High-temperature steam oxidation test device

An oxidation test, high-temperature steam technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of inability to simulate the influence of the oxidation law of dissolved oxygen content, uncontrollable steam quality such as water vapor oxygen content, and influence on oxidation mechanism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

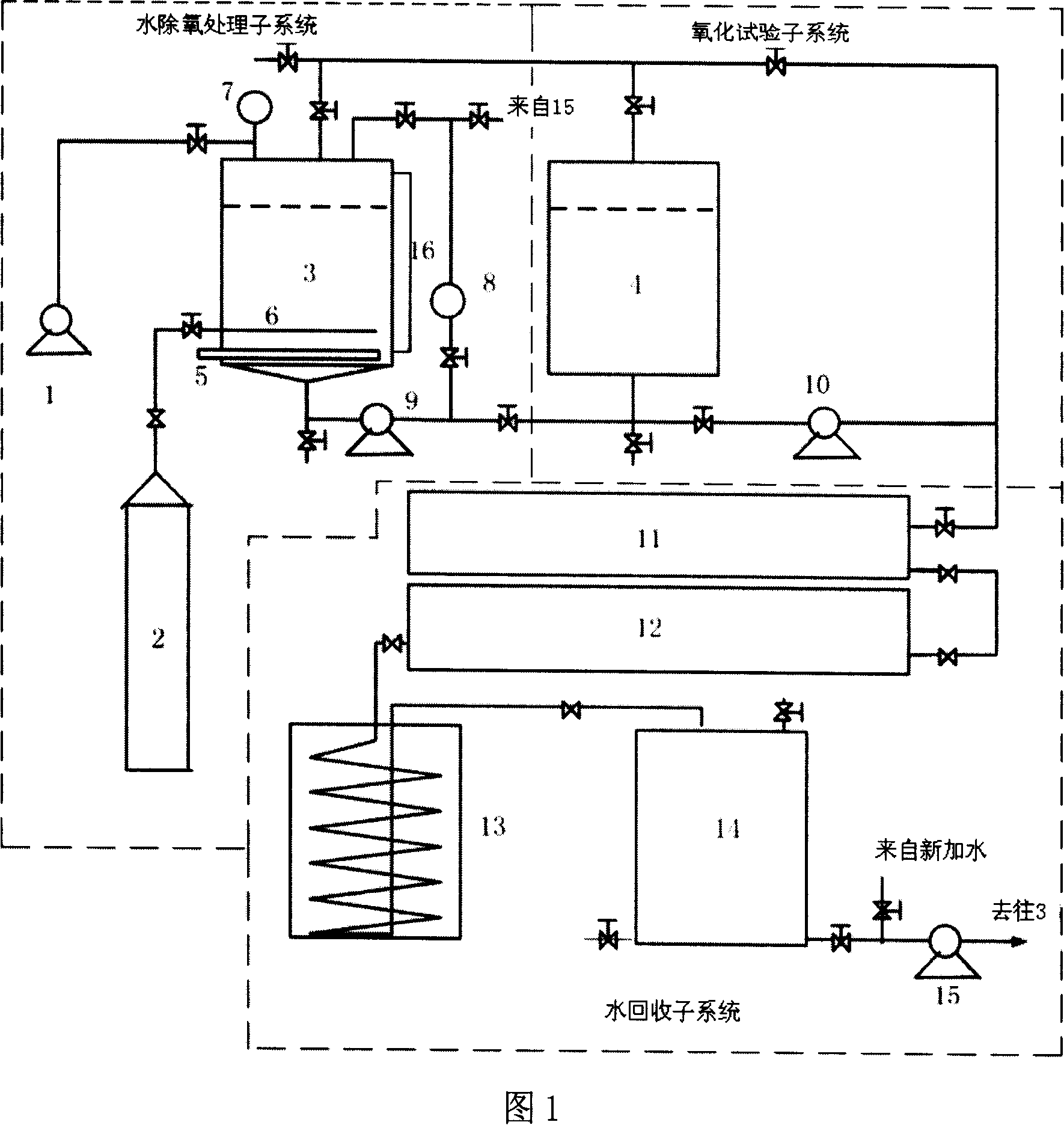

[0008] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0009] Referring to Fig. 1, the present invention includes a water deaeration treatment subsystem, an oxidation test subsystem, and a water recovery subsystem. The water deoxygenation treatment subsystem completes the dissolved oxygen control of the test water; the oxidation test subsystem realizes the adjustment of parameters such as temperature and flow of the steam oxidation test; the water recovery subsystem completes the functions of test exhaust steam condensation and water recovery.

[0010] Wherein the water deaeration treatment subsystem includes a water treatment tank 3, the upper end of the water treatment tank 3 is connected with the vacuum pump 1 and the vacuum pressure gauge 7 through a pipeline, and the lower end of the water treatment tank 3 is provided with a deaeration pipe 6, and the deaerati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com