Floating synchronous curl-up film roller type seedling plastic film collector

A film rolling roller and recycling machine technology, which is applied in the field of agricultural machinery, can solve problems affecting the effect of film collection, achieve the effects of simple structure, low energy consumption, and avoid secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

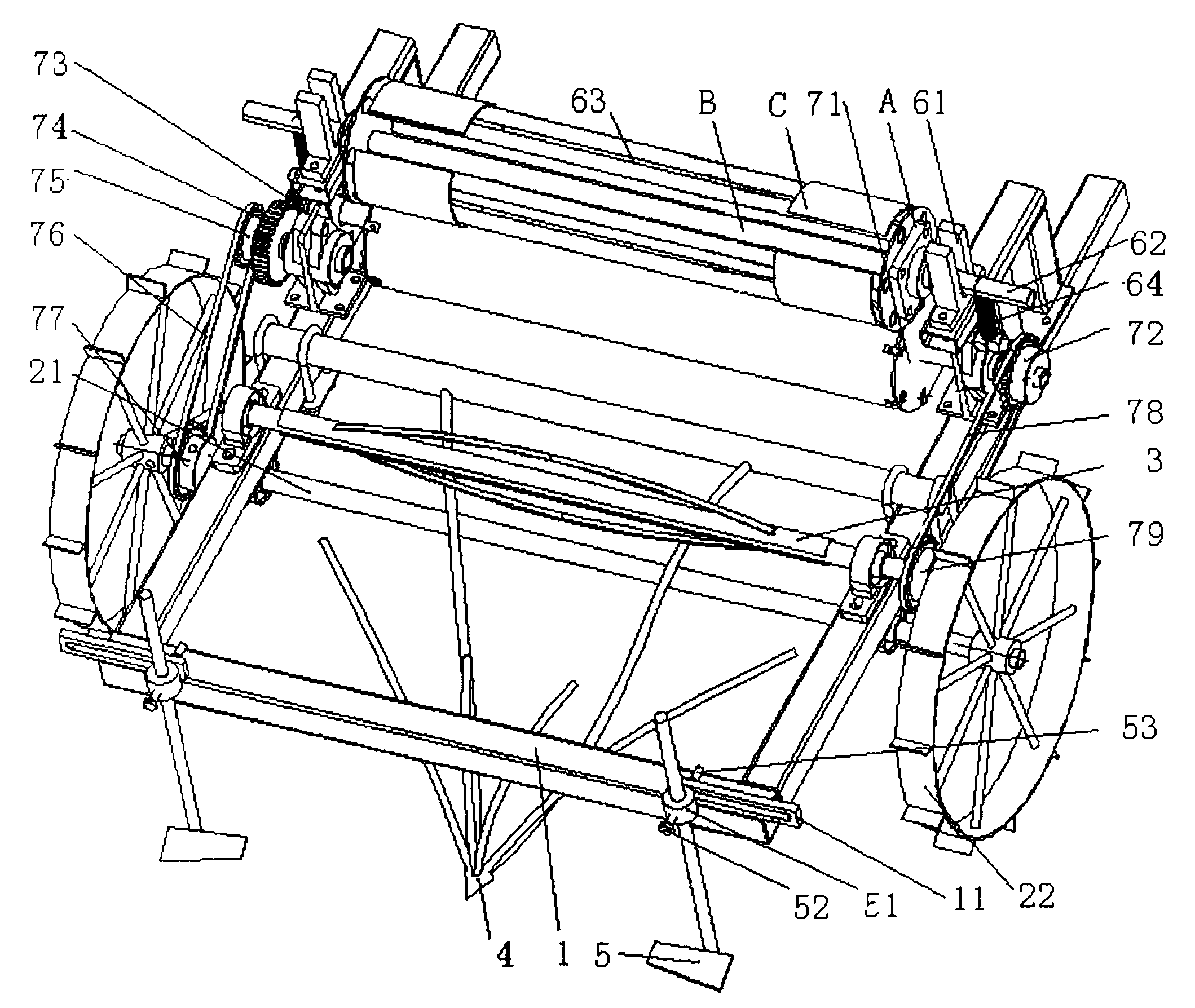

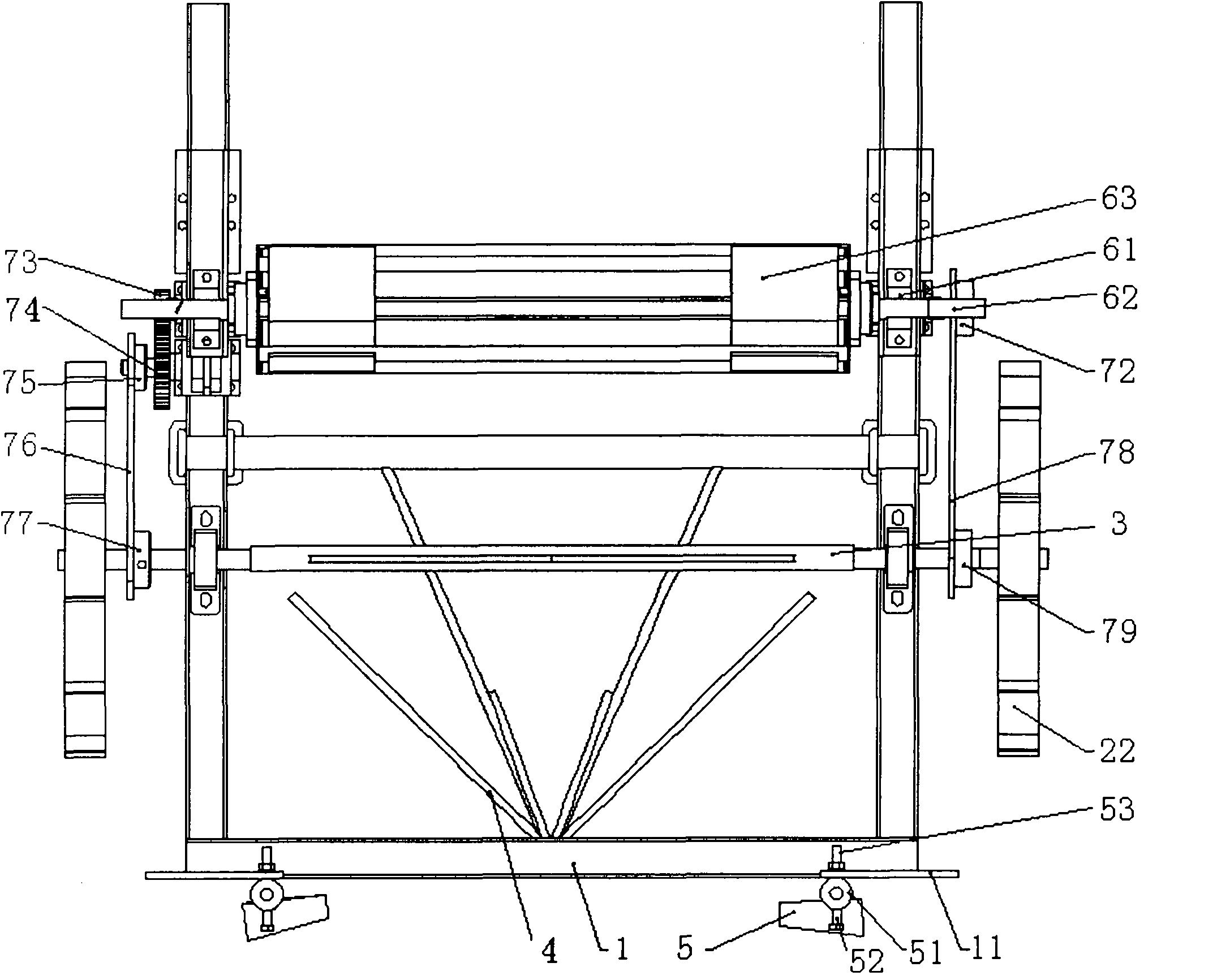

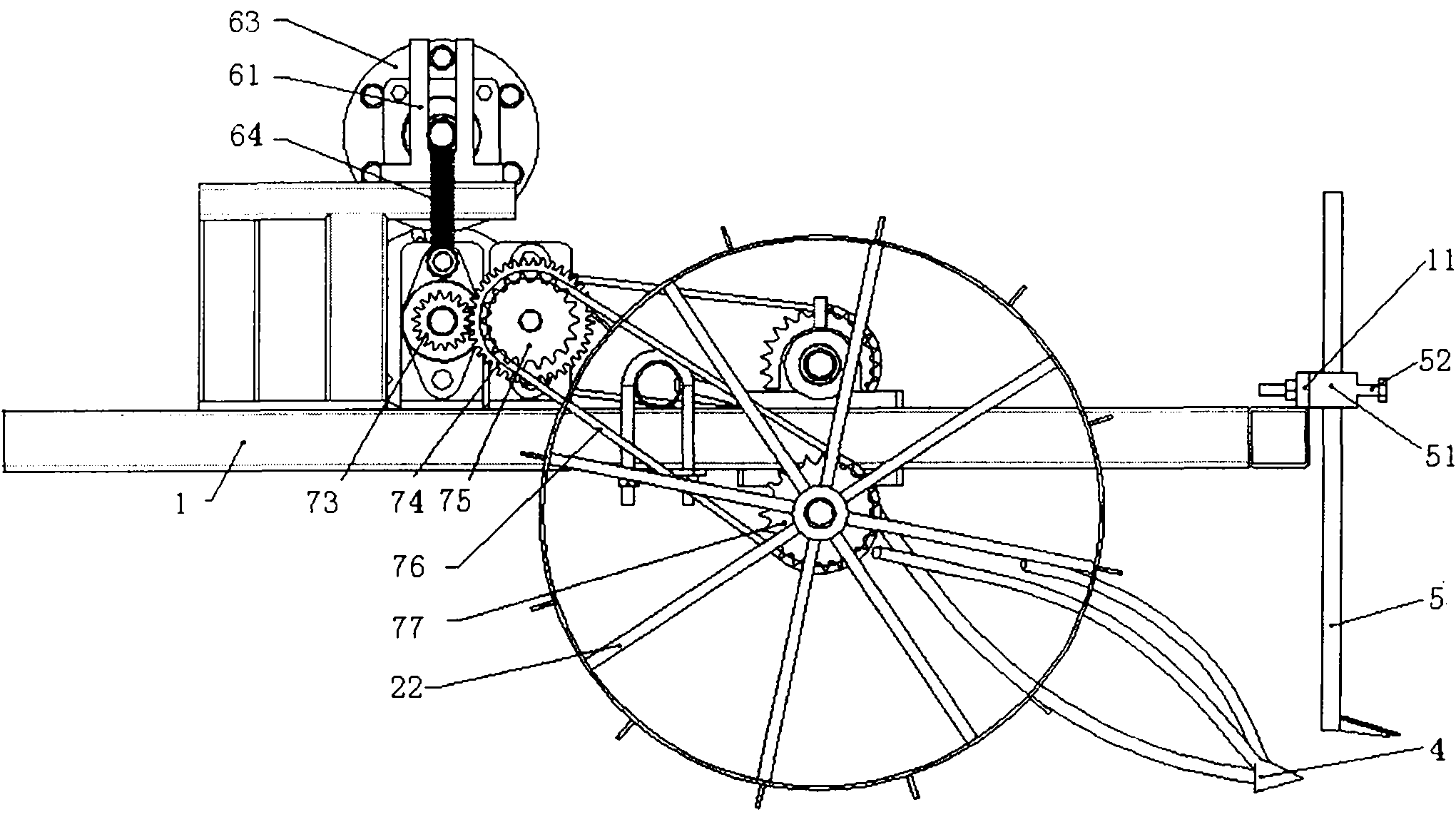

[0018] Such as Figure 1 ~ Figure 3 Shown, the present invention comprises frame 1, ground wheel mechanism 2, shakes earth mechanism 3, claw shape film lifting mechanism 4, soil loosening shovel 5, rolling film mechanism 6 and rolling film driving mechanism 7.

[0019] The ground wheel mechanism 2 is arranged in the middle of the frame 1, and includes a ground wheel shaft 21 rotatably connected to the bottom of the frame, and the two ends of the ground wheel shaft 21 are fixedly connected with a ground wheel 22 by bolts respectively.

[0020] The soil shaking mechanism 3 is arranged on the frame 1 above the ground wheel shaft 21, and it includes a rotating shaft 31 that is rotatably connected to the frame 1, and the rotating shaft 31 is welded with two horizontally opposite arc strips 32. The above-mentioned earth-shaking mechanism 3 can also adopt o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com