Patents

Literature

49results about How to "Reduce pretreatment process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

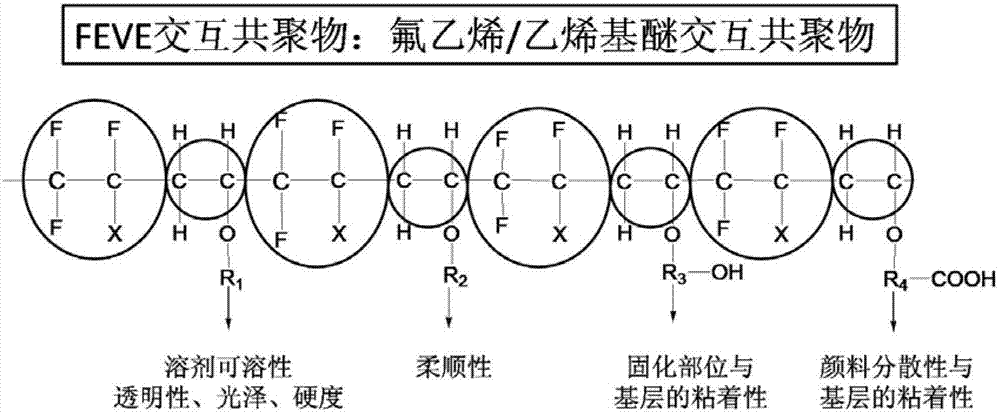

Self-cleaning super-weather-proof powder paint and preparation method thereof

ActiveCN103194140AImprove stabilityProtect against agingPowdery paintsPolyester coatingsPolyesterAging resistance

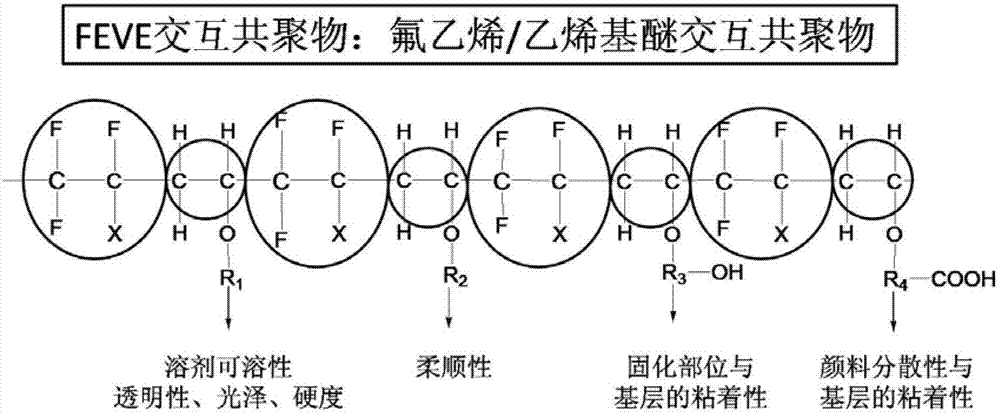

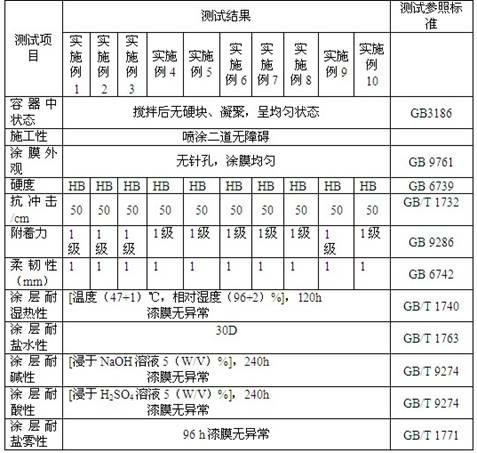

The invention belongs to the field of powder paints and particularly relates to a self-cleaning super-weather-proof powder paint. The self-cleaning super-weather-proof powder paint comprises a carboxyl-terminated polyester particle system and a fluorocarbon resin particle system in a weight part ratio of 4:1-1:4, wherein the fluorocarbon resin particle system contains TiO2 nano-particles. As carboxyl-terminated polyester is introduced into a pure fluorocarbon paint, the phase separation occurs in a solidification process, and the fluorocarbon resin floats up to the surface of a coating to serve as coating protection and ageing resistance; the carboxyl-terminated polyester and the like and a substrate can be well wetted, so that the coating and the substrate can be well adhered and can hardly crack and spall; as the TiO2 nano-particles only exist in a fluorocarbon phase, the resin on a bottom layer cannot be broken, and the excellent stability of the system is guaranteed; and the TiO2 nano-particles are scattered in a dry blending manner, and the complex preprocessing is avoided, so that the preprocessing process can be greatly shortened, the cost is lowered, and the efficiency is improved.

Owner:NINGBO SOUTH SEA CHEM

Baking varnish for magnesium aluminum alloy base material and preparation and using methods thereof

ActiveCN102181214AGood adhesionStrong corrosion resistancePretreated surfacesEpoxy resin coatingsEpoxyPolyester

The invention discloses a baking varnish for a magnesium aluminum alloy base material and preparation and using methods thereof. The preparation method comprises the following steps of: (1) adding polyester modified acrylic resin, epoxy resin, an anti-forming agent, a dispersing agent, a wetting agent, a leveling agent, and a part of solvent in a certain ratio into a stirring kettle sequentially and stirring; (2) adding color paste, filler, and an antisetting agent and stirring in a high speed; and (3) finally adding amino resin, adhesion promoter, and residual solvent and uniformly stirring to finish the whole preparation process of the polyester baking varnish. The using method of the prepared polyester baking varnish for the magnesium aluminum alloy base material comprises the following steps of: weighing the polyester baking varnish for the magnesium aluminum alloy base material, stirring uniformly in the weight ratio of the polyester baking varnish to diluents of 1:(0.4-0.6), spraying to the magnesium aluminum alloy base material, placing for 10 to 20 minutes, baking at the temperature of between 150 and 170 DEG C for 20 to 30 minutes, and baking and curing to obtain the polyester baking varnish layer.

Owner:肇庆千江高新材料科技股份公司

Powder coating with performances of self-cleaning, heavy corrosion protection and super weather resistance and preparation method and application thereof

ActiveCN103146289AUnique photocatalytic propertiesStrong oxidation abilityAntifouling/underwater paintsPaints with biocidesEpoxyWeather resistance

The invention relates to a coating with performances of self-cleaning, heavy corrosion protection and super weather resistance. The coating with performances of self-cleaning, heavy corrosion protection and super weather resistance comprises an epoxy resin particle system which consists of epoxy resin and curing agent A, and a fluorocarbon resin particle system which comprises fluorocarbon resin, curing agent B and TiO2 nanometer particles. The ratio (weight in parts) of the epoxy resin particle system to the fluorocarbon resin particle system is 4-1:1-4. The self-cleaning powder coating with performances of heavy corrosion protection and super weather resistance disclosed by the invention has phase separation during the curing process to form a fluorocarbon face and an epoxy bottom layer, TiO2 nanometer particles only exist in the fluorocarbon face, and photocatalysis decomposition is prevented under the action of TiO2 due to the high chemical stability of fluorocarbon, so that the powder coating has good performances of self-cleaning, heavy corrosion protection and super weather resistance.

Owner:NINGBO SOUTH SEA CHEM

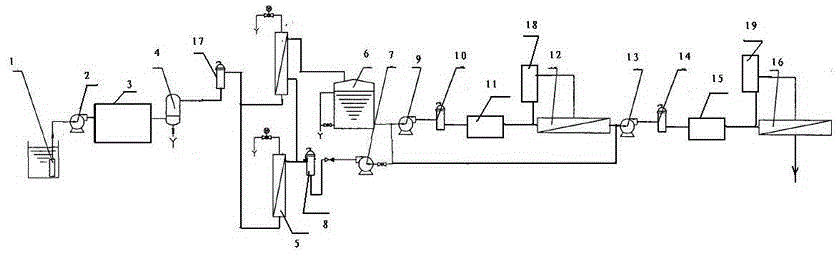

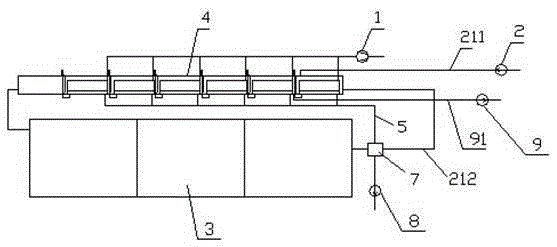

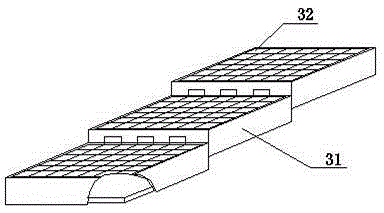

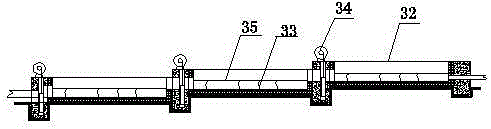

Water processing method and device thereof of seawater desalination system

ActiveCN103601310ANot easy to scaleReduce the burden onGeneral water supply conservationSeawater treatmentEnergy recoverySodium bisulfite

The invention relates to a water processing method and a device thereof, and especially relates to a water processing method and a device thereof of a seawater desalination system. The method comprises the following steps: adding an alkaline agent into seawater to carry out a preset coagulating and clarifying treatment, then pumping the seawater into a cleaning and washing device through a raw water pump; carrying out a pretreatment for the produced water by adopting an external pressure type ultrafiltration membrane component; adding sodium hypochlorite during the ultrafiltration process and / or the backwashing process; pumping the produced water, which has been subjected to the ultrafiltration process, to orderly go through a safeguard filter, a primary high-pressure pump, a scale inhibitor feeding device, and a primary reverse osmosis device, wherein a scale inhibitor is added into the water in the primary reverse osmosis device to carry out a primary reverse osmosis treatment, and acid and sodium bisulfite are added at the same time in order to protect the reverse osmosis membrane; adjusting the pH value of the primary reverse osmosis produced water, making the produced water orderly go through a secondary safeguard filter, a secondary high-pressure pump, and a secondary reverse osmosis device to carry out a secondary reverse osmosis treatment, subjecting the reverse osmosis condensed water to an energy recovery treatment; and finally subjecting the secondary reverse osmosis produced water to subsequent treatments. The reverse osmosis membrane provided by the invention has the advantages of difficulty in scaling and high seawater desalination recovery rate.

Owner:ZHEJIANG THINK ENERGY TECH

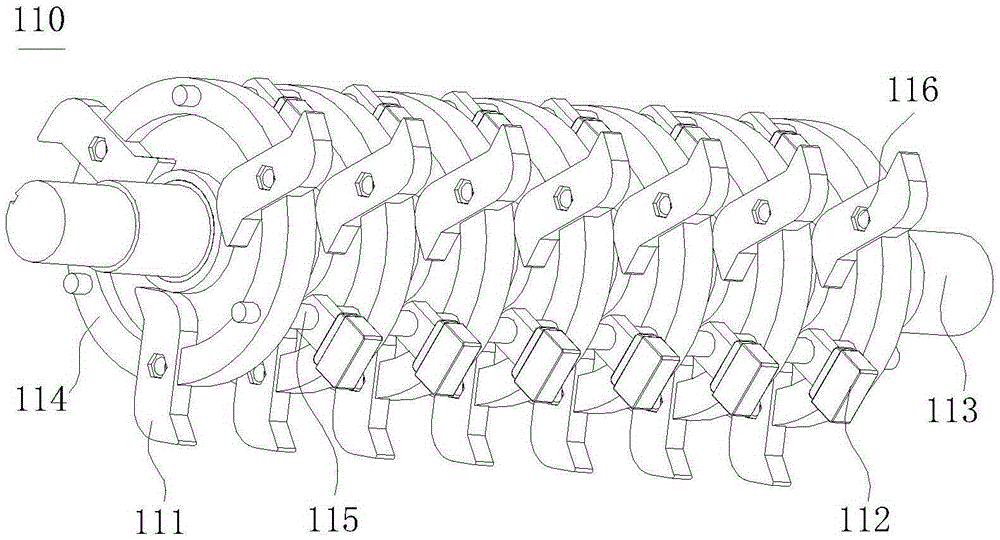

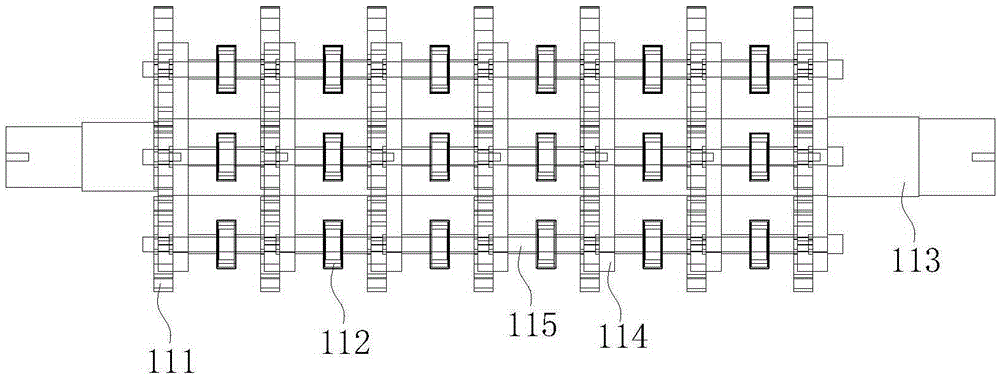

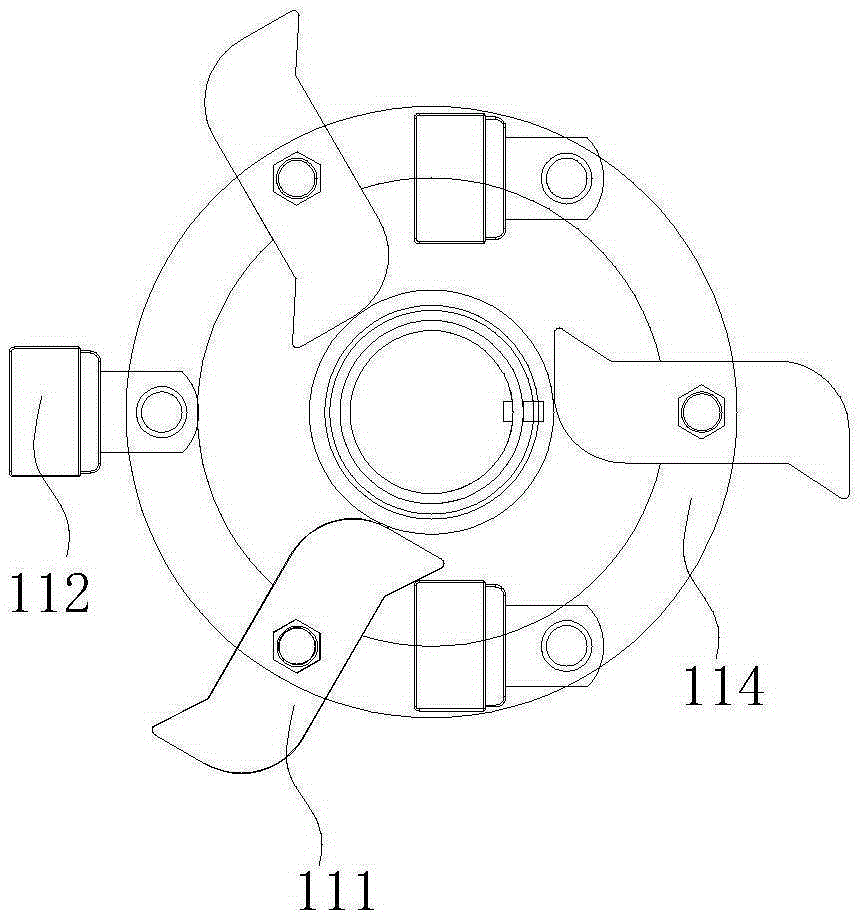

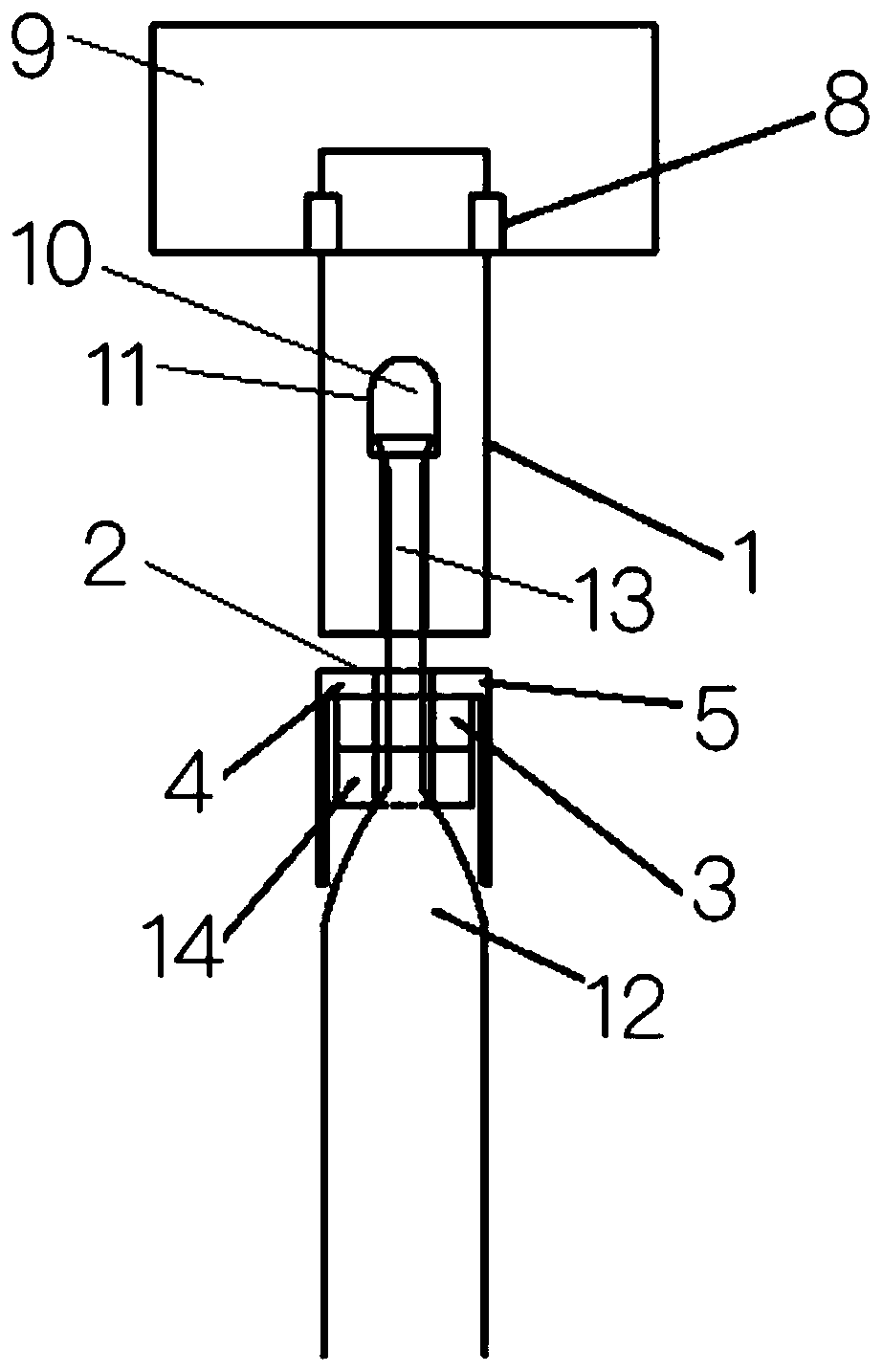

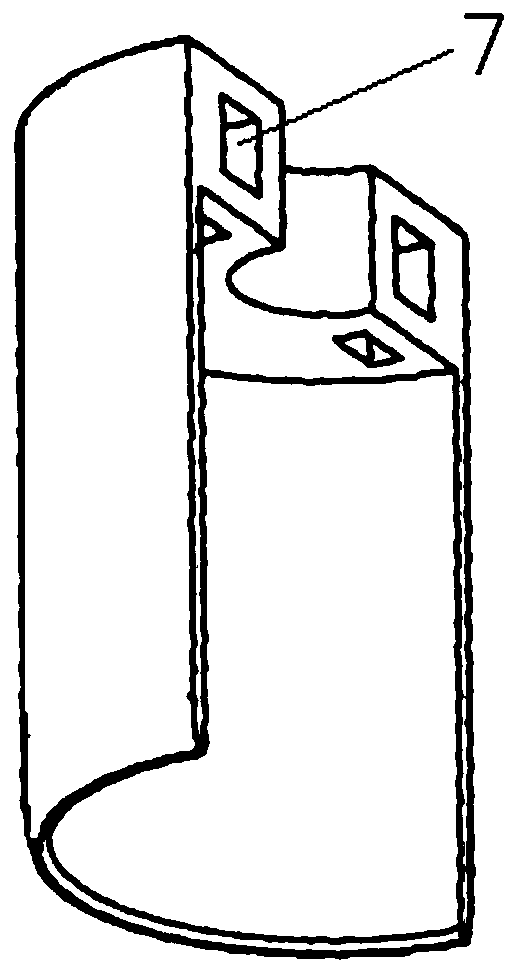

Crushing assembly and crusher comprising same

The invention relates to a crushing assembly. The crushing assembly comprises a first tool, a second tool and a rotary shaft. The first tool and the second tool are arranged on the rotary shaft. The first tool is fixed relative to the rotary shaft. The second tool can swing relative to the rotary shaft. According to the crushing assembly, the first tool is driven to rotate by the rotary shaft so that a plastic shell and other materials can be shredded, and the materials are broken into pieces by the second tool swinging relative to the rotary shaft. By adopting the mode that the first tool and the second tool are combined, tool abrasion is reduced, quick crushing of complex plastic containing screws and other metal impurities is achieved, the metal separation pretreatment procedure is omitted, the production cost is reduced, and the production efficiency is improved. The invention further relates to a crusher comprising the crushing assembly.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

Lyocell fiber containing nano particles and preparation method thereof

ActiveCN104975366AHigh recovery rateSimple spinning processArtificial filaments from cellulose solutionsWet spinning methodsCelluloseNanoparticle

The invention discloses lyocell fiber containing nano particles and a preparation method thereof. The preparation method includes following steps: mixing hydrosol containing nano particles with a 50% NNMO aqueous solution, adding cellulose wood pulp meal chips being 0.1-0.5 mm in length according to proportion, and performing a traditional lyocell fiber spinning process to obtain the lyocell fiber being 0.2-20% in the content of the nano particles. By means of different addition of nano materials, the lyocell fiber achieves a flame-retarding function, an anti-bacterial function, an ultraviolet-proofing function and the like. The method achieves uniform dispersion of the nano particles in the lyocell fiber, integrates the dewatering processes of the nano particle hydrosol and a lyocell cellulose spinning solution, thereby omitting a pre-treatment process of the nano material, simplifying the spinning process and reducing production cost.

Owner:TIANJIN POLYTECHNIC UNIV

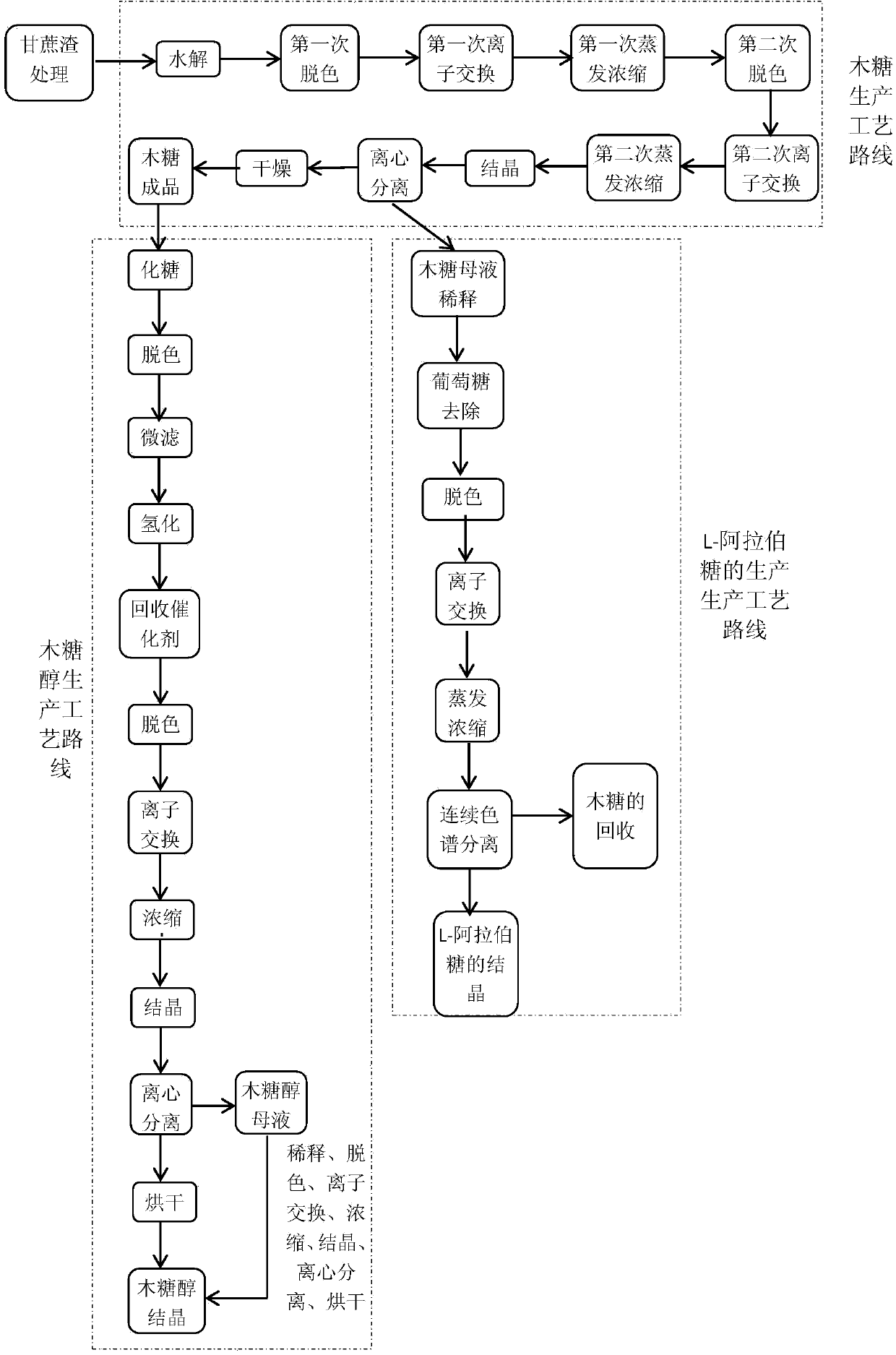

Method of producing xylose and xylitol and co-producing L-arabinose by bagasse

InactiveCN104046705AIncrease profitIncrease added valueSugar derivativesOrganic compound preparationRare sugarAlcohol sugars

The invention relates to a method of producing xylose and xylitol and co-producing L-arabinose by bagasse. The method comprises the following steps: first, treating the bagasse; then, producing xylose by the bagasse; and respectively producing xylitol and arabinose by the product xylose and a xylose mother liquid. By using the bagasse as a raw material, the method provided by the invention obtains crystallized xylose and further products of xylitol and L-arabinose which are high in additional value and are widely applied to the fields of foods and medicines through a whole set of process line. The method provided by the invention is simple to operate, novel in technology, low in cost, diversified in product and high in economic value, is a process method which is initiated at home for co-producing functional sugar alcohols and rare sugar products by bagasse, and has an extremely wide application value.

Owner:SHANDONG WANSHENG ENVIRONMENTAL TECH DEV

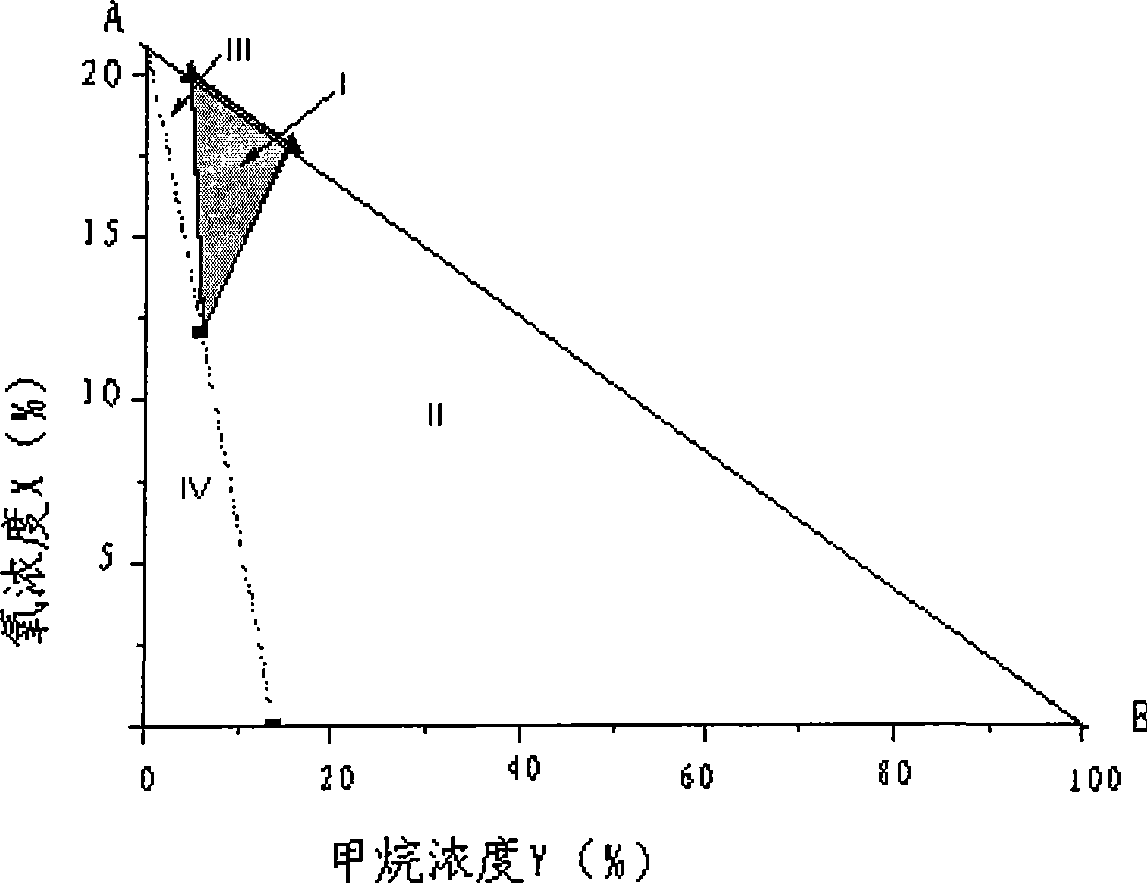

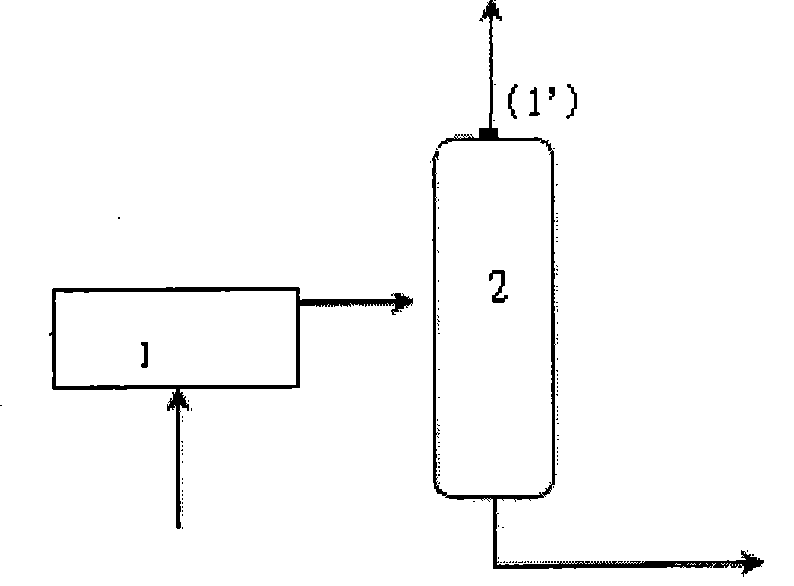

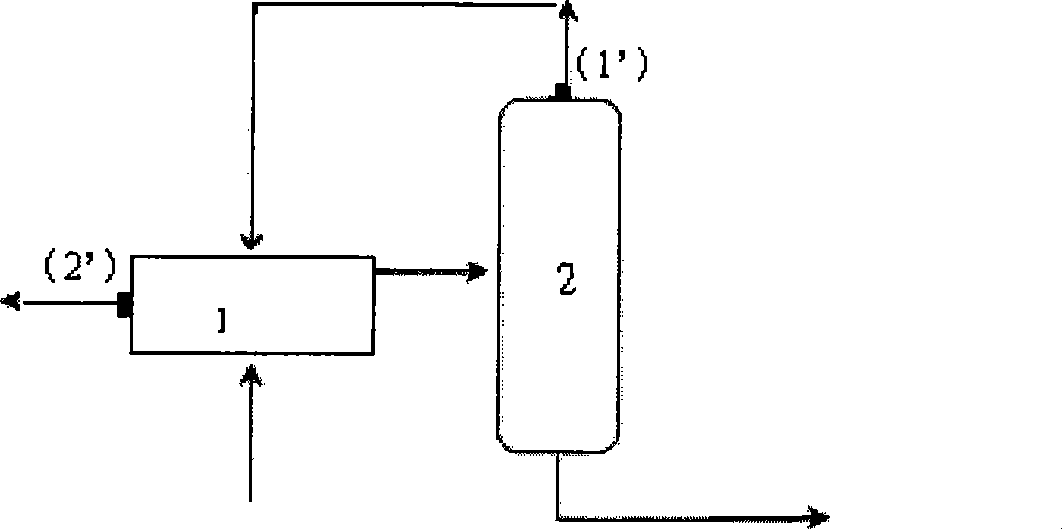

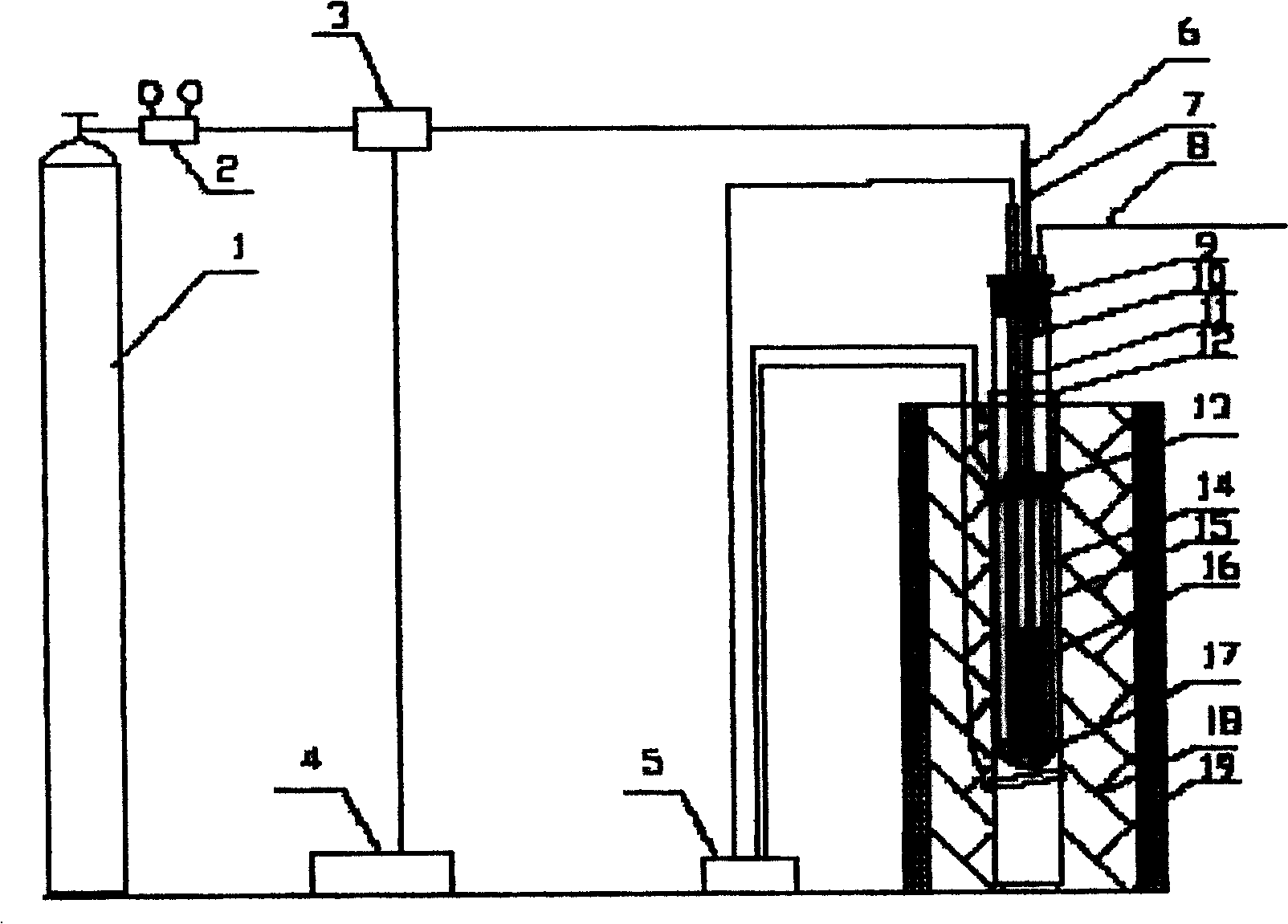

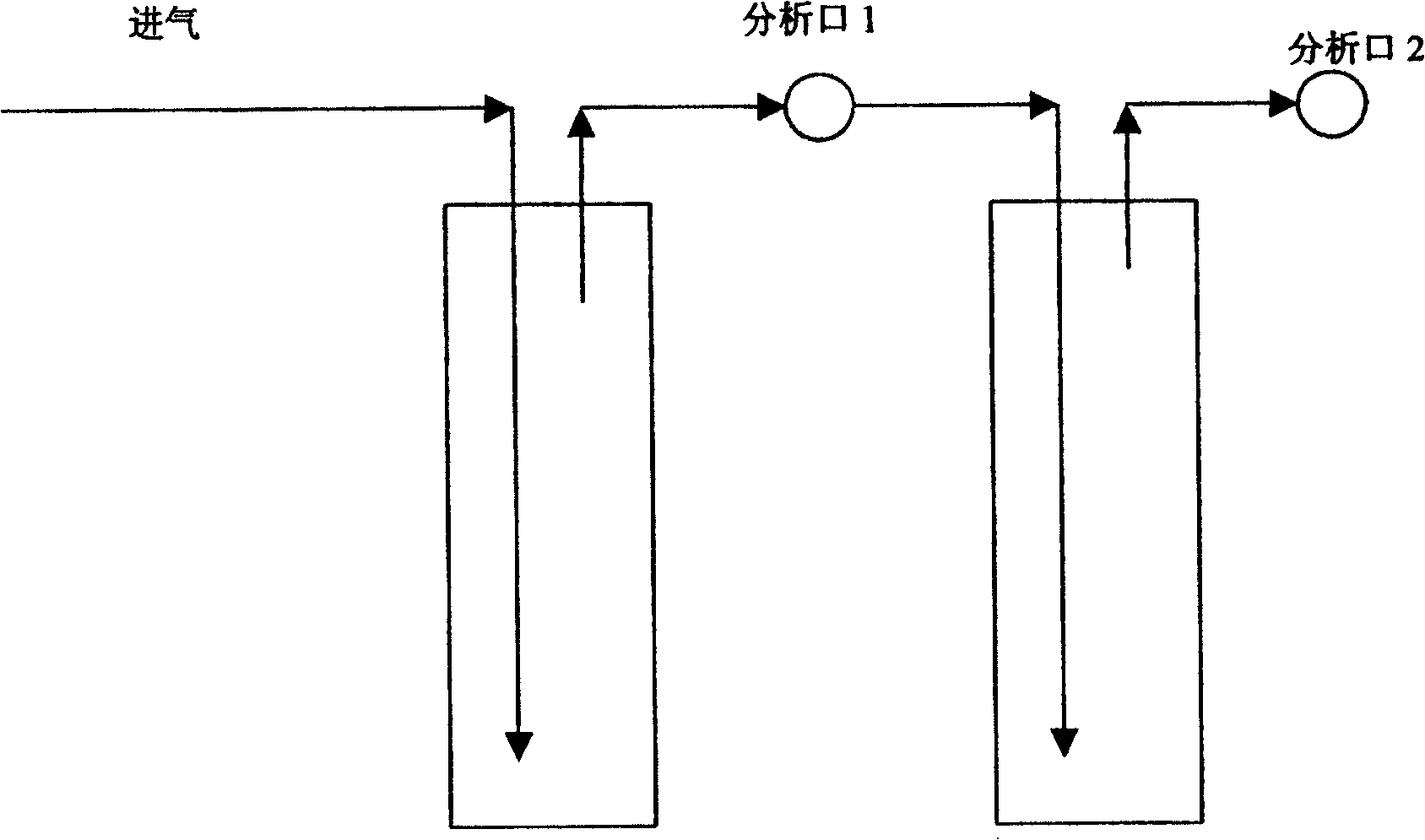

Method for extracting methane from oxygen-containing coal-bed gas through low-temperature liquefying separation

ActiveCN101531560ANo explosionReduce pretreatment processDistillation purification/separationHydrocarbonsSeparation technologyOxygen

The invention provides a method for separating and purifying methane from oxygen-containing coal-bed gas. The separated and purified methane is obtained by firstly cooling feed gas of the oxygen-containing coal-bed gas and then rectifying the oxygen-containing coal-bed gas. The method includes the steps as follows: a) the volume concentration Y of the methane is adopted as an abscissa, and the volume concentration X of the oxygen is adopted as an ordinate, which are used for building an explosion triangle aimed at a position where explosion happens most easily in the process flow of separation technology; b) the original volume concentration Y0 of methane in the feed gas is detected; c) when Y0 is 1.0 to 1.1 times bigger than the upper explosion limit point Y1 of the explosion triangle, the cooling capacity is increased, or the flow of the feed gas is reduced, so the temperature of the position is reduced; and d) the steps b) to c) are repeated until Y0 is 1.0 to 1.1 times bigger thanY1, and the temperature in the current position is the lowest safe separation temperature and the methane can be separated and purified from the oxygen-containing coal-bed gas safely by maintaining the temperature to be 0 to 5 DEG C. With the adoption of the method, the pretreatment technical processes and devices of the feed gas are reduced, thus greatly decreasing the cost.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

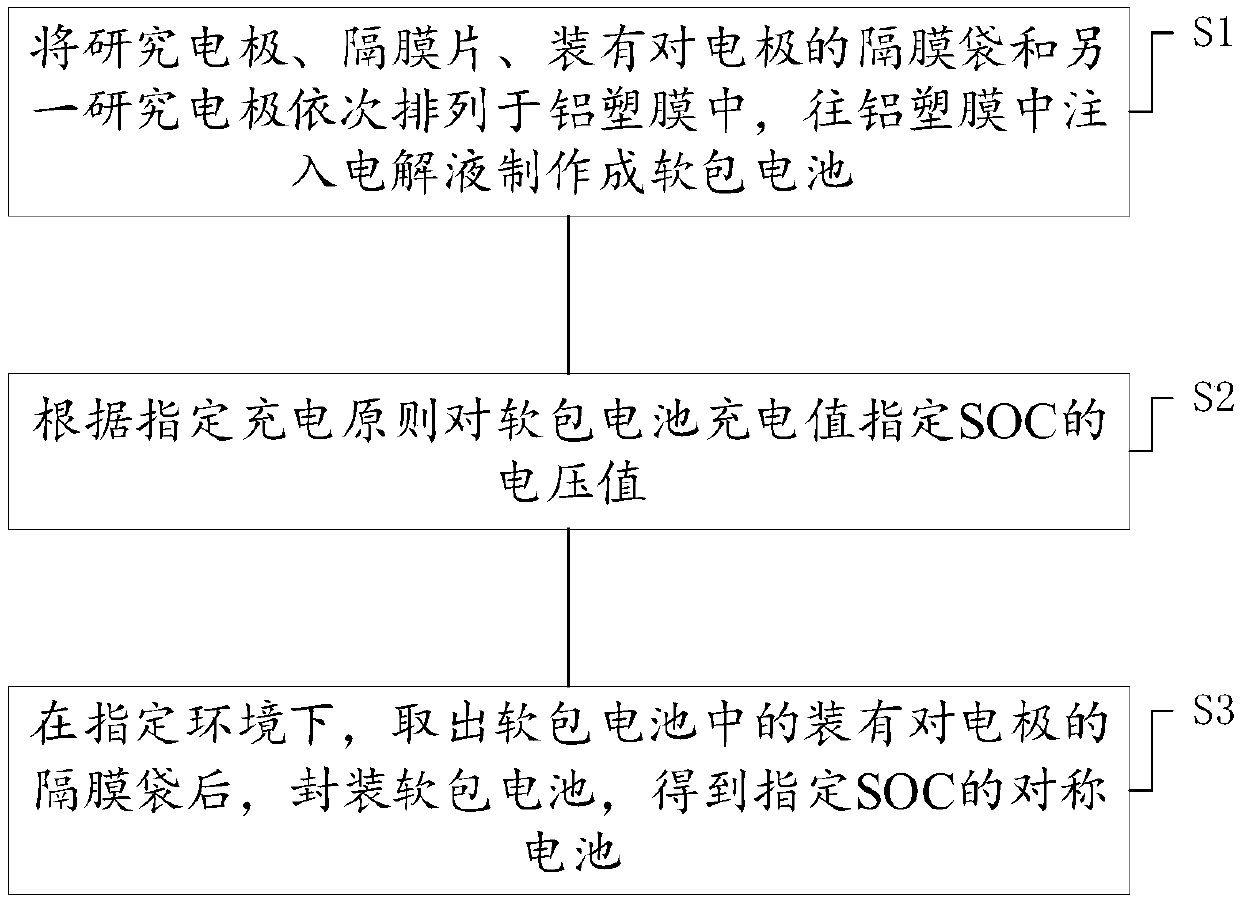

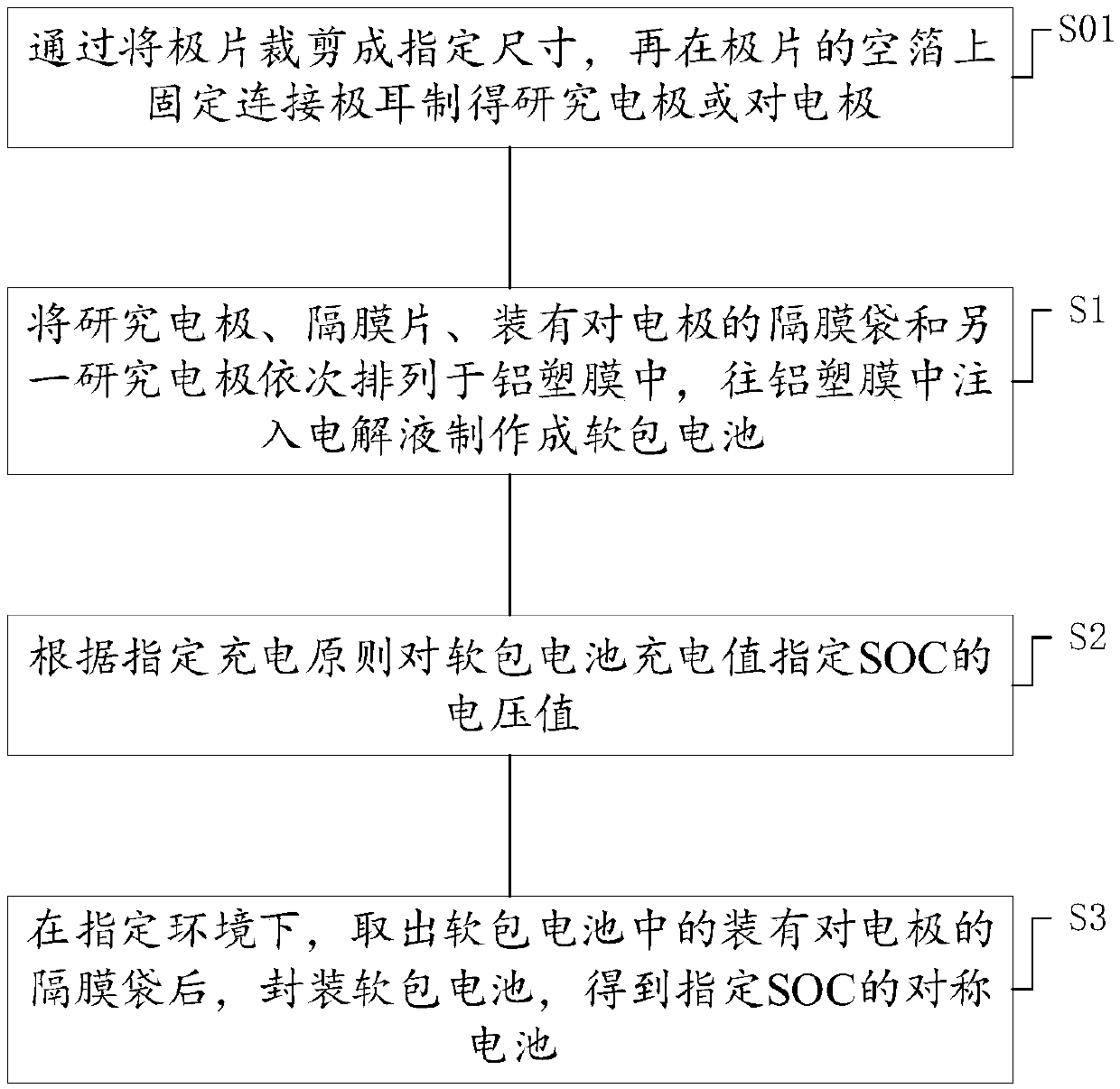

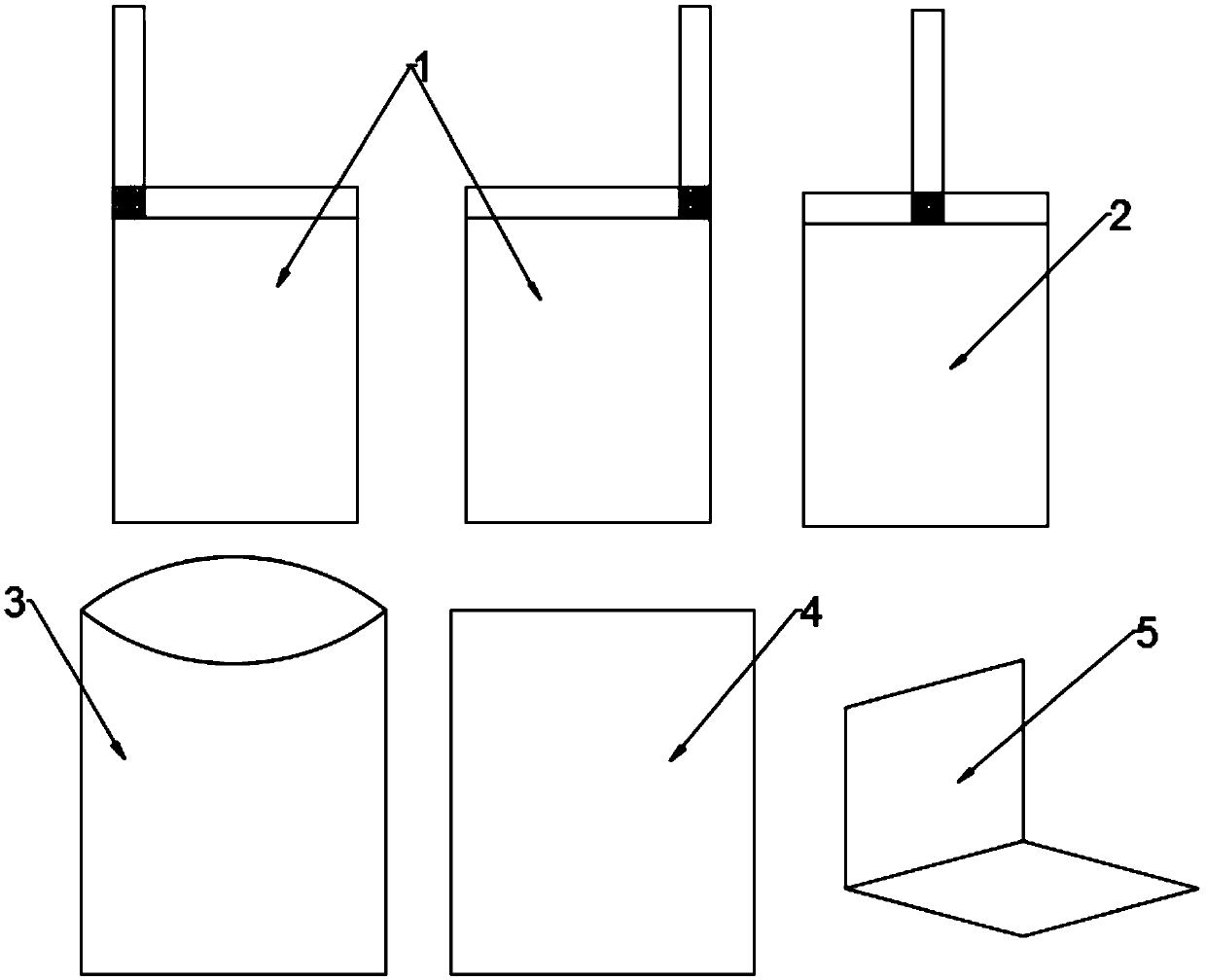

Symmetrical battery and preparation method thereof

ActiveCN109560245AReduce pretreatment processReduce lossElectrode manufacturing processesFinal product manufacturePole pieceEngineering

The invention discloses a symmetrical battery and a preparation method thereof. The method comprises the steps of: arranging a research electrode, a diaphragm piece, a diaphragm bag equipped with a counter electrode and another research electrode in an aluminum plastic film in order, and injecting symmetrical battery and a preparation method thereof into the aluminum plastic film to manufacture asoft pack battery; charging the soft pack battery to voltage value of an assigned SOC according to an assigned charging rule; and in an specified environment, taking out the diaphragm bag equipped with the counter electrode from the soft pack battery, packaging the soft pack battery to obtain the symmetrical battery with the assigned SOC. The symmetrical battery achieves the regulation of the polepiece SOC to obtain the symmetrical battery with the assigned SOC and reduce the loss of the pole piece.

Owner:SUNWODA ELECTRIC VEHICLE BATTERY CO LTD

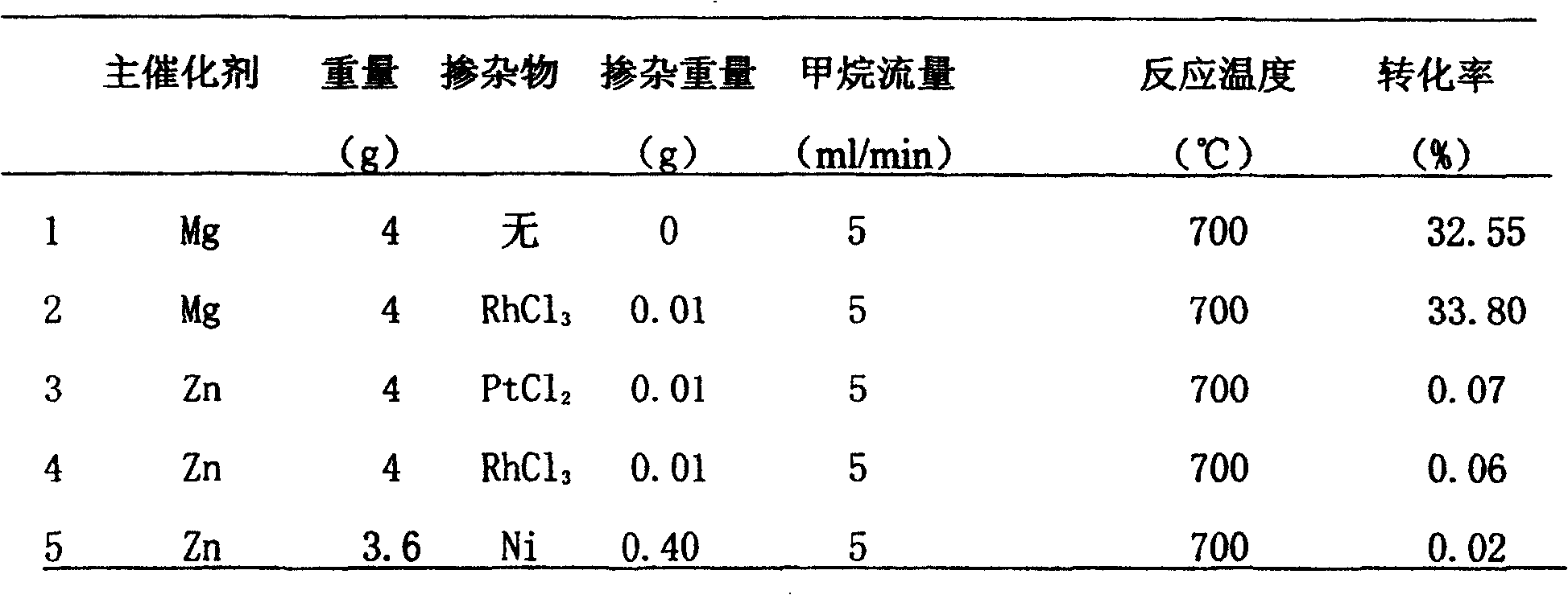

Production of hydrogen by catalyzed decomposing magnesium and its mixture doped with other metals

ActiveCN100439238CNo decrease in activityReduce pretreatment processHydrogenMetal/metal-oxides/metal-hydroxide catalystsHydrogenCatalytic decomposition

A method for producing hydrogen and carbon with mixture of metal magnesium and other metals as catalyst by catalytic decomposition is carried out by reacting at 0.01-10Pa and 200-1500degree and separating catalyst from products. It can re-used and not contain CO and CO2 impurities.

Owner:HUZHOU OCHEM CHEM

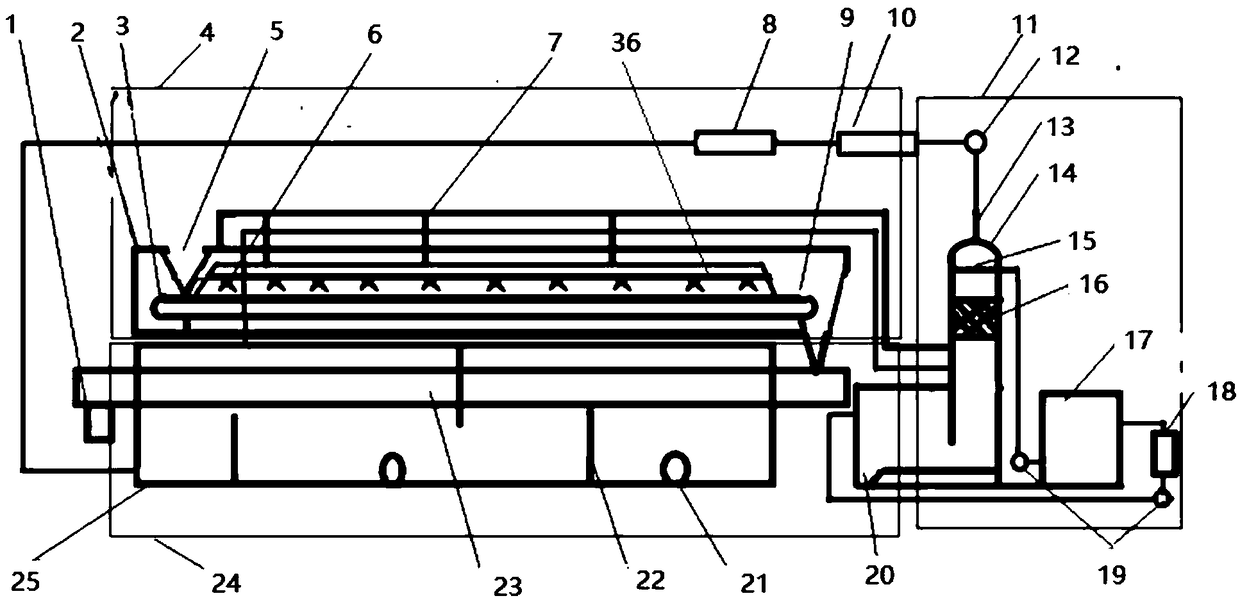

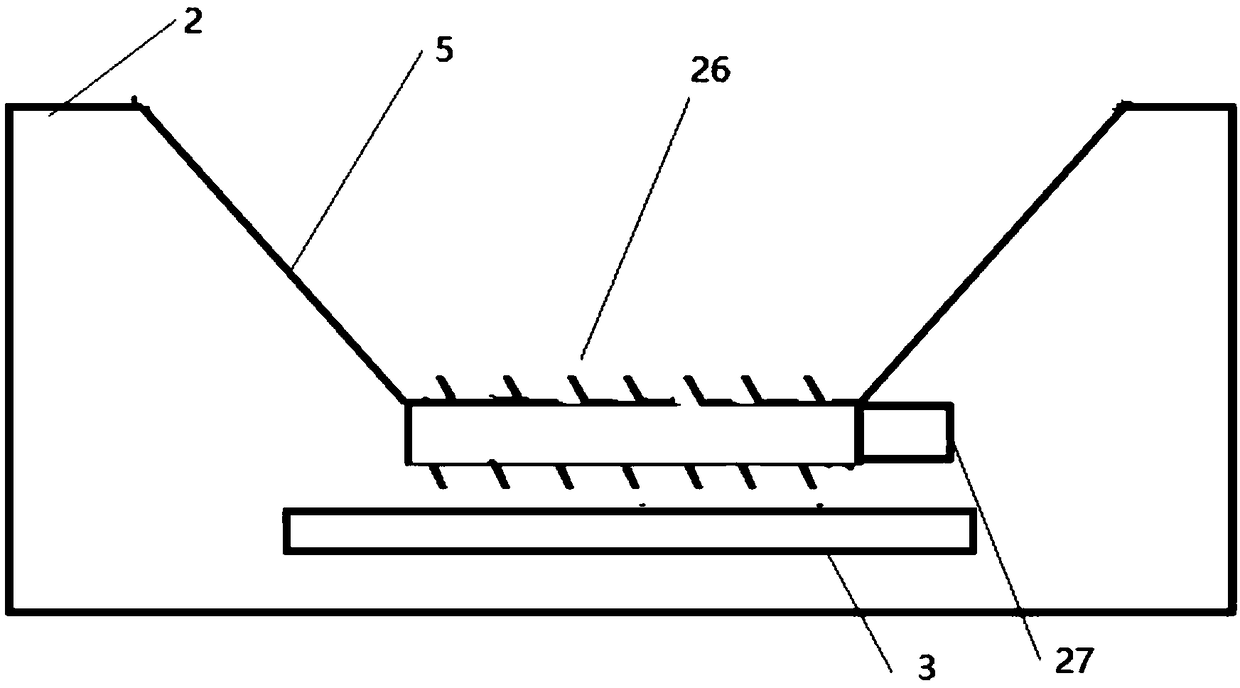

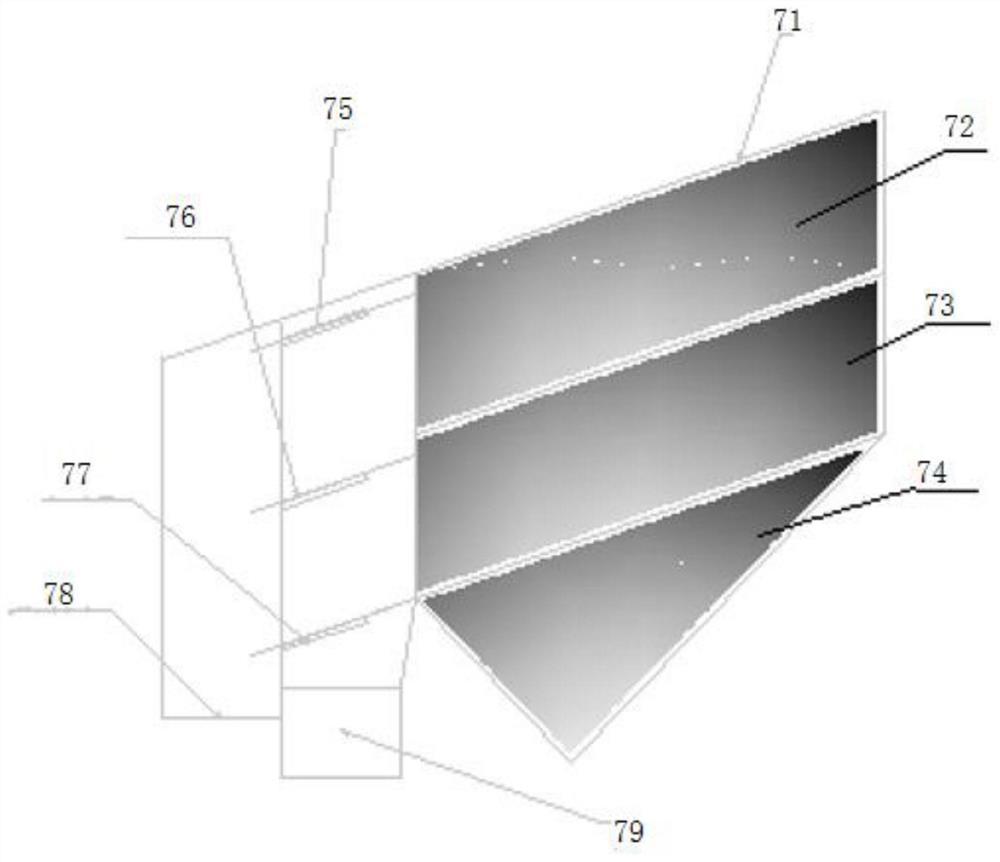

Solar seawater desalination device

InactiveCN105253938AGood light transmissionLow costGeneral water supply conservationSeawater treatmentDistillationEngineering

This invention provides a solar seawater desalination device. The solar seawater desalination device comprises a vacuum pump, a water inlet pump, a solar receiving pond and a low-temperature multi-stage distillation system. A water outlet of the solar receiving pond is connected with the low-temperature multi-stage distillation system. The solar receiving pond comprises multiple stages of water ponds connected in series, and coated vacuum glass is used for the water ponds so that a ceiling can be formed; intercepting filtering cloth is arranged in the water ponds; the low-temperature multi-stage distillation system comprises multiple stages of low-temperature multi-effect vacuum cabins connected in series; an evaporating and condensing heat exchange plate is horizontally arranged in each cabin, the tail end of each evaporating and condensing heat exchange plate is connected with the vacuum pump, and the two ends of each evaporating and condensing heat exchange plate and the bottom of the corresponding cabin are sealed so that a sealed cavity can be formed; a water passing hole is formed in the lower portion of the connection face of every two cabins; the top of the previous-stage cabin and the bottom of the later-stage sealed cavity are connected with a steam pipe; a fresh water flow-out port is formed in the bottom of each sealed cavity; the vacuum degree of each later-stage cabin is lower than that of the corresponding previous-stage cabin due to the vacuum pump. The technical effects of reducing water making cost and improving water making efficiency are achieved.

Owner:周小光

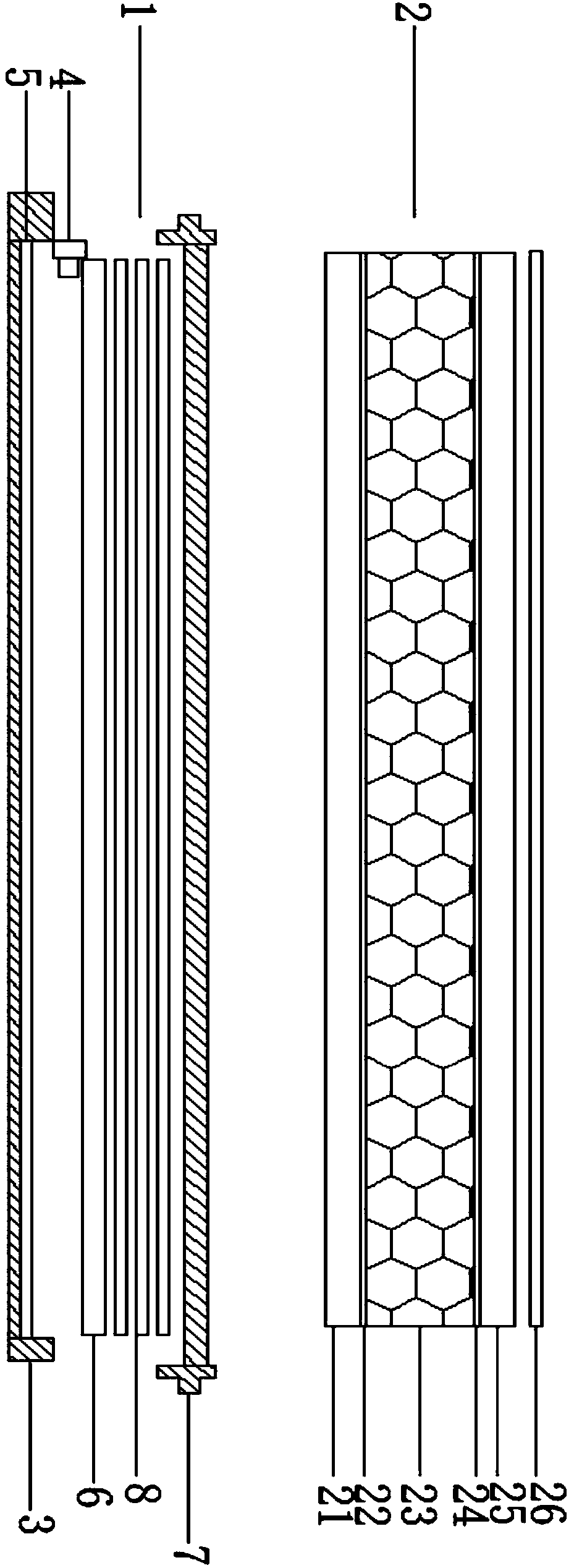

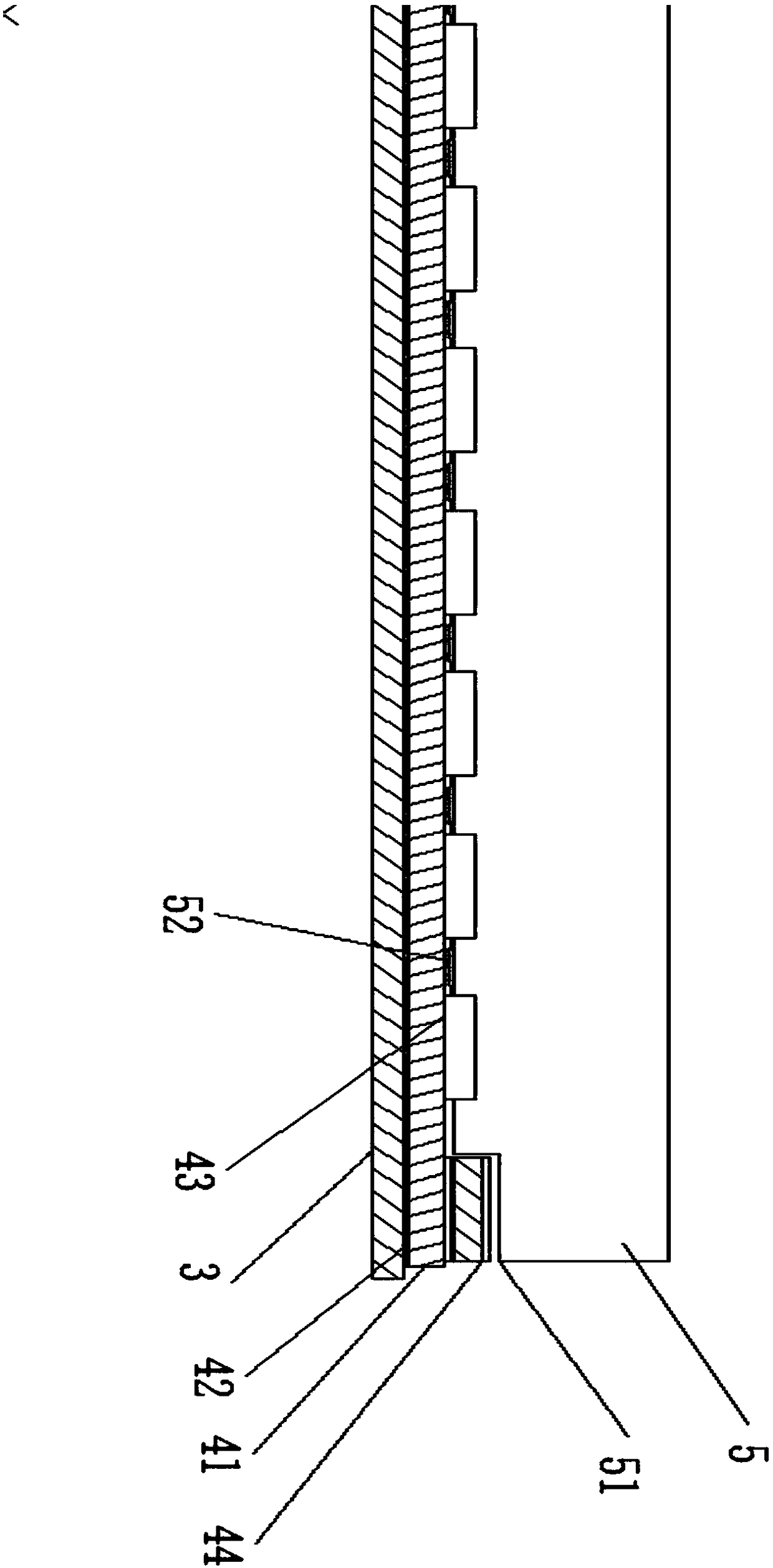

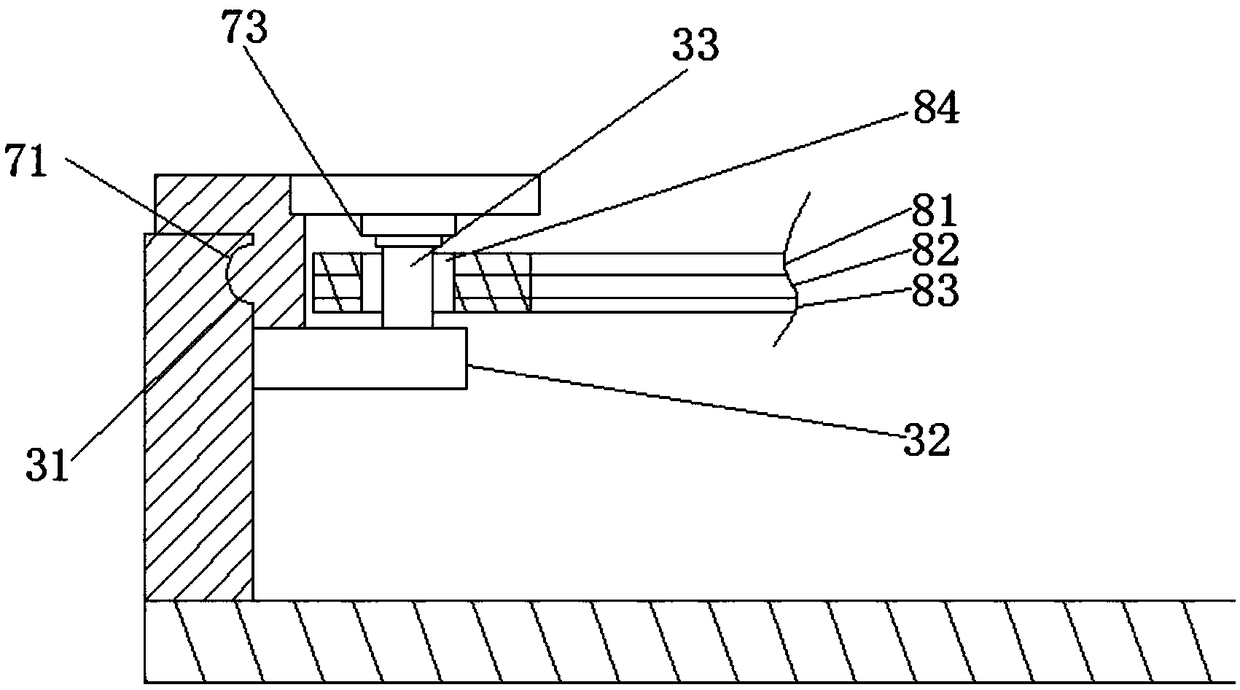

Shading energy-saving type display panel for TPC (transmit power control) model

PendingCN108594530AAvoid the impact of quality problemsReduce optical effectsNon-linear opticsLiquid-crystal displayLight guide

The invention discloses a shading energy-saving type display panel for a TPC (transmit power control) model. The shading energy-saving type display panel for the TPC model comprises a backlight paneland an LCD (liquid crystal display), wherein the backlight panel comprises a backing plate, a light bar, a reflective sheet, a light guide plate, a plastic frame and a film layer; the plastic frame isdesigned along four sides of the backing plate; clamp slots are formed in the four side walls of the backing plate; a plastic frame buckle point is designed on the light incident side of the plasticframe, a backing plate clamp slot is formed in the light incident side of the backing plate, the light incident side of the plastic frame is clamped into the backing plate clamp slot through the plastic frame buckle point in an embedded manner, plastic frame clamp slots are formed in the other three sides except the light incident side of the plastic frame, backing plate buckle points are formed on the other three sides except the light incident side of the backing plate, the light incident side of the plastic frame is clamped in the backing plate clamp slot through the plastic frame buckle point in an outer inlaid manner, and the film layer is laid on the light guide plate. Compared with a full outer-inlaid structure, the shading energy-saving type display panel for the TPC model has thecharacteristics that working efficiency is just reduced by about 10%, however, the overall optical brightness can be increased by about 150-250 cd / m<2>, and a fluctuating value of optical uniformity is smaller than 5%.

Owner:佛山博发智能科技有限公司

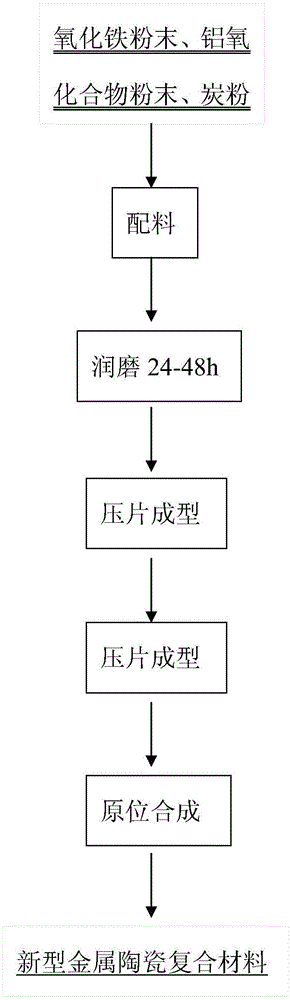

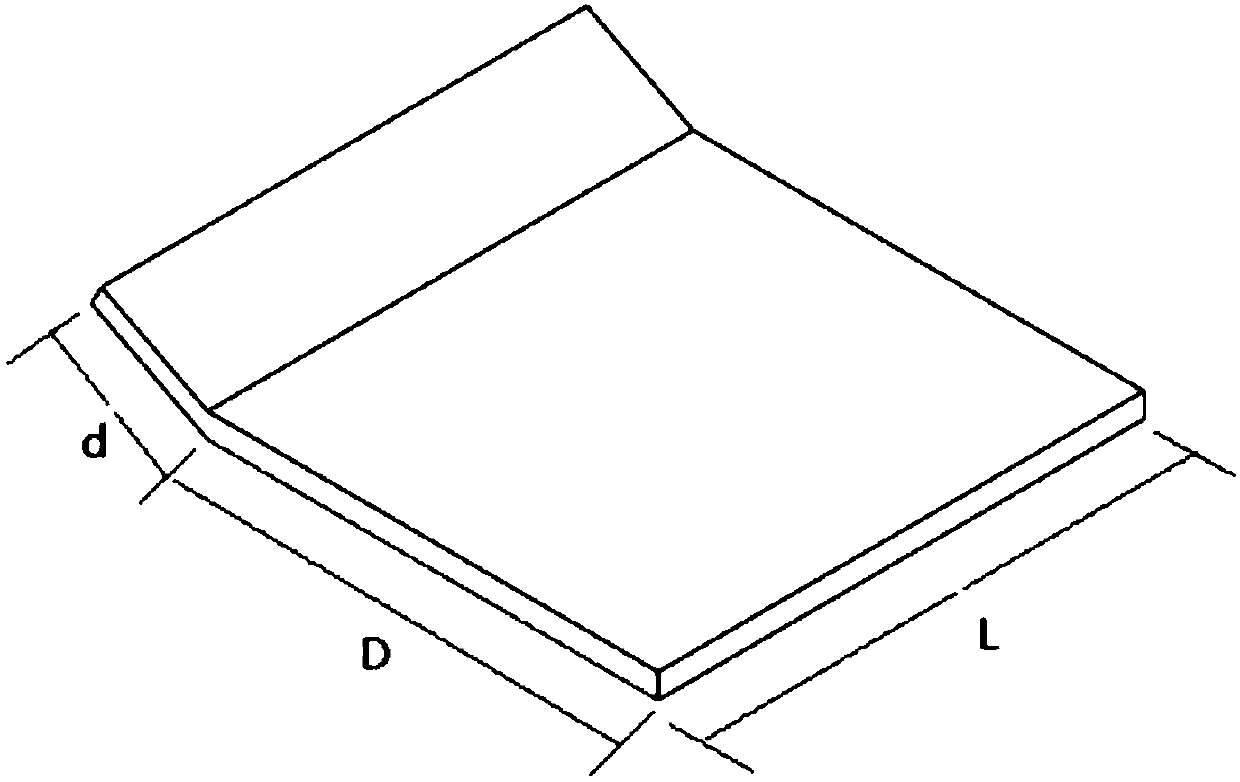

System and preparation method of high-temperature wear-resisting composite material

ActiveCN104894454AResists surface abrasion and erosionImprove toughnessSynthesis methodsSolid particle

The invention relates to a novel high-temperature wear-resisting material adopting Fe-FeAl2O4 as a main phase. The weight percentage contents of a metal phase and a ceramic phase in the material are respectively 33 percent to 45 percent and 67 percent to 55 percent. The novel high-temperature wear-resisting material is high in hardness, high in flexibility, low in abrasion rate, capable of resisting the surface wear and erosion of solid particles in the fields such as metallurgy, materials, heat energy, and the like at the temperature of 1100 DEG C or below and is particularly suitable for protecting devices such as a high-temperature heat exchanger air duct, a cyclone separator lining, a dust-containing ventilation pipeline and the like. The invention also relates to a preparation method of the high-temperature wear-resisting composite material. The preparation method is characterized by adopting iron oxide powder, carbon powder and aluminum oxide powder as raw materials to prepare the novel high-temperature wear-resisting metal ceramic material by virtue of an in-situ synthesis method under high temperature. The process is simple, parameters are controllable, cost is low, the ratio of the metal phase to the ceramic phase is controllable, and the phase interface is clean and good in combination.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

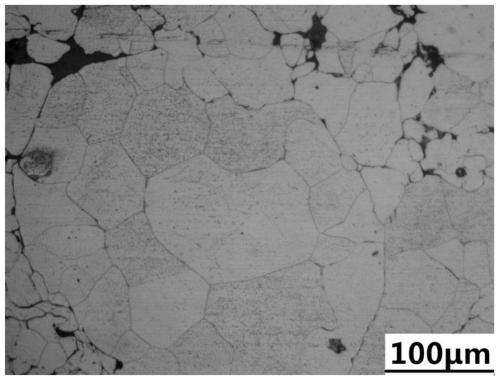

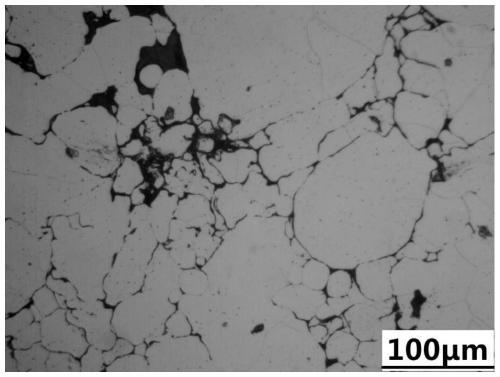

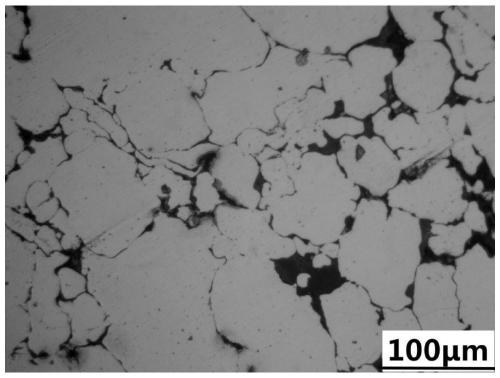

Method for achieving in-situ synthesis of aluminum oxide enhanced ferrum-based powder metallurgy alloy

InactiveCN111118384AReduce pretreatment processHigh hardnessTransportation and packagingMetal-working apparatusAl powderStearic acid

The invention discloses a method for achieving in-situ synthesis of an aluminum oxide enhanced ferrum-based powder metallurgy alloy. The method comprises the following steps that (1) ferrous powder isfirstly subjected to oxidation treatment, the oxidation temperature of oxidation treatment ranges from 100 DEG C to 300 DEG C, and the oxidation time ranges from 0.5 h to 1 h; (2) aluminum powder andzinc stearate are added into the ferrous powder subjected to oxidation treatment to be subjected to ball grinding, the adding content of the aluminum powder is 1%-10% of the total mass, and the content of the added zinc stearate is 1%-2% of the total mass; and (3) alloy powder is pressed and sintered, the sintering temperature ranges from 1,000 DEG C to 1,150 DEG C, the temperature increase speedis 10-20 DEG C / min, and heat insulation is carried out after sintering. In the method, particles of the second phase are generated in situ, the complex enhancer pretreatment procedure in a traditional manner of externally mounting an enhancer is avoided, and production efficiency can be greatly improved; and for a composite prepared through the method, the enhancer is nucleated and grows in a metal matrix, and therefore the surface of the enhancer is free of pollution, the intermiscibility of the matrix and the enhancer is good, the interface bonding strength is high, and the mechanical performance of products can be effectively improved.

Owner:常熟市华德粉末冶金有限公司

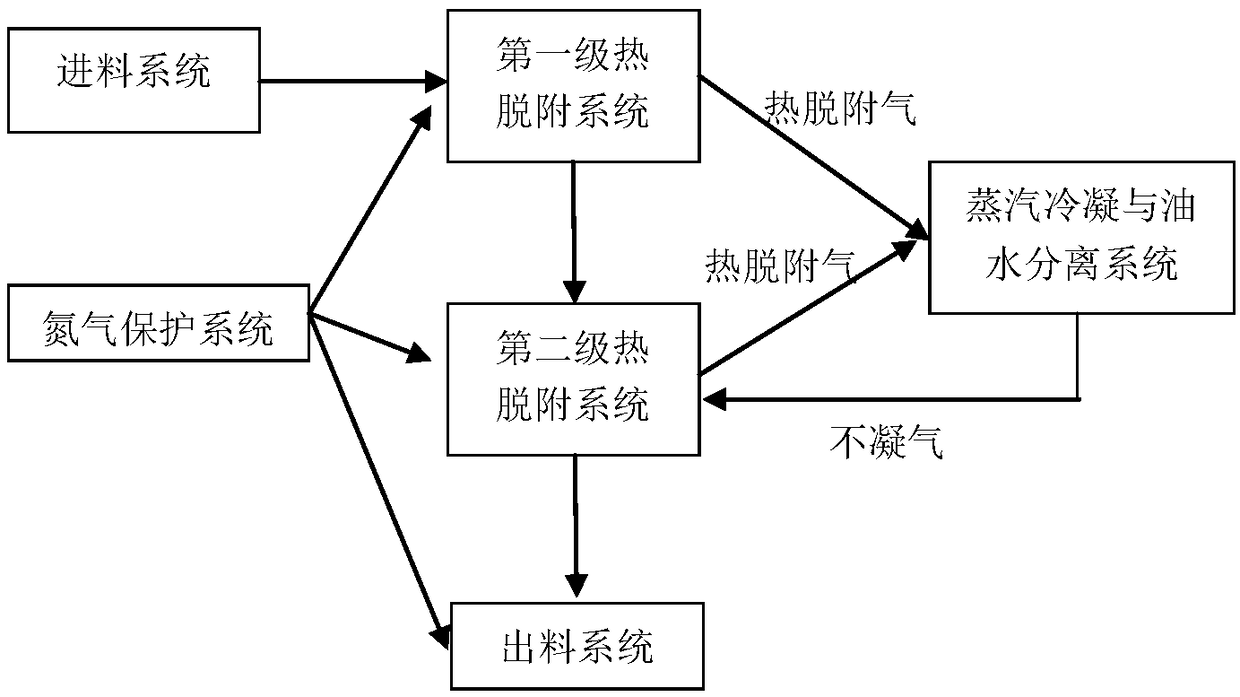

Oil mud two-stage thermal desorption system with high water content and integrated skid-mounted equipment

ActiveCN109354375AReduce energy consumptionIncrease heat absorptionSludge treatmentDispersed particle separationSteam condensationSludge

The invention discloses an oil mud two-stage thermal desorption system with a high water content and integrated skid-mounted equipment, and belongs to the technical field of oil mud treatment devices.The system includes a feeding system, a first-stage thermal desorption system, a second-stage thermal desorption system, a discharge system, a steam condensation and oil-water separation system and anitrogen protection system, which are integrated in the integrated skid-mounted equipment. The system aims at deficiencies of high energy consumption and limited treatment capacity in the oil mud thermal desorption method treatment process, reduces the water content of the oil mud through microwave thermal desorption pretreatment of first-stage thermal radiation, uses the indirect thermal desorption of second-stage heat conduction to separate oil from the soil, and improves the thermal efficiency and the processing capacity of the equipment by a first-stage thermal desorption distributor, a second-stage thermal desorption flame retardant plate and a fire blocking wall to increase the flue gas residence time. The system solves the problem that a microwave belt discharge belt adheres to theoil sludge, a steam releases on the discharge port and the sealing and the safety concern people, the structure is reasonable and compact, and the system is convenient to relocate and install, and has good application prospects.

Owner:广安铭鸿环保科技有限责任公司

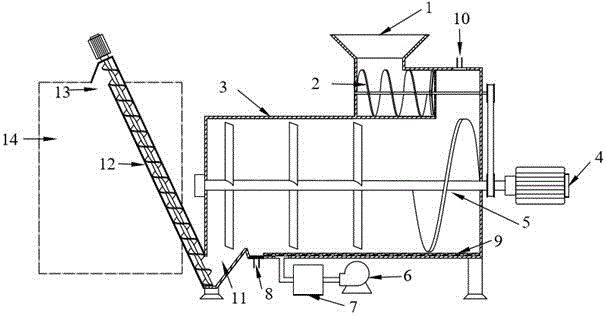

Continuous composting device for organic refuse

PendingCN106495749AWell mixedSuitable temperature for compostingBio-organic fraction processingClimate change adaptationCompostReaction chamber

The invention discloses a continuous composting device for organic refuse. The continuous composting device comprises a primary composting chamber with a feed port and a discharge port, a secondary composting chamber connected with the primary composting chamber through a spiral conveying device, a stirring device, a fed material crushing device and an air supplying device; the stirring device comprises a horizontal stirrer arranged at the center inside the primary composting chamber and a motor which is located at one end of the primary composting chamber and is in driving connection with the horizontal stirrer; the fed material crushing device comprises a crushing device body arranged between the feed port and the primary composting chamber and a motor which is located at one end of the primary composting chamber and is in driving connection with the crushing device; the air supplying device comprises an air inlet located at the bottom of the primary composting chamber, a fan connected with the air inlet and an air uniform distribution layer arranged at the bottom of an inner cavity of the primary composting chamber. According to the continuous composting device for the organic refuse, continuous composting of the organic refuse can be achieved, materials are uniformly stirred in the composting process so as to maintain the temperature of a reaction chamber, and then the treatment amount of the organic refuse can be greatly increased.

Owner:SOUTH CHINA UNIV OF TECH +1

Method for applying nanosecond laser welding in pouch lithium battery

InactiveCN107069070AReduce pretreatment processReduce the number of workersAssembling battery machinesFinal product manufactureEpoxyNew energy

The invention belongs to the technical field of power batteries for new energy vehicles, specifically relates to a method for applying nanosecond laser welding in a pouch lithium battery. The method comprises the steps of sorting cells and binding the cells into a cell group; processing the cell group through high temperature glue coating and epoxy board attaching, and encasing and gluing the cell group; cleaning a conductive copper plate through a laser cleaning machine; enabling the conductive copper plate to pass through a tab of the cell to form a module to be levelled; putting a plurality of the modules to be levelled into a pressing device, bending the tab of the cell, and pressing the conductive copper plate; welding the tab and the conductive copper plate by a nanosecond fibre-optical laser machine; and inspecting the quality of the welding. According to the method for applying nanosecond laser welding in a pouch lithium battery, the nanosecond fibre-optical laser machine is introduced into the field of welding, such that a pretreatment of aluminium-nickel conversion or aluminium-copper conversion before plating is omitted, and the application of nickel strips and red glue materials is cancelled, while the number of workers and the manufacturing cost are also reduced.

Owner:重庆创元新能源科技有限责任公司

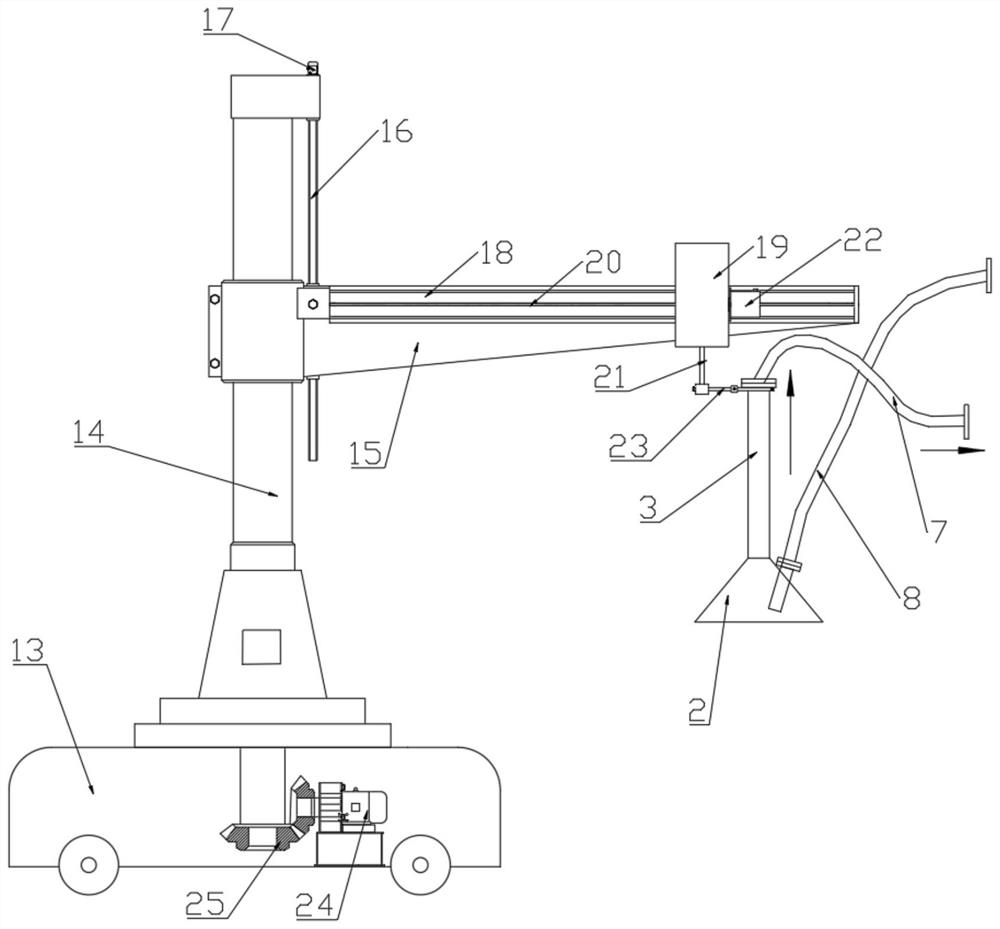

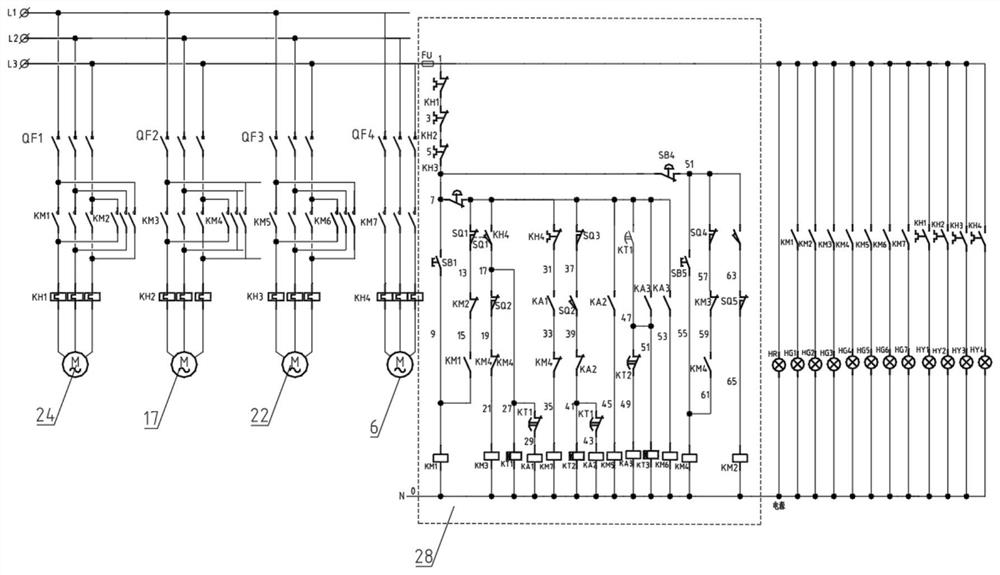

A device for removing low-density scum in metal refining process

ActiveCN112143905BReduce in quantityImprove the level of mechanical automationCasting cleaning apparatusSlagFlue gas

Owner:YUNNAN TIN

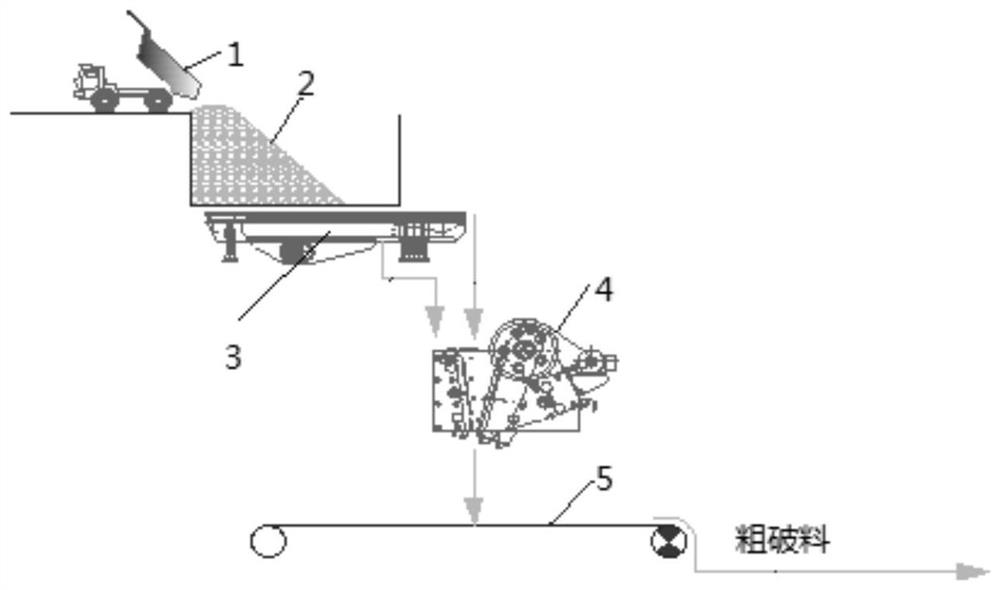

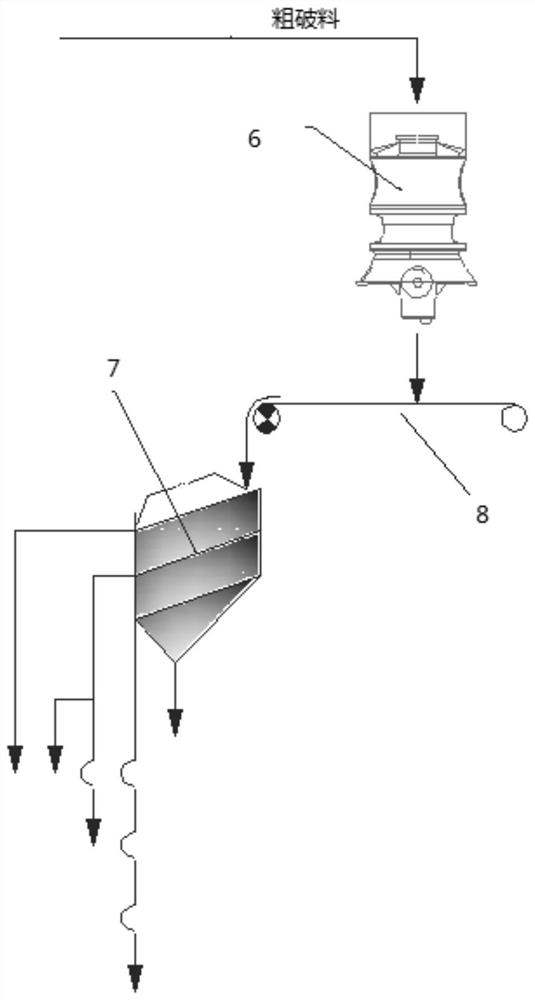

Shell breaking, retention and desliming system of machine-made sand and desliming process thereof

InactiveCN112536132AQuality improvementReduce pretreatment processGrain treatmentsProcess engineeringCrusher

The invention provides a shell breaking, retention and desliming process for machine-made sand. The process comprises the following steps that coarse crushing is carried out, raw materials are directly fed into a primary crusher, primary crushing is carried out on the raw materials by virtue of the crusher to form coarse materials, then medium crushing is carried out, secondary crushing is carriedout on the coarse materials by virtue of a medium crusher to form fine materials, screening is carried out, unused materials are and screened out by virtue of a vibrating screen, the granularity of materials is reduced through a coarse crusher, a part of soil is removed, the materials are crushed into small-granularity materials through the medium crusher to be screened, pretreatment procedures such as pre-screening are reduced, and the quality of finished sand is improved.

Owner:SINOHYDRO BUREAU 9

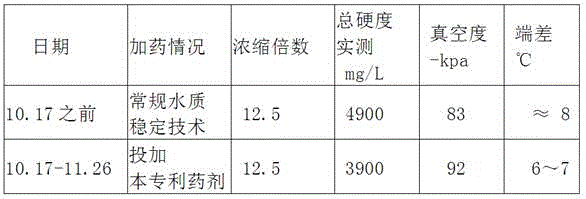

Corrosion and scale inhibition sterilizing agent for circulating cooling water under high concentration multiple

InactiveCN105668812AGood antibacterial effectReduce dosageBiocideSpecific water treatment objectivesHigh concentrationMolybdate

The invention discloses a scale-inhibiting, corrosion-inhibiting and fungicide for circulating cooling water under high concentration ratio, wherein the weight percentage of each component is: 5-15% of alkaline oxide, 30-40% of silicate, boric acid Salt 30-40%, molybdate 0-10% and metal oxide 5-10%.

Owner:JIANGSU SENSE WATER CO LTD

A self-cleaning super weather-resistant powder coating and its preparation method

ActiveCN103194140BImprove stabilityProtect against agingPowdery paintsPolyester coatingsPolyesterAging resistance

The invention belongs to the field of powder paints and particularly relates to a self-cleaning super-weather-proof powder paint. The self-cleaning super-weather-proof powder paint comprises a carboxyl-terminated polyester particle system and a fluorocarbon resin particle system in a weight part ratio of 4:1-1:4, wherein the fluorocarbon resin particle system contains TiO2 nano-particles. As carboxyl-terminated polyester is introduced into a pure fluorocarbon paint, the phase separation occurs in a solidification process, and the fluorocarbon resin floats up to the surface of a coating to serve as coating protection and ageing resistance; the carboxyl-terminated polyester and the like and a substrate can be well wetted, so that the coating and the substrate can be well adhered and can hardly crack and spall; as the TiO2 nano-particles only exist in a fluorocarbon phase, the resin on a bottom layer cannot be broken, and the excellent stability of the system is guaranteed; and the TiO2 nano-particles are scattered in a dry blending manner, and the complex preprocessing is avoided, so that the preprocessing process can be greatly shortened, the cost is lowered, and the efficiency is improved.

Owner:NINGBO SOUTH SEA CHEM

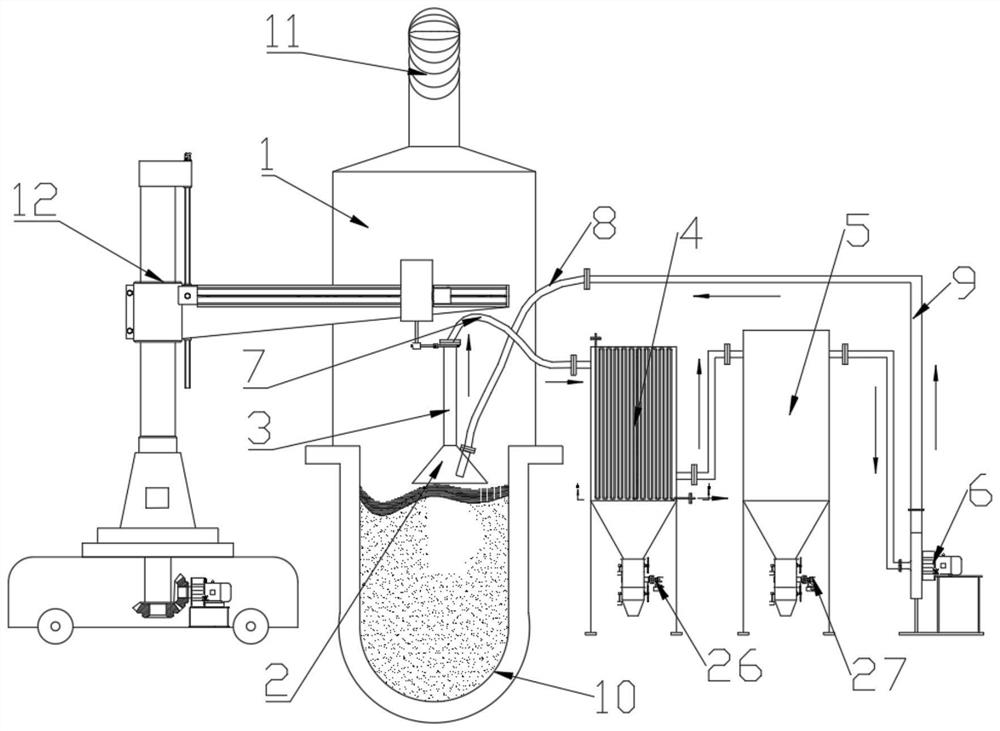

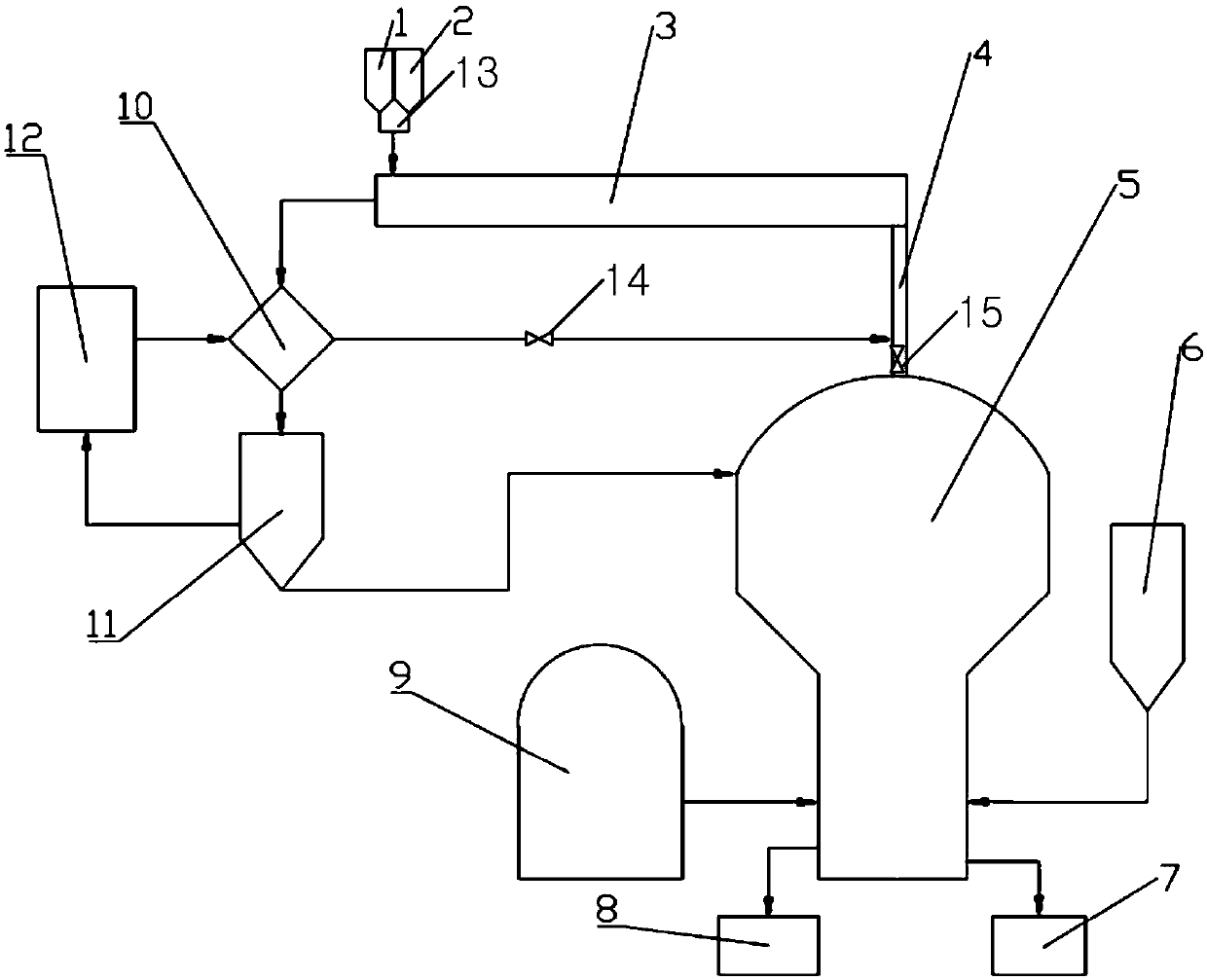

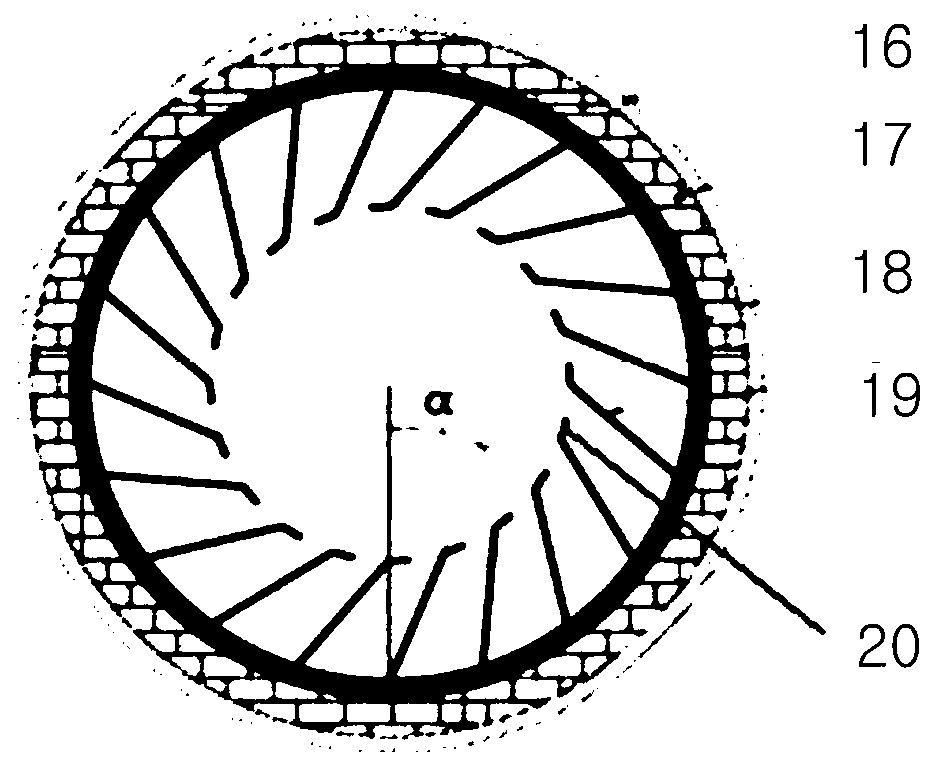

Rotary kiln gas base reduction-total oxygen bath smelting ironmaking device

The invention discloses a rotary kiln gas base reduction-total oxygen bath smelting ironmaking device, belongs to the technical field of non-blast furnace ironmaking, and solves the problems of high fuel ratio of a non-blast furnace ironmaking process and incapability of large-scale low-cost production. The rotary kiln gas base reduction-total oxygen bath smelting ironmaking device comprises a rawmaterial silo, a rotary kiln, a total oxygen bath smelting furnace, a pulverized coal bunker, an oxygen tank, a slag pot and a molten iron jar, wherein the raw material silo, the rotary kiln and thetotal oxygen bath smelting furnace are sequentially connected; a slag iron outlet of the total oxygen bath smelting furnace is connected with the slag pot and the molten iron jar; a discharge hole ofthe pulverized coal bunker and an air outlet of the oxygen tank communicate with an air port of the total oxygen bath smelting furnace; an air outlet of the rotary kiln communicates with an air inletof the rotary kiln; and an air outlet of the total oxygen bath smelting furnace communicates with an air inlet of a rotary kiln head. The ironmaking device provided by the invention can be applied tothe reduction of iron mine powder.

Owner:钢研晟华科技股份有限公司

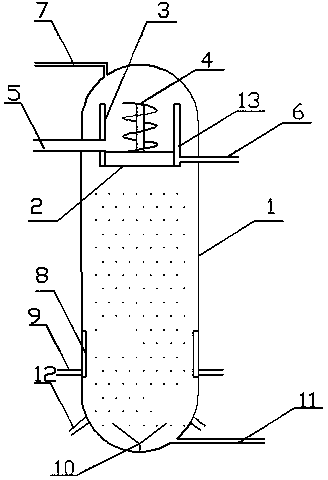

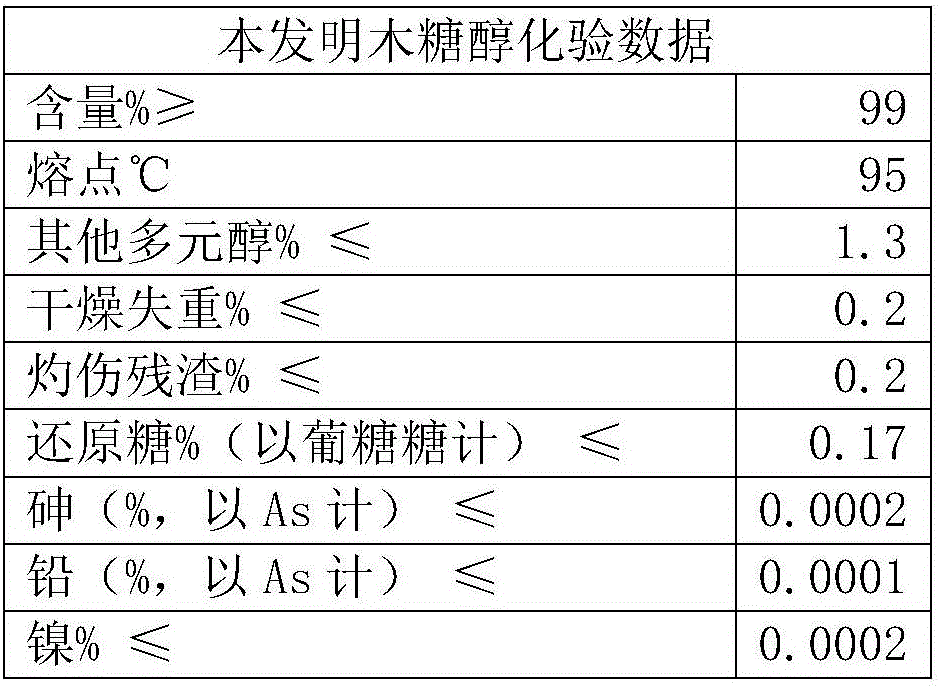

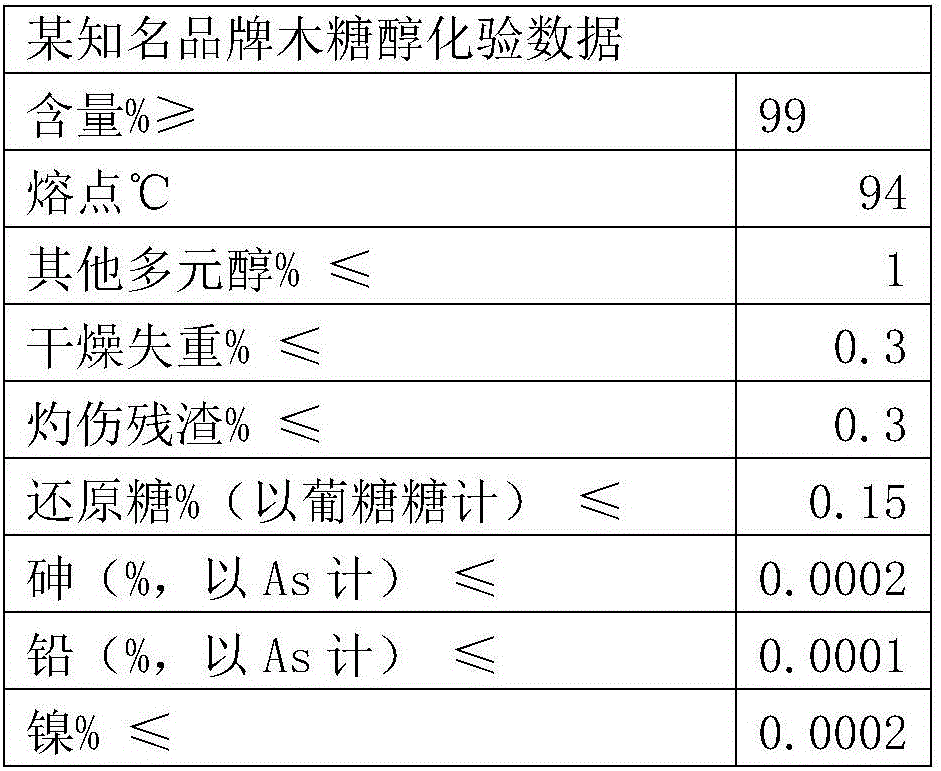

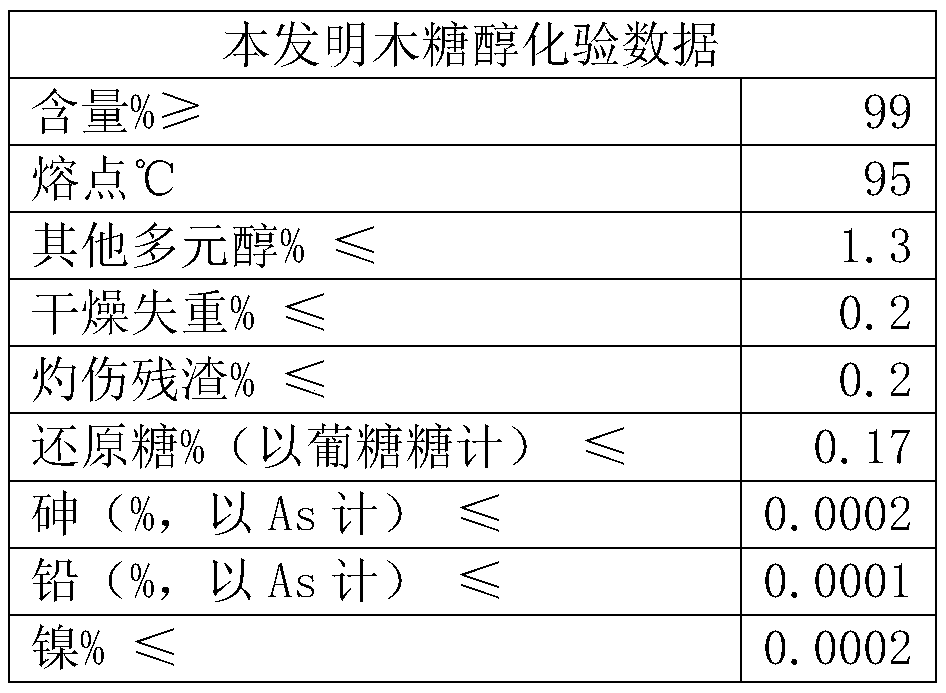

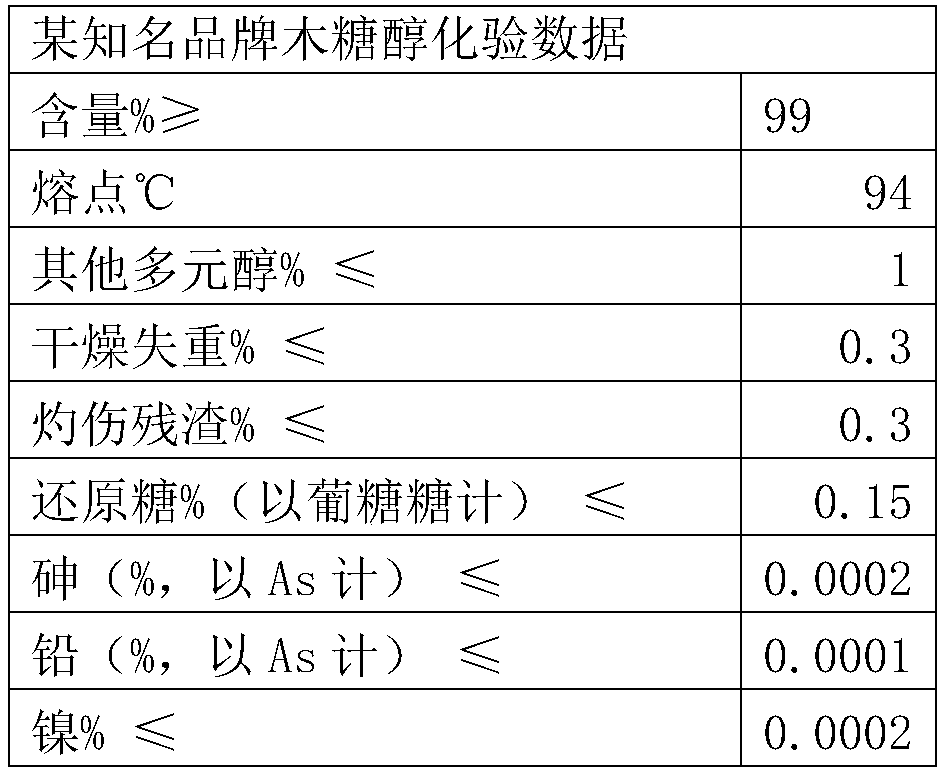

Method for producing xylitol by using eucalypt chip hydrolysis fluid and hydrolyzing tower

ActiveCN102617284BReduce pretreatment processConserve waterOrganic compound preparationHydroxy compound preparationHydrolysateIon exchange

The invention relates to a production method of xylitol, in particular to a method for producing xylitol from eucalyptus dissolving pulp wood chip pre-extraction hydrolyzate, and also to a hydrolysis tower used in the hydrolysis process. A method for producing xylitol by pre-extracting hydrolyzate from eucalyptus dissolving pulp chips, comprising the steps of: pre-hydrolyzing eucalyptus chips, acid hydrolyzing the pre-hydrolyzed hydrolyzate, decolorizing the hydrolyzate, ion exchange purification, Concentration and crystallization treatment to obtain xylose, and then dissolving, hydrogenation, decolorization and purification, and crystallization treatment of xylose to obtain xylitol. It is characterized in that: the pre-hydrolysis of eucalyptus chips is carried out in a hydrolysis tower. After the pre-hydrolysis, The hydrolyzate is extracted from the hydrolysis tower, and then the hydrolyzate is subjected to acid hydrolysis. Since the method of the present invention is continuous feeding and hydrolysis, it reduces the problems of low production efficiency and low production efficiency in the intermittent hydrolysis process in the prior art, such as pot loading, acid addition, hydrolysis, extraction, and unloading. Save time and improve efficiency.

Owner:SHANDONG TAIYANGZHIYE

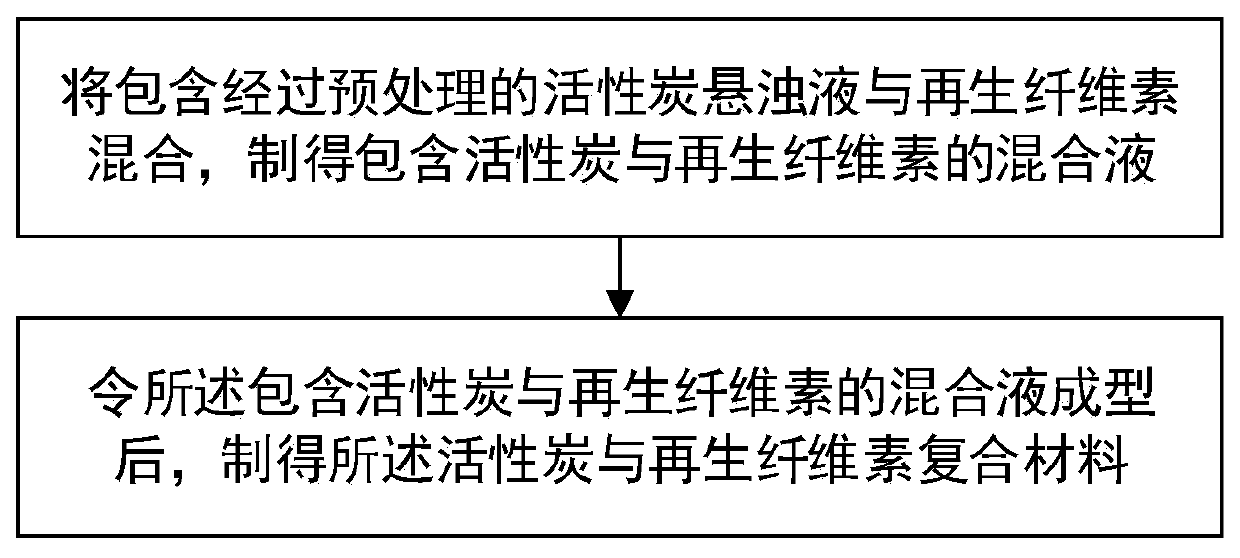

Method for producing xylitol with hemicellulose extracted from liquid waste of regenerated cellulose fiber production or papermaking

ActiveCN106349012AExpand sourceReduce pretreatment processXylose productionPreparation by oxygen reductionLiquid wasteHydrolysate

The invention relates to a method for producing xylitol with hemicellulose extracted from liquid waste of regenerated cellulose fiber production or papermaking. The method includes: collecting the liquid waste of regenerated cellulose fiber production or papermaking as an original hemicellulose solution; splitting the original hemicellulose solution under the sulphuric acid catalyst action and allowing the hemicellulose in the original hemicellulose solution and water to combine to form pentose to obtain hydrolysate; subjecting the hydrolysate to decoloration by the aid of a decolorizing agent; after decoloration, subjecting the hydrolysate to primary ion exchange with anion exchange resin to remove sulfate ions from the hydrolysate; subjecting the hydrolysate to primary concentration, secondary ion exchange, hydrotreating, tertiary ion exchange and secondary concentration to finally obtain the xyliton product. With the method that hemicellulose in the liquid waste of the regenerated cellulose fiber production or papermaking is taken as the raw material, source of the raw material of the xylitol is expanded, and full utilization of the resource is realized; a conventional pretreatment process of the xylitol is omitted, and the problem about pollution caused by acidic water and waste sludge discharge is solved.

Owner:唐山三友集团兴达化纤有限公司

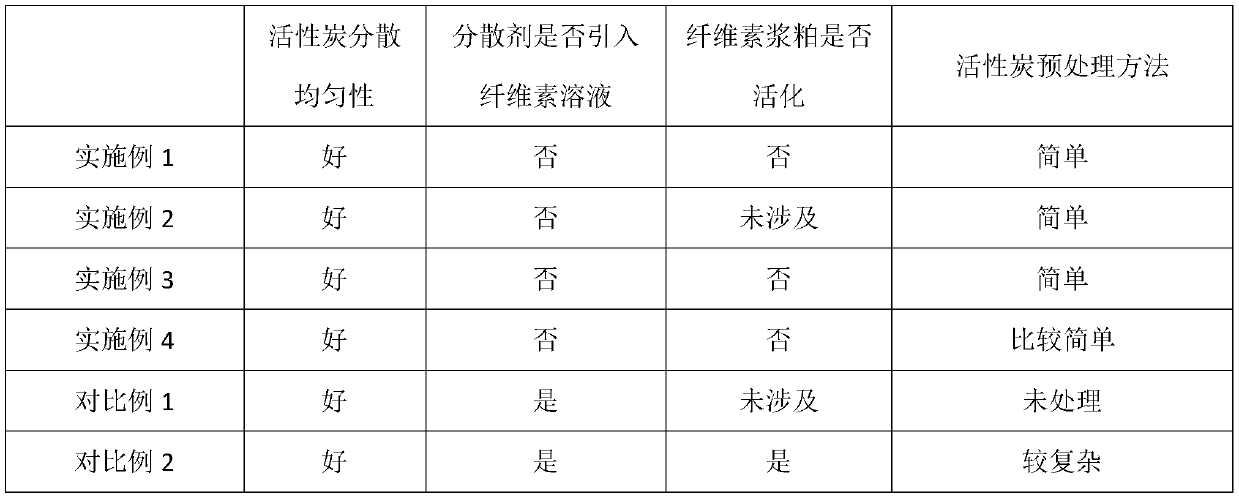

Active-carbon and regenerated-cellulose composite material and preparing method thereof

InactiveCN109853066AReduce self-agglomeration effectGood dispersionArtificial filaments from cellulose solutionsArtifical filament manufactureActivated carbonNanotechnology

The invention discloses an active-carbon and regenerated-cellulose composite material and a preparing method thereof, and belongs to the technical field of spinning. The preparing method of the active-carbon and regenerated-cellulose composite material includes the following steps that turbid liquid containing treated active carbon and regenerated cellulose are mixed, and mixed liquid containing the active carbon and the regenerated cellulose is prepared; the mixed liquid containing the active carbon and the regenerated cellulose is formed, and the active-carbon and regenerated-cellulose composite material is prepared. The active-carbon and regenerated-cellulose composite material is prepared with the preparing method of the active-carbon and regenerated-cellulose composite material, and in the active-carbon and regenerated-cellulose composite material, the value range of the mass percentage content of the active carbon is 1% to 30%. A self-agglomeration effect of the active carbon canbe effectively reduced, the good adsorption characteristic of the active carbon can also be guaranteed, and the composite material also has the advantages of being degradable in regenerated-cellulosefiber, soft in hand feeling and glossy.

Owner:CHINESE TEXTILE ACAD

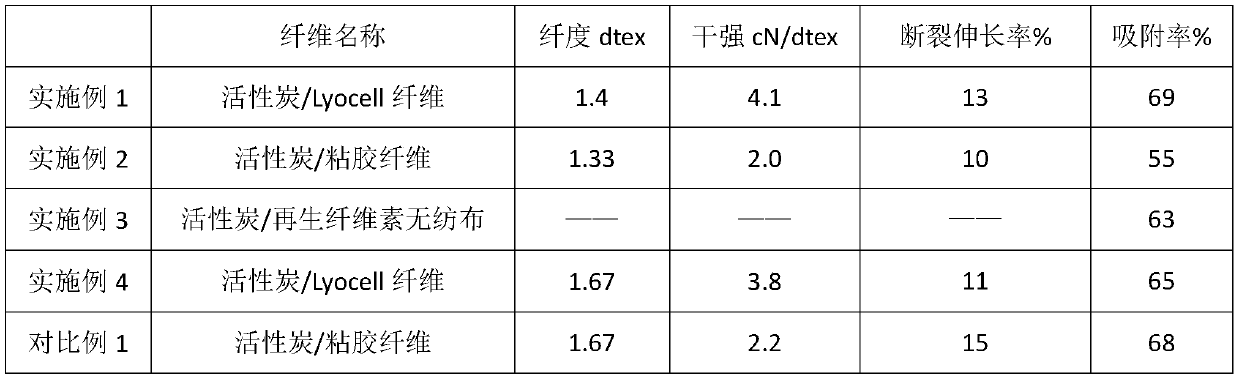

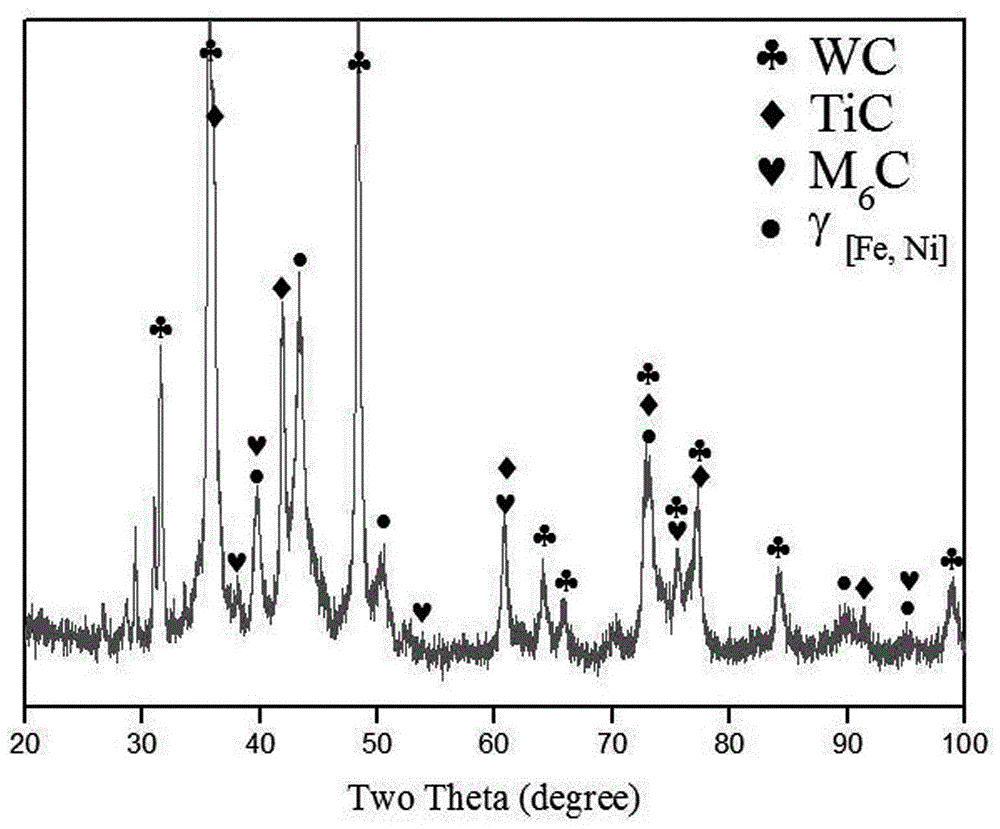

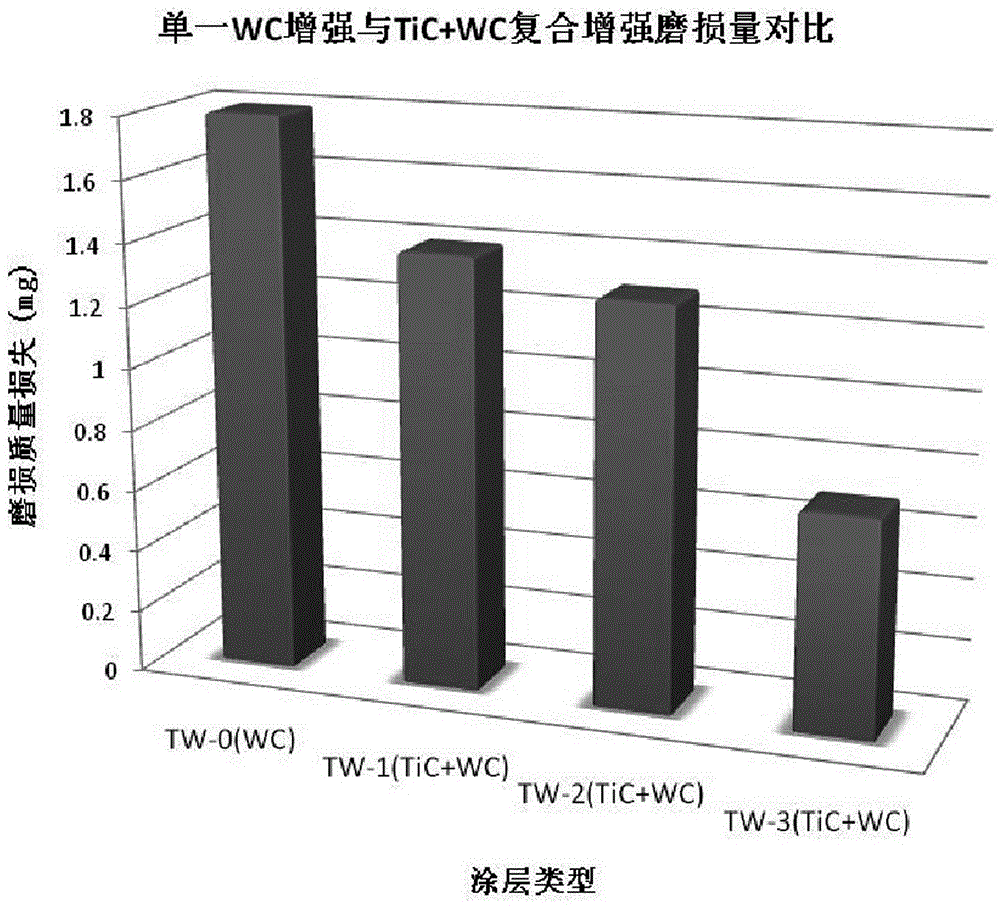

Preparation method of in-situ self-generated wc+tic composite reinforced iron-based wear-resistant coating

InactiveCN104451664BOvercome limitationsImprove bindingMetallic material coating processesSurface layerWear resistant

The invention discloses a preparation method for an in-situ synthesized WC and Tic composite reinforced iron-based wear-resistant coating. The method comprises the following steps: firstly uniformly mixing W, TI, C and Fe-Ni self-flux alloy powder, and then loading the W, TI, C and Fe-Ni self-flux alloy powder into a high-temperature-resistant ceramic bushing bonded to a base plate; prefusing surface layer powder through a plasma non-transferred arc, and fusing inner layer powder and the base plate through the plasma non-transferred arc; finally ensuring that coating melt is naturally cooled in the high-temperature-resistant ceramic bushing. Reinforcement prepared through the method belongs to composite enhancement of TiC and WC of different-scale carbides, compared with single carbide WC, the reinforcement ensures that the coating abrasion loss is reduced by 23 to 62 percent, and the abrasion resistance is greatly improved; the adhesion strength between the in-situ synthesized enhancement phase and a base body is large, and the in-situ synthesized enhancement phase has low probability of falling off from an abrasive surface.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

A method for producing xylitol using hemicellulose extracted from regenerated cellulose fiber production or papermaking waste liquid as raw material

ActiveCN106349012BExpand sourceReduce pretreatment processXylose productionPreparation by oxygen reductionLiquid wasteHydrolysate

The invention relates to a method for producing xylitol with hemicellulose extracted from liquid waste of regenerated cellulose fiber production or papermaking. The method includes: collecting the liquid waste of regenerated cellulose fiber production or papermaking as an original hemicellulose solution; splitting the original hemicellulose solution under the sulphuric acid catalyst action and allowing the hemicellulose in the original hemicellulose solution and water to combine to form pentose to obtain hydrolysate; subjecting the hydrolysate to decoloration by the aid of a decolorizing agent; after decoloration, subjecting the hydrolysate to primary ion exchange with anion exchange resin to remove sulfate ions from the hydrolysate; subjecting the hydrolysate to primary concentration, secondary ion exchange, hydrotreating, tertiary ion exchange and secondary concentration to finally obtain the xyliton product. With the method that hemicellulose in the liquid waste of the regenerated cellulose fiber production or papermaking is taken as the raw material, source of the raw material of the xylitol is expanded, and full utilization of the resource is realized; a conventional pretreatment process of the xylitol is omitted, and the problem about pollution caused by acidic water and waste sludge discharge is solved.

Owner:唐山三友集团兴达化纤有限公司

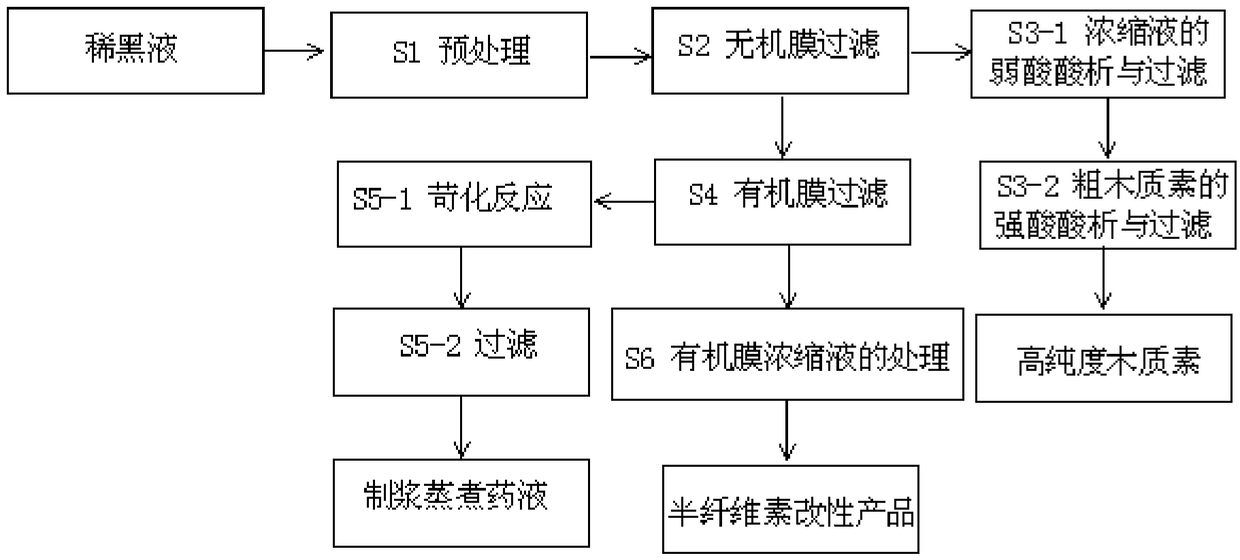

A method for total separation of components of papermaking black liquor

ActiveCN106676931BReduce productionProcess environmental protectionRegeneration of alkali lyeOrganic filmInorganic salts

The invention discloses a full separating method of a papermaking black liquid component; the method includes steps of applying multi-section filtering method of an inorganic film and an organic film, and combining with acid eduction of weak acid and strong acid, effectively treating the black liquid component, separating and recycling lignin, semi-fiber and inorganic salt matter in the papermaking black liquid, acquiring high-purity lignin product; meanwhile, an additive for multi-purpose of the papermaking industry can be acquired; pulping cooking soup capable of circulation is acquired. The technique and handling method belong to a green technique, and method is simple in operation, high in efficiency, and convenient to realize large-scale popularization and application.

Owner:HAINAN JINHAI PULP & PAPER

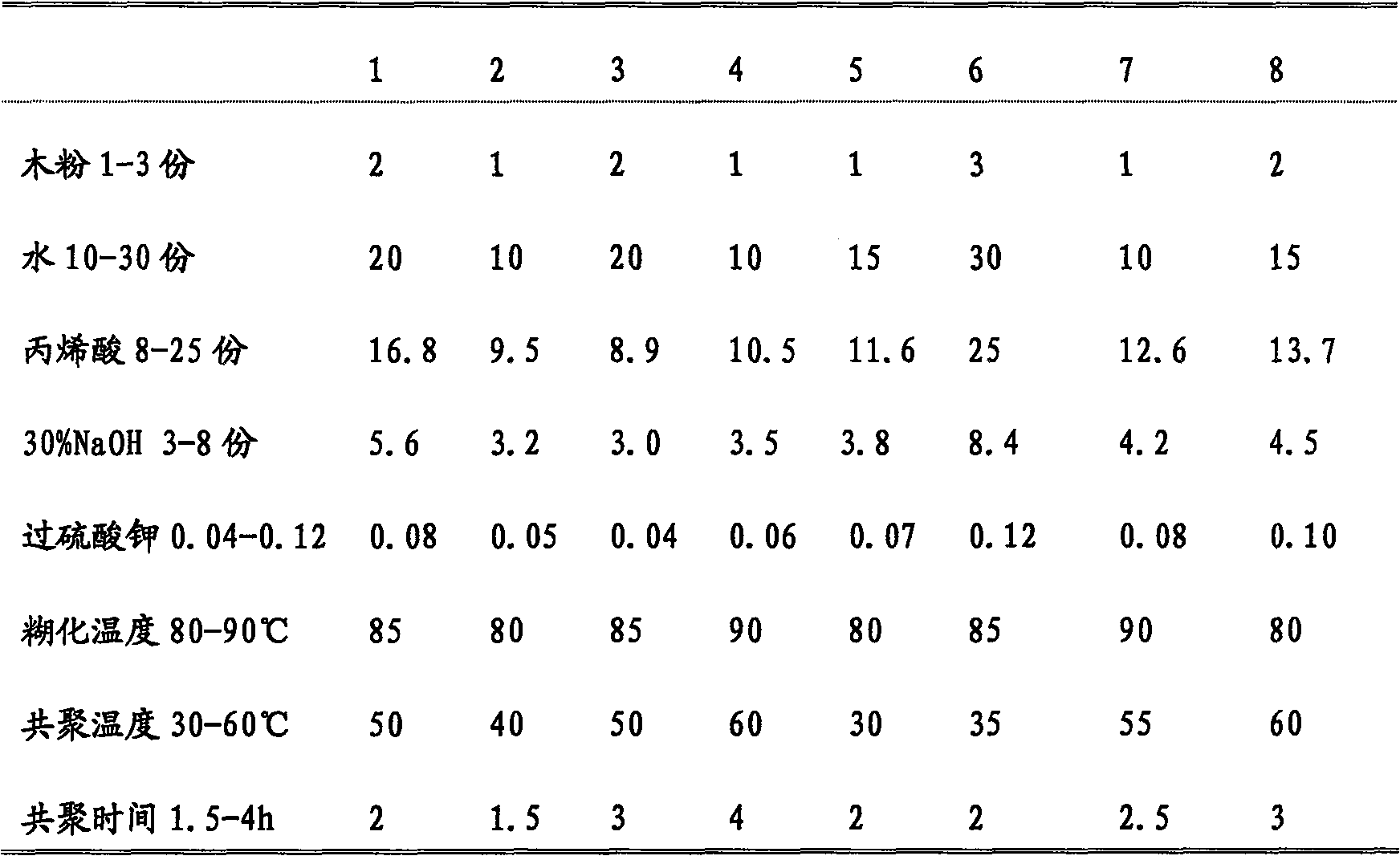

Organic solvent water absorbent and preparation method thereof

The invention provides an organic solvent water absorber, which consists of the following raw materials by weight: 1 to 3 portions of wood flour, 10 to 30 portions of water, 8 to 25 portions of acroleic acid, 3 to 8 portions of sodium hydroxide solution of 30 percent, and 0.04 to 0.12 portion of potassium persulfate. After the raw materials are mixed, the mixture is heated and beaten in nitrogen atmosphere, thus getting high viscosity light brownish yellow cream through copolymerization; after the cream is dried and pulverized, light brownish yellow powder with the granularity from 40 meshes to 100 meshes is got; the water absorption rate is 600 to 800g / g, and the absorption speed is 25g per minute. The water absorber is prepared through the three steps of preparing softened wood flour, preparing a copolymer and preparing the water absorber, which is used as a water absorber for non-medical and non-food used organic solvents which do not require high purity, a soil water retention agent, or a cement curing compound. The water absorber uses the wood flour as a raw material, and comprehensively makes use of cellulose, hemicellulose and lignin in the wood flour as the skeleton and the cross-linking agent of the copolymer; the timber utilization rate is high; the cost is low; and the preparation process does not pollute the environment.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Sealing device and sealing method for optical fiber preform tail handle

PendingCN111056741AAvoid hidden dangers in productionReduce pretreatment processGlass making apparatusMechanical engineeringComposite material

The invention provides a sealing device for an optical fiber perform tail handle, which comprises a quartz tail tube fixed on a rod hanging platform. A tail handle part of the preform is fixed at thelower end of the quartz tail tube, and a quartz assembly for realizing sealing sleeves a reducing area of the tail handle of the preform. According to the optical fiber preform tail handle sealing device provided by the invention, the preform pretreatment process is effectively reduced, the original tail handle does not need to be cut off and then subjected to rod hanging and wire drawing on a tail tube, and the production cost is reduced. And meanwhile, through reasonable structural design, the production hidden danger caused by a large reducing area at the tail part of the preform is avoided.

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com