Patents

Literature

794 results about "Product recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A Product Recovery or Pigging System is used after product transfer to displace and recover residual product and clean the pipe wall. Valuable product is saved that would otherwise have been flushed to waste. CIP chemical usage and waste can be optimized.

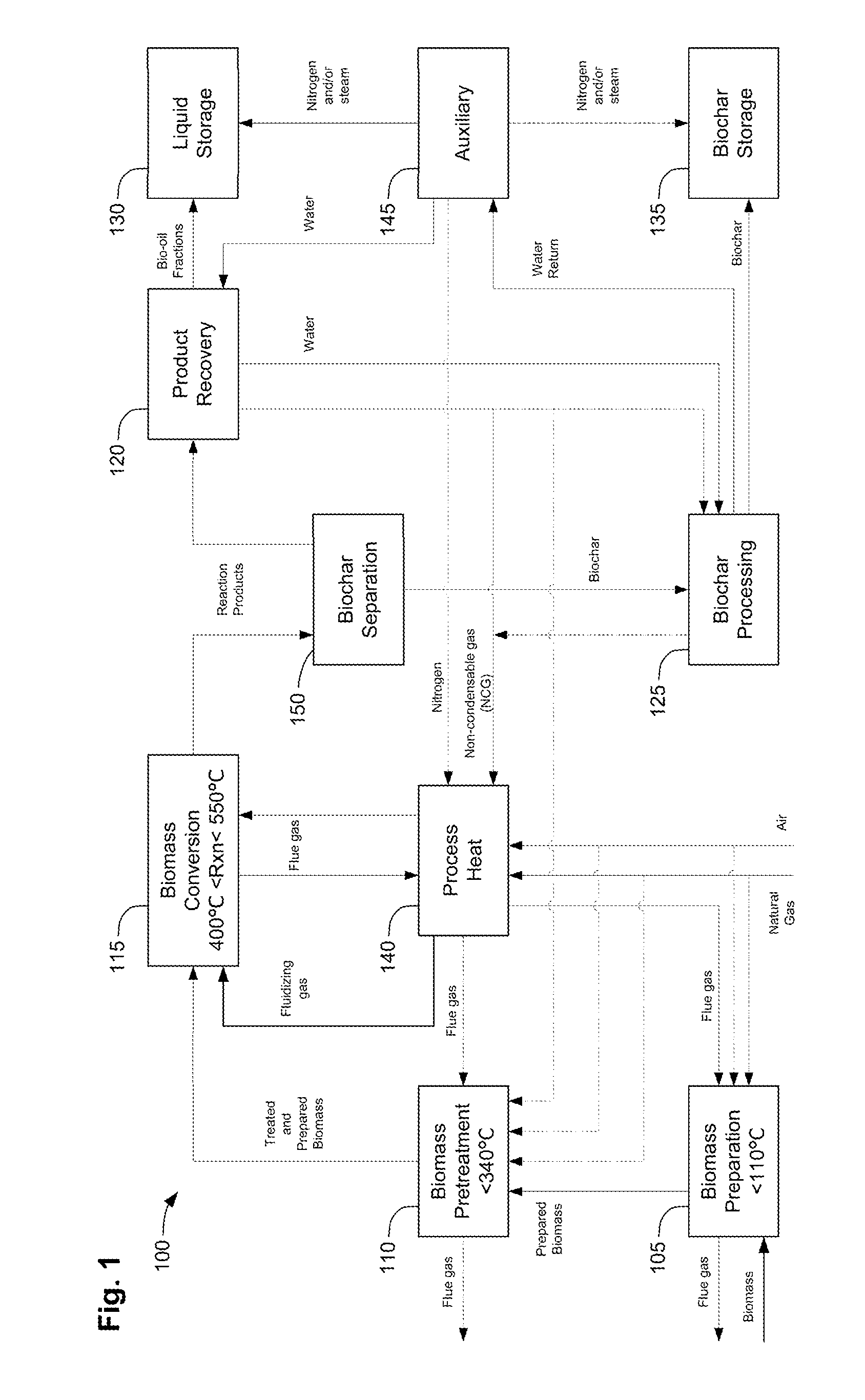

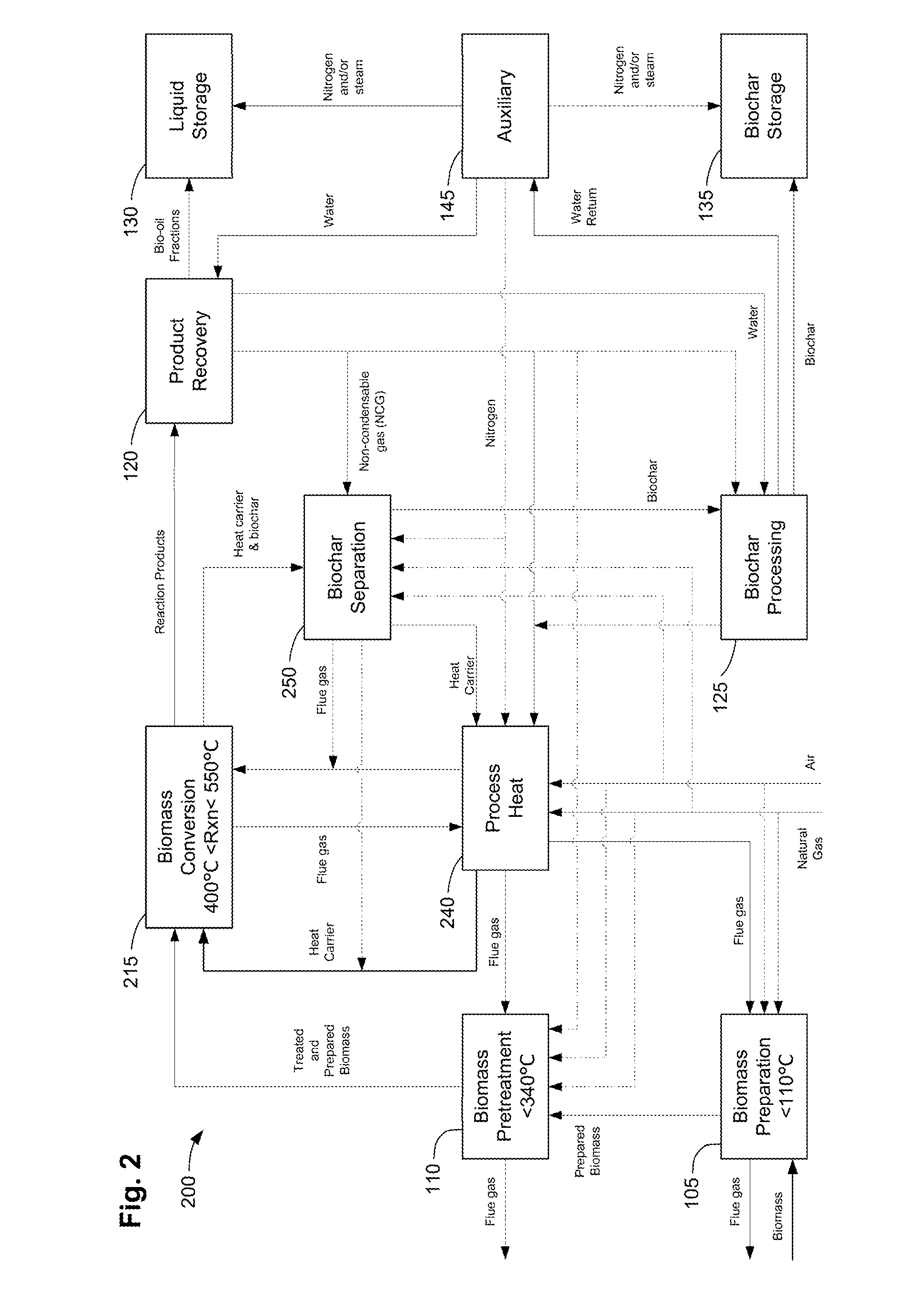

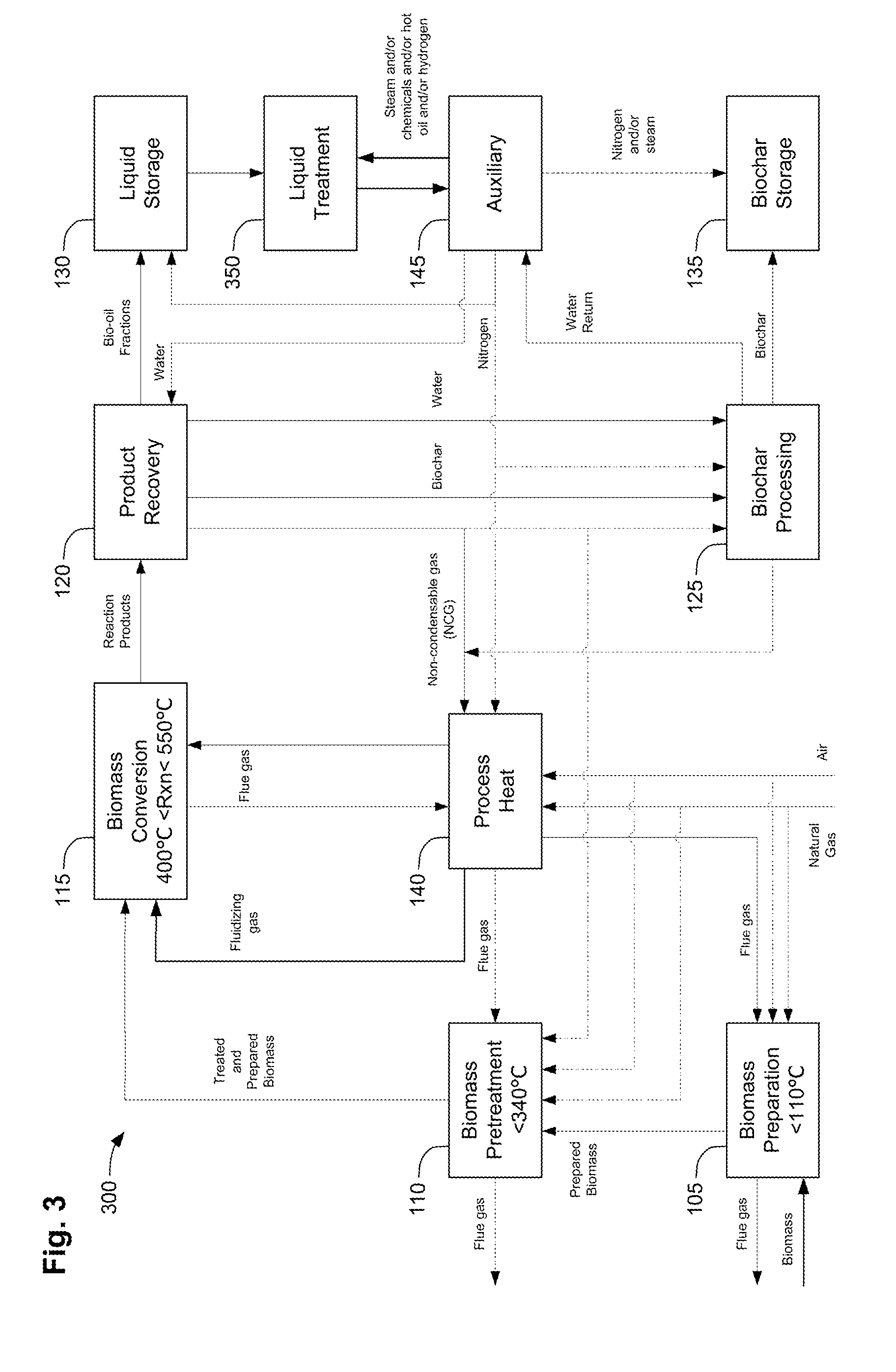

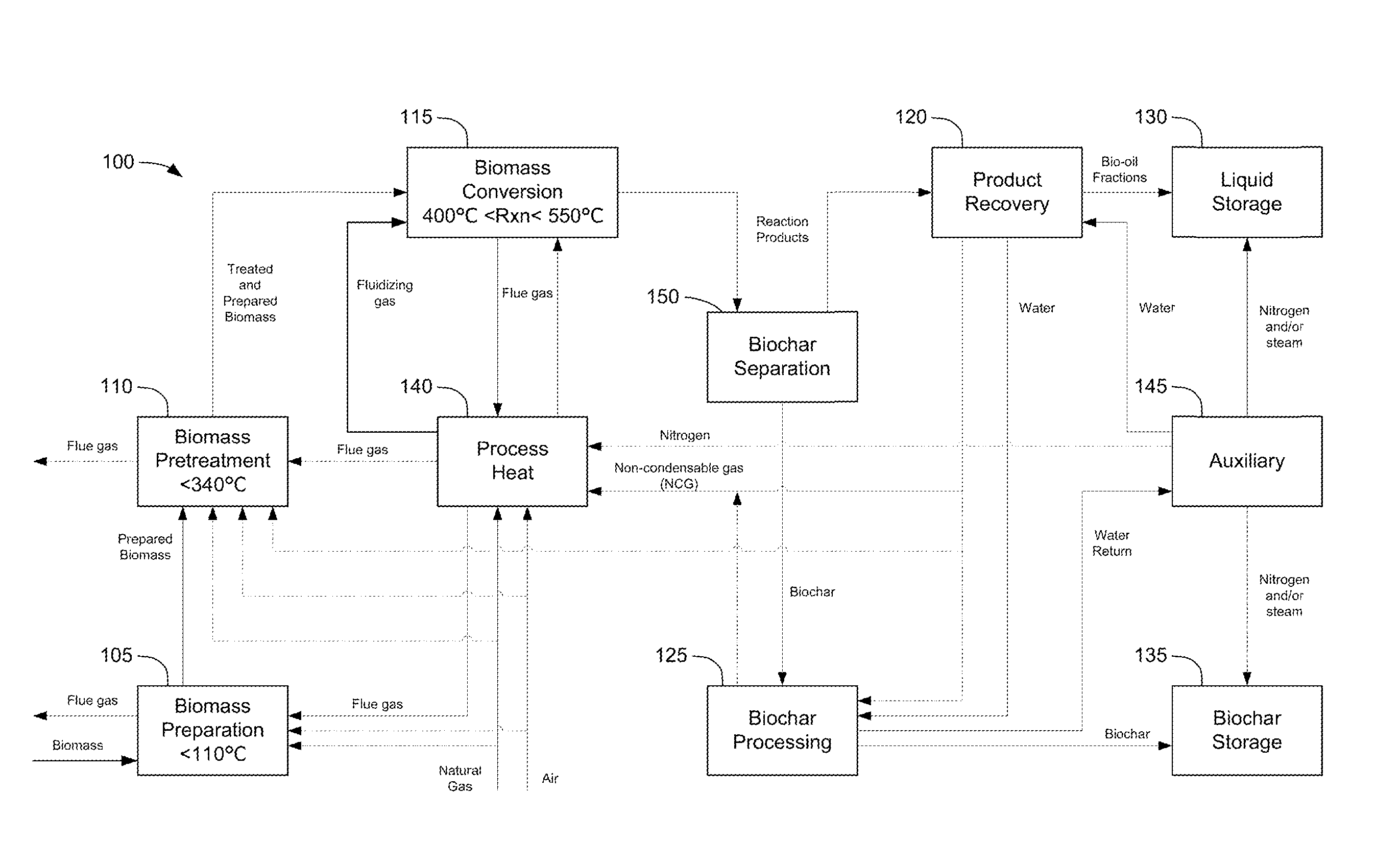

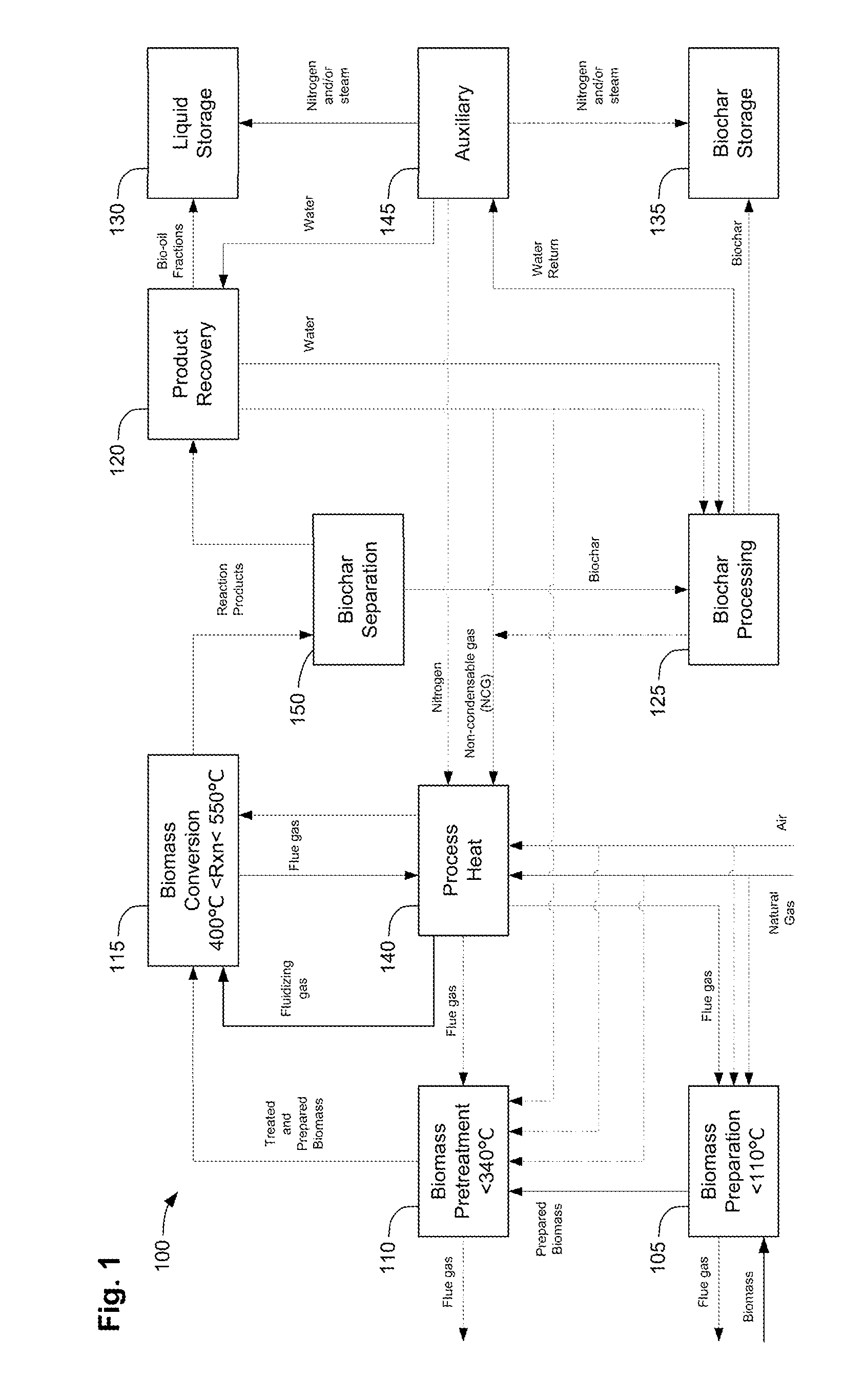

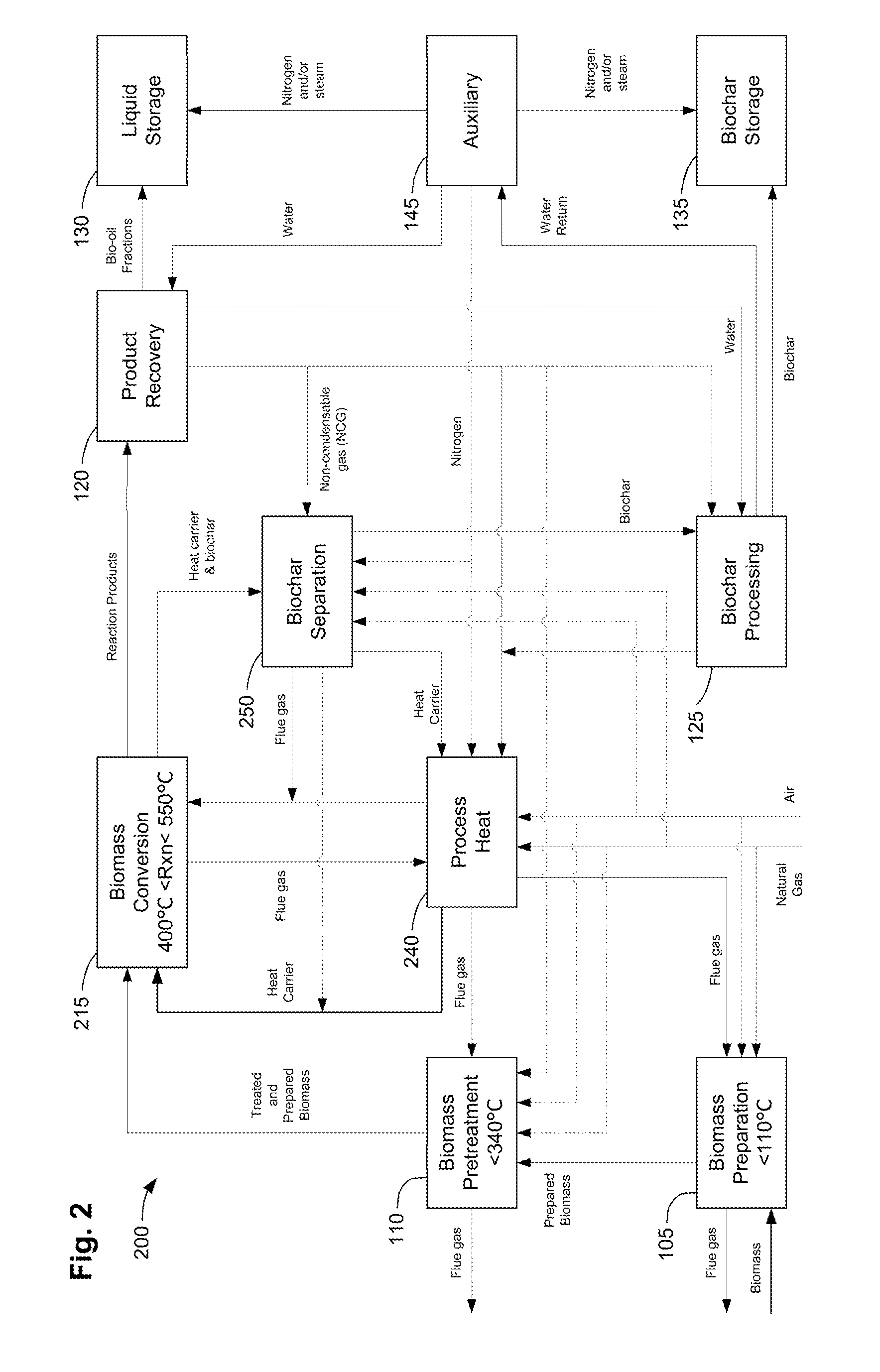

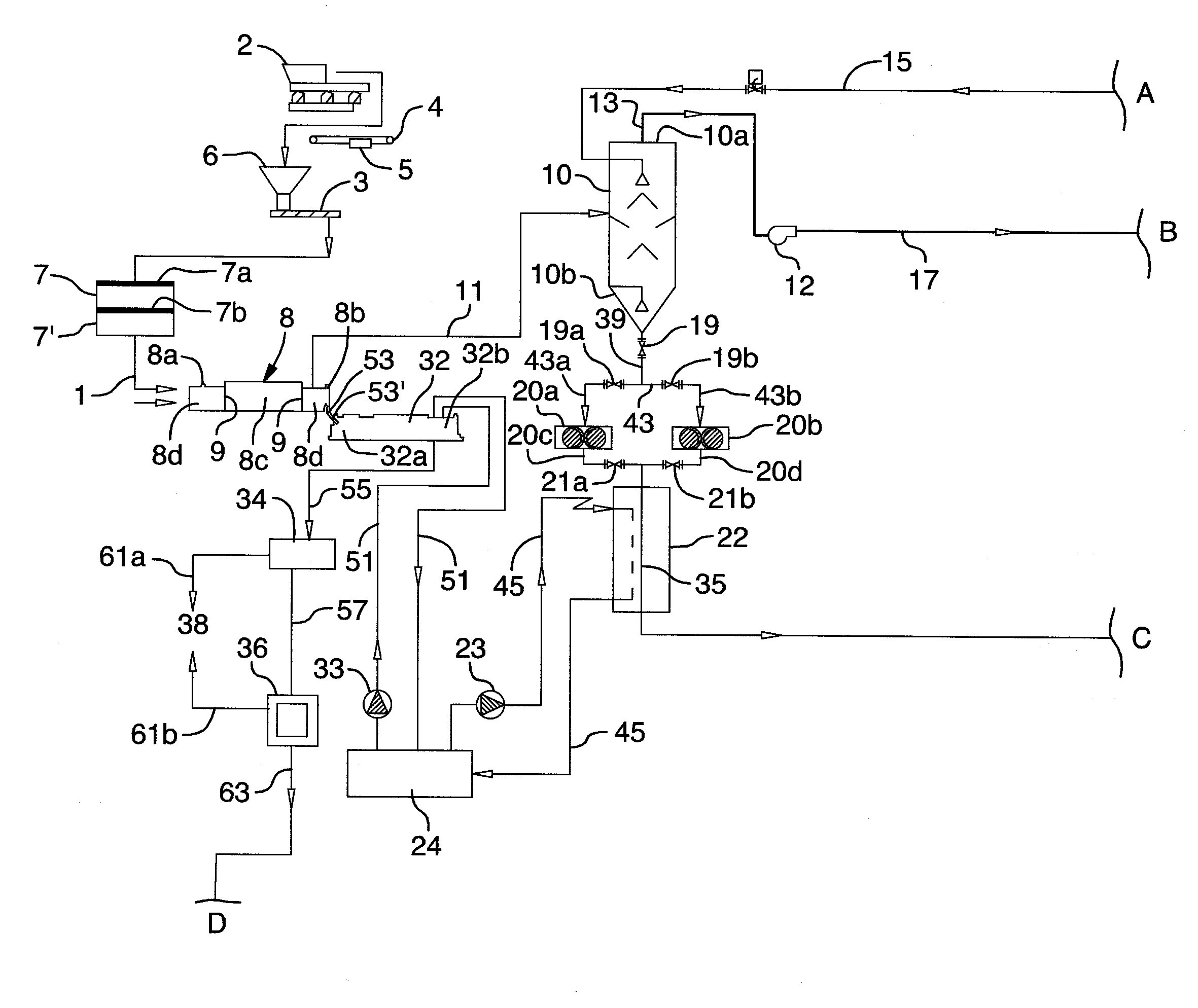

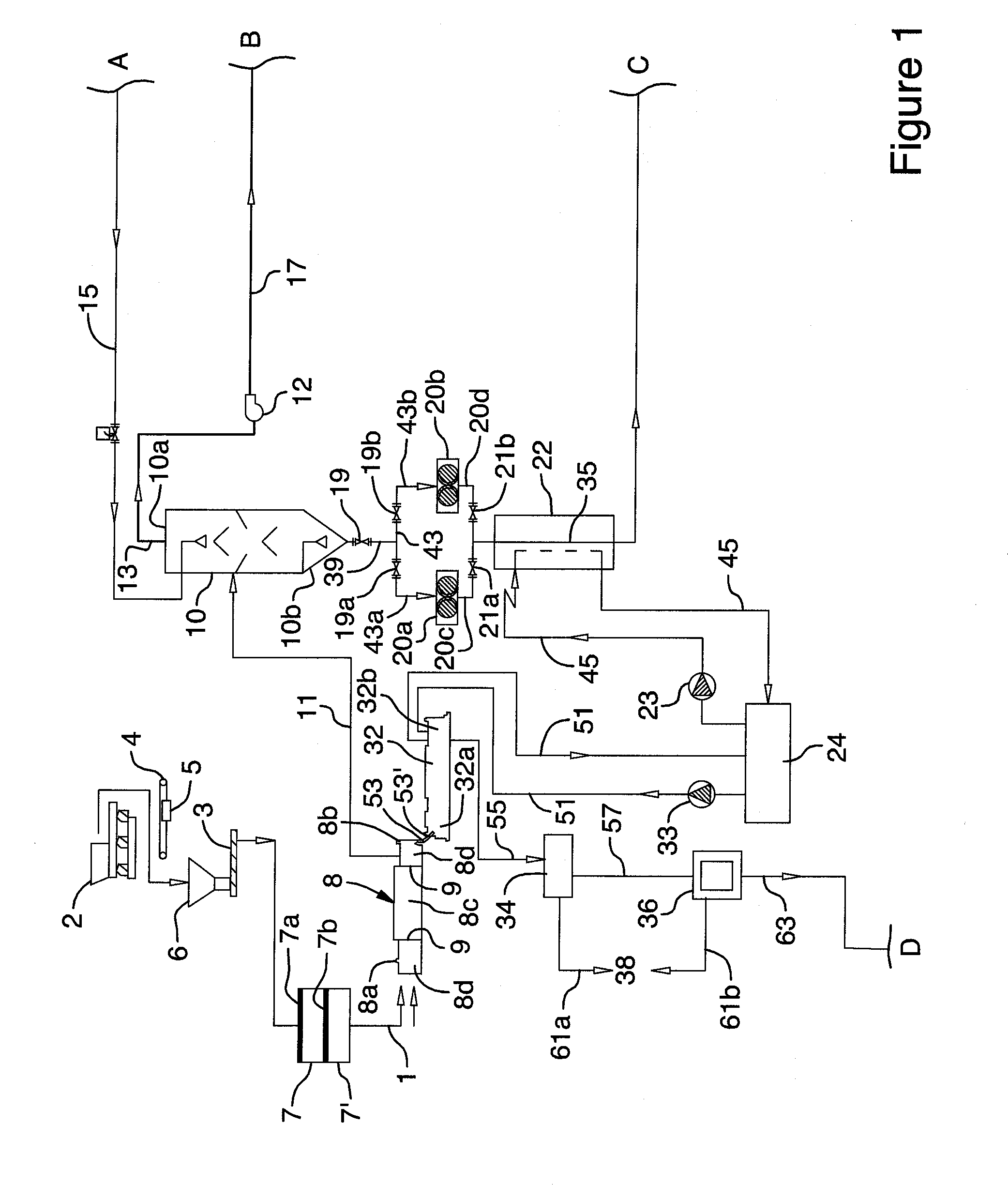

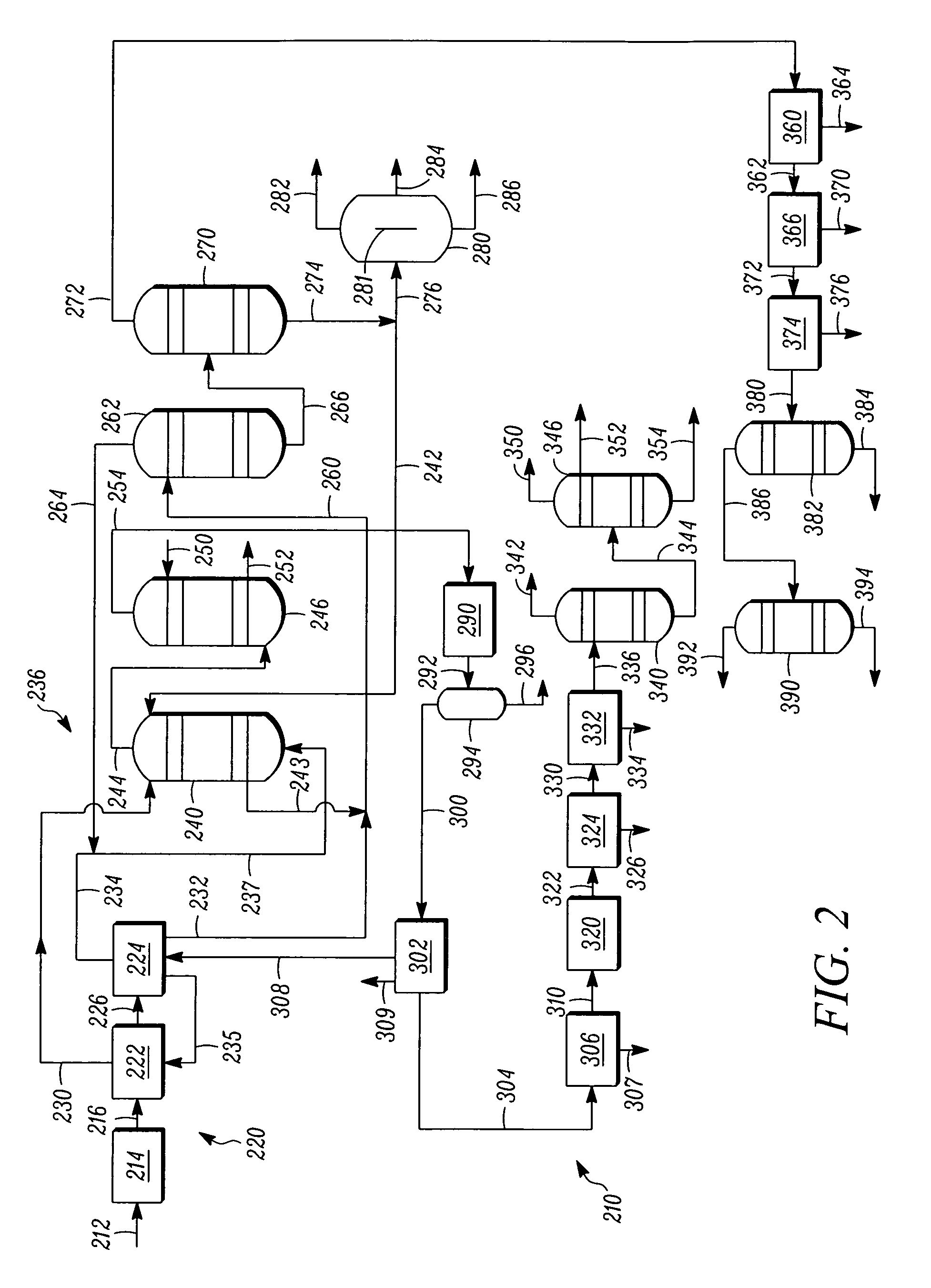

Methods for integrated fast pyrolysis processing of biomass

ActiveUS20110258914A1Improve collection efficiencyMinimizes water contentDirect heating destructive distillationBiofuelsPre treatmentSafe handling

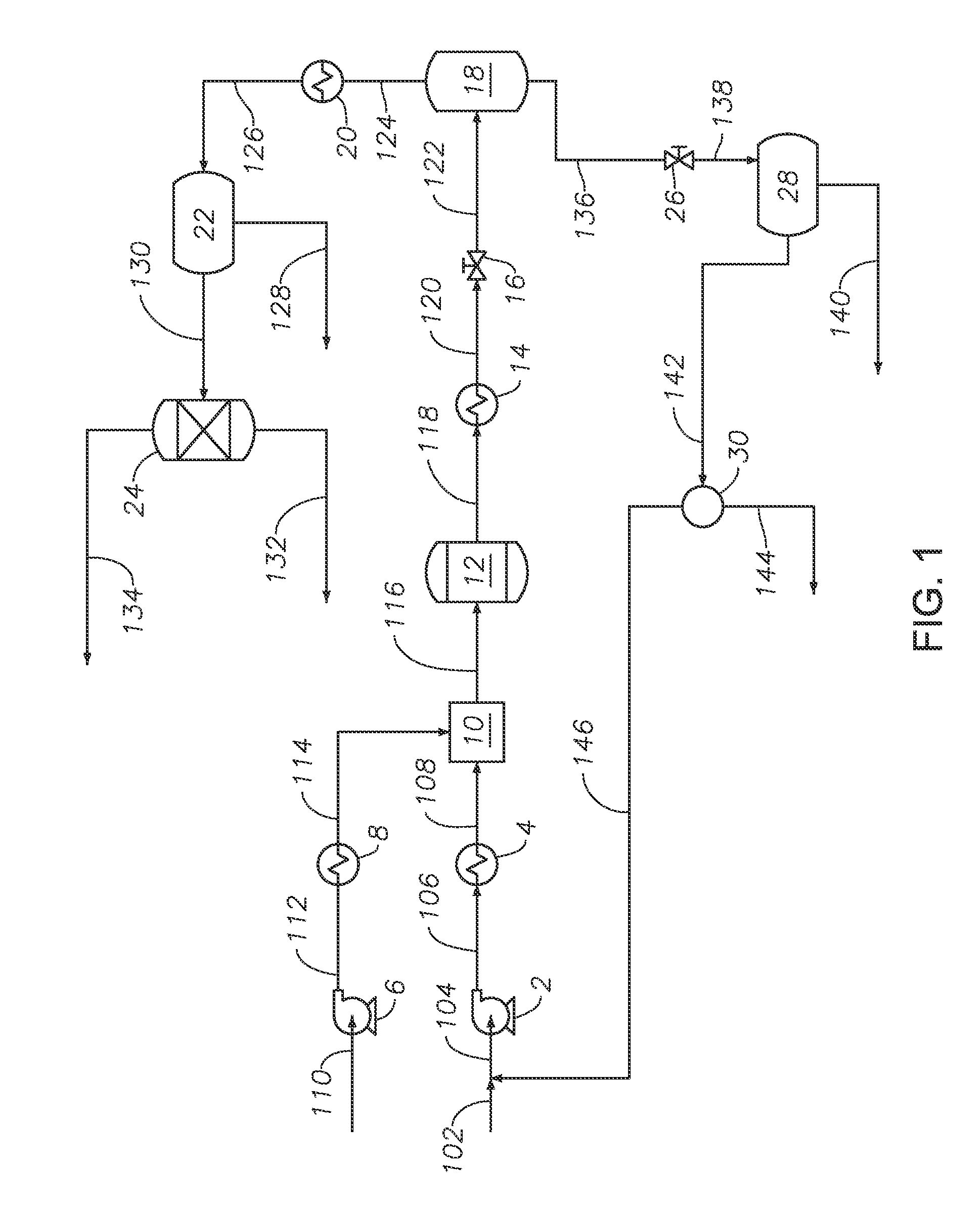

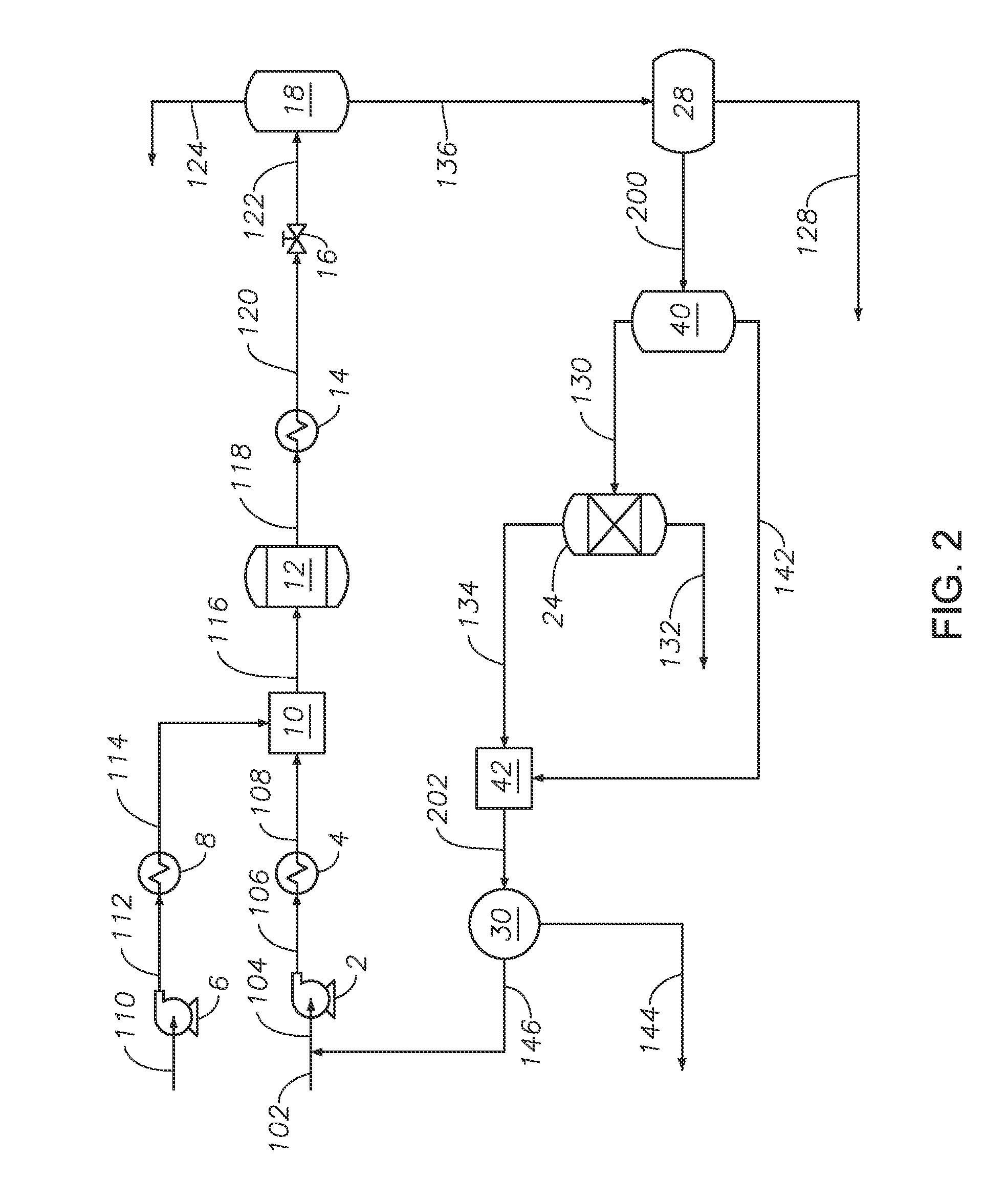

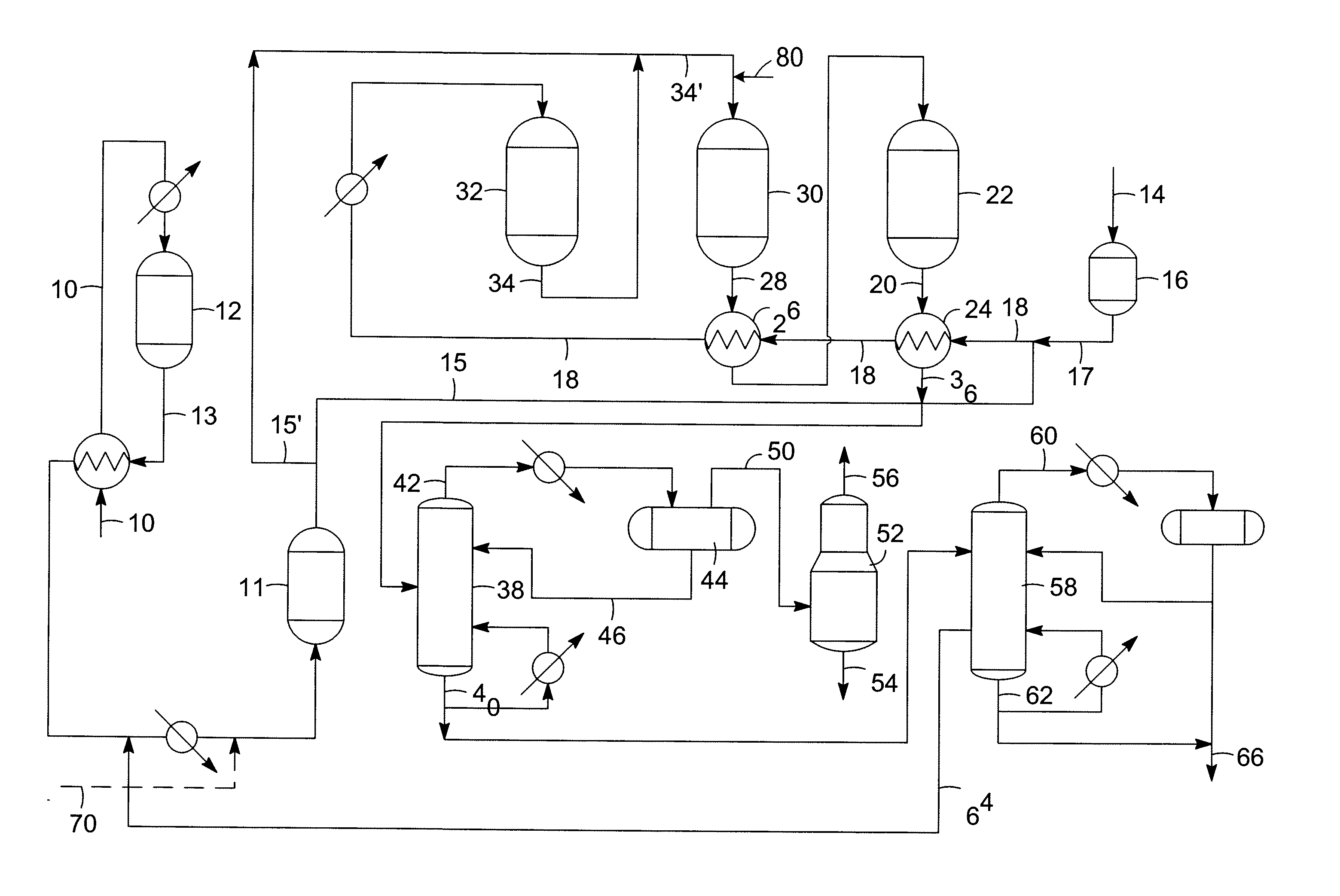

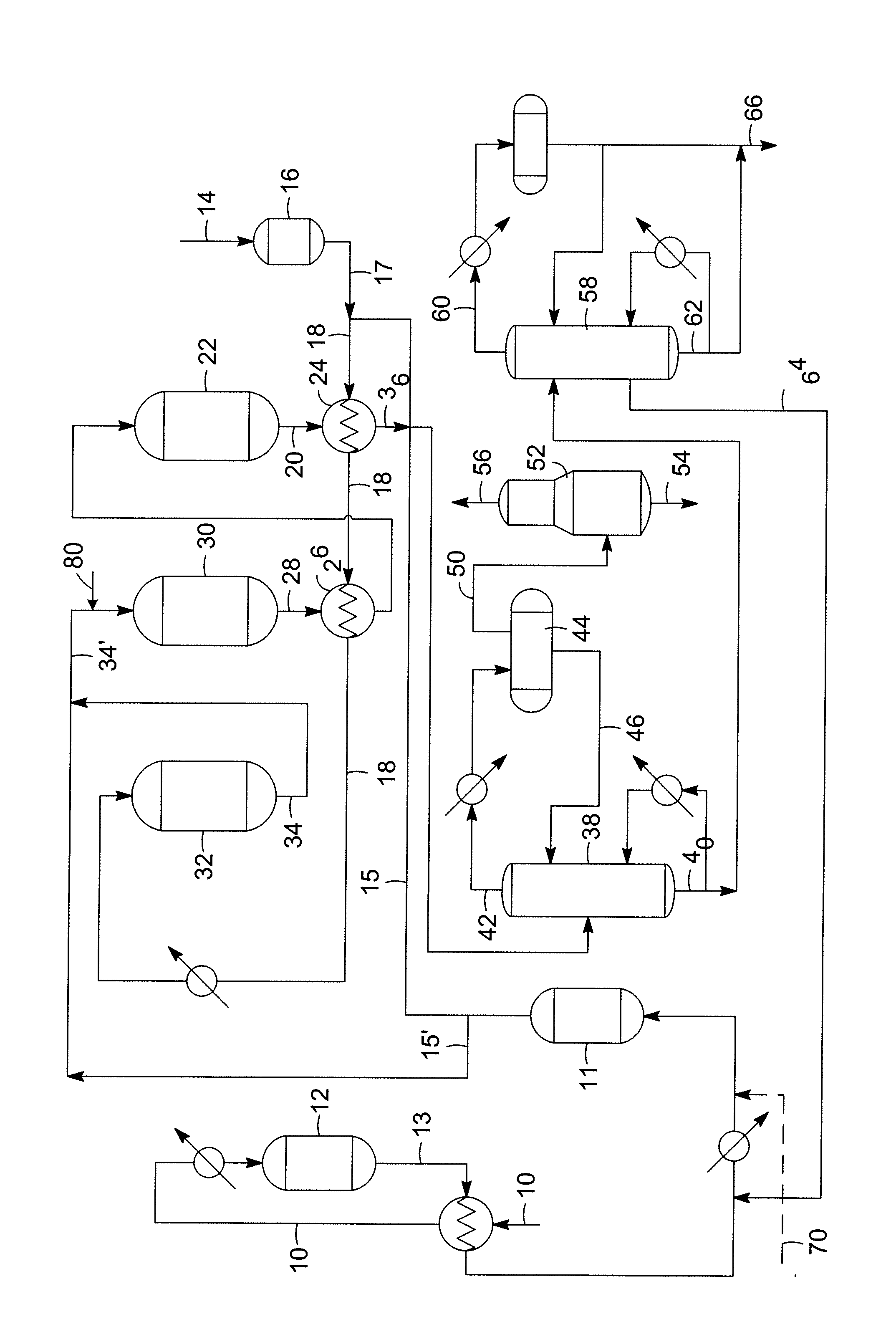

Methods, process, apparatus, equipment, and systems are disclosed for converting biomass into bio-oil fractions for chemicals, materials, feedstocks and fuels using a low-cost, integrated fast pyrolysis system. The system improves upon prior art by creating stable, bio-oil fractions which have unique properties that make them individually superior to conventional bio-oil. The invention enables water and low-molecular weight compounds to be separated into a final value-added fraction suitable for upgrading or extracting into value-added chemicals, fuels and water. Initial bio-oil fractions from the process are chemically distinct, have low-water content and acidity which reduces processing costs normally associated with conventional bio-oil post-production upgrading since fewer separation steps, milder processing conditions and lower auxiliary inputs are required. Biochar is stabilized so that it can be handled safely. The integrated fast pyrolysis process includes biomass storage, preparation, pretreatment, and conversion, product recovery and processing to create and store stable biochar and bio-oil fractions.

Owner:AVELLO BIOENERGY

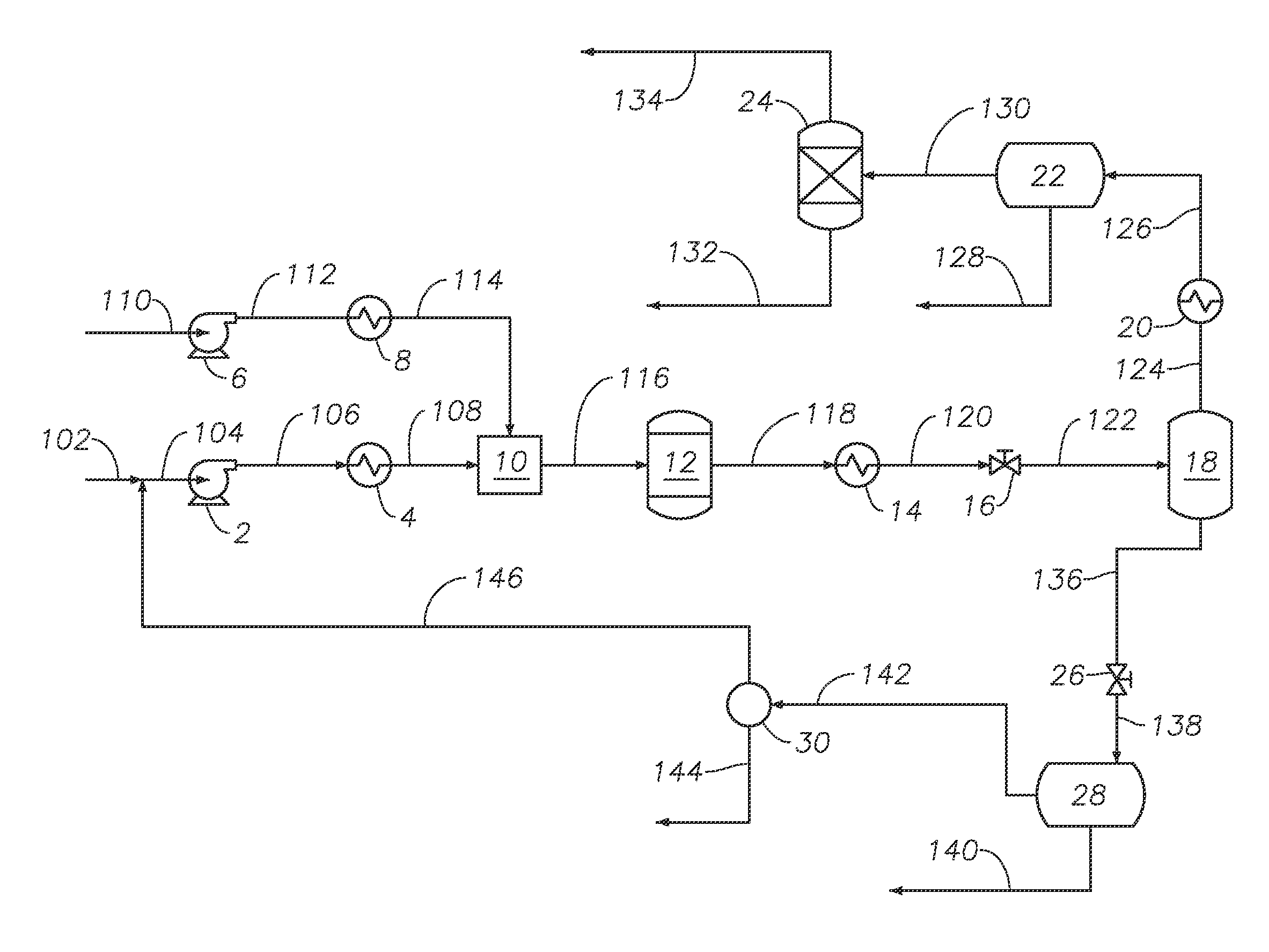

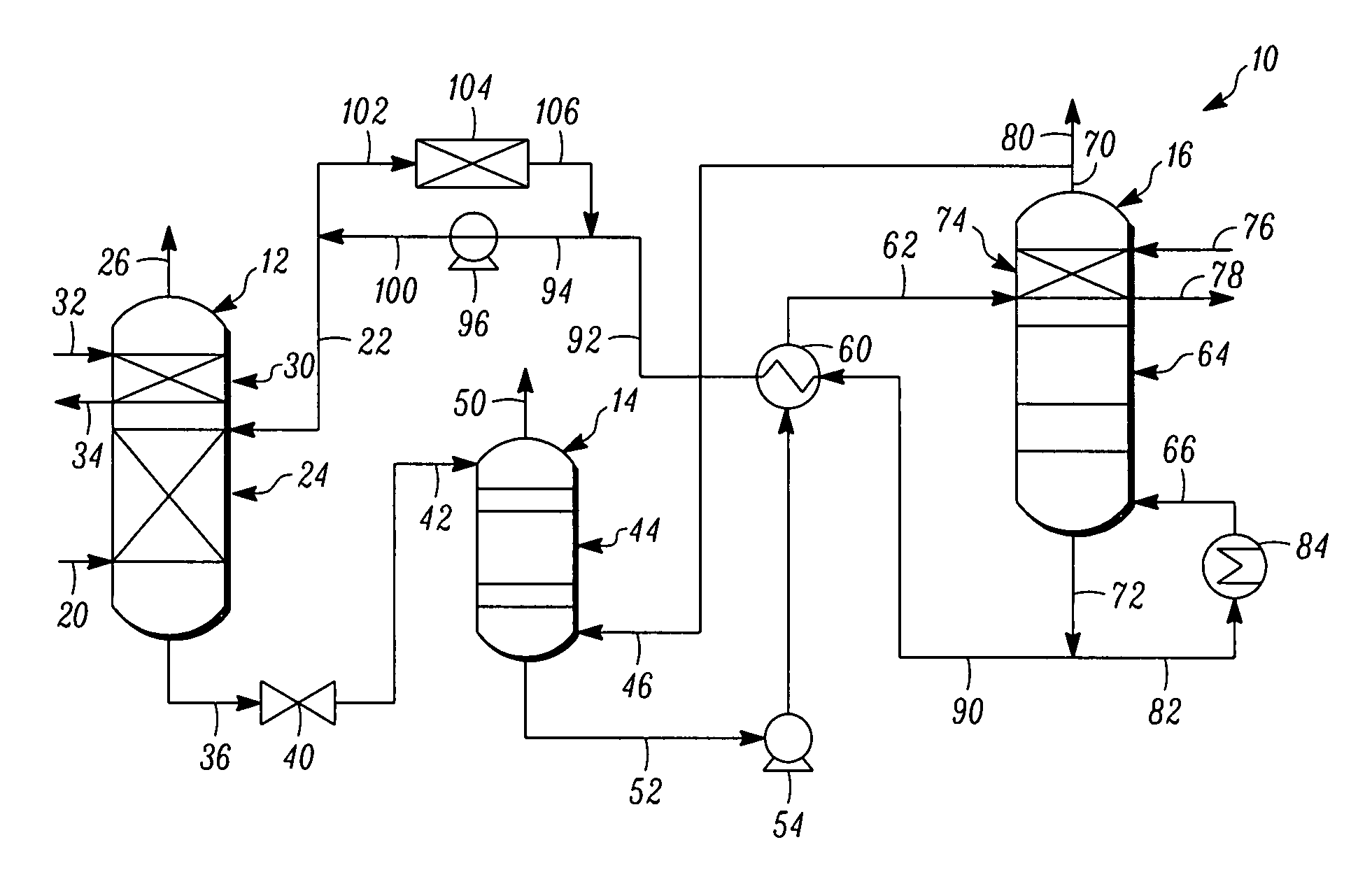

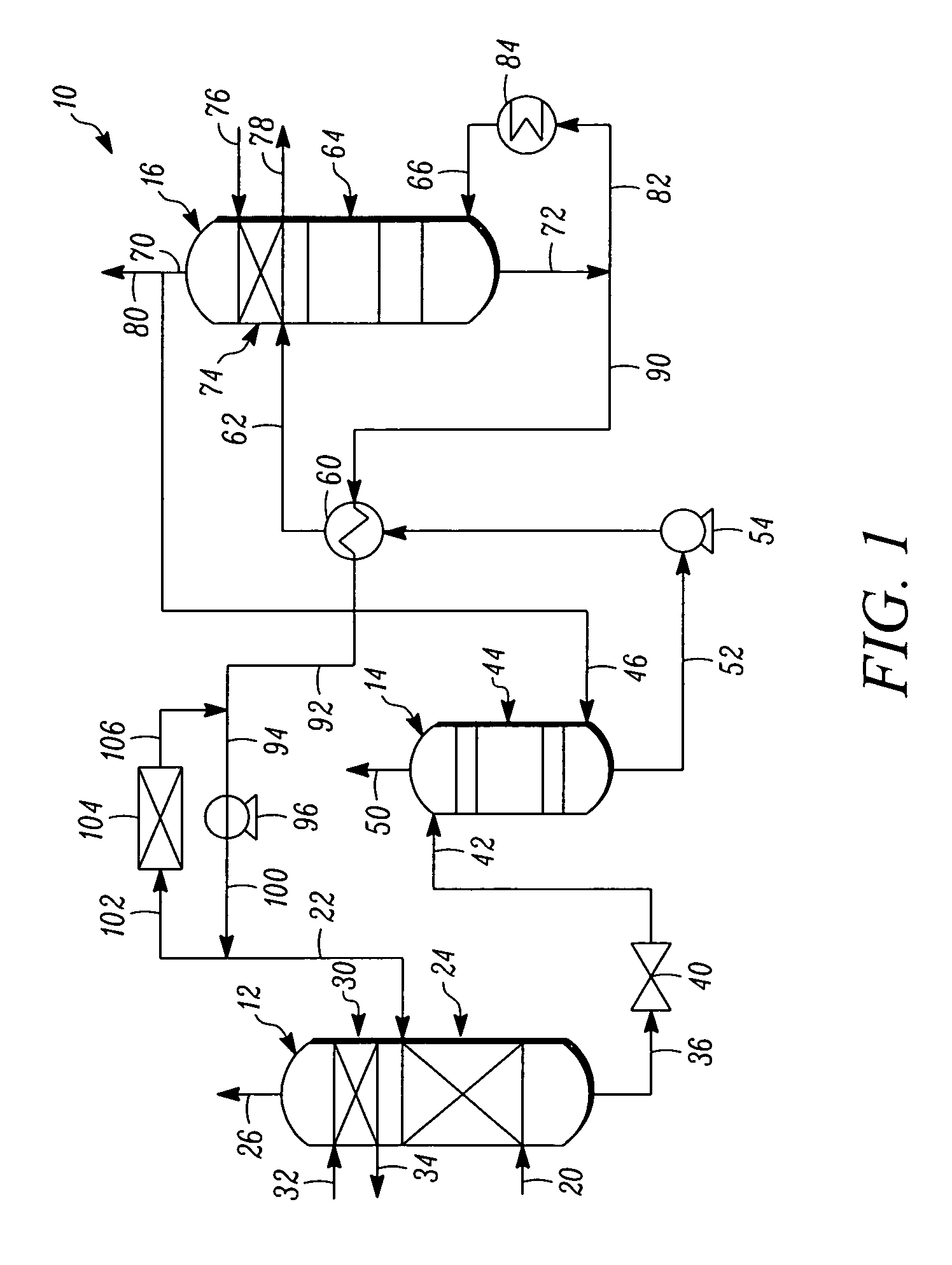

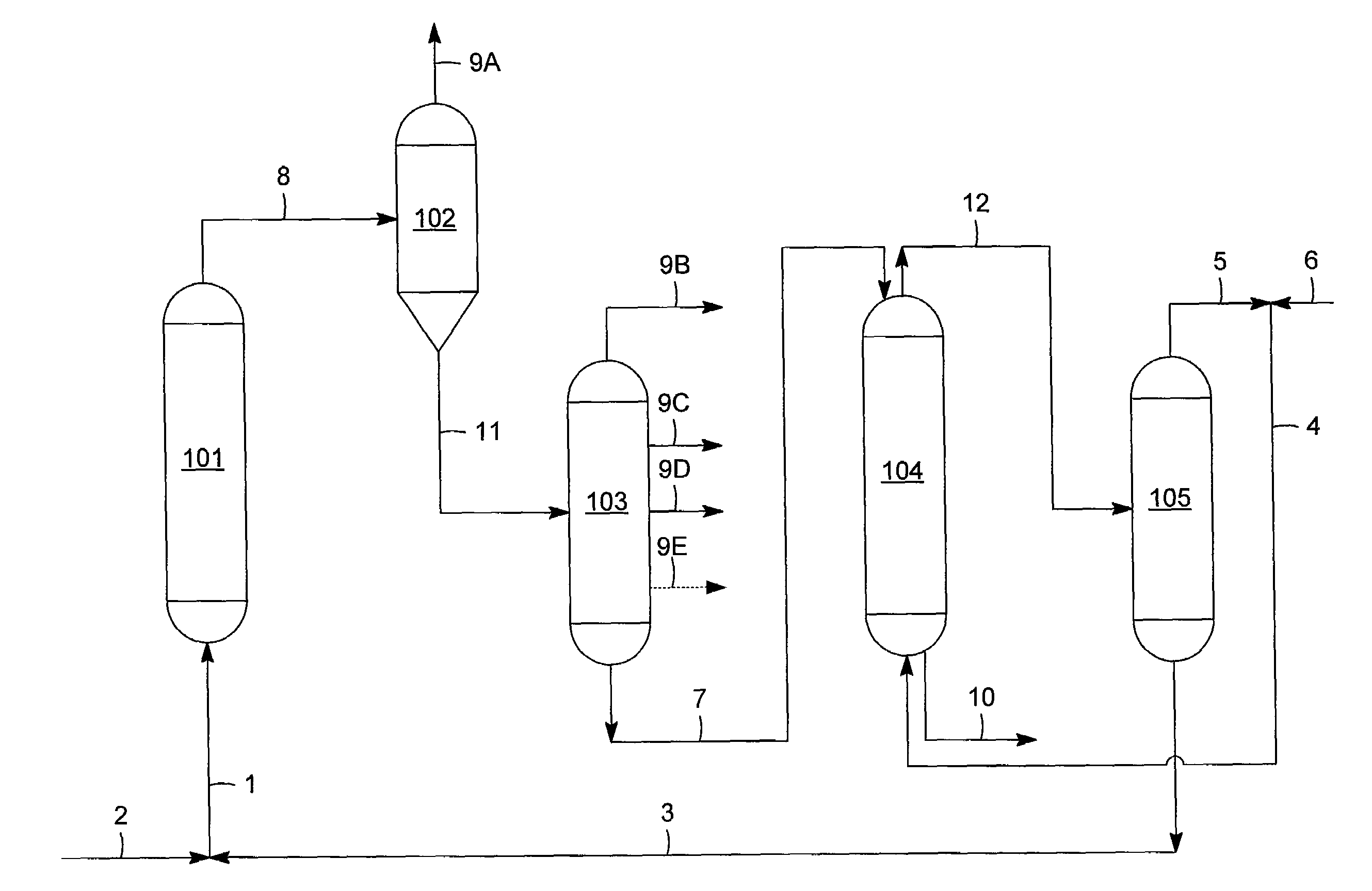

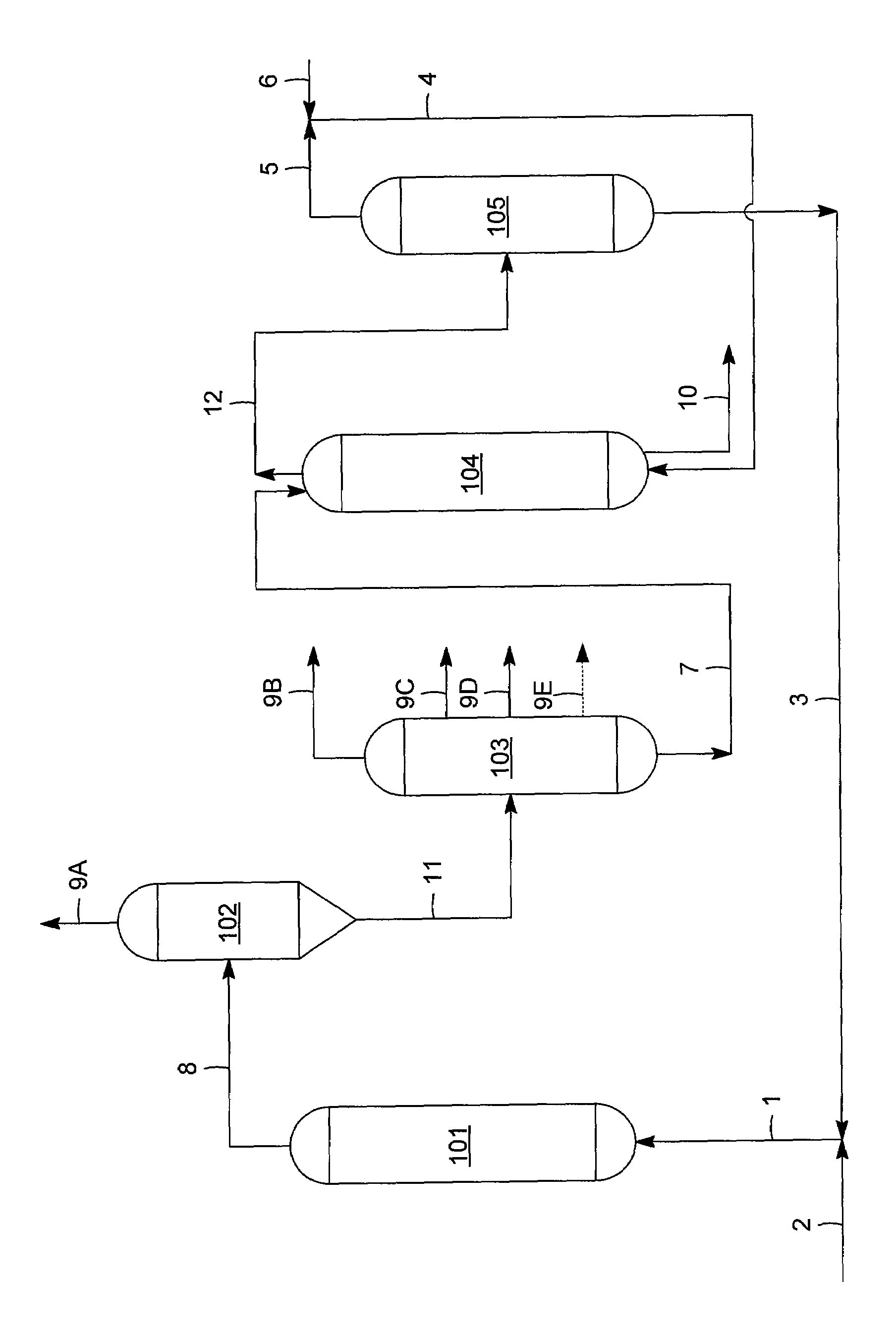

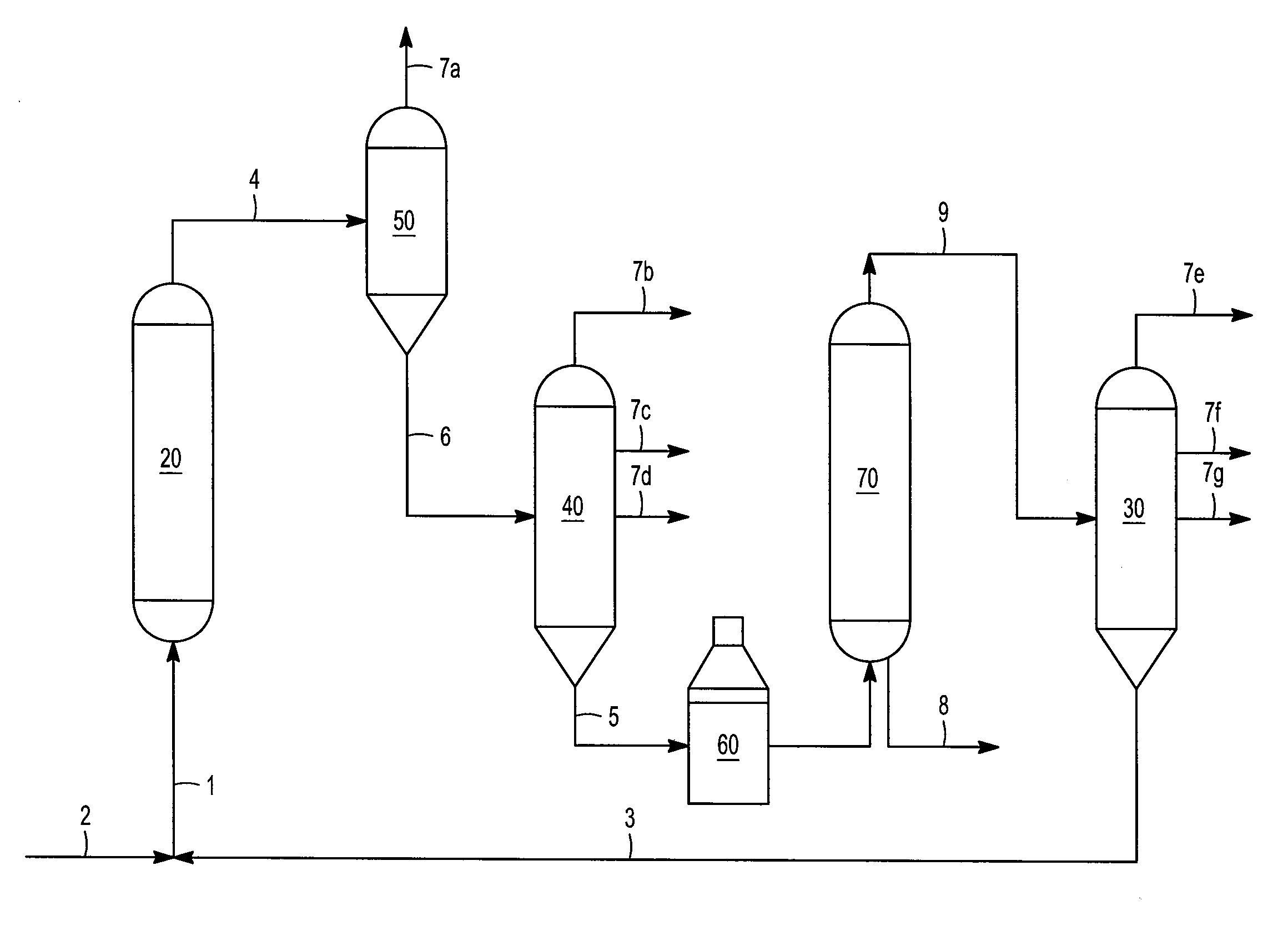

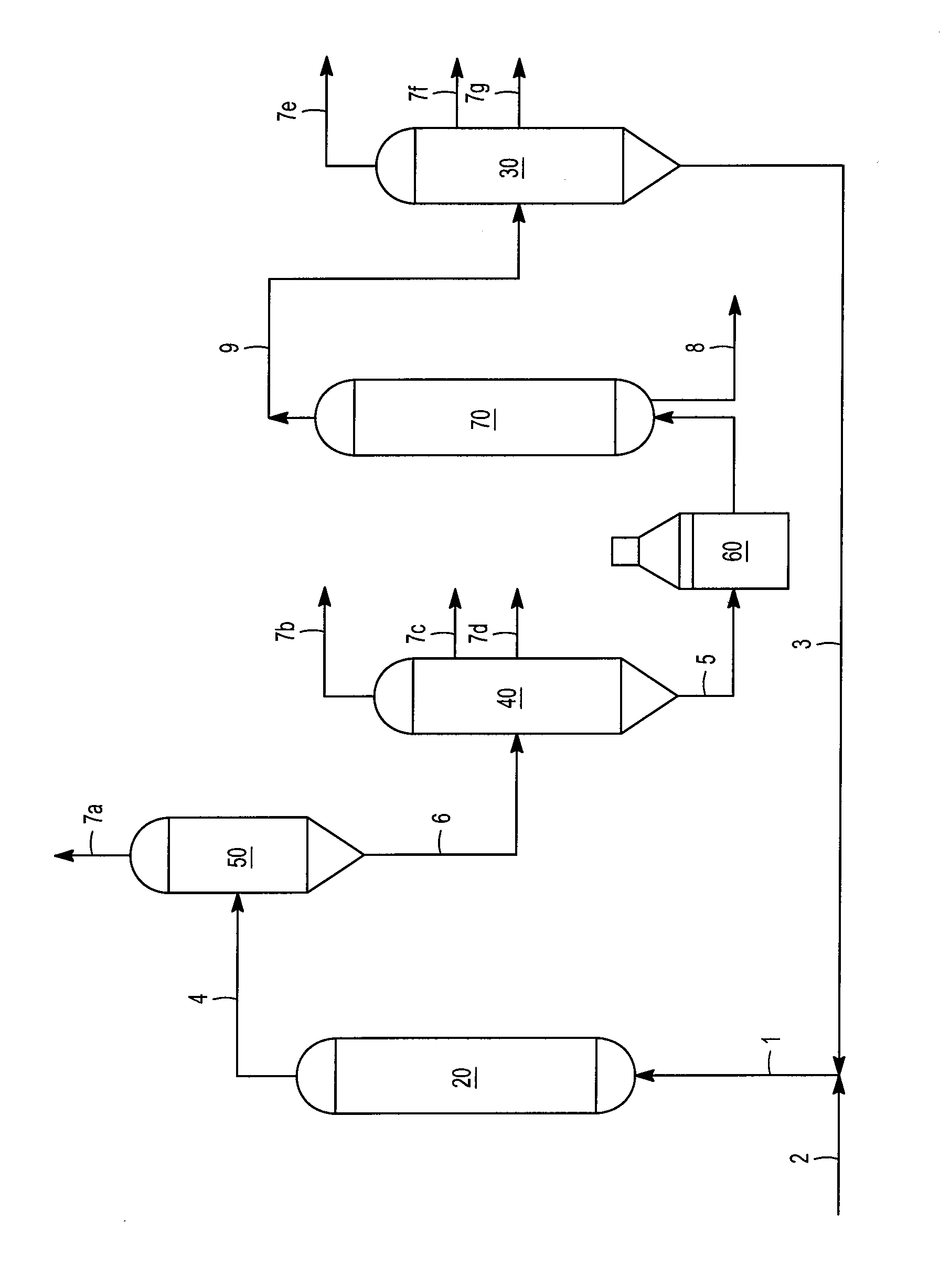

Process to produce aromatics from crude oil

ActiveUS20150321975A1Low impurity contentHigh API gravityThermal non-catalytic crackingTreatment with plural serial stages onlyVapor–liquid separatorWater flow

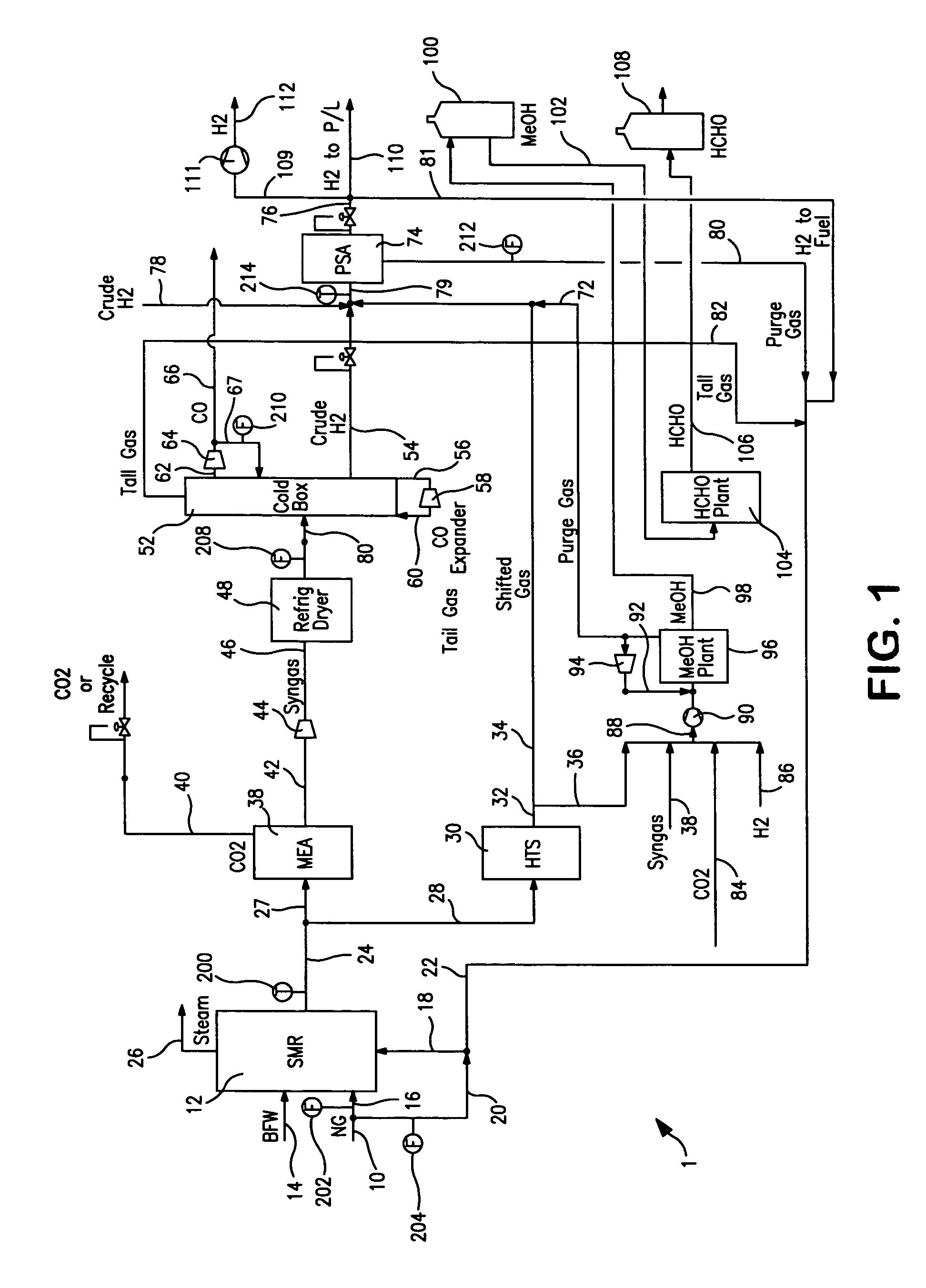

A process for producing aromatics from a hydrocarbon source in the presence of supercritical water comprising the steps of mixing a pressurized, pre-heated water stream with a pressurized, pre-heated petroleum feedstock, the pressurized, pre-heated water stream at a pressure above the critical pressure of water and a temperature above the critical temperature of water, feeding the combined stream to a supercritical water reactor to create a modified stream, cooling and depressurizing the modified stream, separating the depressurized stream in a vapor-liquid separator, condensing the vapor stream, separating the condensed stream into a water recovery stream and a light product recovery stream, extracting the aromatics from the light product recovery stream, depressurizing the liquid stream, separating the depressurized liquid stream in a heavy separator into an upgraded product stream, and recycling part of the upgraded product stream to the pressurized, pre-heated petroleum feedstock as a product recycle.

Owner:SAUDI ARABIAN OIL CO

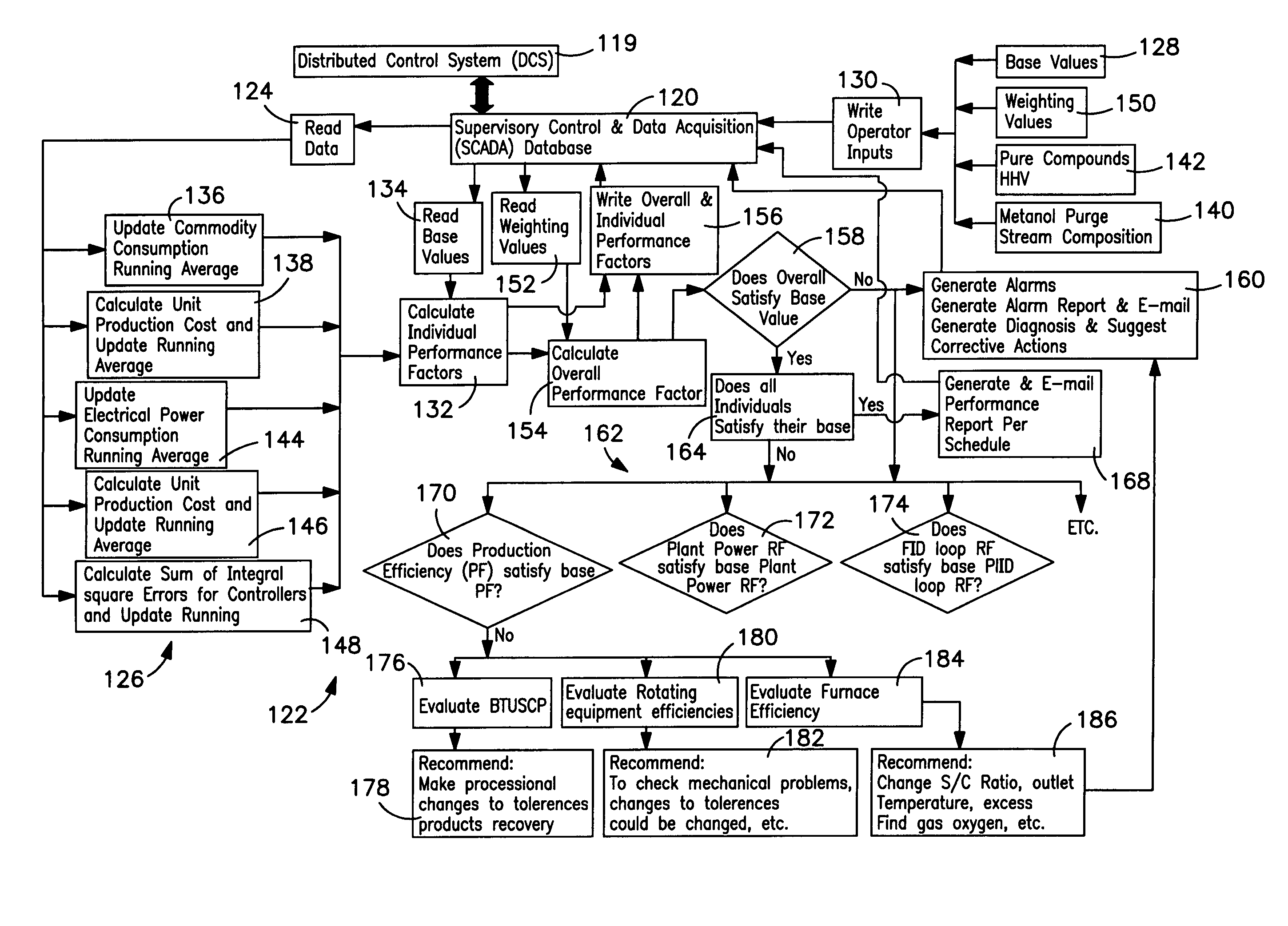

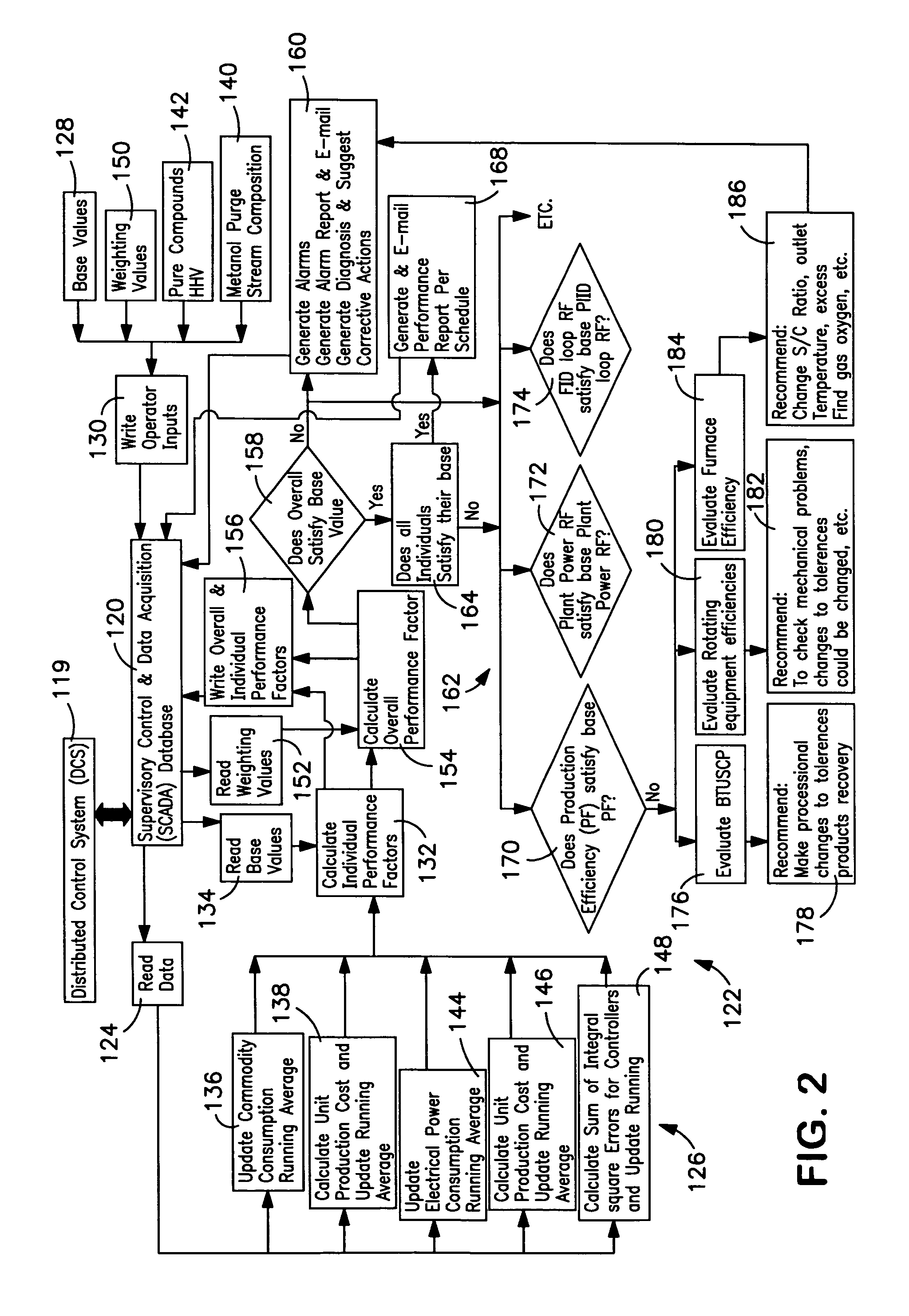

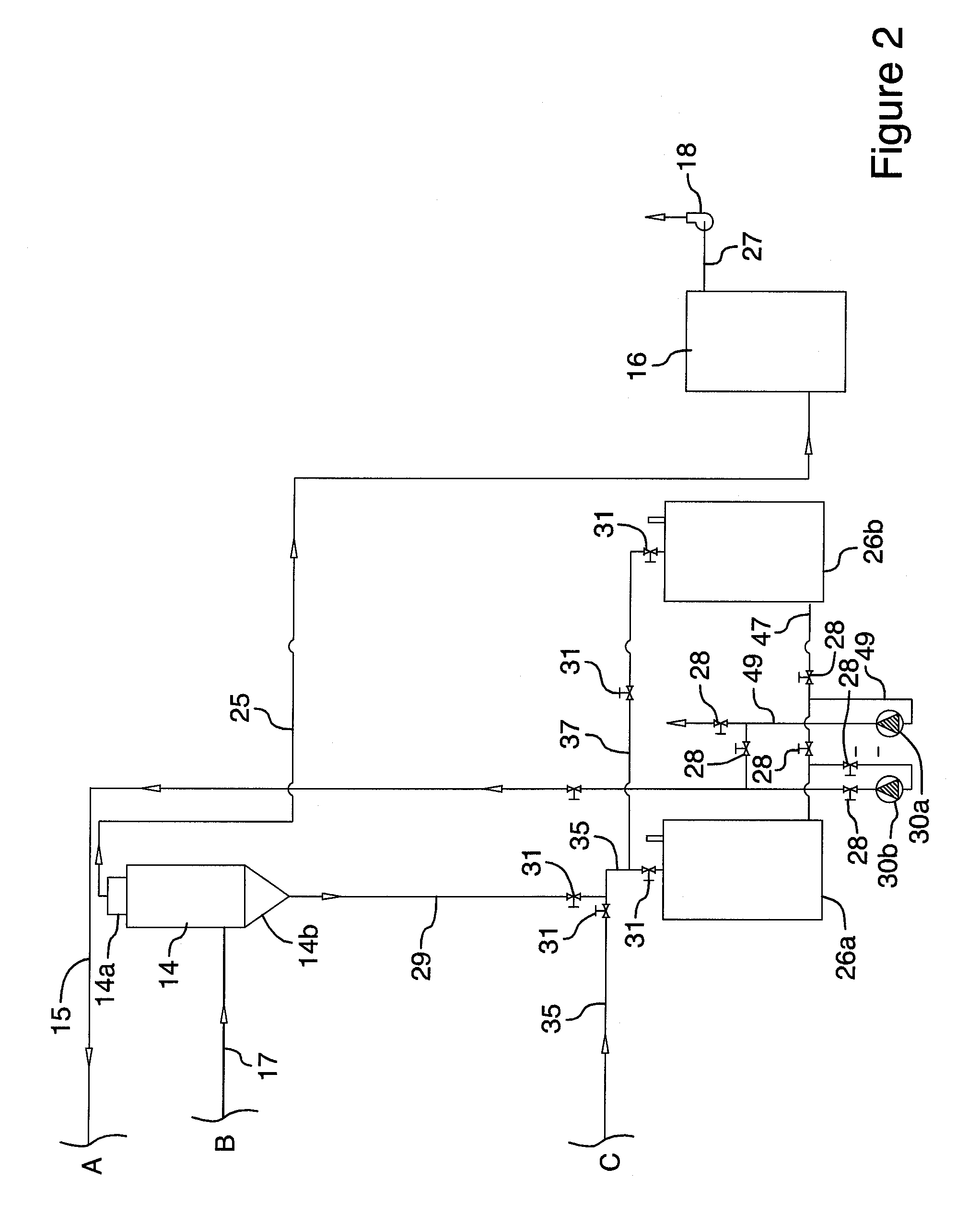

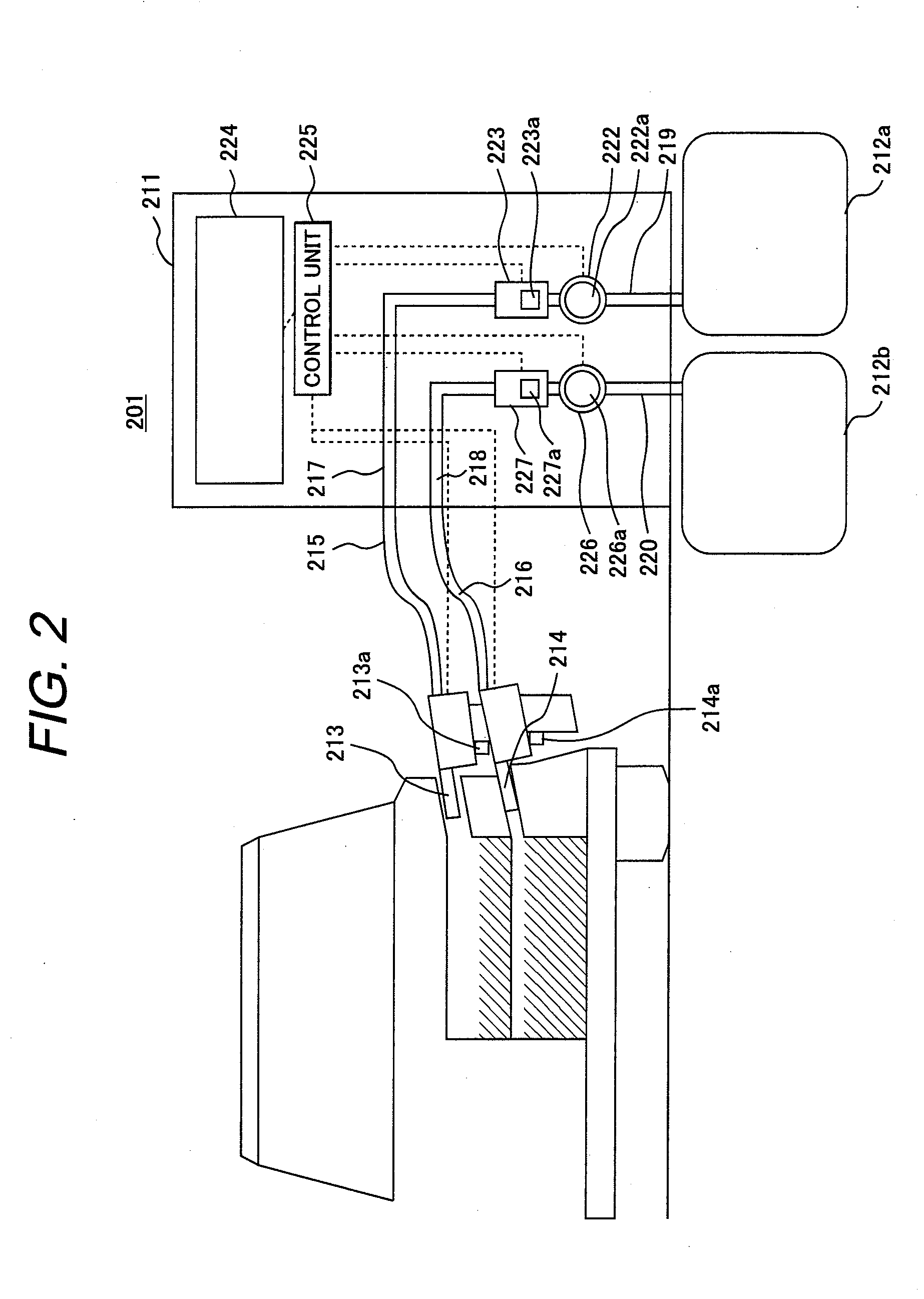

Facility monitoring method

ActiveUS6993403B1Testing/monitoring control systemsDigital computer detailsPower usageMonitoring methods

A method of monitoring plant performance within a facility in which having averages of cost contributing items such as raw material usage, product recovery, unit production efficiency, power usage and controller error performance are evaluated, statistically weighted to determine an overall performance factor. The overall performance factor applies an instantaneous indication of plant operation. Excursions of individual performance factors diagnose plant problems.

Owner:PRAXAIR TECH INC

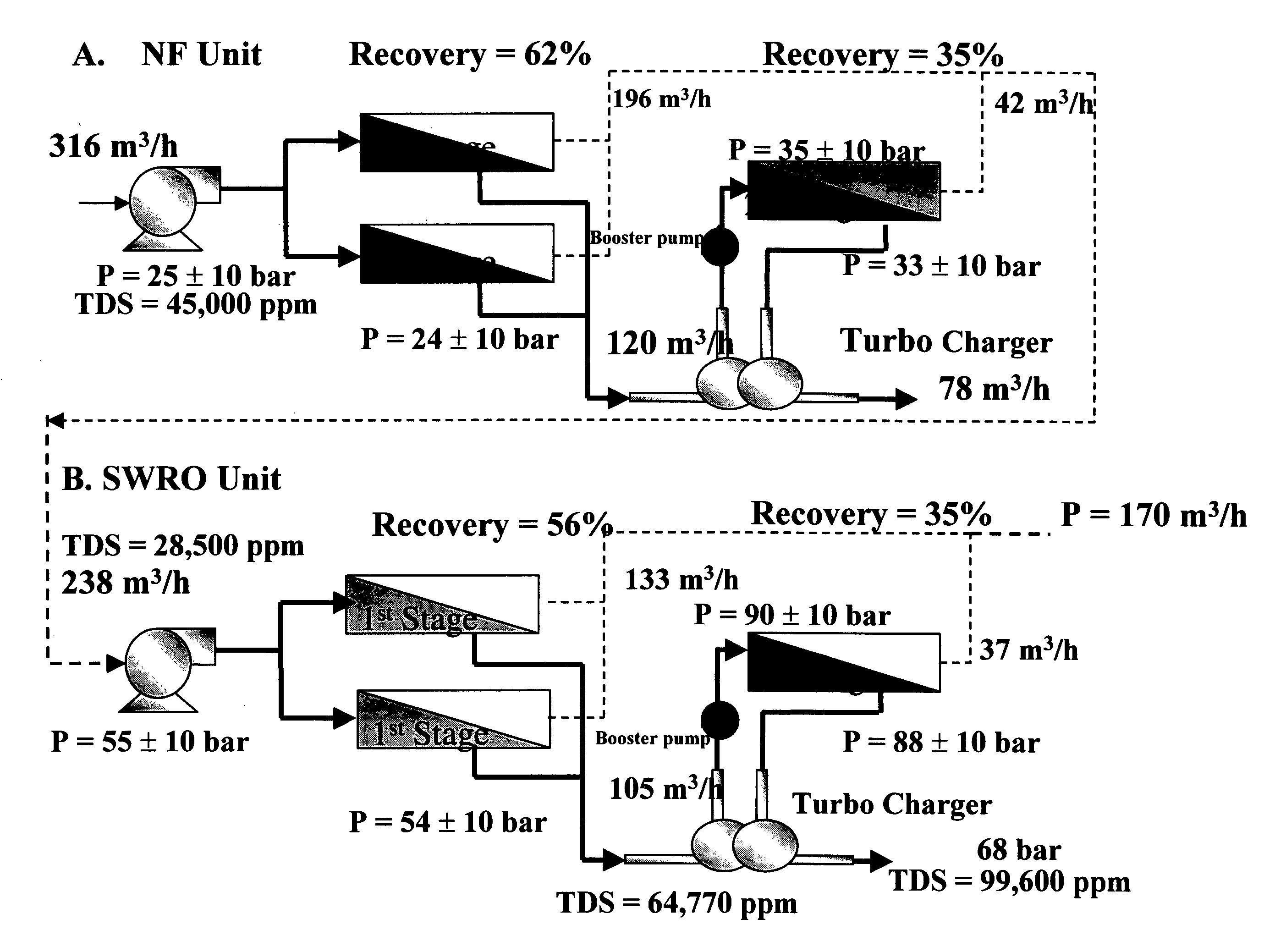

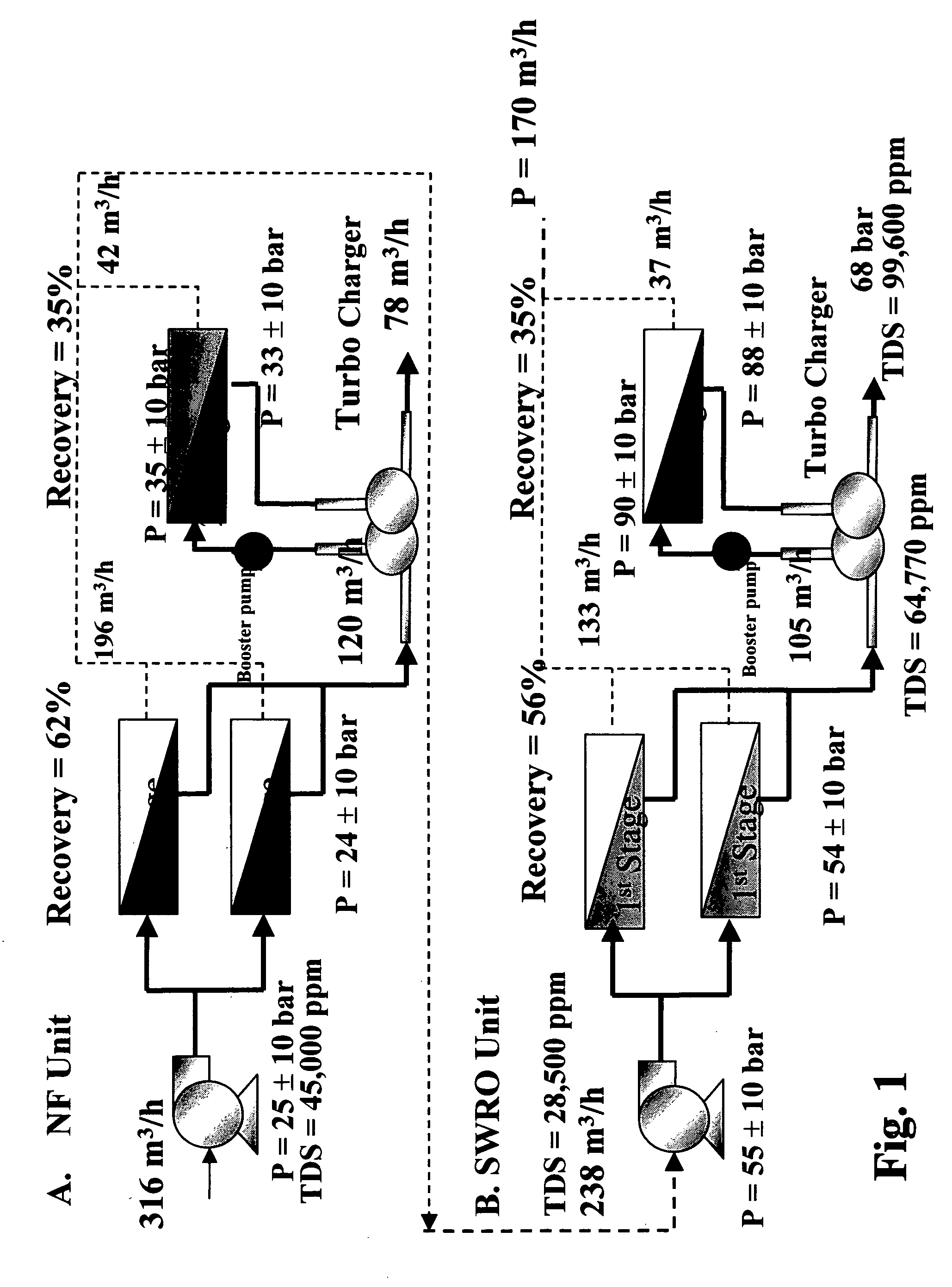

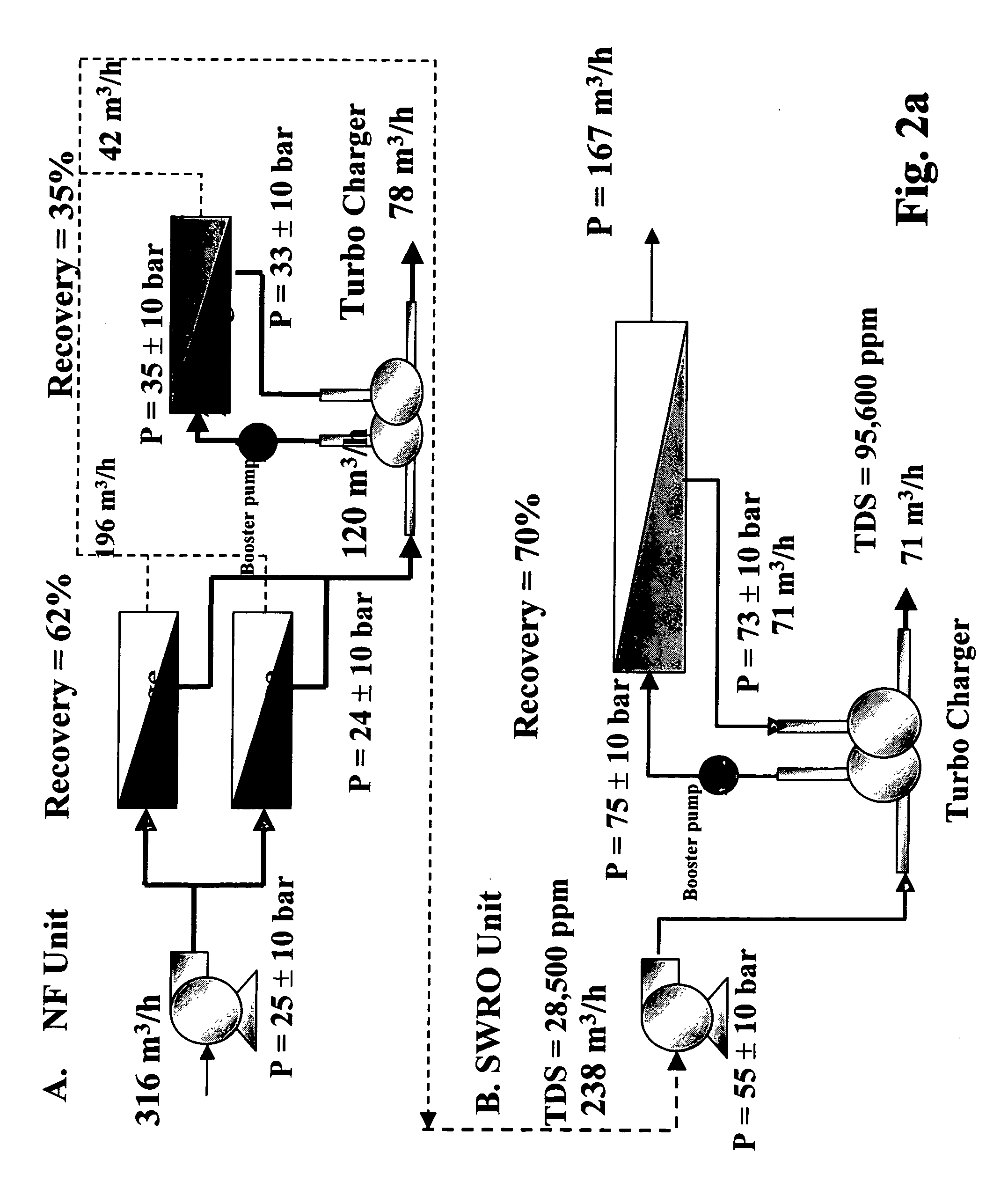

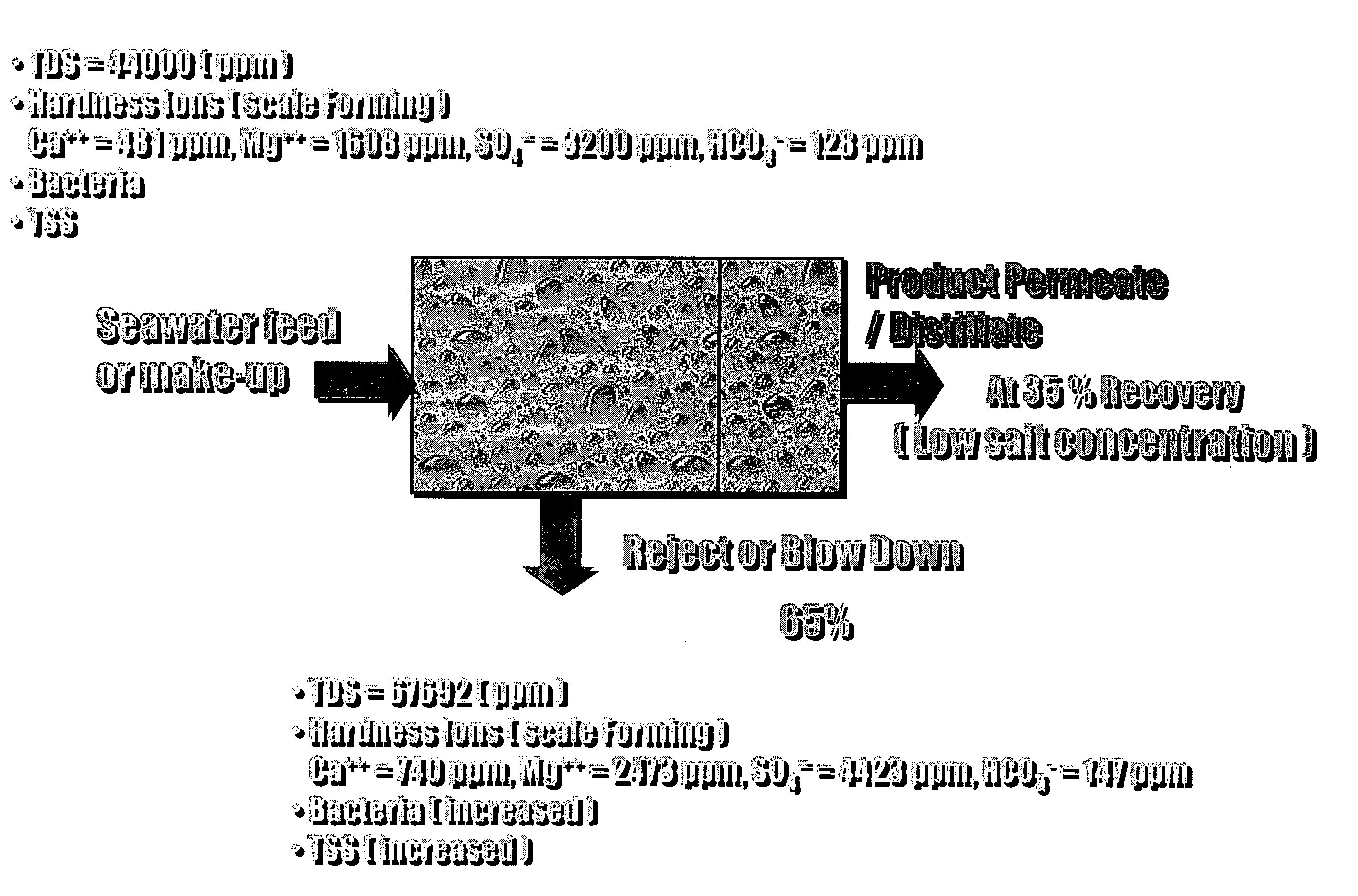

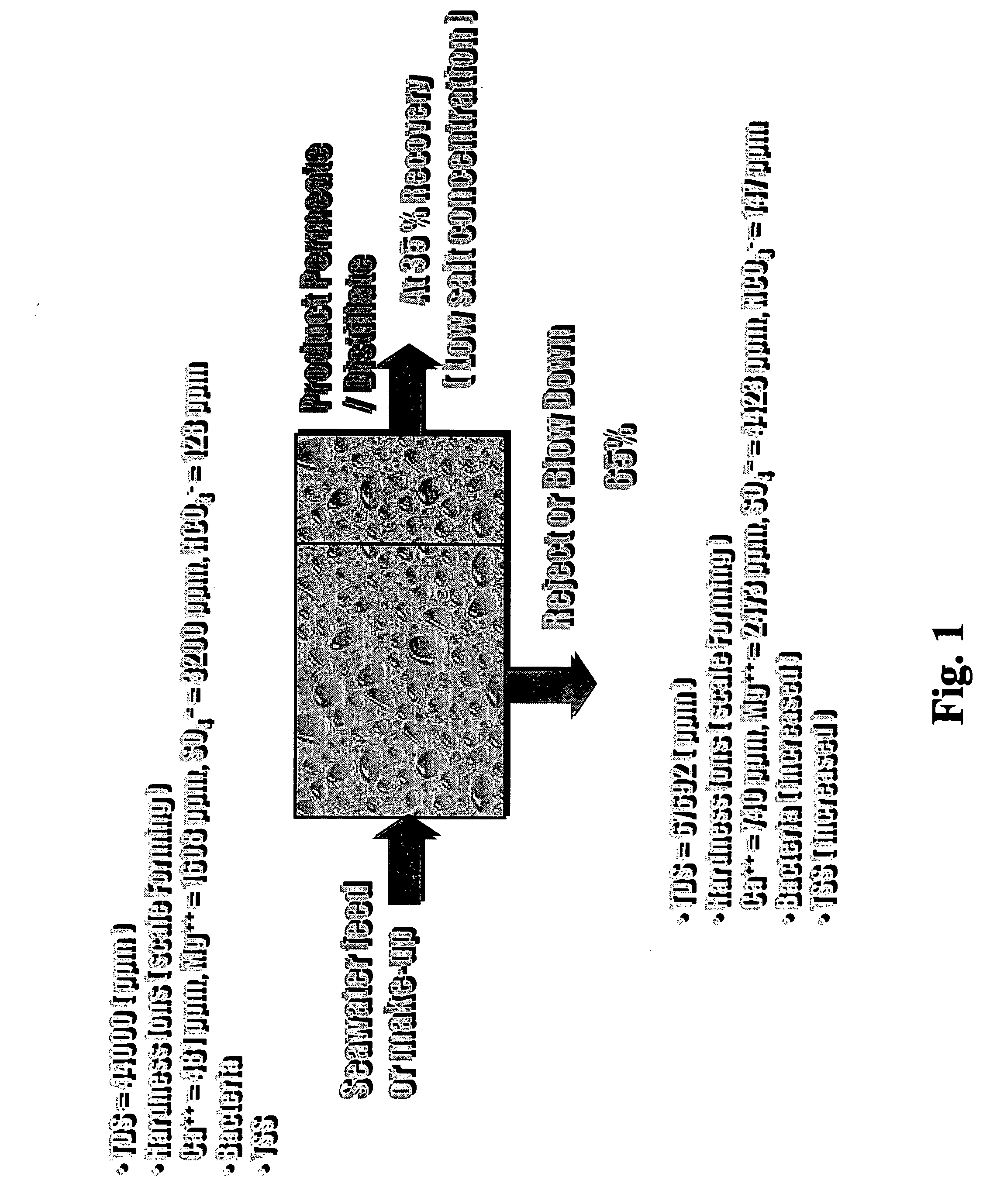

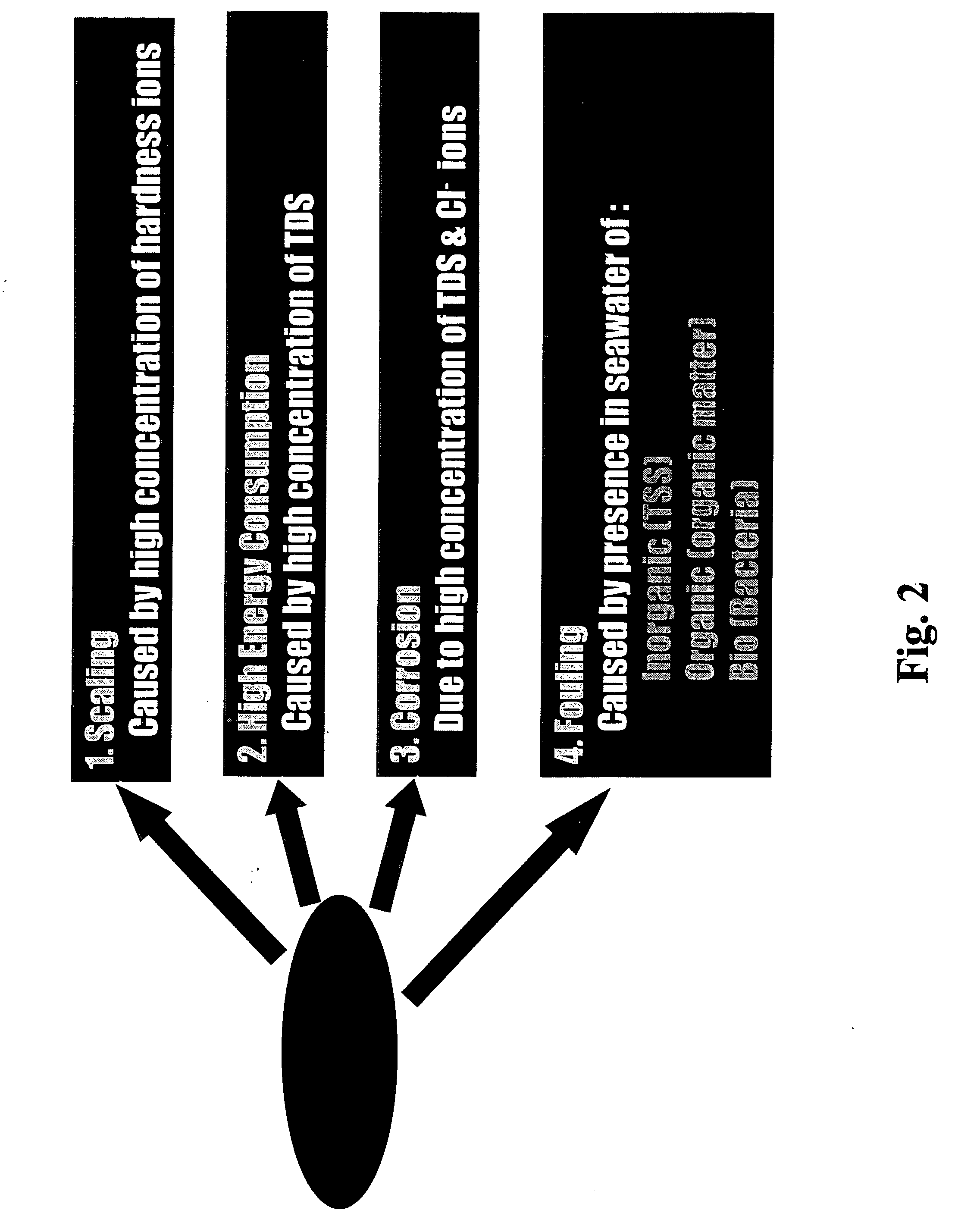

Fully integrated NF-thermal seawater desalination process and equipment

InactiveUS20060157410A1High yieldEffectively and efficiently dealGeneral water supply conservationReverse osmosisDistillationEngineering

An optimal thermal seawater desalination process is disclosed, which combines two or more substantially different water pretreatment processes in a unique manner and in a special configuration, hereto unknown to prior desalination arts, to produce a high yield of high quality fresh water, including potable water. In this process a two stage NF membrane pretreatment unit (NF2) with an energy recovery turbo charger (TC) device in between the stages or equipped with an energy recovery pressure exchanger (PX) is synergistically combined with at least one thermal desalination unit to form a dual hybrid of NF2-Thermal (FIG. 4 ), or alternatively the two stage NF2 unit is synergistically combined with a two stage SWRO unit (SWRO2) with an energy recovery TC in between the stages or combined with one stage SWRO (SWRO1) equipped with an energy recovery TC or PX system and the reject from the SWRO2 or SWRO1 unit is made make-up to a thermal unit to form a tri-hybrid of NF2-SWRO2 reject-Thermal (FIG. 5 ). In both the cases of di- or trihybrids the thermal unit is equivalent to a multistage flash distillation (MSFD) or multieffect distillation (MED) or vapor compression distillation (VCD) or thermal reheat (RH) evaporator. Typically a process of this invention using the two stage NF2 initial pretreatment step will perform a semi-desalination step by reducing feed TDS by about 35 to 50%, but most important, especially to the thermal seawater desalination process, it removes the water recovery limiting, scale forming hardness ions of Ca++ and Mg++ by better than 80% and their covalent anions of sulfate to better than 95% and bicarbonate to about 65%. The removal of scale forming hardness ions, especially SO4=, and bicarbonates allowed for the operation of thermal unit in the above hybrids at top brine temperature (TBT) much greater than its present TBT limit by the singular conventional process of 120° C. for MSFD and operation of MED or VCD or RH unit at TBT much higher than their present TBT limit of 65-70° C., with many advantages gained by this process over prior art sweater desalination processes. The process of this invention exceeds all prior thermal seawater desalination arts in efficiency, including water yield, product water recovery ratio and unit water cost as well as in energy consumption per unit product which is equivalent or less than other efficient prior art seawater thermal desalination processes. By this process, an NF product recovery ratio of 75 and 80% or better is achieved from the high salinity Gulf sea (TDS≈45,000 ppm) and about an equal product recovery ratio is also obtained from the SWRO or thermal unit when it is operated on NF product for a total water recovery ratio in excess of 52% for seawater

Owner:SALINE WATER CONVERSION CORP SWCC

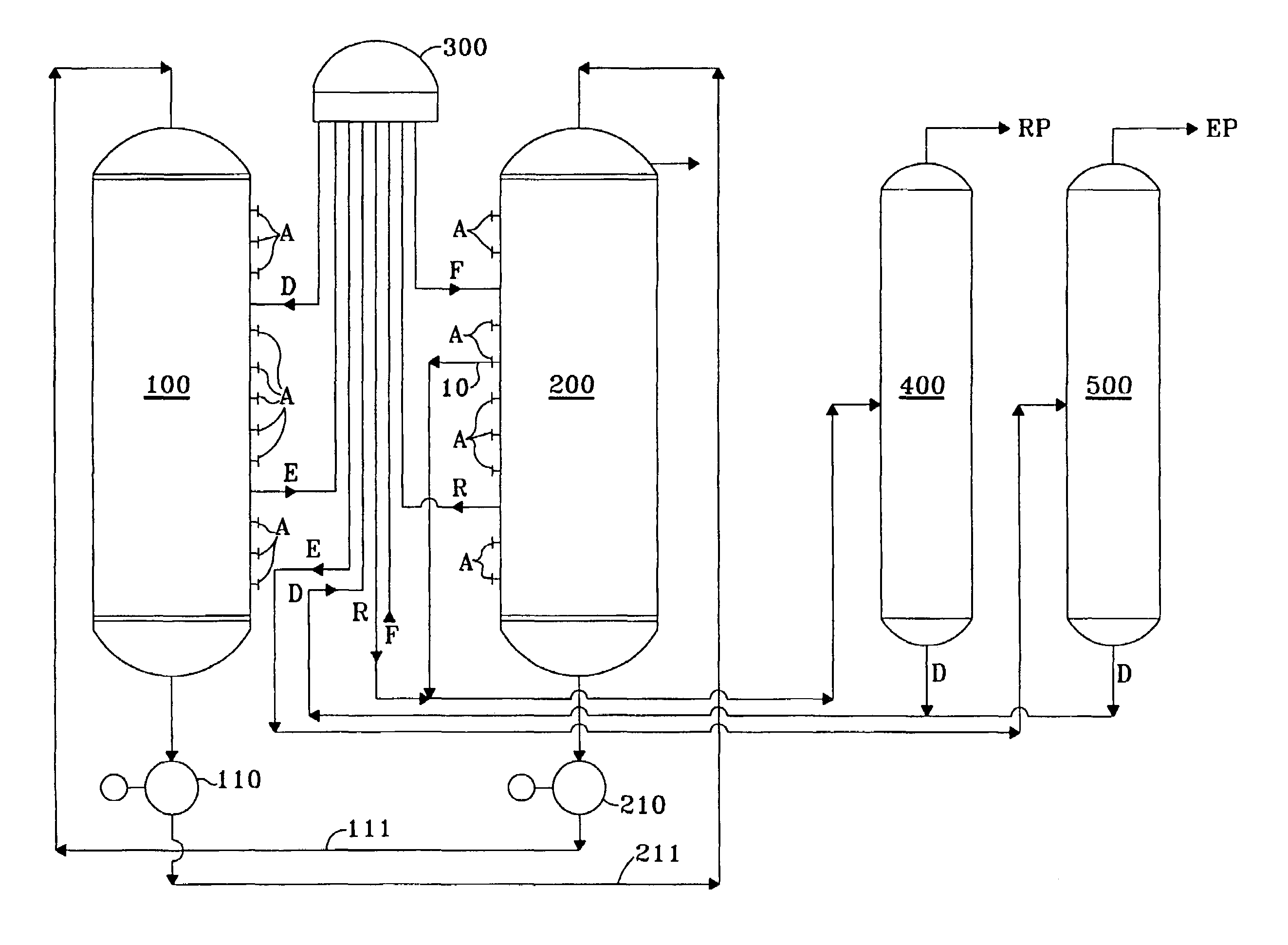

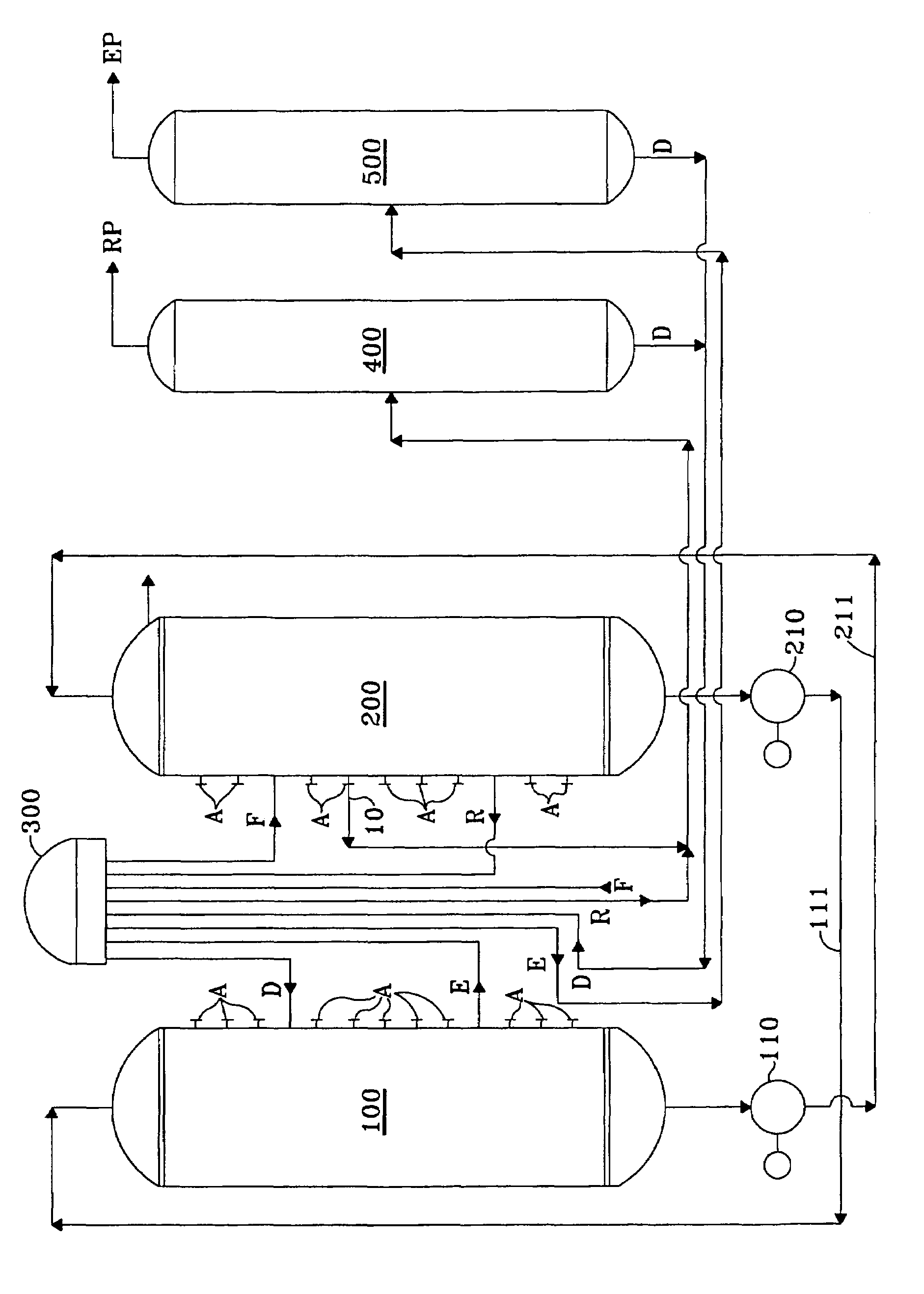

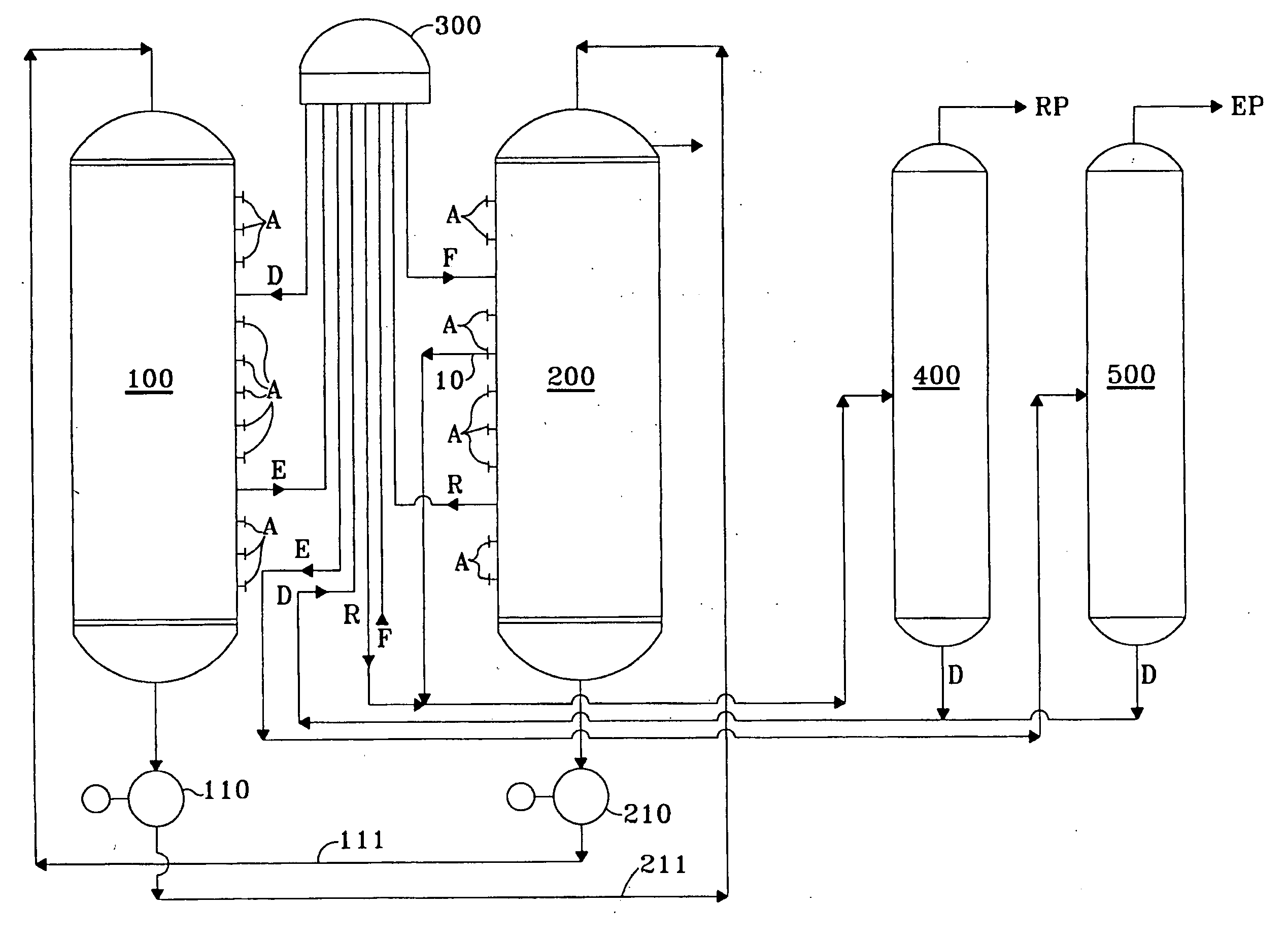

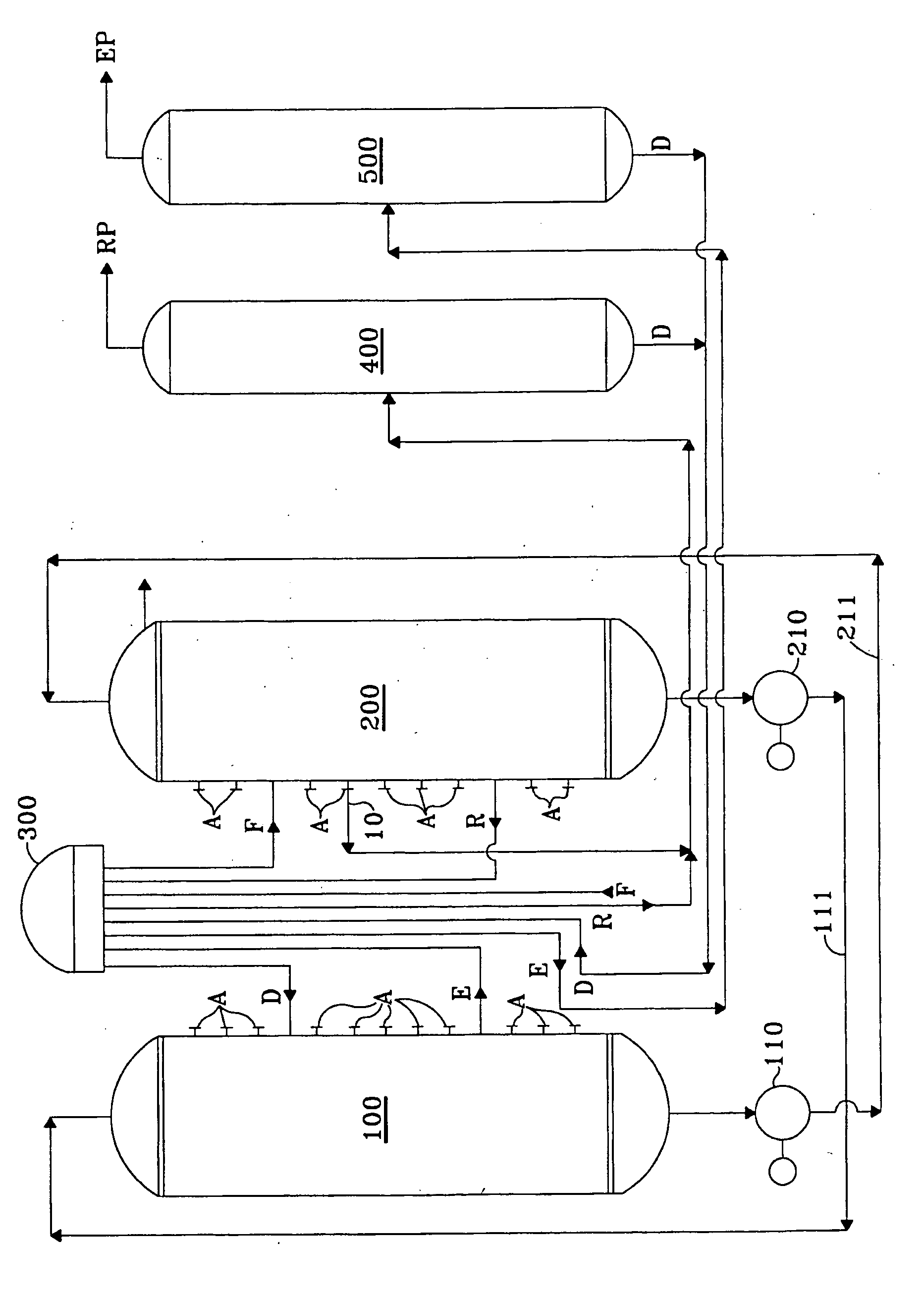

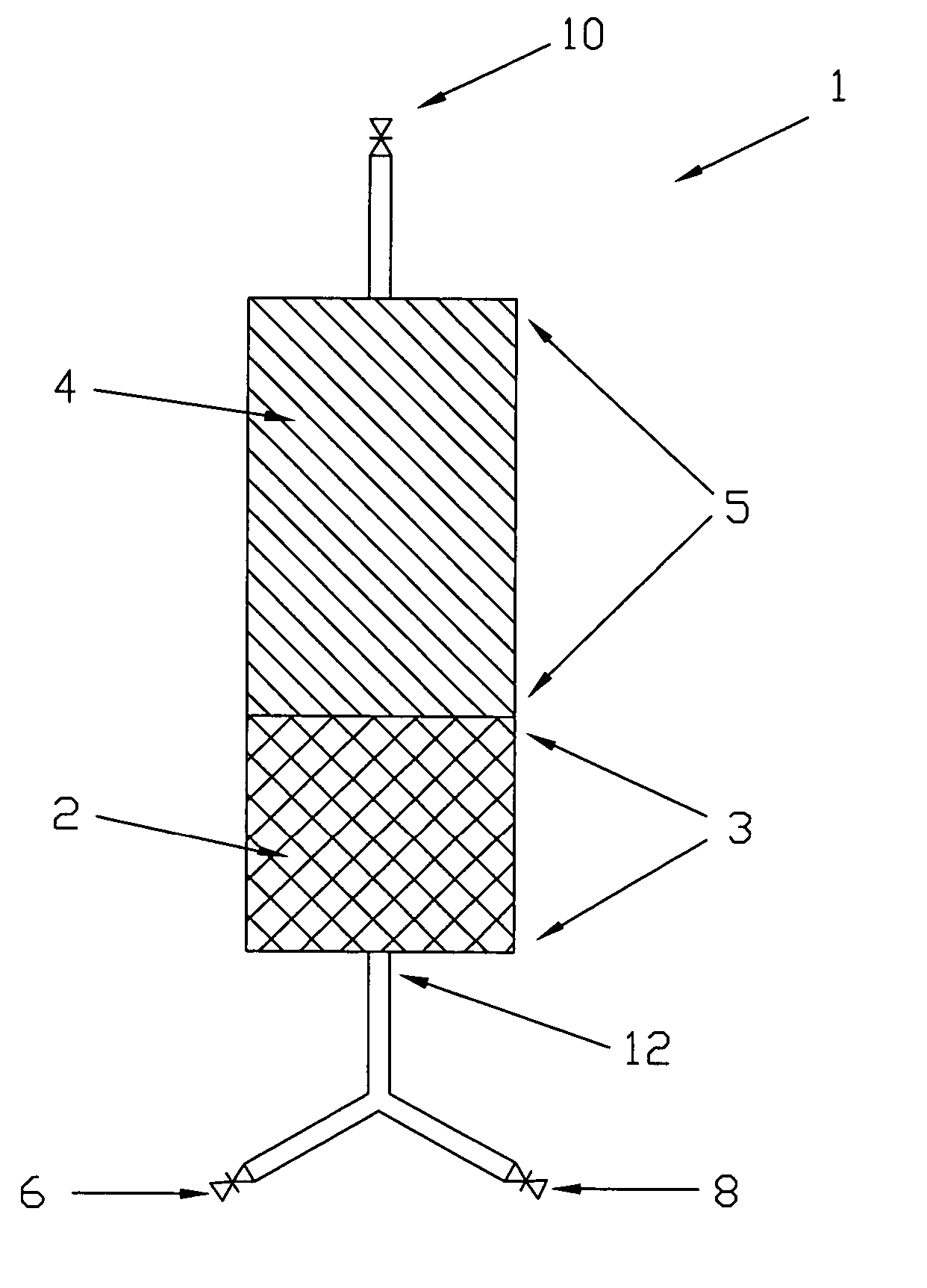

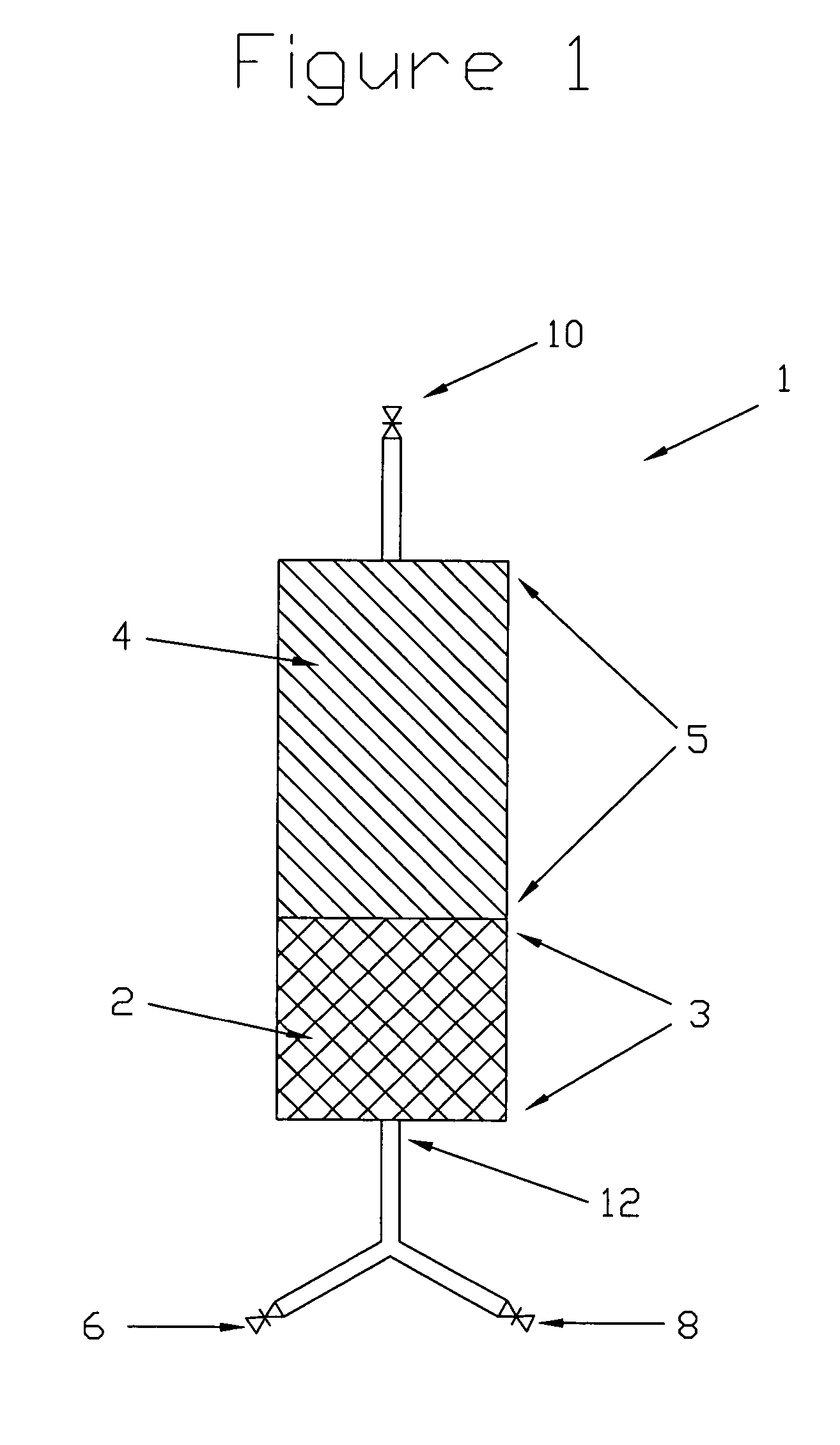

Product recovery from simulated-moving-bed adsorption

Product purity from or capacity of a simulated-moving-bed adsorptive separation process is increased by flushing the contents of the transfer line previously used to remove the raffinate stream away from the adsorbent chamber, preferably into the raffinate column used to separate desorbent from raffinate product. Preferably a stream from the adsorbent chamber at an intermediate point between the feed entry point and raffinate withdrawal is used as the flushing liquid. This flush step eliminates the passage of a quantity of the raffinate material into the adsorbent chamber in the transfer-line flush period or when the process conduit is subsequently used to charge the feed stream to the adsorbent chamber.

Owner:UOP LLC

Hydrocarbon synthesis

InactiveUS20050171393A1Valid conversionMolecular sieve catalystLiquid hydrocarbon mixtures productionHydrogen halideOxygen

A method of synthesizing hydrocarbons from smaller hydrocarbons includes the steps of hydrocarbon halogenation, simultaneous oligomerization and hydrogen halide neutralization, and product recovery, with a metal-oxygen cataloreactant used to facilitate carbon-carbon coupling. Treatment with air or oxygen liberates halogen and regenerates the cataloreactant.

Owner:REACTION 35 LLC

Methods for integrated fast pyrolysis processing of biomass

ActiveUS8100990B2Minimizes water contentImprove collection efficiencyDirect heating destructive distillationBiofuelsPre treatmentSafe handling

Methods, process, apparatus, equipment, and systems are disclosed for converting biomass into bio-oil fractions for chemicals, materials, feedstocks and fuels using a low-cost, integrated fast pyrolysis system. The system improves upon prior art by creating stable, bio-oil fractions which have unique properties that make them individually superior to conventional bio-oil. The invention enables water and low-molecular weight compounds to be separated into a final value-added fraction suitable for upgrading or extracting into value-added chemicals, fuels and water. Initial bio-oil fractions from the process are chemically distinct, have low-water content and acidity which reduces processing costs normally associated with conventional bio-oil post-production upgrading since fewer separation steps, milder processing conditions and lower auxiliary inputs are required. Biochar is stabilized so that it can be handled safely. The integrated fast pyrolysis process includes biomass storage, preparation, pretreatment, and conversion, product recovery and processing to create and store stable biochar and bio-oil fractions.

Owner:AVELLO BIOENERGY

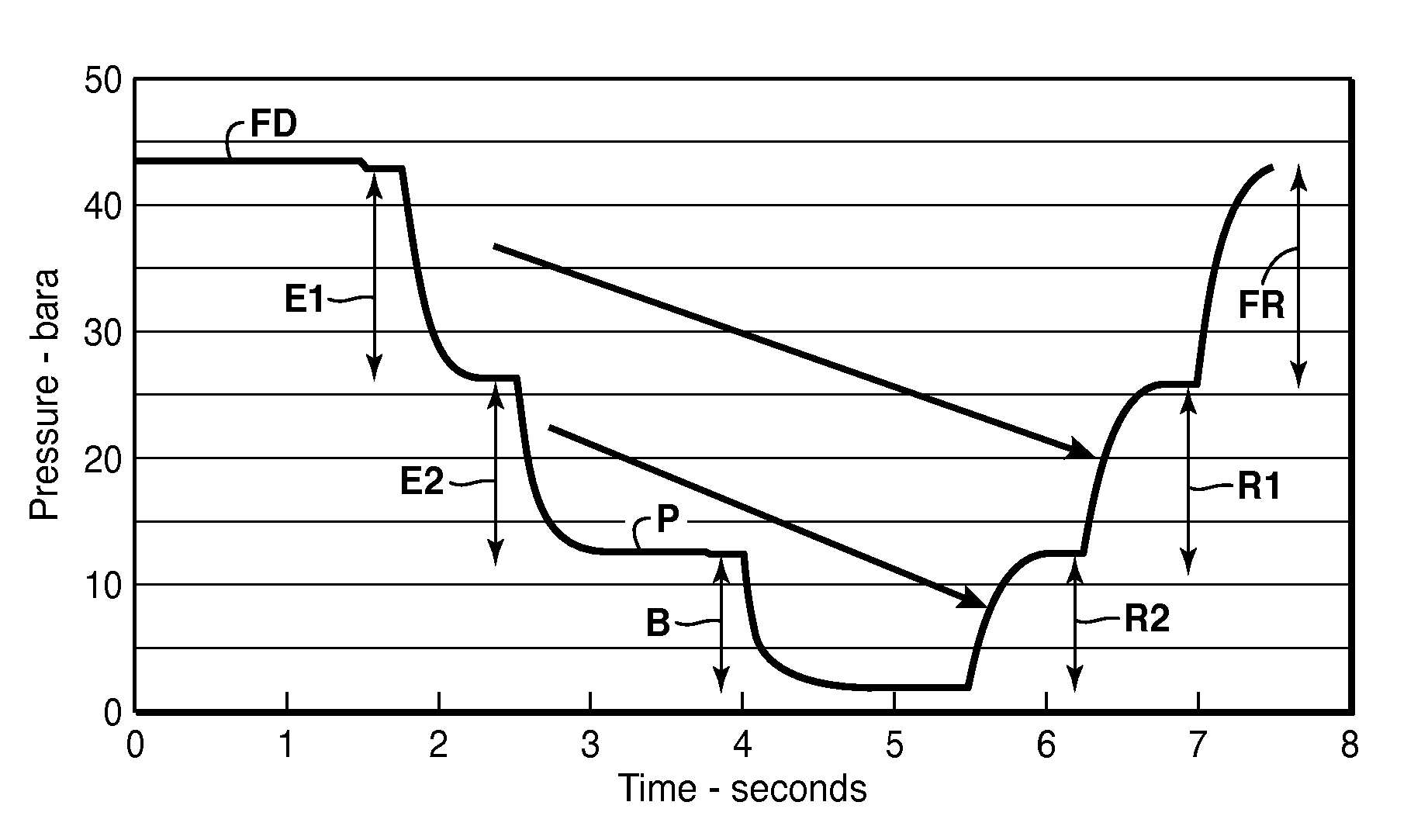

Adsorptive separation of gas streams

Owner:AIR PROD & CHEM INC

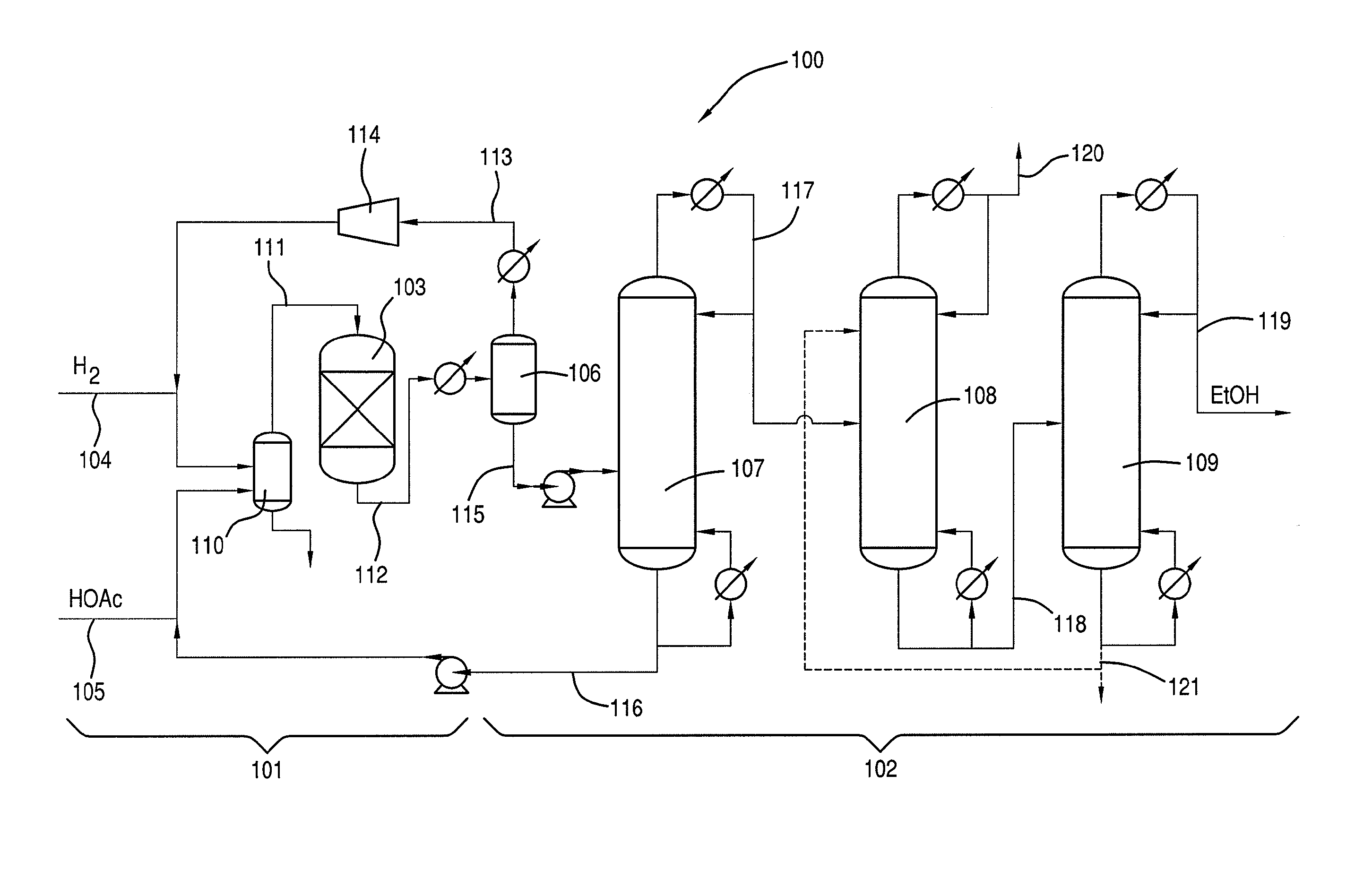

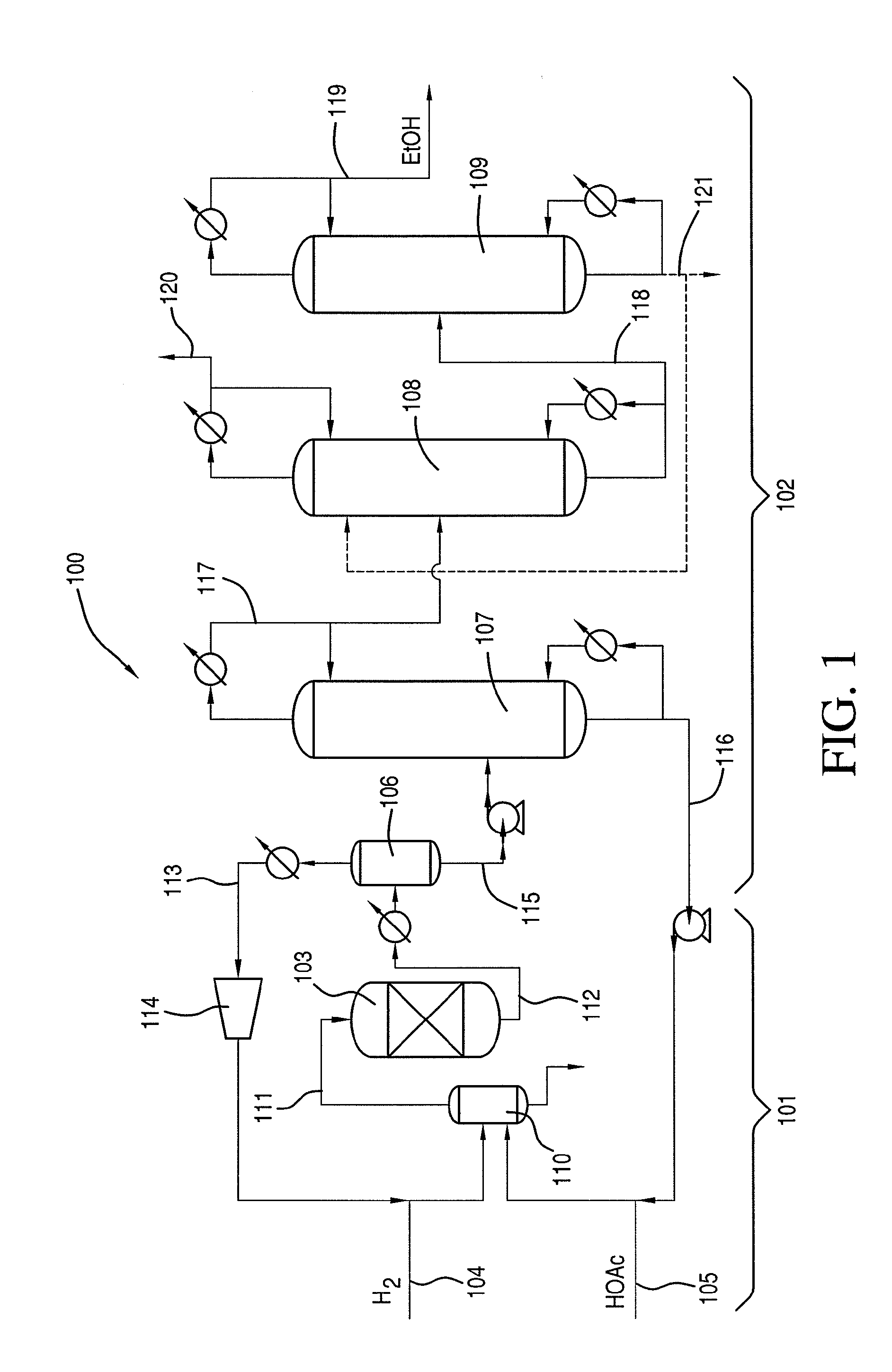

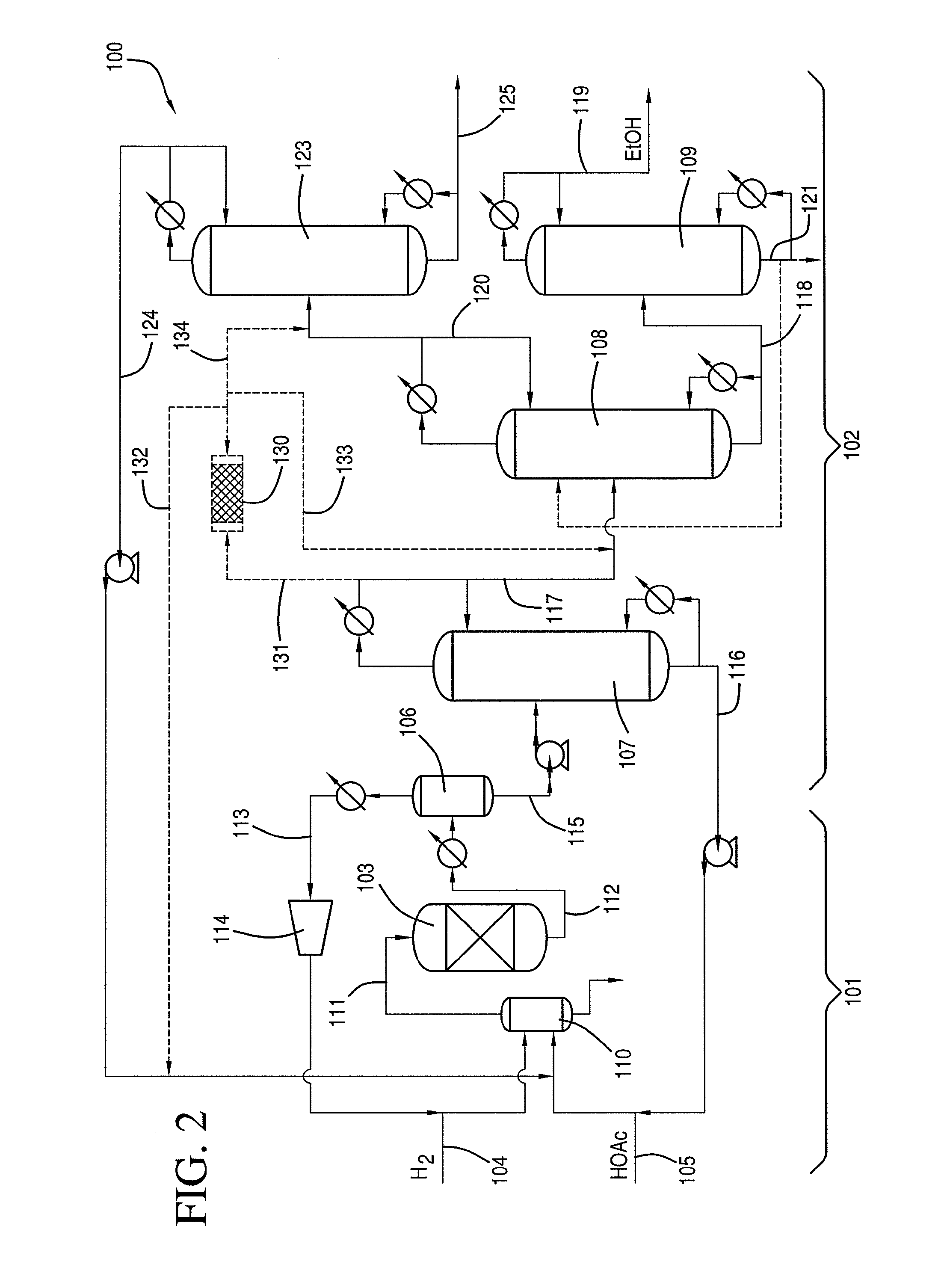

Process for purifying a crude ethanol product

InactiveUS20110275862A1Organic compound preparationOxygen compounds preparation by reductionAcetic acidImpurity

Owner:CELANESE INT CORP

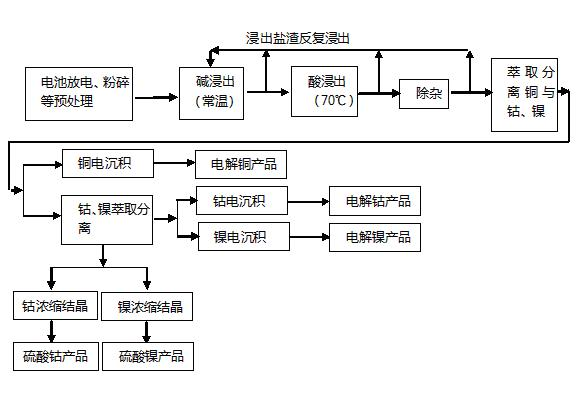

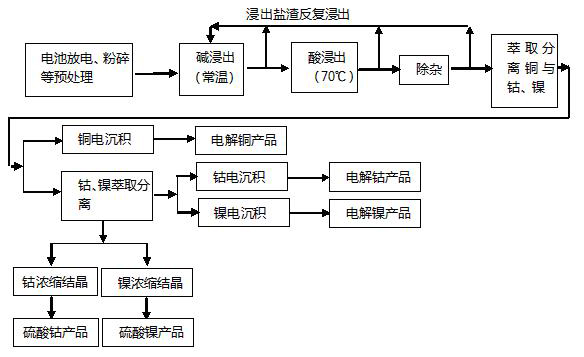

Process for recovering valuable metals from waste lithium batteries

InactiveCN102162034ASimple processReduce energy consumptionProcess efficiency improvementCopperPre treatment

The invention relates to a process for recovering valuable metals from waste lithium batteries, comprising the processing steps of pretreatment, a leaching process, chemical subtraction, extraction separation and the like, thus realizing comprehensive recovery of valuable metals such as cobalt, copper, nickel, aluminum and the like. The invention has the advantages of simple process, low energy consumption and high product recovery rate.

Owner:常州今创博凡能源新材料有限公司 +1

Optimal high recovery, energy efficient dual fully integrated nanofiltration seawater reverse osmosis desalination process and equipment

InactiveUS20060157409A1Reduce yieldHigh water recoveryMembranesSeawater treatmentTurbochargerWater production

An optimal two stage NF2 membrane pretreatment unit is synergistically combined with a following two stage SWRO2 desalination unit, where each of the two stage NF2 and SWRO2 has an energy recovery device (ERD) turbocharger (TC) in between the stages to form a dual hybrid of NF2-SWRO2 (FIG. 1 ); alternatively the two stage NF2 unit is synergistically combined with one stage ERD equipped SWRO, unit operated at up to 85 bar (FIG. 2 a, b); or the two stage NF2 unit combined with one stage ERD equipped SWRO1 unit, with part of its reject recycled constituting part of the feed to the NF units (FIG. 3 a,b). The process of this invention raises significantly the product water recovery ratio, producing SWRO hybrids that exceed all prior arts in efficiency, including water yield, product recovery ratio, dramatically reduces both the energy consumption and water production unit cost.

Owner:SALINE WATER CONVERSION CORP SWCC

Methods of removing contaminants from hydrocarbon stream by swing adsorption and related apparatus and systems

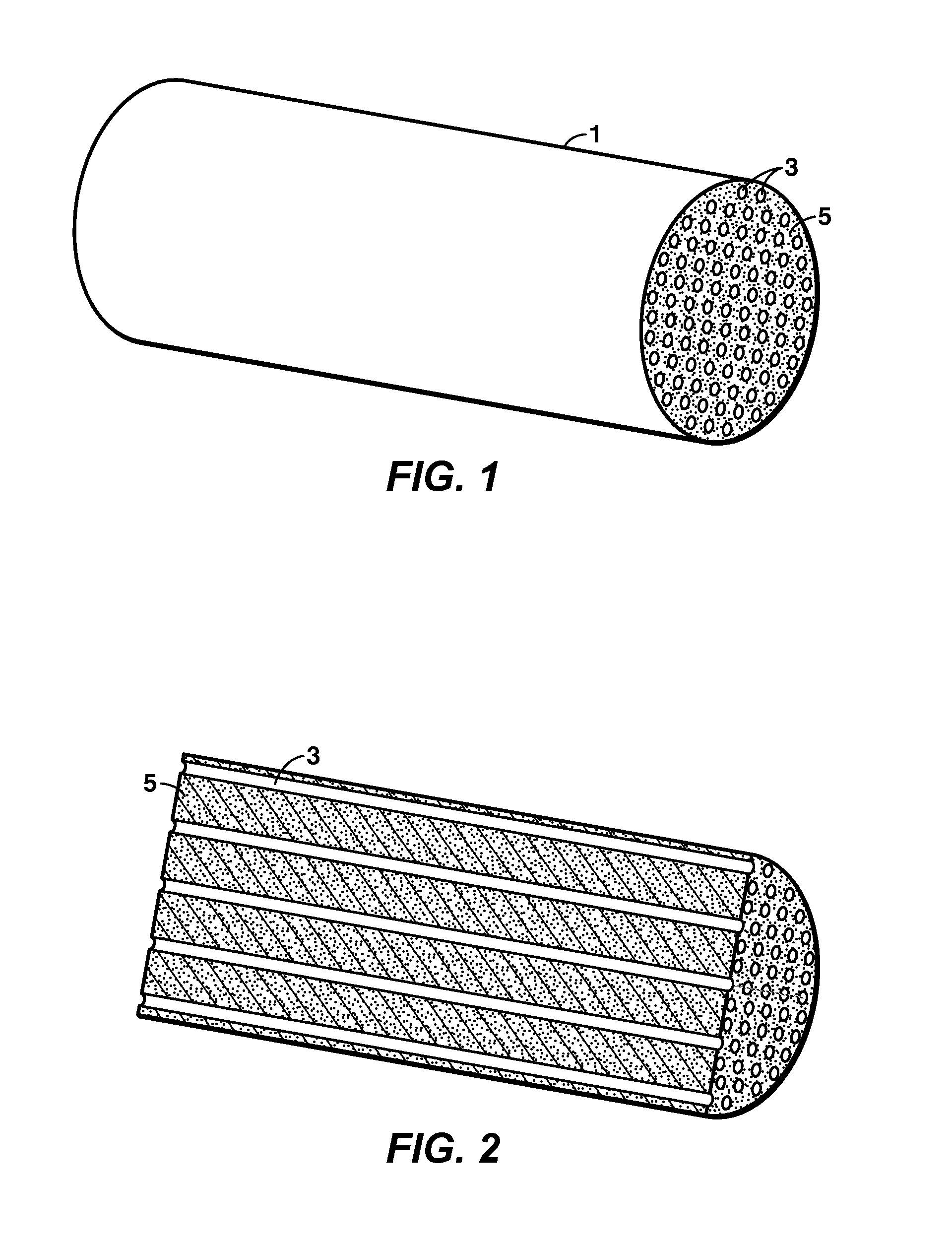

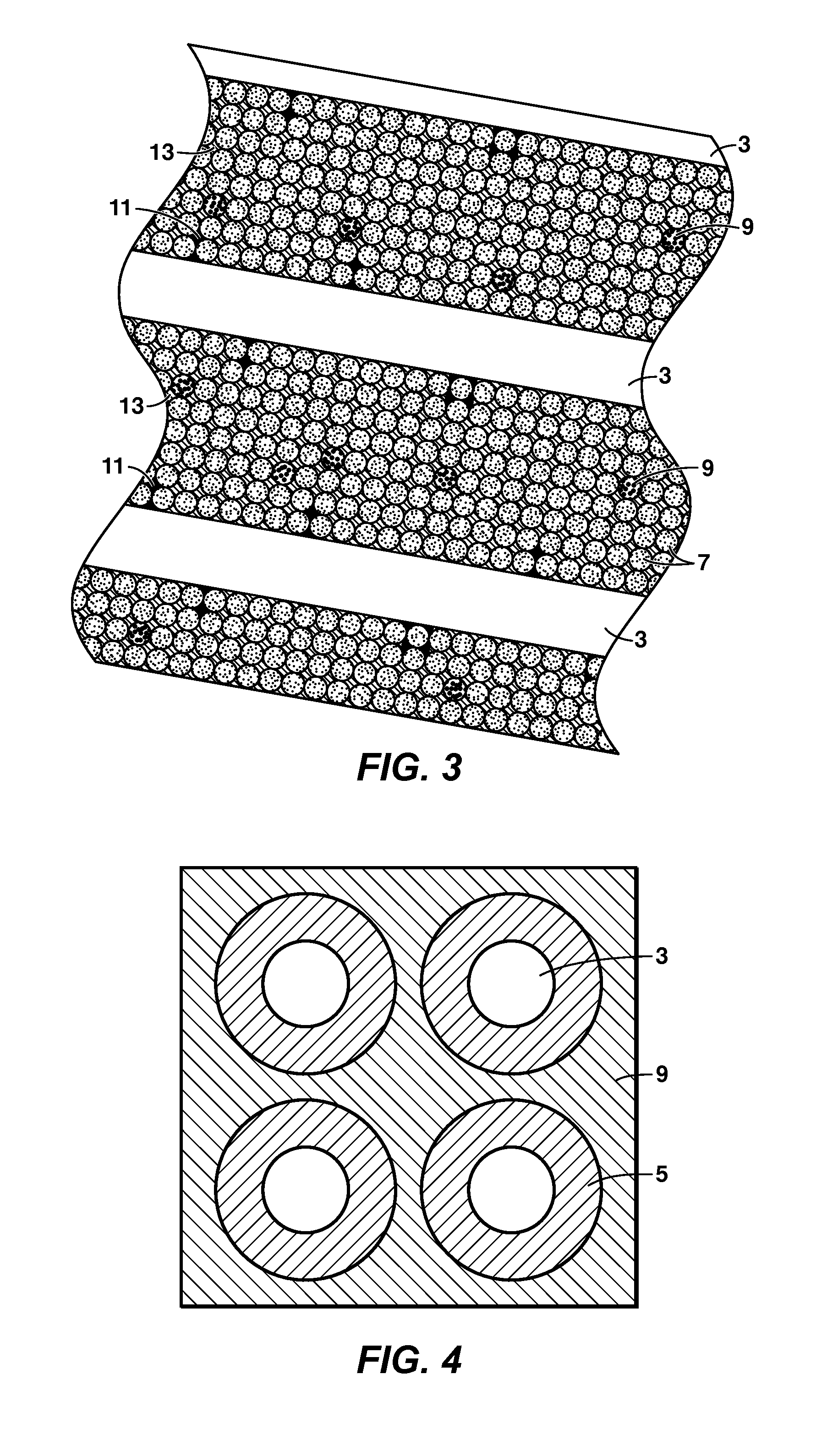

A pressure swing adsorption process for removal of CO2 from natural gas streams through a combination of a selective adsorbent material containing an effective amount of a non-adsorbent filler, adsorbent contactor design, and adsorption cycle design. The removal of contaminants from gas streams, preferably natural gas streams, using rapid-cycle swing adsorption processes, such as rapid-cycle pressure swing adsorption (RC-PSA). Separations at high pressure with high product recovery and / or high product purity are provided through a combination of judicious choices of adsorbent material, gas-solid contactor, system configuration, and cycle designs. For example, cycle designs that include steps of purge and staged blow-down as well as the inclusion of a mesopore filler in the adsorbent material significantly improves product (e.g., methane) recovery. An RC-PSA product with less than 10 ppm H2S can be produced from a natural gas feed stream that contains less than 1 mole percent H2S.

Owner:EXXONMOBIL UPSTREAM RES CO

Hydrocarbon synthesis

A method of synthesizing hydrocarbons from smaller hydrocarbons includes the steps of hydrocarbon halogenation, simultaneous oligomerization and hydrogen halide neutralization, and product recovery, with a metal-oxygen cataloreactant used to facilitate carbon-carbon coupling. Treatment with air or oxygen liberates halogen and regenerates the cataloreactant.

Owner:REACTION 35 LLC +1

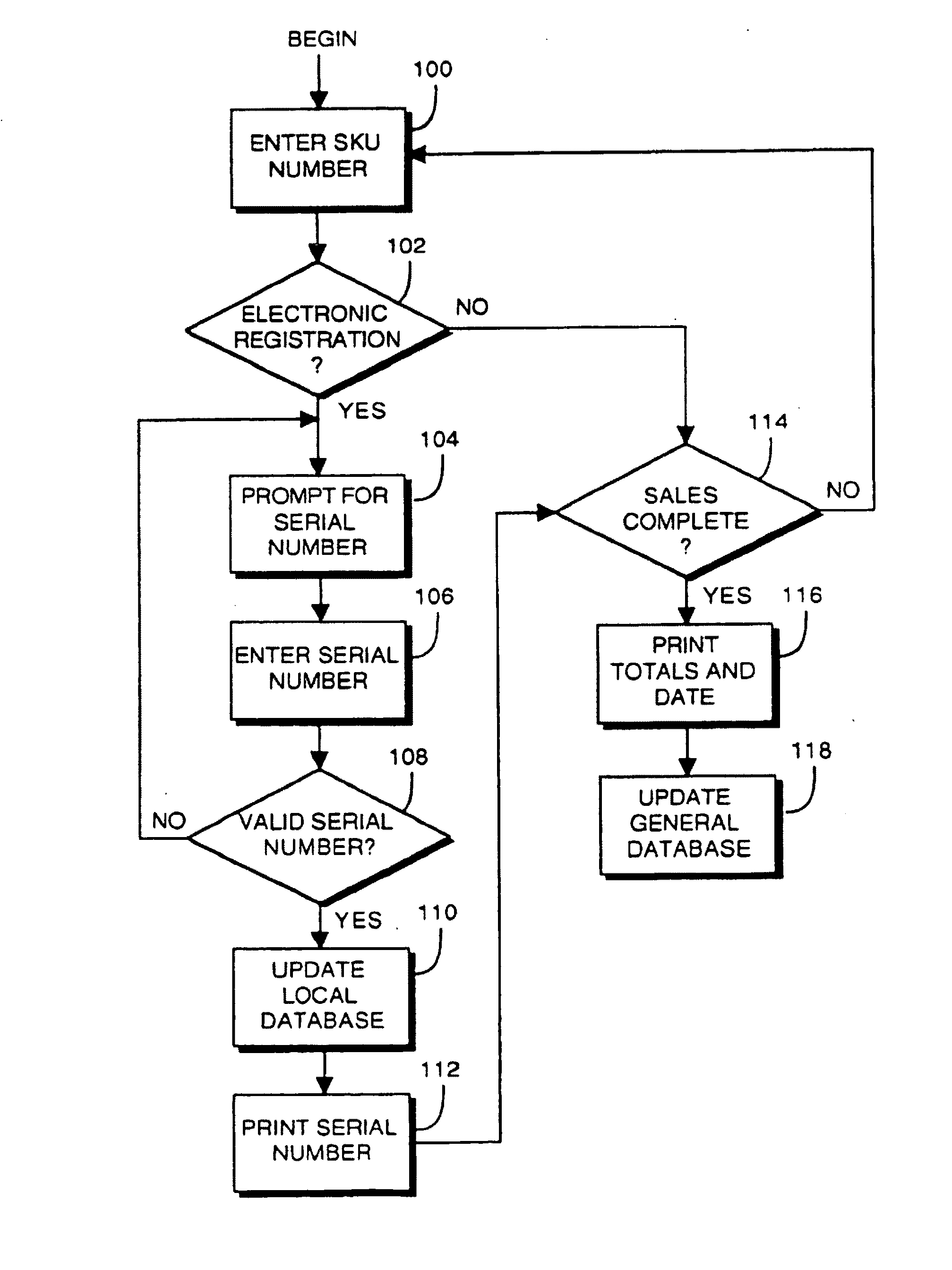

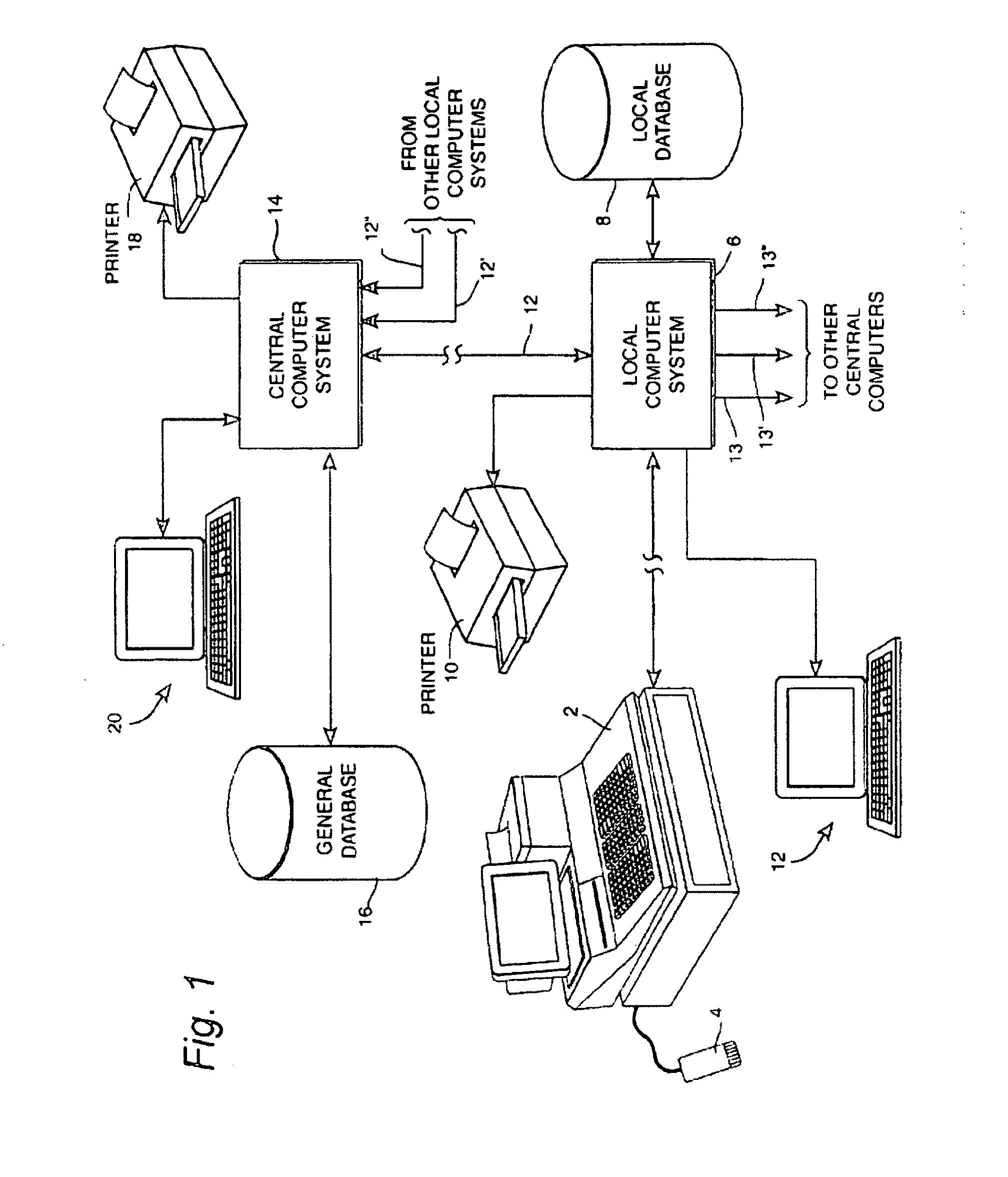

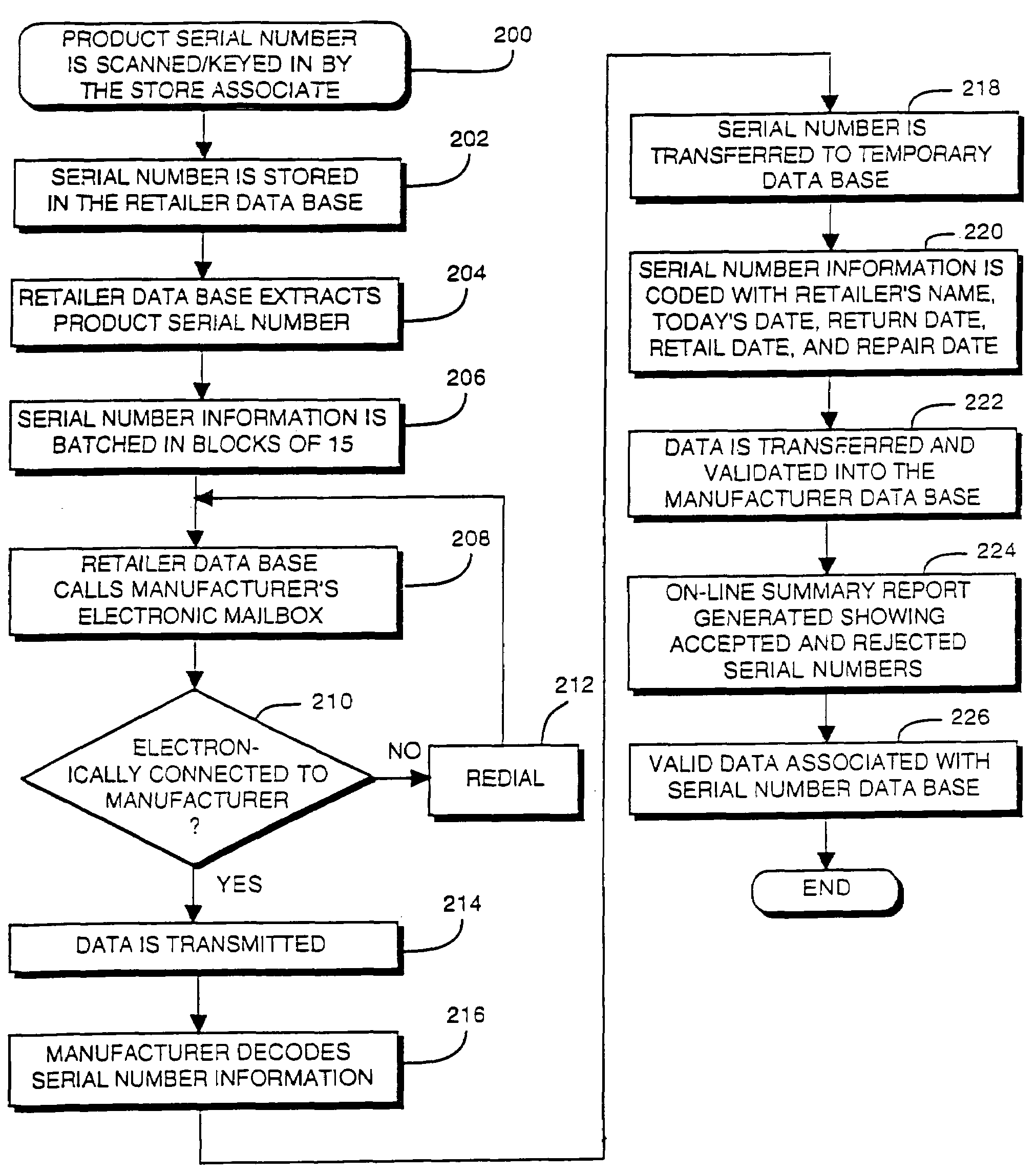

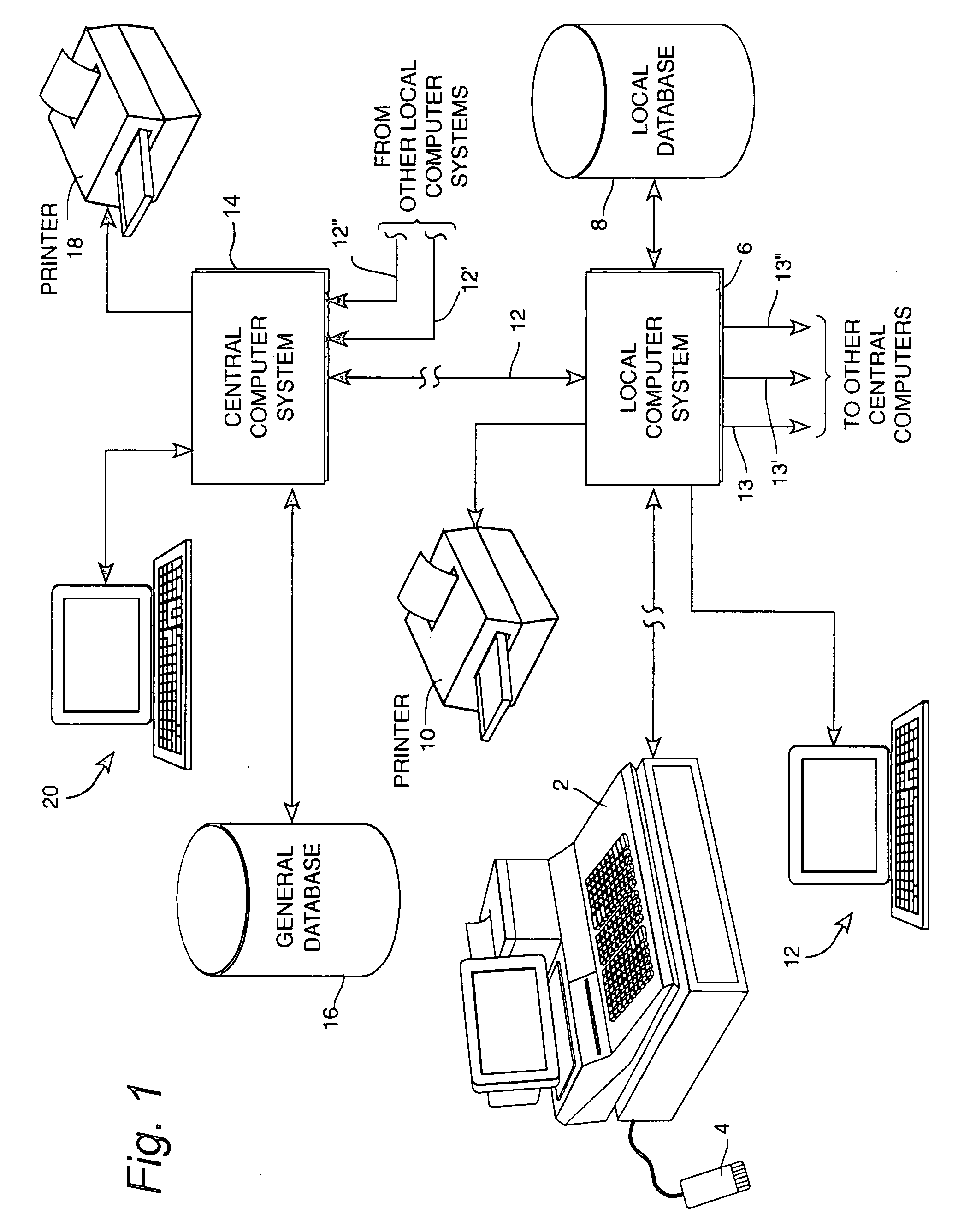

Systems and/or methods for globally tracking items and generating active notifications regarding the same

Certain exemplary embodiments relate to techniques for fraud reduction and / or product recovery. For example, in certain exemplary embodiments, a central repository for item-level data related to stolen, missing, counterfeit, or other items may be provided. The item-level data may be stored as a function of EPC / RFID and / or serial number information in certain exemplary embodiments of this invention. According to certain exemplary embodiments, notification and / or subscription systems may be deployed to search for missing, stolen, or other items throughout the various “touchpoints” in the sales universe by consulting the centralized electronic registration (ER) database. This searching may be performed among and between, and / or on behalf of, interested parties including, for example, retailers, manufacturers, pawnshops, online auction houses, etc. These and / or other parties may be notified, as appropriate, with the notifications being based on subscriptions may by the entities and / or predefined rules.

Owner:E2INTERACTIVE INC D B A E2INTERACTIVE

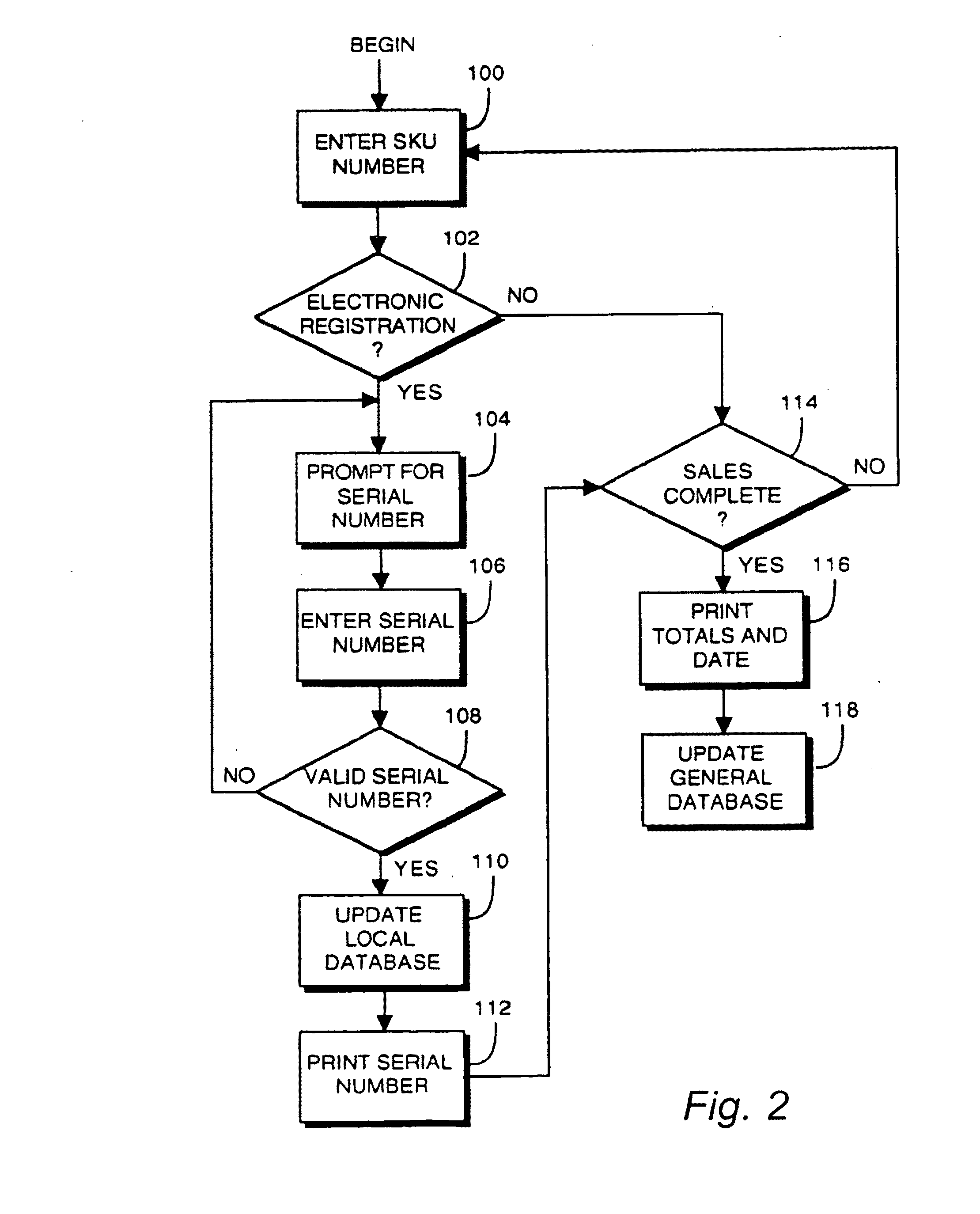

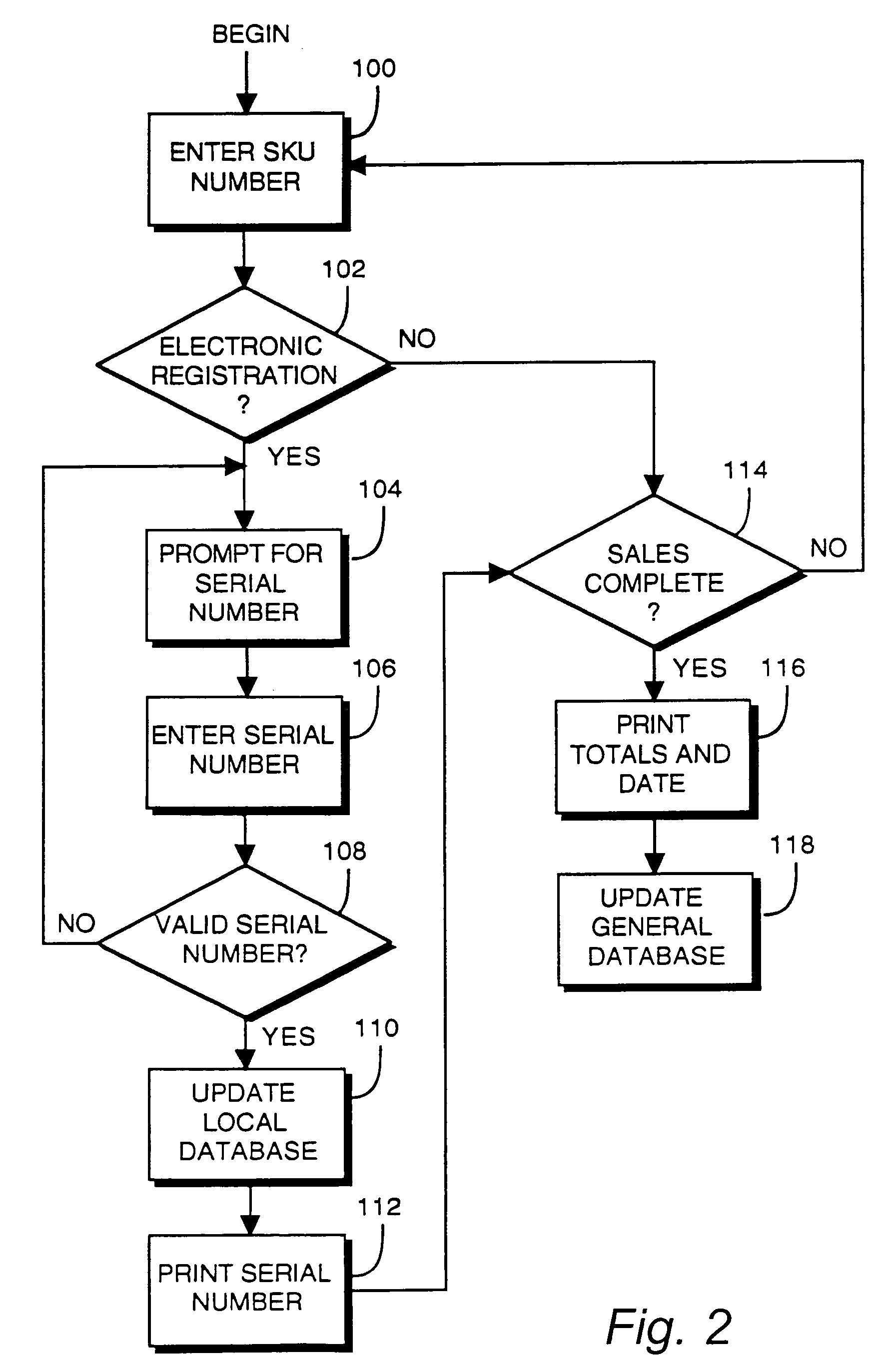

Method and apparatus for fraud reduction and product recovery

Certain exemplary embodiments relate to techniques for fraud reduction and / or product recovery. For example, in certain exemplary embodiments, a database includes a plurality of product entries, with each product entry having at least a status field associated therewith. A first interface to the database is configured to enable a first authorized user to add product entries and / or change the status identifiers of the product entries. A second interface to the database is configured to enable a second authorized user to input information regarding a product to be checked against the database to determine whether it was legitimately acquired. Product checking programmed logic circuitry is configured to determine whether the product to be checked was legitimately acquired. The second interface is further configured to provide an indication to the second authorized user whether the product was legitimately acquired.

Owner:E2INTERACTIVE INC D B A E2INTERACTIVE

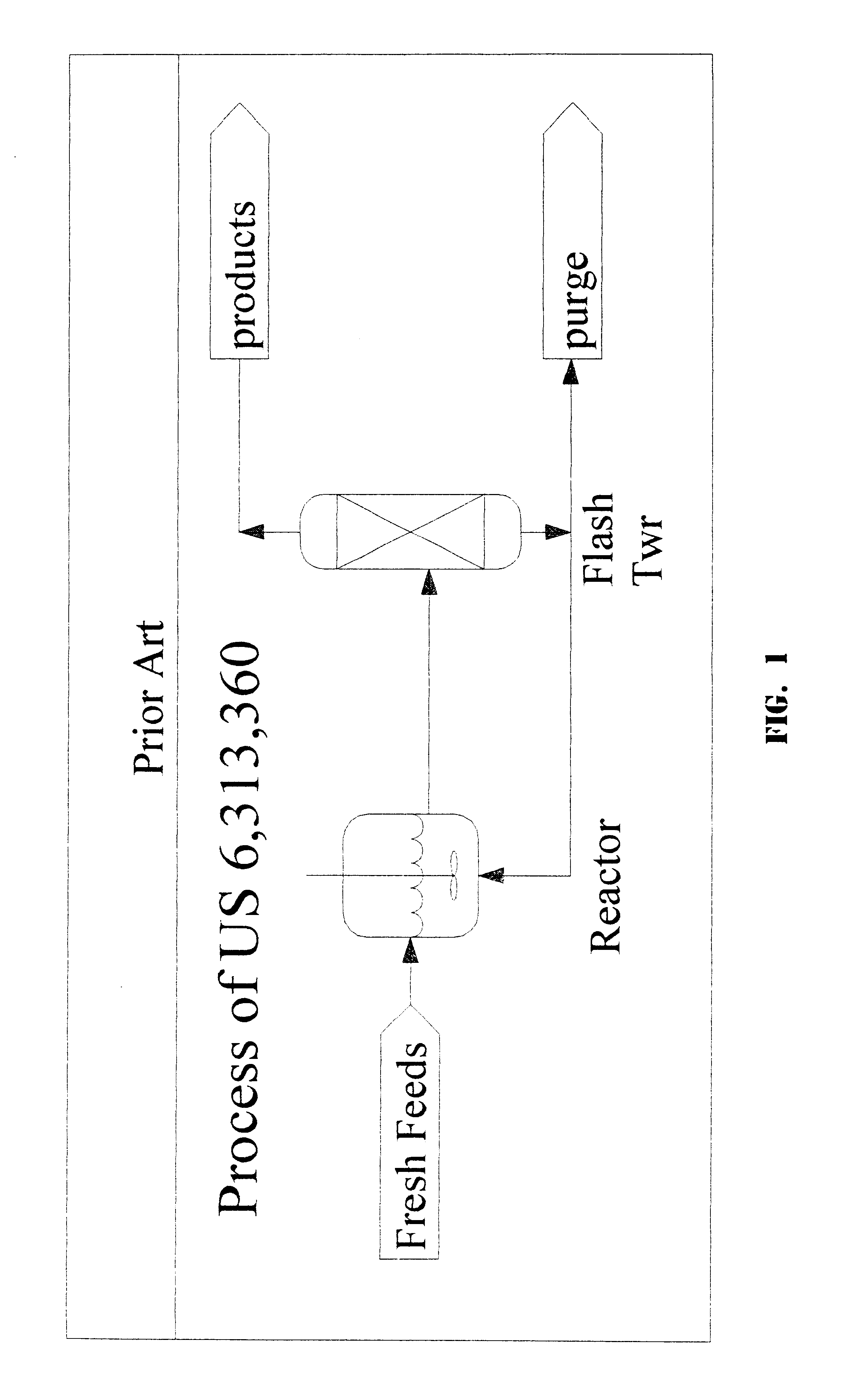

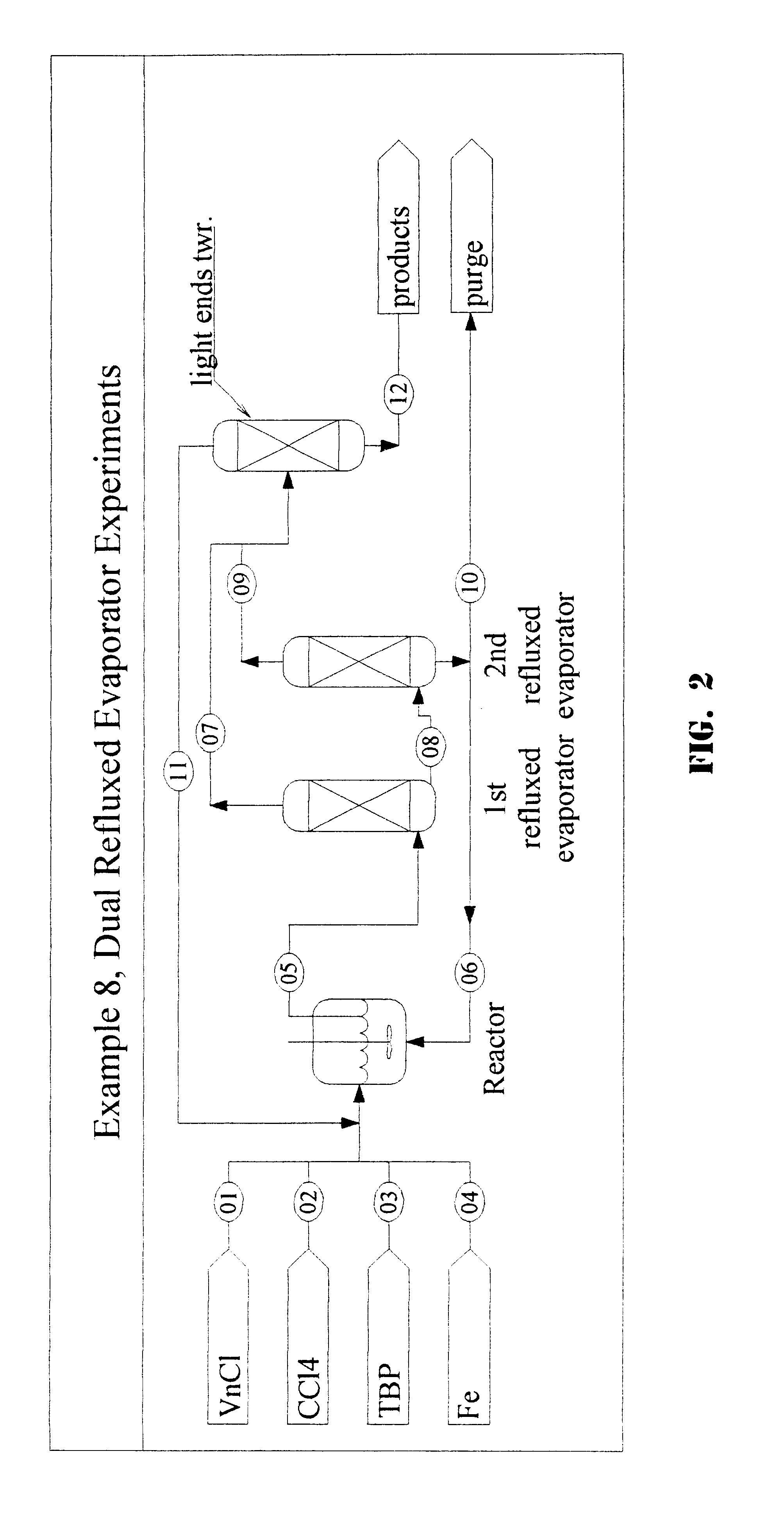

1,1,1,3,3-pentachloropropane process purge stream concentration using a secondary refluxed evaporator and secondary product recovery

InactiveUS6720466B2Maximize recoveryReduce decreaseOrganic chemistry methodsHalogenated hydrocarbon separation/purificationDistillationProduct recovery

A process for economically producing 1,1,1,3,3-pentachloropropane under conditions which preserve the activity of the catalyst. In a preferred embodiment, a two-stage distillation process is employed. In the two-stage process, the size of the equipment, temperature and vacuum are varied.

Owner:OCCIDENTAL CHEM CORP

Method of Reclaiming Carbonaceous Materials From Scrap Tires and Products Derived Therefrom

InactiveUS20100249353A1Constant production environmentQuality improvementGaseous chemical processesPressurized chemical processPyrolytic carbonMetal

The invention relates to recycled rubber produced by a process comprising the steps of: a) shredding cleaned rubber tires into shreds less than 2″ long; b) pyrolyzing the shreds in a reaction chamber of a thermal processor in a first anaerobic environment to produce a char; c) drawing off volatile organics from the reaction chamber; c) removing the char from the reaction chamber; d) cooling the char in a second anaerobic environment; e) removing metal and textile components from the char to obtain pyrolytic carbon black; f) milling and sizing the pyrolytic carbon black so obtained into particles of 325 mesh size or smaller; and, g) utilizing the pyrolytic carbon black from the previous step in a polymerization process that produces said recycled rubber. It also relates to the high quality pyrolytic carbon black recovered from this process.

Owner:BERDEKO TECH +1

Amine treatment in light olefin processing

Processing schemes and arrangements for the amine treatment of high olefin content (e.g., ethylene-rich) carbon dioxide-containing streams such as for the effective separation and removal of carbon dioxide therefrom are provided. Corresponding or associated processing schemes and arrangements for the catalytic cracking of a heavy hydrocarbon feedstock and obtaining light olefins substantially free of carbon dioxide via absorption-based product recovery are also provided.

Owner:UOP LLC

Product recovery from simulated-moving-bed adsorption

Product purity from or capacity of a simulated-moving-bed adsorptive separation process is increased by flushing the contents of the transfer line previously used to remove the raffinate stream away from the adsorbent chamber, preferably into the raffinate column used to separate desorbent from raffinate product. Preferably a stream from the adsorbent chamber at an intermediate point between the feed entry point and raffinate withdrawal is used as the flushing liquid. This flush step eliminates the passage of a quantity of the raffinate material into the adsorbent chamber in the transfer-line flush period or when the process conduit is subsequently used to charge the feed stream to the adsorbent chamber.

Owner:UOP LLC

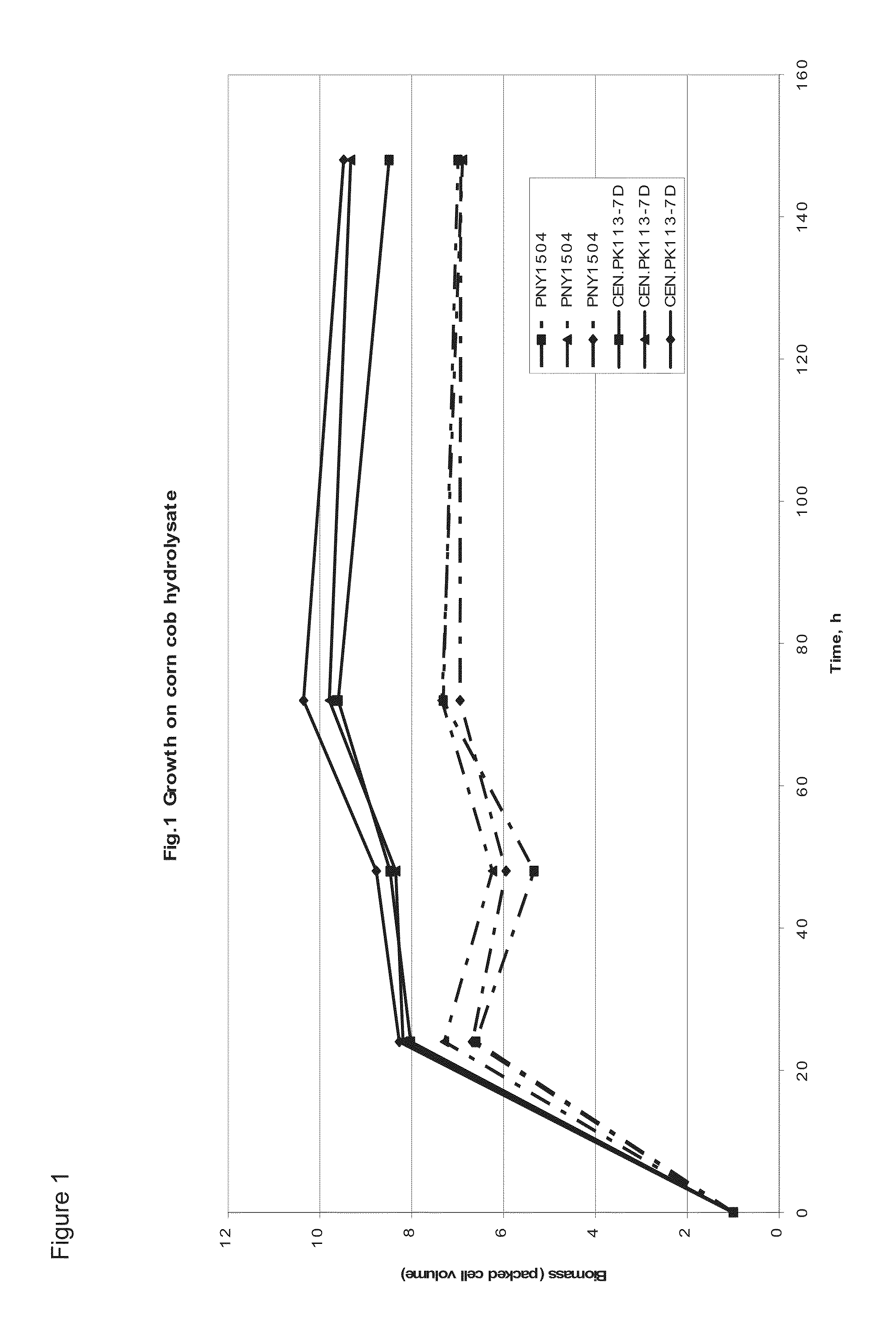

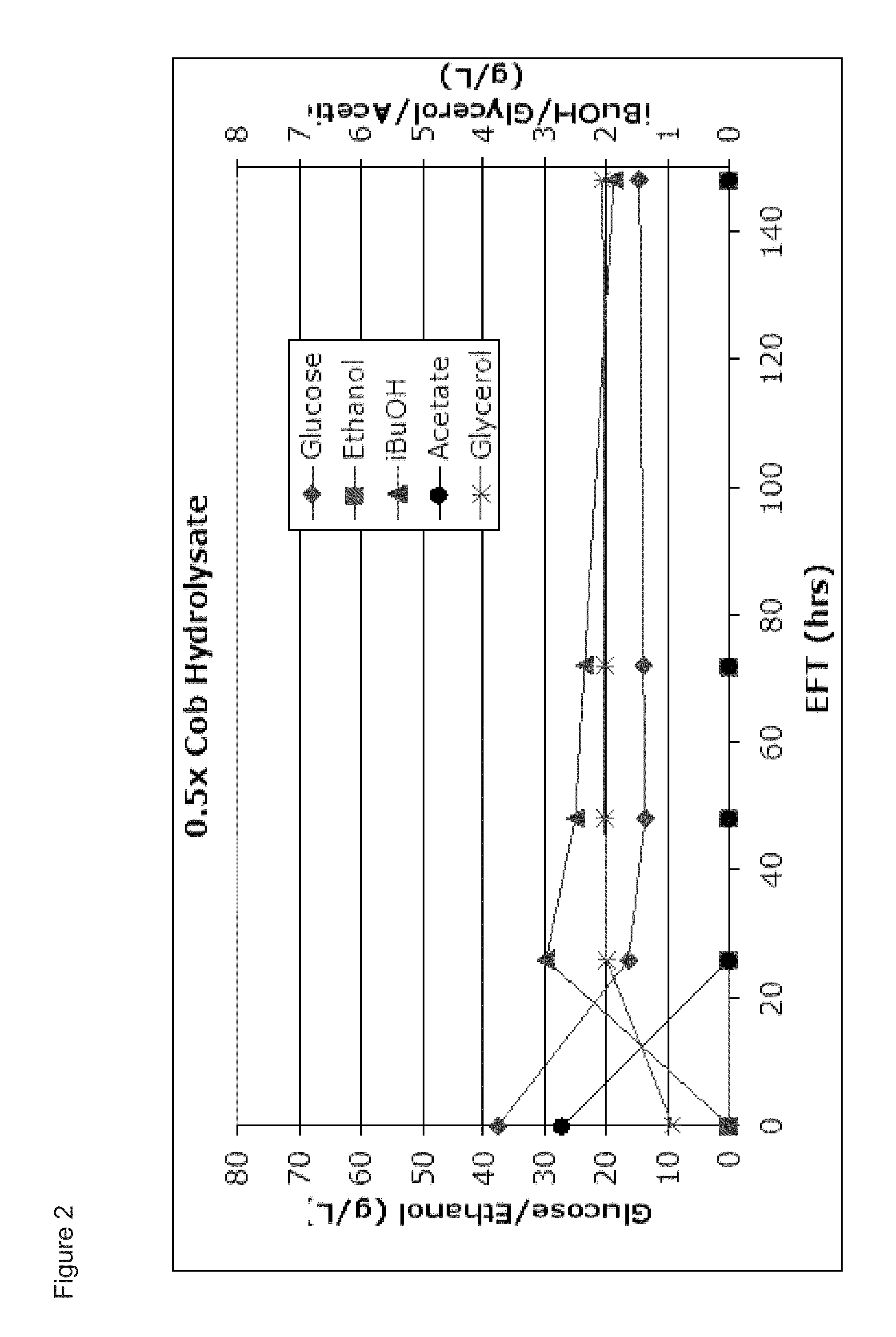

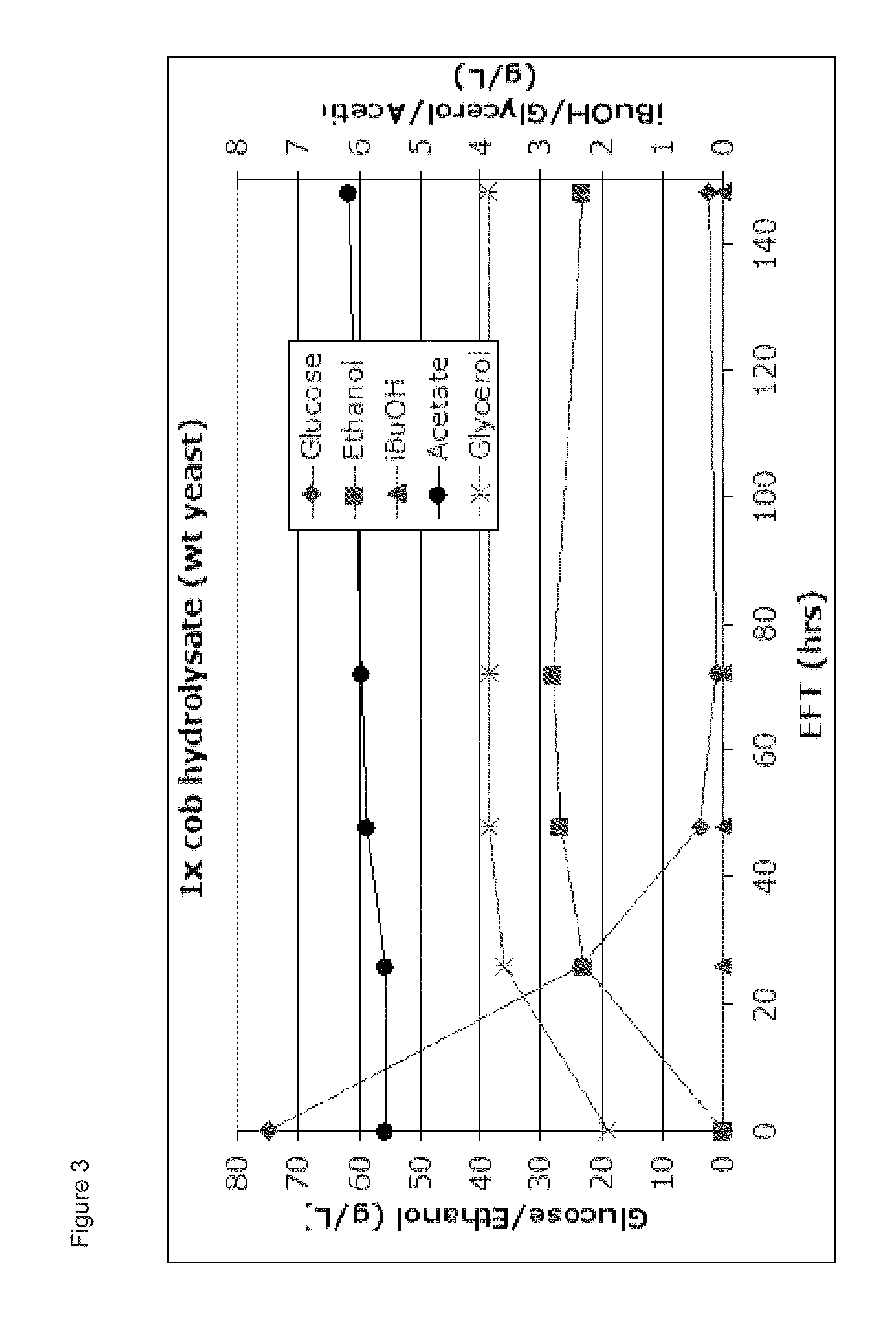

Lignocellulosic hydrolysates as feedstocks for isobutanol fermentation

InactiveUS20130035515A1Improved production of butanolOrganic compound preparationBiofuelsCelluloseIsobutanol

The invention relates generally to the field of industrial microbiology and butanol production from sources of 5-carbon sugars such as lignocellulosic hydrolysates. More specifically, the invention relates to the use of an xylulose or xylulose-5-phosphate-producing enzyme and micro-aerobic or anaerobic conditions to increase butanol production from such sugars and recovery of said butanol through ins situ product recovery methods.

Owner:BUTAMAXTM ADVANCED BIOFUELS

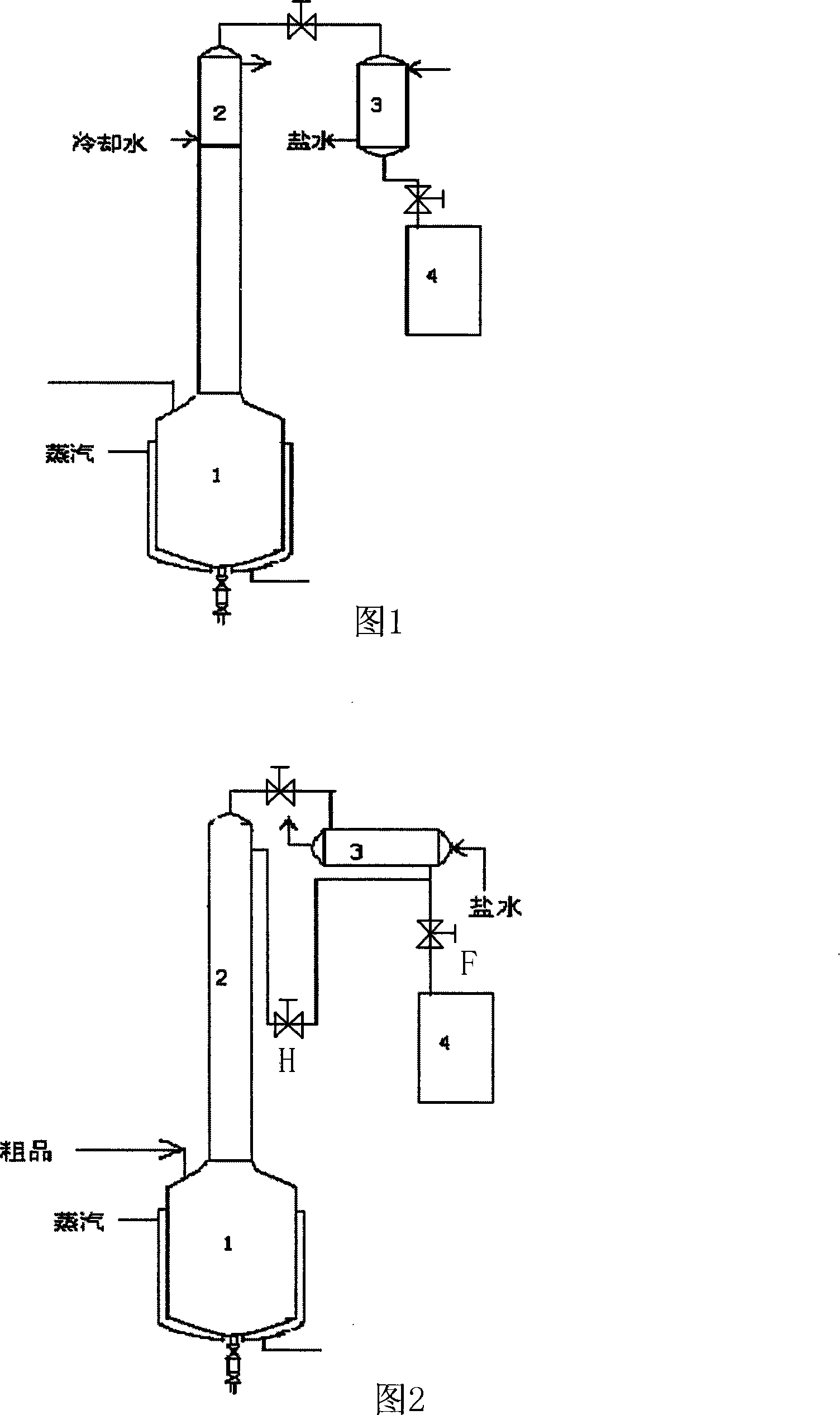

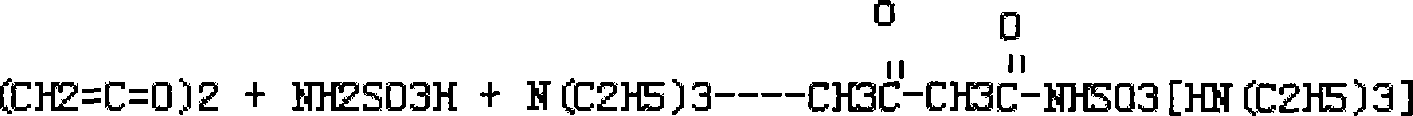

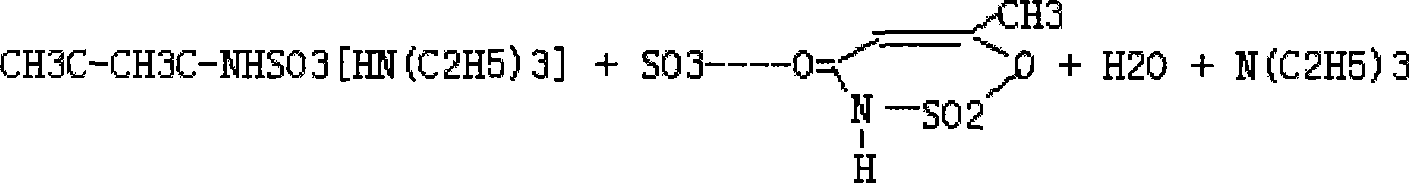

Triethylamine recovery processing method and device for production of acesulfame potassium

ActiveCN101157666AEasy to operateLow costAmino compound purification/separationMolecular sieveBoiling point

The invention relates to a triethylamine reclaim treatment method and the devices in the production of acesulfame-K, which is characterized in that the method includes the following steps: a. the crude triethylamine containing water is put into a distillation kettle (1), which is heated to the temperature of 38 DEG C to 42 DEG C, the time is about 20 to 40 minutes, the dichloromethane and other impurities with the low boiling points which are contained in the crude triethylamine are firstly evaporated, collected and then are condensed and collected by a condenser (3); b. the heating is carried out continually to about 83 DEG C, the temperature is kept for more than 30 minutes, which ensures that the water and triethylamine are placed still for layer separation, a lower layer is water, an upper layer is triethylamine, and triethylamine of the upper layer can be collected after the water is drained completely from the bottom of a kettle. Finally, the collected triethylamine is dried by the solid potassium hydroxide or a molecular screen, so the water content of triethylamine can be lower than 0.1 percent. The invention has the advantages of simple using equipment, convenient operation, safety, reliability, low cost, improved reclaim ratio of the product and significantly reduced operating cost.

Owner:ANHUI JINGHE IND

Extraction process of resveratrol from giant knotweed

InactiveCN1384088ARealize the needs of industrialized productionReduce consumptionOrganic chemistryOrganic compound preparationOrganic synthesisGradient elution

During the extraction of resveratrol from giant knotwood, giant knotwood glycoside is hydrolyzed and enriched through organic synthesis. The extraction process includes mixing giant knotwood raw material and composite stuffing, high pressure chromatography in a high-pressure chromatographic column apparatus, gradient elution with chloroform and ethyl acetate and thin chromatographic tracking detection. The said process can reach a kilogram level yield and high product purity. The present invention may be used in extracting resveratrol and other similar product from giant knotwood material.

Owner:杨建文

Deasphalting of Gas Oil from Slurry Hydrocracking

ActiveUS20100243518A1High value distillateIncrease valueWorking-up pitch/asphalt/bitumen by selective extractionTreatment with hydrotreatment processesSlurryProcess engineering

Integrated slurry hydrocracking (SHC) and solvent deasphalting (SDA) methods for making slurry hydrocracking (SHC) distillates are disclosed. Representative methods involve passing a slurry comprising a vacuum column resid, a recycled, deasphalted oil obtained from SDA, and a solid particulate through an SHC reaction zone in the presence of hydrogen to obtain the SHC distillate. Fractionation or distillation in the SHC product recovery section yields a combined SHC gas oil / SHC pitch stream that is sent to SDA. In a representative embodiment, vacuum distillation in the SHC product recovery is avoided, thereby eliminating equipment that is often most susceptible to fouling.

Owner:UOP LLC

Adsorptive separation of gas streams

ActiveUS20050284291A1Improve adsorption capacitySuitable for useGas treatmentWaste based fuelSorbentProduct gas

A method and system for adsorptive separation of a feed gas mixture provides for increased system efficiency and product recovery. The requirement for purge gas streams consuming desired product gas to regenerate adsorption beds is reduced through an inventive method for adsorbent selection and adsorption bed and process design.

Owner:AIR PROD & CHEM INC

Isomerization of Benzene-Containing Feedstocks

ActiveUS20080287724A1Reduce the temperatureMinimize undesirable hydrocracking reactionHydrocarbon by isomerisationHydrocarbon by hydrogenationAlkaneBenzene

The benzene content in a gasoline pool is reduced by a process that hydrogenates a benzene-containing isomerization zone feedstream. The additional cyclic hydrocarbons produced by the saturation of benzene can be processed in the isomerization zone for ring opening to increase the available paraffinic feedstock or the isomerization zone can be operated to pass the cyclic hydrocarbons through to a product recovery section. The isomerization zone feedstream is treated to remove contaminants and dried before entering the hydrogenation zone.

Owner:UOP LLC

Method for separation and extraction of 1, 3-propylene glycol and its byproducts from fermentation liquid

InactiveCN1634823ASimple process routeReduce energy consumptionOrganic compound preparationHydroxy compound preparationHigh concentrationSolubility

The present invention discloses a process for separation and extraction of 1,3-propylene glycol by fermentation method, which belongs to biochemical separation technical field. A rectification is carried out to separate alcohol in the fermentation liquor, then solids and dissolved protein are separated from the fermentation liquor by composite flocculation of cation type flocculant and non-ion type flocculant. The pH value of the obtained clear liquid is regulated by an acid, and an extraction is performed with an aldehyde. An aldolisation between 1,3-propylene glycol, 2,3-butanediol, glycerine and an aldehyde is carried out to obtain a cyclic acetal to be separated from water phase, salts and other solubility impurity are separated from 1,3-propylene glycol, 2,3-butanediol and glycerine along with the water phase. The acetal hydrolysis applies reacting rectification with solid acid catalyst, can obtain high concentration 1,3-propylene glycol, 2,3-butanediol and glycerine mixture, which is separated again by subsequent common rectification. Excessive aldehyde in the extract phase is recovered by rectification. The invention has the advantages of simple extraction and separation process, low energy consumption, high product recovery, less equipment investment and less land occupation.

Owner:TSINGHUA UNIV

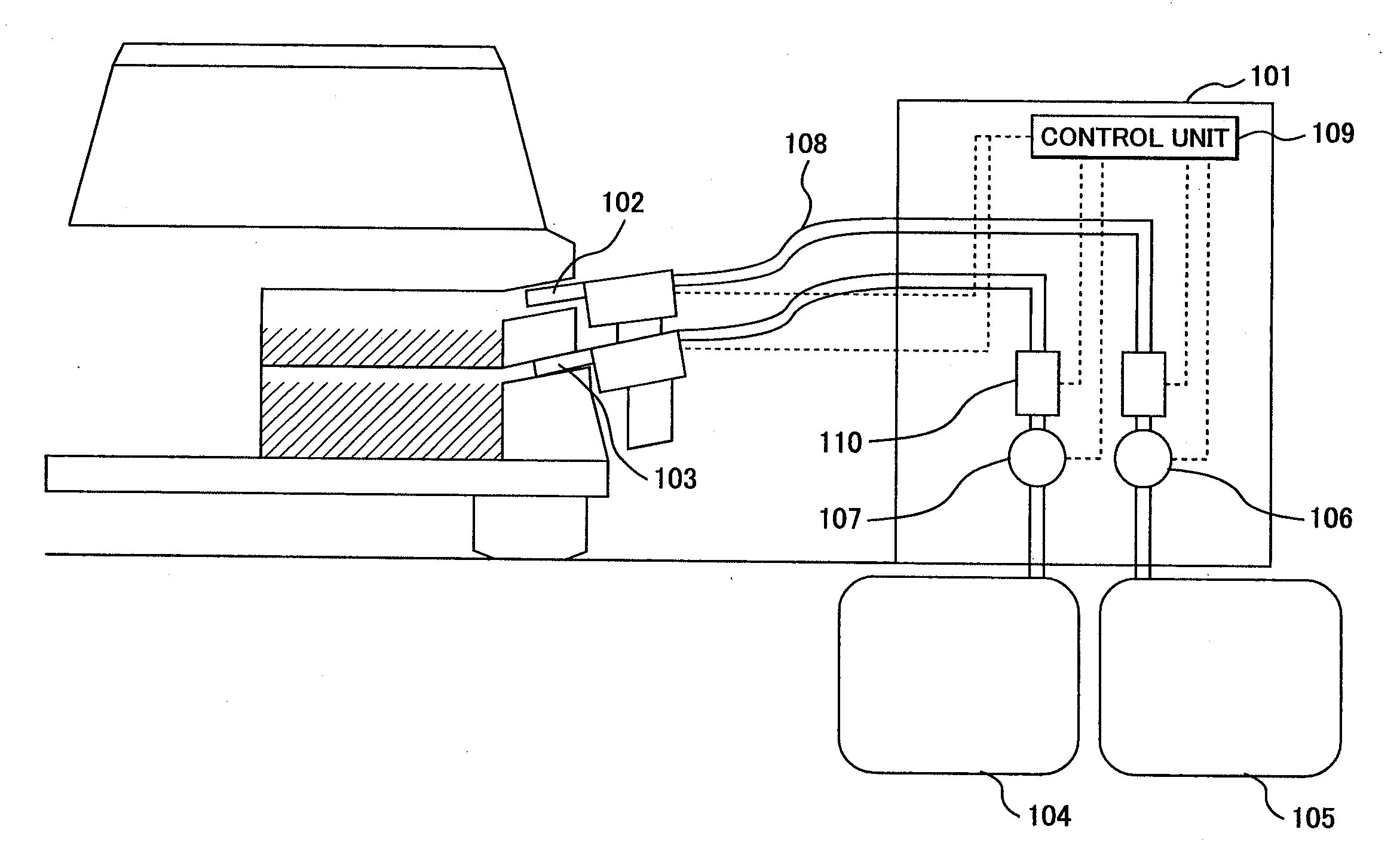

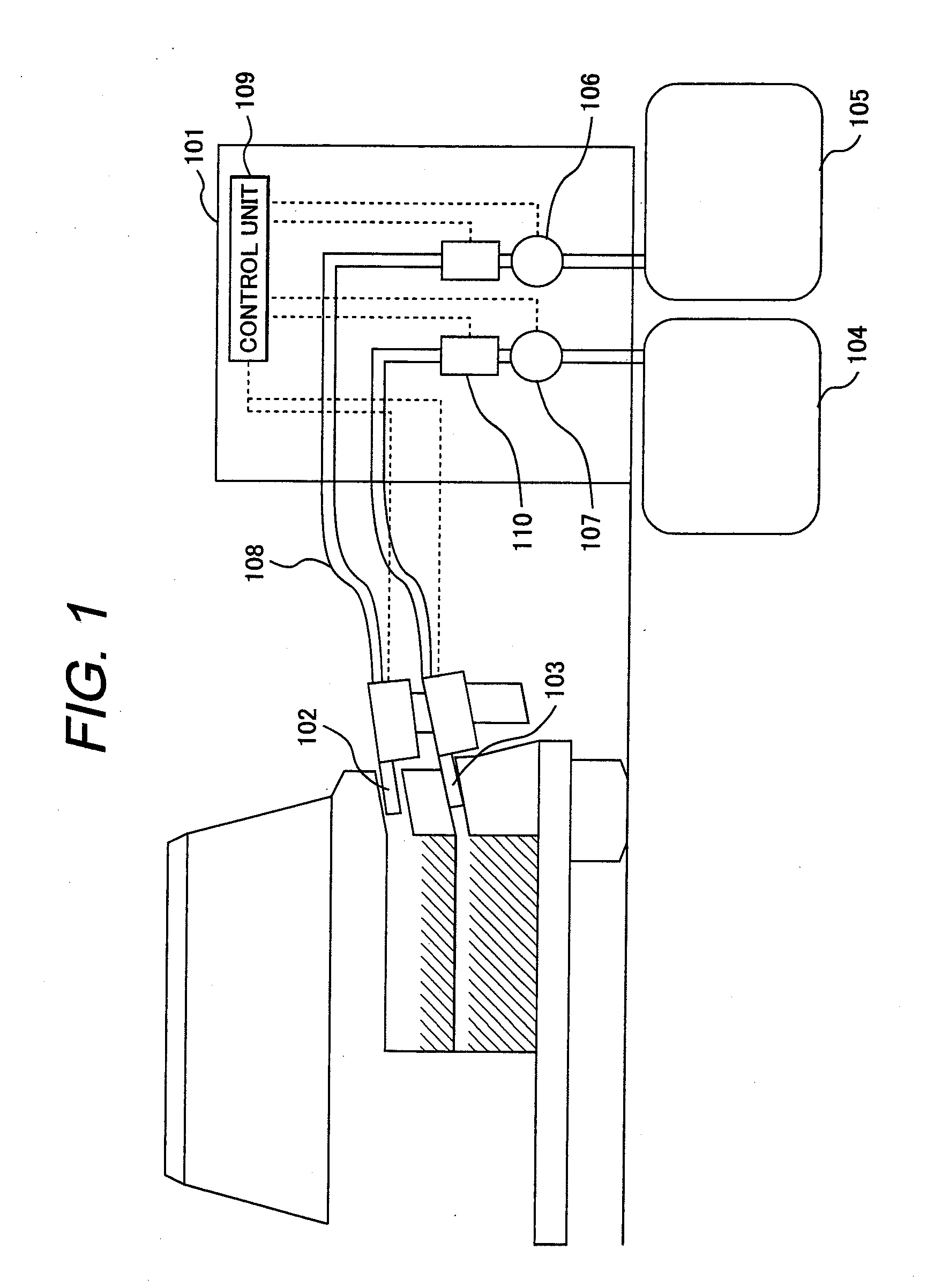

Fuel filling and waste solution recovery apparatus and fuel vessel

InactiveUS20090025824A1EfficientlyGas handling applicationsHydrogen/synthetic gas productionLiquid wasteDehydrogenation

Recovery of dehydrogenation product must be done separately from supply of hydrogen fuel. However, there is a problem that it takes much time when dehydrogenation product recovery and fuel filling are done separately. A fuel filling / waste solution recovery apparatus includes measuring means to measure a volume of supplied fuel and a volume of recovered waste solution by measuring flow rates of solutions passing through a fuel filling nozzle and a recovery nozzle or piping, and a display which shows the volume of supplied fuel and the volume of recovered waste solution which are measured by the measuring means.

Owner:HITACHI LTD

Coking of Gas Oil from Slurry Hydrocracking

ActiveUS20100122931A1Minimizing even eliminating net productionIncrease valueThermal non-catalytic crackingHydrocarbon oil crackingParticulatesHydrogen

Integrated slurry hydrocracking (SHC) and coking methods for making slurry hydrocracking (SHC) distillates are disclosed. Representative methods involve passing a slurry comprising a vacuum column resid, a liquid coker product, and a solid particulate through an SHC reaction zone in the presence of hydrogen to obtain the SHC distillate. Atmospheric distillation in the SHC product recovery section yields a combined SHC gas oil / SHC pitch stream that is sent to coking to generate the liquid coker product. In a representative embodiment, vacuum distillation in the SHC product recovery is avoided, thereby eliminating equipment that is often most susceptible to fouling.

Owner:UOP LLC

Method for preparing biological carbon with high nitrogen-phosphorus adsorption properties

ActiveCN103611497AFast adsorption rateHigh recovery rateOther chemical processesRare-earth elementAgricultural residue

The invention discloses a method for preparing biological carbon with high nitrogen-phosphorus adsorption properties. According to the method, forestry and agricultural residues are taken as raw materials to prepare the biological carbon with the high nitrogen-phosphorus adsorption property by carrying out high-temperature oxygen-deficient themolysis by utilizing the catalytic performance of light rare earth elements. The sources of the utilized raw materials are wide, the cost of a rare earth catalyst is low, and the prepared biological carbon is high in nitrogen-phosphorus adsorption speed and large in nitrogen-phosphorus adsorption capacity; the largest adsorbing capacities of NO3<->, NH4<+> and PO4<3-> can respectively reach 38.44mg / g, 15.58mg / g and 19.74mg / g. The method is simple in process operation, low in investment requirement and cost and high in product recovery rate and application value.

Owner:四川发展环境科学技术研究院有限公司

Hydrocarbon synthesis

InactiveUS20080188697A1Molecular sieve catalystLiquid hydrocarbon mixtures productionHydrogen halideOxygen

A method of synthesizing hydrocarbons from smaller hydrocarbons includes the steps of hydrocarbon halogenation, simultaneous oligomerization and hydrogen halide neutralization, and product recovery, with a metal-oxygen cataloreactant used to facilitate carbon-carbon coupling. Treatment with air or oxygen liberates halogen and regenerates the cataloreactant.

Owner:REACTION 35 LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com