Patents

Literature

323 results about "Crane Equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Crane apparatus equipped with container security scanning system

InactiveUS20050011849A1Eliminate needImprove reliabilityCargo handling apparatusBase supporting structuresEngineeringCrane Equipment

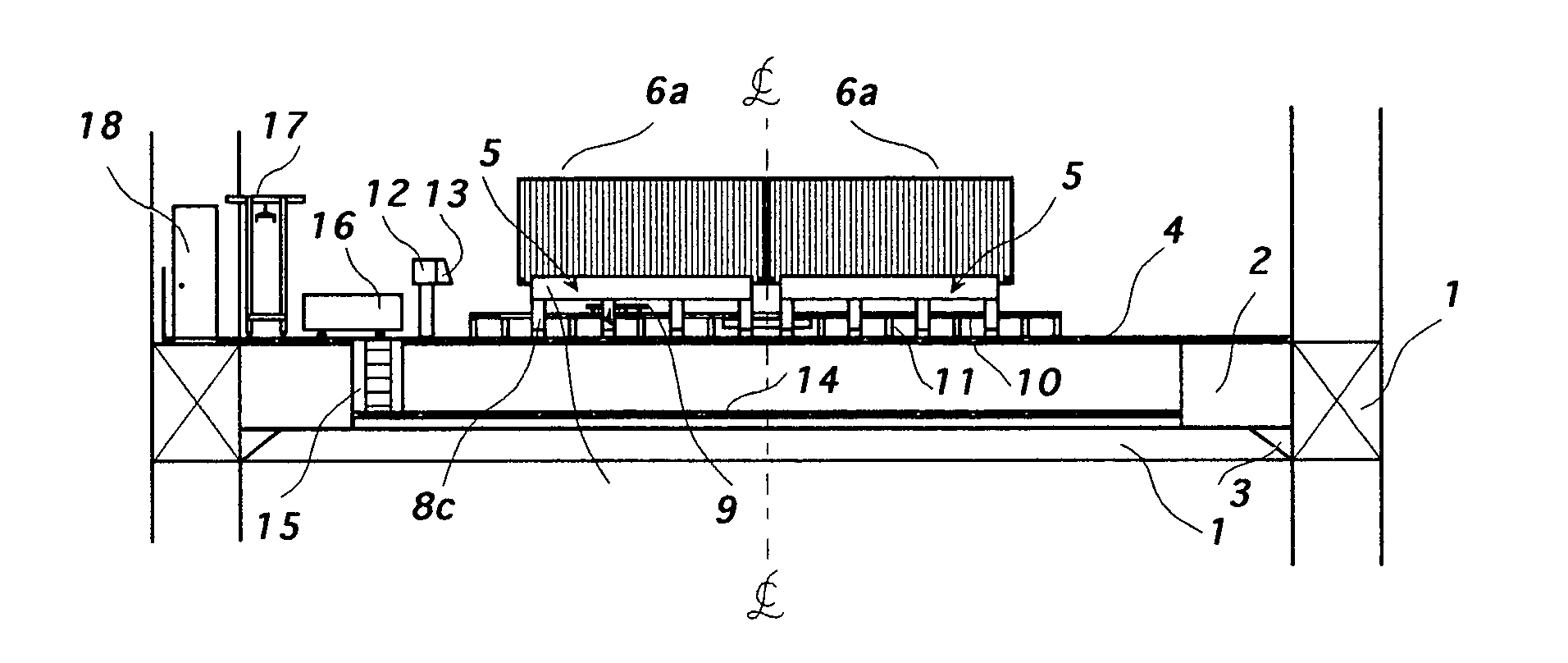

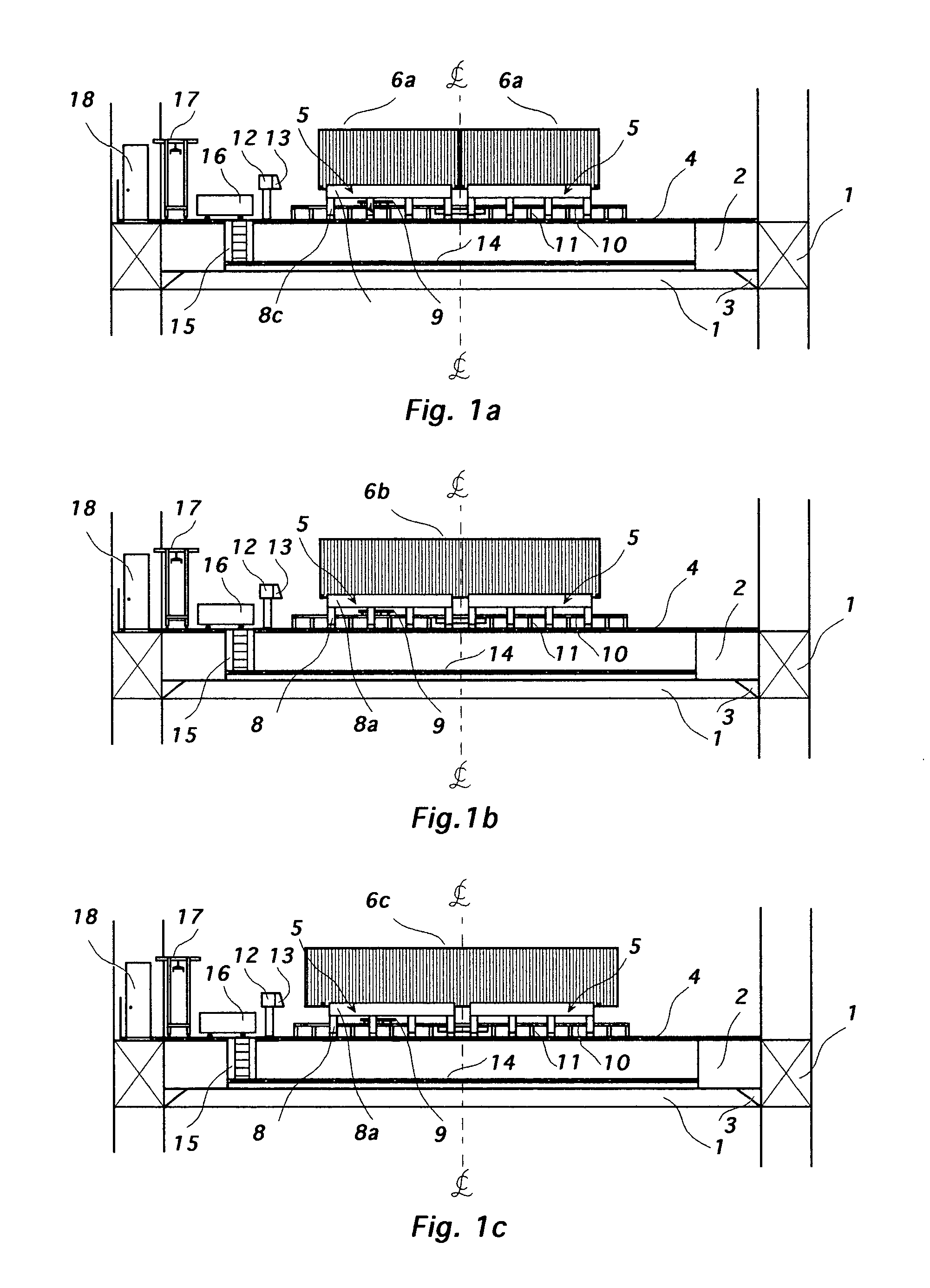

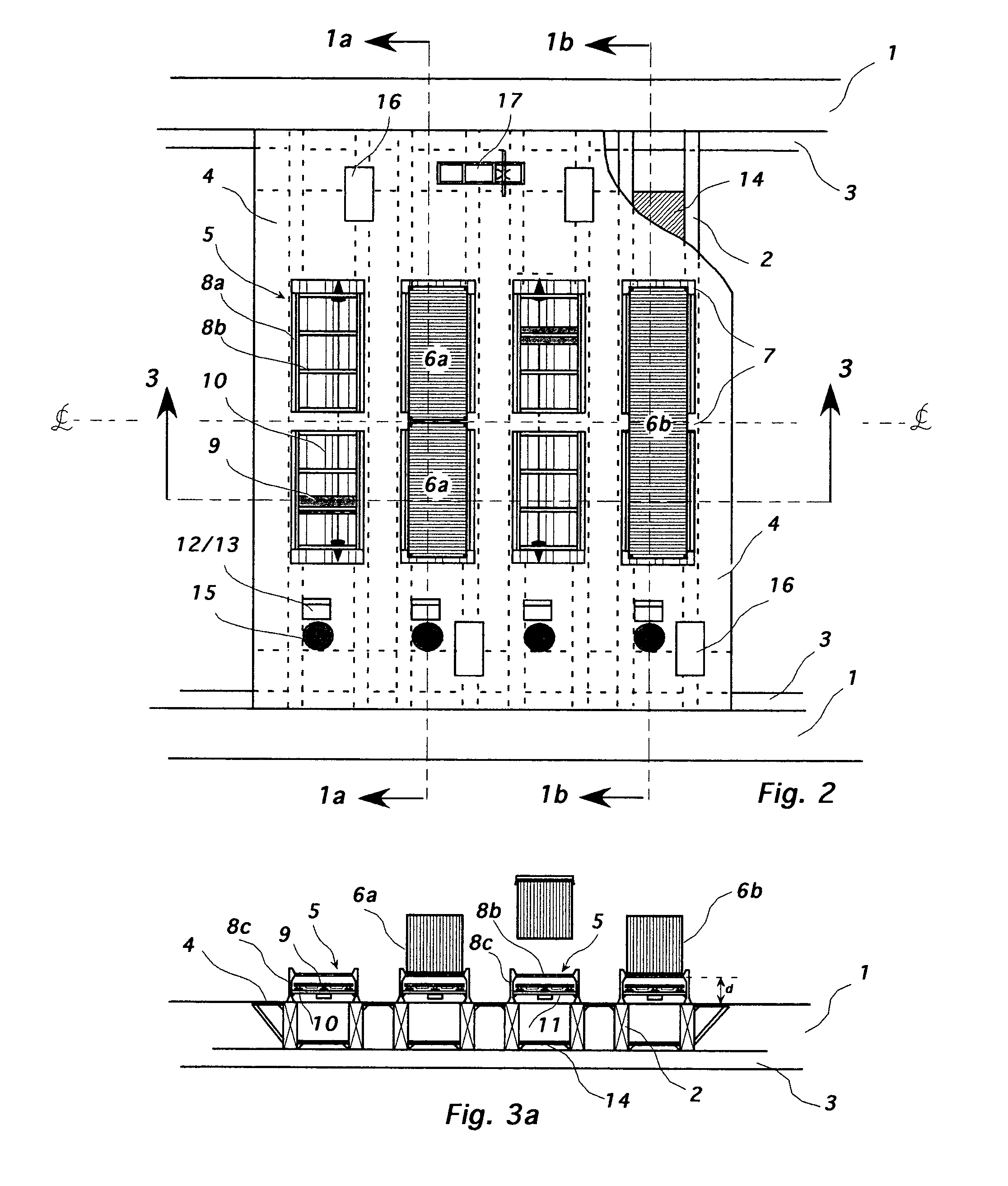

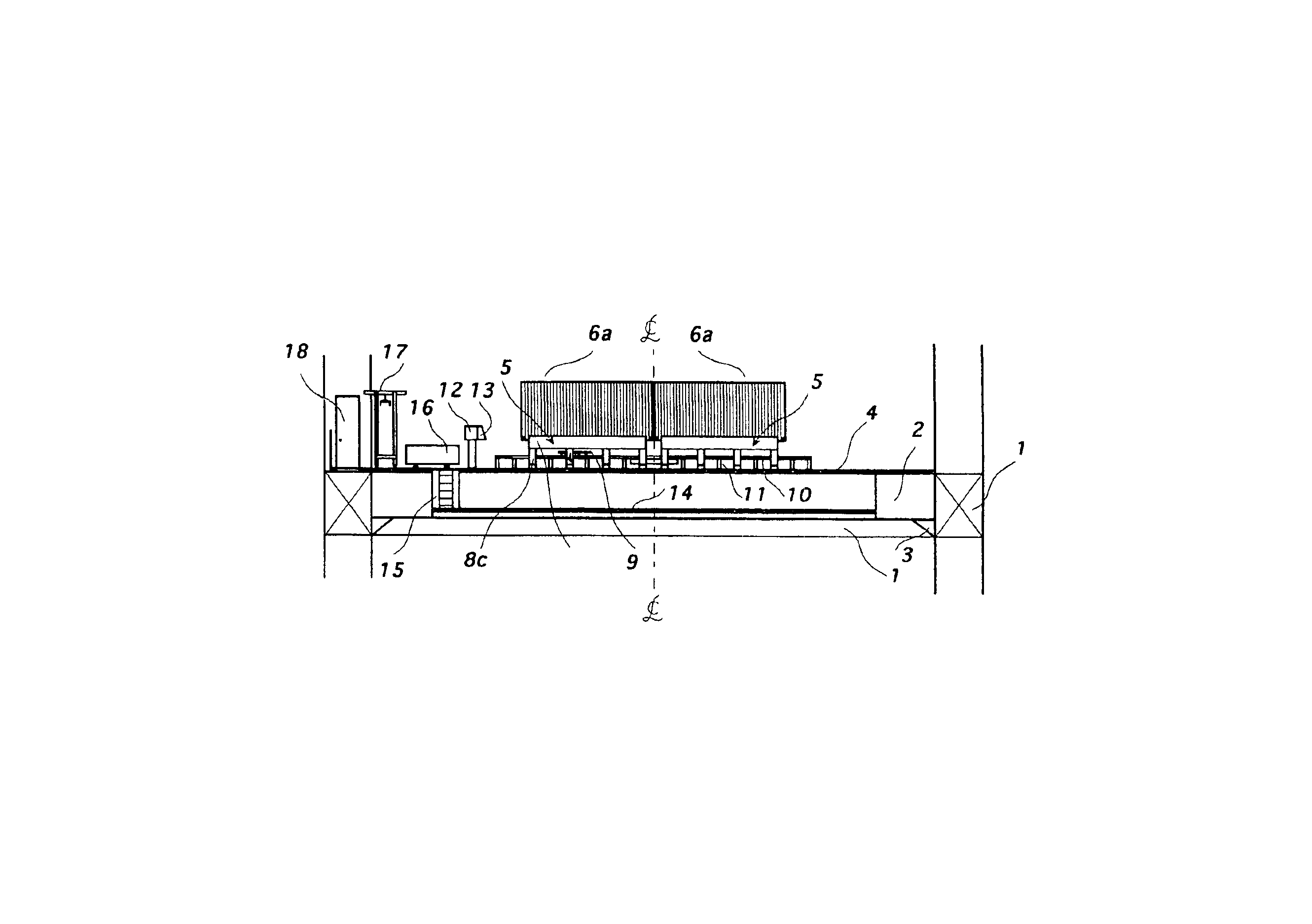

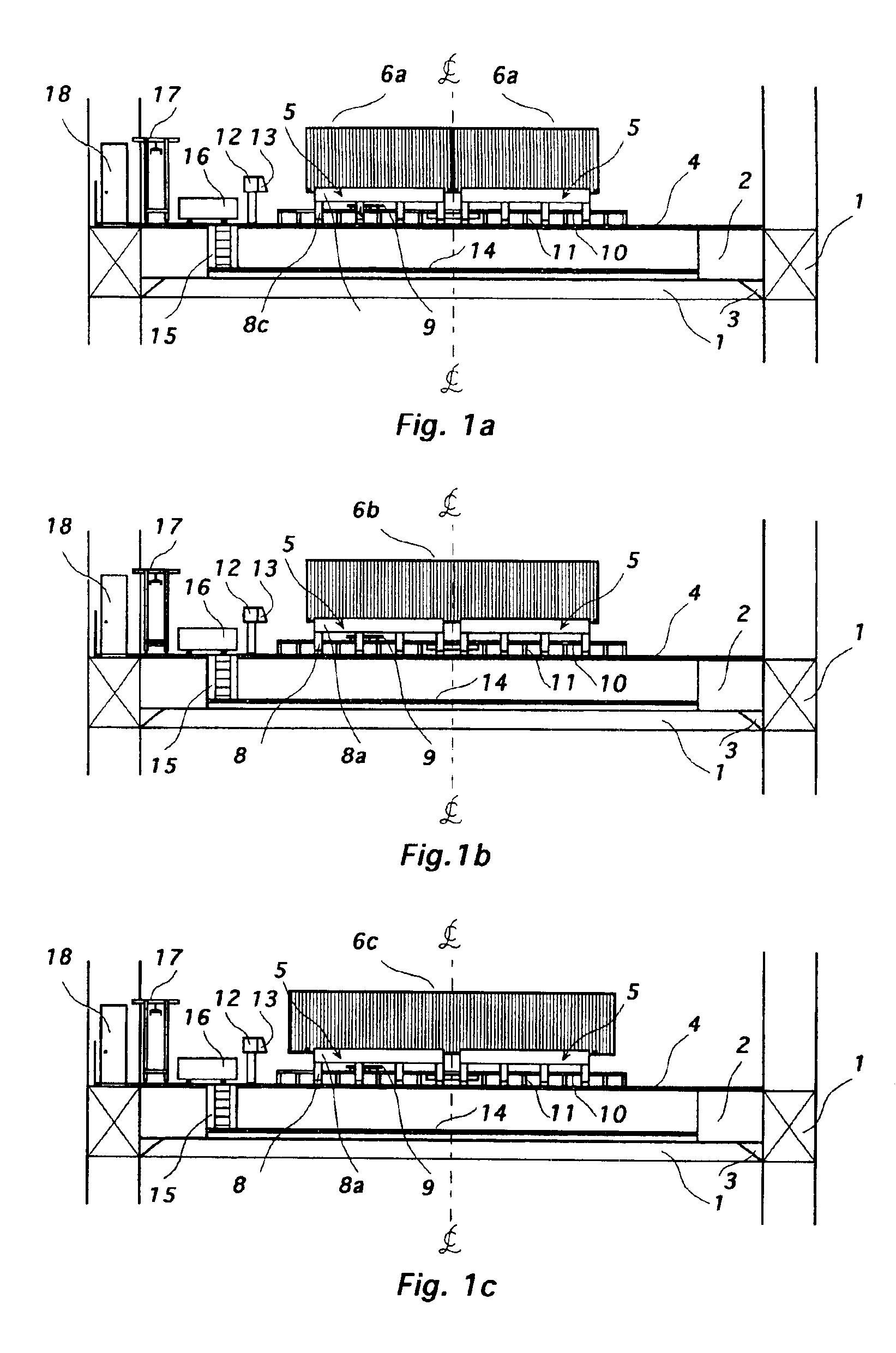

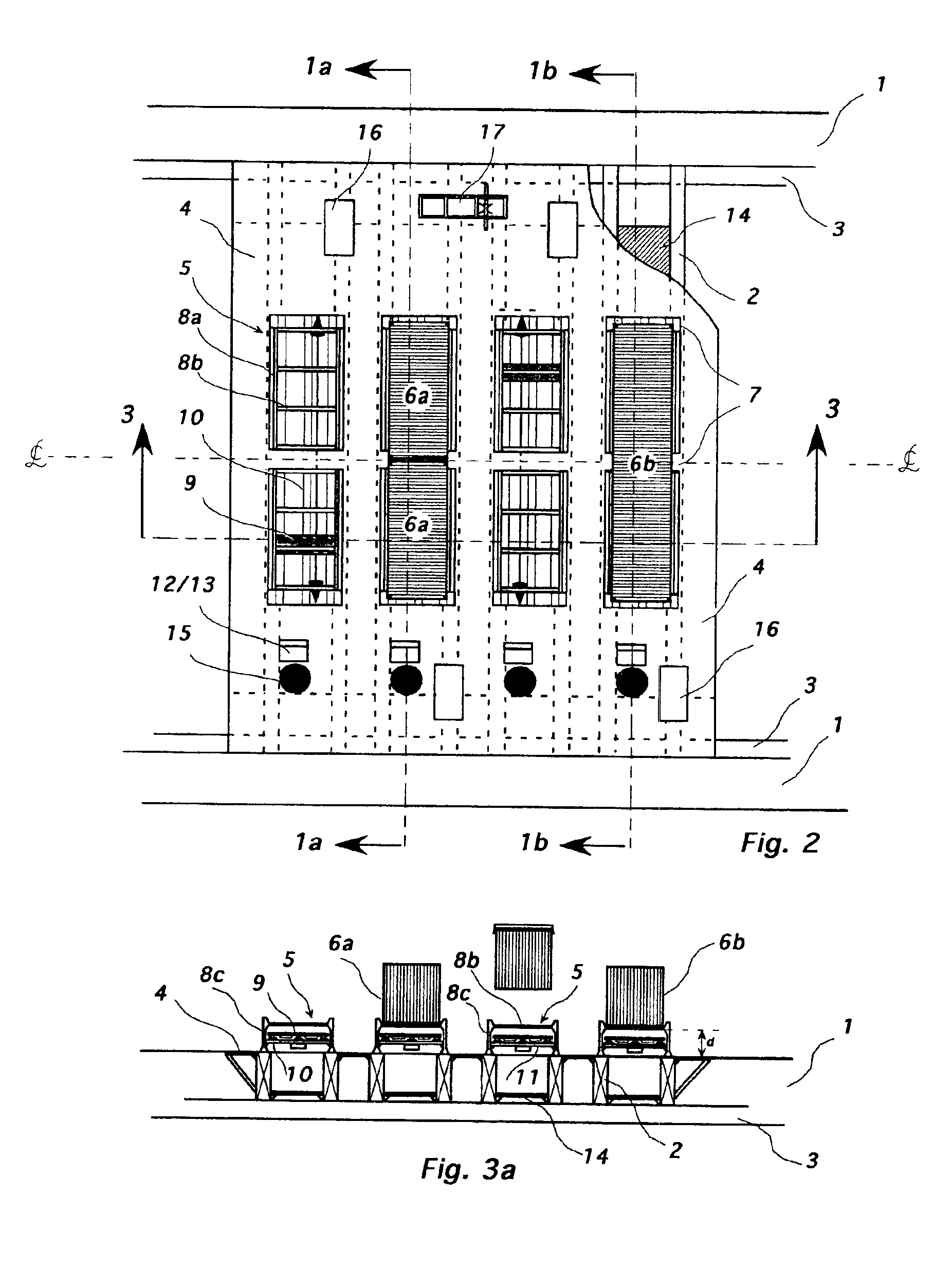

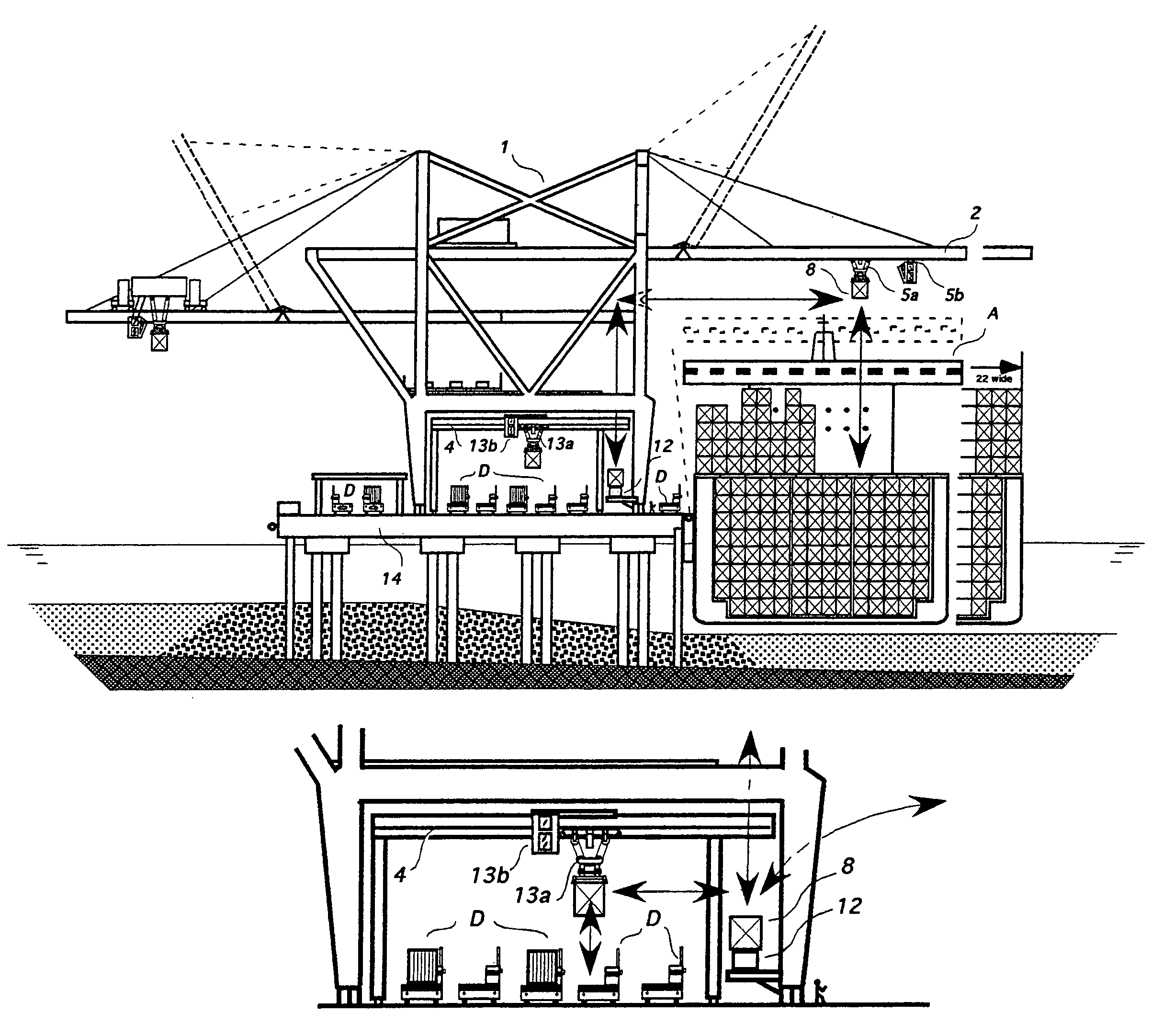

Crane apparatus is equipped with a container security scanning system for scanning containers for radioactive material, such as neutron or gamma ray emissions. The crane apparatus has a crane for unloading containers from a marine vessel and placing the containers on a deck located at the portal girder level of the crane and for transferring the containers from the deck to another location. The container security scanning system comprises one or more scanning units disposed on the deck, each scanning unit having one or more scanning platforms for supporting a container such that a bottom of the container is vertically spaced from the deck. A scanning device is movable beneath the container in a space between the underside of the scanning platforms and the deck for scanning the container to detect whether radioactive material is present. Existing cranes can be retrofitted with the container security scanning system, and newly manufactured cranes can be upgraded to include such a system.

Owner:CHATTEY NIGEL

Crane apparatus equipped with container security scanning system

InactiveUS6845873B1Improve reliabilityCargo handling apparatusBase supporting structuresEngineeringNeutron

Crane apparatus is equipped with a container security scanning system for scanning containers for radioactive material, such as neutron or gamma ray emissions. The crane apparatus has a crane for unloading containers from a marine vessel and placing the containers on a deck located at the portal girder level of the crane and for transferring the containers from the deck to another location. The container security scanning system comprises one or more scanning units disposed on the deck, each scanning unit having one or more scanning platforms for supporting a container such that a bottom of the container is vertically spaced from the deck. A scanning device is movable beneath the container in a space between the underside of the scanning platforms and the deck for scanning the container to detect whether radioactive material is present. Existing cranes can be retrofitted with the container security scanning system, and newly manufactured cranes can be upgraded to include such a system.

Owner:CHATTEY NIGEL

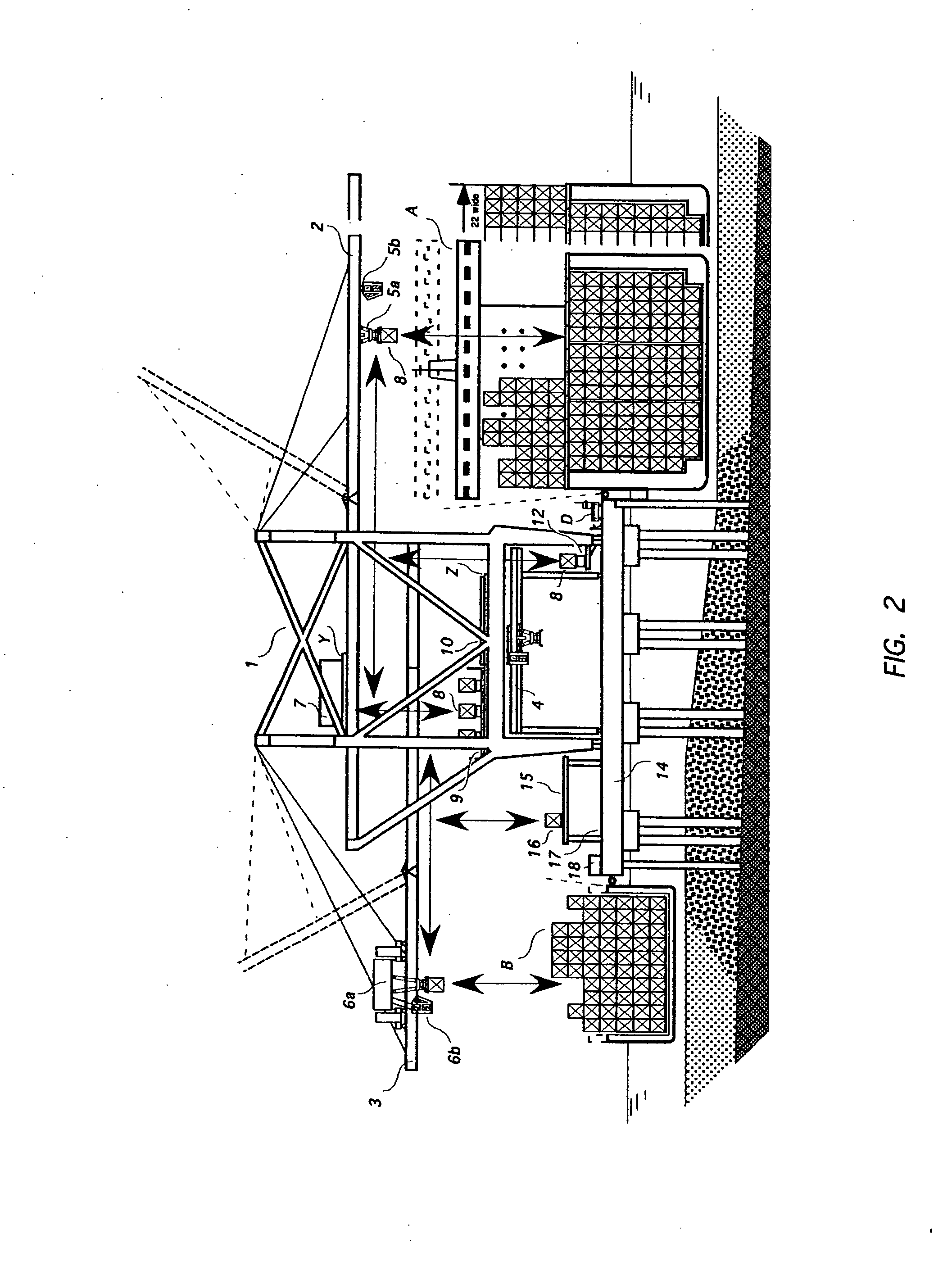

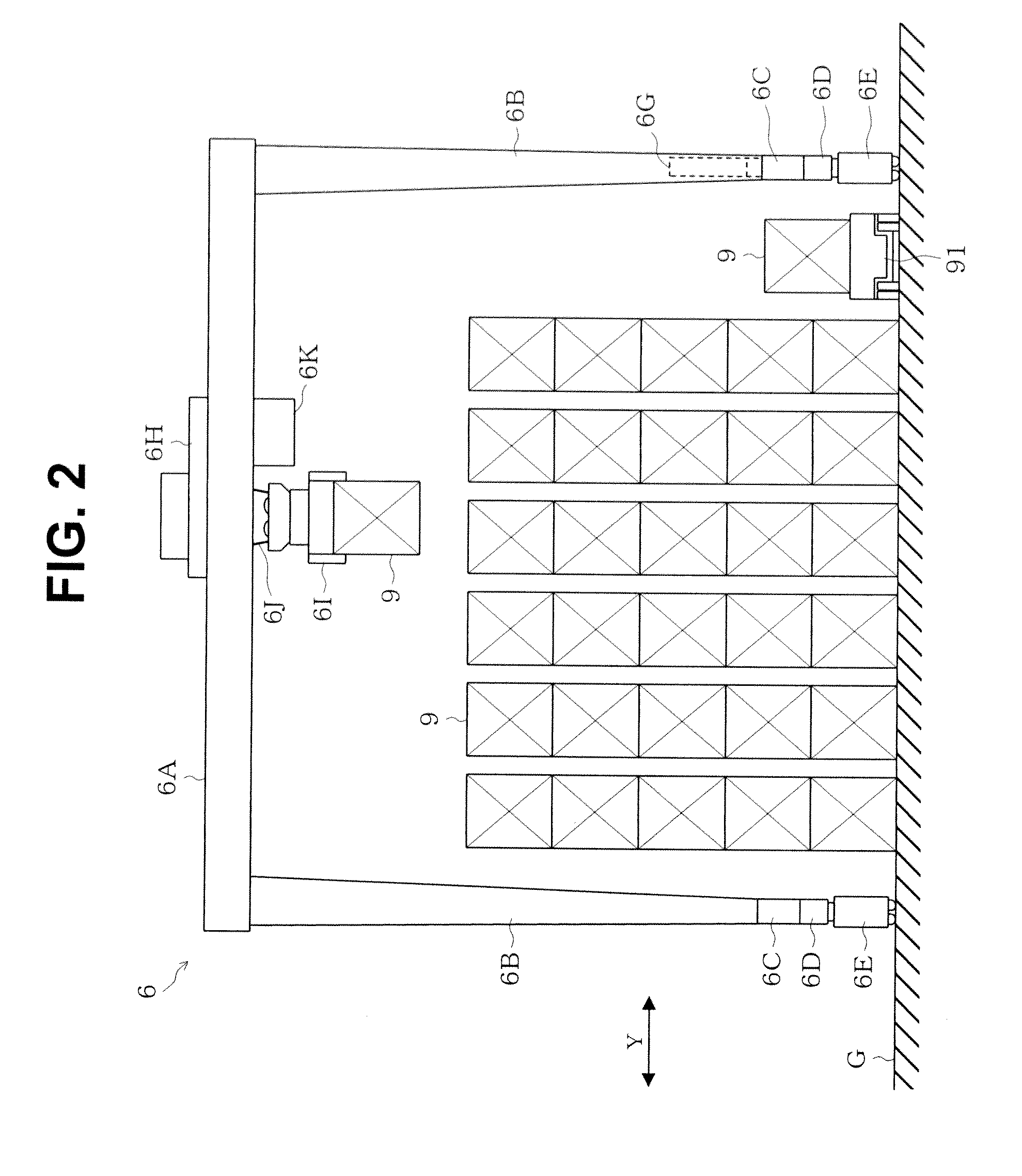

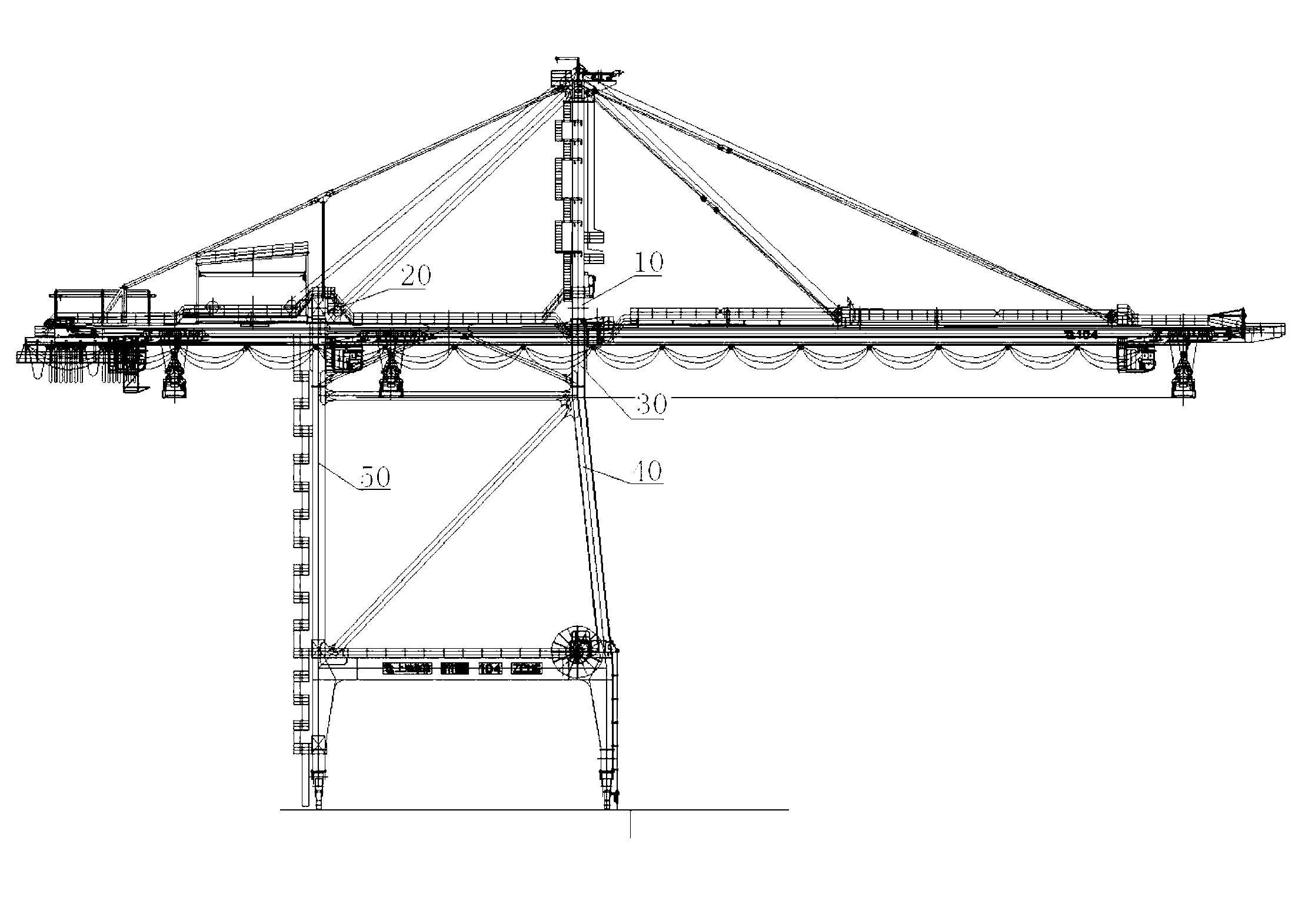

Container crane apparatus and method for container security screening during direct transshipment between transportation modes

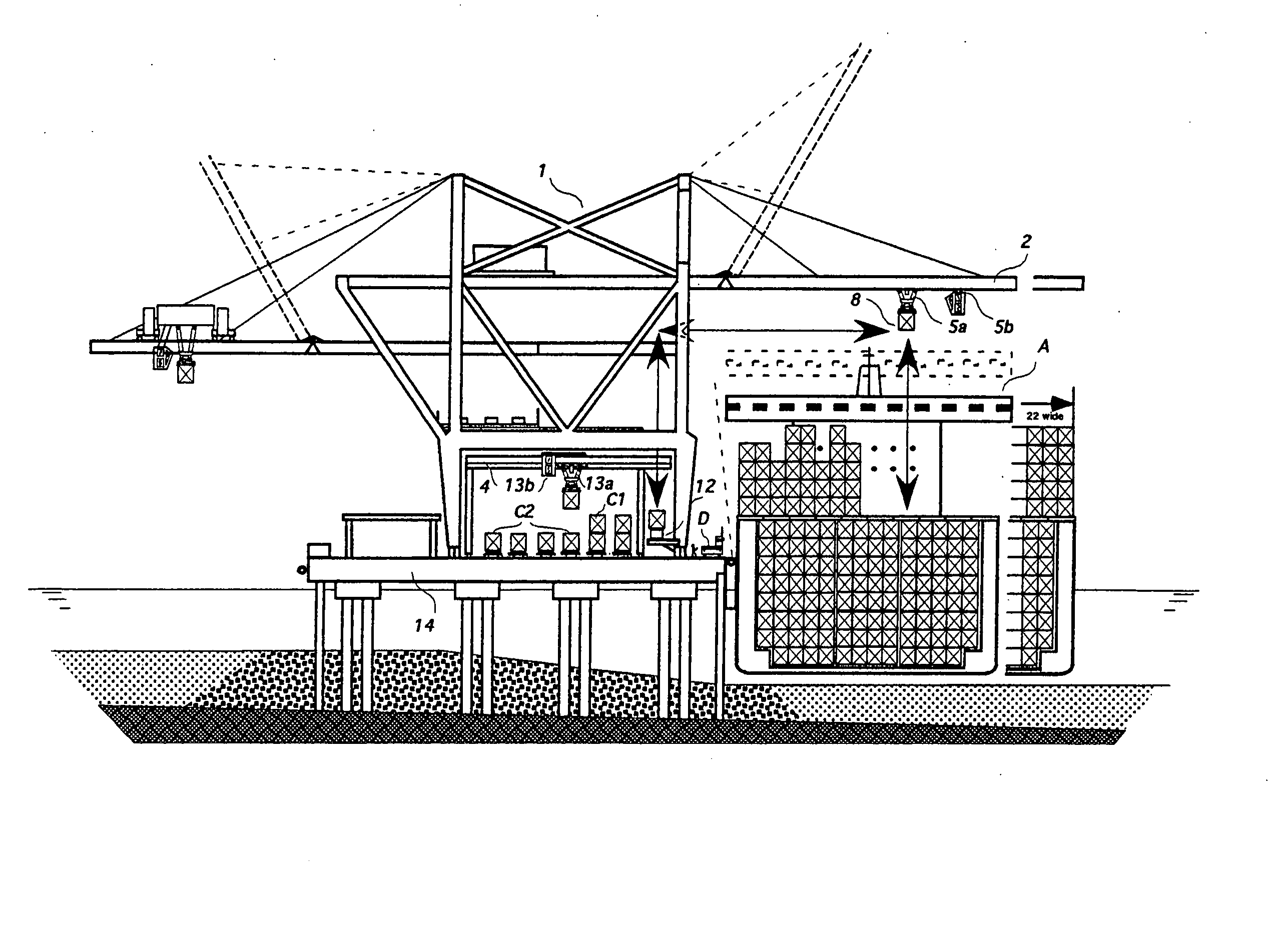

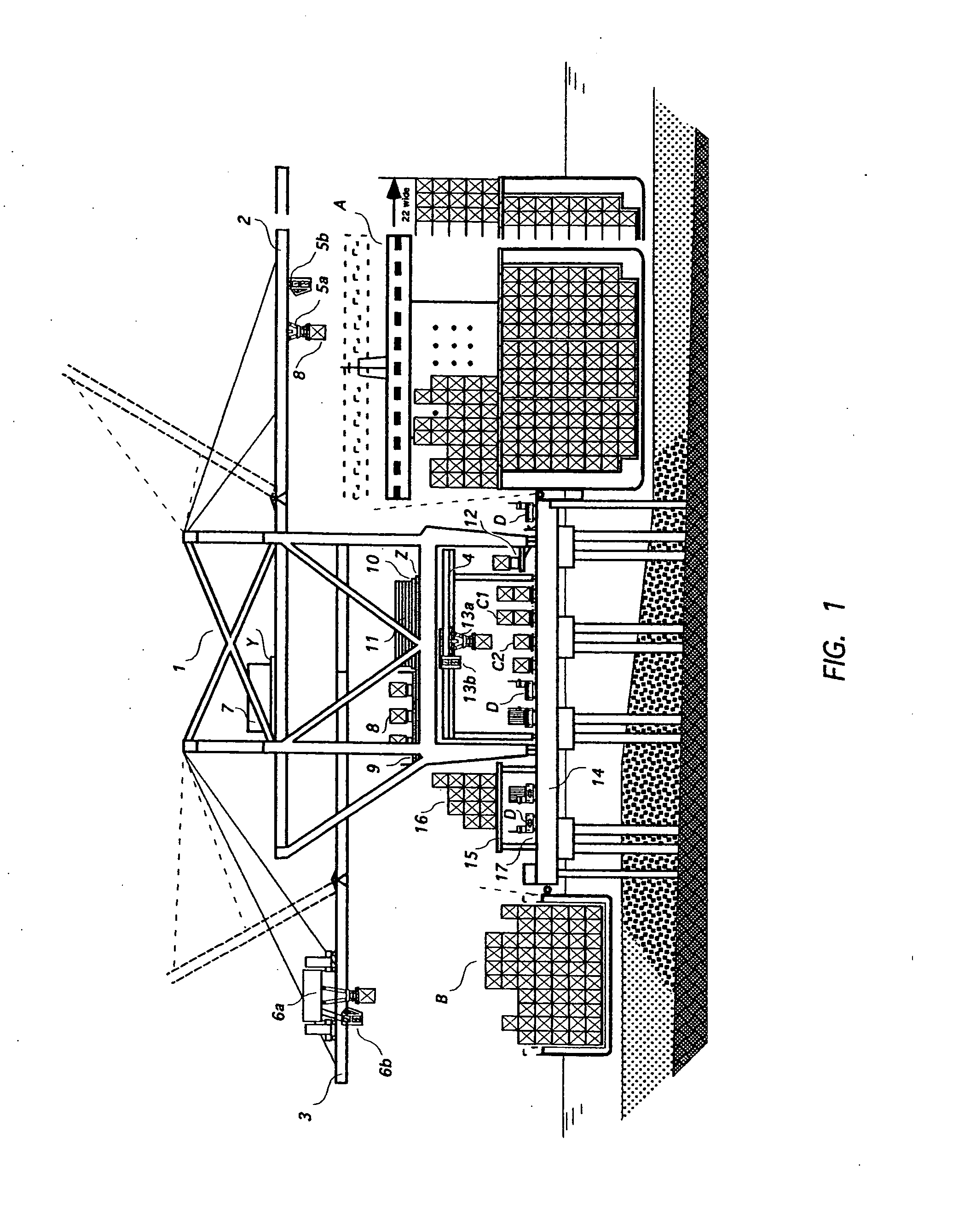

InactiveUS20080219804A1Save a lot of costCargo handling apparatusBase supporting structuresContainer craneGround vehicles

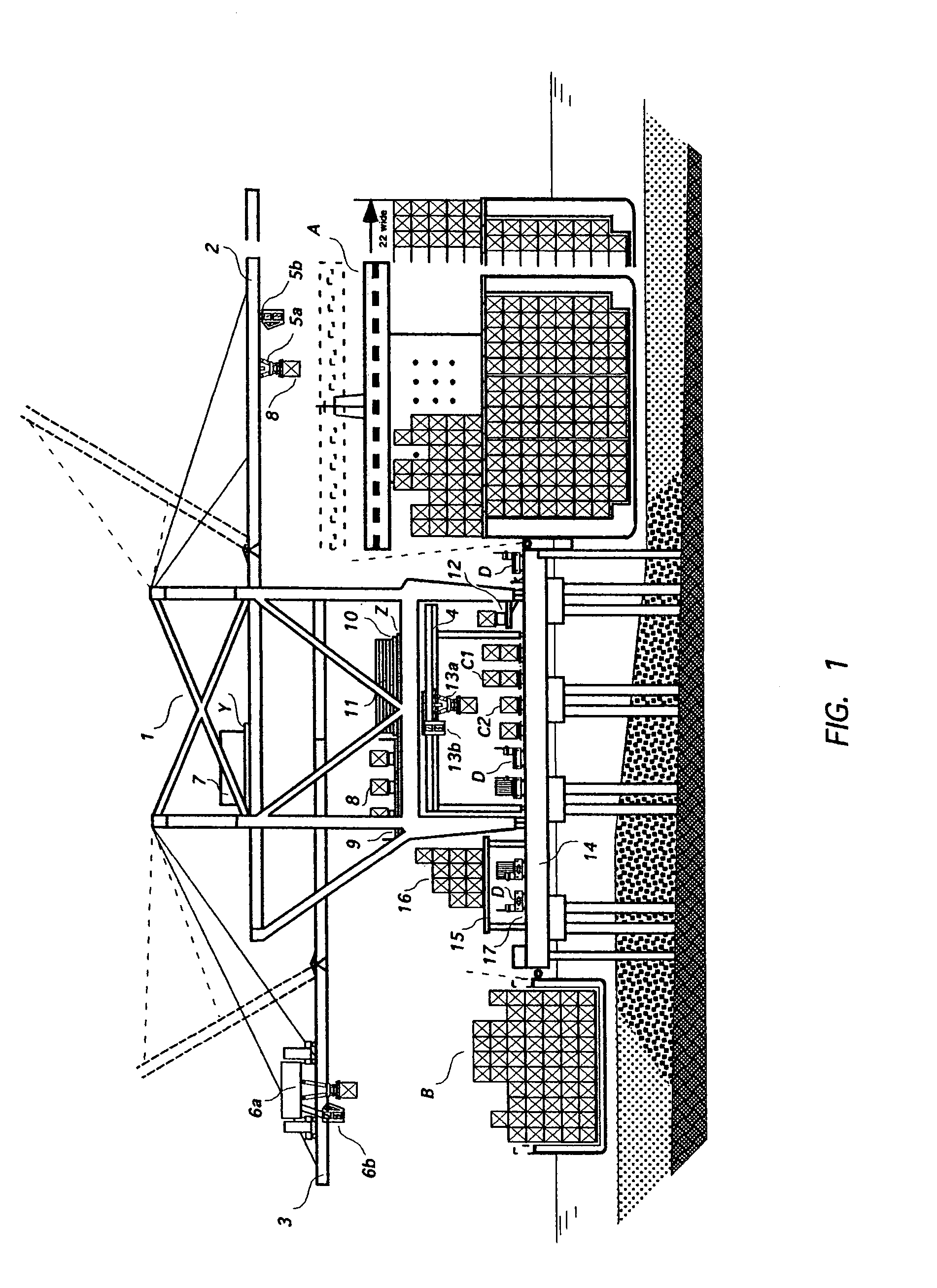

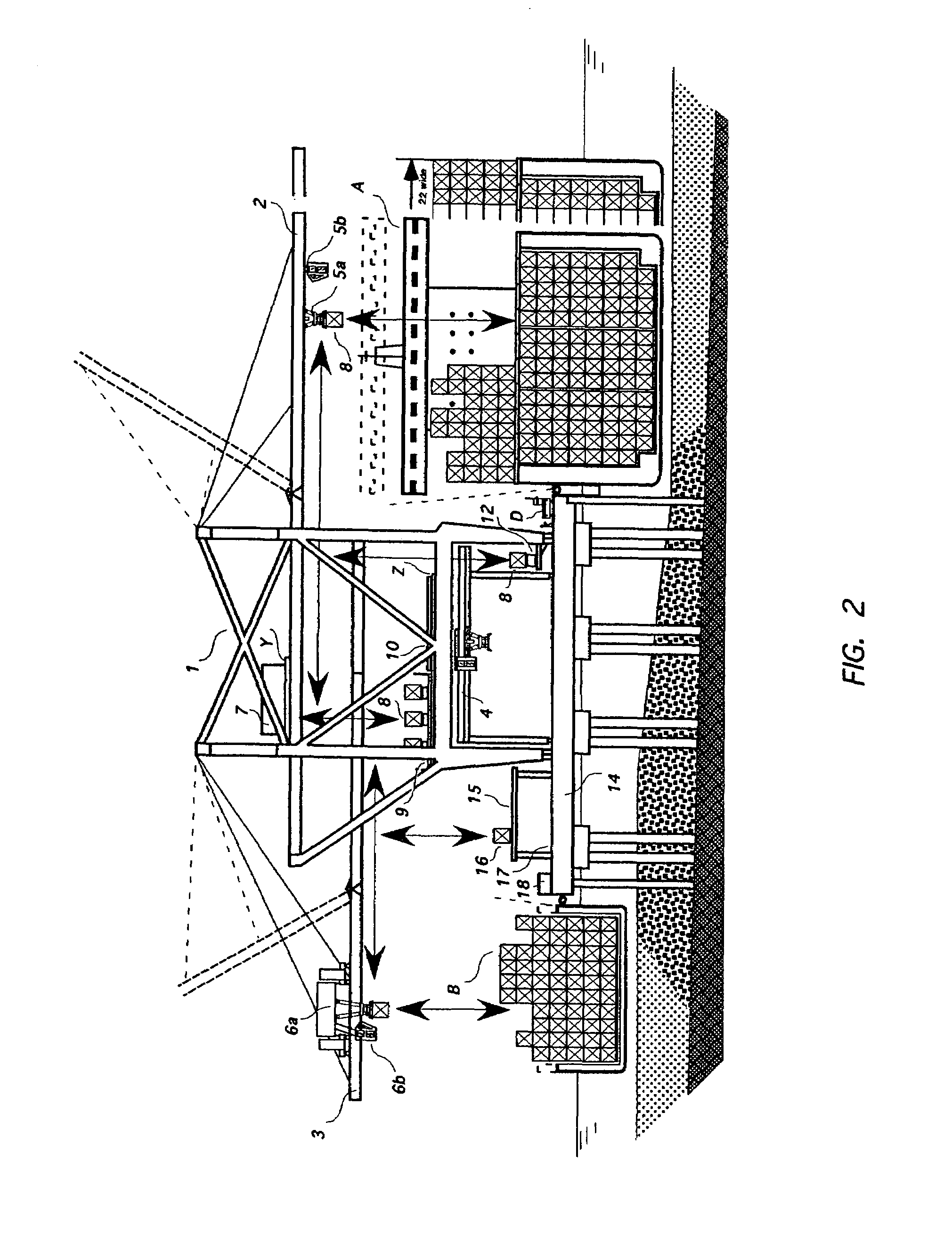

A crane apparatus installed on a pier, wharf, bulkhead wharf or other foundation directly transships containers from a vessel moored alongside the foundation to another transportation mode without ground placement of the containers. The crane apparatus includes a parent crane displaceable along the foundation for unloading containers from the vessel and placing them on a first platform of the parent crane, and a sibling crane displaceable along the foundation independently of displacement of the parent crane for loading containers from the first platform directly onto over-the-ground vehicles or onto another vessel moored alongside the foundation. The parent crane has a first trolley-hoist-spreader movable along an outreach boom for unloading containers from the vessel and placing them on either the first platform or a second platform of the parent crane, and a second trolley-hoist-spreader movable along a backreach boom for loading containers from the second platform onto another vessel or onto over-the-ground vehicles. A container security scanning system may be provided on the second platform for scanning the containers while on the second platform to determine whether one or more preselected chemical, biological, explosive or nuclear materials are present in the containers.

Owner:CHATTEY NIGEL

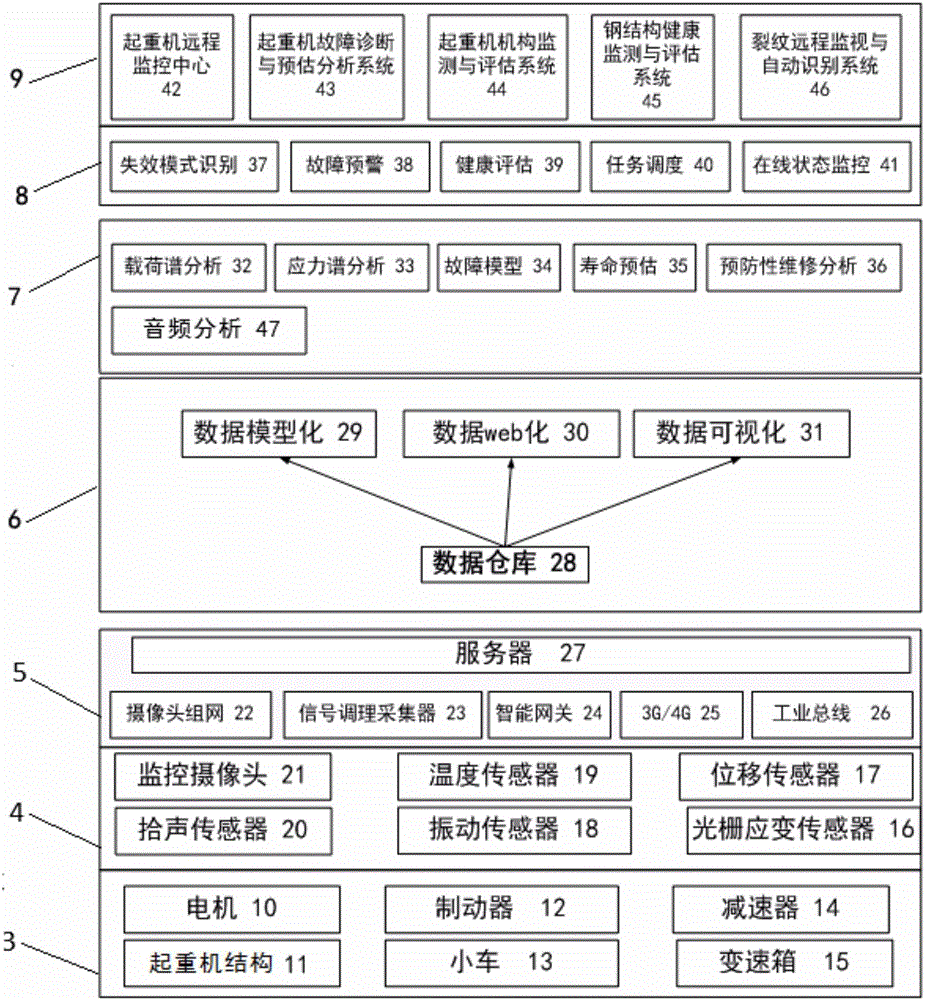

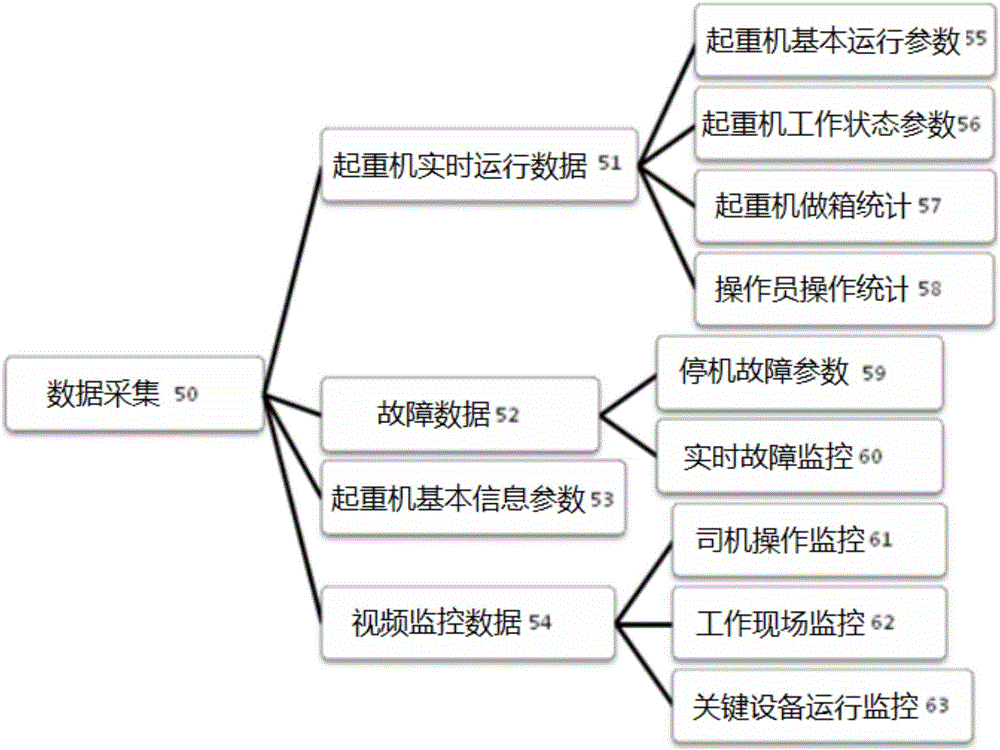

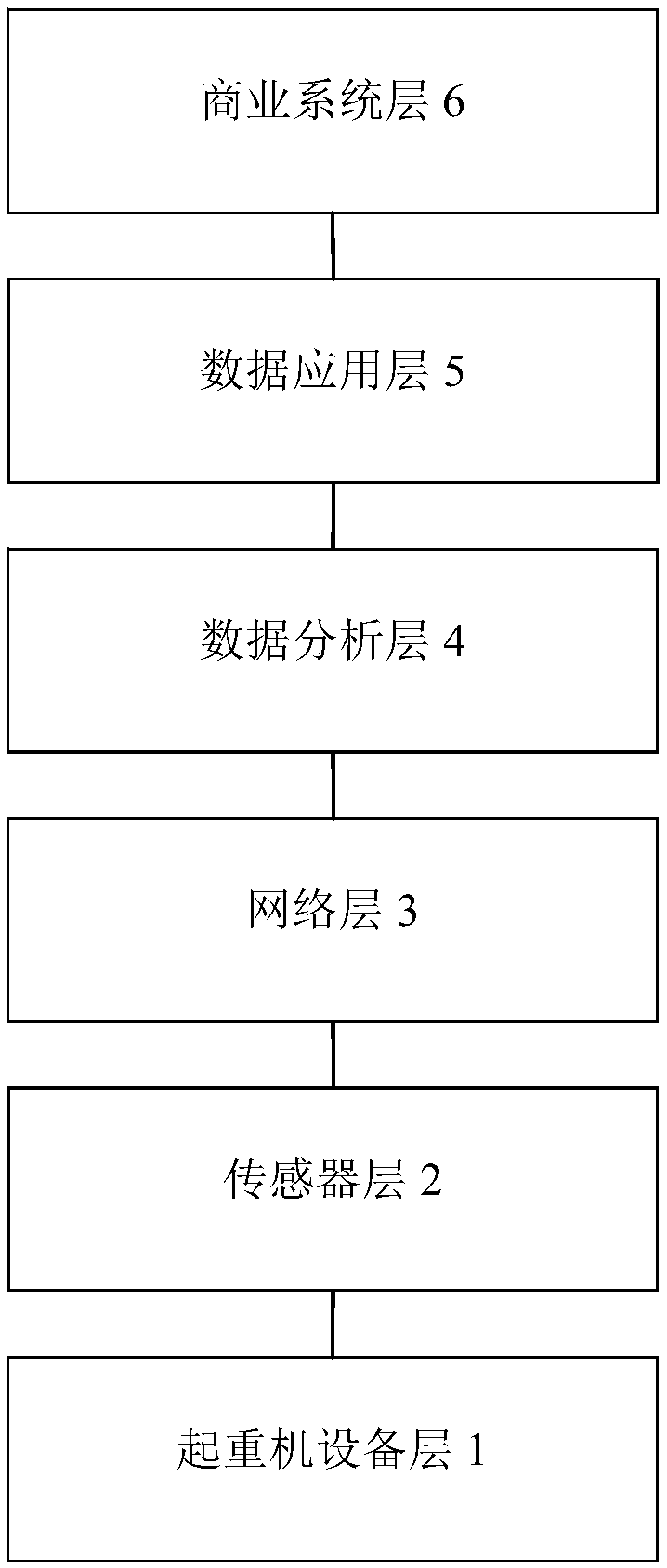

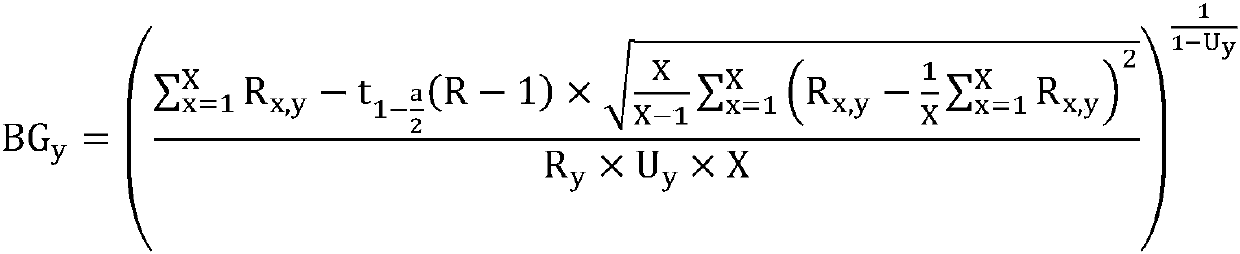

System for online diagnosis and preventive maintenance of container crane based on big data

ActiveCN106698197ARealize scientific testingAvoid wastingDesign optimisation/simulationSpecial data processing applicationsContainer craneFault model

The invention discloses a system for online diagnosis and preventive maintenance of a container crane based on big data. The system comprises a crane equipment layer, a sensor layer, a network layer and a data service layer, wherein the data service layer is further divided into a data analysis and model layer, a data application layer and a business system layer; the crane equipment layer receives operating parameters of the crane; the sensor layer receives sensor signals of key parts of the crane; the network layer transmits the operating parameters and the sensor signals to the data service layer; the data analysis and model layer presets a normal operating model and a fault model of the crane, and compares the operating parameters and the sensor signals with the model, so as to judge the operating state of the crane; the data application layer predicts the operating stable of the crane within a certain period of time in the future according to the operating parameters and the sensor signals, so as to generate a fault early warning; and the business system layer is provided with an external data interface, and outputs data of the data analysis and model layer as well as the data application layer to the outside world.

Owner:SHANGHAI ZPMC ELECTRIC +1

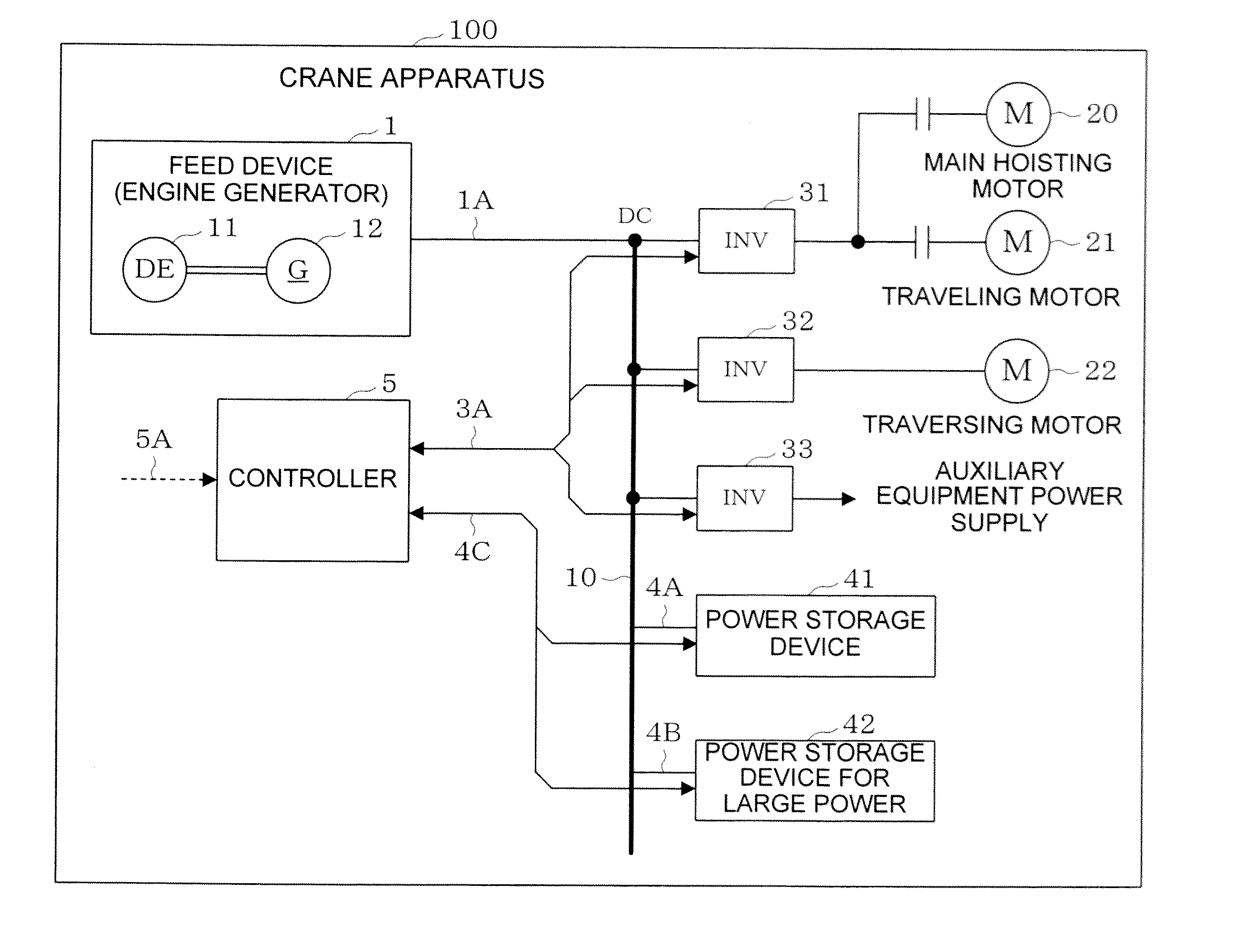

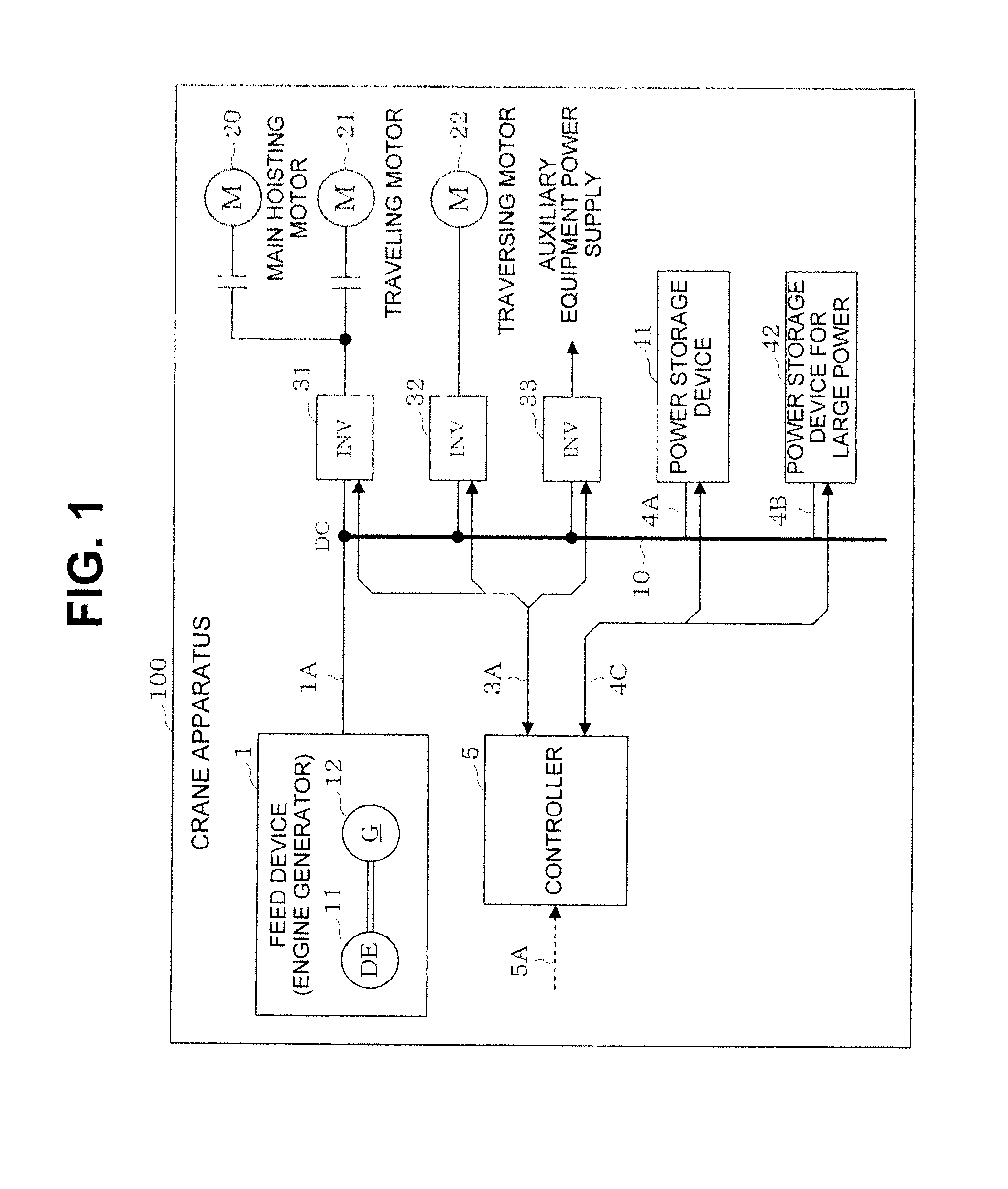

Crane apparatus

InactiveUS20110112731A1High output densitySmall volumeAnalogue computers for trafficPropulsion using engine-driven generatorsVolumetric Mass DensityEngineering

A power storage device (first power storage device) (41) stores part of a supply power, and in case of shortage of the supply power, discharges the storage power to compensate for the supply power. A power storage device (second power storage device) (42) stores part of the supply power, and discharges the storage power at least in a cargo lifting operation by motors to compensate for the supply power. As the power storage device (42), a power storage device having an output density higher than that of the power storage device (41) is used. Alternatively, as the power storage device (41), a power storage device having an energy density higher than that of the power storage device (42) is used.

Owner:MITSUI ENG & SHIPBUILD CO LTD

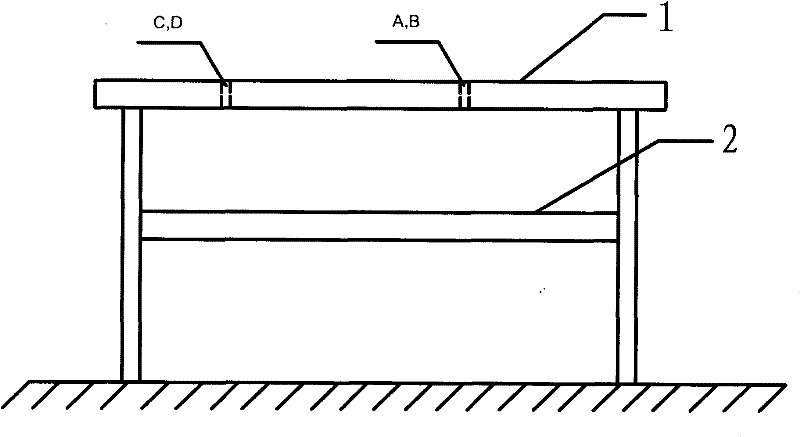

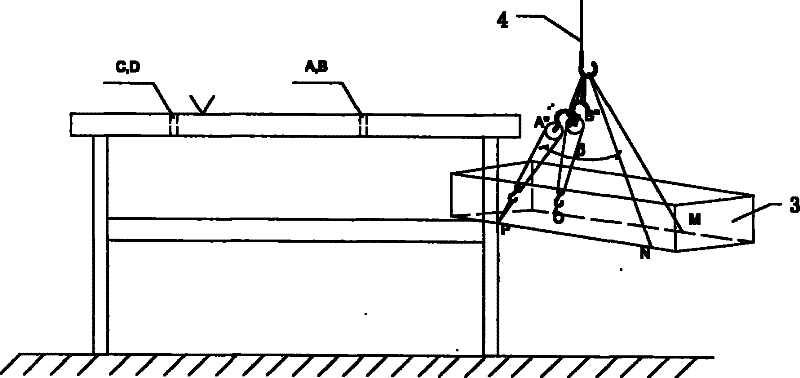

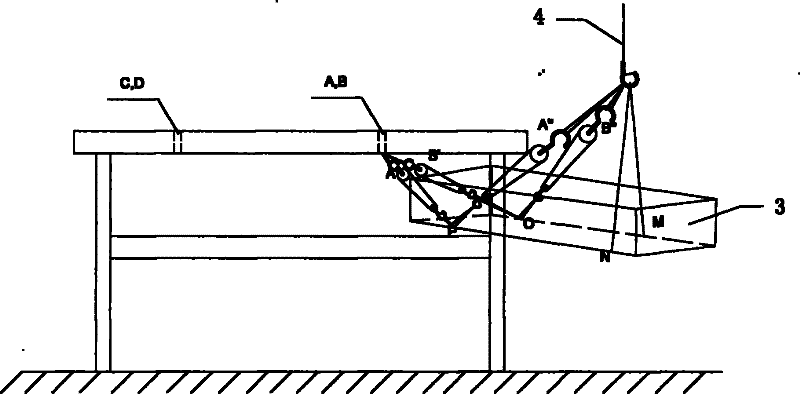

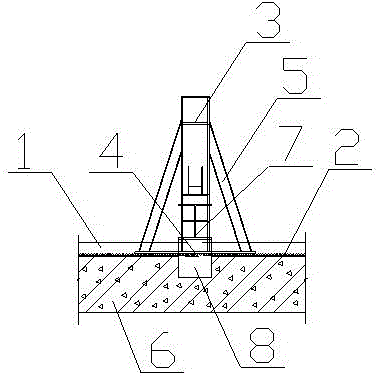

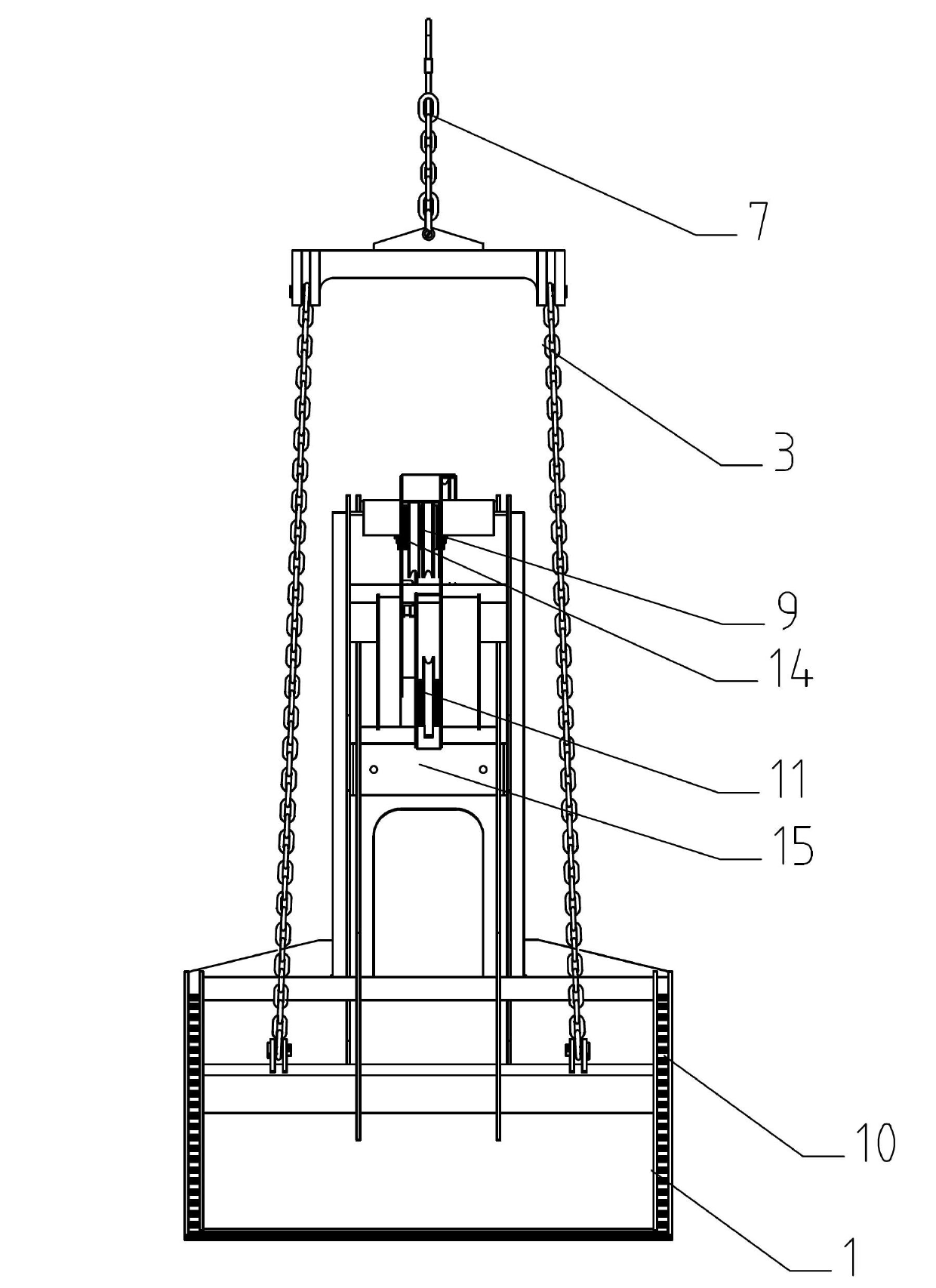

Hoisting method for equipment installation in in-between hollow space of multilayer concrete platforms

ActiveCN102190254AEasy to hoist in placeQuick hoisting in placeWinding mechanismsCranesEngineeringCrane Equipment

Provided is a hoisting method for equipment installation in in-between hollow space of multilayer concrete platforms. The method is characterized in that: it comprises the following steps: (a) arranging a plurality of hoisting apertures above in-between hollow space; (b) using a crane to hoist equipment individually; (c) using hand-drive blocks (A, B) and the crane to lift the equipment together; (d) using hand-drive blocks (A,B,C,D) to lift the equipment and placing the equipment in position. According to the hoisting method for equipment installation in in-between hollow space of multilayer concrete platforms provided in the invention, equipment can be hoisted and placed in in-between hollow space of multilayer concrete platforms simply, fast and safely, the safety of operators is effectively guaranteed, and crane equipment and surrounding facilities can be prevent from damaging owing to collision.

Owner:MCC5 GROUP CORP SHANGHAI

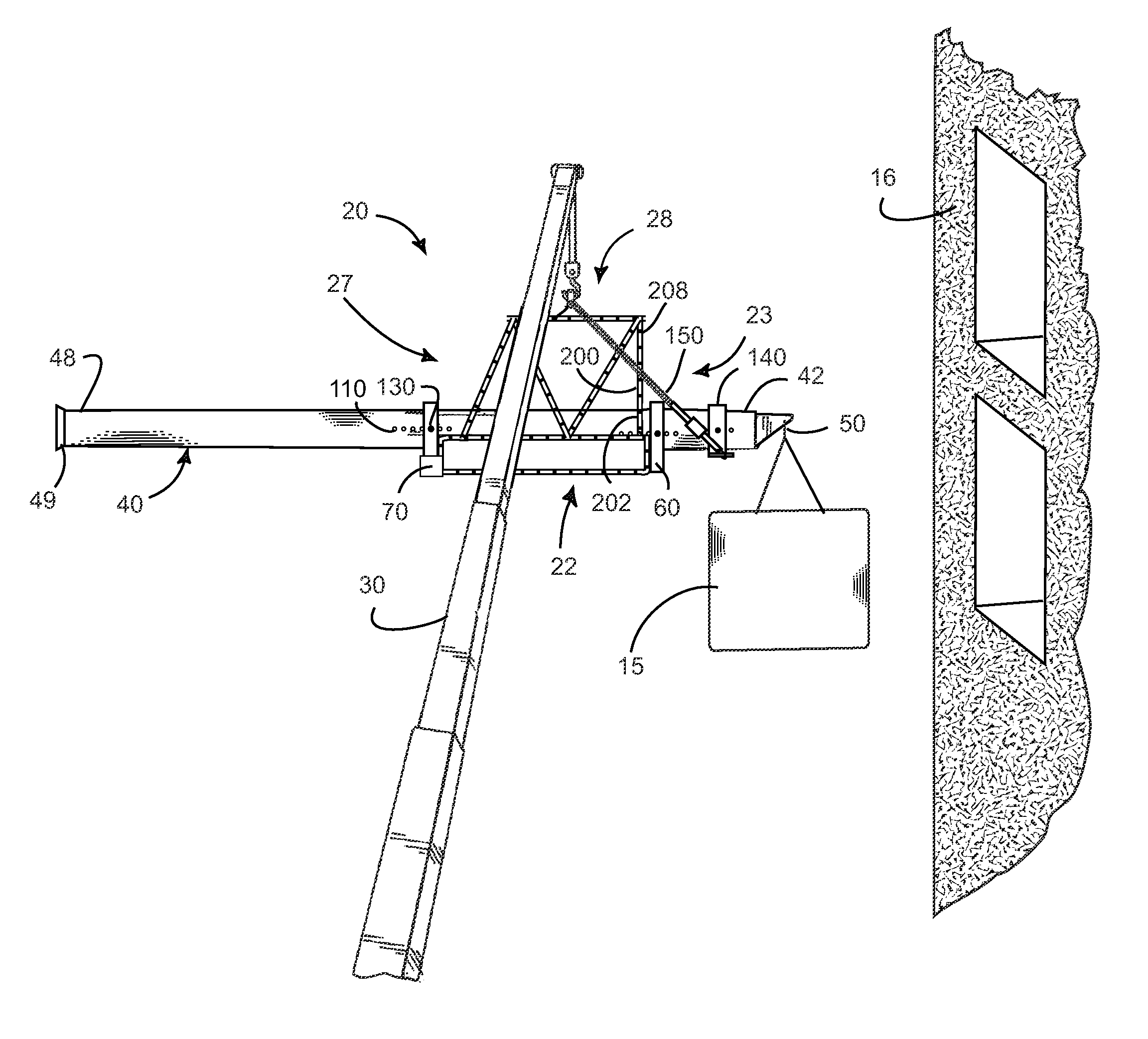

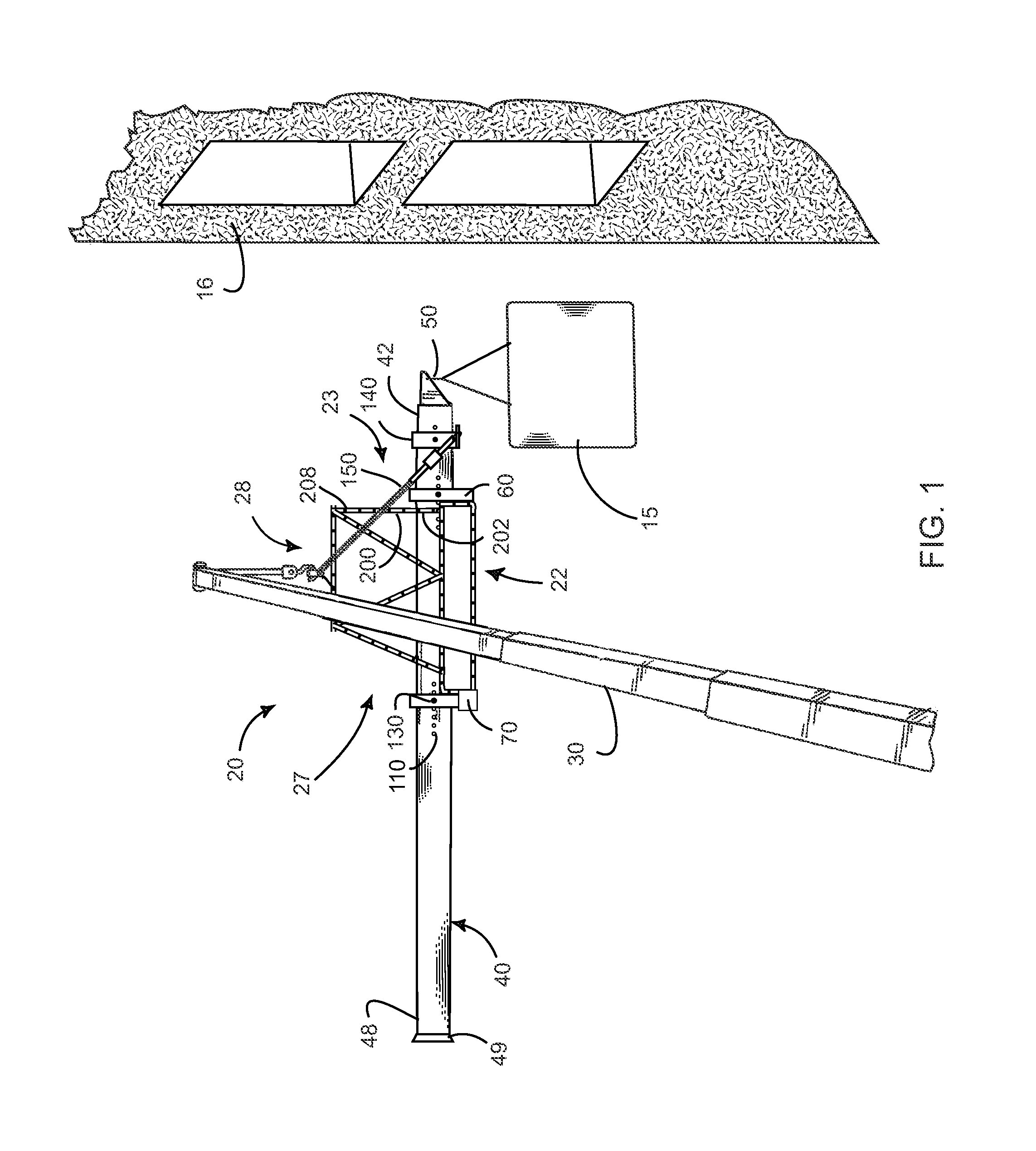

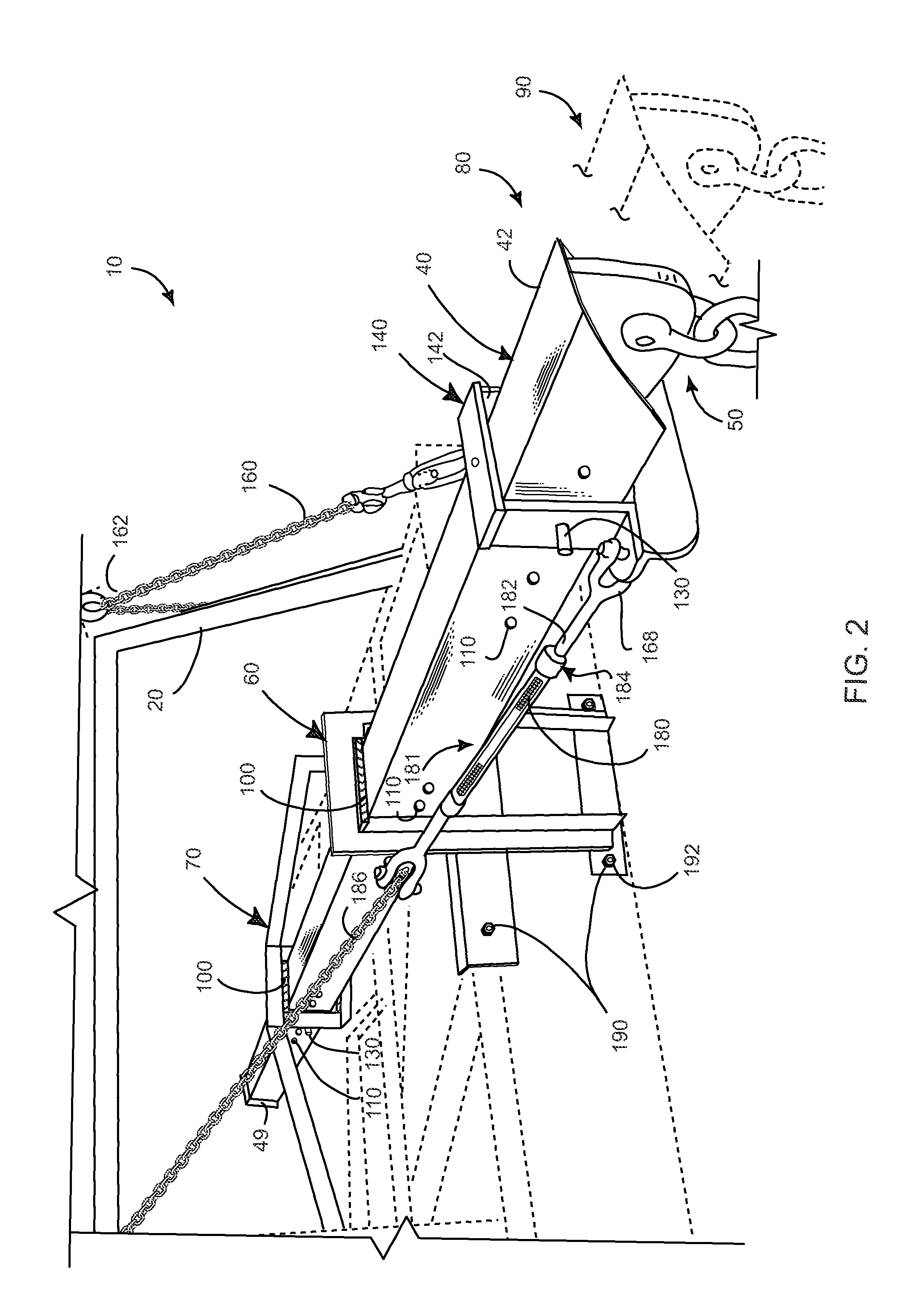

Apparatus and method for positioning an object in a building

ActiveUS8317244B1Less overall consumptionEasy to place safelyLoad-engaging elementsEngineeringCantilever

An offset hoisting apparatus comprises a rigid boom having a hook at a distal end thereof. The offset hoisting apparatus further includes a front mount having a front boom aperture and a rear mount having a rear boom aperture, each being adapted for confining the boom to slidably move therethrough. The invention has a slip collar having a slip collar boom aperture therein for receiving the boom therethrough and an offset hoisting apparatus attachment having a flexible linkage fixed at a distal end thereof with the slip collar. The boom is selectively slid between a retracted and an extended position and the load is secured to the hook. The crane apparatus then lifts and positions the load to a building.

Owner:SCHUYLEMAN JAY WESLEY

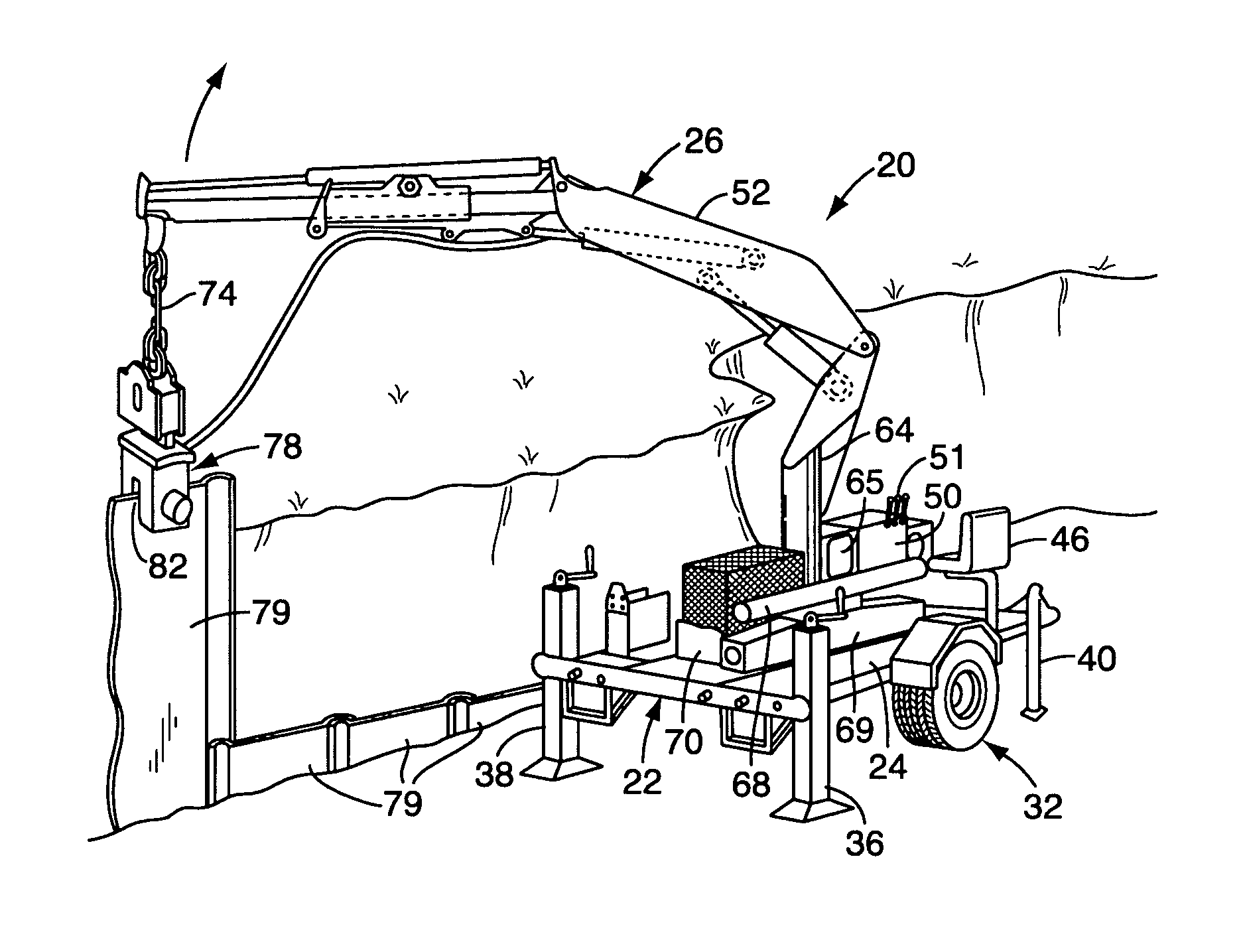

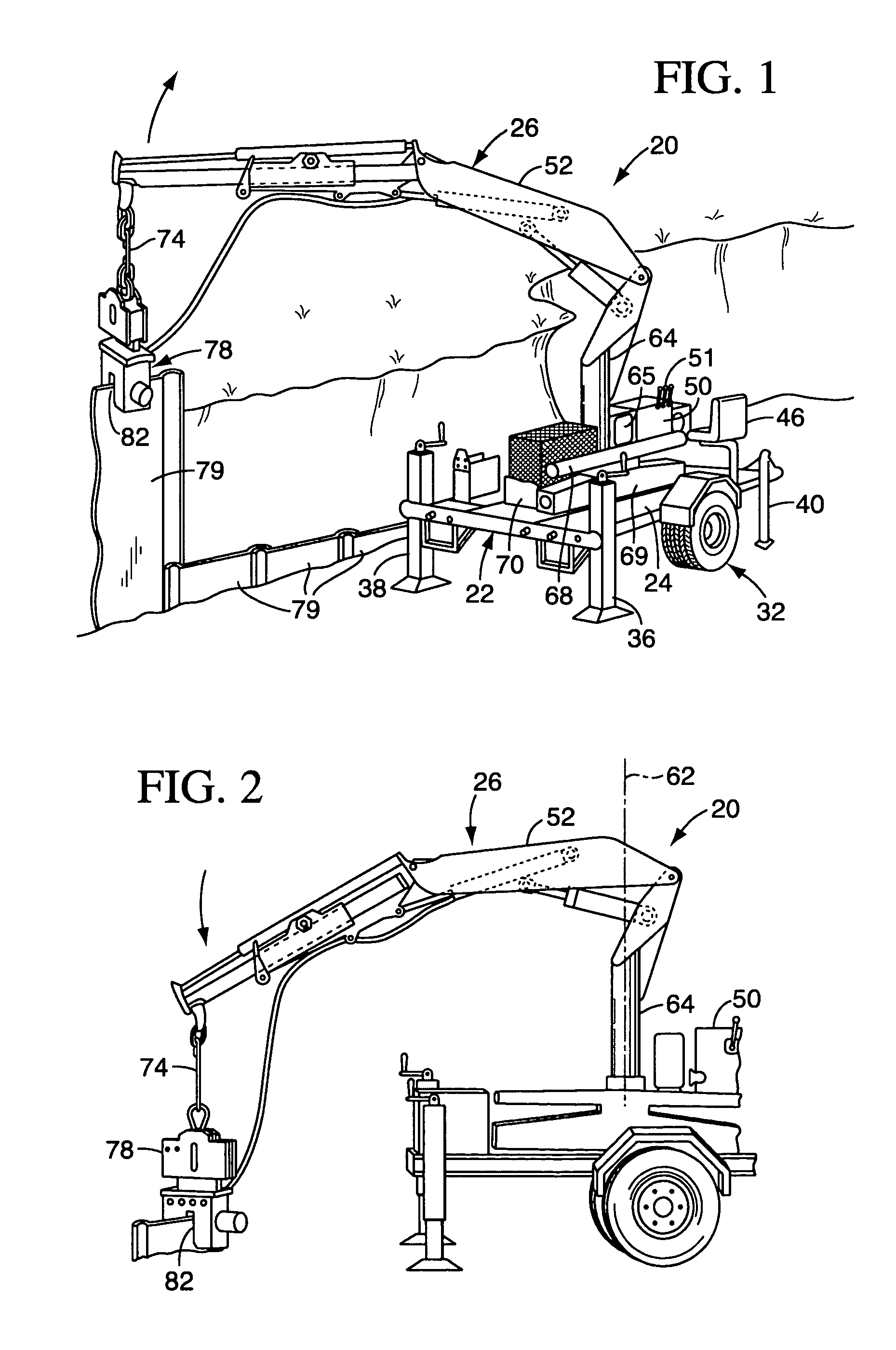

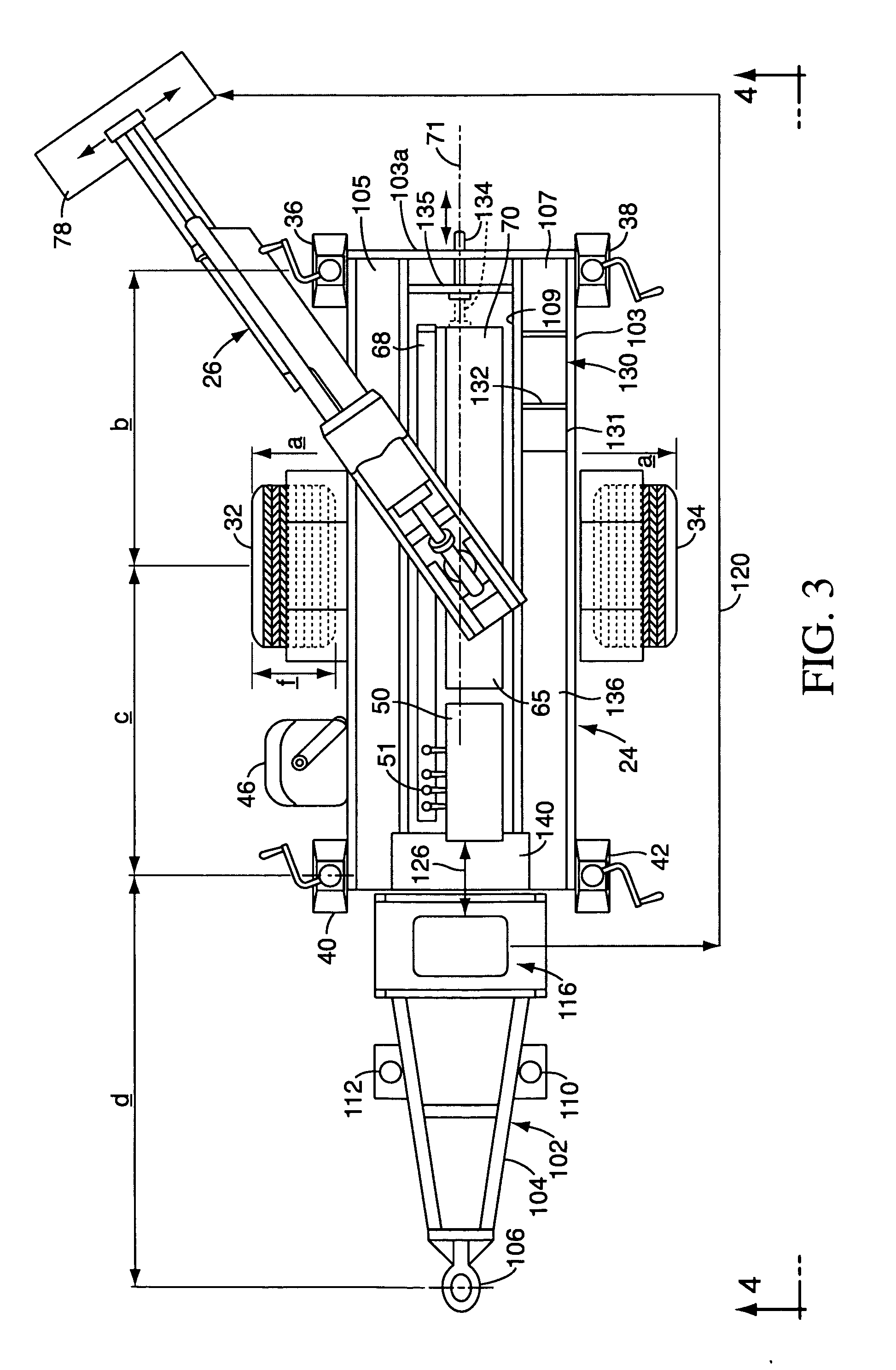

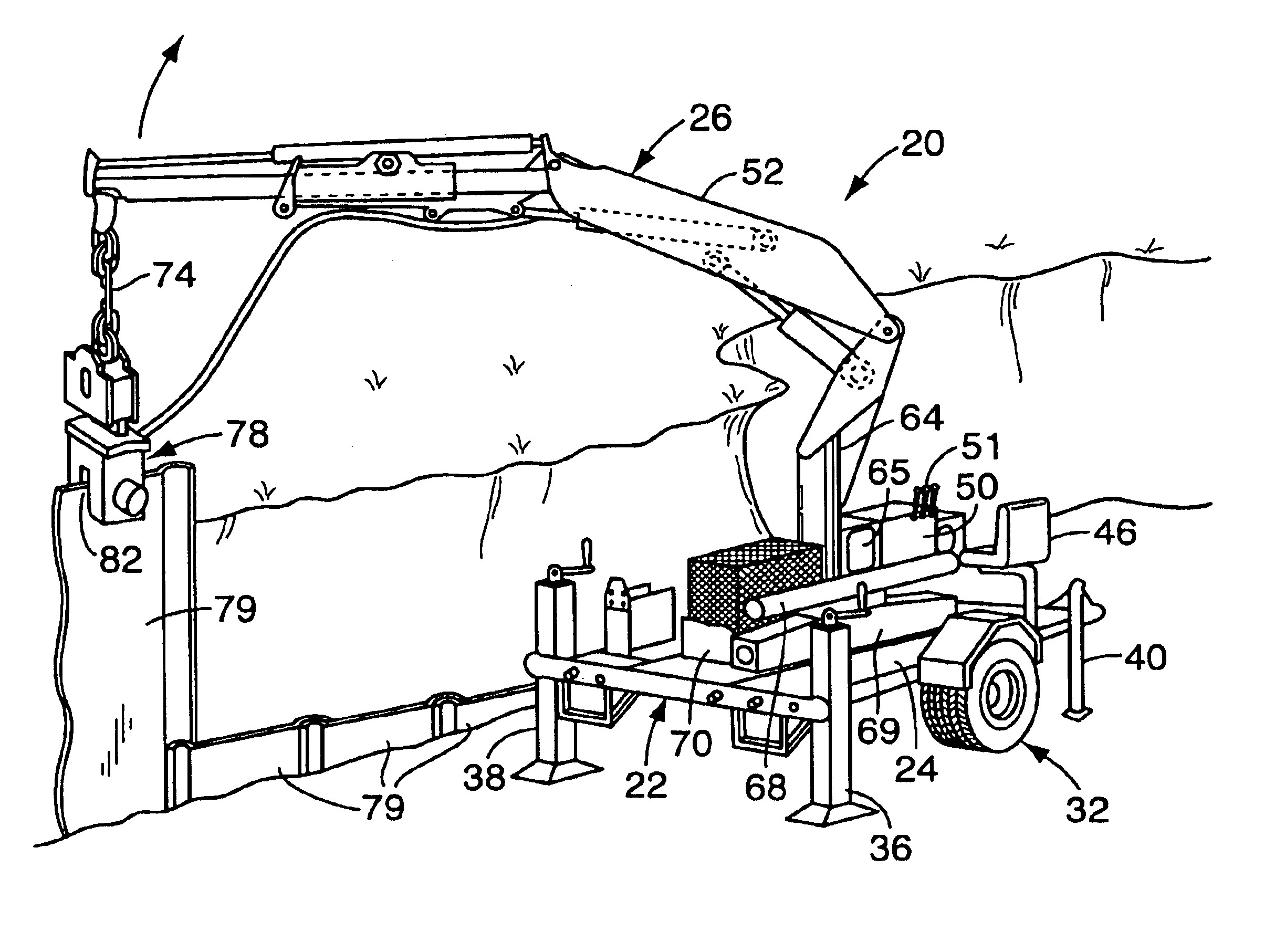

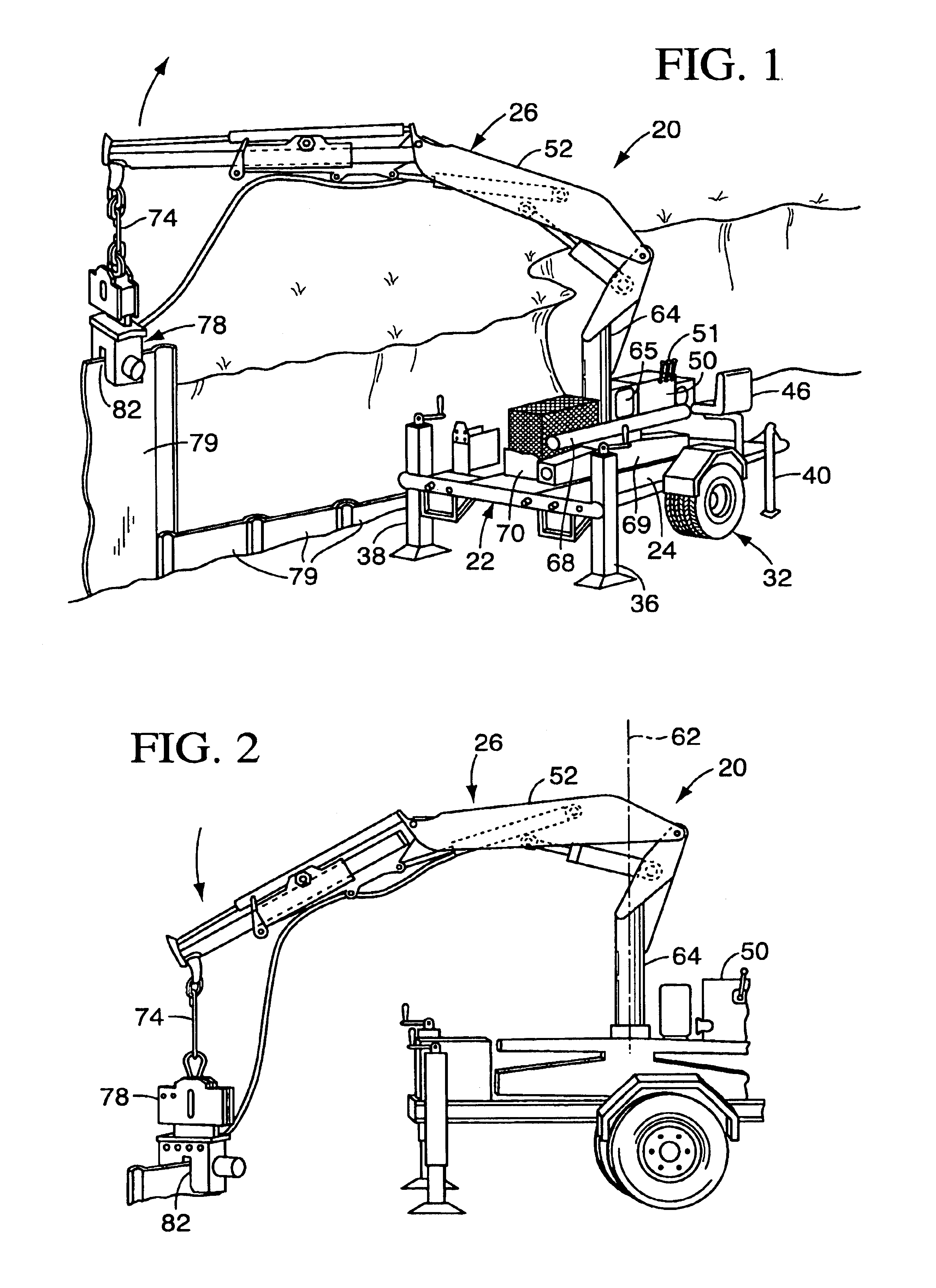

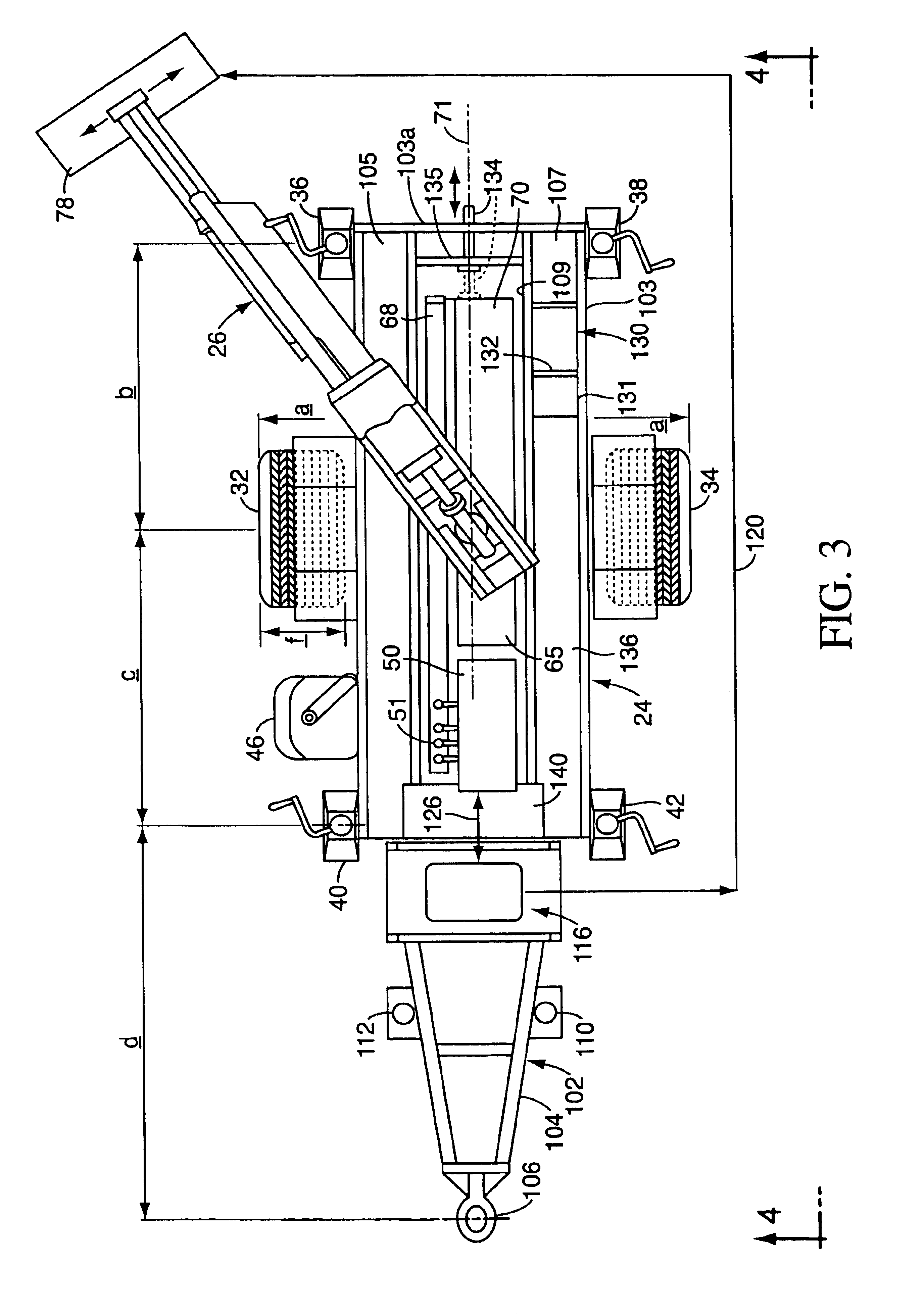

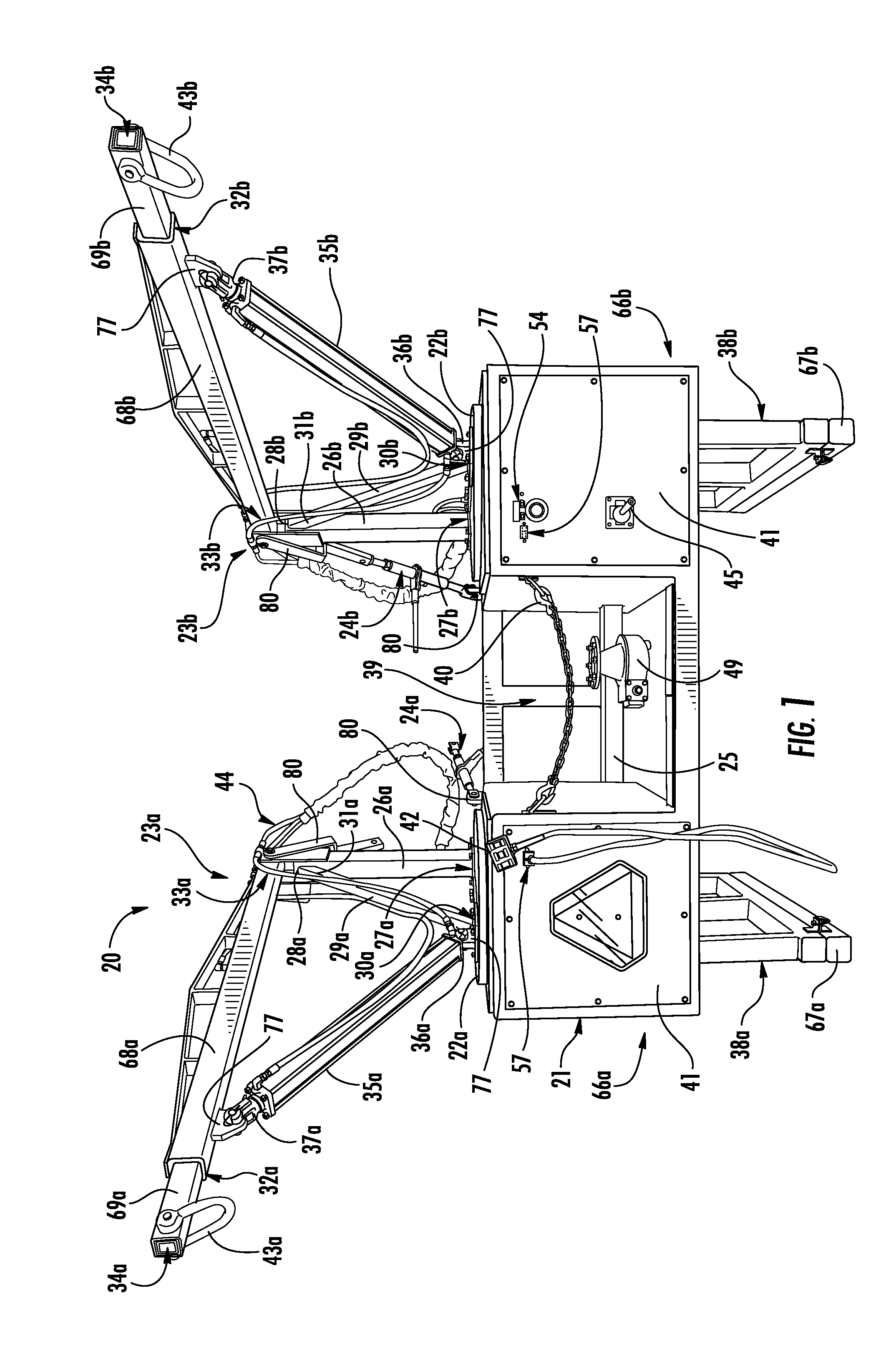

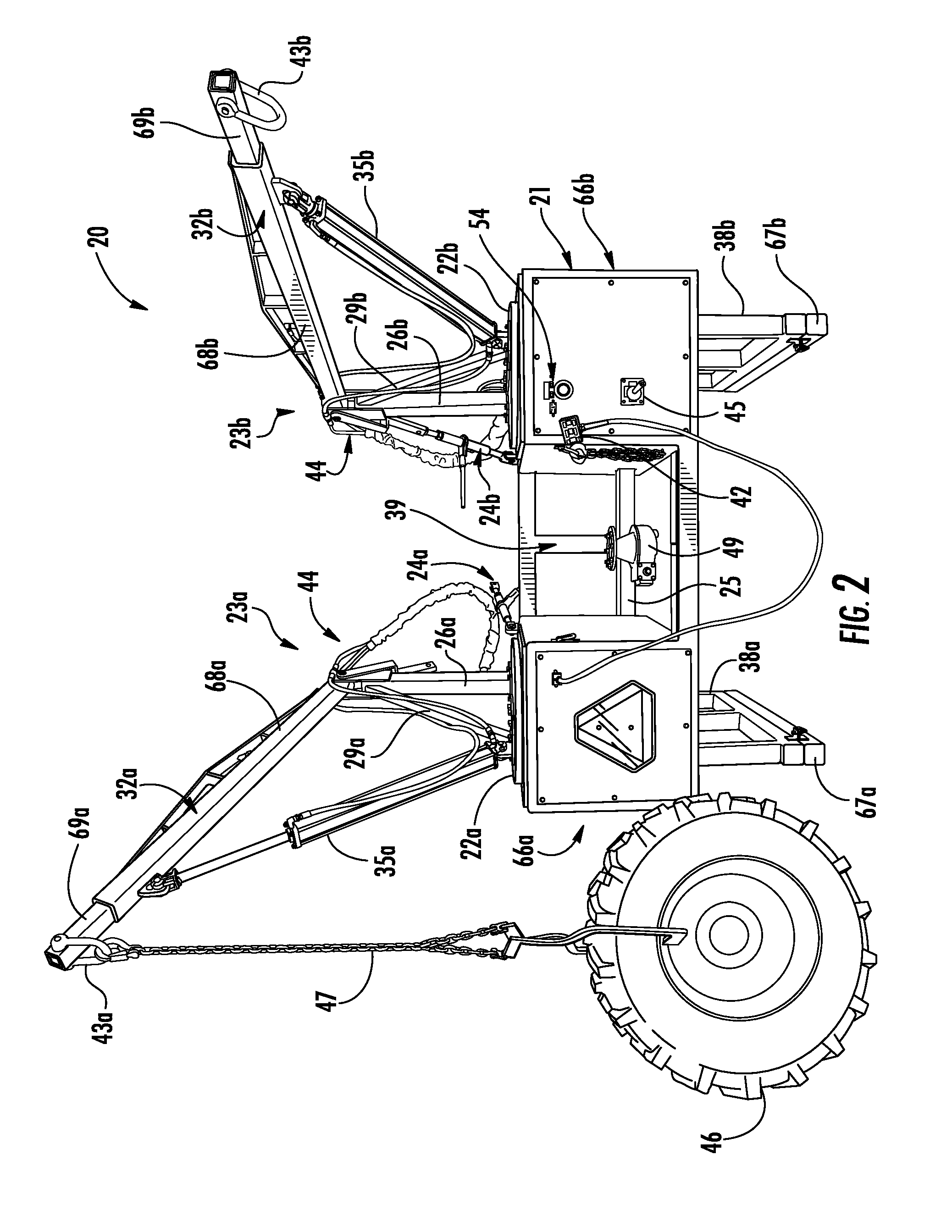

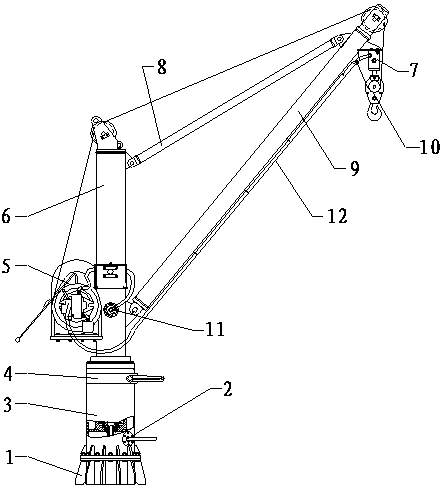

Trailer-mounted crane apparatus

InactiveUS20050220597A1Reduce surface pressureLight weightRefuse receptaclesLoading/unloading vehicle arrangmentDriver/operatorMarine engineering

A trailer-mounted crane apparatus includes a trailer supported from a ground surface on at least two wheels. A hydraulically operated crane arm is mounted to the trailer and is extendable outwardly. A crane hydraulic power unit is mounted to the trailer and supplies pressurized hydraulic fluid to the crane arm. A vibrational sheet piling driver can be supported by the crane arm. A vibrational hydraulic power unit for supplying power to the driver is mounted on the trailer. A control panel for the crane hydraulic power unit and the vibrational driver hydraulic power unit, and an associated operator's seat, are also mounted on the trailer. The crane apparatus includes wide tires for reducing the surface pressure under the apparatus. This allows the apparatus to be transported across and used on delicate surfaces such as golf course greens and other groomed surfaces.

Owner:BURKETT DARRYL S

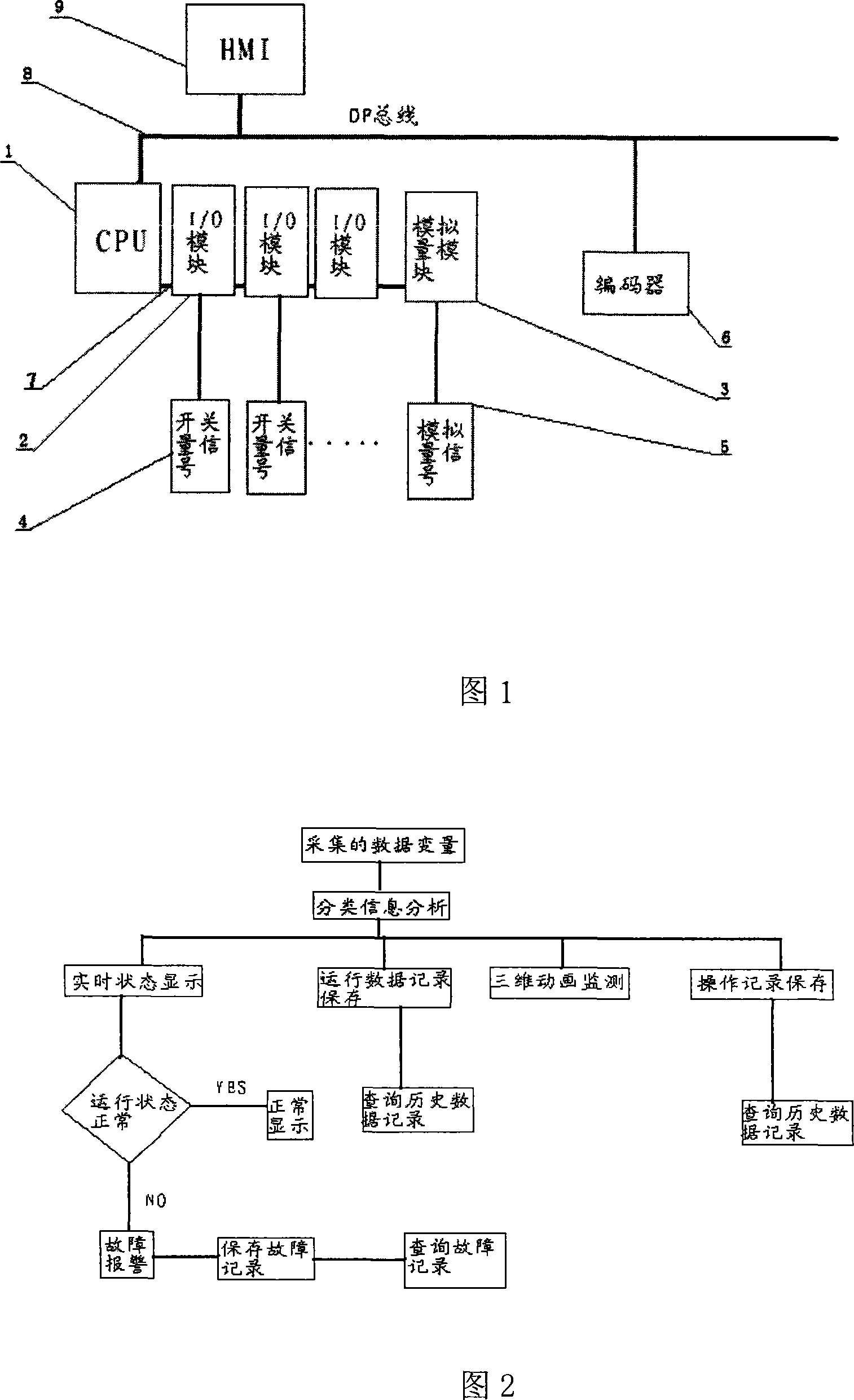

Crane integrated observation system and method

InactiveCN101224854AImprove efficiencyShorten breakdown repair timeSafety gearIntegrated monitoringRepair time

The invention relates to an integrated monitoring system of a crane and a method, belonging to the monitoring system capable of real time monitoring the state of a crane device in an operation process and the method. The invention mainly solves the technical problems of the prior crane that the integrated monitoring can not be done and the time of breakdown maintenance is long. The technical proposal of the invention is as follows: the integrated monitoring system of the crane comprises a plurality of switching value signal collectors used for collecting the operation state data of crane parts, an analogue quantity signal collecting device used for collecting the analogue quantity signal of the crane, a programmable controller used for classifying and analyzing the collected data, an industrial computer or a touch screen used for displaying the operation state and the data of the crane parts, a bus cable used for connecting the programmable controller and the touch screen and an absolute value coder for monitoring the position. The invention has the advantages of integrally monitoring the crane and correctly analyzing the faults, etc.

Owner:TAIYUAN HEAVY IND

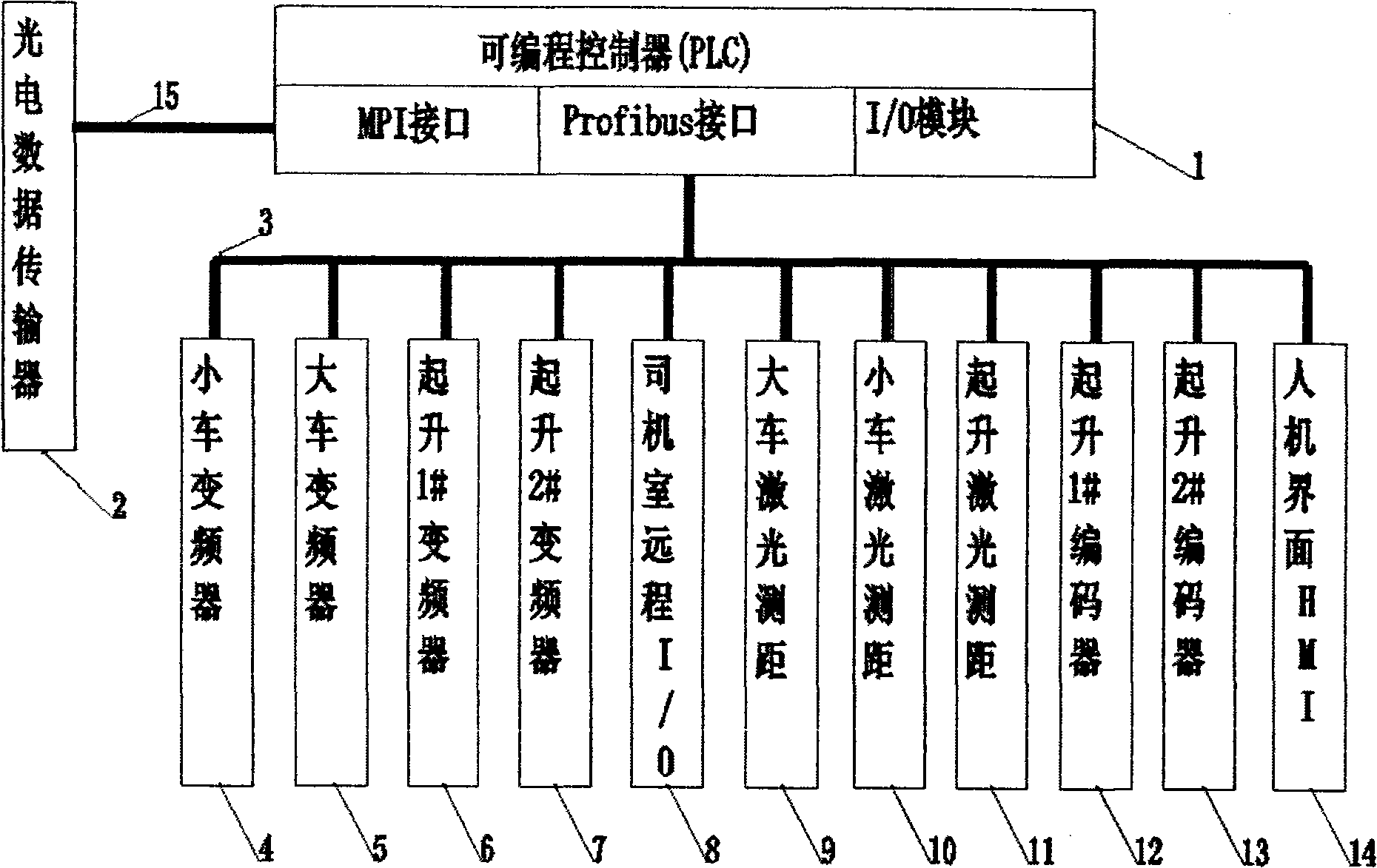

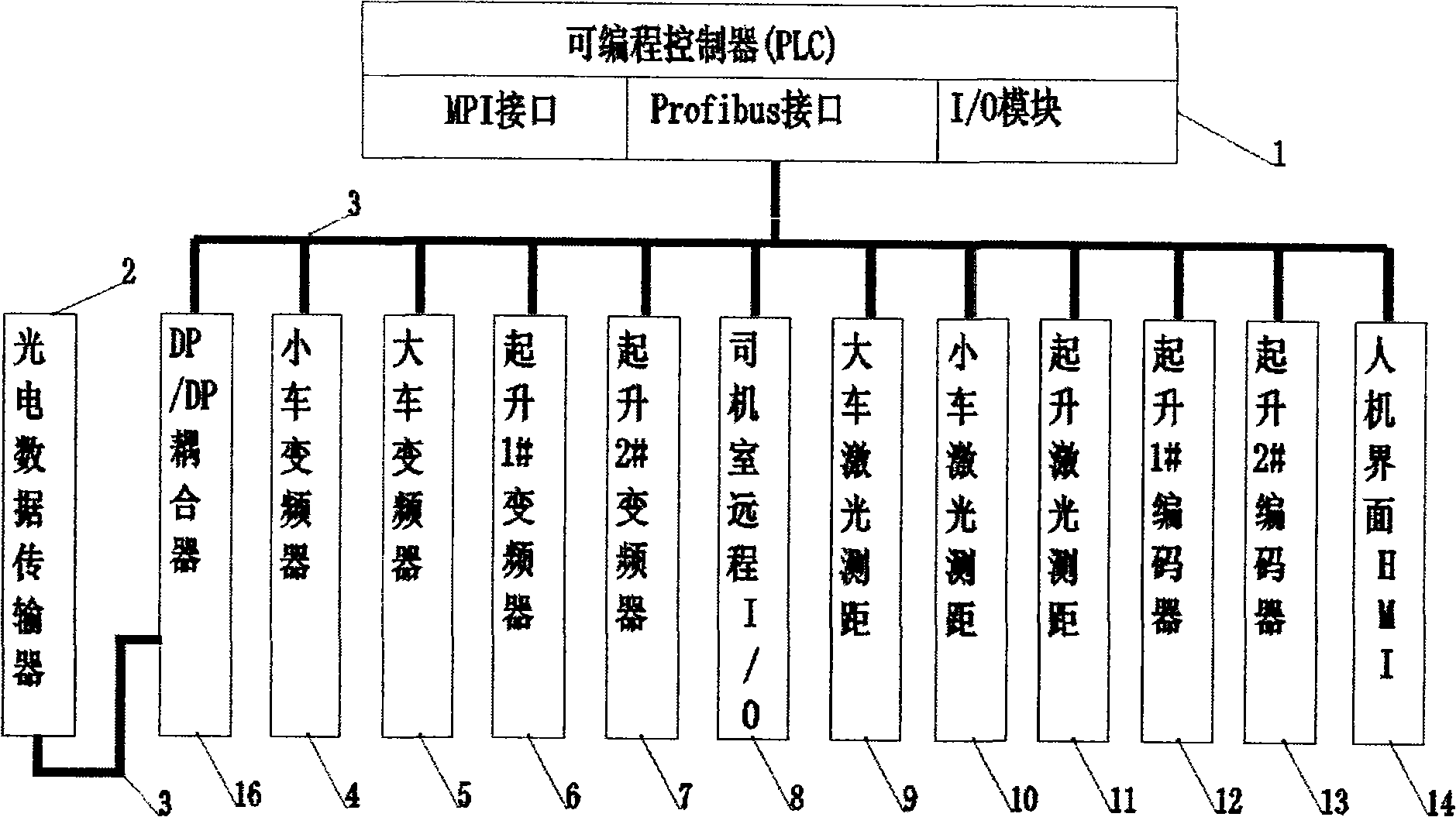

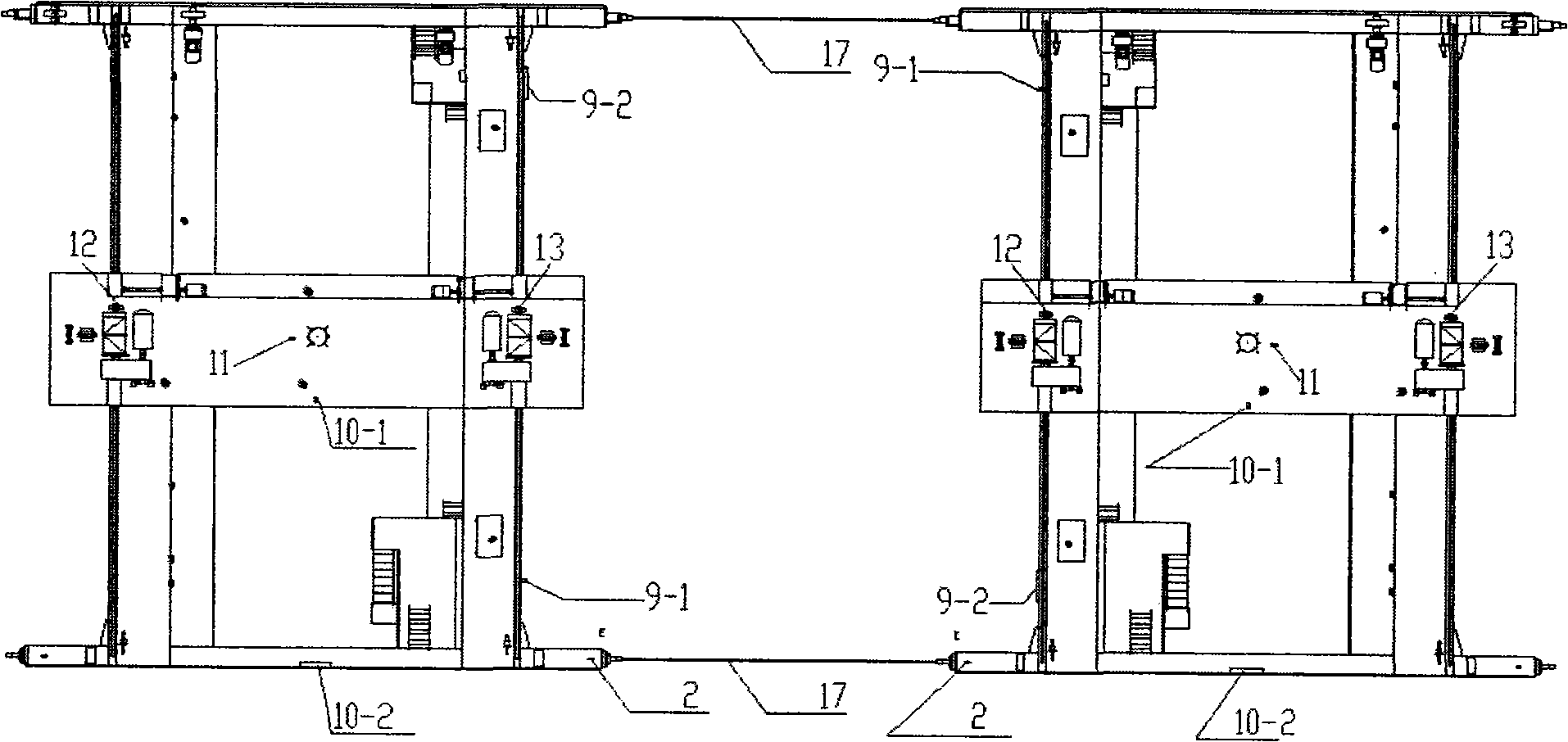

Crane remote wireless parallelling control system and method

InactiveCN101334661ARealize wireless high-speed two-way data transmission functionMeet the lifting requirementsTotal factory controlLoad-engaging elementsFrequency changerHuman–machine interface

The invention relates to a crane remote wireless parallel-operation control system and a method, belonging to the control system and the method which are applicable for remote wireless parallel-operation running when at least two crane equipment hoist ultra-long workpieces. The invention mainly solves the technical difficult point that the existing crane parallel-operation system can not hoist the ultra-long workpieces. The technical proposal of the invention aiming at solving the technical difficult point is that the crane remote wireless parallel-operation control system comprises a PLC which comprises a digital quantity input / output module and an analog signal input / output module, a human-machine interface (HMI) and a crane control system of a transducer; wherein, the crane remote wireless parallel-operation control system also comprises a large vehicle laser range finder, a small vehicle laser range finder, a rising laser range finder, an absolute value encoder and a wireless photoelectric data transmission module (ISD); and the parts are connected with the PLC by field buses.

Owner:TAIYUAN HEAVY IND

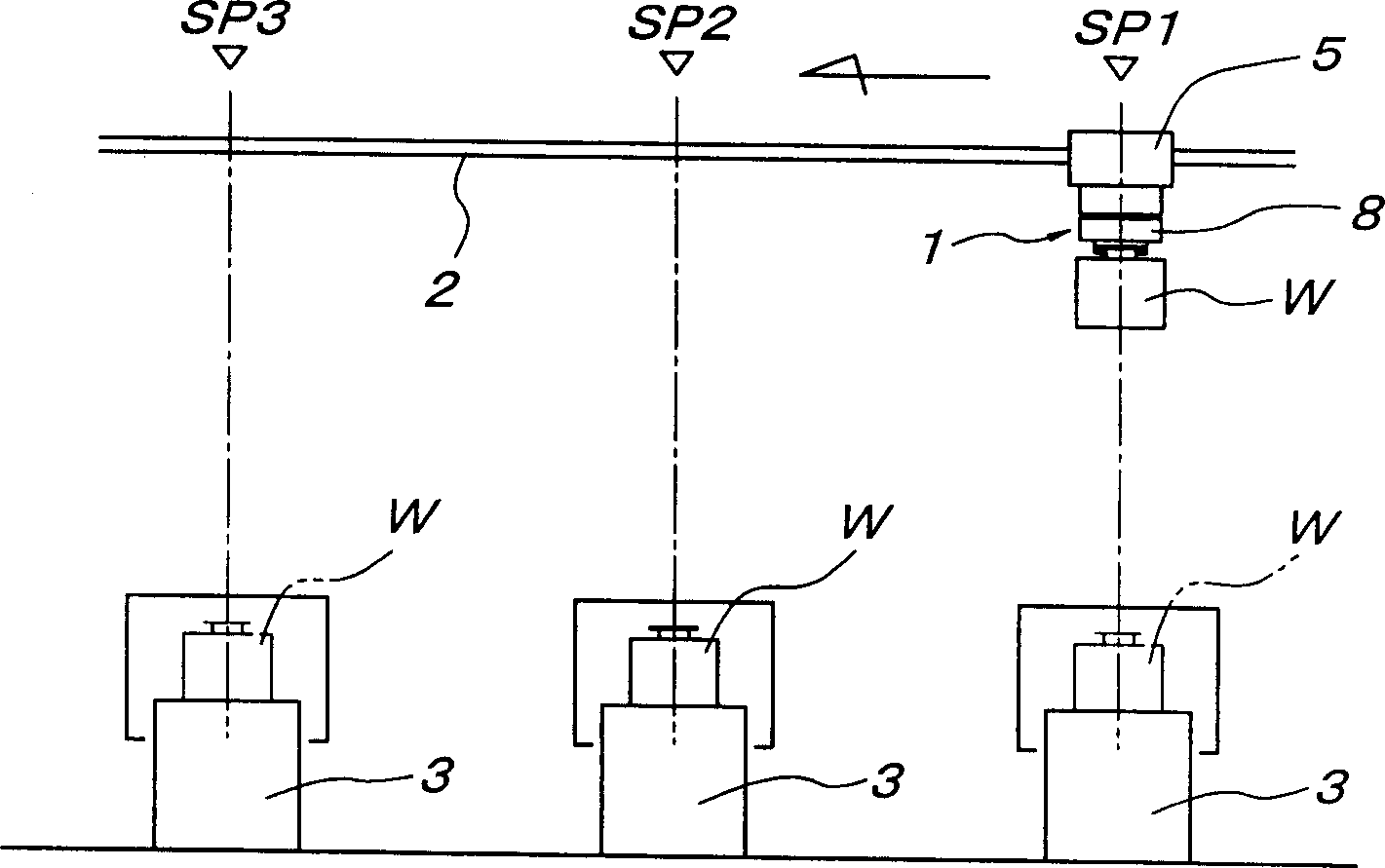

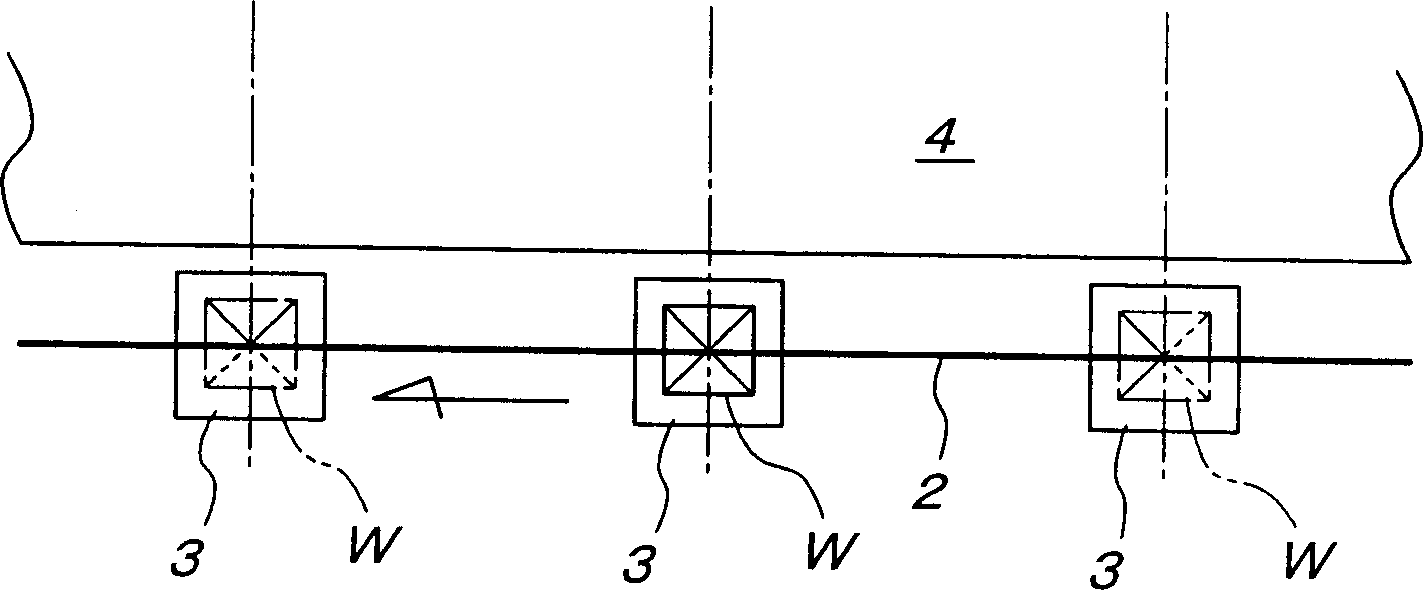

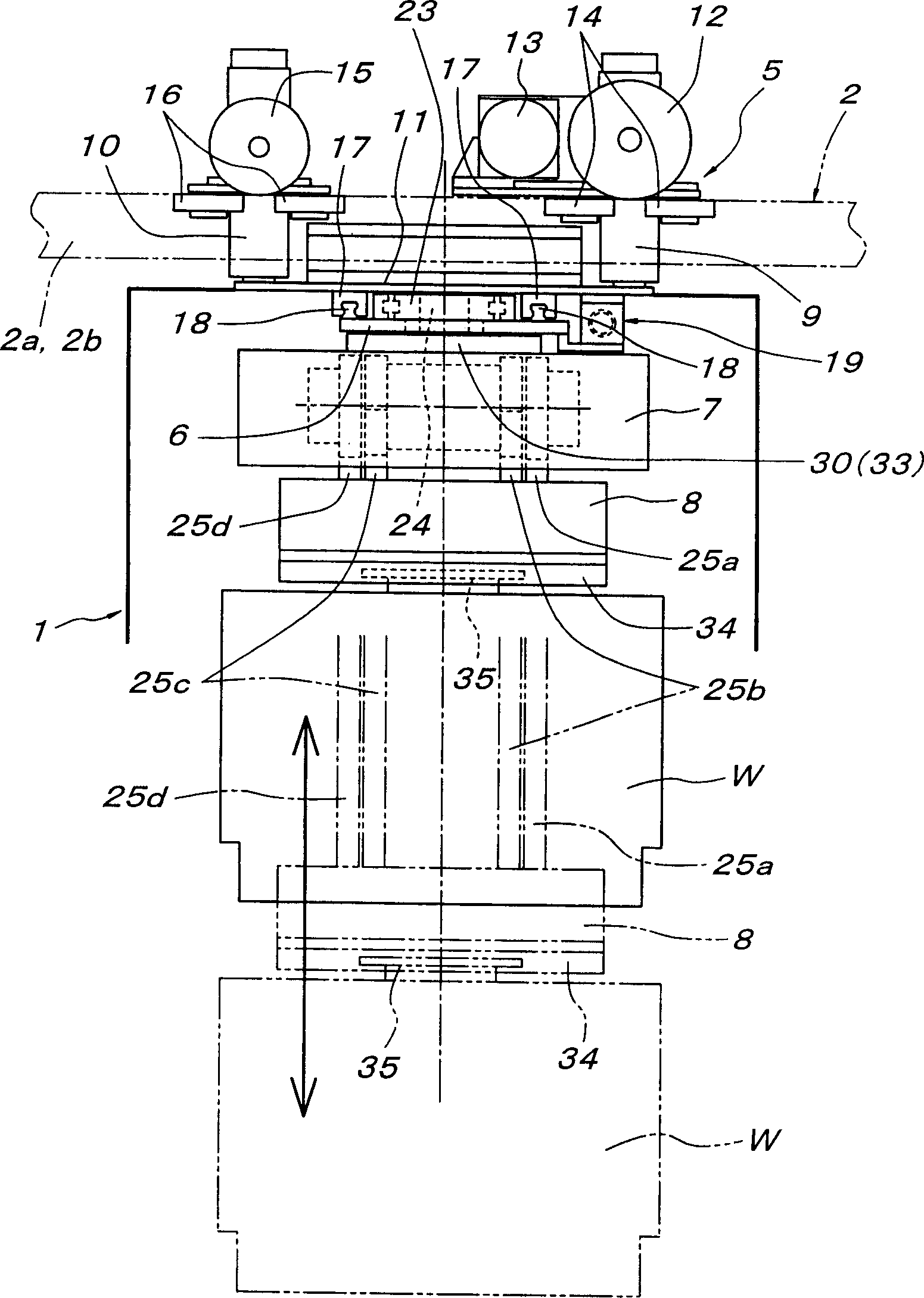

Suspension type crane equipment and its learning device

InactiveCN1412103AEasy to detectLoad-engaging elementsRotary conveyorsManipulatorIndustrial engineering

The invention provides hang type carrying equipment and a learning device which can do load and unload work safely and correctly. In hang type carrying equipment, a work hand which makes a held work elevate in a hung-down state and can rise and fall is installed on the adjustable position in horizontal two-dimensional directions to a conveying travel body. The work W can be loaded up and down by the work hand between a plurality of supporting bases for transferring work arranged below the running route of the conveying travel body. The position adjusting amount for work lifting and the position adjusting amount for work falling are set every supporting base for transferring work. When the work hand is fallen from the conveying travel body stopping at fixed stopping positions SP1 to the supporting bases for transferring work, the positional adjustment is performed in horizontal two-dimensional directions of the work hand by only the position adjusting amount set to the supporting bases for transferring work according to the work lifting work or the work falling work.

Owner:DAIFUKU CO LTD

Installation method for high-altitude large-span steel trusses

InactiveCN106545172AAvoid high-altitude weldingGuarantee welding qualityBuilding material handlingEconomic benefitsArchitectural engineering

The invention discloses an installation method for high-altitude large-span steel trusses. The method comprises the steps that the trusses are lifted to a demanded vertical height outside a building; then, each truss is slid in place through an overhead slide method, and hawsers are installed, fixed and pulled; and above operations are repeated till all the high-altitude large-span steel trusses are installed. According to the invention, the problem that large crane equipment cannot lift high-altitude components of a building light well roof in place can be solved; the method is simple and requires fewer steps; the construction period is shortened; the construction cost is reduced; and the method has very good economic benefits.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

Trailer-mounted crane apparatus

InactiveUS6966448B1Reduce contact pressureUsed for stabilizationLoading/unloading vehicle arrangmentCranesGolf course turfMarine engineering

A trailer-mounted crane apparatus includes a trailer supported from a ground surface on at least two wheels. A hydraulically operated crane arm is mounted to the trailer and is extendable outwardly. A crane hydraulic power unit is mounted to the trailer and supplies pressurized hydraulic fluid to the crane arm. A vibrational sheet piling driver can be supported by the crane arm. A vibrational hydraulic power unit for supplying power to the driver is mounted on the trailer. A control panel for the crane hydraulic power unit and the vibrational driver hydraulic power unit, and an associated operator's seat, are also mounted on the trailer. The crane apparatus includes wide tires for reducing the surface pressure under the apparatus. This allows the apparatus to be transported across and used on delicate surfaces such as golf course greens and other groomed surfaces.

Owner:BURKETT DARRYL SCOTT

Crane apparatus for direct transshipment of marine containers between transportation modes without need of ground placement

InactiveUS7370768B2High lift per hour rateFaster turn around timeCargo handling apparatusBase supporting structuresMarine engineeringGround vehicles

A crane apparatus is installed on a pier, wharf, bulkhead wharf or other foundation extending into the water for directly transshipping containers from a vessel moored alongside the foundation to another transportation mode without necessity of ground placement of the containers. The crane apparatus includes a parent crane displaceable along the foundation for unloading containers from a vessel moored alongside the foundation and placing the containers on a first platform of the parent crane, and a sibling crane displaceable along the foundation beneath the parent crane independently of displacement of the parent crane for loading containers from the first platform onto over-the-ground vehicles. The parent crane has a first trolley / spreader hoist movable along a first boom for unloading containers from the vessel and placing them on either the first platform or a second platform of the parent crane, and a second trolley / spreader hoist movable along a second boom for loading containers from the second platform onto another vessel or over-the-ground vehicles.

Owner:CHATTEY NIGEL

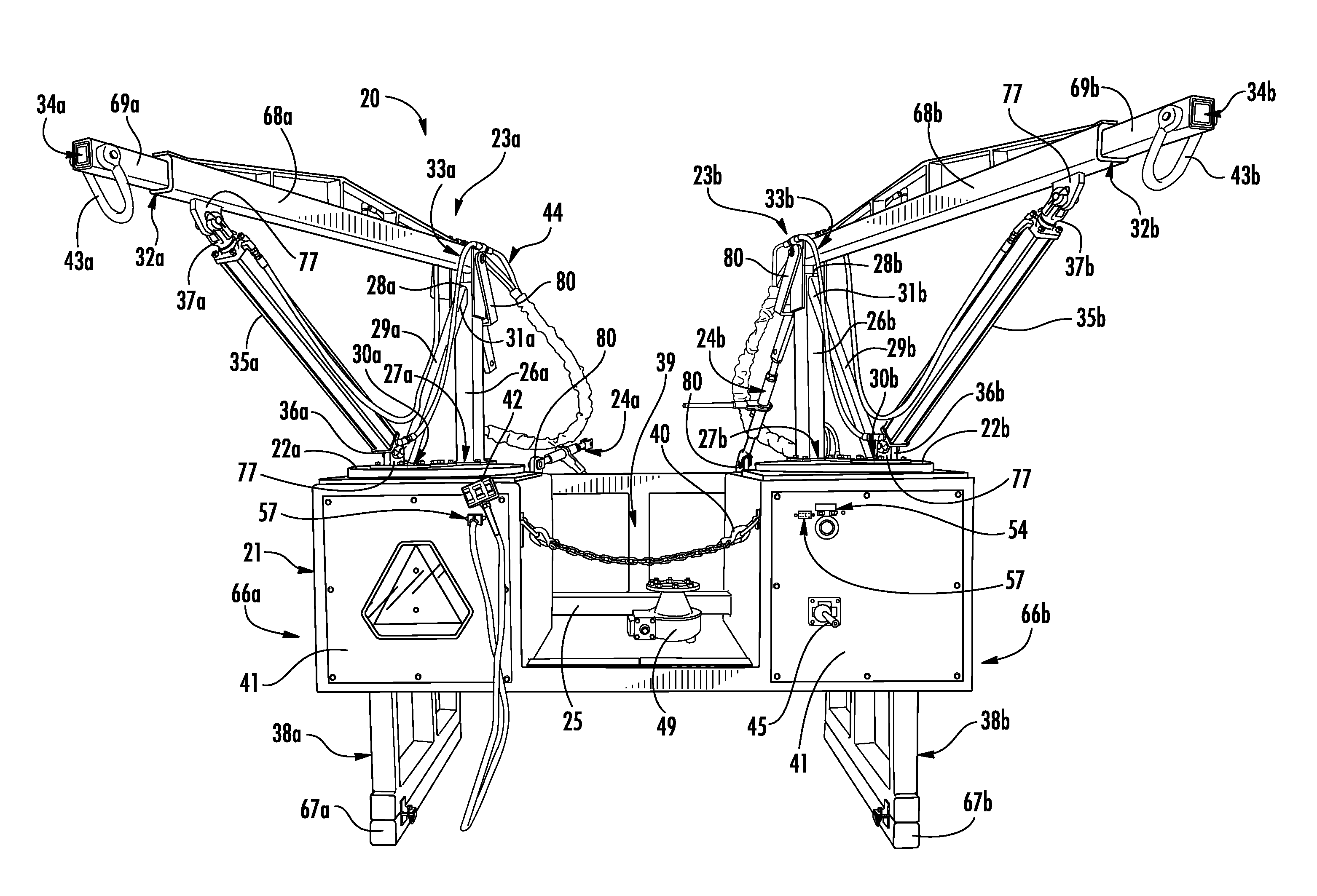

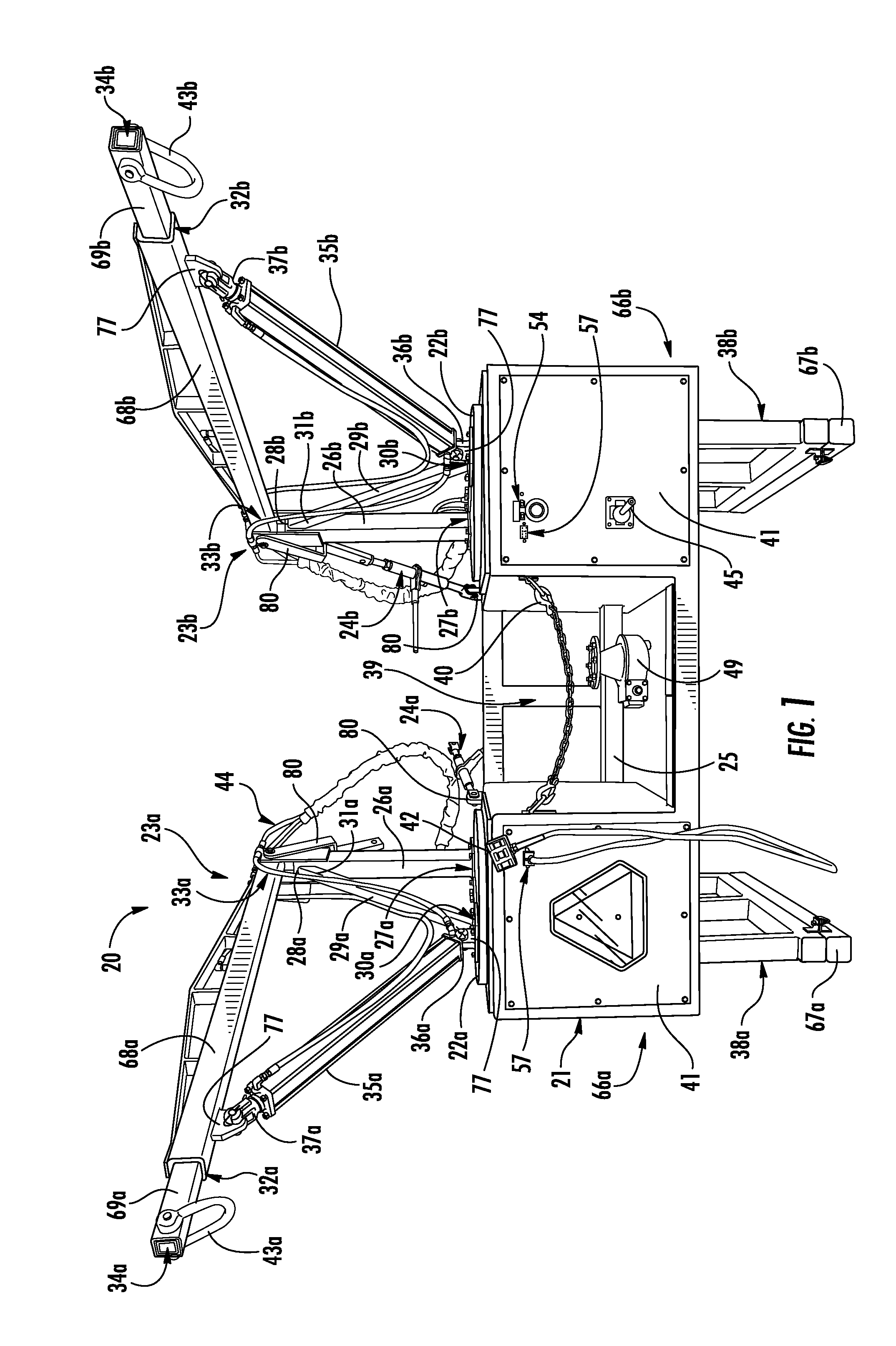

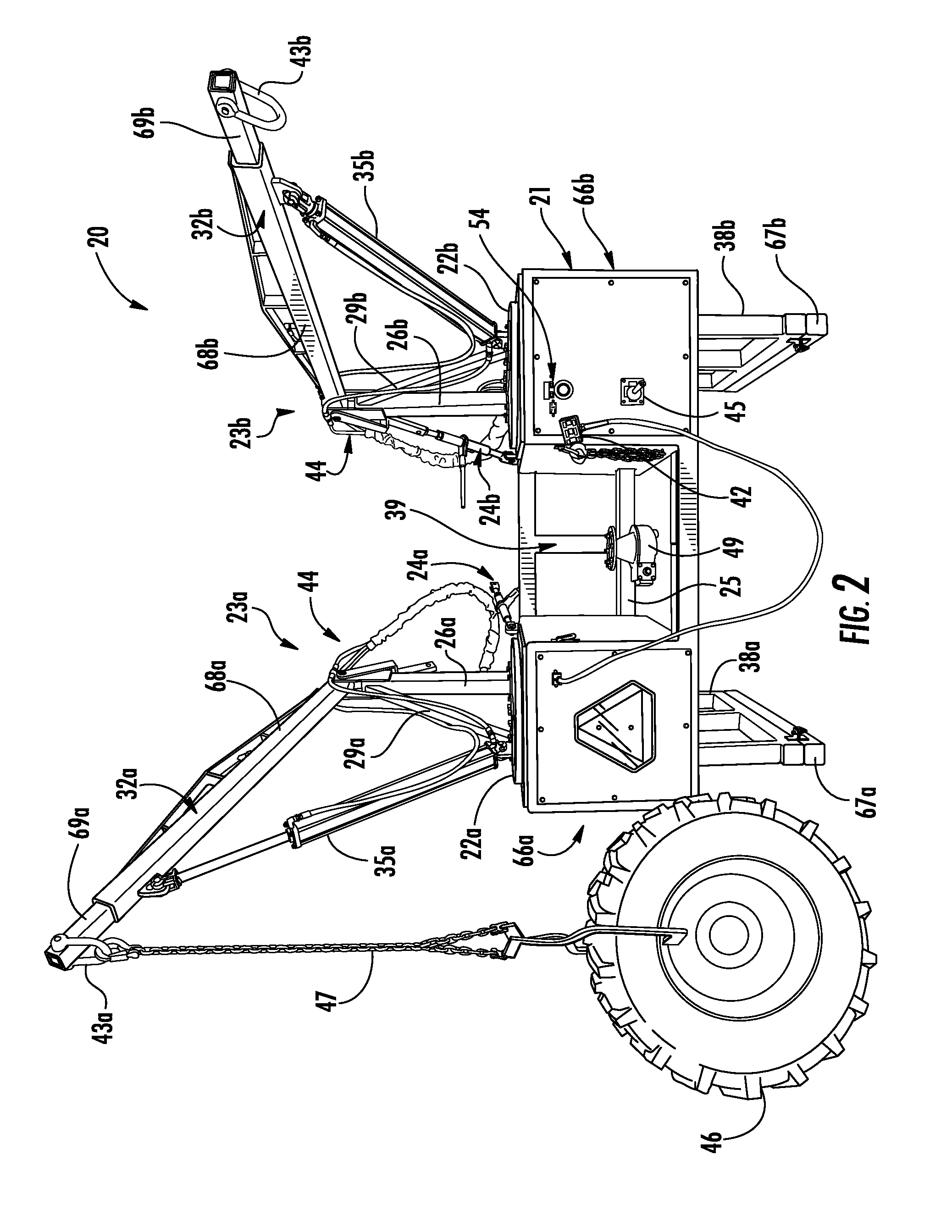

Dual Crane Apparatus and Method of Use

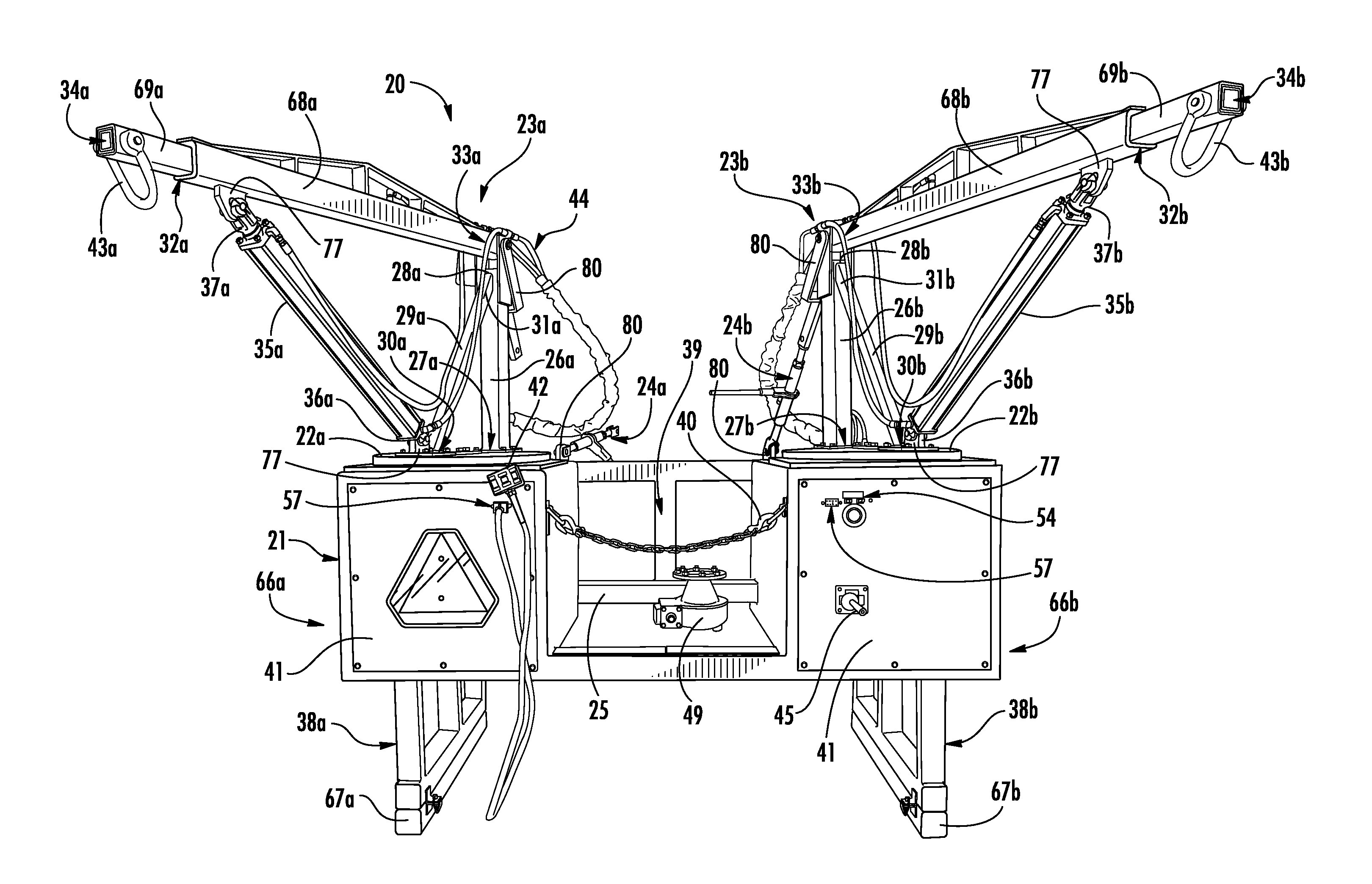

ActiveUS20140150232A1Overcomes drawbackReduces dangerMetal working apparatusCranesEngineeringQuay crane

A dual crane apparatus and a method of use are disclosed herein. The disclosed dual crane apparatus generally comprises a support frame and two rotating crane members mounted to the support frame, wherein the crane members can each independently move up and down in a vertical direction, extend and retract in a horizontal direction, and rotate clockwise and counterclockwise. The disclosed dual crane apparatus can be utilized for servicing mobile irrigation systems.

Owner:ARTHUR BRADY PAUL +1

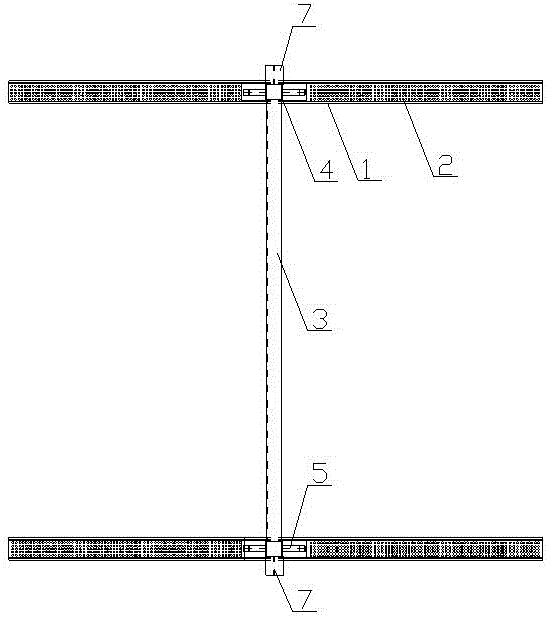

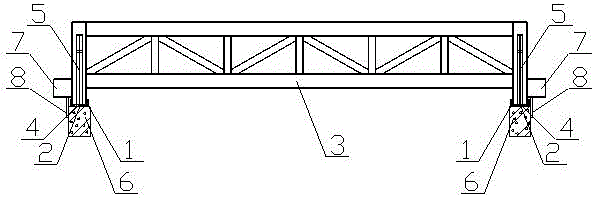

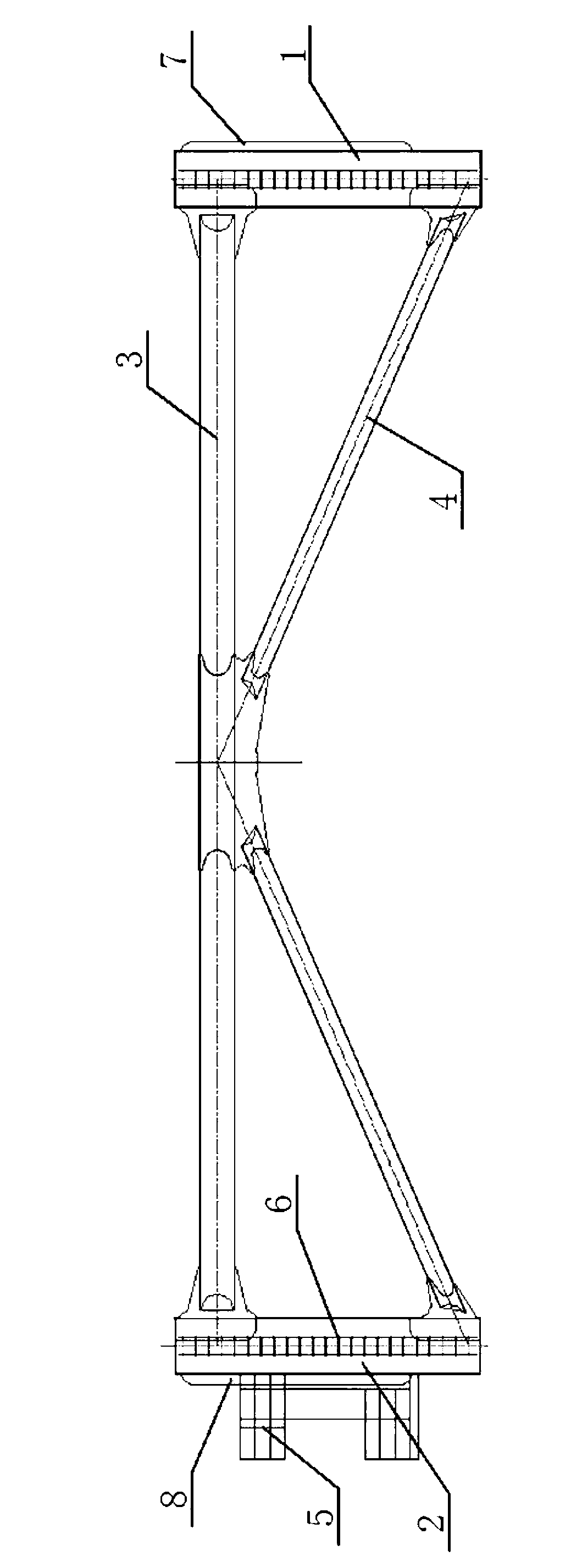

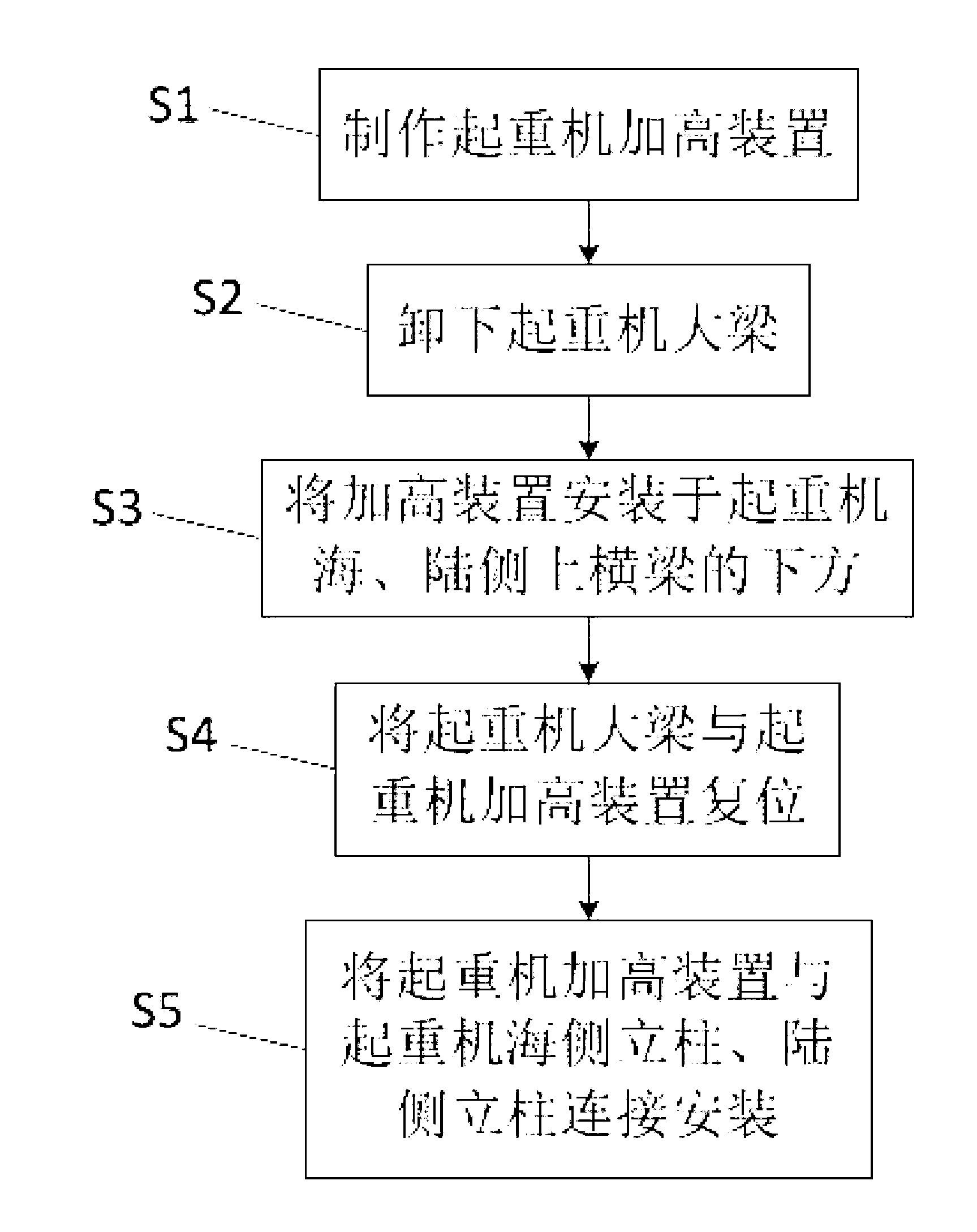

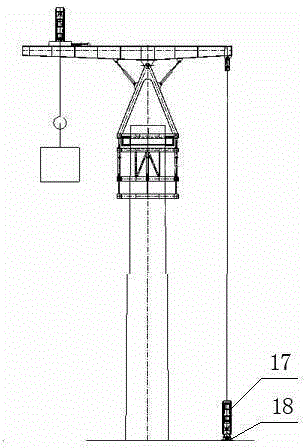

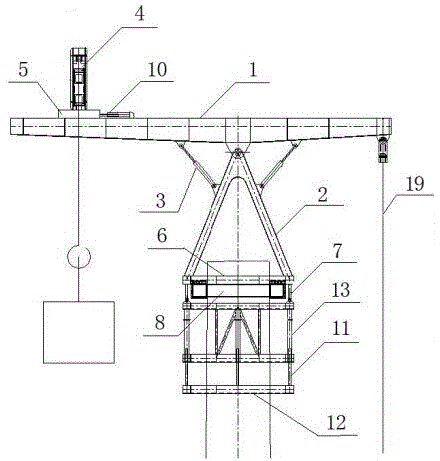

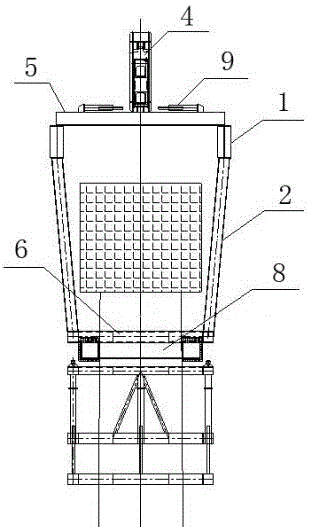

Crane heightening device and method

ActiveCN103193162AMaximize utilizationSimple structureLoad-engaging girdersTravelling cranesEngineeringCrane Equipment

The invention discloses a crane heightening device and a crane heightening method. A crane comprises a large front beam, a large rear beam, an upper cross beam at the sea side, an upper cross beam at the land side, a vertical column at the sea side, a vertical column at the land side and the like; the heightening device comprises a heightening section of the vertical column at the sea side, a heightening section at the vertical column at the land side, a horizontal support rod, a door frame diagonal bracing, a door frame diagonal bracing at the sea side and a door frame diagonal bracing at the land side. The method comprises the following steps of: step 1, manufacturing the crane heightening device; step 2, dismounting the large front beam and the large rear beam of the crane; step 3, installing the heightening device on the ground below the upper cross beam at the sea side and the upper cross beam at the land side; step 4, resetting the large front beam and the large rear beam of the crane and a heightening device assembly; and step 5, connecting and installing the crane heightening device and the top ends of the vertical columns at the sea side and the land side of the crane. By adopting the technical scheme provided by the invention, the existing crane equipment can be utilized to the maximum, and the structure of the heightening device is simplified, so that the heightening method is convenient and rapid, and the cost is saved.

Owner:SHANGHAI ZHENHUA HEAVY IND

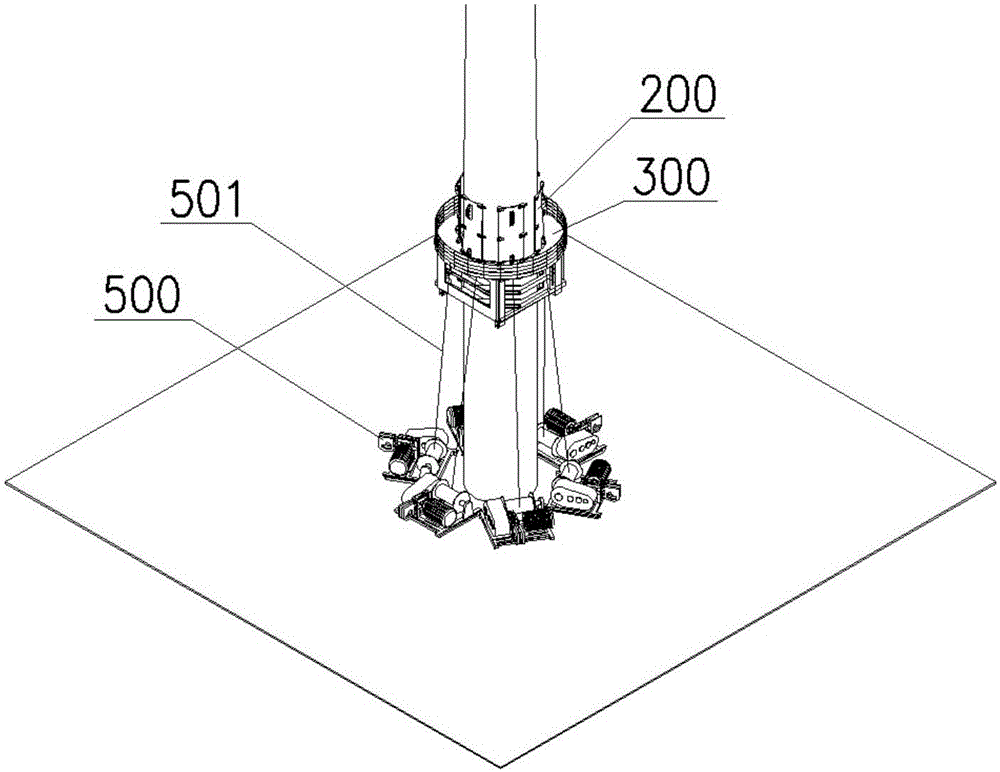

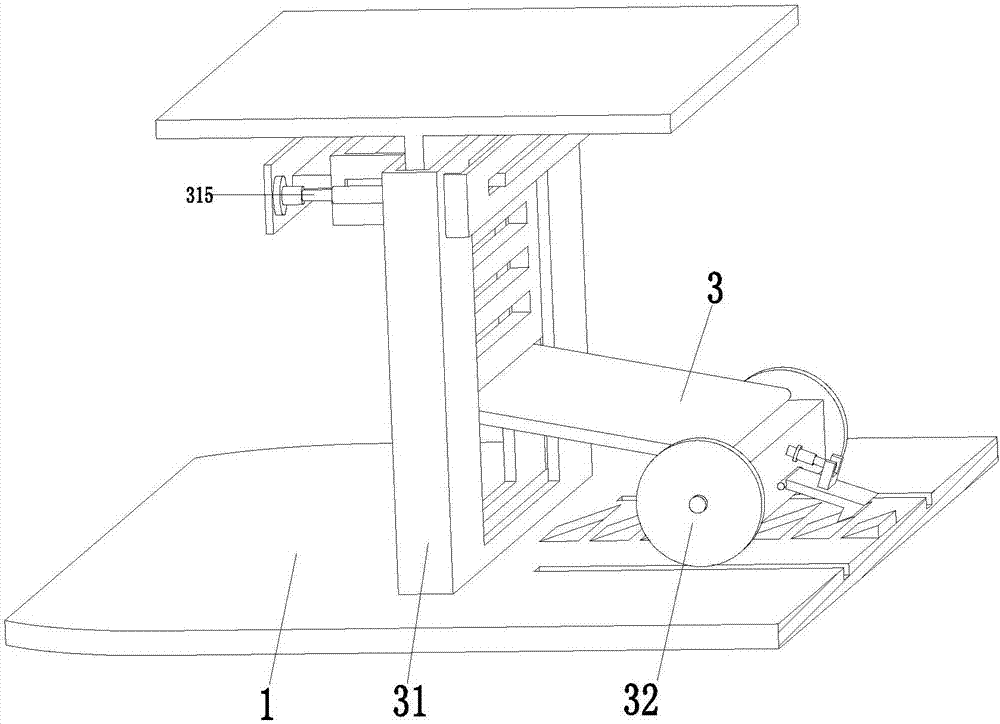

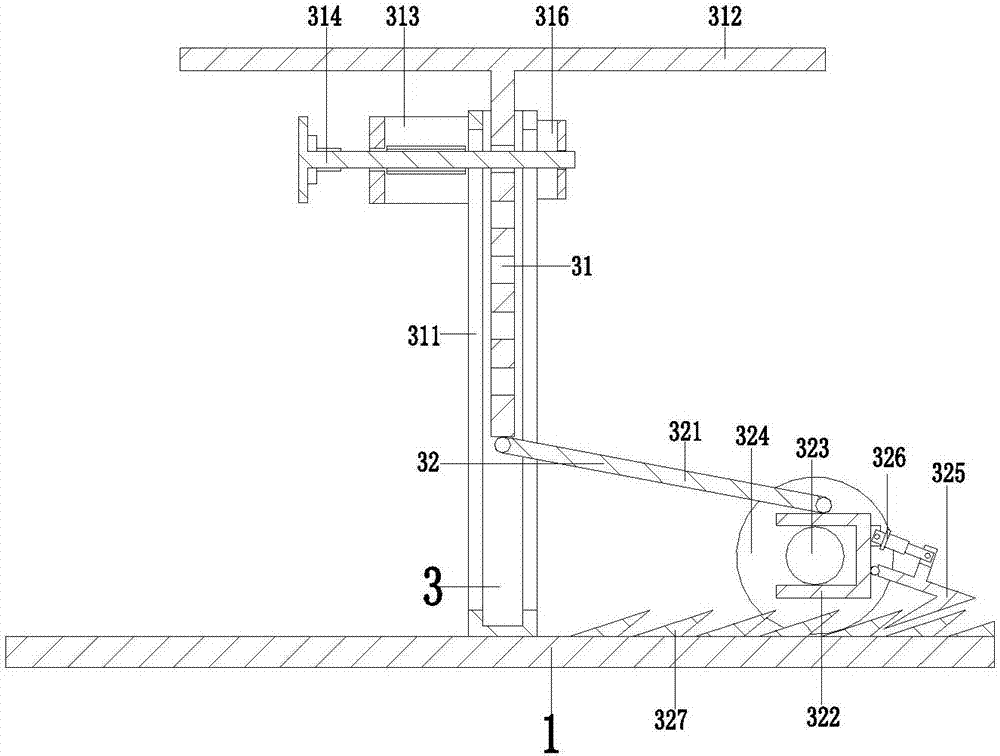

Spanning self-climbing type translational crane of wind power generation tower

The invention discloses a spanning self-climbing type translational crane of a wind power generation tower. The spanning self-climbing type translational crane comprises a supporting device, a lifting device and a ground anchor device and also comprises a climbing device, wherein the climbing device is fixedly arranged under the supporting device and comprises a climbing ring beam, jacking cylinders, sleeve frames, lower inserting pin cylinders and upper inserting pin cylinders; the supporting device comprises supporting legs, a supporting beam and a support; the lifting device comprises a lifting arm, a lifting cylinder and a hydraulic lifting frame; and the ground anchor device comprises a ground anchor embedded part, a ground anchor cylinder and a ground anchor steel strand. The spanning self-climbing type translational crane disclosed by the invention has the advantages that by highly-automatic operation, crane equipment can climb up and down by self and can replace a large-tonnage crawler crane or an automobile crane to lift or maintain fan equipment, so that the lifting cost is saved and the lifting efficiency is improved.

Owner:QINGDAO SINOSTRO TECH CO LTD

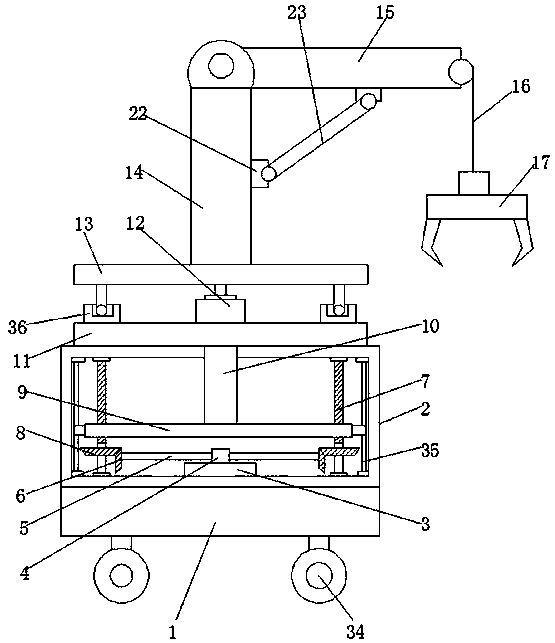

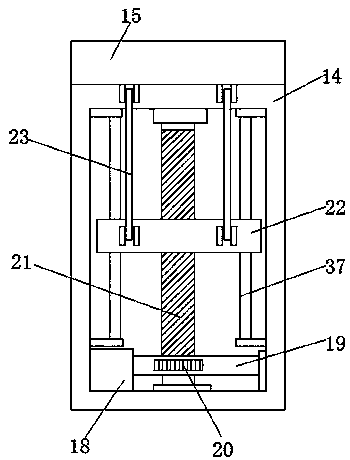

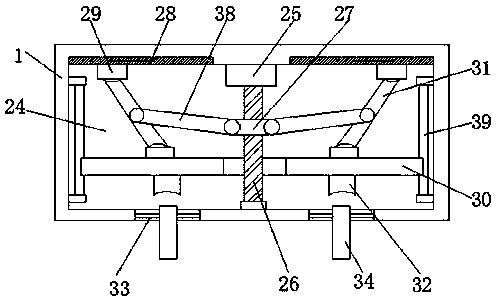

Cargo loading and unloading crane equipment special for railway transportation

InactiveCN111483927AEasy height adjustmentEasy to adjust the angleSupporting partsCranesMarine engineeringElectric machinery

The invention provides cargo loading and unloading crane equipment special for railway transportation. The equipment comprises a base, a lifting box is installed at the top of the base, a first motoris installed at the bottom of an inner cavity of the lifting box, a roller bearing is mounted on an output shaft at the top of the first motor, a rotating rod is connected with the interior of the roller bearing, driving bevel gears are mounted on the two sides of the rotating rod, and first screw rods are movably connected to the interior of the lifting box. According to the cargo loading and unloading crane equipment special for railway transportation, the rotating rod is driven by the first motor to rotate, so that the two driving bevel gears rotate to drive driven bevel gears to rotate, the two first screws rods rotate simultaneously, a lifting plate can move up and down, the height of a clamping jaw can be adjusted conveniently, and loading and unloading are facilitated; a worm is driven to rotate through a third motor, a threaded rod is driven to rotate, and therefore a movable block can move up and down on the surface of the threaded rod; and a second sliding rod is arranged, sothat the movable block moves up and down stably, the angle of a steel rope box is convenient to adjust, and the clamping jaw can conveniently perform clamping and carrying.

Owner:余祥红

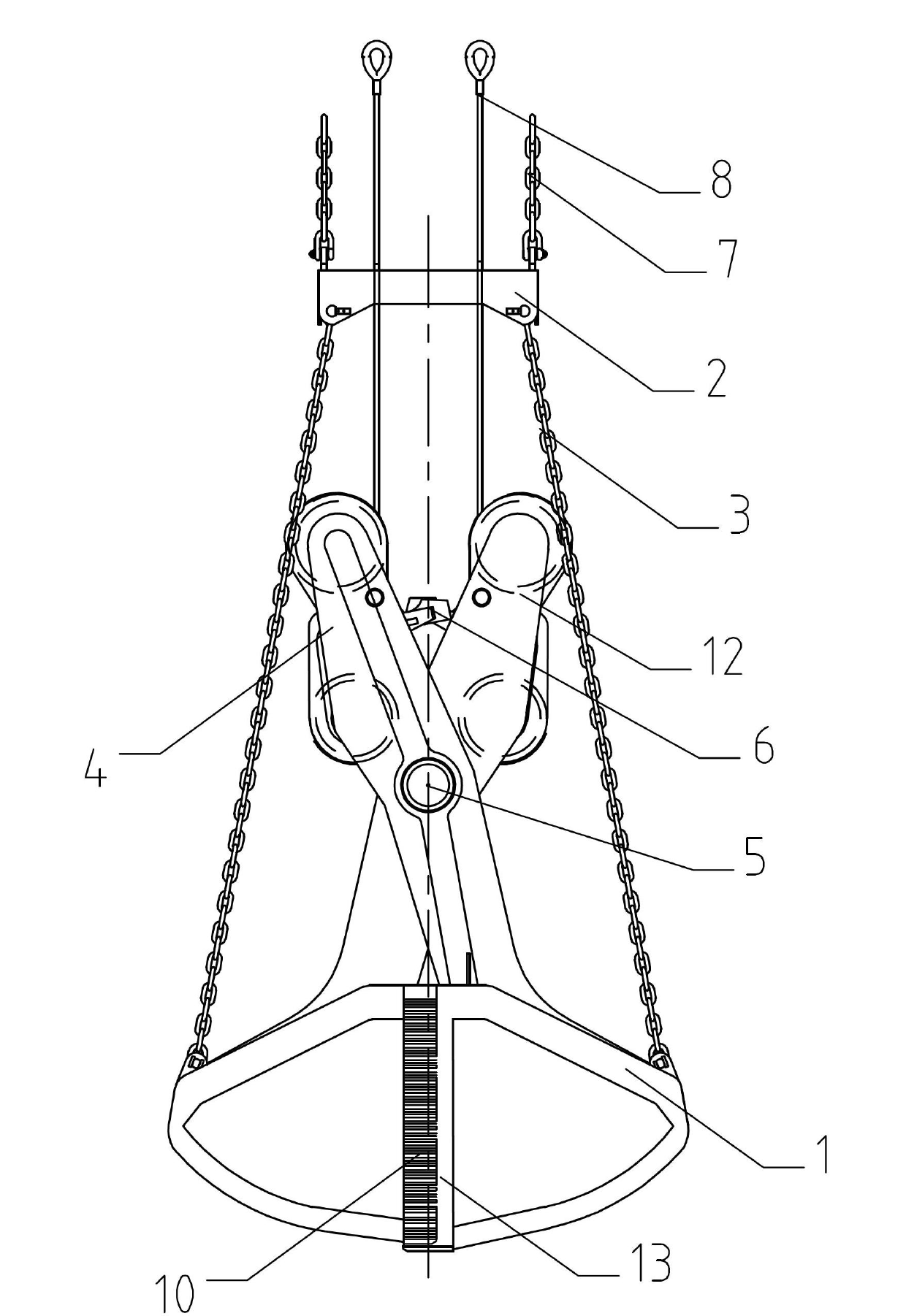

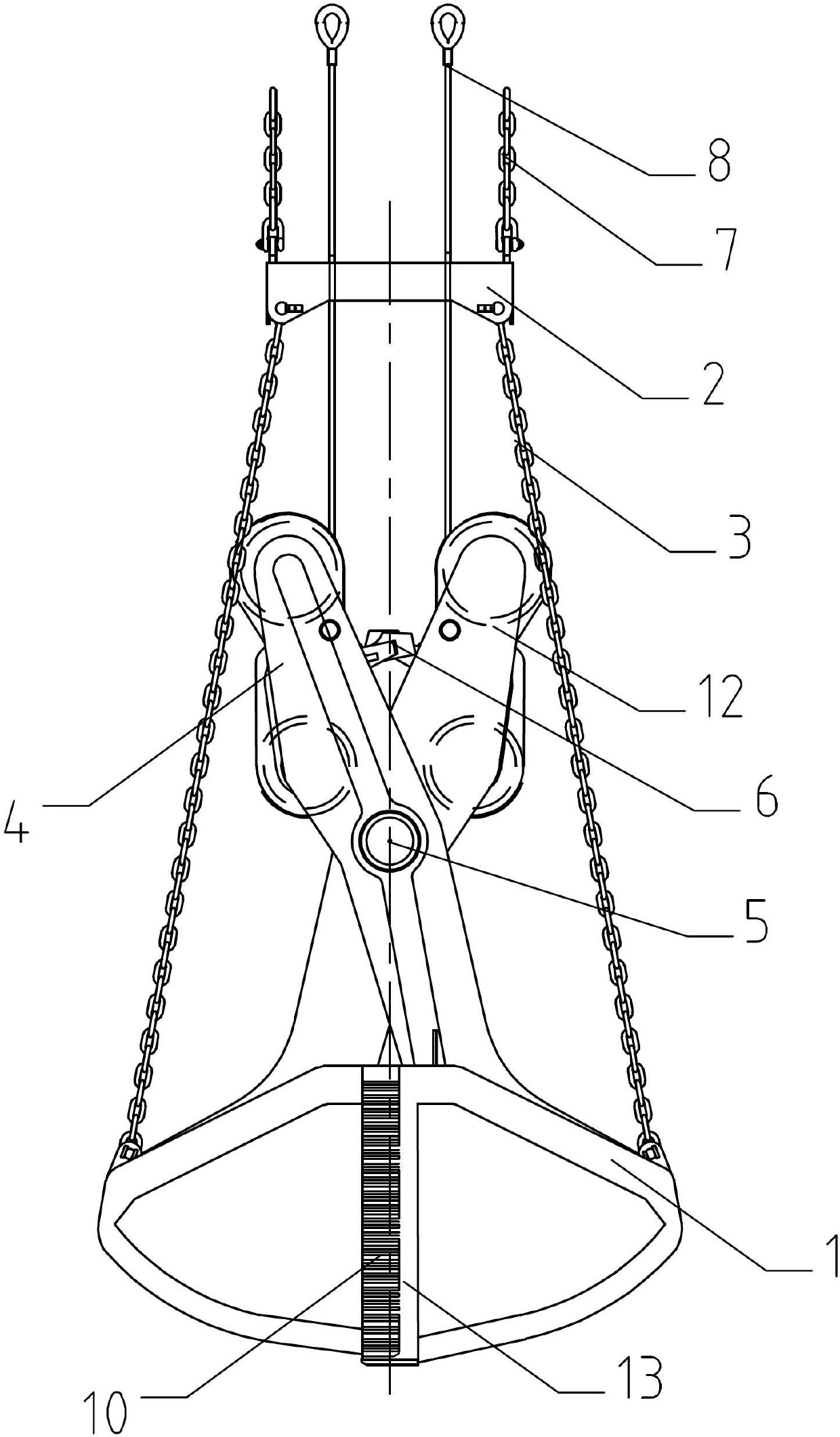

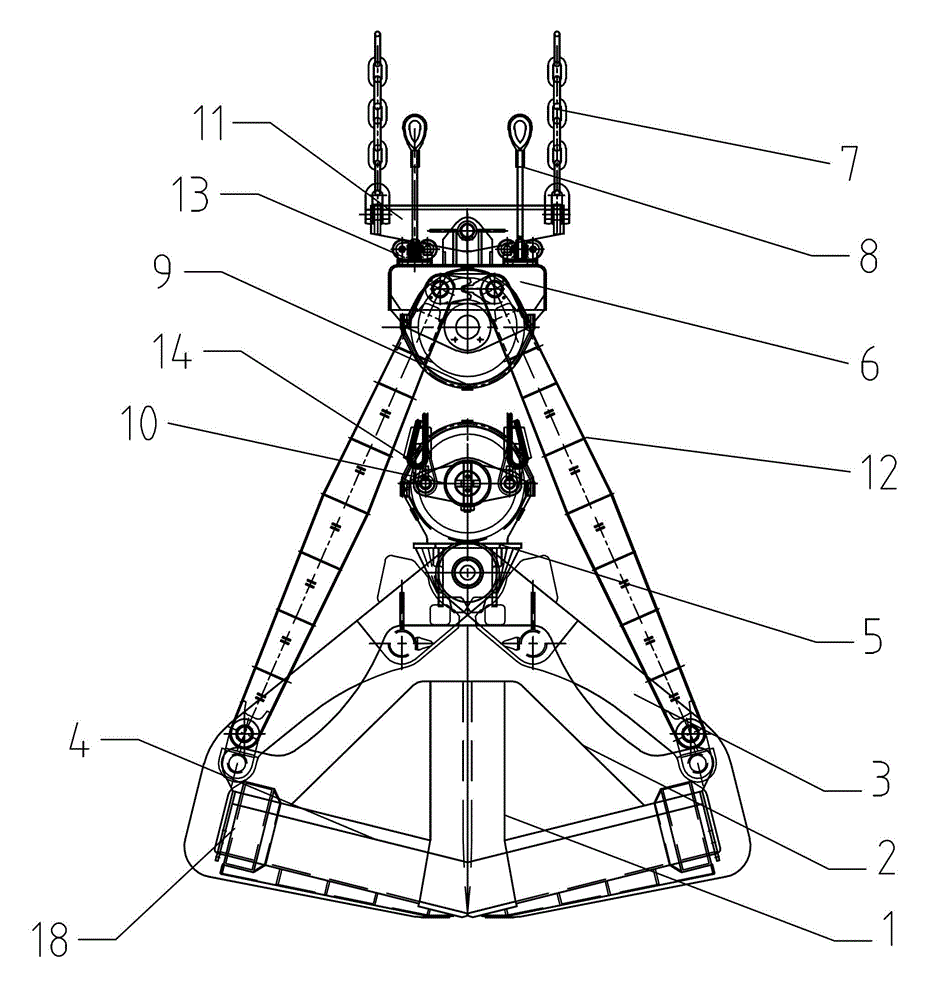

Shear type leakproof grab bucket

InactiveCN102674149AImprove leak resistanceSimple structureLoad-engaging elementsBlock and tackleEngineering

The invention relates to a shear type leakproof grab bucket, which is particularly used for a crane to load and unload cargos, belonging to the technical field of crane equipment. The shear type leakproof grab bucket mainly comprises a leakproof bucket body, a lifting frame, chains, a left grab bucket arm, a right grab bucket arm, an upper pulley block and a lower pulley block, wherein lifting ropes are connected to the upper sides of both ends of the lifting frame; the chains are connected to the lower sides of both ends of the lifting frame; the lower ends of the chains are connected with both sides of the leakproof bucket body; the left grab bucket arm is hinged with the right grab bucket arm through a central pin; and the left grab bucket arm and the right grab bucket arm are provided with the upper pulley block and the lower pulley block respectively. The shear type leakproof grab bucket has a simple, compact and reasonable structure; the leakproof bucket body has a good leakage-proof effect; the closing and opening moment is not reduced in the closing and opening process that the grab bucket grabs materials; the track of a bottom cutting edge of the grab bucket approximates to a straight line when the grab bucket grabs materials; and the shear type leakproof grab bucket has light self weight and large grabbing ratio, and greatly improves the loading and unloading operation efficiency.

Owner:无锡市新华起重工具有限公司

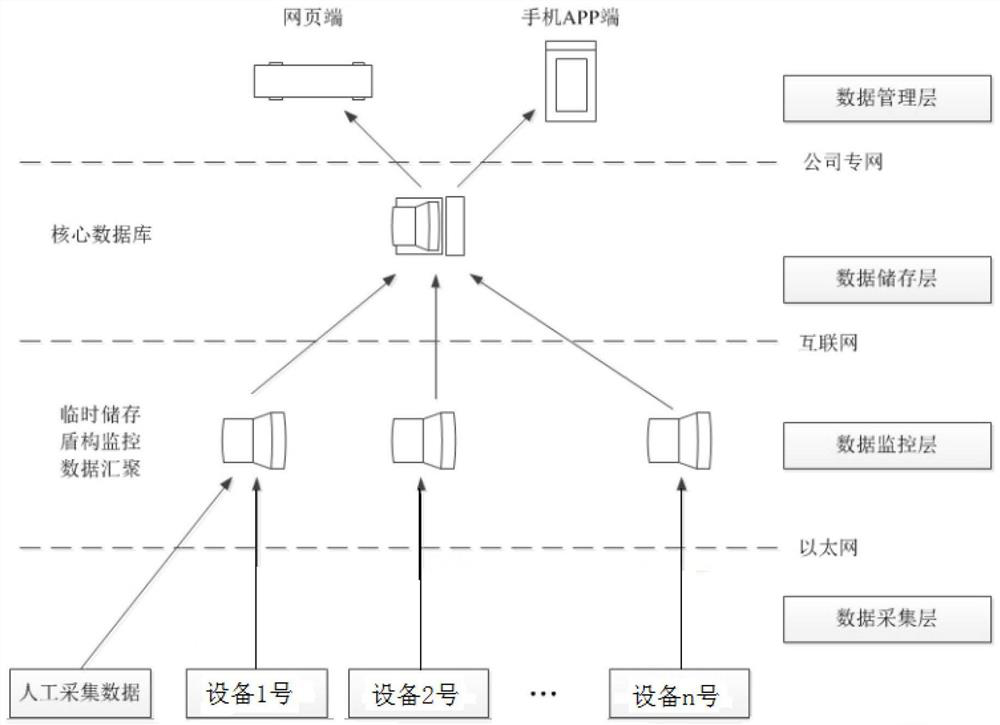

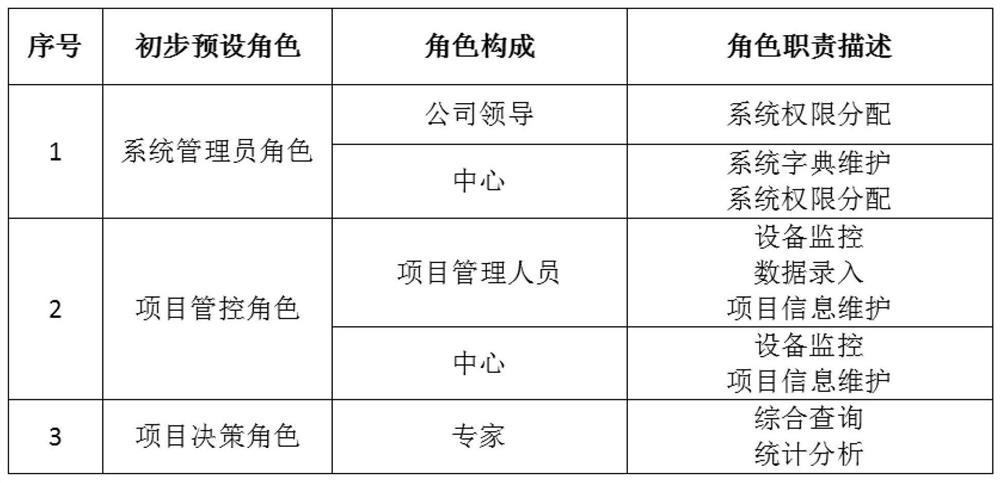

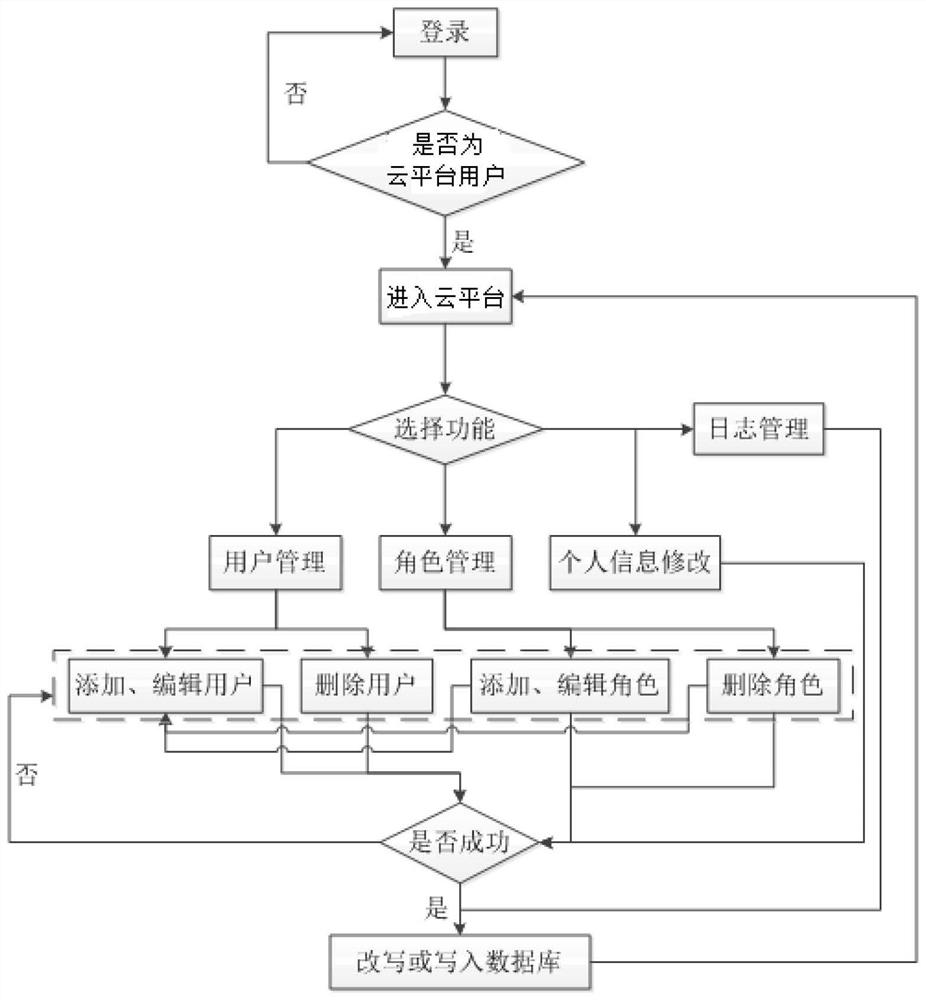

Safety monitoring and management cloud platform for large crane equipment

ActiveCN111866121AIn line with general practiceEasy to shareOffice automationTransmissionInformation resourceData acquisition

The invention discloses a safety monitoring and management cloud platform for large crane equipment. The cloud platform integrates real-time monitoring of the construction process, intelligent auxiliary analysis and management of all devices. In combination with the overall function design of the cloud platform and the function design of each part of the equipment, the cloud platform divides the whole cloud platform architecture into a data acquisition layer, a data monitoring layer, a data storage layer and a data management layer from bottom to top according to a data processing flow. According to the invention, the engineering language managed by the large-scale equipment safety monitoring management platform is adopted to meet the actual requirements of cloud platform management work and related business work, the general convention of special equipment safety management work is met, and key and stable advancement is highlighted in combination with the requirements of early warningand auxiliary decision making; existing hardware facilities, service systems and information resources are fully utilized, integration is enhanced, interconnection and intercommunication and information sharing are promoted, and limited resources can achieve the maximum benefit.

Owner:南京和控电气系统工程有限公司

Dual crane apparatus and method of use

Owner:ARTHUR BRADY PAUL +1

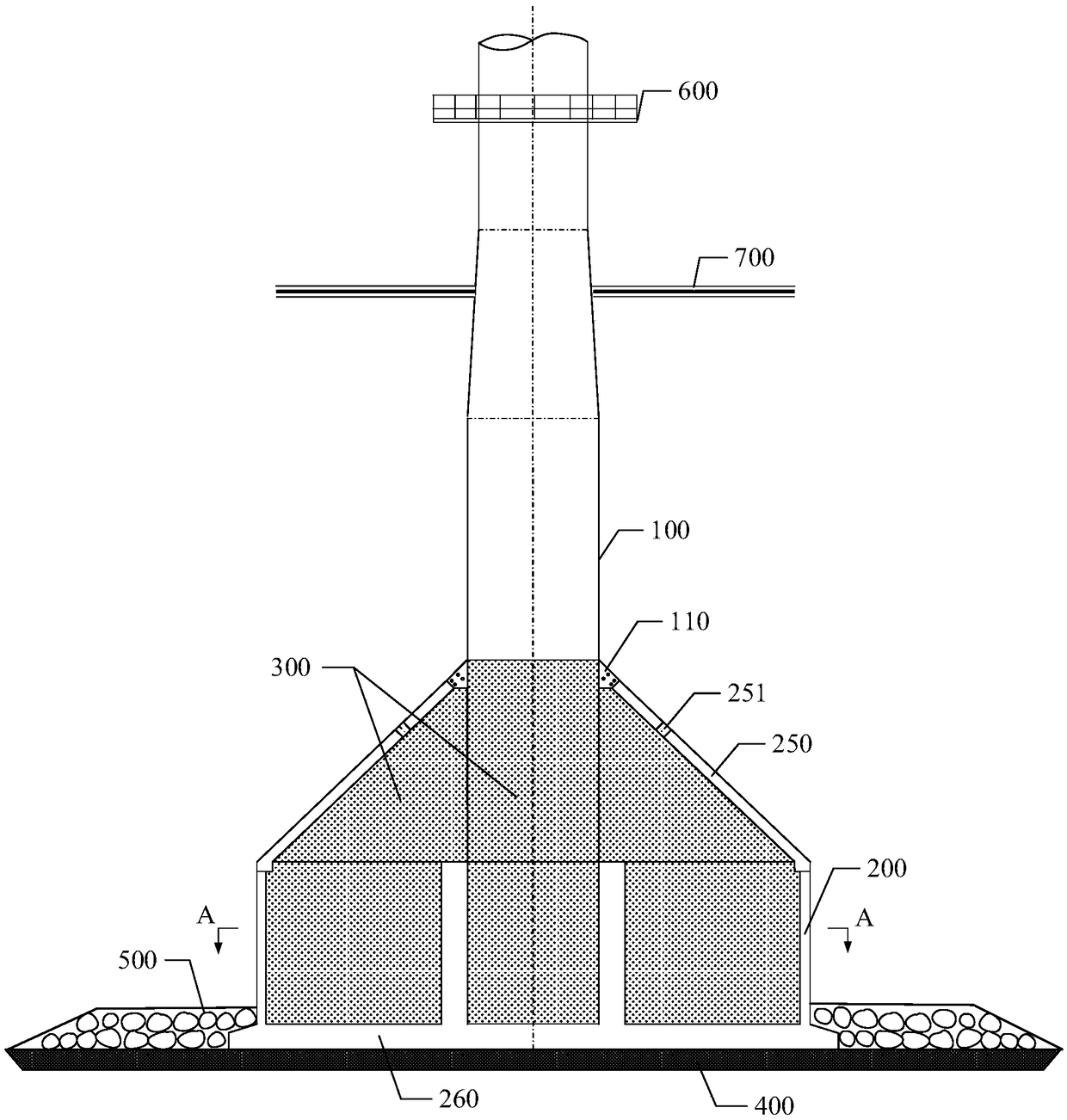

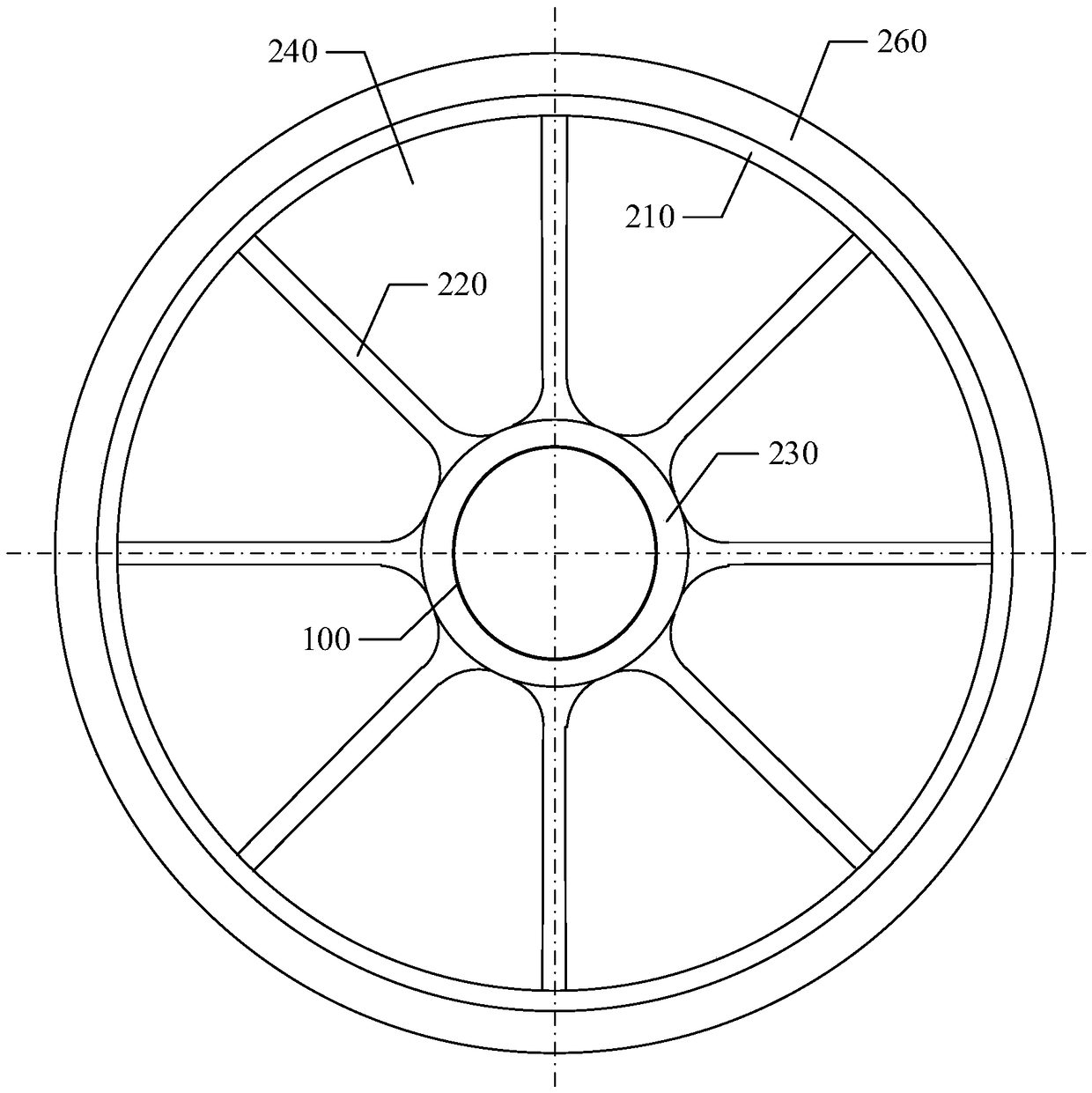

Offshore wind generating set gravity type foundation and mounting method thereof

The invention relates to an offshore wind generating set gravity type foundation and a mounting method thereof. The gravity type foundation comprises a steel pipe pile, a concrete caisson and ballastpadding, wherein the steel pipe pile is a variable cross-section large-diameter steel pipe, a shear key is arranged on the connection portion, between the steel pipe pile and a concrete caisson coverplate along the pile periphery, a bay of the concrete caisson is filled with the ballast padding, and the gravity type foundation is arranged on the seabed surface paved with a broken stone hardcore.The offshore wind generating set gravity type foundation and the mounting method thereof have the advantages that a steel pipe pile-concrete caisson combination gravity type structure is adopted, thesteel pipe pile provides enough strength and stiffness for the foundation structure, the structure weight is reduced, a floating-sinking marine transport installation method is adopted, heavy type floating crane equipment is not needed, the offshore operation is simple and convenient, the prefabricated construction is carried out on land, the construction time and cost are saved, the structure isless affected by waves and ocean current, the stability is good, and the offshore wind generating set gravity type foundation can be used for deepwater sea areas, high-capacity wind generating sets and offshore wind plants of which the geological conditions are shallow covering layers.

Owner:SHANGHAI INVESTIGATION DESIGN & RES INST

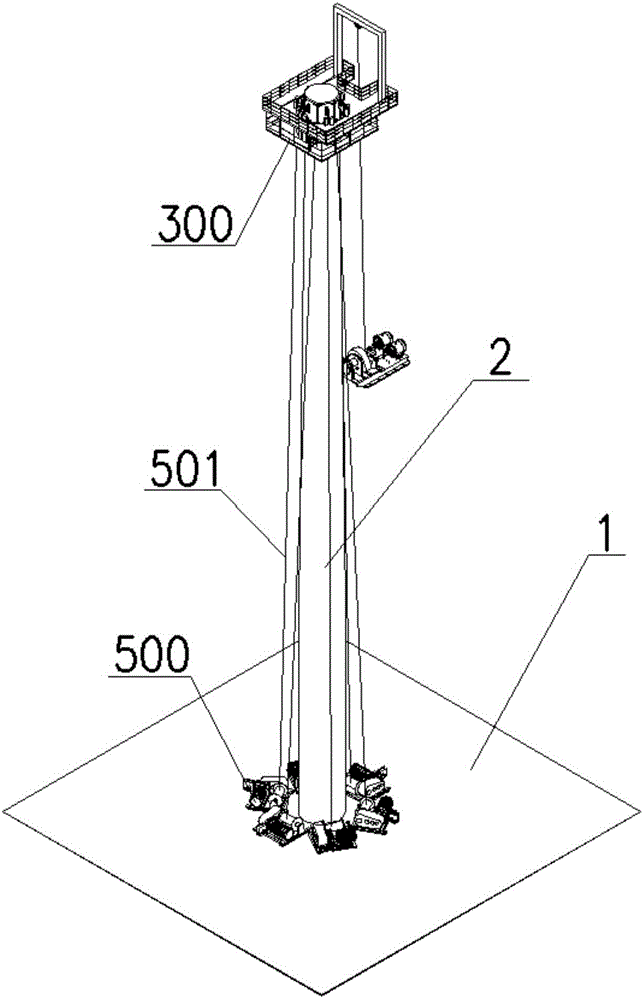

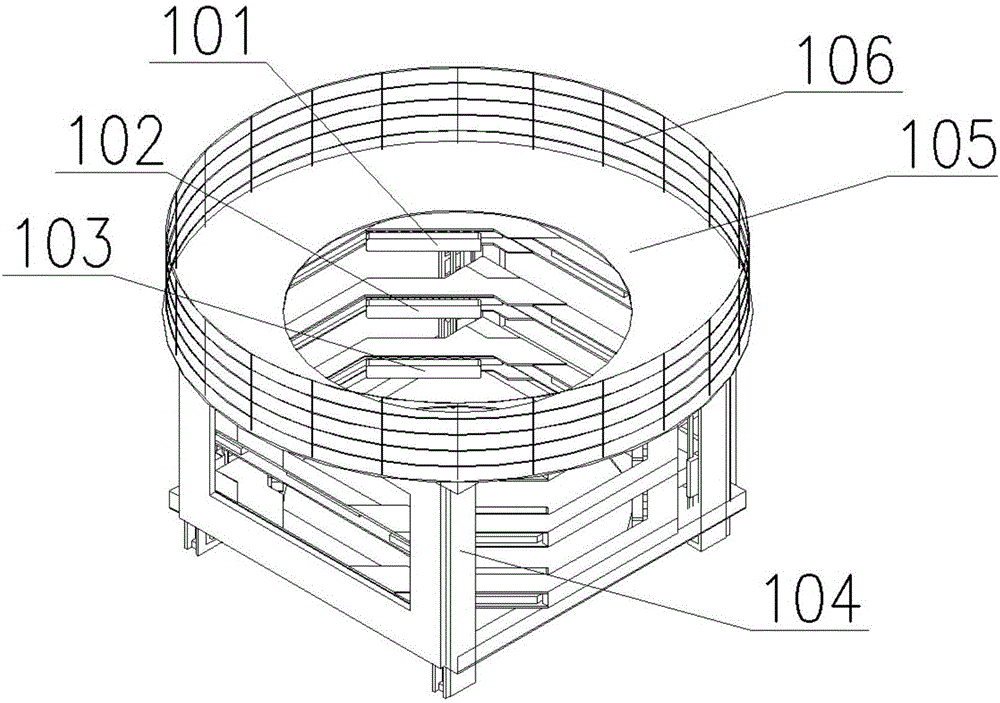

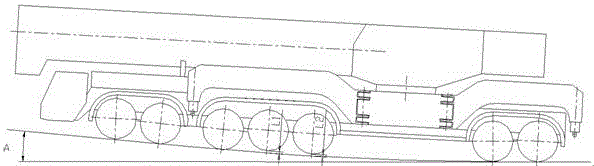

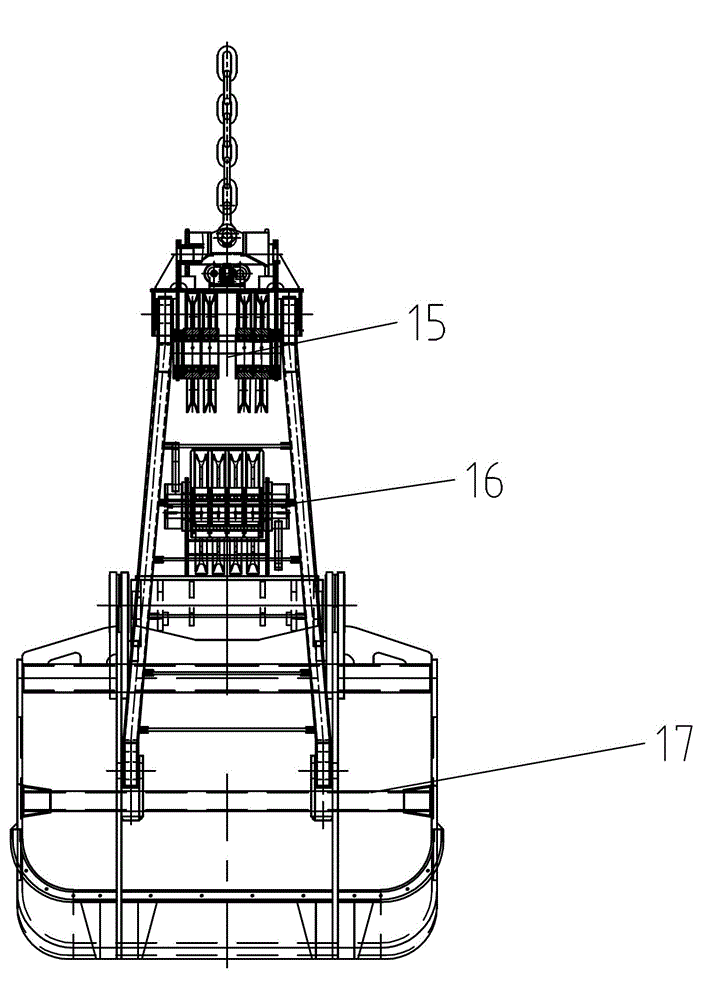

Hoisting equipment of wind power generating set and construction method thereof

ActiveCN106586846AAvoid or reduce useGet rid of dependenceBase supporting structuresBraking devices for hoisting equipmentsElectricityArchitectural engineering

The invention provides hoisting equipment of a wind power generating set and a construction method thereof. The hoisting equipment comprises a climbing mechanism, a holding brake-shoe, a hoisting system, a supporting connecting rod and a ground winding engine. The climbing mechanism is arranged on a tower cylinder and moves up and down along the tower cylinder, and used for conveying the holding brake-shoe from the bottom of the tower cylinder to the top of the tower cylinder. The ground winding engine is fixedly connected to the ground and used for lifting the hoisting system from the bottom of the tower cylinder to the top of the tower cylinder. The hoisting system is fixedly connected with the holding brake-shoe through the supporting connecting rod. The construction process can be simplified through the hoisting equipment, using of a large crane is avoided or reduced, dependence on the large crane equipment is relieved, manpower and financial resources are saved, the equipment usage cost is saved, the construction cycle is shortened, the safety of site construction is improved, the convenience of installing and maintaining of the wind power generating set is improved, and further promoting of sustainable development and the practical application of the wind power generating technology is facilitated.

Owner:浙江新振新海洋工程有限公司

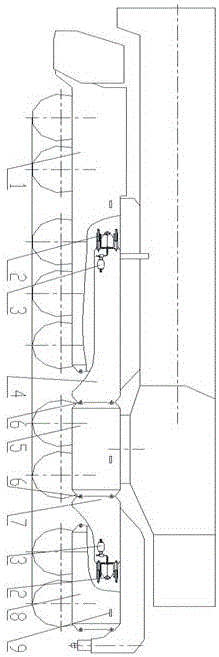

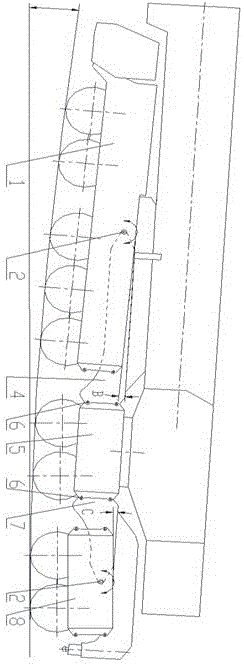

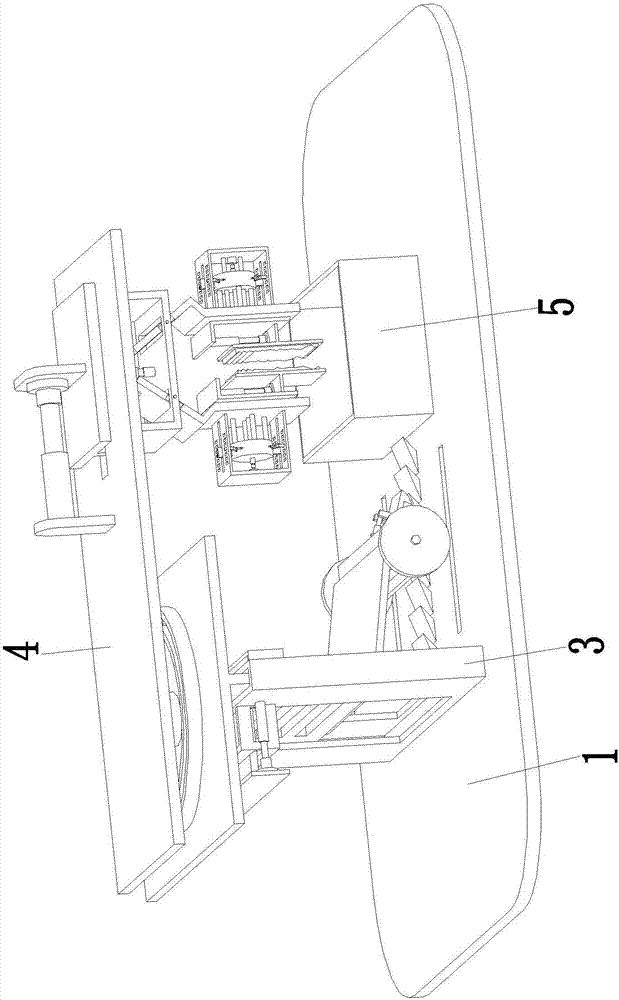

Modular flexible chassis, application thereof and crane thereof

ActiveCN106698210AWide range of usesEasy maintenanceServomotorsServometer circuitsModularityComputer module

The invention discloses a modular flexible chassis, application thereof and a crane thereof, and belongs to the field of crane equipment. The chassis consists of multiple modules with different functions; all the modules adopt different combination and connection modes to realize flexibility and modularization of a vehicle body; the assembled chassis is high in ground self-adaptability; the chassis comprises a driving control driving module positioned at an advancing end, support bearing modules connected with the driving control driving module, a crane operation module arranged between the support bearing modules, and a driven driving module positioned at a tail end; the support bearing modules include a front support bearing module and a back support bearing module; the crane operation module is positioned between the front and back support bearing modules; the driving control driving module is connected with the front support bearing module; and the driven driving module is connected with the back support bearing module. Compared with a traditional structure, the modular flexible chassis has such multiple functions as high ground self-adaptability, multiple purposes, convenience to maintain and high power.

Owner:XUZHOU HEAVY MASCH CO LTD

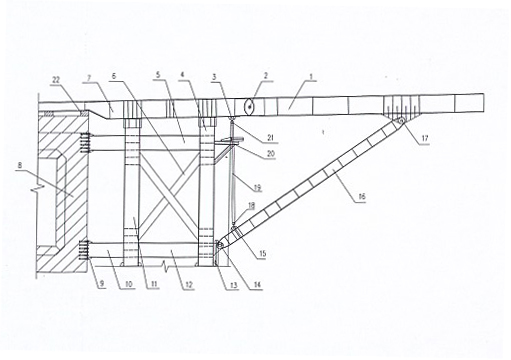

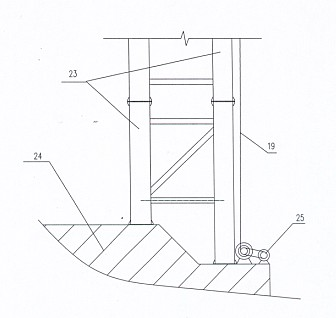

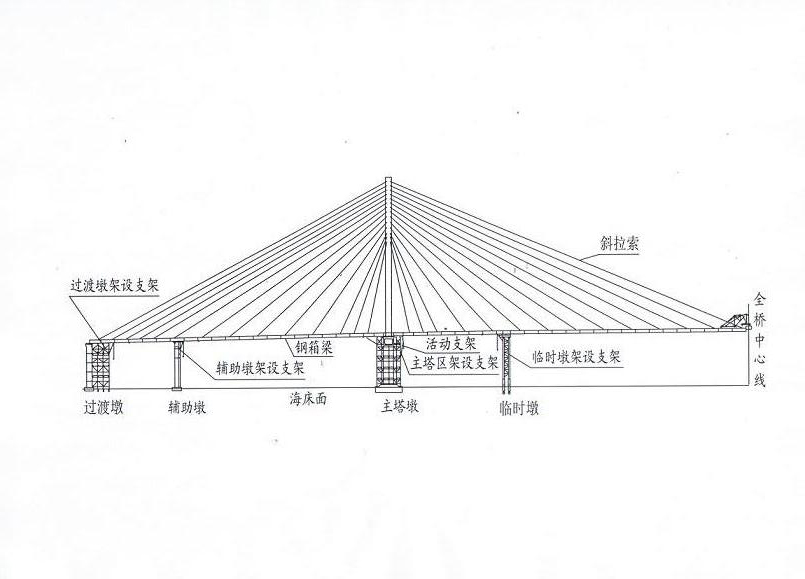

Movable support and movable support assisted method for erecting steel box beams through non-variable amplitude frame beam crane

ActiveCN102134832ALow costReduce construction investmentBridge erection/assemblySocial benefitsCounter-pull

The invention discloses a movable support and a movable support assisted method through a non-variable amplitude frame beam crane. The method for erecting steel box beams comprises the following steps of: installing beam sections in a main tower region; installing standard beam sections; installing beam sections on the tops of temporary piers, auxiliary piers and transition piers; pressing side spans; and installing midspan closures. The movable support comprises slide beams, support main slides, left and right stand columns, upper and lower cross supports, a lifting system and counter pull cones. The method for erecting steel box beams has the advantages of reducing construction investment, reducing frame beam crane cost, erecting the steel beams in the manufacturing sequence, omitting large floating crane equipment and dredging expenses. The movable support has the advantages of assisting the non-variable amplitude frame beam crane to erect a plurality of sections of steel box beams in the main tower region and solving the problem that the non-variable amplitude frame beam crane hoists the beam sections to the support, and has a novel structure and definite stress. The movable support can be reused among all tower piers and has good economical and social benefits.

Owner:THE 5TH ENG MBEC

Steel structure body machining robot capable of automatically pulling out steel sheet pile

The invention relates to a steel structure body machining robot capable of automatically pulling out a steel sheet pile. The steel structure body machining robot comprises a bottom plate, wherein a regulating lifting device is mounted at the upper end of the bottom plate, and a pullout clamping device is mounted on the regulating lifting device; a placing box is mounted on the bottom plate, and the placing box is located below the pullout clamping device; and the regulating lifting device comprises a lifting control mechanism mounted on the bottom plate, the lower end of the lifting control mechanism is connected to a regulating feeding mechanism through a hinge chain, the regulating feeding mechanism is mounted on the bottom plate, and the regulating feeding mechanism is located at the rear side of the lifting control mechanism. The steel structure body machining robot can solve the problem that in the existing process of removing the steel sheet pile during bridge cofferdam construction, the steel sheet pile needs to be manually fixed, the pulled-out steel sheet pile needs to be manually conveyed, the steel sheet pile difficult to pull out needs to be manually pulled out under the assistance of a vibrating tool, the stability is poor when the steel sheet pile is manually pulled out by using the existing crane equipment, the manual fixing stability of the steel sheet pile is poor, and potential safety hazards exist.

Owner:黄远明

Big data based container crane online diagnosis and maintenance system

The invention provides a big data based container crane online diagnosis and maintenance system, which comprises a crane equipment layer, a sensor layer, a network layer, a data analysis layer, a dataapplication layer, and a commercial system layer. The crane equipment layer receives running parameters of a crane. The sensor layer receives sensor signals from important parts of the crane. The network layer transmits the running parameters and the sensor signals to the data analysis layer. A crane normal operation mode and a crane fault mode are stored in the data analysis layer in advance. The running parameters and the sensor signals are compared with the models to judge the operation state of the crane. The data application layer predicts the operation state of the crane in a future period based on the running parameters and the sensor signals and generates fault warning. The commercial system layer is provided with an external data interface and outputs the data of the data analysis layer and the data application layer. The provided system can monitor a plurality of cranes in a plurality of harbors in real time, and effectively manages the cranes in harbors.

Owner:LIXIN COUNTY YURUO INFORMATION TECH CO LTD

Large-span variable-capacity grab bucket

The invention relates to a large-span variable-capacity grab bucket which is particularly used for grabbing materials with different specific gravities, belonging to the technical field of crane equipment. The large-span variable-capacity grab bucket mainly comprises a bucket body, a connecting rod, a main rib plate, a lower bearer, an upper bearer, lifting ropes, an upper pulley wheel set, a lower pulley wheel set, a bearing balance beam, support rods and a variable-capacity plate, wherein two ends of the bearing balance beam are connected with the lifting ropes; the middle of the bearing balance beam is connected with the upper bearer in a hinging way; the two sides of the upper bearer are respectively connected with the two support rods in a hinging way; the lower ends of the support rods are articulated with the bucket body; the lower bearer is connected with the bucket body by the connecting rod; the lower bearer is connected with the connecting rod in a hinging way; and the bucket body comprises two left / right symmetrical bucket valves, and the tail end of the bucket body is connected with the variable-capacity plate. The large-span variable-capacity grab bucket is simple, compact and reasonable in structure, can realize the large-span variable capacity of the grab bucket and grabs the materials with great different specific gravities, such as coal and ore, and is high in work efficiency, so that the equipment cost can be reduced.

Owner:无锡市新华起重工具有限公司

Vertical type pneumatic hanger

InactiveCN103708358ASolve explosion-proofNo pollution in the processCranesLoad-engaging elementsReduction driveReducer

The invention provides a vertical type pneumatic hanger which comprises a body, a gas source inlet fixedly arranged on one side of the body, a rotating mechanism arranged on the body, a rack fixedly arranged on the rotating mechanism, a gearbox arranged on one side of the rack, a hanging rod rotationally arranged below one side of the body, a push rod rotationally arranged at the upper part of the rack and positioned on one same side in which the hanging rod is arranged, a hook arranged at one rotating end of the hanging rod, and a handle rod which penetrates through the bracket below the hanging rod, wherein the rotating end of the push rod is connected with the rotating end of the hanging rod. The hanger is free of anti-explosive requirements, and the problem of anti-explosion of crane equipment is thoroughly solved; energy is saved, and compressed air is adopted as the power, so that no medium is leaked, the environment pollution is prevented, and the sanitary production can be achieved; the continuous and frequent working is achieved, and the working is stable and reliable; the stepless speed regulation is achieved, and the operation speed is simply, conveniently and flexibly regulated through a manual valve; as a lifting mechanism is provided with an overload protection device, the normal operation of a speed reducer is ensured.

Owner:WUJIANG JIA BILLION ELECTRONICS TECH

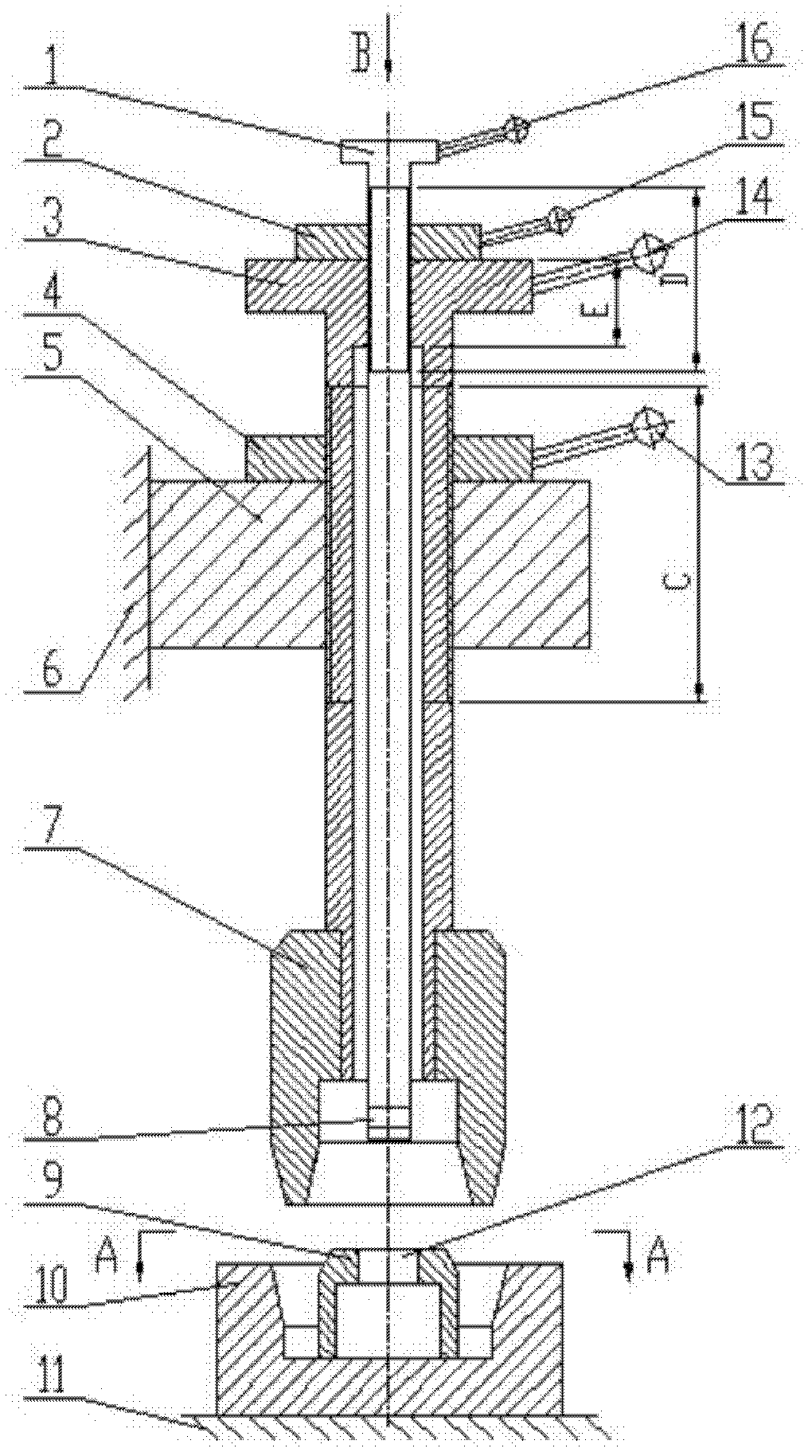

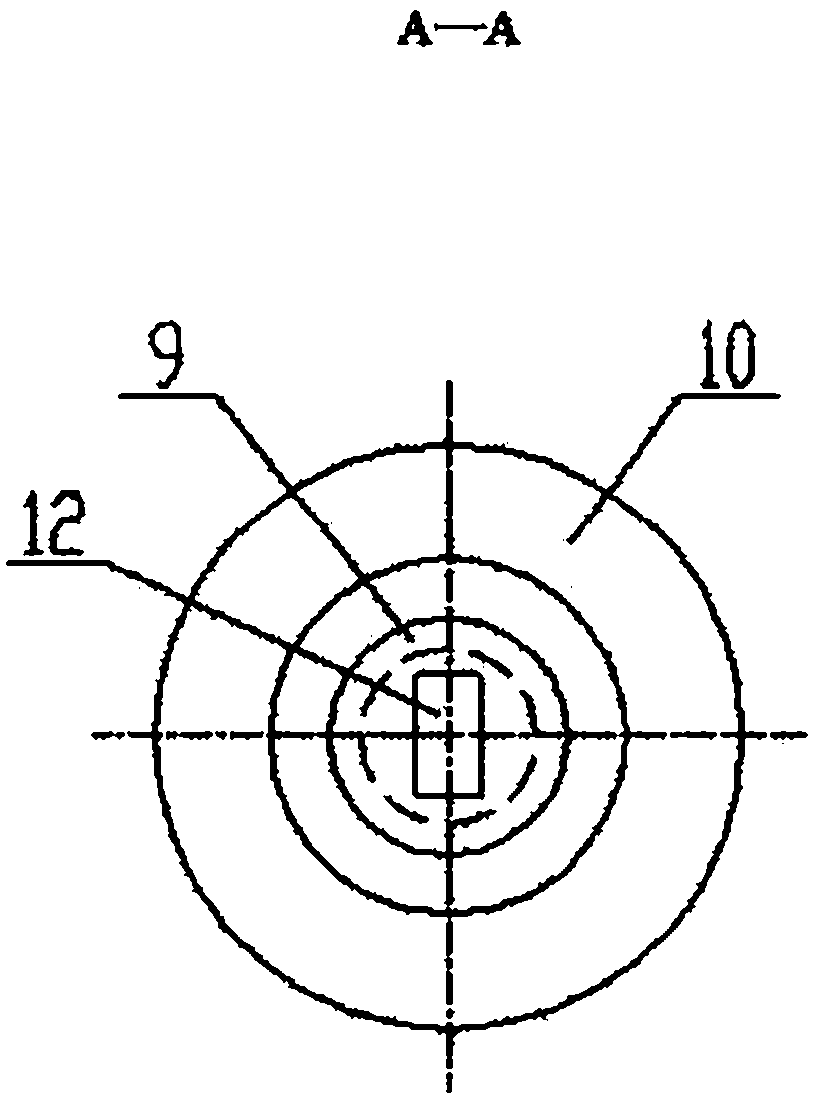

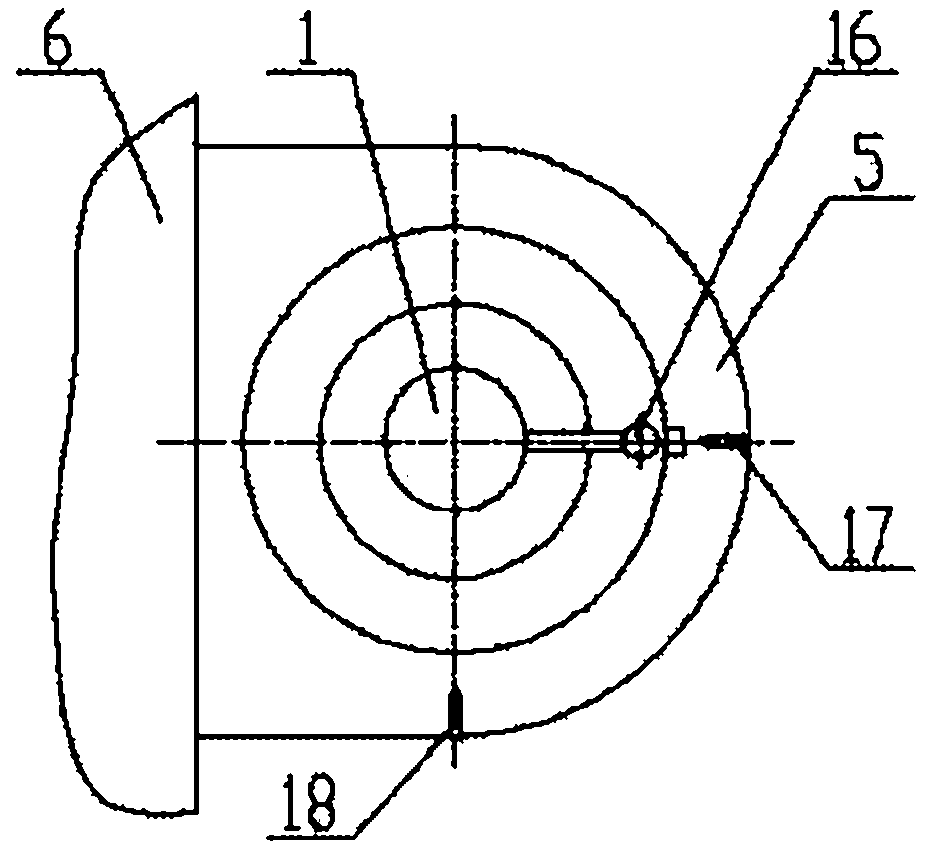

Screwing-in anchoring device for crane

ActiveCN102303817AAchieve lockingAnchor implementationSafety gearNuclear powerBiomedical engineering

The invention belongs to a crane apparatus, and in particular relates to a screwing-in anchoring device for a crane which is suitable for the nuclear power with high safety requirements. The screwing-in anchoring device is characterized in that a trolley frame of the crane is equipped with the screwing-in anchoring device consisting of a supporting plate, a mark A, a mark B, a hollow screw rod, aguide cone head, an inner screw rod, a small nut, a big nut, a square locking block, a locking bush and a guide cone. The screwing-in anchoring device is scientific and rational in design and compactin structure, can realize the anchoring of a vertical direction while holding the anchoring in a horizontal direction, is not only suitable for the protection in earthquake, but also suitable for preventing the invasion of sudden wind; and the screwing-in anchoring device has the advantages of convenience in operation, firmness in anchoring, low fault rate, safety in operation and convenience in use.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com