Patents

Literature

389results about "Monocomponent copolyamides artificial filament" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

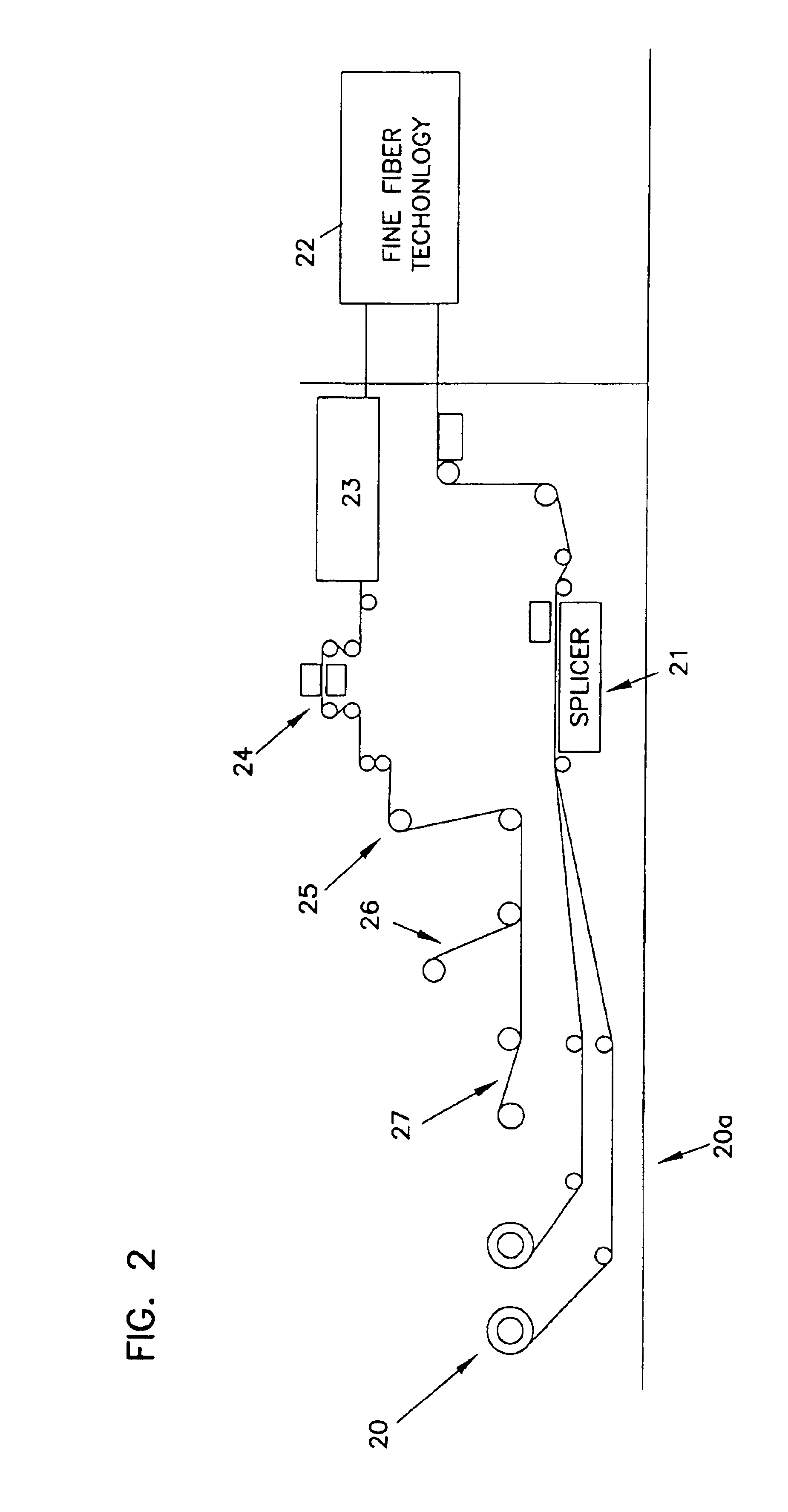

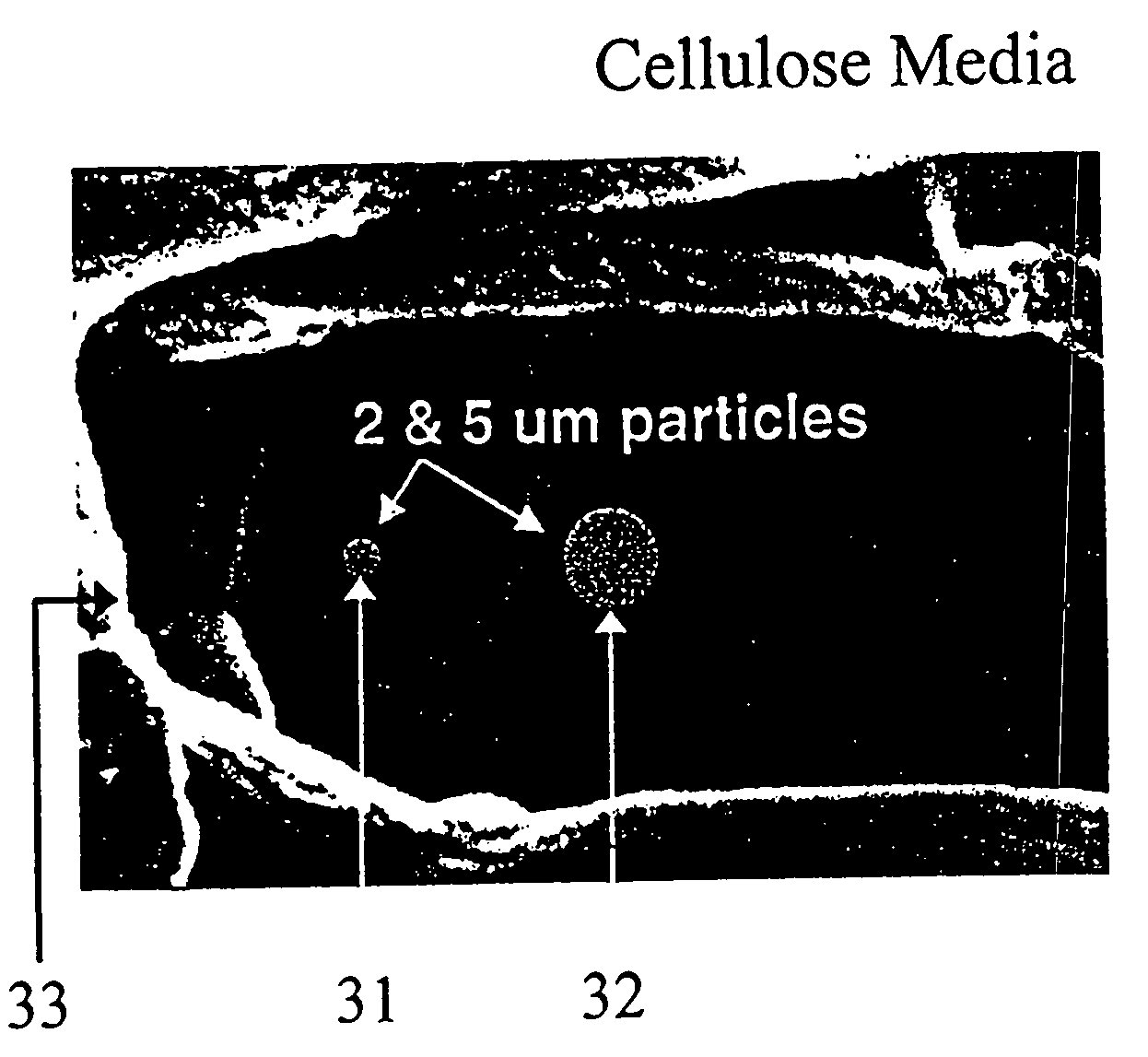

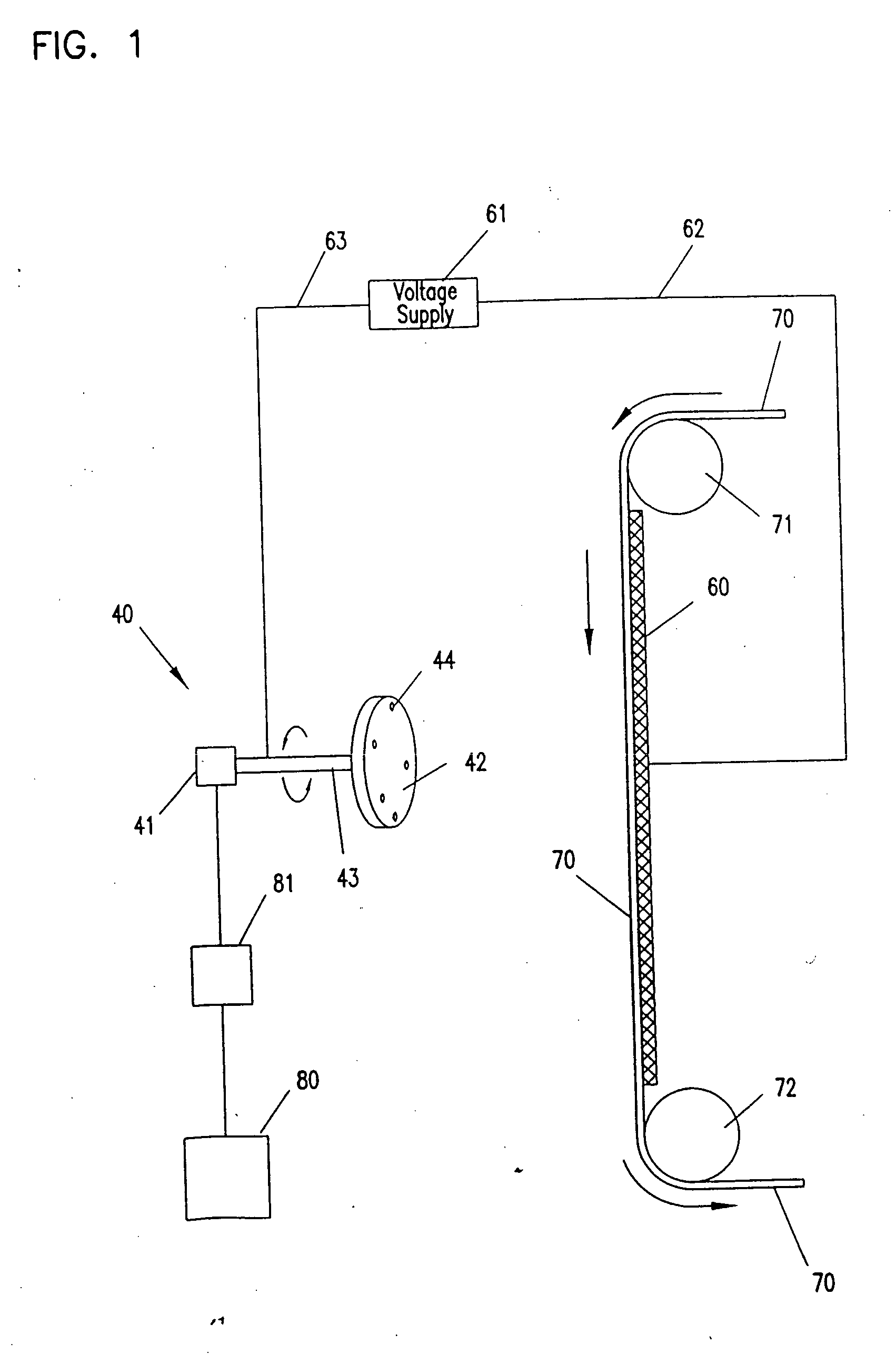

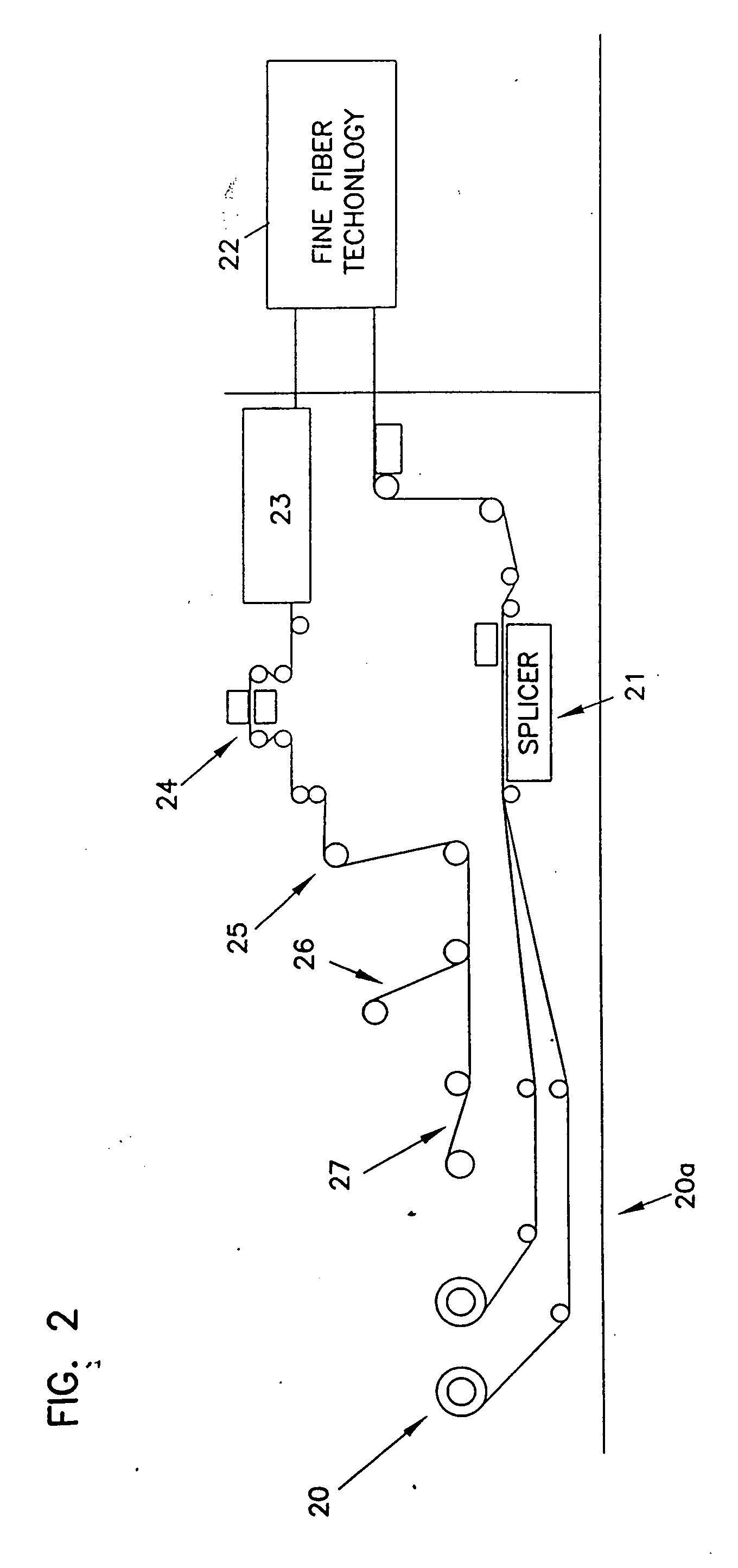

Process if making fine fiber material

Improved polymer materials and fine fiber materials can be made from the improved polymeric materials in the form of microfiber and nanofiber structures. The microfiber and nanofiber structures can be used in a variety of useful applications including the formation of filter materials.

Owner:DONALDSON CO INC

Polymer, polymer microfiber, polymer nanofiber and applications including filter structures

InactiveUS6924028B2Simple materialSubstantial surface loadingCombination devicesMaterial nanotechnologyPolymer scienceNanofiber

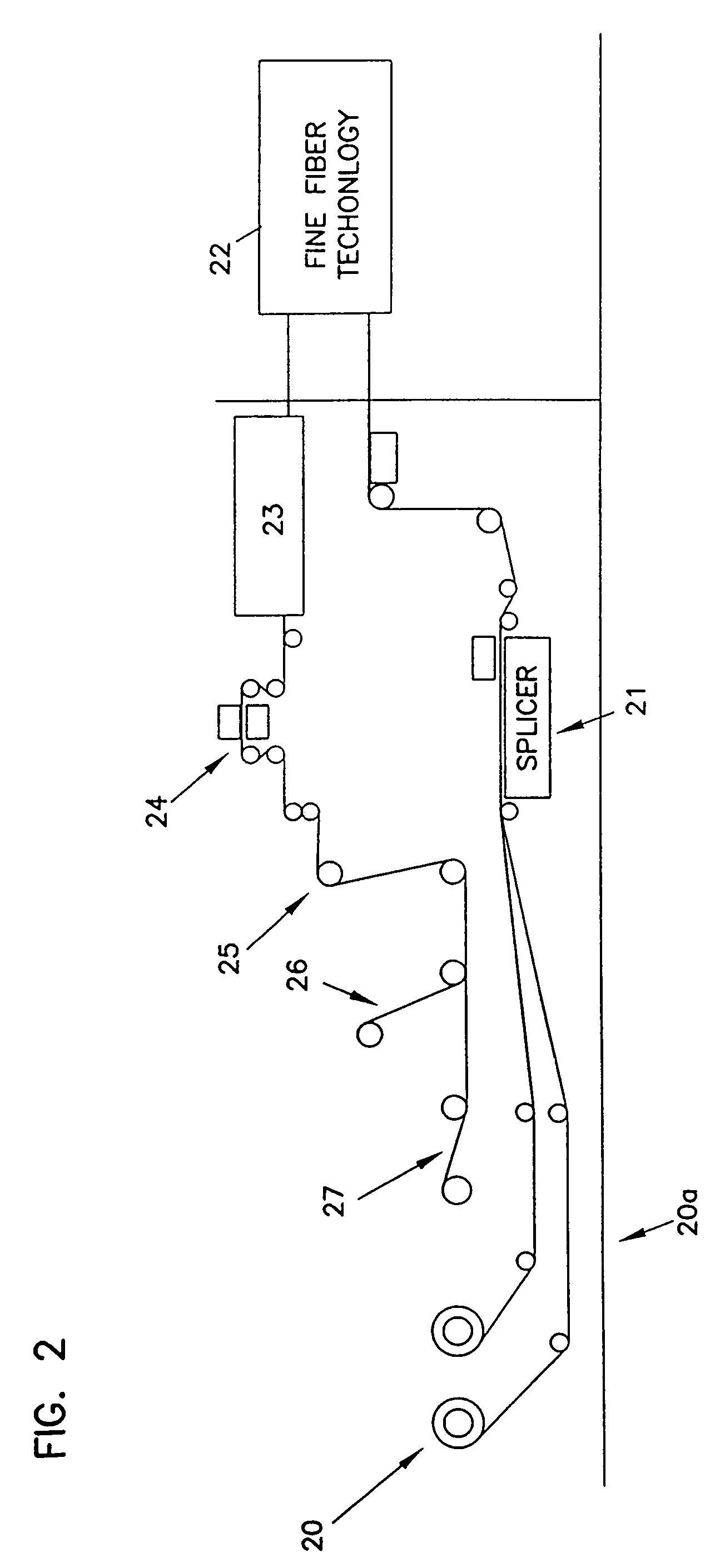

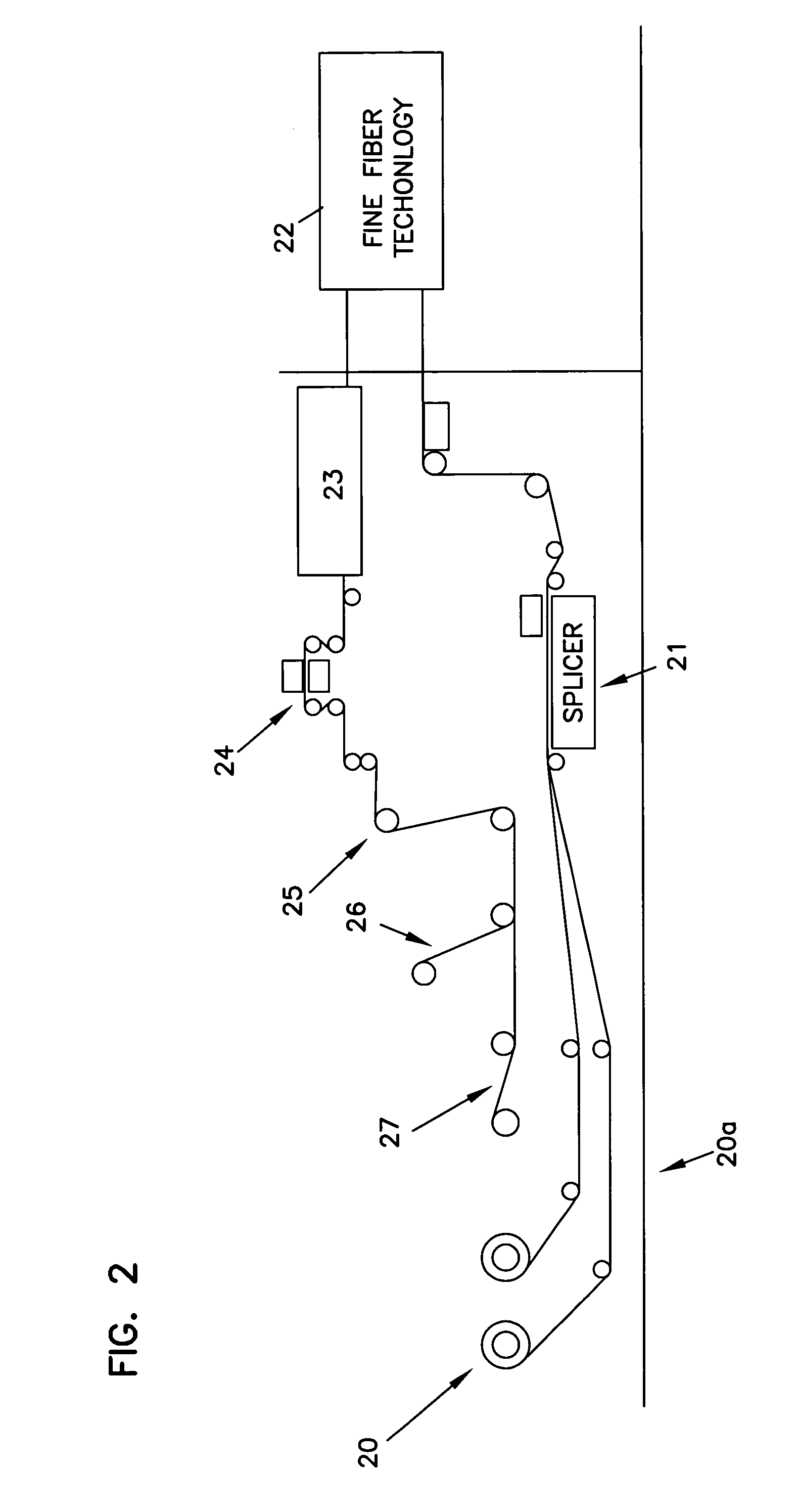

Disclosed are improved polymer materials. Also disclosed are fine fiber materials that can be made from the improved polymeric materials in the form of microfiber and nanofiber structures. The microfiber and nanofiber structures can be used in a variety of useful applications including the formation of filter materials.

Owner:DONALDSON CO INC

Polymer, polymer microfiber, polymer nanofiber and applications including filter structures

Owner:DONALDSON CO INC

Polymer, polymer microfiber, polymer nanofiber and applications including filter structures

Disclosed are improved polymer materials. Also disclosed are fine fiber materials that can be made from the improved polymeric materials in the form of microfiber and nanofiber structures. The microfiber and nanofiber structures can be used in a variety of useful applications including the formation of filter materials.

Owner:DONALDSON CO INC

Nylon fibers and preparation method thereof

ActiveCN104562271AEmission reductionReduce pollutionFilament manufactureMonocomponent copolyamides artificial filamentYarnPolymer science

The invention discloses a preparation method of nylon fibers. The preparation method comprises the following steps: directly spinning after taking raw materials containing 1,5-pentamethylene diamine and adipic acid to react. The invention further provides the nylon fibers prepared by the method. The method adopts a manner of combining nylon polymerization and fusion direct spinning to prepare nylon 56 wires so that the production cost is reduced, the waste gas is reduced and the pollution to the environment is reduced. The high-performance nylon fibers prepared by the method can be further used for preparing textile materials including yarns, woven fabrics, knitted fabrics or non-woven fabrics, can be widely applied to the fields of clothing material industries, decoration carpets and the like, and has a wide industrial application prospect.

Owner:CATHAY R&D CENT CO LTD +1

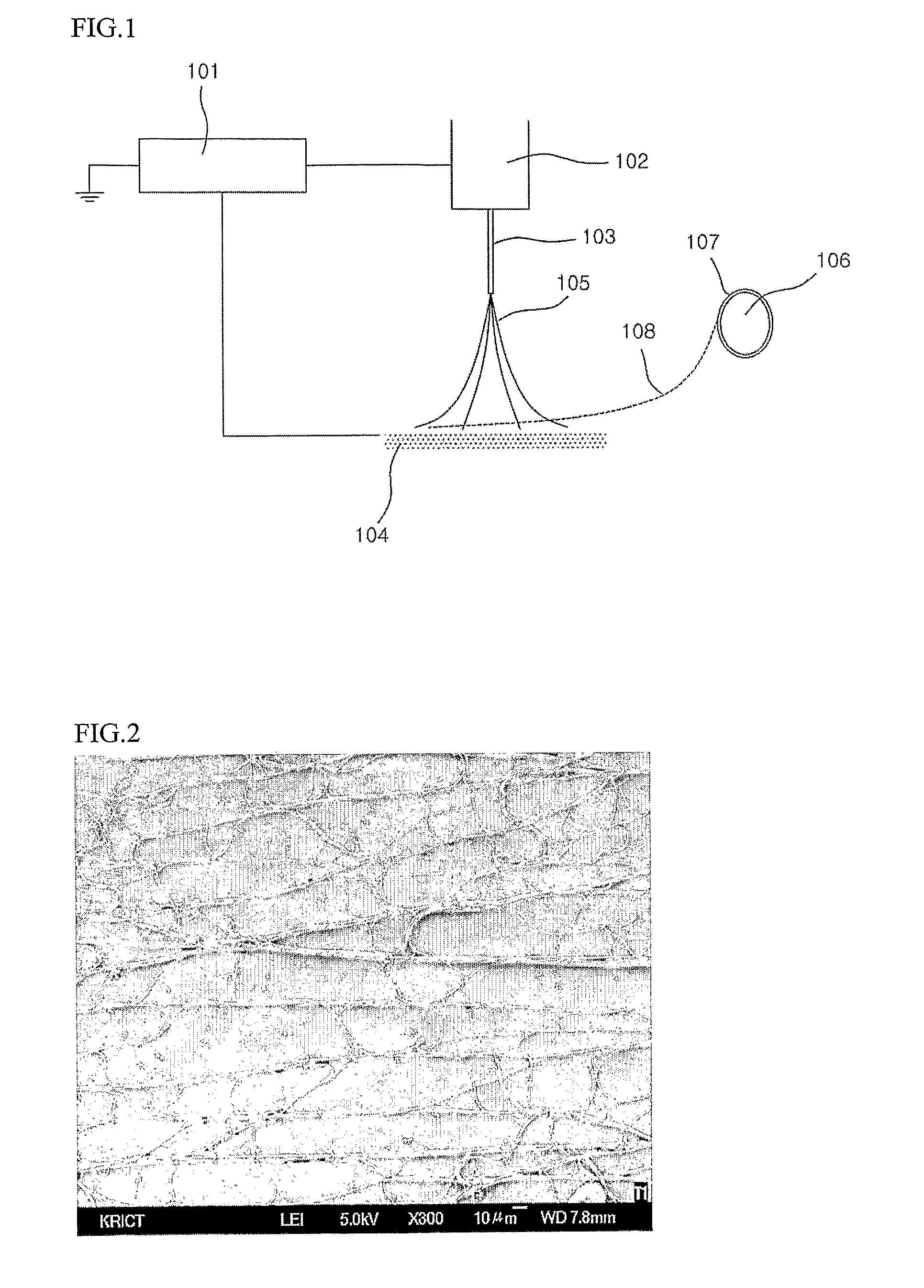

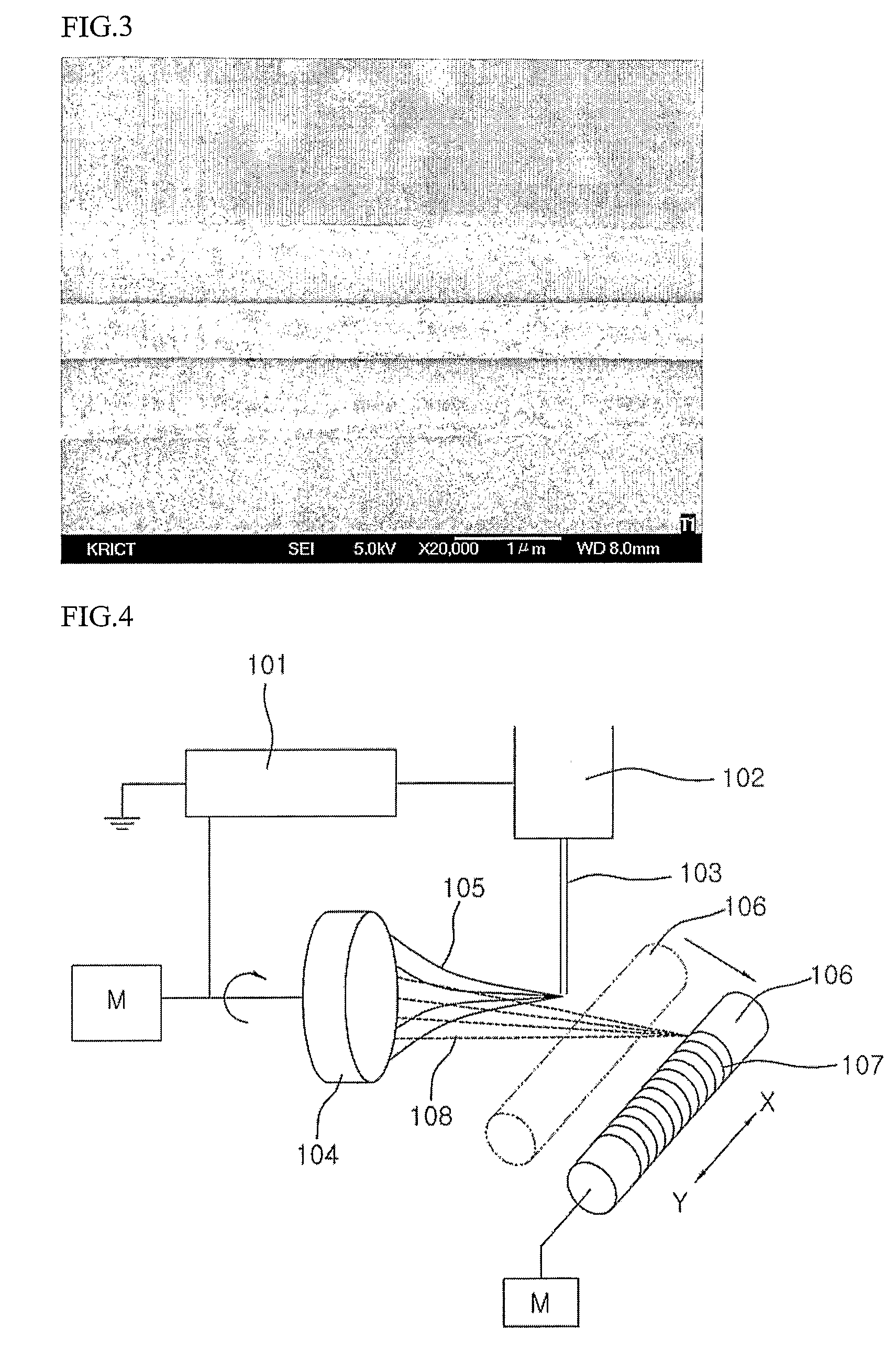

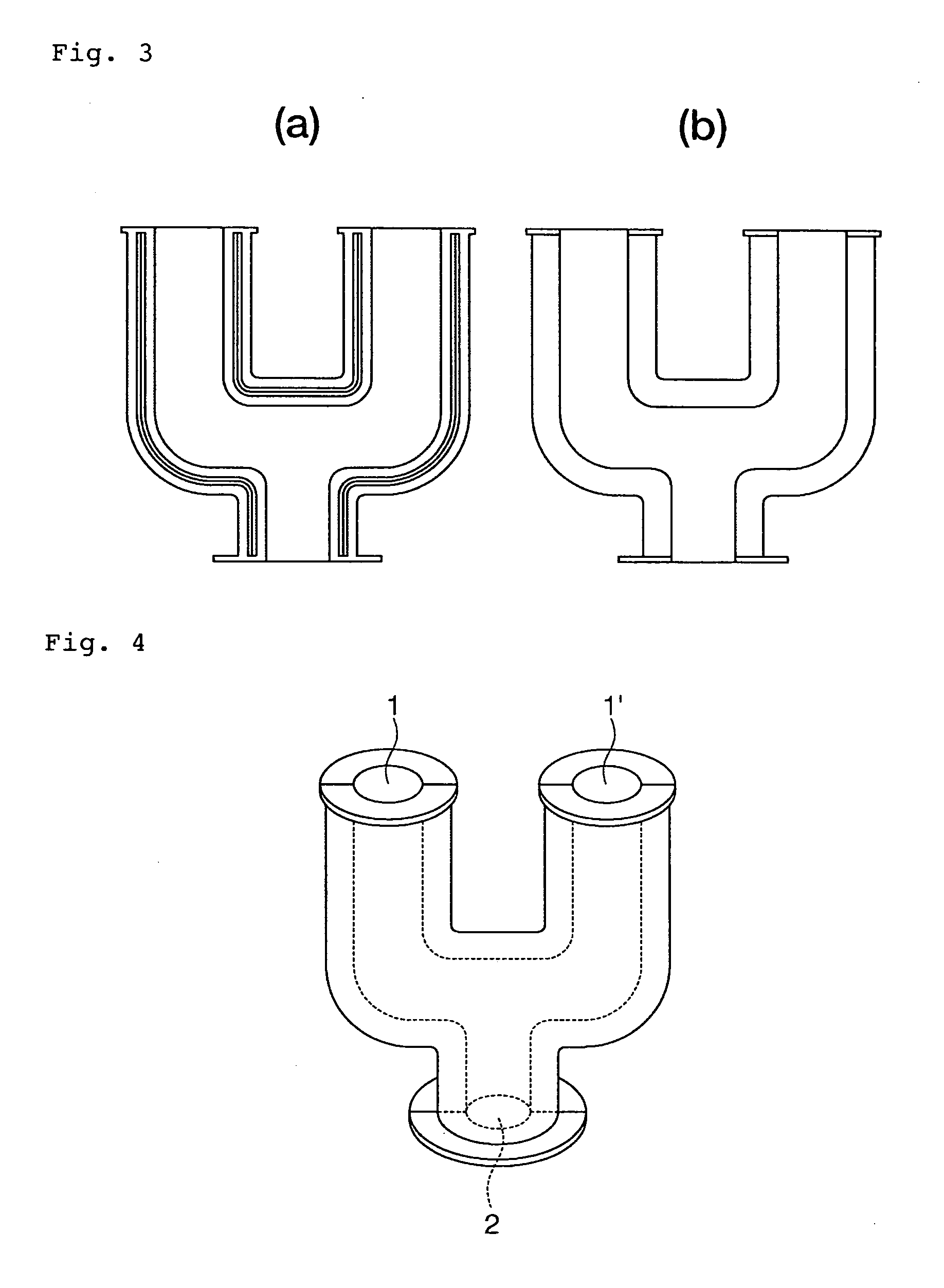

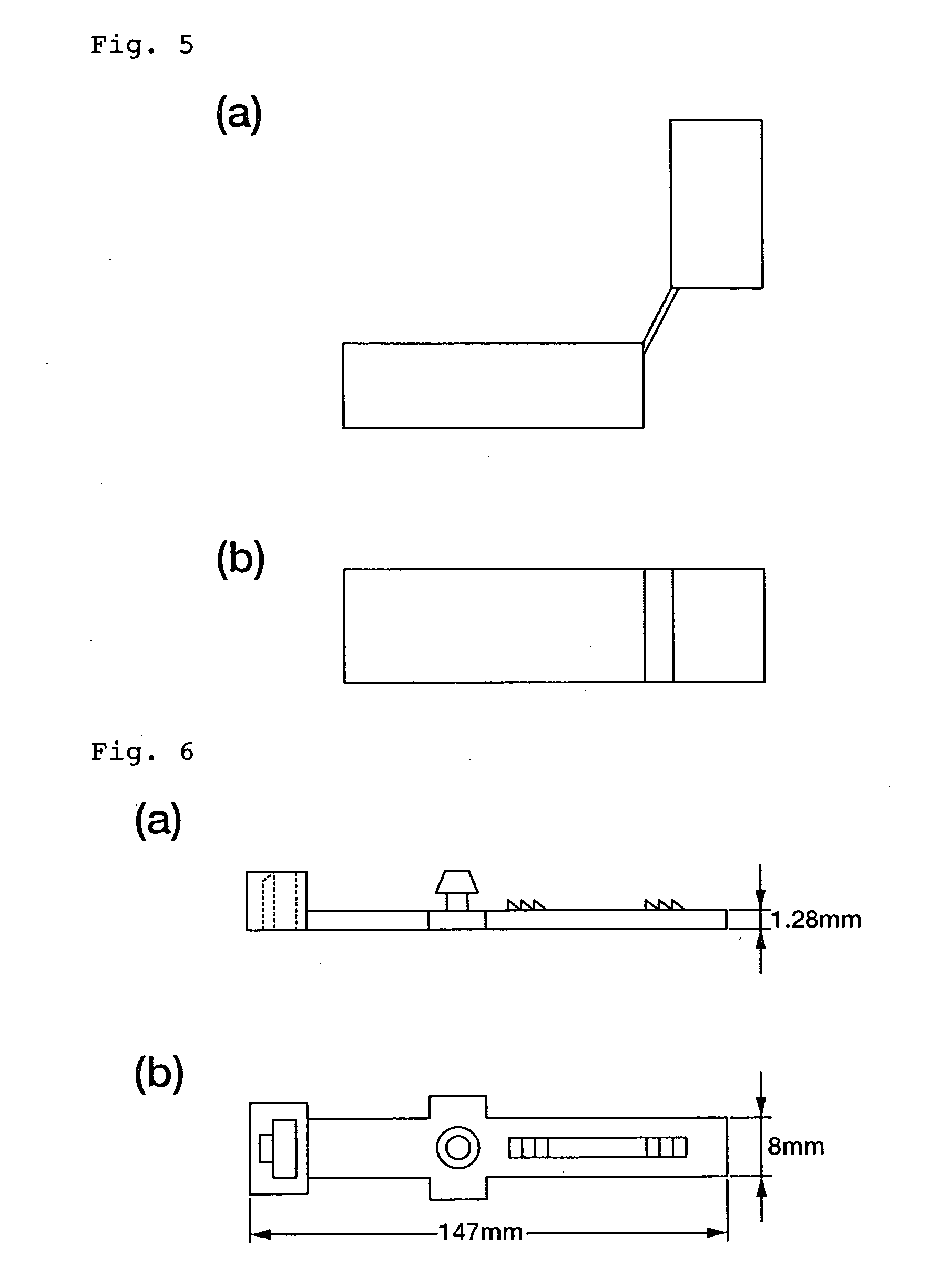

Filament Bundle Type Nano Fiber and Manufacturing Method Thereof

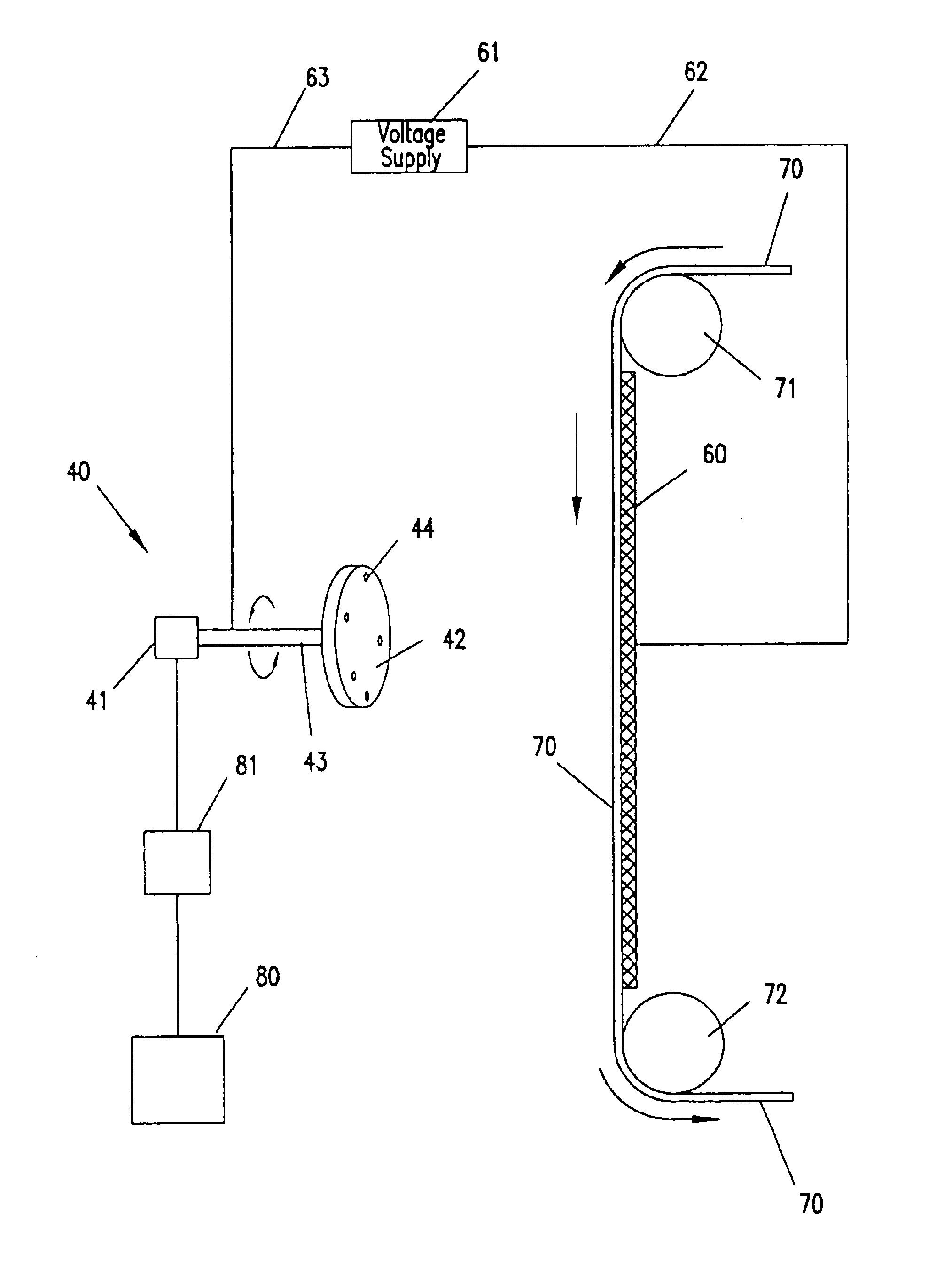

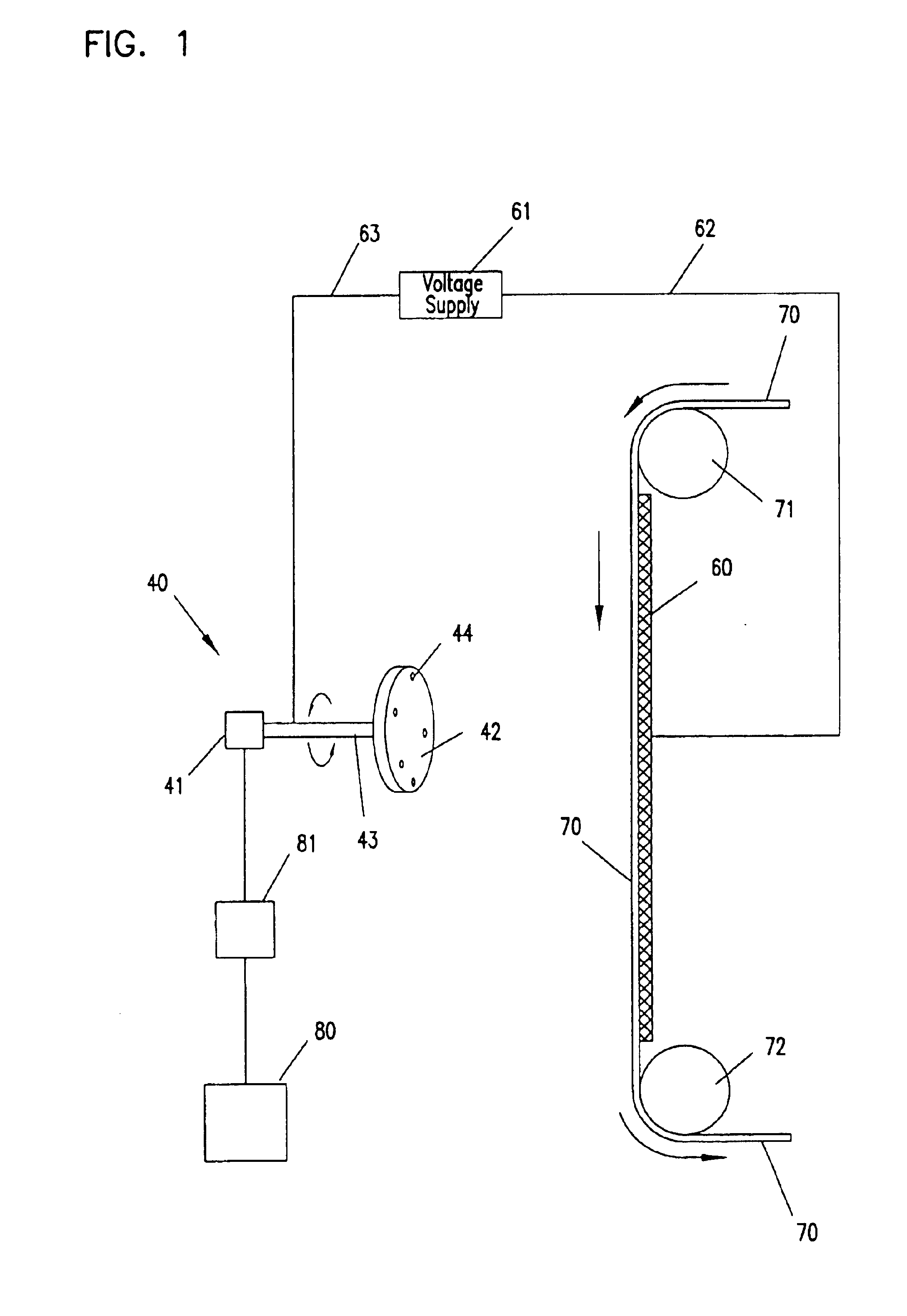

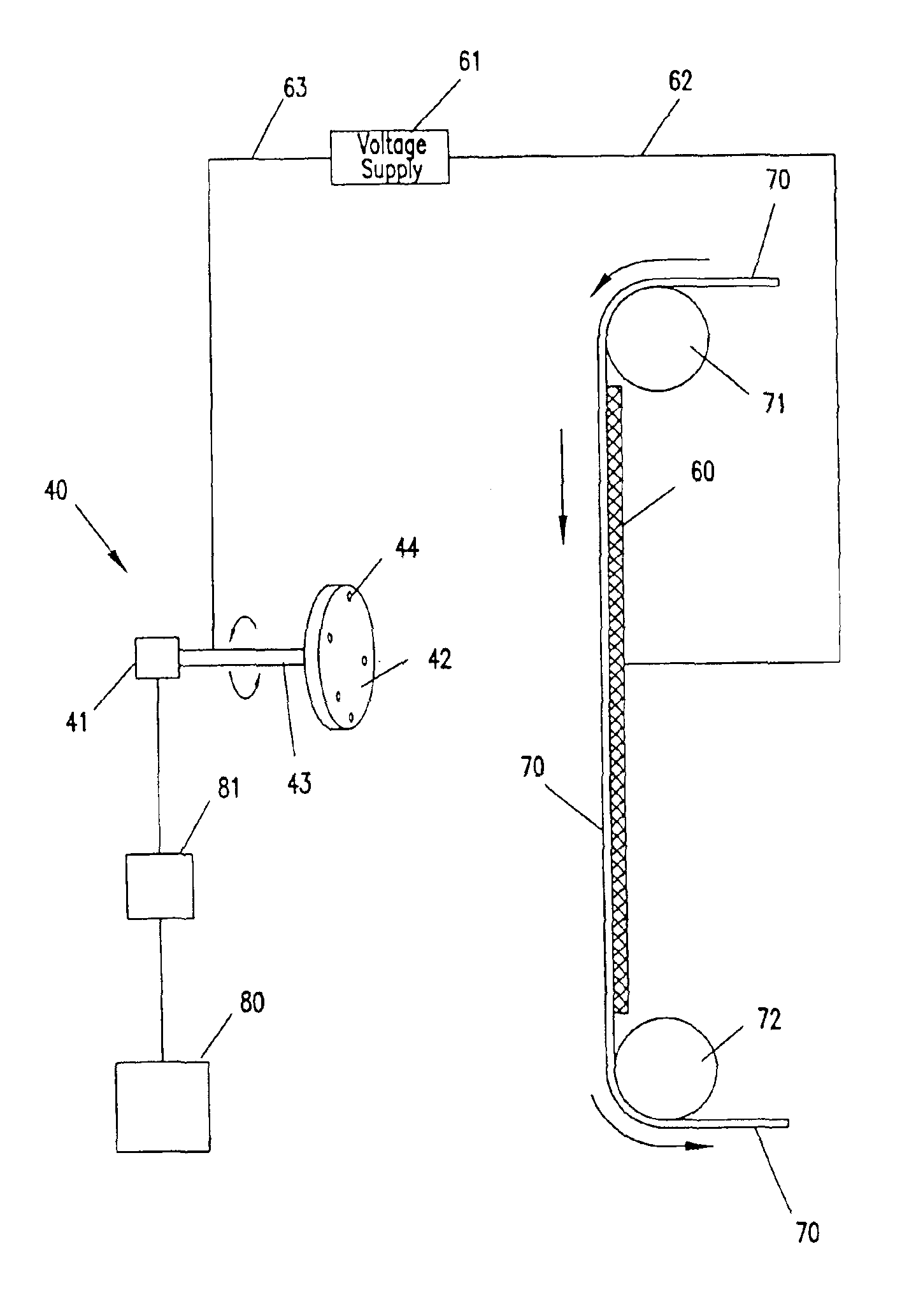

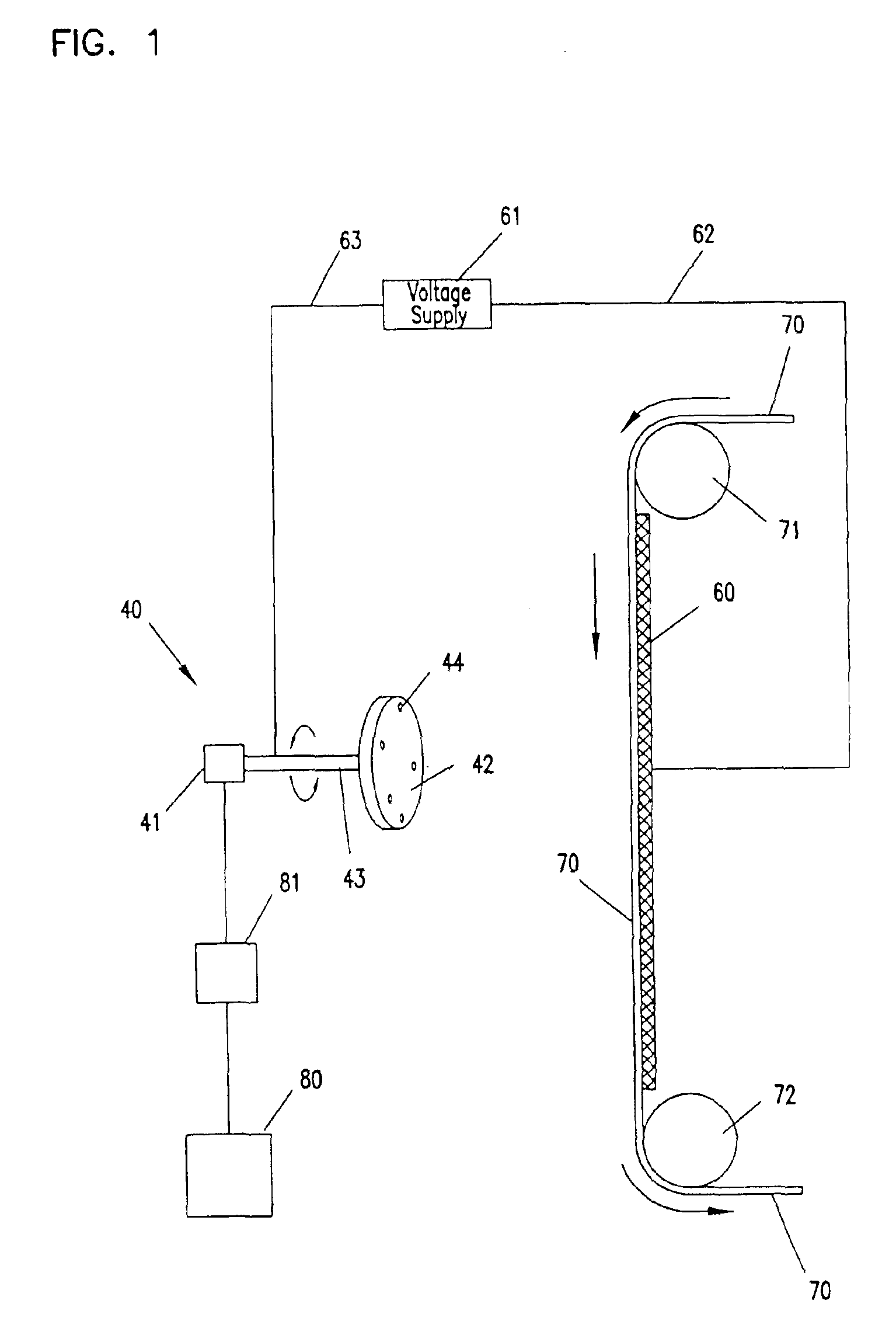

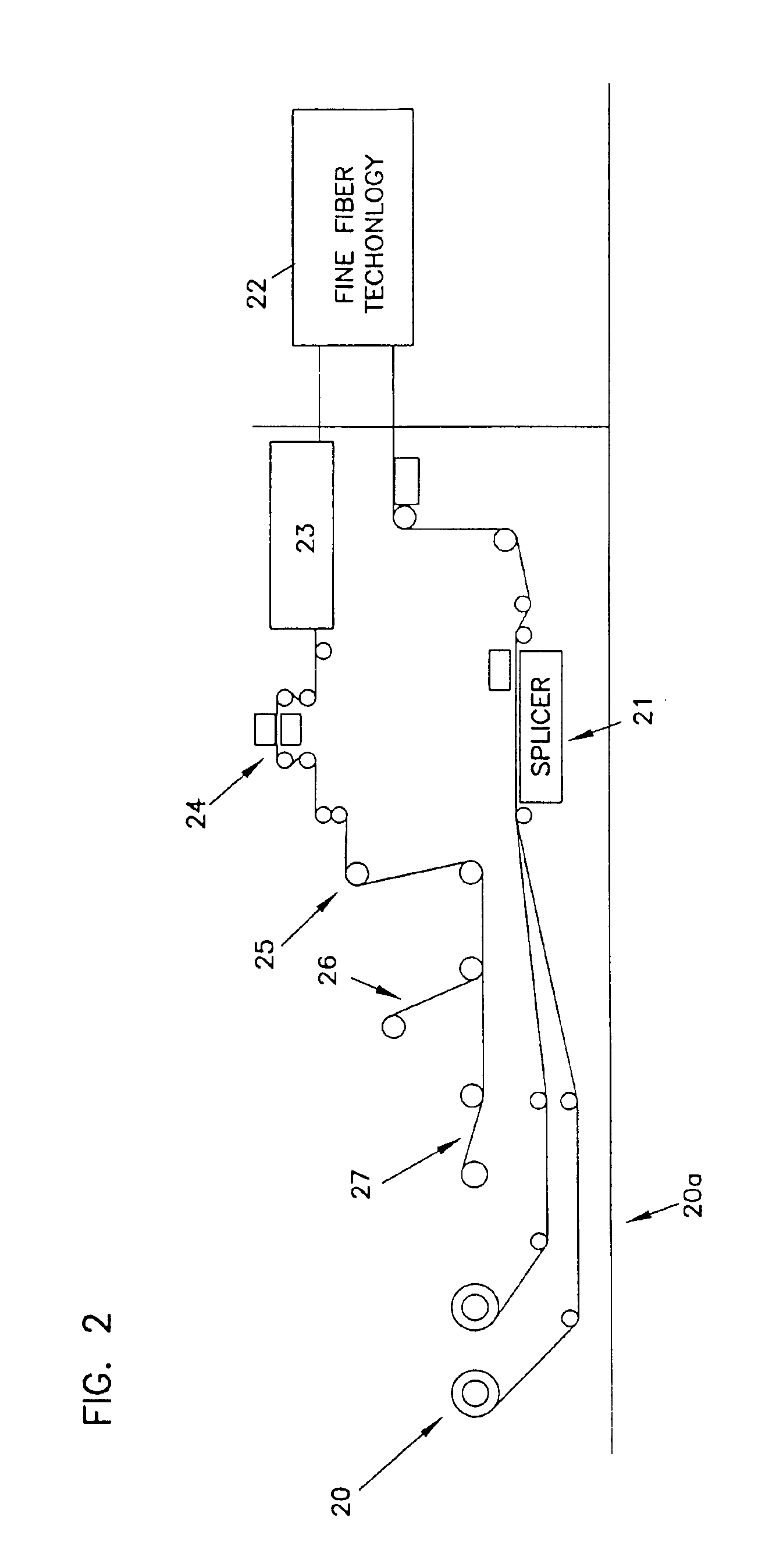

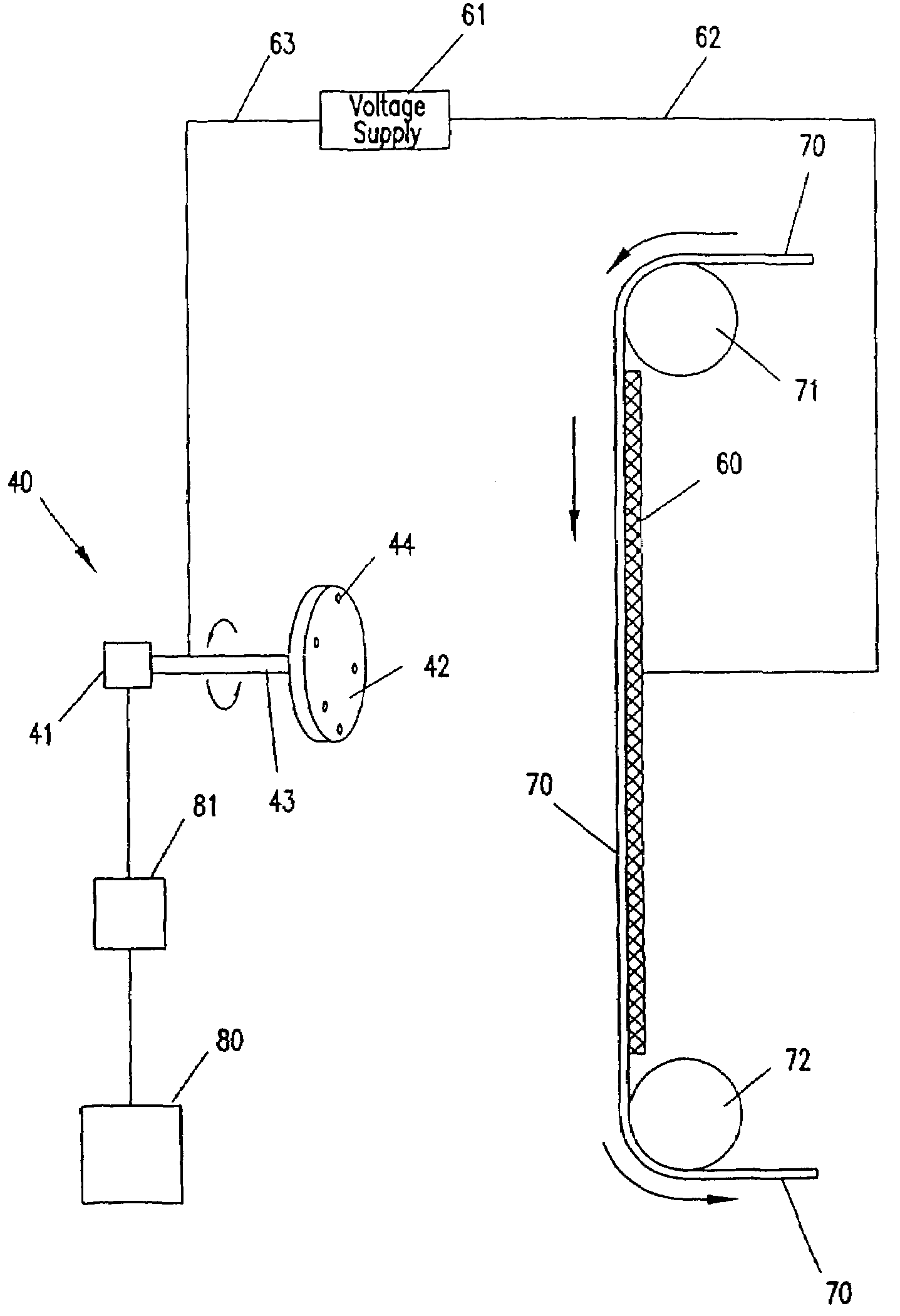

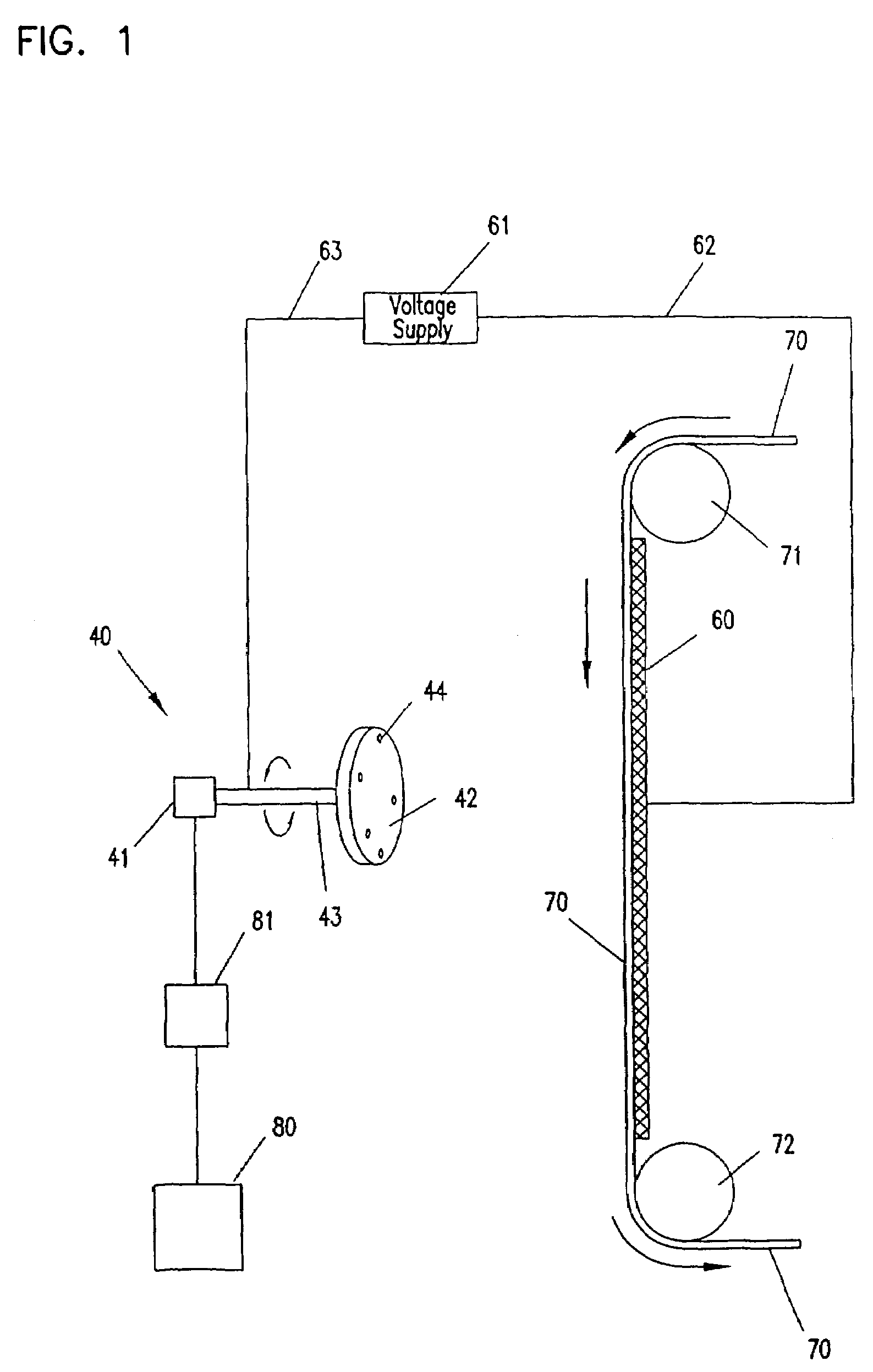

InactiveUS20080241538A1Improve mechanical propertiesMechanical propertyElectric discharge heatingFilament/thread formingFiberYarn

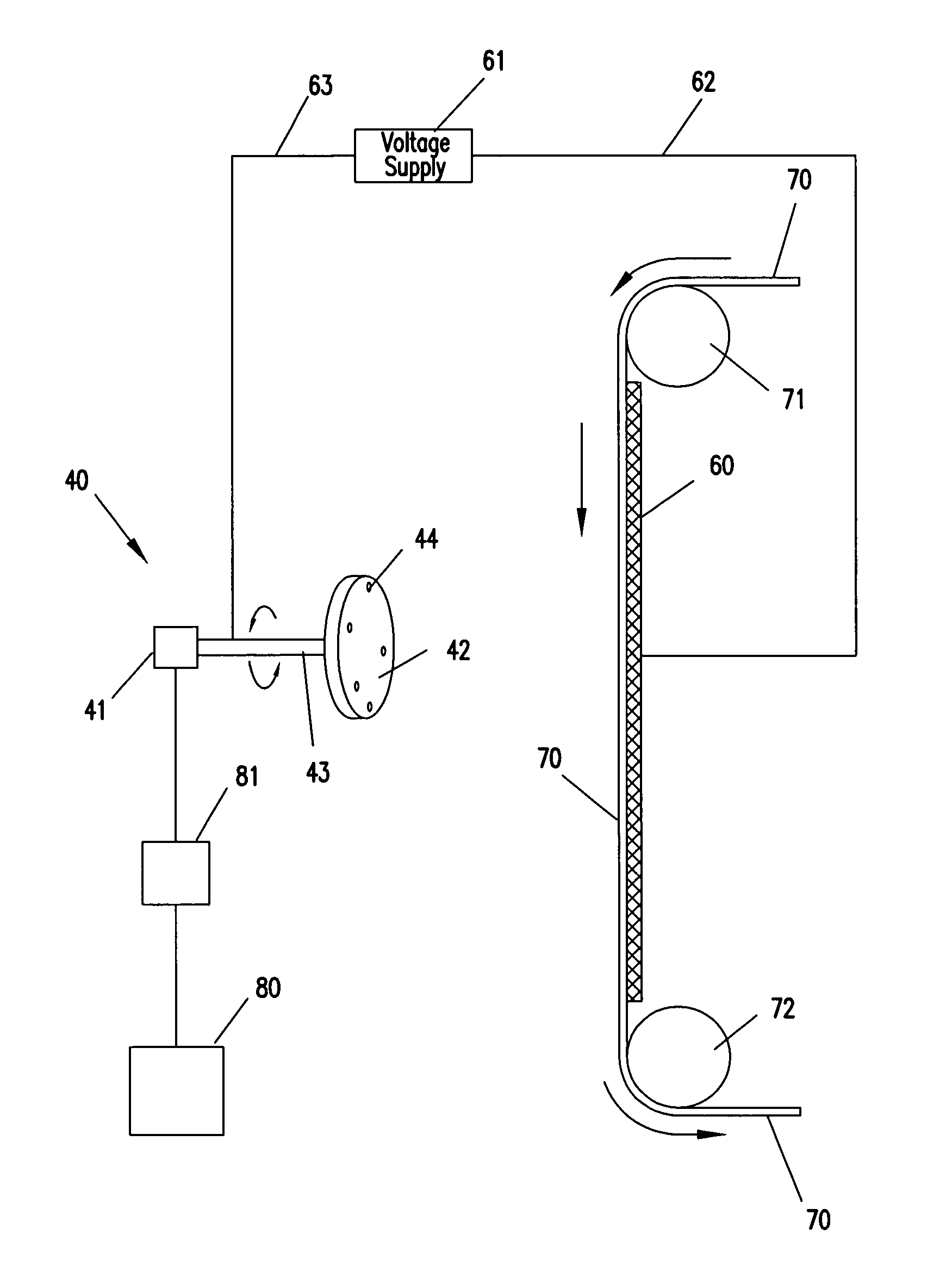

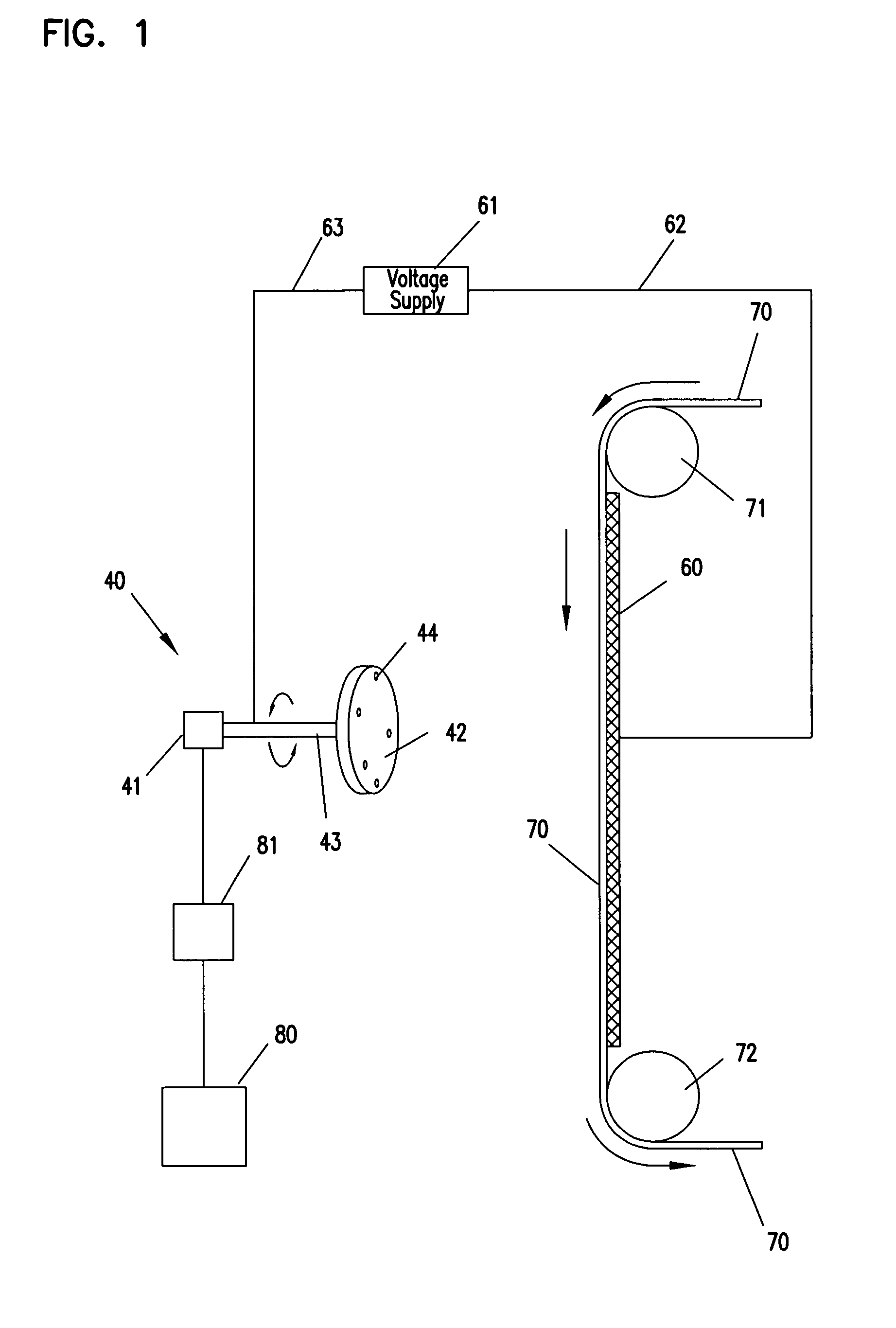

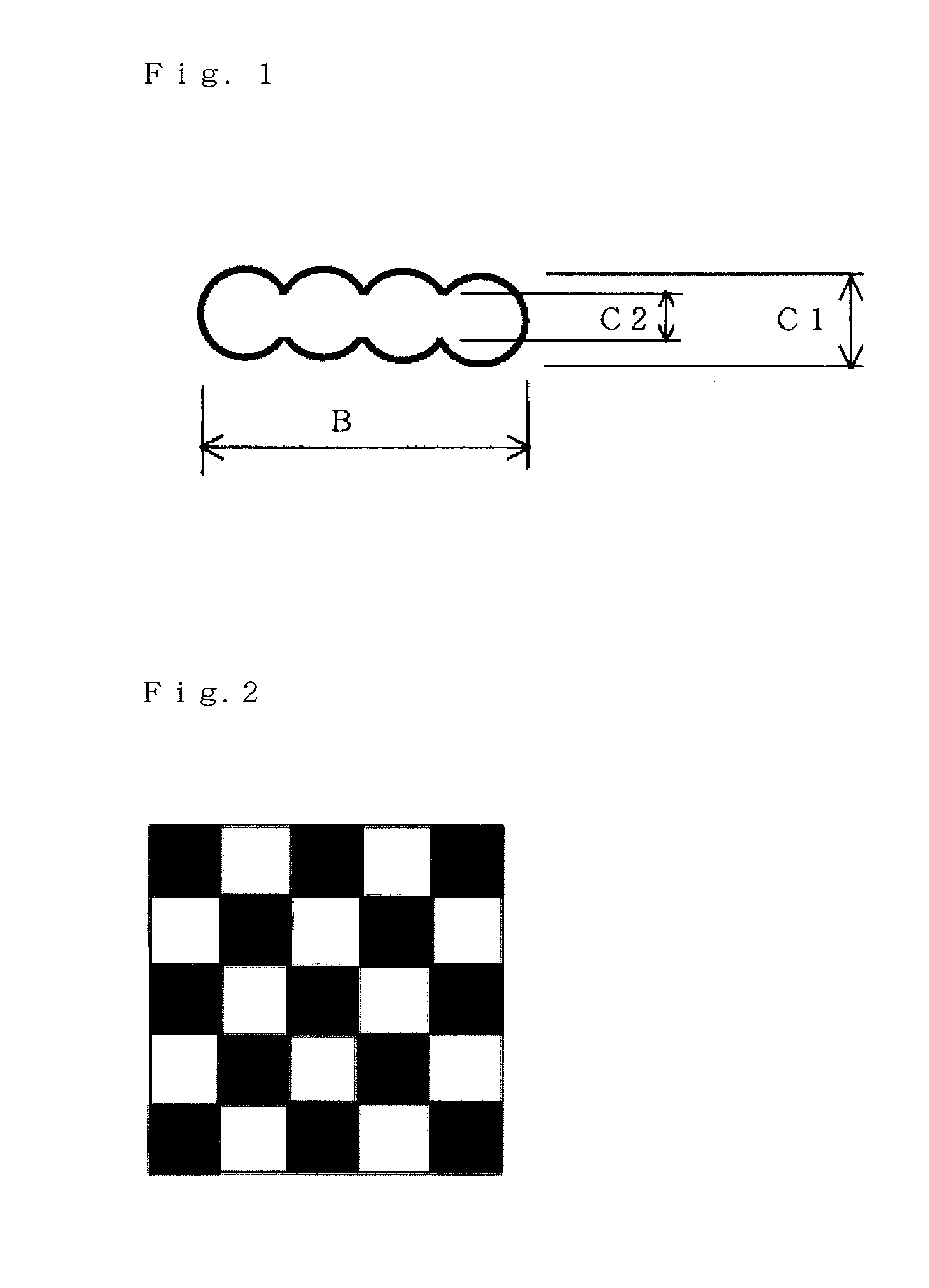

A filament type nano-sized long fiber and a method of producing the same are disclosed. In the method, a spinning solution or a spinning melt is electro-spun in drops using a spinneret to which a critical voltage is applied, and the spun drops are continuously collected on a multi-collector. The spinning solution is produced by dissolving a blend or copolymer consisting of two or more kinds of polymers in a solvent. The spinning melt is produced by melting the polymers. The multi-collector is selected from the group consisting of a plate type collector, a roll type collector, and a combination thereof. The filament type nano-sized long fiber is processed into a yarn through one step during the electrospinning process, and thus, mechanical properties are better than those of a conventional nanofiber non-woven fabric. Consequently, the filament type nano-sized long fiber can be utilized for the extended application.

Owner:KOREA RES INST OF CHEM TECH

Polymer, polymer microfiber, polymer nanofiber and applications including filter structures

InactiveUS20060117730A1Simple materialSubstantial surface loadingCombination devicesDispersed particle filtrationPolymer scienceNanofiber

Disclosed are improved polymer materials. Also disclosed are fine fiber materials that can be made from the improved polymeric materials in the form of microfiber and nanofiber structures. The microfiber and nanofiber structures can be used in a variety of useful applications including the formation of filter materials.

Owner:DONALDSON CO INC

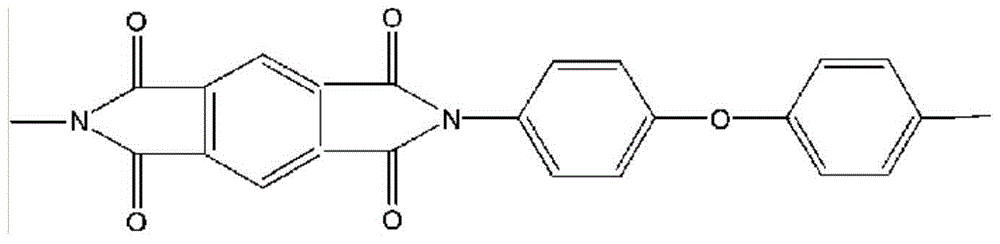

Fiber Comprising Heat Curable Polyamide Resin Composition, Nonwoven Fabric And Producing Method Thereof

InactiveUS20120178332A1Increase resistanceHigh strengthMaterial nanotechnologyElectric discharge heatingEpoxyPolyamide

The present invention relates to a fiber comprising a heat curable polyamide resin composition containing both a) a phenolic hydroxy group-containing polyamide and b) an epoxy resin having two or more epoxy groups in one molecule, a nanofiber comprising said resin composition obtained by electrospinning method, a nonwoven fabric obtained by applying heat treatment to a laminate of said nanofiber, a method for producing said nanofiber by electrospinning method and a heat curable polyamide resin composition for fiber. A nonwoven fabric can be obtained only by subjecting a deposit of the nanofiber obtained by electrospinning method to heat treatment, nanofibers in the obtained nonwoven fabric are bonded to each other by heat-curing, and the nonwoven fabric has such characteristics that its mechanical strength, heat resistance and chemical resistance are excellent and that it has a high strength.

Owner:NIPPON KAYAKU CO LTD

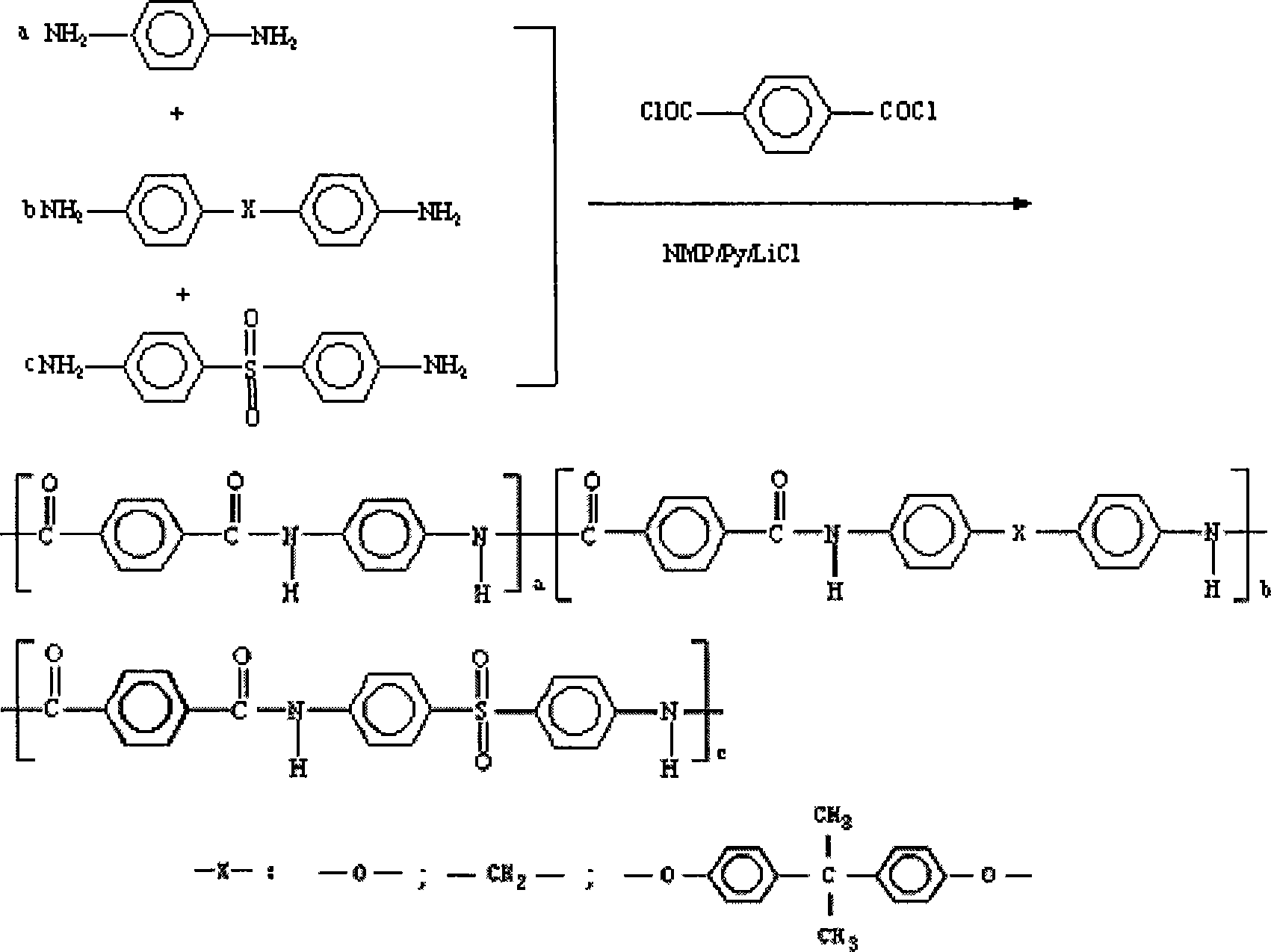

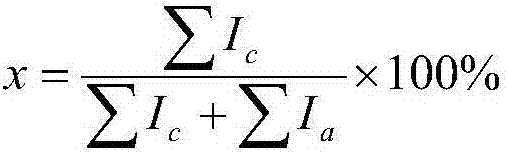

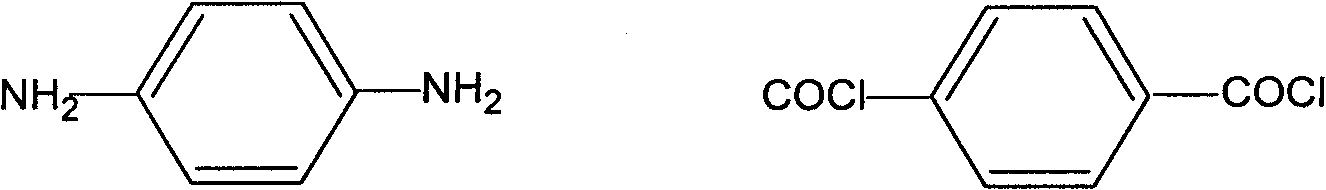

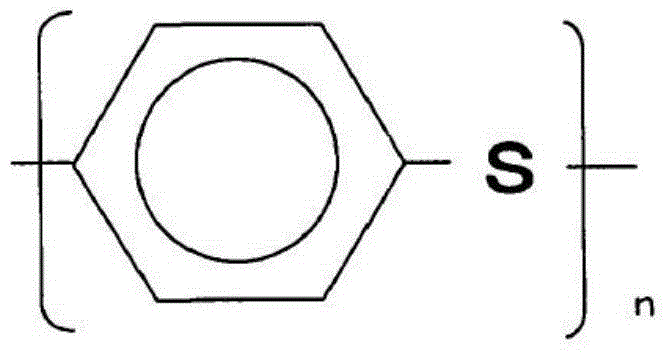

Random copolymerization polysulfonamide spinning liquid and preparation method thereof

InactiveCN101235552ADisruption of regularityImprove flexibilityMonocomponent copolyamides artificial filamentSpinning solutions preparationMetal chlorideMechanical property

The invention relates to random copolymerization poly-sulfone amide spinning fluid which is composited by three species aromatic diamine and terephthaloyl chloride and a method for preparing the random copolymerization poly-sulfone amide spinning fluid, wherein the spinning fluid takes the N-methyl-2pyrrolidone NMP as the dissolvent, monomer and the mole percent which are adopted by the method are as following: the aromatic diamine 40%-60%, the terephthaloyl chloride 60%-40%, taking the above total monomer 100% as a benchmark, further adding 1.0%-4.0% alkali chloride as the solvent. Since the method takes the manifold aromatic diamine as the monomer of the poly-reaction, which properly damages the regularity of the main chain, however, which has no effect to arrange the original crystal lattice, increasing the flexibility of the chain at various degree, the method is beneficial for orienting and crystallizing of the entire molecular chain and for improving the mechanical property of the material. The method has the advantages of simple technology, condition optimized, high operability, convenient manufacture and low cost.

Owner:SHANGHAI UNIV

Polyamide 5X high-strength fiber and preparation method thereof

ActiveCN106868624AHigh strengthLow elongationMonocomponent copolyamides artificial filamentArtifical filament manufactureFiberBreaking strength

The invention provides a polyamide 5X high-strength fiber and a preparation method thereof. The production raw materials of the polyamide 5X high-strength silk at least include 1,5-pentamethylene diamine and dicarboxylic acid, and the breaking strength of the polyamide 5X high-strength silk is 8.0-10.0cN / dtex. The preparation method comprises the following steps: (1) polymerizing 1,5-pentamethylene diamine with dicarboxylic acid, thereby forming polyamide 5X melt, or heating the polyamide 5X resin till reaching a molten state, thereby forming the polyamide 5X melt; (2) spinning the polyamide 5X melt, thereby forming a raw fiber; and (3) treating the raw fiber, thereby obtaining the polyamide 5X high-strength silk. The polyamide 5X high-strength silk provided by the invention has the characteristics of high strength, low elongation and low heat shrinkable property, has the advantages of excellent wear resistance and excellent alkaline resistance, and has an excellent flame retardant effect.

Owner:CATHAY R&D CENT CO LTD +2

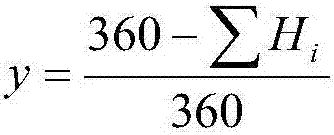

Method for preparing aramid IIII fiber

InactiveCN101851809AImprove spinning efficiencyLow investment costMonocomponent copolyamides artificial filamentDry spinning methodsYarnLithium chloride

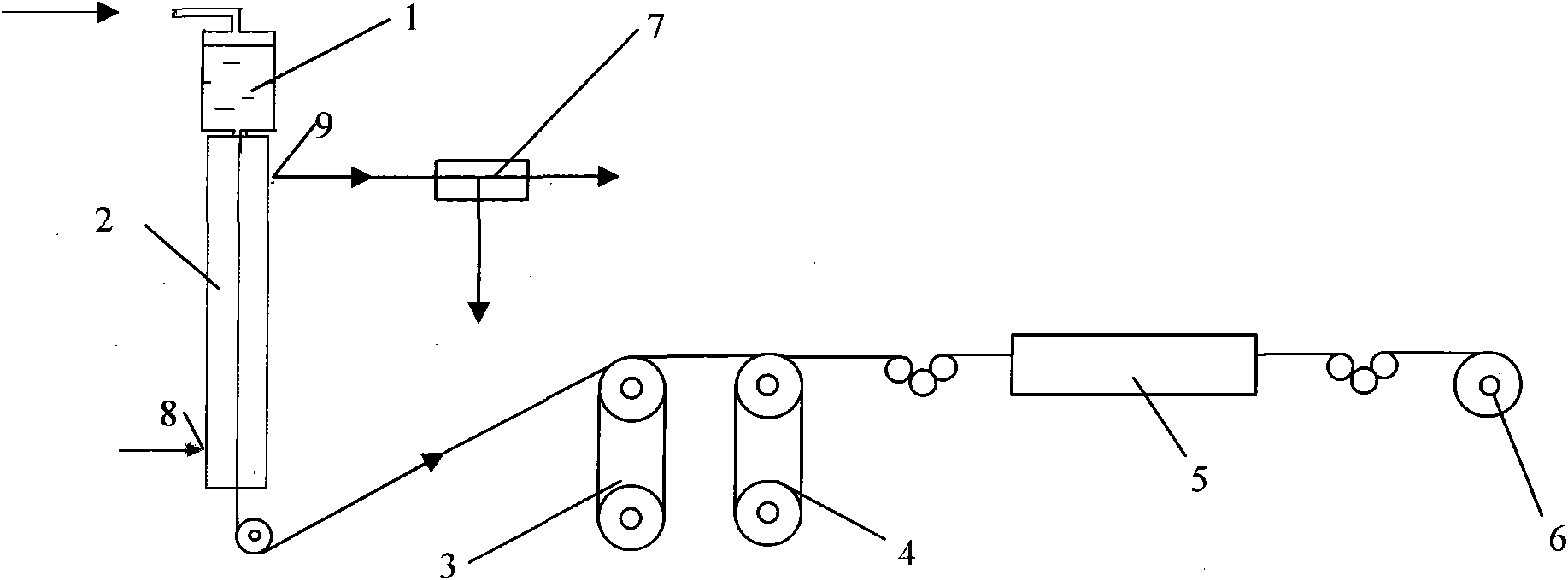

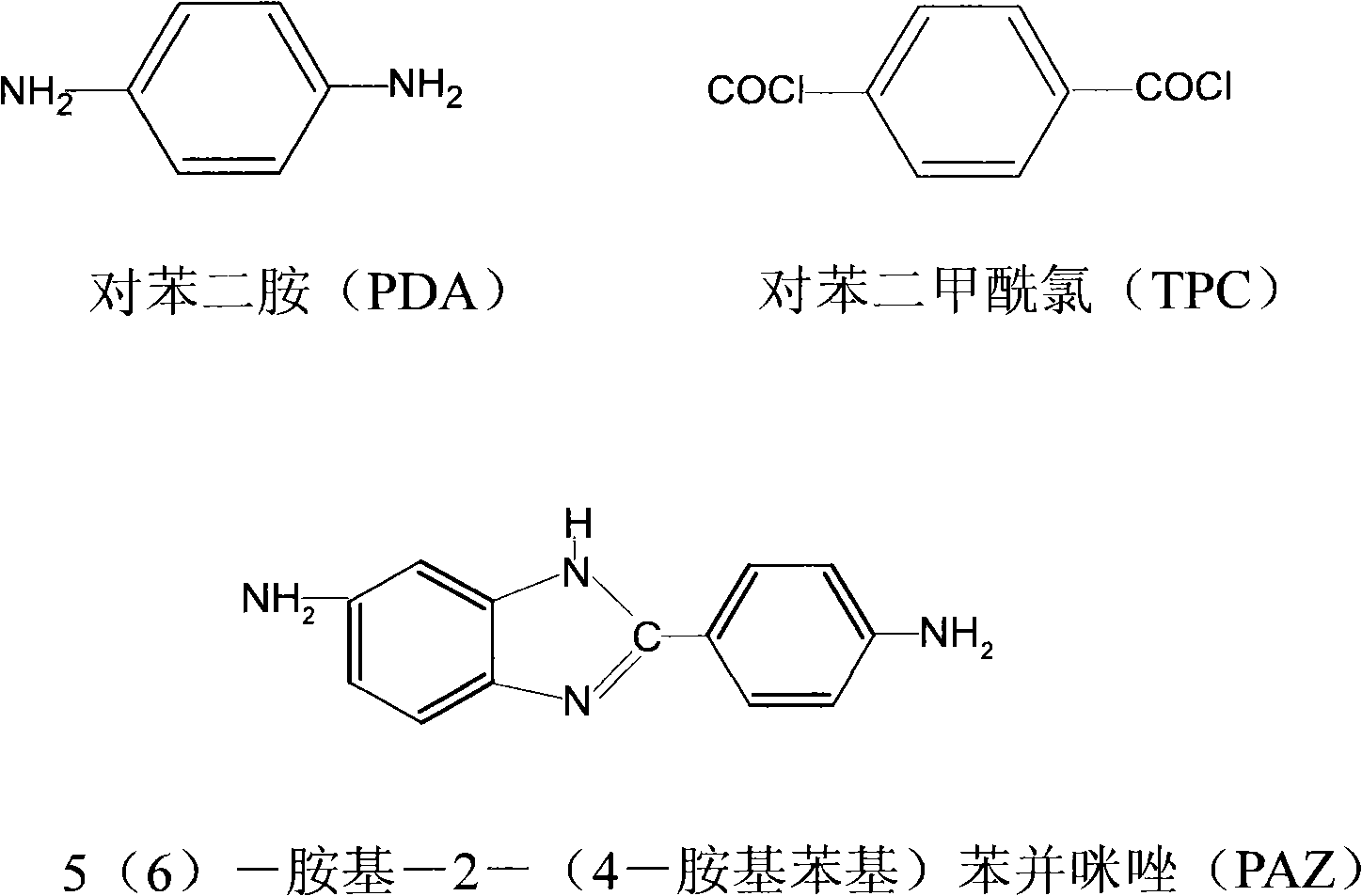

The invention relates to a method for preparing an aramid IIII fiber, which comprises the following steps of: (1) synthesizing a spinning stock solution, carrying out low-temperature copolymerization by adopting three monomers of p-phenylenediamine, paraphthaloyl chloride and 5(6)-amido-2-(4-amidophenyl)benzimidazole as raw materials and adopting dimethylacetylamide / lithium chloride as a solvent; (2) spinning by adopting a dry method spinning process, i.e. leading the spinning stock solution obtained in the previous step to pass through a spinneret and directly enter a hot inert gas channel and evaporating and removing the solvent in the spinning stock solution by utilizing a hot inert gas to obtain cured raw yarn; and (3) carrying out water washing and heat treatment on the raw yarn and winding to obtain the aramid IIII fiber. The method has high solid content of the spinning stock solution, high spinning speed, great improvement of spinning efficiency, obvious reduction of fiber manufacturing cost, improved mechanical performance of the manufactured aramid IIII fiber and wide application prospect.

Owner:SINOSELEN HI TECH

Fiber and fiber structure

ActiveUS20120184166A1Improve working environmentSuppress generationMonocomponent copolyamides artificial filamentMonocomponent copolyesters artificial filamentPolymer scienceChemical compound

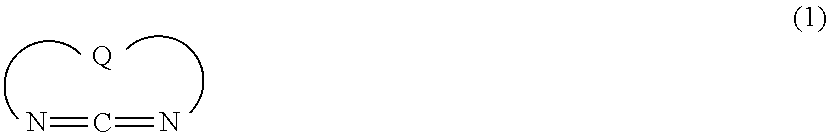

Provided is a fiber containing a composition obtained by mixing a compound having at least a ring structure containing one carbodiimide group, the first nitrogen and second nitrogen thereof being linked together through a linking group, with a polymer compound having an acidic group. Also provided is a fiber structure made thereof. A fiber and a fiber structure, which have improved hydrolysis resistance and from which no free isocyanate compounds are produced, can be provided.

Owner:TEIJIN LTD

Method for producing aramid fiber pulp by aramid fiber waste material

InactiveCN101250771AIncrease productivityShort processArtificial filament recoveryPlastic recyclingSlurryFibrillation

The invention discloses a method for manufacturing aramid pulp by using aramid waste materials, which comprises the following steps: shredding the aramid waste materials by directly arranging the aramid waste materials in a multi-tool mechanical cutter, enabling the average length of the shredded fiber to be 0.1- 5.0mm, dispersing the shredded fiber in water, forming suspending liquid with concentration of 0.1-8.0%, arranging the suspending liquid in a multi-tool bilateral beater, wherein beating time is 0.5-2h, then arranging the beat suspending liquid in a two-plate lapping machine, carrying out the knocking fibrillation, wherein knocking time is 20-300s, forming steady serous fluid, then dehydrating by arranging the serous fluid into a continuous filter and drying by arranging the serous fluid into a continuous drier, then opening, and obtaining the aramid pulp, wherein the aramid waste materials are made of aramid cloth rim leftovers, aramid yarn leftover bits and pieces and aramid filament waste materials, and the aramid waste materials are obtained by recycling used aramid textile such as aramid old gloves and the like. The method of the invention has the advantages of simple process, high manufacturing efficiency and less pollution to environment, simultaneously the method can satisfy the requirements of industrialization.

Owner:上海依极科技有限公司

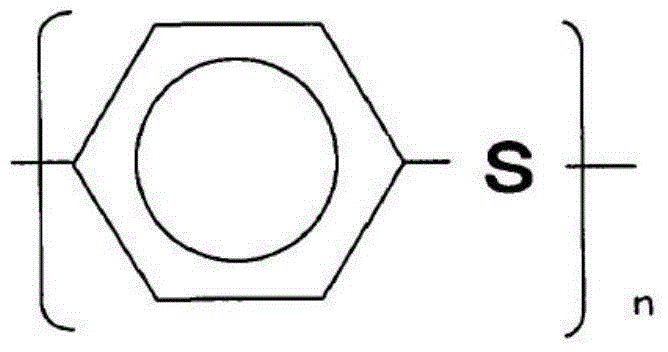

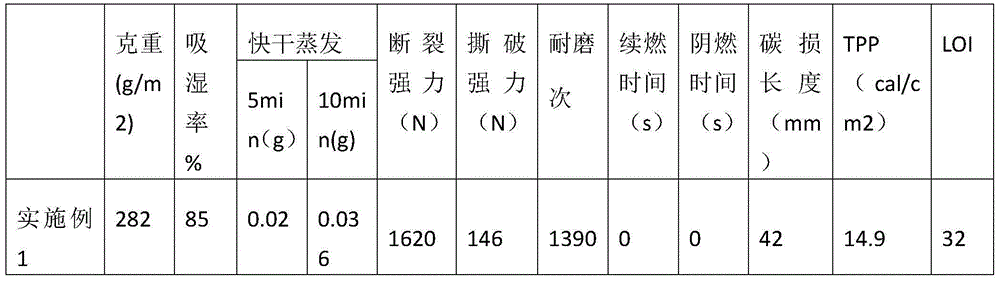

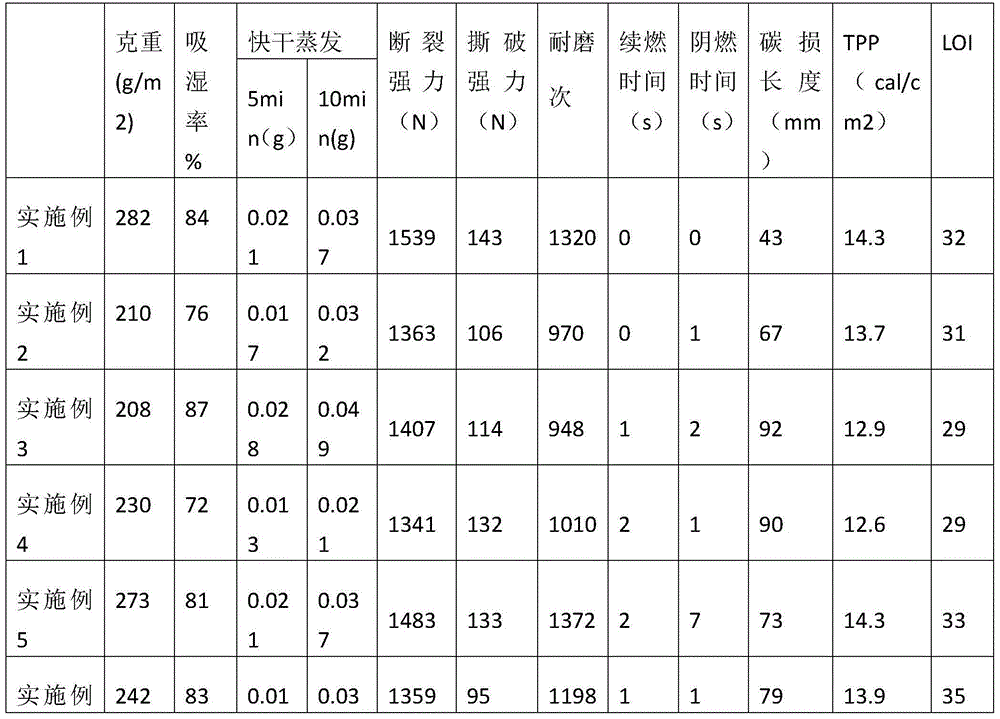

Flame retardant yarn comprising aromatic polymer fiber containing sulfuryl, fabric made of same and preparation method

ActiveCN104611806AHigh mechanical abrasion resistanceGood synergyMonocomponent copolyamides artificial filamentWoven fabricsYarnPolyester

The invention relates to a flame retardant yarn comprising aromatic polymer fiber containing sulfuryl, a fabric and garment made of the same and a preparation method thereof. The yarn comprises a high temperature resistant inherent flame retardant fiber (A), conventional fire-retardant fiber (B) and flame retardant cellulose fiber (C). The conventional fire-retardant fiber (B) can be one of flame retardant nylon, flame retardant polyester and flame retardant acrylic selectively. The yarn is mainly applied to preparation of the protective camouflage fabric and garment with permanent flame retardance, wear resistance and good comfortable performance.

Owner:中芳新材料有限公司

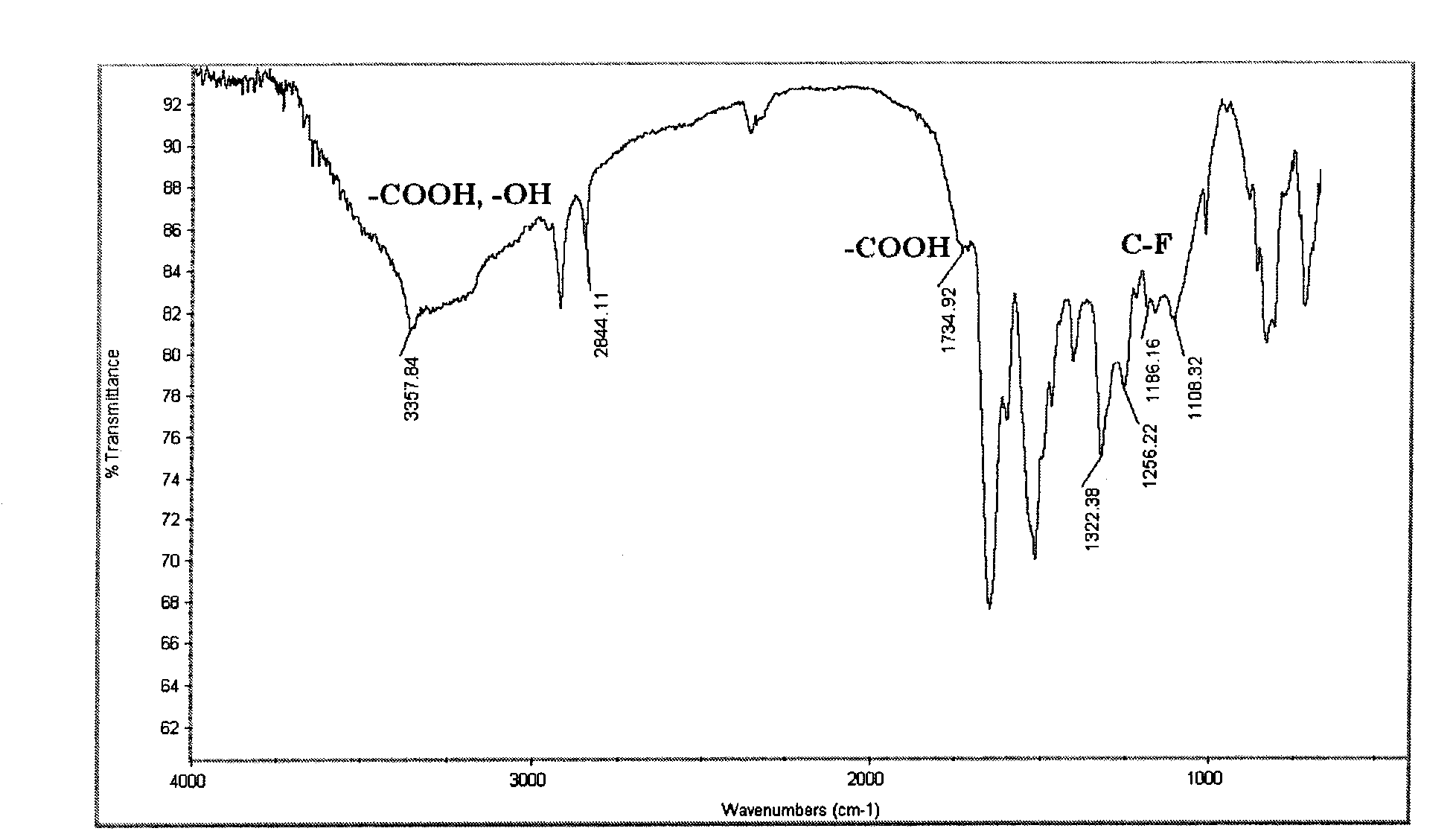

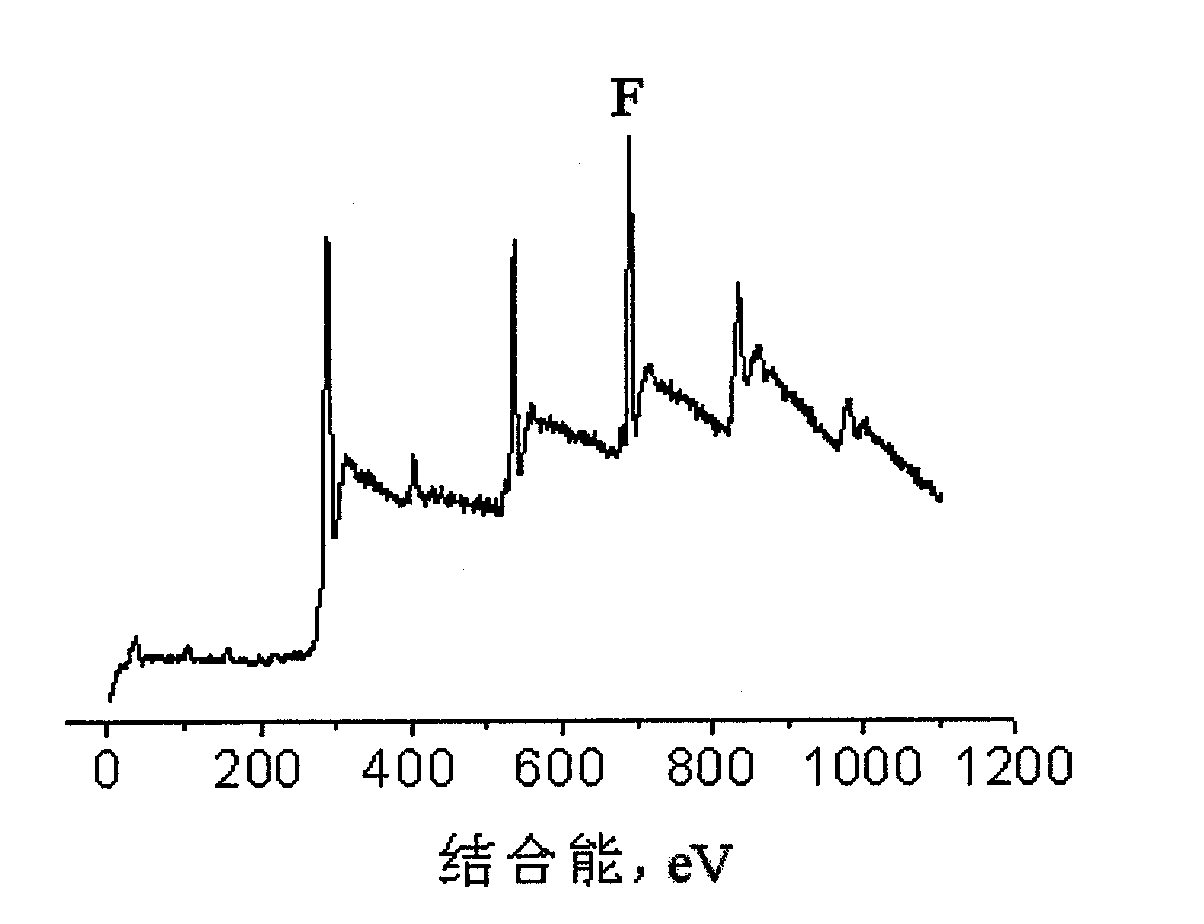

Aramid III fiber with fluorine-containing surface and preparation method thereof

InactiveCN101798748AHigh activityImprove mechanical propertiesFibre typesMonocomponent copolyamides artificial filamentAfter treatmentBiological activation

The invention discloses an aramid III fiber with a fluorine-containing surface, which is characterized in that: the surface of the fiber contains a carbon-fluorine covalent bond structure and a carboxyl-hydroxyl group; the contact angle between the surface of the fiber and water is 68 to 82 degrees; the shear strength between composite material layers prepared from the fiber is 47.3 to 55 MPa; and the tensile strength of gum dipped filaments is 4.6 to 5.4 GPa, and the tensile modulus is 145 to 168 GPa. The invention also discloses a method for preparing the aramid III fiber with the fluorine-containing surface. The fiber surface hydrophilicity of the aramid III fiber subjected to fluoridation is obviously improved; and the shear strength between the prepared composite material layers, and the tensile strength and the tensile modulus of the gum dipped filaments all can be improved by 20 to 30 percent. The method has the advantages of high fluoridation rate, short treatment time, can continuous surface treatment for the fiber on line, high stability of the surface activation effect after treatment, low cost and good application prospects.

Owner:SINOSELEN HI TECH

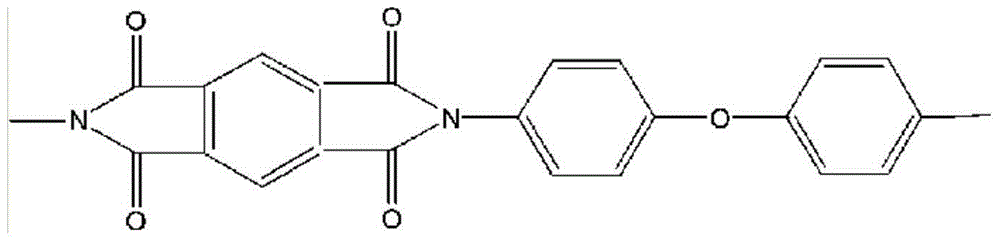

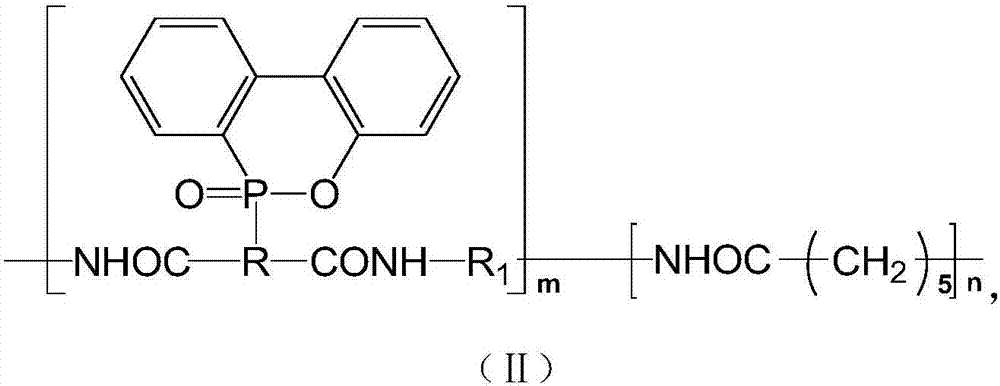

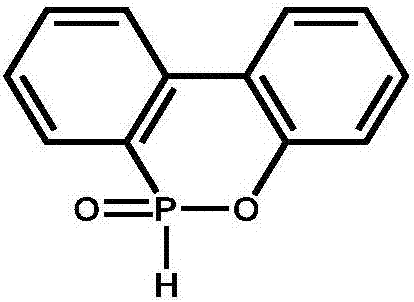

Copolymerized flame-retardant polyamide 66 fiber and preparation method thereof

InactiveCN105155018AAdd lessImprove flame retardant performanceMonocomponent copolyamides artificial filamentMelt spinning methodsPolymer sciencePolyamide

The invention relates to a copolymerized flame-retardant polyamide 66 fiber and a preparation method thereof, especially to a method for preparing the flame-retardant polyamide 66 fiber by preparing a block flame-retardant polyamide 66 copolymer through polymerization of a phosphorus-containing reactive flame retardant, then pelletizing and drying the polyamide 66 copolymer and then carrying out melt spinning. The method is characterized in that the flame-retardant reacts with diamine or dihydric alcohol to produce a flame-retardant prepolymer, then the flame retardant prepolymer reacts with polyamide 66 prepolymer so as to obtain the flame-retardant polyamide 66 copolymer, and finally, the flame-retardant polyamide 66 copolymer is subjected to melt spinning so as to prepare the copolymerized flame-retardant polyamide 66 fiber. The copolymerized flame-retardant polyamide 66 fiber prepared in the invention has excellent mechanical properties, good flame retardation durability and a limit oxygen index of more than 30%. The flame-retardant polyamide 66 fiber can be used for fabricating civil filaments like clothes, carpets, curtains, cloth for furniture, etc. and fabricating industrial filaments like cord fabrics, transport belts, fishing nets, cables, military fabrics, etc.

Owner:DONGHUA UNIV

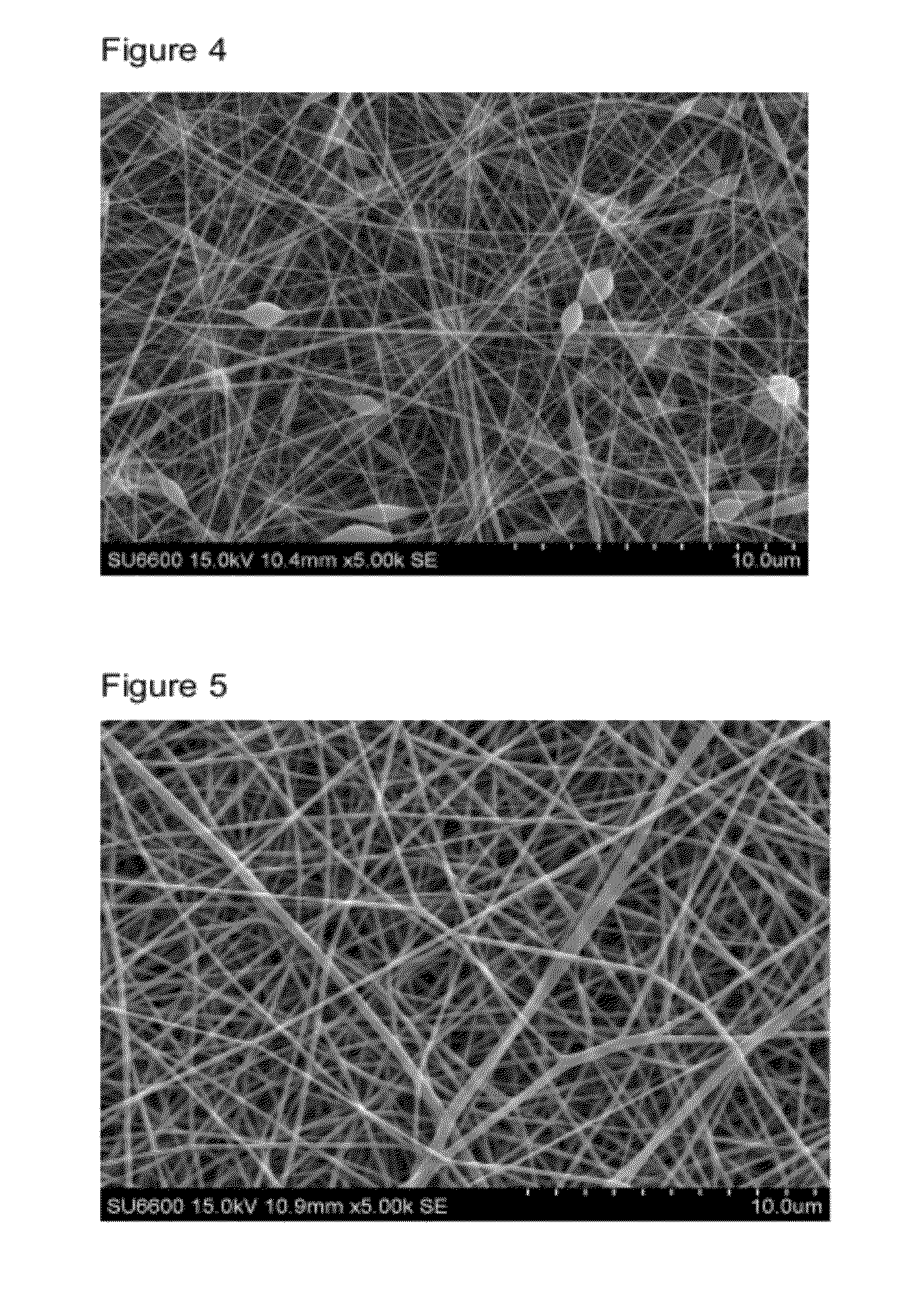

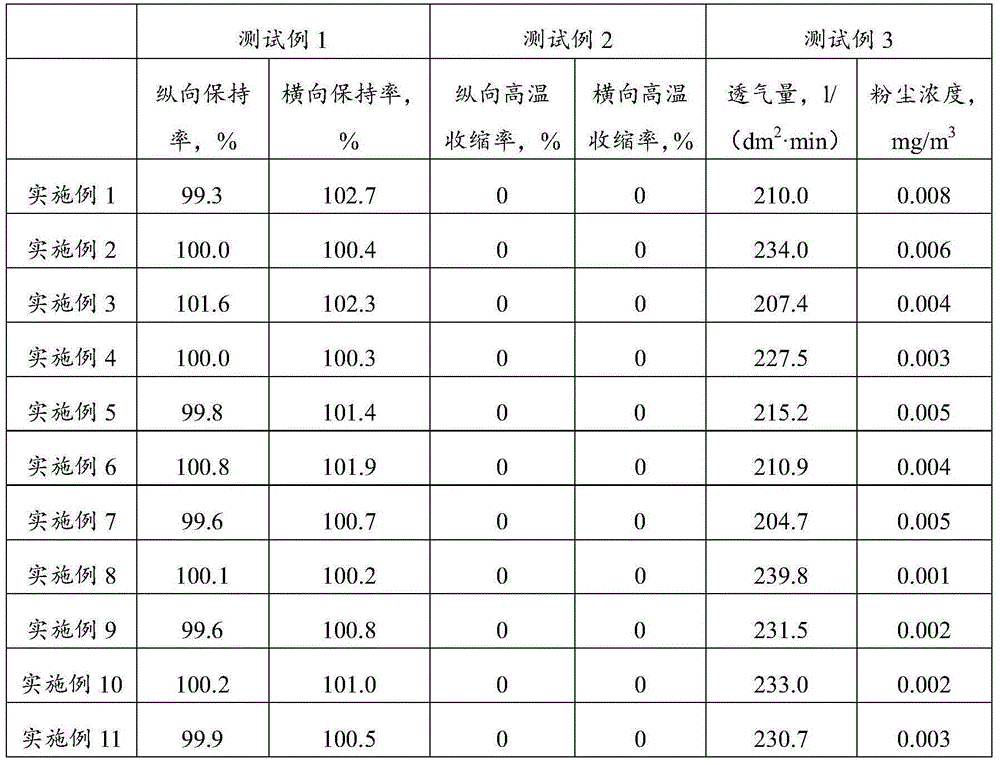

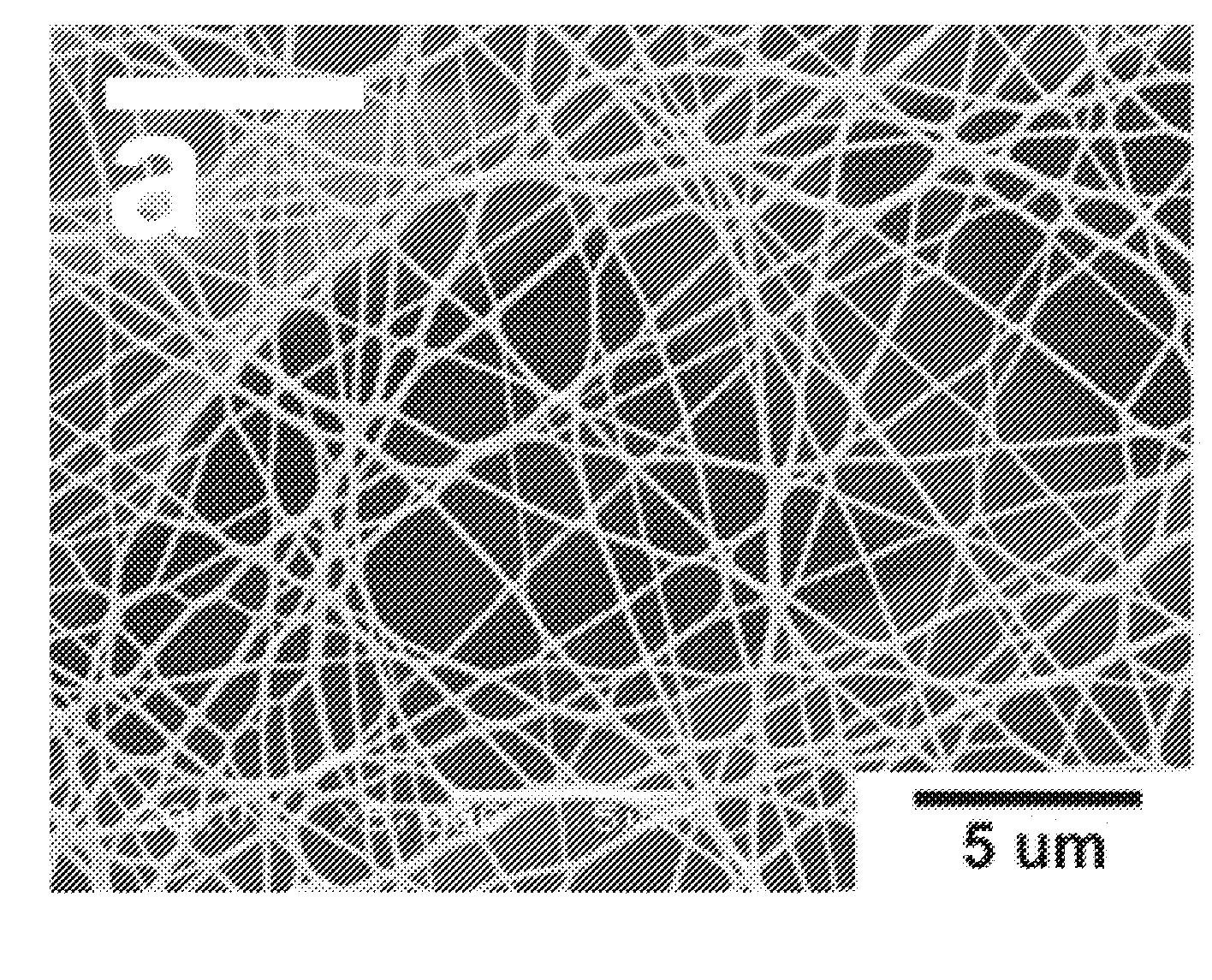

Nanometer fiber filter material and preparation method thereof

InactiveCN105040271AFilament/thread formingMonocomponent copolyamides artificial filamentPorosityCross-link

The invention relates to a nanometer fiber filter material. The nanometer fiber filter material is characterized by comprising a filter base material and a nanometer fiber layer formed on the filter base material, wherein the mass ratio of the filter base material to the nanometer fiber layer is 100:1-600:1. The nanoscale fiber material layer is composited on the surface of a traditional textile through an electrostatic spinning technology; the nanometer fiber fineness ranges from dozens of nanometers to hundreds of nanometers; fibers are cross-linked in an intricating mode; ultra-high magnitude-order nanoscale micro-holes exist, and the porosity is larger than 90%; the thickness of the fiber layer can be designed and machined according to the requirements of different products; PM2.5 and dust with the diameter larger than 2.5 microns can be totally filtered out, zero emission is achieved, different raw materials can be selected to machine the nanometer fiber layer according to the work condition and the characteristics of composited materials, and meanwhile the requirements for filtering precision, work condition temperature, chemical conditions and other aspects can be met. The running resistance of finished products is low, and filtering speed is high. The service life is long, the nanometer fiber filter material can be repeatedly used, and therefore running cost is greatly reduced, and higher cost performance is achieved.

Owner:SHANGHAI TANLON FIBER CO LTD

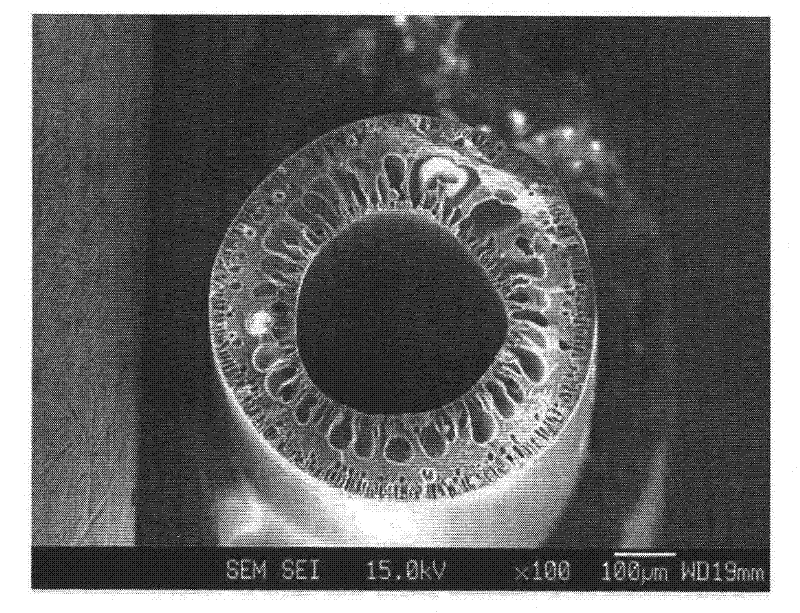

Hollow fiber, dope solution composition for forming a hollow fiber, and method for manufacturing a hollow fiber using the same

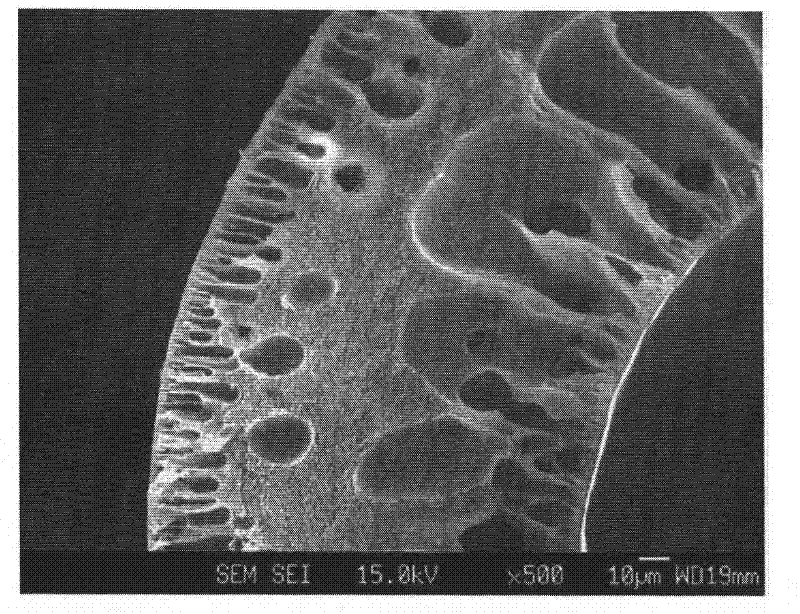

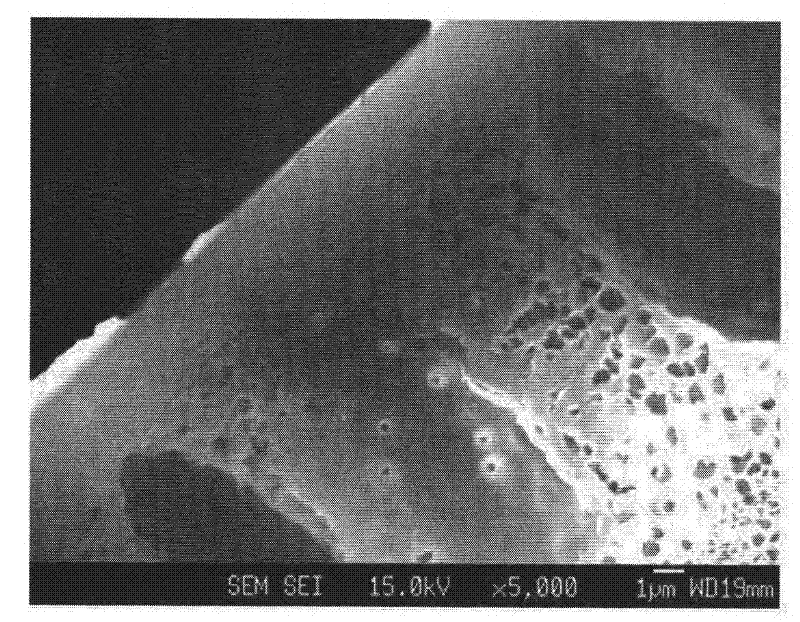

InactiveCN102099513AImprove gas permeabilityGood choiceMethane captureFilament/thread formingHollow fibreFiber

Provided is a hollow fiber with a structure including a cavity positioned at the center of the hollow fiber, macro-pores present in the periphery of the cavity, and meso-pores and pico-pores present in the periphery of the macro-pores, wherein the pico-pores are connected to each other in a three-dimensional manner to form a three-dimensional network. The hollow fiber contains a polymer derived from a polyamic acid, wherein the polyamic acid includes repeating units prepared from aromatic diamines and dianhydrides containing at least one functional group present in an ortho-position relative to an amine group.

Owner:IUCF HYU (IND UNIV COOP FOUNDATION HANYANG UNIV)

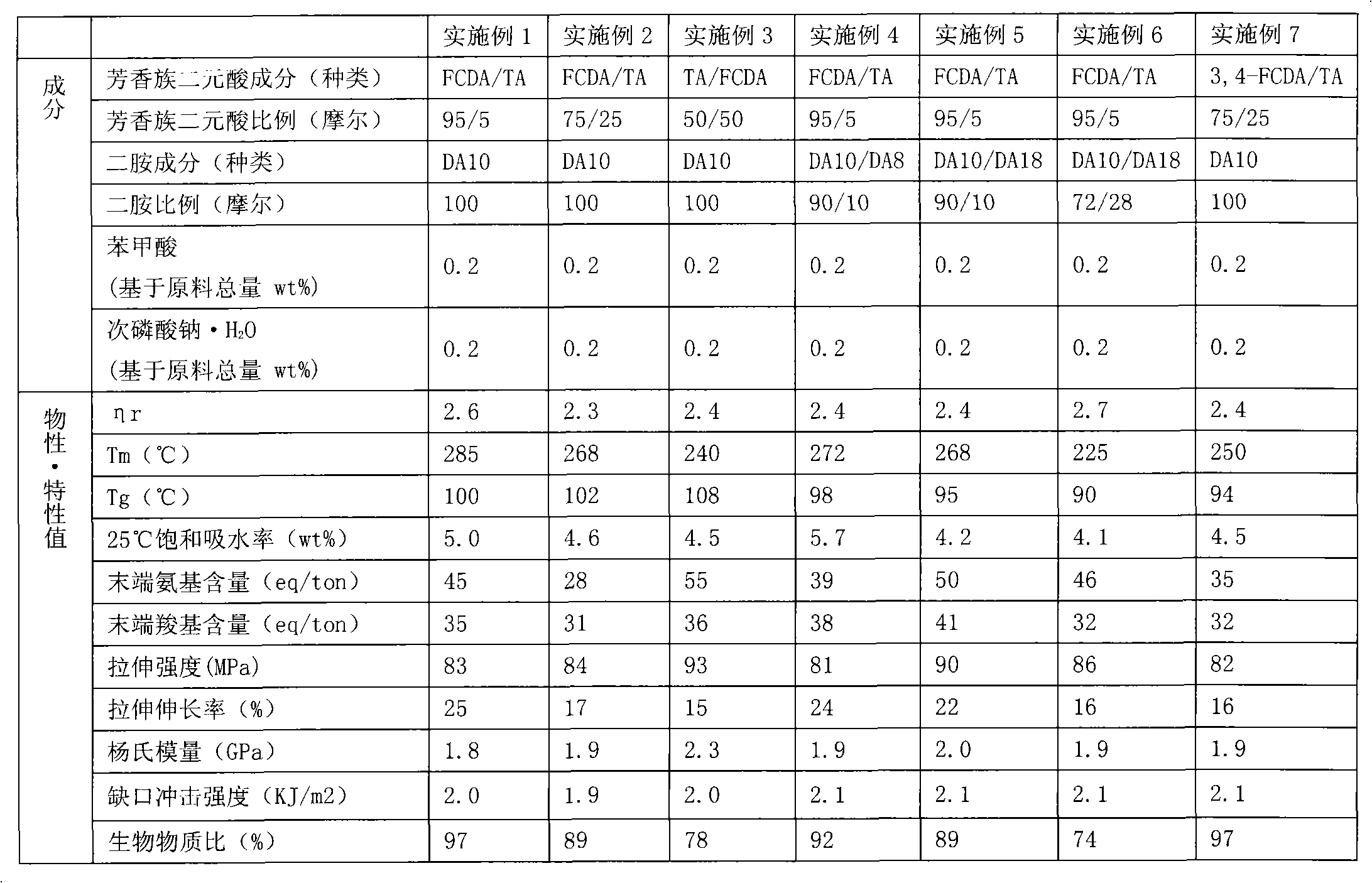

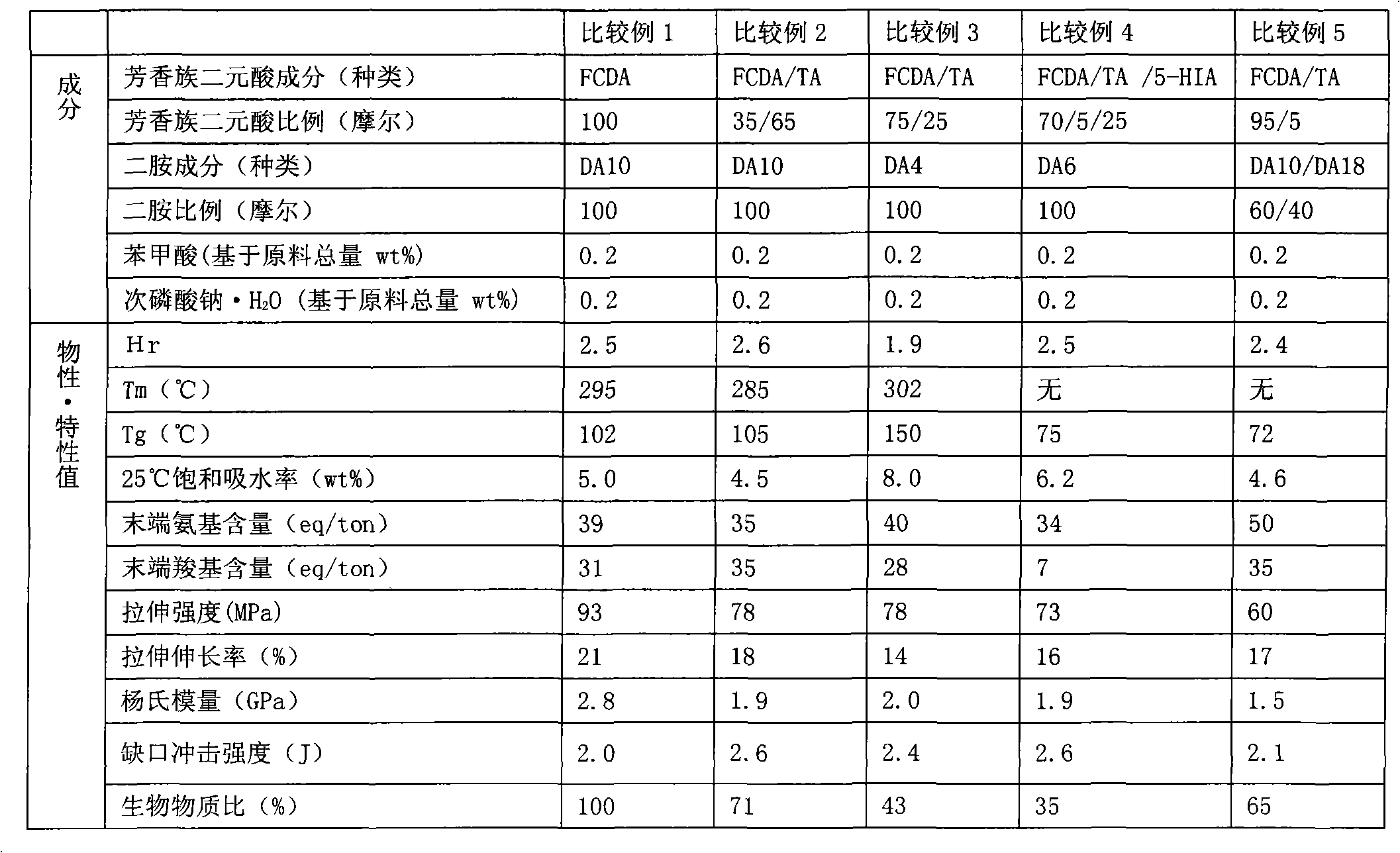

Biomass based polyamide resin

InactiveCN102850541AExcellent thermodynamic propertiesGood chemical resistanceMonocomponent copolyamides artificial filamentCarbon numberPolymer science

The invention discloses a biomass-based semi-aromatic polyamide copolymer having the advantages of excellent thermal property and low water absorption rate. The biomass-based polyamide resin contains a furan diacid unit (a), a terephthalic acid unit (b), a biomass-based 1,10-decamethylene diamine unit (c), and an aliphatic diamine unit (c) with the carbon number of above 4 except the unit (c), wherein the content of the unit (a) is 50-98mol% of the total amount of the unit (a) and the unit (b), and the content of the unit (d) is 0-30mol% of the total amount of the unit (c) and the unit (d). The copolymer has excellent physical and mechanical performance, can be used in engineering plastics, and also can be used in other industrial materials and materials for manufacturing electrical and electronic devices.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Fabric comprising fire-retardant yarn of blended polymer fiber containing aromatic polyamide and polyarylsulfone and production method of fabric

ActiveCN104630958AHigh mechanical abrasion resistanceGood synergyMonocomponent copolyamides artificial filamentYarnYarnPolyester

The invention relates to a fire-retardant yarn of a blended polymer fiber containing aromatic polyamide and polyarylsulfone and fabric and clothes produced by the fire-retardant yarn and production method of the fabric and clothes. The yarn comprises a high temperature resistant nature fire-retardant fiber (A), a conventional fire-retardant fiber (B) and a fire-retardant cellulose fiber (C), and the conventional fire-retardant fiber is selected from fire-retardant polyamide, fire-retardant polyester and fire-retardant acrylic. The yarn is mainly used for producing protective camouflage fabric and clothes which are forever fire retardant, wear resistant and good in comfortableness.

Owner:中芳新材料有限公司

Polamide composition comprising optical brightener yarns made therefrom, and process for heat setting such yarns

InactiveUS20050183216A1Improved in whiteness appearancePermanent whiteness improvementBrassieresMonocomponent copolyamides artificial filamentYarnPolymer science

A polyamide composition, which includes an optical brightener together with either an antimicrobial agent or anti-oxidant stabilizer, or both, is suitable for making yarns, and fabrics, garments, molded articles or other articles such as carpets from these yarns. Processes for incorporating optical brighteners into polyamide compositions, polymers and yarns to make fabrics and molded articles that exhibit superior whiteness after heat-setting are also disclosed.

Owner:INVISTA NORTH AMERICA R L

Polyamide Fine Fibers

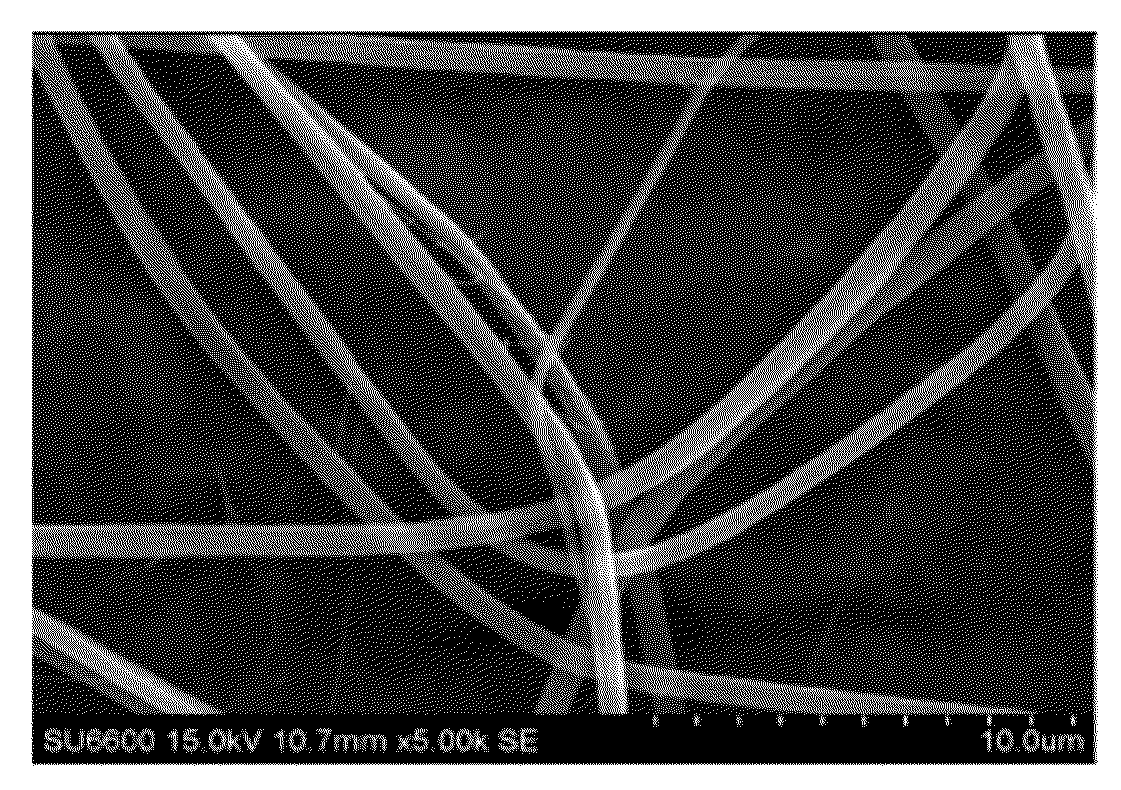

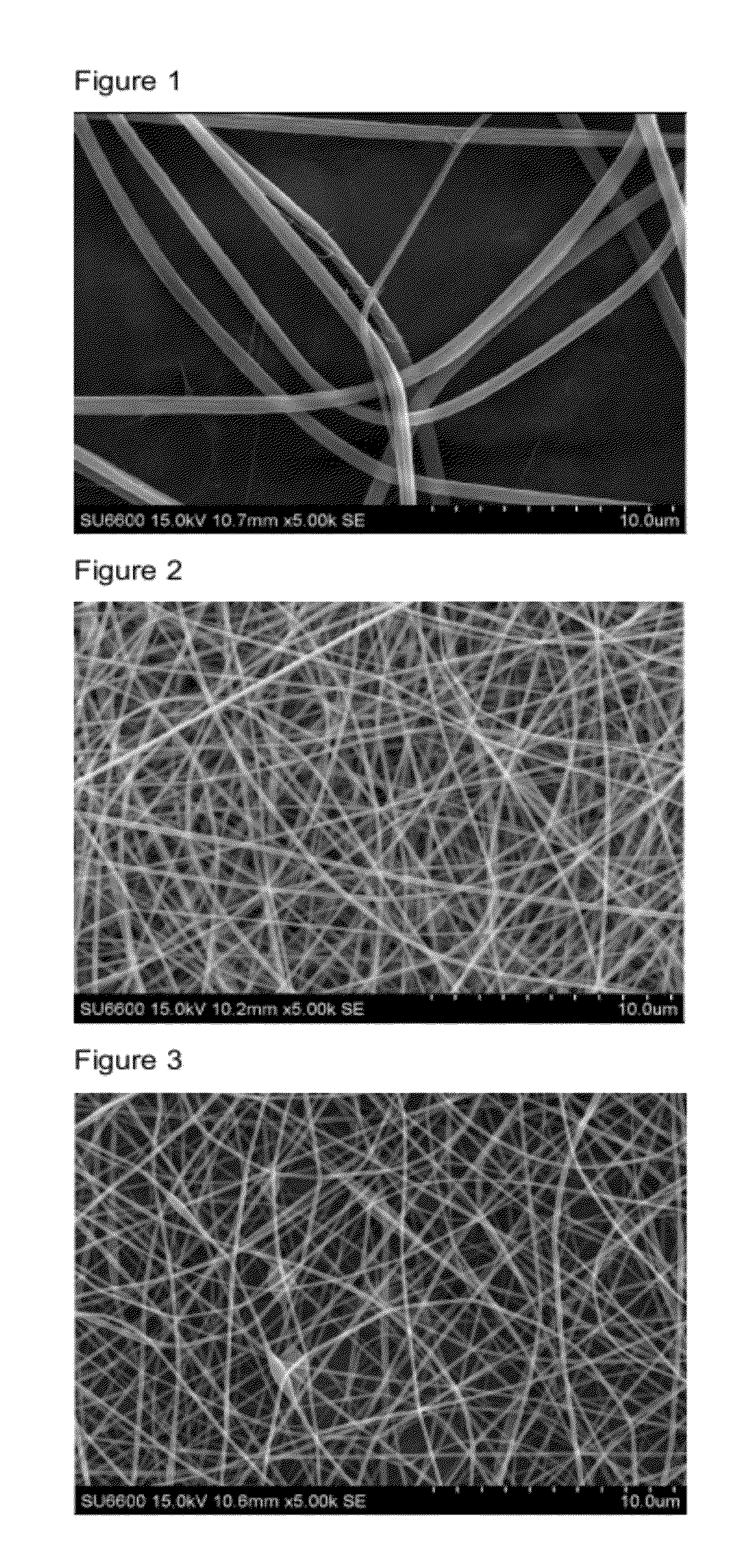

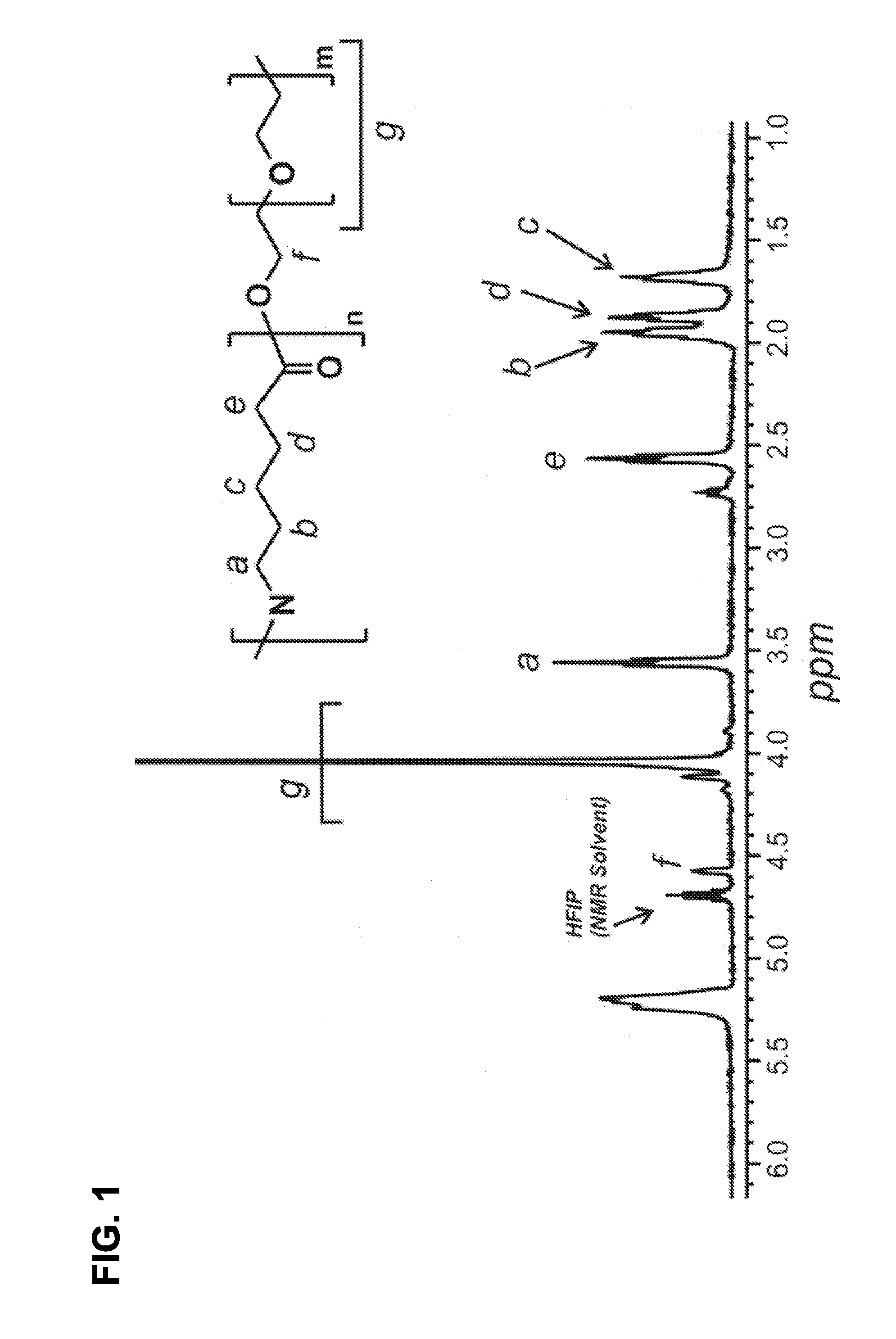

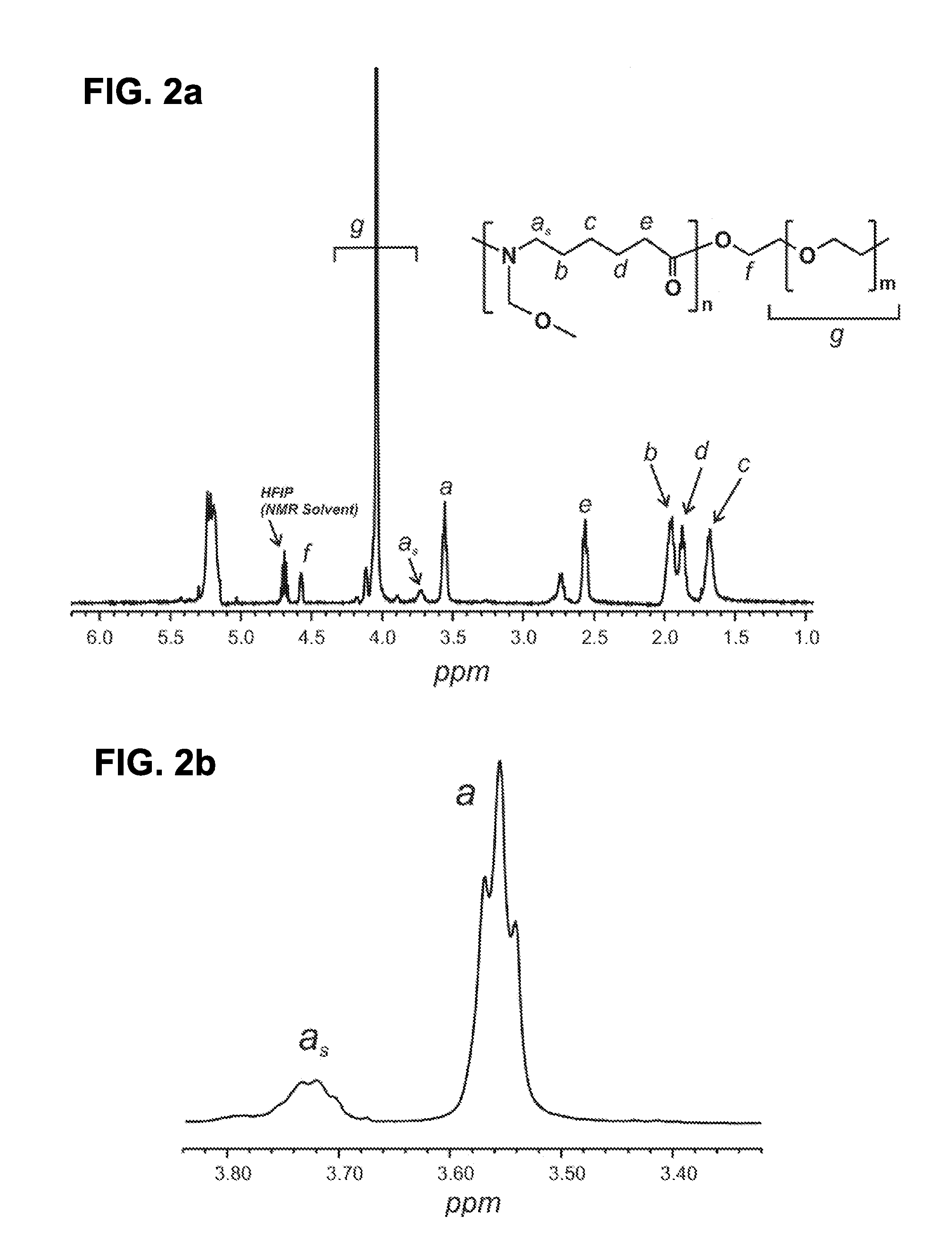

InactiveUS20100175555A1Dispersed particle filtrationSynthetic resin layered productsAlkaneNylon material

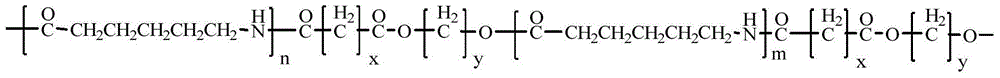

One aspect of an improved microfiber and nanofiber properties can be obtained from a novel nylon material. The nylon can comprise a nylon copolymer comprising (diamino-dicyclohexyl)-alkane, preferably bis-(4 amino-cyclohexyl)methane and at least one other nylon monomer. Another aspect of the novel nylon can comprise a poly alkylene oxide-nylon block copolymer. Such a copolymer can contain block copolymer units wherein the block units comprise segments of ethylene oxide, propylene oxide or mixtures thereof and a nylon block comprising nylon monomers typically comprise a cyclic lactam, an alpha omega diamine and alpha omega diacid or mixtures thereof.

Owner:DONALDSON CO INC

Preparation method for aromatic copolyamide fibers

InactiveCN102926022AMonocomponent copolyamides artificial filamentArtificial filament heat treatmentFiberFiltration

The present invention relates to a preparation method for aromatic copolyamide fibers. According to the preparation method, p-phenylenediamine, one or two diamine monomers and terephthaloyl chloride are adopted to carry out a low temperature solution polymerization reaction in a cosolvent-containing amide solvent system to prepare an aromatic copolyamide solution with a solid content of 2-10%, and the solution is sequentially subjected to deaeration, filtration, spinning, water washing, drying and oiling to prepare the newborn aromatic copolyamide fibers, wherein a breaking strength is 9-16 cN / detx, an elastic modulus is 300-450 cN / detx, and after the newborn aromatic copolyamide fibers are subjected to a heat treatment for 20-60 min at a temperature of 300-500 DEG C under a vacuum condition, the obtained fibers have a breaking strength of 25-35 cN / detx and an elastic modulus of 950-1350 cN / detx.

Owner:曹煜彤 +4

High-temperature resistant cutting preventing composite yarn and application thereof

InactiveCN102560792AImprove cut resistanceMeet the use requirementsMonocomponent copolyamides artificial filamentYarnYarnAramid

The invention relates to a high-temperature resistant cutting preventing composite yarn and the application of the high-temperature resistant cutting preventing composite yarn, belonging to the technical field of special yarn. The high-temperature resistant cutting preventing composite yarn comprises a central fiber and a coated fiber, wherein the central fiber is used as an inner core, and the coated fiber is formed by twisting, winded with the central fiber and coated outside the central fiber. The high-temperature resistant cutting preventing composite yarn is characterized in that the central fiber is the chemical filament and accounts for 30-70% by mass of the composite yarn, the coated fiber is the short aramid fiber 1414 and accounts for 70-30% by mass of the composite yarn. The high-temperature resistant cutting preventing composite yarn integrates the outstanding high-temperature resistance and fire resistance of the short aramid fiber 1414 and the advantage of excellent cutting-preventing performance of the chemical filament, and the fabric made of the high-temperature resistant cutting preventing composite yarn by processing can be used in the high-temperate and sharp work environment. The high-temperature resistant cutting preventing composite yarn is safe and durable.

Owner:苏州兆达特纤科技有限公司

Preparation method of polyphenylene terephthalamide copolymer adopting dimethylacetamide direct spinning

InactiveCN102070781AInhibit aggregationGet rid of the bondageMonocomponent copolyamides artificial filamentPolymer scienceDiaminodiphenyl ether

The invention discloses a preparation method of polyphenylene terephthalamide (PPTA) copolymer adopting dimethylacetamide (DMAC) direct spinning. The method comprises the following steps: 4,4'-diaminodiphenylsulfide or 4,4'-diaminodiphenyl ether is used as third monomer, m-phthaloyl chloride is introduced as fourth monomer to perform copolymerization with p-phthaloyl chloride and p-phenylenediamine in a solvent system and prepare uniform, transparent and thick PPTA copolymer size, and the concentration of the polymer is adjusted to perform dope spinning. The method of the invention effectively avoids of adopting the complicated production equipment to perform the polymerization of PPTA; cheap 4,4'-diaminodiphenylsulfide or 4,4'-diaminodiphenyl ether is used as the third monomer and the fourth monomer with a meta-structure is introduced to prepare the PPTA copolymer which can be directly dissolved in DMAC, thus avoiding of using concentrated sulfuric acid as spinning solvent; and the spinning solvent is consistent to the polymerization solvent, the concentration of the polymer is adjusted to perform dope spinning with DMAC and the production process can be greatly simplified.

Owner:CHANGCHUN UNIV OF TECH

Polyamide Resin and Hinged Molded Product

InactiveUS20070249783A1Excellent vibration welding strengthHigh hinge propertyNon-fibrous pulp additionMonocomponent copolyamides artificial filamentHexamethyldiamineHexamethylenediamine

A polyamide resin comprising a dicarboxylic acid constitutional unit comprising an adipic acid unit and a diamine constitutional unit comprising a pentamethylenediamine unit and a hexamethylenediamine unit wherein a weight ratio of the pentamethylenediamine unit to the hexamethylenediamine unit being in the range of 95:5 to 60:40; a vibration-welded molded product having an excellent vibration welding strength, a hinged molded product and a binding band having an excellent low-temperature toughness, and a filament having an excellent transparency which are obtained from the polyamide resin; and a hinged molded product comprising a polyamide resin constituted of an adipic acid unit and a pentamethylenediamine unit.

Owner:MITSUBISHI CHEM CORP

Caprolactam hydrolyzed polymer fibres and spinning method thereof

ActiveCN104480561AIncrease profitThe polymerization process is simpleNew-spun product collectionMonocomponent copolyamides artificial filamentPolymer scienceEngineering plastic

The invention relates to caprolactam hydrolyzed polymer fibres and a spinning method thereof. The spinning method comprises the following steps: preparing a polyamide 6 prepolymer at low temperature, pre-controlling the content of oligomers in a melt, carrying out auxiliary end-blocking by binary acid to reduce the content of end amino groups in a system, then carrying out end-blocking by ethylene glycol, after that, carrying out chain growth by means of gylcol ester removal exchange, wherein in the obtained product, the content of extractable matters is not greater than 2wt%, and the content of cyclic dimers is not greater than 0.3wt%; then, carrying out direct melt-spinning formation after the condensation polymerization reaction is concluded. The spinning method disclosed by the invention is simple in process, and capable of reducing energy consumption while increasing the utilization rate of caprolactam; the obtained melt is capable of being used for direct melt-spinning, easy in realizing high-capacity large-scale production, and capable of being applied to the fields of garment fibres, industrial silk, engineering plastics and the like.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

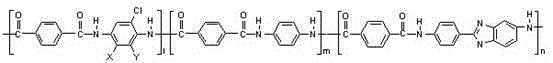

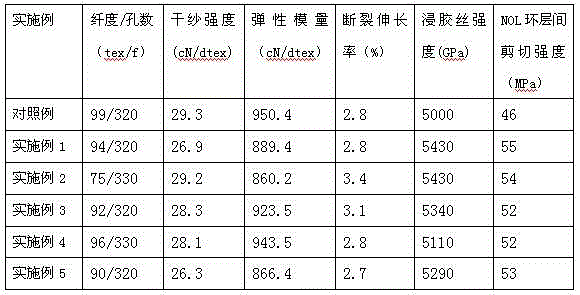

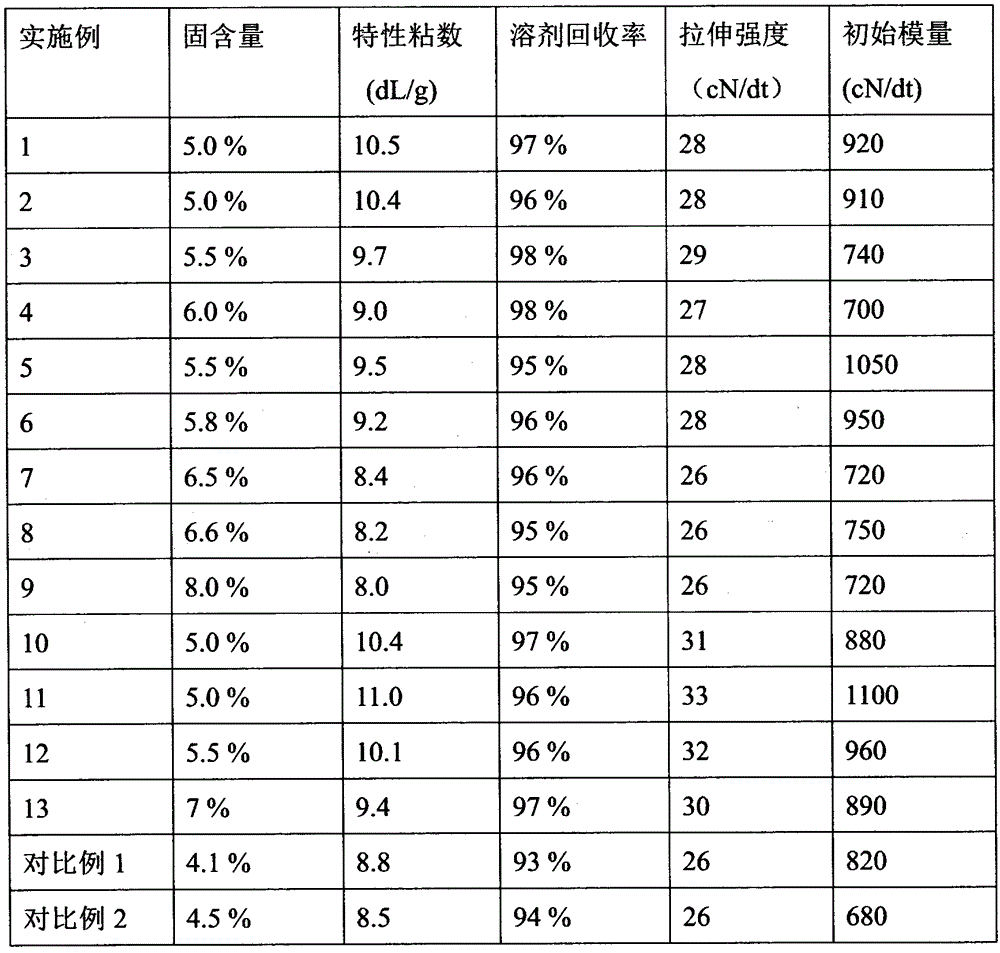

High-performance chloric heterocyclic aramid fiber as well as preparation method and application

ActiveCN104357939AImprove wettabilityImprove bindingArtificial filament washing/dryingMonocomponent copolyamides artificial filamentPolymer sciencePolyamide

The invention relates to a high-performance chloric heterocyclic aramid fiber as well as a preparation method and application. A chloric group and a heterocyclic ring unit are introduced on an aramid fiber macromolecular chain in a copolymerization manner, the binding force of the fiber and resin is improved while the high performance of the fiber is met, and the fiber has good performance conversion rate when being applied to the field of reinforced composite materials. The preparation method comprises the processing steps of preparing chloric heterocyclic polyamide solution, and carrying out defoaming, spinning, solidifying, stretching in a plastifying manner, washing, oiling, drying and heat treatment on the polyamide solution to obtain the high-performance chloric heterocyclic aramid fiber. The high-performance chloric heterocyclic aramid fiber is 24-32cN / dtex in elongation at break, 700-1100cN / dtex in elasticity modulus, is 2.3-4.0% in elongation at break, has excellent performances such as high strength, high modulus and the like, and has good binding property with the resin, and the reinforced resin composite material product has potential application prospect in the fields such as aviation, space flight, ships and warships, weapons, electronic and the like.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

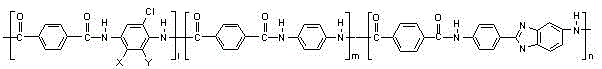

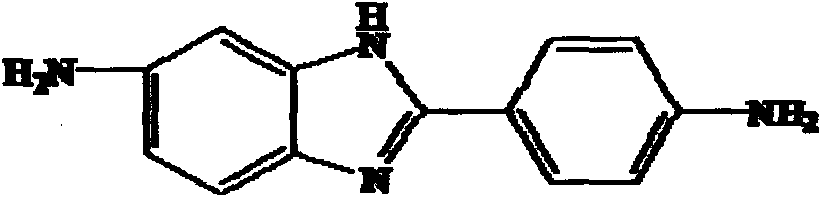

Method for preparing heterocyclic aramid solution

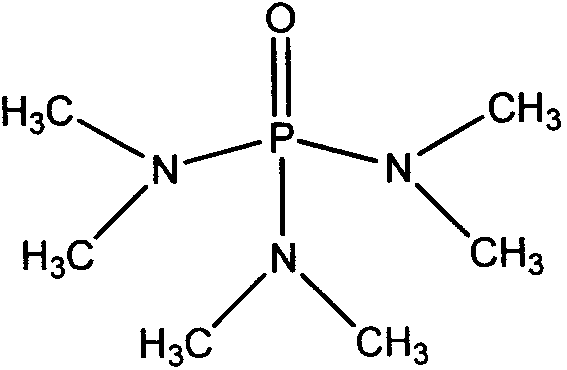

InactiveCN106700065AStrong ability to dissolve heterocyclic aramid fibersHigh solid contentArtificial filament recoveryMonocomponent copolyamides artificial filamentHexamethylphosphoric TriamideChloride

The invention belongs to the technical fields of heterocyclic aramid solution and preparation thereof, and specifically, relates to a method for preparing a heterocyclic aramid solution, wherein the method comprises the steps: a diamine substance and an aromatic dicarbonyl chloride are subjected to a polymerization reaction in an inert gas atmosphere and in a hexamethylphosphoric triamide solution containing no cosolvent, wherein the diamine substance comprises 2-(4-aminophenyl)-5-aminobenzimidazole.

Owner:SICHUAN UNIV

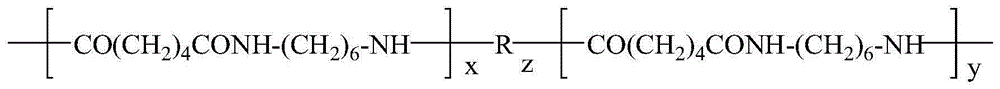

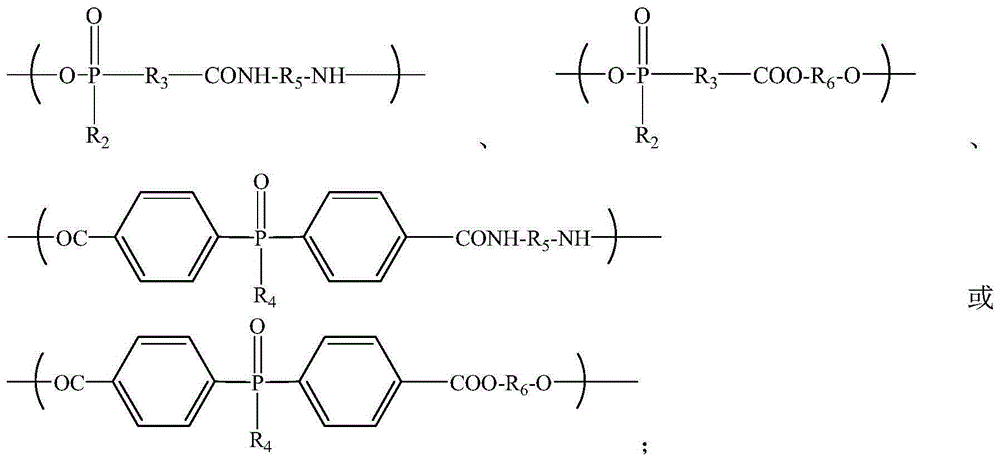

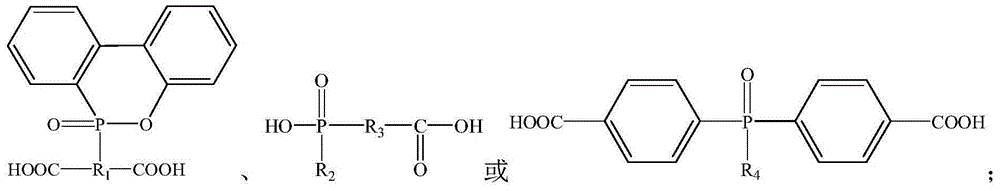

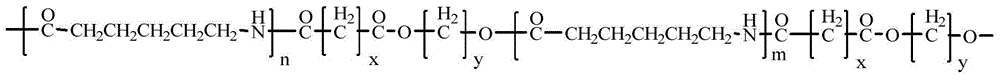

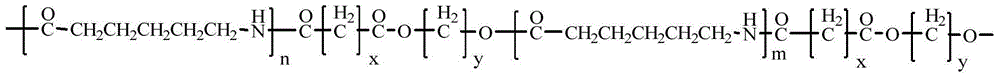

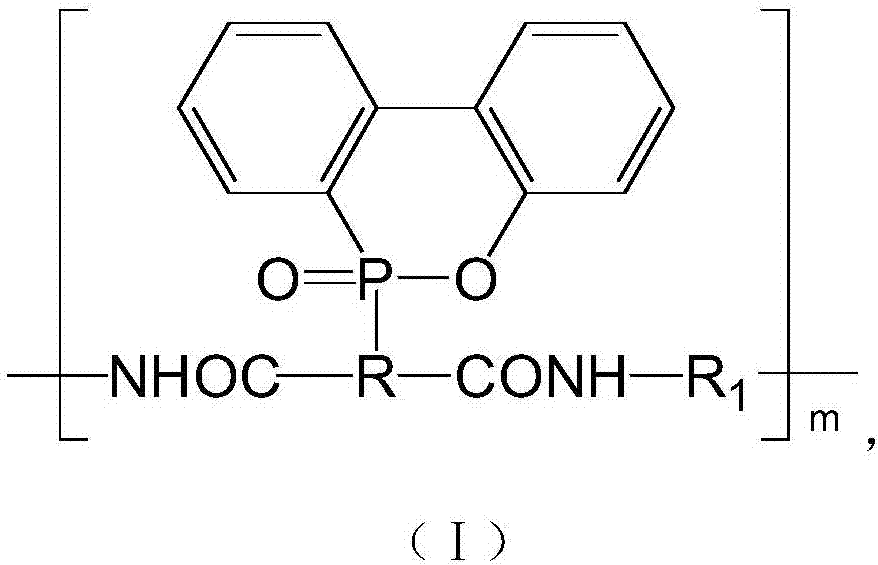

Low-melting-point and flame-retarding copolymerized nylon and preparation method thereof

InactiveCN107189062ALow Melting Point PropertiesExcellent low melting point propertiesMonocomponent copolyamides artificial filamentAdhesivesFatty amineNitrogen gas

The invention discloses low-melting-point and flame-retarding copolymerized nylon shown as a formula (I) and a preparation method thereof. The preparation method of the low-melting-point and flame-retarding copolymerized nylon comprises the following steps: enabling a DOPO (9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide) derivative and diamine to react to synthesize a P-containing flame retardant; then copolymerizing the P-containing flame retardant, fatty acid and fatty amine together, and carrying out pre-condensation reaction for 2h to 3h under conditions that the temperature is 200 DEG C to 230 DEG C and the vacuum degree is 1.7MPa to 2.0MPa; carrying out vacuum polymerization reaction for 1h to 2h under conditions that the temperature is 230 DEG C to 250 DEG C and the vacuum degree is -0.095MPa; cooling to 220 DEG C to 240 DEG C, and introducing nitrogen gas to carry out balance reaction for 0.5h, so as to prepare the low-melting-point and flame-retarding copolymerized nylon with a melting point range of 100 DEG C to 130 DEG C, the relative viscosity of 2.0 to 2.8, a flame-retarding limited oxygen index of 28 percent to 32 percent and a flame-retarding grade of UL-94V0. The product disclosed by the invention is a transparent and non-crystalline glassy mass polymer, and can be used for the fields of hot-melt adhesives and fiber spinning. (The formula (I) is shown in the description) .

Owner:四川东方绝缘材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com