Patents

Literature

3313 results about "Water production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

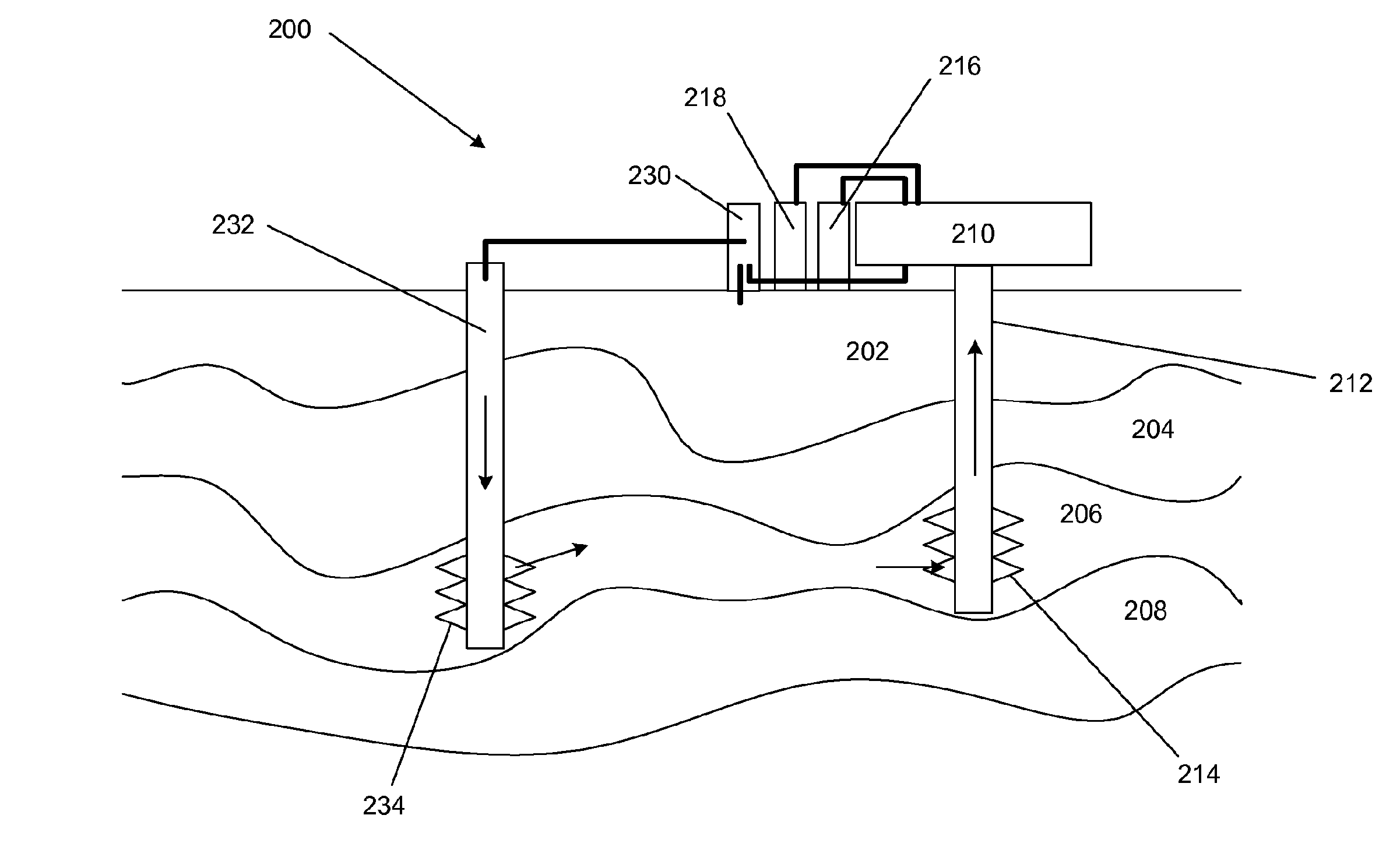

System for improving coalbed gas production

InactiveUS6244338B1Change in permeabilityPromote recoverySurveyDrilling rodsCoal matrixWater production

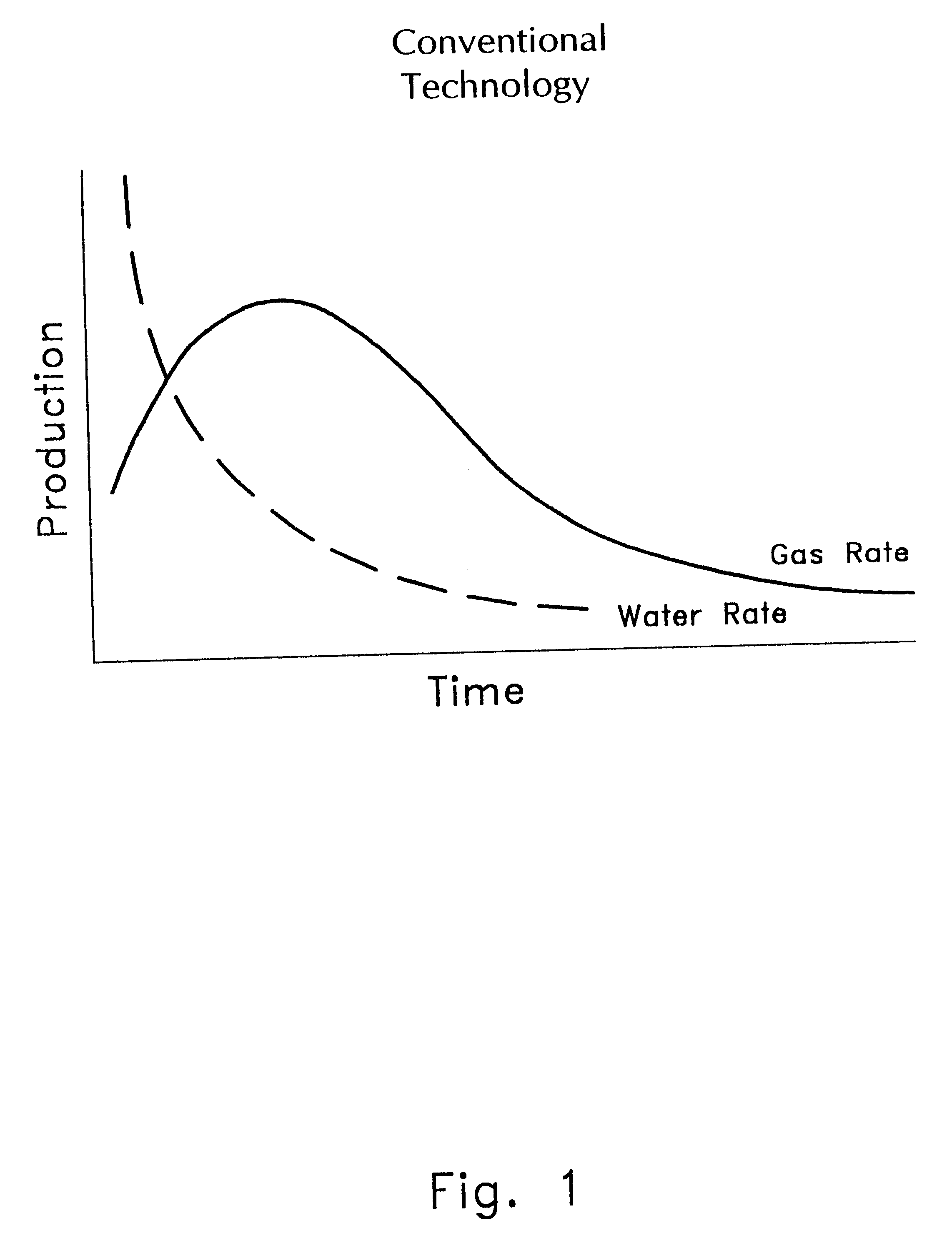

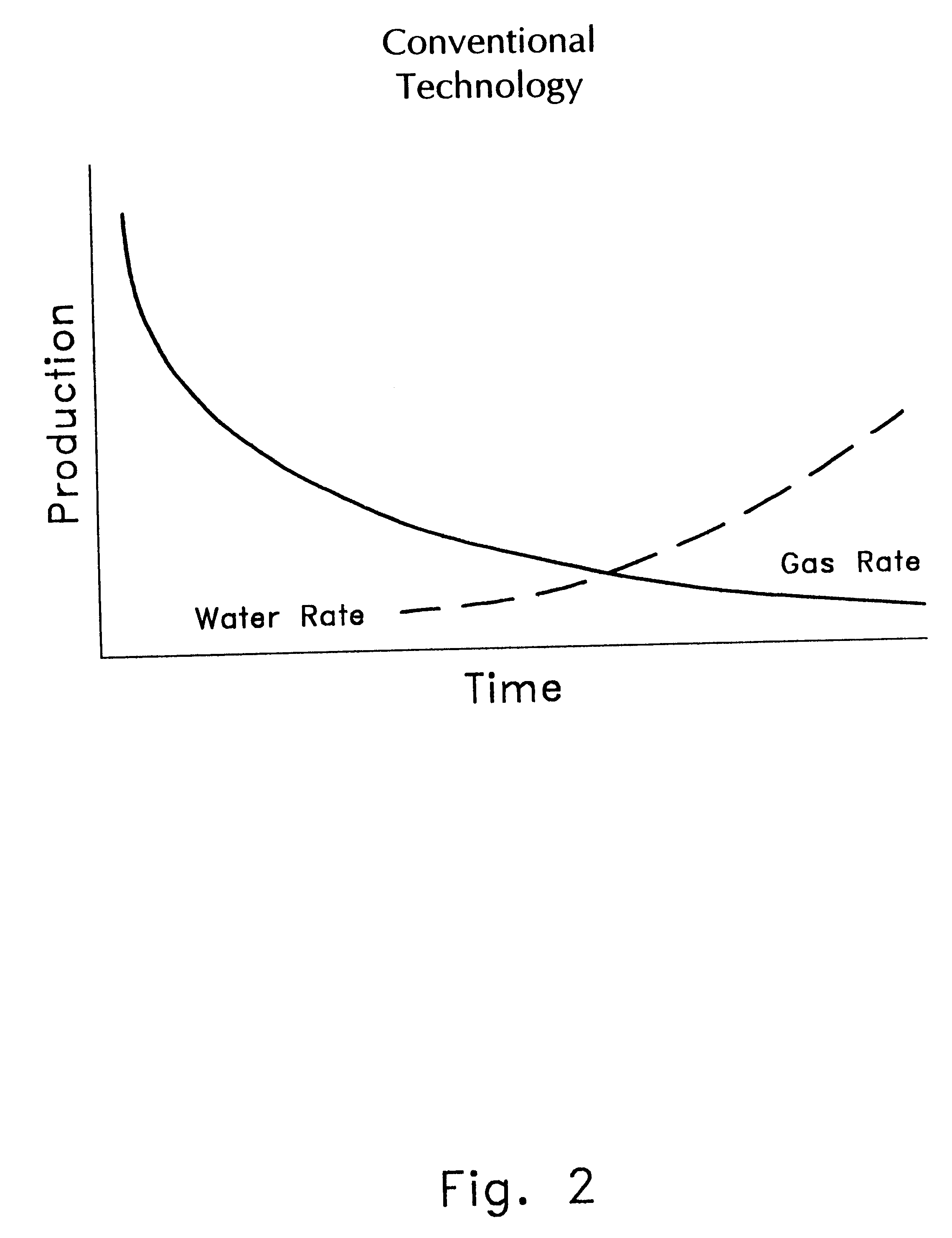

A method of stimulating coalbed methane production by injecting gas into a producer and subsequently placing the producer back on production is described. A decrease in water production may also result. The increase in gas production and decrease in water production may result from: (1) the displacement of water from the producer by gas; (2) the establishment of a mobile gas saturation at an extended distance into the coalbed, extending outward from the producer; and (3) the reduction in coalbed methane partial pressure between the coal matrix and the coal's cleat system.

Owner:THE UNIVERSITY OF WYOMING RESEARCH CORPORATION DBA WESTERN RESEARCH INSTITUTE

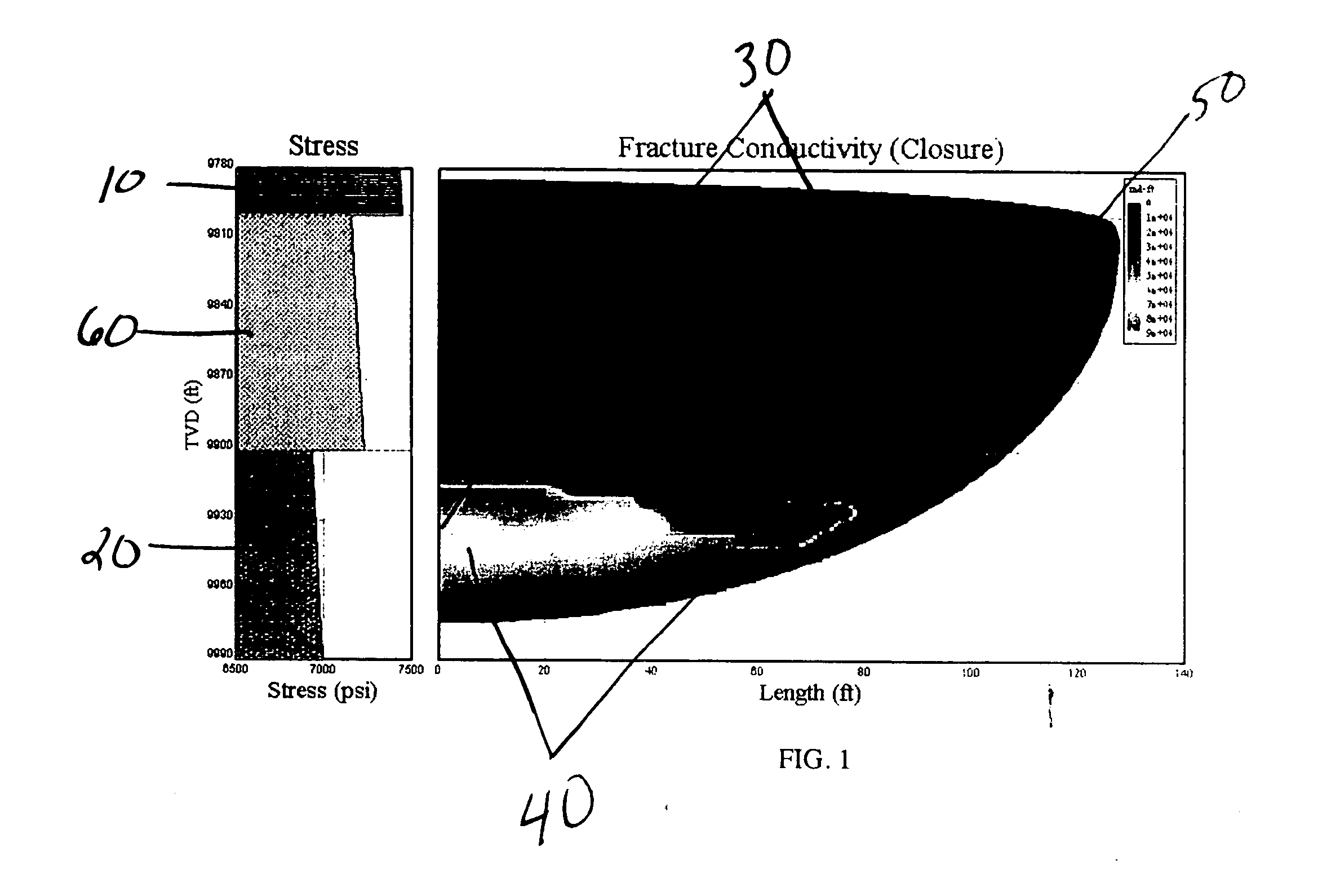

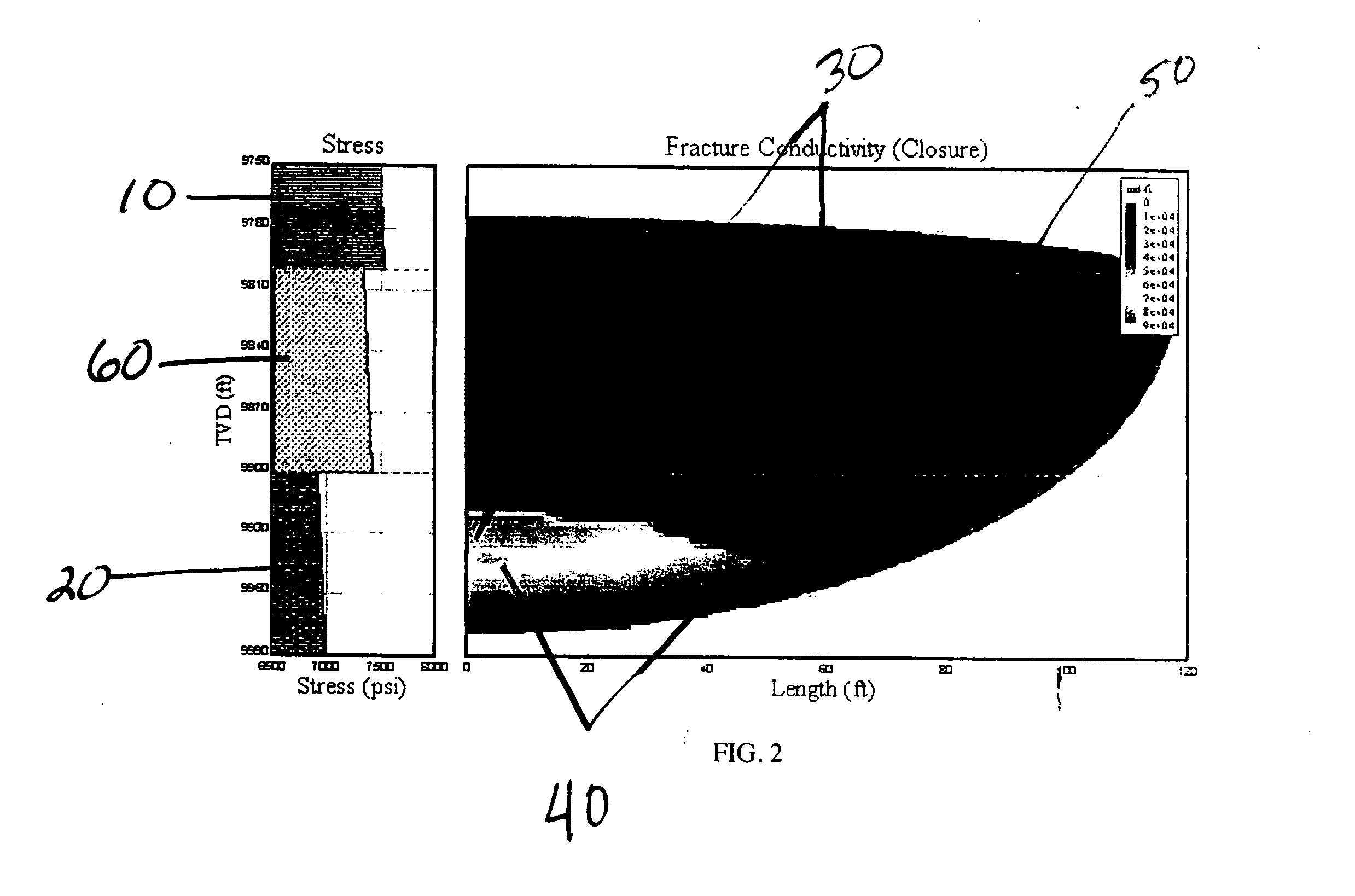

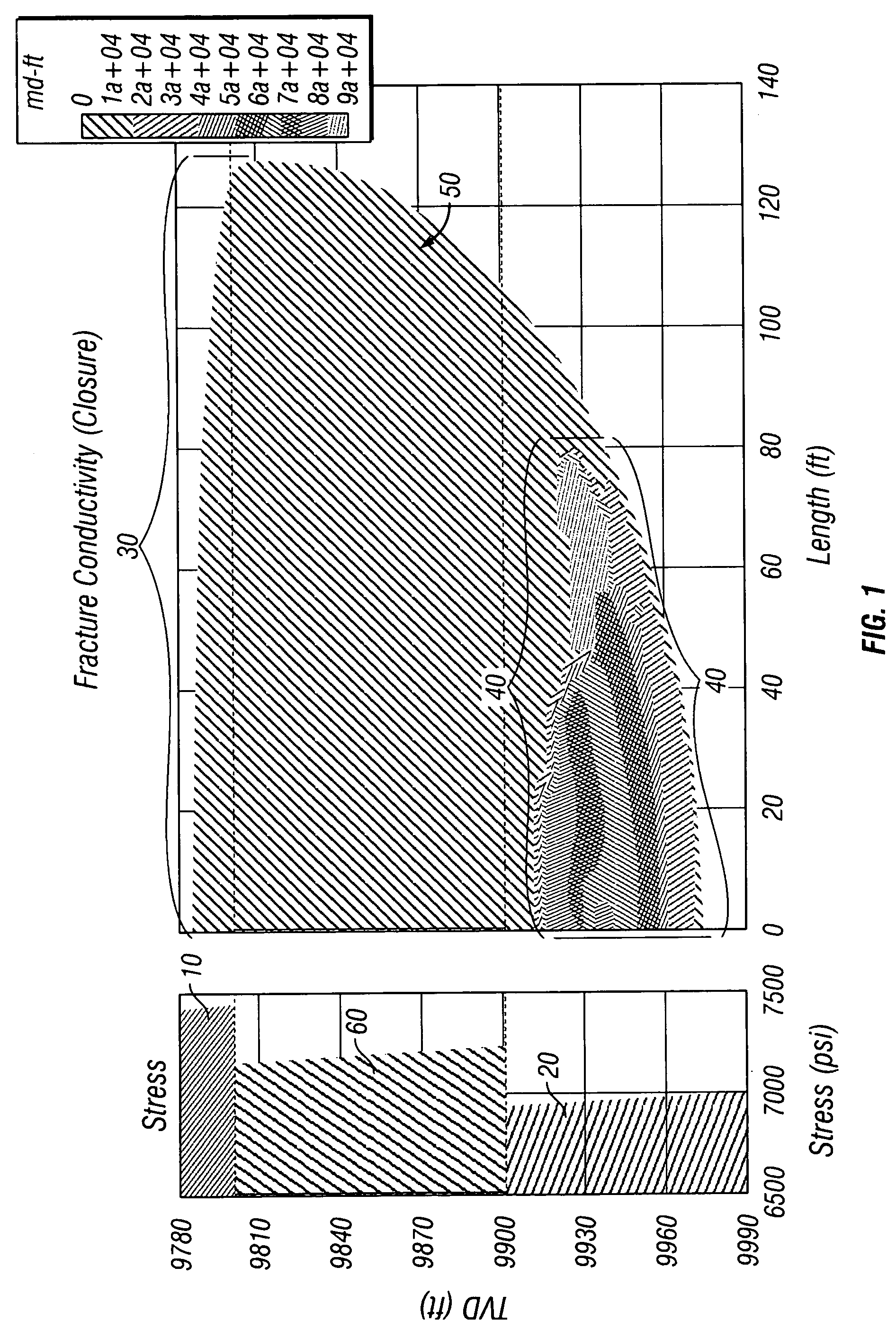

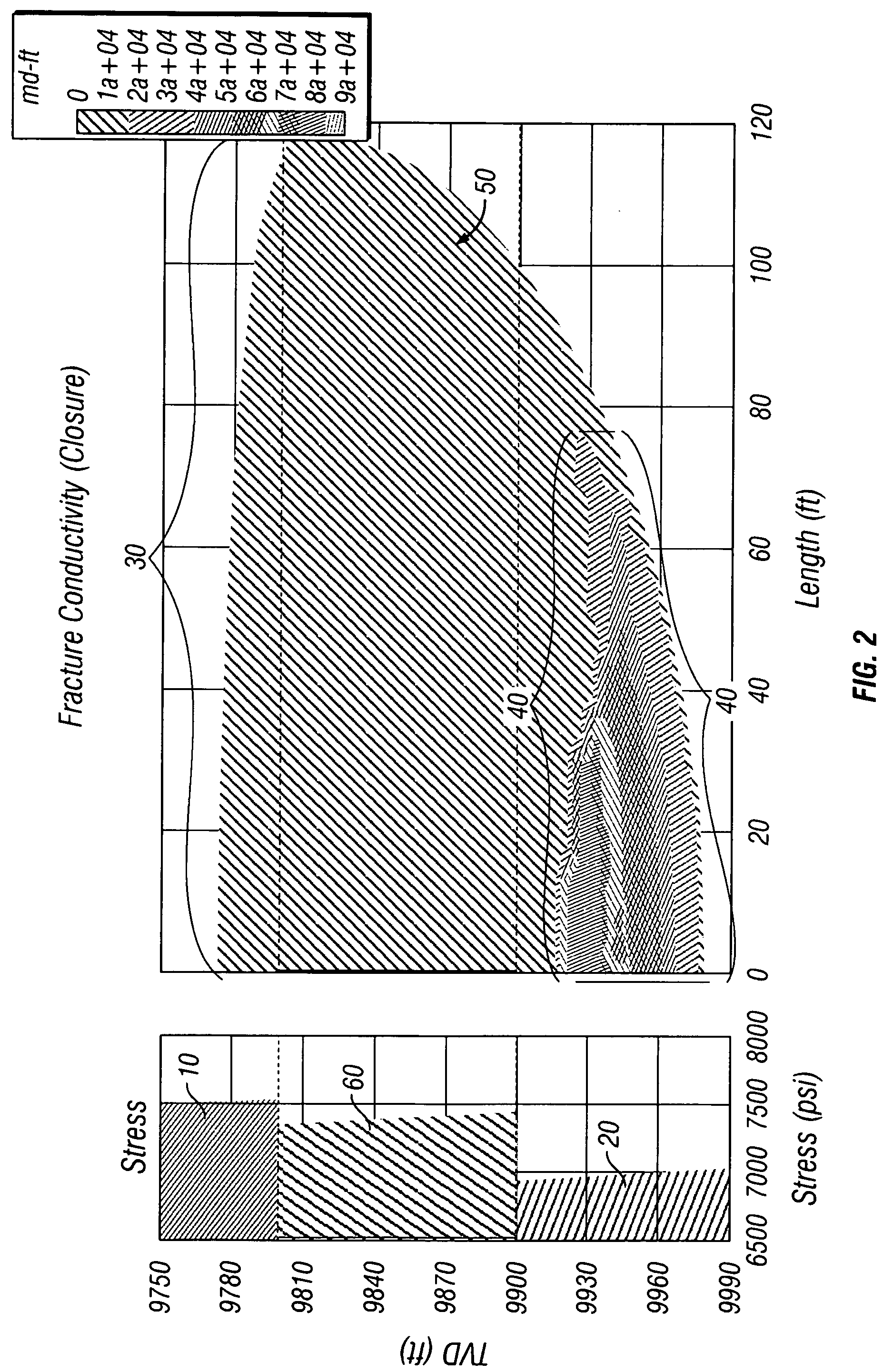

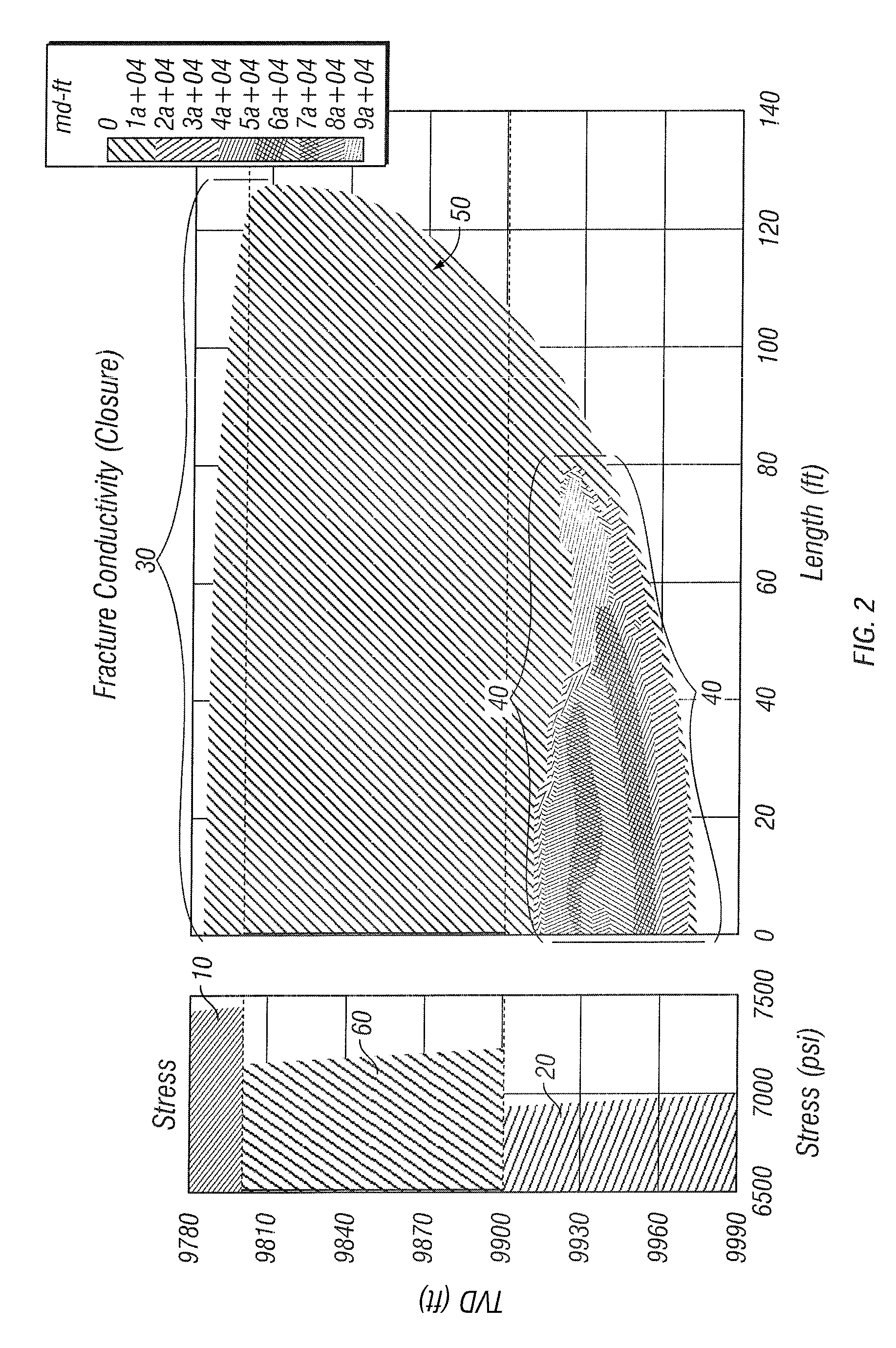

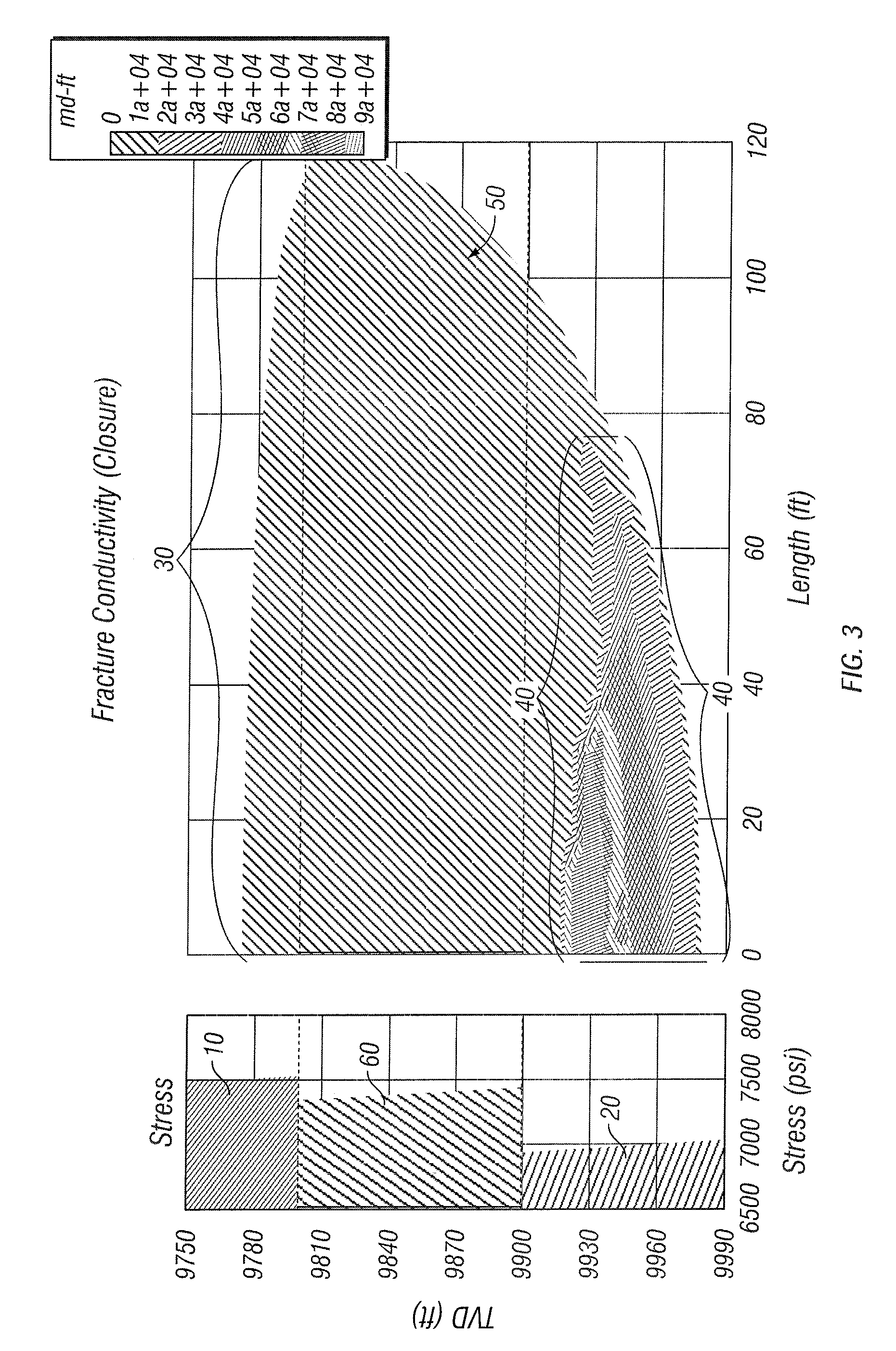

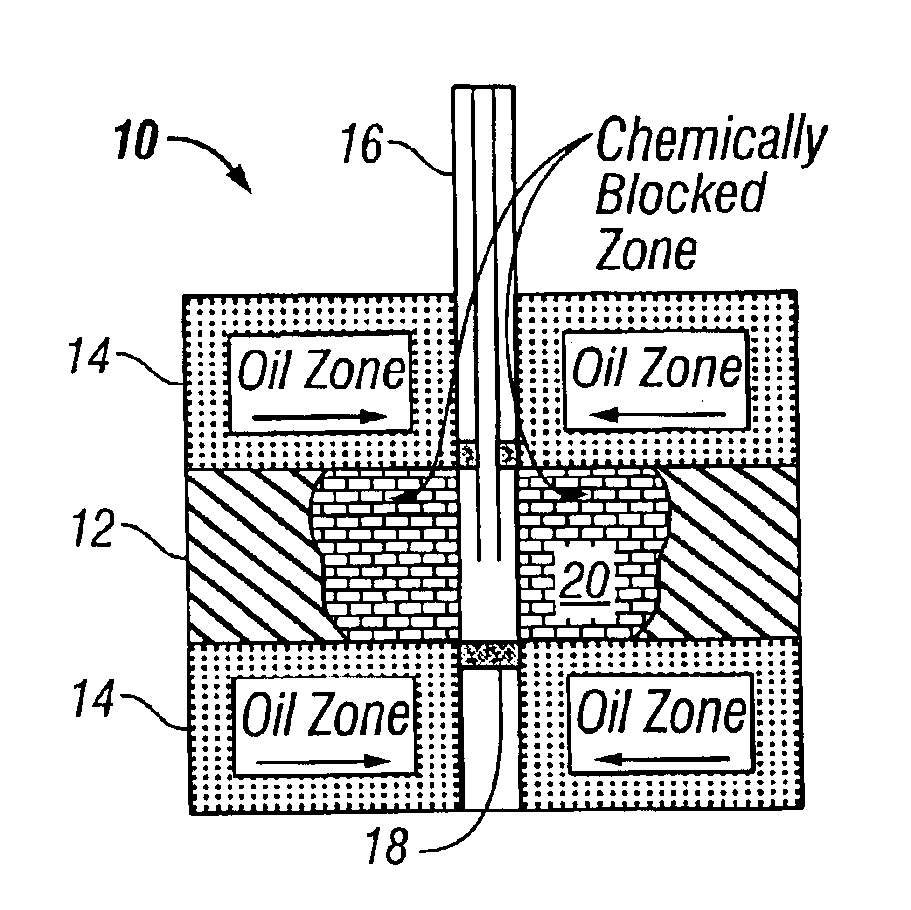

Method of hydraulic fracturing to reduce unwanted water production

ActiveUS20050016732A1Reduce conductivityFluid removalDrilling compositionGeomorphologyWater production

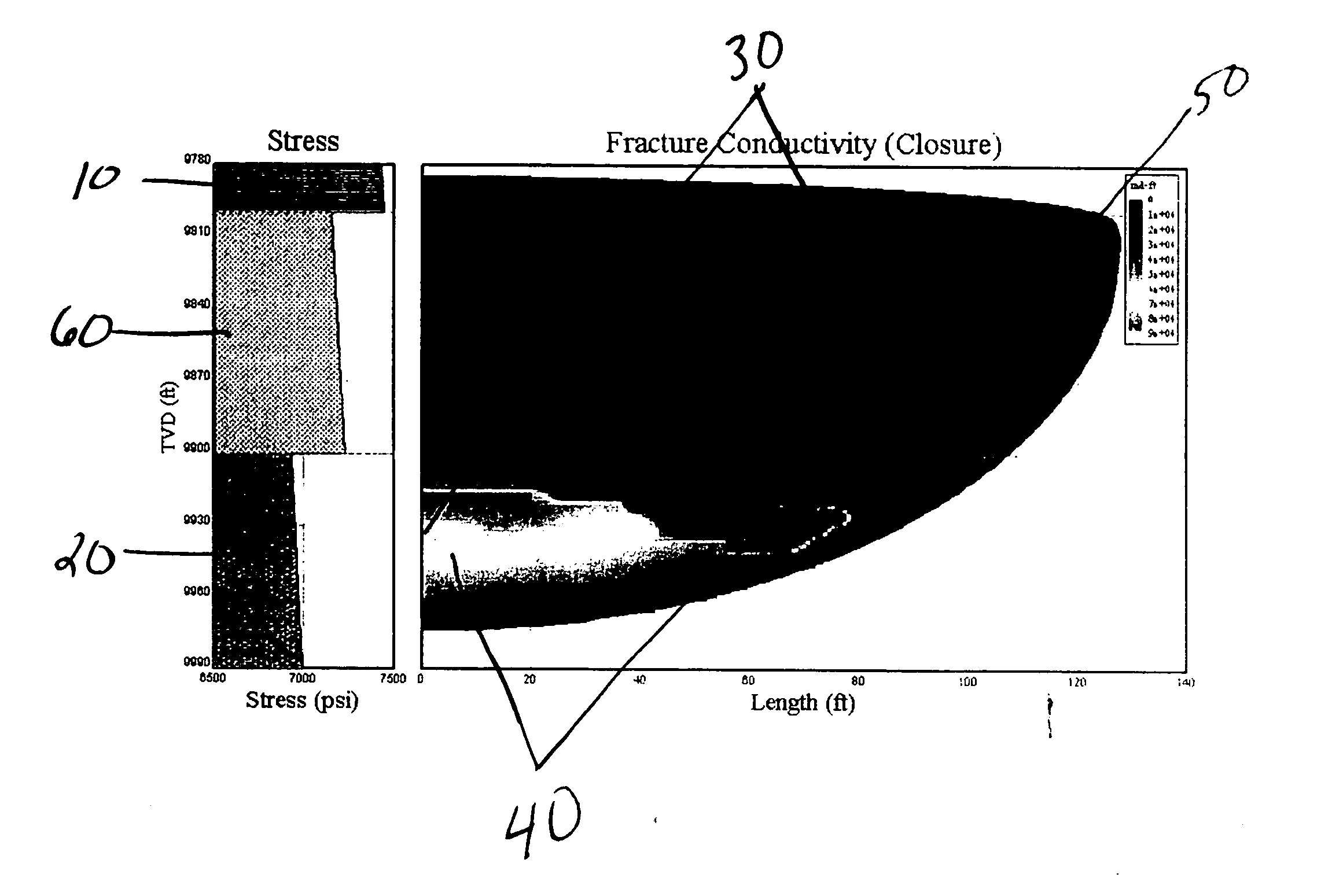

A method of hydraulically fracturing a hydrocarbon-bearing subterranean formation ensures that the conductivity of water inflow below the productive zone of the subterranean formation is reduced. The method consists of two principal steps. In the first step, a fracture in and below the productive zone of the formation is initiated by introducing into the subterranean formation a fluid, free of a proppant, such as salt water, fresh water, brine, liquid hydrocarbon, and / or nitrogen or other gases. The proppant-free fluid may further be weighted. In the second step, a proppant laden slurry is introduced into the subterranean formation which contains a relatively lightweight density proppant. Either the fluid density of the proppant-free fluid is greater than the fluid density of the proppant laden slurry or the viscosity of the proppant-free fluid is greater than the viscosity of the proppant laden slurry. The method limits undesirable fracture height growth in the hydrocarbon-bearing subterranean formation during the fracturing.

Owner:BAKER HUGHES INC

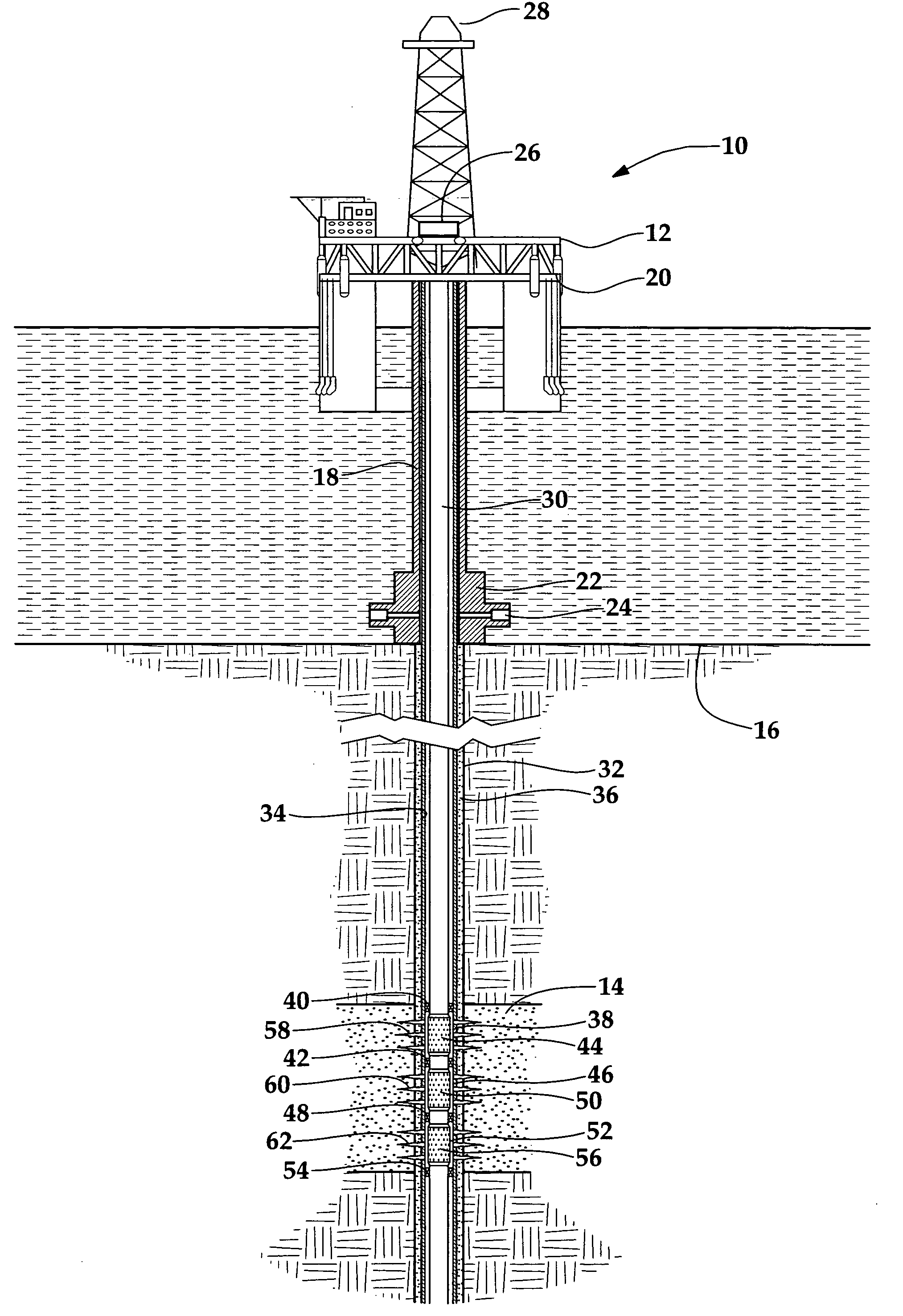

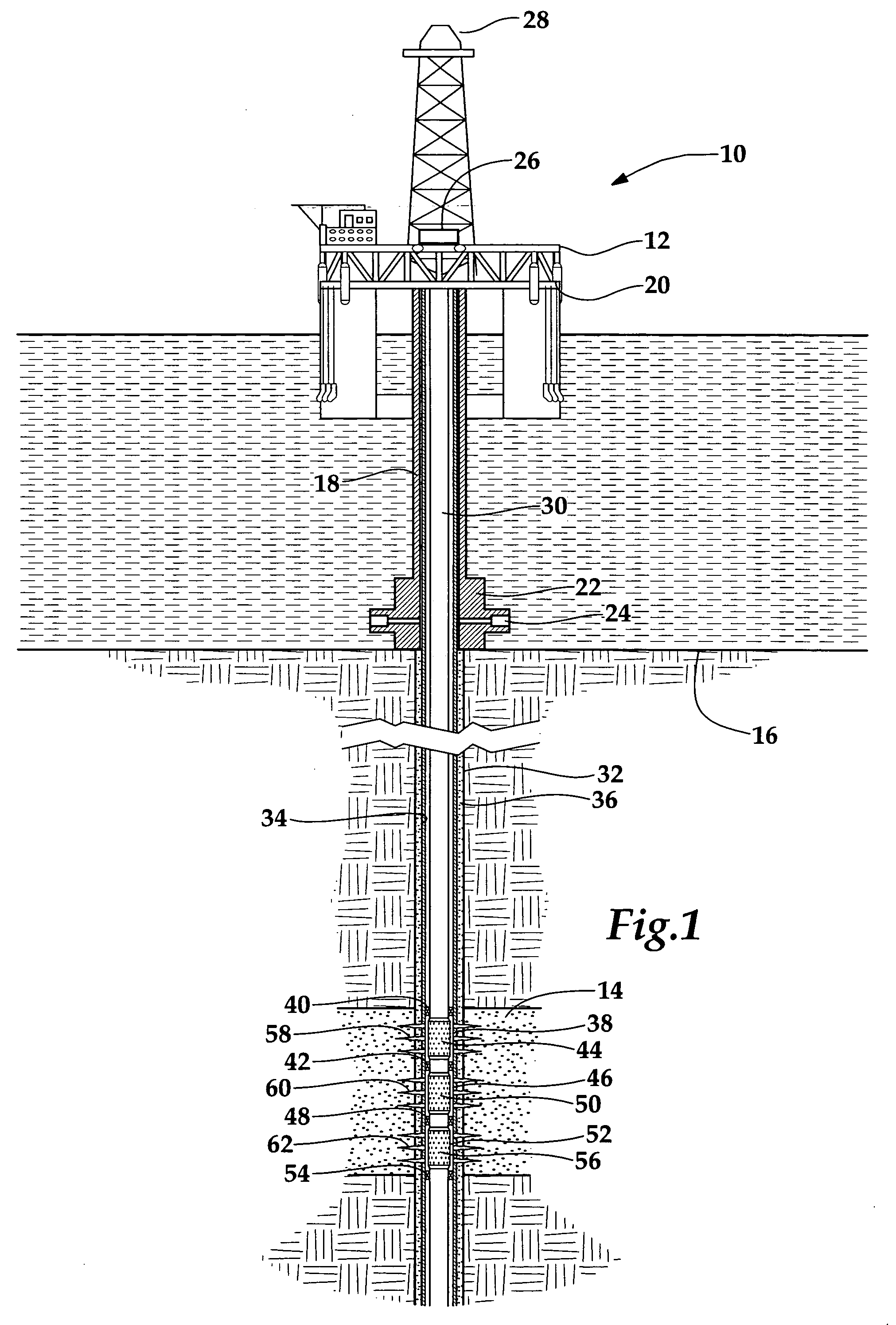

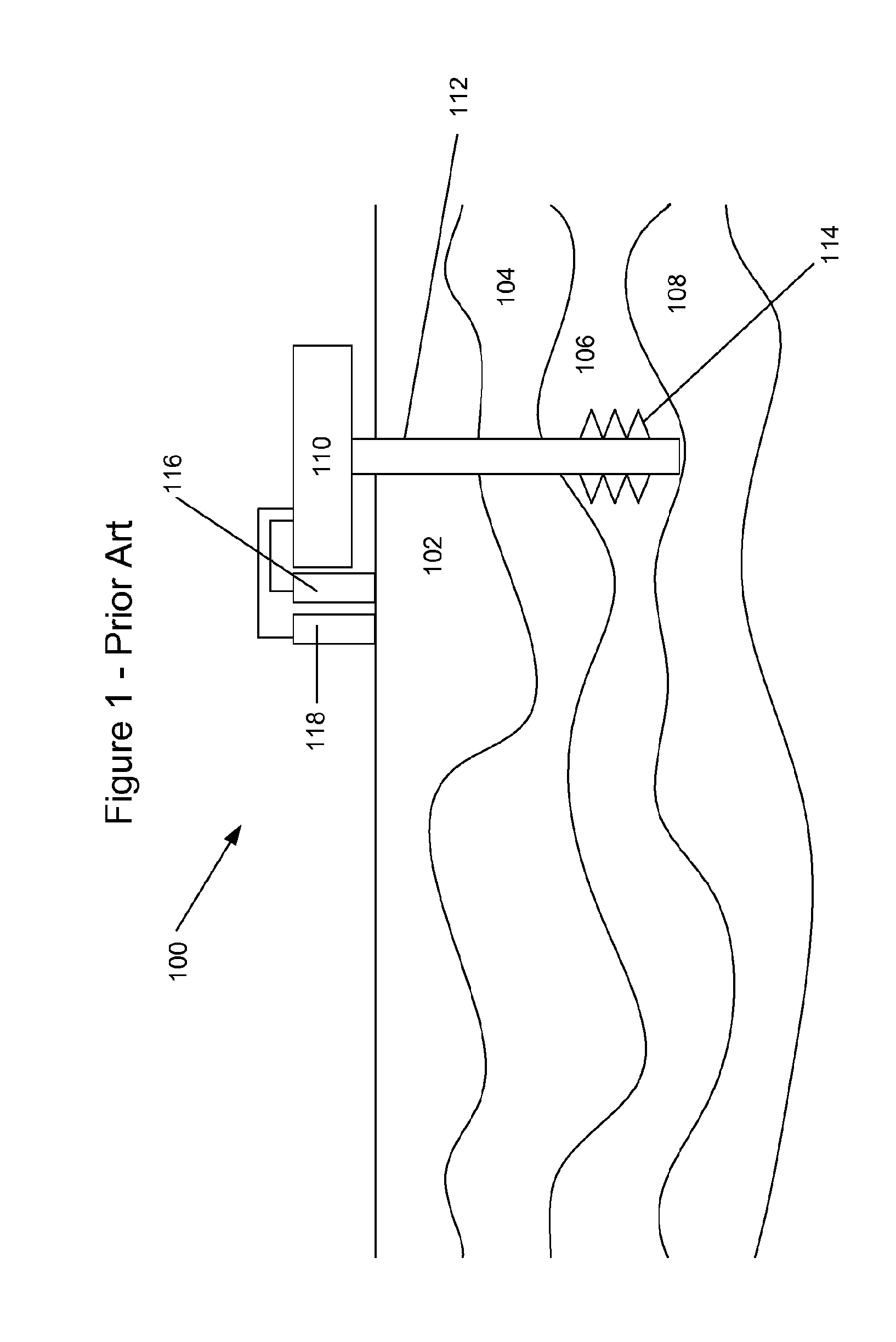

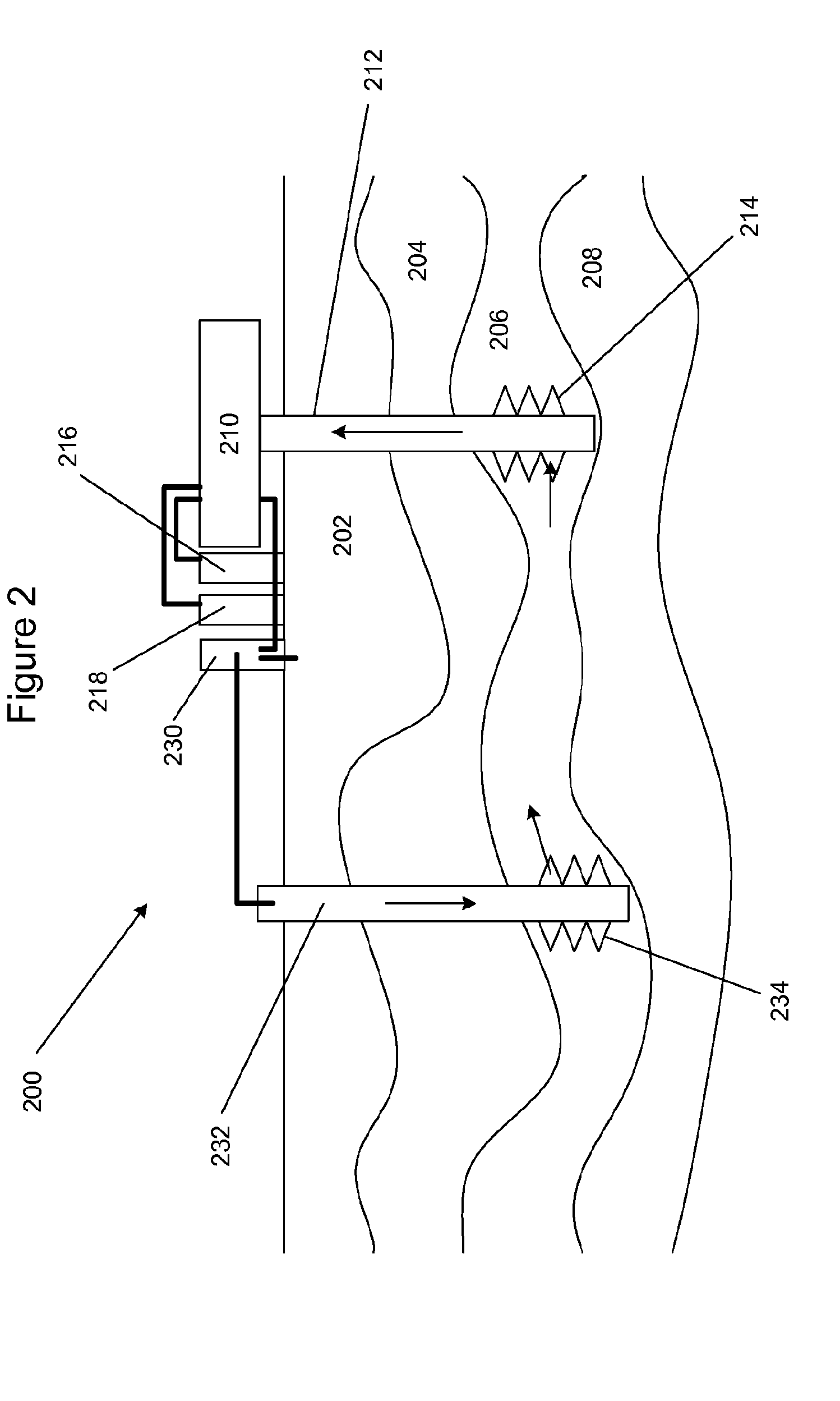

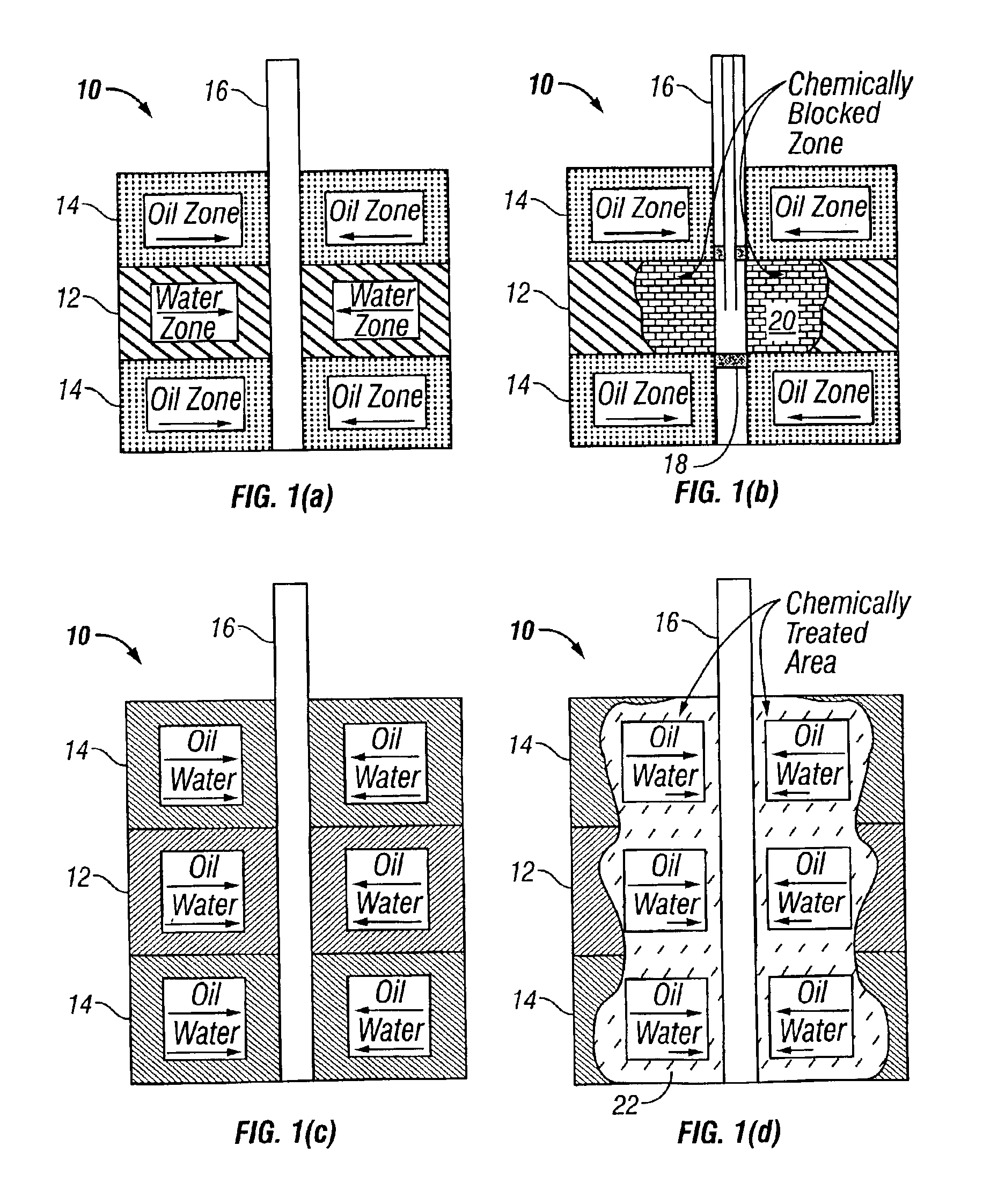

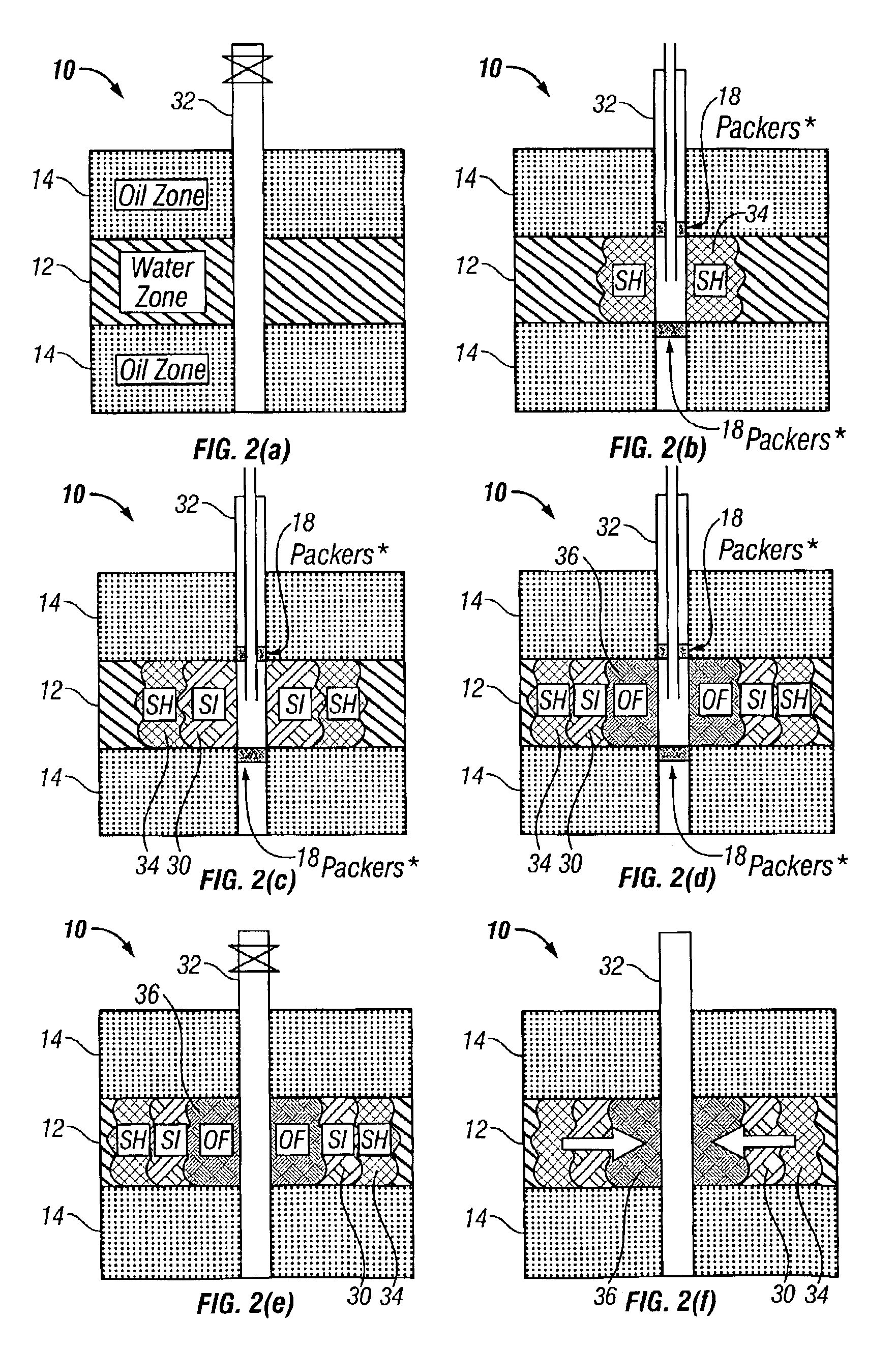

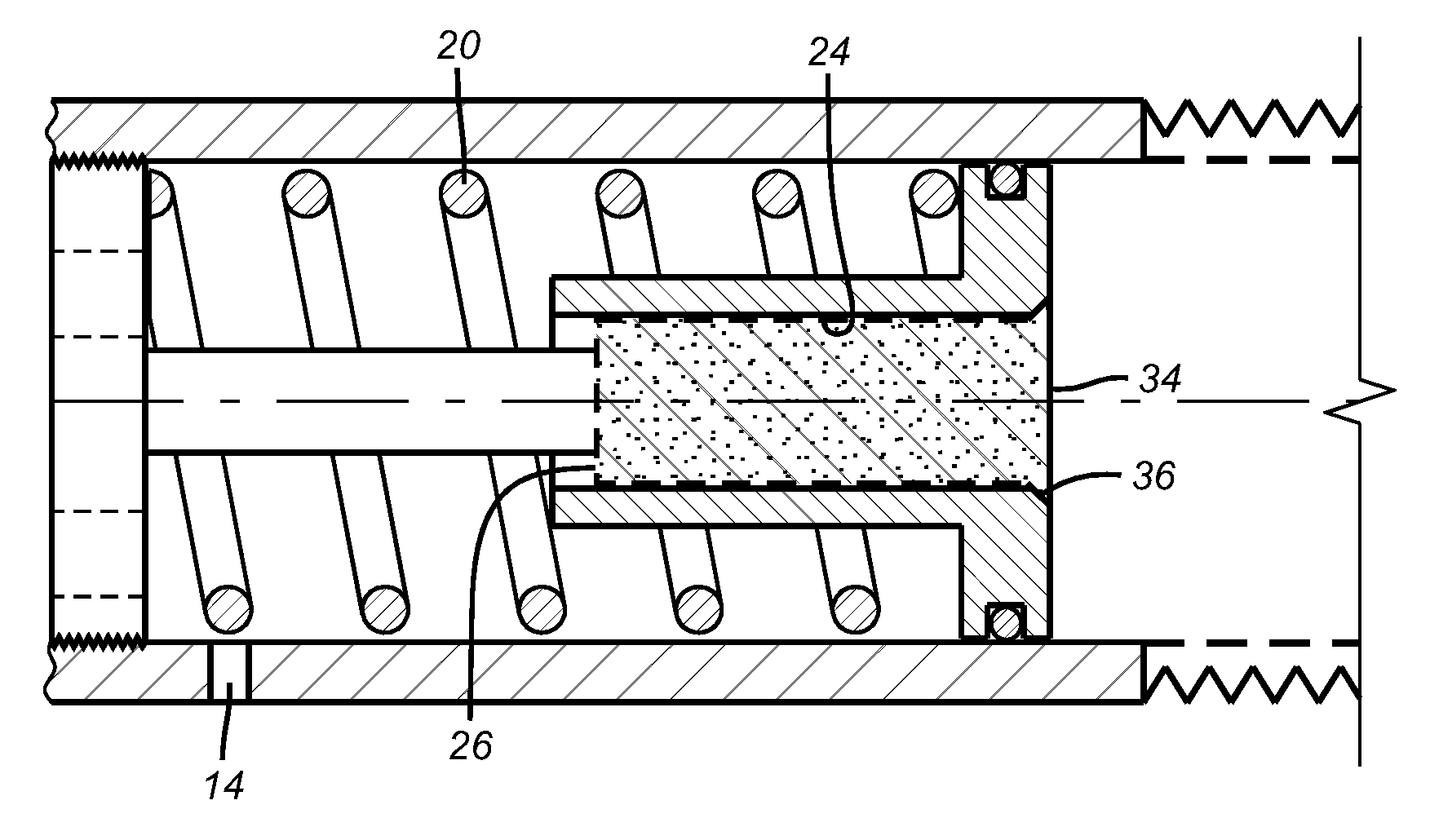

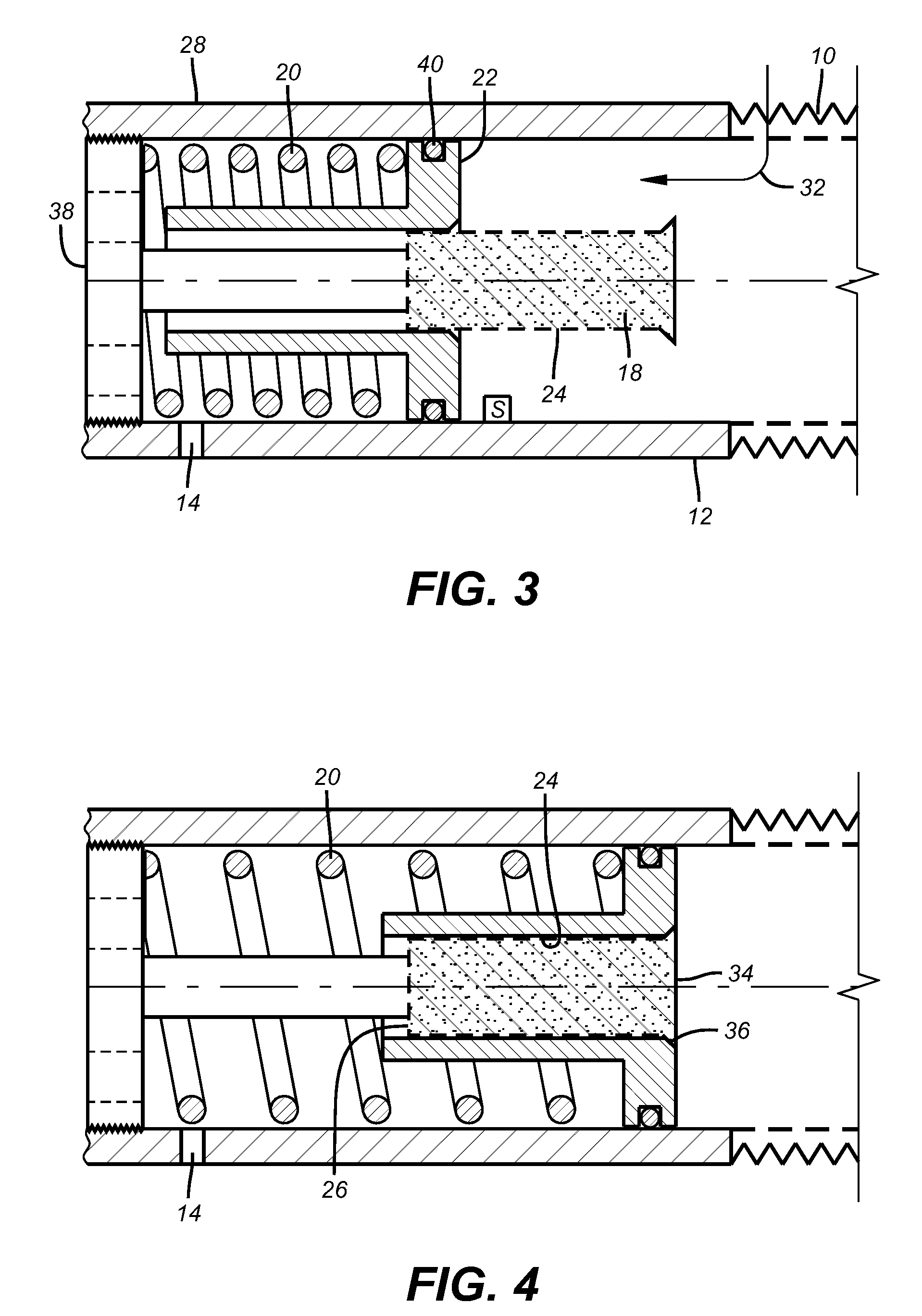

Apparatus and method for reducing water production from a hydrocarbon producing well

InactiveUS20070012444A1Reduce water productionReduce penetrationFluid removalSealing/packingHydrophilic monomerWater production

A filtering apparatus for use in a hydrocarbon producing well for reducing water production therein includes a filtering medium treated with a relative permeability modifier such that the relative permeability modifier reduces the permeability of the filtering medium if the relative permeability modifier contacts water production. The relative permeability modifier may be used to treat a metal portion of the filtering medium in the case of a wire wrap screen or a wire mesh screen or may be use treat a metal portion or the prepacked component of a prepacked screen. The relative permeability modifier may be a polymer of at least one hydrophilic monomer and at least one hydrophobically modified hydrophilic monomer, a hydrophobically modified polymer, a hydrophobically modified water-soluble polymer, hydrophobically modified copolymers thereof or the like.

Owner:HALLIBURTON ENERGY SERVICES INC

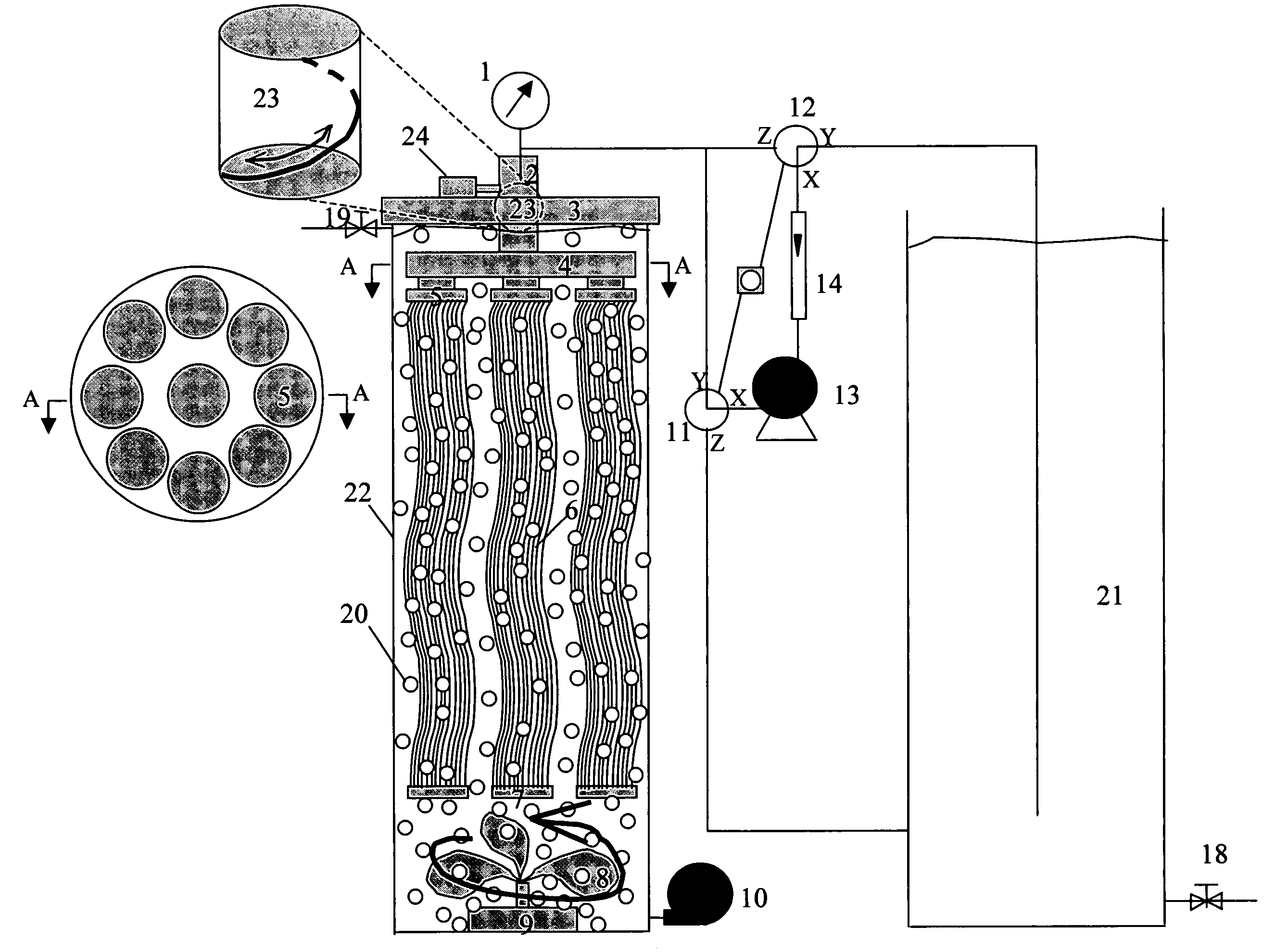

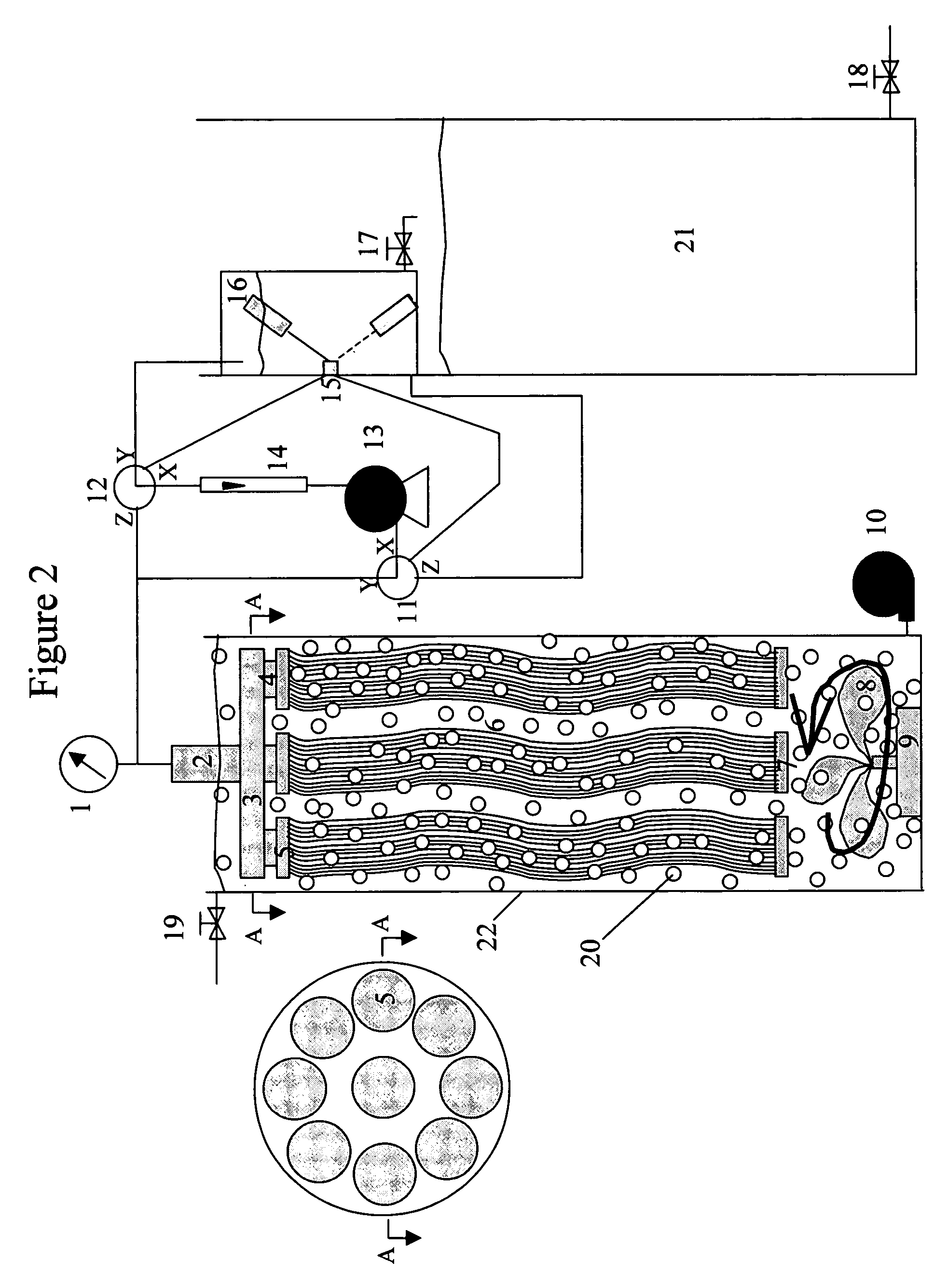

Advanced submerged membrane modules, systems and processes

Advanced submerged membrane systems are provided. Said submerged membrane systems have multiple membrane modules comprising of strips of flat sheet membrane, bundles of self-support hollow fiber membranes braided together for reinforcement, tubular membranes, and braid supported hollow fiber membranes. Said submerged membrane systems have alternating relay, or two-way floating switch or computer to control filtration and back flush / pulse cleaning. Said submerged membrane systems have an oscillating motor, and aerator which can generate liquid vortex (whirlpool) flow around membrane to keep membrane from fouling. The present invention provides advanced submerge membrane systems at very low cost for drinking water production, wastewater treatment and membrane bioreactors for biotech, pharmaceutical and other industries.

Owner:JI JIANG

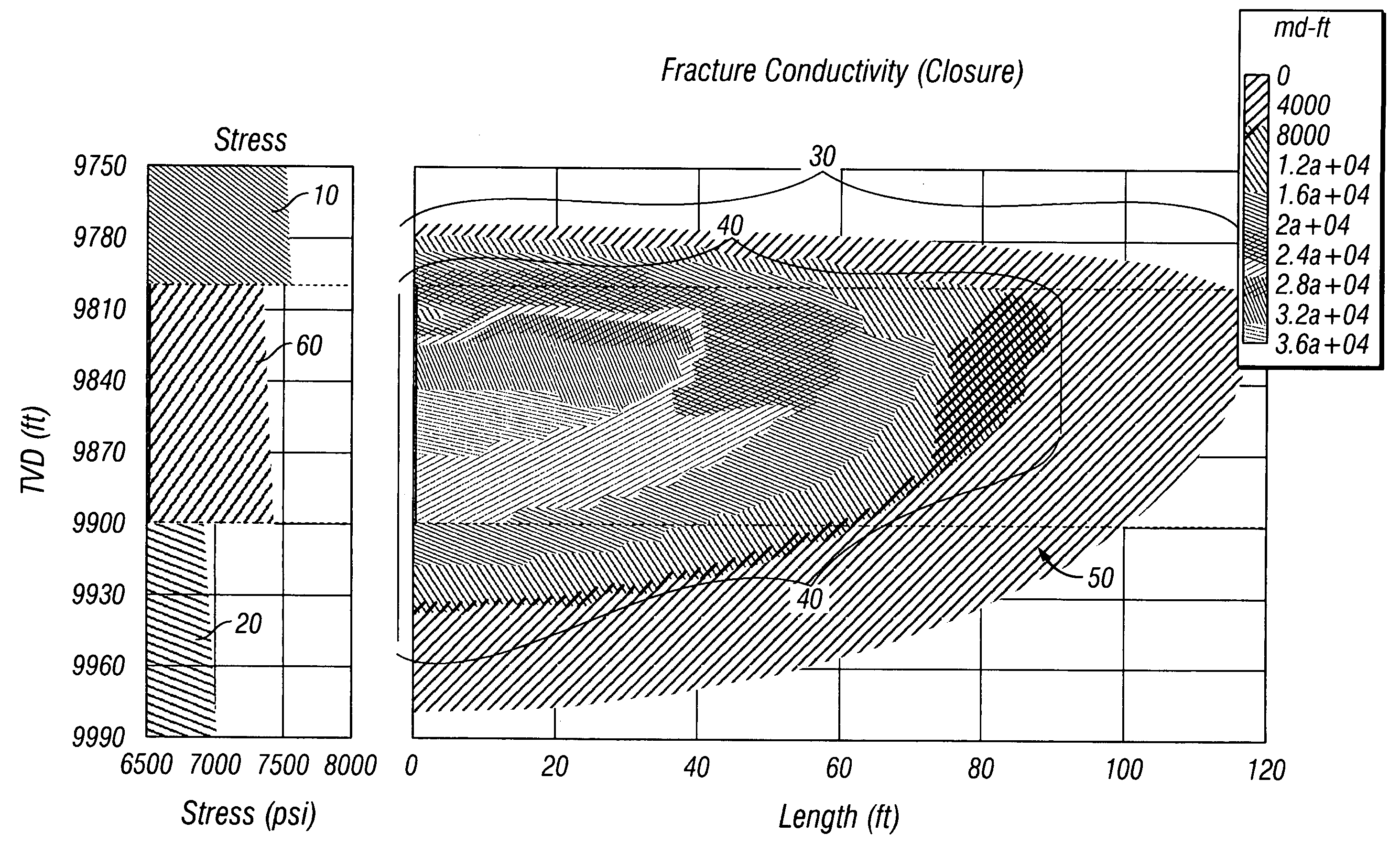

Method of hydraulic fracturing to reduce unwanted water production

ActiveUS7207386B2Limit undesirable height growthFluid removalDrilling compositionSaline waterGeomorphology

A method of hydraulically fracturing a hydrocarbon-bearing subterranean formation ensures that the conductivity of water inflow below the productive zone of the subterranean formation is reduced. The method consists of two principal steps. In the first step, a fracture in and below the productive zone of the formation is initiated by introducing into the subterranean formation a fluid, free of a proppant, such as salt water, fresh water, brine, liquid hydrocarbon, and / or nitrogen or other gases. The proppant-free fluid may further be weighted. In the second step, a proppant laden slurry is introduced into the subterranean formation which contains a relatively lightweight density proppant. Either the fluid density of the proppant-free fluid is greater than the fluid density of the proppant laden slurry or the viscosity of the proppant-free fluid is greater than the viscosity of the proppant laden slurry. The method limits undesirable fracture height growth in the hydrocarbon-bearing subterranean formation during the fracturing.

Owner:BAKER HUGHES HLDG LLC

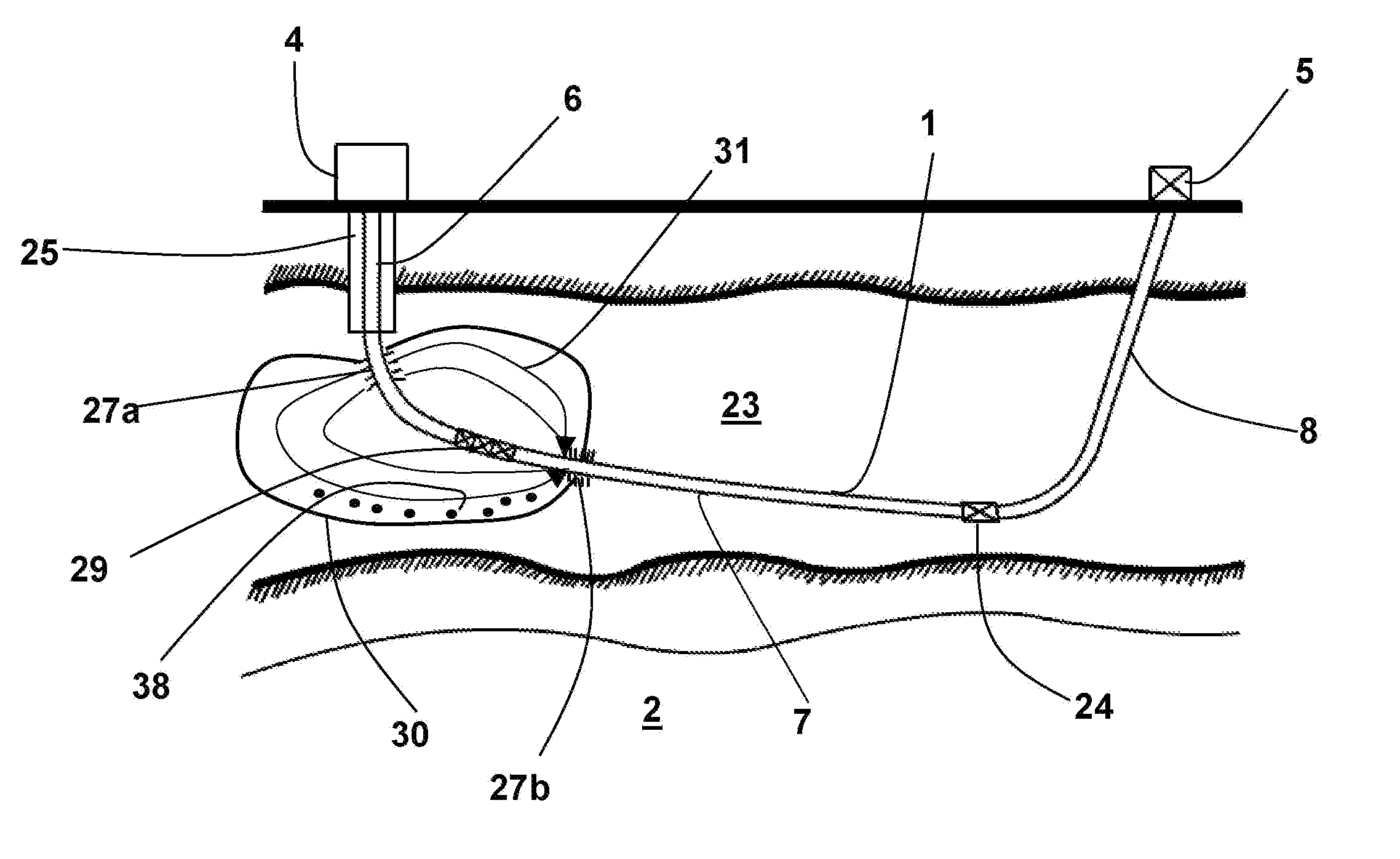

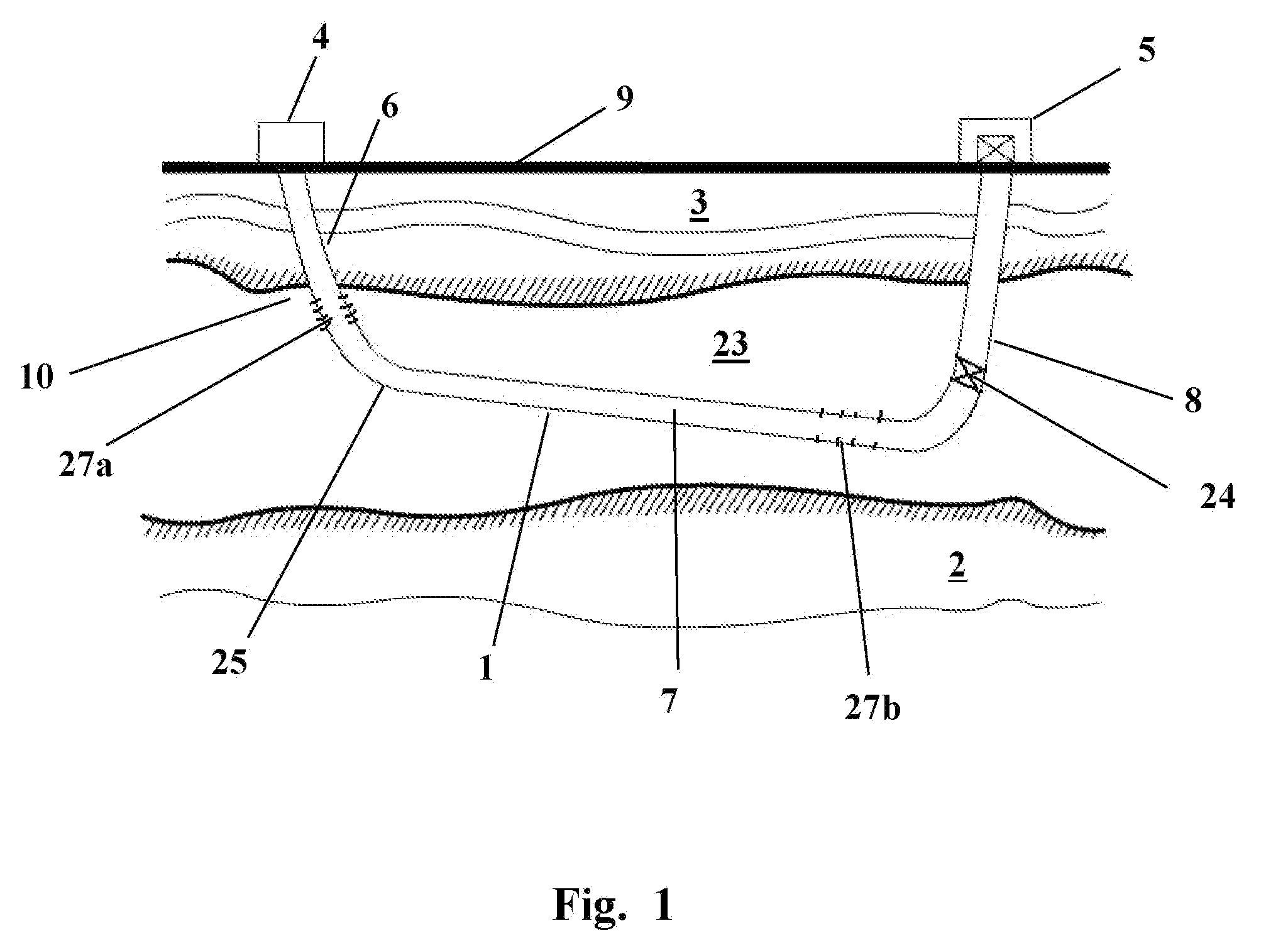

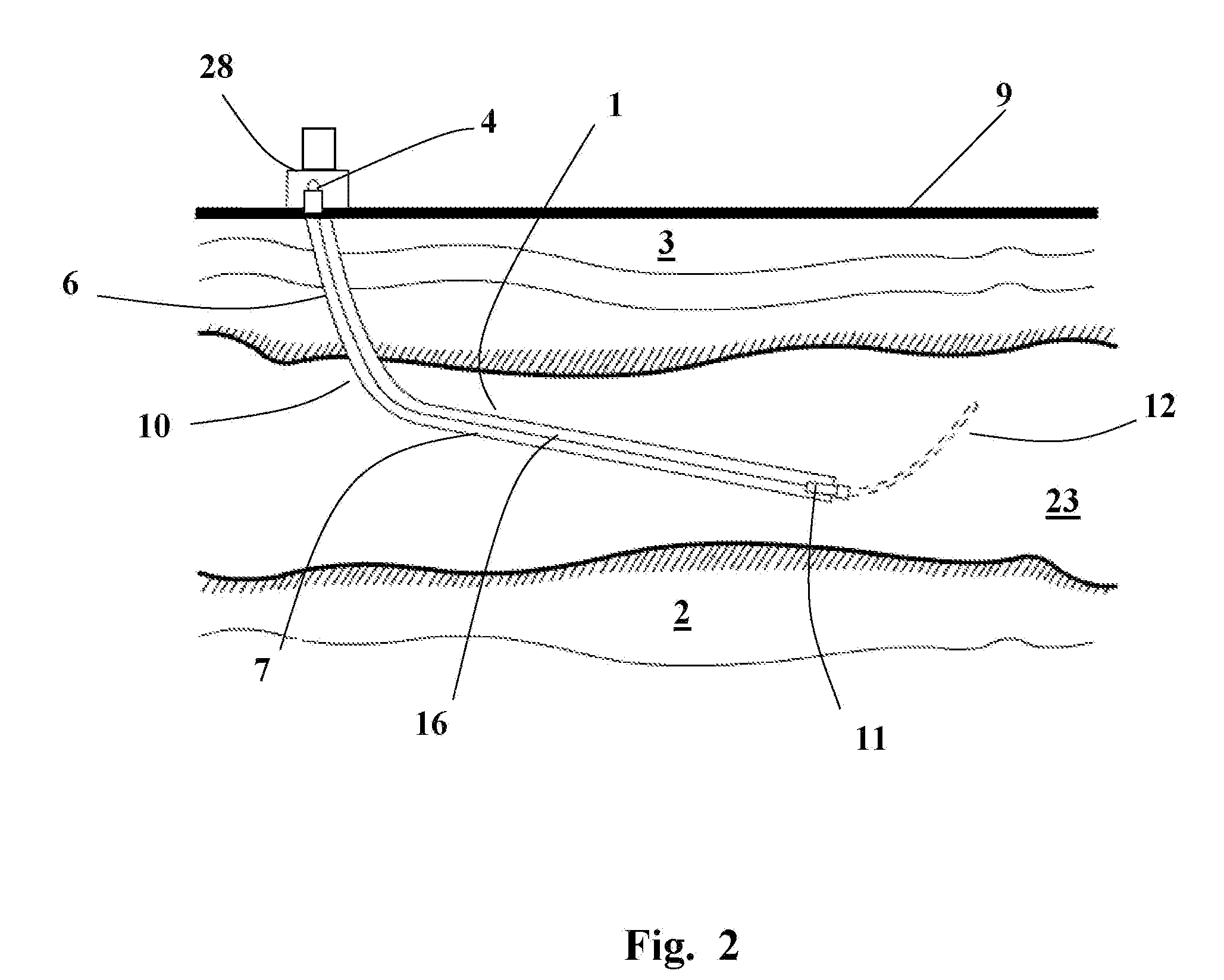

Method for Recovering Hydrocarbons from Subterranean Formations

InactiveUS20060175061A1Minimize damageLimited surfaceInsulationFluid removalWater productionTubes types

Recovery of viscous hydrocarbon from subterranean formations is assisted by using a plurality of novel U-tube type wells, each with dual wellheads, a moveable wellbore packer, a lateral section with a concentric communication zone and with sequential injection production perforations in which heat is injected into the proximal perforations and hot oil and produced fluids are produced from the distal perforations, the whole process being controlled by modulating the production flow where the wellbore fluids are controlled to act as a hydraulic seal to limit bypass of injected fluids. The injection-production displacement process moves axially along the wellbore in a sequential manner as hydrocarbon volumes are depleted by injected fluid displacement of oil and oil and water production.

Owner:CRICHLOW HENRY B

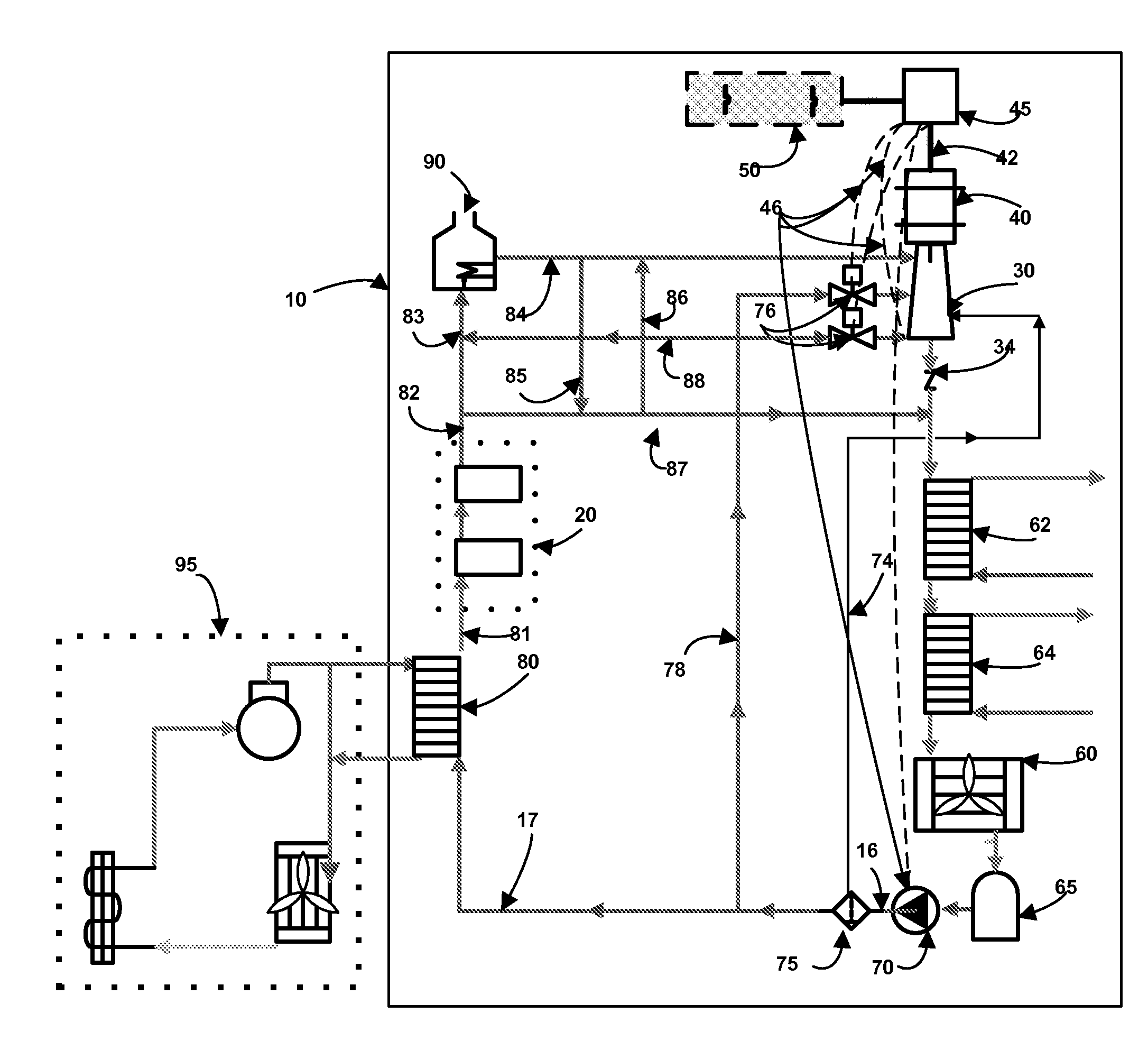

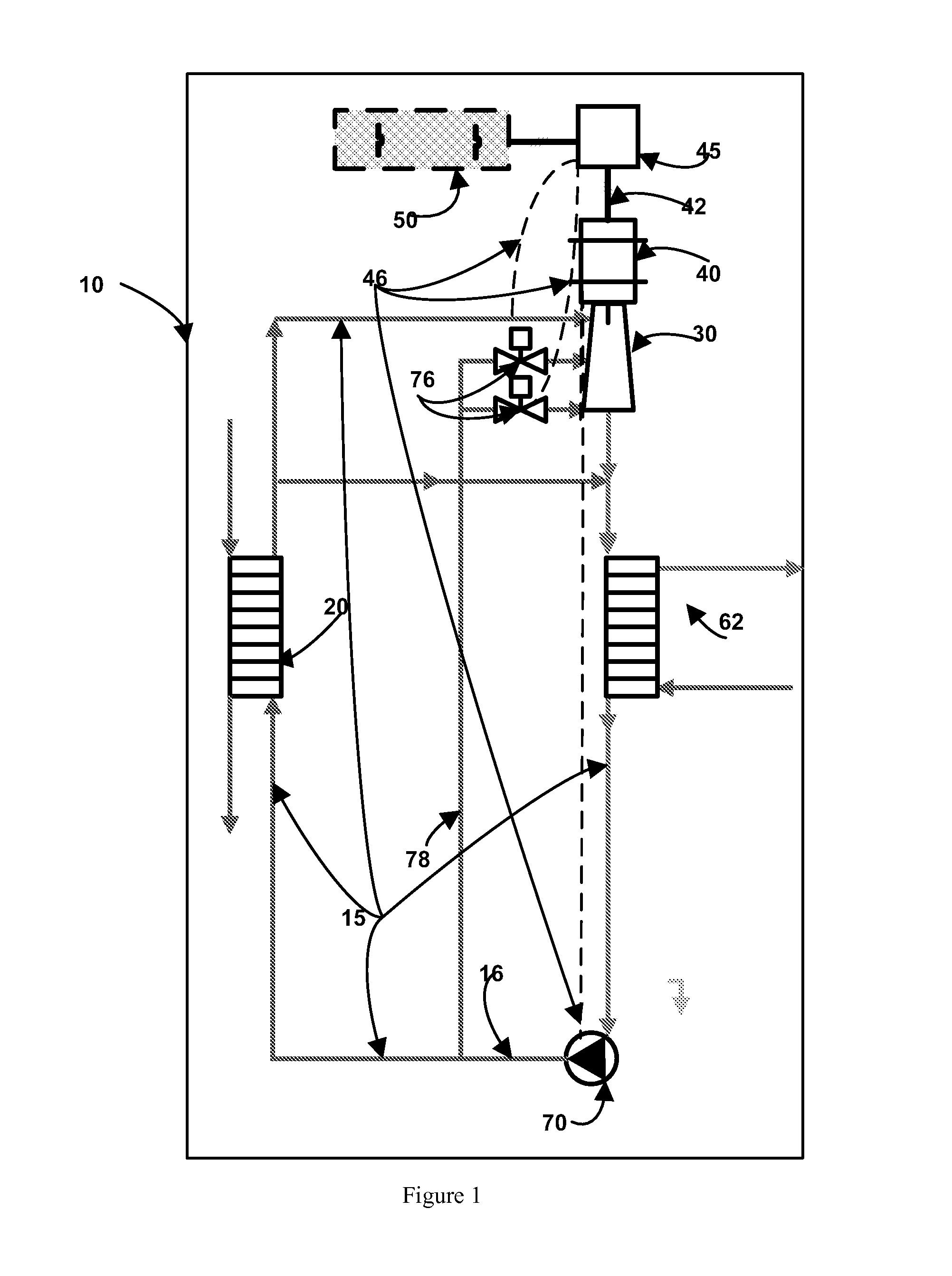

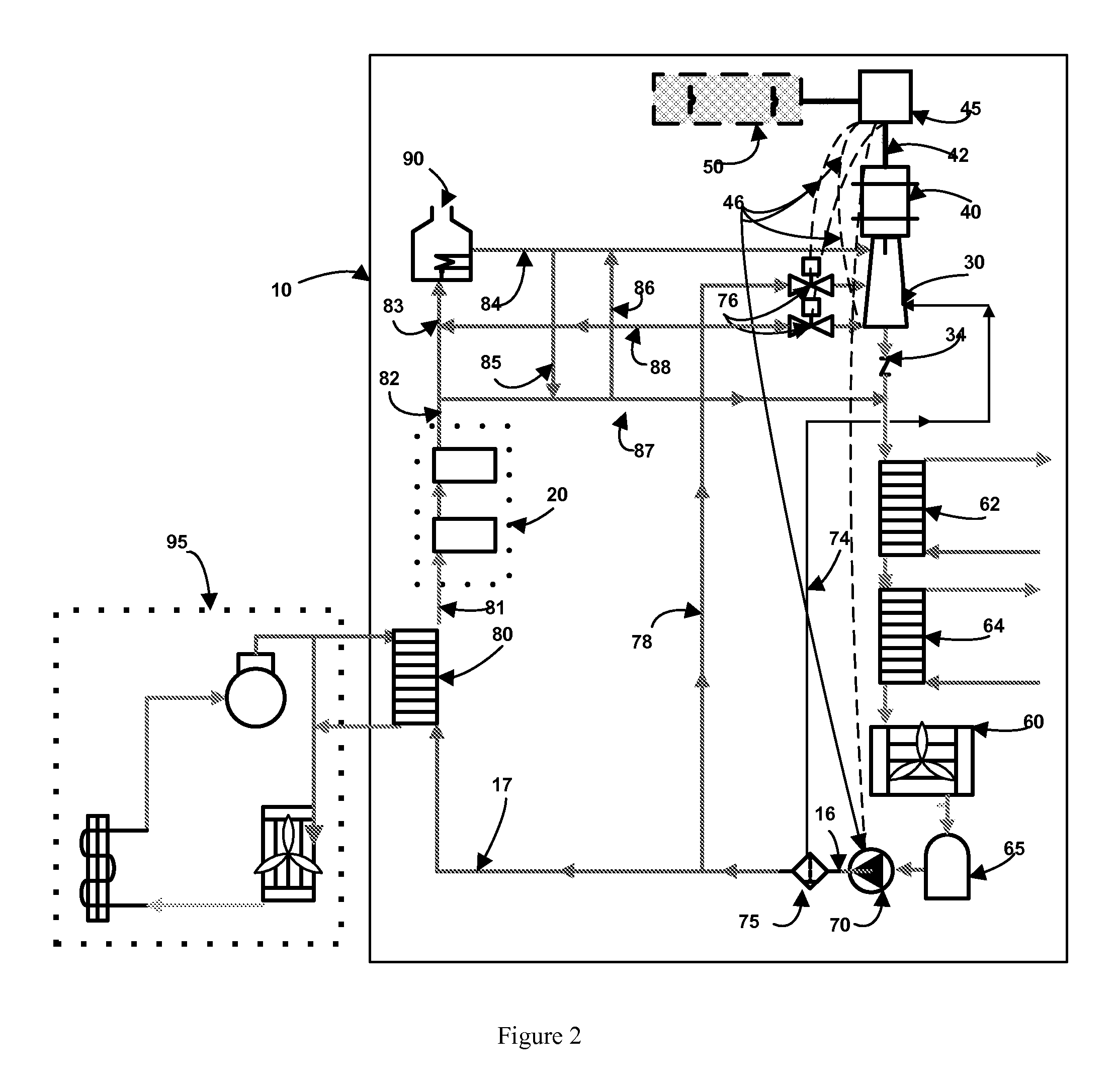

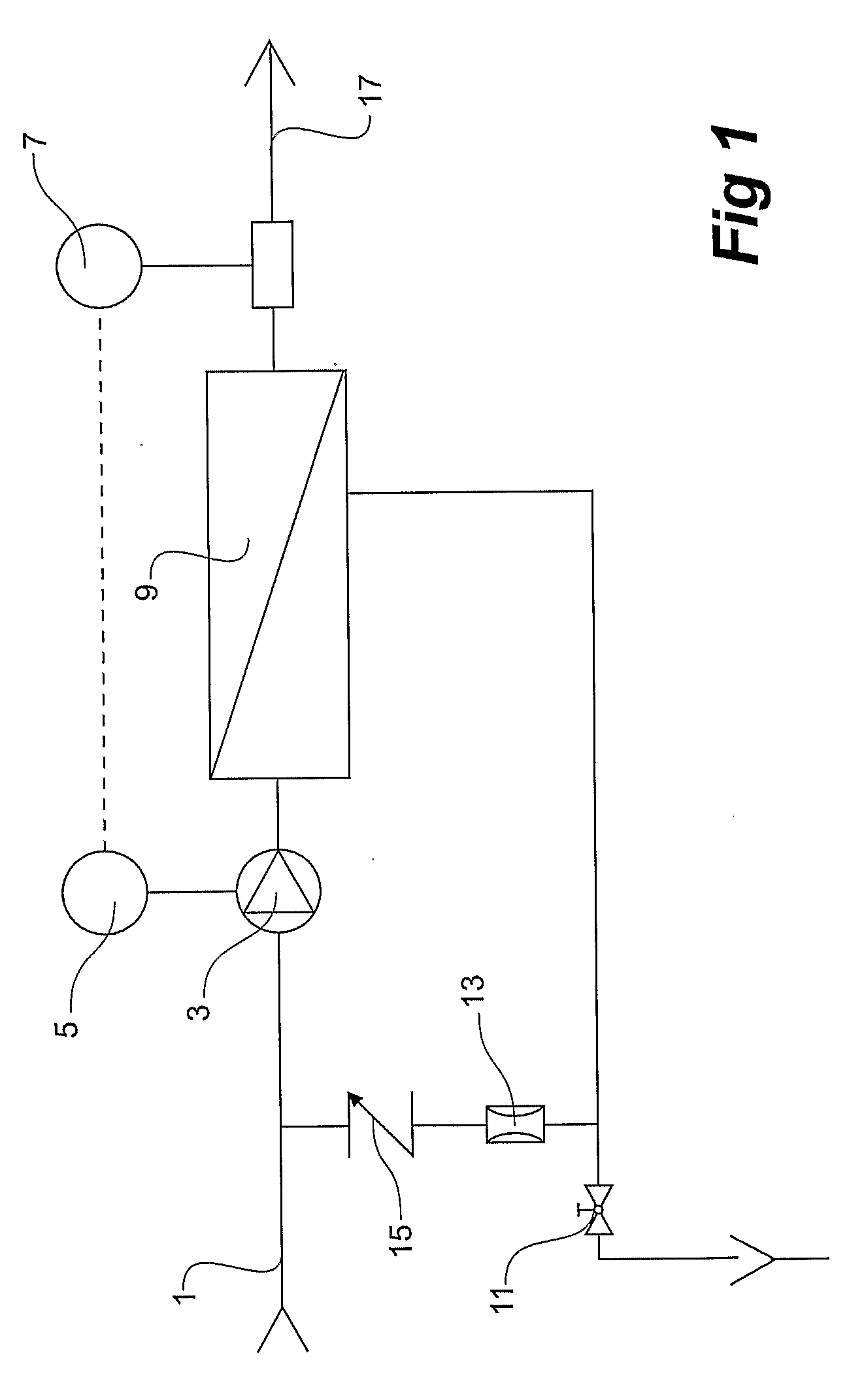

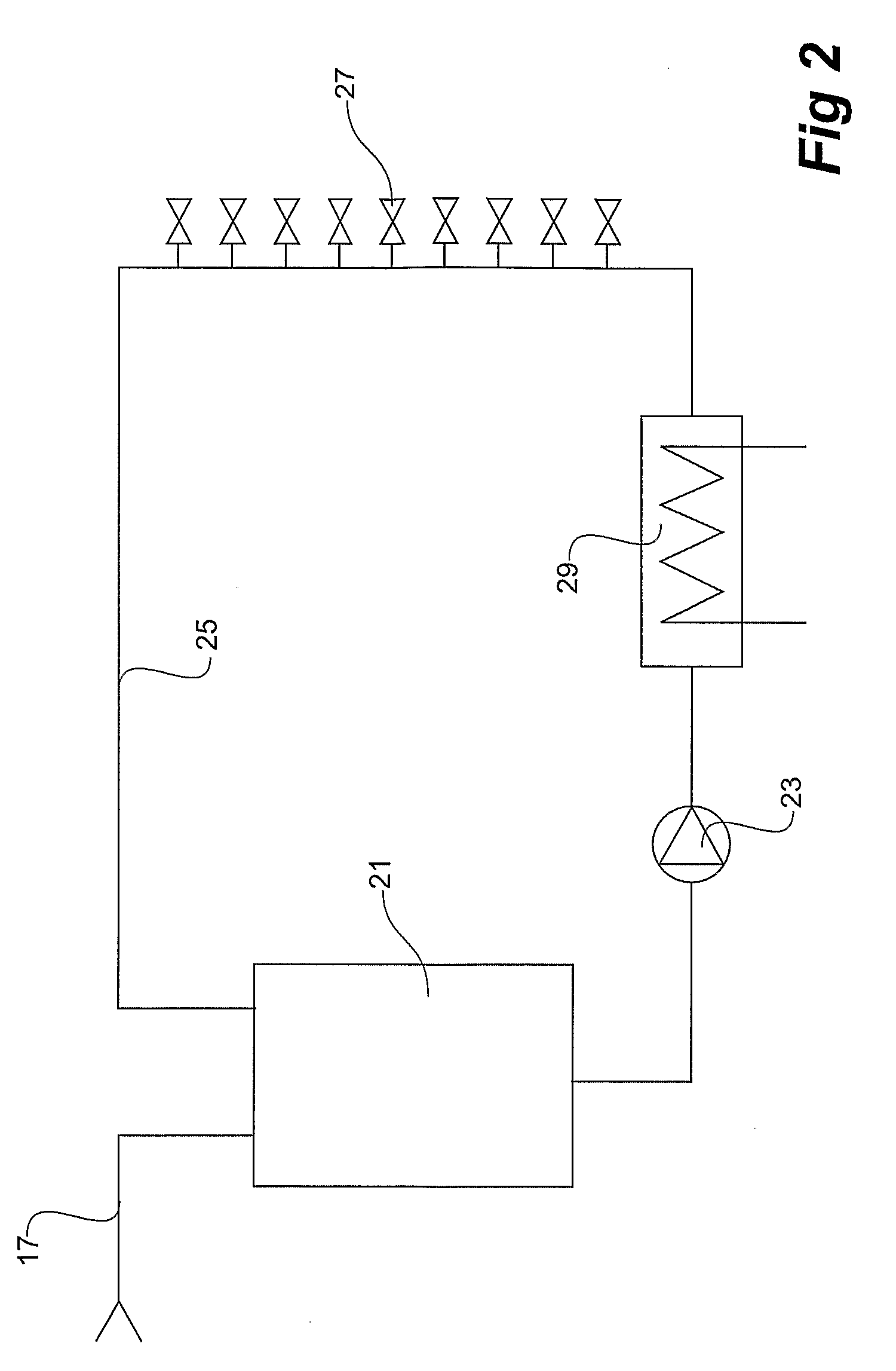

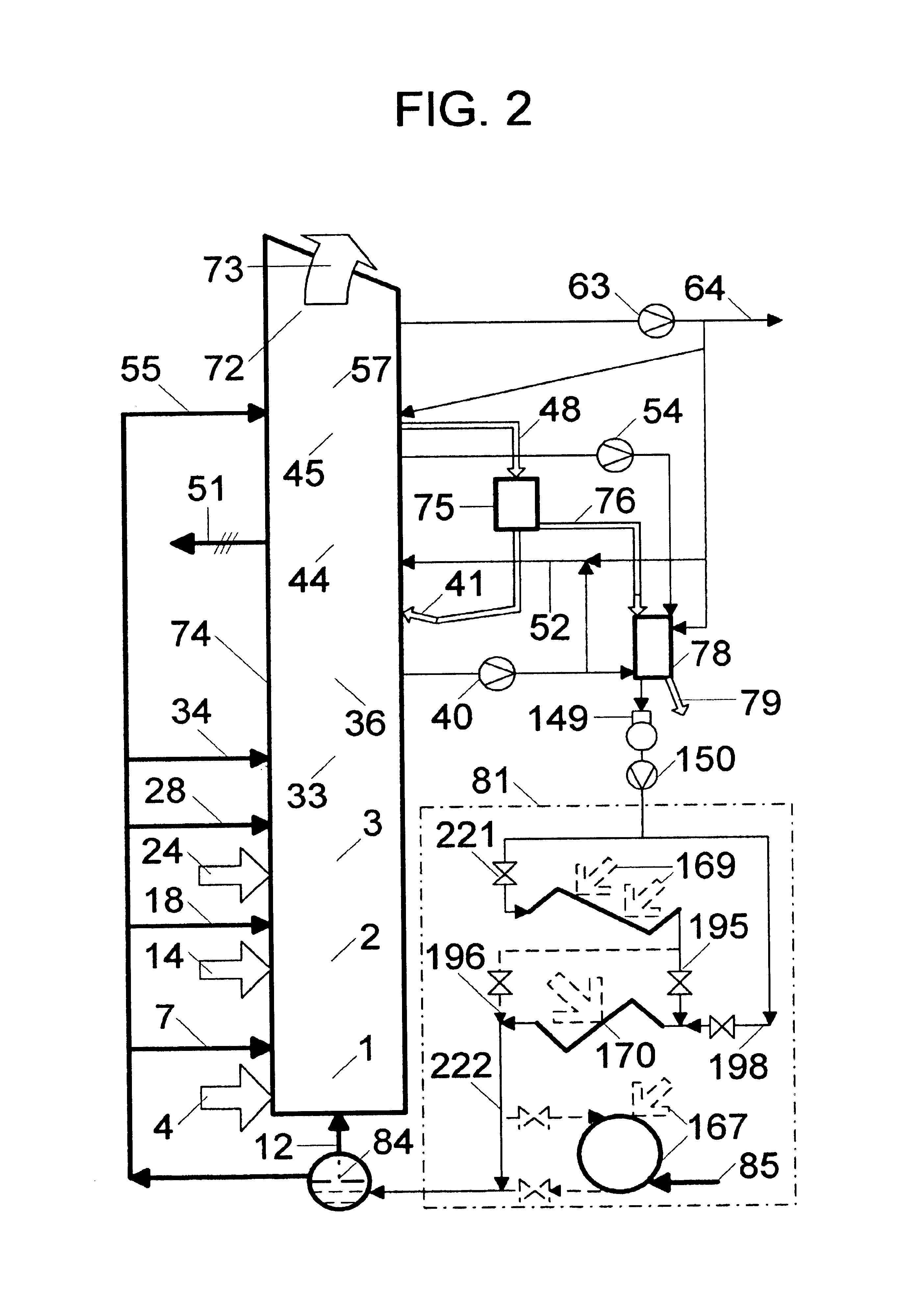

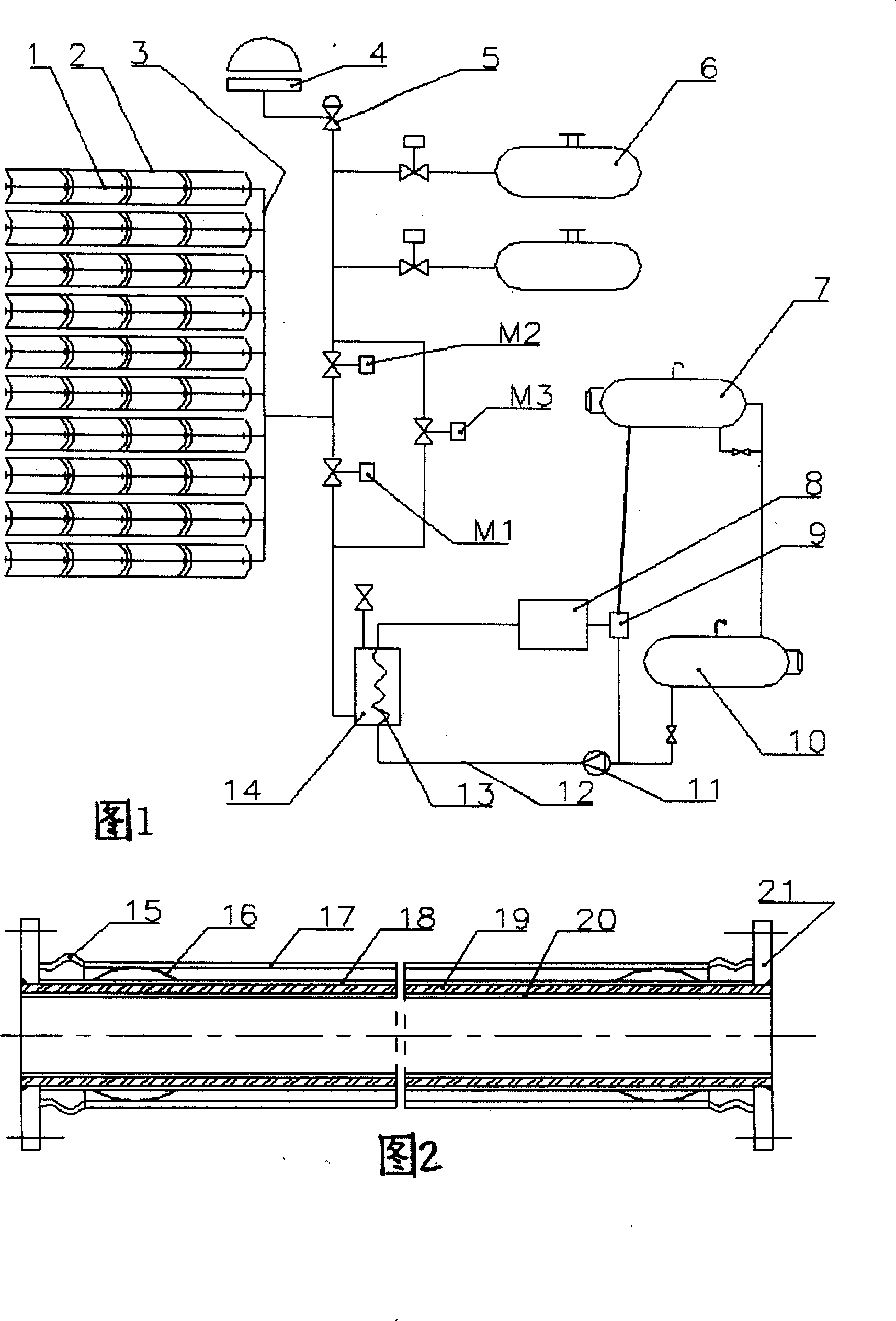

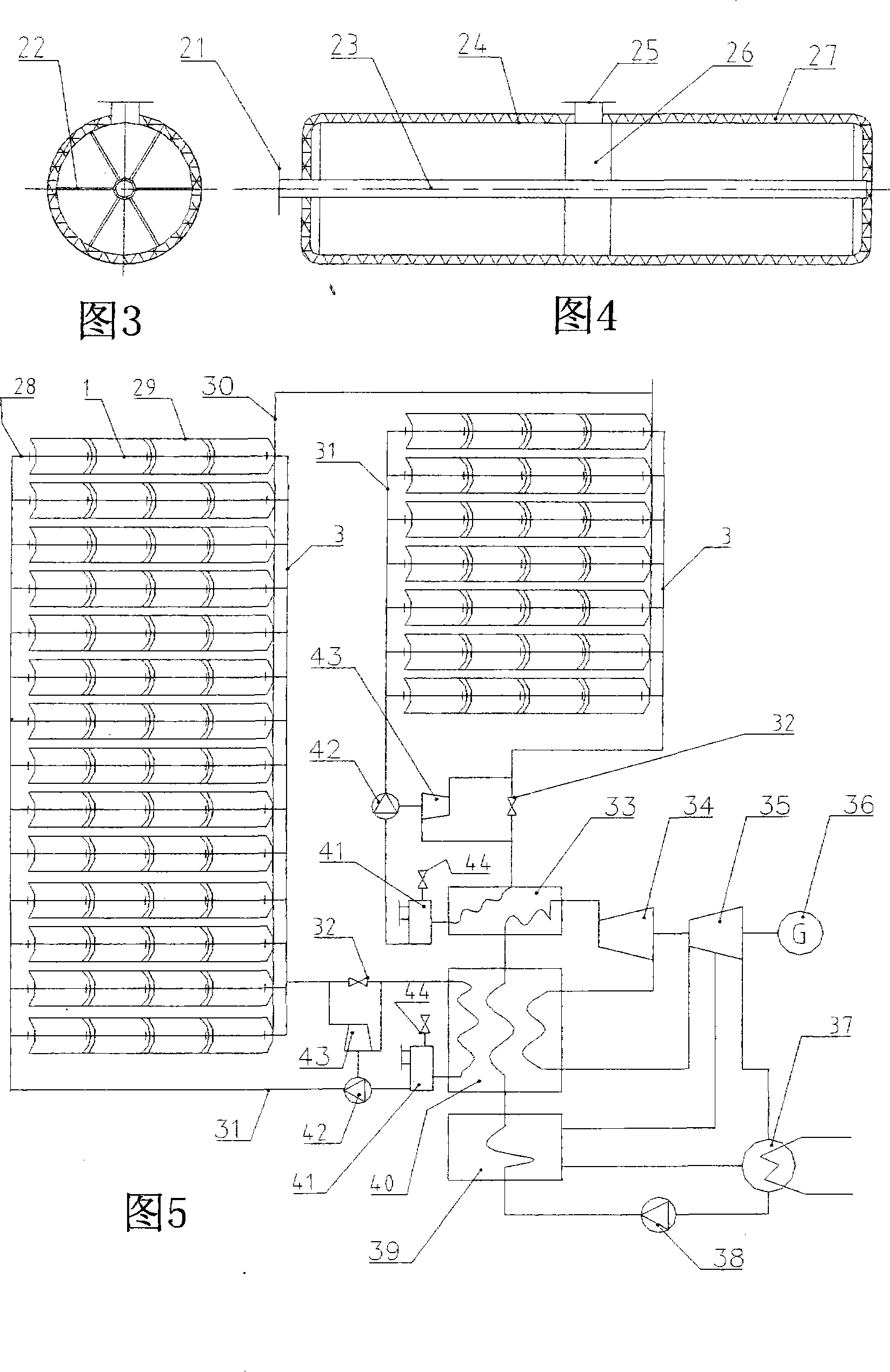

Apparatus and method for producing sustainable power and heat

InactiveUS20080163625A1Maximize energy efficiencyEasy to convertSteam useCombined combustion mitigationWorking fluidWater production

An integrated system provides electricity and heat from solar, waste heat, biomass and fossil fuel energy. The system operates with a volatile organic working fluid that circulates in a variable speed heat engine type cycle, that is heated either to its boiling point, to a saturated state or above its boiling point, or to a superheated gas state, expanded through an expander, with working fluid injected therein such that the fluid exiting the expander is cooled in a condenser in thermal communication with a facility's domestic hot water, space heating or process heating systems, and circulated by a pump. Heat exchange loops define hot water production capability for use in a facility while a generator is coupled to the expander to produce electricity and is connected to the utility grid at fixed frequency and voltage in either a paralleling or island mode.

Owner:OBRIEN KEVIN M

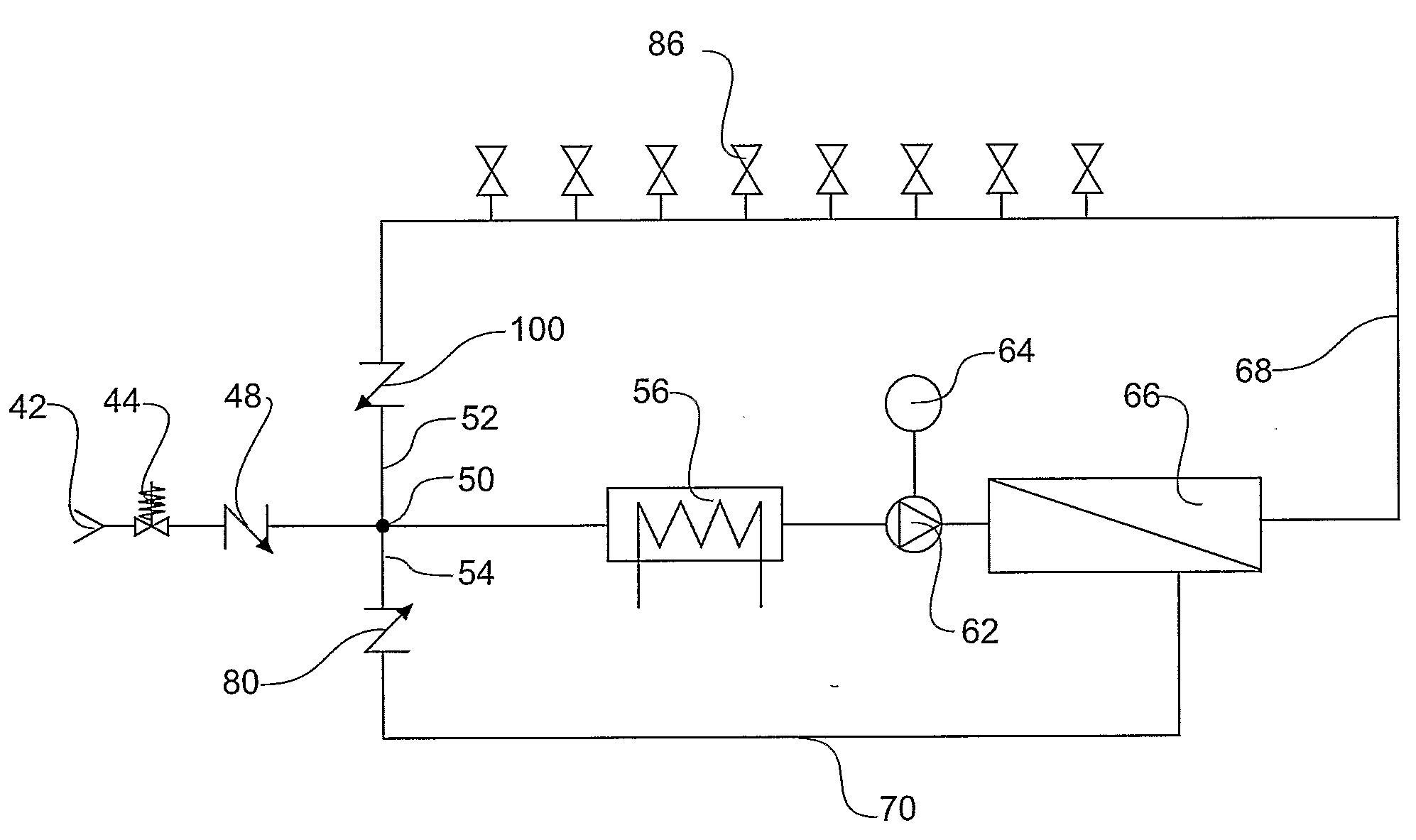

Purified Water Production and Distribution System

InactiveUS20090134080A1Maintain microbiological cleanlinessReduce water wasteWater treatment parameter controlMembranesWater productionClosed loop

A closed loop water purification system comprising a feed water line (42) to supply feed water, a high pressure feed pump (62), a filter assembly (66) having an inlet supplied by the high pressure feed pump, a distribution line (68) and a reject water line (70), the reject line returning reject water from the filter assembly to the feed water line, the distribution line supplying at least one purified water take off point (86) and returning to a junction (50) in the feed water line upstream of the high pressure feed pump. The reject water line is connected to the junction in the feed water line upstream of the high pressure feed pump. A first backflow prevention device (48) is on the feed water line upstream of the junction. A second backflow prevention device (100) is on the distribution line upstream of the junction and a third backflow prevention device (80) is on the reject water line upstream of the junction. A heater system (56) is in one of the distribution line, the reject line or the feed water line.

Owner:OSMOFLO

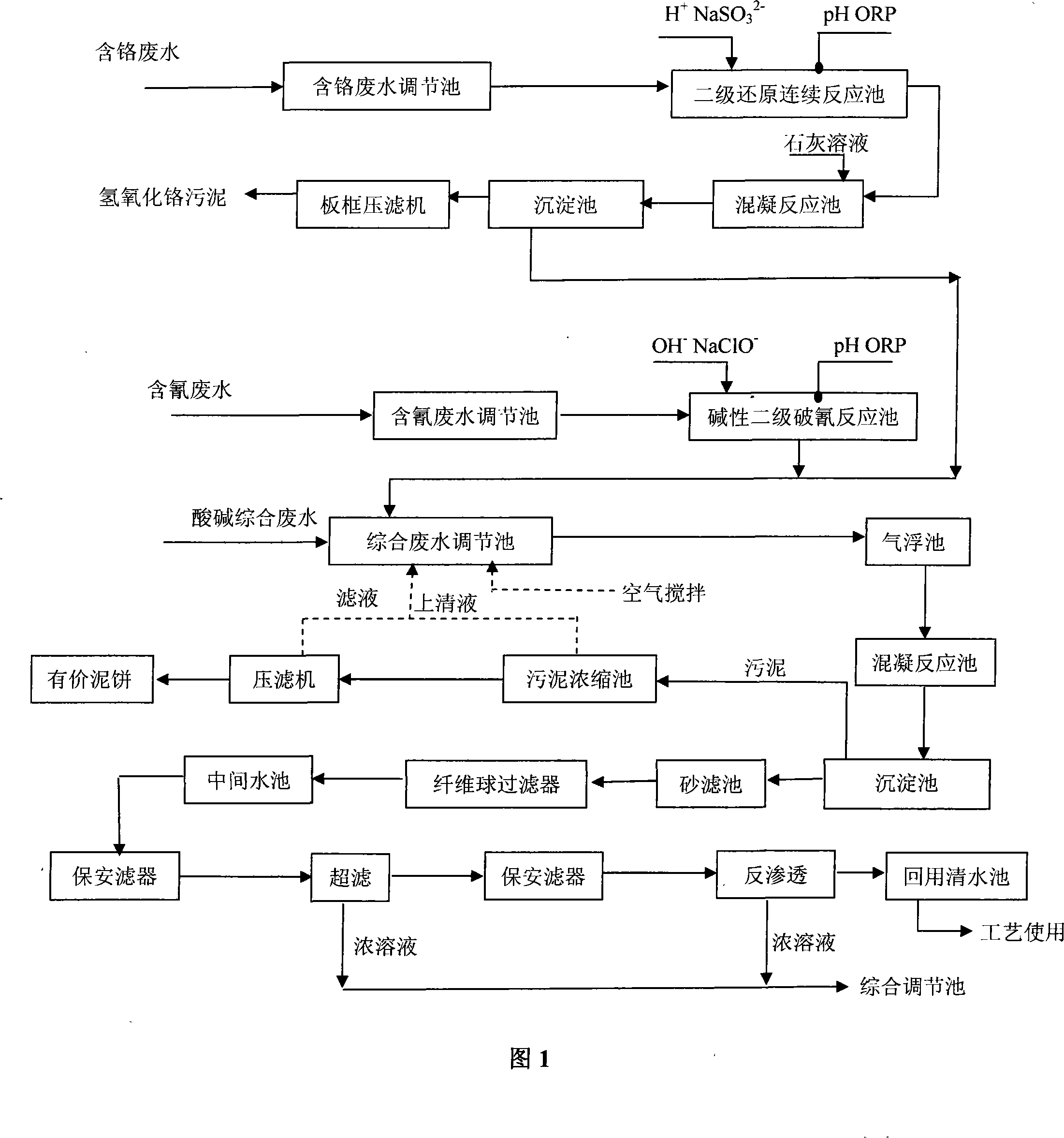

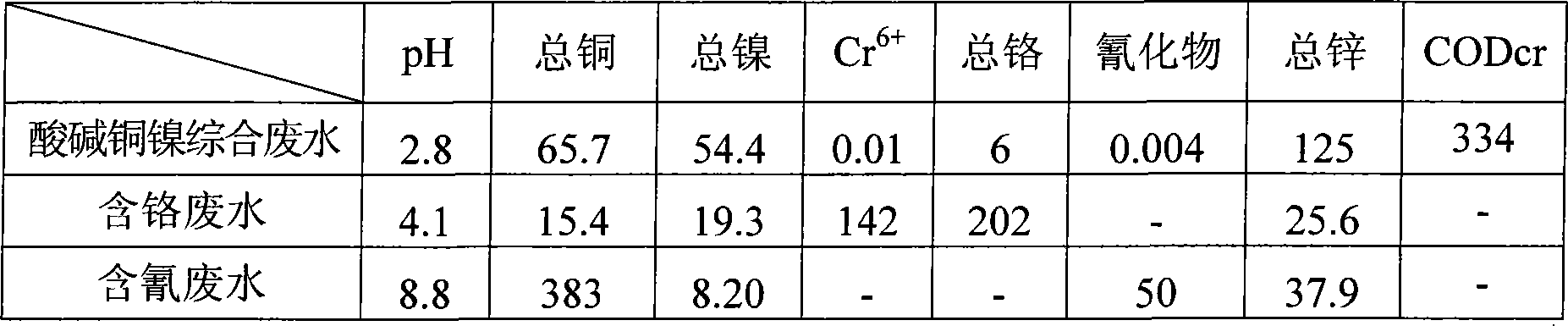

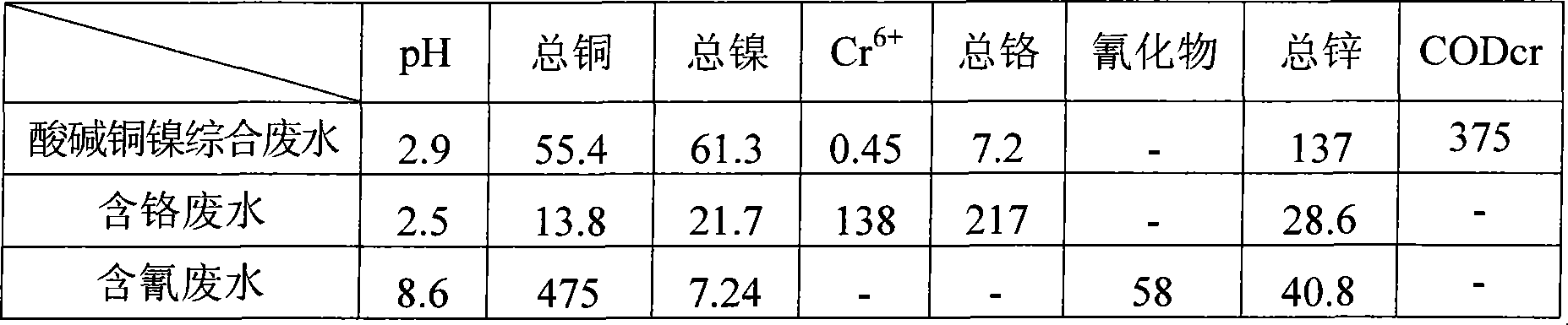

Integrated electroplating treatment method for waste water

InactiveCN101234828AReduce manufacturing costWater contaminantsWaste water treatment from metallurgical processWater productionWater quality

The invention relates to a method for treating comprehensive galvanization wastewater, particularly relating to a technique reclaiming resources of precious metal and recycly utilizing treated and comprehensively discharged galvanization wastewater. The method for treating the galvanization wastewater in the invention is characterized in that the following steps are included: (1) treating the wastewater containing chromium; (2) treating the wastewater containing cyanogen; (3) mixing and treating clear liquid obtained during treating the wastewater containing chromium in step (1) and the wastewater containing the cyanogen during treating the wastewater containing the cyanogen in step (2); (4) leading the clear liquid obtained during mixing and treating in step (3) into a reclaiming clean water pond; (5) leading the concentrated solution in step (4) into a comprehensive regulating pond of wastewater. Through treated by the technique of the method for treating comprehensive galvanization wastewater, each index of water quality of obtained water can reach or exceed the Drinking Water Sanitary Standard (GB5749-2006); the water can be reused in galvanization workshops; the water production rate of the reused water can reach over 80 percent; useful metal ions can be reclaimed; the target of environment protection can be met; benefits can be generated at the same time; the production cost can be reduced.

Owner:TIANJIN UNIV

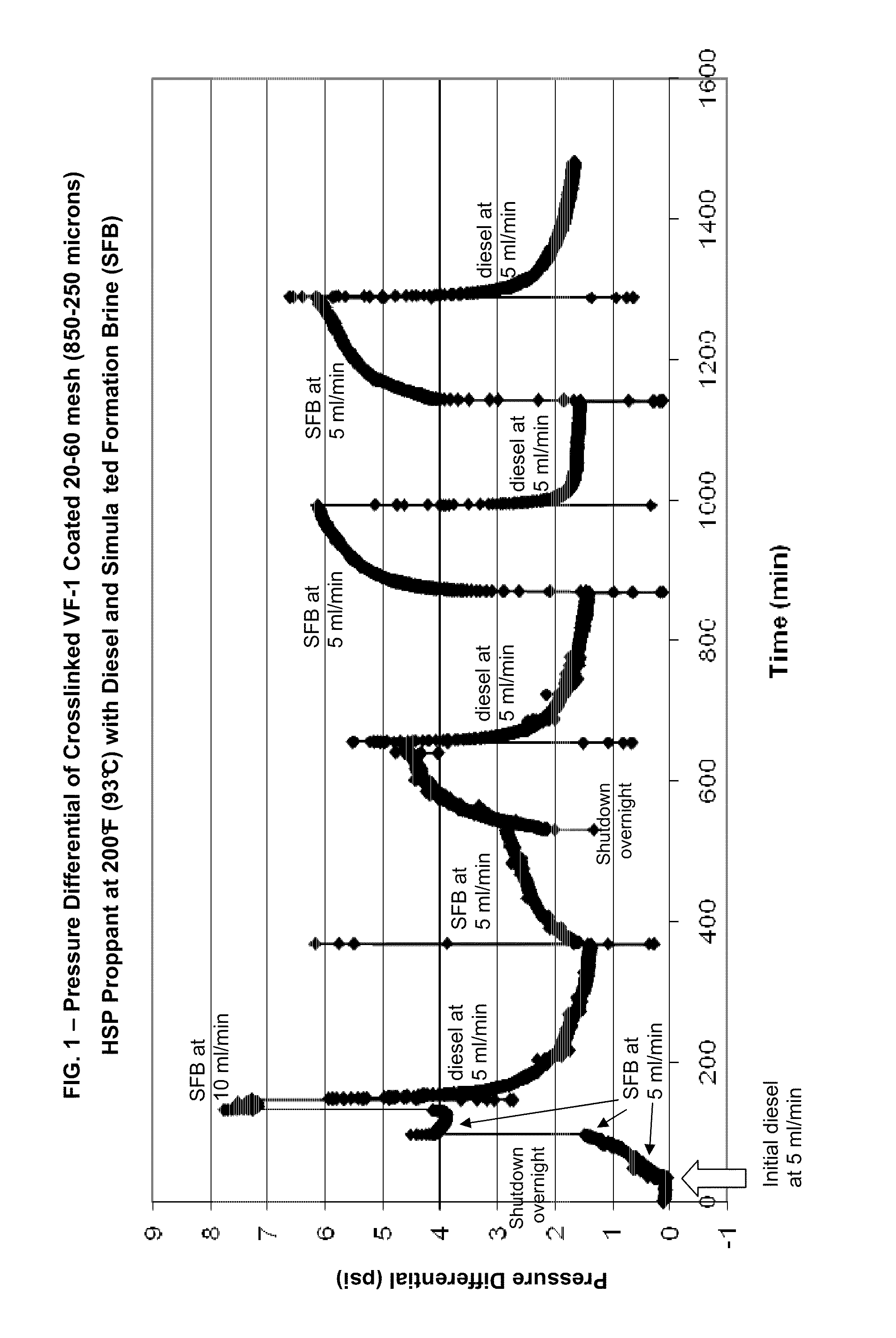

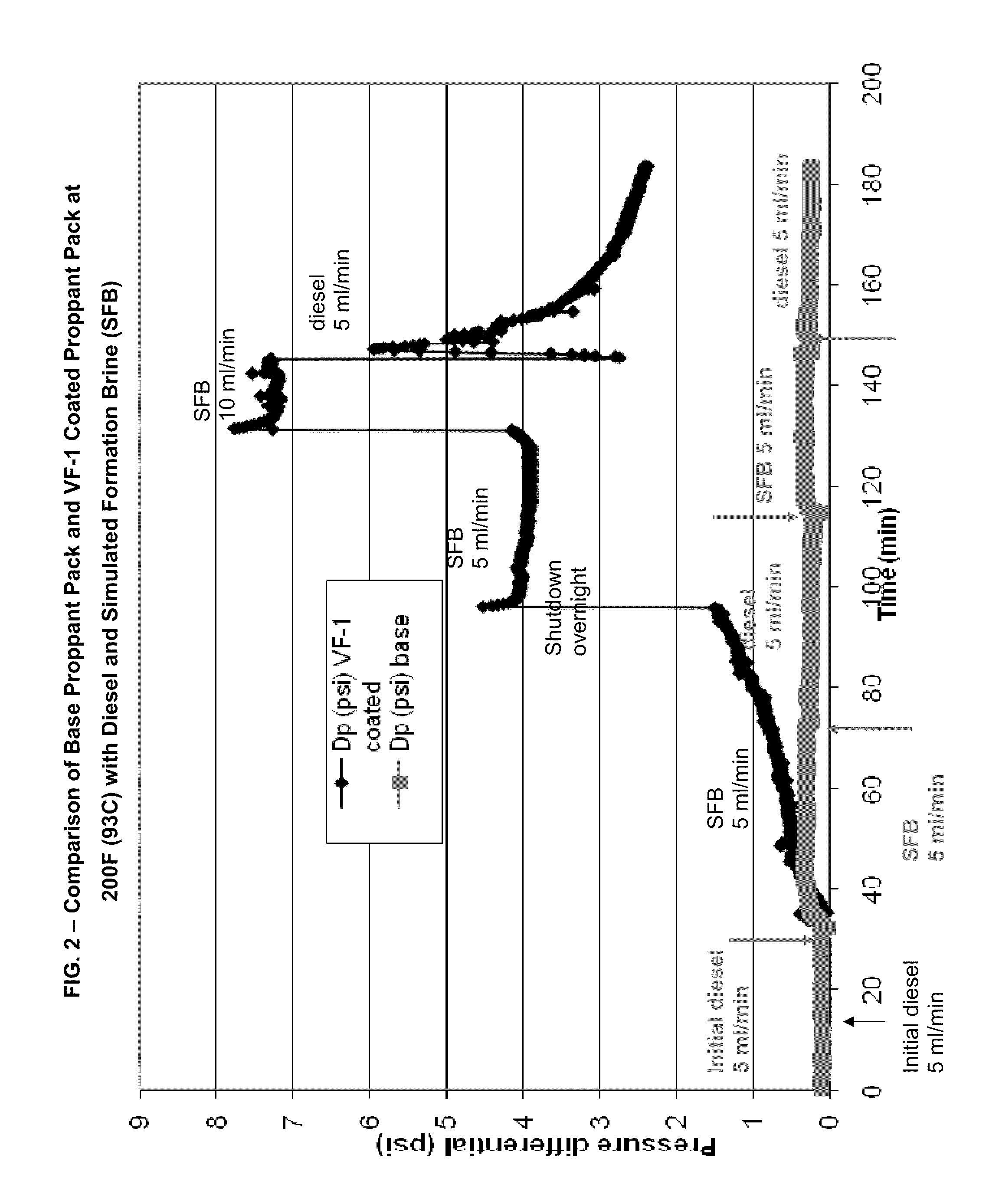

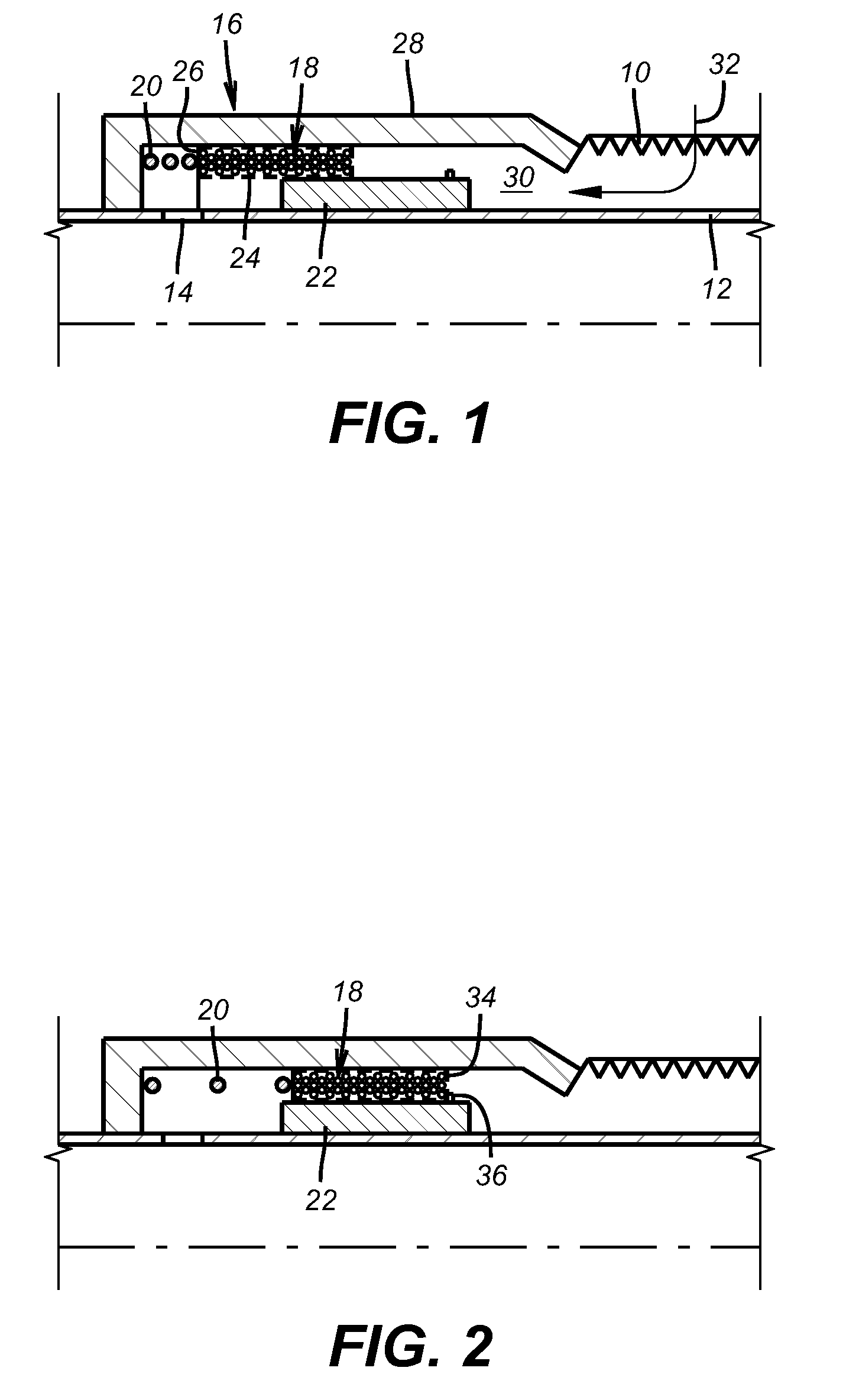

Method of Controlling Water Production Through Treating Proppants With RPMS

ActiveUS20110098377A1Prevent water flowFluid removalDrilling compositionWater productionRelative permeability

Water production from a subterranean formation is inhibited or controlled by pumping a fluid containing coated particles through a wellbore into the formation. The particles have been previously coated with a relative permeability modifier (RPM). Upon contact with water, the RPM coating expands or swells and inhibits and controls the production of water. The RPM may be a water hydrolyzable polymer having a weight average molecular weight greater than 100,000. The particles may be conventional proppants or gravel.

Owner:BAKER HUGHES INC

Water injection systems and methods

ActiveUS20090308609A1High viscosityEnhanced recovery of hydrocarbonFluid removalWell drillingWater production

There is disclosed a system comprising a well drilled into an underground formation; a production facility at a topside of the well; a water production facility connected to the production facility; wherein the water production facility produces water by removing some ions and adding an agent which increases the viscosity of the water and / or increases a hydrocarbon recovery from the formation, and injects the water into the well.

Owner:SHELL USA INC

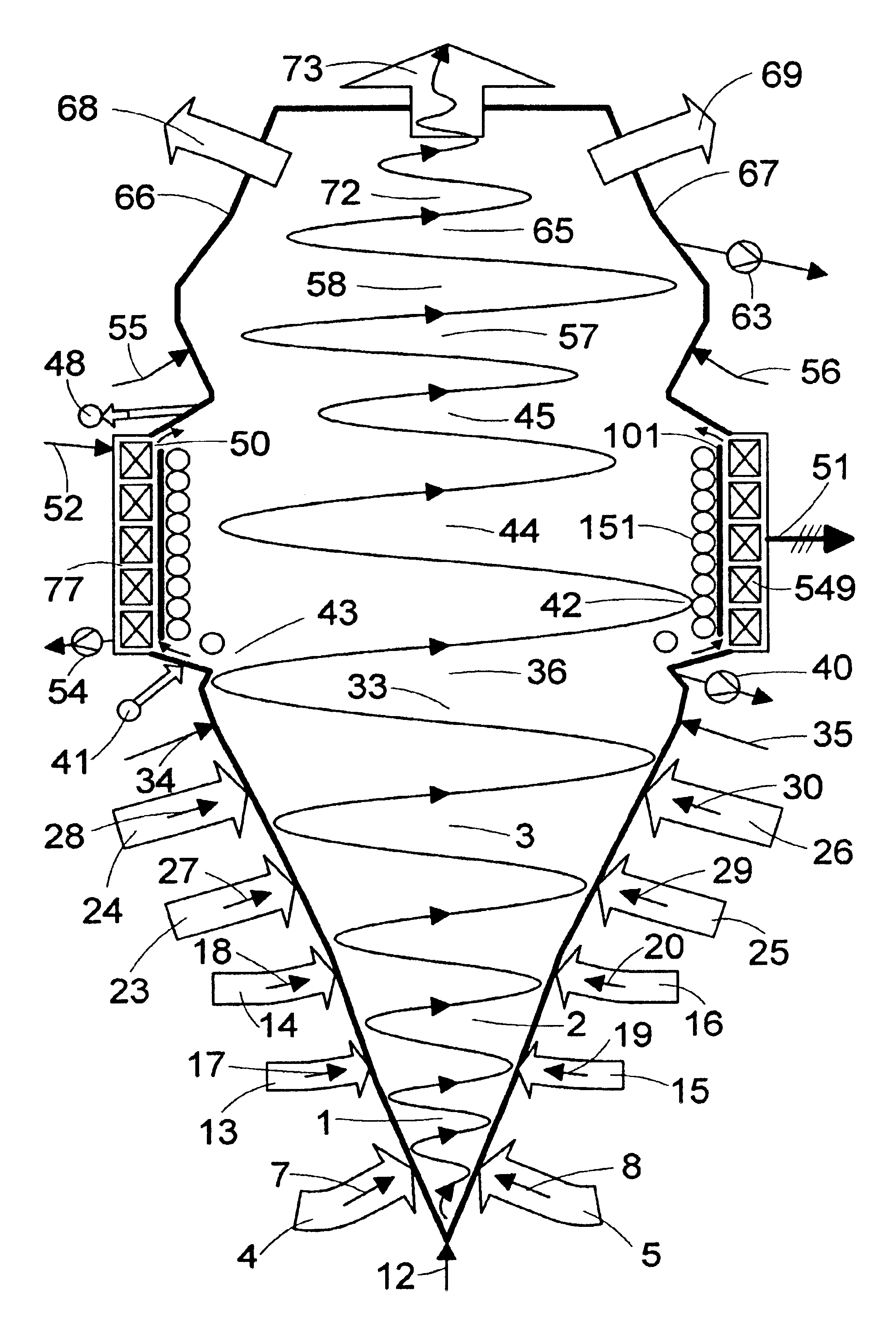

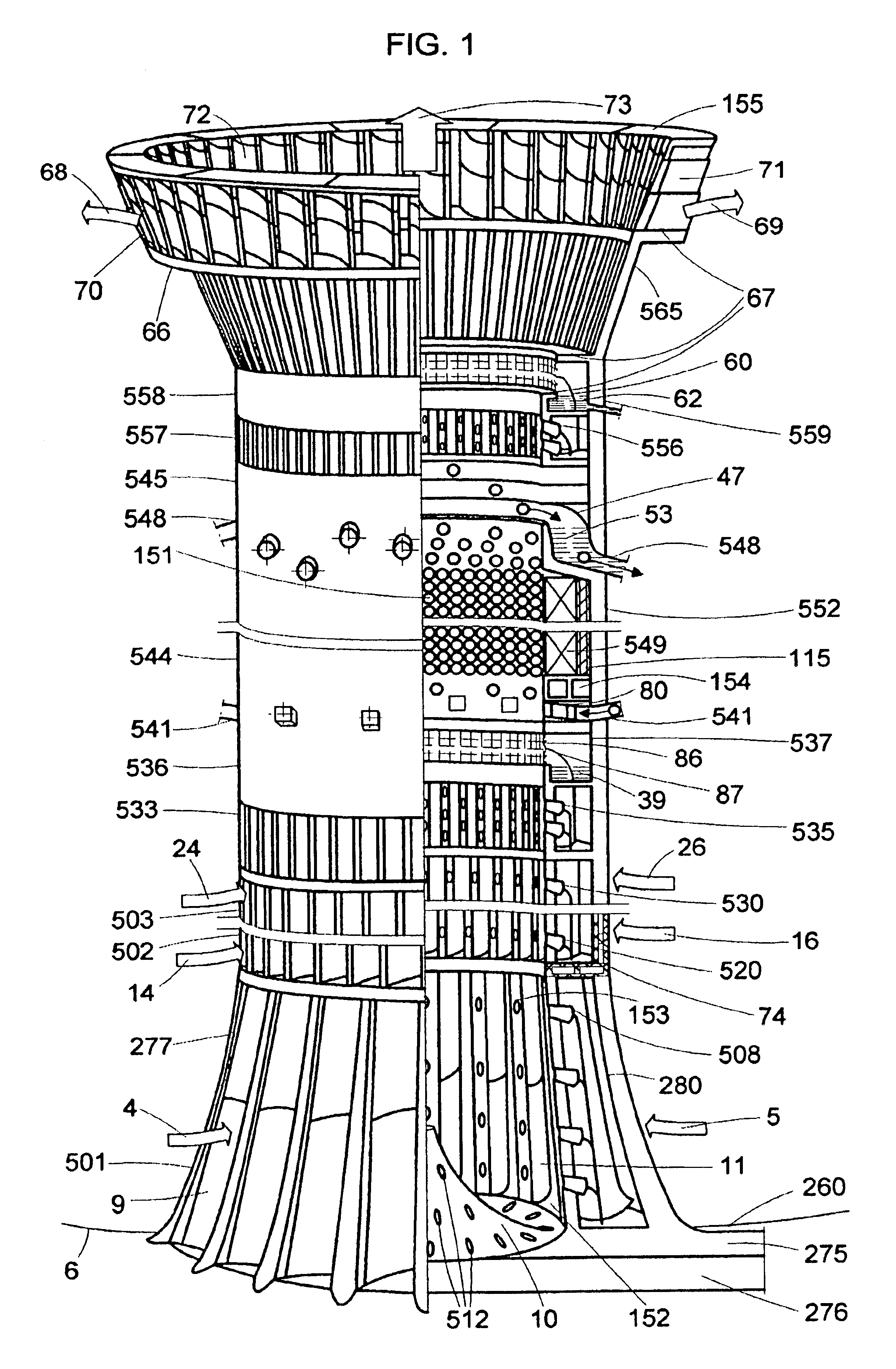

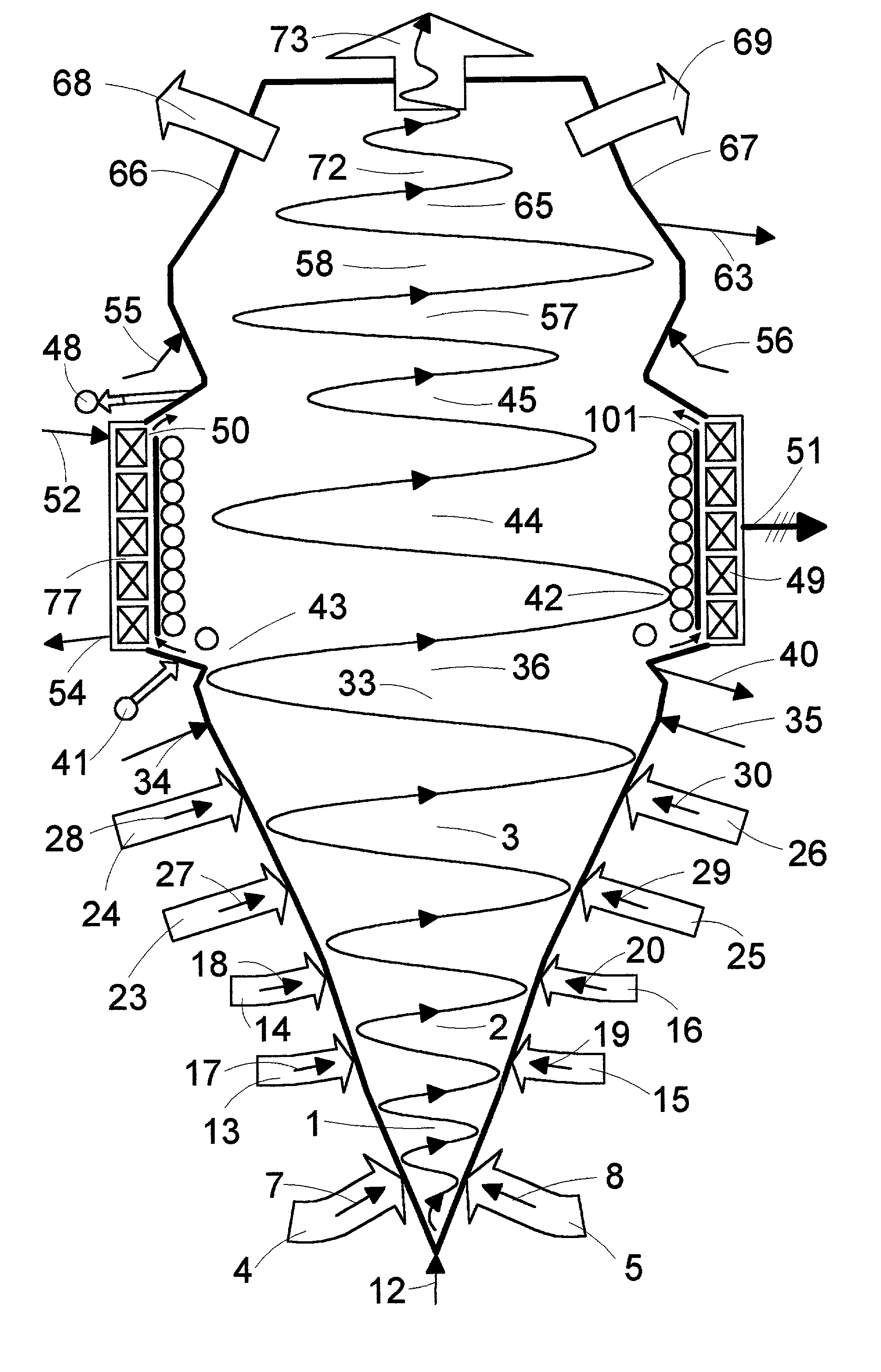

All-weather energy and water production via steam-enhanced vortex tower

InactiveUS6943461B2Improve pressure resistanceQuickly saturateWind motor with solar radiationEngine fuctionsWater productionEngineering

A wind vortex tower is enhanced by kinetic energy and heat of quasi-tangential and upward jets of saturated steam energizing, accelerating tornado-type flow and supporting stable electricity generation during the insufficient winds and calm. For action instead of absent wind at starts and operation over a long time, a staged system of flexible nozzles injects the steam jets into the zones of vortex channel. The system controls the tornado-type flow in the vorticity energizer, swirlers of sucked ambient air, condensate separators, re-enhancer of airflow and top diffuser. The steam is flashed from partially stored condensate heated nearly to 100° C. The condensate is partially delivered after centrifugal separation from saturated vortex core. The outside water heating system has one or two of compatible renewable, waste and secondary, or initial heat sources, and is intensified via sucking of heated water by vortex flow. A large-rating flow-through electric generator has an alternating magnetic whirl formed by magnetic concentrators whirled near vortex core and a three-phase stator with switched modules. The simplified towers are used for water and conditioned air production.

Owner:KAPLOUN SOLOMON

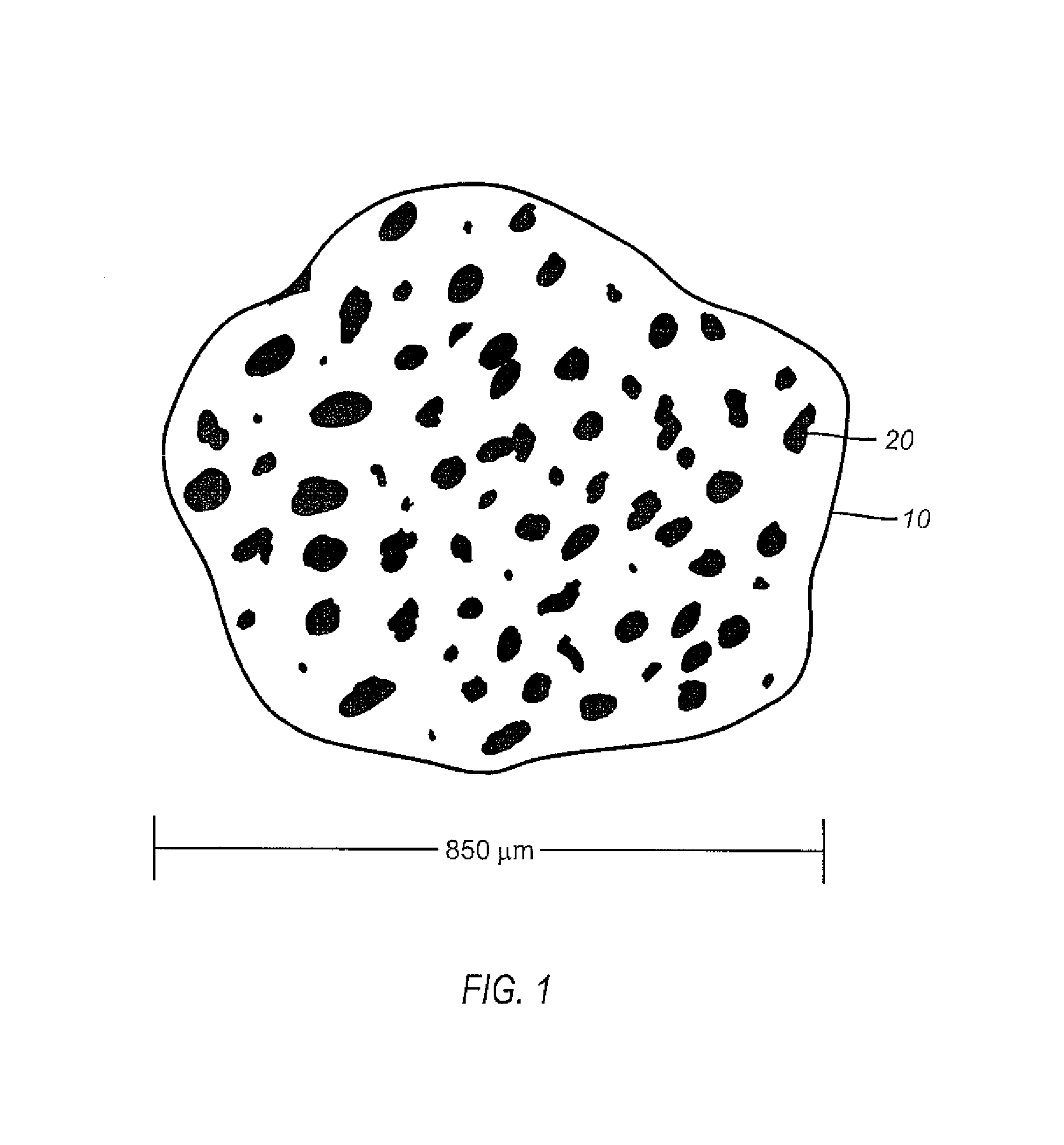

Well treating composite containing organic lightweight material and weight modifying agent

InactiveUS7772163B1Reduce conductivityImprove conductivityOther chemical processesFluid removalParticulatesWater production

Well treating composites are composed of an organic lightweight material and a weight modifying agent. The organic lightweight material preferably forms the continuous phase and the weight modifying agent forms the discontinuous phase. The apparent specific gravity (ASG) of the organic lightweight material is less than the ASG of the well treating composite. The composite of the invention is particularly useful in hydraulic fracturing fluids as lightweight proppants as well as in sand control methods, such as gravel packing and frac packing A subterranean formation may be treated by injecting the well treating composite into the formation in order to increase fracture conductivity, reduce the generation of fines, reduced unwanted water production and / or reduce particulate production.

Owner:BAKER HUGHES INC

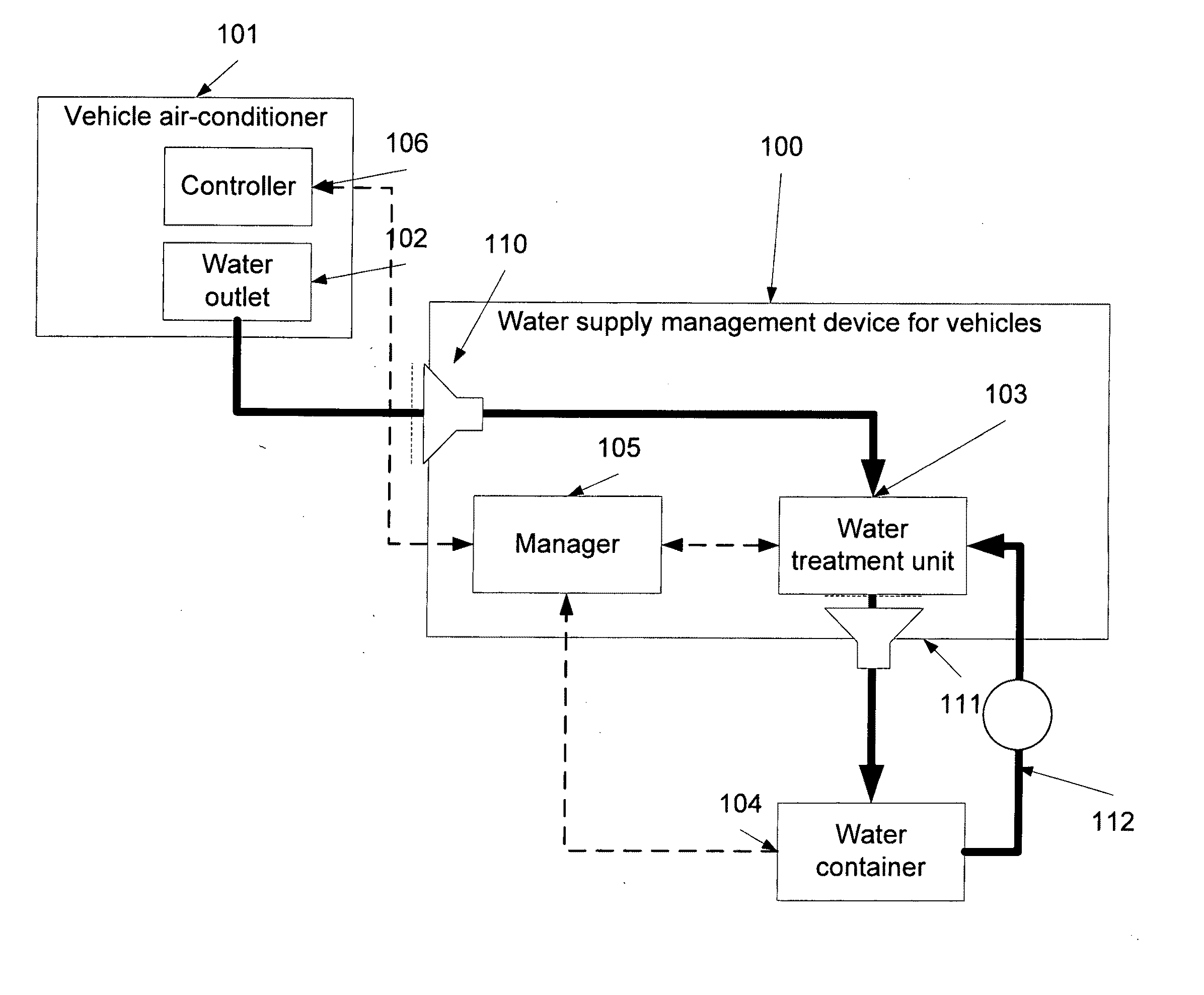

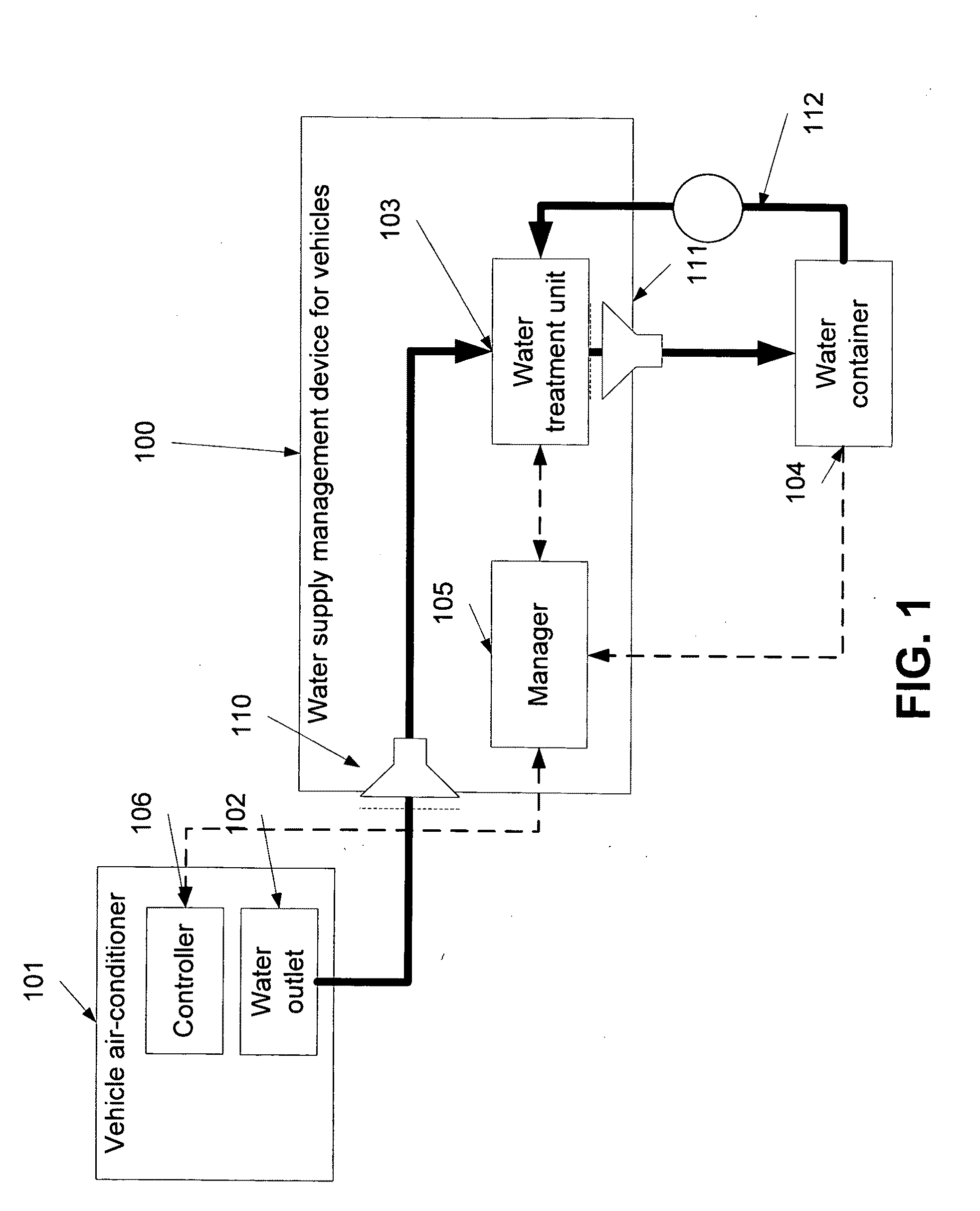

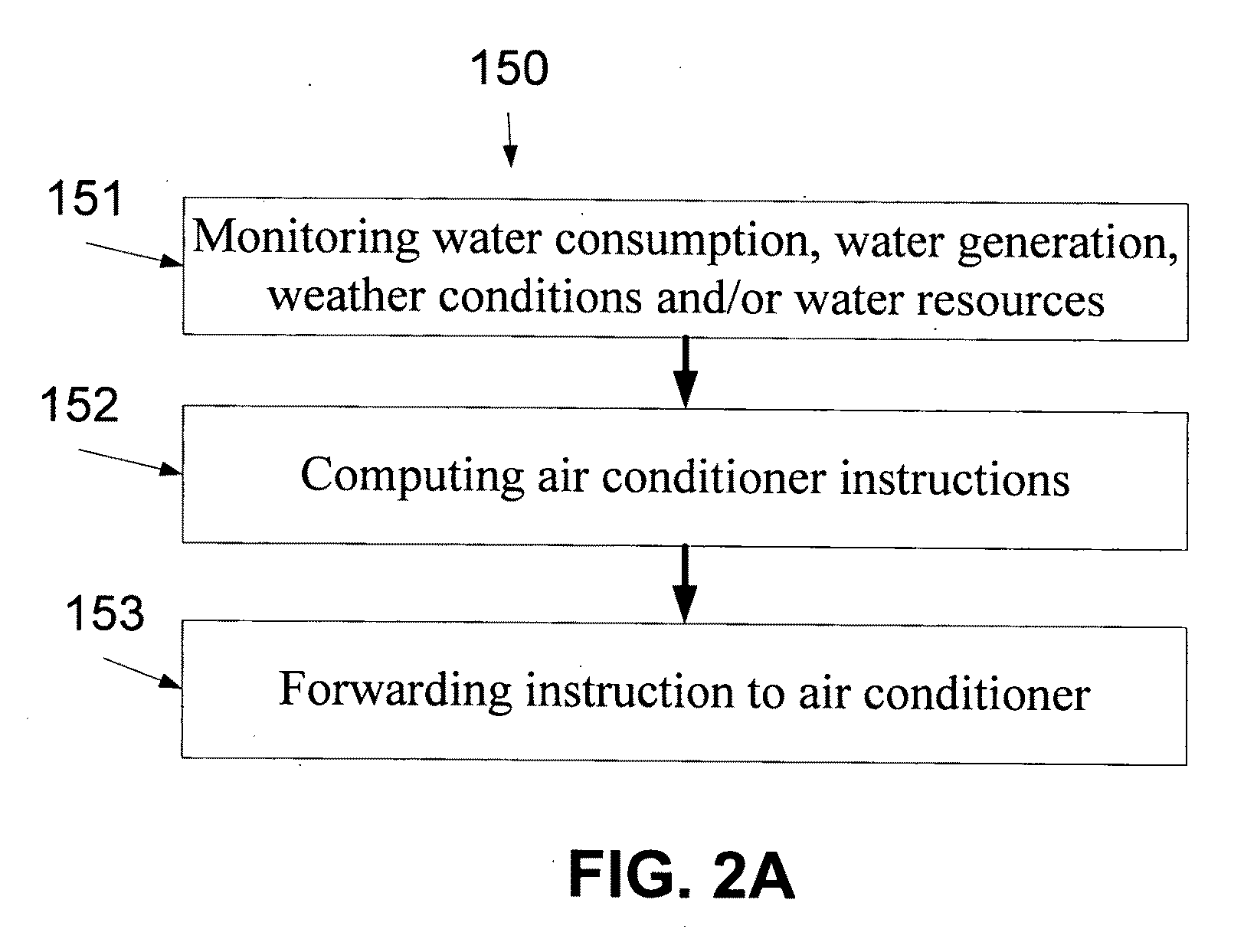

System and method of water supply production and management in vehicles

InactiveUS20110048039A1Lighting and heating apparatusVehicle heating/cooling devicesIn vehicleWater production

A system of managing water production in a vehicle. The system comprises a water conducting element set to receive and conduct water generated as a product of an operation of a vehicle air conditioner of the vehicle to a water container, a gauge that measures the amount of water in the water container, and a manager that receives the measurement and instructs the operation accordingly.

Owner:WATERGEN LTD

Old well re-transformation volume fracturing technology

ActiveCN105275442AImprove diversion capacityLarge reservoir stimulation volumeFluid removalSealing/packingFiberWater production

The invention relates to an old well re-transformation volume fracturing technology, which is characterized by mainly comprising the steps of carrying out primary fracturing analysis, pre-fracturing evaluation and well selection decision making on to-be-refractured wells with excavation potential, and determining a to-be-refractured well with excavation potential; screening fracturing fibers and particle temporary plugging agents; screening out the fracturing fibers and the temporary plugging agents storing re-transformation according to the temperature, the pressure, the water production rate, the mineralization degree and the fracturing fluid type of a reservoir stratum; carrying out dynamic and static performance evaluation on the screened fracturing fibers and the particle temporary plugging agents, and determining the fracturing fibers and the particle temporary plugging agents which are finally required; determining construction parameters; carrying out fracturing construction; completing transformation for reservoir stratum construction; and acquiring great reservoir stratum transformation volume, and enabling a near wellbore area major fracture to keep high flow conductivity. According to the invention, great reservoir stratum transformation volume can be acquired, and the near wellbore area major fracture is enabled to keep the high flow conductivity.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

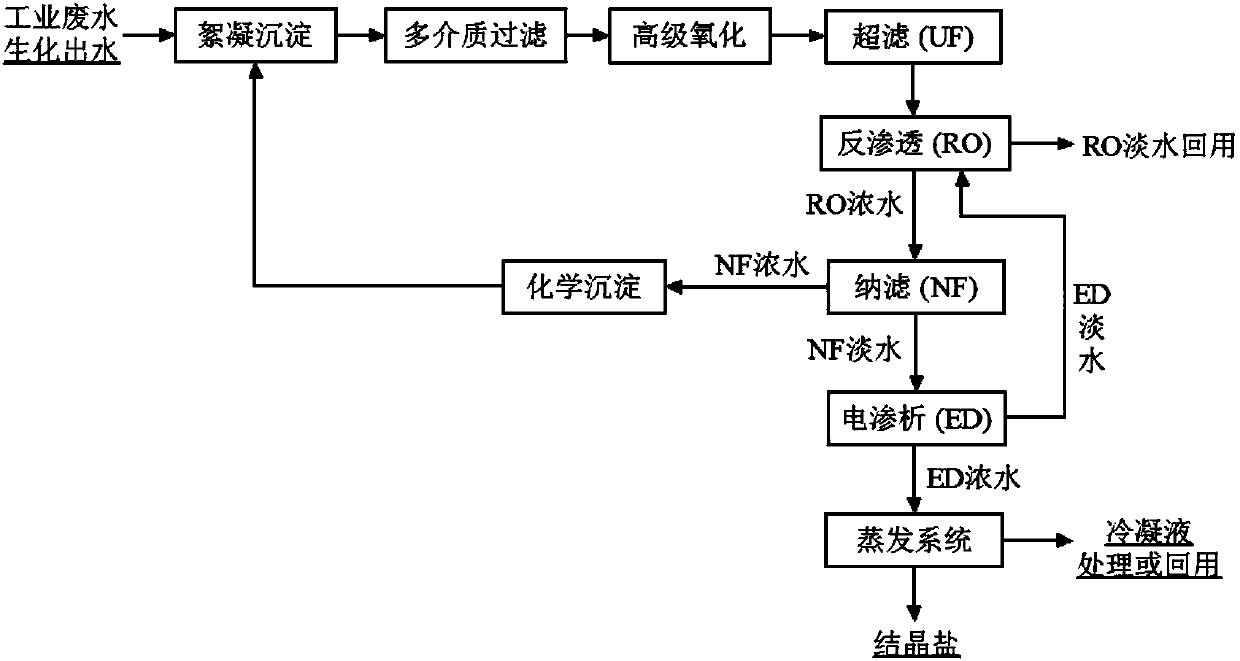

Treatment system and treatment method for biochemical effluent of industrial wastewater

InactiveCN107651794AEfficient removalHigh recovery rate of fresh waterGeneral water supply conservationTreatment involving filtrationHigh concentrationFiltration

The invention provides a treatment system and treatment method for biochemical effluent of industrial wastewater. The treatment system comprises a flocculation sedimentation unit, a filtration unit, an advanced oxidation unit, an ultrafiltration unit, a reverse osmosis unit, a nanofiltration unit, an electrodialysis unit and an evaporation unit which are sequentially connected; and the water production outlet of the ultrafiltration unit is connected with the water inlet tank of the reverse osmosis unit, and the concentrated-water outlet of the reverse osmosis unit is connected with the water inlet of the nanofiltration unit. According to the invention, the treatment system and the treatment method utilize the coupling and synergistic effects of a physical-chemical method and a membrane technology to overcome the limitation of using a single technology, and the advanced treatment and desalination reuse of the industrial wastewater are realized; and the treatment system and the treatmentmethod have the advantages of strong adaptability to raw water, a high recovery rate of fresh water, a high concentration multiple of concentrated water, low energy consumption of evaporation and crystallization and the like, greatly improve the reuse rate of the industrial wastewater, reduce the amount of wastewater discharging, can be applied to the deep treatment and desalination reuse of various effluent wastewater, and promote the promotion and application of the technology in related industries.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

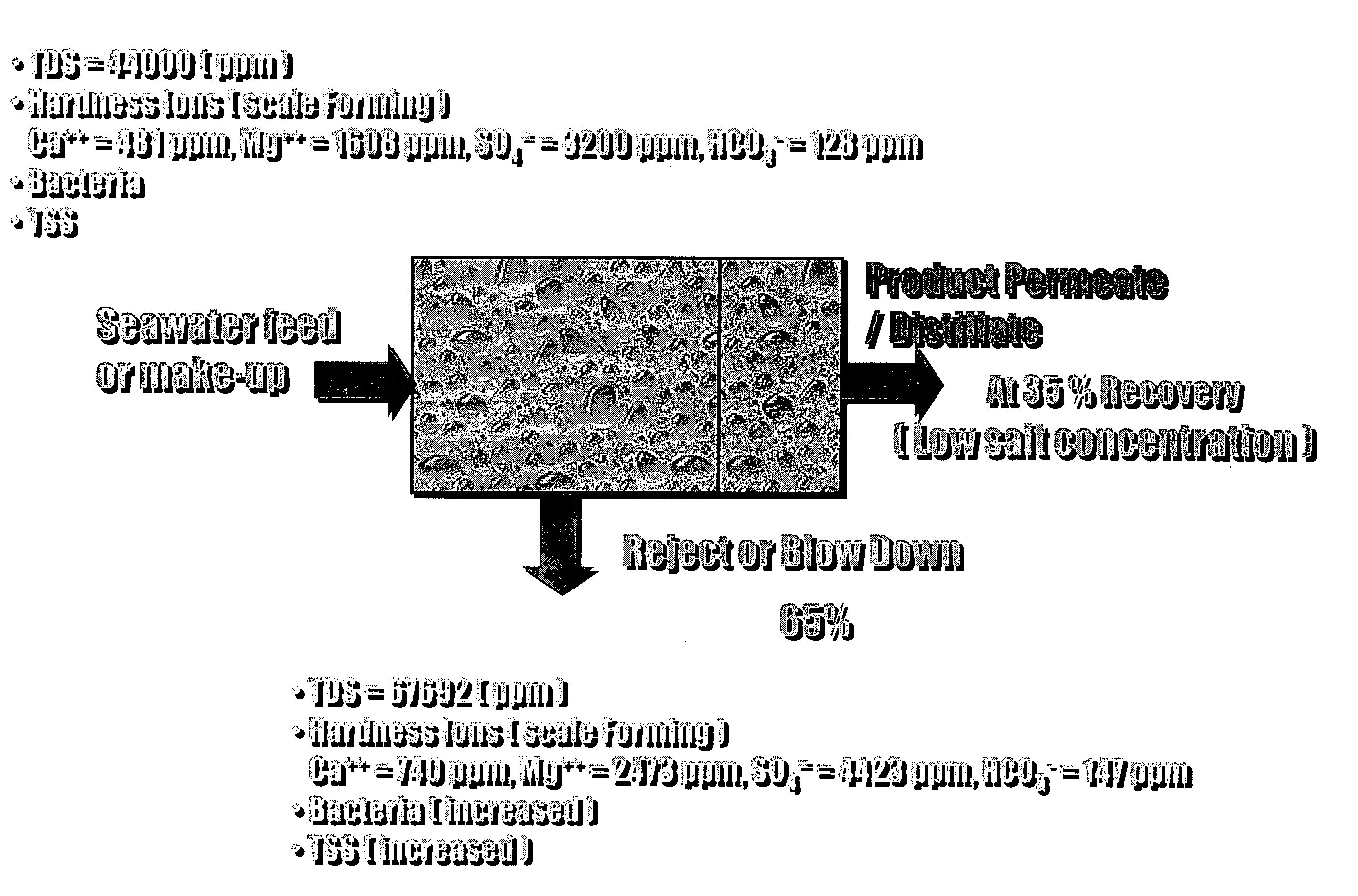

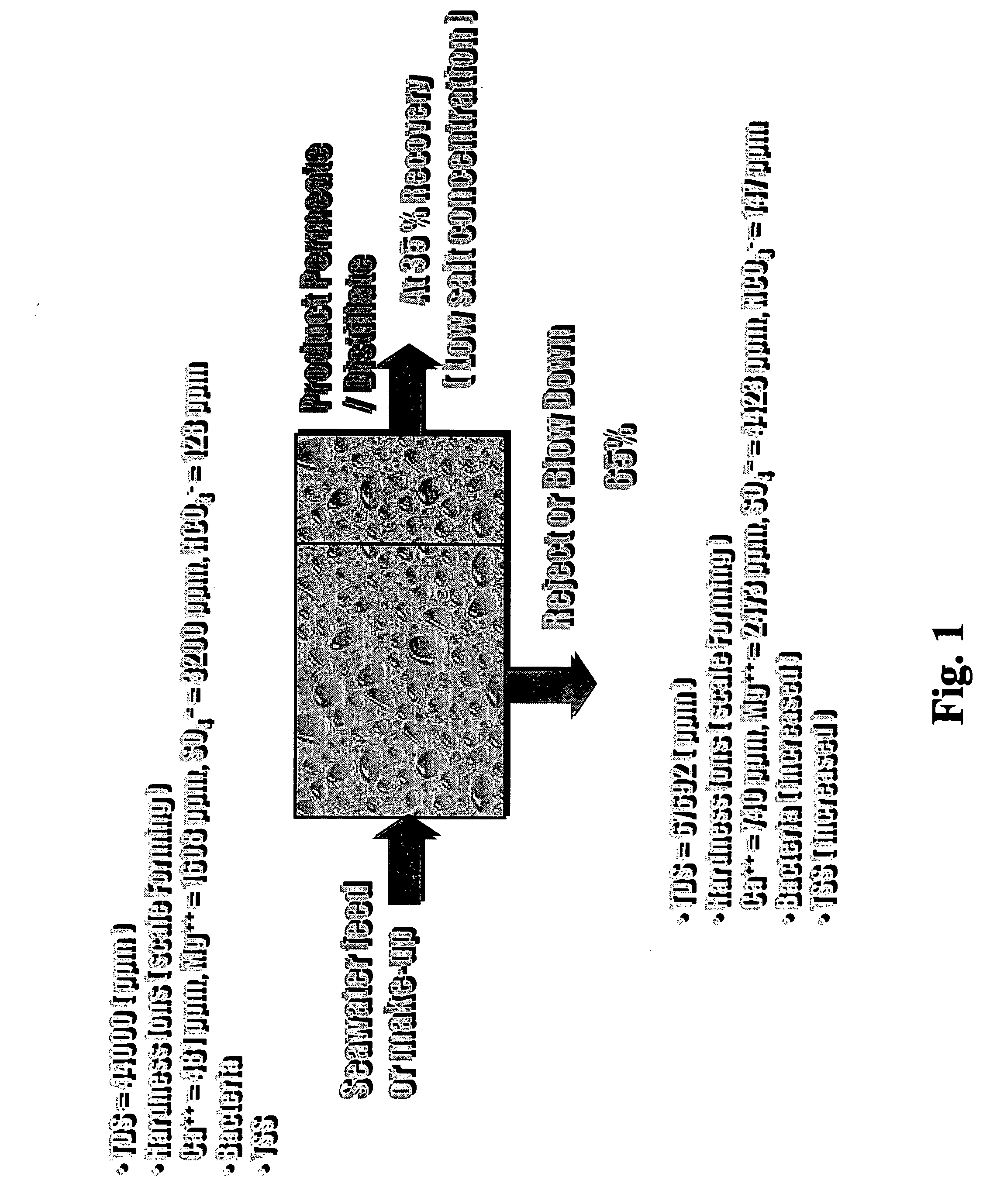

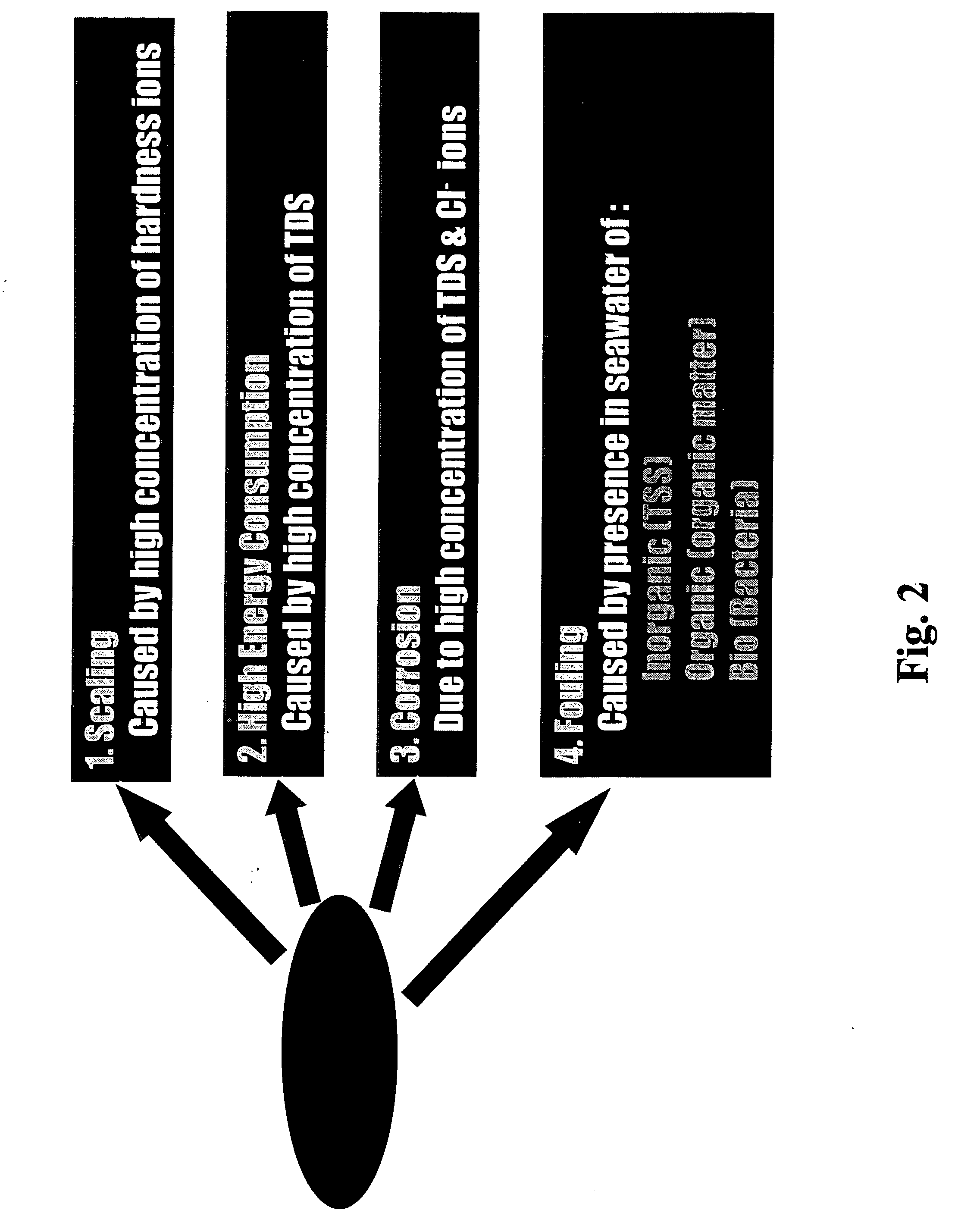

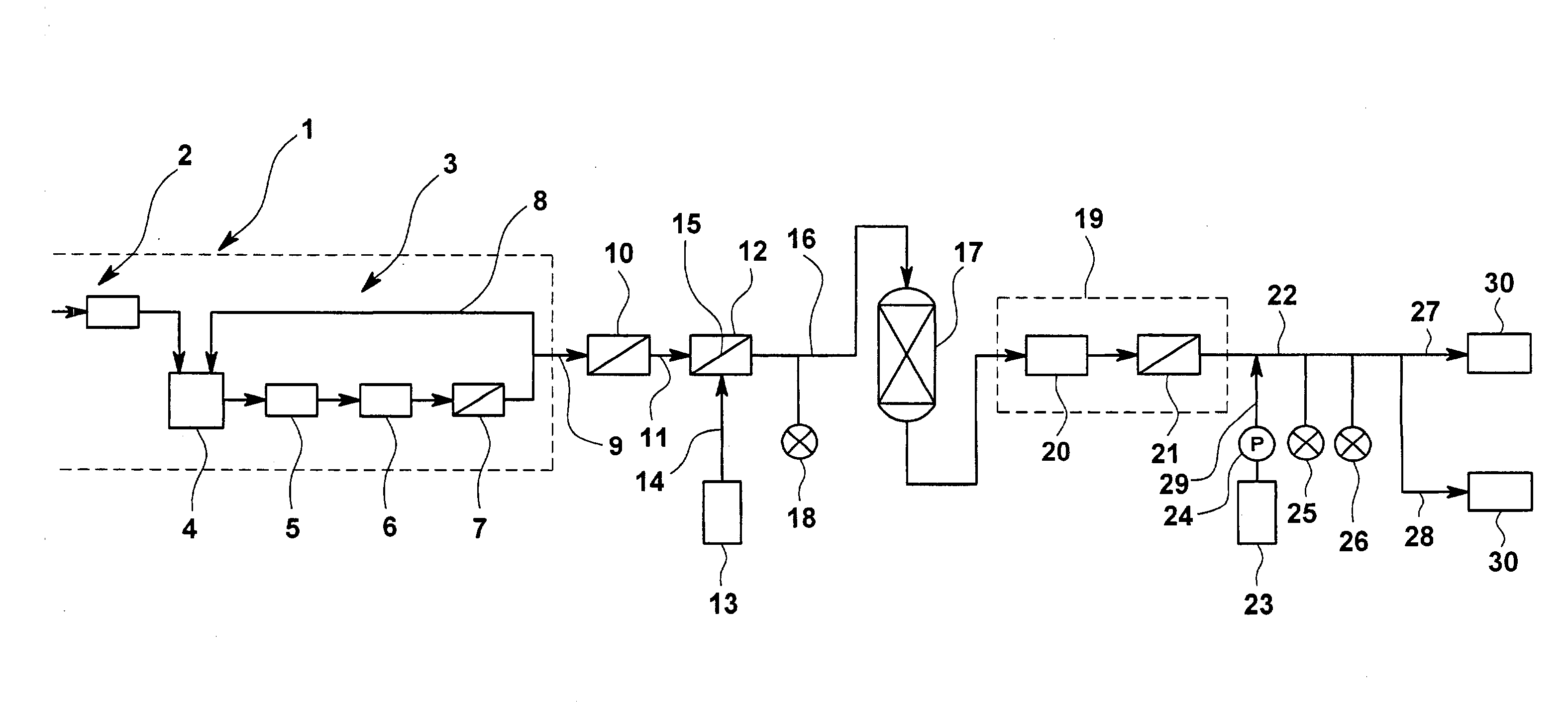

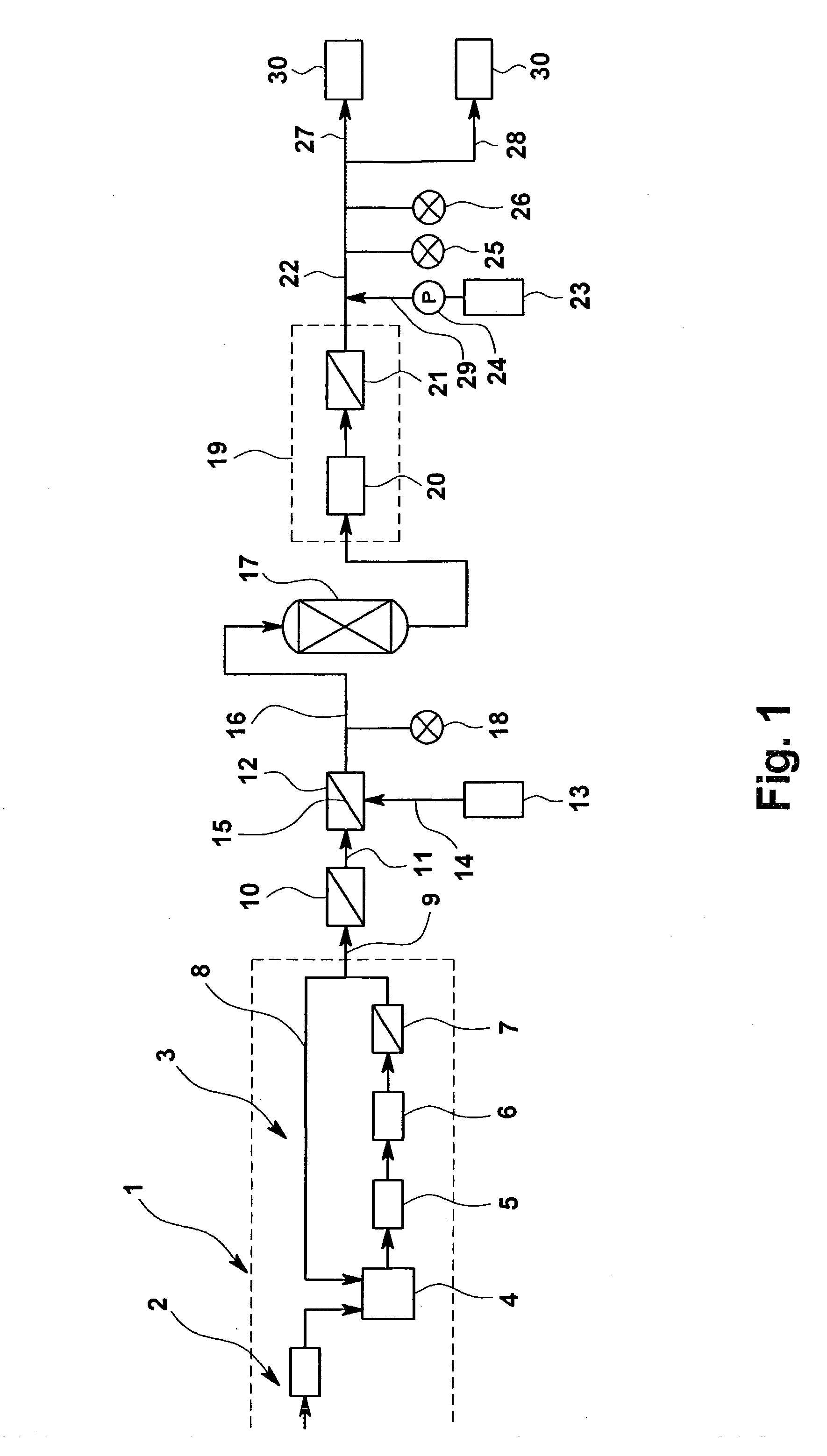

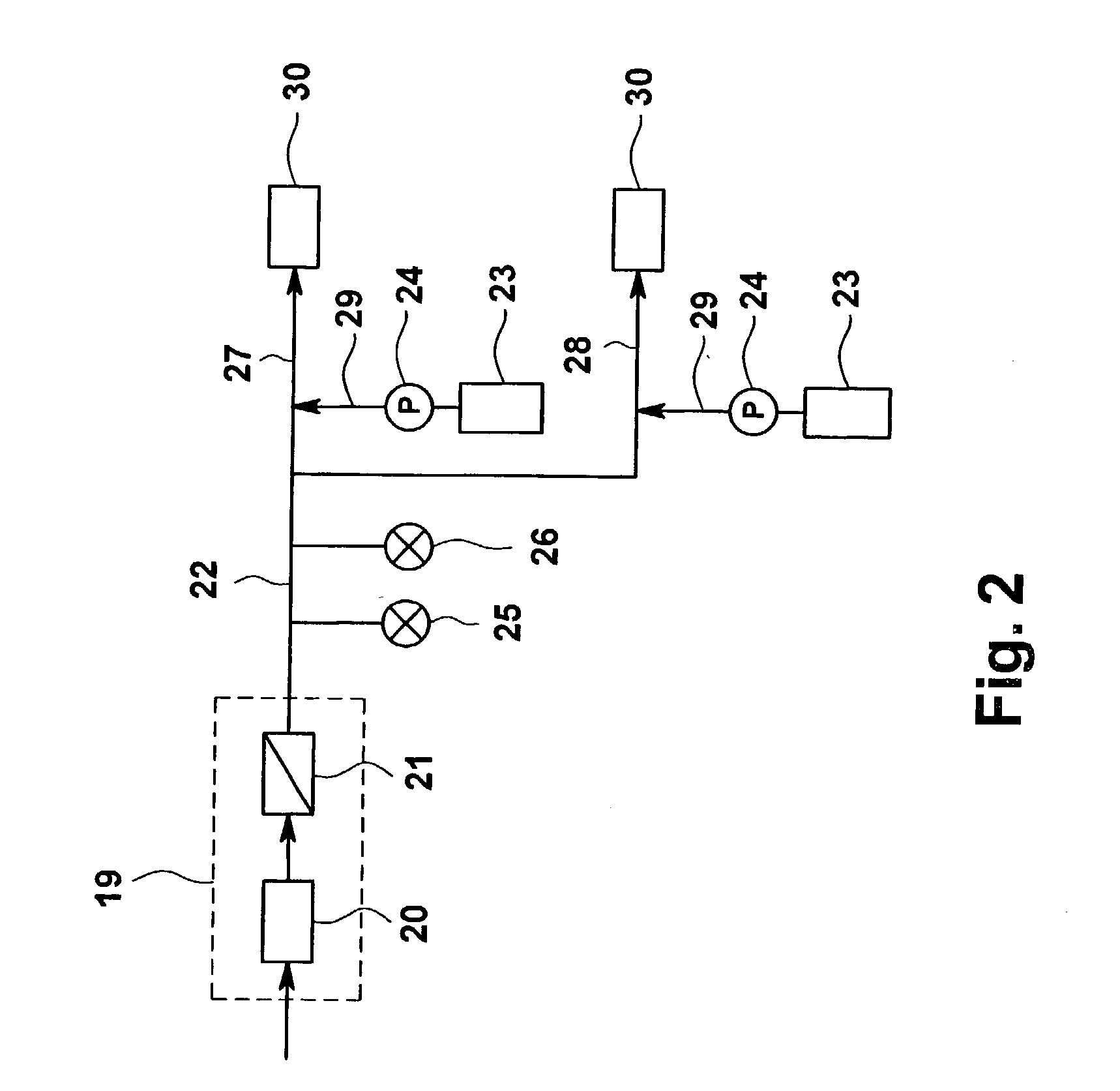

Optimal high recovery, energy efficient dual fully integrated nanofiltration seawater reverse osmosis desalination process and equipment

InactiveUS20060157409A1Reduce yieldHigh water recoveryMembranesSeawater treatmentTurbochargerWater production

An optimal two stage NF2 membrane pretreatment unit is synergistically combined with a following two stage SWRO2 desalination unit, where each of the two stage NF2 and SWRO2 has an energy recovery device (ERD) turbocharger (TC) in between the stages to form a dual hybrid of NF2-SWRO2 (FIG. 1 ); alternatively the two stage NF2 unit is synergistically combined with one stage ERD equipped SWRO, unit operated at up to 85 bar (FIG. 2 a, b); or the two stage NF2 unit combined with one stage ERD equipped SWRO1 unit, with part of its reject recycled constituting part of the feed to the NF units (FIG. 3 a,b). The process of this invention raises significantly the product water recovery ratio, producing SWRO hybrids that exceed all prior arts in efficiency, including water yield, product recovery ratio, dramatically reduces both the energy consumption and water production unit cost.

Owner:SALINE WATER CONVERSION CORP SWCC

All-weather energy and water production via steam-enhanced vortex tower

InactiveUS20030201646A1Wind motor with solar radiationEngine fuctionsAtmospheric airWater production

The large-scale green power, pure chilled, heated water and / or conditioned directed air are produced using wind, heat and vapor of the free humid air in the structured multi-unit space-saving vortex tower providing direct three-phase voltage induction with alternating magnetic whirl formed by pole radial self-orienting magnetic concentrators swirled via all-weather multi-step tornado-like flow supplementary energized, enhanced and controlled by a spatial system of fast directing and accelerating low-temperature steam jets injected through fleshing of recycled, separated and stored condensate slightly heated with any renewable, waste, secondary, or prime source of low-temperature heat, partly via combining with solar pond and heaters or / and geothermal media, or / and waste, secondary or initial heat of large thermal, atomic power plant or intensively energy consuming industry, reducing specific investment, energy and pure water costs, quality requirements, specific pollution and waste heat atmospheric injection, with possibilities of partial local weather corrections through conditioned directed waste tower air; a new sector with various directions can be widened, based on applying of the same principles of energizing, enhancement, control and usage of any kind of fast gaseous confined vortex flow via any kind of supplementary low-temperature steam

Owner:KAPLOUN SOLOMON

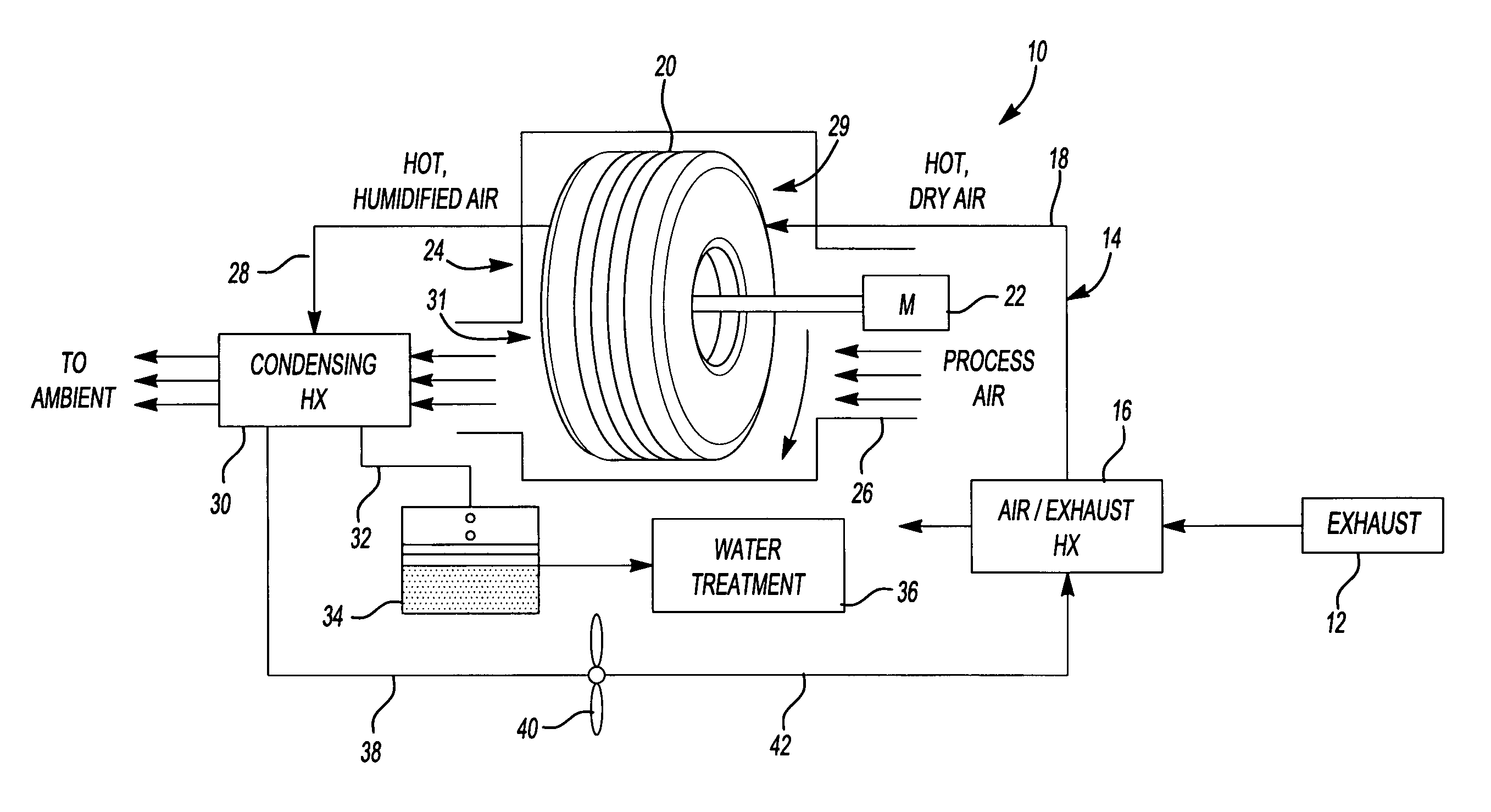

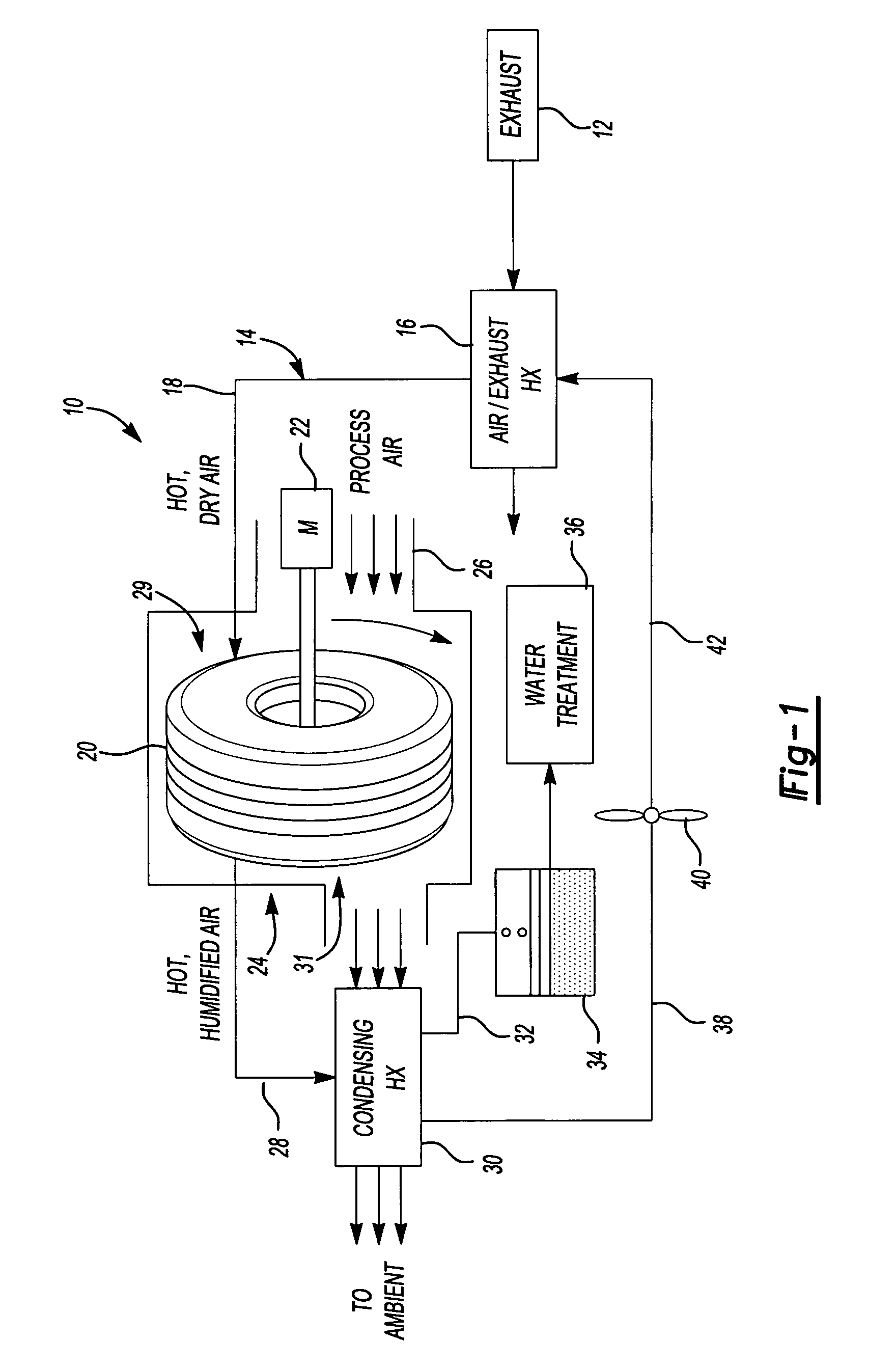

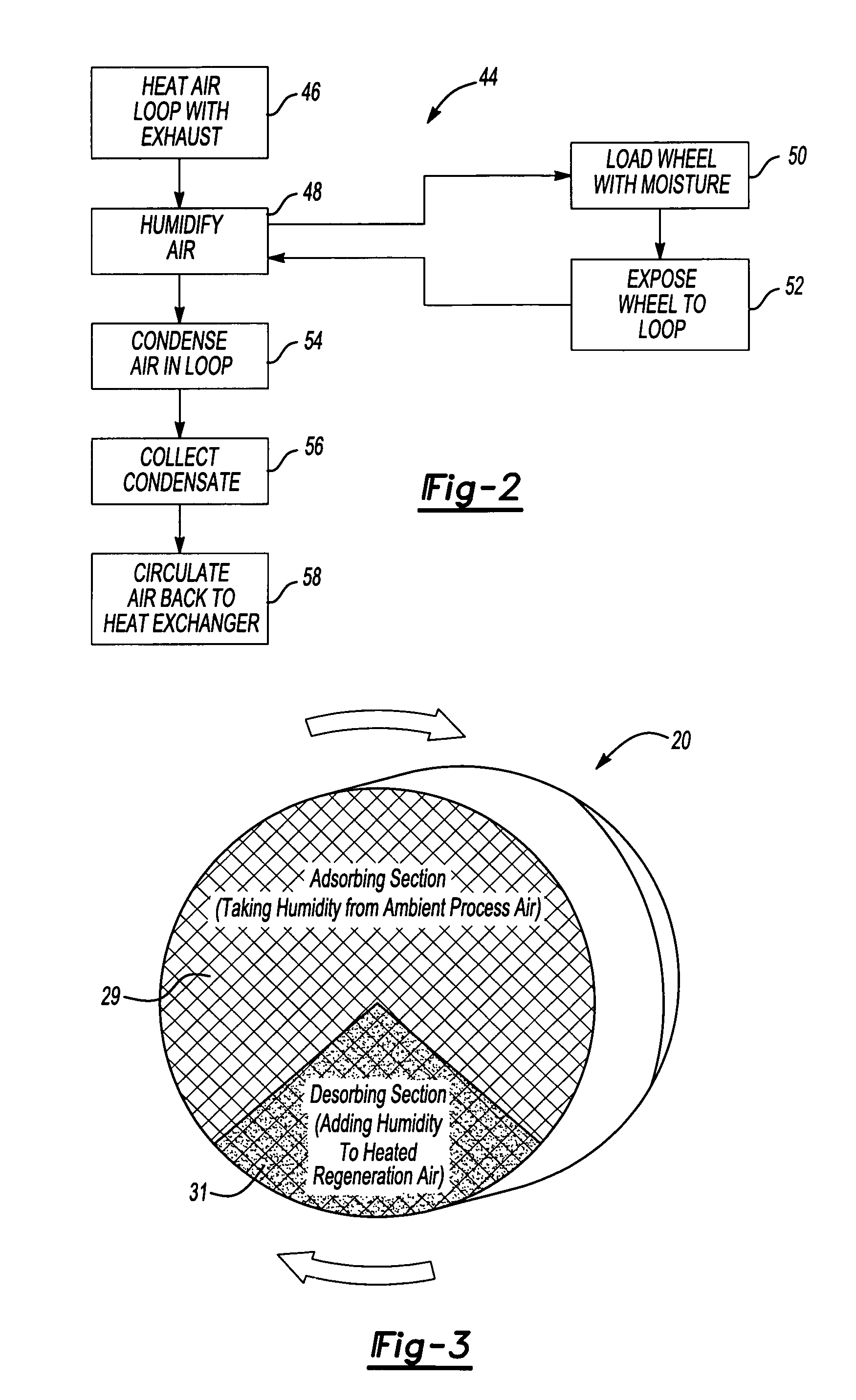

Water-from-air system using desiccant wheel and exhaust

A water production unit is provided that uses a desiccant wheel for extracting water from an air loop. A portion of the air loop is heated using exhaust from, for example, a vehicle to regenerate the desiccant wheel.

Owner:HAMILTON SUNDSTRAND CORP

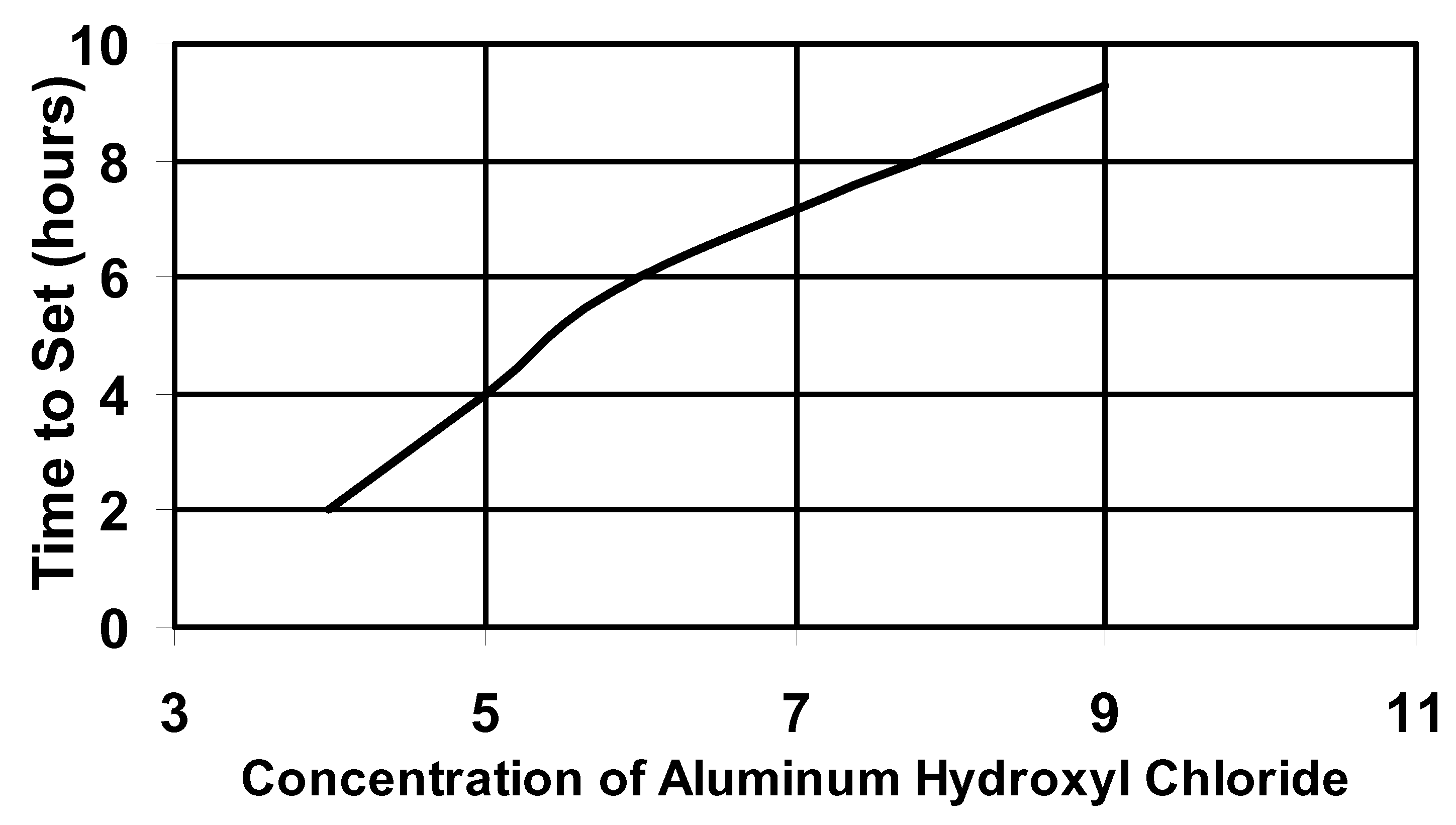

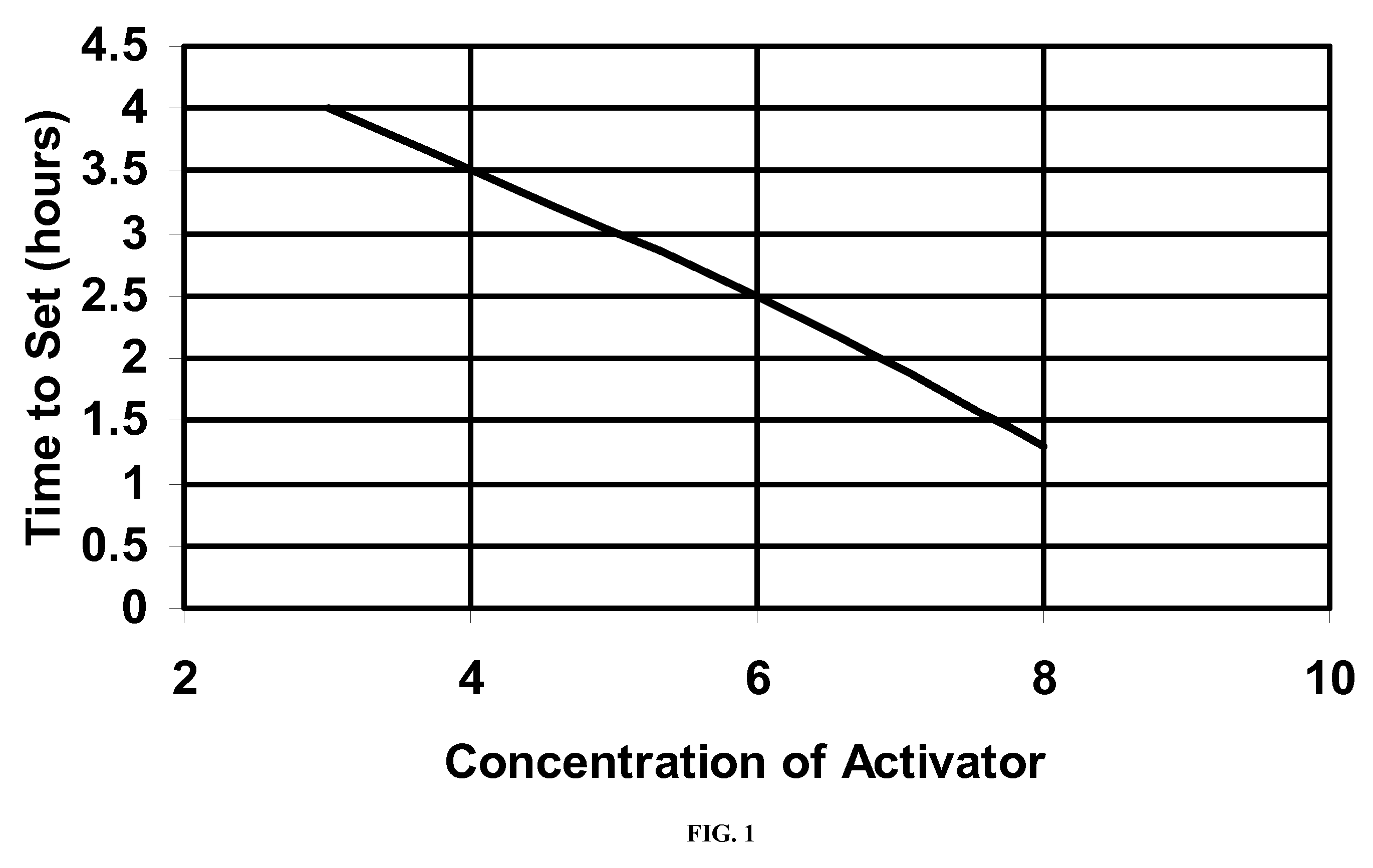

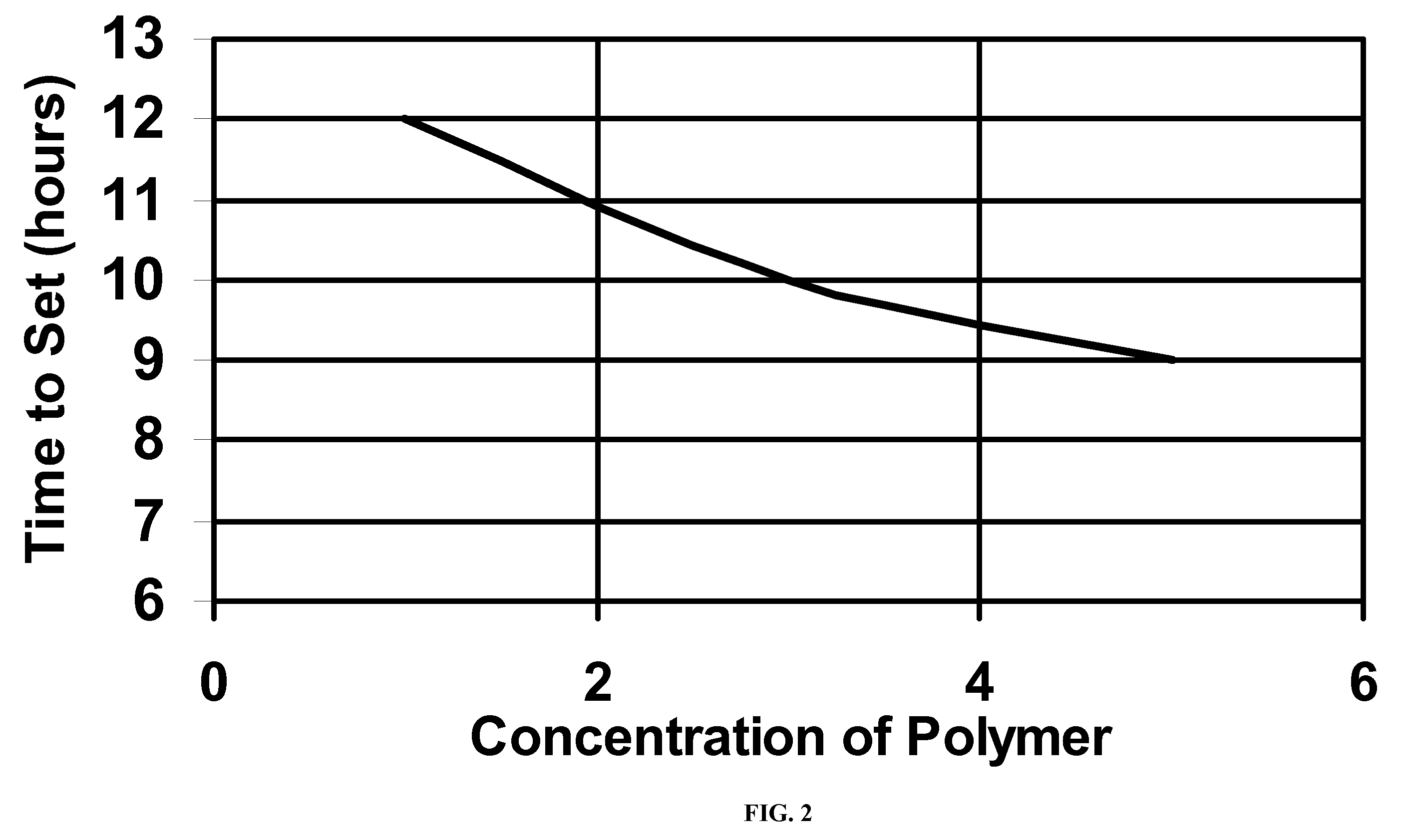

Delayed polyacrylamide-co-aluminum hydroxyl chloride gel

InactiveUS20080035344A1Improve latencyImprove solubilityFluid removalFlushingWater productionConsistency control

A delayed gelling system useful in conformance control in the production of petroleum from subterranean formations is disclosed. The gelling system comprises an acidic aqueous solution of acid-soluble or cationic polyacrylamide, an at least partially neutralized acid aluminum salt, an activator comprising a hydroxyl donor, and an optional gel modifier. The gelling system may be pumped into formations with excessive water production and thermally activated in the formation at downhole conditions to form a co-gel of polyacrylamide interspersed in an inorganic gel network to reduce water production.

Owner:SCHLUMBERGER TECH CORP

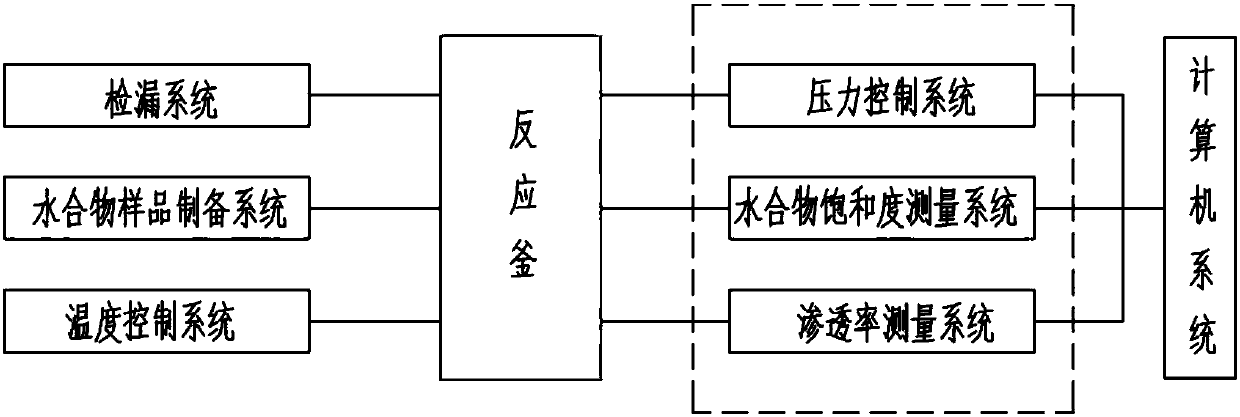

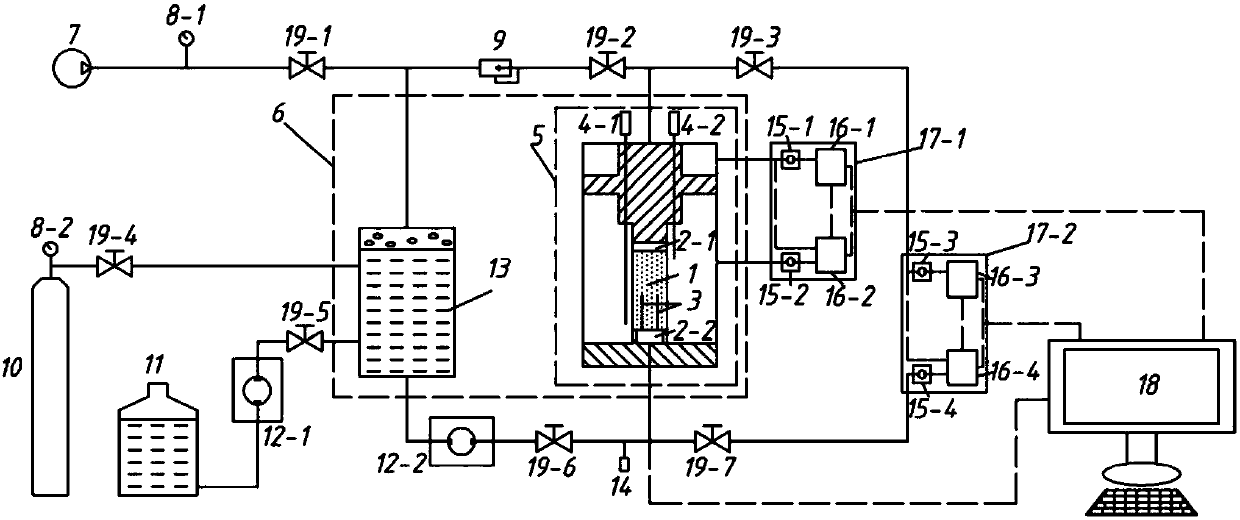

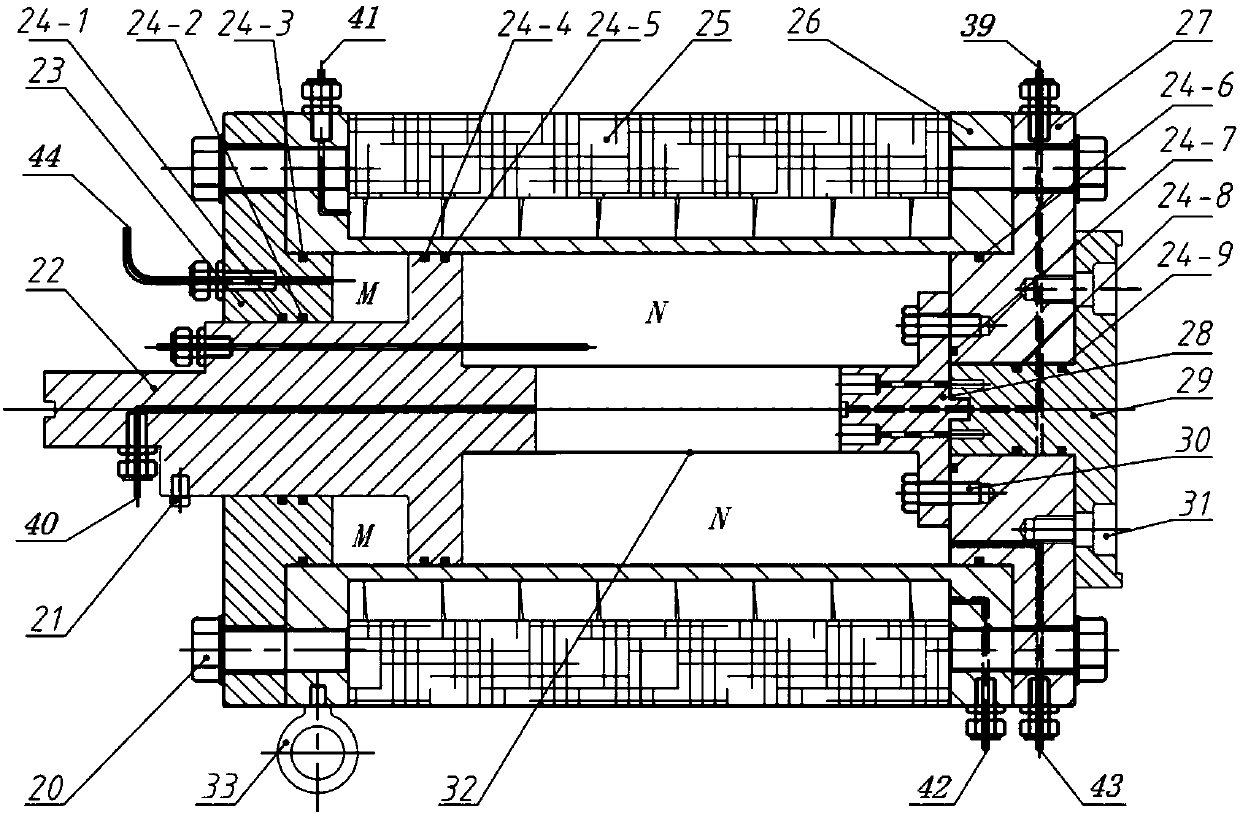

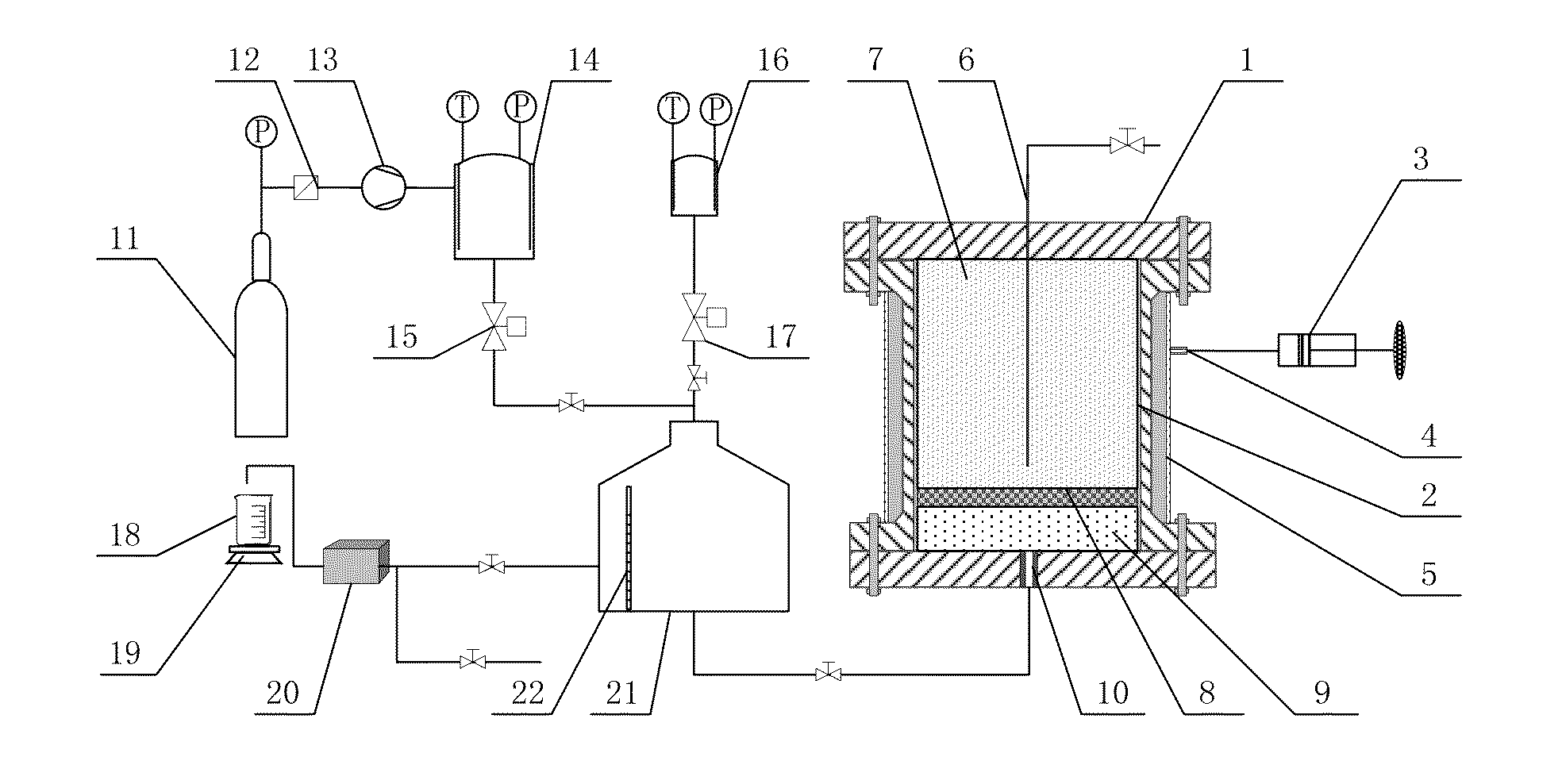

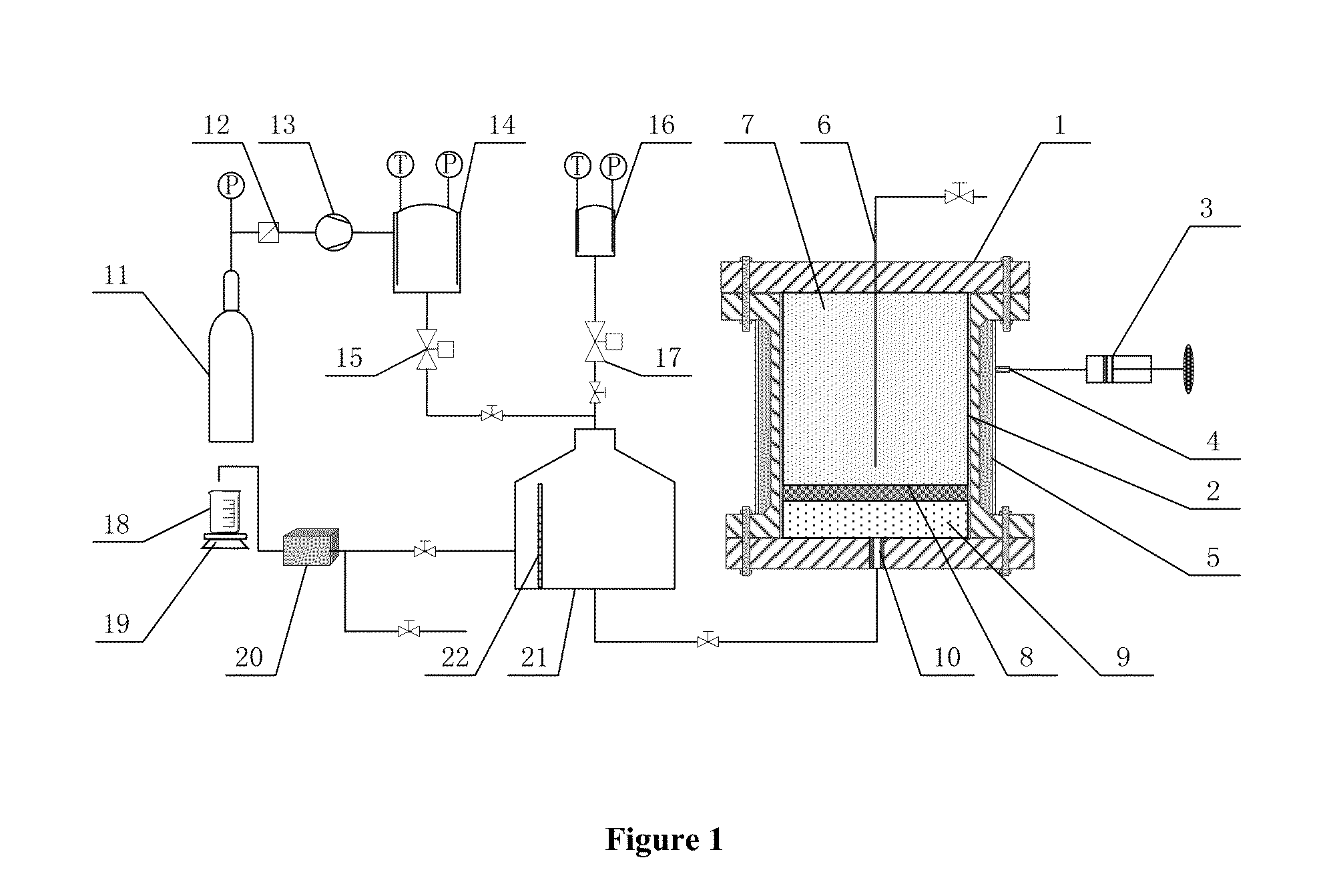

Permeability measuring device and method of hydrate-contained sediments under three-axis stress conditions

PendingCN107894383AAccurately measure the volume change of the measured sampleAccurate measurement of body changesPermeability/surface area analysisMeasurement deviceAxial pressure

The invention discloses a permeability measuring device and method of hydrate-contained sediments under three-axis stress conditions. The measuring device comprises a reaction kettle, a pressure control system, a hydrate saturability measuring system, a permeability measuring system and the like. The pressure control system can synchronously exert axial pressure and peripheral pressure so as to precisely control the axial pressure and the peripheral pressure. The hydrate saturability measuring system reduces the influences on permeation channels to the maximum extent through a flexible time-domain reflection probe. The permeability measuring system detects the pressure variation and liquid outlet volume variation of a pore pressure inlet and outlet in real time so as to automatically obtaining the permeability of samples efficiently and accurately, and artificial errors are avoided. By means of the permeability measuring device and the corresponding measuring method, the permeability simulating experiment of the hydrate-contained sediments under the three-axis stress conditions can be carried out, the simulation data of permeability and saturability of the hydrate-contained sediments under the three-axis stress conditions is obtained, and an effective theoretical basis is provided for the water production and gas production rules of the hydrate depressurizing production process.

Owner:QINGDAO INST OF MARINE GEOLOGY

Combined scale inhibitor and water control treatments

A combined scale inhibitor treatment and water control treatment requires fewer steps than the sum of each treatment procedure practiced separately. The control of water production simultaneously further reduces the amount of scale formed. Conventional water control chemicals and scale inhibitors of a wide variety of types can still be employed to advantage, and the same equipment may be used as employed for the treatments implemented separately.

Owner:BAKER HUGHES INC

Valve Responsive to Fluid Properties

InactiveUS20090145609A1Easy to moveHigh viscosityCheck valvesFluid removalFluid viscosityWater production

A valve for downhole use has the ability to throttle between fully open and closed and is fully variable in positions in between. The valve is preferably responsive to flowing fluid viscosity and uses a three dimensional flow through restrictor in combination with a relatively movable cover. At a given flow, a higher viscosity fluid will create a greater relative movement and make it possible for flowing fluid to bypass more of the flow through member. In a particular application involving production from a zone, an array of such valves can allow more production where the viscosity is higher and less production where the viscosity drops due to, for example, water production.

Owner:BAKER HUGHES INC

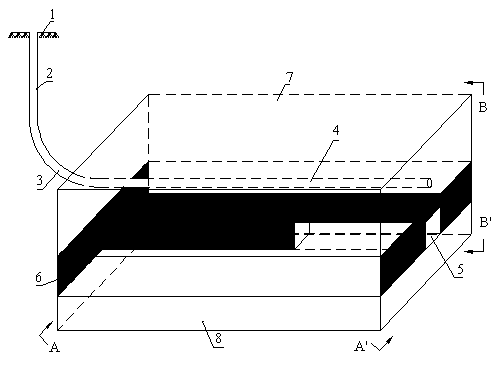

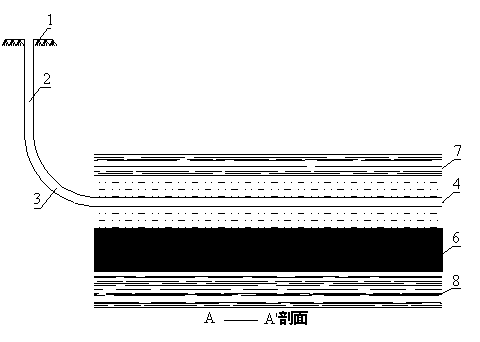

Experimental device for simulating exploitation of natural gas hydrate in permeable boundary layer

ActiveUS20160251943A1Easy to operateStrong practical valueConstructionsGaseous fuelsWater bathsWater production

A device for simulating exploitation of a natural gas hydrate in a permeable boundary layer includes a high pressure reaction kettle, a formation simulation unit and an aquifer maintaining unit. A water bath jacket externally connected with constant temperature water bath is arranged on the outer wall of the high pressure reaction kettle for providing a necessary temperature condition for the high pressure reaction kettle. A simulative well at the center of the top of the high pressure reaction kettle is connected with liquid injection, gas injection, gas production and water production equipment. An aquifer interface at the bottom of the high pressure reaction kettle is connected to the aquifer maintaining unit through a pipeline. The simulation device simulates the geological environment of a hydrate reservoir, allowing comprehensive evaluation of hydrate exploitation under different formation permeability and different formation pressure gradients.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

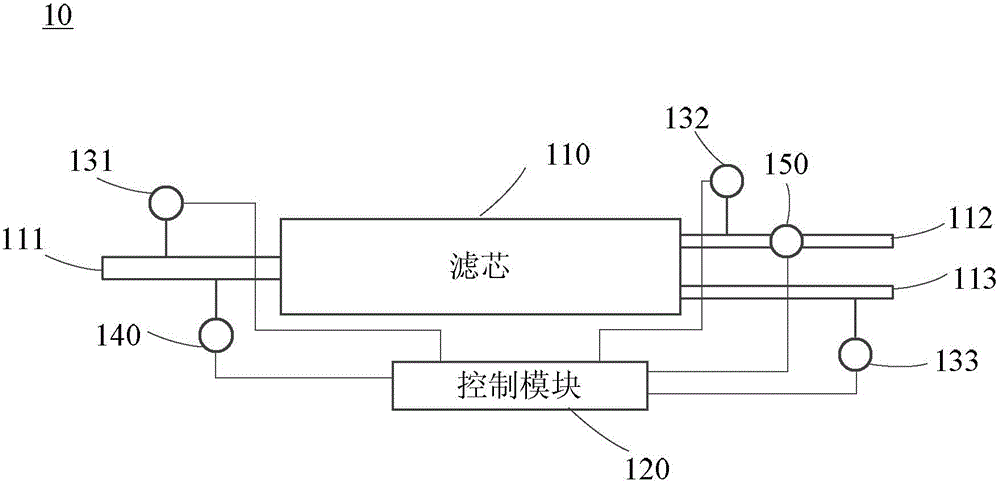

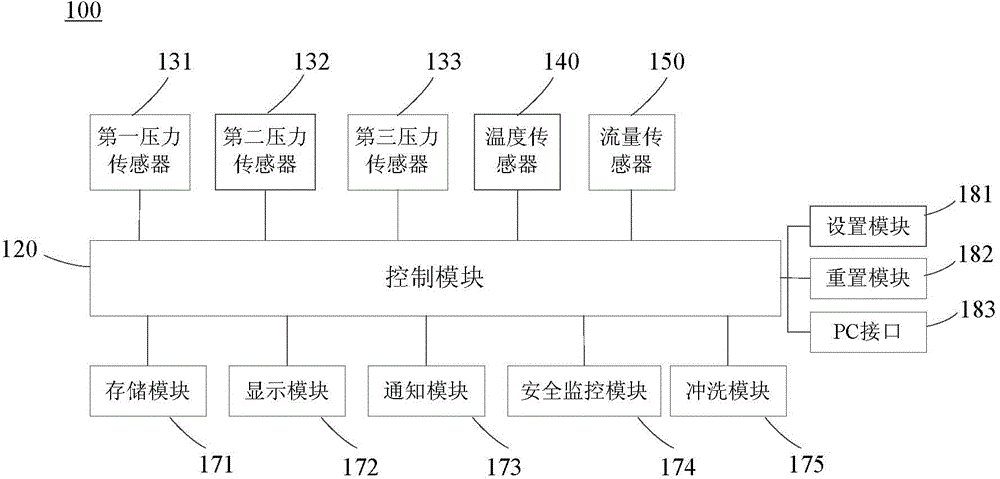

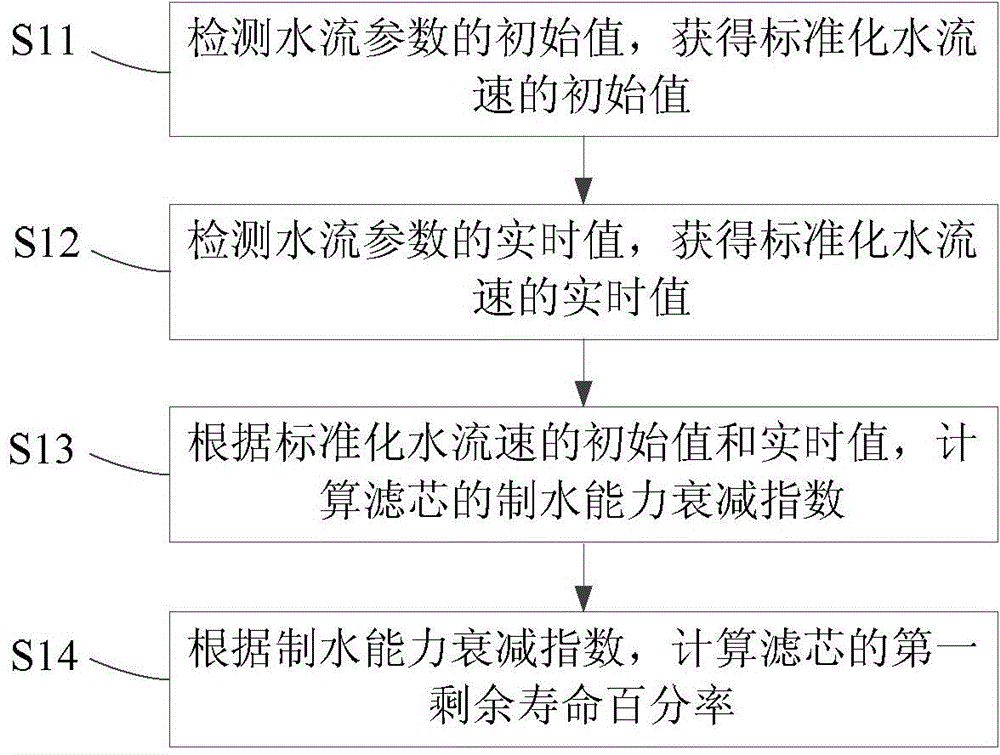

Method for monitoring state of filter element of water purification device, monitoring device and water purification device

ActiveCN104083936AStatus accurateAccurate lifeFiltration separationProgramme control in sequence/logic controllersUltrasound attenuationWater production

The invention provides a method for monitoring the state of a filter element of a water purification device, a monitoring device and the water purification device. The monitoring device detects water flow velocity, water temperature value and water pressure value in real time and obtains standard water flow velocity through an operation relation. A control module of the monitoring device acquires an initial value of the standard water flow velocity; real-time values of multiple water flow parameters are detected in a filter element operating process, and a real-time value of the standard water flow velocity is acquired based on the detected real-time values of the multiple water flow parameters; a water production capacity attenuation index of the filter element is determined based on the initial value of the standard water flow velocity and the real-time values of the standard water flow velocity; the multiple water flow parameters comprise water flow velocity, water temperature, pressure of water flow at the water inlet end of the filter element, and pressure of the water flow at the water purification end. Because the state of the filter element is reflected in aspects of water production capacity and water purification capacity, and the influence of multiple environmental factors on the water flow velocity detection is comprehensively considered, and thus the actual state and the residual service life of the filter element can be accurately monitored.

Owner:BEIJING YADU ENVIRONMENTAL PROTECTION TECH

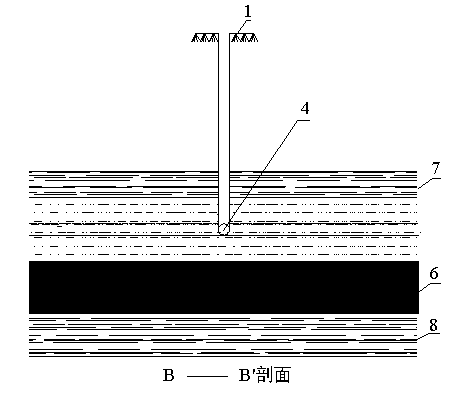

Method for pre-pumping coal roadway stripe gas of single soft protruded coal seam of unexploited area

InactiveCN102852546AAvoid investmentIncrease the lead timeFluid removalDrainageMining engineeringHorizontal wells

The invention provides a method for pre-pumping coal roadway stripe gas of a single soft protruded coal seam of an unexploited area and relates to the technical field of gas pumping. Through the method, outburst removal of the area with a single soft hypotonic protruded coal seam coal roadway stripe can be achieved. The method for pre-pumping the coal roadway stripe gas of the single soft protruded coal seam of the unexploited area comprises building a concordant layer horizontal well which is 3-6m away from the coal seam from the ground to a top plate and a base plate of the single soft protruded coal seam of the unexploited area, performing segmented fracturing after oriented perforating, enabling top plate and base plate rock terrane where coal seam gas is sealed and stored originally to be transformed into a pumping liberation layer with developed fracture networks, enabling the pumping liberation layer to be communicated with the coal seam in a large-area mode through the fracture networks, performing decompression and aerogenesis by dewatering, determining whether to perform negative pressure pumping according to water production conditions, enabling the coal seam gas to be desorbed and diffused continuously, and pumping the gas massively by pumping a horizontal well opening in the liberation layer. By pumping the gas massively, the outburst prevention index in the coal roadway stripe can be reduced to below the safety standard in the outburst prevention rules, and safe and speedy drivage is achieved.

Owner:HENAN COAL CHEM IND GROUP INST

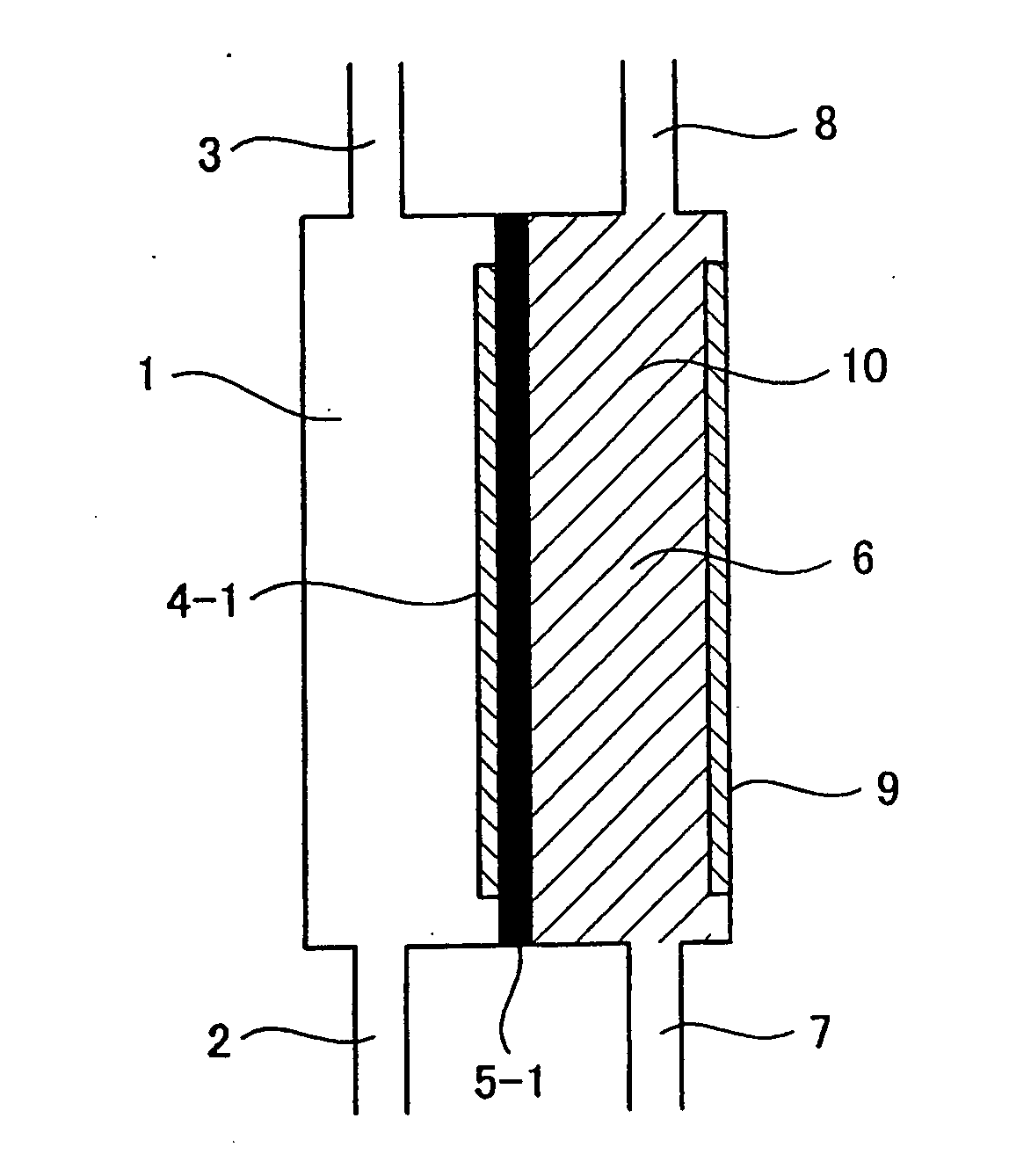

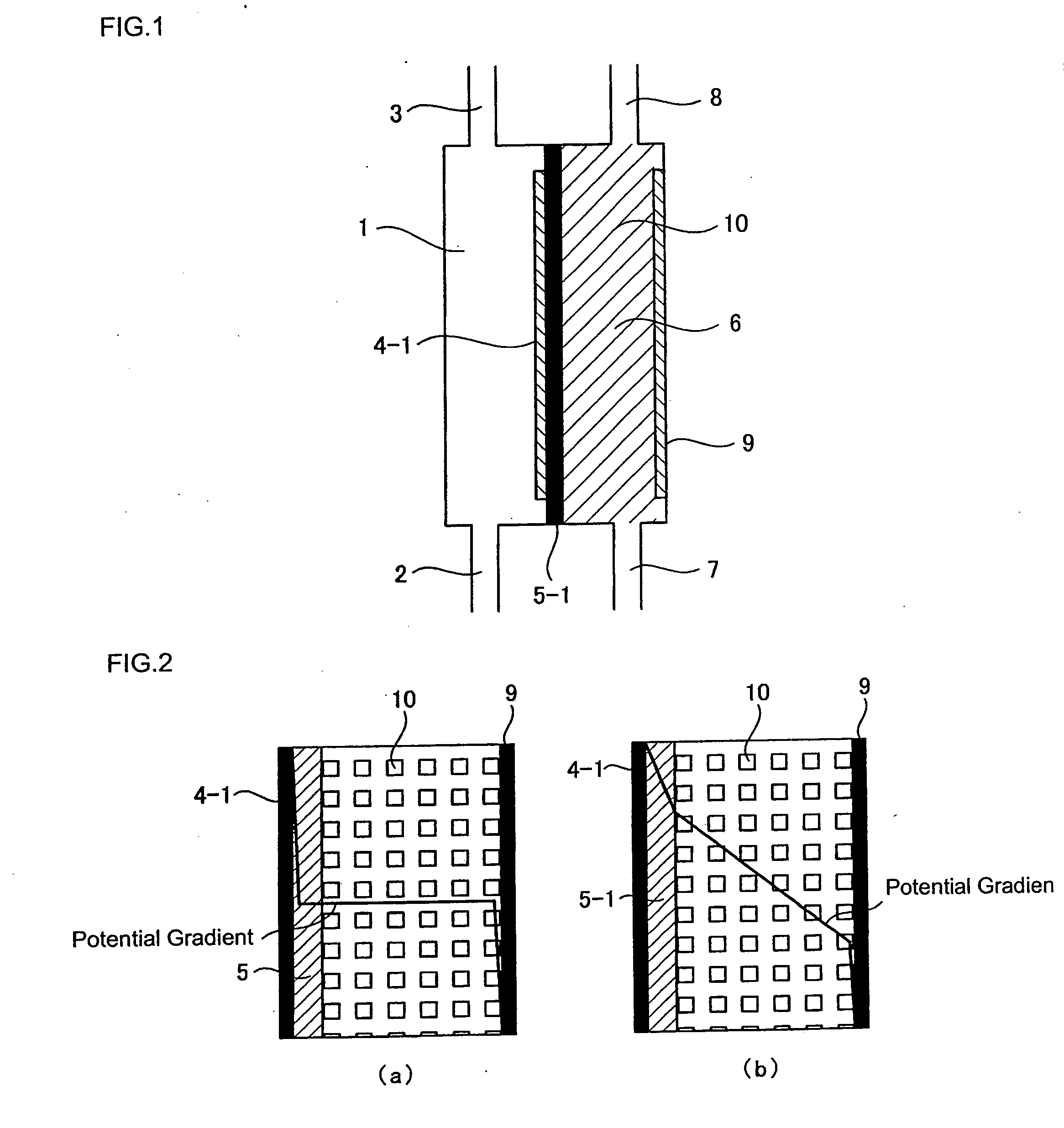

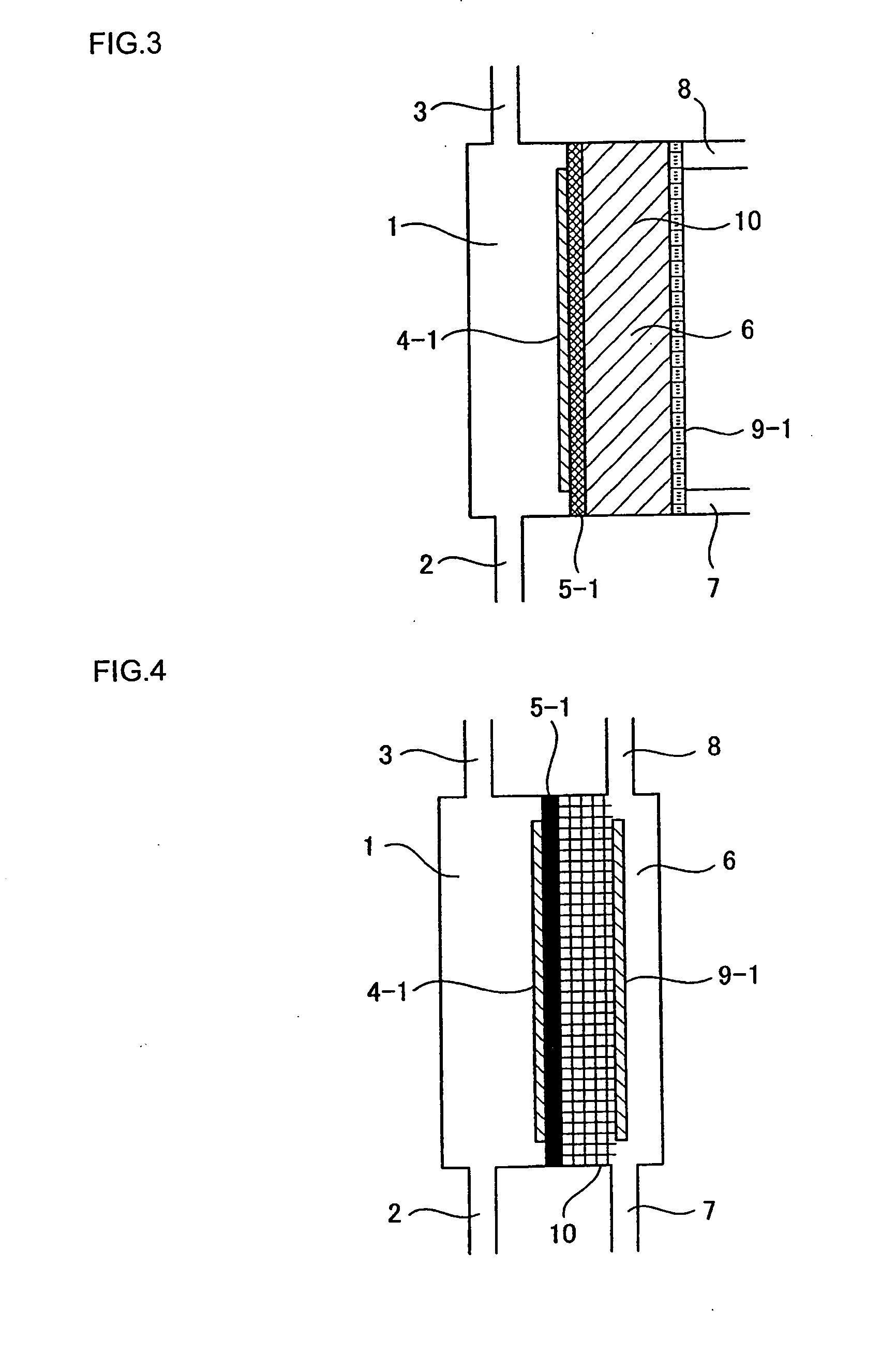

Apparatus and method for producing hydrogen-dissolved drinking water

ActiveUS20110198236A1High dissolved hydrogen concentrationLong dissolved hydrogen concentrationCellsMembranesWater productionIon-exchange resin

An apparatus for producing in the home hydrogen-dissolved drinking water that is suitable for drinking, has a high dissolved hydrogen concentration, and a long dissolved hydrogen life. A hydrogen-dissolved drinking water production apparatus includes an electrolytic cell through which water can pass for producing drinking water having a pH in a range of 2.5 to 8.5, and in particular, in a range of 5.8 to 8.5, and a dissolved hydrogen concentration of 0.1 ppm or more by supplying high-purity water having a conductivity of 50 μS / cm or less. The hydrogen-dissolved drinking water production apparatus is characterized in that the electrolytic cell includes a vertical anode chamber having a water-permeable plate-like anode electrode and a vertical cathode chamber having a plate-like cathode electrode, the anode chamber and the cathode chamber are separated by a diaphragm formed from a fluorine-based cation exchange membrane, the water-permeable plate-like anode electrode is closely adhered to the diaphragm formed from the fluorine-based cation exchange membrane, and an ion-exchange resin is filled in a space between the diaphragm and the cathode electrode.

Owner:TECH CORPORATION CO LTD +1

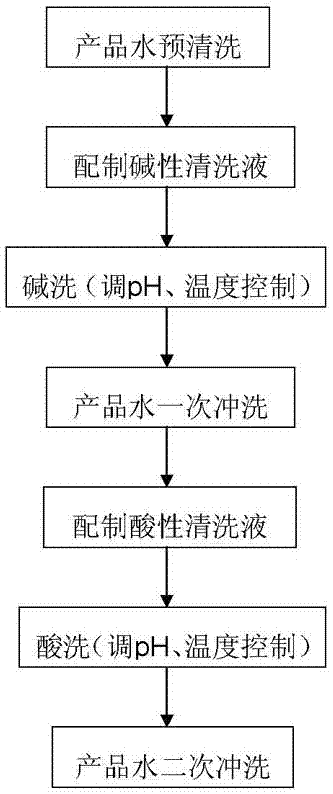

Chemical cleaning method of ultrafiltration membrane

ActiveCN107398185AHigh removal rateIncrease permeate fluxSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisTemperature controlUltrafiltration

The invention discloses a chemical cleaning method of an ultrafiltration membrane. The chemical cleaning method is mainly used for treating the membrane pollution form of inorganic scale coating with organic scales, and comprises the following steps of (1) preparing a basic cleaning solution; (2) performing alkali washing: performing cyclic cleaning on the ultrafiltration membrane by the basic cleaning solution; controlling the pH value of the cleaning solution to be 10.5 to 11.5; controlling the cleaning temperature at 38 to 41 DEG C; (3) performing primary flushing; removing basic cleaning liquid remained in the ultrafiltration membrane; (4) preparing an acid cleaning solution; (5) performing acid washing: performing cyclic cleaning on the ultrafiltration membrane by the acid cleaning solution; controlling the pH value of the cleaning solution to be 1.5 to 3; controlling the cleaning temperature at 38 to 41 DEG C; (6) performing secondary flushing to remove the acid cleaning solution remained in the ultrafiltration membrane. The method provided by the invention has the advantages that various organic matters intercepted on holes of the ultrafiltration membrane can be effectively removed; the water production flow rate of the ultrafiltration membrane can be improved; the operation pressure of the ultrafiltration membrane can be reduced; the stable operation of a landfill leachate ultrafiltration membrane treatment system is ensured.

Owner:HUNAN JUNXIN ENVIRONMENTAL PROTECTION CO LTD

Hydrogen-dissolved water production apparatus

InactiveUS20030132104A1Avoid quality lossQuality improvementUltrafiltrationReverse osmosisParticulatesHydrogen

A degassing device (10), a hydrogen dissolving device (12), and a palladium catalyst column (17) are provided in that order downstream of a high-purity water production device (1), and an impurity removal device (19) is connected to the exit side of treated water of the palladium catalyst column (17). The impurity removal device (19) removes impurity ions which are eluted into the water to be treated or impurity particulates which mix in with the water to be treated during the treatment in the palladium catalyst column (17). The impurity removal device (19) comprises an ion exchange device (20) and a membrane treatment device (21) such as a ultrafiltration membrane device, a reverse osmosis membrane device or the like. By providing an impurity removal device (19) in this manner, it is possible to remove impurities generated during hydrogen peroxide removal treatment by the palladium catalyst and to prevent degradation in quality of hydrogen-dissolved water.

Owner:ORGANO CORP

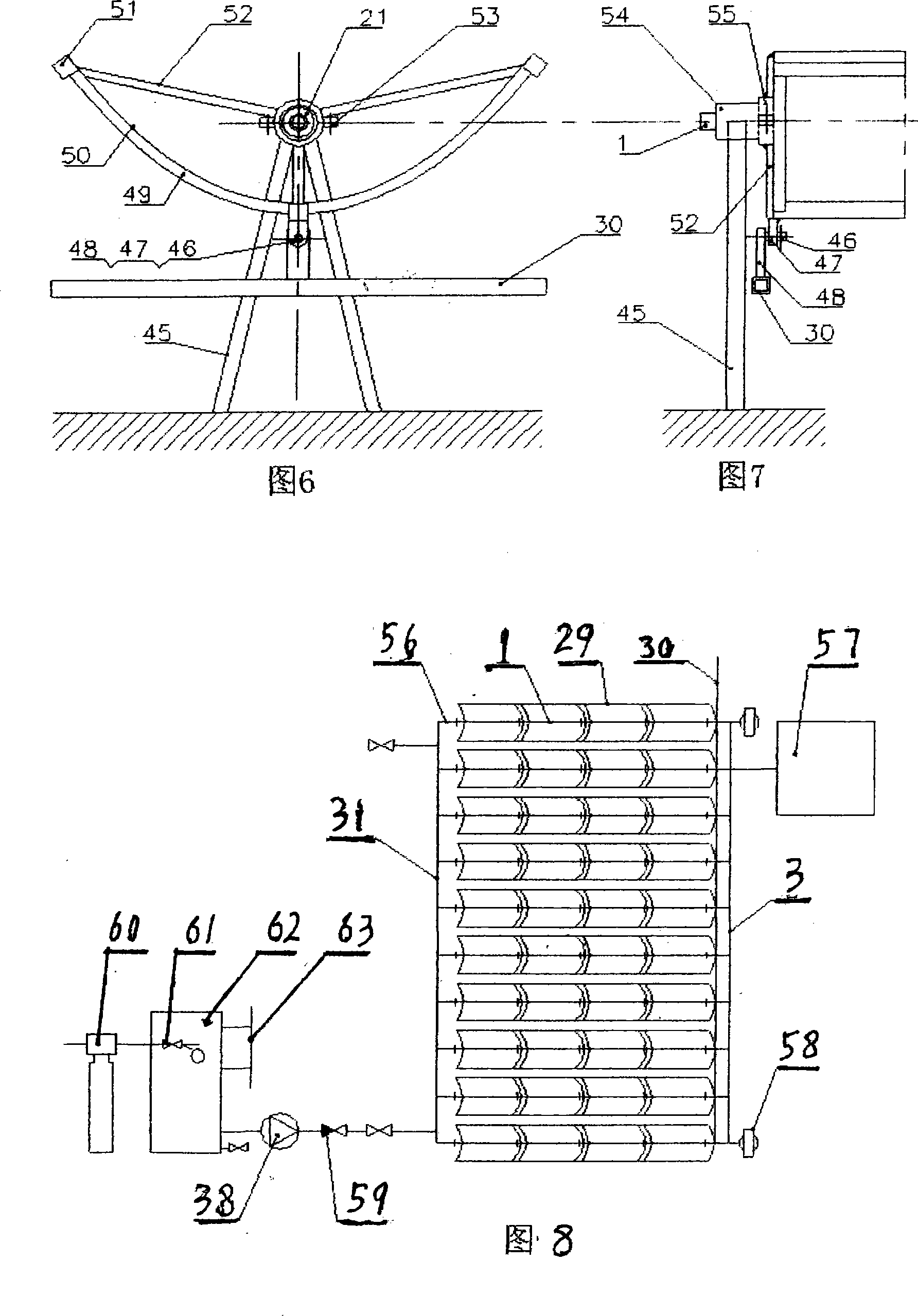

Solar boiler

InactiveCN101126553ATo achieve the purpose of energy savingLow costSolar heating energySolar heat devicesThermal energyFailure rate

The present invention provides a solar boiler and a circulated thermal pipe, and relates to a solar collecting, conversion, heat transfer and heat exchanging device. The solar radiation is reflected and congregated to a heat absorption pipe arranged on a axial line of a reflector of single-curved surface by the reflector of single-curved surface, converted into heat energy after the absorption of sunshine by a coating layer, and the heat energy is delivered to a heat exchanger by a circulated thermal pipe, and the continuous working ranging from dozens of DEG C to 1,700 DEG C is achieved by the adoption of the working fluid of mutual solution. The circulated thermal pipe has automatic adjustment of the flow rate, rapid heat transferring of large power, large falling, long distance and small temperature differences, working of high temperature and low pressure, using of cold regions minus 40 DEG C and safe using. The present invention has lower failure rate by adopting a device intermittently and unified driving the reflector to track the solar device, stable and adjustable heating parameters by phase change thermal storage of paralleled connected small containers, multifunction and combined using of high, middle and low temperature, wide ranges of application, and can be used for the industrial heating of hydrogen production, power generation, refrigeration, freshwater production, pure water production, gas supplying, heat supplying, chemical and oil, etc.

Owner:陈红专

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com