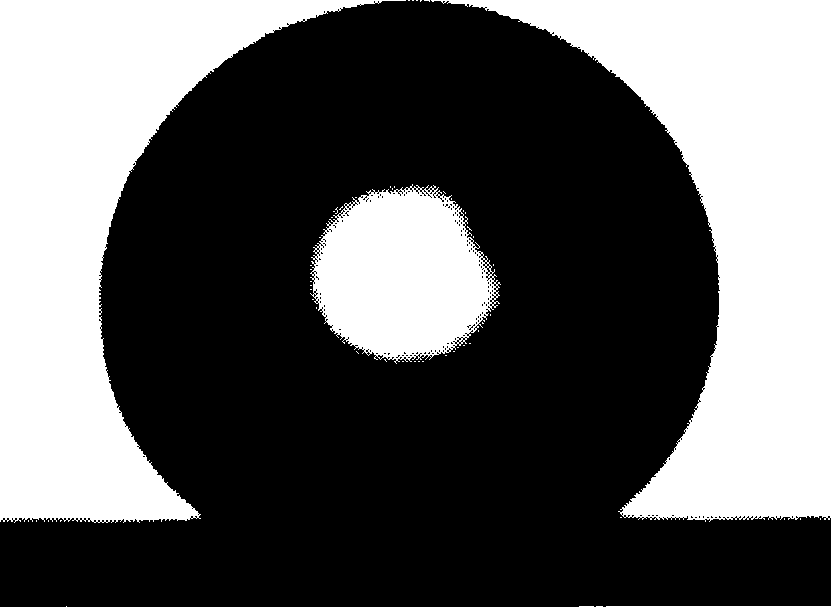

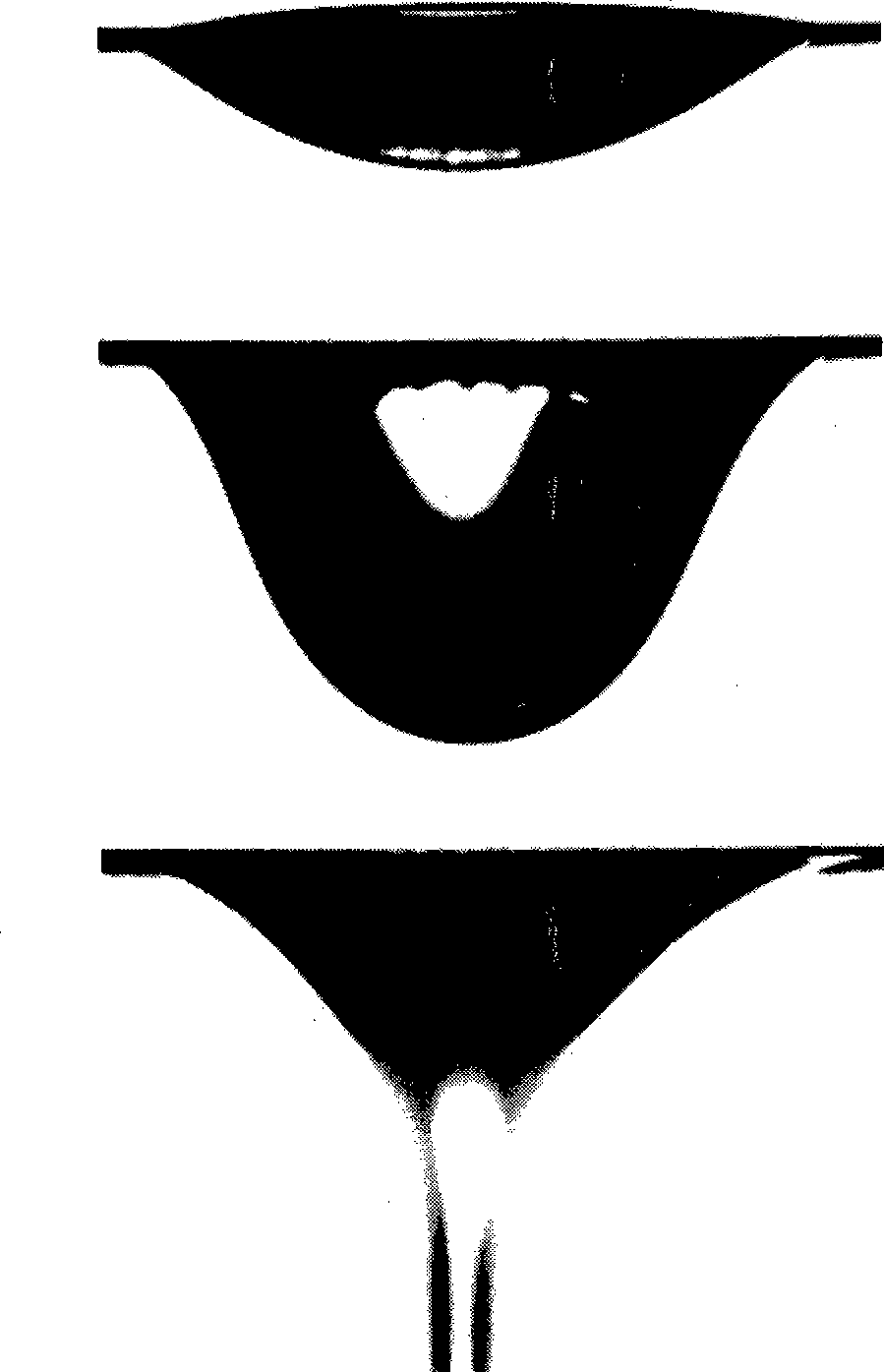

Super-hydrophobic and super-oleophilic oil-water separation mesh membrane and preparation method thereof

An oil-water separation omentum and super-oleophilic technology, applied in separation methods, liquid separation, chemical instruments and methods, etc., can solve problems such as high-temperature curing and complicated manufacturing process, and achieve low cost, simple preparation method, and transparent pores high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

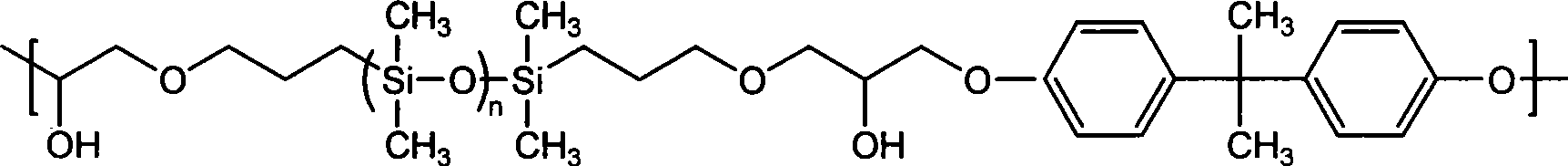

[0029] (1) Add 0.1mol allyl glycidyl ether and 0.5g H 2 PtCl 6 isopropanol solution, drop 0.05mol of α, ω-dihydropolysiloxane (α, ω-dihydropolysiloxane n=5 in the structural formula of the present invention) at 90°C, after the dropwise addition The reaction was continued at 100° C. for 10 hours, the catalyst and impurities were removed by decolorization with activated carbon, and α, ω-diglycidylpropyl polysiloxane (n=5) was obtained after filtration with a yield of 92.0%.

[0030] 1 H-NMR (δ, ppm): 0.02-0.09 (m, SiCH 3 ), 0.54 (m, SiCH 2 ), 1.61 (m, SiCH 2 CH 2 ), 2.61 and 2.79 (m, -CHCH 2 O-), 3.14 (m, -CHCH 2 O-), 3.37-3.48 (m, CH 2 OCH 2 CH) 3.68 (d, CH 2 OCH 2 CH).

[0031] (2) Add 5 mmol of the above-mentioned α, ω-diglycidyl propyl polysiloxane, 5 mmol of bisphenol A and 0.06 g of triphenylphosphine into a 50 mL three-necked flask, and react at 110 ° C for 7 hours to obtain polysilicon The oxane-bisphenol A copolymer has a yield of 91.8%.

[0032] 1 H-NMR ...

Embodiment 2

[0036] (1) Add 0.17mol allyl glycidyl ether and 0.9g H 2 PtCl 6 isopropanol solution, drop 0.085mol of α, ω-dihydropolysiloxane (α, ω-dihydropolysiloxane n=13 in the structural formula of the present invention) at 90°C, after the addition is completed The reaction was continued at 120° C. for 12 hours, the catalyst and impurities were decolorized with activated carbon, and α, ω-diglycidylpropylpolysiloxane (n=13) was obtained after filtration with a yield of 90.3%.

[0037] (2) Add 5 mmol of the above-mentioned α, ω-diglycidyl propyl polysiloxane, 5 mmol of bisphenol A and 0.08 g of triphenylphosphine into a 50 mL three-necked flask, and react at 115 ° C for 8 hours to obtain polysilicon Oxyalkylene-bisphenol A copolymer, the yield is 95.3%.

[0038] (3) The above-mentioned polysiloxane-bisphenol A copolymer is dissolved in toluene to form a 10 mg / mL solution, and a mixture of ethyl orthosilicate and butyltin (orthosilicate: butyltin) with 5% of the mass of the copolymer is ...

Embodiment 3

[0041] (1) Add 0.18mol allyl glycidyl ether and 1.4g H 2 PtCl 6 isopropanol solution, drop 0.09mol of α, ω-dihydropolysiloxane (α, ω-dihydropolysiloxane n=21 in the structural formula of the present invention) at 90°C, after the dropwise addition The reaction was continued at 120° C. for 12 hours, the catalyst and impurities were decolorized with activated carbon, and α, ω-diglycidylpropyl polysiloxane (n=21) was obtained after filtration with a yield of 91.5%.

[0042] (2) Add 5 mmol of the above-mentioned α, ω-diglycidyl propyl polysiloxane, 5 mmol of bisphenol A and 0.12 g of triphenylphosphine into a 50 mL three-necked flask, and react at 115 ° C for 8 hours to obtain polysilicon Oxyalkylene-bisphenol A copolymer, the yield is 96.7%.

[0043] (3) The above-mentioned polysiloxane-bisphenol A copolymer was dissolved in n-hexane to form a 5 mg / mL solution, and a mixture of ethyl orthosilicate and butyltin (ethyl orthosilicate: The mass ratio of butyl tin is 2:1), stir evenly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com