Synchronous and anti-clockwise twist spinning device and synchronous and anti-clockwise twist spinning method

A technology of synchronous and anisotropic, yarn guide device, applied in spinning machine, textile and paper making, continuous winding spinning machine, etc., can solve the problem of reducing the strength of single yarn, increasing maintenance and maintenance, and unable to fully utilize the strength of single fiber and other problems to achieve the effect of improving yarn quality and spinning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

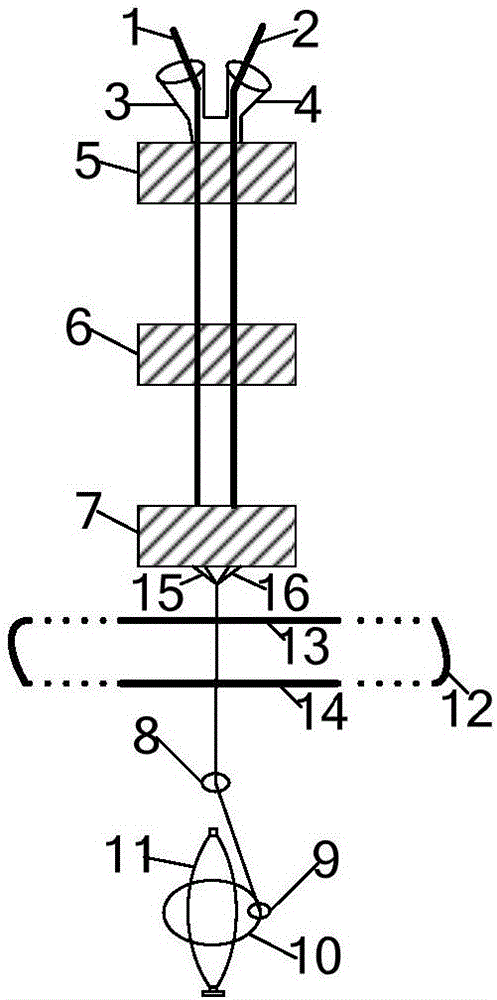

[0011] Depend on figure 1 As shown, a synchronous counter-twisting spinning device includes a drafting mechanism and a winding mechanism. The drafting mechanism includes rear roller drafting pairs 5, middle roller drafting pairs 6, front roller drafting pairs 7, and rear roller drafting pairs. The drafting pair includes the rear bottom roller and the rear top rubber roller, the middle roller drafting pair includes the middle bottom roller and the middle upper rubber roller, and the front roller drafting pair includes the front bottom roller and the front upper rubber roller. There are double roving feeding bell mouths on the top, the double roving feeding bell mouths include left bell mouth 3 and right bell mouth 4, and the winding mechanism includes bobbin 11, which is embedded and installed on the spindle, and the spindle is driven by the motor through the spindle belt Rotate, there is a fixed steel ring 10 around the outside of the bobbin, the steel ring surrounds the middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com