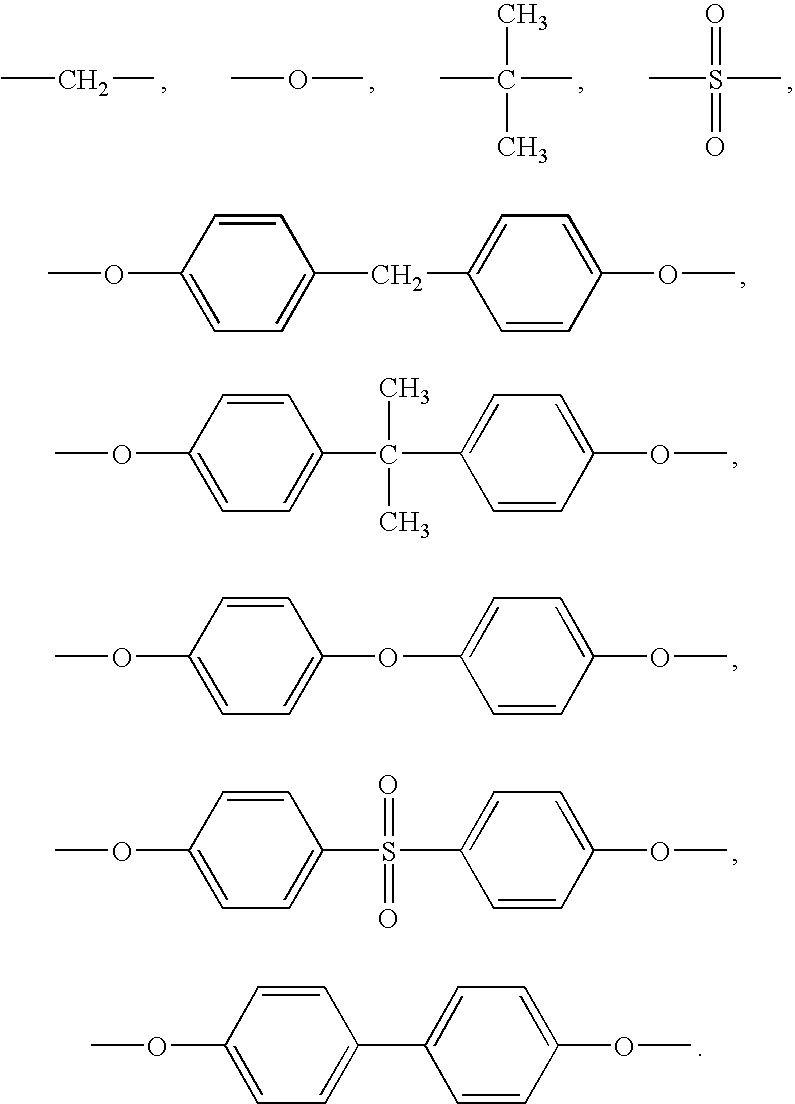

A polyethersulfone composition is disclosed which comprises structural units derived from a monomer mixture comprising fluorenylidene bisphenol-A and at least 50 mole percent of 4,4′-biphenol based on total moles of diphenolic monomers, wherein the polyethersulfone has a minimum glass transition temperature of 235° C. and a notched Izod impact value of 1 ft-lb / in. as measured by ASTM D256.

Owner:GENERAL ELECTRIC CO

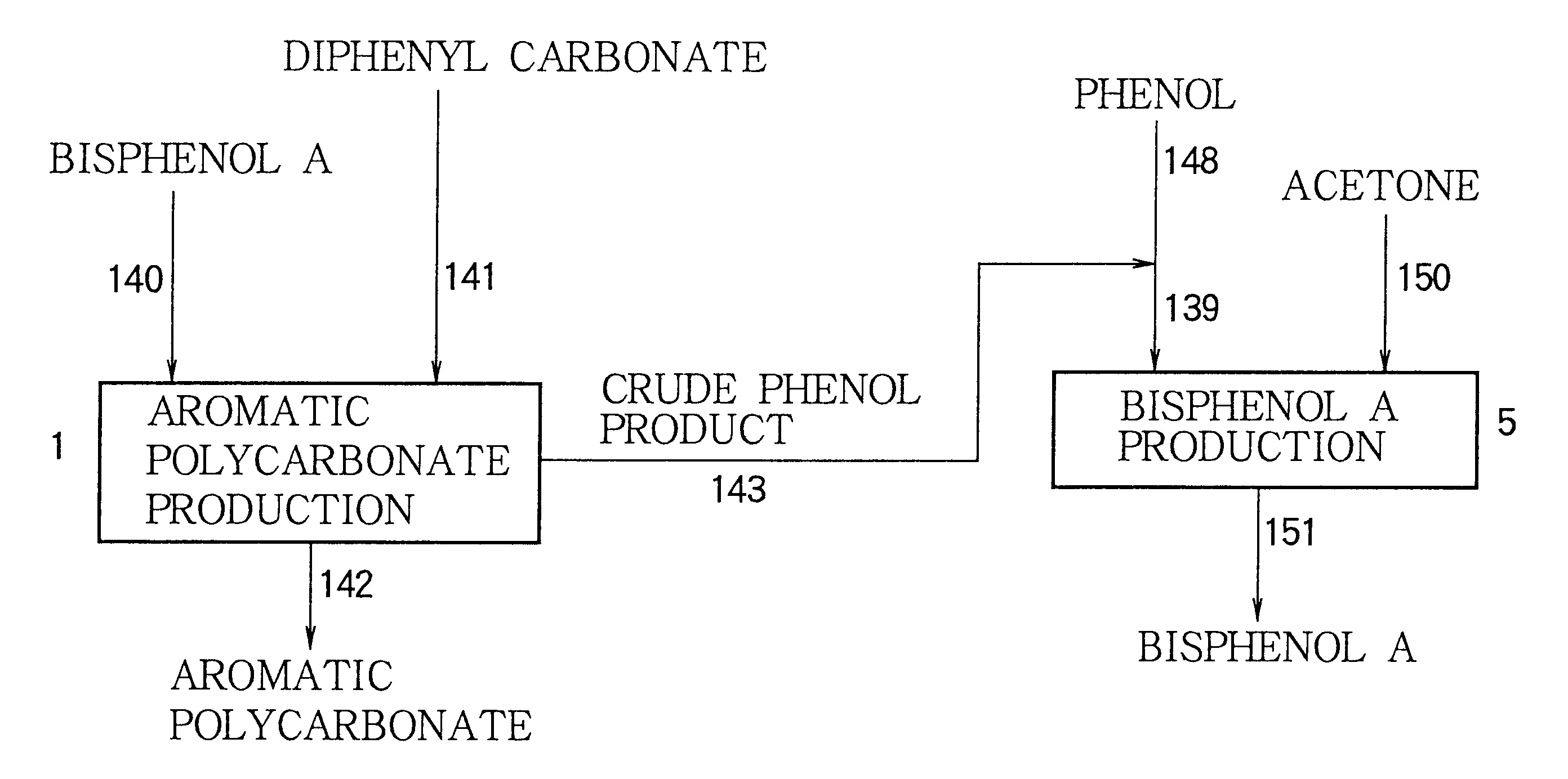

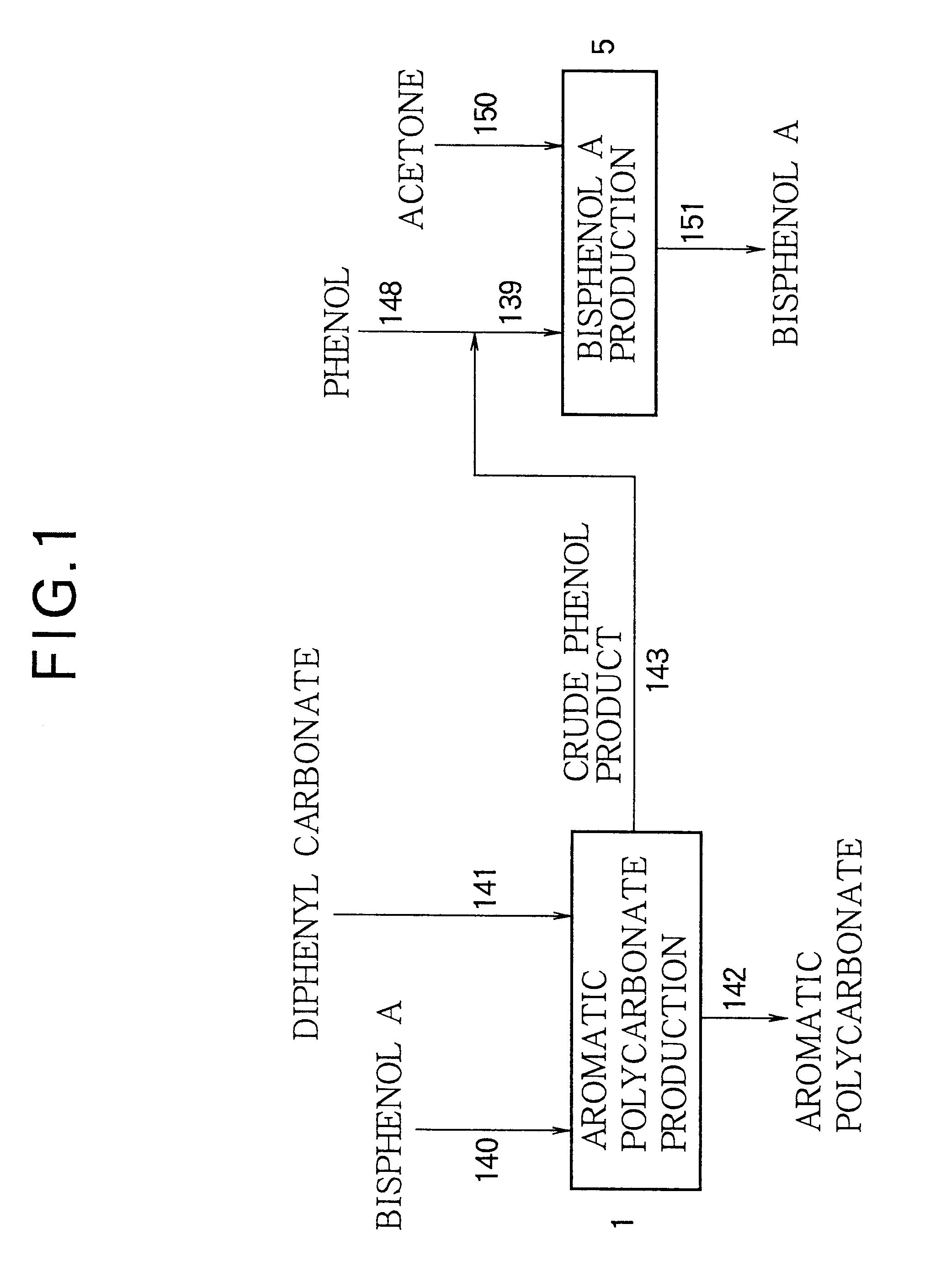

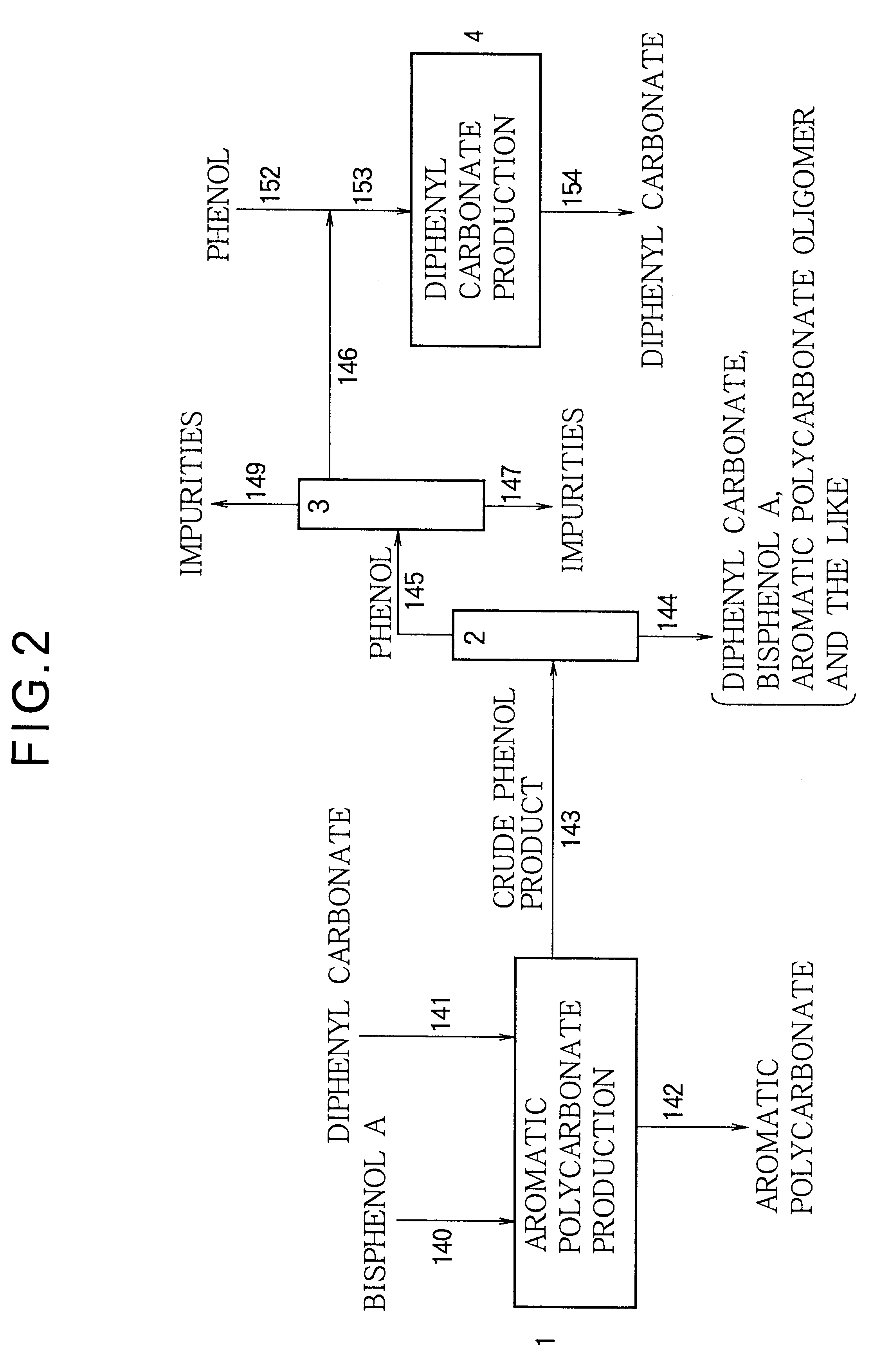

Method for producing an aromatic polycarbonate

Disclosed is a method for producing an aromatic polycarbonate, which comprises reacting acetone with a phenol material, thereby producing bisphenol A, and polymerizing the resultant bisphenol A with diphenyl carbonate to produce an aromatic polycarbonate while producing phenol as a by-product, wherein the by-product phenol is recovered as a crude phenol product containing the by-product phenol as a main component and containing impurities, and the crude phenol product is used as at least a part of the phenol material for producing bisphenol A. According to the method of the present invention, a crude phenol product as such, containing, as a main component, a by-product phenol which is by-produced during the polymerization reaction for producing an aromatic polycarbonate, and containing impurities, can be utilized for producing an aromatic polycarbonate, without any purification or the like. In the method of the present invention, not only can a necessity for complicated operations, such as a purification treatment, be reduced, but also the amount of wastes can be reduced and the yield of the aromatic polycarbonate, based on any of phenol and bisphenol A, can be improved.

Owner:ASAHI KASEI KK

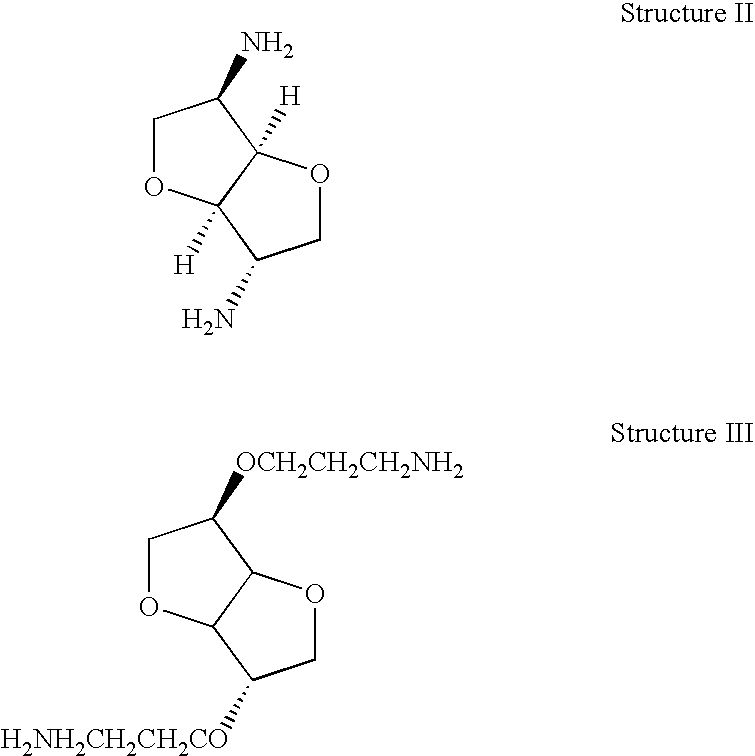

Thermoset epoxy polymers from renewable resources

Novel thermoset epoxy polymers using the bisglycidyl ethers of anhydrosugars, such as isosorbide, isomannide, and isoidide, are disclosed. The bisglycidyl ethers are useful as substitutes for bisphenol A in the manufacture of thermoset epoxy ethers. The anhydrosugars are derived from renewable sources and the bisglycidyl ethers are not xenoestrogenic and the thermoset curing agents are likewise derived form renewable resources.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

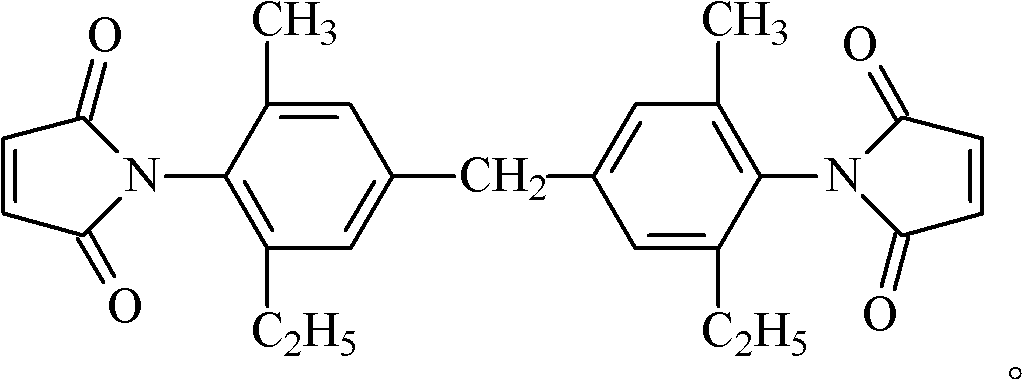

Halogen-free phosphorus-containing flame-retardant polyimide resin composition and preparation method thereof

ActiveCN102276837AImprove flame retardant performanceImprove toughnessGlass/slag layered productsMetal layered productsHalogenCopper

The invention relates to a halogen-free phosphorus-containing flame retardant polyimide resin composite, which is characterized by comprising the following components in part by weight: 150 to 180 parts of bismaleimide, 90 to 110 parts of allyl compound, 10 to 20 parts of bisphenol A epoxy resin and 10 to 50 parts of phosphorus-containing compound. The invention also relates to a preparation method for the halogen-free phosphorus-containing flame retardant polyimide resin composite. The method comprises the following steps of: adding the bismaleimide, the allyl compound, the bisphenol A epoxyresin and the phosphorus-containing compound into a reaction kettle, and reacting at the temperature of between 120 and 140 DEG C for 3 to 5 hours to obtain the halogen-free phosphorus-containing flame retardant polyimide resin composite. The halogen-free phosphorus-containing flame retardant polyimide resin composite is synthesized in one step and does not contain halogens and has high flame retardant performance; according to UL94 V0 flame retardant grade tests, the toughness of the cured composite is improved; and the moist heat resistant performance of the composite is high, and the composite meets the requirements of flame retardance and processing in the process of processing copper-clad plates and has high the storage stability.

Owner:INNOTEK TECH CHINA

Bi-component adhesive composition and preparation method thereof

ActiveCN103305170AHigh bonding strengthImprove heat resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesNitrile rubberHeat resistance

The invention provides a bi-component adhesive composition composed of an A component and a B component. The A component contains an epoxy resin mixture, a first toughening agent, filler and a thixotropic agent; the B component contains a second toughening agent, a normal temperature curing agent, a high-temperature curing agent and an accelerant; the epoxy resin mixture contains a first epoxy resin, a second epoxy resin and a third epoxy resin, the first epoxy resin is a bisphenol A epoxy resin or a bisphenol A epoxy resin, the second epoxy resin is a chelate modified epoxy resin, and the third epoxy resin is a naphthalene-nucleus modified epoxy resin; the first toughening agent is a core-shell structure rubber nano particle, the second toughening agent is an end-isocyanate polyurethane and / or end-carboxy nitrile rubber. The invention further provides a preparation method of the bi-component adhesive. The adhesive composition provided by the invention is high in adhesion strength, high in heat resistance, low in water adsorption, high in impact resistance, and capable of satisfying the use requirement of structural adhesive for connecting structural members of an automobile.

Owner:BYD CO LTD

Polyethersulfone composition, method of making and articles therefrom

A polyethersulfone composition is disclosed which comprises structural units derived from a monomer mixture comprising bisphenol-A and at least 55 mole percent of 4,4′-biphenol based on total moles of diphenolic monomers, wherein the polyethersulfone has a minimum weight average molecular weight which is a function of the mole percent of structural units derived from biphenol monomer. In addition the polyethersulfones possess a notched Izod impact strength value of greater than 470 Joules per meter as measured by ASTM D256.

Owner:GENERAL ELECTRIC CO

Anti-fouling coating material with excellent compatibility and use thereof

InactiveCN102558989AGood compatibilityImprove antifouling performanceAntifouling/underwater paintsPaints with biocidesAcrylic resinSolvent

The invention relates to the field of anti-fouling coating materials, in particular to an anti-fouling coating material with excellent compatibility. The anti-fouling coating material with excellent compatibility contains liquid bisphenol A epoxy resin, polished acrylic resin, at least two thermoplastic resins for a coating film-forming material, at least two antifouling agents, at least two pigments and fillers, at least two solvents and at least two additives. With the adoption of the anti-fouling coating material with excellent compatibility, the excellent compatibility between a new / old anti-corrosion coating layer and an old antifouling coating layer can be provided, a connecting layer cannot be a coating layer necessary to be coated any more, the processes of coating are reduced, and excellent attachment and antifouling performances are shown after the long-term application of the anti-fouling coating material.

Owner:MARINE CHEM RES INST

Method for preparing bisphenol A molecular engram polymer

The invention discloses a method for preparing bisphenol A molecular imprinting polymer, comprising the following procedures: dissolving template molecule bisphenol A and functional monomer according to the mol ratio of 1.5:1 to 2:1 into acetonitrile solution which is no less than 10ml with 10 to 15 crosslinking agent and initiator of catalytic amount to prepare mixed liquor; the mixture liquor is churned up at 55 to 70 DEG C to polymerize for 12 to 24 hours and then white powdery polymer is generated; synthesizing fine white powdery polymer using mixed solution of methanol and acetic acid as extracting solution, removing the template molecules and then extracting acetic acid molecules using pure methanol; after extracting, the polymer is arranged in vacuum drying chamber to dry until reaching balancing weight and then bisphenol A molecular imprinting polymer is obtained. The invention has advantages that the prepared bisphenol A molecular imprinting polymer has special adsorption for bisphenol A molecular in cosmetic samples which can rapidly, delicately and accurately concentrate and purify the cosmetic samples in an efficient way; the rate of recovery is high, the reproducibility is good and the sensitivity is high.

Owner:HUBEI INSPECTION & QUARANTINE TECH CENT

Preparing technology of polyurethane modified ethoxyline resin adapted for composite wear-resistant coating material

InactiveCN101445583ASolve the problem of poor flexibilityHigh bonding strengthPolyurea/polyurethane coatingsDiphenylmethaneWear resistant

The invention discloses a preparing technology of polyurethane modified ethoxyline resin adapted for composite wear-resistant coating material. Polyether dihydroxy alcohol having a degree of functionality of 2 and an average relative molecular weight of 1200 to 2200 is reacted with toluene di-isocyanate or diphenylmethane-4,4'-diisocyanate prepared for preheating to synthetize polyether dihydroxy alcohol polyurethane performed polymer for reservation; one of bisphenol A E-44 and E-51 after pre-dehydration is selected for reservation; polyurethane modified epoxy is formed through polyaddition reaction in which a mass ratio of polyether dihydroxy alcohol polyurethane performed polymer to epoxide resin is 15 to 70: 100. The polyurethane modified epoxy obtained by the technology has high bonding strength, good flexibility and shock resistance with basal bodies of spare parts, totally without using plasticizers, such as dibutyl phthalate, dioctylphthalate, etc., without using or using less plasticizers, such as polysulfide rubber, liquid acrylonitrile butadiene rubber, etc., thereby not only solving the problem that general epoxide resin has bad flexibility but also saving the production cost.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

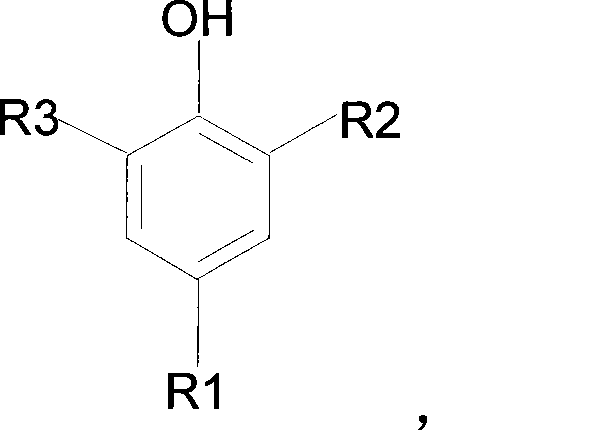

UV curing antibiotic coating and preparation thereof

InactiveCN101353545AImprove antibacterial propertiesSimple preparation processAntifouling/underwater paintsPaints with biocidesUV curingTMPTA

The invention discloses a UV-curable antimicrobial coating, the components of which are as follows: bisphenol A type epoxy acrylate EA; aliphatic PUA; special functional group acrylate PA; TPGDA; TMPTA; photoinitiators; nano acrylate; oxidized silver; and auxiliaries. The preparation method comprises the following steps of: step one, synthesizing special functional group heterocyclic compound PA and later adding phosphorus pentoxide to acrylic acid hydroxy esters so as to react with hydroxyl piperidine and then prepare special functional group heterocyclic compound PA; and step two, taking each component according to the formula, stirring and mixing each component so as to carry out dispersion at the speed of 900 to 1200r per min, then adding silver oxide and photoinitiators after being dispersed evenly, and finally obtaining UV-curable antimicrobial coating through dispersion. The UV-curable antimicrobial coating prepared by the invention has good anti-bacterial effect. As the self-prepared special functional group acrylate PA, the nano acrylate and the silver oxide are added, after UV-curable film-forming, the anti-coli rate can achieve over 99 percent and the anti-staphylococcal rate thereof achieves over 99 percent, and the effectiveness is long.

Owner:苏州市明大高分子科技材料有限公司

Thermosetting resin composition and use

InactiveCN101481490AImprove heat resistanceExcellent dielectric propertiesCircuit susbtrate materialsMetal layered productsGlass fiberTetrabromobisphenol A

The invention discloses a thermoset resin composition, comprising the following ingredients of: bifunctional groups or polyfunctional group epoxy resin, phenylethylene-maleic anhydride copolymer (SMA) as a curing agent, diallyl bisphenol A-like allylphenol as a co-curing agent and a toughening agent, low-bromine or high-bromine BPA-type epoxy resin or tetrabromobisphenol A (TBBPA or TBBA) as a fire retardant, a proper accelerator and a solvent. The inventive resin composition has, after being cured, relatively low dielectric property and superior thermal reliability and toughness, includes, in contrast to a cooper clad laminate manufactured by reinforcing materials such as glass fiber cloth, relatively low dielectric constant (called Dk for short) and electric loss tangent (called Df for short), high Tg, high thermal cracking temperature (called Td for short), excellent toughness and favorable PCB processibility, is quite suitable for manufacturing the cooper clad laminate for PCB and prepreg, and can also applied to general uses of the epoxy resin, such as molding plastics and the like, and to composite materials for construction, automobile and aviation.

Owner:ITEQ DONGGUAN +1

Halogen-Free, Flame Retardant TPU Composite

Halogen-free TPU compositions comprise in weight percent based on the weight of the composition: A. 1 to 99% thermoplastic polyurethane (TPU), B. 1 to 50% tris(2-butoxyethyl)phosphate (TBEP), C. 1 to 70% metal hydrate, and D. 1 to 70% organic phosphate ester other than tris(2-butoxyethyl)phosphate. These compositions exhibit better smoke suppression as compared with conventional organic phosphate flame retardant TPU compositions such as those based on resorcinol bis(diphenyl phosphate) (RDP) and bisphenol-A bis(diphenyl phosphate) (BPADP) in the absence of TBEP.

Owner:DOW GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com