Patents

Literature

1328results about "Other plywood/veneer working apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

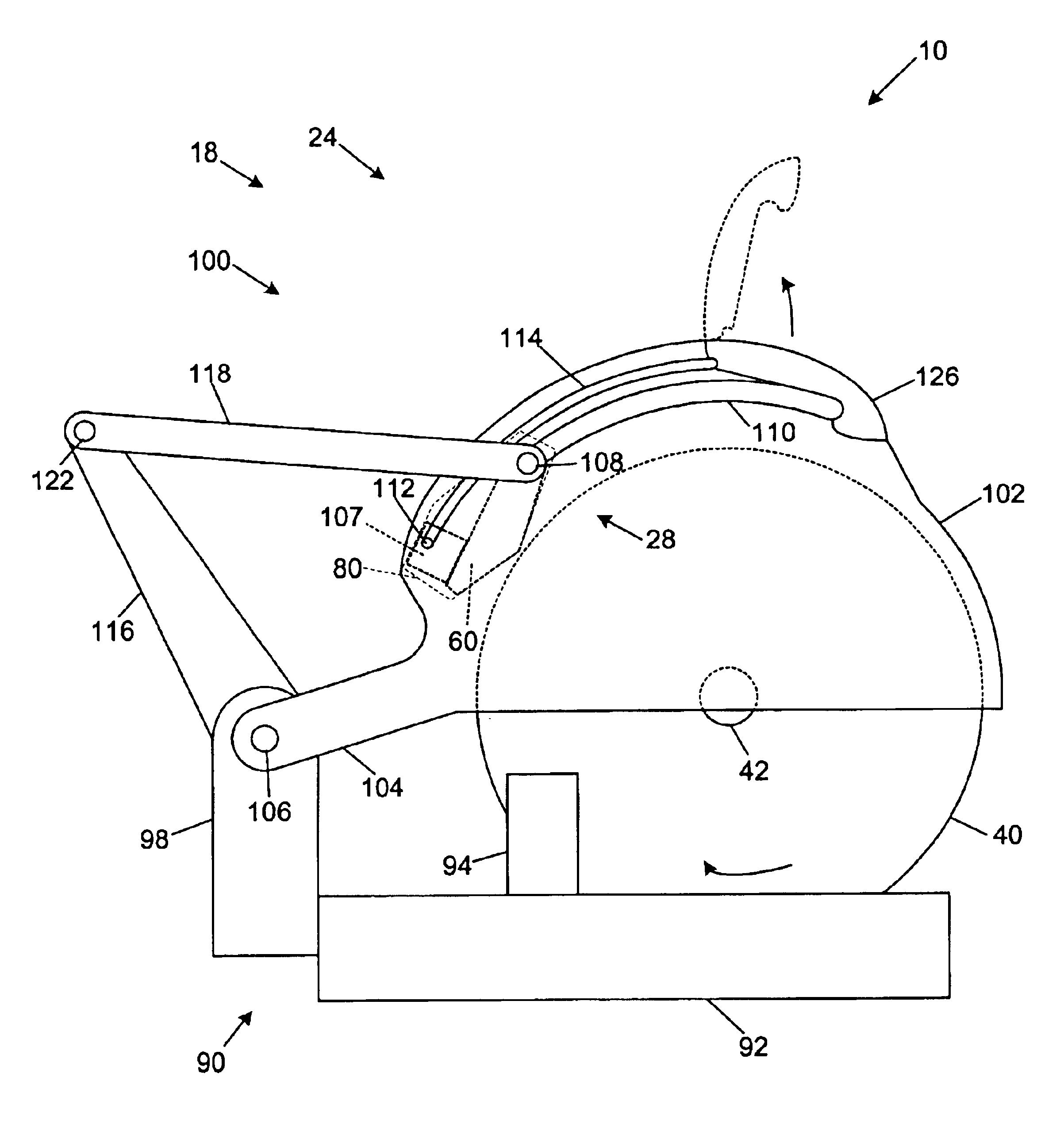

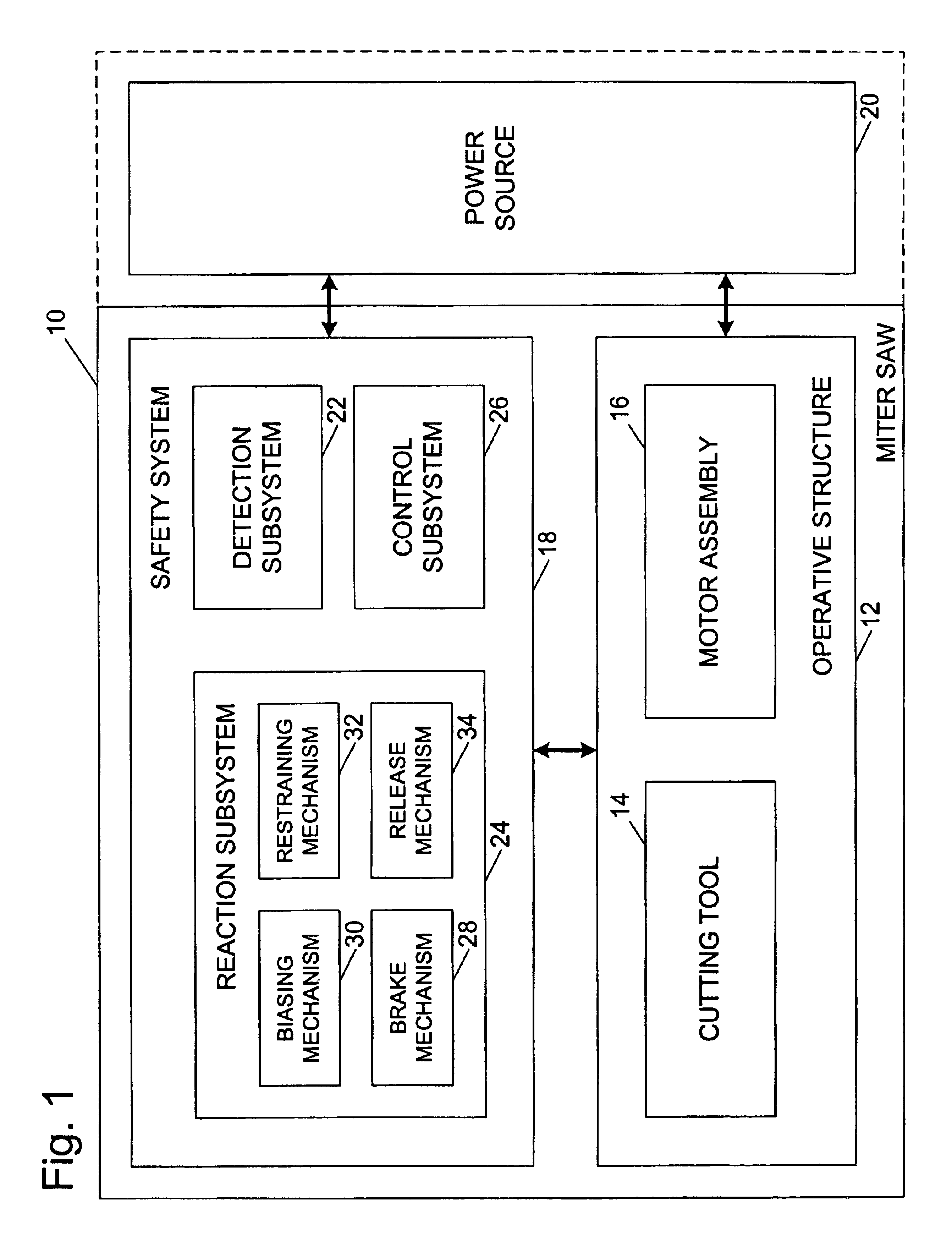

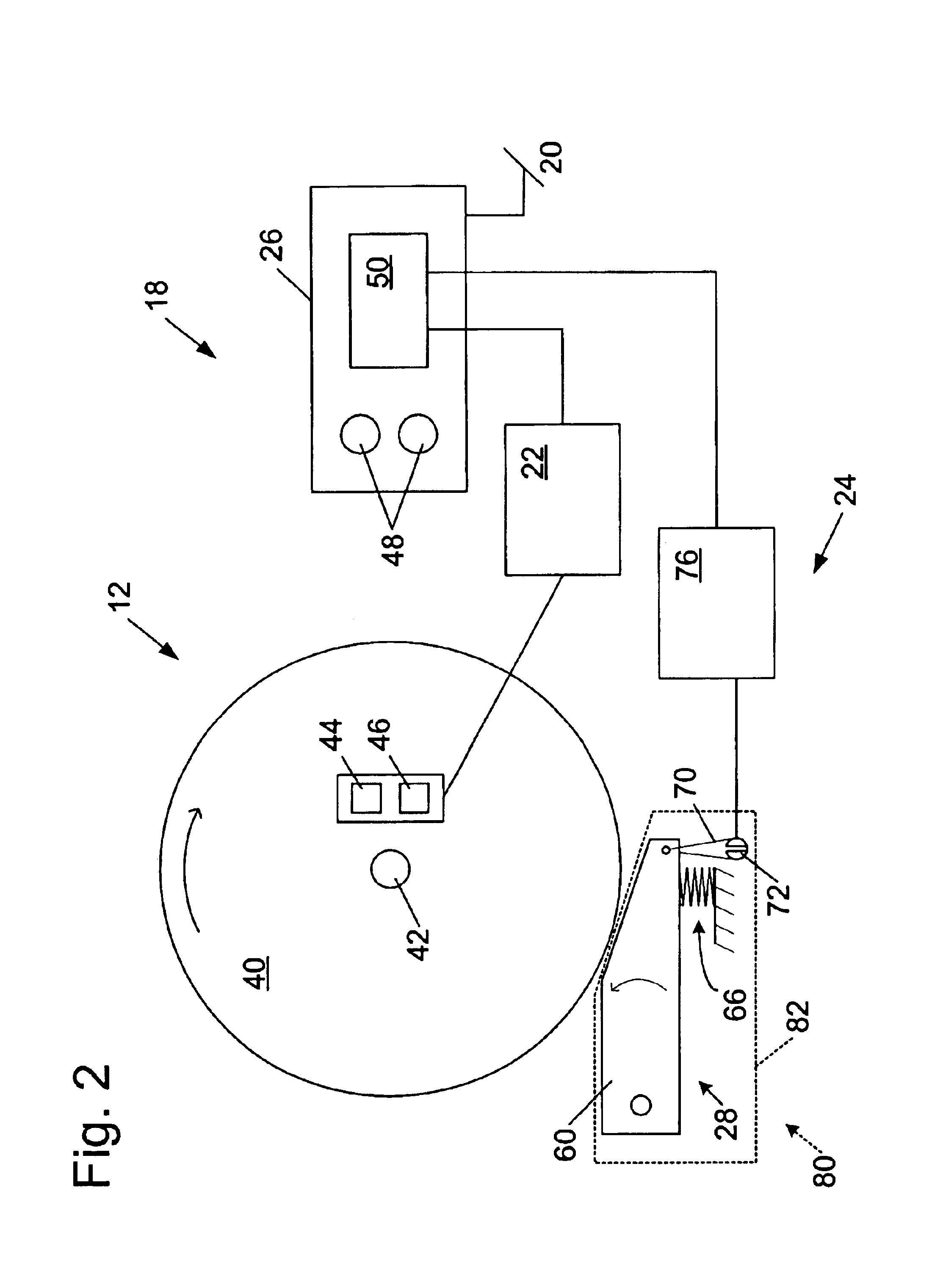

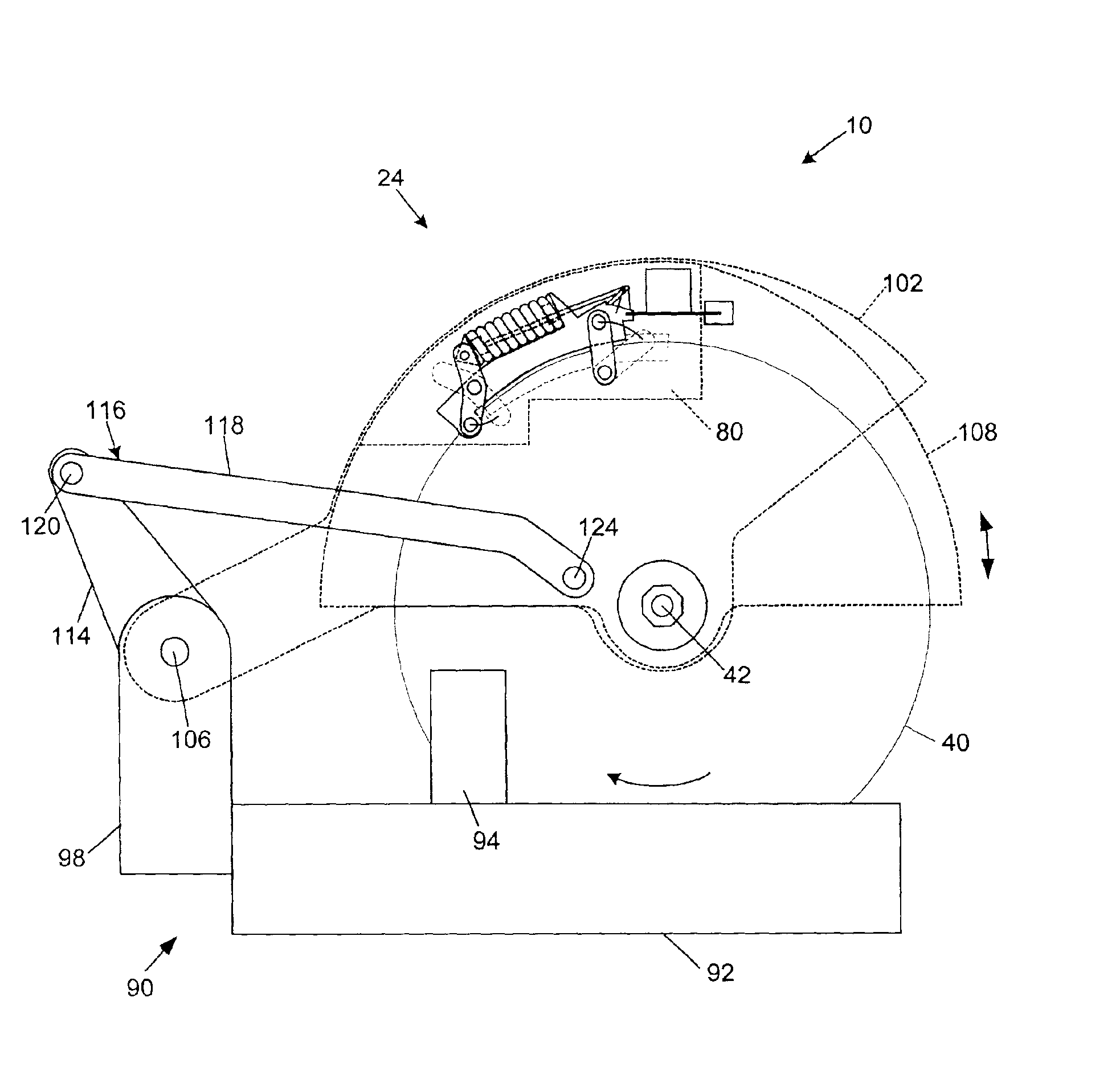

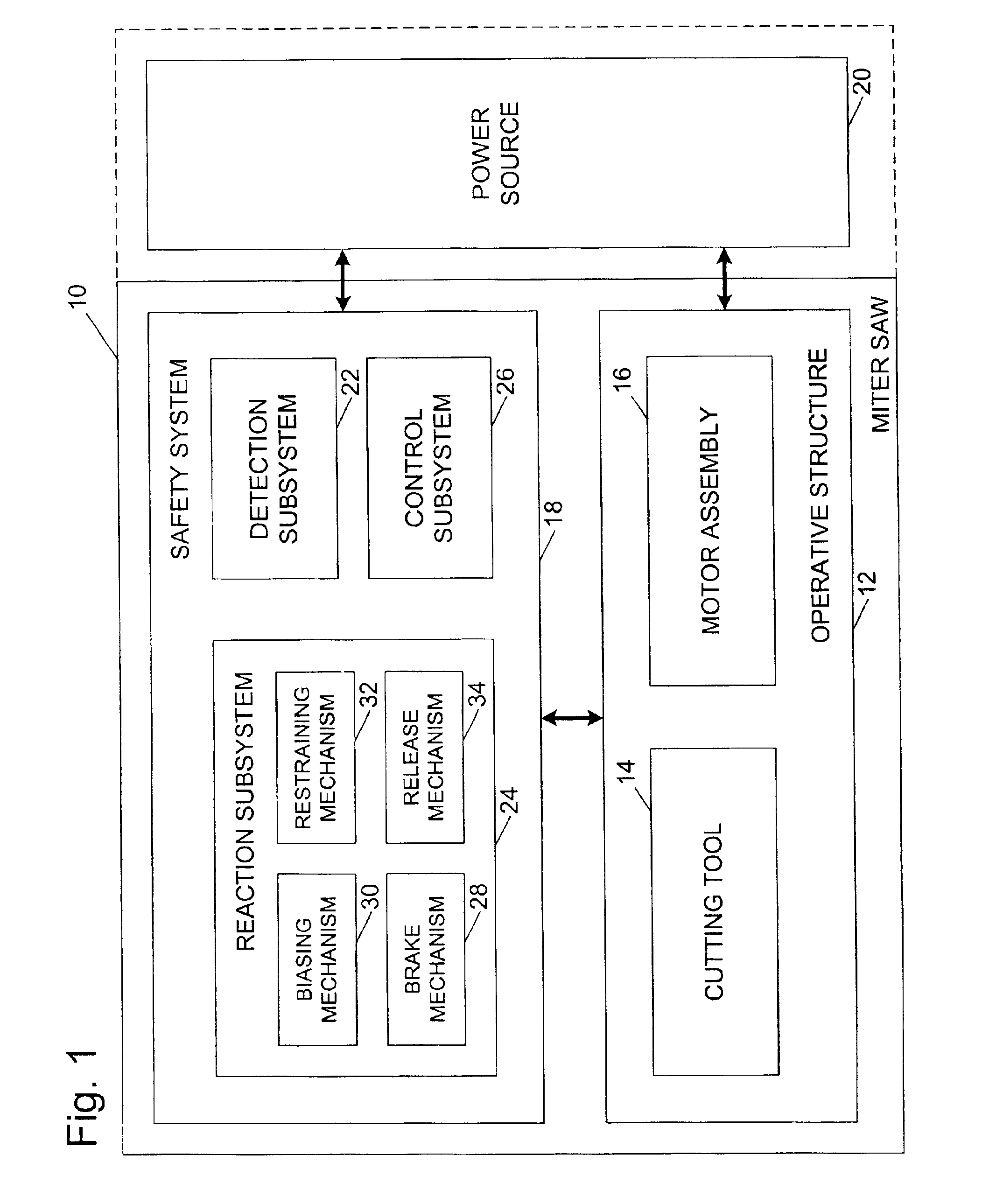

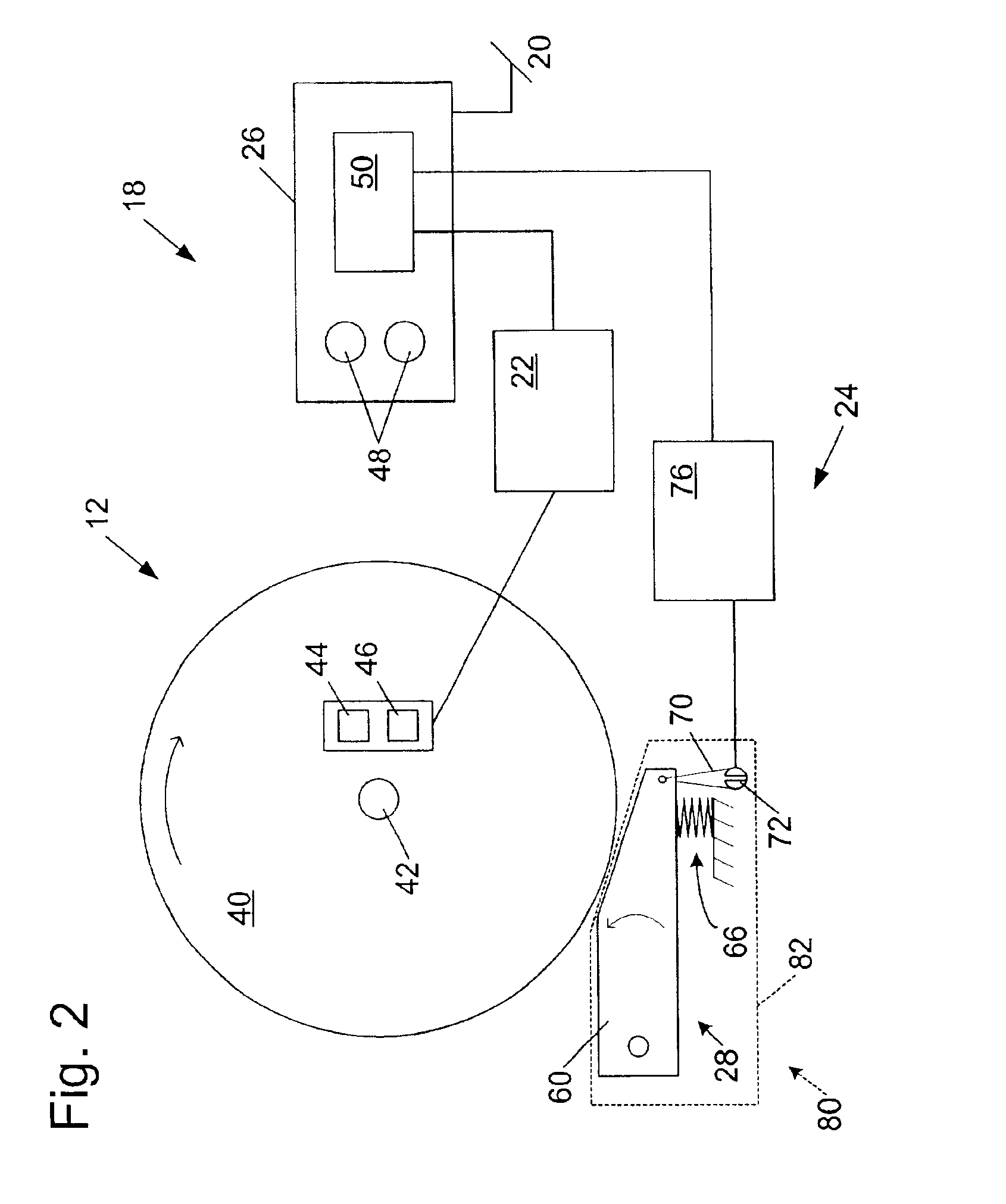

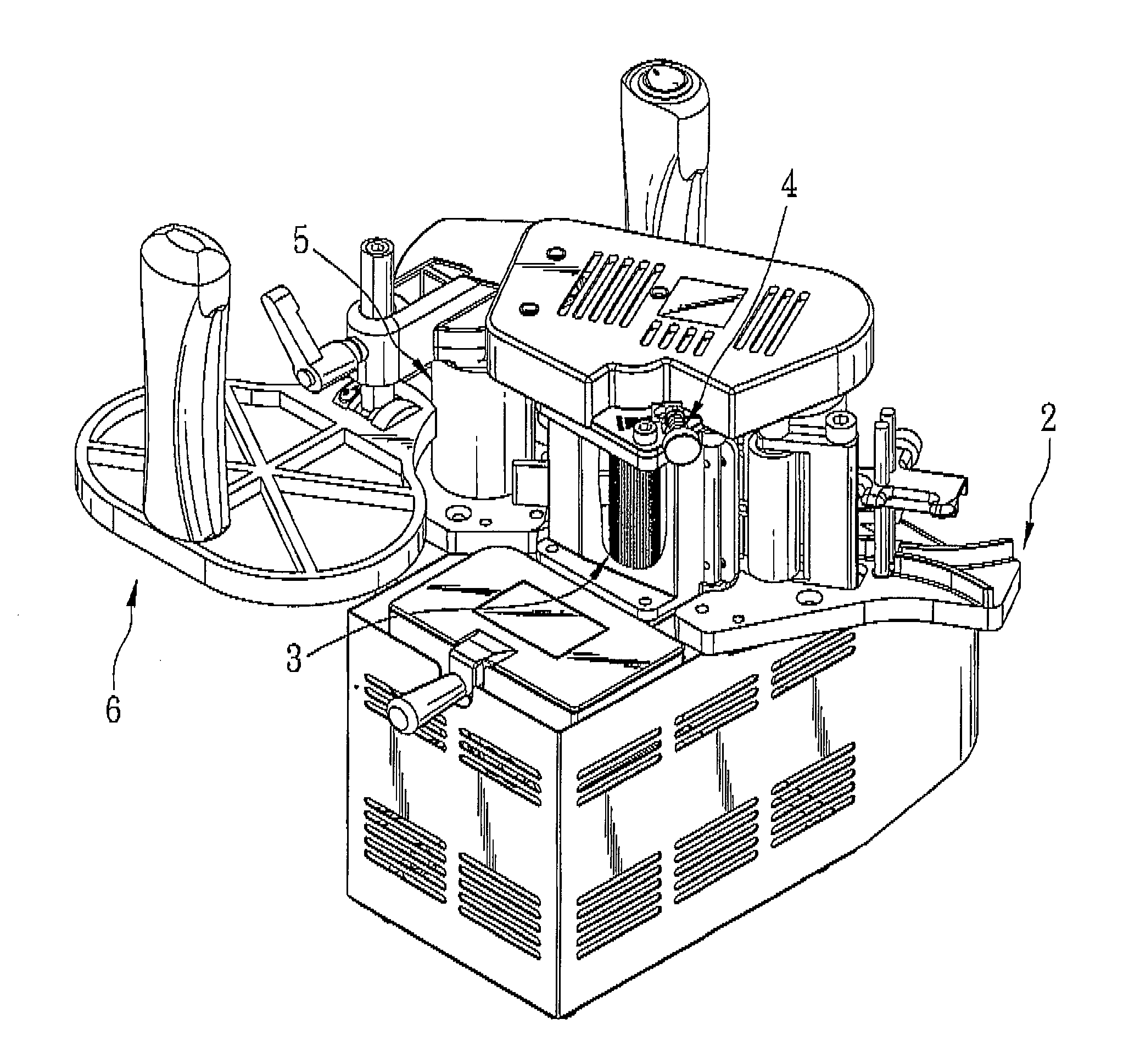

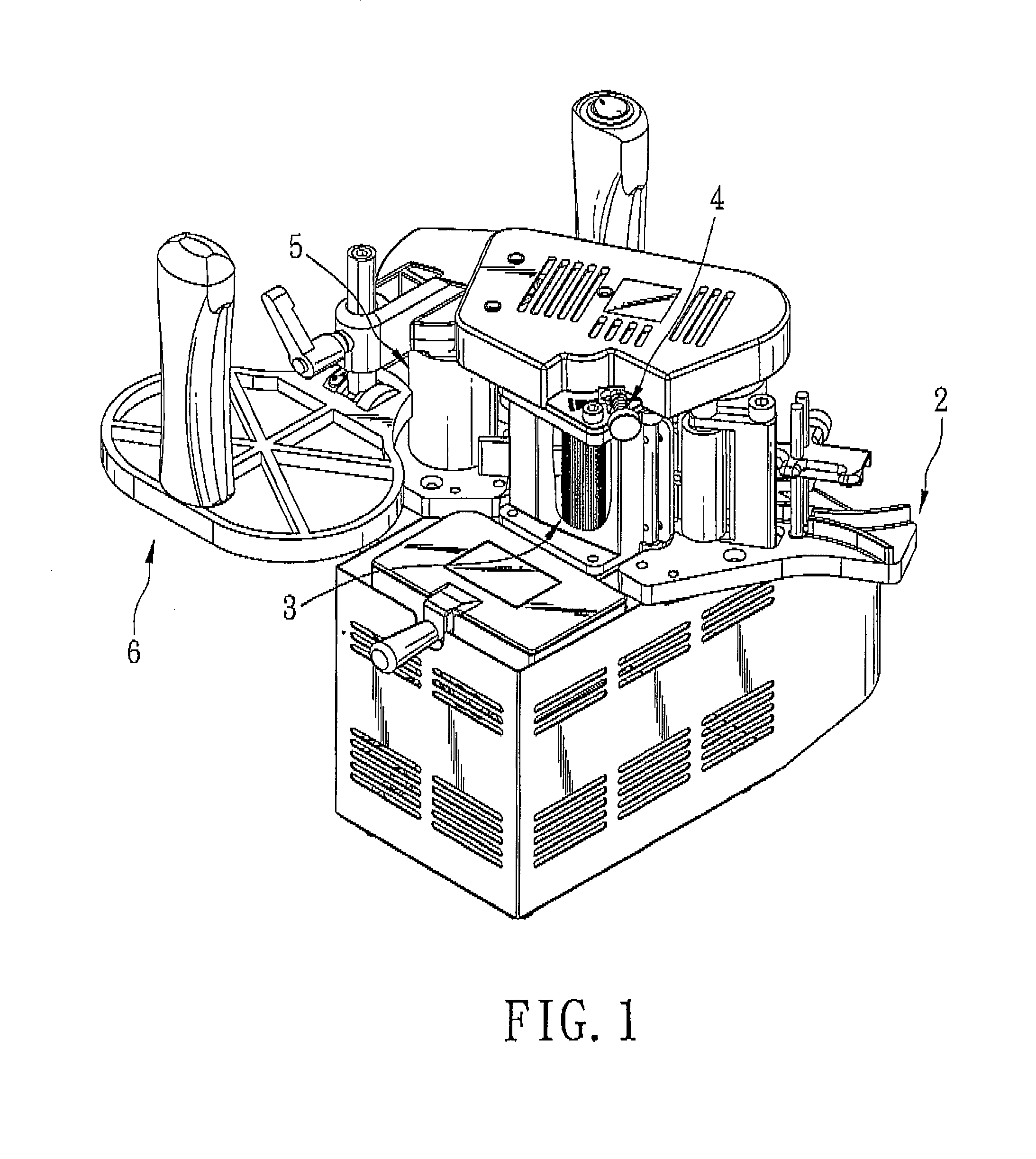

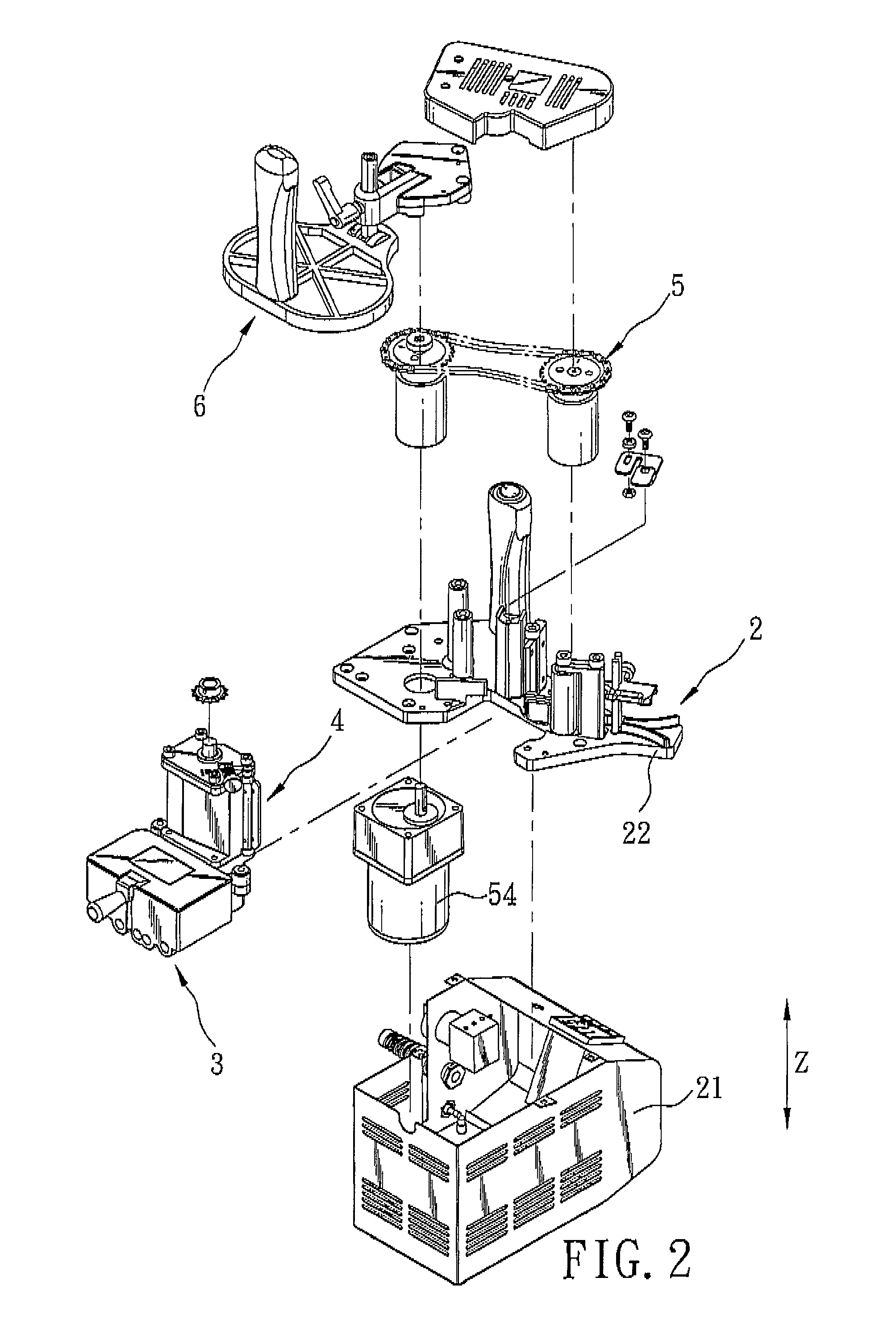

Miter saw with improved safety system

InactiveUS6945148B2Increase opportunitiesLimit and even prevent injuryOther plywood/veneer working apparatusMechanically actuated brakesEngineeringMechanical engineering

A miter saw is disclosed having a base, a blade supported by the base, a detection system adapted to detect a dangerous condition between a person and the blade, and a reaction system associated with the detection system to cause a predetermined action to take place upon detection of the dangerous condition. The blade is rotatable, and moves into a cutting zone to cut a workpiece. The predetermined action may be to stop the blade from rotating, to create an impulse against movement of the blade into the cutting zone, or to cause the blade to move away from the cutting zone.

Owner:SAWSTOP HLDG LLC

Miter saw with improved safety system

InactiveUS6877410B2Increase opportunitiesLimit and even prevent injuryOther plywood/veneer working apparatusMetal sawing devicesMechanical engineeringReaction system

A miter saw is disclosed having a base, a blade supported by the base, a detection system adapted to detect a dangerous condition between a person and the blade, and a reaction system associated with the detection system to cause a predetermined action to take place upon detection of the dangerous condition. The blade is rotatable, and moves into a cutting zone to cut a workpiece. The predetermined action may be to stop the blade from rotating, to create an impulse against movement of the blade into the cutting zone, or to cause the blade to move away from the cutting zone.

Owner:SAWSTOP HLDG LLC

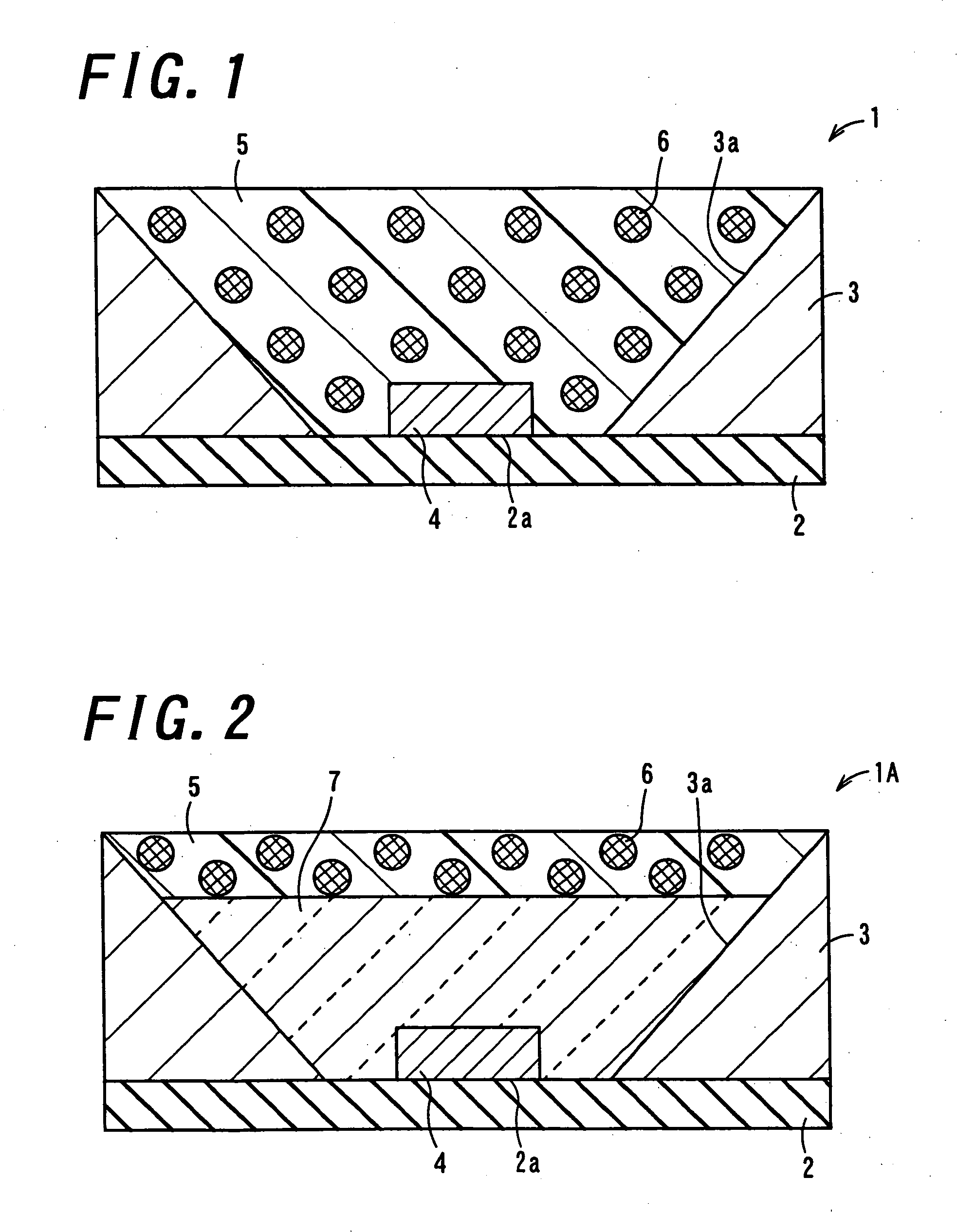

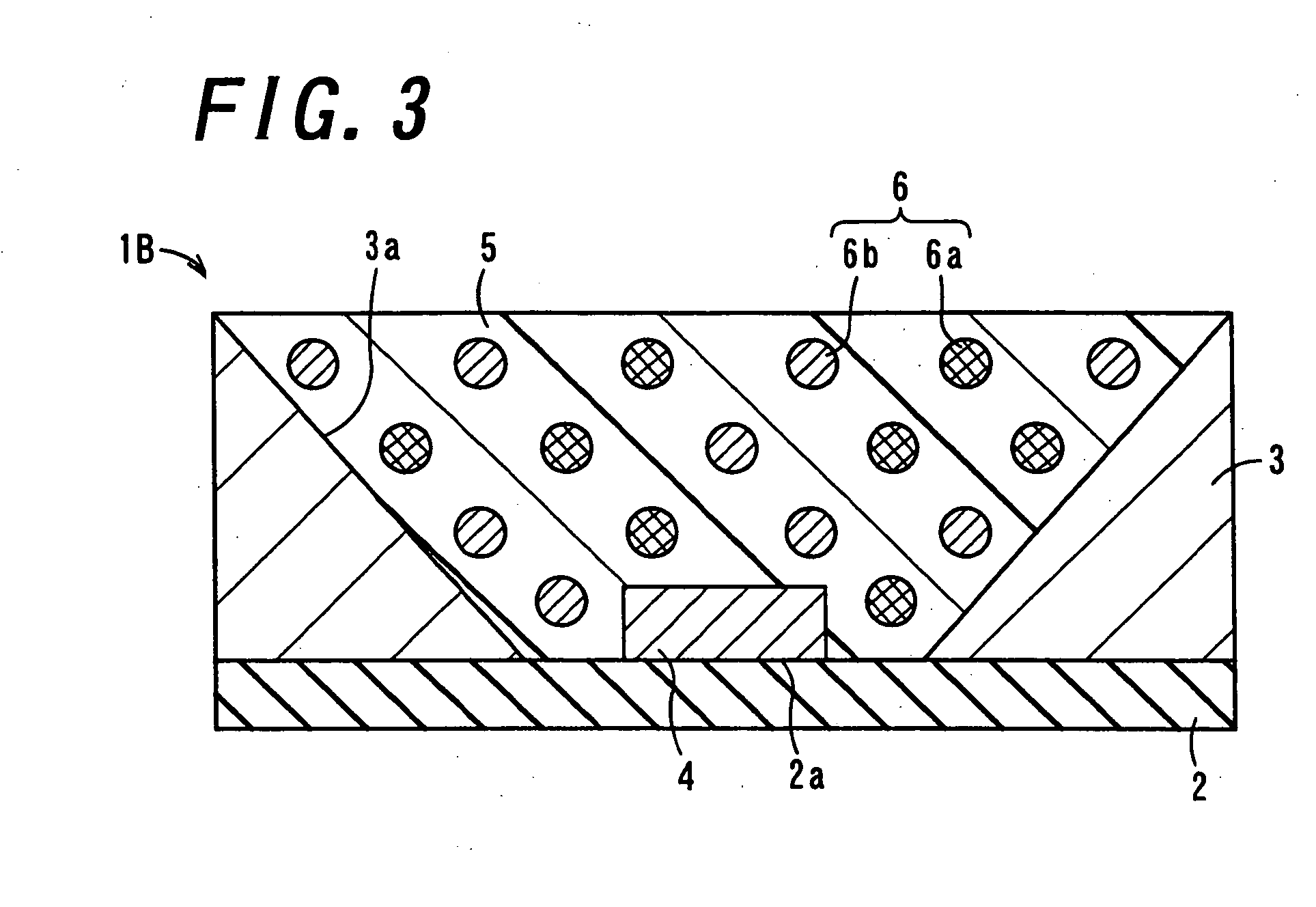

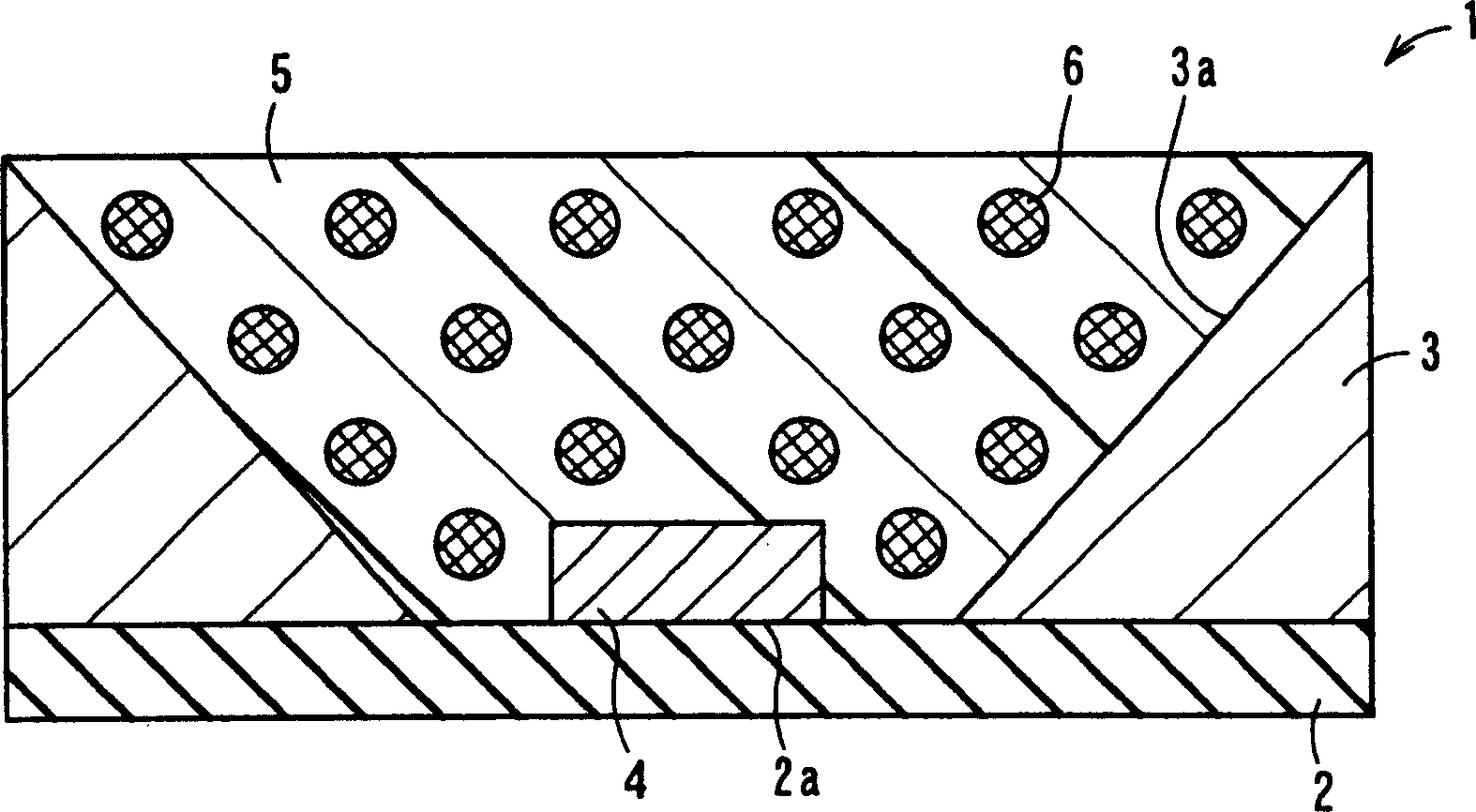

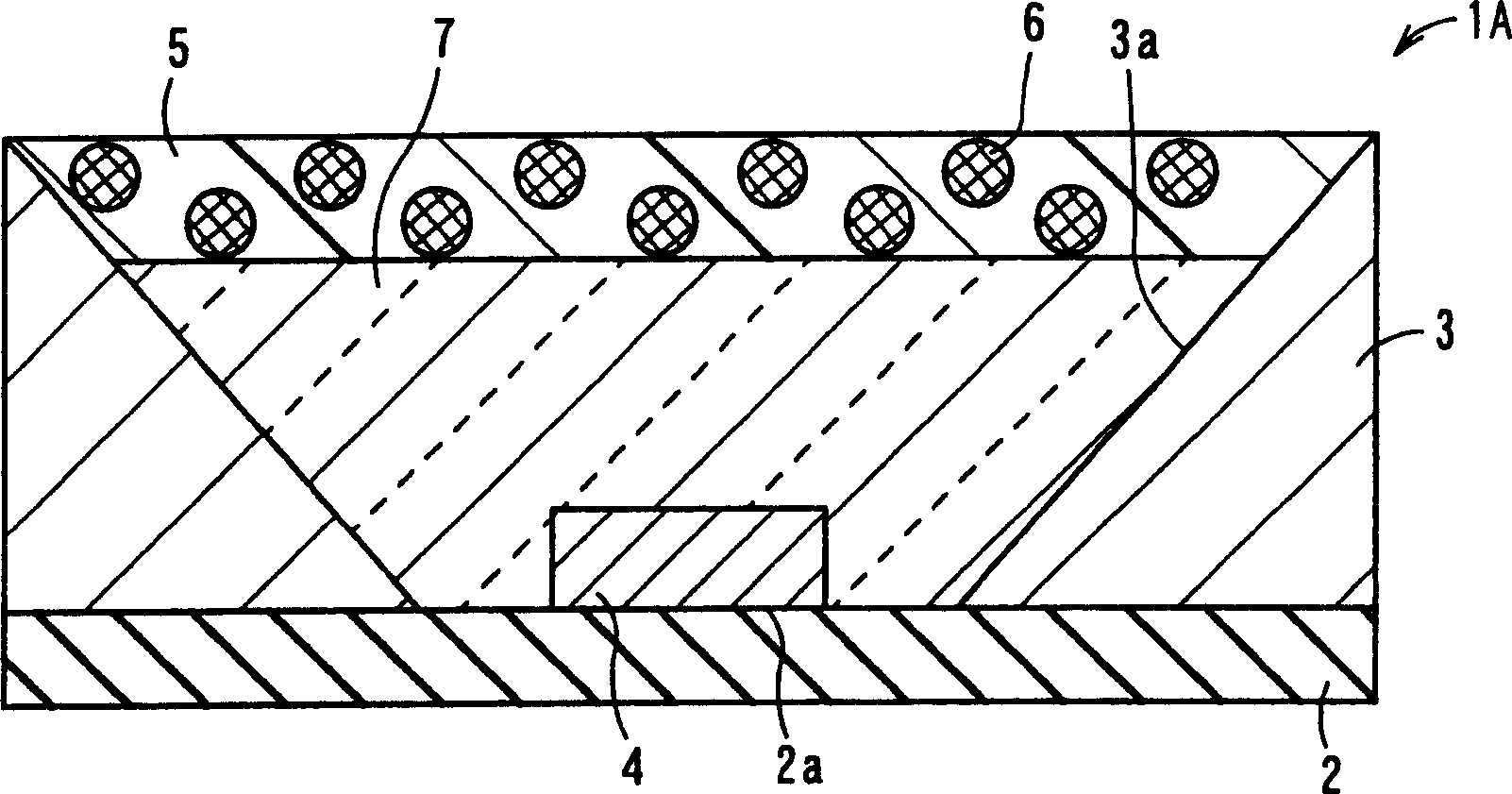

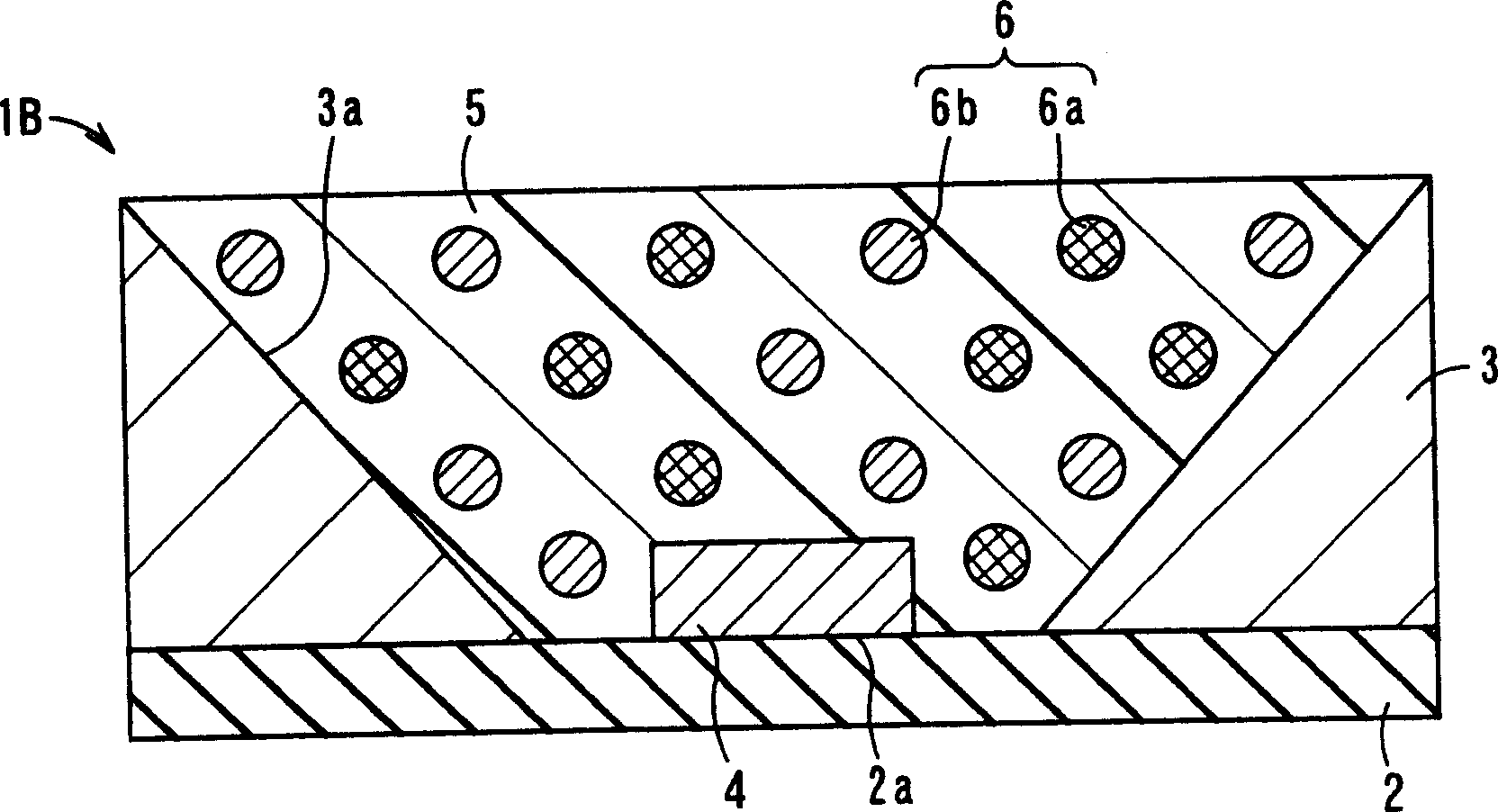

Light-emitting apparatus and illuminating apparatus

InactiveUS20050211991A1Reduce light intensitySignificant rateOther plywood/veneer working apparatusMechanical surface treatmentColor temperatureEngineering

There is provided a light-emitting apparatus with favorable radiation light intensity, which is excellent in light extraction efficiency, color temperature and color rendering property. The light-emitting apparatus includes a light-emitting element, a base body having, on its top surface, a placement portion for emplacing thereon the light-emitting element, a frame body attached to the top surface of the base body so as to surround the placement portion, a light transmitting member disposed inside the frame body so as to cover the light-emitting element, and phosphors contained in the light transmitting member, which performs wavelength conversion on the light emitted from the light-emitting element. The light transmitting member has a pre-cured viscosity ranging from 0.4 to 50 Pa.s.

Owner:KYOCERA CORP

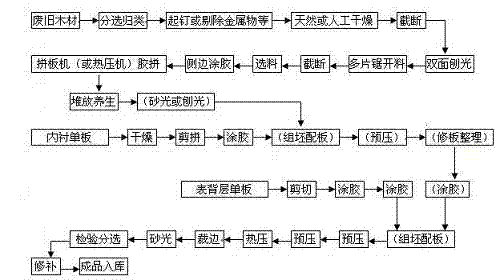

Method for producing flame-retardant glued board

ActiveCN101412231AReduce releaseImprove flame retardant performanceOther plywood/veneer working apparatusWood treatment detailsAdhesivePyrophosphate

The invention discloses a method for producing a flame-retardant veneer plywood, which comprises the following steps: placing wood veneers into a flame retardant aqueous solution to perform dipping treatment, applying the mixed adhesive to the upper surfaces and the lower surfaces of the veneers after the veneers are dried, assembling the veneers into a plate blank according to the principle that odd layers are crossed and symmetrical with even layers, and then performing the processes of cold pressing, hot pressing, cutting edge, sanding, surface treating and the like to obtain the flame-retardant veneer plywood product the thickness of which is between 2.7 and 20 millimeters. The flame retardant in the method is a mixture of low ammonium polyphosphate, ammonium phosphate, ammonium pyrophosphate, urea phosphate, boric acid and pentaerythritol, and the mixed adhesive is a uniform mixture of wood adhesive, filler, and a curing agent. The flame-retardant decorative veneer plywood prepared by the method has the advantages of excellent flame-retardant and fireproof performance, environmental prevention performance, and good mechanical properties.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

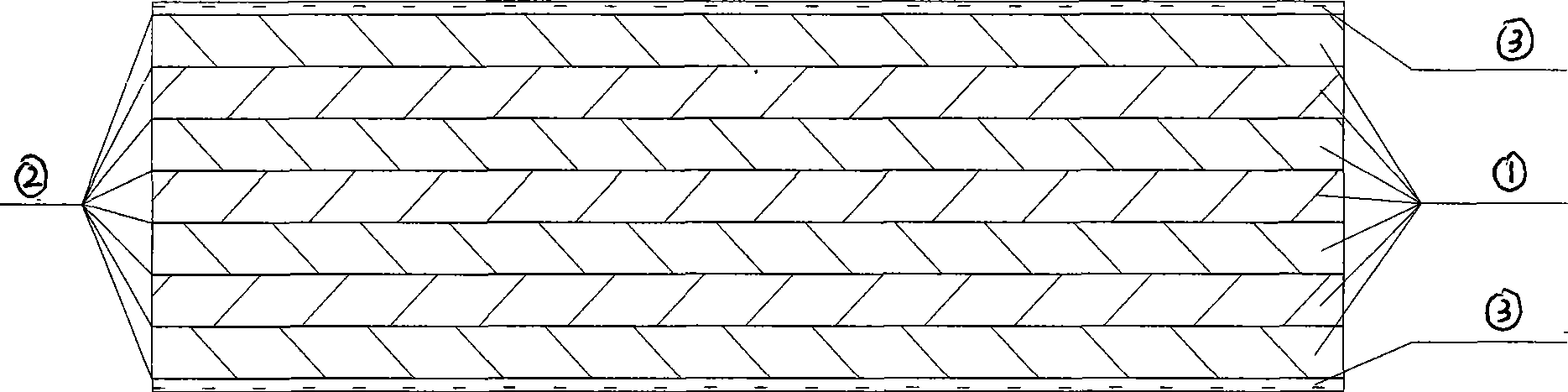

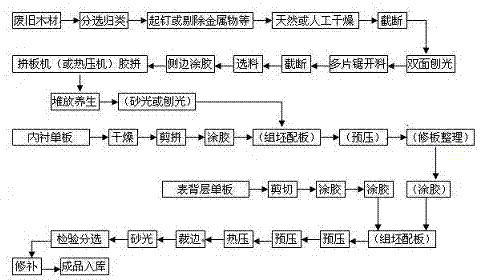

Method for producing recombinant composite board by using waste wood

InactiveCN102229159AFlat surfaceUniform thicknessOther plywood/veneer working apparatusLaminationSolid woodPulp and paper industry

The invention discloses a method for producing a recombinant composite board by using waste wood. The method comprises the following steps of: (1) preparation of a core board, (2) veneer finishing, (3) board blank gluing, blank matching and pre-pressing, (4) hot pressing, (5) trimming and sanding, and (6) inspection, grading and repair. The method has the advantages that: the square board of certain specification is manufactured by making full use of the waste wood, the core layer is spliced by using glue, two layers of veneers are covered on two sides of the core layer respectively, the recombinant composite board with five-layer structure is manufactured by hot pressing, and the reclaimed waste wood is used for substituting solid wood, so the material channel is broadened; low carbon, environment friendliness, greenness and resource property of the recombinant composite board are highlighted; the comprehensive utilization rate of the waste wood is improved, and the additional value and the technological content of the waste wood product are increased; and high use of small material, preferential use of poor material, fine use of coarse material and elaborate use of weak materialare realized in the waste wood.

Owner:玉环市众创人才科技创新服务中心

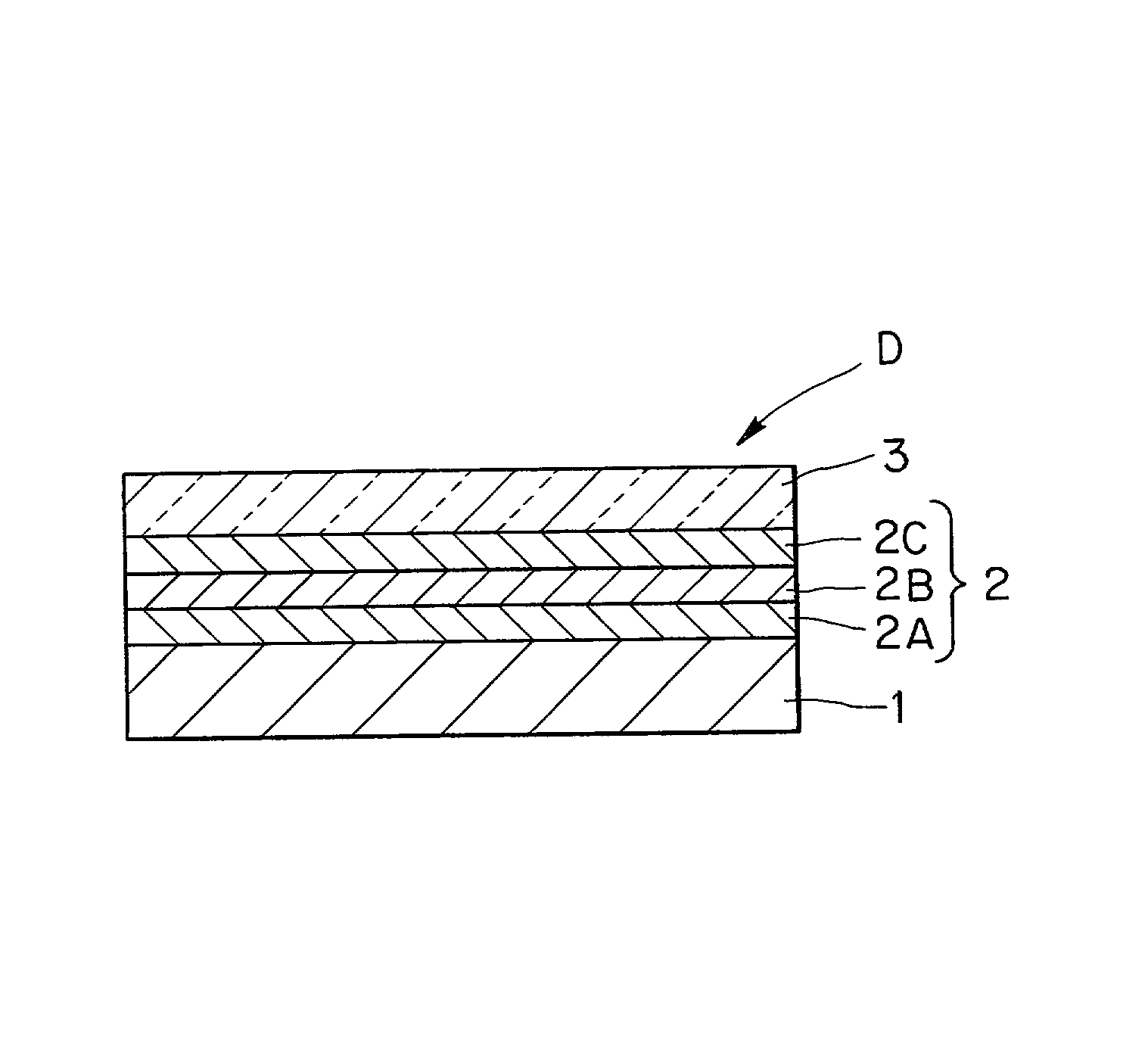

Wood decorative material coated with resin composite film and process for producing the same

InactiveUS6352784B1High bonding strengthCrack and breakOther plywood/veneer working apparatusSynthetic resin layered productsSurface layerLacquer

A wood decorative material coated with resin composite film, comprising a laminate of, arranged in the following order, a wood substrate; a heat bonding layer (A) formed from a heat bonding resin composition comprising 100 parts by weight of a thermoplastic resin (a-1) and 0.001 to 80 parts by weight of a tackifier resin (a-2), the above heat bonding resin composition having a melting point or softening temperature of 170° C. or below and exhibiting a melt flow rate (MFR) at 190° C. of 1 to 500 g / 10 min; and a mar-proof surface layer (B). Not only can beautiful appearance be obtained while retaining natural texture without the application of lacquer but also surface protection and bending working properties are improved.

Owner:TOHCELLO CO LTD (JP)

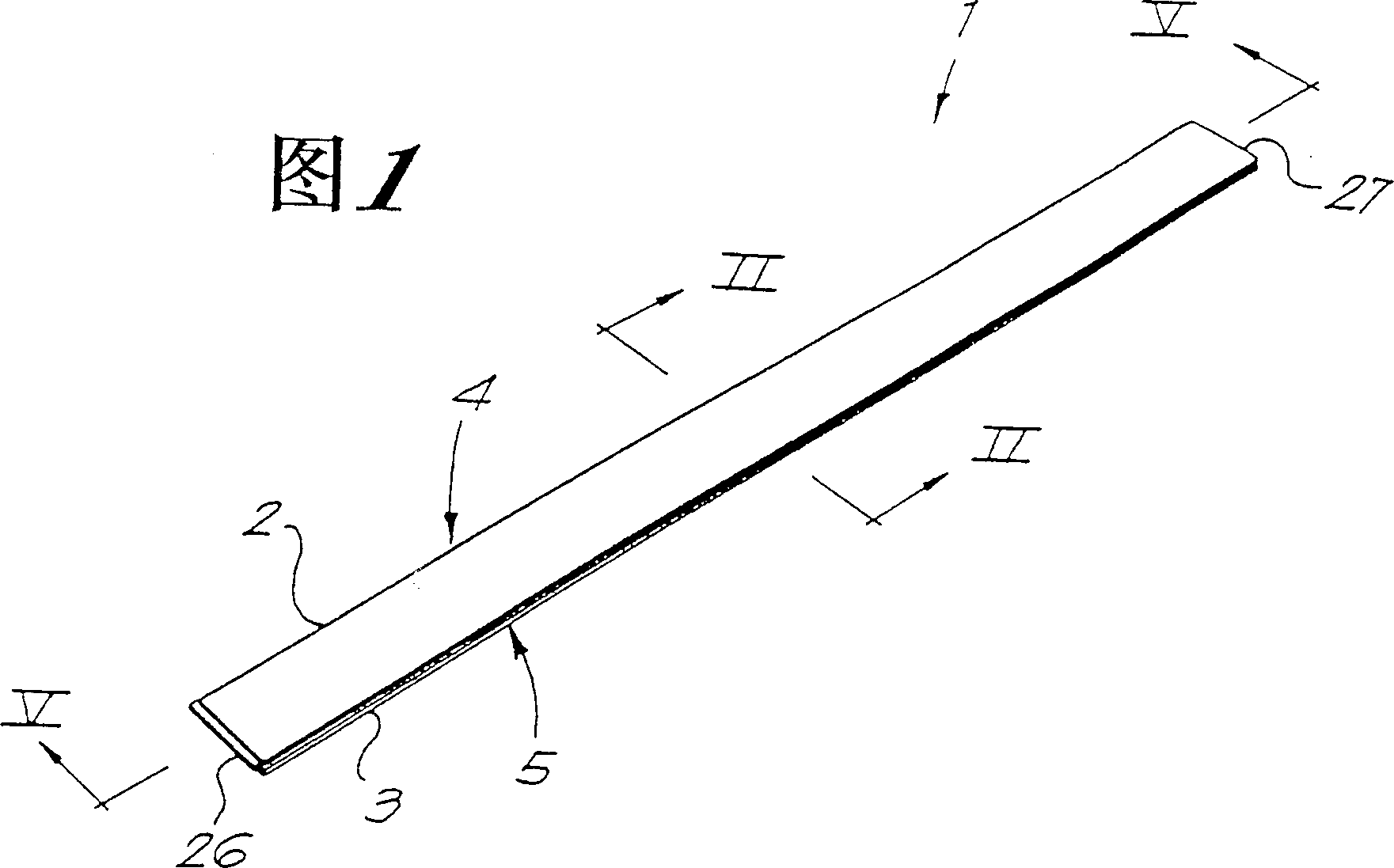

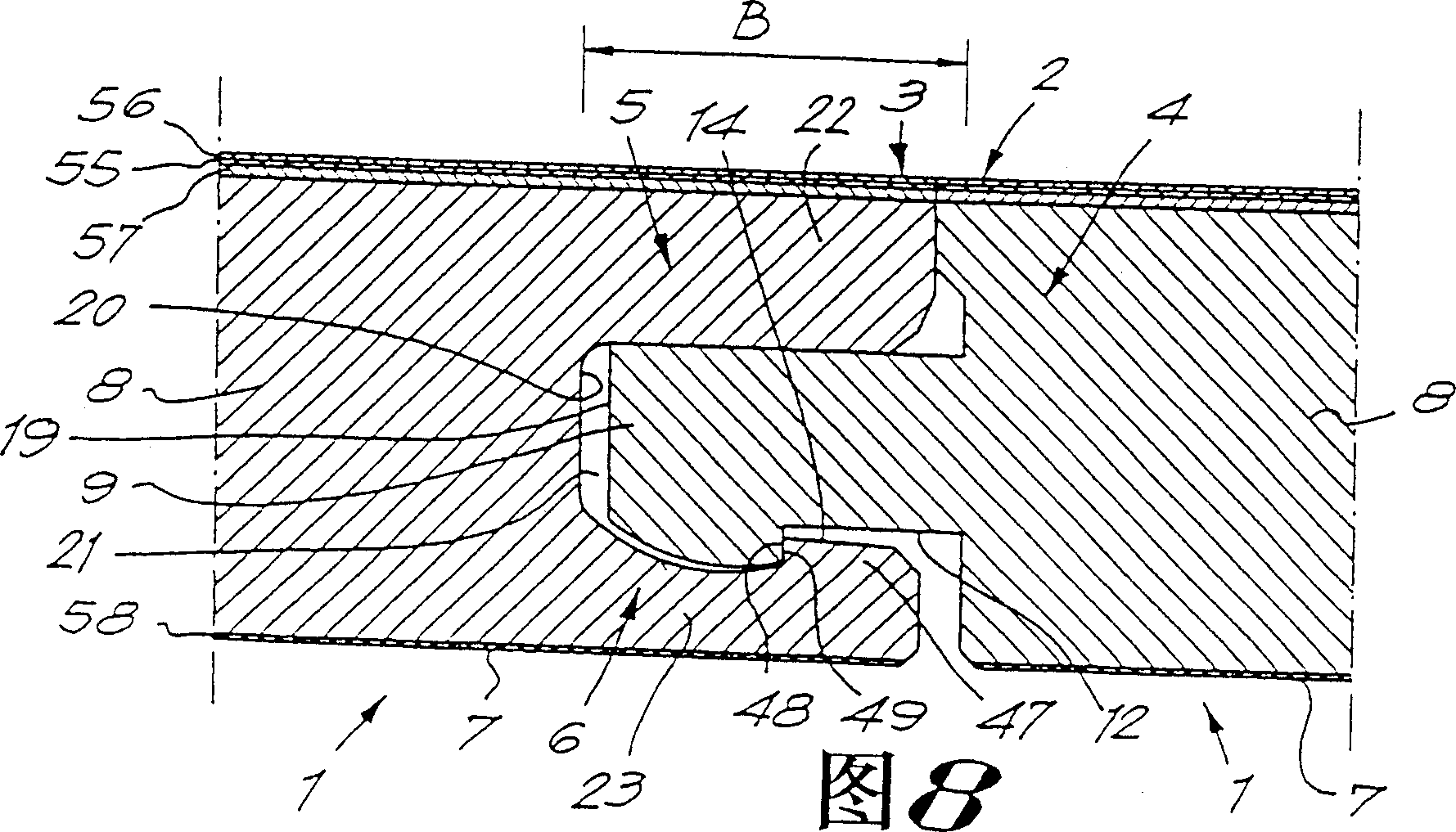

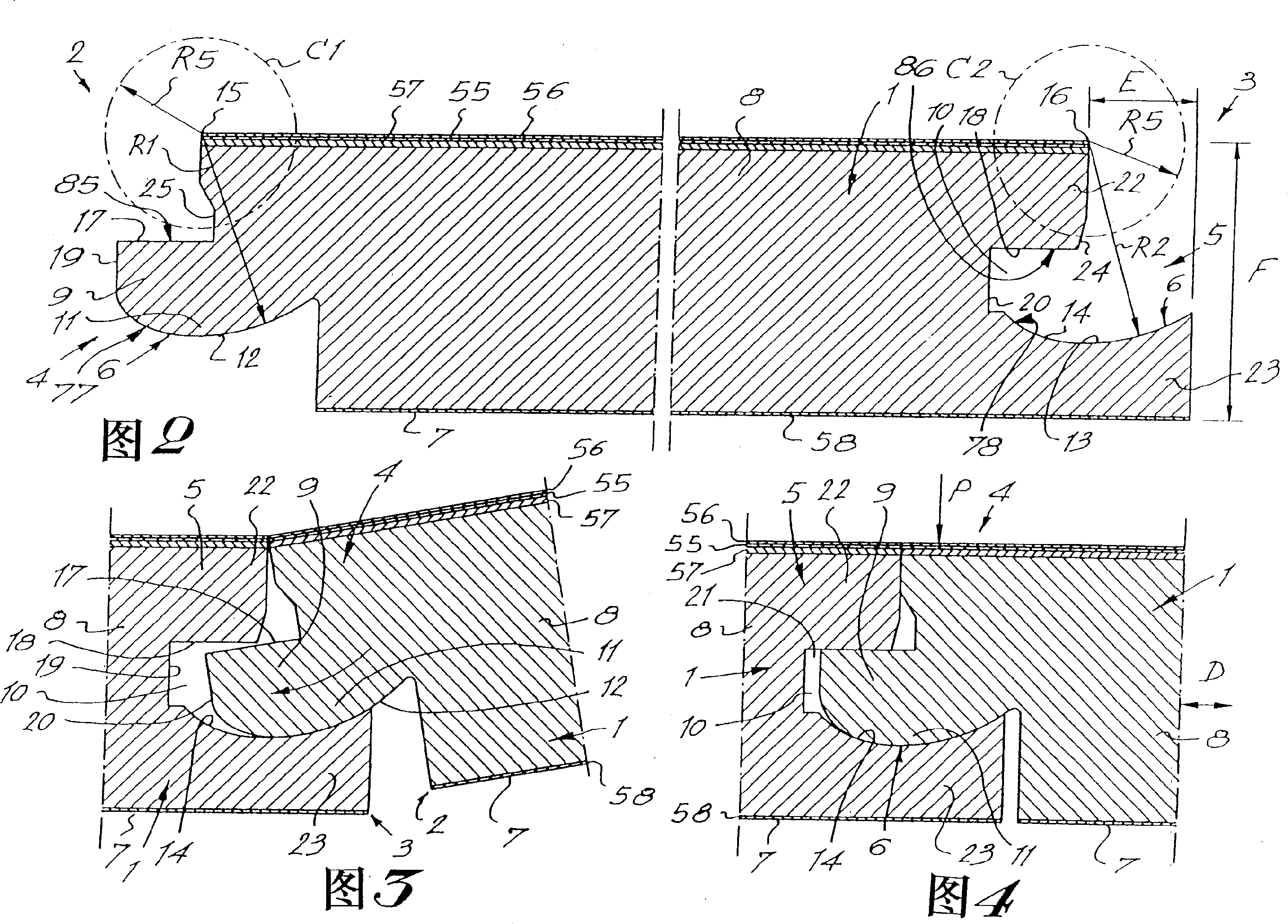

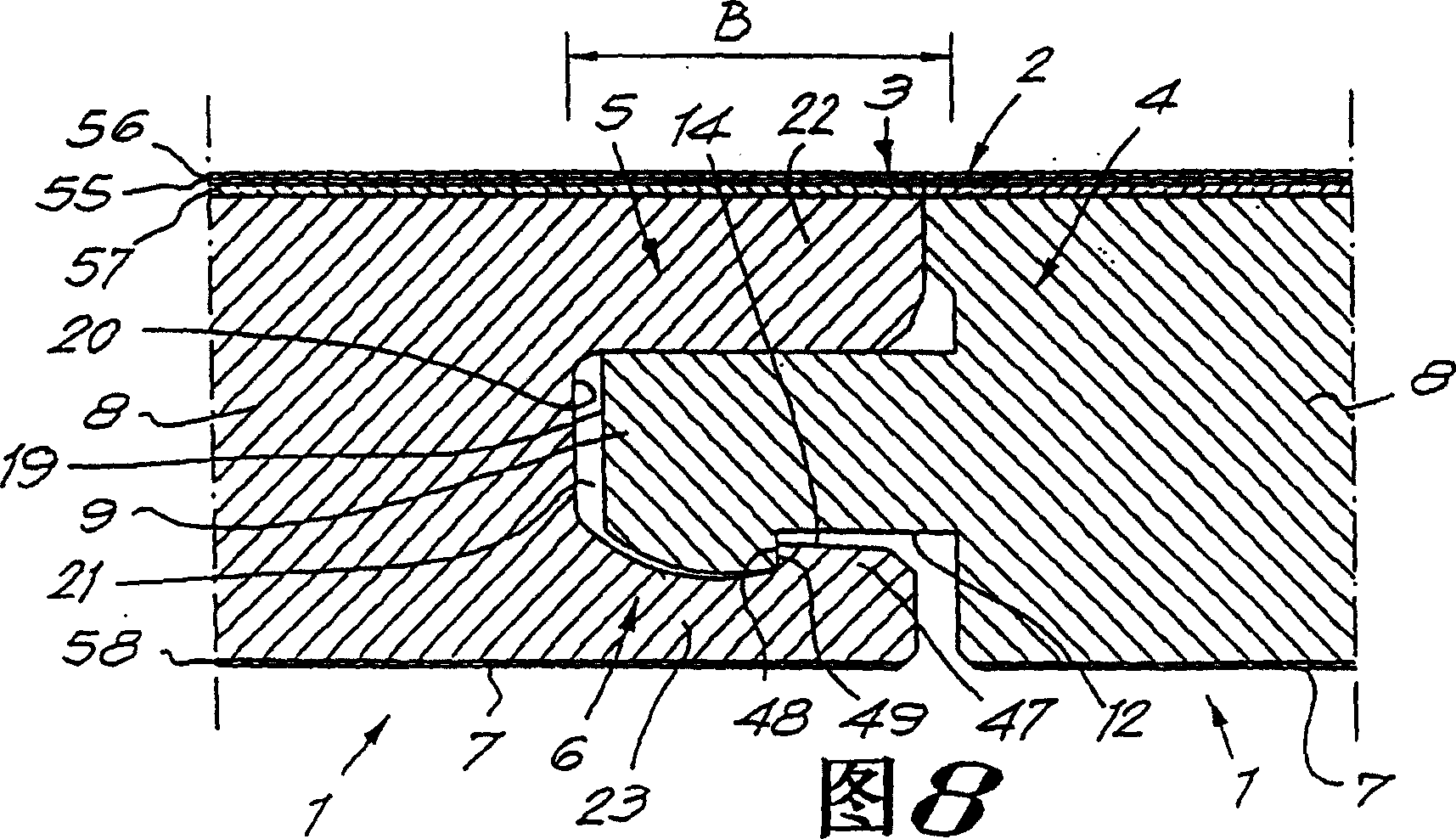

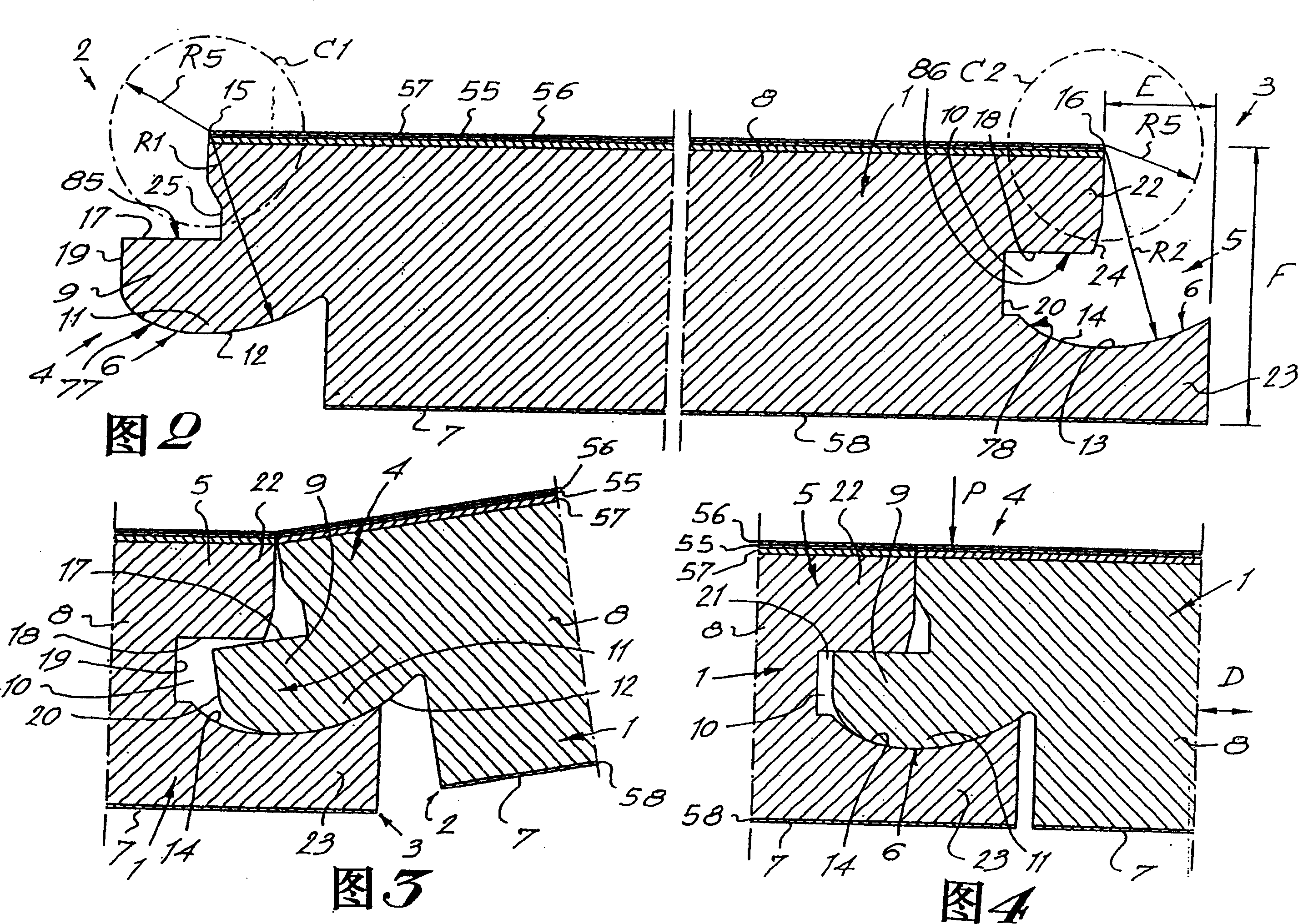

Floor made of hard floor boards and production process of the floor board

InactiveCN1399051AEasy to processCooperate accuratelyTongue/grooves making apparatusWallsClipping - actionEngineering

A method for linking rigid flooring panels has interlocking edge profiles. One edge has a shaped groove in the support layer, into which is clipped a profiled lip of the adjoining panel. The lip and groove are linked by a tilt and clip action resulting in a tension grip between the lip and groove profiles. This ensures that the butting edges of the panels are pulled together at all times, even with the expansion and shrinking of the panels with weathering. The panels present a gap free fitting under all conditions, and can be lifted for repair.

Owner:UNILIN BEHEER

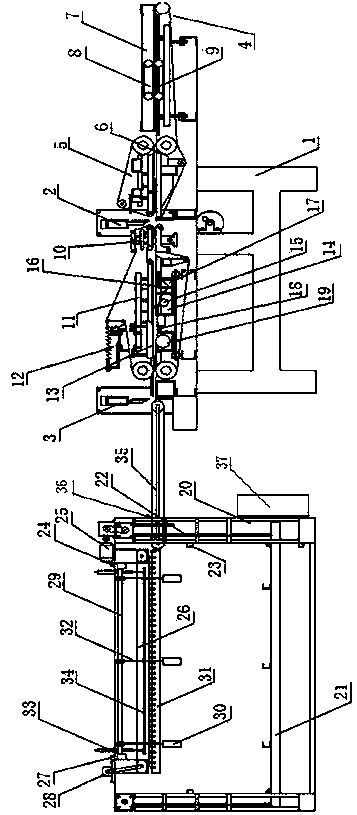

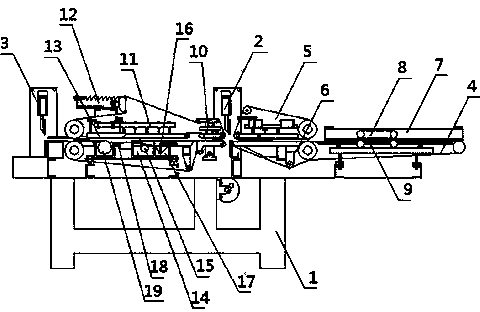

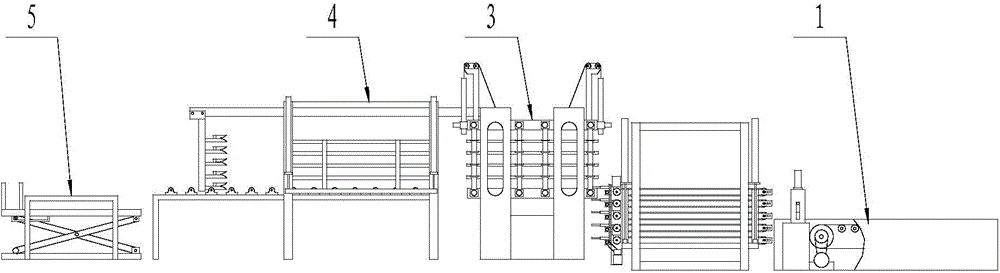

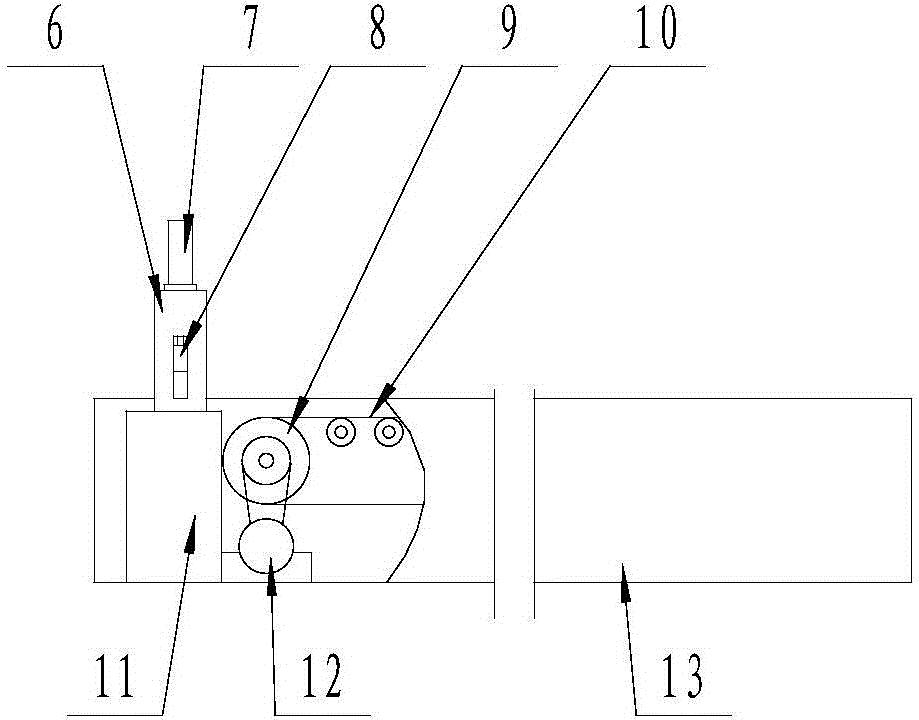

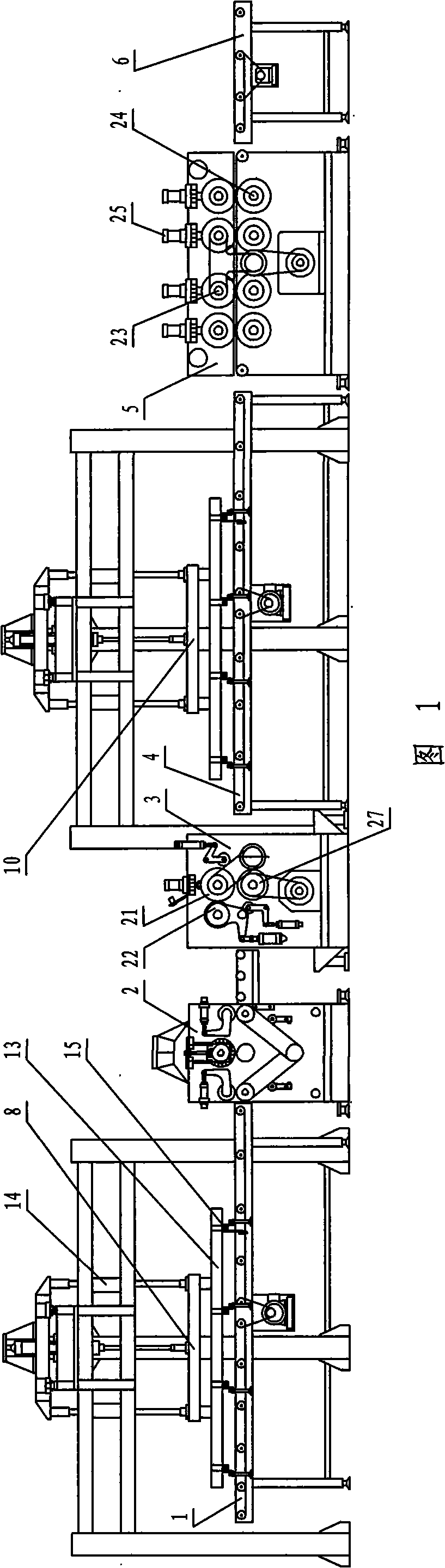

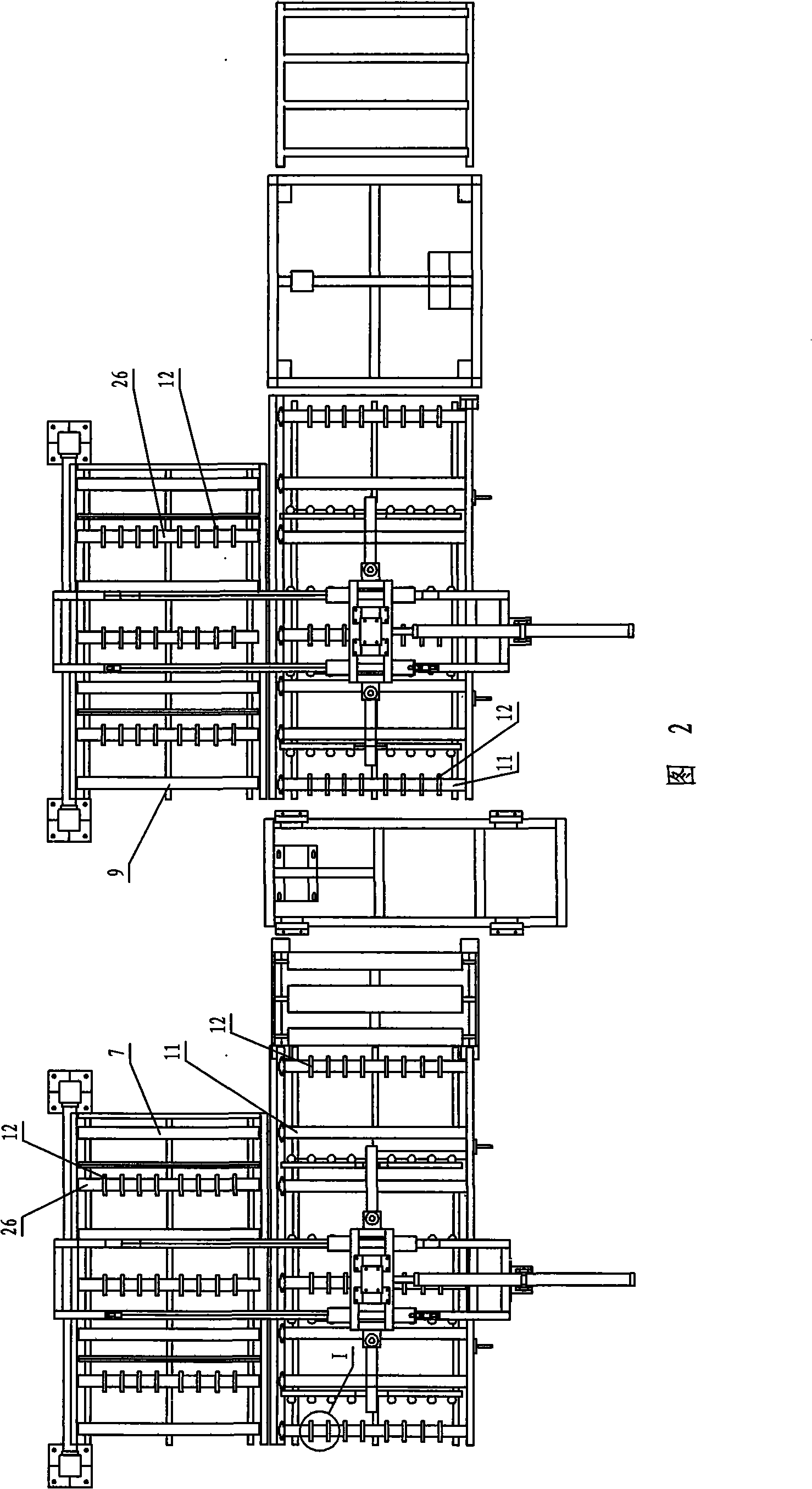

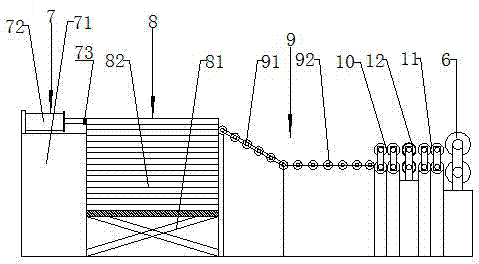

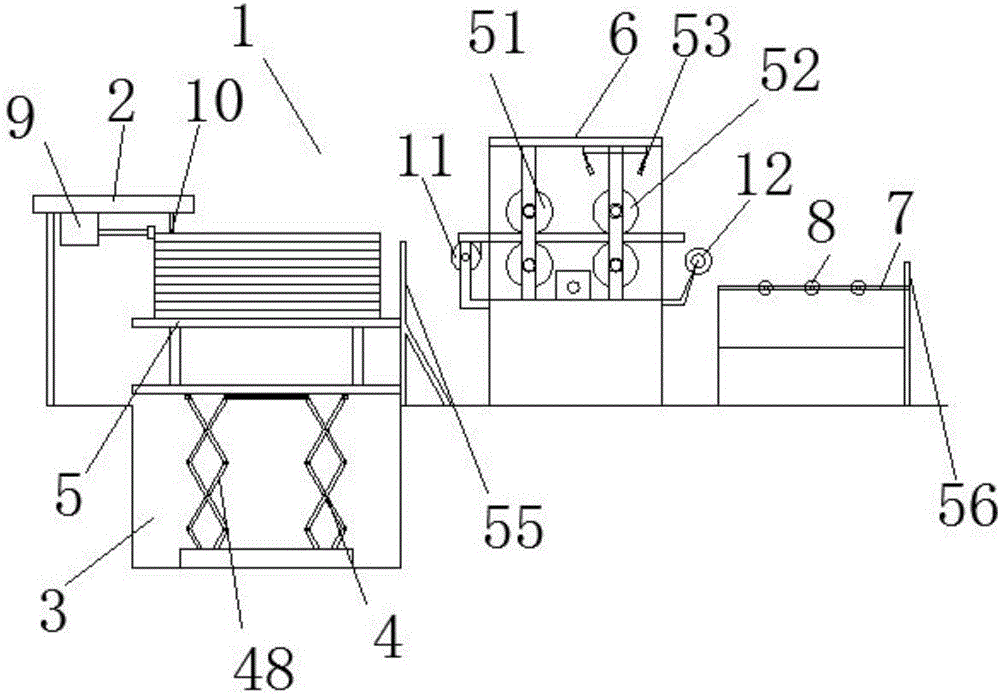

Medium plate splicing machine

ActiveCN103846985AFully automatedRealize fully automatic controlOther plywood/veneer working apparatusWood veneer joiningEngineeringMechanical engineering

The invention discloses a medium plate splicing machine. The medium plate splicing machine comprises a front rack, a feeding belt, a correction mechanism, an edge trimming cutter, a sawdust removing, material receiving and conveying mechanism, a sol tank, a finished product cutting mechanism, a transmission mechanism, a pneumatic mechanism, a coil table, a splicing mechanism and a plate collection device, wherein the splicing mechanism is arranged at a middle-to-rear position of the front rack, a feeding mechanism is arranged at the front end of the front rack, the edge trimming cutter is arranged at the tail end of the feeding mechanism, the correction mechanism is arranged on a conveying rack on one side of the feeding mechanism, and a line adding mechanism, a plate splicing mechanism and the finished product cutting mechanism are sequentially arranged at the middle-to-rear end of the front rack; the plate collection device comprises a rear rack, a lifting mechanism, a plate feeding mechanism, a plate collection device conveying mechanism, a plate receiving mechanism and a plate pressing mechanism. The medium plate splicing machine has the advantages that the design is reasonable, the medium plate splicing machine is integrated with functions of edge cutting, butting, line adding and plate collection, the process is finished in one step, the working efficiency is effectively improved, the labor cost is reduced, the waste small leftovers can be spliced together and the maximum utilization of resources is realized.

Owner:李东生

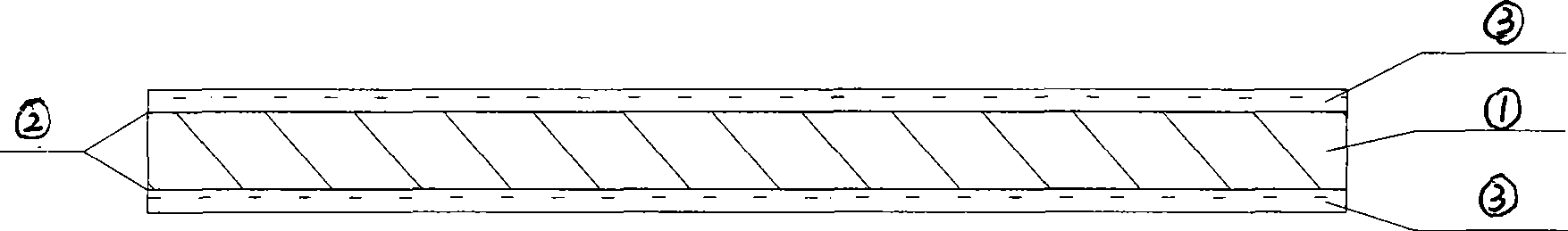

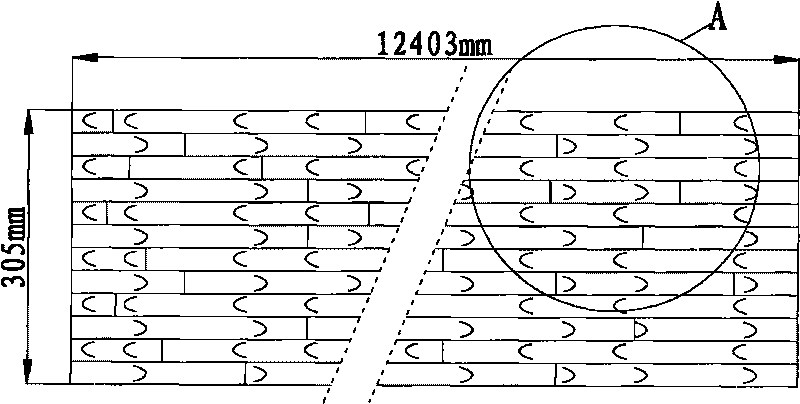

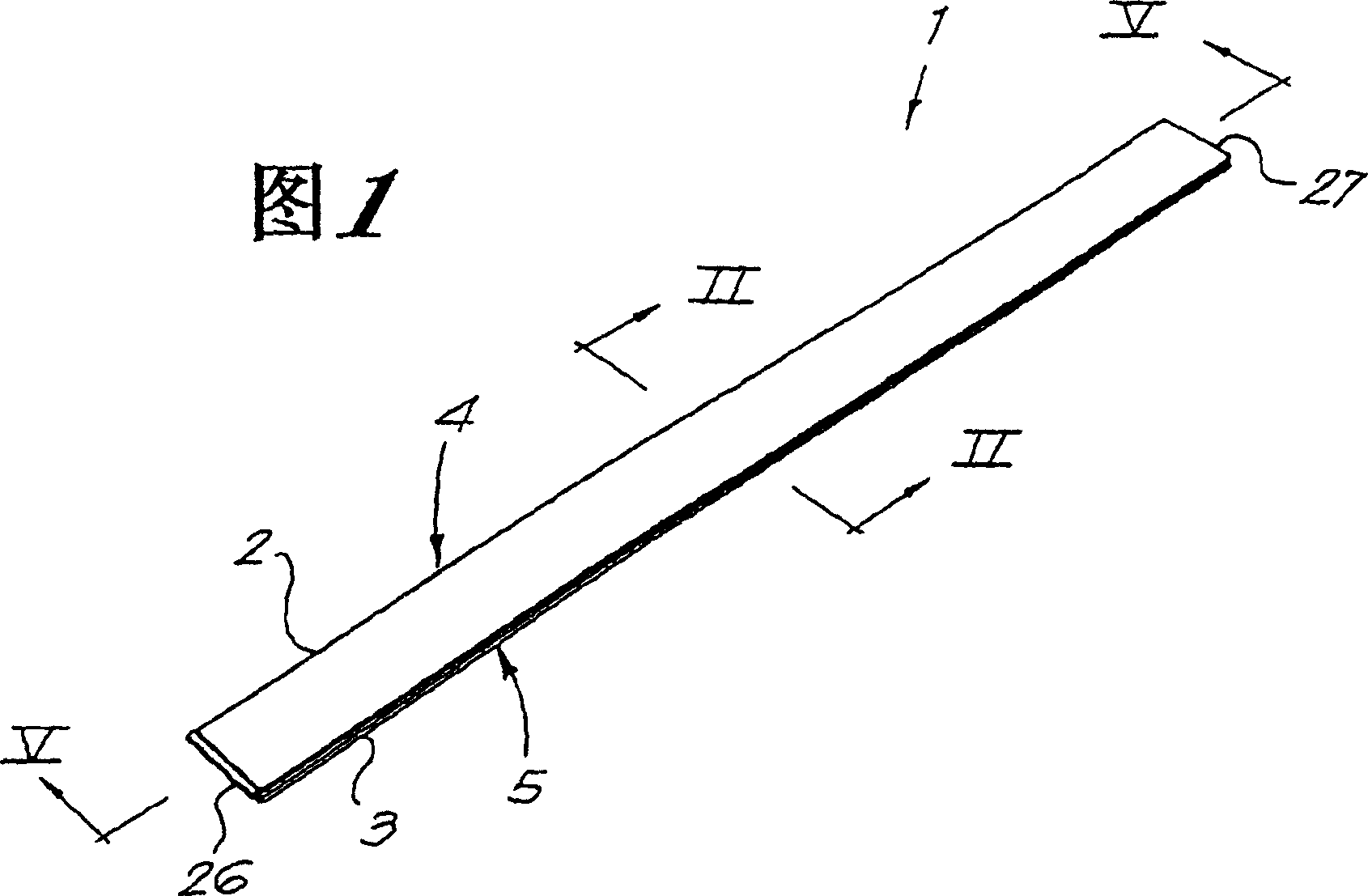

Long-breadth laminted wood and manufacturing method thereof

ActiveCN101722540ARealize continuous productionSatisfy the use effectOther plywood/veneer working apparatusWood veneer joiningPulp and paper industryChassis

The invention discloses a manufacturing method of a long-breadth laminted wood, which is intermittent continuous production. The invention also discloses the laminted wood manufactured by the method, and the laminted wood can be 5mm or any size larger than 5mm in length, can meet the requirement of length of a bottom plate of a container, and reduce the arrangement of a wide bottom crossbeam of the container so as to reduce the manufacturing cost of the container.

Owner:SHENGSHI CONTAINER MANAGEMENT SHANGHAI

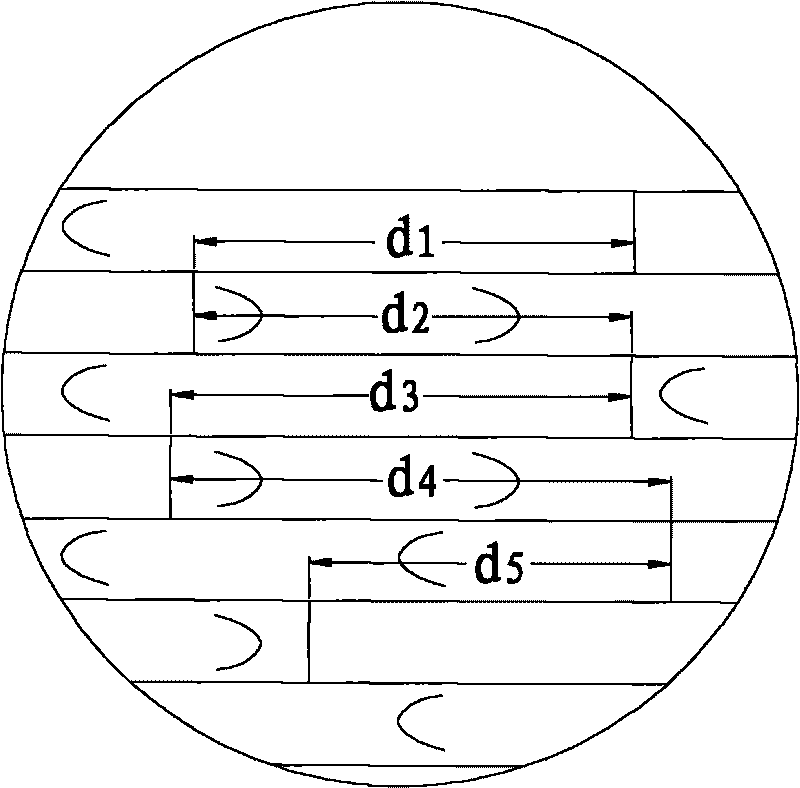

Laminated sheets of tabasheer core layer and the outer bamboo bottom layer and the processing method

InactiveCN101036994ALow costExpand sourceOther plywood/veneer working apparatusWood treatment detailsFiberEconomic benefits

A laminated sheet of tabasheer core layer and bamboo green base layer includes a core layer, a base layer, characterized in that the core layer is composed of the connecting thread sheets cleaved by the raw materials of tabasheer, bamboo base part, bamboo tip part, concave thickness sheet and the glue, the base layer is arranged vertically with bamboo fiber of the base layer, core layer, side jointed board of bamboo green sheet cleaved to inner plane and outer arc face by the raw materials of bamboo green; the manufacturing method of the laminated sheet has following steps made by working procedures of pretreating, cooking, glue blending and drying of the raw material, vertical jointing board, paving and hot pressing of the bamboo green sheet, which can widely use as floor, wallboard, furniture panel, wrapper plate and so on, with advantages of high mechanical strength, high utilization rate, less procedure, quick work efficiency, low cost, remarkable economic benefit and ecological benefit of bamboo material.

Owner:浙江坚林林业股份有限公司

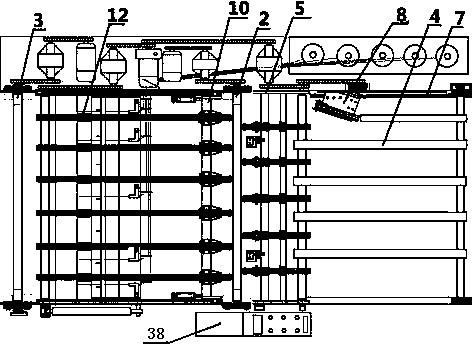

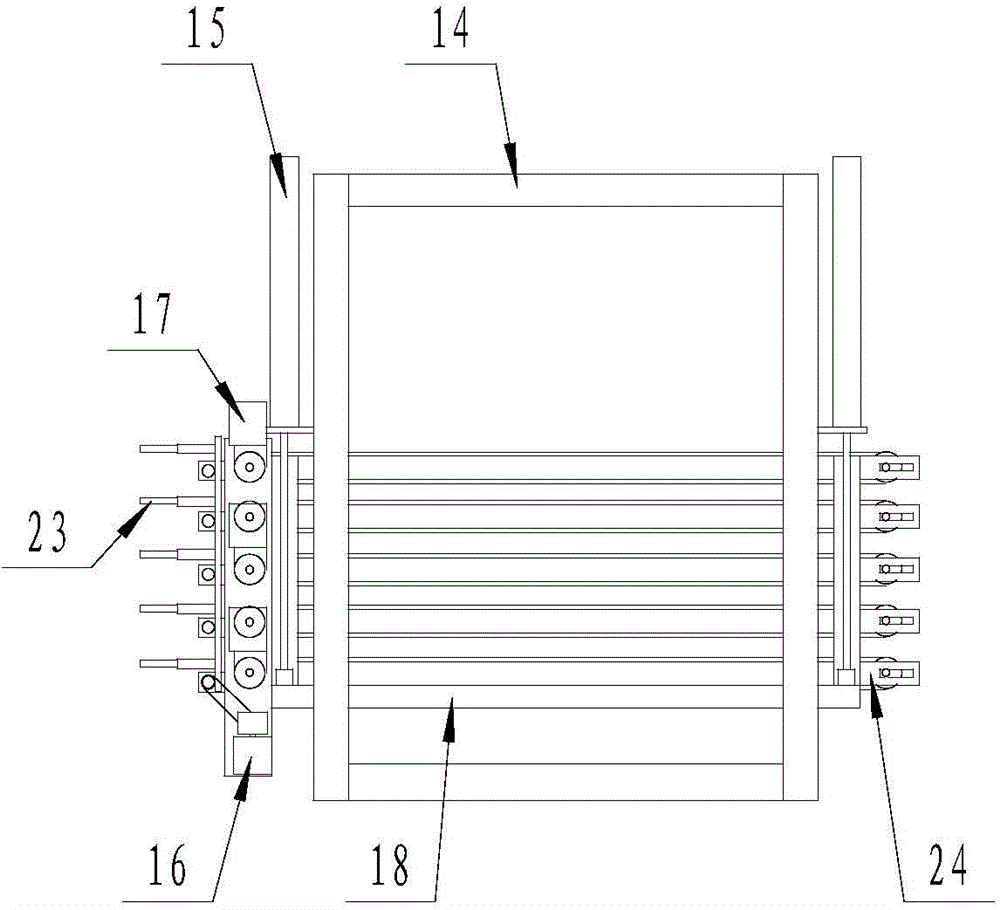

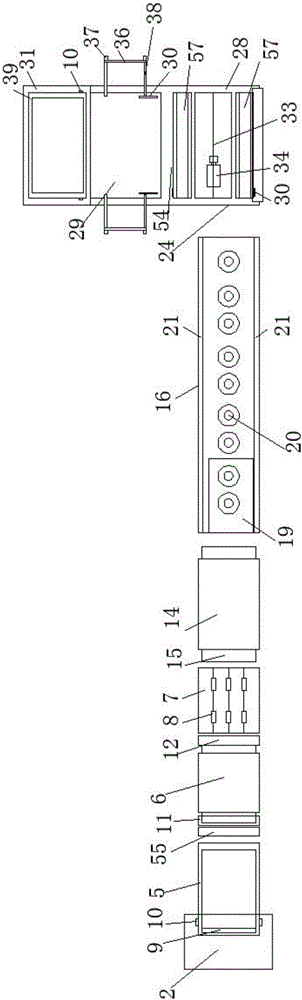

Woodworking plate paving-hot-pressing all-in-one machine

InactiveCN104526796AImprove processing qualityRise steadilyOther plywood/veneer working apparatusPlywood pressesControl systemSlide plate

The invention discloses a woodworking plate paving-hot-pressing all-in-one machine and belongs to the field of plate machining machinery. The woodworking plate paving-hot-pressing all-in-one machine comprises a jointed plate conveying platform, an automatic feeder, a multilayer thermal press, an automatic plate taking device, a plate stacker and a programming control system. The automatic feeder comprises a feeder frame, a lifting table, a lifting oil cylinder I connected with the lifting table and at least two plate storing platform layers arranged on the lifting table. Transmission devices and conveying sliding plates connected with the transmission devices are arranged on the plate storing platforms. The machine is used for woodworking plate production and machining, automatic conveying, automatic sawing, automatic multilayer thermal press placing in, automatic plate taking and automatic stacking can be achieved, following plate joining operation is not affected, the automatic degree and the production efficiency are high, and plate machining quality is high.

Owner:姜皓月

Decorative material

InactiveUS6558799B2Low costImprove surface propertiesOther plywood/veneer working apparatusDecorative surface effectsHydrogenCellophane

Owner:DAI NIPPON PRINTING CO LTD

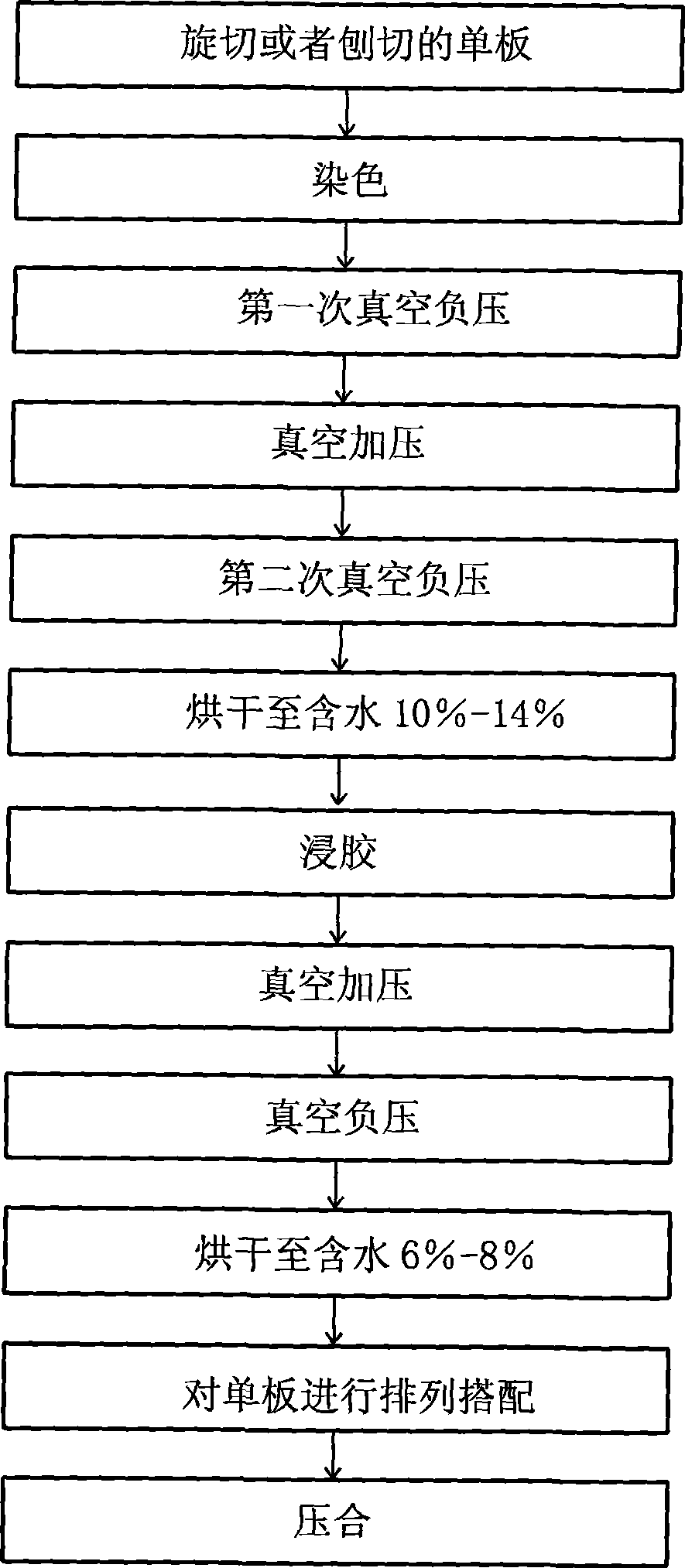

Fabric-like recombined decorated veneer and manufacture method thereof

ActiveCN101456197AClear linesBright colorOther plywood/veneer working apparatusWood treatment detailsEngineeringHigh contrast

The invention relates to a method for processing wood, in particular to a method for producing a recombined decorative veneer by using a dye with bright color to simulate cloth marks and the veneer manufactured by the method. In order to achieve the aim, the invention adopts a method for manufacturing the recombined decorative veneer simulating cloth marks, which comprises the processes of veneer bleaching, veneer dyeing, veneer drying, veneer digging and repairing, veneer combination, veneer sizing, veneer gluing, veneer maintenance, and veneer slicing. The method adopts the dye with the bright color to dye the veneer with the bright color, and adopts the veneer with high contrast grade to combine according to designed patterns; and the produced recombined decorative veneer has clear lines similar to wall cloth. Compared with other recombined decorative veneers, the color is brighter, the lines are clear, and the patterns mainly adopt a wall cloth series.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

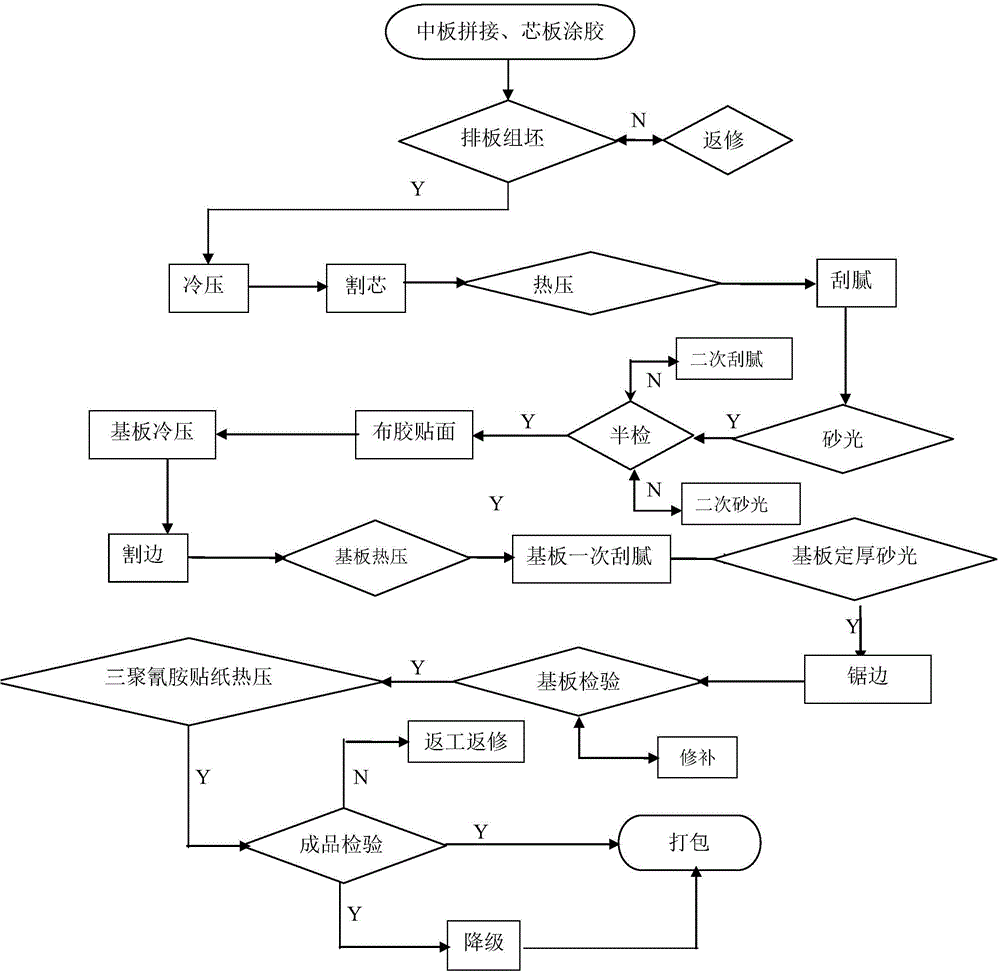

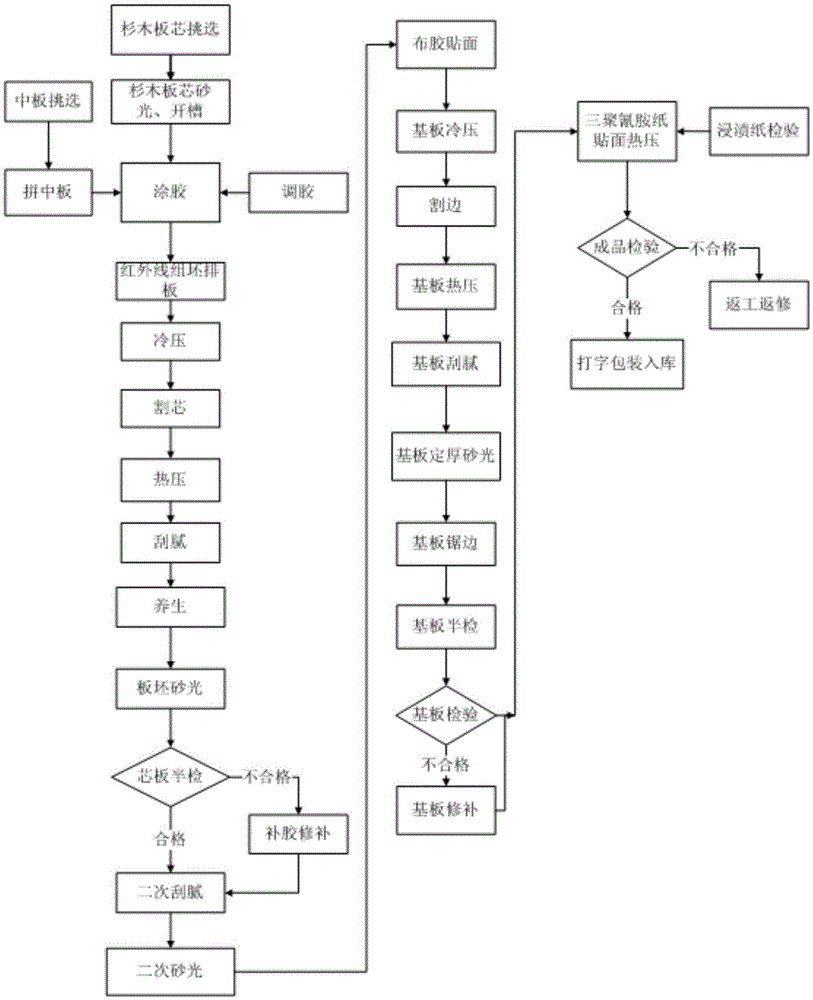

Production technology for melamine ecological plate

ActiveCN104526789ASimple and reasonable colorFlat surfaceOther plywood/veneer working apparatusWood veneer joiningProduct inspectionHeat resistance

The invention relates to a production technology for a melamine ecological plate. The production technology specifically comprises the following steps of (1) middle plate splicing; (2) core plate glue coating; (3) plate arrangement and blank forming; (4) cold pressing; (5) core cutting; (6) hot pressing; (7) putty applying; (8) sanding; (9) semi-inspection; (10) secondary putty applying; (11) secondary sanding; (12) glue coating and face attaching; (13) base plate cold pressing; (14) edge cutting; (15) base plate hot rolling; (16) first-time base plate putty applying; (17) base plate fixed-thickness sanding; (18) edge sawing; (19) base plate inspection; (20) repair; (21) melamine paper attaching and hot pressing; (22) finished product inspection and packaging. Compared with the prior art, melamine impregnated paper is directly pressed and attached to the surface of a base plate, the technology is simple and reasonable, various patterns can be imitated on the melamine ecological plate processed through the technology, the melamine ecological plate is bright in color, smooth in surface, wide in application range, high in hardness, resistant to abrasion, good in heat resistance, capable of resisting the corrosion of common solvents, economical and environmentally friendly.

Owner:ZHEJIANG SHENGHUA YUNFENG GREENEO

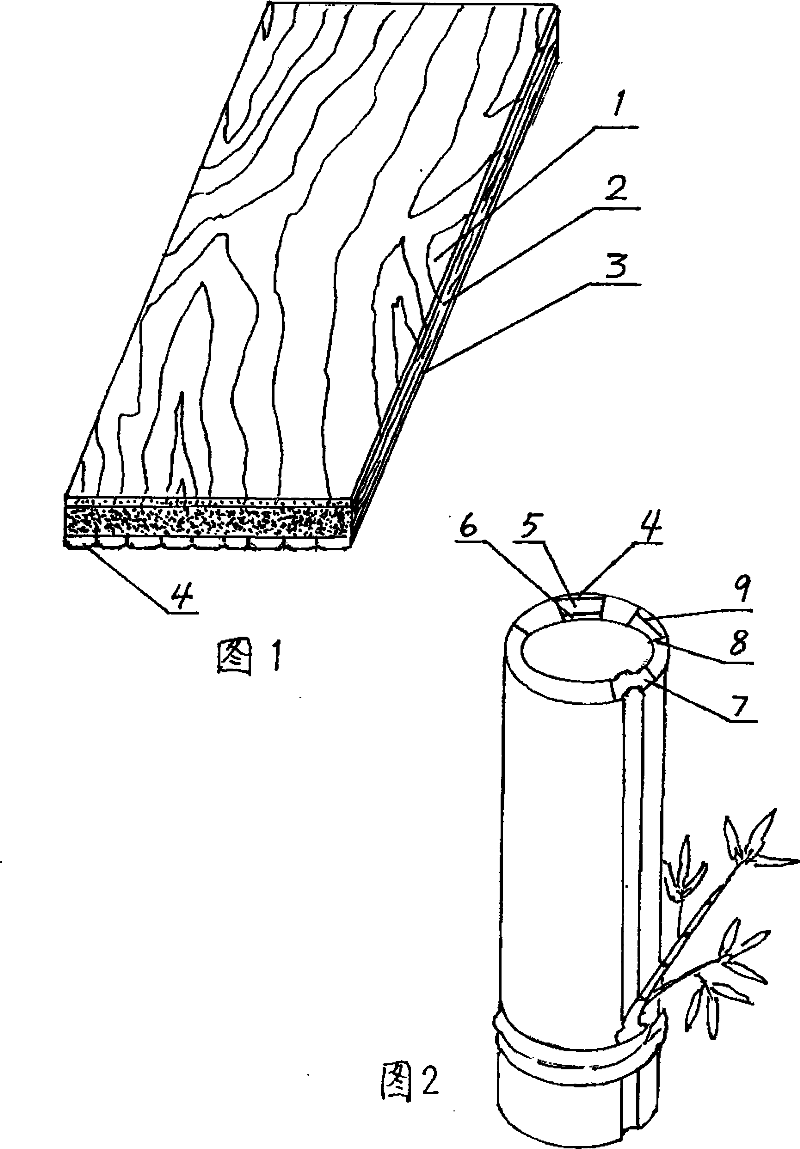

Preparation method of environmental protection type solid-wood composite floor

InactiveCN101396839ATake advantage ofReduce pollutionOther plywood/veneer working apparatusWood treatment detailsSolid woodEngineering

The invention relates to a preparation method for an engineered flooring, in particular to a preparation method for an environment-friendly engineered flooring, belonging to the wood manufacturing industry. The invention aims at providing a preparation method for an environment-friendly engineered flooring which has strong non-deformability, high processing efficiency and can fully use resources, thus overcoming the deficiencies of the prior art. Due to the adoption of the technical program, the invention has the advantages of making full use of wood resources, improving labor efficiency and relieving the pollution of formaldehyde to the environment.

Owner:汤可新

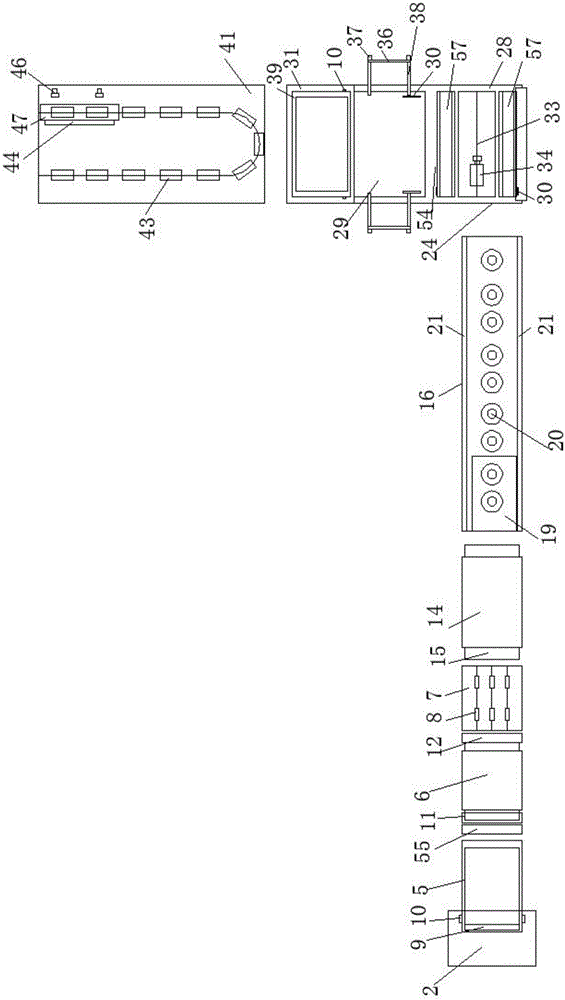

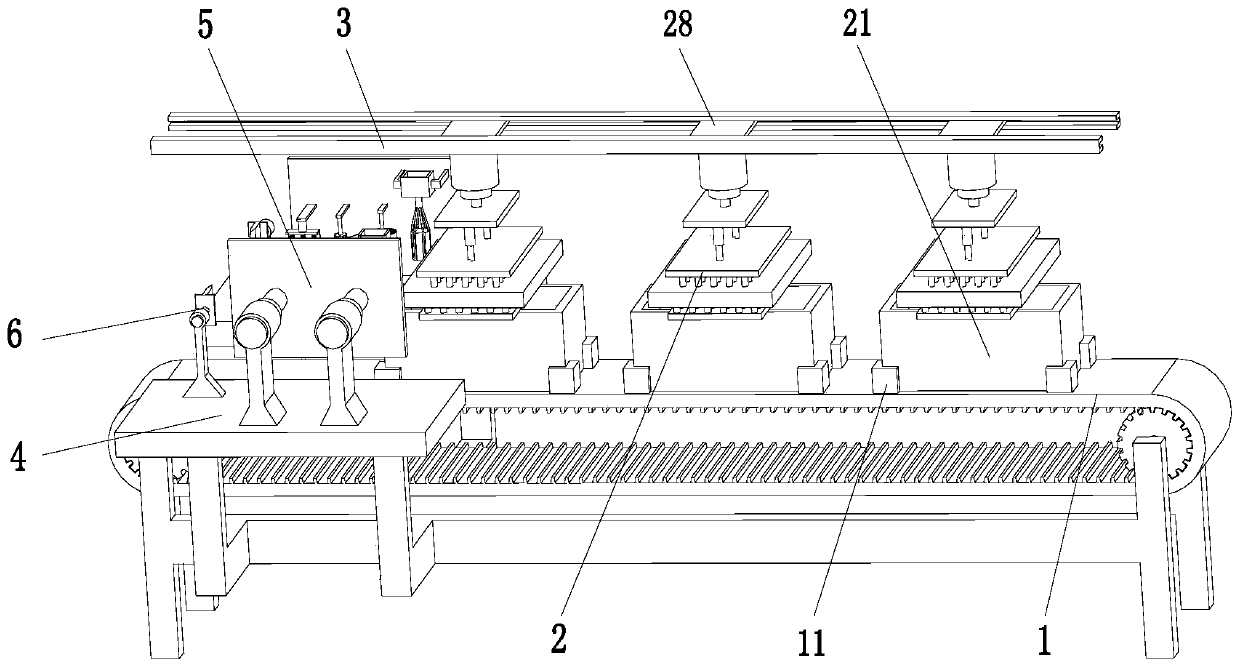

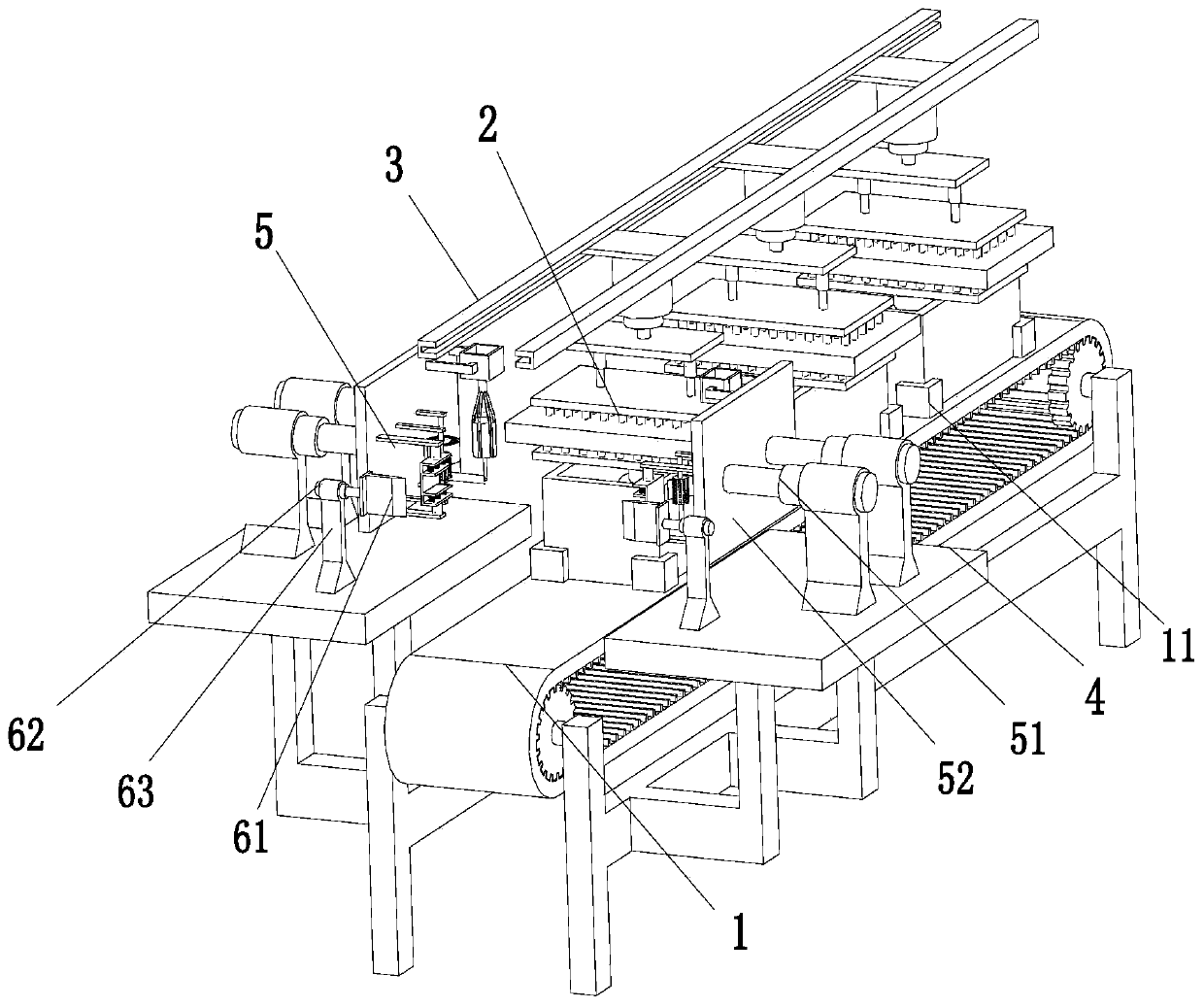

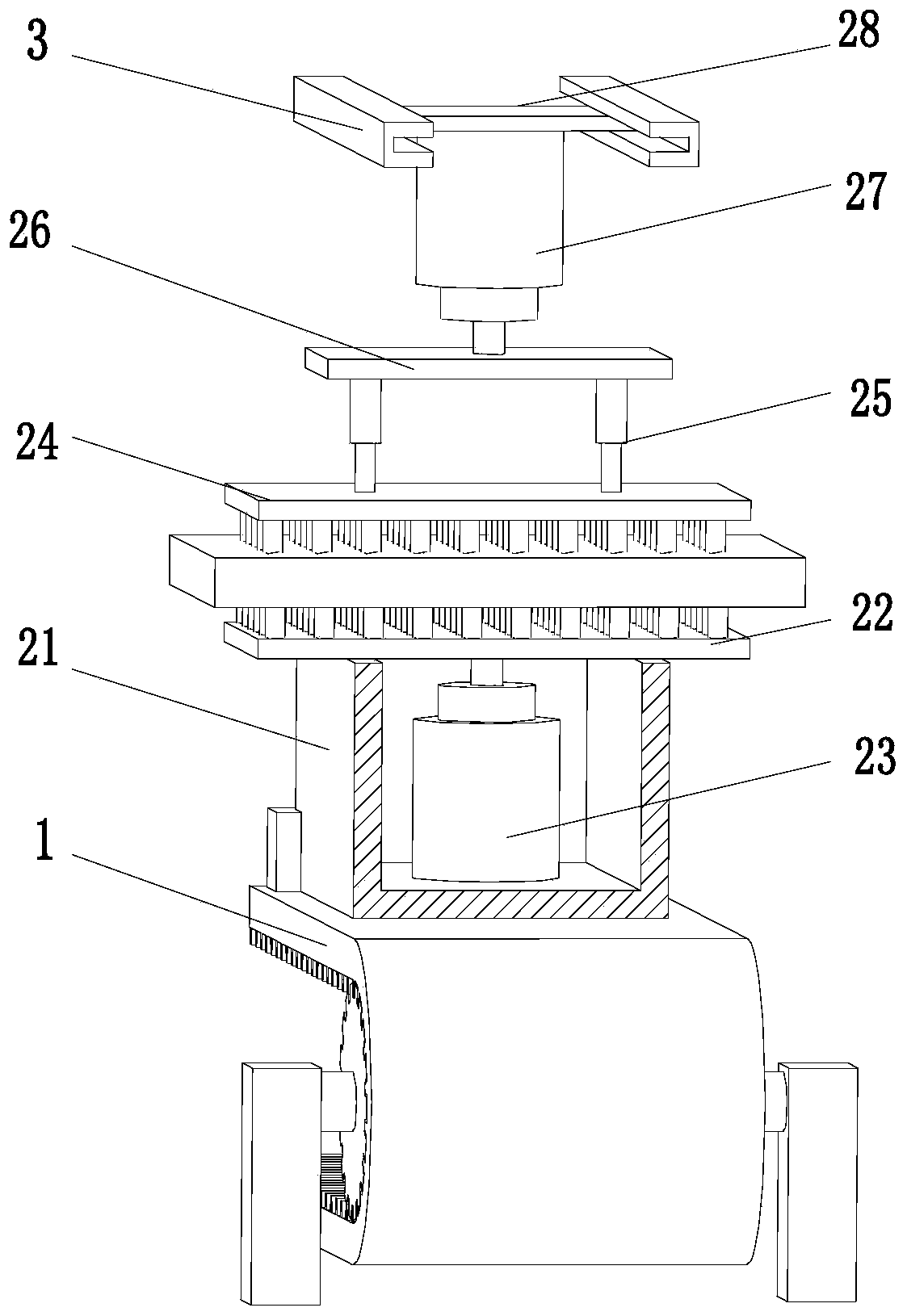

Composite board automatic production line

InactiveCN101306544AReduce labor intensityImprove ergonomicsOther plywood/veneer working apparatusPlywood pressesProduction lineSurface cleaning

The invention discloses an automatic production line of composite boards, which is used for attaching a base plate of a composite board to a faceplate of the composite board and comprises a roller conveyor device, a base plate surface cleaning device, an automatic glue spraying device, a conveying aligning and attaching device, an attaching pressing device and a board conveying device which are arranged in sequence. A base plate piling device is arranged at the side of the roller conveyor device; a base plate moving and carrying device arranged above the roller conveyor device and the base plate piling device; a face plate piling device is arranged at the side of the conveying aligning and attaching device; and a face plate moving and carrying device is arranged above the conveying aligning and attaching device and the face plate piling device. The production line can realize the automatic combination of a plurality of base plates and a plurality of face plates, thus achieving the purposes of improving production benefit, reducing labor intensity, and ensuring the stability and the reliability of the product.

Owner:JINGJIANG WEIYI INTPROP SERVICE

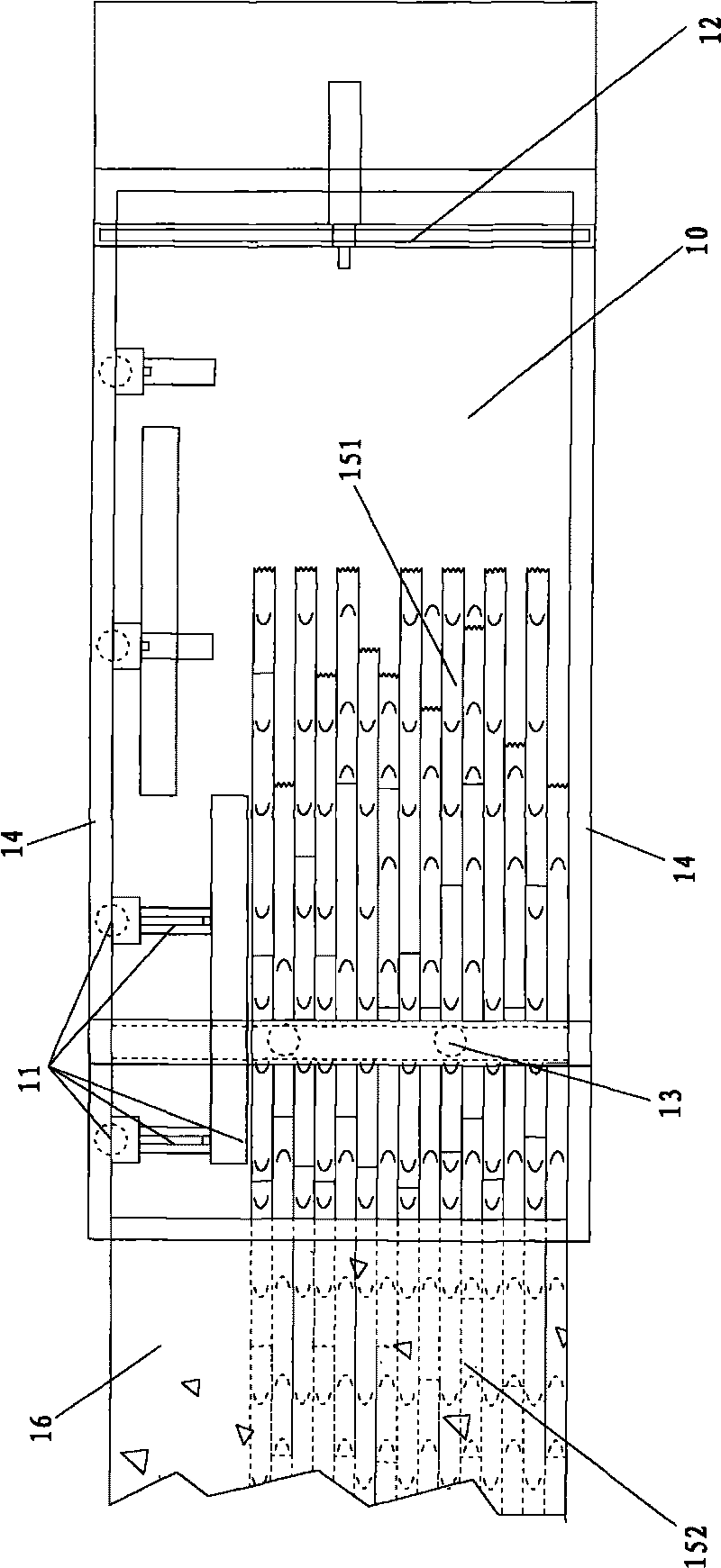

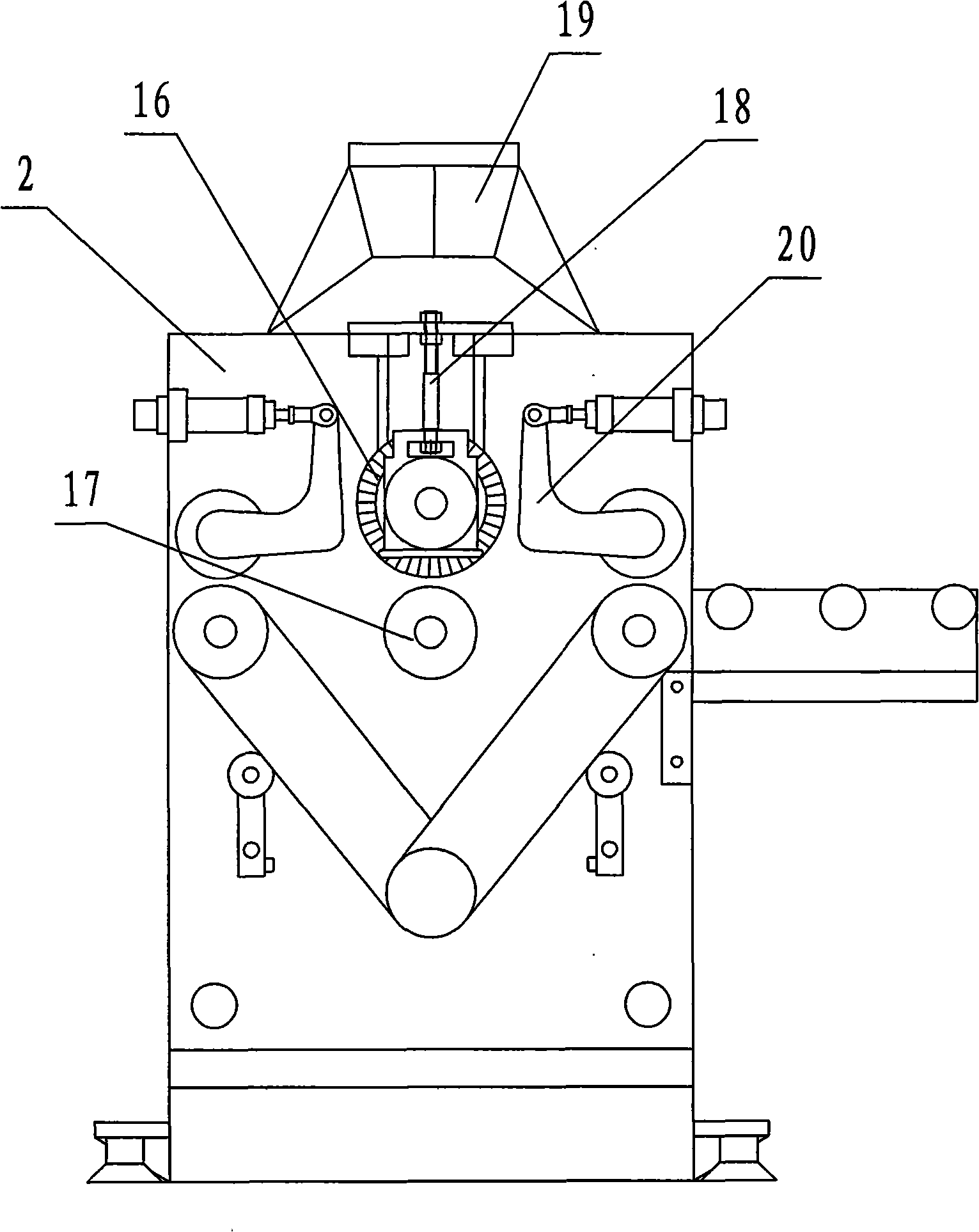

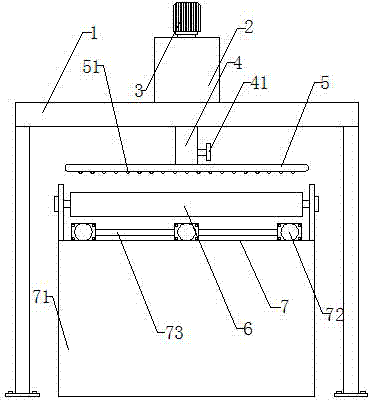

Layer-by-layer automatic feeding, marking and gluing integrated equipment for sheet materials

ActiveCN104708689AFast processingSpread evenlyOther plywood/veneer working apparatusAdhesive application devicesProduction lineEngineering

The invention discloses layer-by-layer automatic feeding, marking and gluing integrated equipment for sheet materials. The layer-by-layer automatic feeding, marking and gluing integrated equipment for the sheet materials comprises a marking device and a gluing device; the gluing device is arranged on one side of the marking device and a layer-by-layer automatic feeding device is arranged on the other side of the marking device; the layer-by-layer automatic feeding device comprises a pushing mechanism, a hoisting mechanism and a sliding mechanism in sequence; and the gluing device comprises a supporting framework, a stirring mechanism arranged at the upper end of the supporting framework, a material scattering mechanism arranged at the bottom of a transverse beam of the supporting framework, and a compression roller gluing mechanism arranged under the supporting framework. According to the layer-by-layer automatic feeding, marking and gluing integrated equipment, marking and gluing are integrated, transmission and interruption of machines are reduced in the process and the consistency of a production line is improved; and the machining time of the whole sheet material is shortened, materials can be automatically fed layer by layer, the transmission is buffered, the gluing can be automatically realized and the gluing is uniform.

Owner:JIANGSU KENTIER WOOD

Novel processing production line and control method for plywood

ActiveCN106042084AReasonable structural designImprove processing productivityOther plywood/veneer working apparatusWood veneer joiningManufacturing engineeringHot pressing

The invention provides a novel processing production line and a control method for plywood, and relates to the technical field of plate processing equipment. The novel processing production line comprises a glue coating device, a hot pressing device, cooling equipment and a trimming device, wherein the glue coating device comprises a front end bracket, a first groove, a first lifting device, a first plate support frame, glue coating equipment and a receiving frame; rollers are arranged at the top of the receiving frame; the hot pressing device comprises a hot press and plate conveyor belts mounted on two sides of the hot press; the cooling equipment comprises a cooling chamber, rails, a material conveying trolley and a cooling device; and the trimming device comprises a bracket, a transversal sliding rail, a sliding seat, a push rod, a first support, a second support, four cutting machines, a second groove, a second lifting device and a second plate support frame. The novel processing production line is reasonable in structural design, and can greatly improve the production efficiency of the plywood.

Owner:ANHUI DONGPING WOOD GRP

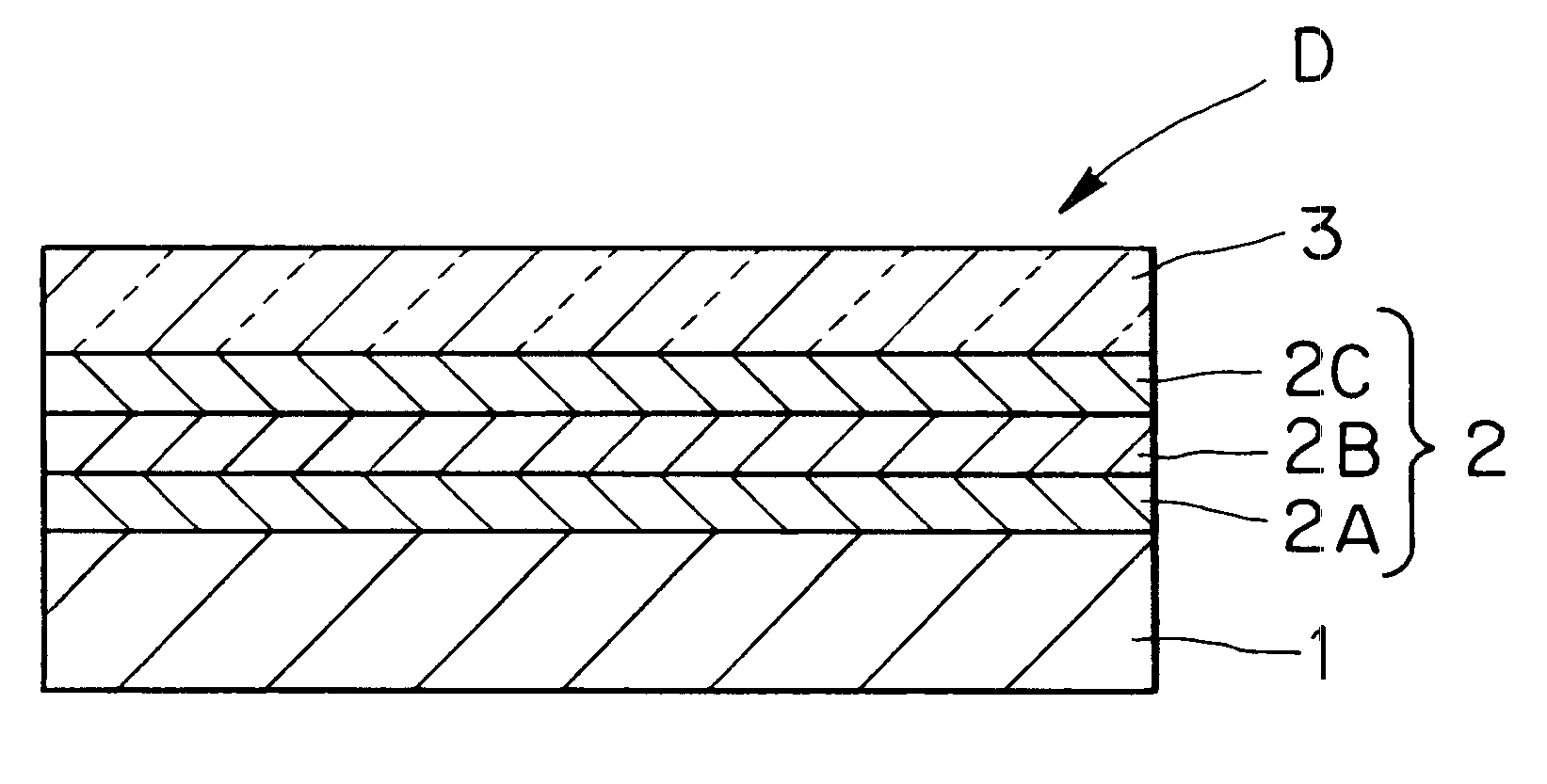

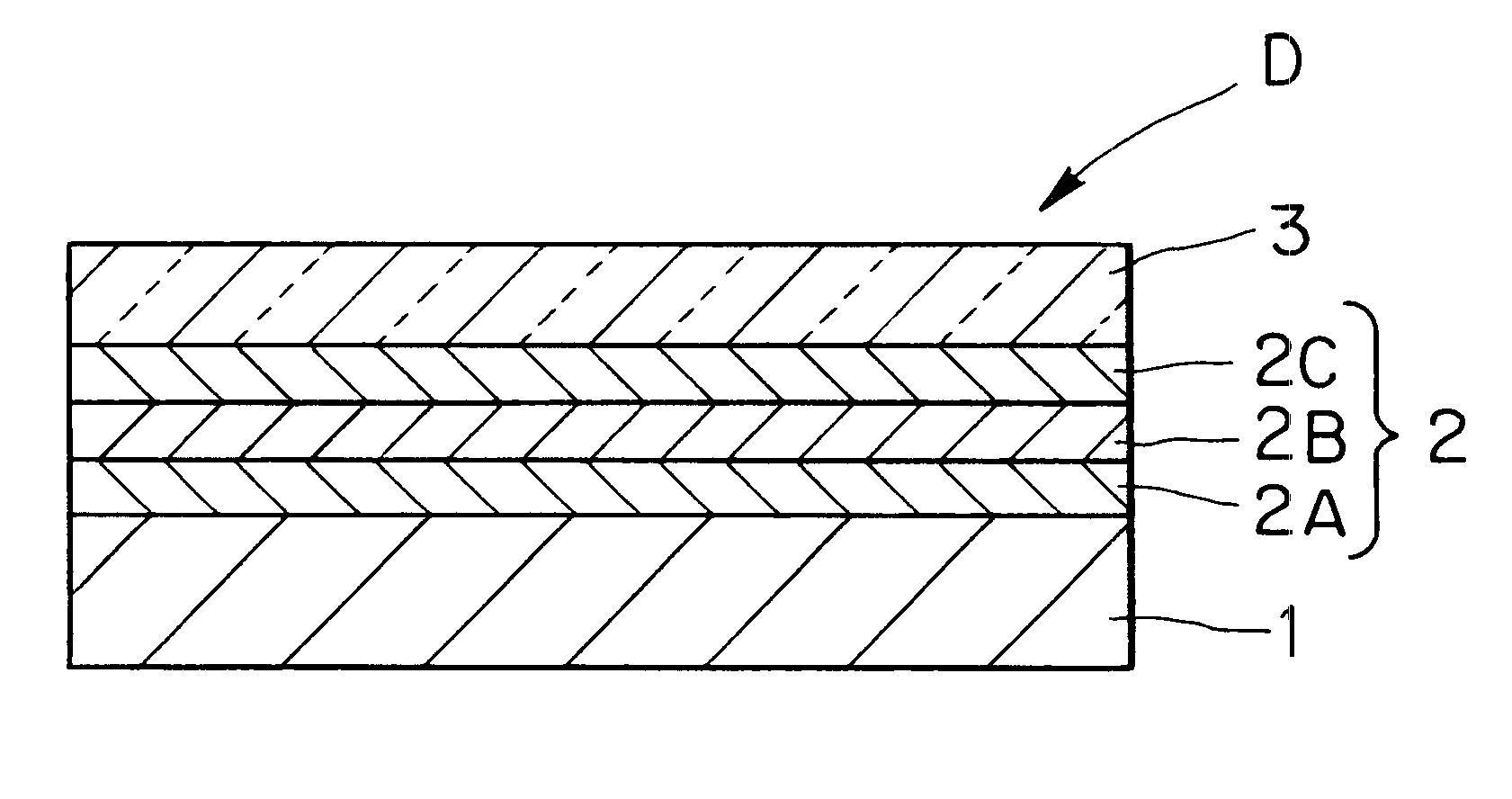

Decorative material

InactiveUS20010049022A1Low costImprove surface propertiesOther plywood/veneer working apparatusDecorative surface effectsHydrogenVolumetric Mass Density

A decorative material is provided which possesses excellent surface properties, such as excellent staining resistance, marring resistance, scratch resistance, abrasion resistance, and anti-transferability to a cellophane pressure-sensitive adhesive tape, and can be produced at low cost. This decorative material comprises: a substrate having at least on its surface an active hydrogen-containing polar functional group; and, provided on the substrate, a two-component cured urethane resin layer and a surface resin layer of a crosslinked coating formed from a ionizing radiation curable acrylate resin, the two-component cured urethane resin layer having a structure of at least three layers, the crosslinking density of the intermediate layer being lower than that of each layer provided on both sides of the intermediate layer.

Owner:DAI NIPPON PRINTING CO LTD

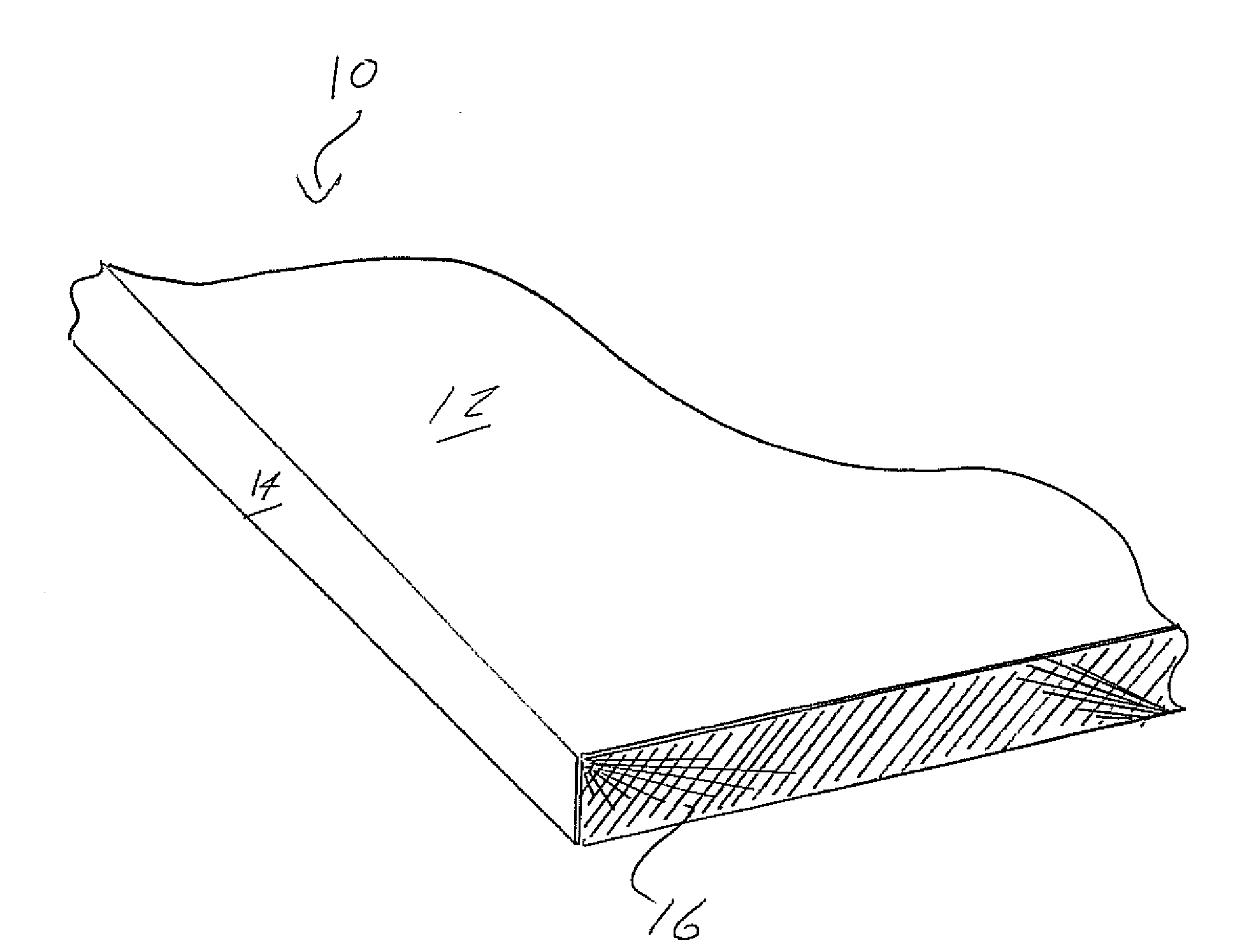

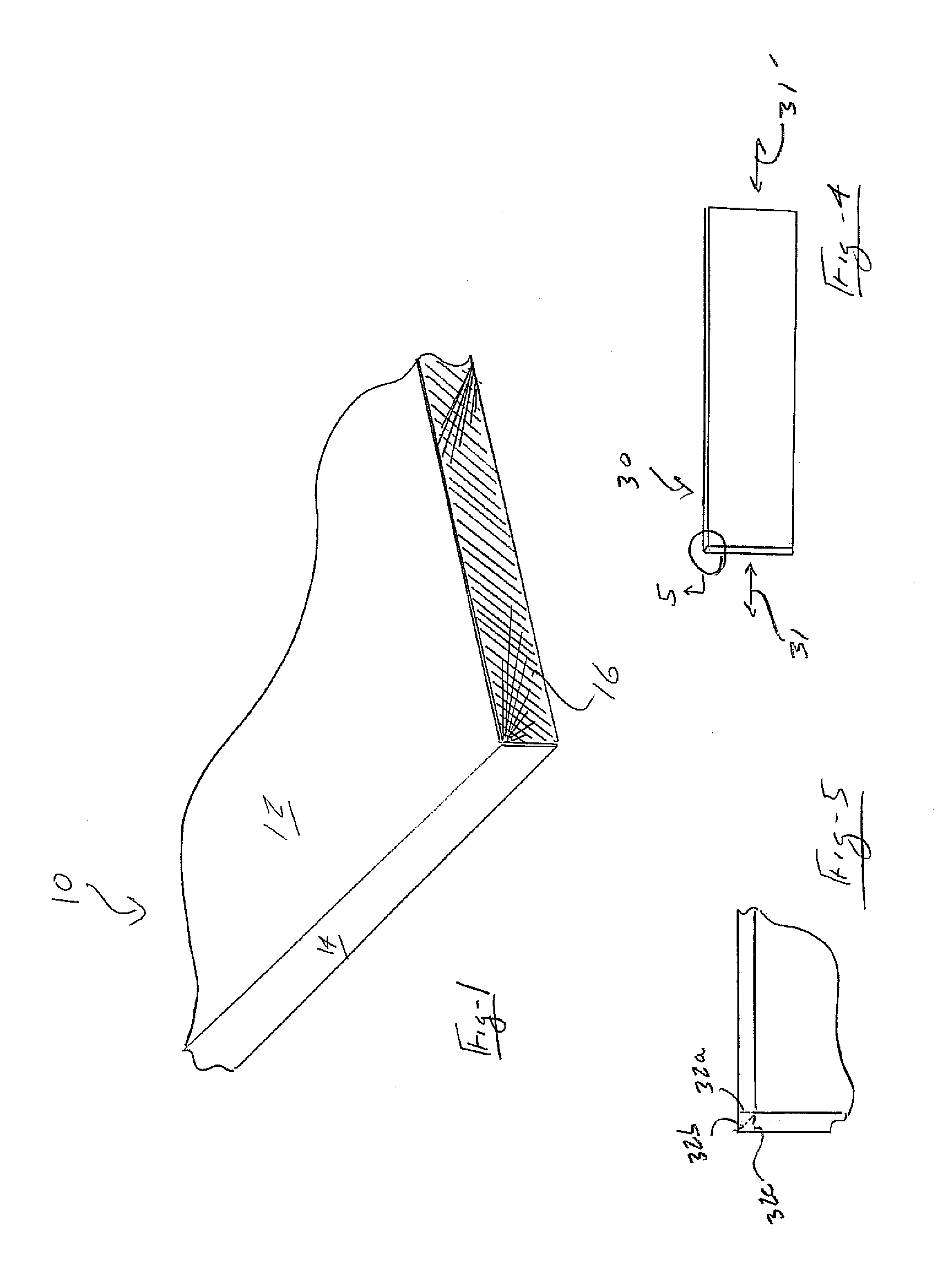

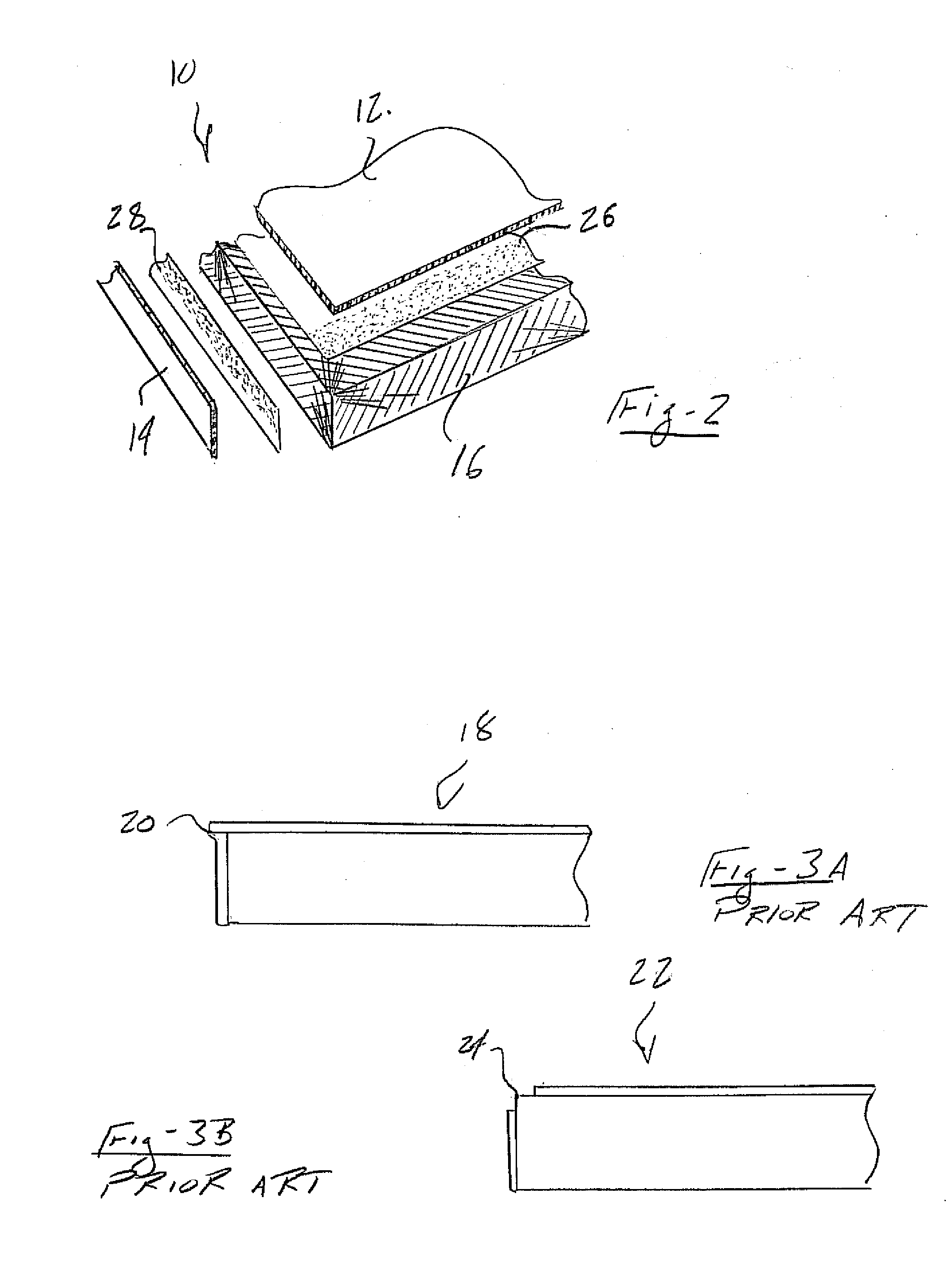

Polymer-Based Face Panel Veneer and Edgeband System for Producing Decorative Panels Having Increased Durability and Decorative Effect and Associated Methods for Producing Such a System

InactiveUS20080118713A1Maintain integrityOther plywood/veneer working apparatusLamination ancillary operationsPolymer resinAdhesive

The present invention discloses a polymeric resin-based veneer laminating system, associated article and method for producing, for maintaining a mating edge profile of top and edge applied laminates secured to a rigid substrate material, and without compromise to fit and finish in response to temperature and humidity variations existing between the materials. A first (typically PVA) adhesive is applied between the top laminate and associated top surface of the substratum according to a first application, a second adhesive (typically EVA) being applied to the adjoining side surface of the substratum and prior to application of the edgeband according to a further expedited heat and / or pressure application.

Owner:BORDENER ROBERT

Production method for manufacturing sliced veneer by bamboo split recombined bamboo wood

ActiveCN103878839AIncrease color varietiesIncrease added valueOther plywood/veneer working apparatusWood treatment detailsPulp and paper industryChemistry

The invention relates to a production method for manufacturing sliced veneer by bamboo split recombined bamboo wood and aims to realize that firstly, bamboo splits can be used for manufacturing bamboo veneer decorating materials and bamboo wood utilization rate is increased; secondly, natural-color, carbonized and dyed bamboo splits can be used for manufacturing bamboo veneers and colors of the bamboo veneers are enriched; thirdly, the technical problem of humidifying square timber of the bamboo splits is omitted and procedures are saved. The production method includes steps of 1) manufacturing the bamboo splits; 2) subjecting the bamboo splits to natural-color, carbonized or dyed treatment; 3) drying the bamboo splits; 4) shaping the square timber of the bamboo splits; 5) conditioning the square timber of the bamboo splits; 6) softening the square timber of the bamboo splits; 7) slicing the square timber of the bamboo splits; 8) post processing.

Owner:NANJING FORESTRY UNIV

Artificial fast growing wood glued board and producing method thereof

ActiveCN101279452AWon't breakHas complete degradation propertiesOther plywood/veneer working apparatusWood veneer joiningAdhesiveEngineering

The invention relate to an artificial quick-growing natural plywood, which comprises a common plywood, a laminated veneer lumber, a blockboard, a wedge joint boardand and a technical wood. A dhesive obtained by chemically modifying a plant protein raw material is used for the invention, and the drying and dewatering are carried out after the steps of glue spreading and assembly in the process of processing the plate. The obtained plywood has a high bonding strength, no harmful gases such as aldehyde, beneze, etc., are discharged in the process of processing the plate and during the using period, and the waste plate does not cause the environmental contamination during the degradation in a natural environment. The artificial quick-growing natural plywood fundamentally terminates the harm done by the material selection and adhesives to the environments and the health of the human beings, realizes true production of environment-friendly artificial boards, and ensures that the artificial boards have the same natural properties as the saw log products made from raw wood both in process of production and use.

Owner:郑州佰沃科技发展有限公司

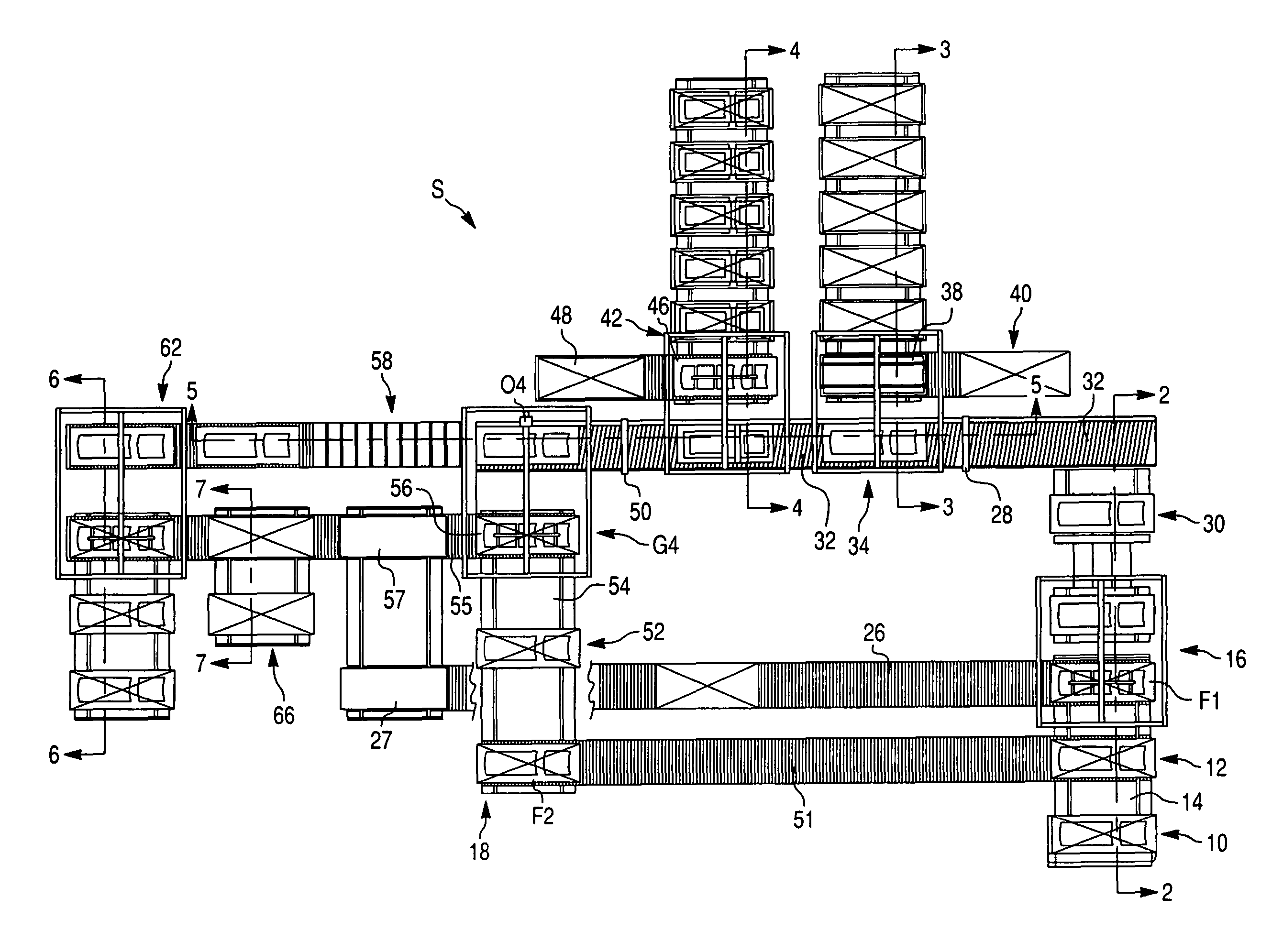

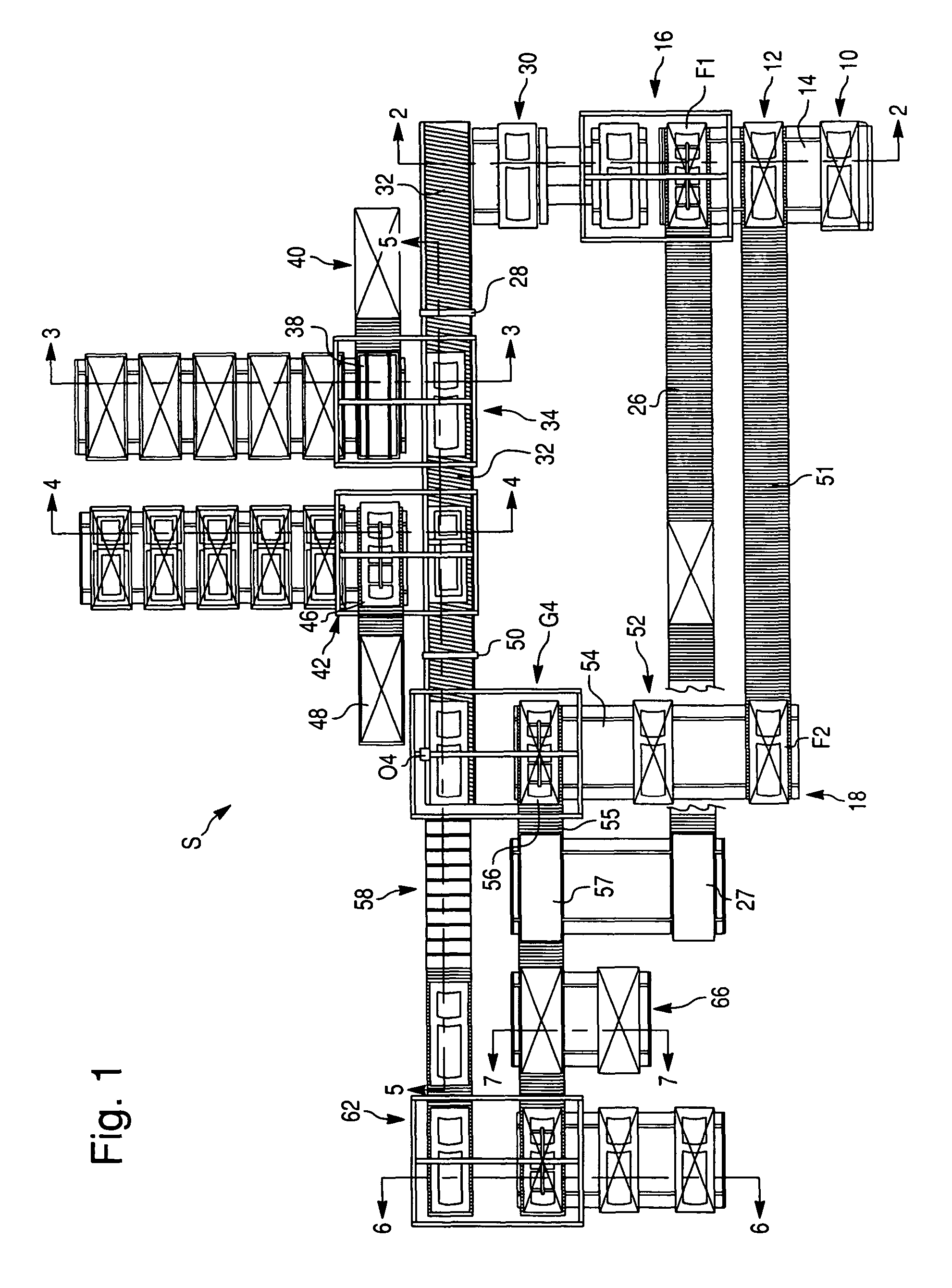

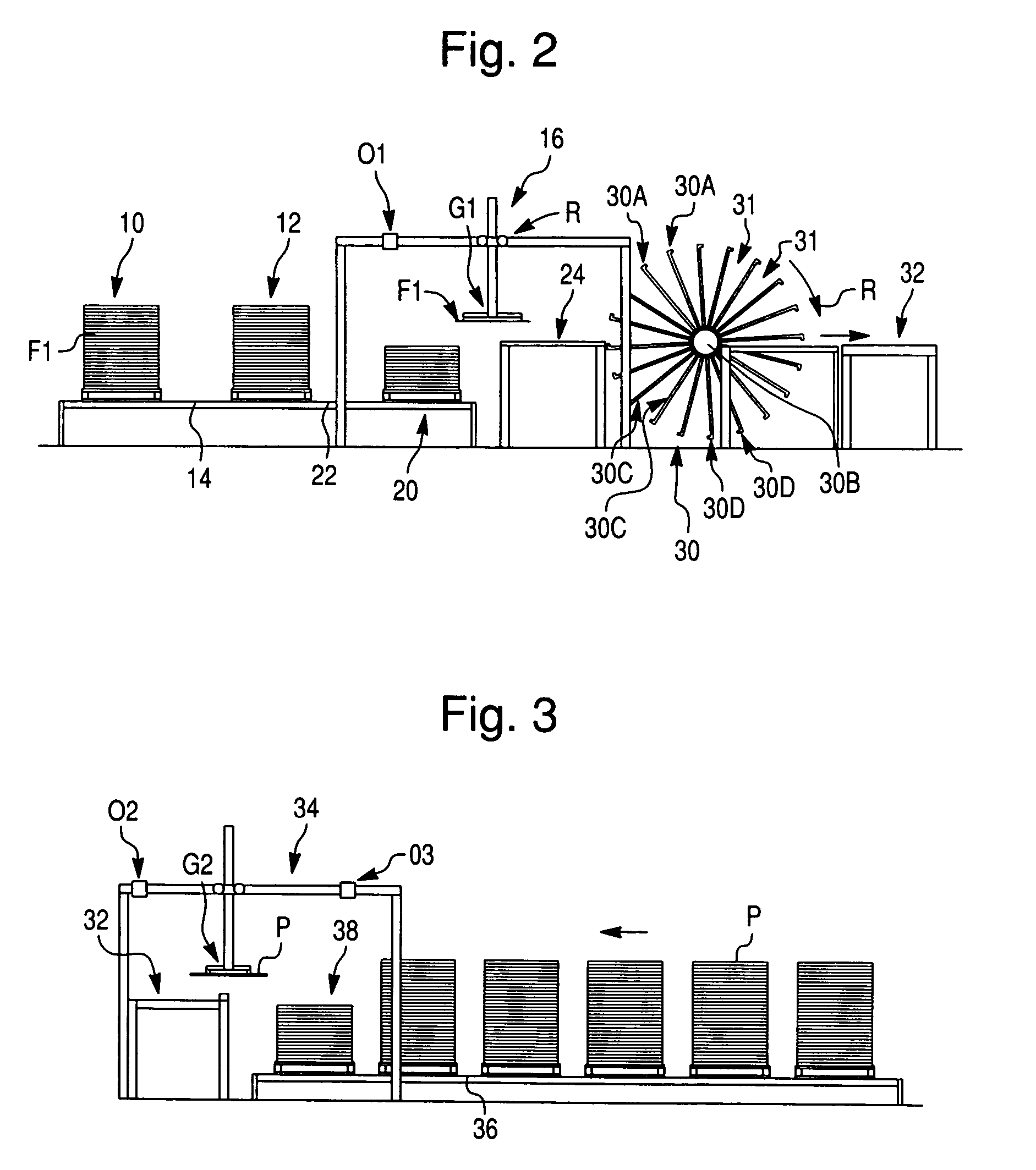

Automated door assembly system and method

InactiveUS7819163B2Other plywood/veneer working apparatusMechanical working/deformationAdhesiveEngineering

The present invention is directed to a method of making a door having first and second door facings and an internal doorframe. An interior side of a first facing is coated with quick acting adhesive. A frame is placed on the coated interior side about the periphery of the first facing. The frame is then coated with quick acting adhesive. An interior side of a second facing is placed on the coated frame. The facings and frame assembly are then compressed to form a door. The present invention also provides for an automated system of making the door.

Owner:MASONITE CORP

Manufacturing technique of cortices assembled and adhered clad plate

InactiveCN101081524AFast softening speedInterpenetrate and moisten wellOther plywood/veneer working apparatusWood treatment detailsComposite plateUltimate tensile strength

The technological process of producing composite plate of spliced bark includes the following steps: sorting bark material, softening, cold pressing of bark and spliced board or hot splicing and curing, ageing, mechanical forming and trimming, sanding, dedusting, etc. During the production process, 10 % concentration alkali solution is added to speed the softening of bark, and eliminate partial starch and saccharide for preventing moth, and the ageing step can moisten bark mutually and volatile partial water. The composite plate of spliced bark made with waste bark as main material has certain strength, tight combination, low cost, natural bark grains and other advantages.

Owner:陈战

Color solid plate manufacture method

InactiveCN101508123AEnvironmentally friendlyFlame retardantOther plywood/veneer working apparatusWood treatment detailsSolid woodPulp and paper industry

The invention provides a method for manufacturing a colored solid wood panel, belongs to a processing method for wood utilization, and in particular relates to a method for manufacturing a multi-layer colored panel. The invention aims to provide a method for manufacturing a multi-layer colored panel which overcomes the defects of natural wood and effectively solves the problems of looseness and softness, susceptibility to corrosion, flammability, and the like of fast growing wood. The multi-layer colored panel has the characteristics of environmental protection, inflame retarding, moisture resistance, corrosion resistance, wearing resistance, difficult deformation and strong plasticity.

Owner:王殿国

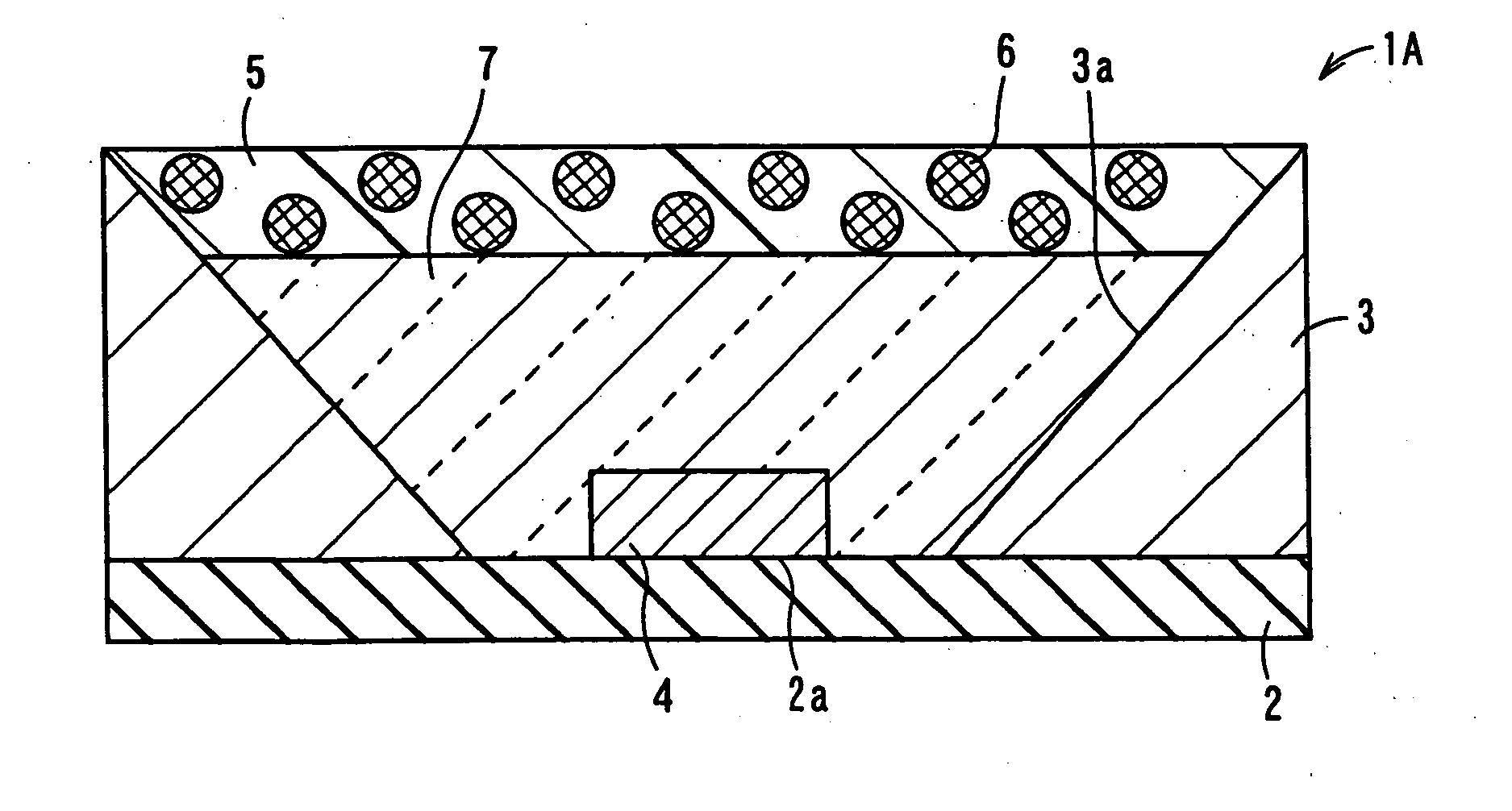

Light-emitting apparatus and illuminating apparatus

InactiveCN1674317AIncrease the intensity of radiant lightReduced light extraction efficiencyOther plywood/veneer working apparatusMechanical surface treatmentPhosphorLight emitting device

There is provided a light-emitting apparatus with favorable radiation light intensity, which is excellent in light extraction efficiency, color temperature and color rendering property. The light-emitting apparatus includes a light-emitting element, a base body having, on its top surface, a placement portion for emplacing thereon the light-emitting element, a frame body attached to the top surface of the base body so as to surround the placement portion, a light transmitting member disposed inside the frame body so as to cover the light-emitting element, and phosphors contained in the light transmitting member, which performs wavelength conversion on the light emitted from the light-emitting element. The light transmitting member has a pre-cured viscosity ranging from 0.4 to 50 Pa.s.

Owner:KYOCERA CORP

Automatic edge banding machine for plywood manufacturing

ActiveCN110524670ASolve the problem that the edge banding efficiency is low and cannot be processed in batchesImprove edge banding efficiencyOther plywood/veneer working apparatusDomestic articlesEngineeringEdge banding

The invention relates to an automatic edge banding machine for plywood manufacturing. The machine comprises a conveying belt, clamping mechanisms, electric sliding rails, workbenches, a laminating device and a shearing mechanism, the conveying belt is fixed to the ground through a support. The clamping mechanisms are arranged above the conveying belt; the clamping mechanisms are uniformly arrangedat the top of the conveying belt; the electric sliding rails are symmetrically arranged above the clamping mechanisms; the tops of the electric sliding rails are mounted on a fixed surface such as awall surface; the tops of the clamping mechanisms are connected with the middles of the electric sliding rails in a sliding fit mode. The workbenches are symmetrically arranged on the front side and the rear side of the left end of the conveying belt, the lower ends of the workbenches are installed at the lower end of the left side of the conveying belt, the bottom of the attaching device is installed on the right side of the tops of the workbenches, the shearing mechanism is arranged on the right side of the attaching device, and the bottom of the shearing mechanism is installed on the left sides of the tops of the workbenches. The machine can solve the problems that when plywood edge sealing is conducted manually, the steps are tedious, and edge sealing treatment of large-batch plywood cannot be conducted.

Owner:广东优逸智能家私有限公司

Edge banding machine

ActiveUS20120240846A1Ensure qualityOther plywood/veneer working apparatusLiquid surface applicatorsEngineeringScratching

An edge banding machine includes a machine body unit having a mounting plate, a glue-applying unit, a glue-scratching unit and a transmission unit. The glue-applying unit includes a glue container mounted fixedly on the mounting plate, a supporting member disposed fixedly and directly above the glue container and a glue-applying roller rotatably extending into the glue container. The glue-scratching unit includes a rotating shaft disposed rotatably on the supporting member, a glue-scratching plate disposed fixedly on the rotating shaft and extending toward the glue-applying roller, an adjustment rod disposed adjustably on the cover, and a connecting member connected between the adjustment rod and the rotating shaft such that movement of the adjustment rod results in rotation of the rotating shaft.

Owner:LIN CHIN CHI

Floor made up of hard floor tile and method for manufacturing the floor tile

InactiveCN1572993AEasy to processCooperate accuratelyTongue/grooves making apparatusWallsStructural engineeringMechanical engineering

A method for linking rigid flooring panels has interlocking edge profiles. One edge has a shaped groove in the support layer, into which is clipped a profiled lip of the adjoining panel. The lip and groove are linked by a tilt and clip action resulting in a tension grip between the lip and groove profiles. This ensures that the butting edges of the panels are pulled together at all times, even with the expansion and shrinking of the panels with weathering. The panels present a gap free fitting under all conditions, and can be lifted for repair.

Owner:UNILIN BEHEER

Production process of high-grade fir melamine ecological board

ActiveCN105459221AReduces surface white bloomsReduce defects such as carbonizationOther plywood/veneer working apparatusLaminationInfraredProduct inspection

The invention belongs to the field of board machining and particularly relates to a production process of a high-grade fir melamine ecological board. The process particularly includes the following steps of poplar middle plate selection, poplar middle plate splicing, fir core veneer selection, fir core veneer sanding, fir core veneer slotting, core veneer gluing, infrared ray board arrangement for forming a blank, cold pressing, core cutting, hot pressing, putty application, maintenance, sanding, semi-checking, secondary putty application, secondary sanding, gluing and veneering, base board cold pressing, base board edge cutting, base board hot pressing, base board putty application, base board fixed-thickness sanding, base board edge sawing, base board inspection, repairing, melamine impregnated paper hot pressing and finished product inspection, packaging and warehousing of finished products. The production process has the advantages that fir core veneers are adopted, the hardness, nail-holding ability and static bending strength of the board is improved; eucalyptus middle plates are replaced with poplar middle plates, and the defects that the surface of the finished products is stained and carbonized caused by multiple burrs and scabs on the surfaces of the gum wood are reduced effectively.

Owner:ZHEJIANG SHENGHUA YUNFENG GREENEO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com