Single-spindle drive wheel disc false-twist spinning device

A roulette and false twisting technology, applied in the direction of textiles and papermaking, can solve problems such as difficult additional installation and use of spinning frames, affect production management and overall benefits, reduce package capacity and production efficiency, and achieve improved false twist quality, The effect of shortening the length of the triangular area and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

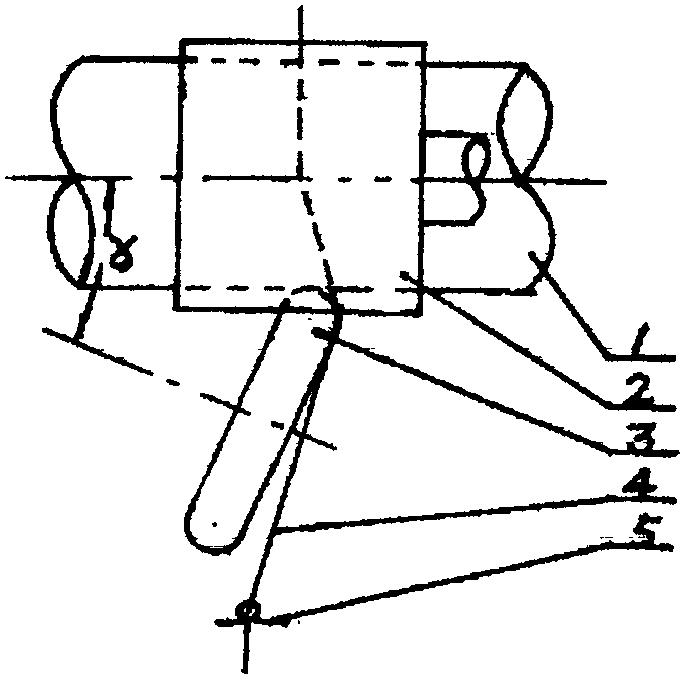

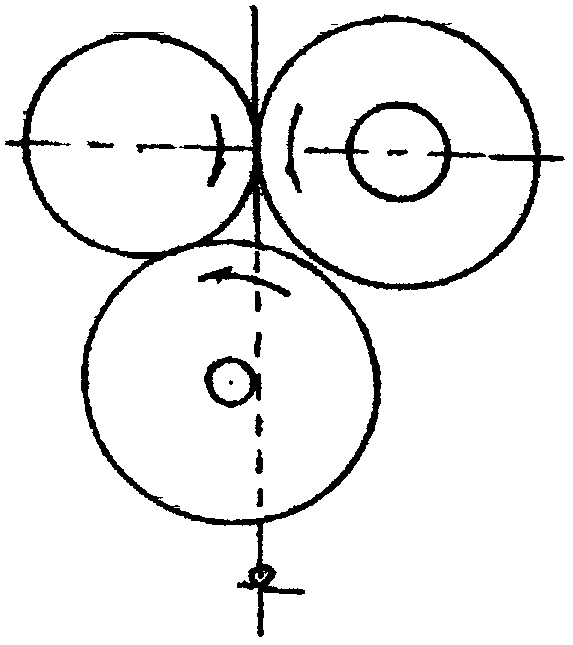

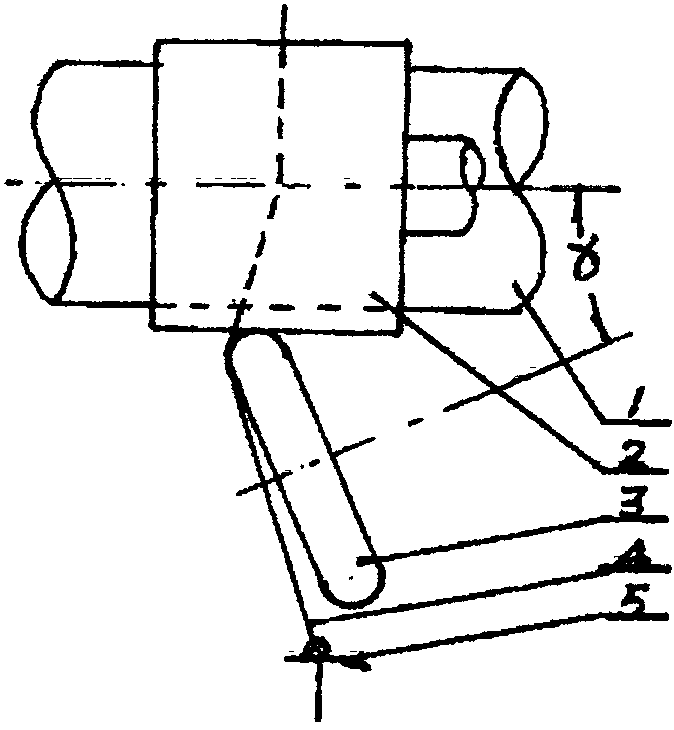

[0040] Single-spindle-driven disc false-twist spinning device uses a rotating disc as a false-twisting element, and the outer periphery of the rotating disc drives the yarn to rotate to generate false twisting. At least one false-twisting disc is installed downstream of the nip of the front roller. The outer circumference of the disc is in pressure contact with the front top roller or the front bottom roller, and the surface friction of the front top roller or bottom roller drives the wheel disc to rotate. There is an angle α between the axis of the wheel disc and the axis of the roller. The yarn output from the nip of the front roller is at least It has a false twist contact section with the outer periphery of a wheel.

[0041] The sliver drives the sliver to make the sliver roll around its own axis, so that the sliver obtains false twist.

[0042] The following examples all take the spinning of Z-twisted yarn as an example, and when spinning S-twisted yarn, the false twist e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com