Preparation method for waterborne acrylic acid modified epoxy ester emulsion and its amino baking varnish

A water-based acrylic and amino baking paint technology, used in epoxy resin coatings, coatings, etc., can solve the problems of poor water resistance and corrosion resistance of paint films, slow drying and hardness of paint films, and difficult to control the reaction process, and achieve glossy The effect of improving dryness and water resistance, and easy control of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

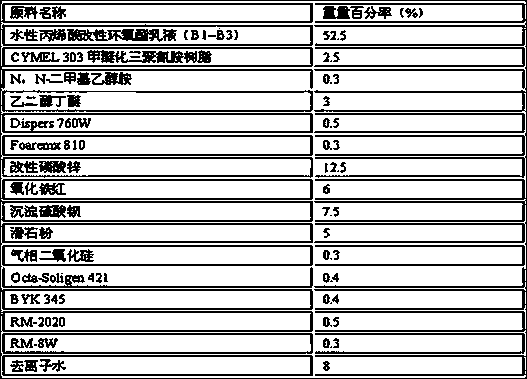

Image

Examples

Embodiment 1

[0040] Preparation of Acrylic Prepolymer A1:

[0041] Put 400 kg of dehydrated castor oil fatty acid into the reaction kettle, and gradually heat up to 135°C--145°C under stirring; add 200 kg of methyl methacrylate, 200 kg of isobutyl methacrylate, 60 kg of styrene, 120 Mix one kilogram of methacrylic acid and 20 kilograms of tert-butyl peroxybenzoate evenly and put it into the drop liquid high level tank, and use a constant flow pump to drop it into the reaction kettle for 6--8 hours; , kept at 135°C-145°C for 3-4 hours, until the conversion rate was 98±1%, the acrylic acid prepolymer A1 was obtained, and the acid value was 156mgKOH / g.

Embodiment 2

[0043] Preparation of Acrylic Prepolymer A2:

[0044] Put 400 kg of linseed oil fatty acid into the reaction kettle, and gradually heat up to 135°C--145°C under stirring; put 150 kg of isobutyl methacrylate, 230 kg of vinyl toluene, 200 kg of methacrylic acid and 20 kg of After the oxidized di-tert-butyl ether is mixed evenly, put it into the dripping high-level tank, and use a constant-flow pump to drip it into the reaction kettle. The dropping time is 6--8 hours; Keeping it warm for 3-4 hours until the conversion rate is 98±1%, the acrylic acid prepolymer A2 is obtained with an acid value of 210 mgKOH / g.

Embodiment 3

[0046] Preparation of Acrylic Prepolymer A3:

[0047] Put 400 kg of linseed oil fatty acid into the reaction kettle, and gradually heat up to 135°C--145°C under stirring; add 150 kg of n-butyl methacrylate, 70 kg of styrene, 160 kg of vinyltoluene, 200 kg of methyl Acrylic acid and 20 kilograms of tert-butyl peroxybenzoate are mixed evenly and put into the drop liquid high level tank, and are added dropwise in the reactor with a constant flow pump, and the drop time is 6--8 hours; ℃--145 ℃ for 3-4 hours, until the conversion rate is 98±1%, the acrylic acid prepolymer A3 is obtained, and the acid value is 210mgKOH / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com