Triethylamine recovery processing method and device for production of acesulfame potassium

A technology for recovery and treatment of triethylamine, applied in the purification/separation of amino compounds, organic chemistry, etc., can solve the problems of large material loss, poor separation effect, complicated operation, etc., and achieve the effects of low cost, convenient operation and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

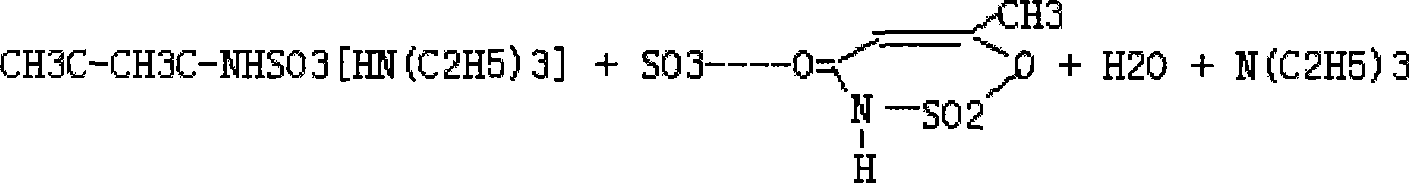

Method used

Image

Examples

Embodiment 1

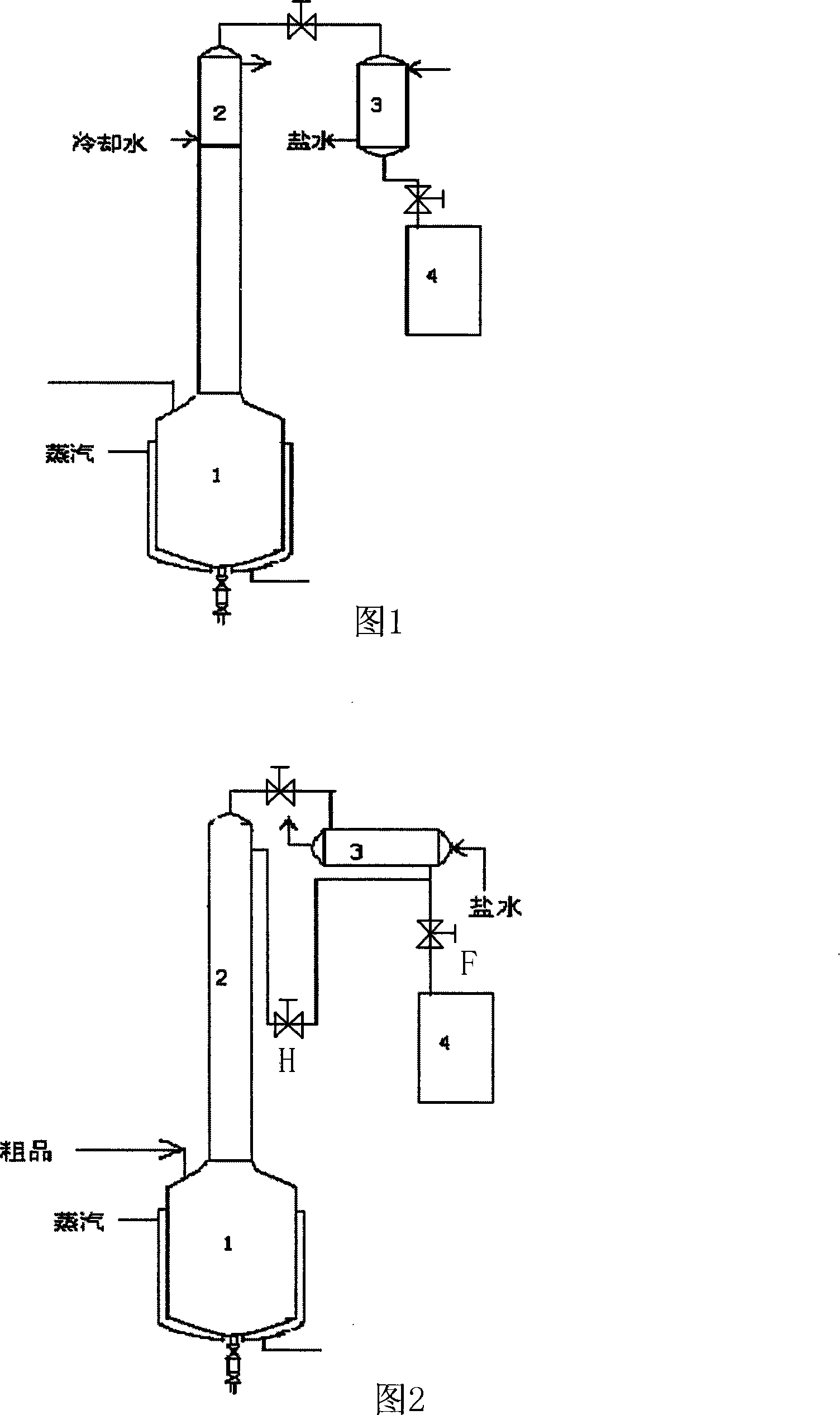

[0023] Embodiment one: as shown in Figure 1, distillation kettle adopts 5000 liters of fractionation tower kettle (1), and its top is provided with elongated neck (2), establishes a water condenser (2a) at the top of neck (2) , Cooled with circulating water, it is only turned on at 80°C-85°C to condense triethylamine. Low-boiling impurities such as dichloromethane are first condensed with a brine condenser (3), and a collector (4) is connected with a pipeline below the brine condenser (3).

[0024] The crude product triethylamine in the previous process is at 30 DEG C, and about 25% of water is dissolved, and it is pumped into the fractionation column (1), and the crude product triethylamine liquid is heated at about 40 DEG C for about 30 minutes. Low-boiling impurities such as methyl chloride are condensed with brine condensation (3), and then collected by collector (4). Then heat up to 83 DEG C again, open the water condenser at the top of neck (2) simultaneously, the triet...

example example 2

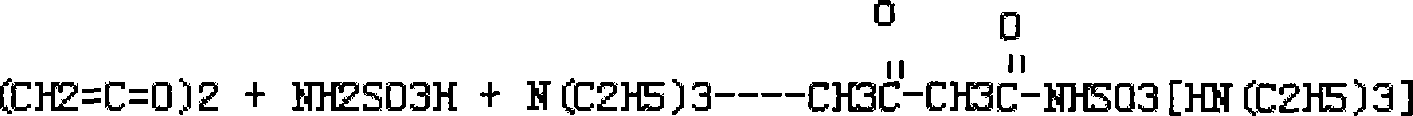

[0025] Example example two: as shown in Figure 2, the top of the slender neck (2) of fractionation column (1) is not provided with circulating water condenser, and vaporized material is all condensed with brine condenser (3), and brine condenser (3) Next pipe a collector (4). Also connect the return pipe to the elongated neck (2) at the outlet of the condenser (3).

[0026] The crude triethylamine in the previous process is about 30°C, and about 20% of water is dissolved. It is pumped into the heating kettle, and the temperature is raised at about 40°C. It takes about 30 minutes. The brine condenser (3) condenses and collects with collector (4). Then close the collection valve F, open the reflux valve H, and continue to heat up to 83°C for 28 minutes, during which the partially vaporized triethylamine is condensed with brine (3) and then refluxed to the elongated neck of the fractionating tower (1) ( 2). When the temperature is 83°C, keep the heat preservation for more than...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com