Patents

Literature

1076 results about "Friction drive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A friction drive or friction engine is a type of transmission that utilises 2 wheels in the transmission to transfer power to the driving wheels rather than a chain and sprockets system. This kind of transmission is often used on scooters, mainly go-peds, in place of a chain. The problem with this type of drive system is they are not very efficient, since the output wheel (leather covered wheel) has width, the area of contact is spread across various radii on the primary disc. Because the tangential velocity varies as radius varies, the system must overcome velocity differentials across the surface. The compromise is slippage of the leather to metal contact area which creates friction, which in turn converts much of the energy transfer of this system into heat. Heat generation also requires a cooling system to keep the transmission working effectively.

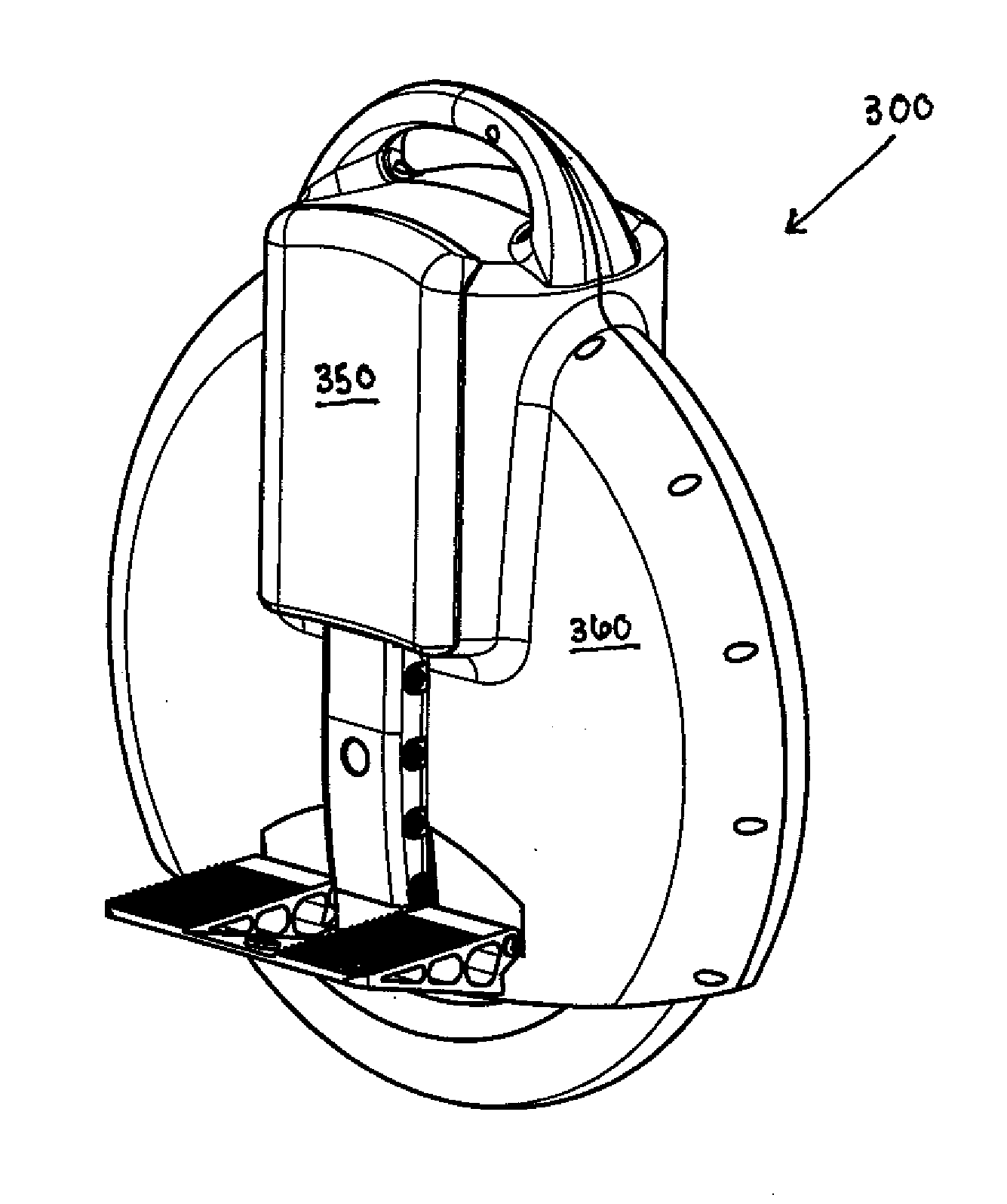

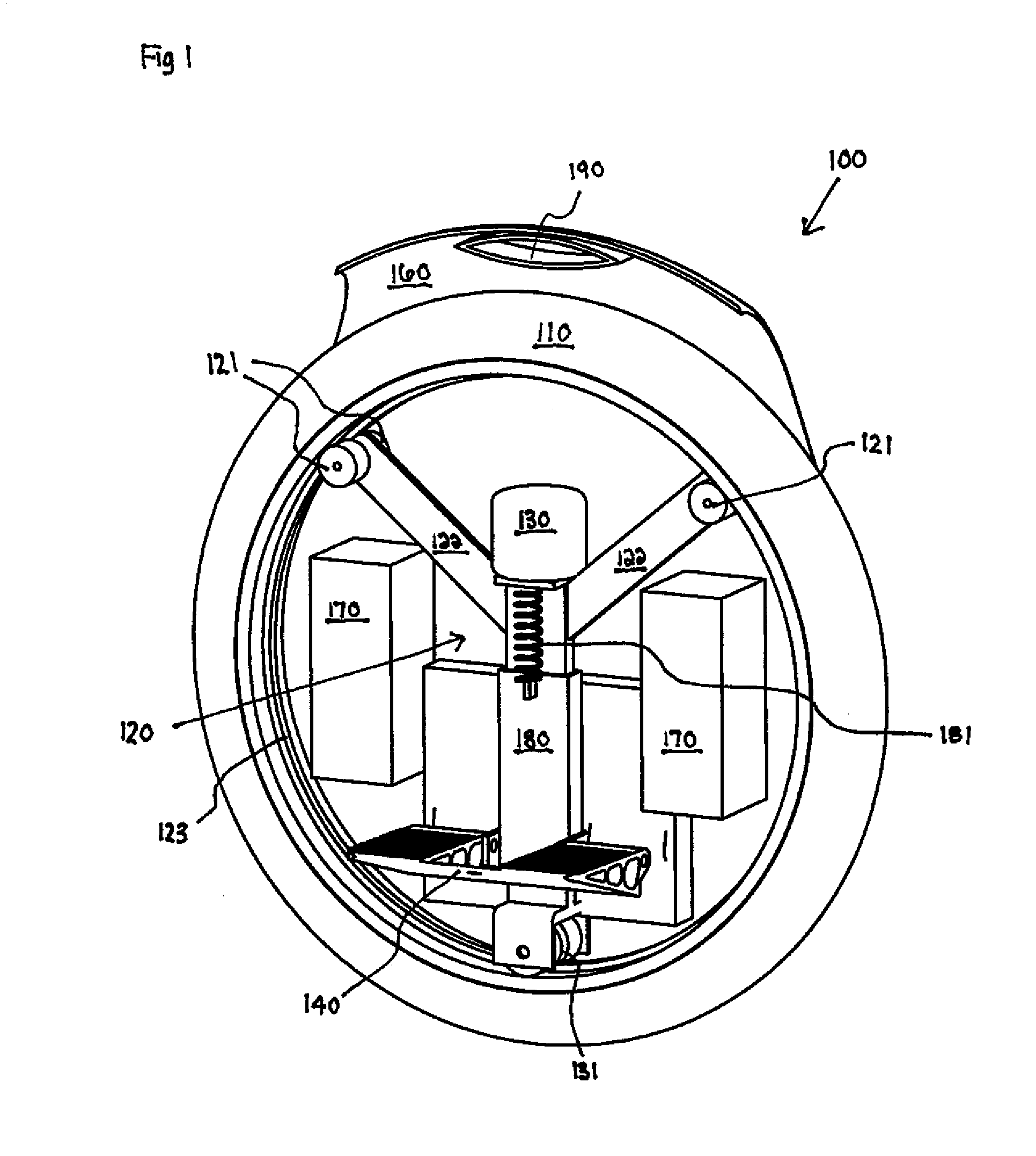

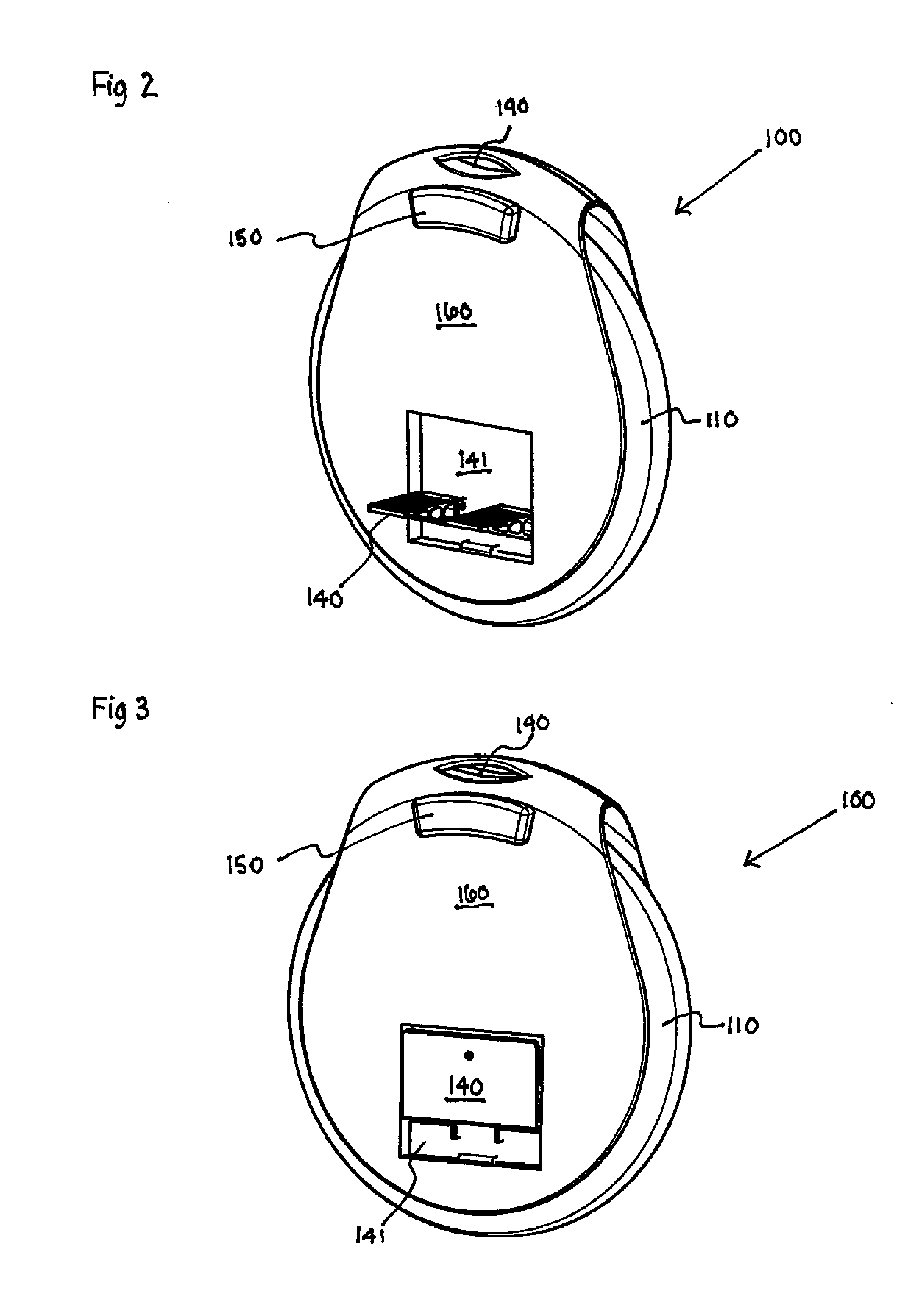

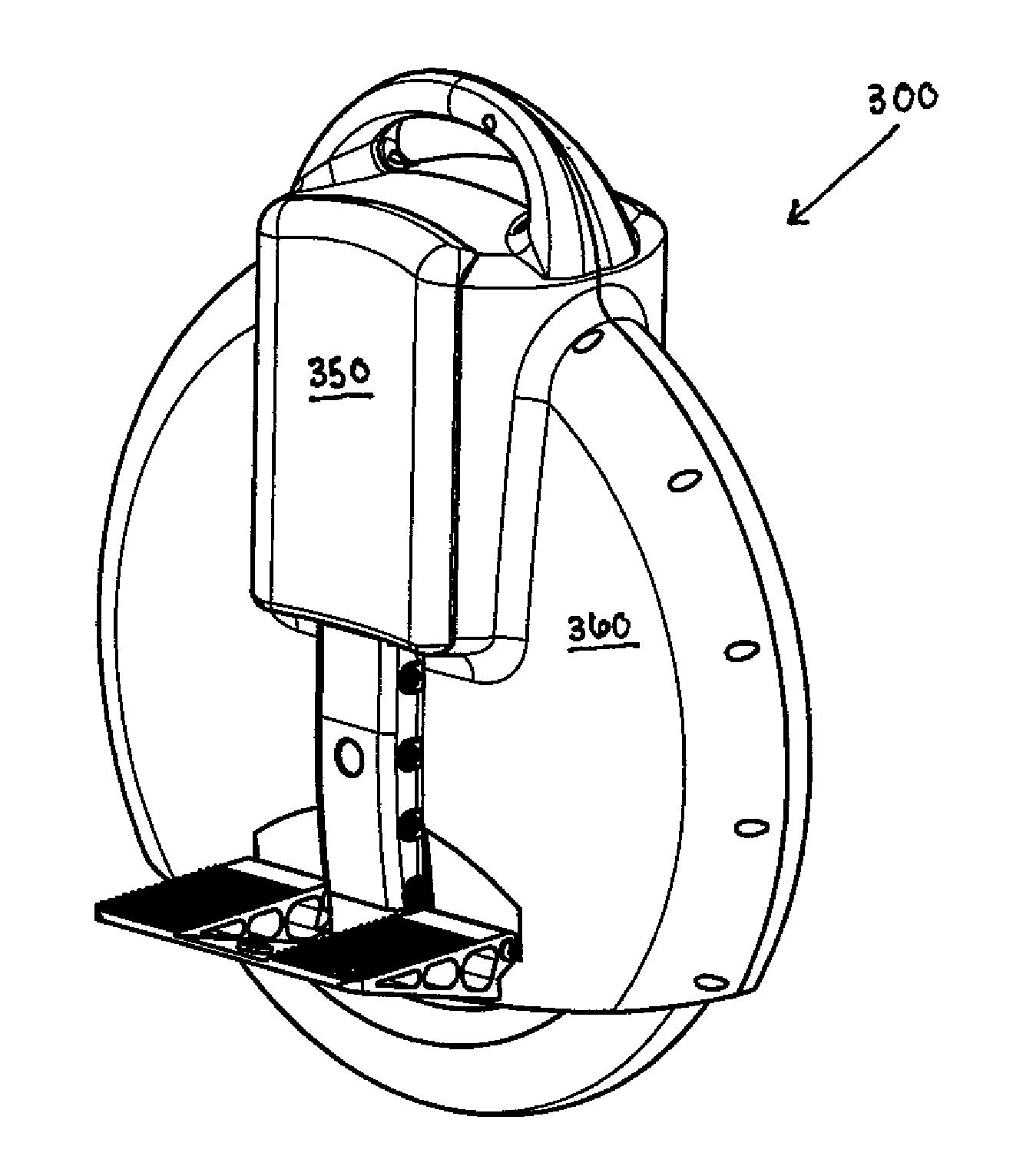

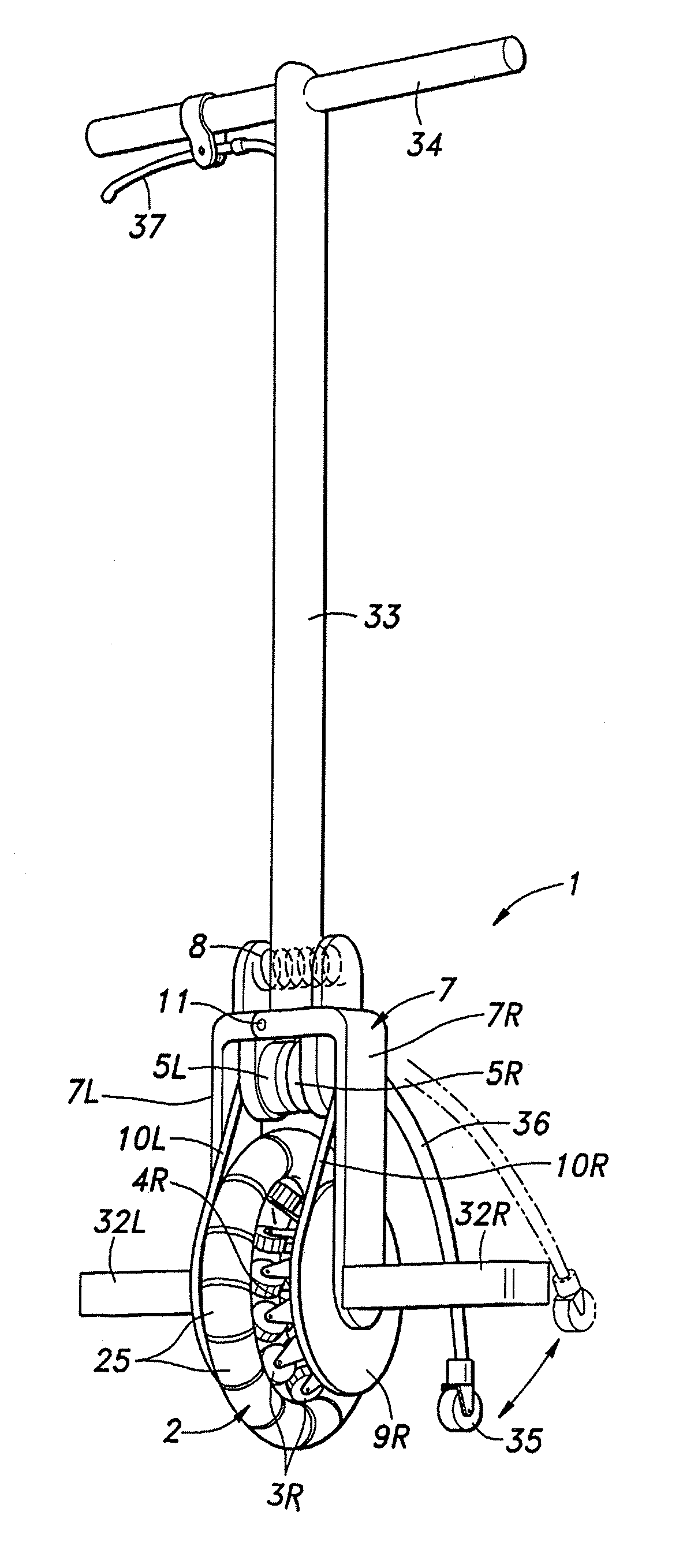

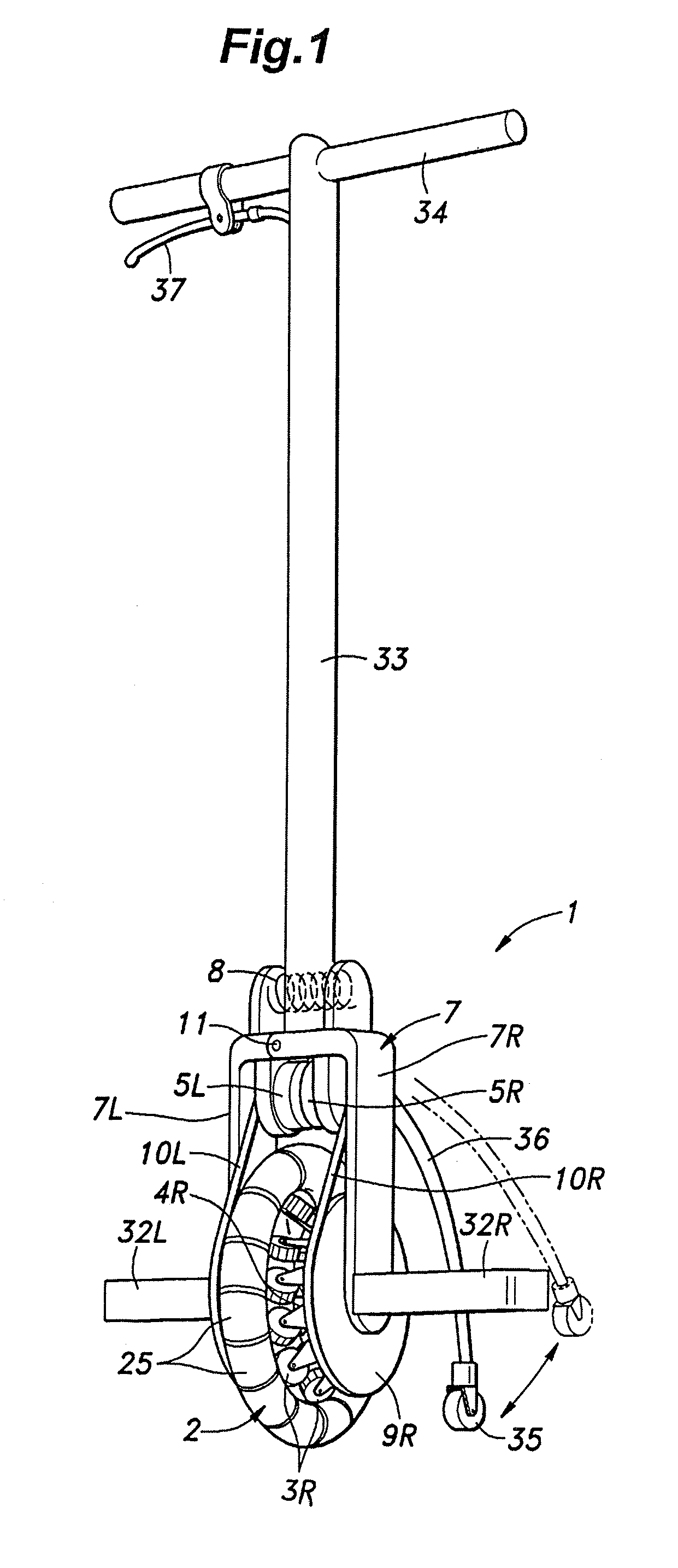

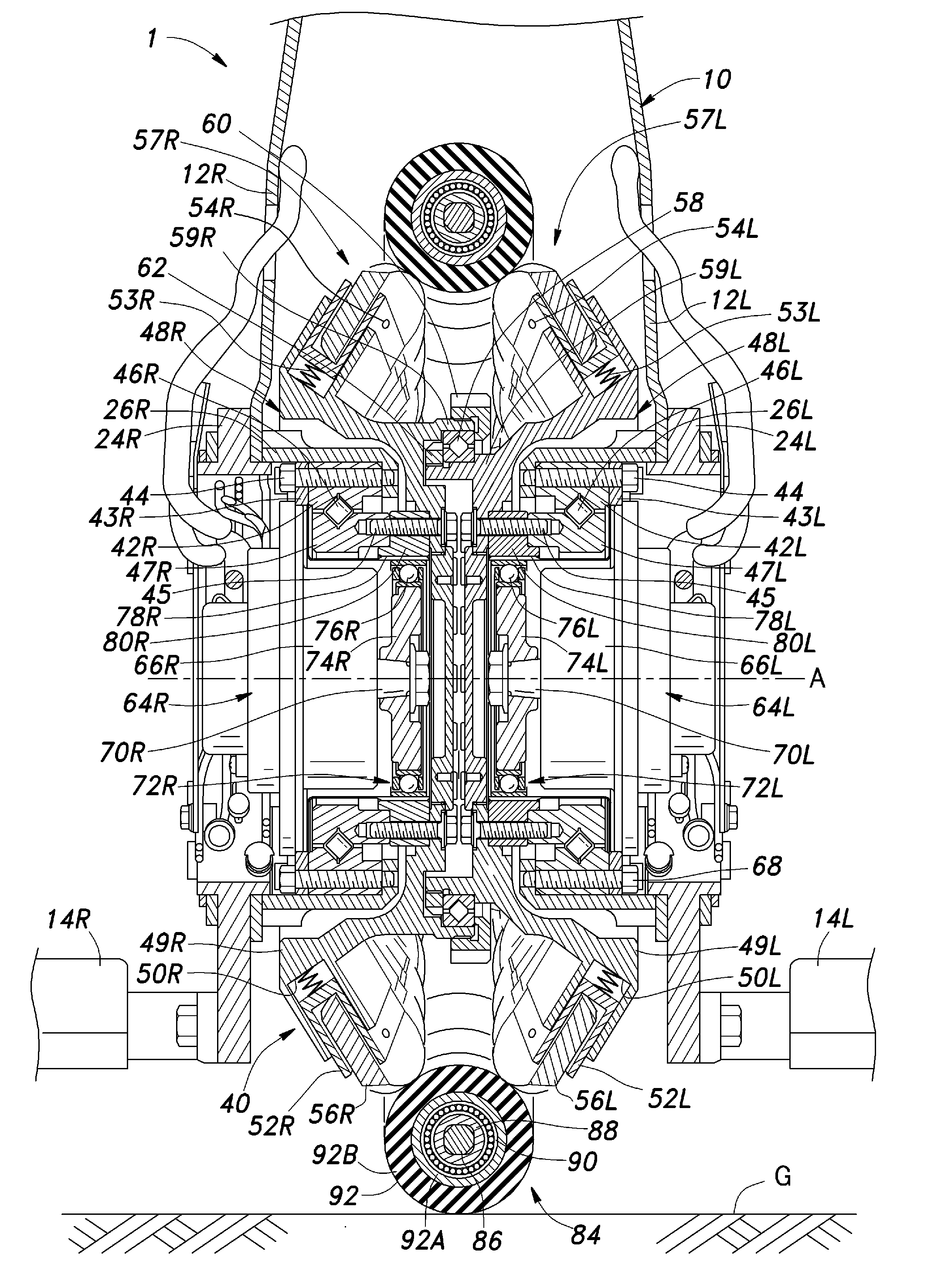

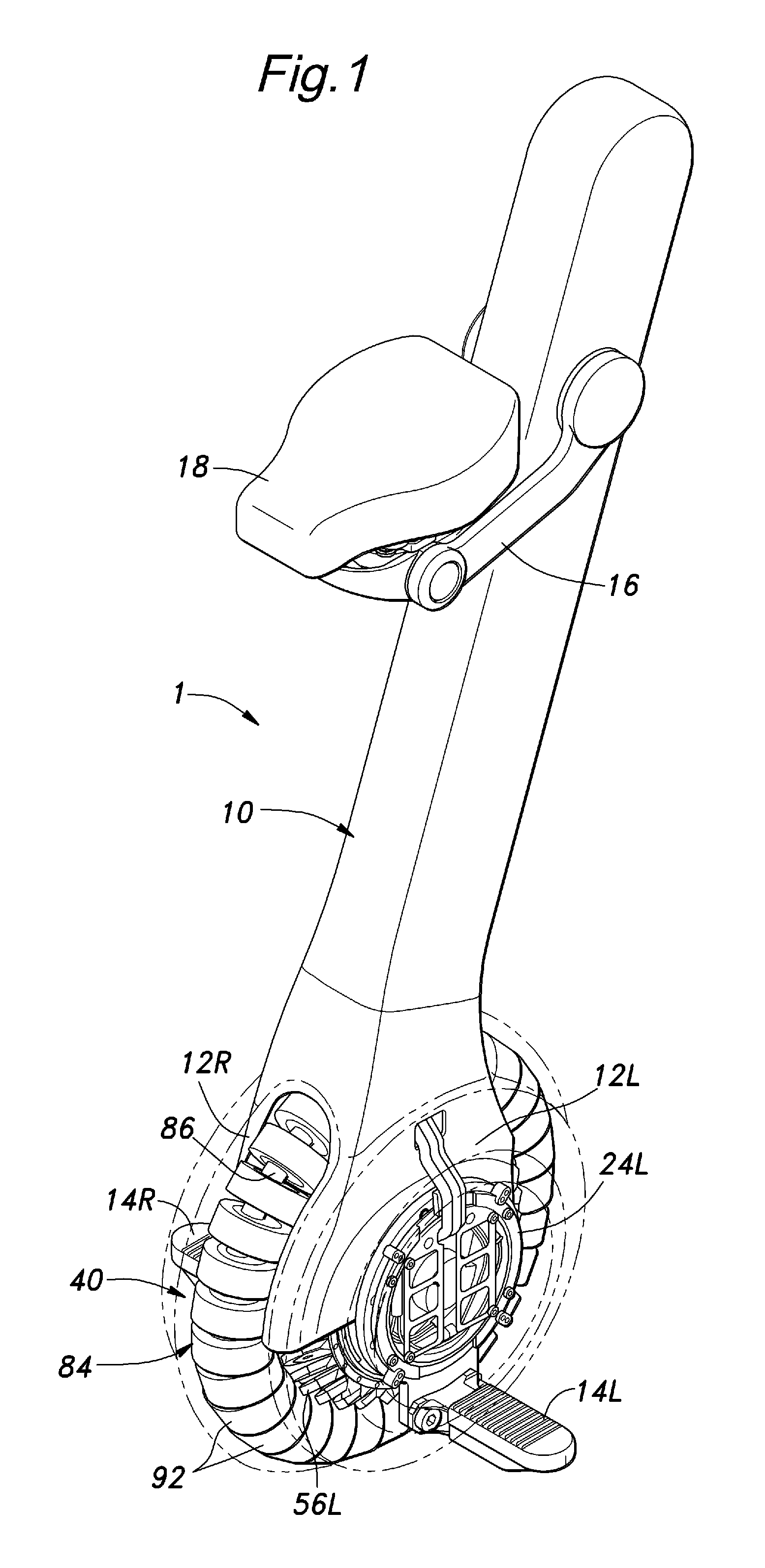

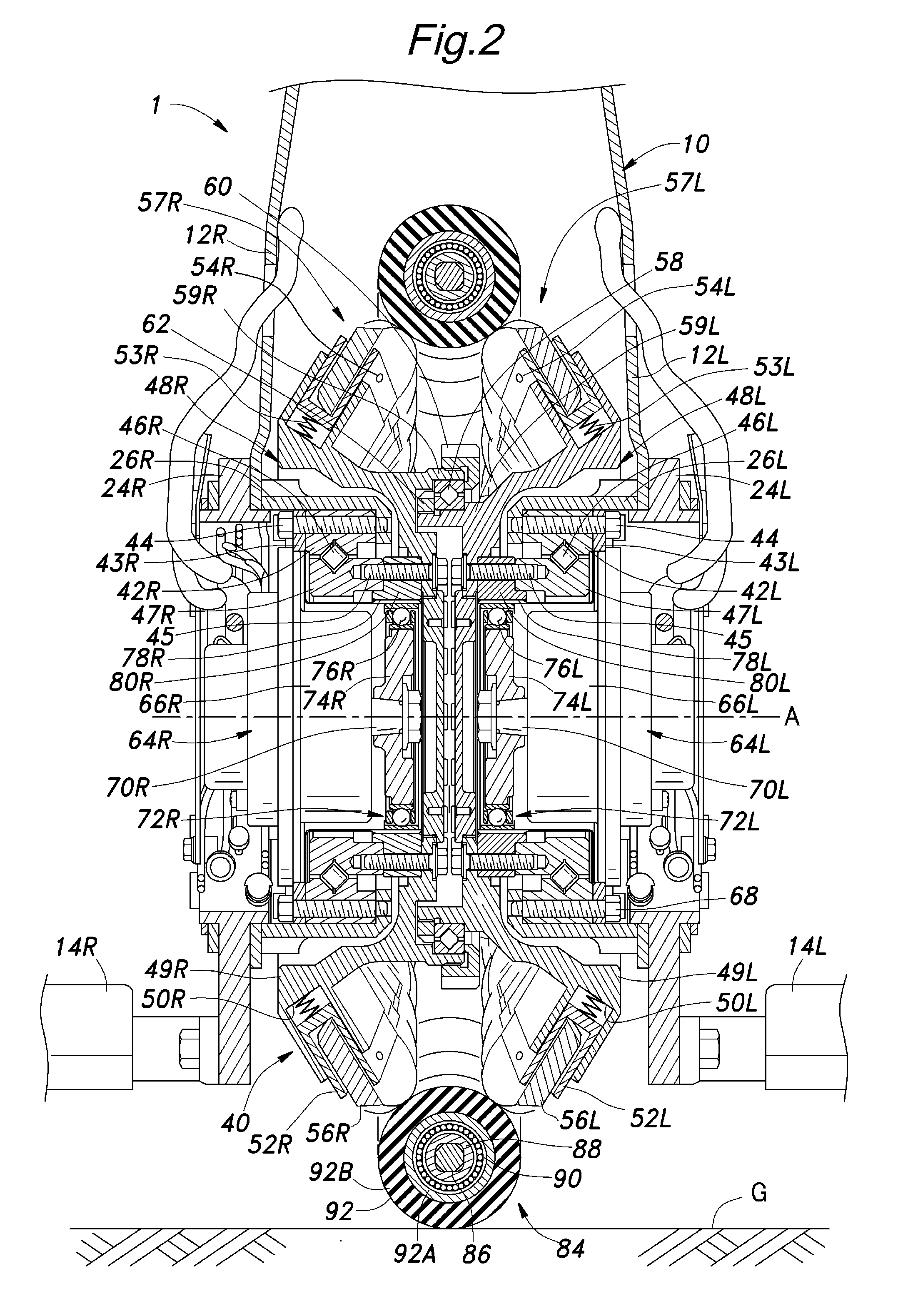

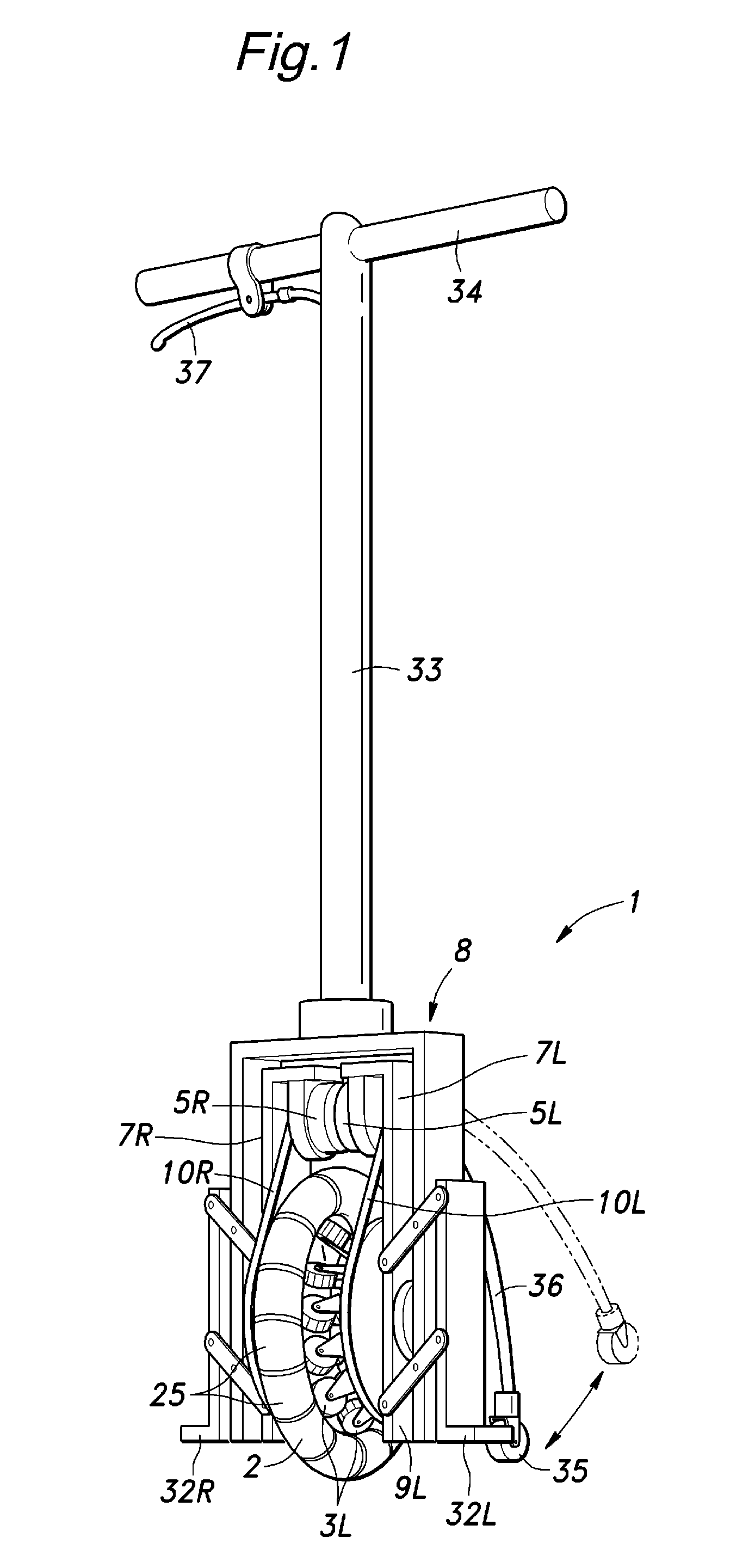

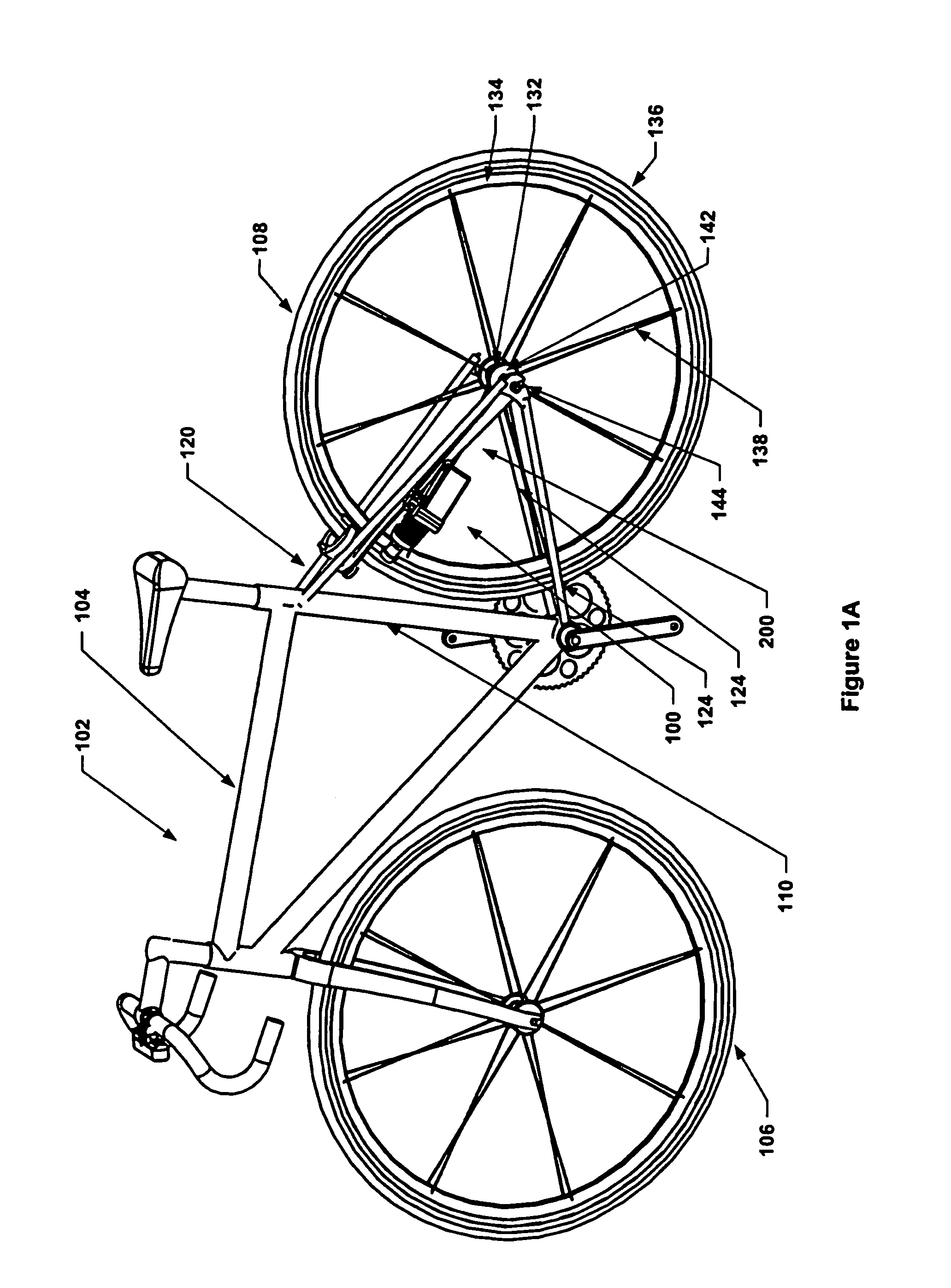

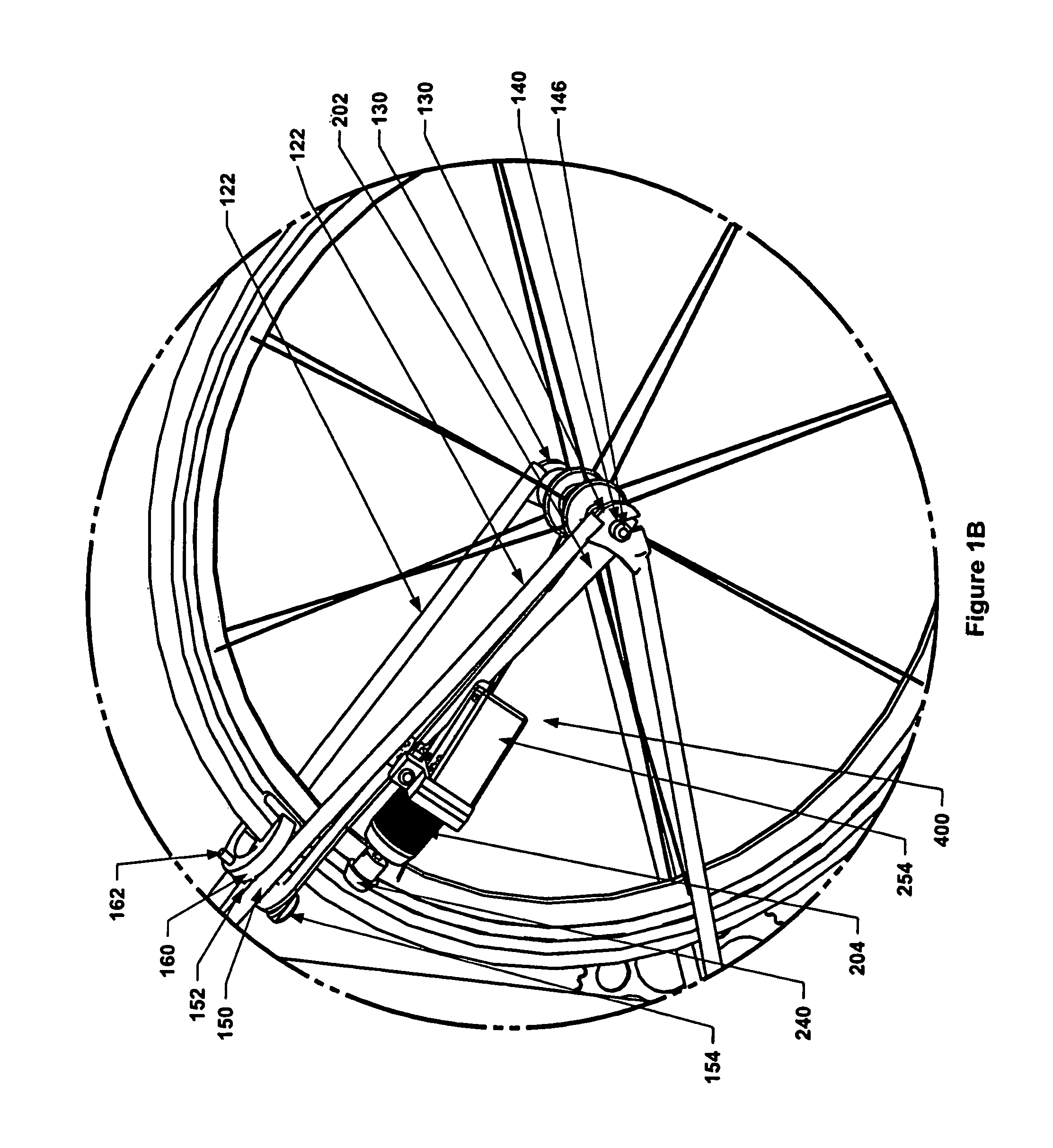

Powered single-wheeled self-balancing vehicle for standing user

ActiveUS20110220427A1Less to manufactureEasy to useUnicyclesFoldable cyclesDrive wheelSoft materials

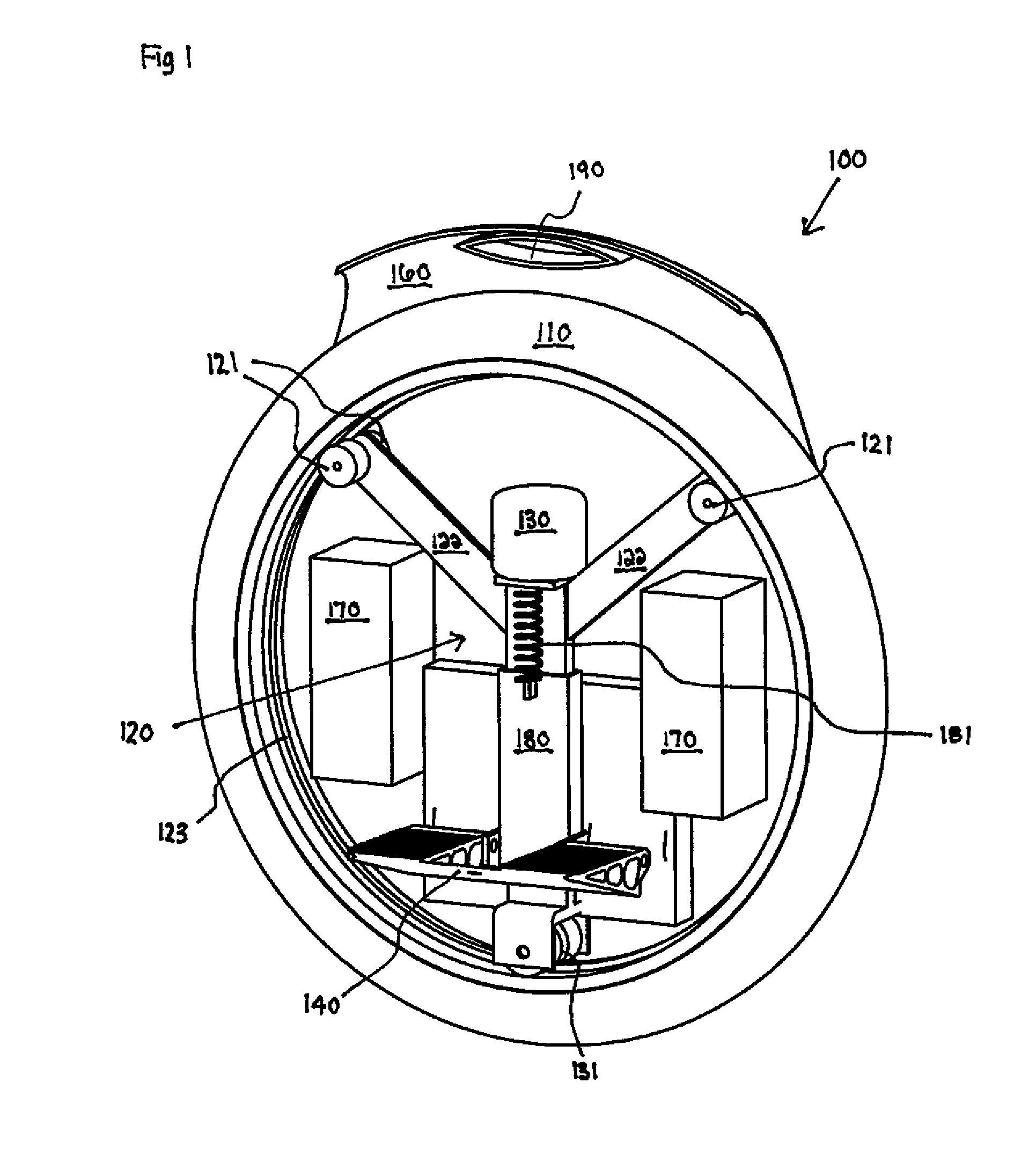

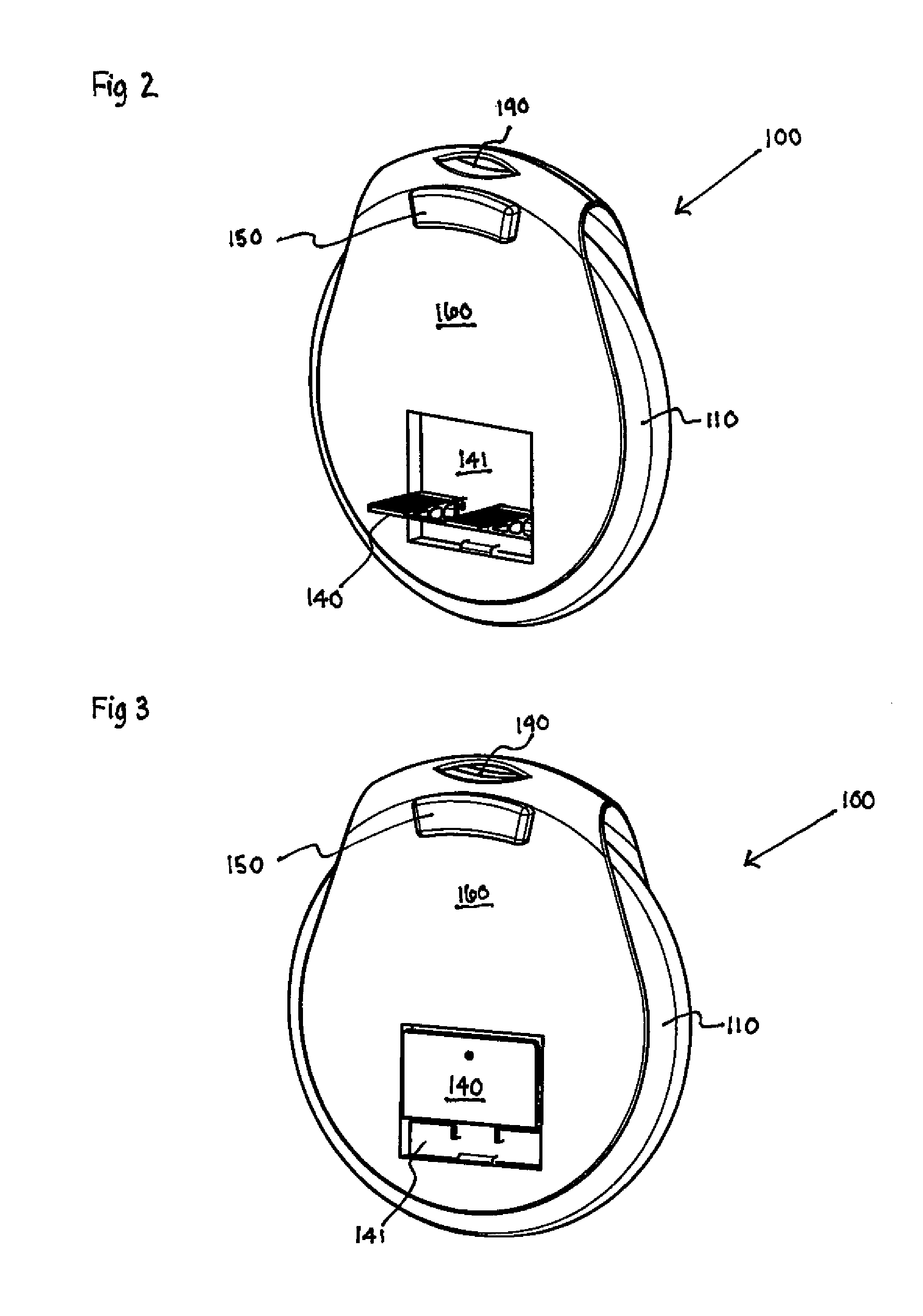

A powered, gyroscopically balanced unicycle device to be used while standing, having leg contact surfaces which are made of a yielding, slightly soft material whose mild friction against the user's legs allows stable, precise control of the device without restraining the legs in any way. In one embodiment a single hubless wheel is driven by a friction drive mechanism which transmits torque from a motor through a drive wheel positioned below the foot platforms and in contact with the inner rim of the wheel. Various structures are provided for supporting the wheel and keeping it in place as it spins; absorbing small vertical movements of the wheel to prevent them from being transmitted to the foot platforms; enabling folding of the foot platforms; and facilitating carrying of the device by hand. Other embodiments are described and shown.

Owner:SHANE CHEN

Powered single-wheeled self-balancing vehicle for standing user

ActiveUS8807250B2Less to manufactureEasy to useUnicyclesElectric propulsion mountingDrive wheelGyroscope

Owner:SHANE CHEN

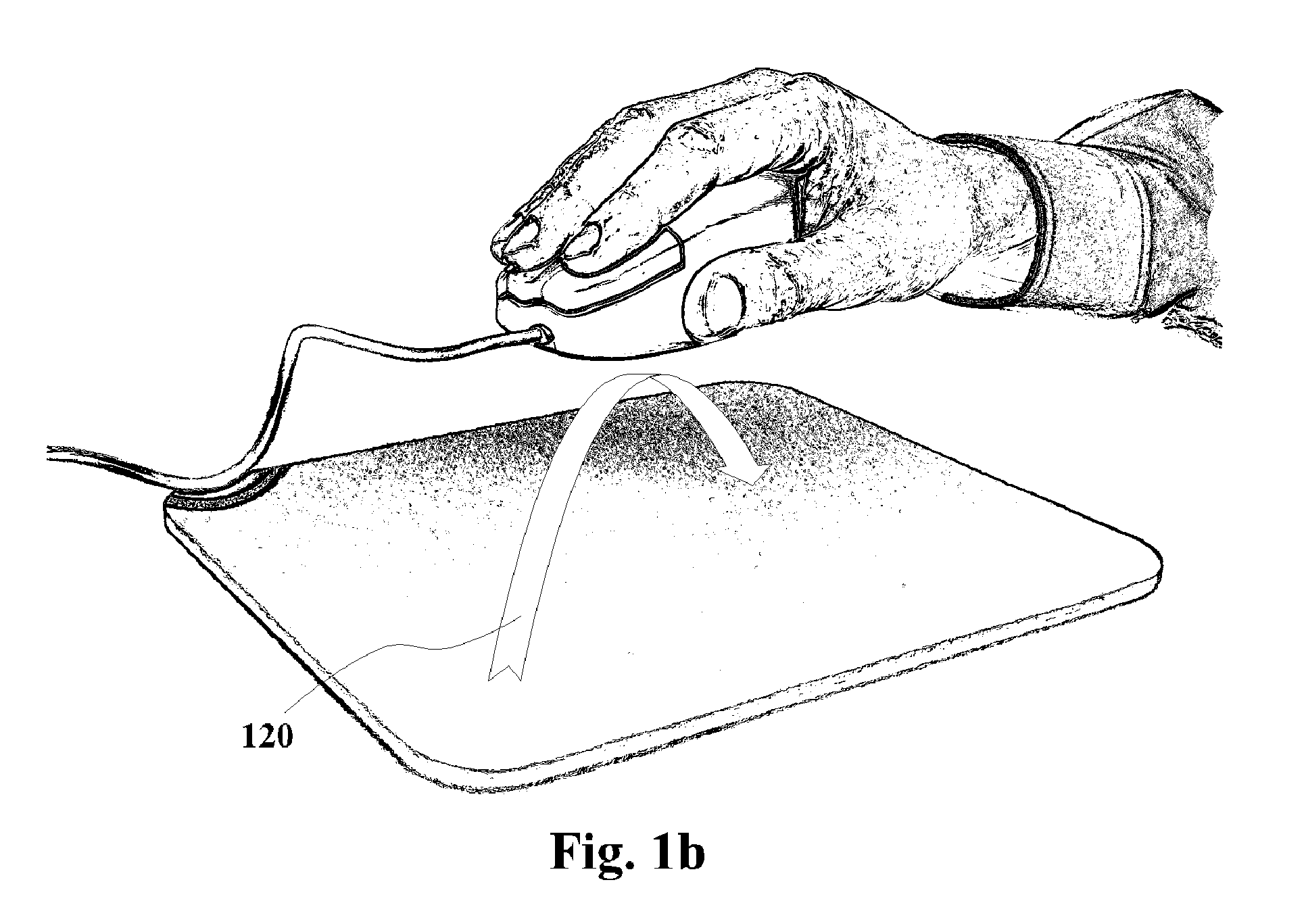

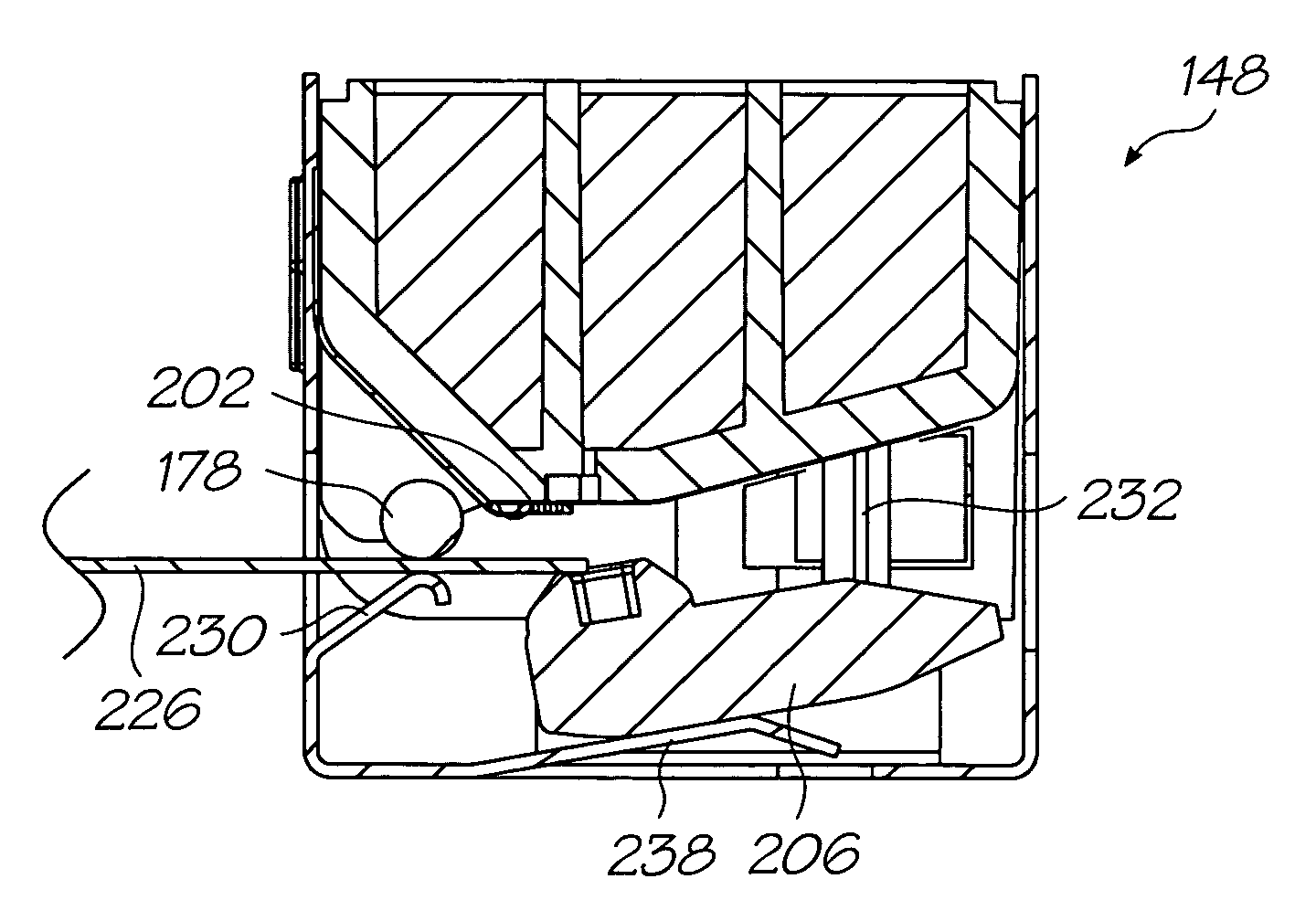

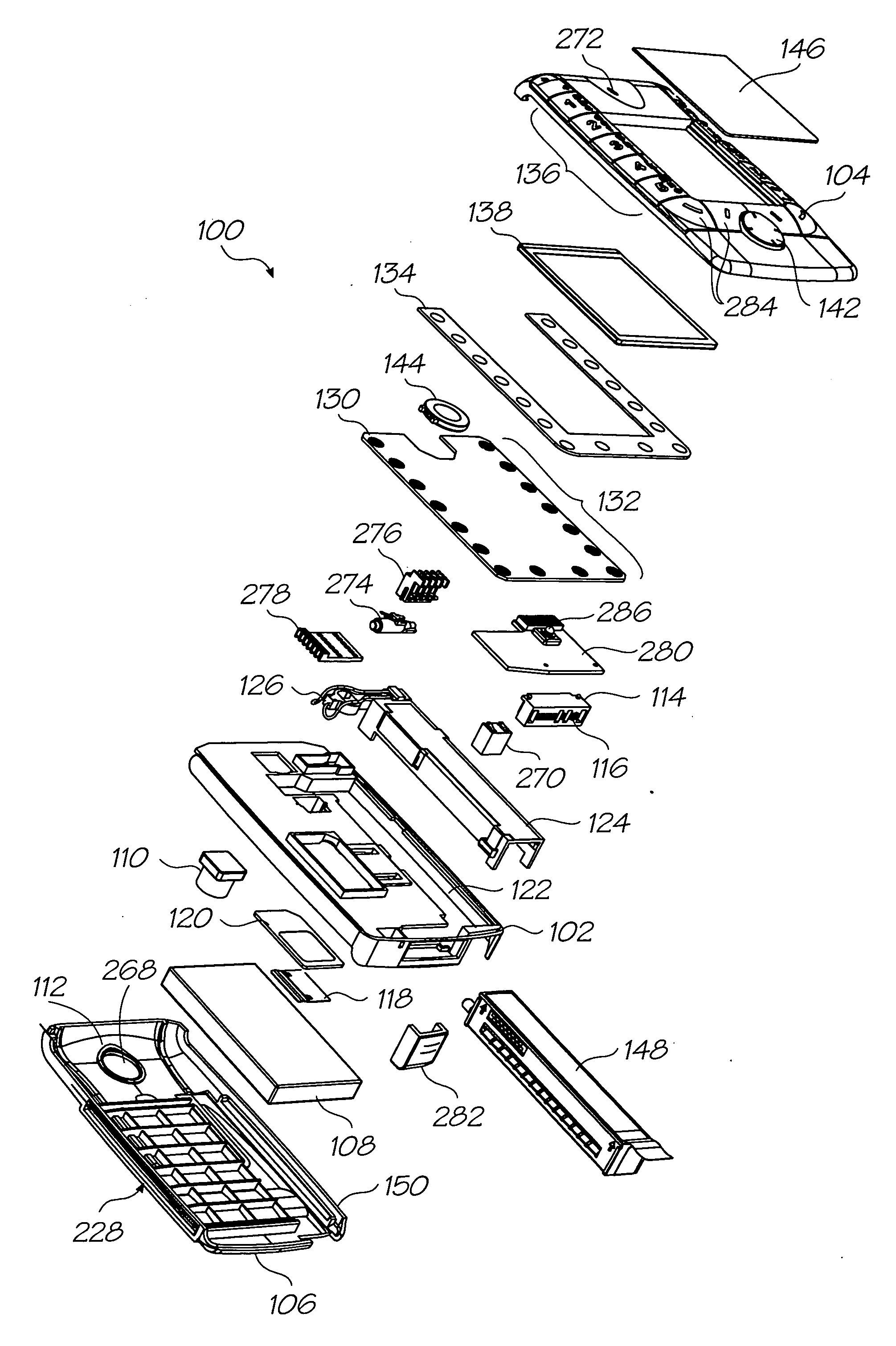

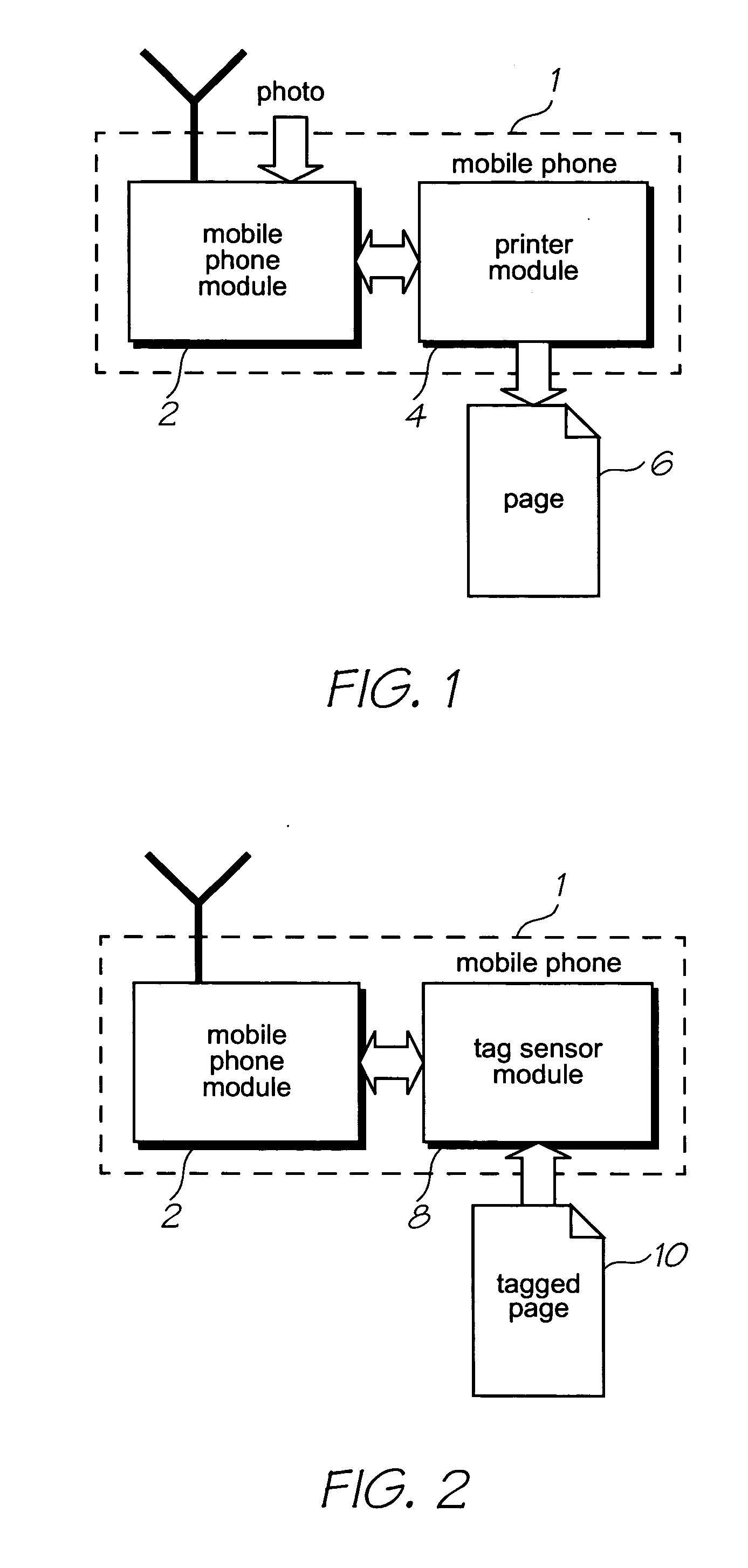

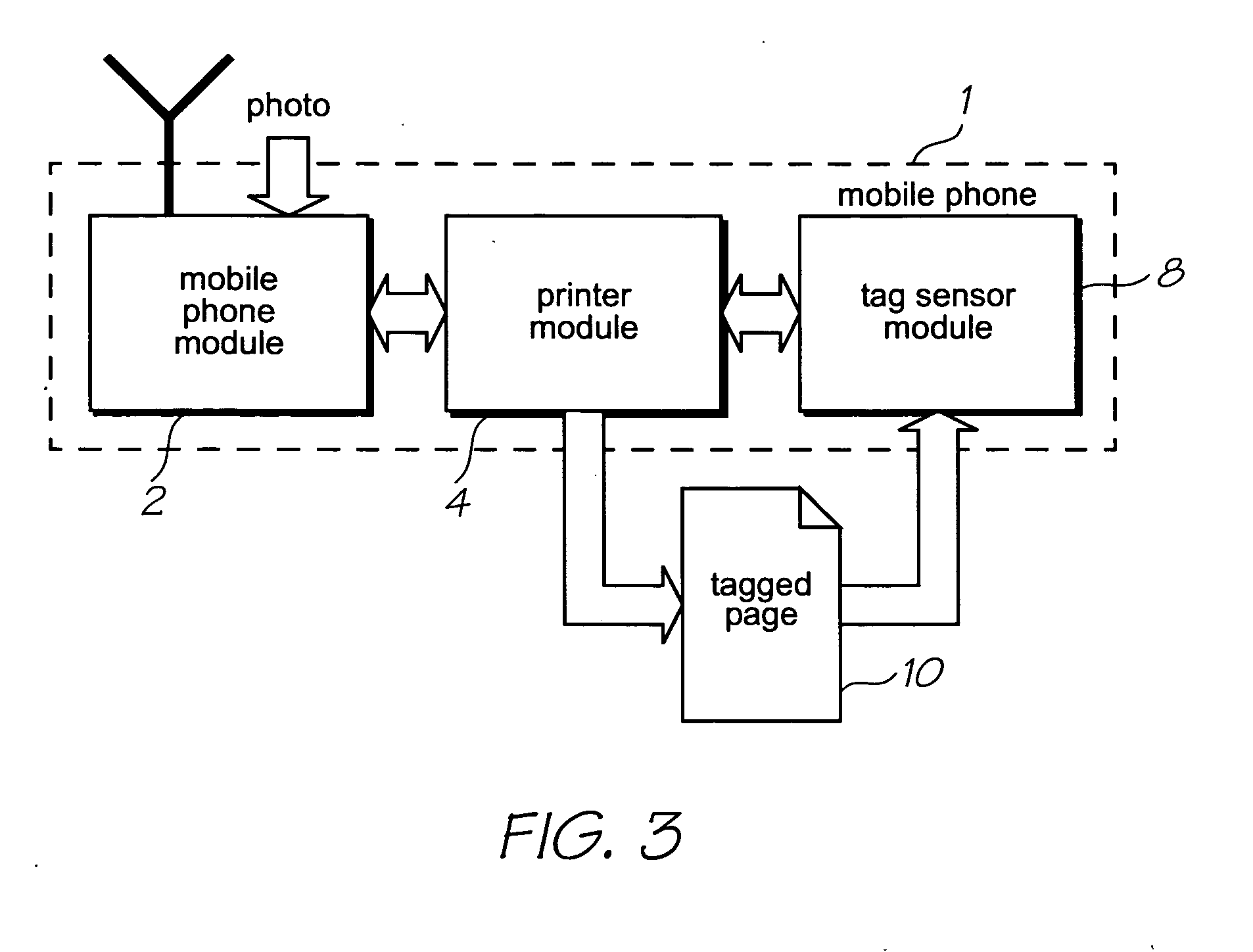

Self-propelled haptic mouse system

InactiveUS20080111791A1Cathode-ray tube indicatorsInput/output processes for data processingComputerized systemDrive motor

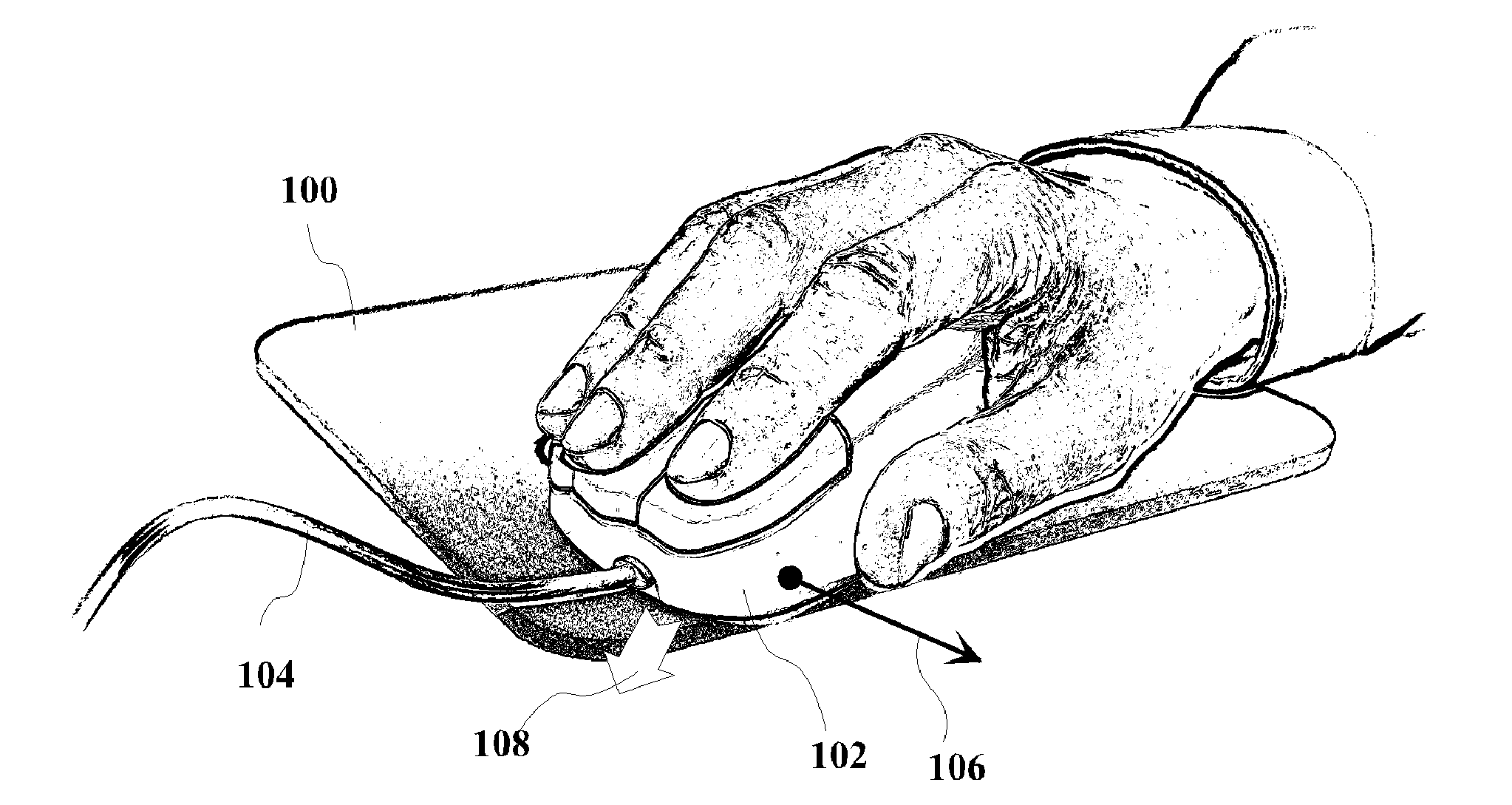

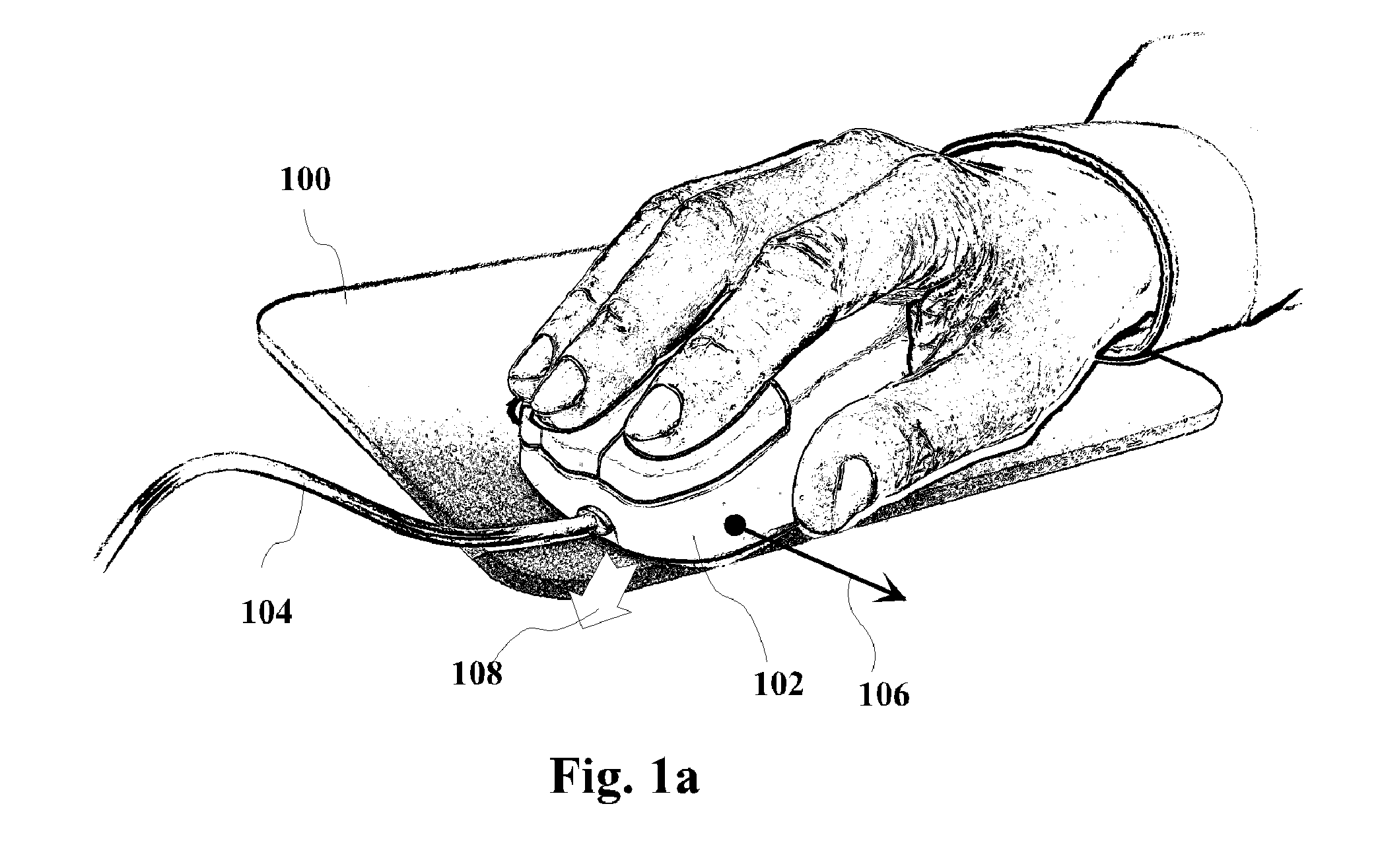

A haptic mouse system, comprising a self-propelled mouse (102) and a mouse pad (100), is intended for use as a mouse pointing device in a computer system. The haptic mouse system can provide directional force feedback to a user in response to commands from the host computer. The self-propelled mouse (102) is moveable over the mouse pad (100) and is separable therefrom, thus allowing the user to operate the device in multiple strokes like a regular mouse. The self-propelled mouse (102) includes a control circuit and a two-dimensionally driving motor having multiple drive elements. The motor can interact with the mouse pad (100) and produce a horizontal propelling force (106), perceptible to the user as a haptic feedback, when the drive elements are activated in a predetermined pattern and only when the self-propelled mouse (102) is placed on the mouse pad (100). The control circuit responds to commands from the host computer by varying the activation pattern in order to control direction and magnitude of the propelling force (106). Several preferred embodiments describe two-dimensionally driving motors of various design and principle of operation, including planar and spherical dynamoelectric motors, friction drives, and different types of vibration motors.

Owner:NIKITTIN ALEX SASHA

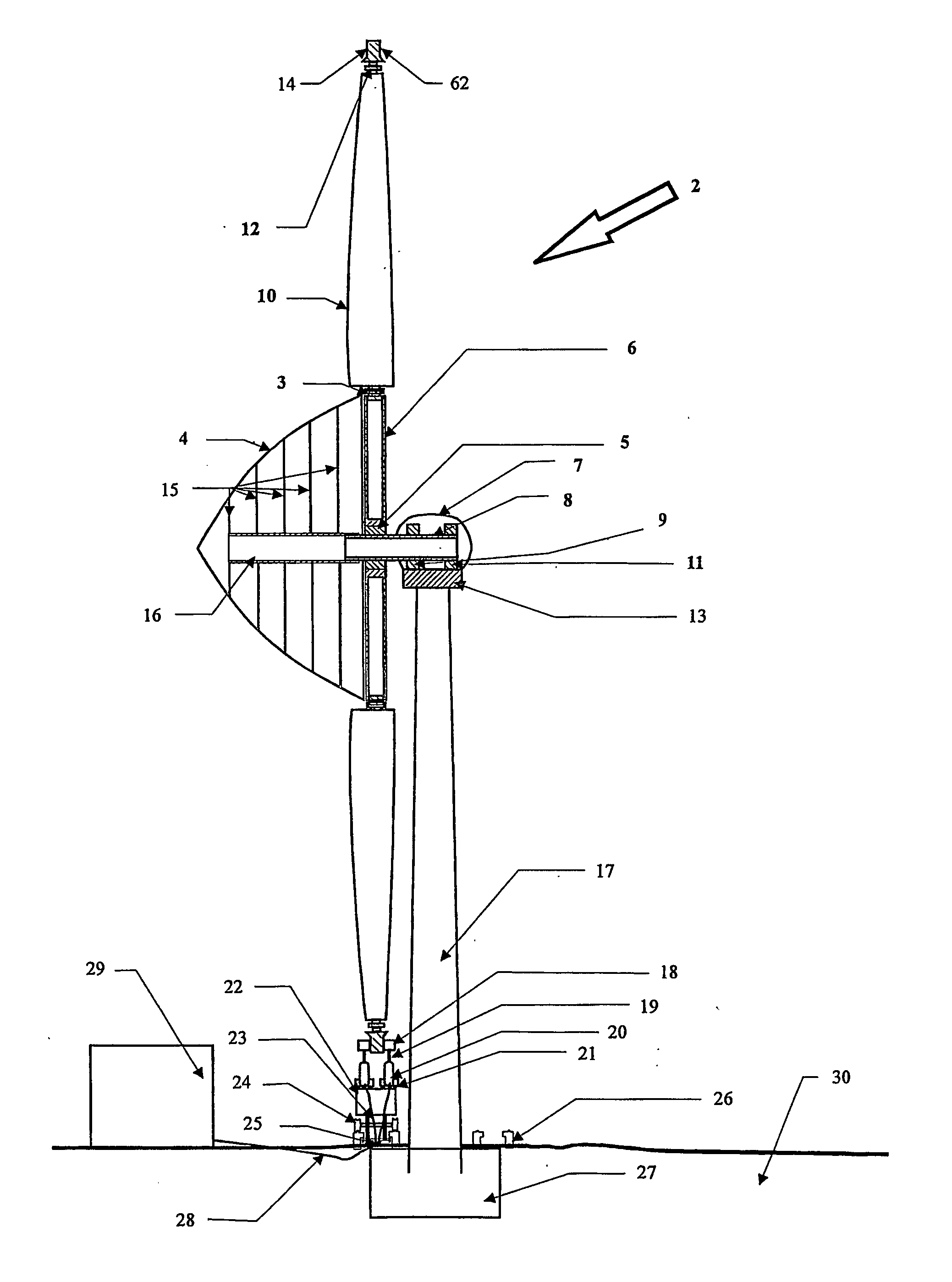

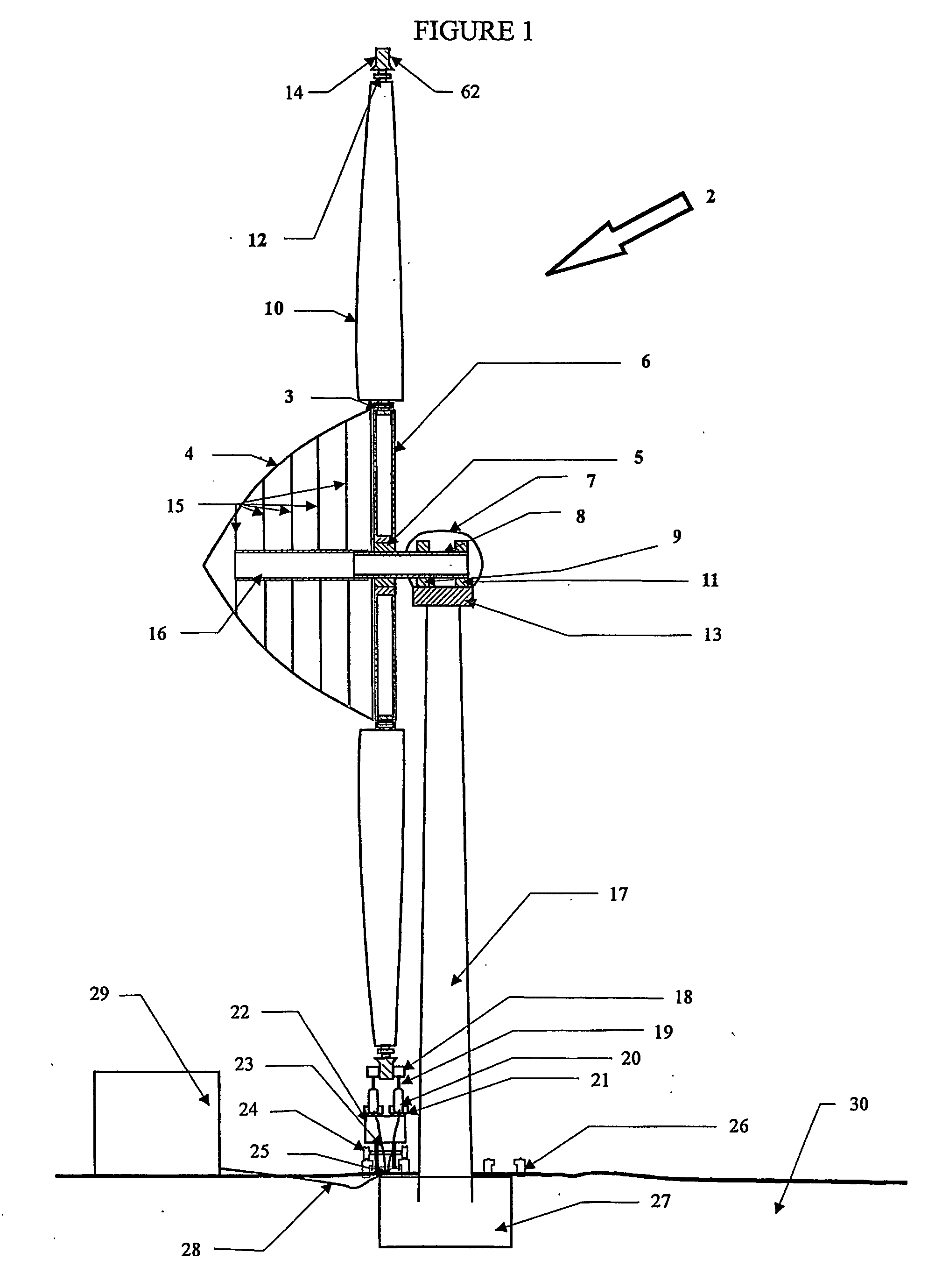

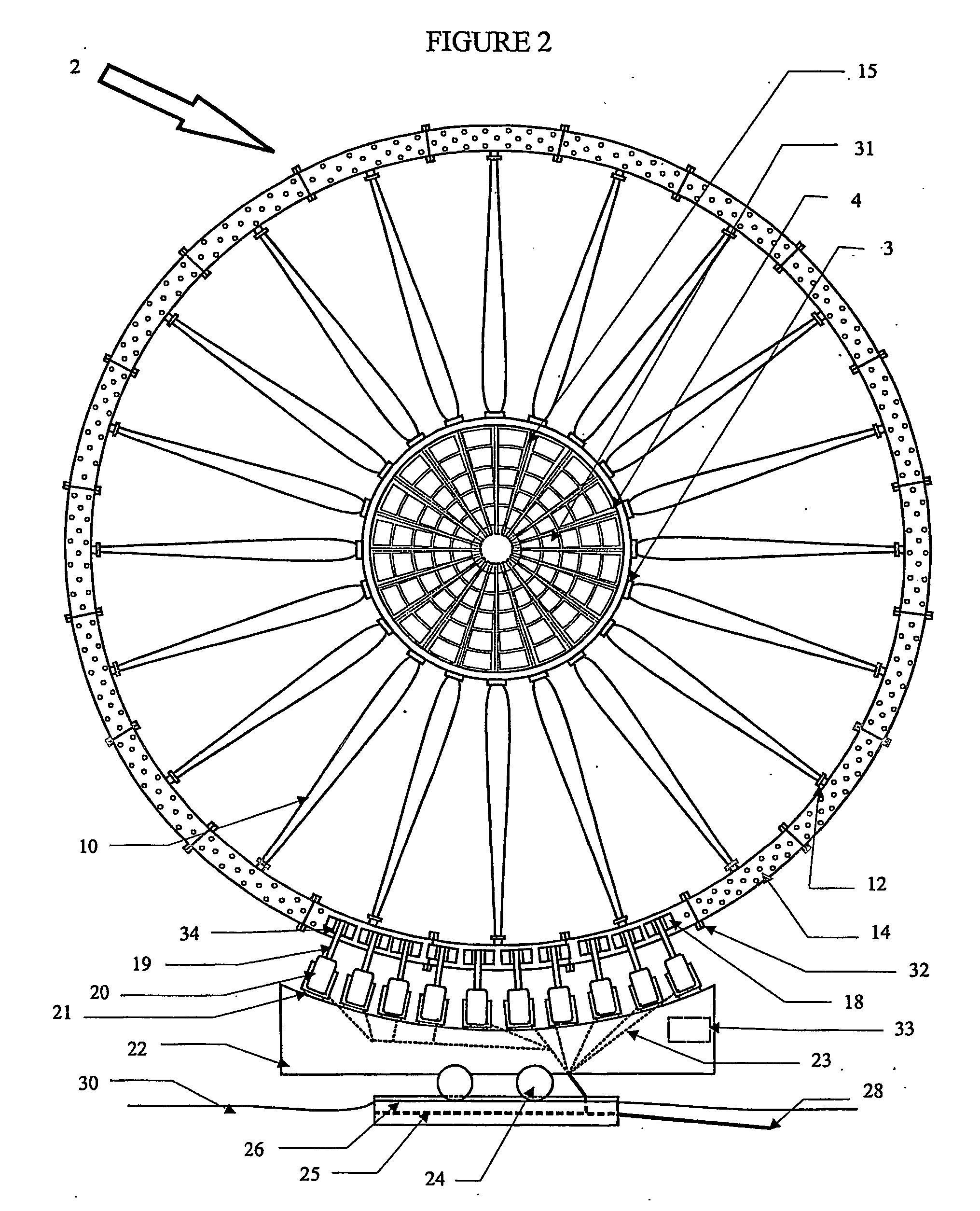

Wind turbine with friction drive power take off on outer rim

A wind turbine has multiple blades (10) that are mounted on a shaft (19) with a ring around a circumference of the blades. There are tires (18) that are arranged to be in contact or out of contact with the ring. The tires draw generators when the tires are in contact with the ring and the ring is rotating. A controller monitors the wind conditions and controls the turbine to produce electricity or other-energy output or to shut down if the wind falls below a predetermined level.

Owner:NEW WORLD GENERATION

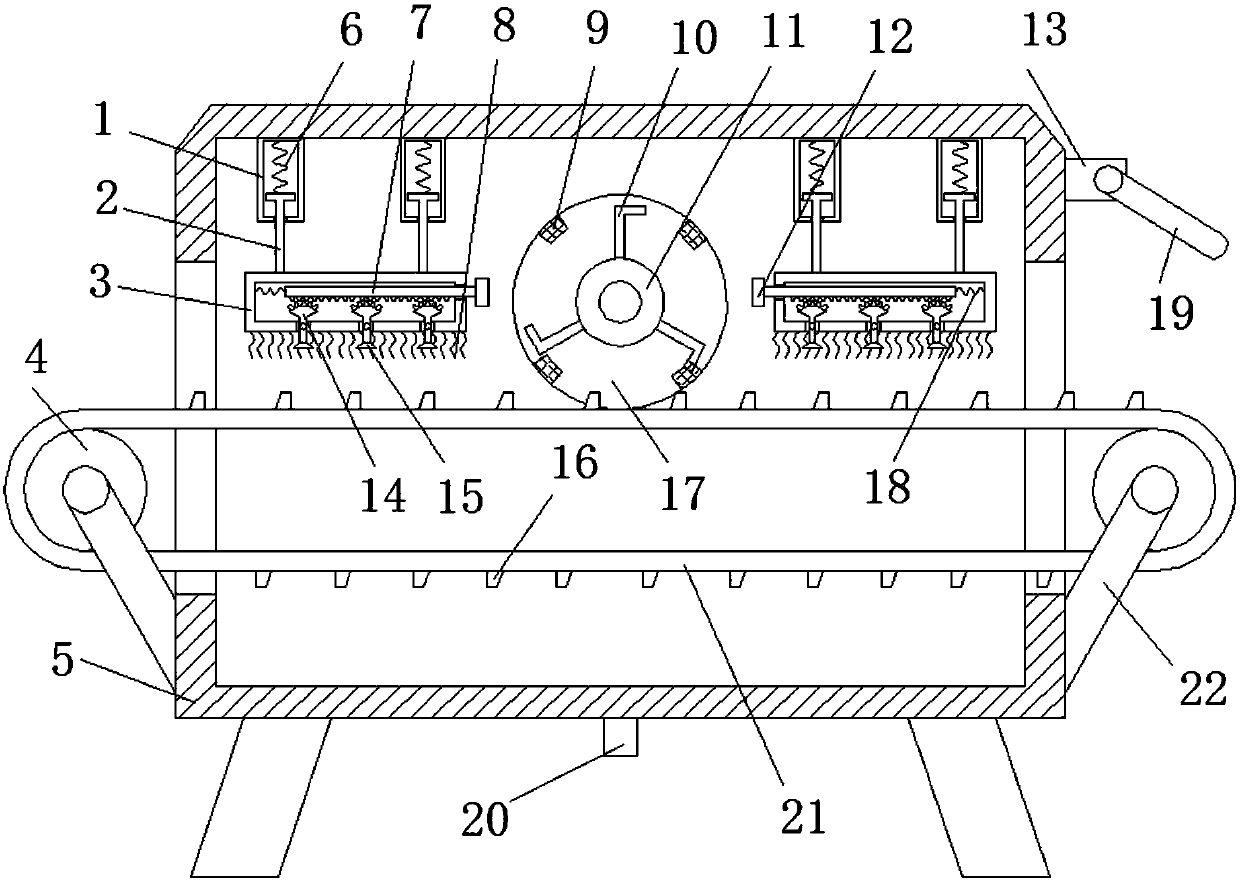

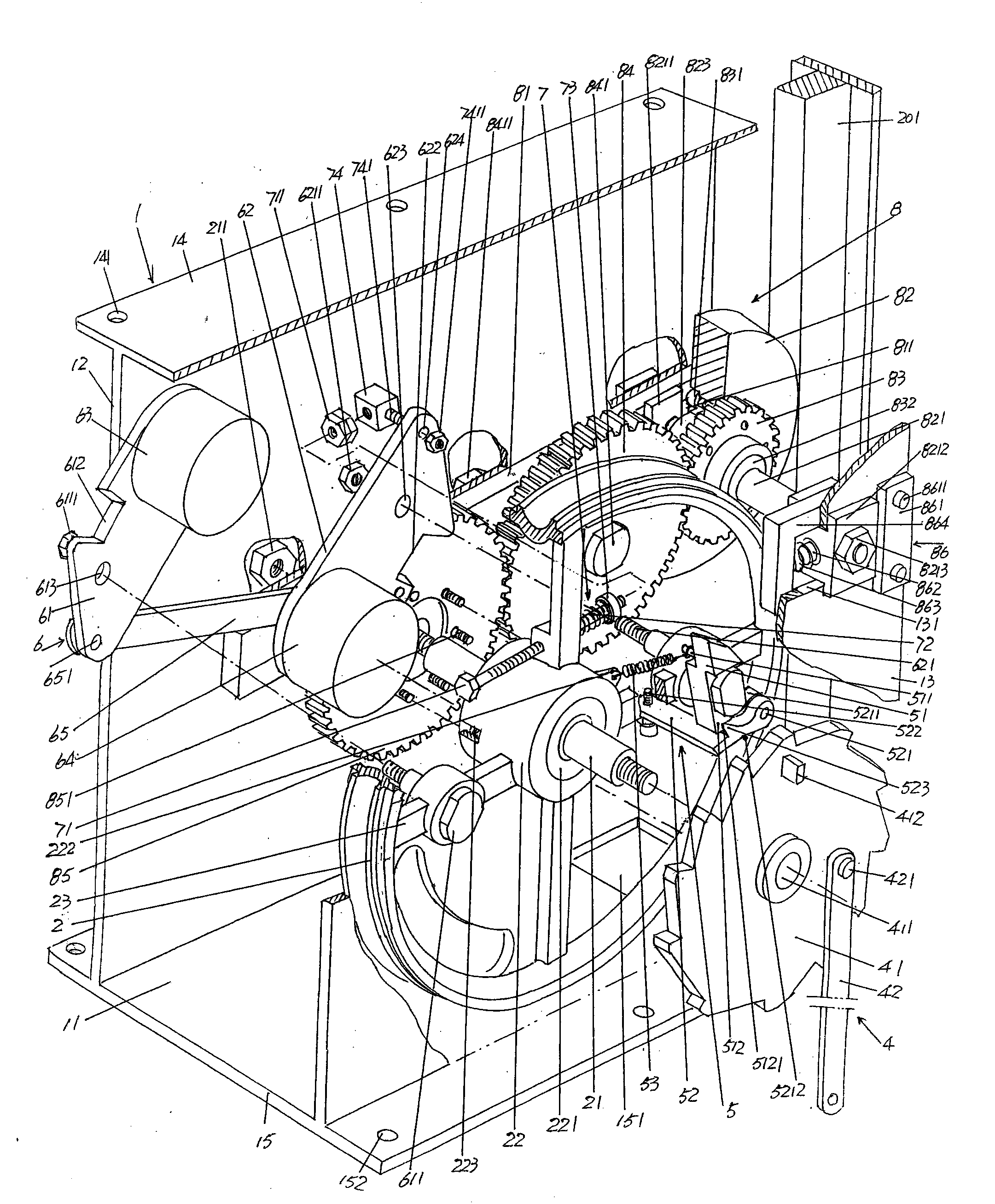

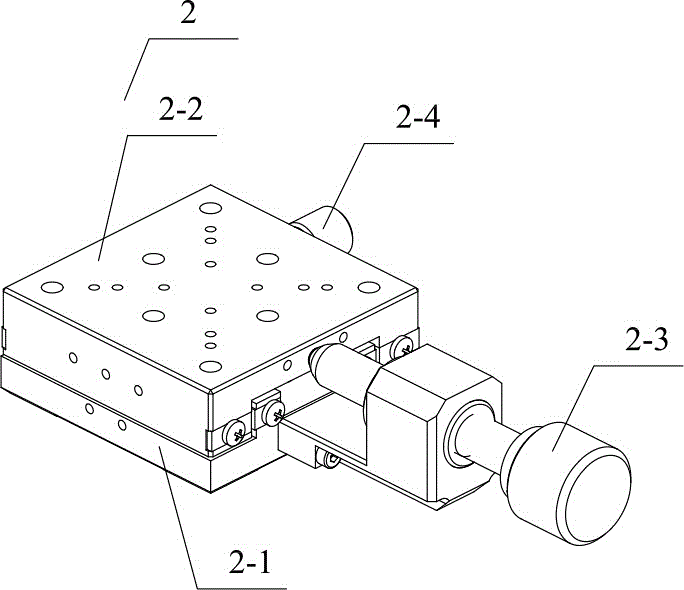

Friction liner-hoisting steel wire rope dynamic friction drive test device and friction liner-hoisting steel wire rope dynamic friction drive test method

ActiveCN104122198AImproved dynamic friction transmission characteristicsGood effectUsing mechanical meansMaterial analysisLongitudinal vibrationDynamical friction

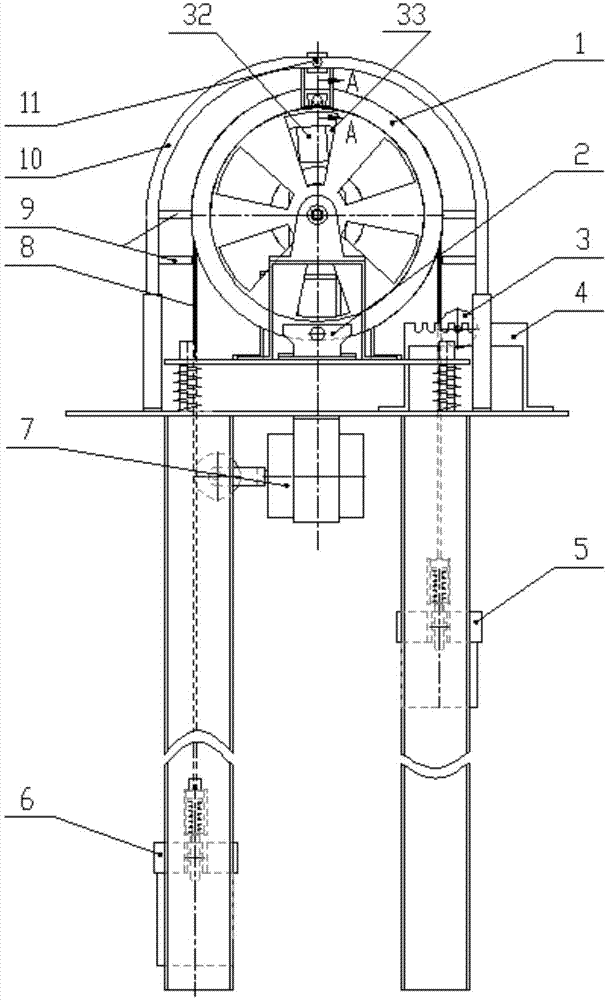

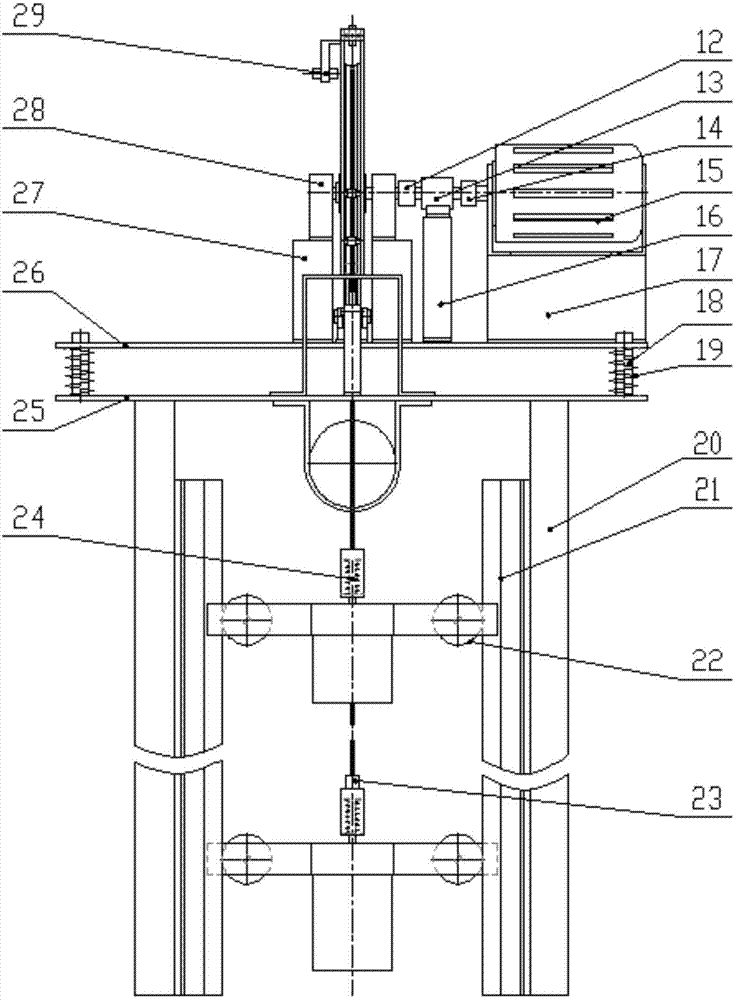

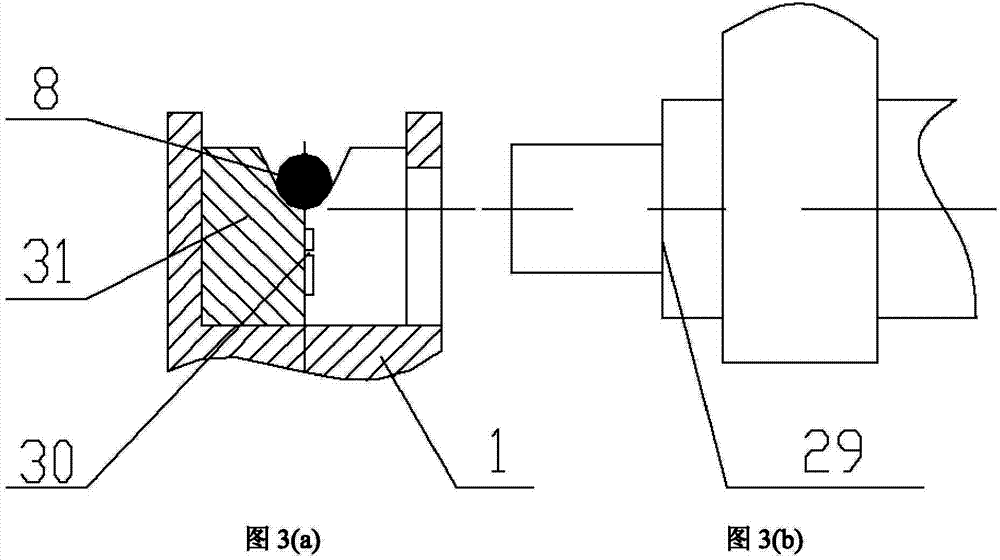

The invention discloses a friction liner-hoisting steel wire rope dynamic friction drive test device and a friction liner-hoisting steel wire rope dynamic friction drive test method. The device comprises a base frame, a driving mechanism, a friction drive mechanism, a surrounding angle adjusting mechanism, a shock excitation mechanism, a steel wire rope and a condition monitoring mechanism, wherein the base frame comprises a stand column, a lower support platform and an upper support platform; the driving mechanism comprises a motor and a torque sensor; the friction drive mechanism comprises a friction wheel and a brake device; the surrounding angle adjusting mechanism comprises a C bracket and an adjusting wheel; the shock excitation mechanism comprises a transverse shock excitation mechanism and a longitudinal shock excitation mechanism; the condition monitoring mechanism comprises a steel wire rope tension monitoring device, a dynamic contact monitoring device, a steel wire rope vibration monitoring device and a micro-slippage monitoring device. After the device and the method are adopted, the dynamic friction drive characteristic between a friction liner and a hoisting steel wire rope can be simulated in a friction hoisting system when the hoisting steel wire rope is in a dynamic coupling vibration state, so that various changes in the friction drive process under the actions of transverse vibration, longitudinal vibration and transverse and longitudinal coupled vibration can be researched.

Owner:CHINA UNIV OF MINING & TECH

Method and system for detecting medicament of liquid in bottles

InactiveCN1760666AImprove detection qualityThe detection process is fastOptically investigating flaws/contaminationSortingDrive wheelComputer module

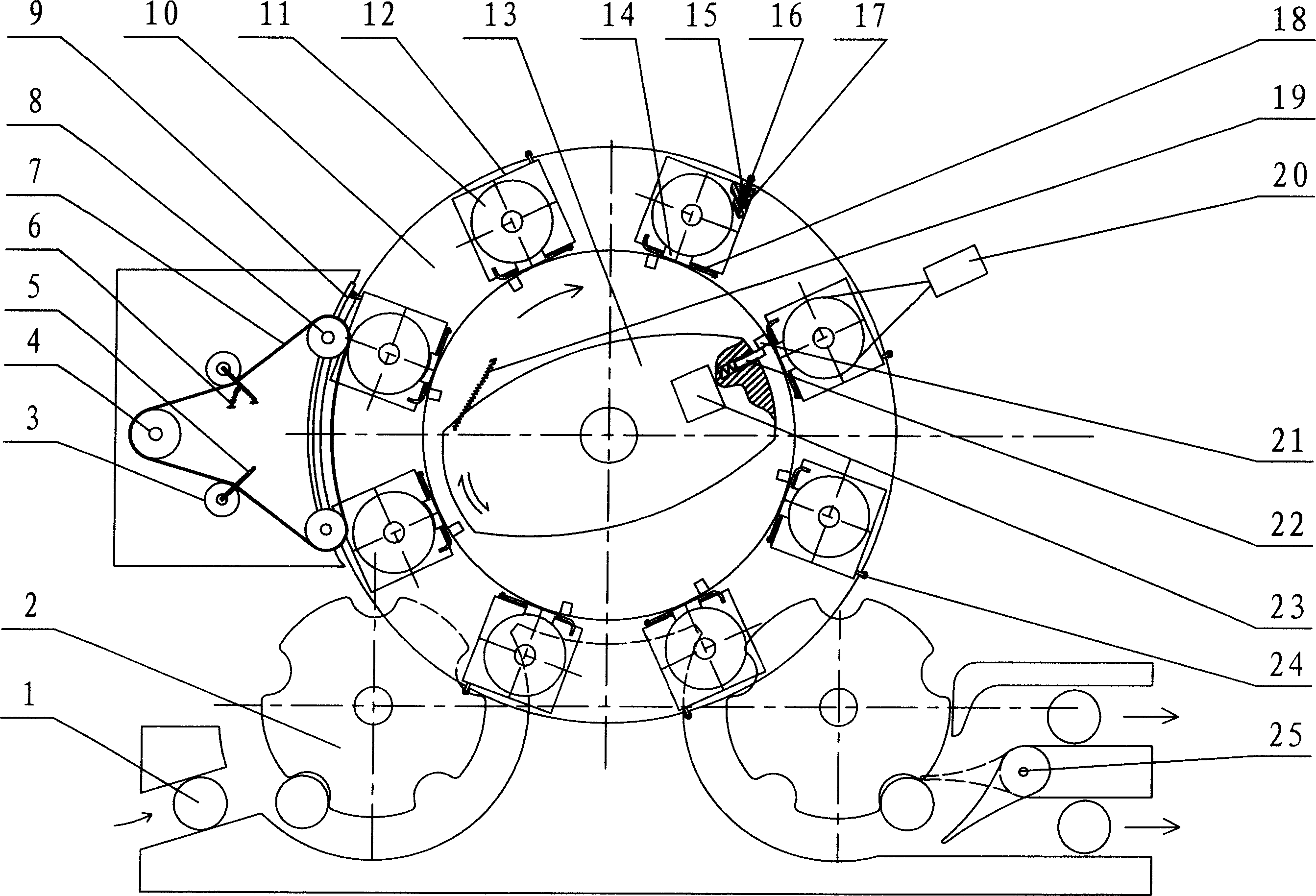

The invention is in use for detecting solid impurity of liquid in bottle full automatically. The method includes procedures: driving arrangement accelerates rotation of bottle body moving in uniform speed to a value of rotation setup; then, braking the bottle body rapidly, transmitting light beam to the bottle body, and taking picture for the bottle body by camera synchronous forwarded with the bottle body; analyzing signal collected by camera, and when abnormal instance occurs, eliminating signal is generated. The system includes detection worktable, strap friction drive device, detection device, and analyzing and controlling module etc. Strap friction drive device includes driving wheel, driven wheel, follow up pulley and friction belt. Comparing with prior art, the invention overcomes disadvantages of slow detection speed, complex system structure, low quality of detection, possessing advantages of safety and high consistency of detection.

Owner:XIAN YIDA INFORMATION SYST

Toy cleaning device

InactiveCN107931175ASpeed up evaporationAvoid re-breedingDrying gas arrangementsCleaning using toolsBristleEvaporation

The invention discloses a toy cleaning device. The toy cleaning device comprises a working box and supporting legs fixed to the bottom of the working box. The top of the working box communicates witha water outlet pipe, and first rotating shafts are symmetrically arranged on the two sides of the working box. The structure is simple; a to-be-cleaned toy is placed on a conveying belt, the conveyingbelt brings the toy into the working box, and the toy is cleaned through bristles; because of frictional force between the conveying belt and a friction wheel, the friction wheel is driven to rotateand drives L-shaped rods through a rotating cylinder to rotate so as to turn over the toy, and thus all the faces of the toy are cleaned; meanwhile, first magnets on the friction wheel rotate with thefriction wheel and attract with second magnets mutually, reciprocating moving of racks is achieved through the effect of second springs, the racks are engaged with sector-shaped gears to drive spraying heads to swing, thus, the toy is washed from various angles, and the cleaning effect is improved; and through a fan, evaporation of residual moisture of the toy can be accelerated, and the situation that bacteria breed again is avoided.

Owner:郭姗姗

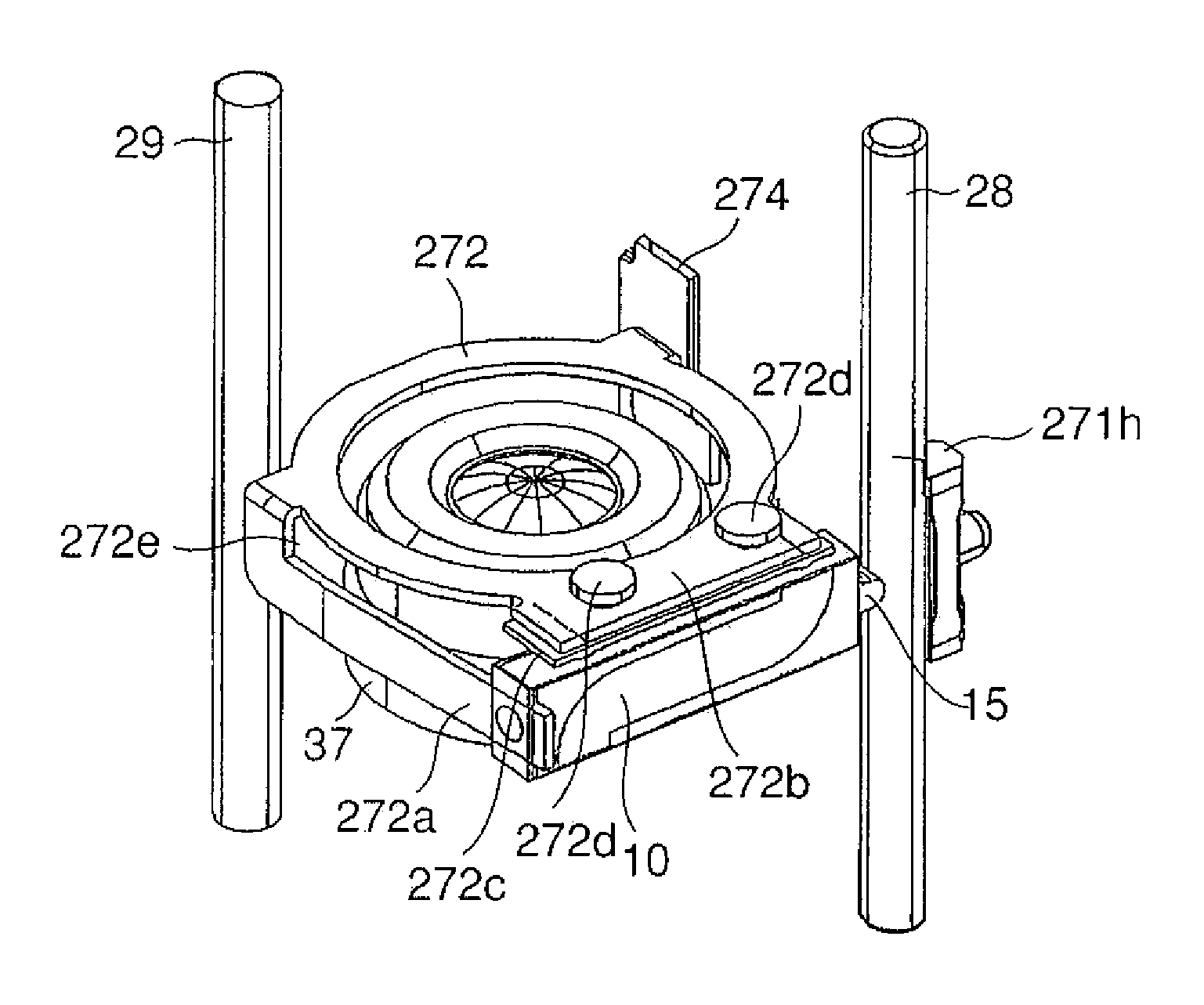

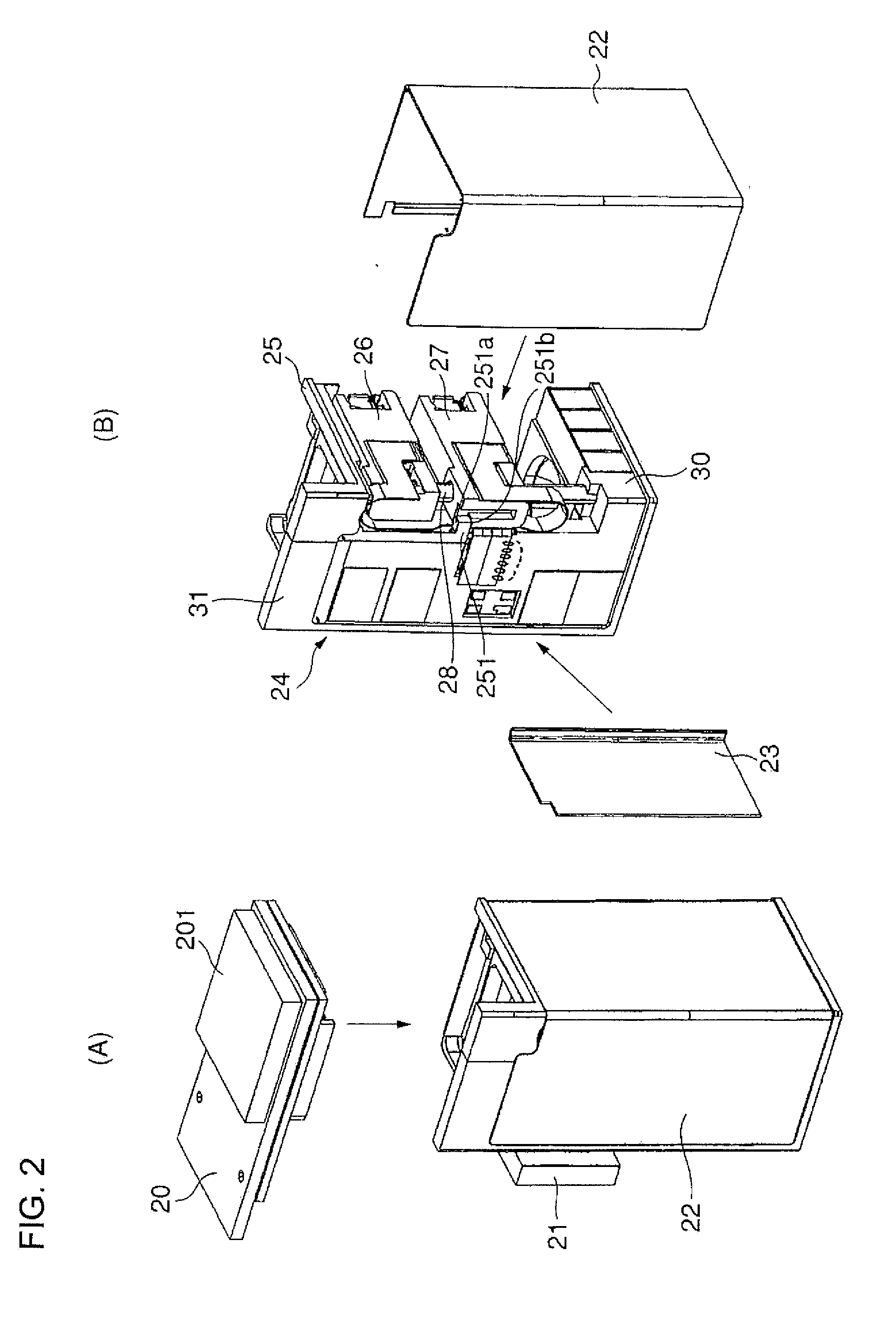

Camera Module, and Portable Terminal and Information Terminal with the Same

InactiveUS20070229702A1Prevent ghost and flarePrevented from exerting influenceTelevision system detailsProjector focusing arrangementOptical axisCamera module

A camera module and a portable terminal comprising the camera module, in which an auto-focus (AF) function and a zoom function are assembled by using a friction drive-type drive source such as a piezoelectric element, which are constructed to be small in size and light in weight, and which are resistant to chips produced through friction contact between the piezoelectric element and driven member. The camera module has a lens holding section for holding at least one or more optical lenses and provided with a shaft hole portion, a shaft member inserted in the shaft hole portion and installed substantially in parallel with the optical axis, a piezoelectric element having at an end an operation portion that is in contact with the shaft member and is placed in the vicinity of the shaft hole portion of the lens holding section, and an adhesive member provided in the vicinity of the shaft hole portion. As a result, the camera module is small in size and light in weight, and chips produced through frictional contact between the piezoelectric element and the driven member are prevented from scattering by the adhesive member.

Owner:KYOCERA CORP

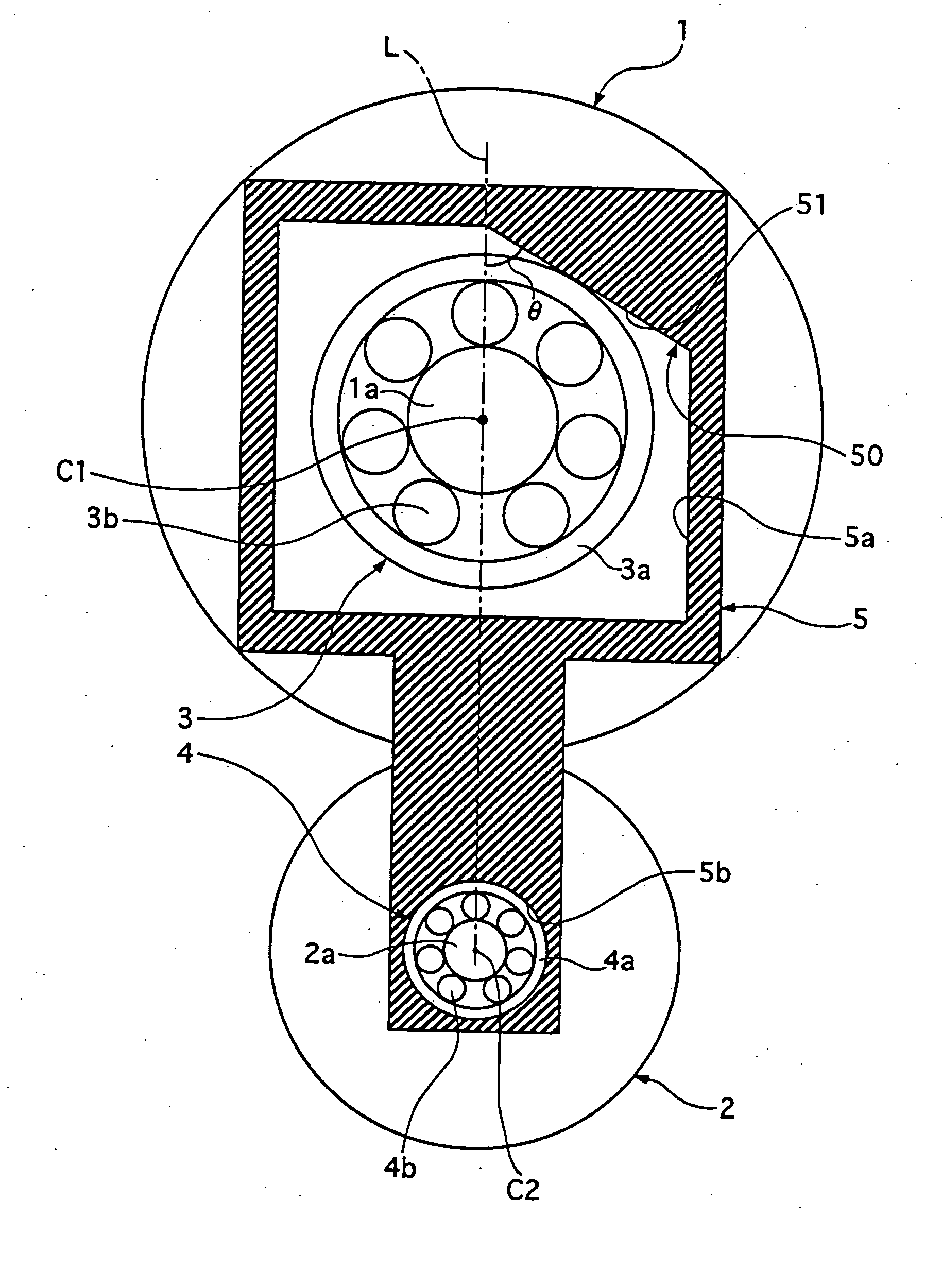

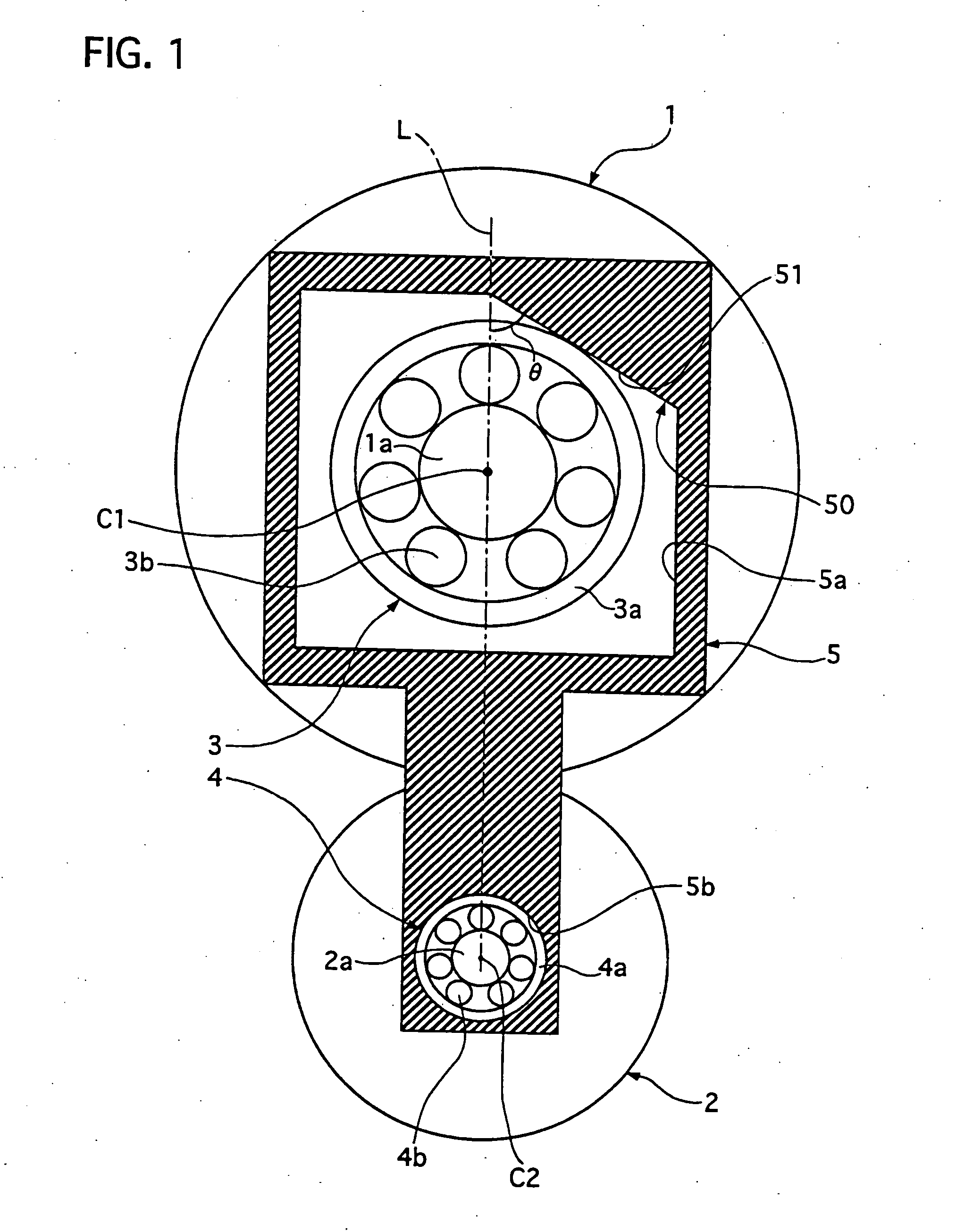

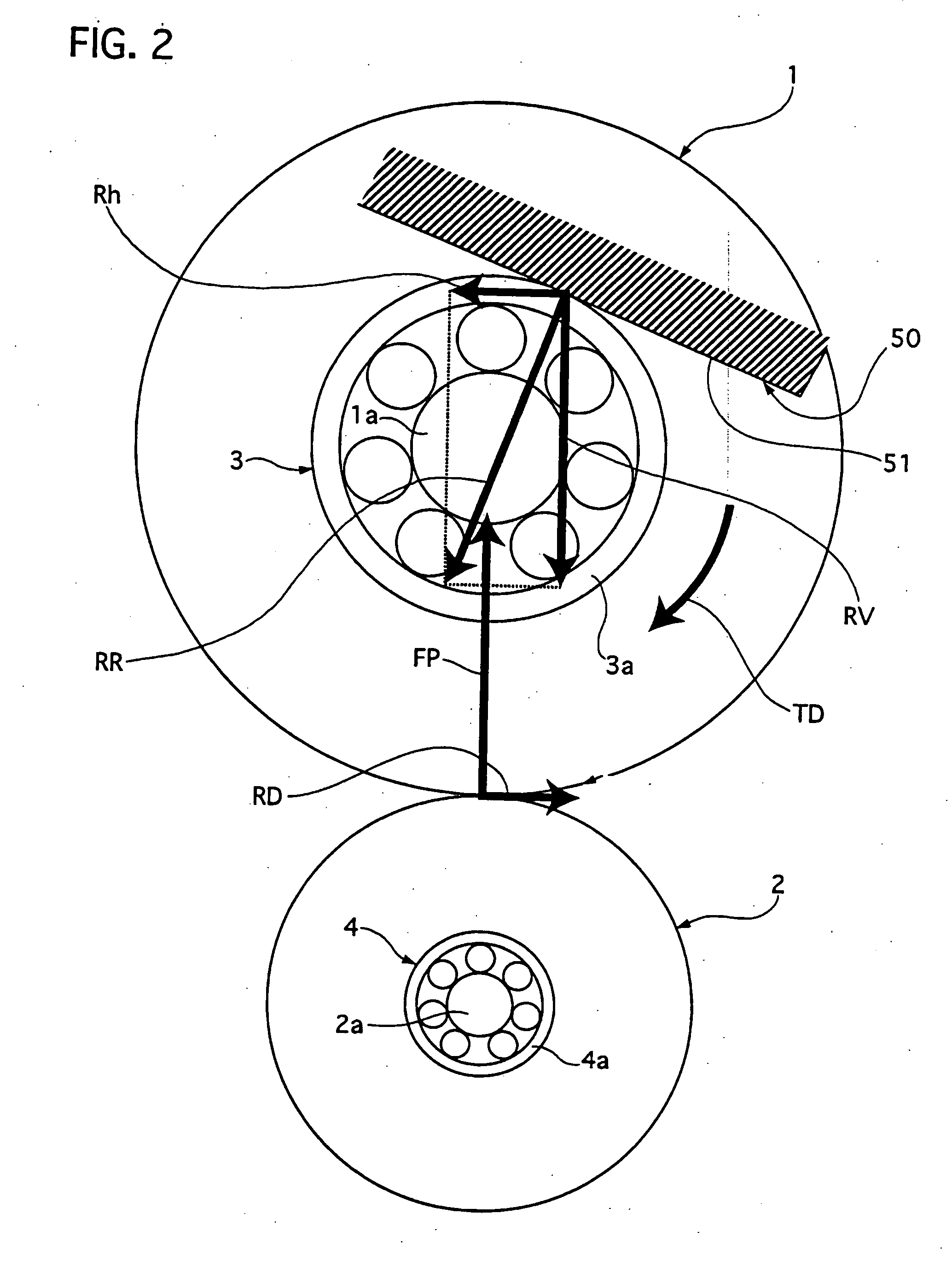

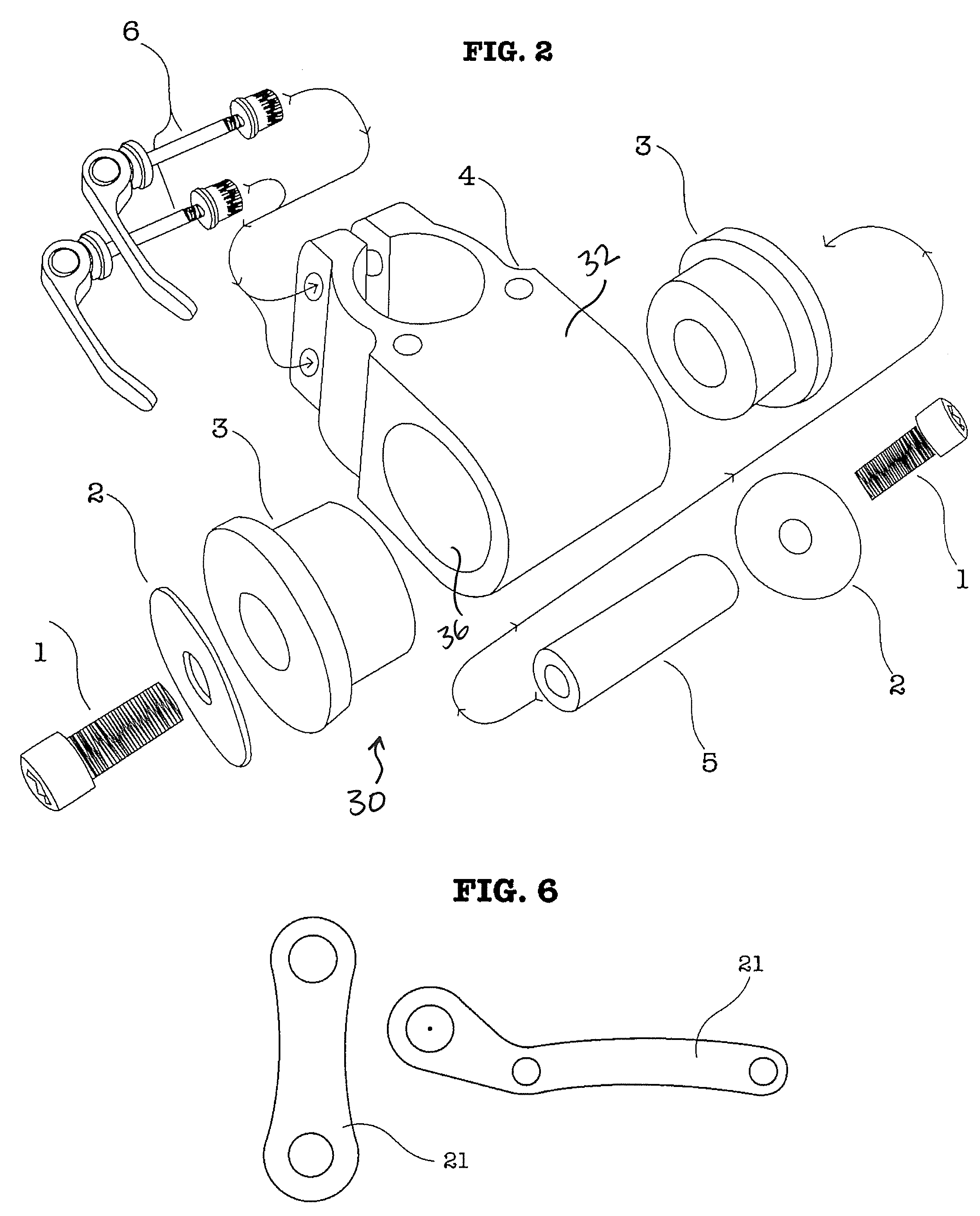

Friction drive device

A friction drive device includes a first roller with a support part, a second roller, and a cam member to support them. The second roller receives press force from the first roller at a contact point of them so as to transmit mechanical power therebetween. The cam member has a cam formed with a cam slope on which the support part of the first roller is pressed by reaction torque from the second roller that is caused by transmission torque applied from the first roller. The cam slope is formed to have an angle with respect a tangent line at the contact point so that the first roller is pressed by reaction force of the cam to apply the press force proportional to the transmission torque to the second roller.

Owner:NISSAN MOTOR CO LTD

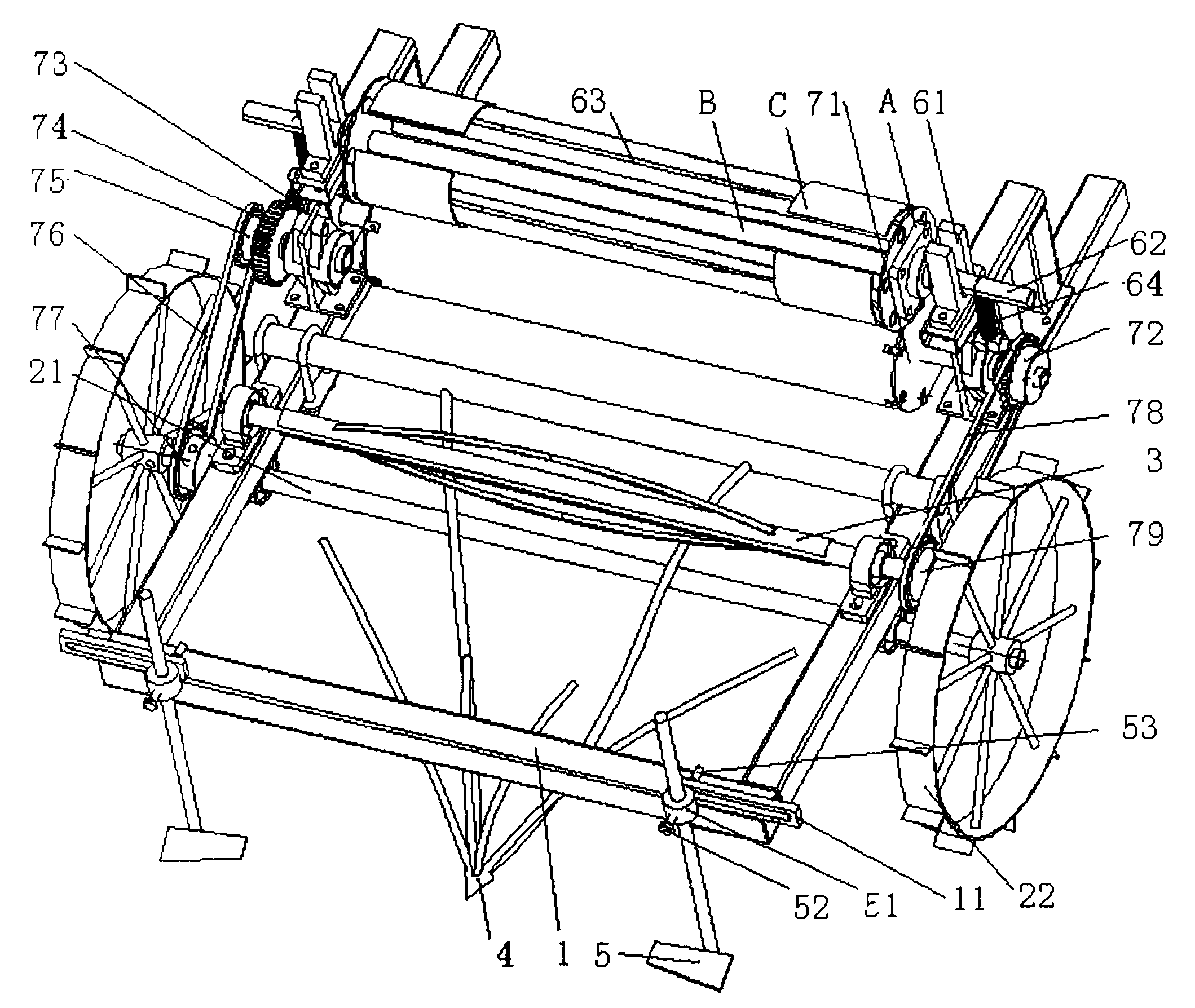

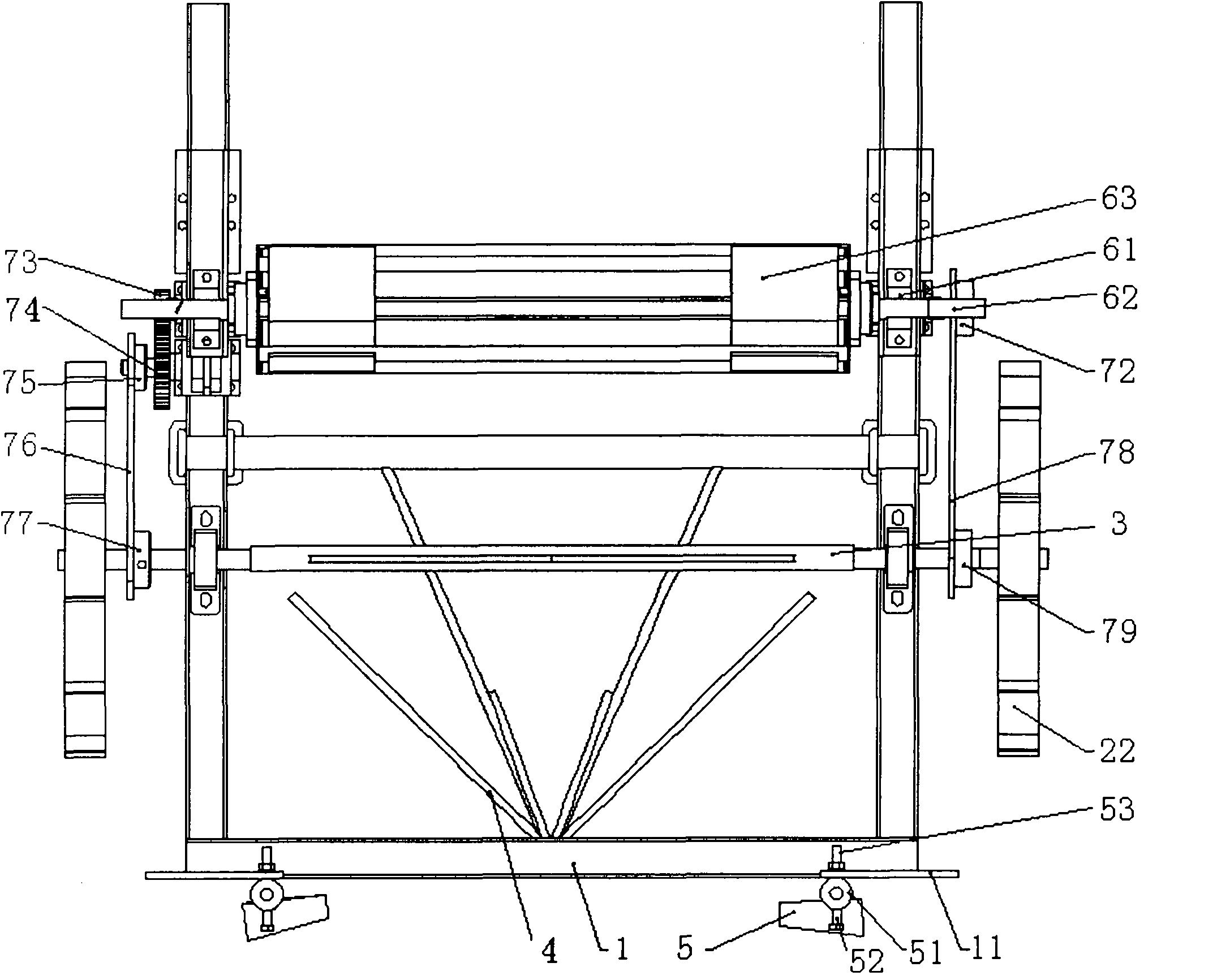

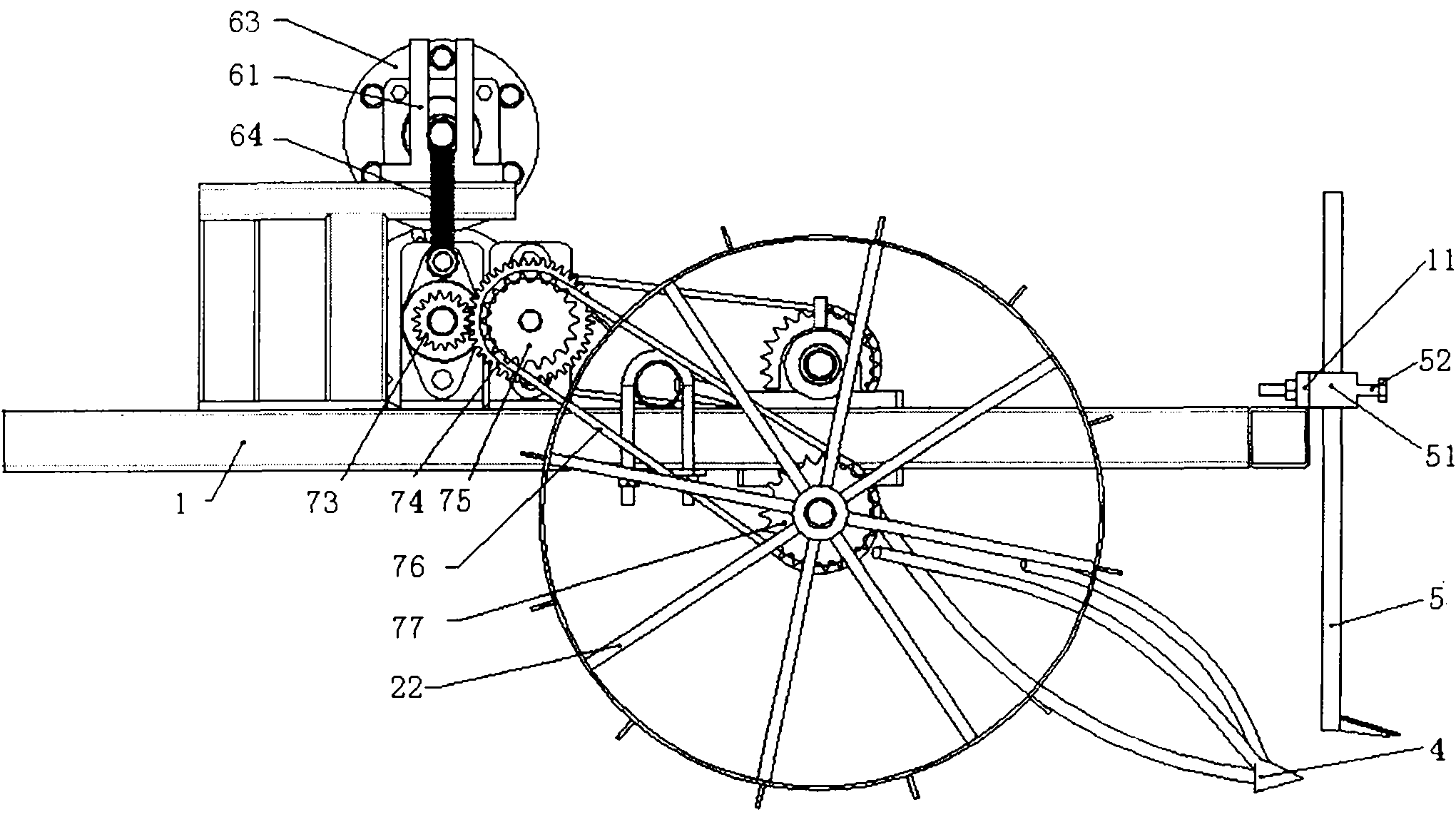

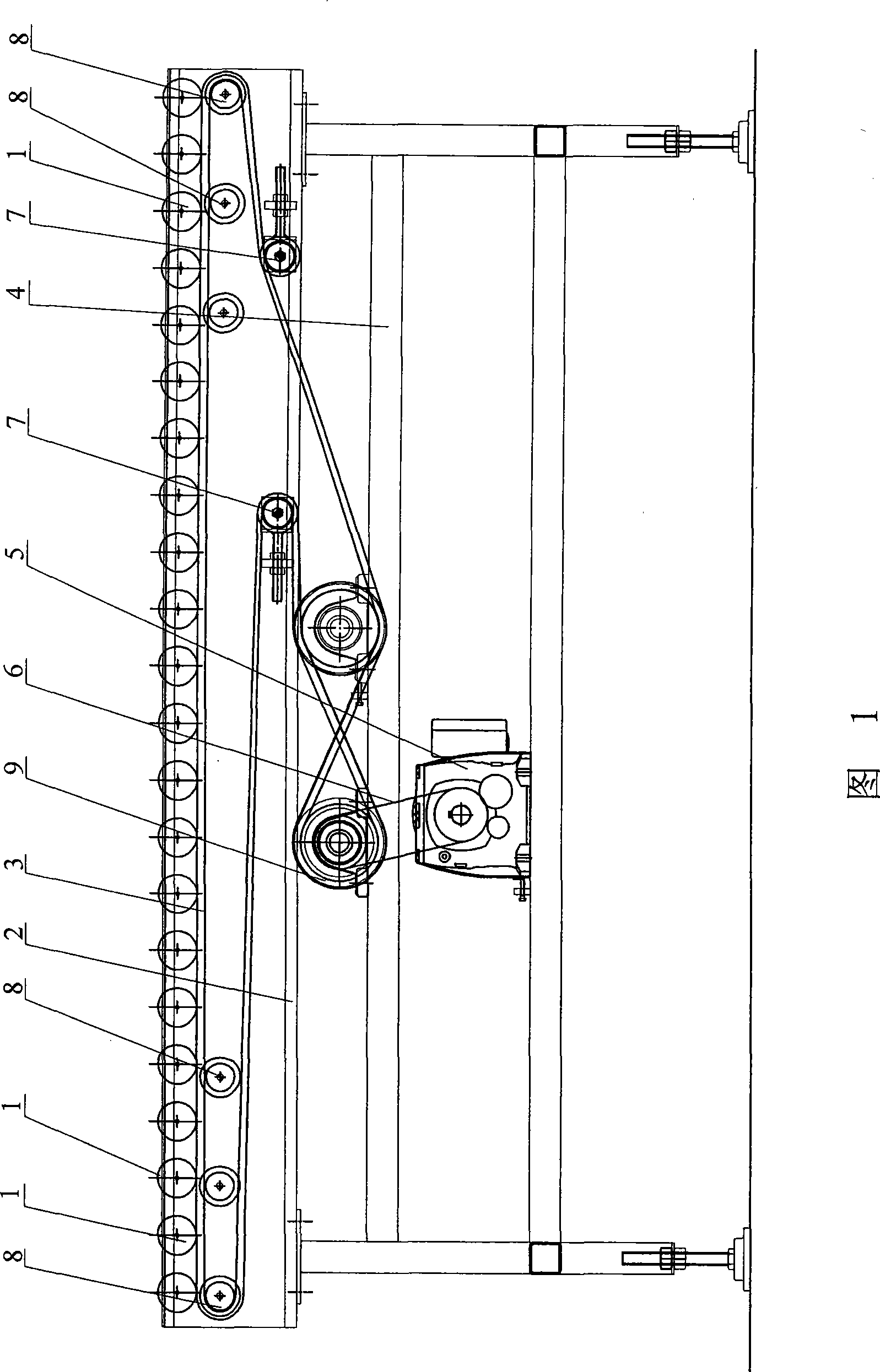

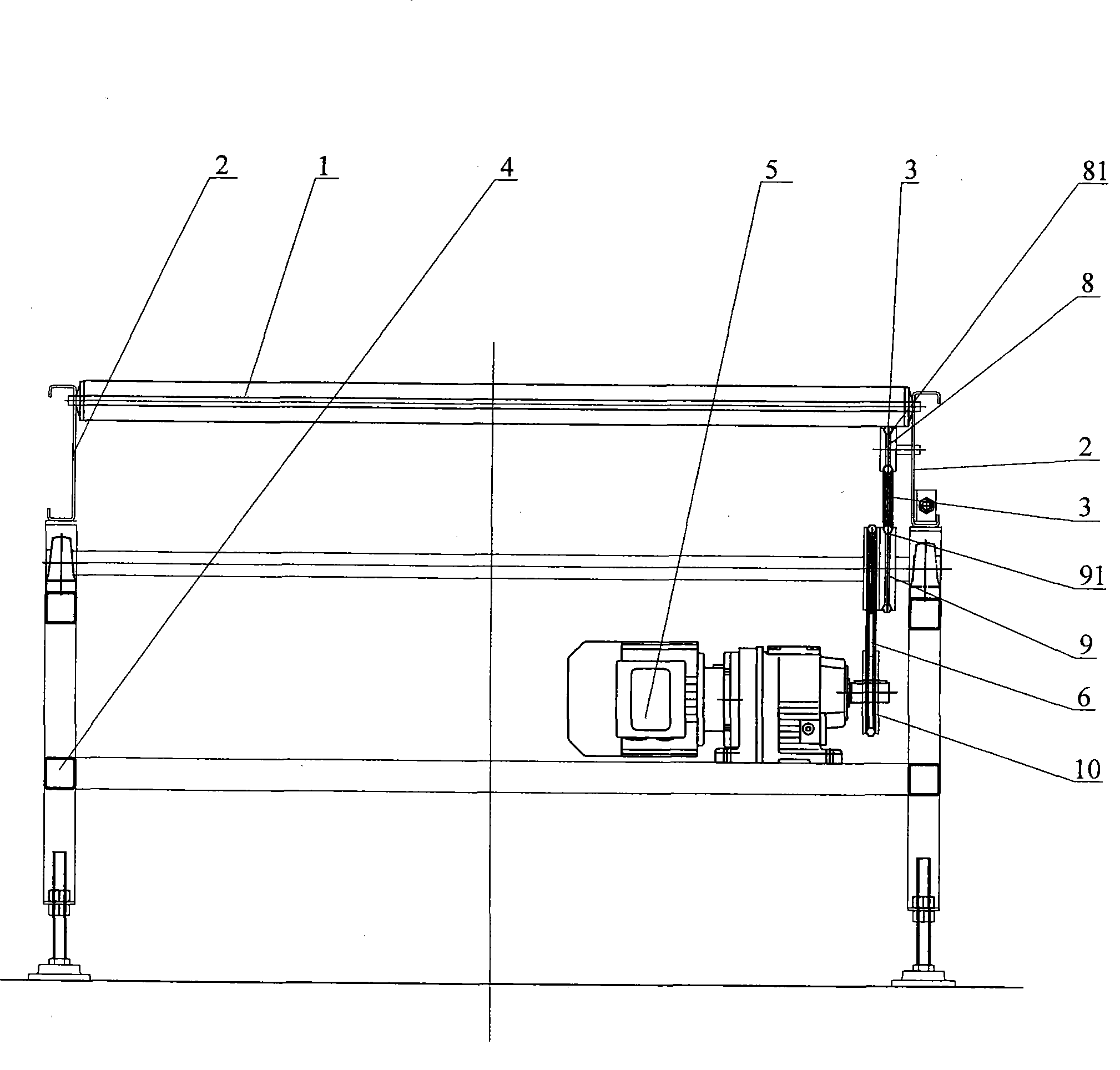

Floating synchronous curl-up film roller type seedling plastic film collector

InactiveCN101911865AAvoid secondary pollutionHigh yieldGatherer machinesWebs handlingAgricultural engineeringWheel cylinder

The invention provides a floating synchronous curl-up film roller type seedling plastic film collector which is characterized by comprising a stand. The middle part of the stand is rotatably connected with a land axle, two land wheels are respectively fixed at both ends of the land axle, a soil shaking mechanism is rotatably connected to the stand arranged above the land axle, a gripper-shaped film loosening mechanism is fixed on the stand arranged behind the soil shaking mechanism, two adjustable break shovels are respectively arranged at both sides of the front end of the stand, two U-shaped brackets are respectively fixed at both sides of the back end of the stand, a curl-up film roller is supported in the two U-shaped bracket through a curl-up film roller axle, a tension spring is respectively connected between each end of the curl-up film roller axle at the outer side of the two U-shaped brackets and the stand, a wheel cylinder which is driven by the curl-up film roller through friction is arranged below the curl-up film roller, extension ends at both ends of the wheel cylinder are rotatably connected to the stand, the extension end at one end is connected with a side land axle through a wheel cylinder transmission mechanism, and the extension end at the other end is connected with the soil shaking mechanism through a soil shaking transmission mechanism. The film curling speed of the invention is consistent with the advancing speed of a machine, thereby efficiently avoiding the phenomena of film tearing and breaking and ensuring normal continuous work of the machine.

Owner:CHINA AGRI UNIV

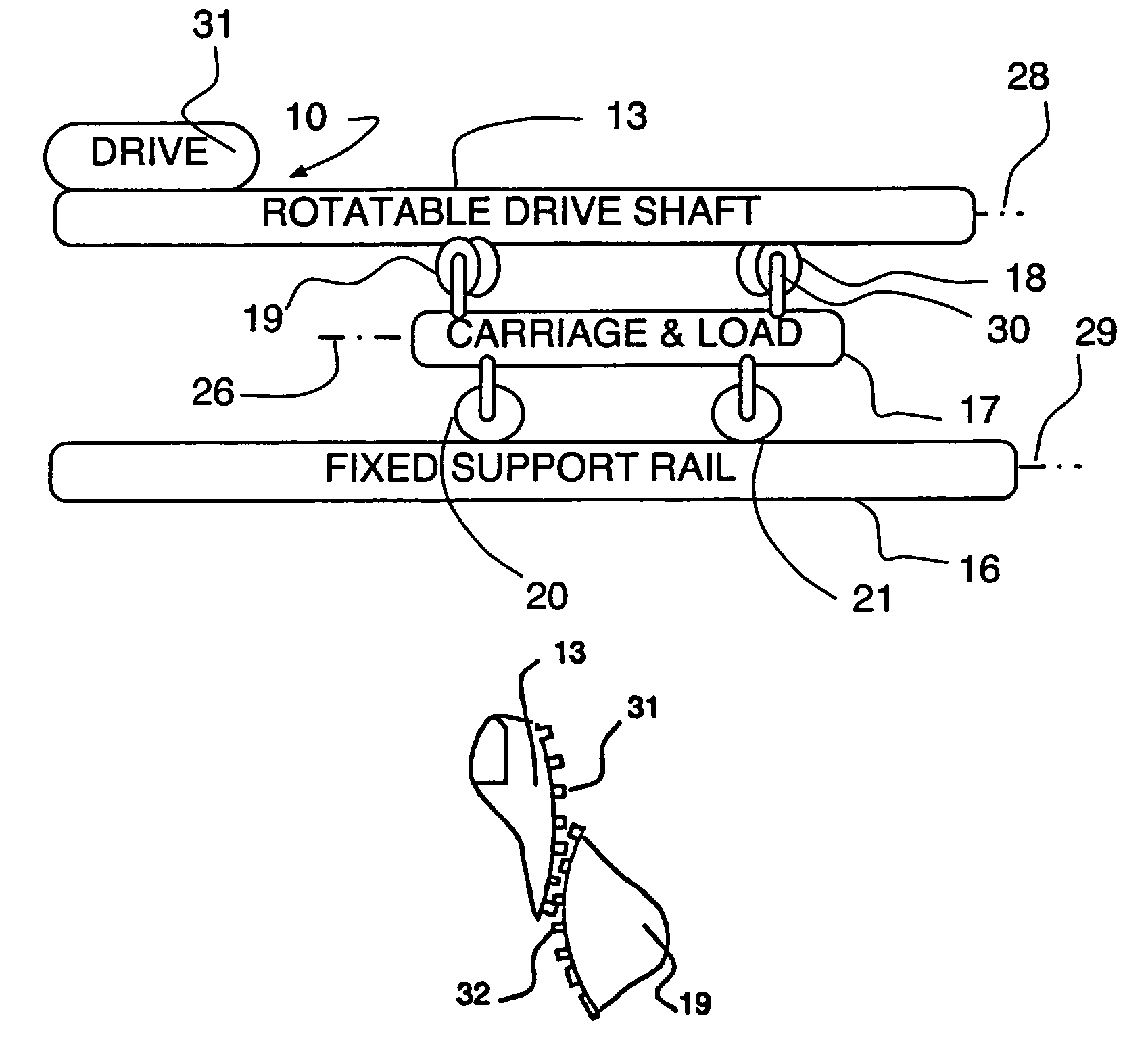

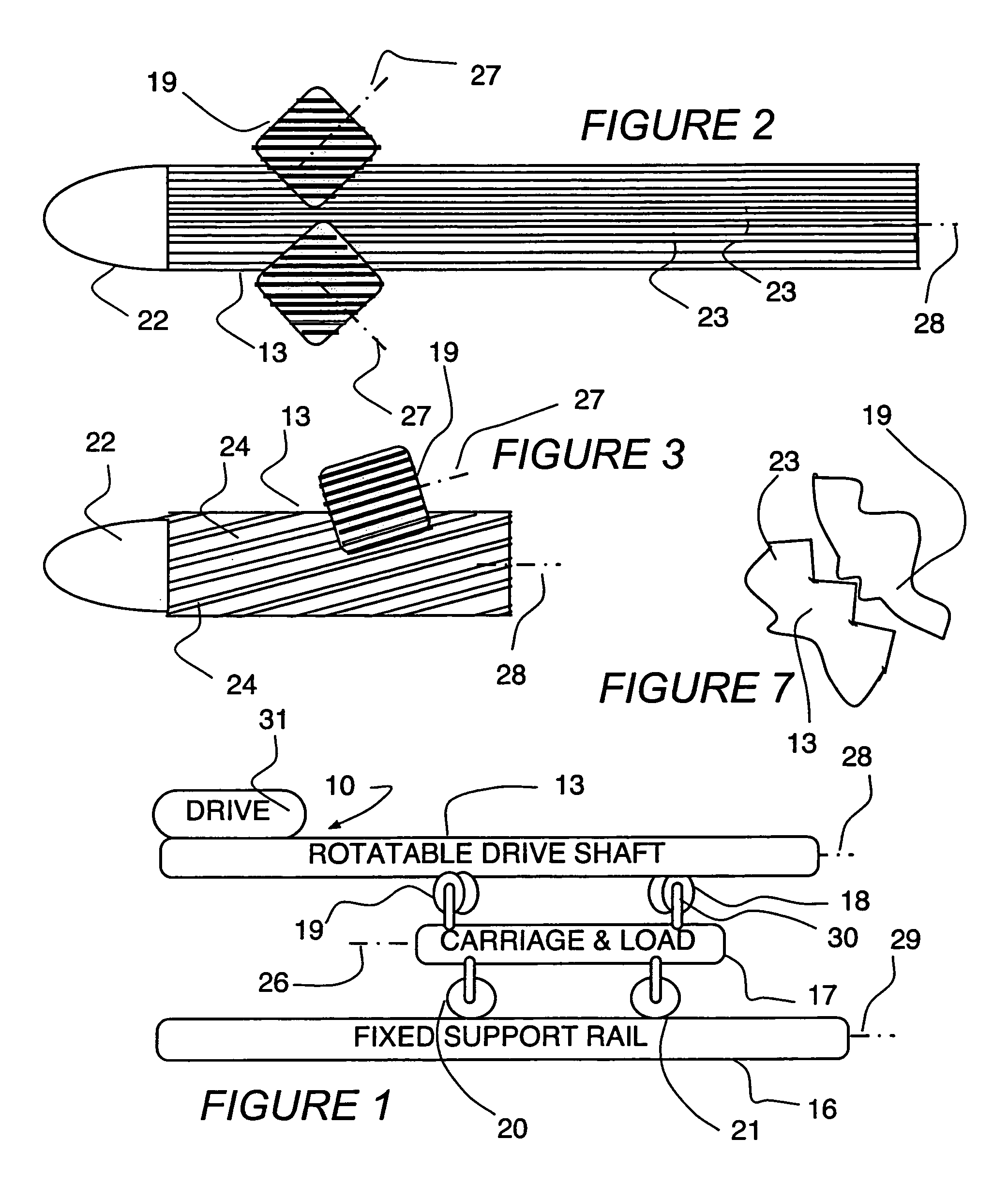

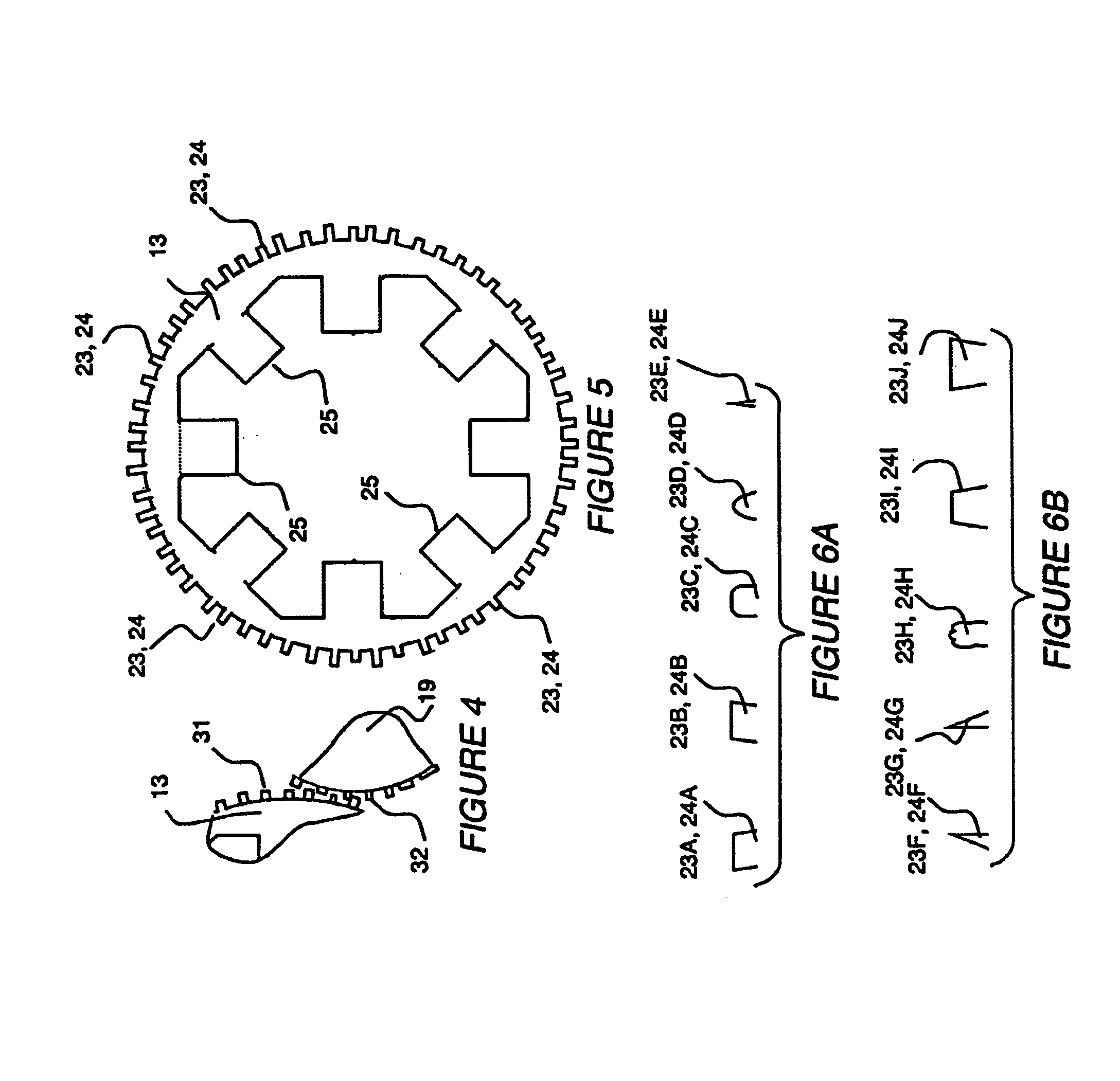

Overhead conveyer with high friction drive tube

InactiveUS7178661B2Great tractionProduction time and costRailway componentsControl devices for conveyorsDrive wheelFree rotation

An overhead rotatably powered conveyer drive shaft has ridges inter-engaged with skewed driven wheels mounted for free rotation on a load carrying carriage to trace a helical loci of engagement and improve traction. The ridges are preferably extruded to be parallel. The driven wheels may also have extruded parallel ridges or have an elastic peripheral surface deformed elastically into spaces between adjacent drive shaft ridges during normal conveying to provide the inter-engaging.

Owner:TABLER CHARLES P

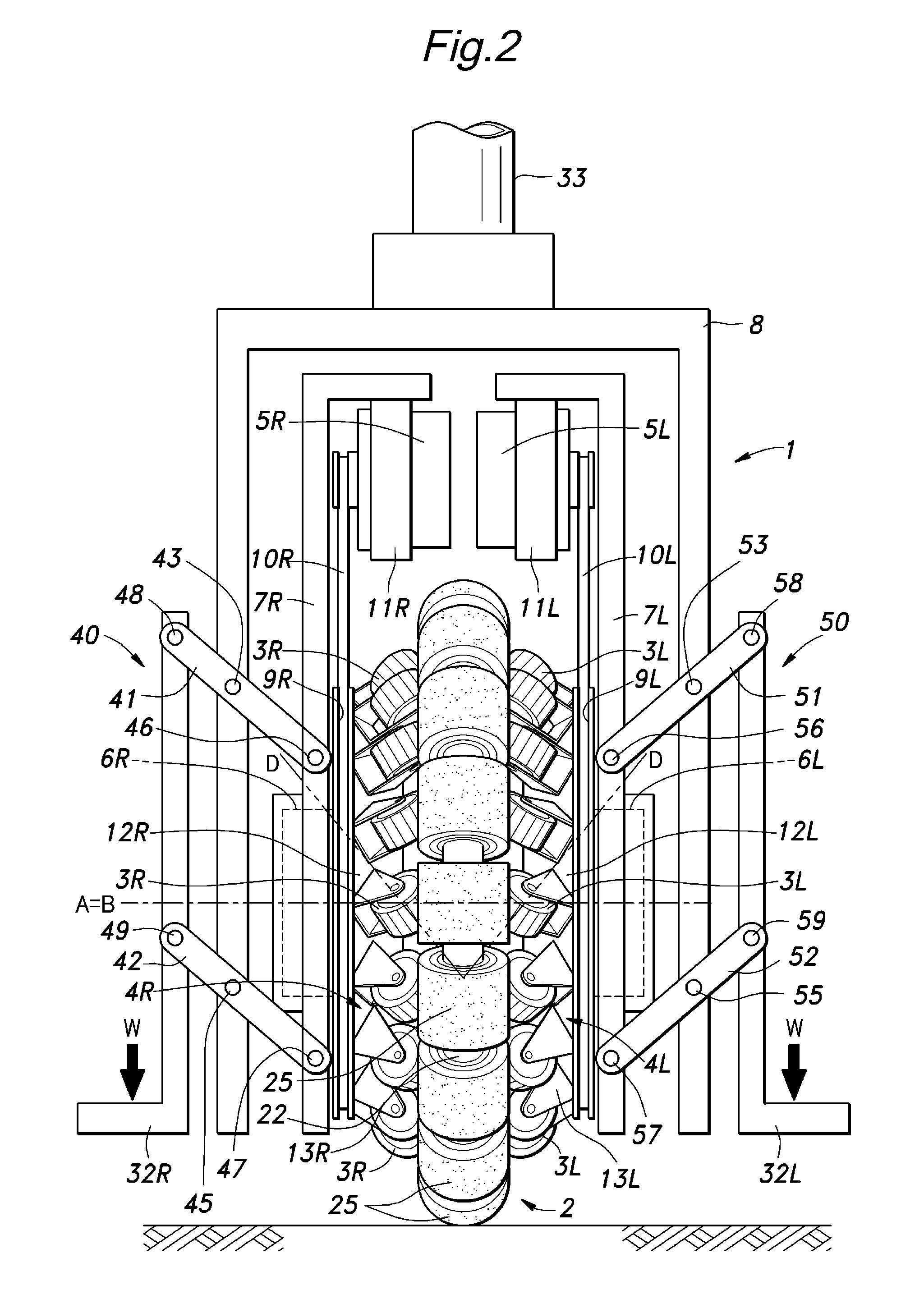

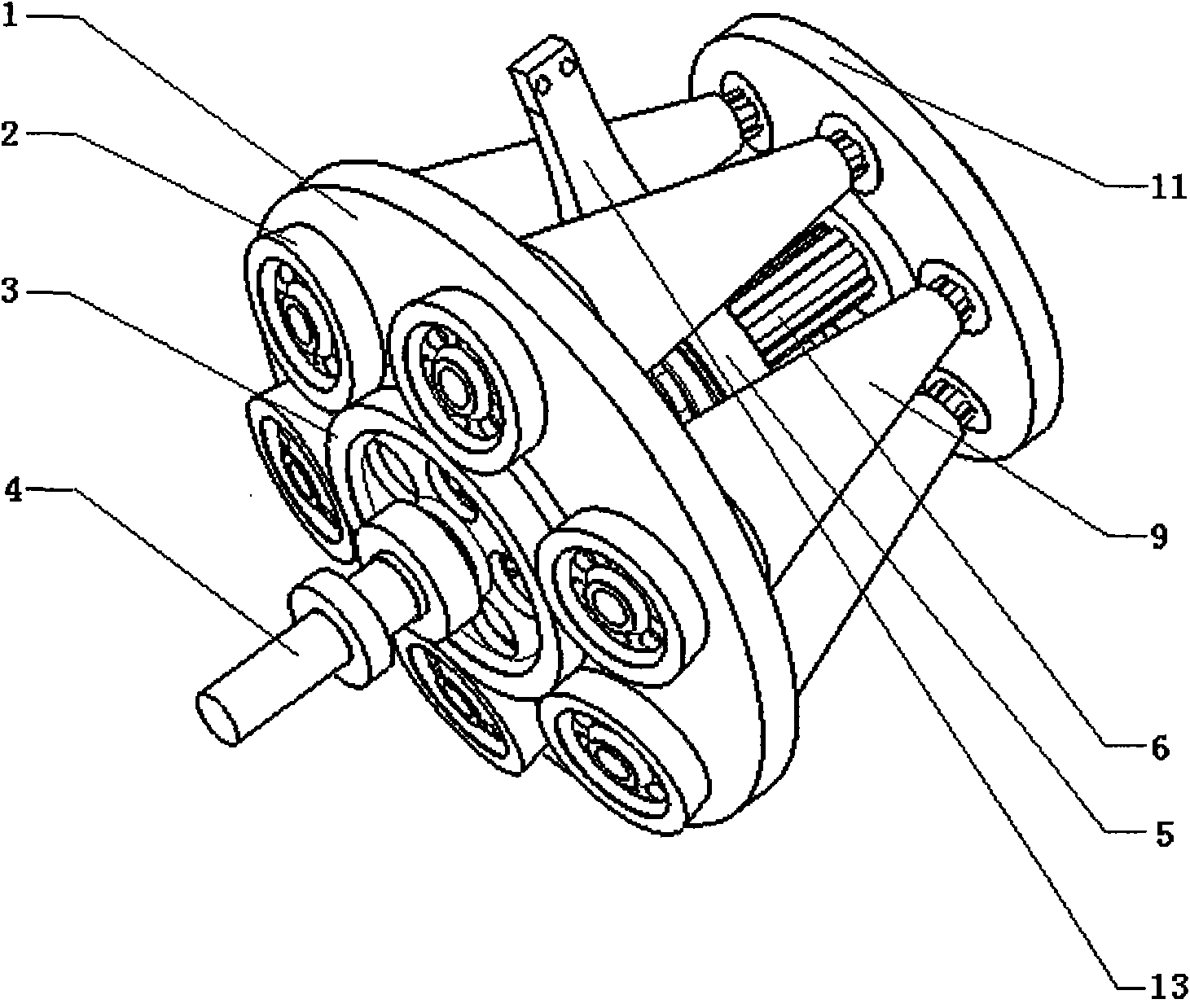

Wheel, and friction drive device and omni-directional vehicle using the same

ActiveUS20110233989A1Reduce violationsTrapped in gapFrictional rollers based transmissionUnicyclesForeign matterEngineering

Owner:HONDA MOTOR CO LTD

Frictional drive device and inverted pendulum type vehicle using the same

InactiveUS20110070997A1Improve efficiencyIncrease torqueElectric machinesWheel manufactureCentre of rotationInverted pendulum

Owner:HONDA MOTOR CO LTD

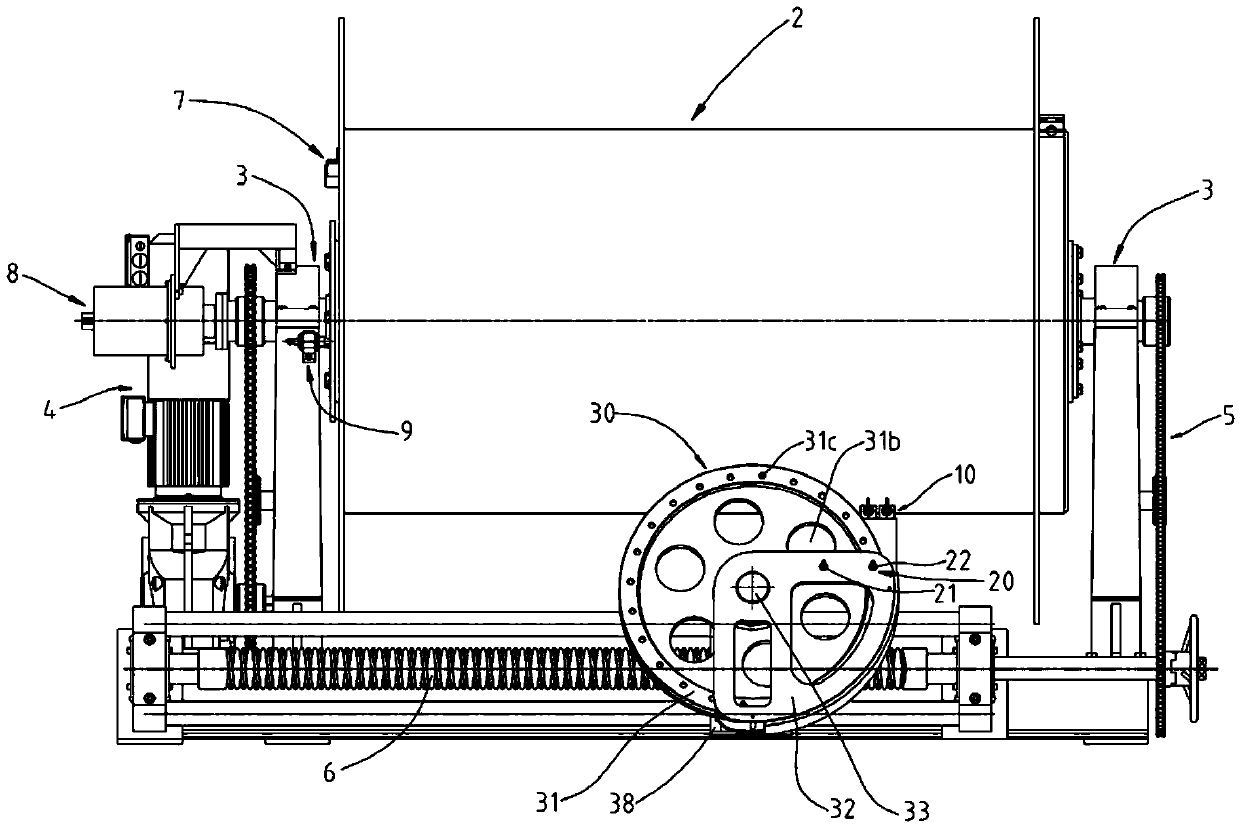

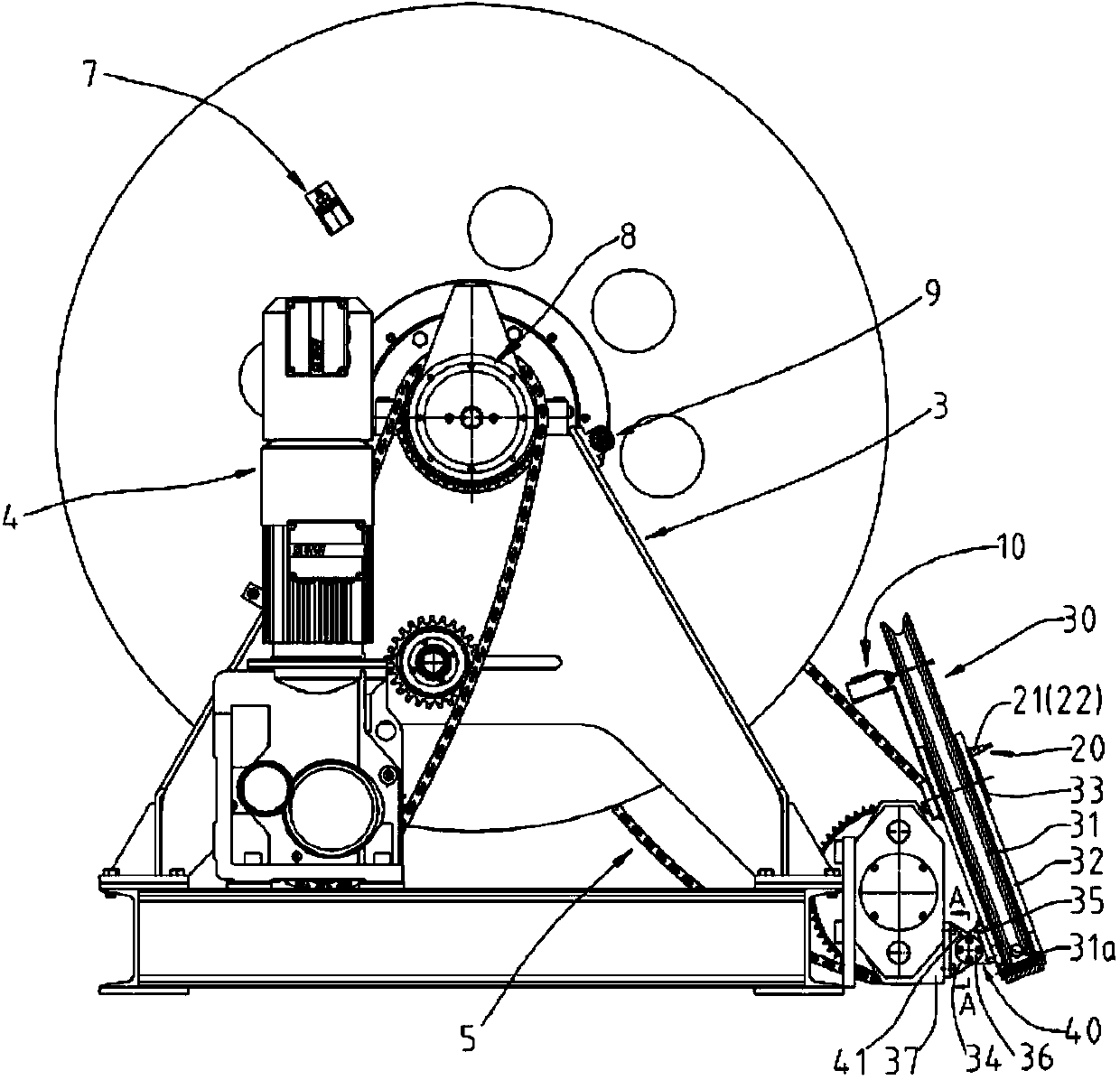

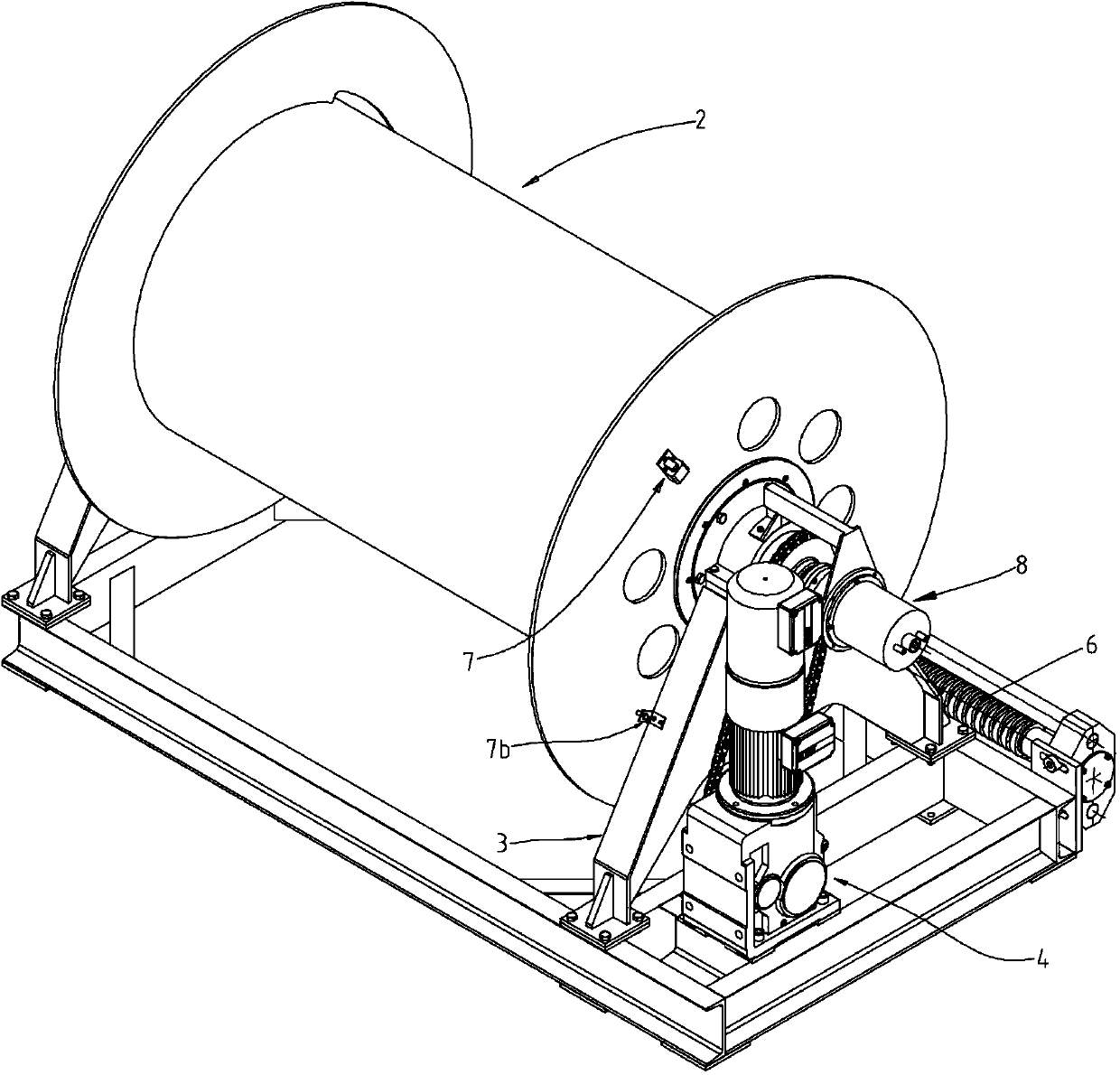

Storage winch with function of measuring tension and length of cable

InactiveCN103616048APrevent extensionPrevent slippageMeasurement devicesWinding mechanismsEngineeringLength measurement

The invention discloses a storage winch with a function of measuring tension and length of a cable. The storage winch comprises a cable storage cylinder, a support device, a cable guide device, a driving component, a cable arranging mechanism, a warning device, a power transmission communication interface connection device, a lightning attractor, a cable tension measuring device and a cable length measuring device. For cable length measurement, two lines of independent but related proximity switches are adopted for improving work reliability and measurement accuracy; for tension measurement, a pressure sensor is adopted, and force application pin rolls at two pin joint support seats between a cable guide support and a cable arranging sliding block are used for transmitting tension of the cable. The storage winch can be matched with a friction drive winch, is applicable to storage of a large volume of cables and arrangement of cables in order based on special support cables, has functions of measuring tension and laying length of the cable, protecting the cable and guaranteeing the operation safety, and meets special task requirements on large load, good safety, reliable operation, long cable laying distance, and the like.

Owner:JIANGSU UNIV OF SCI & TECH

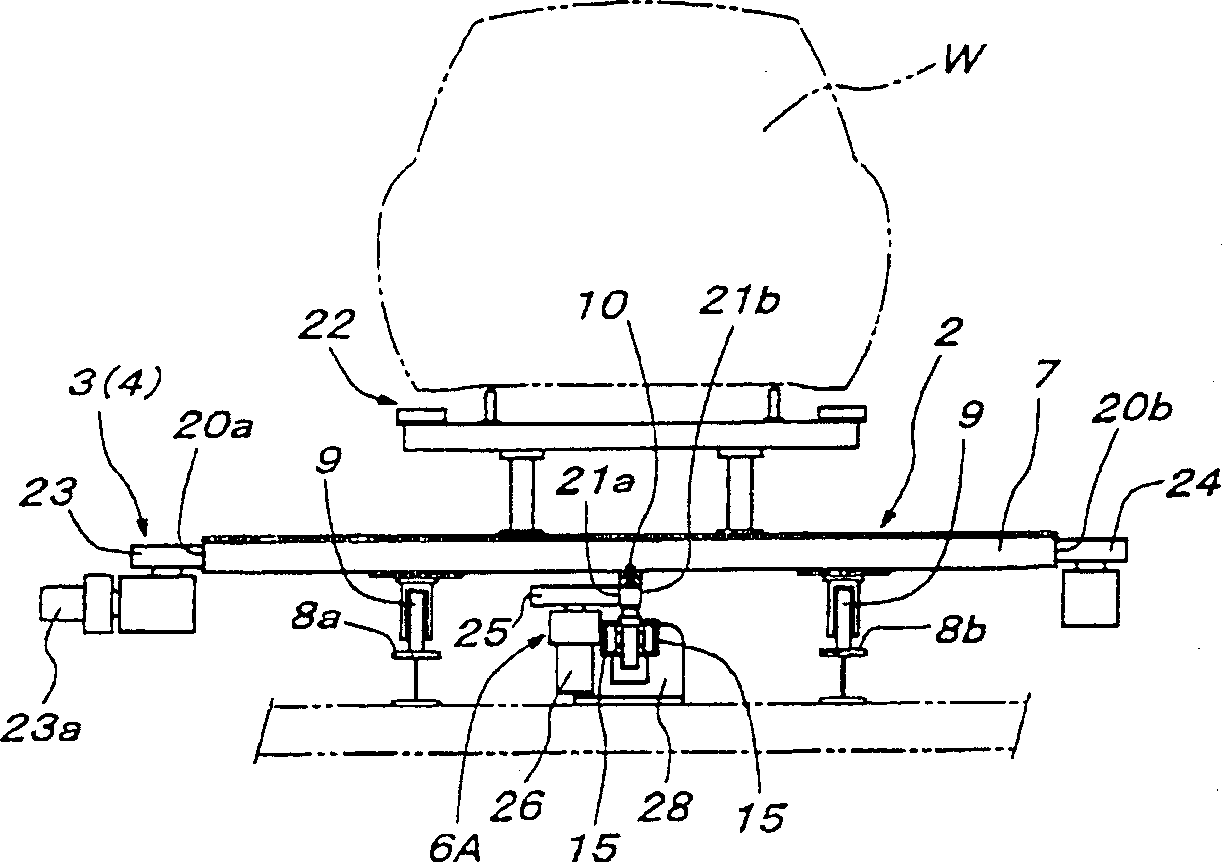

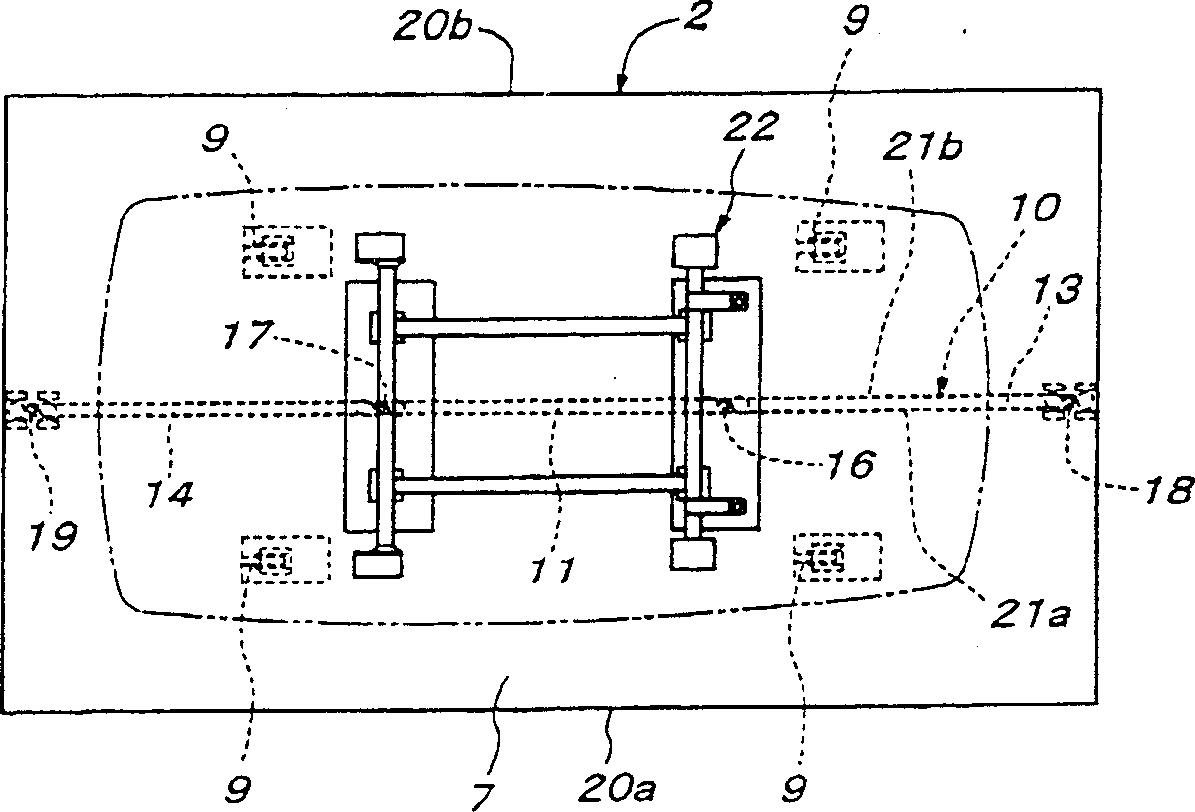

Vehicle conveyer

InactiveCN1370724ALow costSmall radius of curvatureMonorailsRailway componentsDrive wheelEngineering

The vehicle delivery device of the present invention includes a plurality of vehicles and a vehicle running line. Each vehicle includes: a vehicle floor having a main transmission friction surface, the friction surface being a side formed on or close to at least one of the left and right sides of the vehicle floor, which is parallel to the direction of travel of the vehicle; A rod extending along the centerline of the vehicle floor, the centerline being parallel to the direction of travel, the rod has a side forming a friction surface for an auxiliary drive. The running line includes a main conveyor line as a linear conveyor line or an auxiliary conveyor line. The main conveyor line is equipped with a transmission device used as a main driving force. drive wheel. The auxiliary conveying line is equipped with a plurality of transmission devices used as auxiliary driving force, and each transmission device includes a friction drive wheel for pressure contact with the friction surface of the vehicle. The transmissions are arranged at intervals in the direction of travel.

Owner:DAIFUKU CO LTD

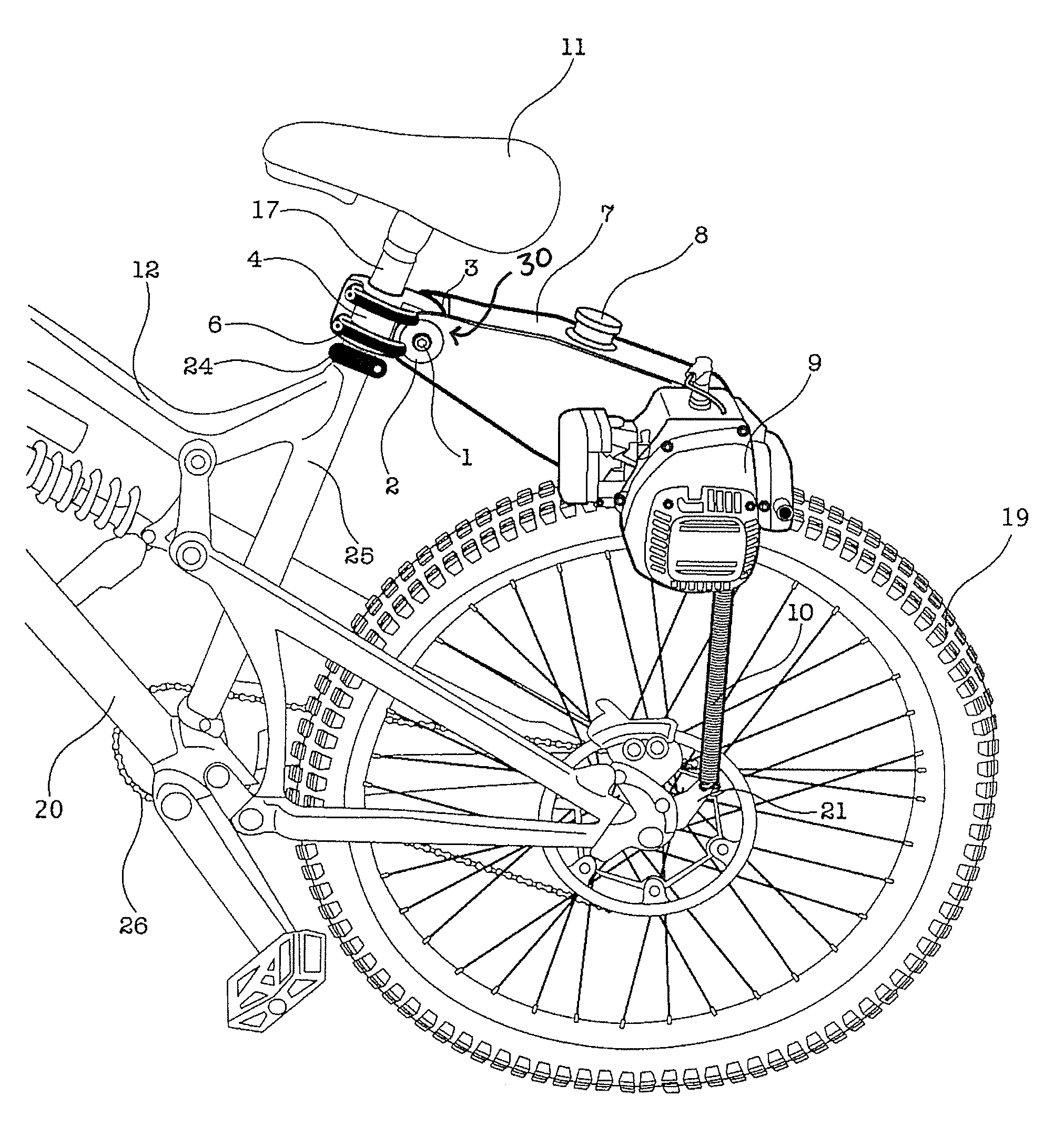

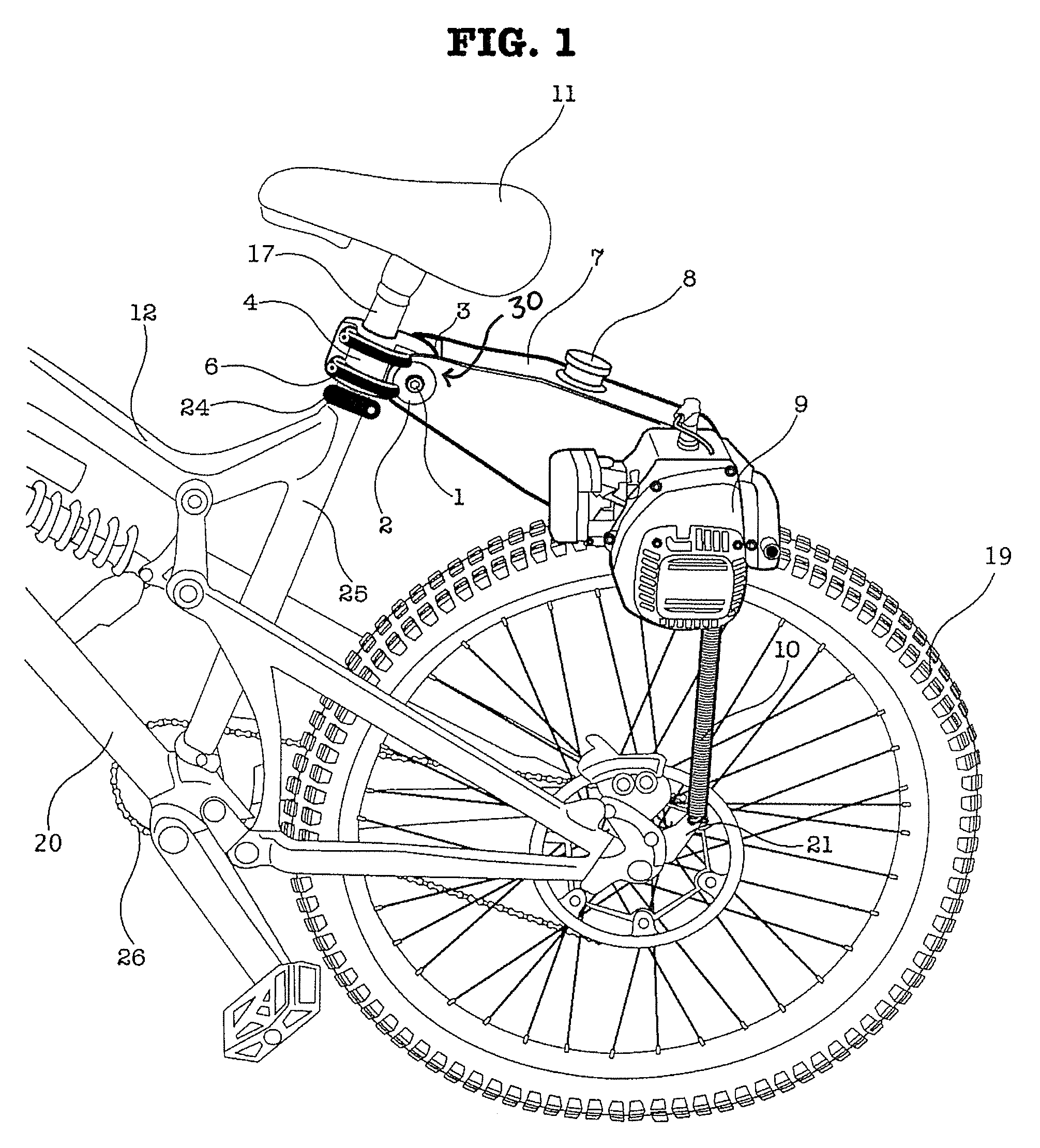

Auxiliary power driven unit for a bicycle

An auxiliary, removable, modular power drive unit has a pivot point that can be attached to any bicycle or vehicle by way of a quick release clamp system. The power for the drive system may be derived from an internal combustion engine or electric motor. The power developed by the engine or motor is delivered to the rear wheel of a bicycle by a friction drive wheel that presses directly onto the tire of the bicycle. The power unit may utilize a clamp joined to an integrated fuel cell by a pivot point, causing the fuel cell to act as a swing arm and a motor mount. This enables the fuel cell to move up and down to compensate for different tire sizes, variations in road conditions, or movement of a suspension system of the bicycle due to imperfections in terrain.

Owner:DUIGNAN MICHAEL DALE

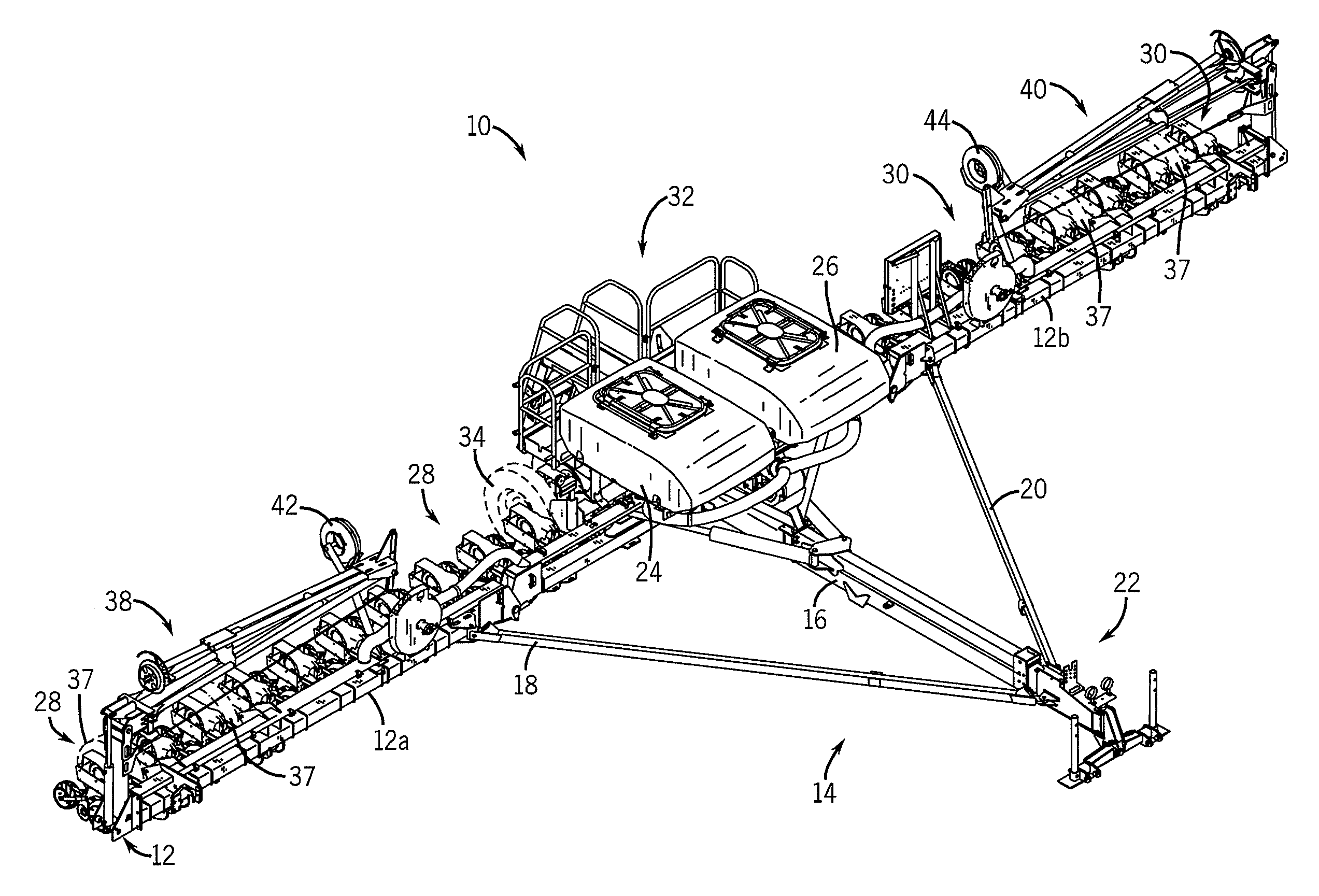

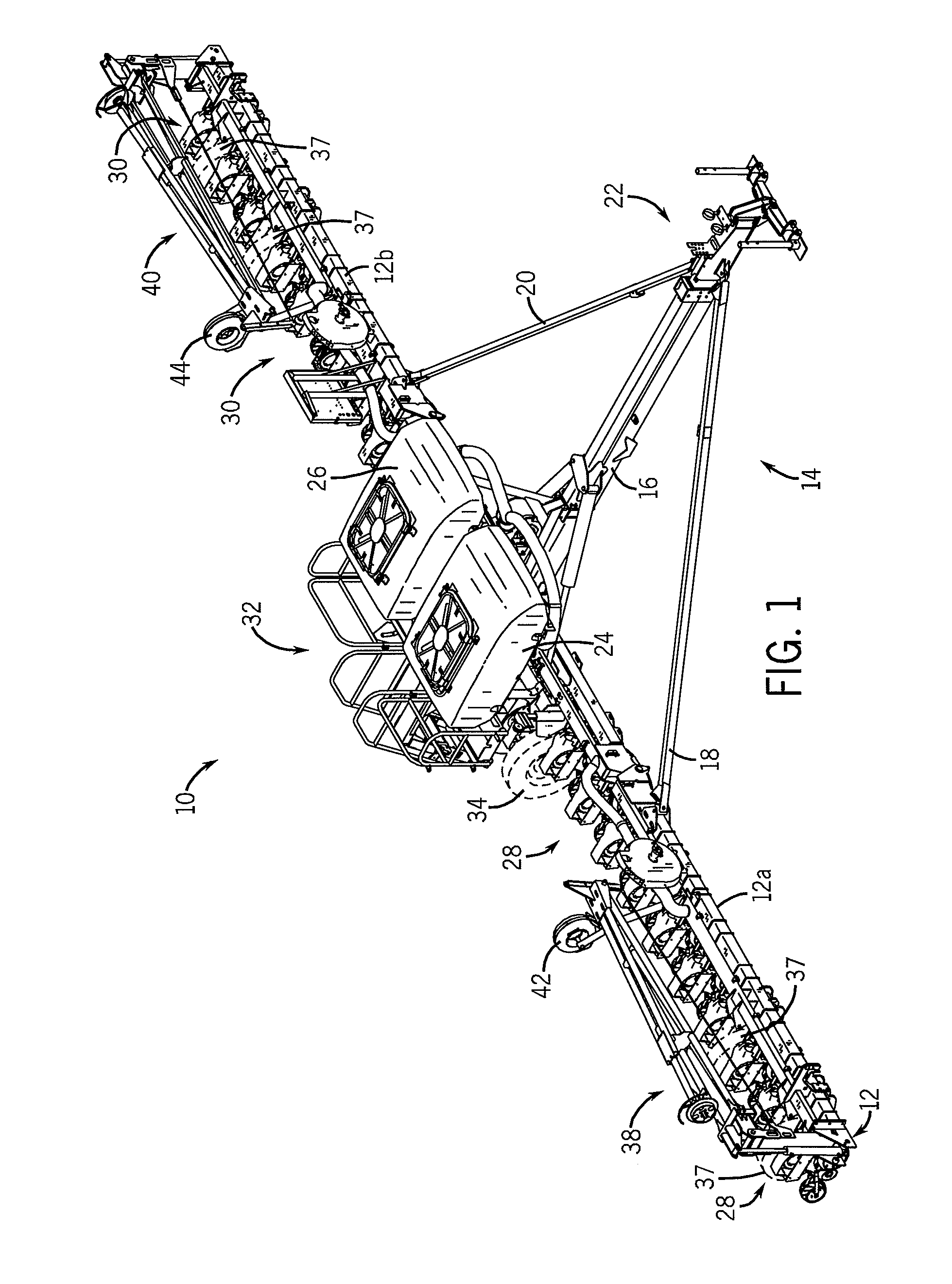

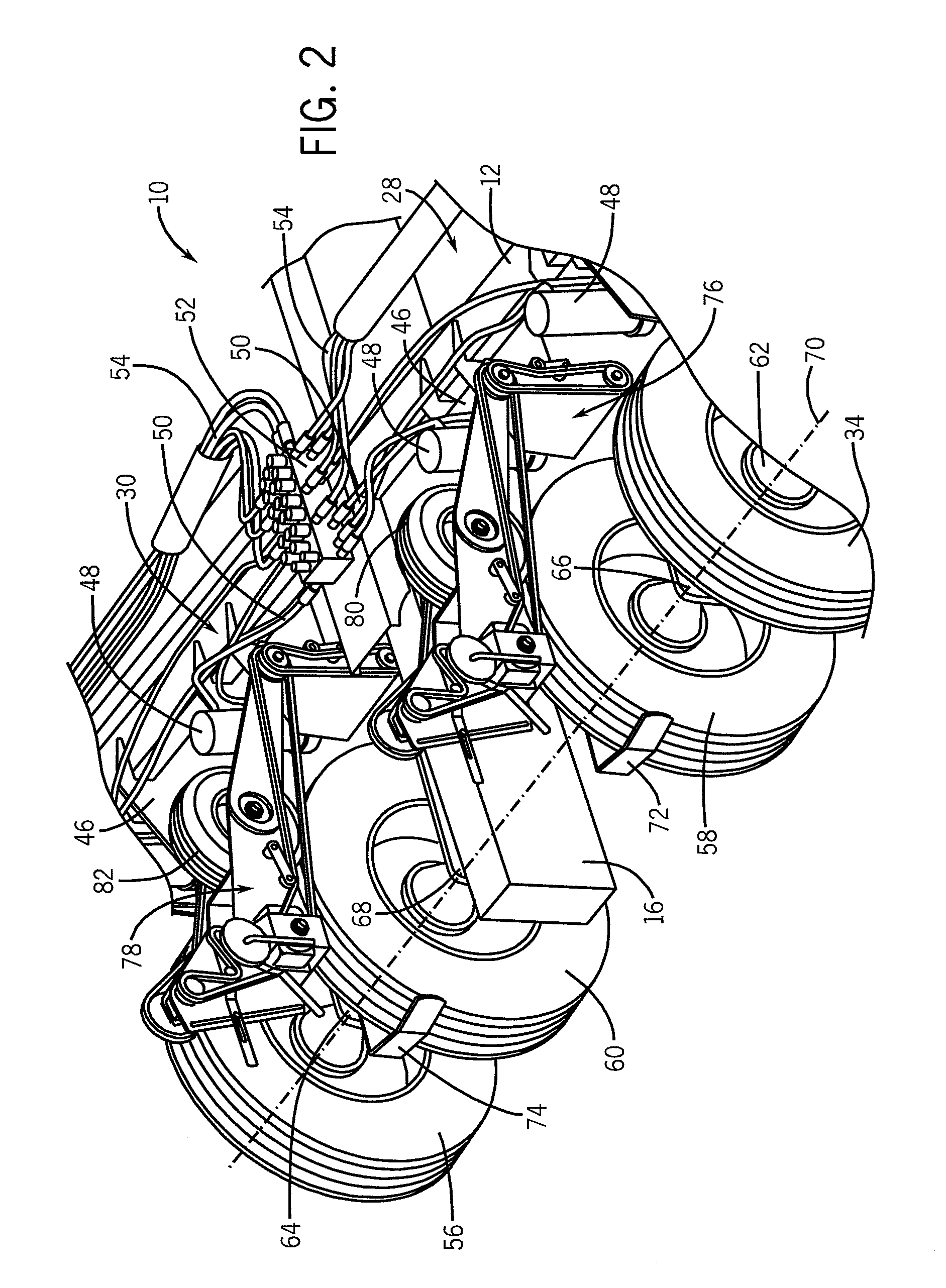

Friction drive population control for a planter

A friction drive for an agricultural planter has a linear actuator, which may be hydraulically or pneumatically controlled, to selectively raise or lower a drive wheel into frictional engagement with a carrying wheel. A valve network is fluidly associated with the linear actuator and allows the operator or pilot to variably define the degree of frictional engagement. This allows the operator to vary the amount of frictional engagement of the drive wheel and the carrying wheel, the output of which is used by a material dispensing system to deposited planting material onto a planting surface.

Owner:BLUE LEAF I P INC +1

Stacking roller conveyor

The invention relates to a power-and-free roller conveyor belonging to the conveyor field. Mounting plates are arranged by interval on both the inner side and the outer side of the upper end of a frame; rollers are arranged parallel on the mounting plates of the inner and outer sides and all the axes of rollers are on the same plane; drive rollers are rotationally connected on the mounting plates of at least one side and the drive rollers are arranged below the rollers of both head part and tail part on the conveying direction; a first depression is arranged on the outer walls of the drive rollers, driven rollers are rotationally connected with the frame and a second depression is arranged on the outer walls of the driven rollers. An annular friction conveying-belt is respectively embedded inside the first depression and second depression. The friction conveying-belt is extended from the first depression to contact the outer walls of rollers and drive rollers; a driving apparatus is arranged on the frame and a driving wheel matching with the driven rollers is arranged on an output shaft of the driving apparatus; and a friction driving belt is respectively arranged around the driven rollers and drive rollers. The roller conveyor can largely reduce the investment cost for equipment and enhance the use environment of equipment.

Owner:MIRACLE AUTOMATION ENG CO LTD

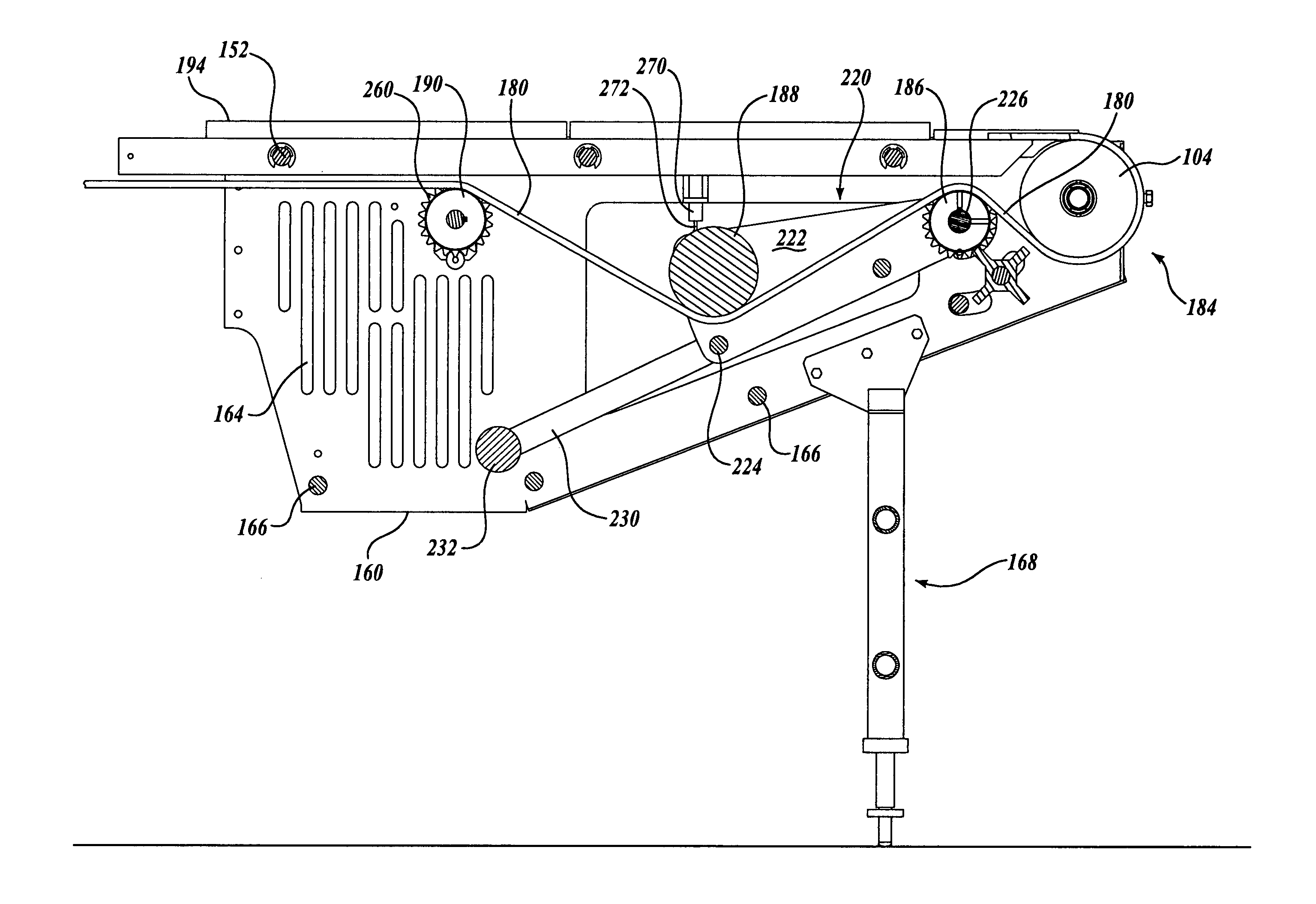

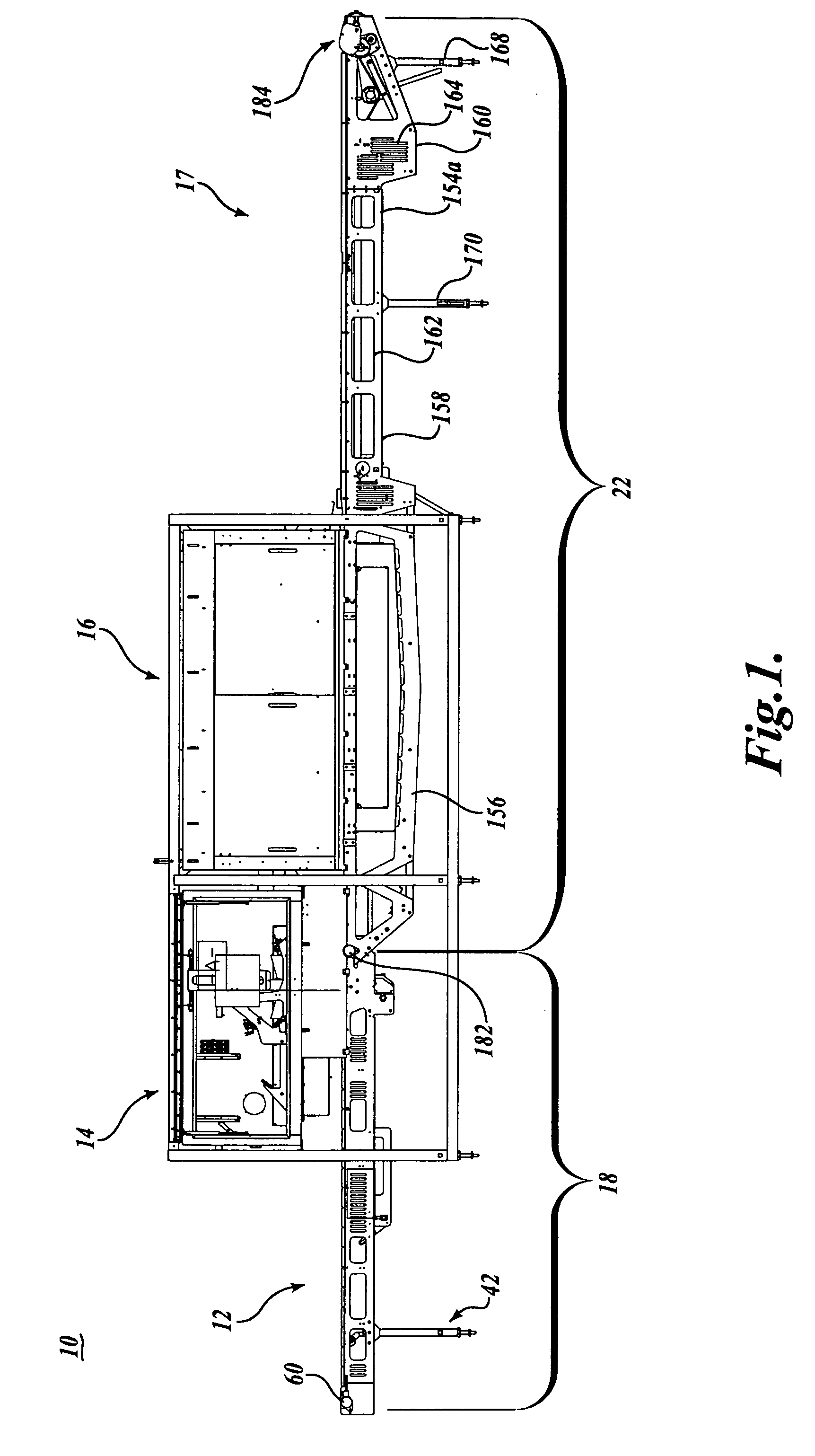

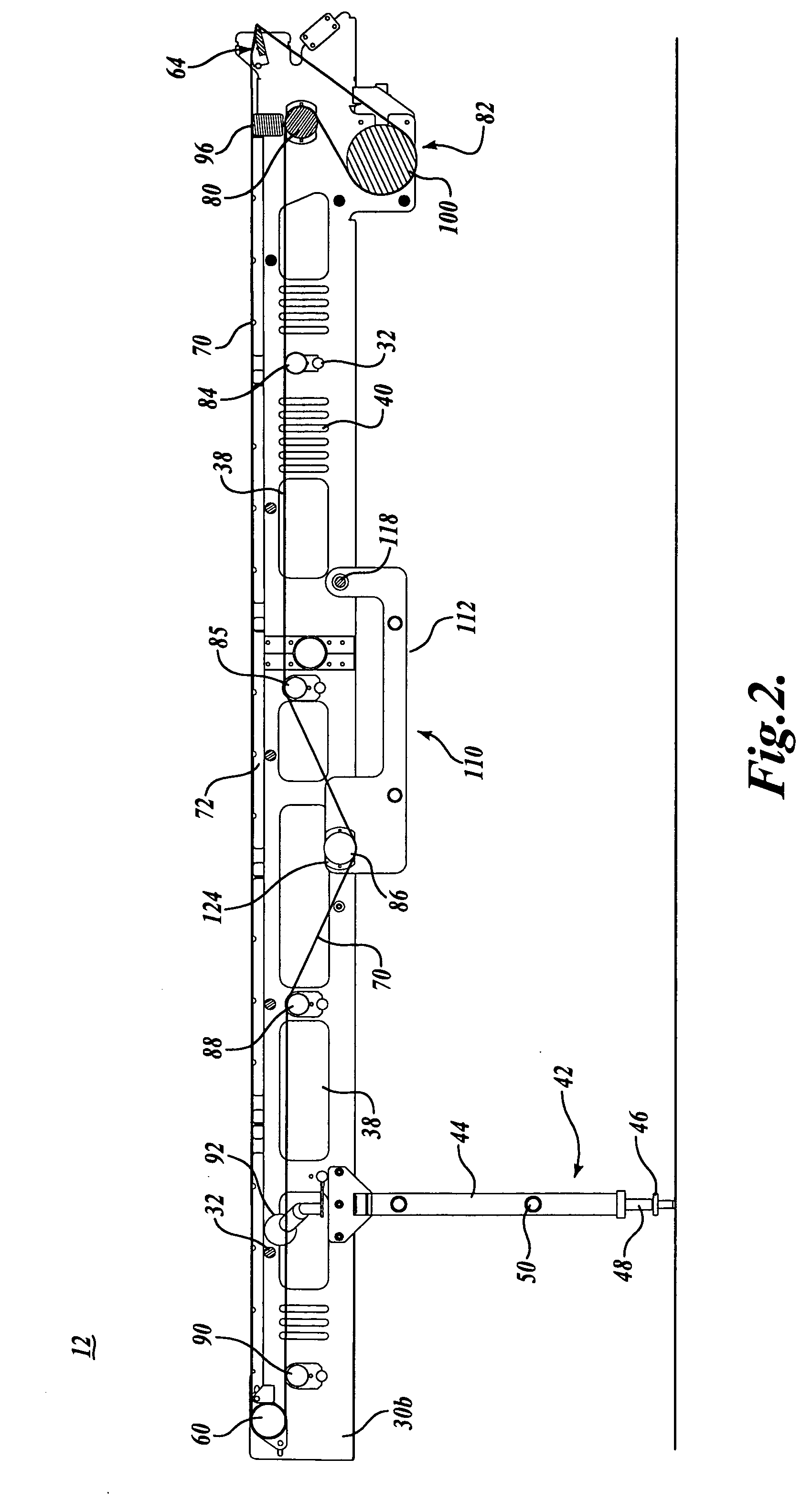

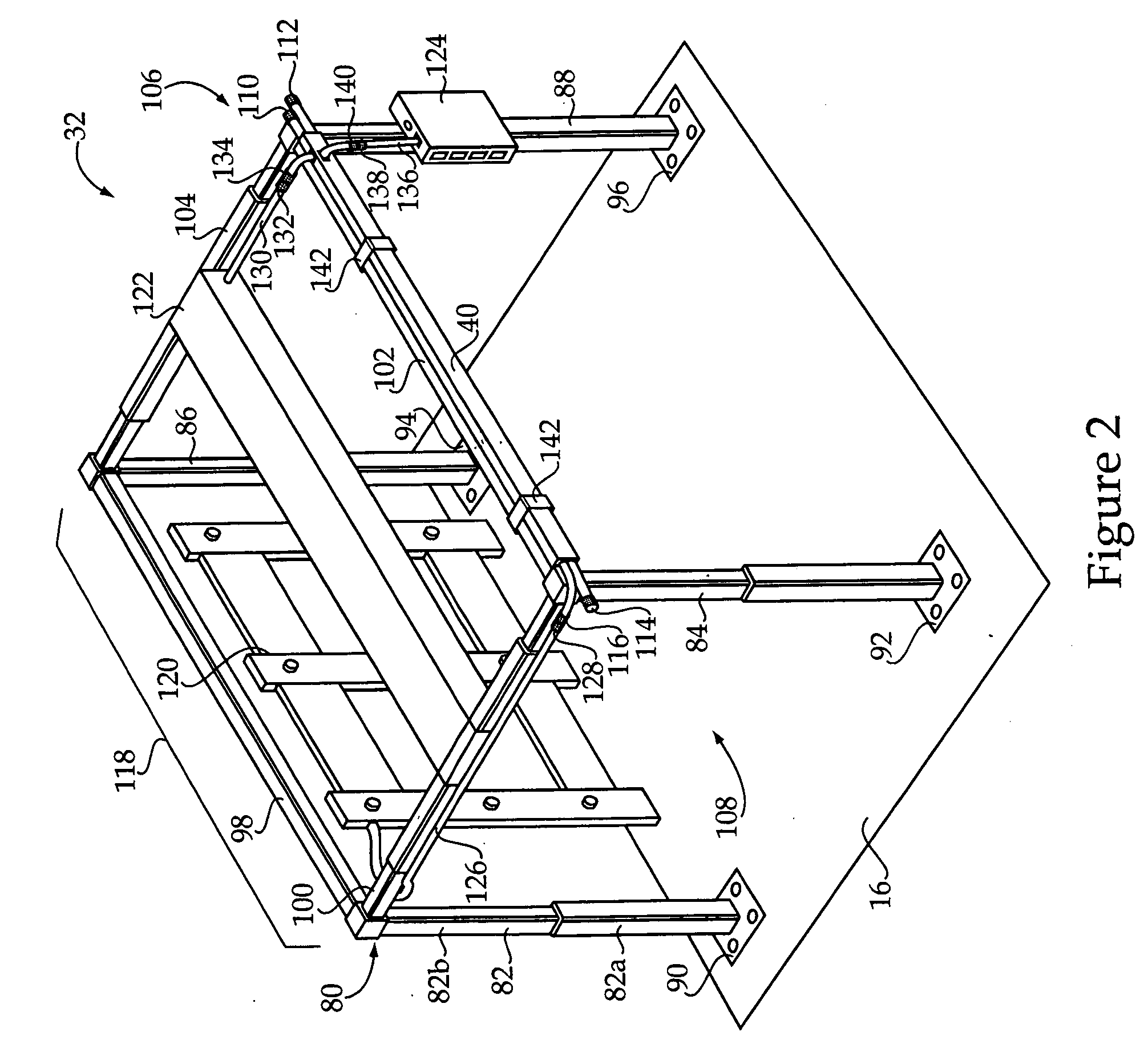

Friction drive conveyor

InactiveUS20050077152A1Avoid insufficient frictionReduce vibrationMetal sawing devicesAutomatic control devicesEngineeringFriction drive

A conveyor 12 includes an infeed / scanning section (18) and a cutting / outfeed section (22). Both sections have an endless belt (70) and (180) each driven by a friction drive roller (100) and (200). Adequate frictional load is applied between the endless belts and corresponding drive rollers by tension assemblies, each having a tensioning roller (86), (188) rotatably mounted on a pivot frame structure (112), (220) allowing the weight of the tensioning roller to be applied to the return run of the endless belts. Dampeners (130) (270) are integrated with the tensioning rollers (86) (188) to dampen vibrations in the endless belts (70) (180).

Owner:JOHN BEAN TECH CORP

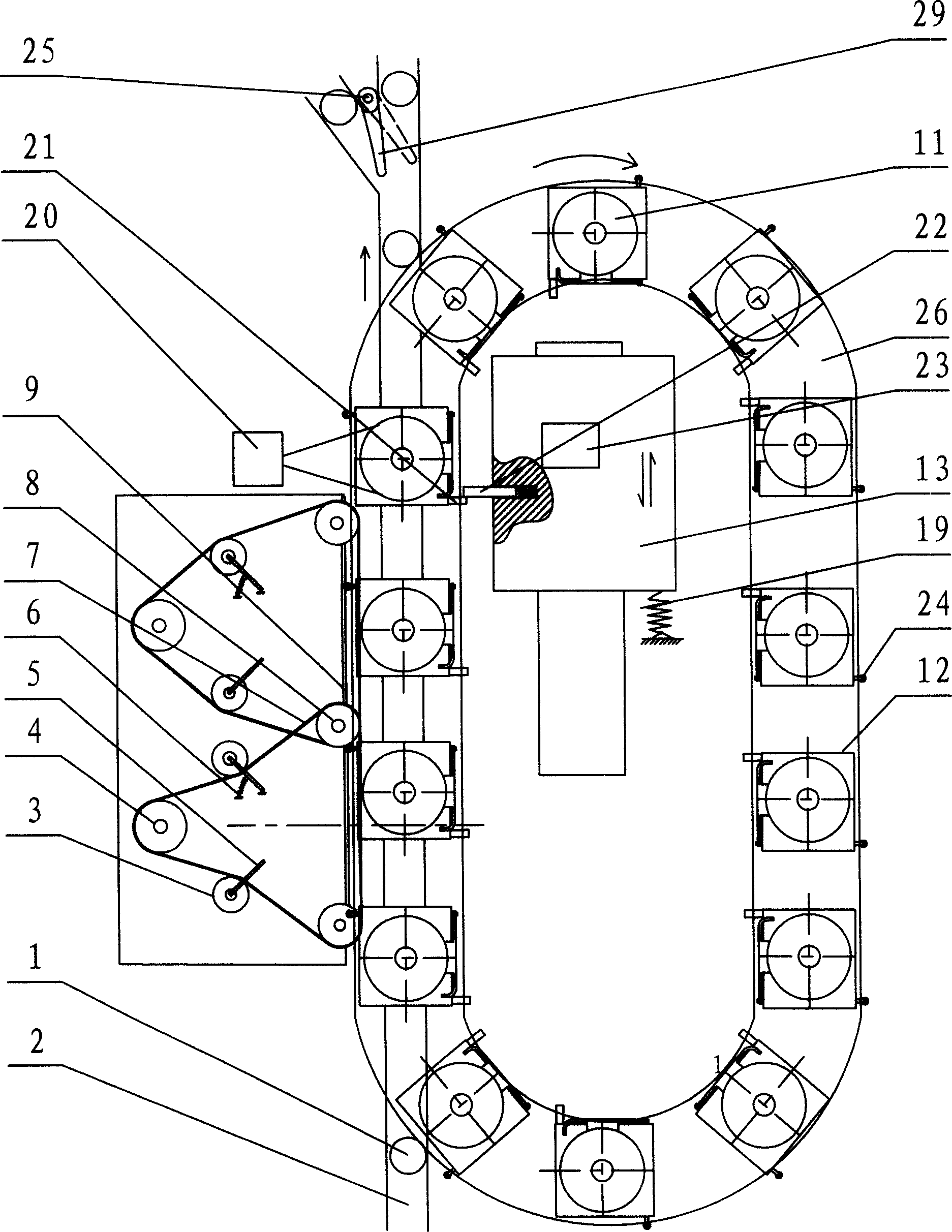

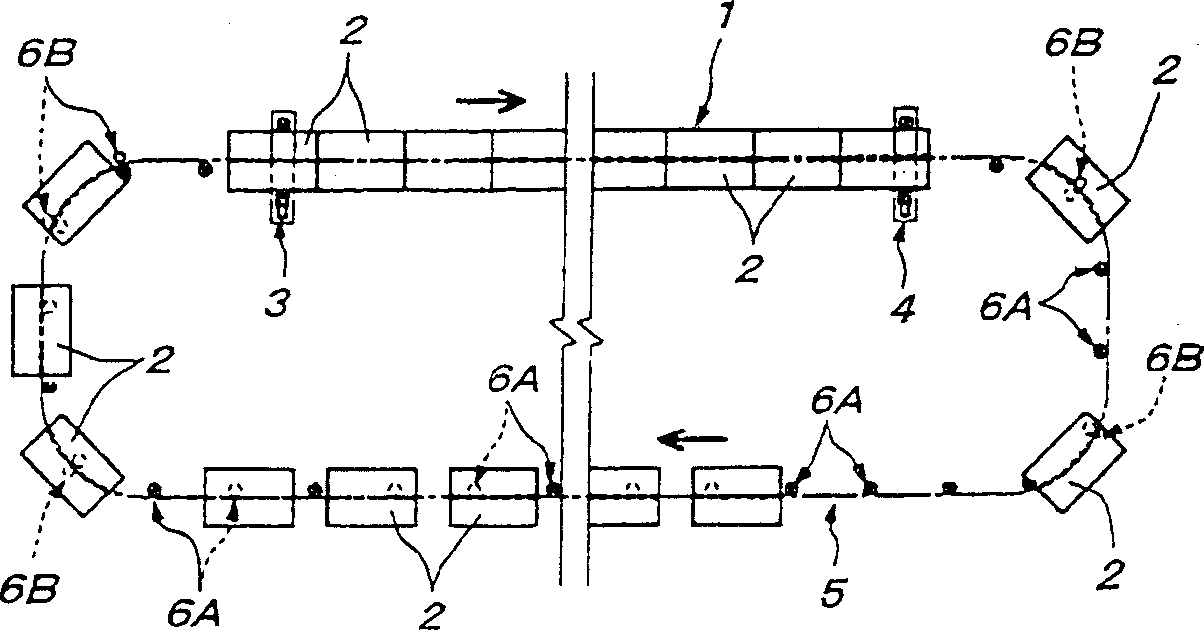

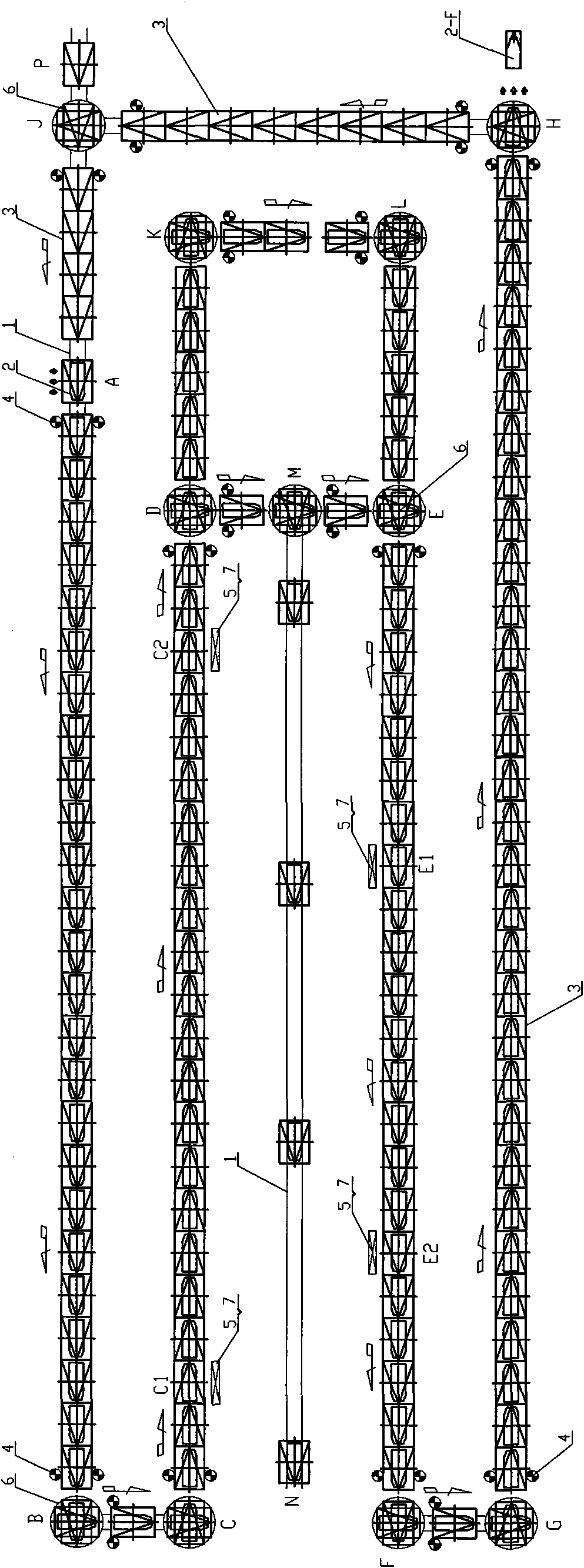

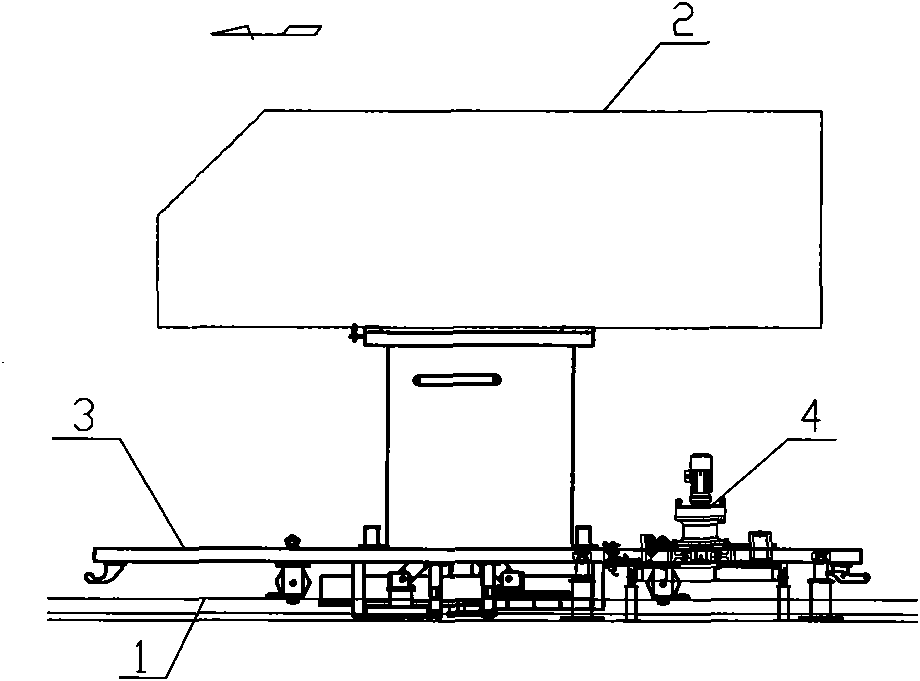

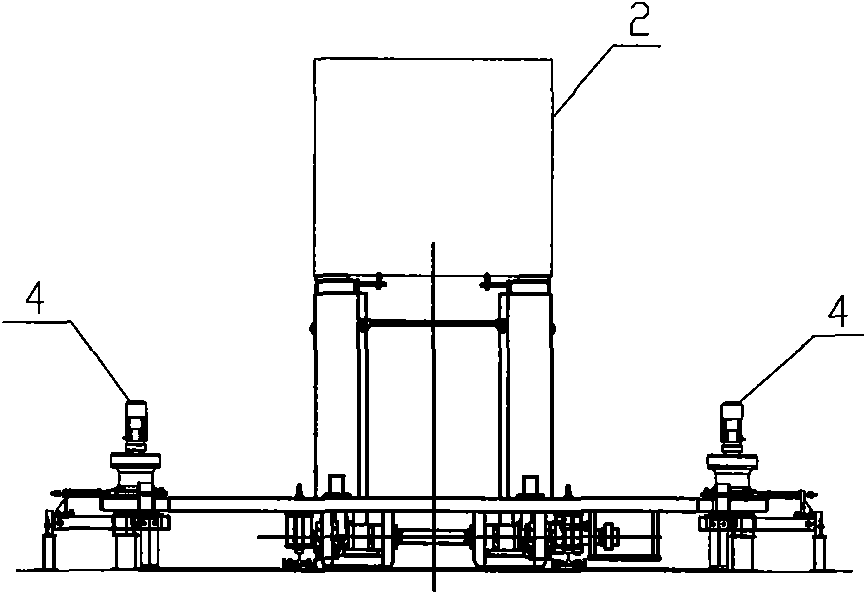

Trolley flexible transport system and application method thereof

ActiveCN102019975AAvoid conversionImprove quality and efficiencyVehiclesProduction lineTransport system

The invention discloses a trolley flexible transport system and an application method thereof. A plurality of trolleys are arranged on an orbit which is arranged in advance; a rotary table is arranged on the bent part of the orbit; a friction drive device drives the trolleys to run and the rotary table to rotate; and bilateral combined lifting devices are arranged on the trolleys, so that a full floor type assembly line that a workpiece only needs to be loaded and positioned at one time, and the height can be controlled through lifting is constructed. The trolleys for assembly complete omnibearing assembly operation of the workpieces of an automobile, the workpieces are loaded and positioned at one time, and the conversion between load change and position reference in the prior art is avoided; and assembly quality and the working efficiency are improved. A floor running mode is adopted in the trolleys serving as main equipment and the rotary table and completely replaces a suspension transportation mode in the prior art, so that a large number of steel structure lifting devices are reduced, the hoist load of plants is greatly reduced, engineering investment is reduced, and the construction period is shortened. The layout design of the production line is more flexible and practical.

Owner:大福(中国)自动化设备有限公司

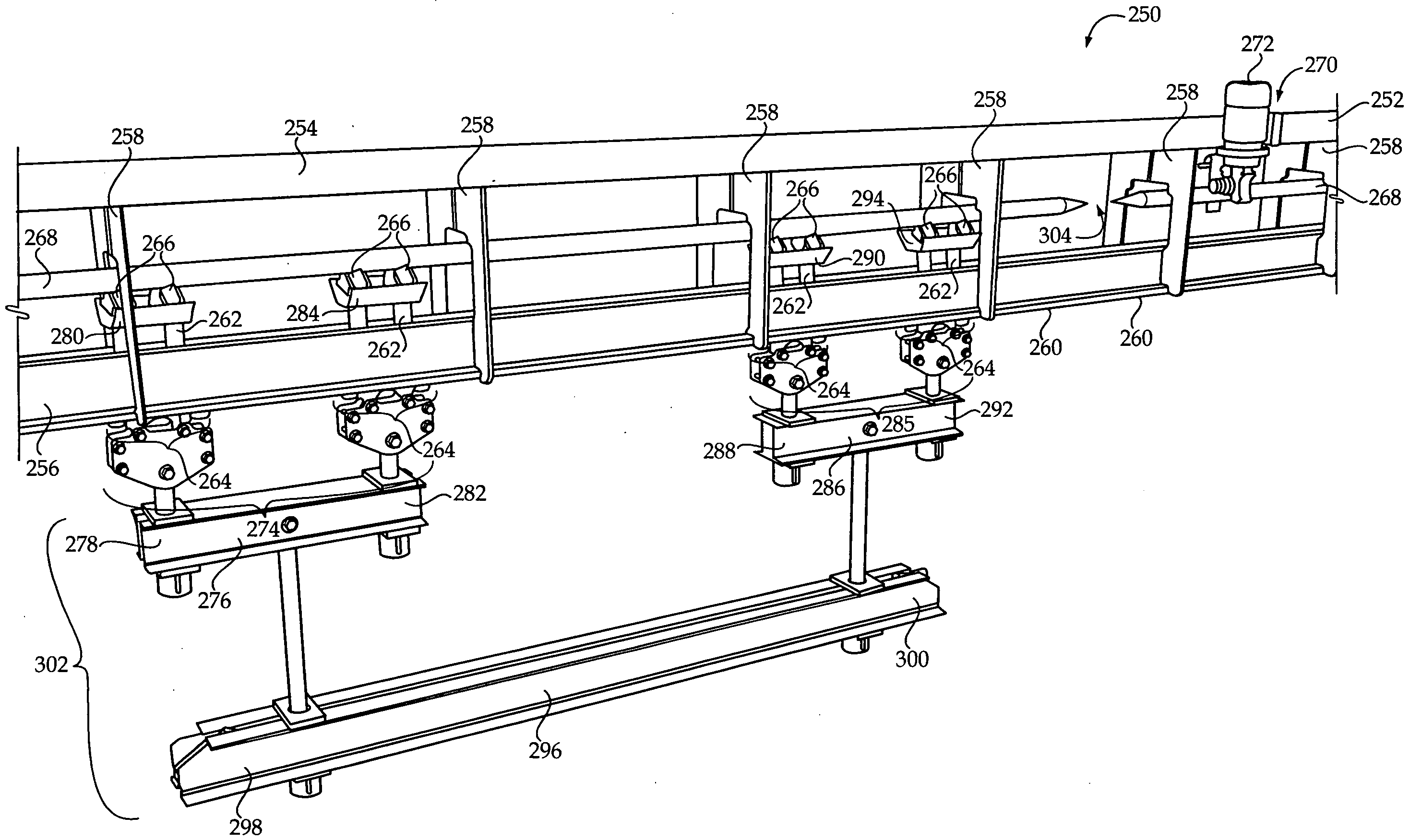

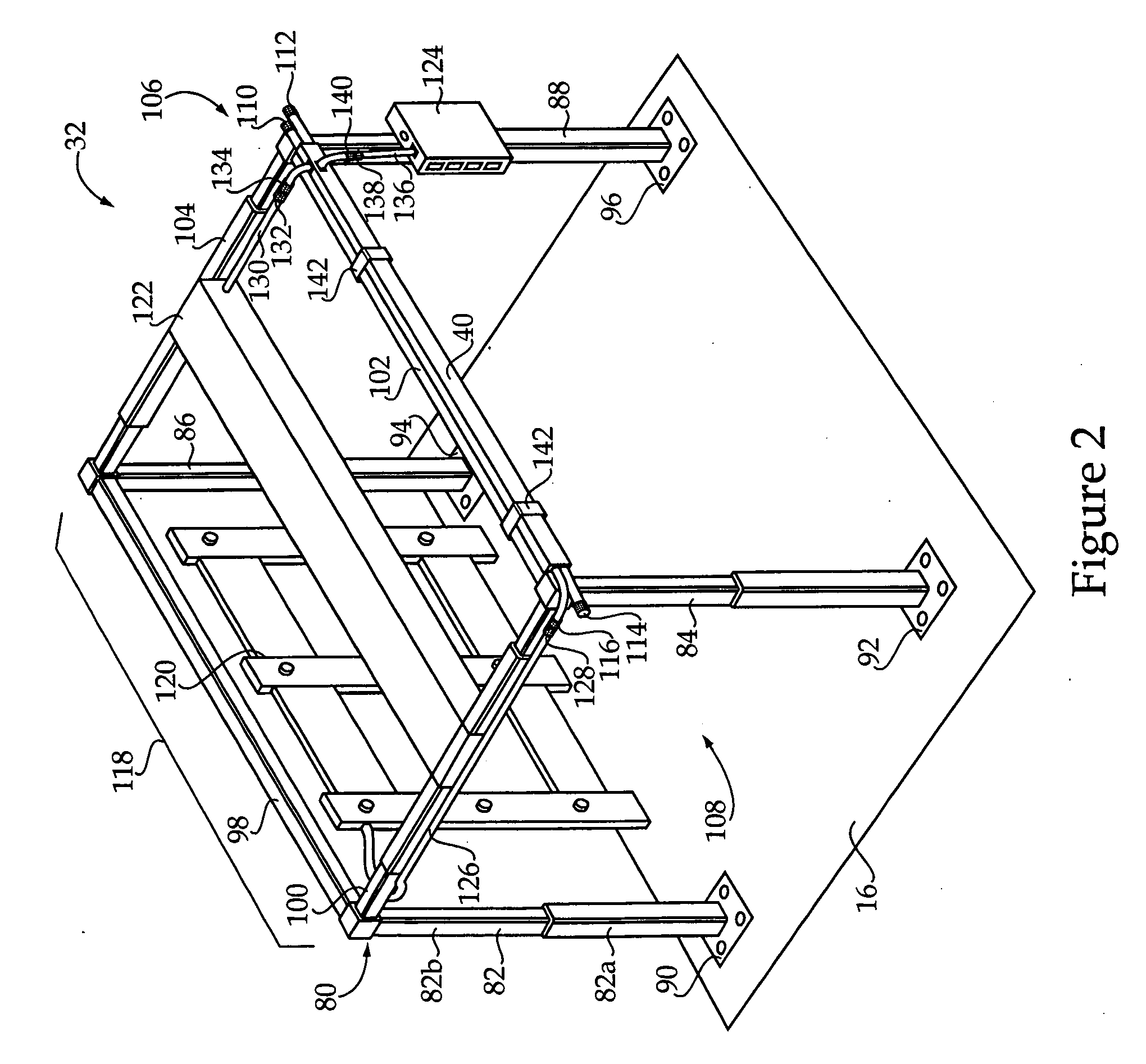

Friction drive material handling system including composite beam and method of operating same

A material handling system includes a composite beam including an upper rail and a lower track connected through a plurality of spaced apart transverse members. A trolley includes an upper set of wheels and a lower set of wheels. The lower set of wheels is received within two parallel channels defined by the lower track. A drive tube is positioned between the upper rail and the lower track such that the upper set of wheels are in frictional engagement with the drive tube. A drive system is configured to rotate the drive tube.

Owner:CATERPILLAR INC

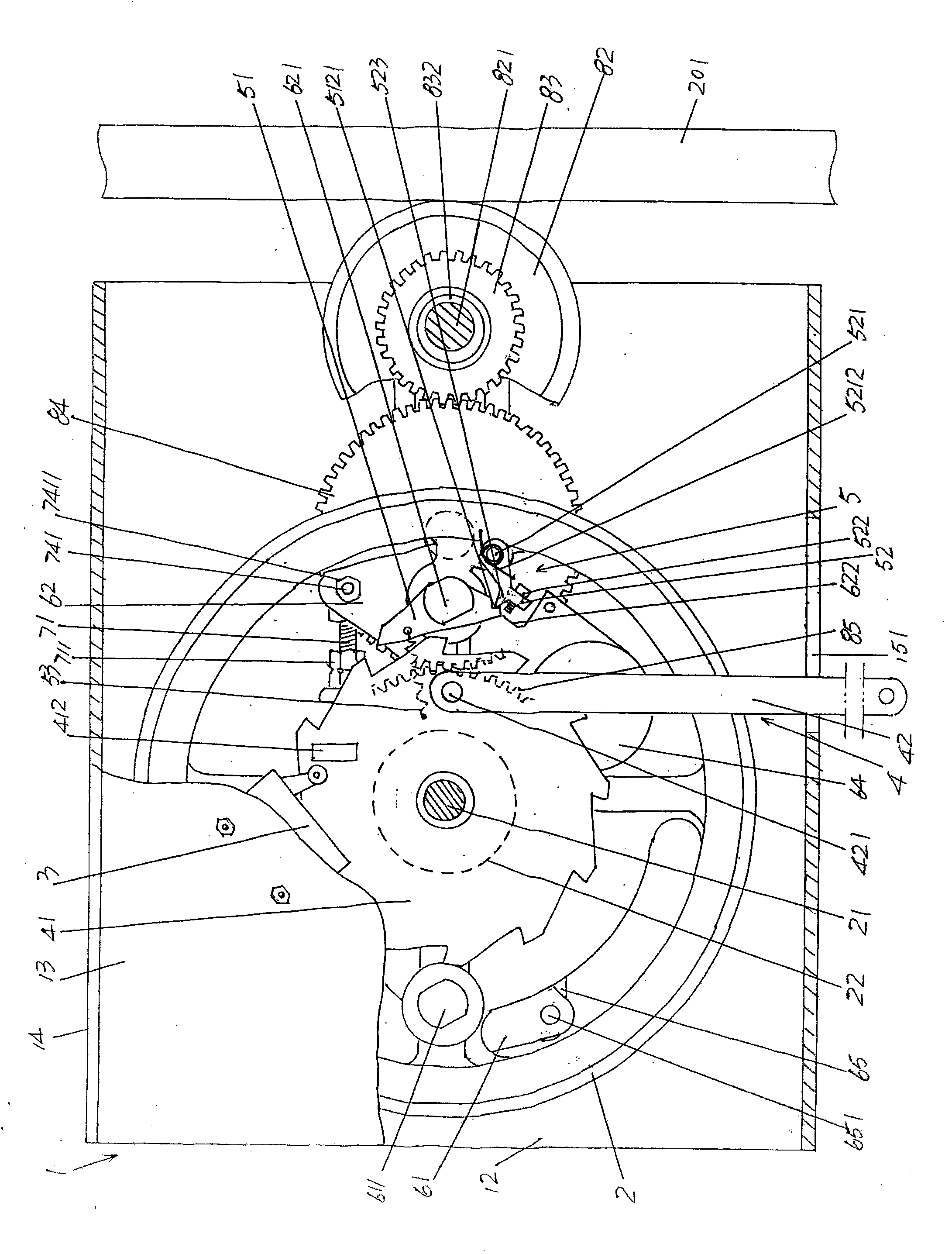

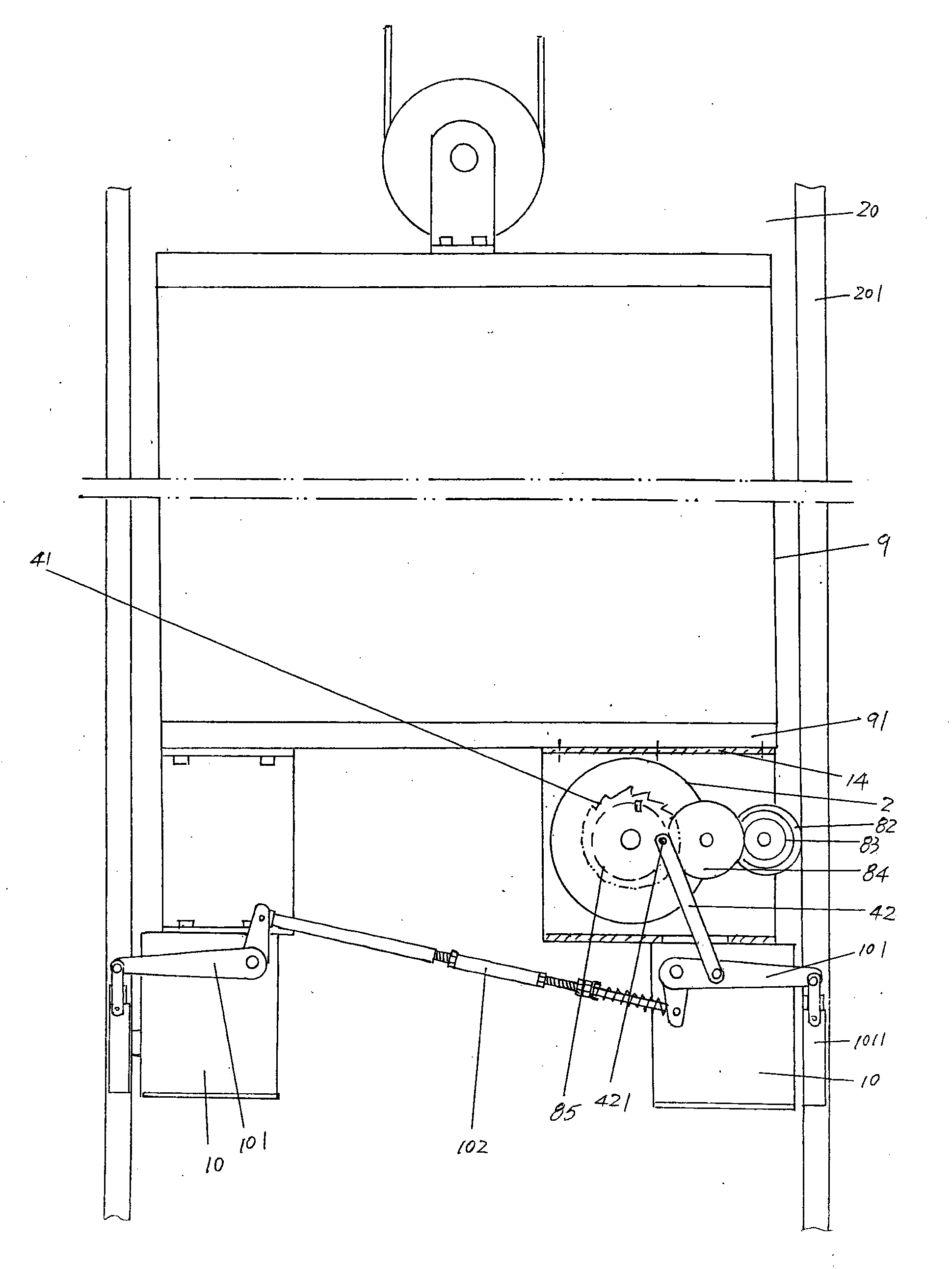

Elevator speed limiter without safety rope

ActiveCN104355197ALong-lasting and stable exercise effectGuaranteed action effectElevatorsEngineeringClutch

The invention discloses an elevator speed limiter without a safety rope, and belongs to the technical field of elevator safety protection devices. The elevator speed limiter comprises a box body, a speed limiter wheel, a ratchet wheel clutch mechanism, a centrifugal hammer mechanism and a centrifugal hammer resetting mechanism, wherein the box body is fixed on an elevator cage; the speed limiter wheel is arranged in the middle of a speed limiter wheel shaft; a signal acquirer and a safety tongs actuation mechanism are respectively positioned in the cavity of the box body; safety tongs are matched with a well guide rail at a position corresponding to the lower side of the box body; the ratchet wheel clutch mechanism is arranged on the speed limiter wheel and is matched with the safety tongs actuation mechanism; the centrifugal hammer mechanism is arranged on the speed limiter wheel and corresponds to the ratchet wheel clutch mechanism; the centrifugal hammer resetting mechanism is arranged on the speed limiter wheel and is connected with the centrifugal hammer mechanism; the elevator speed limiter is characterized by further comprising a speed limiter wheel friction driving mechanism which is connected with the speed limiter wheel and is matched with the surface of one side, which faces the box body, of the well guide rail. The elevator cage is protected, and long-time and stable motion of the speed limiter wheel is guaranteed; the actuation effect of the ratchet wheel clutch mechanism on the safety tongs actuation mechanism is guaranteed; when the elevator cage operates at overspeed, the safety tongs actuation mechanism can be used for reliably operating the safety tongs, so that the safety is guaranteed.

Owner:SUZHOU LAIYIN ELEVATOR CO LTD

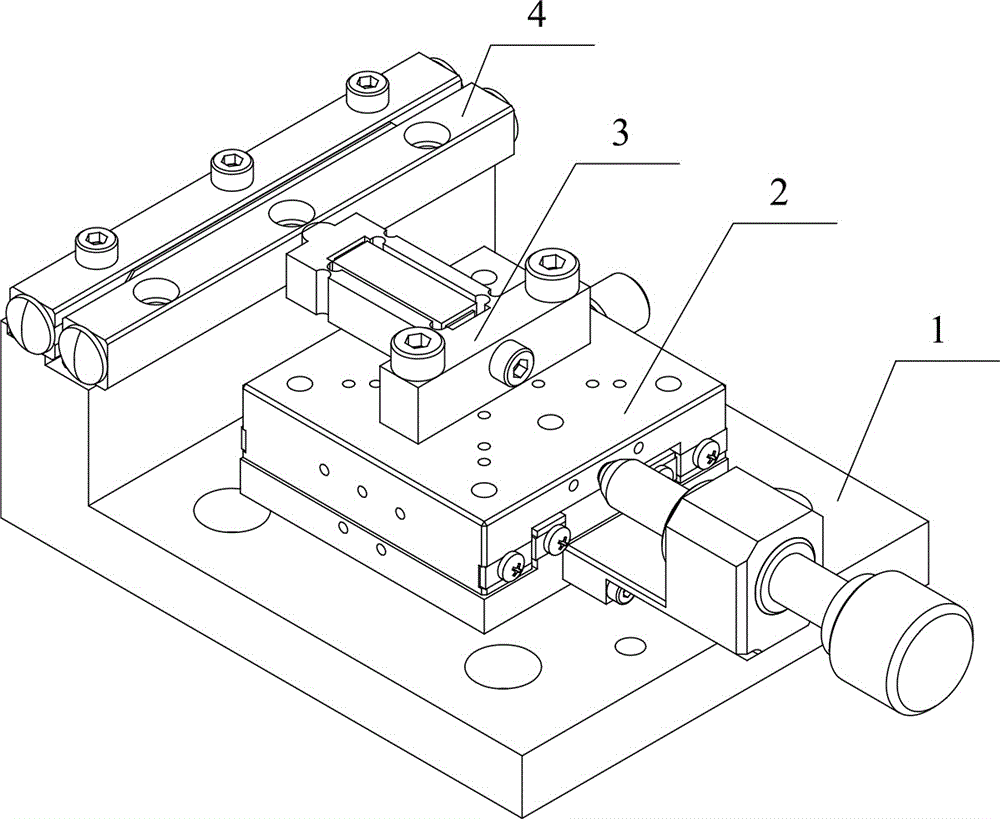

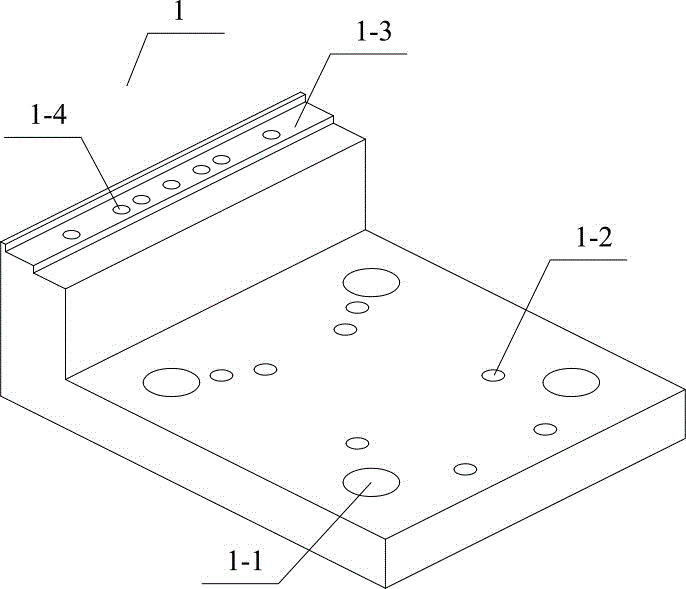

Precise piezoelectric stick-slip linear motor with asymmetric structure and driving method thereof

ActiveCN105827142AIncreased frictional driving forceReduce frictional resistancePiezoelectric/electrostriction/magnetostriction machinesMicro nanoEngineering

The invention provides a precise piezoelectric stick-slip linear motor with an asymmetric structure and a driving method thereof, and aims at solving the problem that mechanical output characteristics of an existing piezoelectric stick-slip linear motor are limited due to the fact that comprehensive regulation of friction is difficult and other problems. The precise piezoelectric stick-slip linear motor is composed of a fixed support, a loading mechanism, a stator and a rotor, and lateral displacement of the stator is produced by means of an asymmetric flexible hinge structure, so that friction driving force is increased, and friction resistance is reduced; meanwhile, a friction regulation wave is complexly superimposed in a sawtooth driving wave in the rapid deformation stage of the stator, therefore, the friction resistance between the stator and the rotor in the rapid deformation stage is reduced, comprehensive regulation of the friction is achieved, and the mechanical output characteristics of the piezoelectric stick-slip linear motor are significantly improved. The precise piezoelectric stick-slip linear motor with the asymmetric structure has the advantages of being simple in structure, high in precision, large in stroke and the like and has good application prospects in the fields of micro-nano precision driving and positioning of aerospace, optical precision instruments, semiconductor machining and the like.

Owner:CHANGCHUN UNIV OF TECH

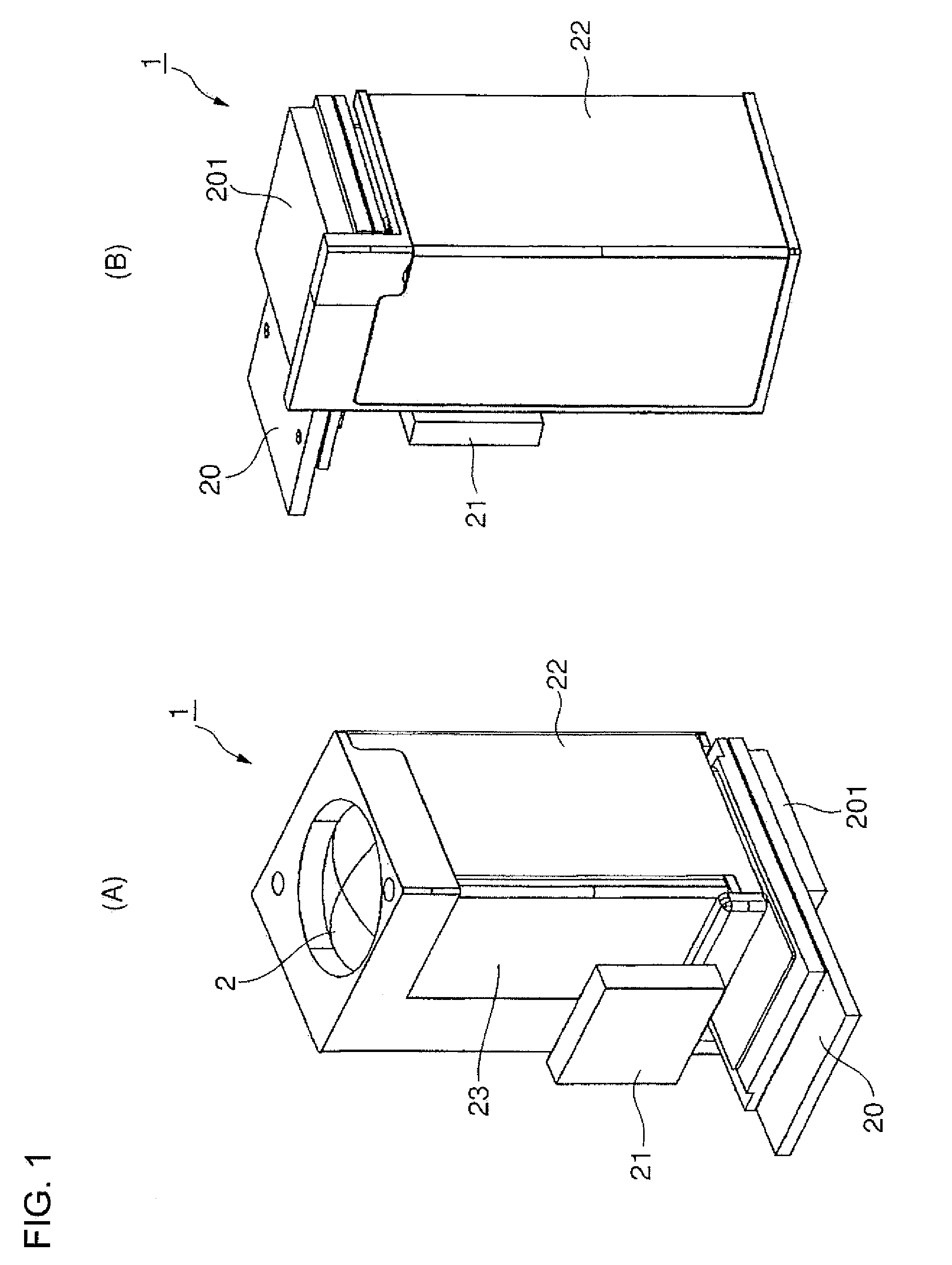

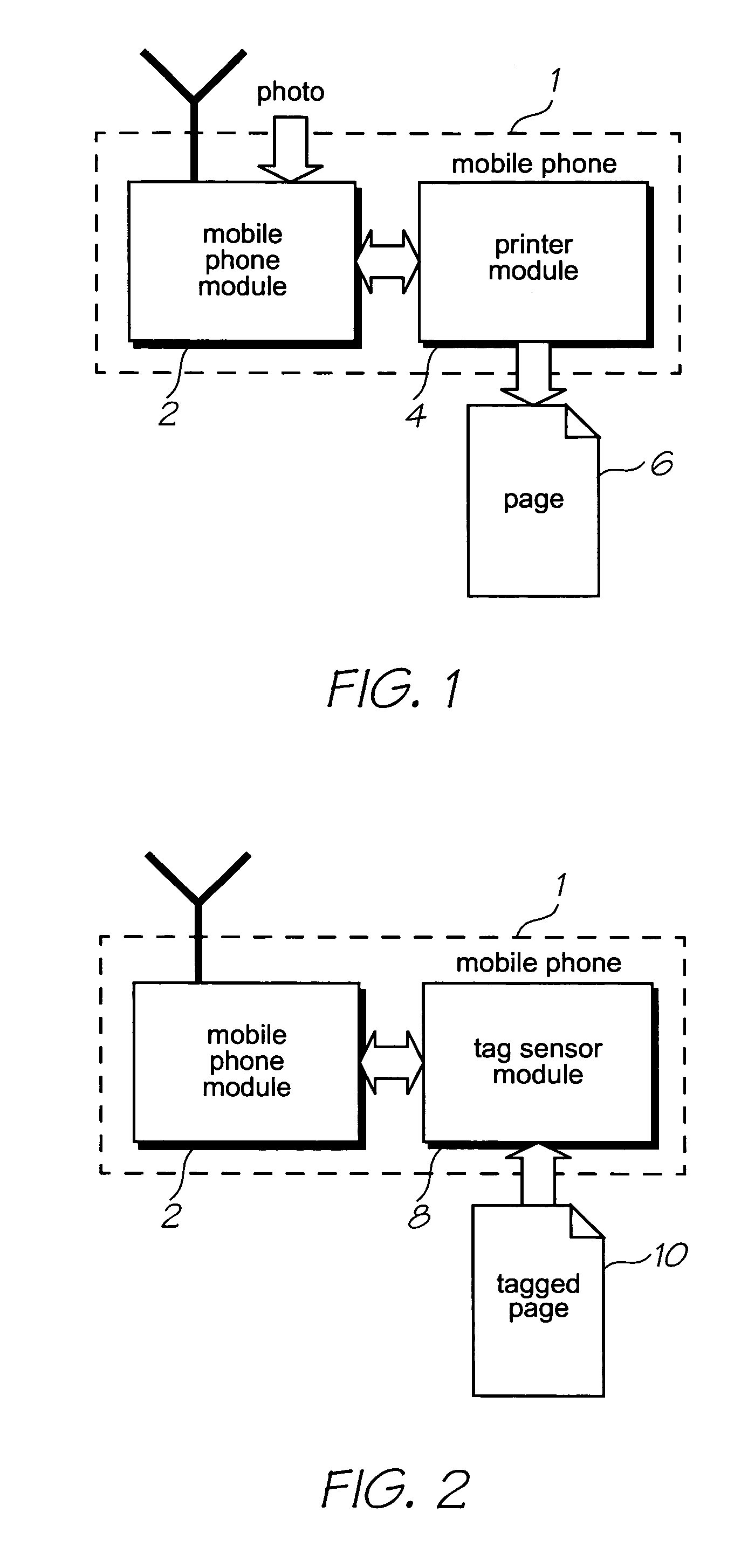

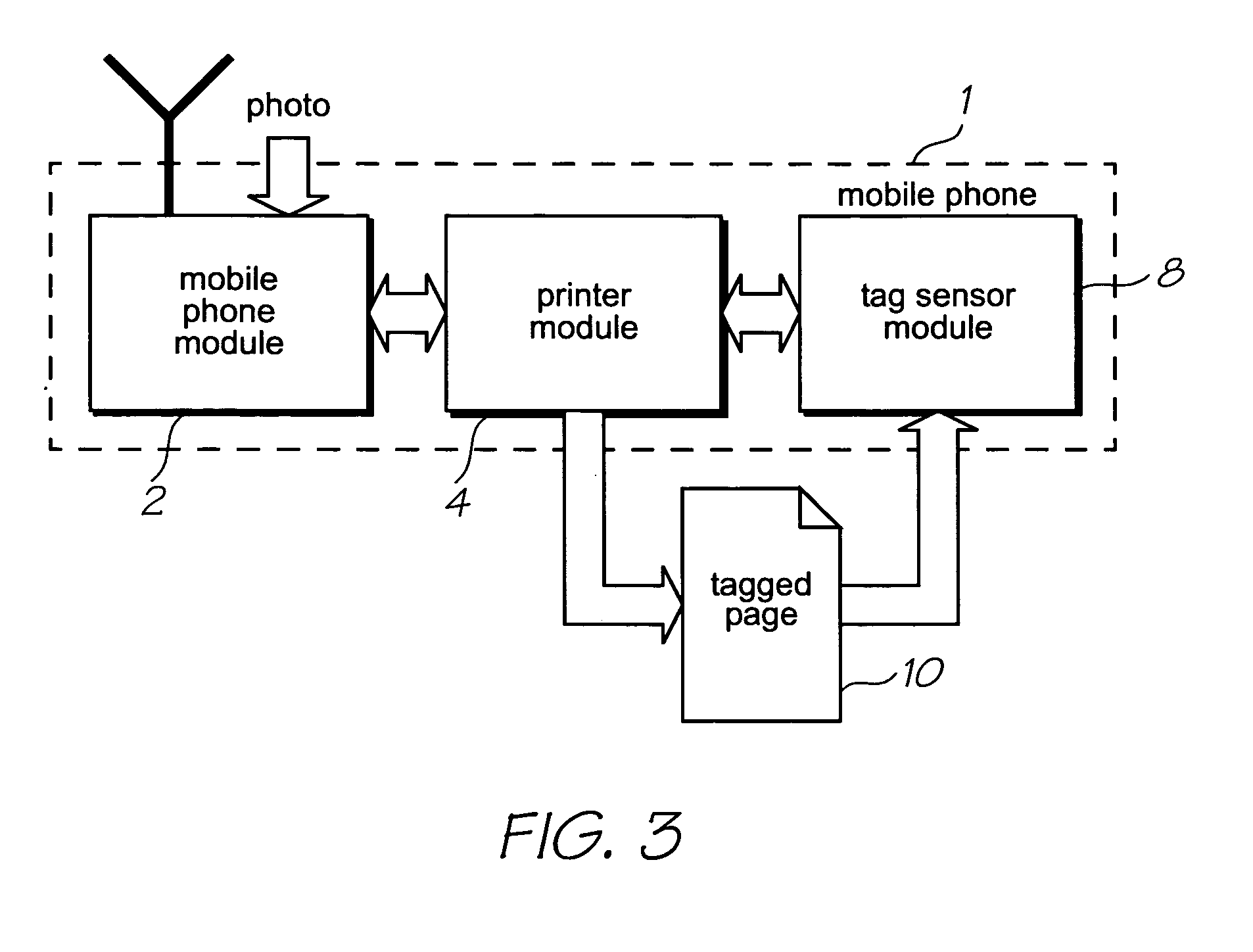

Print cartridge with friction driven media feed shaft

A print cartridge for an inkjet printer with a media drive assembly, the cartridge comprising: a drive shaft for feeding a media substrate past a printhead, the drive shaft positioned such that it engages the media drive assembly upon installation of the cartridge; wherein during use, the drive assembly transfer torque to the drive shaft by contact friction.

Owner:SILVERBROOK RES PTY LTD +1

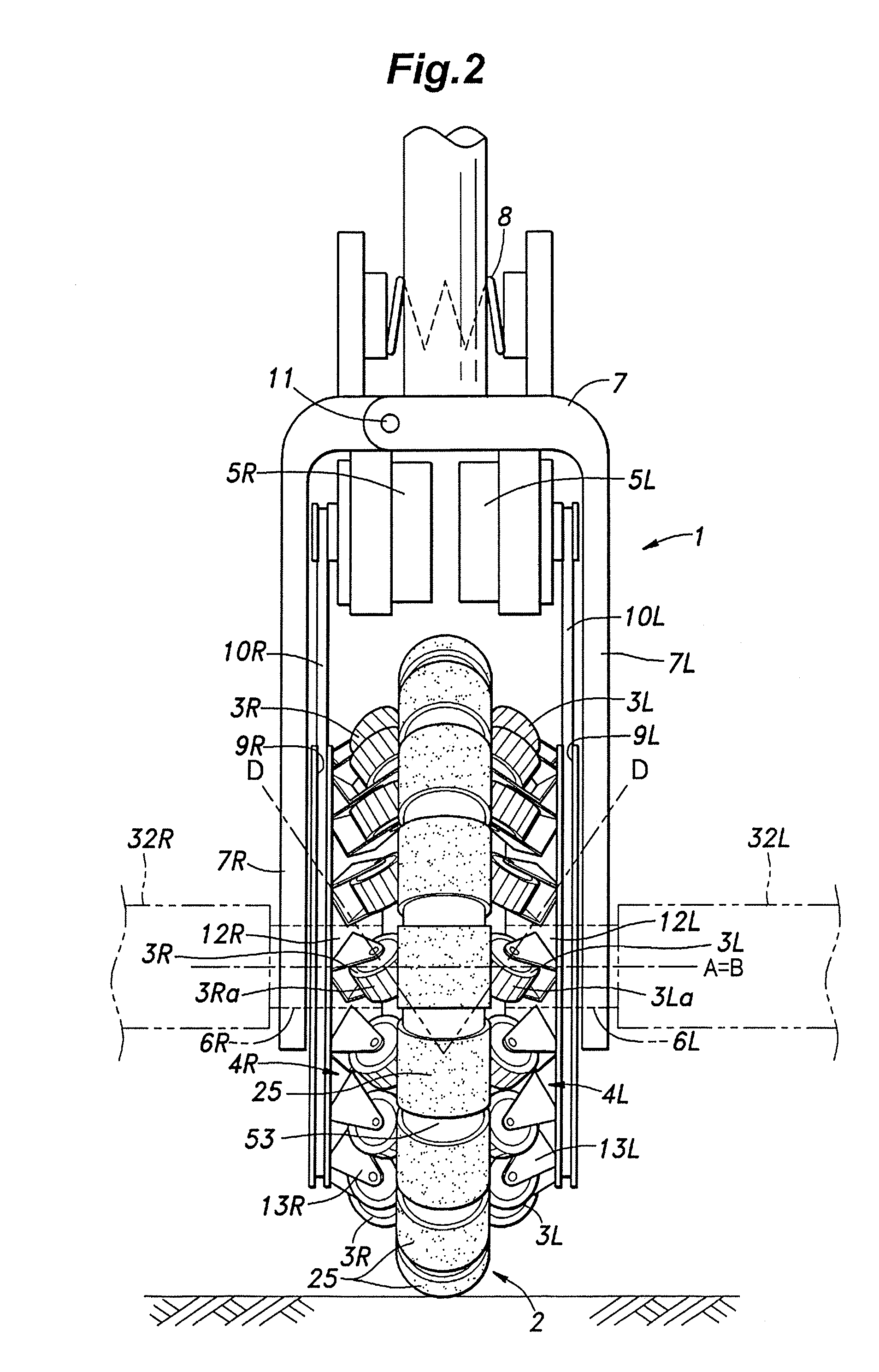

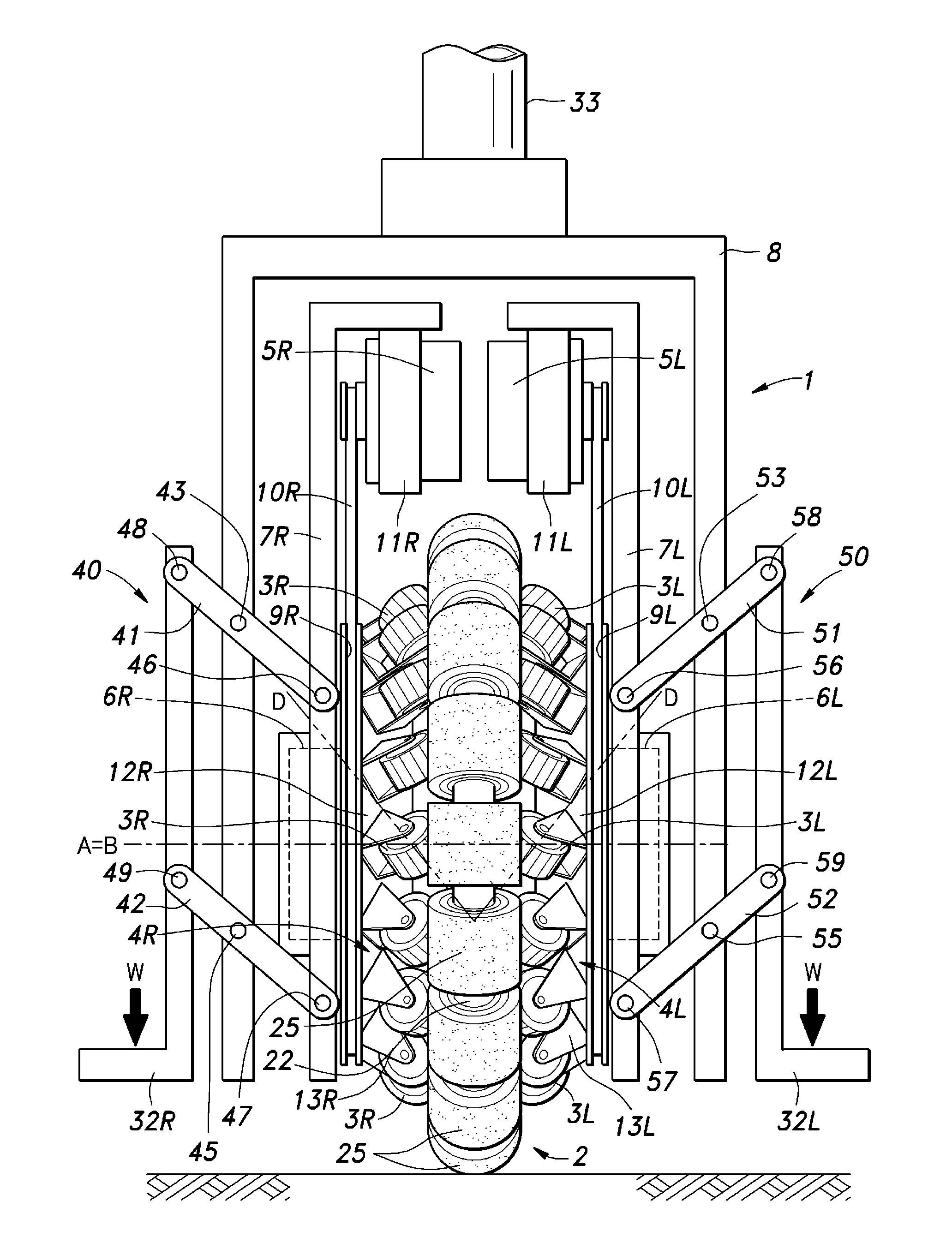

Friction drive vehicle

ActiveUS20100139996A1Optimize contact pressureImprove the level ofFrictional rollers based transmissionUnicyclesContact pressureEngineering

In a frictional drive vehicle, a load acting on the vehicle such as the weight of a rider is converted into a force that urges two frictionally engaging parts (3L, 3R, 25) toward each other. Thereby, the contact pressure between the two frictionally engaging parts is maintained at an optimum level under all conditions. A weight of a rider may be transmitted to a drive member that frictionally engages a main wheel via a four-link parallel link mechanism (40, 50).

Owner:HONDA MOTOR CO LTD

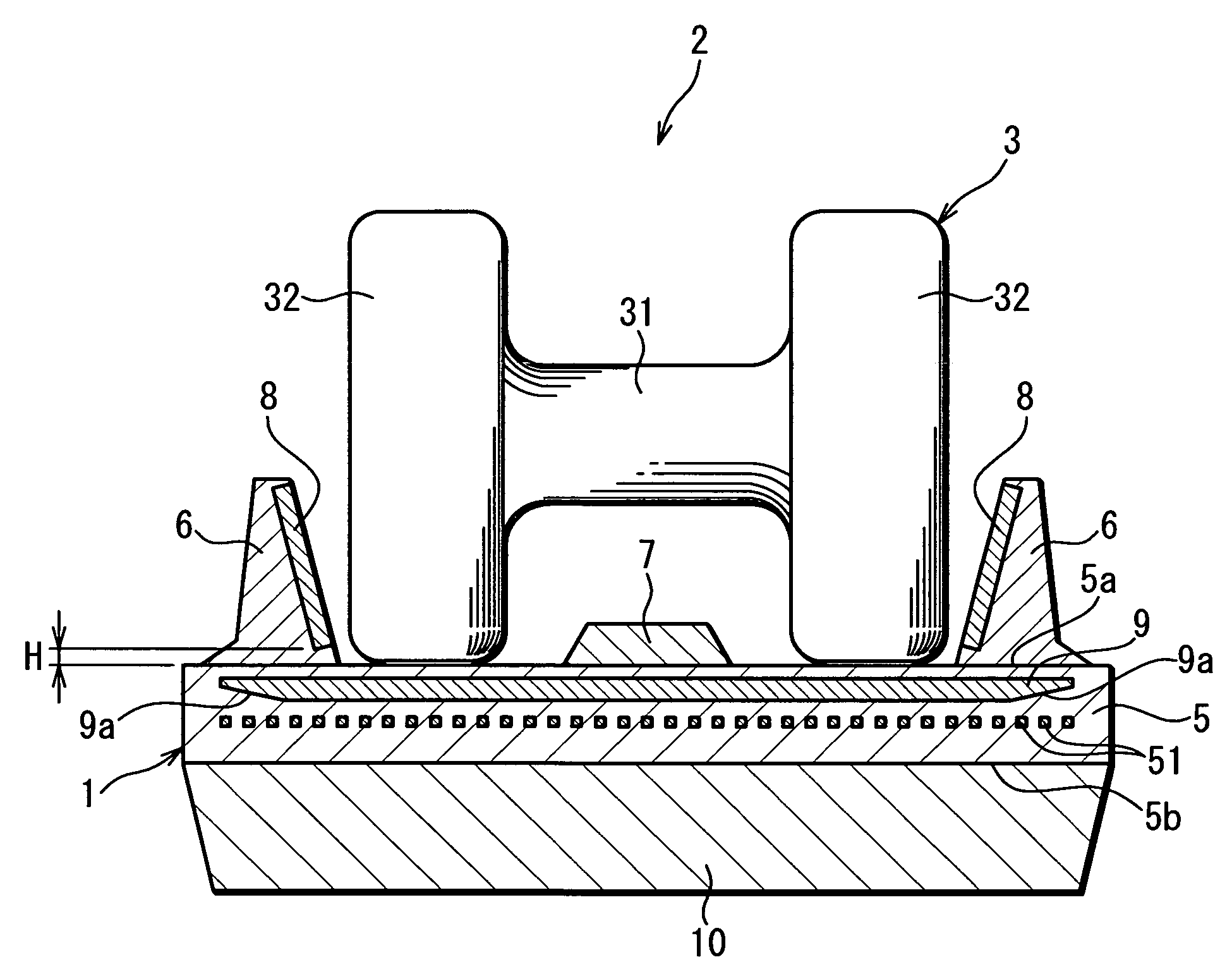

Elastic crawler

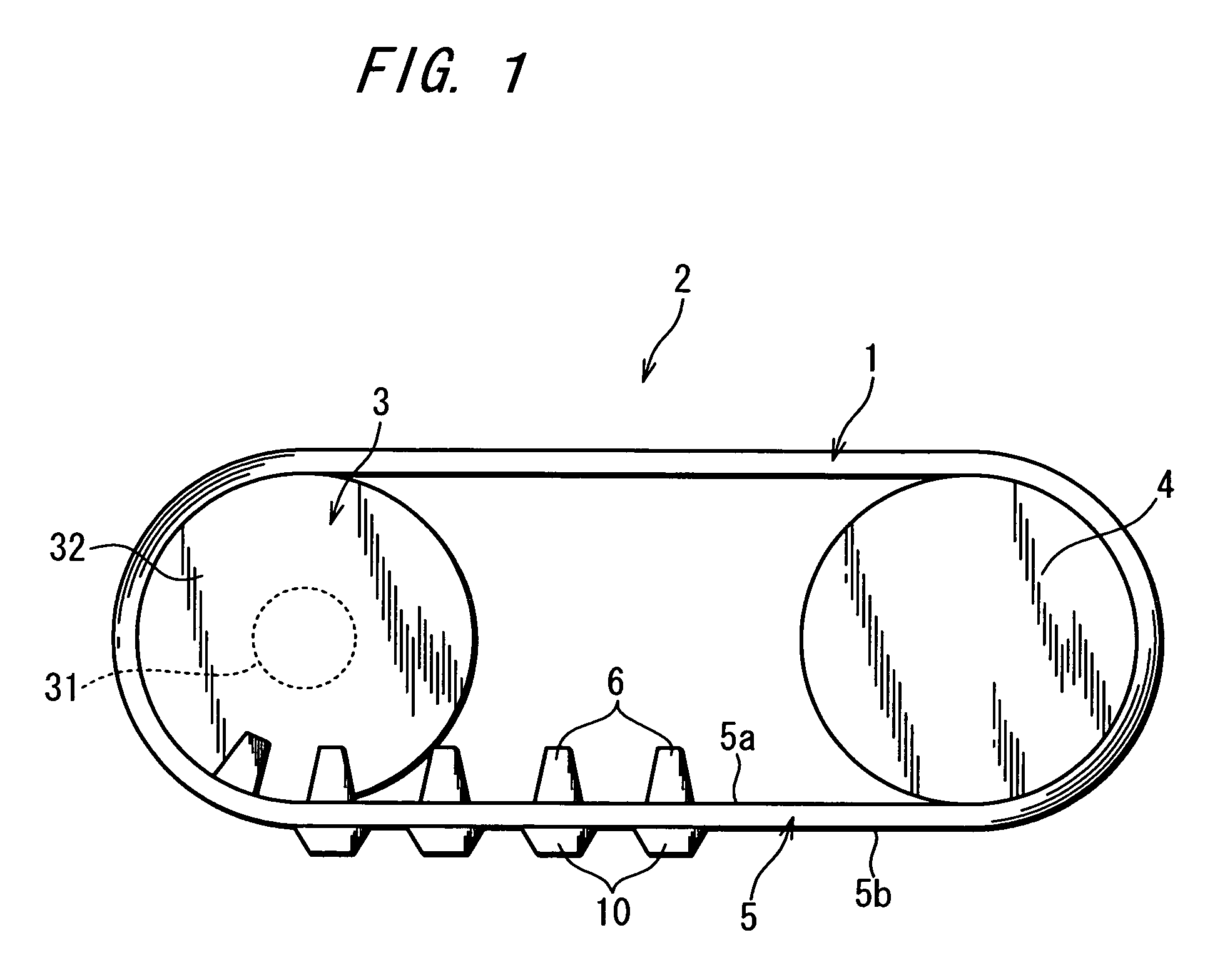

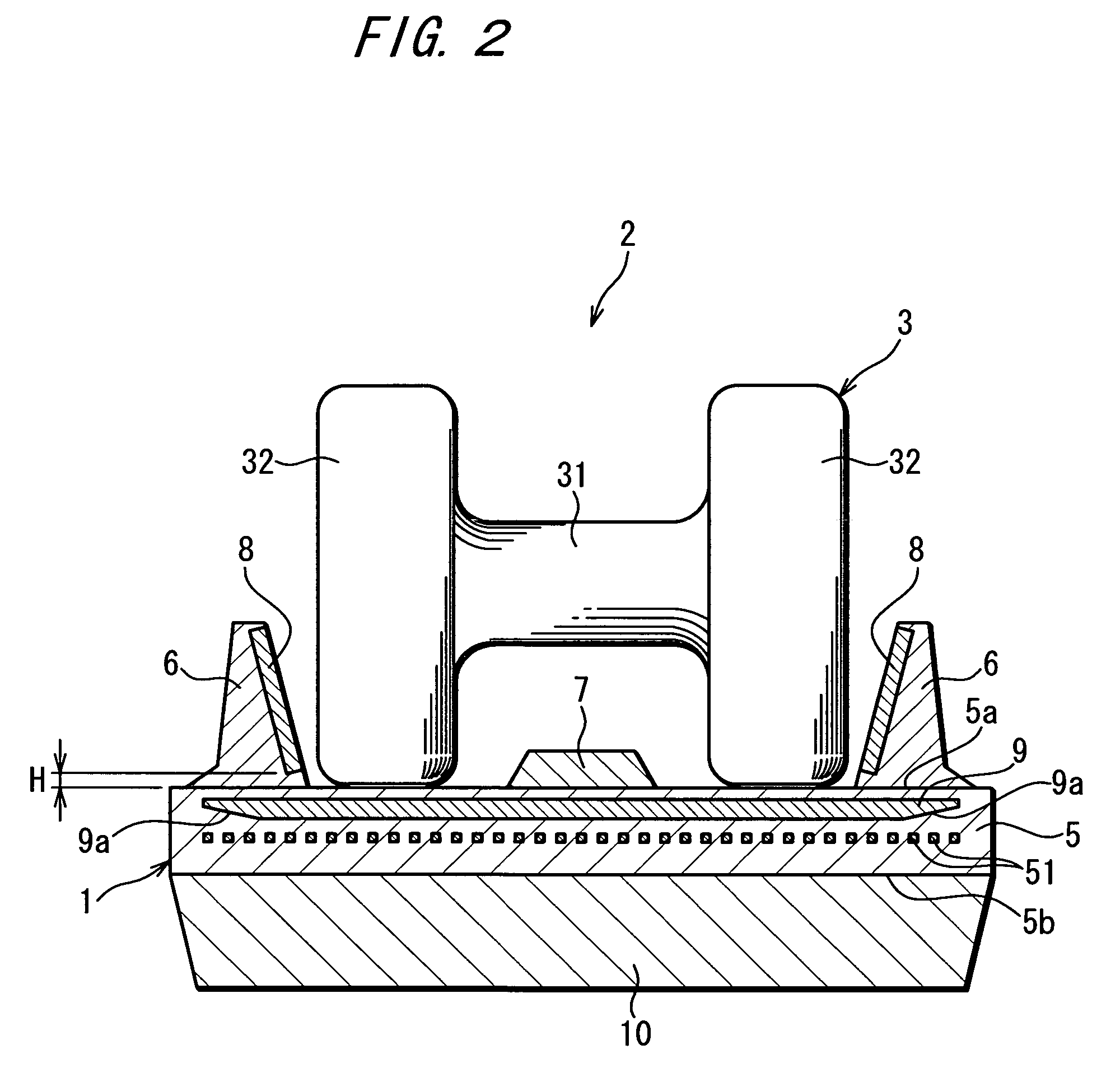

InactiveUS7407236B2Inhibit wearNo drop in rigidityDriving beltsEndless track vehiclesFriction driveEngineering

An elastic crawler having a crawler main body including an endless belt of rubber-like elastic material that is driven by friction with a friction drive wheel. A plurality of guide projections protrude from the inner circumferential surfaces of both lateral edge portions of the crawler main body at specified intervals in the longitudinal direction of the belt. Guide core bodies are embedded to the inside of the respective guide projections in the lateral direction of the belt. A plurality of main body core bodies are embedded in the crawler main body in the same positions as the guide projections in the longitudinal direction of the belt, and a plurality of laterally extending lugs protrude from the outer circumferential surface of the crawler main body at specified intervals in the longitudinal direction of the belt. The guide core bodies and main body core bodies are independent of each other.

Owner:SUMITOMO RUBBER IND LTD

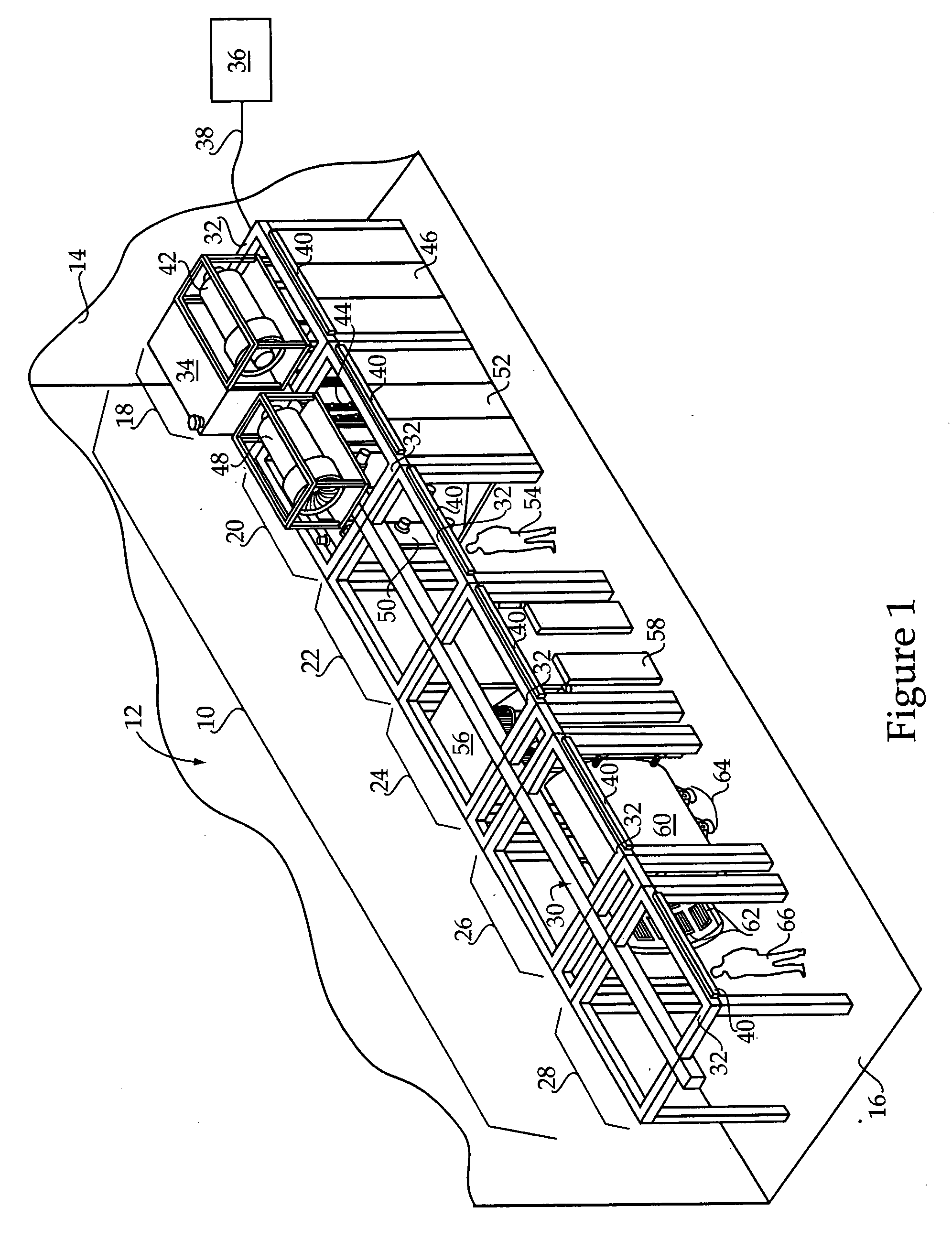

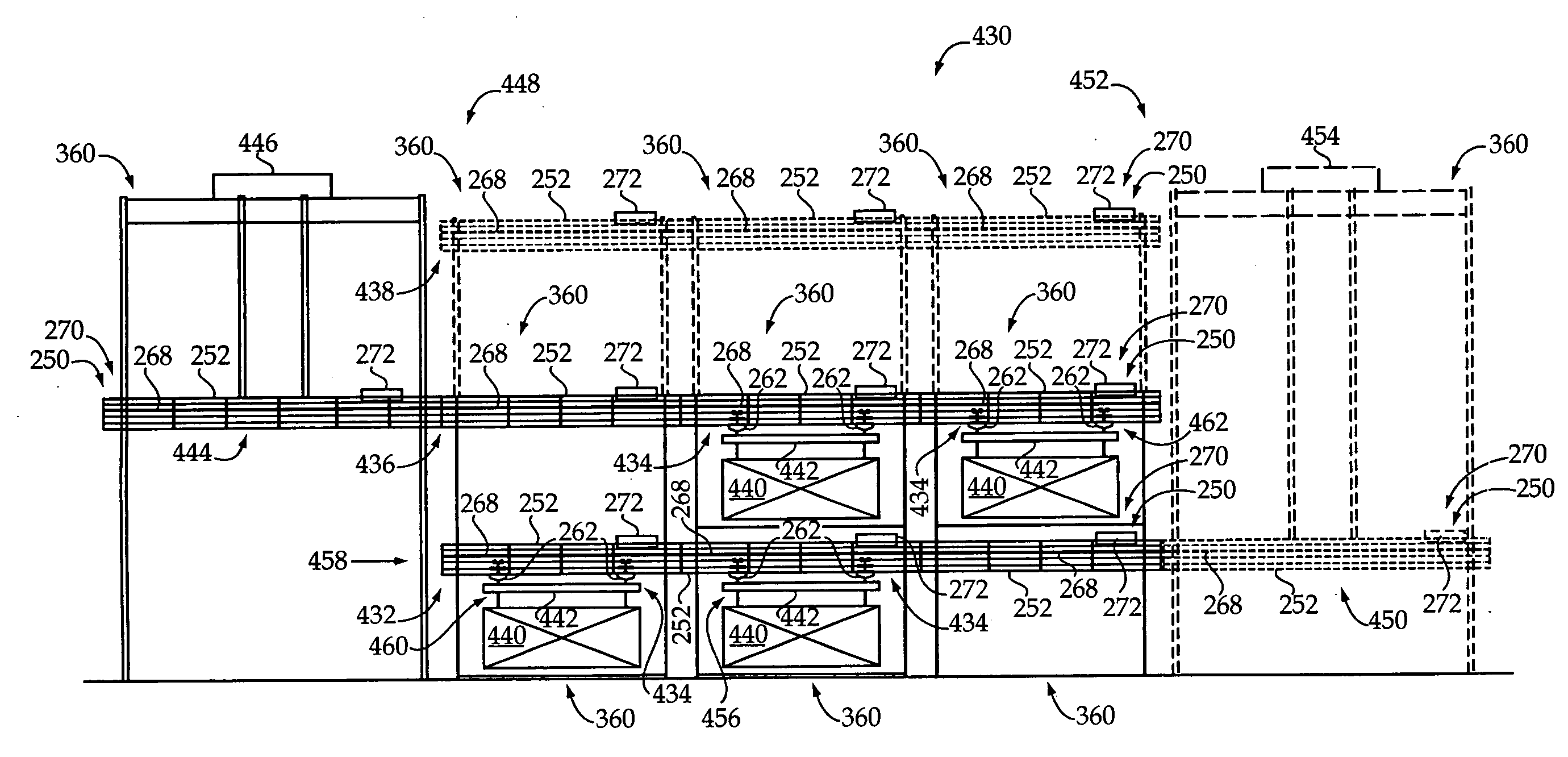

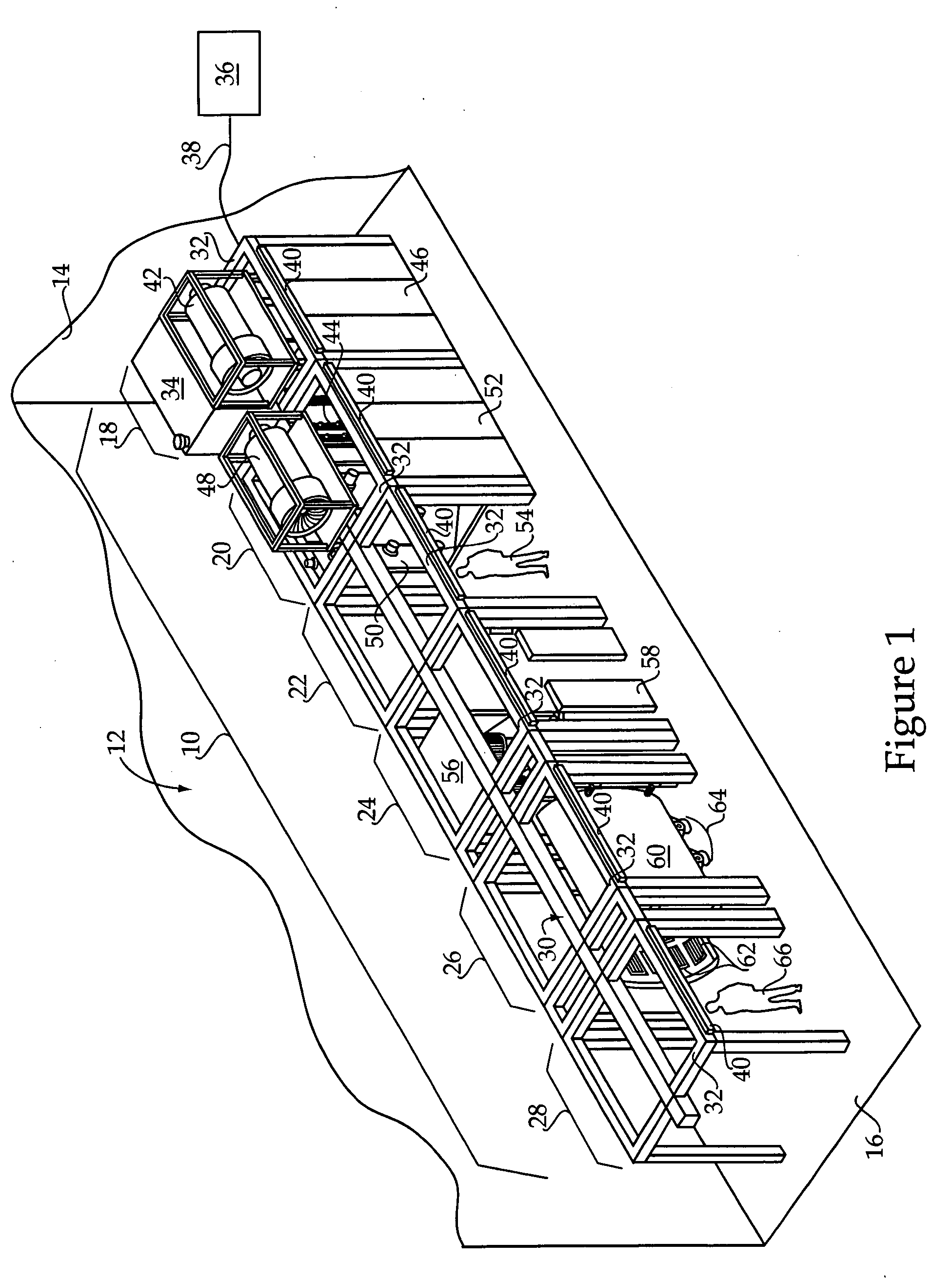

Mobile module for transportating a carrier from a first modular line to second modular line

A manufacturing line includes a first line and a second line. The first line includes a first plurality of stationary modules positioned in series and defining a first path through the first line, and a first friction drive system for transporting an article along the first path. The second line includes a second plurality of stationary modules positioned in series and defining a second path through the second line. The second line also includes a second friction drive system for transporting the article along the second path. A mobile module is supported by ground-engaging elements and includes a third friction drive system for transporting the article along a third path defined by the mobile module. The mobile module is movable between a first position defining a first continuous path along the first path and third path, and a second position defining a second continuous path along the second path and the third path.

Owner:CATERPILLAR INC

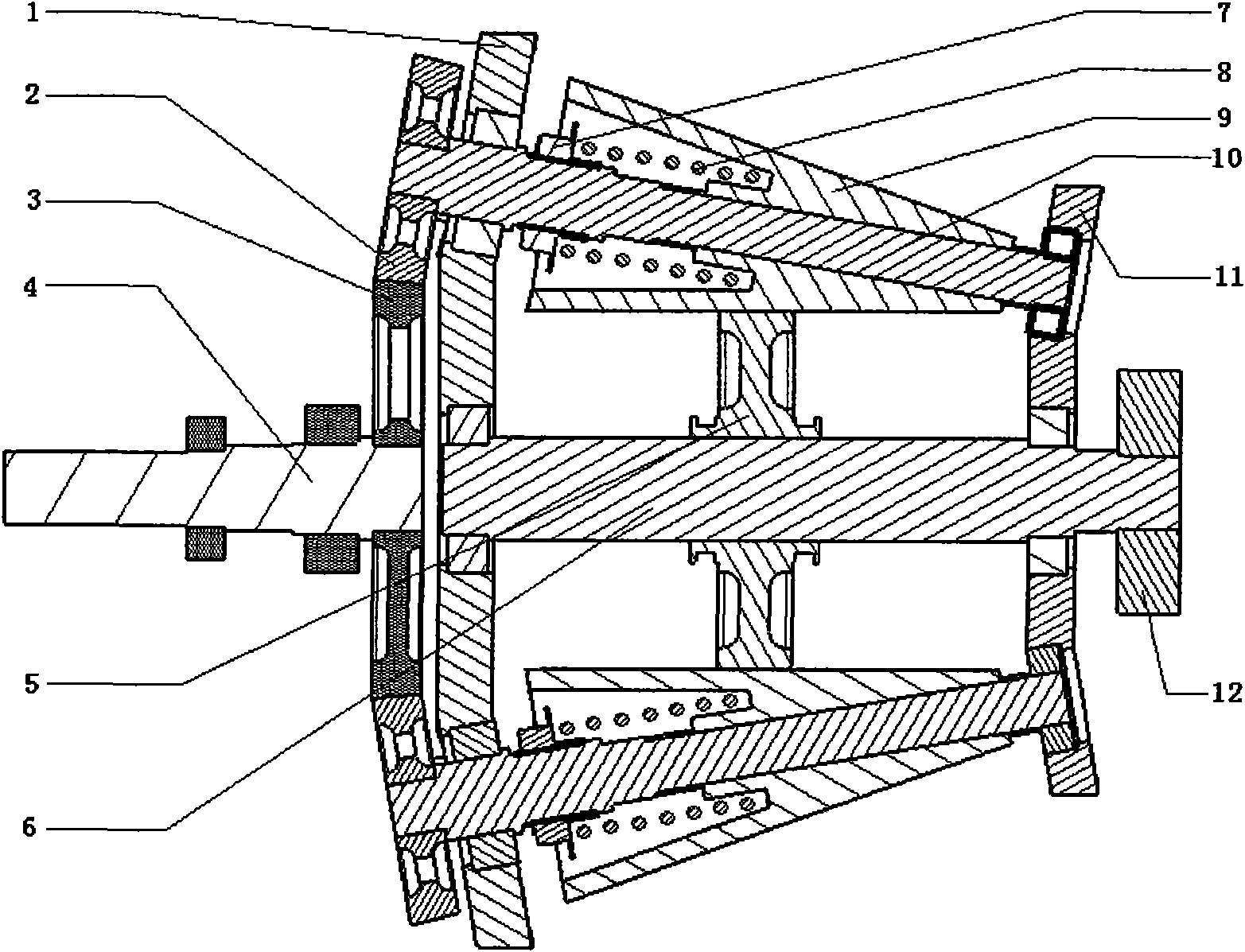

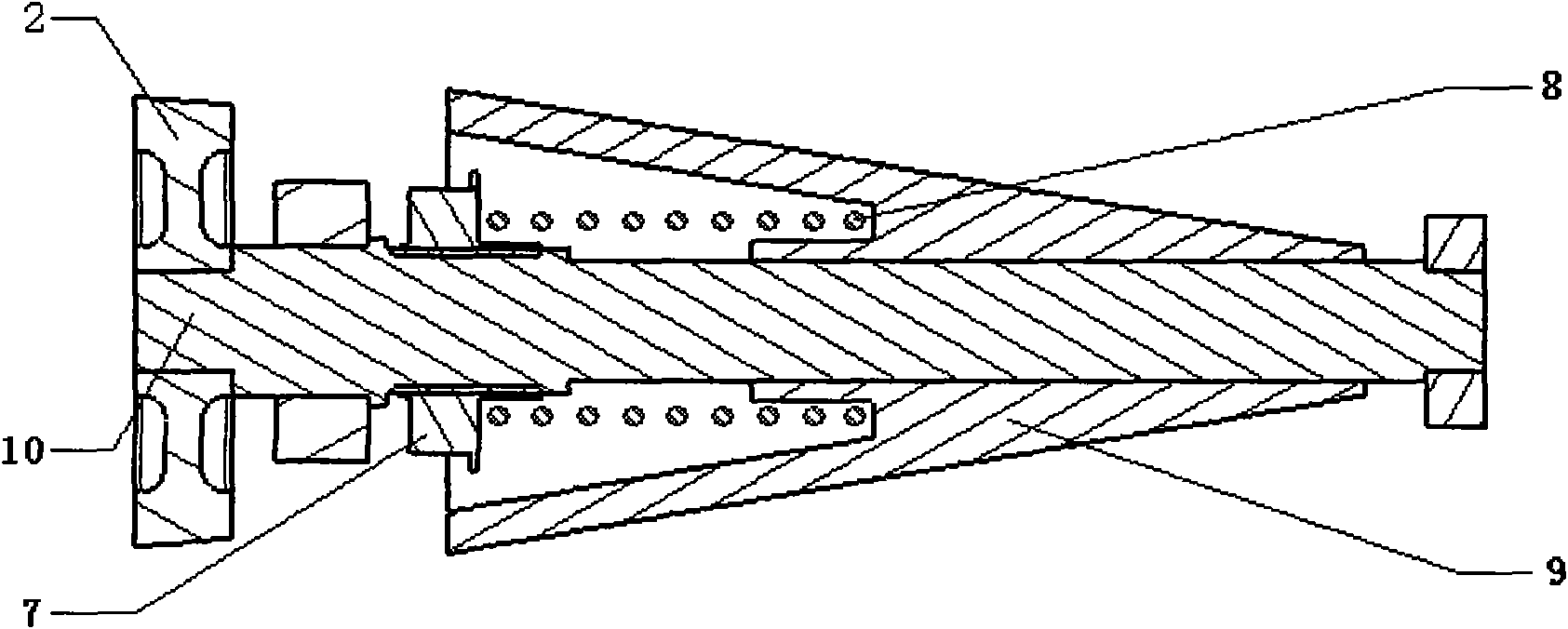

Stepless speed change device of circularly arranged cone pulleys

The invention discloses a stepless speed change device of circularly arranged cone pulleys, comprising a driven shaft and a driving shaft arranged around the driven shaft. The driven shaft is provided with a columnar friction pulley capable of axially moving, which is connected with a position control device; each driving shaft is provided with a conical friction pulley of which the inner conical face contacts with the columnar face of the columnar friction pulley in parallel to form a friction driving face. The stepless speed change device drives through the friction driving face between the conical friction pulley and the columnar friction pulley and can drive relatively high torque in a use rotation speed range. When position of the columnar friction pulley is in stepless change, drive ratio between the conical friction pulley and the columnar friction pulley will be also in corresponding stepless change so as to realize stepless speed change. The stepless speed change device has advantages of simple and compact structure, reliable property, low cost and so on.

Owner:罗斯德尔汽车工程技术(北京)有限公司

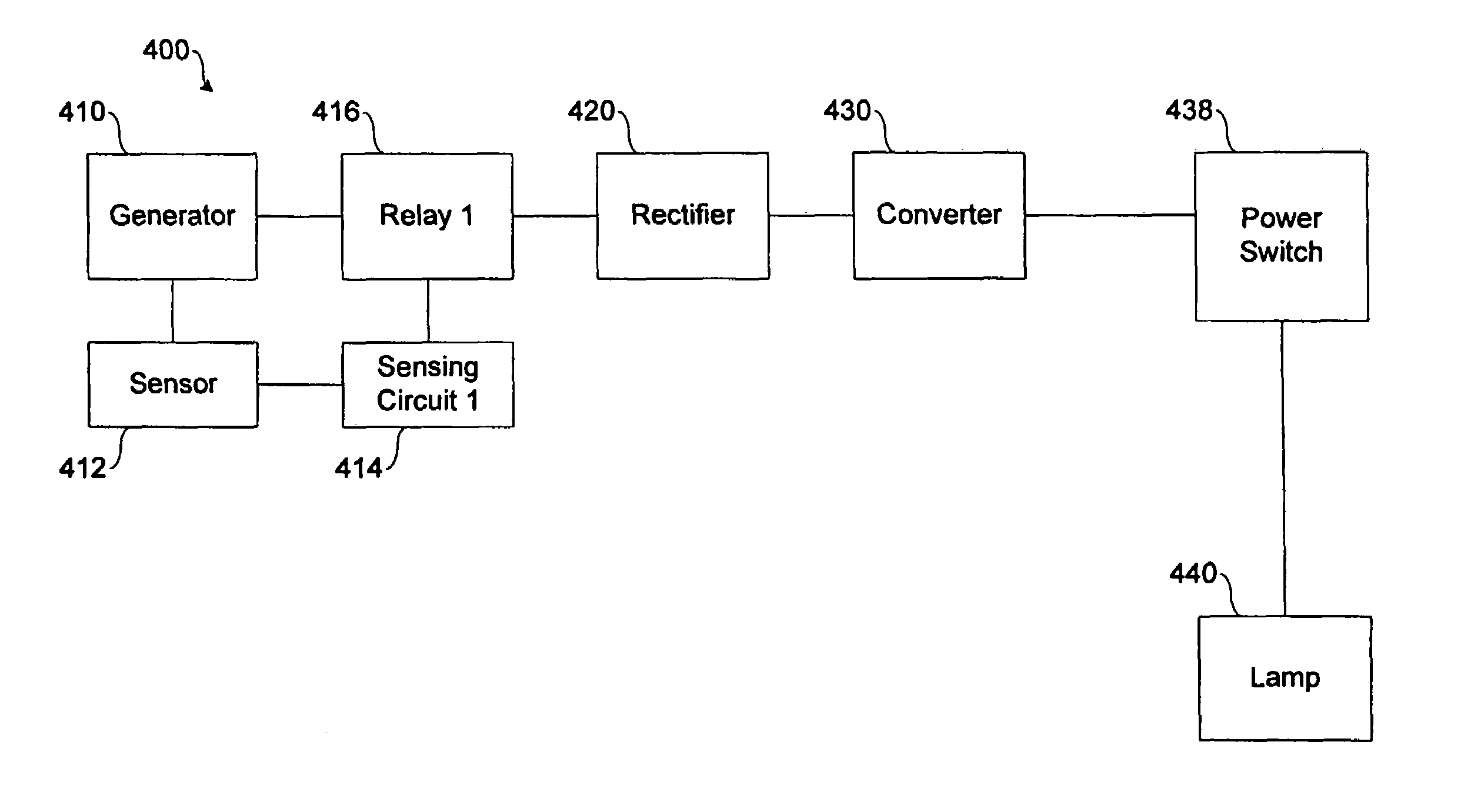

Lighting system for a bicycle

InactiveUS7145256B2Reduce weightImprove efficiencyOptical signalLighting elementsControl signalThree-phase

A lighting system for a bicycle. A lamp and a beam are mounted to the bicycle. A generator is mounted to the beam such that the beam holds the generator in position to be frictionally driven by contact with a bicycle wheel. The generator provides a three-phase output voltage. A sensor monitors the generator and provides an output signal proportional to the speed of the bicycle. A first sensing circuit receives the output signal from the sensor and provides a first control signal when the output signal exceeds a first predetermined value. The first control signal is operative to change the output voltage from the three-phase output voltage to a single-phase output voltage to prevent damage to the system.

Owner:KOHARCHECK ALAN WILLIAM

Print cartridge with friction driven media feed shaft

A print cartridge for an inkjet printer with a media drive assembly, the cartridge comprising: a drive shaft for feeding a media substrate past a printhead, the drive shaft positoned such that it engages the media drive assembly upon installation of the cartridge; wherein during use, the drive assembly transfer torque to the drive shaft by contact friction.

Owner:SILVERBROOK RES PTY LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com