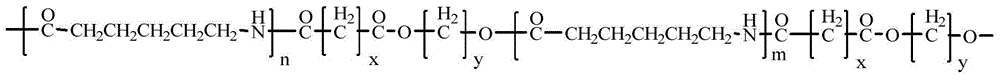

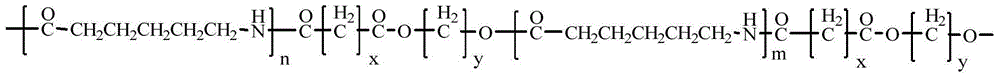

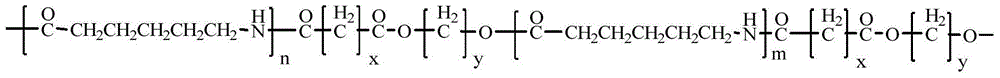

Caprolactam hydrolyzed polymer fibres and spinning method thereof

A caprolactam and polymer technology, applied in the direction of single-component copolyamide rayon, melt spinning, stretch spinning, etc., can solve the problems of low polymer molecular weight, inability to control oligomers, slow reaction speed, etc. , to achieve the effect of reducing the probability of occlusion, reducing energy consumption, and reducing the possibility of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A kind of FDY spinning method of caprolactam hydrolysis polymer, concrete steps comprise:

[0049] The first step: at a temperature of 80°C, caprolactam, capping agent HOOC (CH 2 ) 2 COOH, deionized water and catalyst nylon 66 salt were mixed in proportion, mechanically stirred for 10min, and the rotating speed was 60r / min; wherein relative to caprolactam, the amount of deionized water added was 2wt%, and the capping agent HOOC(CH 2 ) 2 The addition of COOH is 5%, and the addition of catalyst nylon 66 salt is 0.1wt%;

[0050] The second step: pre-polymerize the mixture obtained in the first step under nitrogen atmosphere, the polymerization temperature is controlled at 150 ° C, and the polymerization pressure is controlled at 0.1 MPa; when the following conditions are met, the reaction is terminated: the molecular weight of the obtained prepolymer is 1000 , the content of terminal amino groups is less than 1mmol / kg, the content of extractables is ≤10wt%, and the cont...

Embodiment 2

[0056] A kind of FDY spinning method of caprolactam hydrolysis polymer, concrete steps comprise:

[0057] The first step: at a temperature of 140°C, caprolactam, HOOC (CH 2 ) 10 COOH, deionized water and NH 2 (CH 2 ) 4 COOH was mixed in proportion, mechanically stirred for 60min, and the rotating speed was 240r / min; wherein relative to caprolactam, the amount of deionized water added was 5wt%, HOOC(CH 2 ) 10 The amount of COOH added is 30%, NH 2 (CH 2 ) 4 The amount of COOH added is 5wt%;

[0058] The second step: pre-polymerize the mixture obtained in the first step under a nitrogen atmosphere, the polymerization temperature is controlled at 200 ° C, and the polymerization pressure is controlled at 3 MPa; when the following conditions are met, the reaction is terminated: the molecular weight of the obtained prepolymer is 5000, The content of terminal amino group is less than 1mmol / kg, the content of extractables is ≤10wt%, and the content of cyclic dimer is ≤0.3wt%; ...

Embodiment 3

[0065] A kind of UDY spinning method of caprolactam hydrolysis polymer, concrete steps comprise:

[0066] The first step: under the condition of temperature of 100 ℃, caprolactam, capping agent HOOC (CH2 ) 5 COOH, deionized water and catalyst NH 2 (CH 2 ) 10 COOH was mixed in proportion, mechanically stirred for 30min, and the rotating speed was 100r / min; wherein relative to caprolactam, the amount of deionized water added was 3wt%, and the capping agent HOOC(CH 2 ) 5 The amount of COOH added is 10%, the catalyst NH 2 (CH 2 ) 10 The amount of COOH added is 0.1-5wt%;

[0067] The second step: pre-polymerize the mixture obtained in the first step under nitrogen atmosphere, the polymerization temperature is controlled at 180 ° C, and the polymerization pressure is controlled at 0.5 MPa; when the following conditions are met, the reaction is terminated: the molecular weight of the obtained prepolymer is 3000 , the content of terminal amino groups is less than 1mmol / kg, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com