Process for recovering valuable metals from waste lithium batteries

A technology of valuable metals and lithium batteries, applied in the direction of improving process efficiency, etc., can solve problems such as difficult to guarantee product quality, incomplete dealumination, etc., and achieve high product recovery rate, high recovery rate, and simple process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

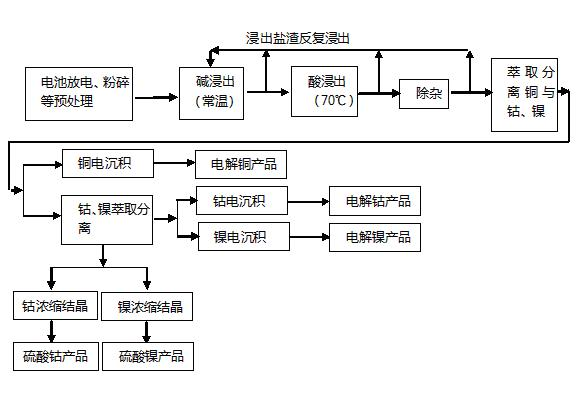

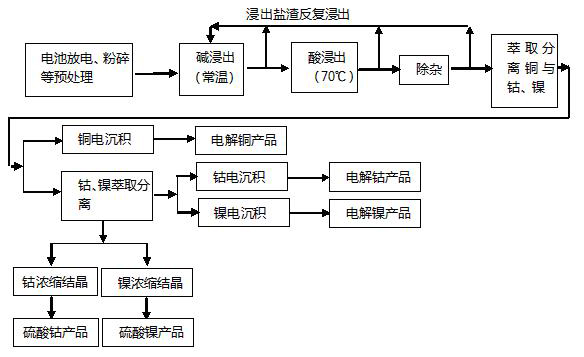

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0023] The invention relates to a process for recovering valuable metals from waste lithium batteries, taking the treatment of one ton of waste lithium ion batteries as an example:

[0024] Such as figure 1 : The first step: remove the outer packaging of the waste lithium battery to obtain single cells, put these single cells into a steel container with water and electronic conductive agent, short-circuit the positive and negative electrodes of the single cells to fully discharge Then remove the shell, because considering that the electrolytic fluid of the lithium battery is an organic solution that dissolves LiPF6, it will react after contacting water and generate highly toxic hydrogen fluoride, so the battery pole core after shelling is soaked in alkali immediately, This can eliminate the impact of the acid generated by the hydrolysis of LiPF6 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com