Construction method and double-layer formwork structure for cast-in-situ slope roof

A double-layer formwork and construction method technology, which is applied in the direction of formwork/formwork/work frame, joints of formwork/formwork/work frame, roof, etc., can solve the problem that the compactness of concrete pouring is difficult to control and the construction quality is difficult to achieve The expected effect, easy seepage and leakage of concrete structure construction, to achieve the effect of reducing the loss of concrete materials, avoiding hidden dangers of leakage, and high cross-sectional dimension accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

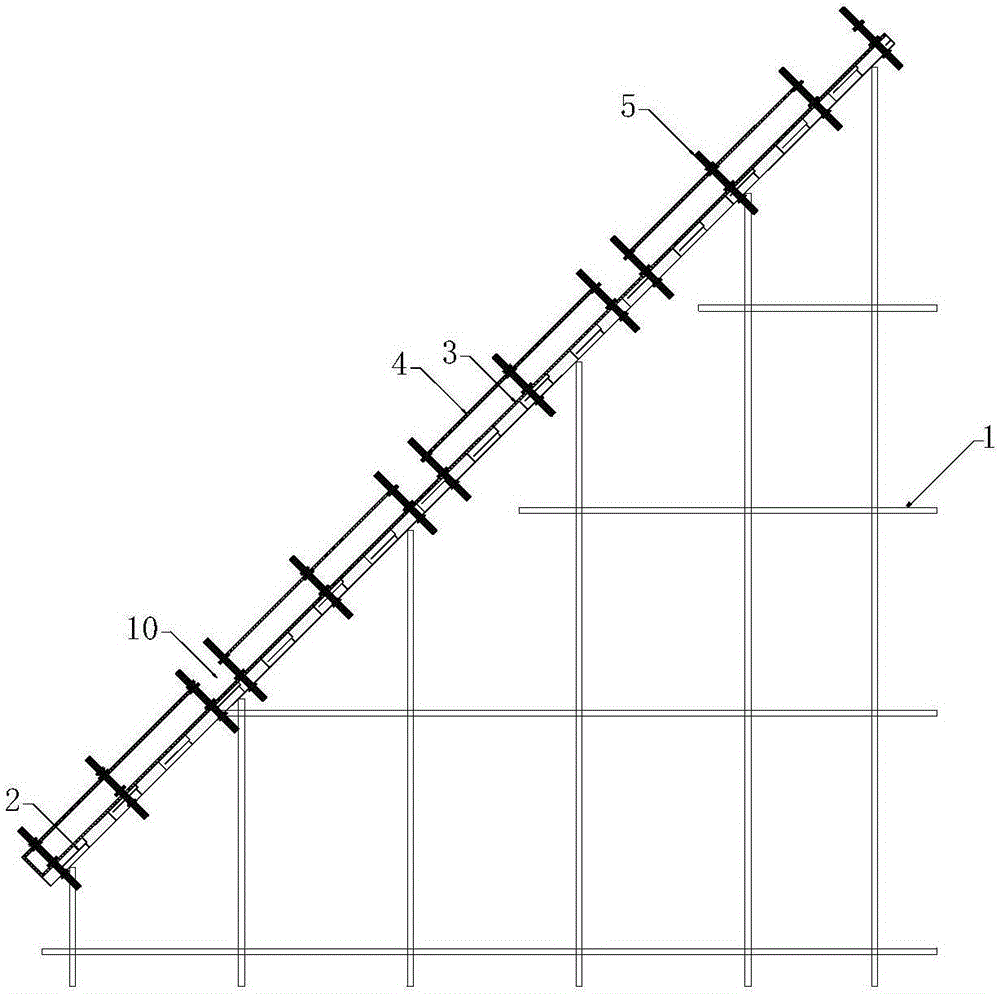

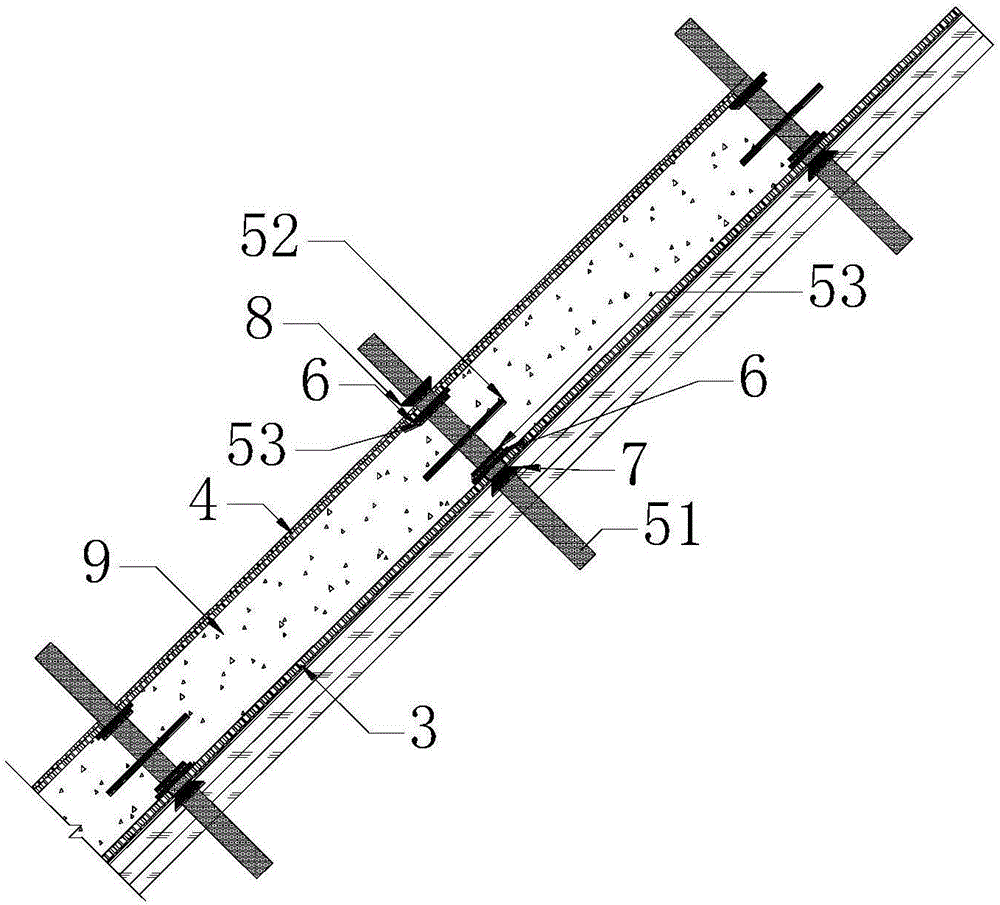

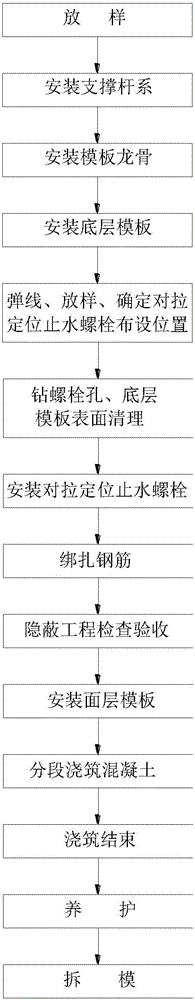

[0035] Such as figure 1 , figure 2 As shown, a double-layer formwork structure for cast-in-place sloping roofs according to the present invention includes a support rod system 1, a formwork keel 2, a bottom formwork 3, a surface formwork 4, and a pair of pull positioning water-stop bolts 5; the formwork keel 2 It is arranged obliquely along the height of the roof, and its inclination is consistent with the slope of the sloping roof, and its bottom is supported and fixed by the support rod system 1; The bottom formwork 3 is arranged in parallel, and the distance between the two is equal to the thickness of the concrete pouring layer 9 of the sloping roof; The outer sides of the formwork 4 are locked and fixed by the bottom nut 7 and the top nut 8 respectively; the surface formwork 4 is composed of a plurality of segmented surface formworks arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com