Movable support and movable support assisted method for erecting steel box beams through non-variable amplitude frame beam crane

A technology of girder erection crane and movable support, which is applied in the field of movable supports, can solve the problems of heavy design change workload of main girders and stay cables, large investment in dredging work in shoal areas, and high cost of strengthening steel box girders, etc., to achieve The effect of saving large-scale floating crane equipment and investment, reducing the cost of girder erecting cranes, and saving dredging costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

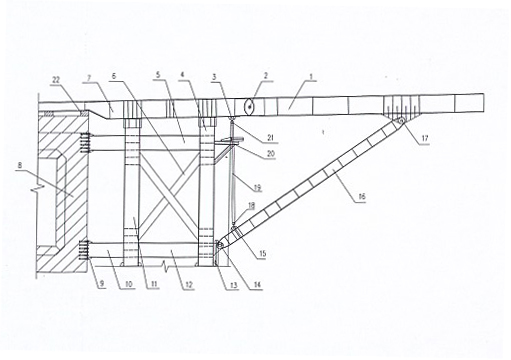

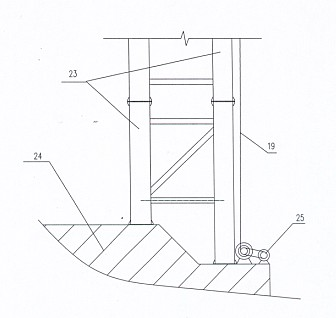

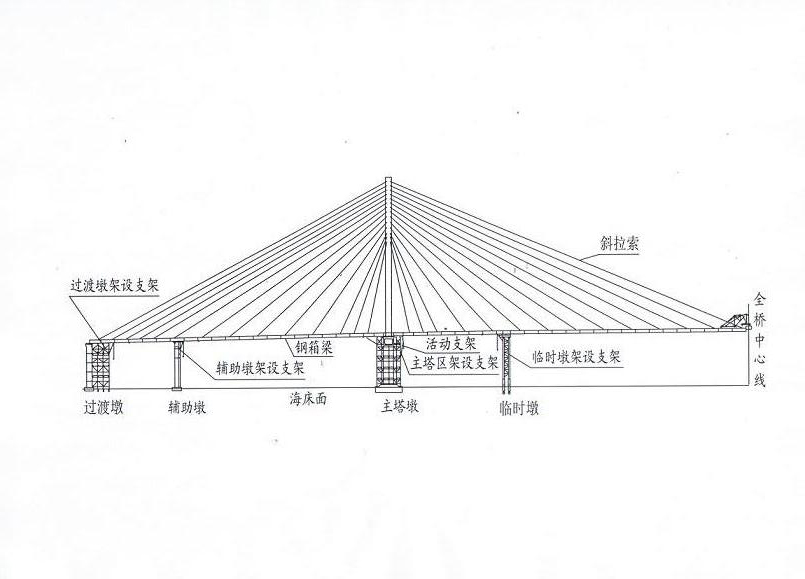

[0019] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

[0020] A method for erecting a steel box girder with an auxiliary constant amplitude girder crane, the construction steps are as follows:

[0021] A: Installation of the beam section in the main tower area: first use the tower crane to assemble the erection bracket, the movable bracket and the beam erecting crane on one side of the beam section in the main tower area next to the pier of the main tower, and hoist the beam section in the main tower area to the movable bracket. Slide the girder erection crane and steel box girder longitudinally to the position of a beam section by means of jacking, then slide the girder erection crane to the hoisting position of the next beam section, continue to erect the remaining beam sections in the same way, and the beam section in the main tower area After the installation is completed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com