Patents

Literature

2556 results about "Dip-coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dip coating is an industrial coating process which is used, for example, to manufacture bulk products such as coated fabrics and condoms and specialized coatings for example in the biomedical field. Dip coating is also commonly used in academic research, where many chemical and nanomaterial engineering research projects use the dip coating technique to create thin-film coatings.

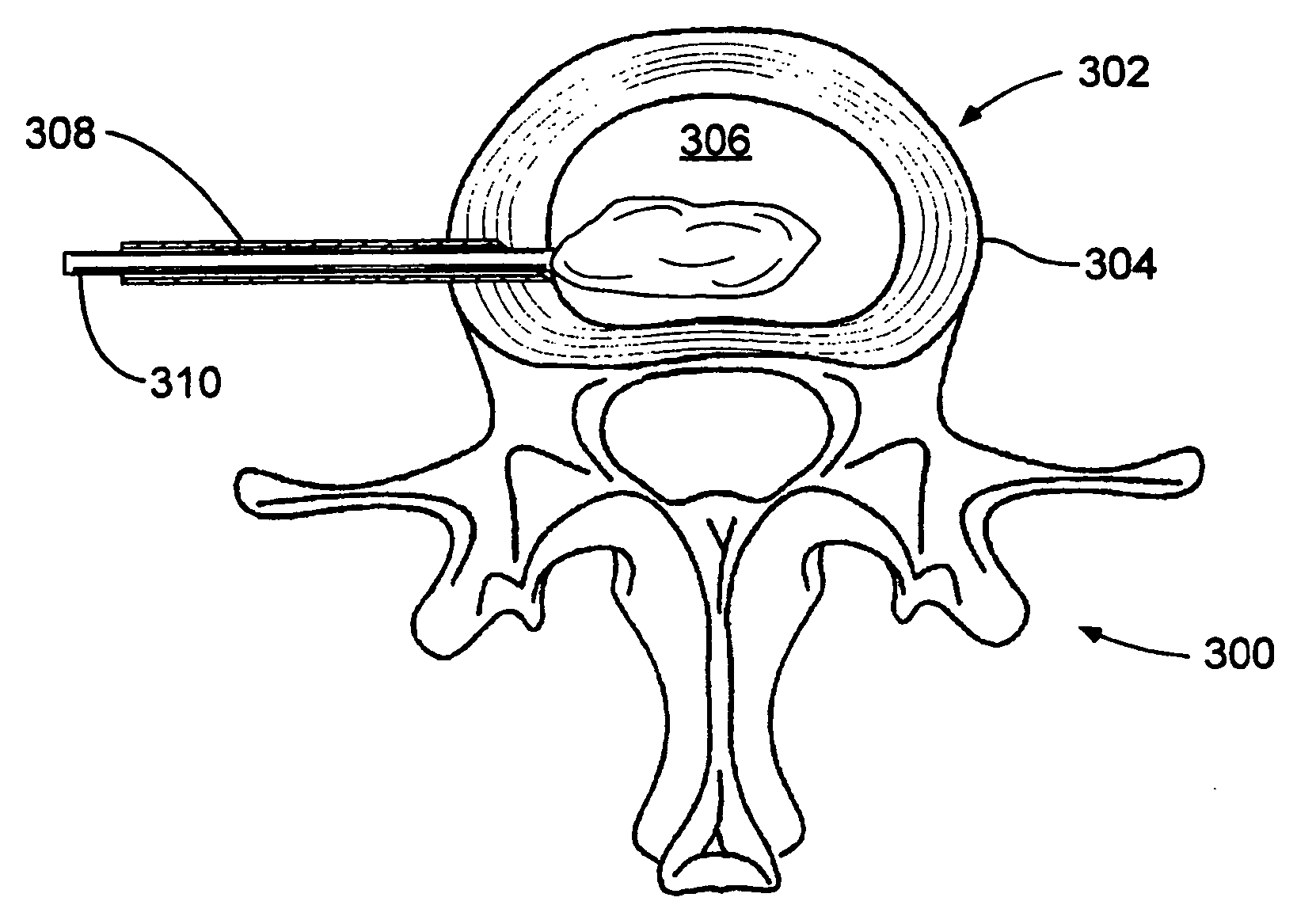

Hydrogel balloon prosthesis for nucleus pulposus

Owner:SYNTHES USA +1

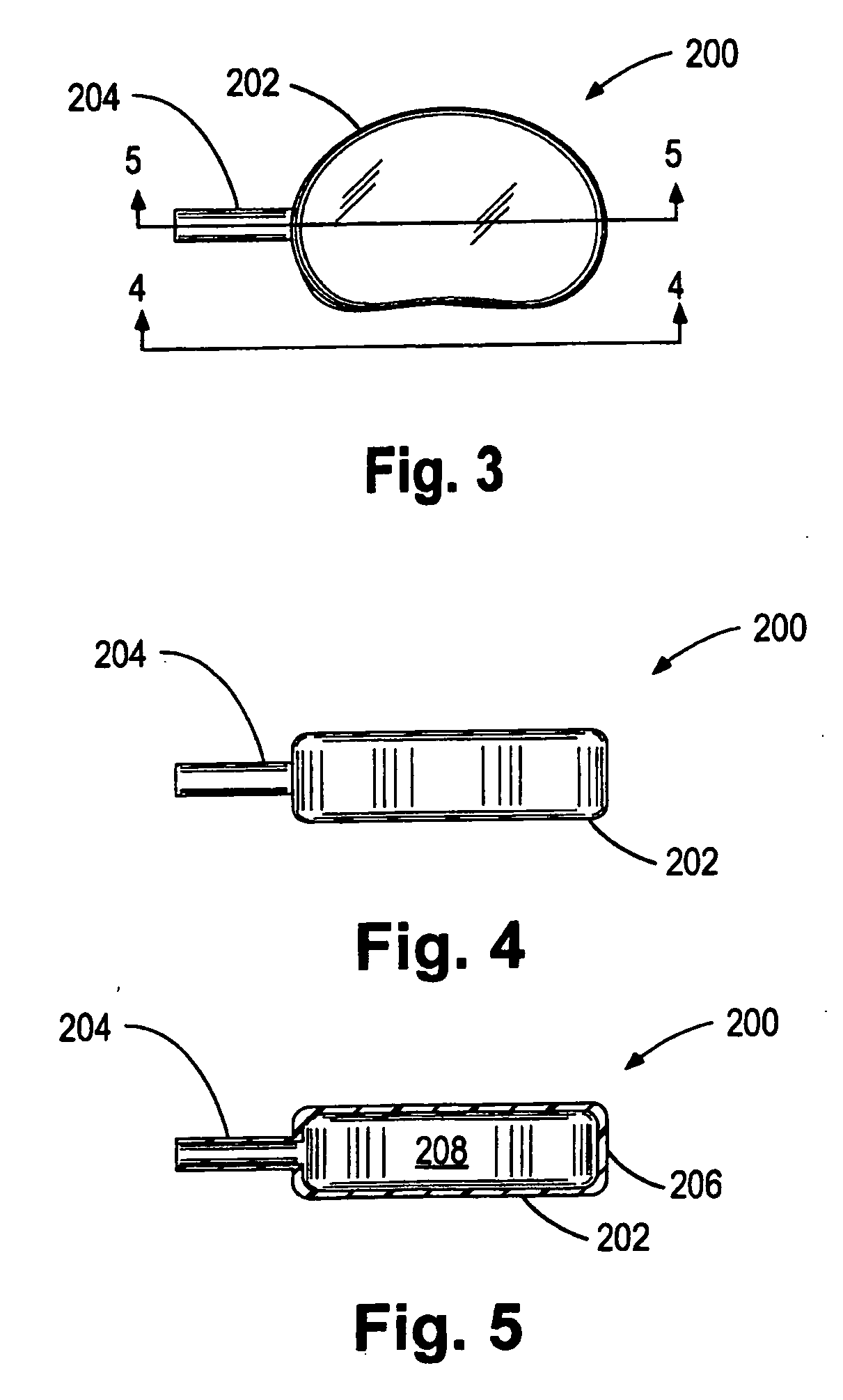

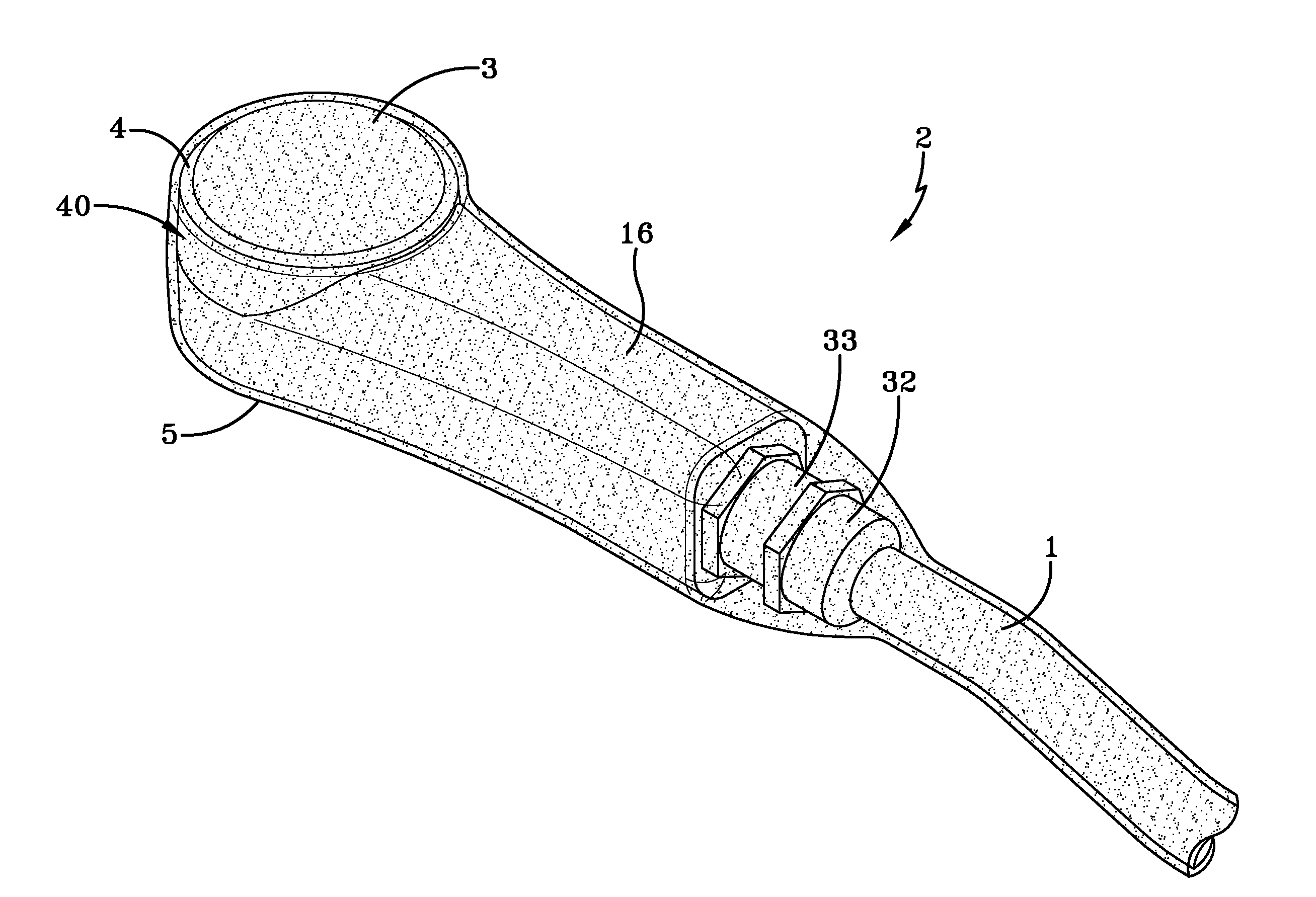

Shock Wave Treatment Device

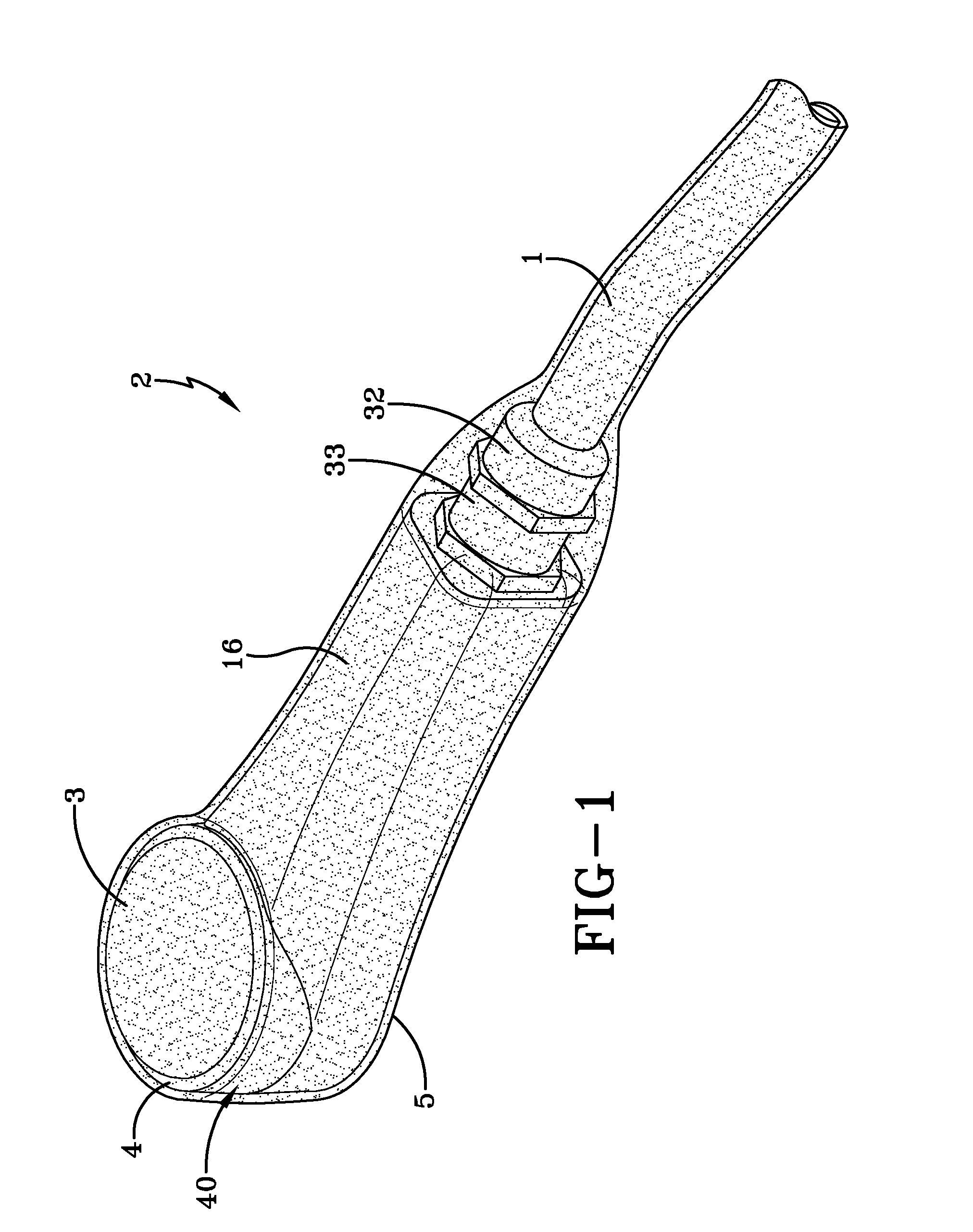

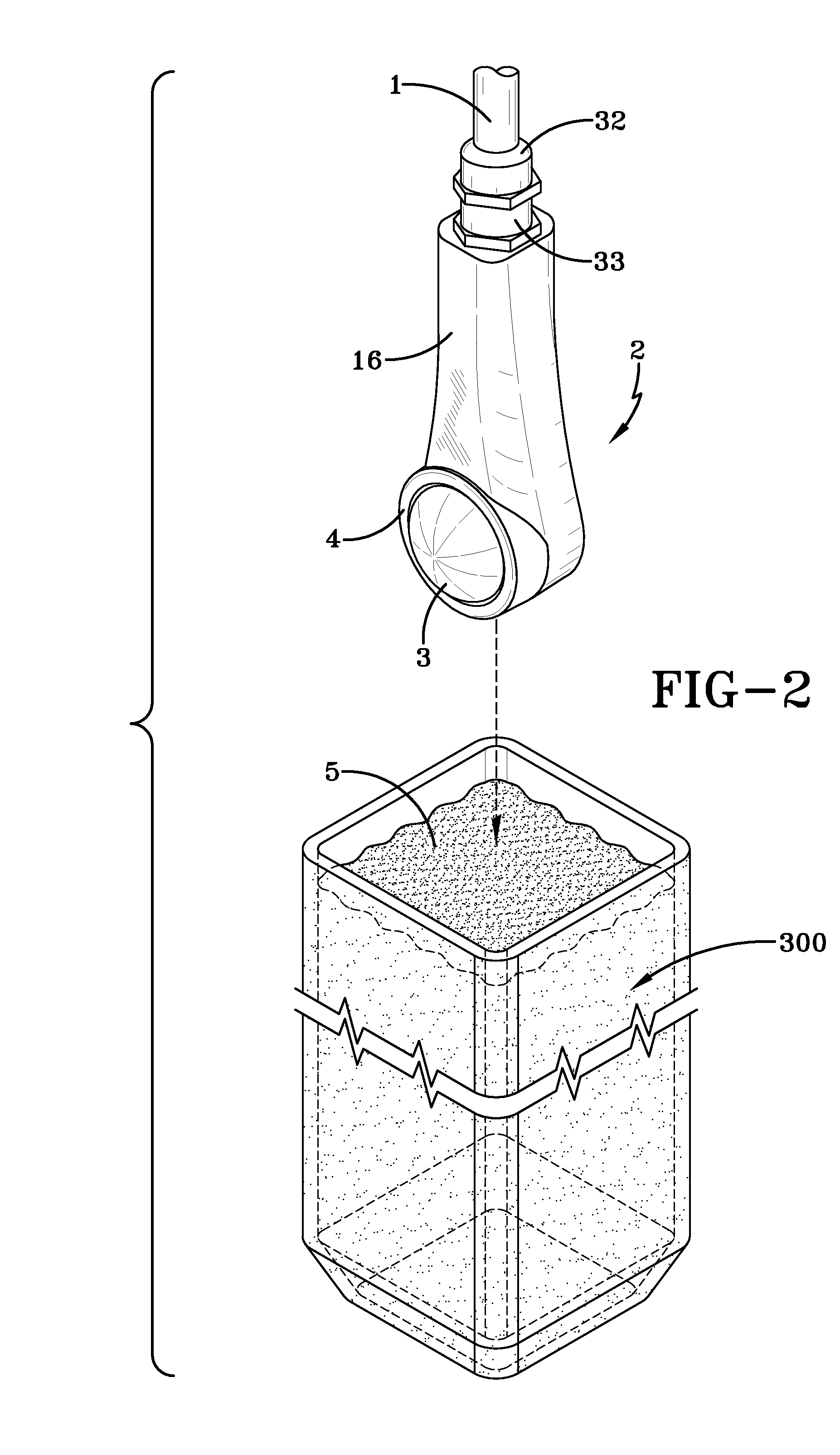

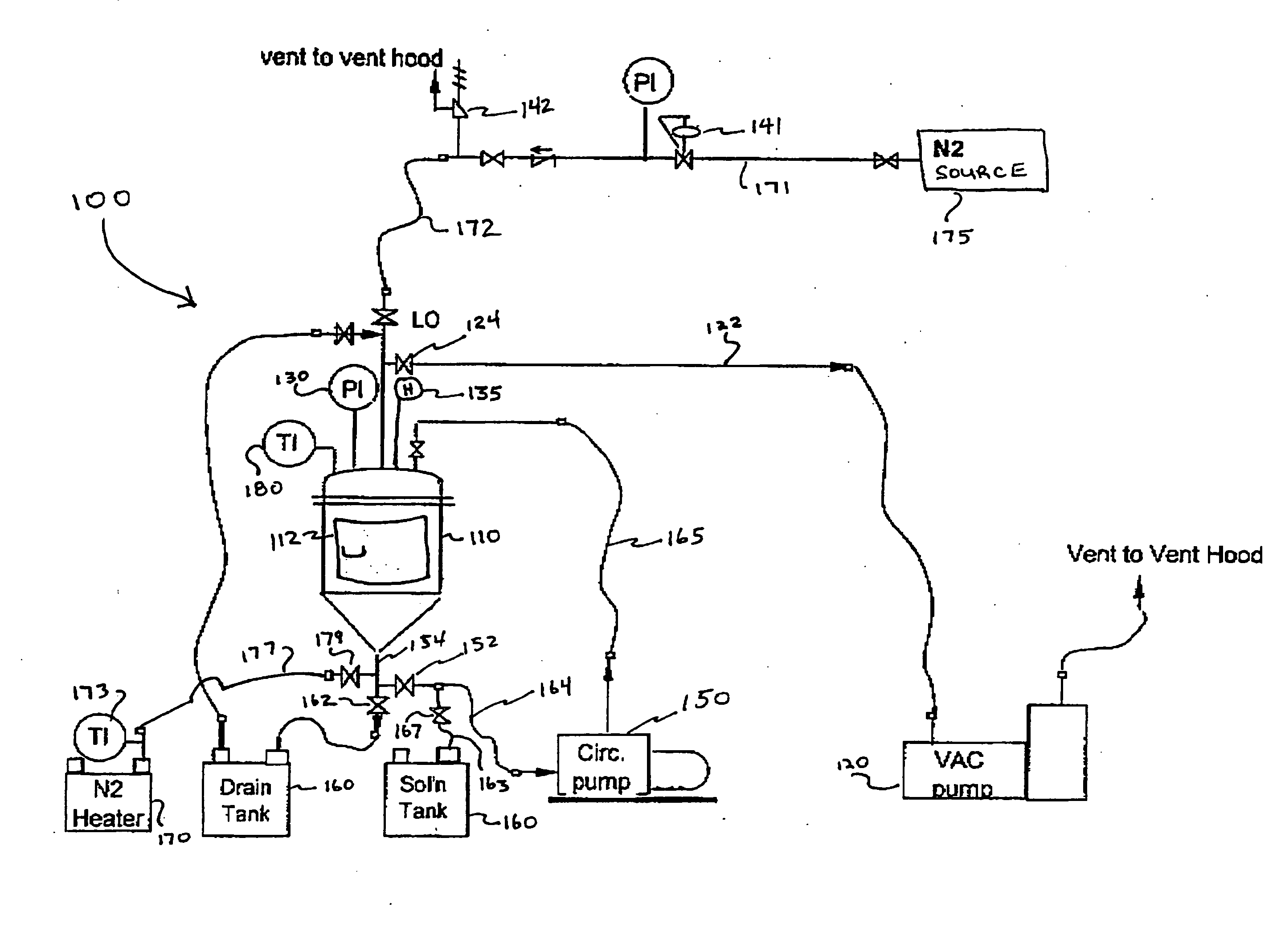

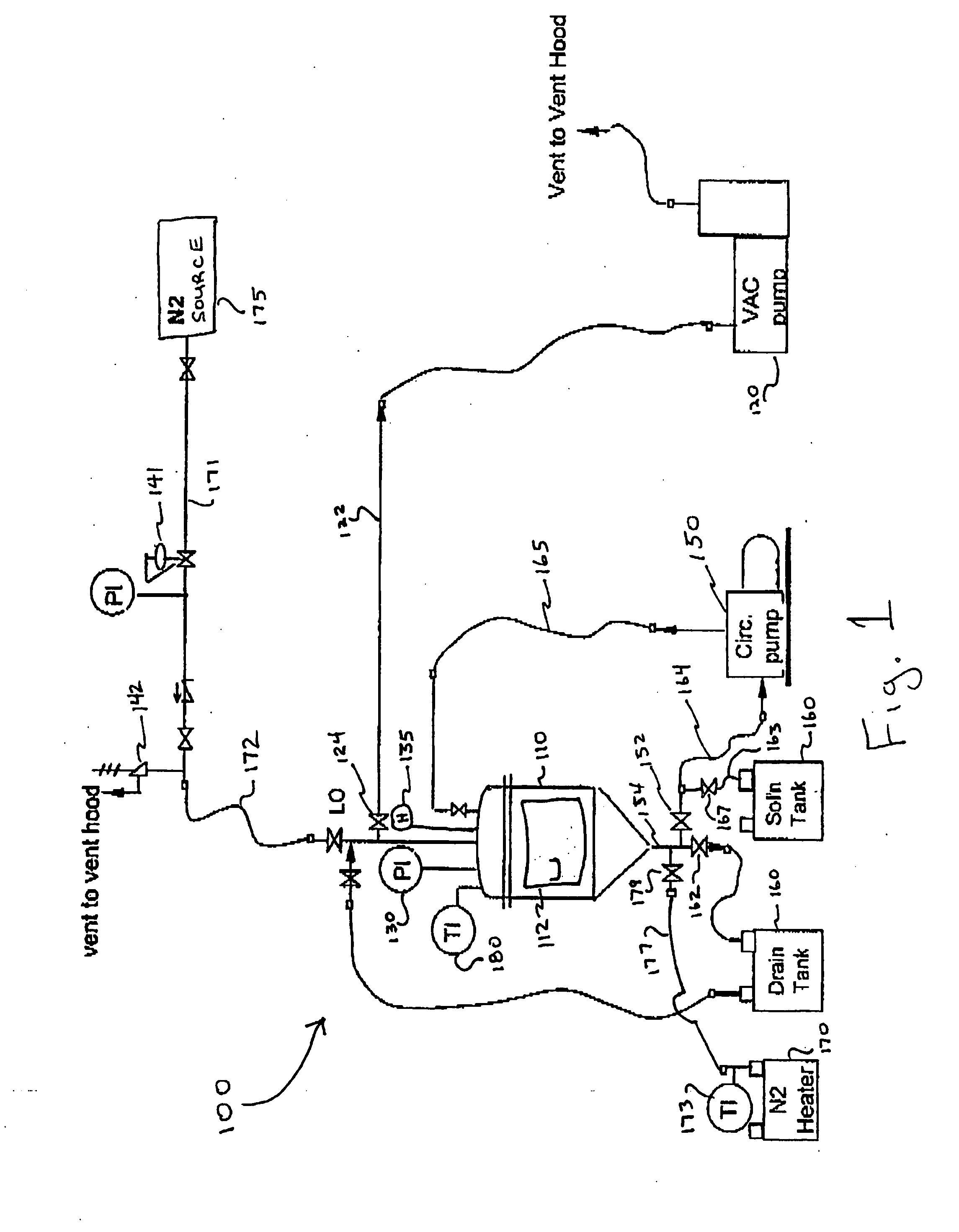

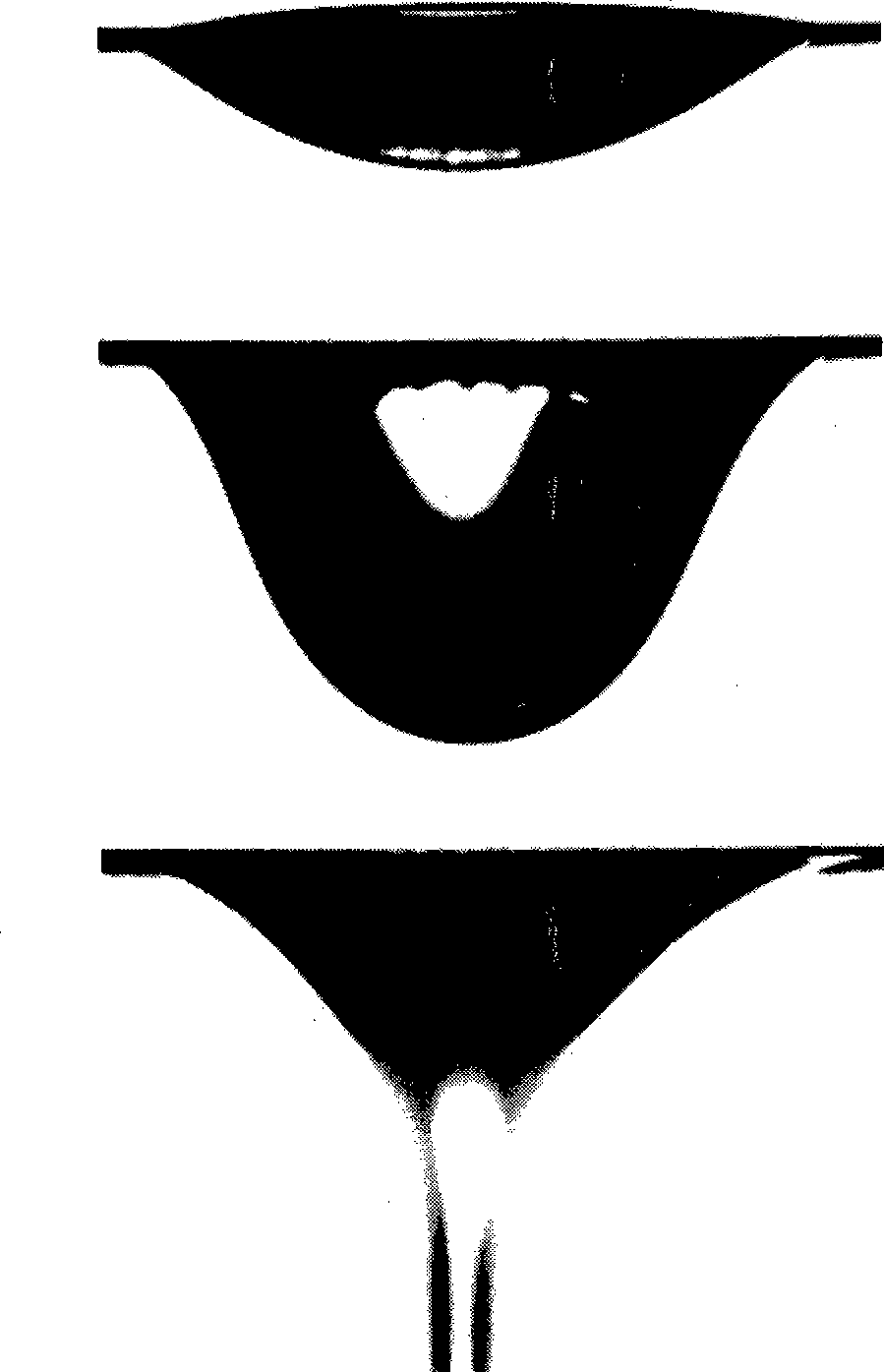

The system for treating an internal organ has a generator source for producing a shock wave connected to a handheld or small shock wave applicator device 2, wherein the external housing 16 of the device 2 is hermetically sealed in a non-electrically conductive insulating skin membrane 5 being of a polymer material, preferably a silicone rubber or polyurethane rubber. Preferably the entire device 2 including the connectors 32, 33 and at least a 20 cm portion of attached cable 1 is sealed using a dip coating process or alternatively can use an insert molding process wherein the device 2 is placed in a mold 400 and the skin membrane 5 is injection molded around the entire housing 16 and the cable 1 has an outer skin 5 that abuttingly seals at a connection 32, 33 to the housing 16. The device 2 may further include an internal vacuum conduit connected to a vacuum system to detect leakages and in use may be used with a sterile sleeve cover with a similar vacuum system for leakage detection.

Owner:TISSUE REGENERATION TECH

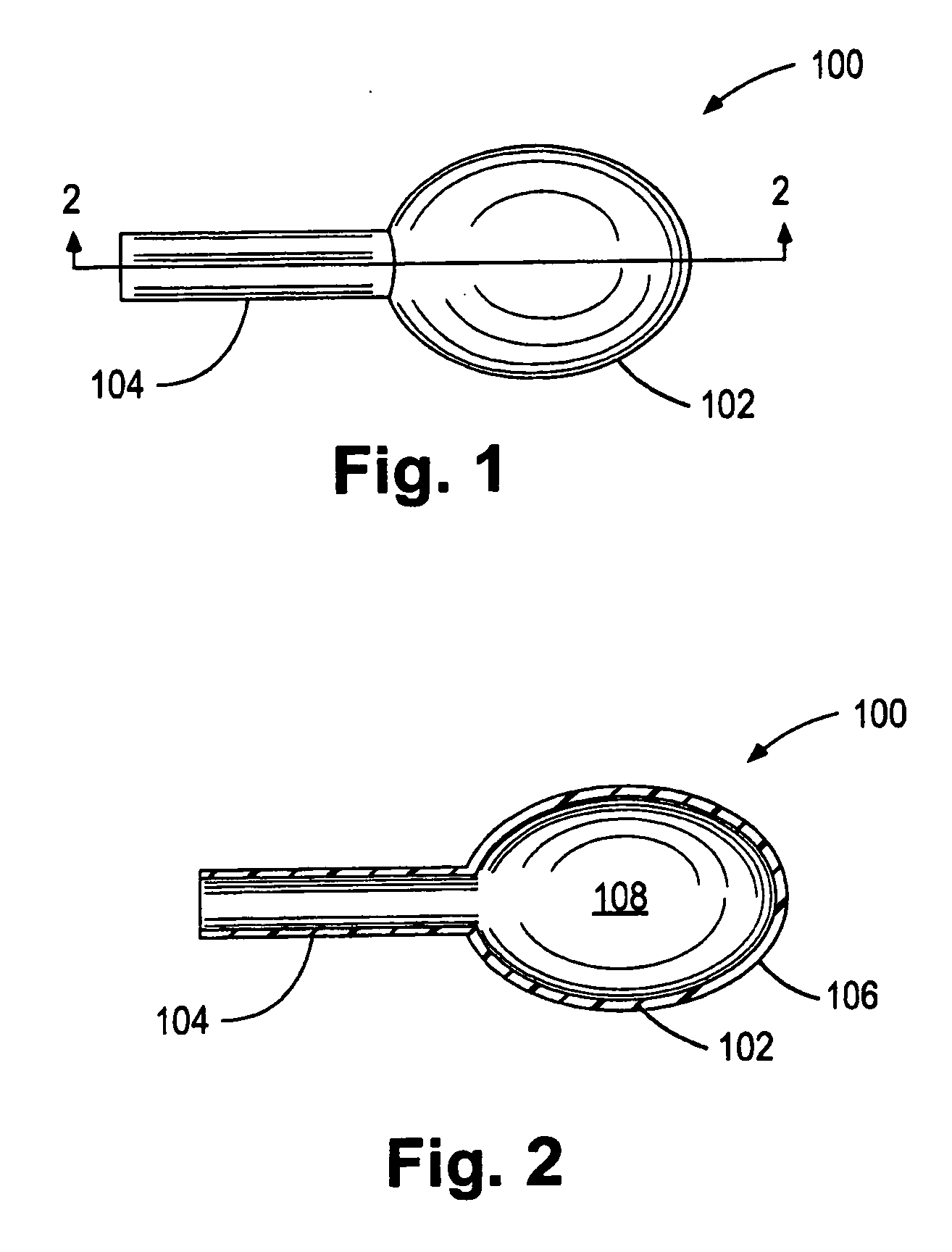

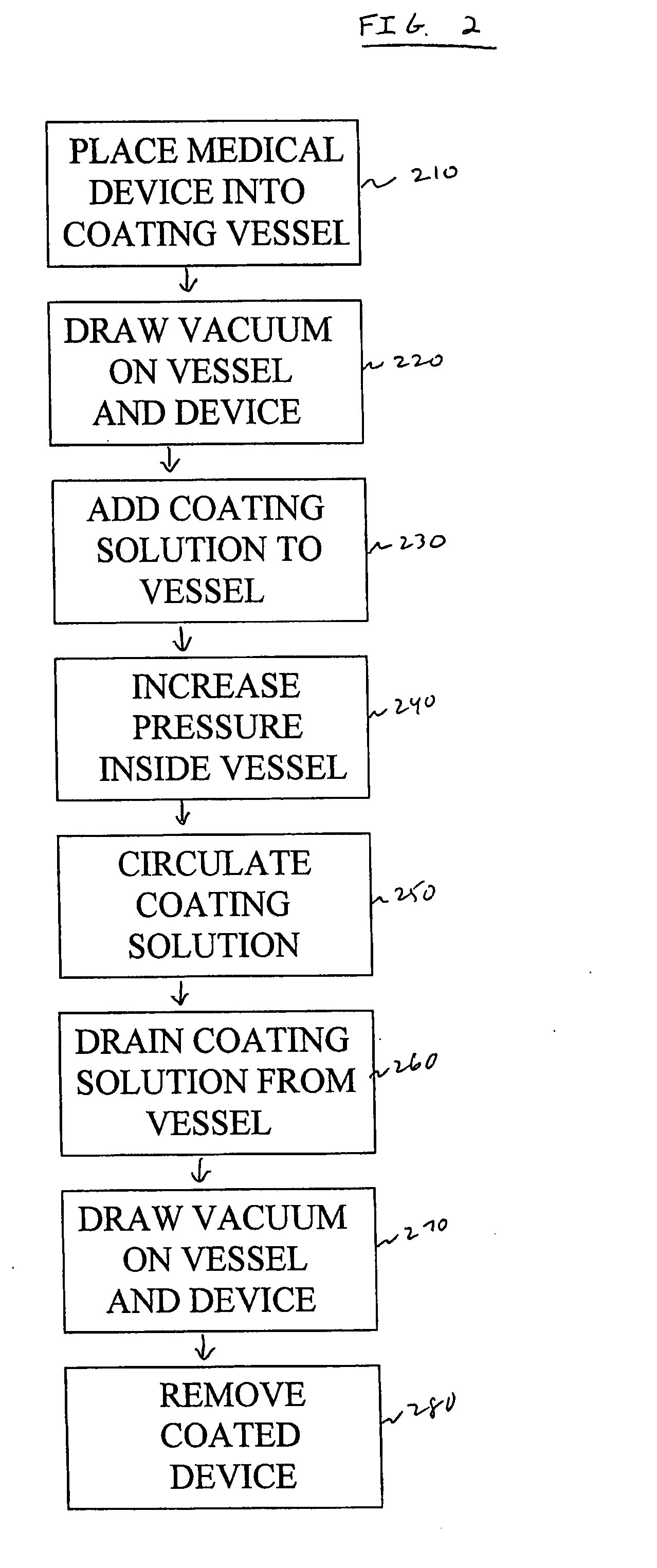

Pressurized dip coating system

InactiveUS20070200267A1Reduce pressureIncrease internal pressureSuture equipmentsGlovesDip-coatingMedical device

Owner:TYCO HEALTHCARE GRP LP

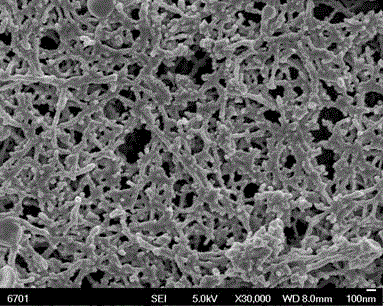

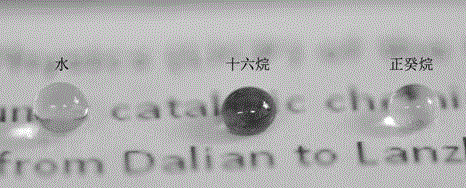

Large-scale preparation method of transparent super-hydrophobic/super-amphiphobic coating

InactiveCN106800885AExcellent superhydrophobic/superamphiphobic propertiesHigh transparencySpecial surfacesCoatingsNanoparticle ComplexAlcohol

The invention discloses a large-scale preparation method of a transparent super-hydrophobic / super-amphiphobic coating. The method comprises the steps of ultrasonically dispersing nano particles into an alcohol-water mixed system and carrying out hydrolysis and condensation reaction on the nano particles and fluoride-free or fluorine-containing organosilane under the acid or alkali catalysis action to prepare a transparent suspension liquid of a fluoride-free or fluorine-containing organosilane polymer-nano particle compound; and applying the transparent suspension liquid of the compound on the surface of a substrate material through spraying or dip-coating to obtain the transparent super-hydrophobic / super-amphiphobic coating with good performance. Preparation of the transparent super-hydrophobic / super-amphiphobic coating of 10-100m<2> can be completed within an hour; large-scale preparation of the large-area transparent super-hydrophobic / super-amphiphobic coating is achieved for the first time; the preparation method is low in cost and simple in process; and the prepared coating has excellent super-hydrophobic or super-amphiphobic property, relatively good mechanical stability, chemical stability and environment stability, and has a wide application prospect.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

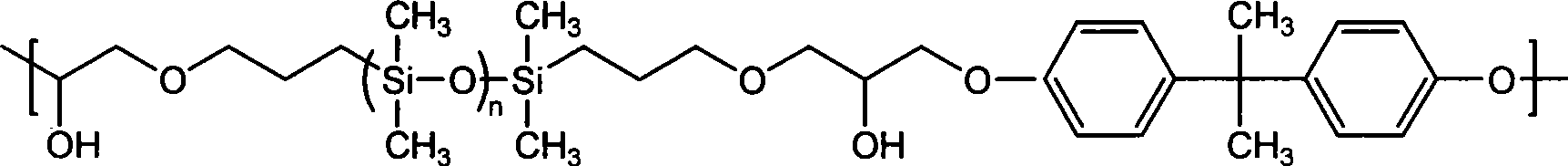

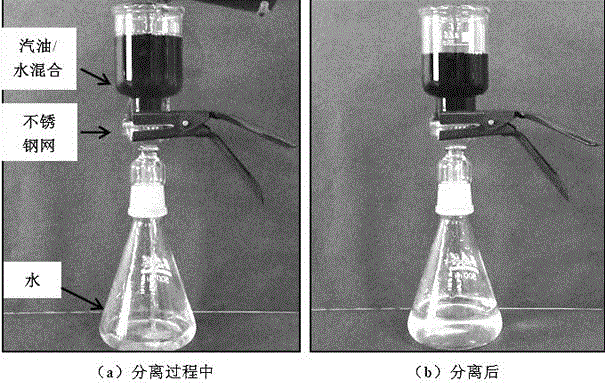

Super-hydrophobic and super-oleophilic oil-water separation mesh membrane and preparation method thereof

The invention pertains to the technical fields of chemistry, chemical industry and functional macromolecular materials, in particular relates to a super-hydrophobic and super-oleophilic oil-water separation mesh membrane and a preparation method thereof. The super-hydrophobic and super-oleophilic oil-water separation mesh membrane is prepared with a dip-coating method which comprises the steps that a proper treating agent is selected, epoxy group-terminated oligomeric siloxane is copolymerized with bisphenol A on a proper condition; the oligomeric siloxane-bisphenol A copolymer is mixed evenly with the treating agent to form a solution; the oligomeric siloxane-bisphenol A copolymer is cured on a fabric net of 100 meshes to 400 meshes to obtain the super-hydrophobic and super-oleophilic oil-water separation mesh membrane. The mesh membrane contains no fluorin, and has high hole penetration and good oil / water separation effect. The preparation method of the mesh membrane is simple.

Owner:INST OF CHEM CHINESE ACAD OF SCI

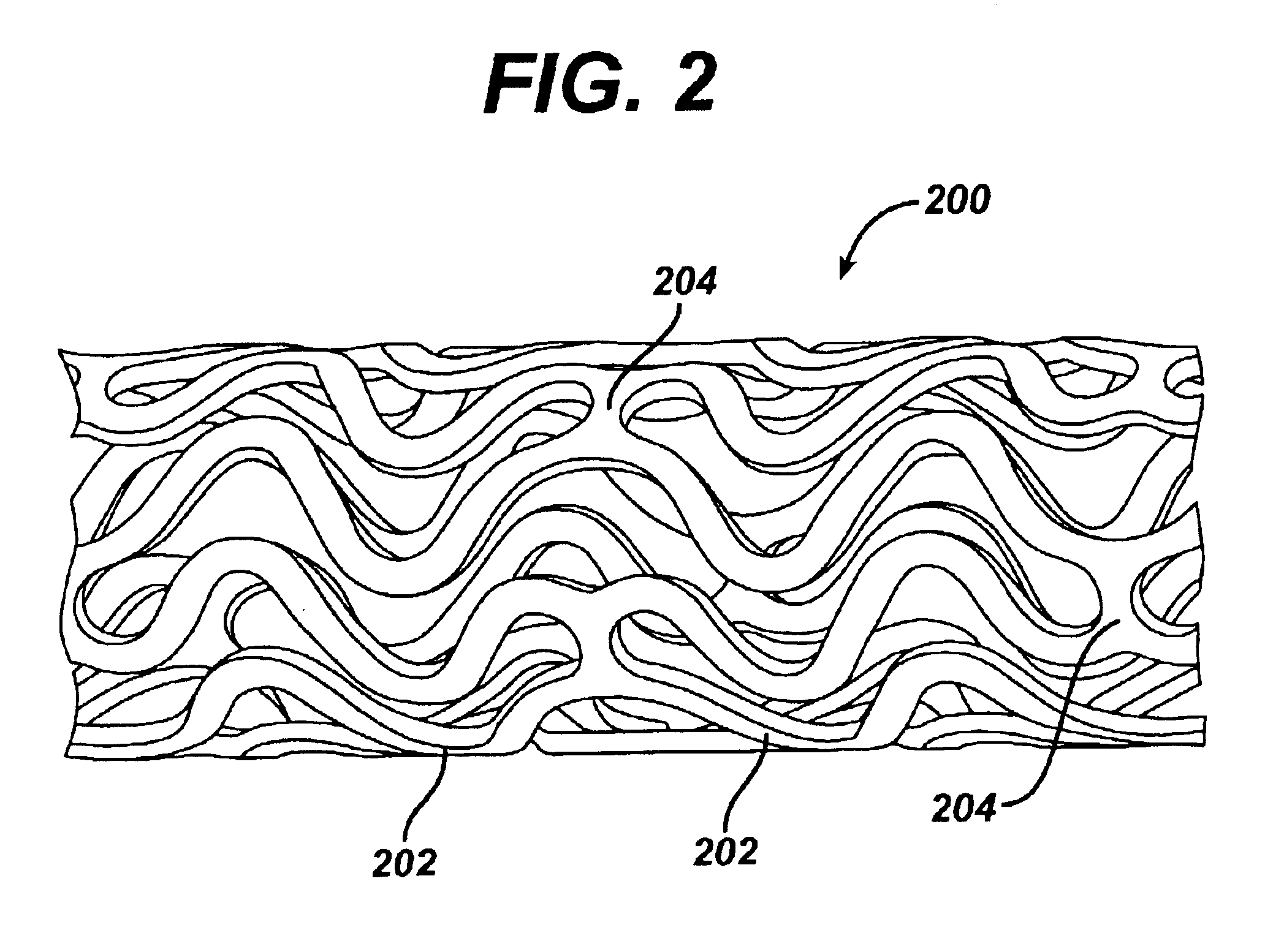

Polymer composite fibrous coating on dipped rubber articles and method

The present invention provides a method of making an elastomeric article including preparing a non-woven fibrous polymer composition for dip-coating onto a layer of carboxylated acrylonitrile-butadiene elastomeric surface and in particular making industrial or household gloves. By dipping a former into a salt-based coagulant, followed by dipping into an elastomeric dispersion, and finally dipping into a polymer composite fibrous coating, a useful elastomeric article is prepared. The invention also provides an elastomeric article having a first layer, the first layer comprising a natural or synthetic polymer; and a second layer bonded to the first layer, the second layer comprising a polymer composite fibrous coating. The polymer composite fibrous coating includes at least one elastomer or elastomer blend, a fiber or fiber blend, a surfactant, and a micronised wax. The coating can be foamed, and provides improved sweat management and non-shredding properties to a user.

Owner:ANSELL HEALTHCARE PRODS

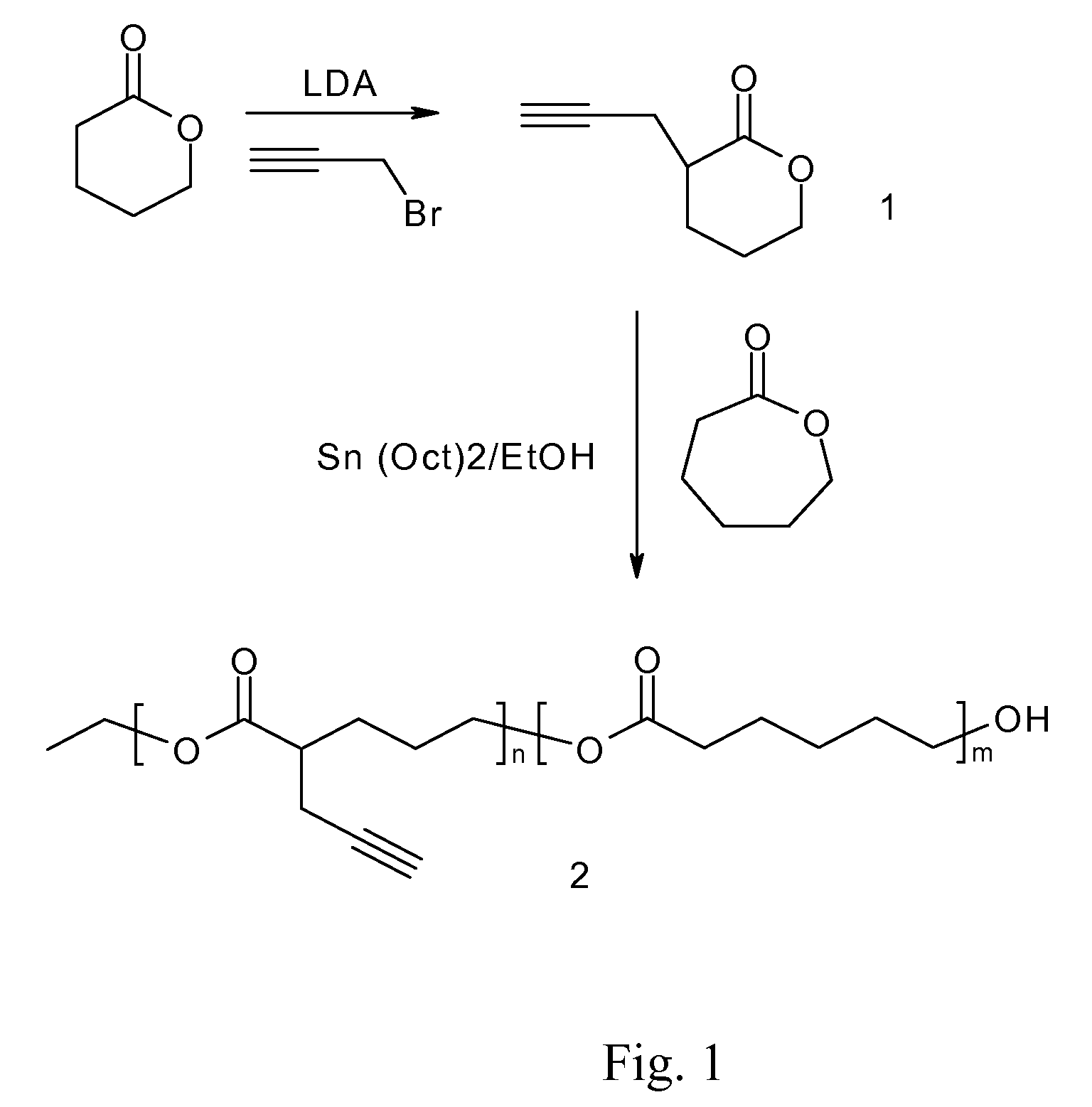

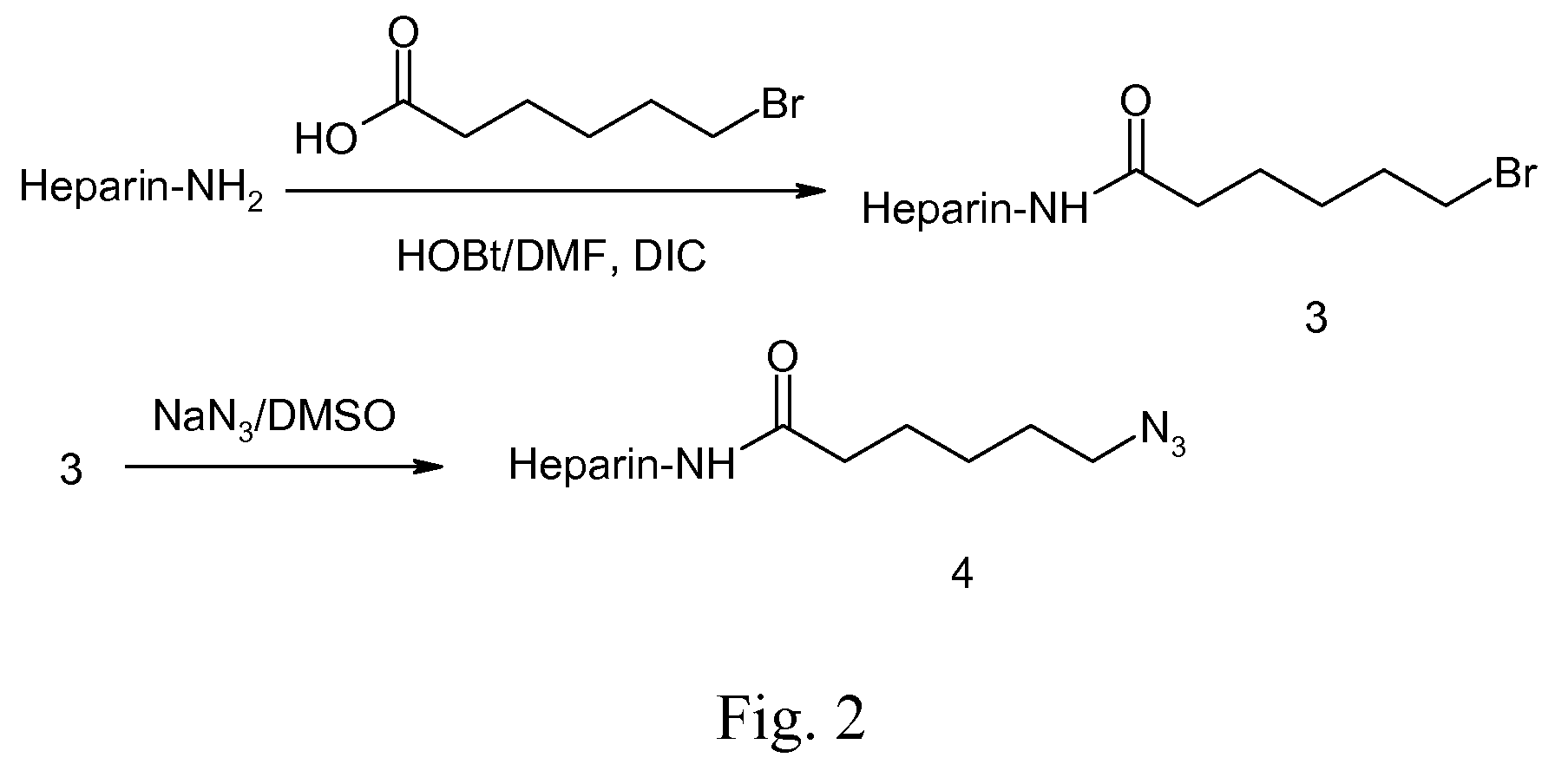

Coating Employing an Anti-Thrombotic Conjugate

InactiveUS20090018646A1Few stepsImprove versatilityStentsOrganic active ingredientsActive agentSide chain

A biodegradable antithrombotic conjugate having heparin and other anti-thrombotic moieties are introduced as side chains to the polymer backbone modified by click chemistry. Various bioabsorbable monomers and dimers such as valerolactone may be used in the monomer derivation, homo- and co-polymerization, and the conjugation with a biologically active molecule by click chemistry. A coating comprising a biocompatible and bioabsorbable polymer anti-thrombotic conjugate is applied to at least a portion of an implantable device to prevent or reduce the formation of thrombosis on the surface of the implantable device. A first or sub-layer of the coating is prepared by mixing a polymeric material and a biologically active agent with a solvent, thereby forming a homogeneous solution. A second or outer layer comprising the present anti-thrombotic conjugate may be applied over the inner drug-containing layers using, for example, a dip coating or spray coating process.

Owner:CORDIS CORP

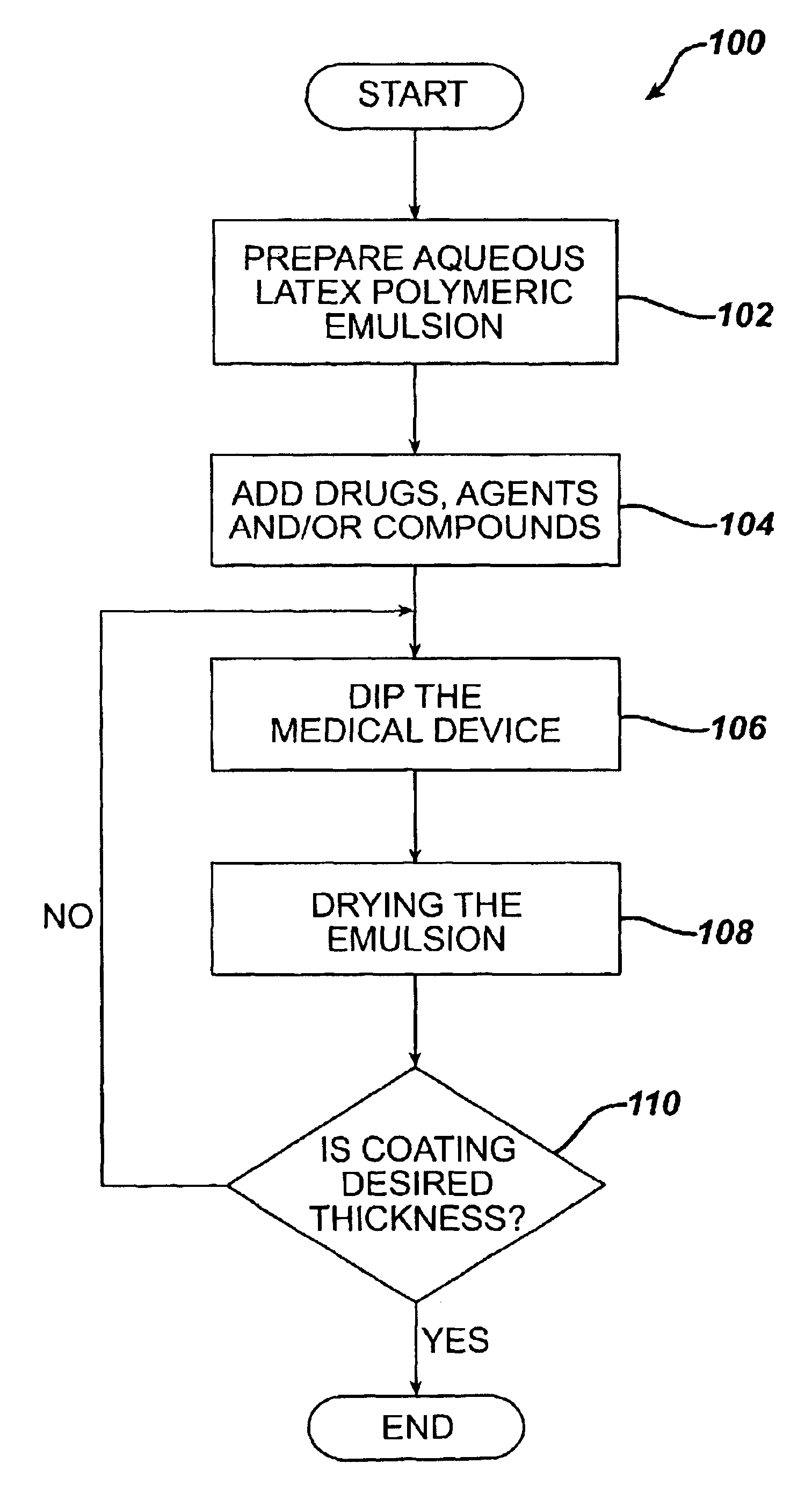

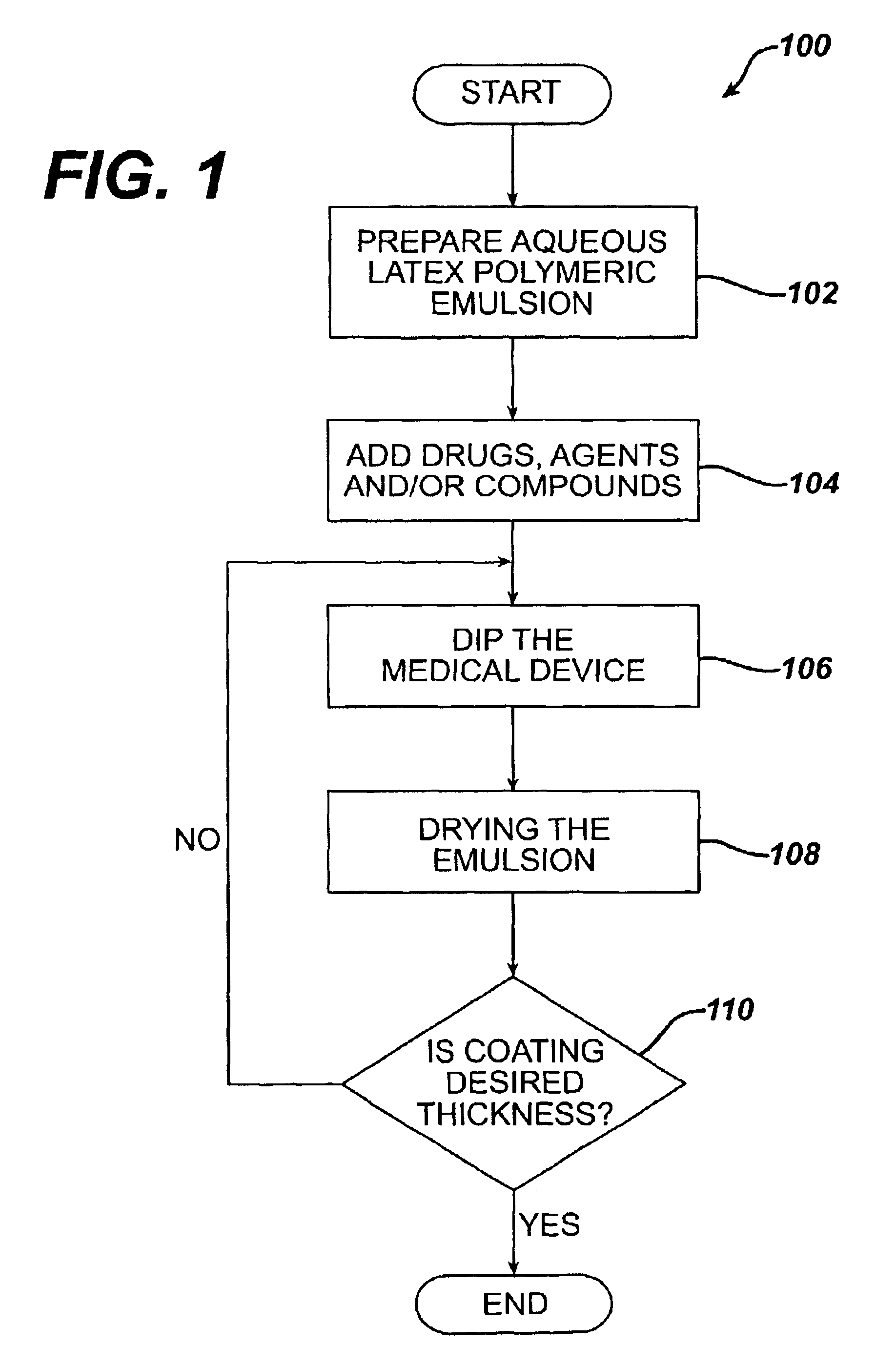

Method for coating medical devices

InactiveUS6919100B2Safe and efficient and effective processSimple and complex configurationOrganic active ingredientsImpression capsBiological bodyOrganic solvent

Medical devices, and in particular implantable medical devices, may be coated to minimize or substantially eliminate a biological organism's reaction to the introduction of the medical device to the organism or to treat a particular condition. A dip coating process is utilized to minimize waste. An aqueous latex polymeric emulsion is utilized to coat any medical device to a desired thickness by allowing for successive dipping and drying cycles. In addition, aqueous latex polymeric emulsions pose less of a chance of the bridging phenomenon associated with organic solvent based polymers.

Owner:WYETH LLC

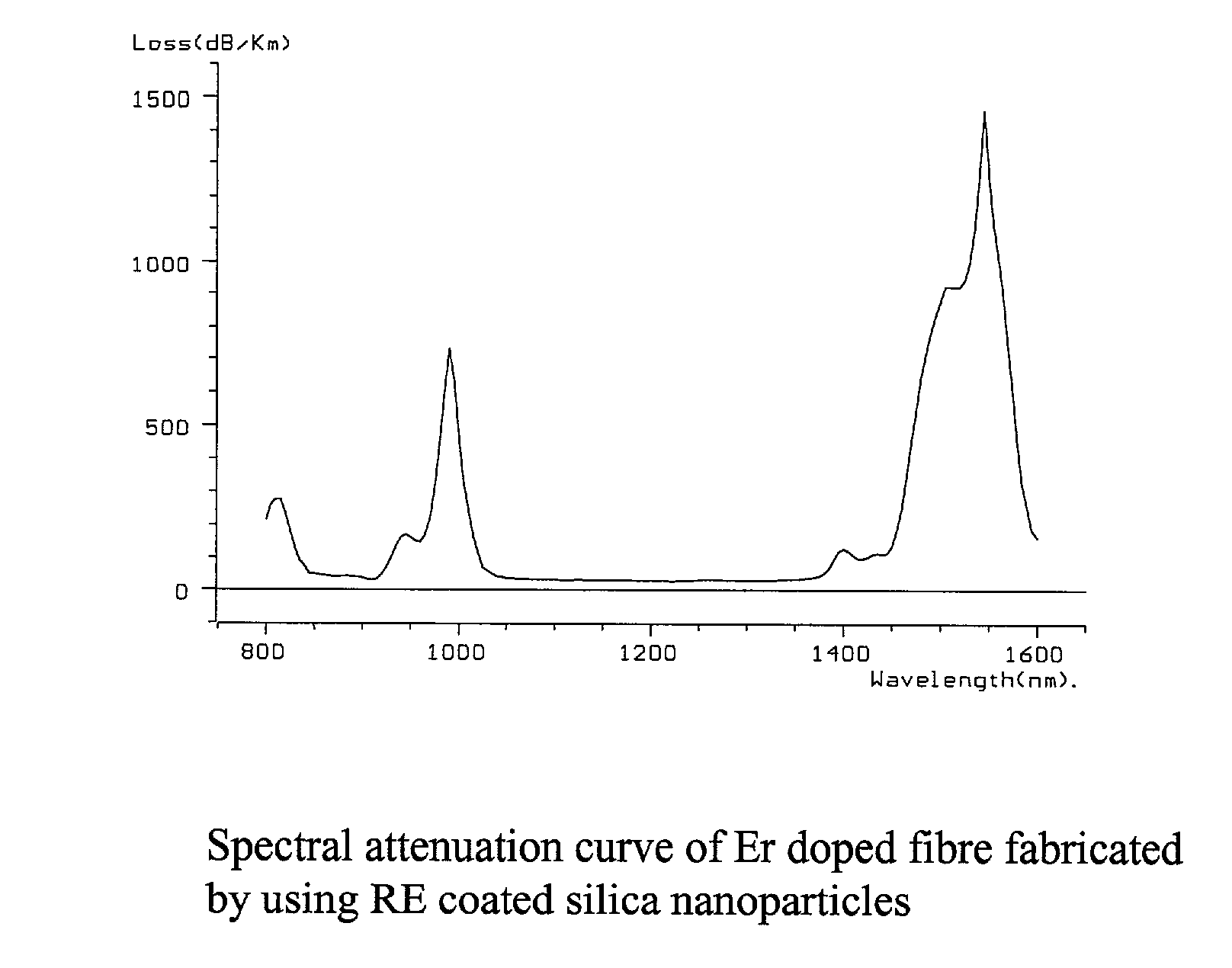

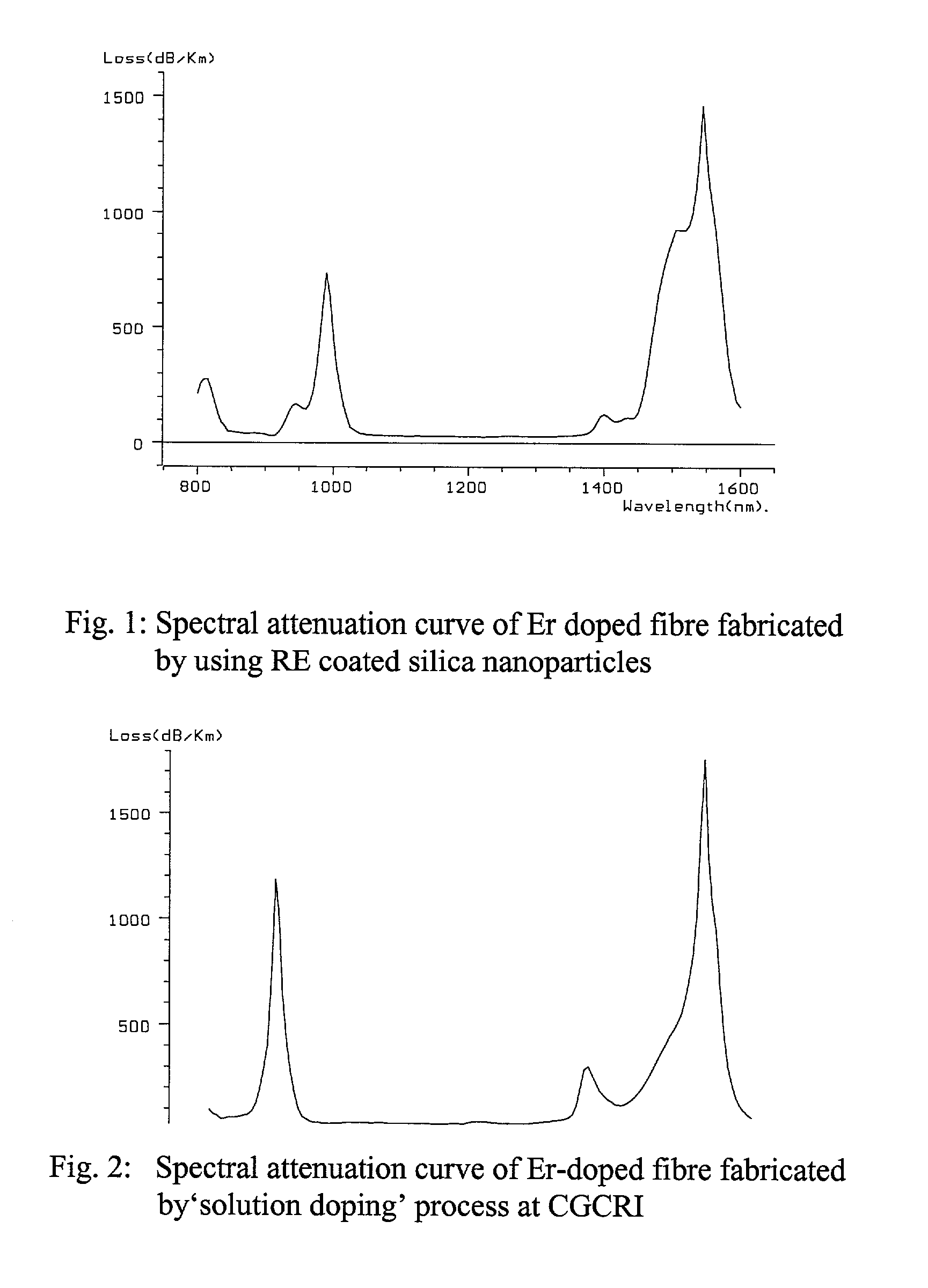

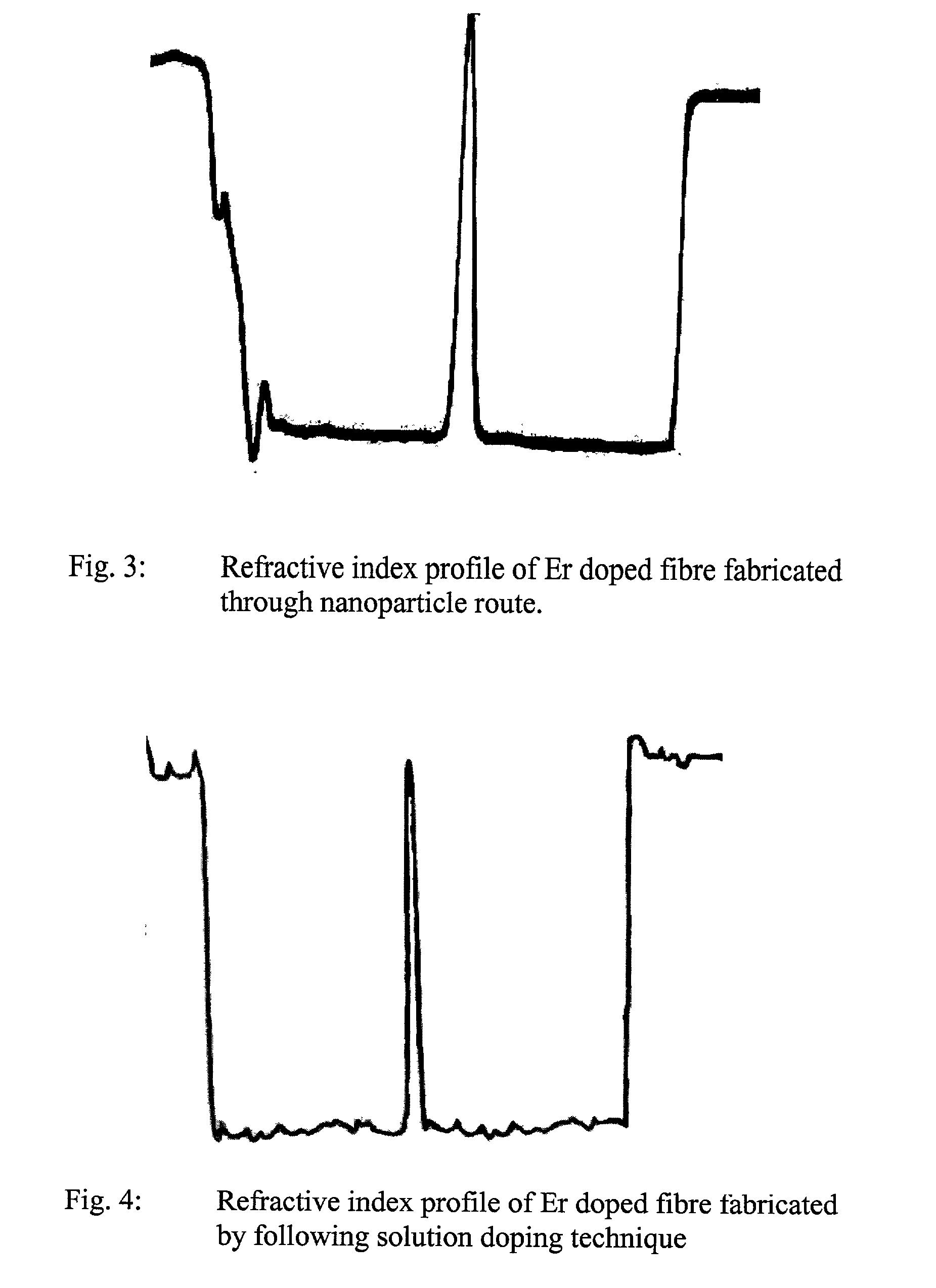

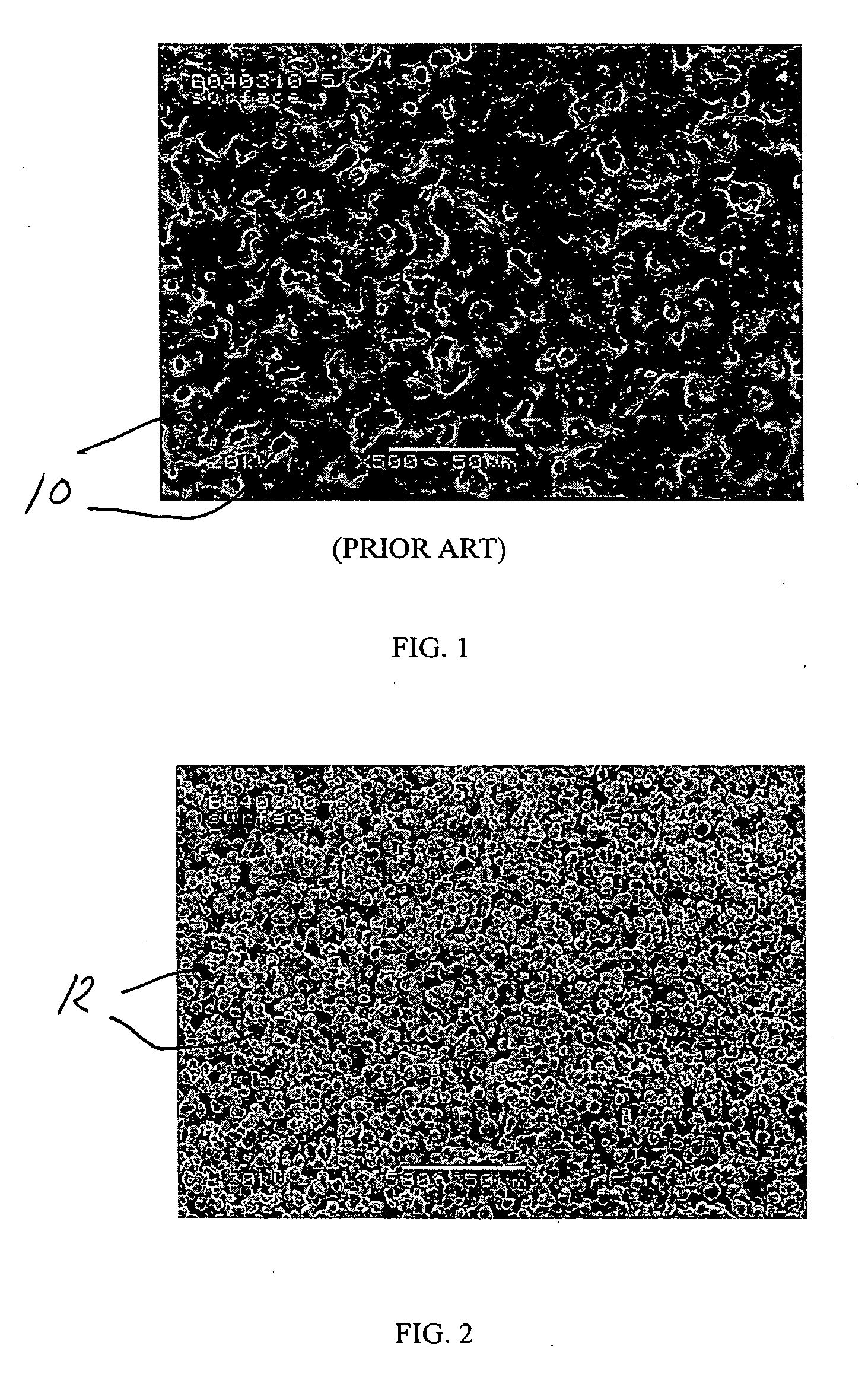

Process of making rare earth doped optical fibre

InactiveUS20040187524A1Reduce in quantityNumber of step involvedMaterial nanotechnologyCladded optical fibreDip-coatingSoot

The present invention discloses a process for making rare earth (RE) doped optical fibre by using RE oxide coated silica nanoparticles as the precursor materia, more particularly the method of the present invention involves preparation of stable dispersions (sol) of RE oxide coated silica nanoparticles at ambient temperature and applying a thin coating on the inner surface of silica glass tube following dip coating technique or any other conventional methods, of the said silica sol containing suitable dopants selected from Ge, Al, P, etc., the coated tubes were further processed into optical preforms by following MCVD technique and fiberised in desired configuration, the novelty lies in eliminating the step of the formation of porous soot layer at high temperature by CVD process inside a fused silica glass tube for formation of the core and also in the elemination of the incorporation of the rare earth ions into the porous soot layer following the solution doping technique or other conventional methods, the direct addition of RE oxides in the sol eliminates the formation of microcrystalites and clusters of rare earth ions and prevents change in composition including variation of RE concentration in the core which results in increase in the reproducibility and reliability of the process to a great extent, further the addition of Ge(OET)4 at ambient temperature in the silica sol reduces the quantity of GeCl4 which is required at high temperature to achieve the desired Numerical Aperture.

Owner:COUNCIL OF SCI & IND RES +1

Organosilicon modified aqueous polyurethane resin and preparation thereof

An organosilicon modified aqueous polyurethane resin comprises the following raw materials in percentage by weight: 10 to 20 percent of isocyanate, 20 to 40 percent of polyester polyol, 0.1 to 5 percent of organic silicon oil, 2 to 5 percent of a hydrophilic chain extender, 2 to 5 percent of a polyol chain extender, 1 to 3 percent of a polybasic amine chain extender, 0.01 to 1 percent of a catalyst, 1 to 4 percent of a salifying agent, 5 to 8 percent of a solvent and the rest of water. The emulsion made by the organosilicon modified aqueous polyurethane resin is obviously better than the emulsion made by a non-modified aqueous polyurethane resin regarding adhesion force, abrasion resistance, heat tolerance, smoothness, etc. The polyurethane emulsion made by the organosilicon modified aqueous polyurethane resin can be applied to the surface of a product through spray coating, brush coating, roller coating and dip coating. At present, the polyurethane emulsion is mainly used for the coating of the surfaces of gloves, condoms, medical ducts, etc.

Owner:SHANDONG INOV POLYURETHANE

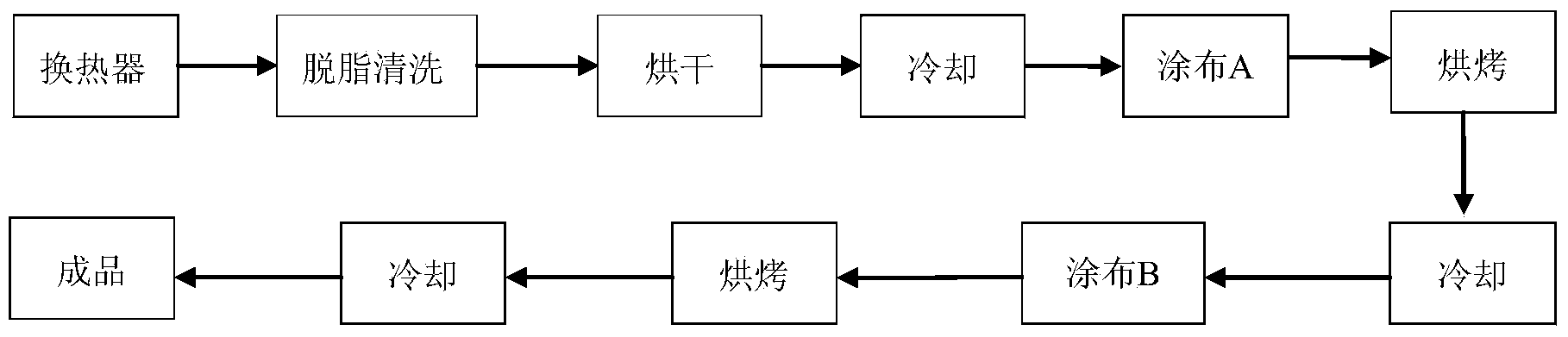

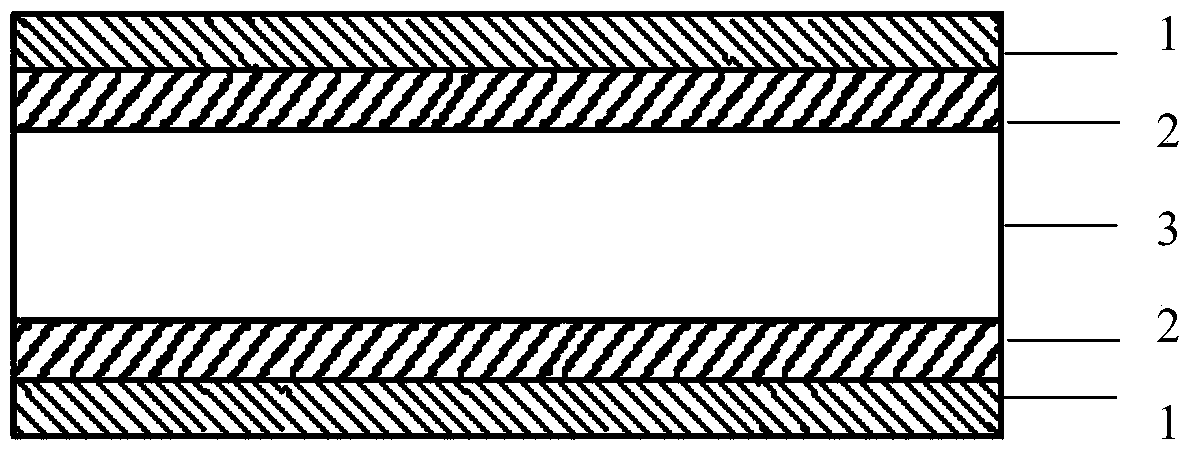

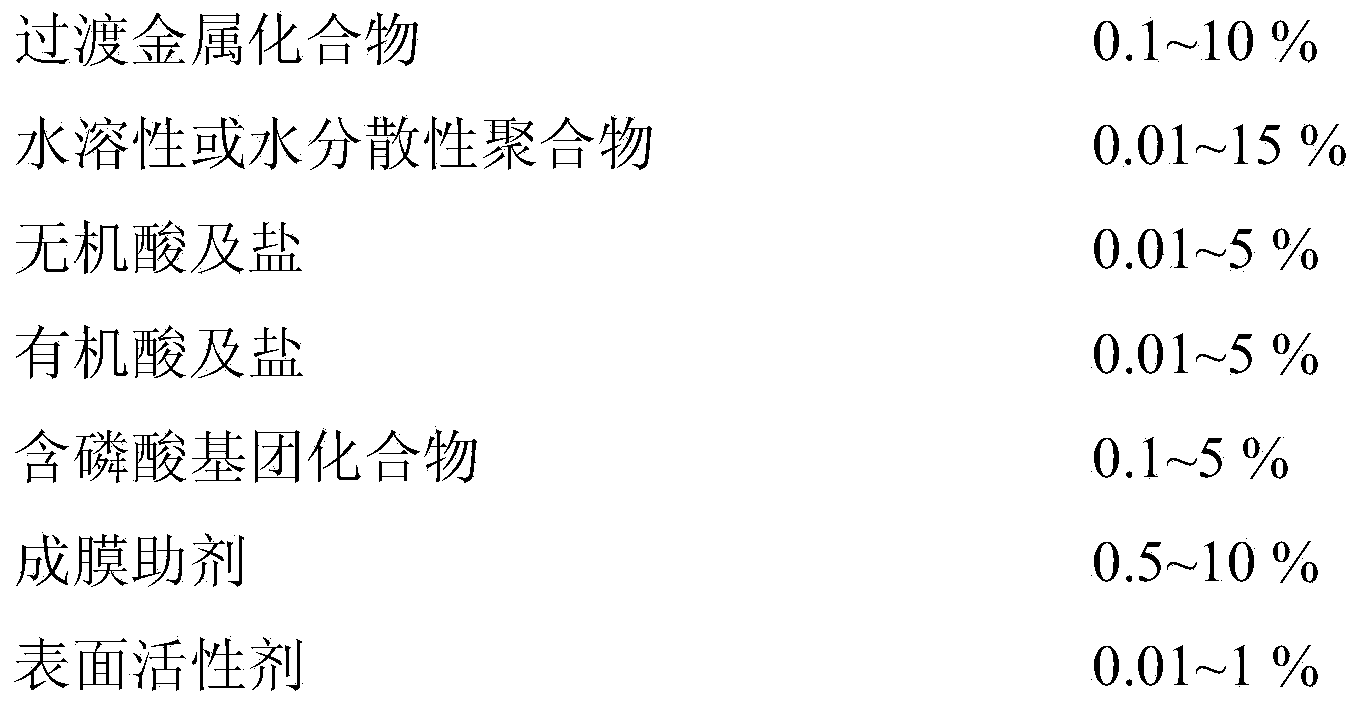

Coating composition for hydrophilic treatment of air-conditioning parallel flow heat exchanger

ActiveCN103555114AImprove hydrophilicityImprove adhesionChemical industrySynthetic resin layered productsHydrophilic coatingBusiness efficiency

The invention belongs to the technical field of hydrophilic coatings and discloses a coating composition for hydrophilic treatment of an air-conditioning parallel flow heat exchanger. The coating composition comprises a coating A and a coating B, wherein the coating A is an inorganic system A-1 which takes inorganic substances as main components or an organic system A-2 which takes organic substances as main components; the coating B is an inorganic system B-1 which takes inorganic substances as main components or an organic system B-2 which takes organic substances as main components. The coating A and the coating B are sequentially coated on the surface of a heat exchanger workpiece in a dip-coating, curtain coating or spraying mode and are sequentially roasted and cured, the heat exchanger can be endowed with lasting hydrophilcity, the formed coating is excellent in hydrophilic performance, high in adhesive force, permanent and effective; the coating is high in corrosion resistance, and the service life of the heat exchanger can be greatly prolonged; the coating is excellent and lasting in hydrophilic performance and high in adhesive force, and the energy efficiency ratio of the heat exchanger can be improved.

Owner:GUANGZHOU HUMAN CHEM

Preparation of hydrophilic polyvinylidene fluoride microporous membrane

InactiveCN1704152AImprove hydrophilicitySimple processSemi-permeable membranesPhysical chemistryFiber type

The invention relates to a method for preparing hydrophilic PVDF microporous barrier. The principal raw material is polyvinylidene fluoride with the range of molecular weight: 5000 to 50000. It prepares hydrophilic PVDF microporous barrier by the method of separating solution and compounding dip-coating modification. It especially suits the occasion of effluent treatment, medicine separation and biochemy. The technology can prepare microporous barriers with plate type and hollow fiber type.

Owner:杨虎

Method for manufacturing high-breathability non-woven wallpaper body paper and product

The invention discloses a method for manufacturing high-breathability non-woven wallpaper body paper and a product. The existing non-woven wallpaper has the disadvantages that the hand feel thereof is not soft enough, the principal plane stereoscopic impression is not strong and the opacity degree is low. The method of the invention comprises the following steps: beating plant fiber containing chemical wood pulp until the beating degree is 20-30OSR, and mixing with non-plant fiber containing chemical fiber; adding chemical addition agent into the mixed fiber; manufacturing the mixed fiber containing the chemical addition agent into body paper semi-finished products by utilizing a fourdrinier wire or inclined wire paper machine; mixing pigment, chemical addition agent and adhesive to form coating liquor, carrying out dip coating on the body paper semi-finished products inside or outside the machine; and drying and finishing the body paper subject to dip coating, and rolling the body paper to form finished paper of body paper, thus obtaining non-woven wallpaper which contains continuous fiber, has high breathability, and can be directly printed. The principal plane has natural lines; and the finished paper has the advantages of soft hand feel, good processability, excellent shape stability, rich color, distinct image and strong stereoscopic impression.

Owner:ZHEJIANG WINBON SPECIALTY PAPER +1

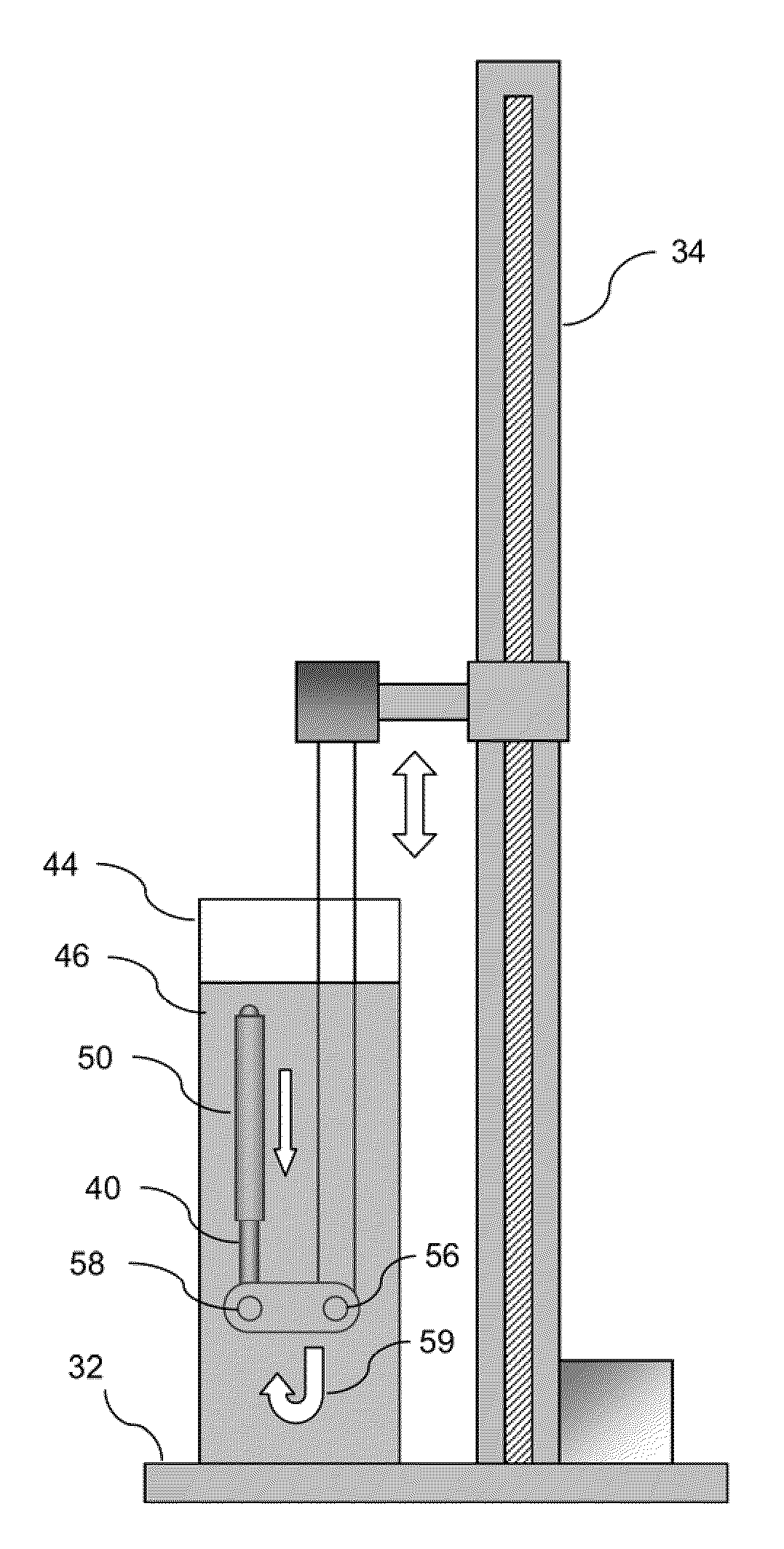

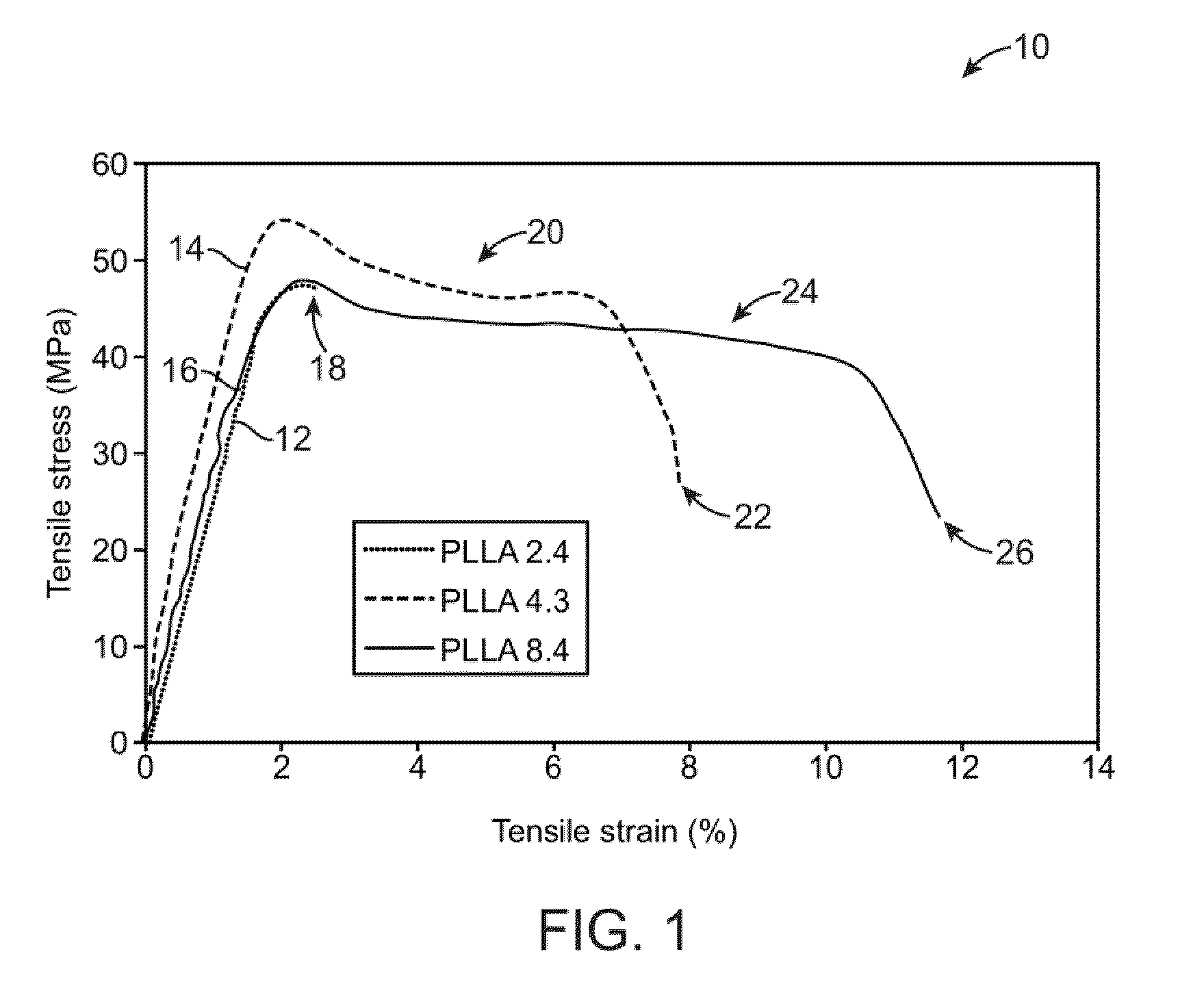

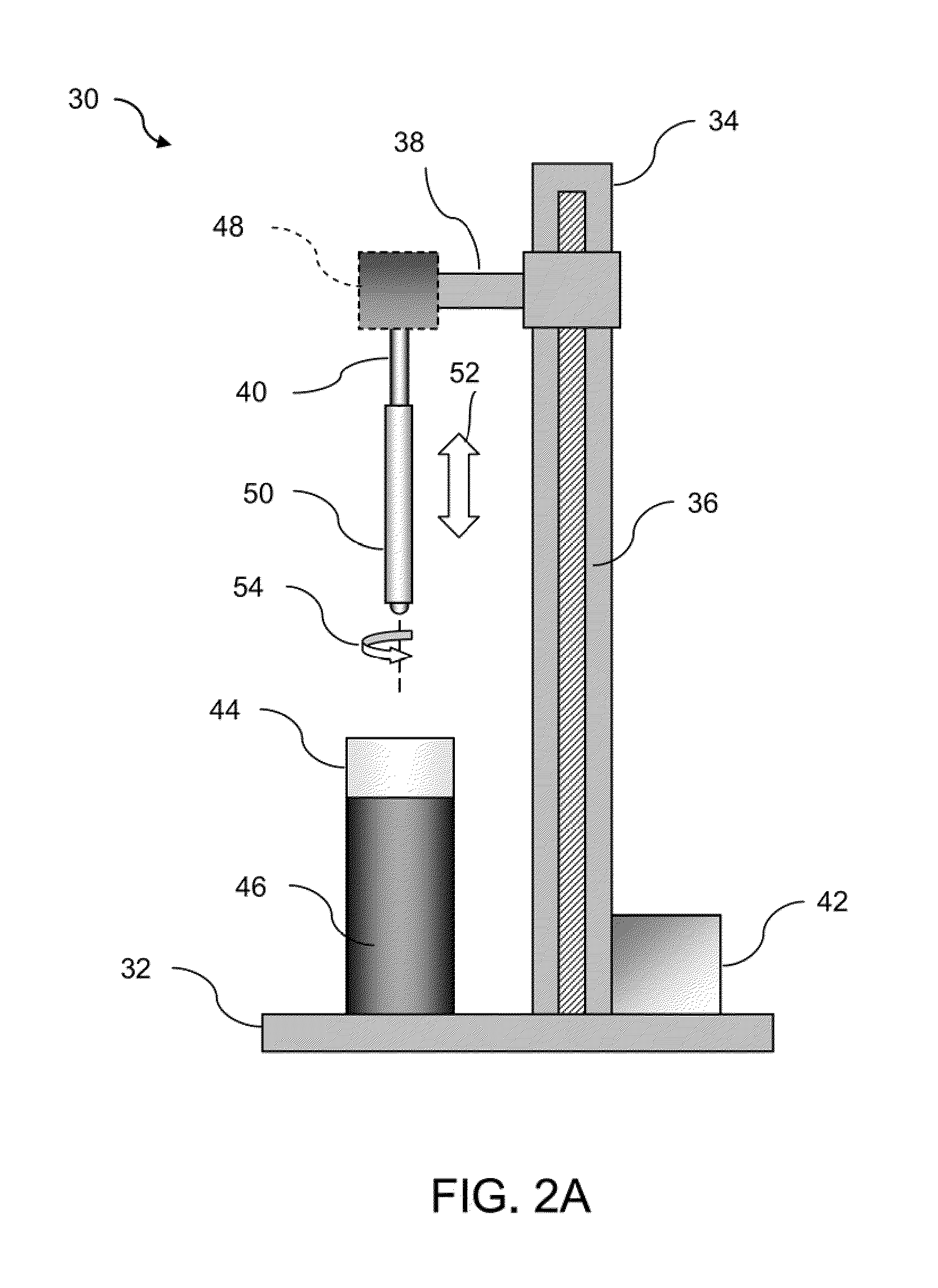

Stent fabrication via tubular casting processes

ActiveUS20100004734A1Improve mechanical propertiesReduced flexibilityOrganic active ingredientsStentsDip-coatingPolymer solution

Tubular casting processes, such as dip-coating, may be used to form substrates from polymeric solutions which may be used to fabricate implantable devices such as stents. The polymeric substrates may have multiple layers which retain the inherent properties of their starting materials and which are sufficiently ductile to prevent brittle fracture. Parameters such as the number of times the mandrel is immersed, the duration of time of each immersion within the solution, as well as the delay time between each immersion or the drying or curing time between dips and withdrawal rates of the mandrel from the solution may each be controlled to result in the desired mechanical characteristics. Additional post-processing may also be utilized to further increase strength of the substrate or to alter its shape.

Owner:RAZMODICS LLC

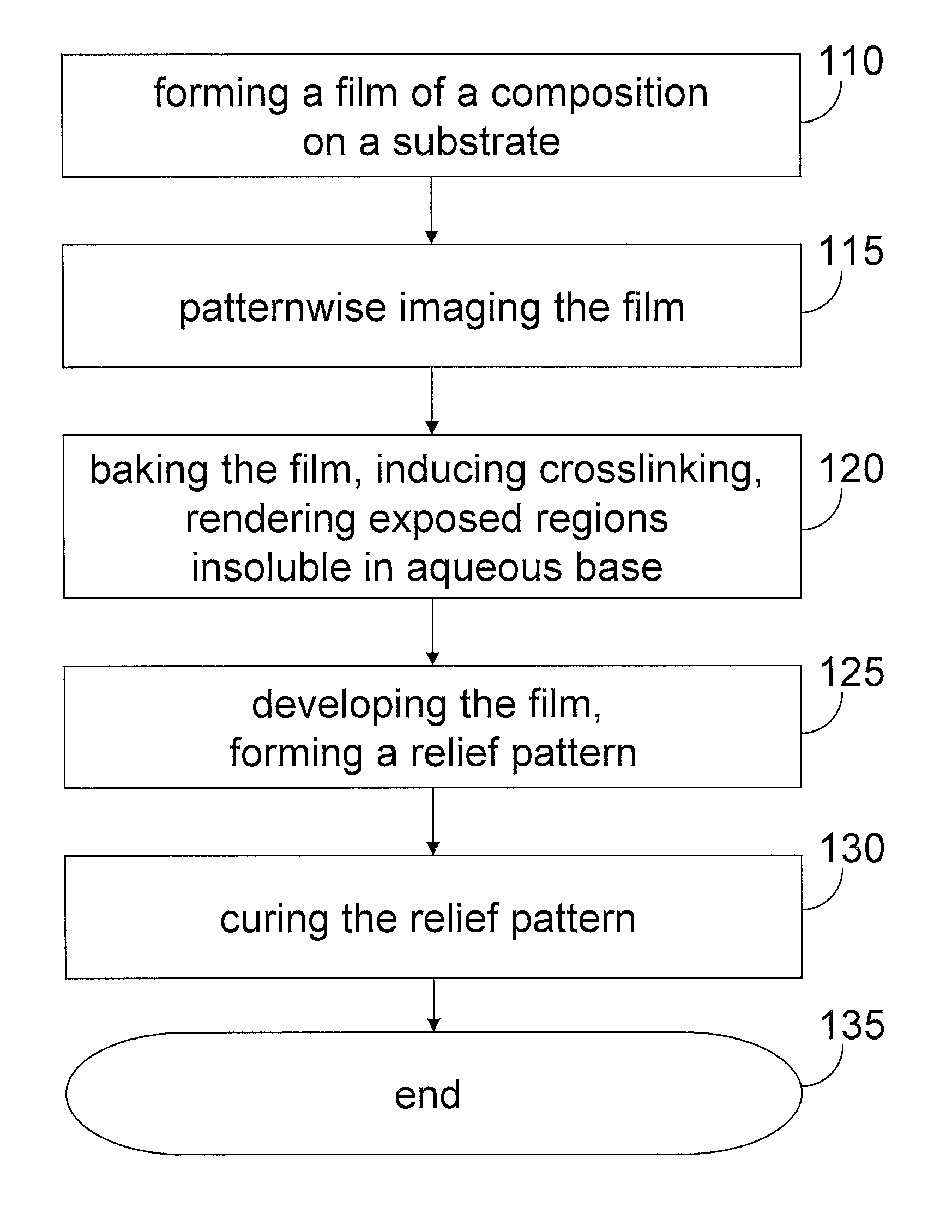

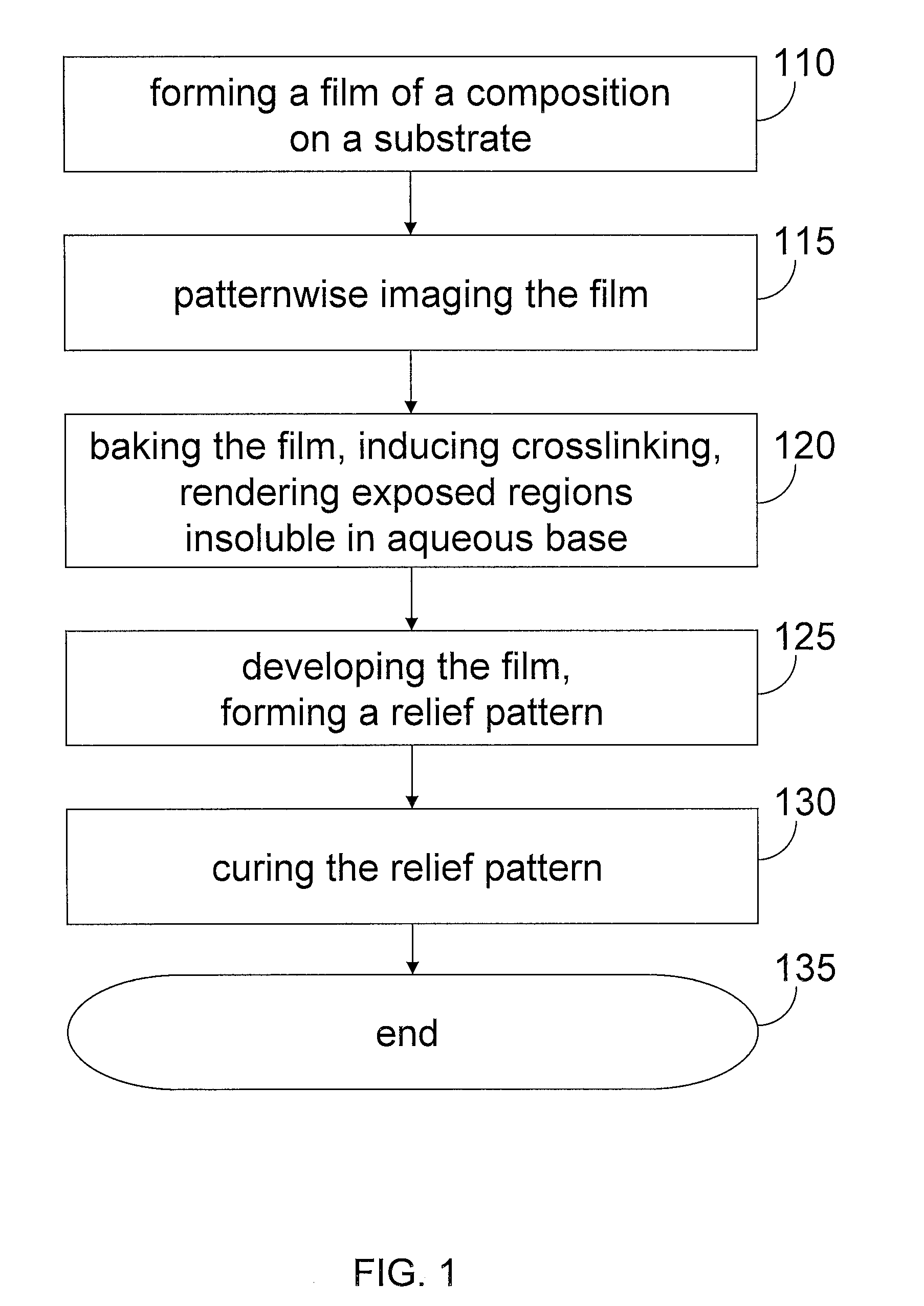

Method of use for photopatternable dielectric materials for beol applications

A method. The method includes dip coating a film of a composition on a silicon wafer substrate. The composition includes a polymer blend of a first polymer and a second polymer. The first polymer is a substituted silsesquioxane copolymer. The second polymer is a polysilsesquioxane having silanol end groups. The composition includes a photosensitive acid generator, an organic base, and an organic crosslinking agent. The film is patternwise imaged and at least one region is exposed to radiation having a wavelength of about 248 nanometers. The film is baked, resulting in inducing crosslinking in the film. The film is developed resulting in removal of base-soluble unexposed regions of the film, wherein a relief pattern from the film remains. The relief pattern is cured at a temperature between about 300° C. and about 450° C., and the curing utilizes a combination of thermal treatment with UV radiation.

Owner:GLOBALFOUNDRIES INC

Preparation method of graphene composite conductive fiber

The invention discloses a preparation method of a graphene composite conductive fiber and relates to the technical field of graphene. The method comprises the following steps: processing a common textile polymer fiber with an organic solvent to remove impurities such as an oiling agent on the fiber surface; dipping the textile polymer fiber into an alkali liquor and an oxidized graphene solution, and enabling the fiber surface to fully contact the oxidized graphene; and dipping the dried fiber with an oxidized graphene coating into a solution containing a reducing agent to obtain the graphene composite conductive fiber. By adopting a simple dip coating method, the obtained composite fiber has mechanical property, high temperature resistance and flexibility performance of a traditional high polymer material and also has good conductivity. The method is easy to operate, environment-friendly and convenient to industrialize.

Owner:宁国市龙晟柔性储能材料科技有限公司

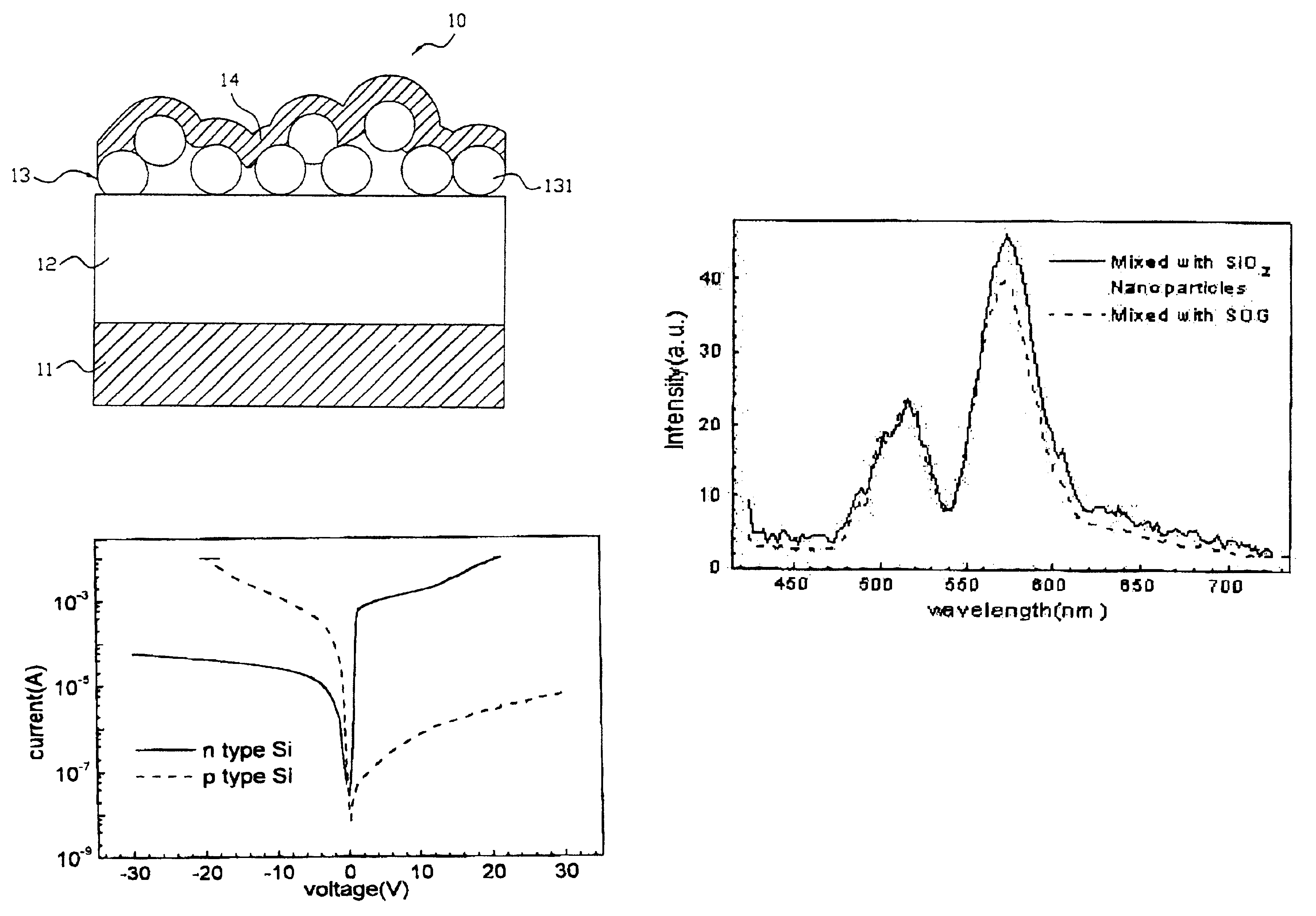

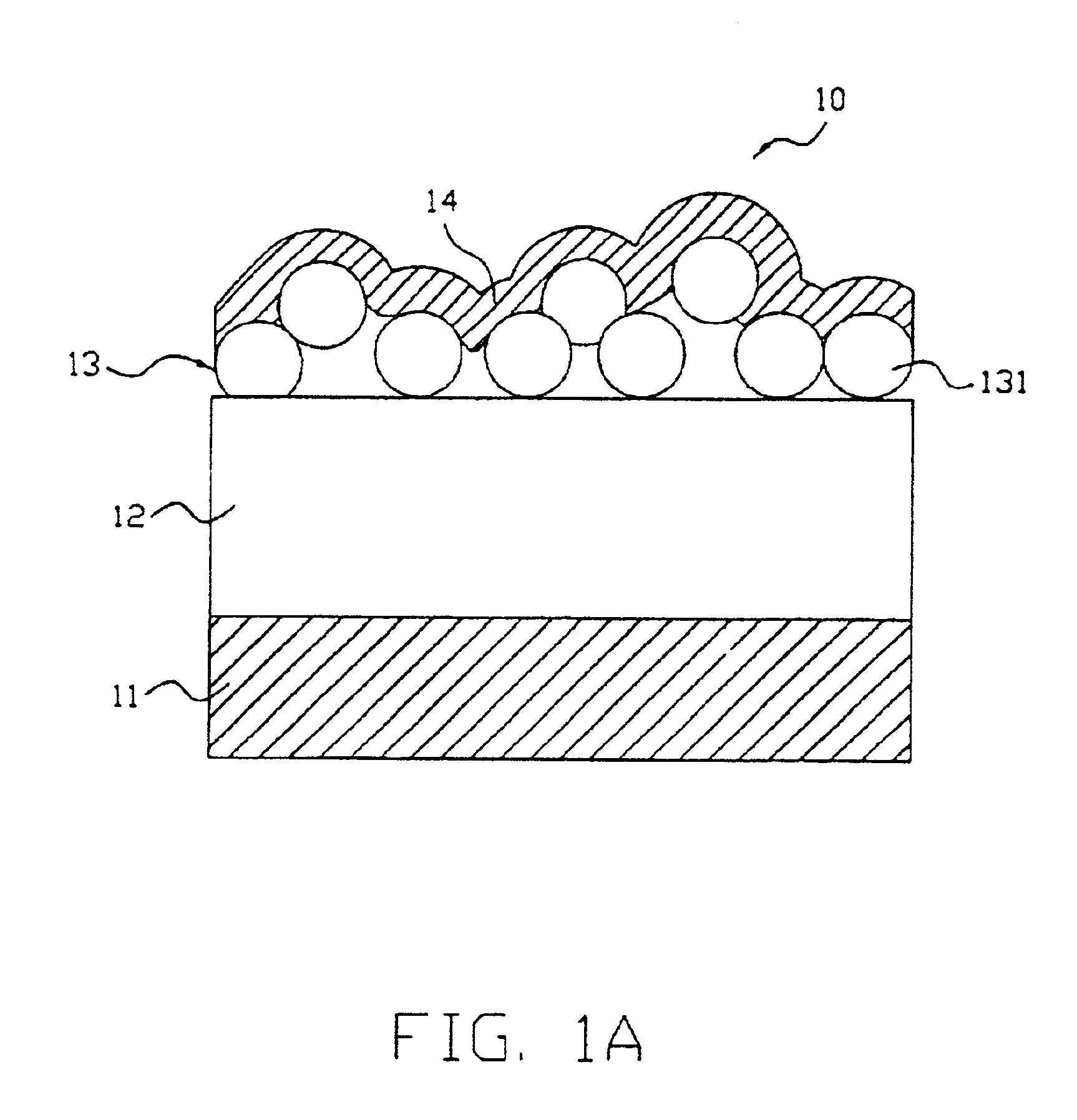

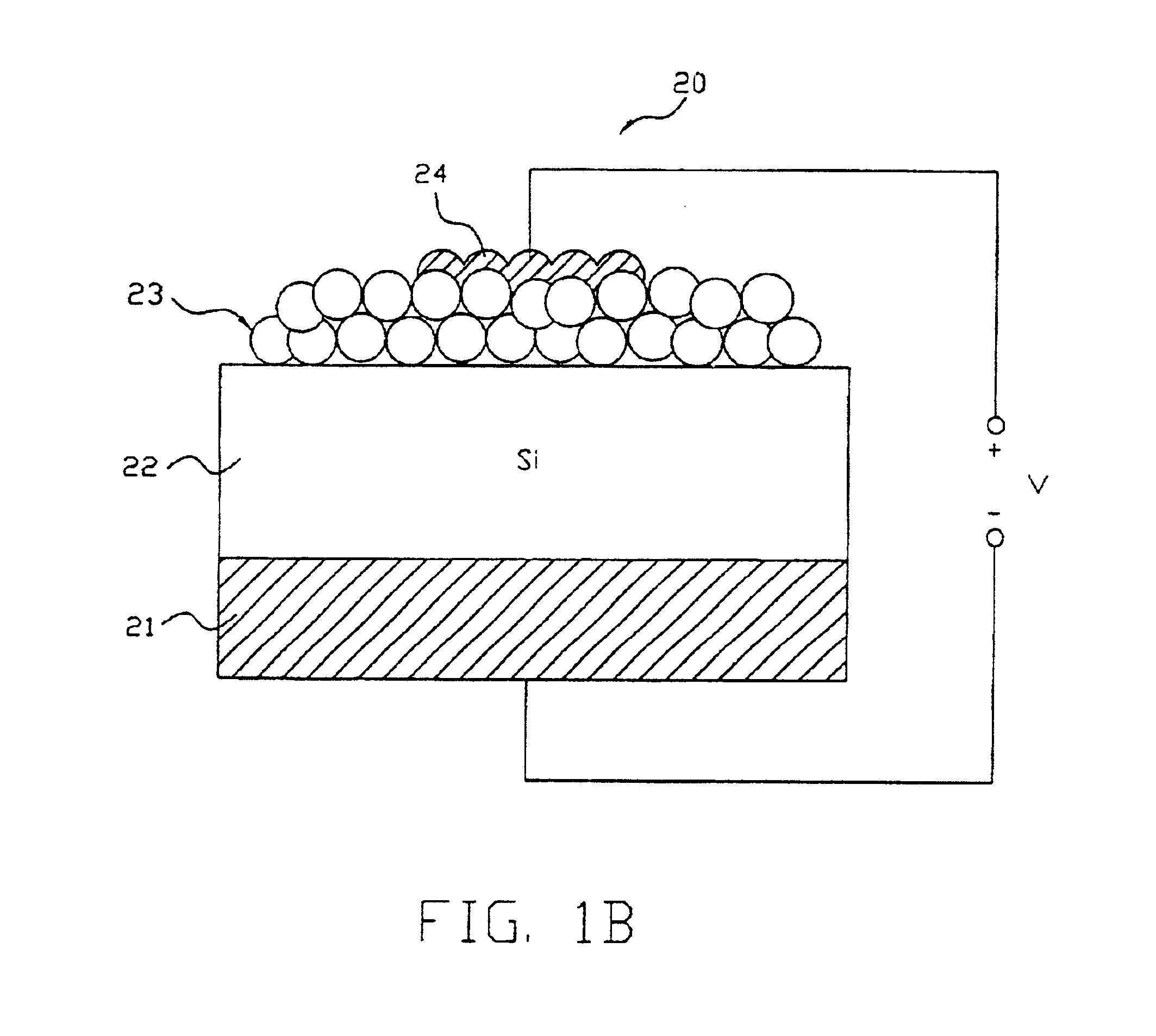

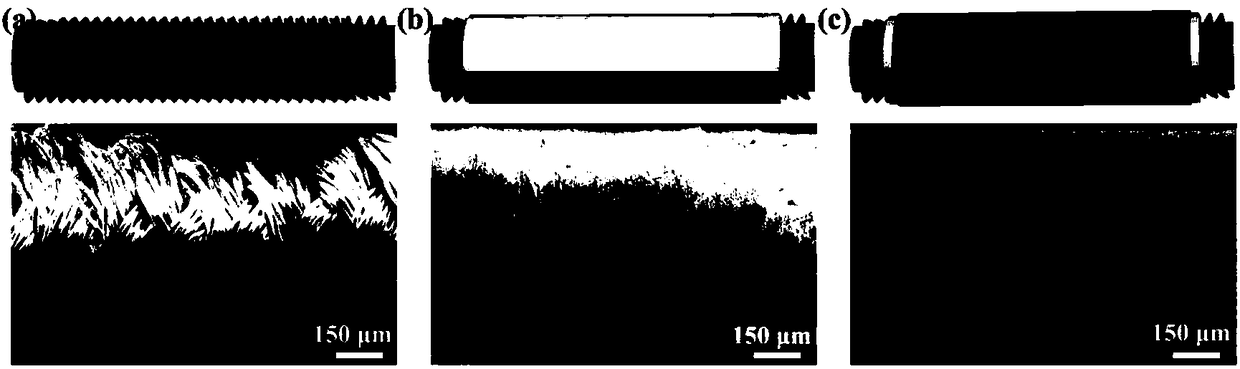

Light emitting diode with nanoparticles

InactiveUS6838816B2Fixed microstructural devicesCathode ray/electron stream lampsNanoparticleColloid

The present invention discloses a simple, low cost method to fabricate light emitting source using luminescent colloid nanoparticles. It uses monodispersed colloid light emitting nanoparticles of oxides, semiconductors, and polymers to fabricate high quality, narrow bandwidth light emitting source. The colloid particles can be dispersed homogeneously in liquid that can be coated easily on a substrate using a simple coating method such as spray, dip coating or spin coating. There is no restriction on the size or shape of the substrate. Therefore, a low cost, large area, high efficiency and reproducible light emitting source can be made easily.

Owner:TRANSPACIFIC IP LTD

Powdery paint for lost foam casting of cast iron

The invention discloses a special coating for pulverous expendable pattern casting and casting iron, and the special coating comprises 60-70 percent of 180-200 mesh refractory materials, 2.0-3.0 percent of suspending agent, 1.5-2.5 percent of adhesive, 0.3-0.6 percent of organosilicon defoamer, 0.01-0.03 percent of preservative agent and 180-200 mesh residual mica powder in balancing amount. When the special coating is prepared, various pulverous materials are weighed according to the required proportion, interposed into the powder stirrer in sequence to stir for 20 to 40 minutes at a low speed and then discharged and packed. When the coating is used, appropriate water is interposed into the stirred vessel by the powder-to-water ratio of 1 to (1.1-1.4). After the stirred vessel is turned on, the powder coating weighed is interposed in batches. The coating is utilized after preparing into slurry; therefore, the special coating has the advantages of good suspension property, high intensity, uniform coating, good thixotropy, good leveling property, glabrous surface, no bubbles, no cracks and the like. Moreover, the user can adopts the dip-coating method, the hang-coating method and the brush-coating method, the viscosity change of coating materials can be decided upon the demands of the user, and different viscosities can realize different coating thicknesses.

Owner:HUAZHONG UNIV OF SCI & TECH

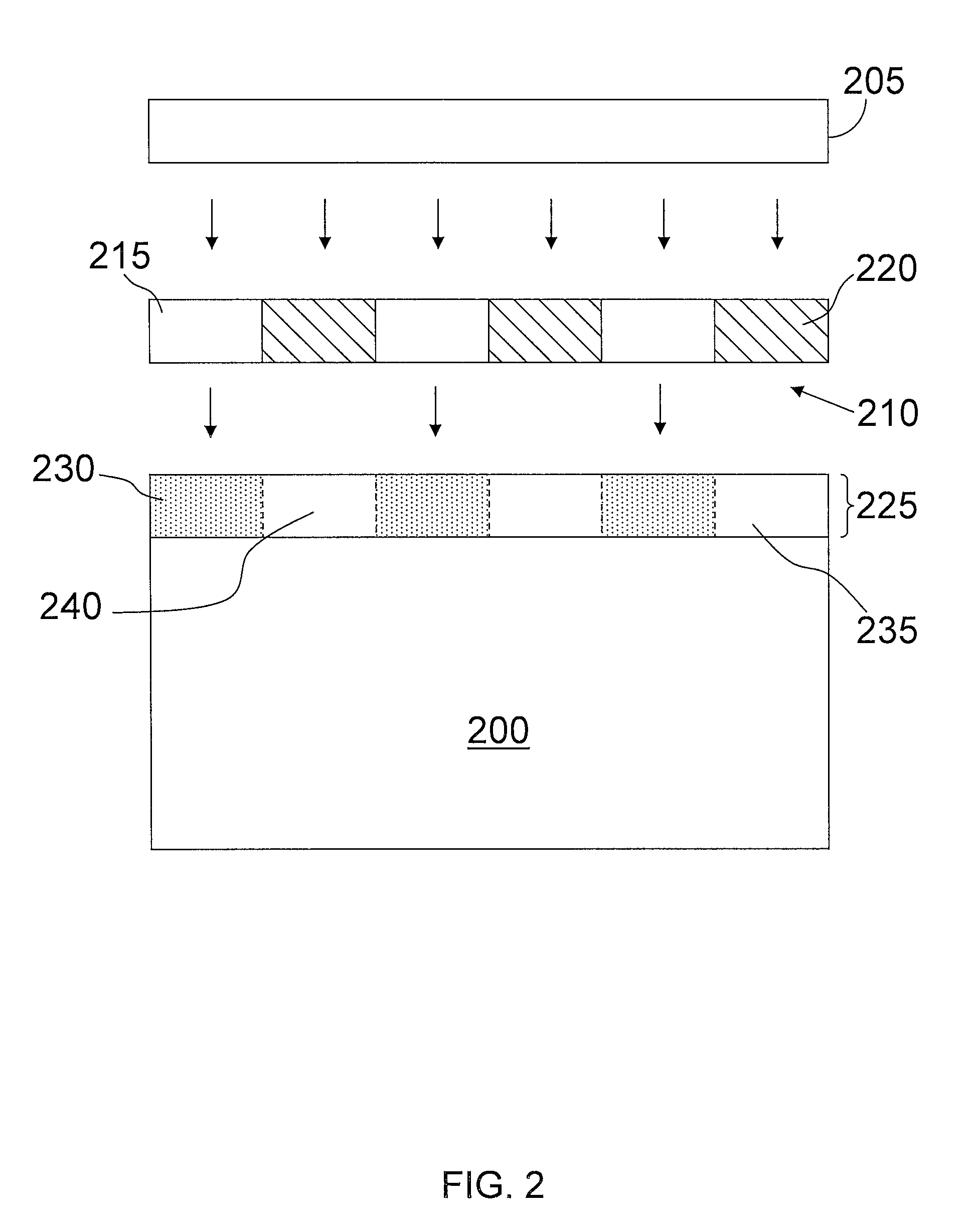

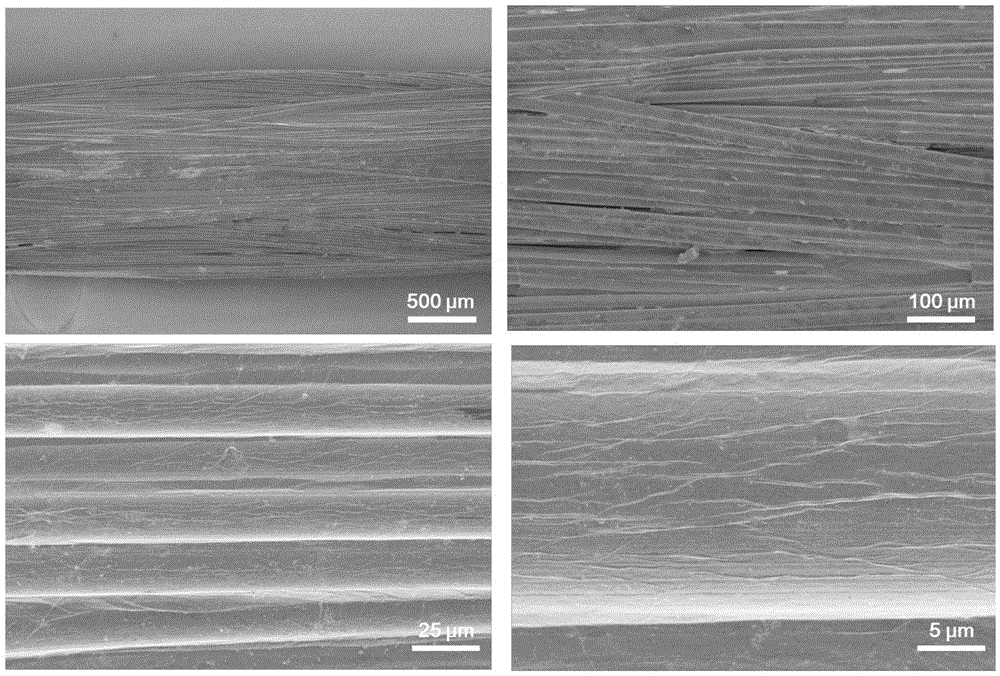

Preparation method of flexible strain sensor based on conductive fiber and application thereof

ActiveCN108560250AHigh ability to adapt to deformationExpand the detection rangeFibre treatmentCatheterYarnFiber

The invention provides a preparation method of a flexible strain sensor based on conductive fiber and application thereof. The conductive fiber comprises a metal nanowire as a conductive layer, an electrospun polymer nanofiber membrane as a protective layer and an elastic yarn as an elastic carrier. In the preparation process, the surface of the elastic yarn is coated with a layer of polymer nanofiber membrane by an electrospinning technology first and then the metal nanowire is deposited on the surface structure thereof through multiple dip coating. The prepared flexible strain sensor based on the conductive fiber has the ability of quickly detecting various deformations such as stretching, bending and twisting, and the sensitivity thereof is still maintained to be 90% or above after thenumber of stretching cycles reaches 10,000; the flexible strain sensor can achieve simultaneous detection of human pulse beat, vocal cord vibration and more complex multiple sites, and has a great application potential in smart wearable devices such as virtual reality, human-machine interfaces and health monitoring.

Owner:GENERAL HOSPITAL OF PLA +1

Method for evaporative pattern precise composite casting

InactiveCN101590513APrevent shrinkageAvoid shrinkage defectsFoundry mouldsFoundry coresSurface layerPolystyrene

The invention discloses a method for evaporative pattern precise composite casting. The method comprises the following steps: making a mould by polystyrene foam to form a casting system; coating a surface modifying agent on the surface of the mould; preparing a mould shell including a surface layer mould shell, a transitional layer mould shell and a back layer mould shell; taking the mould out after placing the mould in a pre-wetting agent for 2 to 3s, dipping the mould in a container filled with surface layer coating, turning the mould so as to evenly coat the mould, sprinkling zircon sand on the mould, and drying the mould for 4 to 6h to prepare a surface layer mould shell; dip-coating the surface layer mould shell by a transitional layer coating, sprinkling and drying the sand for 8 to 12h; preparing the transitional layer mould shell and the back layer mould shell by the similar method; sealing pulp by the back layer coating, and drying for 14 to 18h; roasting the mould at a temperature of between 950 and 1,050 DEG C, and keeping warm for 30 to 60min; and pouring the molten metal in the mould shell to form a casting. The method has the advantages of preparing the metallic mould without the conventional precise casting, saving processing time, lowering cost and simultaneously ensuring the product quality.

Owner:郑州神牛铸造有限公司

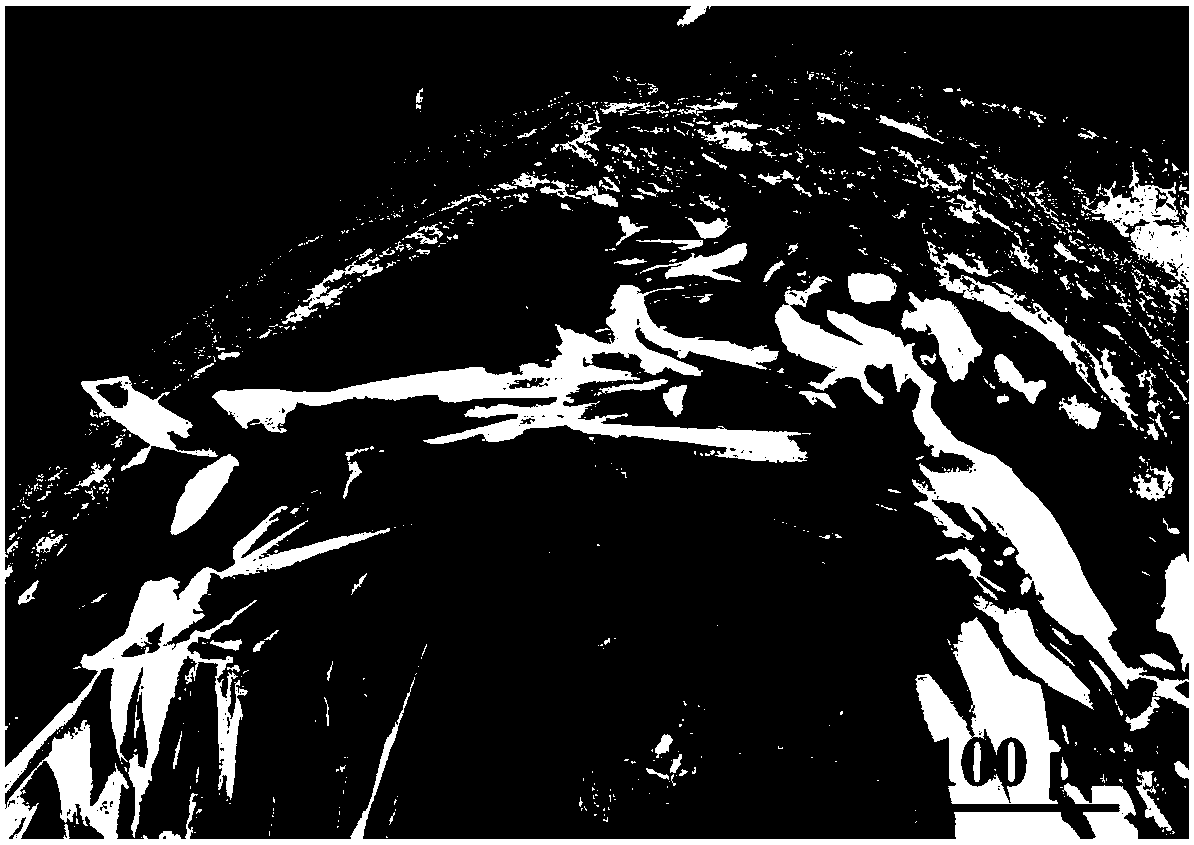

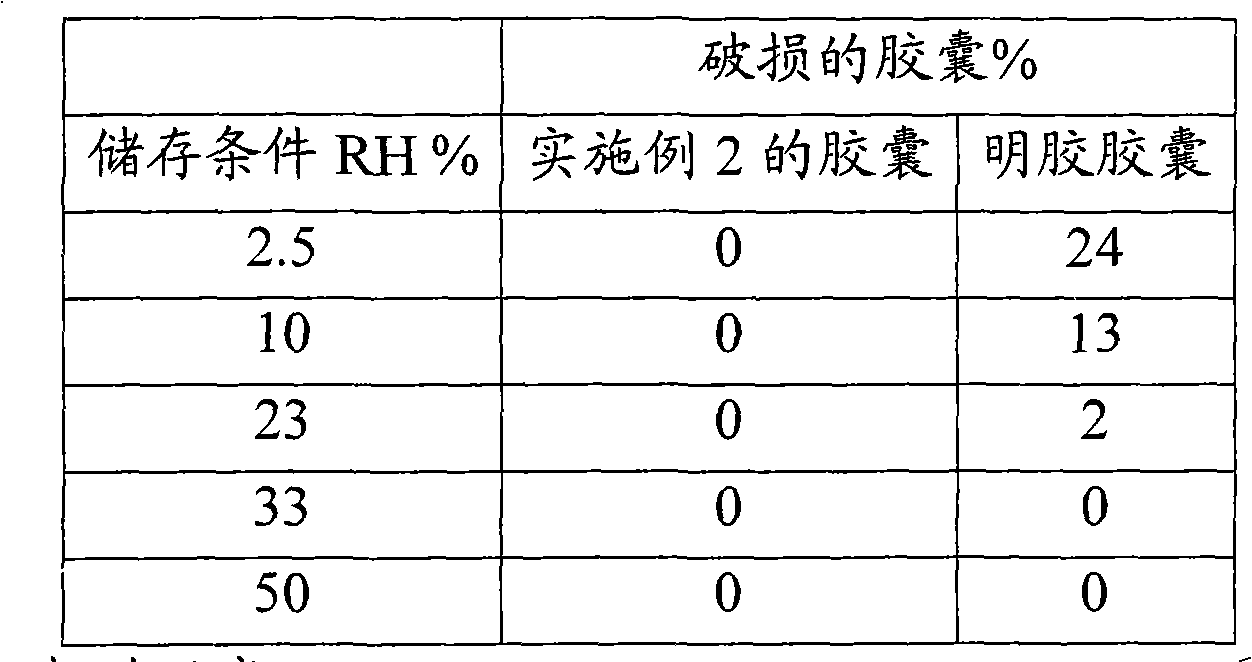

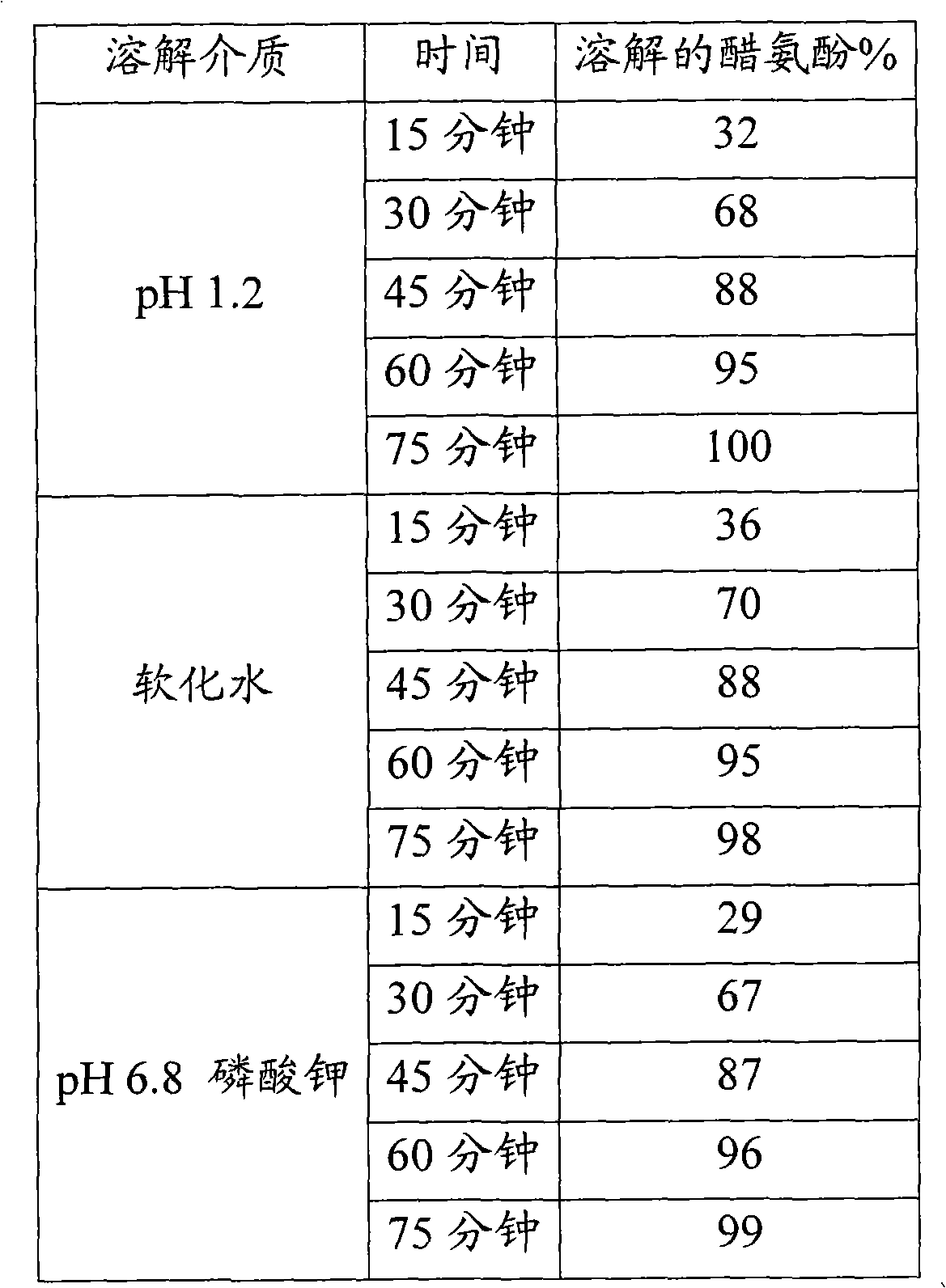

Hydroxypropyl methyl cellulose hard capsules and process of manufacture

ActiveCN101595133ASolubility effectCost effectivePowder deliveryCapsule deliveryPolymer scienceHard Capsule

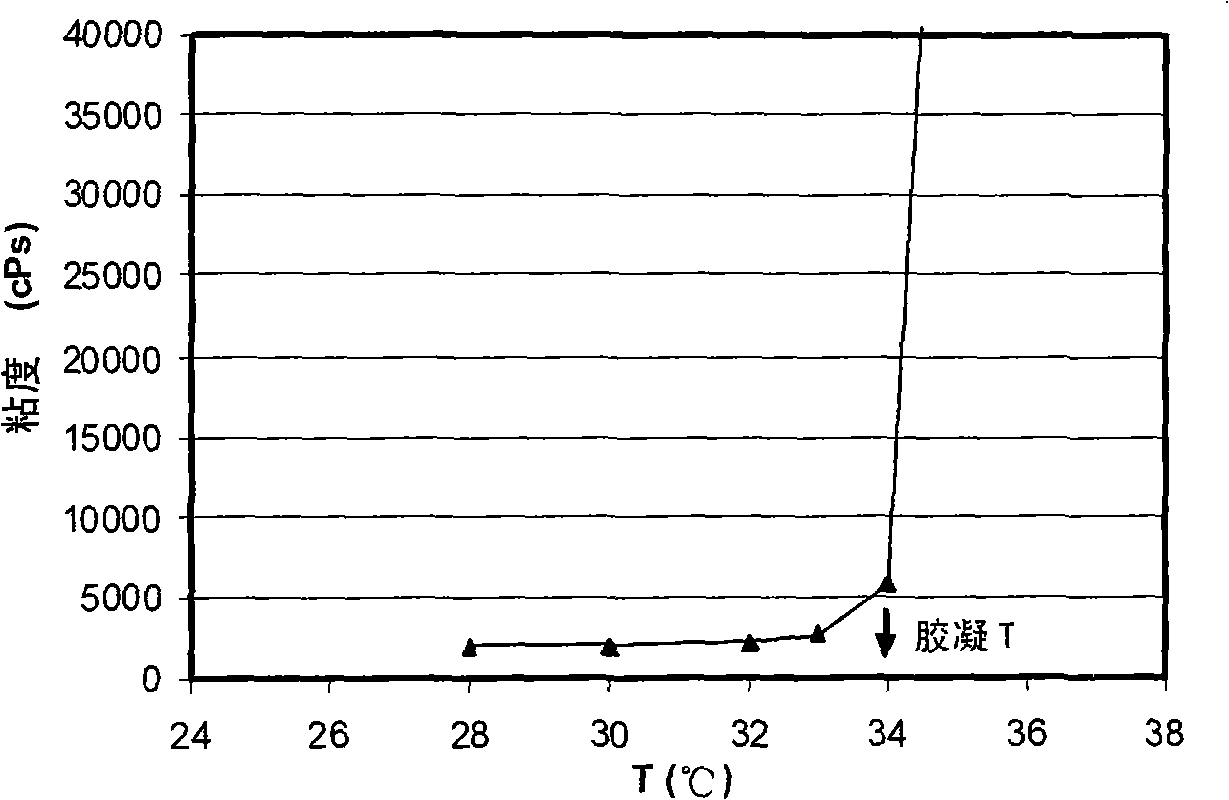

A composition for manufacture of hard hydroxypropyl methyl cellulose capsules comprising a film forming material of hydroxypropyl methyl cellulose having a methoxy content of 27.0-30.0% (w / w), and a hydroxypropoxy content of 4.0 - 7.5% and as a 2% weight solution, a viscosity of 3.5 - 6.0 cPs at 20 DEG C, dipping compositions, process for manufacture of hard hydroxypropyl methyl cellulose capsules according to a dip coating process and hard capsule shells.

Owner:CAPSUGEL BELGIUM NV

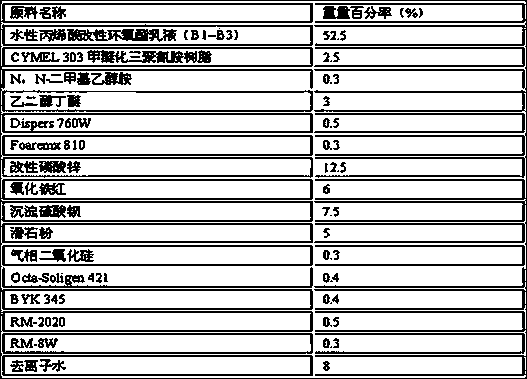

Preparation method for waterborne acrylic acid modified epoxy ester emulsion and its amino baking varnish

InactiveCN103467748AGood storage stabilityGood self-crosslinkingEpoxy resin coatingsEpoxyMethacrylate

The invention relates to a waterborne acrylic acid modified epoxy ester emulsion, the synthetic formula of which consists of the following components (by weight percentage): 12%-17% of epoxy resin; 14%-19% of unsaturated fatty acid; 4%-6% of a (methyl) acrylic ester or vinyl monomer; 2%-4% of methacrylic acid; 0.1%-0.5% of an initiator; 4%-6% of a cosolvent; 1.5%-2.5% of a neutralizing agent; and 45%-55% of deionized water. The waterborne epoxy ester amino baking varnish based on the waterborne acrylic acid modified epoxy ester emulsion involved in the invention adopts water as the diluent, takes the pigment and filler that both are free of harmful lead or chromium compound, has no risk of combustion, explosion, poisoning and environmental pollution, and is safe and environment friendly. The amino baking varnish can employ brush coating, spray coating, dip coating and other construction methods.

Owner:JIAXING QINGHE GAOLI INSULATION MATERIAL

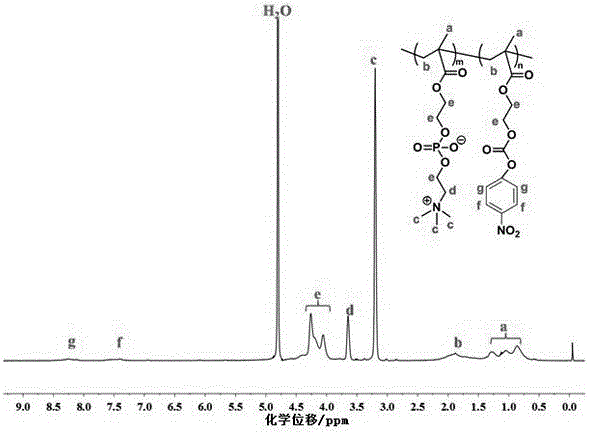

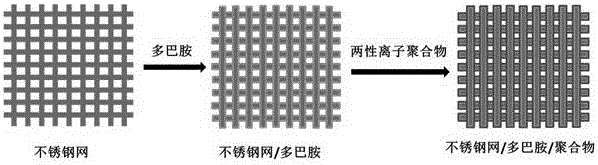

Method for preparing hydrophilic/oleophobic oil-water separation stainless steel net films

ActiveCN105964014AHigh strengthCorrosion resistantMembranesSemi-permeable membranesDip-coatingPollution

The invention relates to a method for preparing hydrophilic / oleophobic oil-water separation stainless steel net films. Stainless steel nets are used as bases. The method includes constructing a poly-dopamine medium layer on the surface of each stainless steel net in dip-coating or spraying modes; dipping the stainless steel nets with the poly-dopamine medium layers in zwitter-ionic polymers with active ester groups; or spraying the zwitter-ionic polymers with the active ester groups on the surfaces and meshes of the stainless steel nets with the poly-dopamine medium layers; carrying out amidation coupling reaction on the zwitter-ionic polymers and each poly-dopamine medium layer to form a stable hydrophilic polymer film on the surface and the meshes of the corresponding stainless steel net. The method has the advantages that the hydrophilic / oleophobic oil-water separation stainless steel net films prepared by the aid of the method are super-hydrophilic and are high in water flux, stable in structural performance and high in anti-pollution capacity; the method has a broad application prospect in the aspects of recycling marine oil slick, removing water from crude oil, treating oily sewage and the like.

Owner:NORTHWEST UNIV

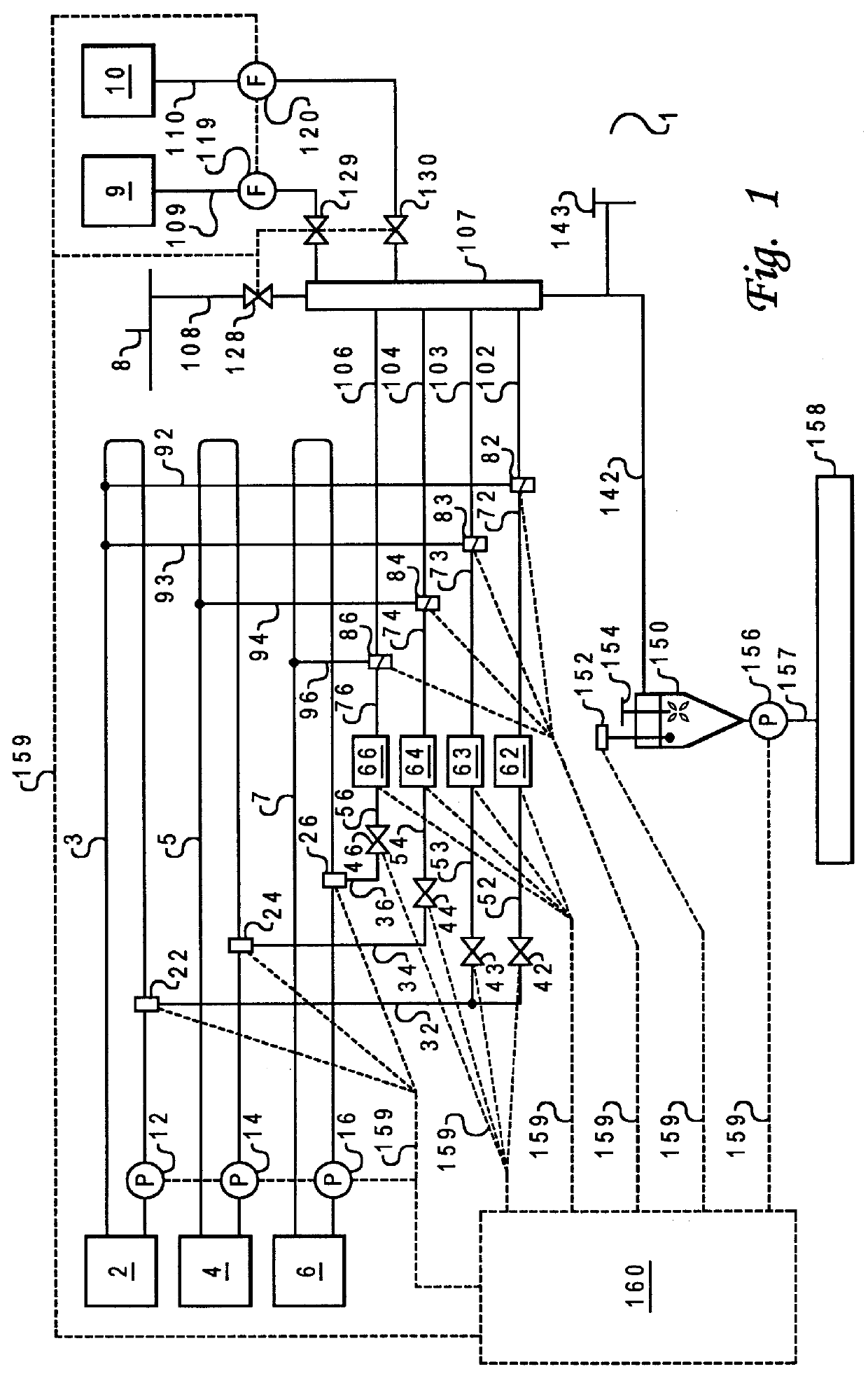

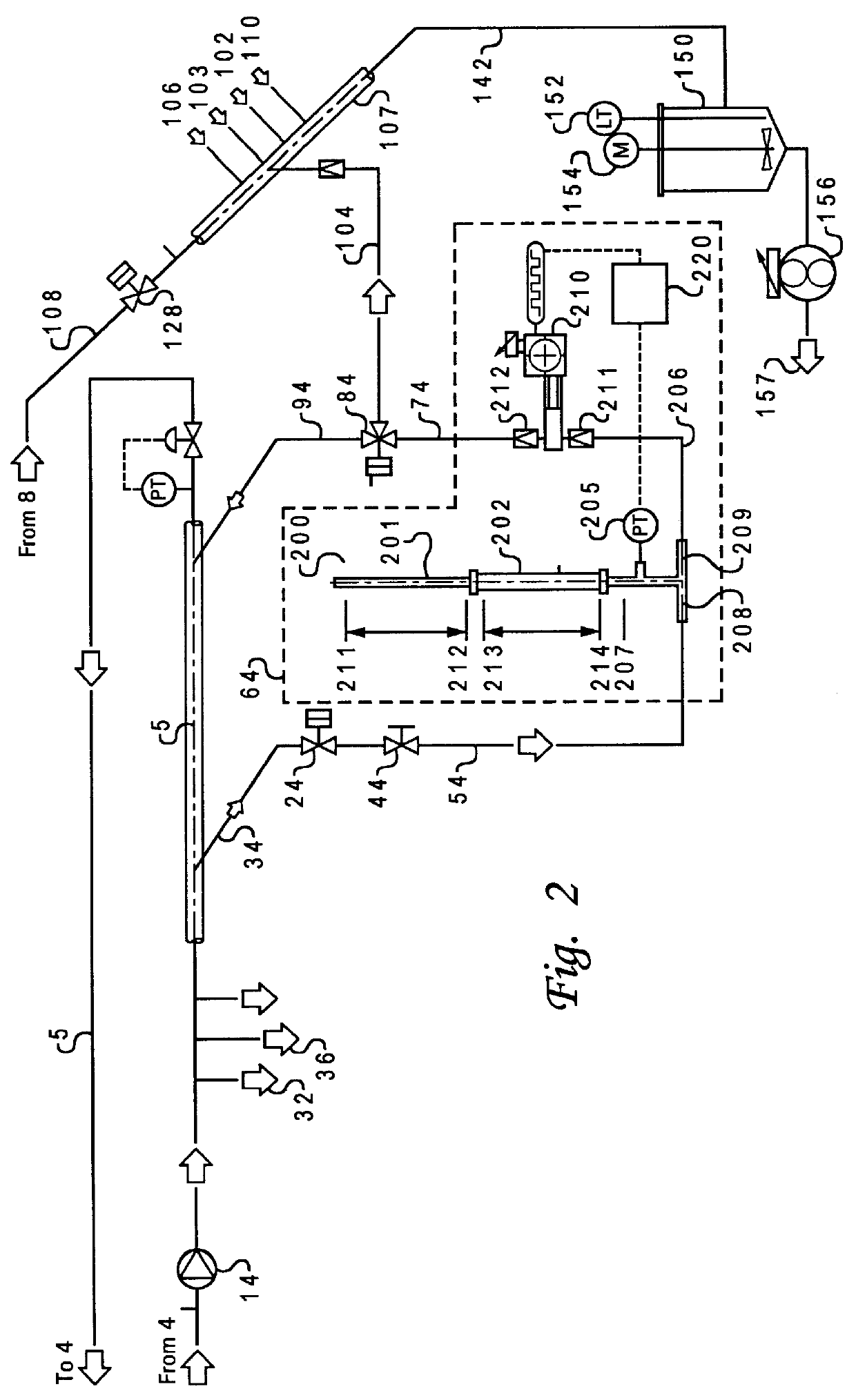

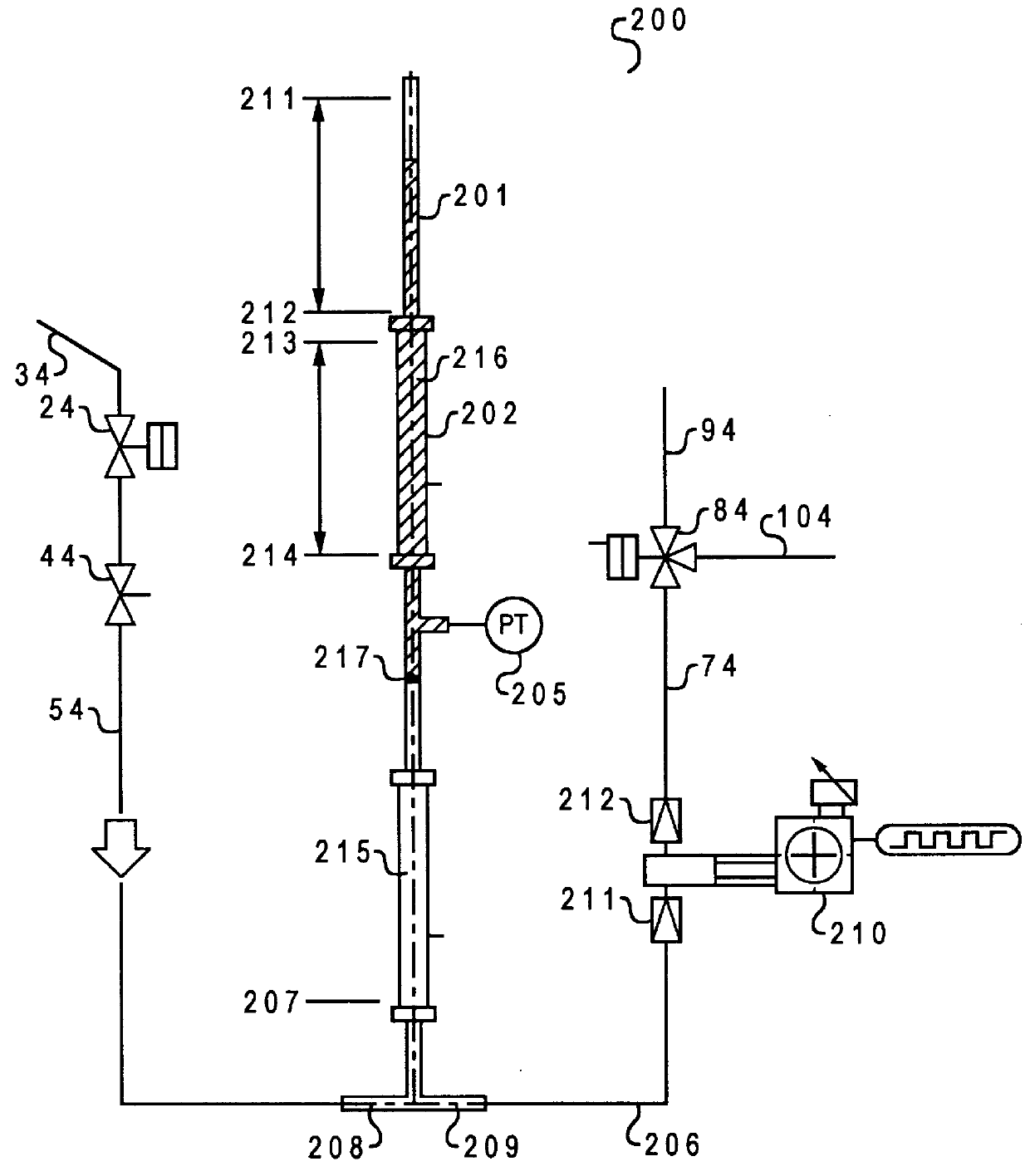

Continuous dispensing system for liquids

InactiveUS6010032ALower Level RequirementsOpening closed containersBottle/container closureEngineeringDip-coating

The present invention relates to the continuous production of coated, dyed, printed, or painted materials by dip coating, spraying or printing in which a plurality of flowable materials including a liquid color concentrate are fed to a continuous mixing chamber with a substantially continuous input and output. The liquid color concentrate is dispensed by a dispensing apparatus including at least a first substantially vertical hollow chamber; a controllable pump device having an inlet fluidly connected to an outlet of said first hollow chamber for pumping the liquid color concentrate to the mixing chamber; a sensor for outputting substantially continuously a signal dependent upon a height of a liquid in the first hollow chamber; and a control device suitable for controlling at least one flow rate determining characteristic of the controllable pump in response to the output signal of the sensor so as to maintain the flow rate of the liquid to be dispensed through the pump device at a predetermined value. The method and apparatus are particularly useful in the manufacture of printed carpets.

Owner:E M E NV +1

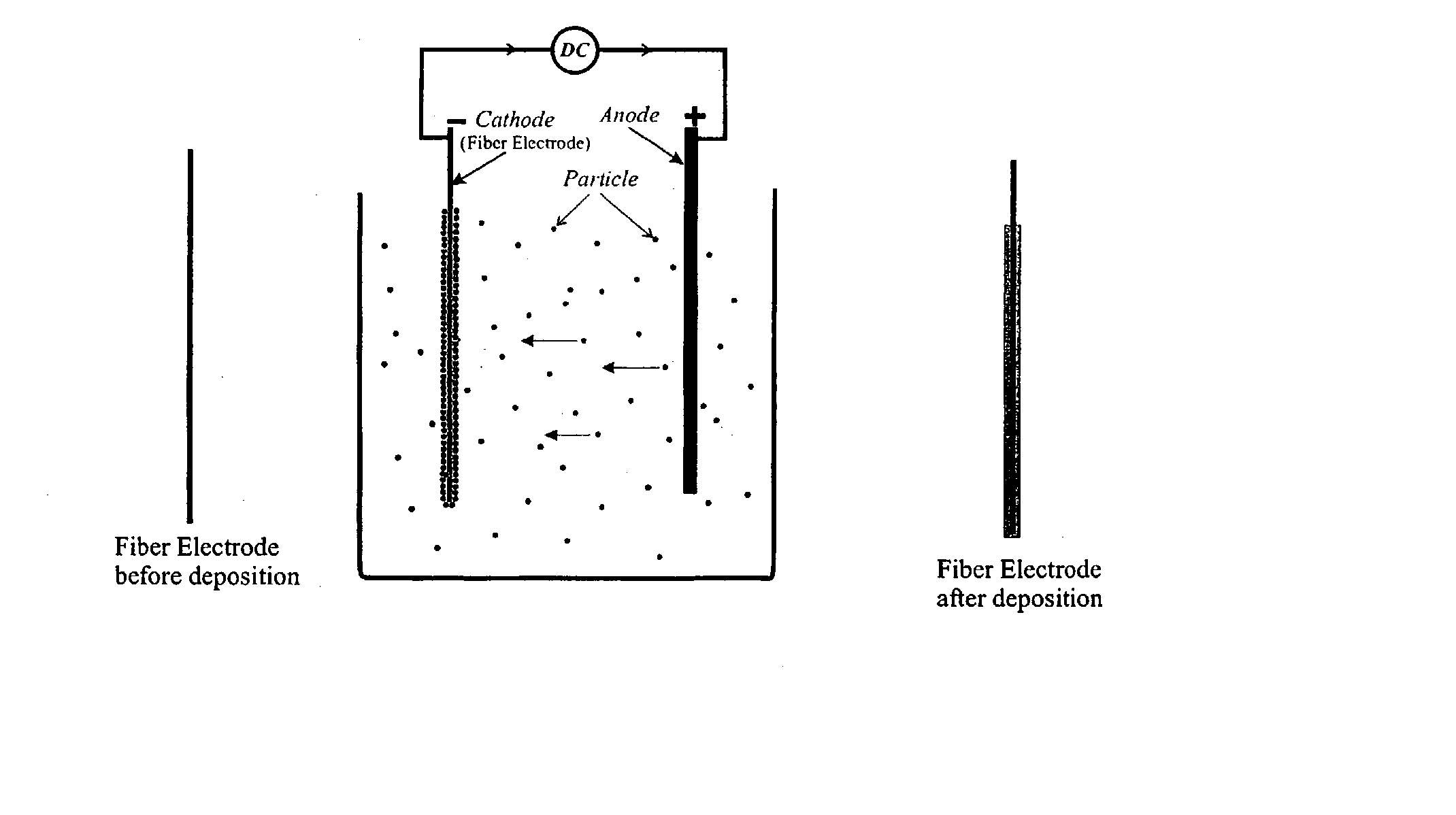

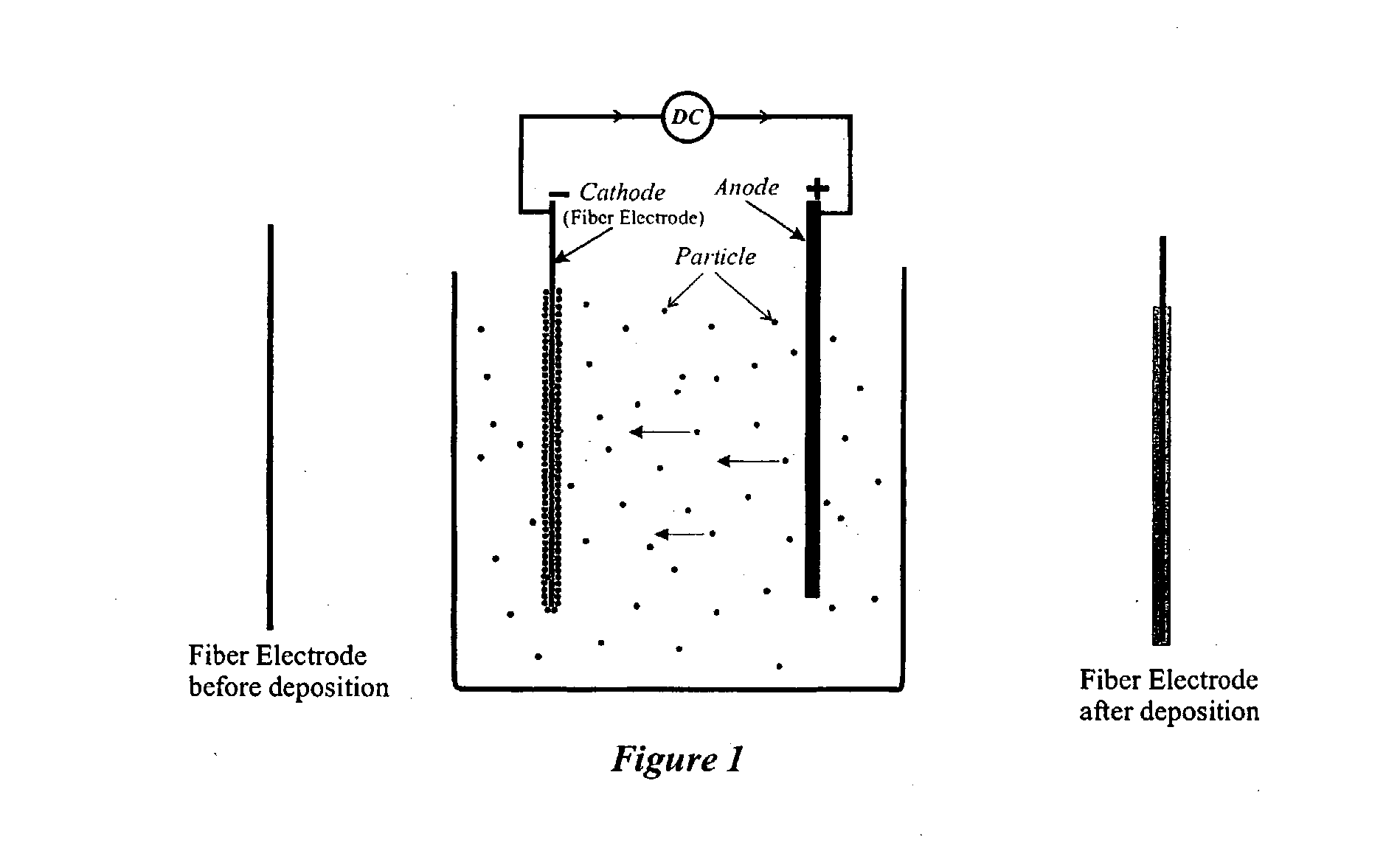

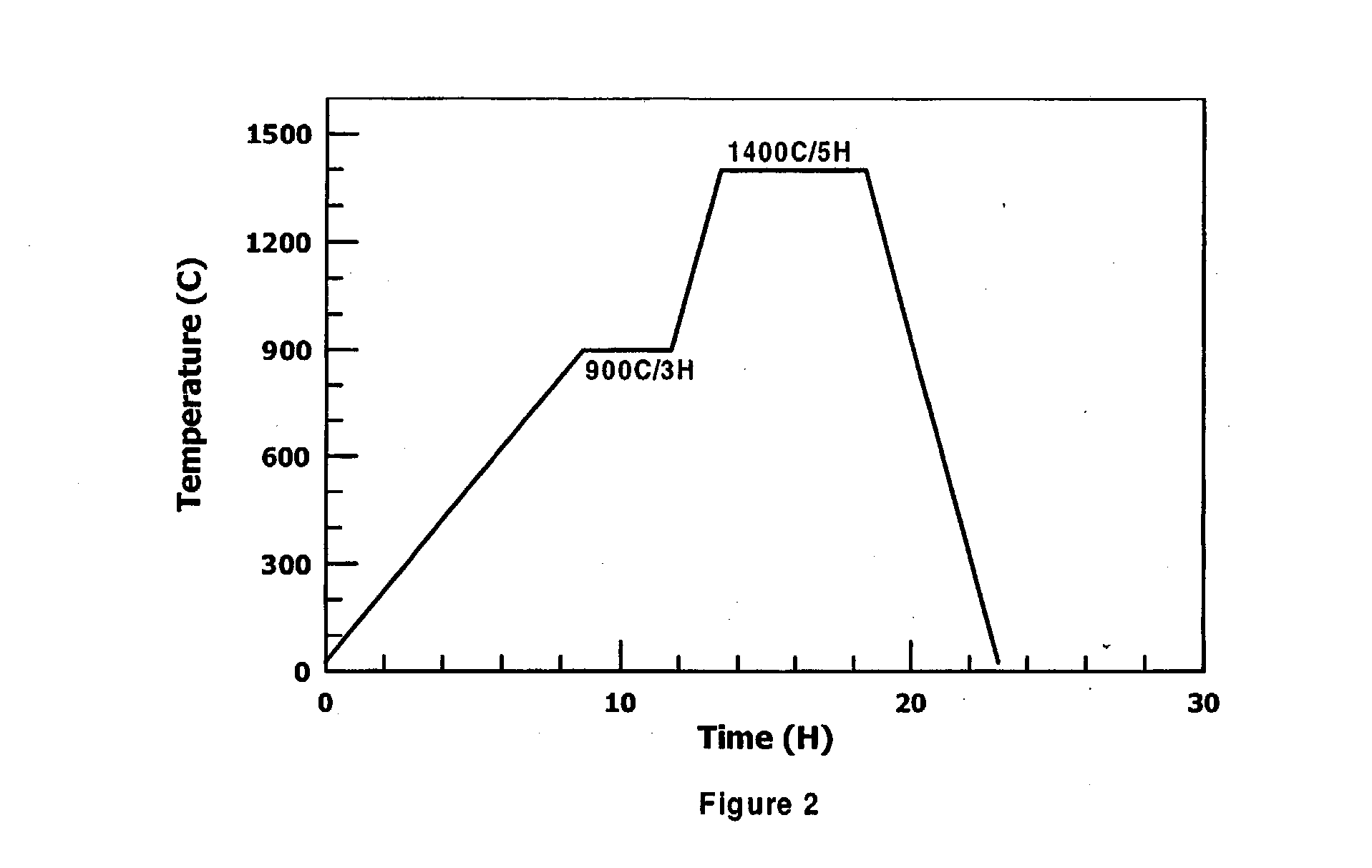

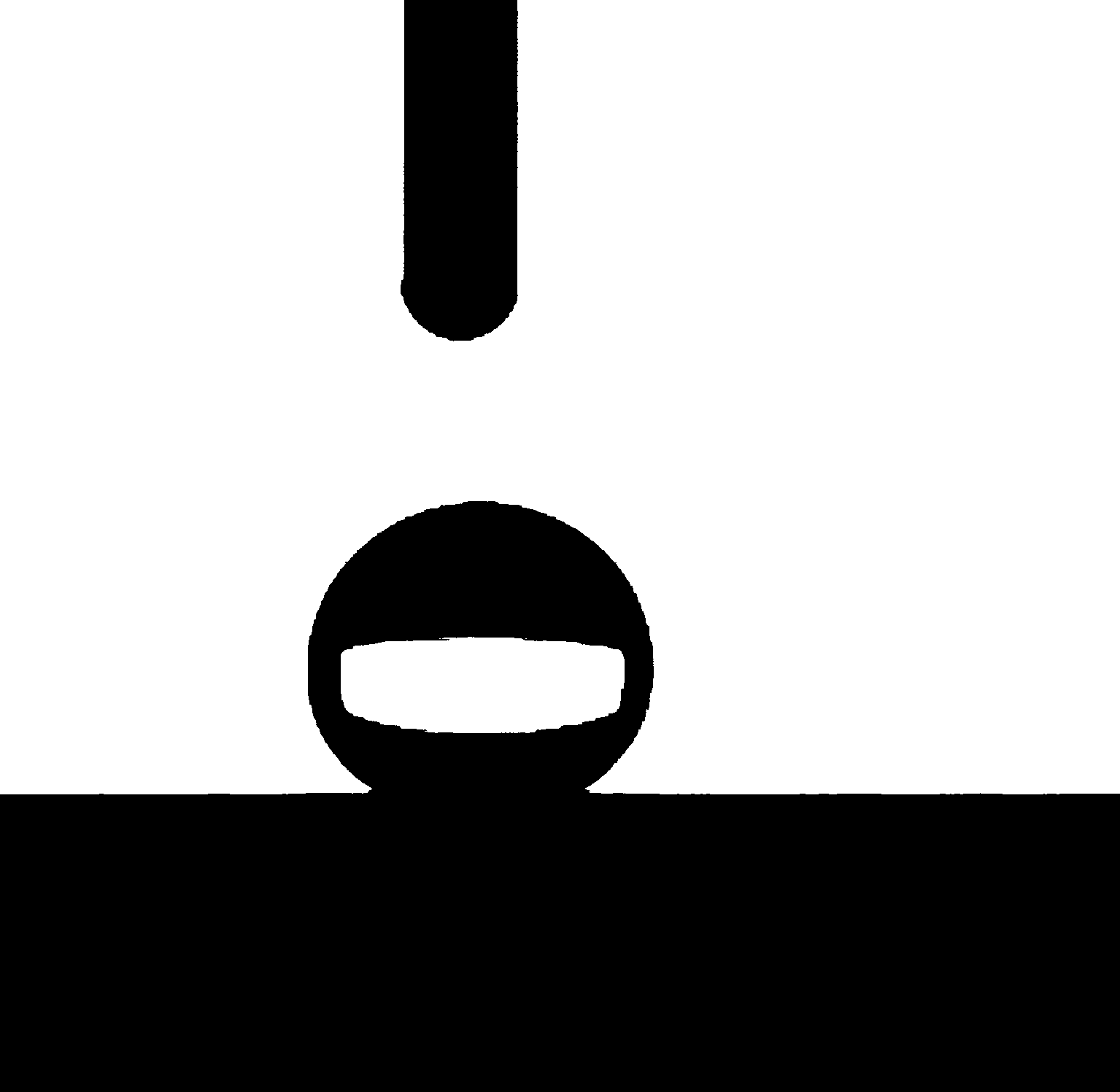

Production of hollow ceramic membranes by electrophoretic deposition

InactiveUS20030178307A1Prevent penetrationReduce porosityFinal product manufactureCell electrodesMetallurgyElectrophoresis

The present invention provides methods for producing hollow ceramic membranes by electrophoretic deposition. The hollow ceramic membranes may have a small cross-sectional area of about 1.0x10<-5 >mm<2 >to about 25 mm<2>. The cross-sectional configuration of the hollow ceramic membranes may be any geometry such as circular, square, rectangular, triangular or polygonal. The hollow ceramic membranes produced by the methods of the present invention may have multiple layers but always the innermost layer, or the first deposited layer is porous and made by electrophoretic deposition. Subsequent layers may be porous or non porous and deposited before or after sintering the first layer. If it is deposited after sintering, it may require additional sintering steps. Additional layers may be deposited by further electrophoretic deposition, sol-gel coating, dip coating, vacuum casting, brushing, spraying or other known techniques.

Owner:INNOTECH ALBERTA INC

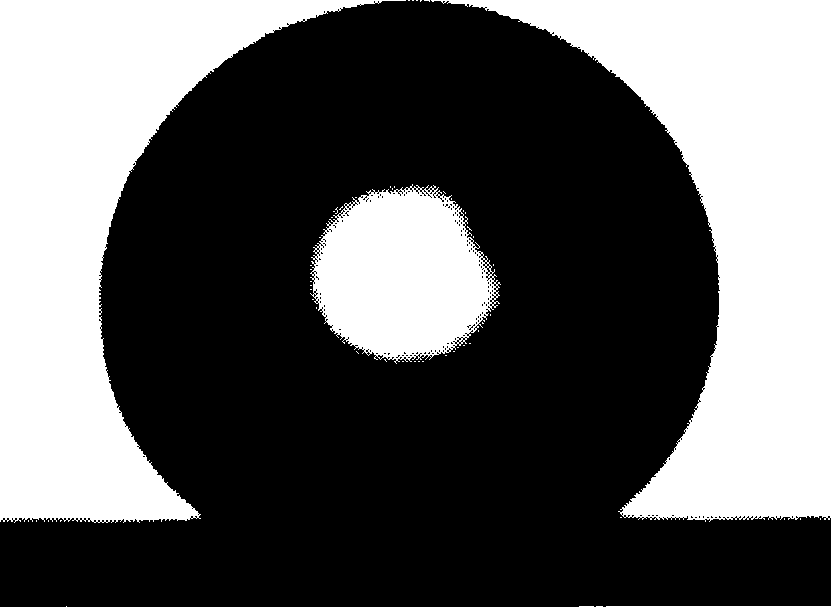

Super-hydrophobic nano coating and preparation method thereof

The invention provides a super-hydrophobic nano coating. The super-hydrophobic nano coating is characterized by consisting of the following components in percentage by weight: 0.5-1.5% of nano dioxide, 0.5-1.5% of nano silicon dioxide, 0-20% of barium sulfate, 0-20% of talcum powder, 40-70% of a thinner and 20-50% of organic silicon resin. The preparation method comprises steps of preparing a dispersion solution from filler particles, the thinner and a dispersing agent in a certain proportion, mixing with the organic silicon resin, adding a curing agent, uniformly stirring, coating on a substrate in a spin-coating or dip-coating way, and drying at 50-80 DEG C. The prepared coating has a contact angle of 145-160 degrees with water drops on the surface of the substrate, and a rolling angle is lower than 10 degrees. The method is wide in raw material resource, simple in process, convenient to use, low in cost, suitable for industrial production, and applicable to surface self-cleaning, icing resistance, water and fog resistance, fluid drag reducing and other situations.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Membrane-laminated fiberglass filter medium capable of denitration and dust removal

ActiveCN103463871ADoes not affect inherent performanceAchieve emissionsNitrous oxide captureDispersed particle separationGlass fiberFilter media

The invention discloses a membrane-laminated fiberglass filter medium capable of denitration and dust removal. The membrane-laminated fiberglass filter medium capable of denitration and dust removal comprises a fiberglass filter base material, a NOX catalyst removing dip coating layer and an expanding micropore polytetrafluoroethylene filtering film; the membrane-laminated fiberglass filter medium capable of denitration and dust removal is characterized in that firstly, soakage drying post treatment is carried out on the fiberglass filter base material by using a NOX catalyst removing batch mixture, the NOX catalyst removing dip coating layer is formed on the surface of fiberglass, high-temperature hot pressing is carried out on the NOX catalyst removing dip coating layer and a polytetrafluoroethylene surface film, and the functional membrane-laminated filter medium which has a NOX catalyst removing function and can prevent the PM2.5 is prepared. The membrane-laminated fiberglass filter medium capable of denitration and dust removal provided by the invention can not only avoid the detrimental effect on a catalyst caused by flying ash particles, but also effectively reduce tiny dust such as PM2.5, and the discharge of the smoke dust which is below 5mg / Nm<3> is realized; the combination of catalyst powder and the filter medium are firm, the inherent properties of the filter medium are not affected, and the filter medium is particularly suitable for industrialized production.

Owner:ANHUI JINHON GREENISM TECH

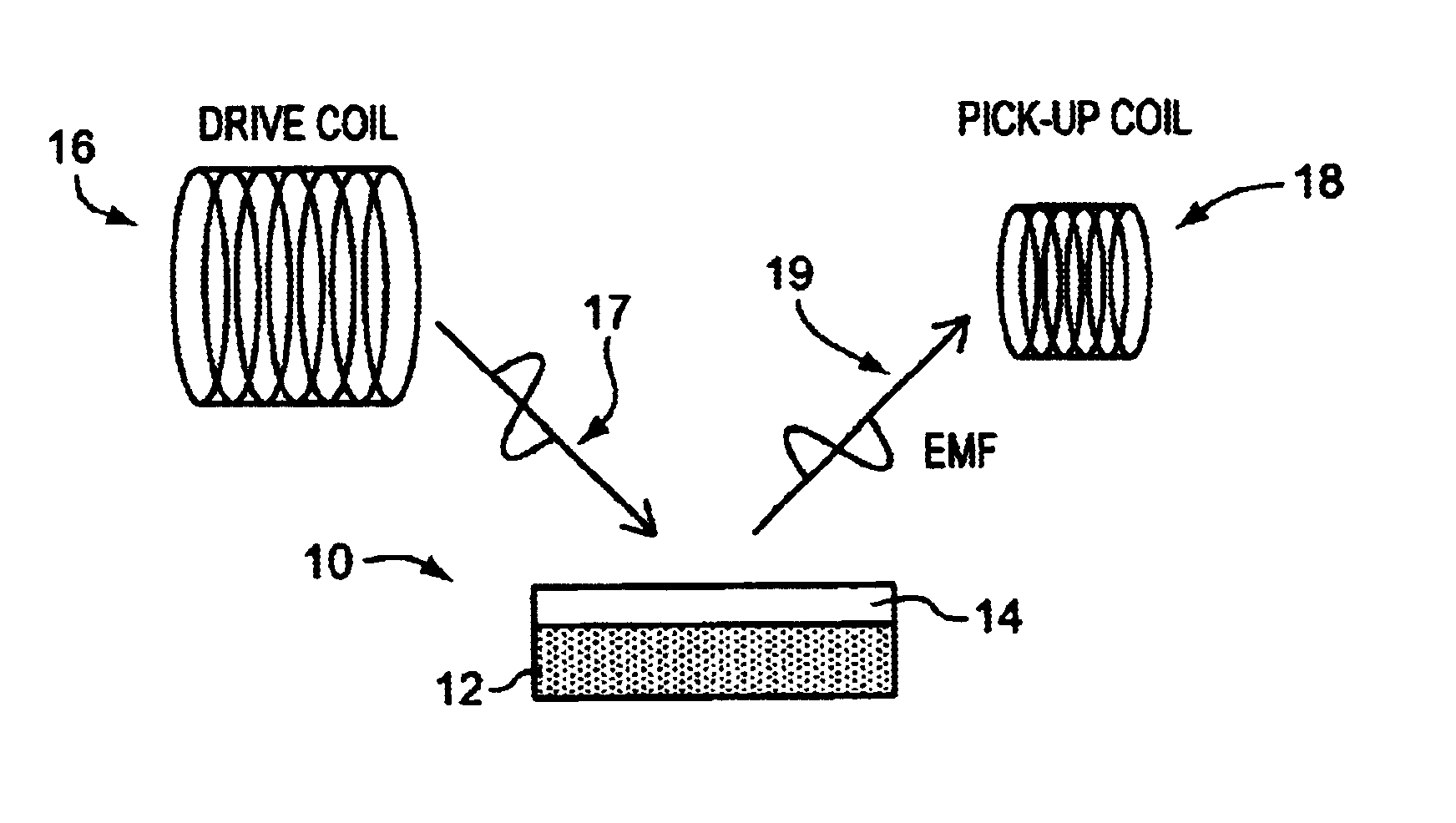

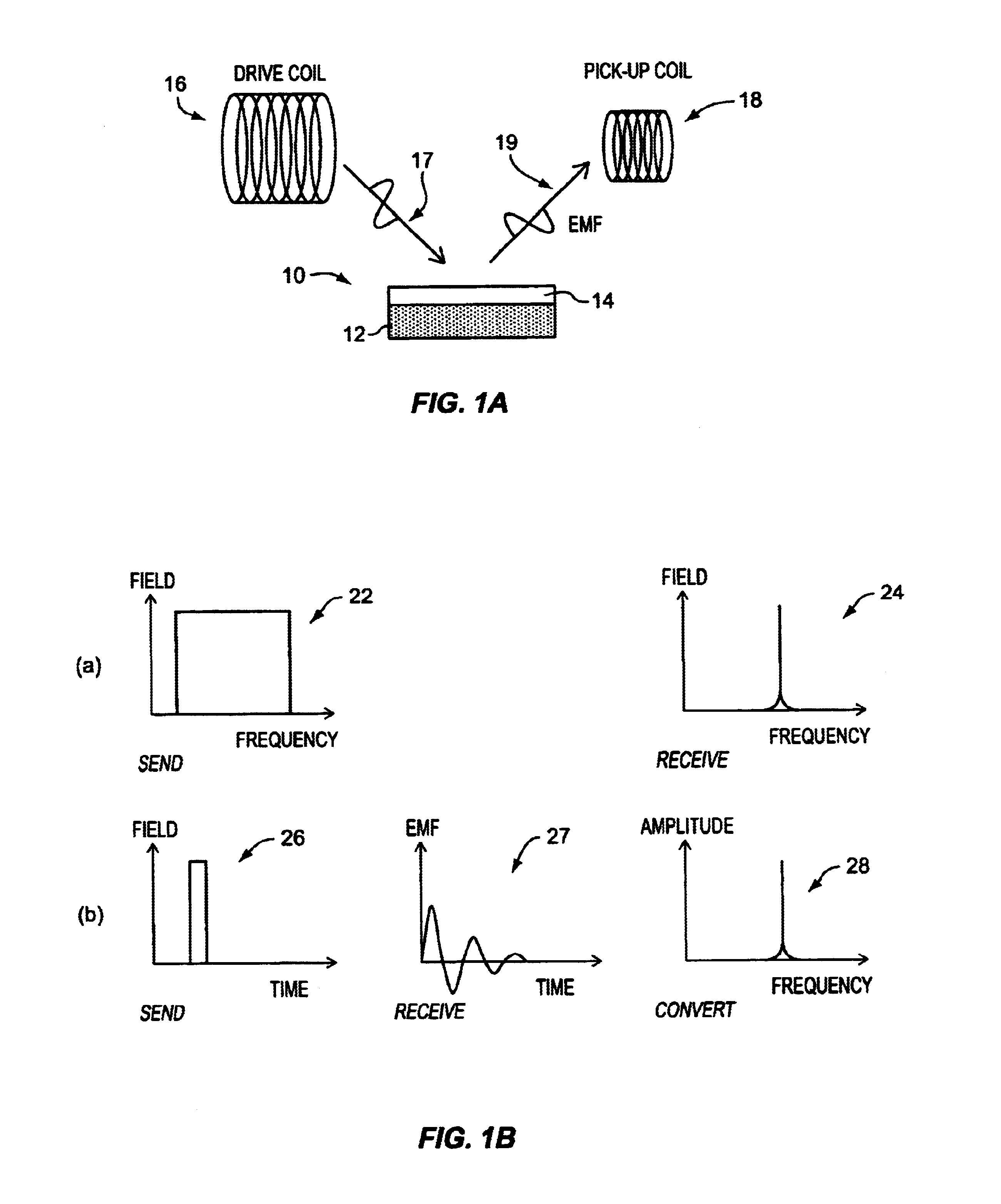

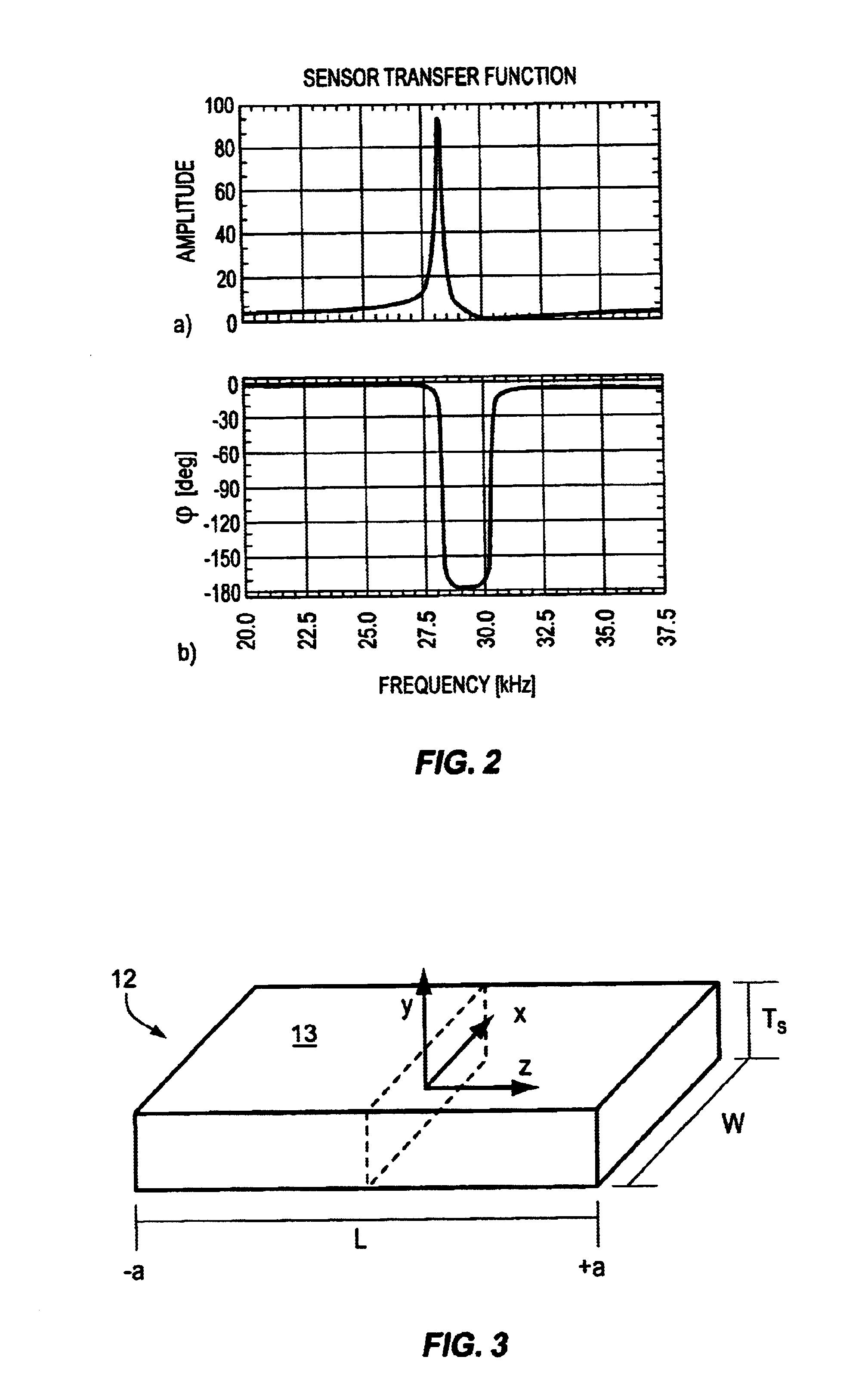

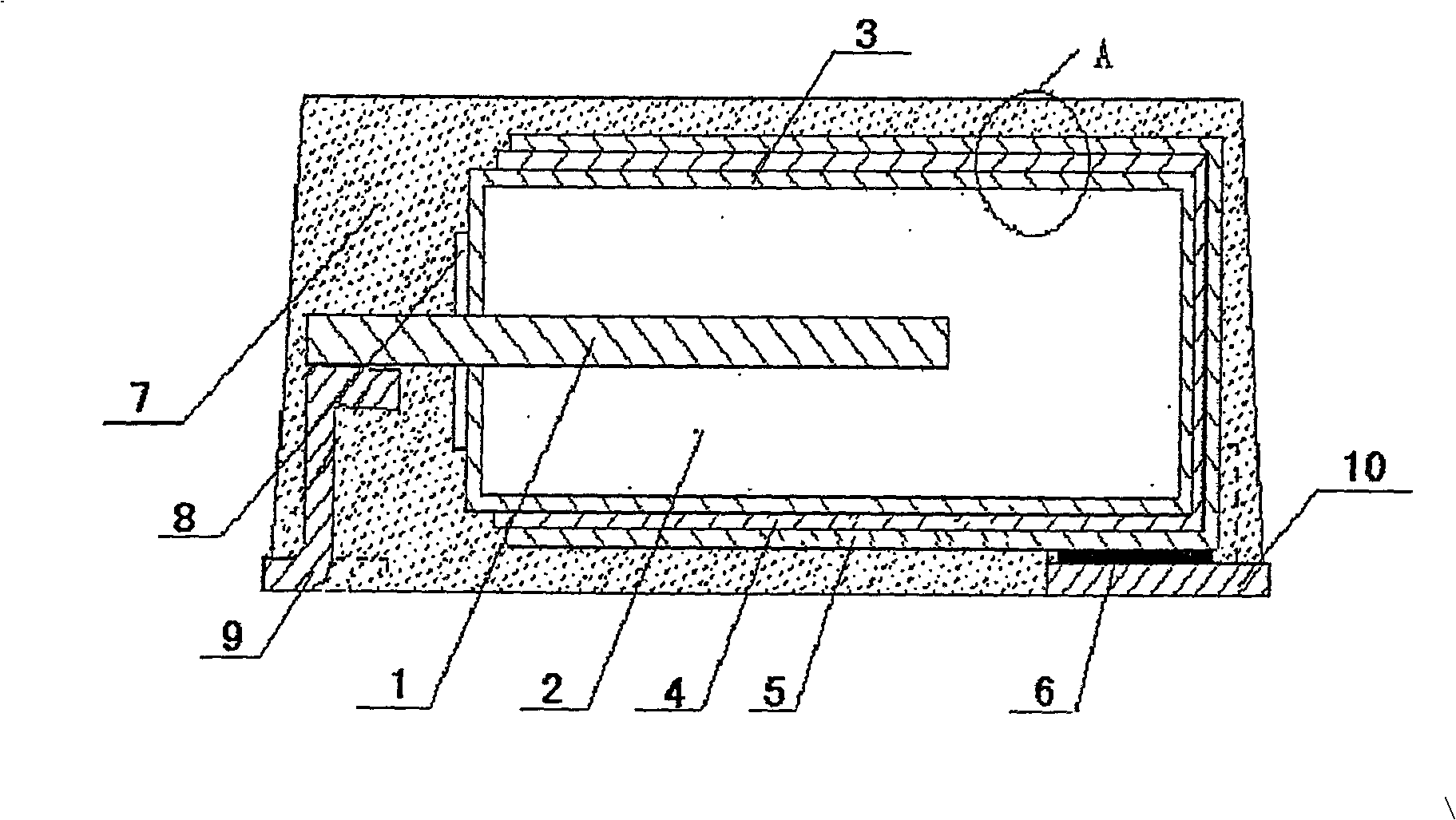

Magnetoelastic sensor for characterizing properties of thin-film/coatings

InactiveUS6688162B2Vibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesEtchingAdhesive

An apparatus for determining elasticity characteristics of a thin-film layer. The apparatus comprises a sensor element having a base magnetostrictive element at least one surface of which is at least partially coated with the thin-film layer. The thin-film layer may be of a variety of materials (having a synthetic and / or bio-component) in a state or form capable of being deposited, manually or otherwise, on the base element surface, such as by way of eye-dropper, melting, dripping, brushing, sputtering, spraying, etching, evaporation, dip-coating, laminating, etc. Among suitable thin-film layers for the sensor element of the invention are fluent bio-substances, thin-film deposits used in manufacturing processes, polymeric coatings, paint, an adhesive, and so on. A receiver, preferably remotely located, is used to measure a plurality of values for magneto-elastic emission intensity of the sensor element in either characterization: (a) the measure of the plurality of values is used to identify a magneto-elastic resonant frequency value for the sensor element; and (b) the measure of the plurality of successive values is done at a preselected magneto-elastic frequency.

Owner:UNIV OF KENTUCKY RES FOUND

Solid electrolyte capacitor with ultra-low equivalent series resistance and manufacturing method thereof

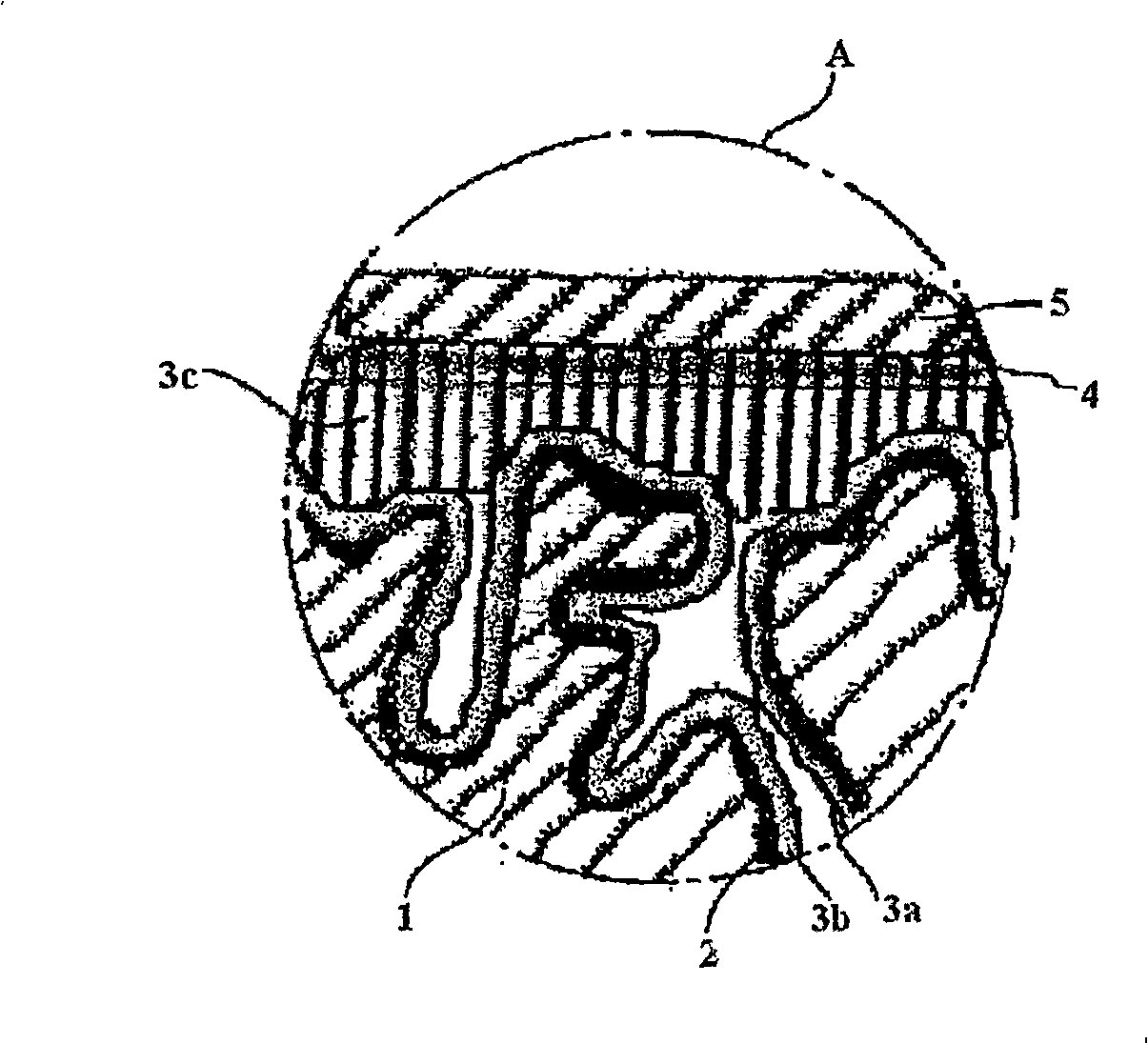

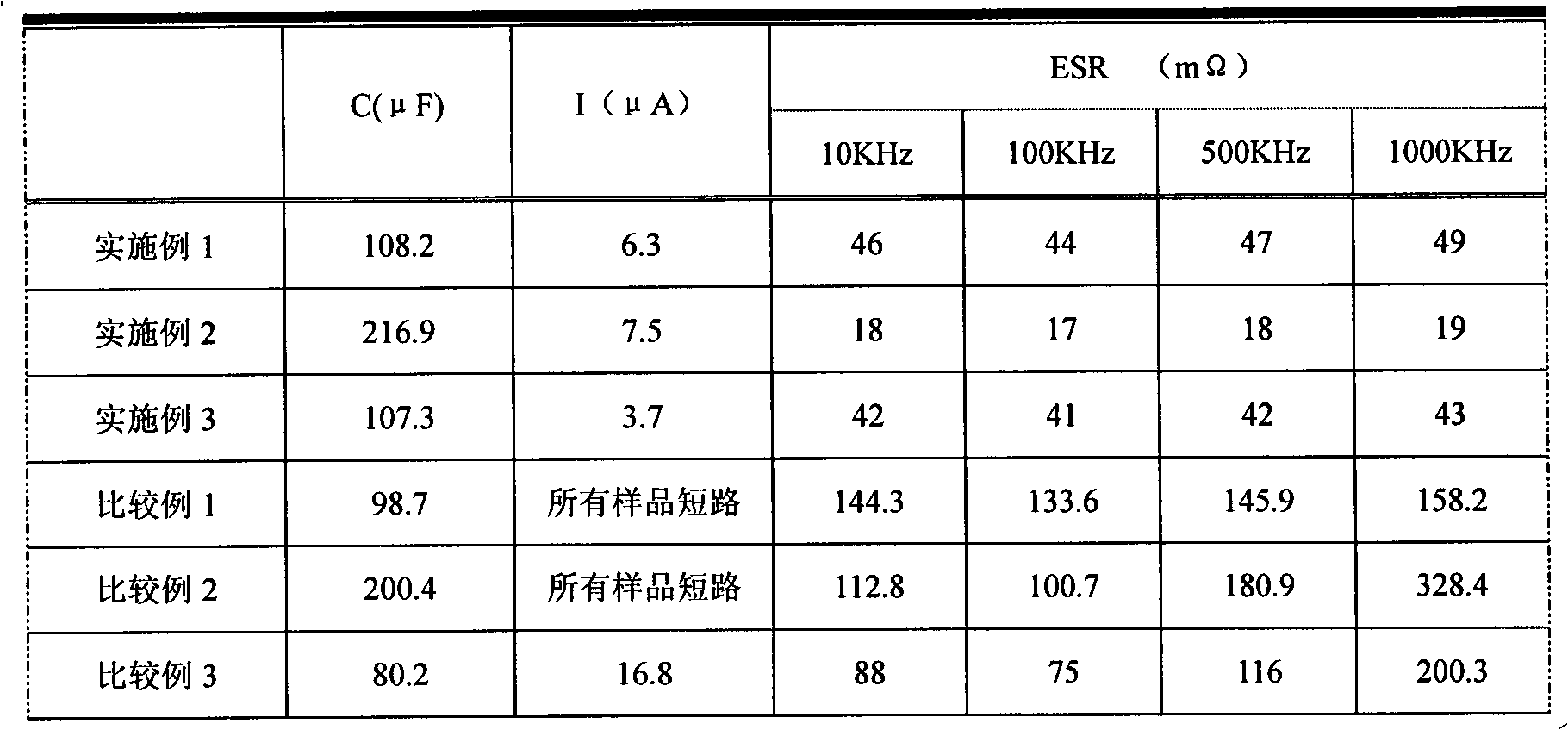

ActiveCN101350253AImprove volumetric efficiencyTightly boundSolid electrolytic capacitorsCapacitor terminalsElectrolysisNiobium

The invention relates to a solid electrolytic capacitor and the method for preparing the solid electrolytic capacitor, wherein the solid electrolytic capacitor takes solid conducting high molecular polymer as electrolyte and takes valve metals, such as tantalum, niobium, titanium, aluminum and the like as an anode. The solid electrolytic capacitor is characterized by sufficiently explaining the techniques for the design of the anode, the function assignment, the chemical oxidative in-situ polymerization, the dip-coating graphite silver paste, the making of bottom extraction electrode and the like, with the technical proposal of the invention, a high polymer film, a graphite layer and a silver layer can be compactly combined, the manufactured electrolytic capacitor can be provided with very low equivalent series resistance (ESR), very high volumetric efficiency and good impedance frequency characteristic, the ESR value can be stable in the range of 10KHz-1000KHz, and the requirements of the frequency of a modern electronic equipment can be satisfied.

Owner:CHINA ZHENHUA GRP XINYUN ELECTRONICS COMP ANDDEV CO LTD

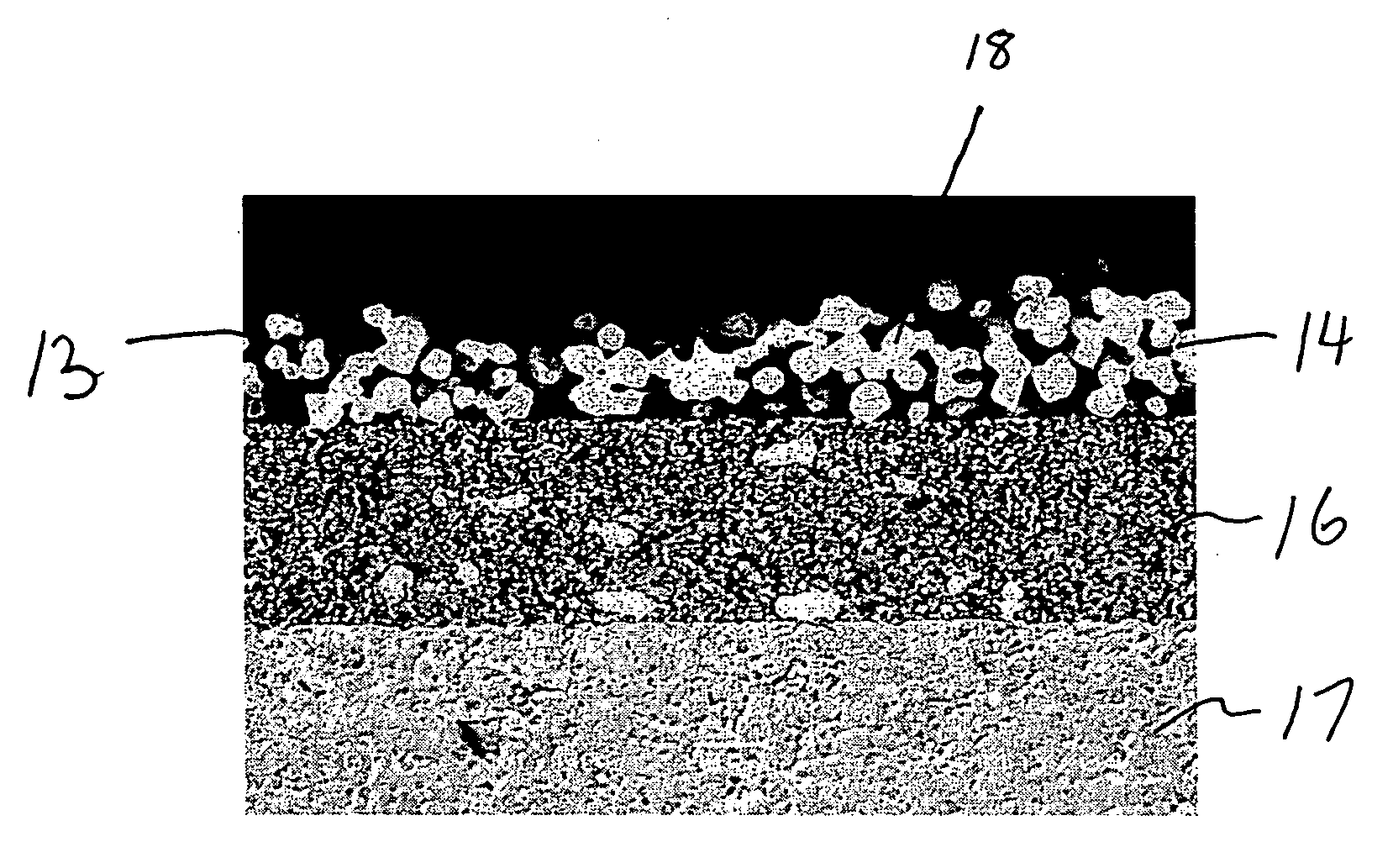

Manufacturing method and current collector

InactiveUS20060127749A1Improve adhesionGood mechanical integrityTransportation and packagingCell electrodesPorosityElectrical conductor

A method of forming a current collector layer on electrode layers of an electrochemical air separation element and a current collector. A slurry is prepared that contains electrically conductive particles having surface deposits of a metallic oxide on a metal or metal alloy conductor. The metallic oxide surface deposit constitutes a lower weight percentage of the electrically conductive particles than the metal or metal alloy. The slurry is applied to a structure that contains an electrolyte and electrode layers. The slurry can be applied by dip coating techniques. The resultant coated form is then fired to partly sinter the electrically conductive particles and thereby to obtain porous current collector layers affixed to the electrode layers. The current collector of the present invention is between about 5 microns and about 100 microns thick and preferably has a porosity of between about 10 percent and about 70 percent with pores having a pore size of between about 0.1 microns and about 20 microns.

Owner:PRAXAIR TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com