Method for preparing aramid IIII fiber

A fiber and aramid fiber technology, applied in the field of preparation of aramid fiber III, can solve the problems of low spinning efficiency, investment cost and high spinning cost, and achieve lower spinning cost, investment cost and spinning cost, investment cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

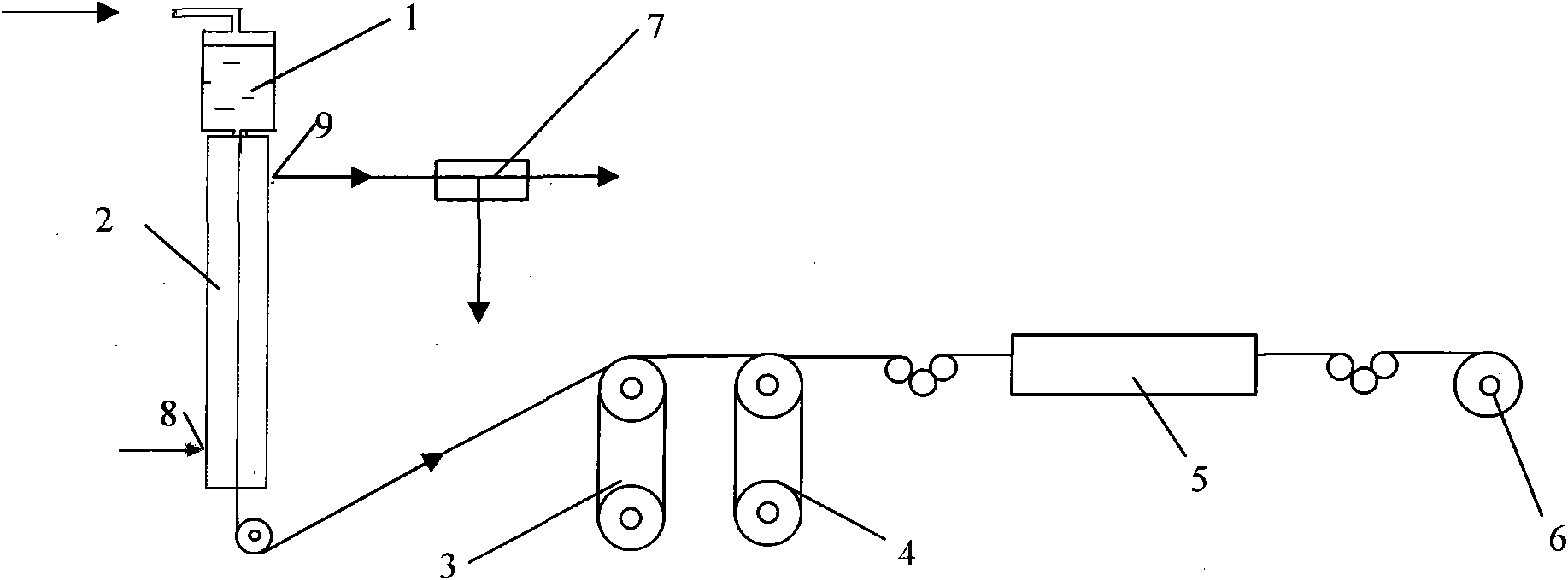

[0023] Referring to Figure 1, the preparation method of aramid III fiber is as follows:

[0024] 1. Synthetic spinning dope.

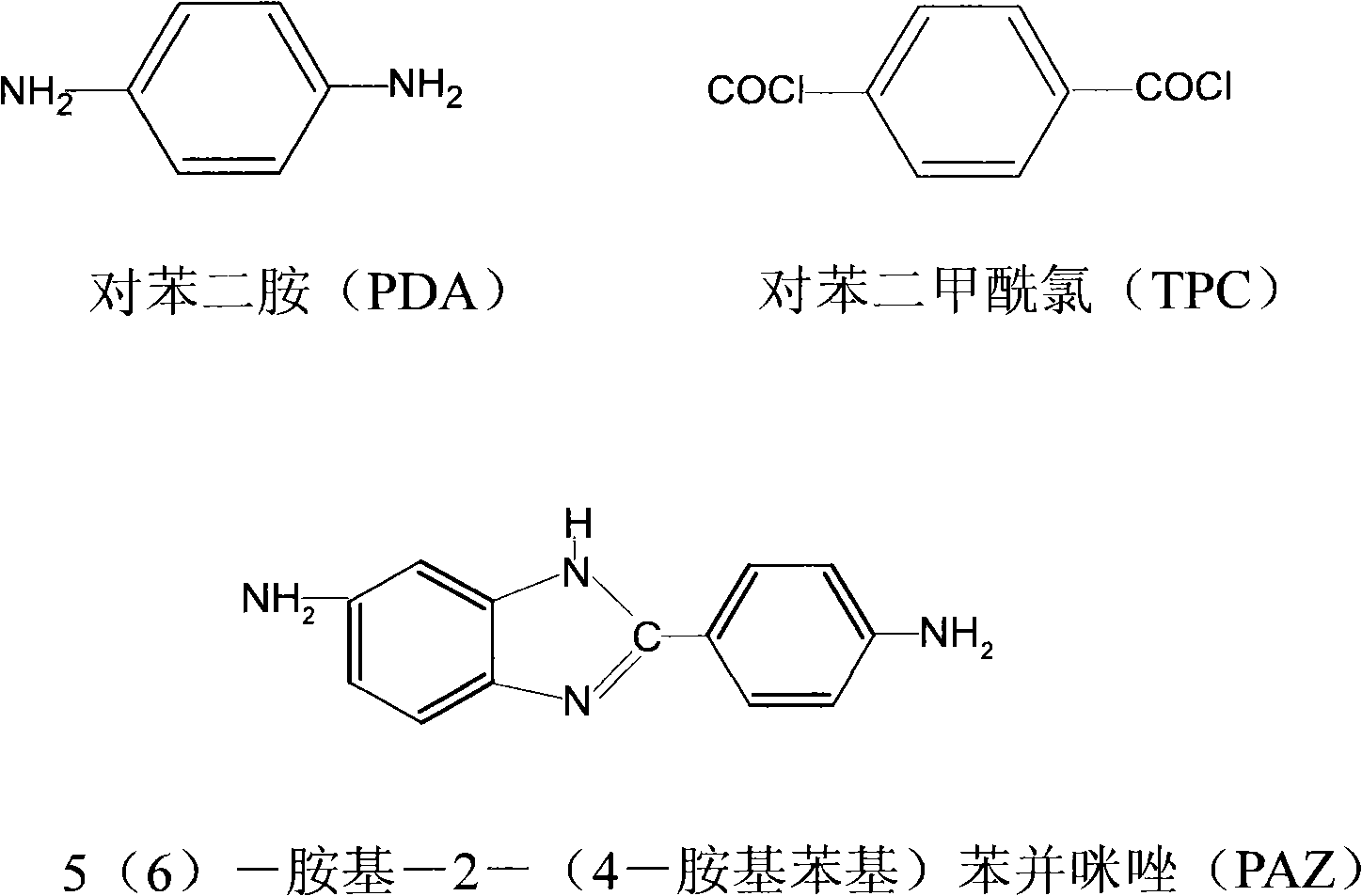

[0025] Using p-phenylenediamine (abbreviated as PDA), terephthaloyl chloride (abbreviated as TPC), 5(6)-amino-2-(4-aminophenyl) benzimidazole (abbreviated as PAZ) three monomers are The raw material is low-temperature copolymerization with dimethylacetamide / lithium chloride as the solvent system, the temperature is 0-20°C, and the time is 3-5 hours, and the spinning stock solution of aramid fiber III or aramid fiber III polymer is obtained stock solution.

[0026] The dosage of TPC, PAZ, PDA and solvent dimethylacetamide, lithium chloride is: TPC: 203.0 grams, PAZ: 67.2 grams, PDA: 75.6 grams, dimethylacetamide: 1960.0 grams, lithium chloride: 68.6 grams , the molar ratio of the three monomer raw materials is: TPC:PAZ:PDA=100:30:70, liquid crystal phenomenon does not appear in the stock solution, and the concentration of the polymer formed by the pol...

Embodiment 2

[0034] The dosage of TPC, PAZ, PDA and solvent system dimethylacetamide and lithium chloride is: TPC: 203.0 grams, PAZ: 67.2 grams, PDA: 75.6 grams, dimethylacetamide: 1960.0 grams, lithium chloride: 68.6 gram, the molar ratio of three kinds of monomer raw materials is: TPC: PAZ: PDA=100: 30: 70, liquid crystal phenomenon does not appear in stock solution. The polymer concentration in the spinning stock solution was 15 wt%, the spinning speed was 300 m / min, and the temperature of the hot nitrogen gas was 230°C. The prepared aramid III raw silk is washed and dried, and then processed by continuous heat treatment process. The heat treatment temperature is 450°C, the tension of the tow is controlled at 0.5CN / tex, and the heat treatment time is 20 seconds. Ten samples of the obtained aramid fiber III were tested, and the average value was taken. The tensile strength was 5.32GPa, and the modulus was 182GPa.

Embodiment 3

[0036] The dosage of TPC, PAZ, PDA and solvent system dimethylacetamide and lithium chloride is: TPC: 203.0 grams, PAZ: 67.2 grams, PDA: 75.6 grams, dimethylacetamide: 1383.2 grams, lithium chloride: 48.4 gram, the molar ratio of three kinds of monomer raw materials is: TPC: PAZ: PDA=100: 30: 70, liquid crystal phenomenon does not appear in stock solution. The polymer concentration in the spinning stock solution was 20 wt%, the spinning speed was 250 m / min, and the temperature of the hot nitrogen gas was 210°C. The prepared aramid III raw silk is washed and dried, and then processed by continuous heat treatment process. The heat treatment temperature is 450°C, the tension of the tow is controlled at 0.5CN / tex, and the heat treatment time is 15 seconds. Ten samples of the obtained aramid fiber III were tested, and the average value was taken. The tensile strength was 5.16GPa, and the modulus was 176GPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com