Patents

Literature

62results about How to "Simple spinning process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

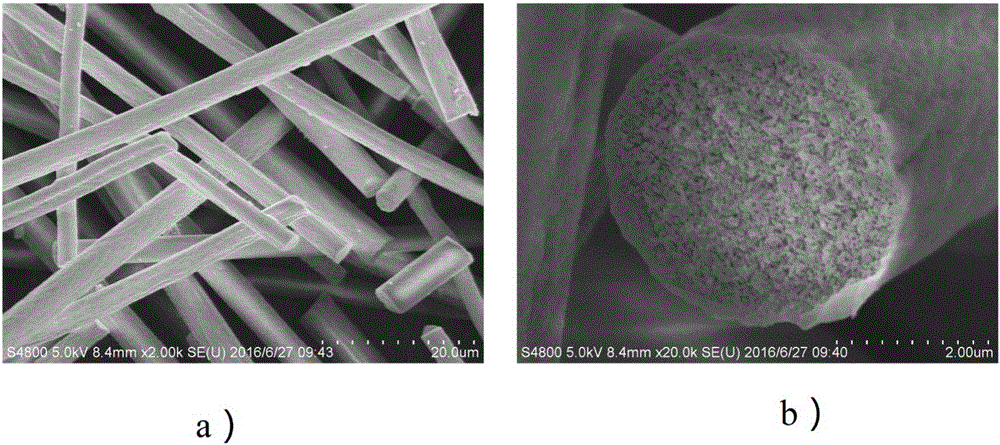

Flame retardant cellulose fiber and preparation method thereof

InactiveCN101608348ASuitable for processingEasy to useFlame-proof filament manufactureMonocomponent cellulose artificial filamentMass ratioCellulose fiber

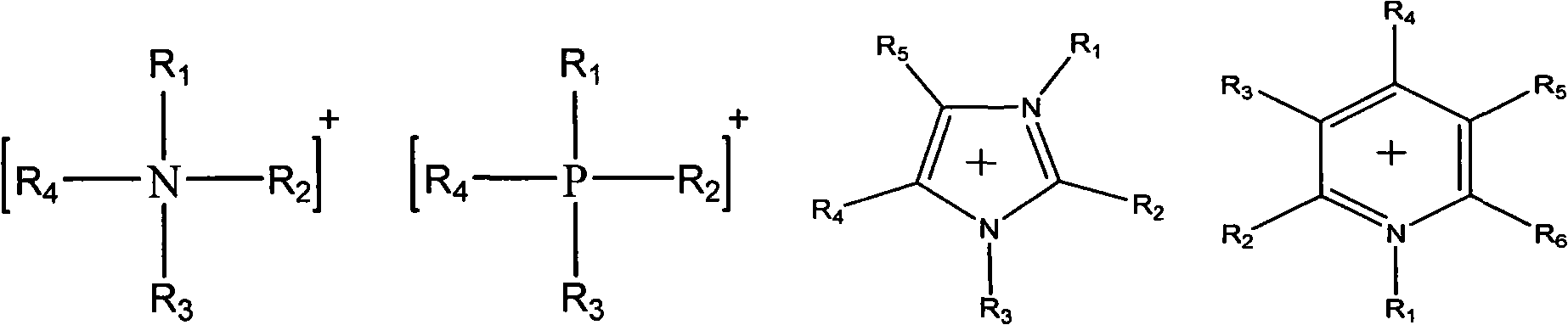

The invention discloses a flame retardant cellulose fiber and a preparation method thereof. The fiber has the components of fire retardant and cellulose which have the mass ratio of 10-25:100; wherein the fire retardant is novel phosphorus fire retardant having the average grain diameter being less than 1mum; the cellulose is wood pulp or cotton pulp having the polymerization degree of 400-1000 and alpha-cellulose content being more than or equal to 90%. According to the components with the mass ratio of the fiber, the preparation method of the fiber comprises the technique as follows: 1. preparation of flame retardant spinning solution as the following: according to the mass ratio, firstly adding the fire retardant into ionic liquid at the normal temperature, and leading the fire retardant to be uniformly dispersed in the ionic liquid under mechanical agitation; then adding the cellulose into the mixed ionic liquid to be fully dissolved with the dissolving temperature of 70-110 DEG C to prepare flame retardant spinning solution; ensuring the mass ratio between the cellulose and the ionic liquid to be 5-35:95-65: 2. preparation of the flame retardant cellulose fiber: preparing the flame retardant cellulose fiber according to the conventional spinning process flow.

Owner:TIANJIN POLYTECHNIC UNIV

Method for preparing bletilla striata hemostatic gauze

ActiveCN102961776ANo side effectsNo pollution in the processAbsorbent padsWet spinning methodsSolubilitySide effect

The invention relates to a method for preparing a bletilla striata hemostatic gauze and belongs to the technical field of textile engineering. The preparation method provided by the invention employs the manner of carrying out the process of soaking bletilla striata stem blocks in distilled water a plurality of times, filtering and collecting the filtrate, and further comprises the following steps of: concentrating the collected filtrate, adding absolute ethyl alcohol to the concentrated bletilla striata gum solution, thoroughly standing and performing alcohol precipitation, thereby obtaining white precipitate; washing the white precipitate using absolute ethyl alcohol, and drying the precipitate for future use; preparing the dried bletilla striata gum into a spinning solution with water as a solvent and spinning the solution into long filaments with the absolute ethyl alcohol as a coagulating bath; knitting the long filaments into the gauze through needle weaving, machine weaving or non-weaving; and then cutting, disinfecting and packing the gauze, thereby obtaining the water-soluble hemostatic gauze. The raw material employed by the preparation method provided by the invention is the bletilla striata gum extracted from the bletilla striata stem blocks; the bletilla striata gum has excellent water-solubility; the bletilla striata long filaments can be degraded and absorbed in body and is good in compatibility with the organism without side effect on the wound. Chemicals involved with the preparation of the bletilla striata hemostatic gauze is only the absolute ethyl alcohol which can not generate harmful substances and has no pollution on the environment; and the coagulating bath for spinning by the wet method and the spinning process are simple and low in cost.

Owner:宜昌百吉生物科技有限公司

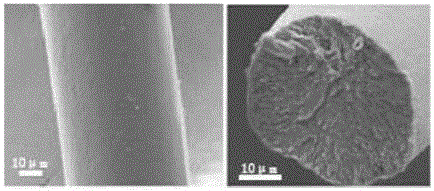

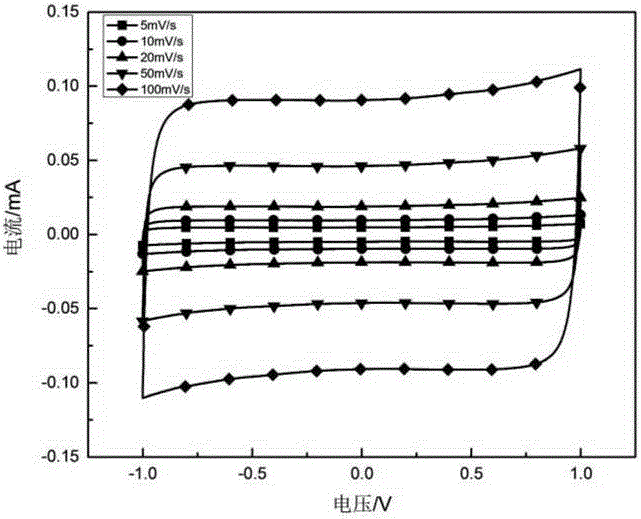

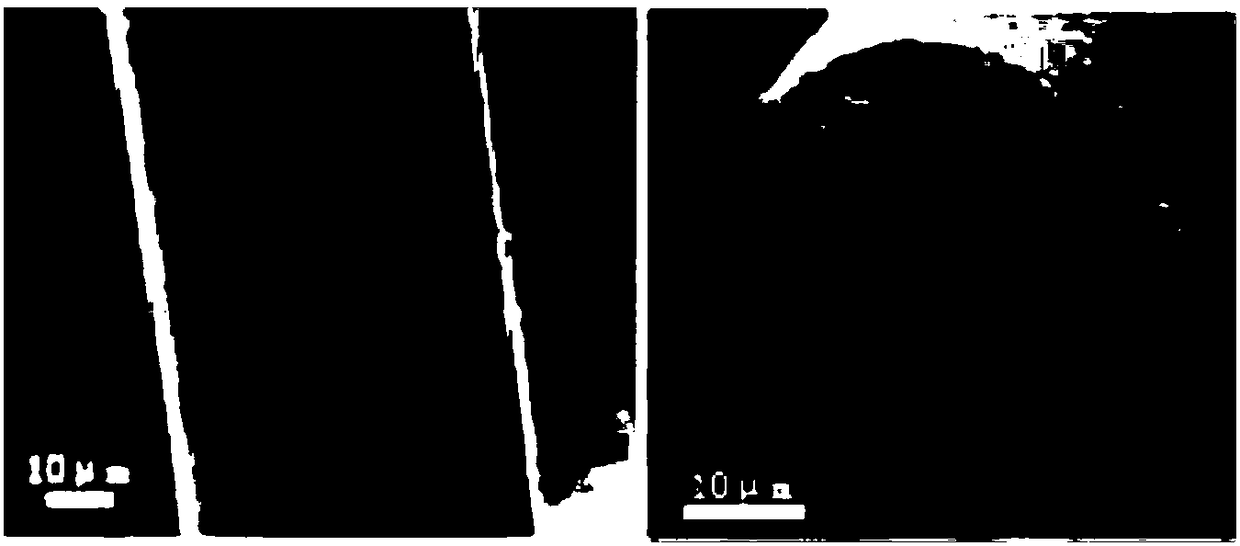

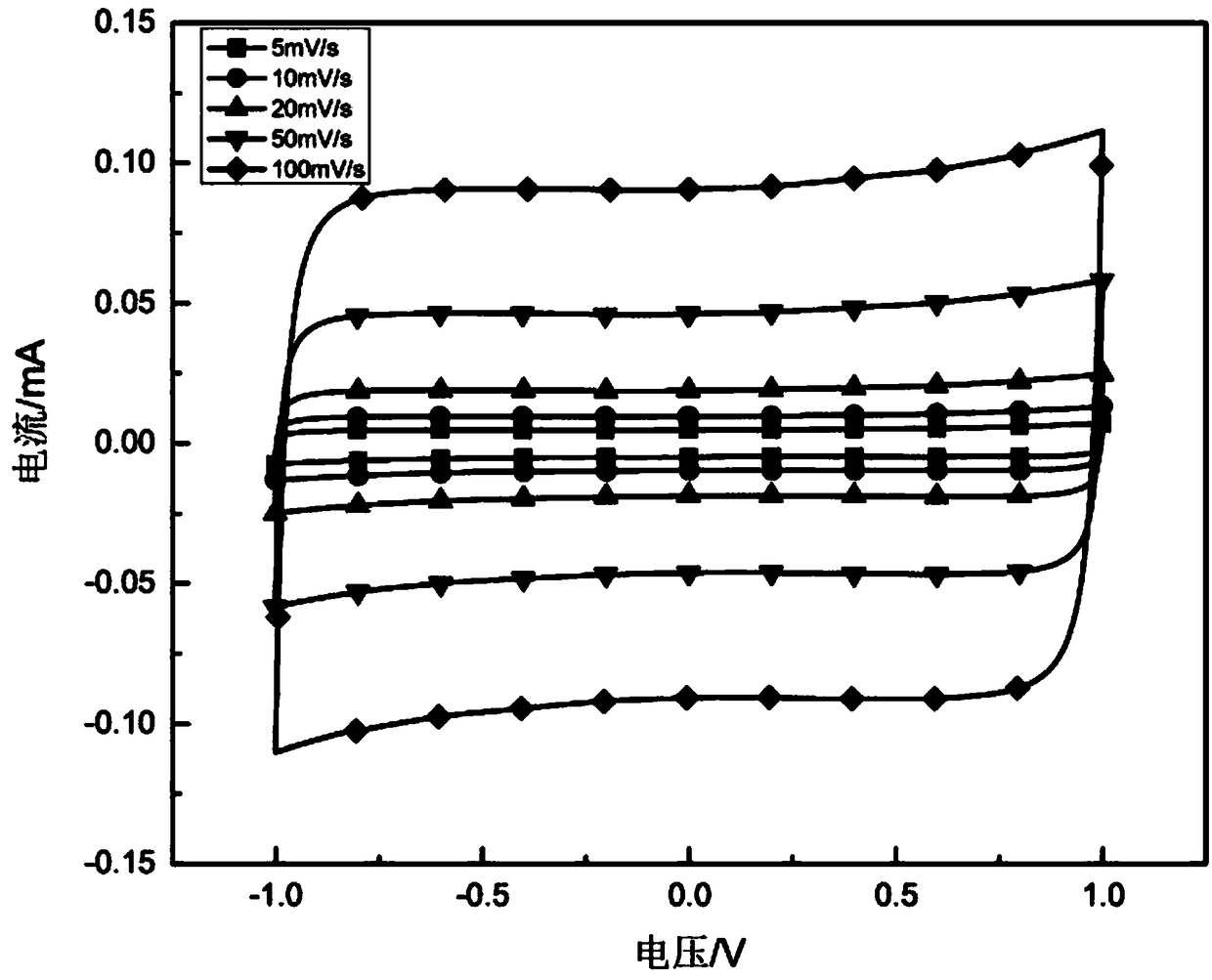

PEDOT:PSS fiber and preparation method thereof

ActiveCN106381571ASimple spinning processGood effectArtificial filament washing/dryingArtificial filament heat treatmentFiberChemical treatment

The invention discloses a PEDOT:PSS fiber and a preparation method thereof. A wet spinning technology is adopted, low toxicity and low harm, green and environment-friendly mixed solution of inorganic salt, ethanol and water is adopted as coagulation bath, a PEDOT:PSS aqueous solution is taken as the main raw material, through a simple chemical treatment method, the PEDOT:PSS fiber with excellent electrical conductivity and mechanical properties can be prepared. The PEDOT:PSS fiber can be used directly as a lightweight flexible lead, also can be used for the electrode of a linear flexible capacitor, and can exhibit rapid voltage change response and high specific capacity. Compared with the prior art, the method provided by the invention has the prominent advantages of safety, green and environmental protection, and the fiber has large strength and good flexibility. At the same time, the equipment and method are simple, and can achieve large-scale production of PEDOT:PSS fiber with good mechanical properties, high electrical conductivity and good electrochemical properties.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS +1

Electromagnetic shielding fabric for carbon fiber

InactiveCN101188927AShielding hazardsIncrease productivityMagnetic/electric field screeningFibre chemical featuresYarnCarbon fibers

The invention provides a whole new weaving process of carbon fiber electromagnetism shielding fabric, and a method thereof. Regenerated cellulose fiber or polyacrylonitrile fiber yarn is used for weaving to barrier fabric, graphite fiber yarn mesh is obtained by heating in high temperature to be served as basic cloth, and filature is sprayed by using a dry method to form the carbon fiber electromagnetism shielding fabric which has the function of well shielding the electromagnetic wave and has the advantages of simple spinning process and high production efficiency, thereby improving the production value of the product.

Owner:SHENGHONG GRP CO LTD

Caprolactam hydrolyzed polymer fibres and spinning method thereof

ActiveCN104480561AIncrease profitThe polymerization process is simpleNew-spun product collectionMonocomponent copolyamides artificial filamentPolymer scienceEngineering plastic

The invention relates to caprolactam hydrolyzed polymer fibres and a spinning method thereof. The spinning method comprises the following steps: preparing a polyamide 6 prepolymer at low temperature, pre-controlling the content of oligomers in a melt, carrying out auxiliary end-blocking by binary acid to reduce the content of end amino groups in a system, then carrying out end-blocking by ethylene glycol, after that, carrying out chain growth by means of gylcol ester removal exchange, wherein in the obtained product, the content of extractable matters is not greater than 2wt%, and the content of cyclic dimers is not greater than 0.3wt%; then, carrying out direct melt-spinning formation after the condensation polymerization reaction is concluded. The spinning method disclosed by the invention is simple in process, and capable of reducing energy consumption while increasing the utilization rate of caprolactam; the obtained melt is capable of being used for direct melt-spinning, easy in realizing high-capacity large-scale production, and capable of being applied to the fields of garment fibres, industrial silk, engineering plastics and the like.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

Method for creating cultivated silkworm chromatic cocoon by using pigment protein

InactiveCN101255423ASolve technical bottlenecksAchieve diversificationMicroinjection basedVector-based foreign material introductionInstabilityHuman health

A colorful silkworm cocoon creation method by pigment protein is disclosed. A pigment protein determining color of coral reed and related marine creature is fusion expressed in bombyx mori silk fibroin by genetic modification of silkworm and especially genetic modification for diapause varieties, so that novel colored silkworm cocoon is created. Exogenous pigment protein is fusion expressed in silk fibroin, and exists stably and uniformly in silk fibroin molecular, so pigment protein will not be lost in silk reeling procedure, and color variety of pigment protein is abundant. The method used by the invention solves two problems of little variety in color of silkworm cocoon and instability in pigment binding, simplifies spinning process of silk fabrics, eliminates harm of dyeing process to silk fiber quality and human health.

Owner:重庆拓桑生物科技有限公司

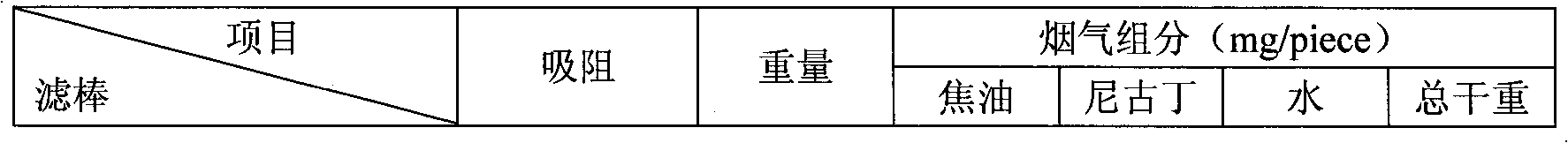

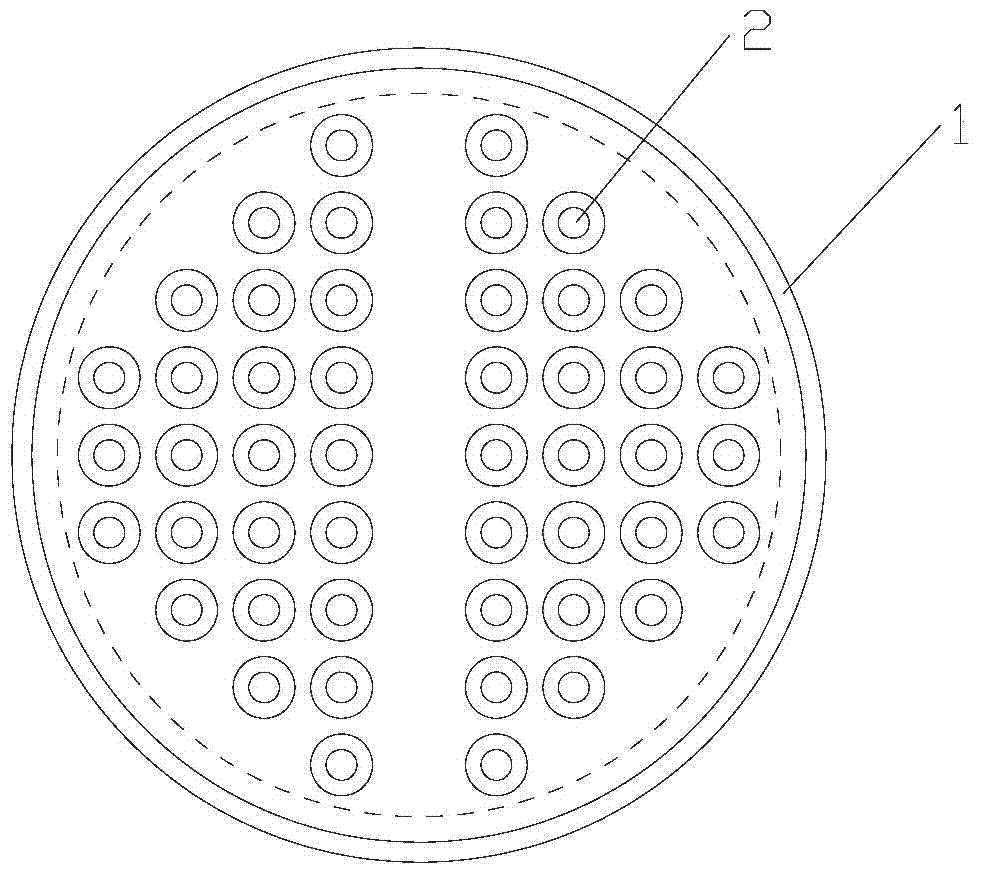

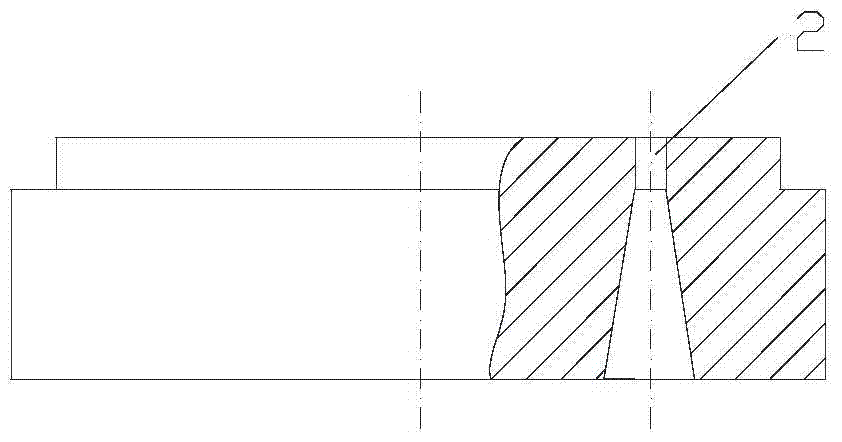

Method for preparing tows for modified cigarettes

ActiveCN102134758ALight weightSimple spinning processArtificial filament physical treatmentMelt spinning methodsFiberPolymer science

The invention relates to a method for preparing tows for blended modified polylactic acid cigarettes. Fiber grade polypropylene particles, functional master batches and polylactic acid particles are uniformly mixed according to a certain ratio, and the tows for polylactic acid cigarettes are prepared through the working procedures of spinning, oiling, drafting, wrapping and drying. The method has a simple process and high speed to form, the produced product can reduce the specific weight of polylactic acid fiber, the operational performance is increased, the surface area of the fiber is increased, grain phase particles in smoke can be effectively absorbed, and a good filtering effect is generated.

Owner:JIANGSU DAYA CIGARETTE FILTER MATERIAL CO LTD

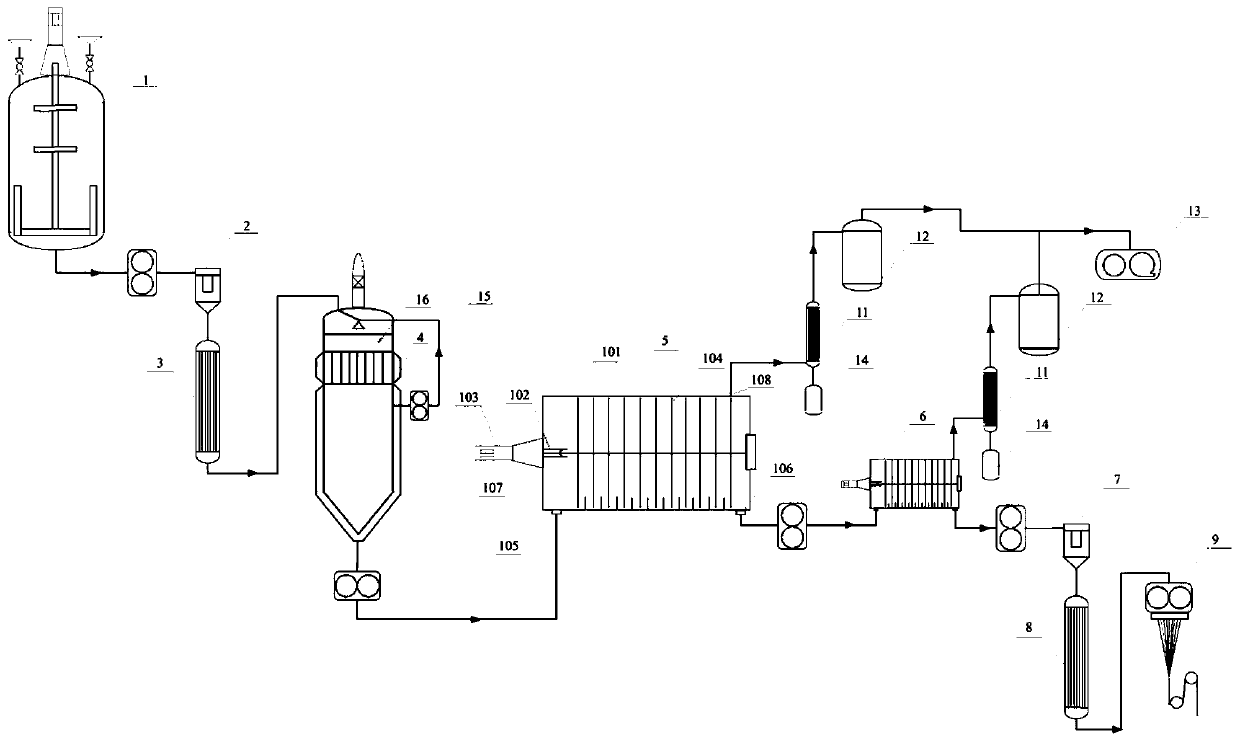

Ultra-high-molecular-weight polyethylene monofilament filter cloth and preparation method thereof

InactiveCN104492160AReduce processing costsShort processSpinnerette packsHeating/cooling textile fabricsEngineeringUltimate tensile strength

The invention discloses ultra-high-molecular-weight polyethylene monofilament filter cloth and a preparation method thereof. The filter cloth is in a single-layer structure or a double-layer structure, wherein warps of the filter cloth with the single-layer structure are woven by one monofilament and wefts are woven by another monofilament; the diameter of each monofilament is 0.07mm-0.2mm; the arraying ratio of exterior and interior warps to exterior and interior wefts of the filter cloth with the double-layer structure is 4 to 1; a tying method is a tying weft method; the warps of exterior tissues and interior tissues are woven by one monofilament and the wefts are woven by another monofilament; the diameter of the monofilament of each exterior tissue is 0.07mm-0.2mm and the tensile strength is more than 1100MPa; and the diameter of the monofilament of each tissue is 0.6mm and the tensile strength is more than 1000MPa. The monofilaments are woven by ultra-high molecular weight polyethylene through a melt spinning method, and are obtained by heat shaping and calendering treatment in sequence after weaving. The filter cloth disclosed by the invention has the advantages of high strength, good surface performance, long service life and the like; and the preparation process is simple and the cost is low.

Owner:王庆昭

Melting direct-spinning method of copolymerized modified low-melting-point nylon fibers

ActiveCN111304771ADisruption of regularityLow melting pointMonocomponent copolyamides artificial filamentEvaporationNylon materialCaprolactam

The present invention relates to the field of nylon materials, and discloses a melting direct-spinning method of copolymerized modified low-melting-point nylon fibers. The method comprises the steps of 1) material preparation, wherein caprolactam, a copolymerized modified component, an end-capping agent, water and a catalyst are heated and mixed; 2) ring opening, wherein a mixture is heated for ring opening; 3) pre-polycondensation, wherein a pre-polymerization reaction and devolatilization are performed; 4) final polycondensation, wherein a final polycondensation reaction and devolatilizationare performed; 5) devolatilization before spinning; and 6) spinning, wherein a product is directly conveyed to spinning threads for spinning to obtain the copolymerized modified low-melting-point nylon fibers. According to the method, the copolymerized modified component is added for destroying the regularity of nylon molecular chains and reducing the hydrogen bond density and crystallinity of the nylon molecular chains, thereby achieving the purpose of lowering the melting point of nylon; and according to different varieties and content of added copolymerized components, the melting point ofthe nylon can be controlled to be 90-200 DEG C, so that the application range of the low-melting-point nylon is greatly expanded.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

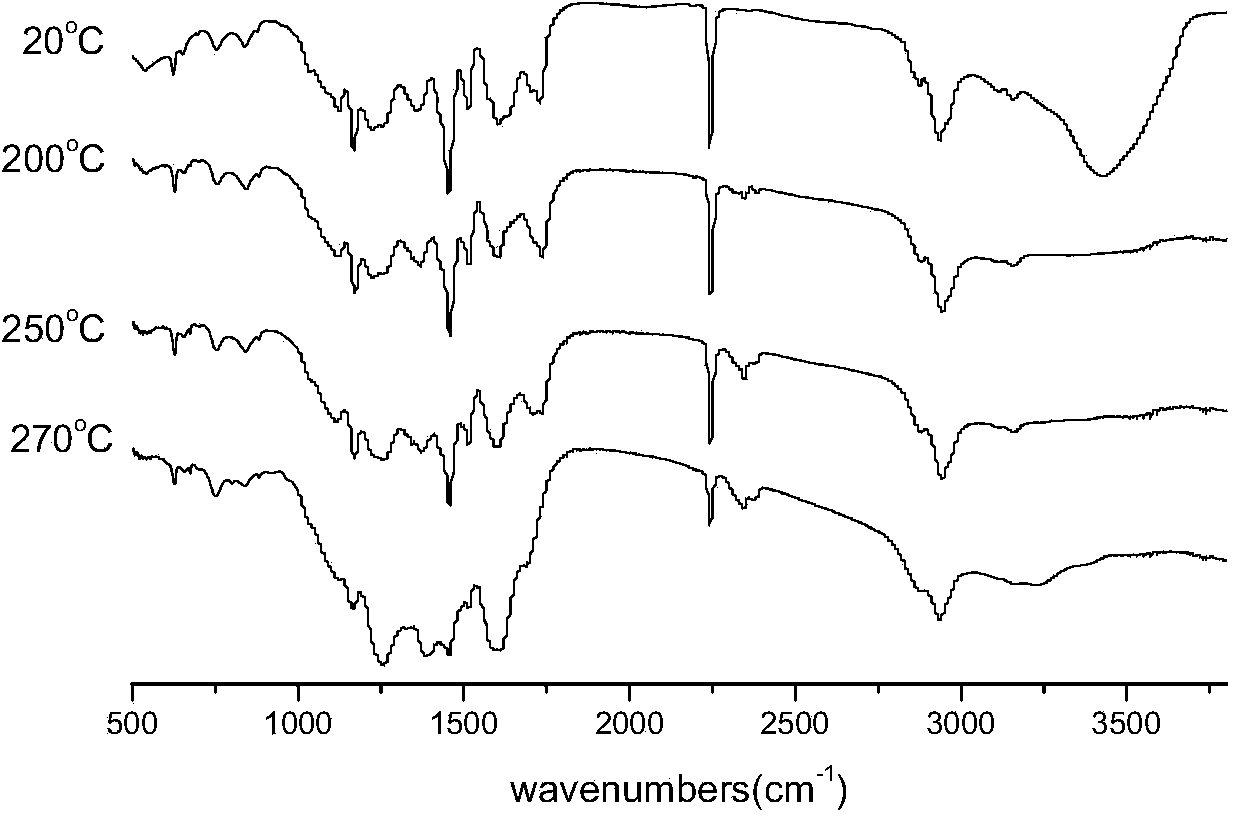

Novel weaving method of carbon fiber electromagnetic shielding textile fabric

InactiveCN102465459AShielding hazardsIncrease productivityHeating/cooling textile fabricsShieldingSocial benefitsPolymer science

The invention relates to a novel weaving method of a carbon fiber electromagnetic shielding textile fabric, which is characterized by comprising the following steps of: utilizing regenerated cellulose fiber or polyacrylonitrile filament yarn to weave a barrier fabric; heating at the speed of 10 DEG C / min of an electrothermal furnace to 280 DEG C, and then carrying out pre-oxidization; carrying out heat preservation for 2 hours; heating at the speed of 15 DEG C / min of the electrothermal furnace to 1,000 DEG C under inert gas protection; carrying out heat preservation for 3 hours; obtaining a carbon fiber yarn mesh with 90 percent of carbon content; heating to 2,000-3,000 DEG C; obtaining a graphite fiber yarn net with more than 99 percent of carbon content; and by taking the net as a base fabric, utilizing a dry method to inject and spin so as to make various non-woven fabrics or wall shielding materials. According to the method, harm of electromagnetic wave to a human body can be shielded well, the spinning process is simple, the production efficiency is high, and better economic and social benefits can be achieved.

Owner:DALIAN ZHAOYANG SOFTWARE TECH

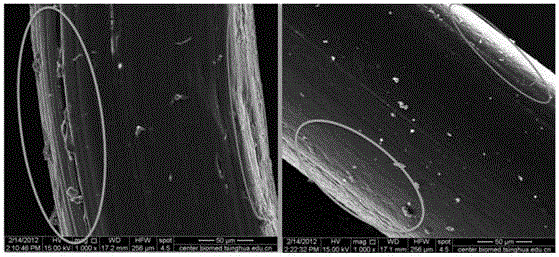

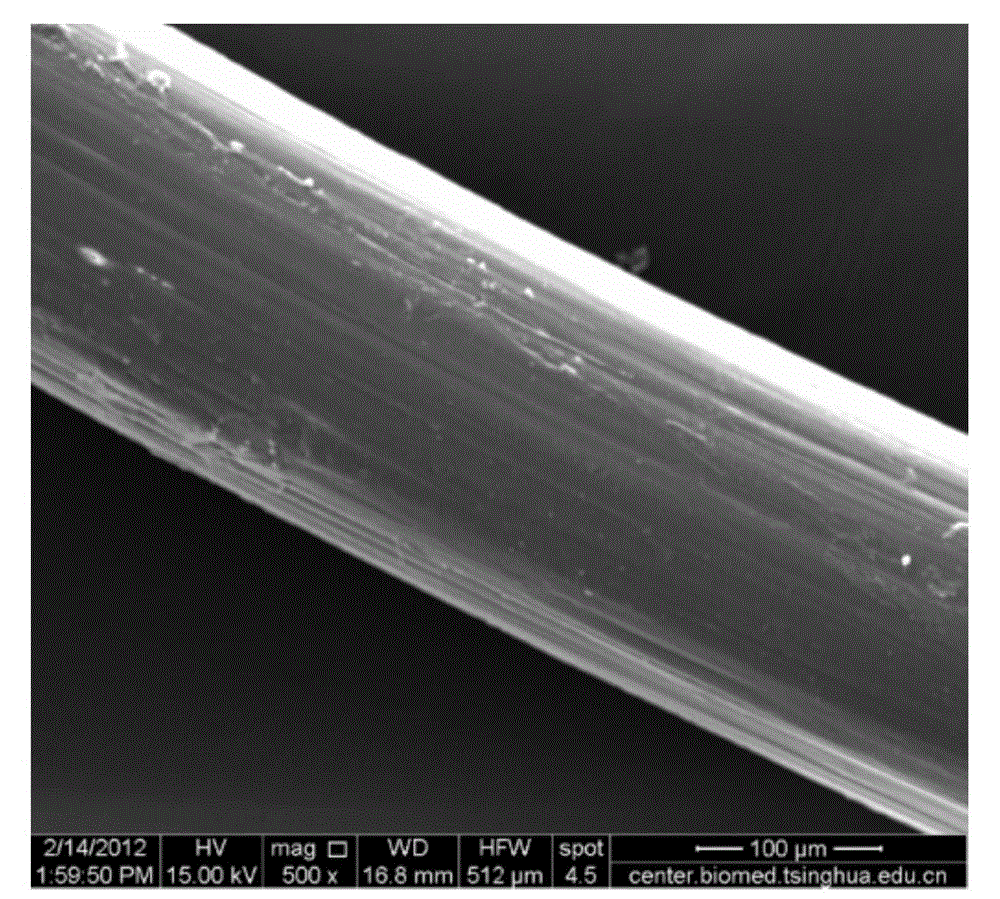

Method for improving pre-oxidation speed of polyacrylonitrile fiber through physical blending

ActiveCN103993382ASimple spinning processProcess is easy to controlFilament forming substance formingArtificial filament heat treatmentPlasticizerHydrogen bond

The invention relates to a method for improving pre-oxidation speed of polyacrylonitrile fiber through physical blending. The method comprises the following steps: performing vacuum drying on polyacrylonitrile, lignin and a plasticizer, and uniformly stirring and mixing, thus obtaining a mixed material; spinning, setting and winding to obtain a melt spun fiber, wherein a mass ratio of polyacrylonitrile to lignin to the plasticizer is (5-30):(10-30):(50-70); and performing water bath drawing on the melt spun fiber, and performing pre-oxidation to obtain the pre-oxidation polyacrylonitrile fiber. The raw material lignin is low in cost and slight in environmental pollution and is suitable for industrial production; lignin contains lots of hydroxyl groups which can achieve hydrogen-bond interaction with a polar group cyano on a polyacrylonitrile molecular chain, and lignin and polyacrylonitrile have high compatibility; moreover, the oxygen content in the lignin structure is high, the oxygen can be released in the pre-oxidation process, a uniform oxygen source is provided for an oxidation reaction of a polyacrylonitrile precursor, and a prepared pre-oxidation thread sheath-core is small in difference and dense and uniform in structure.

Owner:优聚新材料(浙江)有限公司

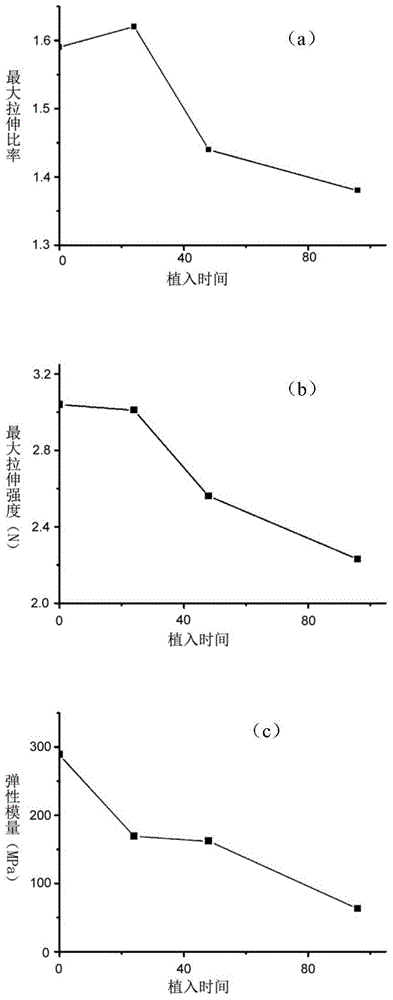

Absorbable suture containing PHBHHx/PLA (poly-3-hydroxybutyrate-co-3-hydroxyhexanoate/polylactic acid)

InactiveCN105063789AHigh mechanical strengthEasy to holdSuture equipmentsMonocomponent copolyesters artificial filamentFiberBiocompatibility Testing

The invention discloses an absorbable suture containing medium-chain PHA (Polyhydroxyalkanoate) (PHBV (Polyhydroxylbutyrate Valerate) or PHBHHx (poly (3-hydroxybutyrate-co-3-hydroxyhexanoate))). The invention specifically discloses a PHBHHx monofilament fiber, a PHBHHx / PLA (Poly Lactic Acid) monofilament fiber and a PHBV / PLA bunched fiber and preparation methods thereof. Blending with the PLA is performed, so that a spinning process is simple, complementary material performance is achieved, and the PHBHHx and the PHBV fibers are good in handfeel. Compared with the conventional material, the absorbable suture has the advantage of higher biocompatibility in the field of nerve and vascular repair due to the use of the PHA material. Moreover, the PHA is high in mechanical strength and slow in degradation speed, so that the PHA is excellent in application effect on the suture repair of cartilages and bone tissues. On the aspect of novel minimally invasive surgical repair, the PHBHHx and the PHBV contain nontoxic and non-irritant degradation products with high compatibility, so that surgical scars can be effectively reduced, and the absorbable suture has an application prospect in esthetic restoration.

Owner:TSINGHUA UNIV

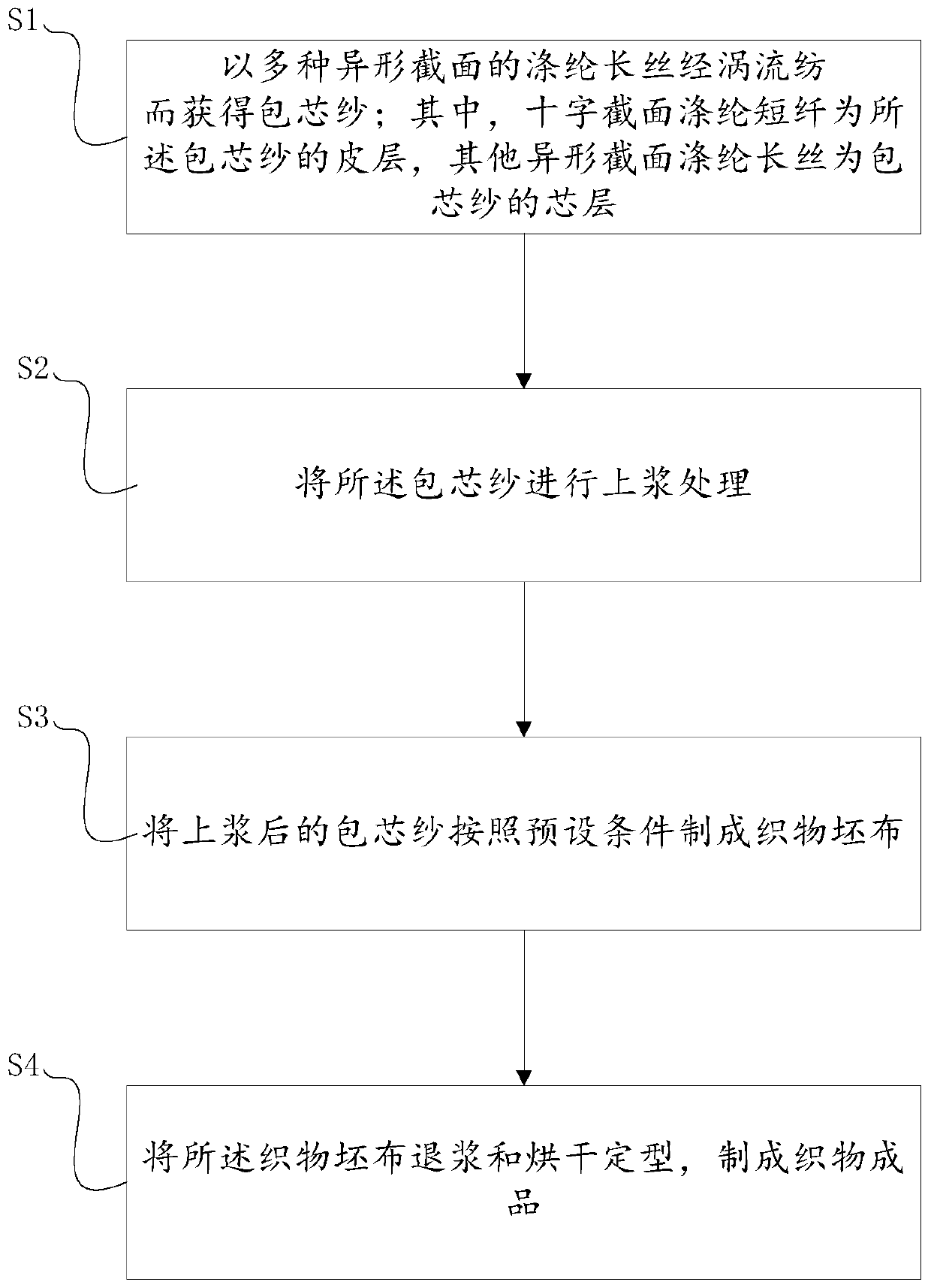

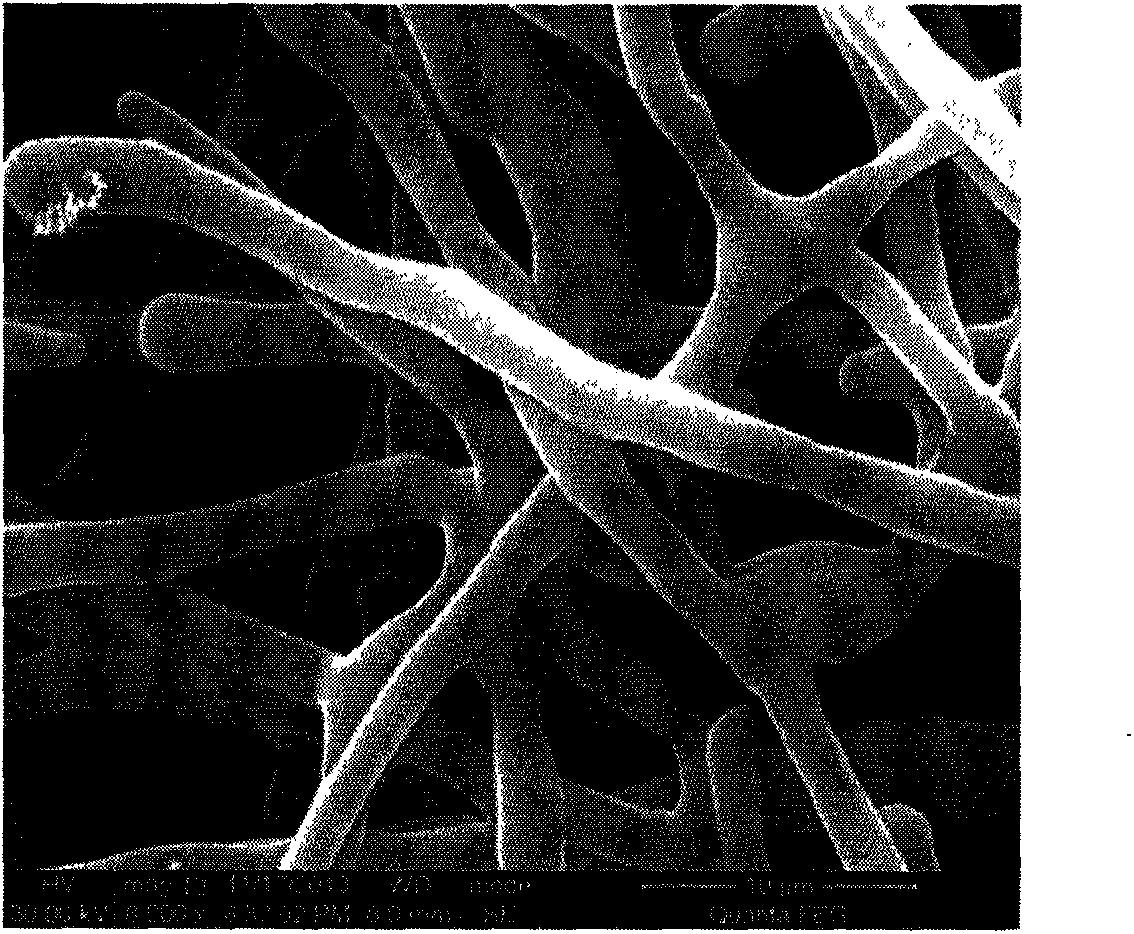

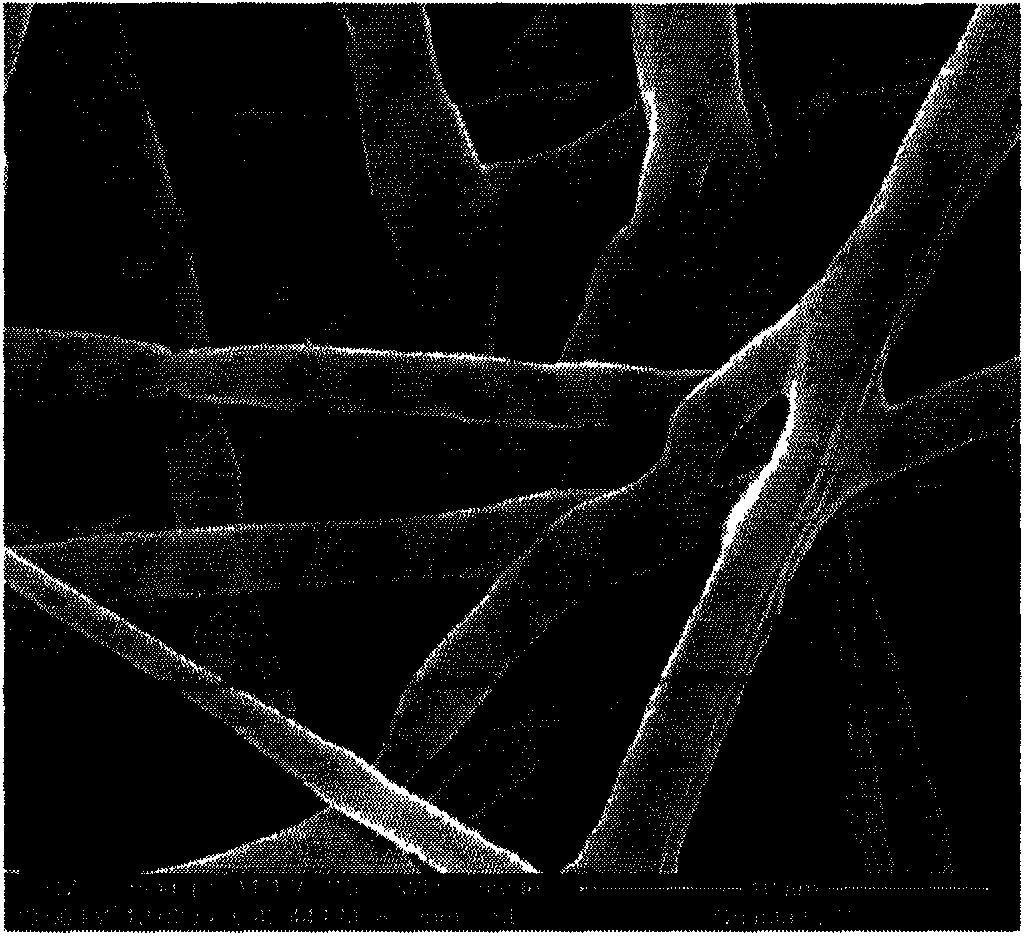

Spinning method adopting core spun yarn and fabric

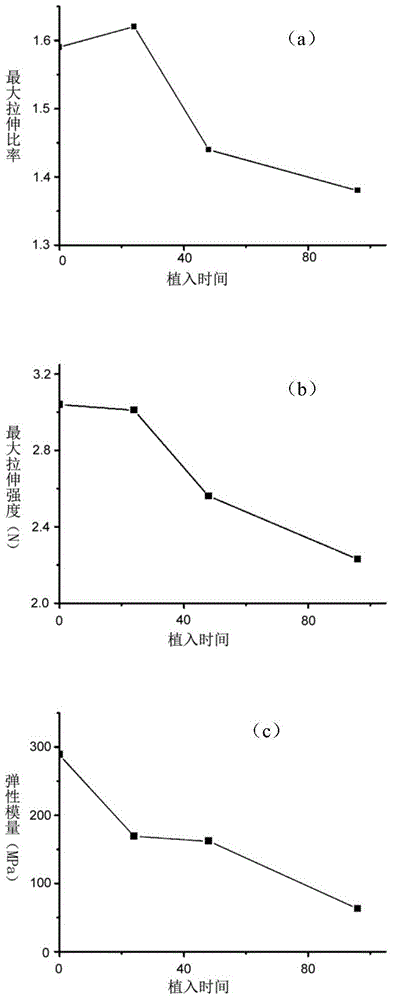

InactiveCN110144659AGood physical and mechanical propertiesGood moisture wicking functionFilament/thread formingContinuous wound-up machinesMoisture permeabilityMoisture absorption

The invention discloses a spinning method adopting core spun yarn and fabric. The method comprises steps as follows: polyester filaments with multiple special-shaped sections are subjected to vortex spinning, and the core spun yarn is obtained, wherein polyester staple fibers with a cross section constitute a skin layer of the core spun yarn and the polyester filaments with other special-shaped sections constitute a core layer of the core spun yarn; the core spun yarn is subjected to sizing treatment; the core spun yarn after sizing is woven according to preset conditions, and fabric grey cloth is obtained; the fabric grey cloth is subjected to desizing and drying setting, and a finished fabric product is prepared. The spinning method adopts a simple process, the prepared fabric has good moisture absorption and moisture permeability, and the core spun yarn has excellent physical and mechanical properties of both filament core yarn and covered staple fibers.

Owner:SUZHOU UNIV +1

Composite shape memory fiber with thermosetting/thermoplastic core-shell structure and preparation method of composite shape memory fiber

ActiveCN104032409ASimple spinning processLow costFilament/thread formingConjugated synthetic polymer artificial filamentsSolventFiber structure

The invention discloses a composite shape memory fiber with a thermosetting / thermoplastic core-shell structure and a preparation method of the composite shape memory fiber. According to the composite shape memory fiber, thermosetting epoxy resin serves as a core layer, and a thermoplastic polycaprolactone serves as a shell layer. The method comprises the following steps: dissolving polycaprolactone and an initiator in a solvent as a shell-layer spinning solution; dissolving epoxy resin E51 and a curing catalyst in a solution as a core-layer spinning solution; preparing the composite shape memory fiber by using a coaxial electrostatic spinning method. The composite shape memory fiber is excellent in shape memory performance, and a quick shape recovery process can be realized within 5-7s; meanwhile, the composite shape memory fiber has a stable network structure and a simple spinning process, and is low in cost; a membrane material with a composite fiber structure is easily prepared.

Owner:HARBIN INST OF TECH

Flame retardant cellulose fiber and preparation method thereof

InactiveCN101608348BSuitable for processingEasy to useFlame-proof filament manufactureMonocomponent cellulose artificial filamentCellulose fiberFire retardant

The invention discloses a flame retardant cellulose fiber and a preparation method thereof. The fiber has the components of fire retardant and cellulose which have the mass ratio of 10-25:100; wherein the fire retardant is novel phosphorus fire retardant having the average grain diameter being less than 1mum; the cellulose is wood pulp or cotton pulp having the polymerization degree of 400-1000 and alpha-cellulose content being more than or equal to 90%. According to the components with the mass ratio of the fiber, the preparation method of the fiber comprises the technique as follows: 1. preparation of flame retardant spinning solution as the following: according to the mass ratio, firstly adding the fire retardant into ionic liquid at the normal temperature, and leading the fire retardant to be uniformly dispersed in the ionic liquid under mechanical agitation; then adding the cellulose into the mixed ionic liquid to be fully dissolved with the dissolving temperature of 70-110 DEG Cto prepare flame retardant spinning solution; ensuring the mass ratio between the cellulose and the ionic liquid to be 5-35:95-65: 2. preparation of the flame retardant cellulose fiber: preparing theflame retardant cellulose fiber according to the conventional spinning process flow.

Owner:TIANJIN POLYTECHNIC UNIV

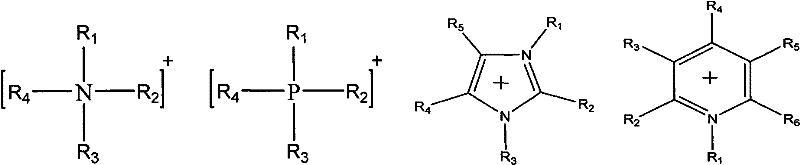

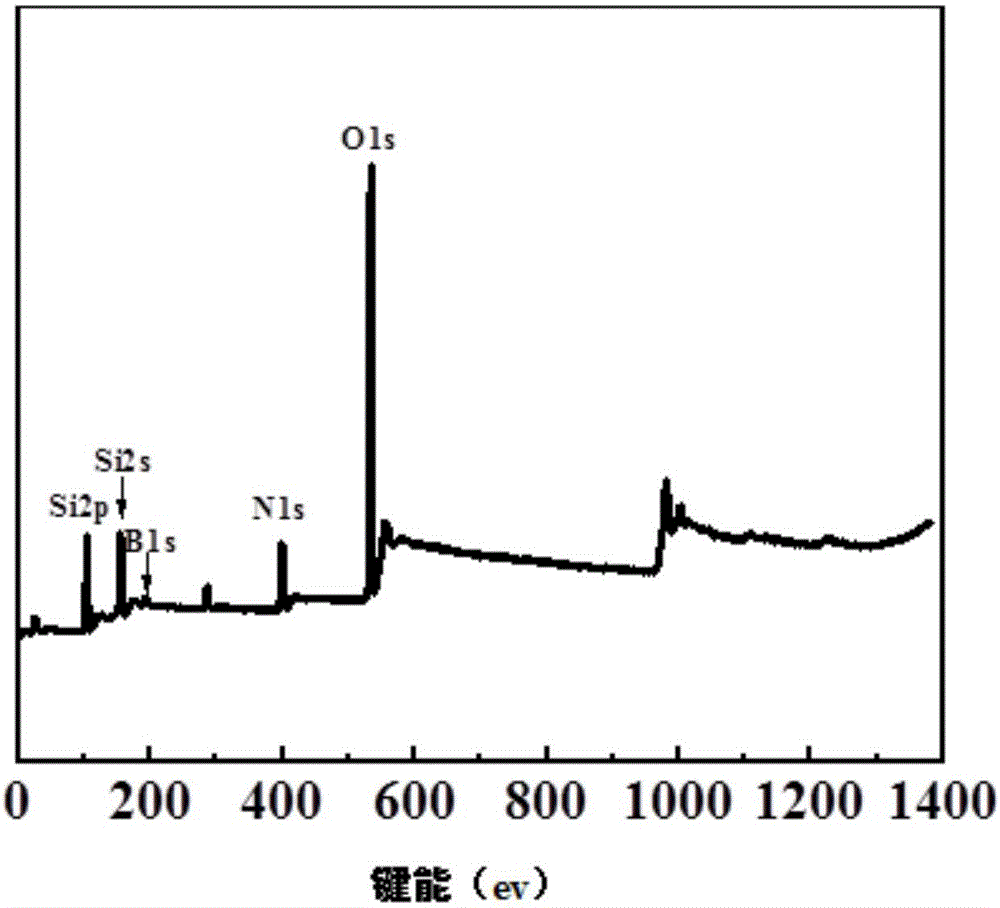

Porous Si-B-N-O ultra-fine fiber preparation method

ActiveCN106337217AUniform porous structureLow costInorganic material artificial filamentsFiberUltra fine

A porous Si-B-N-O ultra-fine fiber preparation method includes the steps that 1, a micromolecular boron source, siloxane and modified siloxane serve as solutes, dilute acid and alcohol serve as solvents, a spinning additive is added to prepare a spinning solution, and electrostatic spinning is performed to prepare PBSO (polyborosiloxane) fibrils; 2, the fibrils are put in a drying oven for processing before drying, the dried fibrils are put in a high-temperature furnace in in the atmosphere of NH3 and / or N2 mixed gas for high temperature firing, and porous Si-B-N-O ultra-fine fibers with the diameter of 0.5-5 microns are obtained after the room temperature is reached after cooling. The prepared porous Si-B-N-O ultra-fine fibers are in shapes of fiber felt, are uniform in diameter and have uniform pores internally, the residual carbon content inside the material is low, and the pore range is 2-50 nm. The porous Si-B-N-O ultra-fine fibers have excellent dielectric properties and high temperature resistant performance and have the wide application prospect in aerospace.

Owner:NAT UNIV OF DEFENSE TECH

PHBV/PLA absorbable suture

InactiveCN105063790AHigh mechanical strengthEasy to holdSuture equipmentsMonocomponent copolyesters artificial filamentFiberAbsorbable suture

The invention discloses an absorbable suture containing medium-chain PHA (Polyhydroxyalkanoate) (PHBV (Polyhydroxylbutyrate Valerate) or PHBHHx (poly (3-hydroxybutyrate-co-3-hydroxyhexanoate))). The invention specifically discloses a PHBHHx monofilament fiber, a PHBHHx / PLA (Poly Lactic Acid) monofilament fiber and a PHBV / PLA bunched fiber and preparation methods thereof. Blending with the PLA is performed, so that a spinning process is simple, complementary material performance is achieved, and the PHBHHx and the PHBV fibers are good in handfeel. Compared with the conventional material, the absorbable suture has the advantage of higher biocompatibility in the field of nerve and vascular repair due to the use of the PHA material. Moreover, the PHA is high in mechanical strength and slow in degradation speed, so that the PHA is excellent in application effect on the suture repair of cartilages and bone tissues. On the aspect of novel minimally invasive surgical repair, the PHBHHx and the PHBV contain nontoxic and non-irritant degradation products with high compatibility, so that surgical scars can be effectively reduced, and the absorbable suture has an application prospect in esthetic restoration.

Owner:TSINGHUA UNIV

Preparation method and application of nanofibers

InactiveCN111455498AGood biocompatibilityImprove hydrophilicityFibre typesConjugated synthetic polymer artificial filamentsPolymer scienceSpinning

The invention relates to nanofibers as well as a preparation method and an application thereof. The nanofibers are prepared from polyvinylpyrrolidone, acetone, an alkaline regulator, a surfactant andone or more of polylactic acid, polylactic acid-polyglycolic acid and poly(epsilon-caprolactone) with a gas spinning process and a compatible finishing process. The spinning process is simple, the nanofibers with smaller diameter can be obtained, furthermore, the alkaline regulator is introduced into a fiber material in the process, acidic substances produced by degradation can be regulated and controlled, the degradation speed of raw materials is reduced, and the pH value of a degradation solution is slowly increased in the later stage of degradation. According to the spinning process, the obtained fiber structure can be uniform and components can be stable with addition of the surfactant. Polyvinylpyrrolidone has good hydrophilicity, so that hydrophilicity of the nanofibers can be improved with addition of polyvinylpyrrolidone, and biocompatibility is promoted.

Owner:ZETTA NANO TECH CO LTD

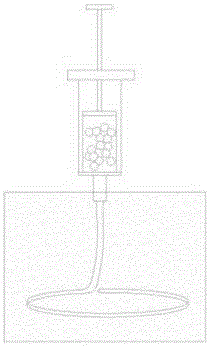

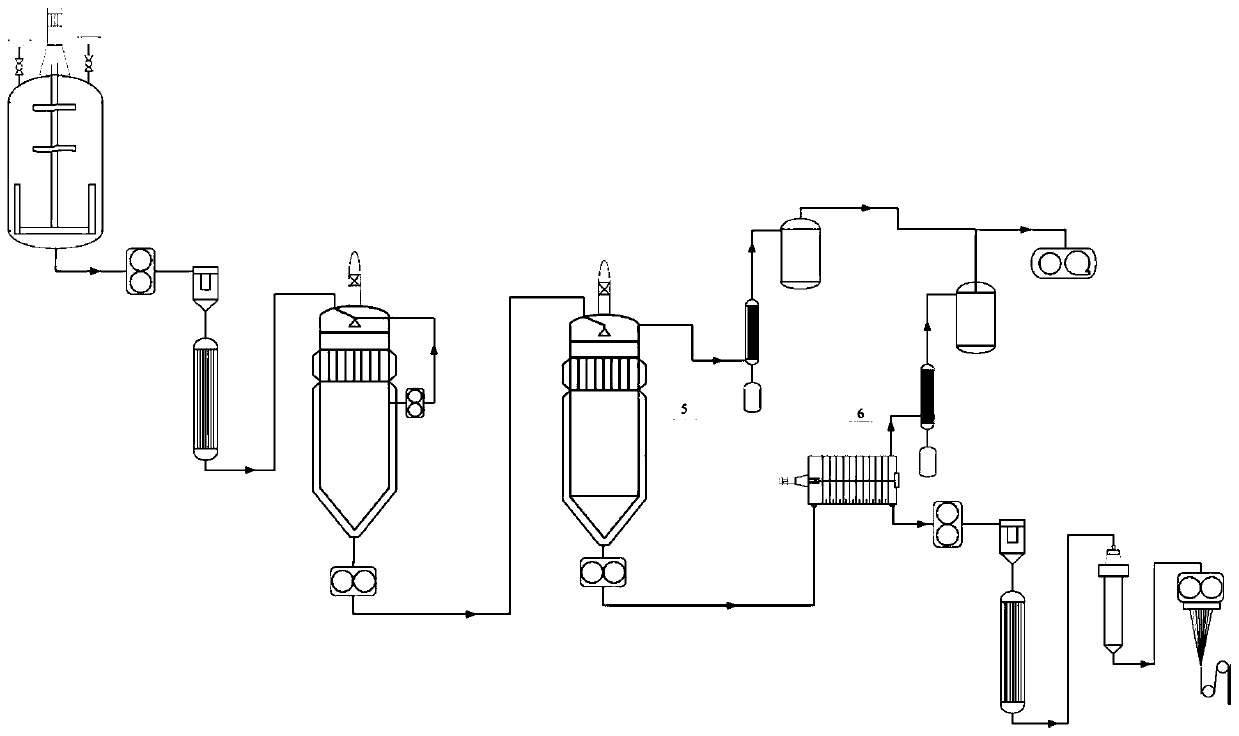

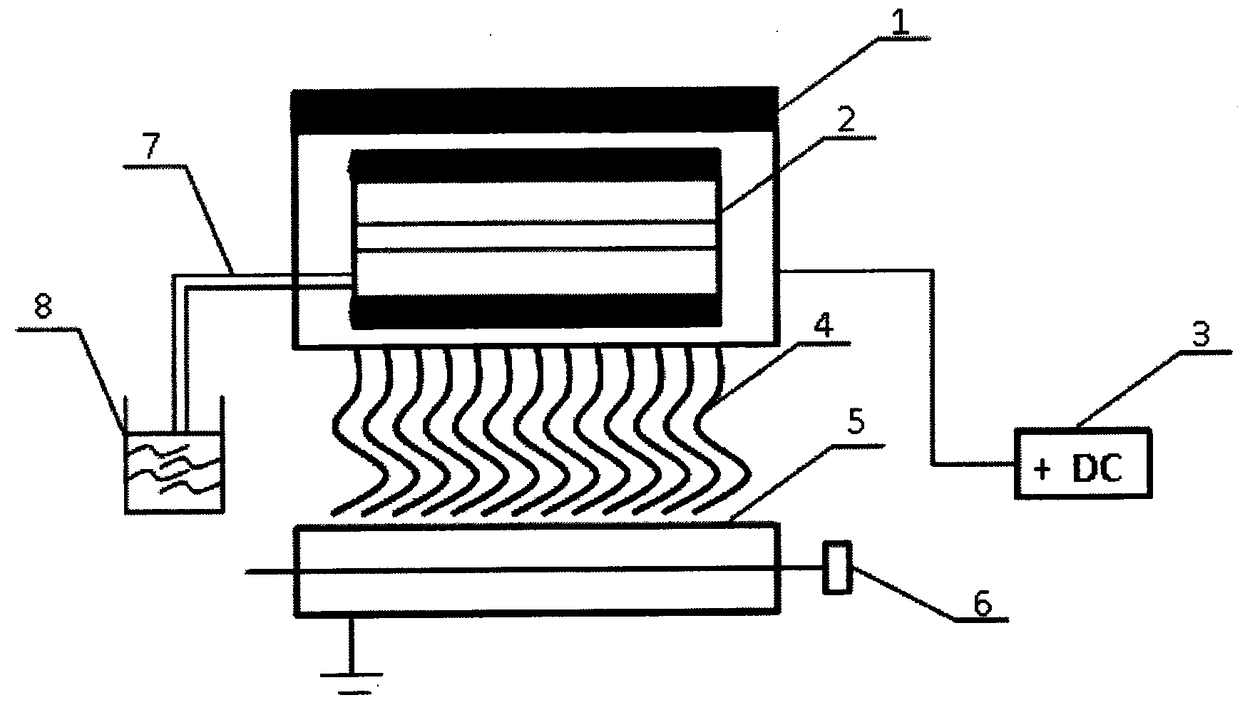

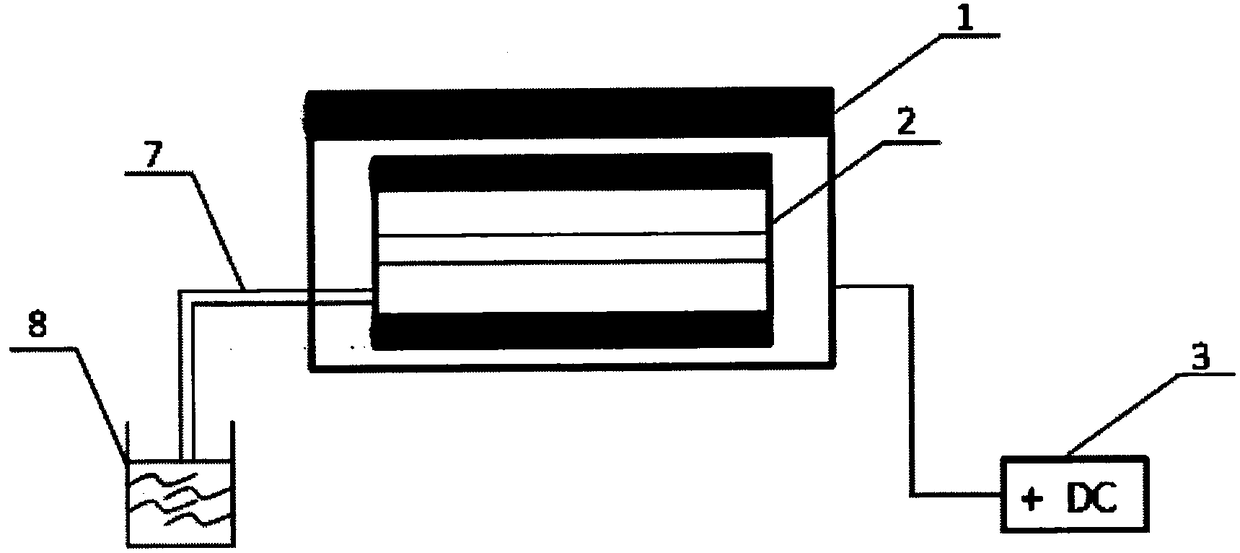

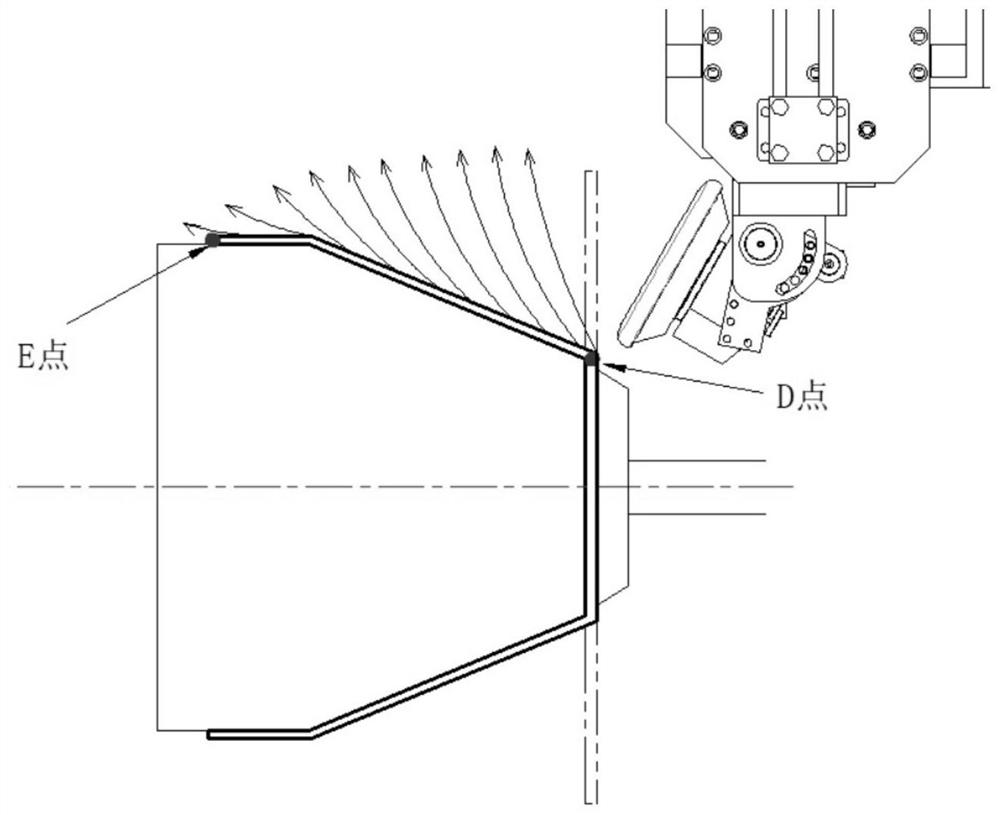

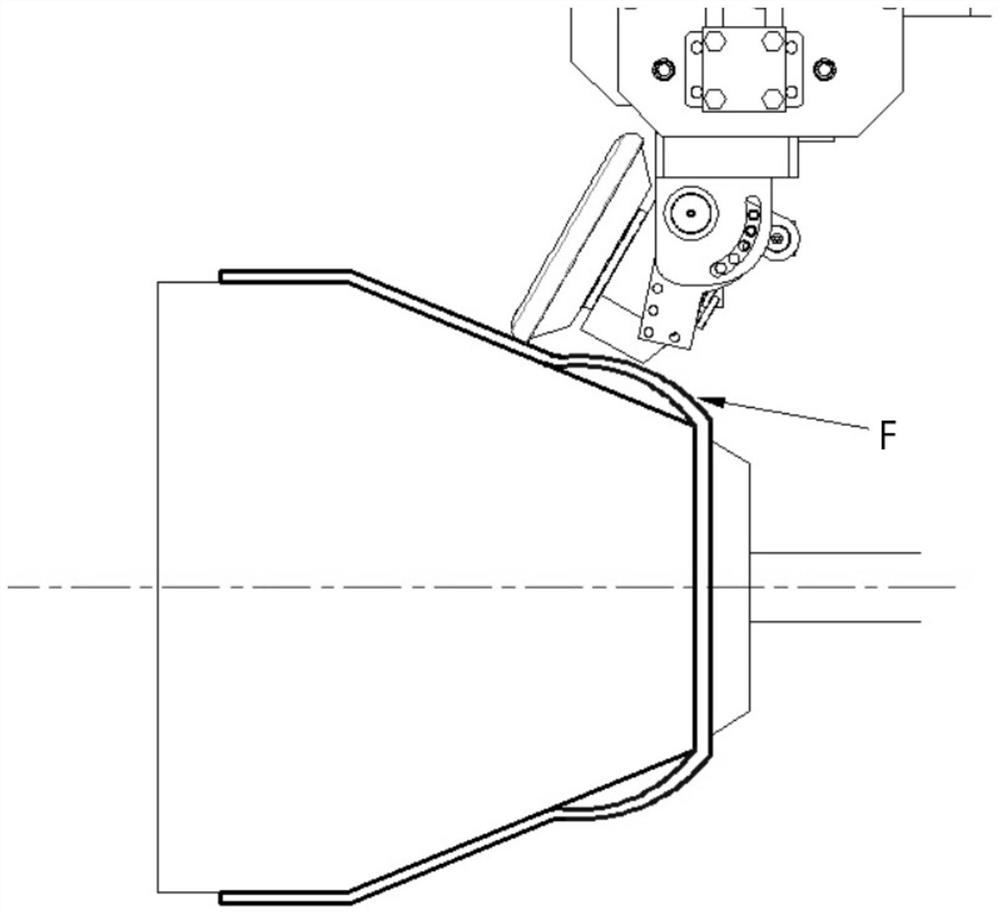

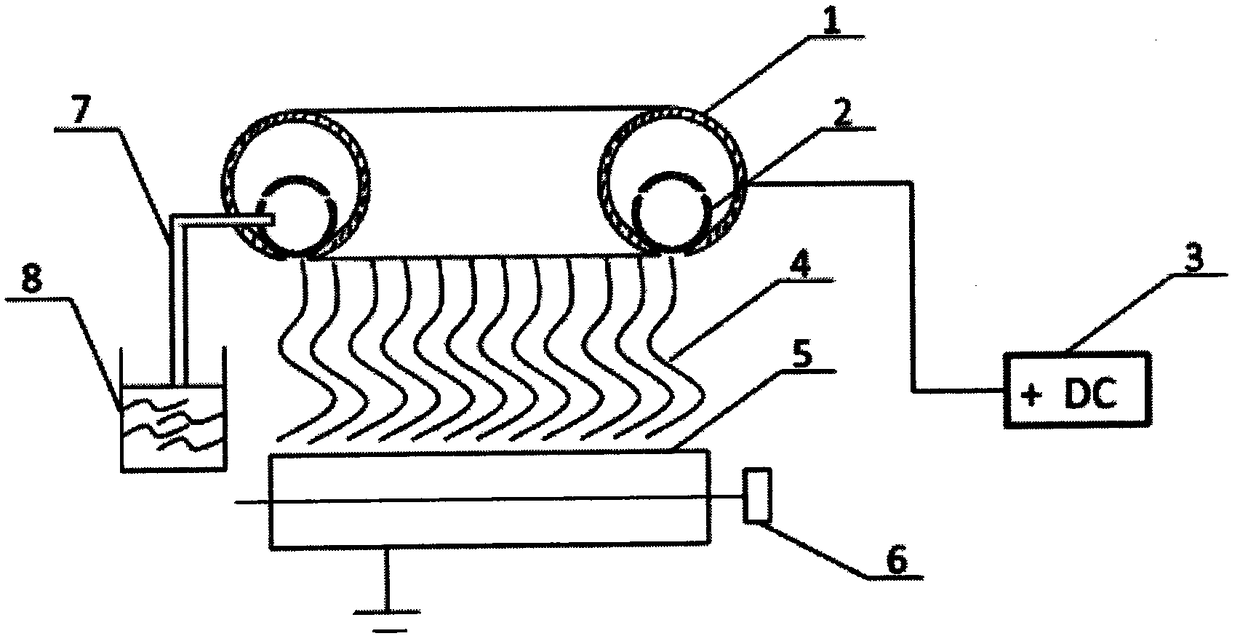

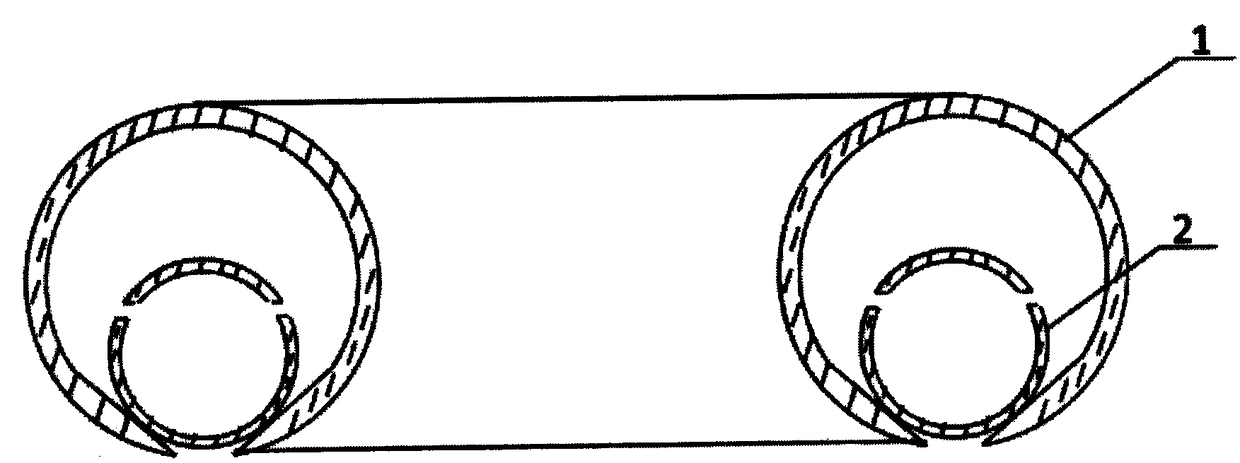

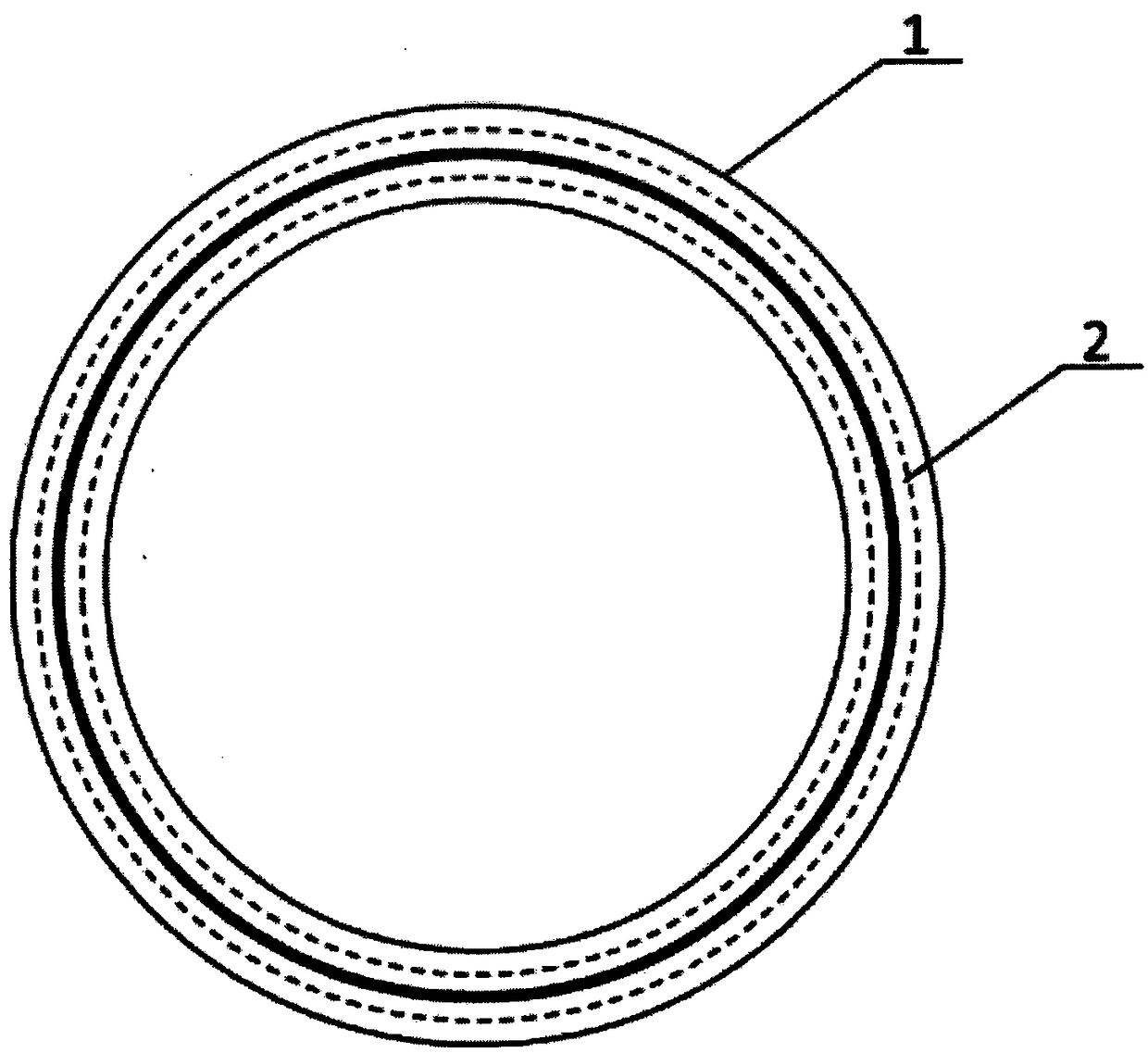

Gravity-following cylindrical electrostatic spinning device and method

ActiveCN108411384ARealize the limitations in the production directionAvoid limitations in production directionElectro-spinningTextile/flexible product manufactureVoltage generatorElectrospinning

The invention discloses a gravity-following cylindrical electrostatic spinning device and method. The device comprises a cylindrical spray head, a cylindrical liquid supply device with a notch is arranged in the cylindrical spray head and connected with a solution propeller at the outer side of the cylindrical spray head through a hose, and a shell of the cylindrical spray head is connected with ahigh voltage generator. The spinning method comprises the steps that the solution propeller is turned on, a solution is injected into the cylindrical liquid supply device through the hose, and when the liquid surface of the solution exceeds the notch of the cylindrical liquid supply device and the solution overflows, the portion between the cylindrical spray head and the cylindrical liquid supplydevice is filled with the spinning solution; the high voltage generator is turned on and applies positive voltage to the cylindrical spray head, and jet flows are formed on the spinning surface and quick move towards a metal rolling cylinder under the effect of electric field force; along with volatilization of a solvent, the jet flows are deposited on the surface of the metal rolling cylinder atlast. According to the gravity-following cylindrical electrostatic spinning device, the overflow-type liquid supply device controls the solution, electric charge accumulation is generated in the edgeof a gap in the cylindrical surface, and accordingly electrostatic spinning in the gravity-following direction is achieved.

Owner:DONGHUA UNIV

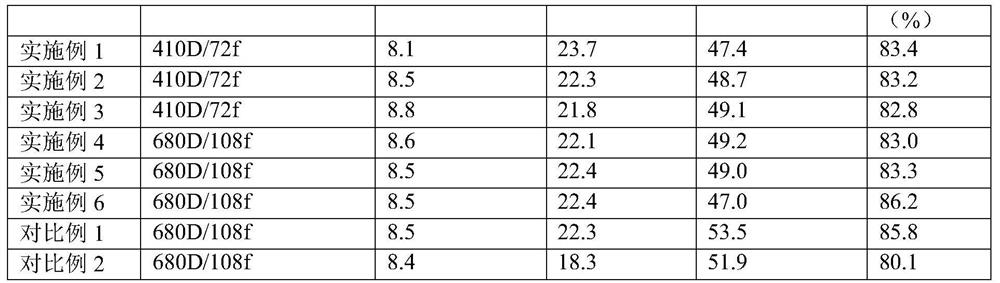

Tussah silk yarn and spinning process thereof

The invention provides tussah silk blended yarn. The tussah silk blended yarn comprises, by weight, 20% to 30% of mulberry silk, 20% to 30% of modal long fibers and 40% to 50% of tussah silk. The invention further provides a spinning process of the tussah silk blended yarn. The spinning process comprises the steps of blow carding, drawing, roving, spinning and spooling. A compact siro spinning mode is adopted, the advantages of siro spinning and compact spinning are combined in compact siro spinning, the evenness CV value and nub and snick indexes are very good, the single thread strength is high, the structure is compact, wear resistance is good, less hair is generated, the amount of harmful hair of 3 mm or above is extremely small, the yarn is smooth and clean, and the fabric quality ishigh. The yarn made through the process can be used for making common underwear, bath towels and other comfortable, soft and high-moisture absorption textile raw materials next to the skin.

Owner:上海纺织(集团)大丰纺织有限公司

Manufacturing method of polyamide 56 industrial yarn for airbags

ActiveCN111826737ADoes not affect orientationThe polymerization process is simpleArtificial filament heat treatmentTextile/flexible product manufactureYarnSpinning

The invention relates to the field of polyamide fibers, and discloses a manufacturing method of polyamide 56 industrial yarn for airbags. The manufacturing method comprises the steps of a salifying stage, a polymerizing stage, a spinning stage, a drafting stage and the like. According to the manufacturing method, a nucleating agent is added, and therefore the grain size of polyamide 56 can be reduced; orientation and crystallization are conducted in sequence through the saturated water vapor bath drafting working procedure, the hot roller drafting working procedure and the like, the grain sizeof the polyamide 56 is controlled through a heat setting technology, polyamide 56 fibers with the high orientation and the low grain size are obtained, and therefore the polyamide 56 industrial yarnwith the high strength and the low modulus is finally obtained. The obtained product can be widely applied to the field of airbags, and the storage performance and the flexibility of the airbags can be improved.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

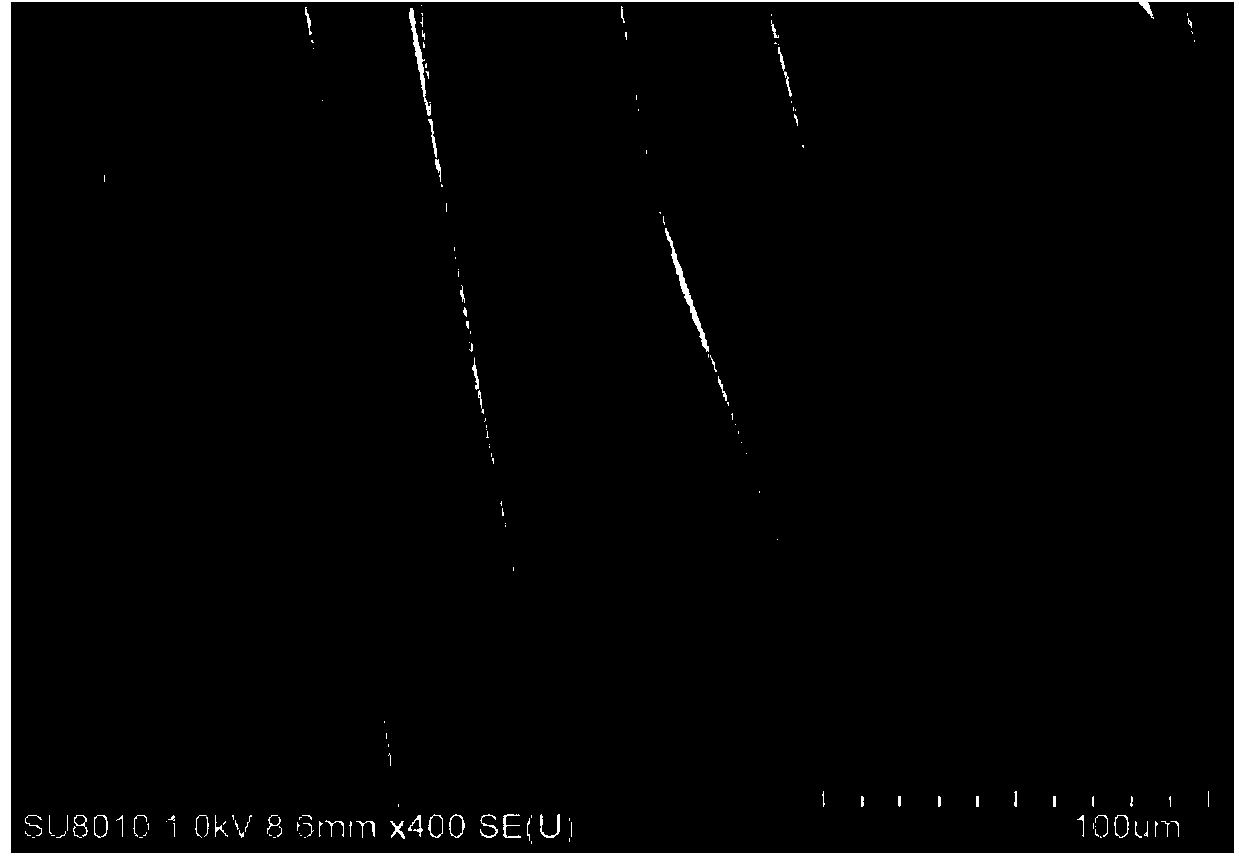

Spinning method of PEDOT:PSS conductive fiber high in elongation

ActiveCN111793853ASimple preparation processLow costElectroconductive/antistatic filament manufactureWet spinning methodsFiberSpinning

The invention relates to a wet spinning method of PEDOT:PSS conductive fiber high in elongation in an organic polymer conductive fiber preparation technology. The method includes the following steps that firstly, PEDOT:PSS spinning fluid is prepared; then, the spinning fluid enters an ethyl alcohol and water mixed coagulating bath through a wet spinning spinneret plate to be subjected to coagulation forming, wherein LiCl is added in the ethyl alcohol and water mixed coagulating bath, and the addition concentration is 0.1-0.5 mol / L; and fiber obtained after coagulation forming is dried and cooled after being subjected to drafting, and the PEDOT:PSS conductive fiber high in conductivity and elongation is prepared. According to the method, one-step method wet spinning is adopted, the water / ethyl alcohol system coagulating bath is adopted as the main body, lithium ions are added in the coagulating bath to assist in fiber solidification forming, the lithium ions are doped in the fiber, andtherefore the fiber tensile elongation and conductivity are obviously improved, the application range of the fiber in textile materials is widened, and processing adaptability of the fiber is improved.

Owner:YANGZHOU UNIV

Method for producing polyvinyl chloride fibers for artificial hair through ultrahigh pressure spinning

ActiveCN102560715AHigh viscosityImprove liquidityArtificial filament heat treatmentMelt spinning methodsUltra high pressureResin matrix

The invention relates to the technical field of manufacturing artificial filaments and analogues through polyvinyl chloride resin, in particular to a method for producing polyvinyl chloride fibers for artificial hair through ultrahigh pressure spinning, wherein the ultrahigh pressure spinning is adopted to convert cohesive energy of melts into system friction heat; material in a system is prompted to be heated uniformly; the utilization of heat resistant chlorinated vinyl chloride resin and heat stabilizers is reduced at the same time; the spinning fluidity is improved; the method chooses and utilizes the ultrahigh pressure melt spinning technology to prepare the polyvinyl chloride fibers, and the spinning pressure can reach 800 to 1000 kg / cm<2>; the application of the ultrahigh pressure spinning technology can improve the situations that the viscosity of vinyl chloride series resin is high and the fluidity is not good to a great extent; meanwhile, additives such as compatible chlorinated vinyl chloride resin matrix heat resistant chlorinated vinyl chloride resin can be omitted; in addition, the method enables the spinning process to be simplified and can improve the efficiency, and finished products have excellent performances.

Owner:HENAN REBECCA HAIR PRODS TNC

Process for preparing precursor fiber of cellulose base carbon fiber

InactiveCN1255585CImprove thermal stabilityImprove carbonization yieldMonocomponent cellulose artificial filamentFiberCarbon fibers

The preparation method of the precursor fiber of cellulose-based carbon fiber in chemical fiber production, first stirs and mixes the concentrated NMMO aqueous solution and the carbon black contained in the carbon black water dispersion at a weight ratio of 20 to 10000:1, and distills under reduced pressure to obtain a water-containing 24-28% NMMO / carbon black solution, and then add the cellulose pulp cut into small pieces and NMMO / carbon black solution into the dissolution kettle at a weight ratio of 5-15:100, and pass through static at 70-90°C. After swelling and strong stirring, the temperature is raised to 90-120°C, and the water is removed by stirring and vacuum distillation to generate a cellulose / NMMO / carbon black spinning stock solution with a water content of 12%-14%. The filaments yield precursor fibers of cellulose-based carbon fibers. Due to the addition of carbon black in the present invention, the carbonization yield and mechanical properties of the carbon fiber prepared after oxidation and carbonization treatment are all significantly improved; the carbon black aqueous dispersion with a smaller particle size or even nano-scale is used as an additive to make spinning The silk stock solution has good spinnability; the solvent used is non-toxic, the recovery rate is high, and the spinning process is simple and environmentally friendly.

Owner:DONGHUA UNIV

Control method of spinning pressure in spin forming and control system applied by same

InactiveCN111672959AImprove technical levelImprove molding efficiencyShaping toolsPressesControl systemControl engineering

The invention discloses a control method of a spinning pressure in spin forming and a control system applied by same. The control method comprises the following steps of by taking preset tracks as driving targets by spinning wheels for spin forming of a material in multiple passes, wherein the spinning wheels carry out curve interpolation to achieve position control through linked driving controlof an X-axis servo driving unit and a Y-axis servo driving unit; in spinning of at least final pass, by taking a separation distance between each spinning wheel and a driving rotary die which is 0 asa driving target, executing double modes of pressure control and position control to the spinning wheels, wherein when the thrusts of the spinning wheels reach a preset target pressure, pressure control is carried out on the spinning wheels to ensure that the separation distance between each spinning wheel and the driving rotary die is 0. The invention further relates to the control system appliedby the control method. By arranging the specific control method and control system, the technical level and the forming efficiency of spin forming are improved effectively.

Owner:AOKEN CNC EQUIP SUZHOU CO LTD

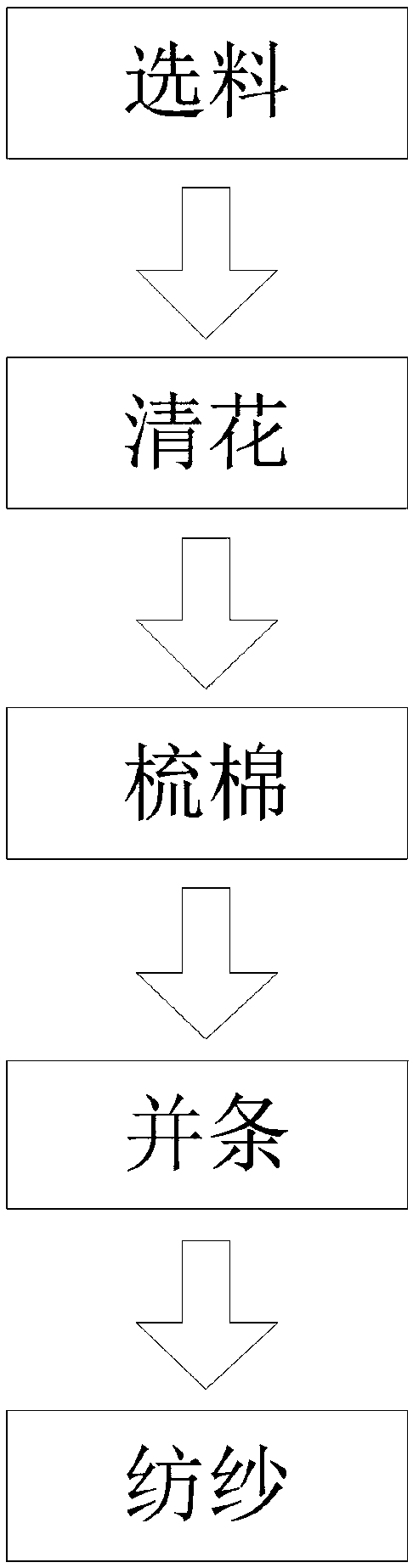

Spinning process of combed cotton yarn

An embodiment of the invention discloses a spinning process of a combed cotton yarn. The process comprises the steps of material selection, wherein the following raw materials in percentage by mass are selected: 20-30% of long stapled cotton, 20-30% of sea island cotton and 40-50% of Egyptian cotton; cotton cleaning; cotton carding, wherein combed noil fiber rolls are treated with a cotton cardingmachine to obtain cotton fiber slivers; drawing, wherein drawing is performed for three times; and spinning, wherein a full-automatic rotor spinning machine is adopted, the cotton slivers obtained bythe drawing process are fed into the rotor spinning machine, and air spinning is performed to obtain a cotton yarn product. An adopted spinning mode is compact siro spinning, the compact siro spinning combines the advantages of siro spinning and compact spinning, the spinning process is simple, the occupied area of a machine is small, the production cost is reduced on the basis of ensuring the product quality, and a theoretical basis is provided for development and research of preparation of an environment-friendly ordinary blended yarn. Furthermore, the rolling step in the cotton cleaning step can be reduced, so that the use of one machine is reduced and the cost is reduced.

Owner:湖北妙虎纺织有限责任公司

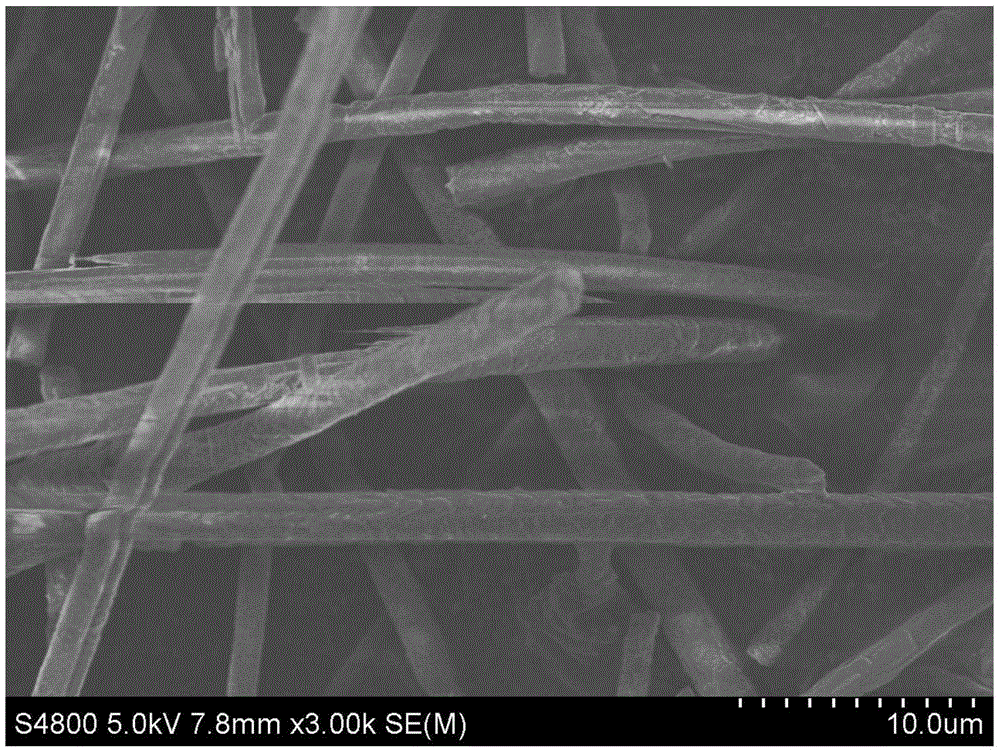

Blended yarn of wool and ramie and manufacturing method thereof

InactiveCN106637560ASimple spinning processMoisture absorption and quick dryingTextile treatment by spraying/projectingYarnYarnWool fiber

The invention discloses a blended yarn of wool and ramie and a manufacturing method thereof. The manufacturing method uses the following raw materials for the blended yarn in the following weight ratio: 30 - 70% of wool fiber with the main length between 70 and 80 mm, and 70 - 30% of ramie fiber with the main length between 120 and 130 mm. The manufacturing method adopts a process flow as follows: cutting the ramie fiber to the main length of the wool fiber, adding wool lubricating oil to the wool fiber and finishing the wool fiber, then blending the ramie fiber and the wool fiber, and obtaining the blended yarn of wool and ramie through processing steps of loosening, carding, joining, roving, spinning, twisting and winding. The wool lubricating oil accounts for 0.8 to 1% of the weight of the raw materials. The wool lubricating oil is sprayed on each layer of wool fiber. After the finishing, the fiber is covered for standing for 24 to 36 hours. A wool type roller carder is used for carding. A roving frame and a spinning frame are both wool type spinning devices. The rotation speed of a cylinder of the carder is between 580 and 620 r / min; the rotation speed of a flyer of the roving frame is between 350 and 450 r / min; the doffing speed of the flyer is between 250 and 350 r / min; and the flyer speed of the spinning frame is between 10500 and 11500 r / min. Through blending of the wool fiber and the ramie fiber, the blended yarn with good performance is obtained.

Owner:TIANJIN POLYTECHNIC UNIV

Dust collecting bag

ActiveCN105251279ASimple spinning processSuitable for large-scale industrial productionDispersed particle filtrationFiberPolyamide

The invention discloses a dust collecting bag. The dust collecting bag is formed by weaving of modified graphene fibers which are prepared through the following steps: (1) sufficiently dissolving modified graphene and polyamide according to the weight percent ratio of x to y or dispersing modified graphene and polyamide into a solvent to form a spinning solution, and adding polyvinylpyrrolidone (PVP) with the solute mass being 0.1-10% so as to adjust the viscosity of the spinning solution, wherein x is more than or equal to 1% and smaller than or equal to 20%, and x+y is equal to 1; and (2) carrying out electrostatic spinning on the prepared spinning solution, and controlling the spinning voltage to be 7-18KV, receiving distance to be 5-60cm, and extrusion speed to be 0.01-1ml / min in the spinning process, thus preparing the fiber materials. The woven dust collecting bag has the characteristics of high temperature resistance, light weight, high strength, incapability of water absorption, and surface smoothness on the premise of ensuring the same filter efficiency; blockage possibility caused by water absorption of the bag can be effectively reduced, the use efficiency of the bag can be improved, the use service life of the bag can be prolonged, and the replacement and cleaning frequency can be reduced.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

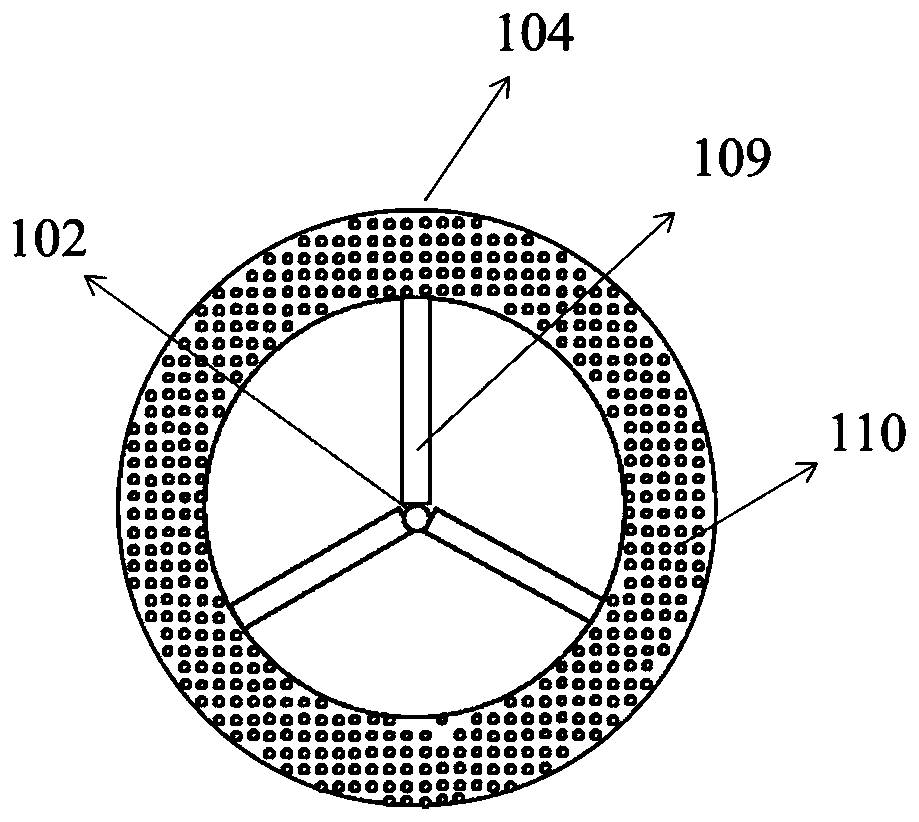

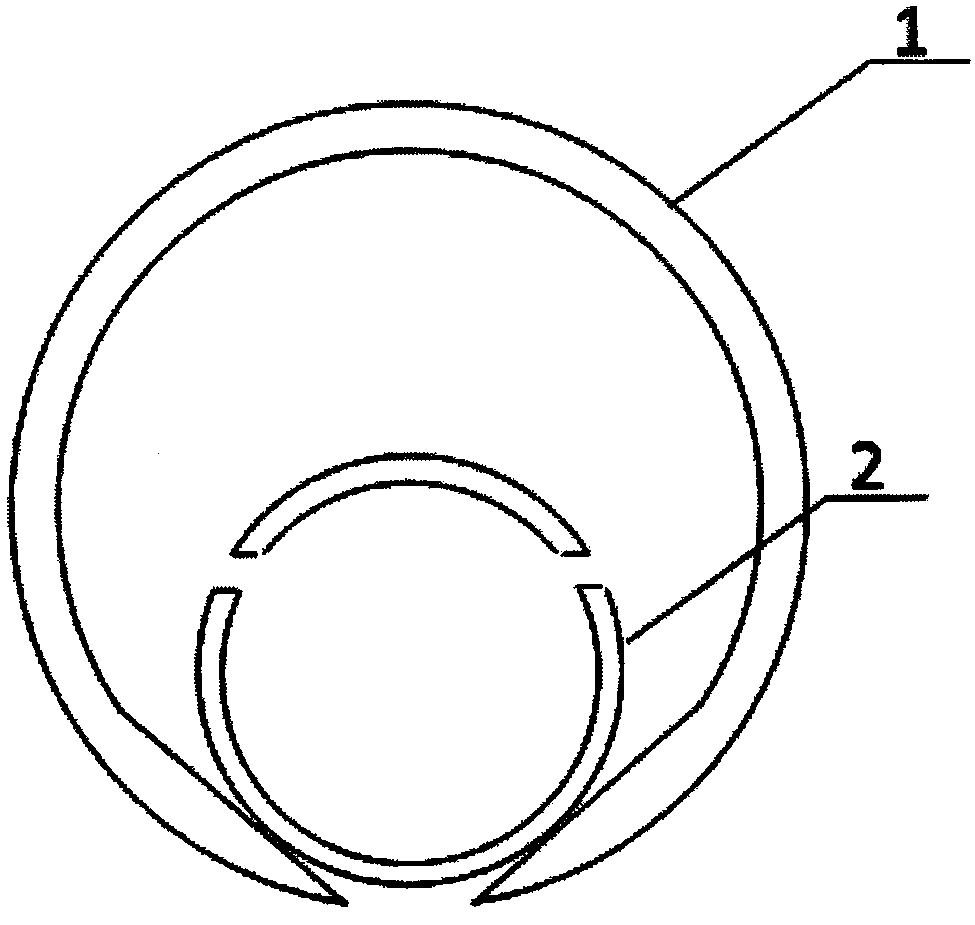

Device and method for ring-shaped electrostatic spinning in gravity direction

ActiveCN108588861ARealize the limitations in the production directionAvoid limitations in production directionSpinning head liquid feederFilament/thread formingJet flowElectrospinning

The invention discloses a device and a method for ring-shaped electrostatic spinning in the gravity direction. The device comprises ring-shaped nozzles and ring-shaped liquid supply devices, wherein the ring-shaped liquid supply devices are arranged in hollow structures in the ring-shaped nozzles and connected with a solution propeller outside the ring-shaped nozzles through a hose, and the ring-shaped nozzles are connected with a high-voltage generator; notches are formed in the upper parts of the ring-shaped liquid supply devices. The spinning method comprises steps as follows: a solution isinjected into the ring-shaped liquid supply devices, and the solution continuously flows into the hollow structures of the ring-shaped nozzles when overflowing; the high-voltage generator applies positive voltage to the ring-shaped nozzles, when the voltage exceeds a critical threshold, multiple jet flows are formed at jet tips below the ring-shaped nozzles, and the jet flows move to a roller under the action of electric field force and are finally deposited on the surface of the roller with volatilization of a solvent. According to the device and the method, the solution is controlled by theoverflowing type liquid supply devices, charges are accumulated on gap edges below rings, and accordingly, electrostatic spinning in the gravity direction is realized.

Owner:DONGHUA UNIV

A kind of pedot:pss fiber and preparation method thereof

ActiveCN106381571BSimple spinning processGood effectArtificial filament washing/dryingArtificial filament heat treatmentFiberChemical treatment

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com