Method for processing oil-gas field fracturing waste liquor

A technology for fracturing waste fluid and treatment method, applied in chemical instruments and methods, adsorption water/sewage treatment, neutralization water/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

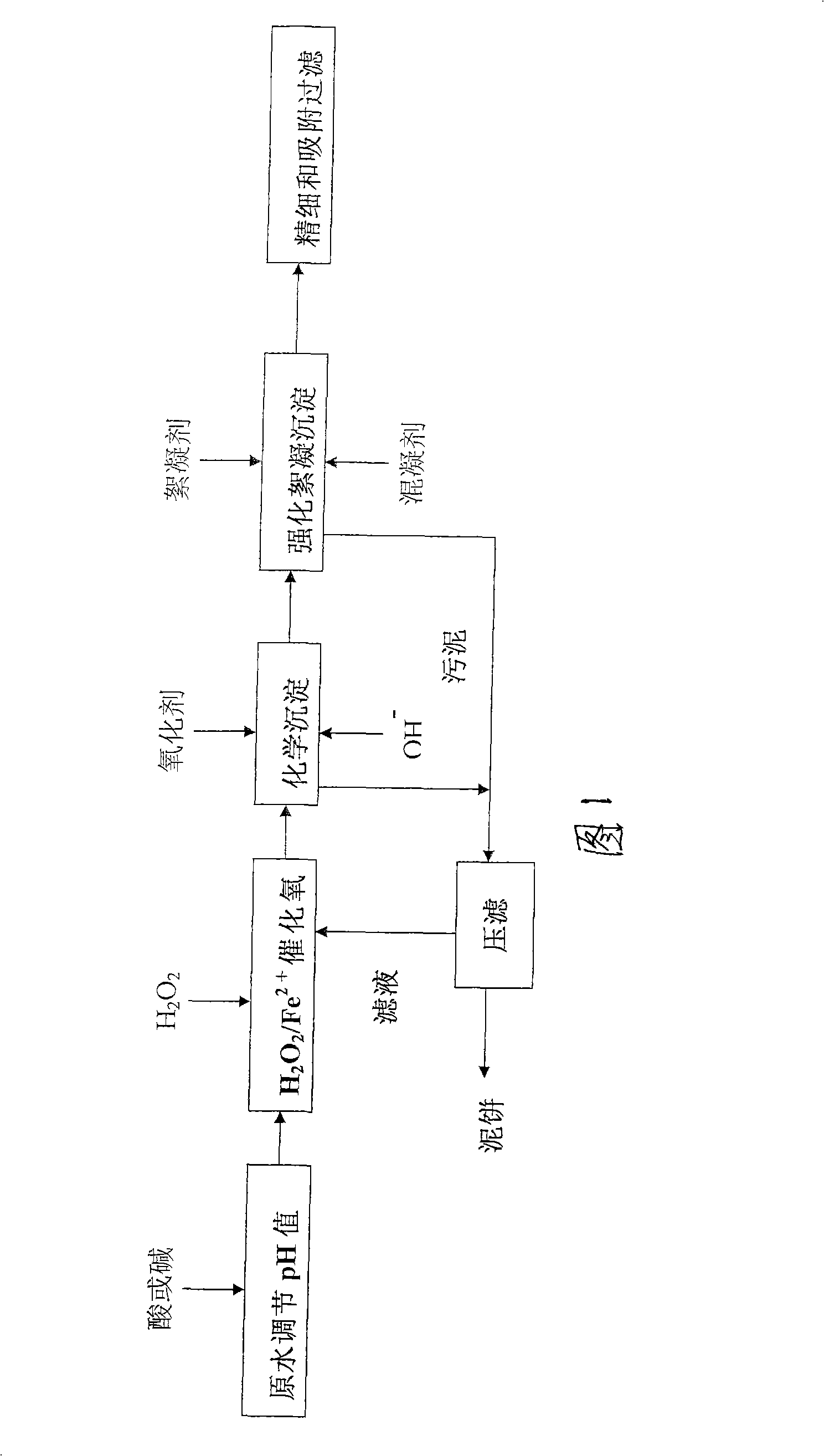

Method used

Image

Examples

example 1

[0019]Example 1: The total iron content of the fracturing waste fluid recovered by the Daniudi Gas Field Waste Fluid Centralized Treatment Station of Sinopec North China Branch is 89mg / L, the pH value is 5, and the COD content is 12000mg / L. Add 30% concentration of H to the waste 2 o 2 Stir the solution at 2%, react in the reaction tank for 5 hours, use an air compressor to feed air into the reaction tank for 10 hours, first add lime milk to adjust the pH value to 8, add amphoteric polyacrylamide 7ppm after stirring, and enter the sedimentation tank after stirring Settling, the supernatant of the settling tank overflows into the buffer tank, is lifted by the sewage pump into the fine filter and then filtered through two-stage activated carbon, and the effluent reaches the water injection standard and is reinjected into the safe formation. The settled sludge in the system is dehydrated and biscuitized by the filter press to make bricks, and the filtrate is returned to the reac...

example 2

[0020] Example 2: The fracturing waste liquid recovered from the fracturing waste liquid centralized treatment station of Sinopec Henan Oilfield Branch has a ferrous iron content of 58 mg / l, a pH value of 9, and a COD content of 8900 mg / L. Add dilute sulfuric acid to the waste liquid to adjust the pH value to 4 , add 30% concentration of H to the waste liquid 2 o 2 Stir the solution at 3%, react in the reaction tank for 6 hours, use an air compressor to feed air into the reaction tank for 24 hours, add aluminum sulfate solution to the treated sewage, and stir to make the pH value between 6 and 9 , Stirring rate is 30r / min, add amphoteric polyacrylamide 7ppm and stir, stop stirring when alum flowers are formed, settle for more than 50min, supernatant overflows into the buffer pool, lifts into the fine filter through the sewage pump, and then filters through two-stage activated carbon , the effluent reaches the discharge standard. The settled sludge in the system is dehydrated...

example 3

[0021] Example 3: The fracturing waste fluid recovered by the Centralized Treatment Station of Fracturing Waste Fluid at the No. 1 Oil Production Plant of Tahe Oilfield of Sinopec Northwest Branch has a ferrous iron content of 46 mg / L, a pH value of 3, and an oil content of 400 mg / L. Use the jet pump to circulate the jet flow into the air for 48 hours, add the milk of lime solution to the treated sewage first, stir to make the pH value between 6 and 9, and the stirring rate is 30r / min, add amphoteric polyacrylamide 7ppm and stir, When the alum flowers are formed, stop stirring and settle for more than 6 hours. The supernatant overflows into the buffer tank, is lifted by the sewage pump into the fine filter, and then filtered through two-stage activated carbon. The effluent oil, pH value, and suspended matter meet the specified standards. The settled sludge in the system is dehydrated and biscuitized by the filter press to make bricks, and the filtrate is returned to the reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com