Patents

Literature

279results about How to "No explosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Powder metallurgy component and production method of powder metallurgy component with through hole

The invention discloses a powder metallurgy component which is compressed by powder materials. The powder materials includes, by weight, 100 parts of iron powder, 1.8-2.2 parts of copper powder, 0.-1.0 part of graphite powder, 2.0-3.0 parts of nickel powder, 0.4-0.8 part of molybdenum powder, 0.5-1.0 part of micro powder wax, and 0.5-1.0 part of calcium fluoride. The invention further disposed a production method of the powder metallurgy component with a through hole. The method includes: well mixing the powder materials, placing the mixed alloy iron-based powder in a die for compressing forming, sintering, mechanically drilling, thermally processing, and surface vibration grinding to obtain the powder metallurgy component. The produced powder metallurgy component is high in precision, strength and hardness, good in wear resistance, widely applicable to manufacturing of various bevel gears, and the like.

Owner:江苏宏创精密制造有限公司

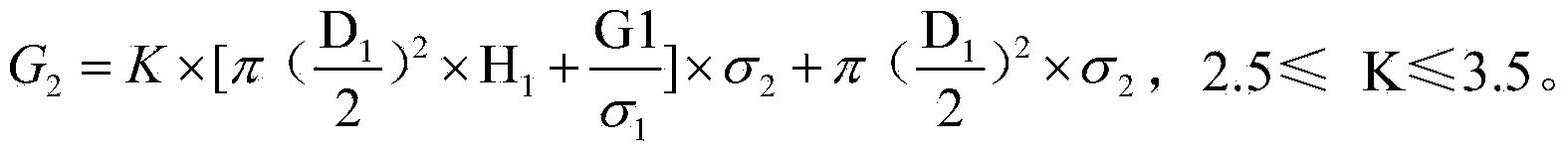

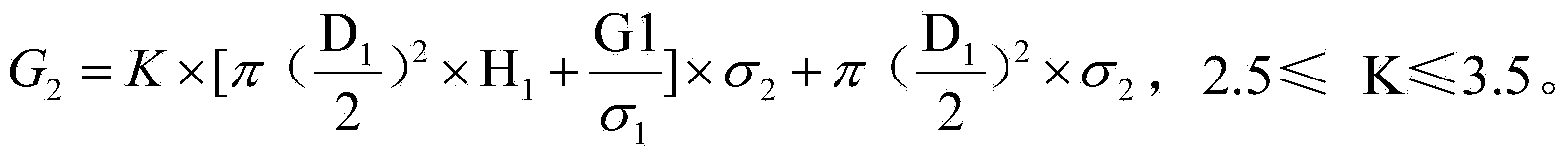

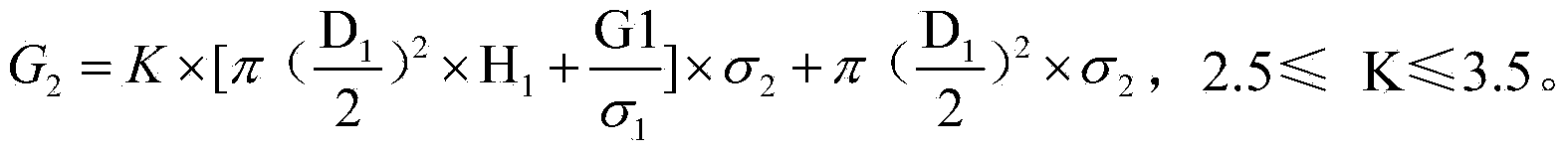

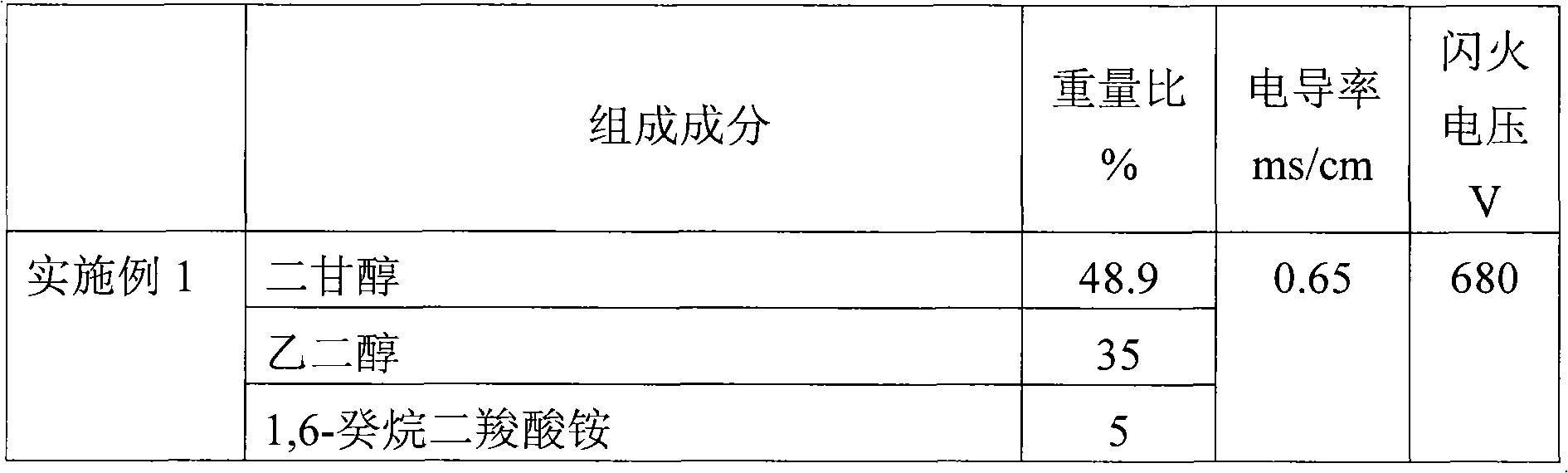

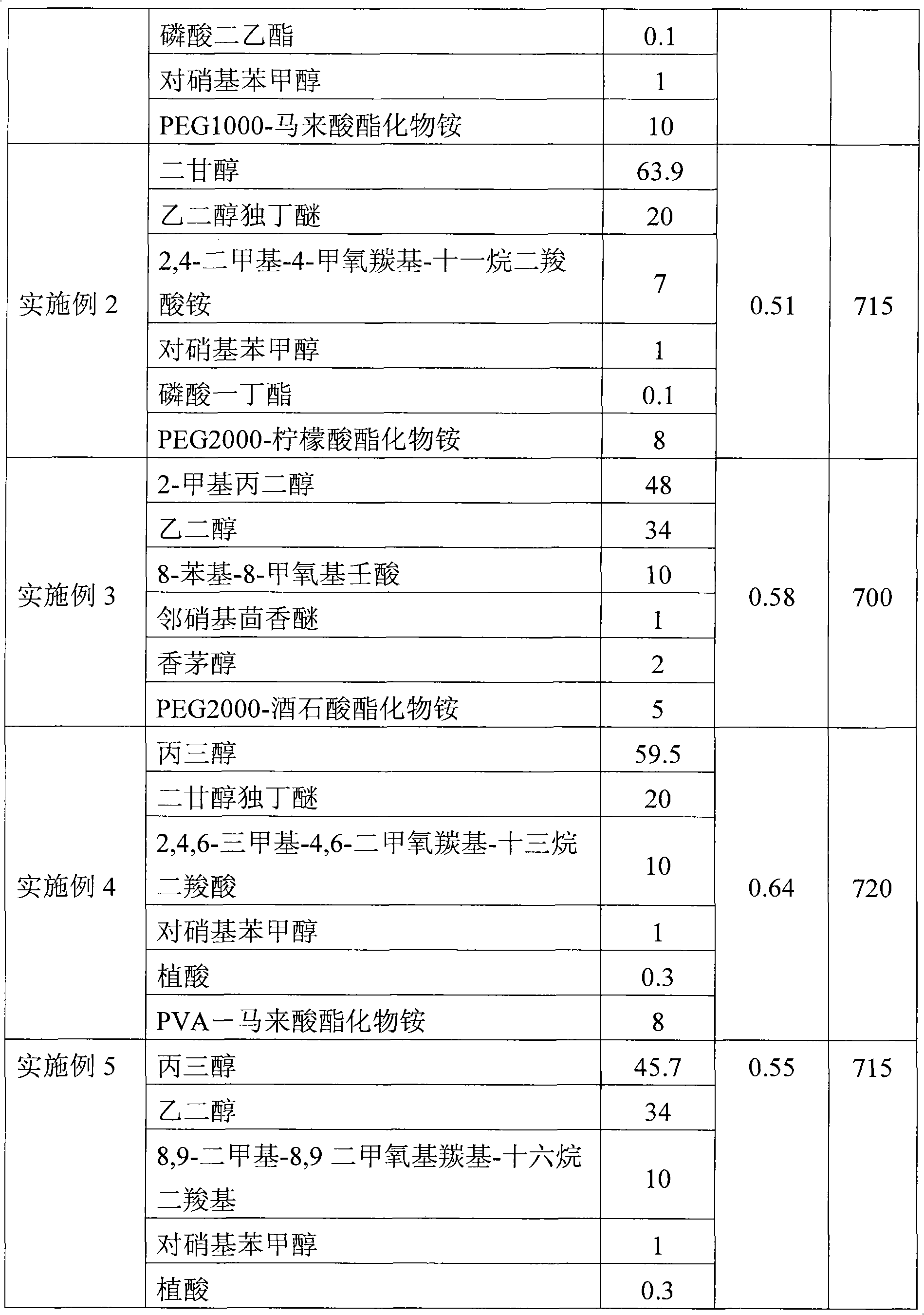

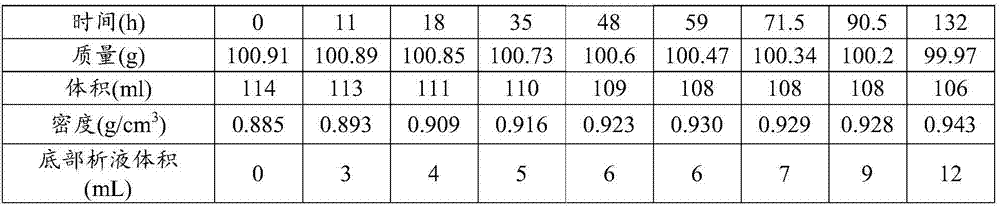

Electrolyte for driving ultrahigh voltage large-sized aluminium electrolytic capacitor and solute thereof

ActiveCN101866752AIncrease the flash voltageImprove conductivityElectrolytic capacitorsSolventEsterification reaction

The invention provides an electrolyte for driving an ultrahigh voltage large-sized aluminium electrolytic capacitor and a solute thereof. The solute of the electrolyte for driving the ultrahigh voltage large-sized aluminium electrolytic capacitor is a high-molecular solute, and the preparation process comprises the following steps of: uniformly mixing a polyalcohol polymer with hydroxyl at a tail end and a saturated or unsaturated binary or polybasic acid according to a certain proportion; adding a certain amount of catalyst; carrying out condensation and esterification reaction at certain temperature under the condition of decompression, cooling, and separating an ester, wherein the total number of carbon atoms positioned on a main chain of the ester is 15 or more than 15; and dissolving the ester into a solvent to prepare a solution with certain concentration, then introducing ammonia so that the pH of the solution reaches a certain range, and stopping introducing the ammonia so that the ester reacts with the ammonia to form ester ammonium salt, wherein the ester ammonium salt is the high-molecular solute used for the electrolyte. The aluminium electrolytic capacitor has very high voltage resistance, larger ripple current bearing and high reliability and finished product ratio when using the electrolyte prepared by the solute.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN +1

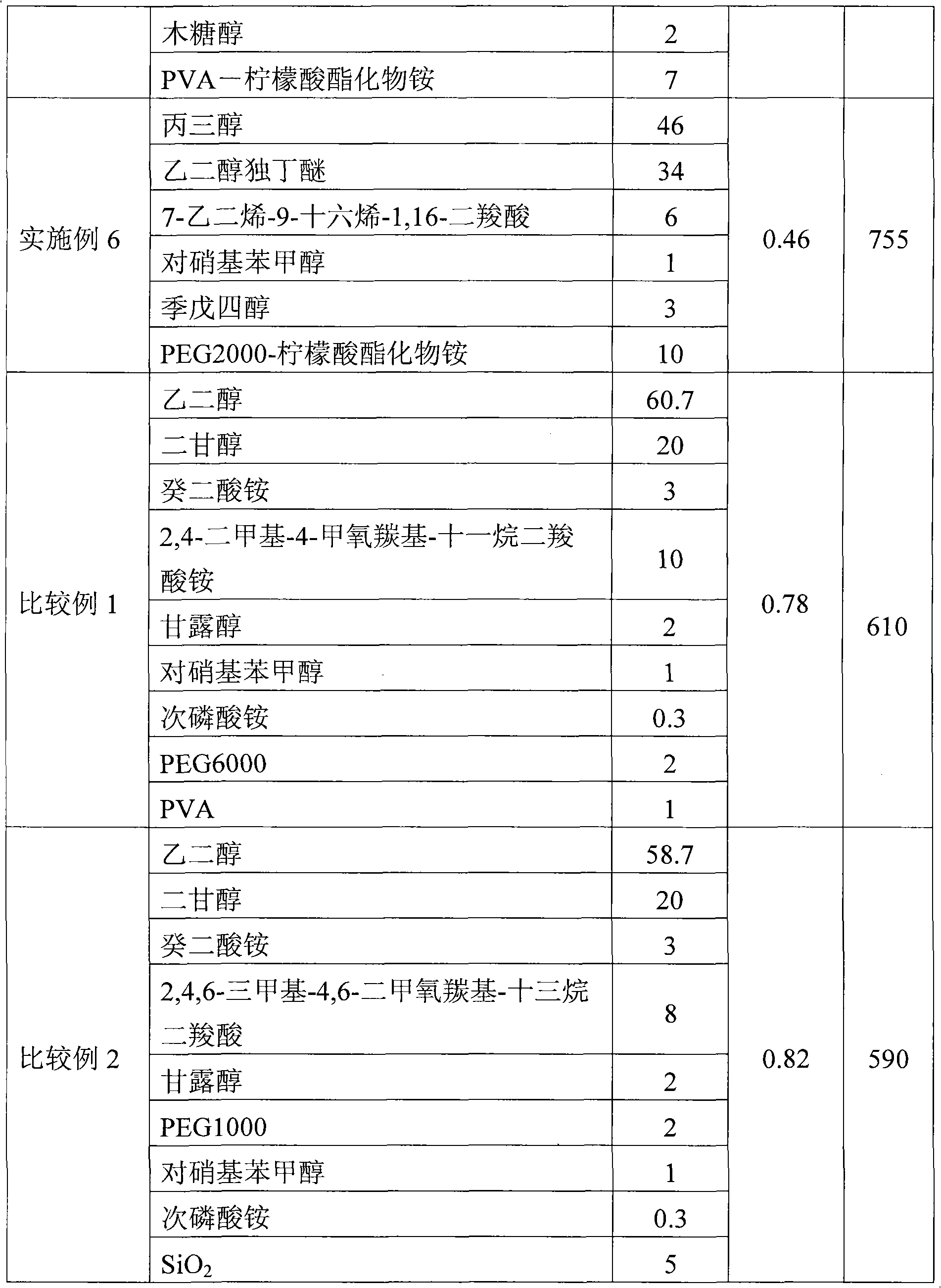

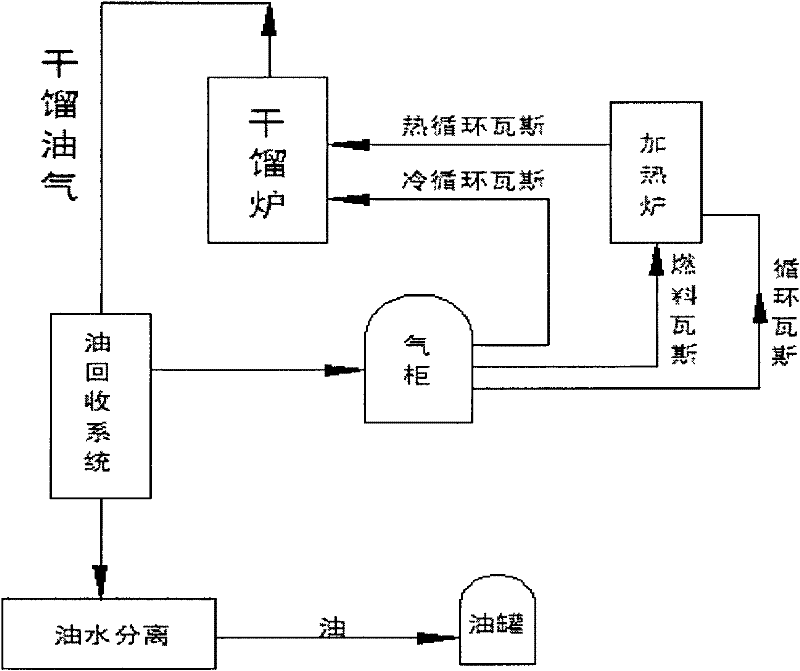

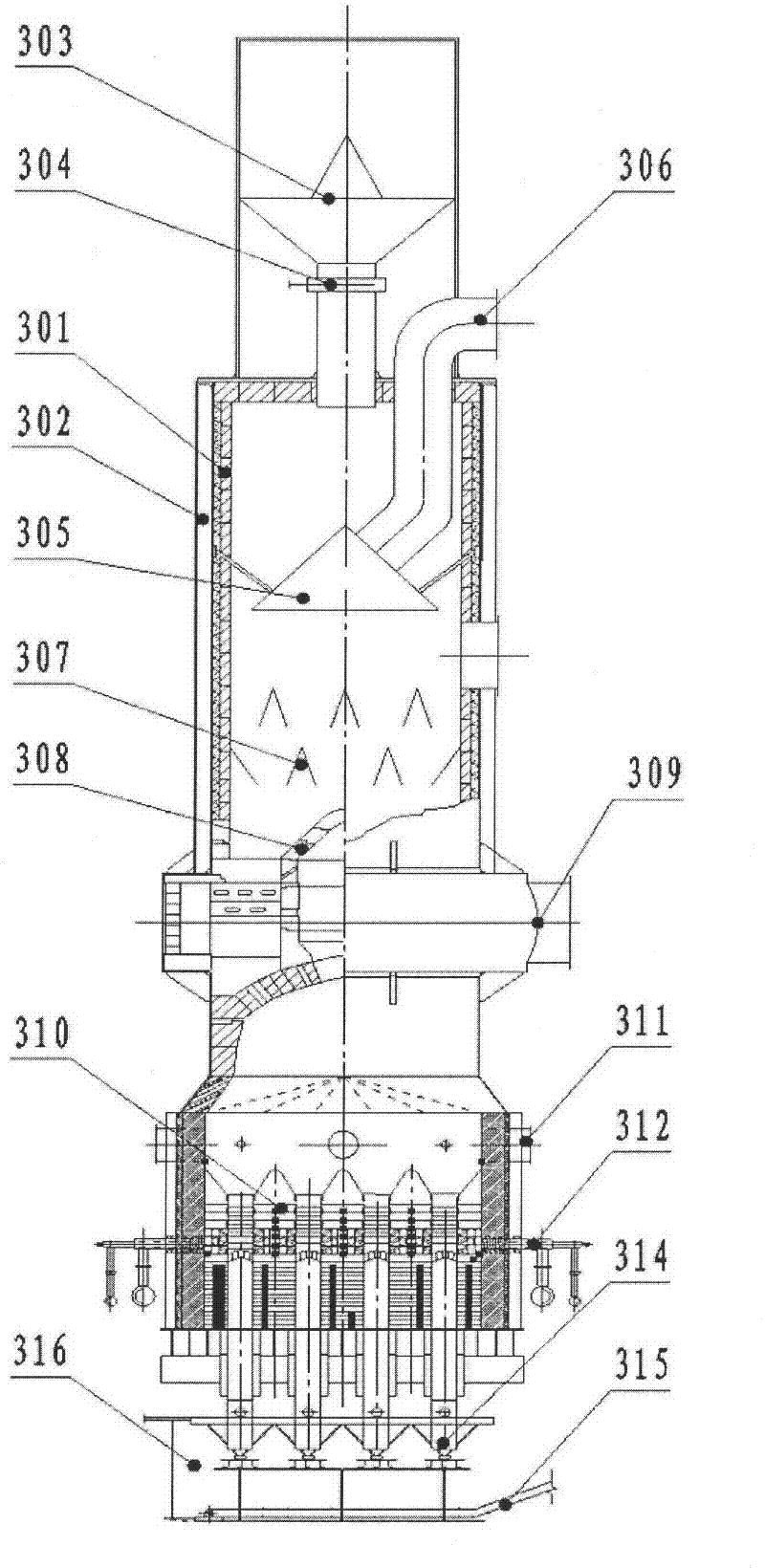

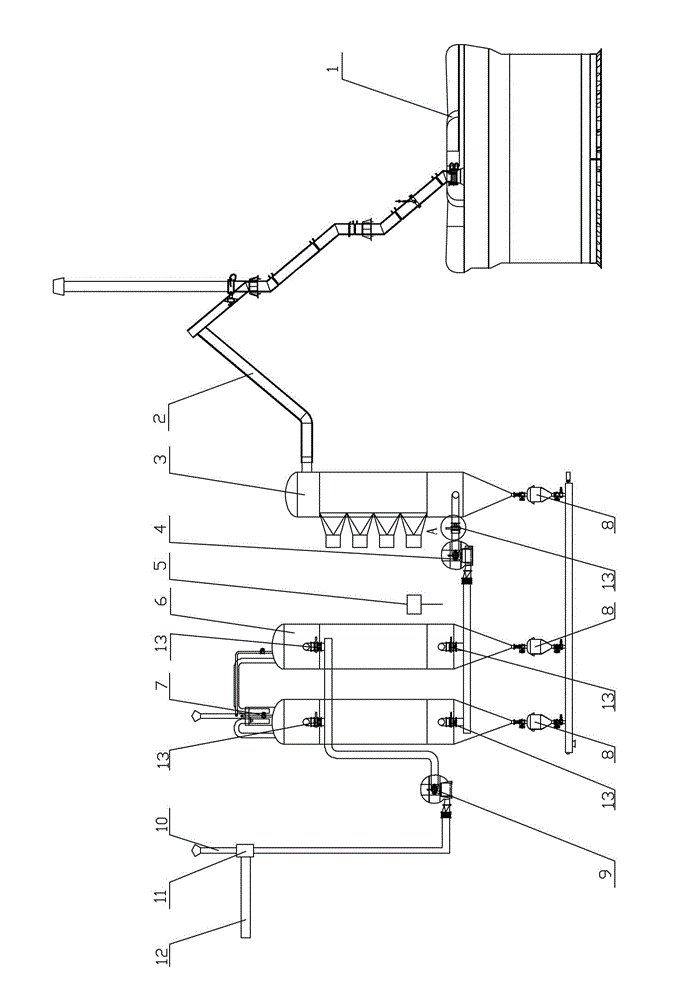

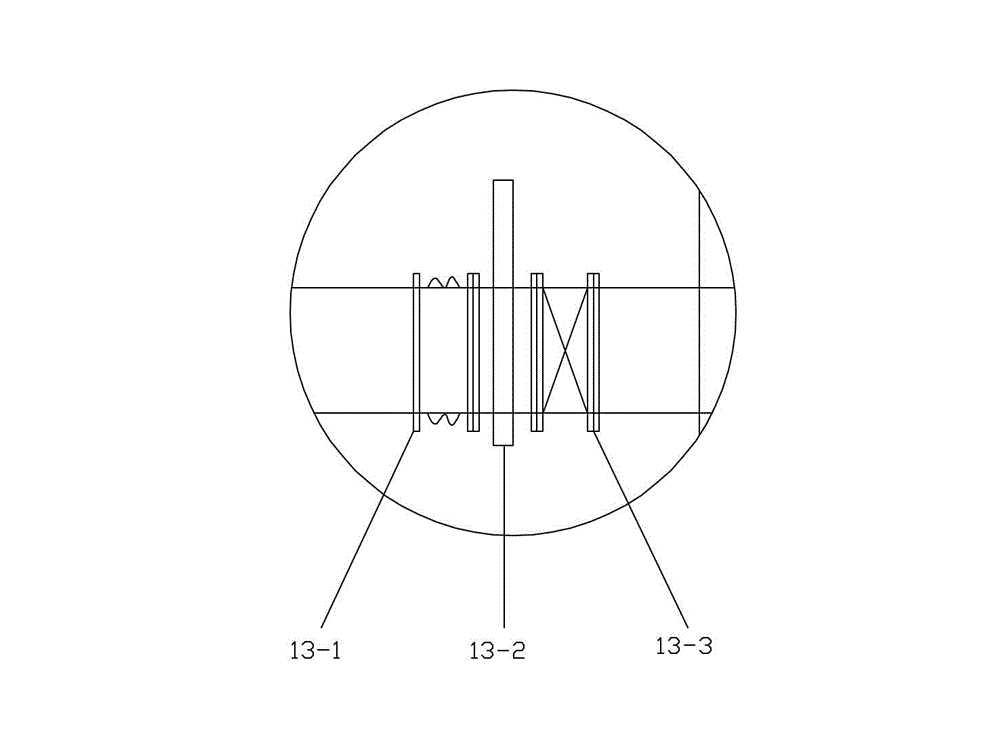

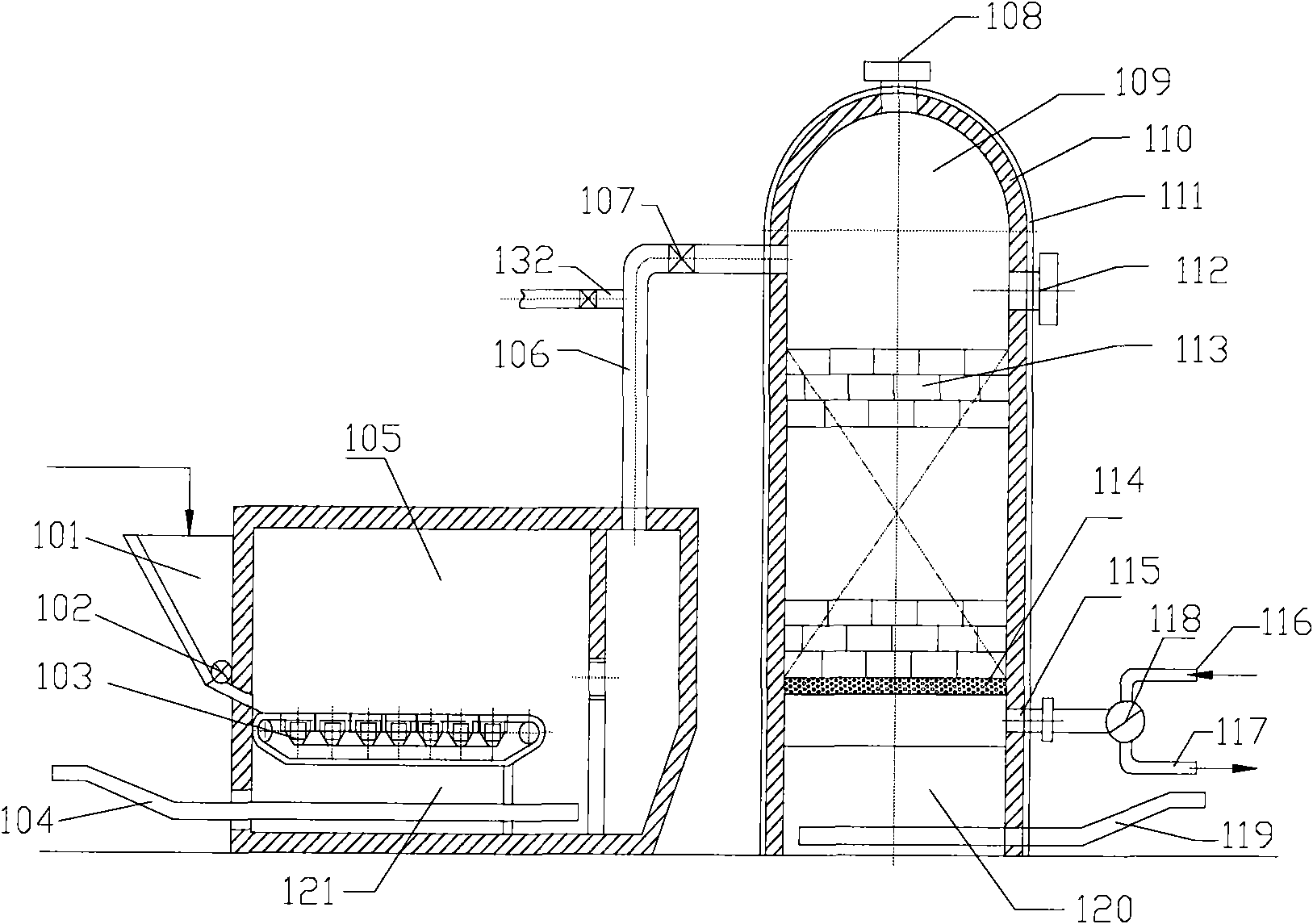

Methane-circulating retort capable of handling 500 to 1,000 tons of oil shale daily

InactiveCN102260509ASmall pressure lossReduce masonry costsDirect heating destructive distillationSpecial form destructive distillationWater contentChemistry

The invention discloses a process and a device for refining oil by dry distillation of oil shale. The process is characterized in that methane generated in the dry distillation process of the oil shale can be repeated used as a hot carrier in the dry distillation of the oil shale. The retort for realizing the dry distillation oil refining process is characterized in that: the retort has a vertical round-square structure, namely the cross section of the upper part is round, the cross section of the lower part is square, and the inside diameters of the upper and lower parts are the same; and array umbrellas, a herringbone baffle plate, a device shaped like a Ding(ancient cooking vessel of China) or in an Asi structure, an air distribution and material distribution tracery wall, a coke discharging tank, a cooling water jacket, a water seal pool, a coke pushing machine and a scraper conveyor are arranged in the retort from top down in turn. The daily handling capacity of the retort is 500 to 1,000 tons. The invention is suitable for refining oil by dry distillation of oil shale with low methane content, low solid carbon content, low water content and a particle size of 5 to 75 milliliters, and the recovery rate of the oil is 85 to 90 percent.

Owner:辽宁成大能源科技有限公司

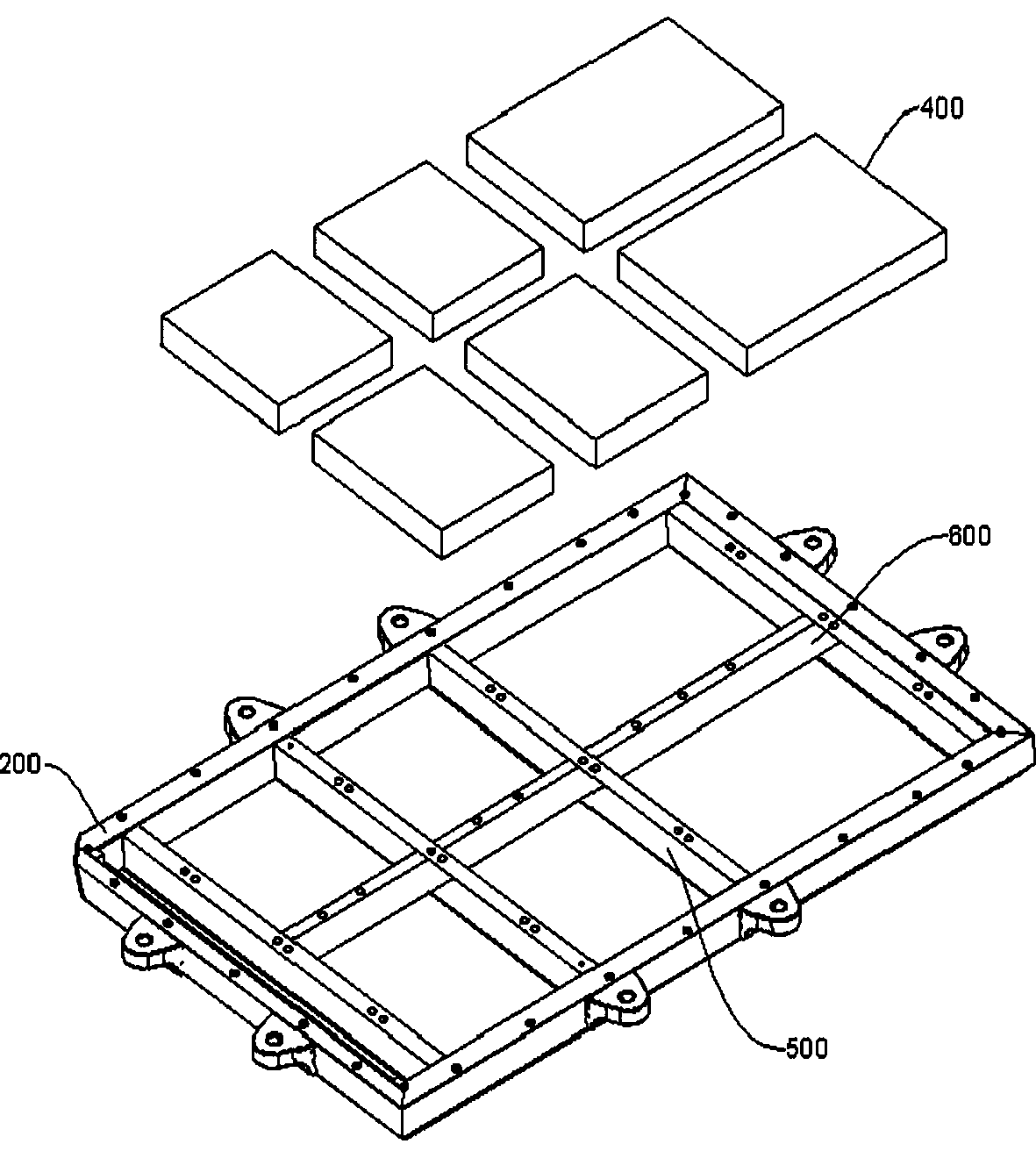

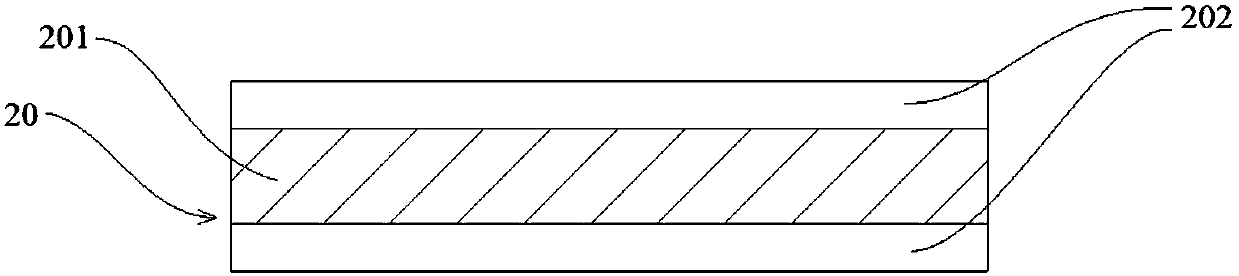

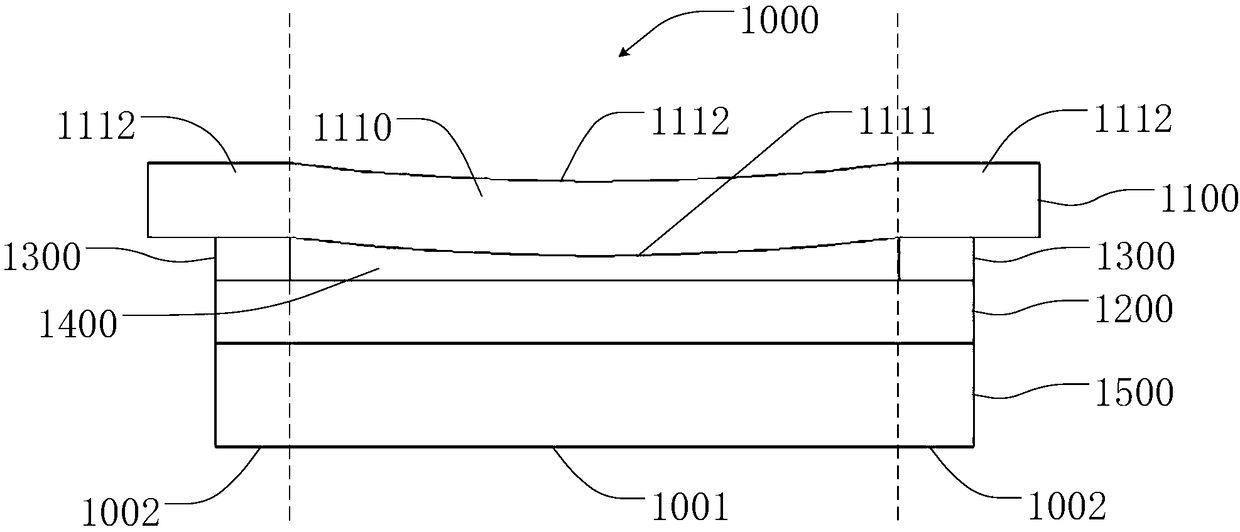

Battery pack, vehicle and energy storage device

ActiveCN110165116AMuch layoutImprove securitySmall-sized cells cases/jacketsElectric propulsion mountingElectrical batteryParallel plane

The invention discloses a battery pack, a vehicle and an energy storage device. The battery pack comprises a battery array and a support member, wherein the battery array includes a plurality of single batteries, the single batteries have a first size, and the first size is the maximum value of the distance between two parallel planes virtually clamping the single battery; at least one single battery satisfies the following conditions: the first size is greater than or equal to 600mm and less than or equal to 2500mm, and the single battery is supported on the support member; the normal direction of the two parallel planes corresponding to the first size is the Q-direction, the battery pack is internally provided with a battery placement area, the battery array is located in the battery placement area, and the single battery extends from one side of the battery placement area to the other side of the battery placement area in the Q-direction. According to the battery pack of the invention, the plurality of long single batteries form the battery pack, so that the battery capacity of the battery pack is improved. Meanwhile, the first size within the specific range is adopted, and thusthe space utilization ratio of the battery pack can be improved.

Owner:BYD CO LTD

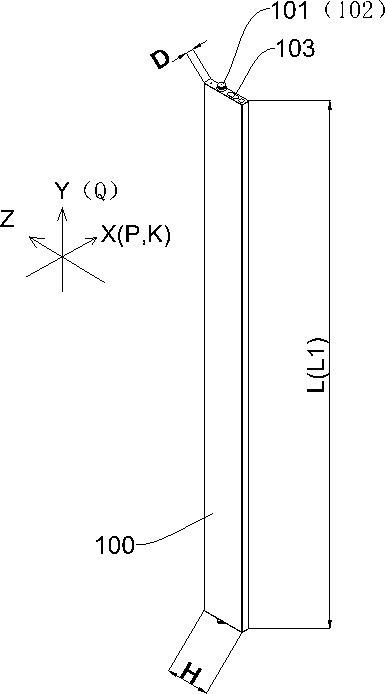

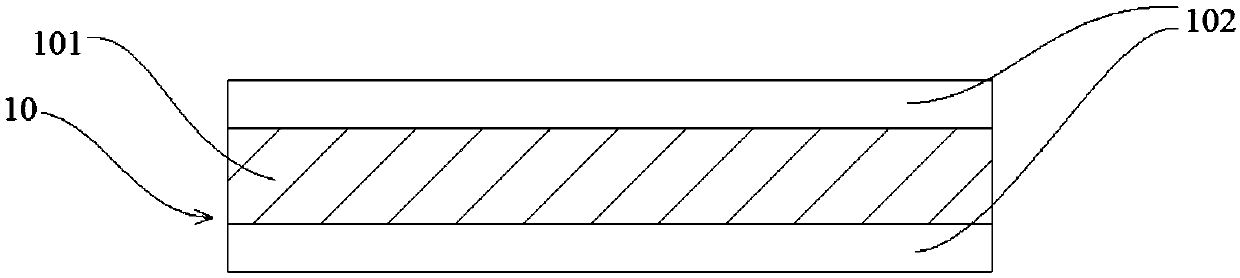

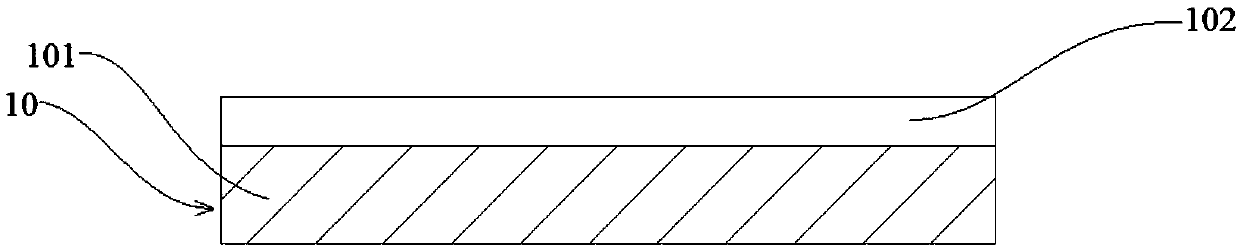

Current collector as well as pole piece and battery and application thereof

ActiveCN109873163AImprove job stabilityExtended service lifeFinal product manufactureElectrode carriers/collectorsElectrical batteryCurrent collector

The invention relates to the field of batteries, in particular to a current collector as well as a pole piece and a battery and an application thereof. The current collector comprises an insulation layer with a supporting function and a conductive layer with a conductive and current collection function, wherein a normal-temperature thin-film resistance RS of the conductive layer satisfies: RS is greater than or equal to 0.01 omega and less than or equal to 0.15 omega. By adopting the current collector, the short-circuit resistance when in short circuit under the abnormal condition of a batterycan be greatly increased, so that the short-circuit current is greatly reduced, the short-circuit heat can be greatly reduced, and the safety performance of the battery can be greatly improved; and in addition, due to the small heat yield, the heat produced at a point having the internal short circuit can be completely absorbed by the battery, the temperature increase of the battery is small, sothat the influence of the short-circuit damage for the battery can be limited in a range of the point, and only the point short circuit is formed without influencing the normal work of the battery ina short time.

Owner:CONTEMPORARY AMPEREX TECH CO

Self-generating foam kill fluid and preparation method and self-generating foam composition

A self-generating foam composition relates to the field of oilfield chemistry. The self-generating foam composition comprises 2-6wt% of a polymer, 0.1-3wt% of a crosslinking agent, 1-3wt% of a foaming agent, 6-10wt% of a blowing agent and the balance of water. The blowing agent comprises carbonate and an acid substance. The mass ratio of the acid substance and carbonate in the blowing agent is 1: (1-3). A self-generating foam kill fluid forms a gel by taking the polymer and the crosslinking agent as a framework and has the characteristics of being low in density, low in damage and good in stability by taking carbon dioxide generated by a reaction on carbonate and the acid substance as gas filling. A preparation method of the self-generating foam kill fluid is quite simple in preparation process and is free of gas injecting equipment and high-speed stirring equipment. The self-generating foam kill fluid can be obtained by simple mixing. Limited production conditions can be met, and the production cost is hugely lowered.

Owner:SOUTHWEST PETROLEUM UNIV

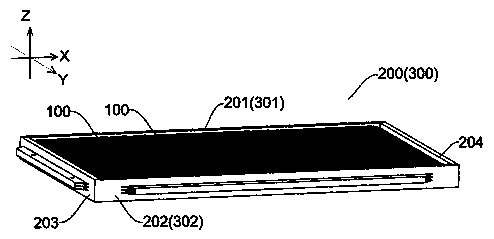

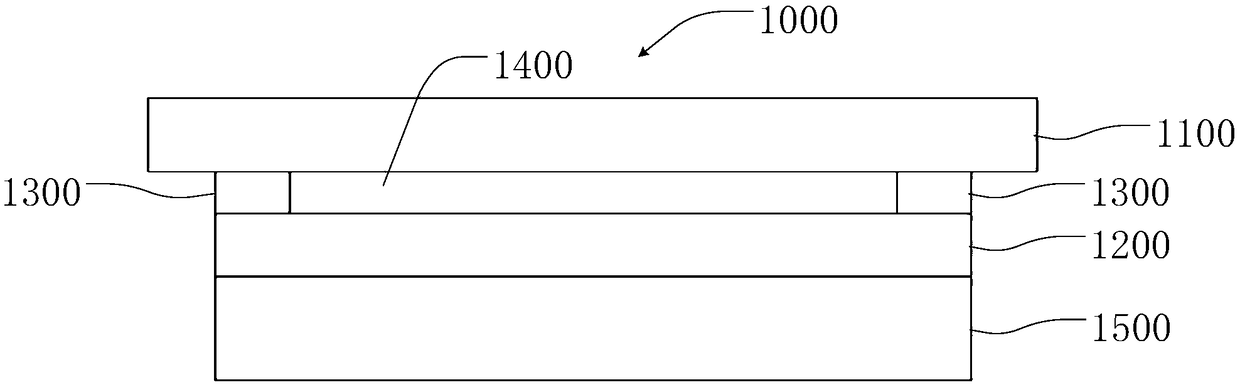

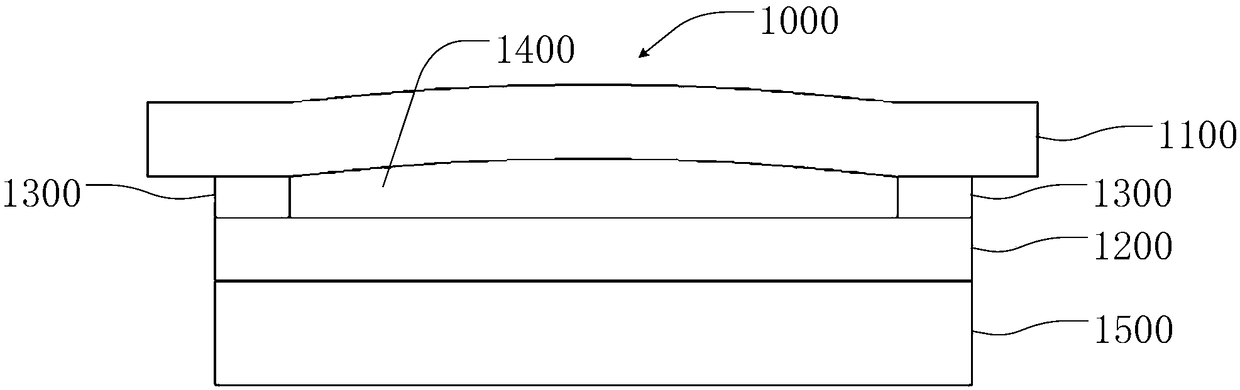

Touch screen and display device

ActiveCN109508121ADoes not affect touch sensitivityEasy to useInput/output processes for data processingGlass coverDisplay device

The invention provides a touch screen and a display device. The touch screen includes a display area and a non-display area surrounding the display area. The touch screen further comprises a touch panel and a glass cover plate. The glass cover plate has a bending portion corresponding to the display area. The bending portion of the glass cover plate is a convex first arcuate surface on one side facing the touch panel, and a concave second arcuate surface on the other side away from the touch panel. The bending portion of the glass cover plate is a convex first arcuate surface on one side facing the touch panel. The utility model solves the problems that the glass cover plate of the prior art will bulge outward, so that the thickness of the air layer becomes larger, thereby causing the explosion point, lowering the touch control sensitivity, affecting the user's sense of use, and the like.

Owner:HUIZHOU CHINA STAR OPTOELECTRONICS TECHNOLOGY CO LTD

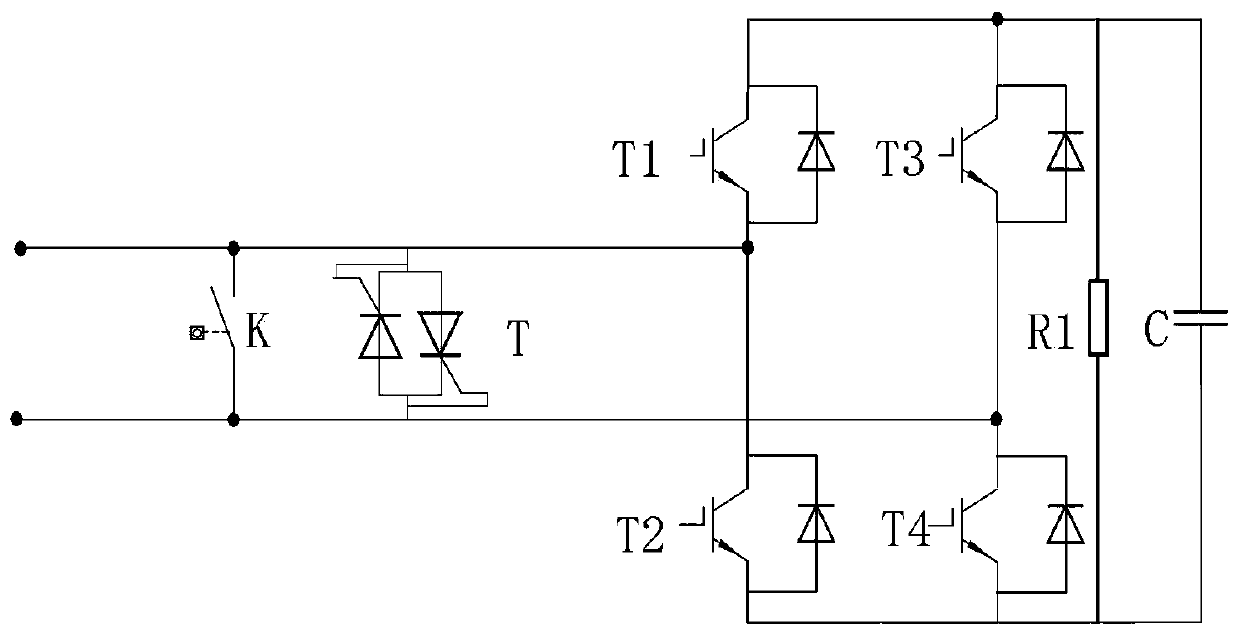

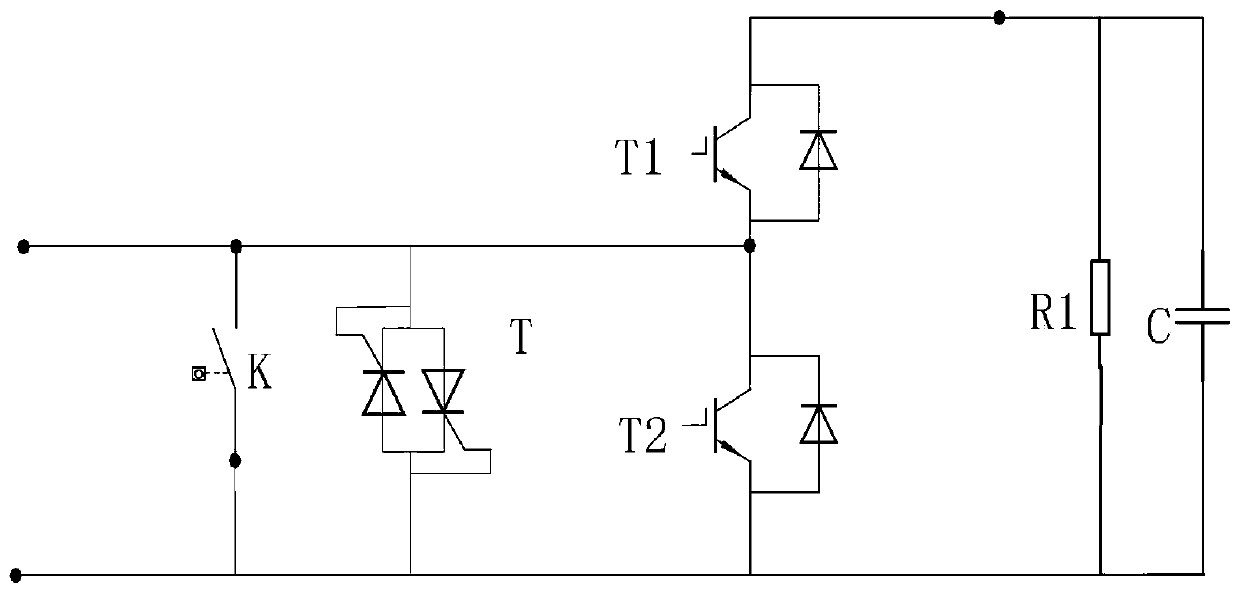

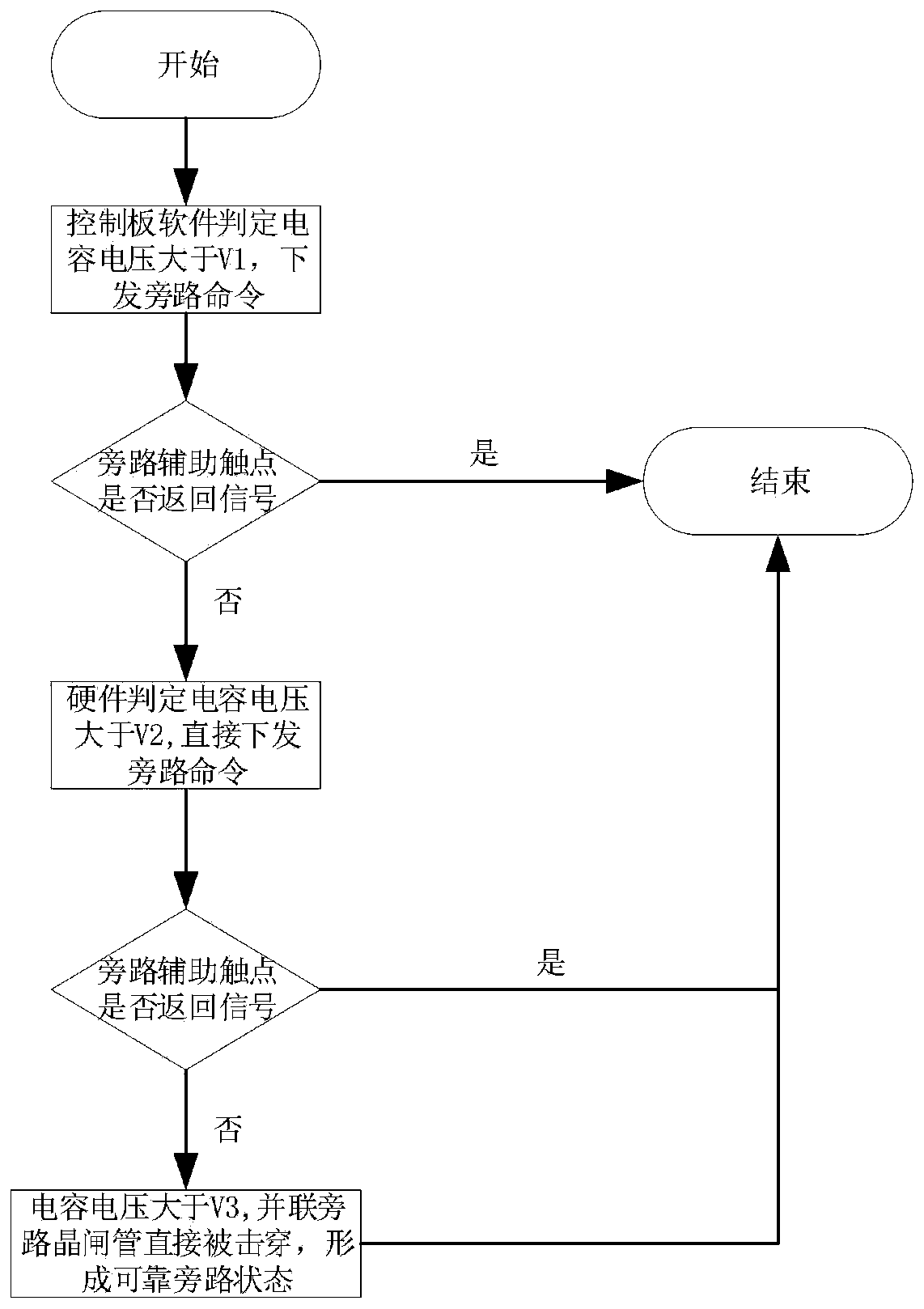

MMC power module overvoltage protection circuit and multistage bypassing method

PendingCN110829811AGuaranteed not to be controlledDoes not affect operationPower conversion systemsOvervoltageCapacitor voltage

The invention discloses an MMC power module overvoltage protection circuit and a multistage bypassing method. The circuit comprises a bypass switch connected to the two ends of an MMC power module inparallel and thyristors connected to the two ends of the MMC power module in parallel. When the capacitor voltage of the MMC power module exceeds a set safety value, the bypass switch is closed, so that the MMC power module is bypassed. When the thyristors are broken down due to overvoltage, a reliable short-circuit path is formed, so that the MMC power module is bypassed, and a capacitor of the MMC power module stops charging. The breakdown voltage values of the thyristors are larger than the set safety value and smaller than a rated voltage value of an IGBT of the MMC power module. Accordingto the invention, the bypass switch and the thyristors are arranged for double insurance. When the IGBT of the power module is out of control and the power module is continuously charged, the power module can be reliably bypassed, the IGBT and the capacitor do not explode, other power modules are not influenced, and the continuous operation of an MMC converter valve flexible DC system is not influenced. Therefore, the reliability of the system is improved.

Owner:EXAMING & EXPERIMENTAL CENT OF ULTRAHIGH VOLTAGE POWER TRANSMISSION COMPANY CHINA SOUTHEN POWER GRID

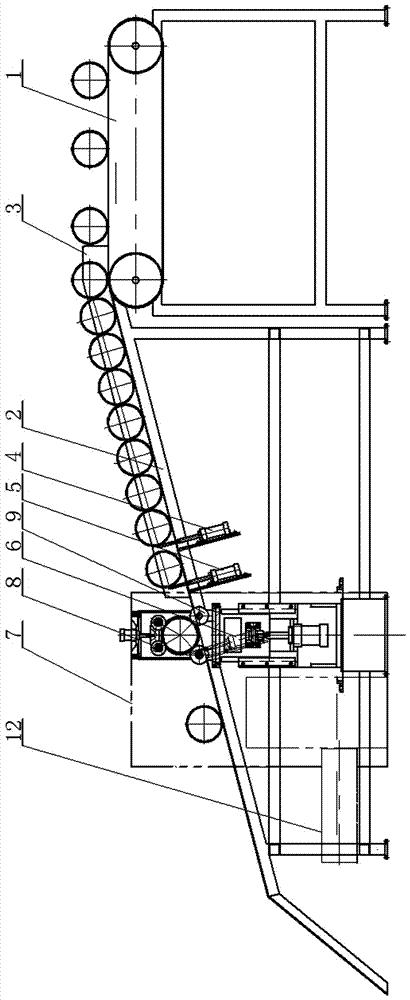

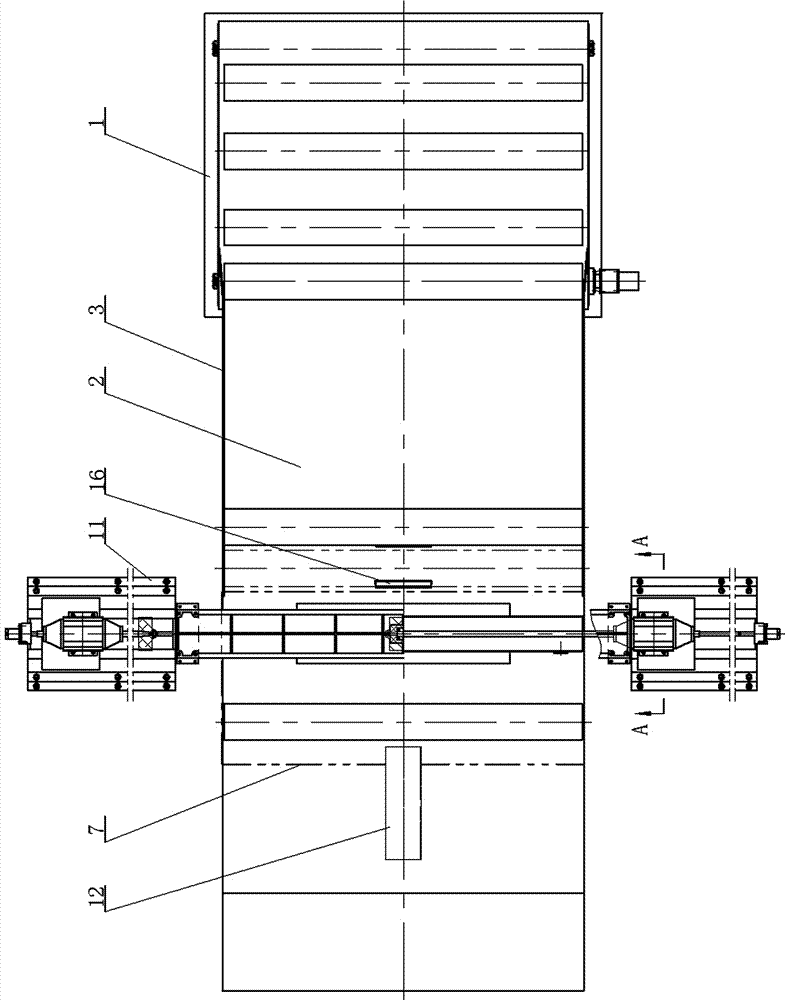

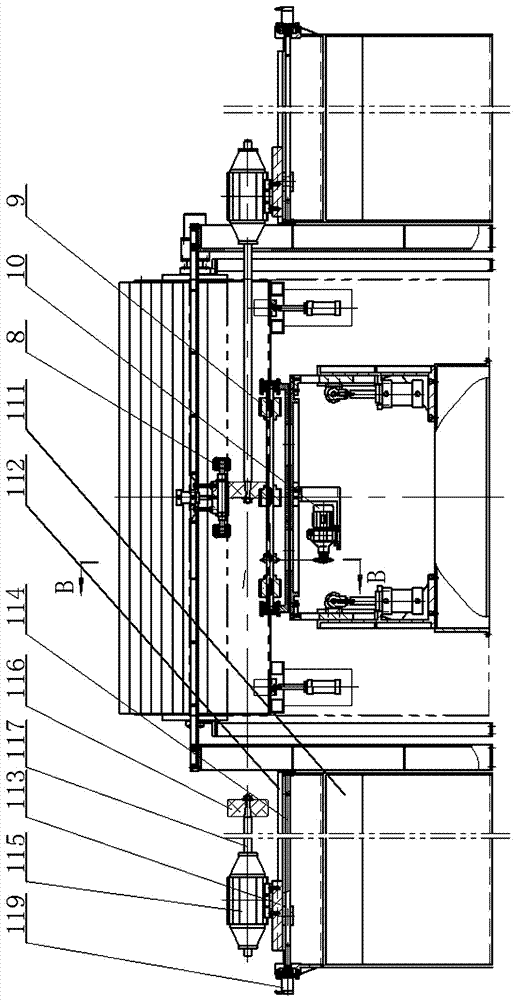

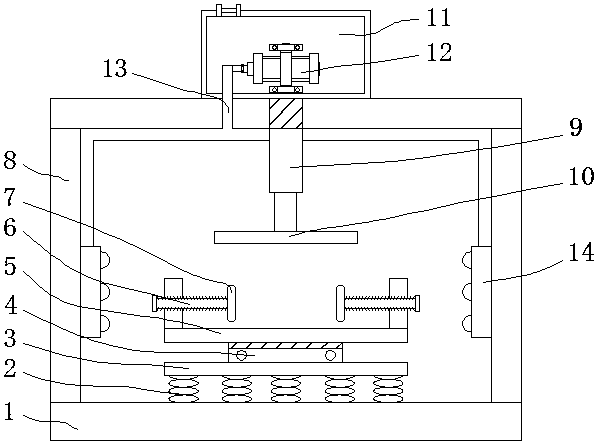

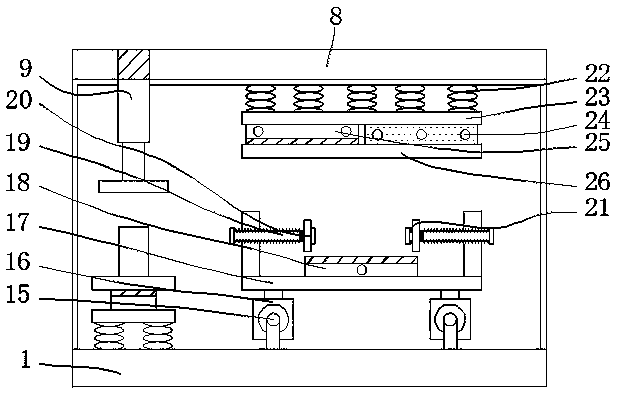

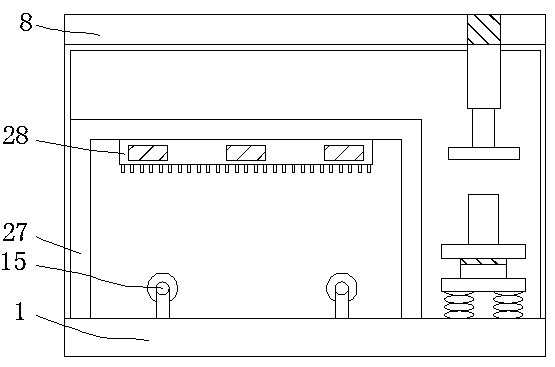

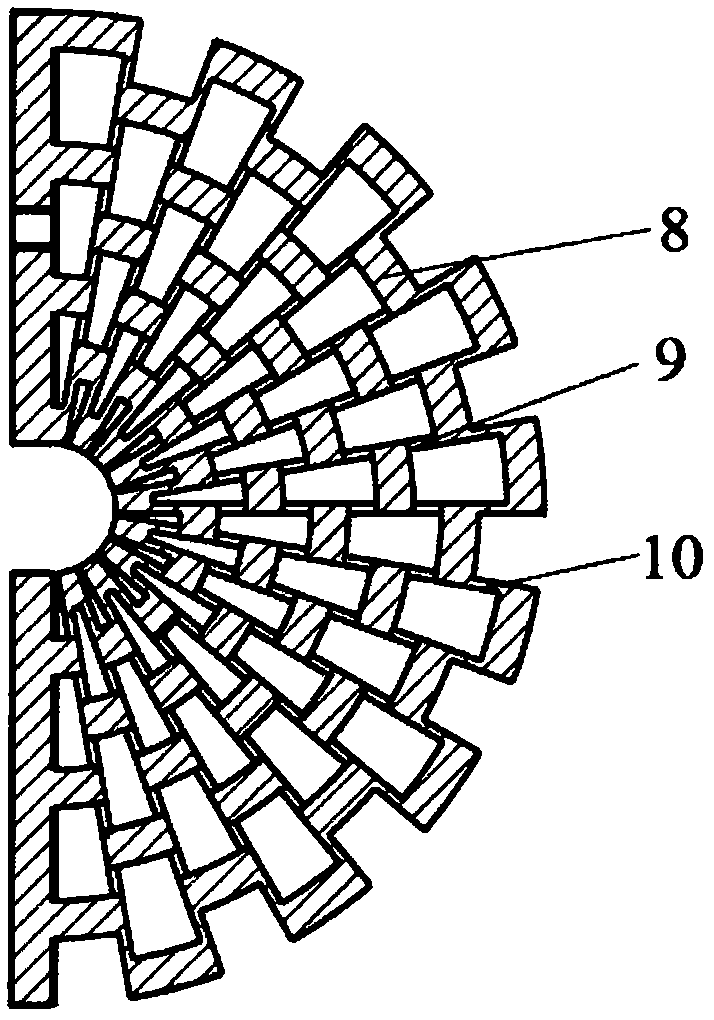

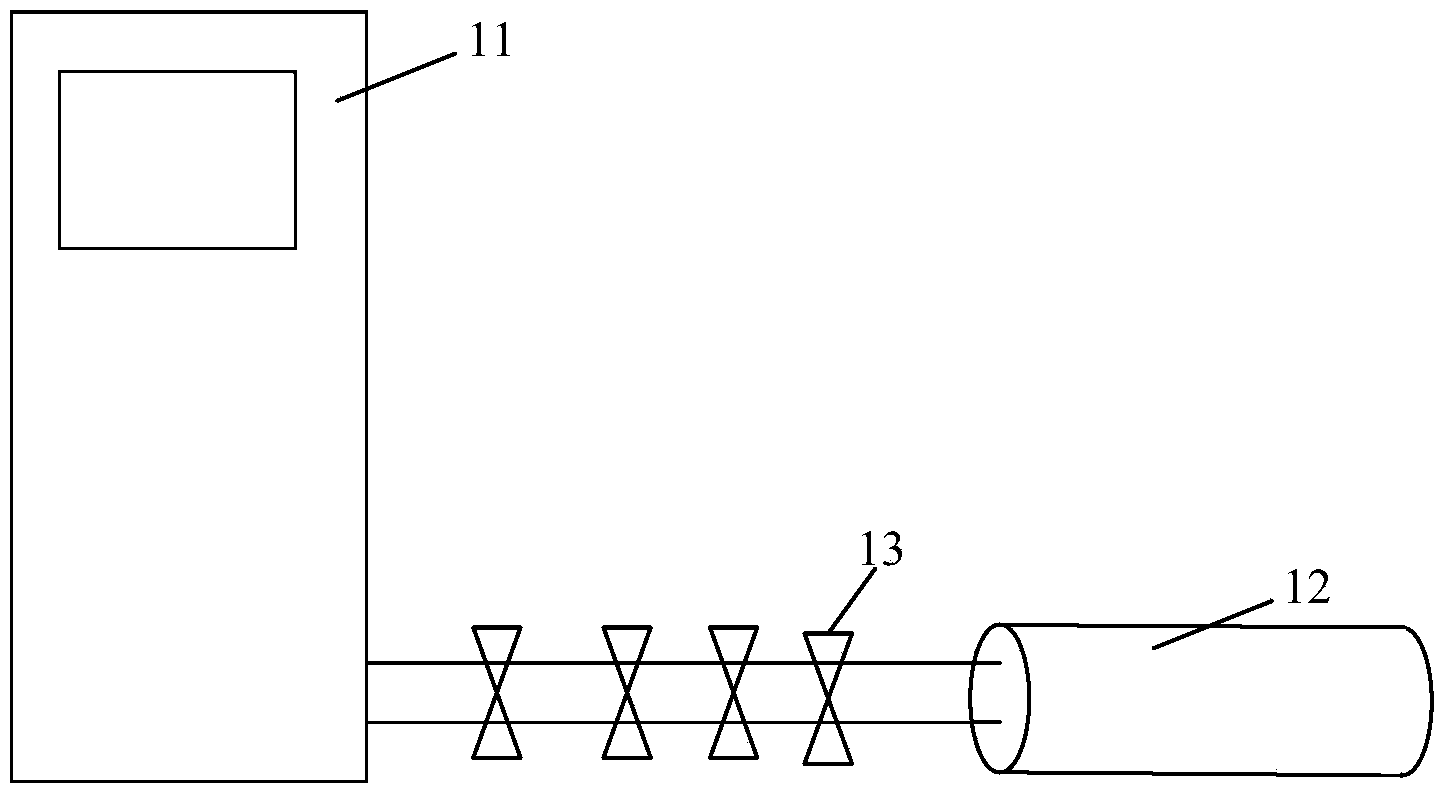

Automatic polishing and grinding equipment for inner hole of metal pipe

ActiveCN107571156AProtect your healthNo explosionGrinding/polishing safety devicesDust explosionEngineering

The invention relates to automatic polishing and grinding equipment for an inner hole of a metal pipe. According to the automatic polishing and grinding equipment for the inner hole of the metal pipe,the problems that when the inner wall of the metal pipe is polished and ground, the production efficiency is low, the workshop environment is polluted, and explosion is likely to occur are solved. The automatic polishing and grinding equipment is characterized in that a pressing wheel device (8) and a supporting wheel device (9) are arranged on the upper portion and the lower portion, at a thirdmaterial blocking device (6), of an inclined sliding table (2) correspondingly; polishing devices (11) are arranged on the two sides of a dustproof shell (7) correspondingly, and the dustproof shell (7) communicates with a draught fan through an air suction pipeline (12). The automatic polishing and grinding equipment can be controlled through a PLC, the automation degree is high, and the production efficiency is effectively improved; and a relatively-closed polishing space is formed in the dustproof shell, so that dust generated during polishing does not diffuse in a workshop, pollution to the workshop environment is avoided, dust explosion accidents are avoided, and the anti-explosion requirement is met.

Owner:山东鹤鹏技术有限公司

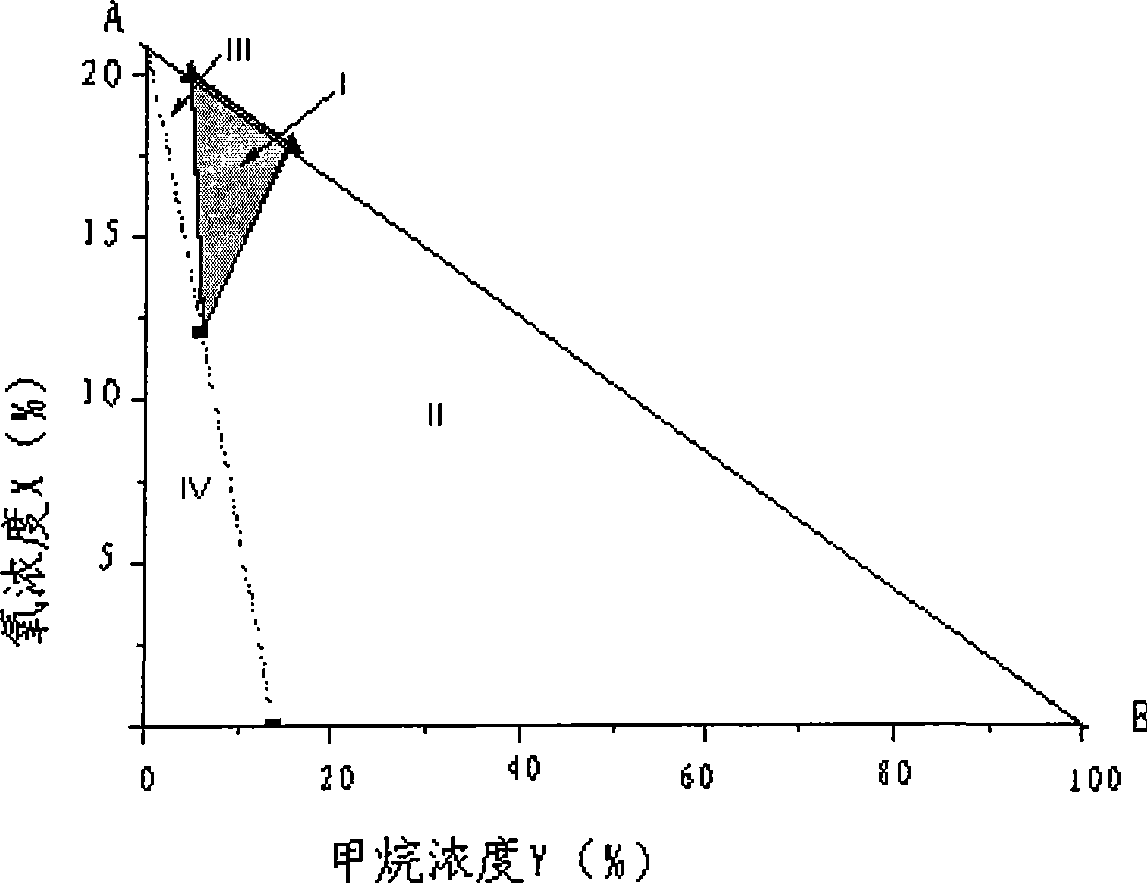

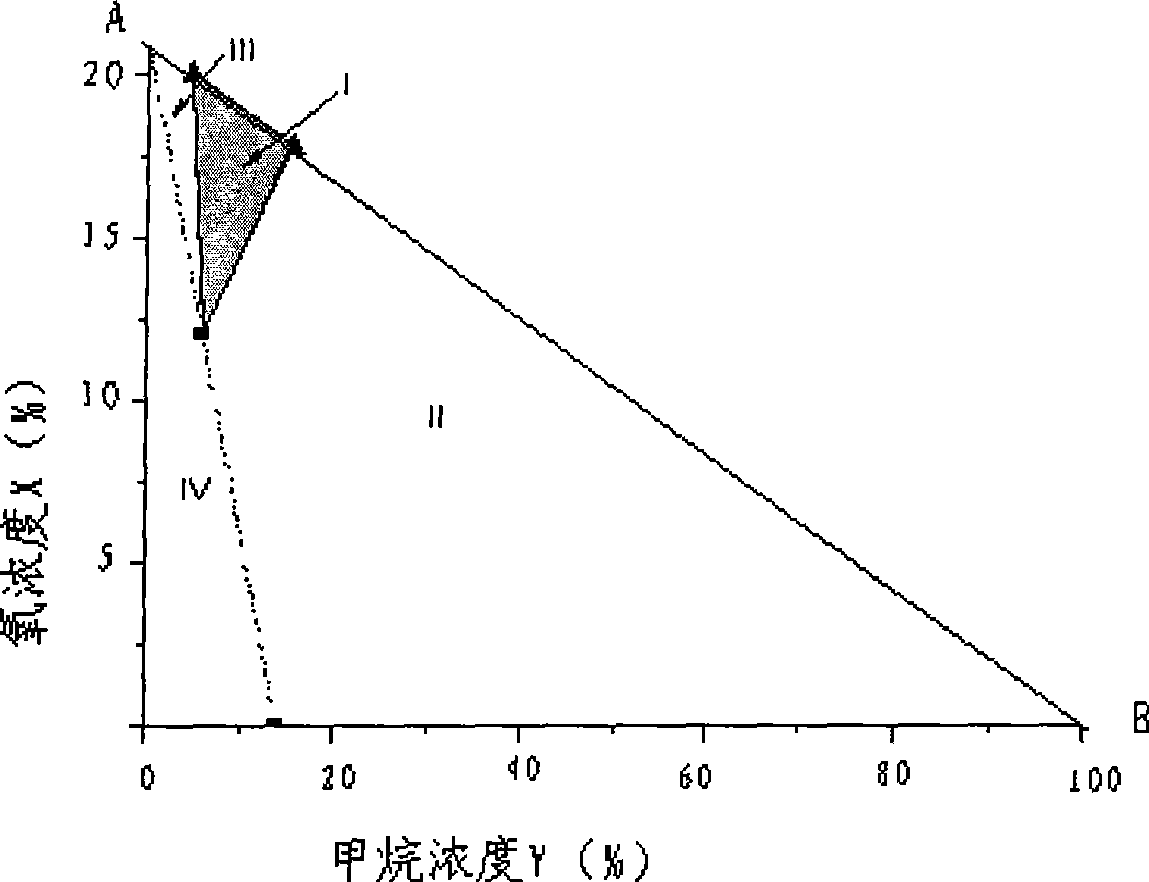

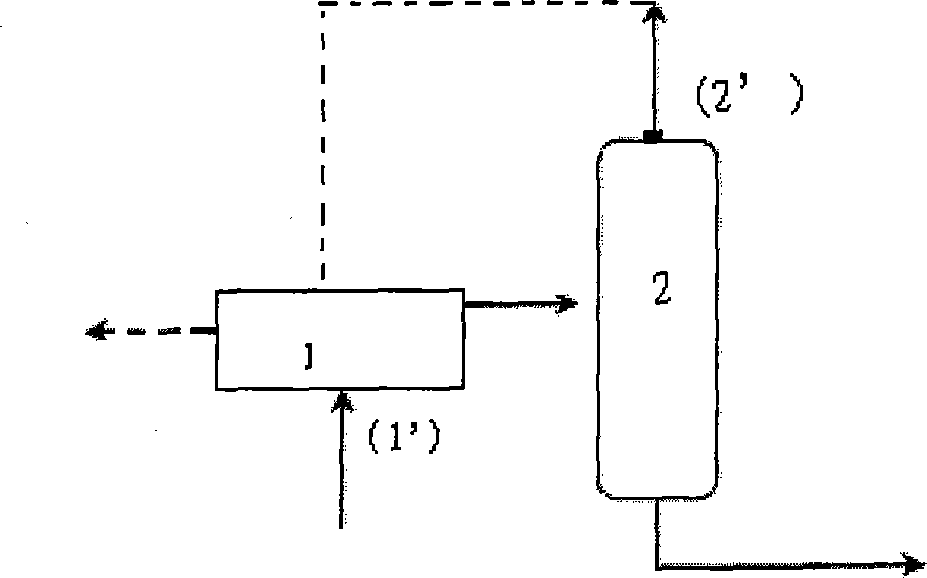

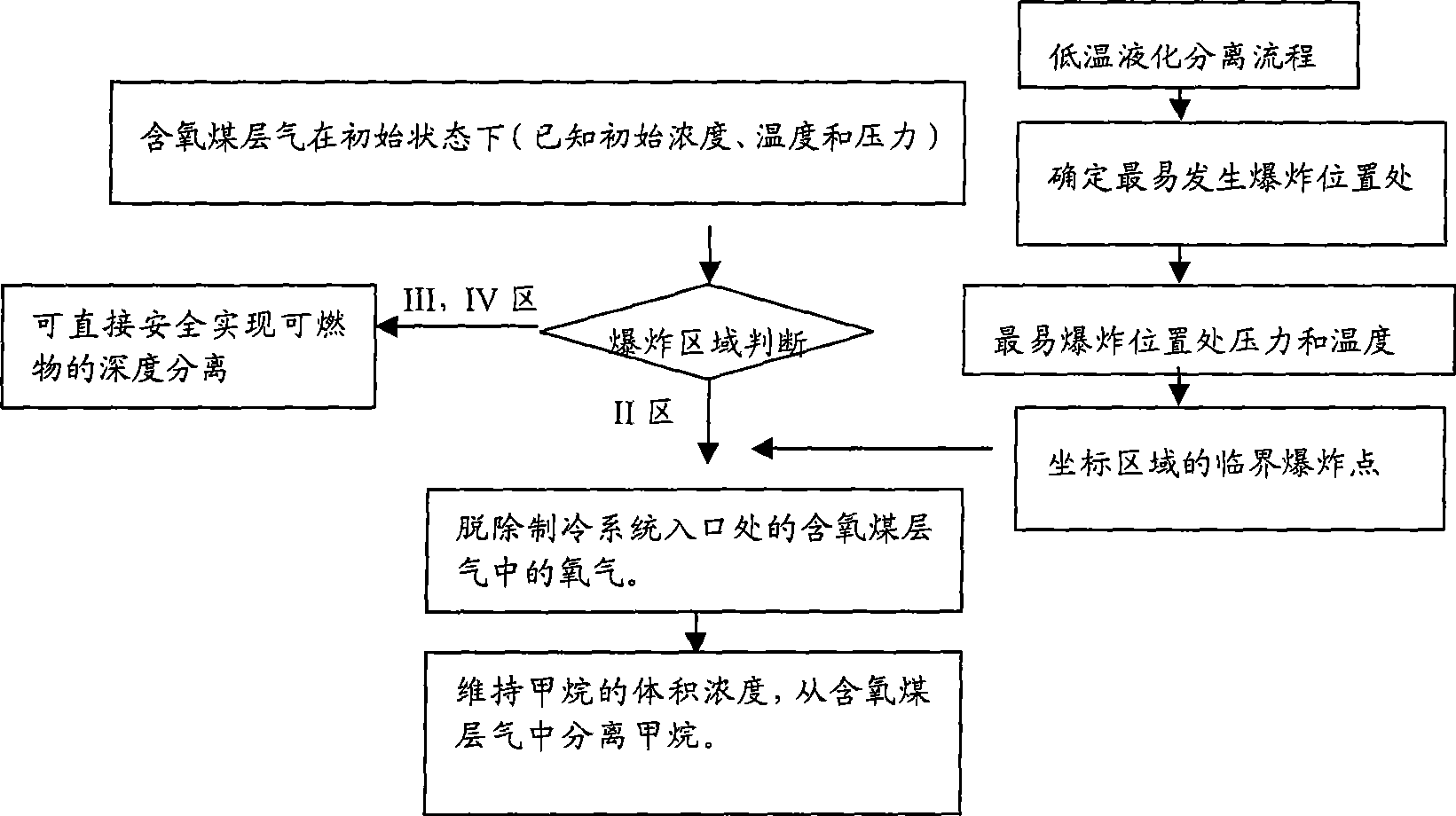

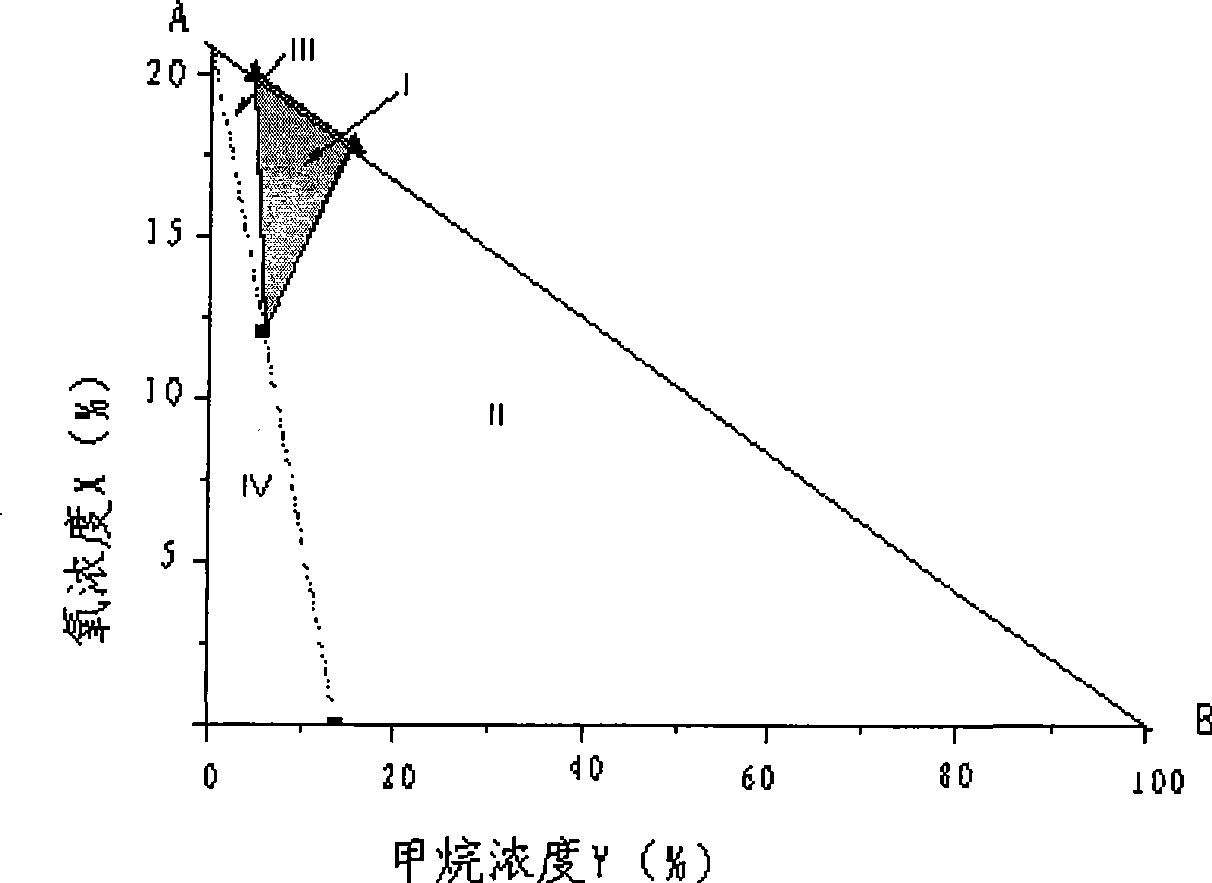

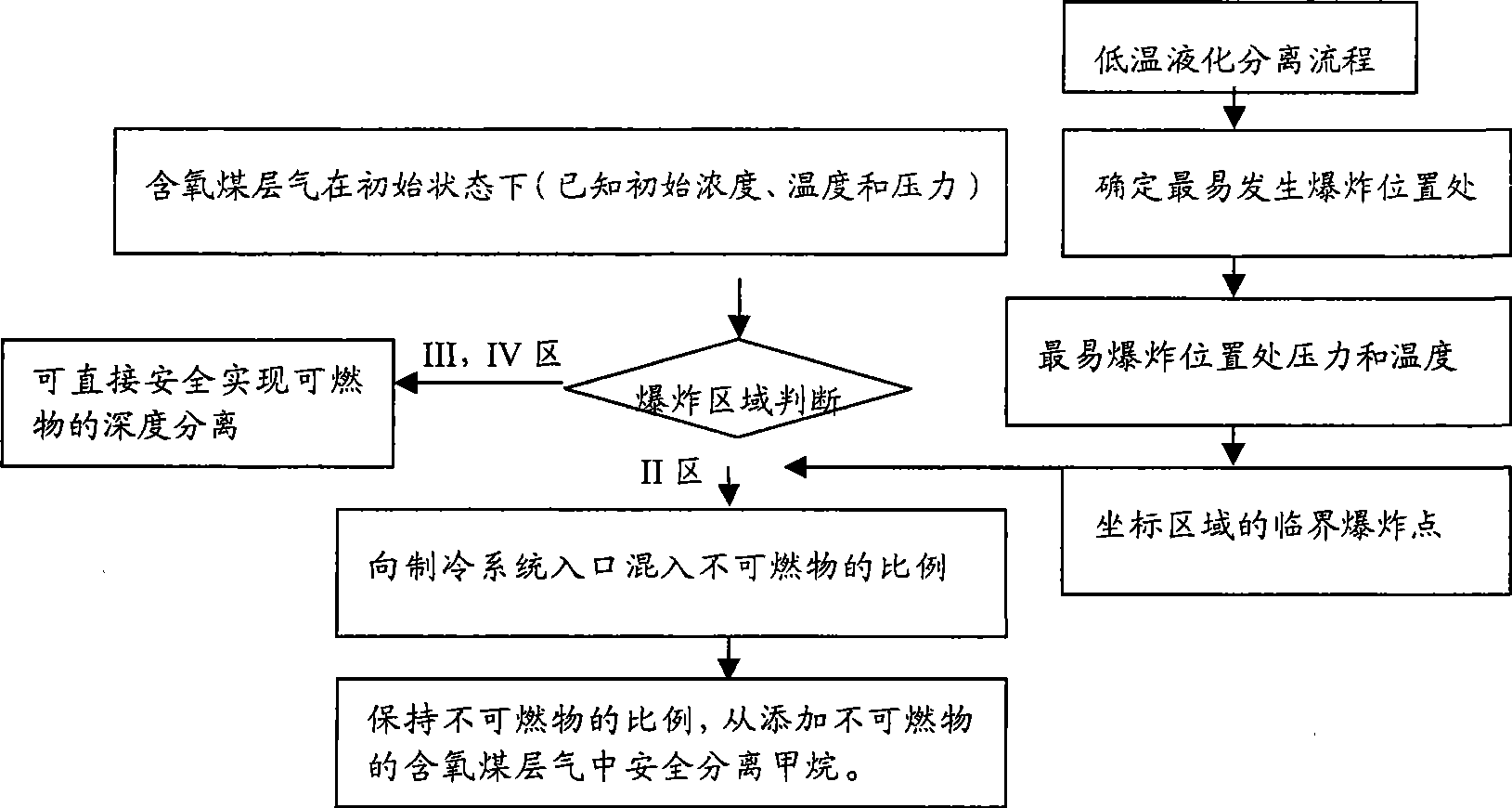

Method for extracting methane from oxygen-containing coal-bed gas through low-temperature liquefying separation

ActiveCN101531560ANo explosionReduce pretreatment processDistillation purification/separationHydrocarbonsSeparation technologyOxygen

The invention provides a method for separating and purifying methane from oxygen-containing coal-bed gas. The separated and purified methane is obtained by firstly cooling feed gas of the oxygen-containing coal-bed gas and then rectifying the oxygen-containing coal-bed gas. The method includes the steps as follows: a) the volume concentration Y of the methane is adopted as an abscissa, and the volume concentration X of the oxygen is adopted as an ordinate, which are used for building an explosion triangle aimed at a position where explosion happens most easily in the process flow of separation technology; b) the original volume concentration Y0 of methane in the feed gas is detected; c) when Y0 is 1.0 to 1.1 times bigger than the upper explosion limit point Y1 of the explosion triangle, the cooling capacity is increased, or the flow of the feed gas is reduced, so the temperature of the position is reduced; and d) the steps b) to c) are repeated until Y0 is 1.0 to 1.1 times bigger thanY1, and the temperature in the current position is the lowest safe separation temperature and the methane can be separated and purified from the oxygen-containing coal-bed gas safely by maintaining the temperature to be 0 to 5 DEG C. With the adoption of the method, the pretreatment technical processes and devices of the feed gas are reduced, thus greatly decreasing the cost.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Method of viscosity reduction and cold production of shallow oil reservoir

The invention relates to the technical field of thickened oil development, and discloses a method of viscosity reduction and cold production of a shallow oil reservoir. The method is carried out by the first step, firstly confirming that the oil reservoir has the following characteristics: the ground crude oil viscosity is 50 mPa.s-20000 Mpa.s when the temperature is 20 DEG C, the acid value of the thickened oil is 0.6 mgKOH / g-2.3 mgKOH / g, the reservoir thickness is more than 5 m; the bury depth of the heavy oil reservoir is less than 800 m, the reservoir porosity is more than 15%; the permeability is more than 50x10<-3> mu m2; the reservoir is a reverse rhythmic stratum. Compared with the steam driving method, the development cost of the shallow oil reservoir by the method is reduced by 28-36%; for the shallow oil reservoir is developed without using the steam driving and other methods, the problems of steam channeling at post period of development, serious 'over-coating' phenomenon, and low gas injection utilization efficiency at post period are also not existed; meanwhile, high-temperature steam is also not produced without fuel gas; therefore, boiler explosion, high-temperature scalding and other safety accidents cannot be happened; greenhouse gases are not generated; compared with the steam driving development, the output is further improved.

Owner:XINJIANG KELI NEW TECH DEV

Device and method for purifying and recycling furnace gas of hermetic ore smelting furnace

ActiveCN102878822AEliminate consumptionAvoid secondary pollutionIncreasing energy efficiencyWaste heat treatmentBaghouseProcess engineering

The invention relates to a device and a method for purifying and recycling furnace gas of a hermetic ore smelting furnace. The technical scheme of the device for purifying and recycling furnace gas of the hermetic ore smelting furnace includes that the hermetic ore smelting furnace is connected with a cooler via a water-cooling flue, the cooler is connected with a waste furnace gas draught fan, an online gas detecting analyzer is mounted at an outlet of the waste furnace gas draught fan which is connected with bag-type dedusters via pipes, an explosion venting safety device is arranged on the bag-type dedusters, a gas outlet of the bag-type dedusters is connected with an inlet of a pure furnace gas pressurizing fan, the pure furnace gas pressurizing fan is connected with a three-way changeover valve, the online gas detecting analyzer is interlocked with the three-way changeover valve which is connected with a user pipe and a diffusing tower, and the lower ends of a mechanical air cooler and the pulse bag-type dedusters are respectively connected with dust removing devices. The device for purifying and recycling furnace gas of the hermetic ore smelting furnace is simple in systematic flow path and stable and reliable in running, dust content of furnace gas purified is less than 5mg / m<3>, dust recycled can be reutilized, and secondary pollution to water can be avoided.

Owner:HUANYU PURIFYING ENG EQUIP MFG DASHIQIAO CITY

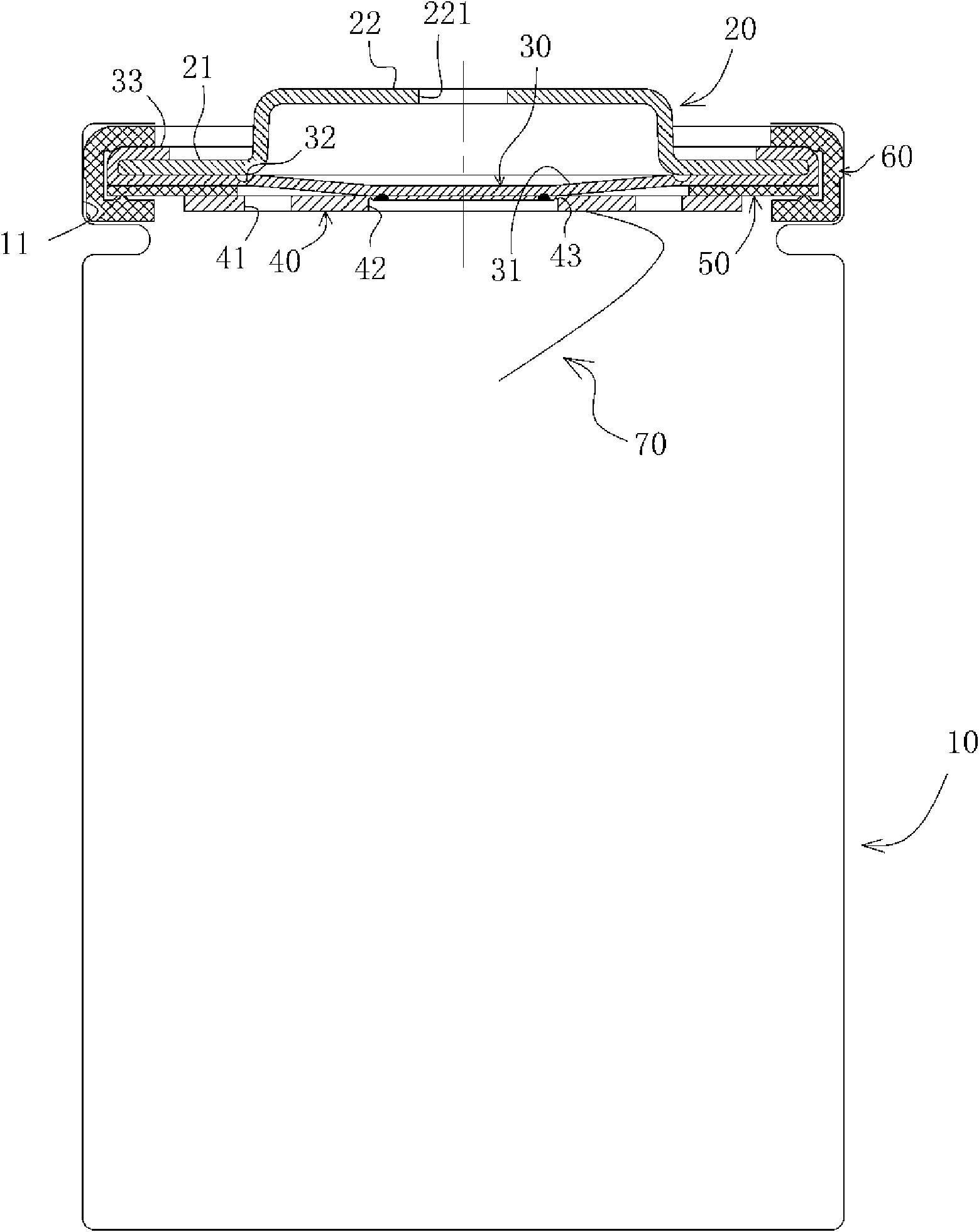

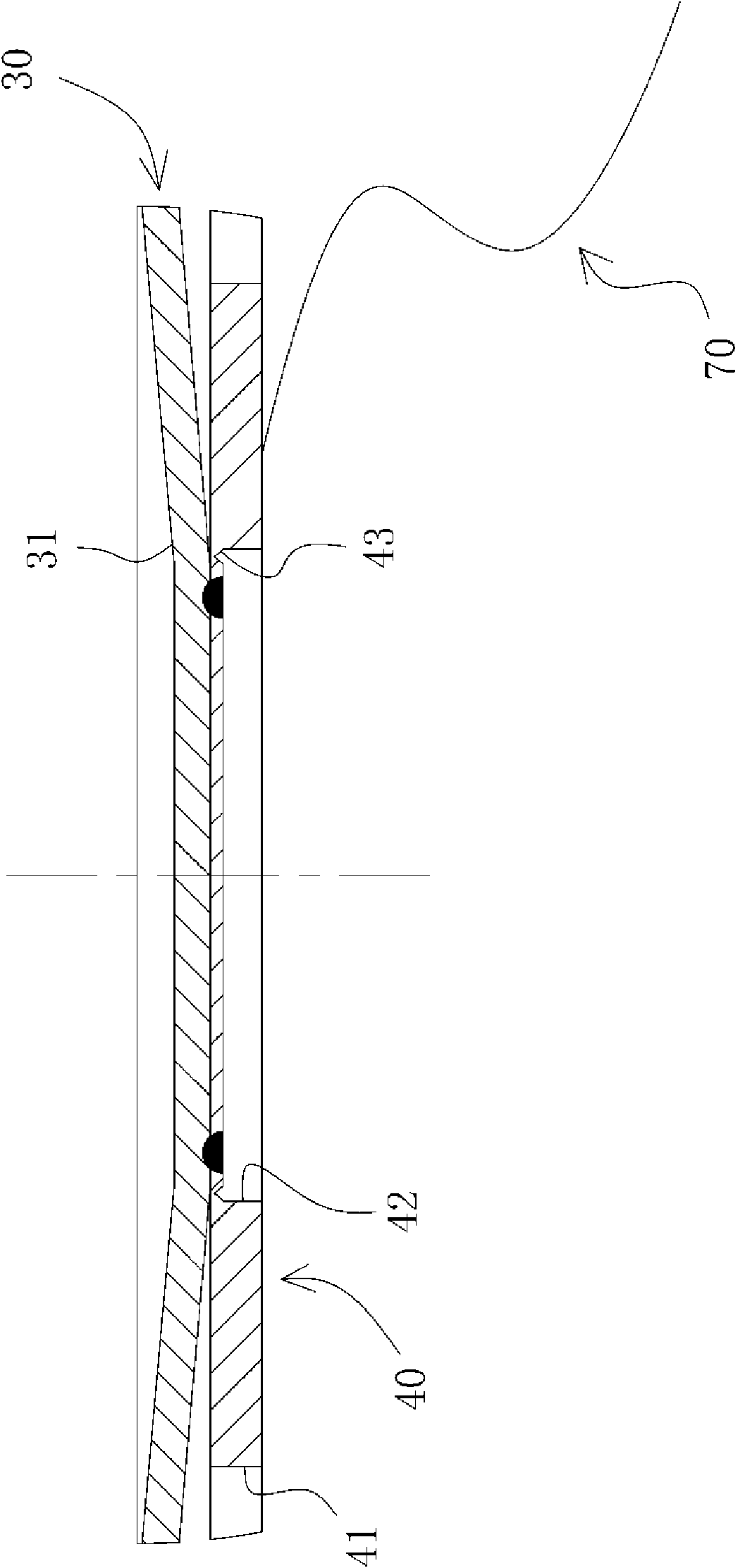

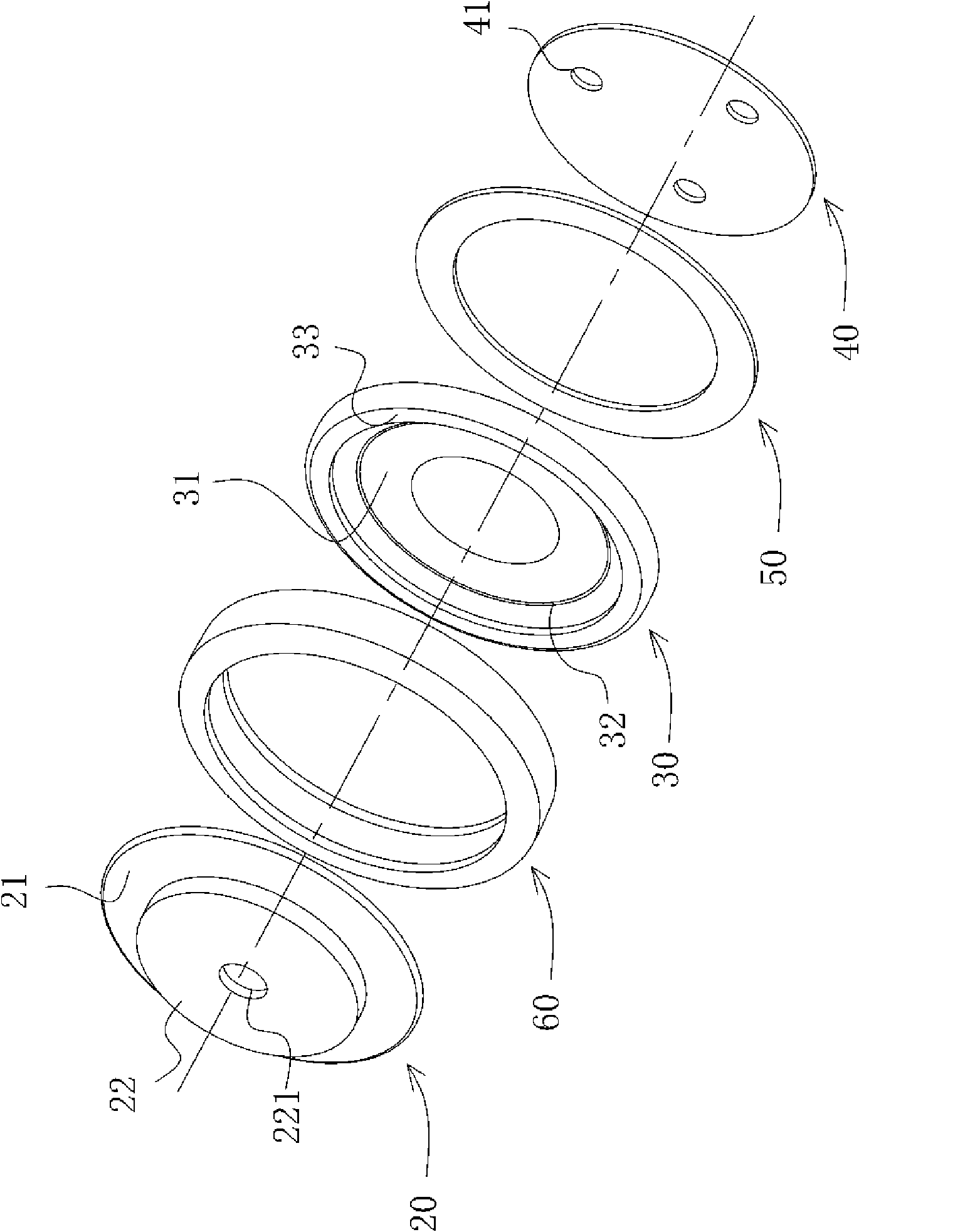

Lithium battery electric core explosion prevention and power-off protection device and producing method

ActiveCN101567432ANo explosionExplosion safetyFinal product manufactureSecondary cellsProof constructionInternal pressure

A lithium battery electric core explosion prevention and power-off protection device and a producing method. The device comprises an electric core casing, a metal top cover, a metal rupture disc, a metal vent hole plate, an annular insulation spacer, an annular sealed ring and an electric core tab. The explosion-proof construction are arranged on the rupture disc and the vent hole plate and comprises a V-shaped ring groove on the vent hole plate and a ring groove on the rupture disc. The rupture disc and the vent hole are connected through multi-point connection mode. The method comprises: stamping molding of top cover, rupture disc, vent hole plate and insulation spacer, injection moulding of sealing ring at high temperature, edging of rupture disc and laser welding of rupture disc and vent hole plate and sealing connection of parts and with the electric core. When the inner pressure of the electric core is higher than the preset value, an upward pressure through the vent hole lifts the recess of the rupture disc and cuts off the V-shaped ring groove of the vent hole plate and switches out the circuit by separating from the rupture disc. If the inner pressure enhances continuously, the ring groove of the rupture disc is cut off for pressure relief.

Owner:SHENZHEN KEDALI IND CO LTD

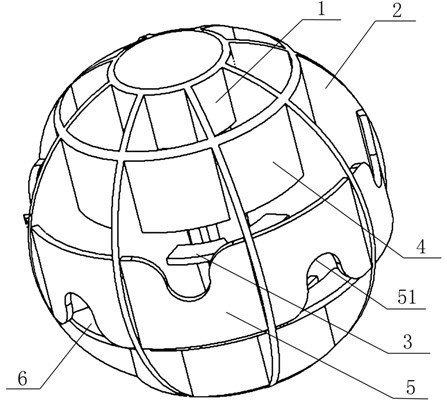

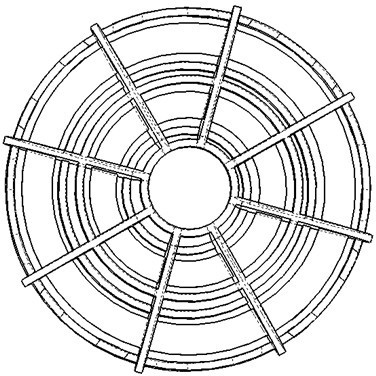

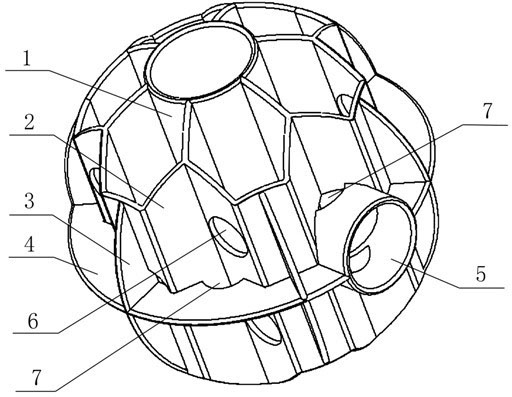

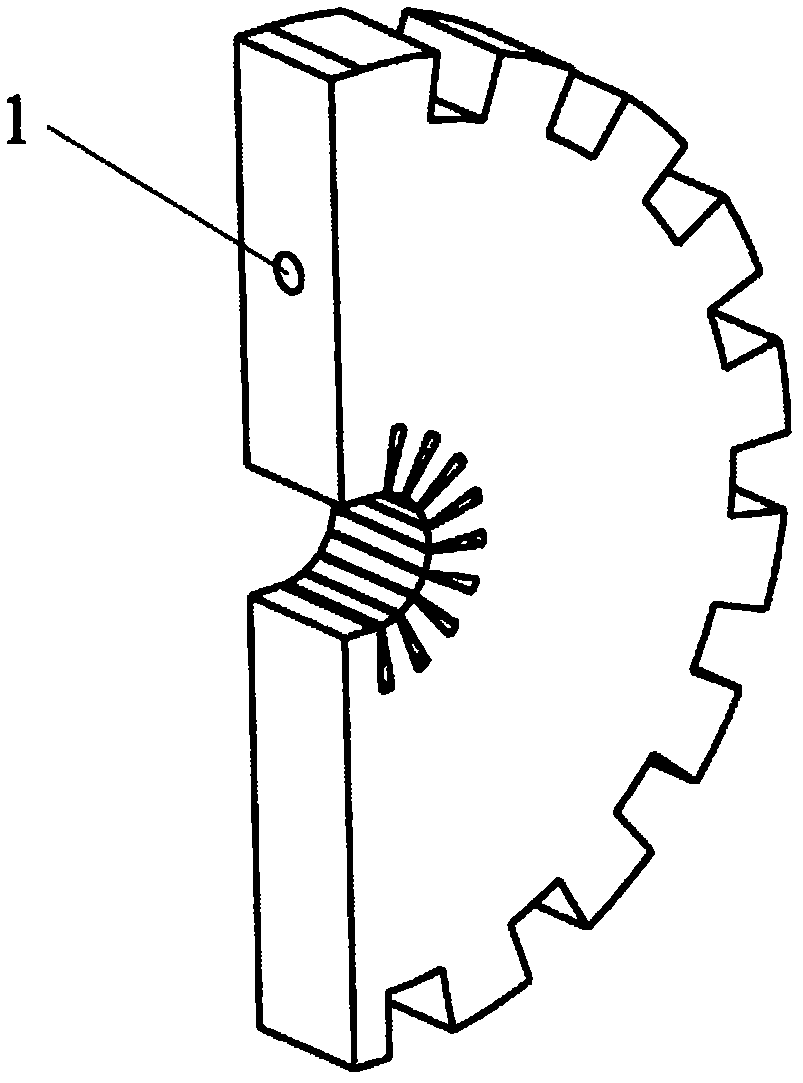

Labyrinth-shaped spherical hollow filler

InactiveCN102614606AEliminate explosion pointsFlame suppression effectContainer filling methodsFire rescueEngineeringSpherical shaped

The invention discloses a labyrinth-shaped spherical hollow filler which is characterized in that coaxial tubular bodies are arranged at the two ends of the filler respectively, and a plurality of fan-shaped bodies are uniformly connected to the circumference of the two tubular bodies; a ring-shaped body is arranged at the middle parts of the two tubular bodies respectively and connected with each fan-shaped body; two large tubular bodies are arranged on the outer side of each tubular body and have a larger radius than that of the tubular bodies; and a ring-shaped belt is arranged in the position close to the vertex of each fan-shaped body. The internal structure of the labyrinth-shaped spherical hollow filler is spatially divided into a plurality of cells. Compared with the prior art, the cells are communicated to ensure the movability of liquid in the internal space, so as to, on one hand, suppress the spread of fire, and on the other hand, rapidly dissipate the local heat by virtue of the excellent heat absorptivity and extended surface area of the porous filler. Therefore, the labyrinth-shaped spherical hollow filler achieves the purpose of eliminating explosion points and suitable conditions for explosion of the explosion points.

Owner:常熟市新港农产品产销有限公司

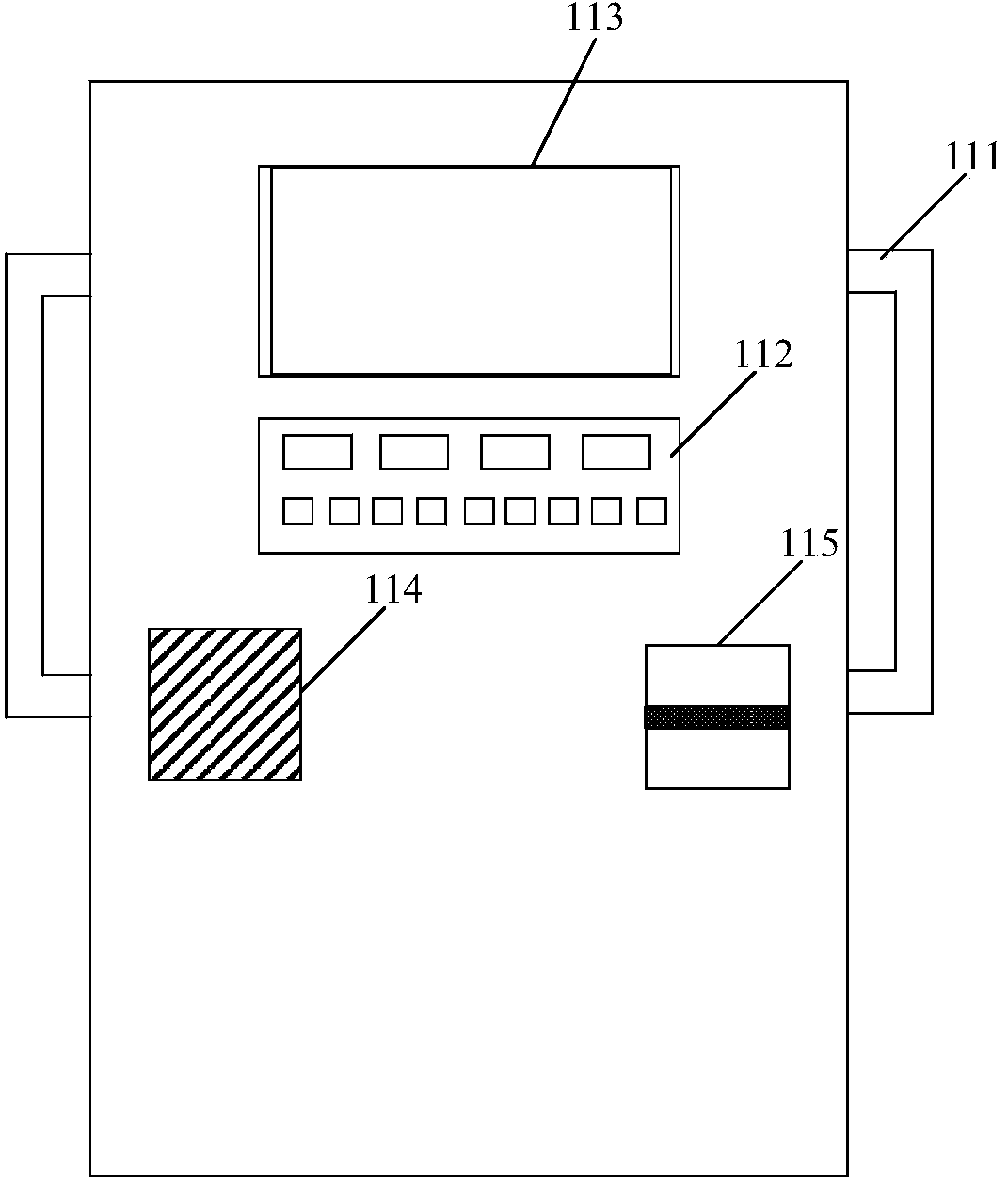

Explosion-proof performance detecting device with fire extinguishing function for battery production

InactiveCN109283468APlay a buffer rolePrevent crushingElectrical testingMaterial strength using tensile/compressive forcesElectrical batteryEngineering

The invention relates to an explosion-proof performance detecting device with a fire extinguishing function for battery production, and relates to the technical field of an explosion-proof performancedetecting device for battery production. The explosion-proof performance detecting device comprises a bottom plate and a first spring plate; the upper end of the bottom plate is provided with first springs; the first spring plate is disposed at upper ends of the first springs; and a first pressure sensor is embedded in the upper end of the first spring plate. The beneficial effects of the invention are that the first spring plate is connected to the bottom plate by using the first springs, when the pressure plate starts to exert pressure to a battery and a first tray apply, the first spring plate is elastically lowered by the first springs on the bottom plate after being pressed, so that the first pressure sensor can be buffered, and when the applied pressure and the first pressure sensorpair are utilized to detect the explosion-proof performance of the battery, the first pressure sensor can be simultaneously protected to prevent the applied pressure from being excessively large to cause the first pressure sensor to be crushed.

Owner:DONGGUAN UNIV OF TECH

Maca essence tablets and preparation method thereof

The invention provides a preparation method of maca essence tablets. The method comprises the following steps: S1 washing and draining fresh maca; S2 slicing maca and naturally drying maca slices in the sun; S3 grinding maca slices dried in the sun into 50-80-mesh coarse powder, and further grinding at 2-5 DEG C until the granularity is larger than 800 meshes; S4 sterilizing the powder for more than 60 minutes by adopting ozone with concentration more than 200ppm; S5 tabletting the powder after dry granulation.

Owner:香格里拉县天丽斯生物科技发展有限公司

Method for purifying and separating methane from oxygen-containing coal bed gas

InactiveCN101531559AEnsure safetyReduce pretreatment costsDistillation purification/separationHydrocarbonsVolume concentrationCoal

The invention provides a method for purifying and separating methane from oxygen-containing coal bed gas, the method comprises the following steps of firstly cooling raw material gas of the oxygen-containing coal bed gas and then carrying out rectification treatment on the oxygen-containing coal bed gas; exhaust gas flows out from the top part of a rectification system, pure methane flows out from the bottom part of the rectification system, a) the initial volume concentration y<0> of the methane in the raw material gas is detected; b) the volume concentration Y of the methane is taken as an x-coordinate and the volume concentration X of oxygen is taken as a y-coordinate for establishing the coordinate region against the oxygen-containing coal bed gas in the separation process flow and determining an explosion triangle in the corresponding coordinate region of the oxygen-containing coal bed gas in the initial state; c) when the y<0> is positioned in the oxygen deficiency region of the coordinate region of the oxygen-containing coal bed gas at the position, the oxygen in the raw material gas to be cooled is removed; and d) the volume concentration of the methane is maintained, and the methane is separated from the raw material gas. The coarse oxygen removal according to the technical proposal of the invention can reduce the pretreatment cost of the raw material gas under the premise of more accurately ensuring no explosion.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

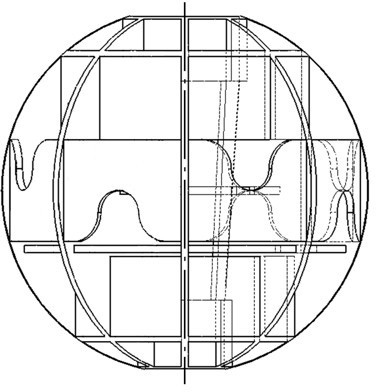

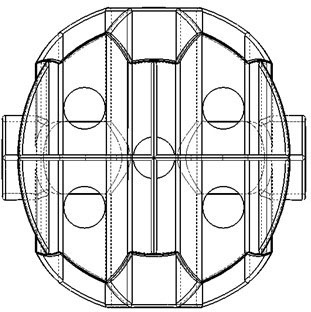

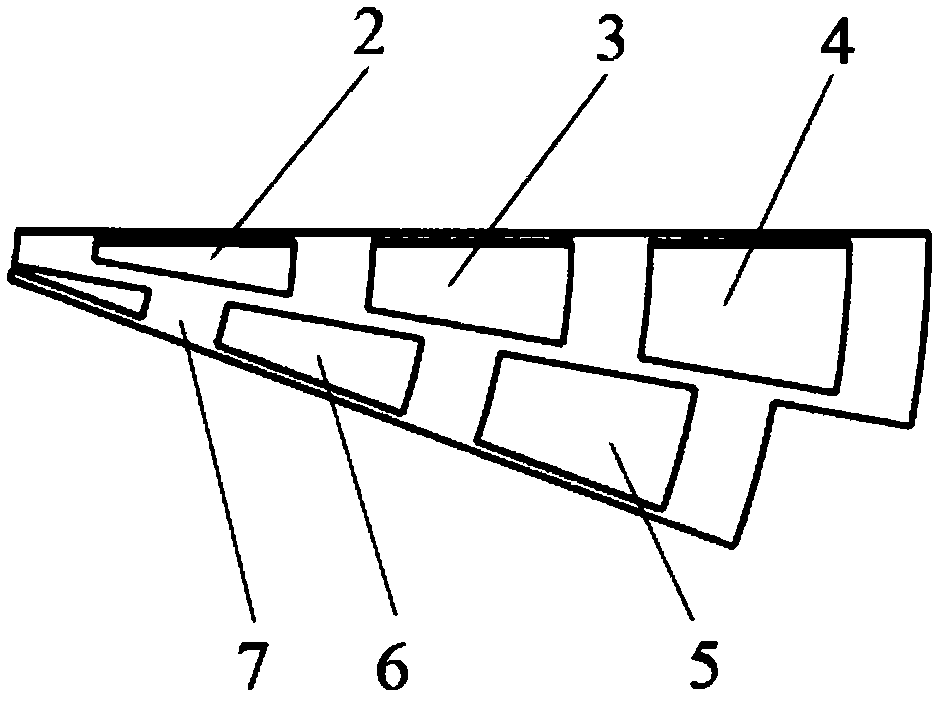

Honeycombed spherical hollow filler

InactiveCN102614604AEliminate explosion pointsFlame suppression effectContainer filling methodsFire rescueEngineeringSpherical form

The invention discloses a honeycombed spherical hollow filler which is characterized in that a central pipe is arranged at the center of the filler in a penetrating manner, six honeycombed hexagonal parts are arranged on the circumference of the central pipe in a way that each two of the six honeycombed hexagonal parts are connected, a longitudinal fan-shaped wing is connected to the outer side face of each honeycombed hexagonal part, a round fin is arranged on the middle cross section of the central pipe and connected with the outer side face of each honeycombed hexagonal part, and one or two honeycombed hexagonal through-pipes are arranged on the middle cross section of the central pipe and communicated with the central pipe and the outside of the central pipe. The internal structure of the honeycombed spherical hollow filler is spatially divided into a plurality of cells. The cells are communicated to ensure the movability of liquid in the internal space, so as to, one the one hand, suppress the spread of fire, and on the other hand, rapidly dissipate the local heat by virtue of the excellent heat absorptivity and extended surface area of the porous filler. Therefore, the honeycombed spherical hollow filler achieves the purpose of eliminating explosion points and suitable conditions for explosion of the explosion points.

Owner:常熟市新港农产品产销有限公司

Highly aqueous and high-stability electrolyte used for aluminum electrolytic capacitor and preparation method therefor

ActiveCN105469990AGood electrochemical propertiesHigh impedanceElectrolytic capacitorsElectrolytic agentPhosphoric acid

The present invention relates to the technical field of electrolytes, in particular to a highly aqueous and high-stability electrolyte used for an aluminum electrolytic capacitor and a preparation method therefor. The electrolyte comprises the following raw materials in parts by weight: 10-14 parts of ammonium adipate, 6-10 parts of a water-proofing agent, 4.5-7 parts of ammonia, 3-5 parts of ammonium formate, 1-2 parts of p-nitrobenzoic acid, 0.5-1 part of phosphoric acid, 6-10 parts of glycol and 50-70 parts of deionized water. The electrolyte is prepared by means of interaction among the raw materials and by strictly controlling a weight proportion of the raw materials; the sparking voltage of the prepared electrolyte can reach 102 V and the conductivity rate of the prepared electrolyte can reach 100 ms / cm; and the electrolyte has good electrochemical properties, has the advantages of high frequency, low impedance and high stability, and can be applied to manufacturing of the aluminum electrolytic capacitors.

Owner:DONGGUAN JIUZHI ELECTRONICS CO LTD

Container internal-surface water-based anticorrosive paint and production method

ActiveCN103805029AExtended service lifeReduce wasteAnti-corrosive paintsEpoxy resin coatingsEpoxyWater based

The invention discloses a container internal-surface water-based anticorrosive paint and a production method. The container internal-surface water-based anticorrosive paint comprises the following components in parts by weight: 50-60 parts of water-based acrylate epoxy modified resin, 5-10 parts of rutile type titanium dioxide pigment R237, 20-30 parts of antirust material aluminum tripolyphosphate, 2-5 parts of Ilspersant PE-100 nonionic surfactant, 0.5-1 part of Alex F-252 anticorrosive mildew-proof bactericide, 1-5 parts of nonionic surfactant Ilydropalat 3204 and 5-10 parts of Hydropalat 100 dispersing agent. The invention aims at providing a container internal-surface water-based anticorrosive paint and a production method, wherein grains, food, medicines, clothes and the like can be directly loaded and transported by containers, ships and vehicles without influencing human health, the waste of packaging materials is reduced, and the energy consumption in transportation processes is reduced.

Owner:宝骏涂料有限公司

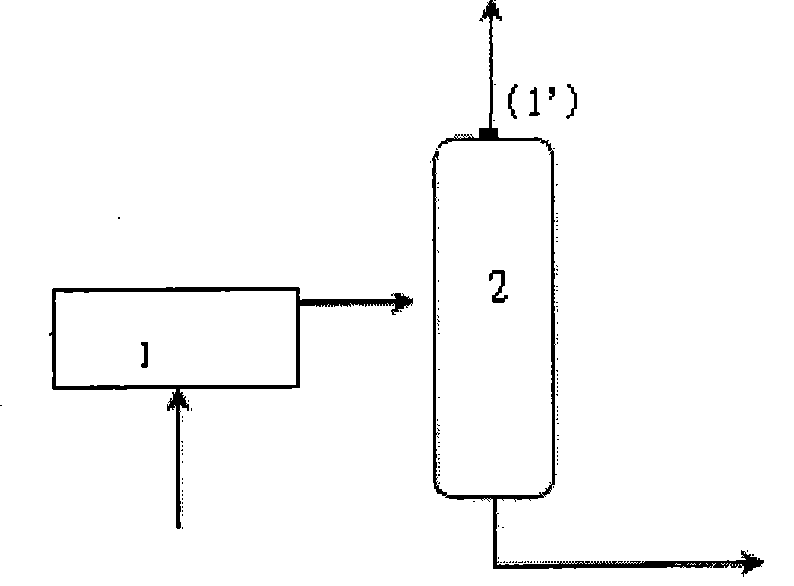

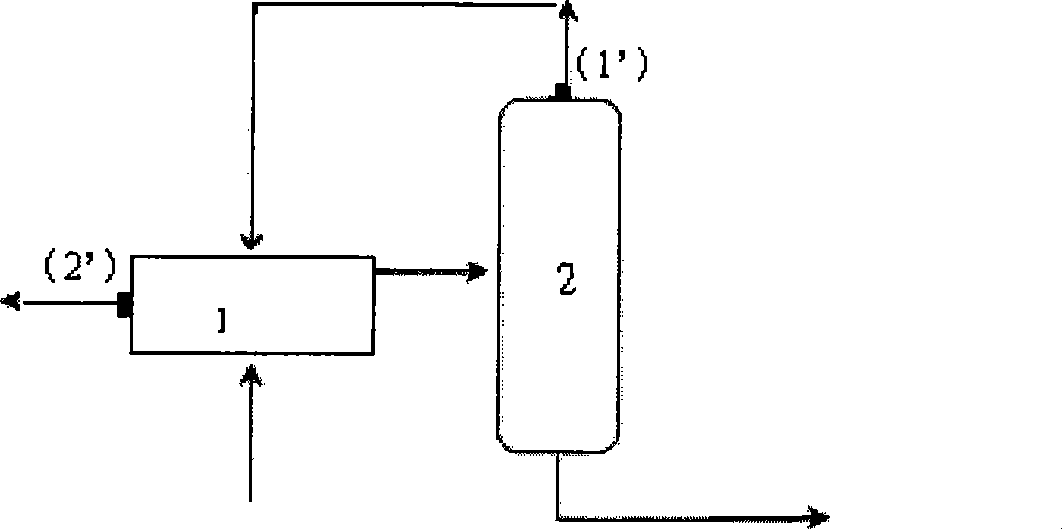

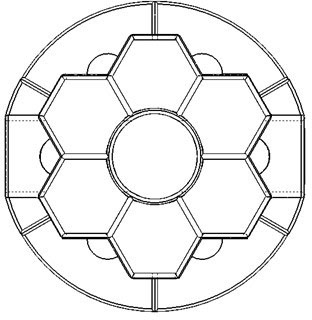

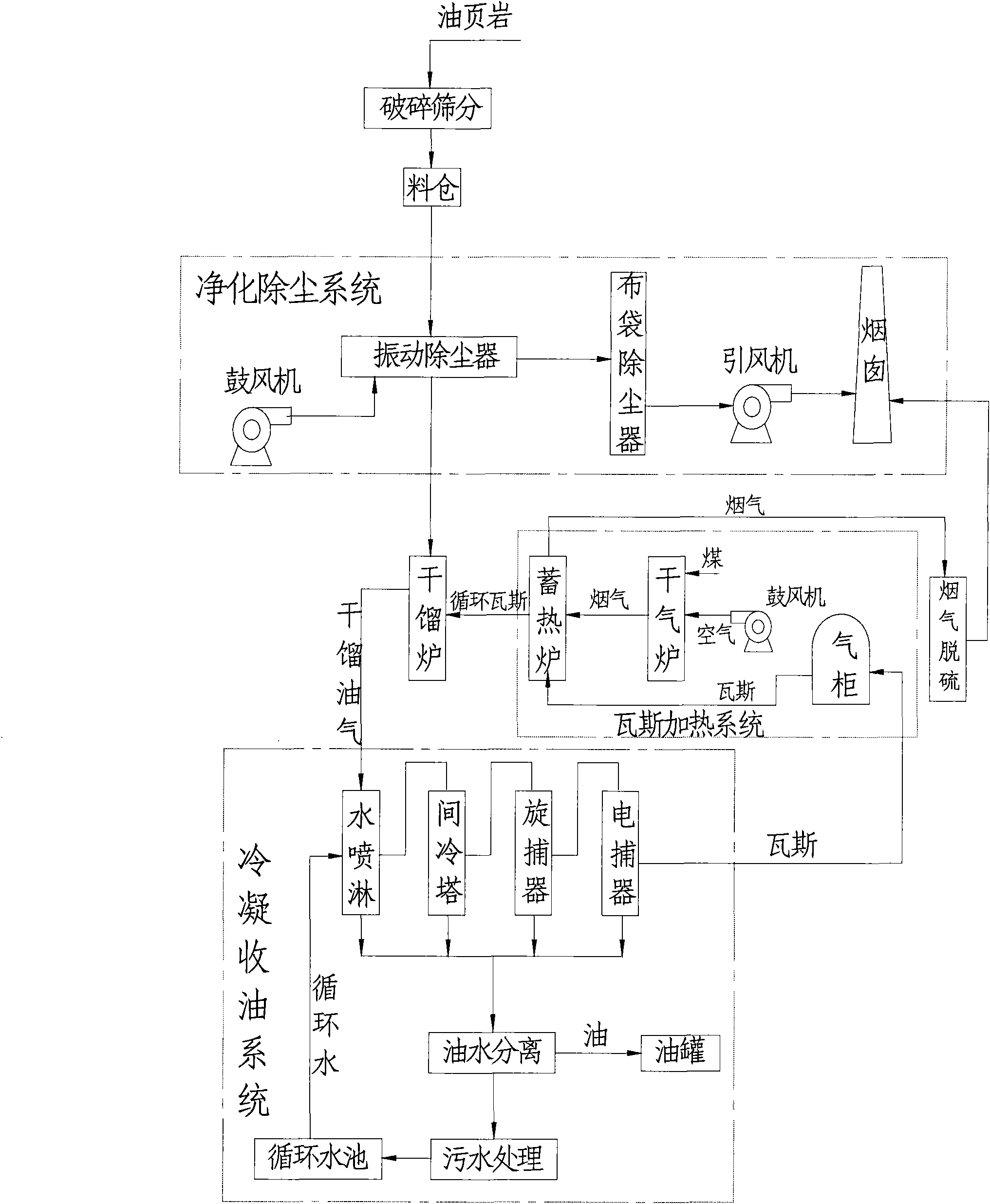

Process and device for dry distillation of oil shale with low gas content

InactiveCN102134498ALow recovery rateGuaranteed normal operationDirect heating destructive distillationSpecial form destructive distillationHeat carrierFlue gas

The invention discloses a process and a device for dry distillation refining of oil shale with low gas content, low fixed carbon content and low water content. The invention is characterized in that: tiny dust in the oil shale is removed by a vibration deduster; gas generated through dry distillation serves as a heat carrier for dry distillation refining of the oil shale; and the gas is heated and cycled by an external combustion regenerative heating furnace. The process flow comprises the following steps of: crushing and screening; grading and warehousing; purifying and dedusting; performing dry distillation refining; condensing and collecting oil; heating the gas; and desulfurizing flue gas. The device for dry distillation refining is an optimized combination of general equipment and proprietary equipment, and the oil recovery rate is over 85 percent.

Owner:吴启成

Water-resistant abrasive base paper and production method thereof

ActiveCN105297526AGood waterproof and oil-proof performanceImprove toughnessWater-repelling agents additionPaper coatingSolventPaper sheet

The invention discloses water-resistant abrasive base paper and a production method thereof. The water-resistant abrasive base paper is prepared from the following raw materials in parts by weight: 32-35 parts of softwood pulp fibers, 32-35 parts of hardwood pulp fibers, 5-10 parts of polyester fibers, 10-15 parts of modified thermoplastic resin, 3-5 parts of a water-proofing agent and 3-5 parts of an oil-proofing agent. The preparation method comprises the following steps: (1) mixing, crushing, pulping and repulping the softwood pulp fibers, the hardwood pulp fibers and the polyester fibers in parts by weight; (2) starching by a fourdrinier machine; (3) molding and drying a paper sheet on the fourdrinier machine, and carrying out gumming treatment once online, wherein the glue quantity is 10%-15%; (4) after drying the glue obtained in the step (3), carrying out secondary gumming on the front surface of the paper sheet, wherein the glue quantity is 6%-10%; and (5) calendaring the paper sheet which is gummed for the second time in the step (4) by a soft calendar. The Water-resistant abrasive paper prepared from the water-resistant abrasive base paper has the advantages of good waterproofness, softness, solvent resistance, dimension stability, high dry strength, good high temperature resistance and good weathering resistance.

Owner:SHANDONG LUNAN NEW MATERIALS

Negative pressure rotating type artificial muscle

InactiveCN108582058ANo explosionAchieve rotary motionProgramme-controlled manipulatorEngineeringPneumatic artificial muscles

The invention discloses a negative pressure rotating type artificial muscle. The negative pressure rotating type artificial muscle is made of elastic materials and is overall of a fan-shaped structure, internal air chambers and supporting columns are arrayed in a staggered mode, and the more the air chamber is away from the circle center, the larger the size of the air chambers is; and when the interior of the artificial muscle is vacuum, the circumferential supporting columns of the pneumatic artificial muscle are inserted into the adjacent air chambers, finally, the whole artificial muscle generates the fan-closing movement along the circle center, and the rotating moment is provided. The negative pressure rotating type artificial muscle can be applied to the field, such as medical rehabilitation, software robots, and bionic robots, needing flexible driving.

Owner:黄郁惠 +1

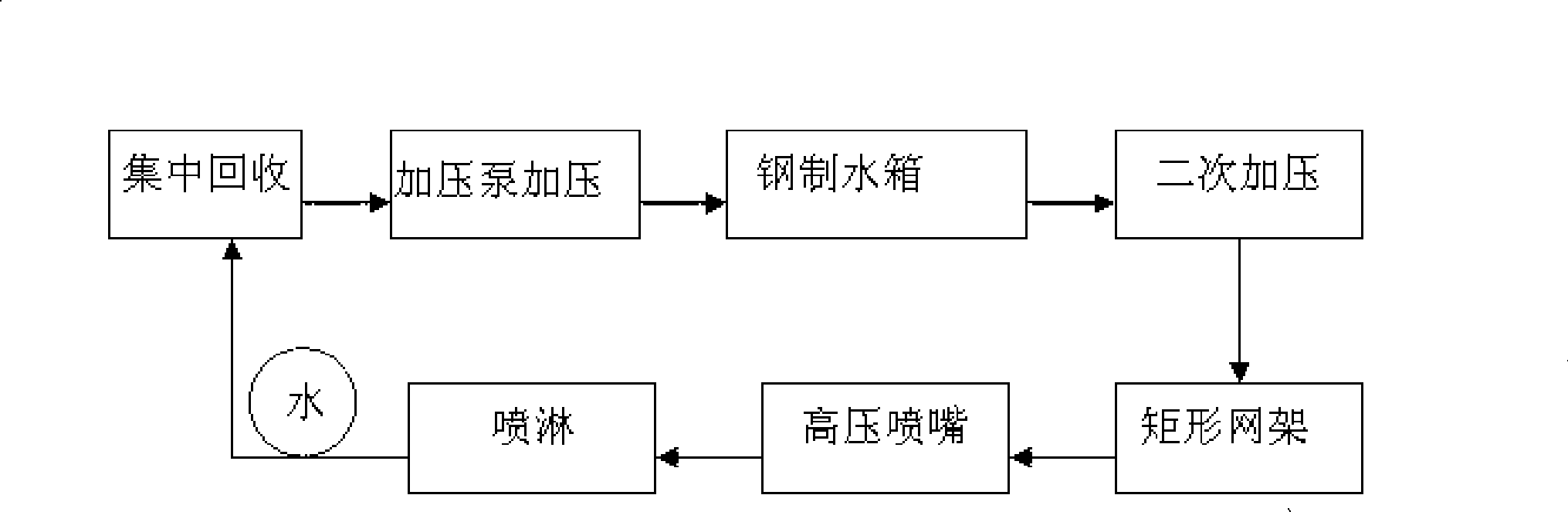

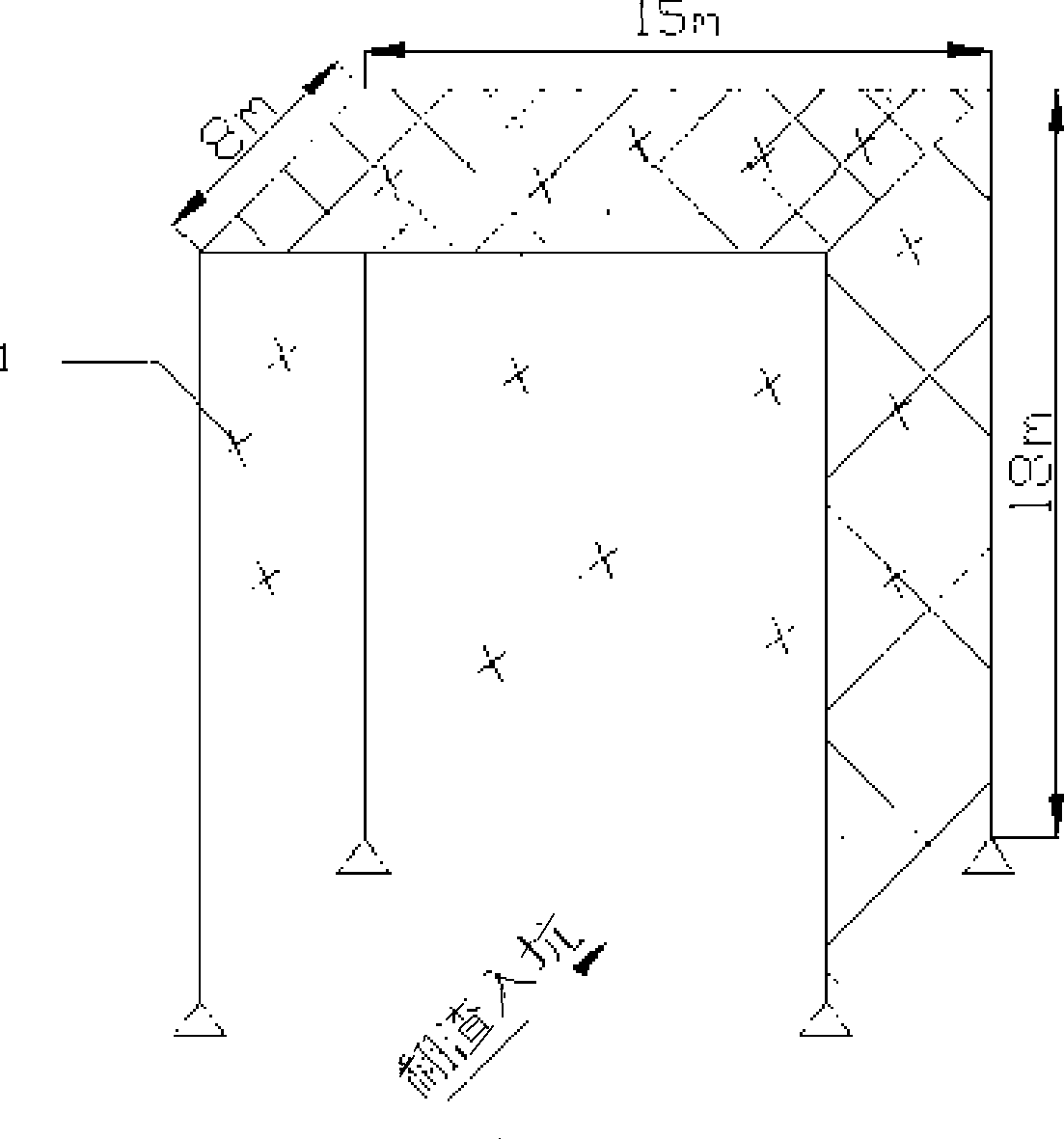

Method for treating high-titanium desulfurized furnace cinder

The invention relates to a method for treating high titanium type desulfurized blast furnace slag and belongs to the field of slag treatment. To solve the technical problem, the method provides a method for treating the high titanium type desulfurized blast furnace slag, which can reduce the generating capacity of soot. The method for treating the high titanium type desulfurized blast furnace slag is to use a three-dimensional water curtain to spray the high titanium type desulfurized blast furnace slag. The method for treating the high titanium type desulfurized blast furnace slag can reduce the soot amount of the high titanium type desulfurized blast furnace slag by more than 50 percent, has no explosion in the spraying process, guarantees the operation safety, and has wide application prospect.

Owner:PANZHIHUA HUANYE METALLURGICAL SLAG DEV CO LTD

Smelting technique of brown corundum

InactiveCN102815731AReduce smelting power consumptionImprove securityEnergy inputAluminium oxides/hydroxidesThermal insulationElectricity

The invention discloses a smelting technique of brown corundum, which comprises the following steps: 1. adding pulverized raw alumina, which satisfies the particle size requirement, into a rotary kiln or shaft kiln, and roasting to 1200 DEG C by using heat from coal gas generated by a generating furnace; 2. sending the roasted alumina material into a thermal insulation charging basket, proportionally adding a carbon material and iron chips, and transferring into a thermal insulation storage bin; and 3. sending the material in the thermal insulation storage bin in the step 2 into an electric furnace by using a feeder, continuing heating for smelting until the reaction is complete, inspecting, cooling and grading to obtain the finished product. The smelting can also be carried out after pulverizing, mixing, granulating and roasting the three raw materials. The invention can lower the power consumption for smelting and enhance the safety of the smelting technique. The smelting technique does not need to use cured alumina, but only uses raw alumina, thereby greatly lowering the raw material cost; and the material is roasted in the rotary kiln or shaft kiln, and added into the electric furnace for smelting while the material is hot, thereby utilizing the waste heat of roasting and saving the electric power.

Owner:王洪仁

High temperature resistant, ripple resistant, and long life electrolyte for aluminium electrolytic capacitor and preparation method thereof

ActiveCN105513801AReliable continuous workThere is no cracking or burningElectrolytic capacitorsElectrolysisO-Nitroanisole

The invention relates to the electrolyte technical field, and particularly to a high temperature resistant, ripple resistant, and long life electrolyte for an aluminium electrolytic capacitor and a preparation method thereof. The electrolyte comprises the following raw materials by weight parts: 4-6 parts of ammonium sebacate, 1.5-2.5 parts of ammonium pentaborate, 0.8-1.2 parts of mannitol, 10-14 parts of branch-chain carboxylic acid, 16-20 parts of spark improvers, 0.2-0.4 part of organic phosphoric acid, 2.5-3.5 parts of o-nitroanisole, 0.2-0.3 part of ammonium hypophosphite, and 45-70 parts of ethylene glycol. The prepared electrolyte has the spark voltage reaching 510V and the electric conductivity reaching 1.8ms / cm through interaction of the above raw materials and strict control of the weight ratios of the raw materials, has the advantages of good electrochemical property, high temperature resistance, ripple resistance and long life, and can be applied to the preparation of the aluminium electrolytic capacitor.

Owner:DONGGUAN JIUZHI ELECTRONICS CO LTD

Method for purifying and separating methane from oxygen-containing coal-bed gas

InactiveCN101531561ANo explosionLow costDistillation purification/separationHydrocarbonsSeparation technologyVolume concentration

The invention provides a method for safely purifying and separating methane from oxygen-containing coal-bed gas, which includes the steps of cooling feed gas of the oxygen-containing coal-bed gas firstly and then rectifying the oxygen-containing coal-bed gas: a)the original volume concentration y<0> of methane in the feed gas is detected; b) the volume concentration Y of the methane is adopted as an abscissa, and the volume concentration X of the oxygen is adopted as an ordinate, which are used for building a coordinate region aimed at the oxygen-containing coal-bed gas in the process flow of separation technology and determining a corresponding explosion triangle of the oxygen-containing coal-bed gas in the original state; c) when y<0> is in an oxygen-inadequate area of the coordinate area, noncombustible articles are added to the feed gas which are to be cooled; and d) the proportions of the noncombustible articles are maintained and the methane is safely separated from the feed gas added with the noncombustible articles. With the adoption of the method, the methane can be safely purified and separated from the oxygen-containing coal-bed gas without deoxidization pretreatment of the feed gas, thus reducing the cost.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

High-hardness waterborne environmental-friendly anticorrosive paint and production method thereof

ActiveCN103805030AExtended service lifeImprove water resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyEnvironmental resistance

The invention discloses a high-hardness waterborne environmental-friendly anticorrosive paint and a production method thereof. The high-hardness waterborne environmental-friendly anticorrosive paint comprises the following components in parts by weight: 40-50 parts of modified waterborne epoxy resin, 5-10 parts of rutile type titanium dioxide pigment R237, 30-50 parts of glass flake, 2-5 parts of non-ionic surfactant Hydropalat 3204, 1-5 parts of PE100 wetting agent, 5-10 parts of Hydropalat 100 dispersing agent, 1-5 parts of LS4110 organic tin catalyst, 1-5 parts of BYK-093 defoaming agent, 5-10 parts of water, 0.5-1 part of waterborne multifunctional PH modifier AMP-95 and 5-10 parts of nano silicon dioxide hardening agent. The invention aims at providing a high-hardness waterborne environmental-friendly anticorrosive paint with good oil resistance, water tolerance, alkali resistance and acid resistance, high anticorrosive coating hardness and long service life and a production method thereof.

Owner:宝骏涂料有限公司

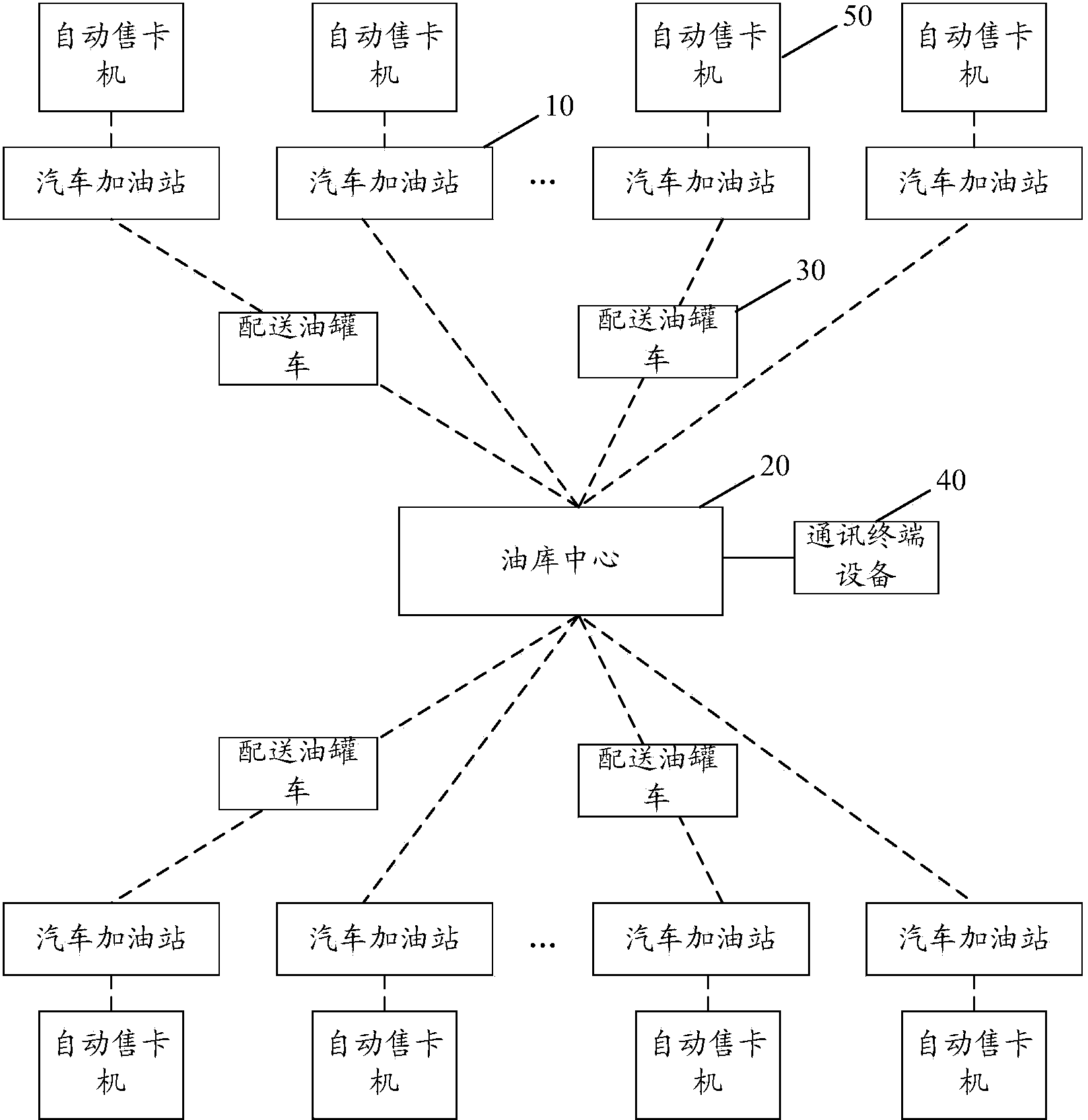

Community automobile fuel loading system

ActiveCN103448689AEasy to refuelMeet the needs of refueling and printing invoicesLiquid flow controllersLarge containersInvoiceThe Internet

The invention relates to the technical field of gas stations and provides a community filling station system which specifically comprises a filling station arranged inside a community, and an oil depot center in remote connection and communication with the filling station. According to the invention, the filling station is transplanted into the community, which is convenient for community oil filling, reduces traffic pressure brought by automobile owners driving automobiles to fill oil out of the community and the waste of fuel, and saves resources; the filling station is equipped with a self-help oiling machine and an anti-explosion oil tank, wherein the self-help oiling machine is provided with a control plate, a printer, an oil gun, a card reader and the like, and has the function of reading card and paying, is convenient and efficient; the printer of the self-help oiling machine is communicated with the Internet through a communication module, so that the printing of invoices and oiling receipts is achieved and the requirements of oil filling and invoice printing of the automobile owners are met.

Owner:DAYANG PARKING CO LTD

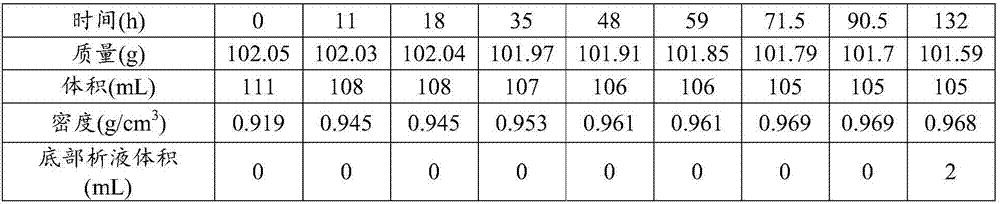

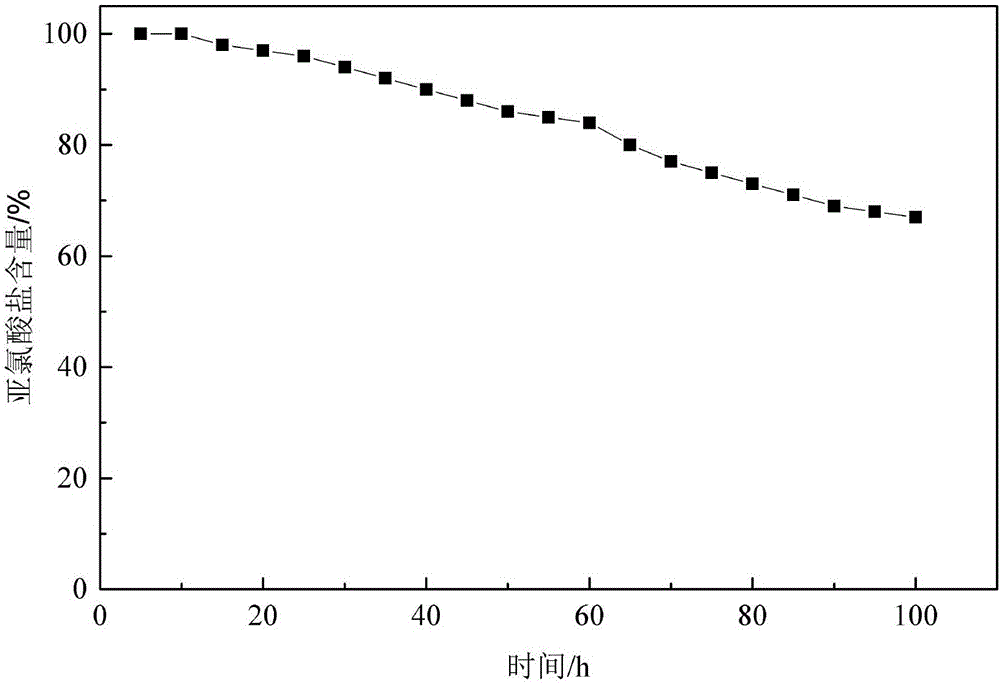

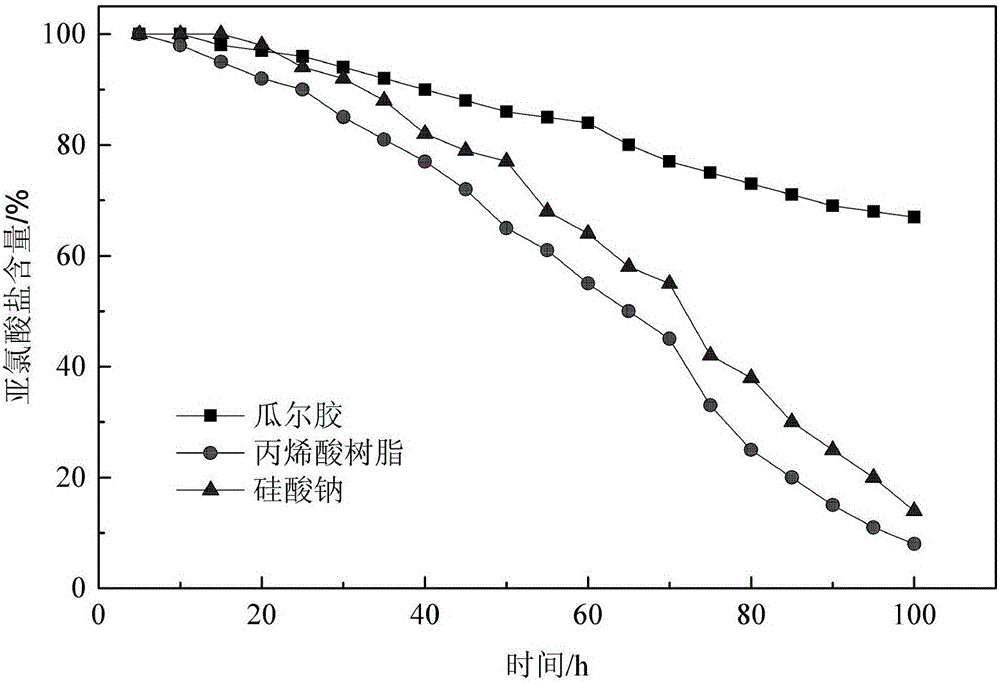

Stable chlorite compound and preparation method thereof

ActiveCN106538599AGood dispersionEasy to transportBiocideDead animal preservationInorganic saltsSolid component

The invention discloses a stable chlorite compound which is prepared from chlorite, guar gum or derivative thereof, a buffer liquid and an inorganic salt. The invention also discloses a preparation method of the stable chlorite compound. In the stable chlorite compound provided by the invention, the chlorite is dispersed and stabilized by the guar gum or derivative thereof, so that the chlorite can be stably stored for a long term under a solid gel state at room temperature. The stable chlorite compound can be conveniently transported and stored, and the safety in storage and transportation processes is promoted; the stable chlorite compound is prevented from explosion and combustion when the stable chlorite compound is mixed with organic matters, is abraded or is impacted; in a use process, when the stable chlorite compound is in contact with activating agents, such as acid, again, the two components can slowly react so as to generate chlorine dioxide; and an acceleration test at 54 DEG C proves that the chlorite content is still more than or equal to 70% after the chlorite solid component is stored for 85 hours at 54 DEG C.

Owner:世倍安生态科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com