Sunken carton packaging machine

A packaging machine and carton technology, applied in the direction of packaging, packaging bottles, transportation and packaging, etc., can solve the problems of affecting bottle separation and transportation, inconvenient packing, and the inability to adjust the whereabouts of bottled goods, so as to improve the scope of application and prevent dumping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

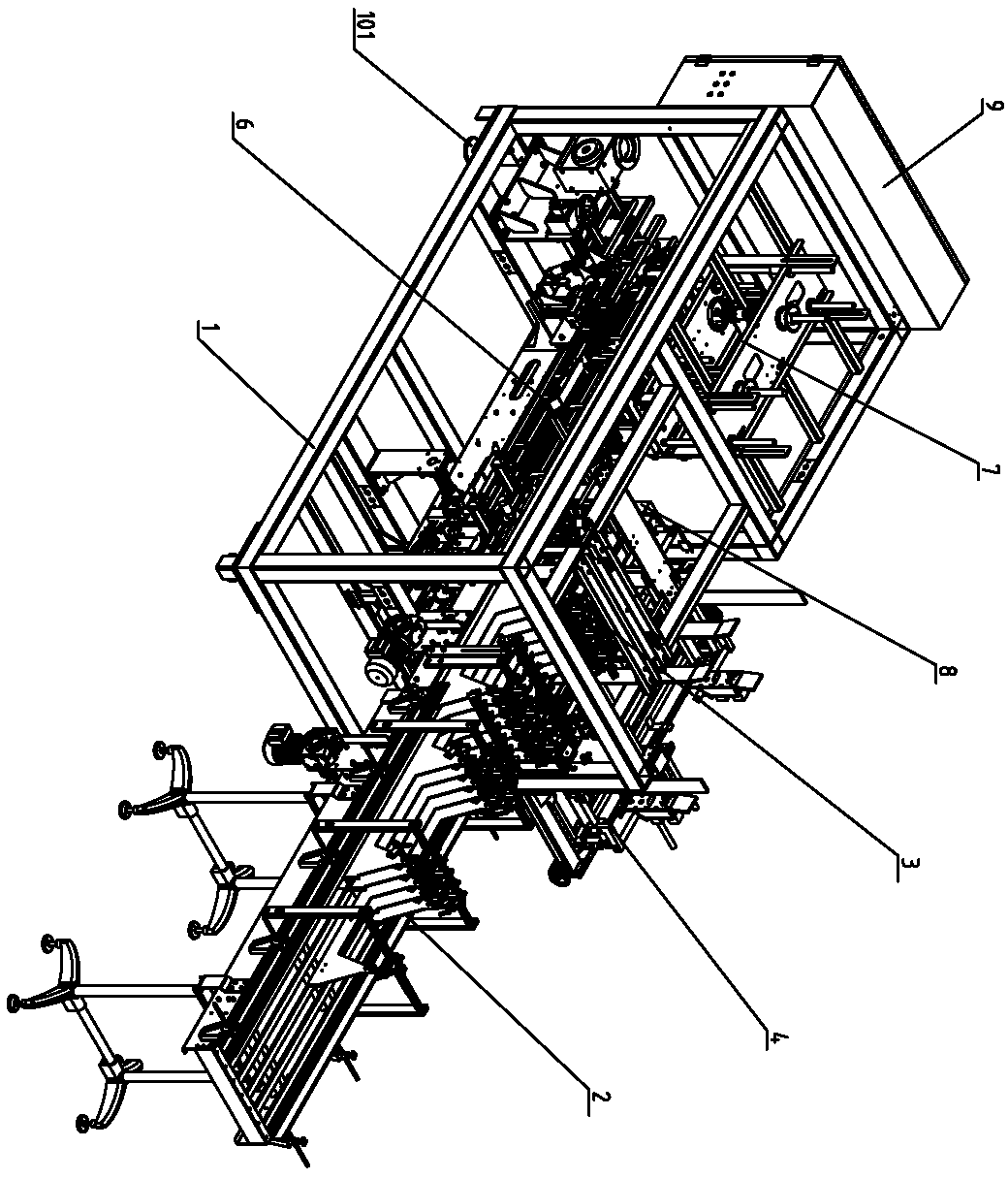

[0011] Such as figure 1 and figure 2 As shown, the sinking carton packaging machine includes a frame 1, a bottle separating mechanism 2, a bottle dropping mechanism 3, a board warehouse 4, a box receiving mechanism 5, a packaging conveying mechanism 6, a box pressing mechanism 7, a hot melt glue machine 8 and an electric cabinet9.

[0012] Such as figure 2 As shown, the frame 1 is welded by square steel, and an adjustment foot 101 is installed at the bottom of the frame 1 .

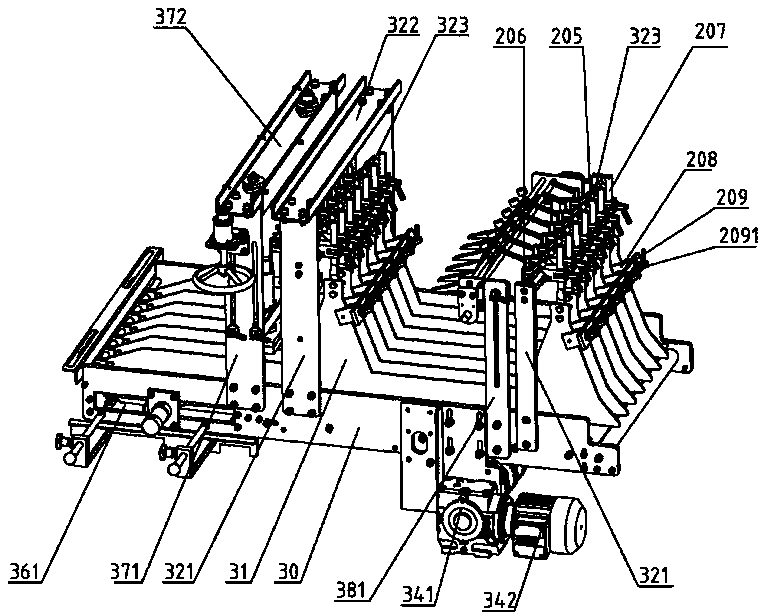

[0013] Such as image 3 and Figure 4 As shown, the bottle dividing mechanism 2 includes a bottle dividing frame 21, and the bottle dividing frame 21 is made up of a bottle dividing frame body 211, a bottle dividing support leg 212 and a bottle dividing adjusting foot 213, wherein the bottle dividing frame body 211 is composed of a left side plate 2111 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com