Method for recovering lead oxide by waste lead-acid storage battery

A waste lead-acid battery, lead oxide technology, applied in the direction of improving process efficiency, can solve the problems of heavy pollution, low lead recovery rate, environmental pollution, etc., and achieve the effect of low energy consumption and small pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

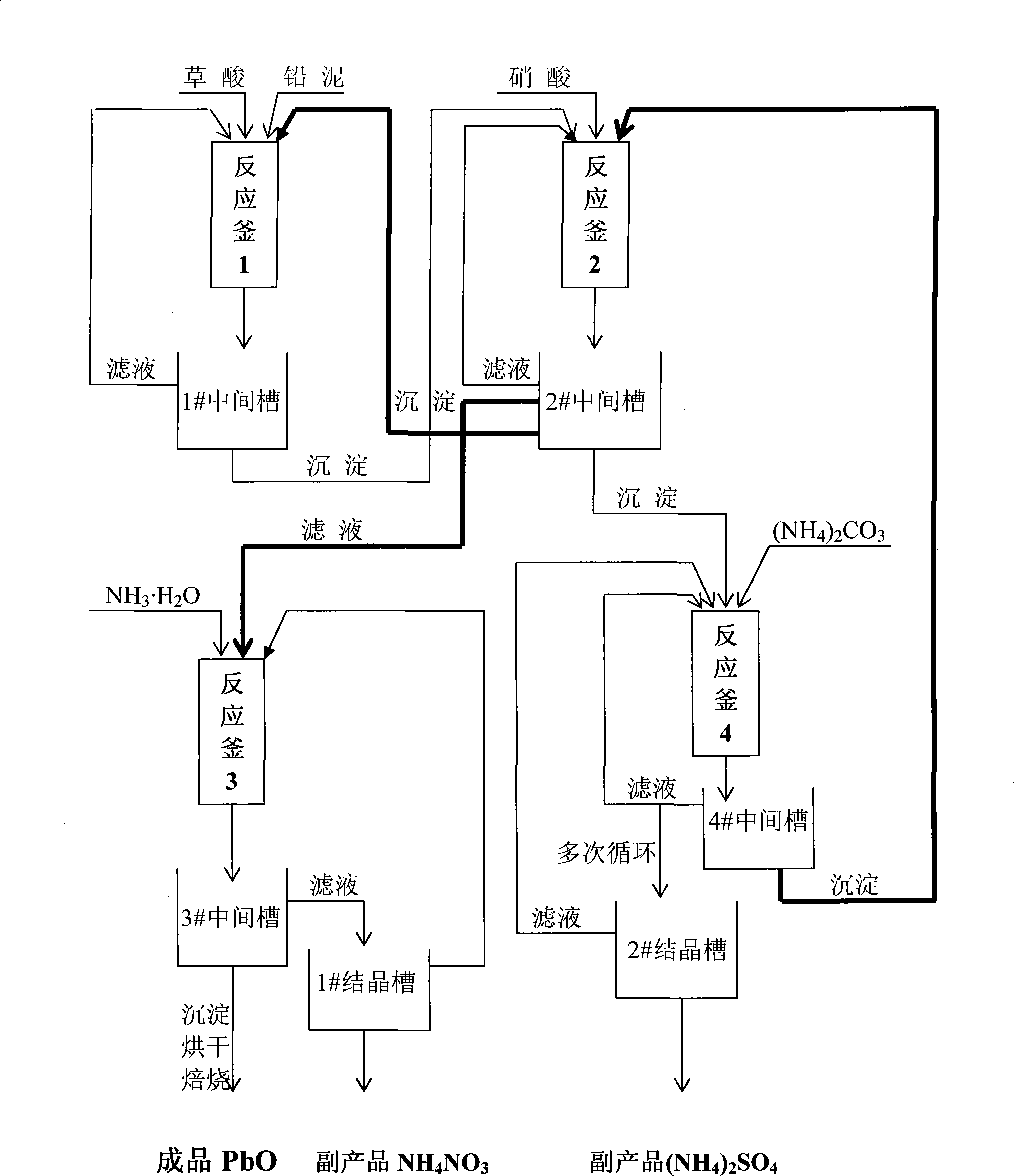

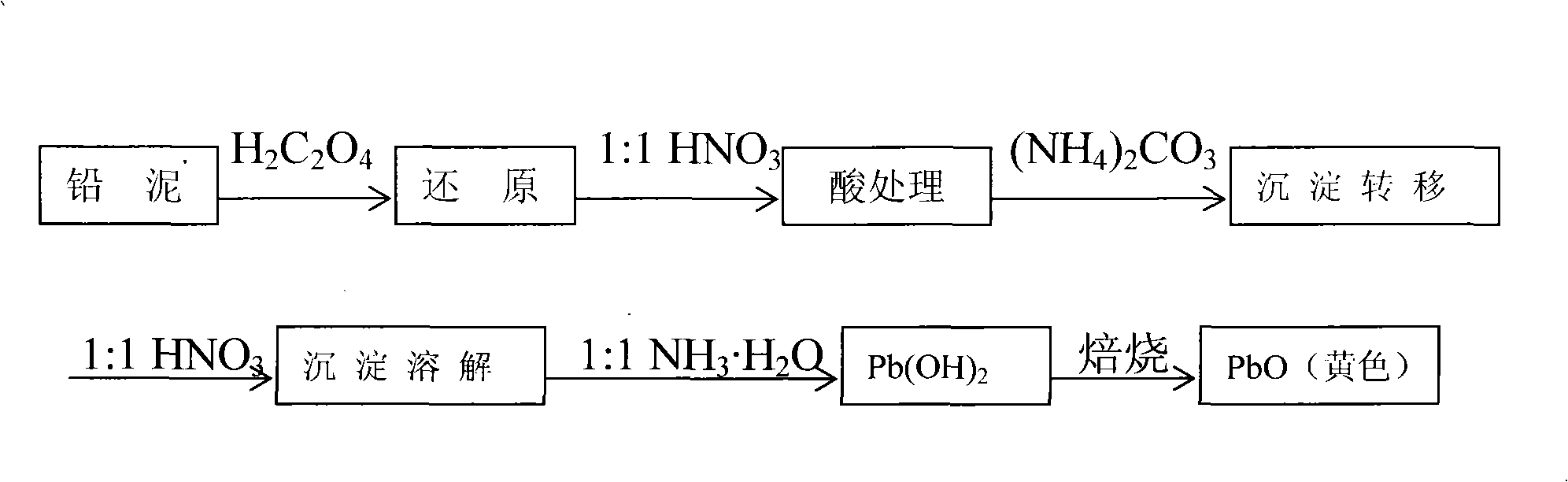

[0033] This embodiment includes three parts: pretreatment, lead oxide synthesis, by-product recovery

[0034] 1. Pretreatment

[0035] 1.1 After the battery is poured acid, the upper cover is cut off by a cutting machine and the plate is poured out. After acid washing, the plate is sent to the pulverizer, and the grid plate and filler (including lead mud) are obtained by screening after crushing;

[0036] 1.2 The grid plate is directly melted and cast into a finished alloy ingot, and the filler enters the ball mill to be finely ground to 60 mesh, and then enters the lead oxide recovery process.

[0037] 2. Lead oxide recovery

[0038] 2.1 Restoration

[0039] Add the ground filler (including lead mud) to the saturated solution of oxalic acid at room temperature at a ratio of 1:10 (mass:volume), react at 45°C for 1 hour, filter and dry after the reaction is complete.

[0040] Its process chemical reaction formula:

[0041] PbO 2 +H 2 C 2 o 4 →PbO↓+2CO 2 +H 2 o

[004...

Embodiment 2

[0064] The difference from Example 1 is: 2.1 The reduction temperature is 55° C., and a light yellow PbO product is finally obtained with a raw material utilization rate of 91.1% and a yield of 96.2%. Others are the same as in Embodiment 1.

Embodiment 3

[0066] The difference from Example 1 is: 2.1 The reduction temperature is 35° C., and a light yellow PbO product is finally obtained with a raw material utilization rate of 90.4% and a yield of 95.3%. Others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com