Deep treatment method for cyanide-containing waste water of tailings pond in gold industry

A technology for industrial tailings and advanced treatment, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of resource waste, poor treatment effect, etc., and reduce treatment costs , Strong impact load resistance, good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

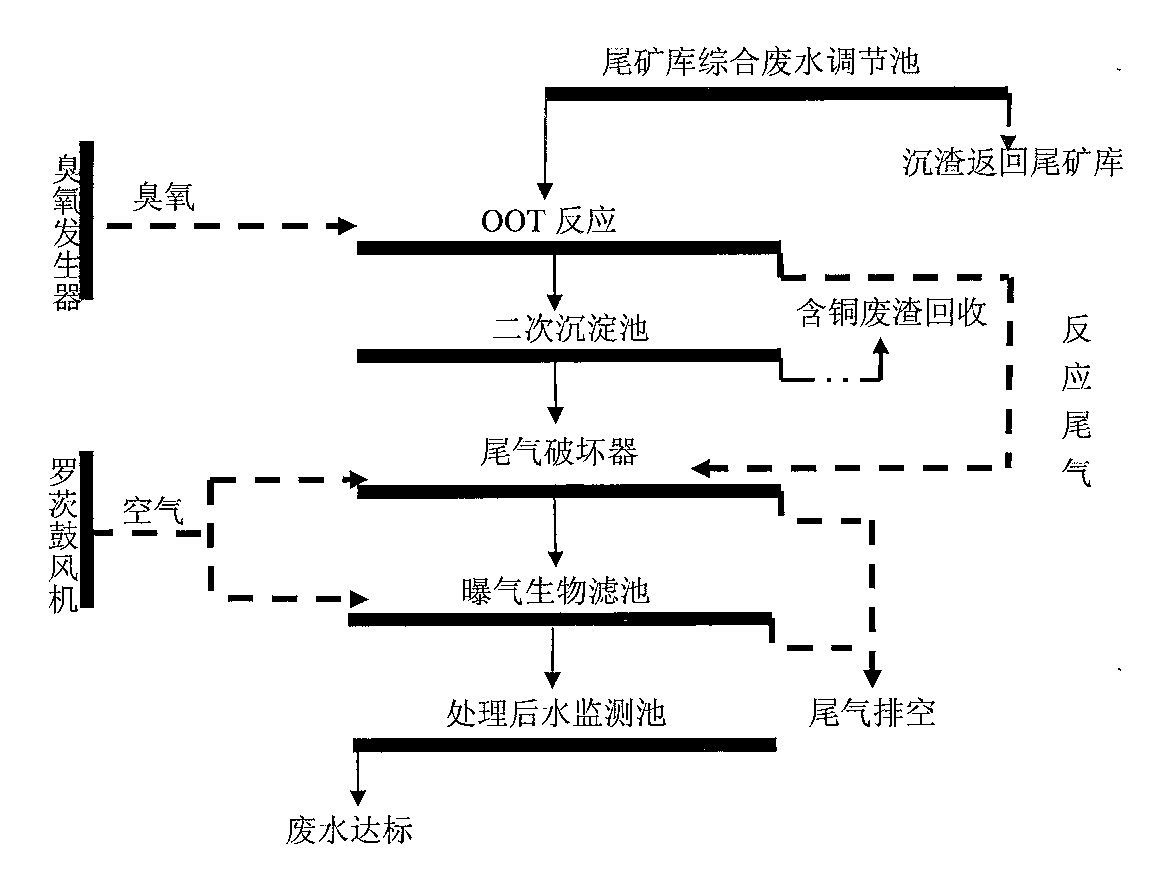

Method used

Image

Examples

Embodiment 1

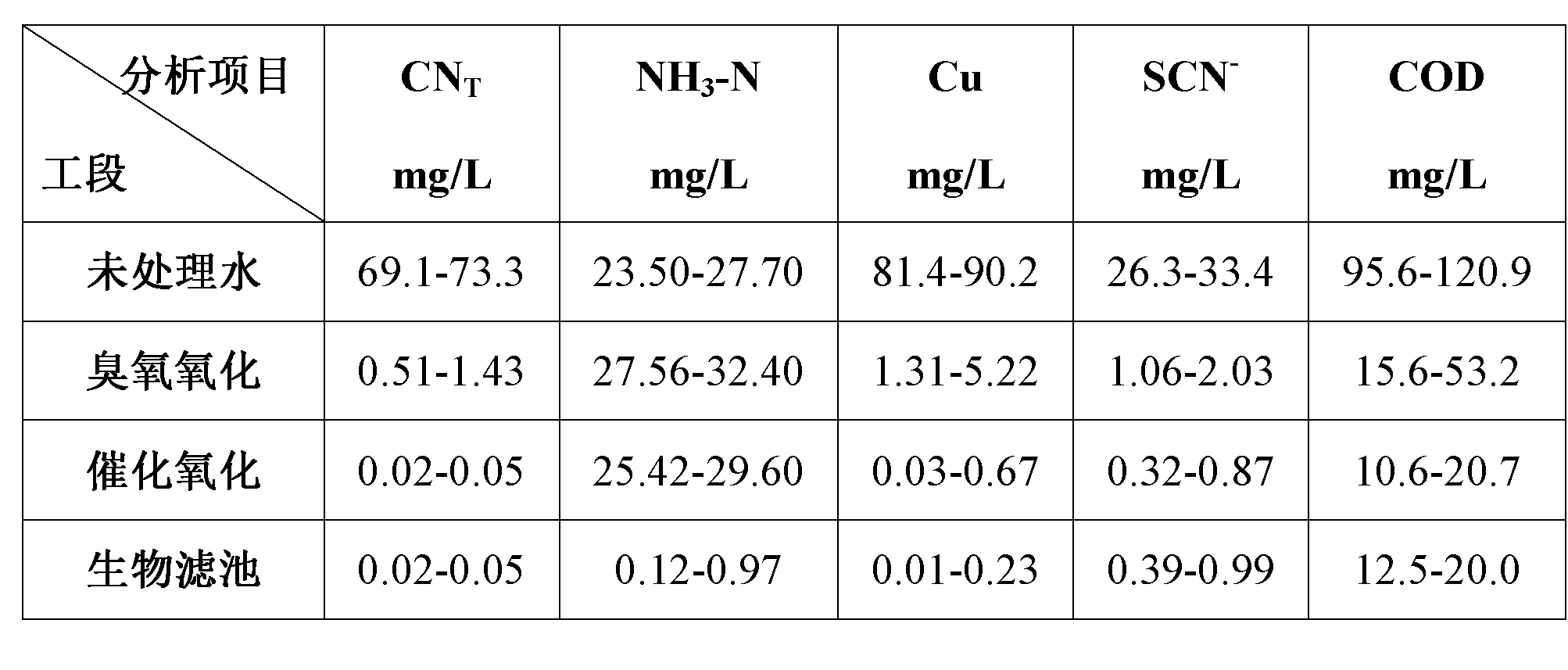

[0022] Example 1 - Small Test

[0023] The waste water from a tailing pond of a gold mine was taken as a test water sample, and its water quality composition is as follows:

[0024] Composition of main pollutants in cyanide-containing wastewater

[0025] serial number

chemical symbol

Concentration value (mg / L)

1

total cyanide

CN T

87.17

2

free cyanide

CN f

17.69

3

SCN -

20.51

4

Cod

COD

89

5

Ammonia nitrogen

NH 4 -N

0.13

6

Cu

83.63

[0026] (1) Ozone oxidation test

[0027] Test conditions

[0028] Reaction container: Φ100mm×H1000mm plexiglass column; treatment method: continuous treatment; PH: 8~9; ozone addition amount: 0.33g / L waste water; gas volume: 0.15m 3 / h; wastewater treatment capacity: 1L / h; hydraulic retention time: 1h.

[0029] test results

[0030] Ozone oxidation test res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com