Automatic batten plate splicing machine

A technology of jigsaw and wood strips, which is used in the joining of wooden veneers, wood processing appliances, and other plywood/plywood appliances, etc. It can solve the problems of slow speed, loud noise, and easy to hit too hard, and achieve high efficiency. , to solve the effect of loud noise and clear division of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

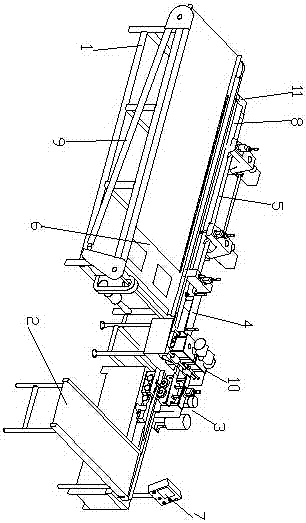

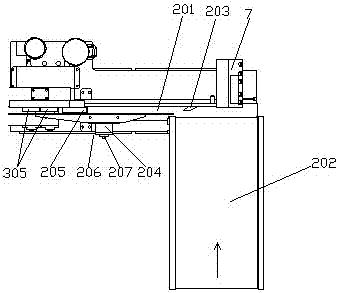

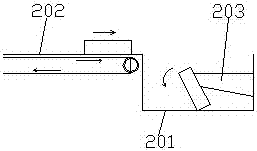

[0030]As shown in the figure, an automatic wooden strip puzzle machine includes a working frame 1, a feeding device 2 for storing wooden strips, a pressure wheel buffer device 3 for buffering and conveying wooden strips, and a coating for gluing the sides of wooden strips. Gluing device 10, sawing device for sawing completely placed wooden strips 4, directional pushing device for splicing wooden strips after sawing 5, push plate device for pushing away directional placed wooden strips 6, control jigsaw The electrical automation control system 7 and the main conveyor belt 8 for machine operation, the feeding device 2 is arranged at the starting end of the main conveyor belt 8, and the end of the main conveyor belt 8 is provided with a retractable limit mechanism for adjusting the cutting length of wooden strips 11. The li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com