Patents

Literature

55 results about "Feed technique" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Platform for feeds

InactiveUS20060161845A1Digital data processing detailsNatural language data processingFeed techniqueWeb site

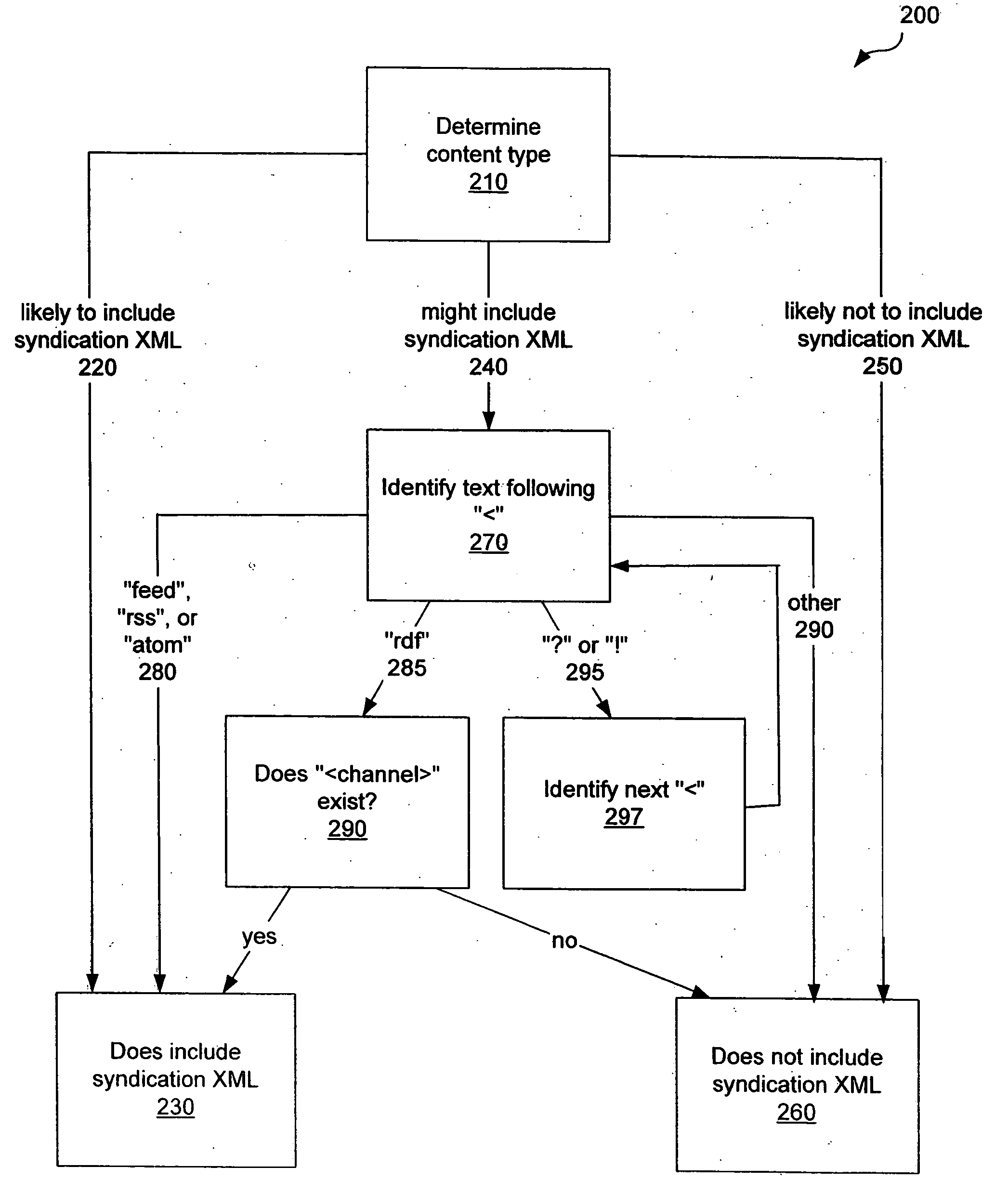

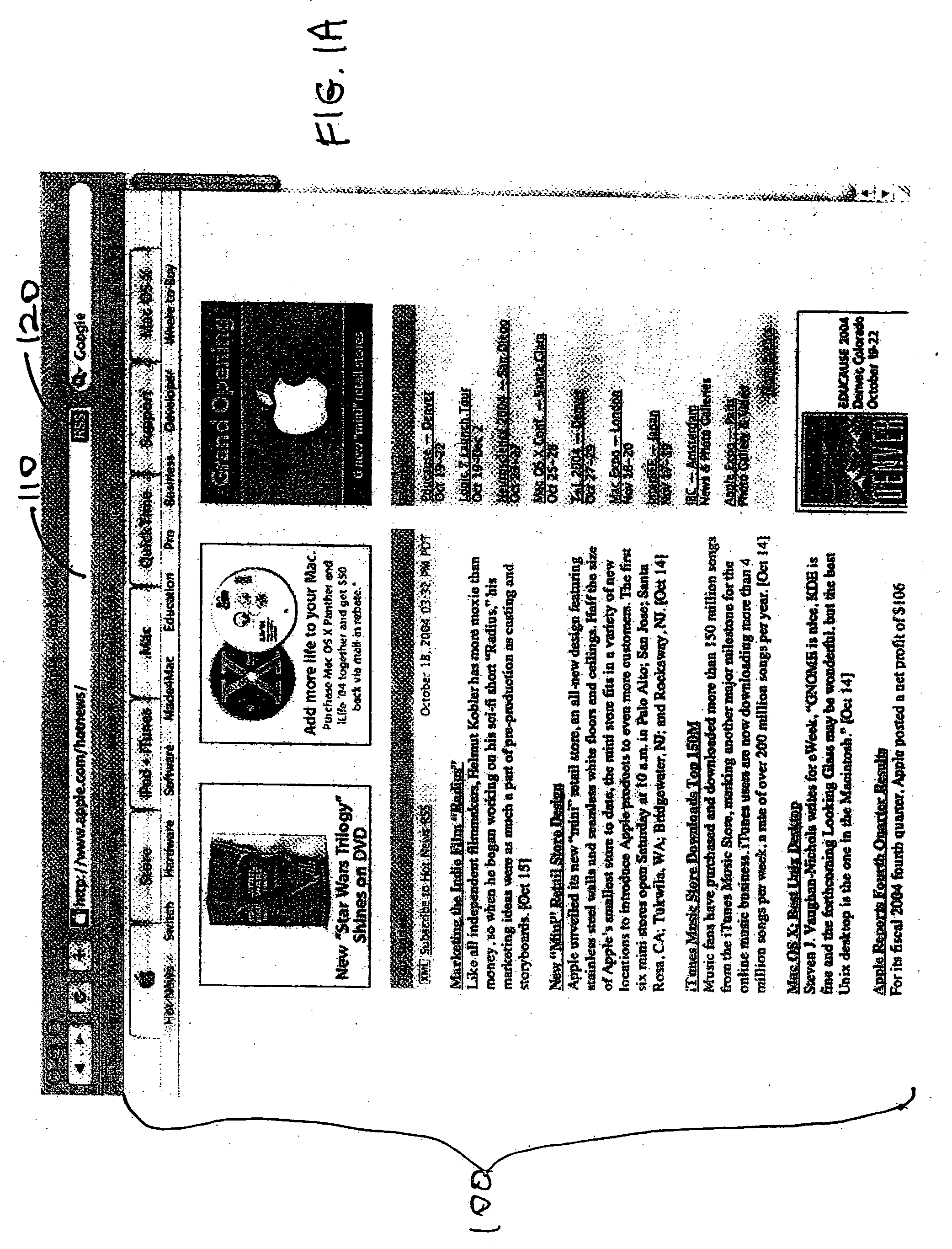

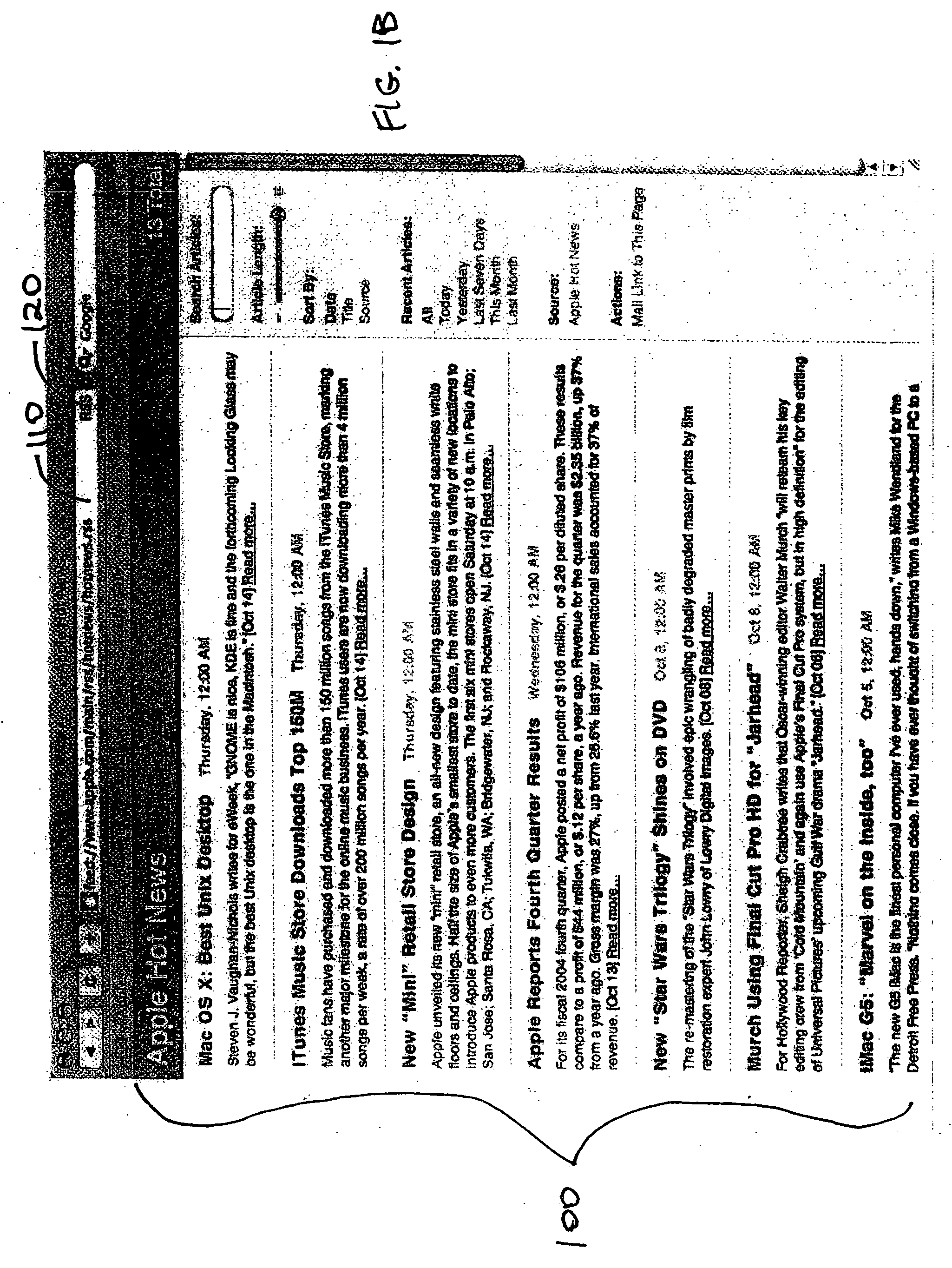

Techniques for detecting, managing, and presenting syndication XML (feeds) are disclosed. In one embodiment, a web browser automatically determines that a web site is publishing feeds and notifies the user, who can then access the feed easily. In another embodiment, a browser determines that a web page or feed is advertising relationship XML, and displays information about the people identified in the relationship XML. In yet another embodiment, a browser determines that a file contains a feed and enables the user to view it in a user-friendly way. In yet another embodiment, feed state information is stored in a repository that is accessible by applications that are used to view the feed. In yet another embodiment, if a feed's state changes, an application notifies the repository, and the state is updated. In yet another embodiment, a feed is parsed and stored in a structured way.

Owner:APPLE INC

Seasoner sponging drying machine group

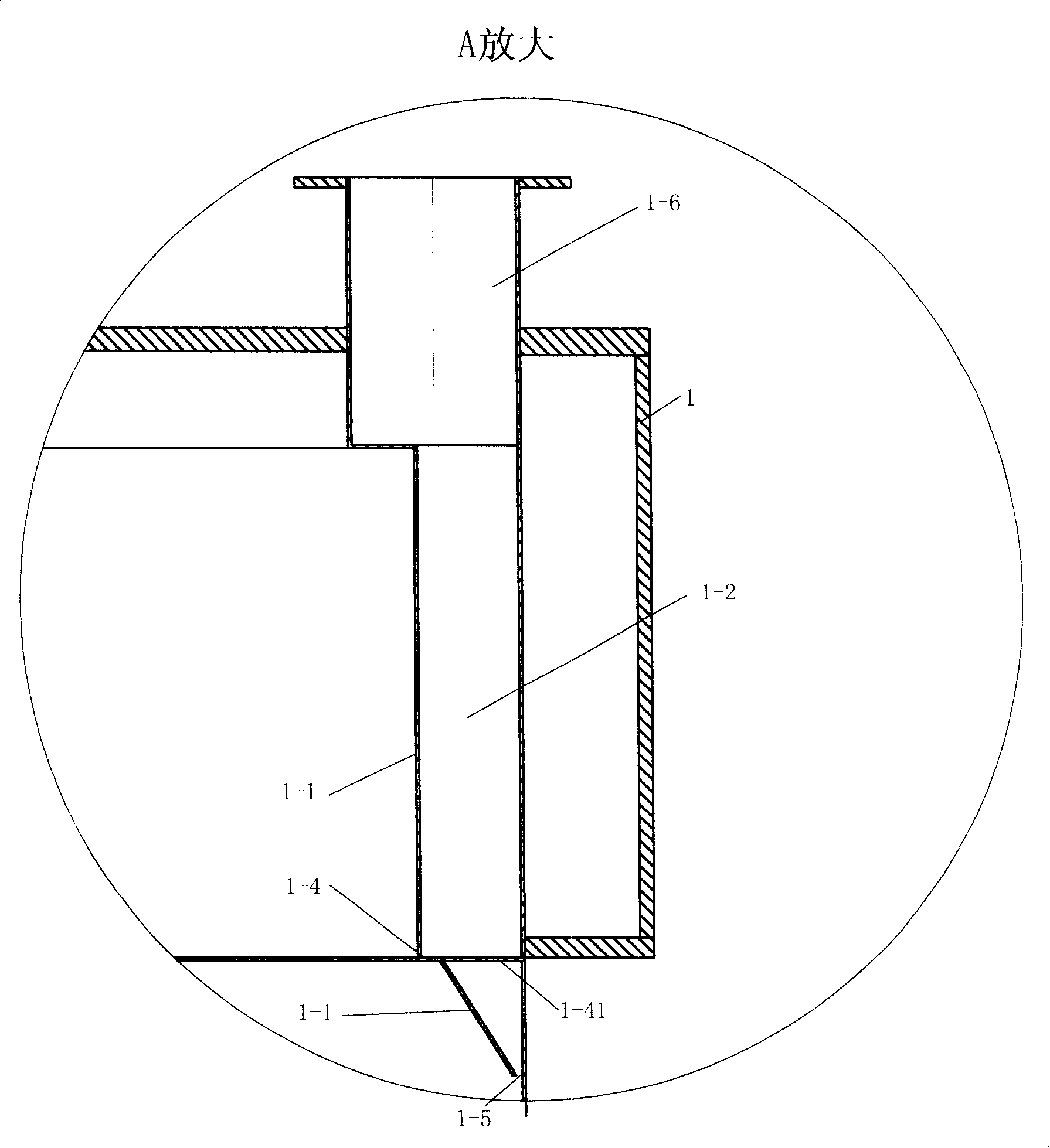

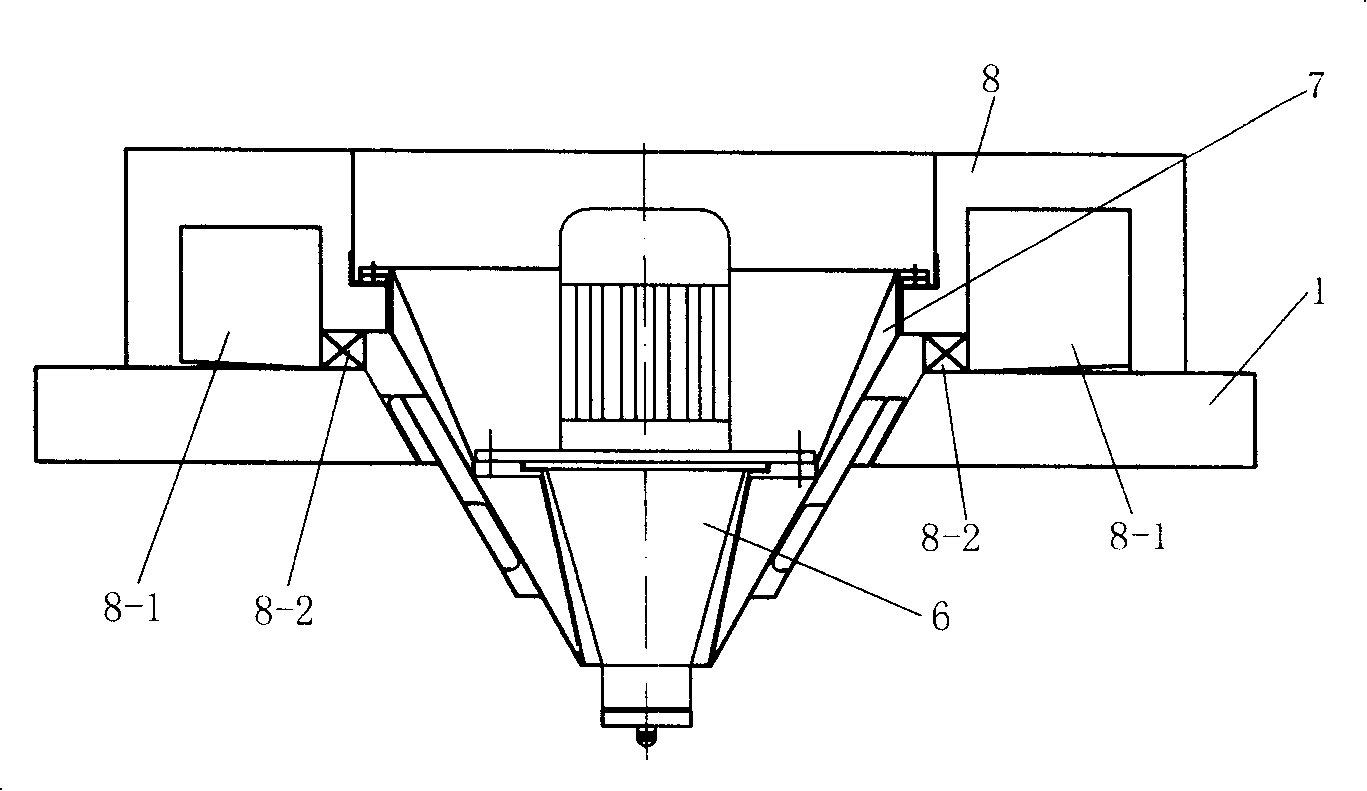

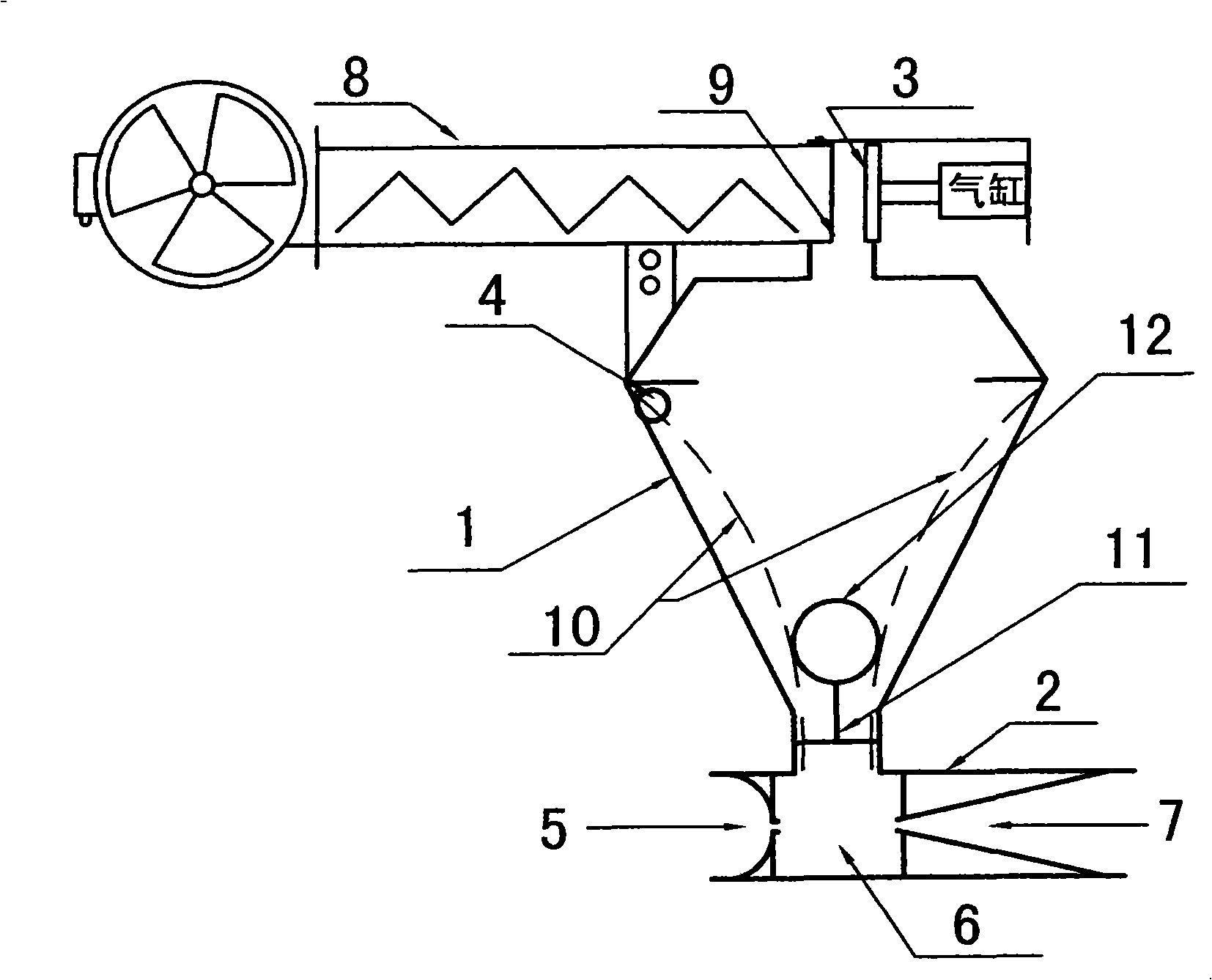

InactiveCN101178283AReduce stuck problemsReduce sticky topDrying solid materials with heatHearth type furnacesCycloneFeed technique

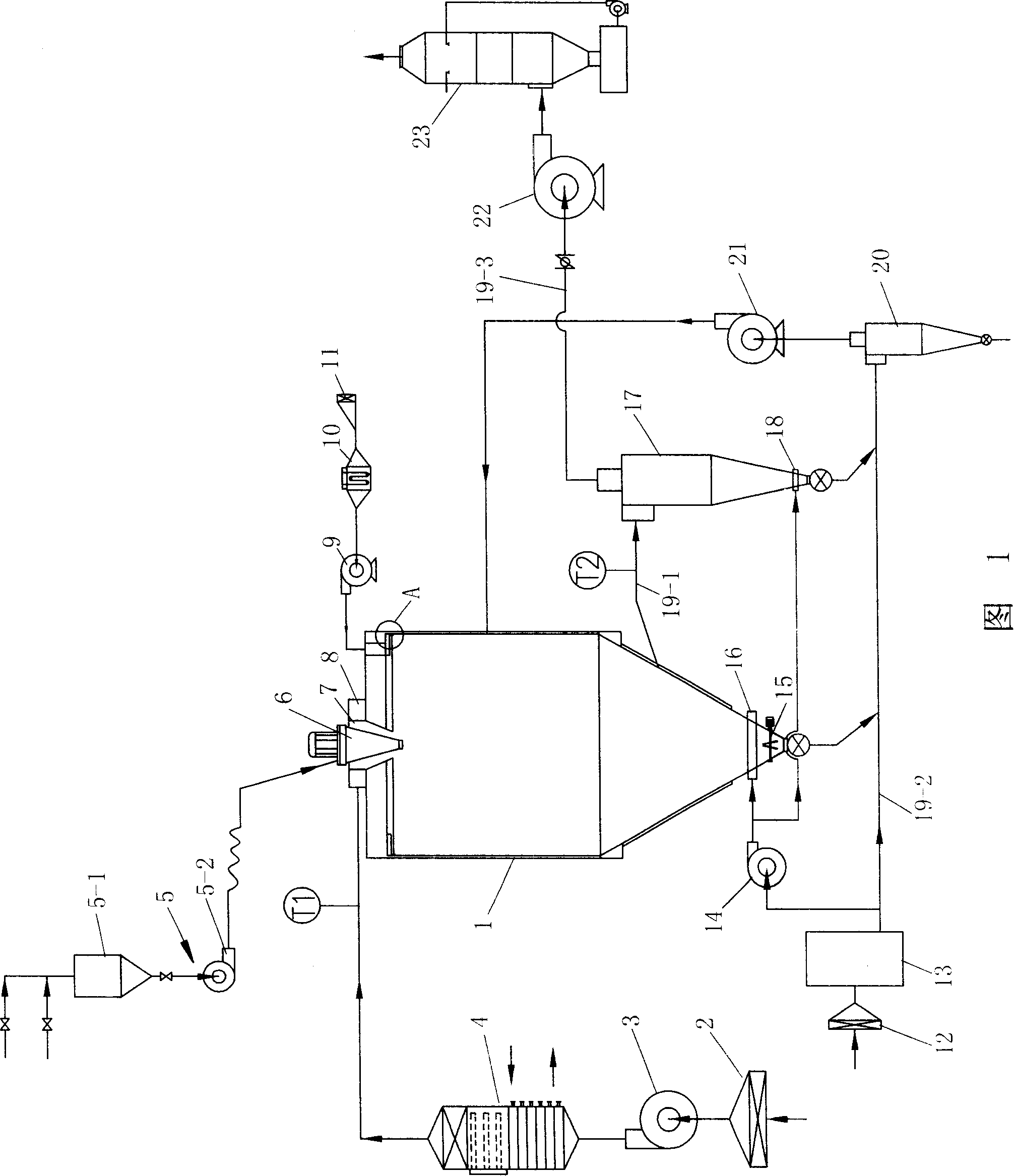

The invention comprises a material feeding device, a drying tower, a No 1 fan, a No 1 heater, a first-level cyclone separator and water-membrane dust remover. A hot air distributor and an atomizer which is arranged at the center of the hot air distributor and is connected with the material feeding device are arranged on the top of the drying tower. An air channel disk with a spiral-case shaped air channel is arranged on the top of the drying tower. The inlet of the air channel disk is connected with the output pipeline of the No1 heater, and the outlet of the spiral-case shaped air channel is connected with the inlet of the hot air distributor. A clamp sleeve is arranged in the internal tower body and near the top of the drying tower. A wall-blowing air channel is a space between the clamp sleeve and the inner side wall of the tower body. An annular clearance between the clamp bottom and the inner wall of the tower body is an air vent, and the air forms the wall-blowing air through the annular clearance. The invention adopts the air channel disk spiral air-feeding and wall-blowing feeding technique of the spiral-case shaped air channel, which not only can enhance drying efficiency but also can provide the wall-blowing air to form an air membrane in the drying tower. The air membrane can isolate powder materials from the tower wall so as to avoid a wall-sticking phenomenon.

Owner:JIANGSU XIANFENG DRYING ENG

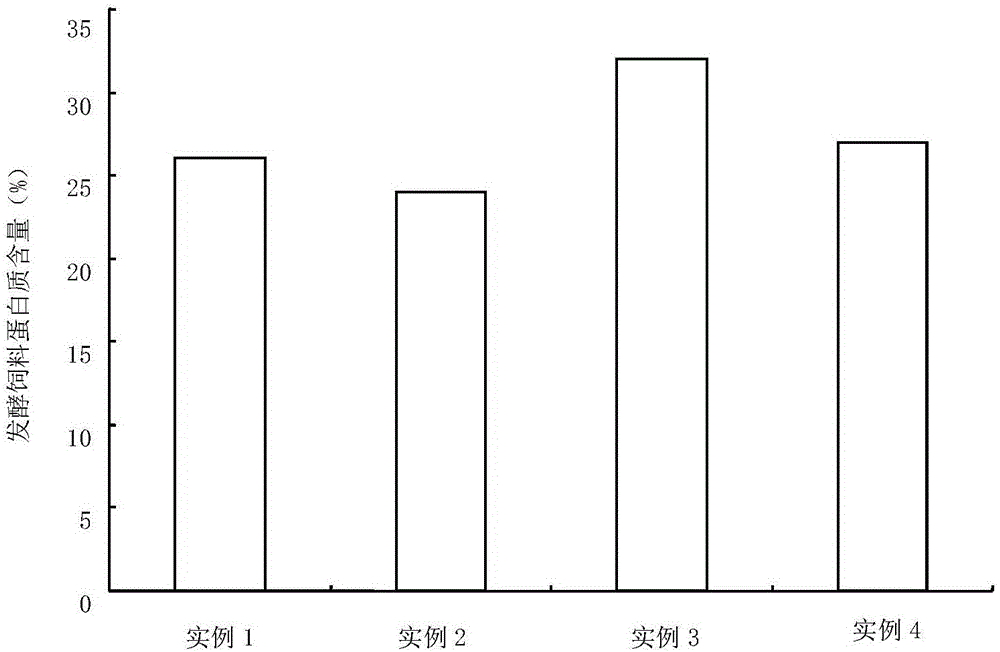

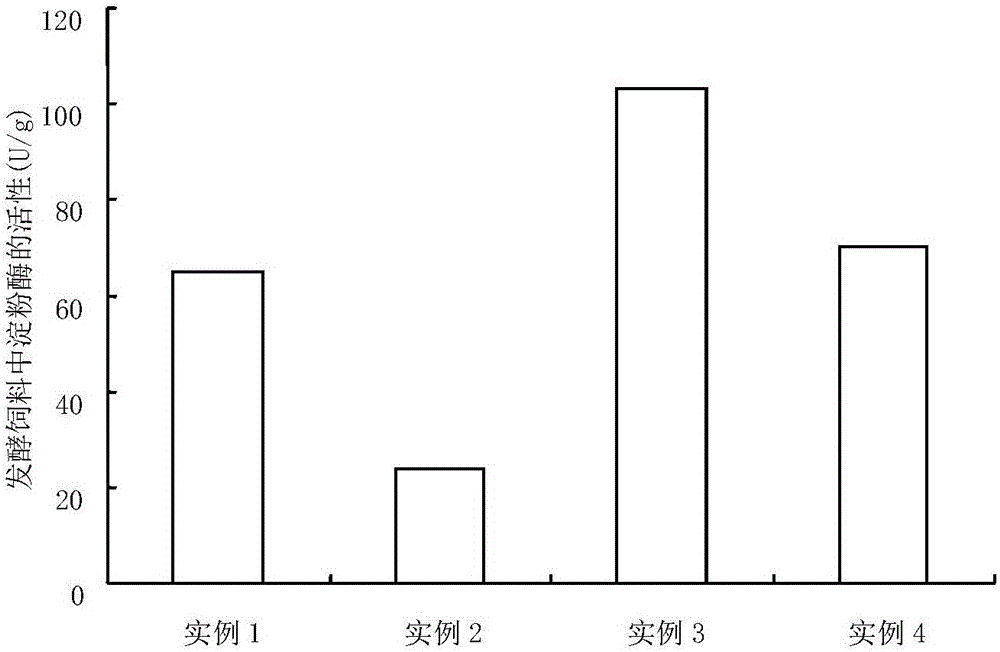

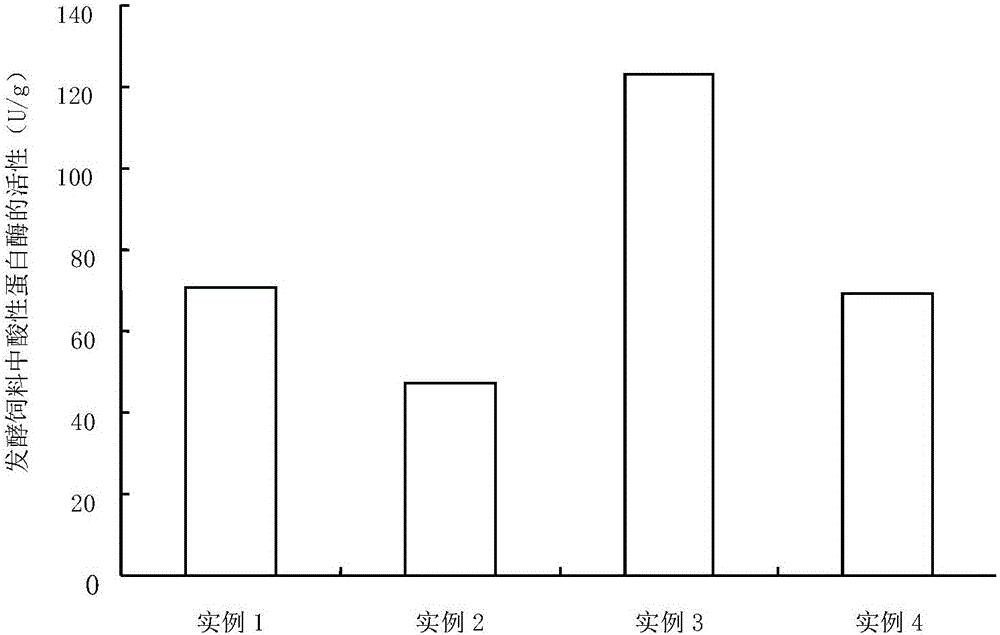

Method of two-step united multi-strain fermented feed

ActiveCN104996722AHigh activityConducive to vigorous growth and reproductionAnimal feeding stuffFeed techniqueBiotechnology

The invention discloses a method of a two-step united multi-strain fermented feed, and belongs to the technical field of feeds. The fermented feed disclosed by the invention is obtained through two steps of aerobic fermentation and anaerobic fermentation by using maize flour, palm dregs, soybean meal, bran and middling as raw materials and by using rhizopus nigricans, aspergillus oryzae, bacillus subtilis, lactobacillus plantarum and beer yeast as fermenting strains. The feed fermented through the method disclosed by the invention has the advantages that the protein content is as high as 30-34% which is increased by 45-62% than that of raw materials, the content of alpha-amylase is as high as 90-110U / g, the enzyme activity of acidic protein is as high as 110-130U / g, and the feed is rich in protein, rich in probiotics and high in enzymic activity. The method disclosed by the invention has the characteristics of high maneuverability, being suitable for large-scale industrial production and the like, and has favorable market prospects.

Owner:JIANGNAN UNIV

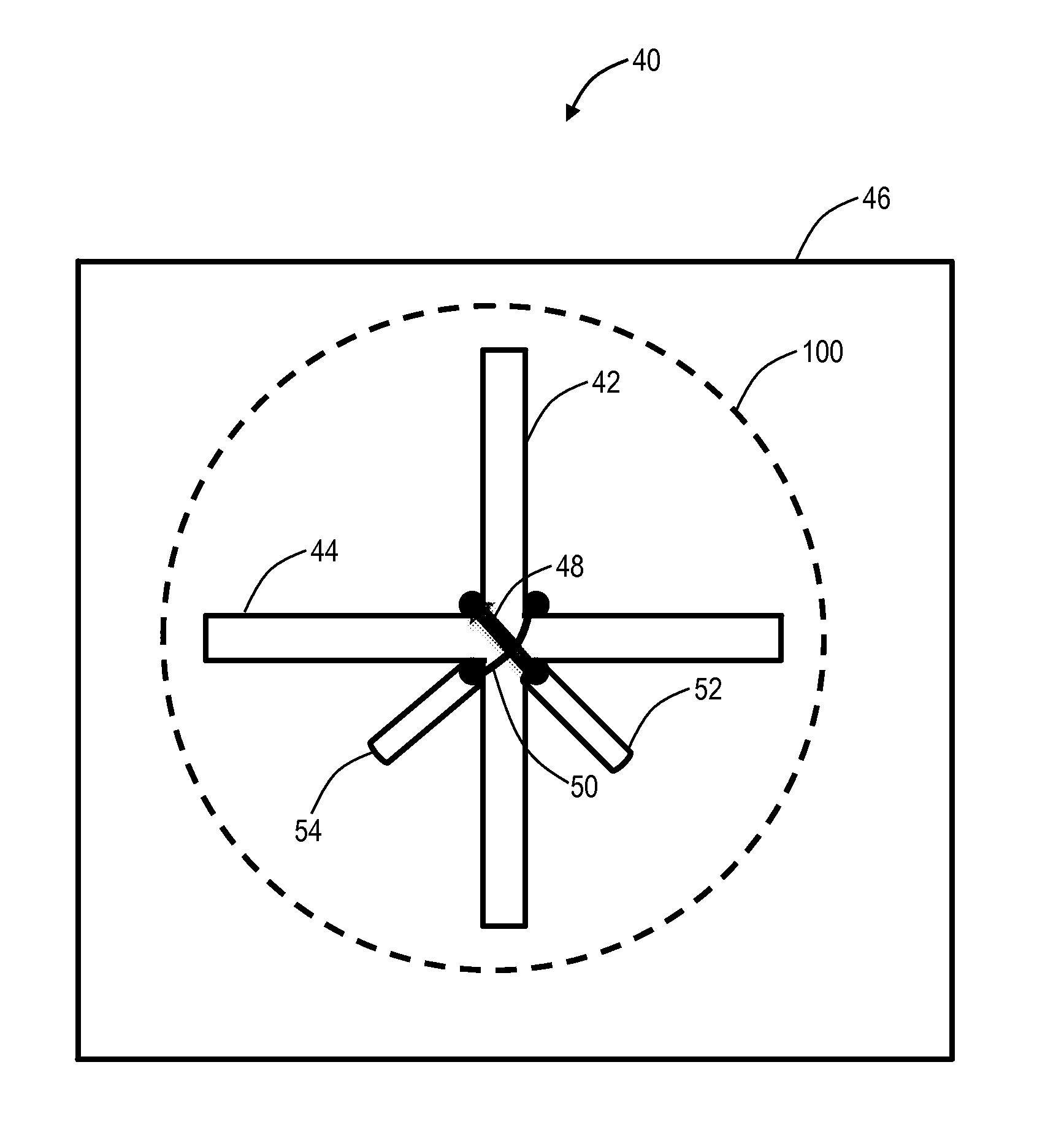

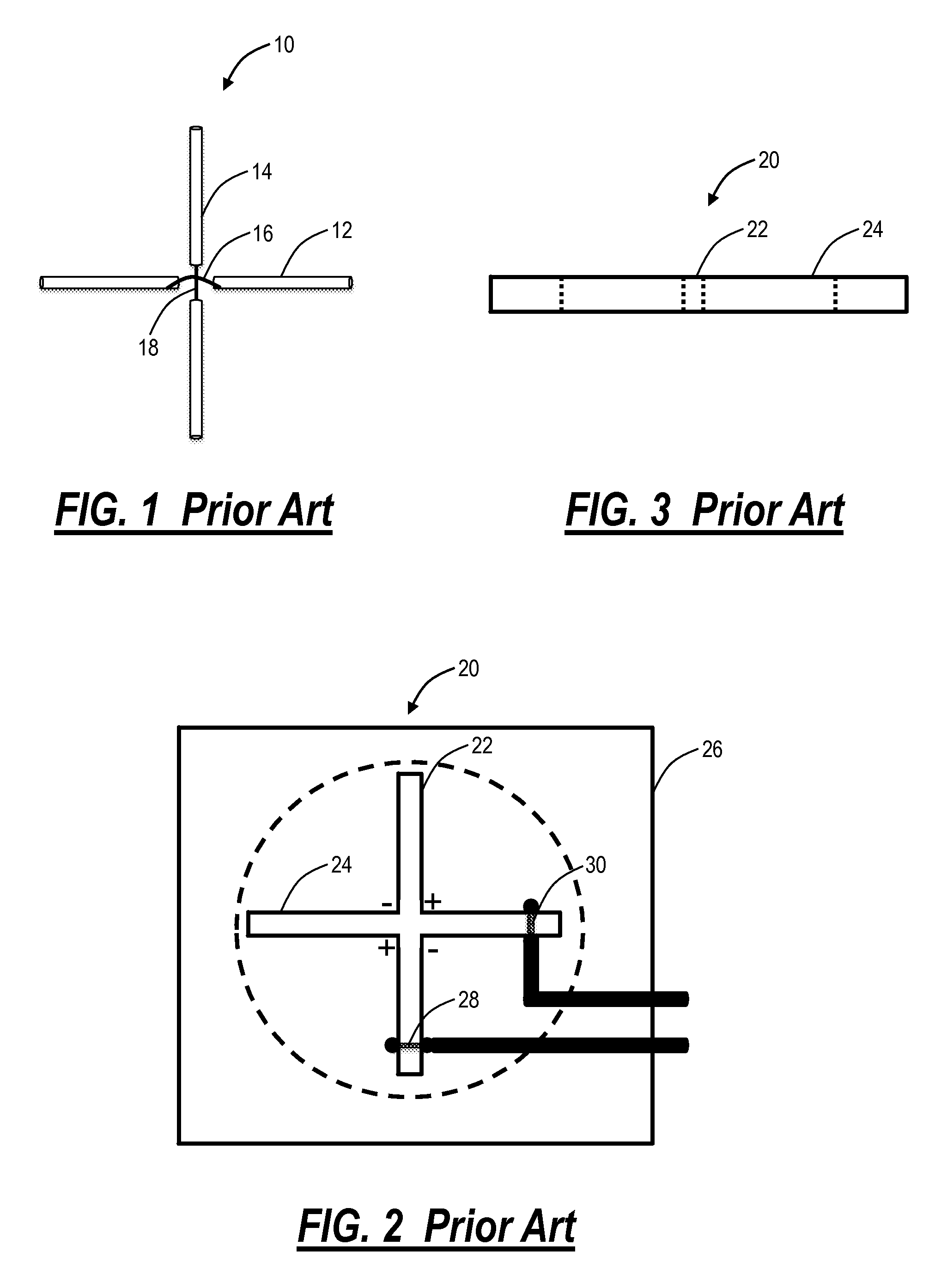

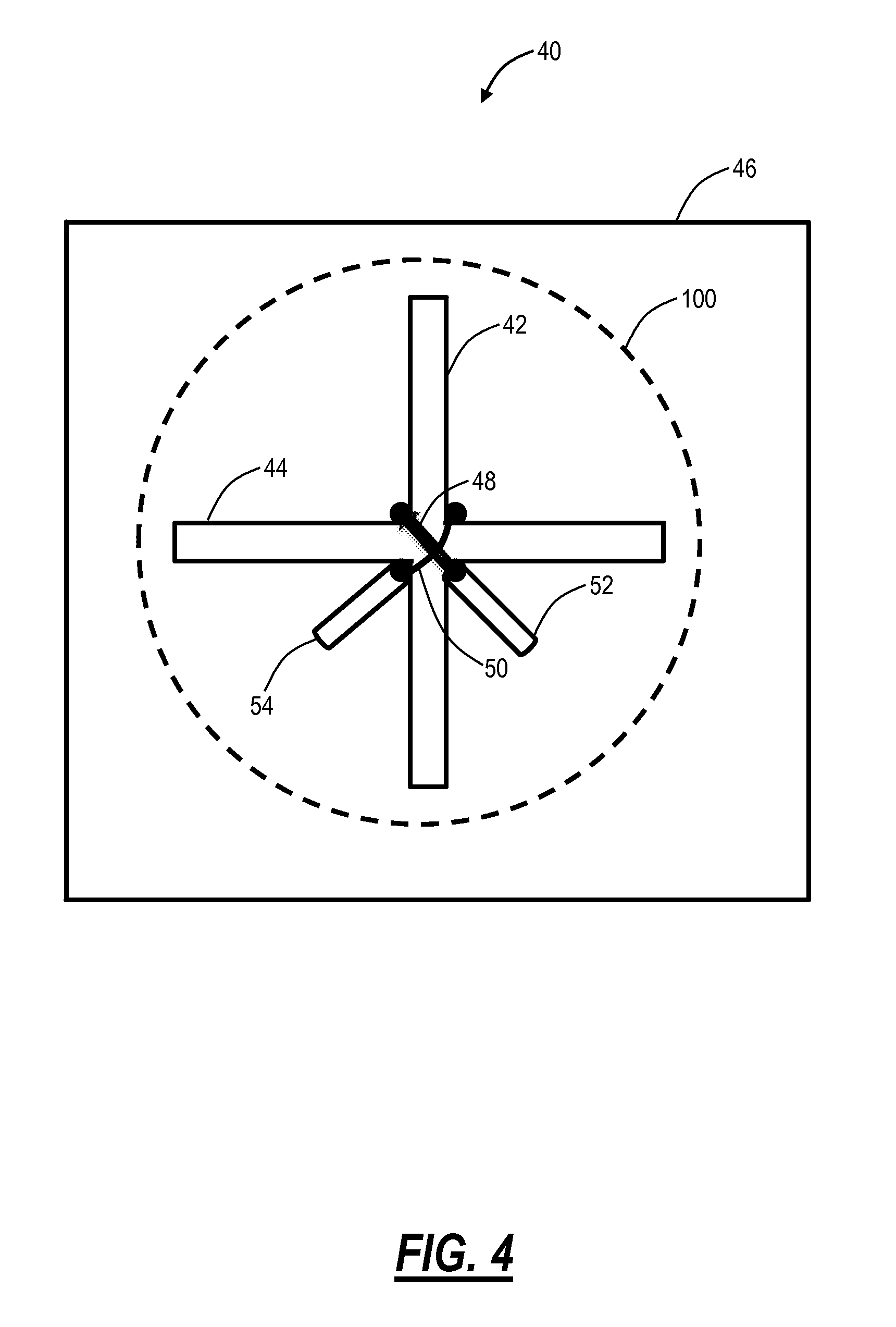

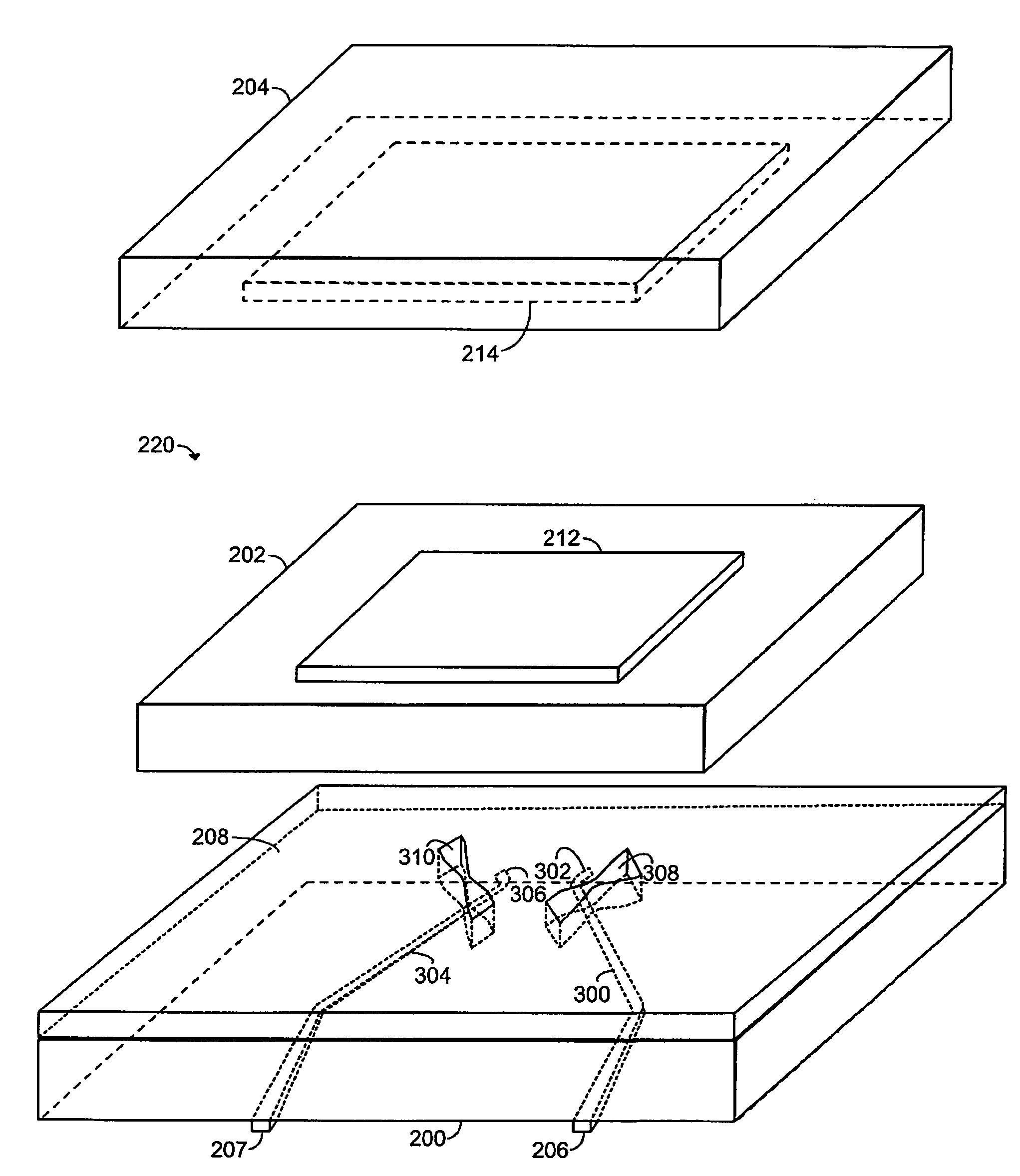

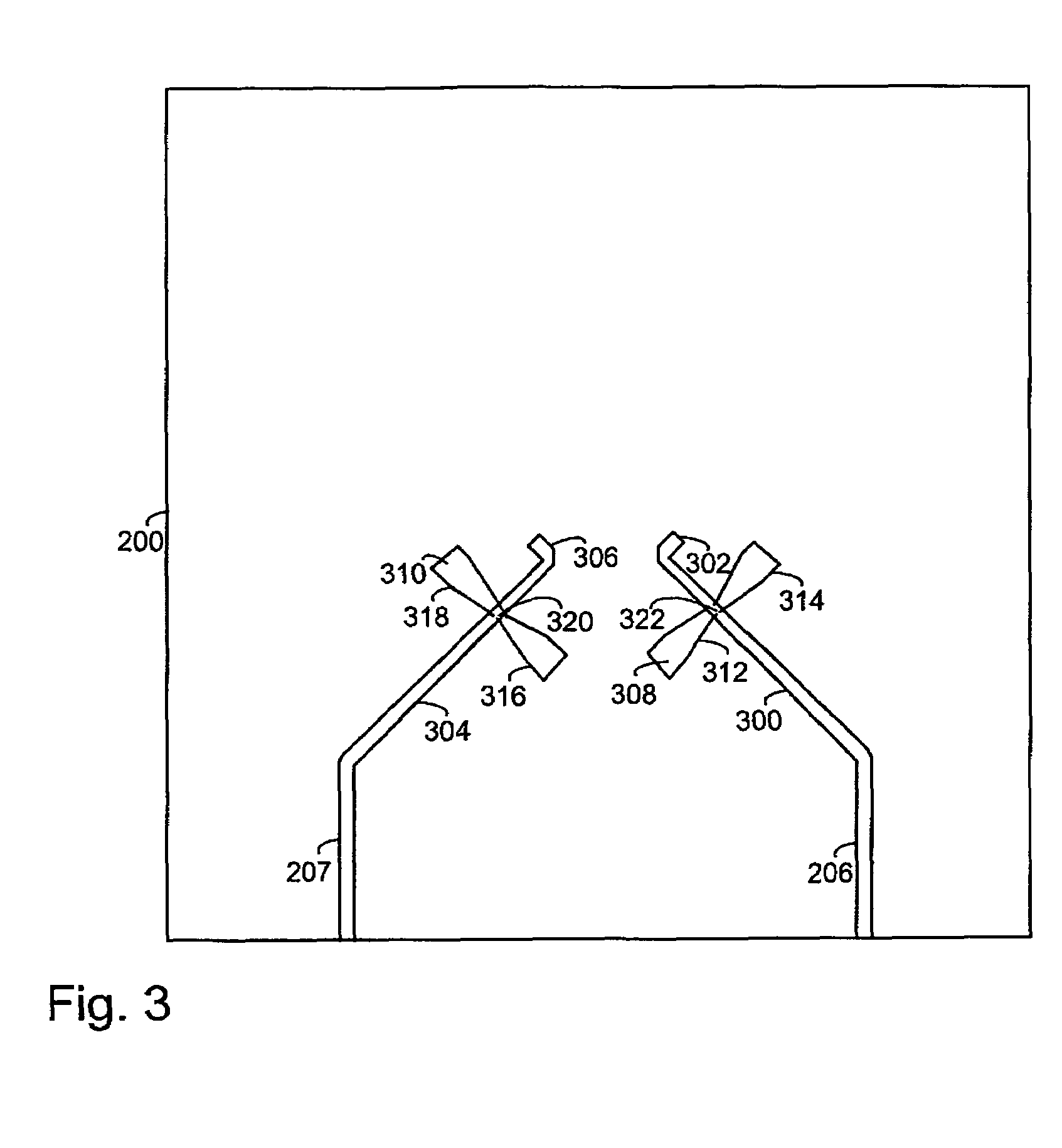

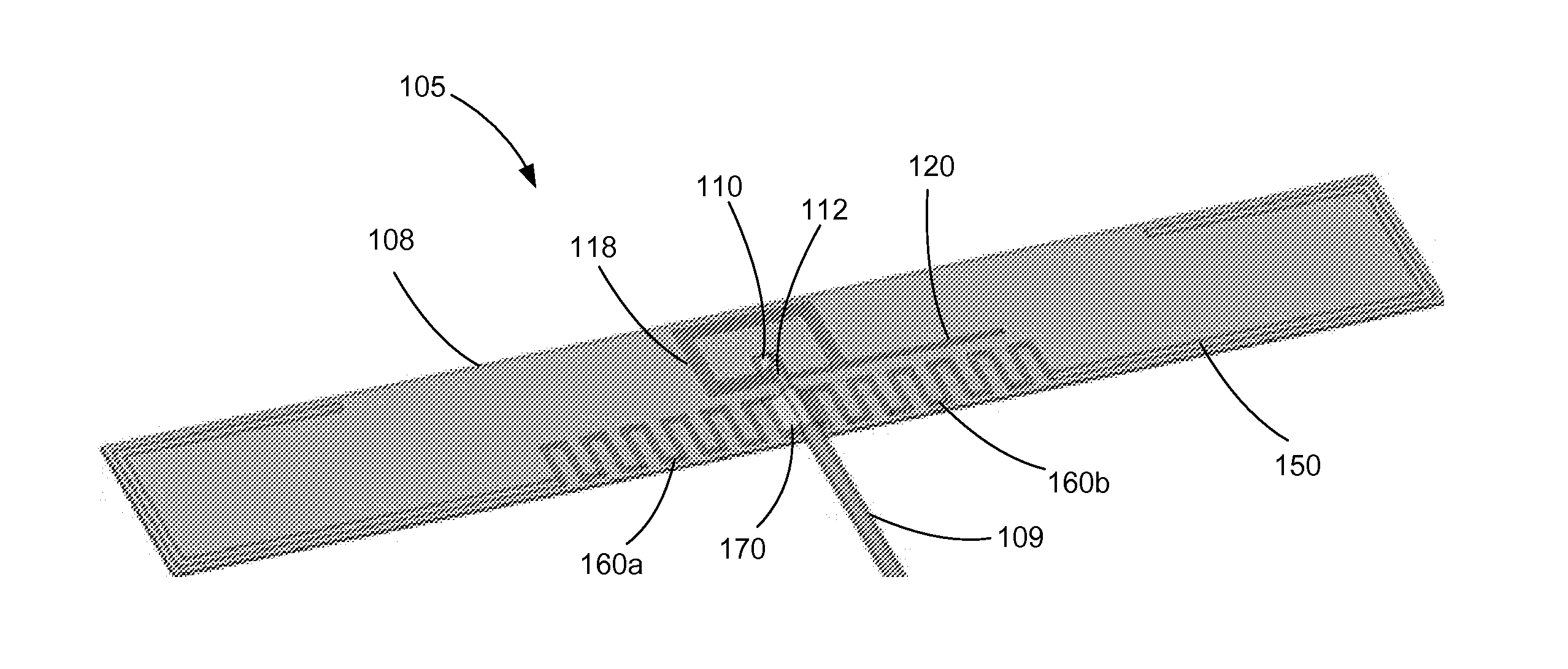

Cavity backed cross-slot antenna apparatus and method

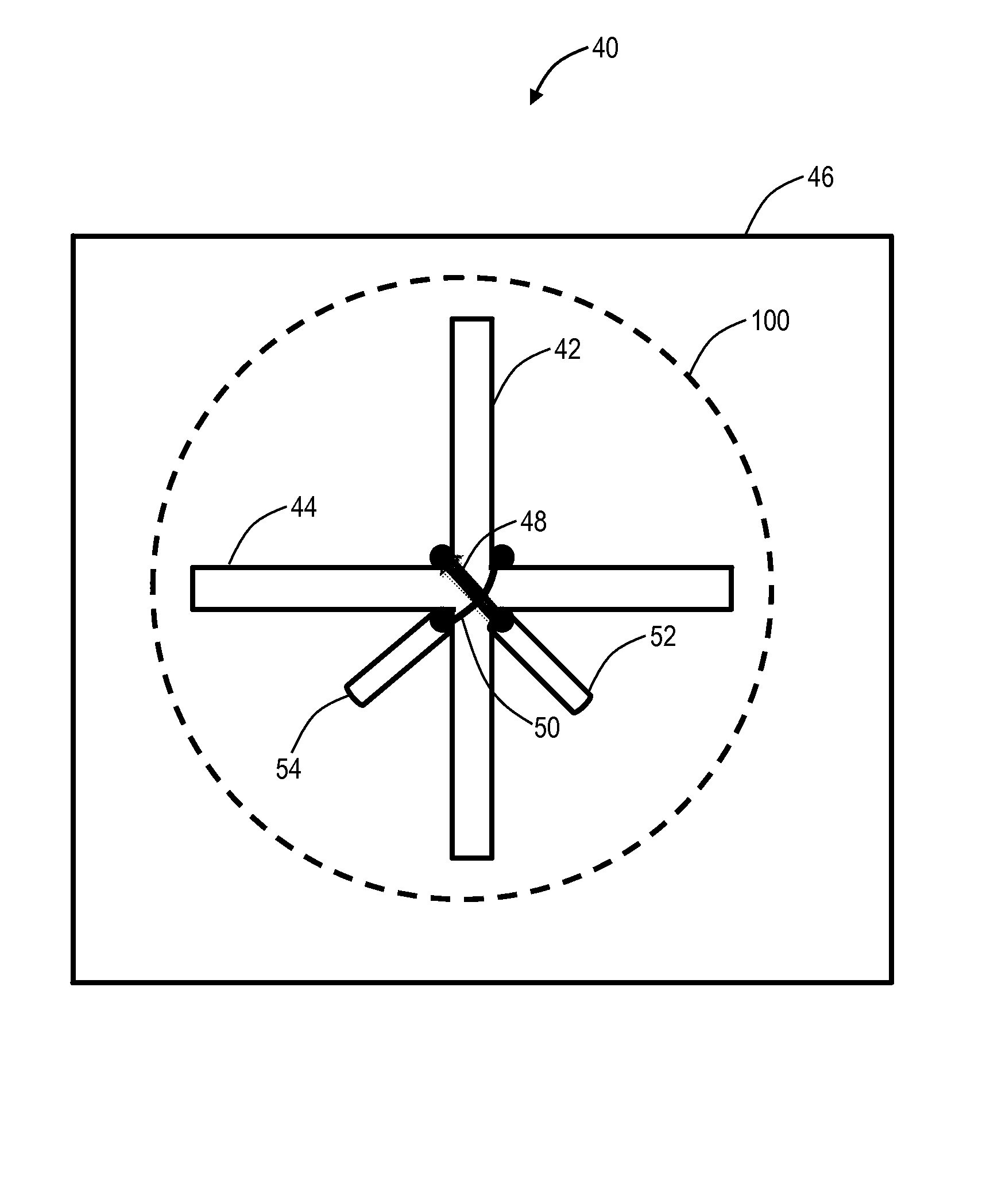

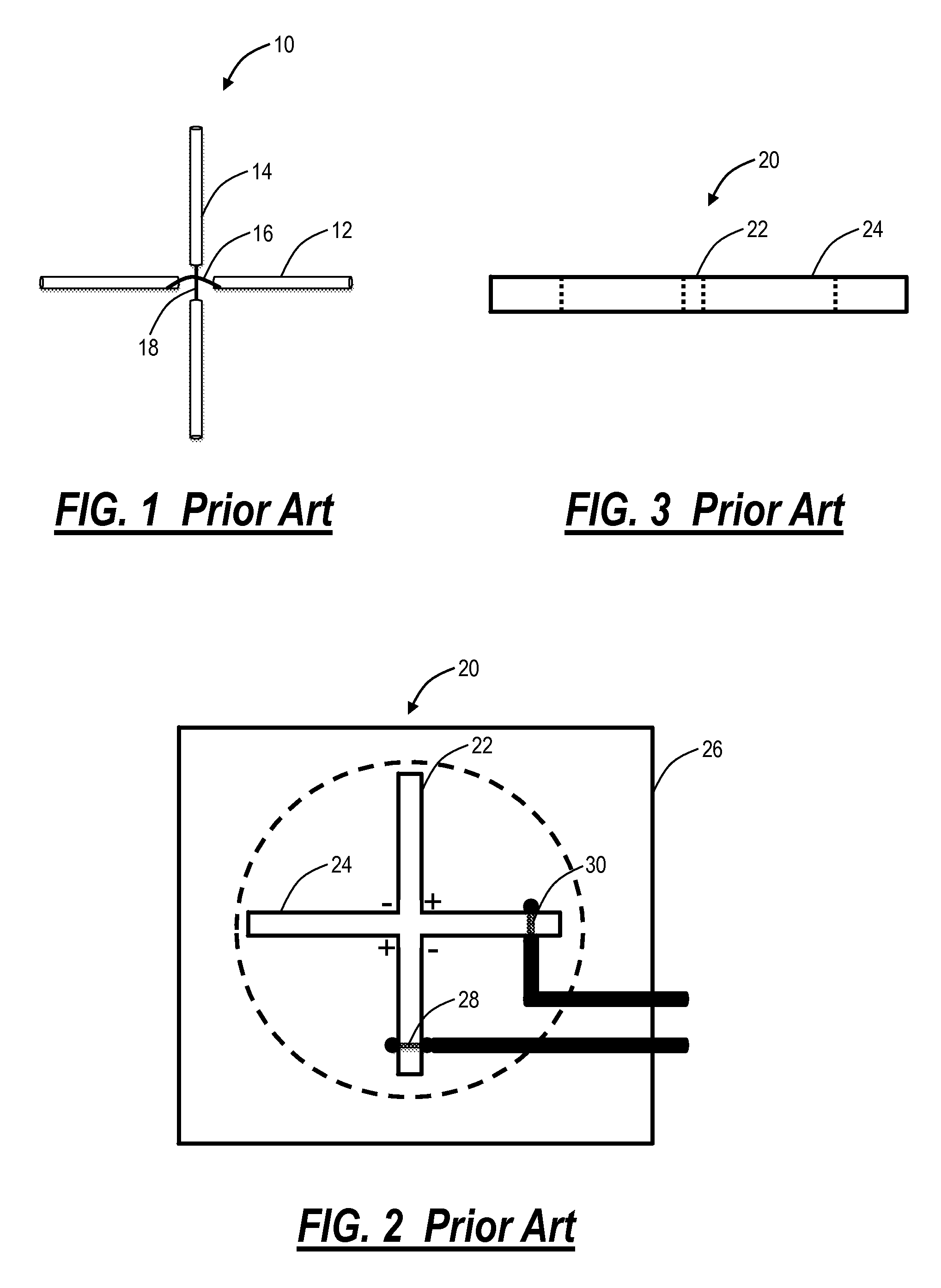

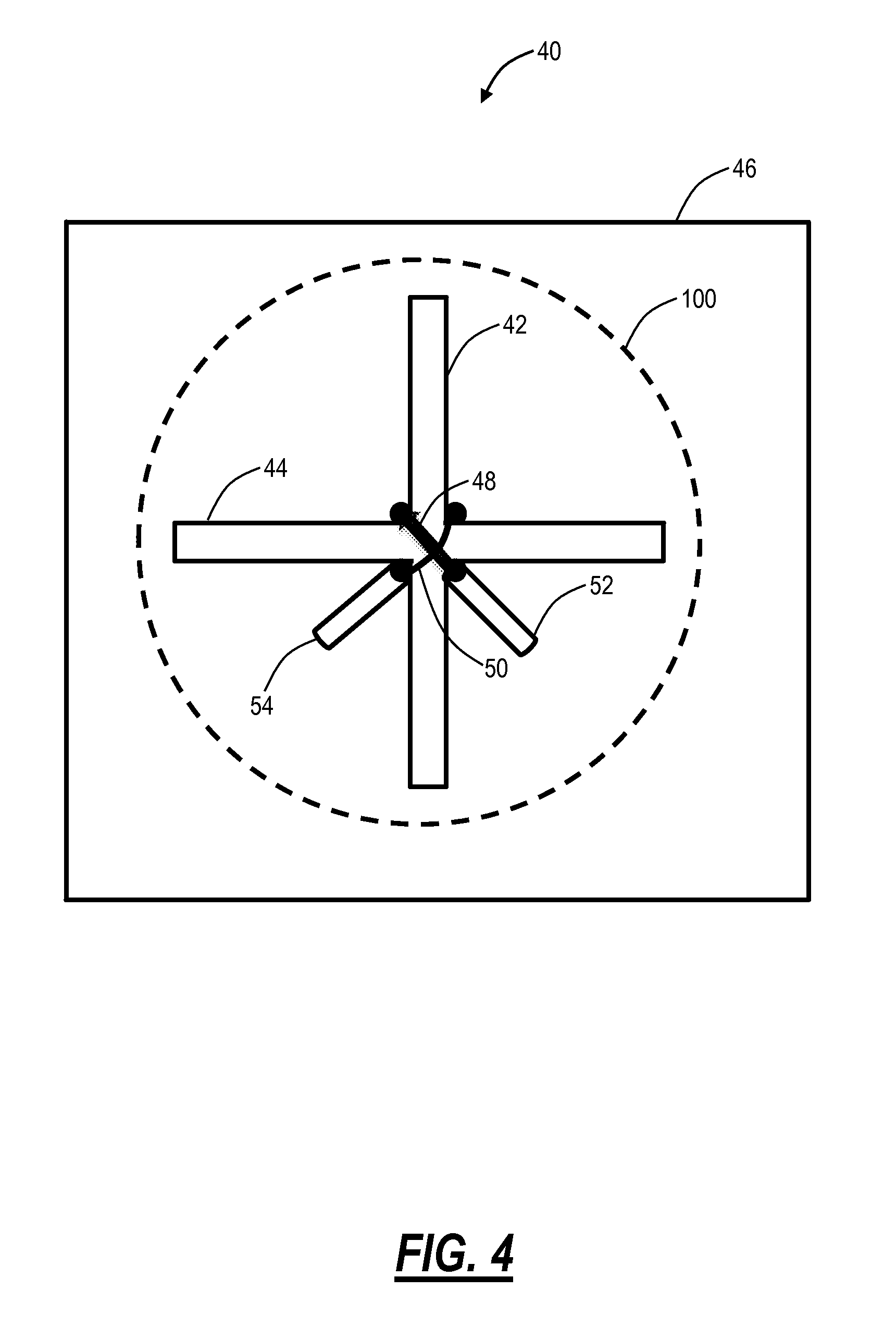

ActiveUS20130141296A1Polarised antenna unit combinationsAntenna detailsFeed techniqueFeeding techniques

An antenna apparatus and method includes an orthogonal slot antenna which overcomes the limitations associated with RF choke between the adjacent slots through various feed techniques. A cavity backed cross-slot antenna includes a horizontal slot antenna, a vertical slot antenna sharing a center portion with the horizontal slot antenna, a first feed for the horizontal slot antenna, and a second feed for the vertical slot antenna, the first feed and the second feed provided to the shared center portion. Another cavity backed cross-slot antenna includes a horizontal slot antenna, a vertical slot antenna, the horizontal slot antenna and the vertical slot antenna share a center portion therebetween, a first feed feeding both halves of the horizontal slot antenna, and a second feed feeding both halves of the vertical slot antenna.

Owner:SYMBOL TECH LLC

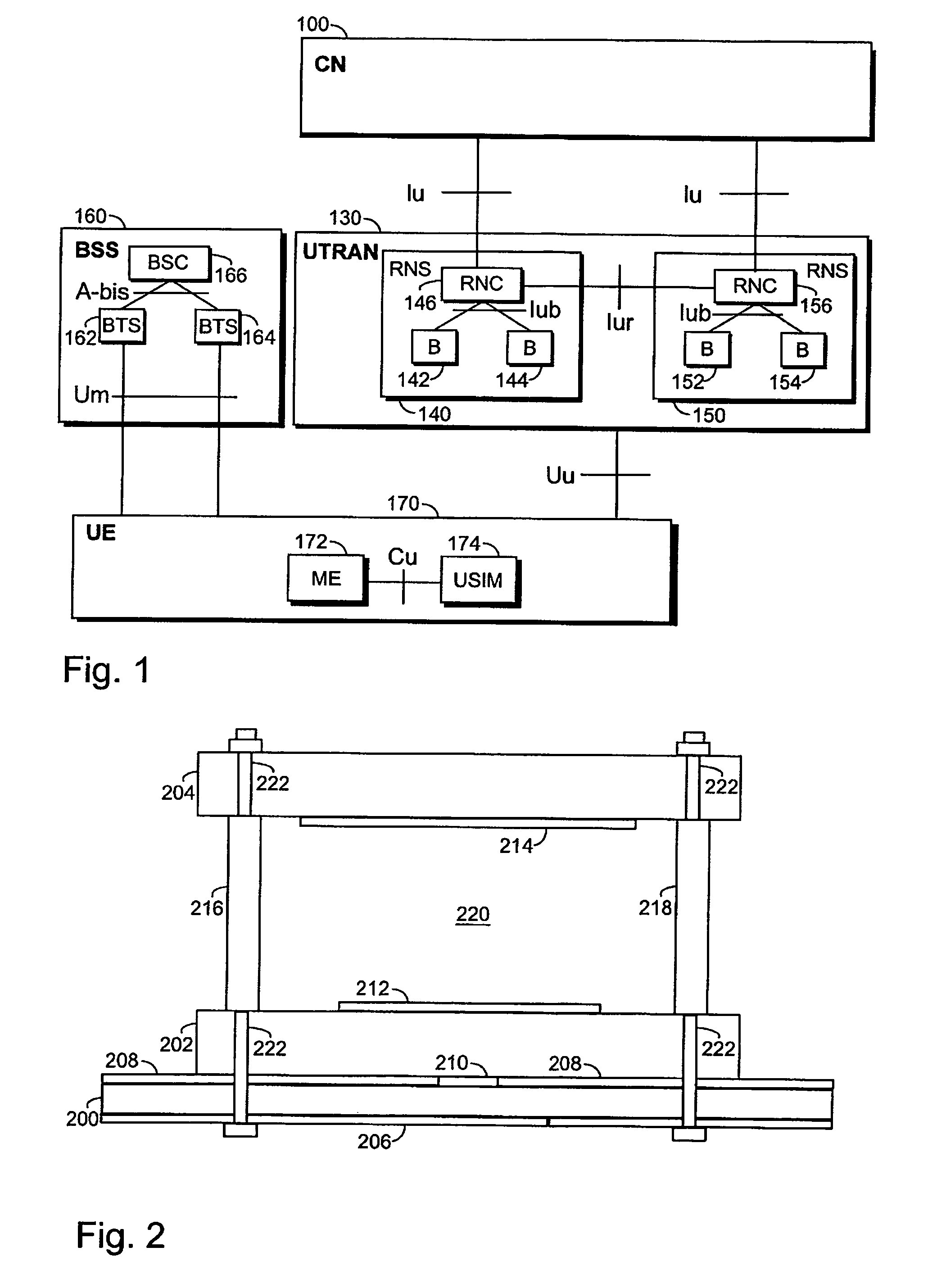

Dual-polarized microstrip structure

ActiveUS7423595B2Improve toleranceLoss in performanceSimultaneous aerial operationsRadiating elements structural formsMicrostrip patch antennaFeed technique

A dual-polarized microstrip patch antenna structure comprising: a dual microstrip feed line circuitry underneath a bottom dielectric substrate; a ground plane layer overlying the bottom dielectric substrate, the ground plane layer having coupling apertures etched to the ground plane layer; a middle metallized patch layer stacked over a middle dielectric substrate; a top metallized patch layer stacked underneath a top dielectric substrate; and an air layer between the middle dielectric substrate and the top dielectric substrate separating the middle metallized patch layer and the top metallized patch layer. The microstrip feed line circuitry is configured to utilize corner-feeding techniques for enabling diagonal modes of the patch layers, and the coupling apertures of the ground plane layer are provided with a non-resonant bow-tie shape for enabling aperture coupling between the microstrip feed line circuitry and the patch layers.

Owner:HMD GLOBAL

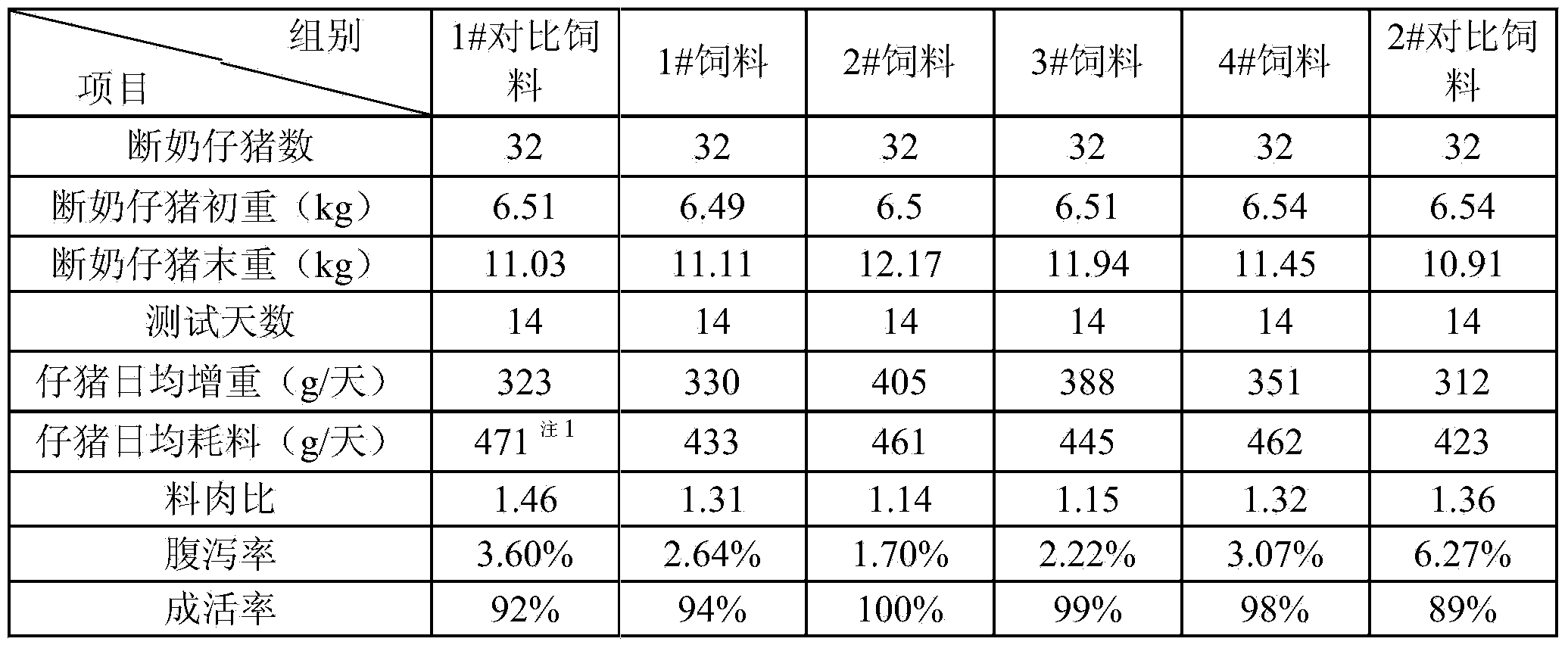

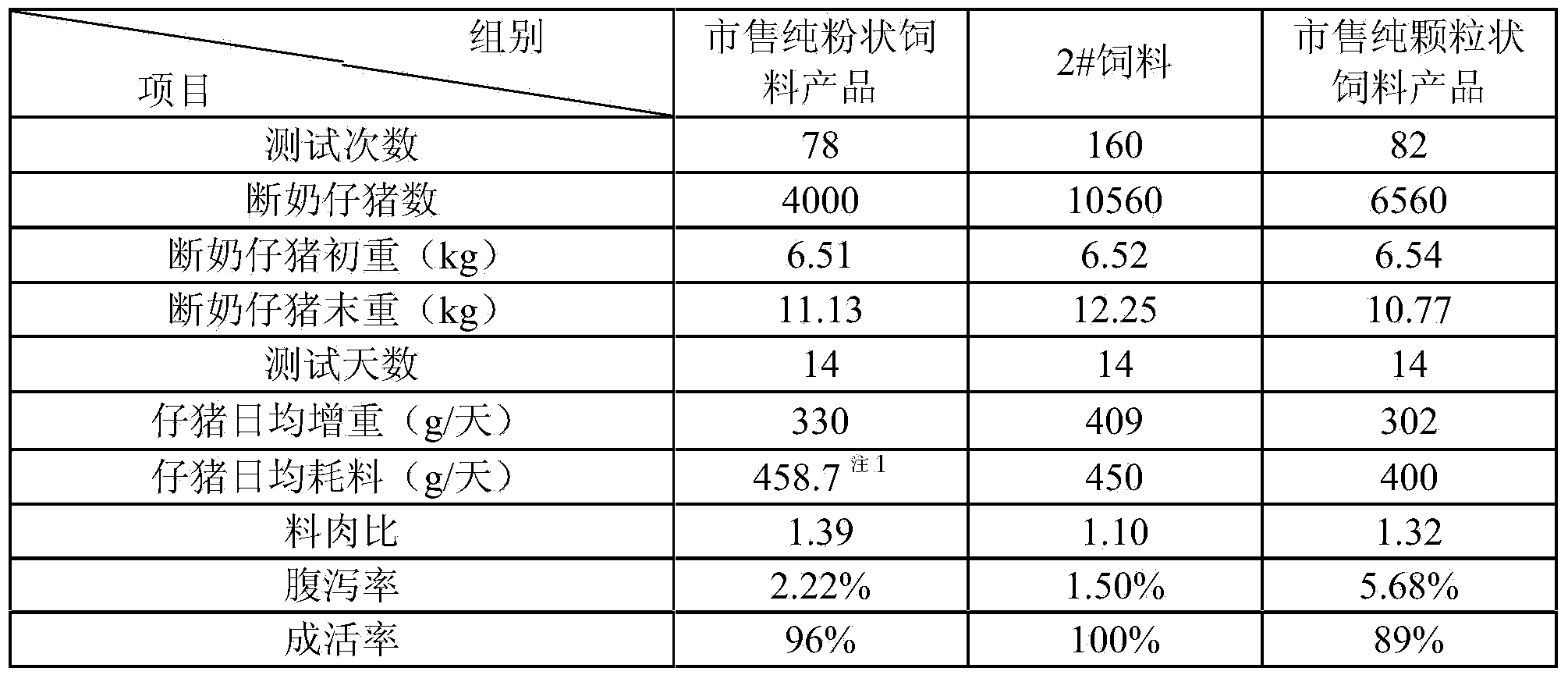

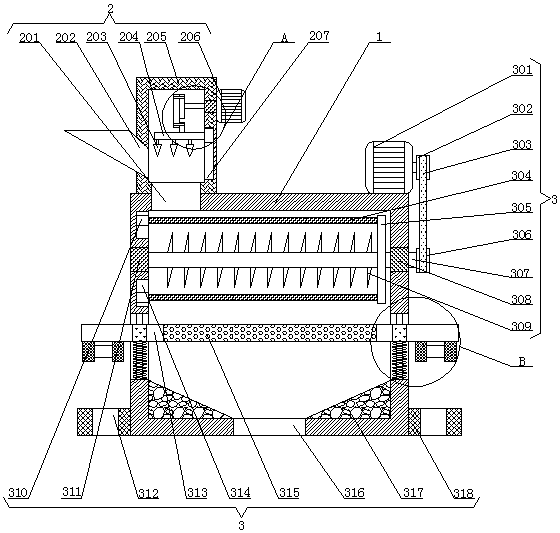

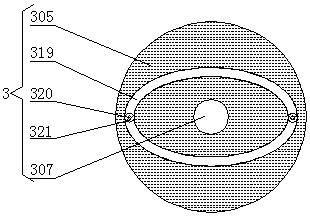

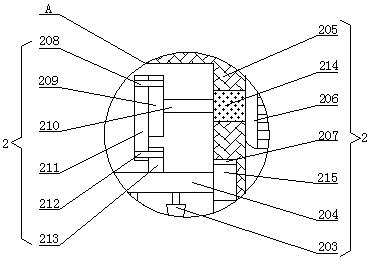

Powder-particle mixed type weaned piglet feed and preparation method thereof

ActiveCN104106737AAvoid destructionIncrease attractivenessFood processingAnimal feeding stuffHybrid typeFeed technique

The invention belongs to the technical field of feed, and discloses a powder-particle mixed type weaned piglet feed and a preparation method thereof. The preparation method comprises the following steps: (1) mixing powdered raw materials of piglet feed, processing the mixed raw materials at a room temperature so as to obtain a powdered material; (2) mixing granular raw materials of piglet feed, processing and granulating the mixed raw material at a high temperature so as to obtain a granular material; (3) mixing the powdered material and the granular material according to a certain mass ratio so as to obtain the powder-particle mixed type weaned piglet feed; wherein the mass ratio of the powdered material to the granular material is 10:90-50:50. The powder-particle mixed type weaned piglet feed is suitable for piglets 3 to 5 days before the weaning. The feed is fragrant, and can promote the appetite of piglets. Moreover, part heat-sensitive vitamins and high-temperature intolerant microecological preparations are effectively protected. The crisp taste of the granular feed is fully accord with the feeding habits of piglets which has been weaned for 5 days. Furthermore, the feed can promote the digestion liquid secretion, and effectively exercise the gastrointestinal function of piglets.

Owner:HUIZHOU JIUDING FEED SCI & TECH

Equipment for preparing feed from straw and preparation method of feed

The invention discloses equipment for preparing feed from straw and a preparation method of the feed, and relates to the technical field of feed preparation. The equipment comprises a box body, and afeeding mechanism is fixedly connected to the left side of the upper surface of the box body; a crushing mechanism is arranged in the box body; the feeding mechanism comprises a connecting pipe, a feeding hopper, a cutter, a transverse plate, a feeding box body, a first motor, a first sliding groove, a first pin shaft, a round plate, a rotating rod, a first connecting rod and a second pin shaft. According to the equipment for preparing the feed from the straw and the preparation method of the feed, the feeding mechanism is fixedly arranged on the upper surface of the box body, the straw entering a feeding cylinder can be cut off and cut into sections, and the cut straw can easily enter the box body; the transverse plate moves up and down in a reciprocating mode so that the straw can be pushed into the box body, then feeding is more convenient, the straw can be prevented from being accumulated in the feeding box body, and the problem that the straw cannot conveniently enter the equipment is solved.

Owner:山东纪华家禽育种股份有限公司

Feed for laying hen and feeding technique of laying hen

InactiveCN104222491AMeeting nutritional needsExtended peak periodAnimal feeding stuffFeed techniqueAnimal science

The invention relates to a feeding method of a laying hen, and particularly relates to a feed for a laying hen and a feeding technique of the laying hen. As the laying hen is fed in an earlier egg laying stage, a middle egg laying stage and a rear egg laying stage, feeds in all stages are different. According to the feeding method, the nutritional requirement of the laying hen in each stage is effectively met, the peak season of the laying hen is greatly prolonged, the quality of eggs is effectively improved, and the market competitiveness of the eggs is improved.

Owner:ANHUI LIN YUAN FARM & SIDELINE PROD

Cavity backed cross-slot antenna apparatus and method

An antenna apparatus and method includes an orthogonal slot antenna which overcomes the limitations associated with RF choke between the adjacent slots through various feed techniques. A cavity backed cross-slot antenna includes a horizontal slot antenna, a vertical slot antenna sharing a center portion with the horizontal slot antenna, a first feed for the horizontal slot antenna, and a second feed for the vertical slot antenna, the first feed and the second feed provided to the shared center portion. Another cavity backed cross-slot antenna includes a horizontal slot antenna, a vertical slot antenna, the horizontal slot antenna and the vertical slot antenna share a center portion therebetween, a first feed feeding both halves of the horizontal slot antenna, and a second feed feeding both halves of the vertical slot antenna.

Owner:SYMBOL TECH LLC

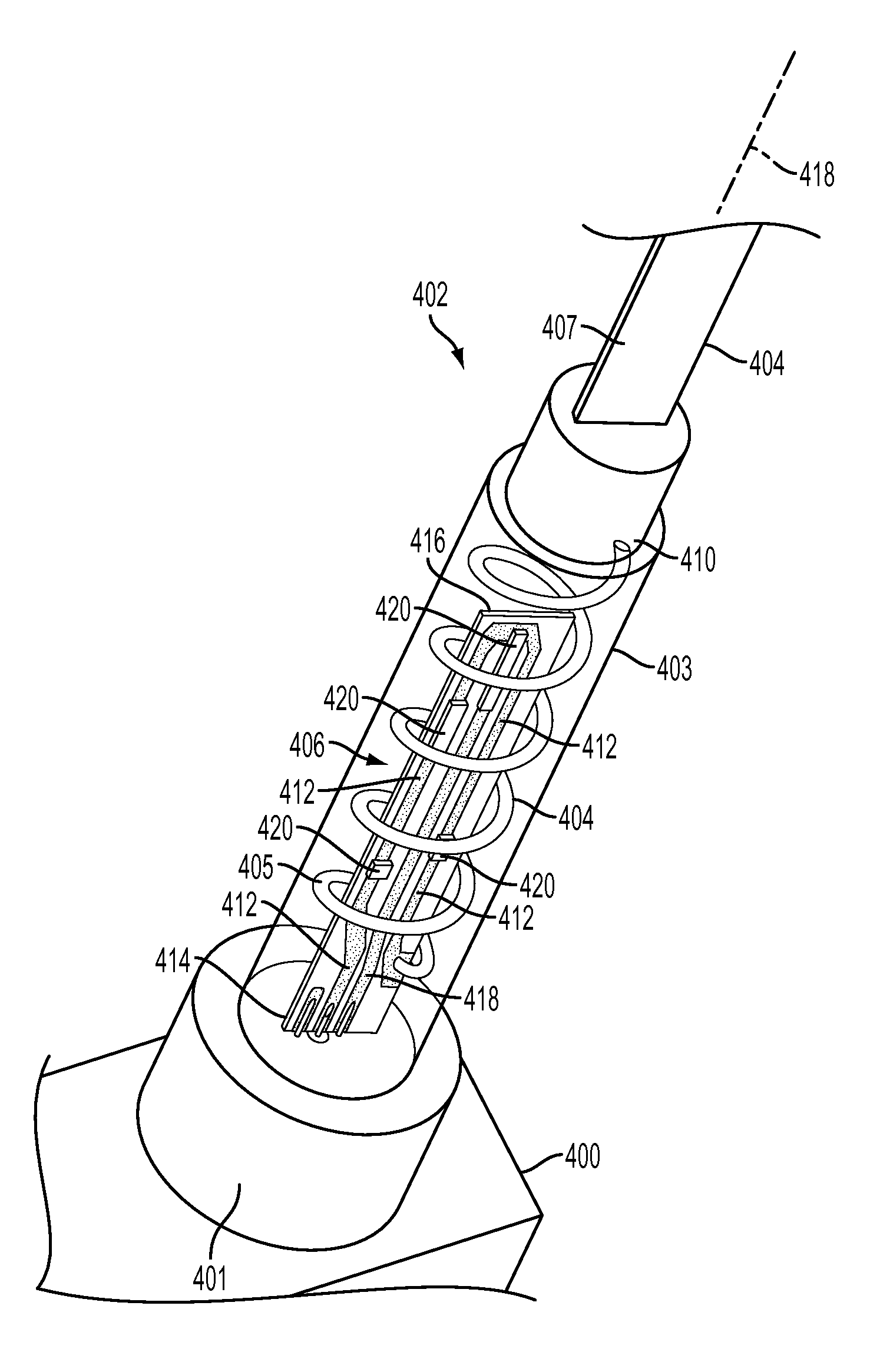

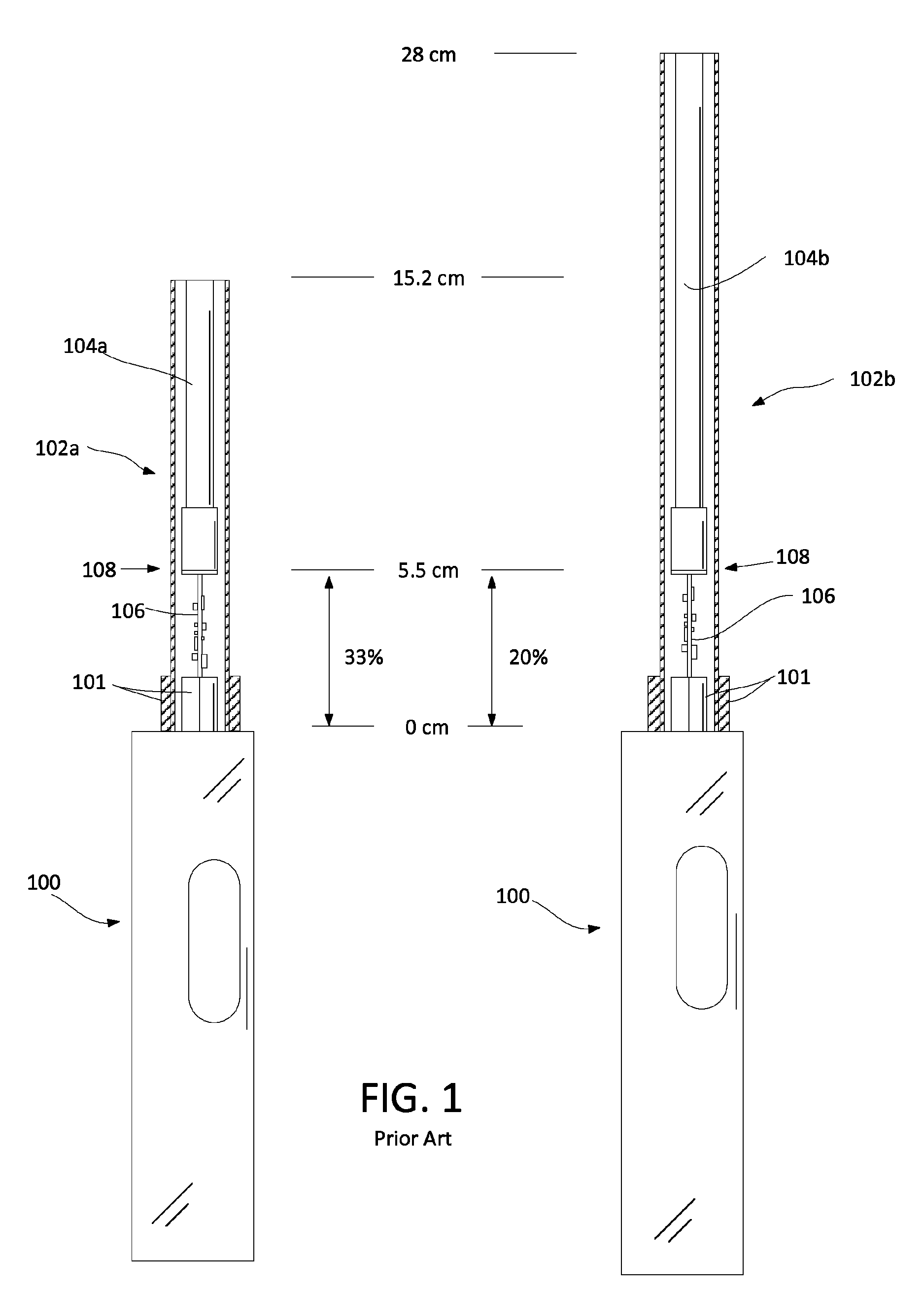

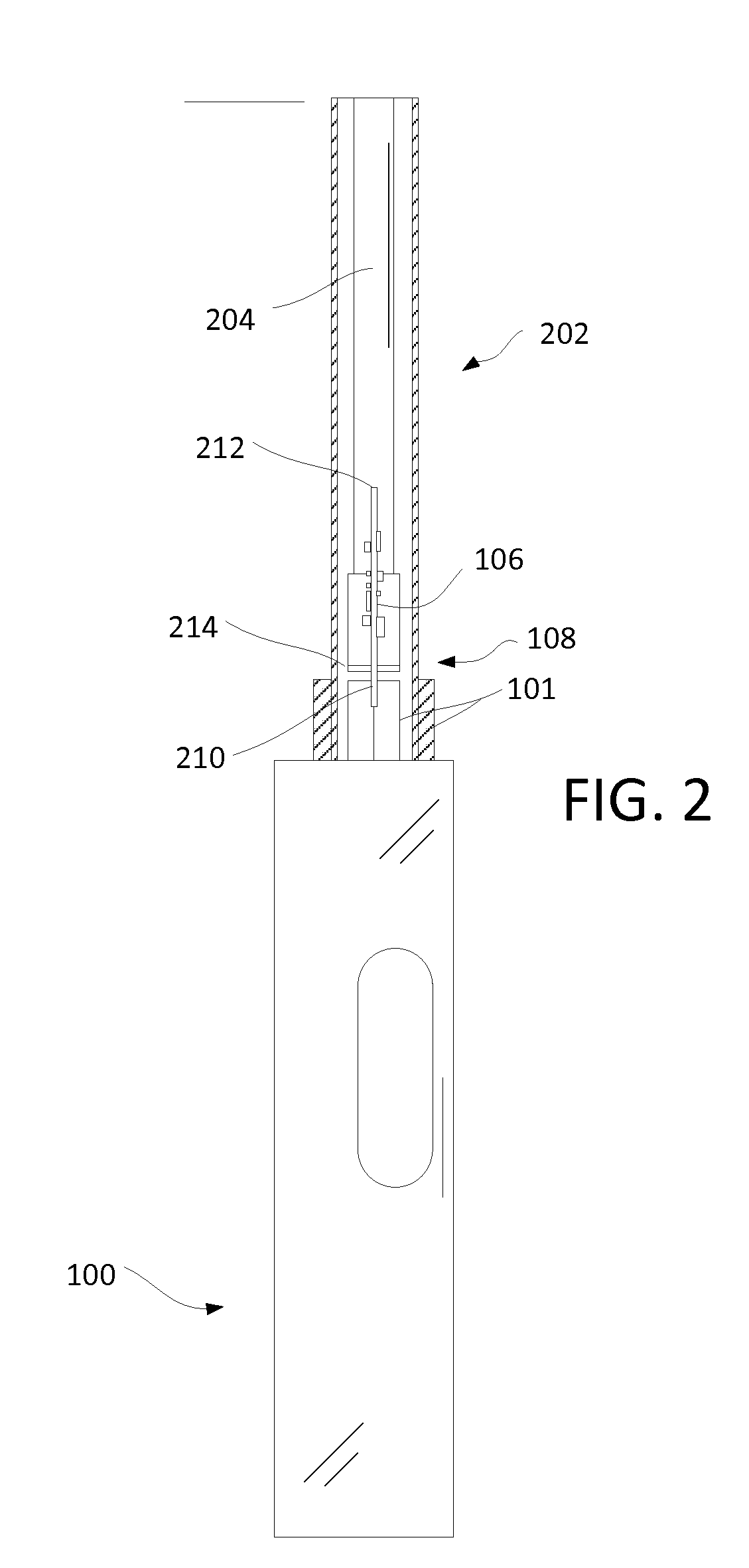

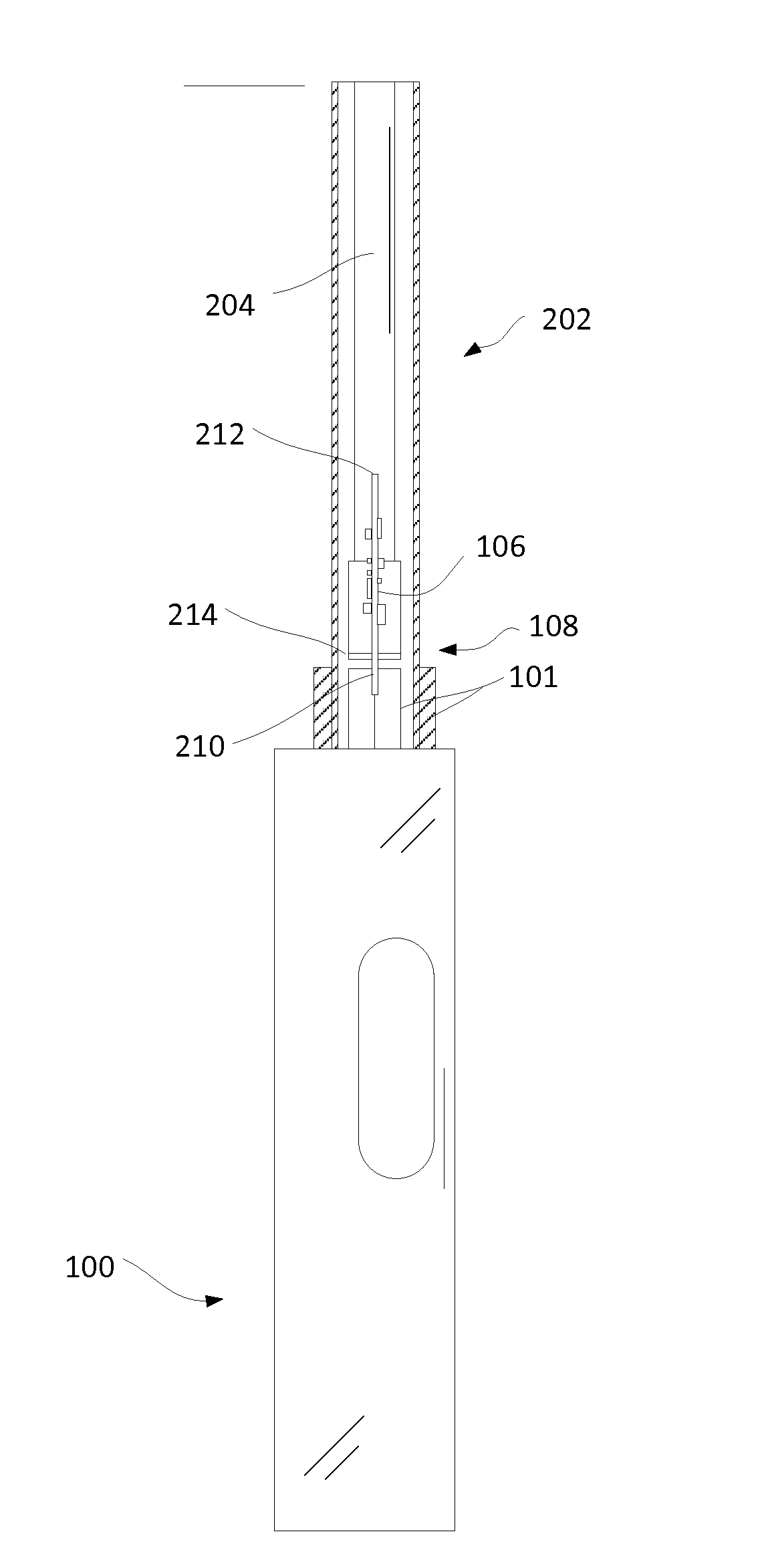

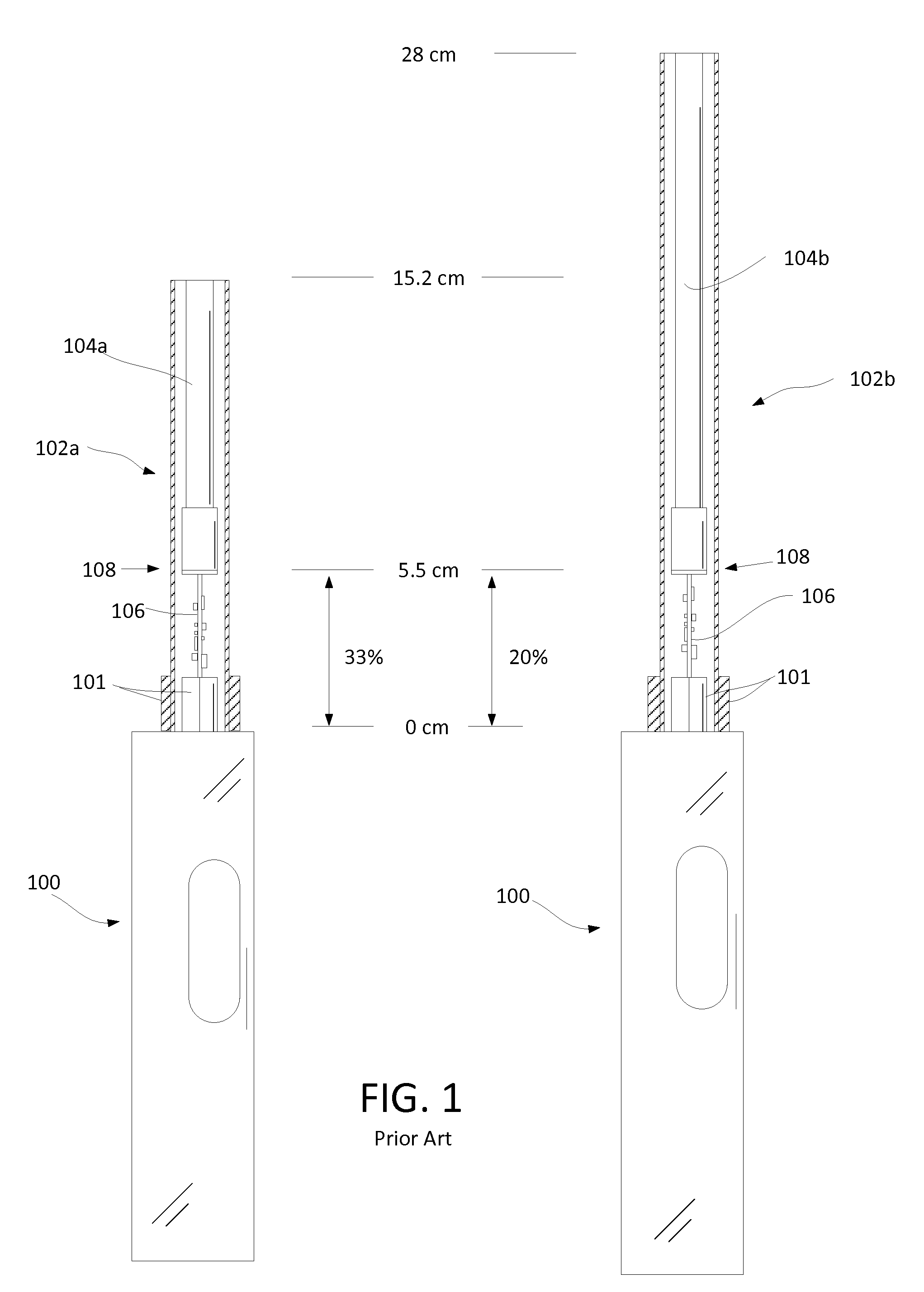

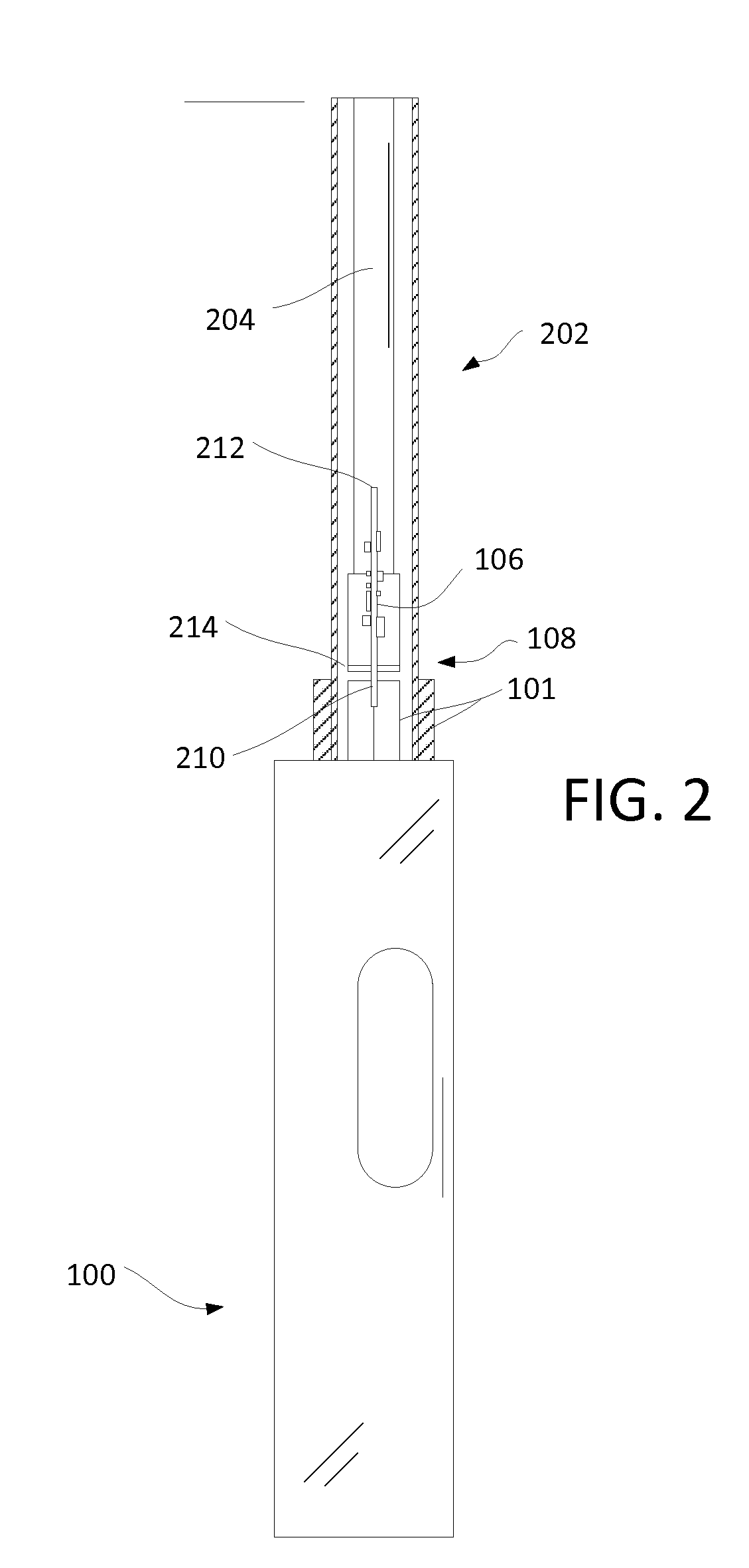

Orthogonal feed technique to recover spatial volume used for antenna matching

ActiveUS8743009B2Convenient lengthShorten the vertical lengthSimultaneous aerial operationsElongated active element feedFeed techniqueElectrical conductor

A method and apparatus for reducing a length of an antenna (402) involves an arrangement which includes an orthogonal antenna feed. An antenna includes a radiating element (404) with a length extending along an axis (418). The orthogonal feed arrangement permits recovery of a portion of the spatial volume comprising the antenna which is normally used for antenna matching circuitry (406). An end portion of the radiating element is chosen to be helically shaped and includes an RF feed gap. The RF feed gap is coupled to a matching network which includes elongated conductors (412). The matching circuitry is positioned so that the elongated conductors are adjacent to the first end portion and extend in a direction aligned with the axis, but orthogonal to the coils forming the helically shaped end portion.

Owner:HARRIS GLOBAL COMM INC

Open feeding technique of Amblyseius barkeri

InactiveCN103070137AImprove factory production capacityAvoid infectionAnimal husbandryFeed techniqueAnimal science

The invention discloses an open feeding technique of Amblyseius barkeri, which comprises the following steps of: 1. putting wheat bran in a closed space, sterilizing the wheat bran, taking out the wheat bran and storing the wheat bran for future use; 2. humidifying the sterilized wheat bran, containing the wheat bran in a culture cup, inoculating flour mite stocks in the culture cup for culture and obtaining feed flour mites; 3. putting Amblyseius barkeri stocks and the feed flour mites in the culture cup for culture, and obtaining stocks for open packaging bag feeding and propagation expansion; and 4. taking sterilized and humidified wheat bran, the Amblyseius barkeri stocks cultured in the step 3 and the feed flour mites cultured in the step 2, and evenly mixing the Amblyseius barkeri stocks and the feed flour mites for packaging bag feeding to obtain products which can be delivered for use. The open feeding technique of Amblyseius barkeri has the advantages that the large-scale production can be formed rapidly, the infection of other mites can be more effectively prevented, and the factory production capacity and the pest mite control effect through field application of the Amblyseius barkeri are further improved.

Owner:陈楚安

Method for preparing whole wheat capable of being fed for cows and pigs

ActiveCN103931951AEasy to operateLow costFood processingAnimal feeding stuffFeed techniqueProcessing cost

The invention discloses a method for preparing whole wheat capable of being fed for cows and pigs, which belongs to the field of a feed technique, a microorganism technique and livestock breeding, and solves the problems that the wheat processing cost is high, the whole wheat cannot be digested when being fed for cows and pigs, and the price of corn rises, the feed cost is increased, and has no proper substitution. The method comprises the following steps: mixing the taken whole wheat, fresh distiller's grains and strain uniformly, keeping the moisture of a mixture to be 33-53wt%, bagging, sealing or storing in a cellar, carrying out anaerobic fermentation for more than 35 days, or carrying out anaerobic fermentation until pH value is 4.0-3.8. The method is simple to operate, and is easy for industrialization; the prepared whole wheat is not required to be crushed or grinded, can be fed directly or can be stored for a long time, and the cost is reduced by 17.4-43.5% compared with the cost of non-prepared whole wheat; the whole wheat can act as the unique refined supplementary food of beef cattle, can replace 50% of high productive diary cow refined supplementary food and 65% of concentrated feed for growth and fattening of pigs, and the feed cost consumed for weight increasing per unit / milk production can be greatly reduced.

Owner:INST OF ANIMAL SCI & VETERINARY MEDICINE SHANDONG ACADEMY OF AGRI SCI

High-stability aquatic product feed granules and preparation method thereof

PendingCN109601763AWon't release quicklyGood film formingClimate change adaptationAnimal feeding stuffSodium bicarbonateFeed technique

The invention belongs to the technical field of feeds, and particularly relates to high-stability aquatic product feed granules and a preparation method thereof. The high-stability aquatic product feed granules provided by the invention sequentially comprise a feed core layer, a slow-release layer and a coating layer from the inner part to the outer part, wherein the coating layer consists of a hydrophilic light material and a hydrophobic light material; the slow-release layer consists of vital wheat gluten; and the feed core layer is prepared through the steps of mixing a feed with an appropriate amount of two-CHO group nanocellulose and a sericin solution, performing homogenizing, adding sodium bicarbonate, performing atomizing, spraying calcium chloride to obtain solid matter, and thenperforming drying. The aquatic product feed granules have a three-layer structure, the core layer adopts the sericin and the two-CHO group nanocellulose as carriers, the density ratio is low, more active components can be adsorbed, and slow release of the active components is facilitated. The coating layer consists of light materials, and can separate water from entering the feed core layer; and the slow-release layer achieves a certain delaying effect on infiltration of moisture. The prepared feed granules are good in stability, and high in biological availability.

Owner:ZHEJIANG UNIV

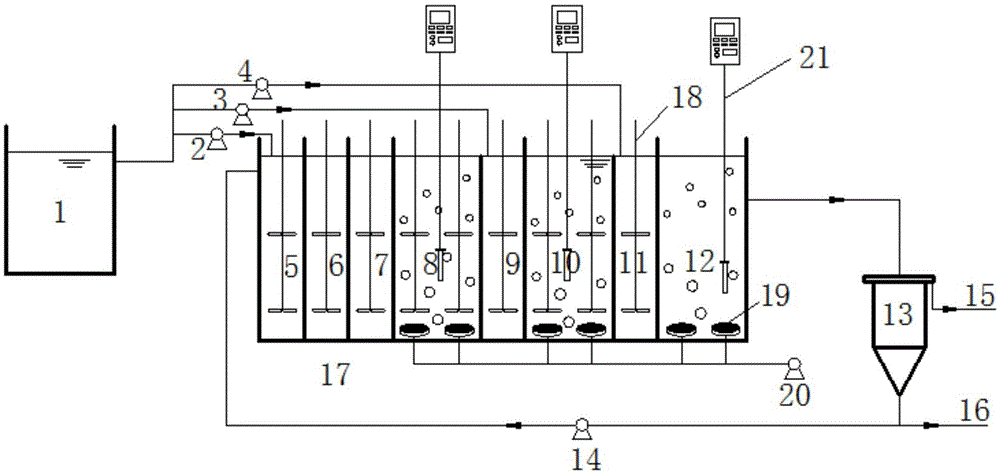

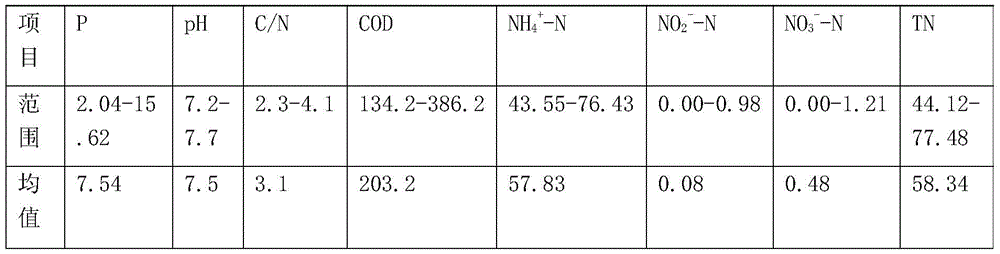

Inverted A2/O step feed coupled aerobic particle sludge reinforced synchronous nitrification/denitrification dephosphorization device

ActiveCN105621615AInhibit swellingReduce generationTreatment with aerobic and anaerobic processesFeed techniqueReflux

The invention relates to an inverted A2 / O step feed coupled aerobic particle sludge reinforced synchronous nitrification / denitrification dephosphorization device, belonging to the technical field of biological methods. In order to solve the problems of high energy consumption by sludge internal reflux, low water-quality water-flow fluctuation resistance and influence of reflux mixed sludge on anaerobic-section phosphorus release effect in the existing UCT step feed, the device combines an inverted A2 / O step feed technique and an aerobic particle sludge process. The new technique has the characteristics of stable denitrification and dephosphorization effects, energy saving, consumption reduction, high water-quality water-flow fluctuation resistance and the like.

Owner:BEIJING UNIV OF TECH

Orthogonal feed technique to recover spatial volume used for antenna matching

ActiveUS20130044038A1Convenient lengthShorten the vertical lengthSimultaneous aerial operationsElongated active element feedFeed techniqueElectrical conductor

A method and apparatus for reducing a length of an antenna (402) involves an arrangement which includes an orthogonal antenna feed. An antenna includes a radiating element (404) with a length extending along an axis (418). The orthogonal feed arrangement permits recovery of a portion of the spatial volume comprising the antenna which is normally used for antenna matching circuitry (406). An end portion of the radiating element is chosen to be helically shaped and includes an RF feed gap. The RF feed gap is coupled to a matching network which includes elongated conductors (412). The matching circuitry is positioned so that the elongated conductors are adjacent to the first end portion and extend in a direction aligned with the axis, but orthogonal to the coils forming the helically shaped end portion.

Owner:HARRIS GLOBAL COMM INC

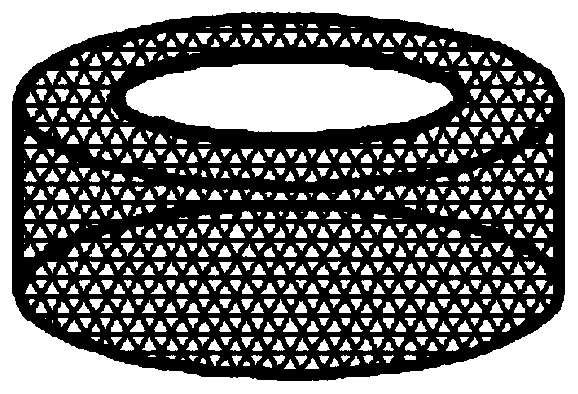

Anti-splash device of conical dissolvers

InactiveCN101254426AOvercoming the phenomenon of splashingPrevent moistureSedimentation separationWater/sewage treatment by flocculation/precipitationFeed techniqueSteel ball

A splash-proof device used with a tapped dissolver is provided, which belongs to the technology field of environment protection, more particularly the field of dissolution feed technique of flocculating agent in sewage treatment. The structure of the splash-proof device is that: an inverted T-shaped frame is arranged at the symmetric center of the junction of a tapped dissolver and an outlet water pipe so that two ends of the horizontal portion of the T-shaped frame are welded with the two walls of the tapped dissolver and the vertical portion thereof extends inside the tapped dissolver, and the ends are threaded for the engagement with screw nuts that are welded on the steel balls thereon; the diameter of the steel bass is 3 / 4 to 4 / 5 of horizontal diameter of the tapped part where the steel ball is located. The splash-proof device has the advantages that: with the splash-proof device, the tapped dissolver can efficiently and feasibly block the passage where water drops move upwards without changing the running state of the original equipment, overcome the defect of upward water splash, prevent the dissolution feed equipment from being wetted, ensure the normal operation and efficiency of the original equipment, and solve the long-term problem of unsafe, unstable and non-continuous operation in the industry.

Owner:张彦海

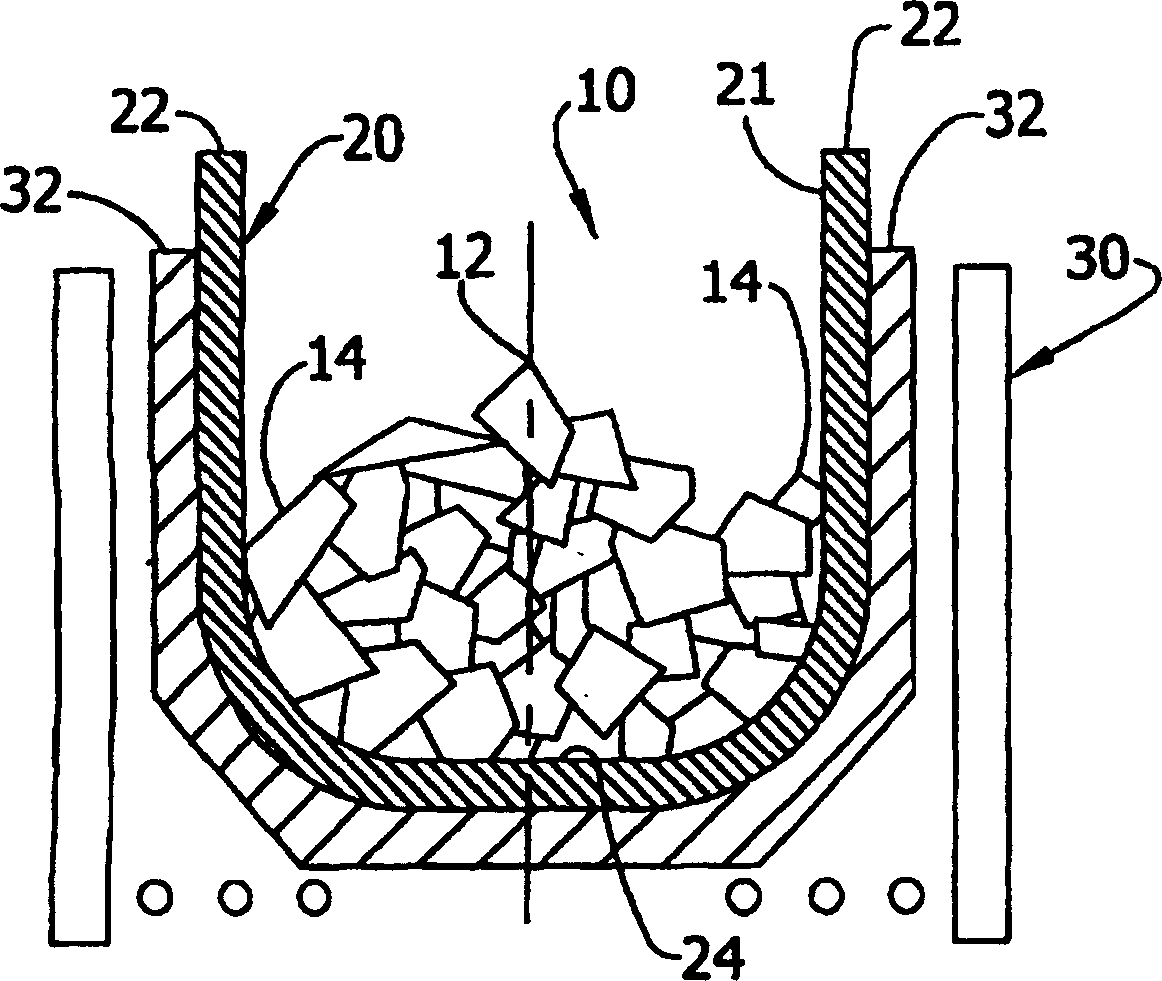

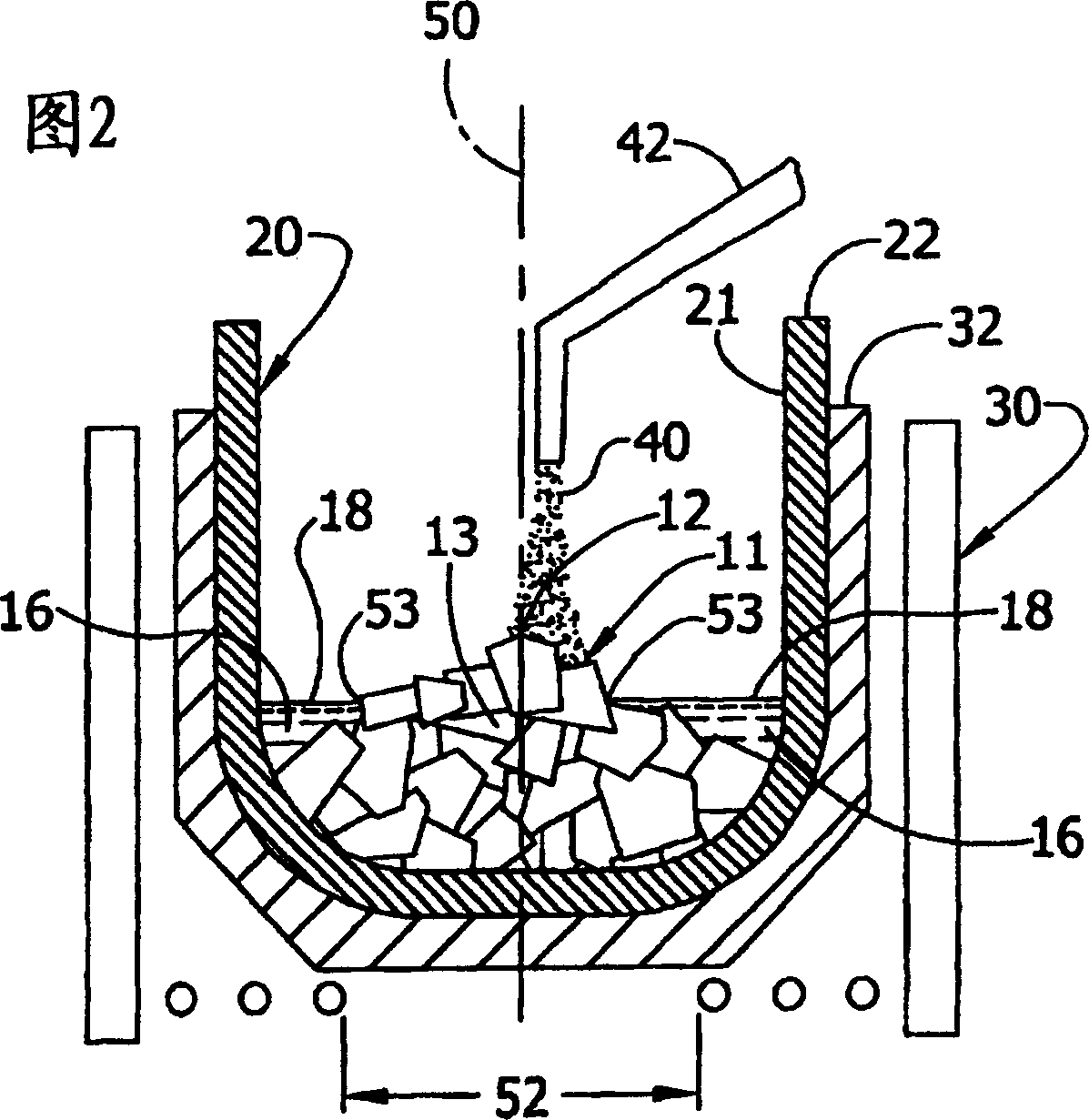

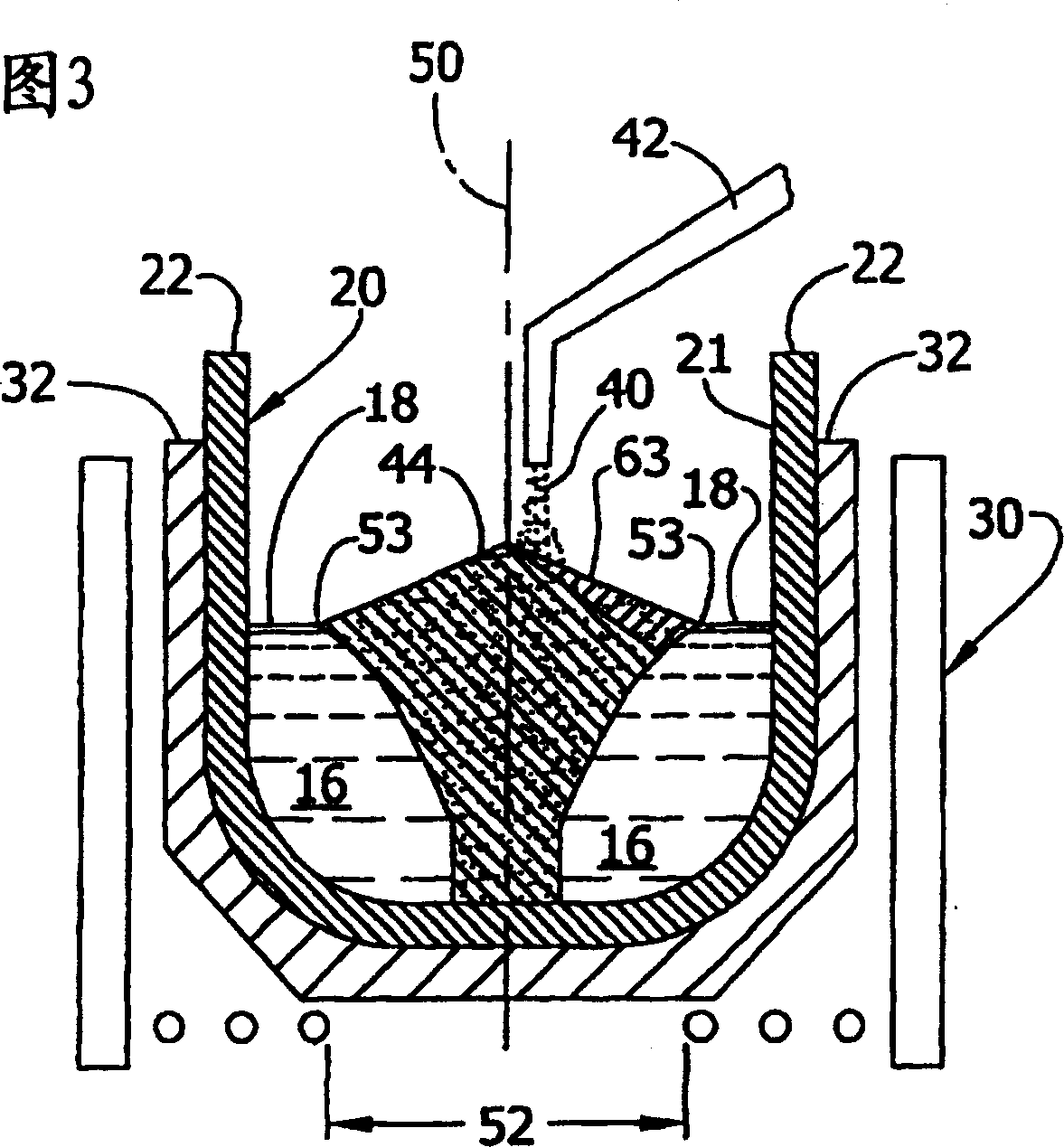

Intermittent feeding technique for increasing the melting rate of polycrystalline silicon

InactiveCN1585838AMelting fastControl the position of feedingPolycrystalline material growthBy pulling from meltFeed techniqueCzochralski method

A process for preparing a silicon melt in a crucible for use in growing a single crystal silicon ingot by the Czochralski method. The crucible is first loaded with chunk polycrystalline silicon and heated to partially melt the load. Granular polycrystalline silicon is then fed onto the exposed unmelted chunk polycrystalline silicon to complete the charge of silicon in the crucible. The granular polycrystalline silicon is intermittently delivered using a plurality of alternating on-periods and off-periods. During each on-period, granular polycrystalline silicon is flowed through a feed device that directs the granular polycrystalline silicon onto the unmelted chunk polycrystalline silicon. During each off-period, the flow of the granular polycrystalline silicon is interrupted. The loaded chunk polycrystalline silicon and the fed granular polycrystalline silicon are melted to form the silicon melt.

Owner:MEMC ELECTONIC MATERIALS INC

Cattle and sheep universal feed additive and preparation method thereof

InactiveCN101715895AImprove immunityEliminate picaAnimal feeding stuffAccessory food factorsFeed techniqueAnimal science

The invention relates to cattle and sheep universal feed additive and a preparation method thereof, belonging to the technical field of feeds and aiming at solving various problems of cattle and sheep caused by microelement deficiency in feeds. The additive comprises the raw materials of nickel salts, molybdate, CuSO4, MnSO4, FeSO4, ZnSO4, MgSO4, KI, CoCI2, Na2SeO4, amino acid, vitamin, flavoring agent, NaSO4, CaPHO4 and CaCO3. The additive is prepared from the raw materials by adopting the steps of crushing, mixing, and the like. In the additive, nickel element and molybdenum element are added on the basis of reasonably adapting multiple microelements, therefore, the matching of the microelements is more all-sided. The additive can enhance the immunity of cattle and sleep, coordinate and absorb nutrient substances and discharge toxic substances, eliminate parorexia of cattle and sheep, enhance the digestion and absorption functions and solve the problems of low production performance, easy morbidity, difficult hybridization and low baby animal survival ratio of cattle and sheep.

Owner:张六十

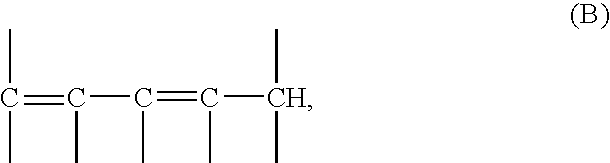

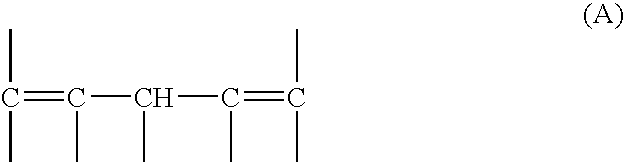

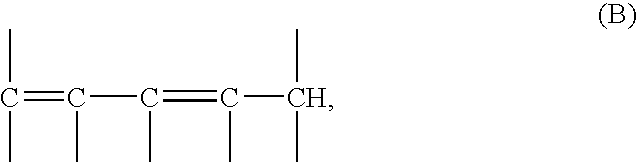

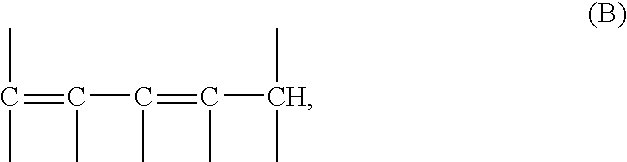

Method for producing aqueous styrene-butadiene polymer dispersions II

A process for preparing an aqueous styrene-butadiene polymer dispersion by free-radical aqueous emulsion polymerization of a monomer mixture M containing from 40 to 80% by weight of styrene as monomer M1, from 20 to 60% by weight of butadiene as monomer M2, and from 0 to 40% by weight, based on 100% by weight of monomers, of ethylenically unsaturated comonomers M3 other than styrene and butadiene by a monomer feed technique in the presence of from 0.05 to 0.5% by weight, based on 100% by weight of monomers, of at least one hydrocarbon HC having 6 to 20 carbon atoms selected from compounds which on abstraction of a hydrogen atom form a pentadienyl radical or a 1-phenylallyl radical and α-methylstyrene dimer comprises raising, at a point in time when at least 70% of the monomers to be polymerized have been supplied to the polymerization reaction, the concentration of butadiene in the monomer feed for a period of at least 1% of the total feed time by at least 10% by weight, based on monomers in the feed.

Owner:BASF AG

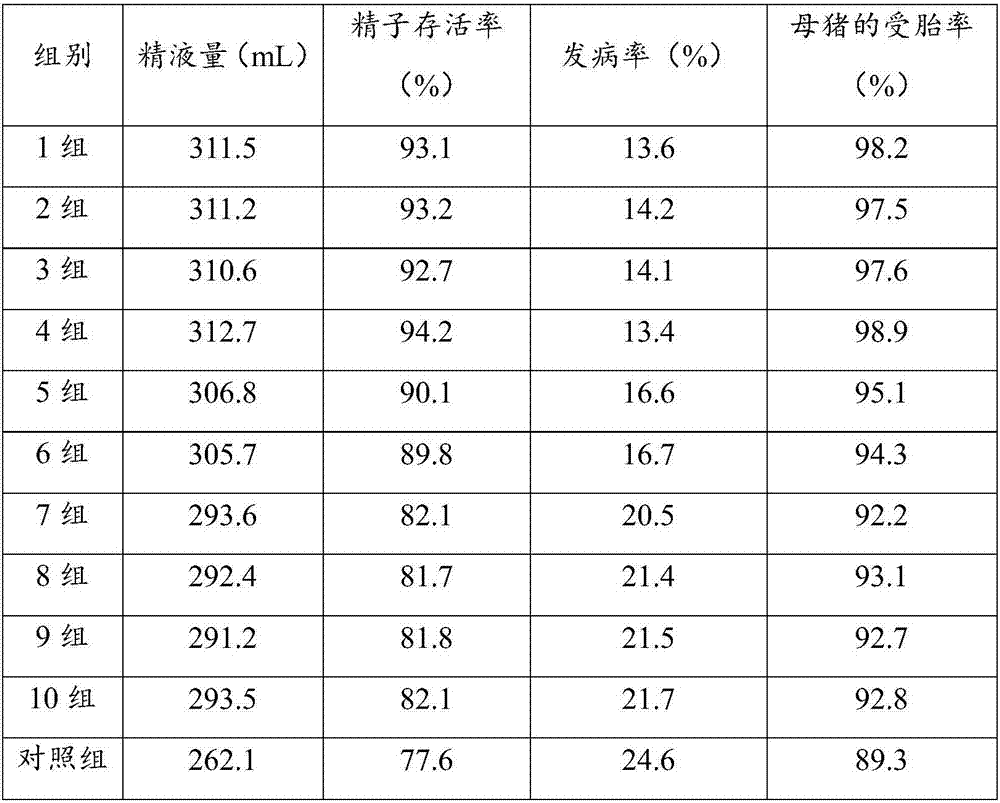

Mixed feed for breeding boars and preparation method of mixed feed

InactiveCN106983022AGood health effectImprove palatabilityFood processingAnimal feeding stuffFeed techniqueHordeum vulgare

The invention discloses mixed feed for breeding boars and a preparation method of the mixed feed, and relates to the technical field of animal feed, aiming to solve the technical problems of unreasonable feed component matching, easily-caused poor reproductive performance of the breeding boars and high breeding cost in the prior art. The mixed feed comprises main materials, 25-40 parts of premix and 12-18 parts of additives. The main materials comprise, by weight, 500-520 parts of corn, 40-60 parts of sorghum, 90-110 parts of hulled barley, 115-135 parts of bean pulp, 5-15 parts of egg powder, 40-60 parts of fermentation distillers' grains, 50-70 parts of biological fermentation feed and 40-60 parts of wheat bran. The preparation method is mainly applied to production of the mixed feed for the breeding boars.

Owner:湘西芙蓉资源农业科技有限公司

A technology for producing functional biological feed using edible fungus to ferment soy sauce residue

The invention provides a technology for producing functional biological feed by utilizing edible mushroom fermented sauce residue, belonging to the fields of feed processing technology, resource regeneration technology and biological technology. In the technology, fermented sauce residue of edible mushrooms comprising oyster mushroom and lucid ganoderma mushroom is used for producing the functional biological feed capable of improving animal immunity. The main process comprises the following steps of: firstly inoculating stored slope strains onto a PDA (potato dextrose agar) culture medium containing 20% of sauce residue (containing 78% of water), cultivating for 6 days at the temperature of 26 DEG C, then respectively inoculating into a liquid culture medium containing the sauce residue in certain inoculating quantity and carrying out swing bed liquid seed culture for 4 days under the conditions that swinging speed is 158rpm and temperature is 26 DEG C so as to be taken as production strains, and then inoculating the production strains into a solid sauce residue fermentation culture medium in the proportion of 1:1. By adopting the technology, the functional biological feed can be produced.

Owner:活泼

Method for producing aqueous styrene-butadiene polymer dispersions

A process for preparing an aqueous styrene-butadiene polymer dispersion by free-radical aqueous emulsion polymerization of a monomer mixture M containing from 40 to 80% by weight of styrene as monomer M1, from 20 to 60% by weight of butadiene as monomer M2, and from 0 to 40% by weight, based on 100% by weight of monomers, of ethylenically unsaturated comonomers M3 other than styrene and butadiene by a monomer feed technique in the presence of from 0.05 to 0.5% by weight, based on 100% by weight of monomers, of at least one hydrocarbon HC selected from compounds having 6 to 20 carbon atoms which on abstraction of a hydrogen atom form a pentadienyl radical or a 1-phenylallyl radical and from α-methylstyrene dimer comprises supplying the monomers to be polymerized to the polymerization reaction over the course of 3 hours.

Owner:BASF AG

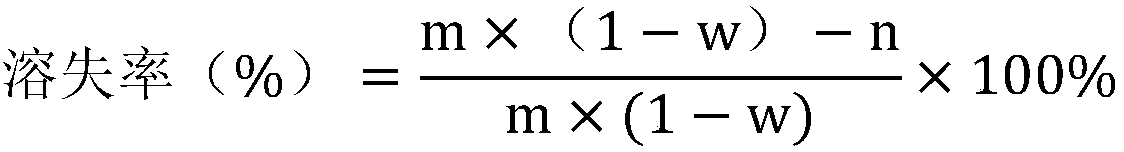

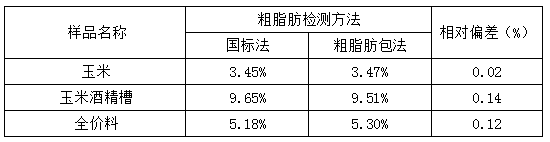

Method for batch detecting crude fat content in feed raw materials

InactiveCN109323952AHigh precisionSolve Surface Hardening ProblemsWeighing by removing componentFeed techniqueFreeze-drying

The invention discloses a method for batch detecting a crude fat content in a feed raw material. The invention belongs to the field of feed technology detection. According to the method, time can be reasonably utilized and a speed of crude fat extraction is accelerated by splitting the extraction of the crude fat in a sample into pretreatment and extraction by Soxhlet extractor. According to the method for batch detecting the crude fat content in the feed raw material, the sample is subjected to freeze drying before extraction, so that not only the effects of moisture contained in the sample and the oxidation of crude fat by heating on the detecting result are avoided, but also the contact area of petroleum ether and the sample is increased, the detecting time is shortened, and the detecting precision is improved.

Owner:日照普惠动物营养科技有限公司

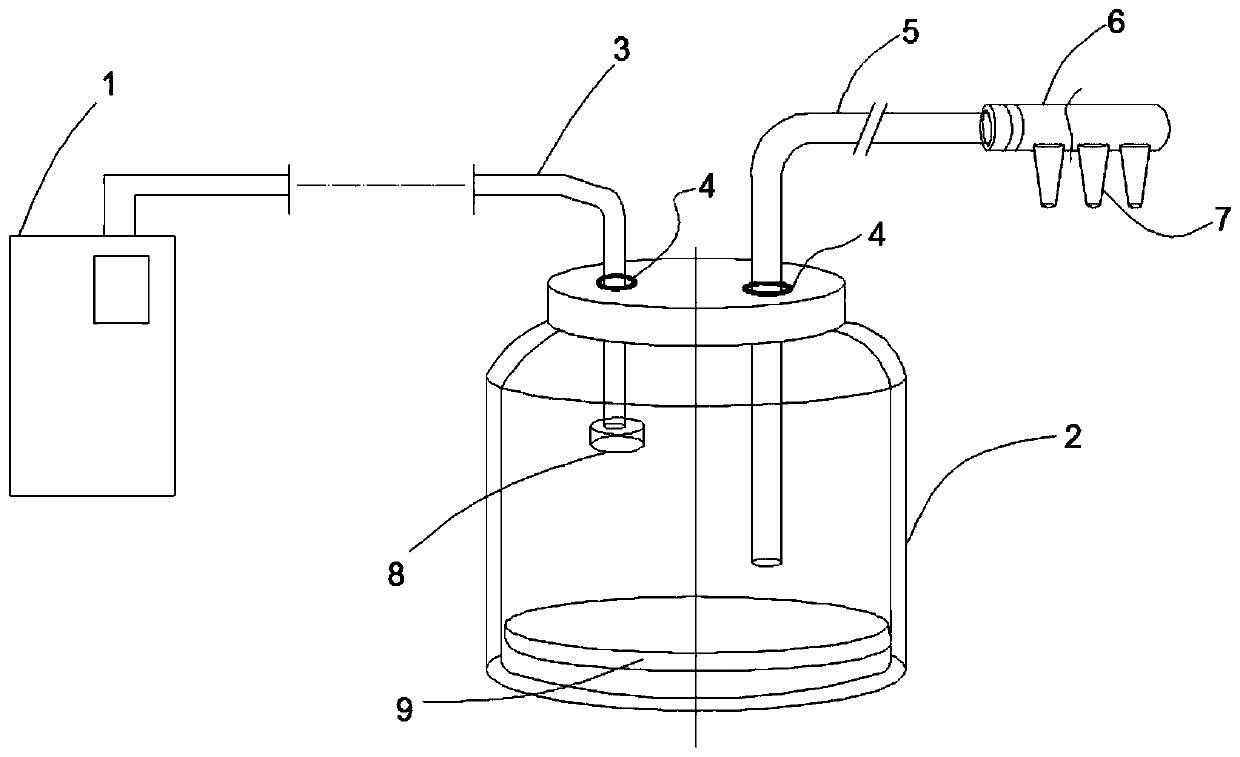

Individual bee or honey collector and collection method

PendingCN110024717AFine management improvementFeeding technology improvementHoney collectionFeed techniqueBee products

The invention discloses an individual bee or honey collector and a collection method, and belongs to the technical field of honey breeding. The individual bee or honey collector comprises a negative pressure suction mechanism, a collection bottle and a collection pipeline, two orifices are formed in the collection bottle, the negative pressure suction mechanism is connected with one orifice in thecollection bottle through a pipeline, another orifice is connected with a collection pipeline, and a collection end of the collection pipeline is provided with a sampling nozzle. The individual bee or honey collector solves the problem of difficulty in accurately collecting specific individual bees in a bee colony or bee products in a specific area. The individual bee or honey collector has significance for improving bee fine management and feeding techniques and ensuring smooth scientific research. The collector can be operated by an electrified vacuum pump, can also form negative pressure by human mouth suction, is simple to assemble and disassemble, convenient to use and low in sample requirement and saves time and labor.

Owner:云南省农业科学院蚕桑蜜蜂研究所

Large-scale propagation method of the small flower stinkbug

InactiveCN105325377BEfficient reproductionEfficient multiplicationAnimal feeding stuffFeed techniqueZoology

The invention discloses a method for large-scale propagation of the small flower bug. In the present invention, western flower thrips and broad bean aphid are combined to feed southern flower bugs, which fully utilizes the advantage of fast growth rate of the broad bean aphid population, and at the same time utilizes western flower thrips to improve the survival rate of newly hatched nymphs and adult reproduction of southern flower bugs The characteristics of the force, that is, feeding the newly hatched nymphs of the southern flower bug to the western flower thrips to improve the survival rate, combined with the 2-5th instar nymphs to feed the broad bean aphid to reduce the feeding cost, and then achieve the purpose of low-cost and high-efficiency breeding of the southern flower bug. Created a set of breeding technology process suitable for large-scale breeding of small flower bugs, which can quickly and efficiently multiply the southern flower bugs in large quantities, and can be used for field control of thrips, spider mites, aphids and other pests.

Owner:贵州省植物保护研究所

Ingredients for fire refining of scrap copper and smelting method

InactiveCN103451448AFilling ingredientsFilling the gap in feeding technologyFeed techniqueElectrolysis

The invention provides ingredients for fire refining of scrap copper and a smelting method. The ingredients include 96-97.5% by mass of raw materials and 2.5-4% by mass of auxiliary materials, wherein the raw materials include 59-79% of lump scrap copper baling materials or / and blister copper lumps, 17-29.6% of bottoming copper, 2.5-5.8% of a waste anode plate or / and an electrolytic residual anode plate and 2.5-5.6% of bulk materials; the auxiliary materials include quartz, pig iron and lime which are in the ratio of (2:8): (0.5-1): (0.5-1). For feeding, the bulk materials are fed at first, and then 60-90% of lump scrap copper baling materials or / and blister copper lumps, the lime and 25-50% of quartz are fed; next, the bottoming copper and the left 10-40% of lump scrap copper baling materials or / and blister copper lumps are fed; after the materials are molten in a furnace, the pig iron and the left 50-75% of quartz are fed to begin the stage of oxidization; finally, the waste anode plate or / and electrolytic residual anode plate is / are added. The ingredients provided by the invention fill a vacancy in the burdening and feeding techniques in the existing high-grade scrap copper refining process; and as a result, the service life of a metallurgical furnace is prolonged and the smelting period of the scrap copper is shortened.

Owner:NANTONG REPAIR AIR CHEM BIOENG

Slot fed dipole antenna

InactiveUS20150249290A1Total current dropHigh bandwidthAntenna earthingsAntenna feed intermediatesFeed techniqueCoaxial cable

A dipole antenna system is disclosed. An indirect feed technique is used to feed the antenna and the radiating elements are connected to a shield of a coax cable. The balanced termination allows for improved bandwidth compared to conventional dipole antenna configuration and helps manage current on the shield of the coax cable.

Owner:MOLEX INC

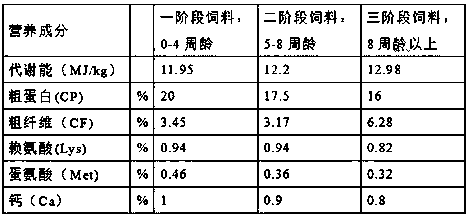

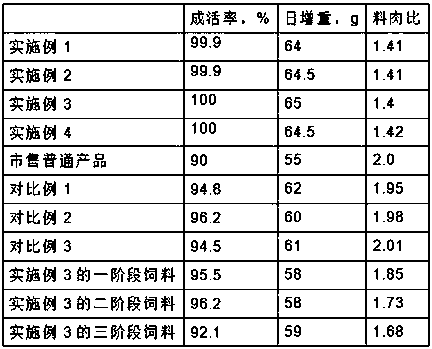

Three-stage feed for local broiler chickens and preparation method thereof

InactiveCN108271946AImprove palatabilityPromote digestion and absorptionFood processingAnimal feeding stuffFeed techniqueBiotechnology

The invention relates to three-stage feed for local broiler chickens and a preparation method thereof and belongs to the technical field of feed. The three-stage feed for local broiler chickens comprises first-stage feed, second-stage feed and third-stage feed; and the three-stage feed is mainly prepared from corn, rice bran, bean meal, calcium hydrogen phosphate, stone powder, trace element premix, vitamin premix, salt, a microecological preparation and the like. The three-stage feed for local broiler chickens has good palatability and low feed conversion ratio, is easy to digest and absorb and can meet the nutritional requirements of local broiler chickens, improve the disease resistance of the local broiler chickens and improve the immunity of the chickens. Meanwhile, the three-stage feed for local broiler chickens has moderate metabolic energy value and high nutritional level, the local broiler chickens have fast growth and low mortality after the feed is used, occurrence of respiratory disease in the chickens can be effectively prevented, and the fed broiler chickens maintain the due meat quality and mouthfeel of local chickens and have a delicious meat taste and high popularization value.

Owner:ZHAOTONG GAOSHAN ANIMAL HUSBANDRY

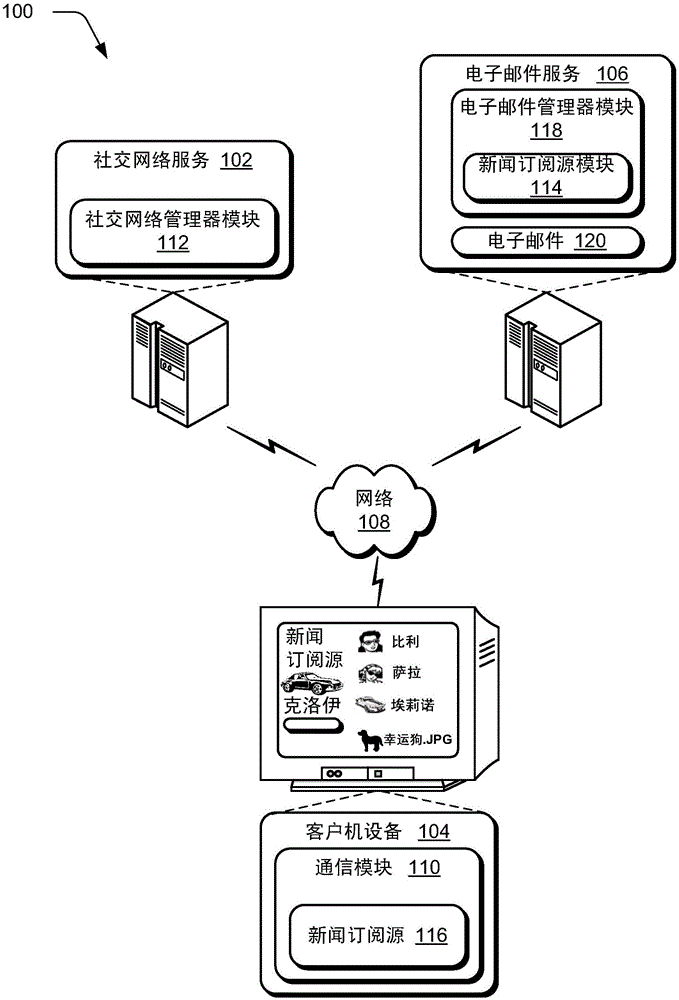

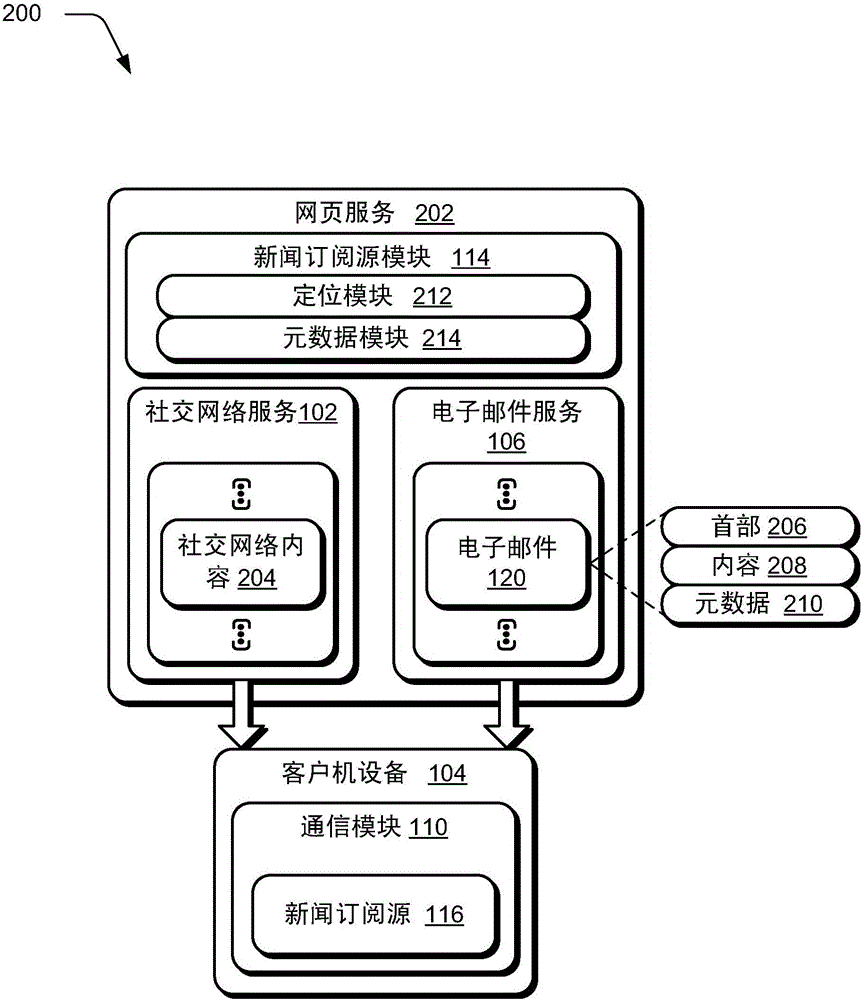

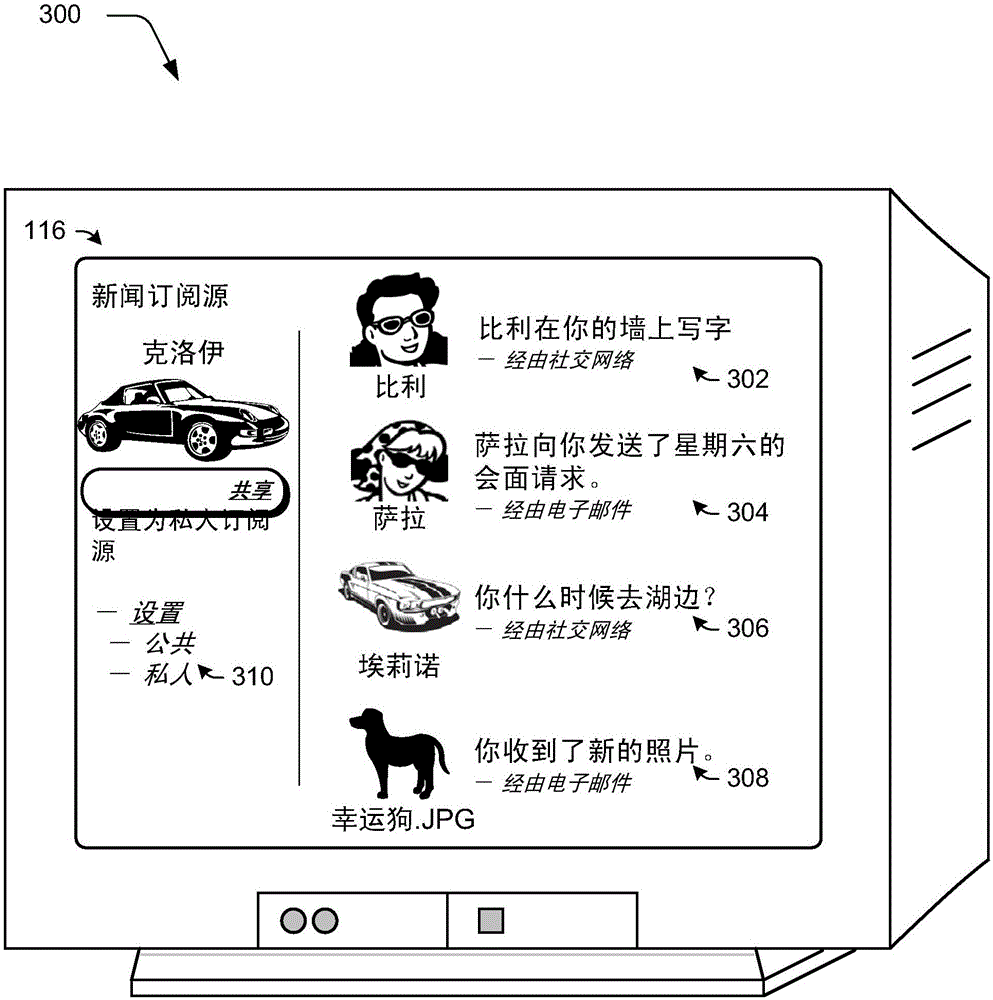

News feed techniques

Owner:MICROSOFT TECH LICENSING LLC

Method for producing aqueous styrene-butadiene polymer dispersions III

A process for preparing an aqueous styrene-butadiene polymer dispersion by free-radical aqueous emulsion polymerization of a monomer mixture M containing from 40 to 80% by weight of styrene as monomer M1, from 20 to 60% by weight of butadiene as monomer M2, and from 0 to 40% by weight, based on 100% by weight of monomers, of ethylenically unsaturated comonomers M3 other than styrene and butadiene by a monomer feed technique in the presence of from 0.05 to 0.5% by weight, based on 100% by weight of monomers, of at least one hydrocarbon HC having 6 to 20 carbon atoms, which is selected from compounds which on abstraction of a hydrogen atom form a pentadienyl radical or a 1-phenylallyl radical and from α-methylstyrene dimer comprises including at least 30% of the hydrocarbon HC in the initial charge to the polymerization vessel and supplying the remainder of the hydrocarbon HC to the polymerization reaction in the course of that reaction.

Owner:BASF AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com