Patents

Literature

167results about How to "Does not affect placement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

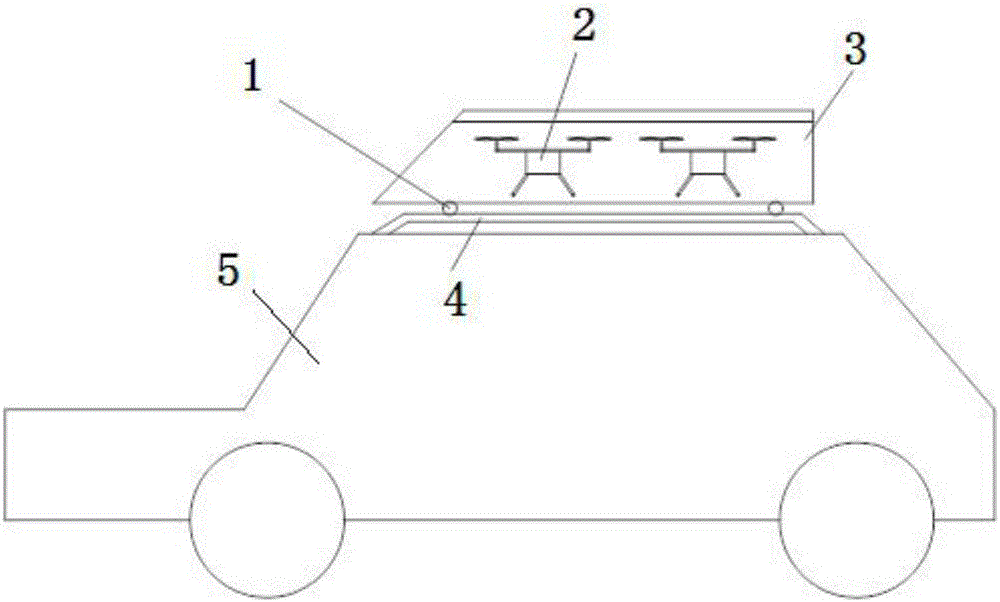

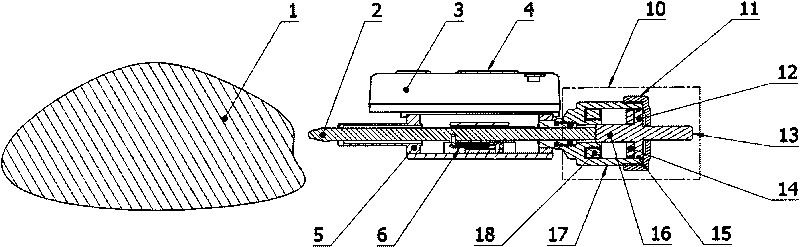

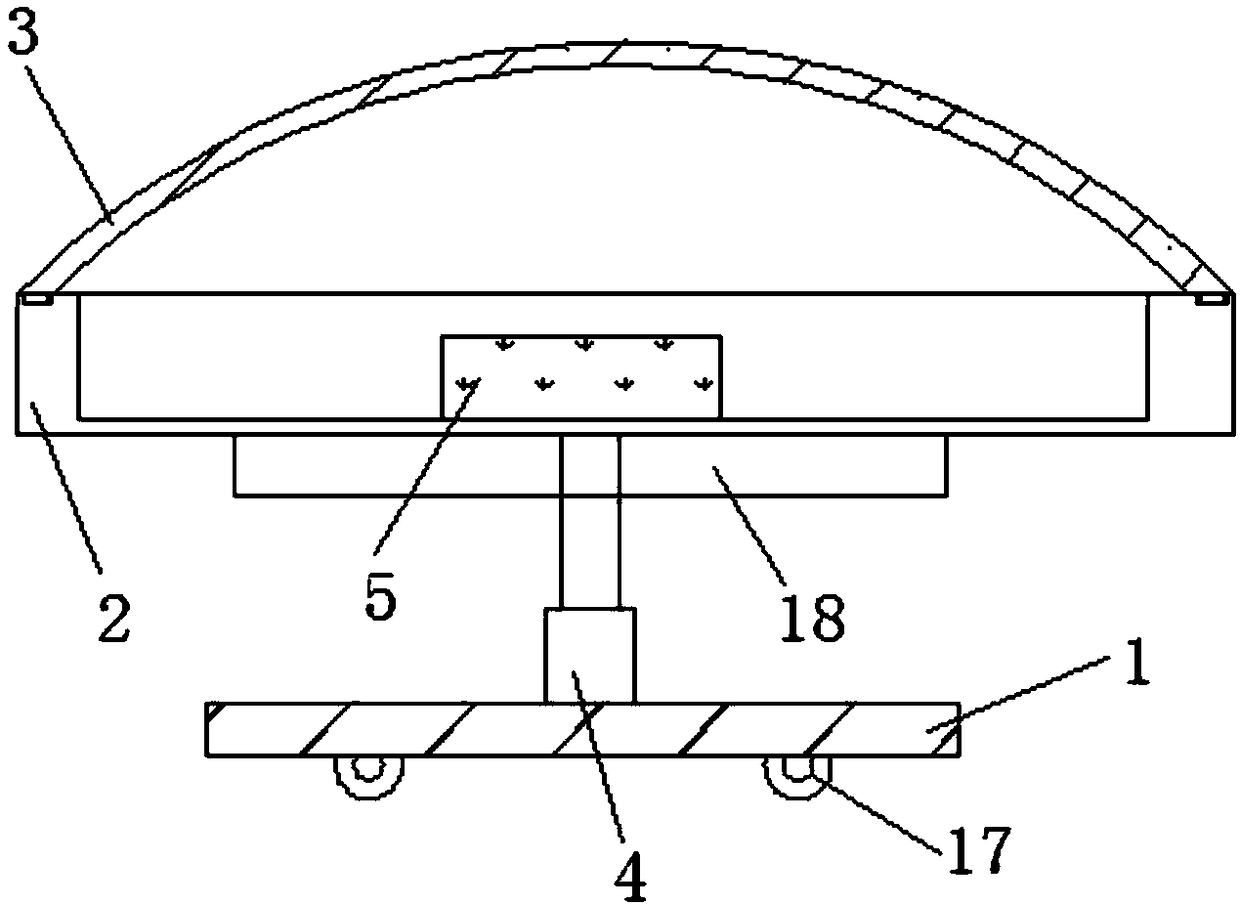

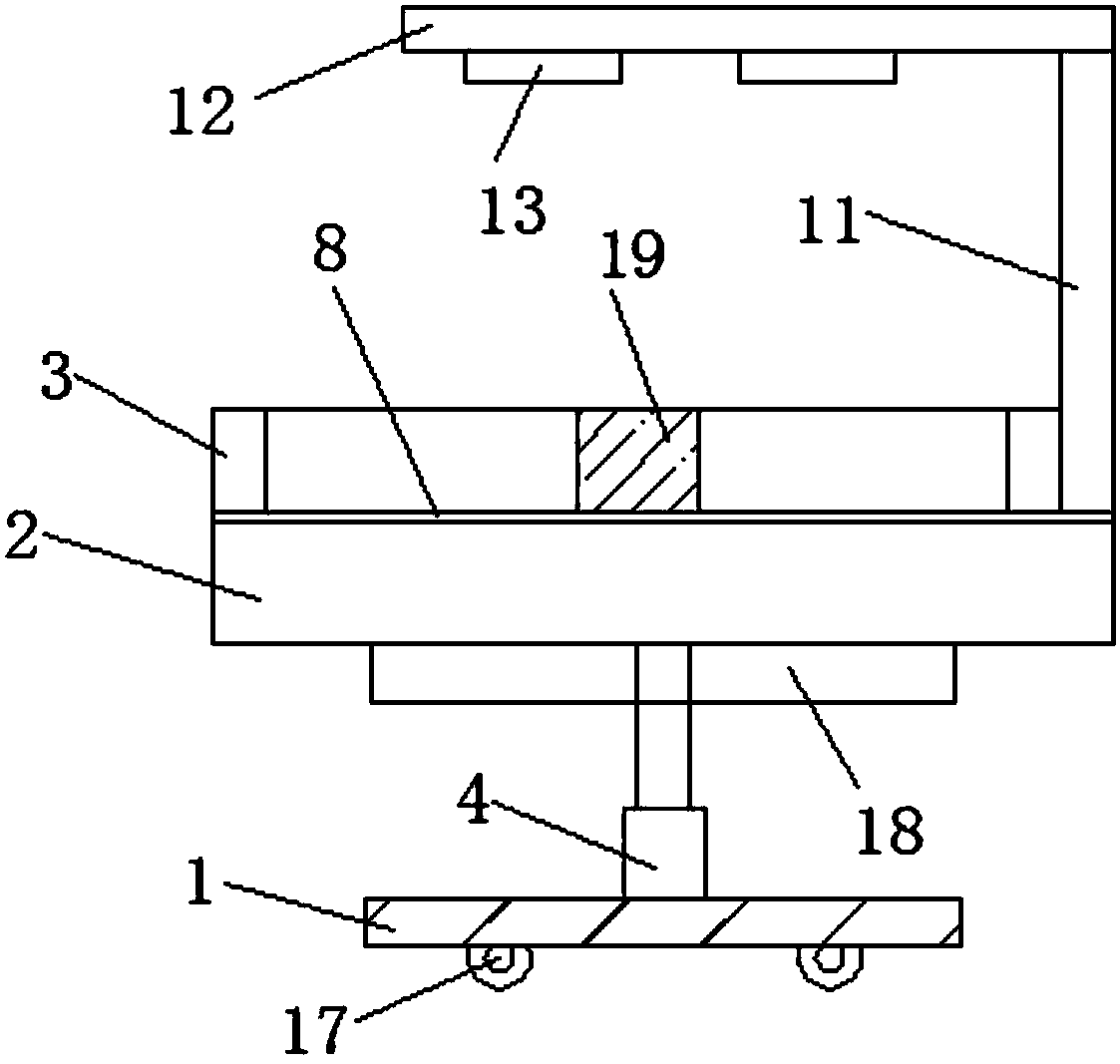

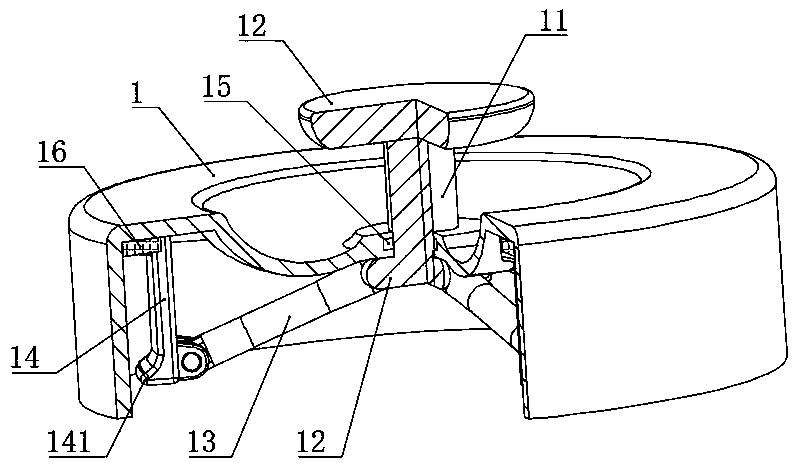

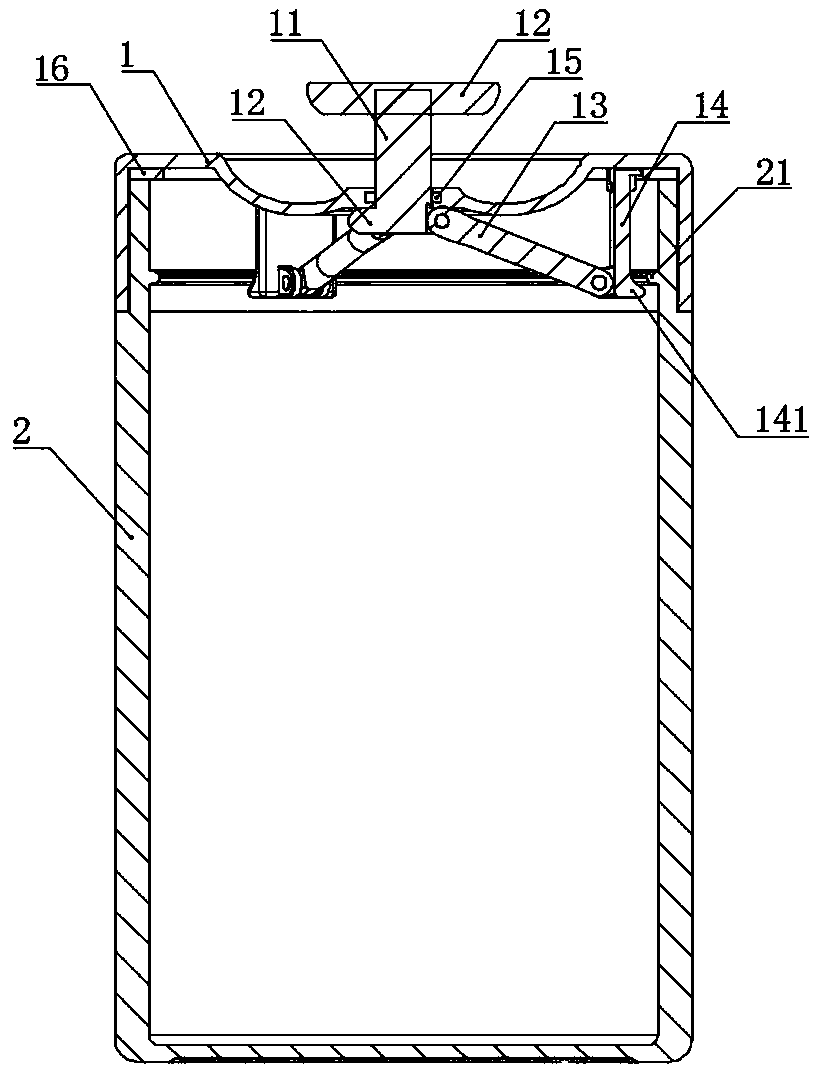

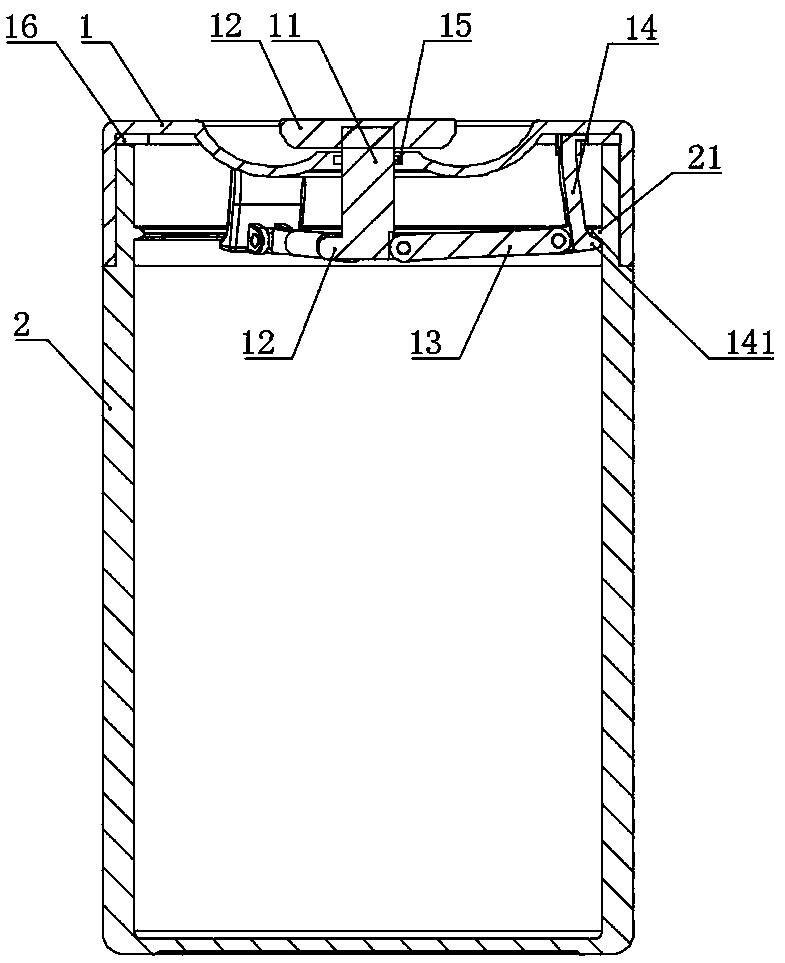

Vehicle-mounted multifunctional platform of unmanned aerial vehicle

InactiveCN106004626ATurn on the implementationAchieve closureAnchoring installationsVehicle carriersIn vehicleRemote control

The invention discloses a vehicle-mounted multifunctional platform of an unmanned aerial vehicle. The vehicle-mounted multifunctional platform of the unmanned aerial vehicle comprises a multifunctional platform bin detachably connected with a roof of the vehicle. A movable bin door is arranged on the top of the multifunctional platform bin and connected with the side wall of the multifunctional platform bin through a bin door control mechanism. A plurality of undercarriage lock control mechanisms are arranged at the bottom of the multifunctional platform bin. The bin door control mechanism and the undercarriage lock control mechanisms are connected with a control circuit board through data lines. The control circuit board is connected with a power source through an external power connection line and connected with a remote control operation terminal via electric signals. The vehicle-mounted multifunctional platform of the unmanned aerial vehicle has the characteristics that the unmanned aerial vehicle can fly at any time, assembling is not needed, the vehicle-mounted multifunctional platform is convenient to carry and transport and can be fixed to a luggage carrier on the roof, all-weather storage is achieved, and the platform can contain a plurality of unmanned aerial vehicles; a controller can follow the unmanned aerial vehicle after the unmanned aerial vehicle takes a flight, the unmanned aerial vehicle can fly by the maximum distance and then land automatically in a specific location, and the unmanned aerial vehicle can be charged in time when not taking a flight.

Owner:郭永

Information display device

The invention discloses an information display device which comprises an underframe and a displayer, wherein the underframe is provided with a sliding joint chamber inside and a bearing plate fixed on the rear end, and meanwhile, a pressing groove with extended two ends is symmetrically disposed inside the upper end wall of the underframe and interconnected with the sliding joint chamber; an upper sliding-joint plate and a lower sliding-joint plate are installed inside the sliding joint chamber in an up-and-down slip connection mode, and both sides of the upper sliding-joint plate are symmetrically provided with sliding joint blocks which penetrate into the pressing groove; inside the upper end wall, interconnecting grooves interconnected with the sliding joint blocks are symmetrically arranged in a fore-and-aft direction and a left-and-right direction; a plug arm coordinately connected to the interconnecting groove is fixedly installed on the upper end of the lower sliding-joint plate, and a plug groove with a notch facing downwards is mounted inside the bottom wall of the displayer, and cooperates with the plug arm; an installing groove provided with a fixing arm inside in a slip connection mode, is arranged inside the outer end wall of the plug groove and interconnected with the plug groove; a locking groove which cooperates with the fixing arm, is arranged inside the sliding joint blocks.

Owner:GUANGDONG RAYMON TECH

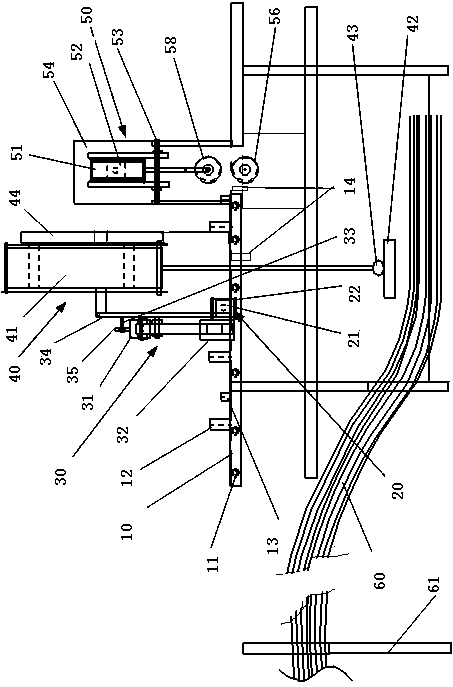

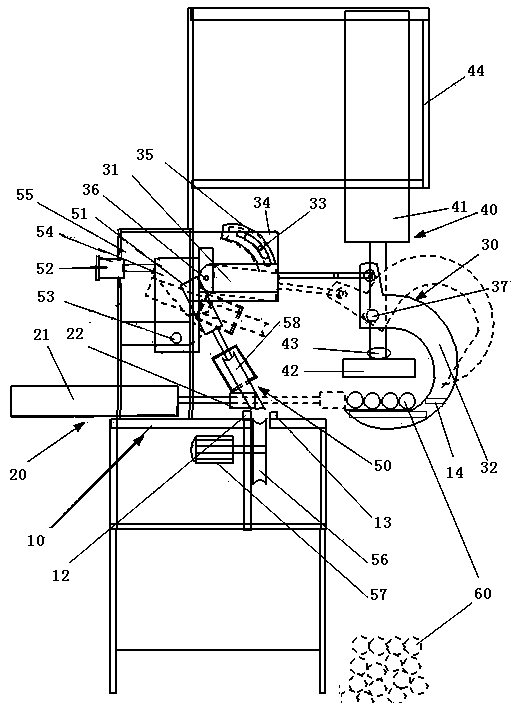

Automatic batten plate splicing machine

ActiveCN106863497AClear division of laborImprove efficiencyOther plywood/veneer working apparatusWood veneer joiningRotational axisAutomatic control

The invention relates to an automatic batten plate splicing machine which comprises a work frame, a feeding device, a pressing wheel buffering device, a gluing device, a sawing device, a one-way pushing device, a plate pushing device, an electrical automatic control system and a main conveying belt. The tail end of the main conveying belt is provided with a limiting mechanism. The pressing wheel buffering device comprises a power mechanism, a moving mechanism and a transmission mechanism. A buffer drives rotating shafts to move vertically through a connecting piece to buffer vertical displacement changes, brought by movement, of rolling pressing wheels. The automatic batten plate splicing machine is reasonable in structure, ingenious in design, capable of conducting discharging conveniently, high in conveying speed and stable; plate splicing and gluing are integrated; a buffering mechanism is arranged so that the service life can be effectively prolonged, and the technical problems that in an existing batten plate splicing machine, discharging is not stable, battens are likely to be stacked, the conveying speed is too low, noise is large, battens need to be glued in advance for standby use, manual work is wasted, and the service life is affected are solved; and the automatic batten plate splicing machine is an important technical innovation for the prior art and has very good market prospects and development space.

Owner:PINGDINGSHAN ANTAIHUA MINING SAFETY EQUIP MFG

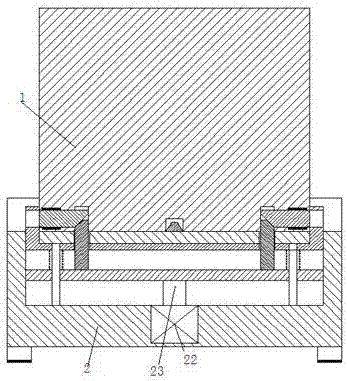

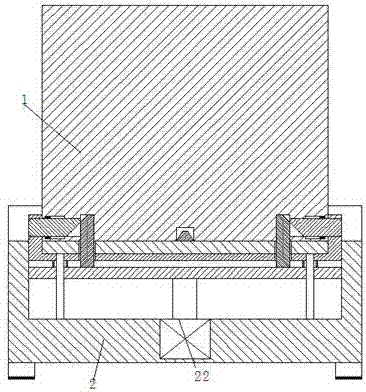

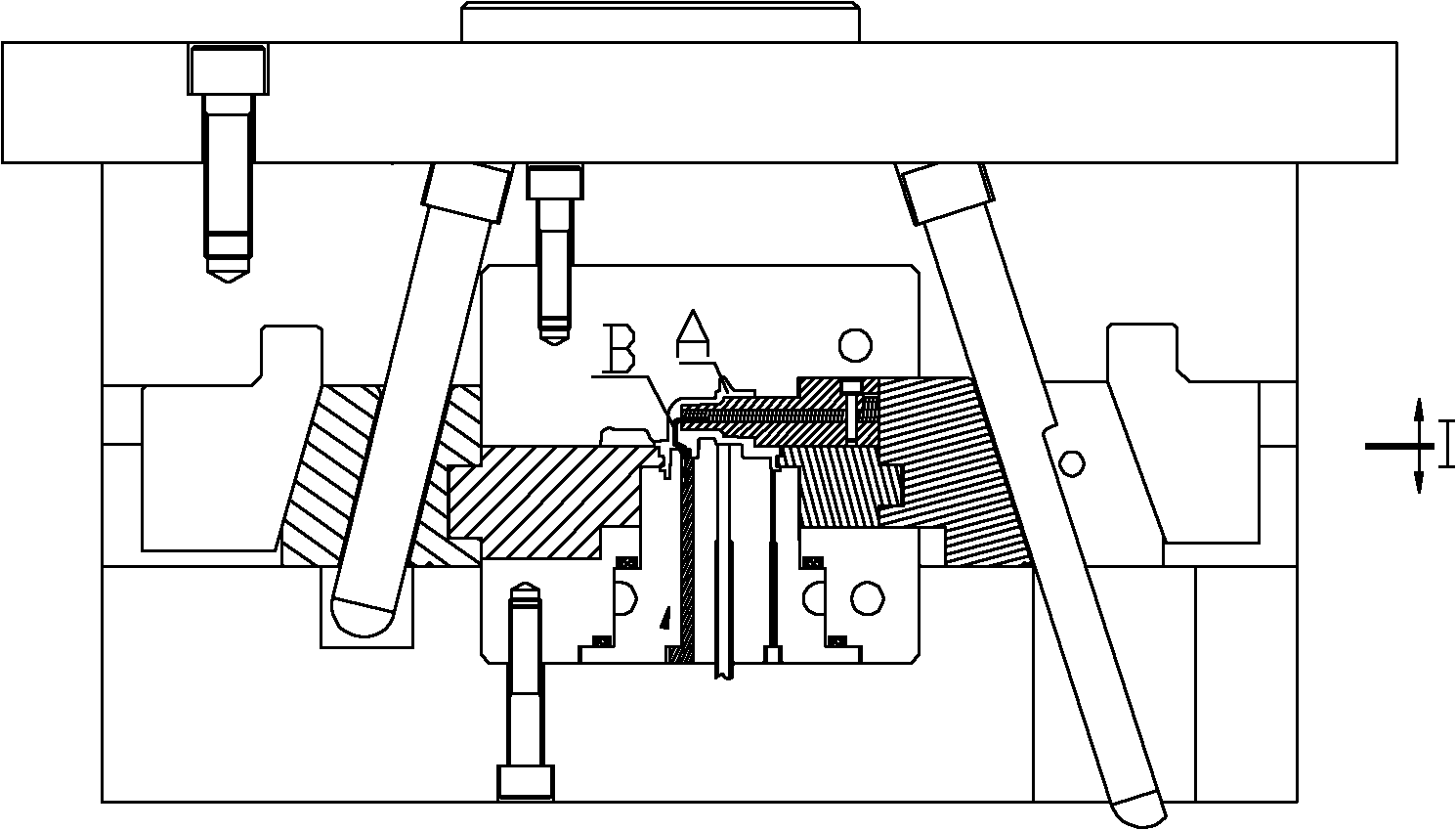

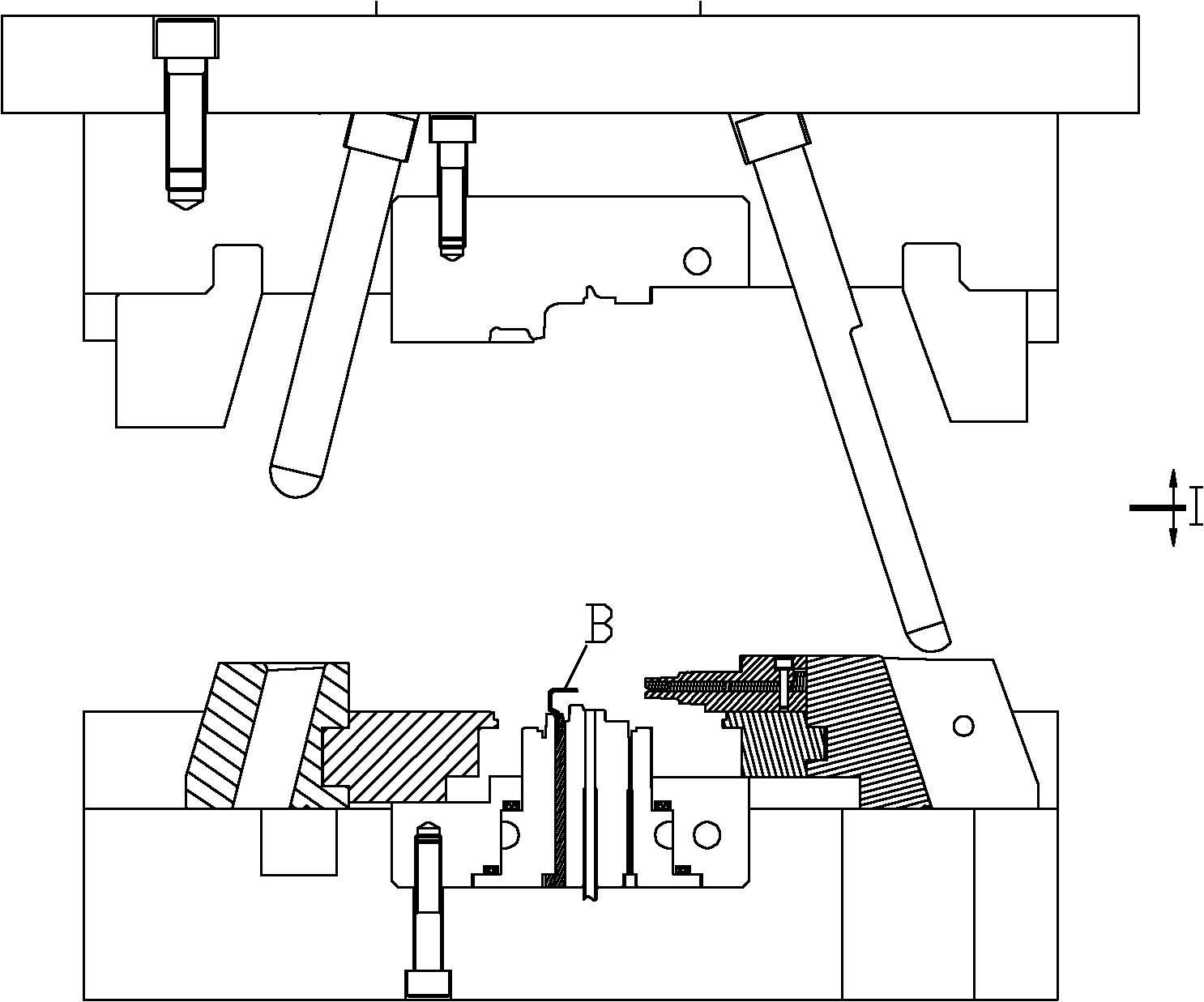

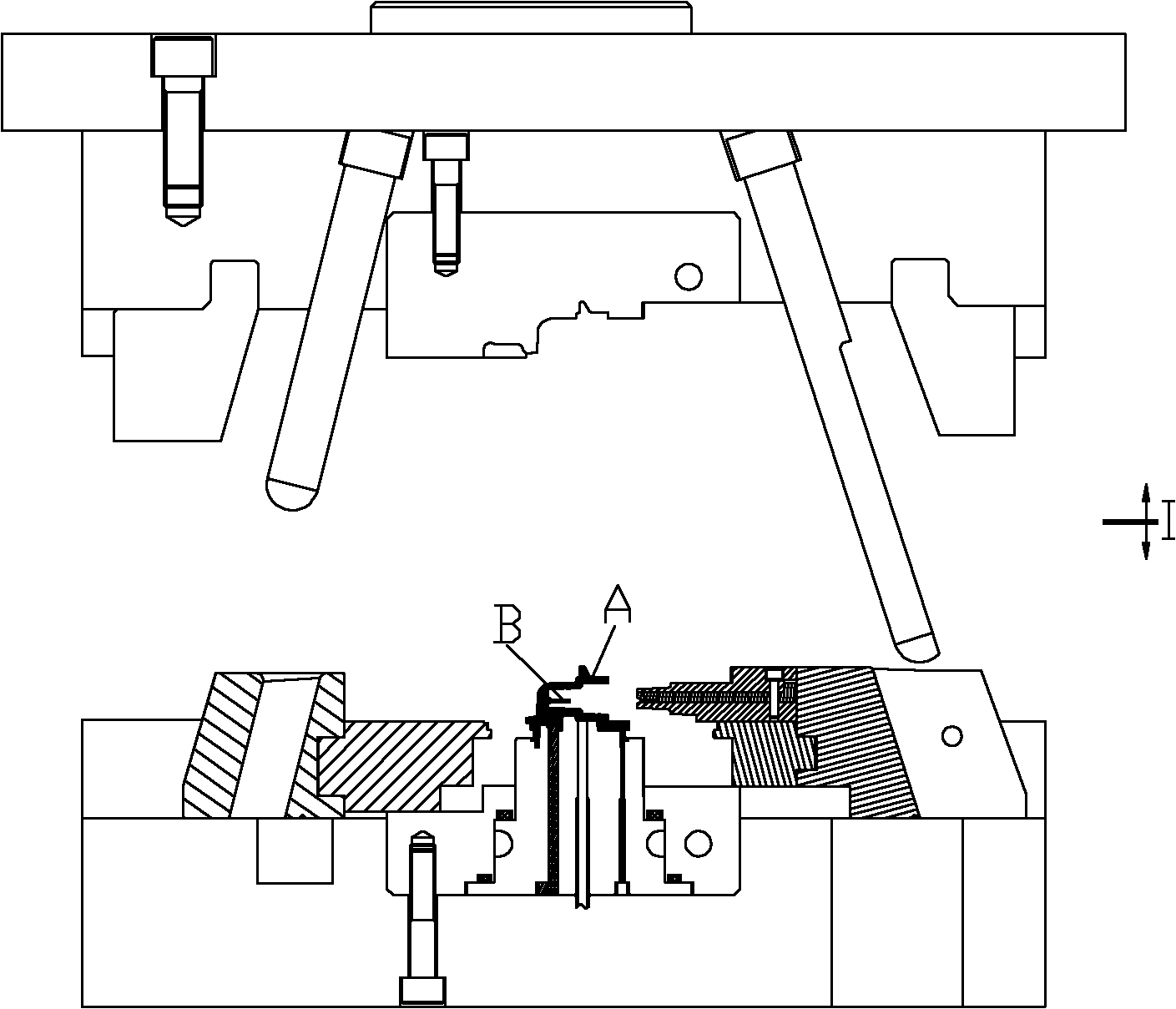

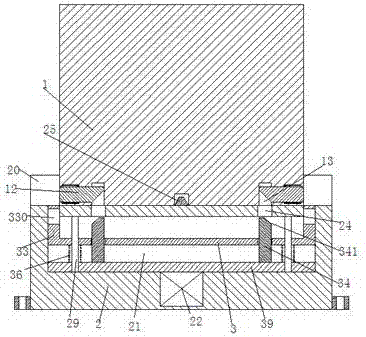

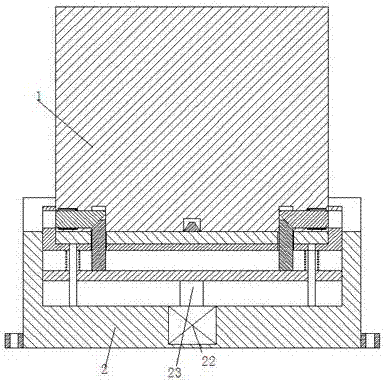

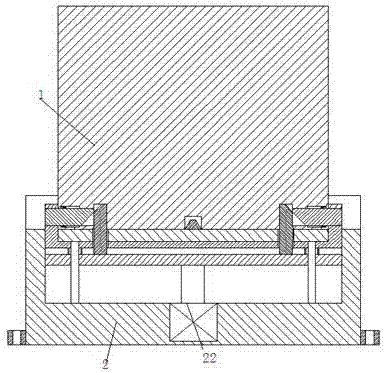

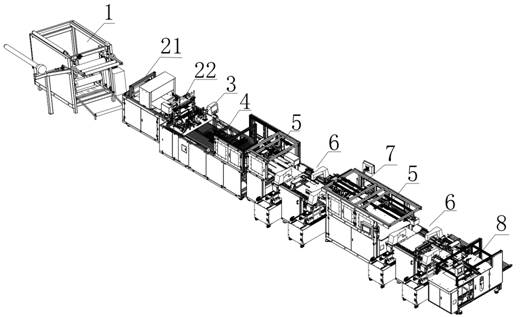

Double-mould-opening and double-core-pulling mechanism

The invention discloses a double-mould-opening and double-core-pulling mechanism. The mechanism comprises an upper template, a middle template and a lower template, wherein a lateral core pulling mechanism is arranged between the middle template and the lower template and comprises a first lateral slide block and a first inclined guide pillar; the first lateral slide block is slidably arranged onthe lower template and is provided with an inner poking block and an outer poking block; a mould opening spring is arranged between the upper template and the middle template; the middle template is connected with the lower template through a mould locking snap; the first inclined guide pillar is fixedly connected with the upper template; the middle template is provided with a guide groove which is matched with the first inclined guide pillar; the first lateral slide block consists of an upper slide block and a lower slide block; the lower slide block is slidably connected with the lower template; the upper slide block is slidably connected with the upper surface of the lower slide block; both the upper slide block and the lower slide block are provided with an inner poking block and an outer poking block; and the outer poking block of the upper slide block is closer to the first inclined guide pillar than the outer poking block of the lower slide block. The mechanism has the advantages of guaranteeing no deformation of a plastic product during core pulling, guaranteeing accuracy of size of the product, not influencing placement of a metal insert and achieving a simple structure and easiness and convenience for operation.

Owner:NINGBO TIANLONG ELECTRONICS

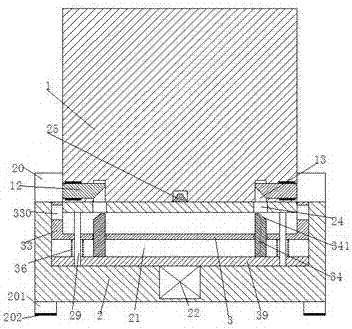

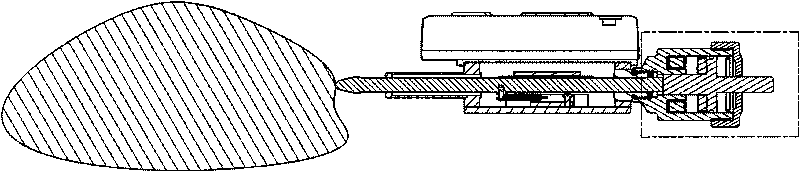

Impulse sensor with damper for actively measuring linear displacement

InactiveCN101750008AEasy to assembleMature technologyUsing electrical meansFast measurementEngineering

The invention discloses an impulse sensor with a damper for actively measuring linear displacement, which comprises a base, a measuring rod, a control circuit, and a drive component. The impulse sensor is characterized in that: after sending an instruction to the drive component, the measuring rod extends forwards to contact with a measured workpiece; the control circuit acquires a measuring point position (namely, a displacement value) through measuring the amount of movement of the measuring rod; the measuring rod completes the extension action to contact the measured object, pauses and automatically retracts to an initial state to finish a measuring cycle; and the measuring value is maintained in the measuring cycle so as to display, read or upload to an external circuit for further processing. The whole measuring process can be finished under the control of the external circuit. The power of the drive component can be electromagnetic, pneumatic or hydraulic and in other modes. A damper is arranged in the sensor for reducing the measuring oscillation. The impulse sensor has the characteristics of actively extending, automatically measuring, maintaining the numerical reading, and the like. Batch measurement or on-line automatic rapid measurement of the measured object can be realized. A plurality of the sensors can build a large-scale automatic error measurement system.

Owner:涂成生

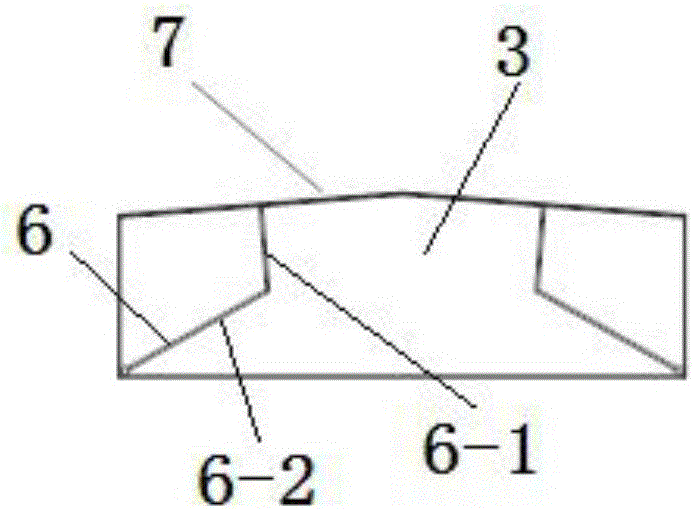

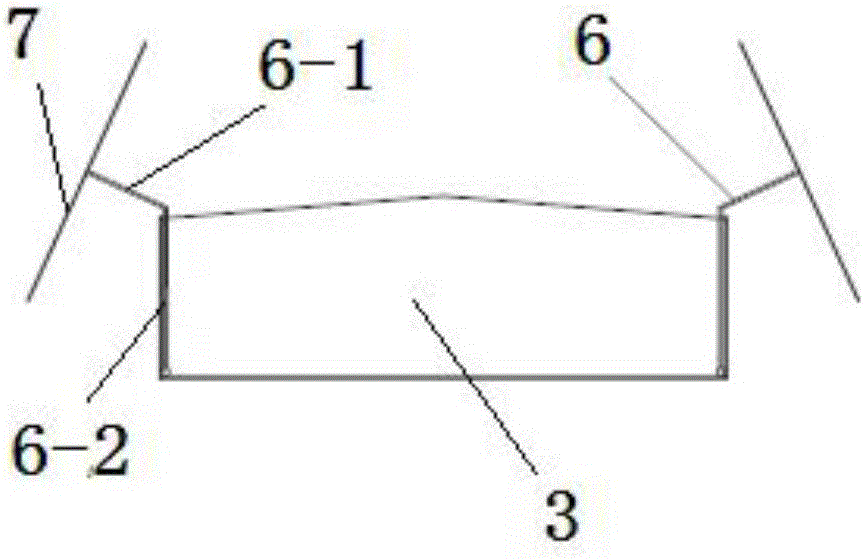

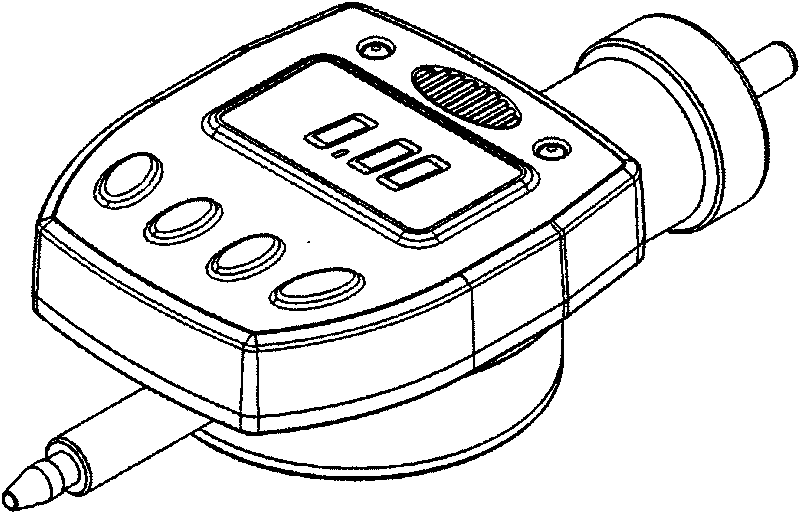

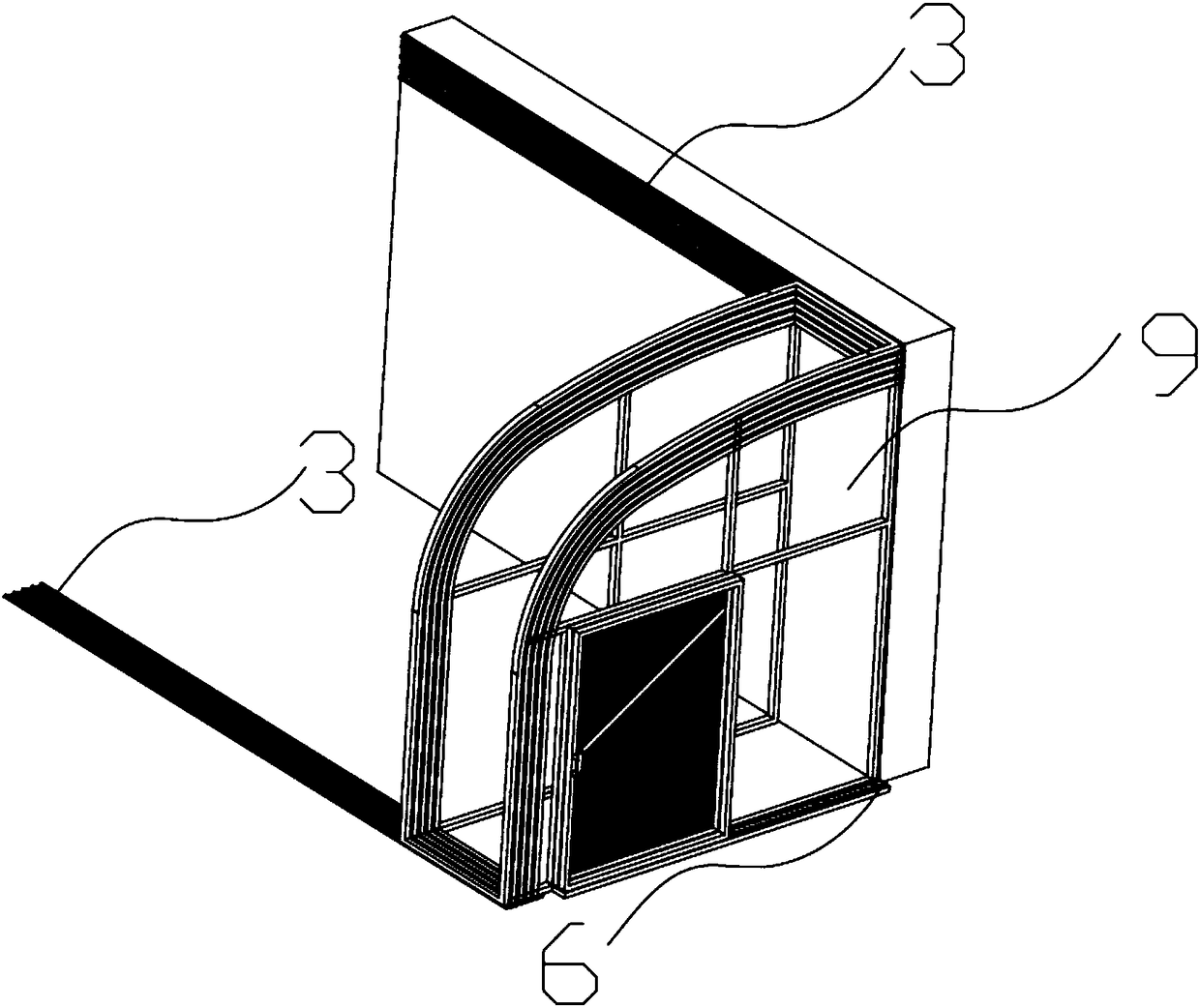

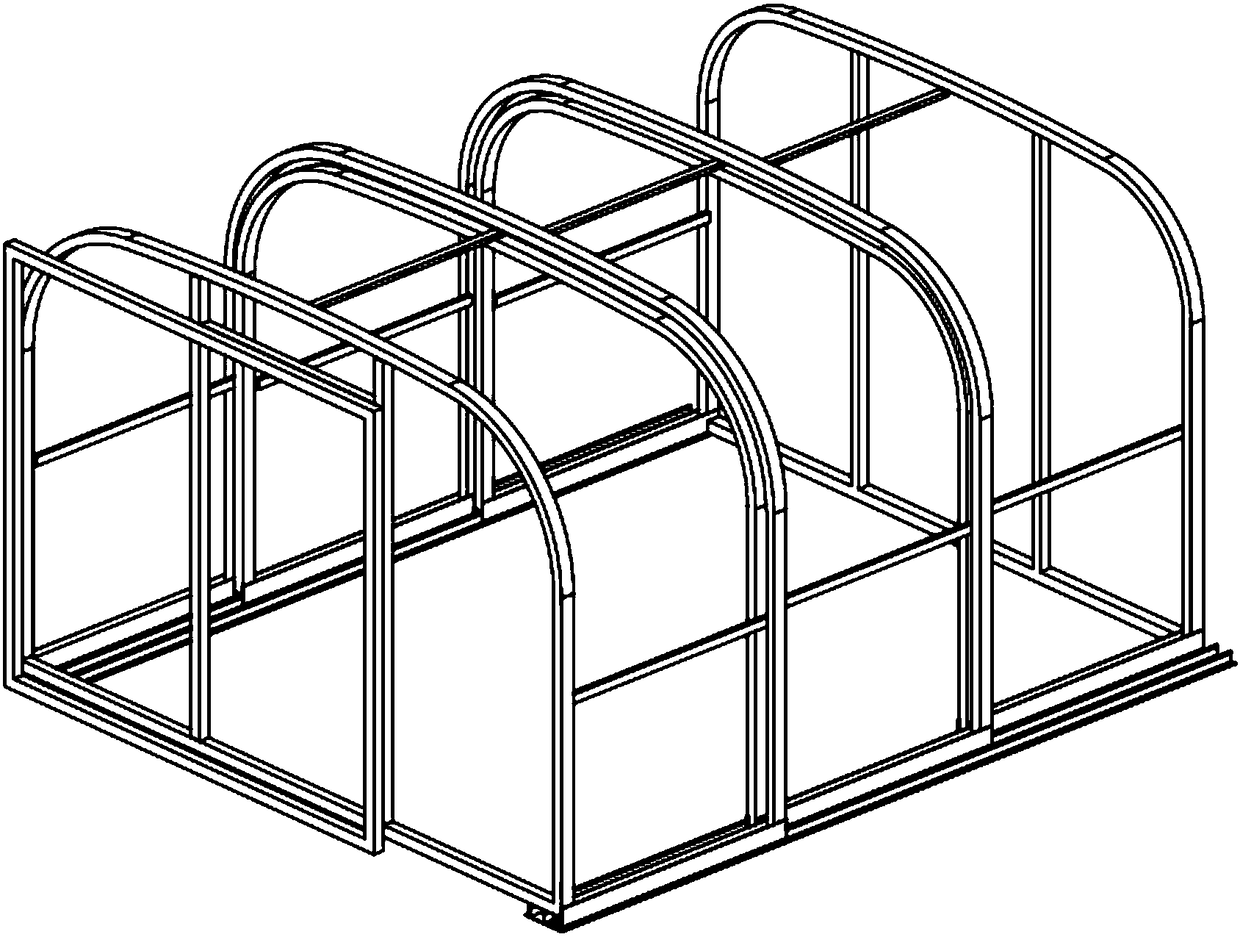

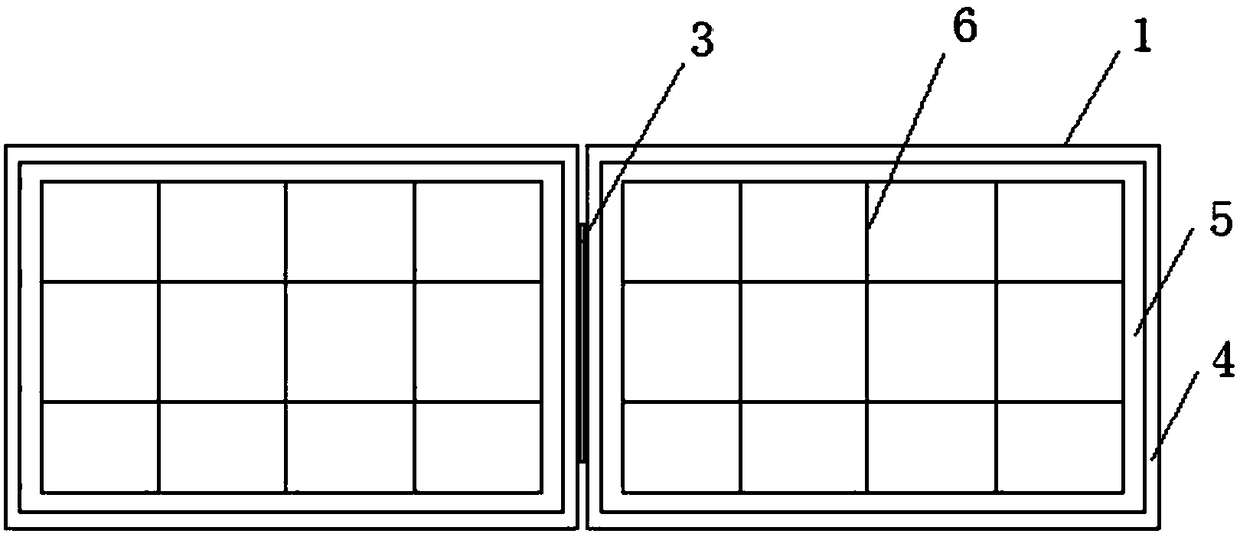

Retractable sunlight room

PendingCN108265821ASave spaceSmall footprintWallsInsect protectionThermal insulationStructural engineering

The invention provides a retractable sunlight room which comprises a curtain wall and gable walls. The curtain wall is constituted by at least two curtain wall material bodies, and each curtain wall material body comprises a profile frame and a transparent wall body wrapped with the profile frame. The curtain wall material bodies are mutually nested, and the two ends of each curtain wall materialbody are arranged in a sliding rail. The gable walls are independent fixed-type gable walls or conjoined gable walls, the conjoined gable walls are fixed to the head curtain wall material body and thetail curtain wall material body and slide together with the head curtain wall material body and the tail curtain wall material body, and the independent fixed-type gable walls are fixed to the groundon the two sides of the sunlight room and do not slide along with the curtain wall material bodies. According to the retractable sunlight room, overall contraction of the whole sunlight room is achieved, the place is saved, the occupied area is small after contraction, and illegal buildings can be prevented; retraction and extension are convenient, almost 90% of the retractable sunlight room canbe extended, the ventilating effect is good, and the characteristics of thermal insulation, flame retarding and good heat-preservation effect are achieved.

Owner:苏州苏伊士智能科技有限公司

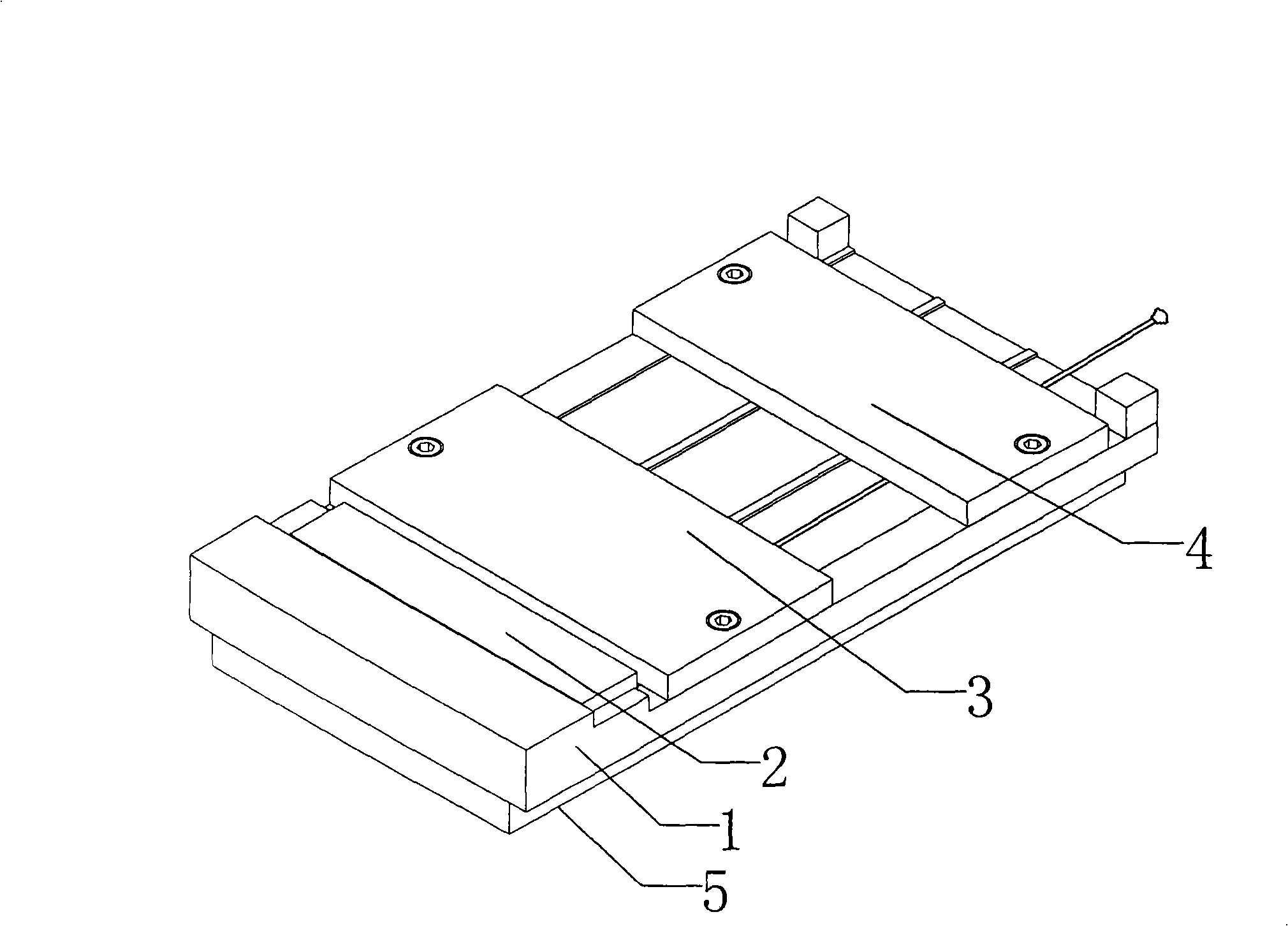

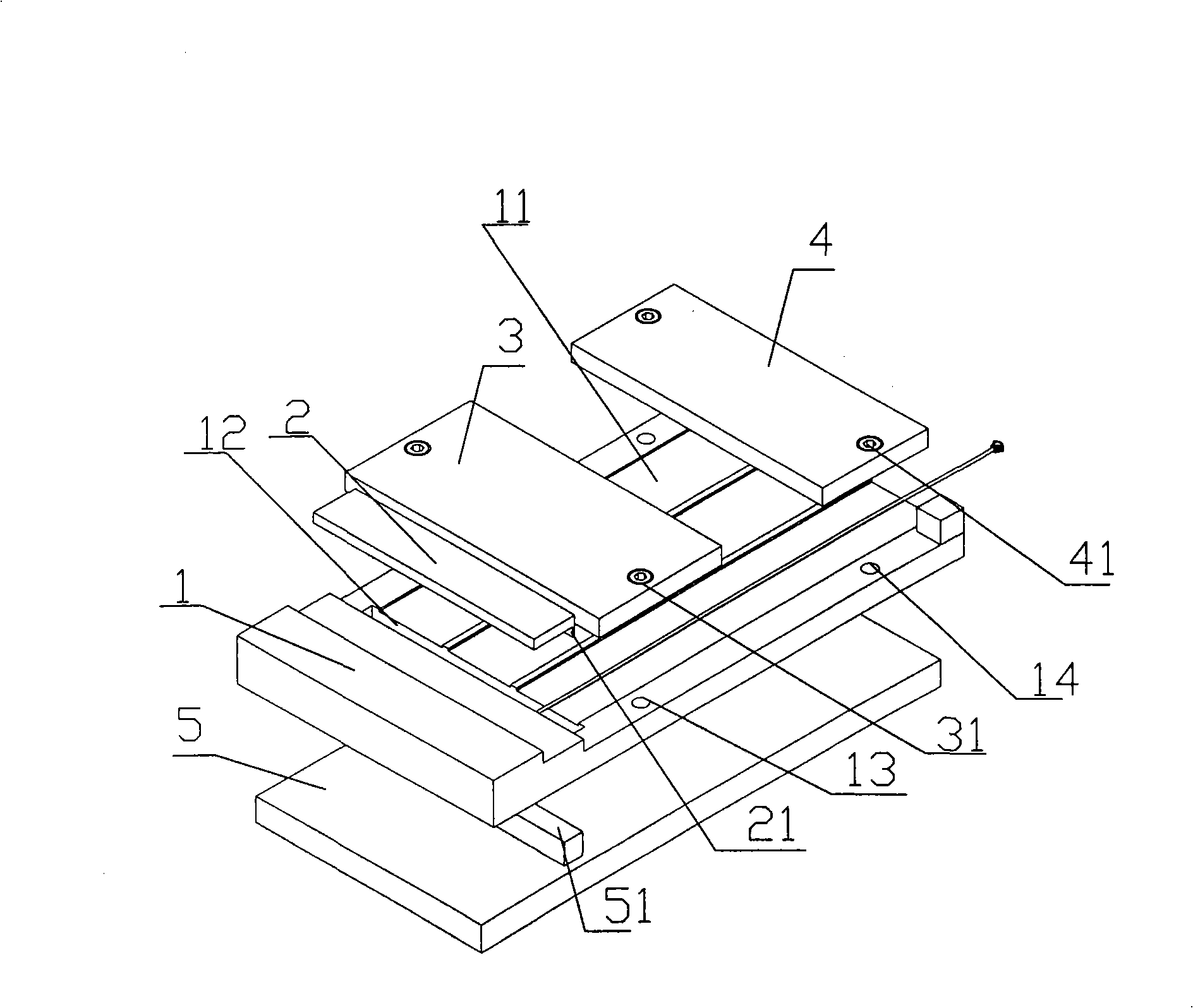

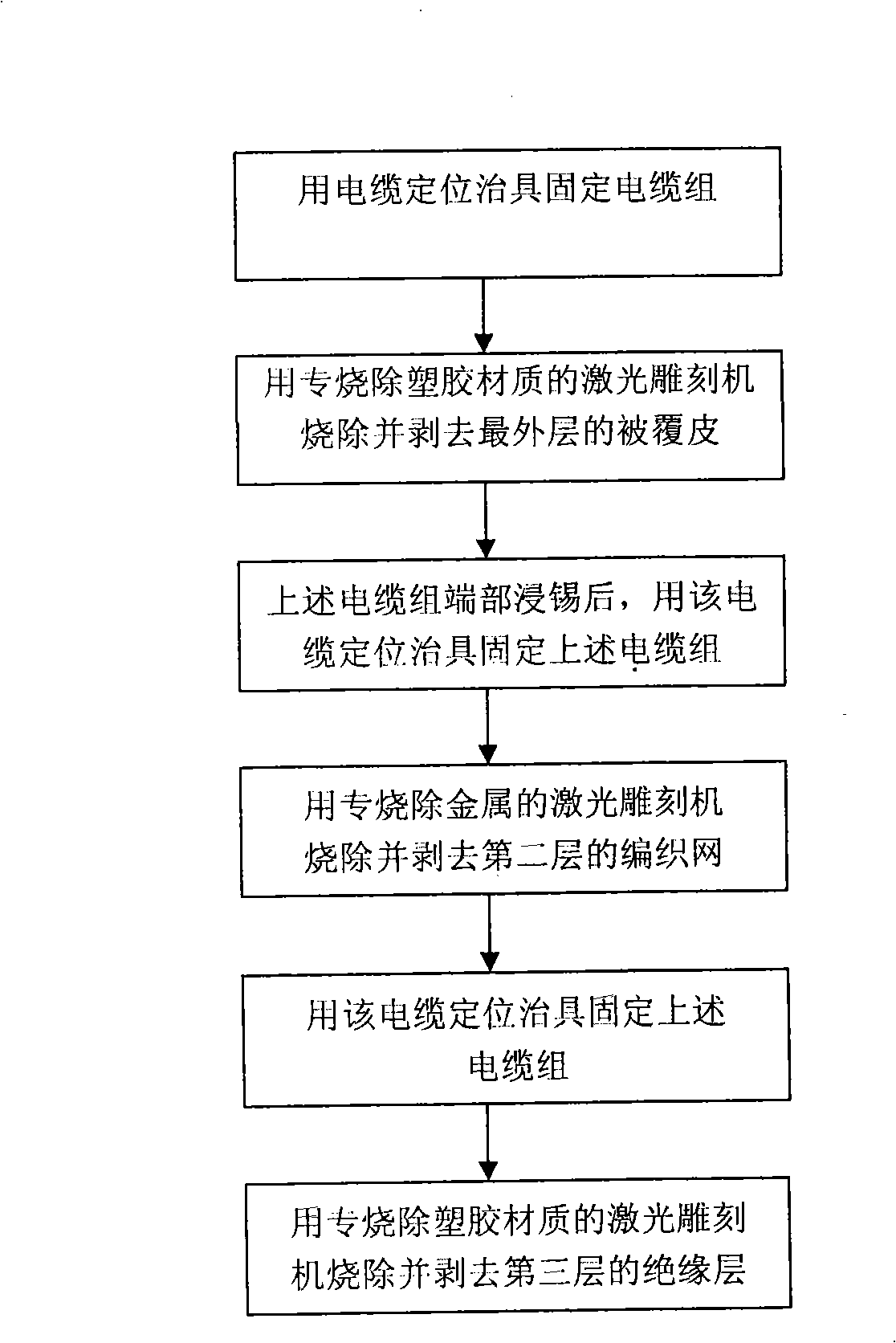

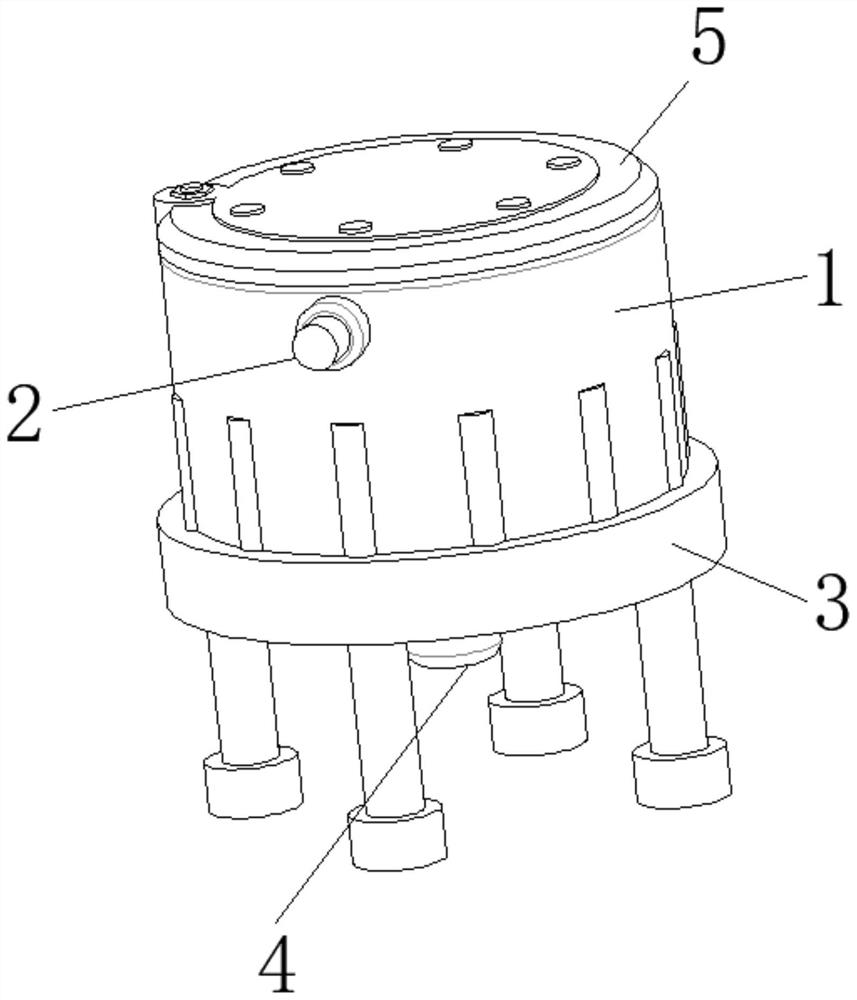

Cable locating jig and cable wire stripping method based on the same

InactiveCN101494351AEasy to fixEasy to placeLine/current collector detailsApparatus for removing/armouring cablesMesh gridFront cover

The invention discloses a cable locating jig, which comprises a substrate, a buckle plate, and a front cover plate; the substrate is provided with a table facet for placing a cable group; a laser groove is arranged at the front end of the table facet; the buckle plate is arranged on one side of the laser groove and is provided with an upright plane convenient for aligning with an end head of the cable group; the front cover plate is arranged on the other side of the laser groove; a pair of locating rods and a pair of locating holes are respectively arranged between the front cover plate and the substrate, which are convenient for compressing the head of the cable group; the abreast cable groups are arranged on the table facet of the substrate; the end head of the cable group is aligned with the upright plane of the buckle plate; and then the front cover plate and a back cover plate are respectively fixed on the table facet through covering the locating rods and the locating holes; the cable locating jig is arranged on a laser engraving machine; after the locating table facet is put on the laser groove, exterior coating of the cable is burnt; the cable group with coating pulled out is then dipped in tin at a position of an exposed cable mesh grid and is placed on the cable locating jig again; the mesh grid is burnt by the laser engraving machine; the cable group with the mesh grid removed is placed on the cable locating jig again; and an insulating layer is burnt by the laser engraving machine.

Owner:张志辉

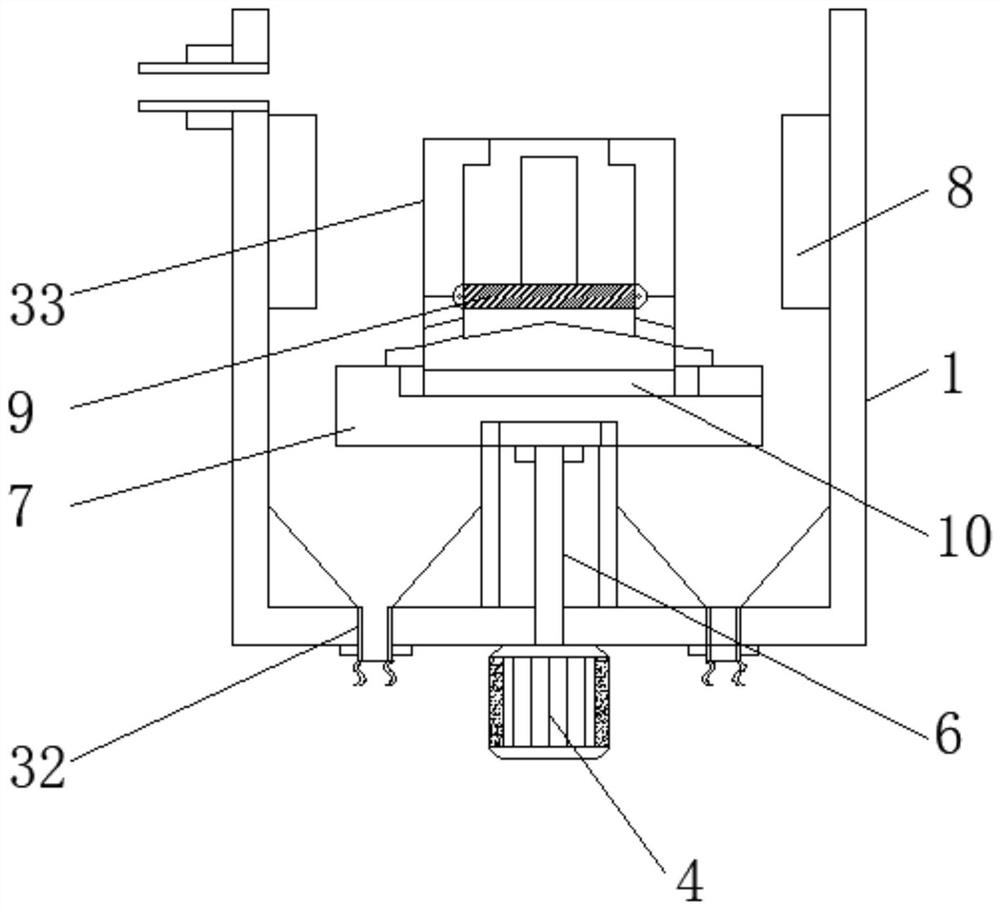

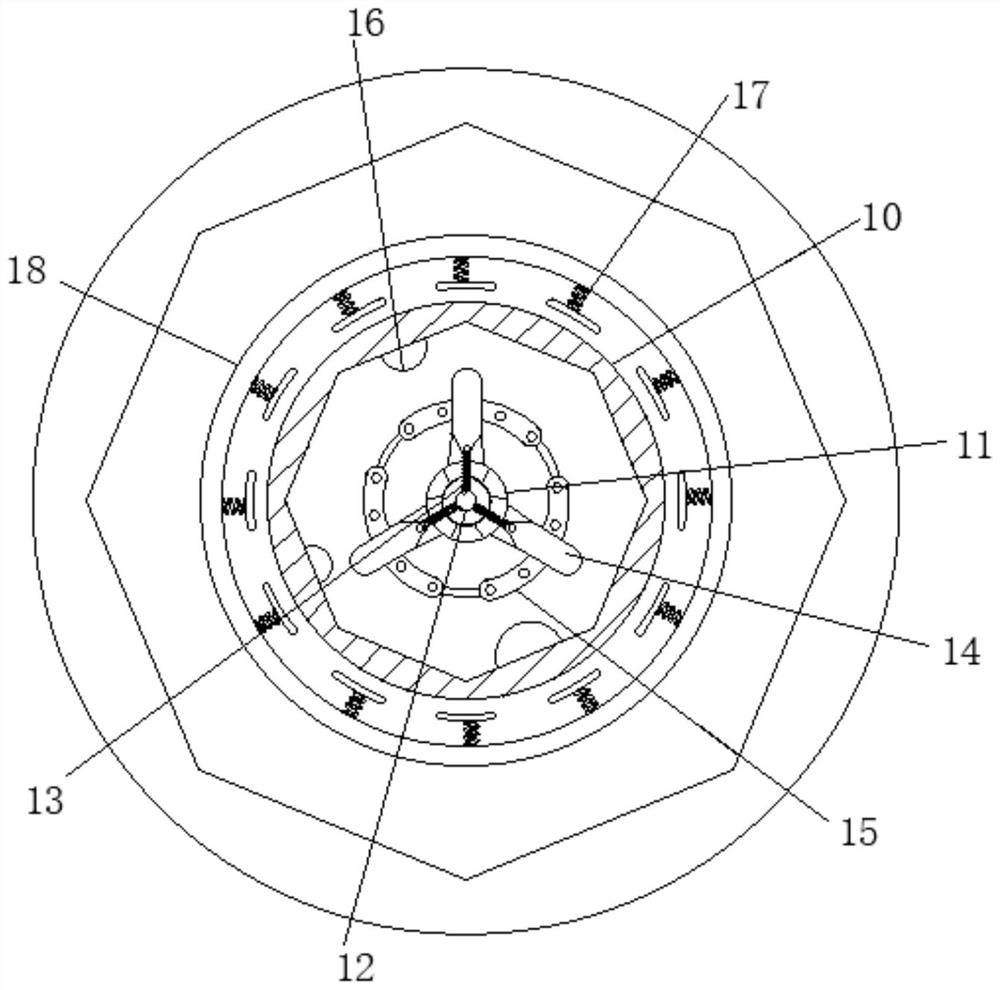

Mechanical part cleaning device

PendingCN113070272AConstantly changing impact forceThe impact force intensifiesCleaning using toolsCleaning using liquidsElectric machineryDrive motor

The invention provides a mechanical part cleaning device, and relates to the field of mechanical part cleaning. The mechanical part cleaning device comprises a cleaning box, a water inlet pipe, a mounting frame, a driving motor and a cover plate, the mounting frame is arranged on the outer wall of one side of the cleaning box, the cover plate is hinged to the outer wall of one side of the cleaning box, the driving motor is arranged on the outer wall of the bottom end of the cleaning box, the output of the driving motor is connected with a rotating shaft through a coupler, a protection plate is arranged on the outer wall of the rotating shaft, a supporting plate is arranged on the outer wall of the top end of the protection plate, a rotating mechanism is arranged outside one end of the rotating shaft, a cleaning cylinder is arranged on the outer wall of one side of the supporting plate, and a polygonal plate is arranged on the inner wall of the cleaning box. According to the mechanical part cleaning device, the impact force of water flow on parts is intensified, so that the cleaning effect is enhanced, impurities on the parts can rapidly fall off, mutual collision between the parts in the cleaning process can be reduced, and the parts are protected in the cleaning process.

Owner:白林

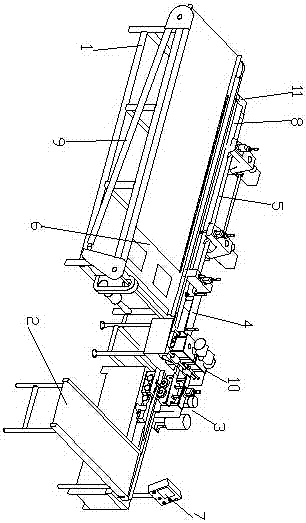

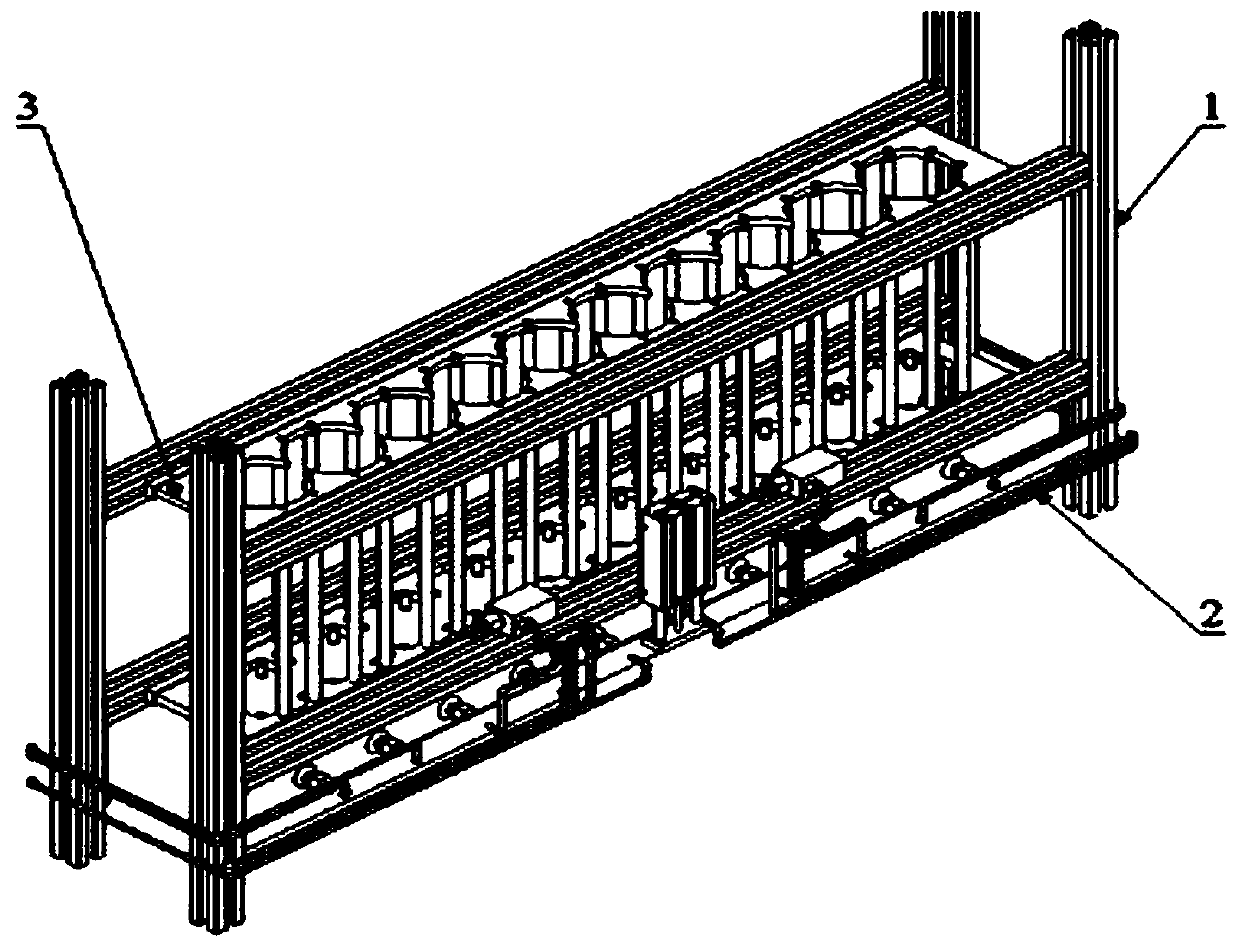

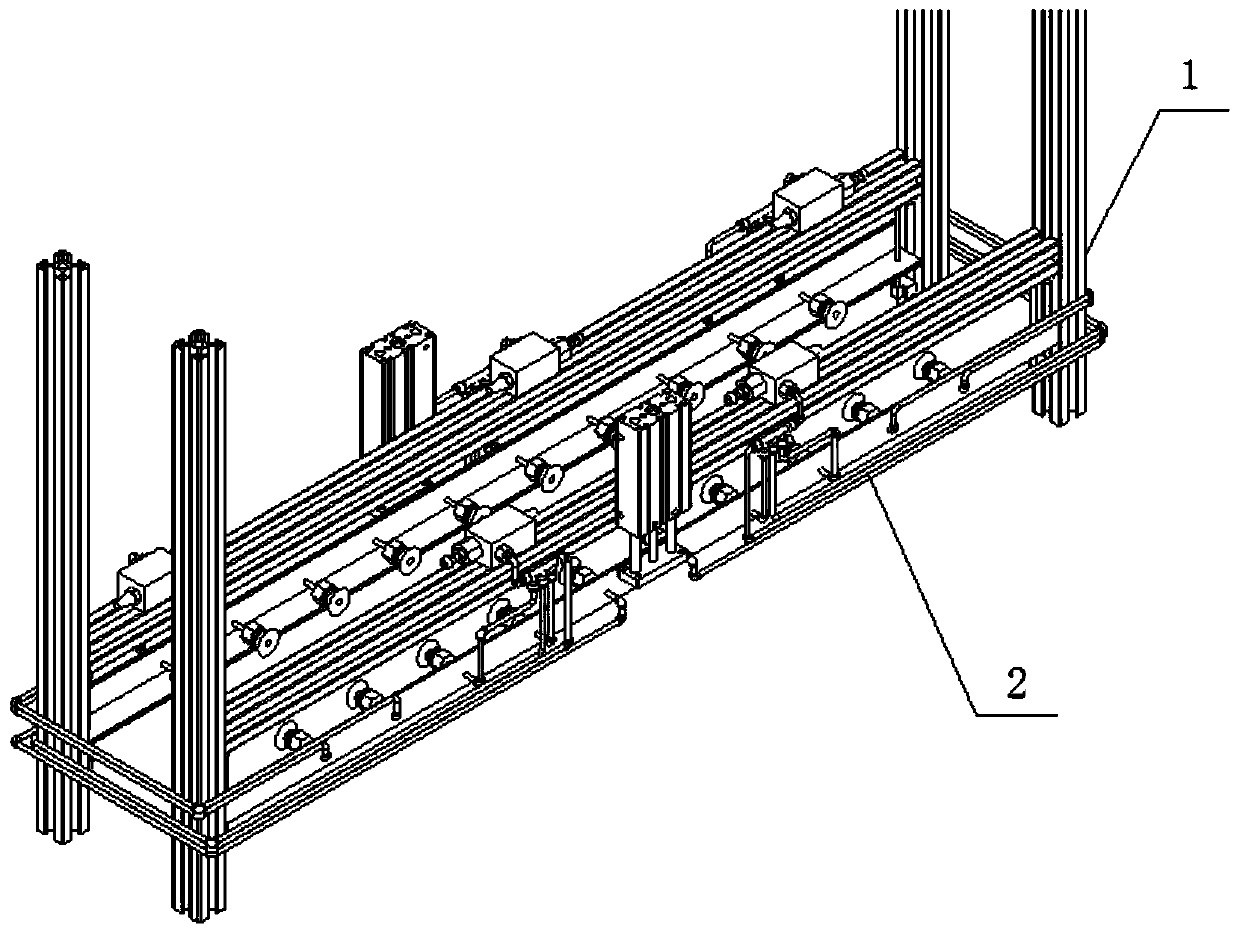

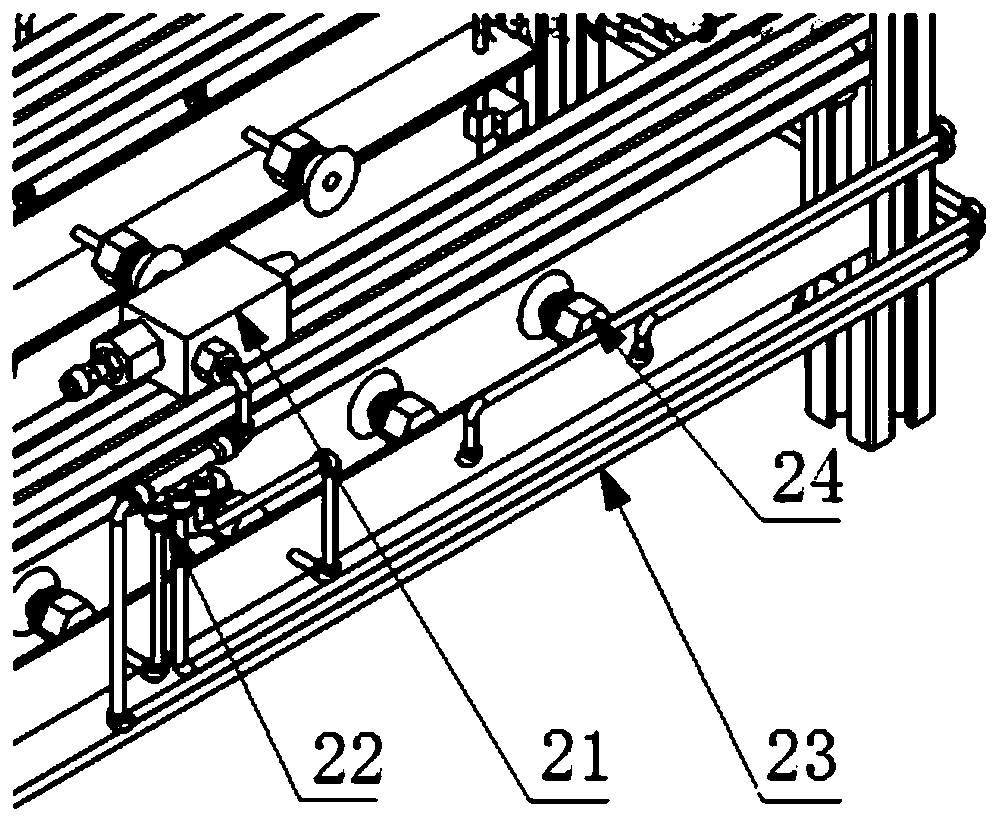

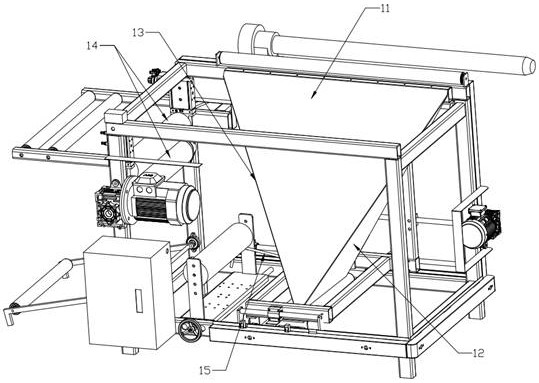

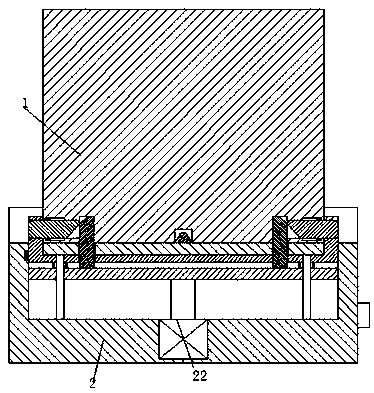

Basin fetching and separating mechanism for full-automatic transplanter for potted flower plug seedlings

The invention relates to the flower transplanting field and particularly relates to a basin fetching and separating mechanism for a full-automatic transplanter for potted flower plug seedlings. The basin fetching and separating mechanism comprises a stander (1), transverse sectional materials (11), longitudinal sectional materials (12), a basin fetching and separating part (2), a basin storage part (3) and part U-shaped slide ways (31), wherein the transverse sectional materials (11) and the longitudinal sectional materials (12) are arranged on the stander (1), and the part U-shaped slide ways(31) are formed in the basin storage part (3); and the part U-shaped slide ways (31) are formed in the upper and lower transverse sectional materials (11) of the stander (1), the basin storage part (3) is detachably arranged on the stander (1) through the U-shaped slide ways (31), and parts in the basin fetching and separating part (2) are fixed on the stander (1) through bolts. The basin fetching and separating mechanism is simple in structure and relatively low in cost, can be matched with supporting facilities to finish the assembly line work of the transplantation of flowers and is reliable in performance; and flower seedlings can be precisely grabbed from a hole tray in the transplantation process and transplanted into an earthen basin, so that the manual operation is replaced with machine operation, and the labor is saved.

Owner:SHENYANG AGRI UNIV

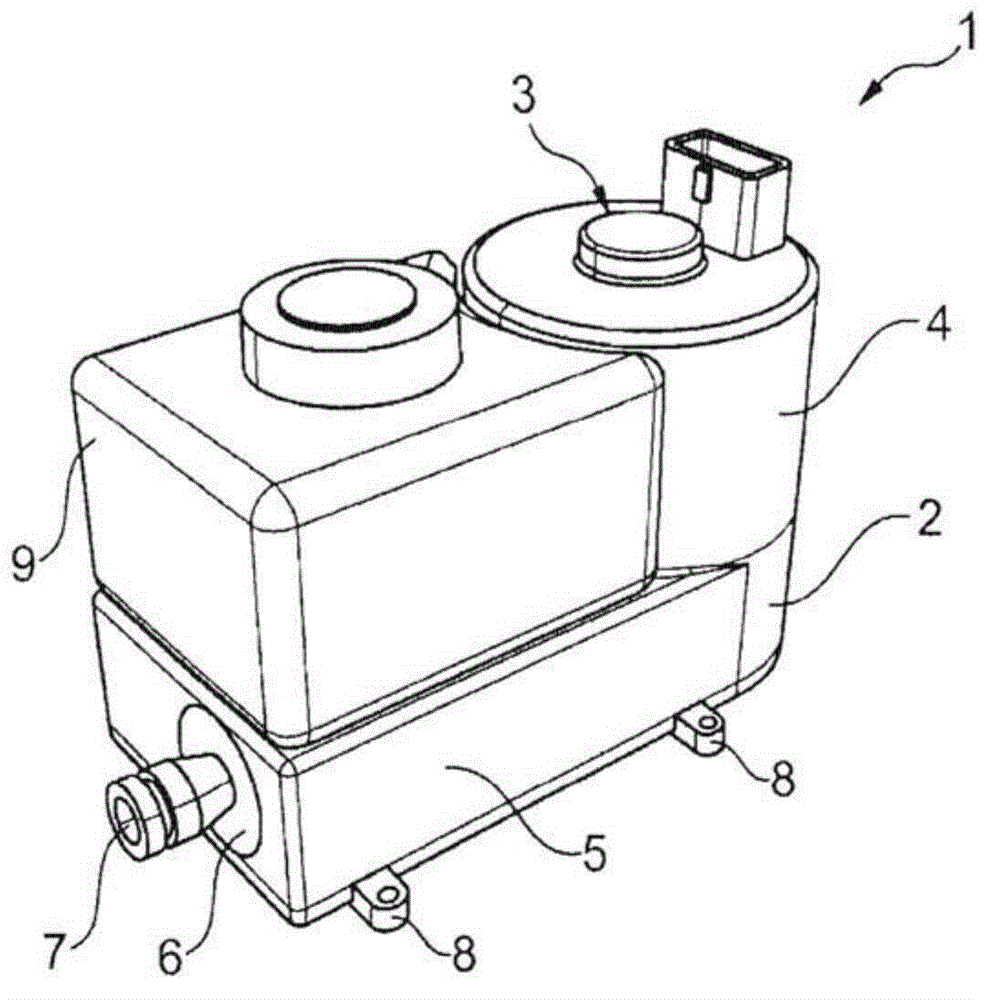

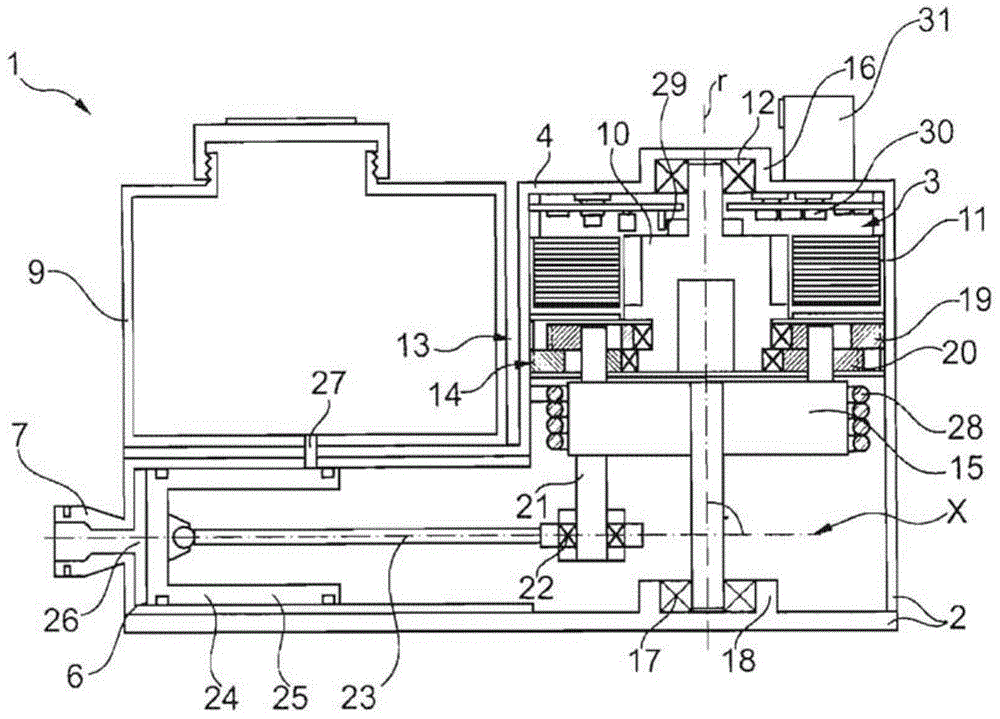

Hydrostataktor

The invention refers to a hydrostataktor which is provided with an active cylinder piston with a hydrostatic section and linearly operated by means of a piston rod by a motor, and a transmission device for converting rotation of a rotator of the motor into the linear movement of the piston and converting the rotator into low speed rotation. In order to favorably and partially simplify construction of an installation space of the hydrostataktor, a rotator axis of the rotator and the longitudinal axis of the active cylinder are substantially perpendicular to each other.

Owner:SCHAEFFLER TECH AG & CO KG

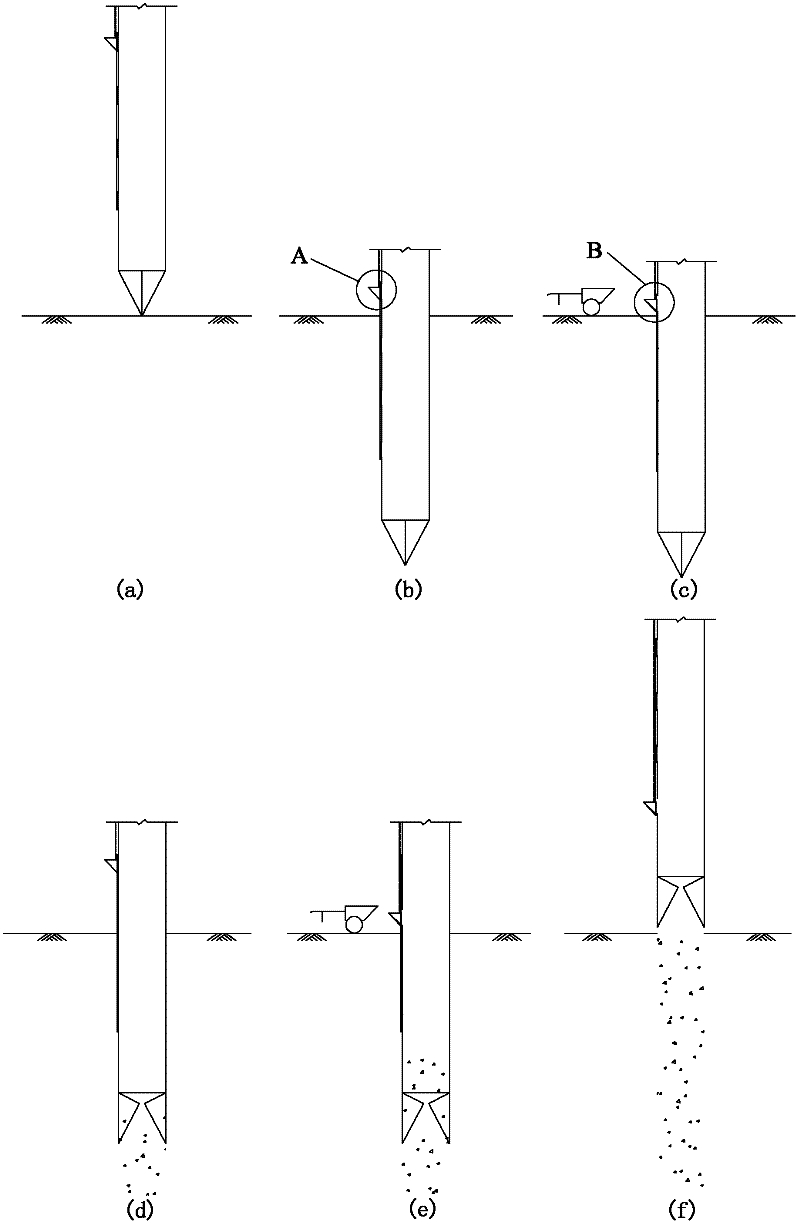

Movable feed hopper of tube-sinking cast-in-place pile and construction method

ActiveCN102444129ASave energyEasy to operateBulkheads/pilesStructural engineeringArchitectural engineering

The invention discloses a movable feed hopper of a tube-sinking cast-in-place pile and a construction method. A vertical guide rail is arranged on the outer surface of a pile formwork, the feed hopper is connected with the guide rail through connecting edges extending from the left side and the right side of the feed hopper, the upper portion of the feed hopper is connected with a hauling rope and the feed hopper can slide vertically along the guide rail. Two or more feed inlets are arranged on the pile formwork at a certain interval and disposed along the pile formwork. Openable cover plates are arranged outside the feed inlets and attached to the outer wall of the pile formwork when the pile formwork sinks into the foundation, and are opened when the pile formwork is pulled out and concrete needs to be poured, and sealing strips are arranged among the inner edges of the cover plates and the pile formwork. The construction method includes steps of taking the pile formwork to the place, sinking the pile formwork, moving the feed hopper downwards, opening one of the cover plates of the feed inlets, pouring the concrete, pulling the pile formwork upwards, moving the feed hopper downwards again, opening the next cover plate of the feed inlets, pouring the concrete and repeating the above processes until a pile is formed after the pile formwork is completely pulled out. The movable feed hopper is simple and convenient in operation, construction efficiency is improved, energy is saved and pile forming quality is guaranteed.

Owner:HOHAI UNIV +1

Feeding method of steel bar feeding machine

ActiveCN108946151AAvoid runningEasy to sendConveyorsWelding/cutting auxillary devicesProduction lineEngineering

The invention provides a feeding method of a steel bar feeding machine, and belongs to the field of prefabricated slabs. According the feeding method of the steel bar feeding machine, the steel bar feeding machine comprises a lifting device, a temporary storage mechanism, a horizontal moving device and a conveying device, wherein the lifting device, the temporary storage mechanism, the horizontalmoving device and the conveying device are arranged on a rack and are connected with respective cylinders. The feeding method of the steel bar feeding machine comprises the steps that a vertical suction head descends to suck a steel bar and then lifts the steel bar to place the steel bar on a horizontal temporary table of the temporary storage mechanism, a horizontal suction head of the horizontalmoving mechanism moves the steel bar onto a lower wheel of the conveying device from the horizontal temporary platform in the Y direction, and the steel bar is pressed by an upper wheel to be conveyed to the next procedure in the X direction. By adoption of the feeding method of the steel bar feeding machine, the labor intensity of workers is relieved, the requirement for an automatic welding production line is met, the feeding stability is improved, and normal operation of production equipment is ensured.

Owner:河南省鼎鼎实业有限公司

Medical cabinet device

ActiveCN107007358ACompact structureGuaranteed uptimeSurgical furnitureAmbulance serviceEngineeringMechanical engineering

A medical cabinet device comprises a base and a medical cabinet, wherein a slippage cavity is formed in the base, a base plate is fixedly arranged at the rear end of the base, extending grooves communicated and connected with the slippage cavity and extending in a front-back mode are bilaterally and symmetrically formed in the upper end wall of the base, a lower slippage plate and an upper slippage plate can be vertically installed in the slippage cavity in a slipping mode, slippage blocks are symmetrically arranged on two sides of the upper slippage plate and penetrate into the extending grooves, communicating grooves communicated with the slippage cavity are formed in the upper end wall of the base in a front-back and left-right symmetrical mode, insertion rods in matched connection with the communicating grooves are fixedly installed at the upper end of the lower slippage plate, the bottom wall of the medical cabinet is provided with insertion grooves provided with downward openings and matched with the insertion rods, placement grooves communicated with the insertion grooves are also formed in the outer side end walls of the insertion grooves, locking arms are installed in the placement grooves in a slipping mode, and locking grooves matched with the locking arms are also formed in the slippage blocks.

Owner:湖南德荣医疗器械物流配送服务有限公司

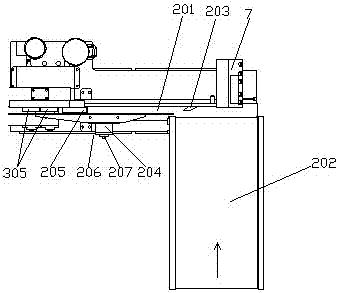

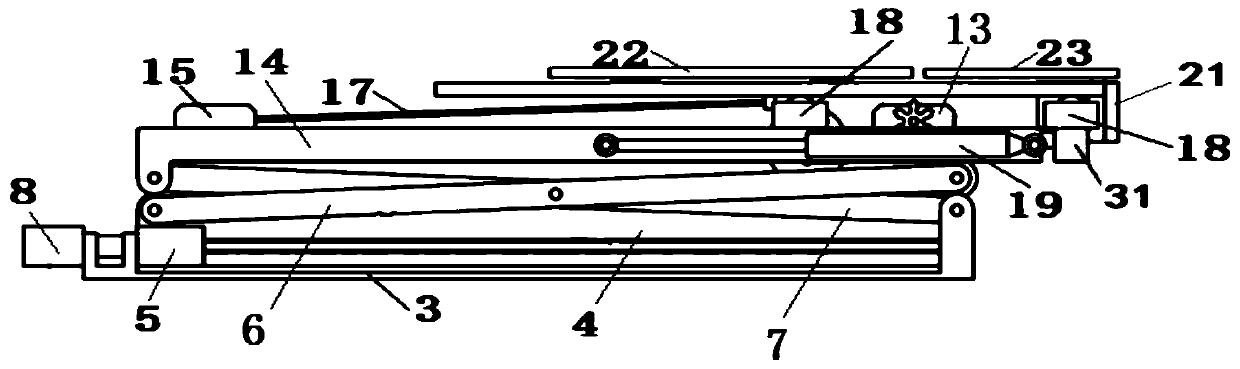

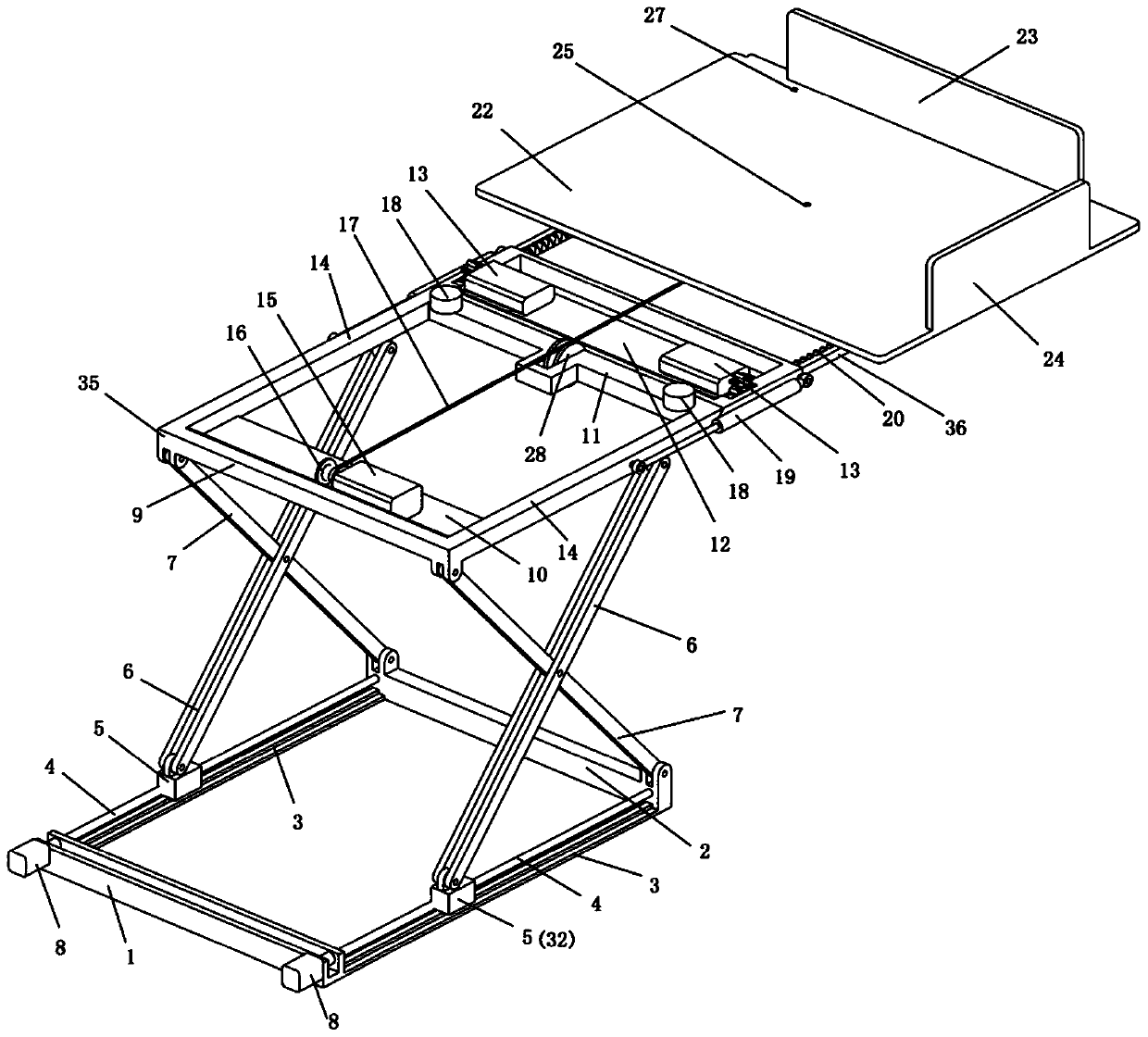

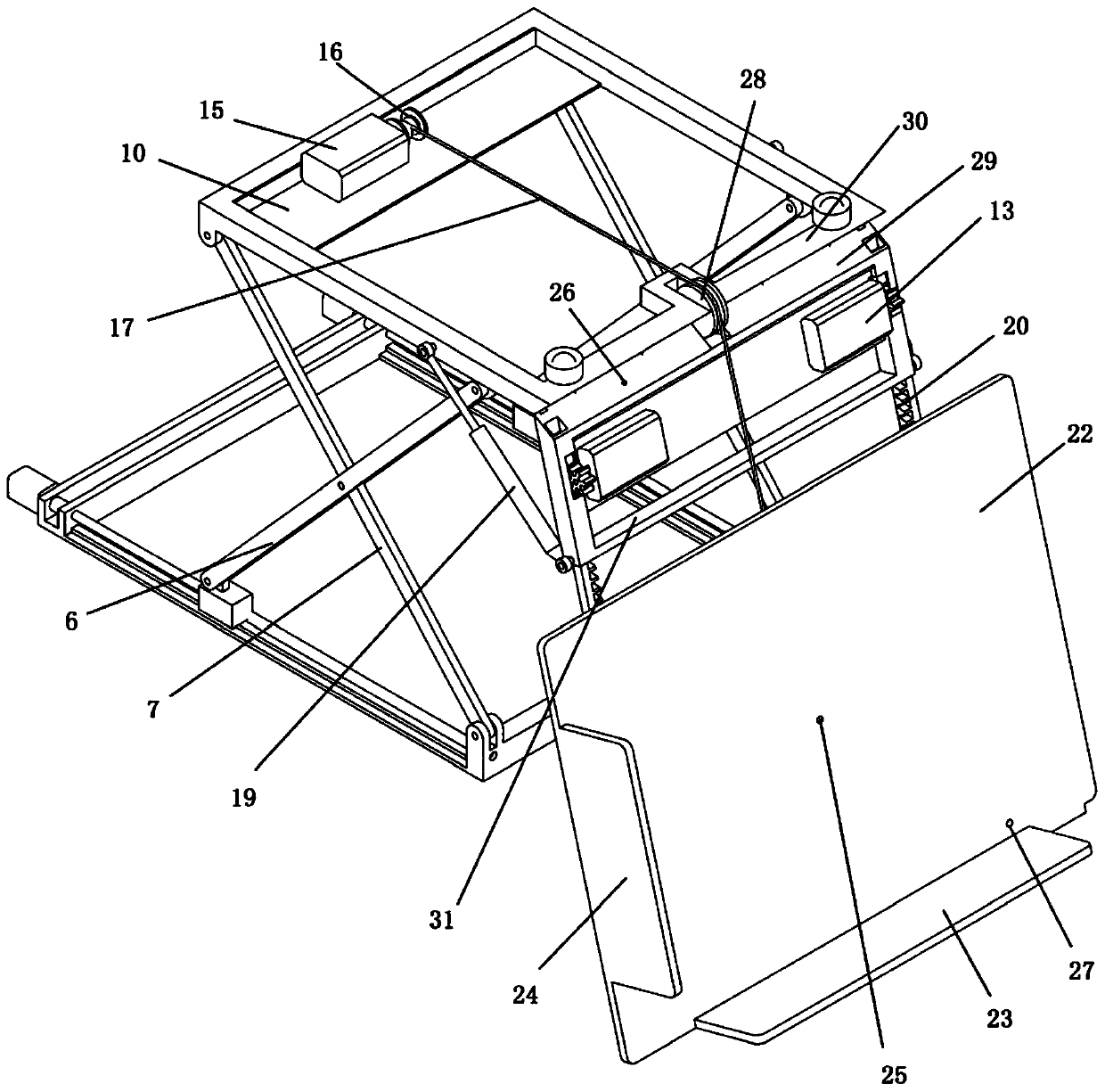

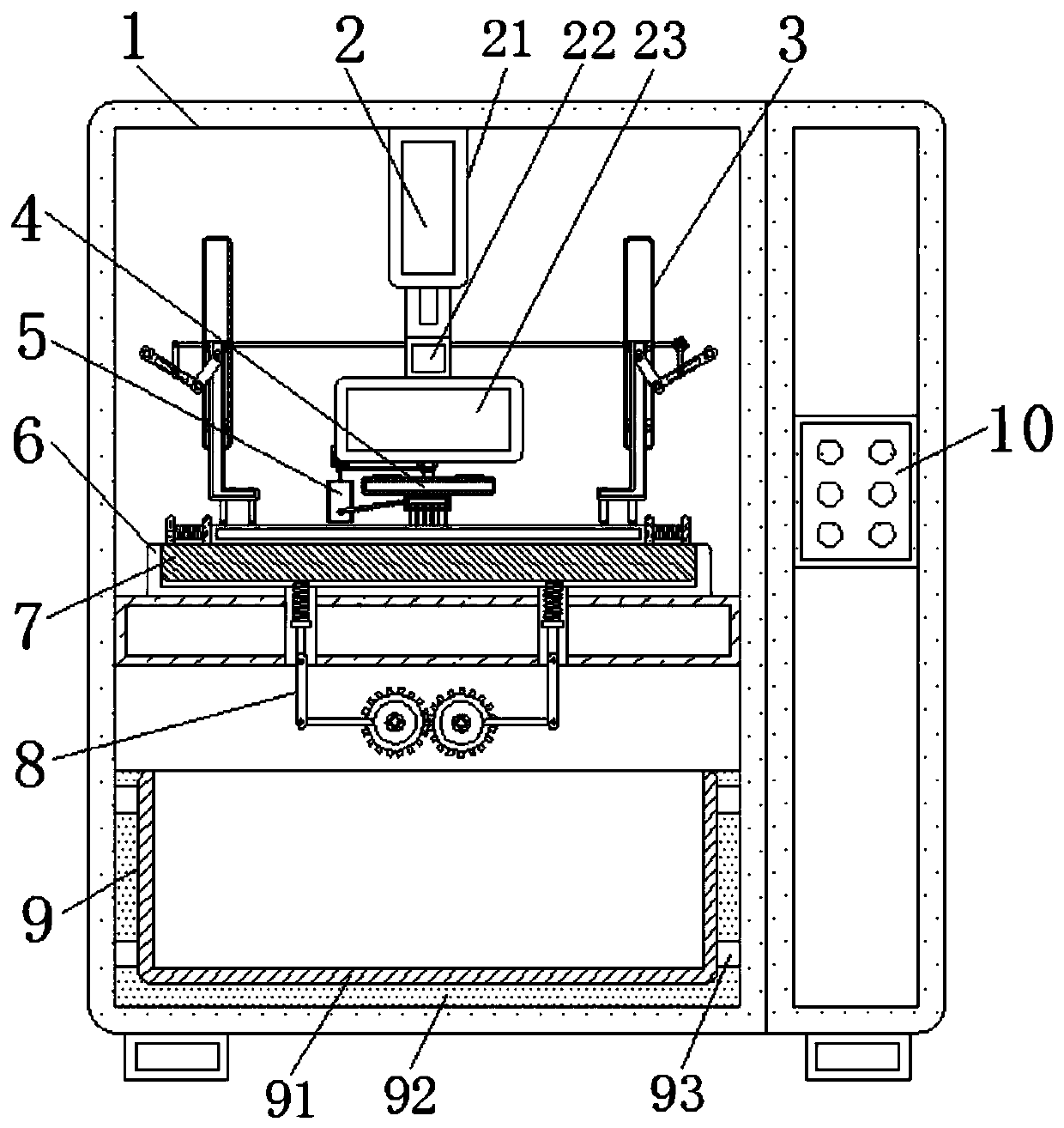

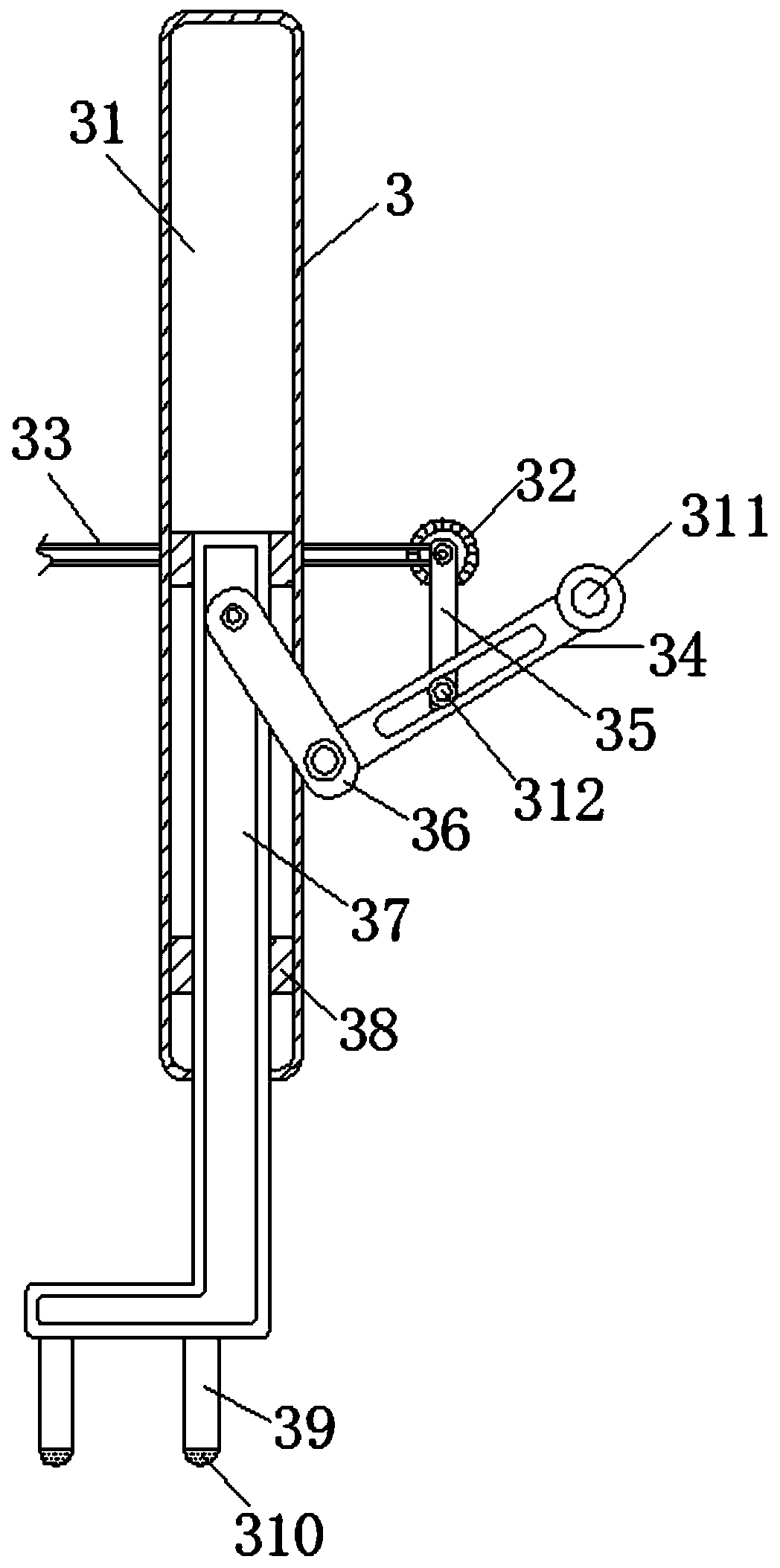

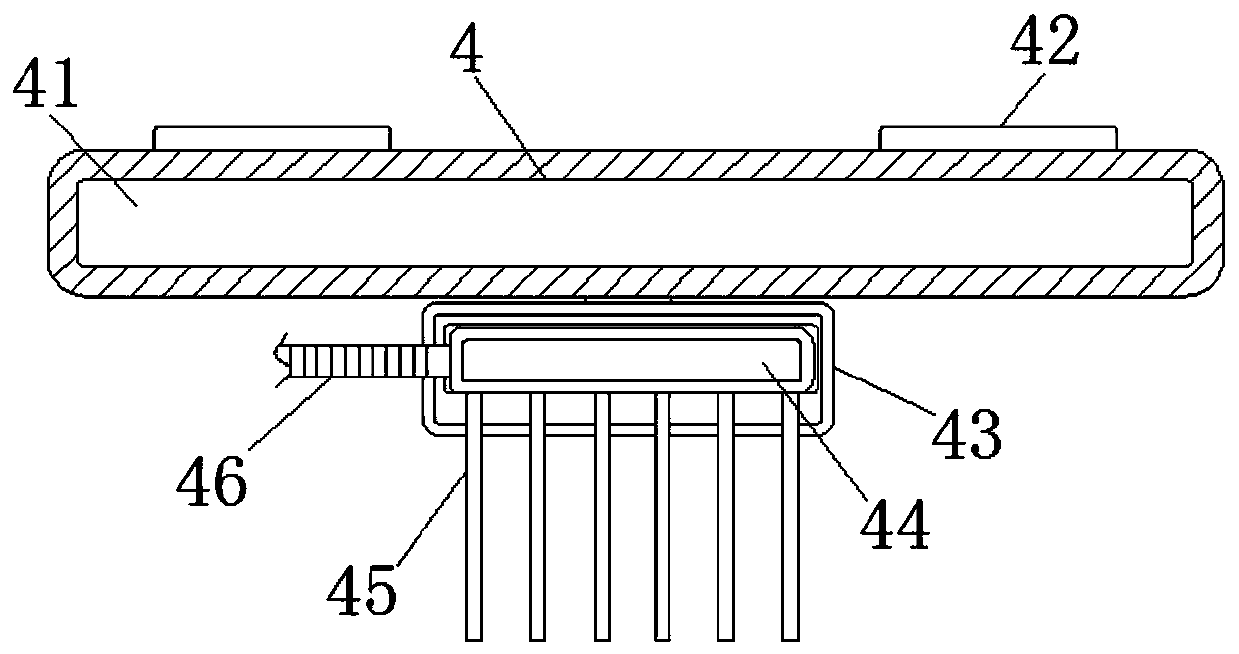

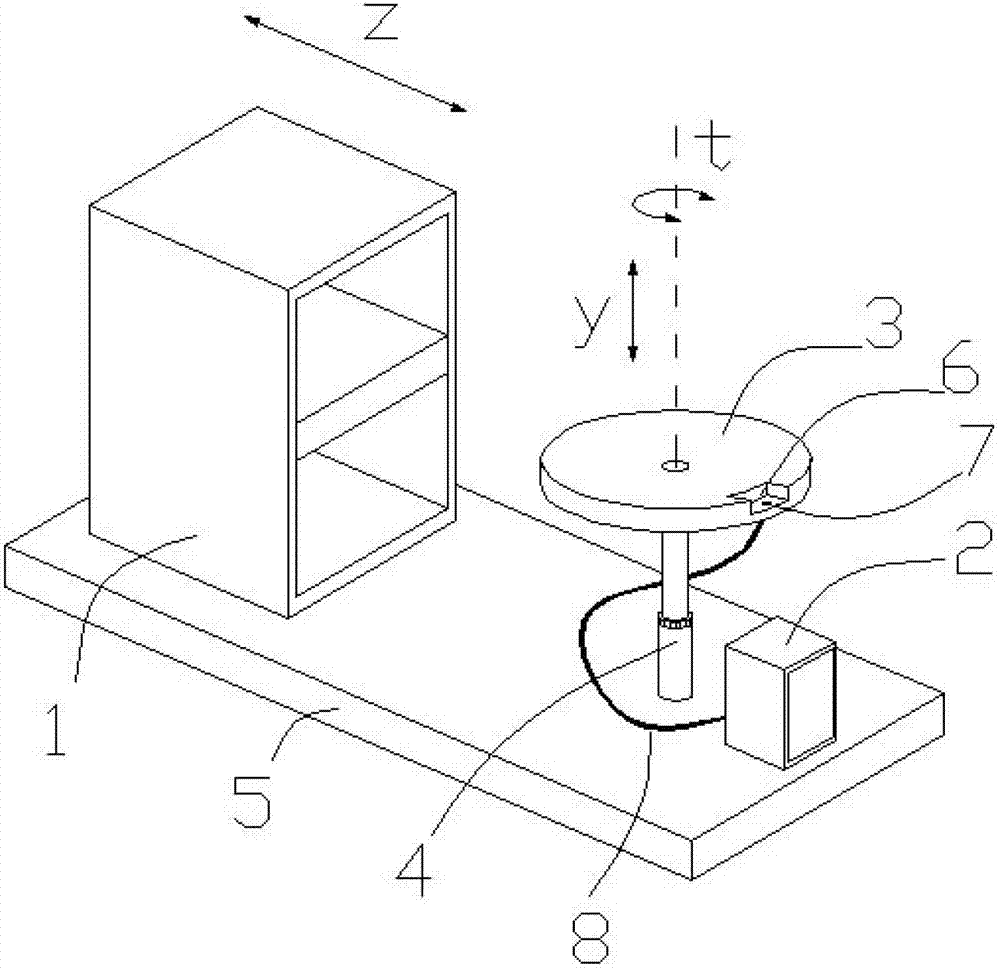

Passenger car trunk luggage automatic loading and unloading system and control method

PendingCN111055775ADoes not affect placementSafe loading and unloadingLifting devicesVehicle componentsGear wheelElectric machinery

The invention relates to the technical field of transportation, in particular to a passenger car trunk luggage automatic loading and unloading system and a control method. The loading and unloading system comprises a base, a main frame, a moving-out frame and a goods shelf arranged on the moving-out frame, and the base is movably connected with the main frame through a fork arm mechanism; the moving-out frame comprises a moving-out rack, a moving-out motor and a moving-out frame cross beam; the main frame comprises a front joint plate and a rear cross beam joint plate which are connected in ahinged mode, the front joint plate is movably connected with the fork arm mechanism, and the rear cross beam joint plate is fixedly connected with the mounting bottom plate of the moving-out motor; the main frame is further provided with a sliding rail in sliding connection with the moving-out rack. One end of the moving-out rack is meshed with the gear of the moving-out motor, and the other end is connected with the moving-out frame beam; the main frame is connected with a goods shelf through a rope wheel mechanism, and the goods shelf is connected with the moving-out rack. The safety, convenience, comfort and intelligent degree of trunk luggage loading and unloading are improved.

Owner:GUANGDONG MECHANICAL & ELECTRICAL COLLEGE

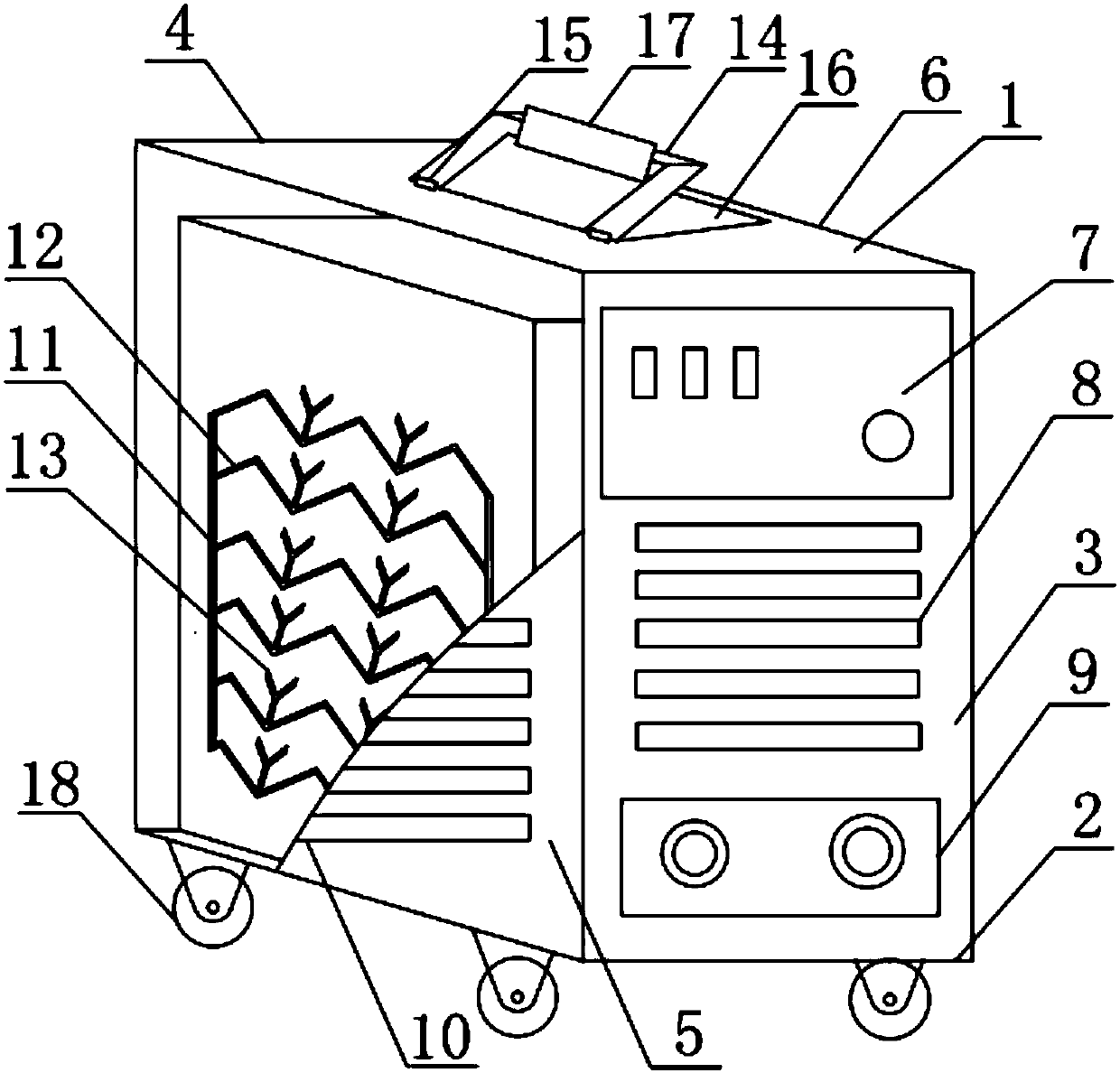

Inverter direct current pulse argon arc welding machine

InactiveCN107695481AIncrease cooling areaImprove cooling efficiencyWelding accessoriesCooling effectEngineering

The invention relates to the field of welding technology, and provides an inverter DC pulse argon arc welding machine, which includes a cabinet and a control circuit installed in the cabinet. The cabinet consists of a top panel, a bottom panel, a front panel, a rear panel, a left panel and a right panel. The upper part of the front panel is provided with an operation panel, the middle part is a waterproof louver, and the lower part is a quick-plug output panel. The left panel is provided with a ventilation and heat dissipation window. A heat sink is provided, and the heat sink includes fixed plates on both sides and heat sinks in the middle. A handle is arranged in the middle of the top plate, the two ends of the handle are fixedly connected with the top plate, a sponge sleeve is arranged in the middle of the handle, and a pulley is arranged on the bottom plate. The invention has the beneficial effects of good heat dissipation effect and convenient carrying and moving.

Owner:天津鑫星云焊接设备科技有限公司

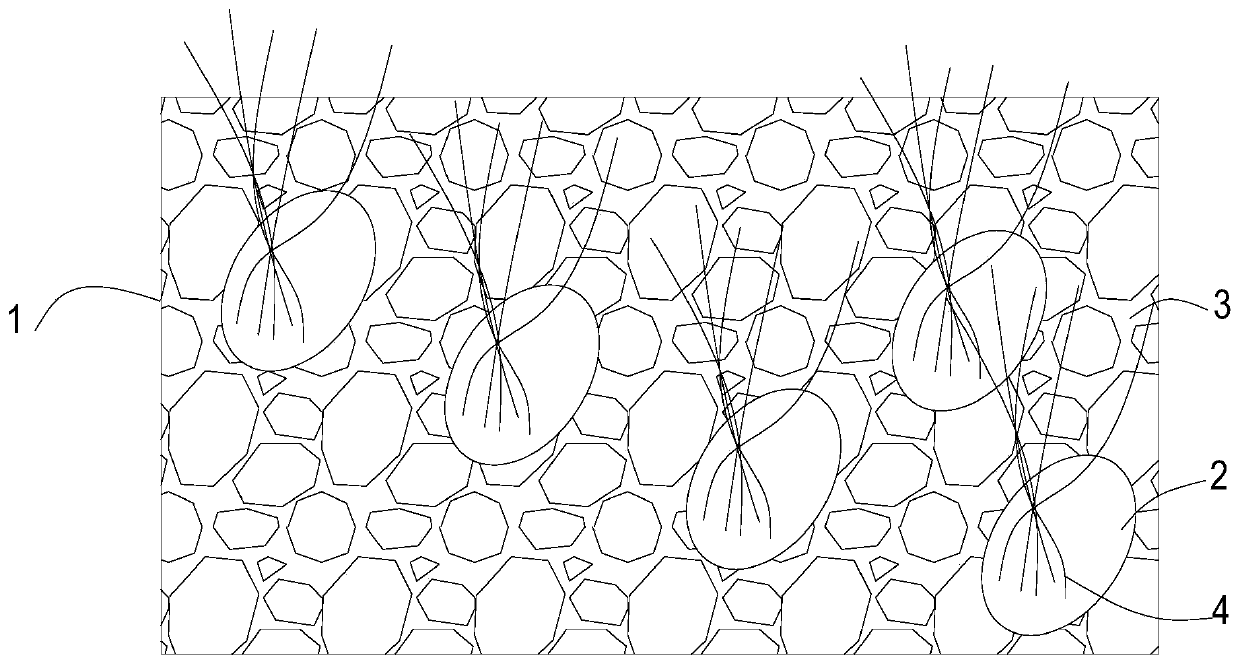

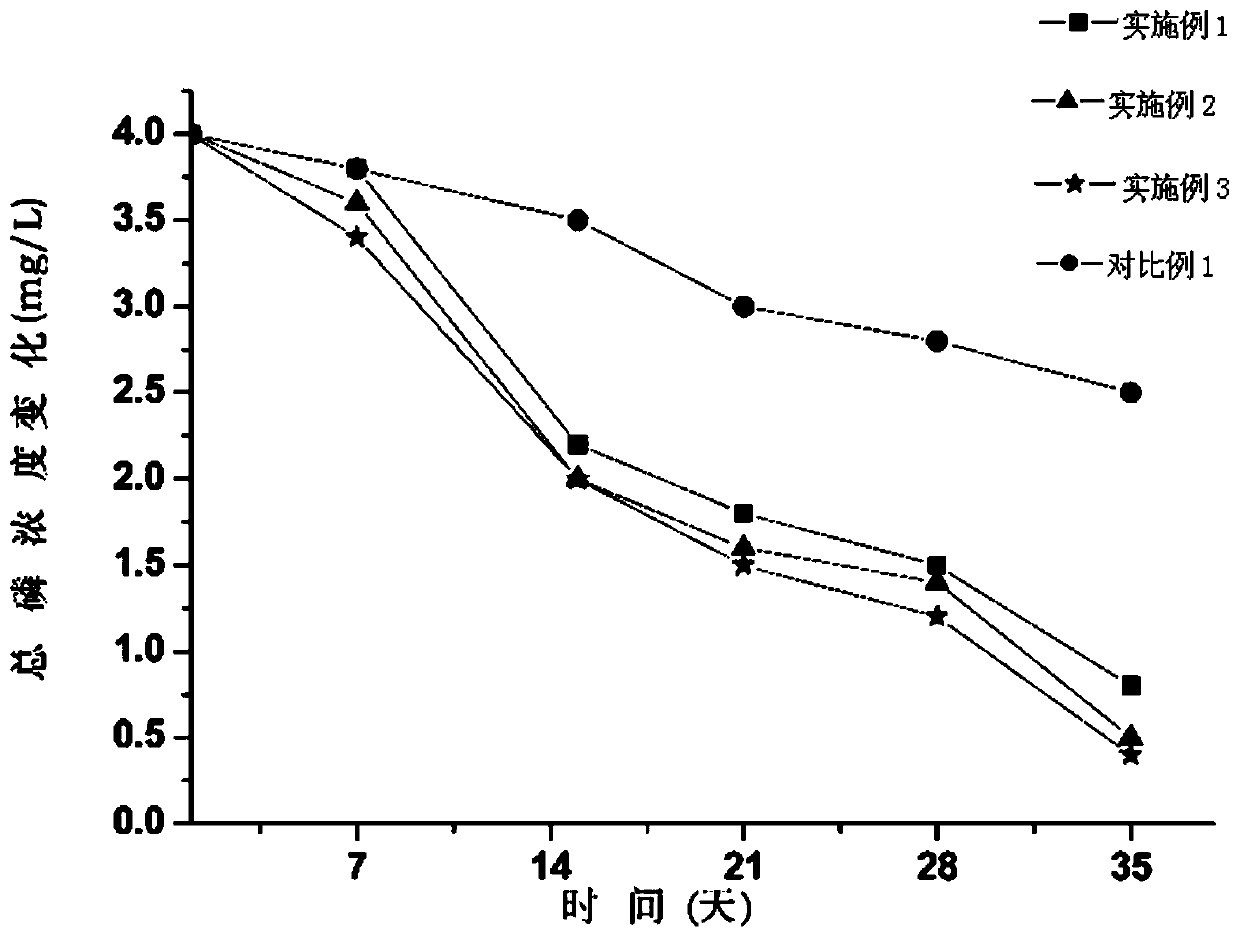

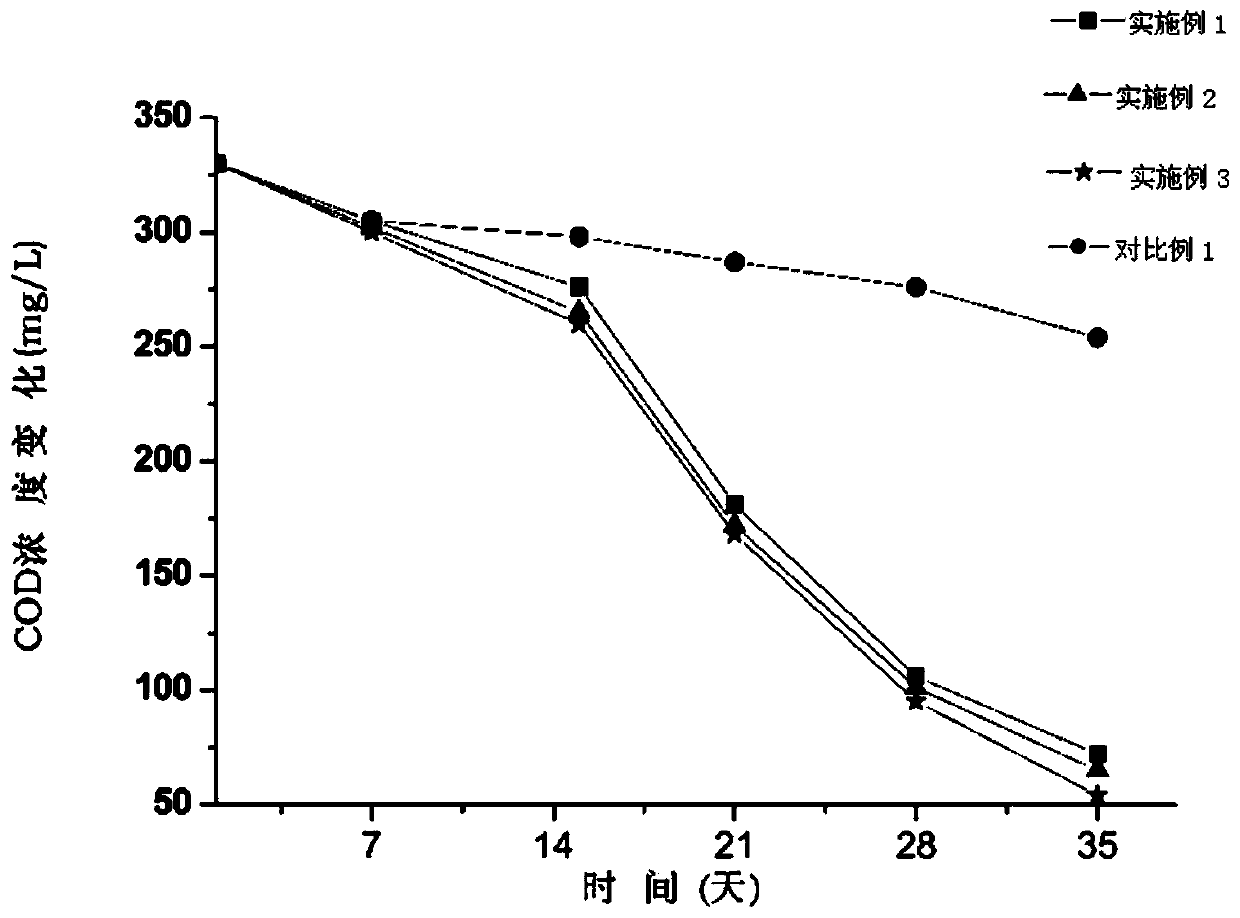

Aquatic plant growth bed and preparation method thereof

ActiveCN110117076ARestoring the ecological environmentEasy to transportWater treatment compoundsBiological treatment apparatusGrowth plantWater quality

The invention discloses an aquatic plant growth bed and a preparation method thereof. The aquatic plant growth bed comprises a bed body, a plant growth body and a microbe filling body; the plant growth body is arranged in the bed body; the plant growth body is wrapped by roots of aquatic plants; plant growth composite bacteria are arranged in the plant growth body; a gap is formed in the bed body;a gap of the bed body is filled with the microbe filling body; water body purifying microbes are arranged in the microbe filling body; the plant growth body and the microbe filling body are filled with a microbial culture. The preparation method comprises the following steps: preparing the plant growth body; preparing the bed body; executing microbe filling. The aquatic plant growth bed saves thecomplicated steps of firstly pumping water, dredging sediment, planting plants and pumping water back during conventional planting, the plants can be planted on the growth bed first and then put intowater, the putting efficiency is greatly improved, the growth bed has a good fixing effect on microbes, and the water quality can be continuously improved.

Owner:广州博嵩生物环保科技有限公司

Ultrasonic metal pushing device

ActiveCN111545633AReduce labor intensityEasy to operateShaping toolsPerforating toolsClassical mechanicsStructural engineering

The invention discloses an ultrasonic metal pushing device which comprises a device box. A punching mechanism is fixedly mounted at the center position of the inner side of the device box, and a separating mechanism is mounted on the back face of the bottom end of the punching mechanism. The left side of the separating mechanism is connected with an air supply mechanism. Fixed mechanisms are mounted on the two sides in the device box, and the bottom ends of the fixed mechanisms are connected with a limiting mechanism. The outer side of the limiting mechanism is connected with a first limitingblock. The bottom end of the limiting mechanism is fixedly connected with a lifting mechanism, and a collection mechanism is arranged below the lifting mechanism. The fixed mechanisms and the limitingmechanism are arranged, manual fixing is not needed, it is guaranteed that the metal part punching positions are accurate, and the manual labor strength is reduced; and the air supply mechanism worksto cool the metal part punching positions, metal parts and waste parts are separated through the separating mechanism, the manual labor strength and operation steps are reduced, and operation is simple.

Owner:HEZE UNIV

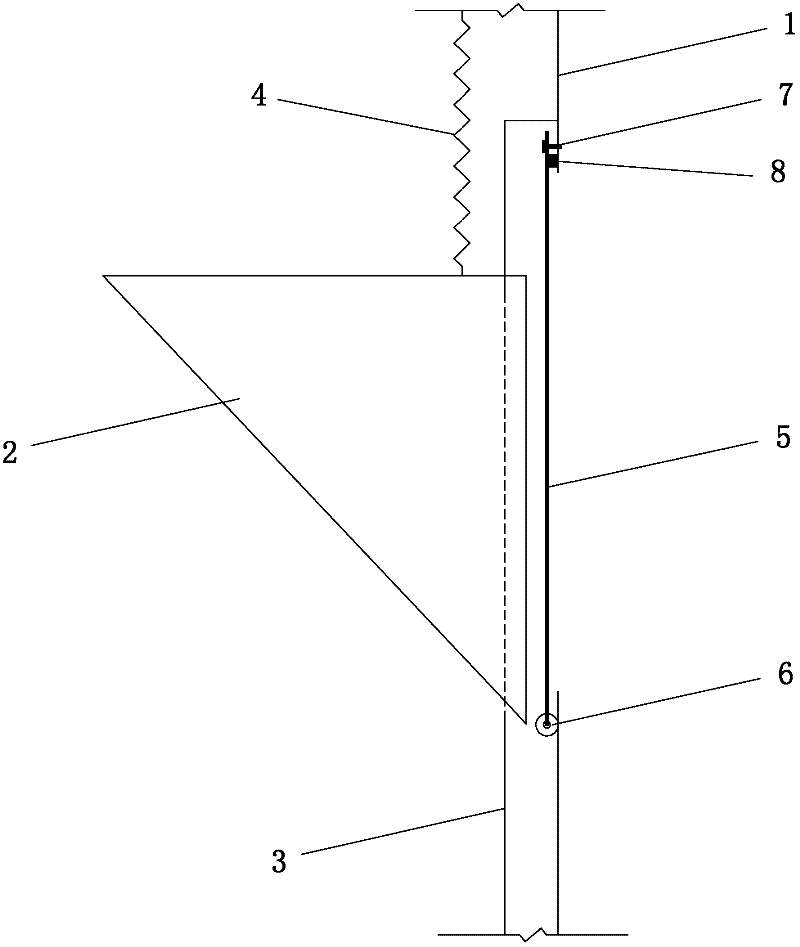

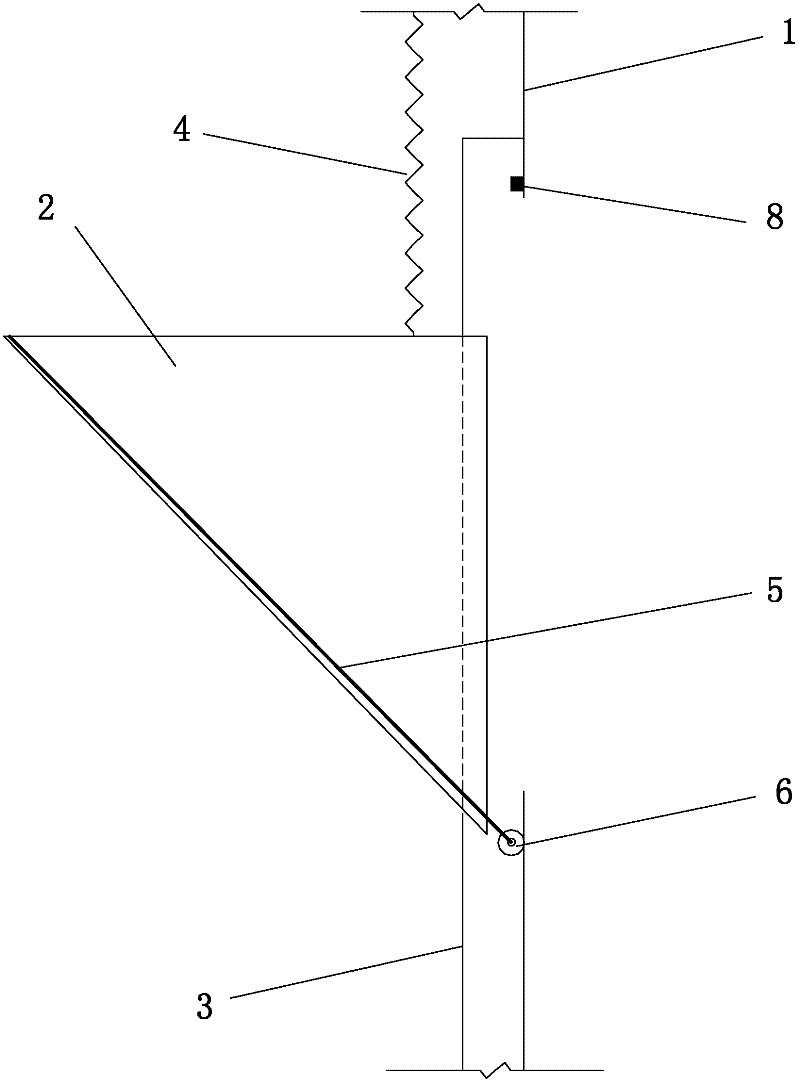

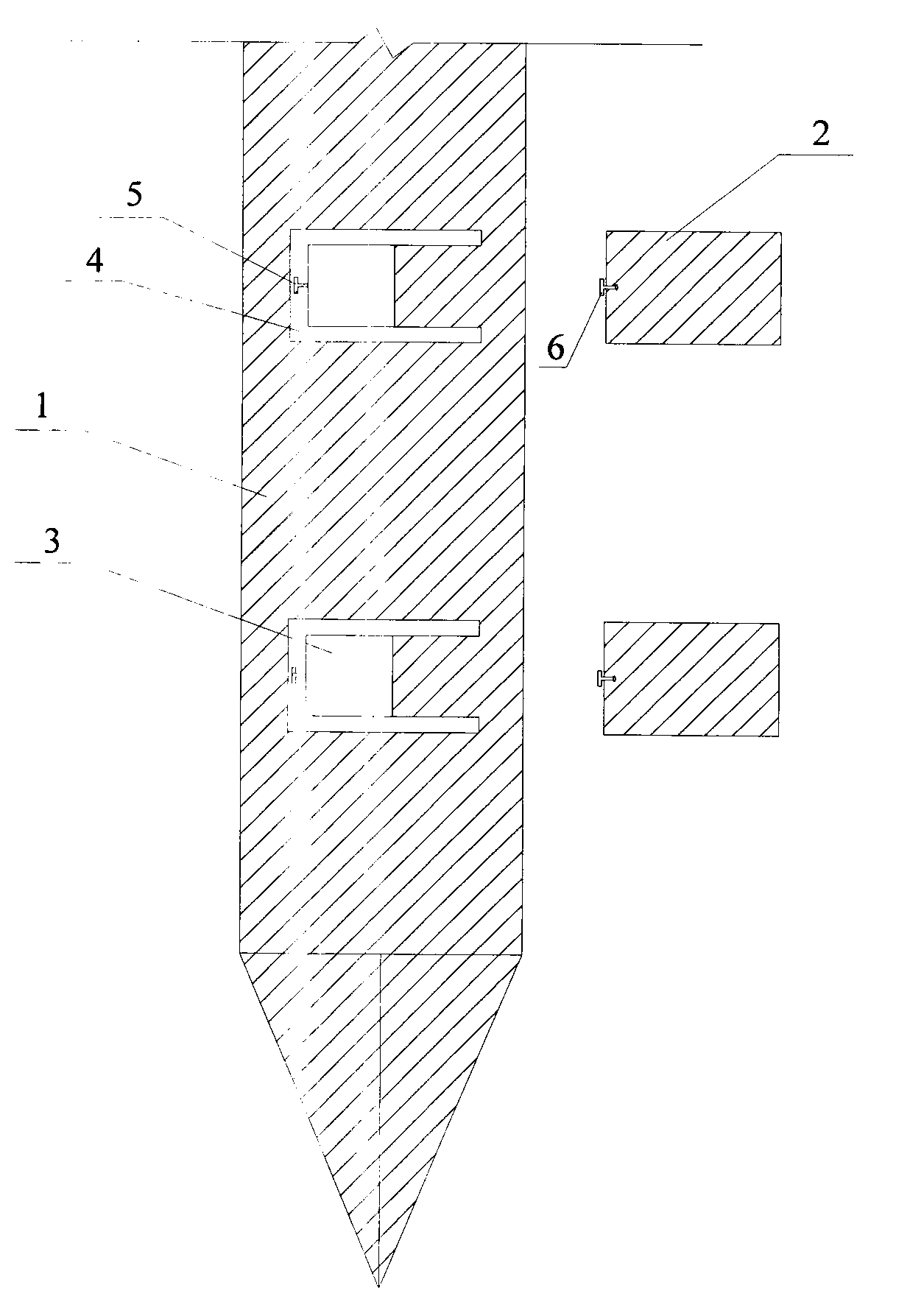

Pile mould with draw-pull type movable feed ports and construction method

The invention relates to a pile mould with draw-pull type movable feed ports and a construction method. A plurality of draw-pull type movable feed ports are arranged on the lateral side of the immersed tube pile mould in the longitudinal direction. Each draw-pull type movable feed port is composed of a rail, an open hole, an arc inserting plate and a movable connector, wherein the open hole is formed in the lateral side of the pile mould, the rail is fixedly connected with the periphery of the pile mould with the open holes, the rail is in a U shape, the inner side of the rail is provided or connected with a waterproof rubber gasket, the movable connector is arranged on the arc inserting plate, the movable connector is in a T shape, the movable connector is hinged to one end of the arc inserting plate, a clamping groove is formed in the bottom of the U-shaped rail, the clamping groove is matched with the movable connector, and the movable connector is inserted into the clamping groove to fix the arc inserting plate. The pile mould overcomes the defects that the feed ports are large in power demand with the increasing height, can damage formed piles and the like. The draw-pull type movable inserting plates are convenient, quick and easy to operate, capable of saving energy, good in sealing performance and high in pile forming quality.

Owner:JIANGSU DONGHENG DADI ENG TECH

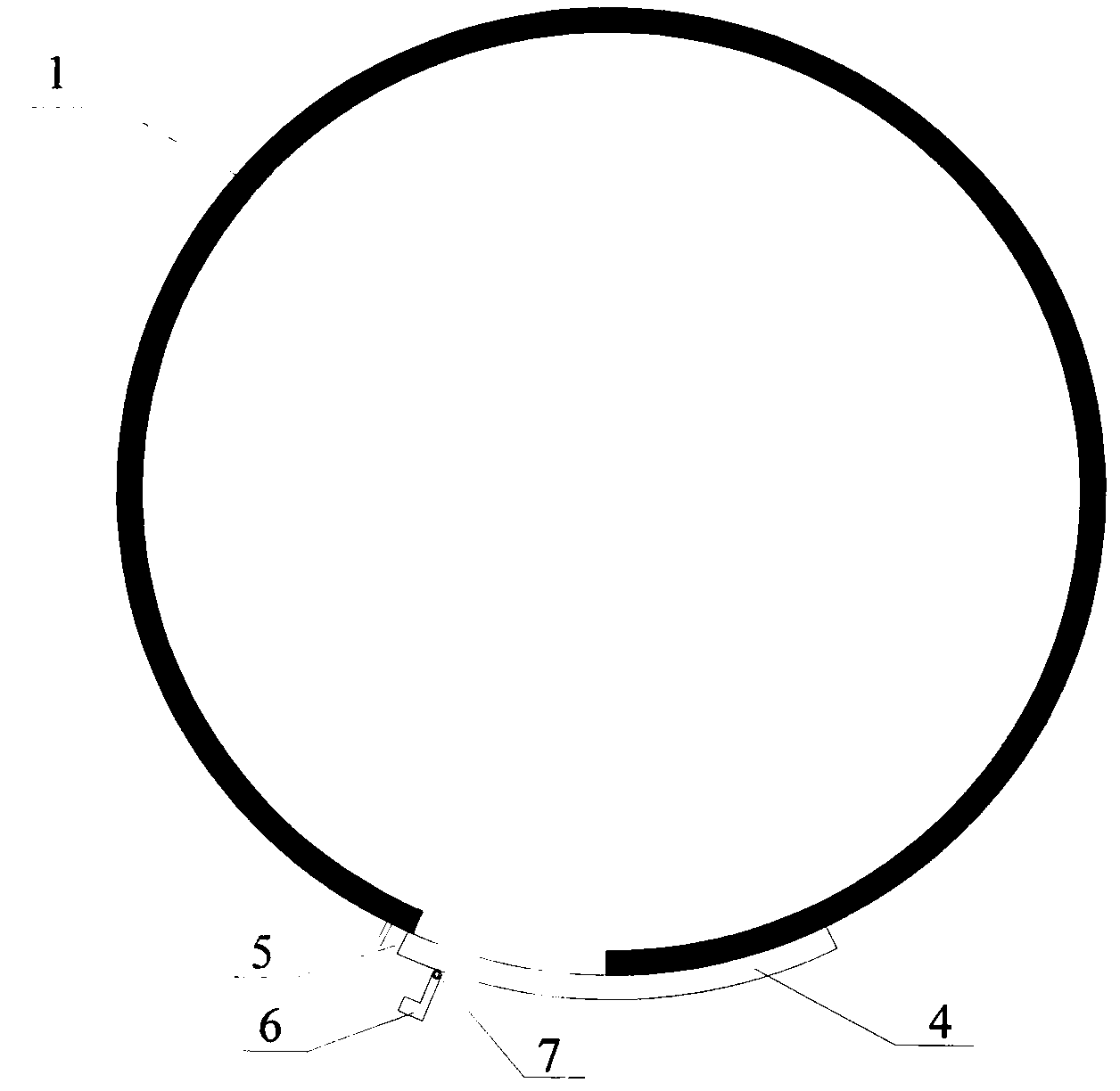

Printer paper quantity real-time monitoring system

ActiveCN107878045AMake up for the disadvantages of paper shortage alarmKnow in real timeOther printing apparatusPictoral communicationMicrocontrollerAccelerometer

The invention discloses a printer paper quantity real-time monitoring system. A sensor module is mounted on a lifting assembly in each paper box of a printer and comprises an accelerometer chip, a microcontroller and a wireless chip, wherein the accelerometer chip senses the lifting variable quantity of the lifting assembly; the variable quantity is processed by the microcontroller to obtain paperquantity data; the paper quantity data is sent to a receiving module; the receiving module summarizes the paper quantity data and then transmits the summarized paper quantity data to a PC; and the PCdisplays the paper quantity in each paper box of the printer in real time and remotely monitors the paper quantity of the printer in real time. The printer paper quantity real-time monitoring systemhas the advantages of making up the defect that the traditional printer only gives out an alarm in the case of paper shortage, knowing the present paper quantity information and the like in the paperbox in real time and being simple and convenient to mount as the high value-added accessory of the printer.

Owner:上海喜塑电子科技有限公司

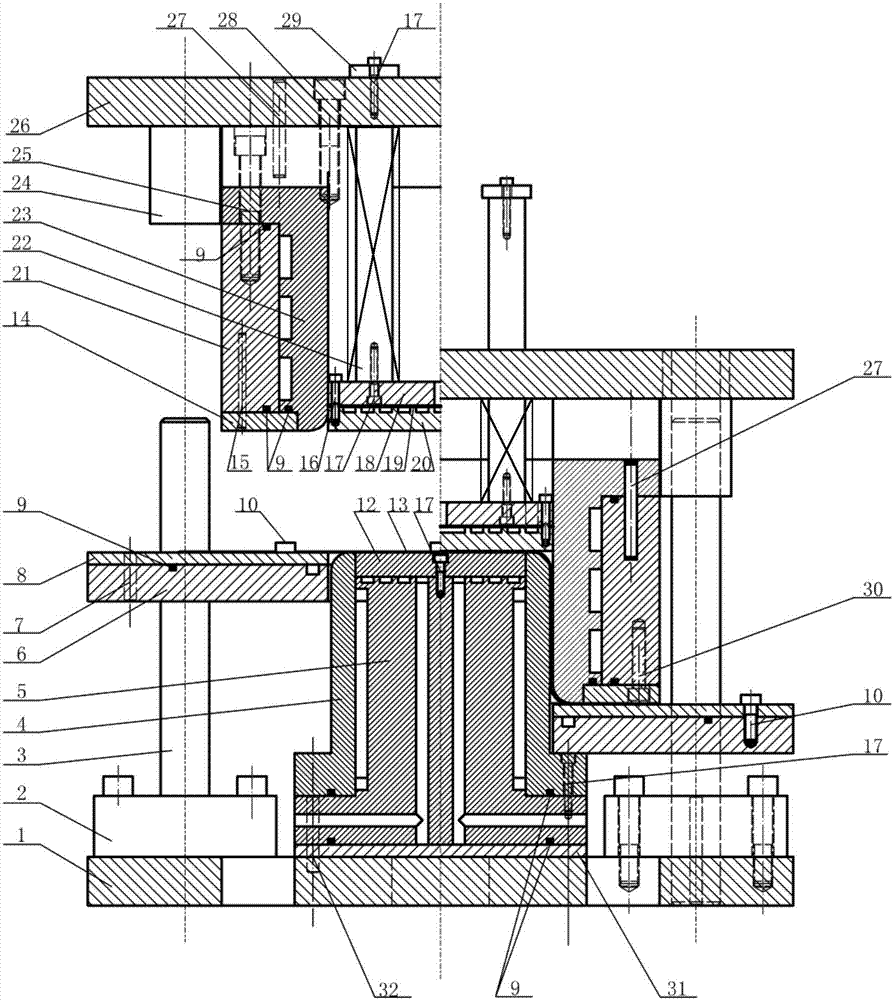

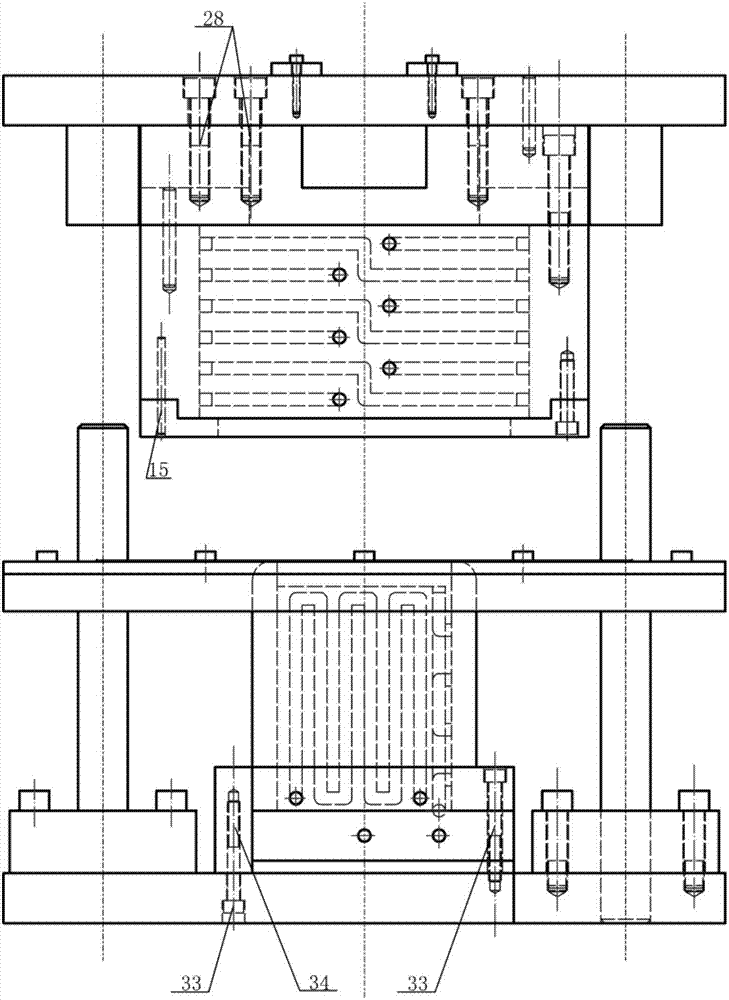

Hot stamping deep drawing mold of ultrahigh-strength steel box-shaped part

ActiveCN107008809AGuaranteed completenessDoes not affect placementShaping toolsHollow articlesHot stampingResearch Object

The invention relates to a hot stamping deep drawing mold of an ultrahigh-strength steel box-shaped part, and belongs to the technical field of hot stamping forming equipment. The box-shaped part can serve as a research object; on the basis of combining an external press with a servo ejector rod system, such deep drawing forming performances as blank holder force and stamping speed of ultrahigh-strength boron manganese steel under different forming process parameters are researched; a blocking structure is adopted to uniformly distribute cooling water ways in a mold convex mold, a concave mold, a blank holder and a movable cushion block; and on the basis of combining with an external cooling water flowing speed control system, the influence on overall performances of the final box-shaped part by different quenching control processes can be researched.

Owner:江苏宏晟模具钢材料科技有限公司

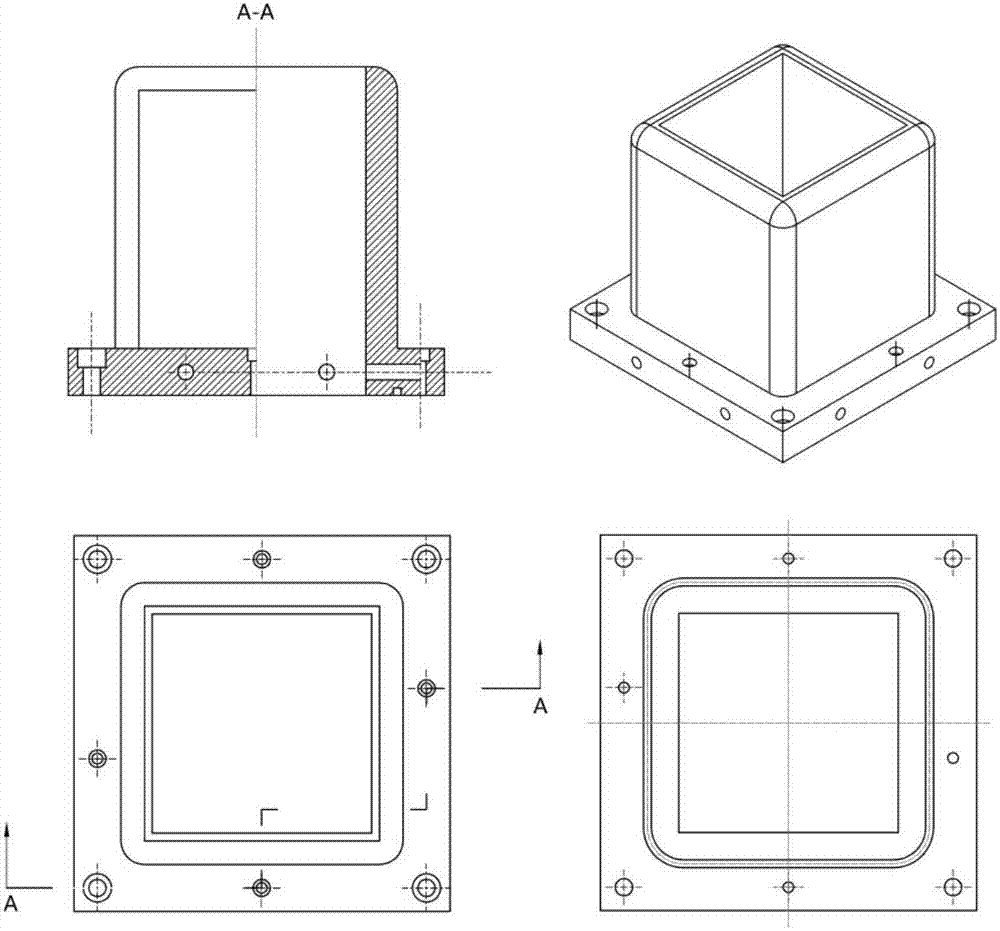

Three-person inflatable seesaw

The invention discloses a three-person inflatable seesaw which comprises a first inflatable bench, a second inflatable bench and a third inflatable bench. The three benches are mutually connected through gas-guide tubes on the side faces of bench bodies, wherein the gas-guide tubes are in heat seal. Due to the gas-guide tubes, cavities in the three inflatable benches are mutually communicated. Due to the facts that the three inflatable benches are mutually connected through the gas-guide tubes on the side faces of the bench bodies, wherein the gas-guide tubes are in the heat seal, and the cavities in the three inflatable benches are mutually communicated due to the gas-guide tubes, when a person sits on any one of the inflatable benches, gas pressure in the bench is increased, gas can flow into another two benches and another two benches are inflated. In the same way, when persons sit on two of the benches, another one bench can also be inflated. When three persons sit in turn, the opposite sides can sit on the inflatable benches in an up-and-down motion mode. Therefore, the recreation effect similar to seesaws is achieved, and the three-person inflatable seesaw is very interesting.

Owner:杜志刚

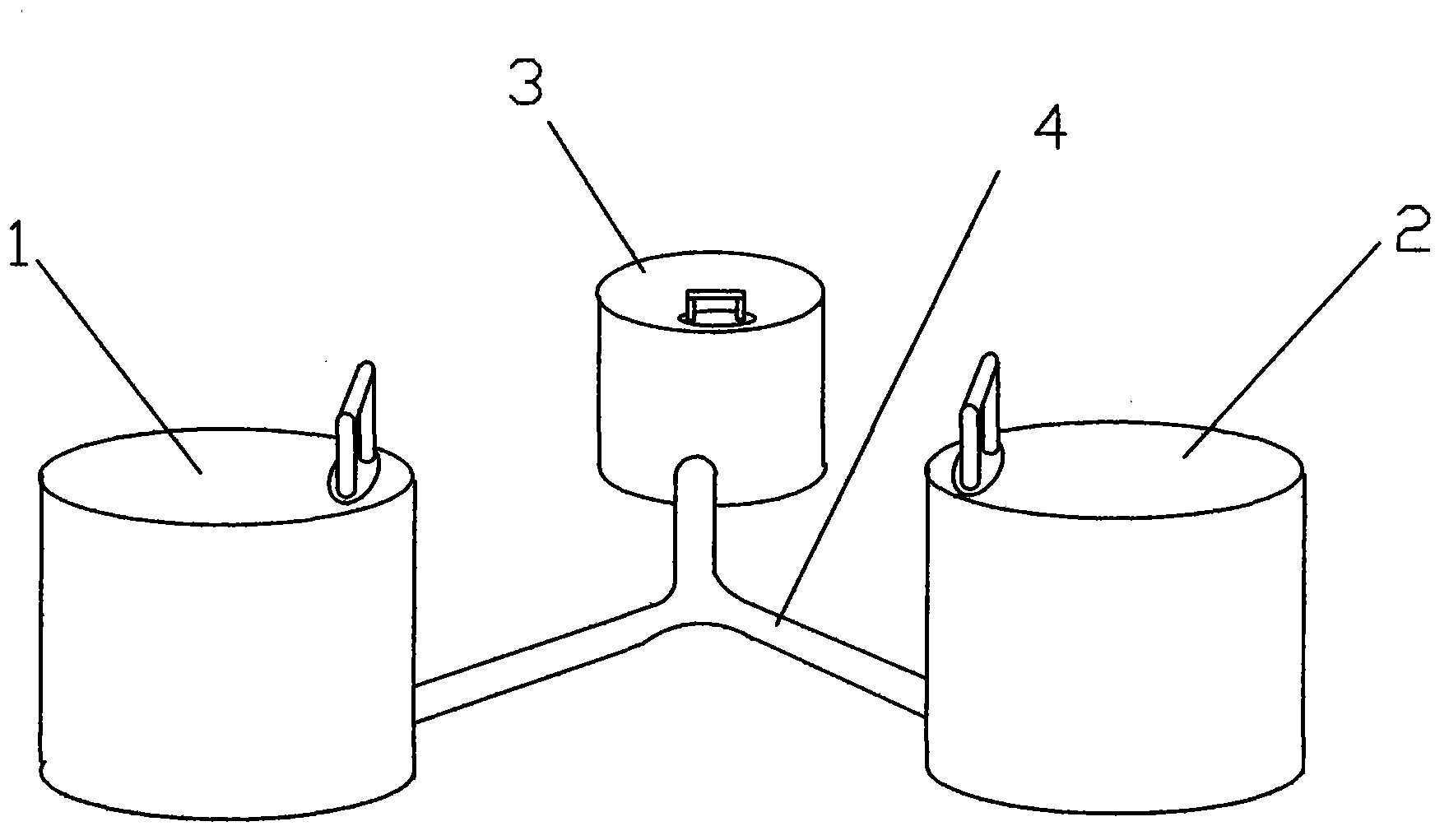

Abdominal pad sewing processing system

ActiveCN112726034AImprove yieldDoes not affect placementWorkpiece carriersWork-feeding meansEngineeringAbdominal pad

The invention relates to the technical field of abdominal pad processing equipment, and discloses an abdominal pad sewing processing system. The abdominal pad sewing processing system comprises a fabric edge folding unit, a label body placement unit, a folding transfer unit, two groups of sewing units, a rotary transfer unit and a material receiving unit which are sequentially arranged along the fabric conveying direction, and is characterized in that the rotary transfer unit is arranged between the two groups of sewing units; the fabric edge folding unit is used for inwards folding exposed burrs of a fabric; the label body placement unit is used for fixedly placing a glue label and a cotton label in a label body placement area of the fabric; the folding transfer unit is used for folding the fabric subjected to edge folding work and transferring the folded fabric to the sewing units; the first sewing unit sews two groups of opposite sides of a square fabric; and the rotary transfer unit is used for rotating the square fabric with the two groups of opposite sides sewed by a first angle and transferring the square fabric to the second sewing unit to be sewed again. The product qualification during fabric sewing can be improved, and therefore the production and processing efficiency is improved.

Owner:SUZHOU TRANSPARENT TECH CO LTD

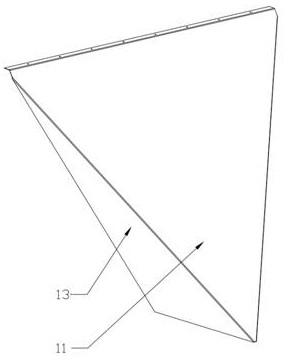

Electromagnetic positioning splicing apparatus and method for coded light three-dimensional measurement

InactiveCN102818535ASimple structureReduce volumeUsing optical meansThree dimensional measurementEngineering

The invention provides an electromagnetic positioning splicing apparatus and method for the coded light three-dimensional measurement. The electromagnetic positioning splicing apparatus comprises a measurement unit frame, a splicing unit frame, a round stage, a support pillar and a base station; the upper surface of the round stage is provided with one groove; and the bottom surface of the groove is provided with one through hole. The splicing apparatus disclosed by the invention has a simple structure; the multi-view measurement can be implemented only by the rotation and lifting of the stage; each local part of a measured object can be basically measured. The invention designs the scheme of the movable measured object (a moving coordinate system) and a fixed coded light three-dimensional measurement system (a stationary coordinate system); and the scheme is beneficial for reducing the volume and the complexity of the splicing apparatus and has low requirement on the structural strength. According to the invention, both the rotating splicing and the splicing in the vertical direction (the y direction) are considered and the measured object can be more comprehensively measured.

Owner:HARBIN UNIV OF SCI & TECH

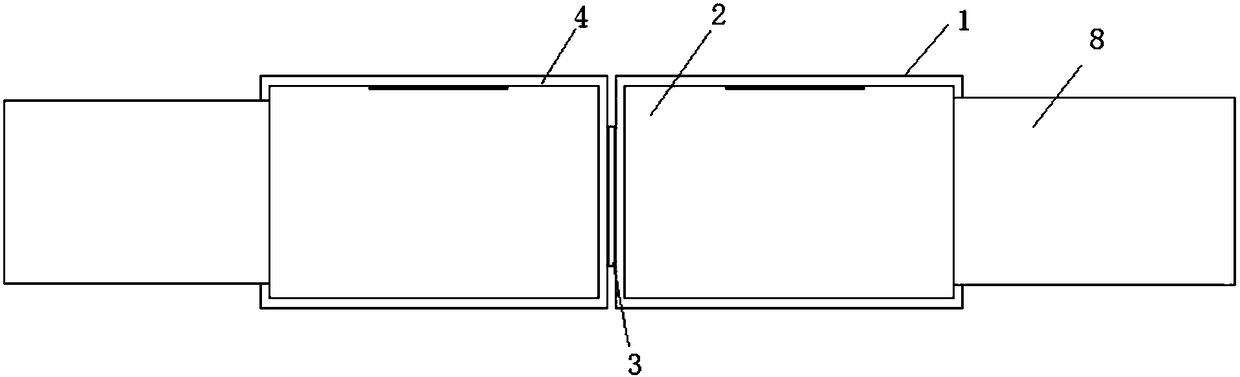

Trolley case

InactiveCN108185610ASuitable for recliningDoes not affect placementLuggageOther accessoriesEngineeringBed boards

The invention discloses a trolley case, solves the technical problem that people have no bed for rest when going out, and belongs to the technical field of bags and suitcases. The trolley case comprises two oppositely arranged sub boxes, the two sub boxes are movably connected, bed plates are arranged at the openings of each of the sub boxes, and the bed plates and the sub boxes are movably connected. The trolley case has a function of a bed for people to lie down for rest after the sub boxes are opened, and the trolley case has a simple structure, saves space and is convenient to carry.

Owner:长春光速科技有限公司

Orthopedic dressing change device and use method thereof

InactiveCN108309656AEasy to replaceImprove comfortDiagnosticsAmbulance serviceDressing changeEngineering

The invention discloses an orthopedic dressing change device which comprises a bottom plate, a base and a bearing plate, wherein the upper end of the bottom plate is connected to the lower end of thebase through an electric telescopic rod; the bearing plate is mounted at the upper end of the base; an infrared heater is mounted inside the base; a placement plate is arranged in the middle of the bearing plate; a through hole is formed inside the placement plate; a protective pad is arranged at the upper end of the placement plate; a supporting rod is arranged on the side surface of the base; across rod is erected at the end part of the supporting rod; an ultraviolet lamp is mounted at the lower end of the cross rod; a fastener base is arranged on one side of the upper end of the bearing plate; the other side of the upper end of the bearing plate is connected with a fastener plug through an elastic band; dressing change use is completed through steps of preheating of the bearing plate,fixing of a wounded part, height adjustment, sterilization, disinfection and the like in sequence. The orthopedic dressing change device is simple in structure, can improve the use comfort, kill germsin time, avoid interactive infection and reduce the labor of medical staff, and is safe and convenient to use.

Owner:王林一

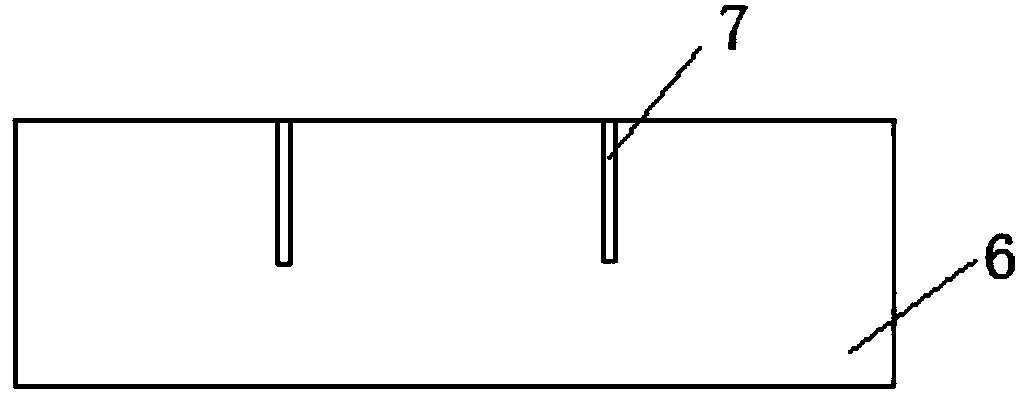

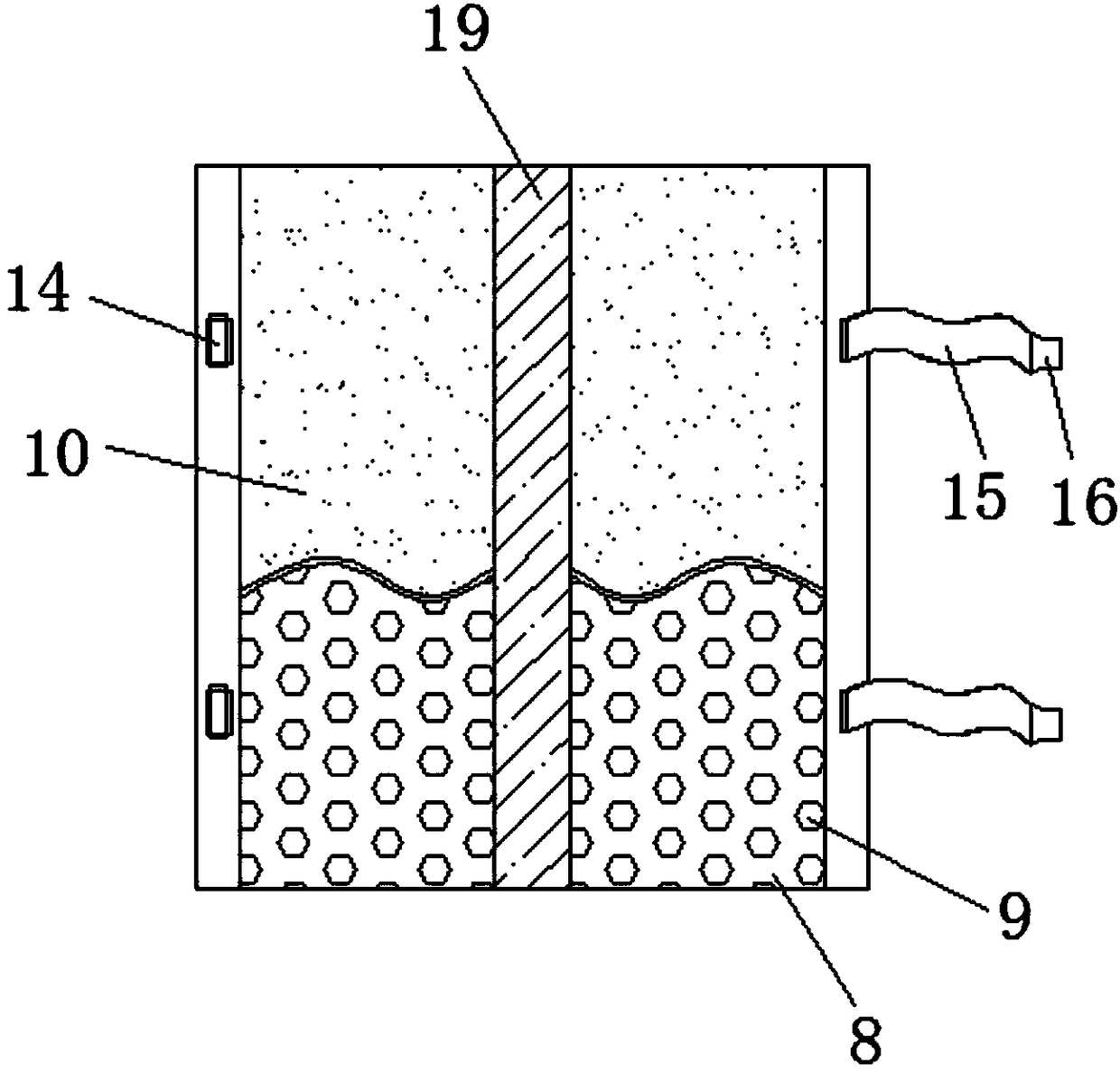

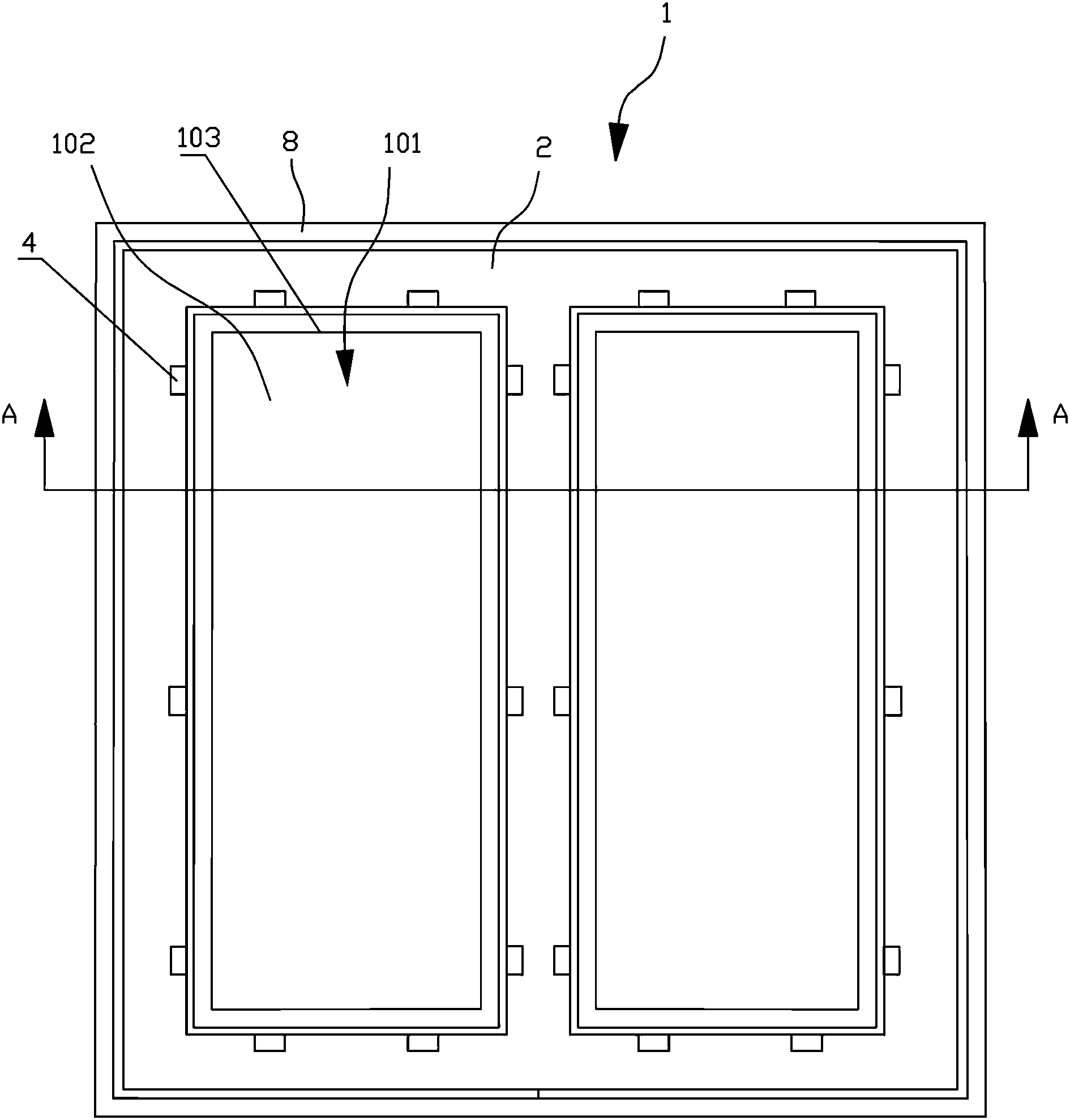

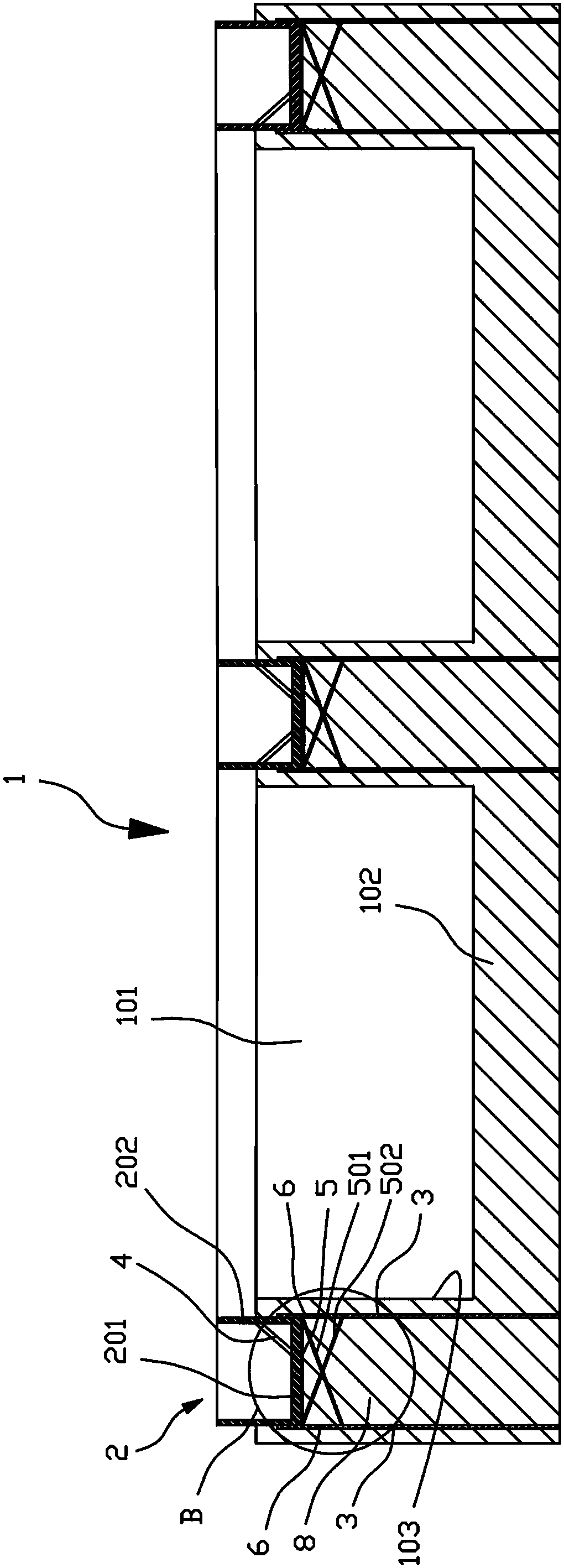

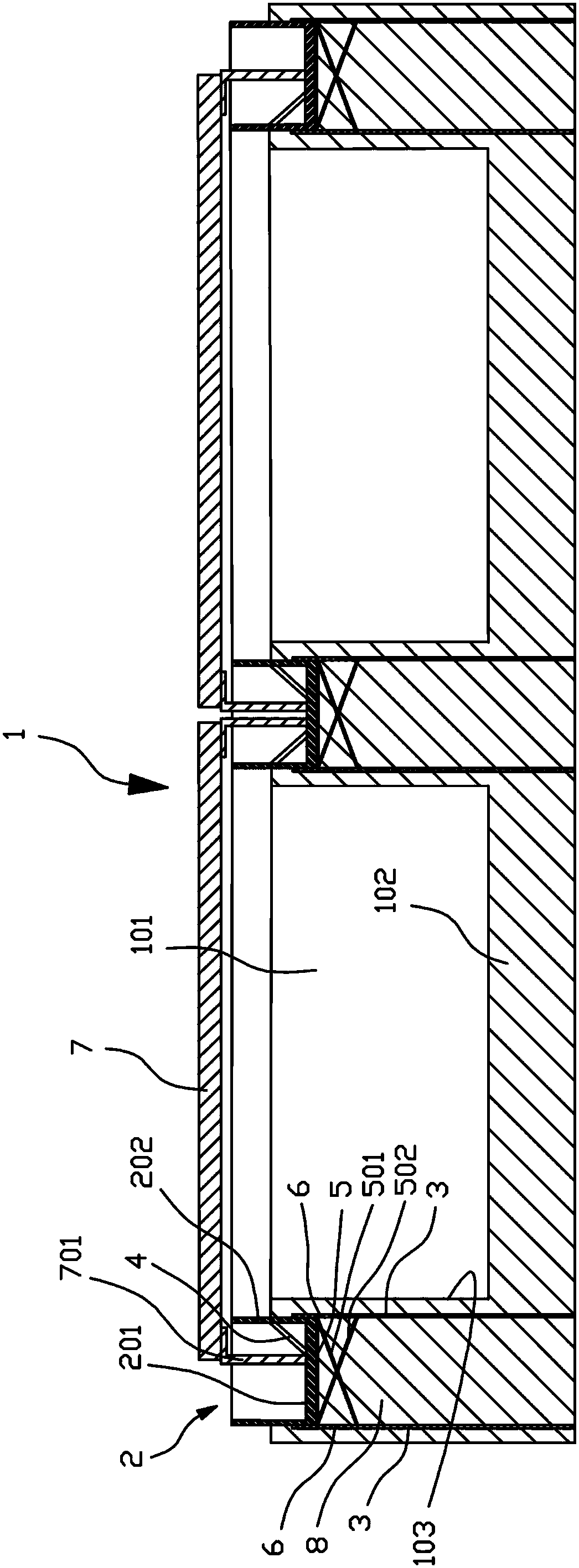

Concrete precast pile stream curing pool

ActiveCN103381620APrecise positioningDoes not affect placementCeramic shaping apparatusMarine engineering

The invention discloses a concrete precast pile stream curing pool comprising a plurality of pool bodies (101), wherein water seal tanks (2) are arranged on the outer sides of the top ends of the four side walls of each pool body (101), surround the pool body (101) and are communicated with one another; the two adjacent side walls of every two adjacent pool bodies (101) share the same water seal tank (2); each pool body is provided by a pool cover (7); a cover rim (701) is arranged on the edge of each pool cover (7) and extends downwards into the corresponding water seal tank (2); guiding and positioning devices, which are used for guiding and positioning the pool covers (7) in the process that the pool covers (7) are lifted to cover the pool bodies (101), are arranged in the water seal tanks (2) on the outer sides of the top ends of the side walls of the pool bodies (101) or on the pool covers (7). According to the concrete precast pile stream curing pool, the pool covers (7) can be positioned accurately and the water seal tanks can be prevented from being deformed due to collision.

Owner:宁波中淳高科股份有限公司

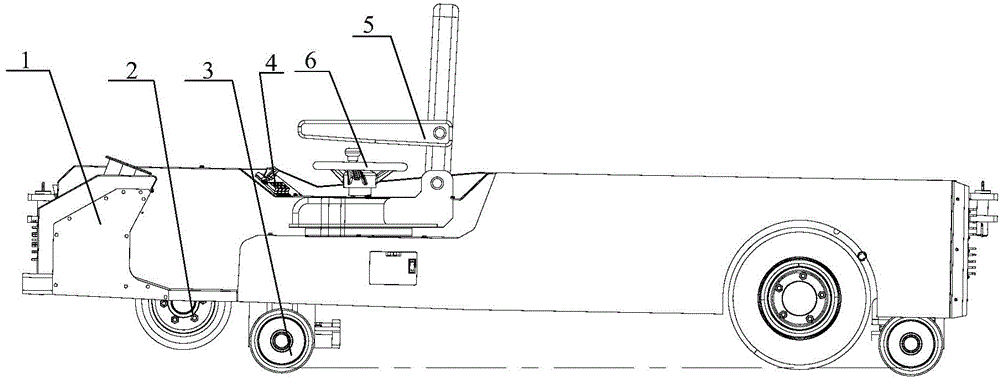

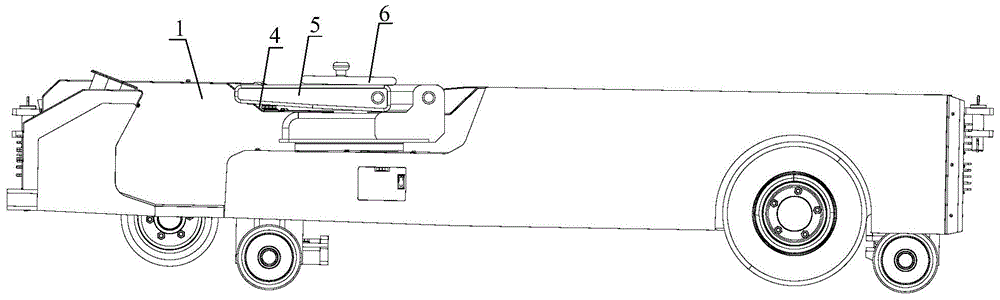

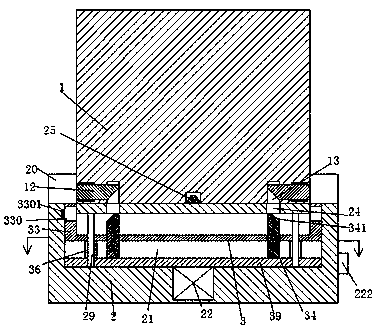

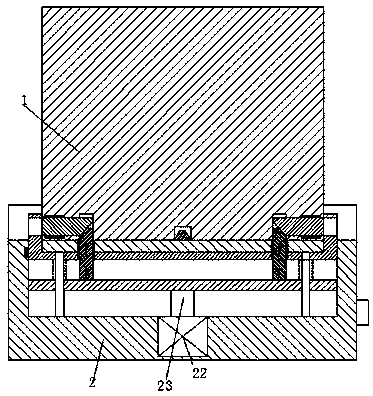

Roadway and railway two-purpose tractor

InactiveCN104442244ADoes not affect placementEasy to transportVehicle seatsRail and road vehiclesVehicle frameSteering wheel

The invention discloses a roadway and railway two-purpose tractor which comprises a tractor frame, seats arranged on the tractor frame and a steering wheel arranged on the tractor frame. The seats are foldable; the steering wheel is as high as the top end of the tractor frame or is lower than the top end of the tractor frame; when the roadway and railway two-purpose tractor needs to pass through a roadway or a tunnel or goods are long and the front ends of the goods extend to the upper side of the tractor and block the view of a driver or a drive position, the seats can be folded, so backrests of the seats are flush with the tractor frame, and the steering wheel is flush with the top end of the tractor frame or the steering wheel is a little higher than the top of the tractor frame. After the seats are folded, the height of the whole tractor can be effectively reduced, the steering wheel does not influence placement of the goods and the goods can be transported conveniently.

Owner:HENGYANG HELI INDAL VEHICLE

Novel container transport device of logistics

A novel container transport device of logistics comprises a transport vehicle frame and a container, wherein a sliding mounting cavity is arranged in the transport vehicle frame; a position-fixing plate is fixedly arranged at the rear end of the transport vehicle frame; stretching-out grooves which communicate with the sliding mounting cavity and extend forwards and backwards are symmetrically arranged at left and right sides of the upper end wall of the transport vehicle frame; a lower sliding plate and an upper sliding plate which can slide vertically are mounted in the sliding mounting cavity; sliding side plates are symmetrically arranged at both sides of the upper sliding plate; the sliding side plates stretch into the stretching-out grooves; the upper end wall of the transport vehicle frame is internally provided with through grooves which are symmetrical in front and back and symmetrical in left and right and communicate with the sliding mounting cavity; acting arms which are matched and connected with the through grooves are fixedly mounted at the upper end of the lower sliding plate; the bottom wall of the container is provided with stretching-in grooves which are matchedwith the acting arms and are provided with openings facing downwards; the outer end walls of the stretching-in grooves are also provided with transverse telescopic grooves which are orthogonal to thestretching-in grooves; telescopic arms are slidably mounted in the transverse telescopic grooves; and the sliding side plates are also internally provided with position-limiting grooves matched with the telescopic arms.

Owner:广西南宁尼科安全技术服务有限公司

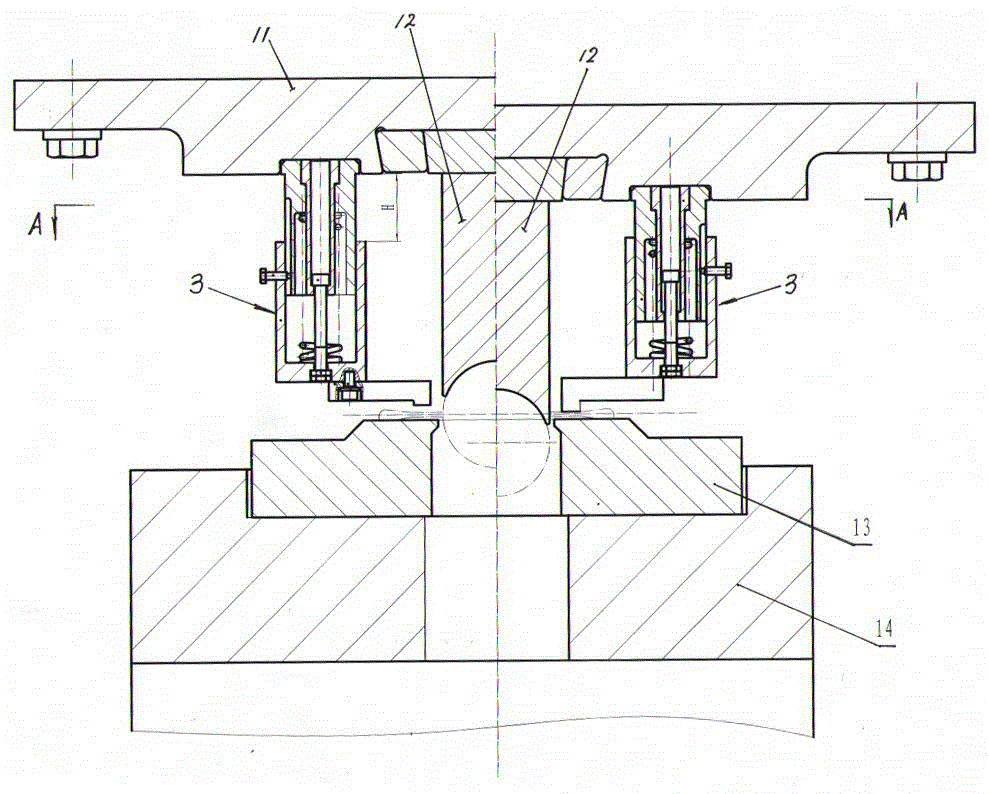

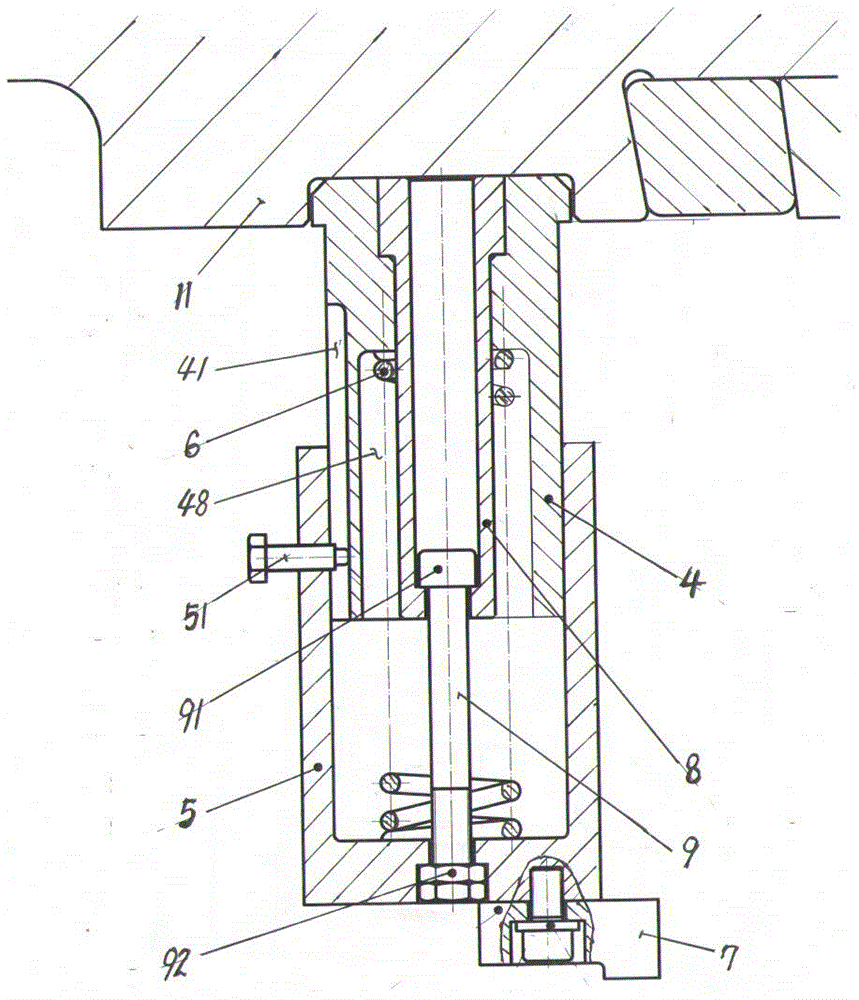

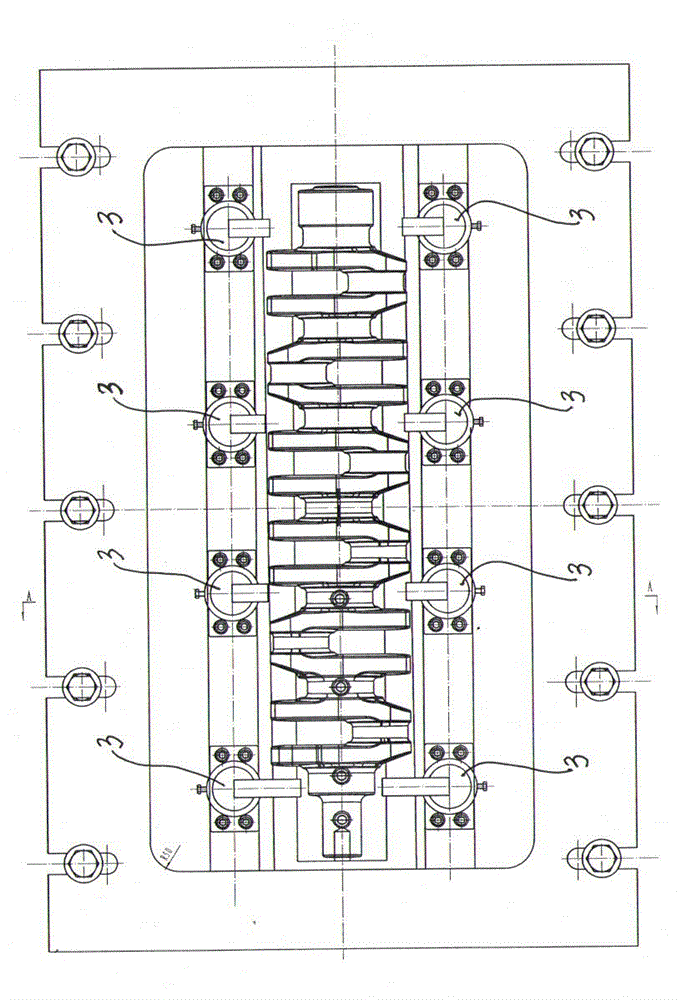

Die forging crankshaft and connecting-rod flash cutting die device

ActiveCN104384417ASimple structureReduce volumeForging/hammering/pressing machinesEngine componentsSize changeCrankshaft

The invention provides a die forging crankshaft and connecting-rod flash cutting die device. A plurality of flash removing devices (3) are distributed on an upper die plate (11), each of the flash removing devices (3) consists of an inner sleeve (4), an outer sleeve (5), a spring (6), an ejection block (7), a guide rod sleeve (8) and a pull rod (9), the outer sleeve (5) is matched with the inner sleeve (4) in a sliding-limiting mode, the spring (6) is installed in the inner sleeve (4) and exerts pressure on the outer sleeve (5), and the lower end face of the outer sleeve (5) is connected with the ejection block (7) through a screw. According to the size and shape of a die forging subjected to flash cutting, two or more flash removing devices (3) are distributed and installed on the upper die plate (11). The flash removing devices (3) are small in size, universal and convenient to adjust and use and is not influenced by the complication degree of die forging shapes and size change.

Owner:LIAONING 518 INTERNAL COMBUSTION ENGINE FITTINGS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com