Patents

Literature

5021results about How to "Prevent dumping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

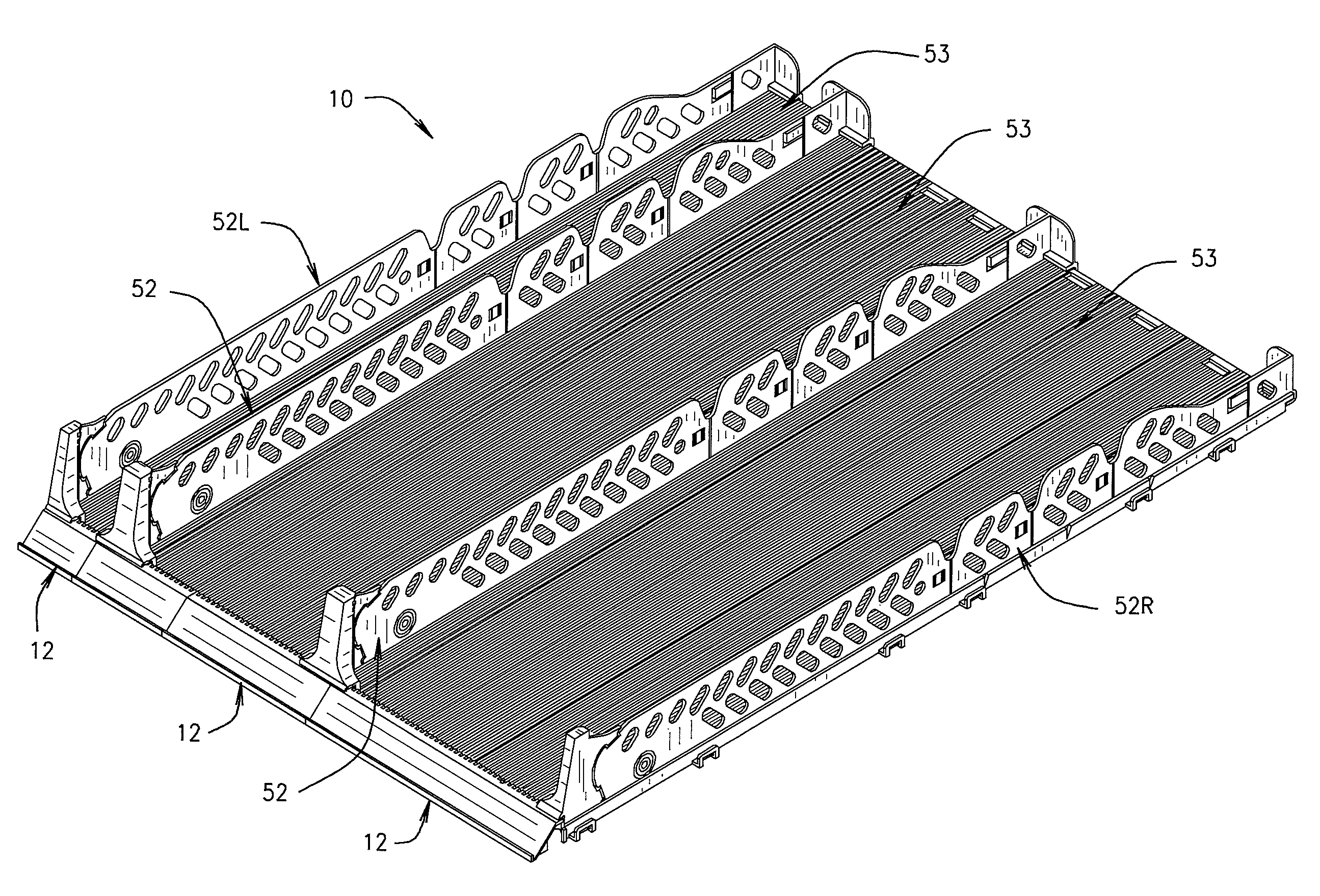

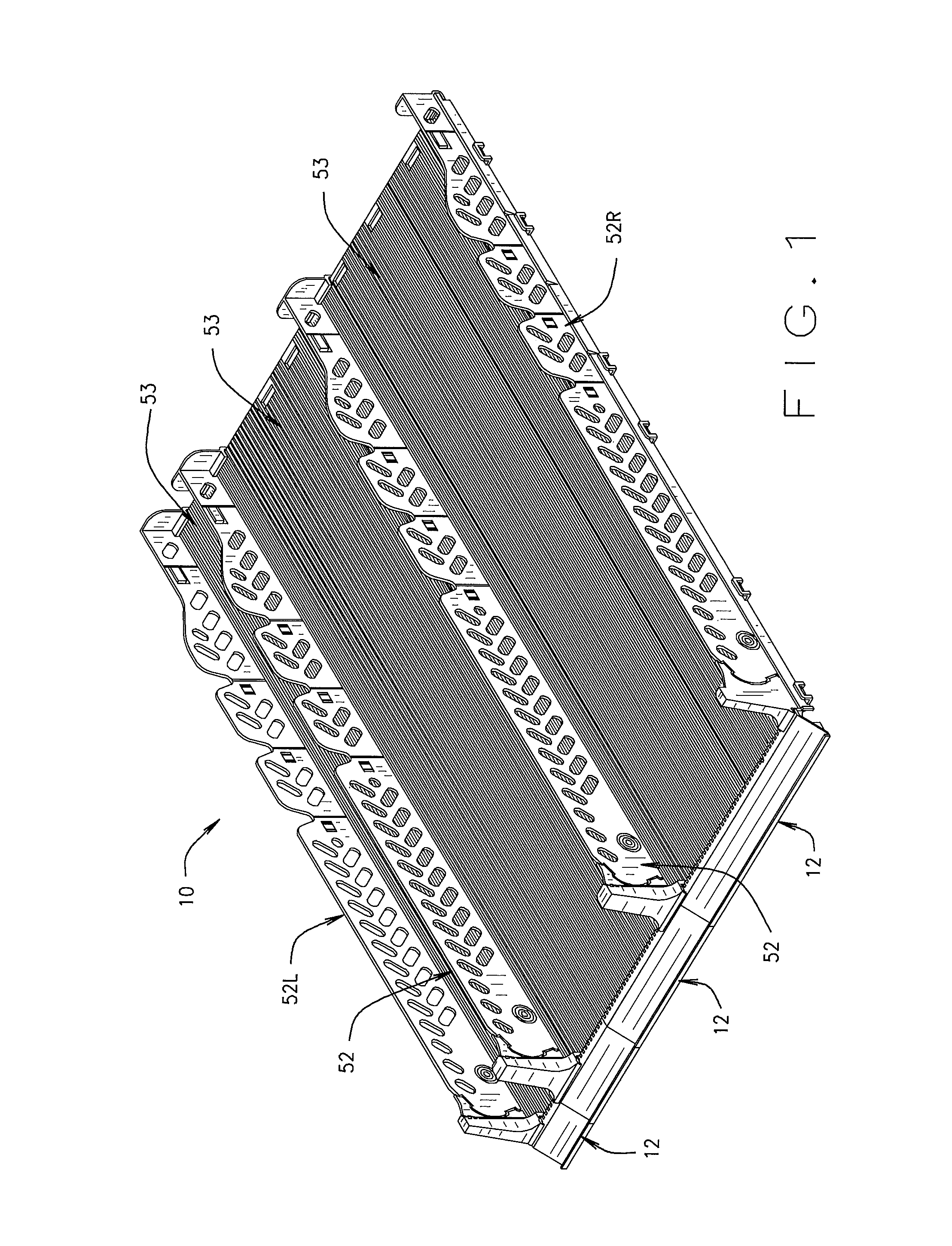

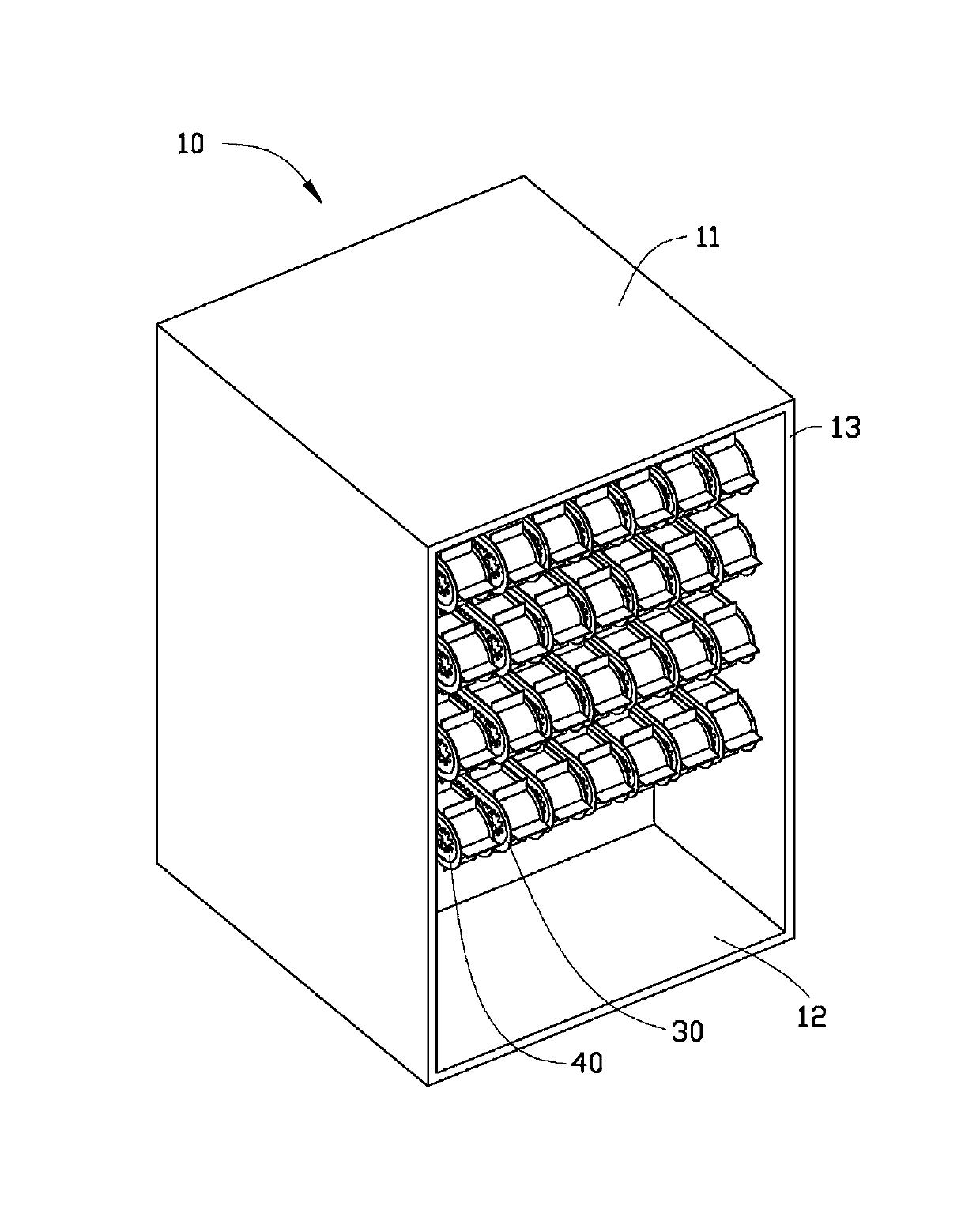

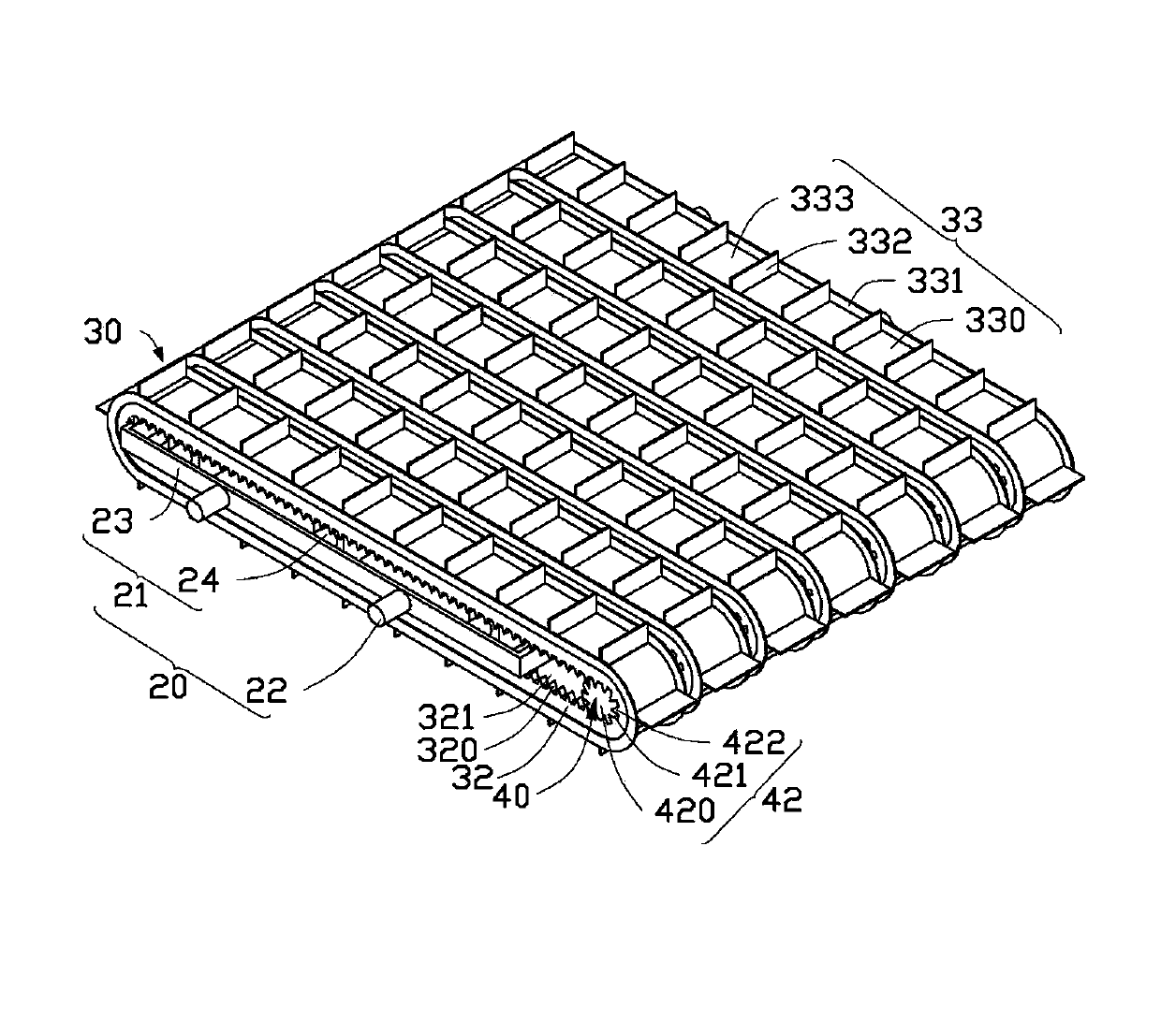

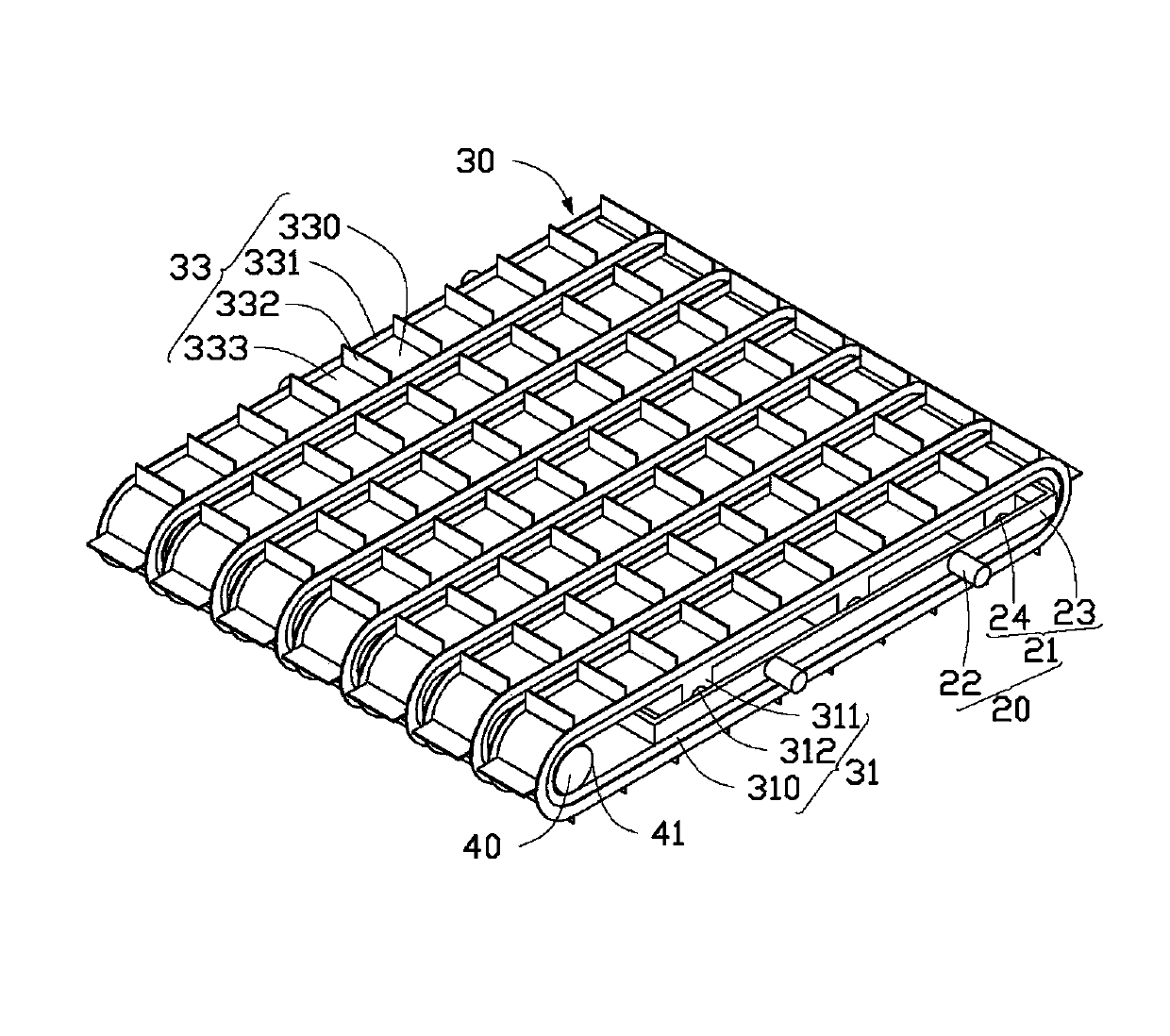

Glide system with adjustable dividers and modular floor members

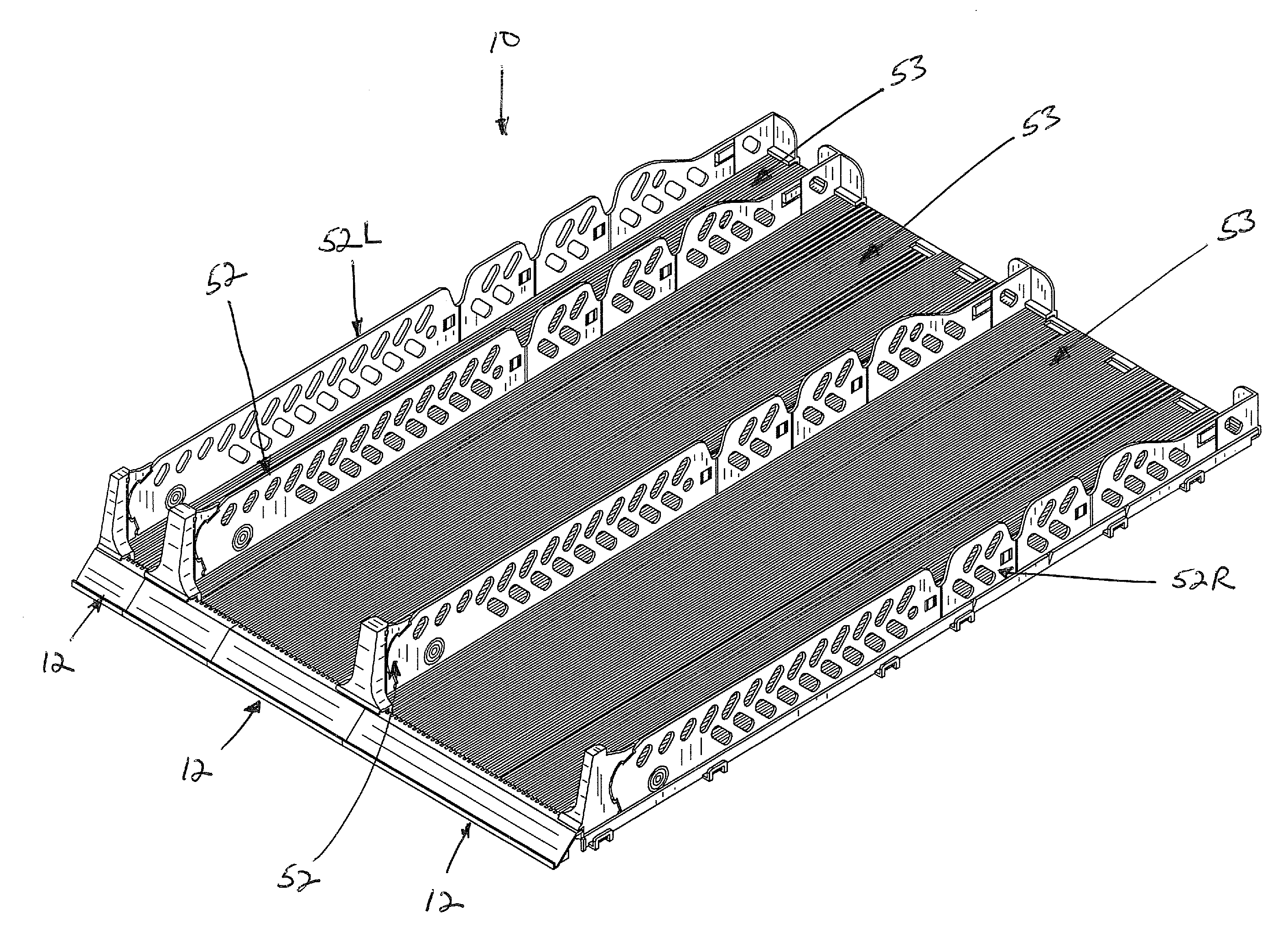

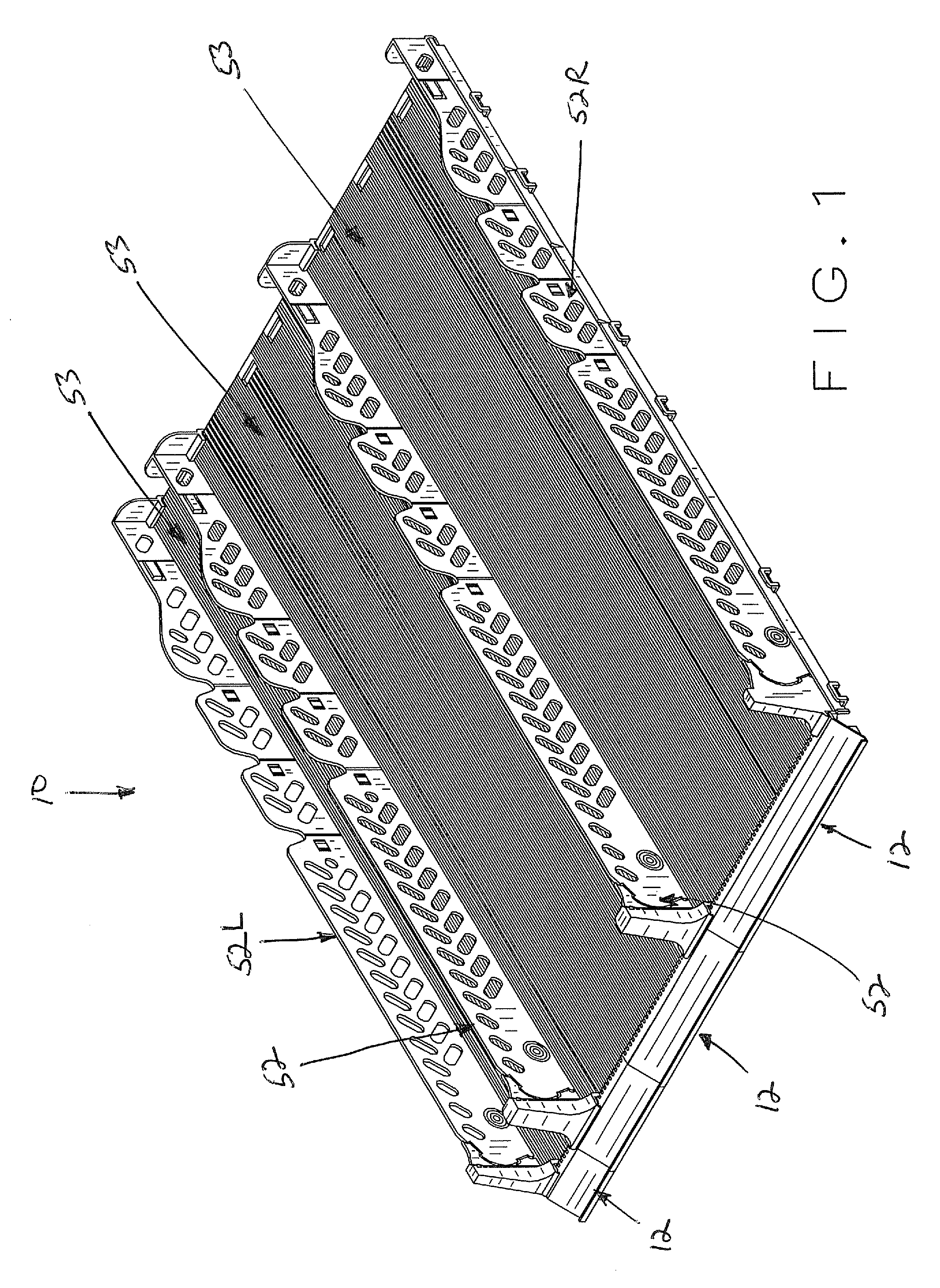

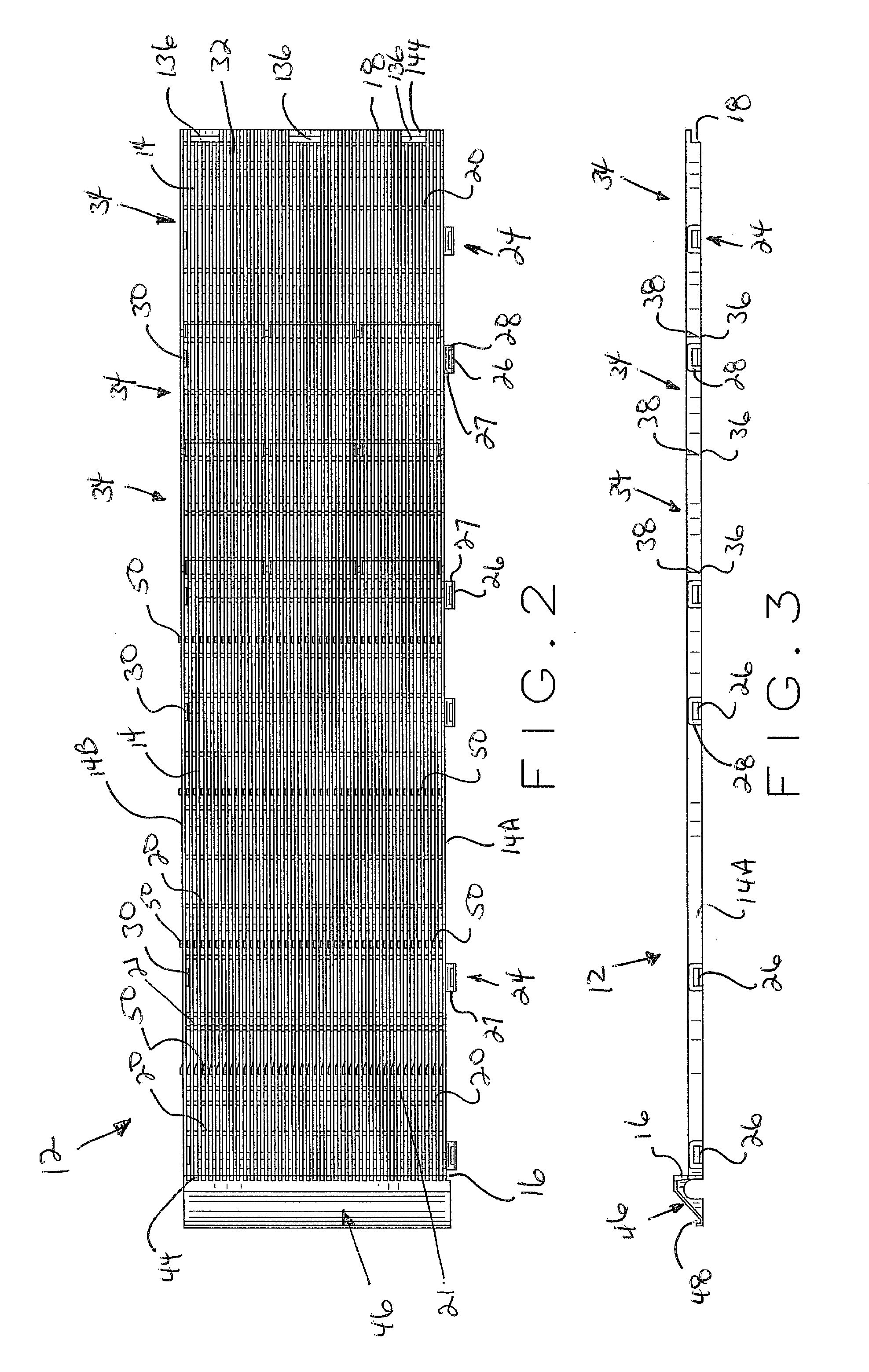

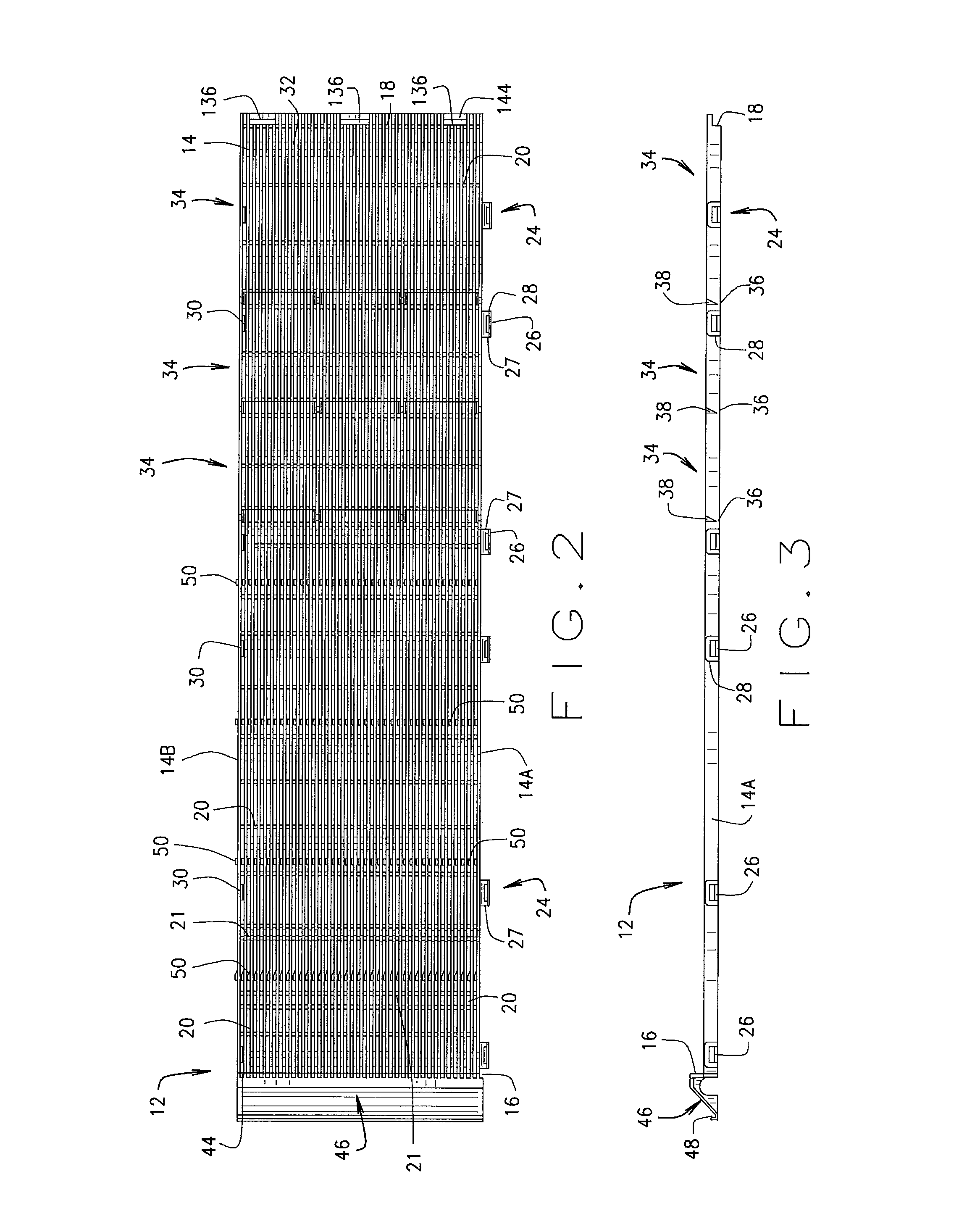

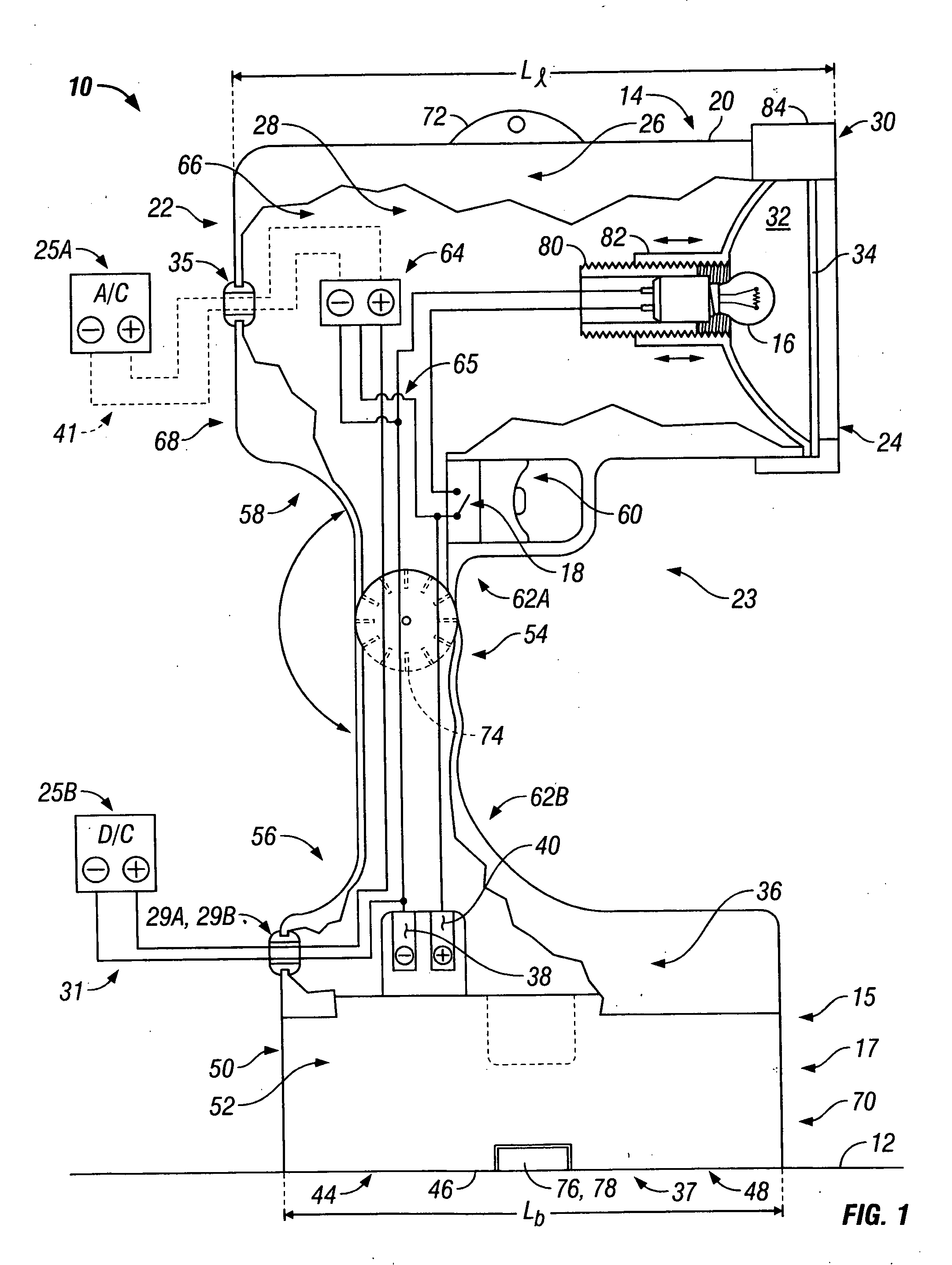

A variable shelf organizer glide system for merchandising products therefrom capable of being assembled to accommodate any shelf length and width and any product dimension including a plurality of cooperatively engageable adjustable floor members having a plurality of transverse projection members associated with each respective track rib, the transverse projection members extending laterally across only a portion of the respective longitudinal slots formed between adjacent track ribs, and a plurality of adjustable divider members, each divider member being selectively engageable with the transverse projection members to form any number of segregated product channels for arranging products therebetween. Each floor member includes frangible break-away portions for adjusting the overall length thereof, and each divider member includes a frangible break-away front product stop member as well as a plurality of frangible break-away rear portions for likewise controlling the overall length of each divider member.

Owner:PRESENCE FROM INNOVATION

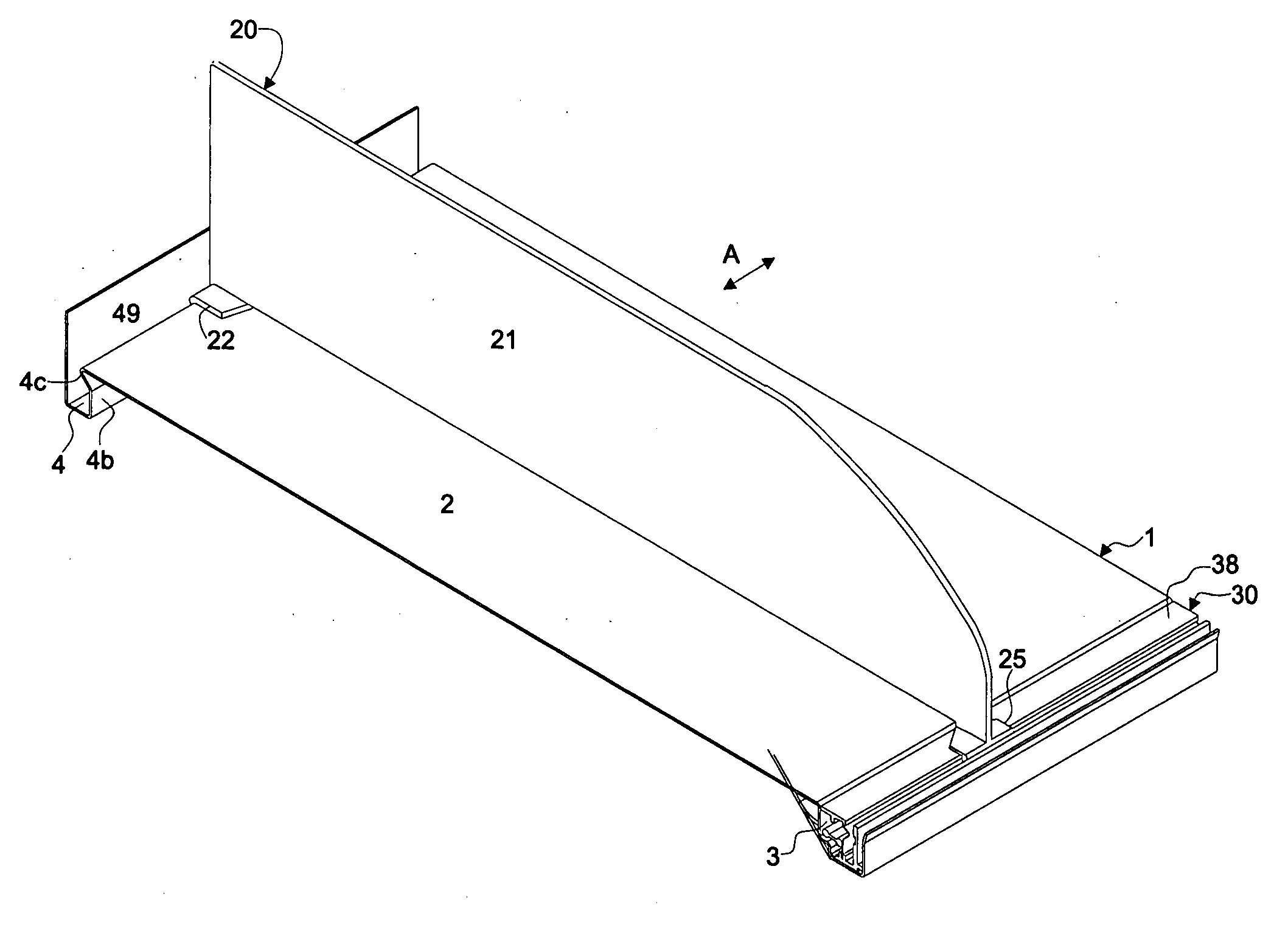

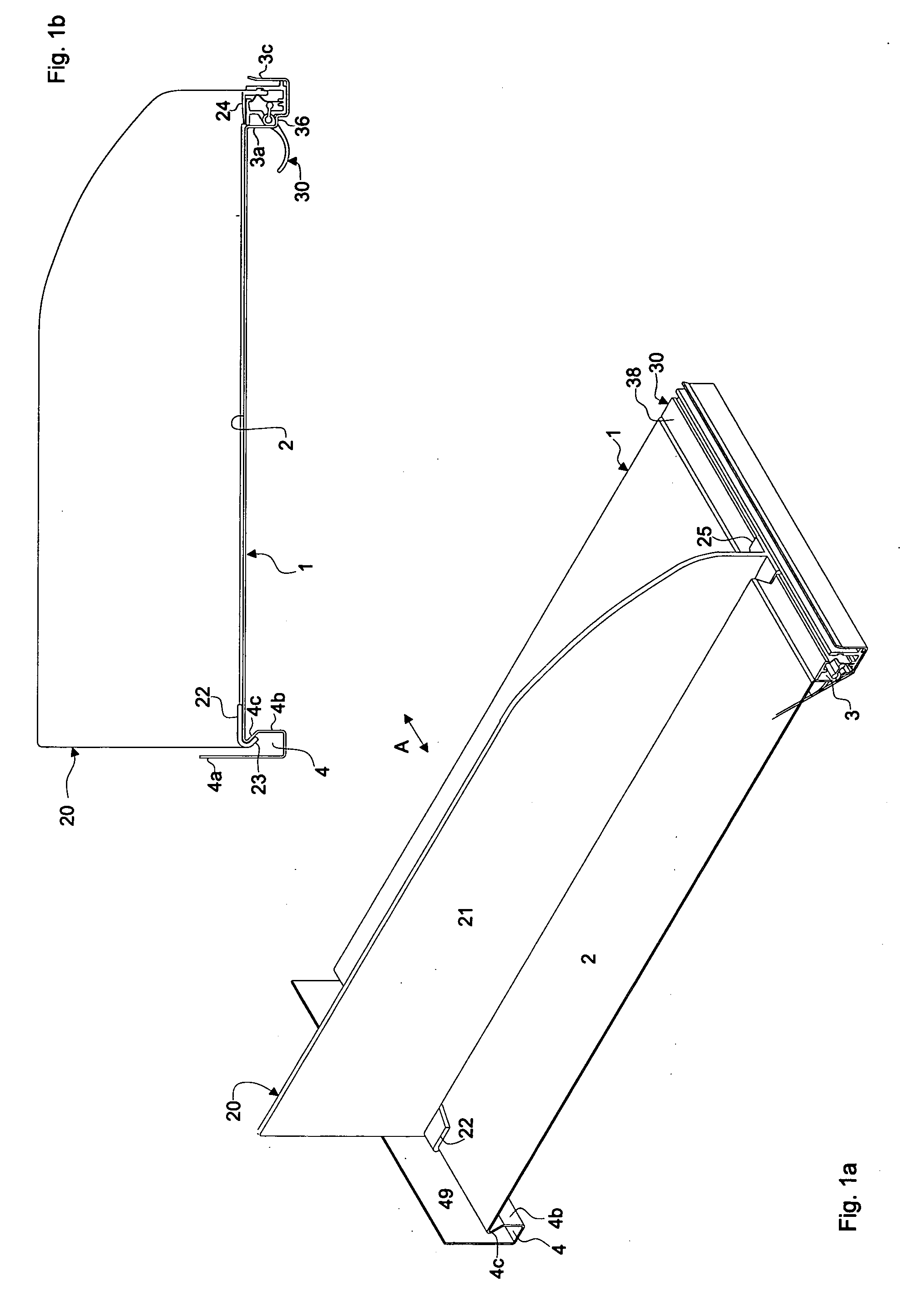

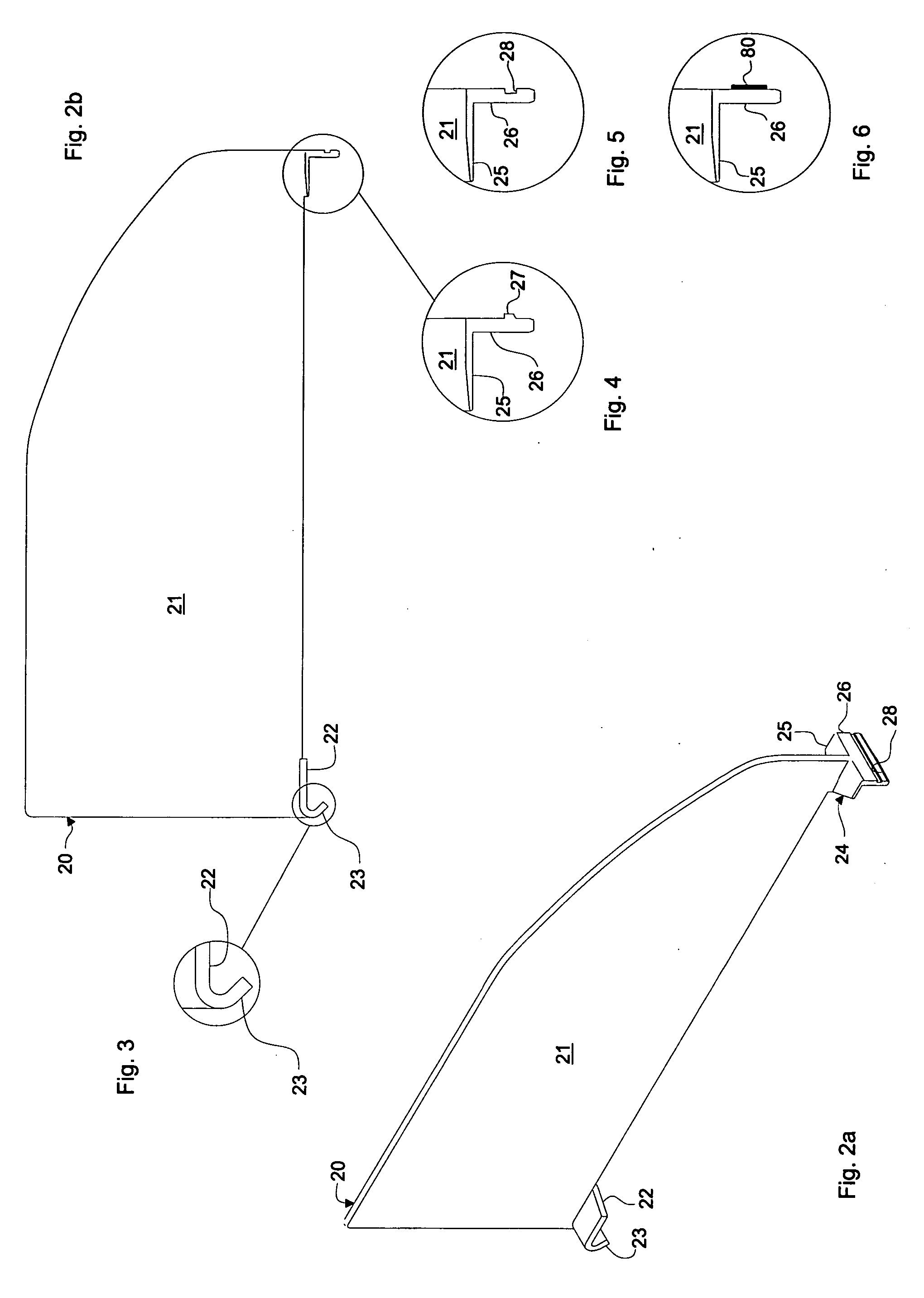

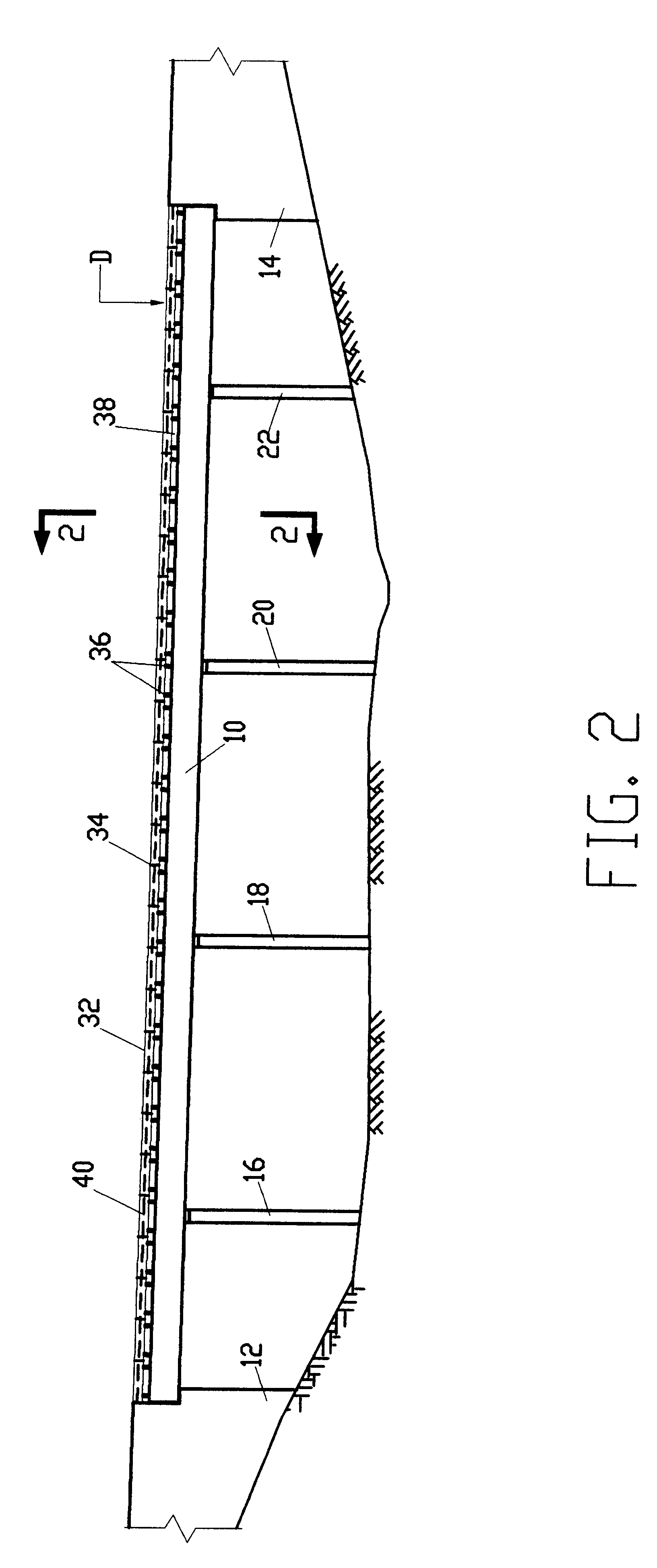

System for attaching accessories to a shelf

InactiveUS20060260518A1Facilitate workConvenience to workStampsShow shelvesFixed positionEngineering

A system for fixing accessories, such as shelf dividers, feed devices, holders for information carriers etc. to a shelf, to which self a number of accessories may be fixed detachably in various different positions along the length of the shelf. The system includes at least one accessory provided with a foot, and a clamping device, which includes a channel element, extending in parallel with the longitudinal direction of the shelf and presenting an open longitudinal side for forming an open channel, a actuable holding member, extending along the channel element for holding at least one foot in the channel and a control member for transferring the holding member between a holding position, in which the foot is held in a fixation position in the channel and a release position at which the foot is freed.

Owner:HL DISPLAY

Glide system with adjustable dividers and modular floor members

ActiveUS8016139B2Increase the lengthShorten the lengthRacksShow shelvesModularityMechanical engineering

A variable shelf organizer glide system for merchandising products therefrom capable of being assembled to accommodate any shelf length and width and any product dimension including a plurality of cooperatively engageable adjustable floor members having a plurality of transverse projection members associated with each respective track rib, the transverse projection members extending laterally across only a portion of the respective longitudinal slots formed between adjacent track ribs, and a plurality of adjustable divider members, each divider member being selectively engageable with the transverse projection members to form any number of segregated product channels for arranging products therebetween. Each floor member includes frangible break-away portions for adjusting the overall length thereof, and each divider member includes a frangible break-away front product stop member as well as a plurality of frangible break-away rear portions for likewise controlling the overall length of each divider member.

Owner:PRESENCE FROM INNOVATION

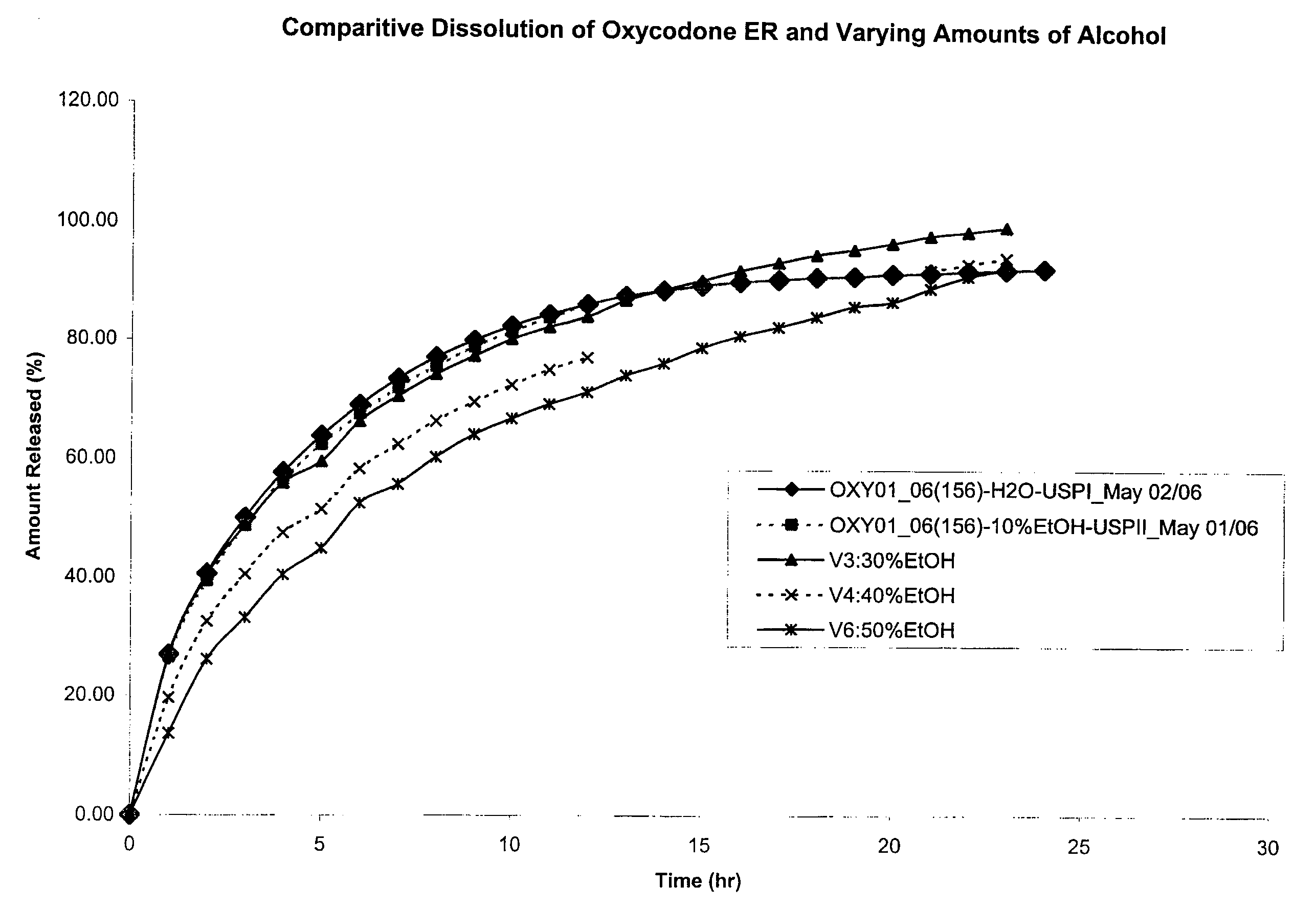

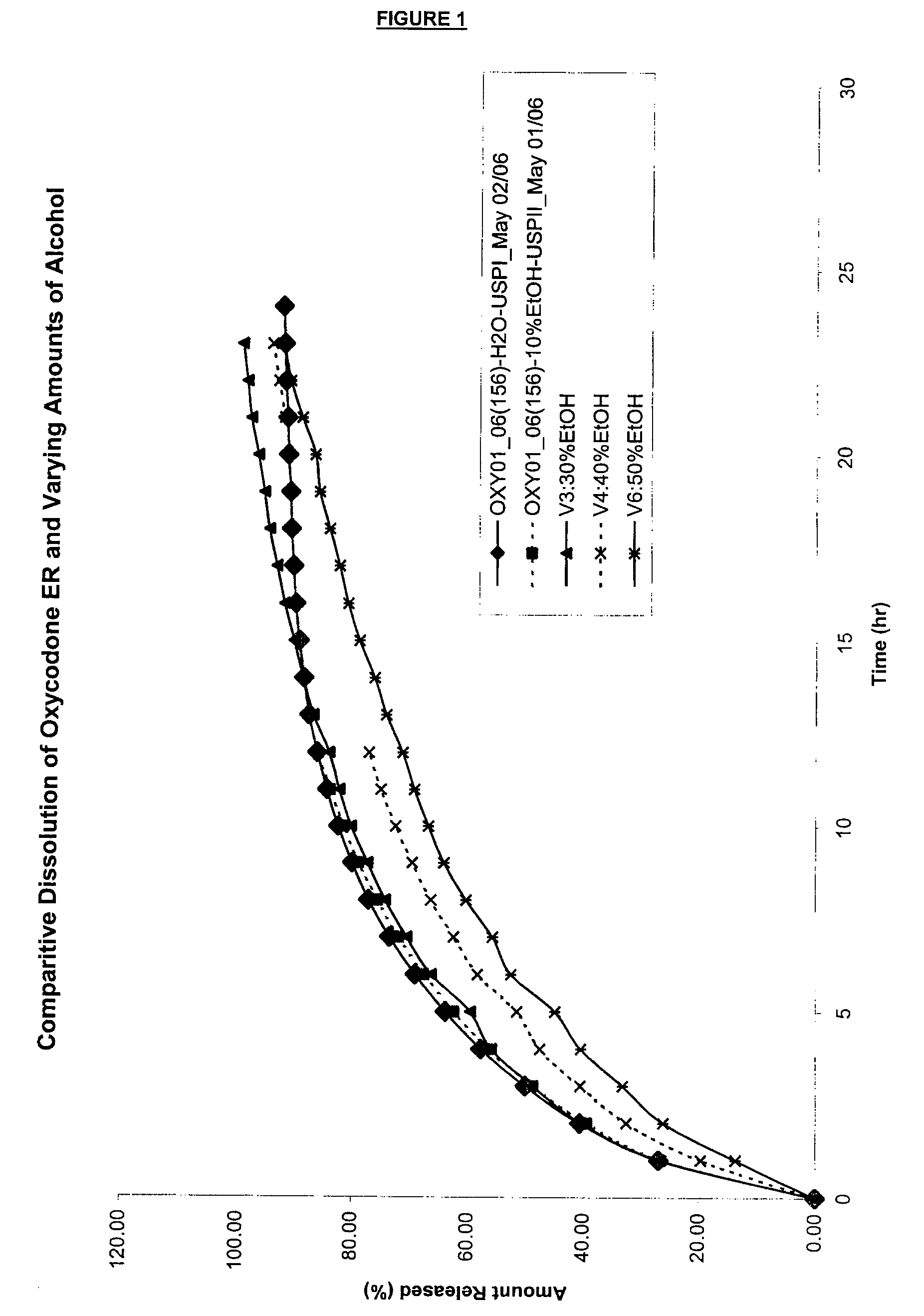

Pharmaceutical composition having reduced abuse potential

ActiveUS20090232887A1Efficiently employedReduce decreaseBiocideOrganic active ingredientsControl releaseAdditive ingredient

A pharmaceutical paste composition comprising an active ingredient such as an addictive substance, a controlled release agent, and a pharmaceutically suitable aqueous or non-aqueous carrier. The composition may comprise one or more of a clay, or an oily, waxy, or fatty substance. The composition may be filled into a capsule or other dispensing device. The composition may reduce dose dumping of an active ingredient. Methods of making and using the composition are also described.

Owner:INTELLIPHARMACEUTICS

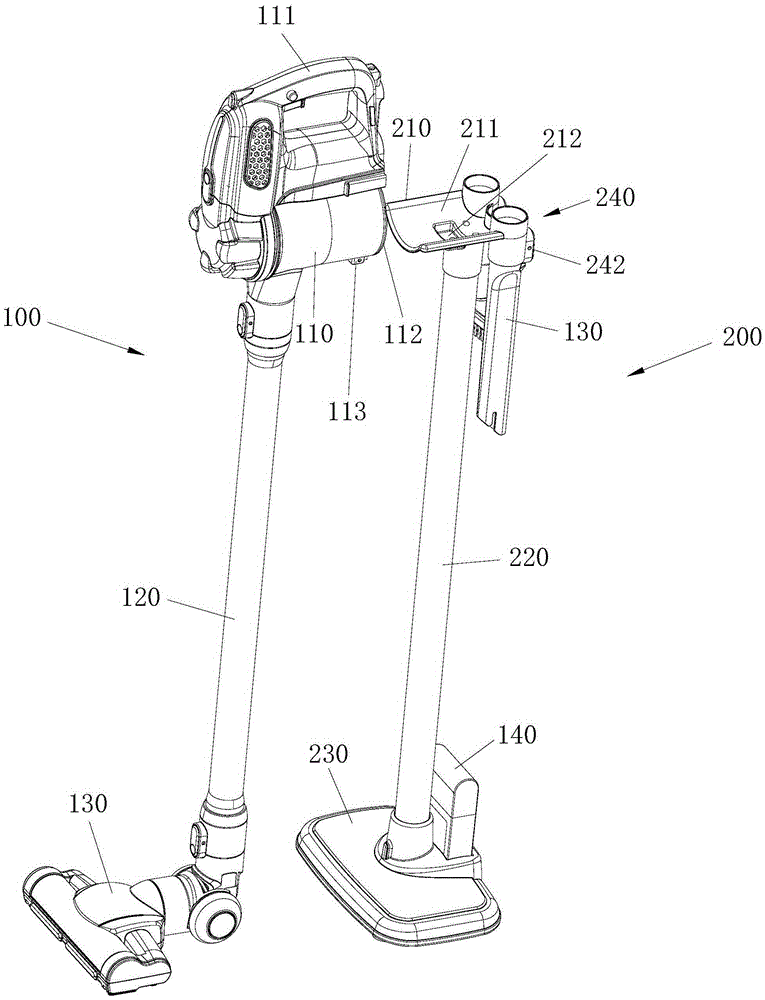

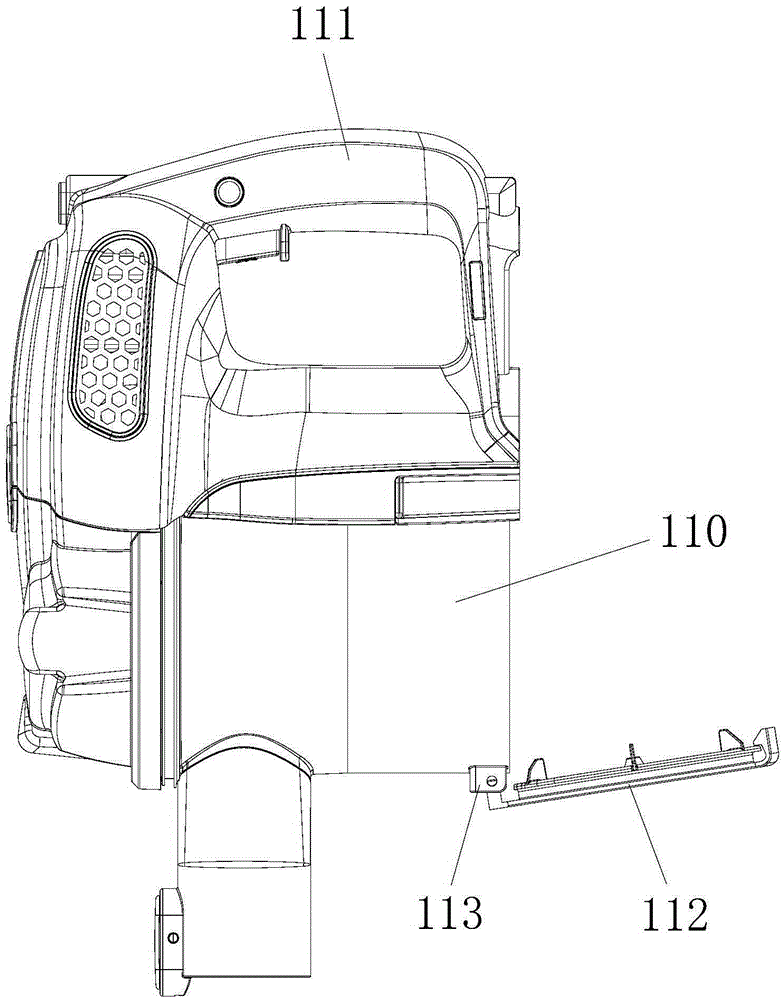

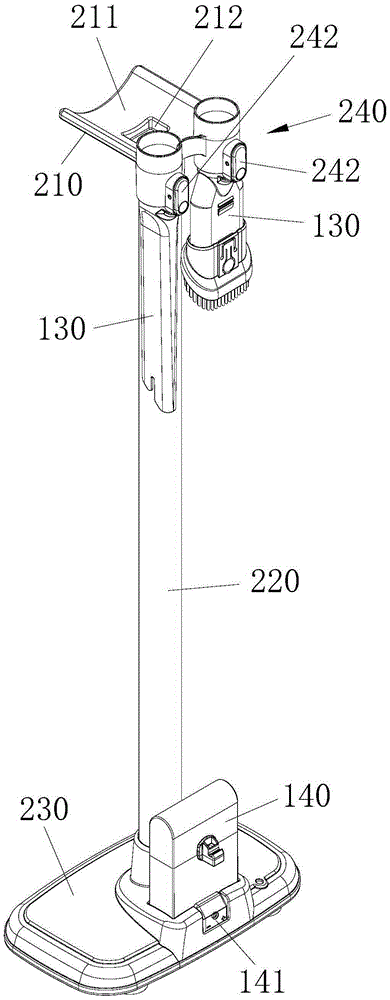

Handheld dust collector with bracket

InactiveCN105395132AImprove cleanlinessFirmly connectedSuction cleanersHand heldStructural engineering

The invention discloses a handheld dust collector with a bracket. The dust collector comprises a handheld dust collection device and the bracket, wherein the handheld dust collection device comprises a shell provided with a handle, a suction fan and a dust collection box which are arranged inside the shell, and a dust suction head which is connected to the shell in a separated mode; a cover, which can be opened and closed, is connected to the shell, and the dust collection box can be taken out of the shell when the cover is opened; a convex connecting block is arranged on the outer wall of the shell; the cover is rotatably connected to the connecting block; the bracket comprises a base, a brace rod with lower end connected to the base and a supporting frame connected to the upper end of the brace rod; the shell and the supporting frame are connected in a separated mode; a locating groove, which is matched with the connecting block, is formed in the supporting frame; and the connecting block is located in the locating groove when the shell and the supporting frame are connected.

Owner:SUZHOU AIJIAN ELECTRIC APPLIANCE

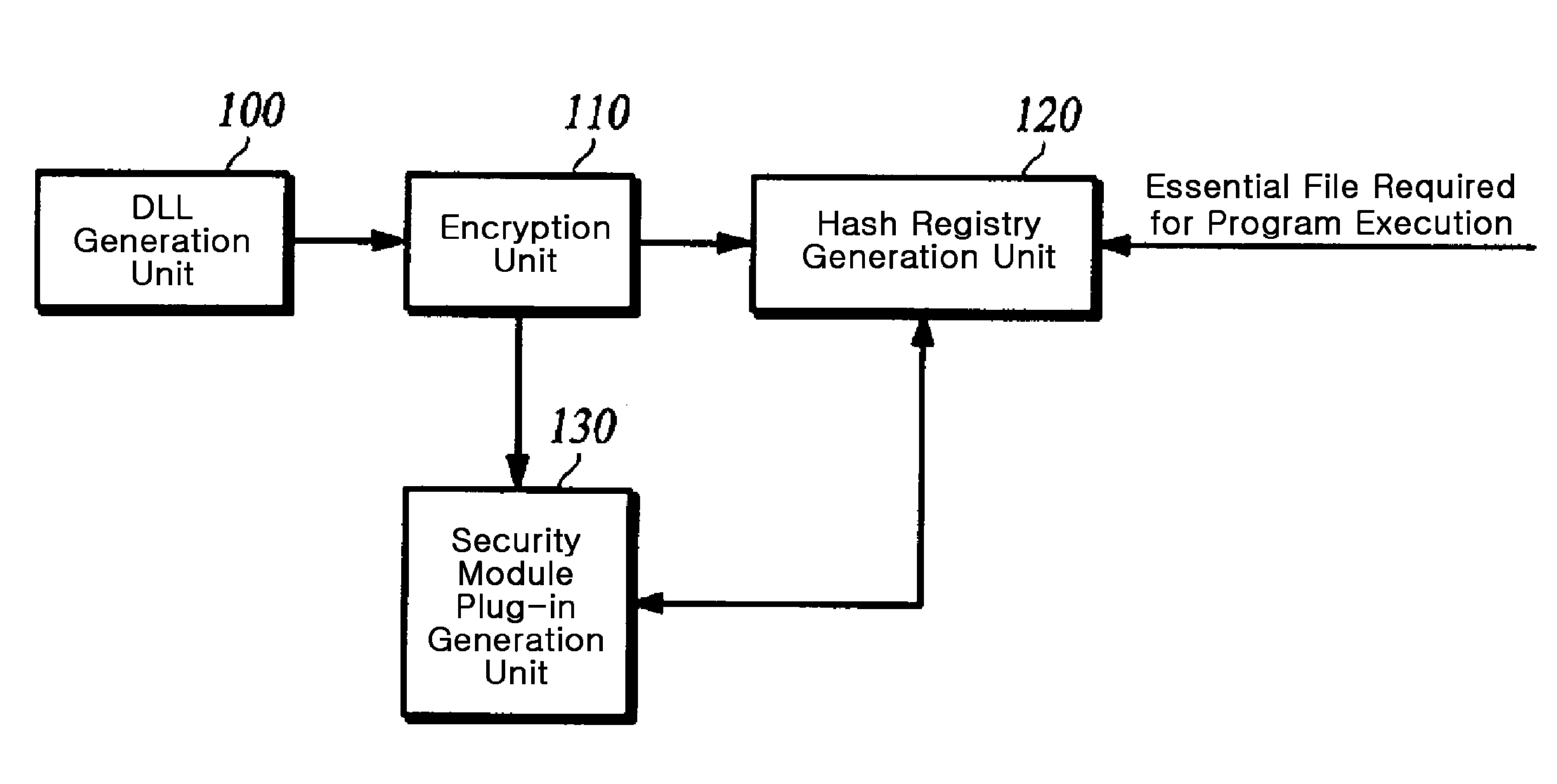

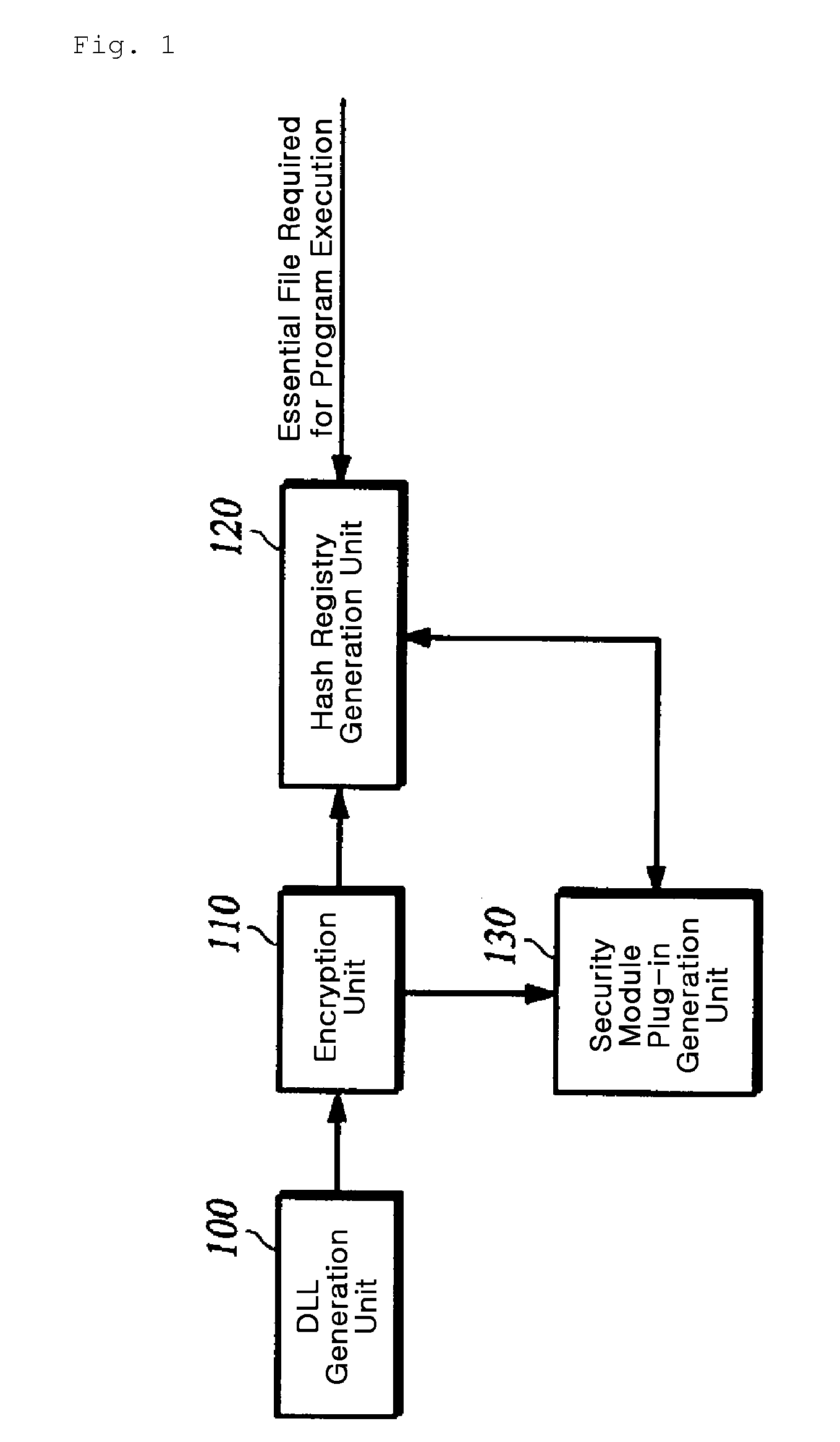

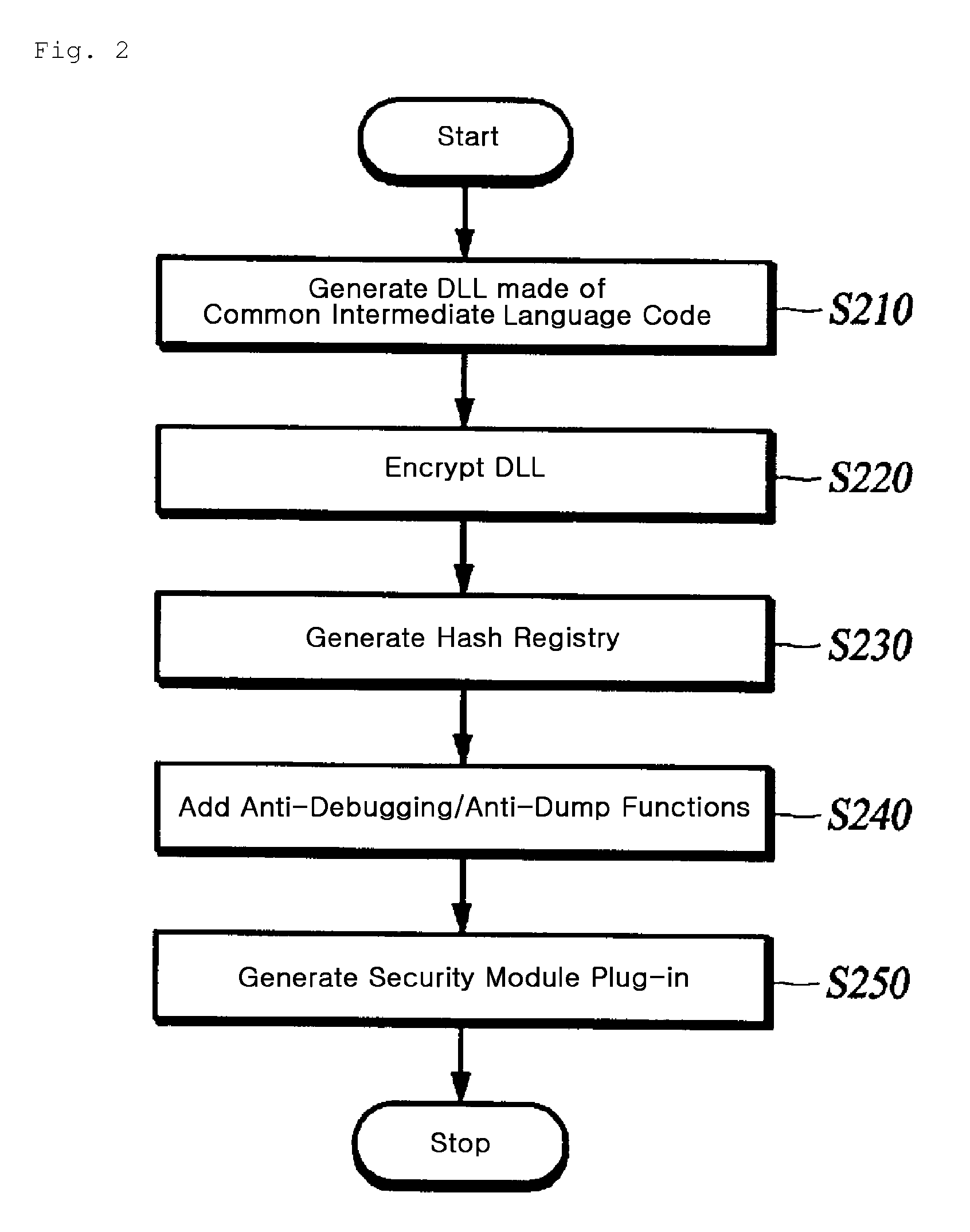

Method for providing security for common intermediate language-based program

InactiveUS20160203087A1Debugging be preventStop executionMemory architecture accessing/allocationUnauthorized memory use protectionSpecific functionApplication software

Disclosed is a method for providing security of a program made in a script language. In a method for providing security for a common intermediate language-based program, which provides security for a user DLL used in a platform supporting an application made of common intermediate language code and a plug-in made of native code, the method comprises: a specific function call step of calling a specific function within an application which calls a specific module in a security logic DLL including one or more modules while an application is loaded into a main memory and executed; a DLL request step of requesting the security logic DLL from a security module plug-in in which the security logic DLL is encrypted and stored; a DLL generation step of generating the security logic DLL by decrypting the encrypted DLL in the security module plug-in; a step of transmitting the security logic DLL to the specific function within the application; and a DLL module call step of calling the specific module included in the security logic DLL.

Owner:INKA ENTWORKS INC

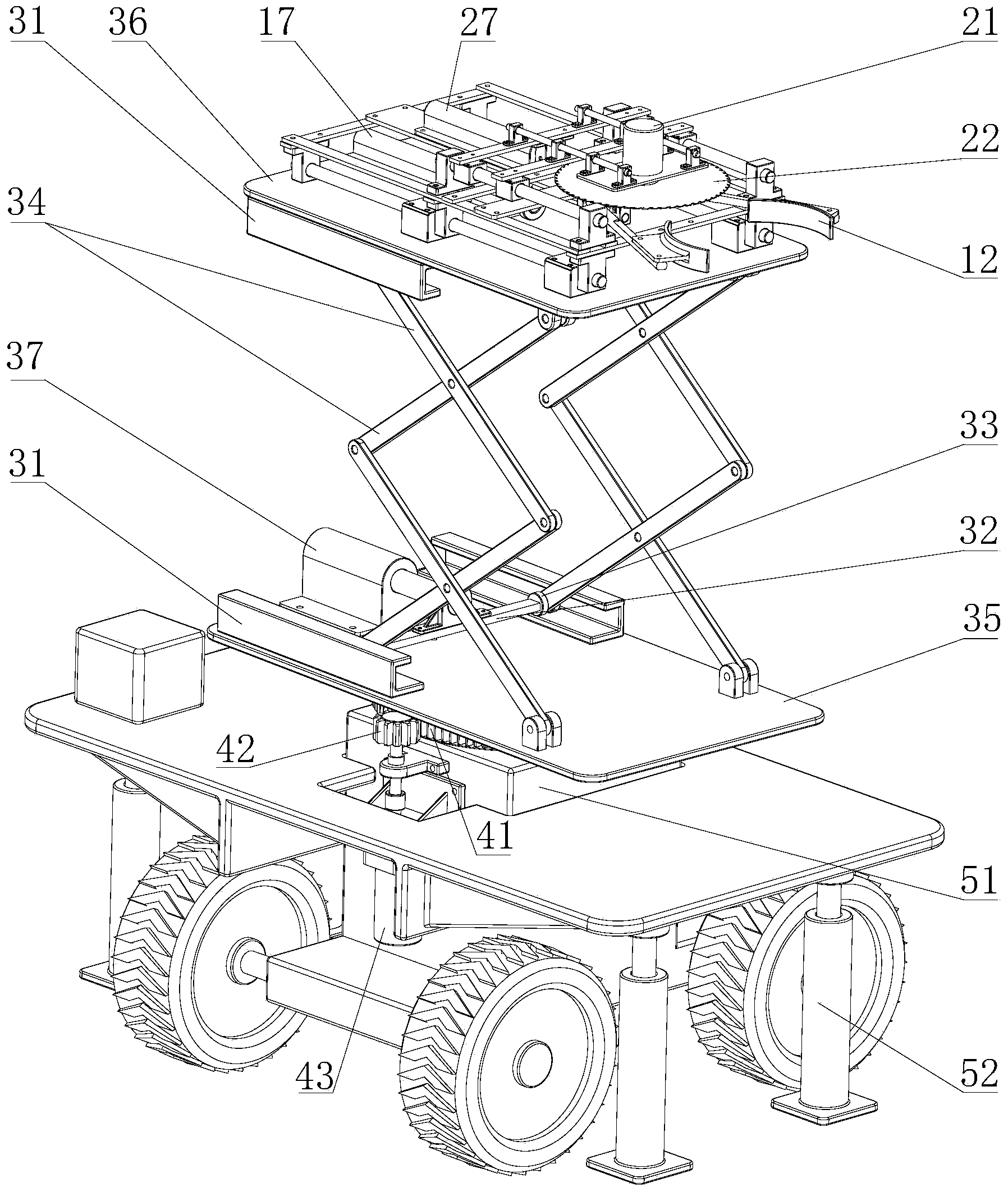

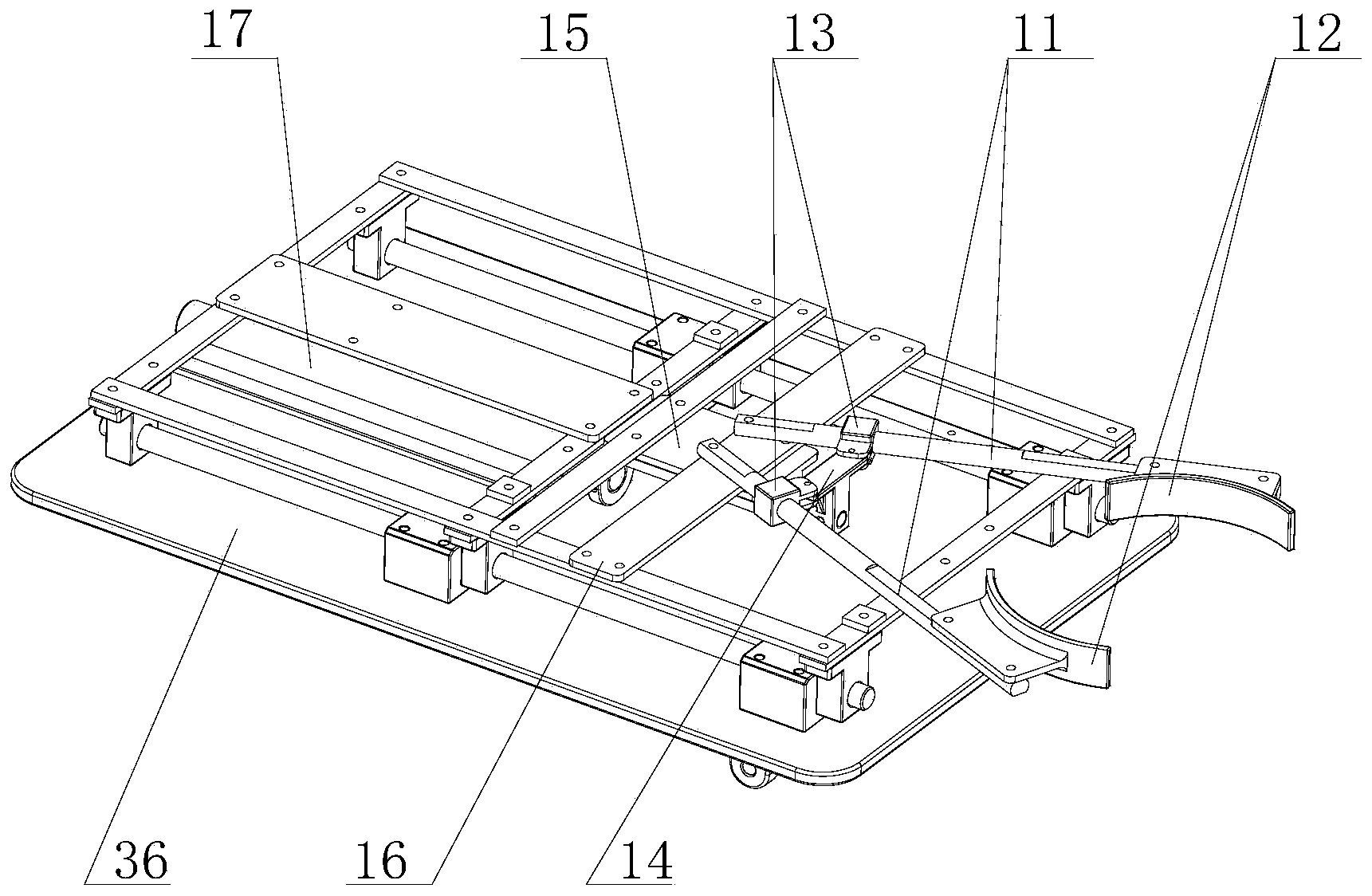

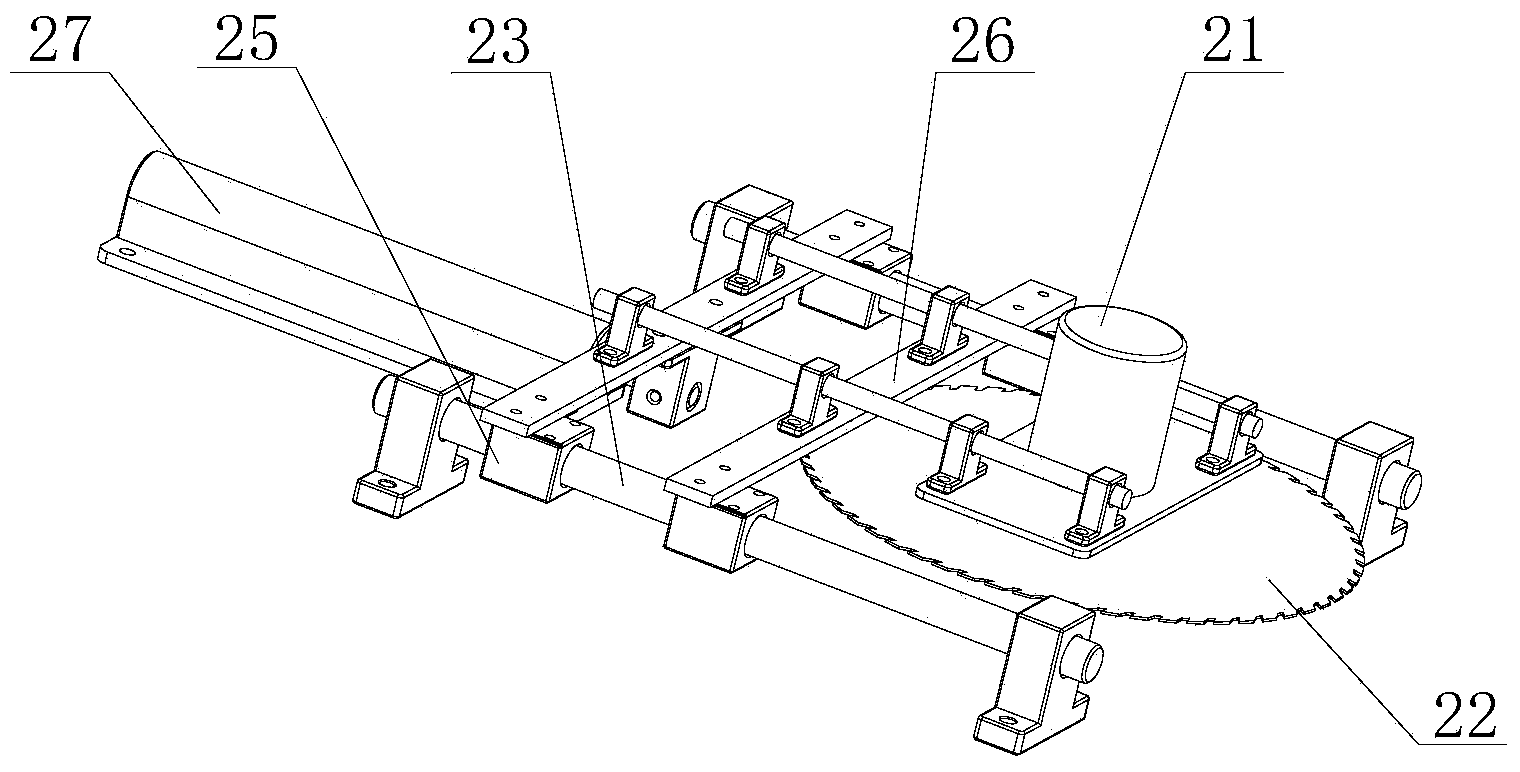

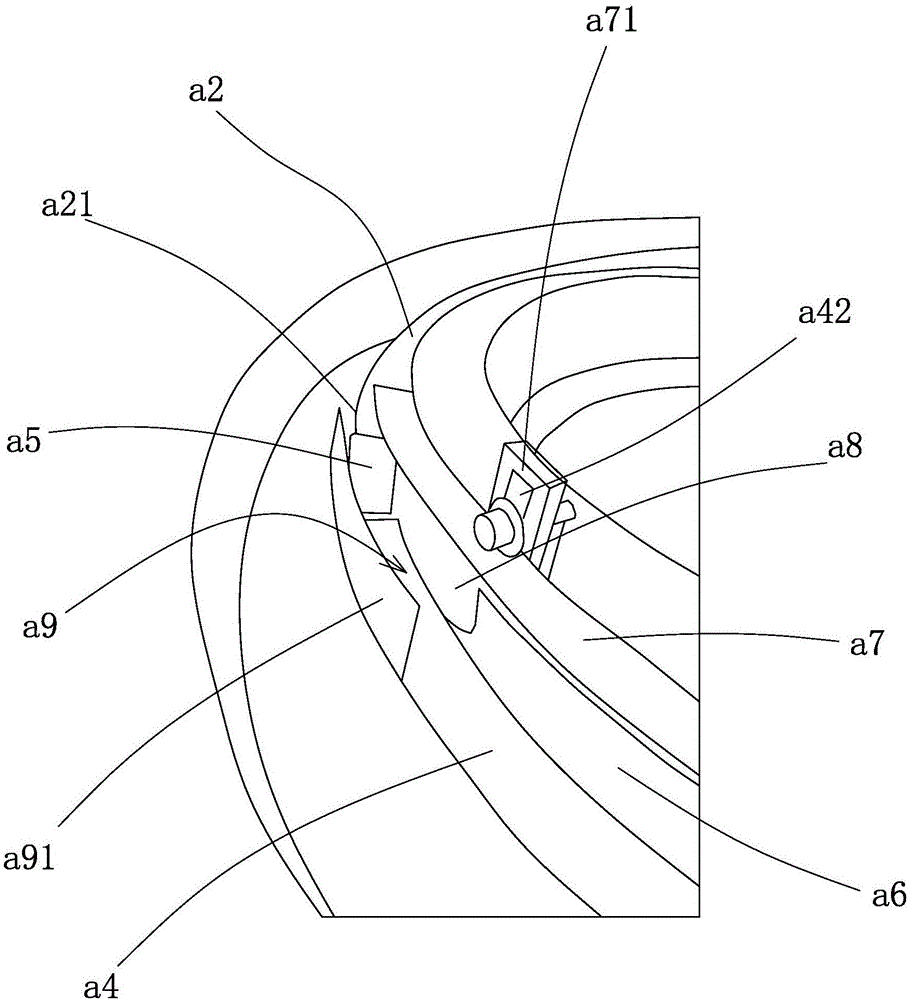

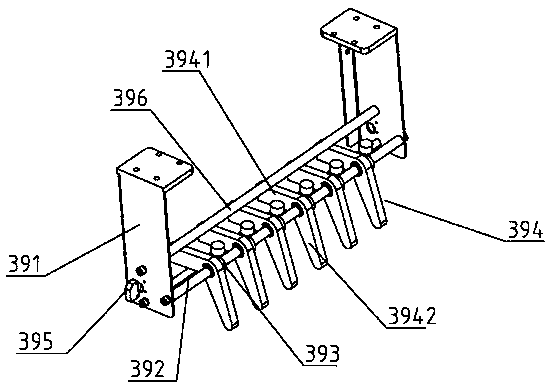

Banana picking device and picking method

The invention discloses a banana picking device, which comprises a rack, a cutter, clamping manipulator sliding blocks and a clamping manipulator opening and closing driving mechanism. A clamping manipulator comprises clamping rods. One ends of the clamping rods are hinged on the rack. The sliding blocks are slideably connected onto the clamping rods. The clamping manipulator opening and closing mechanism drives the clamping manipulator to open or close. The clamping manipulator opening and closing driving mechanism is hinged with the sliding blocks. The invention additionally discloses a banana picking method, which comprises the steps of propelling a walking trolley to a position under a banana tree; horizontally supporting the walking trolley through hydraulic supporting legs; lifting a scissor-type lifting mechanism to a position beside a banana fruit string; stretching the clamping manipulator to clamp a fruit stem; cutting off the fruit stem by using the cutter; after the fruit stem is cut off, lowering the scissor-type lifting mechanism; and after the scissor-type lifting mechanism is lowered down, restoring the clamping manipulator, taking down bananas and restoring the hydraulic supporting legs to complete the picking. The banana picking device and the banana picking method have the advantages that the problem that the clamping manipulator is difficult to open is solved, the clamping force lasts long, the clamping stability and reliability are high, the clamping manipulator can be opened and closed smoothly and sensitively, and the working efficiency is improved.

Owner:SOUTH CHINA AGRI UNIV

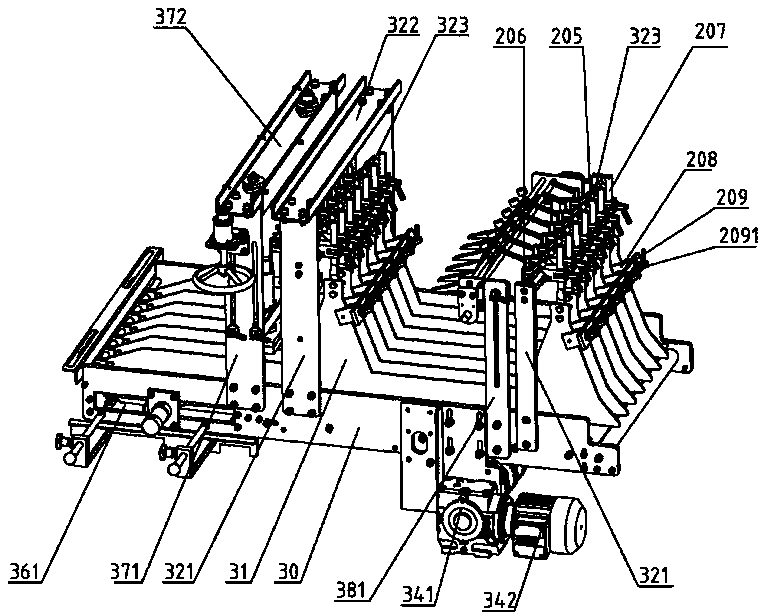

Cleaning machine for dirty marks on screens

The invention discloses a cleaning machine for dirty marks on screens, and in particular relates to a cleaning machine for cleaning silk screens. The cleaning machine for the dirty marks on the screens is provided with a to-be-cleaned screen storage part for storing screens to be cleaned, an automatic cleaning part for cleaning, a dirty mark collection device, a dirty mark filtration device, a screen movement device, a liquid storage part, a deflector, a cleaned screen storage part and an accessory cleaning part. According to the cleaning machine, before the silk screens containing the dirty marks are cleaned by using a cleaning fluid, the screens containing the dirty marks are subjected to dirty mark collection first and then are cleaned, so the disadvantage that the cleaning fluid is frequently replaced because the cleaning fluid directly flushes the screens containing the dirty marks and is quickly turbid is effectively overcome; and according to the cleaning machine, frames of thescreens are protected by using an anti-splash device so as to prevent the cleaning fluid from splashing onto the frames of the screens, so that the service life of the screens is prolonged, and the work of cleaning the screens containing the dirty marks is simpler and quicker, energy-saving and environment-friendly.

Owner:李世武

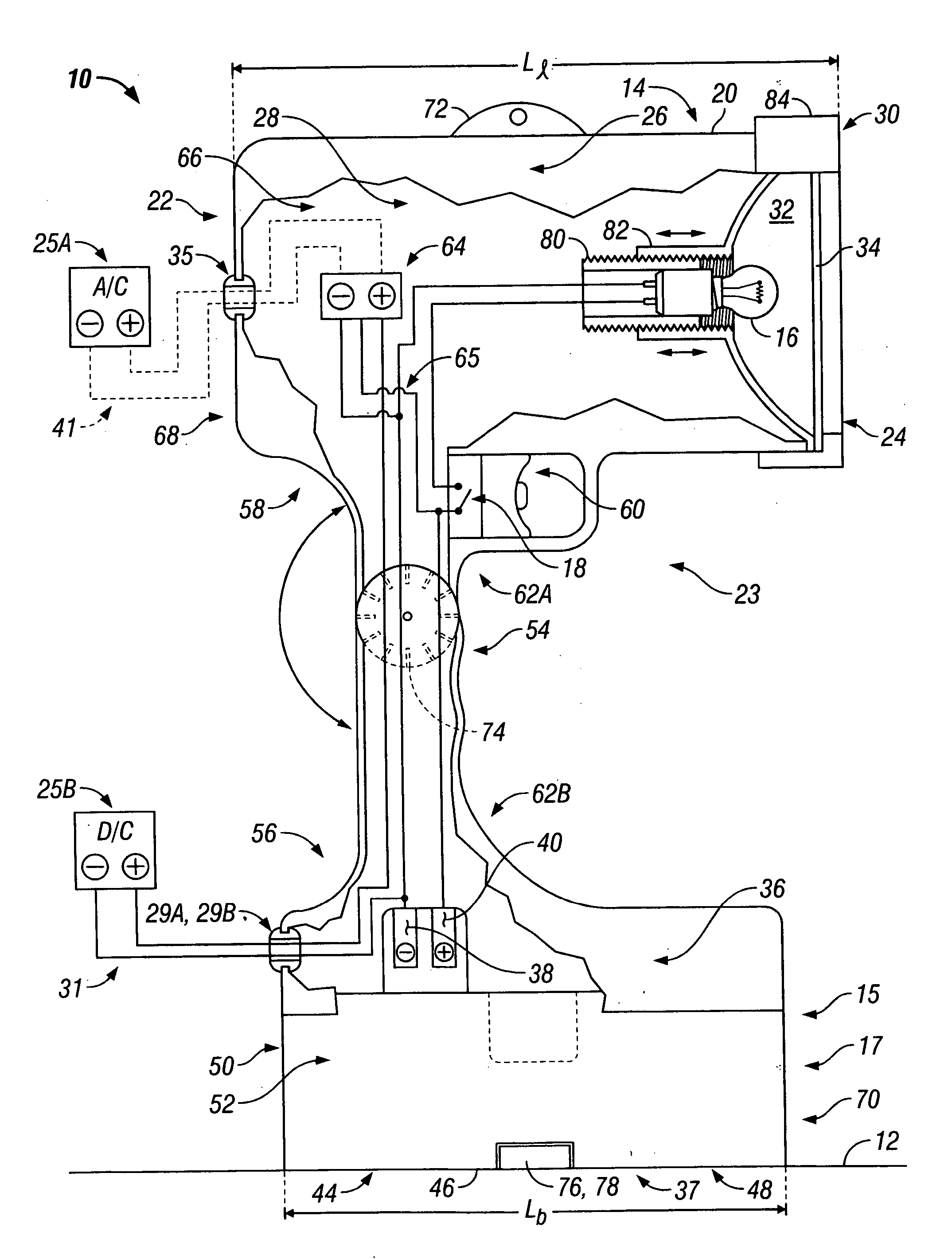

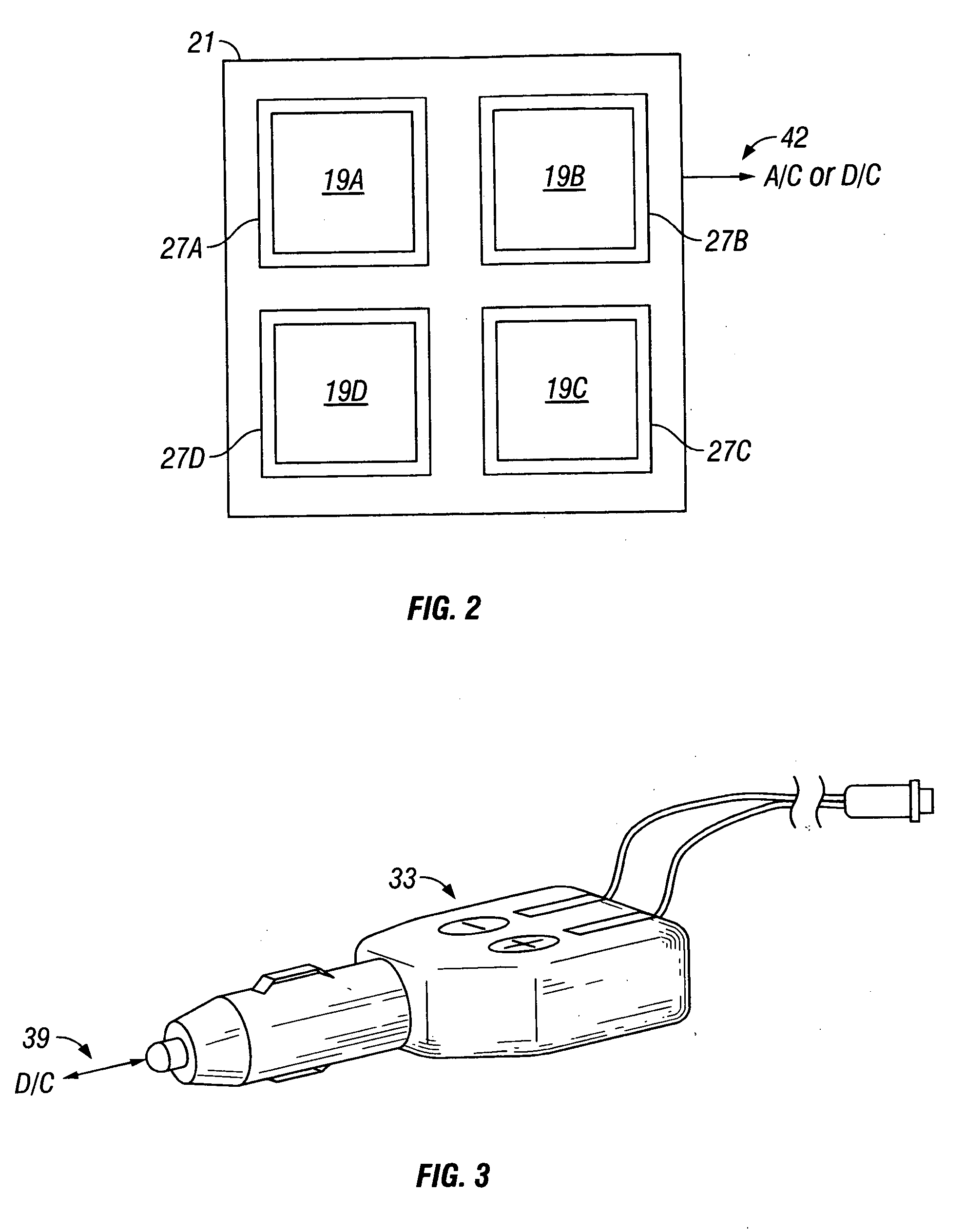

Spotlight system and method

InactiveUS20060072306A1Easy to replaceReadily replaceable critical componentsLighting elementsWith electric batteriesElectrical batteryHand held

A spotlight system is adaptable for use with preferably one or more power sources so as to provide lighting where needed. The spotlight system preferably includes a spotlight assembly comprising a lamp housing which includes at least one bulb, a switch, and an enclosure. The spotlight system may be operated utilizing DC power with or without a rechargeable battery. The rechargeable battery may be recharged utilizing DC power or AC power while still connected to the lamp housing. When the lamp housing is operated without a battery, then the lamp housing is extremely light for hand held operation with a preferably high power beam.

Owner:WOODYARD JOE E

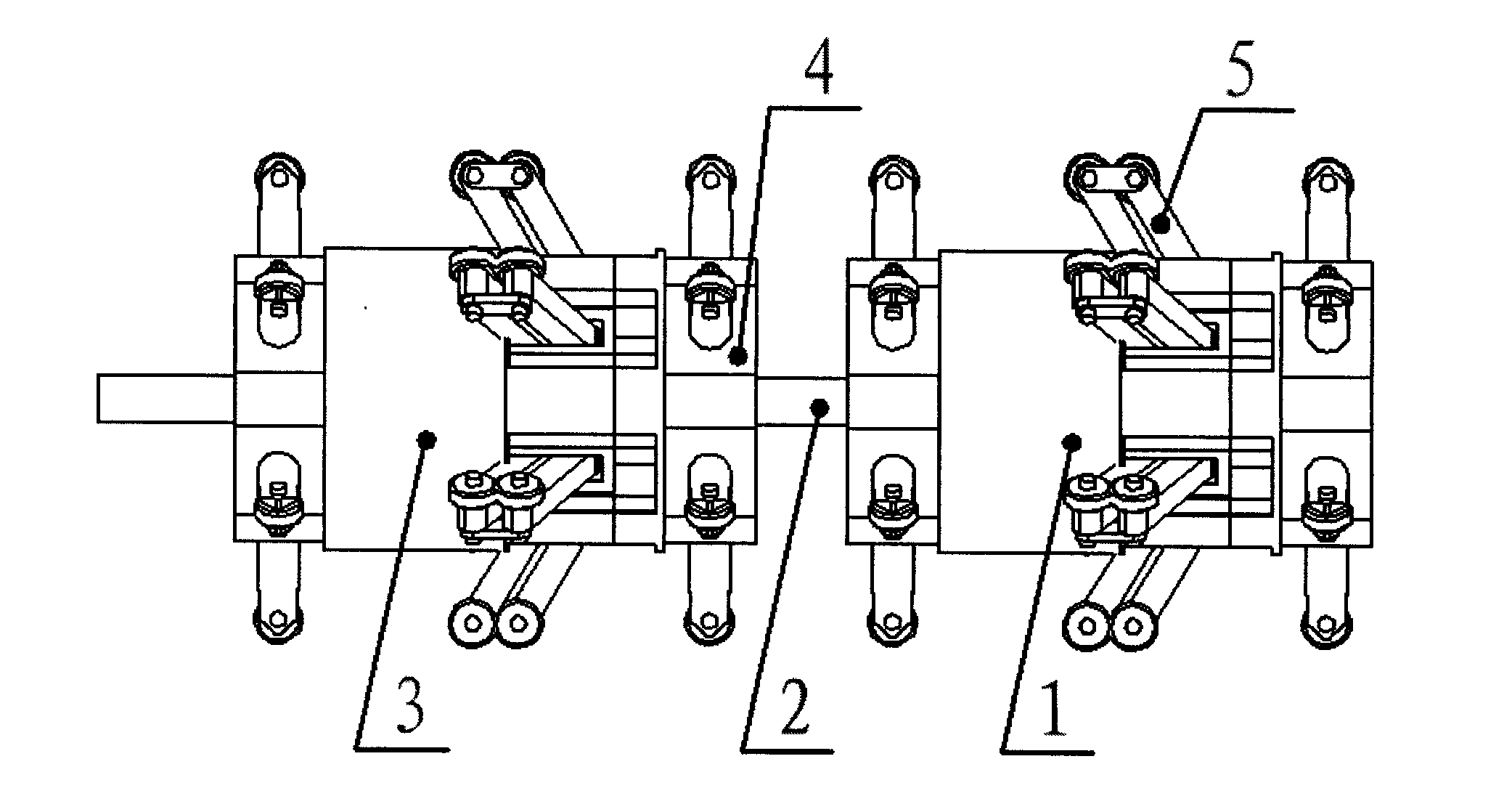

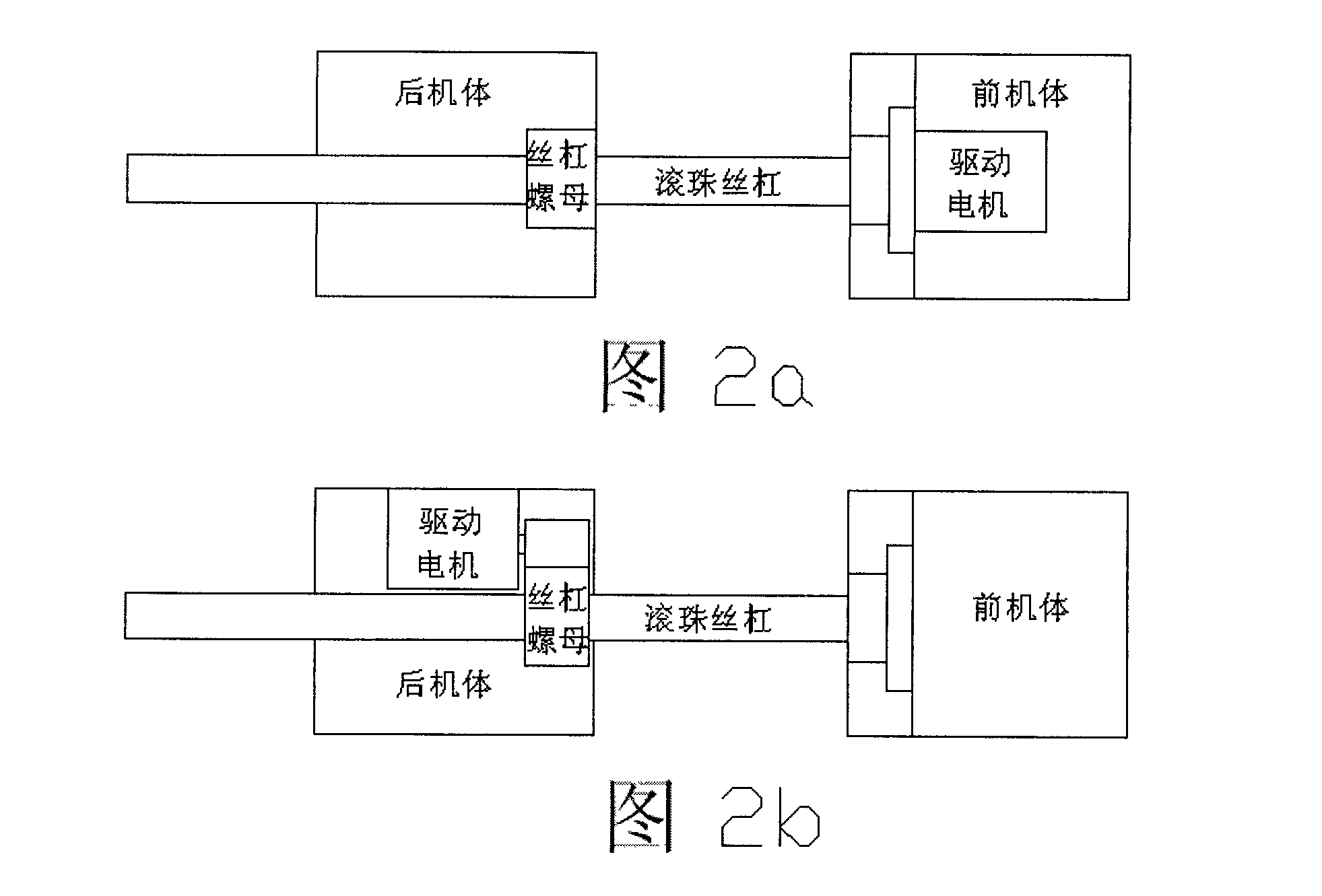

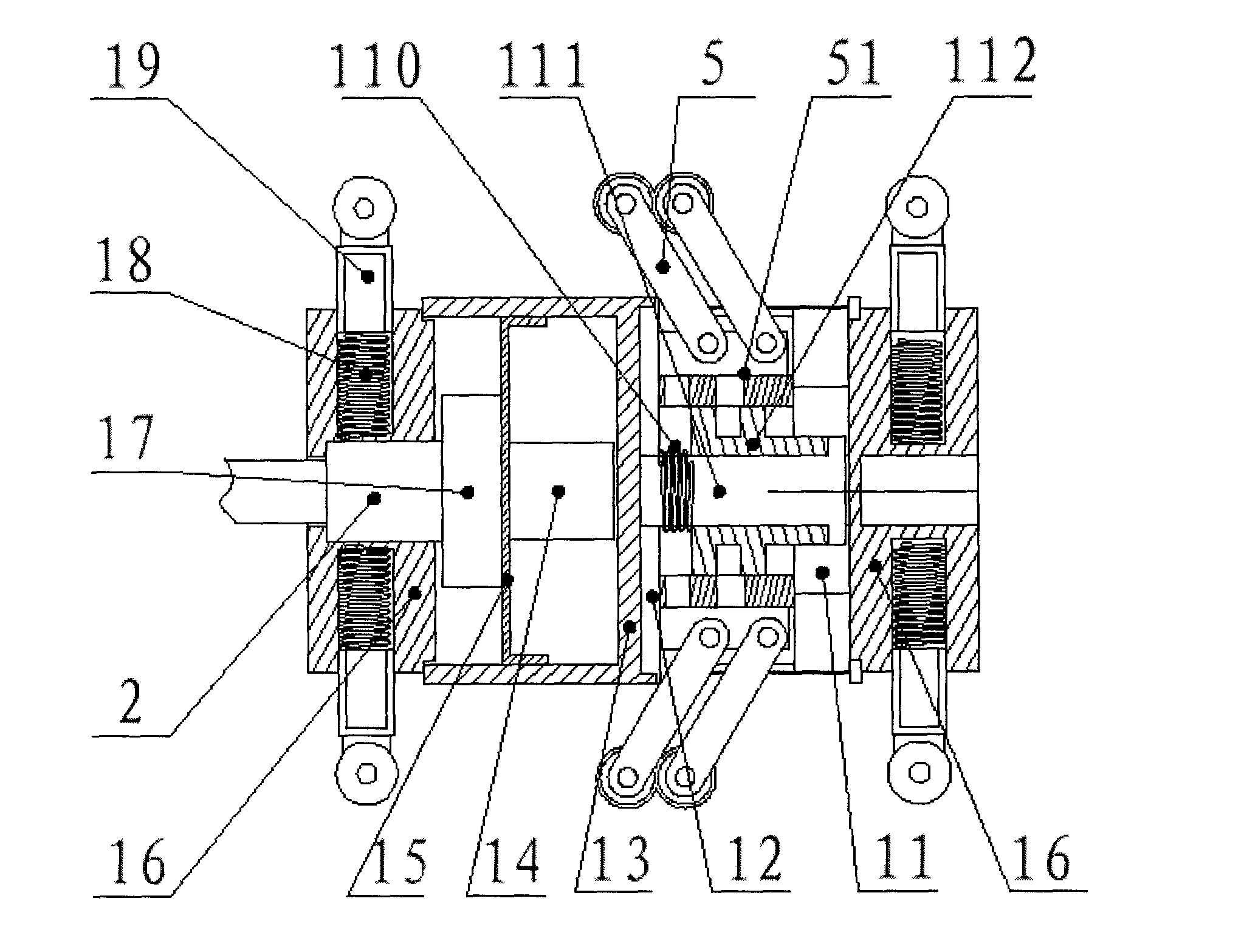

Novel crawling pipeline robot

ActiveCN102661470ACompact structureImprove transmission efficiencyPipe elementsBall screwMechanical engineering

The invention provides a novel crawling pipeline robot. According to the technical field, the invention relates to the research field of a pipeline robot, in particular relates to a novel crawling pipeline robot, which is provided with single-direction travelling mechanisms and can go backwards. The invention discloses a novel crawling pipeline robot, which is provided with the single-direction travelling mechanisms and a ball screw, and has a back function in a pipeline. The novel crawling pipeline robot comprises a front machine body, the ball screw, a rear machine body, a supporting wheel structure and the single-direction travelling mechanisms; the ball screw is fixed with the front machine body, passes through the rear machine body, and forms a driving device for crawling travel with a screw nut mounted on the rear machine body. Supporting wheel mechanisms are respectively mounted at the both ends of the front machine body and the rear machine body of the robot; and each supporting wheel mechanism is provided with a plurality of supporting wheel legs which are uniformly distributed in the circumference direction, so that the robot is prevented from falling down in the pipeline. Meanwhile, a plurality of the single-direction travelling mechanisms are respectively mounted on the front machine body and the rear machine body, so that the robot walks forwards, and the single-direction travelling mechanisms can be non-efficient by manually pulling a wire, so that the robot goes backwards in the pipeline. The robot provided by the invention has high driving efficiency, can smoothly pass through the linear pipelines, and has the certain tapered pipeline adaptability and strong drawing capability. Meanwhile, the robot further can go backwards in the pipeline.

Owner:BEIJING UNIV OF POSTS & TELECOMM

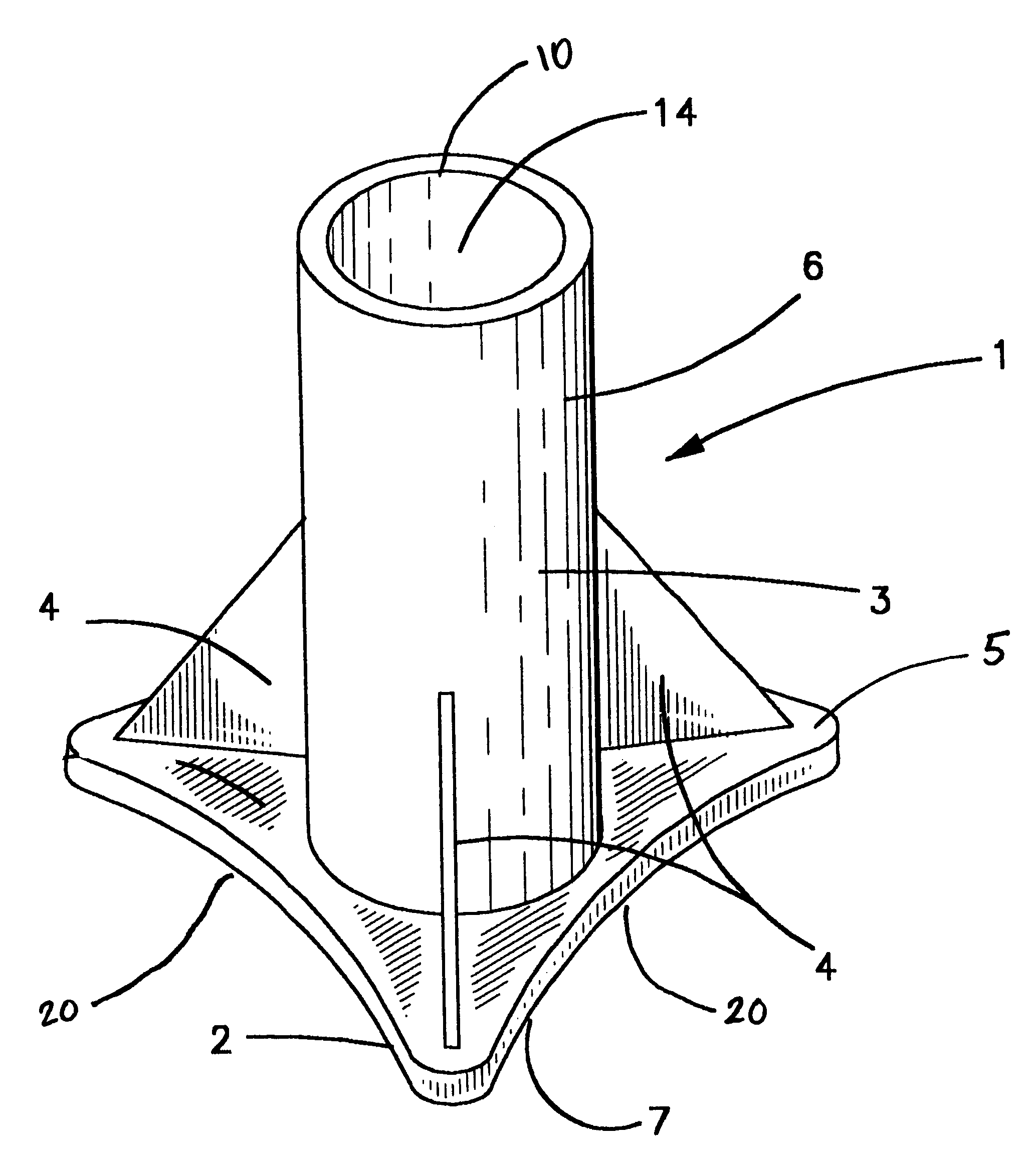

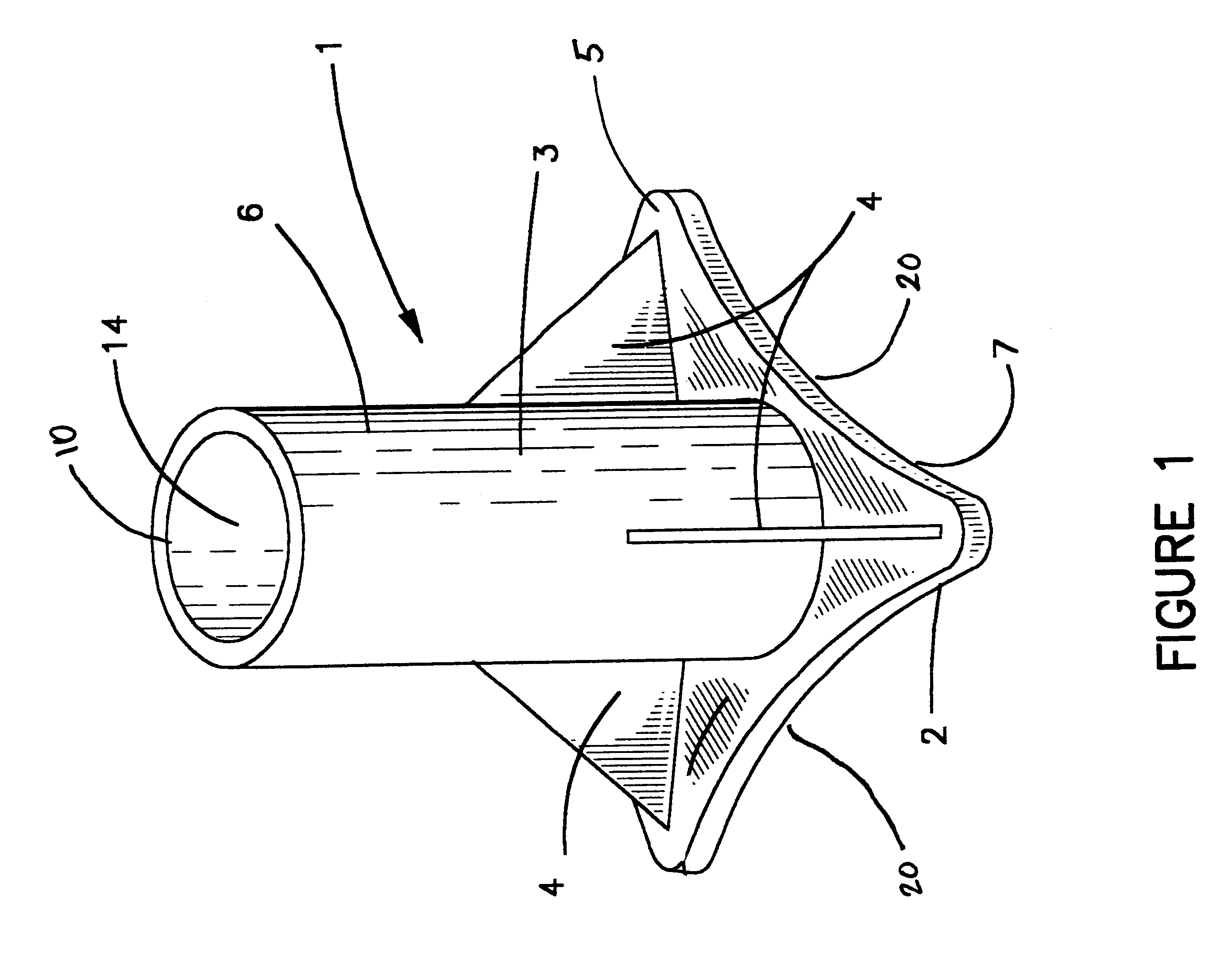

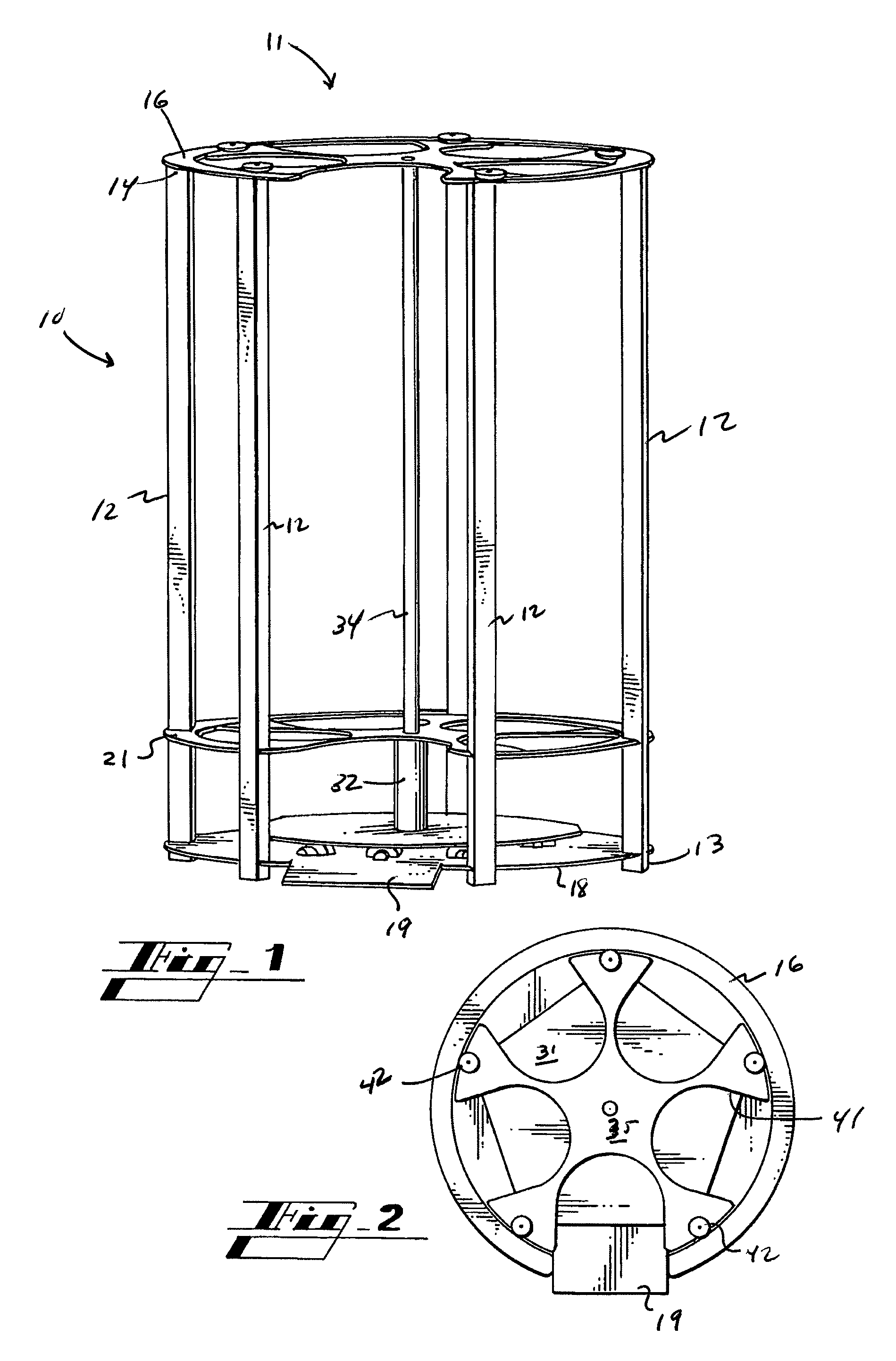

Apparatus for cooking meats

InactiveUS6349632B1Efficient and even cookingImprove insulation effectCooking vesselsRoasting apparatusEngineering

An apparatus and method for cooking meats, such as chicken are disclosed. The apparatus comprises a base having an upstanding member positioned thereon. The upstanding member has a chamber to receive food seasoning. The chamber is adapted to form a seal with the cavity of the chicken to promote seasoning of the meat from within during cooking and to allow the seasoning vapors to enter the meat, thereby promoting a moister cooked product.

Owner:BECK JR JOHN P

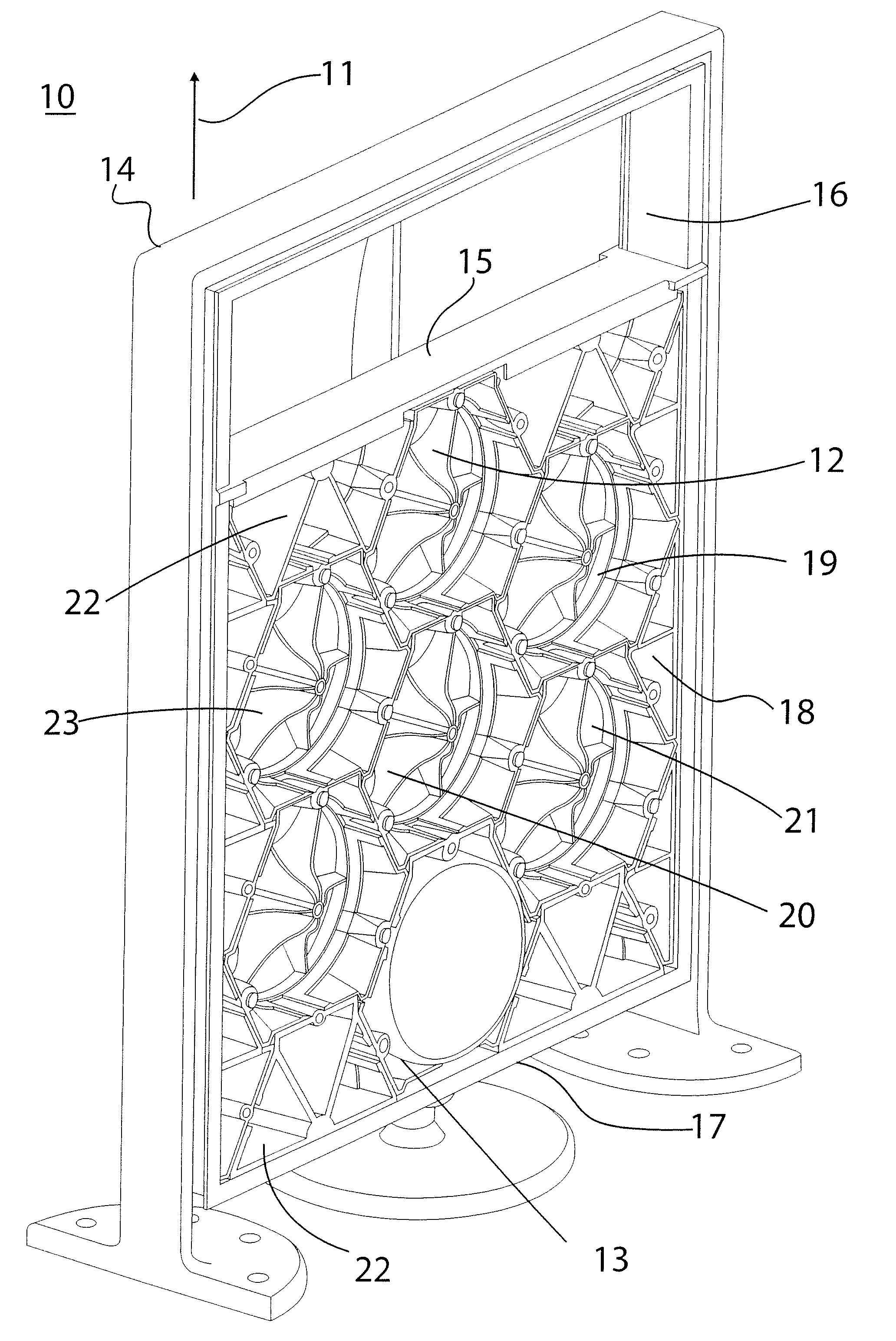

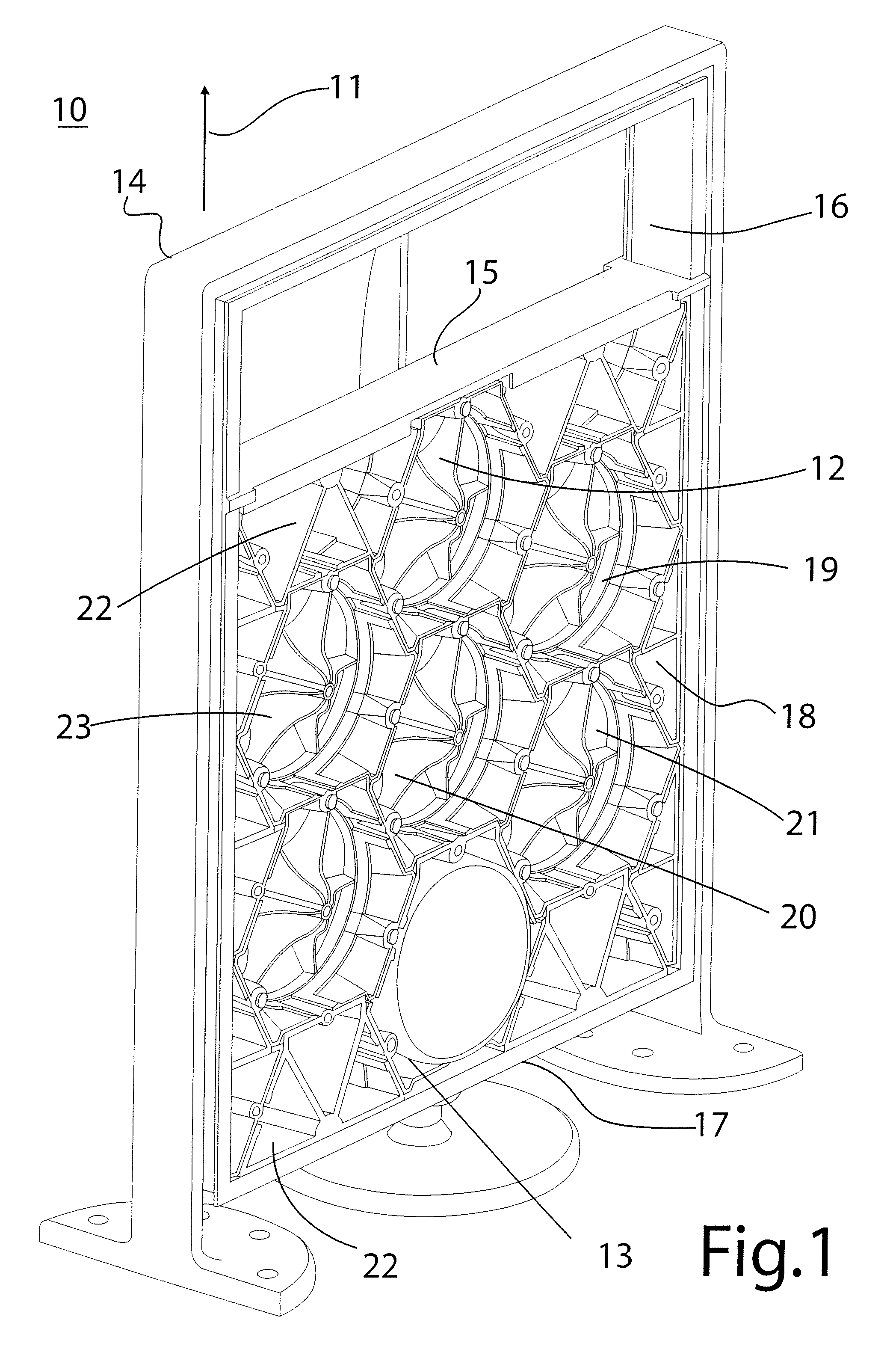

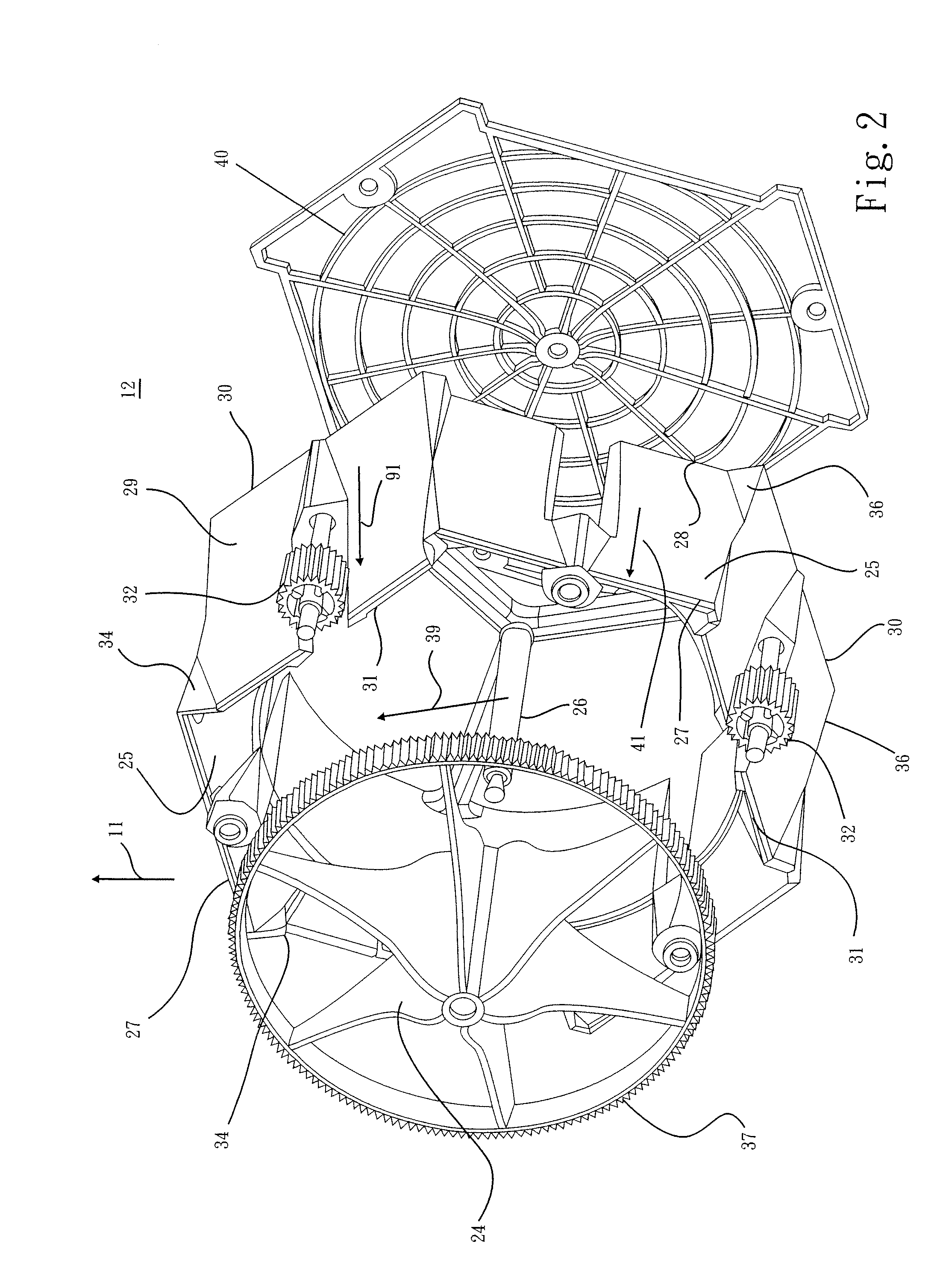

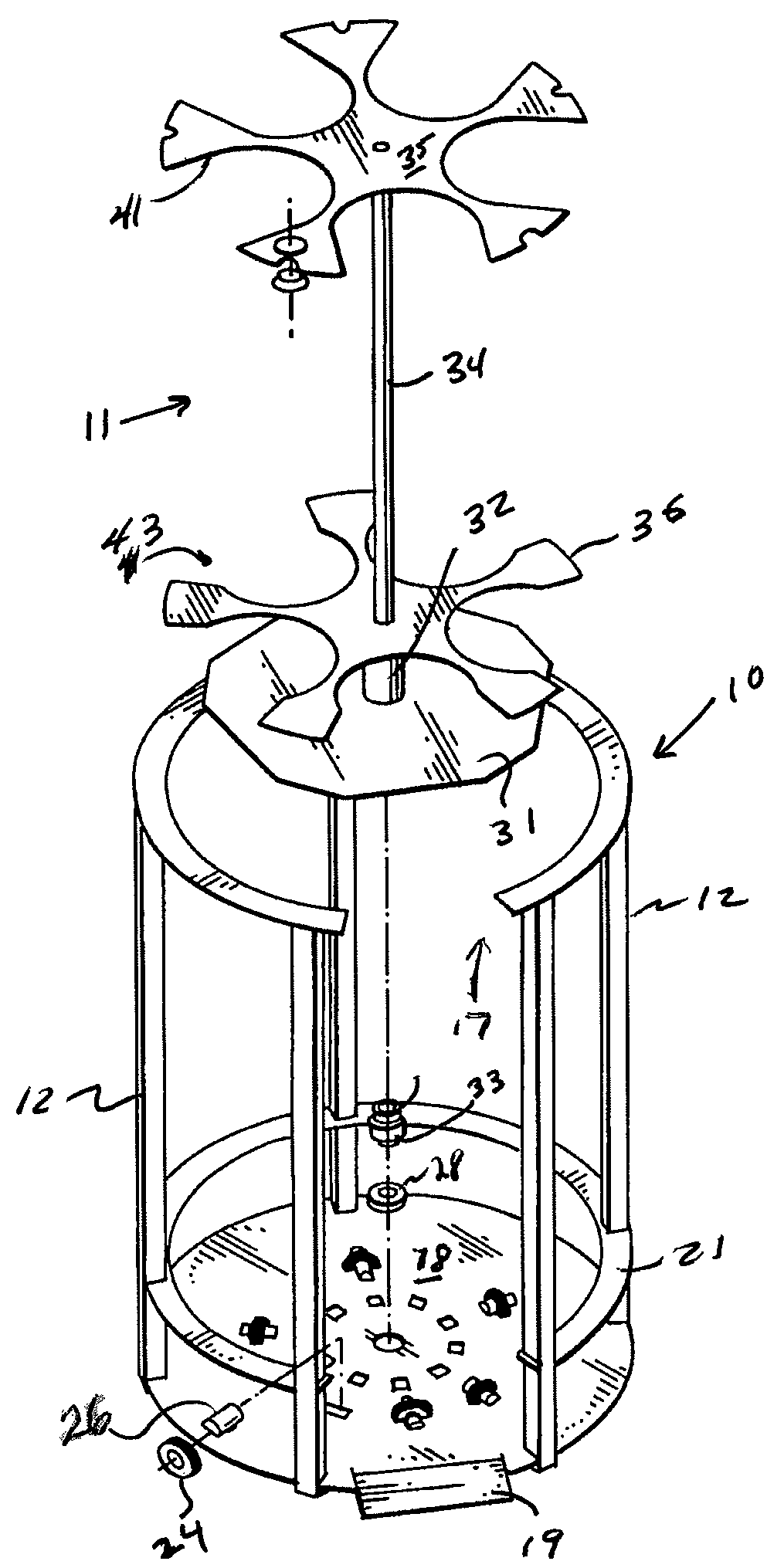

Wind power system

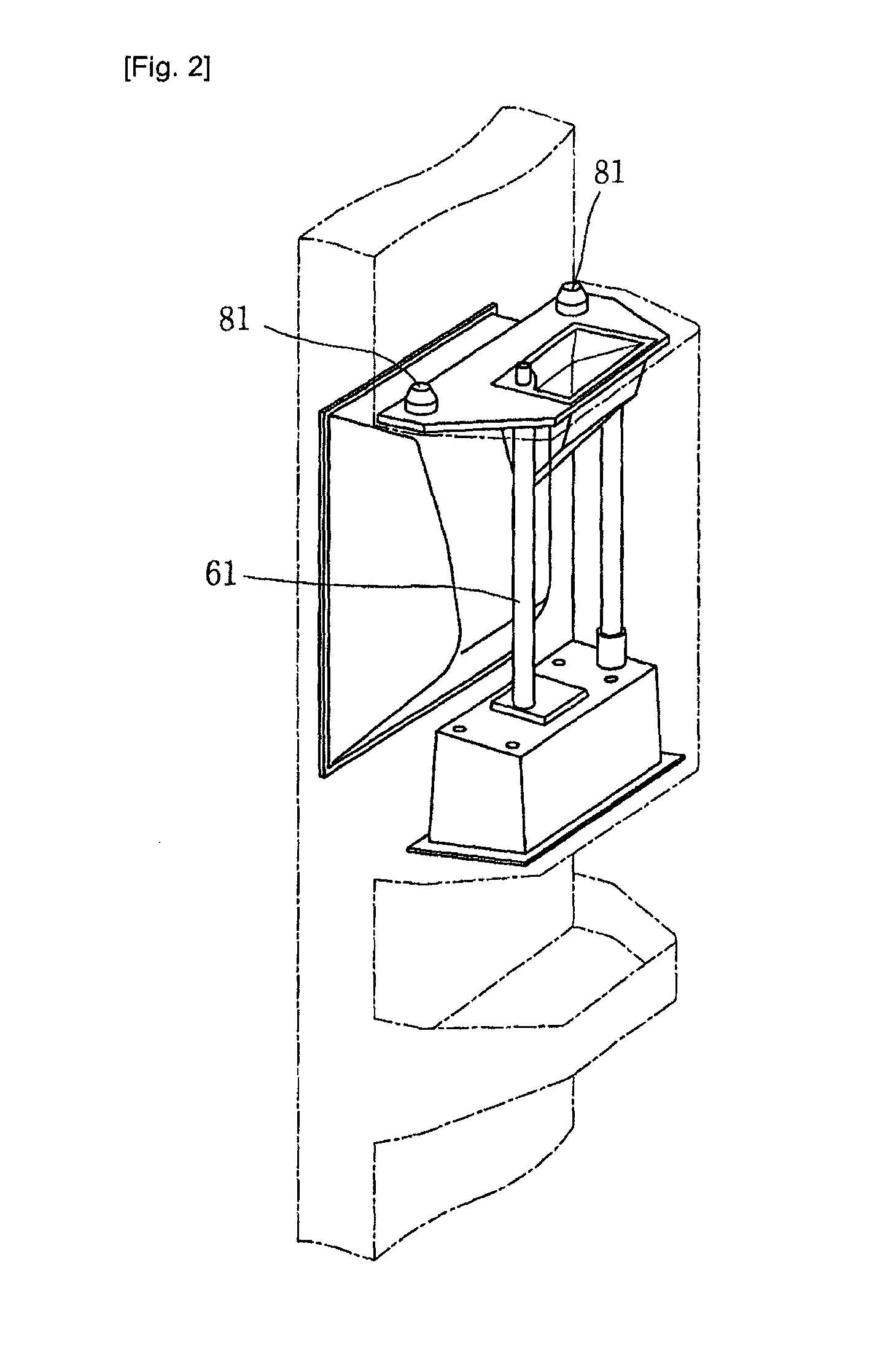

InactiveUS7528498B2Prevent dumpingPrevent movementWind motor controlWind motor assemblyElectricityComputer module

The provided wind power system includes a frame, at least a power module installed in the frame and a motor, wherein the number of the at least a power module is increasable, and the respective power module is extractable from the frame through an extraction direction. The respective power module has a fan, a plurality of first wedging surfaces and a plurality of second wedging surfaces, wherein the first and second wedging surfaces respectively manage to cooperate with a second wedging surface of a first additional power module and a first wedging area of a second additional power module, and the motor is connected to the respective power module, thereby the fan of the respective power module being driven by a wind to cause the motor to generate the electricity.

Owner:OA FURNITURE

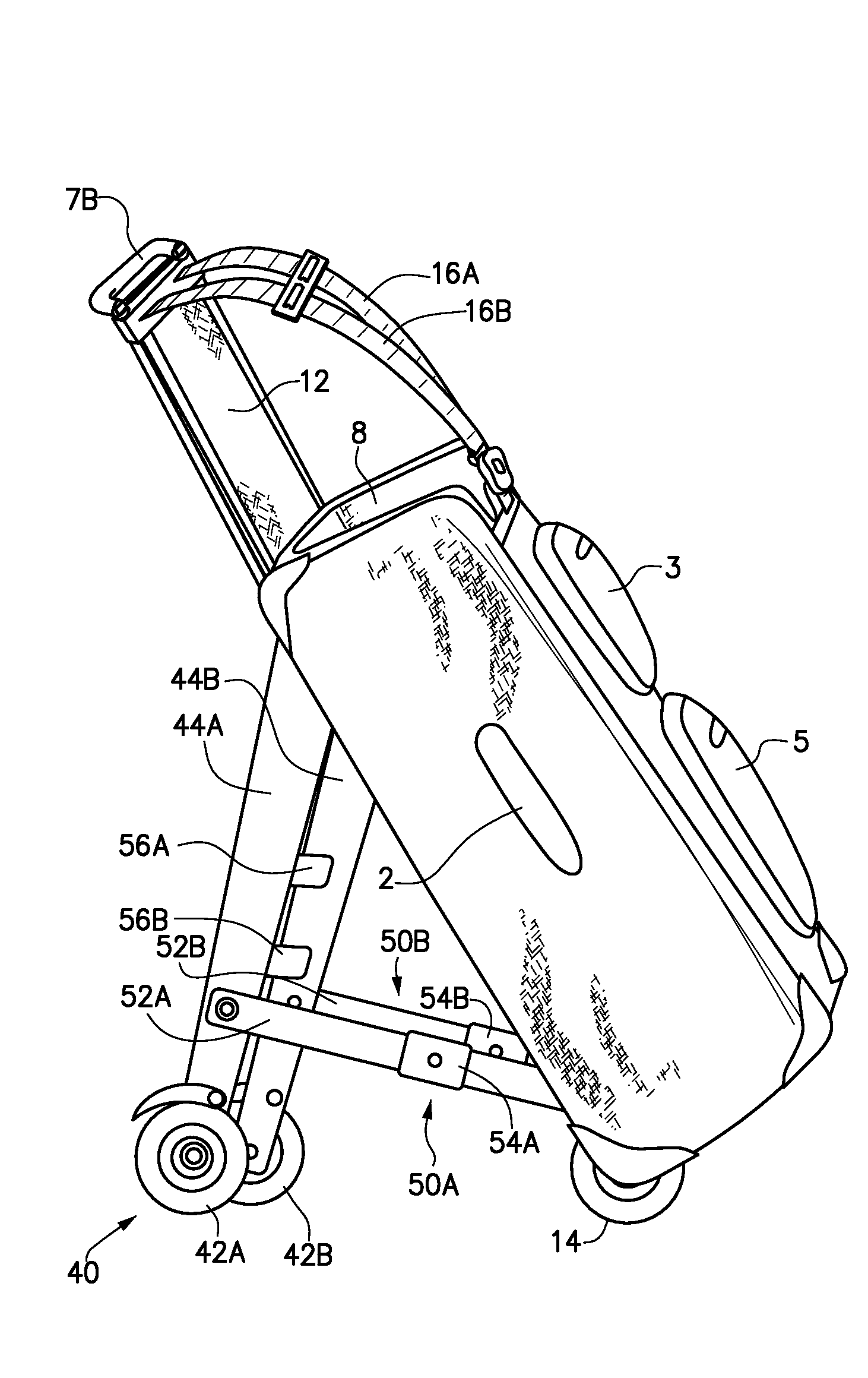

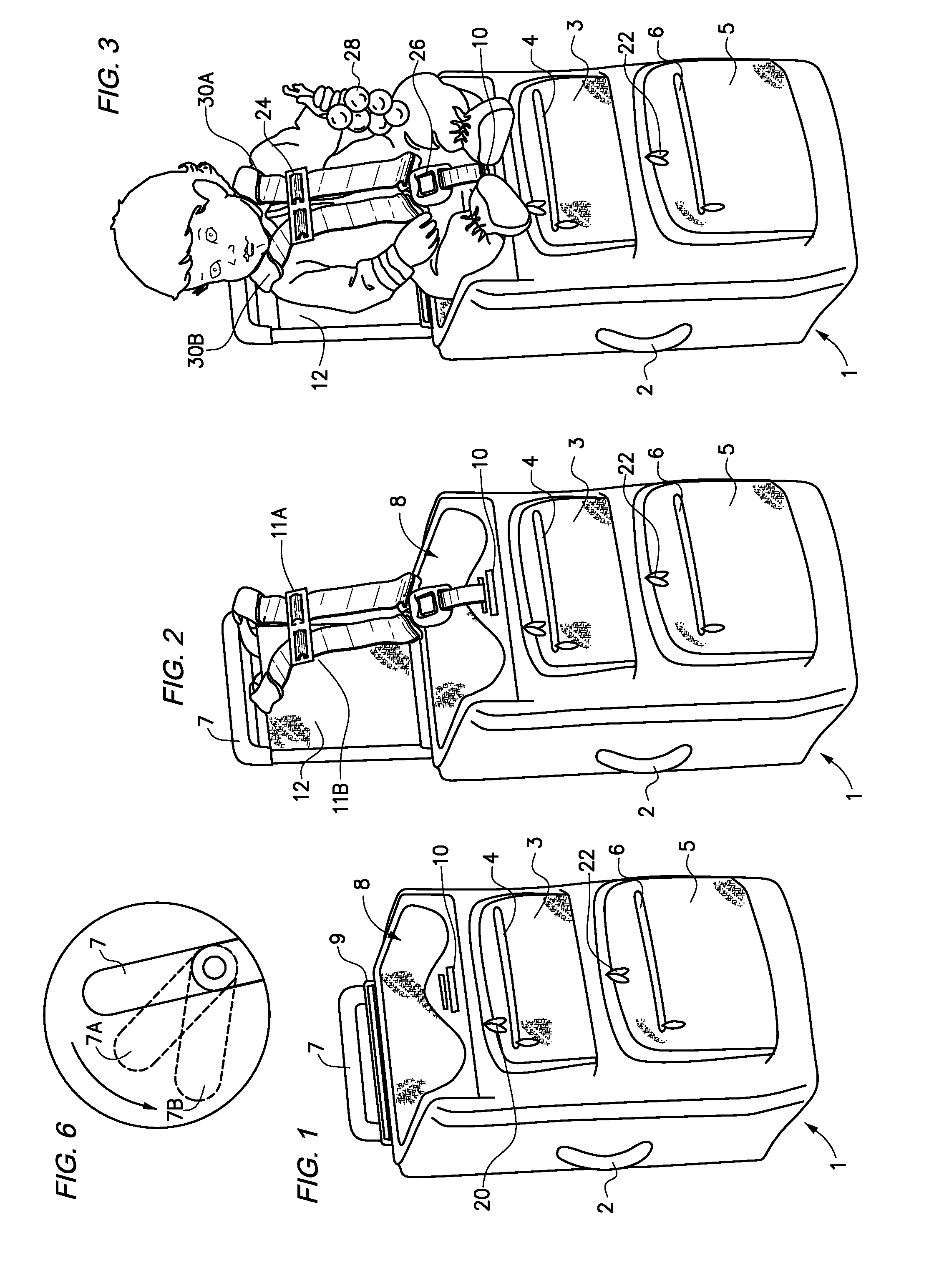

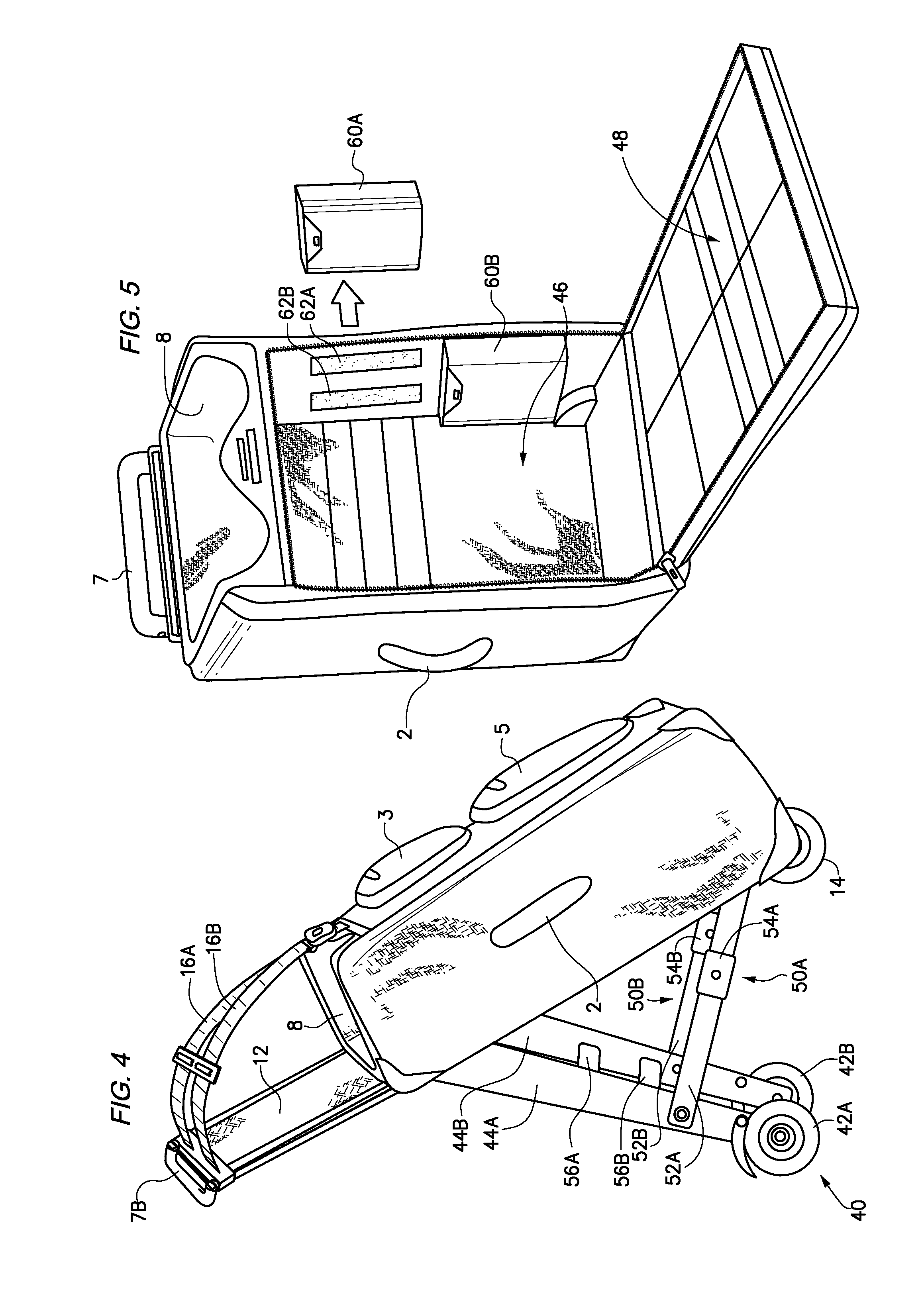

Baby Carry On

InactiveUS20120161408A1Improve stabilityPrevent over-boostingCarriage/perambulator accessoriesLuggageEngineeringTrunk compartment

Owner:SIDHU GURAVTAR

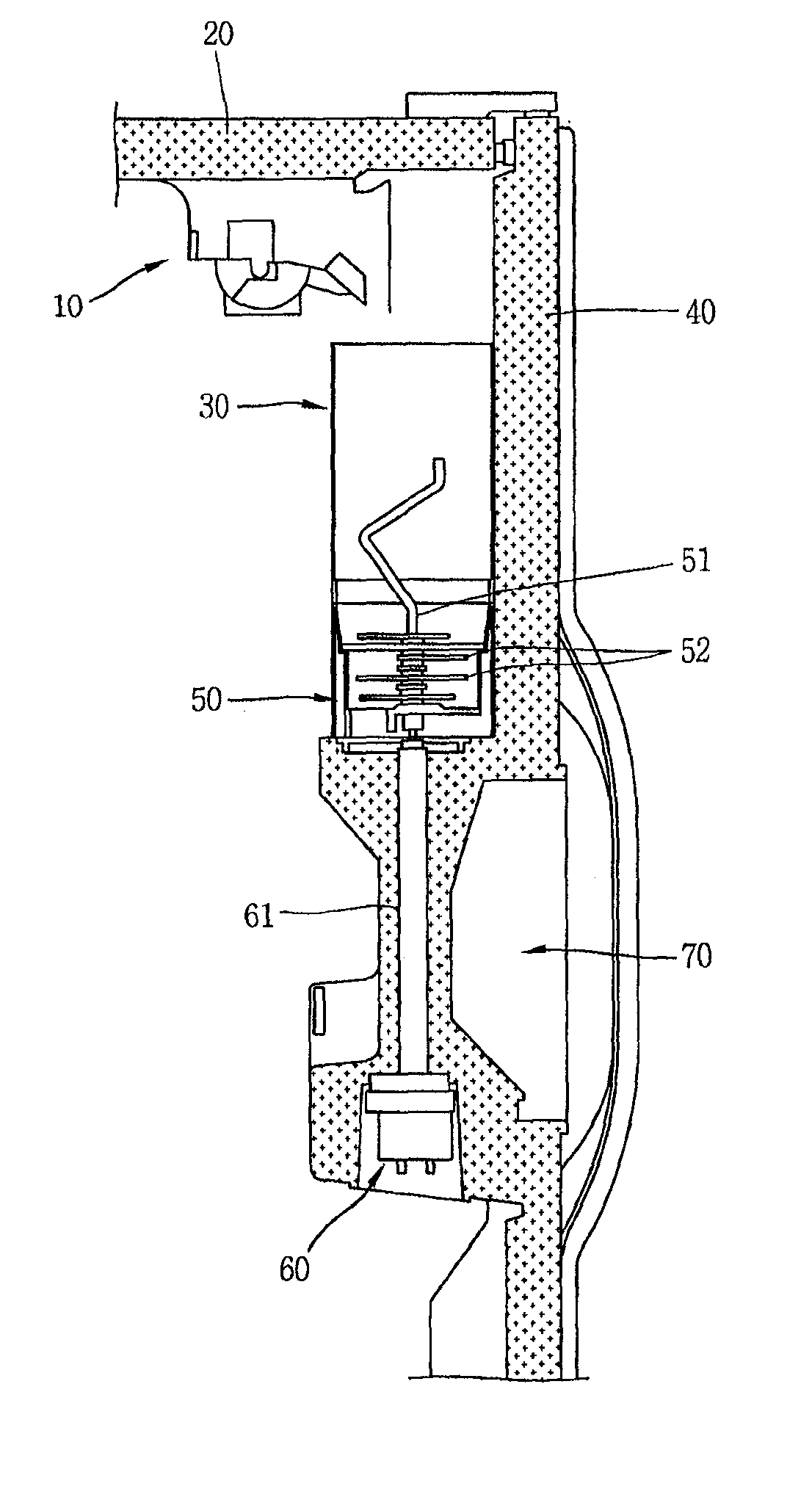

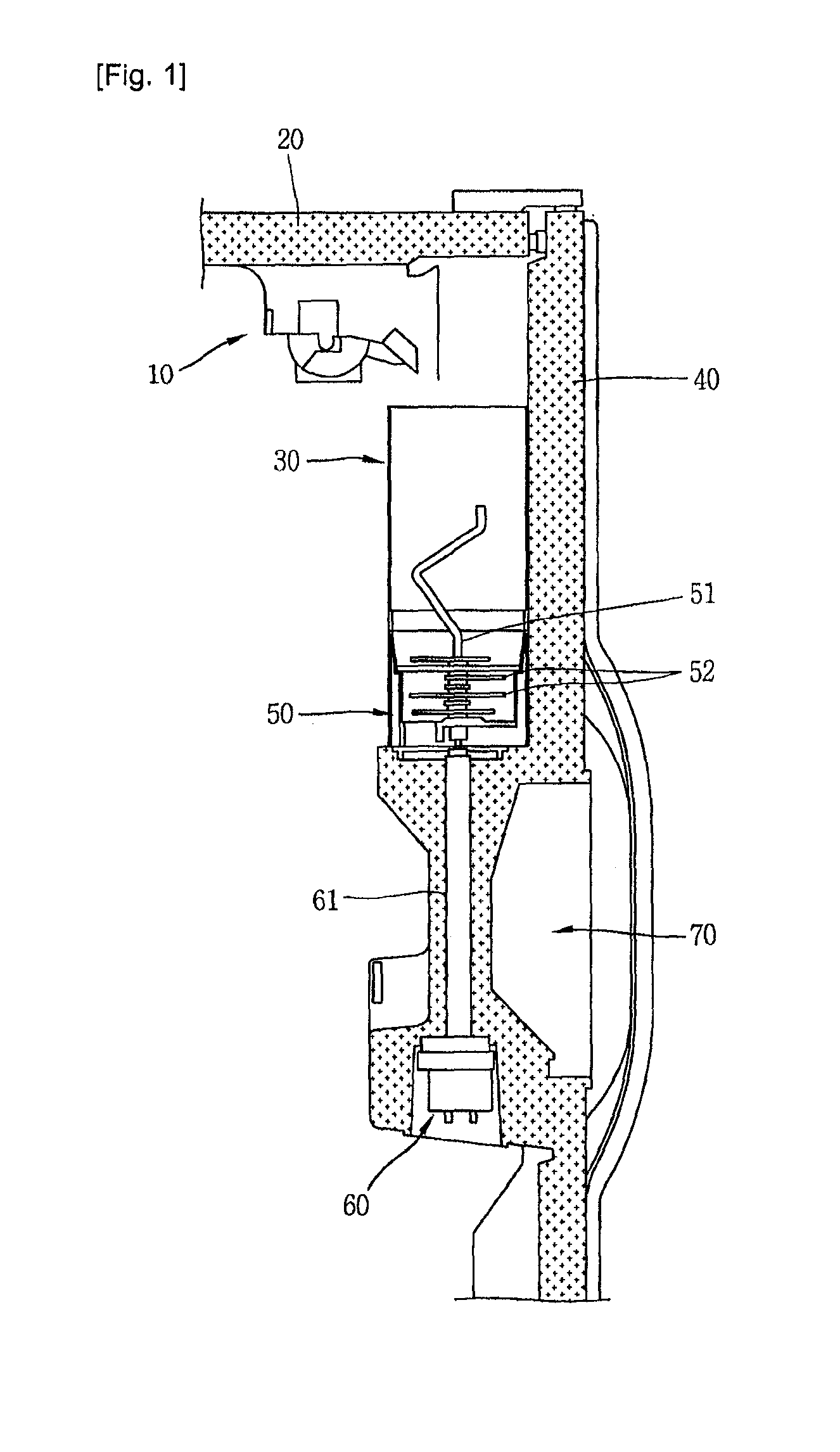

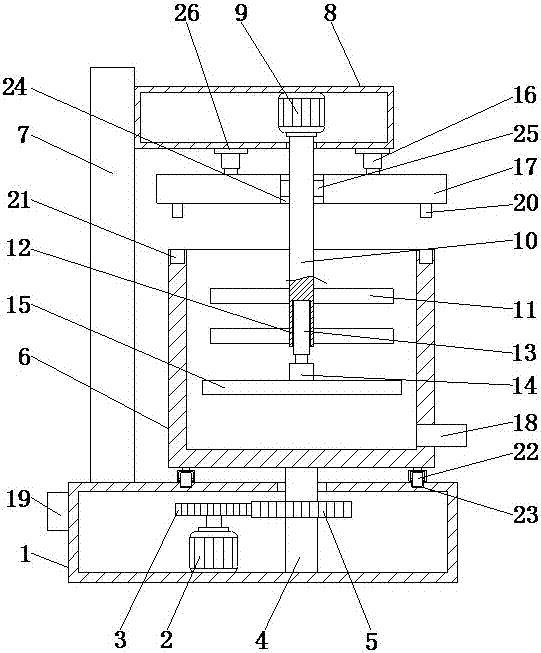

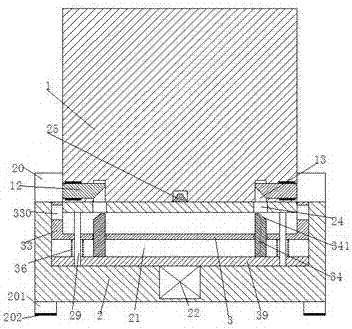

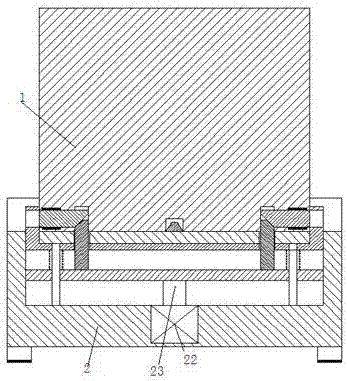

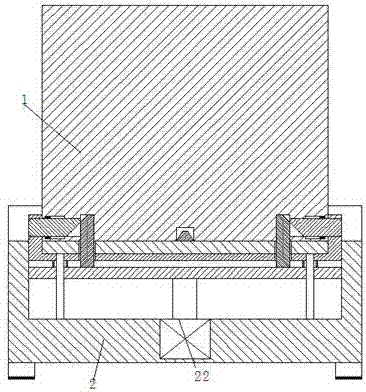

Ice making system

ActiveUS20100257887A1Enhance convenienceIncrease profitLighting and heating apparatusIce productionIcemakerMotor shaft

An ice making system for a refrigerator, comprises: a base member; an icemaker mounted to a front surface of the base member for making ice pieces; a driving unit mounted to a rear surface of the base member such that a motor shaft thereof is in a horizontal state; an ice bank horizontally inserted into the base member in a detachable manner, for storing the ice pieces made by the icemaker; a detachable mounting unit for detachably mounting the ice bank to the base member; and an ice crusher assembly provided at the ice bank so as to be connected to or separated from the driving unit, for crushing the ice pieces. Since the ice bank has only to be horizontally pushed into the base member for coupling, or horizontally pulled out of the base member for separation, processes for coupling or separating the ice bank to / from the base member are facilitated. This prevents the ice pieces stored in the ice bank from being discharged out of the ice bank.

Owner:LG ELECTRONICS INC

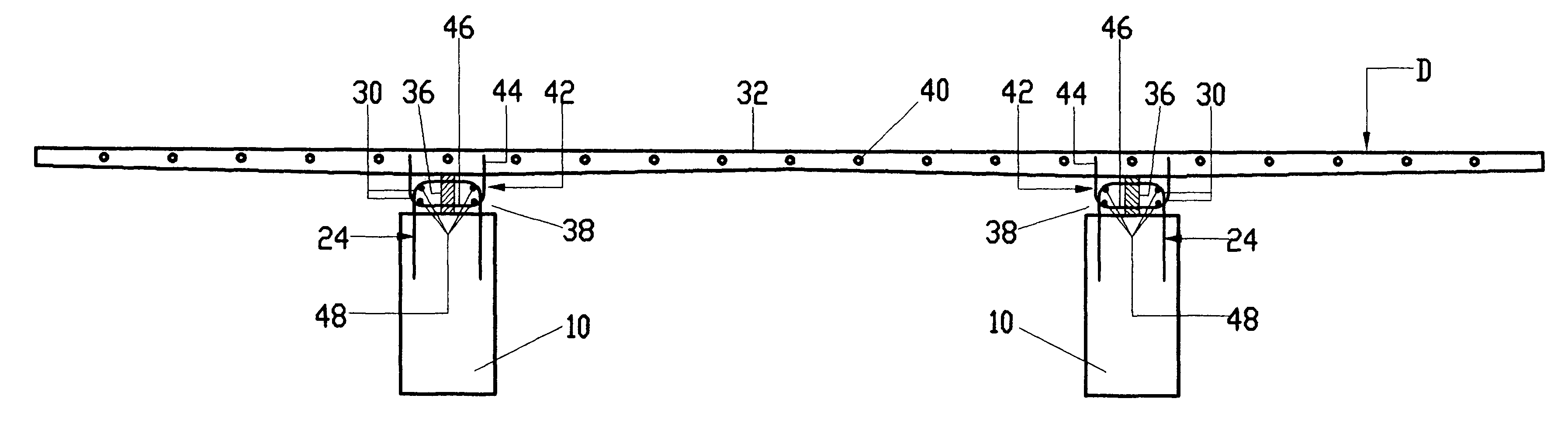

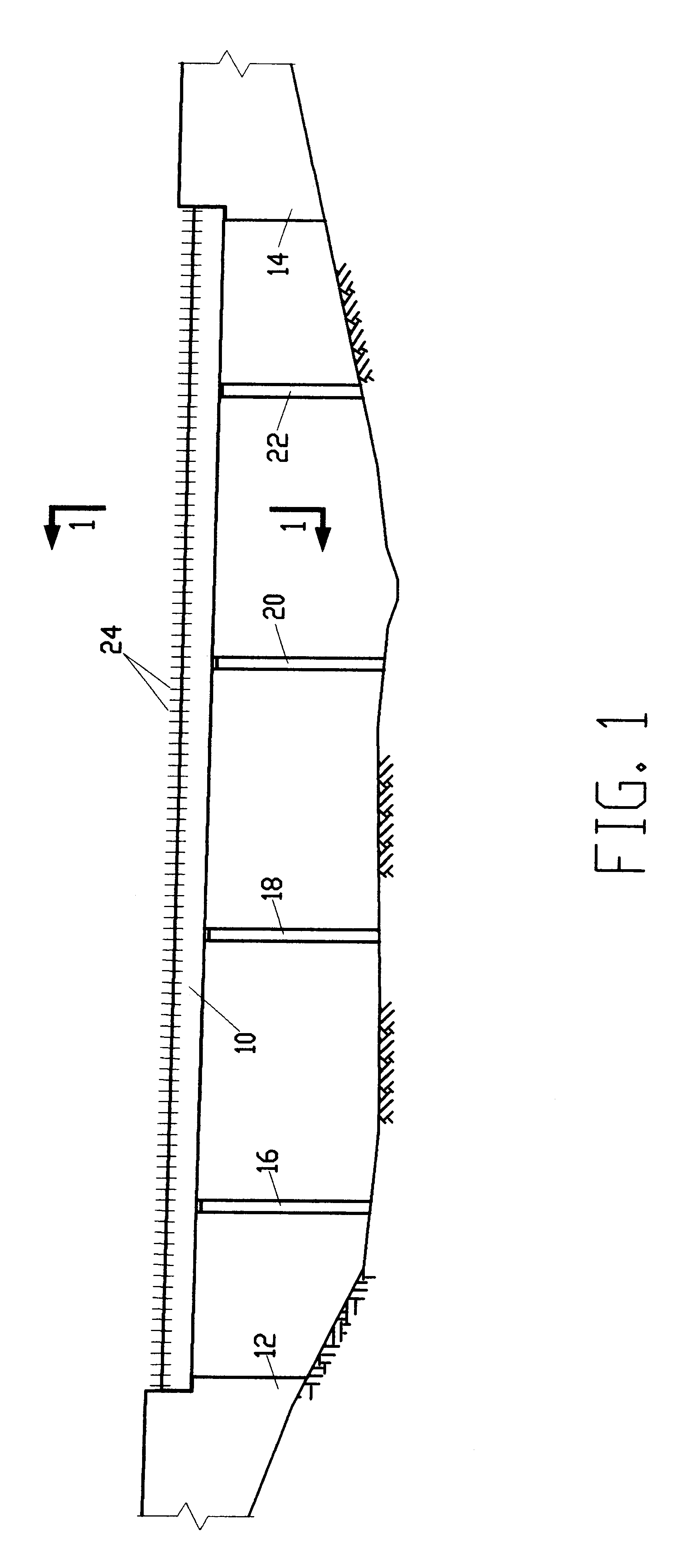

Composite bridge superstructure with precast deck elements

InactiveUS6470524B1Good ride qualitySaving maintenance costBridge structural detailsBridge erection/assemblyPre stressCrack free

A method for constructing a composite bridge superstructure of simple precast elements. According to the method, the bridge superstucture is comprised of one or more prestressed beams aligned substantially parallel to the bridge longitudinal axis. On top of the prestressed beams, there is placed a plurality of full width, precast deck slabs forming the bridge deck, with the precast deck slabs being transversely disposed side by side, with adjacent slabs attached by joints to complete the bridge deck structure. The deck slabs are spaced from the beams by spacing devices, such that a gap is left between the beams and the deck slabs and the bridge deck structure is prestressed separately from the beams. Subsequent to the prestressing of the deck structure and the beams, the bridge deck structure is connected to the beams by a concrete layer cast in situ in the gap between the bottom face of the precast deck slabs and the top face of the prestressed beams. The concrete is preferably of the low shrinkage type but normal shrinkage concrete may also be employed. The connection is further reinforced by a plurality of shear stirrups. The method is characterized by separate prestressing of the deck structure and the beams and by natural compression of the connecting concrete layer resulting in significant savings of construction time and costs. The construction sequence according to the method enables the deck structure as well as the cast in place concrete layer connecting the deck structure to the beams to undergo a natural compressing process due to time dependent creep and shrinkage contraction of the beams relative to the connecting layer and the deck structure, thereby eliminating the need to apply additional prestressing. In addition, the substantially separate longitudinal prestressing of the deck structure and the beams is highly effective, achieving considerable saving of prestressing steel. The natural compressing of the deck structure and the cast-in-place concrete layer result in crack-free condition and better riding quality of the deck, thereby eliminating the well known drawbacks of additional prestressing, and saving maintenance costs.

Owner:MAIRANTZ BENJAMIN

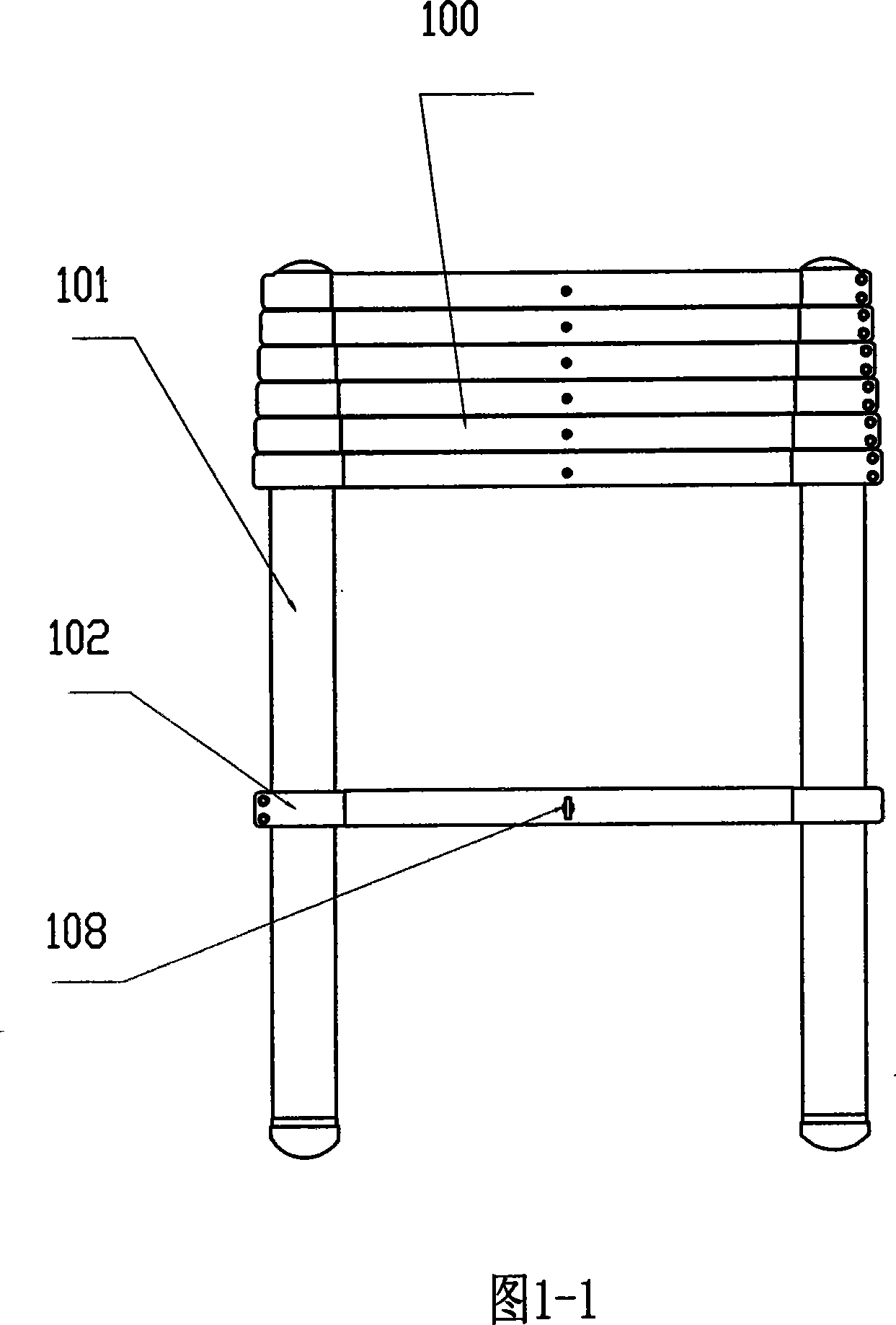

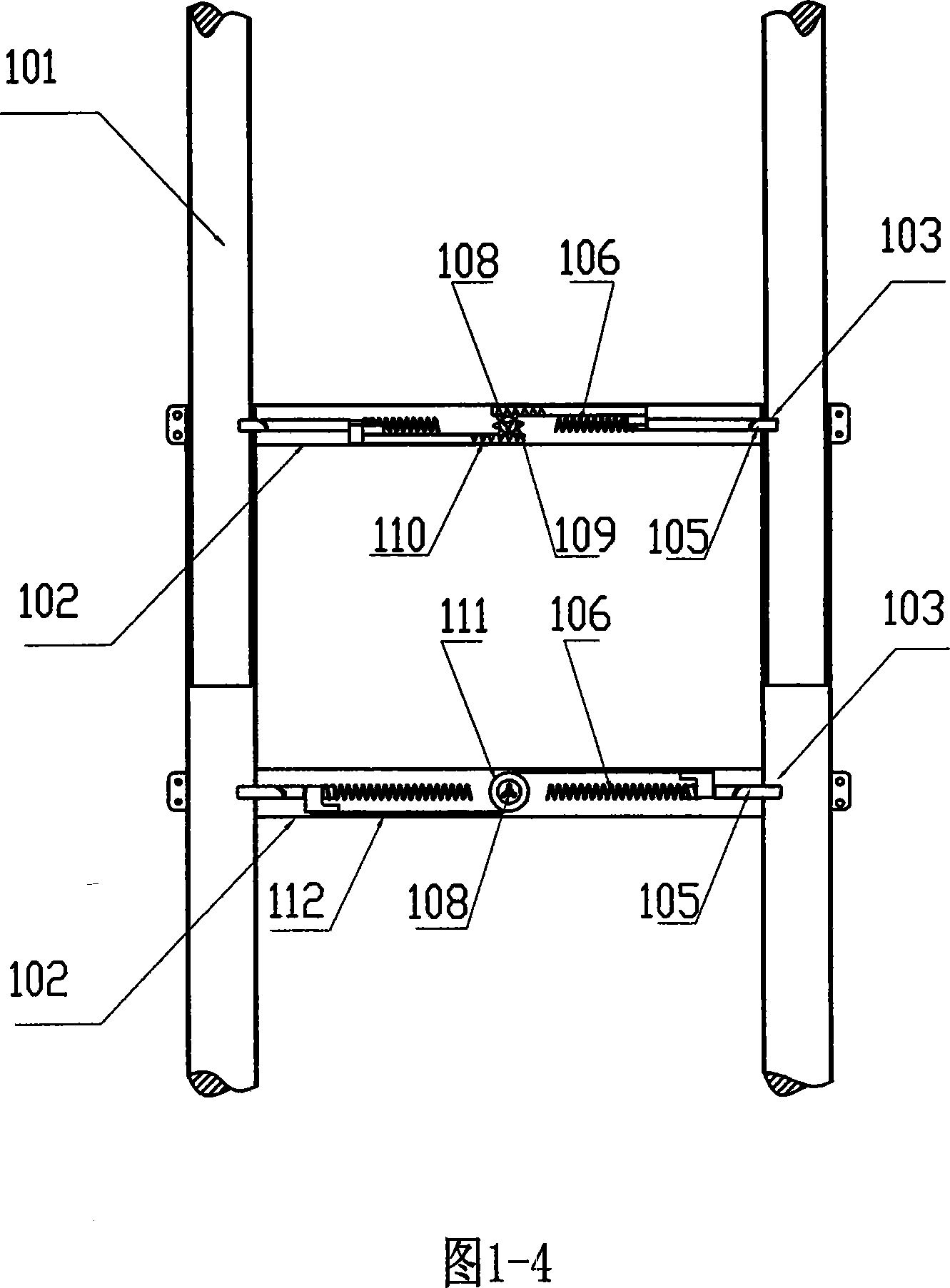

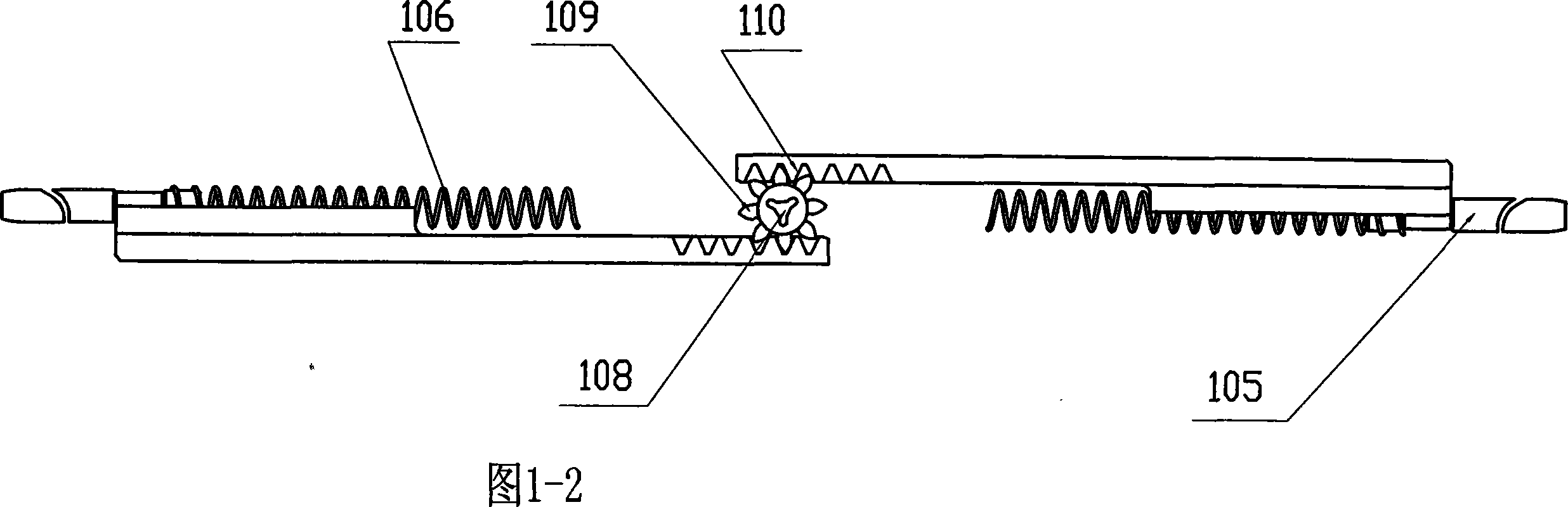

Telescopic ladder and its vertical combined ladder, platform high stool and herringbone ladder

InactiveCN101050687APrevent dumpingImprove securityStep stoolsBuilding scaffoldsDrive wheelSelf locking

Owner:王克诚

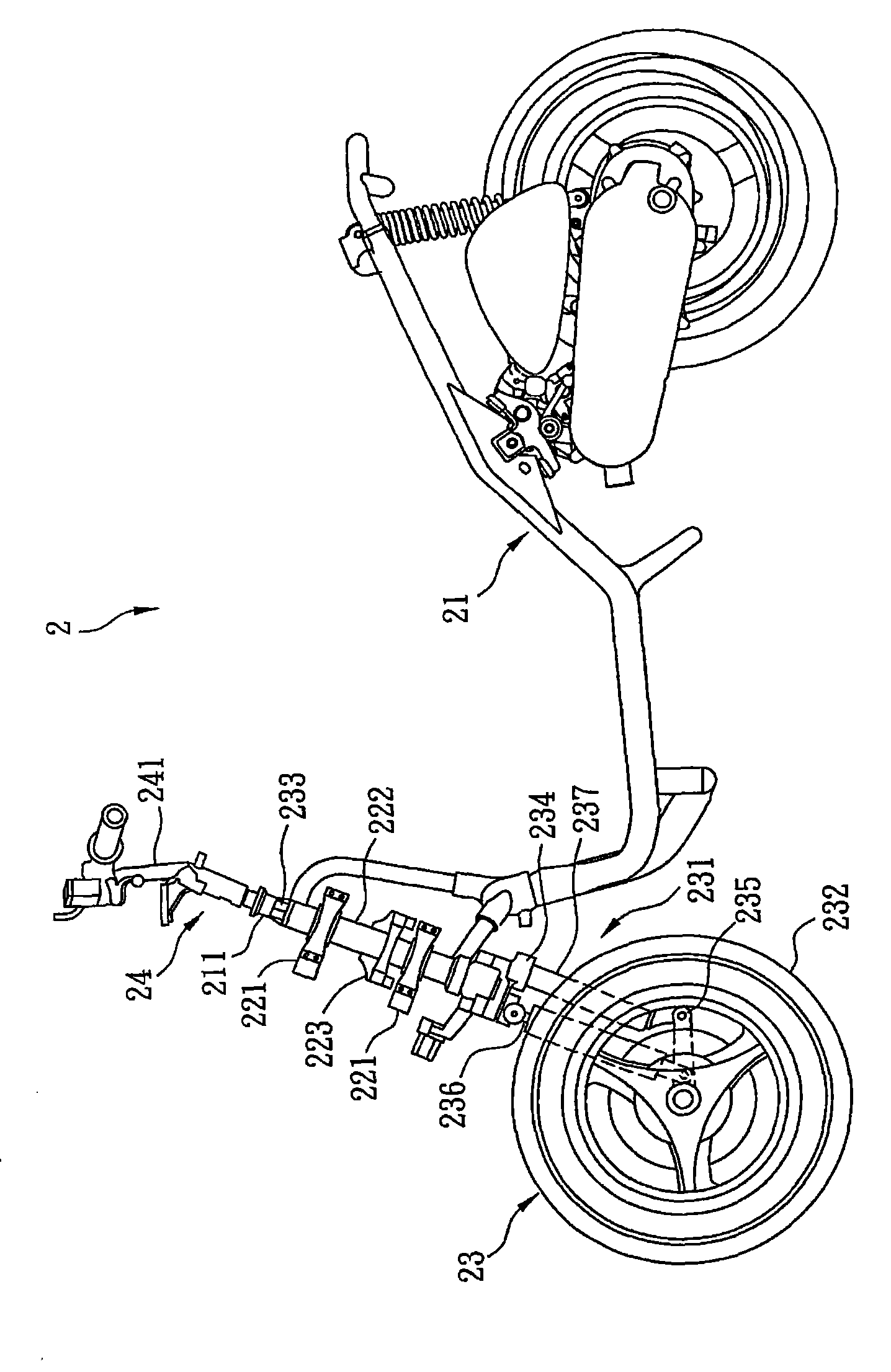

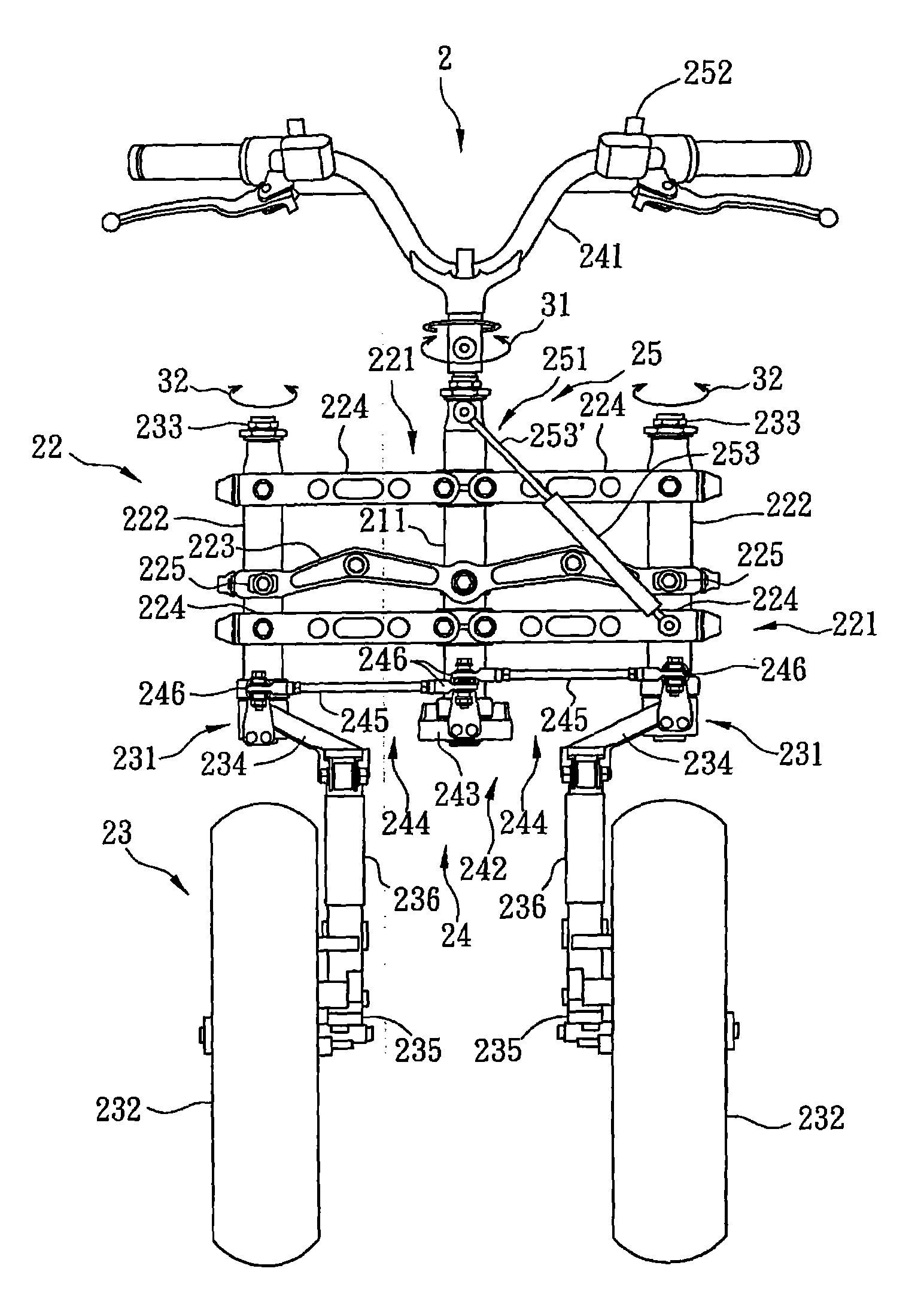

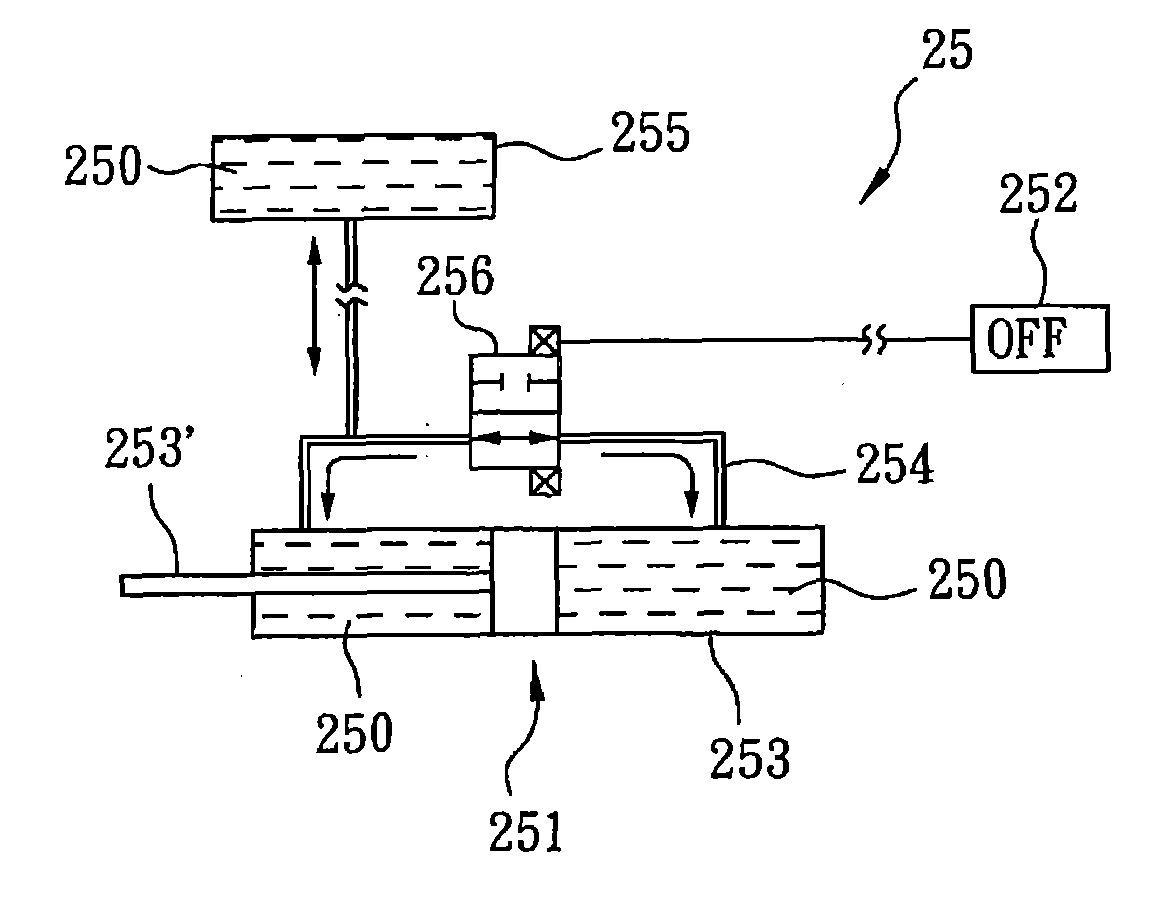

Overturn preventing device for vehicle with two front wheels

The invention discloses an overturn preventing device for a vehicle with two front wheels. The vehicle with the two front wheels comprises a frame with a hollow positioning piece, a front wheel unit corresponding to the positioning piece, and a steering unit used for controlling the front wheel unit. The overturn preventing device comprises a tilting unit pivoted to the positioning piece, and a locking unit used for locking the tilting unit, wherein the locking unit is provided with a hydraulic locking mechanism integrated on the tilting unit. The tilting unit is controlled to tilt relative to the positioning piece through the hydraulic locking mechanism, so that the tilting unit is locked in time to be prevented from tilting relative to the positioning piece so as to avoid the overturn of the vehicle with the two front wheels; and the device is simple in integral structure, the installation procedure can be effectively simplified and the waste of space can be reduced.

Owner:KYMCO

Fuzz fabric hot-air setting machine

ActiveCN101654853APrevent dumpingImprove viewing effectHeating/cooling textile fabricsTextile treatment by spraying/projectingWall plateEngineering

The invention relates to a fuzz fabric hot-air setting machine belonging to the technical field of fabric afterfinish machinery and comprising a stand, a setting main drum, a fuzz fabric guidance mechanism, an actuating mechanism, a pair of air heating injection mechanisms and a cold air injection mechanism, wherein the stand has a left wall plate and a right wall plate and is also provided with ablast box and a wheel box, the setting main drum is rotatably supported on the left wall plate and the right wall plate, the fuzz fabric guidance mechanism is rotatably arranged on the lower part ofthe left wall plate and the right wall plate in the height direction, the actuating mechanism is arranged in the wheel box and is in transmission connection with the setting main drum and the fuzz fabric guidance mechanism, the air heating injection mechanisms are connected to the left wall plate and the right wall plate in parallel and correspond to the upper parts of both sides of the setting main drum in the length direction, and the cold air injection mechanism is connected to the left wall plate and the right wall plate, is connected with a pipeline of the blast box and corresponds to thelength direction of one side of a cloth outlet of the setting main drum. The invention has the advantages that the fuzz is enabled to present the natural vivid texture, thereby being beneficial to improving the sight effect and enhancing the flexibility, the warmth retention property and the ventilation property.

Owner:CHANGSHU CITY QUNYING KNITTING MFG

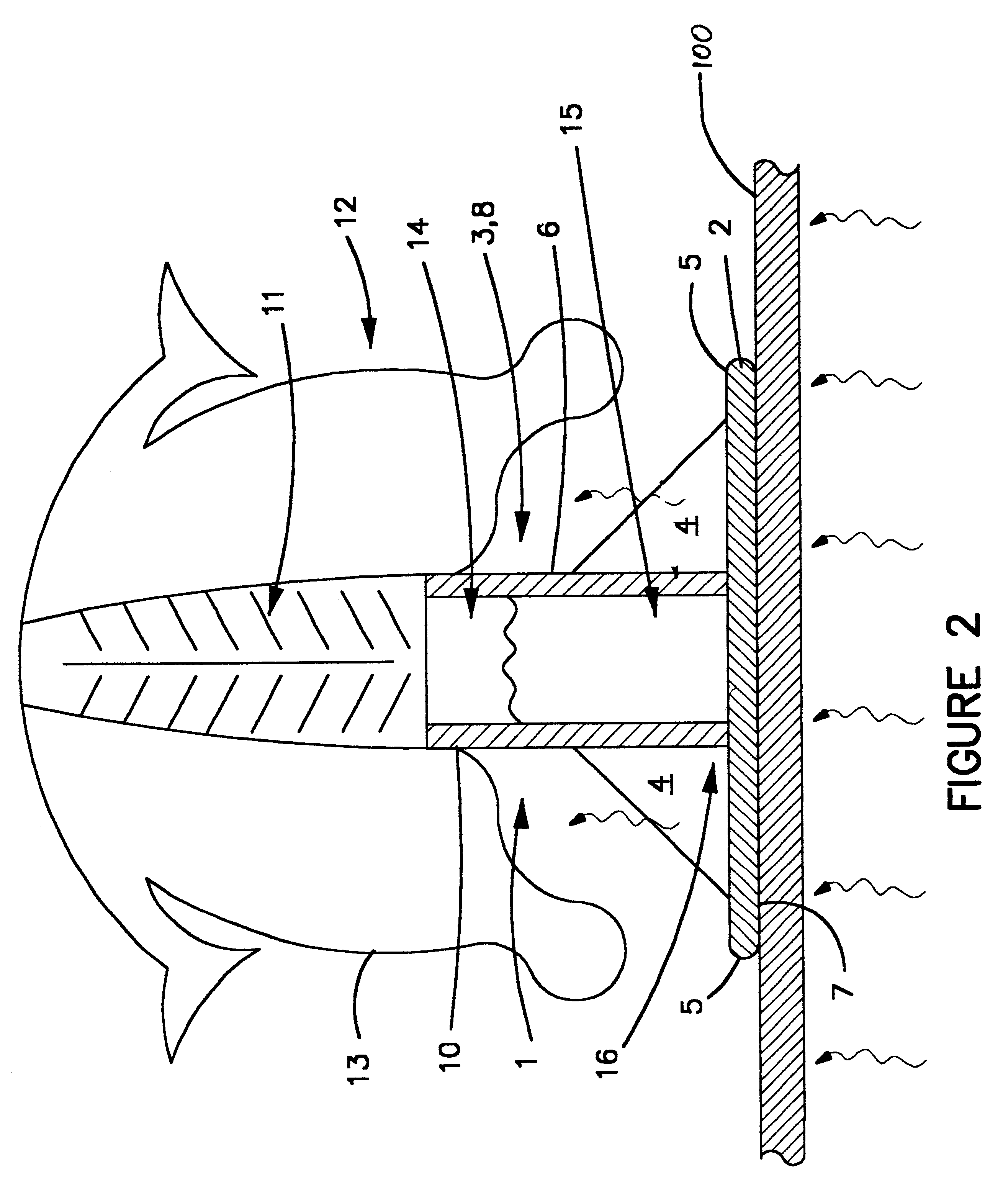

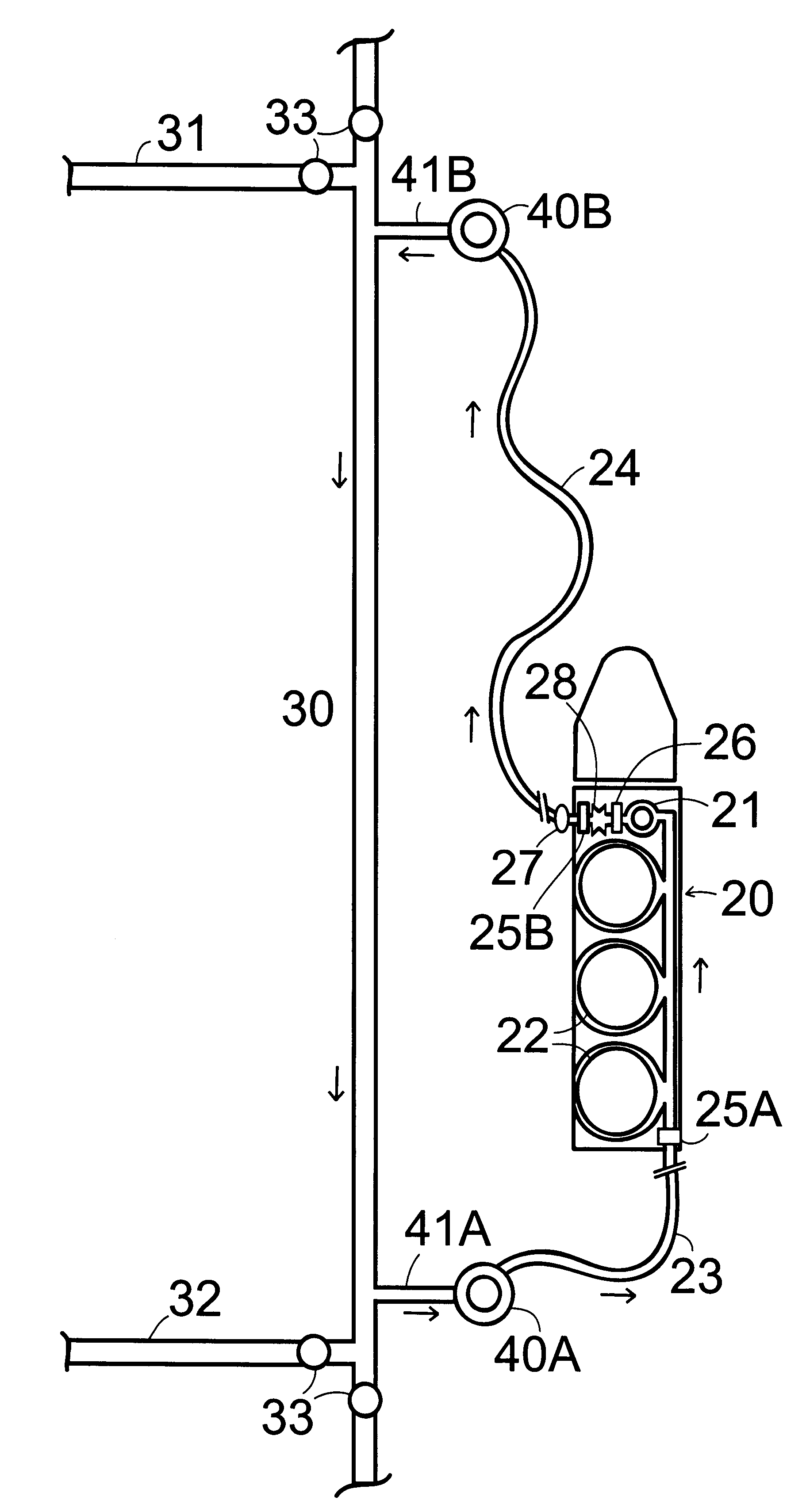

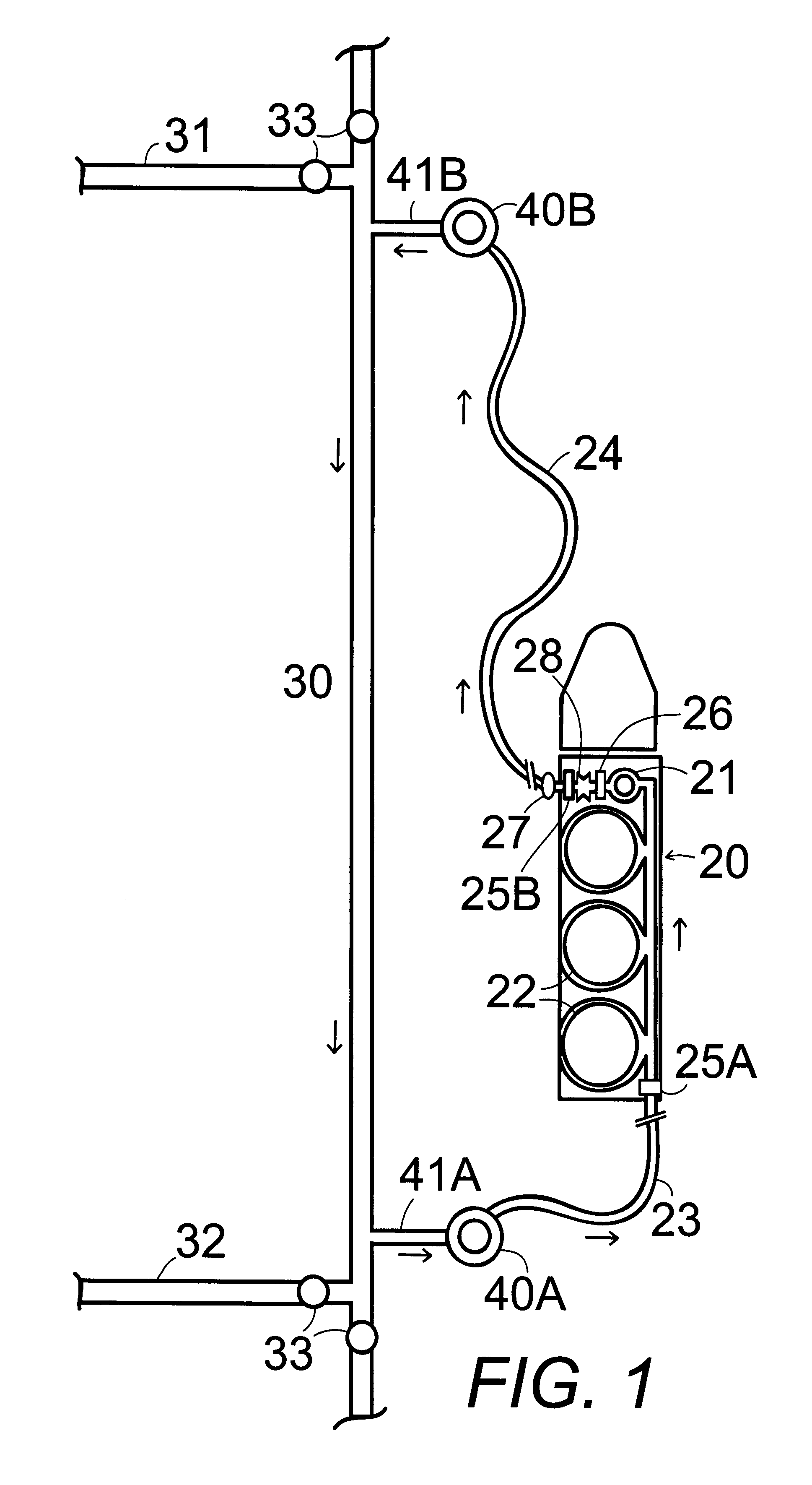

Water main recirculating/filtering/flushing system and method

InactiveUS6627089B1Not to wastePrevent dumpingLiquid separation auxillary apparatusSolid sorbent liquid separationParticulatesWater flow

A truck houses a closed recirculation system having a series of hoses, filters and pumps interconnecting a first point and second point, preferably hydrants, of a water supply system. A flow of water pumped outside of the water supply system through the filters causes an increased water flow within the section of the water supply system between the second and the first point to clean the section of deposits, sediment, particulates and other undesirable matter. All of the filtered water is returned to the water supply system. The water may be inspected and chlorinated.

Owner:NO DES INC

Standing bag box filler

Owner:广州市万世德智能装备科技有限公司

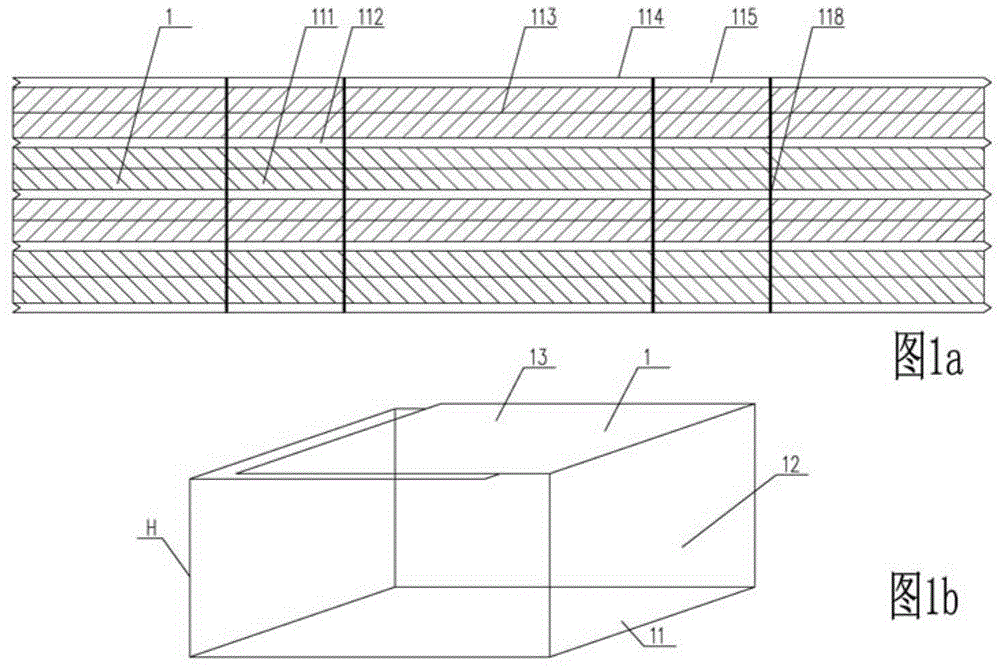

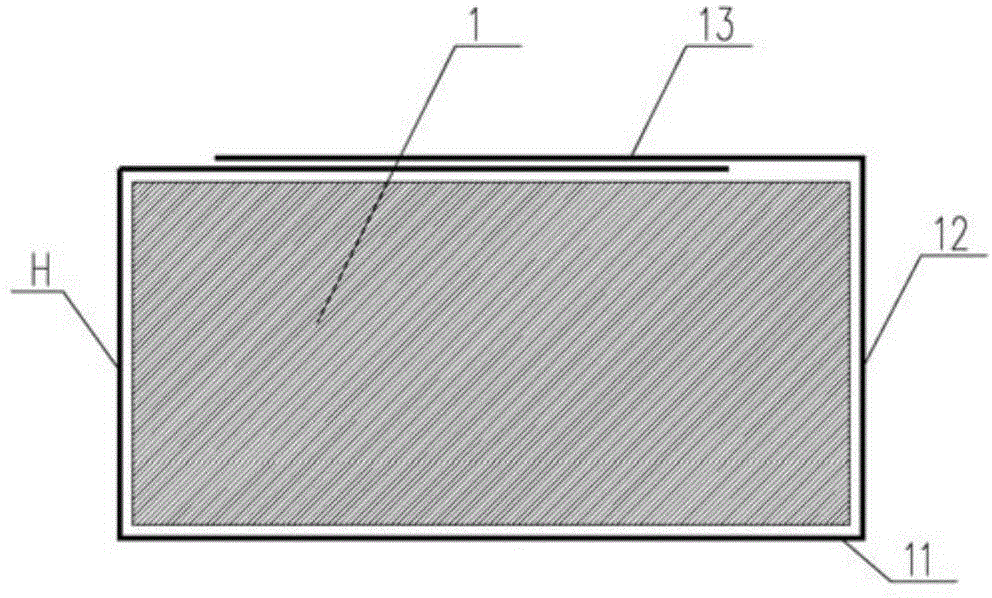

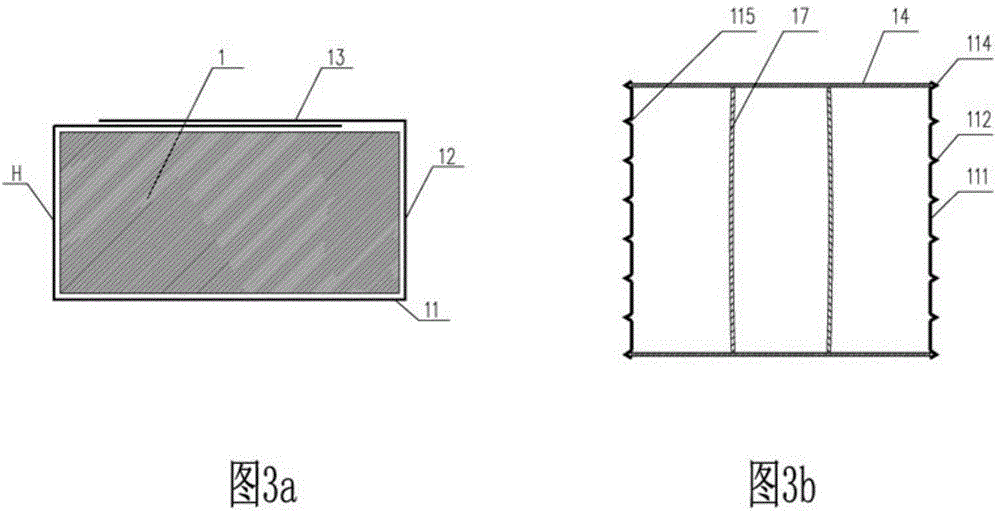

Hollow floor using steel mesh and thin plate combination for hole forming

InactiveCN104631679ARealize multifunctional applicationReinforced top surface against construction loadsFloorsCalcium silicateThin slab

A hollow floor using steel mesh and thin plate combination for hole forming comprises columns, beams, flange plates, and a cavity component formed by steel meshes and thin plates, wherein the beams are reinforced concrete beams or steel reinforced concrete combined beams; the flange plates are I-shaped section plates or T-shaped section plates; the cavity component is formed by the steel meshes and the thin plates which acts on each other; the steel meshes form the overall forming tetrahedron of the top plate, the bottom plate and two lateral walls of the hexahedron cavity component; the head and tail ends of the steel meshes overlap on one optional face of the tetrahedron; the thin plates include calcium silicate plates, plastic plates, composite plates, gypsum plates or corrugated plates; the thin plates form the other two lateral wall plates of the cavity component and the support plates between the top plate and the bottom plate of the cavity component; the two lateral wall plates formed by the thin plates are placed in edge reinforcing rib grooves at two edges of the steel meshes; in-situ concrete pouring is performed on the columns, the beams and the flange plates.

Owner:王本淼 +2

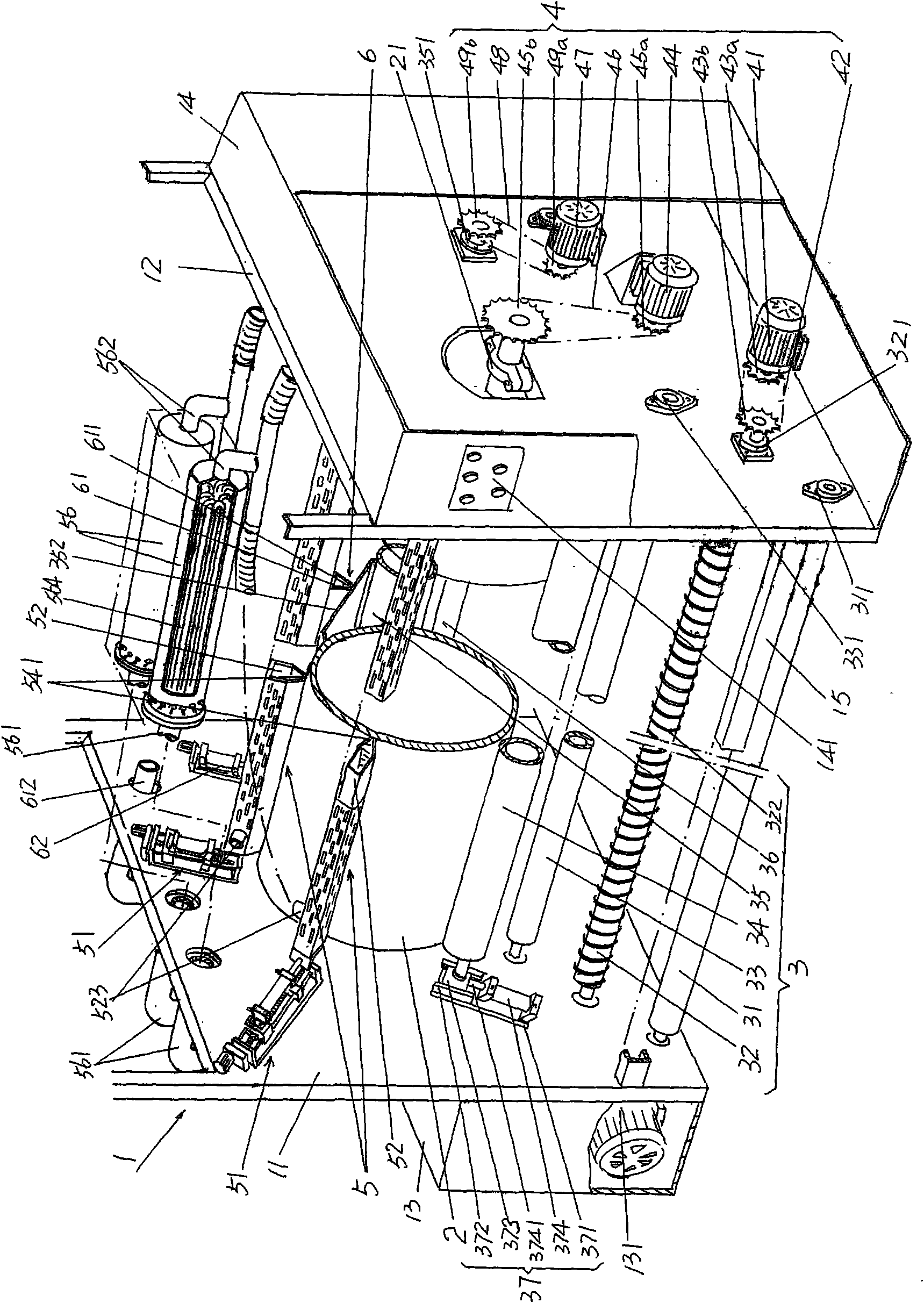

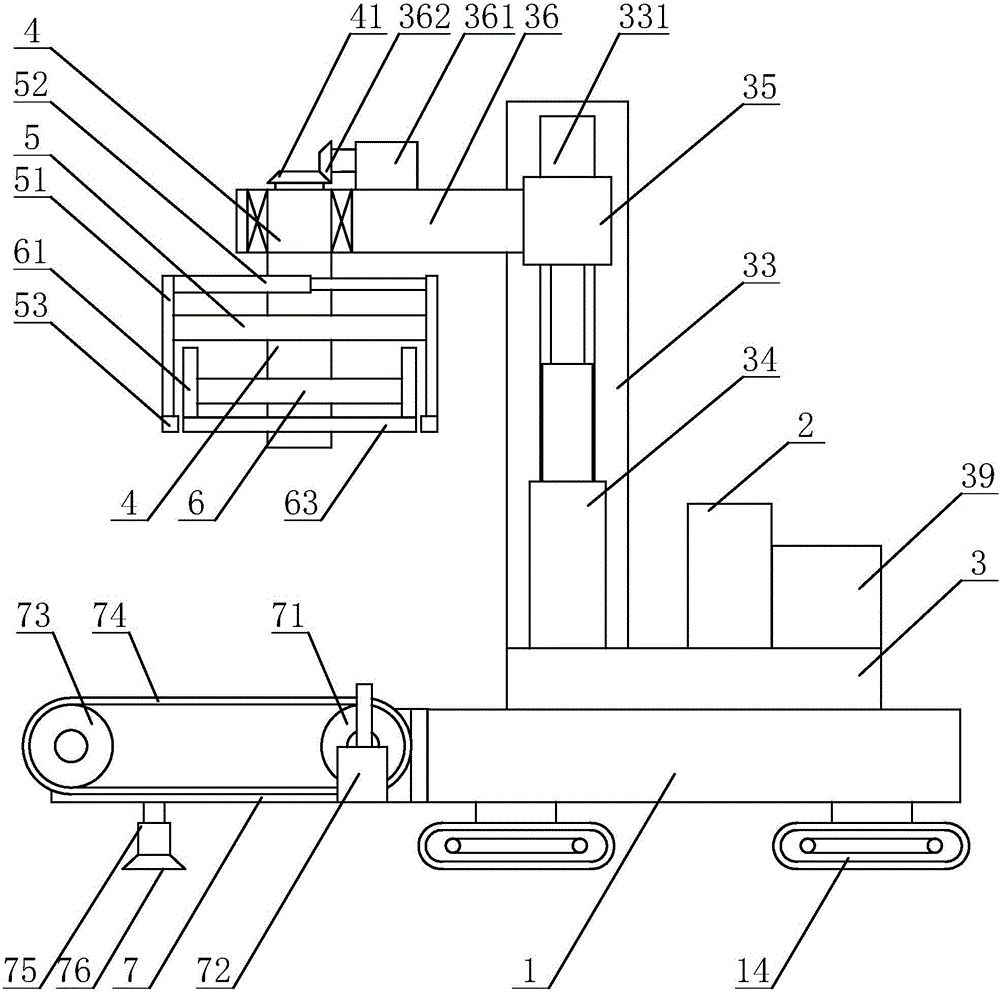

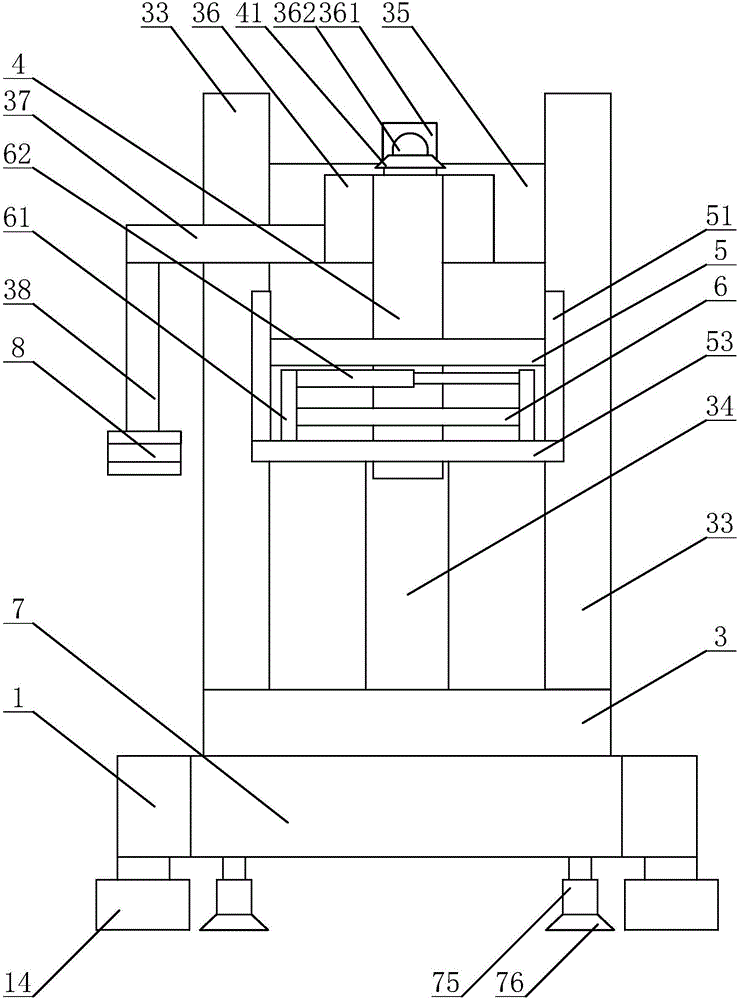

Intelligent brick stacking machine

ActiveCN106429465AMake sure to staggerStack stableStacking articlesConveyor partsBrickAgricultural engineering

The invention discloses an intelligent brick stacking machine and mainly relates to the technical field of building material machinery. The intelligent brick stacking machine comprises a support and a PLC controller, wherein a rotating platform is arranged on the support; a supporting frame and a servo air cylinder are arranged on the rotating platform; a bearing frame is arranged at the upper end of the servo air cylinder; a bearing cross rod is arranged at the front end of the bearing frame; a transmission rod is vertically arranged at the front end of the bearing cross rod; one end, far away from the bearing cross rod, of the transmission rod is connected with a clamping mechanism; the clamping mechanism comprises a transverse clamping part and a longitudinal clamping part; a balancing weight is arranged on the rotating platform. The intelligent brick stacking machine has the beneficial effects that the intelligent brick stacking machine can stack the bricks quickly and efficiently, can increase the working frequency, can move automatically according to the actual stacking requirement and can adjust the placing position of the bricks so as to guarantee the brick stacking stability.

Owner:LUOYANG INST OF SCI & TECH

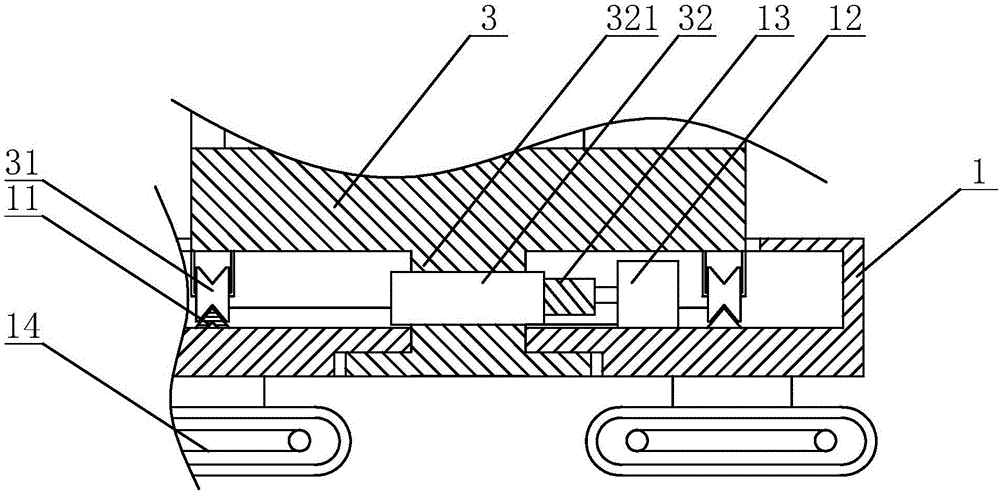

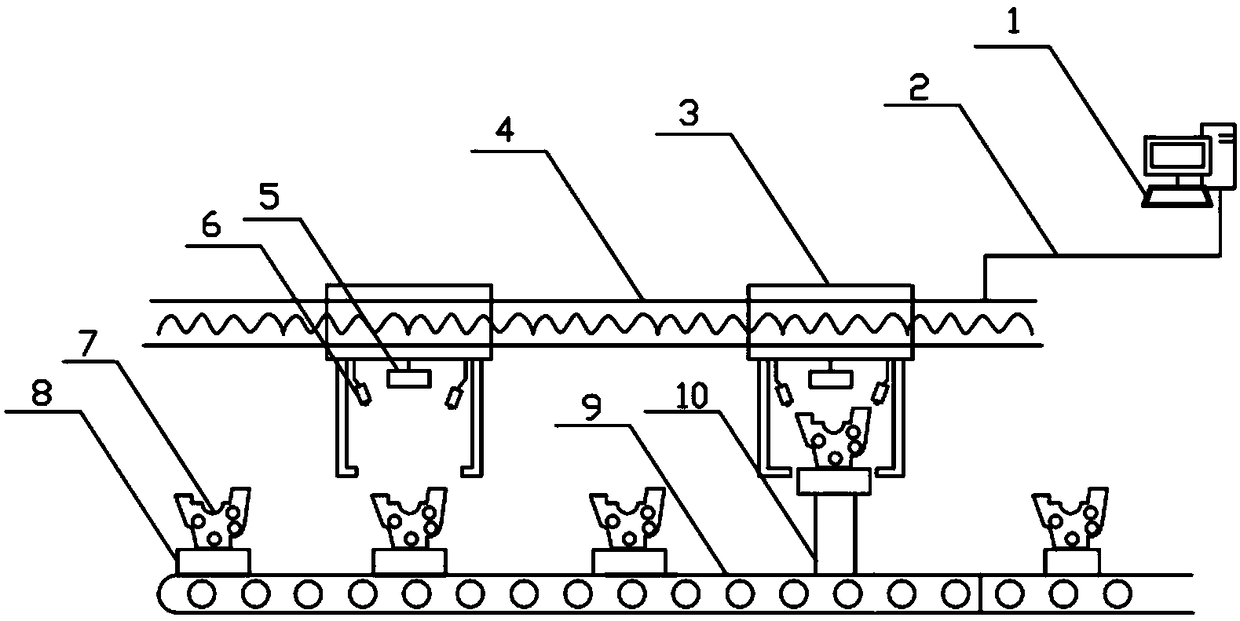

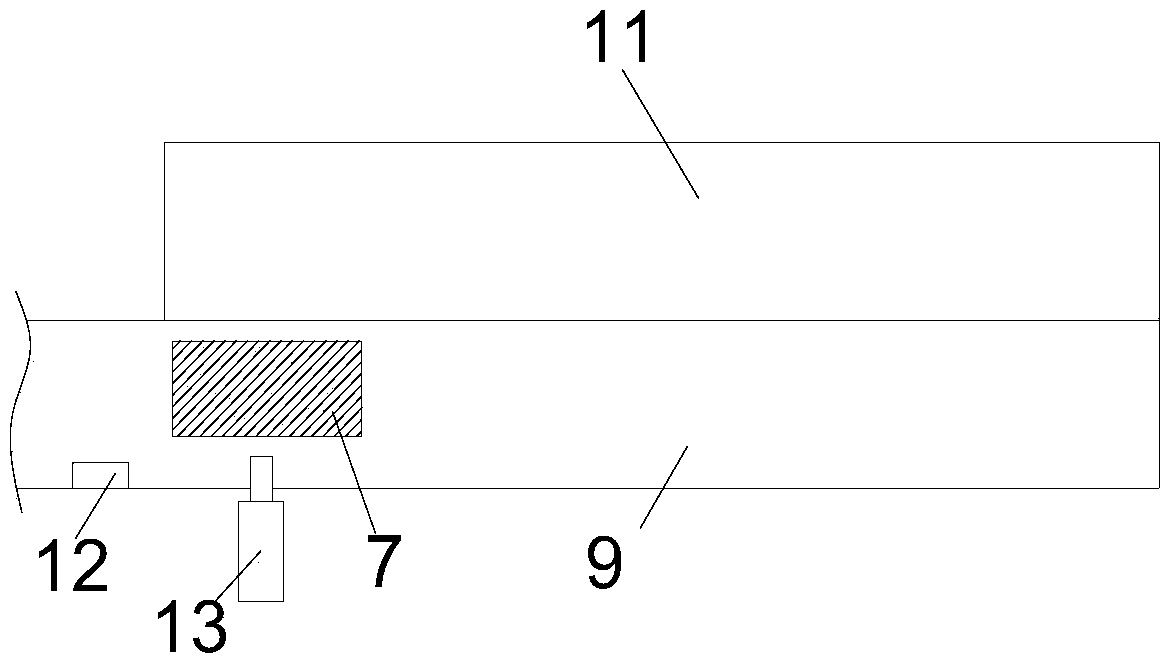

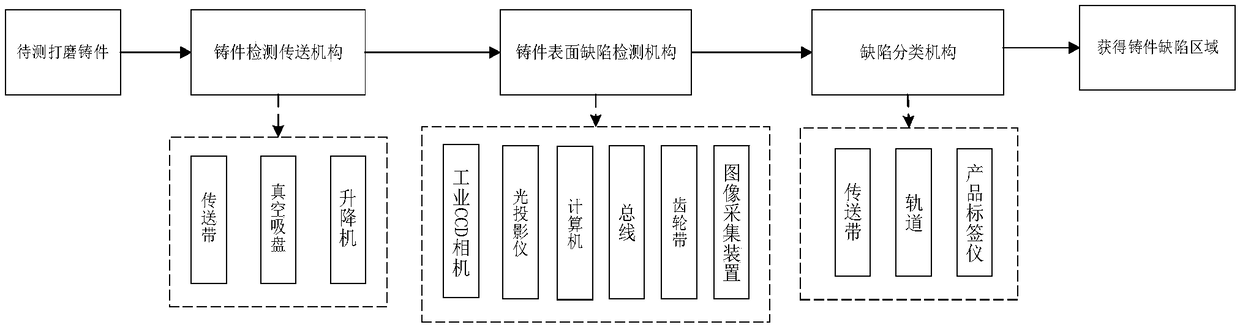

Casting polishing quality test method and device and application method of device

ActiveCN109115785AOvercome the problem of low quality inspection efficiencySolve the low detection efficiencyOptically investigating flaws/contaminationDefect sizeCcd camera

The invention discloses a casting quality test method and device and an application method of the device. The casting quality test device comprises three parts including a casting test conveying mechanism, a casting surface defect test device and a defect identification and classification mechanism, wherein the casting test conveying mechanism can be used for fixing a polished casting to be testedon a vacuum suction disc; the polished casting to be tested is conveyed into the casting surface defect test device through a conveyor belt; the device mainly applies a digital image processing technology, and a mounted industrial CCD (Charge Coupled Device) camera is used for acquiring an image; and a digital image processing algorithm designed on a background is used for carrying out defect identification on a casting surface polishing image. In an identification process, surface defect positions of the casting need to be obtained, and defect size and area also need to be calculated, so that defect grades are judged and classification of defect types is realized. A parameter report is generated according to a final identification result and a tested casting body is marked; and castingswith qualified polishing and castings with unqualified polishing are classified and output through the defect identification and classification mechanism.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

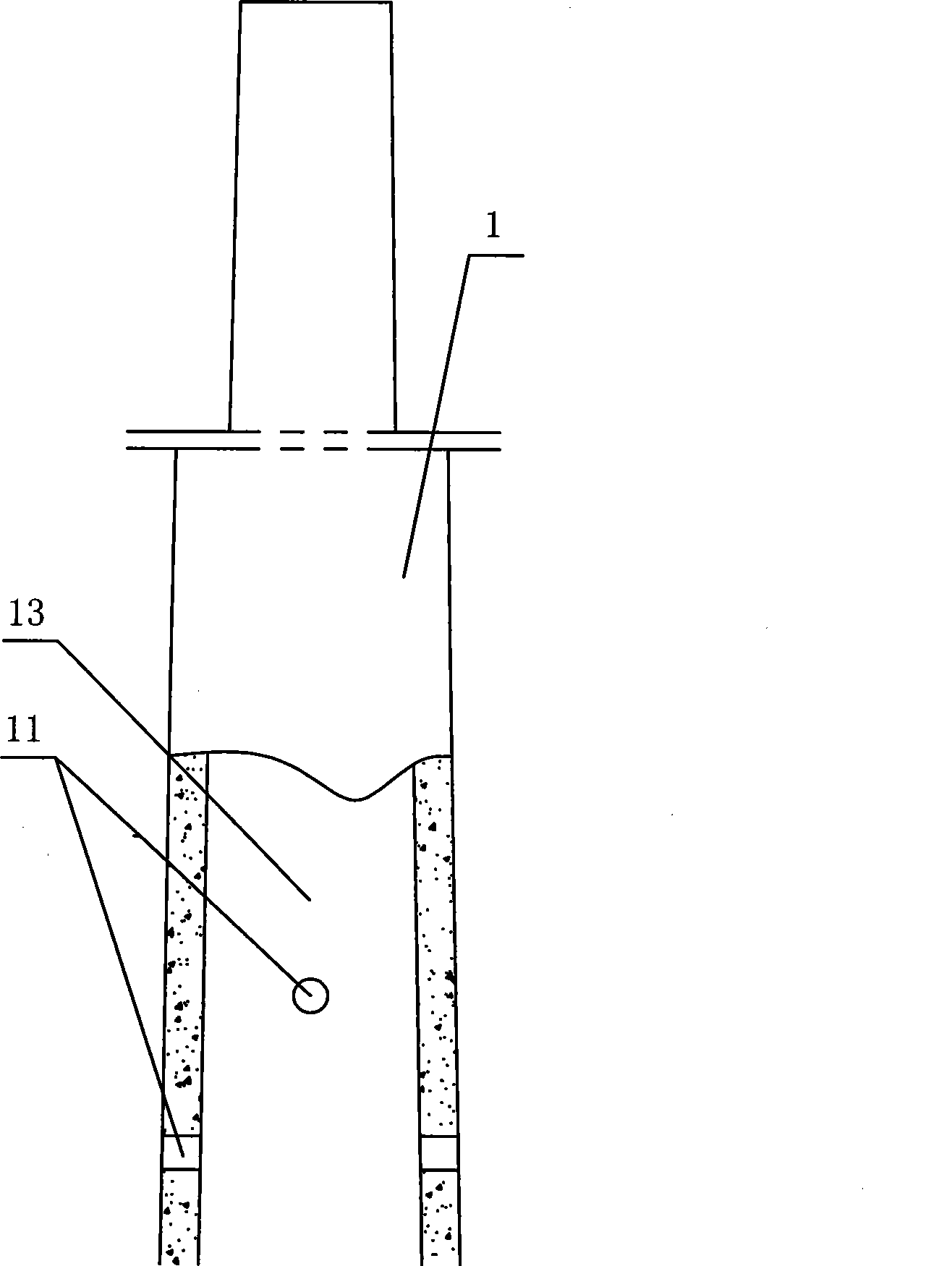

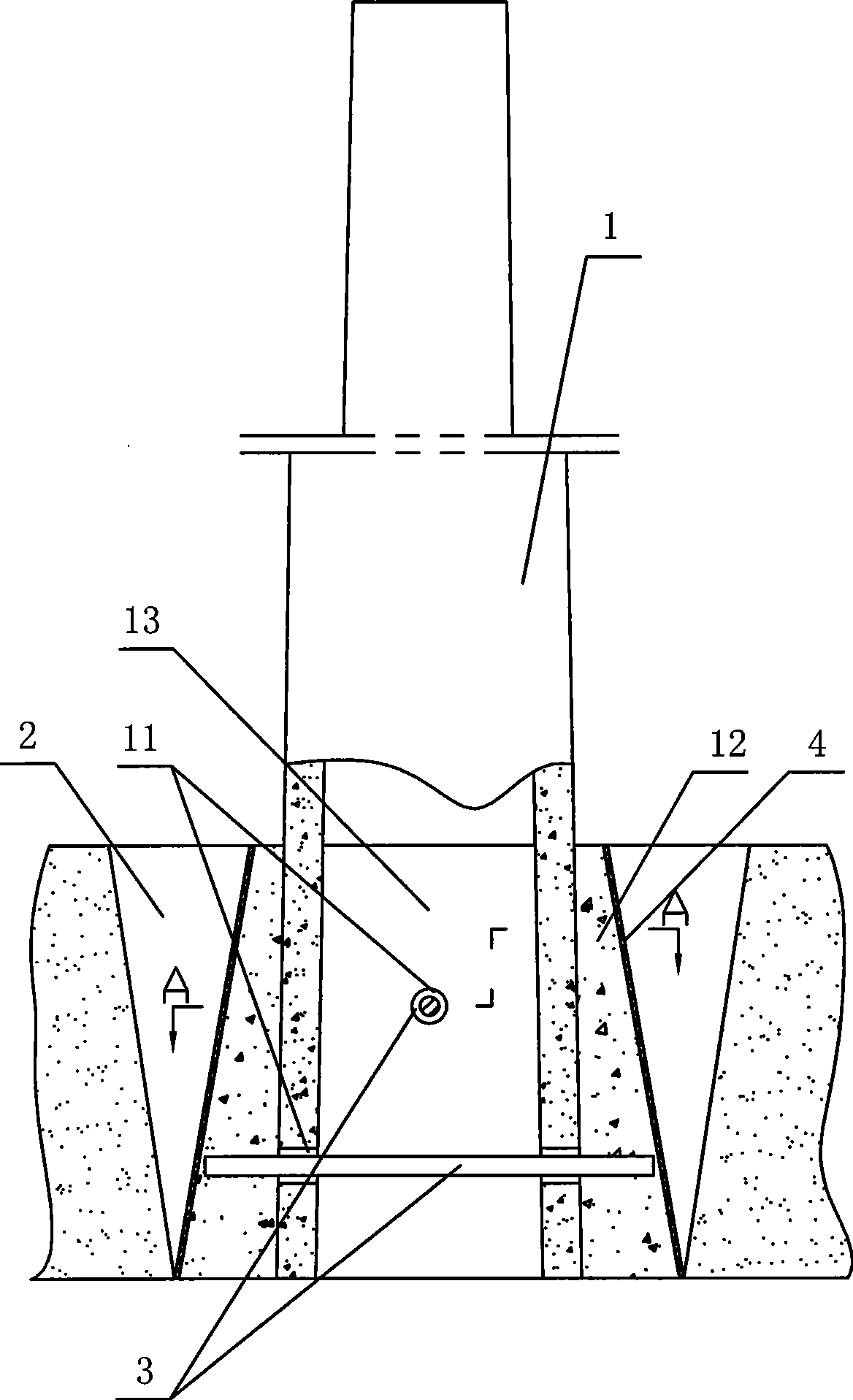

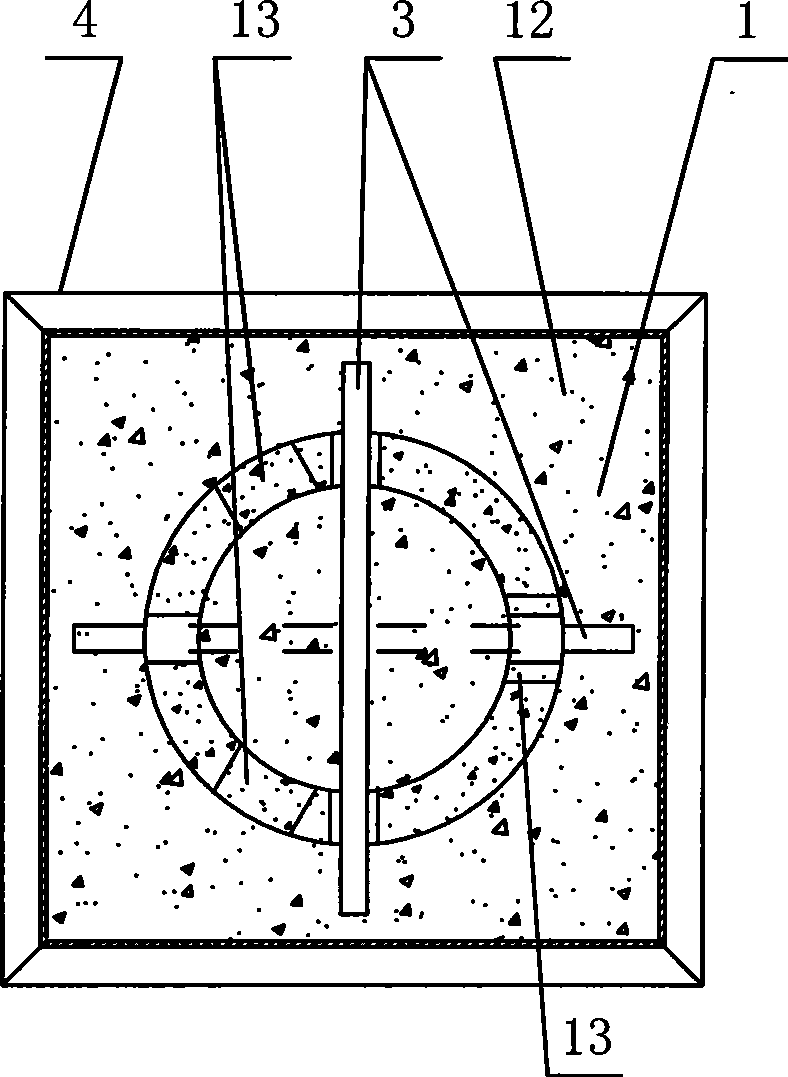

Telegraph pole and its mounting and fixing method

The invention discloses a telegraph pole and an installing and fixing method thereof. The lower end of the telegraph pole is provided with through holes which cross through the telegraph pole body; the installing and fixing method comprises the following steps: a pre-buried pit is dug at the installing position of the telegraph pole, a steel bar is penetrated into the through holes at the lower end of the telegraph pole, the two ends of the steel bar are arranged outside the telegraph pole which is upright in the pre-buried pit, and a pouring frame with the shape being adapted to that of the pre-buried pit is constructed outside the two ends of the steel bar; and pouring is carried out in the pouring frame by using concrete, thus forming a base seat which is integrated with the telegraph pole. At least two pairs of through holes at the lower end of the telegraph pole are distributed uniformly and alternately; the cross section of the pre-buried pit is a regular quadrangle; the pouring frame is in the shape of a regular quadrangle frustum with small top and big bottom, and the pouring frame consists of hollow-out net boards. As the cast-in-situ base seat which forms into one firm body with the telegraph pole is added, and the surface is unsmooth, the force bearing area of the telegraph pole is increased, the gravity center is reduced, the anti-inclination and anti-toppling capacity of the telegraph pole is increased, and the telegraph pole is safe and reliable.

Owner:廖力锋

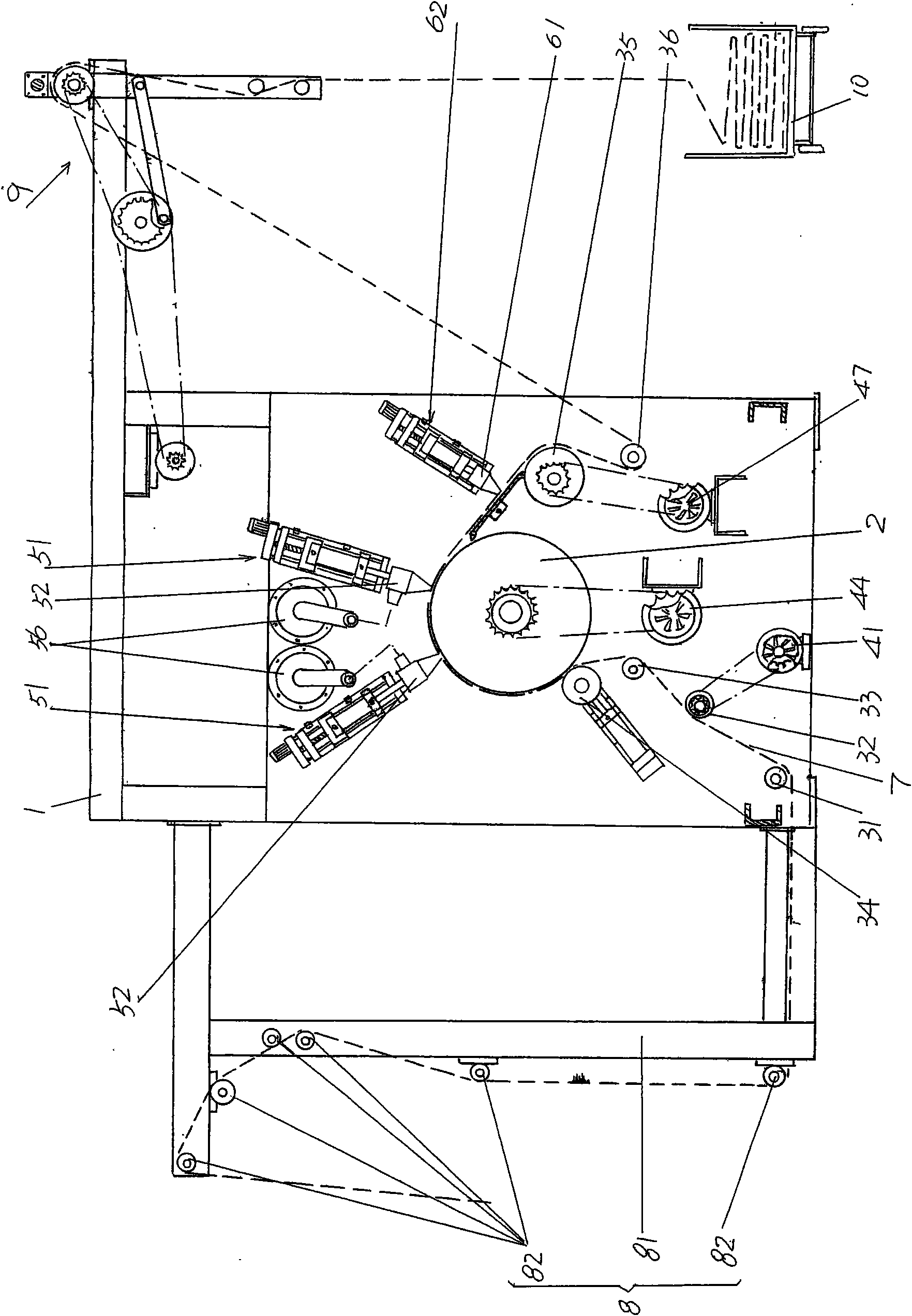

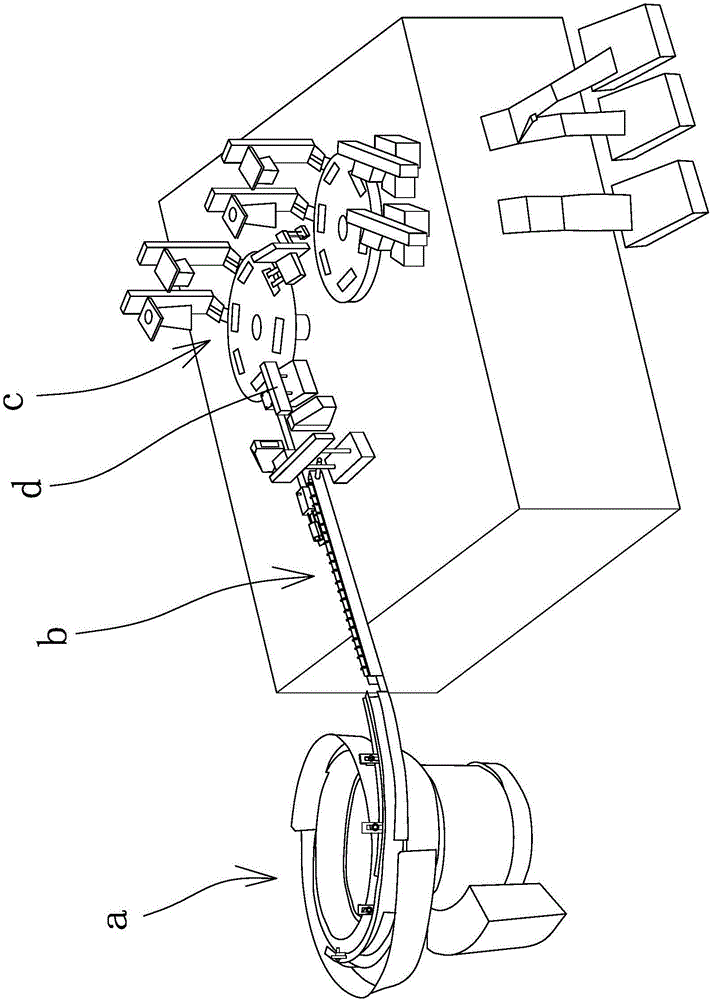

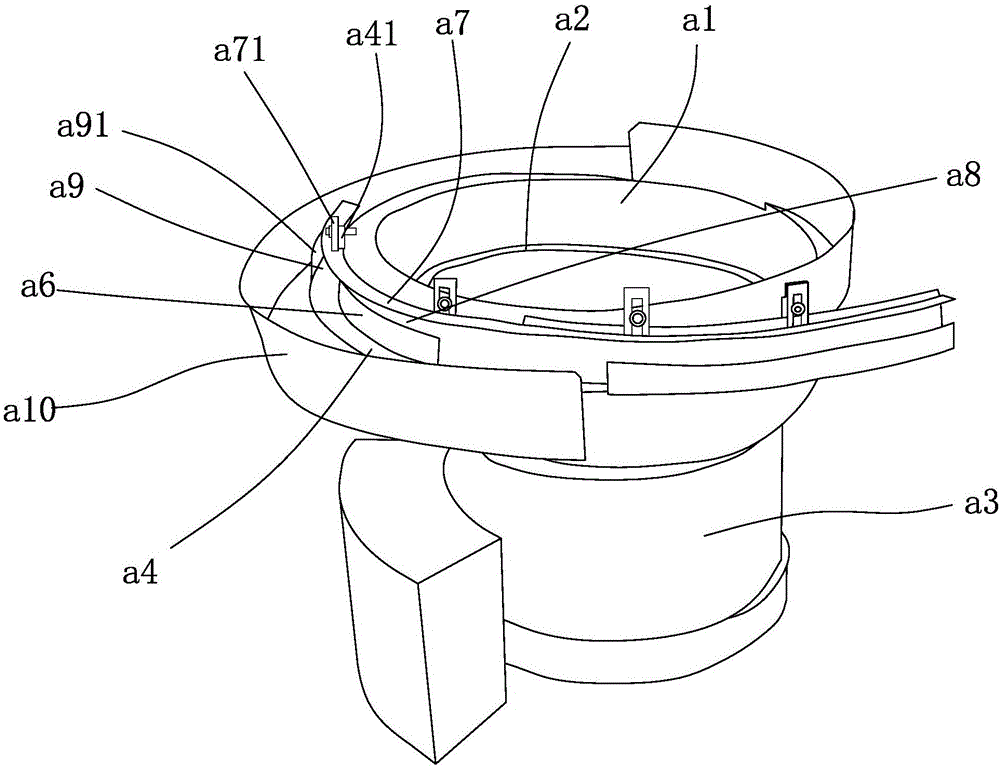

Optical automatic screening machine for springs

The invention provides an optical automatic screening machine for springs. The optical automatic screening machine comprises a work platform. A vibration discharging mechanism is arranged on the work platform. The springs output by the discharging end of the vibration discharging mechanism is transferred to a detection device through a conveying mechanism to be detected. The detection device comprises at least one detection mechanism arranged on the work platform. Each detection mechanism comprises a rotating disc which is arranged on the work platform, used for containing the springs and driven by a rotation driving assembly to intermittently rotate. Each detection mechanism further comprises at least one optical detection assembly arranged on the work platform. When the rotating discs rotate the springs to a detection station, the optical detection assemblies can detect the spring quality. According to the optical automatic screening machine for the springs, quality detection can be automatically conducted on the end faces of the springs, the screening efficiency of the springs is improved, and the springs input to the market have the high qualification rate.

Owner:ZHEJIANG ISRI SHUANGDI SPRING

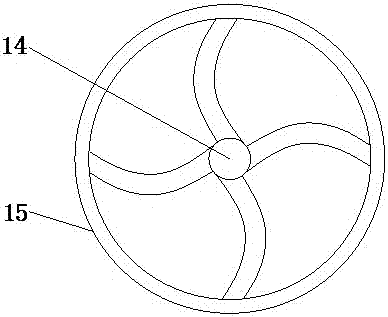

Stirring device for producing ferric phosphate

InactiveCN107261954AAchieve the effect of rotationStir evenly and efficientlyRotating receptacle mixersTransportation and packagingRotational axisPhosphate

The invention discloses a stirring device for producing ferric phosphate. The stirring device comprises a base, wherein the left side of the bottom of an inner cavity of the base is fixedly connected with a first motor; a rotary shaft of the first motor is fixedly connected with a driving gear; the right side of the bottom of the inner cavity of the base is fixedly connected with a rotating shaft; a driven gear, which is matched with the driving gear to use, sleeves the surface of the rotating shaft; the driving gear is engaged with the driven gear; and the top of the rotating shaft penetrates through the base and extends to the outer part of the base to be connected with a stirring tank. According to the stirring device disclosed by the invention, the first motor is arranged so that the effect of driving the driving gear to rotate is realized; the effect of driving the rotating shaft and the stirring tank to rotate is realized through the driving gear and the driven gear; the effect of driving a first connecting rod, a stirring rod and a stirring disc to rotate is realized through a second motor; a first electric telescopic pole is arranged so that the effect of driving the stirring disc to move is realized; and the ferric phosphate can be uniformly and efficiency stirred and people can produce the ferric phosphate conveniently.

Owner:田曼丽

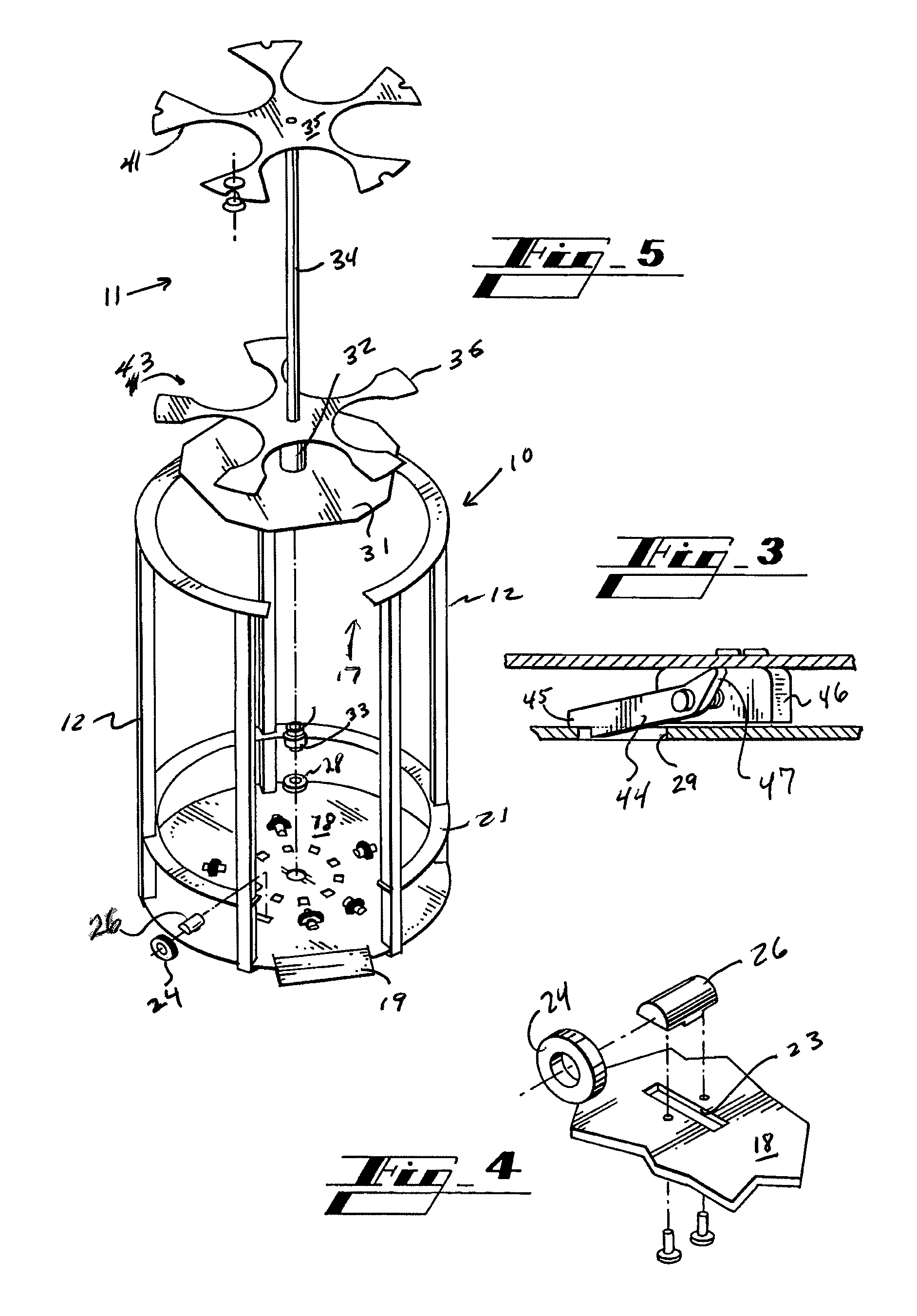

Method and apparatus for retaining gas cylinders

InactiveUS7748545B2Rapid and easy deploymentPrevent dumpingContainer filling methodsGas handling applicationsGas cylinderEngineering

Owner:ALABAMA LASER TECH

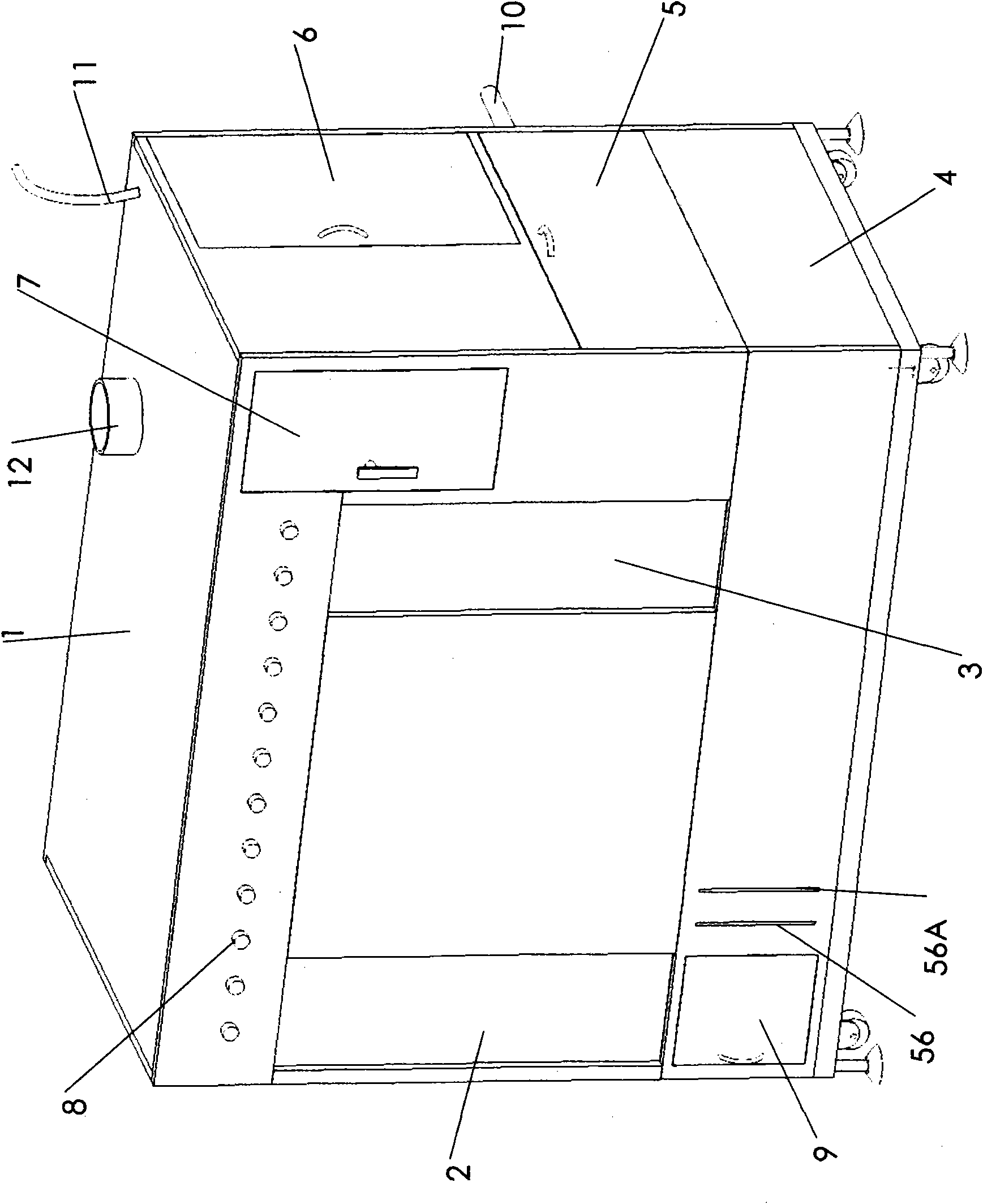

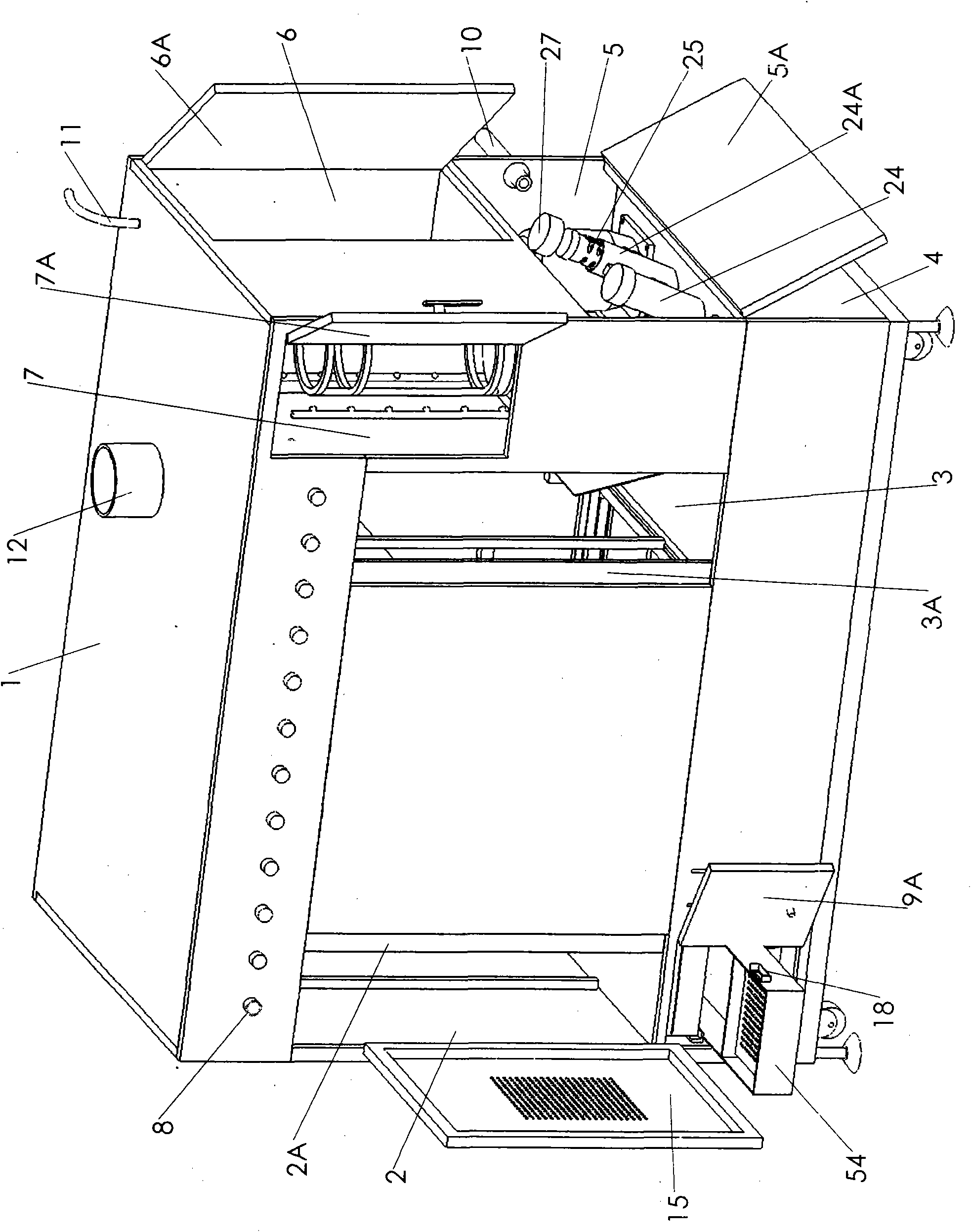

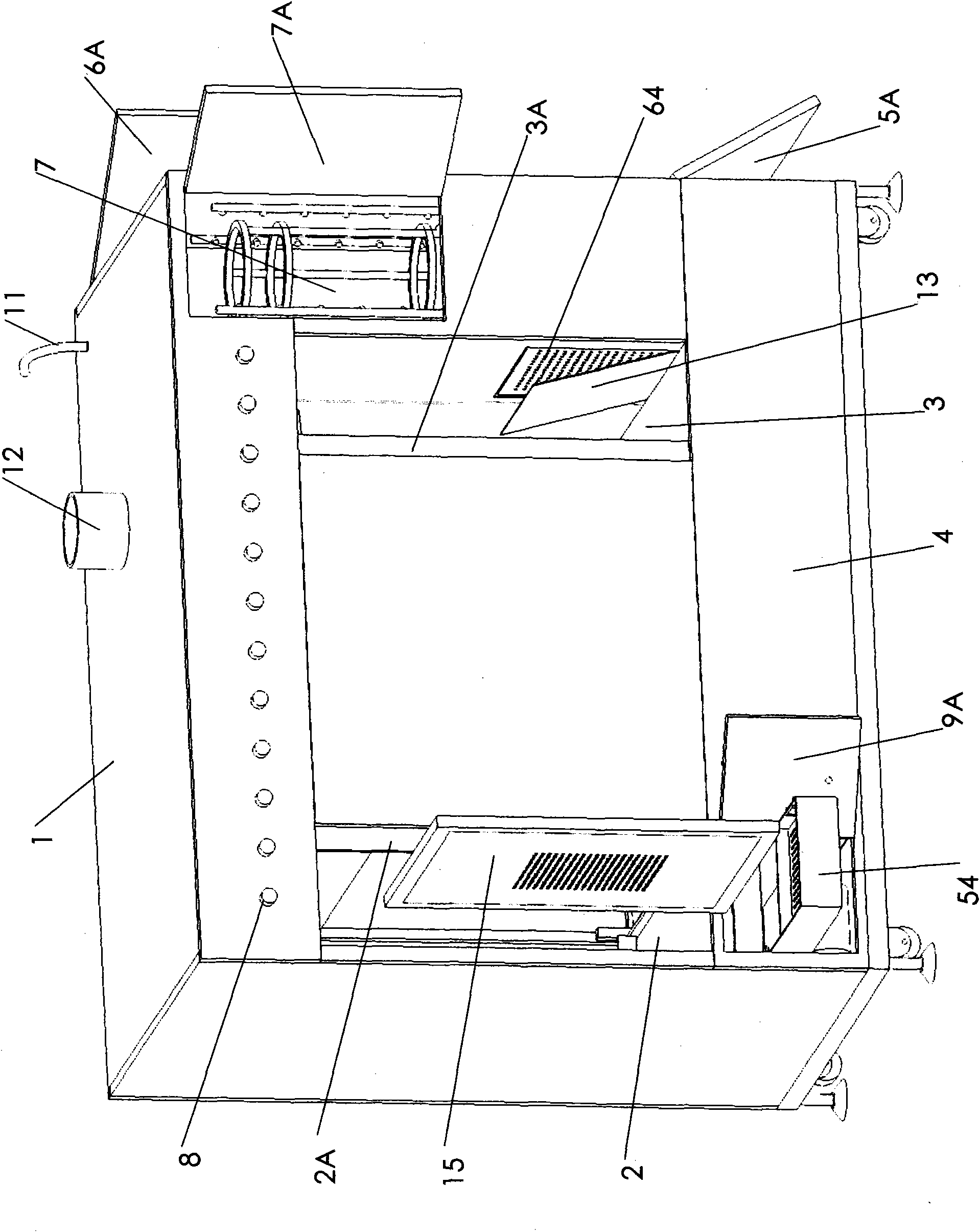

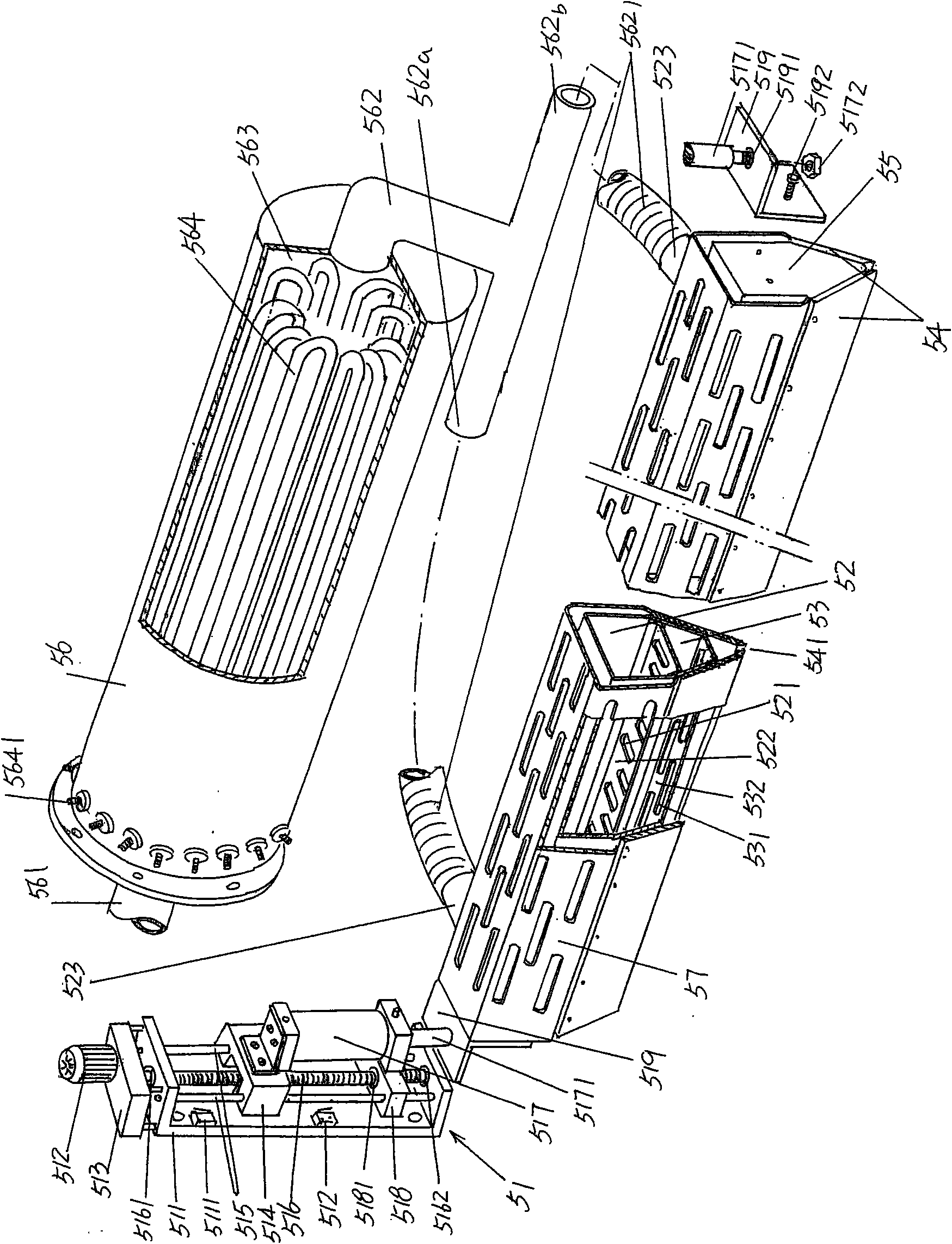

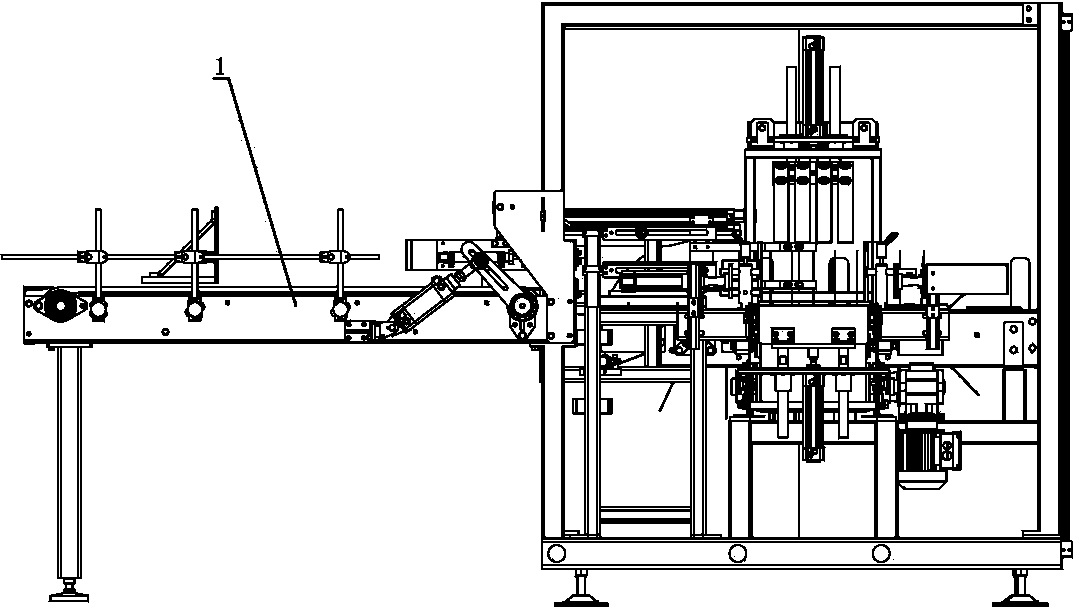

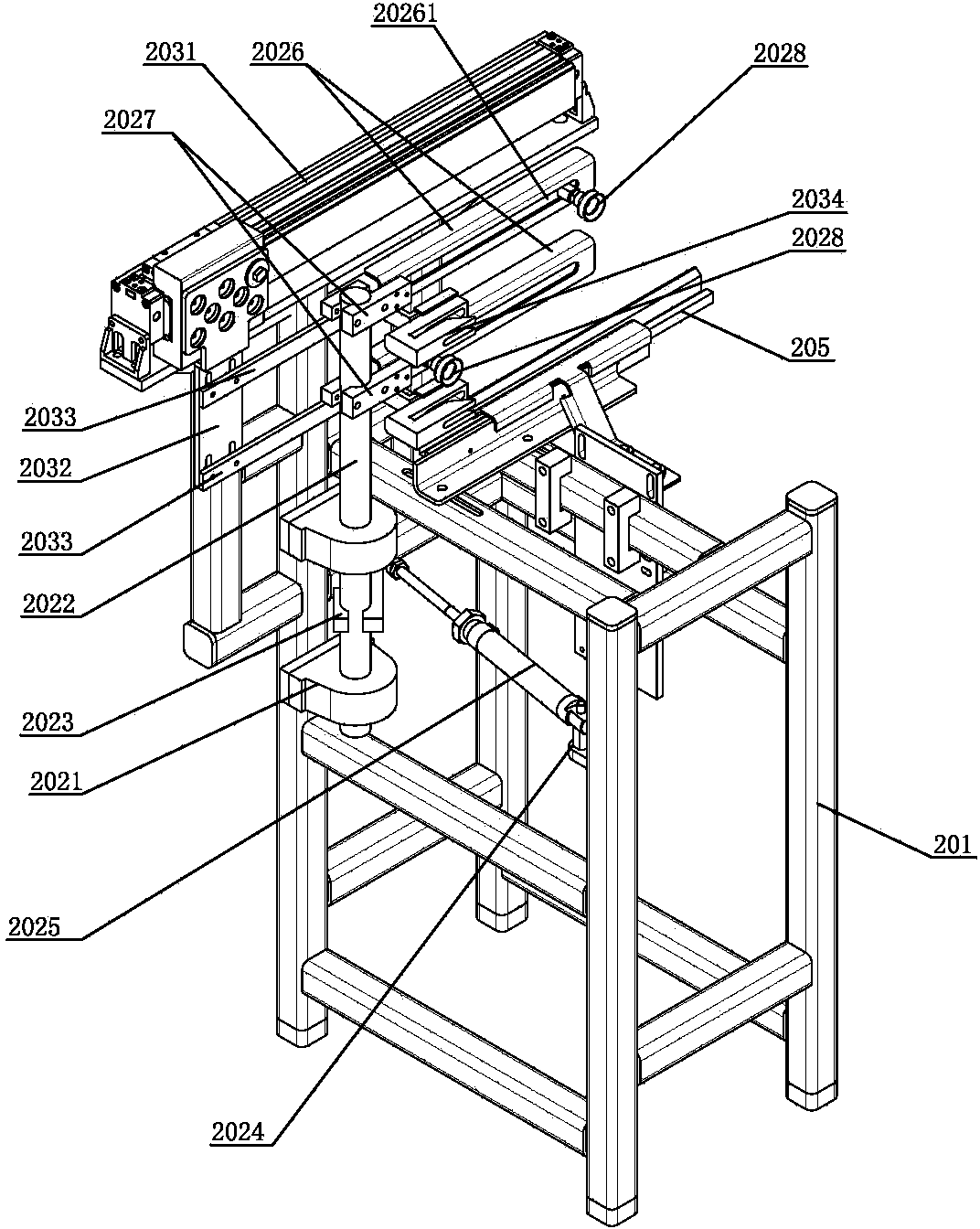

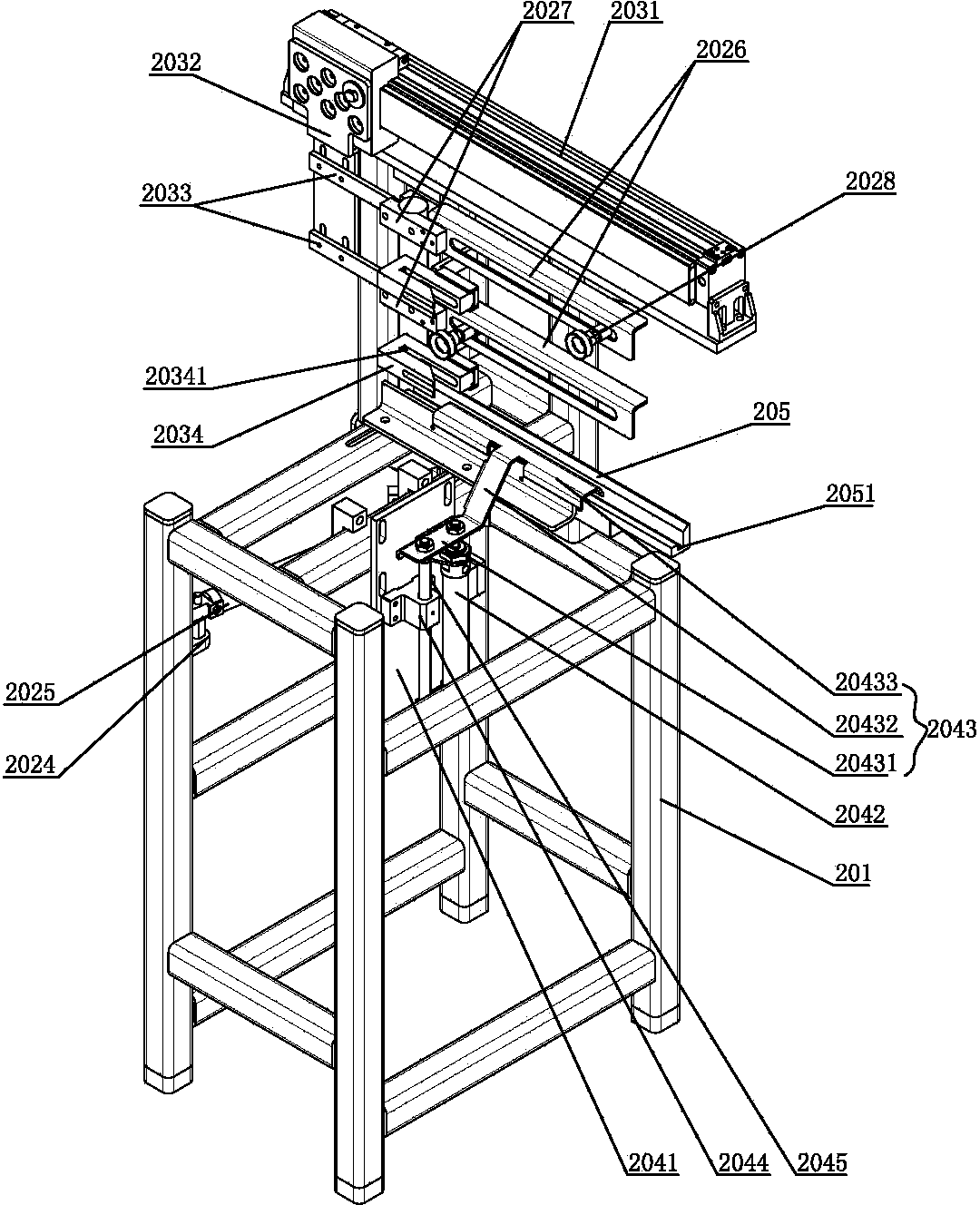

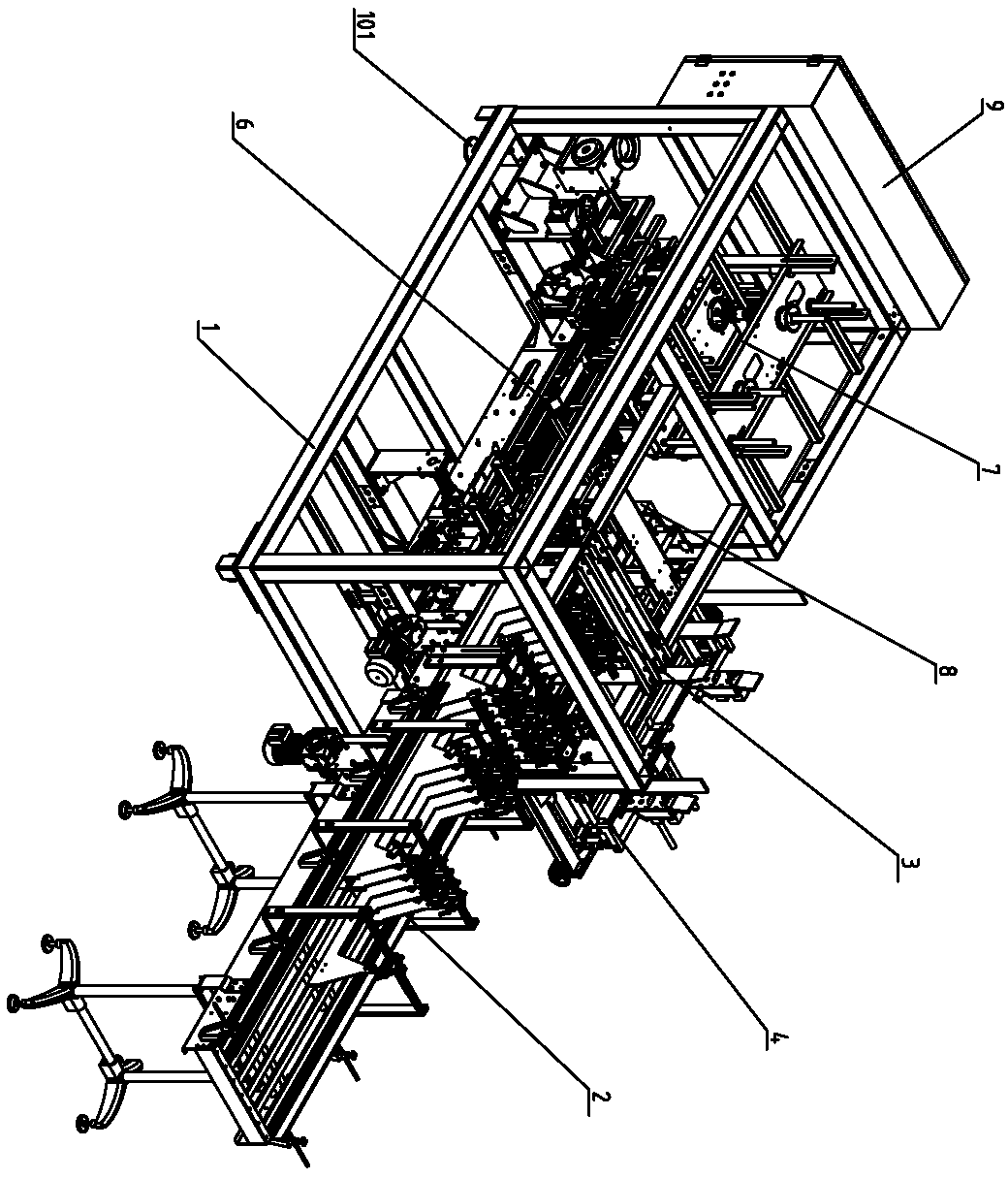

Sunken carton packaging machine

The invention discloses a sunken carton packaging machine. The sunken carton packaging machine comprises a machine frame (1), a bottle dividing mechanism (2), a bottle falling mechanism (3), a carton bin (4), a carton receiving mechanism (5), a packaging and conveying mechanism (6), a carton pressing mechanism (7), a hot-melt adhesive coating machine (8) and an electrical cabinet (9). By adopting the structure, the sunken carton packaging machine can achieve reliable and smooth bottle division, can conveniently and quickly adjust positions of a left bottle protecting plate, a right bottle protecting plate and a middle bottle protecting plate, and can conveniently adjust the distance between a first dial block and a second dial block.

Owner:广州宝德凯智能装备有限公司

Information display device

The invention discloses an information display device which comprises an underframe and a displayer, wherein the underframe is provided with a sliding joint chamber inside and a bearing plate fixed on the rear end, and meanwhile, a pressing groove with extended two ends is symmetrically disposed inside the upper end wall of the underframe and interconnected with the sliding joint chamber; an upper sliding-joint plate and a lower sliding-joint plate are installed inside the sliding joint chamber in an up-and-down slip connection mode, and both sides of the upper sliding-joint plate are symmetrically provided with sliding joint blocks which penetrate into the pressing groove; inside the upper end wall, interconnecting grooves interconnected with the sliding joint blocks are symmetrically arranged in a fore-and-aft direction and a left-and-right direction; a plug arm coordinately connected to the interconnecting groove is fixedly installed on the upper end of the lower sliding-joint plate, and a plug groove with a notch facing downwards is mounted inside the bottom wall of the displayer, and cooperates with the plug arm; an installing groove provided with a fixing arm inside in a slip connection mode, is arranged inside the outer end wall of the plug groove and interconnected with the plug groove; a locking groove which cooperates with the fixing arm, is arranged inside the sliding joint blocks.

Owner:GUANGDONG RAYMON TECH

Automatic vending machine

InactiveCN103971458ASolve the problem of self-fallingPrevent dumpingCoin-freed apparatus detailsApparatus for dispensing discrete articlesEngineeringMechanical engineering

Owner:HONG FU JIN PRECISION IND WUHAN CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com