Solar boiler

A technology of solar energy and boilers, which is applied in the field of solar boilers and circulating heat pipes, and can solve problems such as large flow resistance of condensate, difficulty in high-temperature work, and large heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with embodiment.

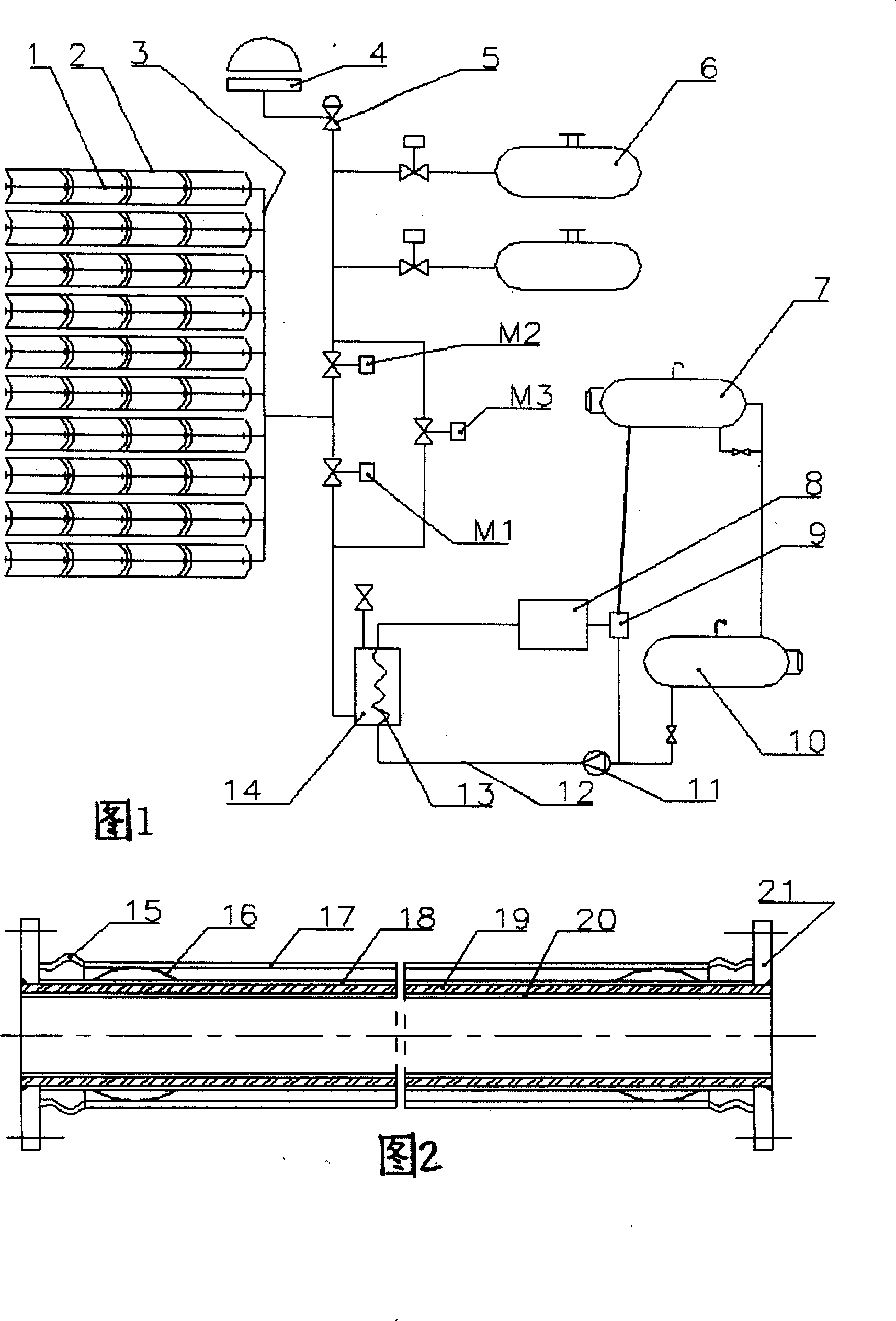

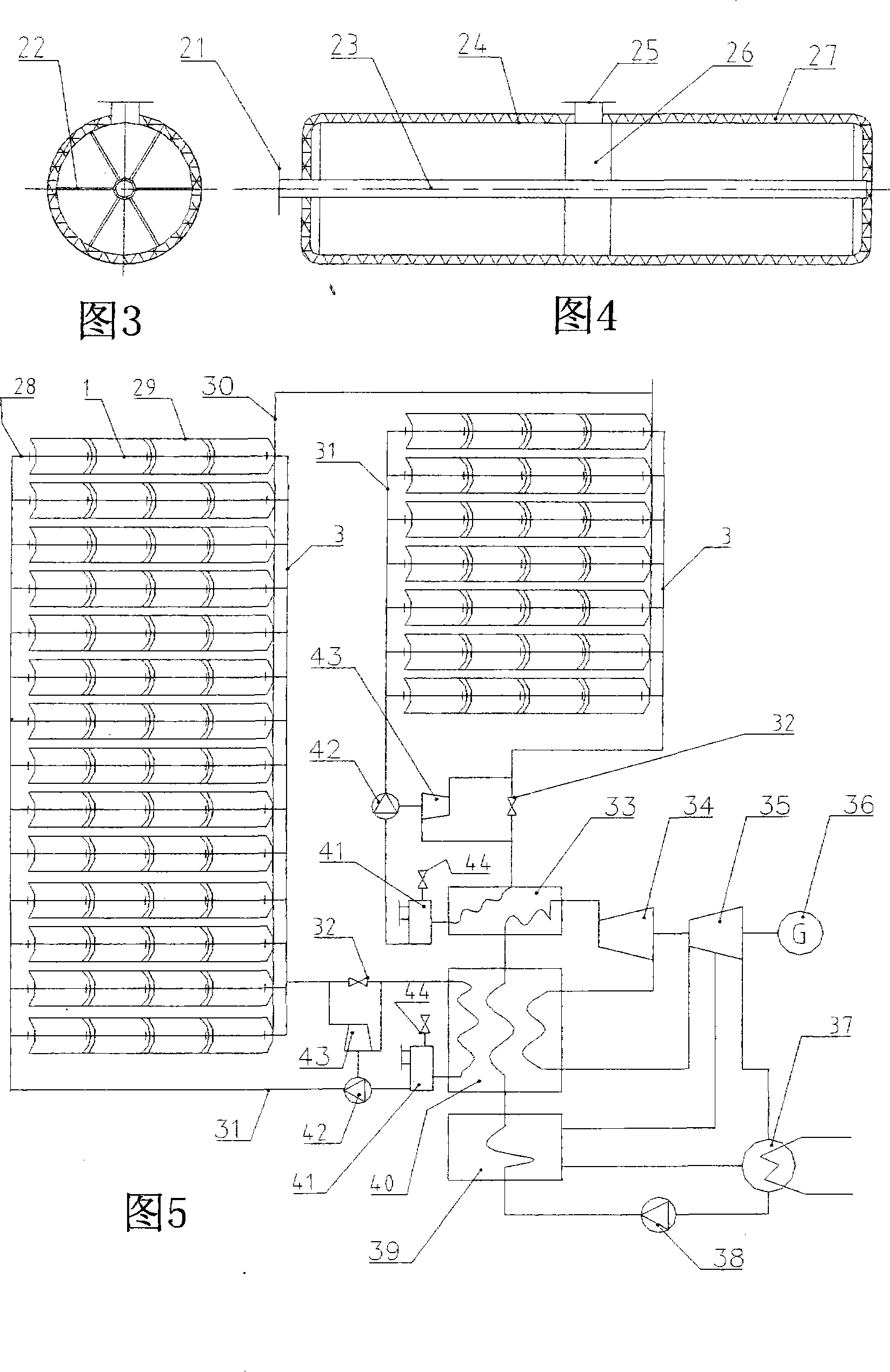

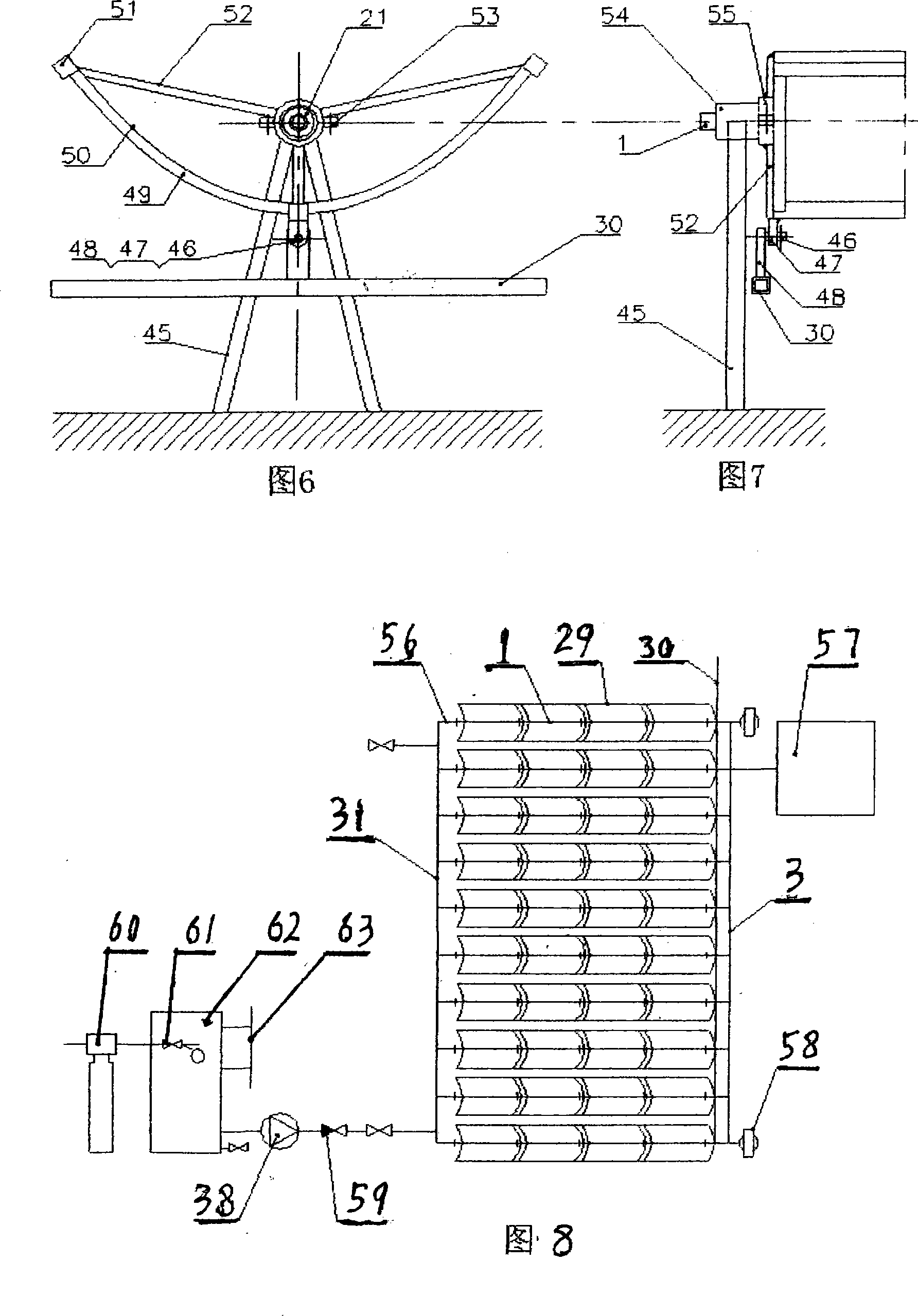

[0050] The first embodiment is the embodiment where the solar boiler is used to convert into a heat carrier furnace. Figure 1 is a system diagram of a solar heat carrier boiler. The composite parabolic reflector 2 is installed obliquely to the south, that is, its axis is north-south; the heat-absorbing pipe 1 is installed obliquely at the axis of the composite parabolic reflector 2, and one end of the heat-absorbing pipe 1 is closed with a sealing plate, and the other end is connected with a flange 21 The air collecting pipe 3 and the closed end of the heat absorbing pipe 1 are slightly lower than the other end. The air collecting pipe 3 is respectively connected to the lowest point of the heat exchanger 14 and the heat exchange tube 23 of the heat storage container 6 through the solenoid valves M1 and M2. The air collecting pipe 3 Also connect the cooling tower 4 through the safety...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com