Patents

Literature

113 results about "Counter-pull" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Counter· pull. Definition of counterpull: a countering attraction or force. ... History and Etymology for counterpull. counter- + pull. Keep scrolling for more. Learn More about counterpull. Share counterpull. Resources for counterpull. Time Traveler! Explore the year a word first appeared .

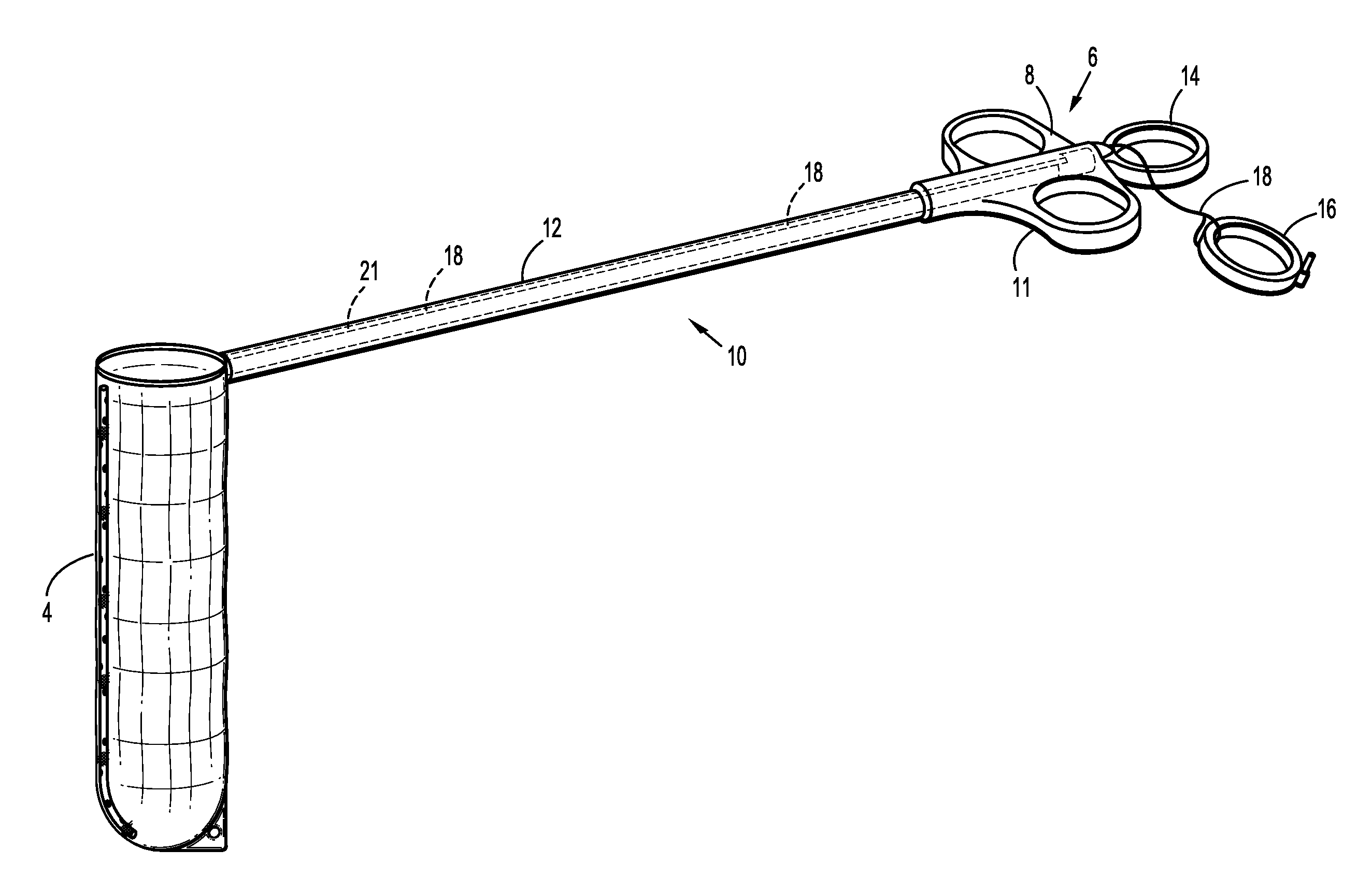

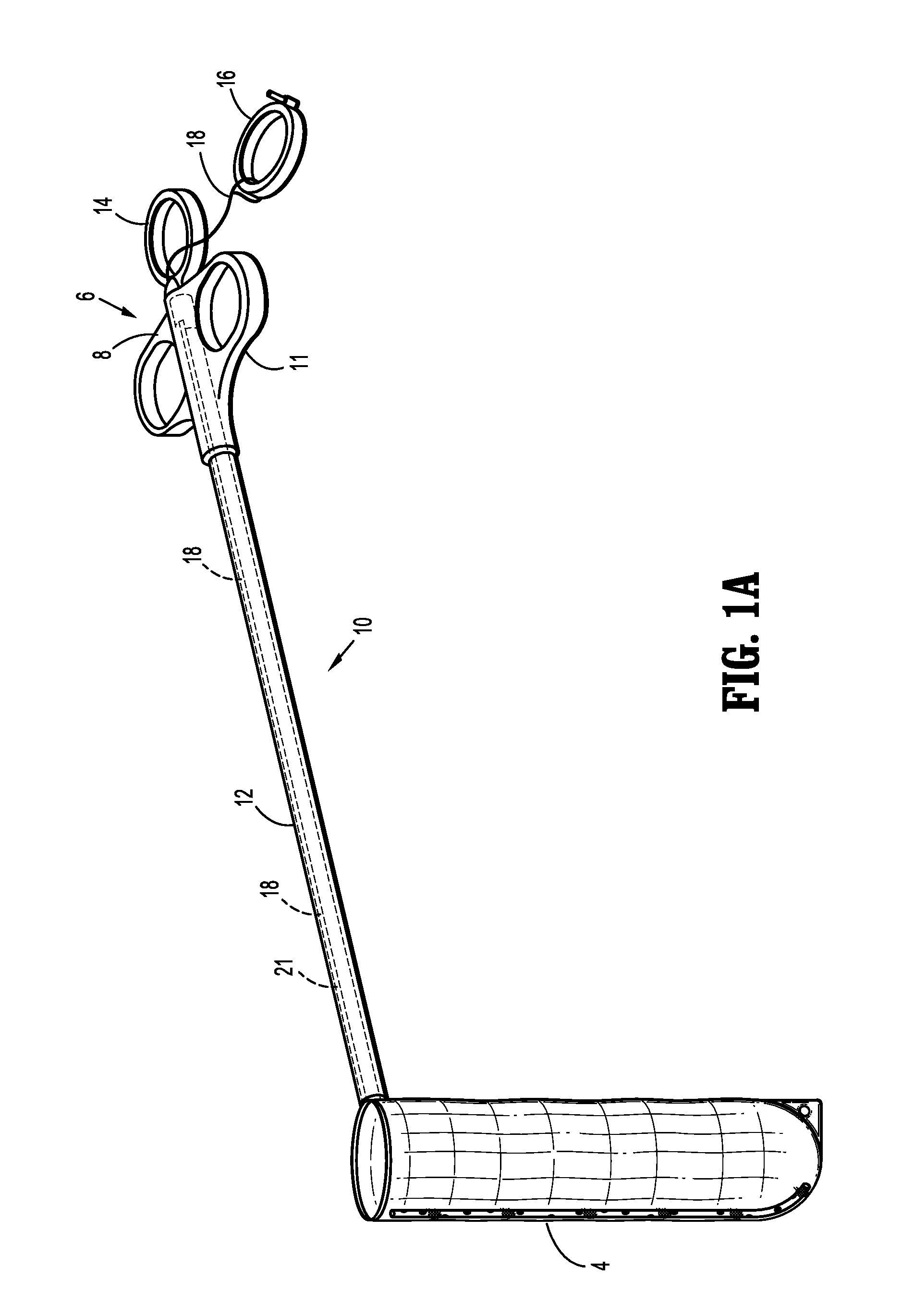

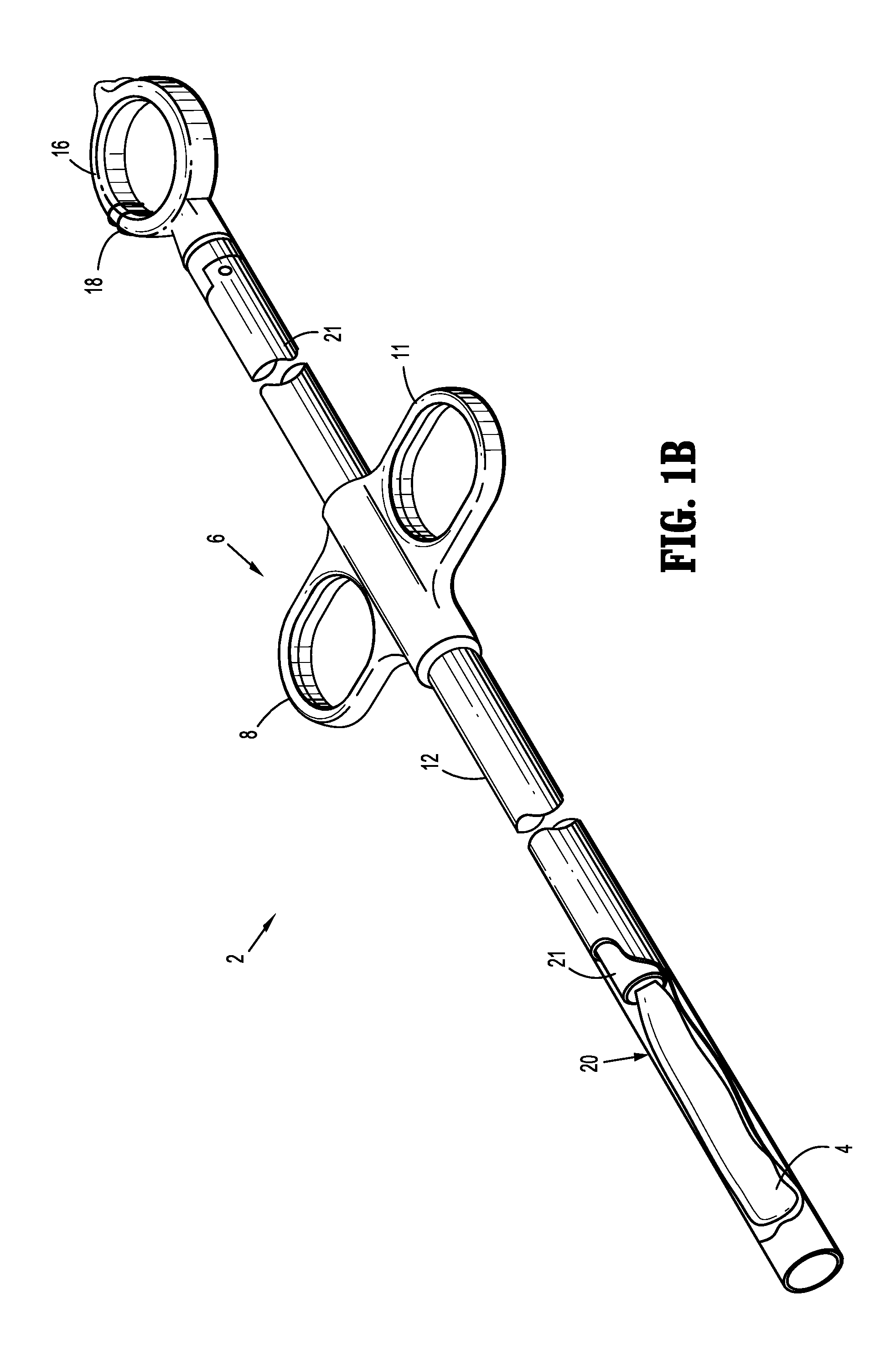

Specimen Retrieval Device

A specimen retrieval pouch (pouch) is provided. The pouch including a closed bottom portion, an open upper portion and an elongated tube operably coupled to an interior wall of the pouch. The elongated tube has a plurality of openings positioned along a length thereof. A suture accessible at a proximal end of the pouch is positioned within the elongated tube and extends past a distal end thereof. The suture is movable within the elongated tube and relative to the pouch. The suture has either a needle or a loop at a distal end thereof for attaching to tissue and subsequently drawing the tissue into the pouch when the suture is pulled. One or more reinforced tabs are operably disposed on the pouch. The reinforced tab(s) is / are configured to be grasped by a user to provide a counter pull force as the suture is being pulled through the elongated tube.

Owner:TYCO HEALTHCARE GRP LP

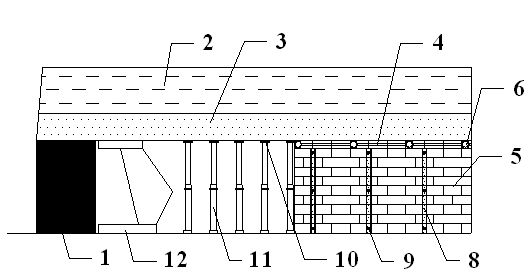

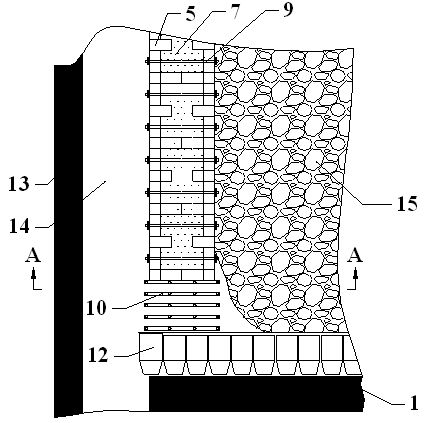

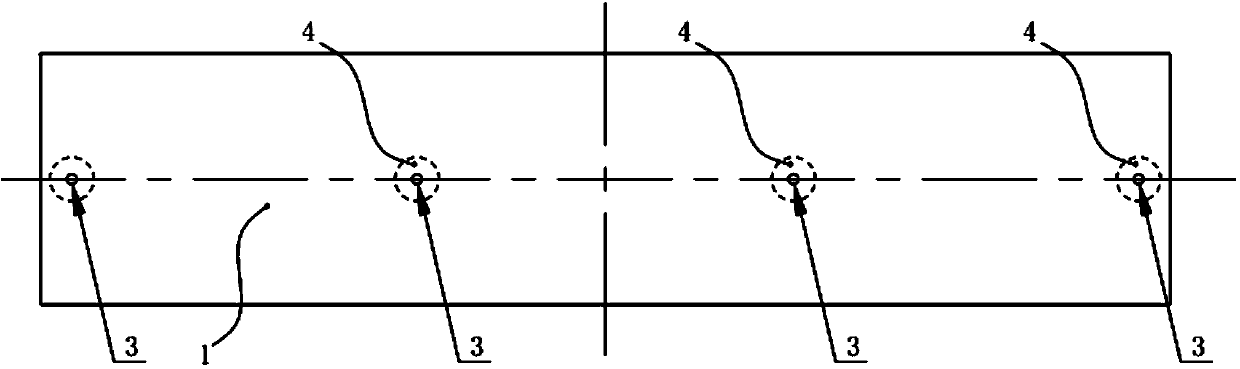

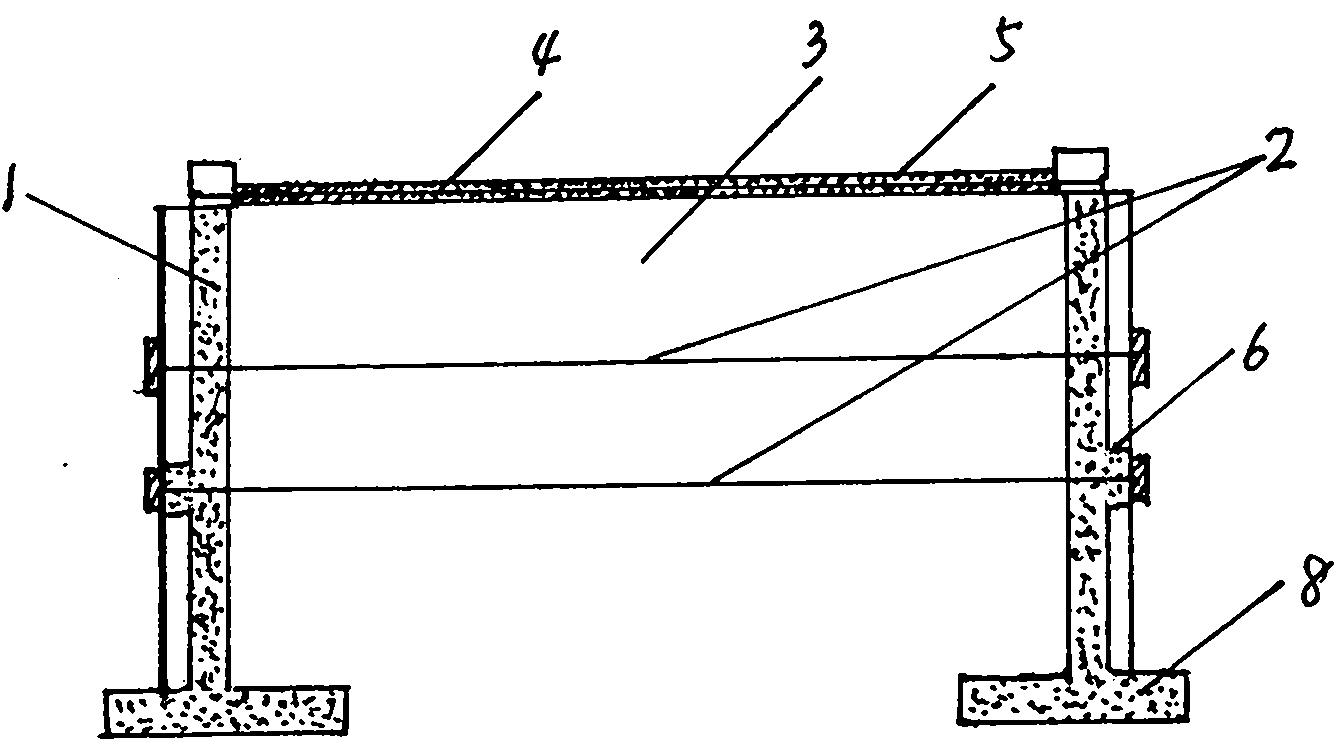

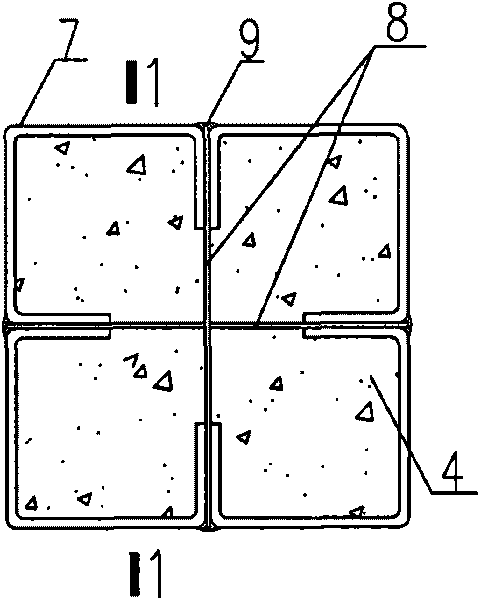

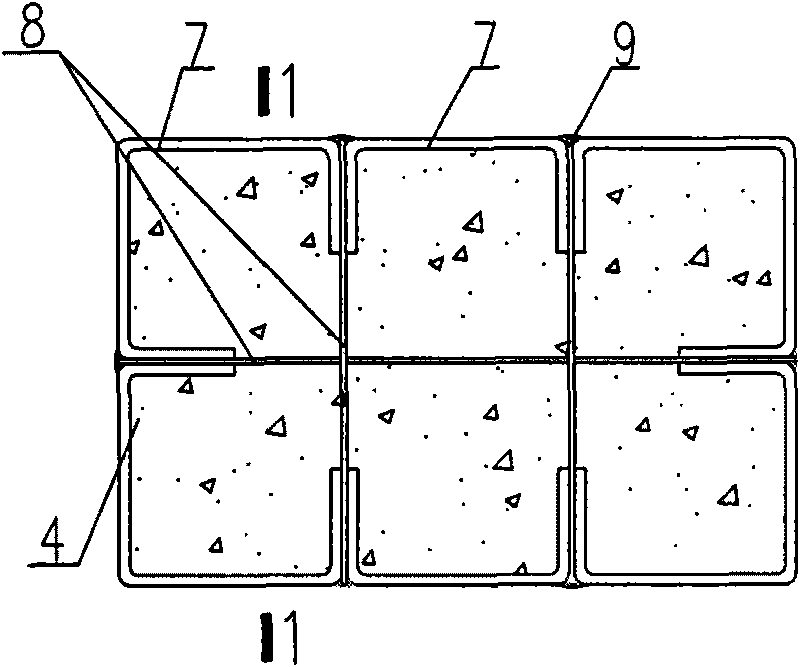

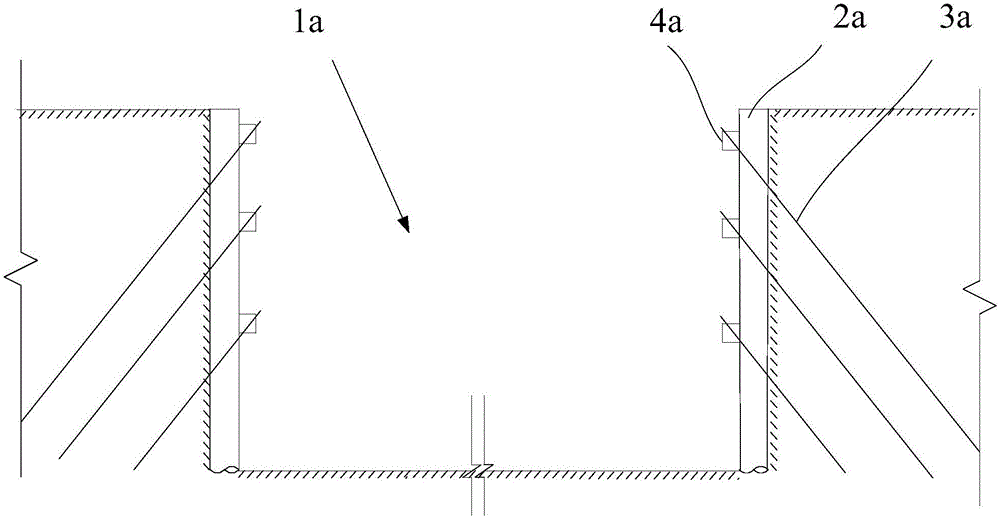

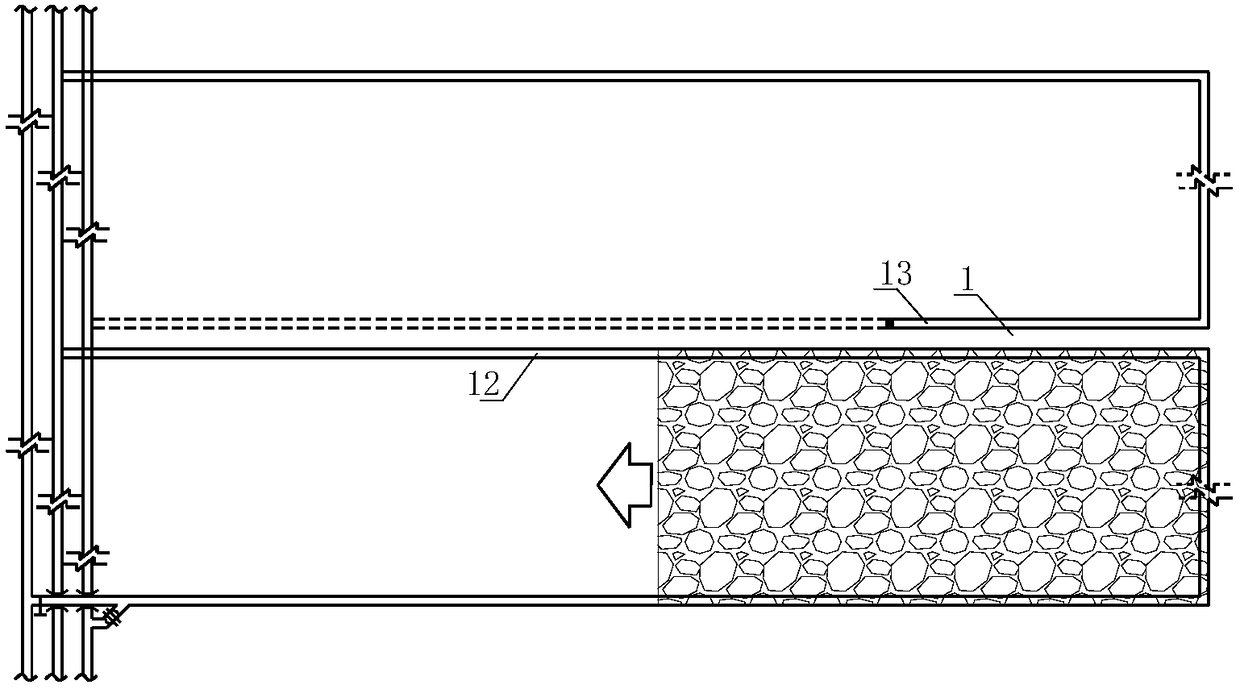

Construction method of walling and filling combined gob-side entry retaining wall body

The invention relates to a construction method of a walling and filling combined gob-side entry retaining wall body. The construction method comprises the following steps of: closely following forward propulsion of a stope face, erecting dense single supports at a gob retaining side at the rear part of a fully mechanized mining bracket, so that a space of a tunnel at the rear part of the stope face is retained; walling a square template wall with concrete pier blocks under the mask of the dense single props; meanwhile, installing counter-pulled anchor rods which penetrate through the template wall bodies, and carrying out lateral reinforcing on the template wall bodies; carrying out grouting filling on a hollow part defined by the template walls through injected holes reserved on the template walls till the internal spaces of the template walls are filled with grout; carrying out uniform whitewashing treatment on the wall at one side of a gob retaining tunnel to form a concrete spray layer; and sequentially circulating the steps along with propulsion of the stope face till construction of the whole gob-side entry retaining wall body is finished. According to the construction method disclosed by the invention, a brickwork wall and a filling support are combined together, so that the construction method is simple and convenient and simple to operate and ensures that the wall body has high strength and can yield pressure suitably; and length of each walling of the wall body is consistent with the everyday propulsion degree of the stope face, and the construction method is flexibly suitable for actual mining.

Owner:CHINA UNIV OF MINING & TECH

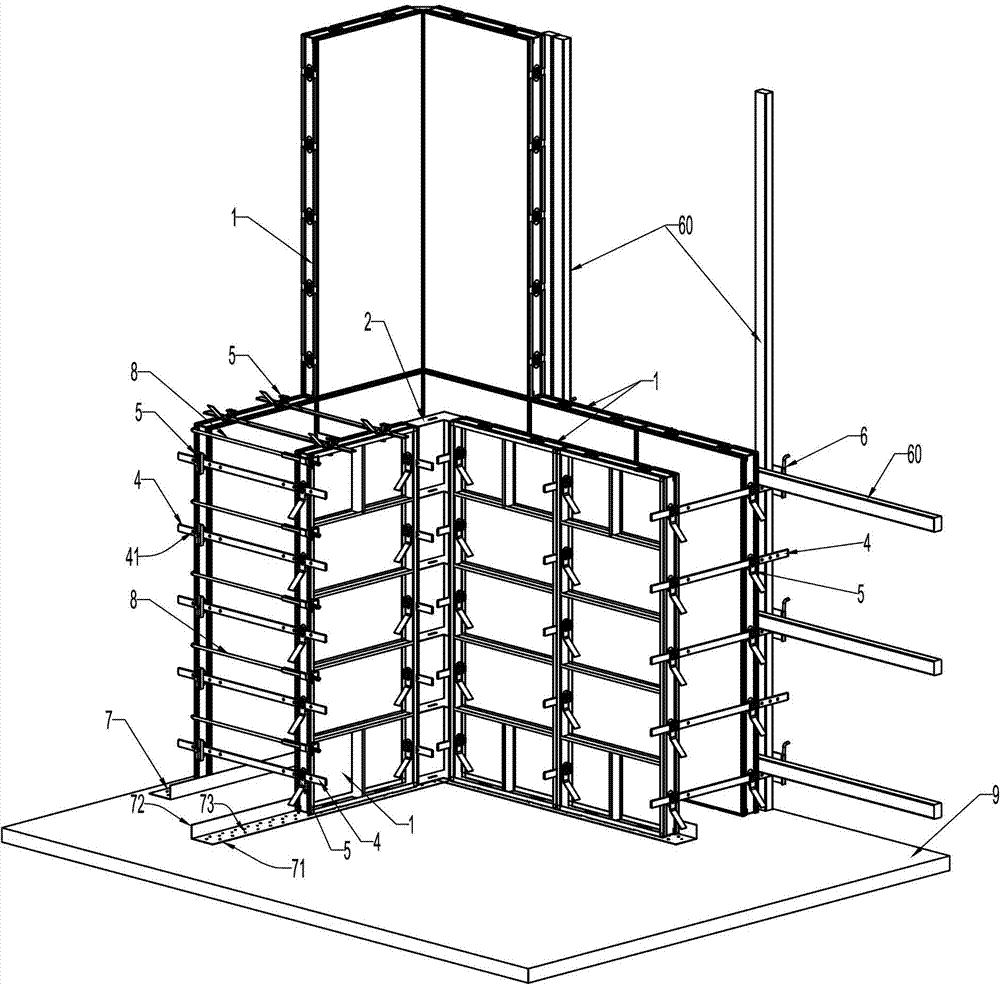

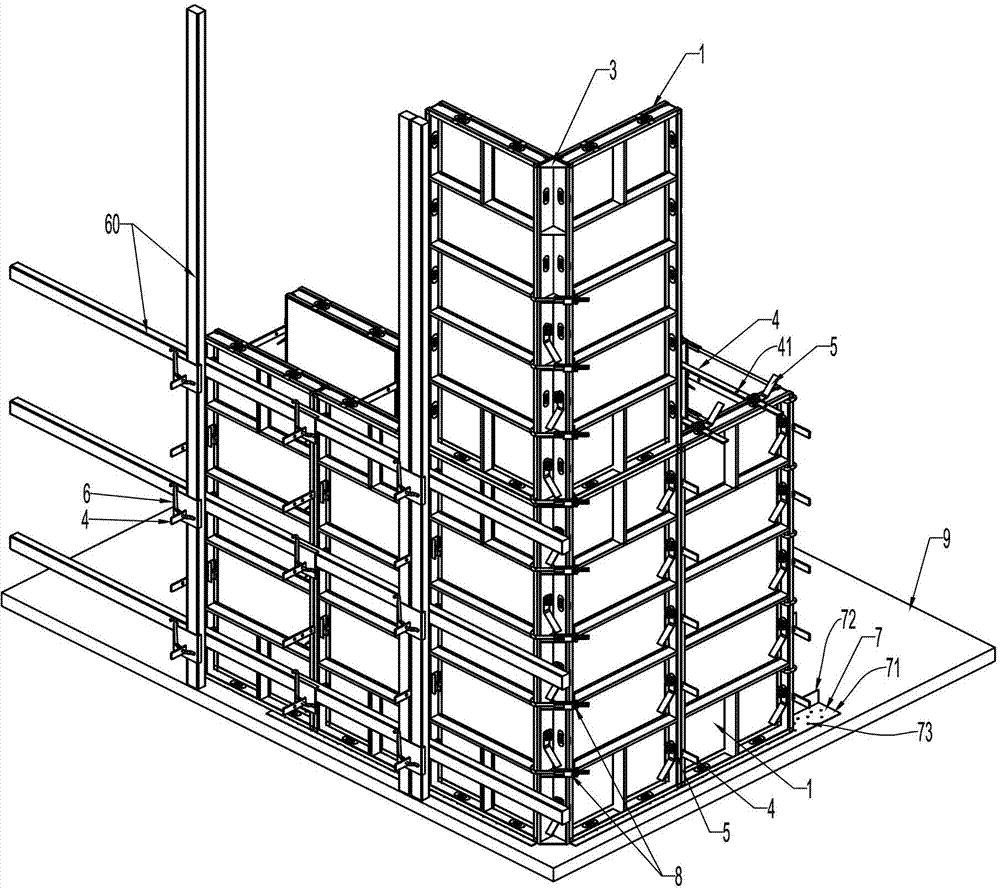

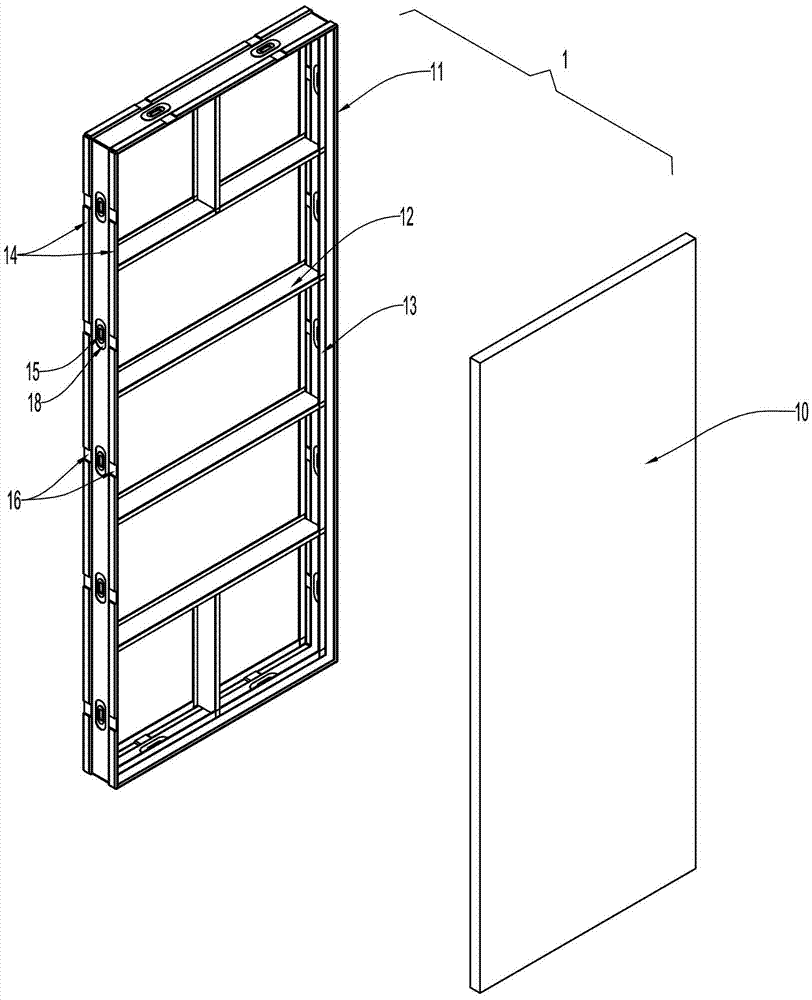

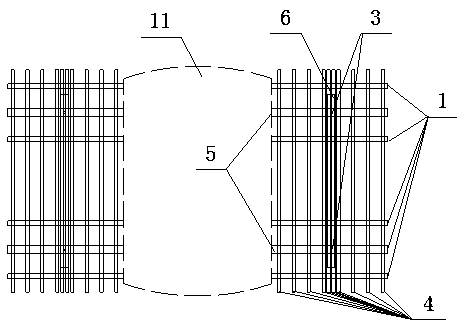

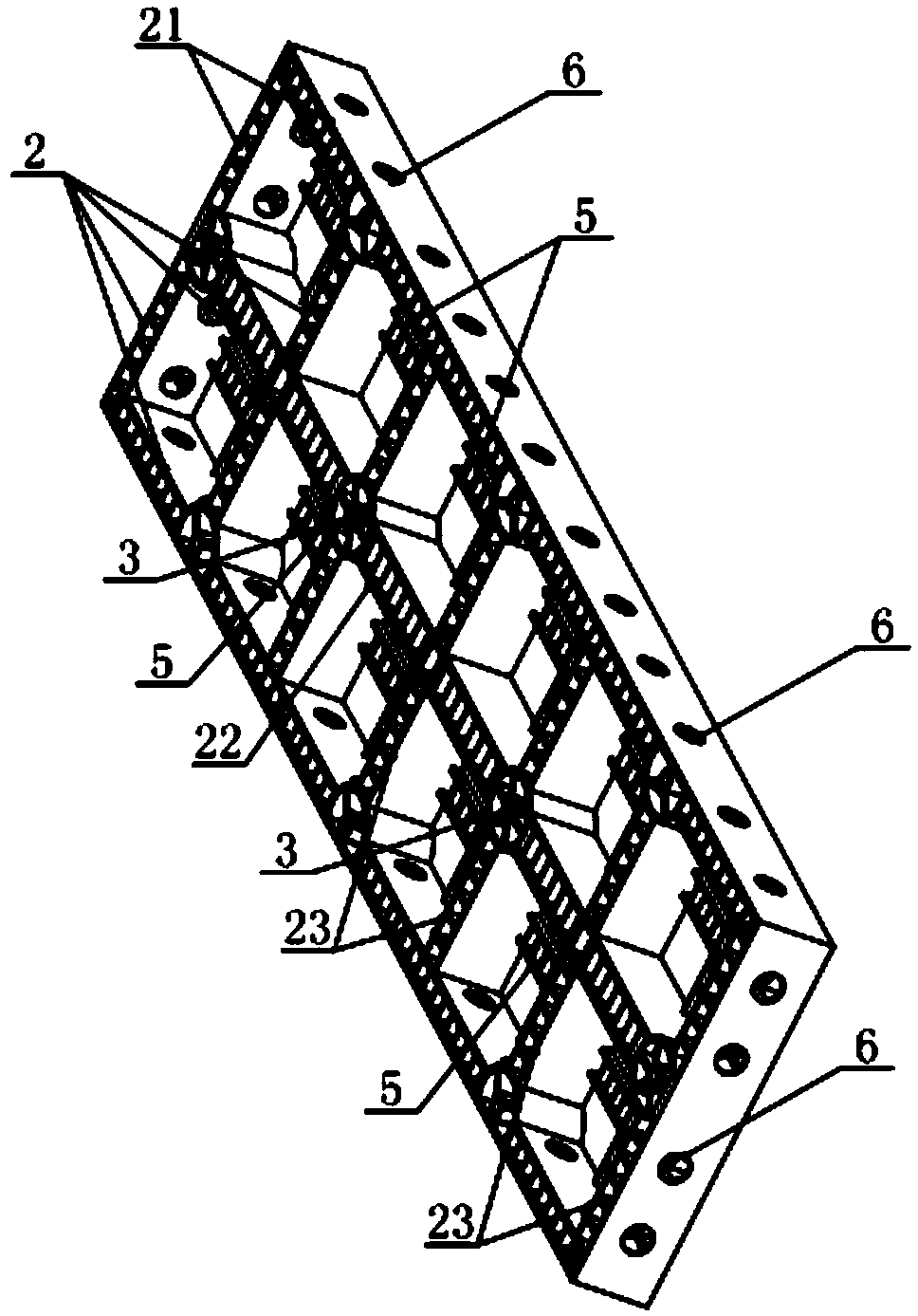

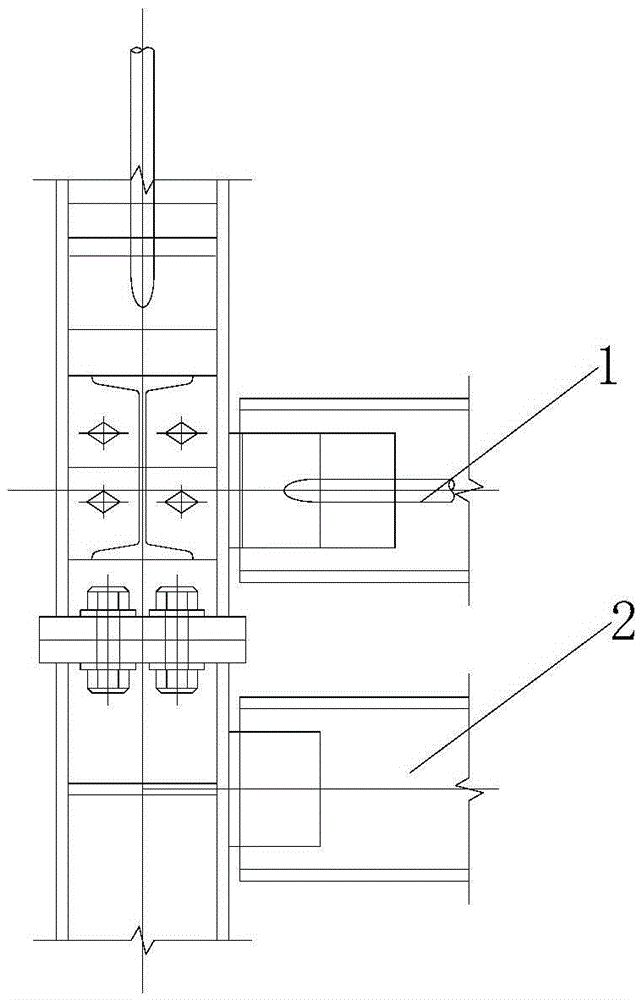

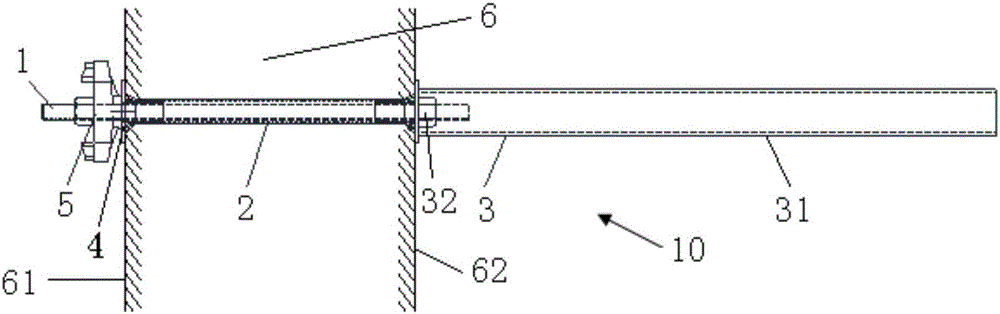

Steel frame formwork assembly

InactiveCN102926530AIncreased Strength and RigidityChange the defect that the tightness is difficult to graspForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksCounter-pullSteel frame

The invention relates to a steel frame formwork assembly, comprising steel frame formworks, an internal corner formwork for connecting spliced formwork internal corners, an external corner formwork for connecting spliced formwork internal corners, a leader for counter pulling the steel frame formworks on two sides of a wall body, a split joint fastener for fixing the adjacent steel frame formworks, a main edge fastener for fixing the outer side steel frame formworks and the main edges, a ground pin locating piece for solving leakage between the formwork and the floor, and a corner fastener for reinforcing the corner formwork and the wall body sectional formwork. By virtue of the innovative design to the leader and the steel frame formworks, the steel frame formworks are free from holes, and the leader can pass through a recess between the adjacent steel frames, so only one fastener is needed to lock and fix between the steel frames, and between the steel frame and the leader; and the leader can be used for counter pulling the two side formworks and locking the main edges. The assembly is reasonable to design, matched accurately, standard in construction, steady and free from hidden troubles, simplifies the locking link structure, avoids errors due to human factors, and ensures the construction quality.

Owner:福建安厦新型机械租赁有限公司

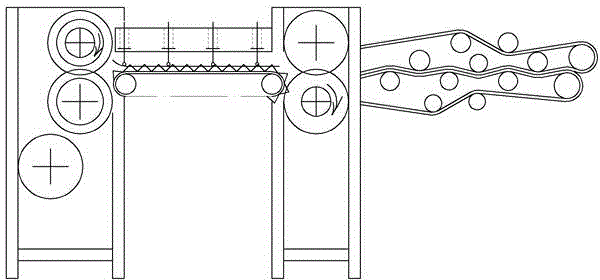

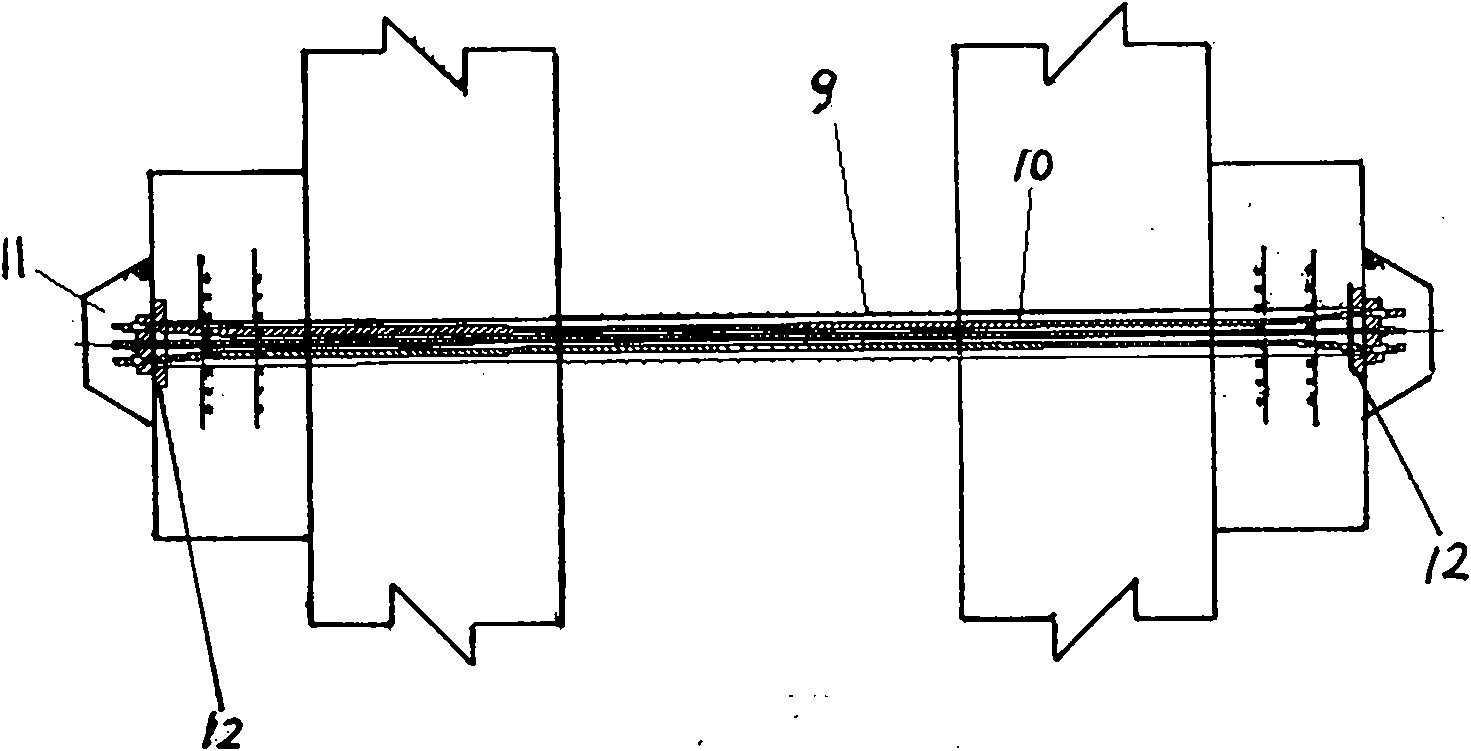

Automatic high-efficiency ramie peeling machine

ActiveCN104641807AContinuous automatic desensitizationIncrease productivityThreshersFiberCounter-pull

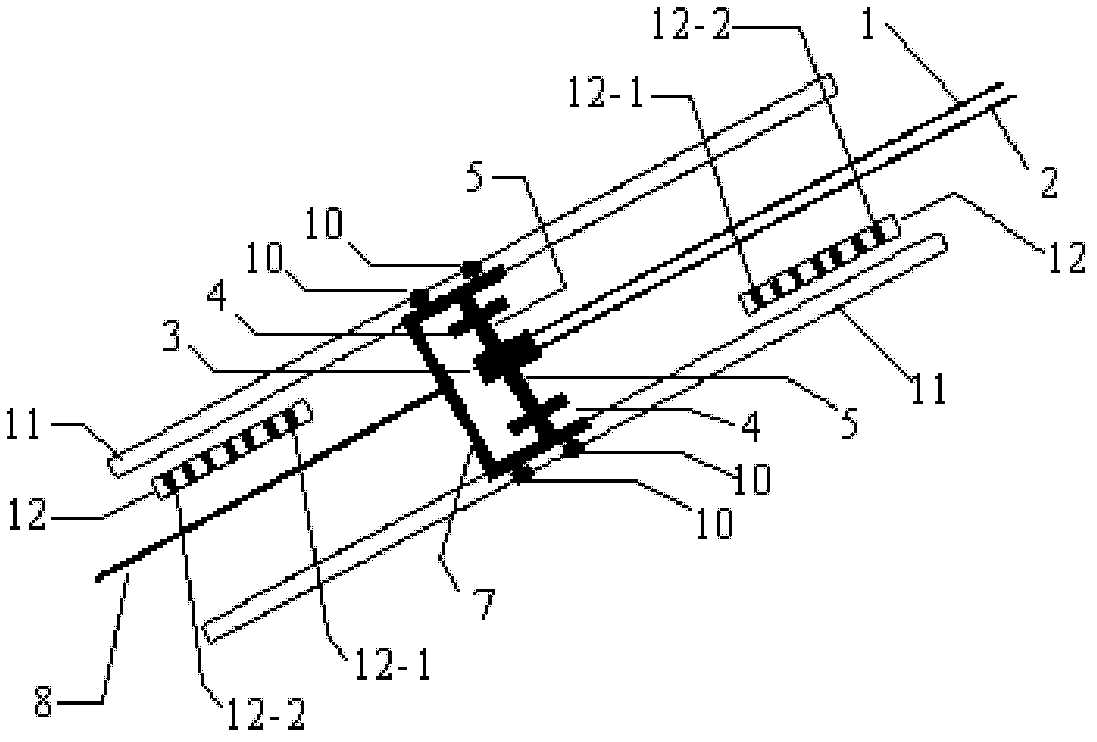

The invention discloses an automatic high-efficiency ramie peeling machine, which solves the technical difficulty of the prior art that the ramie peeling efficiency is not high and the combined harvesting cannot be realized. The automatic high-efficiency ramie peeling machine consists of three ramie peeling mechanisms and a ramie stalk and fiber clamping conveying mechanism, a ramie stalk is fed and peeled on the front section of a left ramie peeling mechanism, the counter-pulling clearing is carried out on the rear section of the left ramie peeling mechanism, and the feeding and ramie peeling and the counter-pulling clearing are respectively completed by a middle ramie peeling mechanism and a right ramie peeling mechanism. The ramie stalk and fiber clamping conveying mechanism and the ramie peeling mechanism are obliquely arranged, a ramie stalk feeding chain and a ramie stalk withdrawing clamping chain are slightly overlapped in an end-to-end manner on the same straight line so as to complete the reversing connection, a ramie stalk clamping counter-pulling feeding chain and a fiber clamping conveyor belt are connected in an overlapping manner in an end-to-end manner, and after the basic part is peeled, the fiber is pulled out in an opposite direction by the fiber clamping conveying mechanism. The automatic high-efficiency ramie peeling machine is mainly used for the centralized primary processing of ramie fibers and for being matched with a ramie cutting machine to realize the combined harvesting.

Owner:XIANNING AGRI ACADEMY OF SCI

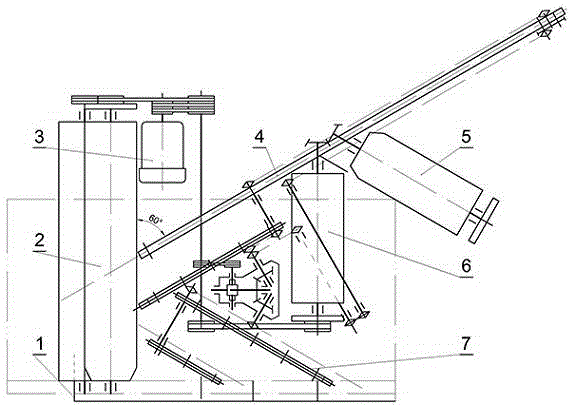

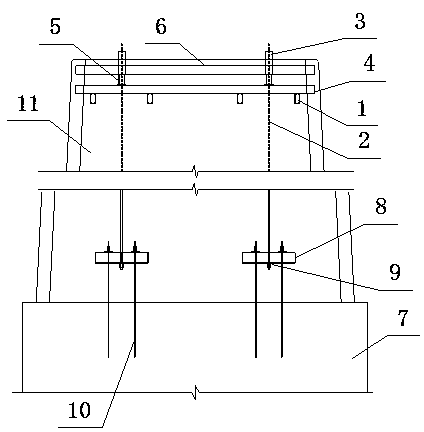

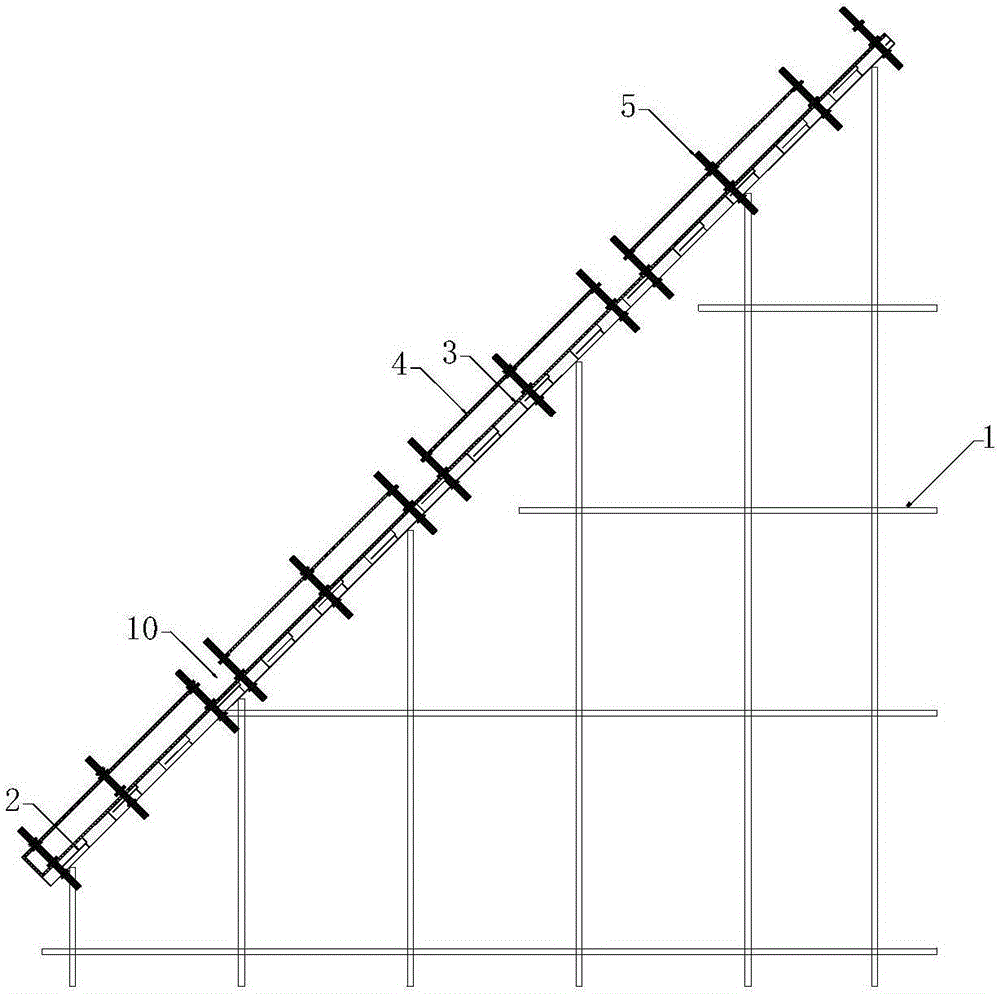

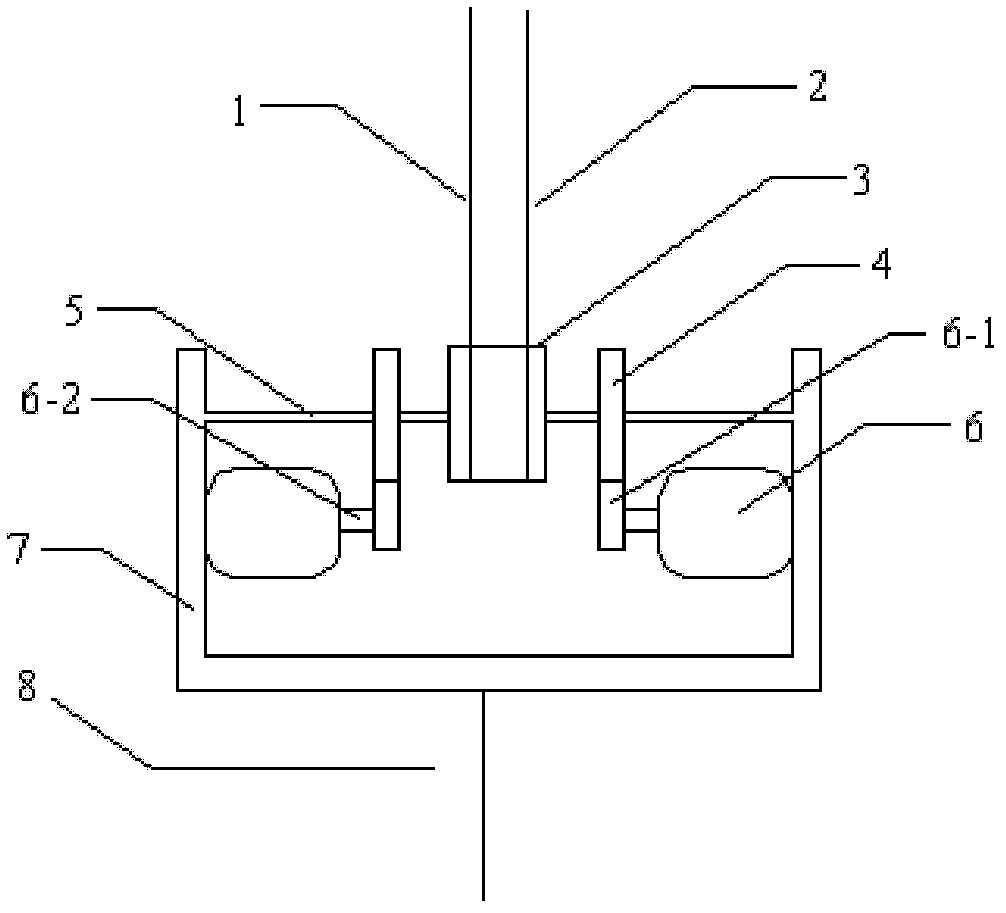

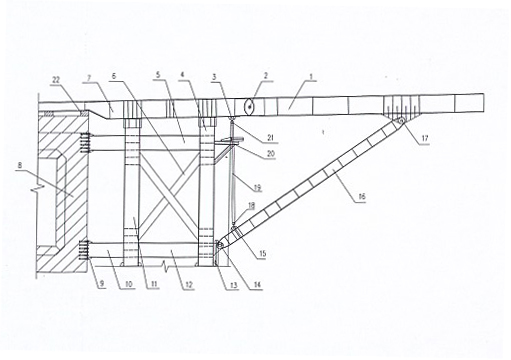

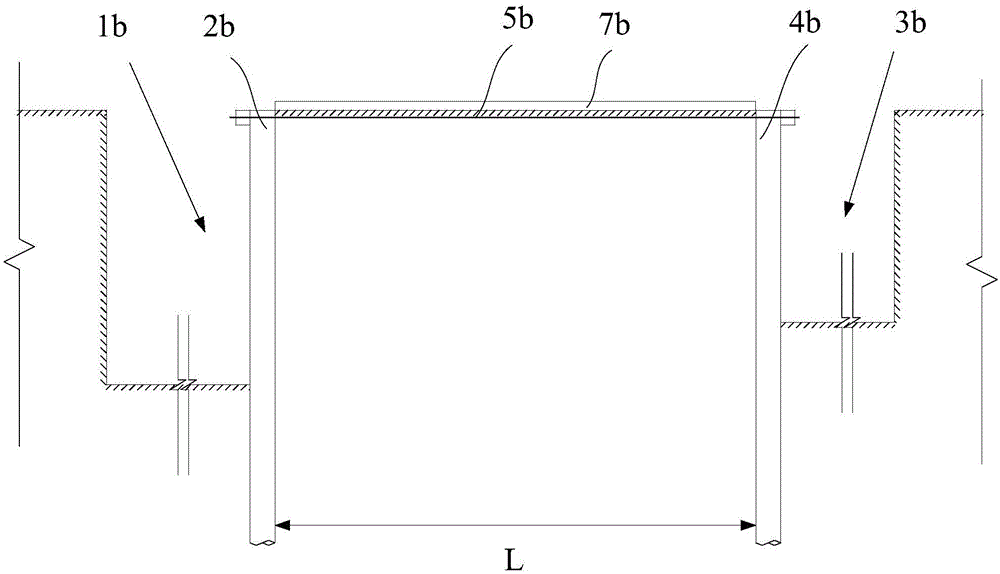

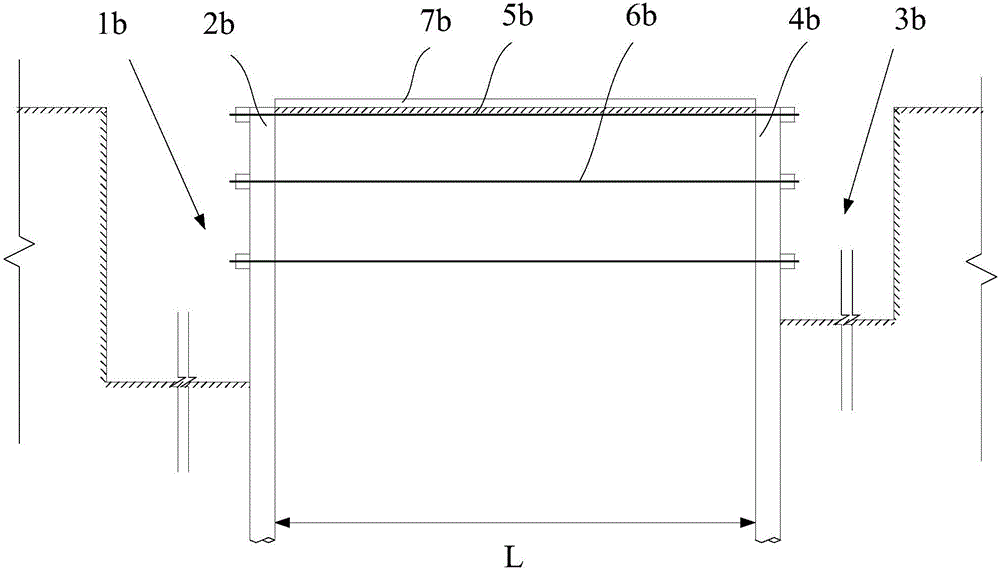

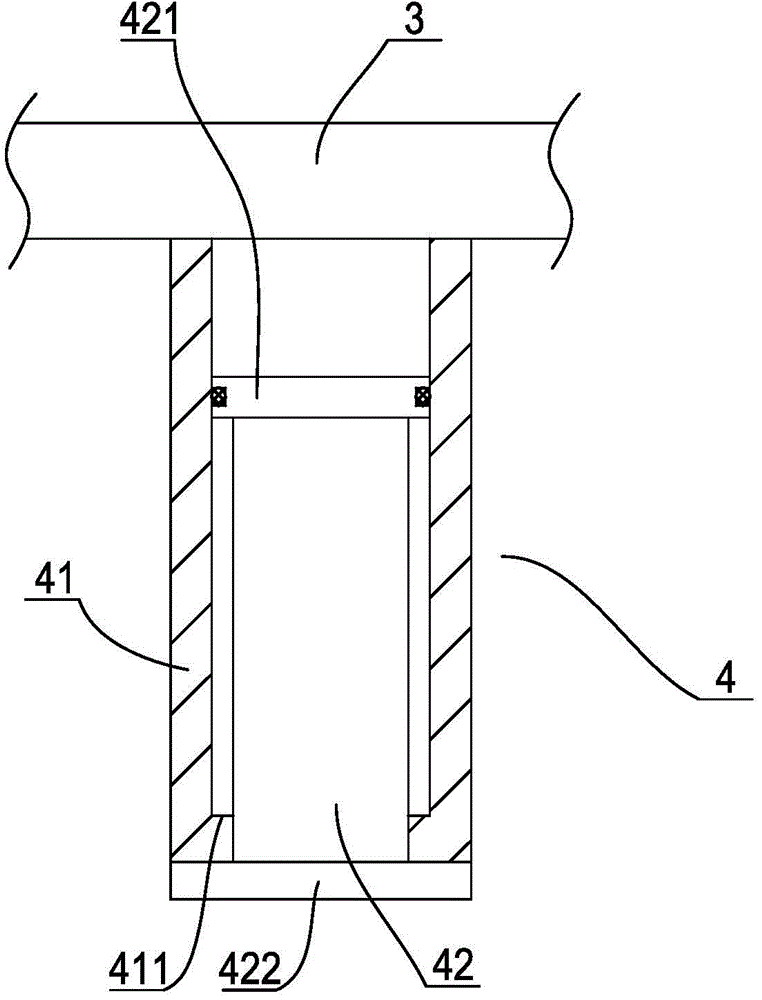

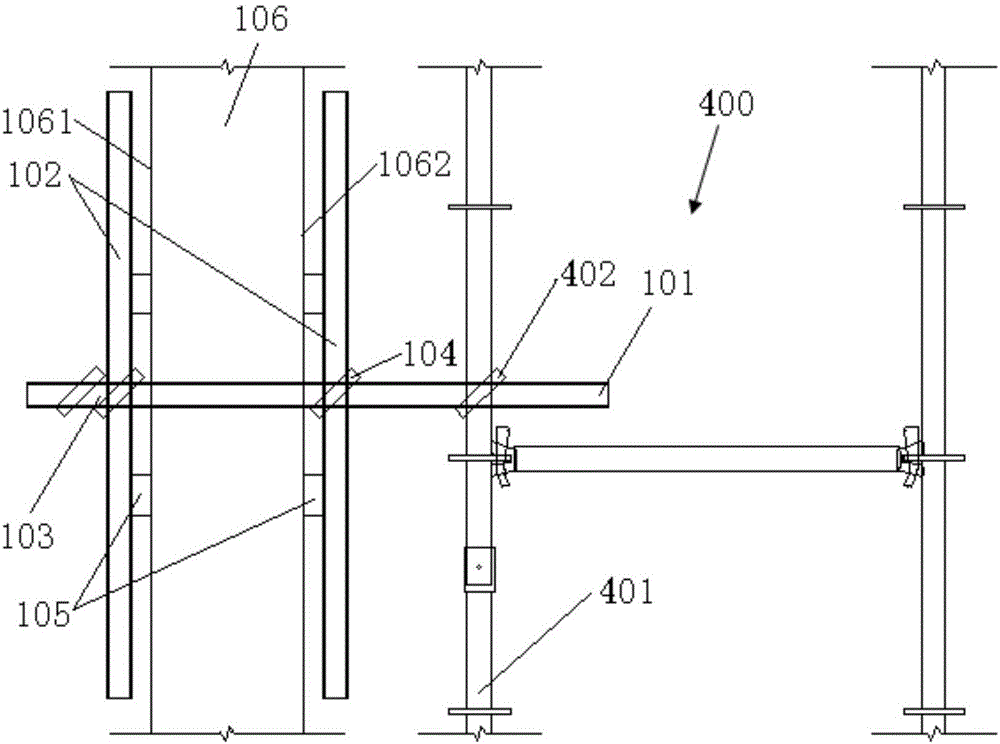

Bracket counter pull loading pre-pressing device and tensioning pre-pressing method thereof

ActiveCN103352429AShorten the preload timeSave pre-pressing costBridge erection/assemblyCounter-pull

The invention discloses a bracket counter pull loading pre-pressing device and a tensioning pre-pressing method of the bracket counter pull loading pre-pressing device, and belongs to the technical field of bridges. The bracket counter pull loading pre-pressing device is composed of an upper anchor system, a lower anchor system, steel strand bundles and tensioning jacks, wherein the upper anchor system is placed on a bracket, the lower anchor system is located below the upper anchor system, and the steel strand bundles connect the upper anchor system and the lower anchor system. The upper anchor system is composed of a plurality of distribution cross beams, at least two reinforcing longitudinal beams, a reinforcing cross beam and the tensioning jacks, wherein the distribution cross beams are placed on the top of the bracket, the reinforcing longitudinal beams are placed on the tops of the distribution cross beams, the reinforcing cross beam is placed on the tops of the reinforcing longitudinal beams, and the tensioning jacks are installed on the intersections of the reinforcing cross beam and the reinforcing longitudinal beams and on the top face of the reinforcing cross beam. The lower anchor system is composed of a plurality of sets of connection columns, double-splicing I-steel beams and anchor base plates, wherein the double-splicing I-steel beams connect the steel strand bundles and each set of connection columns, and the other ends of the steel strand bundles are fixed on the tensioning jacks. The bracket counter pull loading pre-pressing device and the tensioning pre-pressing method of the bracket counter pull loading pre-pressing device are rapid, effective and applicable.

Owner:CHINA RAILWAY NO 8 ENG GRP CO LTD

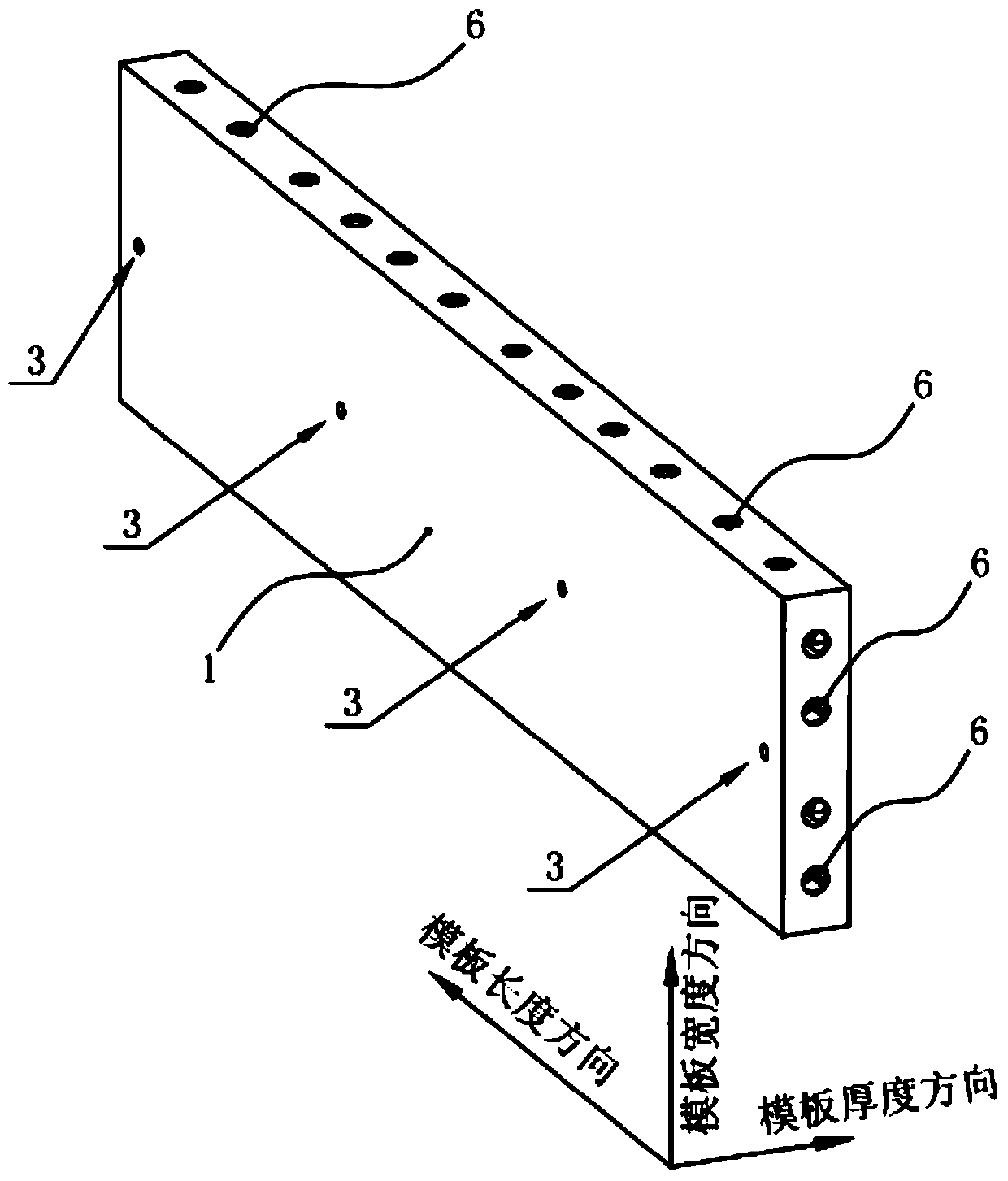

Fast installation formwork and connection structure

InactiveCN104196230AImprove structural strengthEasy to installFoundation engineeringAuxillary members of forms/shuttering/falseworksCounter-pullEngineering

The invention discloses a fast installation formwork and a connection structure, and belongs to the field of installation formworks. The fast installation formwork and the connection structure are light, convenient to install, high in structural strength and suitable for emergency work or large-size concrete pouring projects. The structural strength of the formwork is improved by arranging main reinforcing ribs on the back of the formwork. Corresponding counter pull holes are formed in the formwork, and the installation strength and the stability of the formwork are improved through connection between the formwork and a reinforcing rod. Under the condition of meeting the use requirements for the formwork in the emergency work or the large-size concrete pouring projects, the mass of the formwork is lowered, and the formwork is more convenient to carry and install. When made of plastic, the formwork has more outstanding advantages and becomes lighter and more convenient to carry and install. The formwork is more convenient to produce and low in cost and does not rust easily.

Owner:中国人民武装警察部队水电第九支队

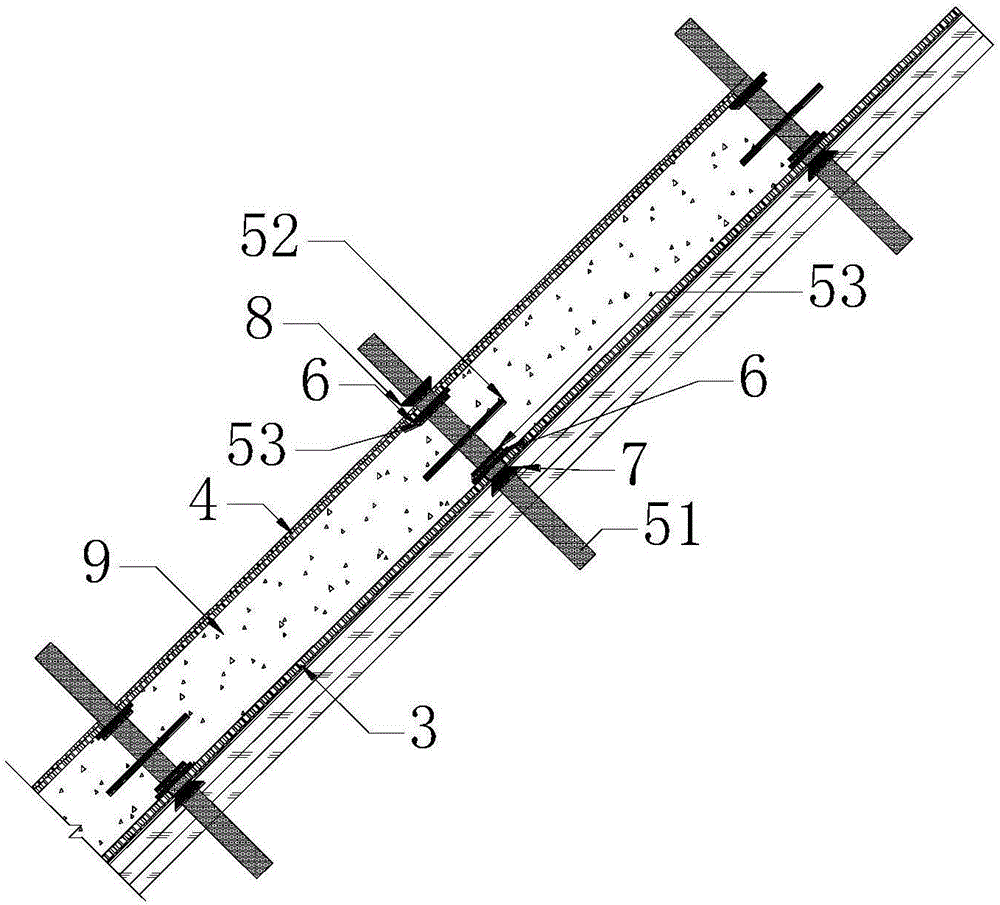

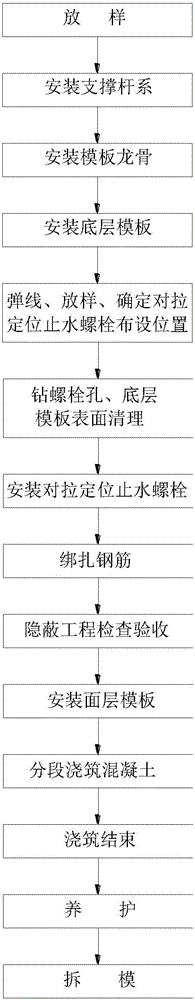

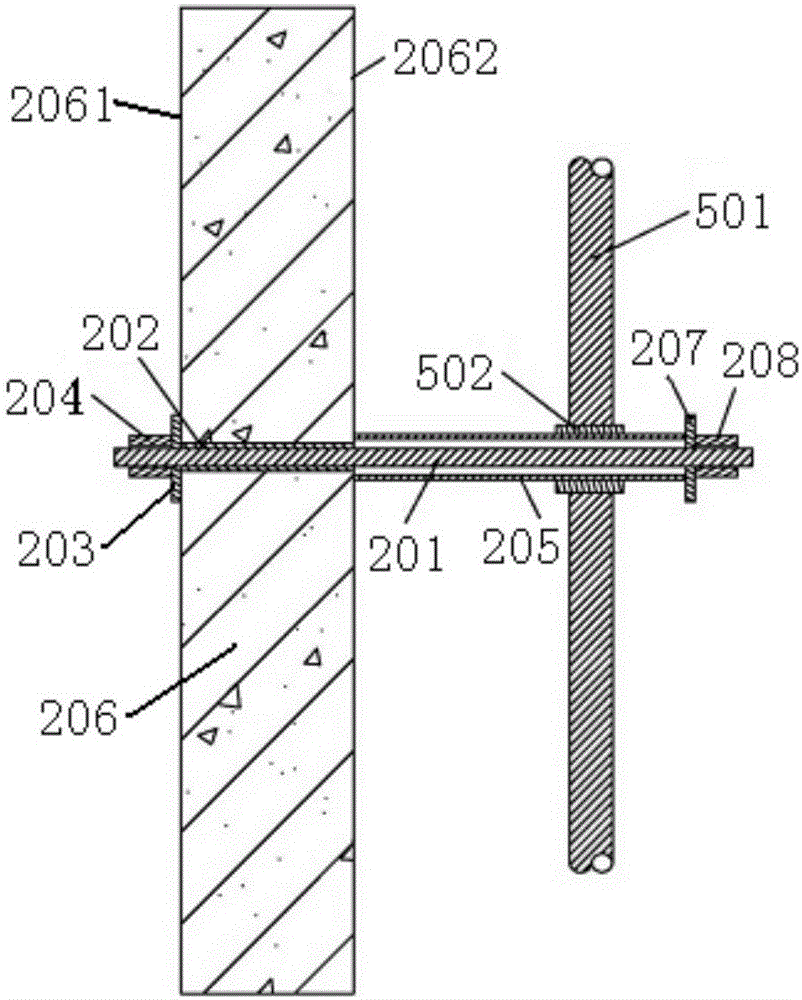

Construction method and double-layer formwork structure for cast-in-situ slope roof

InactiveCN106437142AImprove pouring and tamping construction efficiencyGuarantee molding qualityBuilding roofsForms/shuttering/falseworksKeelCounter-pull

The invention relates to a construction method and a double-layer formwork structure for a cast-in-situ slope roof. The double-layer formwork structure comprises a supporting rod system, a formwork keel, a bottom formwork, a surface formwork and counter-pull positioning waterproof bolts. The bottom of the formwork keel is fixedly supported by the supporting rod system; the bottom formwork is laid on the upper surface of the formwork keel, the surface formwork is parallel to the bottom formwork, and a distance between the surface formwork and the bottom formwork is equal to the thickness of a concrete pouring layer of the slope roof; the bottom formwork and the surface formwork are positioned through the counter-pull positioning waterproof bolts; the surface formwork is formed by a plurality of segmented surface formworks at intervals, and a trough formed by ends of the adjacent segmented surface formworks and the bottom formwork serves as a vibration tamping trough for segmented pouring of concrete. By adoption of the double-layer formwork structure and a segmented concrete pouring and vibration tamping method, the problem of proneness to slipping of concrete in construction of the slope roof is solved, structural compactness, high section size precision and high surface quality of concrete after pouring and tamping are achieved, and the construction method is simple and feasible.

Owner:CHINA THIRD METALLURGICAL GRP

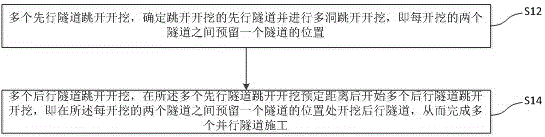

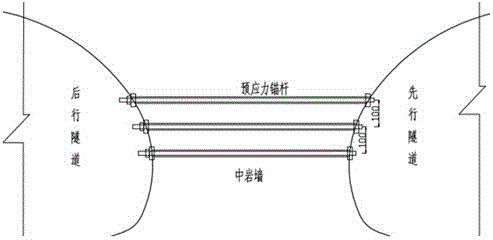

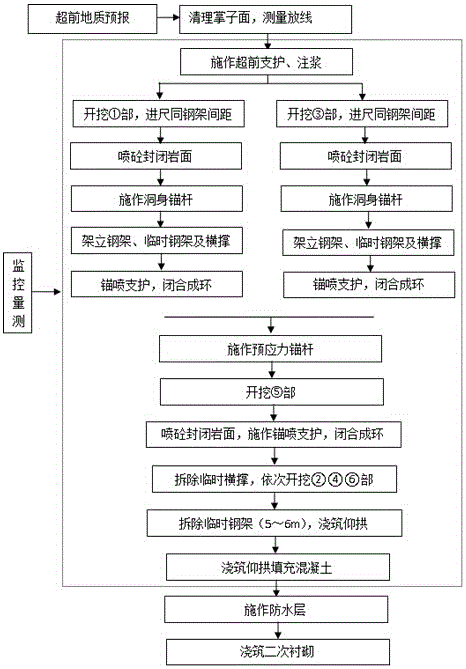

Super-shallow-buried small-spacing large-section multi-tunnel concurrent construction method

ActiveCN106050243ASolve Bias ProblemsAddresses side pressure effectsTunnelsCounter-pullEnvironmental geology

The invention discloses a super-shallow-buried small-spacing large-section multi-tunnel concurrent construction method for excavating multiple parallel tunnels. The super-shallow-buried small-spacing large-section multi-tunnel concurrent construction method comprises the steps that S12, multiple antecedent tunnels are excavated in a spaced mode, antecedent tunnels excavated in the spaced mode are determined, and multi-hole spaced excavation is performed, namely one tunnel position is reserved between every two adjacent excavated tunnels; S14, multiple following tunnels are excavated in a spaced mode, spaced excavation of the multiple following tunnels is performed after the antecedent tunnels are excavated in the spaced mode for a predetermined distance, namely each following tunnel is excavated at the tunnel position reserved between every two adjacent excavated tunnels, and accordingly multi-tunnel concurrent construction is completed. On the basis that a single-side double-side pit guiding excavating method and a composite lining principle are adopted, the problem of pressure bias is effectively solved during replacement and filling at opening top low-lying positions, prestressed counter-pulled anchor rods are arranged among openings to connect the openings to form a whole, surrounding rocks among the openings are further stabilized, and the lateral pressure influence of the openings is effectively solved.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

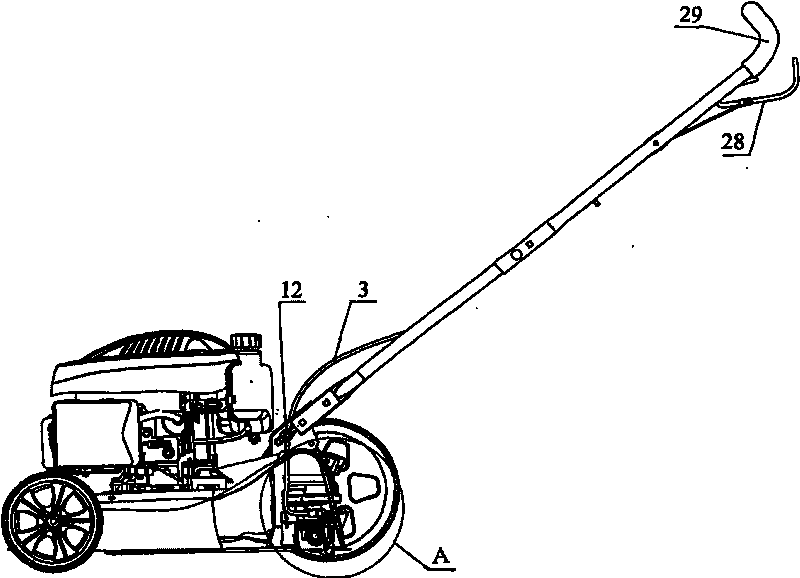

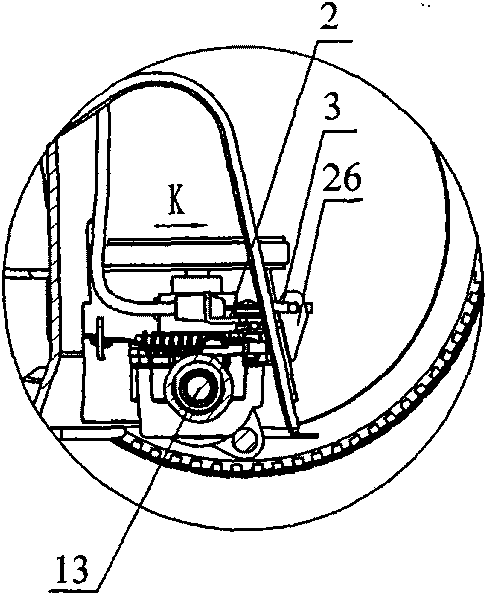

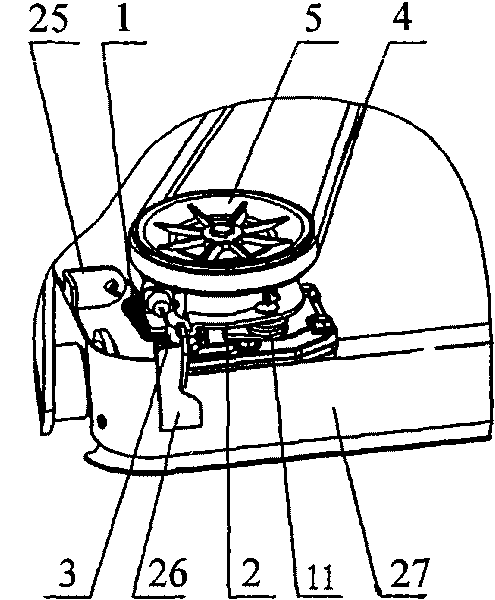

Integrated control mechanism for automatic walking device clutch and continuously variable transmission of lawn mower

InactiveCN101697680ARealize integrated controlIngenious ideaHarvestersAgricultural undercarriagesDrive shaftCounter-pull

The invention relates to an integrated control mechanism for an automatic walking device clutch and a continuously variable transmission of a lawn mower, which comprises a variable speed pulling rod, a pulling cable, a pulling cable fixing plate, a stroke plate, a belt pulley, a belt, and a small bevel gear, a large bevel gear, a return torsional spring, a return tension spring, a shifting fork, a clutch, a driving shaft, a compression spring and the like which are arranged in a chamber consisting of a box body and a box cover. When the integrated control mechanism is controlled, the variable speed pulling cable drives the stroke plate to drive the shifting fork so as to push the clutch to axially move through counter pull of the pulling cable fixing plate; and the clutch is meshed with the large bevel gear by combining elastic force of the compression spring on the driving shaft so as to drive the driving shaft to rotate. When the pulling cable is loosened, the shifting fork drives the clutch to separate from the large bevel gear in a reverse direction. Meanwhile, the integrated control mechanism achieves variable speed through clenching degree of the belt pulley and the belt, achieves integrated control of one pulling cable and has the advantages of ingenious design and simple structure.

Owner:NINGBO DELIN MACHINERY

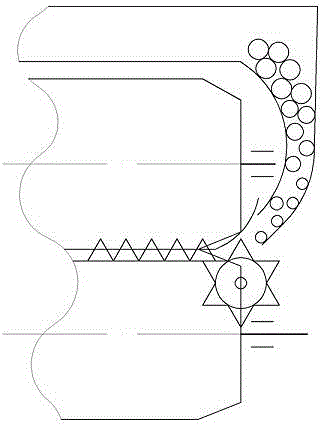

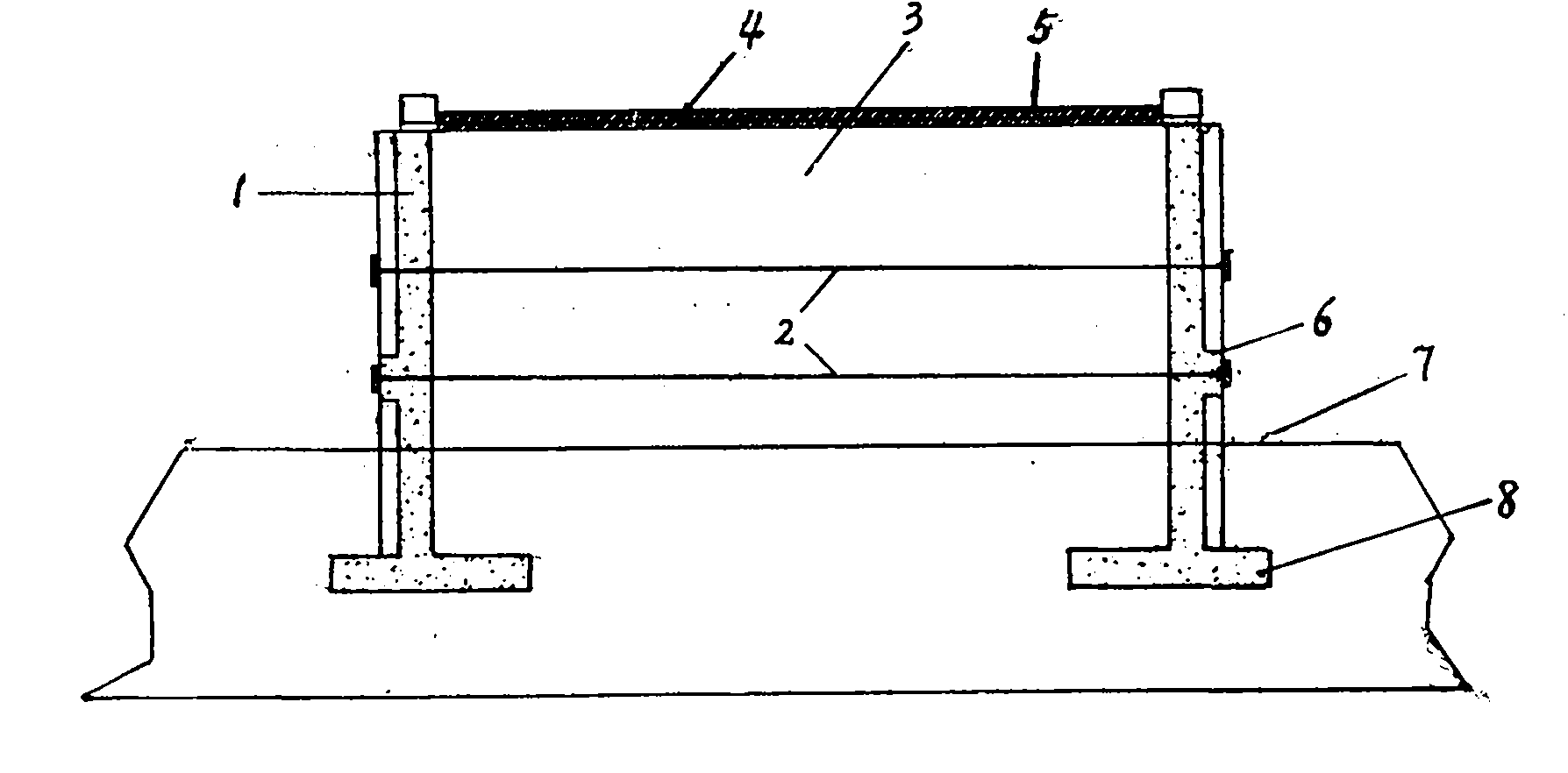

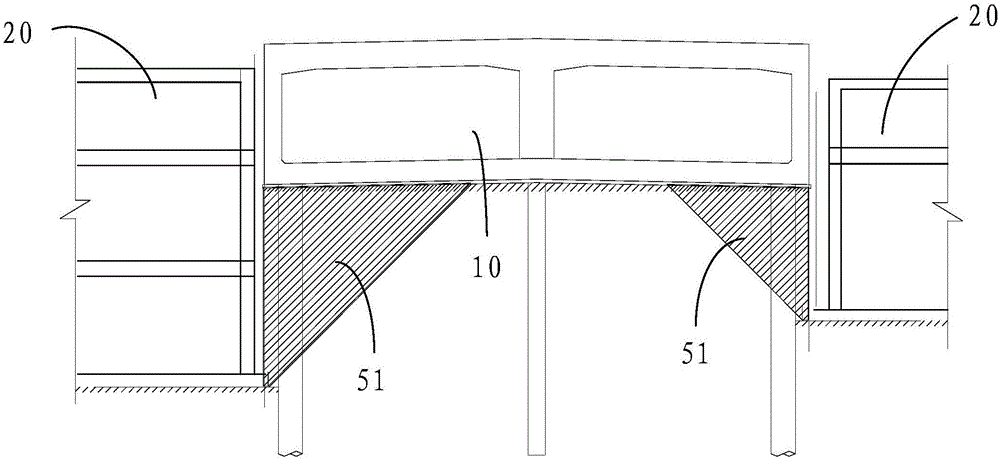

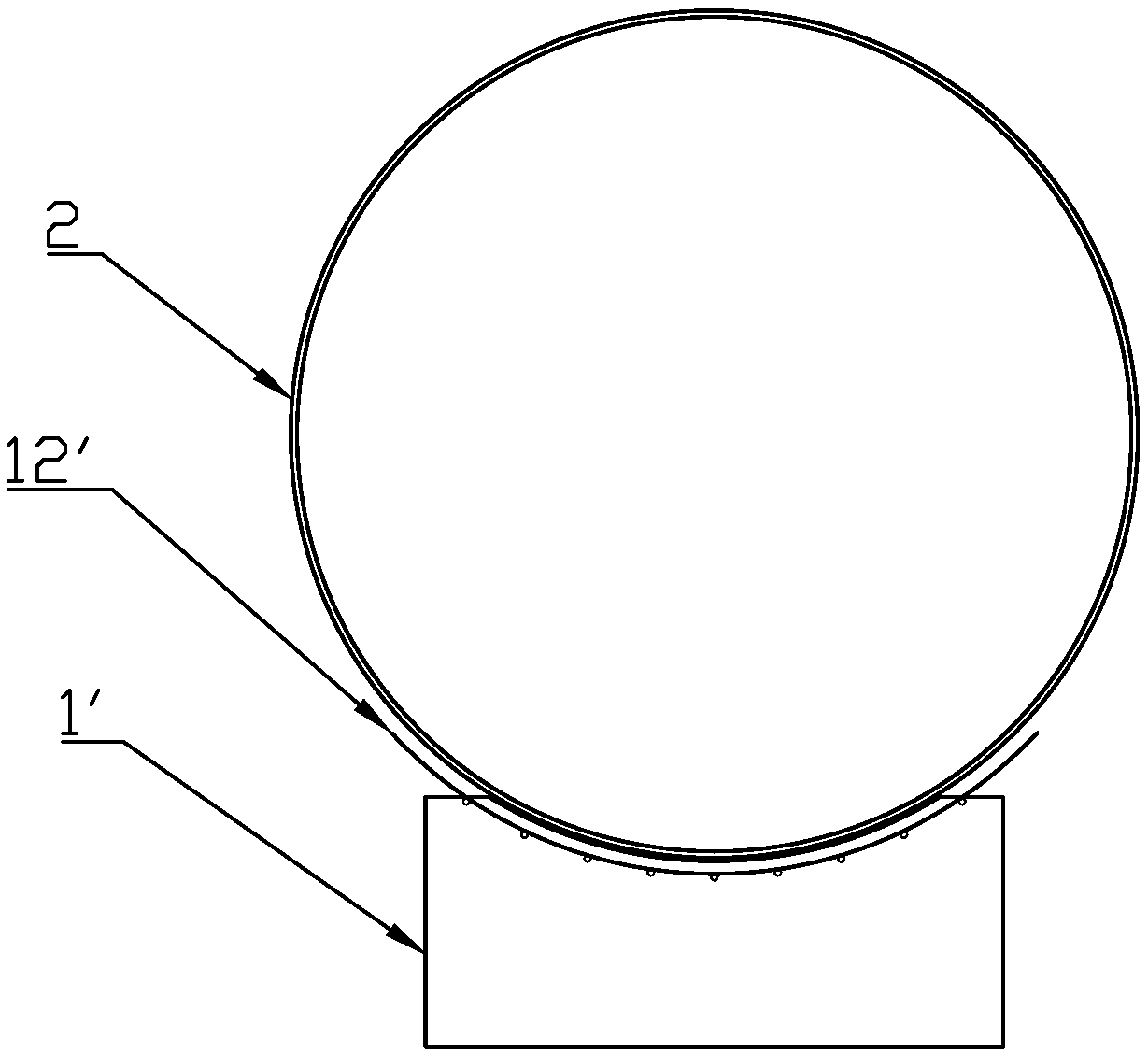

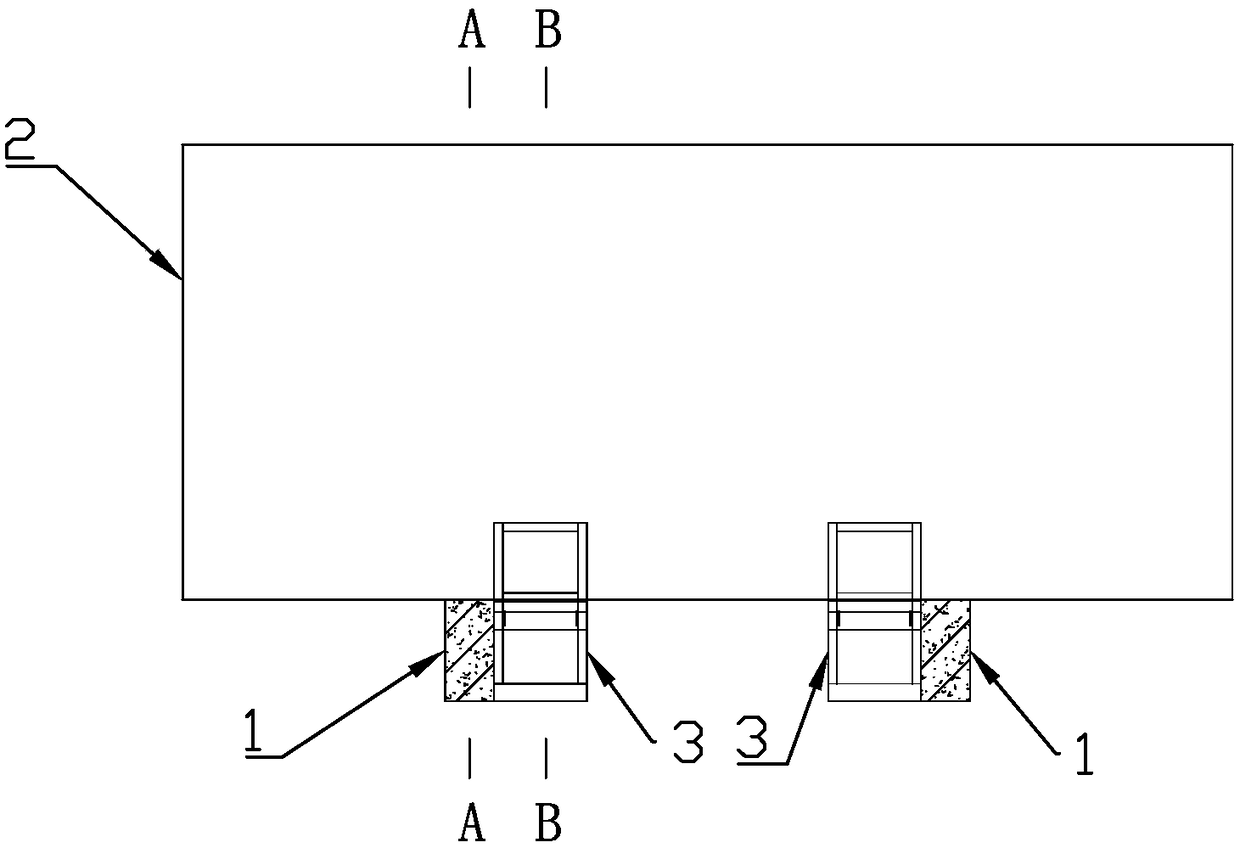

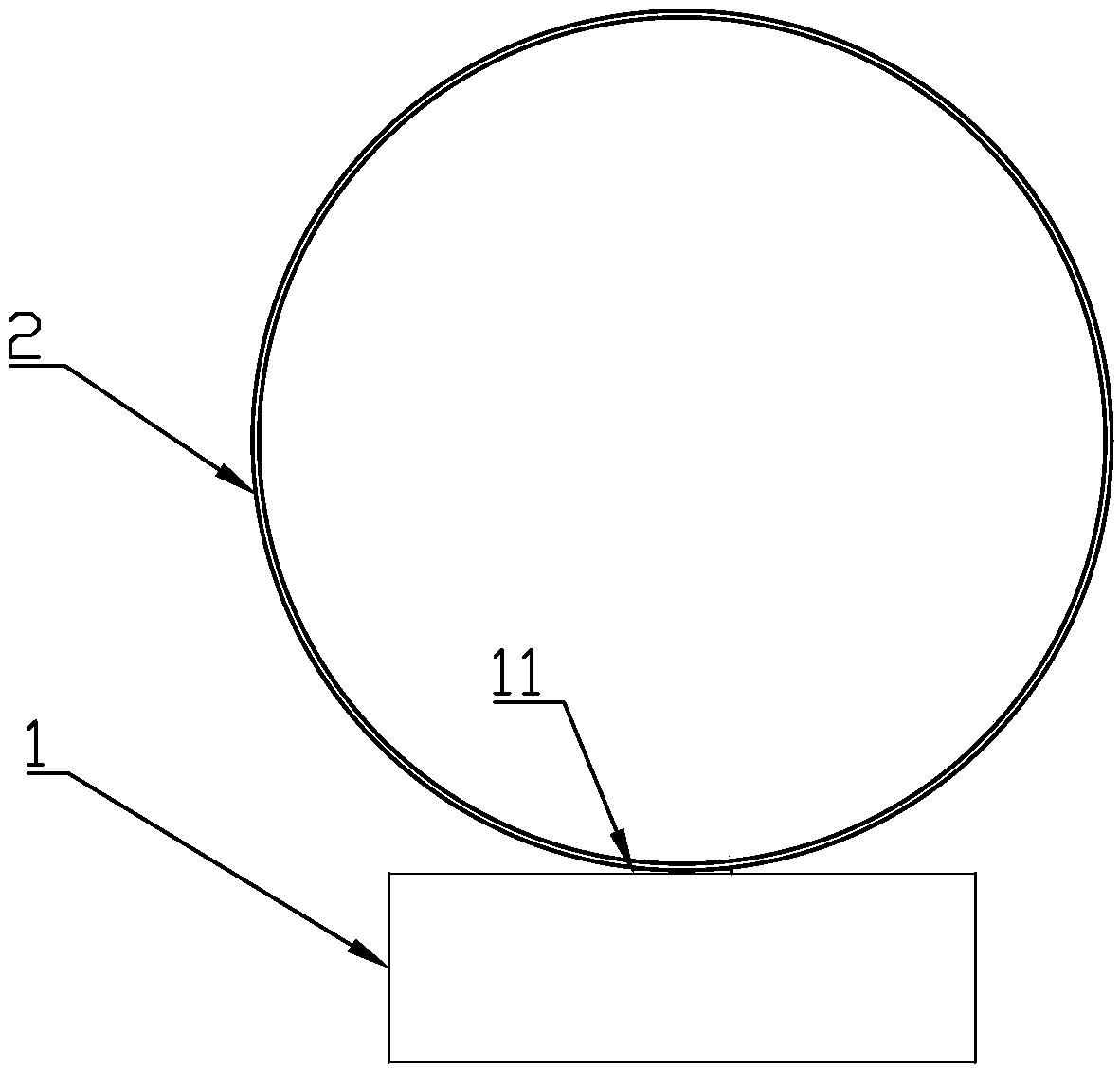

Counter-pulled type rib retaining wall of pre-stressing force cantilever

InactiveCN101899839AHigh altitudeReduced bearing capacity requirementsArtificial islandsUnderwater structuresEarthquake resistanceReinforced concrete

The invention provides a counter-pulled type rib retaining wall of a pre-stressing force cantilever. The retaining wall is formed by connecting cantilever type reinforced concrete earth-retaining wall bodies, which are symmetrically arranged on two sides of a roadbed, with a counter-pulled anchor rope which runs through the width of the roadbed, wherein the cross sections of the earth-retaining wall bodies have single-layered shapes or ladder-type multi-layer shapes. A base plate is arranged below the earth-retaining wall bodies, and ribs for mounting anchor piers are arranged in the middle parts of the earth-retaining wall bodies; a plastic pipe sleeve is arranged outside the counter-pulled anchor rope; the counter-pulled anchor rope comprises n bundles of steel stranded wires; and a grouting protective layer is arranged between the plastic pipe sleeve and the steel stranded wires. The integrity, the skid resistance, the overturn resistance, the collision resistance and the earthquake resistance of the earth-retaining wall can meet operating requirements, the limit height of the earth-retaining wall is higher than that of the conventional earth-retaining wall, and the earth-retaining wall has a wide application range and a low requirement on the foundation bearing capacity.

Owner:SHANDONG UNIV

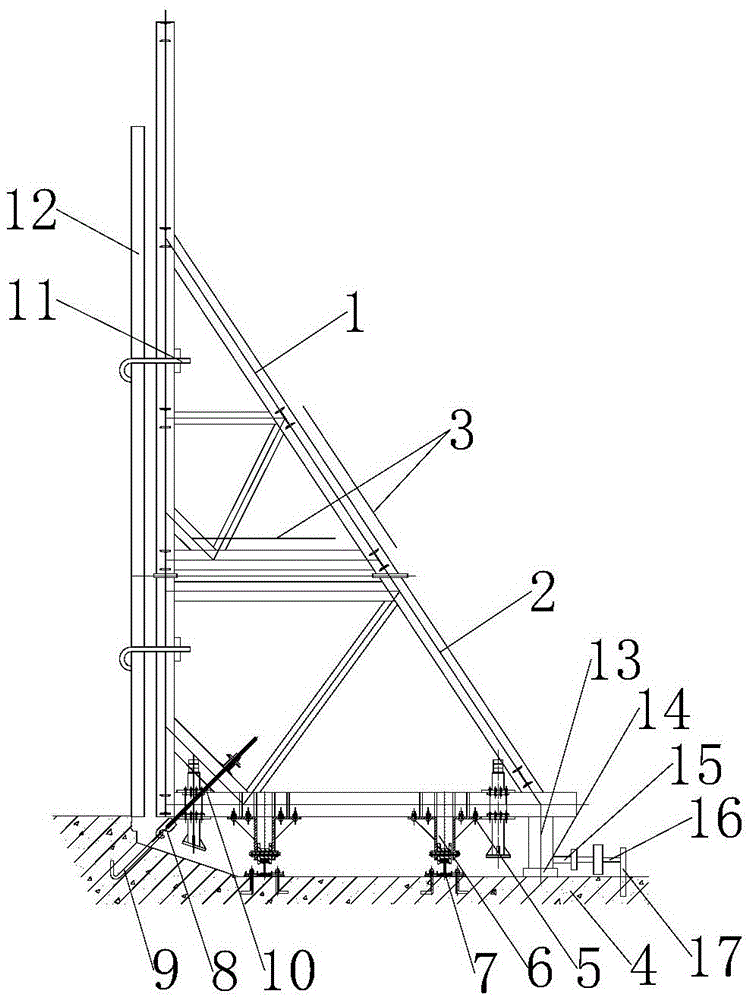

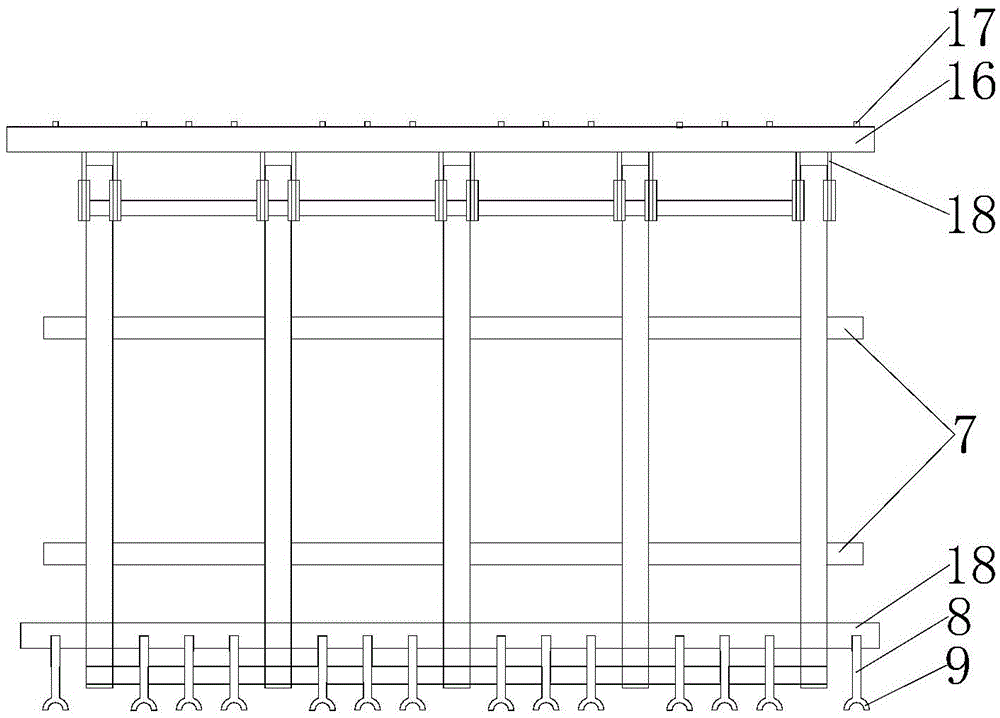

Side wall self-propelled type triangular truss and construction method thereof

PendingCN105672655ALow installation accuracy requirementsEasy to adjustAuxillary members of forms/shuttering/falseworksBuilding material handlingCounter-pullUpper segment

Owner:POWERCHINA RAILWAY CONSTR +1

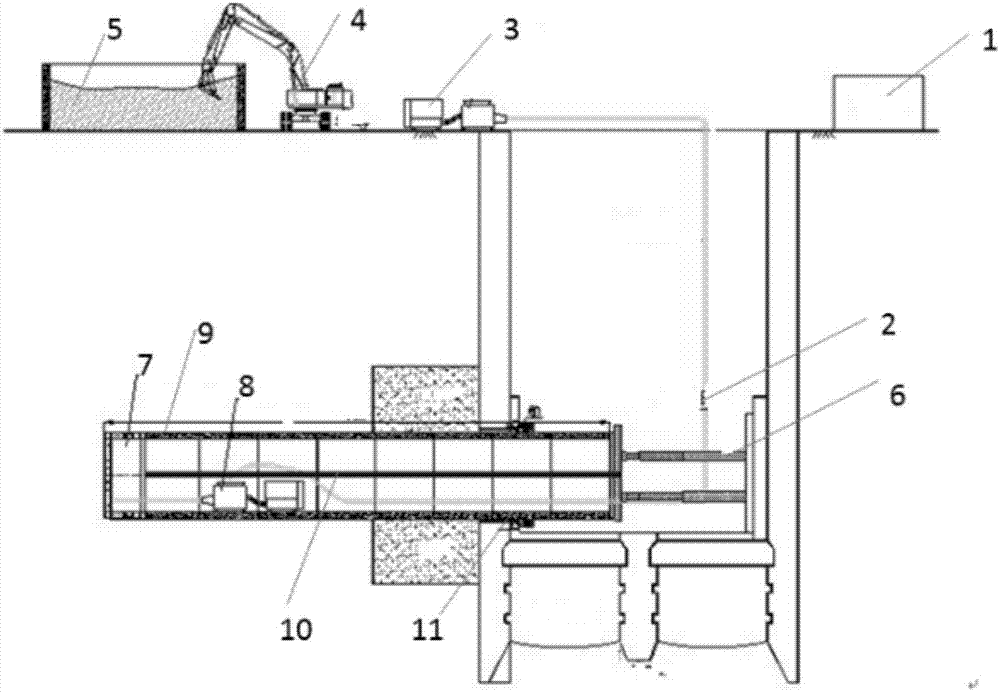

Construction method for pipe retreating of cross-river pipe jacking pipeline in soft soil stratum

InactiveCN107504262ARealize large-distance pipe withdrawal projectStrong pullPipe laying and repairEmbankmentsHydraulic cylinderCounter-pull

The invention discloses a construction method for pipe retreating of a cross-river pipe jacking pipeline in a soft soil stratum. The method comprises the following steps that firstly, original equipment devices in a pipe retreating pipeline are dismounted and removed, a steel seal door, a reverse jacking hydraulic cylinder, a counter pull steel beam, a steel strand set and other pipe retreating equipment devices are installed, safety measures of the steel seal door, the reverse jacking hydraulic cylinder, the counter pull steel beam, the steel strand set and other pipe retreating equipment devices are checked, and pipe retreating construction is conducted after debugging. In the method, measures of arrangement of a dewatering well and a packing water stop ring are adopted for solving the problem of water stop, and for solving the problem of collapse risks existing after pipe retreating, the manner that pipe retreating and soil filling are conducted at the same time is adopted; and meanwhile, in the later stage of pipe retreating, injected soil slurry is switched into cement slurry, and a hole is strengthened. According to the disclosed technical scheme, the collapse problem is effectively solved, and meanwhile long-distance pipe retreating is achieved.

Owner:SHANGHAI ROAD & BRIDGE (GRP) CO LTD

Method and device for pushing instant message

ActiveCN106533932AMeet different transmission requirementsData switching networksMessage typeCounter-pull

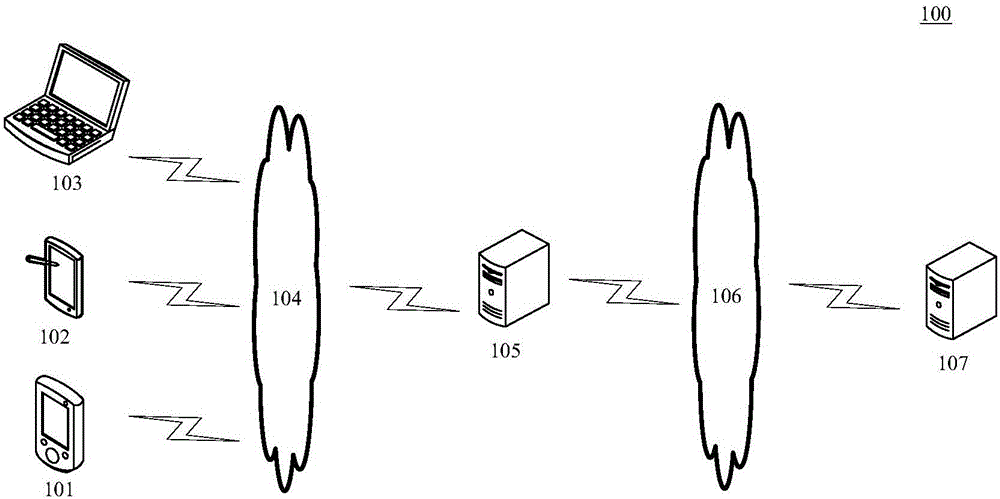

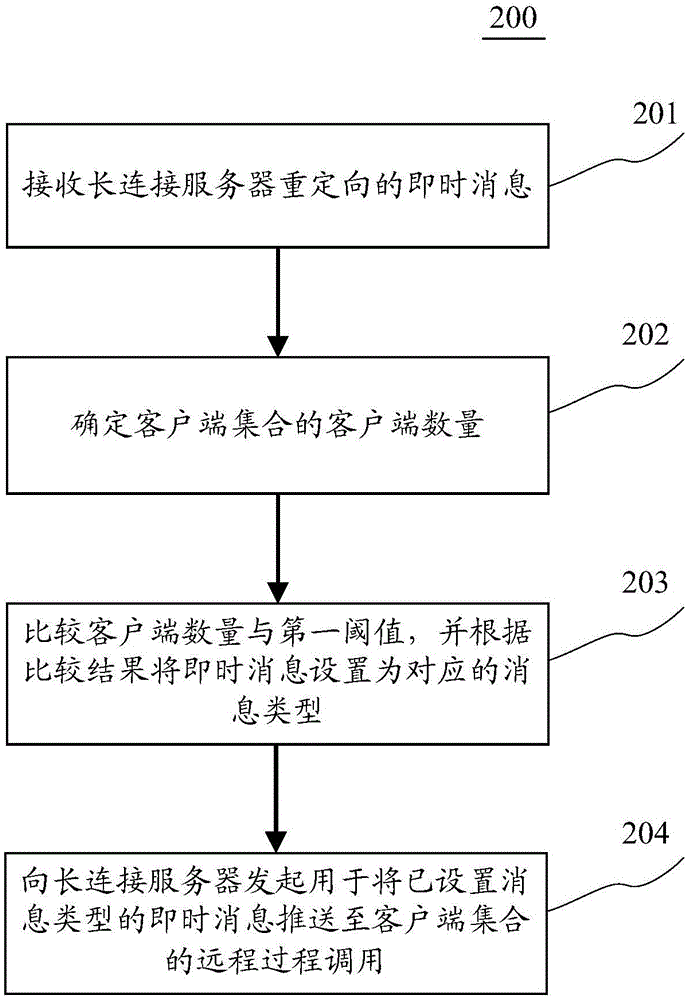

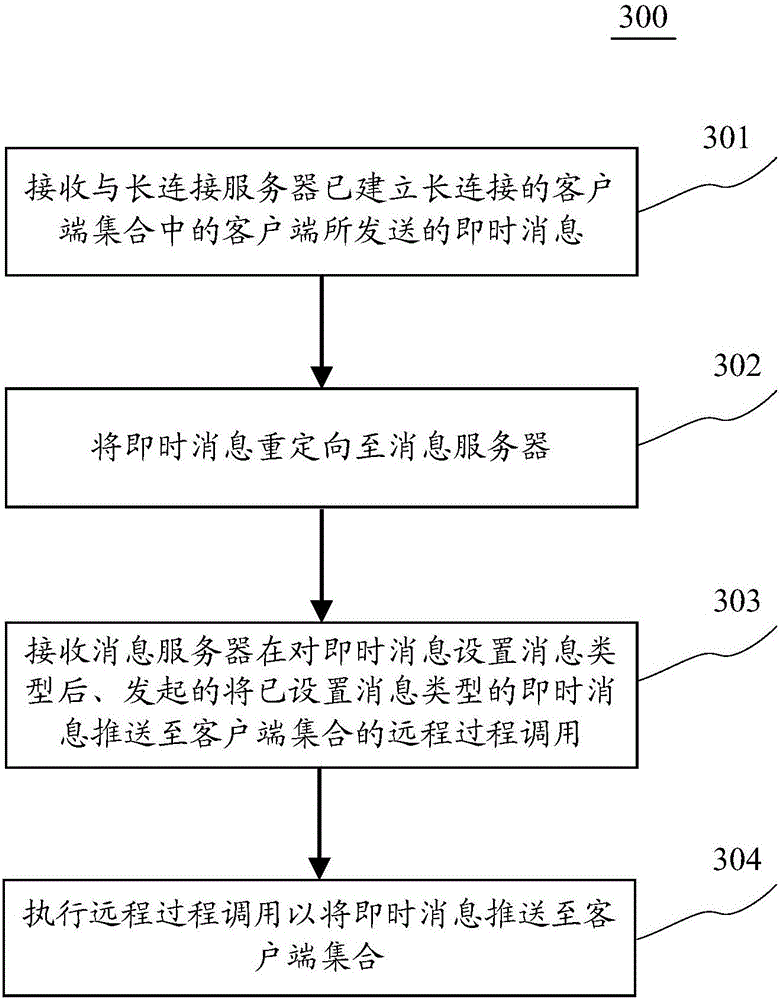

The invention discloses a method and device for pushing an instant message. An embodiment of the method comprises the following steps: receiving an instant message re-oriented by a long connection server, wherein the instant message is an instant message sent by a client in a client set that has established a long connection with the long connection server; determining the number of the clients in the client set; comparing the number of the clients with a first threshold, and setting the instant message as a corresponding message type according to a comparison result, wherein when the number of the clients is smaller than or equal to the first threshold, the corresponding message type is a counter pull mode, and when the number of the clients is greater than the first threshold, the corresponding message type is a direct push mode; and initiating remote process calling used for pushing the instant message with the message type set to the client set to the long connection server. The embodiment flexibly selects the push mode of the instant message according to the scene.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

Cable controller, kite, kite drive operating mechanism, kite power generator and automobile and boat wind-driving method

InactiveCN102602751ADeformation stableAvoid enteringFinal product manufactureWind motor combinationsNuclear powerWater reservoir

A cable controller, a kite, a kite drive operating mechanism, a kite power generator and an automobile and boat wind-driving method all relate to a counter-pulling cable controller and a completely-deformable double-cable kite which form a reciprocating discharging and collecting kite. The kite spreads to collect energy at a starting point and can flow to a finish point linearly, folds to discharge energy and backflows to the starting point linearly, and then re-spreads to collect energy to flow and draws a working machine round and round to run. The reciprocating discharging and collecting kite and the engine are combined to form a wind-kite power generator or a water-kite power generator, the same power generator can be pulled by hundreds of large-sized kites jointly, the maximum single-machine capacity of the two kinds of the power generators can reach or excess that of thermal-power generation and nuclear power. A pond energy storage power generation mechanism is a new combination of wind power generation and water power generation, river blocking and damming of water power generation are omitted, and electric quantity equal to that of larger power generation stations can be generated by low investment and small water reservoirs. The automobile and boat wind-driving method includes: utilizing trade-wind zones, westerlies and easterlies on the earth, and upper reverse wind and lower reverse wind of the stratosphere so that automobiles and boats can run with or against the wind and the crosswind.

Owner:罗琮贵

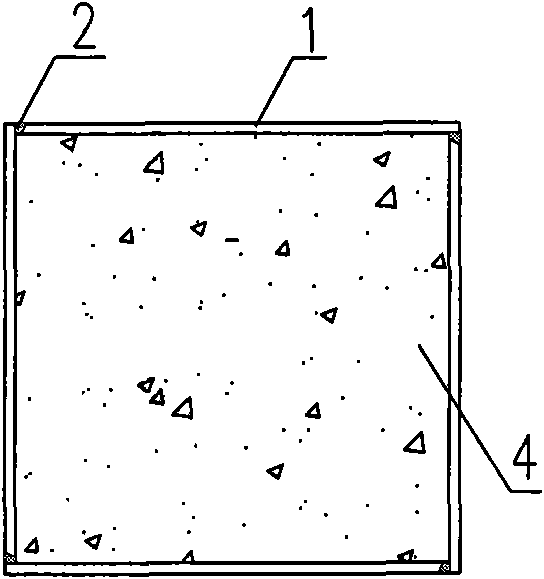

Concrete post provided with counter pulling sheet profile steel welding rectangular steel tube

InactiveCN101748860AAvoid weak spotsEliminate adverse effects on bearing capacityStrutsPillarsWelding residual stressCounter-pull

The present invention discloses a concrete post provided with a counter pulling sheet profile steel welding rectangular steel tube, which relates to a rectangular steel-tube concrete post which is composed of a steel tube and concrete, wherein the steel tube is welded by belt rib profile steel and counter pulling sheets arranged transversely. The counter pulling sheet profile steel welding rectangular steel-tube concrete post enables welding seam positions not at four angle positions stressed largely and while at positions stressed little at the middle of a pipe wall. At the same time, the wall thickness and welding seam volume of the steel tube can be reduced, the constraint force of the middle of the pipe wall for the concrete is increased, and the bearing force of the total component is improved.

Owner:中国建筑东北设计研究院有限公司

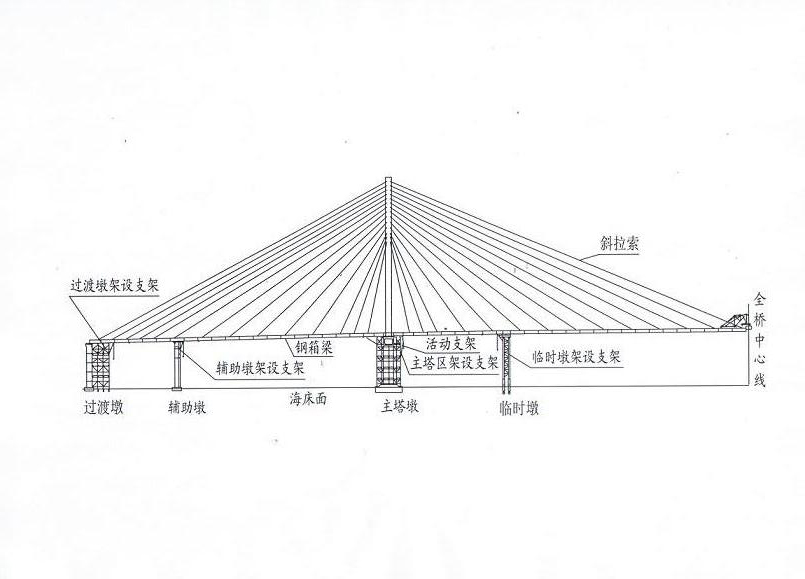

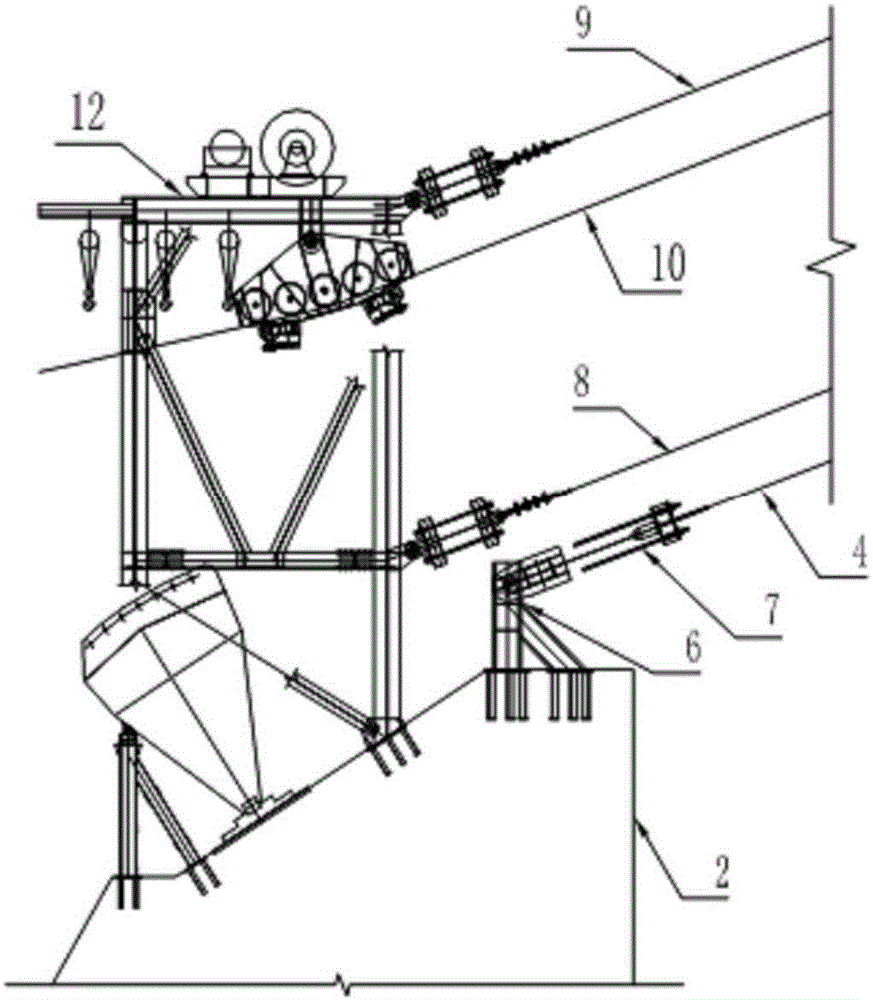

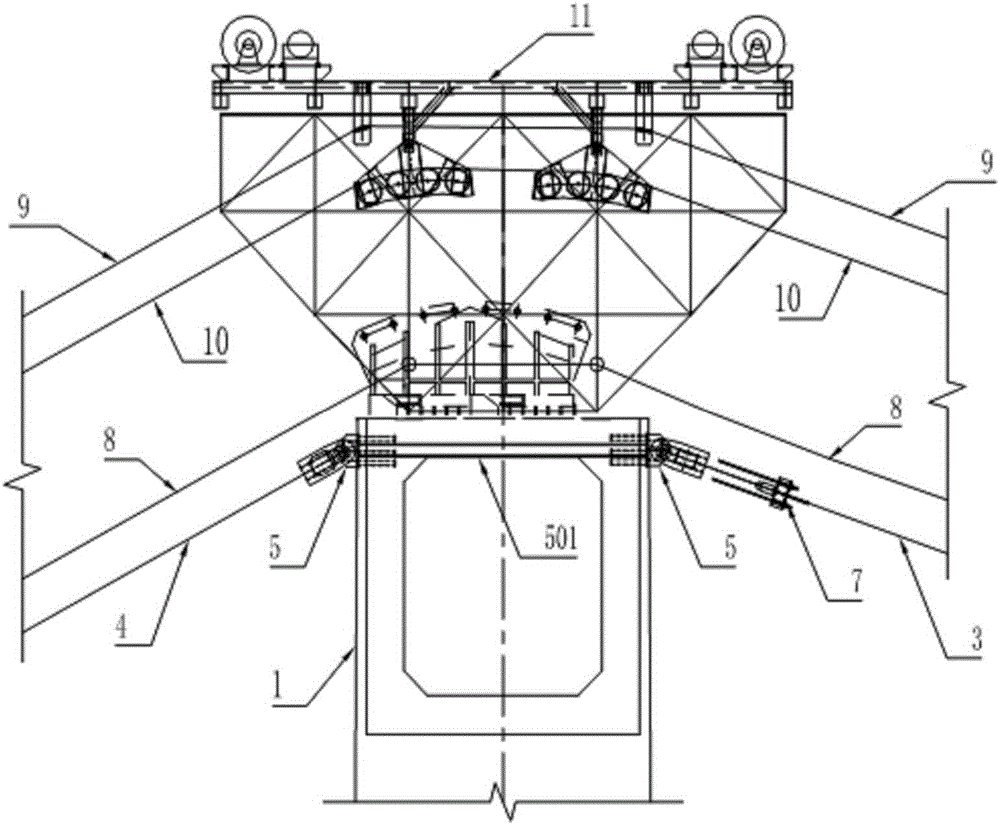

Movable support and movable support assisted method for erecting steel box beams through non-variable amplitude frame beam crane

ActiveCN102134832ALow costReduce construction investmentBridge erection/assemblySocial benefitsCounter-pull

The invention discloses a movable support and a movable support assisted method through a non-variable amplitude frame beam crane. The method for erecting steel box beams comprises the following steps of: installing beam sections in a main tower region; installing standard beam sections; installing beam sections on the tops of temporary piers, auxiliary piers and transition piers; pressing side spans; and installing midspan closures. The movable support comprises slide beams, support main slides, left and right stand columns, upper and lower cross supports, a lifting system and counter pull cones. The method for erecting steel box beams has the advantages of reducing construction investment, reducing frame beam crane cost, erecting the steel beams in the manufacturing sequence, omitting large floating crane equipment and dredging expenses. The movable support has the advantages of assisting the non-variable amplitude frame beam crane to erect a plurality of sections of steel box beams in the main tower region and solving the problem that the non-variable amplitude frame beam crane hoists the beam sections to the support, and has a novel structure and definite stress. The movable support can be reused among all tower piers and has good economical and social benefits.

Owner:THE 5TH ENG MBEC

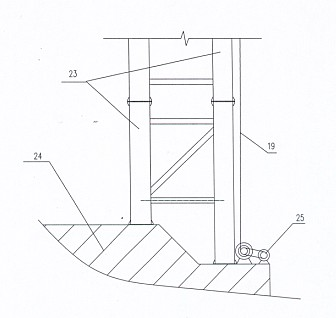

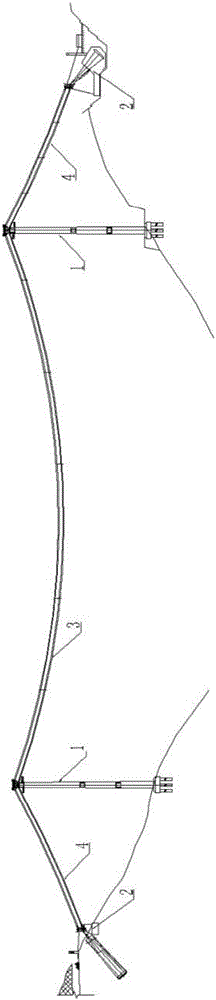

Suspension bridge sectional-type catwalk and construction method thereof

ActiveCN106758767ALow temperatureSmall lengthSuspension bridgeBridge structural detailsCounter-pullEngineering

The invention discloses a suspension bridge sectional-type catwalk and a construction method thereof, which relate to the field of the construction of suspension bridges. The suspension bridge sectional-type catwalk is used for connecting two main towers respectively disposed at two sides of a main span of a suspension bridge and anchorages disposed at two sides of the suspension bridge. Two sides of each main tower are respectively and fixedly provided with a first anchoring apparatus, wherein the two first anchoring apparatuses of the same main tower are connected with each other by virtue of a counter-pulling apparatus pre-embedded in the main tower, and a main span load bearing rope is arranged between the two opposite first anchoring apparatuses of the two main towers; and each anchorage is provided with a second anchoring apparatus, and a side span load bearing rope is arranged between each second anchoring apparatus and the first anchoring apparatus of the opposite main tower.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

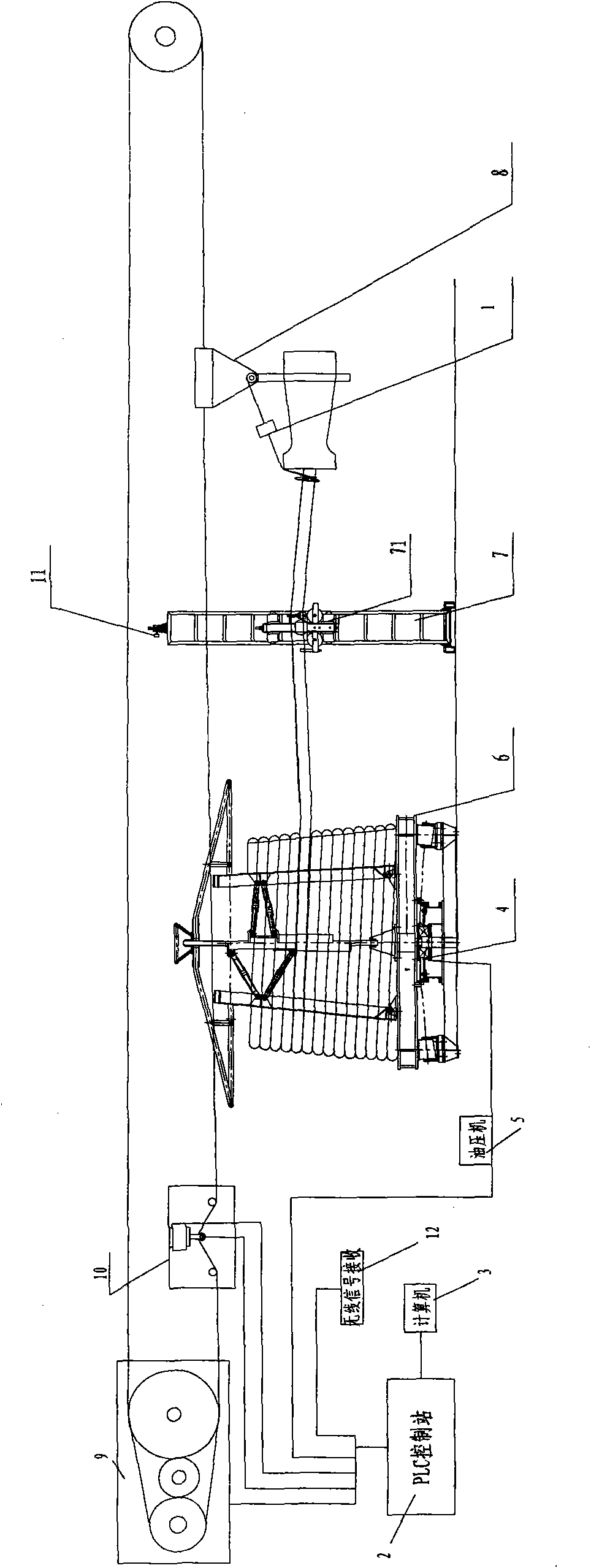

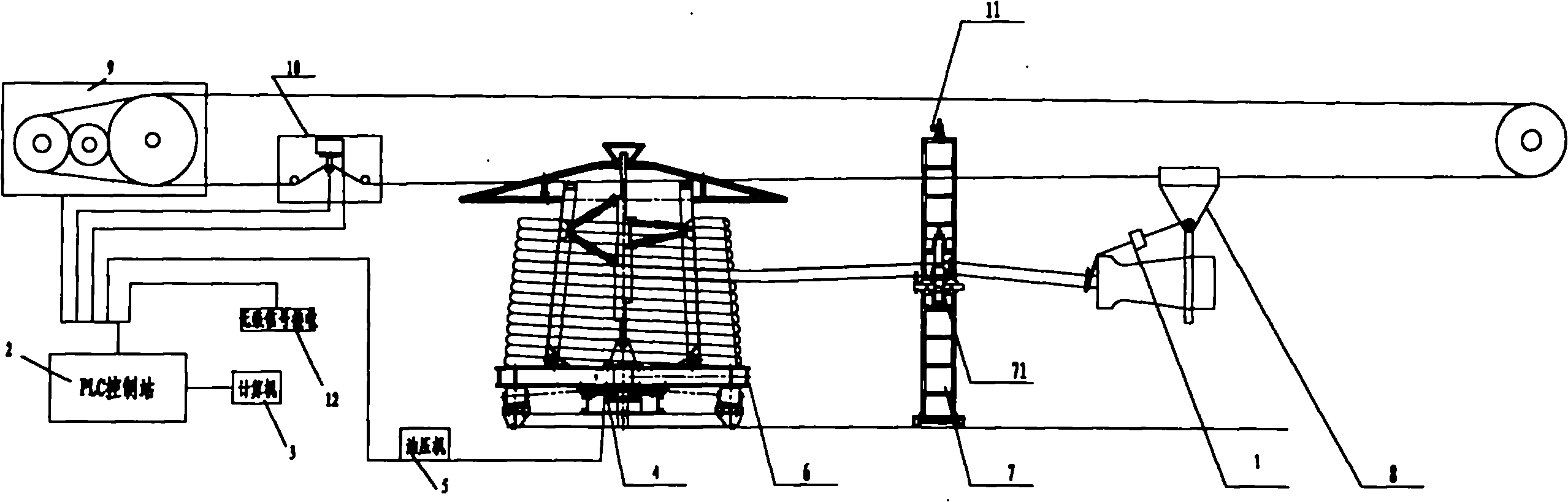

Intelligent horizontal cable releasing method

ActiveCN102031754AQuality improvementImprove efficiencyComputer controlSimulator controlCounter-pullOil temperature

The invention relates to mounting of a cable used for bridges and structures, in particular to an intelligent cable releasing method. PLC (programmable logic control) control is adopted, so as to display, store and regulate various data in cable releasing process. The method comprises the steps as follows: selecting an automatic or manual cable releasing mode; releasing a cable according to the set velocity and resistance; automatically regulating and recording the height of a guide pulley, wherein emergency stop can be realized; measuring and recording the released length and releasing speedof the cable; and displaying and recording oil press motor current, oil pressure and oil temperature. Tractive force, counter pull and pulling speed in the suspension cable band releasing process aremonitored in real time, and key data are displayed and stored, so as to draw a curve graph. The invention can realize high quality and high efficiency for cable releasing construction.

Owner:SHANGHAI PUJIANG CABLE +1

Capon operation table

The invention discloses a capon operation table which comprises a table plate and a telescopic supporting frame, wherein the table plate is provided with a counting hole, fixed big clips, fixed small clips, a big upper clip moving hole, a big lower clip moving hole, a big lower clip pull wire hole, a small upper clip shifting activity slotted hole and a small clip fixing shifting slotted hole; and a main pull wire pedal rack drives a main pull wire to pull a main pull wire rod, a counter pull rod, a small upper clip pull wire rod and a big upper clip pull wire rod to operate a small upper clip, a big lower clip and a big upper clip of the table plate, so that the fixed big clips and the fixed small clips open or close simultaneously. When the capon operation table is not used, telescopic rod fixing bolts are loosened, the supporting frame, the table plate and a supporting plate are pushed and pressed, so that the capon operation table is placed and carried conveniently. The capon operation table is simple in structure, easy to assemble and disassemble, small in size, convenient to carry and use, easy to operate, high in efficiency, safe and reliable, can be used for castrating a large batch of chickens, is safe and effective for henneries and rural capon operators, and has high economic benefits and social benefits.

Owner:王磊

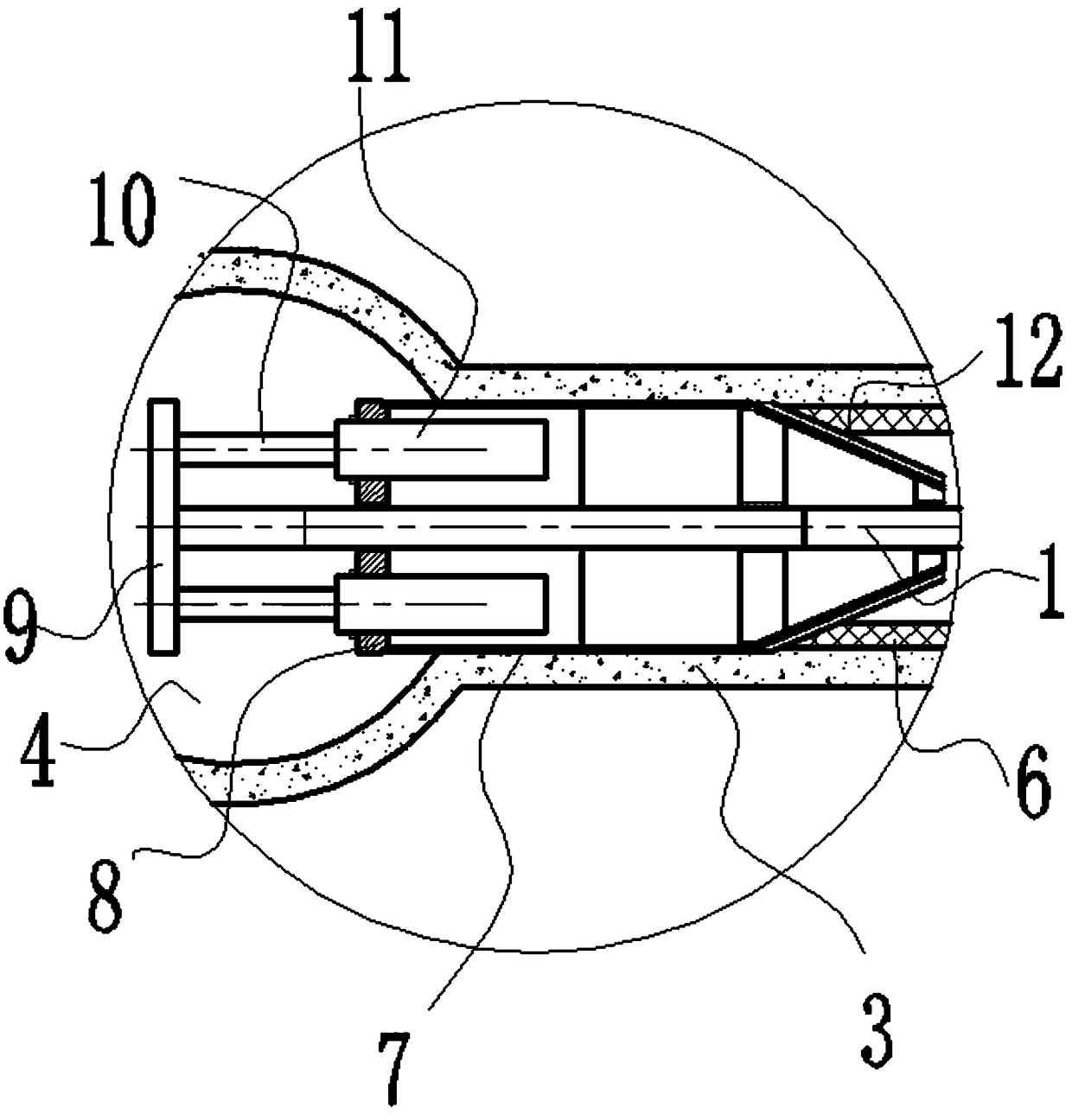

Concealed type disposable safety blood collecting needle

InactiveCN104434135ASimple structureEasy to useSensorsBlood sampling devicesCounter-pullInjection molding process

The invention provides a concealed type disposable safety blood collecting needle. The blood collecting needle structurally comprises a front needle handle, a rear needle handle and a needle body. The blood collecting needle is characterized in that the needle body is arranged in the front needle handle and the rear needle handle through the injection molding process, a needle point is machined at the left end of the needle body and located in the front needle handle, an anti-disengaging structure is arranged at the right end of the needle body and arranged in the rear needle handle, and the front needle handle and the rear needle handle are connected through a connecting rib. The blood collecting needle has the advantages of being simple in structure, easy to machine and convenient to use, and saving raw materials; a rotating pulling mode is adopted for pushing the needle point out of the front needle handle, after being used, the needle point extending out of the front needle handle is contracted into the front needle handle to be isolated and concealed through counter pulling, secondary pollution to the environment and accidental injuries to the human body by the needle point are prevented, and the blood collecting needle has the good safety pollution-preventing effect.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

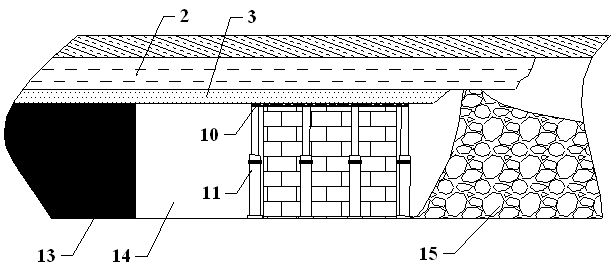

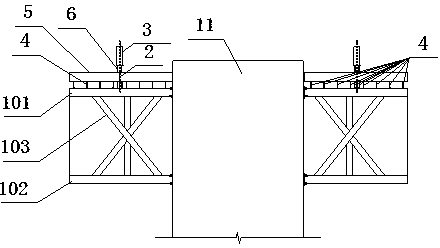

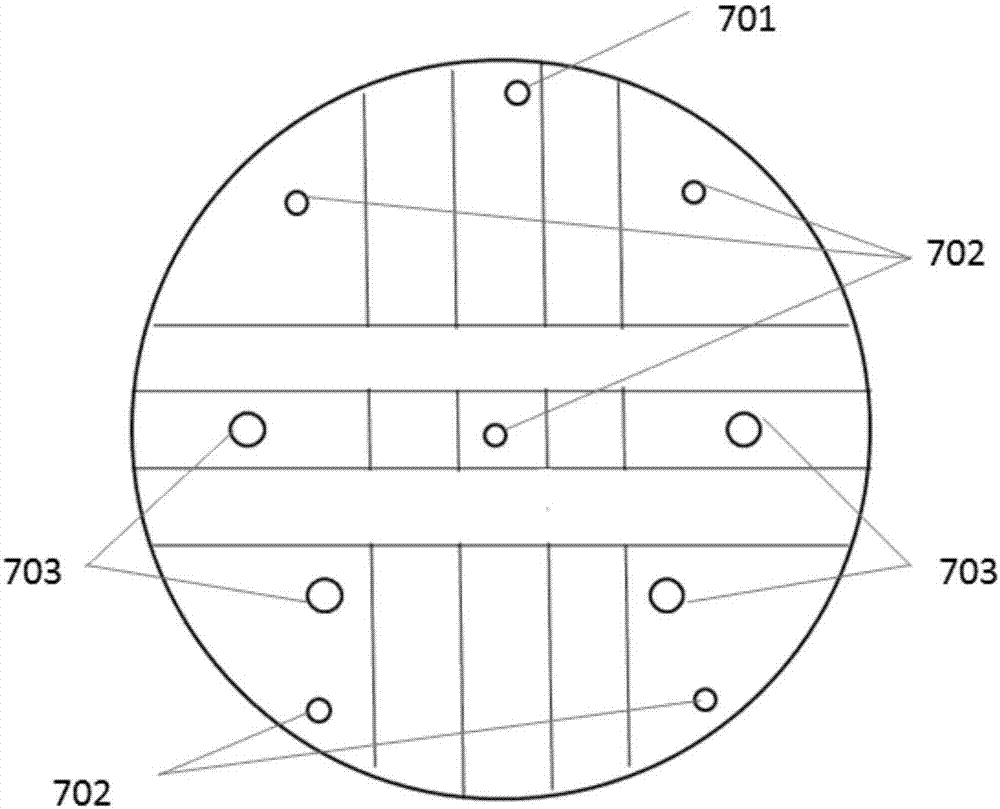

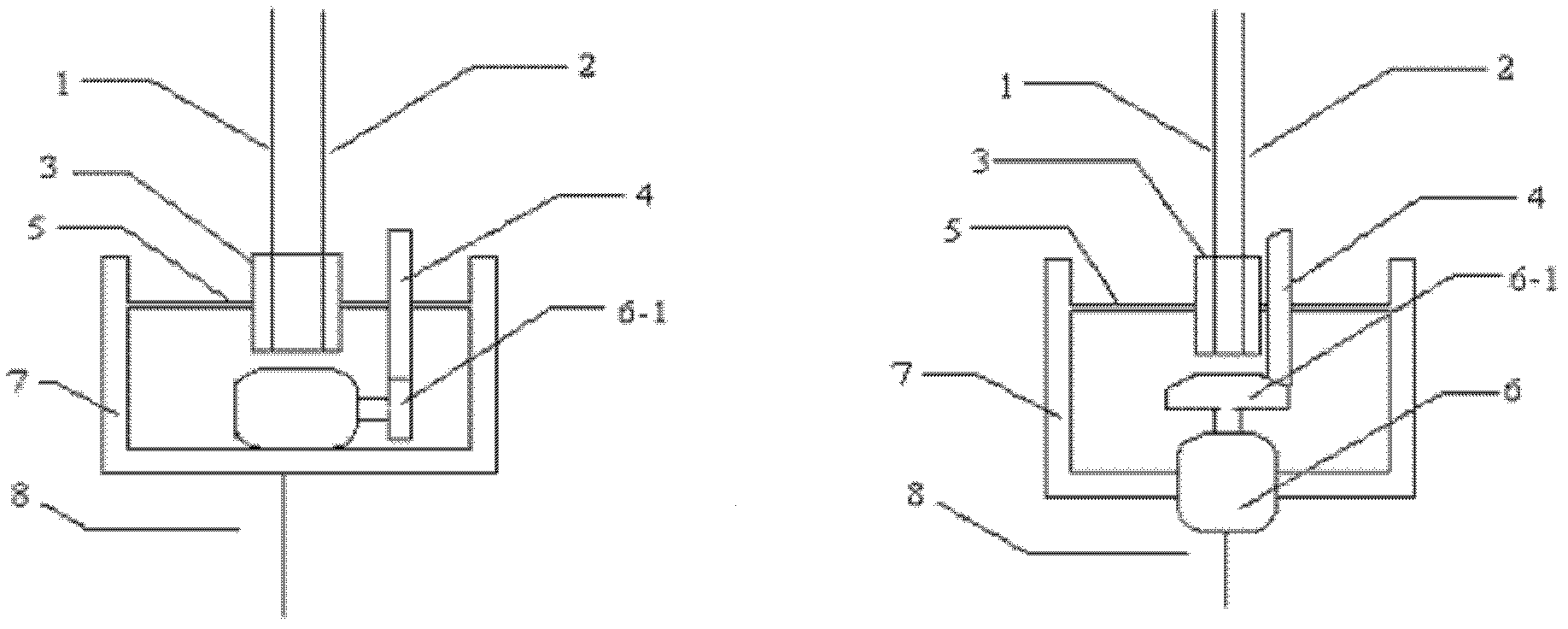

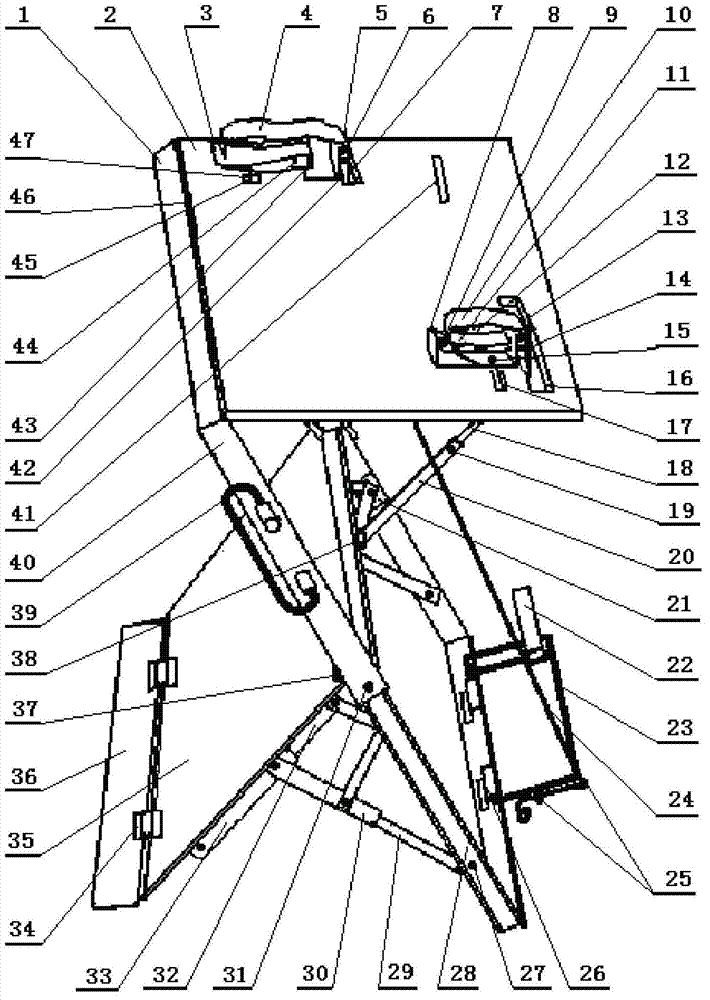

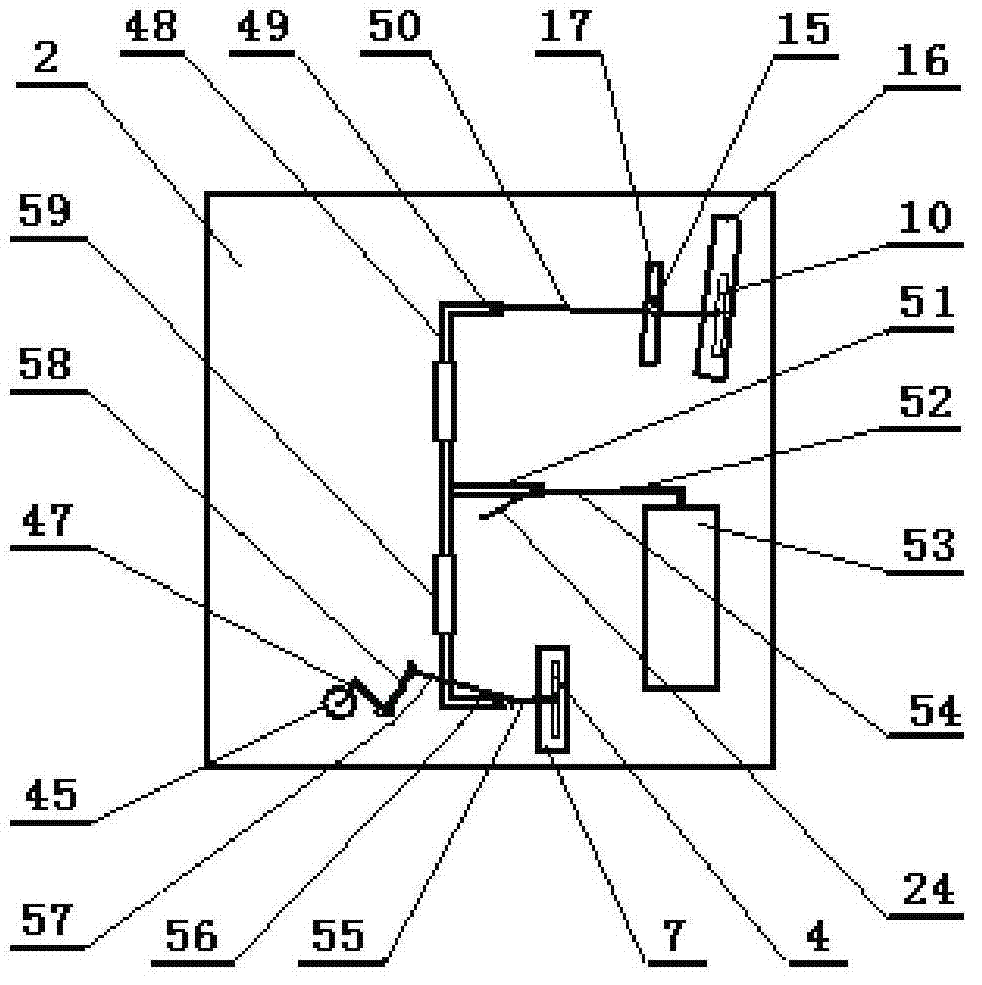

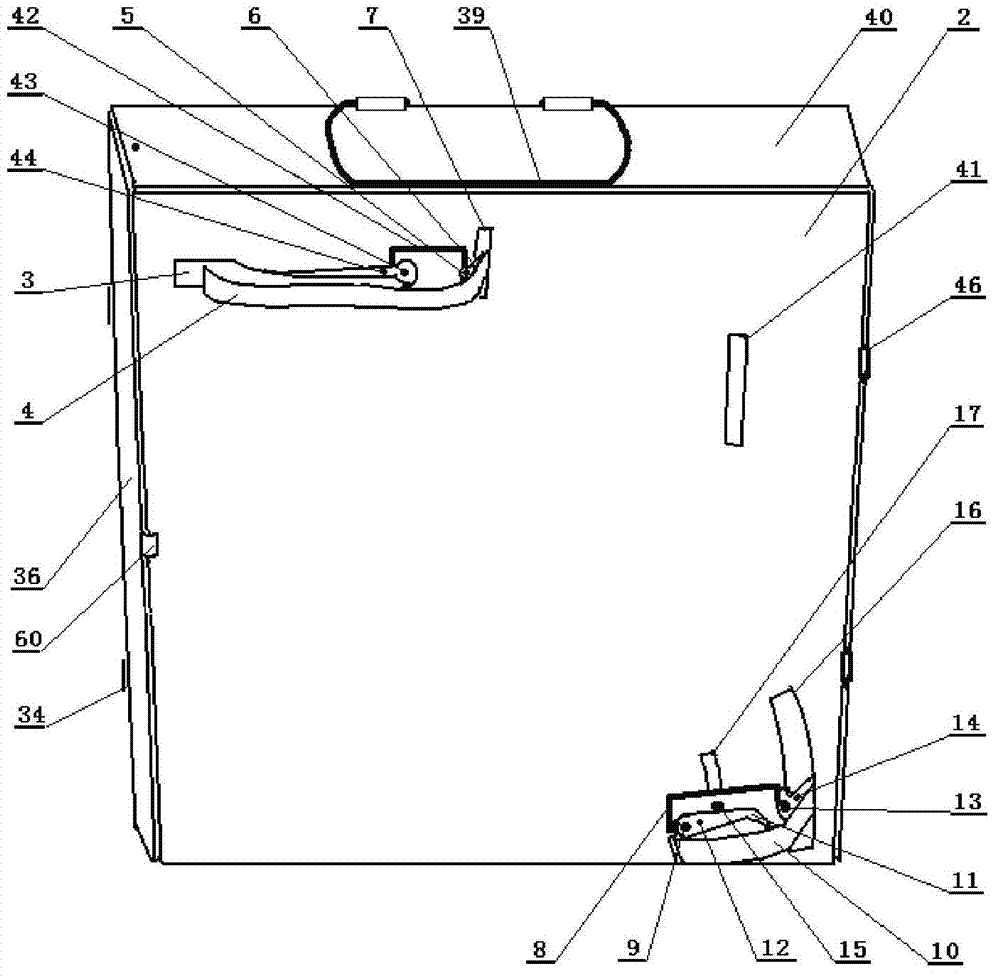

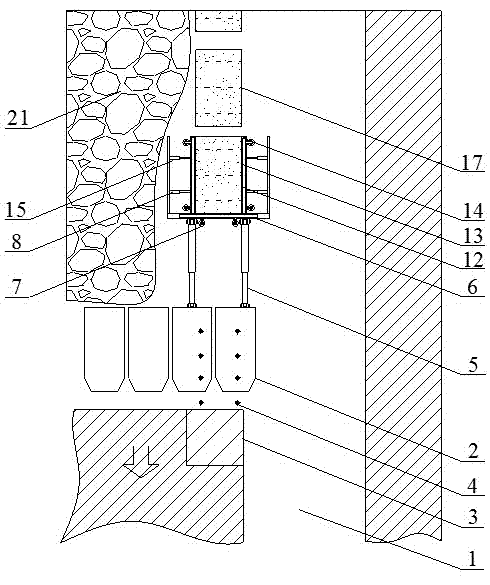

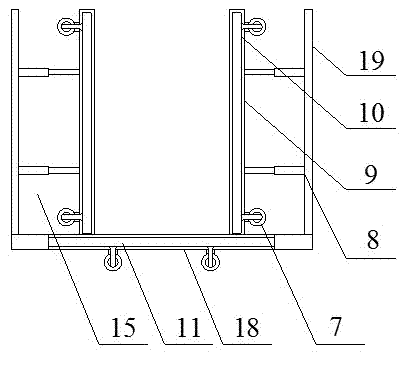

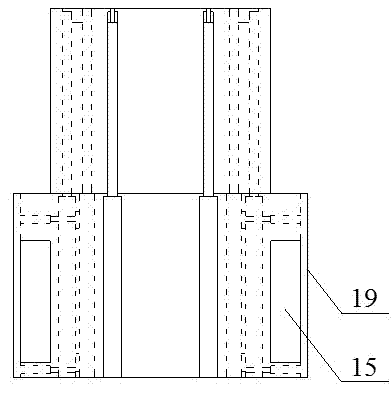

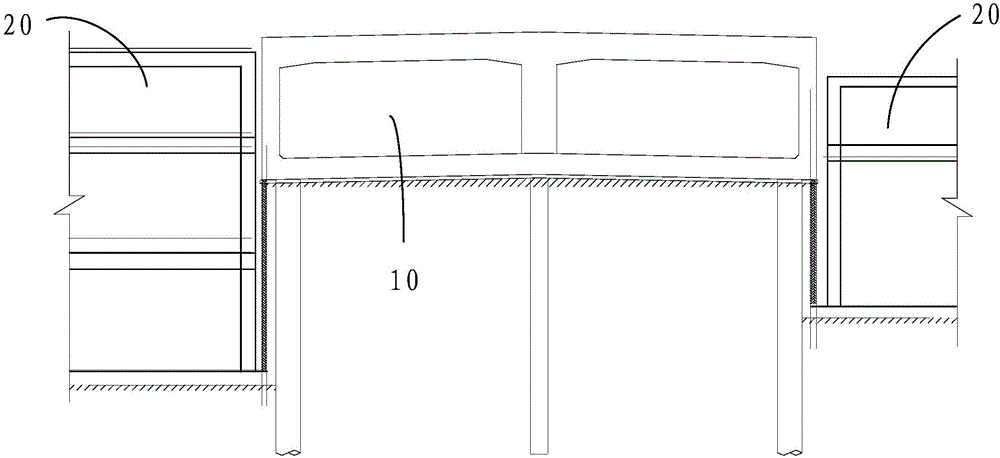

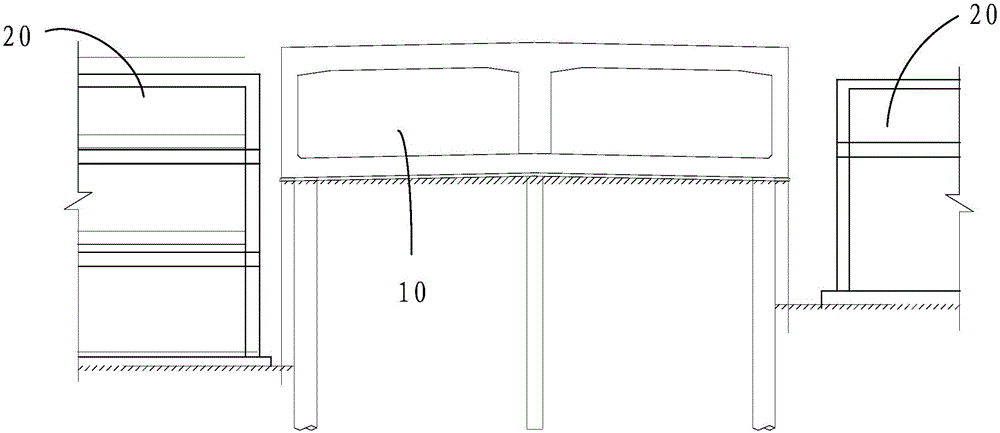

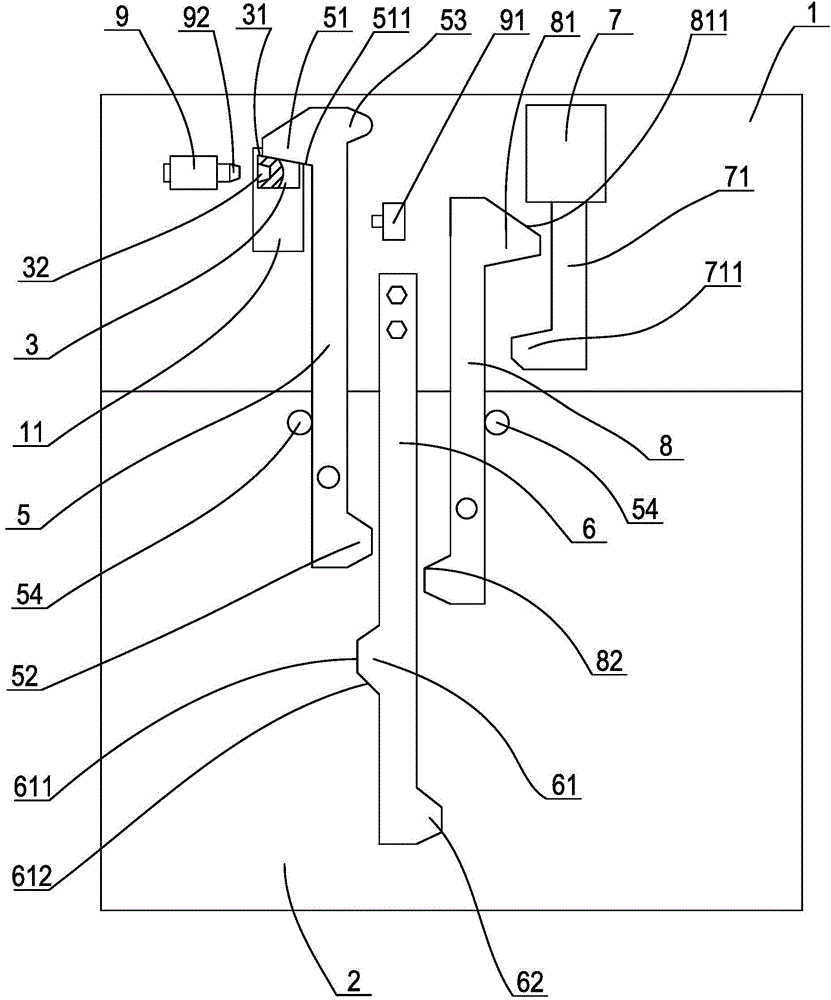

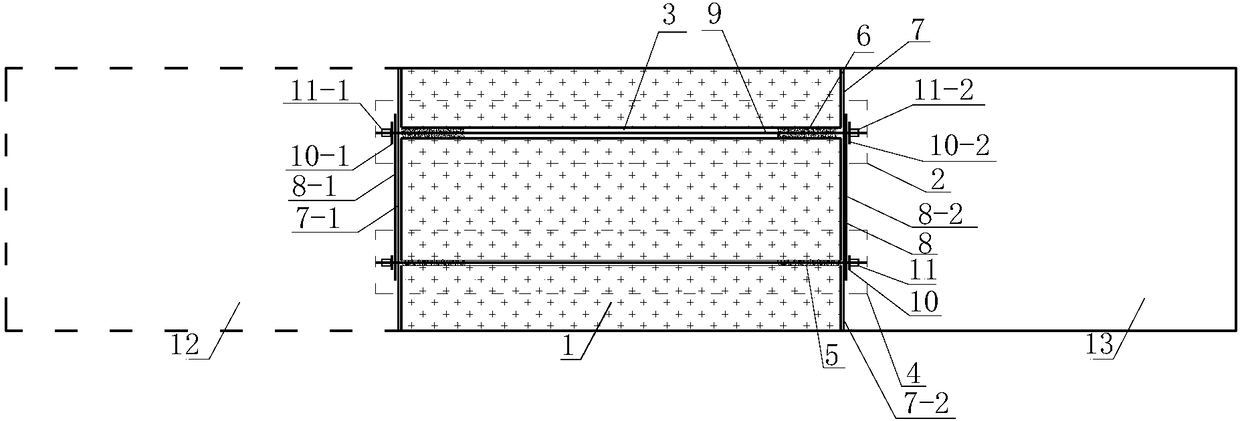

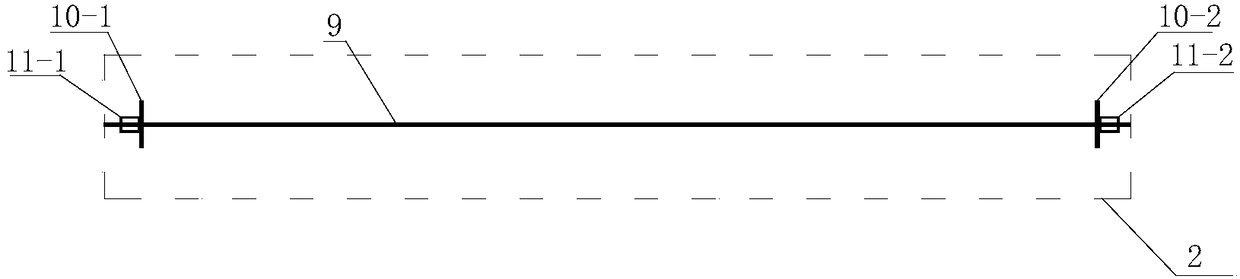

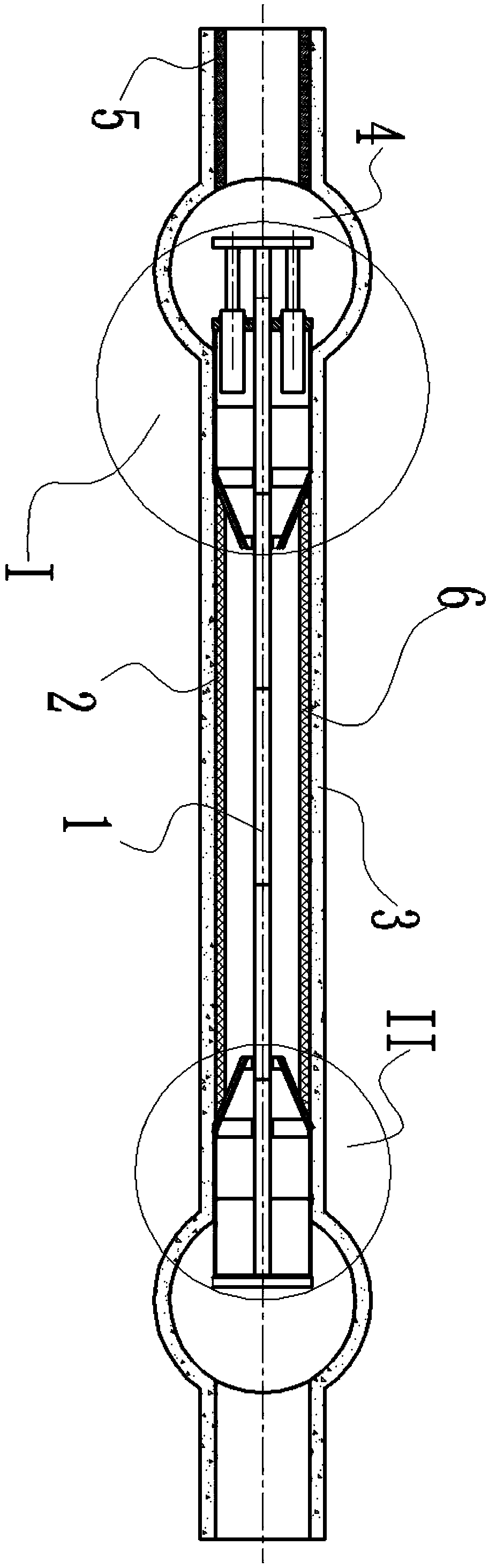

Adjustable high-adaptability formwork support for large mining height fully-mechanized face and gob-side entry retaining method

The invention relates to an adjustable high-adaptability formwork support for a large mining height fully-mechanized face and a gob-side entry retaining method. The adjustable high-adaptability formwork support for the large mining height fully-mechanized face and the gob-side entry retaining method are applicable to the large mining height working face and complicated roof conditions. The adjustable high-adaptability formwork support comprises an inner box body and an outer box body which are combined in a nested mode, a pre-excavated niche is formed in the front of an end support of a stoping face, and a top plate in the niche is supported through an anchor pole and an anchor rope; the adjustable high-adaptability formwork support is arranged behind the end support, a reinforcing mesh is laid in the adjustable high-adaptability formwork support, filling bags are hung in the adjustable high-adaptability formwork support, and a counter-pulled anchor pole is installed in an installing hole of a side plate anchor pole; pasty fluid or high-water-material grout is injected into the filling bags; a side plate oil cylinder is adjusted after filling bodies are solidified, side plates are pushed and expanded, the support is moved as a whole, and construction is completed. The method is safe, reliable, high in integrity, high in mechanization degree and high in adaptability to different mine pressure conditions and different top plate conditions of a roadway, and the filling bodies are regularly formed.

Owner:CHINA UNIV OF MINING & TECH

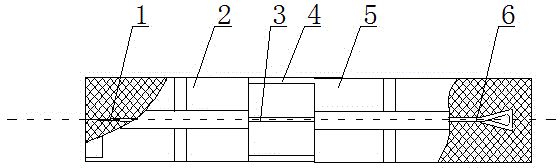

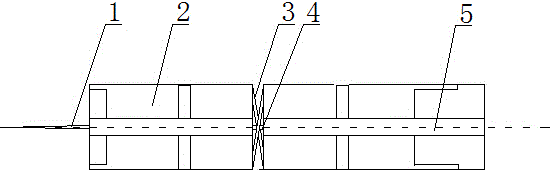

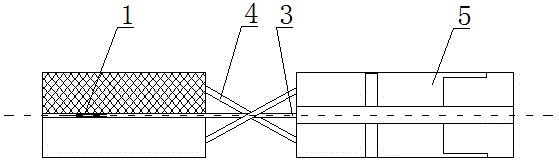

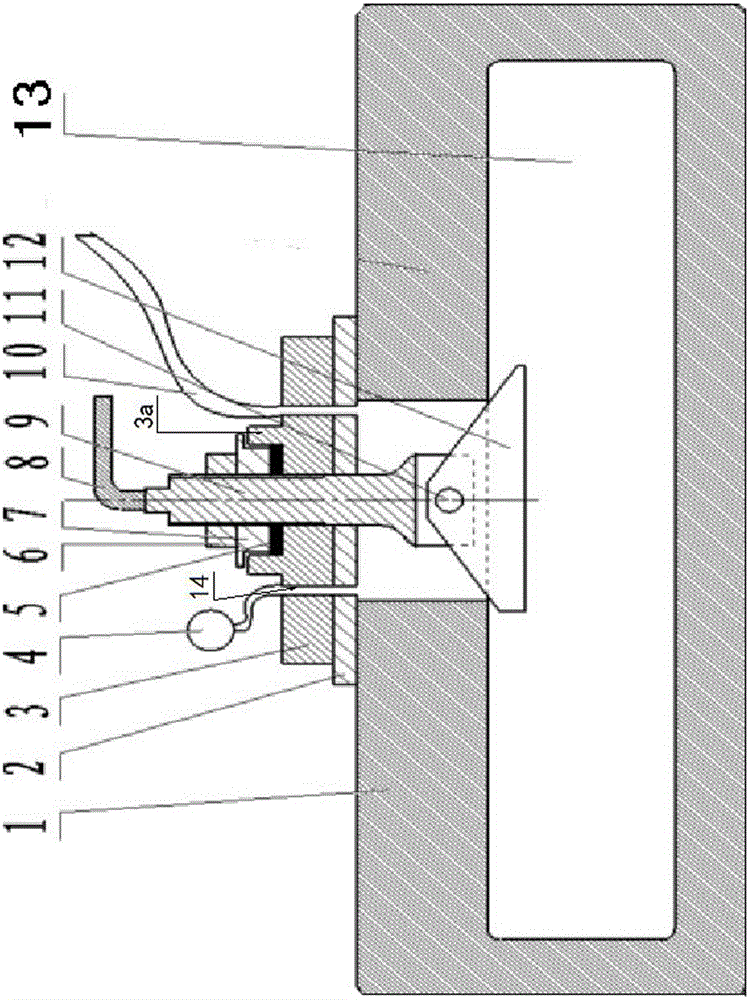

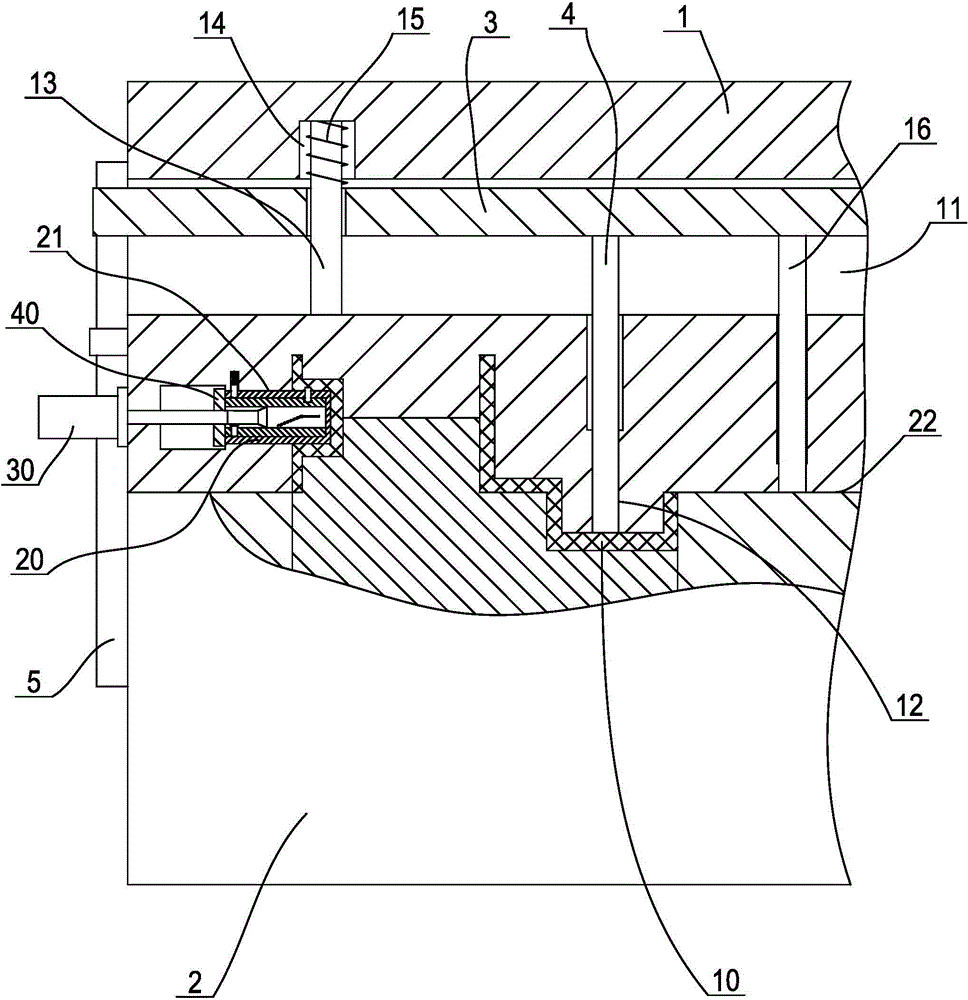

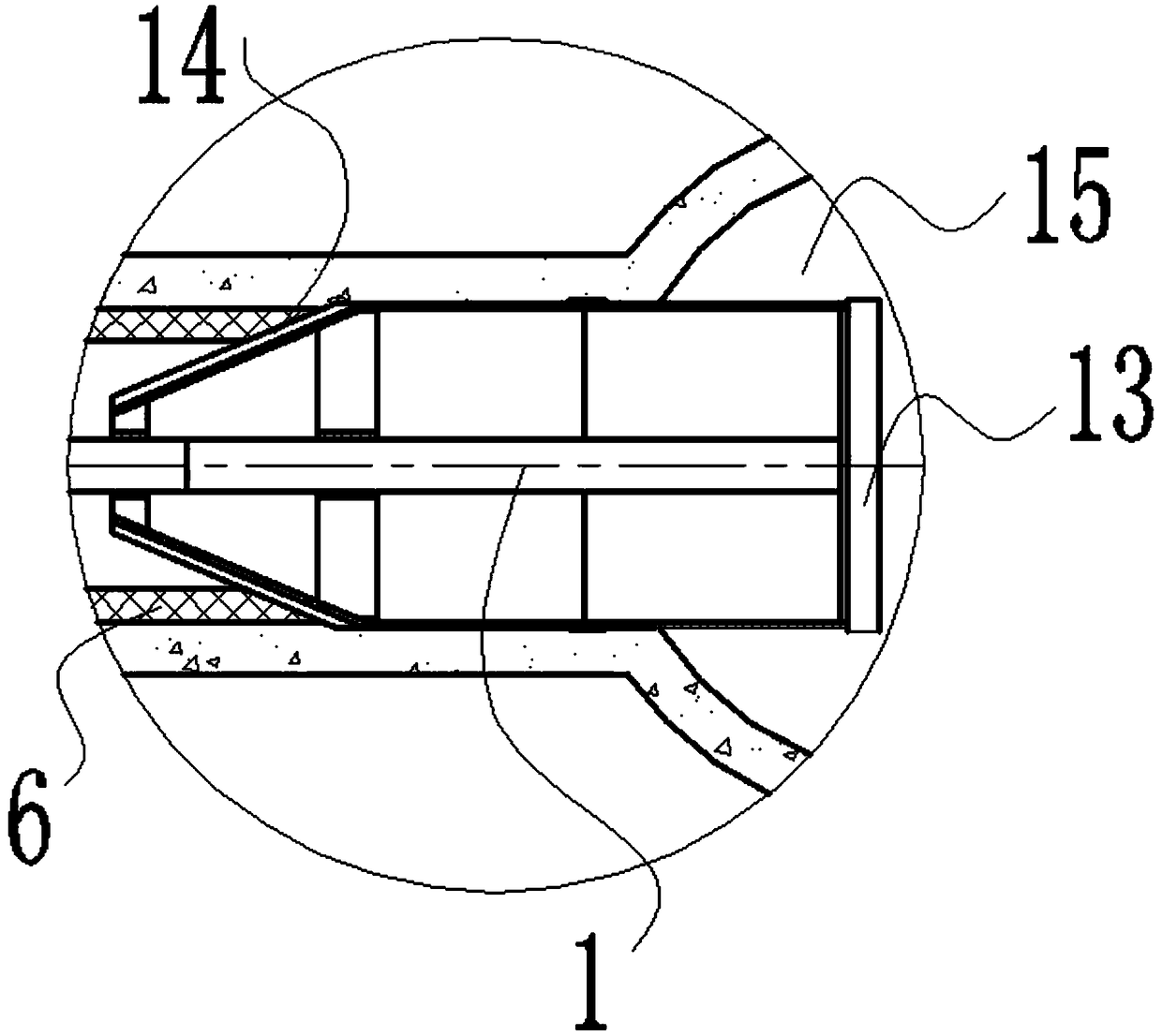

Counter-pull pressure detection apparatus for a casting having a cavity with an opening in a cavity wall

InactiveCN105092186AGuaranteed tightnessMeasurement of fluid loss/gain rateCounter-pullTransverse plane

The invention relates to a counter-pull pressure detection apparatus for a casting having a cavity with an opening in a cavity wall. The apparatus comprises an eccentric draw plate abutting against in an opening of a casting. A press plate is arranged on the outer transverse plane of the opening. A rubber gasket is arranged between the press plate and the outer transverse plane of the opening. The press plate is provided with an inlet pipe and an outlet pipe that are communicated with a cavity of the casting. The outlet pipe is connected to a pressure gauge. The eccentric draw plate and the press plate are tightly drawn by a forcible pull screw that penetrates the press plate and the rubber gasket. The forcible pull screw, above the press plate, is connected to a compression nut. The eccentric draw plate is shaped like a triangle or a trapezoid that becomes increasingly larger from top to bottom. The upper end of the eccentric draw plate is in rotatable connection with the lower end of the forcible pull screw through a penetrating pin. When the eccentric draw plate rotates about the penetrating pin to a corresponding angle, the eccentric draw plate can pass through the opening of the casting along with the lower end of the forcible pull screw. The length of the bottom edge of the eccentric draw plate is greater than the caliber of the opening of the casting, the bottom edge corresponding to the penetrating pin.

Owner:KOCEL EQUIP

Construction method of horizontal counter-pulled anchor cable

ActiveCN106759378ASimple construction methodImprove construction efficiencyExcavationsBulkheads/pilesCounter-pullEngineering

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Structure for shoring of foundation trench and construction method

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Die-casting die

The invention discloses a die-casting die which comprises an upper die and a lower die. Elongated slots penetrating the left side and the right side of the upper die are formed in the upper die, a beam is movably arranged in the elongated slots, a counter pull rod extending to a cavity of the upper die is arranged on the beam, beam pressure springs abutted to the beam are arranged on the upper sides of the elongated slots, first pull hooks and corresponding limit structures are rotatably arranged on the left side and the right side of the lower die respectively, hook portions are arranged at the upper ends of the first pull hooks, first projections extending to the other side are arranged at the lower ends of the first pull hooks, the hook portions hook ends of the beam extending out of the upper die, torsion springs pinning the first pull hooks are arranged on rotating shafts of the first pull hooks, a poke rod is fixedly arranged on the upper die and beside the first projections of the first pull hooks, a projecting first push block is arranged on the lower portion of the poke rod and close to the first projections, and guide inclined surfaces are arranged at two ends of the first push block. All products can stay on the lower die in forming, so that bending deformation of the formed products is effectively avoided.

Owner:NINGBO BEILUN HUASHENG MOLD FACTORY

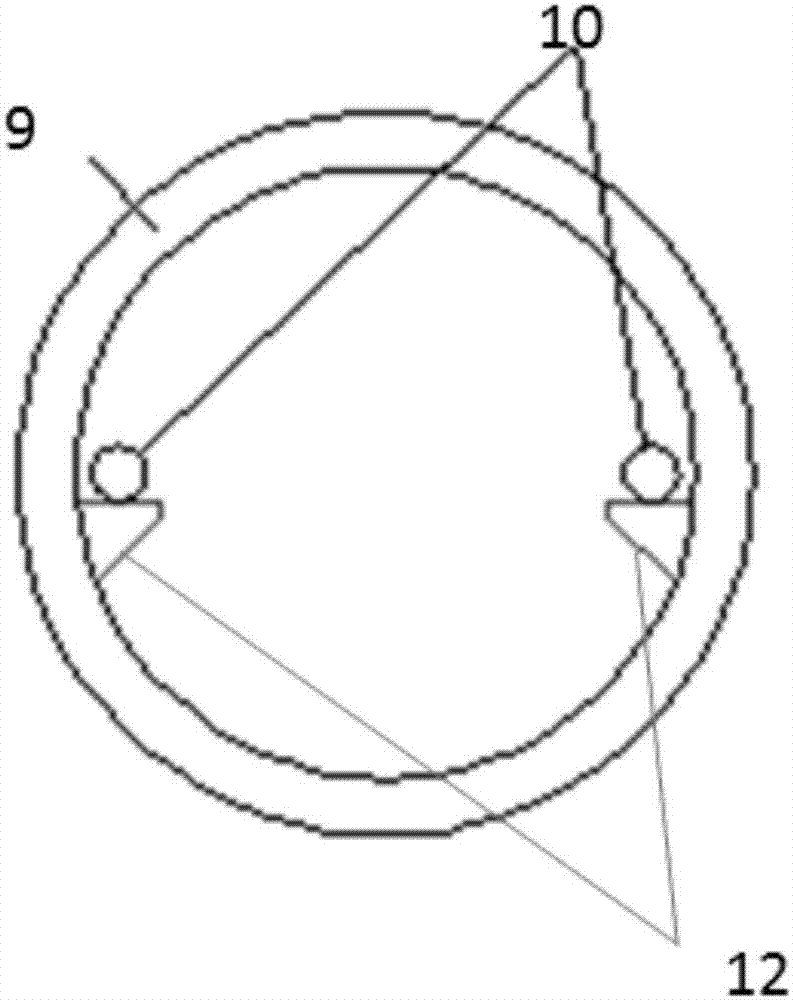

Gob-side entry driving small coal pillar anti-impact pressure-releasing and counter-pulled anchoring integrated structure and construction method thereof

PendingCN108590723AAvoid hurtingReduce the number of punch holesAnchoring boltsDual effectCounter-pull

The invention discloses a gob-side entry driving small coal pillar anti-impact pressure-releasing and counter-pulled anchoring integrated structure and a construction method thereof. An upper row of counter-pulled anchor cables and a lower row of counter-pulled anchor cables are adopted at gob-side entry driving small coal pillars for reinforced supporting, drill holes of the upper row of counter-pulled anchor cables adopt anti-impact pressure-releasing large-diameter drill holes, the two ends of each large-diameter drill hole are filled with concrete to be closed, and the middle of each large-diameter drill hole is hollow. The large-diameter drill holes are constructed in the coal pillars, and the counter-pulled anchor cables are mounted on the coal pillars, the functions of anti-impact pressure releasing and anchor cable mounting are integrated, the dual effects of coal pillar anti-impact pressure releasing and coal pillar bidirectional reinforcing through the counter-pulled anchor cables are achieved, the stability of the coal pillars is improved, deformation of entry sides is reduced, the counter-pulled anchor cables can be prevented from being broken under pulling and then flying off through the mode that the two ends of each drill hole are closed through the concrete, and poisonous and harmful gas and gob accumulated water are prevented from entering a gob-side entry driving roadway. The gob-side entry driving small coal pillar anti-impact pressure-releasing and counter-pulled anchoring integrated structure and the construction method thereof are suitable for anti-impact pressure releasing and reinforcing of the coal pillars of coal mines.

Owner:中煤能源研究院有限责任公司

Counter-pulling wall connecting component

The invention provides a counter-pulling wall connecting component which comprises a counter-pulling screw with external threads. The two ends of the counter-pulling screw are in screwing fit with fastening devices correspondingly. The outer wall of the counter-pulling screw is sleeved with a hollow embedded pipe, and hollow plugs are inserted into the two ends of the embedded pipe correspondingly. The fastening device located at one end of the counter-pulling screw is composed of a gasket and a nut, and the fastening device located at the other end of the counter-pulling screw is a wall connecting tube assembly. According to the counter-pulling wall connecting component, concrete is prevented from entering the embedded pipe through the design of the plugs at the two ends of the embedded pipe, and thus the possibility of repeated utilization of the counter-pulling screw is increased, and waste of aluminum formworks is reduced. A counter-pulling screw used in the wall pouring process is certainly suitable for the wall connecting component, and the universality of the counter-pulling screw is improved. In addition, nut-gasket assemblies at the two ends of the counter-pulling screw both can be manually fastened, installation is convenient, and potential safety hazards and wall damage in assembling of the wall connecting component and a scaffold are eliminated.

Owner:SHANGHAI HONGJIN EQUIP & ENG CO LTD

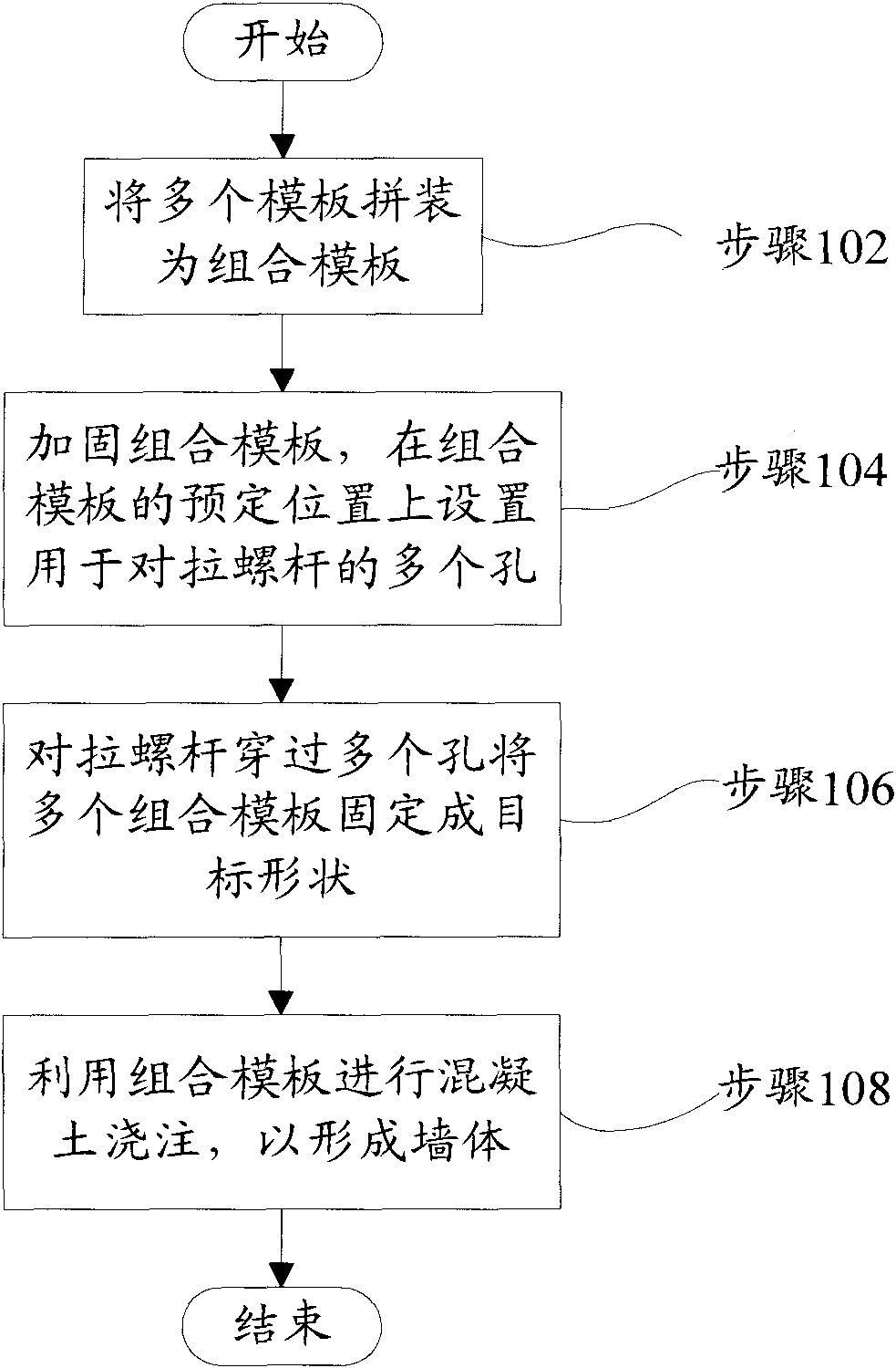

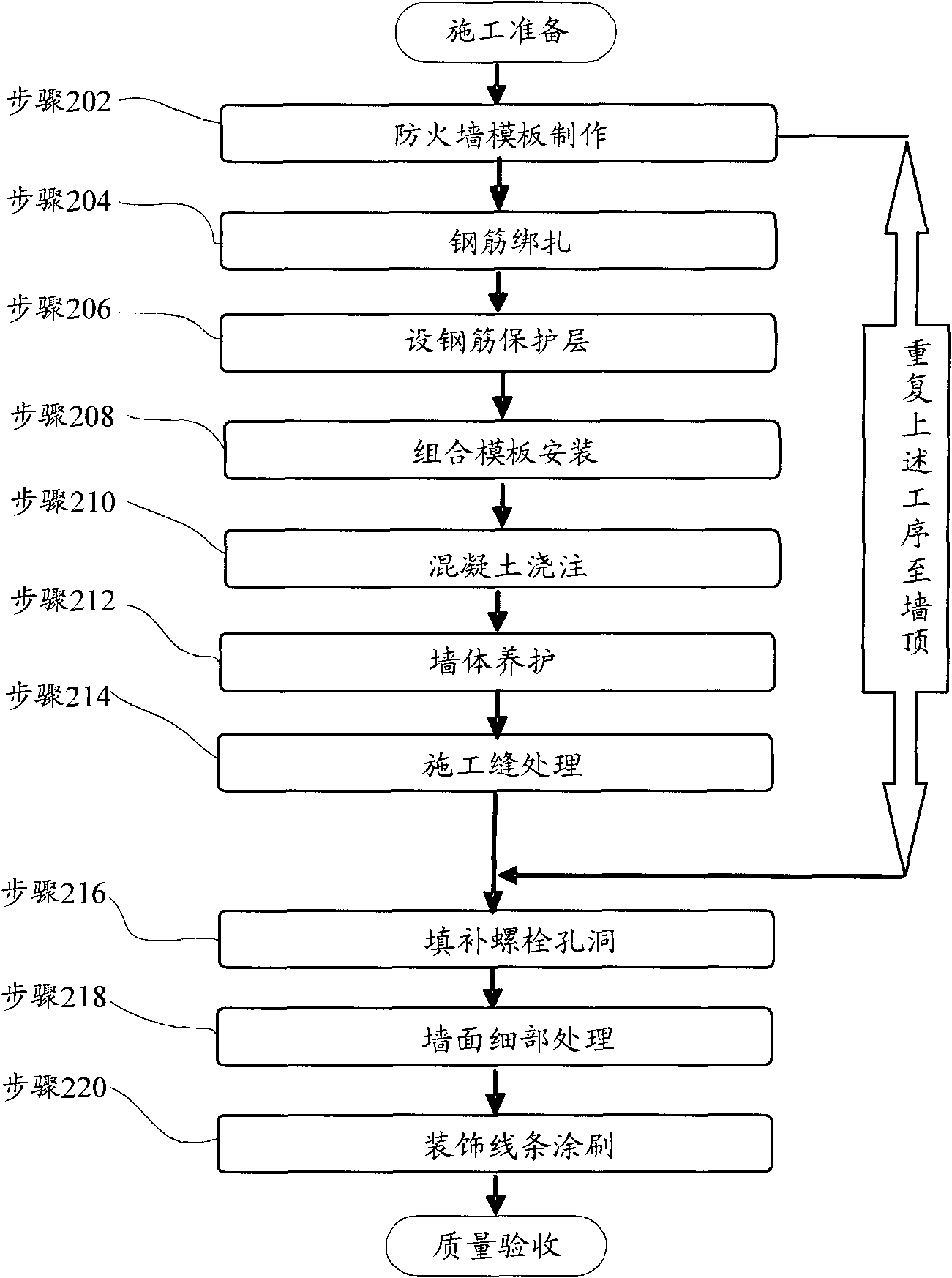

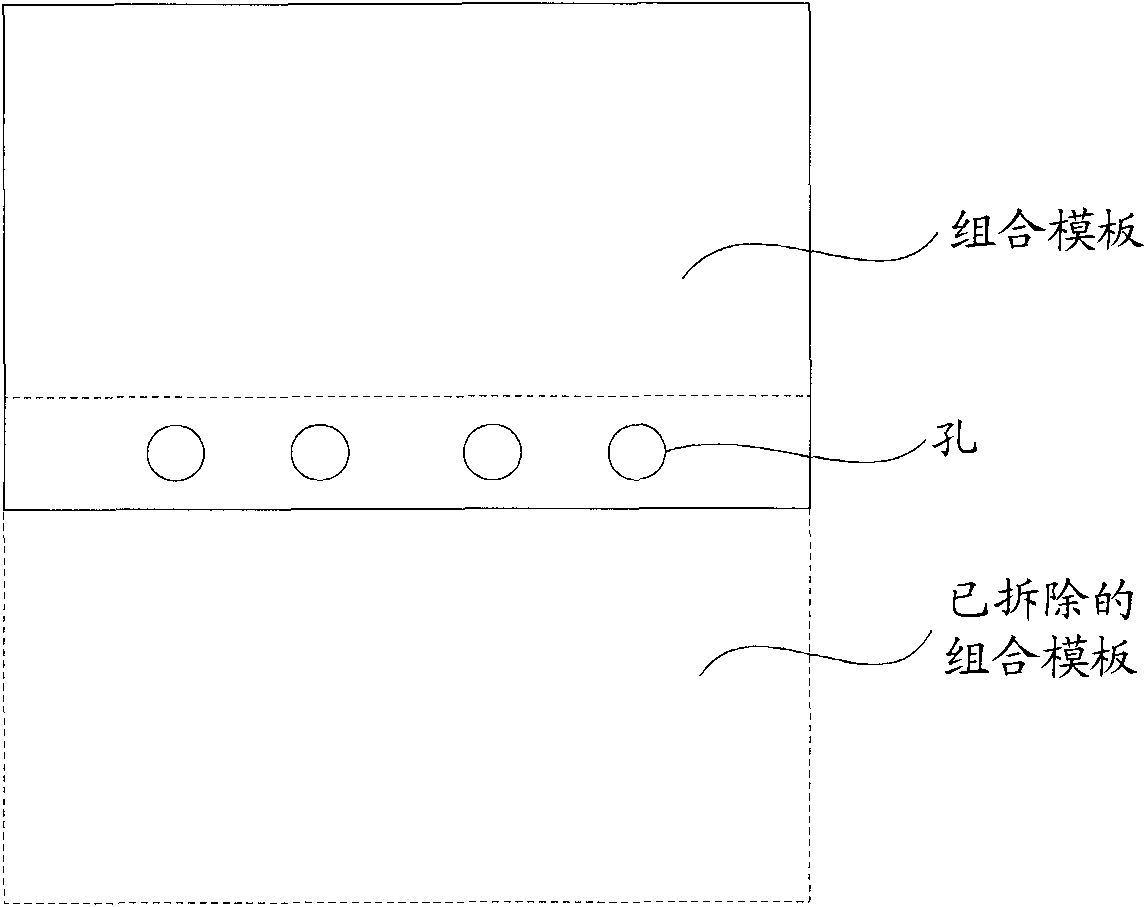

Method for building wall

InactiveCN101818571ASolve the impact of aestheticsBeautiful wallWallsBuilding material handlingCounter-pullEngineering

Owner:STATE GRID CORP OF CHINA

Steel pipe full-encapsulating concrete pouring pipe stabilization supporting structure and construction method thereof

PendingCN108277803AGuarantee the progress of the installationEasy to adjustFoundation engineeringButtressCounter-pull

The invention provides a steel pipe full-encapsulating concrete pouring pipe stabilization supporting structure and a construction method thereof. The steel pipe full-encapsulating concrete pouring pipe stabilization supporting structure comprises a flat top-shaped buttress and a pipe stabilization bracket; the pipe stabilization bracket comprises two oppositely arranged counter-pulled brackets and a pull rod which is adjustable in length and is connected between the counter-pulled brackets; each counter-pulled bracket is provided with an arch-shaped steel plate; and the radian of each arc isconsistent to the radian of the steel plate, wherein the steel plates are collaboratively supported and positioned by at least two buttresses and at least two auxiliary pipe stabilization brackets, and the end part of each steel pipe extends out of the buttress with a certain length. By adopting the technical scheme of the invention, the mounting progress of the steel pipe can be guaranteed, and two parameters, including an elevation and an axis position, of the accuracy are separately controlled; as the buttress is in a flat top shape, curve surface construction can be reduced, the elevationand the axis position can be conveniently regulated on the flat top-shaped buttress, and the accuracy is easily ensured; and the pipe stabilization bracket is adopted to limit the axis position, and limitation is convenient and accurate.

Owner:北京清河水利建设集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com