Patents

Literature

70 results about "Oxidation test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

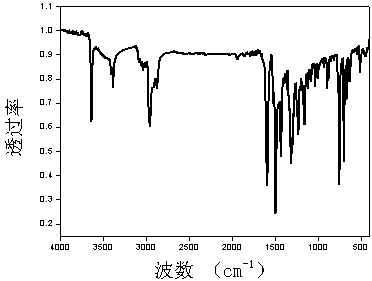

Testing of Oxidation. The testing of oxidation is done in our laboratory by using (FTIR) Fourier transform infrared spectrometer, which can be coupled with Acid Number Test and Viscosity to determine the extent of oxidation and degradation of the oil.

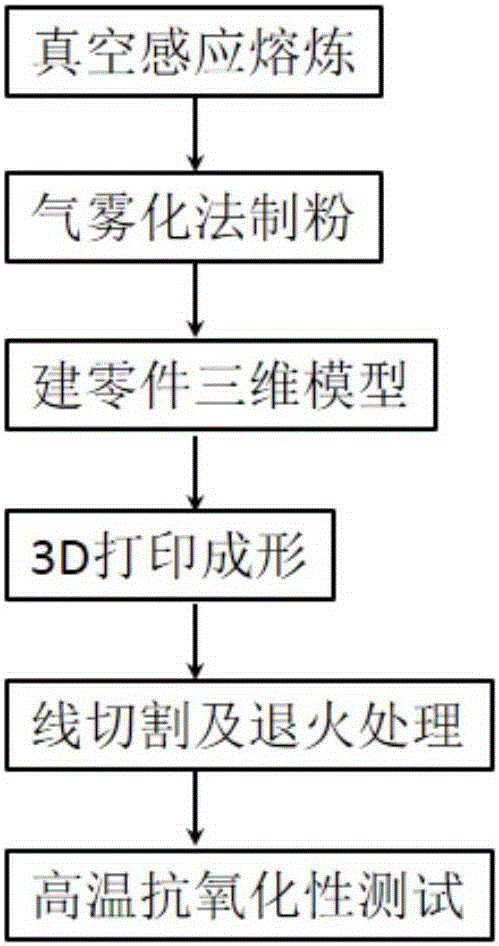

Method for preparing high temperature titanium alloy by adopting selective laser melting rapid formation technique

ActiveCN105154701AIncrease the content of low melting point elementsIncrease the content of melting point elementsIncreasing energy efficiencyManufacturing cost reductionSelective laser melting

The invention discloses a method for preparing high temperature titanium alloy by adopting a selective laser melting rapid formation technique. The method comprises the following steps: (1), preparing powder of elements in nominal chemical components of titanium alloy according to the mass proportion of all the elements, then carrying out vacuum induction melting; (2), milling titanium alloy formed by melting by adopting a gas atomization milling method; (3), establishing a part three-dimensional model, and importing the part three-dimensional model into selective laser melting rapid formation equipment; (4), placing powder into the selective laser melting rapid formation equipment, and carrying out part forming on a substrate; (5), separating the formed part from the substrate by adopting a wire cutting process, annealing the part, so as to improve the plasticity and the toughness of titanium alloy; (6), performing a high temperature oxidation test on the part, so as to determine the high temperature oxidation resistance of the novel titanium alloy. According to the method for preparing high temperature titanium alloy by adopting the selective laser melting rapid formation technique, provided by the invention, a high temperature titanium alloy part with a complex structural shape is quickly formed, and the characteristics of rapid manufacturing, accurate manufacturing and reduction of manufacturing cost and the like are achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

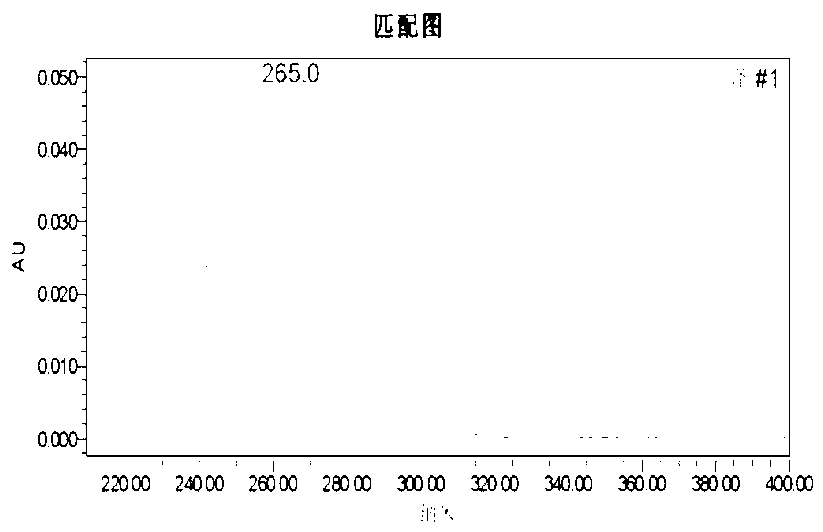

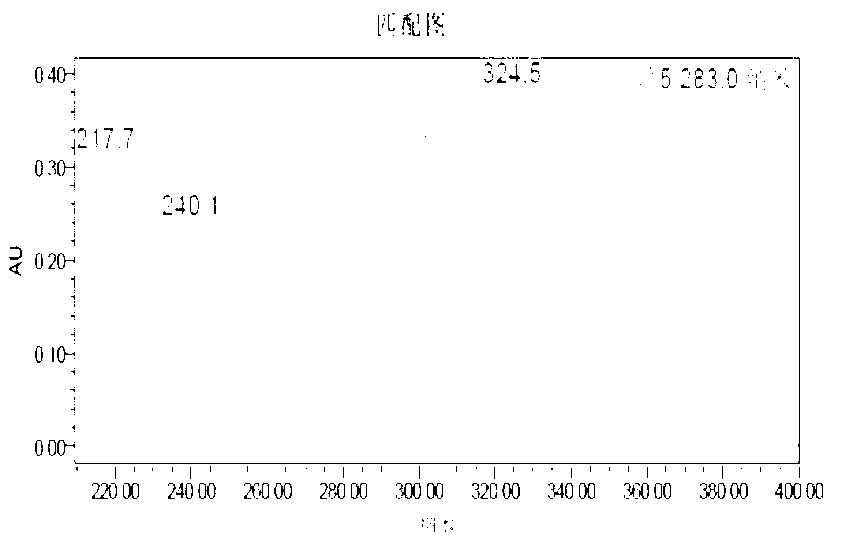

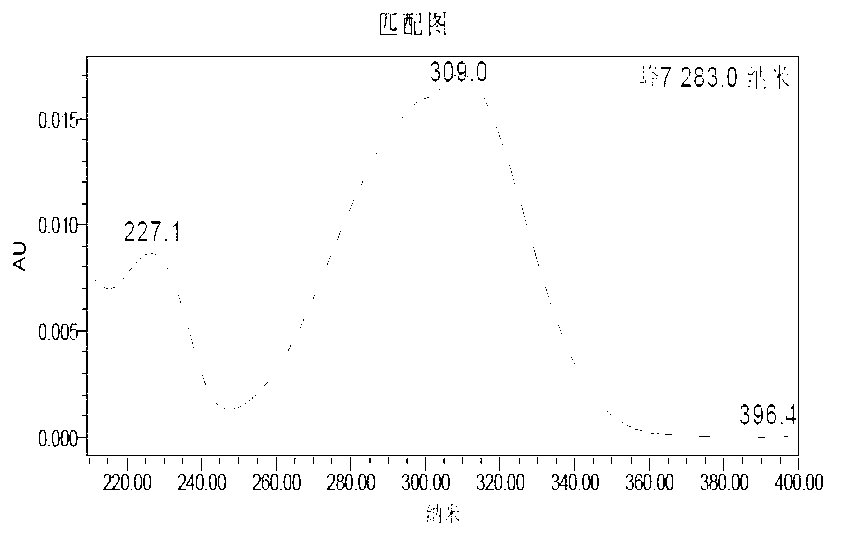

Spectrum-effect relationship-based propolis quality control method

ActiveCN102980952AJudging the strength of antioxidant effectJudging strengthComponent separationMaterial analysis by observing effect on chemical indicatorDPPHPhosphomolybdic acid

The invention provides a spectrum-effect relationship-based propolis quality control method. The spectrum-effect relationship-based propolis quality control method can forecast the antioxidant activity of propolis according to a propolis fingerprint. The spectrum-effect relationship-based propolis quality control method utilizes high performance liquid chromatography (HPLC) to build a propolis fingerprint and realizes evaluation of antioxidant activity according to potassium permanganate fading time, a DPPH free radical clearance rate, a phosphomolybdic acid binding rate and a hydroxyl radical clearance rate. Through analysis of a propolis fingerprint chromatograph and spectral characteristics, the spectrum-effect relationship-based propolis quality control method determines 25 characteristic peaks and 5 characteristic peak groups. Through fitting of a polynomial, the spectrum-effect relationship-based propolis quality control method builds a mathematical model for forecasting the antioxidant activity of propolis according to a propolis fingerprint. According to the characteristic peaks and the characteristic peak groups, only through the mathematical model, the spectrum-effect relationship-based propolis quality control method can directly determine strength of the antioxidant activity of a propolis drug without an anti-oxidation test thereby determining quality. The spectrum-effect relationship-based propolis quality control method has the advantages of simple processes, strong objectivity and more characteristic peaks and realizes perfect and scientific propolis quality control.

Owner:GUANGZHOU CITY TANSHAN APICULTURE

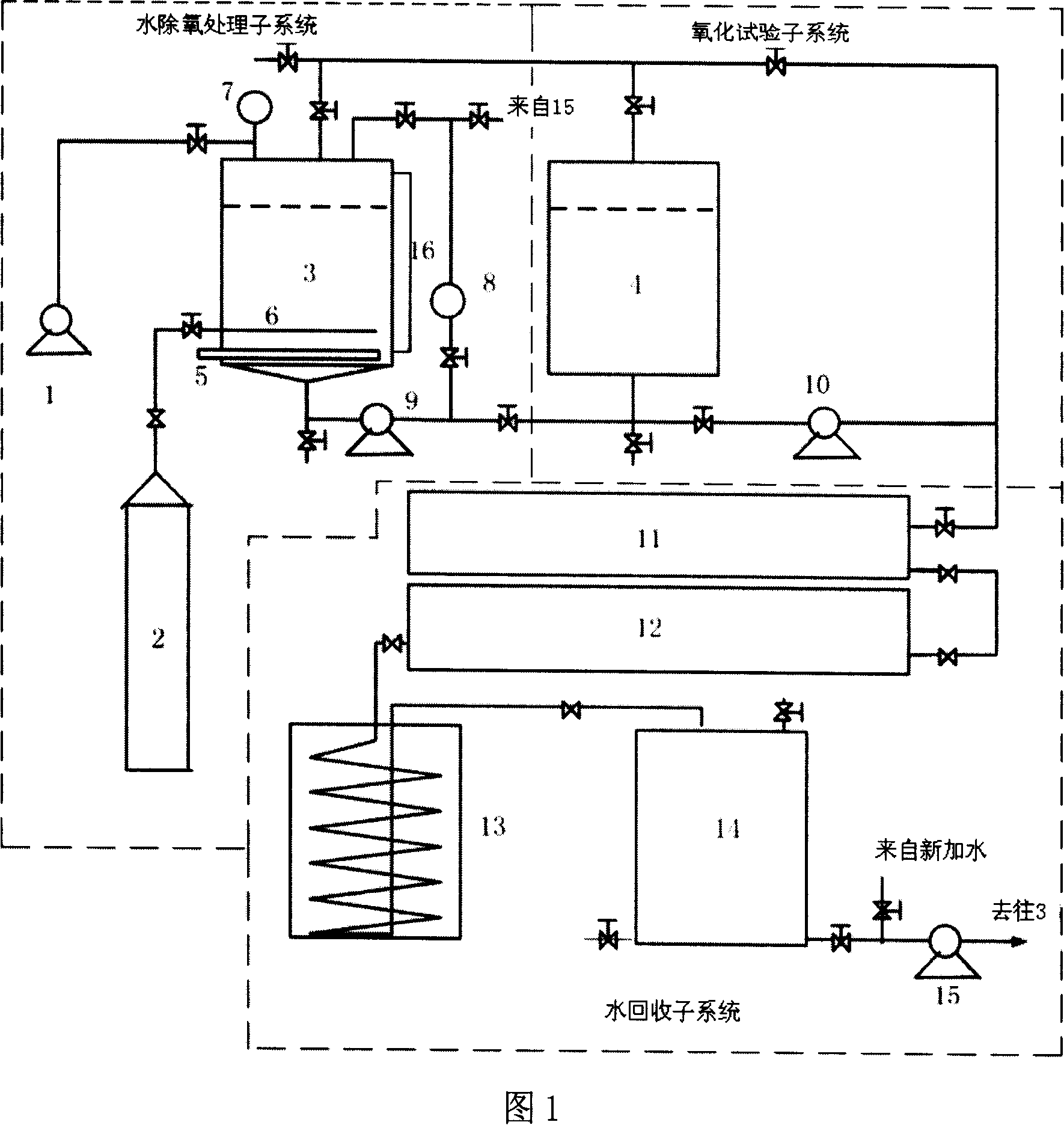

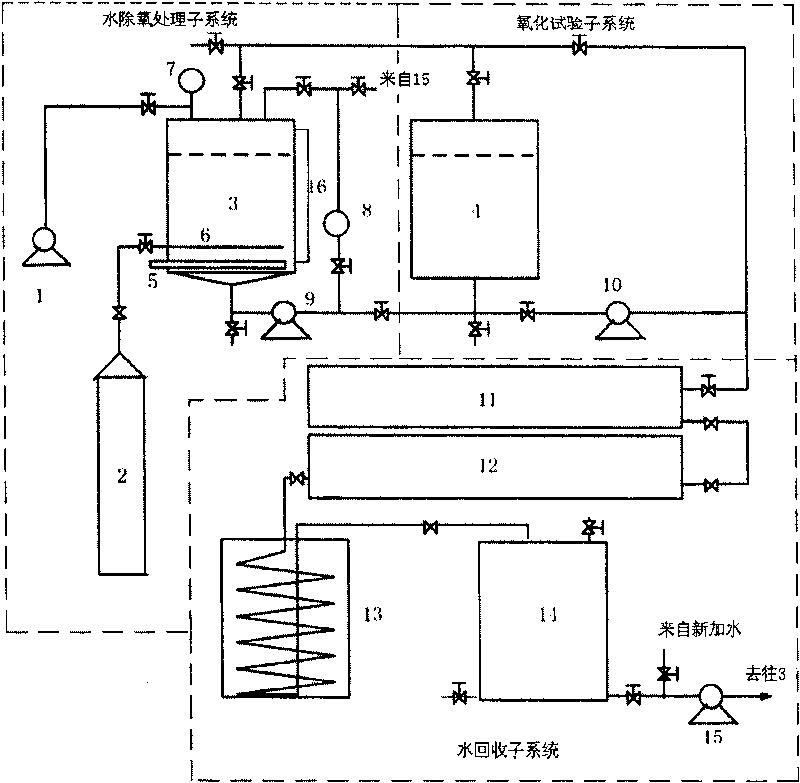

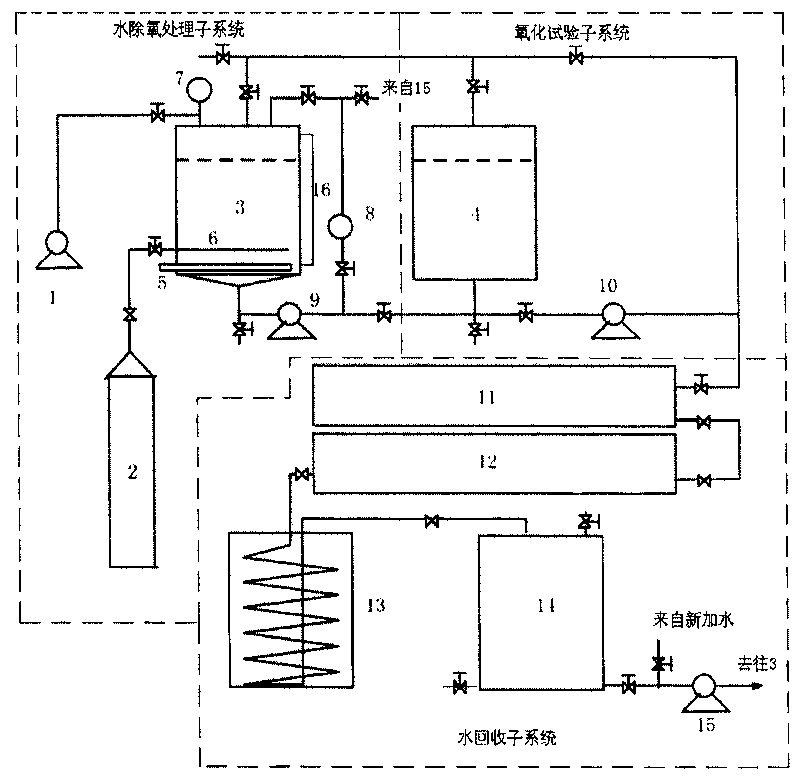

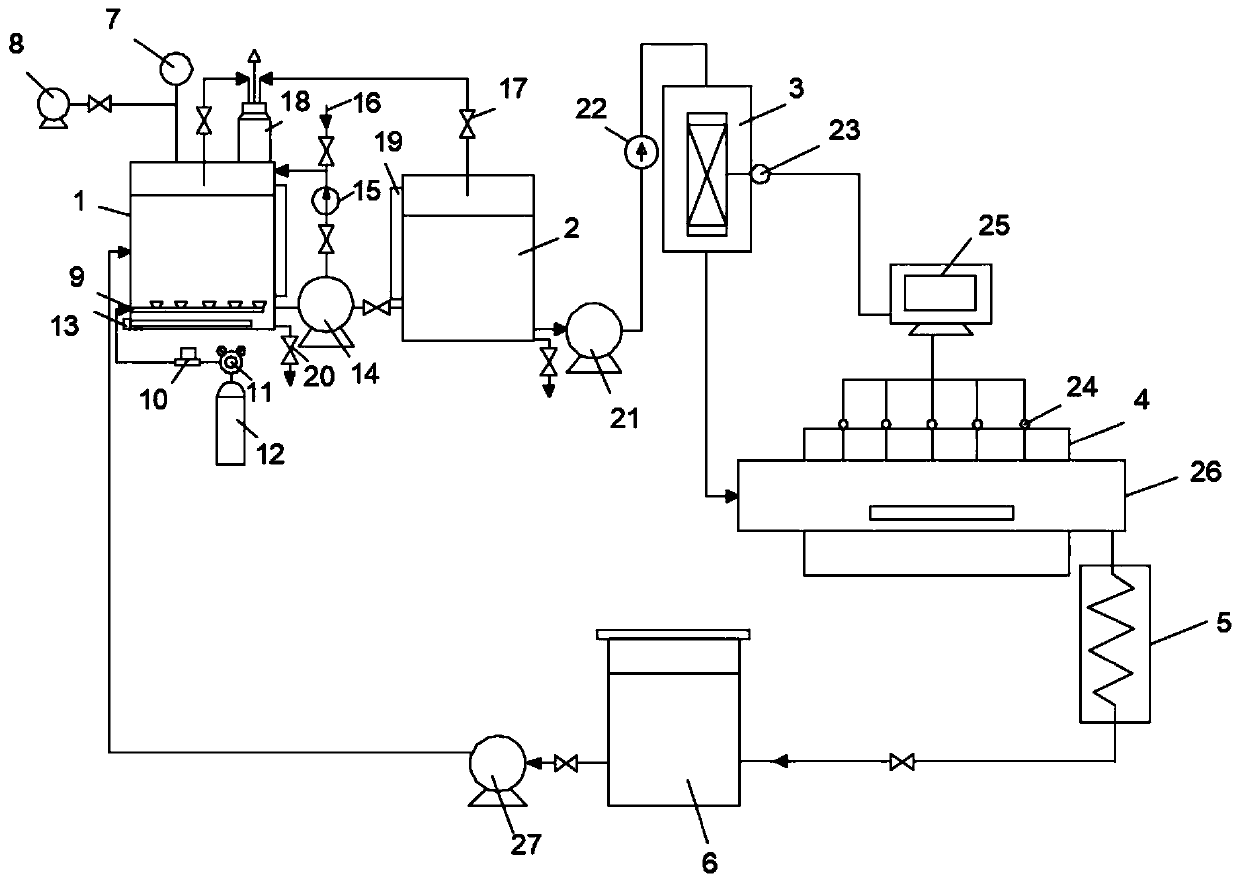

High-temperature steam oxidation test device

The present invention relates to a high-temperature steam oxidation experimental device, and comprises a processing subsystem which can remove oxygen in water, an oxidative experiment subsystem and a water recovering subsystem. The processing subsystem which can remove oxygen in water comprises a water processing bucket which is connected with a vacuum pump. The lower end of the water processing bucket is provided with an oxygen removing tube which is connected with an inert gas bottle. The upper part and the lower part of the water processing bucket are all connected with the upper part and the lower part of the water storage bucket of the oxidative experiment subsystem. The lower part of the water storage bucket is connected with the steam generating preheating furnace of the water recovering subsystem via a pipeline and a valve. A metering pump is arranged on the pipeline. The steam generating preheating furnace is also connected with a reacting furnace which is provided with a steam outlet. The processing subsystem which can remove oxygen in water of the present invention can adjust the content of dissolved oxygen in the experiment water. The other quality parameter of the experiment water can be adjusted through controlling the water quality. The flowing amount of the steam can be adjusted via the metering pump of the oxidative experiment subsystem. The steam temperature of the oxidative experiment can be adjusted by changing the setting temperature of the steam generating preheating furnace and the reacting furnace.

Owner:XIAN THERMAL POWER RES INST CO LTD

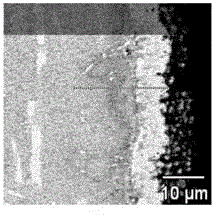

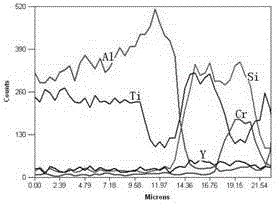

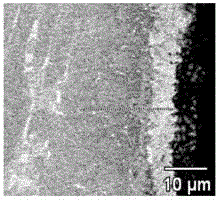

Preparation method of high-temperature-resistant, heat-corrosion-resistant and abrasion-resistant coating and penetrating agent

InactiveCN104862639ASolve the technical problem of poor high temperature resistance, heat corrosion resistance and wear resistanceImprove bindingMolten spray coatingAlloyTemperature resistance

The invention relates to a preparation method of a high-temperature-resistant, heat-corrosion-resistant and abrasion-resistant coating and a penetrating agent. The penetrating agent is characterized by comprising the following components in percentage by weight: 6-10 percent of Cr, 4-8 percent of Si, 2-6 percent of Al, 1-2 percent of Y2O3, 6-10 percent of AlCl3 and the balance of Al2O3. The preparation method of the high-temperature-resistant, heat-corrosion-resistant and abrasion-resistant coating and the penetrating agent have the benefits that a Cr-Al-Si-Y penetrating layer is prepared on the surface of a TiAl alloy, the technical problem of poor in high-temperature resistance, heat corrosion resistance and abrasion resistance of the TiAl alloy is solved, the process is stable and reliable, the coating binding force is good, and tissues are uniform and compact; moreover, the penetrating agent has the advantages of being simple in process, convenient in operation, high in efficiency, low in cost, easy in implementation and the like. The binding force is detected by adopting an edge filing method, a scratching method, a friction method and a polishing method, the binding force between a coating layer and a matrix is good, and a high-temperature oxidation test, a frictional wear test and a heat corrosion test show that the coating has excellent performance.

Owner:BEIFANG UNIV OF NATITIES

High-temperature steam oxidation test device

The present invention relates to a high-temperature steam oxidation experimental device, and comprises a processing subsystem which can remove oxygen in water, an oxidative experiment subsystem and awater recovering subsystem. The processing subsystem which can remove oxygen in water comprises a water processing bucket which is connected with a vacuum pump. The lower end of the water processing bucket is provided with an oxygen removing tube which is connected with an inert gas bottle. The upper part and the lower part of the water processing bucket are all connected with the upper part and the lower part of the water storage bucket of the oxidative experiment subsystem. The lower part of the water storage bucket is connected with the steam generating preheating furnace of the water recovering subsystem via a pipeline and a valve. A metering pump is arranged on the pipeline. The steam generating preheating furnace is also connected with a reacting furnace which is provided with a steamoutlet. The processing subsystem which can remove oxygen in water of the present invention can adjust the content of dissolved oxygen in the experiment water. The other quality parameter of the exper iment water can be adjusted through controlling the water quality. The flowing amount of the steam can be adjusted via the metering pump of the oxidative experiment subsystem. The steam temperature ofthe oxidative experiment can be adjusted by changing the setting temperature of the steam generating preheating furnace and the reacting furnace.

Owner:XIAN THERMAL POWER RES INST CO LTD

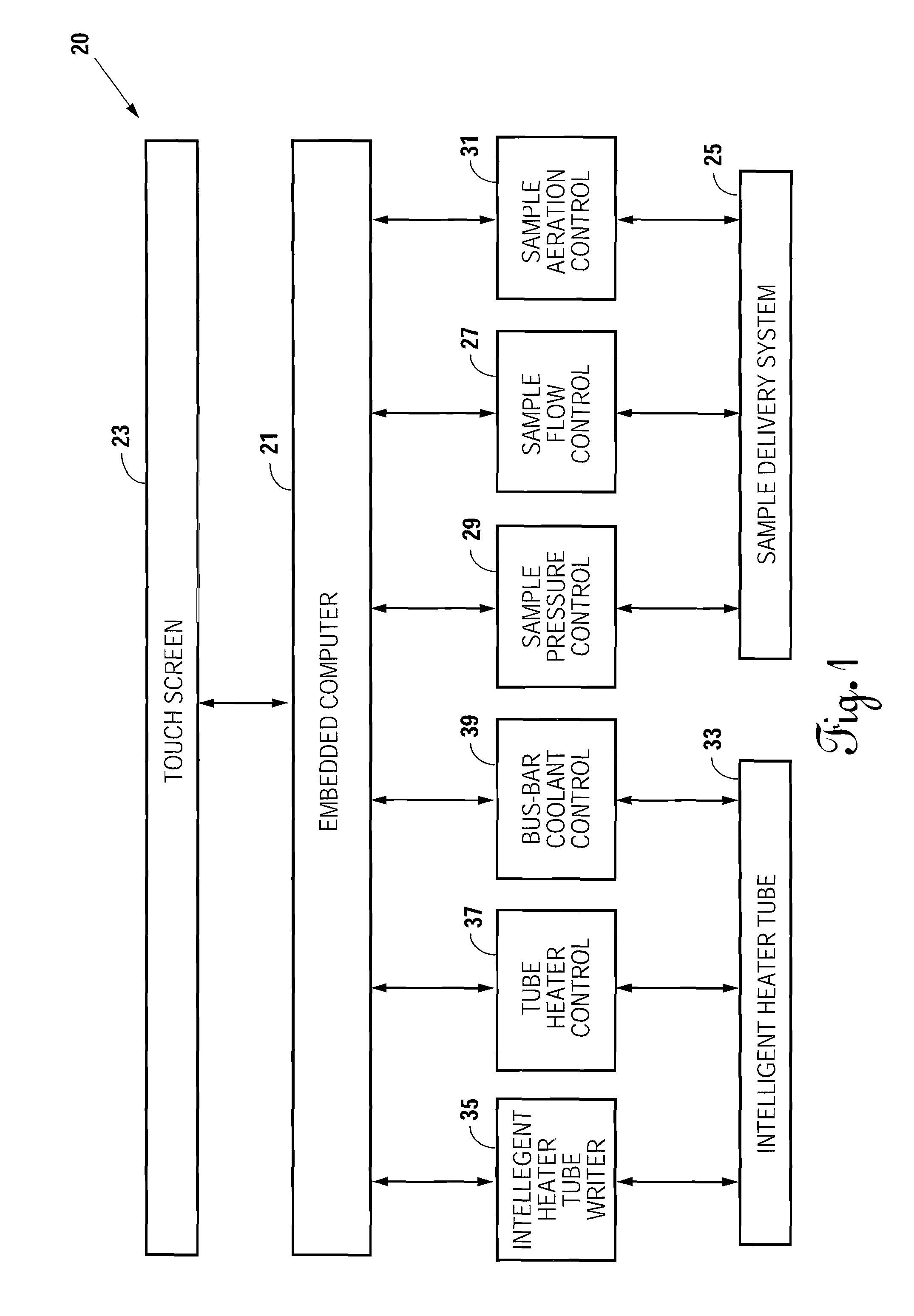

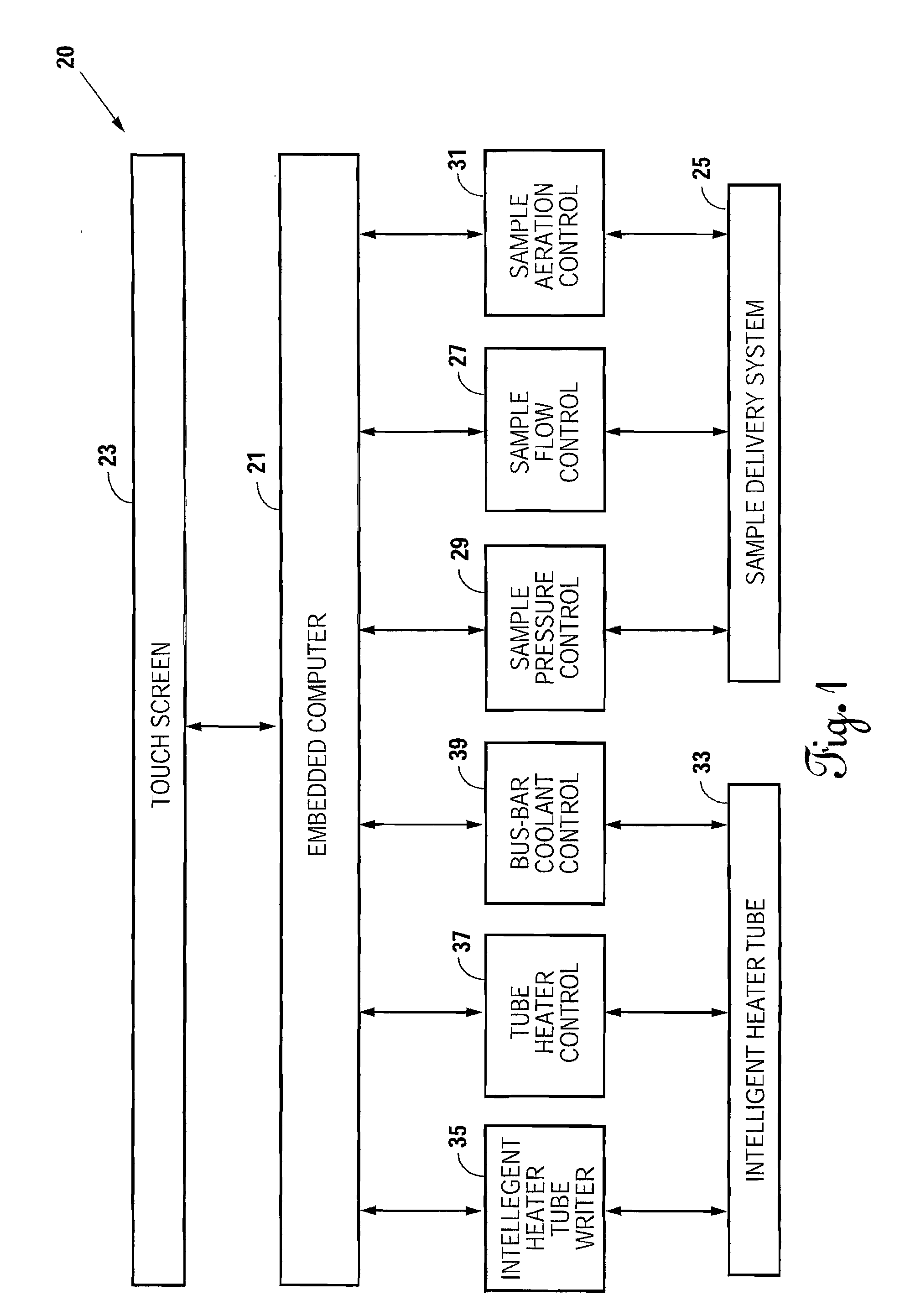

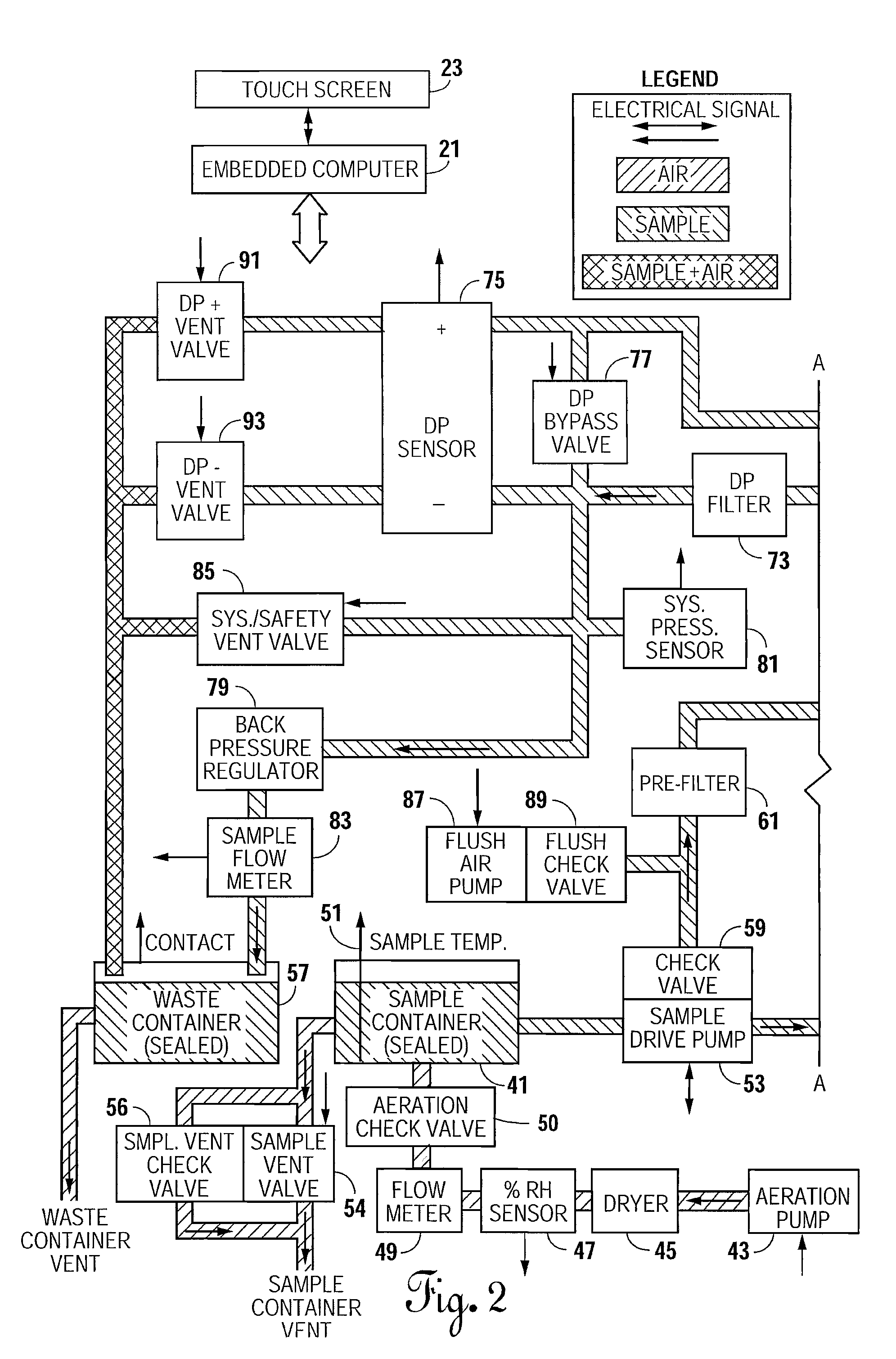

Apparatus and Method for Determining the Thermal Stability of Fluids

A thermal oxidation tester is shown for determining thermal stability of a fluid, particularly hydrocarbons when subjected to elevated temperatures. The tendency of the heated fluid to oxidize and (1) form deposits on a surface of a heater tube and (2) form solids therein, are both measured at a given flow rate, temperature and time. The measured results are used to determine whether a fluid sample passes or fails the test. Results of measurements are recorded in a memory device on one end of the heater tube on which the deposits were made.

Owner:PETROLEUM ANALYZER COMPANY

Test method of oxidation stability of transformer oil

InactiveCN102507467AComponent separationColor/spectral properties measurementsAntioxidantOxidation stability

The invention discloses a test method of oxidation stability of transformer oil, comprising the following steps of: (1) measuring the mass percentage concentration of antioxidant in the transformer oil by use of the national standards; (2) preparing an oil sample and standing at 100-199 DEG C, adding red copper and oxygen for the accelerated oxidation test; (3) measuring the mass percentage concentration of the antioxidant in the oil sample obtained in step (2); and (4) calculating the consumption rate of the antioxidant in the oil sample with a computational formula and characterizing the oxidation stability of the transformer oil according to a value of the consumption rate. According to the method, the oxidation stability of the transformer oil can be characterized by the consumption rate of the antioxidant obtained through the accelerated oxidation test, and the consumption rates of the antioxidant measured in the same accelerated oxidation test conditions with regard to different transformer oil samples can be used for comparatively evaluating the oxidation safeties of different transformer oil samples.

Owner:STATE GRID HUNAN ELECTRIC POWER CO LTD ELECTRIC POWER SCI RES INST +1

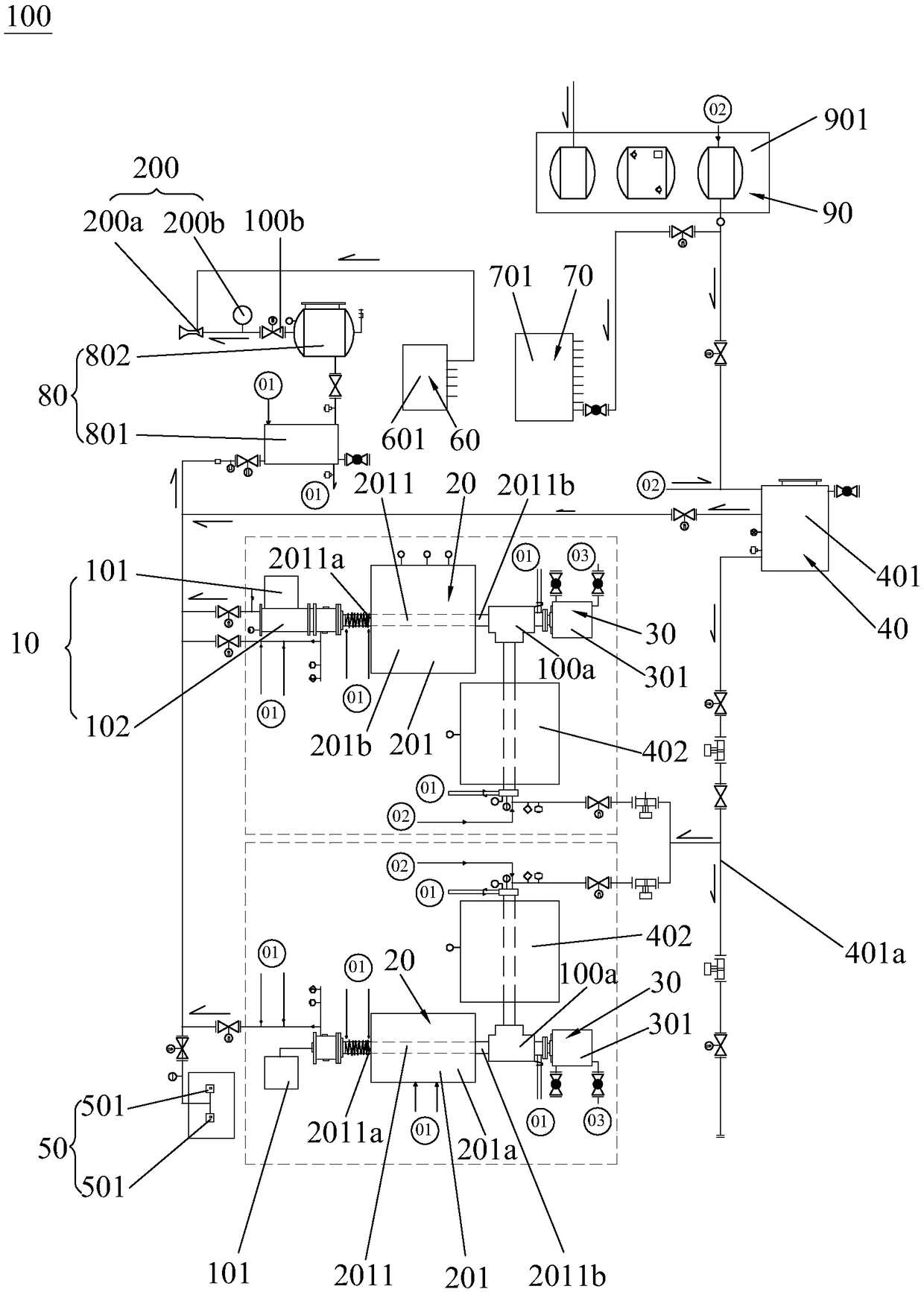

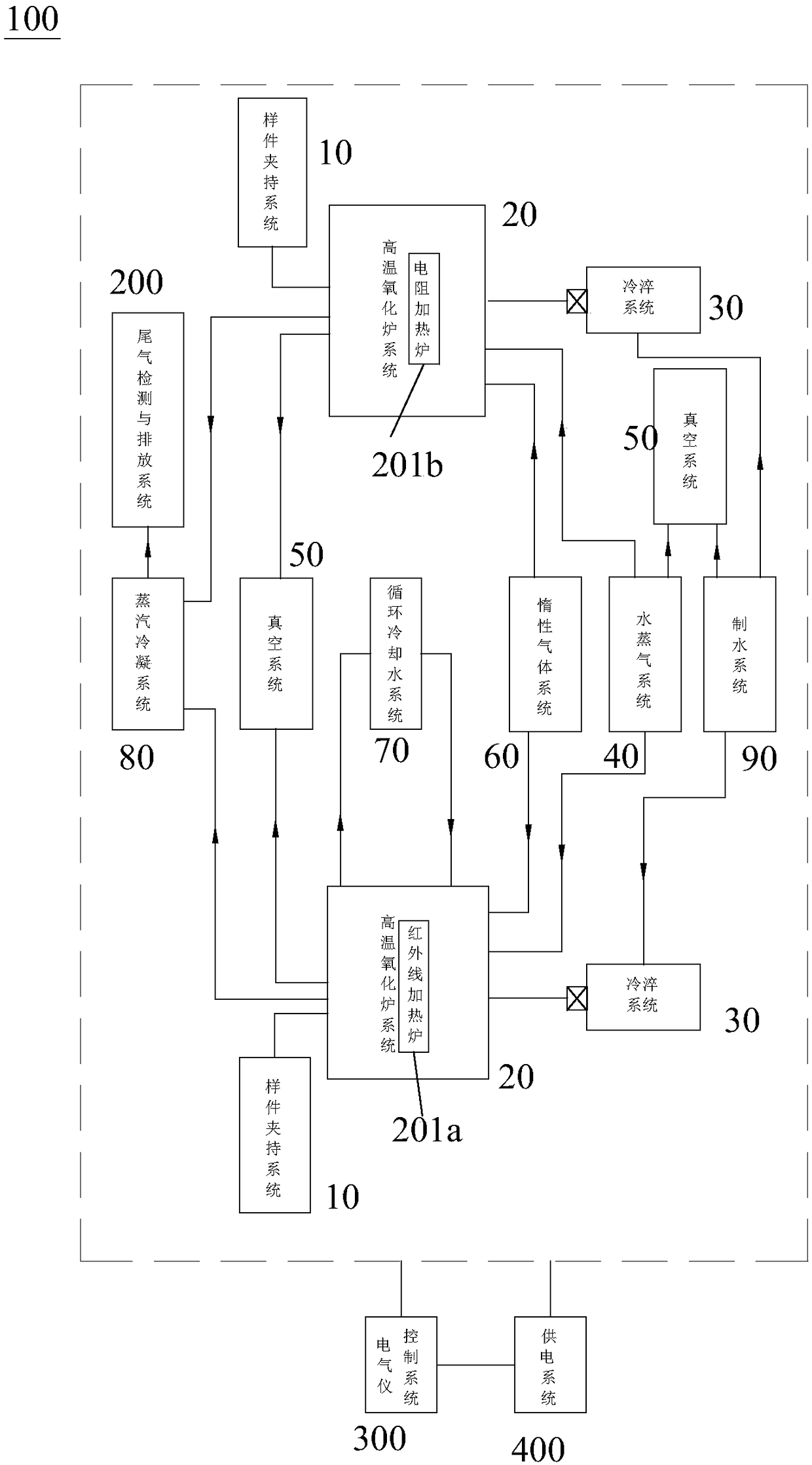

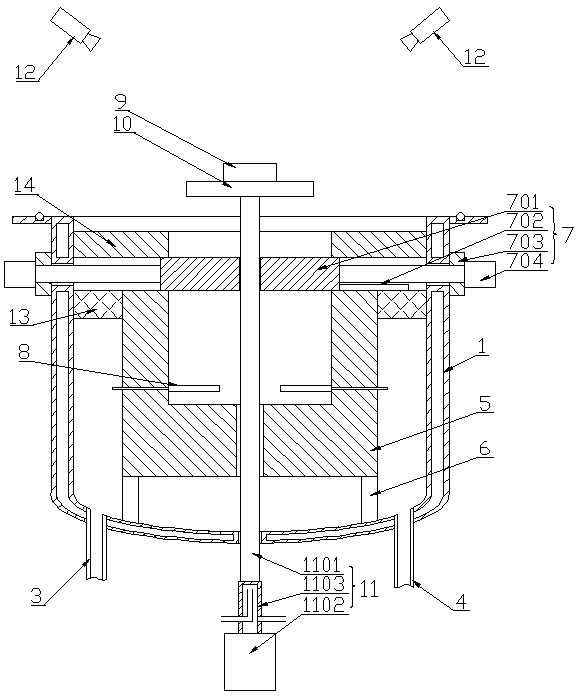

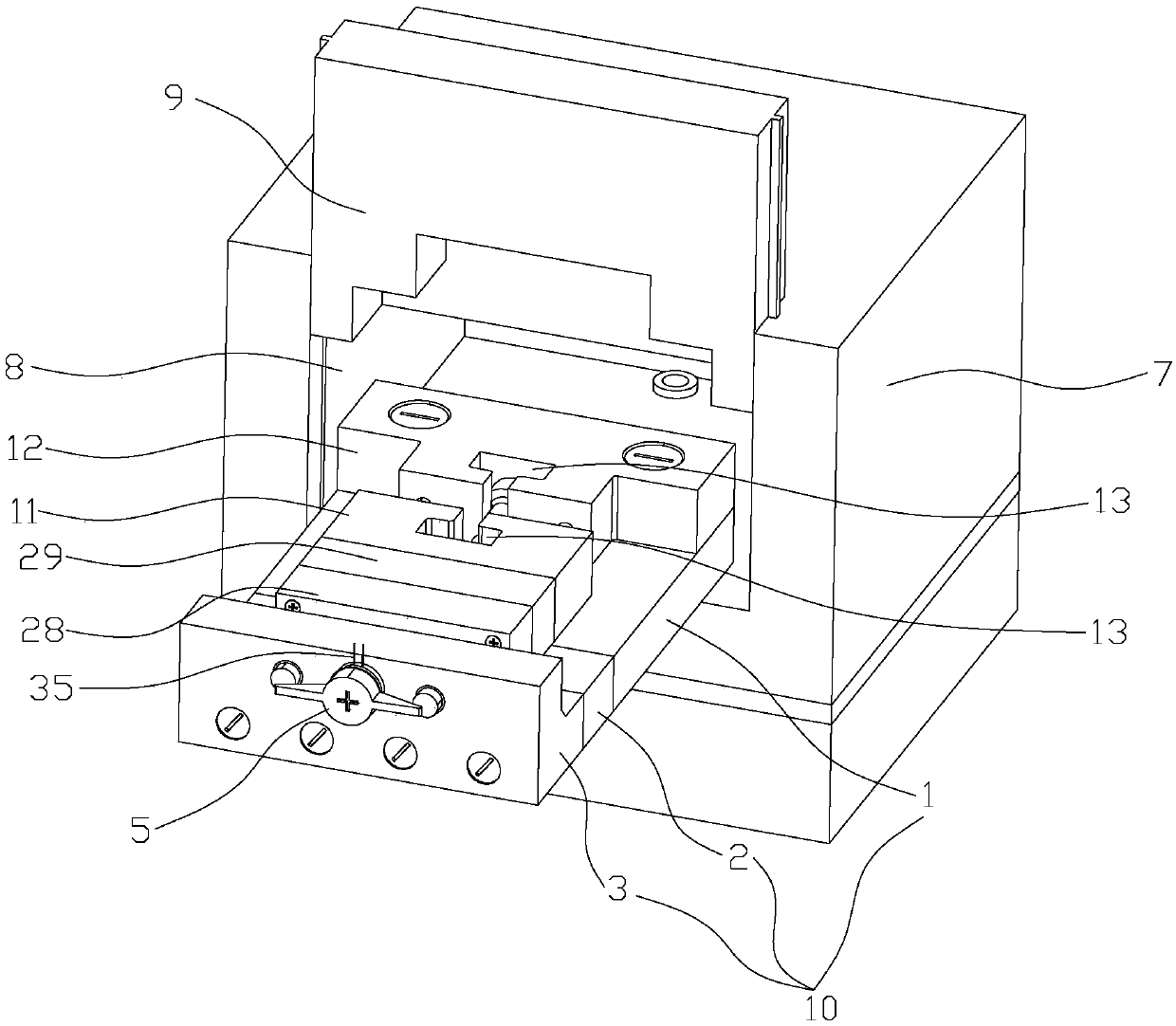

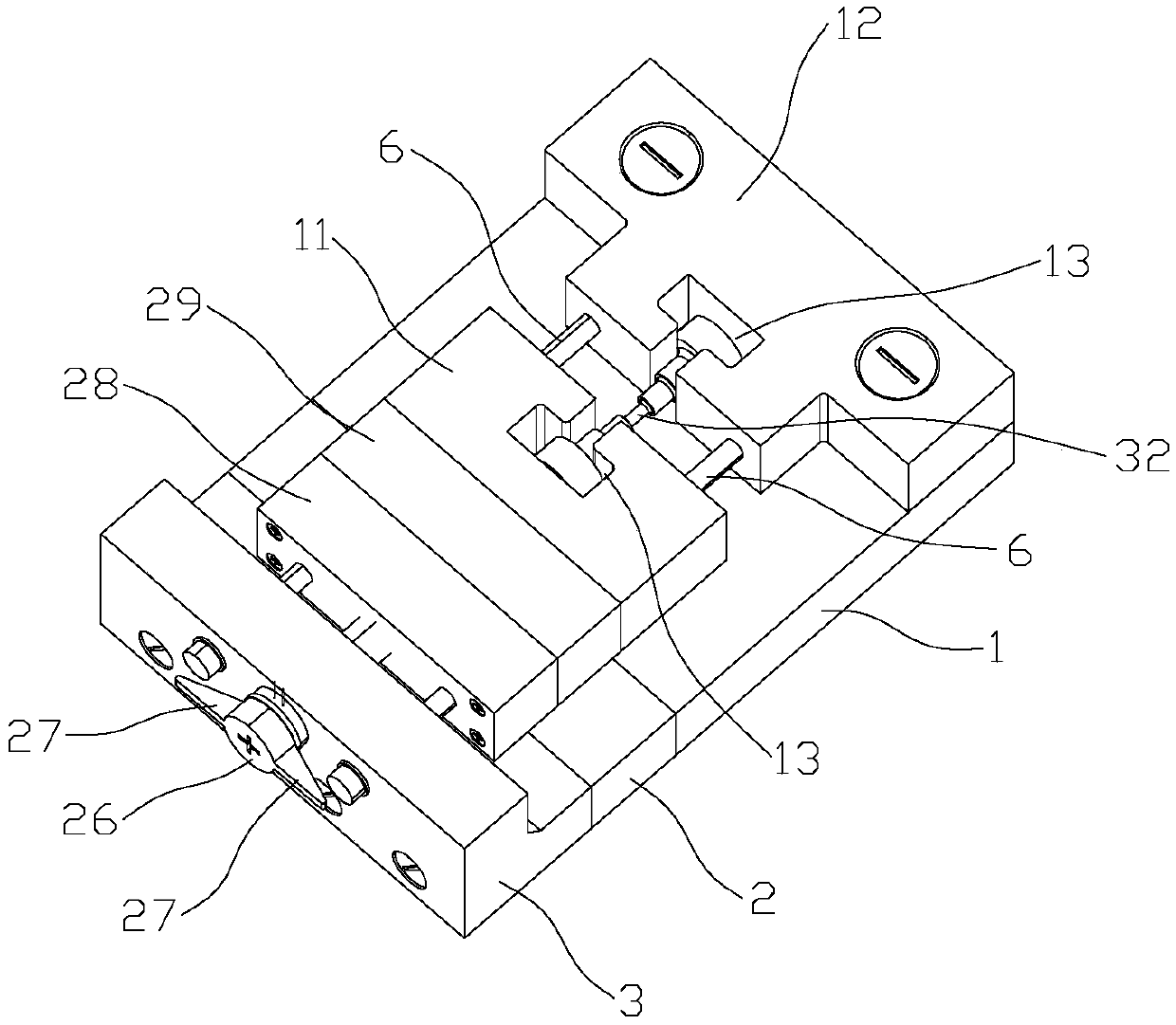

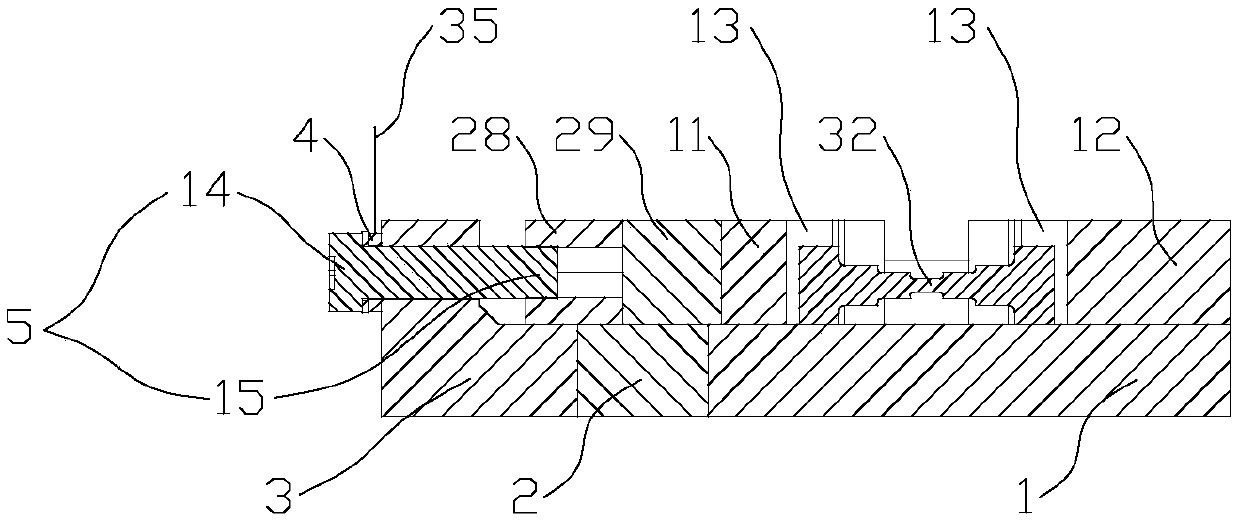

LOCA simulation test device for fuel cladding

ActiveCN109147970AEasy and stable deliveryNuclear energy generationNuclear monitoringThermal impactEngineering

The invention provides an LOCA simulation test device for fuel cladding, which comprises a sample clamping system, a high-temperature oxidation furnace system and a cold quenching system, wherein thehigh-temperature oxidation furnace system comprises a high-temperature oxidation furnace, the high-temperature oxidation furnace comprises a furnace chamber arranged in an axial direction and used forcontaining a sample for the fuel cladding, the top and bottom of the furnace chamber are respectively provided with a top opening and a bottom opening for conveying the sample; the cold quenching system comprises a cooling pool, wherein the cooling pool is positioned below a bottom opening and communicated with the bottom opening through a joint; the sample clamping system is positioned above theopening and is communicated with the top opening; the sample clamping system is used for suspending and fixing the sample and conveying the sample between the high-temperature oxidation furnace and the cooling pool. According to the invention, the chamber of the high-temperature oxidation furnace is arranged in the axial direction, the sample clamping system is positioned at the top opening of the furnace chamber, the cooling pool is positioned at the bottom opening of the furnace chamber, the sample can be hung and fixed and conveyed to the furnace chamber and the cooling pool through the sample clamping system, a high-temperature oxidation test and a thermal impact test of longer rod-like fuel cladding can be achieved.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +2

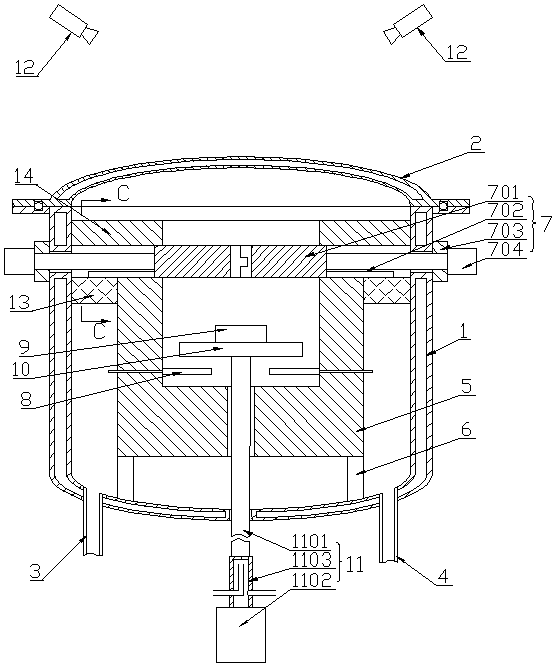

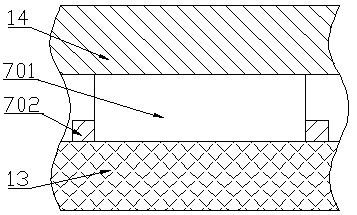

Superhigh temperature oxidation resistance testing platform and testing method

ActiveCN108226154AExtend your lifeMeet the requirements of ultra-high temperature oxidation resistance testMaterial analysis by optical meansMaterial thermal analysisShielding gasEngineering

The invention belongs to the field of material performance detection and particularly relates to a superhigh temperature oxidation resistance testing platform which comprises a vertical type furnace body and a furnace door at the upper end of the furnace body; the lower part of the furnace body is provided with a vacuum device and a protective gas replenishment device; the furnace body is internally provided with an insulating layer; the top of the insulating layer is provided with an insulating door component; the middle part of the insulating layer is provided with a supporting plate used for placing a sample piece; the supporting plate is connected with an ejection device; the ejection device can eject the insulating door component; and a detection instrument is arranged above the furnace door. By adopting the superhigh temperature oxidation resistance testing platform provided by the invention, a heating element heating environment is separated from an oxidation test environment; during heating, protective gas rushes into the furnace body as a gas protection environment; after heating is finished, the heated sample piece is rapidly moved from the gas protection environment intoan oxidation environment, so that the high-temperature sample piece is subjected to oxidation at the oxidation atmosphere, the heating element is still in the gas protection environment to be protected from not being oxidized, the service life of the heating element is greatly prolonged, the test cost is reduced, and the superhigh temperature oxidation resistance testing platform has better market value.

Owner:洛阳西格马高温电炉有限公司

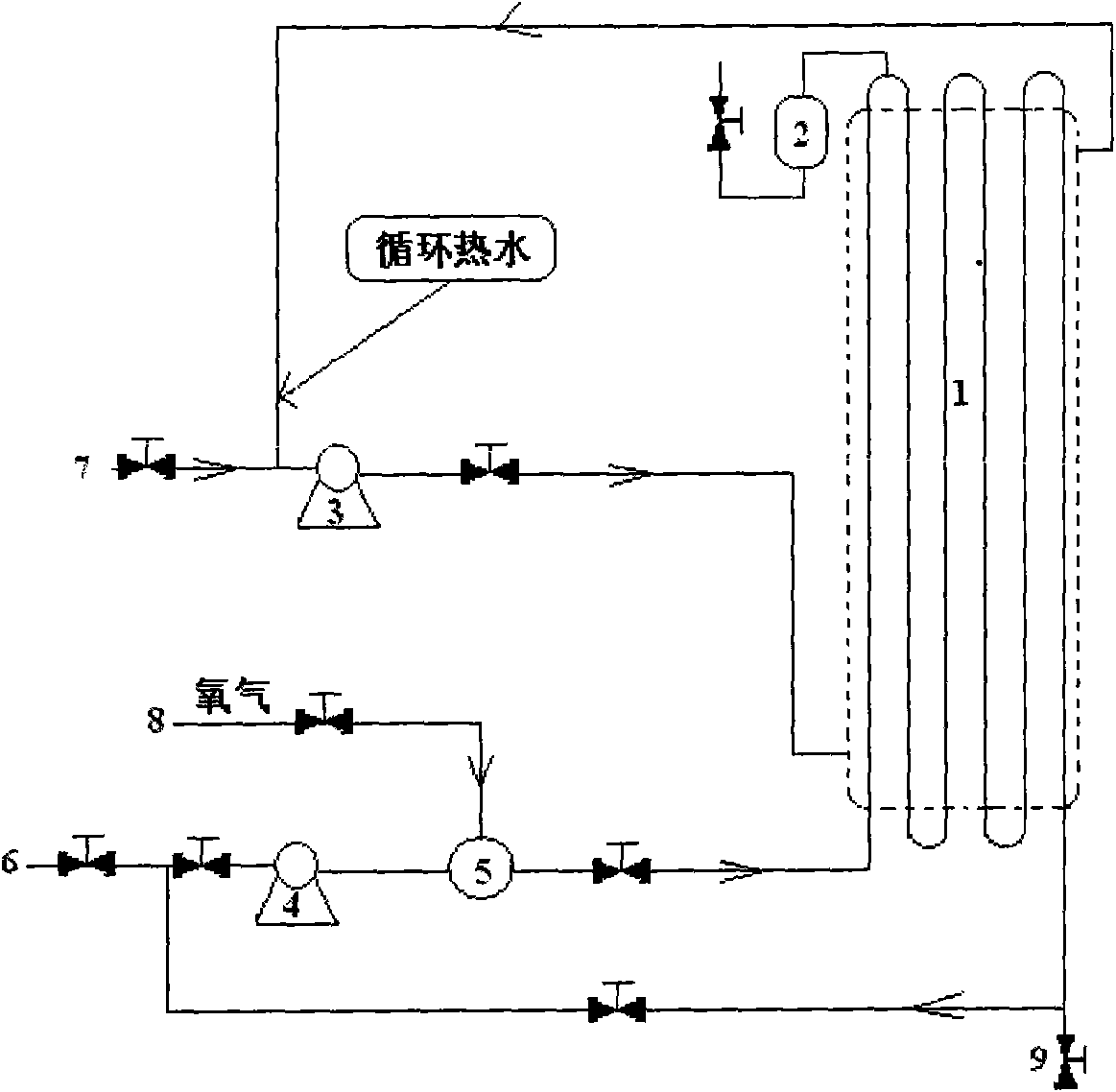

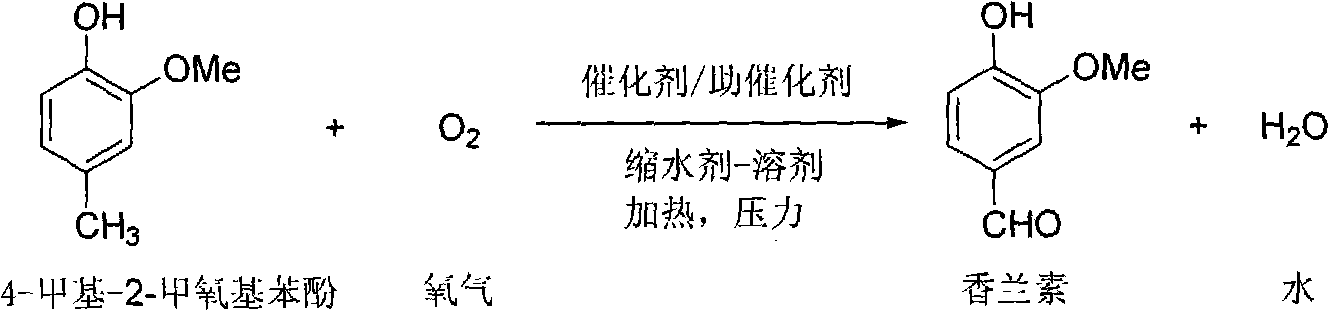

Method for synthesizing vanillin

InactiveCN102030625AAvoiding Explosion HazardsAvoid deep oxidationOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSlurry reactorVanillin synthesis

The invention relates to a method for synthesizing vanillin, comprising the following steps of: carrying out material thermal pretreatment by adopting a pressured reaction axe, and then pouring the materials into a cannular slurry reactor for vanillin synthetic oxidation reaction; and by using 4-methyl-2-metoxyphenol as a raw material, using ethylene glycol monomethyl ether or ethylene glycol monoethyl ether as a solvent and using oxygen as an oxidant, carrying out the oxidation reaction for synthesizing vanillin in a way of intermittently feeding oxygen. The conversion rate of the 4-methyl-2-metoxyphenol as the raw material reaches more than 99%, the selectivity of the vanillin reaches more than 93%, and the separation yield reaches about 82%. The oxidation test carried out in the cannular slurry reactor proves that the oxidation reaction of the 4-methyl-2-metoxyphenol can be successfully carried out in the reactor under a milder condition to synthesize vanillin, and the method avoids a danger of easy explosion of the traditional axe type oxidation technology process for synthesizing vanillin by using methanol as the reaction solvent and has the advantages of environmental-protection process and high efficiency.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +2

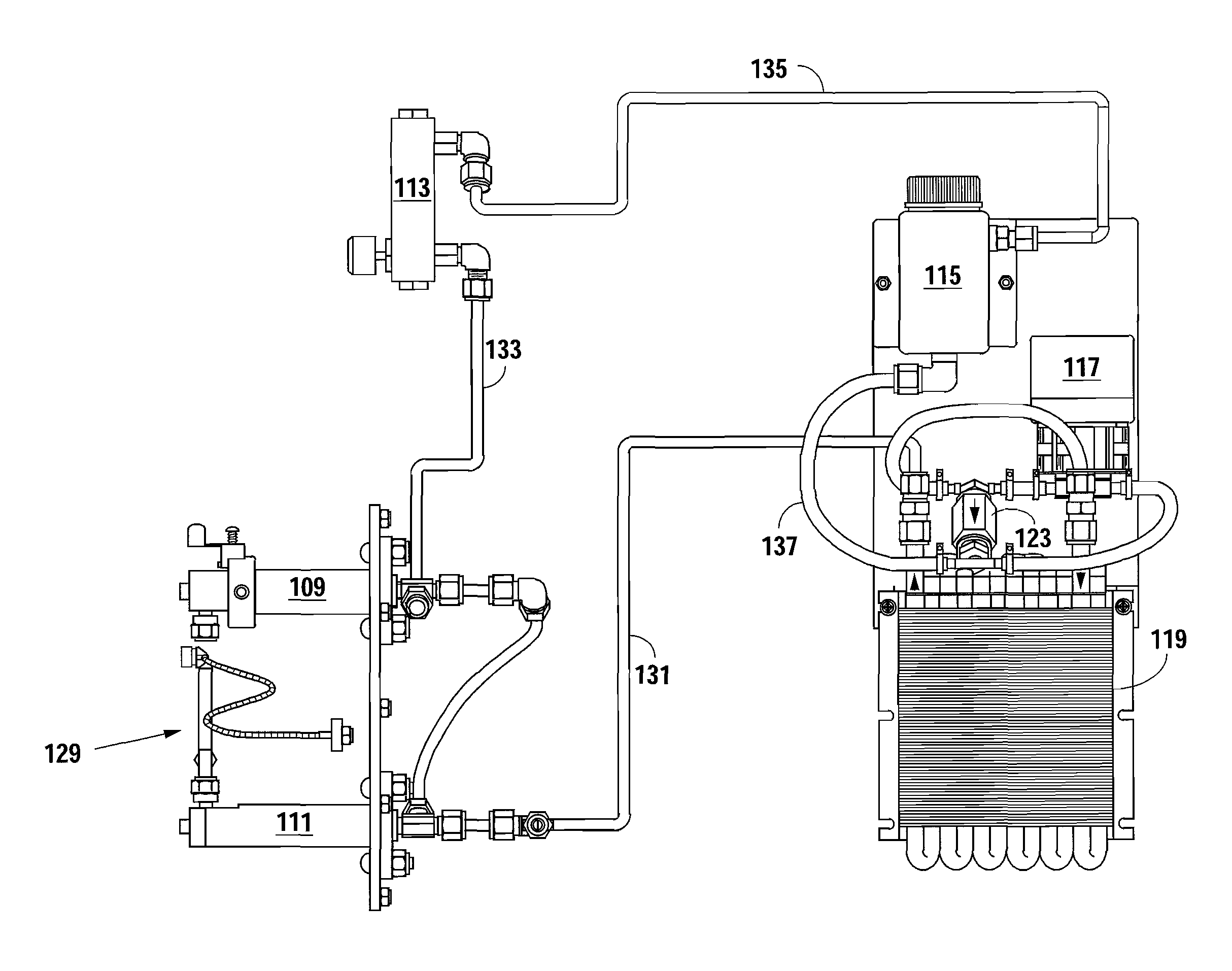

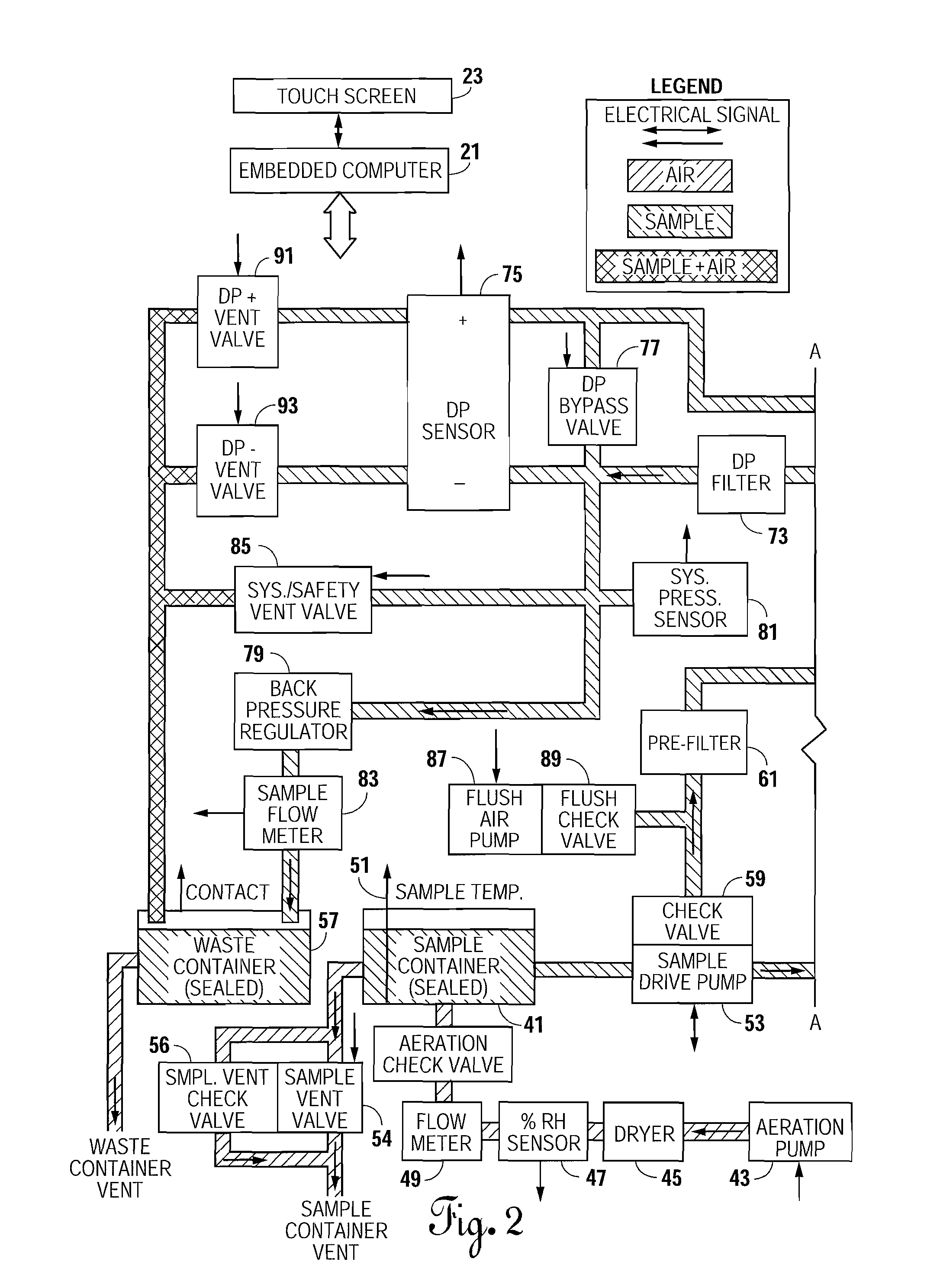

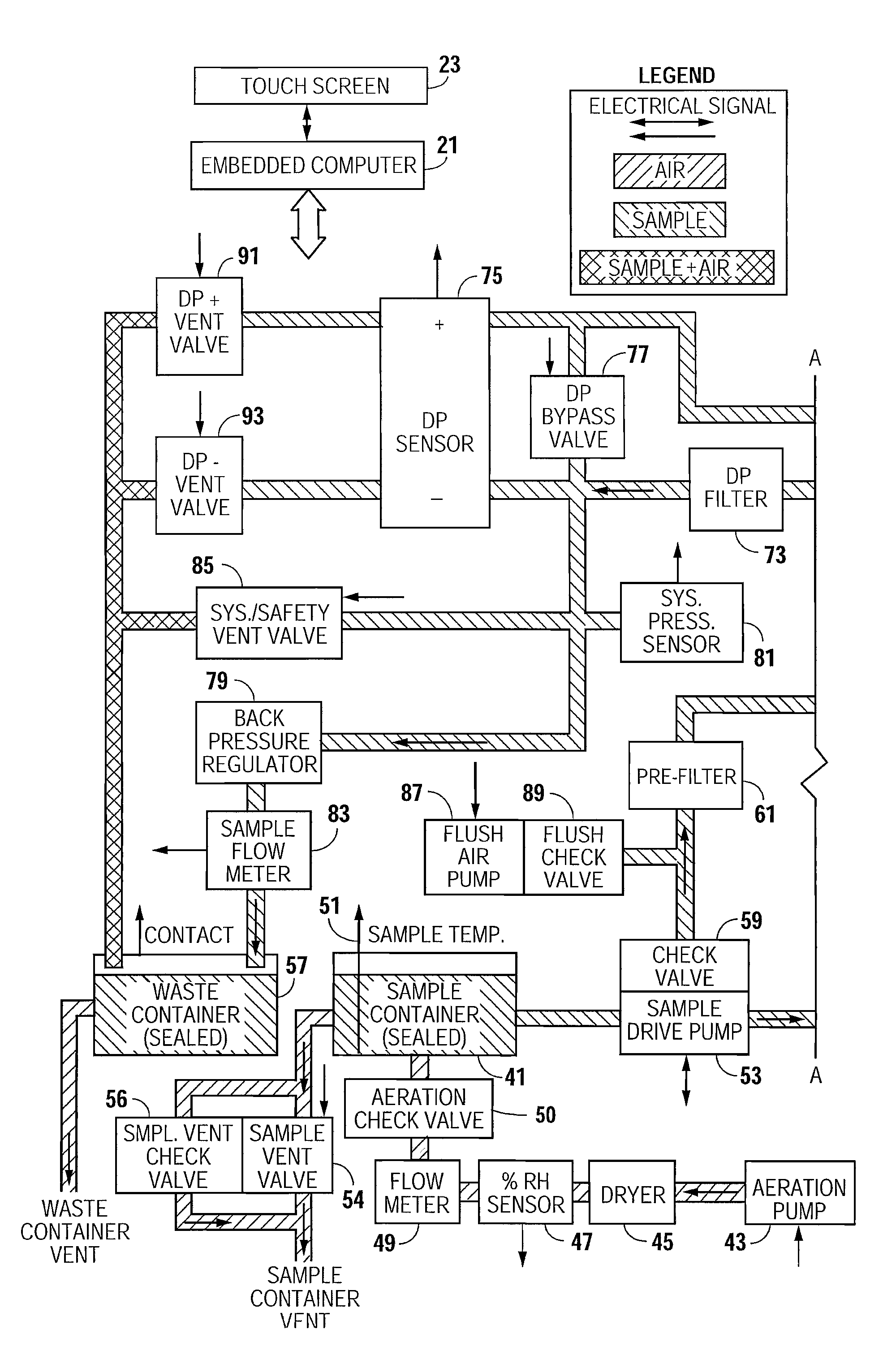

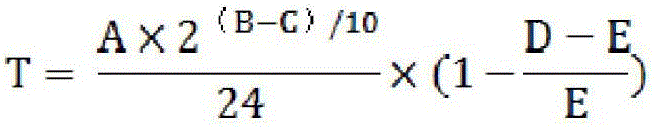

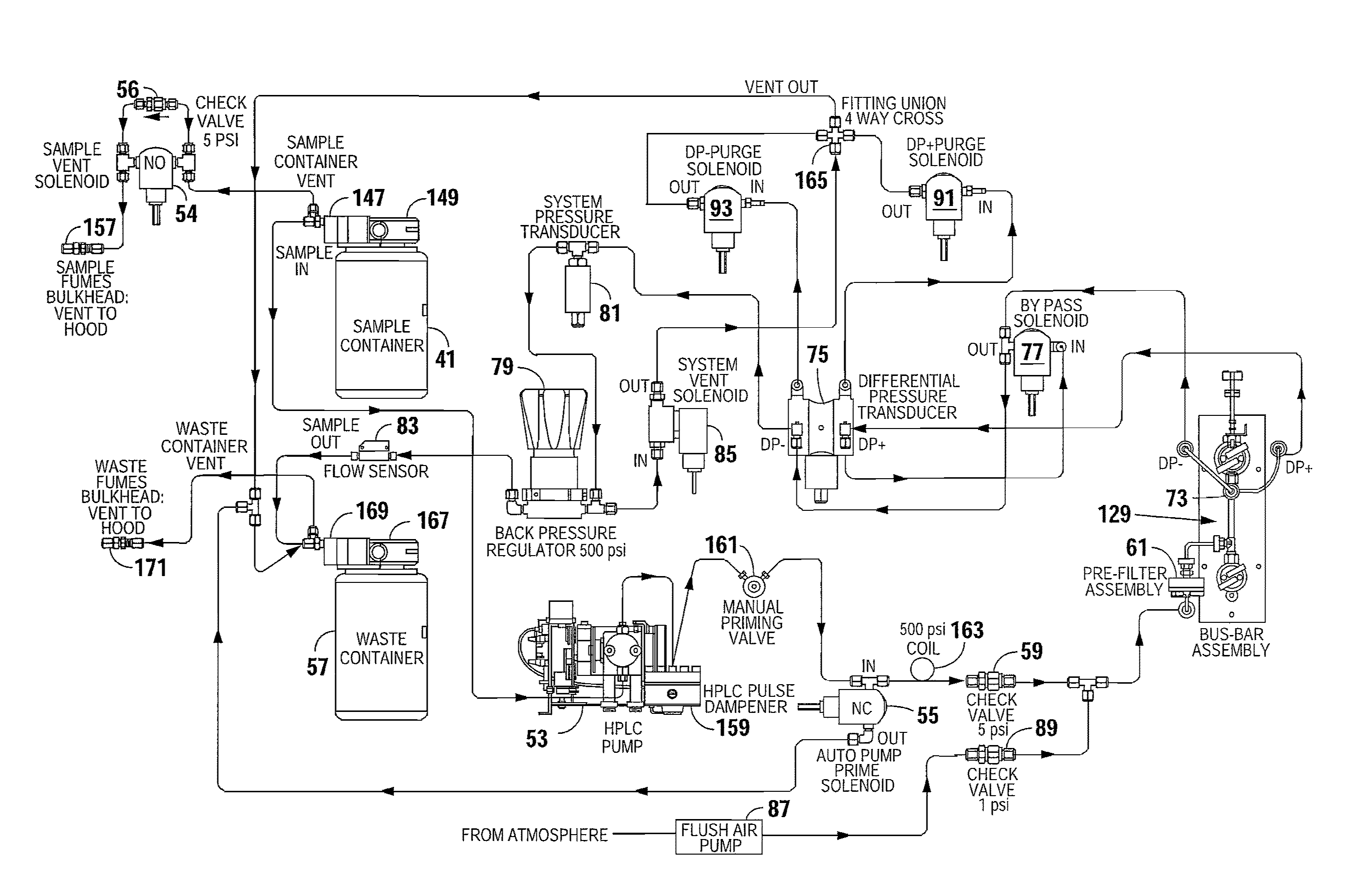

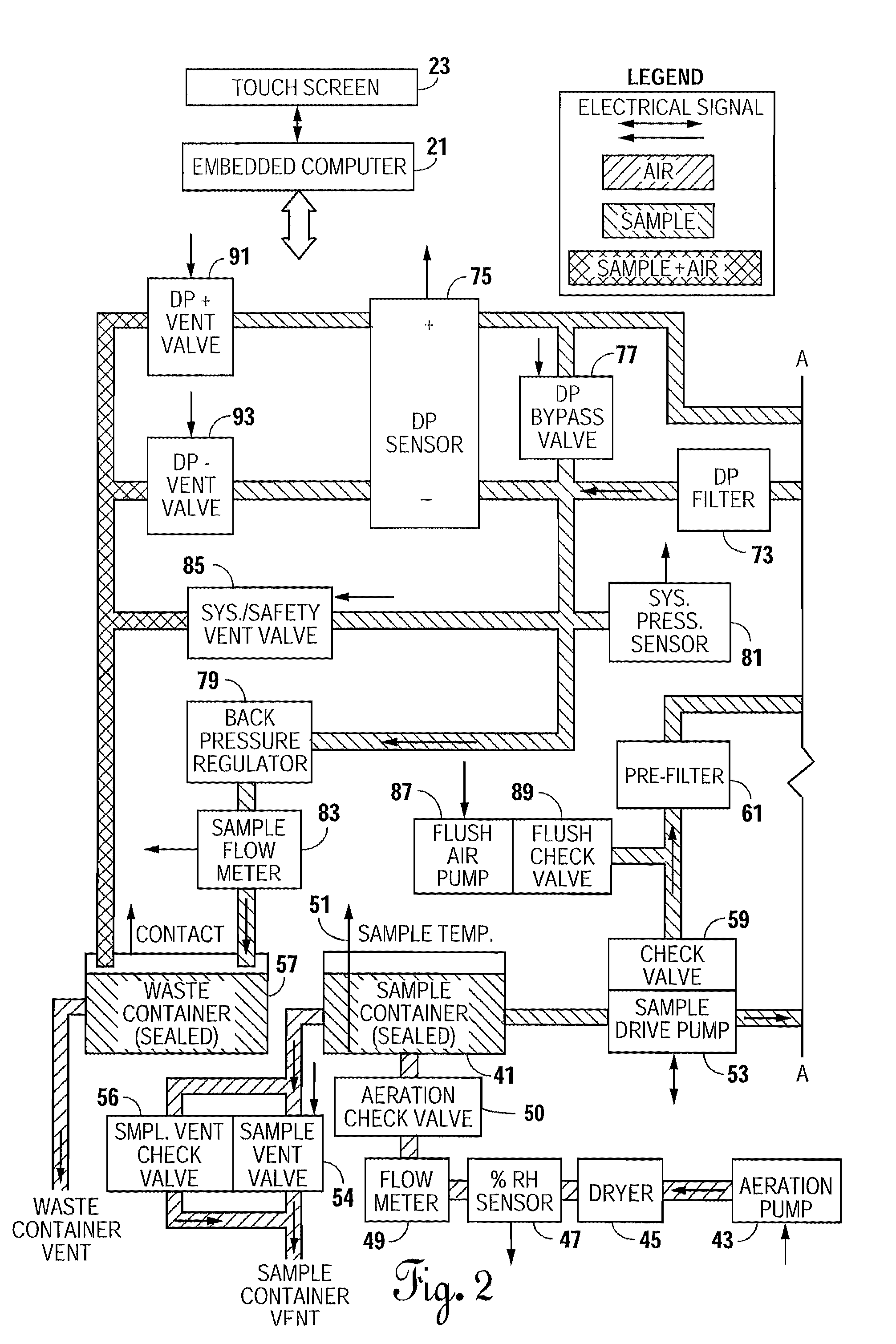

Auto Priming and Flushing an Apparatus for Determining the Thermal Stability of Fluids

A thermal oxidation tester is shown for determining thermal stability of a fluid, particularly hydrocarbons when subjected to elevated temperatures. The tendency of the heated fluid to oxidize and (1) form deposits on a surface of a heater tube and (2) form solids therein, are both measured at a given flow rate, temperature and time. The measured results are used to determine whether a fluid sample passes or fails the test. At the beginning of each test, the test sample is aerated with dry air until saturation. Simultaneously, the test equipment is primed to remove pockets of air there from. After each test, the test equipment is flushed to remove the test sample there from.

Owner:PETROLEUM ANALYZER COMPANY

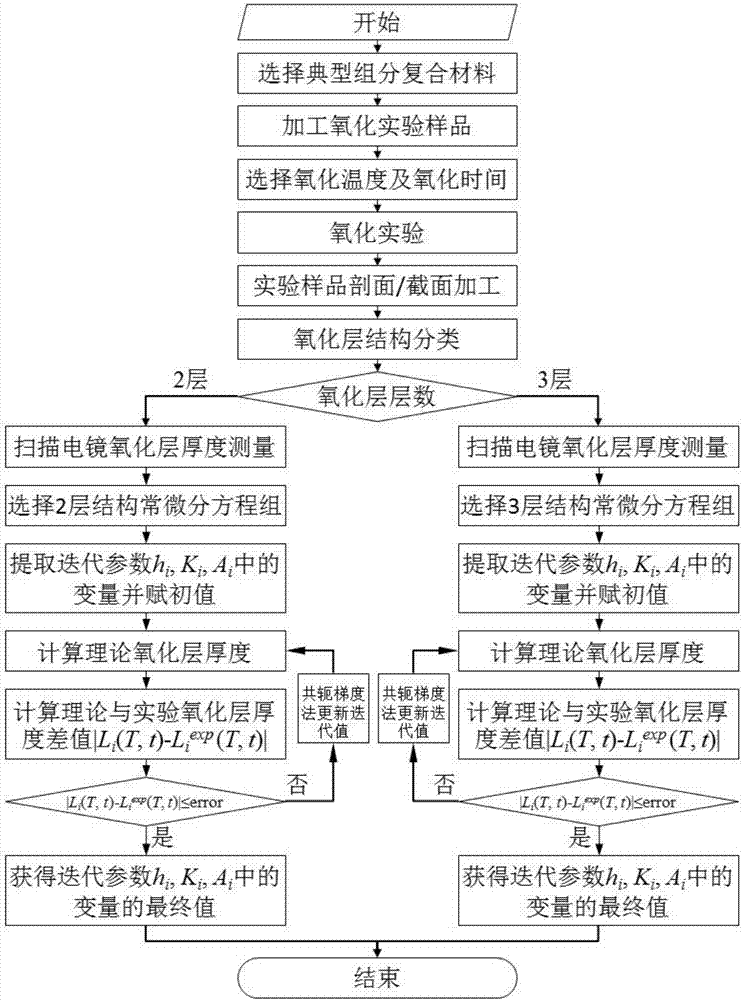

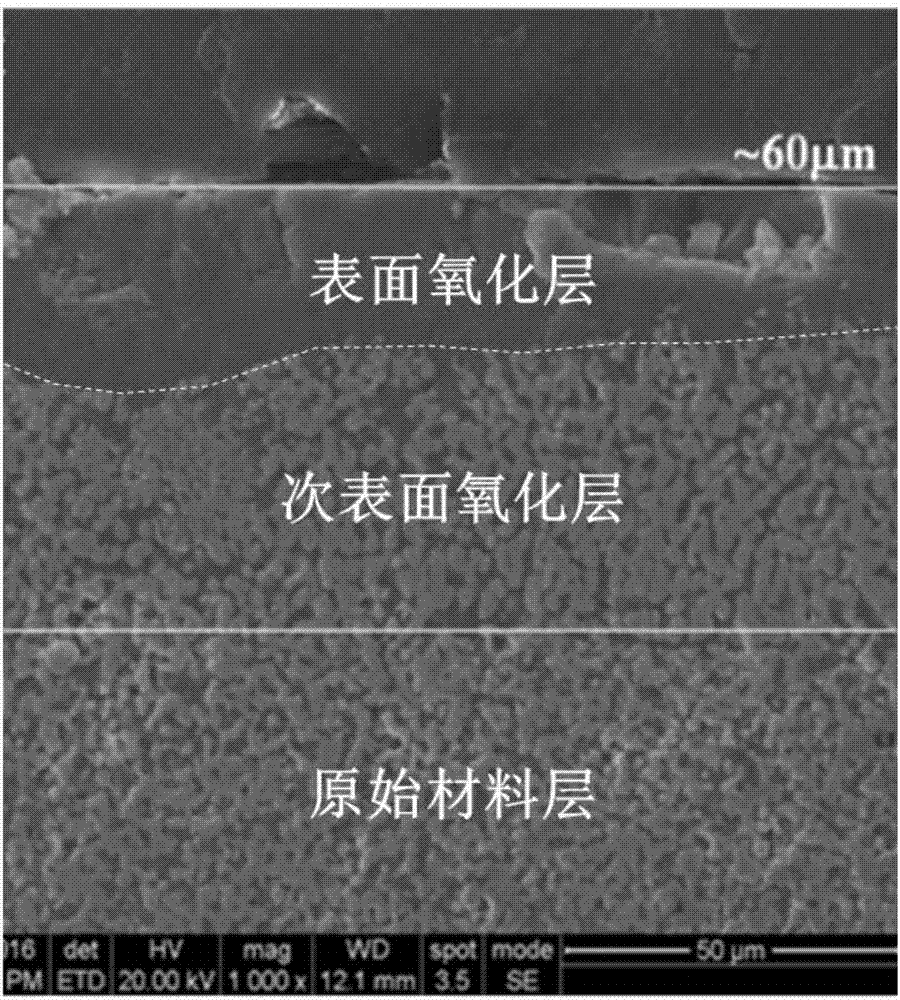

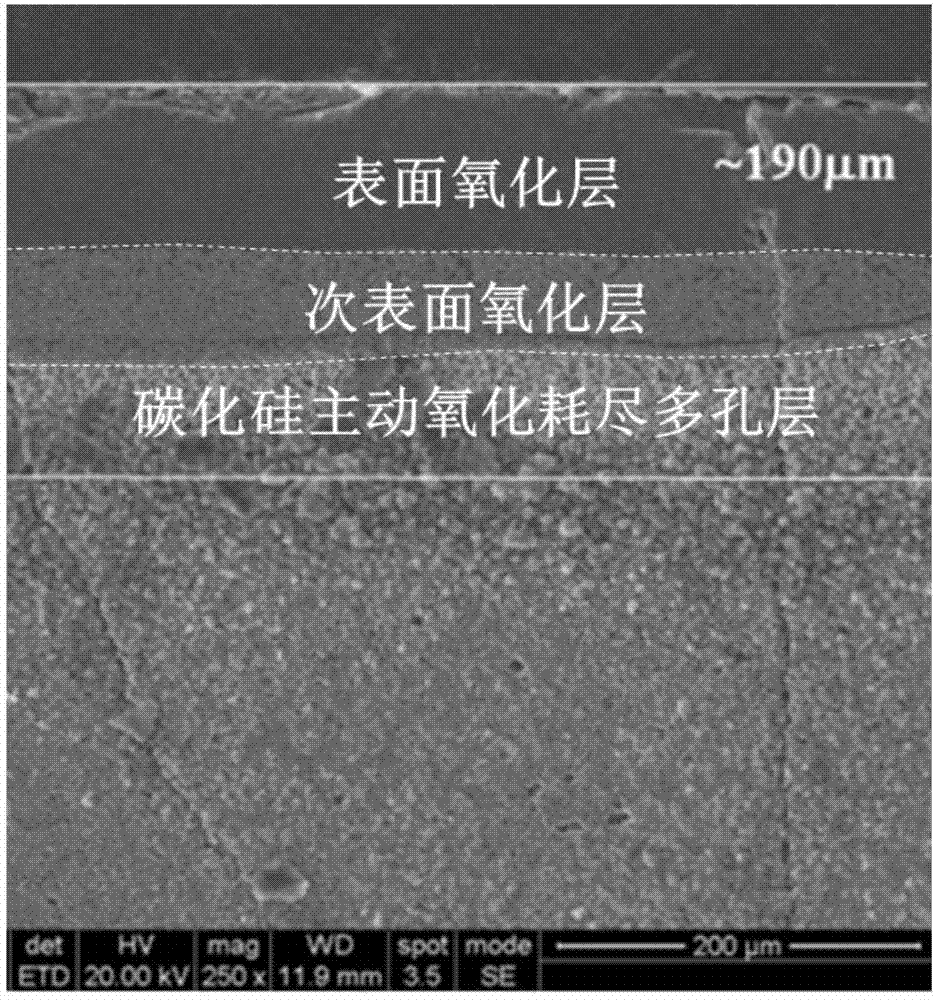

Non-linear evolution calculating method of zirconium diboride-silicon carbide composite material oxide

ActiveCN106871826AReduce workloadCalculation method is simpleUsing optical meansUsing wave/particle radiation meansEvolution ruleFeature parameter

The invention relates to a non-linear evolution calculating method of zirconium diboride-silicon carbide composite material oxide. The non-linear evolution calculating method of zirconium diboride-silicon carbide composite material oxide includes the steps: 1) performing isothermal oxidation tests for no less than 3 insulation time quantums on a zirconium diboride-silicon carbide composite material test sample; 2) cooling the sample to be tested to an indoor temperature and processing the sample to be tested to obtain a profile or cross section structure, drying and saving, and preventing the oxide shedding; 3) determining the oxide layered structure of the profile or cross section of the test sample; 4) measuring the thickness of each oxide layer; 5) according to difference of the oxide structures, respectively establishing differential equations that the thickness of the oxide evolves following the time; 6) solving the differential equations to obtain theoretical calculating values of the thickness of oxides; 7) by changing characteristic parameter values, performing iterative computations until the deviation absolute values between the thickness of all the test oxides and the thickness of the calculated oxides are all smaller than a specified accuracy, and determining the characteristic parameters of the equations, satisfying the accuracy requirement, according to the results of iterative computations; and 8) fixing the characteristic parameters of the differential equations, and solving the oxide thickness quantitative evolution rules in different temperatures and any oxidation time.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

High-temperature stress oxidation testing system

PendingCN109580333AIncrease usageImprove scalabilityMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesTemperature stressDisplay device

The invention relates to the field of mechanical testing, in particular to a high-temperature stress oxidation testing system. An existing high-temperature stress oxidation test device has poor expansibility, low utilization rate and high single testing cost. The high-temperature stress oxidation testing system comprises a heating furnace with an inlet and a furnace door, a stress testing device and a stress application device which can be put into the heating furnace, wherein the stress testing device comprises a pressure display and a pressure sensor which are connected by wires, and the pressure sensor is arranged on the stress application device. The stress application device drives a sliding block to move transversely by the rotation of an adjusting bolt, so that a clamp is loaded onthe workpiece to be tested in the horizontal direction, and tensile, bending and compression tests corresponding to the clamp are completed; the tensile, bending and compression tests only need to bedismounted and replaced with the corresponding clamp, and other parts can be used universally; and the testing system has good expansibility, high utilization rate and low single test cost.

Owner:ZHEJIANG ZHENENG TECHN RES INST

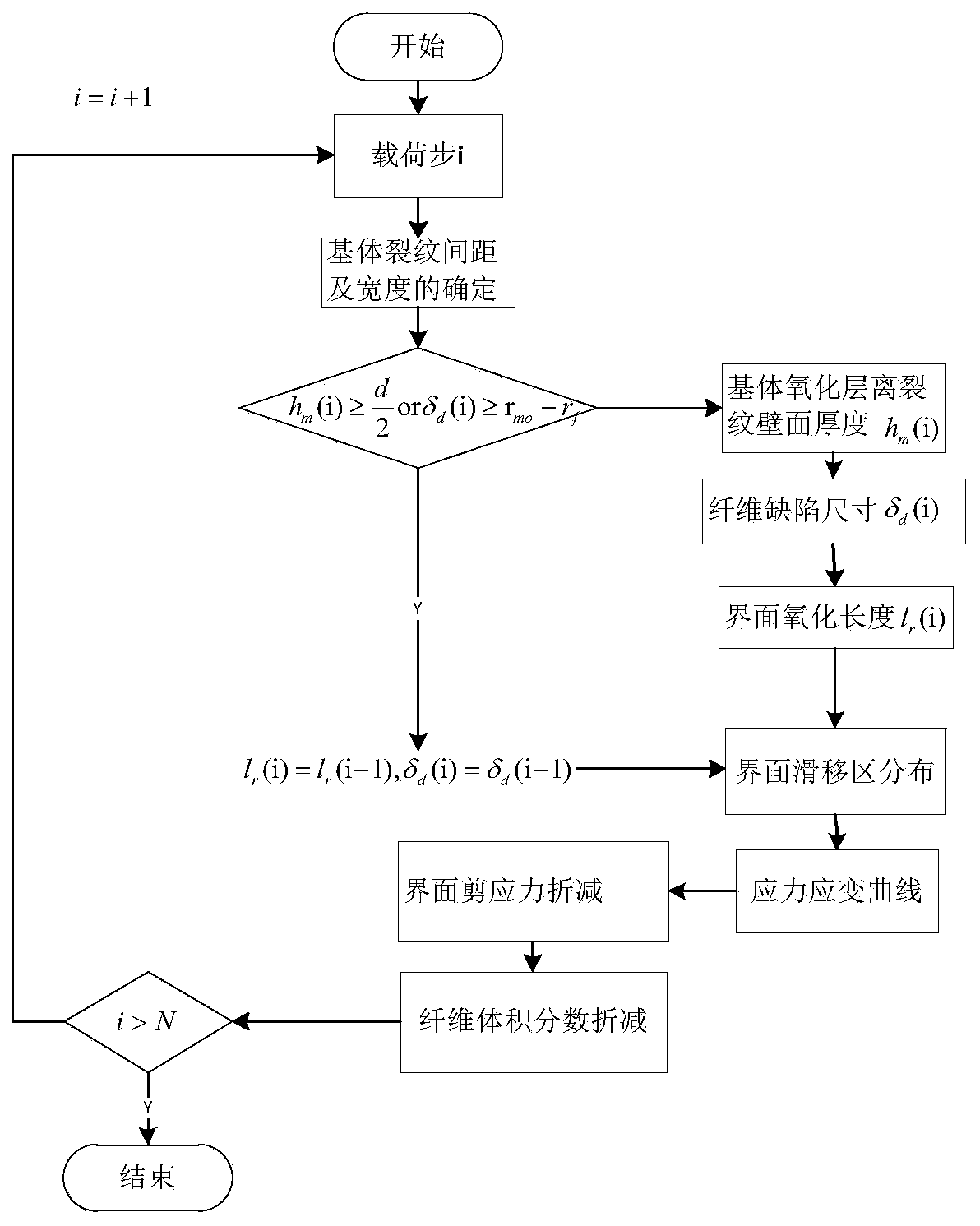

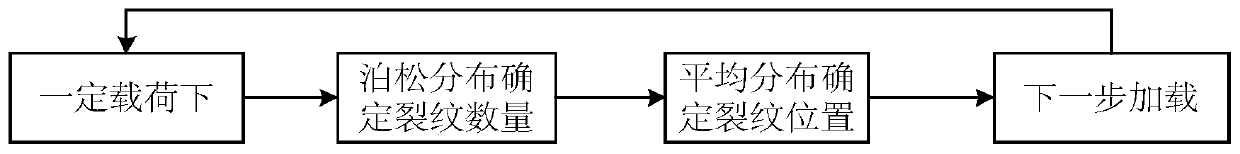

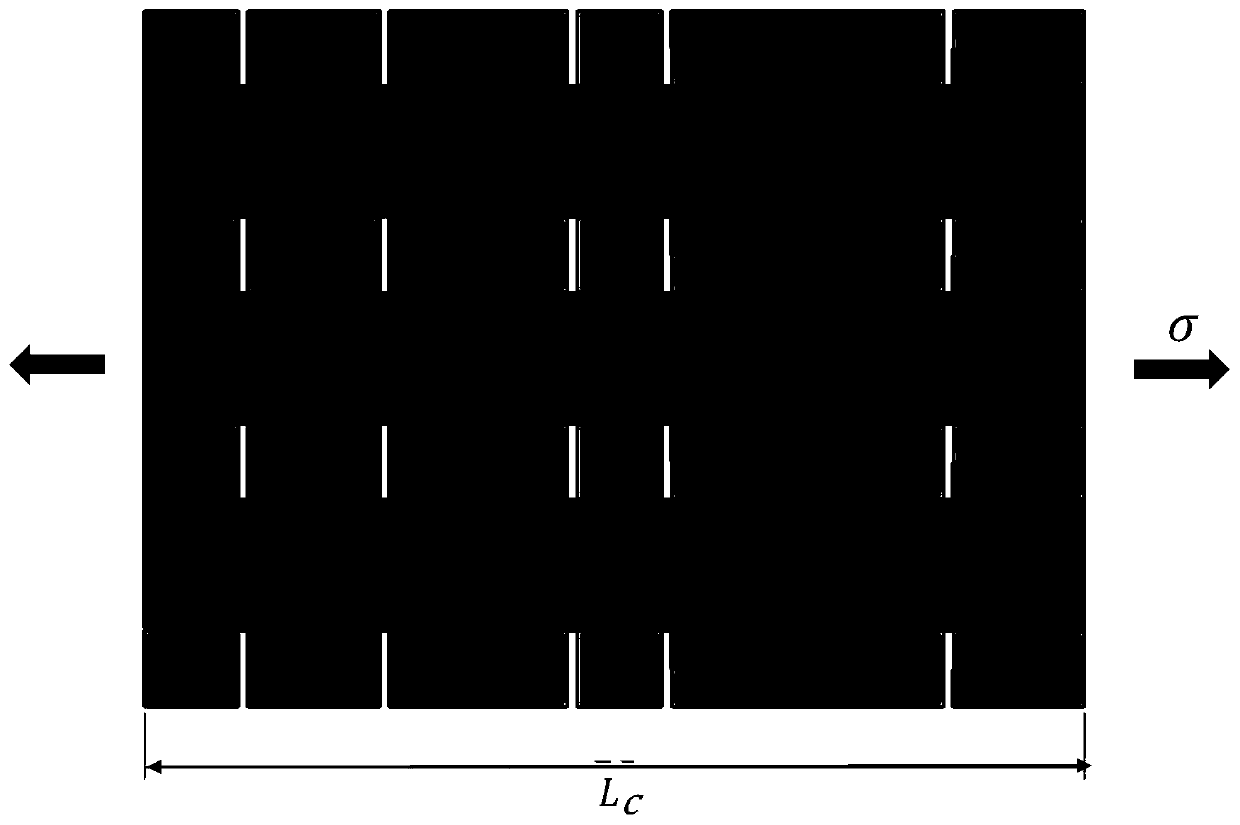

Method for predicting arbitrary loading and unloading stress-strain curve of ceramic-based composite material in high-temperature oxidation environment

ActiveCN111241686ASave manpower and material resourcesGeometric CADDesign optimisation/simulationCrazingMaterial resources

The invention discloses a method for predicting an arbitrary loading and unloading stress-strain curve of a ceramic-based composite material in a high-temperature oxidation environment. The method caneffectively simulate the arbitrary loading and unloading stress-strain curve of a unidirectional SiC / SiC composite material in a high-temperature oxidation environment; according to the method, the influences of the matrix crack density and width, the interface oxidation consumption length and the fiber tensile strength on the length and distribution of an interface slip region during loading ona stress-strain curve of the composite material in a high-temperature oxidation environment are considered; according to the method, a theoretical basis can be provided for the calculation of the fatigue life of the unidirectional SiC / SiC composite material under spectral load loading in the high-temperature oxidation environment; the method overcomes the defects of high test cost and high manpower and material resource consumption in the oxidation test of the arbitrary loading and unloading of the unidirectional ceramic-based composite material, and can save a large amount of manpower and material resources.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

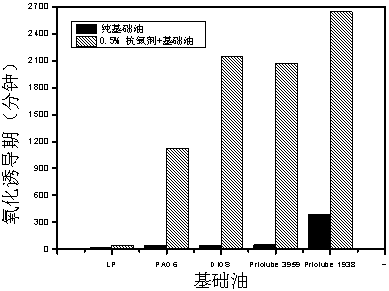

Method for improving the oxidation stability of ashless oil

InactiveUS20090029883A1Improve Oxidation StabilityReduce volatilityLiquid carbonaceous fuelsAdditivesSulfurOxidation stability

A method for improving the oxidation stability of an ashless hydraulic fluid or an ashless paper machine oil, comprising:a. selecting a base oil having greater than 90 wt % saturates, less than 10 wt % aromatics, a base oil viscosity index greater than 120, less than 0.03 wt % sulfur, a sequential number of carbon atoms, greater than 35 wt % total molecules with cycloparaffinic functionality, and a ratio of molecules with monocycloparaffinic functionality to molecules with multicycloparaffinic functionality greater than 2.1; andb. replacing a portion of an original base oil in the ashless oil with the selected base oil to produce an improved ashless lubricating oil; wherein the improved ashless lubricating oil has a result in the rotary pressure vessel oxidation test that is at least 50 minutes greater than the result in the rotary pressure oxidation test of the ashless hydraulic fluid or ashless paper machine oil.

Owner:CHEVROU USA INC

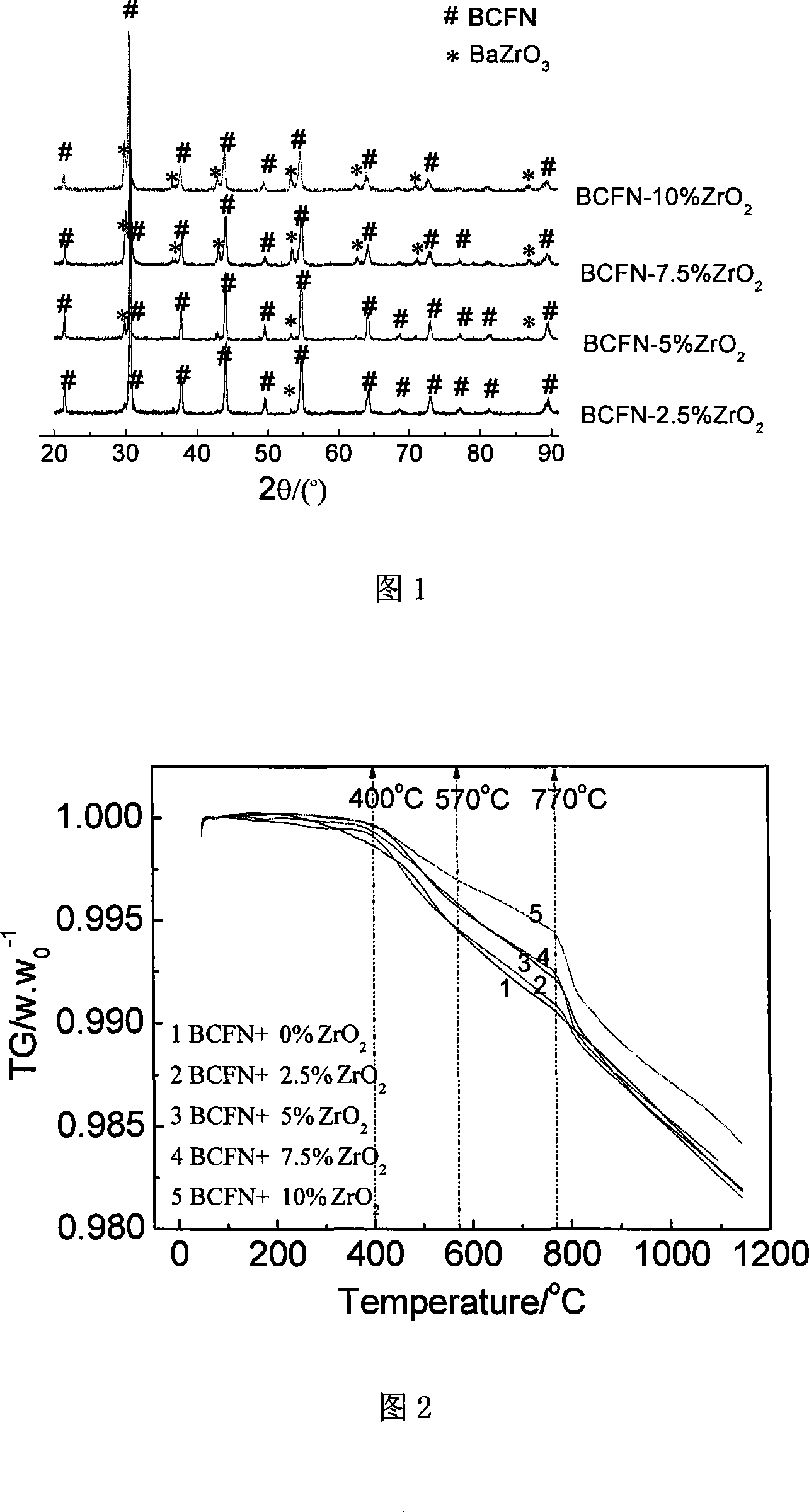

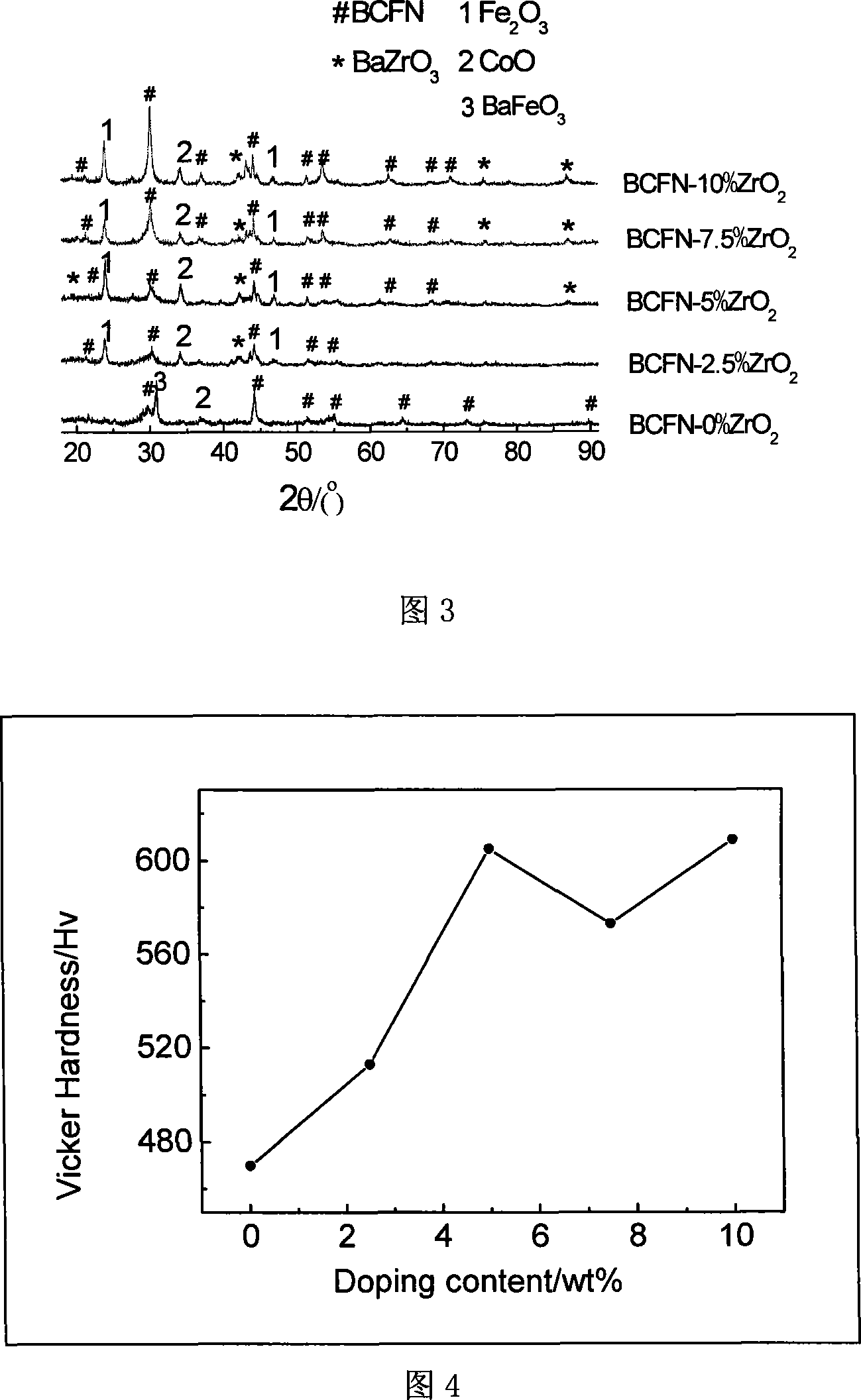

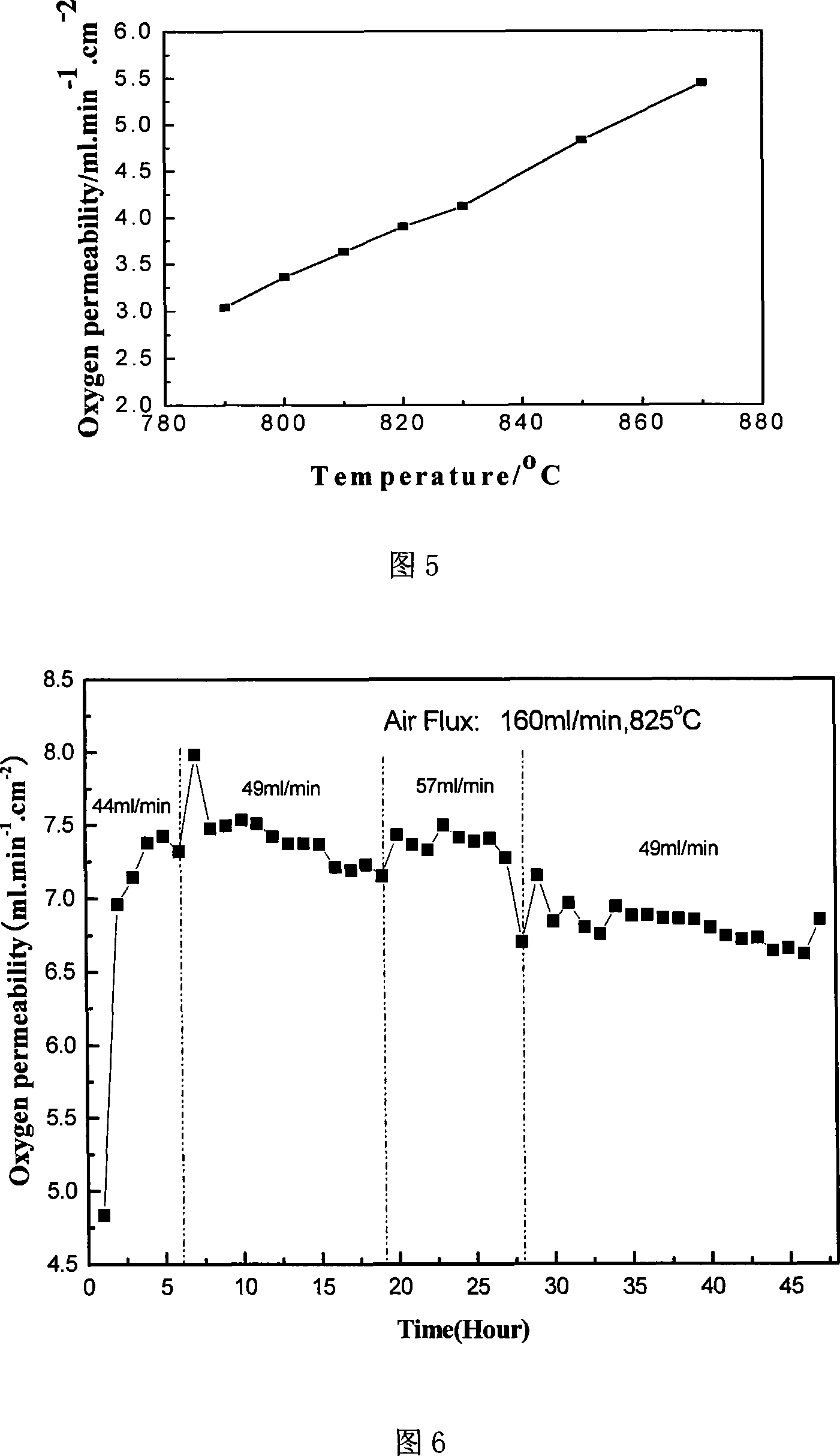

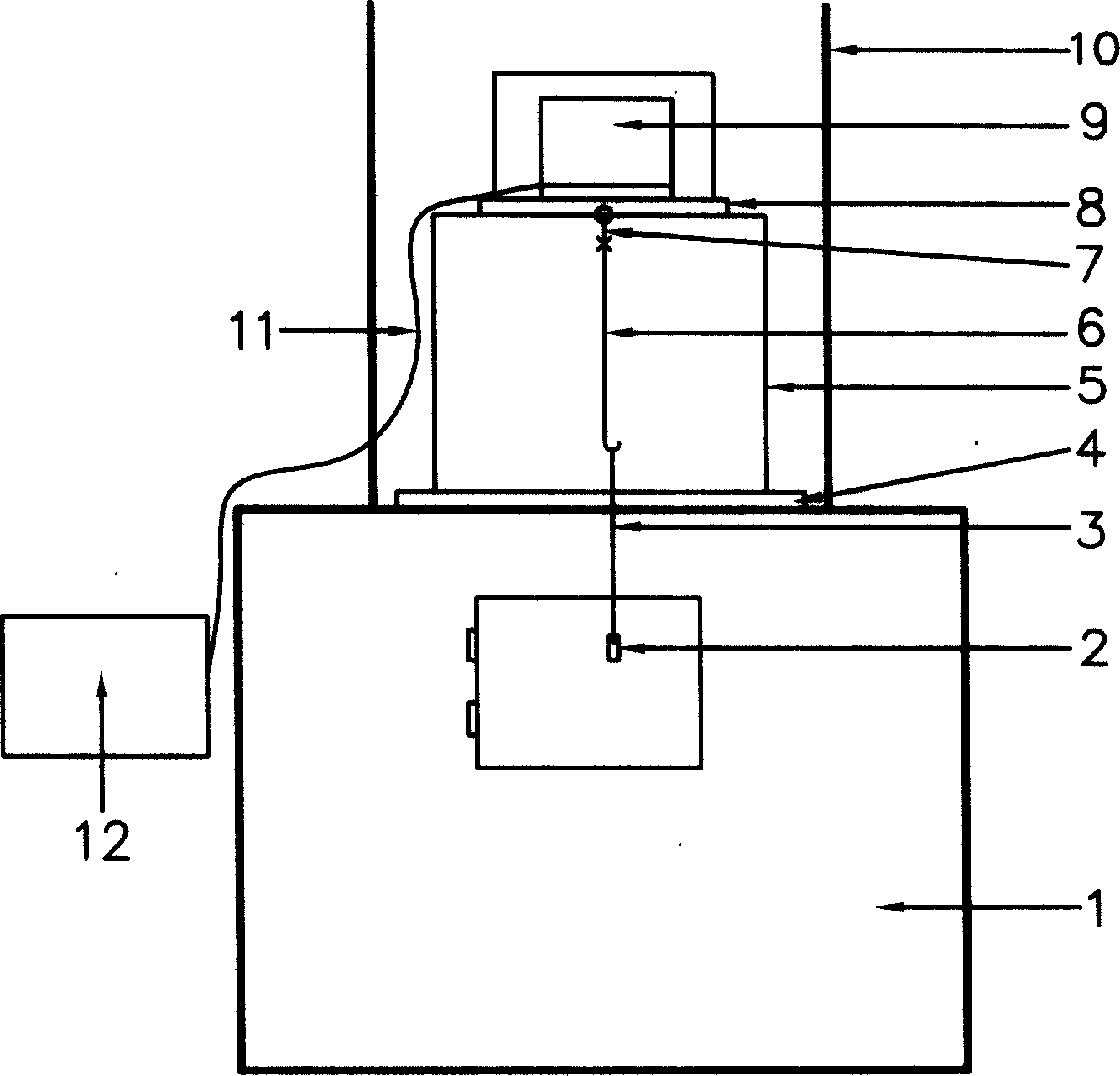

Multi-phase ion-electron mixing conductor powder material, manufacturing method and application thereof

InactiveCN101219889AImprove stabilityHigh oxygen permeabilityNon-metal conductorsCell electrodesPartial oxidationOxygen ions

The invention relates to a multi-phase ionic-electronic mixture conductor material and a preparation method and the application thereof. A first phase of the conductor material is BaCoxFeyNbzO3-Delta, that is BCFN, wherein x, y, and z represent mole fractions, x is no less than to 0 and no more than 0.9, y is no less than 0 and no more than 0.9, z is no less than 0 and no more than 0.3, and x plus y and plus z is no less than 0.95 and no more than 1.1; a second phase is dopant ZrO2, Al2O3 or SnO2, wherein the mole fraction of the dopant corresponding to the BCFN is no more than 20 percent. The invention adopts a method of doping modification to obtain the multi-phase ionic-electronic mixture conductor material which has good structural stability in inert atmosphere and strong reducing atmosphere, and excellent oxygen permeation performance in oxidation test of methane in COG (coke oven gas); at the same time, the material has oxygen ion conductivity and electron conductivity performance with high stability, which is a mixture conductive material. Therefore the material can be used not only as membrane material of optionally separated oxygen from oxygen mixture gas, but also as an electrode material of a fuel cell of solid oxide and an oxygen sensor, and the film is called the mixture conductive oxygen permeable film. The material is used in a film reactor to dynamically provide oxygen for high-temperature oxidation reactions such as partial oxidation of methane for preparing syngas (POM) and oxidative coupling of methane (OCM); the invention can simplify the operation process and reduce the operation cost.

Owner:SHANGHAI UNIV

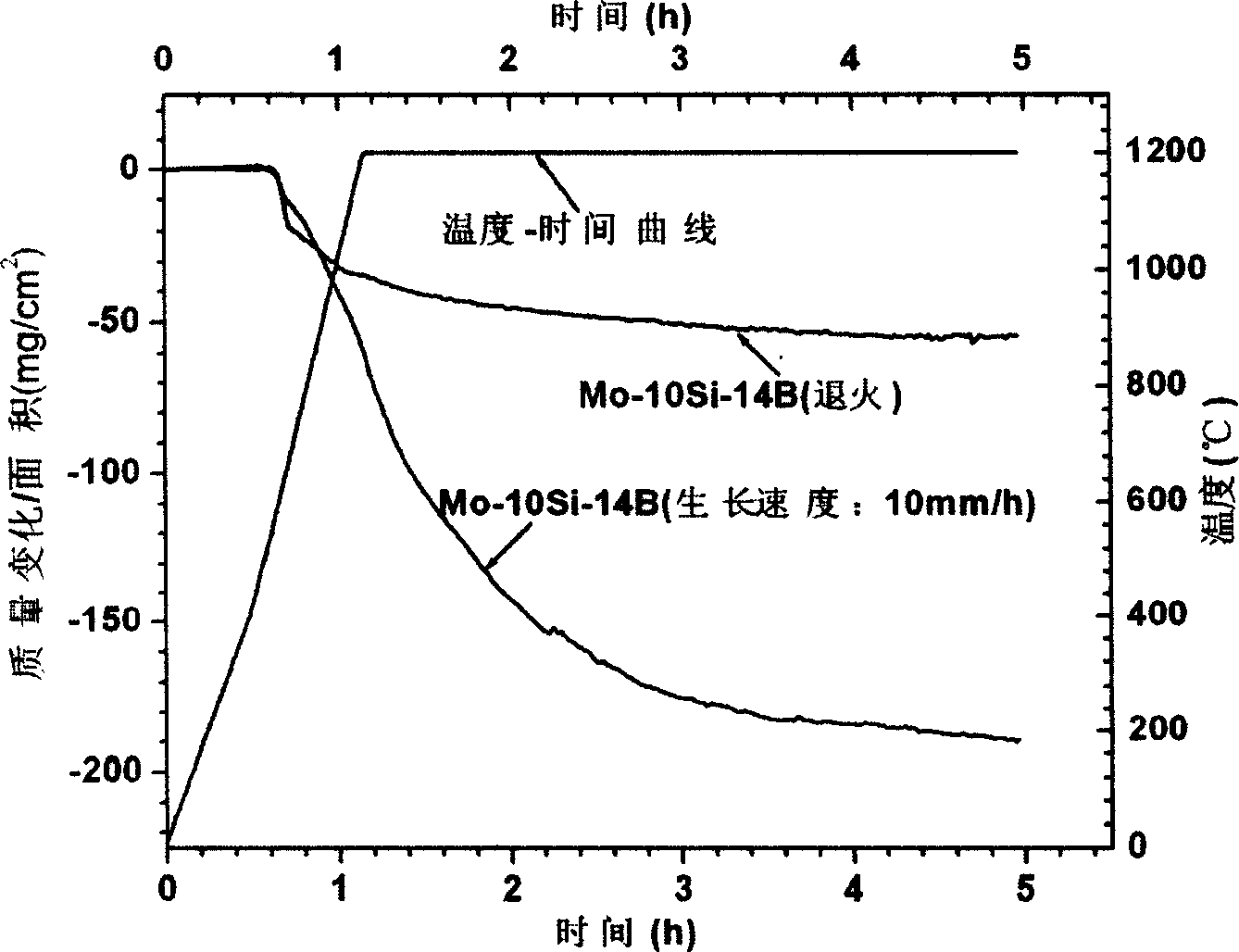

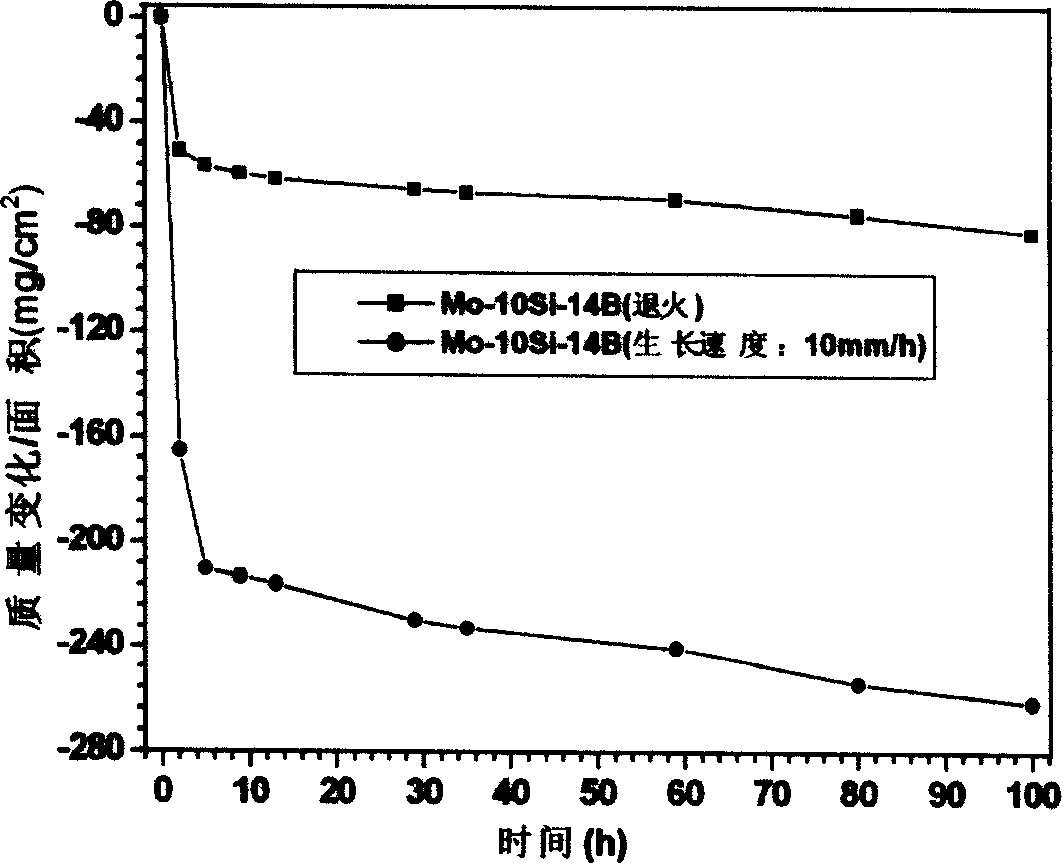

Detection method of ternary silicide high-temp in-situ oxidation

InactiveCN1869641AOvercoming the Limitations of High Temperature Oxidation Testing TechniquesOvercome limitationsWeighing by removing componentHearthOxidation resistant

The invention is a method for detecting ternary silicide high temperature in situ oxidization, belonging to material high-temperature oxidization test field. And the invention hangs ternary silicide sample with round bore and measured surface area through Pt-Rh wire burnt to constant weight, where one end of the Pt-Rh wire connected with the sample extends to the middle position of a high temperature hearth and the other end is outside the hearth and connected with a Ni-Cr wire, which is hung under a cotton line, and the cotton line is fixed on a hook at an electronic balance base, the electronic balance is connected with computer data lines, and the sample is heated in the high temperature furnace, and when the temperature is up to 540 deg.C, the sample starts oxidizing and the sample mass changes and the computer continuously records the sample mass change, and reflects antioxidant property of the sample according to the change. And the method is easy to apply, and the test device is simple, not only able to be used to in situ oxidization but also able to be used to circulating oxidization, and the invention can completely visually and conveniently test high temperature antioxidant ability of ternary silicide.

Owner:SHANGHAI JIAO TONG UNIV

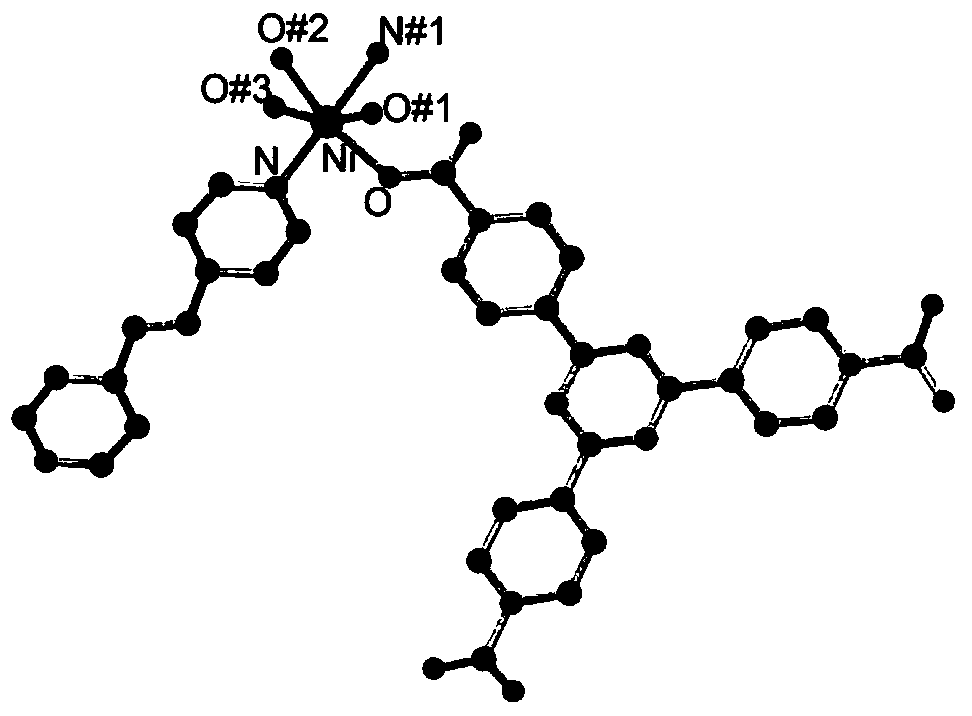

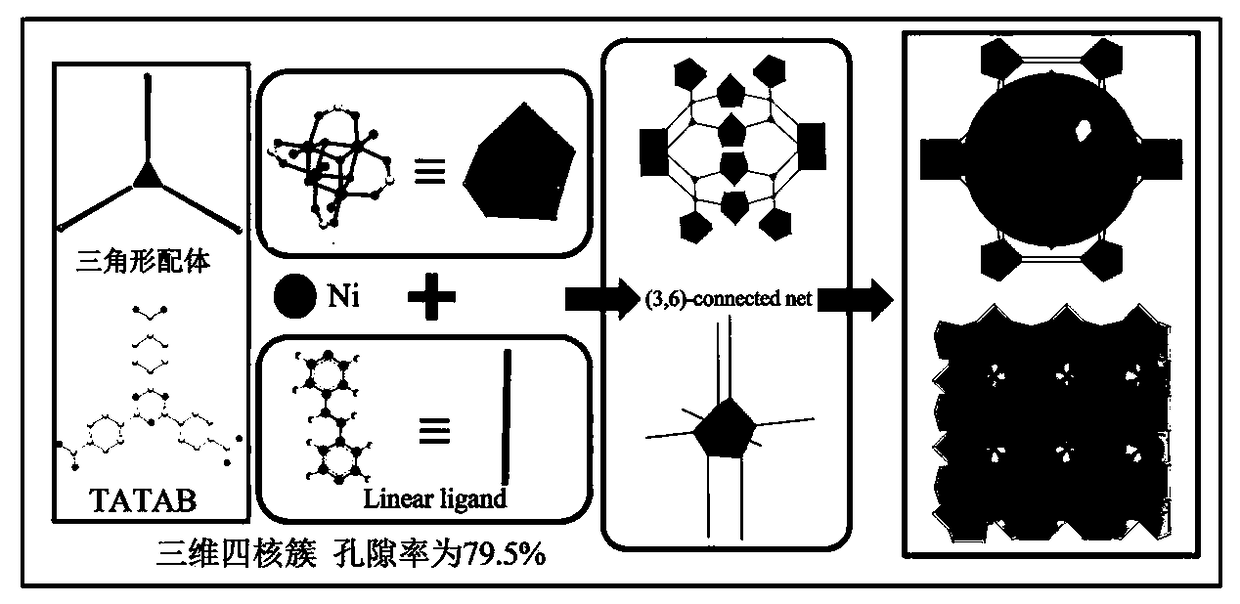

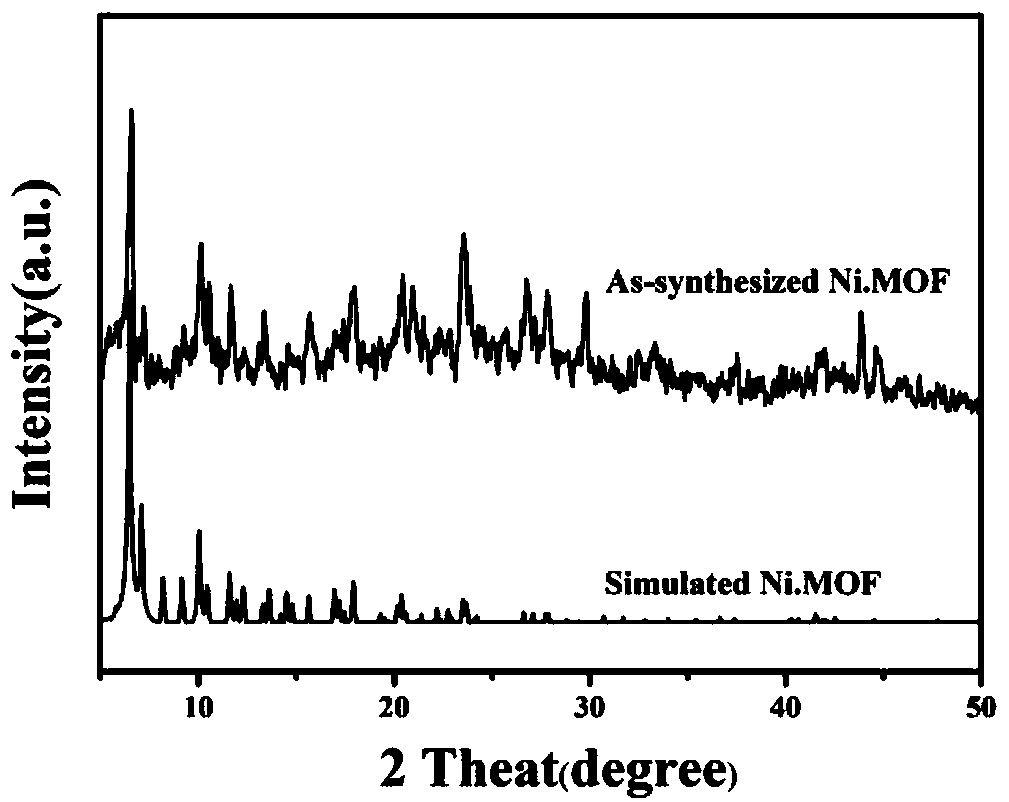

Nickel-based crystalline state frame material and preparation and application in methanol oxidation thereof

ActiveCN109096496AOrganic-compounds/hydrides/coordination-complexes catalystsFluoboric acidOxidation Activity

The invention discloses a nickel-based crystalline state frame material and a preparation method and application thereof. The preparation method comprises the specific steps that a macroporous Ni.MOFis newly synthesized through a hydrothermal method, the macroporous Ni.MOF is taken as an anodic catalyst material of methanol oxidation, and the application of the macroporous Ni.MOF in the methanoloxidation is explored. According to the nickel-based crystalline state frame material and the preparation method and application thereof, organic ligand 2,4,6-tris(4-carboxyl phenyl)-1,3,5-triazine, 1,2,-di(4-pyridyl) ethylene and nickelous perchlorate are self-assembled in a mixed solution of N,N-dimethylacetamide, water and fluoboric acid to obtain a porous metal organic framework material, thesynthetic materials are assembled into a three-electrode system for the methanol oxidation test, and through data analysis, the material has excellent methanol oxidation activity.

Owner:CHINA THREE GORGES UNIV

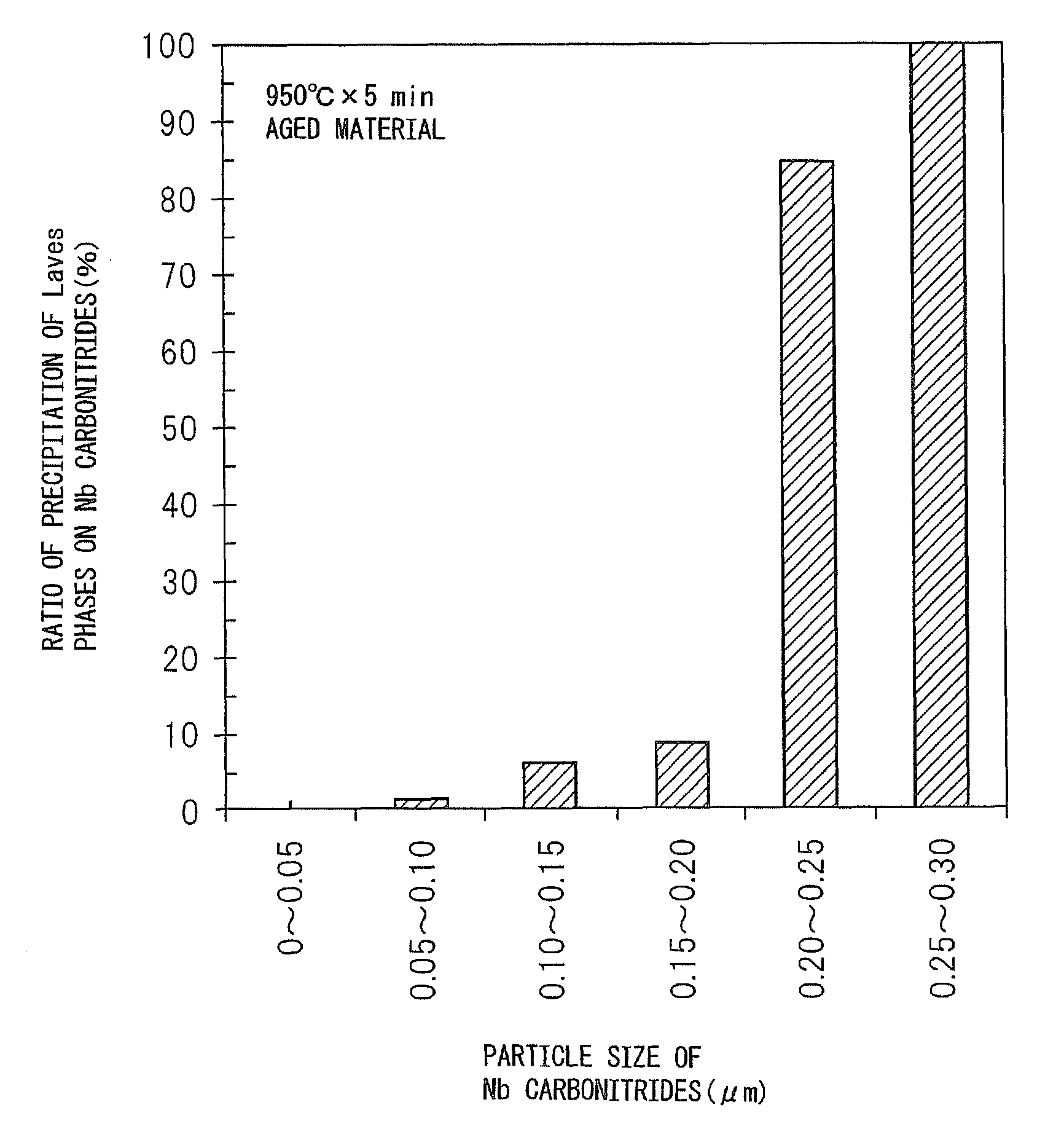

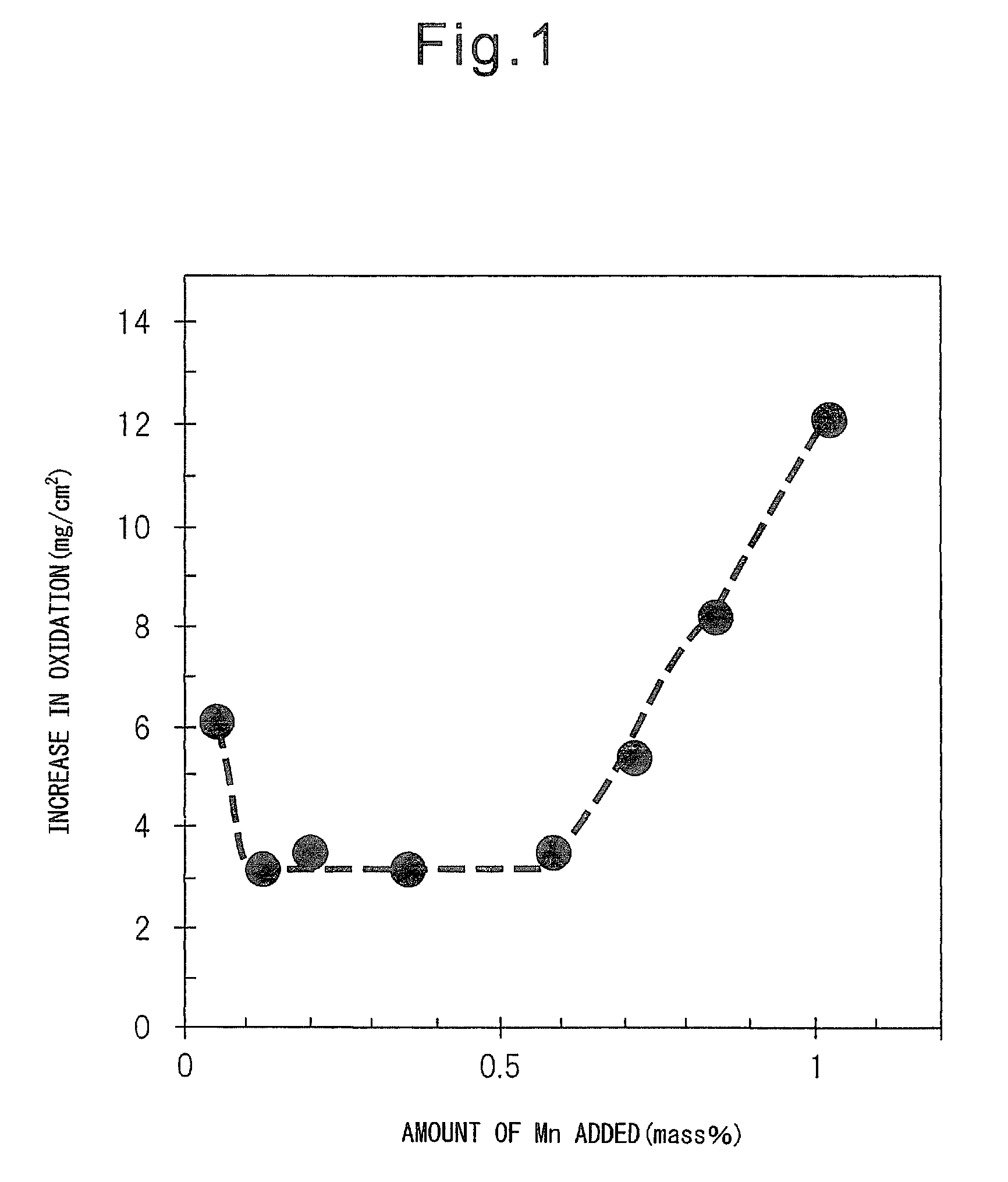

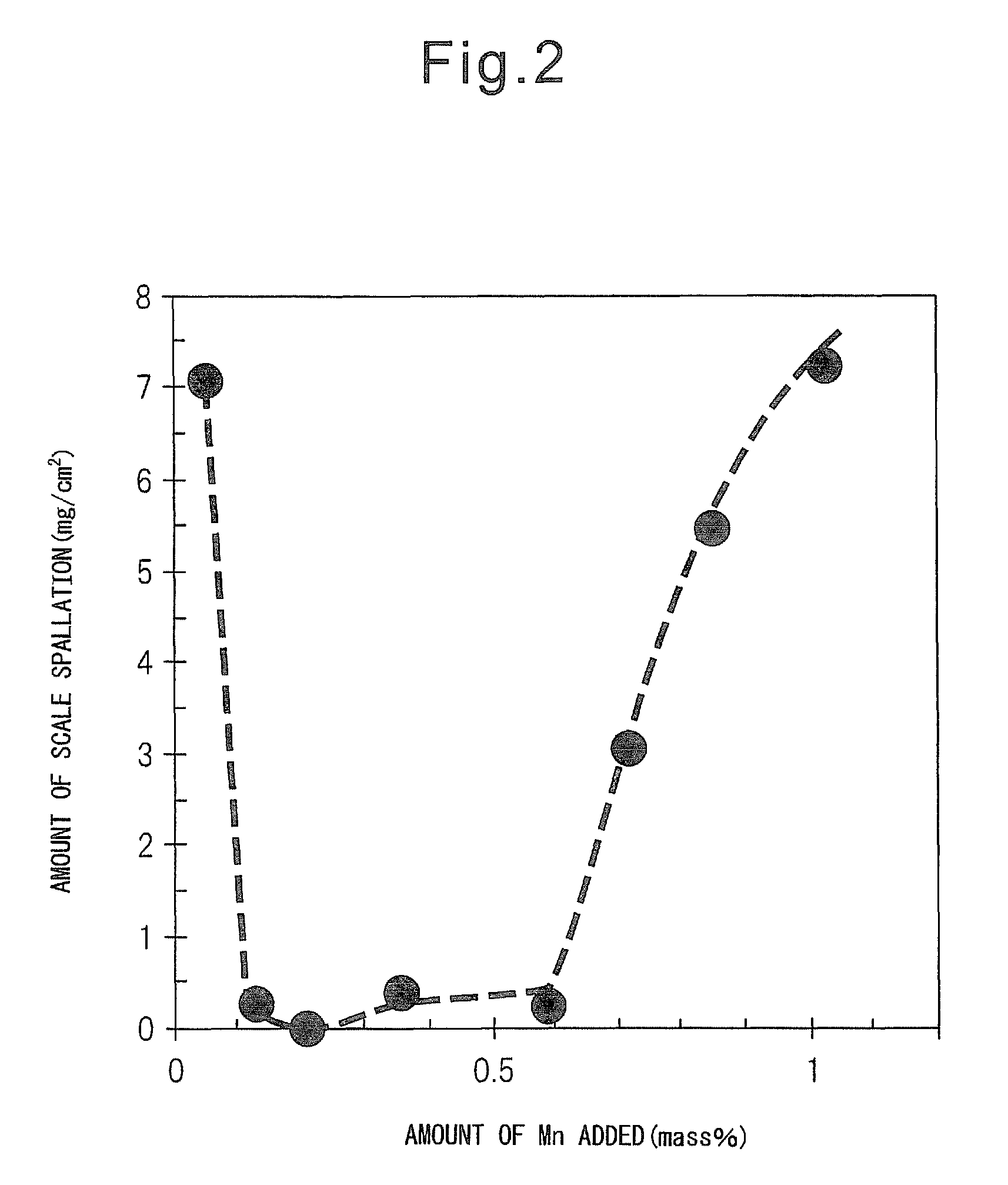

Ferritic stainless steel sheet excellent in oxidation resistance

ActiveUS9243306B2Increase temperatureImprove featuresFurnace typesHeat treatment furnacesOxidation test

Ferritic stainless steel sheet which has a high oxidation resistance and scale spallation resistance even at a high temperature near 1000° C., characterized by containing C: 0.020% or less, N: 0.020% or less, Si: over 0.10 to 0.35%, Mn: 0.10 to 0.60%, Cr: 16.5 to 20.0%, Nb: 0.30 to 0.80%, Mo: over 2.50 to 3.50%, and Cu: 1.00 to 2.50%, having an amount of increase of oxidation after a continuous oxidation test in the air at 1000° C. for 200 hours of 4.0 mg / cm2 or less, and having an amount of scale spallation of 1.0 mg / cm2 or less.

Owner:NIPPON STEEL & SUMIKIN STAINLESS STEEL CORP

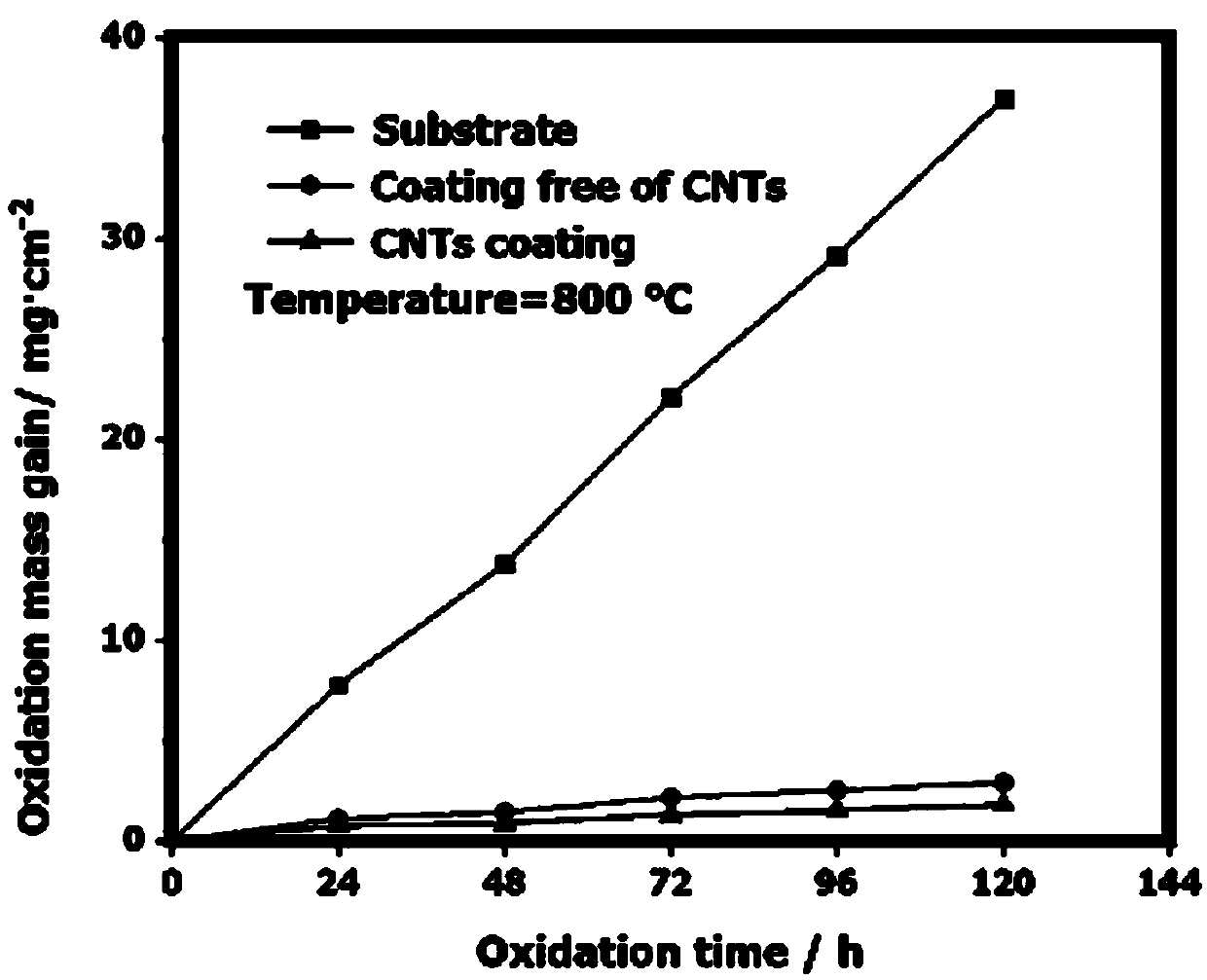

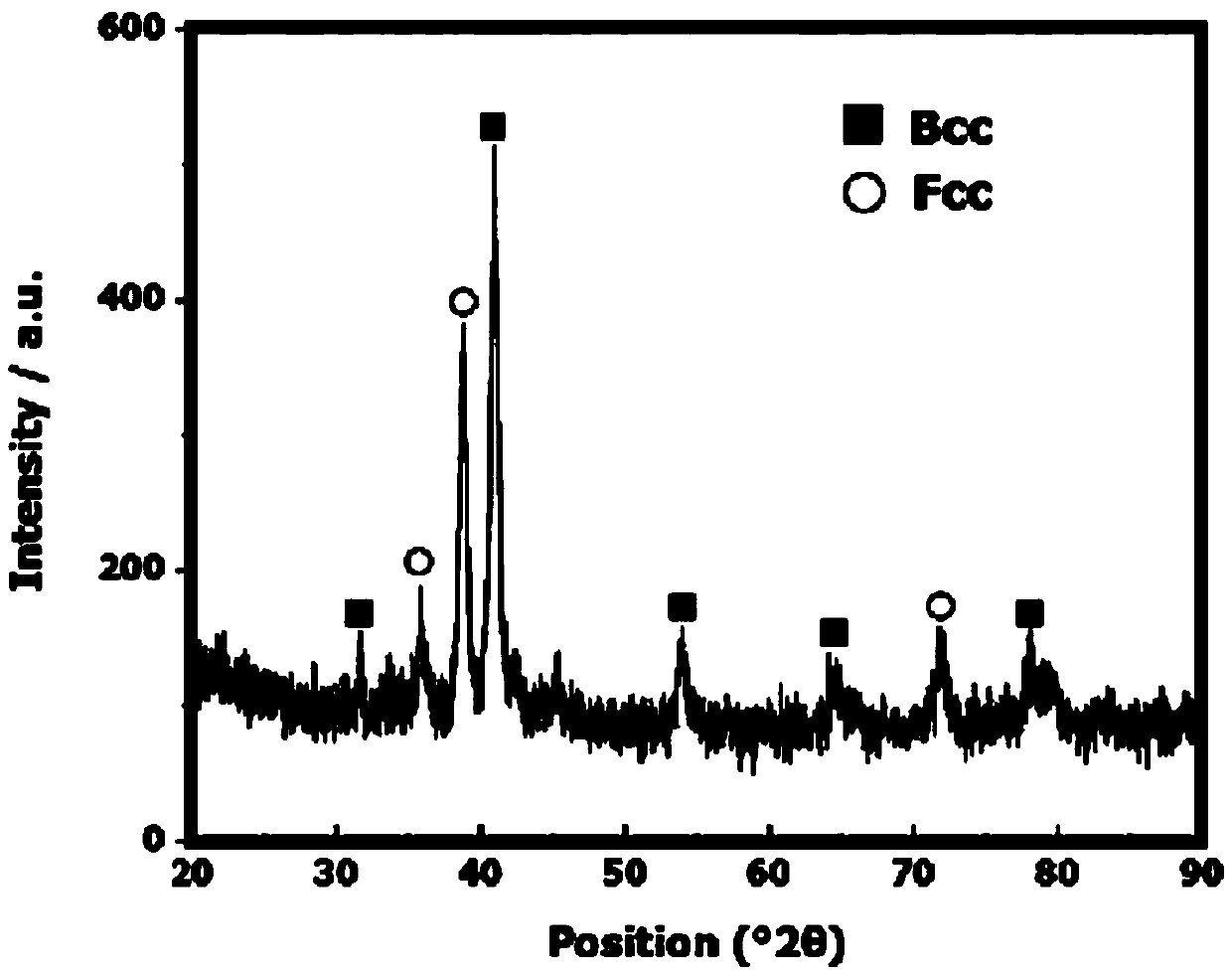

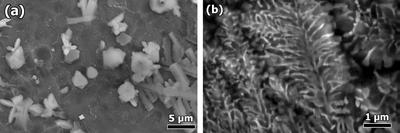

Method for preparing CNTs (carbon nanotubes) reinforced high-entropy alloy laser deposition composite material

ActiveCN110438493AFully protectedHigh hardnessAdditive manufacturing apparatusMetallic material coating processesHigh entropy alloysArgon atmosphere

The invention discloses a method for preparing a CNTs (carbon nanotubes) reinforced high-entropy alloy laser deposition composite material. According to the method, FeCoCrAlCu-SiB6-(Ni / Ag coated-CNTs)mixed powder is deposited on the surface of a TA2 titanium alloy by laser melting with a coaxial powder feeding method in argon atmosphere, an LMD (laser metal deposition) coating is formed, the coating has bcc and fcc structures, hardness of the bcc structure is higher and toughness of the fcc structure is better; a large quantity of CNTs are attached to the surface of ceramic crystallization phase in the coating, growth of the crystallization phase can be effectively inhibited, the organization structure is refined, and therefore, the structure property of the prepared composite material isremarkably enhanced; a high-temperature oxidation test result indicates that high-temperature oxidation property of the CNTs reinforced LMD coating is obviously better than that of a FeCoCrAlCu-SiB6laser deposition layer and the TA2 titanium alloy base material without addition of CNTs. The CNTs reinforced high-entropy alloy laser deposition composite material with compact organization structureand good high-temperature oxidizability can be obtained.

Owner:SHANDONG JIANZHU UNIV

Paeonia suffruticosa peel flavonoid extraction process and extracts thereof

InactiveCN108578485AImprove developmentEfficient use ofCardiovascular disorderPlant ingredientsPL ExtractPaeonia suffruticosa

The invention relates to a paeonia suffruticosa peel flavonoid extraction process and extracts thereof. The extraction process of paeonia suffruticosa 'Feng Dan' peel flavonoids is optimized with theyield of paeonia suffruticosa 'Feng Dan' peel flavonoids as the index, the influence of the four factors of ethanol volume fraction, liquid-material ratio, extraction temperature and ultrasonic poweron the yield of peel flavonoids is investigated, and the optimal extraction process parameters for paeonia suffruticosa 'Feng Dan' peel flavonoids are determined by analyzing the test result. An in-vitro anti-oxidation test on the flavonoid extracts in paeonia suffruticosa 'Feng Dan' peel shows that the flavonoid extracts in paeonia suffruticosa 'Feng Dan' peel have a scavenging effect on ABTS andDPPH within a concentration range selected in the test, the phenomenon of great waste of paeonia suffruticosa peel at present is avoided, and the paeonia suffruticosa peel resource is better developed and utilized.

Owner:ZHENGZHOU NORMAL UNIV

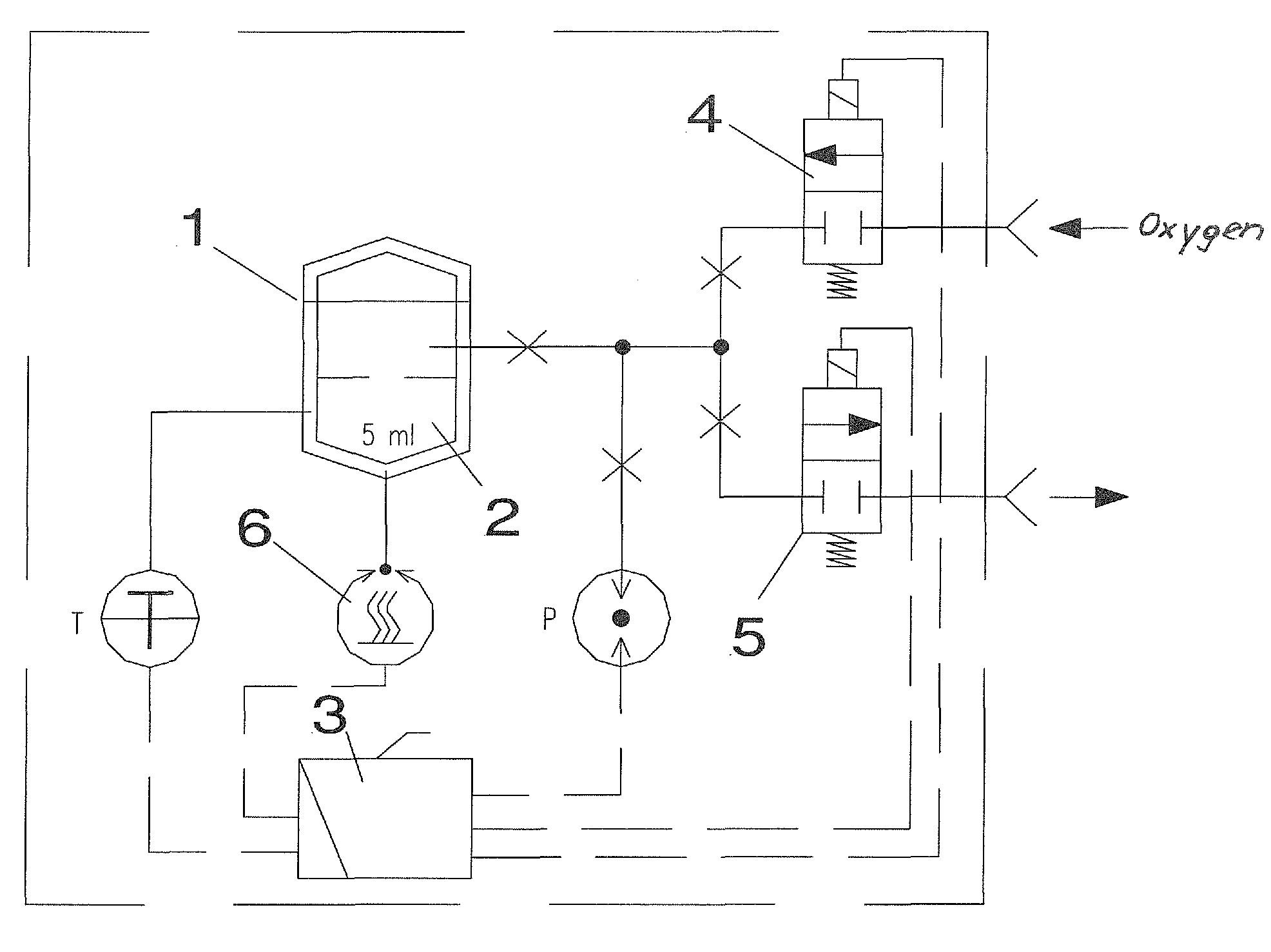

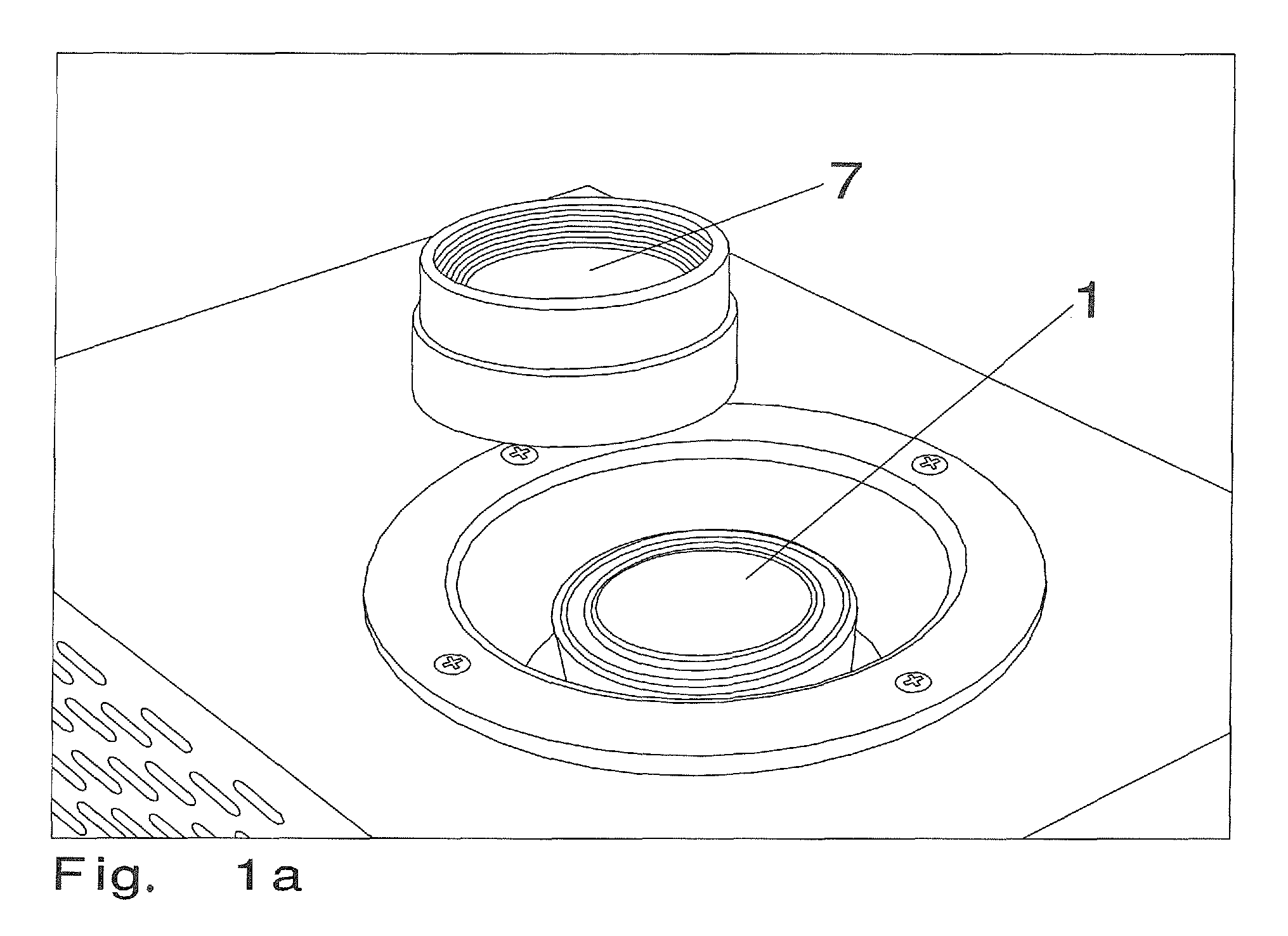

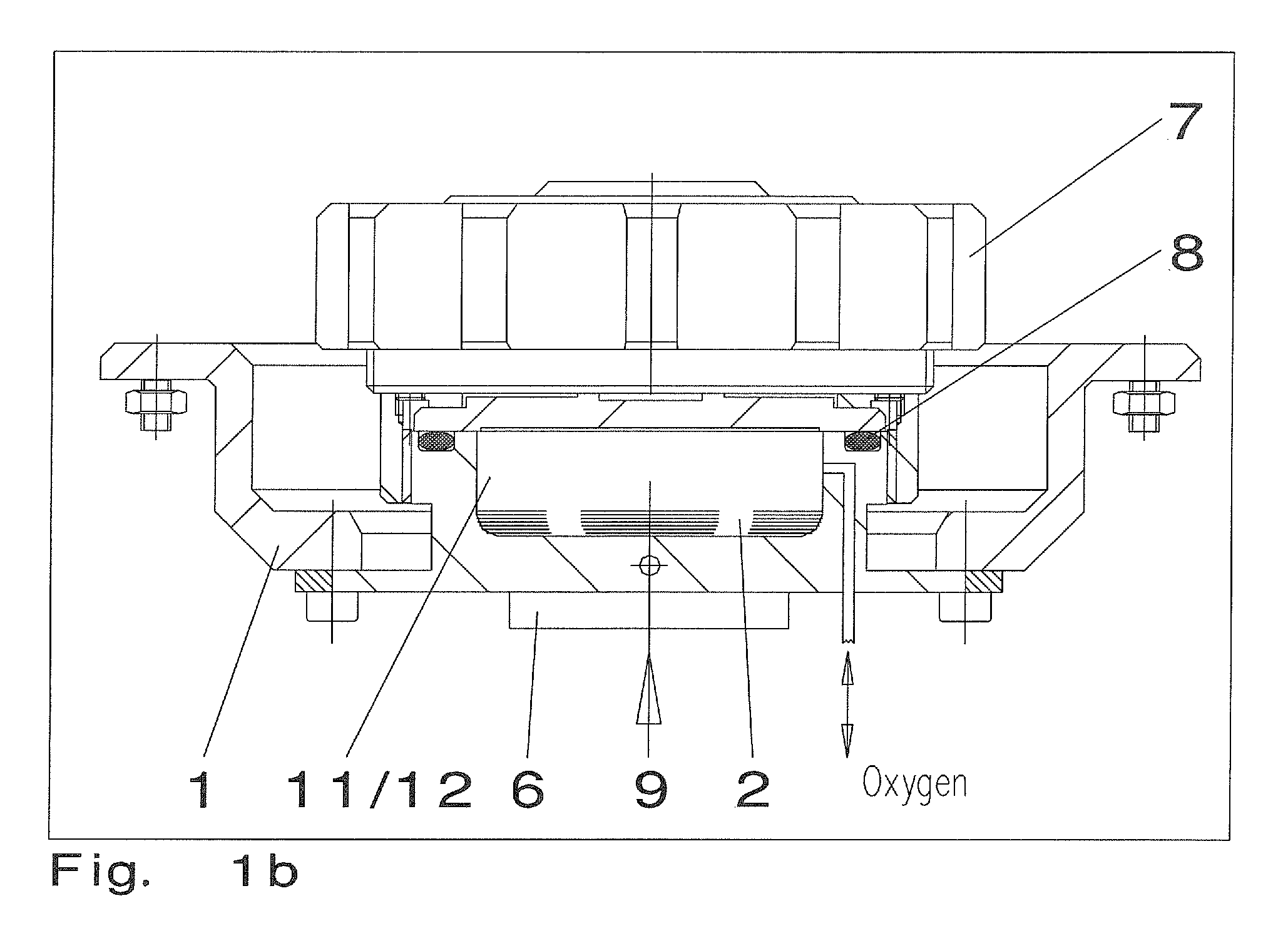

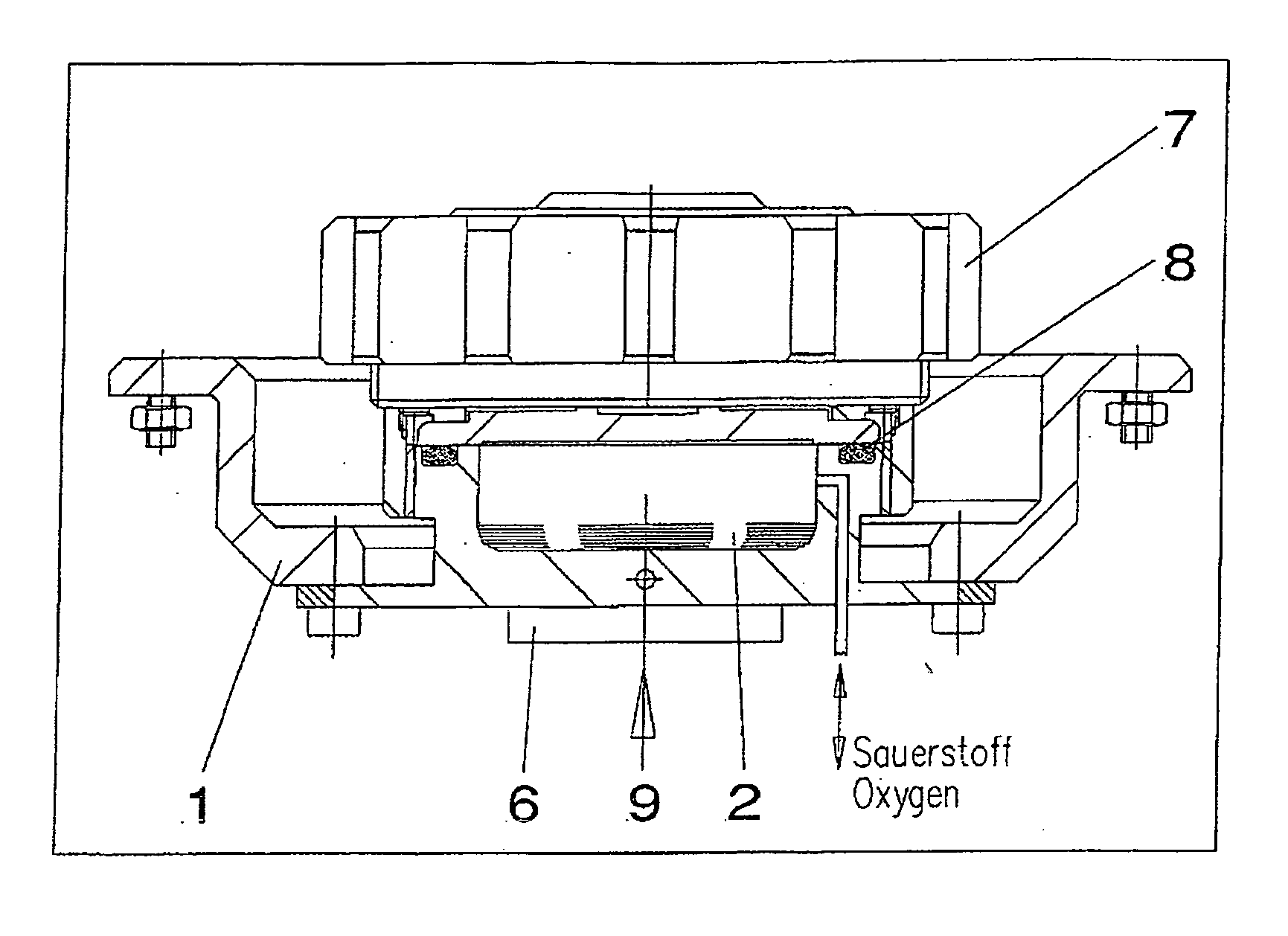

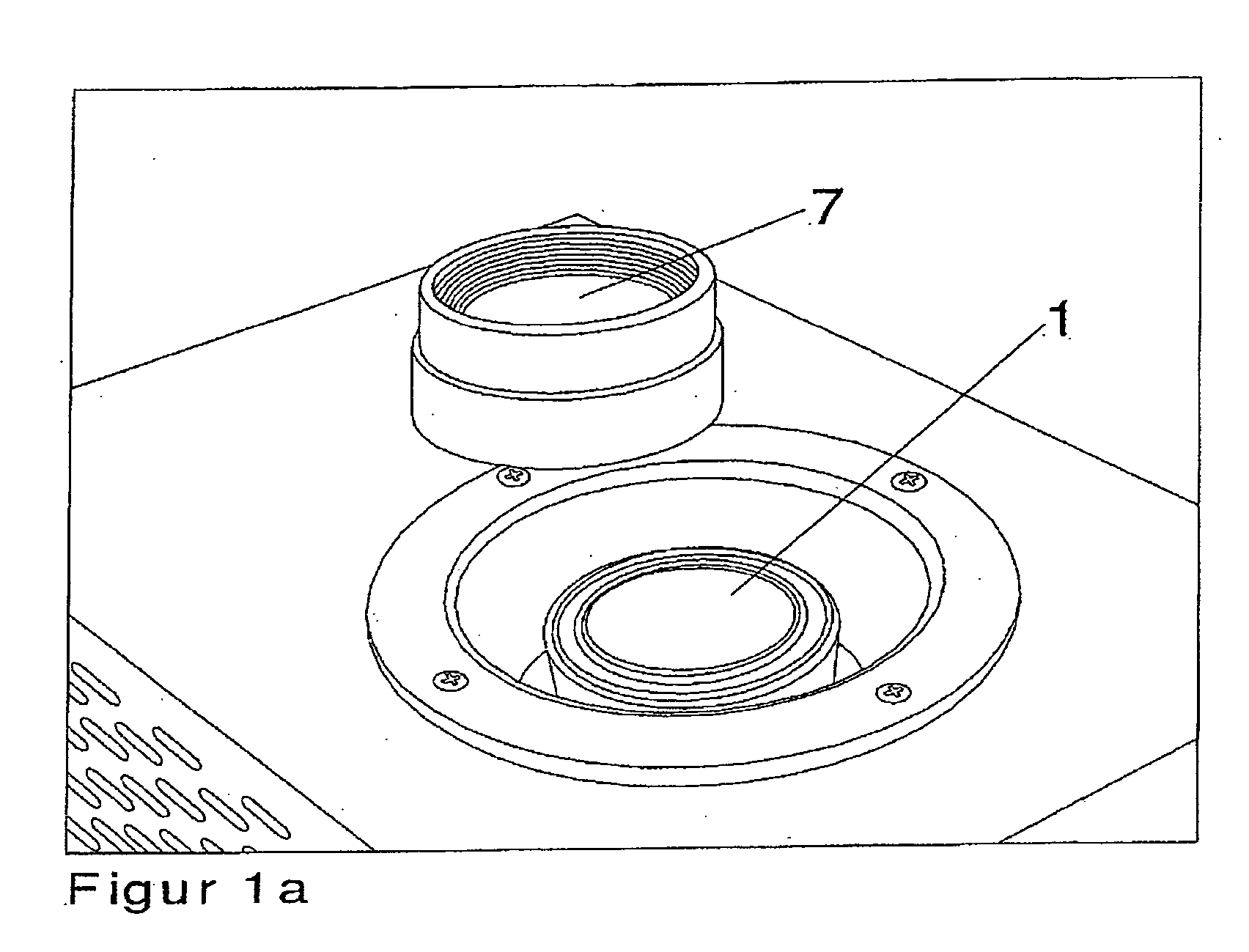

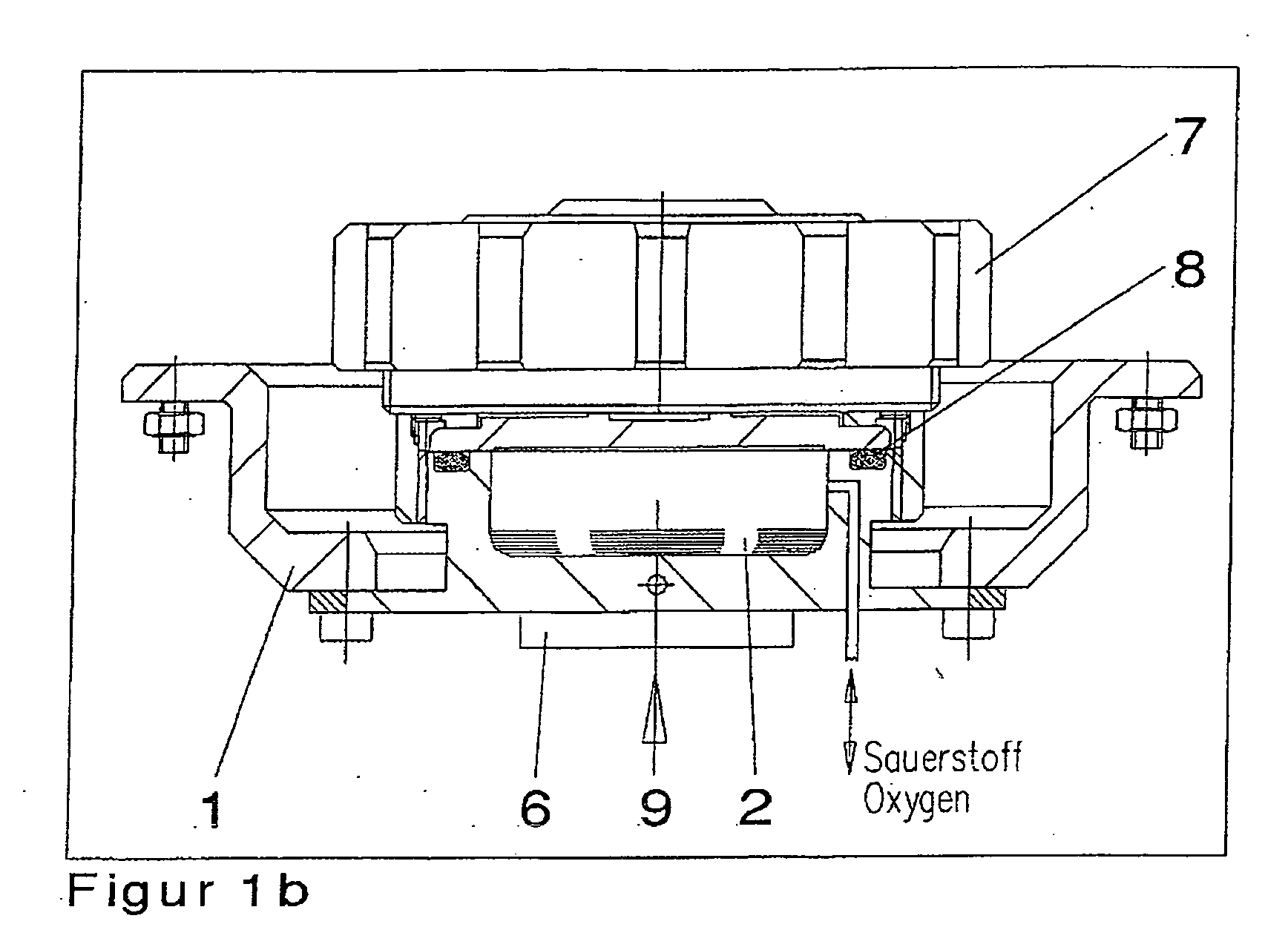

Method and device for an accelerated oxidation test of fuels or petroleum products, as well as a computer program for controlling such a device, and a corresponding computer readable storage medium

A device and a method for an accelerated oxidation test of fuels or petroleum products, as well as a computer program for controlling such a device, and a corresponding computer readable storage medium, which are applicable, in particular, for the simulation of the aging of fuels or petroleum products. A device for an accelerated oxidation test of fuels or petroleum products is proposed, whereby the device comprises of a pressure vessel (1) to hold specimen (2) of fuels or petroleum products, and the pressure vessel (1) contains at least one device to change the temperature. A corresponding method provides that a specimen (2) of fuel or petroleum product is placed in a pressure vessel (1), the specimen is brought to a predefined temperature above 100° C. by at least one device to change the temperature, which is placed in the pressure vessel (1) and / or in the specimen (2), and the absolute pressure value is monitored so as to determine the oxidation.

Owner:ANTON PAAR PROVETEC

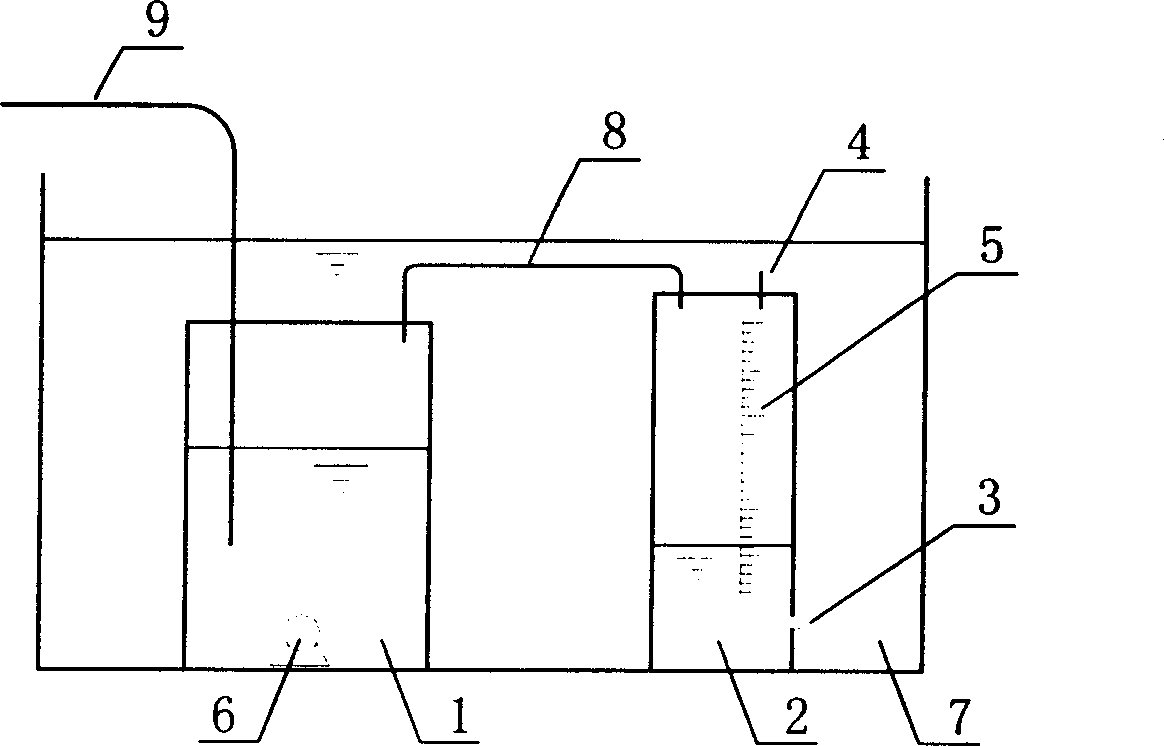

Anaerobic ammonia oxidation test device and method for biological denitrification treatment for waste water

InactiveCN1683257AAccurate measurementImprove sealingTreatment with anaerobic digestion processesWater bathsSludge

The anaerobic ammonia oxidizing test device for biologically denitrifying waste water consists of anaerobic ammonia oxidizing reactor, converter and water bath. Both the reactor and the converter are sealed container immersed in the water bath; the reactor has gas pipe and flow guide pipe in the top, active sludge inside it and underwater stirrer; the converter has temporary gas guide hole and gas pipe, which is connected to that of the reactor, in the top, scales on side wall, gas guide hole connected to the water bath in the lower part; and the water bath is maintained in constant temperature and has water surface higher than the top of both the reactor and the converter. The present invention has simple structure, good sealing effect, condition suitable for anaerobic ammonia oxidizing bacteria to grow, easy operation and high in sludge intercepting capacity.

Owner:CHONGQING TECH & BUSINESS UNIV

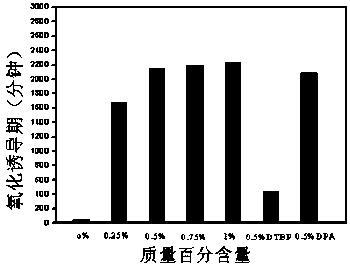

High temperature antioxidant for lubricating oil and preparation method thereof

ActiveCN105038904BExtension of timeImprove solubilityOrganic compound preparationAdditivesSolubilitySolvent

Owner:道骐科技有限公司

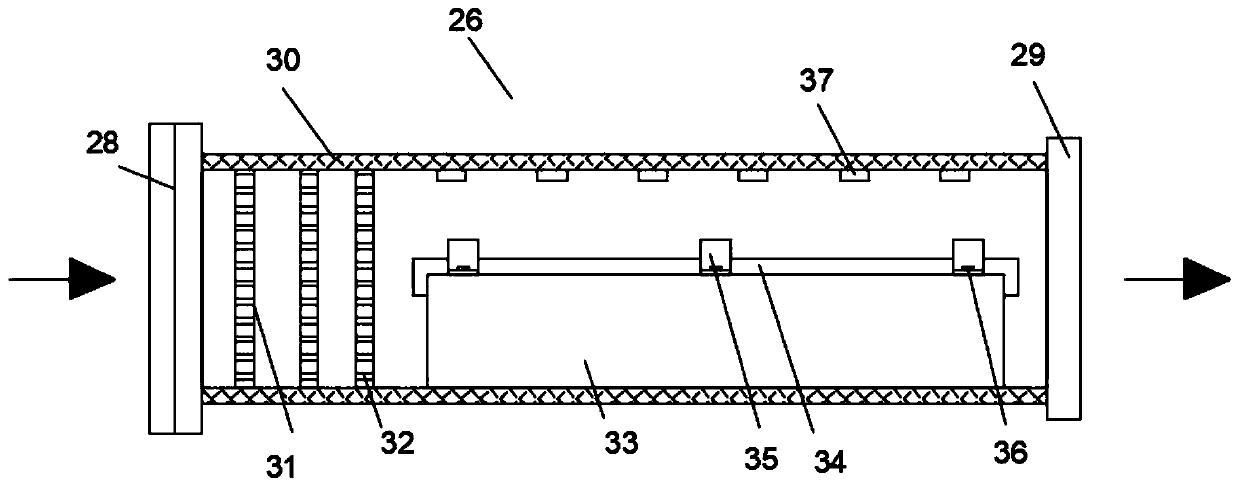

High-temperature steam oxidation test device

The invention discloses a high-temperature steam oxidation test device in the technical field of oxidation test devices, and the high-temperature steam oxidation test device comprises a deoxygenationwater tank, a water supply tank, an evaporator, an electric furnace, a condenser, a circulating water tank, a water pump, a metering pump, a circulating water pump, a plurality of valves and pipelines, wherein the upper end of the deoxygenation water tank is also connected with a water replenishing port through the pipelines and the valves arranged on the pipelines; a deoxygenation pipe is arranged in the evaporator; a test bin is arranged in the electric furnace; a plurality of samples subjected to different treatment processes are placed in the electric furnace of the high-temperature steamoxidation test device; and data of oxidation tests at different temperatures are obtained by changing the test temperature. According to the oxidation test results of the samples treated by differentprocesses under the same parameter condition, the oxidation resistance of the materials can be compared, the difference of different surface treatment processes of each pressure-bearing parts of the samples on the oxidation resistance can be analyzed, the process for changing the oxidation resistance of each sample is provided, and the process can be practically realized in engineering.

Owner:THERMAL POWER TECH RES INST OF CHINA DATANG CORP SCI & TECH RES INST

Detection process in a power line production system

InactiveCN108801332AComprehensive indicator detectionExtended service lifeMeasurement devicesWear resistantEngineering

The invention discloses a detection process in a power line production system. The process includes the steps of sampling and testing, wherein the end of the raw material in the power line productionprocess is cut by the aid of wire nippers, the raw material is selected from a power line which is not provided with a charging head or a USB connector, and matched raw material information of the intercepted power line is recorded to serve as the general catalogue of the subsequent test data to facilitate the processing of unqualified products in the later stage. The detection is simple and convenient. All indexes of the power line are comprehensively detected, the various environment for later use of the power line can be simulated including diameter detection, a power-on test, a temperaturetest, a wear-resistant test, a corrosion test, an oxidation test and a bending test, the service life of the qualified product in the later period can be effectively prolonged, and the safety degreeof use can be effectively improved. The unqualified product can be recycled, waste of resources is reduced, and high practicability is achieved. The detection process is suitable for being widely popularized and used.

Owner:浙江海宁普赛自动化科技有限公司

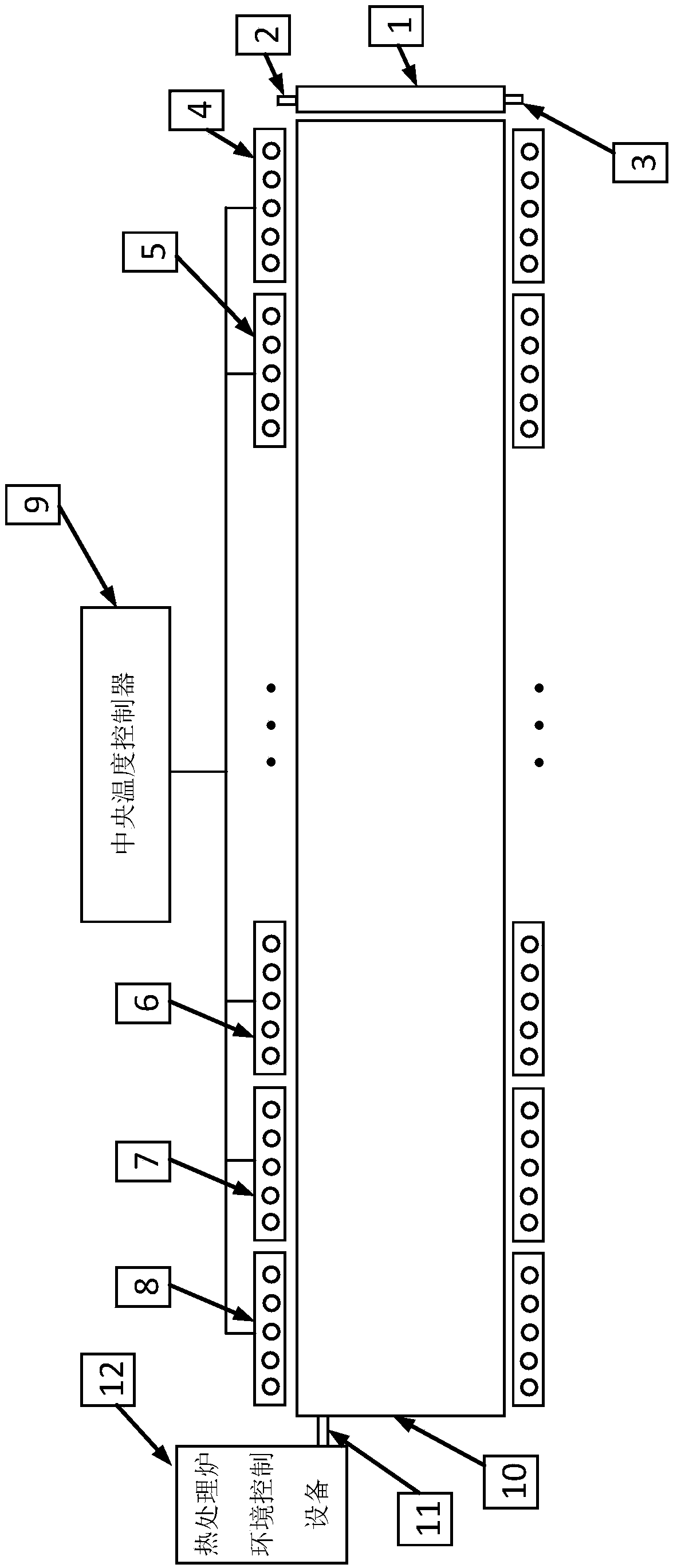

Heat treatment furnace and oxidation test method

InactiveCN110857842AImprove test efficiencyVacuum gaugesFurnace typesLiquid nitrogen coolingWater cooling

The invention designs a heat treatment furnace for an oxidation test and a test method. The heat treatment furnace for the oxidation test comprises a furnace body, a plurality of heating units and a controller, wherein the furnace body comprises a furnace door, and an opening of the furnace body can be closed through the furnace door; the multiple heating units are independent of each other to heat a space inside the furnace body; the controller controls the heating powers of all of the independent heating units; and the multiple independent heating units are distributed in the length direction of the furnace body, the multiple heating units are in one-to-one correspondence to a plurality of temperature zones distributed in the length direction of the furnace body, the furnace door is located at one end of the length direction of the furnace body, the furnace door further comprises a water cooling or liquid nitrogen cooling system for cooling the furnace door, and the temperature of the temperature zones is decreased from one end to the other end to form a gradient temperature field with the lowest temperature being room temperature to 100 DEG C and the highest temperature to 1300DEG C. The heat treatment furnace and the test method have the advantages of high test efficiency and the like.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

Method and device for an accelerated oxidation test of fuels or petroleum products, as well as a computer program for controlling such a device, and a corresponding computer readable storage medium

A device and a method for an accelerated oxidation test of fuels or petroleum products, as well as a computer program for controlling such a device, and a corresponding computer readable storage medium, which are applicable, in particular, for the simulation of the aging of fuels or petroleum products. A device for an accelerated oxidation test of fuels or petroleum products is proposed, whereby the device comprises of a pressure vessel (1) to hold specimen (2) of fuels or petroleum products, and the pressure vessel (1) contains at least one device to change the temperature. A corresponding method provides that a specimen (2) of fuel or petroleum product is placed in a pressure vessel (1), the specimen is brought to a predefined temperature above 100° C. by at least one device to change the temperature, which is placed in the pressure vessel (1) and / or in the specimen (2), and the absolute pressure value is monitored so as to determine the oxidation.

Owner:ANTON PAAR PROVETEC

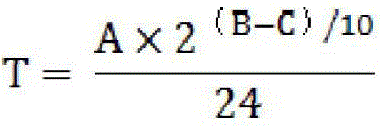

Antioxidant-containing feed antioxidation effect assessment method and feed quality guarantee period prediction method

ActiveCN106198869AScientificComparablePreparing sample for investigationAntioxidantControl substances

The invention discloses an antioxidant-containing feed antioxidation effect assessment method and a feed quality guarantee period prediction method. The assessment method comprises adding different antioxidants into base feed, carrying out mixing to obtain a test sample, utilizing base feed without an antioxidant as a blank control substance, putting all the test samples and the blank control substance into a thermostat, carrying out accelerated oxidation at a high temperature, when the blank control substance produces a rancidity smell, smelling all the test samples at fixed time intervals until the last sample produces a rancidity smell, then determining peroxide values of all the samples, predicting a quality guarantee period T according to the test cases and utilizing the time, peroxide value and quality guarantee period acquired when a rancidity smell is not found at the last time as antioxidation effect assessment basis. The assessment method utilizes a high temperature accelerated oxidation test to assess feed antioxidant effects and has the advantages of rancidity degree quantification, good comparability, good repeatability and quality guarantee period prediction at the normal temperature.

Owner:重庆新威士生物科技有限公司

Containers used in determining the thermal stability of fuels

ActiveUS8246244B2Accurate connectionMaterial heat developmentWithdrawing sample devicesThermodynamicsHydrocotyle bowlesioides

A thermal oxidation tester is shown for determining thermal stability of a fluid, particularly hydrocarbons, when subjected to elevated temperatures. The tendency of the heated fluid to oxidize and (1) form deposits on a surface of a heater tube and (2) form solids therein which are both measured at a given flow rate, temperature and time. The measured results are used to determine whether a fluid sample passes or fails the test. Specifically constructed containers used in a thermal oxidation tester are shown. These containers (1) reduce physical contact to hydrocarbon test fuels, (2) reduce exposure to hydrocarbon fuel vapors, (3) reduce environmental impact by reducing chemical spills, and (4) improve overall work flow of test.

Owner:PETROLEUM ANALYZER COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com