Detachable adjustable long shuttle type nozzle for solution jet spinning and application method thereof

A long-shuttle, liquid-jet technology, which is applied in dry spinning, spinneret assemblies, textiles and papermaking, etc., can solve the problem of weakening fiber stretching and refining drafting force, affecting fiber preparation, and is not conducive to improving fiber draft. Problems such as stretching and spinning process parameters, to achieve the effect of improving efficiency, convenient installation and debugging, and convenient loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

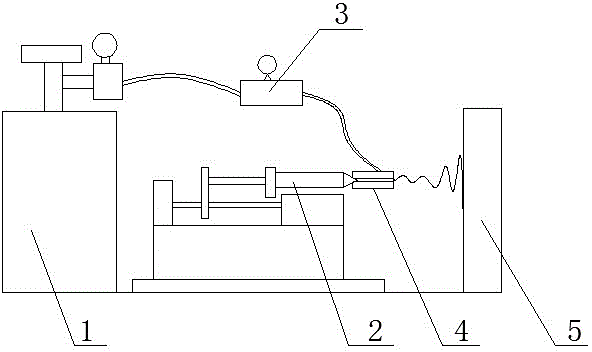

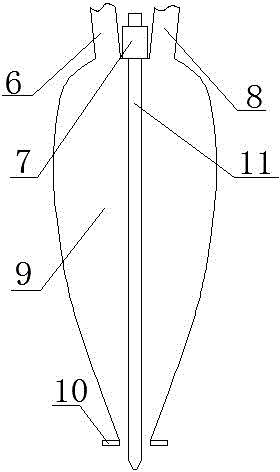

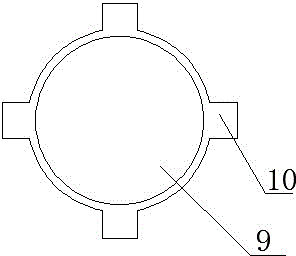

[0032] Dissolve 8 g of polyethylene oxide (PEO, molecular weight 500,000) in 92 mL of deionized water, stir in a water bath at room temperature to prepare a transparent polymer spinning solution with a mass concentration of 8% without precipitation, and put it into a micro-syringe 2, insert the needle 11 into the rubber plug 7, squeeze the polymer spinning liquid into the needle 11 through the micro-injector 2, turn on the air compressor 1, set the angle between the air inlet branch pipe A6 and the air inlet branch pipe B8 to be 45°, and the needle head 11 The radius is 0.8cm, and the outlet area of the detachable nozzle is 3.14cm 2 , adjust the airflow valve from 3 to 1.3 Mpa, and the distance from the needle 11 to the outlet is 0.4 cm, and the micro-nano fibers are obtained, and the fiber diameters are distributed between 800 nm and 3000 nm, see Figure 4 .

Embodiment 2

[0034] Dissolve 15g of polyacrylonitrile (PAN, molecular weight 70,000) in 85g of dimethylacetamide, stir in a 60-degree water bath to prepare a transparent polymer spinning solution with a mass concentration of 15% without precipitation, and put it into In the micro-syringe 2, insert the needle 11 into the rubber stopper 7, squeeze the polymer spinning liquid into the needle 11 through the micro-syringe 2, turn on the air compressor 1, and set the angle between the air inlet branch pipe A6 and the air inlet branch pipe B8 to be 15° , the radius of the needle 11 is 0.6 cm, and the outlet area of the adjustable detachable nozzle is 3.0 cm 2 , adjust the airflow valve 3 to 1.2-1.4 Mpa, and the distance from the needle protruding outlet is 0.5cm, and PAN micro-nano fibers are prepared, and the fiber diameter is distributed between 400nm and 1200nm, see Figure 5 .

Embodiment 3

[0036] Polylactic acid (PLLA, with a relative molecular mass of 1.0×10 5 ) 19.7g was dissolved in 200mL deionized water, stirred in normal temperature water to prepare a polymer spinning solution with a mass concentration of 9% transparent and no precipitation, and put it into the micro-syringe 2, insert the needle 11 into the rubber plug 7 , squeeze the polymer spinning solution into the needle 11 through the micro-syringe 2, turn on the air compressor 1, set the angle between the air inlet branch pipe A6 and the air inlet branch pipe B8 to be 30°, and the radius of the needle head to be 0.6cm, and adjust the outlet area of the detachable nozzle 3.14 cm 2 , adjust the airflow valve from 3 to 1.5 Mpa, and the distance from the outlet where the needle 11 protrudes is 0.6 cm, and the PLLA micro-nano fibers are prepared, and the fiber diameters are distributed between 300 nm and 1500 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com