Patents

Literature

643results about How to "Improve processing productivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

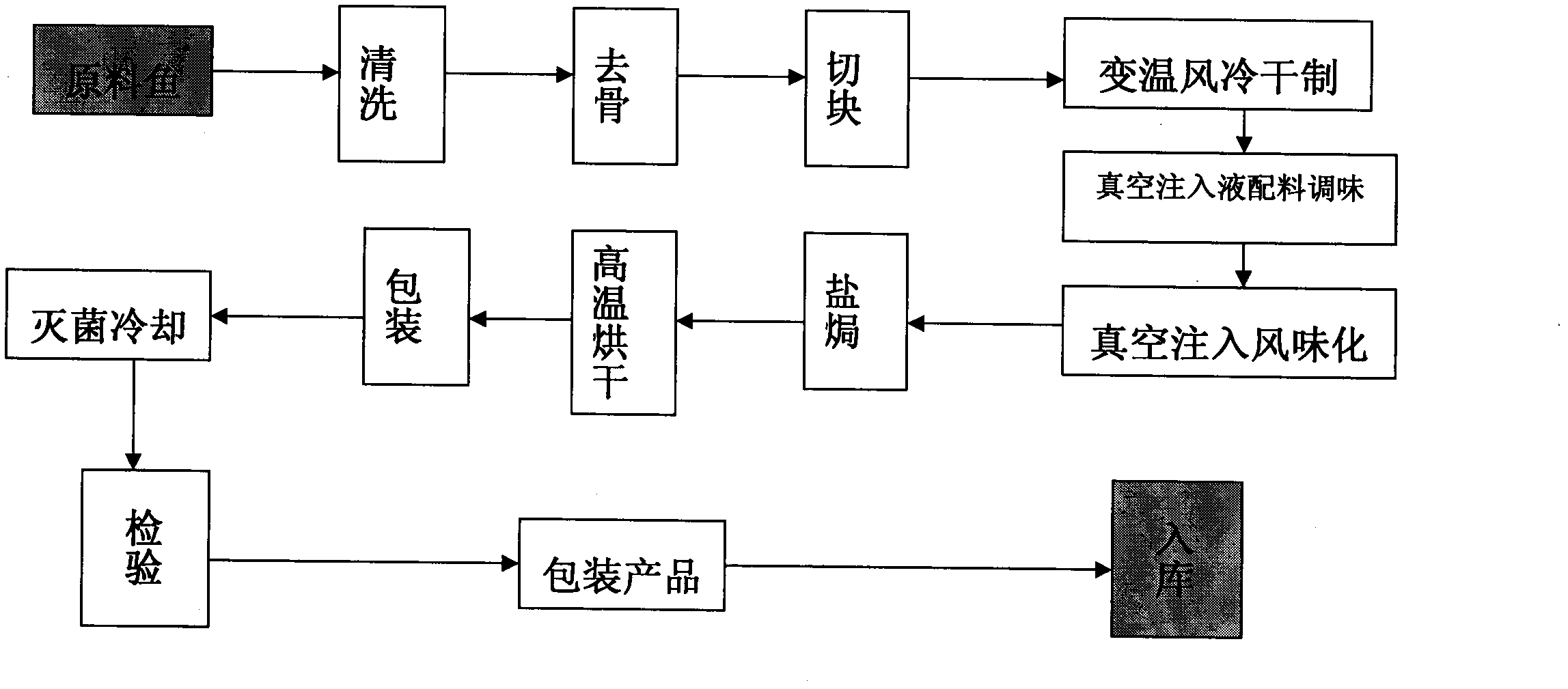

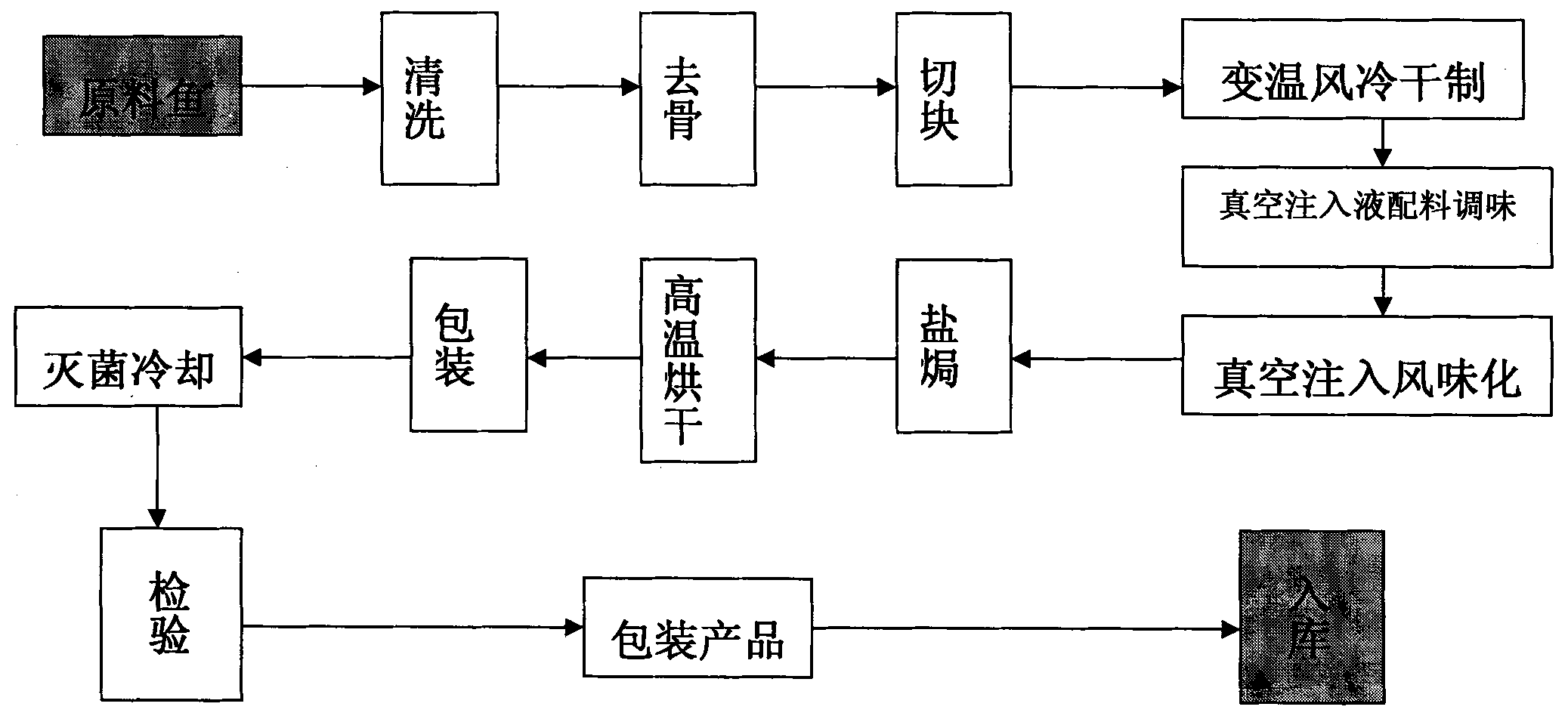

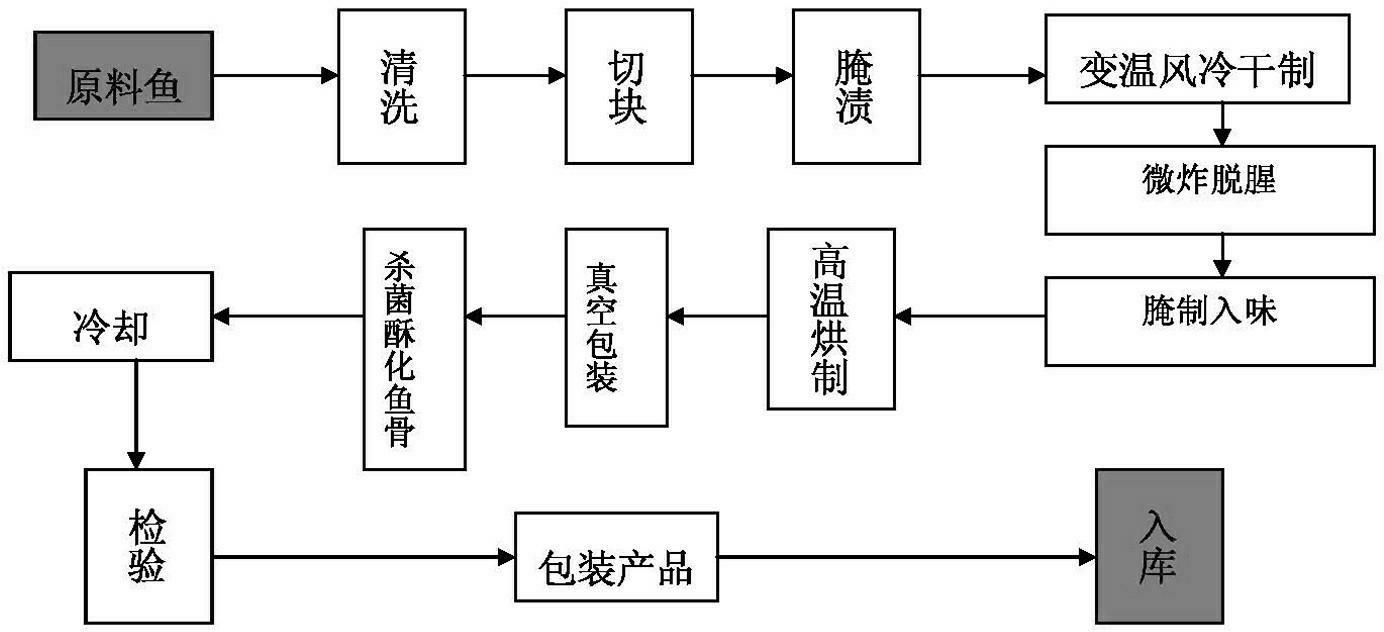

Instant salt baked fish processing method

InactiveCN101912126AImprove processing productivityImprove qualityFood preparationFlavorFish processing

The invention relates to an instant salt baked fish processing method, which comprises the following steps of: selecting raw material fish, cleaning, removing bones, cutting into blocks, drying through variable temperature air cooling, mixing and seasoning, injecting flavors in vacuum, performing salt baking, drying at high temperature, packaging, sterilizing and cooling, inspecting, packaging into a finished product, warehousing and other procedures. The instant salt baked fish has the advantages of high processing and production efficiency, good quality, long storage time, convenient eating, and delicious meat.

Owner:佛山六奇食品科技有限公司

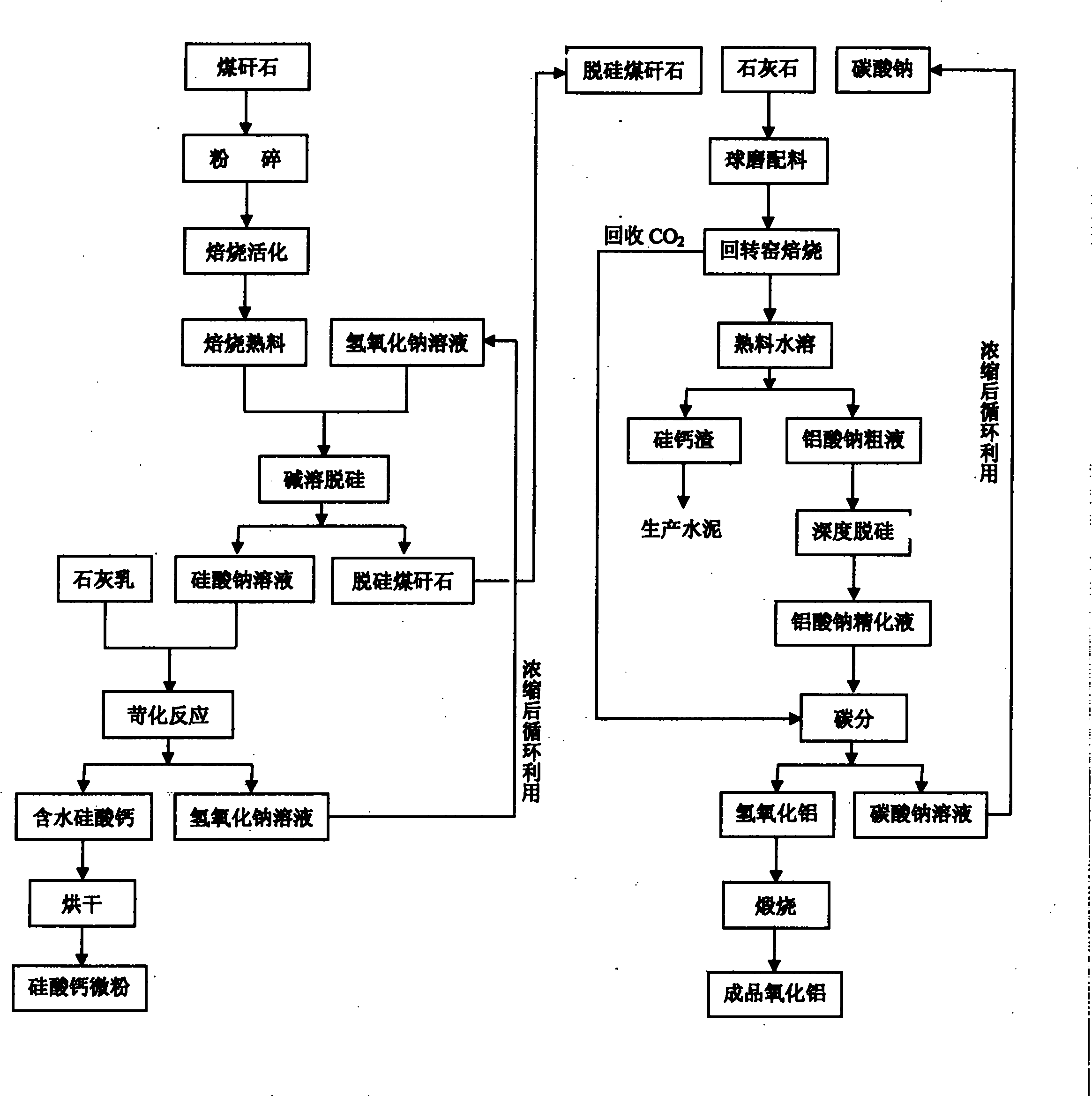

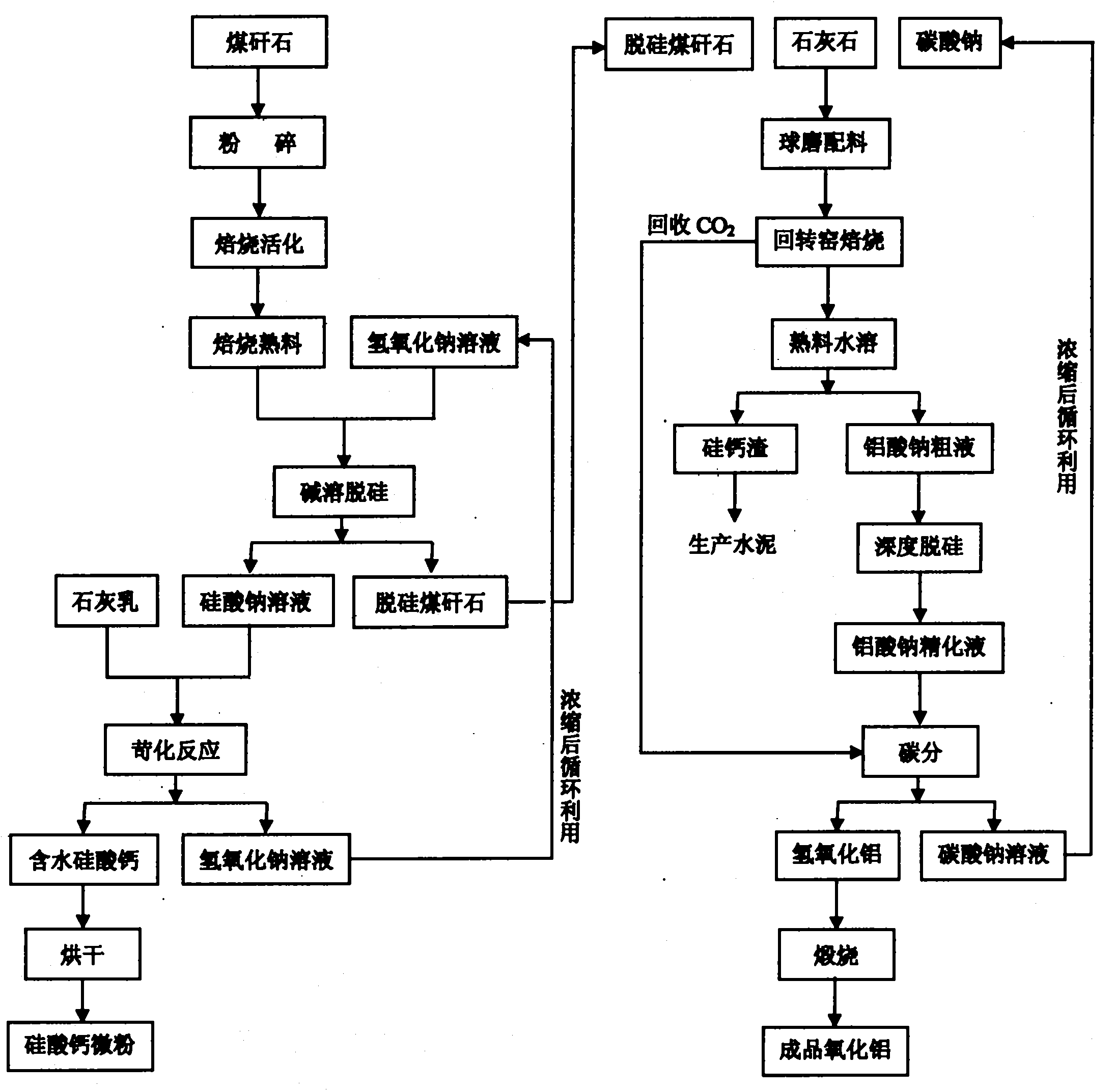

Method for extracting aluminum oxide from coal gangue and co-producing active calcium silicate

ActiveCN101941725ALow firing temperatureHigh activityAlkaline-earth metal silicatesCement productionCoal gangueAluminium oxide

The invention provides a method for extracting aluminum oxide from coal gangue and co-producing active calcium silicate, and relates to the technical field of producing aluminum oxide and the active calcium silicate. The method comprises the following steps of: grinding coal gangue, and roasting and activating the ground coal gangue; performing alkali soluble desilication of coal gangue clinker to obtain desilication coal gangue and solution of sodium silicate; performing causticizing reaction of the solution of sodium silicate to obtain water-containing calcium silicate and solution of sodium hydroxide, and drying the water-containing calcium silicate to obtain micro powder of active calcium silicate; adding limestone and solution of sodium carbonate into the desilication coal gangue, and ball-grinding the mixed solution to obtain raw slurry; dissolving out the clinker which is obtained by roasting the raw slurry with water to obtain crude solution of sodium aluminate and silicon and calcium residues, wherein the silicon and calcium residues can be used as cement raw materials after post-treatment; performing deep desilication of the crude solution of sodium aluminate to obtain the purified solution of sodium aluminate; feeding CO2 into the purified solution of sodium aluminate to obtain aluminum hydroxide and solution of sodium carbonate; and calcining the aluminum hydroxide to obtain the aluminum oxide products. The method has the advantages of simple process, low production cost, low energy consumption and little consumption of raw materials; in addition, by the method, two kinds of silicon-containing byproducts are simultaneously produced, and no waste is generated.

Owner:TONGFANG ENVIRONMENT

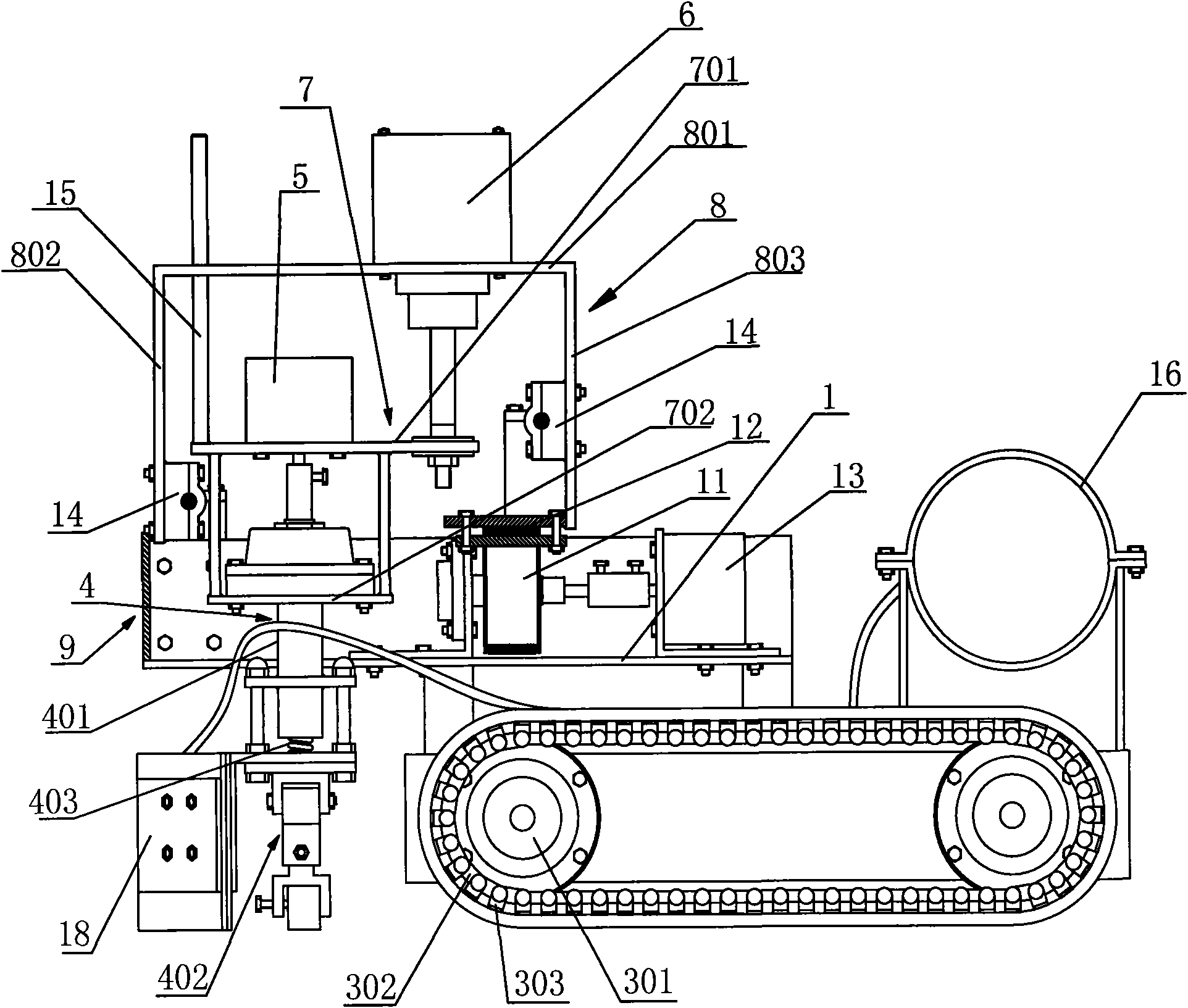

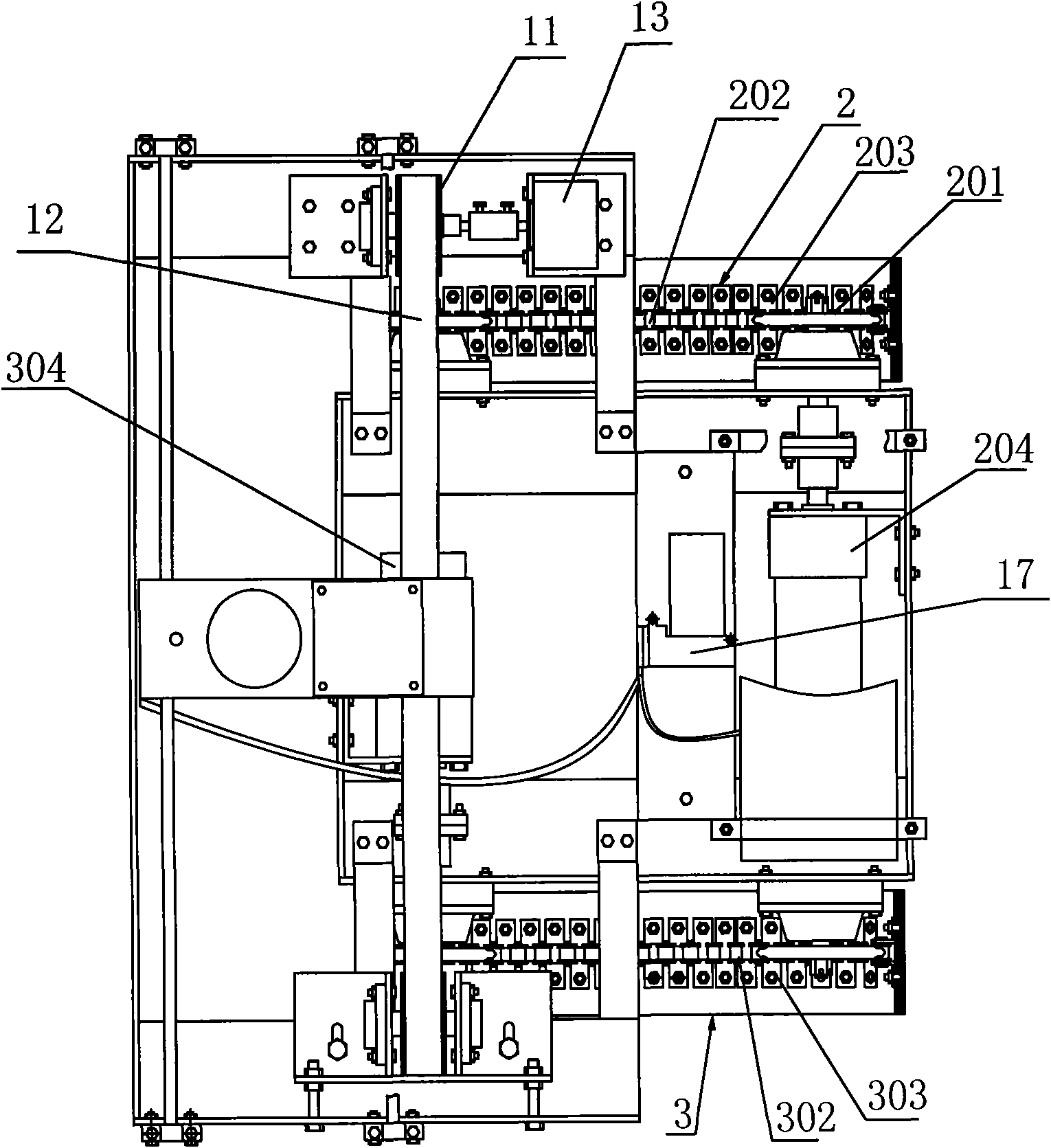

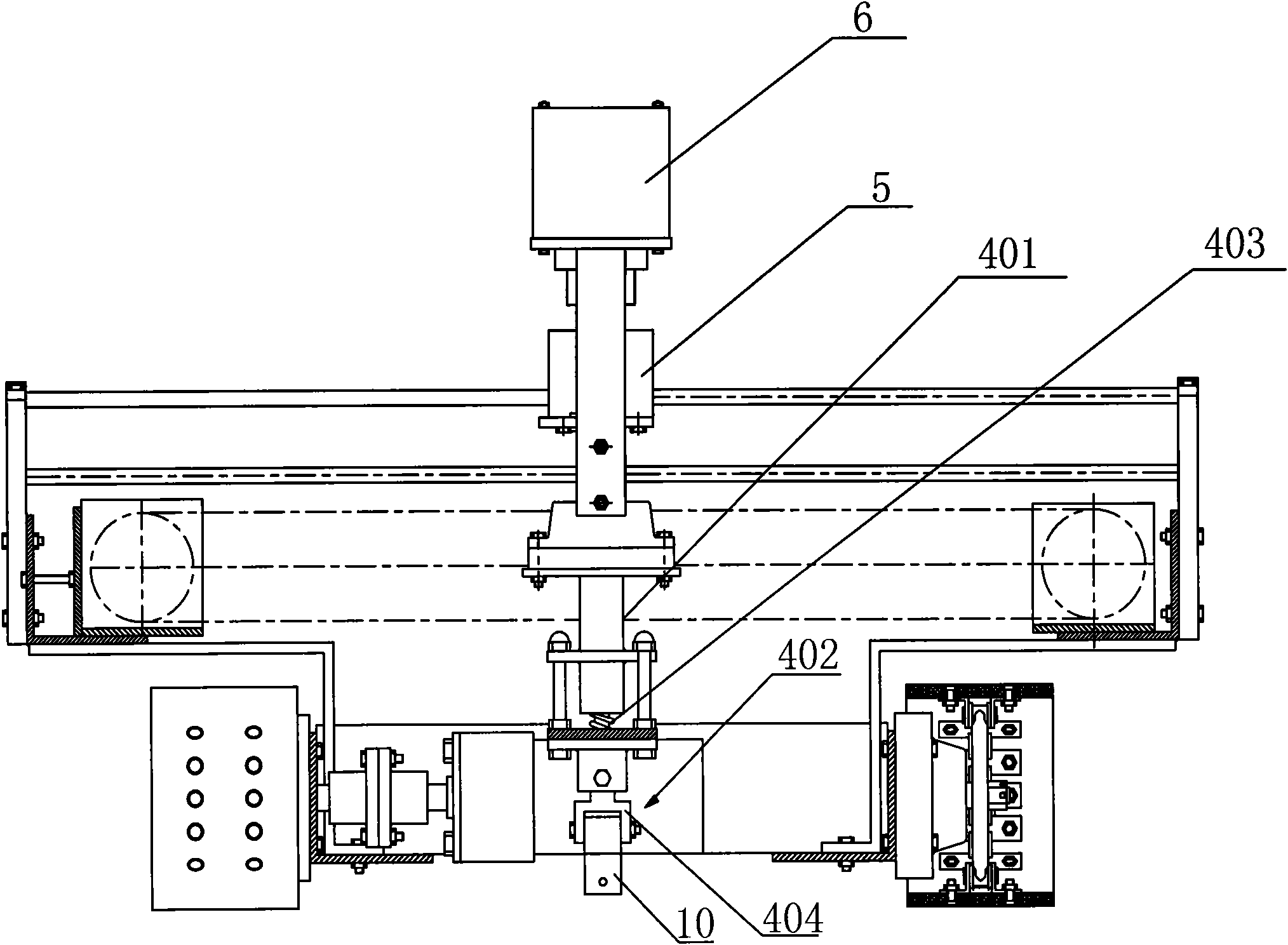

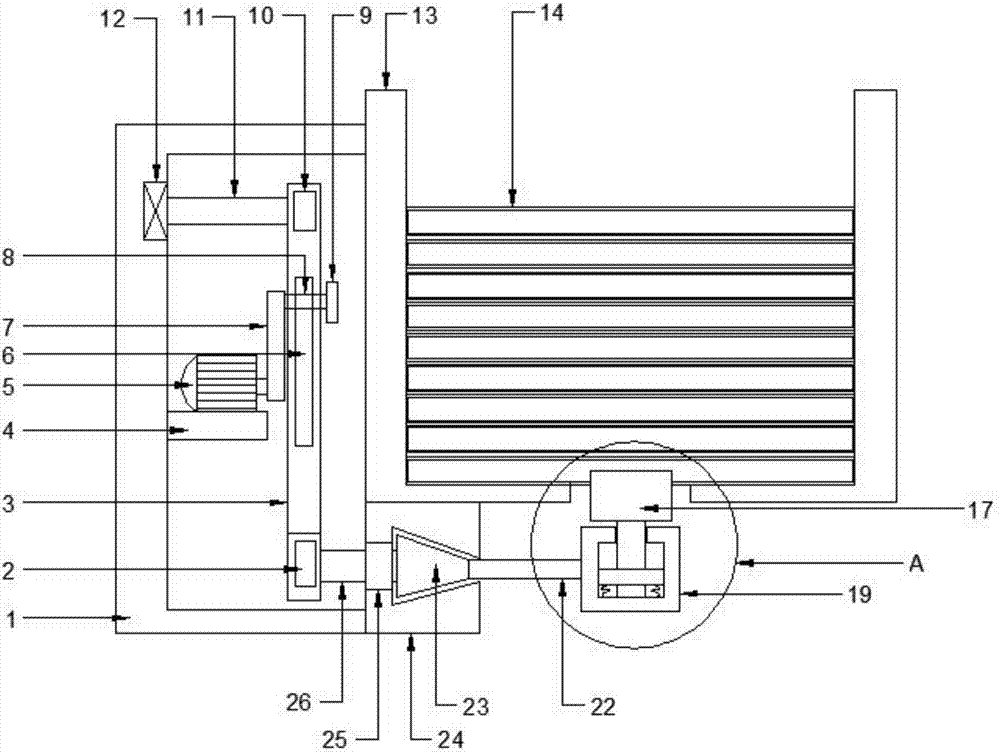

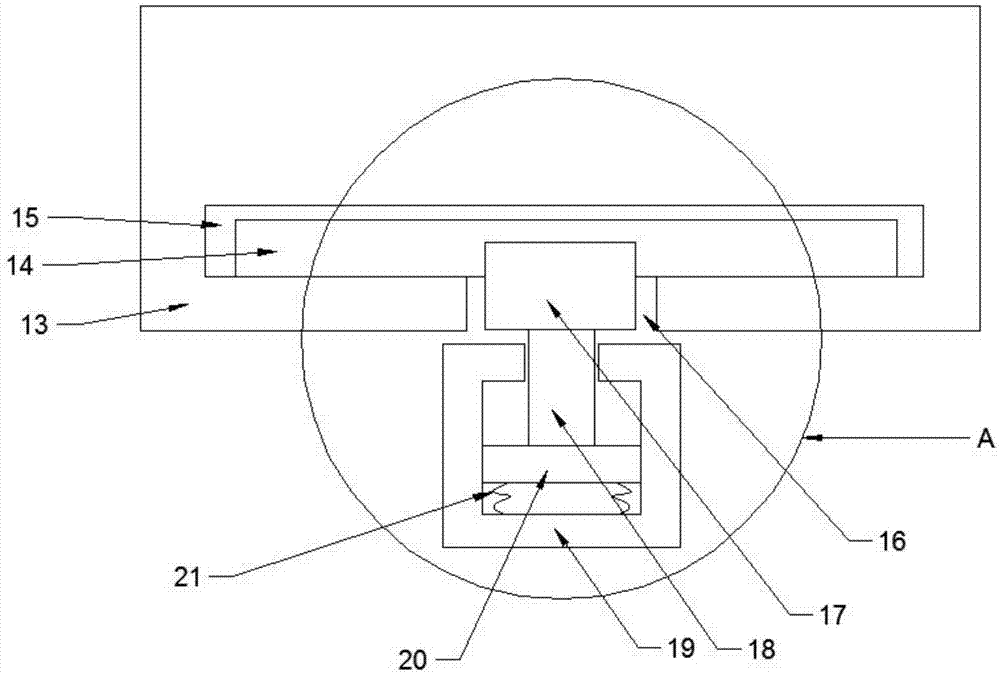

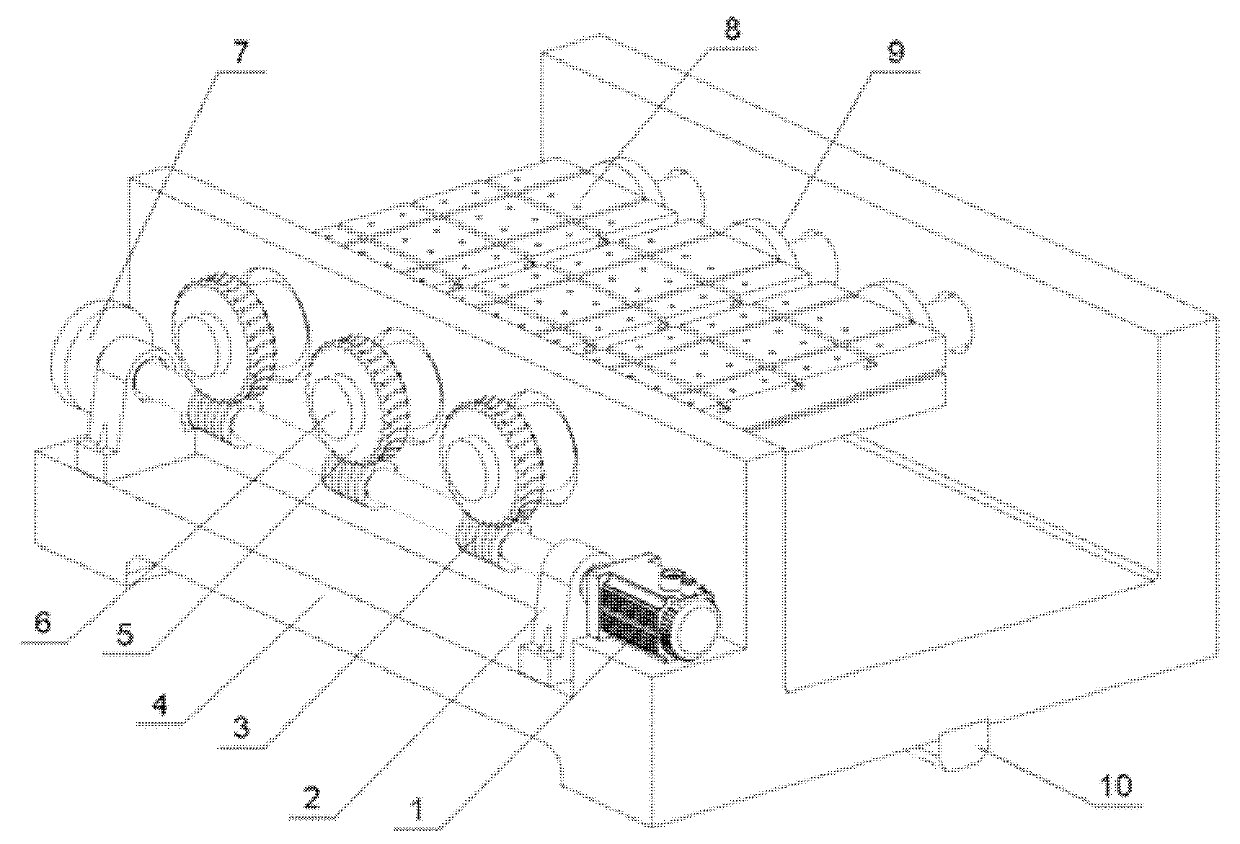

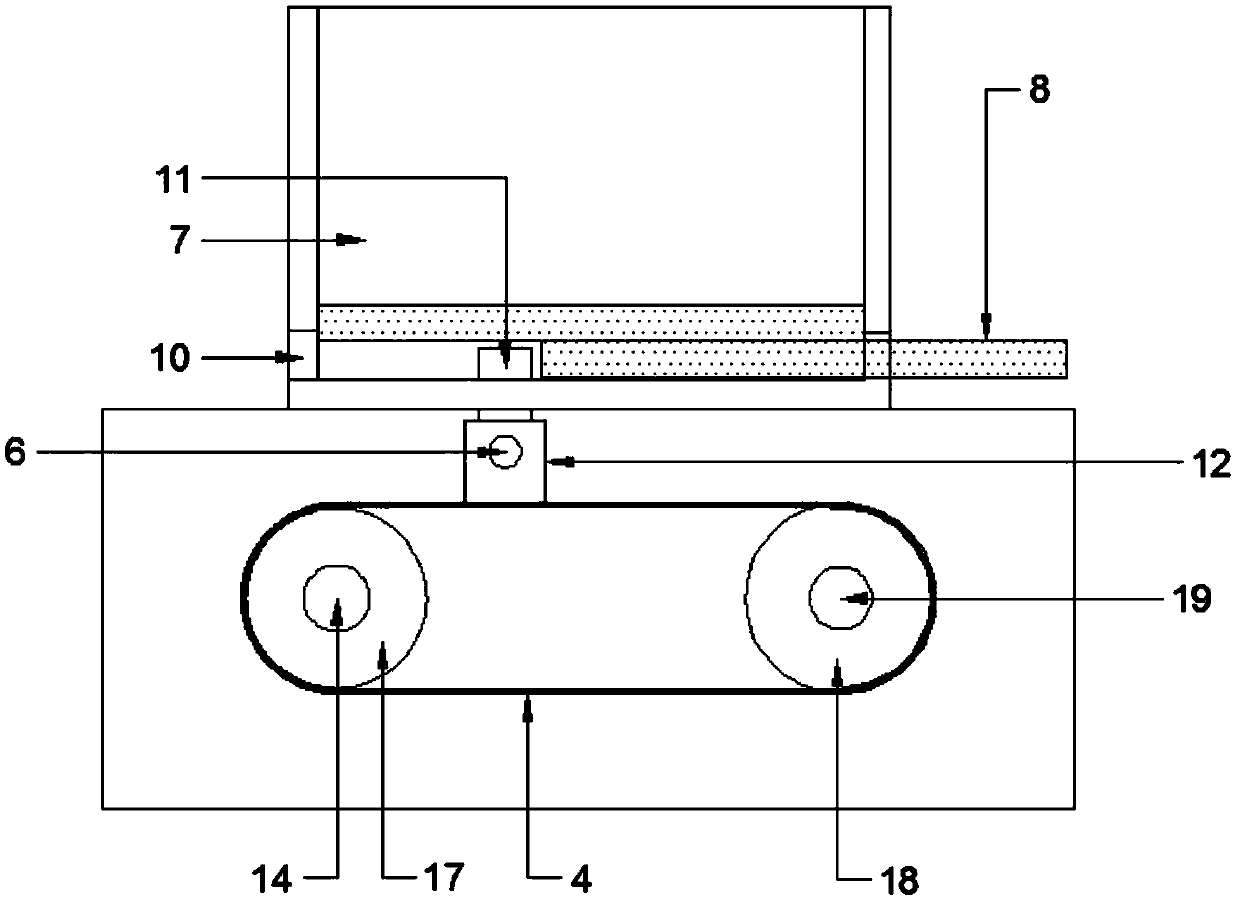

Auxiliary robot for ultrasonic flaw detection

InactiveCN101852778AReduce labor intensityImprove work efficiencyMaterial analysis using sonic/ultrasonic/infrasonic wavesElectric machineryDrive motor

The invention discloses an auxiliary robot for ultrasonic flaw detection, which comprises a frame, a frame travel mechanism, a detection executing part, a coupling agent coating part and a moving mechanism for the executing part. In the frame travel mechanism, each pedrail drive motor acts separately or cooperatively to enable the frame to go forward, backward or turn. The detection executing part is moved by a synchronous belt in the moving mechanism for the executing part. A probe rotating motor and an ultrasonic probe clamping part are arranged on an internal mounting bracket. An ultrasonic probe clamping part is moved up and down by a linear reciprocating motor through the internal mounting bracket. In the coupling agent coating part, a coupling agent brush is fixed on the ultrasonic probe clamping part. The coupling agent brush coats the coupling agent in the front, and then the ultrasonic probe executes the process of flaw detection behind the coupling agent brush. The invention accomplishes heavy works such as coupling agent coating, probe clamping and the like per se, which greatly reduces labor intensity of detectors and improves the efficiency and precision of detection.

Owner:SHANDONG UNIV OF SCI & TECH

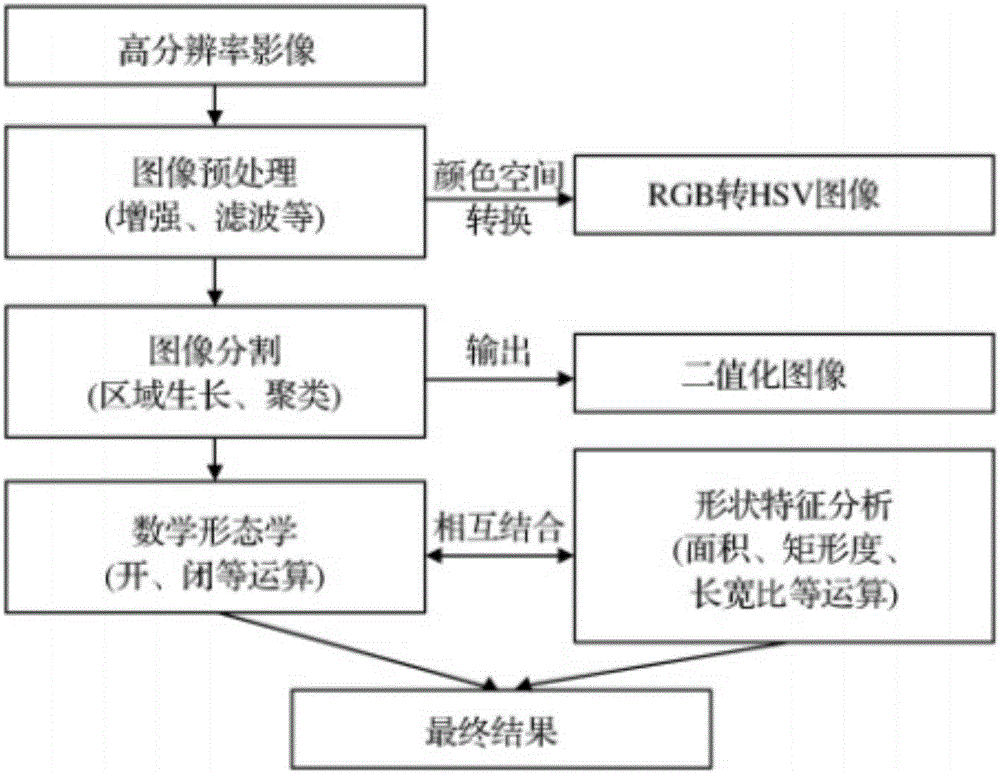

High-resolution remote sensing image road information extraction method

InactiveCN106295562AImprove adhesionWith tenacityCharacter and pattern recognitionRgb imageImage segmentation

The present invention discloses a high-resolution remote sensing image road information extraction method. The method comprises the following steps: image preprocessing: employing an enhanced and filtering method to realize the purpose of the difference of a road image and a background image; a road image segment method: improving the traditional area growth algorithm and adding a secondary cluster method after growth to remove the complex small plates distributed in the image as much as possible so as to allow the ground object connected with the road to be separated from each other as far as possible; image analysis and identification: and employing a mathematical morphology method and structural elements with a certain shape to measure and extract the corresponding shaped in the image to reach the purpose of the analysis and identification of the image, convert the RGB image to an HSV image in the image processing process and improve the area growth algorithm to adapt for the extraction road so as to greatly improve the quality of the road segment, have high precision of the extraction of the city road, and especially adapt for the extraction of the city main road.

Owner:INST OF REMOTE SENSING & DIGITAL EARTH CHINESE ACADEMY OF SCI

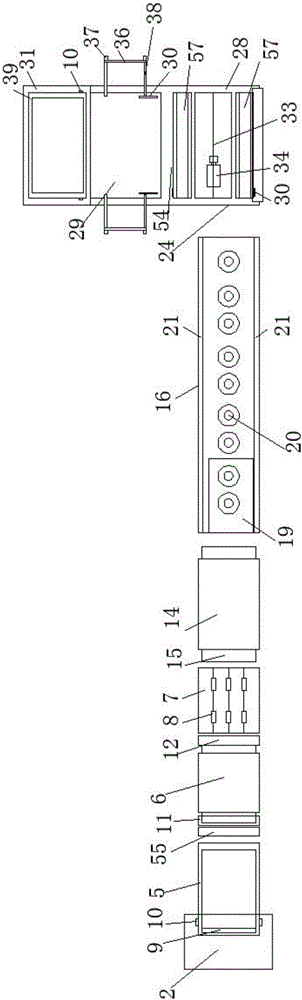

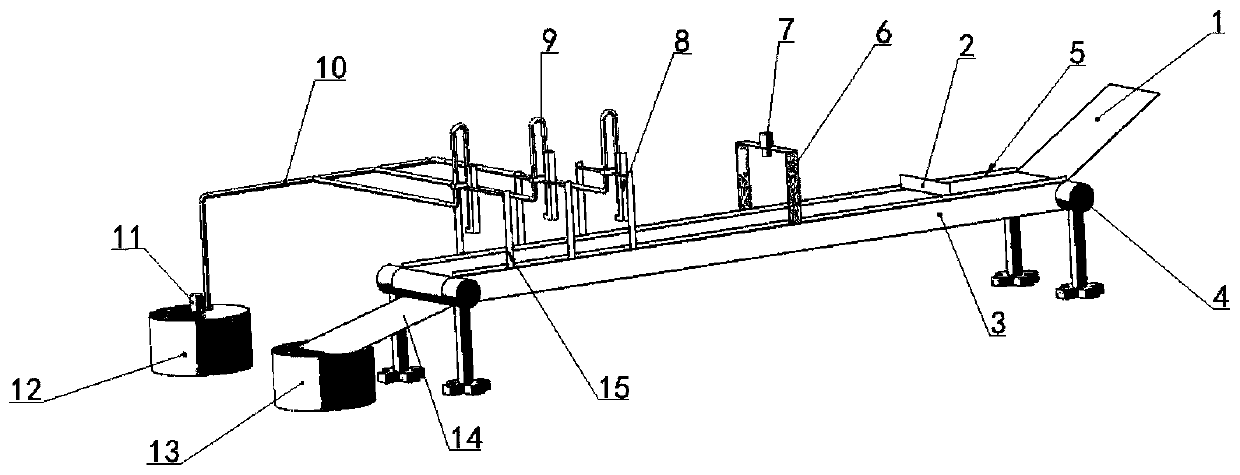

Novel processing production line and control method for plywood

ActiveCN106042084AReasonable structural designImprove processing productivityOther plywood/veneer working apparatusWood veneer joiningManufacturing engineeringHot pressing

The invention provides a novel processing production line and a control method for plywood, and relates to the technical field of plate processing equipment. The novel processing production line comprises a glue coating device, a hot pressing device, cooling equipment and a trimming device, wherein the glue coating device comprises a front end bracket, a first groove, a first lifting device, a first plate support frame, glue coating equipment and a receiving frame; rollers are arranged at the top of the receiving frame; the hot pressing device comprises a hot press and plate conveyor belts mounted on two sides of the hot press; the cooling equipment comprises a cooling chamber, rails, a material conveying trolley and a cooling device; and the trimming device comprises a bracket, a transversal sliding rail, a sliding seat, a push rod, a first support, a second support, four cutting machines, a second groove, a second lifting device and a second plate support frame. The novel processing production line is reasonable in structural design, and can greatly improve the production efficiency of the plywood.

Owner:ANHUI DONGPING WOOD GRP

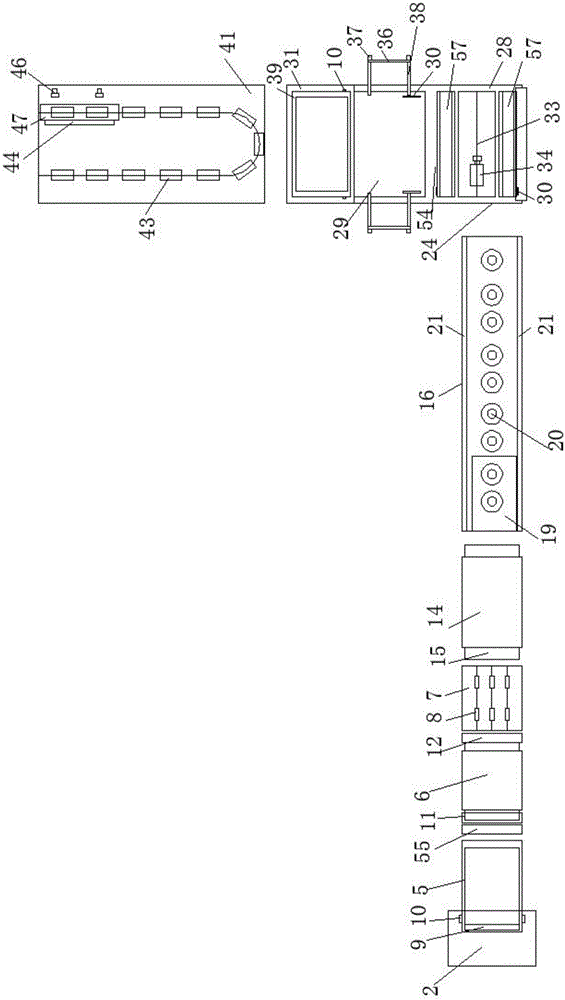

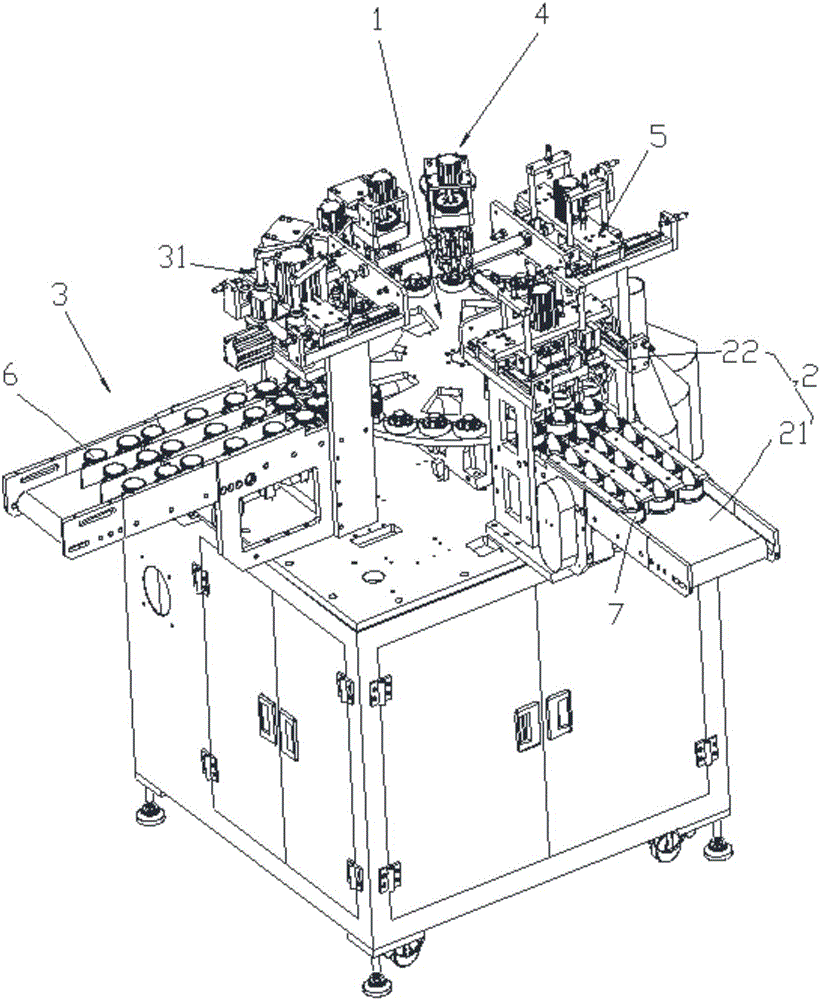

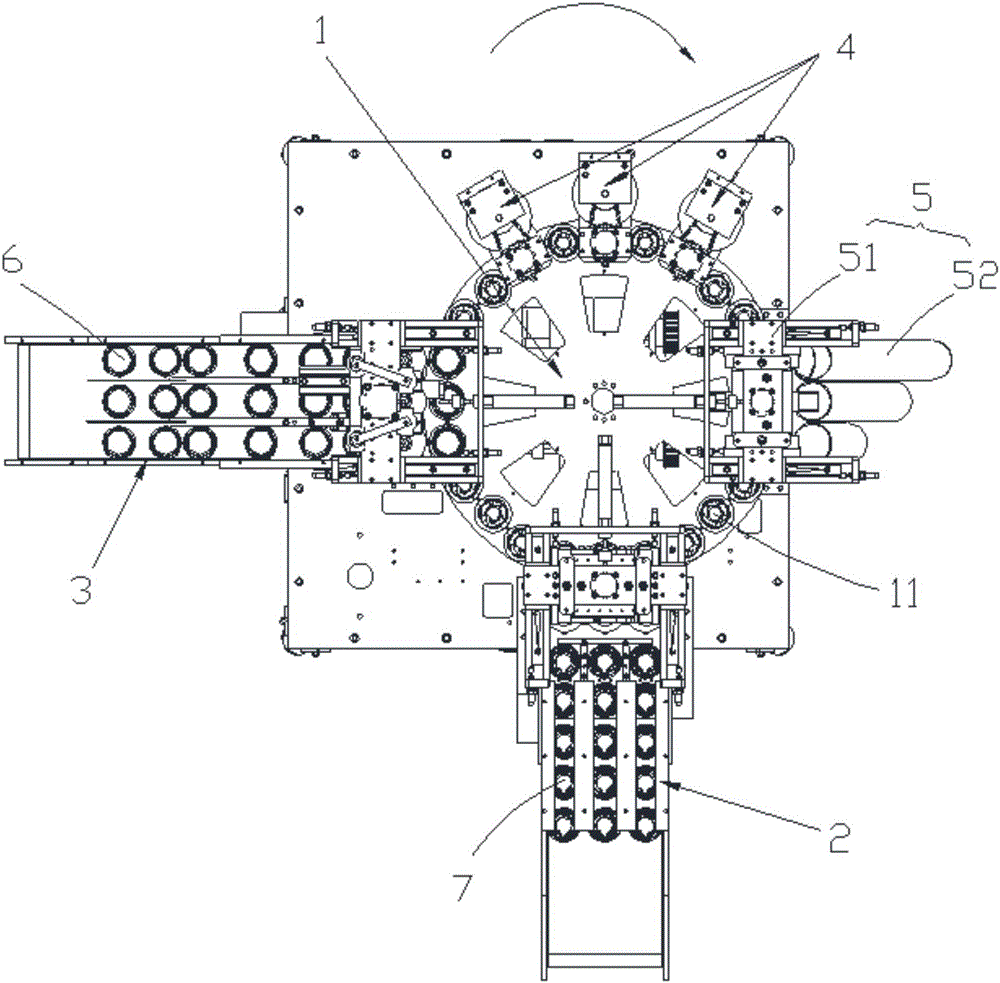

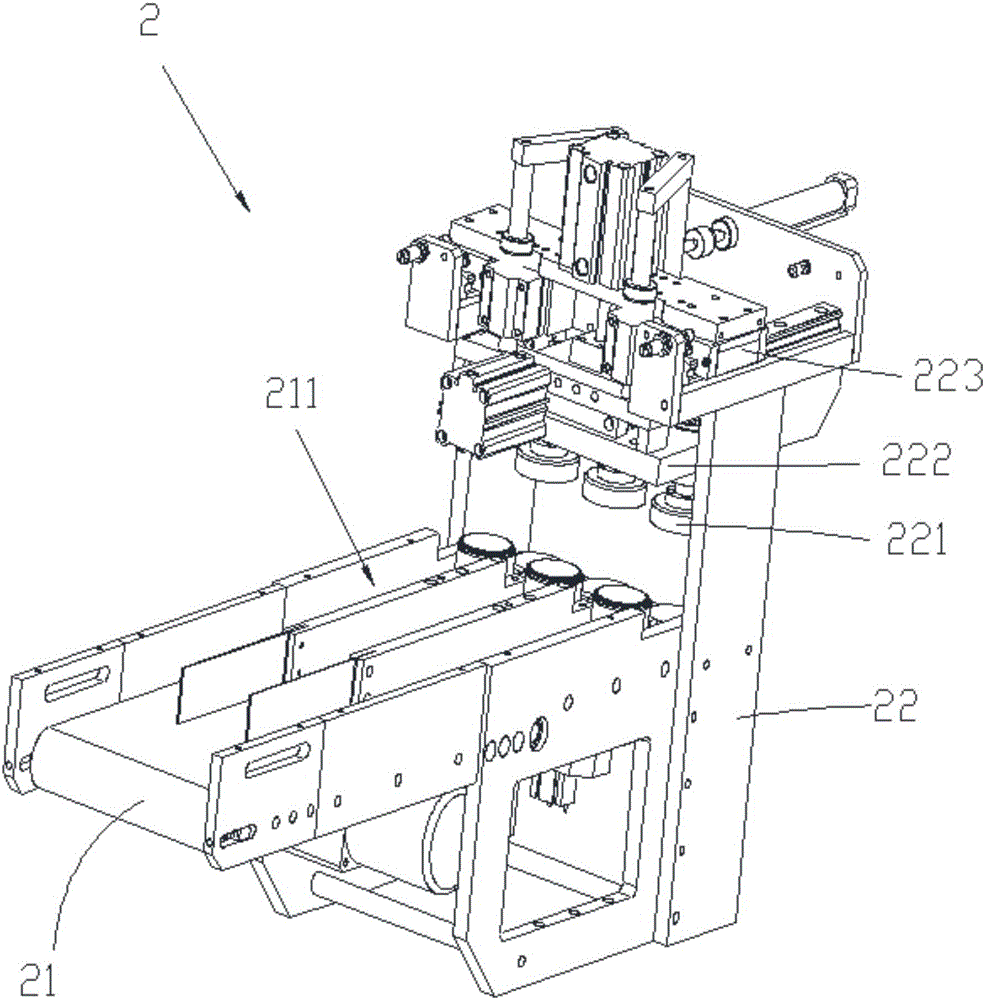

Automatic assembly device for screw cap

ActiveCN105731328AImprove processing productivityReduce labor costsThreaded caps applicationEngineeringBottle

The invention relates to the technical filed of automatic processing and discloses an automatic assembly device for a screw cap. The automatic assembly device comprises a rotation workbench, a plurality of working positions, a bottle opening feeding mechanism, a cap feeding mechanism, an assembly mechanism and a discharging mechanism. The multiple working positions are arranged on the rotation workbench in a surrounding mode. The bottle opening feeding mechanism, the cap feeding mechanism, the assembly mechanism and the discharging mechanism are arranged on the periphery of the rotation workbench sequentially in the rotation direction of the rotation workbench in a surrounding mode. The rotation direction can rotate intermittently. The bottle opening feeding mechanism comprises a bottle opening transferring structure. The cap feeding mechanism comprises a cap transferring structure. The assembly mechanism comprises a rotation manipulator. The discharging mechanism comprises a discharging channel and a discharging transferring structure which is used for discharging the assembled screw cap. Through the automatic assembly device, for the screw cap, provided by the invention, feeding, transferring and assembly of a bottle opening and the cap can be achieved automatically, and automatic discharging is achieved; labor is not needed in the whole assembly process, and the automatic assembly device has the characteristics of being high in processing and production efficiency, low in labor cost and the like.

Owner:MODERN PRECISION PLASTIC & MOLD SHENZHEN CO LTD

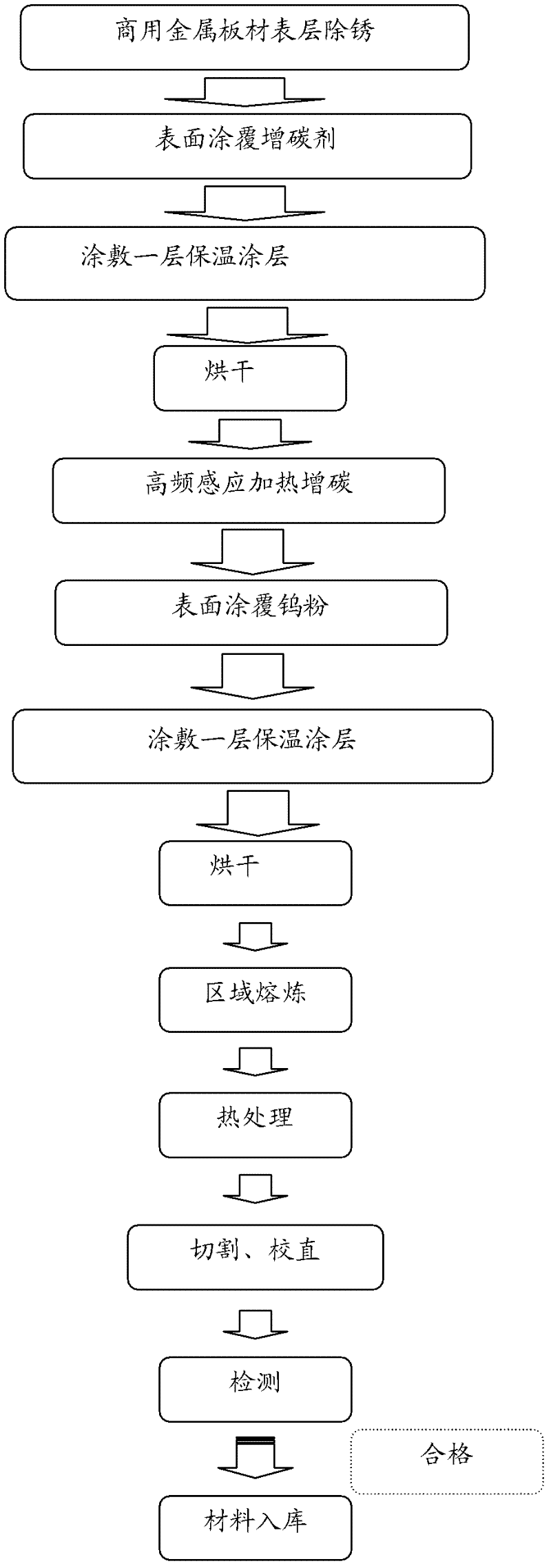

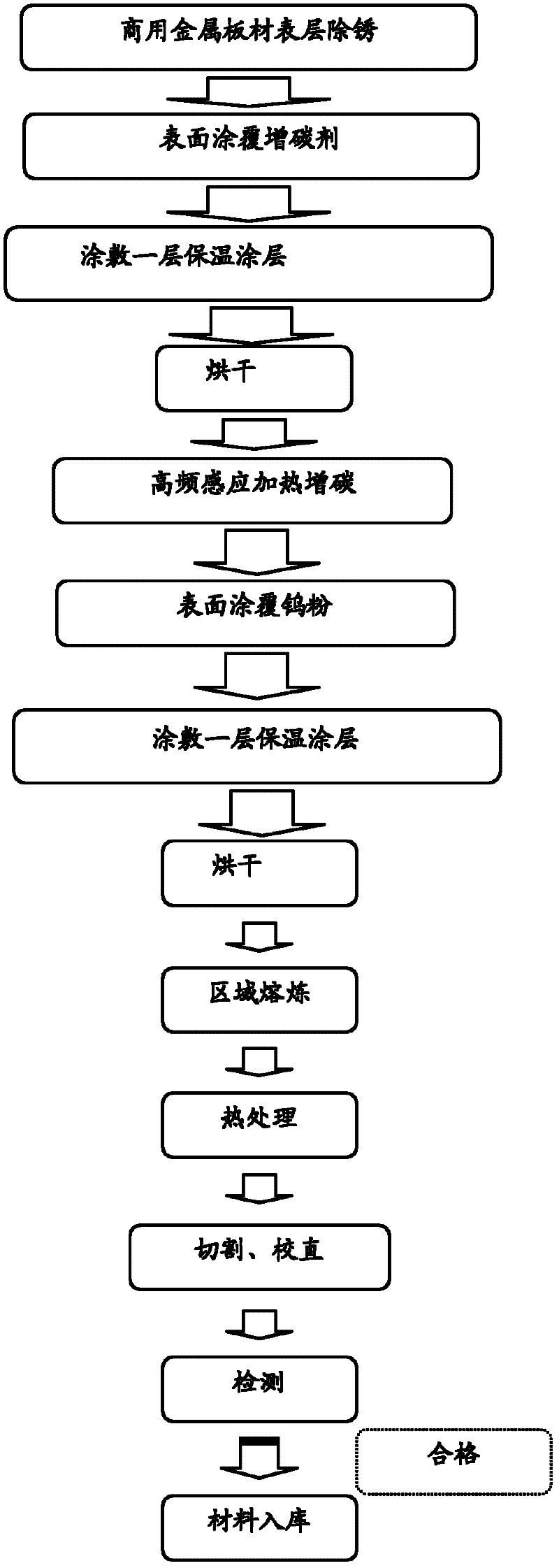

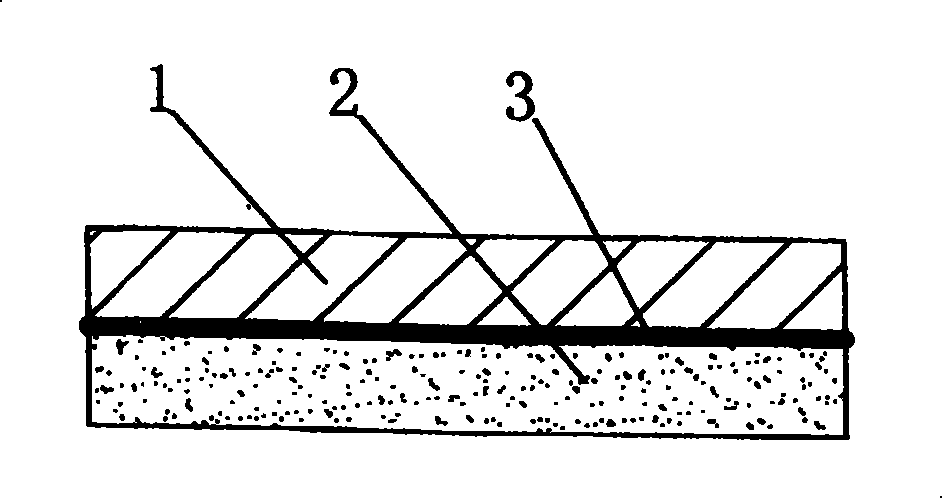

Preparation technology for in-situ synthesis tungsten carbide particle reinforced composite wear-resisting layer on metal plate surface layer

InactiveCN102337536AImprove wear resistanceHigh bonding strengthMetallic material coating processesRustTungsten carbide

The invention discloses a preparation technology for an in-situ synthesis tungsten carbide particle reinforced composite wear-resisting layer on a metal plate surface layer, which comprises the following steps of: carrying out surface rust removal to a metal plate which needs to be subjected to surface layer reinforcement; then, carrying out surface layer recarburization processing on the steel plate; coating metal tungsten powder on the surface of the steel plate; then, coating one layer of heat-insulation coating on the surface of the steel plate coated with the metal tungsten powder; quickly melting the steel plate surface layer by a high-frequency sensor; after the surface layer is solidified, removing the coating layer on the surface layer of the plate material; and finally, obtaining the in-situ synthesis tungsten carbide particle reinforced alloy steel plate material. The alloy steel plate material not only keeps the metal toughness and plastics characteristics of steel plate base material metal but also has higher abrasion resistance. The thickness of the WC (Wolfram Carbide) composite layer can be 1-2mm, and the hardness HRC (Rockwell hardness) is 56-60. The alloy steel plate material has the performances that the alloy steel plate material can deform and can be welded and the like, and the alloy steel plate material can be directly curled, deformed, cut and punched and can be processed by other machining links like the steel plate to be processed into various engineering components (such as pipelines and the like). The in-situ synthesis tungsten carbide particle reinforced composite wear-resisting layer has the advantages of low cost and the like and is easy to industrially produce on a large scale.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

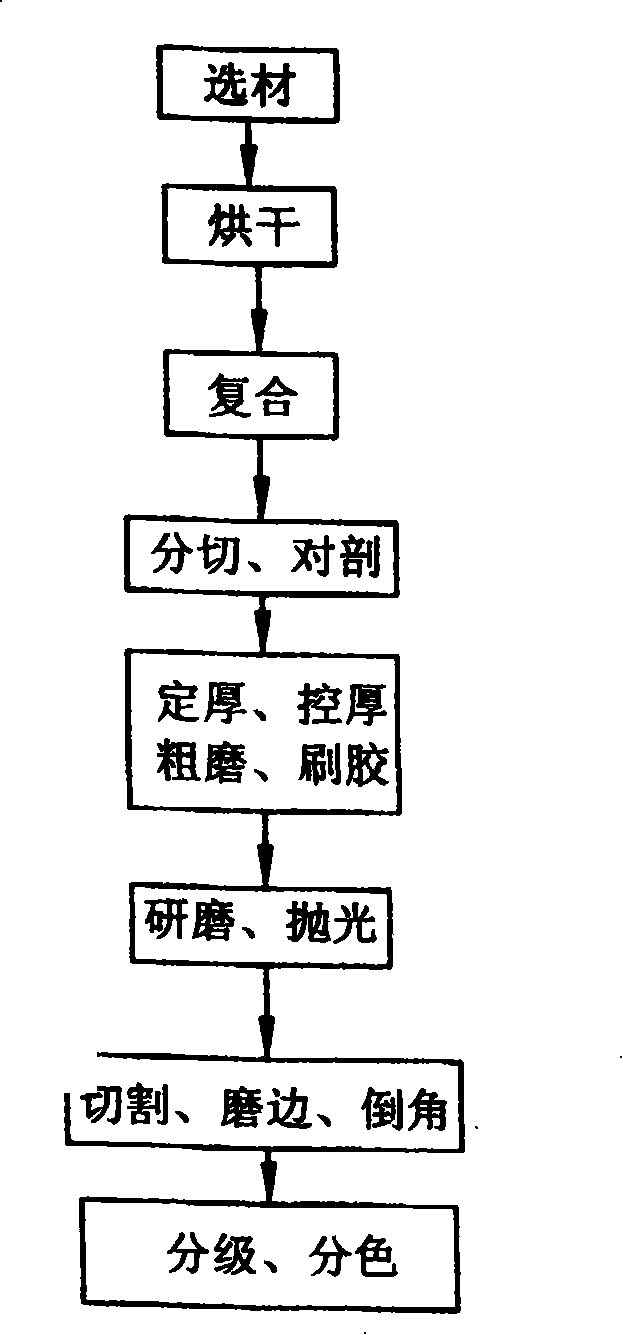

Marble composite board processing technique

InactiveCN101195255AHigh strengthHigh glossStone-like material working toolsResource consumptionAdhesive

The invention relates to the field of building decoration materials, in particular to a manufacturing process of marble clad plates. The manufacturing process of marble clad plates is characterized in that the steps of the process include materials selecting, drying, compounding, dividing and cutting, bisecting, thickness defining, thickness controlling, roughly grinding, glue brushing, abrading, polishing, cutting, chamfering or edging, chamfering, grading, color separating and packing. The process has advantages of high production efficiency, short cycle and large outputs, and the multi-purpose marble clad plates manufactured by the production process has the advantages of shock resistance, countering bending, twist resistance and low costs. Furthermore, the manufactured product has the advantages of light weight, strong intensity, high yielding rate and pressure resistance, which is difficult to be broken after continuous grinding. After abrading and polishing, the marble clad plates have higher glossiness than original marbles, which has the advantages of light weight, strong intensity, high glossiness and the like. Furthermore, the marble clad plates have light weight and reduce resources consumption, thereby reducing production and construction costs, which are capable of being fixed on walls by utilizing composite adhesives. The economic benefic of the marble clad plates is increased by nearly one time of the original high-grade marbles.

Owner:杨加强

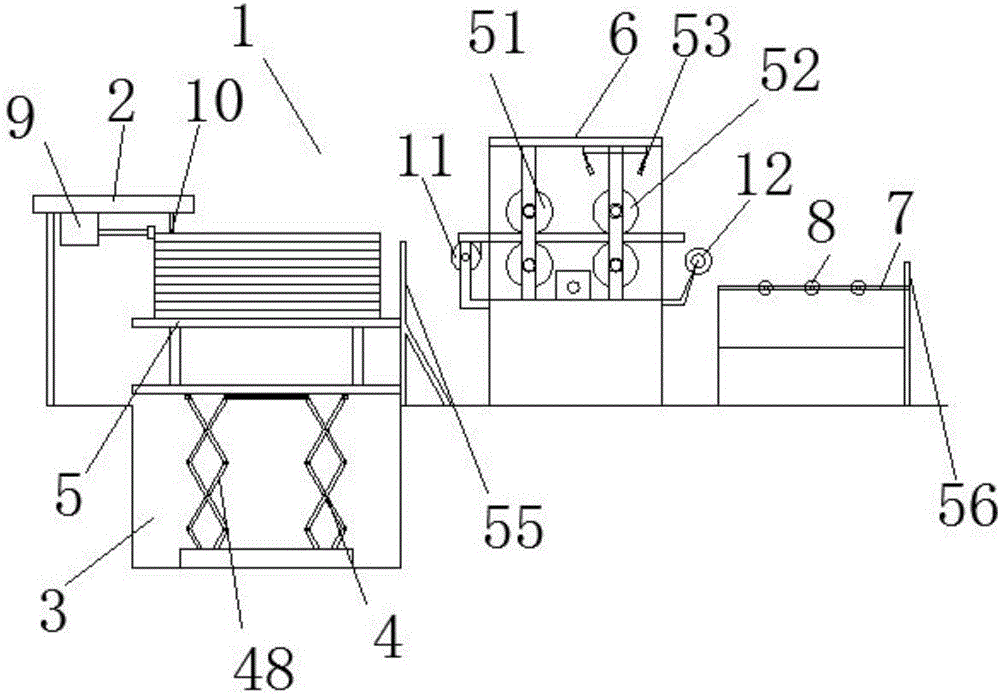

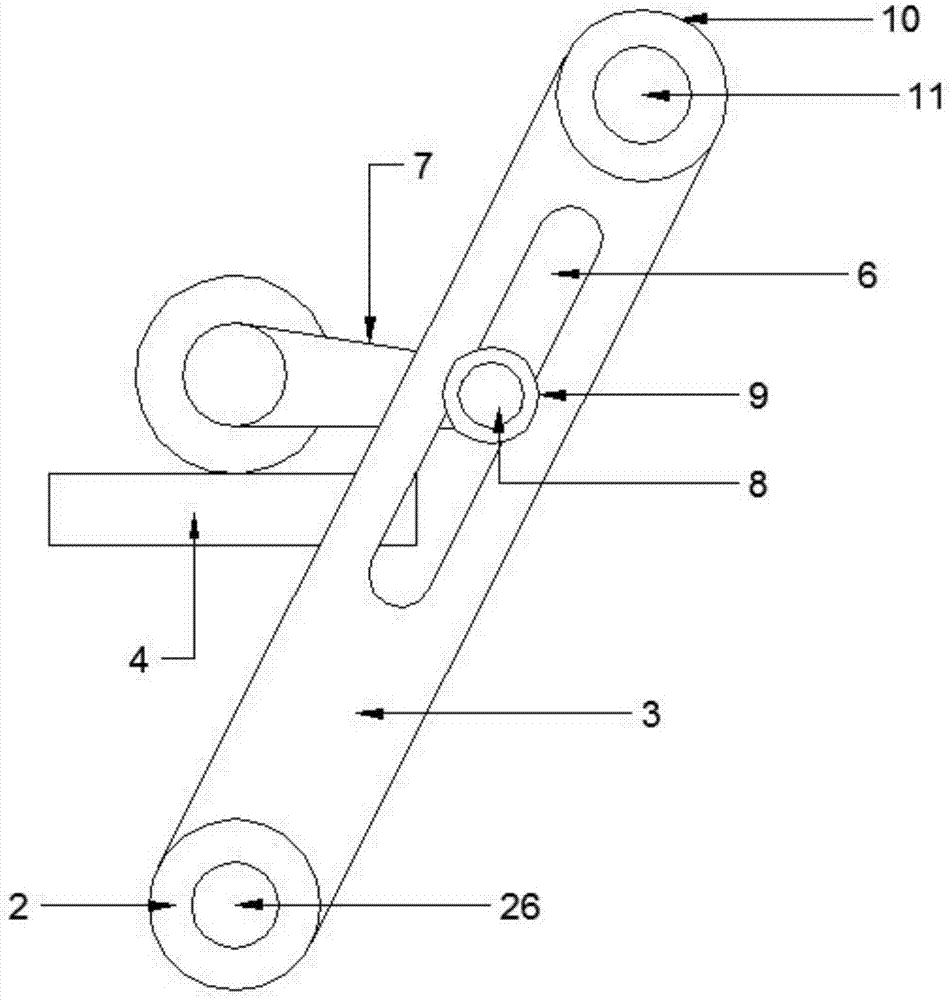

Plate material feeding device

InactiveCN108002016AFast feedingImprove processing productivityConveyorsDe-stacking articlesReciprocating motionDrive motor

The invention discloses a plate material feeding device. A driving box is included, and is internally provided with a driving motor; a motor shaft of the driving motor is fixedly connected with a motor rotating rod; a sliding rod is rotationally fixed to the top end of the motor rotating rod; a limiting block is fixed to the top end of the sliding rod; a swinging groove is formed in a swinging rod; a follow-up ring is arranged at the top end of the swinging rod; a follow-up rod is rotationally fixed tin the follow-up ring; a driving ring is arranged at the bottom of the swinging rod; a pushingplate driving rod is fixed to the right side wall of a travel slider; a telescopic rod is arranged in a telescopic box; a pushing plate is located in a pushing plate slide way; the pushing plate slide way is formed at the bottom of a discharging box; plate materials are stacked on the inner layer of the discharging box; and the side walls of the portions, above the two ends of the pushing plate slide way, of the discharging box are provided with pushing plate openings. According to the plate material feeding device, the driving motor is used for driving the pushing plate to reciprocate leftwards and rightwards at the bottom of the discharging box, the plate materials are pushed out of the discharging box one by one, manual and mechanical carrying is not needed, and the efficiency of machining and producing of the plate materials is greatly improved.

Owner:季元吉

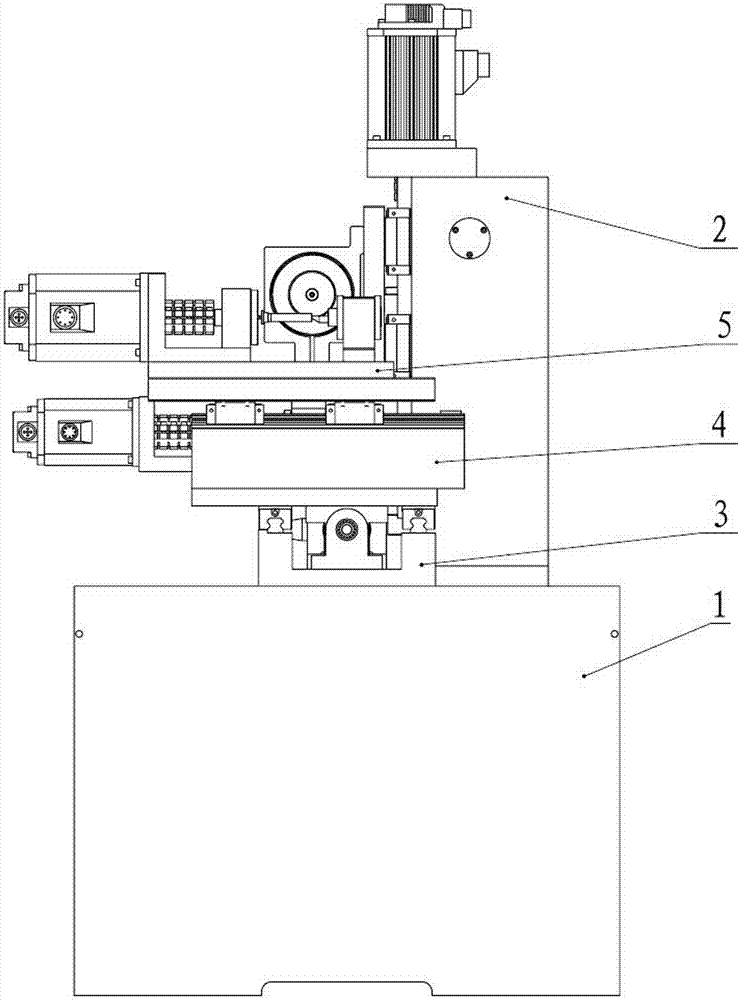

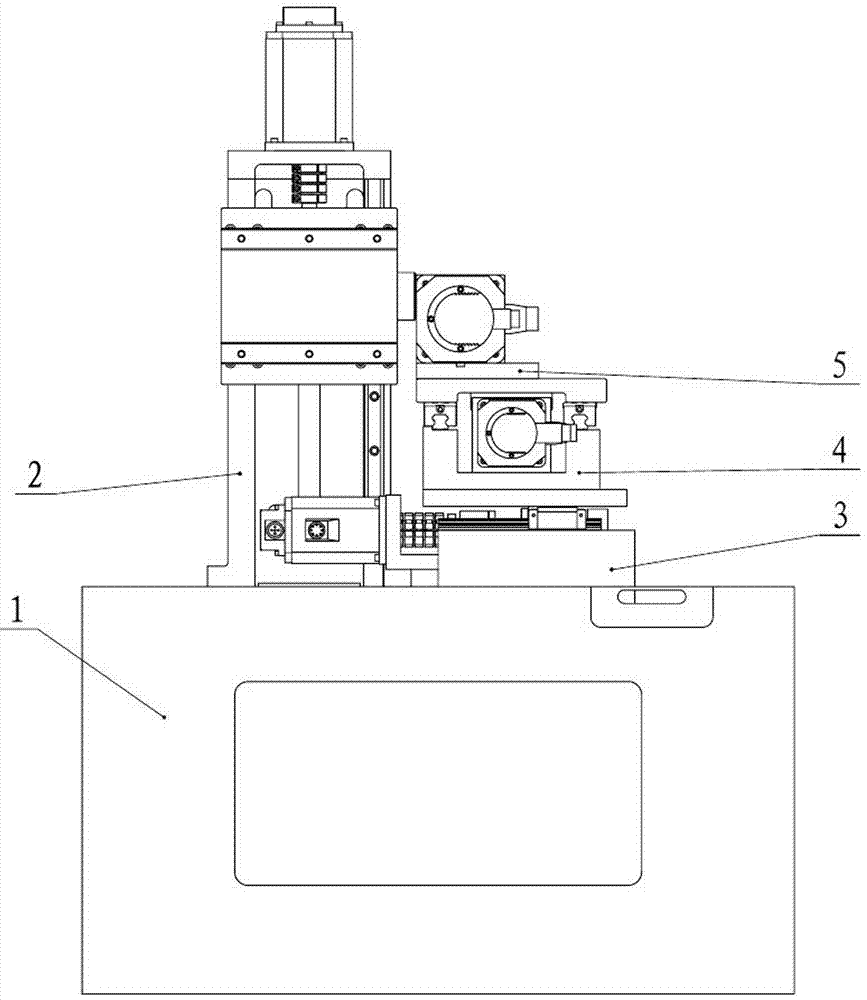

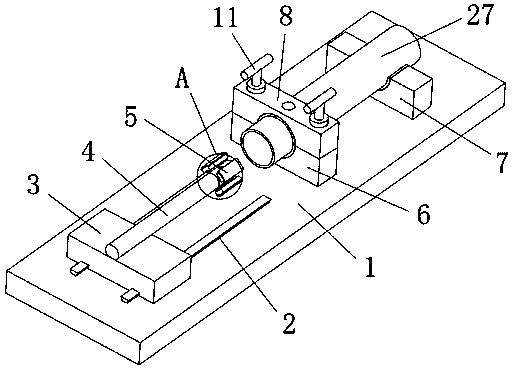

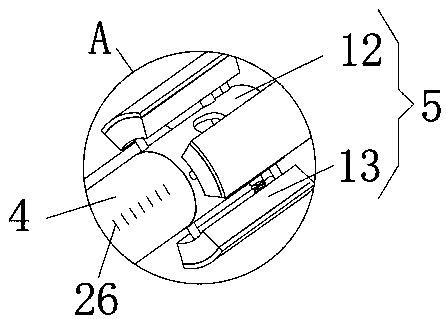

Numerical control mill groove machine tool

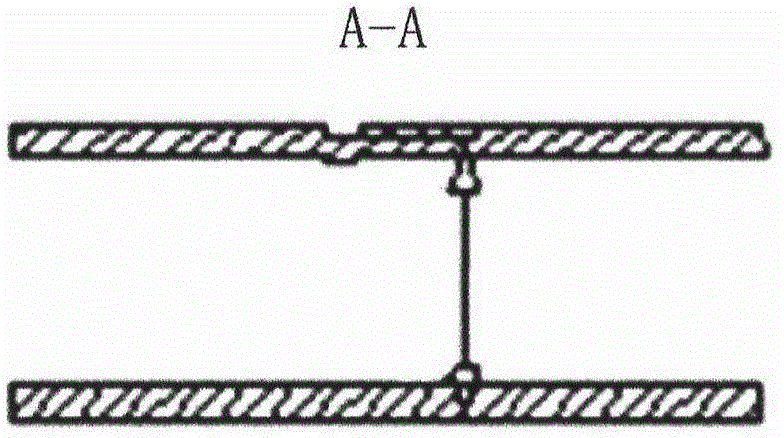

The invention discloses a numerical control mill groove machine tool, and relates to a mechanical product precision machining device, in particular to a numerical control machine tool for processing different standard straight channels on a precise outer cylindrical surface. The numerical control mill groove machine tool comprises a tool body, a lifting moving part unit, a moving forward and back part unit, a moving left and right part unit and a rotary jig part unit, wherein the lifting moving part unit is installed on the upper portion of the tool body, the moving forward and back part unit is installed on the upper portion of the tool body, the moving left and right part unit is installed on the upper portion of the moving forward and back part unit, and the rotary jig part unit is installed on the upper portion of the moving left and right part unit. The numerical control mill groove tool is matched with a numerical control unit. The numerical control unit comprises a computer numerical control (CNC) system part, a servo driving part and a relative relay. By the adoption of a numerical control machining tool and a combined abrasive tool grinding wheel structure, straight channels with different length and different width are processed by clamping one time, and all the process requirement indicators of component drawings are met.

Owner:江苏瑞普机床有限公司

Special energy-saving and environment-friendly paint spraying machine capable of conducting drying and used for floor machining

PendingCN106733377AScientific and reasonable structureSafe to useLiquid surface applicatorsCoatingsElectric heatingEngineering

The invention discloses a special energy-saving and environment-friendly paint spraying machine capable of conducting drying and used for floor machining. The special energy-saving and environment-friendly paint spraying machine comprises a paint spraying box, a sprayer, a machine case, a paint pump and a suction fan. Supporting feet are arranged on the lower surface of the machine case. A case door is arranged on the front surface of the machine case. The part, close to the right end of the upper surface of the paint spraying box, of the right side of the suction fan is provided with an electric fan. The sprayer is arranged above the interior of the paint spraying box. The paint pump, a servo motor, an electric heating wire, the electric fan and the suction fan are electrically connected with a control panel. The special energy-saving environment-friendly paint spraying machine is scientific and reasonable in structure, safe and convenient to use, easy to operate and fast and convenient in work; a filter and the suction fan are arranged, smelly gases emitted by floor paint can be filtered and purified so that air cannot be polluted, and environment friendliness is achieved during using; meanwhile, the electric fan and the electric heating wire are arranged, integrated floor paint spraying and drying can be achieved, accordingly, time and labor force are saved, energy is saved during using accordingly, and the floor machining and producing efficiency is effectively improved.

Owner:天津浩华民生科技发展有限公司

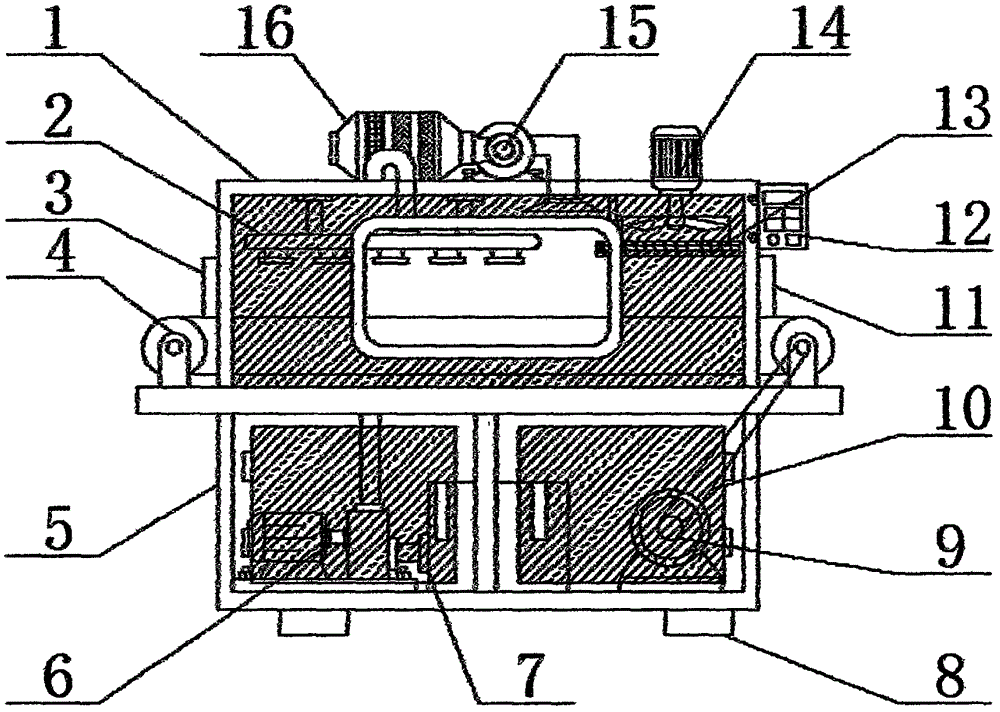

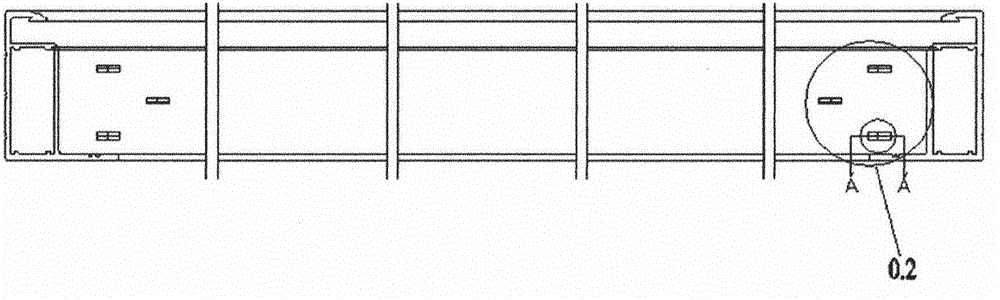

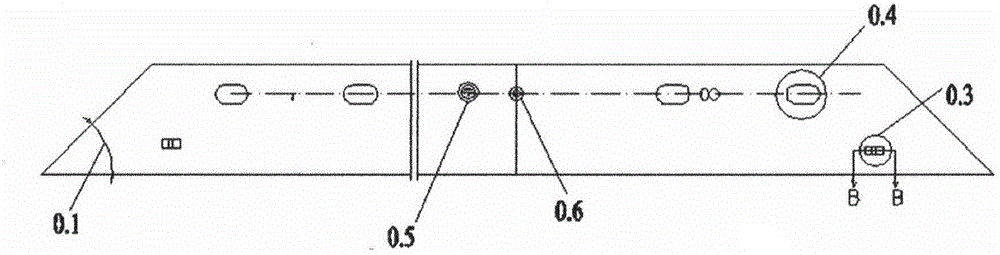

Flexible automatic machining unit of photovoltaic module aluminum frame

ActiveCN104924091AImprove consistencyQuality improvementShaping toolsOther manufacturing equipments/toolsPhotovoltaic industryControl system

The invention discloses a flexible automatic machining unit of a photovoltaic module aluminum frame, and relates to the technical field of manufacturing related photovoltaic module aluminum frame in the photovoltaic industry. A feeding system, a blanking system, an angle code pressing system, a water falling hole stamping system, a mounting hole and landmark stamping system, a material supplying system and a hydraulic system are all connected with a control system; and the hydraulic system, the angle code pressing system, the water falling hole stamping system and the mounting hole and landmark stamping system are connected with a hydraulic execution part through hydraulic pipelines. The flexible automatic machining unit is good in product consistency, high in precision, and good in quality; a mould replacement process is simple and efficient; and the unit is high in automation level, high in machining production efficiency and low in manufacturing cost.

Owner:山东金博利达精密机械有限公司

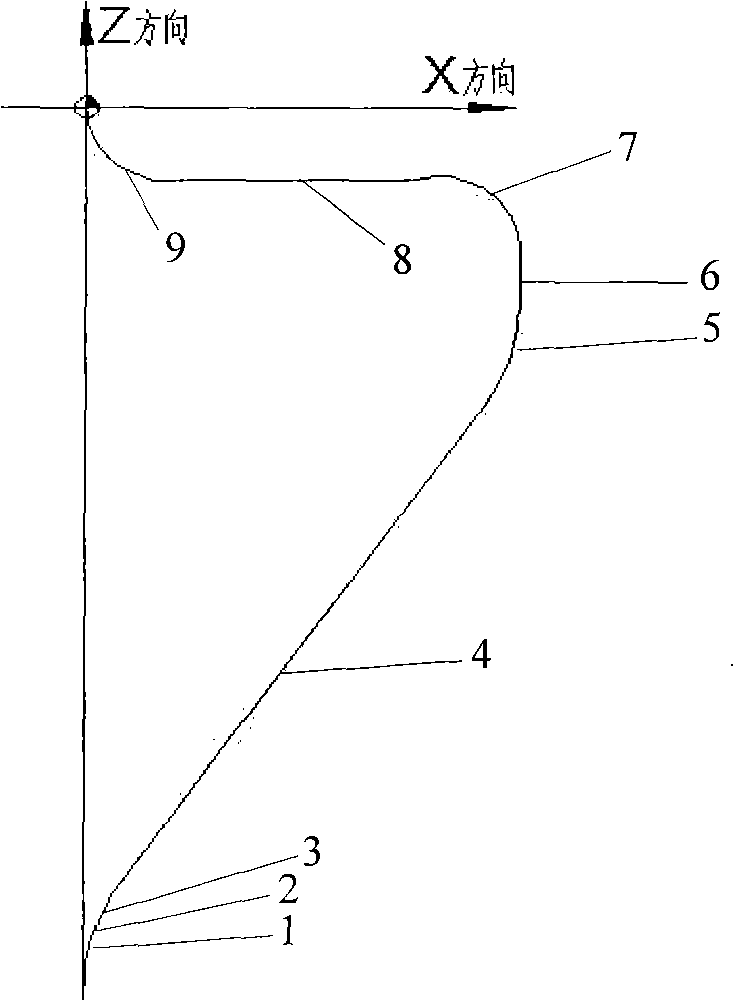

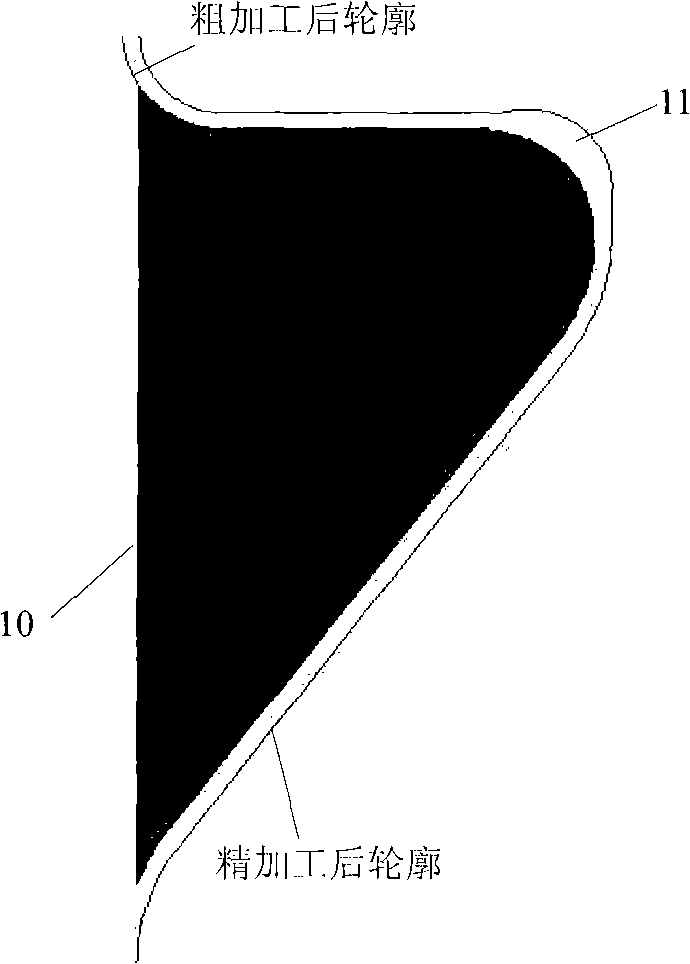

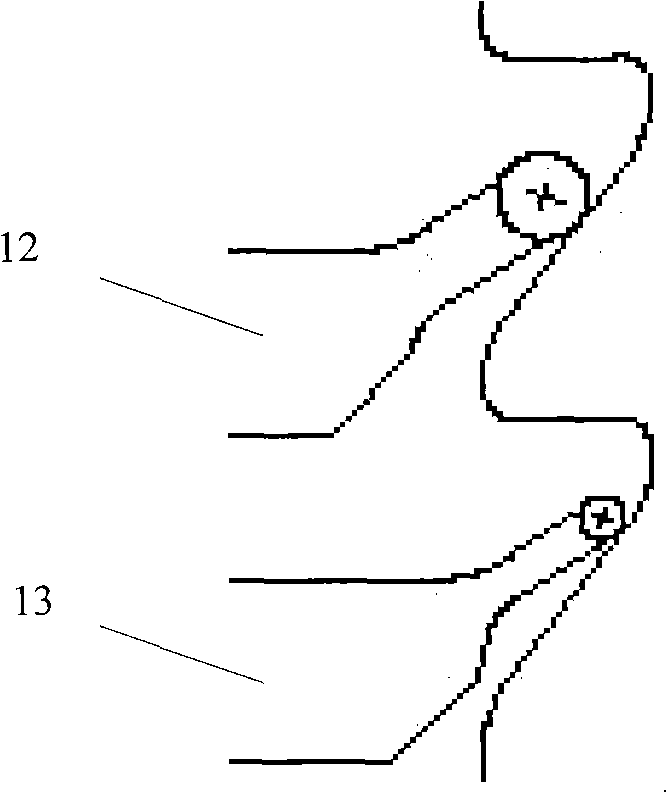

Giant non-standard trapezoidal thread processing method

ActiveCN101266476AImprove processing productivityImprove processing quality and precisionNumerical controlProcessing accuracyHigh pressure

The invention relates to a processing method of high-pressure exterior cylinder component of million grade super critical steam turbine, especially to a processing method of S2099*P50 giant nonstandard trapezoidal thread. A processing method of giant nonstandard trapezoidal thread uses a numerically controlled machine to execute processing, which is carried out according to the following sequences: executing mathematics modeling to the screw thread type wire; using coarse and fine processing methods, determining suitable radius lathe cutters respectively adopted by the coarse and fine processing methods according to required processing wire and required surface accuracy and roughness concentration, and determining suitable deepness allowance of the line face after the coarse processing; determining the coarse processing lathe cutter center track area and the fine processing lathe cutter center track area, and modeling for the cutter center track boundary; determining spacing of every layer during processing and spacing of every cutter in a same layer according to the material to be cut, the selected cutter, machine performance and cutting position; programming the coarse and fine processing lathe cutter walking procedure; and executing the process according to the programmed procedure. The inventive processing method has high process efficiency and high machine precision.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

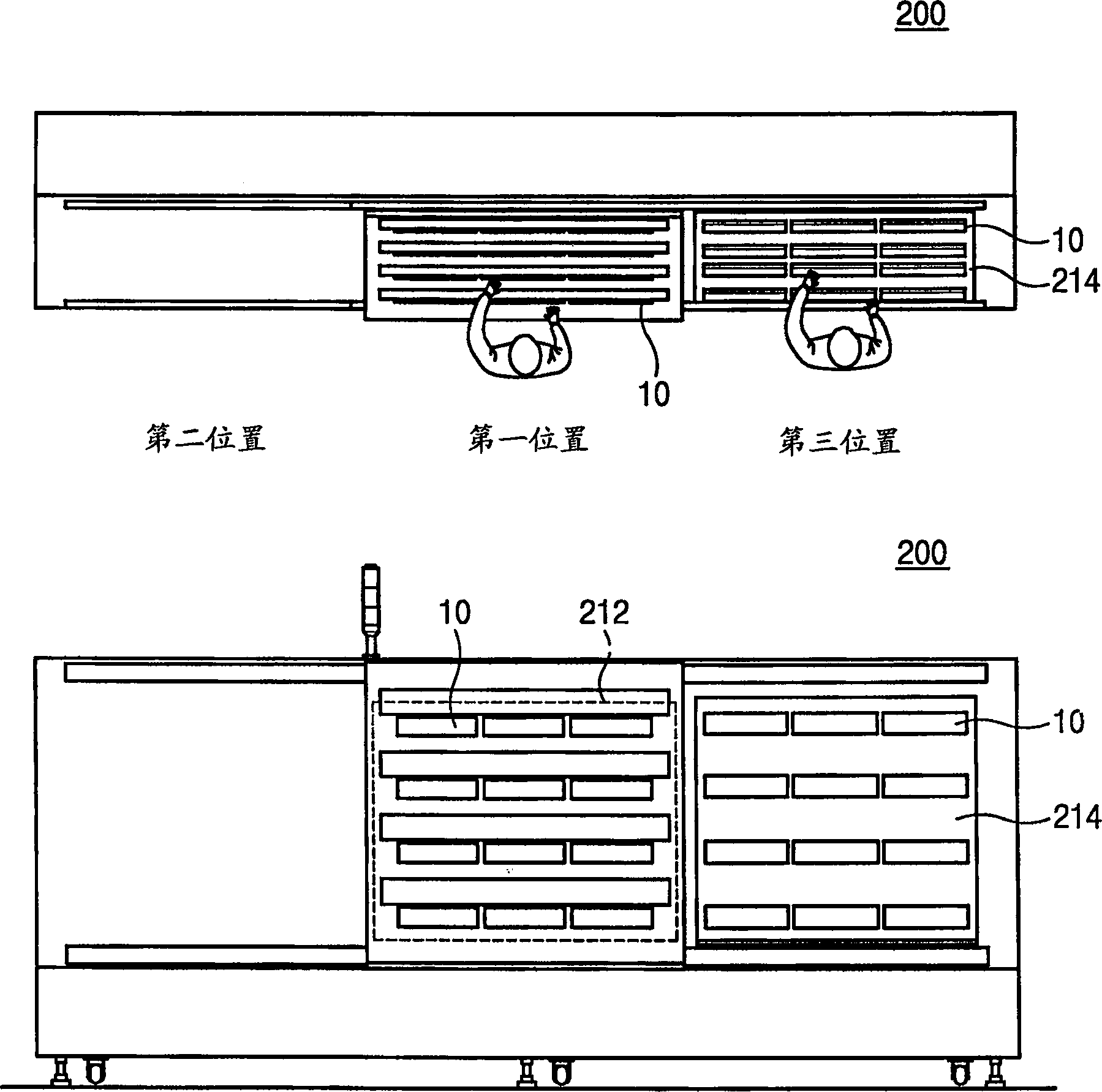

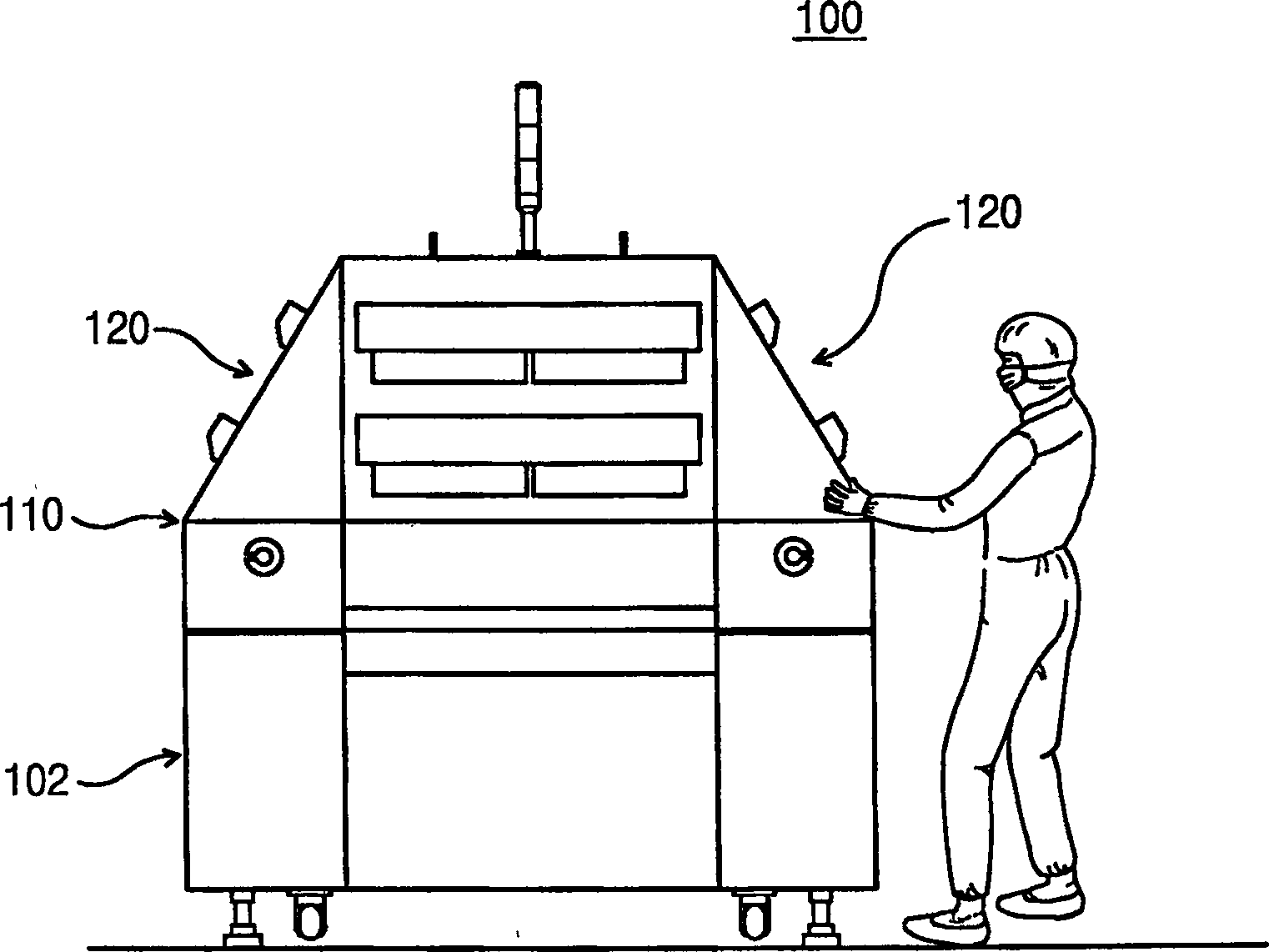

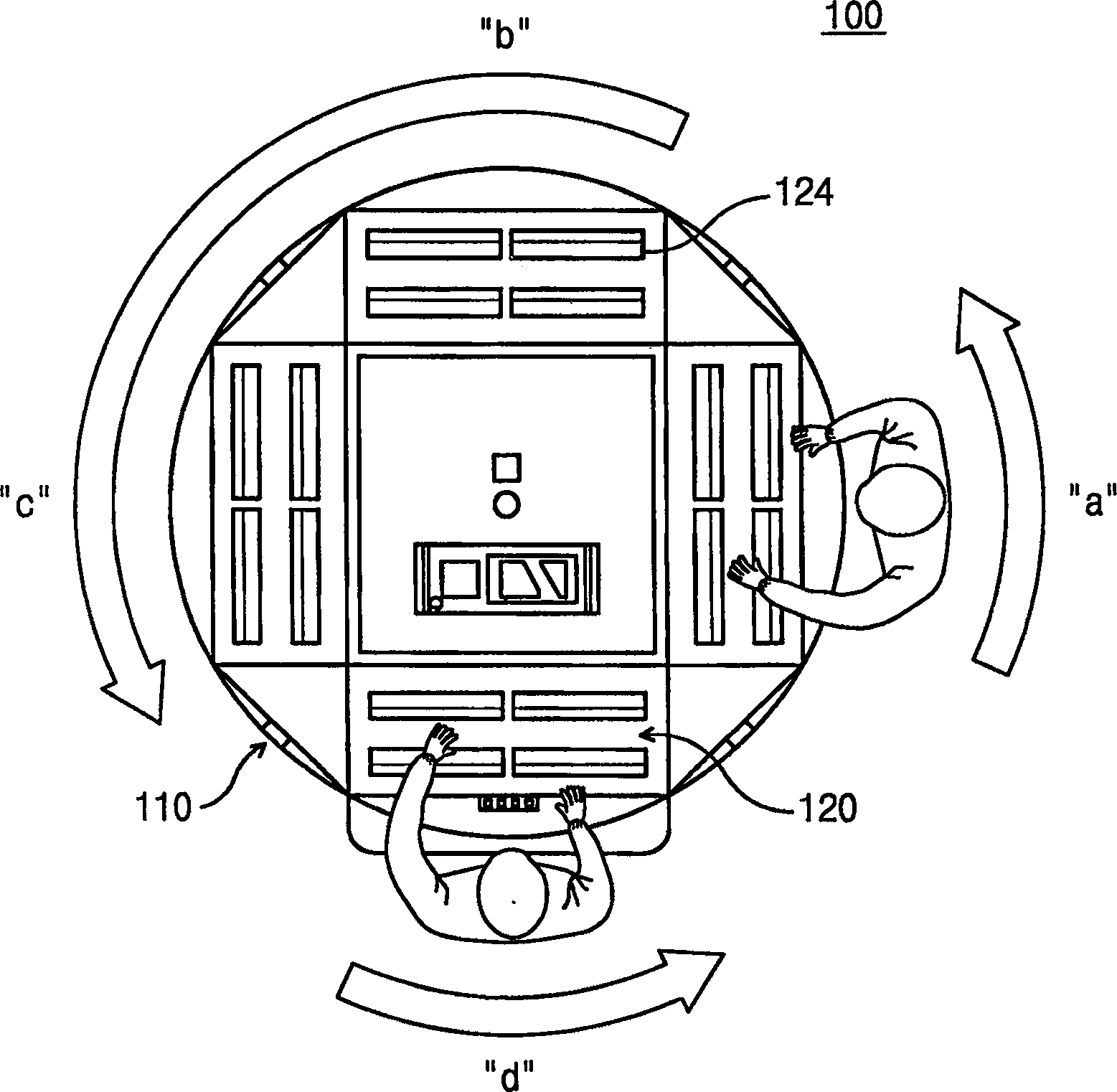

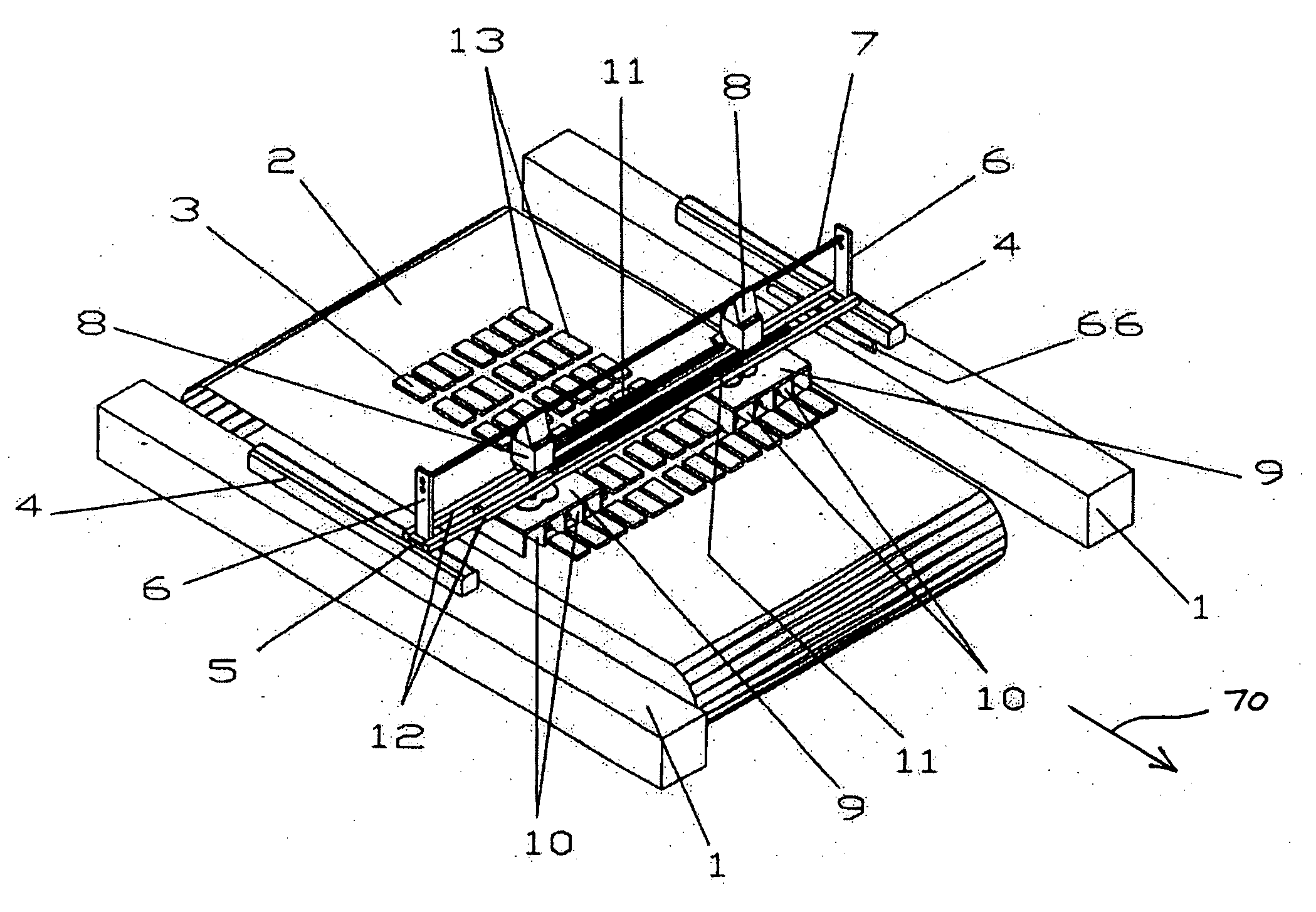

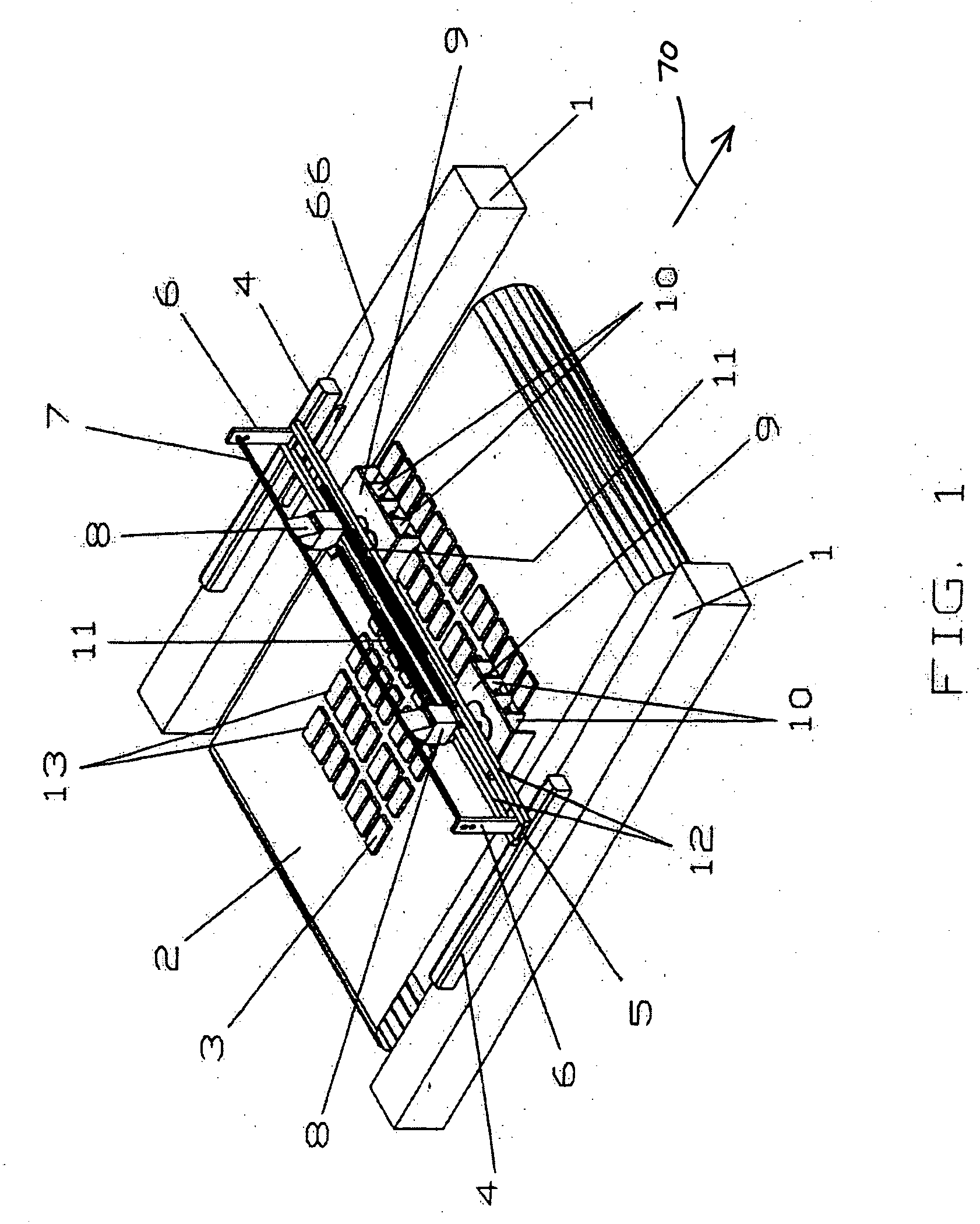

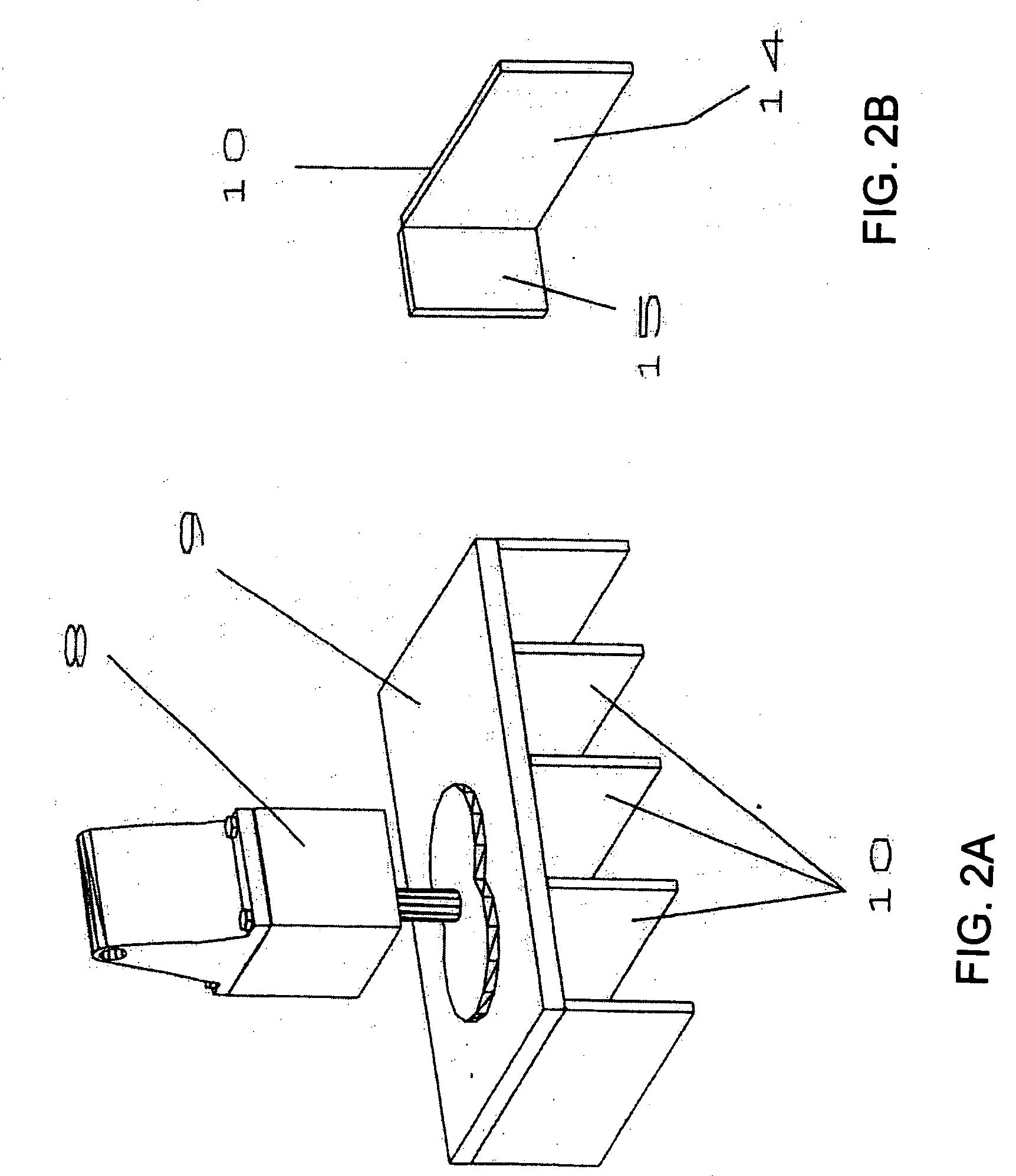

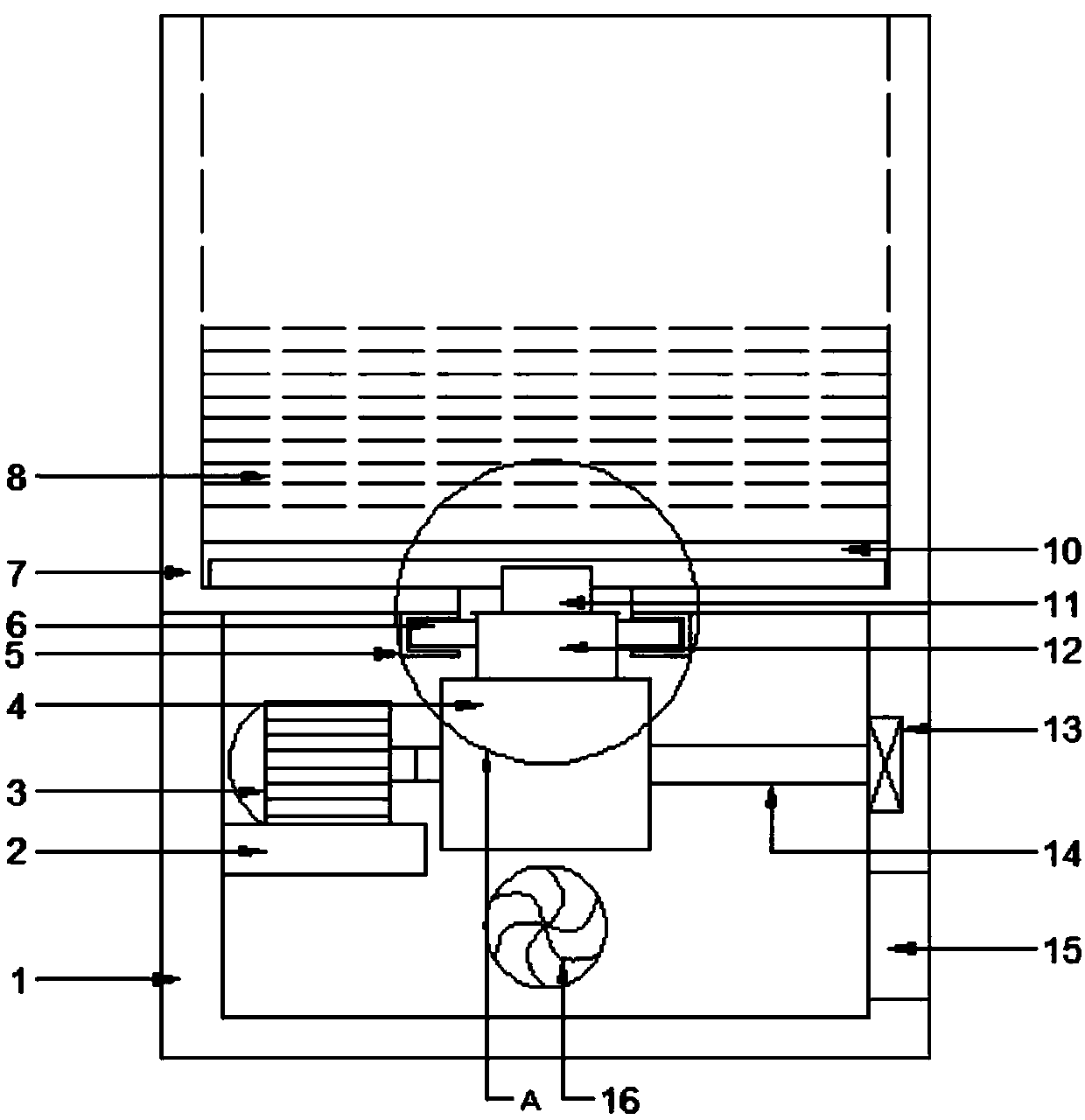

Rotation-type display panel testing device and display panel testing method using the same

InactiveCN1873744ASmall sizeReduce fatigueStatic indicating devicesSemiconductor/solid-state device manufacturingProduction rateDisplay board

The invention relates to rotary measuring device for display board, comprising rotary table installed on chassis and measuring unit installed on said rotary table for measuring display board. The rotary table rotates with regular angle and said measuring units are mounted around rotary axis of rotary table with their regular angle. The display board can be measured continuously by using said device, so the productivity is improved.

Owner:PHICOM CORP

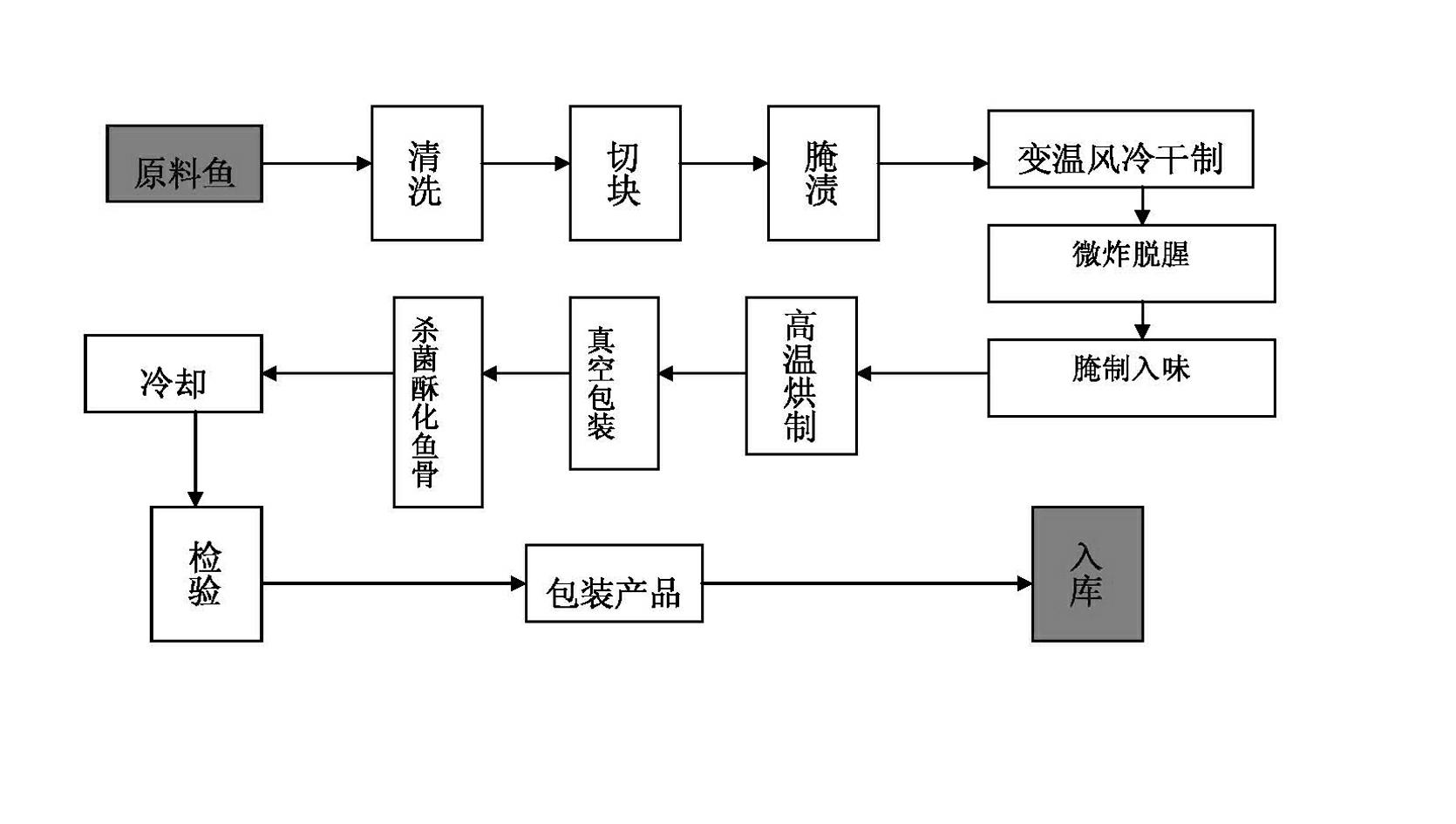

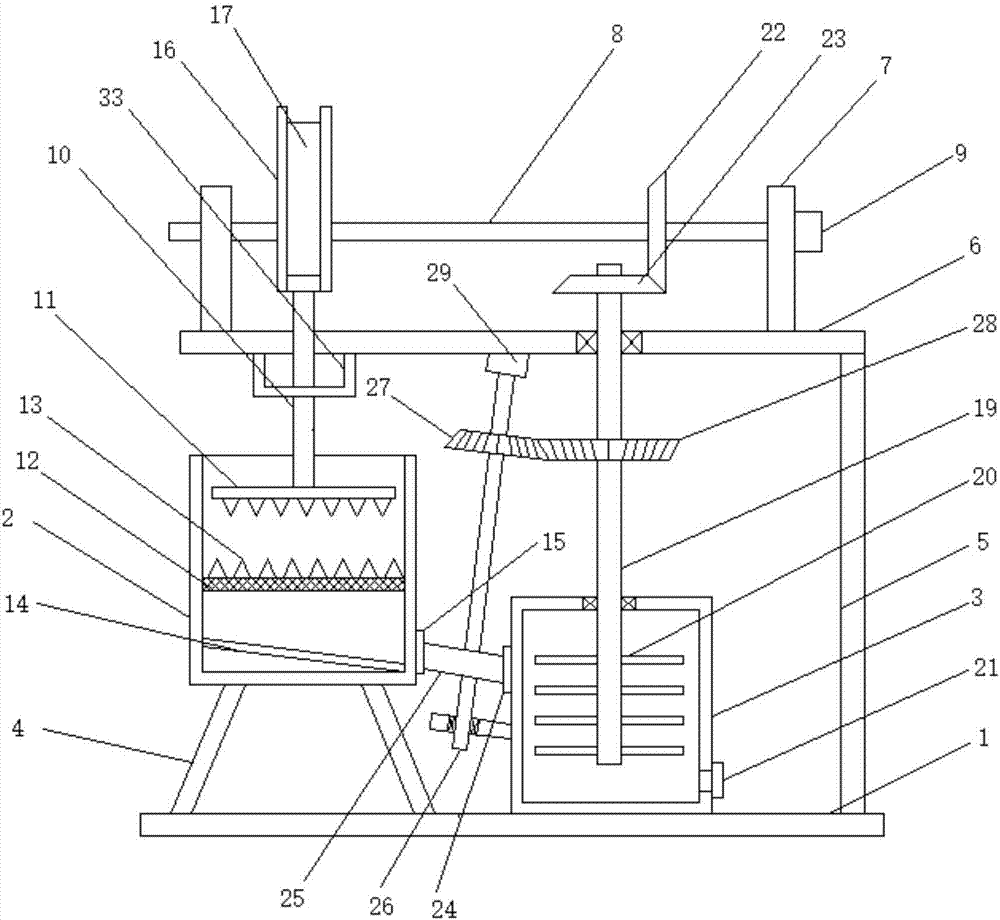

Instant hand-ripped fish and preparation method of instant hand-ripped fish

The invention relates to instant hand-ripped fish and a preparation method of the instant hand-ripped fish. The instant hand-ripped fish is characterized in that a basic production process is completed through raw material fish preparation, pickling, variable-temperature air cooling drying, slight frying deodorization, pickling for taste enhancing, vacuum package, fish bone sterilization and crisping and outer package. The color of the produced instant hand-ripped fish is shallow brown, the fragrance is intense, and the fish is crispy but not mushy and can be directly eaten through being ripped into small blocks by hand. The invention also provides a processing method of the instant hand-ripped fish with the advantages that the eating is safe, no any additives are added, the quality guarantee period can reach more than 180 days, and all of the color, the fragrance and the taste are good.

Owner:佛山六奇食品科技有限公司

Integrated crushing, stirring and mixing device for construction coating particles

InactiveCN107442031AAvoid affecting useMix in timeTransportation and packagingMixer accessoriesDrive shaftArchitectural engineering

The invention discloses an integrated crushing, stirring and mixing device for construction coating particles, which comprises a bottom plate, a crushing groove and a mixing box, wherein a driving shaft is mounted on a support rack; one end of the driving shaft is connected with a driving motor arranged on the support rack; a vertical upward pressure rod is arranged at a port of the crushing groove; a crushing pressure plate is arranged at the lower end of the pressure rod; a sieve plate is arranged in the crushing groove; a material inlet is formed in a side wall, close to the crushing groove, of the top end of the mixing box, and connected with a material outlet by a material guide channel; a stirring shaft is arranged in the crushing groove; the upper end of the stirring shaft is connected with the driving shaft by a gear mechanism; a plurality of stirring and mixing rods arrayed in a circular ring manner are arranged at the lower end of the stirring shaft; and a discharge port is formed in a side wall of the bottom end of the mixing box. The device is simple in structure, higher in processing and production efficiency, better in linkage, stable in transmission, uniform and sufficient in mixing, easy and simple to operate and higher in practicability, and can simultaneously perform crushing and mixing.

Owner:林红英

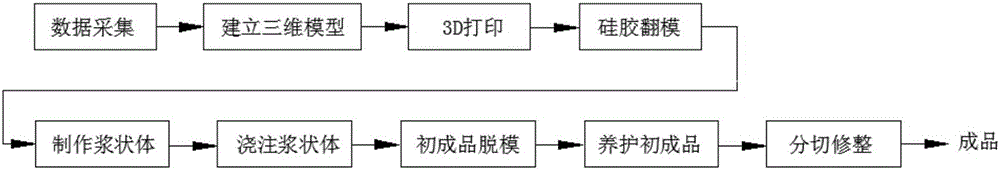

Formula of antique facing black brick and production method of formula

InactiveCN105906287AReduce dosageEnhanced Antique ColorsAdditive manufacturing apparatusCeramic shaping apparatusFiberBrick

The invention relates to a formula of an antique facing black brick and a production method of the formula. The formula consists of the following raw materials in percentages by weight: 92-96% of cement paste, 2.5-5.5% of a coloring agent, 0.2-0.4% of an anti-ageing agent, 0.6-0.8% of an early strength agent, 0.2-0.4% of a nano plasticizer, 0.1-0.3% of a water reducing agent, and 0.4-0.6% of fibers. Compared with the prior art, the formula of the antique facing black brick takes cement as a main material, is simple in ingredient, effectively reduces the cost, and is high in strength, not easy to damage and lifelike in antique effect.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Parallel multi-turntable numerical control clamp

InactiveCN104084816AImprove CNC Machining Production EfficiencyRealize clampingWork clamping meansLarge fixed membersBatch productionWorm drive

The invention discloses a parallel multi-turntable numerical control clamp. The parallel multi-turntable numerical control clamp comprises a clamp body and a rotating mechanism, wherein the clamp body adopts a U-shaped structure; the rotating mechanism which controls turntables to rotate is mounted on one side of the clamp body of the U-shaped structure; a second rotating shaft and a bearing which support the turntables to rotate are mounted on the other side of the clamp body of the U-shaped structure; the rotating structure comprises a servo motor; an output shaft of the servo motor is connected with a worm; the worm is erected on one side of the clamp body through a pair of bearing seats; the other end of the worm is fixed with a pulse encoder; a plurality of first rotating shafts are mounted on the side wall of the side, provided with the worm, of the clamp body; worm wheels matched with the worm are mounted on the first rotating shafts; the other ends of the first rotating shafts are connected with second rotating shafts; the turntables are respectively mounted on each second rotating shaft in parallel. The invention discloses the numerical control clamp that a plurality of parallel turntables are controlled to rotate together through a precise worm wheel-worm transmission mechanism; a plurality of workpieces can be clamped; a plurality of working station surfaces can be machined; the machining efficiency of a numerical control machine tool is improved; the batch production capacity of the numerical control machine tool can be played.

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

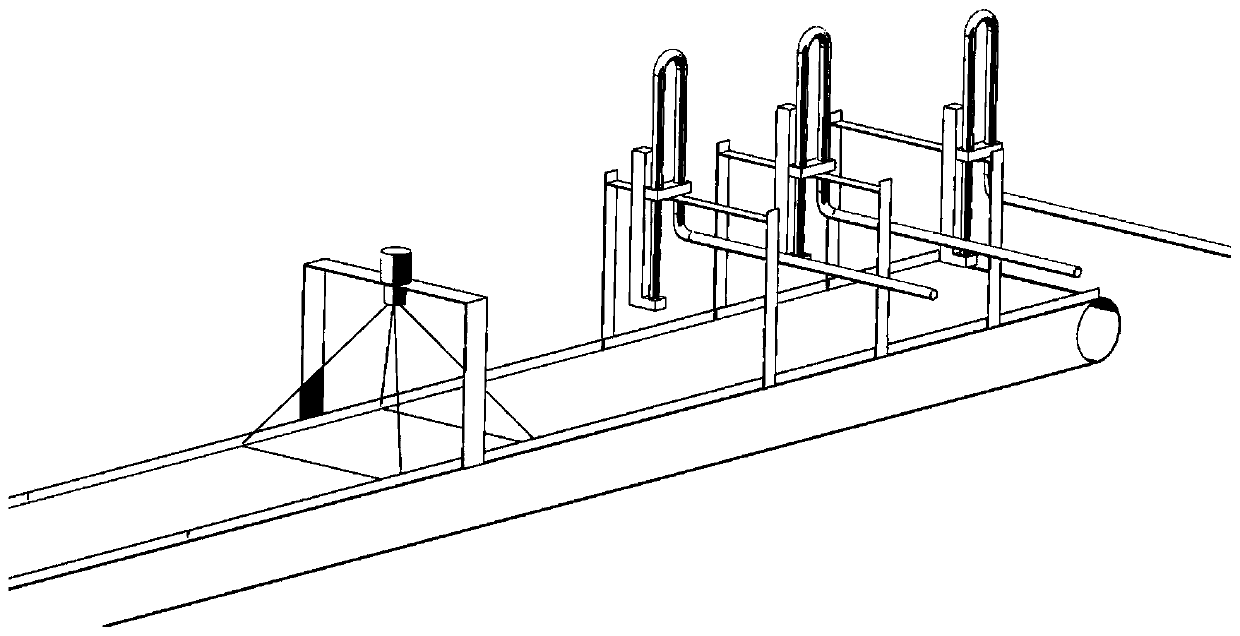

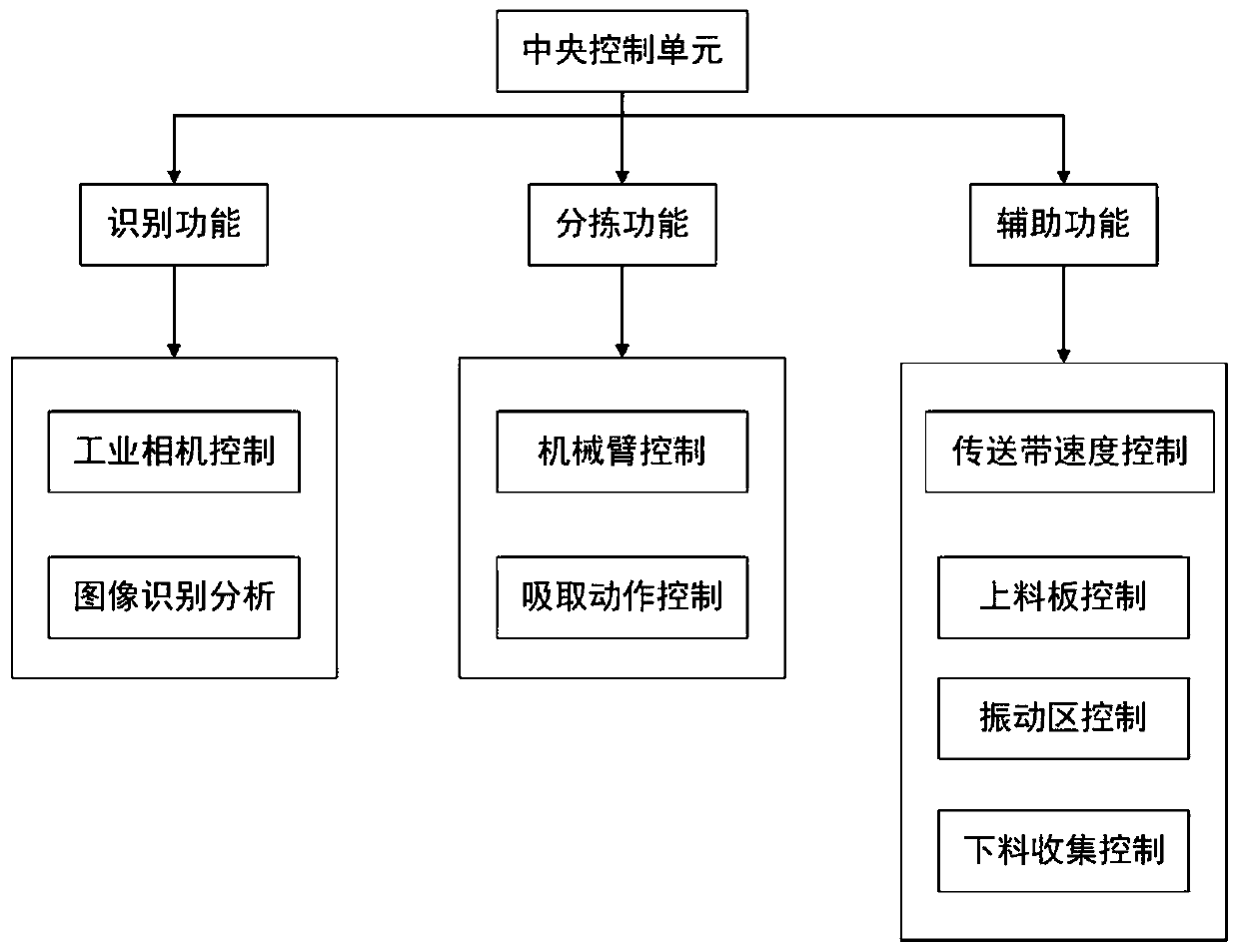

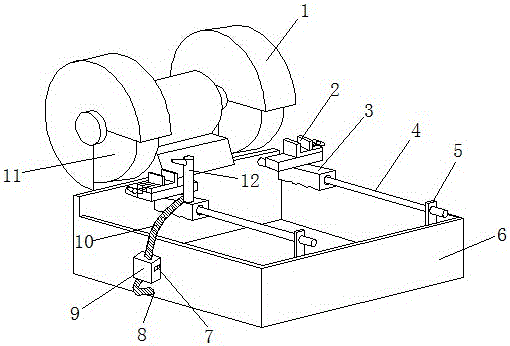

Foreign matter recognition and sorting device for quality inspection of dehydrated vegetable products and control method

The invention provides a foreign matter recognition and sorting device for quality inspection of dehydrated vegetable products and a control method, and belongs to the technical field of quality detection in the production process of dehydrated vegetables. According to the foreign matter recognition and sorting device for quality inspection of the dehydrated vegetable products and the control method, with computer vision and robot technology as the core, a dehydrated vegetable finished product foreign matter sorting line is formed by a fully-automatic feeding, discharging, sorting and collection device, and a sorting line system comprises a feeding area, a vibration uniform-distribution area, an image recognition area, a foreign matter removal area, a finished product collection area and adetection and control system. According to the foreign matter recognition and sorting device for quality inspection of the dehydrated vegetable products and the control method, the images of productsare acquired through the advanced visual sampling technique after the products are uniformly distributed, the acquired images are pre-processed, then foreign matter in the products is effectively recognized through a deep learning algorithm, and the foreign matter is grabbed by a multi-stage mechanical arm to be effectively removed according to recognized positioning information, so that high-intensity manual operation by workers is replaced, and efficient, low-cost and unmanned operation is realized.

Owner:UNIV OF SCI & TECH BEIJING

Grinder with cooling function

InactiveCN105773324ASimple structureWorking principle is clearGrinding carriagesPortable grinding machinesWater storage tankSpray nozzle

The invention discloses a grinder with the cooling function and belongs to the technical field of machining equipment. The grinder comprises a grinding machine which is composed of a grinding disc and a grinding machine housing, wherein a water storage tank body is arranged below the grinding machine; fixing blocks are arranged at the front end of the water storage tank body; a guide rod is arranged between each fixing block and the back end of the water storage tank body; a handheld handle is arranged on each guide rod; workpiece clamps and a water outlet nozzle are arranged on the corresponding handheld handles; the water outlet nozzle is formed behind one workpiece clamp; a water outlet is formed in the bottom end of one side of the water storage tank body; a water suction pump body is fixedly arranged above the water outlet on the same side; one end of the water suction pump body is connected with the water outlet; and the other end of the water suction pump body is connected with the water outlet nozzle. According to the grinder, the structure is simple, and the working principle is clear; with arrangement of a movable type clamp on the traditional grinder, the grinder has all the functions of the traditional grinder, the movable type clamp can also operated by replacing the traditional handheld type workpiece; and the design of a water outlet structure also ensures the cutter grinding process not to be influenced by burning hot of the workpiece, so that the metal mechanical properties of a ground part and the processing production efficiency are both improved.

Owner:DANYANG ZHENGLIAN INTPROP OPERATIONS MANAGEMENT CO LTD

Stainless steel tube drilling machining device

InactiveCN111266896AAffect qualityEffective protectionPositioning apparatusMetal-working holdersPipe fittingMachining

The invention discloses a stainless steel tube drilling machining device which comprises a base and a guide rail arranged on the base. The base is a rectangular slab. The guide rail is arranged at thefront end of the slab body. A sliding base is arranged above the guide rail. The sliding base is a rectangular platform and is slidably arranged on the guide rail through a guide rail groove formed in the lower surface. The sliding base is driven by a telescopic electric cylinder arranged at one end of the base, a supporting rod is fixedly welded to the upper surface of the sliding base, an innersupporting structure is arranged at the front end of the supporting rod, and a lower-position clamping base is arranged at the back side of the guide rail. Due to cooperative use of the inner supporting structure and an outer fixing structure, a steel tube to be drilled is internally supported through the interior of the steel tube. Compared with a traditional supporting structure for tube fixing, the phenomenon that due to excessively large exterior pressure, the tube to be fixed is extruded and deforms can be effectively avoided, and the phenomenon that due to excessively small clamping force, the tube offsets in the drilling process, and the drilling precision is affected can be effectively avoided.

Owner:宋鹏

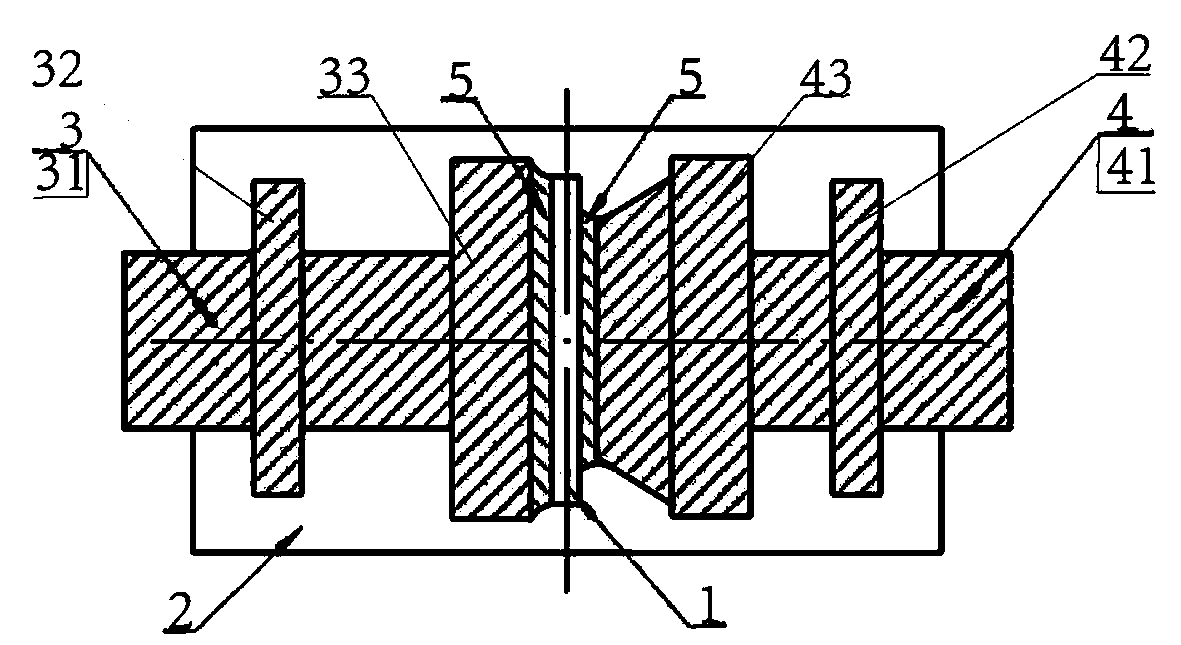

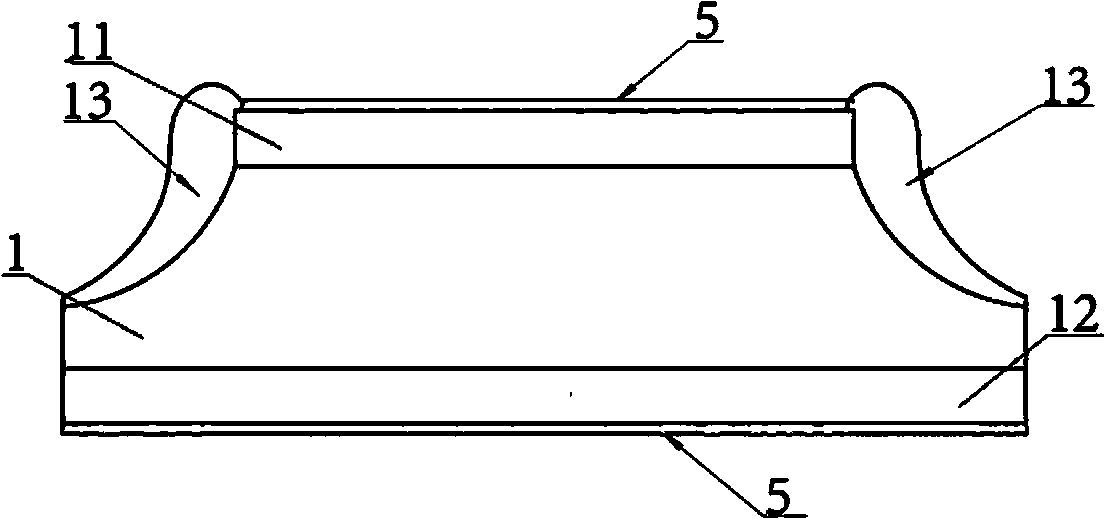

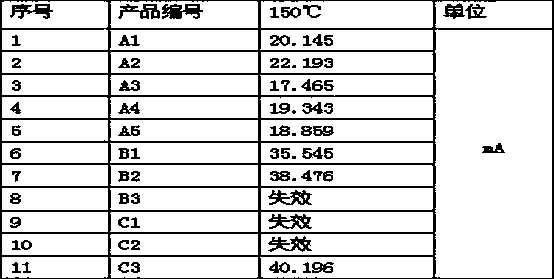

Novel photovoltaic diode and production process thereof

InactiveCN104112784AIngenious structureThe process is perfect and matureFinal product manufactureSemiconductor/solid-state device detailsEpoxyMode-locking

The invention relates to the field of a photovoltaic diode and specially relates to a novel photovoltaic diode and a production process thereof. The photovoltaic diode is ingenious in structure, perfect and mature in process, high in product processing and production efficiency, good in heat radiation of the product, low in temperature rise and long in service life. The advantages are that the photovoltaic diode is ingenious in structure, perfect and mature in process, high in product processing and production efficiency, good in heat radiation of the product, low in temperature rise and long in service life; epoxy resin is injected from the large nail head surface and recoiled to the surface of a chip, thereby reducing the impact on the chip to the largest degree and reducing injection molding stress effectively; in the product using process, the contact surface between the chip and leading wires is increased, and the heat produced by the chip can be dissipated quickly, thereby reducing chip junction temperature, prolonging the service life of the product, and improving the rectification efficiency; and the design of annular round plates on the leading wires of the photovoltaic diode plays a mode locking effect in the processing process, and the mechanical strength of the product is enhanced after injection moulding.

Owner:NANTONG HORNBY ELECTRONICS

Processing method of instant salted pork kidney

InactiveCN105166960AImprove processing productivityImprove qualityFood preparationPork KidneyHigh pressure

The invention discloses an instant salted pork kidney and a processing method thereof. A preparation process comprises the following nine steps of preparing a raw material pork kidney, pickling the pork kidney, rapidly cooling by air and drying, slightly frying to remove the odor, pickling the pork kidney to be tasty, salting, packaging in vacuum, sterilizing at high pressure and externally packaging. The produced instant salted pork kidney has light brown color and luster and rich aroma, is crispy and is not broken, and can be torn into suitable small blocks by hands or a cutter to be directly eaten.

Owner:刘富来

Automatic grouping system for food products

ActiveUS20070125239A1Increase bakery product capacityImprove productivityConveyorsCooking vesselsEngineeringLinear actuator

An automated grouping system of bakery products increases a quantity of bakery products that may be fed to equipment having a larger processing capacity. The automated grouping system includes a supporting structure laterally arranged adjacent to a conveyor of bakery products. The structure includes two longitudinally-arranged lateral rails. Sliding supports, along with first linear driving actuators of regulated stroke, are mounted on the lateral rails. Each sliding support includes a vertical post and a cross guide fixed at an upper portion thereof. The structure also includes a pair of second linear vertical actuators, which support and actuate a pair of pulling plates and positioning mechanisms of bakery products. The pulling plates are also actuatable by third linear actuators of regulated stroke, which are provided on a lower cross member, to position the pulling plates in a direction transverse to a conveying direction of the bakery products.

Owner:GRUPO BIMBO B DE C V

Continuous galvanizing flat knurling process

The invention relates to a continuous galvanizing flat knurling process. The process includes the following steps of (1) uncoiling, (2) welding, (3) degreasing, (4) drying, (5) annealing, (6) continuous galvanization, (7) cooling conducted after galvanization, (8) flat knurling, (9) withdrawal and straightening, (10) surface treatment, (11) coiling and (12) divided winding. Compared with the prior art, the process has the following advantages that the whole process is simple, operation is easy, additional investment of capital for additional arrangement of a knurling production device is not needed for the process, and a continuous galvanizing knurling process can be finished simply by properly adjusting an existing production line; the production efficiency of the whole process is high and a continuous galvanizing process and a flat knurling process are finished on the same production line at the same time; the field use requirements of the process are lowered and labor cost is reduced; the logistic process of a galvanized sheet is omitted through the process and logistic cost and loss are reduced; a continuous galvanized knurled sheet produced through the process is good in quality and is widely accepted by customers.

Owner:江苏江南精密金属材料有限公司

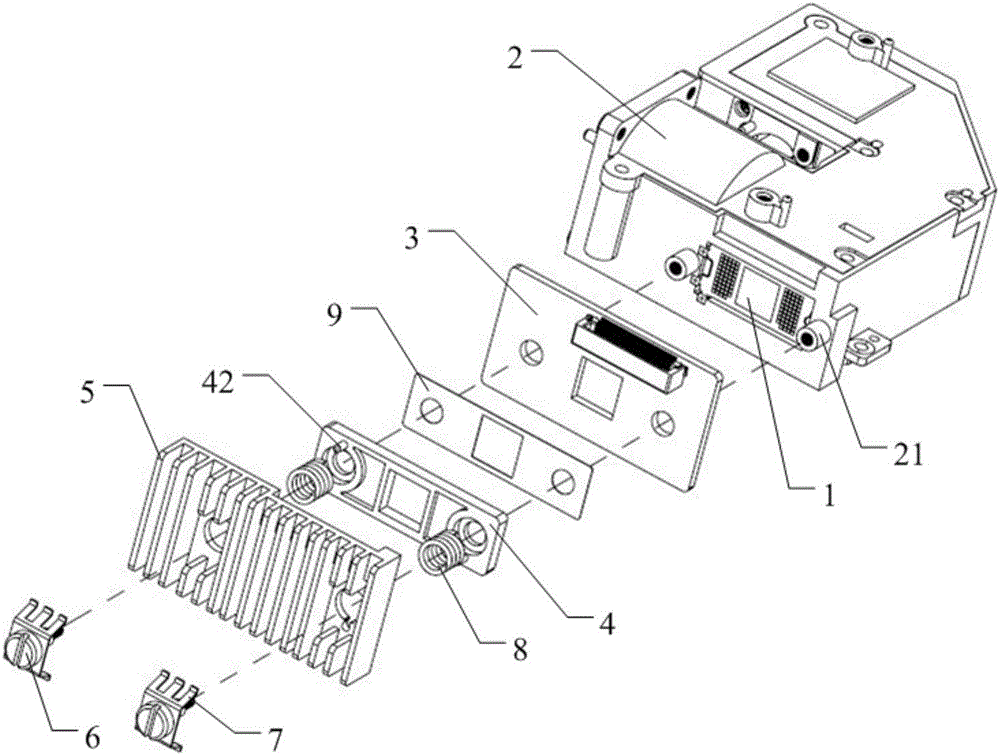

Plate conveyor belt type feeding device

InactiveCN108016865AFast feedingImprove processing productivityConveyorsDe-stacking articlesDrive motorConveyor belt

The invention discloses a plate conveyor belt type feeding device which comprises a drive box; a heat dissipation hole is formed in the back side of the drive box; a maintenance door is arranged on the right side wall of the drive box; a drive motor is arranged on the inner wall of the left side of the drive box; a drive rod is fixed on a motor shaft of the drive motor and is fixed with a drive drum; the drive drum is connected with a follow-up pulley through a conveyor belt; the conveyor belt is fixed with a slideway base; sliding blocks which are fixed on the two sides of the slideway base respectively are clamped into chutes respectively; the chutes are fixed on the two sides of the center of the bottom of a material box respectively; a plurality of plates are stacked in the material box; a push plate slideway is arranged at the middle part of the bottom of the material box; material push holes are formed in the bottoms of the front side wall and the back side wall of the material box respectively; and a push plate is fixed on the top of the sliding base. For the plate conveyor belt type feeding device provided by the invention, by utilizing the conveyor belt to drive the push plate to perform circulation movement at the bottom of the material box, the plates are pushed out of the material box one by one, and the plate feeding speed is increased; and without man-powered andmechanical transportation, the plate processing and production efficiency is greatly improved.

Owner:季元吉

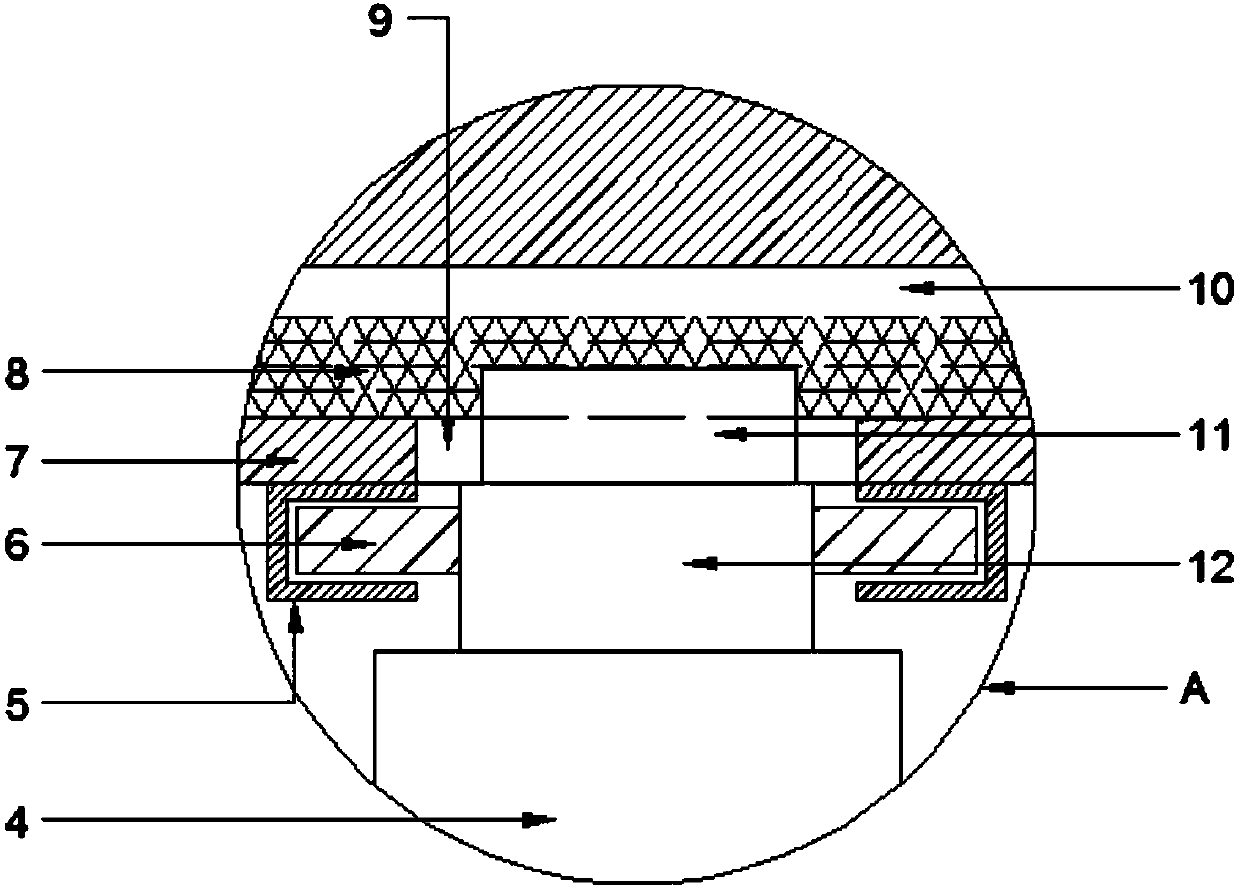

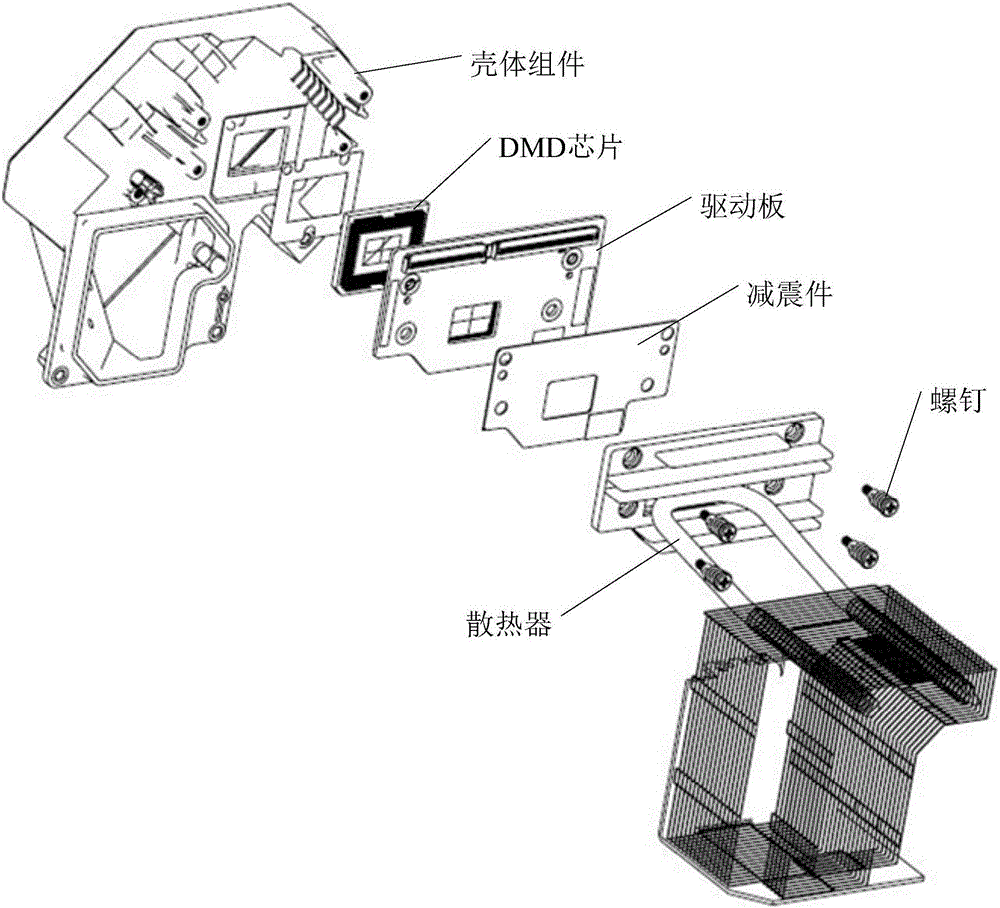

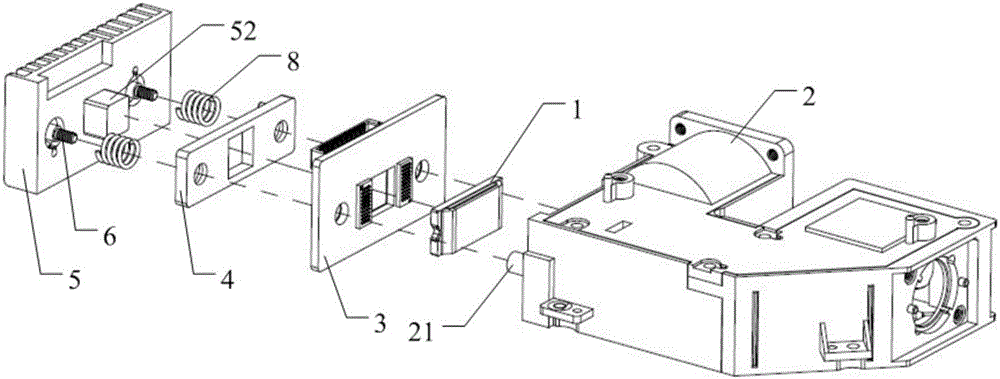

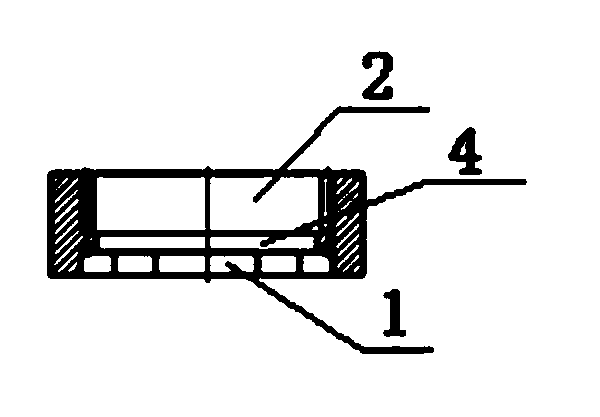

DMD module, DLP machine and DLP projection device

InactiveCN106647121AEvacuate in timePoor contactProjectorsOptical elementsHeat spreaderComputer engineering

The invention relates to the field of optical and projection technology, and more particularly to a DMD module, a DLP machine and a DLP projection device. The DMD module includes a DMD chip, a main housing, a driving plate, a fixing member, a radiator and a connecting member. The radiator includes a radiating block. Through holes are disposed in the fixing member and the driving plate. The DMD chip is fixedly mounted on the main housing, the connecting member is connected to the main housing through the radiator, the fixing member and the driving plate in sequence, and the radiating block is in contact with the back surface of the DMD chip through the through holes in the fixing member and the driving plate. A spring piece is disposed between a stopper portion of the connecting member and the radiator, a spring is disposed between the stopper portion of the connecting member and the fixing member, and the spring passes through the radiator. Therefore, the invention can radiate the heat generated by the DMD chip in time, and ensure the contact accuracy and stability between the DMD chip and the driving plate, thereby improving the quality of a final output image.

Owner:HISENSE

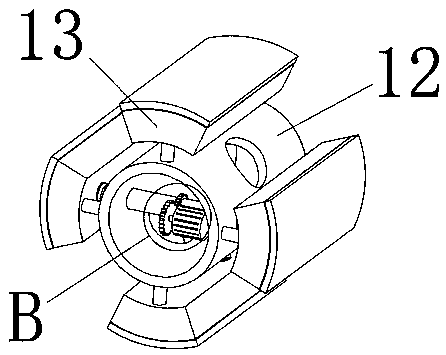

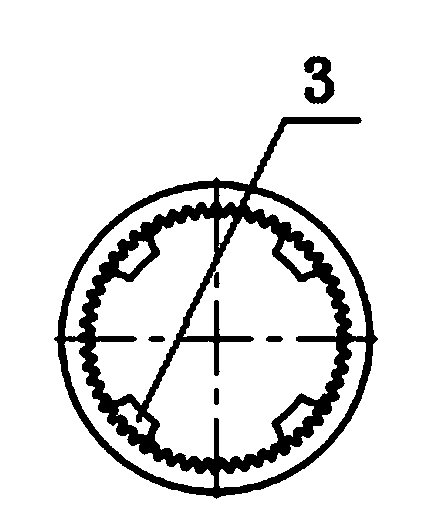

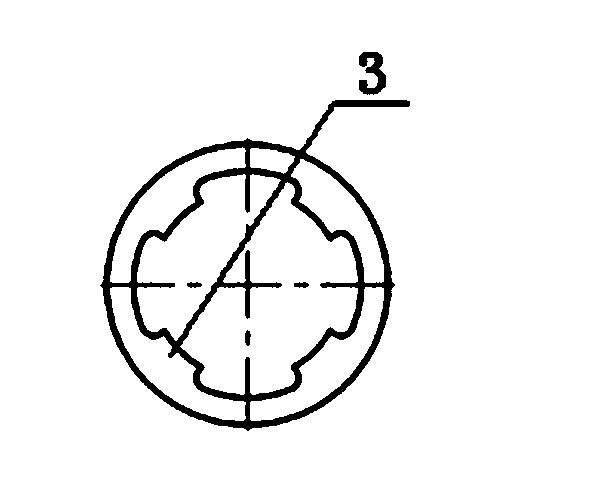

Precision forging and plastic molding process for inner toothed ring of winch

ActiveCN103624506AMeet the needs of useImprove processing productivityWheelsSurface strengthPlastic molding

The invention discloses a precision forging and plastic molding process for an inner toothed ring of a winch. The process comprises the following steps: (1) hot forging and plastic molding: heating a solid cylindrical metal blank material to a forging temperature, and die-forging to form an assembling end and a preserved extrusion inner toothed blank material, wherein the two end surfaces of the assembling end and the preserved extrusion inner toothed blank material are sunken inward, share the same bottom and form blind hole structures respectively; (2) machining to remove the bottom to form a through hole structure, wherein the part corresponding to the bottom is called the combination part of the assembling end and the preserved extrusion inner toothed blank material; (3) cold forging and plastic molding: in a cold forging molding female die, die-forging the inner wall of the preserved extrusion inner toothed blank material or the inner wall of the combination part of the assembling end and the preserved extrusion inner toothed blank material by utilizing a tooth-shaped die to form the tooth form of an inner tooth. The process is high in production efficiency and low in production cost; the produced product has high tooth-shaped surface strength and high precision; particularly, the extruded product quality is stable; the comprehensive mechanical property is high; the requirement on the use of the winch of crane equipment can be met; the process is accordance with the development trend of the manufacturing industry of the present world.

Owner:江苏威鹰机械有限公司

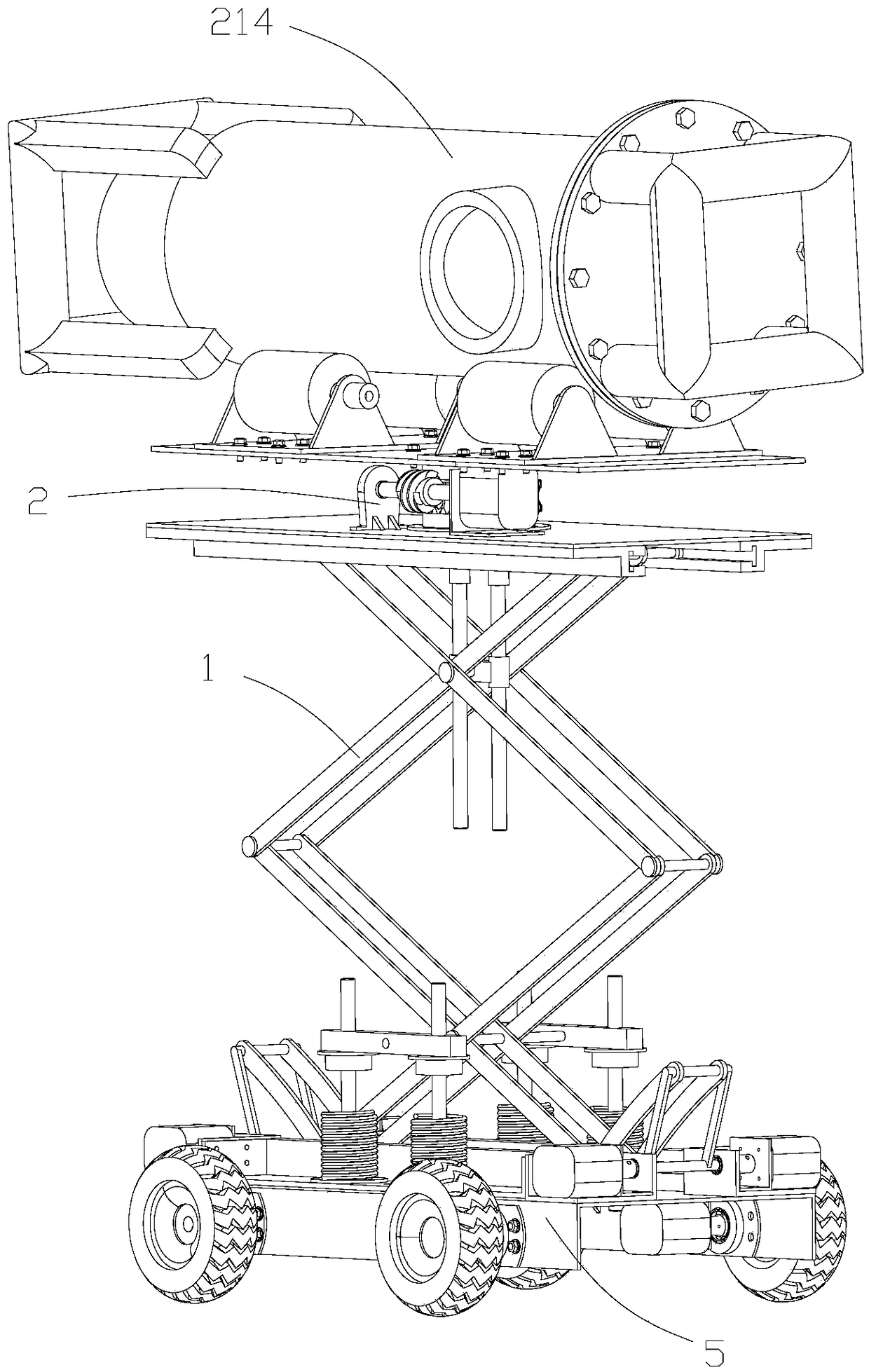

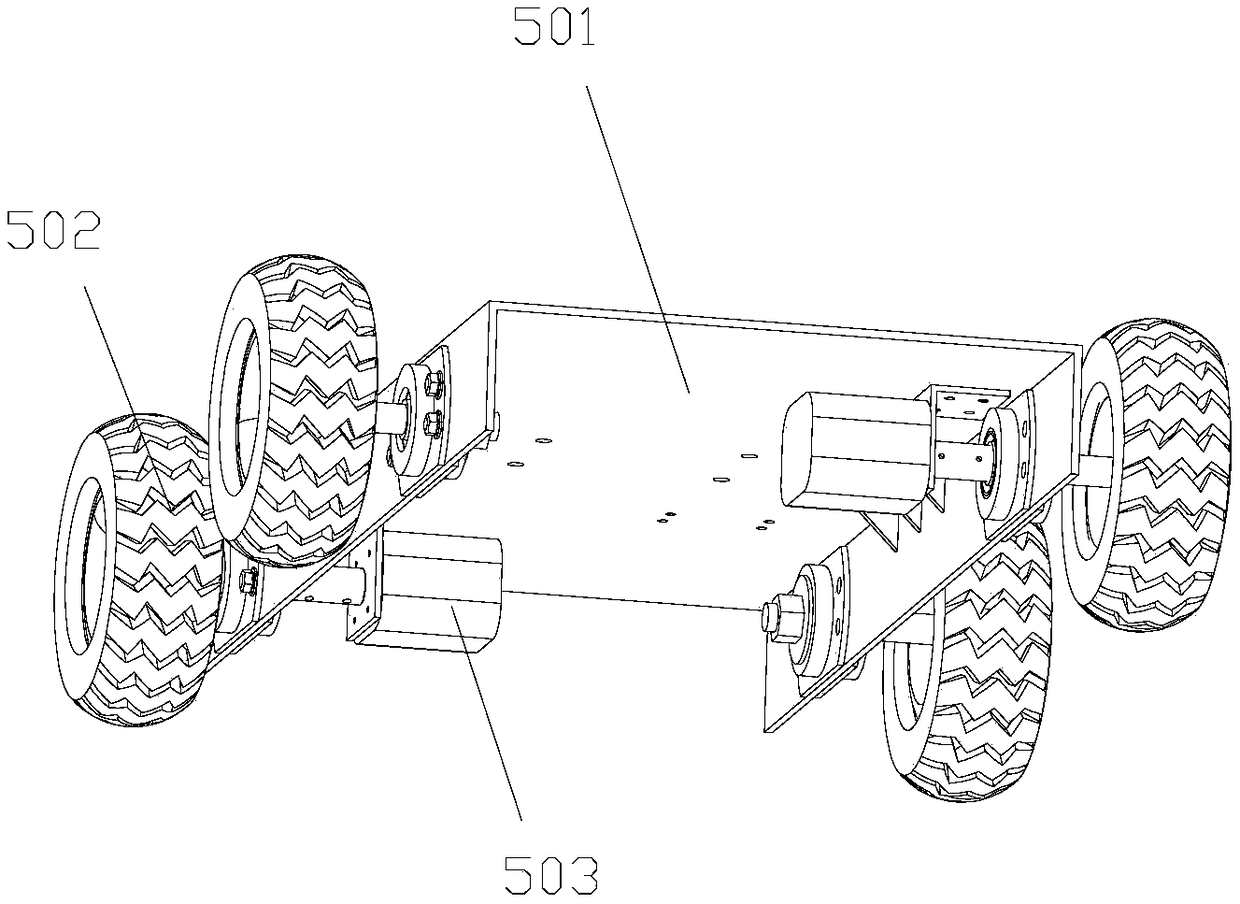

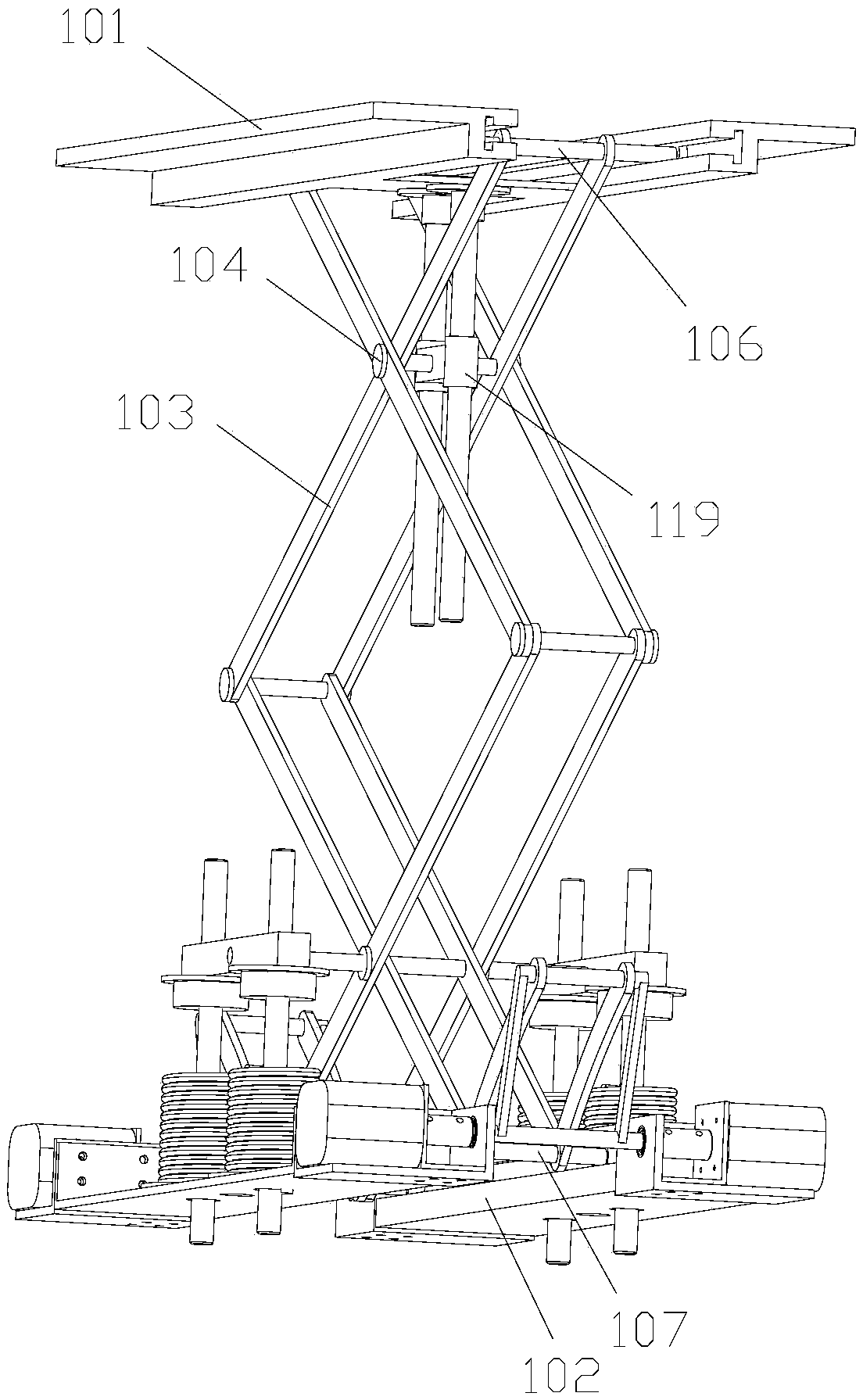

Radiographic inspection robot

ActiveCN109250646AReduce labor intensityImprove work efficiencyLifting framesManipulatorEngineeringMechanical engineering

The invention discloses a radiographic inspection robot, comprising a traveling mechanism, a lifting mechanism and a rotating mechanism which are arranged sequentially from bottom to top, wherein thetraveling mechanism is used for enabling the radiographic inspection robot to move forward and back or make turns, the lifting mechanism is used for allowing an X-ray inspector to lift, and the rotating mechanism is used for allowing the X-ray inspector to horizontally rotate and vertically roll. The heavy works, such as ray transmitter position adjustment, are completed via the radiographic inspection robot, so that labor intensity is reduced greatly for inspection personnel. Radiographic inspection can be achieved by inspection personnel just by operating in an operating room without entering a radiographic inspection room or the operations such as manual adjustment of ray emitter position detection, so that inspection efficiency is greatly improved; with increase in the inspection efficiency, production efficiency is increased, and lost labor due to low detection efficiency is decreased. In addition, the radiographic inspection robot helps reduce personal injury to operators due toradiation.

Owner:山东泽明能源科技有限公司

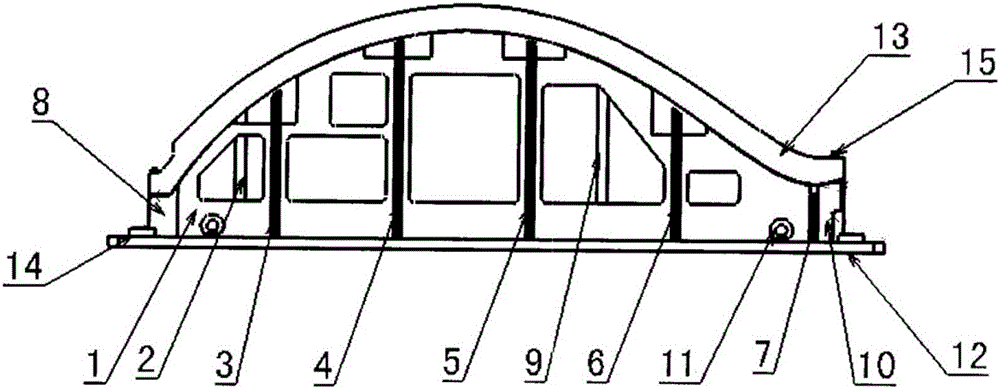

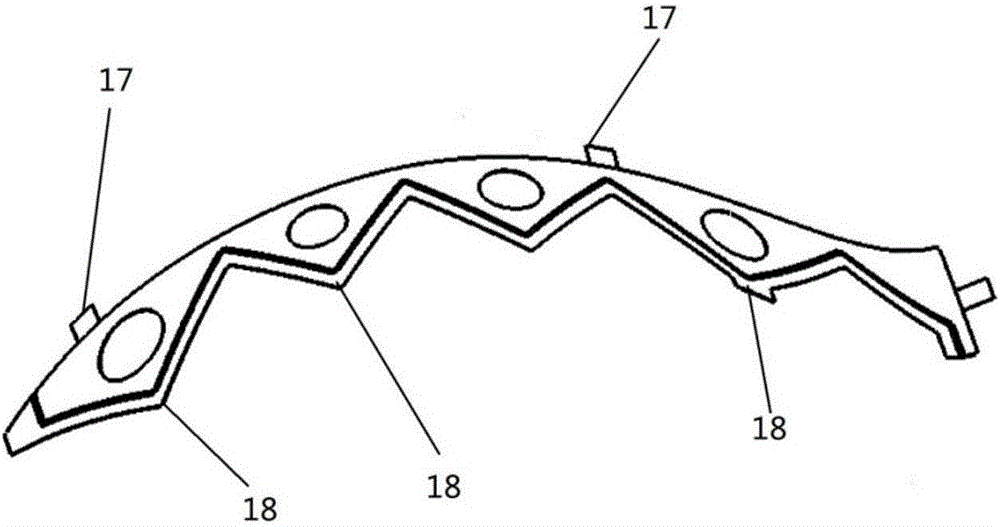

Large thin plate laser cutting clamp and machining method thereof

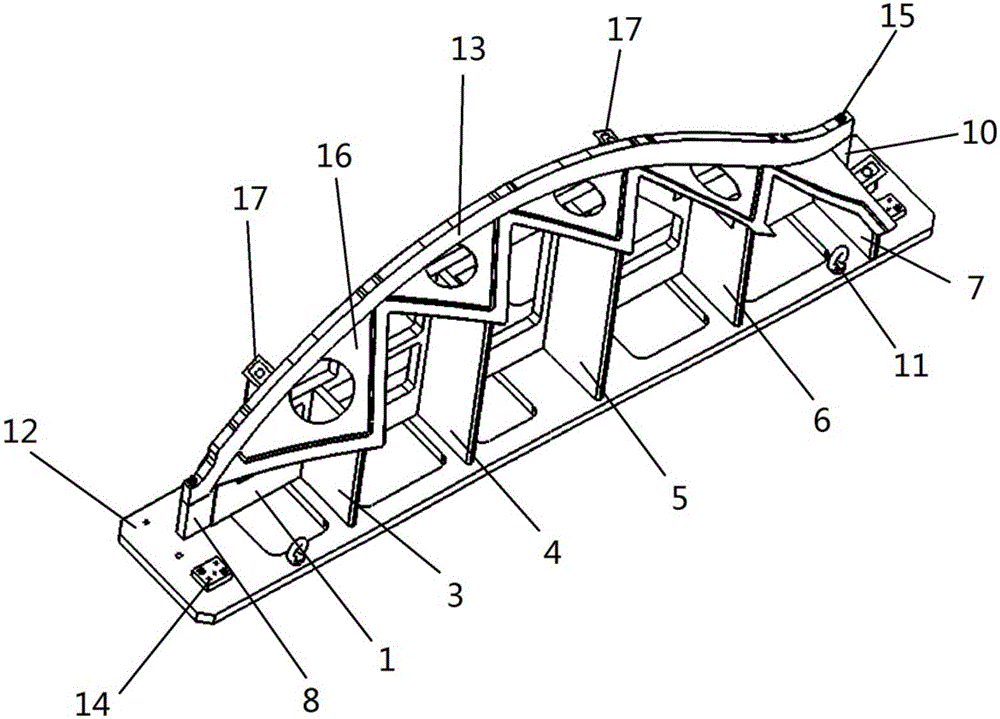

ActiveCN105904108AResolving volatileSolve difficultyMetal working apparatusLaser beam welding apparatusThin slabLaser cutting

The invention discloses a large thin plate laser cutting clamp and a machining method thereof. The clamp is simple in structure and provided with a base plate; a support frame is arranged on and perpendicular to the base plate; the length of the support frame is matched with the length of a skin part; the top face of the support frame is a curved face I, and the curved face I is matched with the skin part in curvature; a plurality of brackets I of variable heights are arranged on one side of the support frame and on the base plate and are used for supporting the surface of the skin part; the brackets I are installed perpendicular to the base plate and the support frame; the height of each bracket I is matched with the height of the portion, corresponding to the bracket I in installation location, of the support frame; a plurality of brackets II are arranged on the other side of the support frame and on the base plate; and the brackets II are perpendicular to the base plate and the support frame correspondingly and used for supporting and fixing lugs on the skin part. According to the machining method, the problems that thin plate type laser cutting clamps are prone to deformation, high in machining difficulty and the like can be effectively solved.

Owner:SHENYANG AIRCRAFT CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com